Patents

Literature

236 results about "Ion beam sputtering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

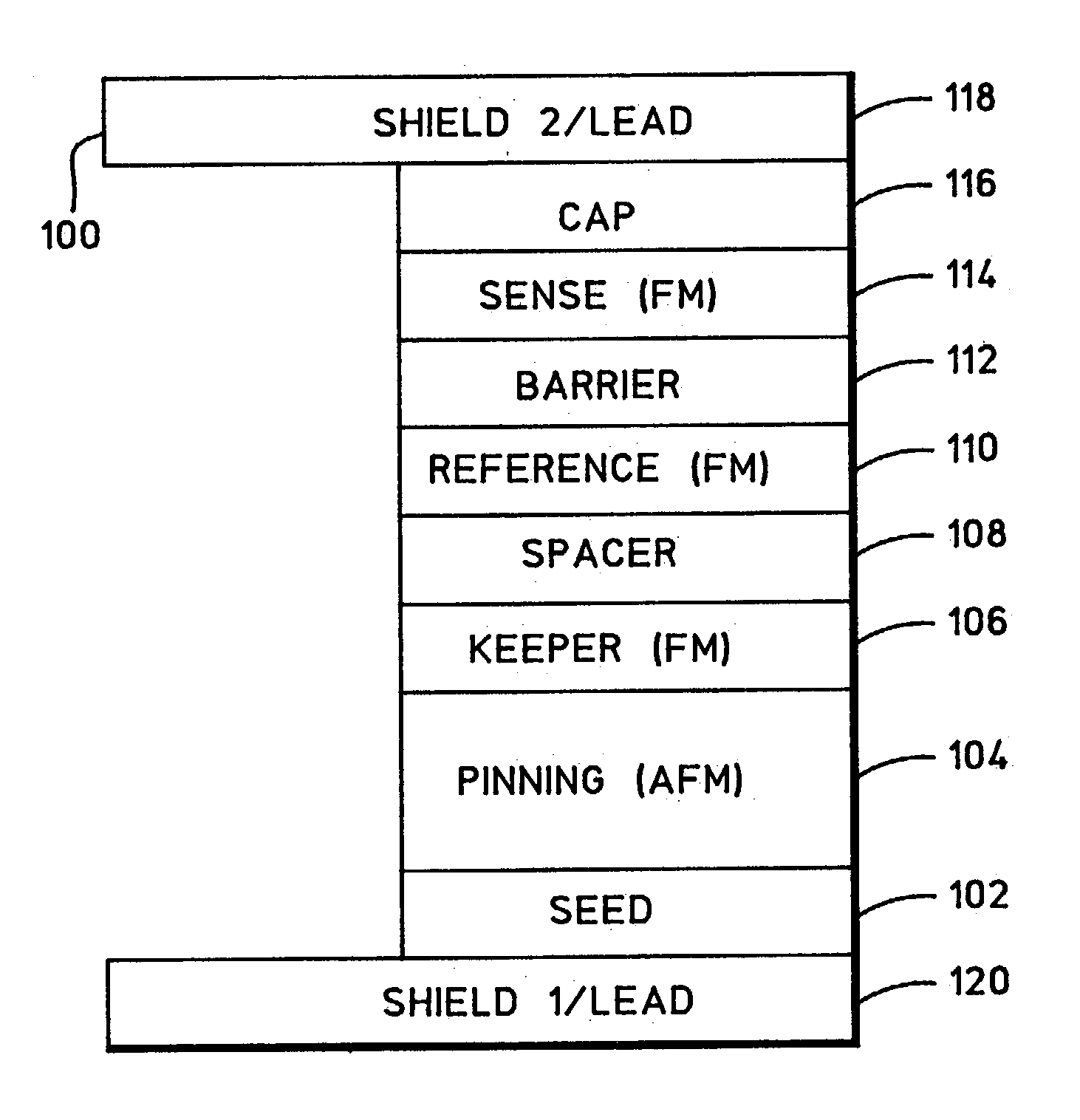

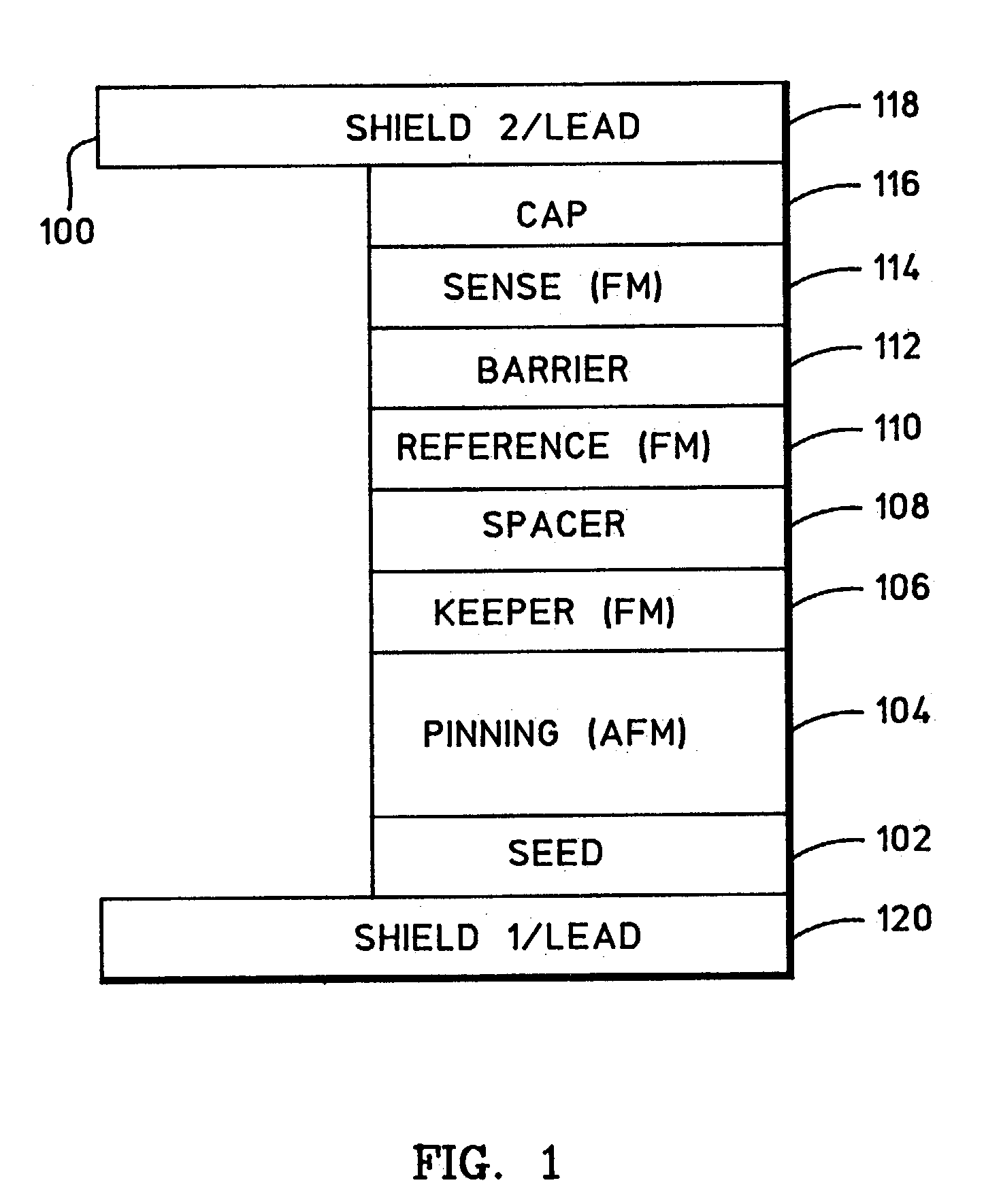

Method of forming a barrier layer of a tunneling magnetoresistive sensor

InactiveUS6841395B2Prevent electrostatic dischargeMagnetic and TMR propertyNanostructure applicationNanomagnetismIon beamXenon

Owner:GLOBALFOUNDRIES INC

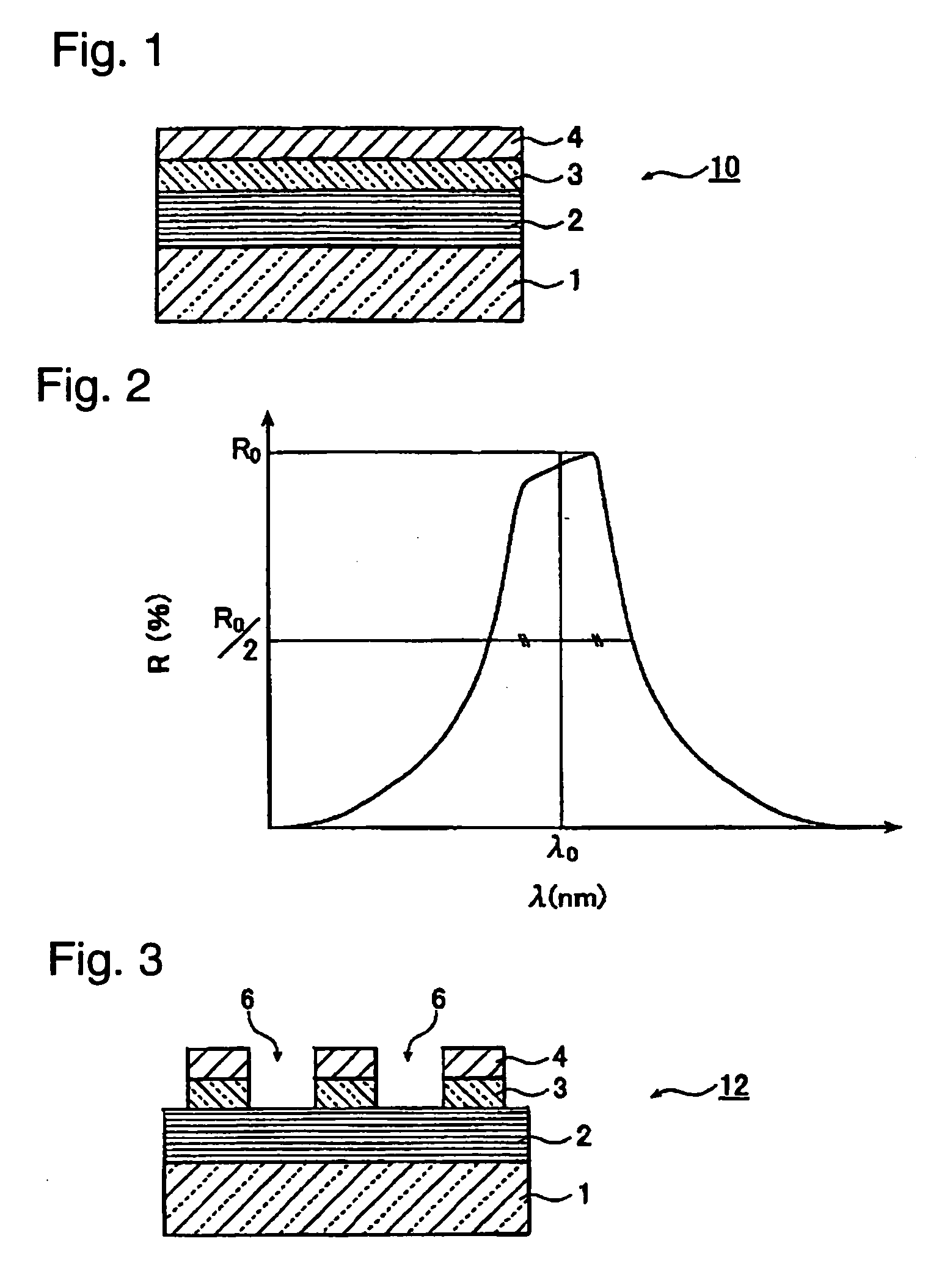

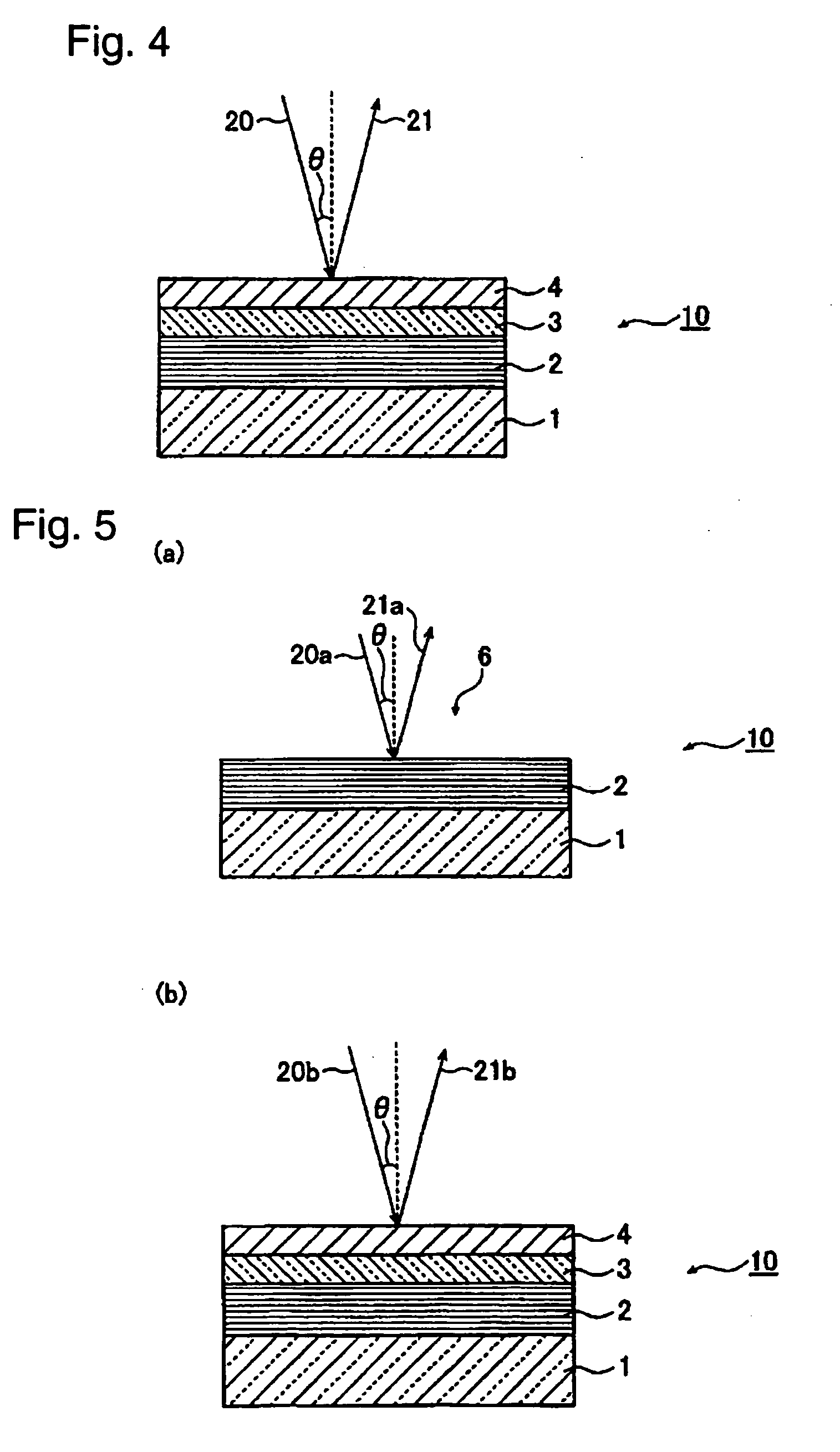

Reflective-type mask blank for EUV lithography and method for producing the same

InactiveUS20060251973A1Increase contrastImprove accuracyRadiation/particle handlingNanoinformaticsLithographic artistReflective layer

A reflective-type mask blank for EUV lithography for reducing the EUV ray reflectance at the absorbing layer and a method for producing the mask blank are presented. A reflective-type mask blank for EUV lithography comprising a substrate and a reflective layer for reflecting EUV light and an absorbing layer for absorbing EUV light, which are formed on the substrate in this order, the reflective-type mask blank for EUV lithography being characterized in that the absorbing layer is a Cr layer of low EUV ray reflectance deposited by an ion beam sputtering method.

