Preparation method of anisotropic rare earth permanent magnet alloy material and magnetic powder

An anisotropic, rare earth permanent magnet technology, applied in magnetic materials, magnetic objects, electrical components, etc., can solve the problems of complex process, low magnetic performance and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

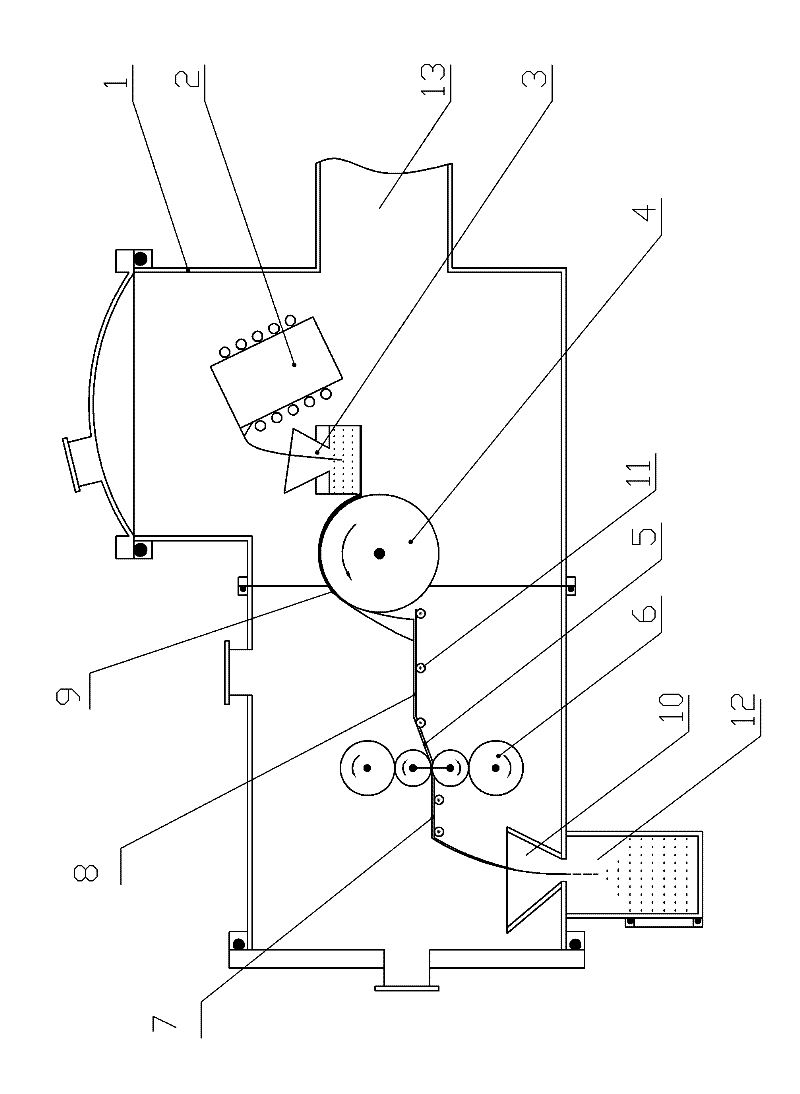

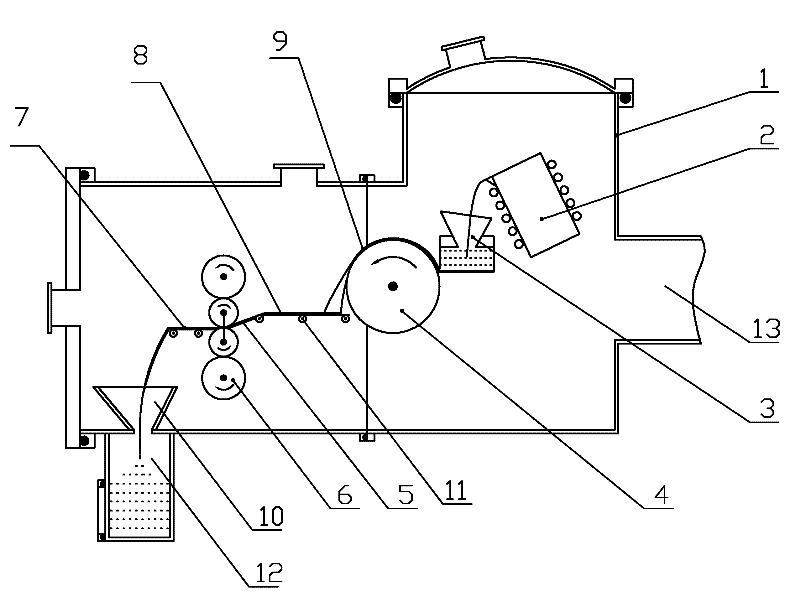

Image

Examples

Embodiment 1

[0022] Example 1: Press Sm 2+X (Fe 1-y m y ) 17 Composition formulation of the original Sm-Fe alloy, considering the volatilization of Sm and the inhibition of the formation of α-Fe phase, more Sm must be added. In this example, X=0.7, M is Cu, y=0.1, and only Cu element is added. Its function: refine the grain, increase the contact resistance and improve the coercive force Hcj; at the same time, it is also beneficial to the processing deformation, reduces the deformation resistance, and improves the anisotropy field of the alloy; the ingredients in this example are: Sm 2.7 (Fe 0.9 Cu 0.1 ) 17 Sm-Fe alloy raw materials. In the device 1 for preparing anisotropic alloy magnetic powder, Sm 2.7 (Fe 0.9 Cu 0.1 ) 17 Alloy raw materials are put into the crucible of medium frequency induction melting furnace 2, and the vacuum is ≤5×10 -2 Pa, fill with argon Ar to 0.04MPa, medium frequency induction heating to melting, temperature control within 1390-1430°C, adopt strip cast...

Embodiment 2

[0025] Embodiment 2: In this example, press Sm 2.8 (Fe 0.84 Ga 0.01 Nb 0.15 ) 17 Composition preparation of the original Sm-Fe alloy, in the device 1 for preparing anisotropic alloy magnetic powder, the Sm-Fe alloy raw material is put into the crucible of the medium frequency induction melting furnace 2, and the vacuum is ≤5×10 -2 Pa, filled with argon Ar to 0.04MPa, medium frequency induction heating to melting, the temperature is controlled within the range of 1390-1430°C, using quick-setting process, water-cooled copper wheel 5 speed V 铜轮速 =2.5m / s, through the outlet of the tundish 3 close to the upper right of the water-cooled copper wheel 4, the molten Sm 2.8 (Fe 0.84 Ga 0.01 Nb 0.15 ) 17 The original ingredient alloy melt is 10 2 -10 4 ℃ / S speed cooling into 0.1-0.45mm thick, isotropic soft magnetic Sm 2.8 (Fe 0.84 Ga 0.01 Nb 0.15 ) 17 Quick-setting alloy flakes9. Then by the conveying roller table 8, the Sm under the state of 600-900°C 2.8 (Fe 0.9 Cu ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| magnetic energy product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com