Process of growing self-organized Ge quantum dot by means of ion beam sputtering in low growth beam flux

A technology of ion beam sputtering and quantum dots, which is applied in the field of preparation of nano-quantum materials, can solve the problems of unfavorable large-scale production, low production efficiency, and high production cost, and achieve the effects of low price, improved production efficiency, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

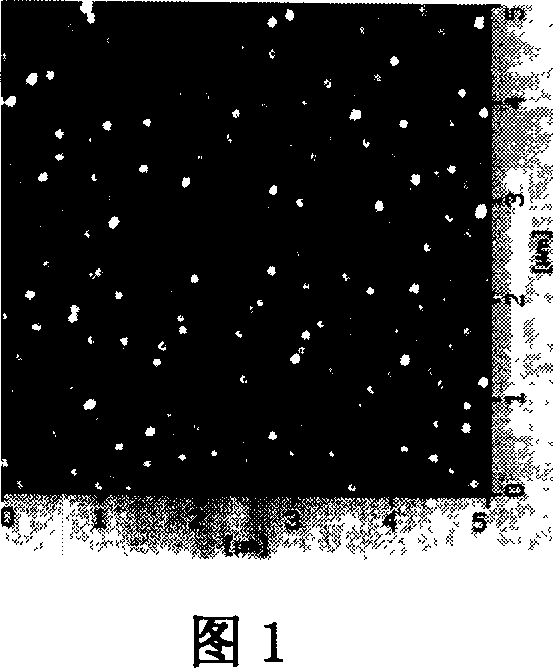

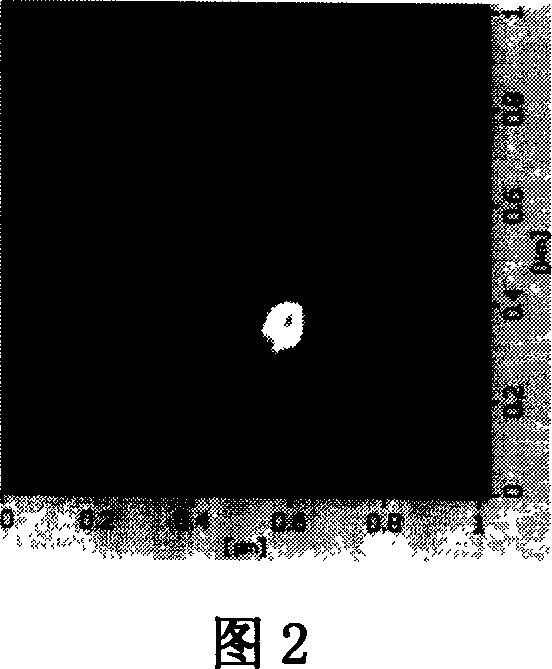

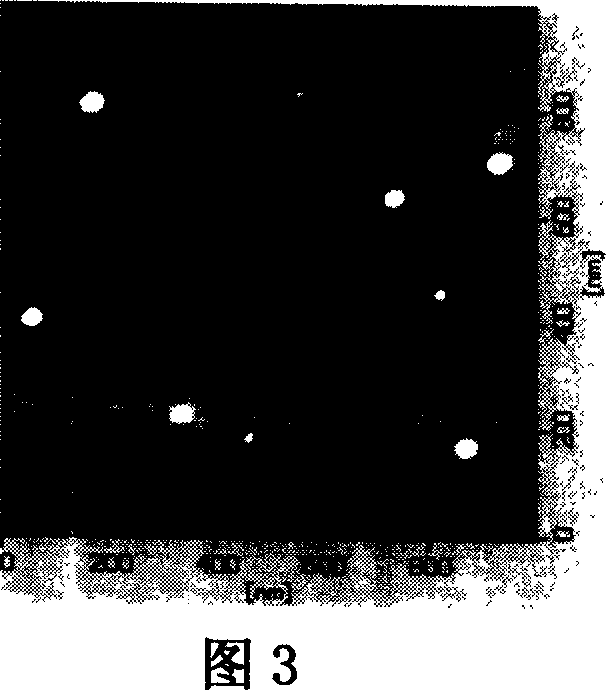

Image

Examples

Embodiment 1

[0021] The equipment used is the ion beam sputtering chamber of the FJL560III type ultra-high vacuum multi-target magnetron and ion beam combined sputtering equipment, and a Kaufman ion gun is placed in the growth chamber. The materials used are: the target material is a high-purity Ge square target of 5N (above 99.999%), a high-purity Si square target of 5N (above 99.999%), and the sputtering gas is a high-purity argon gas of 5N (above 99.999%). A P-type single crystal Si sheet with a crystal orientation of (100) is used as a substrate, and the resistivity is 5Ω / cm. For ultrasonic cleaning, a commercially available ultrasonic cleaner was used.

[0022] specifically is:

[0023] 1. Processing of silicon (Si) base material:

[0024] A, select the Si substrate material whose crystal orientation is (100), and ultrasonically clean it with acetone and absolute ethanol for 20 minutes respectively to remove surface organic and inorganic impurities;

[0025] B. Put the cleaned Si s...

Embodiment 2

[0031] The equipment and materials used are all the same as in Example 1. specifically is:

[0032] 1. Processing of silicon (Si) base material:

[0033] A, select the Si substrate material whose crystal orientation is (100), and ultrasonically clean it with acetone and absolute ethanol for 20 minutes respectively to remove surface organic and inorganic impurities;

[0034] B. Put the cleaned Si sheet into the following solution and soak for 20s to rinse off the oxide layer: the concentration is 40% HF: H 2 O=1:20.

[0035] 2. Alternate sputtering of Ge / Si multilayer self-organized Ge quantum dots by ion beam:

[0036] A. Place the pre-treated Si substrate material in the sputtering chamber until the background vacuum in the sputtering chamber is greater than 4.0×10 -4 Pa, adjust the temperature of the sputtering chamber to 400°C, fill the sputtering chamber with Ar gas with a purity of 5N until the pressure of the sputtering chamber is 4.0×10 -2 Pa;

[0037]B. Under the...

Embodiment 3

[0040] The equipment and materials used are all the same as in Example 1. specifically is:

[0041] 1. Processing of silicon (Si) base material:

[0042] A, select the Si substrate material whose crystal orientation is (100), and ultrasonically clean it with acetone and absolute ethanol for 20 minutes respectively to remove surface organic and inorganic impurities;

[0043] B. Put the cleaned Si sheet into the following solution and soak for 20s to rinse off the oxide layer: the concentration is 40% HF: H 2 O=1:20.

[0044] 2. Alternate sputtering of Ge / Si multilayer self-organized Ge quantum dots by ion beam:

[0045] A. Place the pre-treated Si substrate material in the sputtering chamber until the background vacuum in the sputtering chamber is greater than 4.0×10 -4 Pa, adjust the temperature of the sputtering chamber to 100°C, fill the sputtering chamber with Ar gas with a purity of 5N until the pressure of the sputtering chamber is 2.0×10 -2 Pa;

[0046] B. Under th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com