Owner:ASAHI GLASS CO LTD

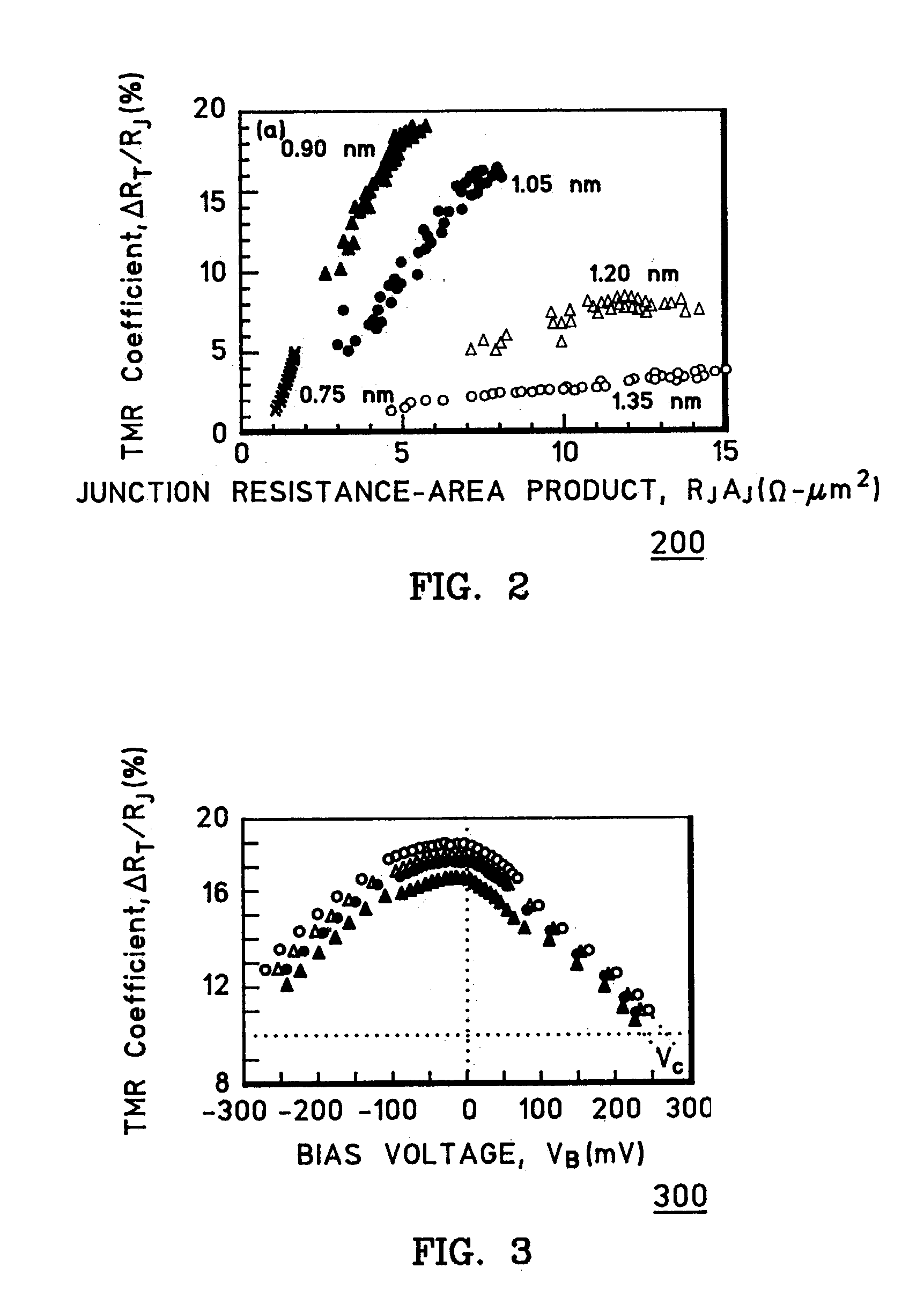

Method of forming a barrier layer of a tunneling magnetoresistive sensor

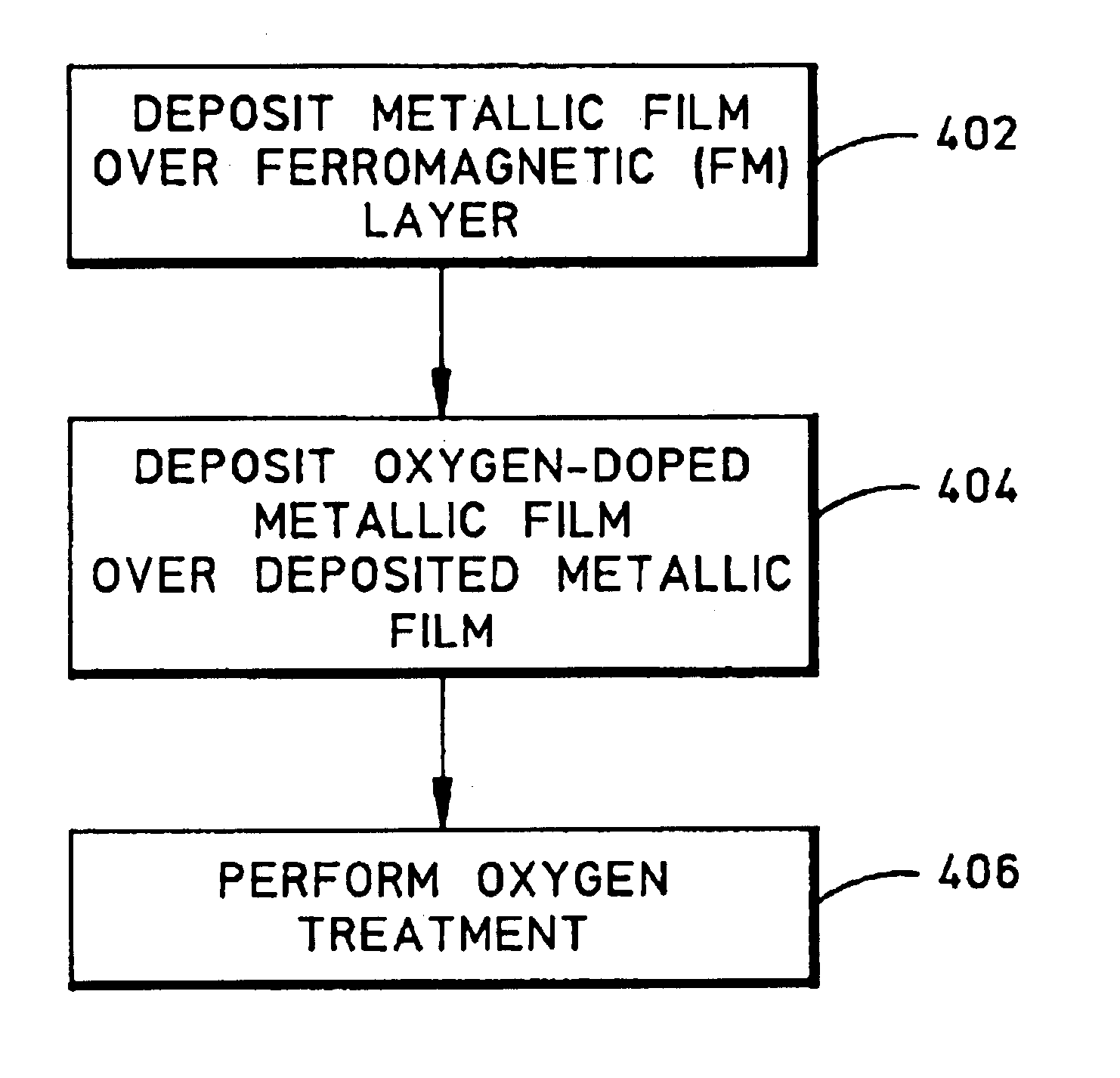

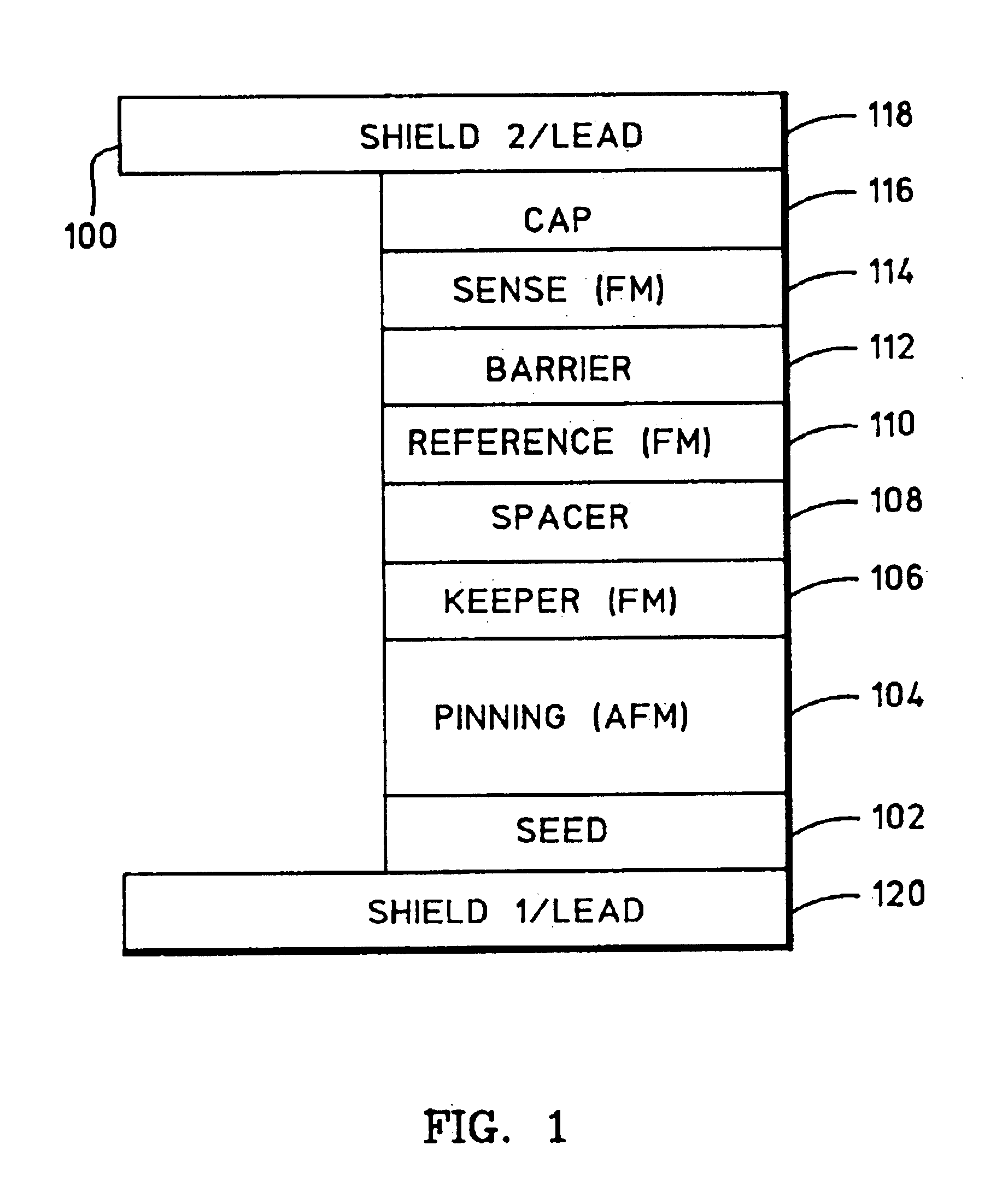

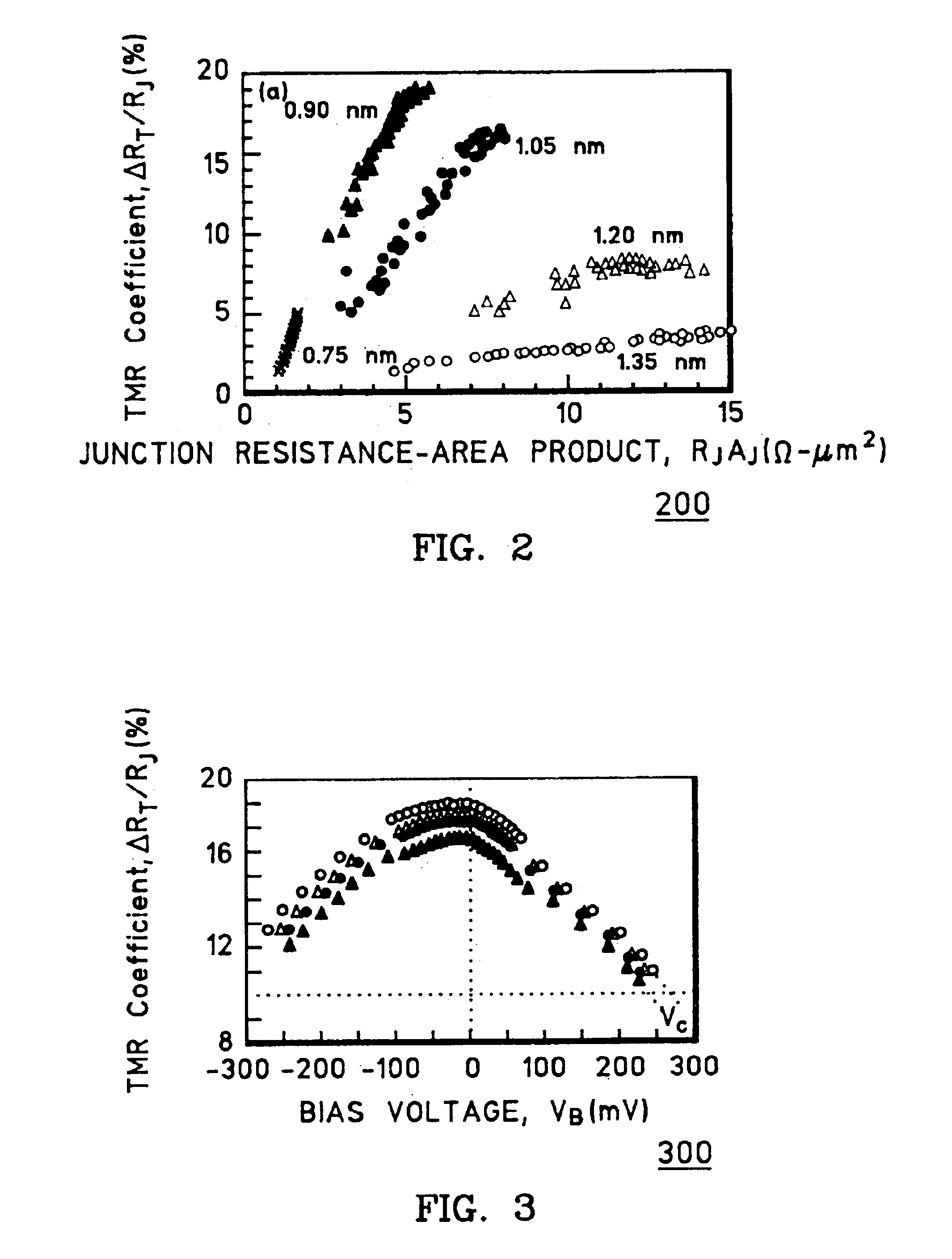

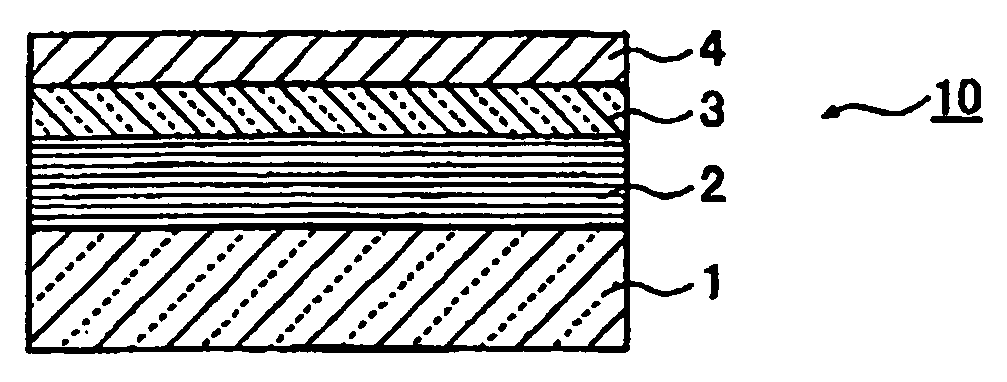

A fabrication process for a tunneling magnetoresistance (TMR) sensor is disclosed. In particular, a unique method of forming a barrier layer of the TMR sensor is utilized so that the TMR sensor exhibits good magnetic and TMR properties. In one particular example, the barrier layer is formed by depositing a metallic film in an argon gas in a DC magnetron sputtering module, depositing an oxygen-doped metallic film in mixed xenon and oxygen gases in an ion-beam sputtering module, and oxidizing these films in an oxygen gas in an oxygen treatment module. This three-step barrier layer formation process minimizes oxygen penetration into ferromagnetic (FM) sense and pinned layers of the TMR sensor and optimally controls oxygen doping into the barrier layer. As a result, the FM sense and pinned layers exhibit controlled magnetic properties, the barrier layer provides a low junction resistance-area product, and the TMR sensor exhibits a high TMR coefficient.

Owner:GLOBALFOUNDRIES INC

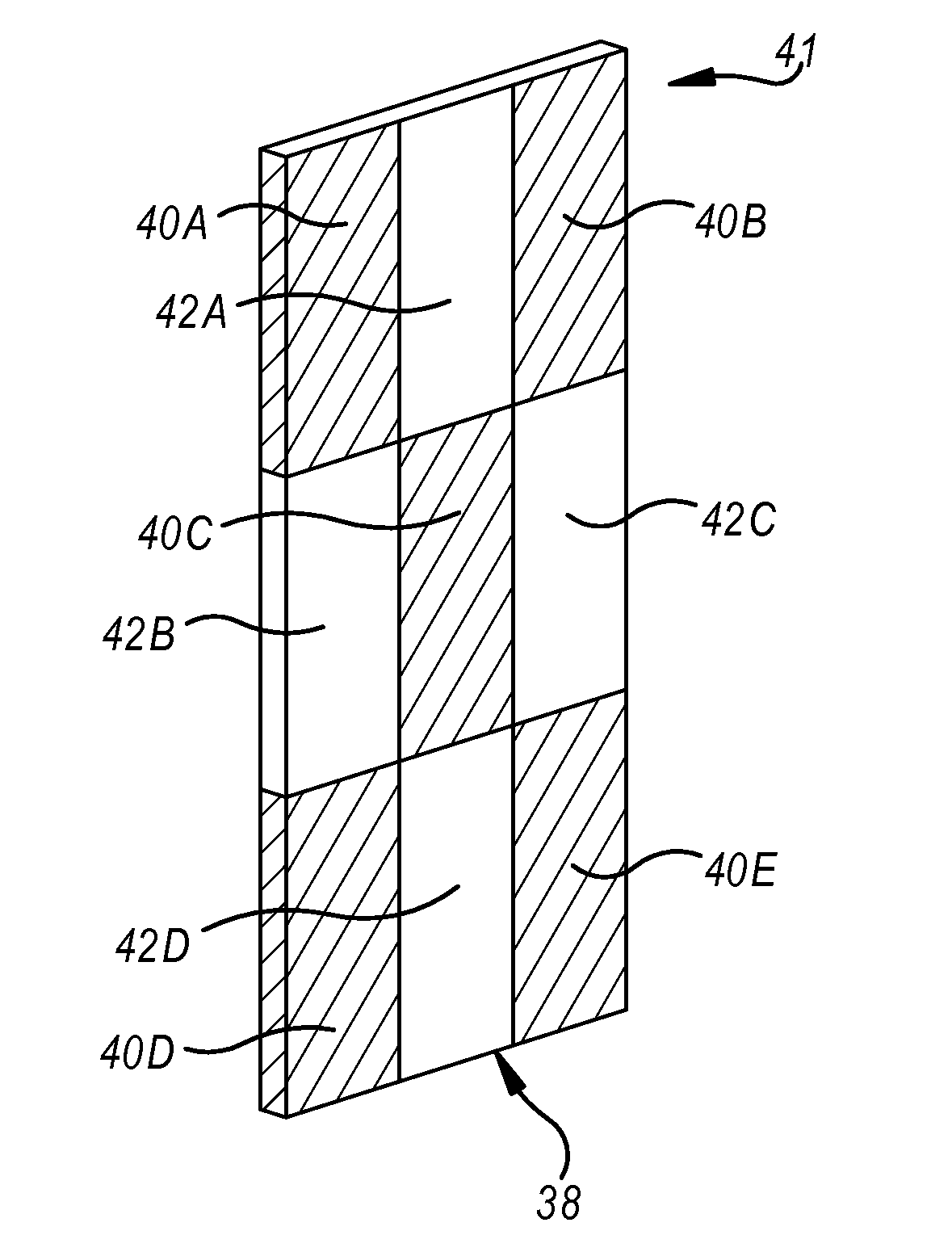

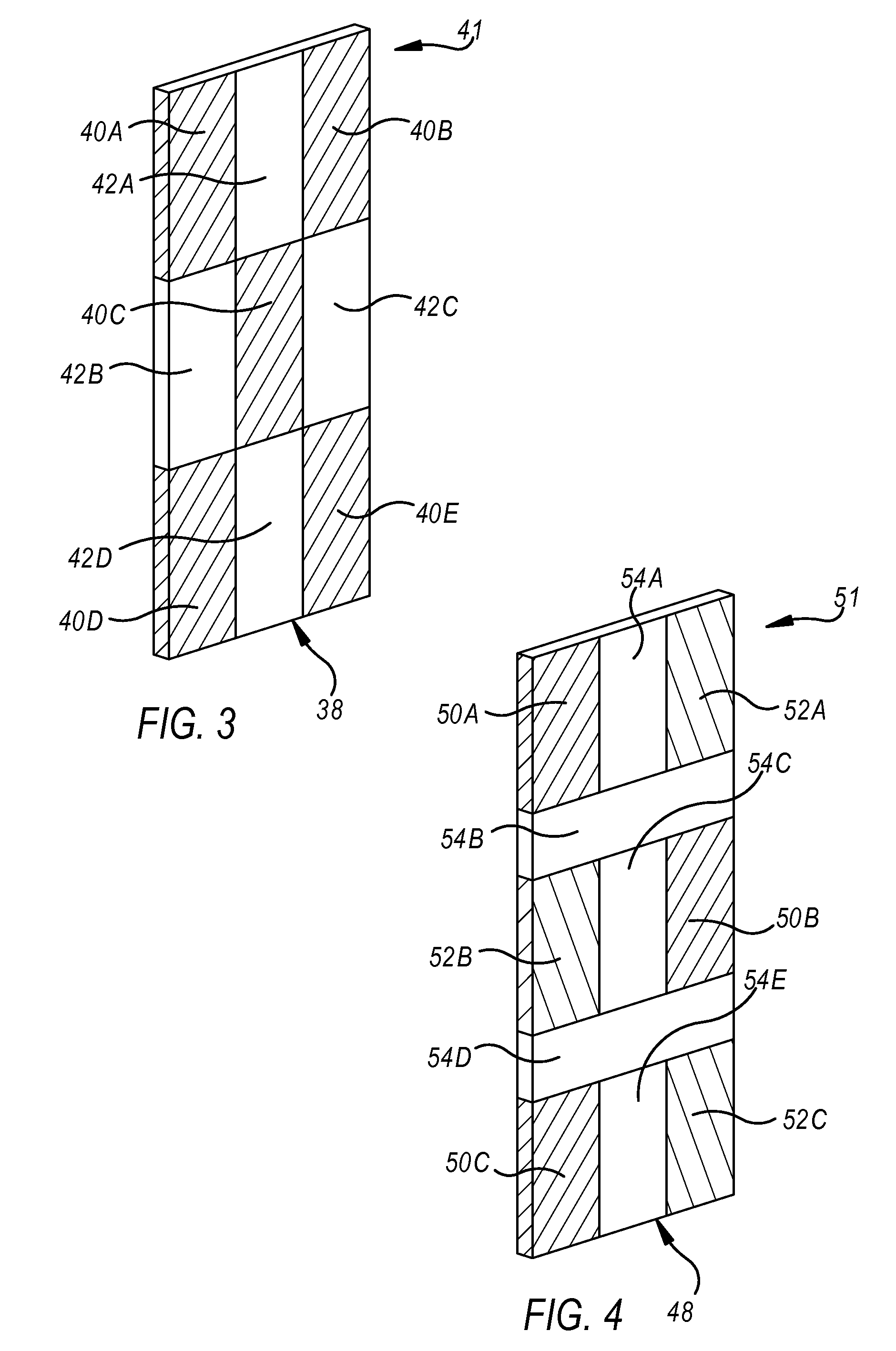

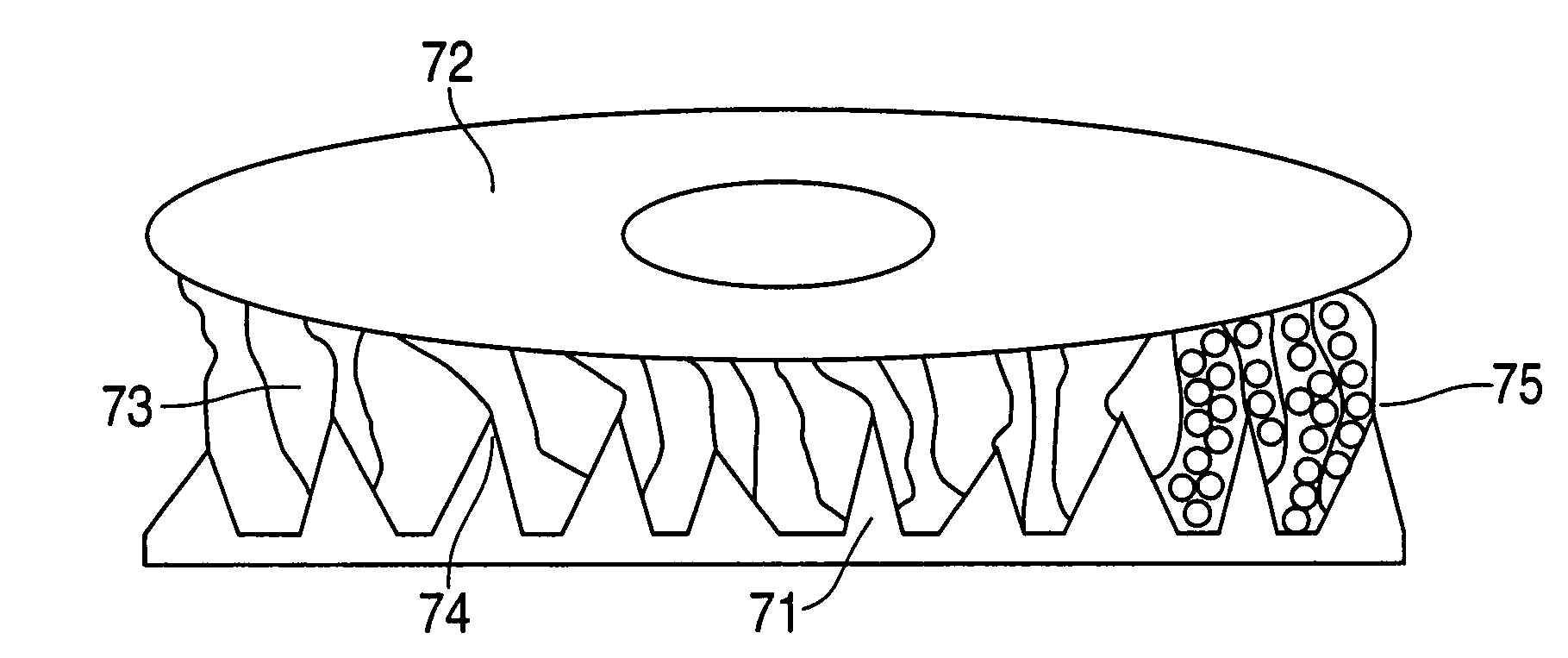

Ion beam sputter target and method of manufacture

A target for use in an ion beam sputtering apparatus made of at least two target tiles where at least two of the target tiles are made of different chemical compositions and are mounted on a main tile and geometrically arranged on the main tile to yield a desired chemical composition on a sputtered substrate. In an alternate embodiment, the tiles are of varied thickness according to the desired chemical properties of the sputtered film. In yet another alternate embodiment, the target is comprised of plugs pressed in a green state which are disposed in cavities formed in a main tile also formed in a green state and the assembly can then be compacted and then sintered.

Owner:UT BATTELLE LLC +2

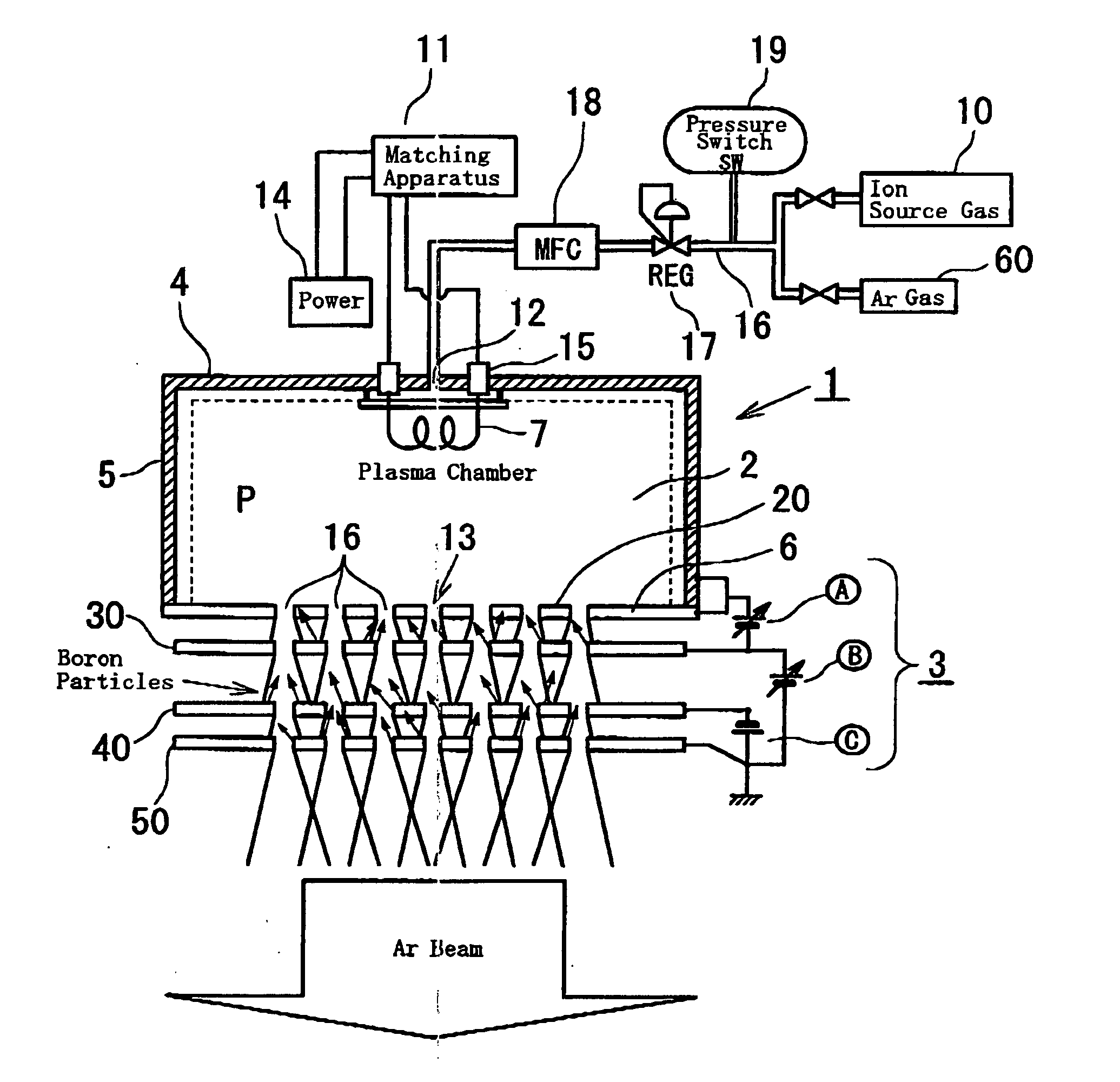

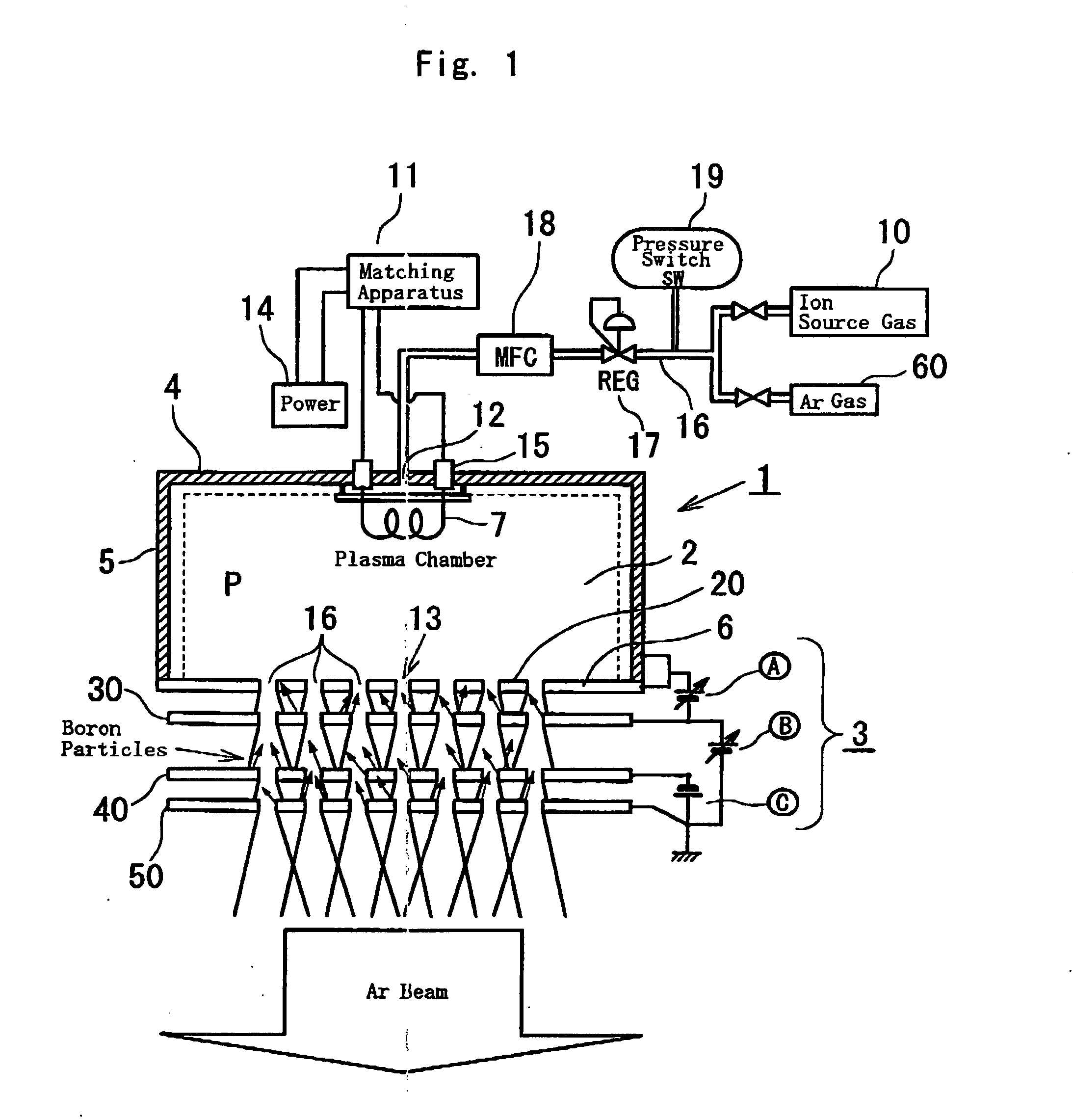

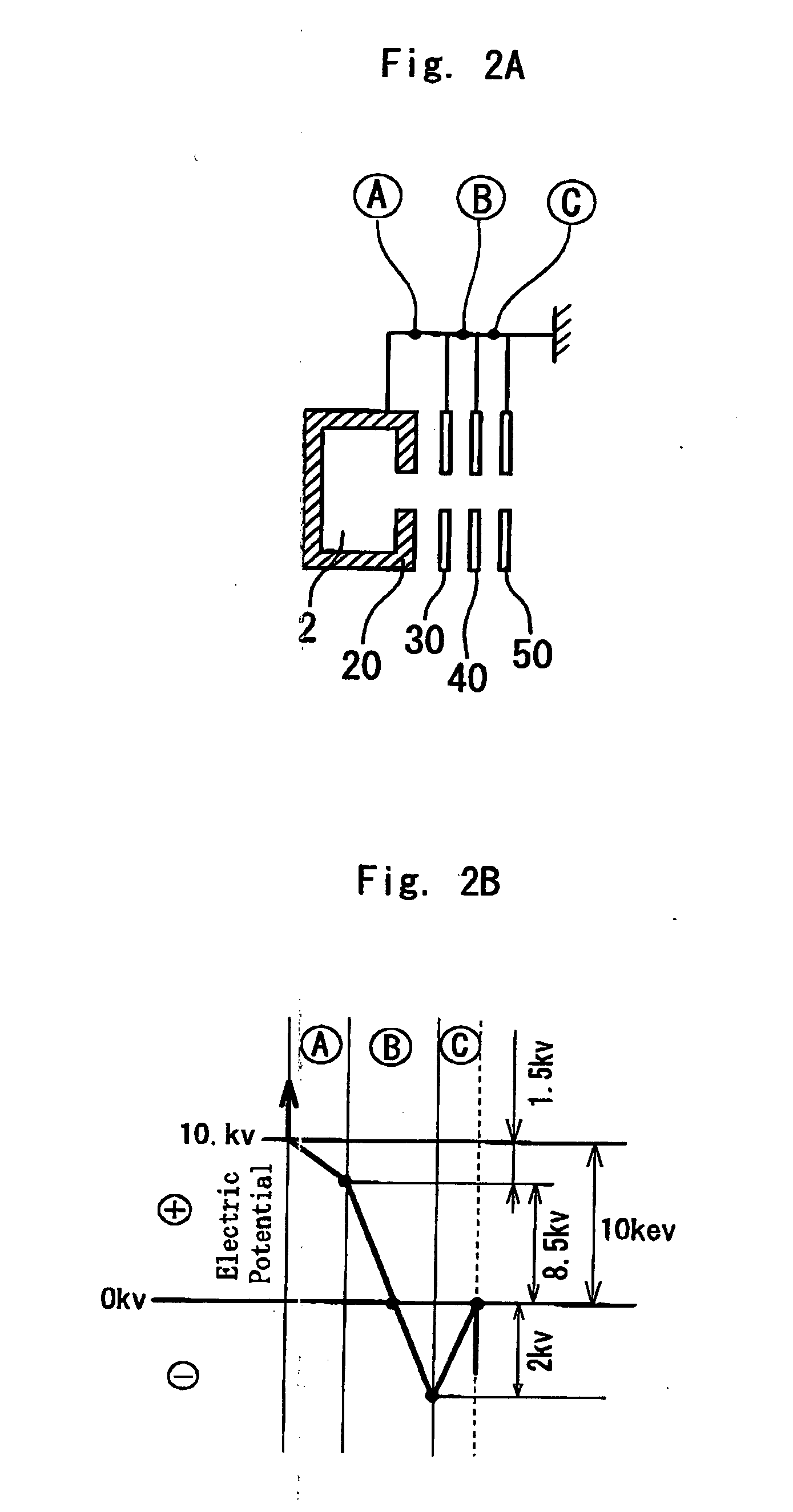

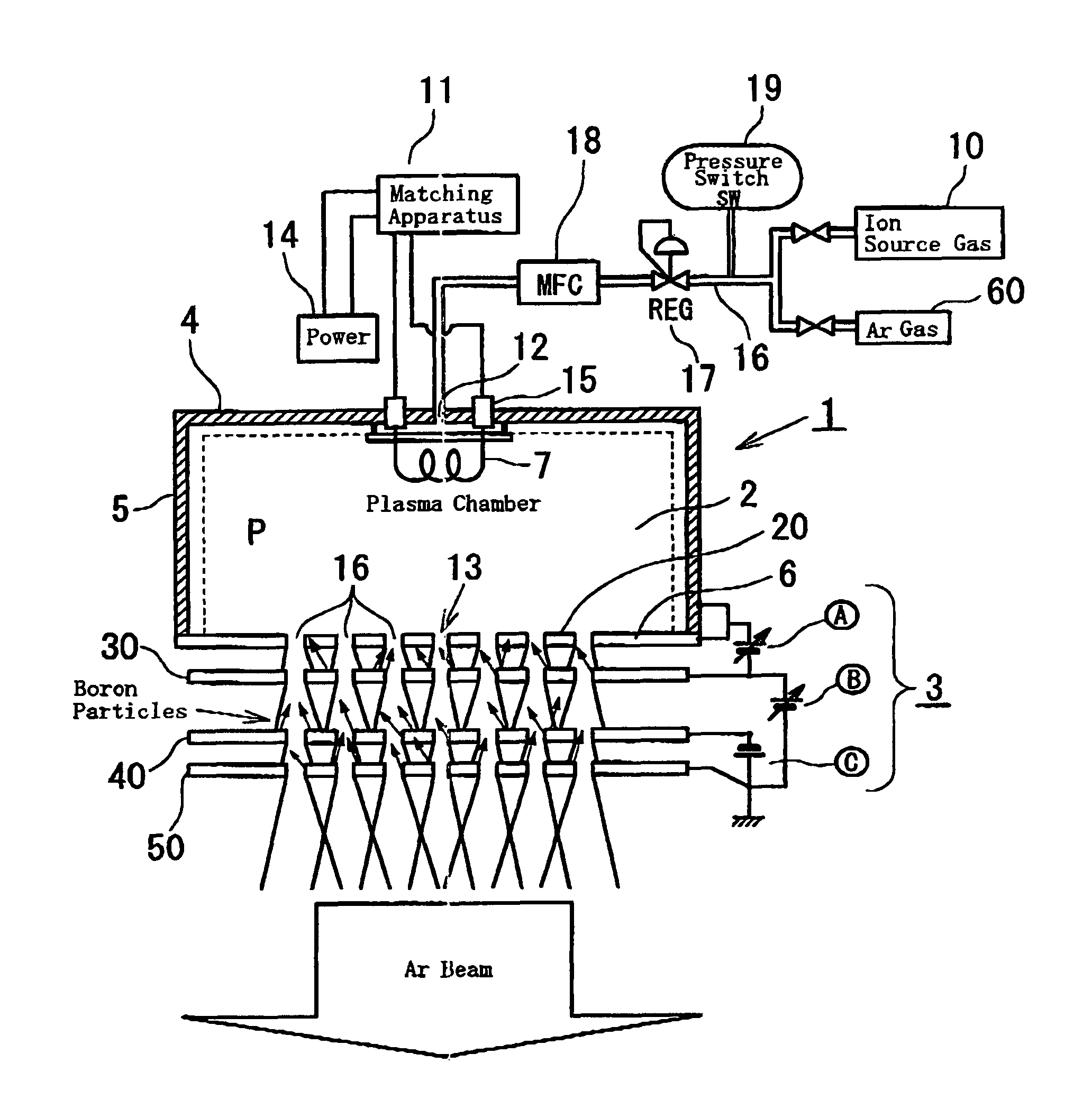

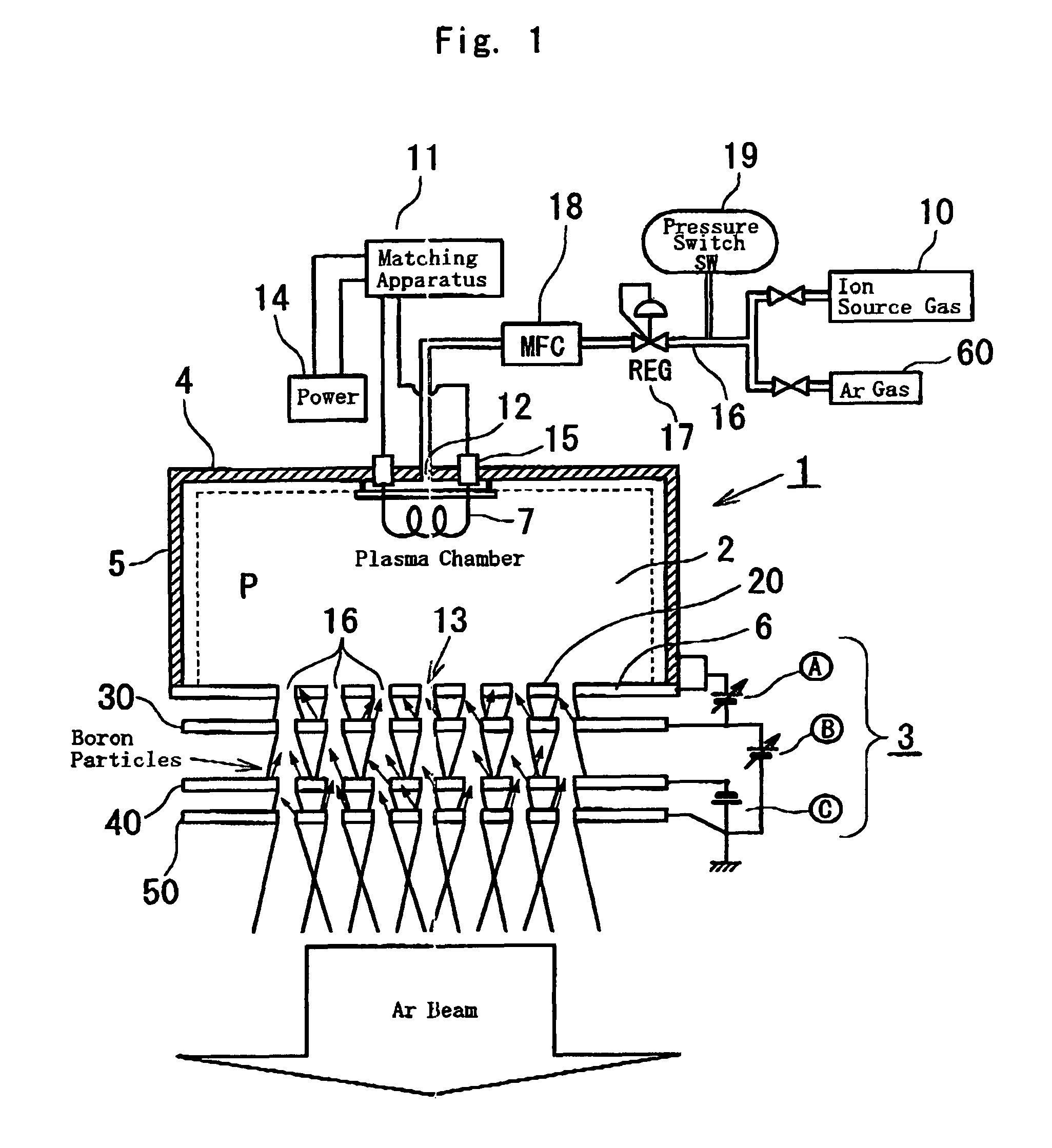

Ion source apparatus and cleaning optimized method thereof

InactiveUS20050016838A1Optimized diameterIncreased durabilityCellsVacuum evaporation coatingNoble gasInsulation layer

An ion source apparatus includes a rare gas supply source supplying rare gas instead of ion source gas to a plasma chamber, means to determine time and timing for cleaning electrodes in consideration of a collecting amount of insulation layers accreting to the electrodes of an extraction electrode system. Based on the above, the ion source apparatus removes the insulation layers by sputtering with ion beam of the rare gas while adjusting extraction or accelerate voltage and supply amount of the rare gas as a setting parameter. Moreover, by adjusting the setting parameter which changes a diameter of ion beam based on the rare gas when the ion beam collides onto each electrode surface of the extraction electrode system, the beam diameter is focused within an effective range in which intension of the sputtering of the insulation layers is maximized thus evenly removing the insulation layers.

Owner:SEN CORP AN SHI & AXCELIS

Method for producing a magnetic tunnel junction and magnetic tunnel junction thus obtained

According to this method for producing a magnetic tunnel junction, a film of a dielectric material capable of acting as a tunnel barrier is deposited between two nanocrystalline or amorphous magnetic films. The dielectric material constituting the tunnel barrier consists of an at least partially crystalline perovskite, and said material is deposited by ion beam sputtering in a vacuum chamber.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

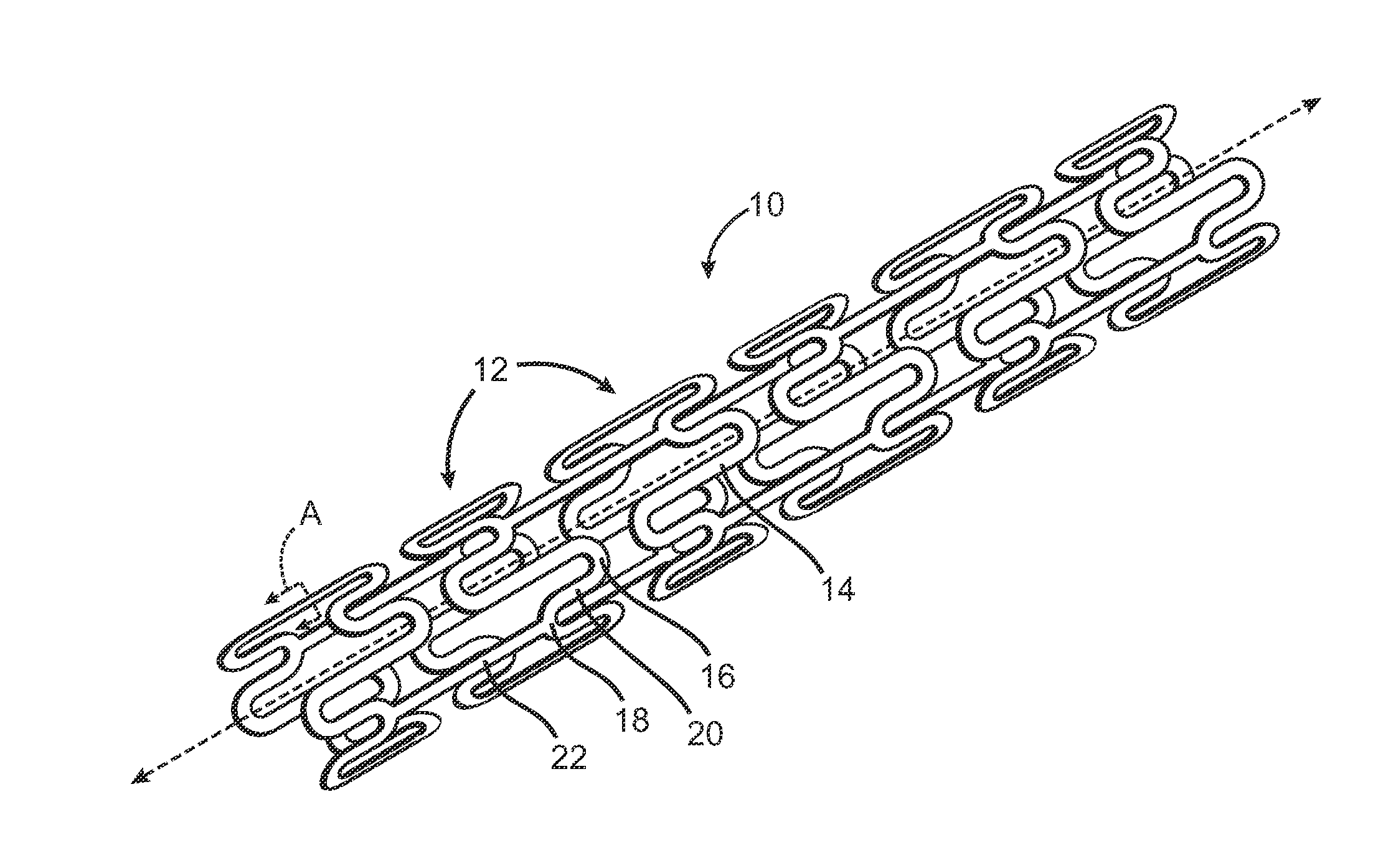

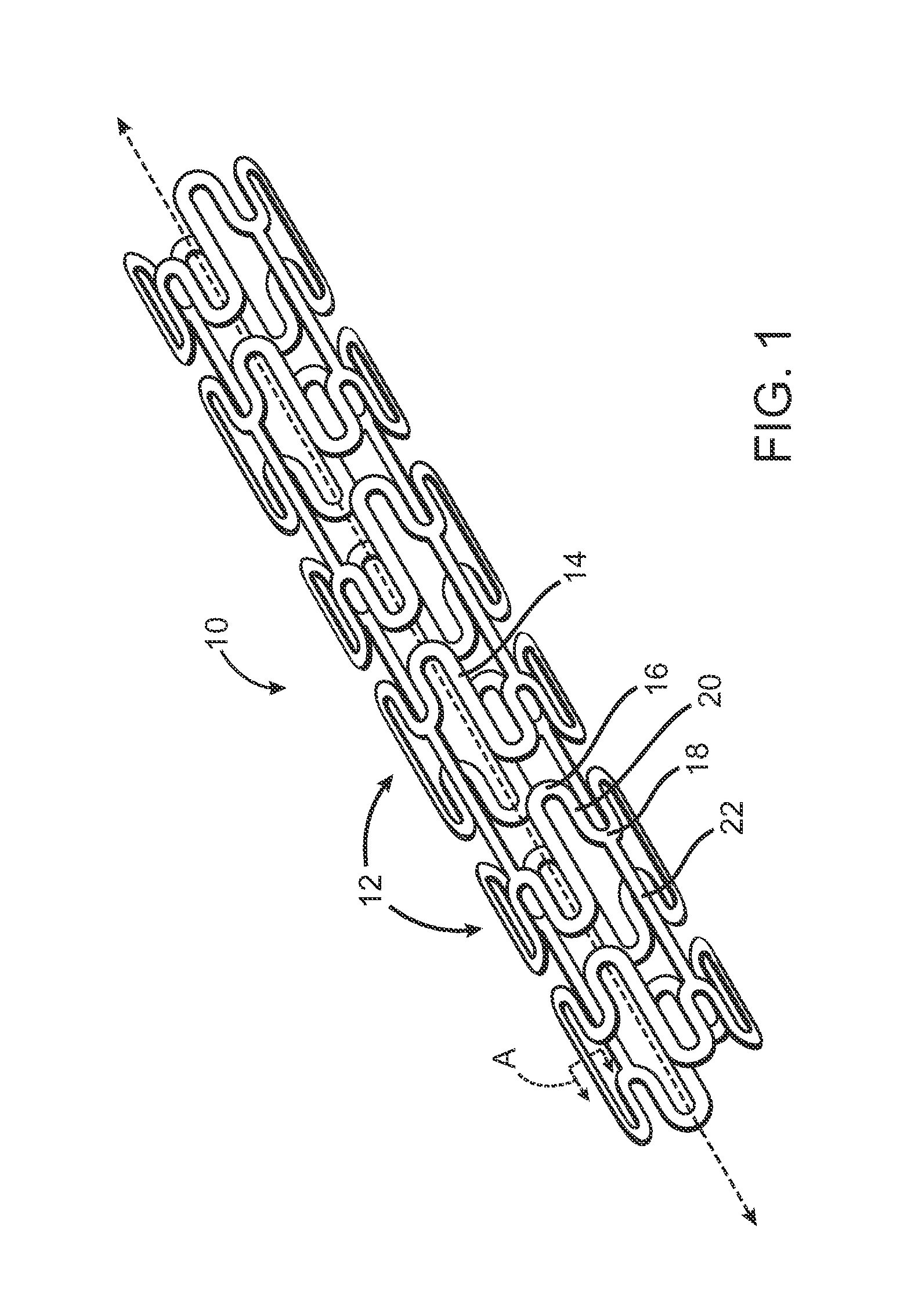

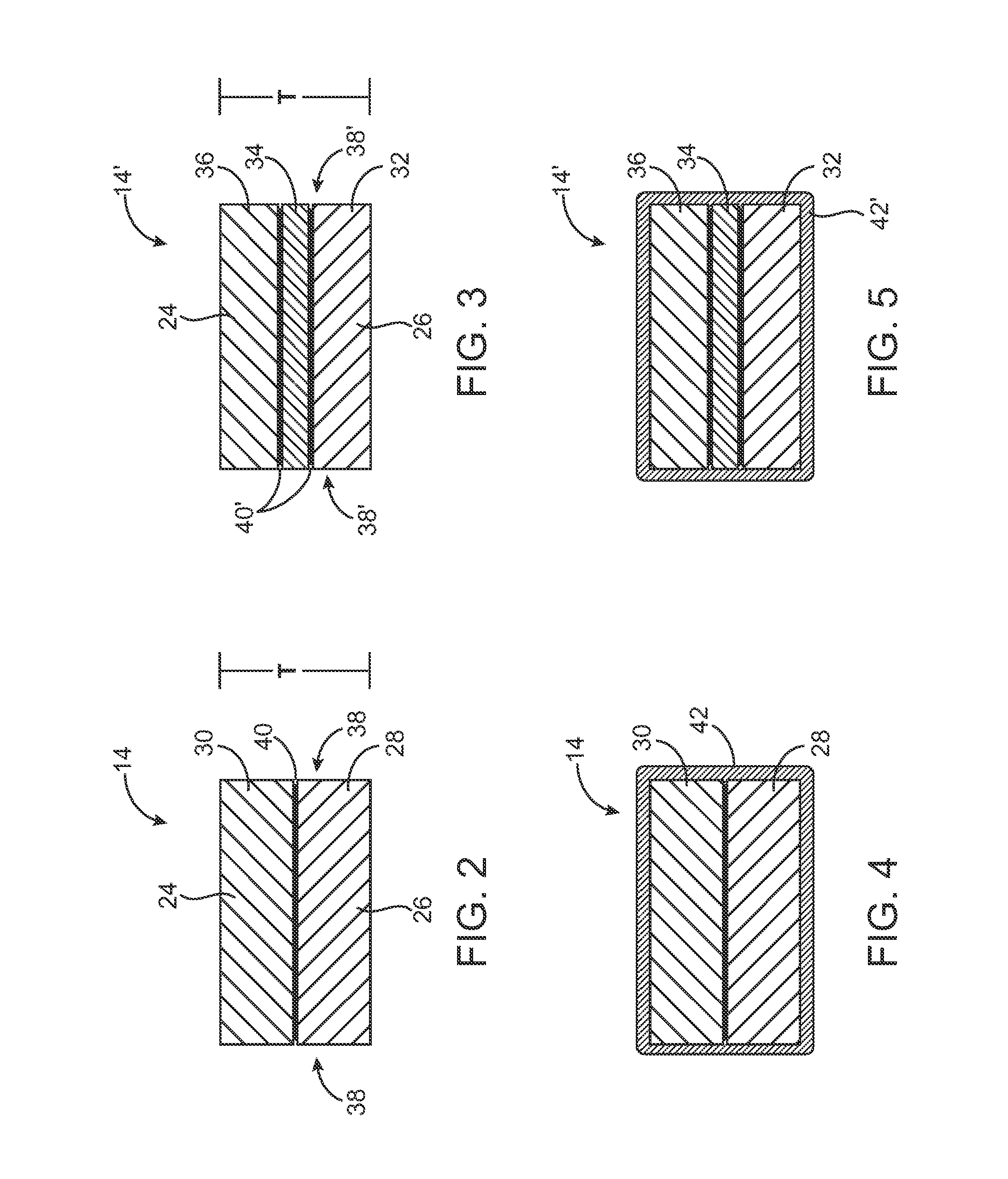

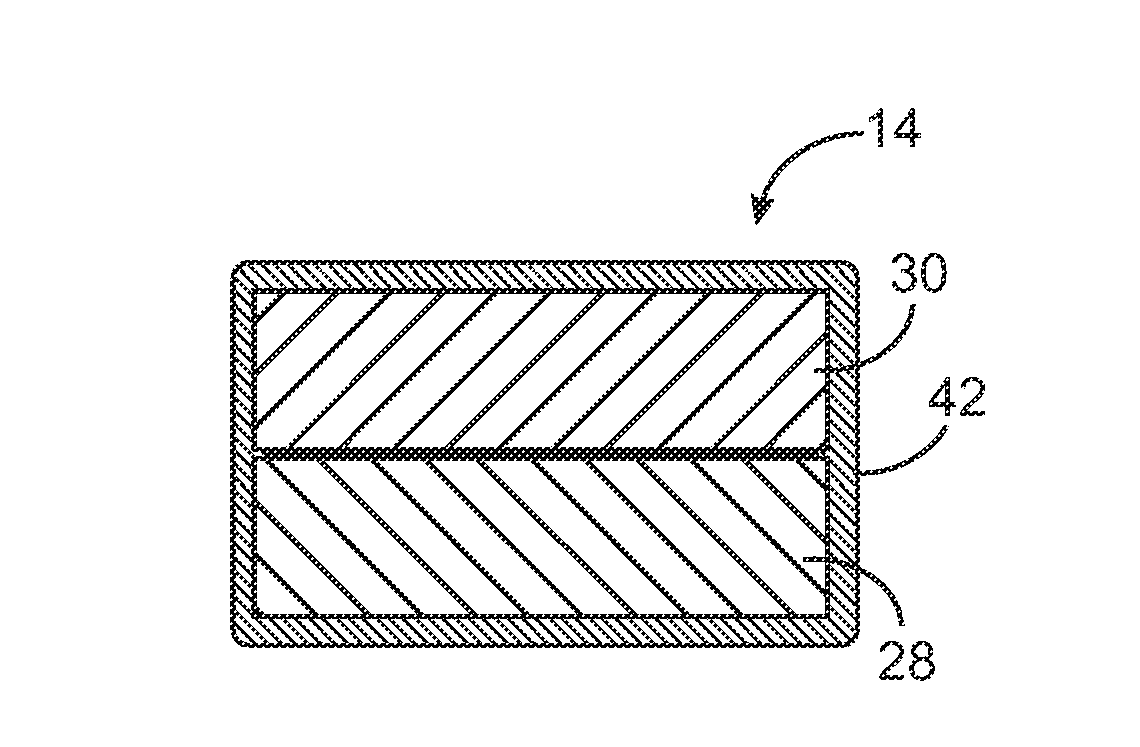

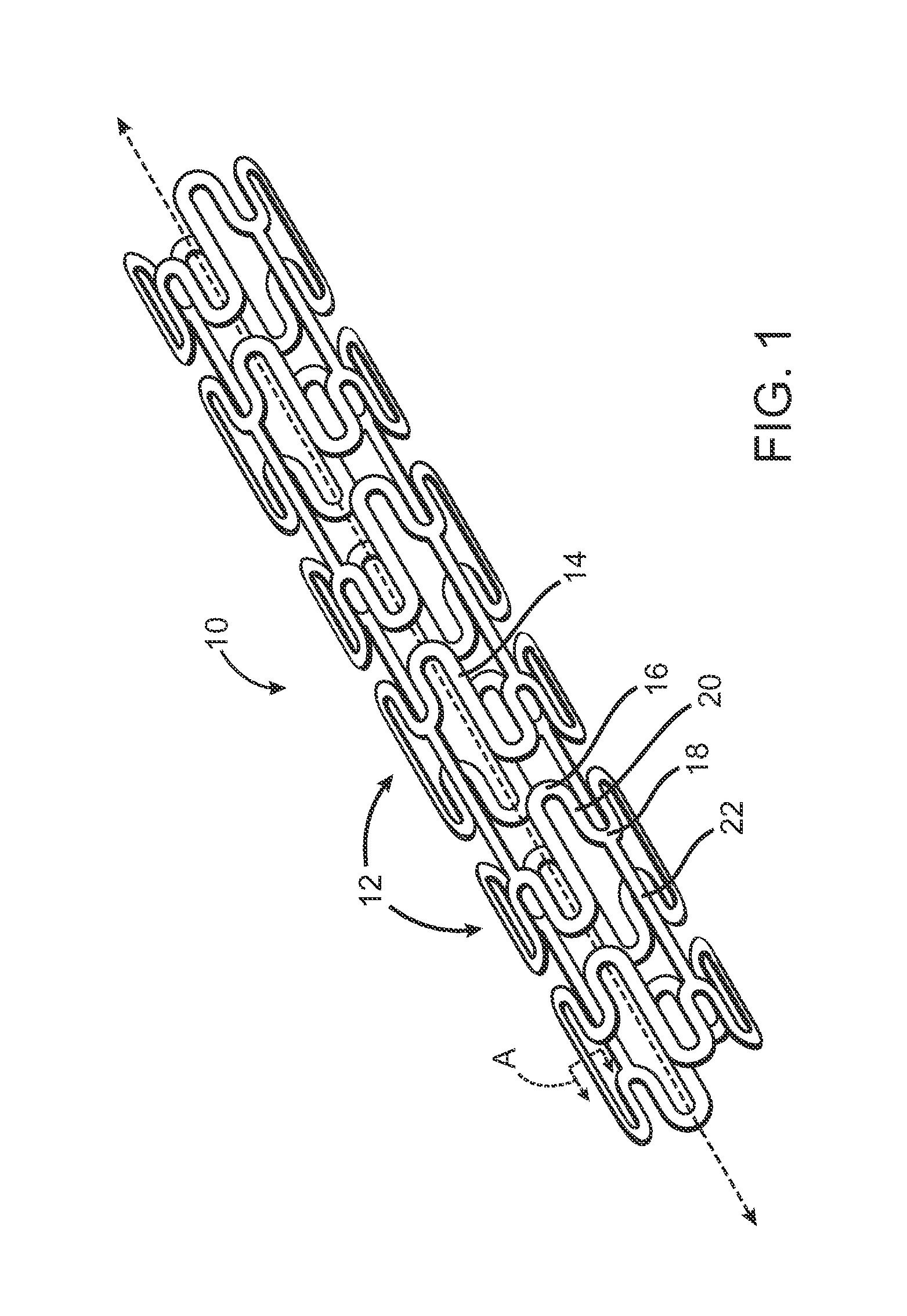

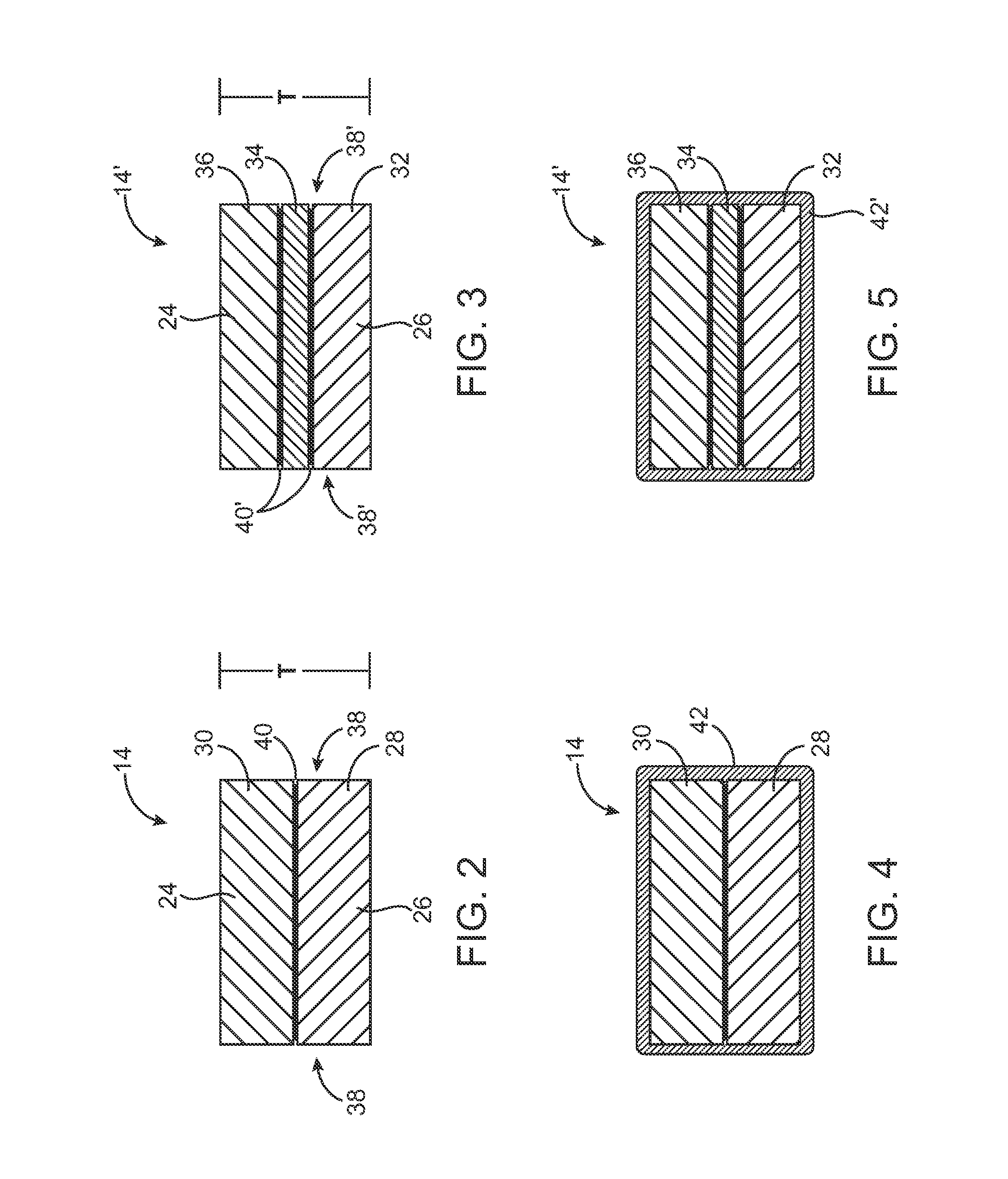

Laminated Implantable Medical Device Having a Metallic Coating

A laminated stent encapsulated with a metal coating is provided. The metal coating may be a very thin metal coating. Portions of the metal coating may be removed such that the metal coating covers voids in the laminate, particularly in the area where the different layers of the laminated stent come together. The metal coating for the laminated stent may be provided by sputtering, such as vacuum deposition or ion beam sputtering, spraying, dipping, or other known methods.

Owner:MEDTRONIC VASCULAR INC

Laminated implantable medical device having a metallic coating

A laminated stent encapsulated with a metal coating is provided. The metal coating may be a very thin metal coating. Portions of the metal coating may be removed such that the metal coating covers voids in the laminate, particularly in the area where the different layers of the laminated stent come together. The metal coating for the laminated stent may be provided by sputtering, such as vacuum deposition or ion beam sputtering, spraying, dipping, or other known methods.

Owner:MEDTRONIC VASCULAR INC

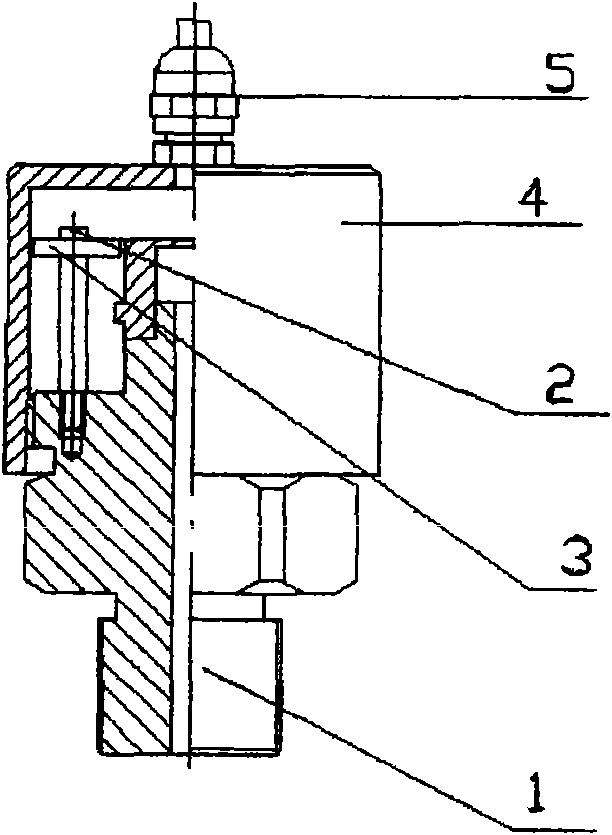

Integrated temperature thin film pressure sensor

InactiveCN101566514AHigh measurement accuracyRealize integrated measurementFluid pressure measurement using ohmic-resistance variationThermometers using electric/magnetic elementsElastomerTemperature sensitive

The invention relates to an integrated temperature thin film pressure sensor, which consists of a suction pressure connecting pipe with threads and a seal ring, a sensitive component, an external circuit board, a shell and a socket connector. A sensitive elastomer is provided with a transition layer, an insulating layer, resistive layers (including a strain resistive layer and a temperature sensitive resistive layer), a welding layer and a passivation protective layer, wherein the resistive layers are connected with the external circuit board through conducting wires. The insulating layer of the sensor is formed by superimposing SiO2 and Ta2O5 or superimposing the SiO2 and Al2O3, the strain resistive layer is formed by photoetching a NiCr alloy layer, the temperature sensitive layer is formed by photoetching Ni metal, and the temperature sensitive layer not only can solve the problem of actual temperature measurement, but also can compensate the temperature sensitivity more precisely so that the pressure measurement is more accurate. The integrated temperature thin film pressure sensor adopts an ion beam sputtering process, thus the long-term stability of the sensor is good, the temperature zero drift is minimum and the comprehensive precision is high.

Owner:SHAANXI ELECTRICAL APPLIANCE RES INST

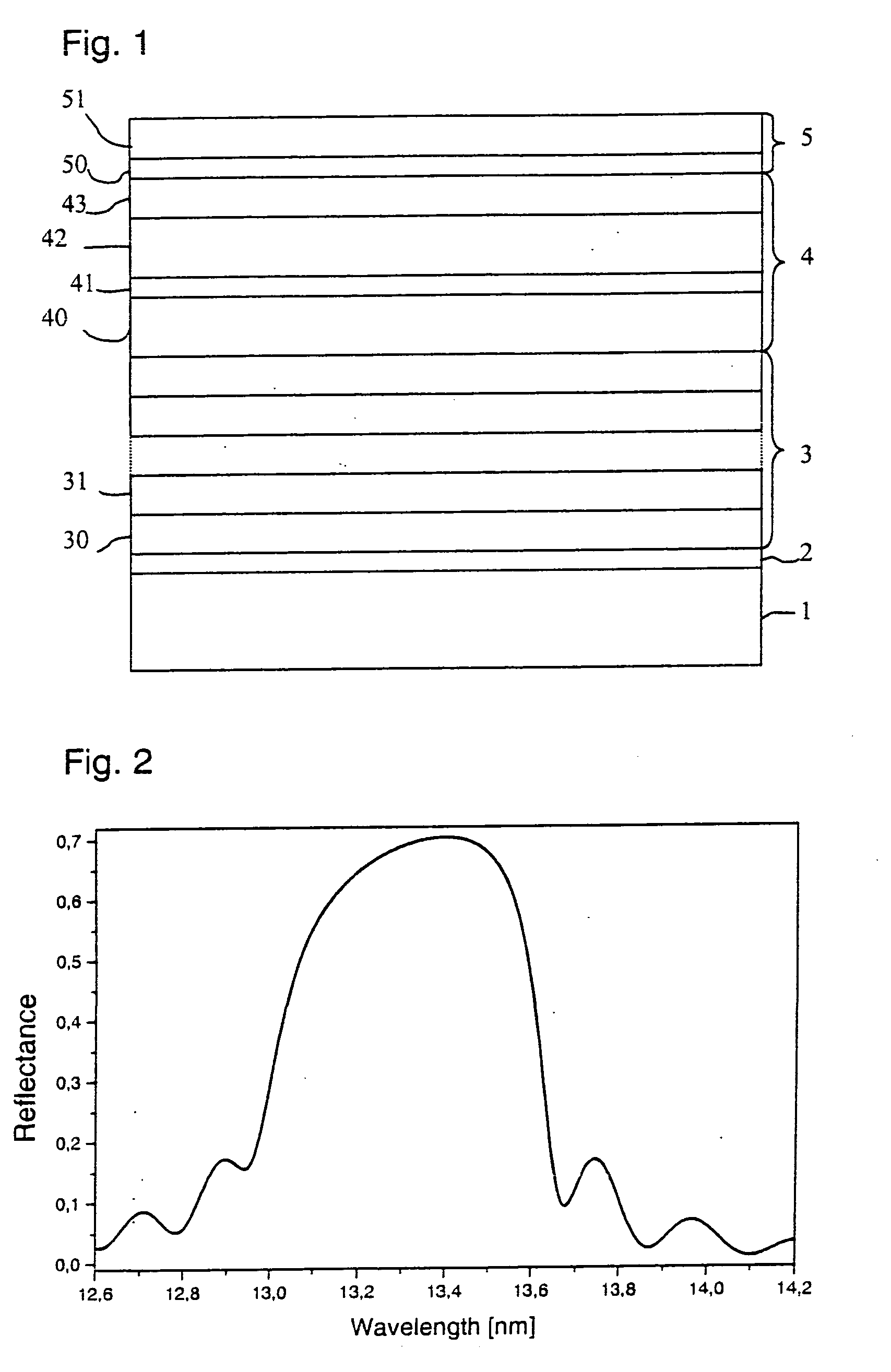

Protective coating system for reflective optical elements, reflective optical element and method for the production thereof

A limiting factor in the operation of EUV lithographic devices is the lifetime or the reflectivity of the reflective optics that is reduced by contamination with carbon-containing substances. Protective coatings that are resistant to oxidation or are inert against water are already known. According to the invention it is proposed to deposit protective coatings on, for example, multilayers that suppress the growth of carbon-containing substances in combination with layers that are inert against residual gas atmosphere and energy input. Even with a long operating time a high reflectivity is thereby retained. The protective coatings may be deposited by electron-beam vaporization, magnetron- or ion-beam sputtering.

Owner:CARL ZEISS SMT GMBH

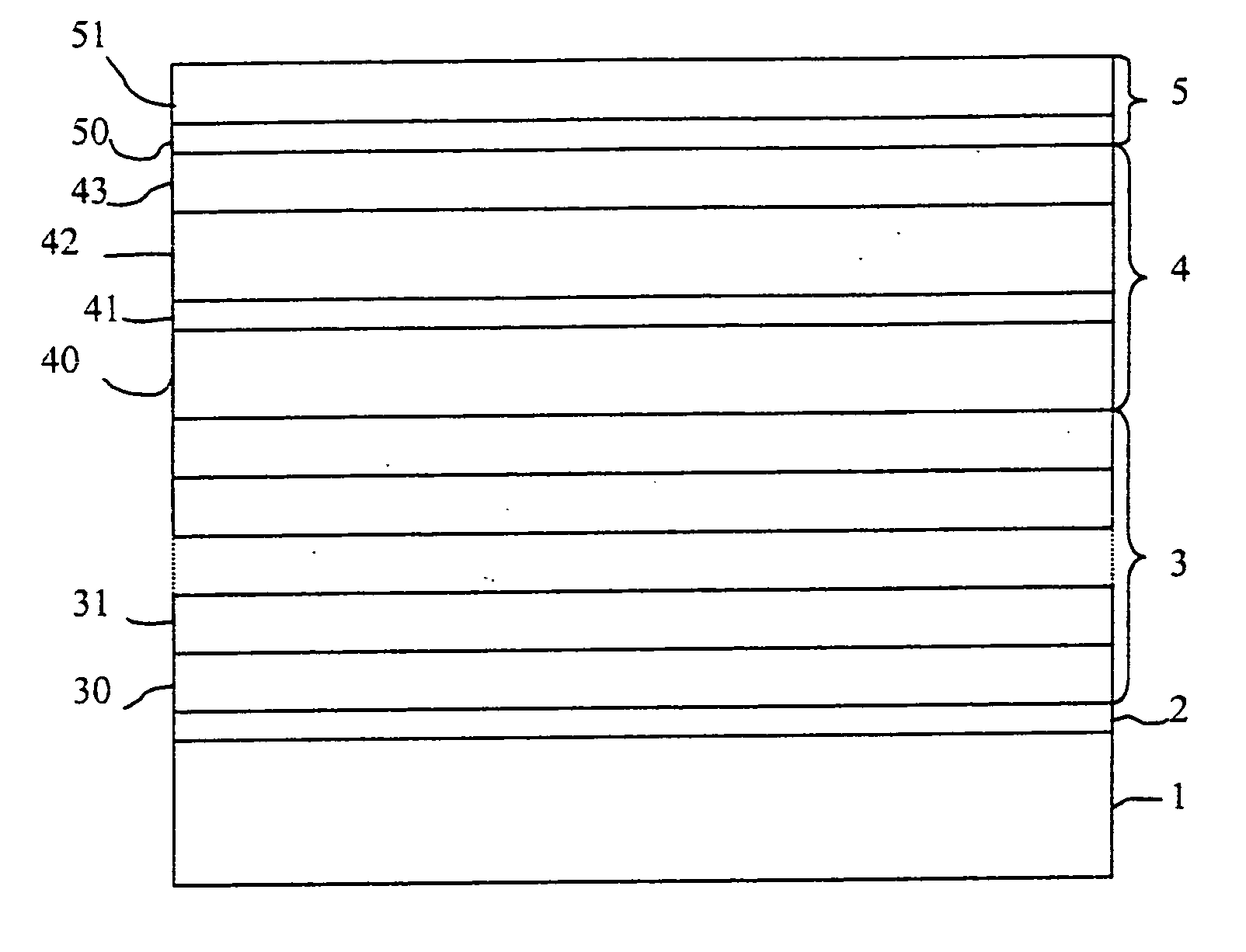

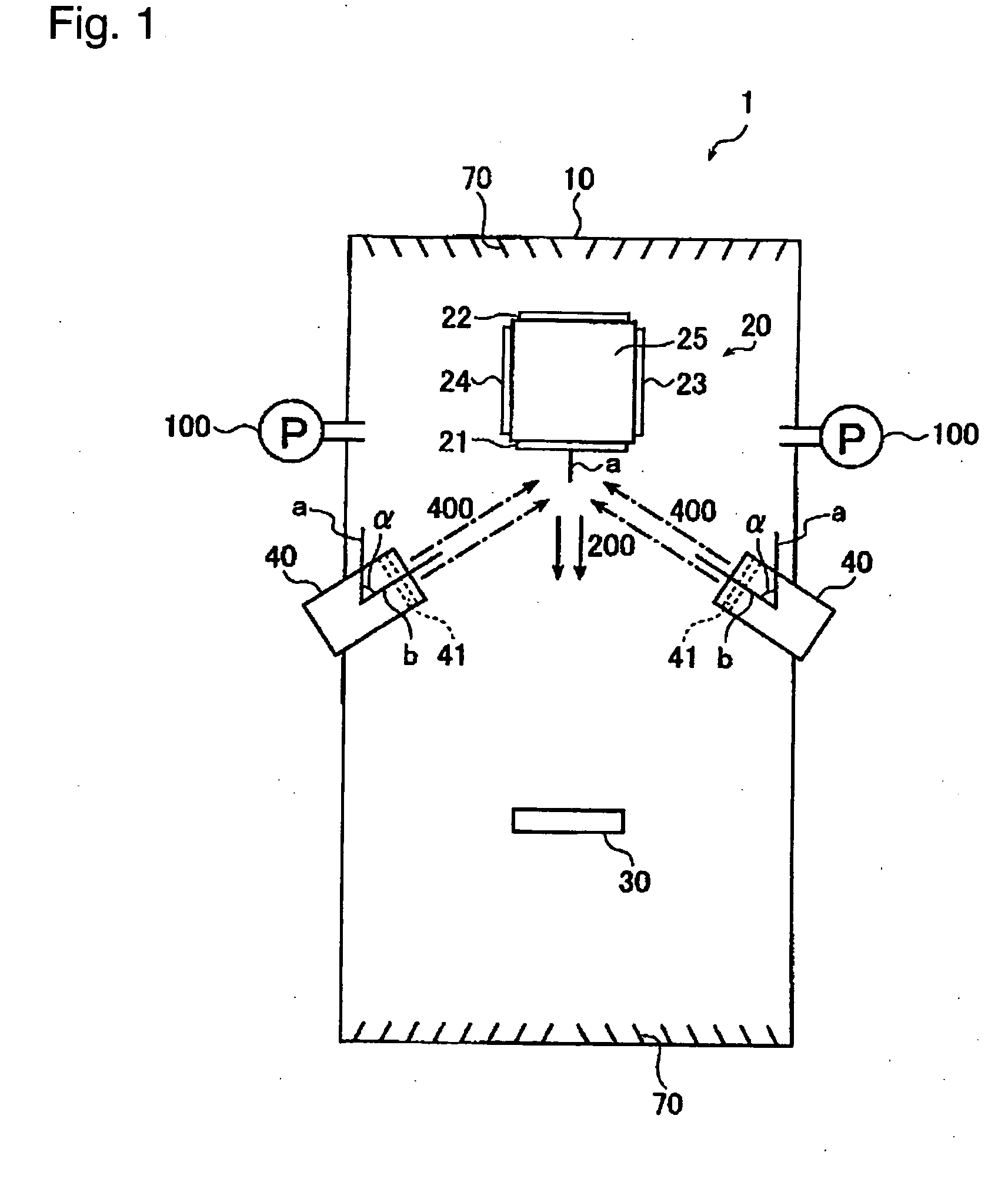

Method for depositing multi-layer film of mask blank for EUV lithography and method for producing mask blank for EUV lithography

ActiveUS20070077499A1Easy to useEfficient manufacturingNanoinformaticsVacuum evaporation coatingIon beamReflectivity

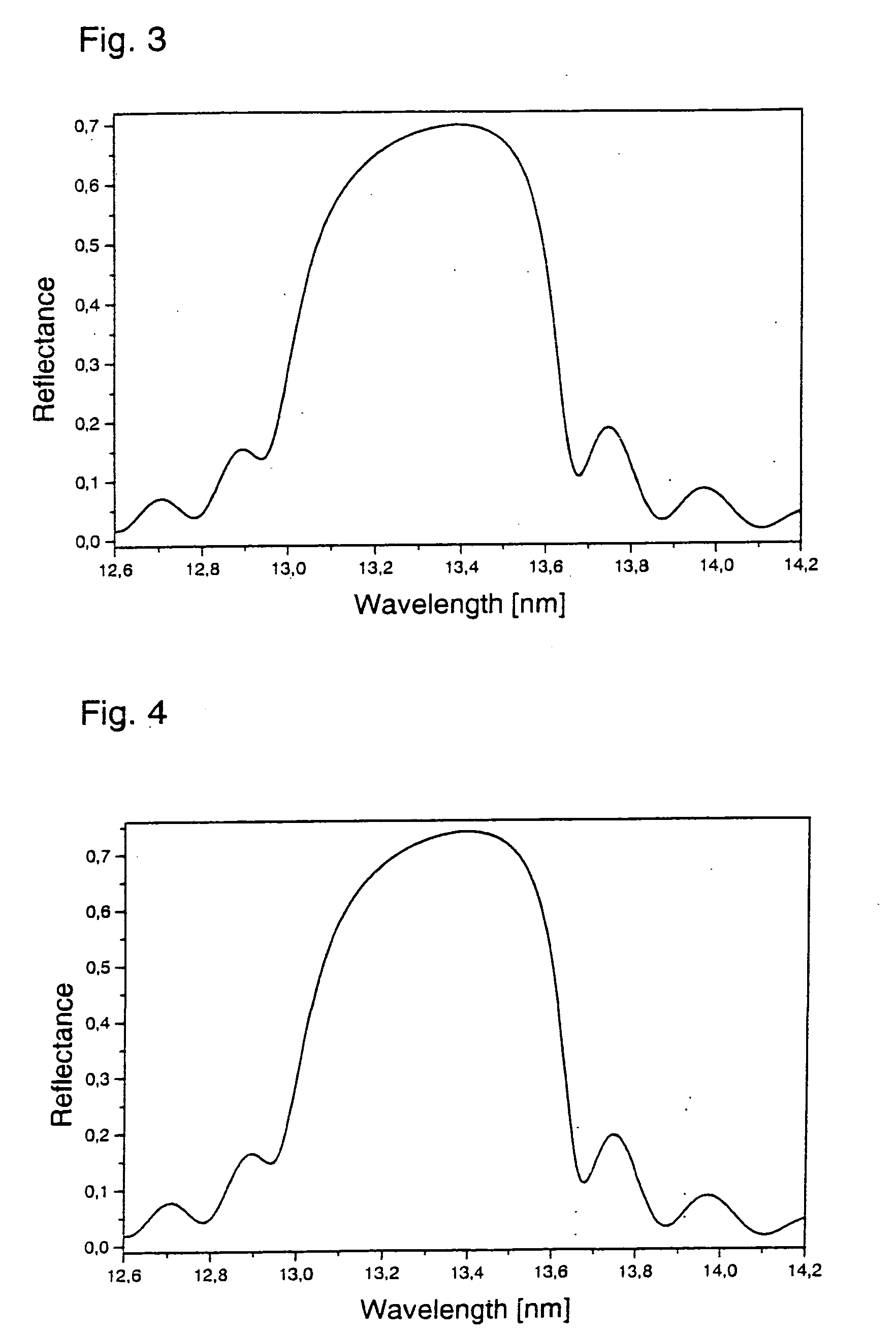

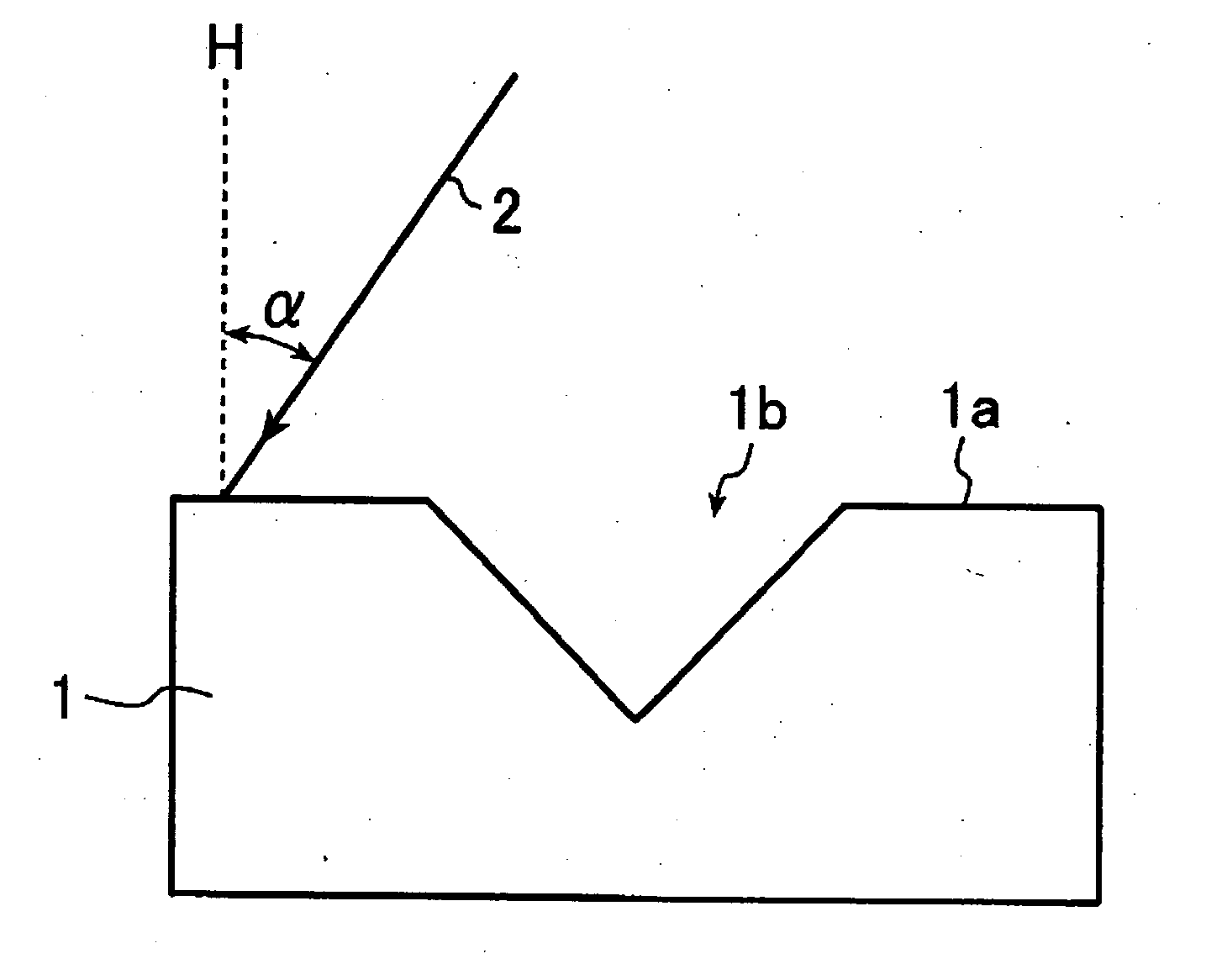

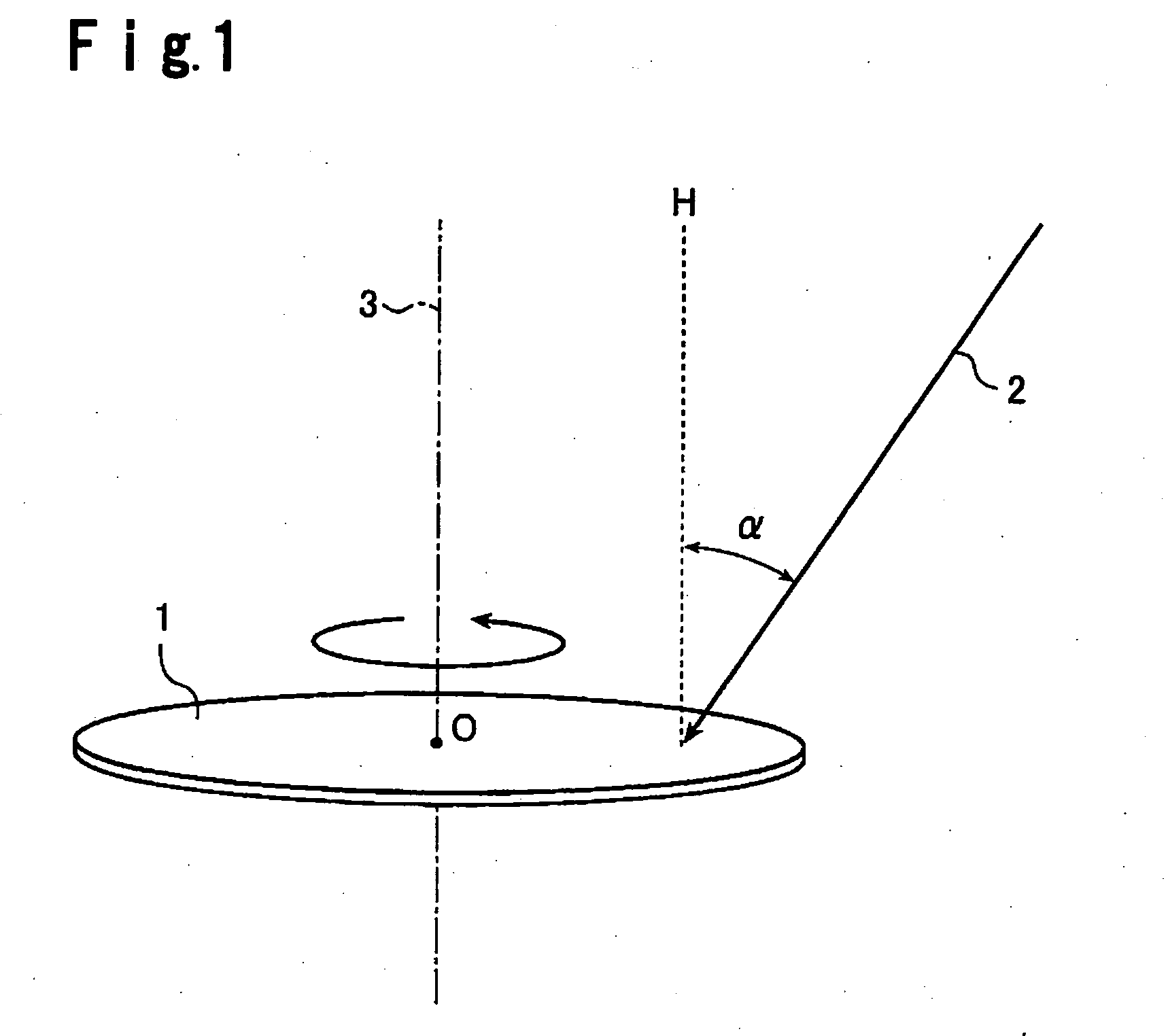

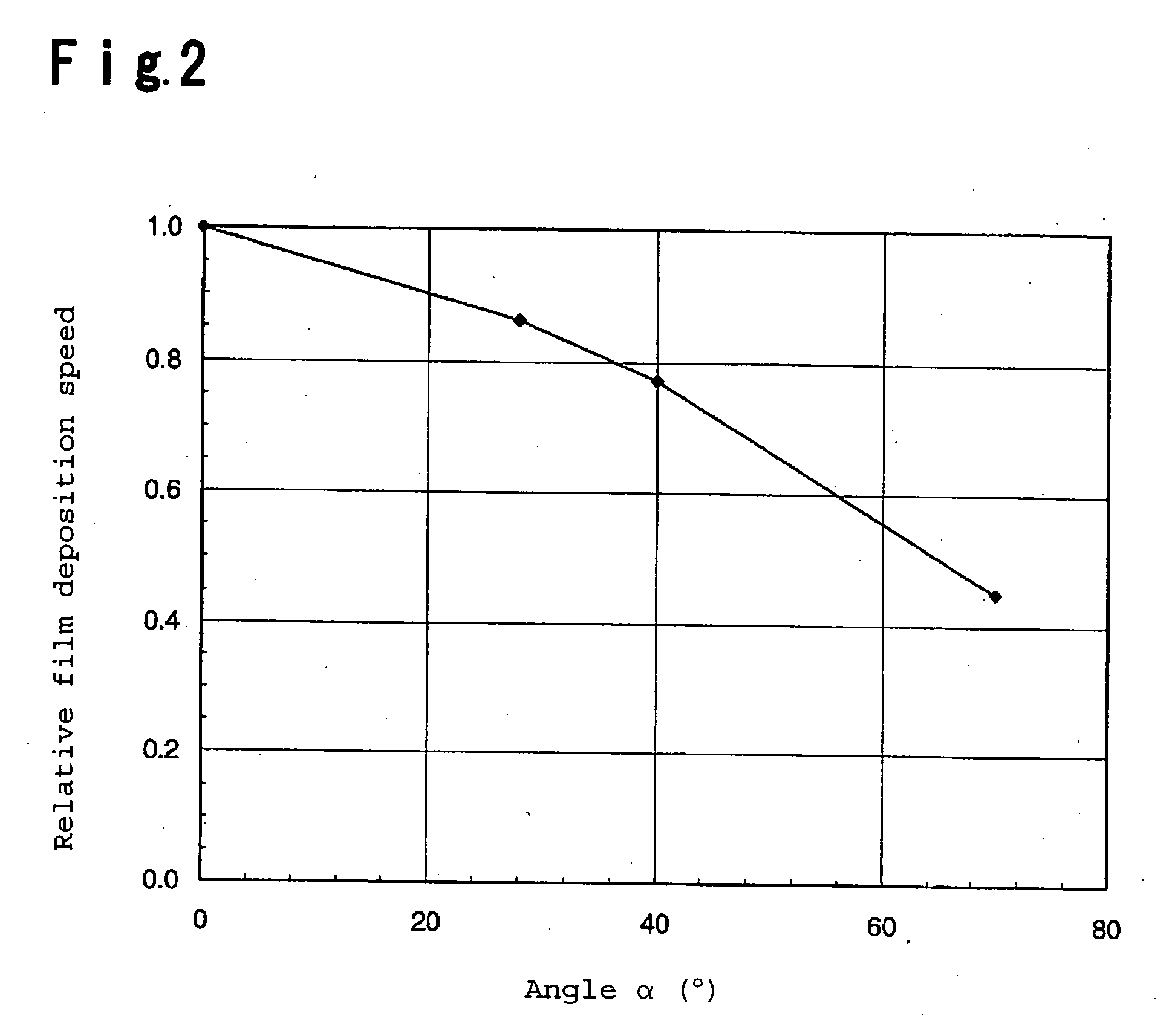

A method for depositing, by ion beam sputtering, a multilayer reflective coating of a reflective mask blank for EUV lithography on a substrate having a concave defect formed thereon, characterized in that the method comprises carrying out ion beam sputtering so that an absolute value of an angle α formed between a normal line of a substrate and sputtered particles landing on the substrate is maintained so as to satisfy the formula of 35°≦α≦80° while rotating the substrate about a central axis thereof.

Owner:ASAHI GLASS CO LTD

Ion source apparatus and cleaning optimized method thereof

InactiveUS7947129B2Adjustable diameterMaximize the effectVacuum evaporation coatingElectrostatic cleaningInsulation layerNoble gas

An ion source apparatus includes a rare gas supply source supplying rare gas instead of ion source gas to a plasma chamber, means to determine time and timing for cleaning electrodes in consideration of a collecting amount of insulation layers accreting to the electrodes of an extraction electrode system. Based on the above, the ion source apparatus removes the insulation layers by sputtering with ion beam of the rare gas while adjusting extraction or accelerate voltage and supply amount of the rare gas as a setting parameter. Moreover, by adjusting the setting parameter which changes a diameter of ion beam based on the rare gas when the ion beam collides onto each electrode surface of the extraction electrode system, the beam diameter is focused within an effective range in which intension of the sputtering of the insulation layers is maximized thus evenly removing the insulation layers.

Owner:SEN CORP AN SHI & AXCELIS

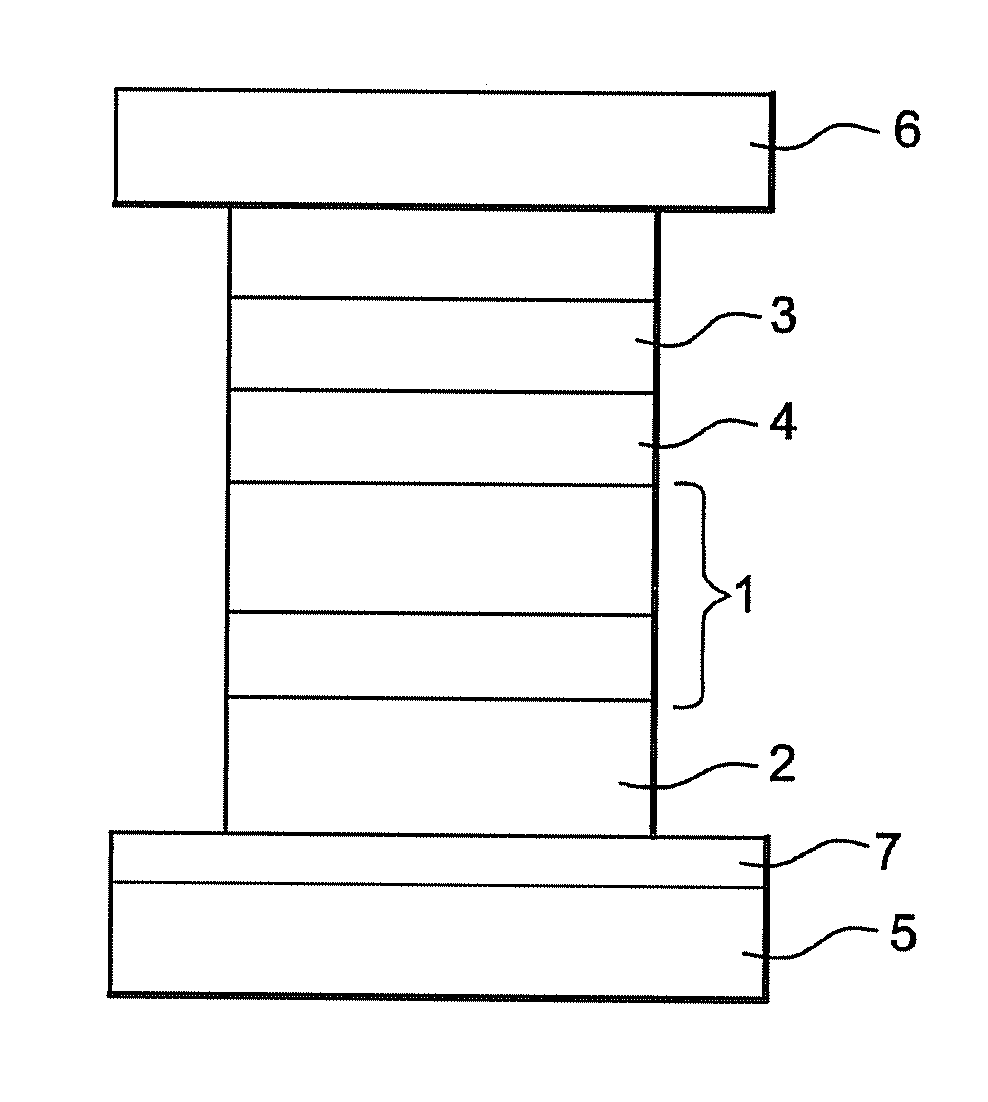

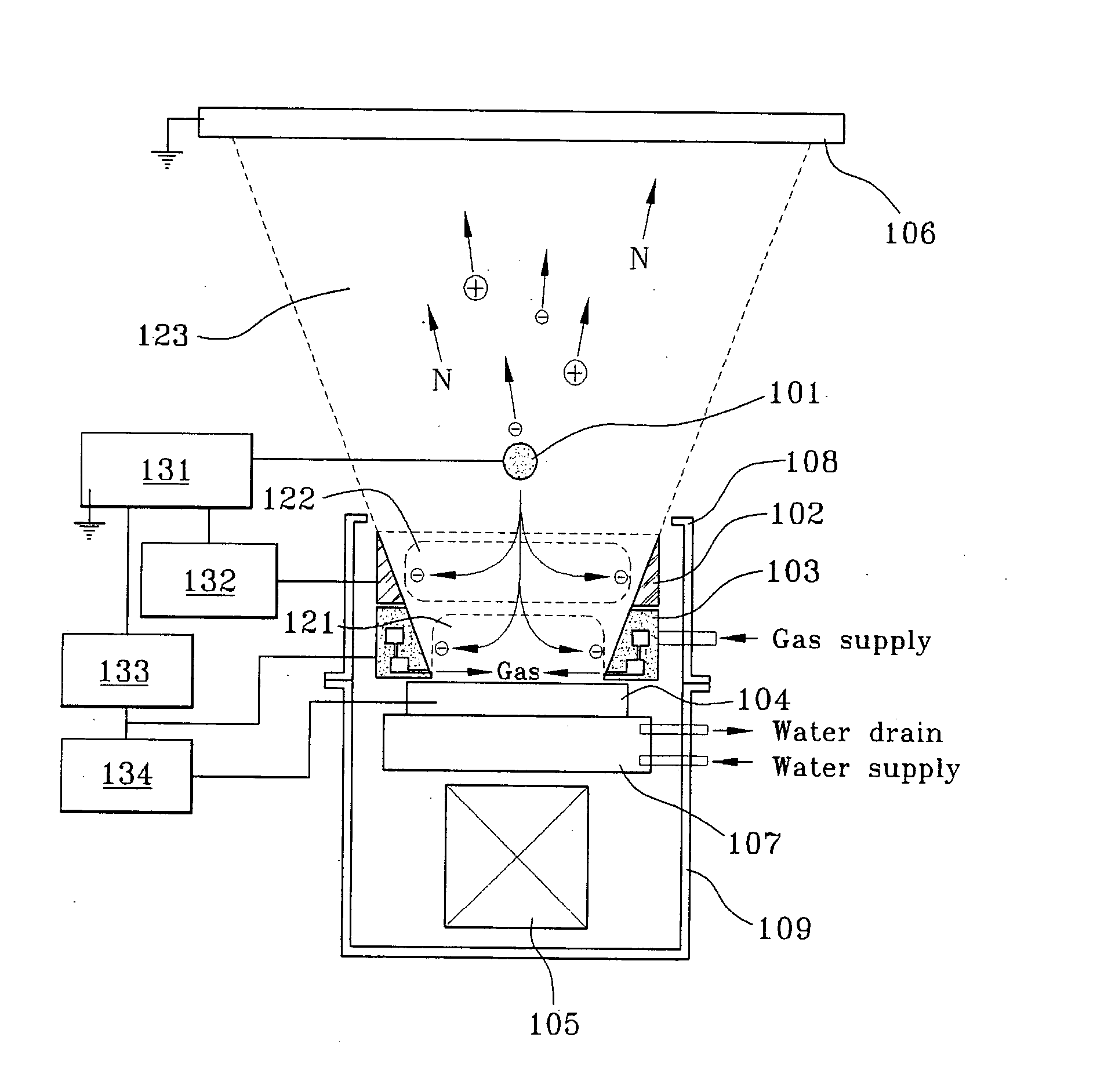

Film deposition apparatus and method of film deposition

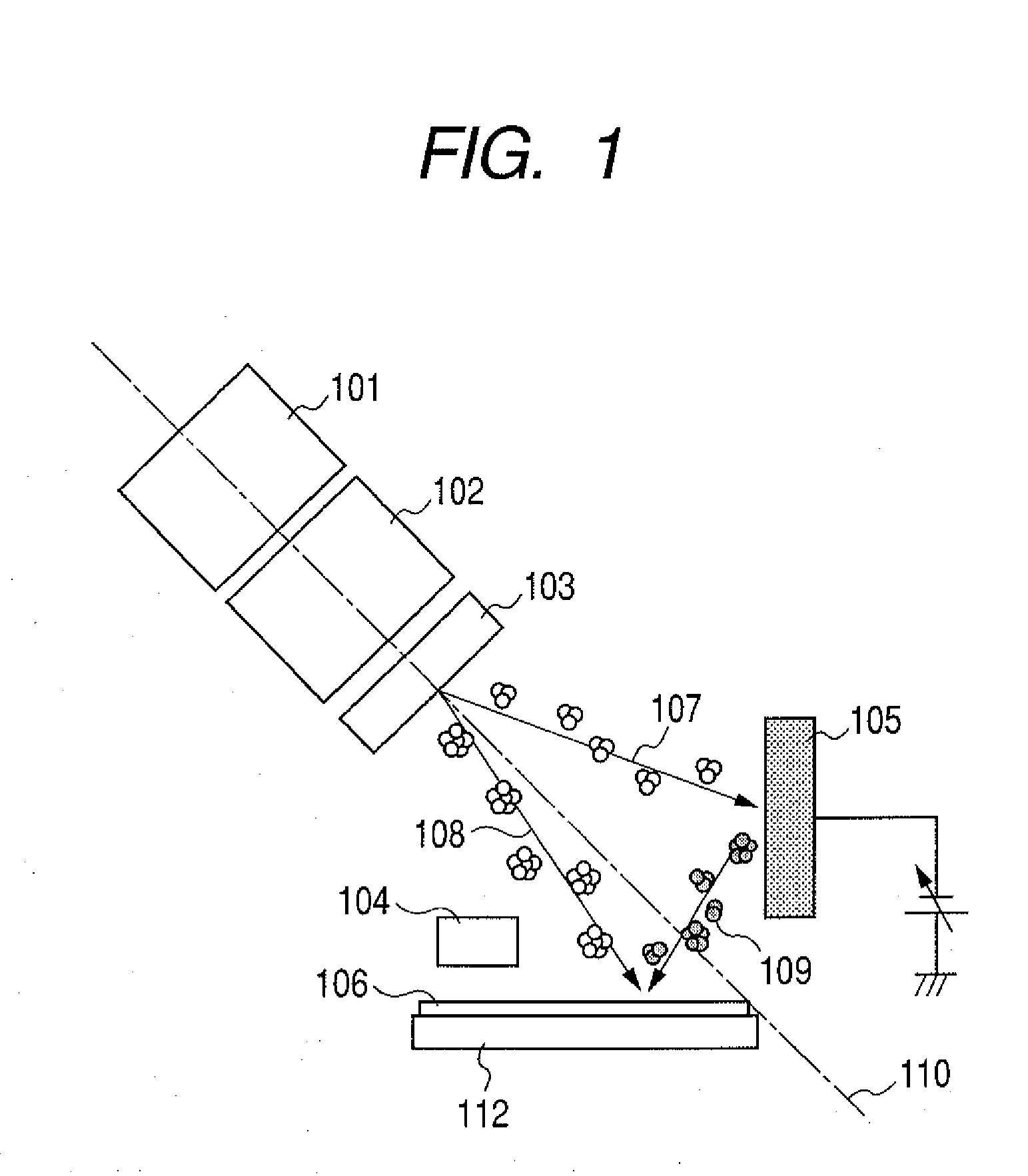

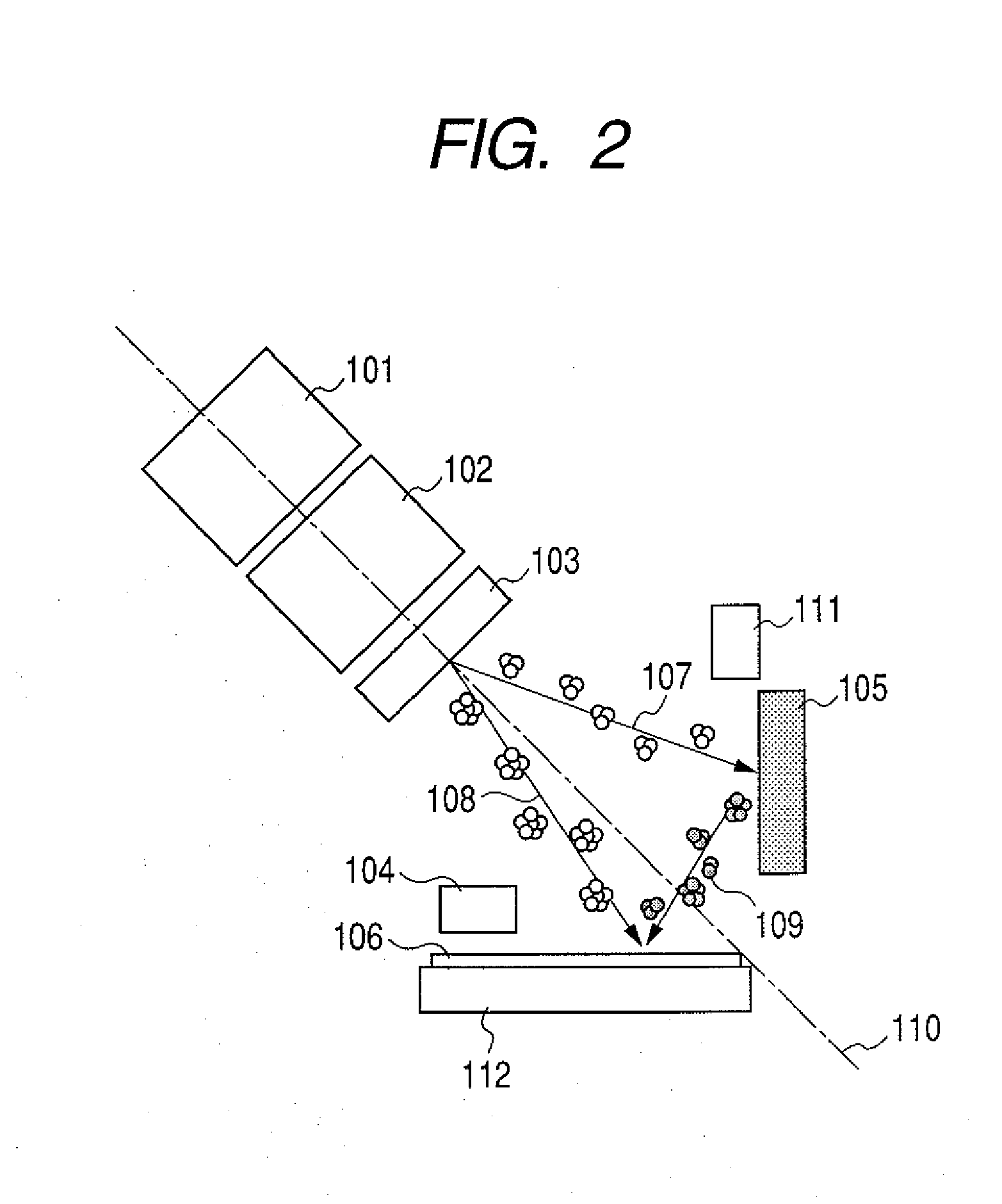

InactiveUS20090071818A1Quality improvementCellsElectric discharge tubesOptoelectronicsIon beam sputtering

An ion beam sputtering film deposition apparatus is provided which can form a high-quality thin film that is dense, smooth and faultless. The film deposition apparatus has ion beam irradiating unit, a target 105 containing a film forming substance to be sputtered, and holding unit 112 to hold a substrate 106 on which the sputtered film forming substance is deposited. The ion beam irradiating unit irradiates gas cluster ions to both the target 105 and the substrate 106.

Owner:CANON KK

Thin film forming apparatus

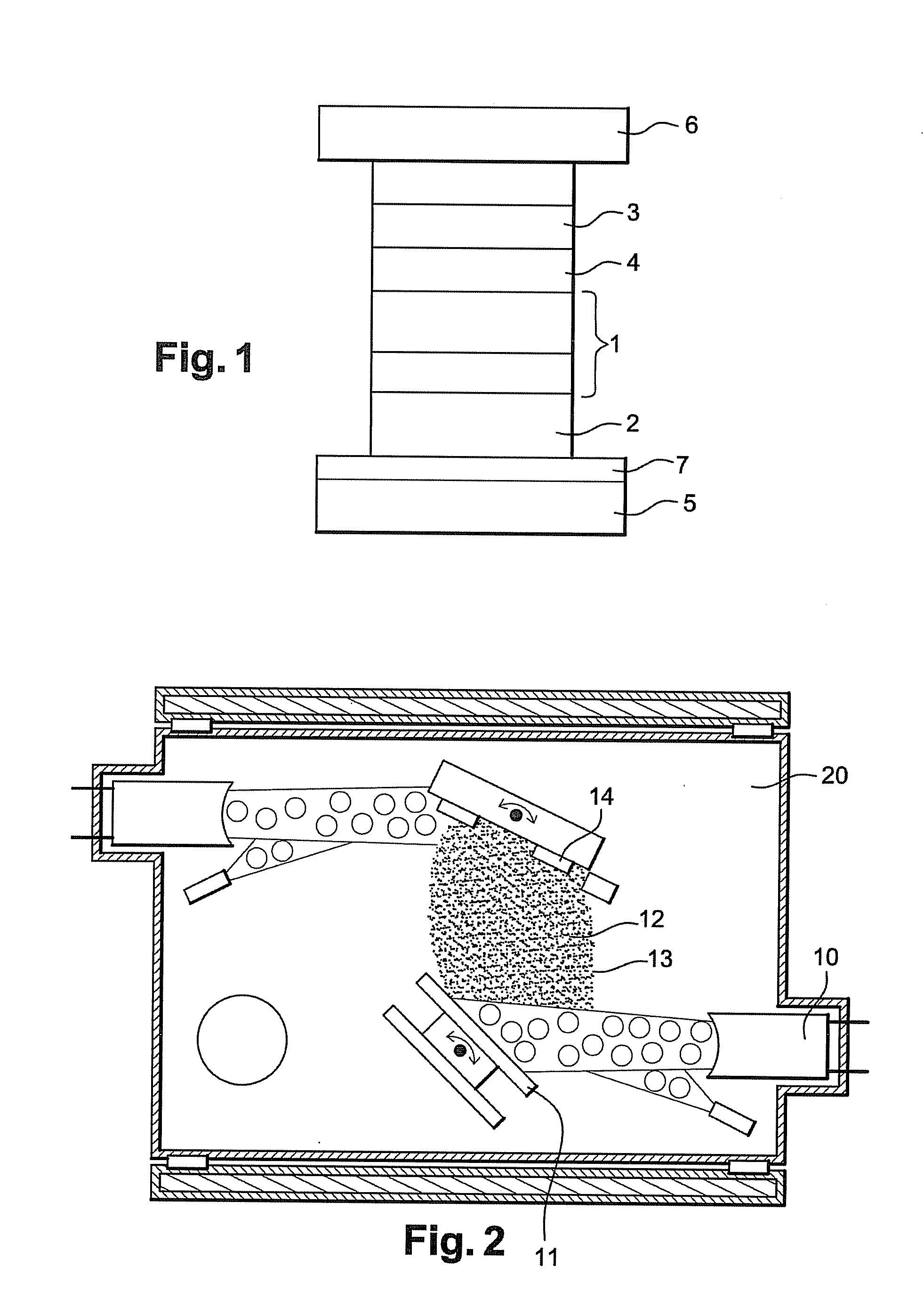

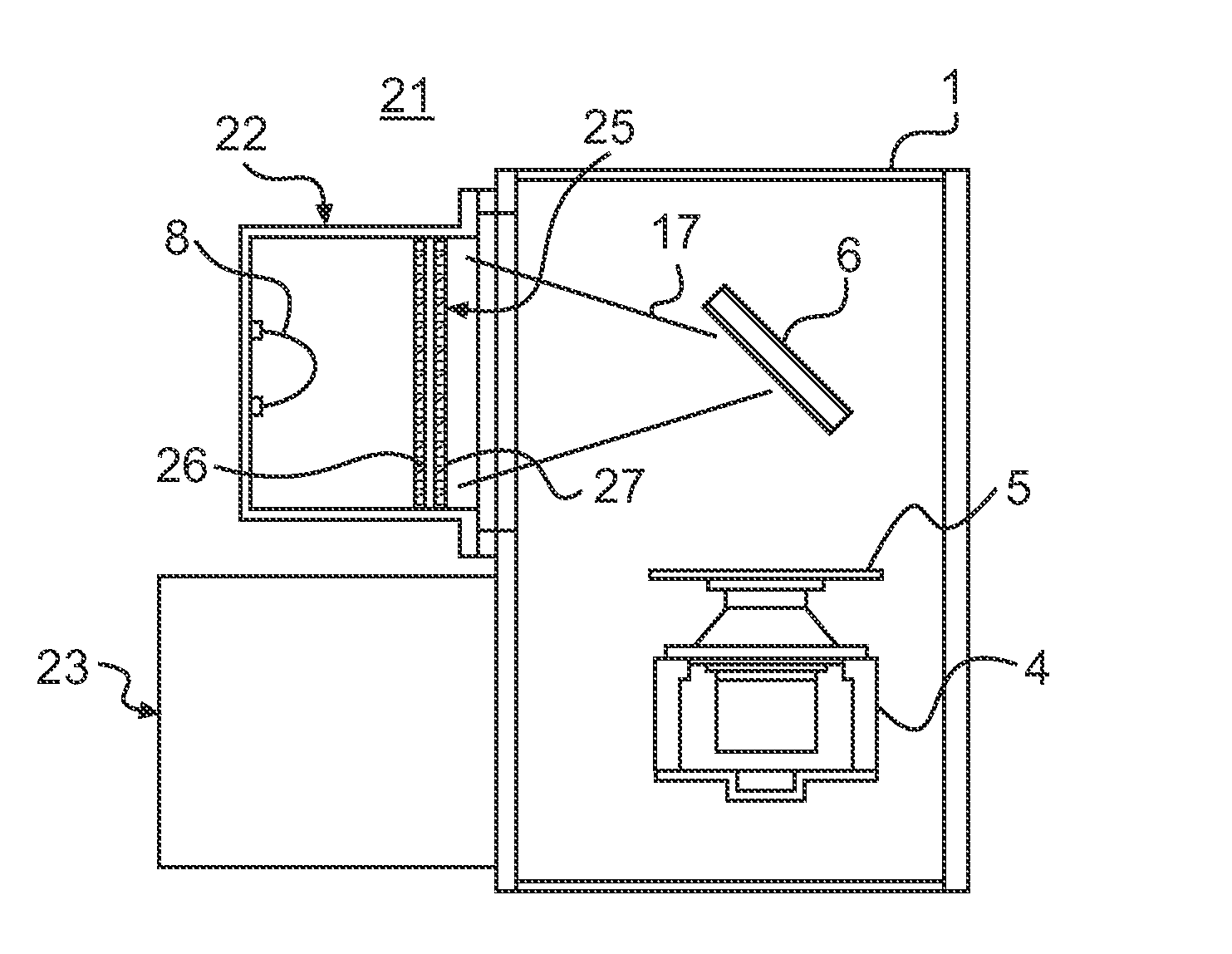

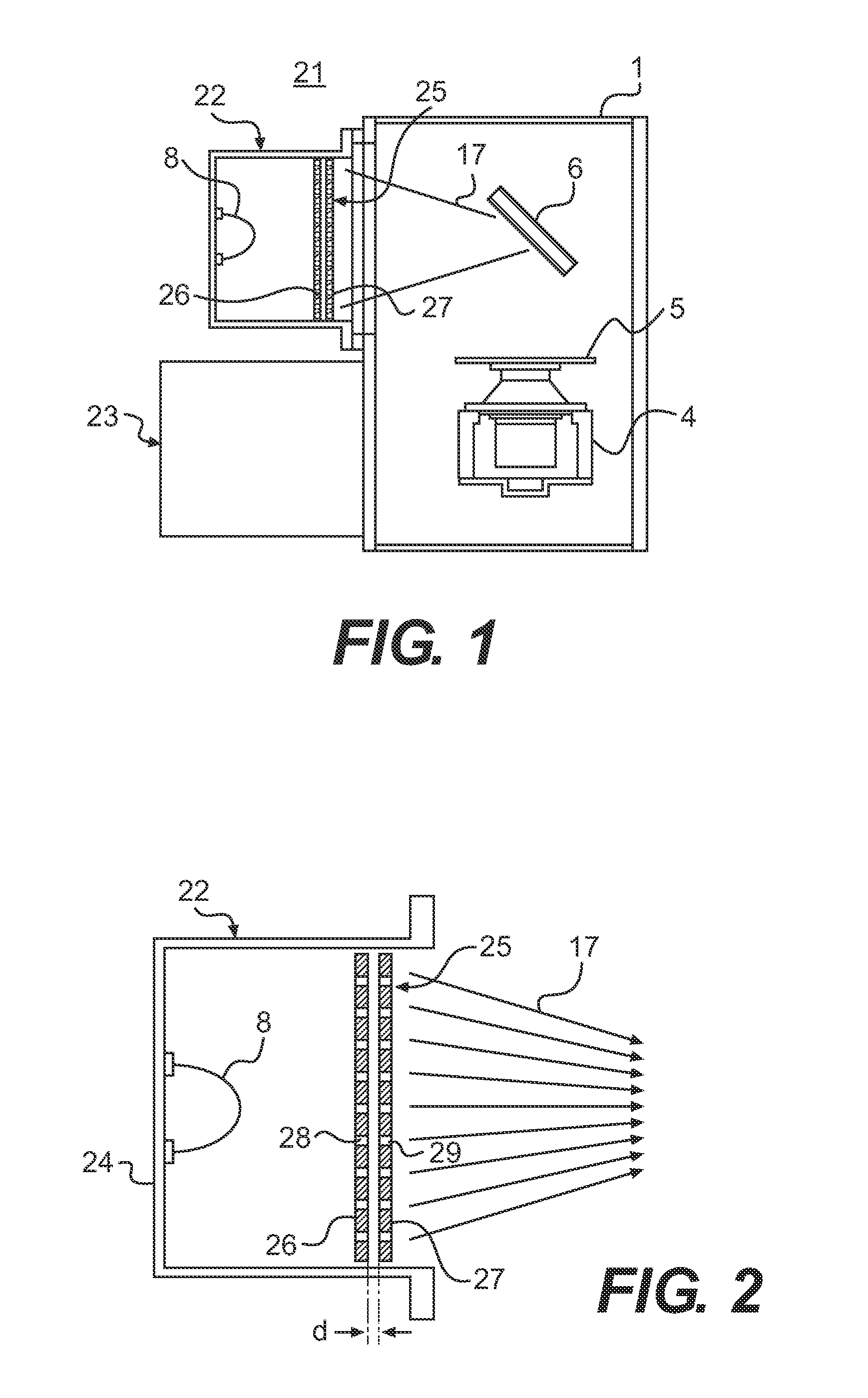

InactiveUS20080179186A1Reduce manufacturing costCellsVacuum evaporation coatingManufacturing cost reductionIon beam

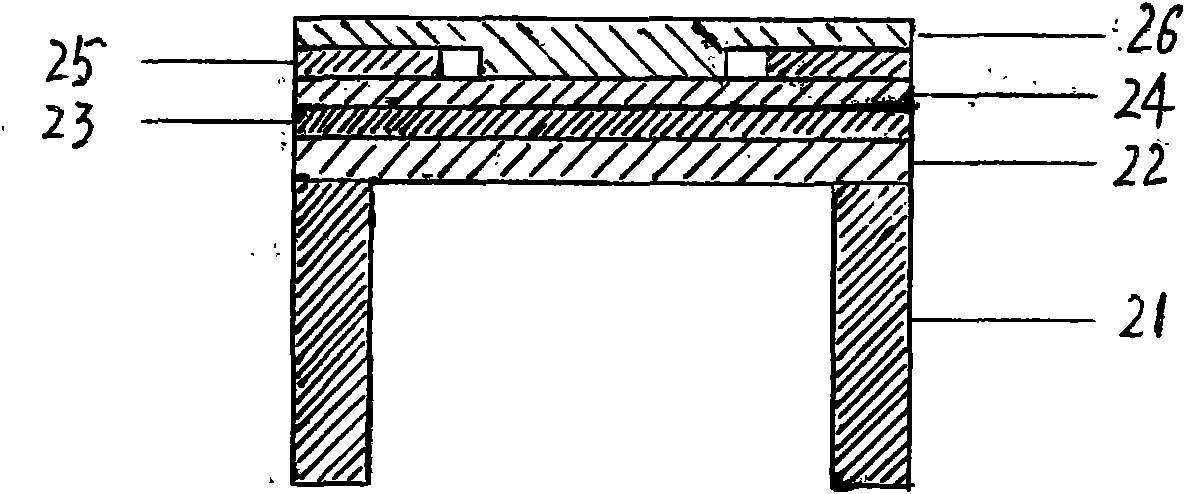

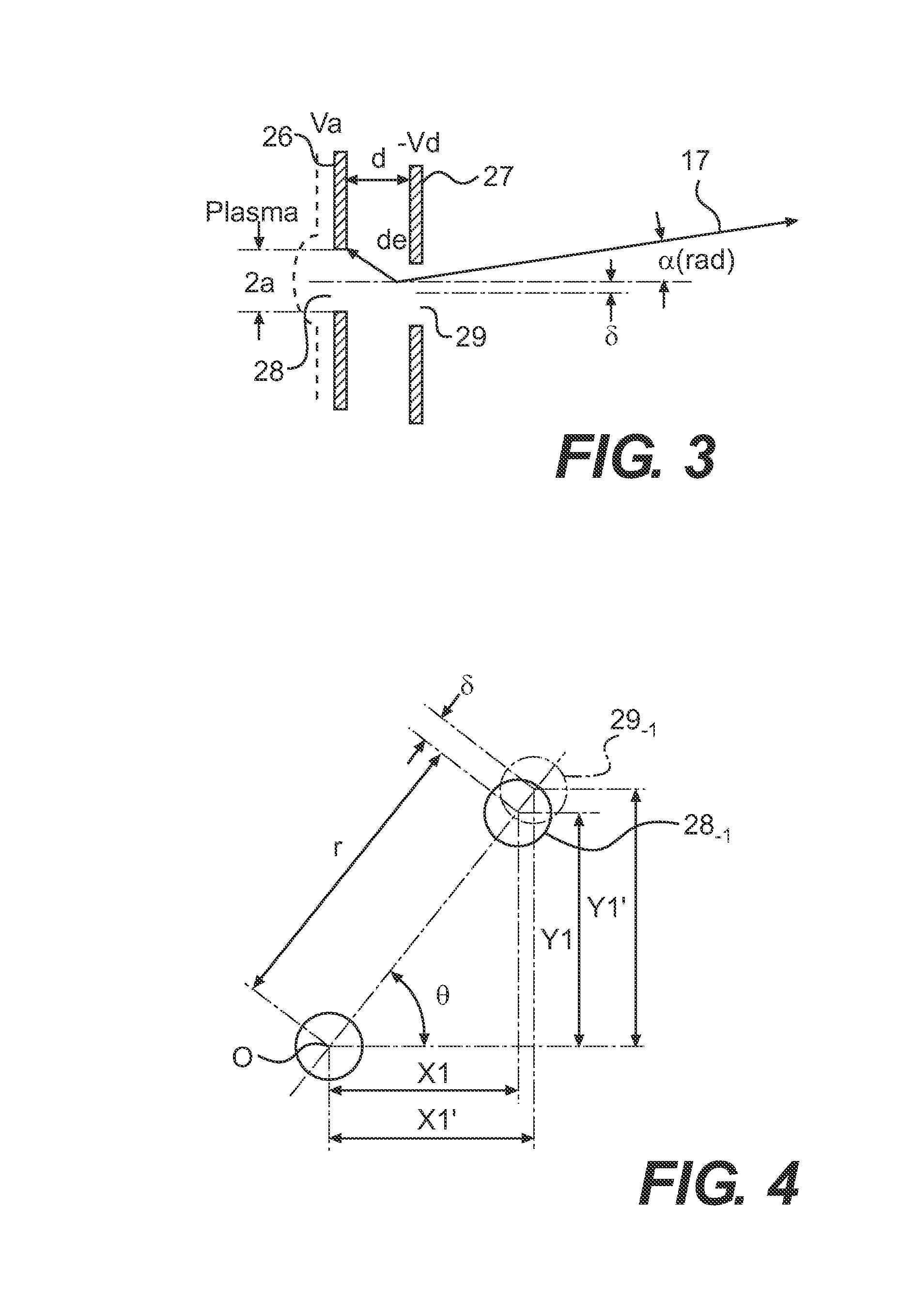

Provided is a thin film forming apparatus that can focus ion beams onto a target and reduce a manufacturing cost. In a thin film forming apparatus radiating an ion beam (17) from an ion source (22) toward a target (6) and forming a thin film on a surface of a substrate (5) with particles sputtered by the ion beam, the ion source (22) includes an electrode for extracting ions from plasma and accelerating the extracted ions. The electrode includes a plate-shaped accelerator electrode (26) in which a plurality of accelerator apertures are bored, and a plate-shaped decelerator electrode (27) in which a plurality of decelerator apertures are bored. The plurality of accelerator apertures and the plurality of decelerator apertures are aligned and offset to focus the ion beams (17).

Owner:KOKUSA ELECTRIC CO LTD

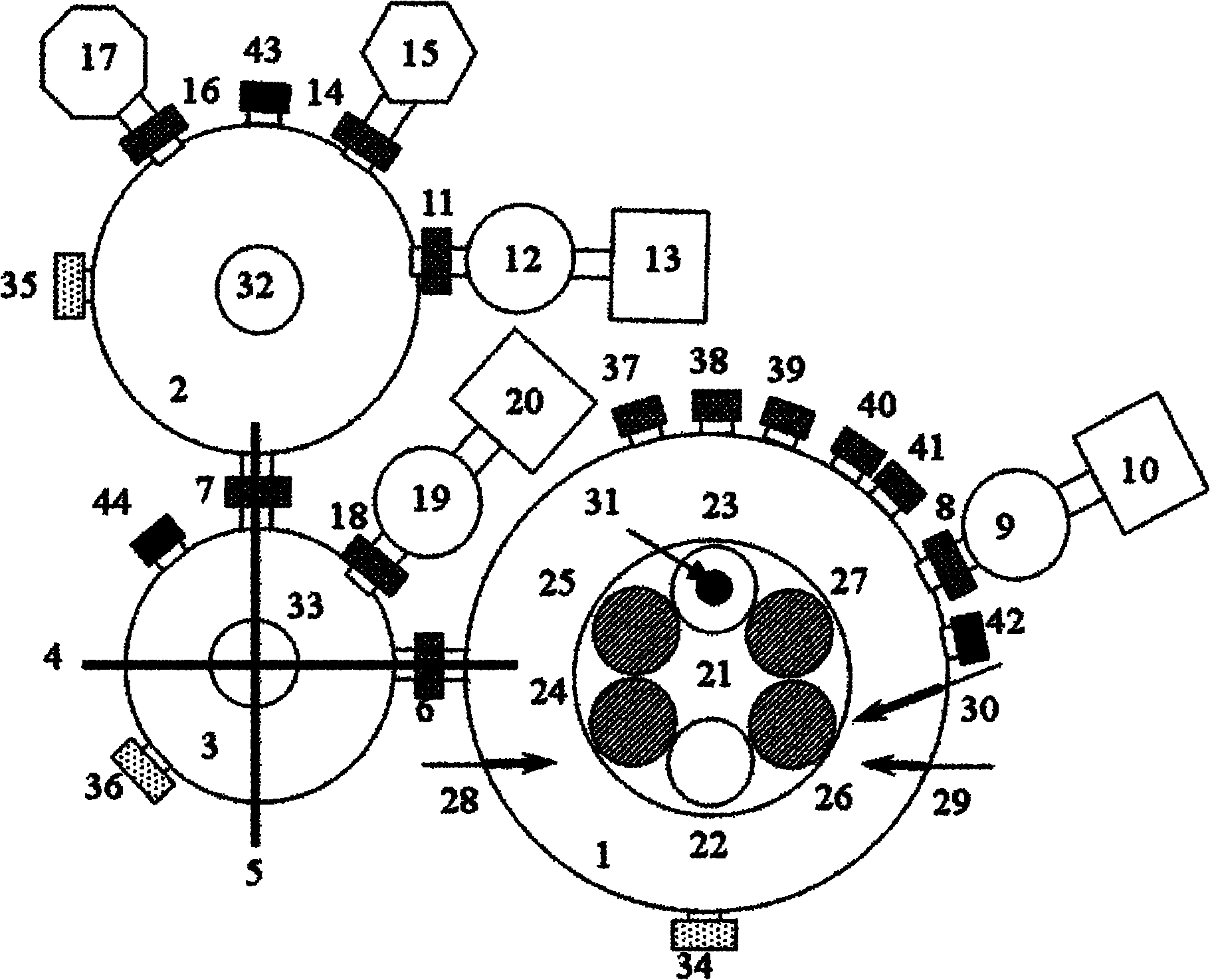

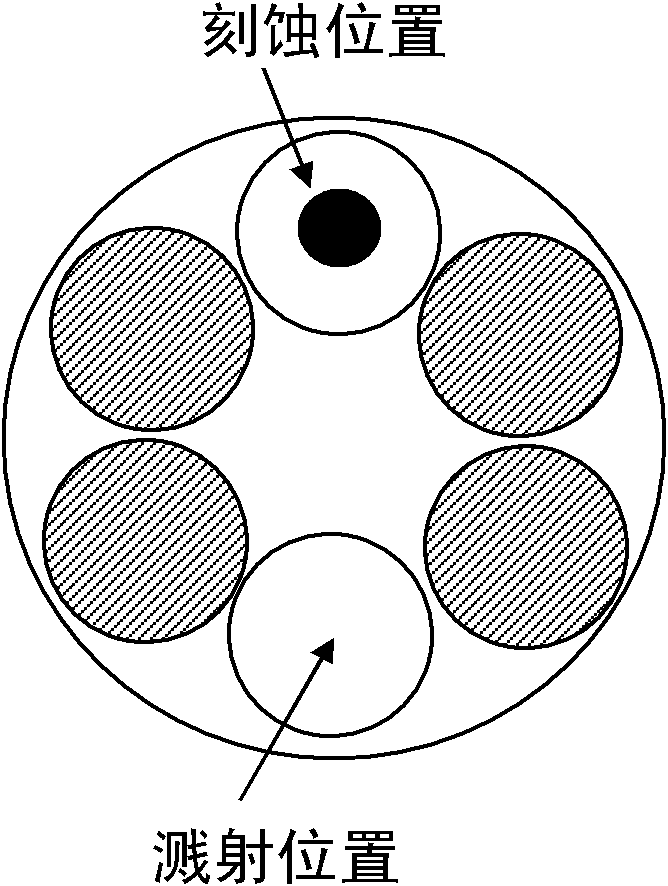

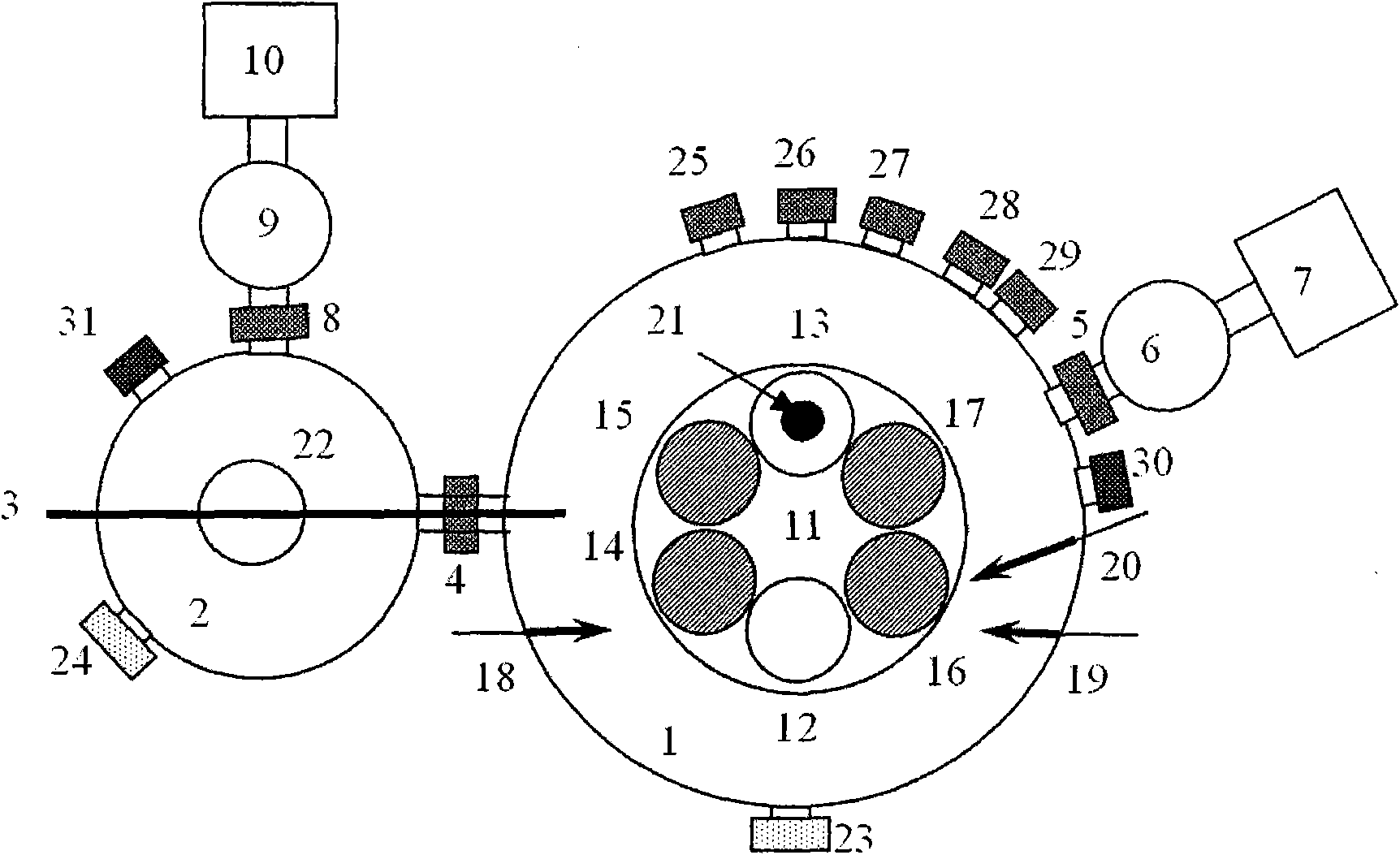

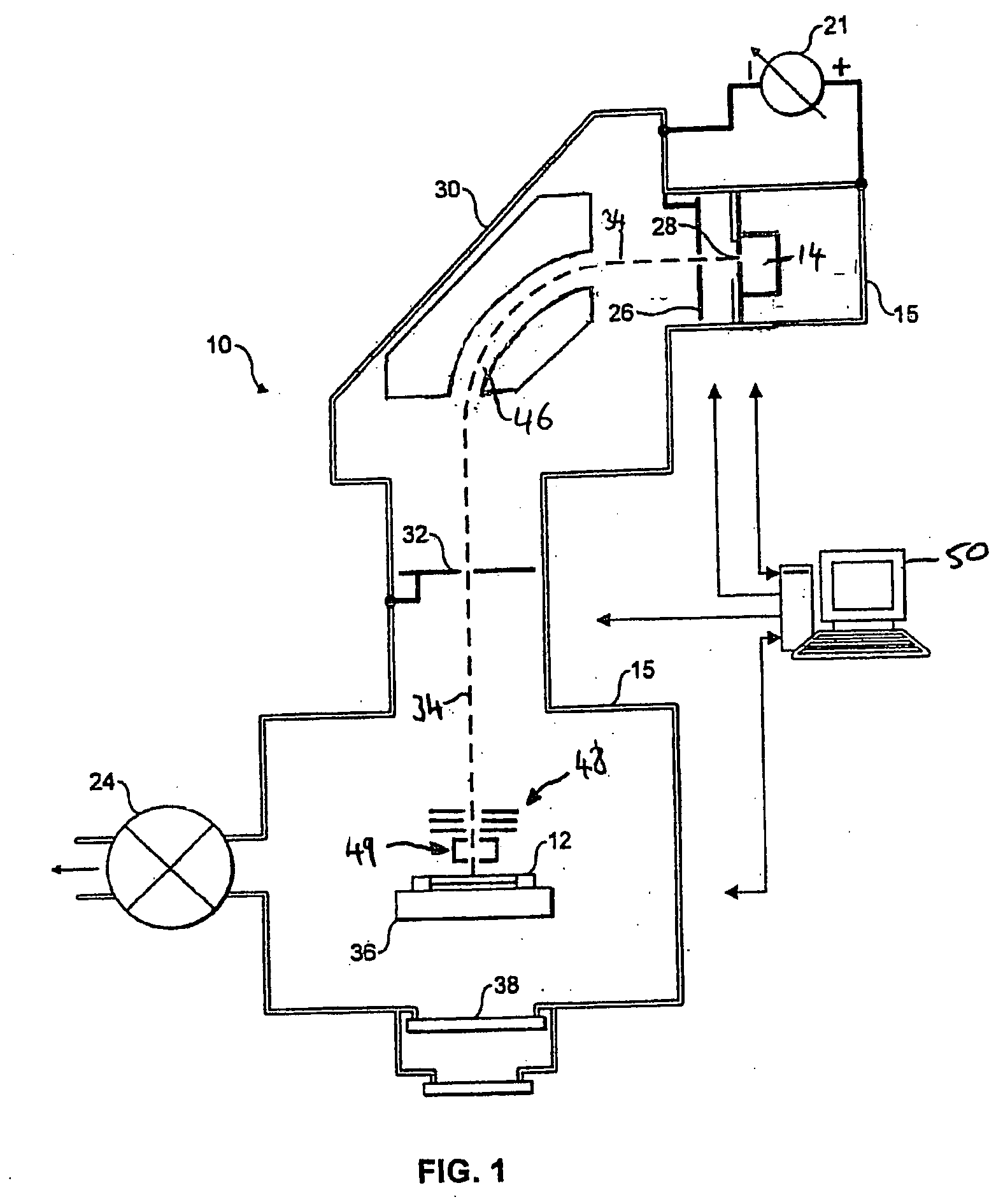

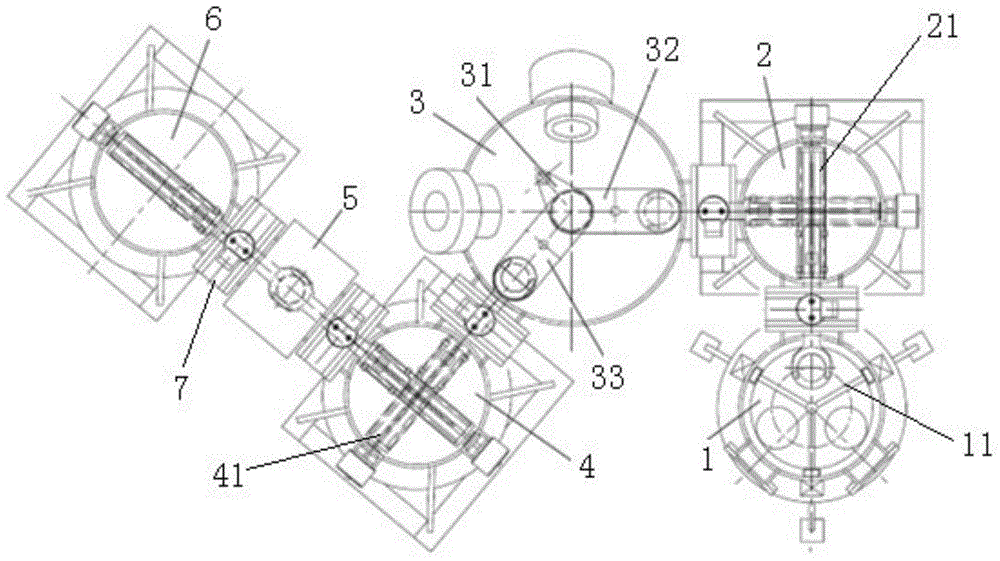

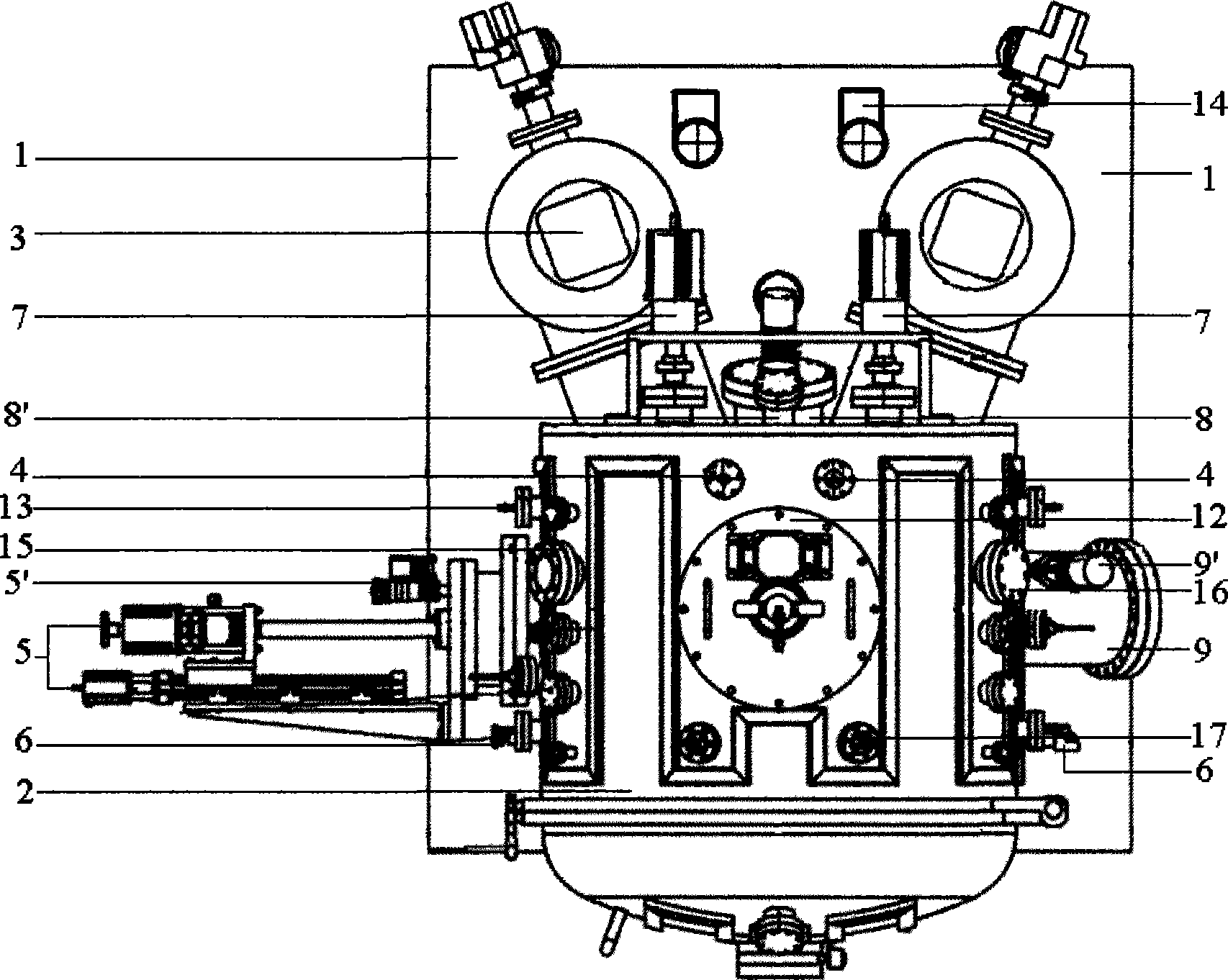

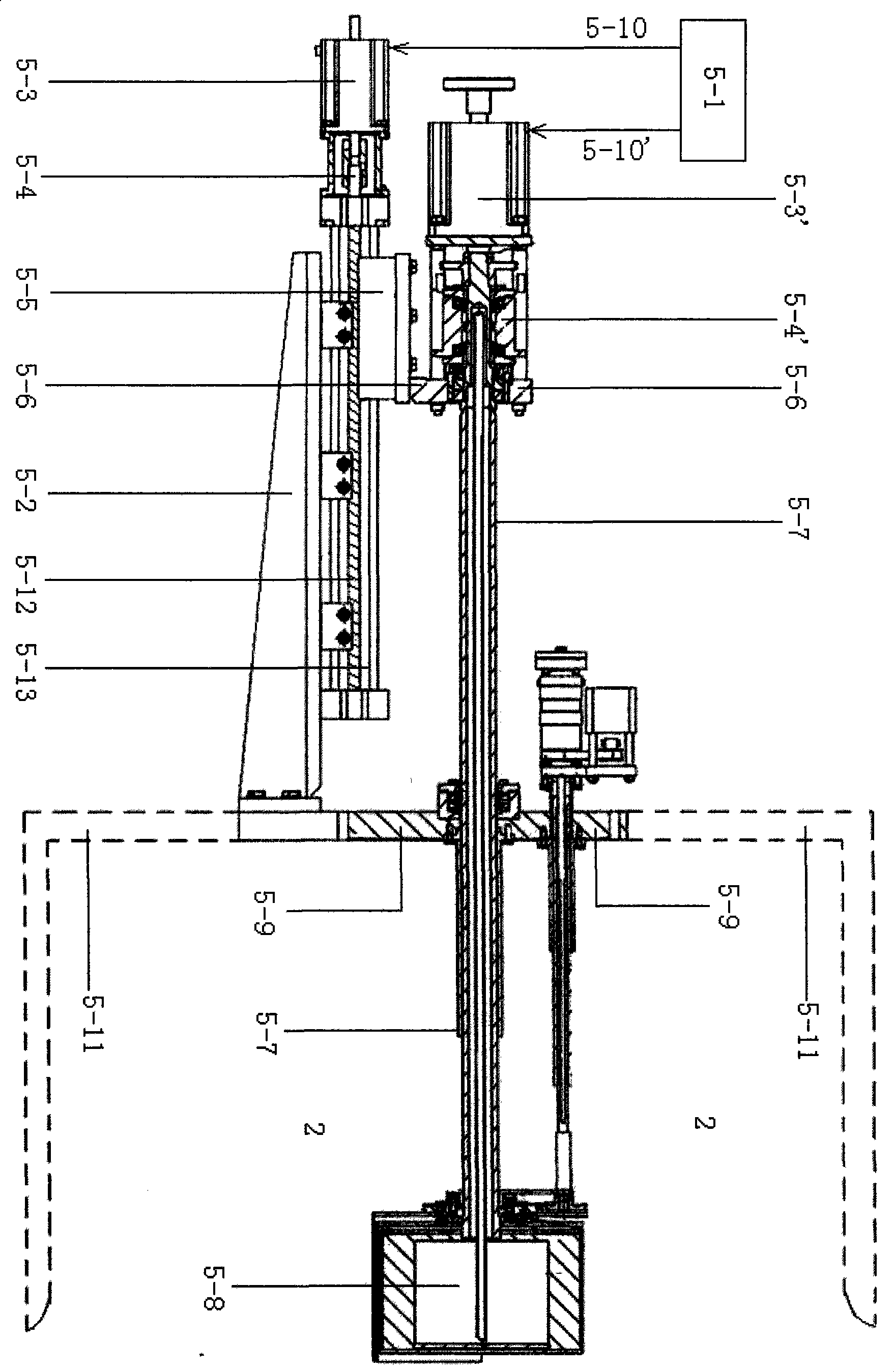

Multifunctional ion beam sputtering and etching and in-situ physical property analysis system

ActiveCN102486465AEasy to manufactureSimple structureMaterial analysis using wave/particle radiationVacuum evaporation coatingSputter depositionThinning

The invention discloses a multifunctional ion beam sputtering and etching and in-situ physical property analysis system. The system comprises an ion beam sputtering and etching chamber, a physical property analyzing chamber, a sample exchange vacuum cavity, a sputtering sedimentation and etching workpiece stage arranged at the center on the top of the sputtering and etching chamber, an etching ion source arranged at the center on the bottom of the sputtering and etching chamber, two sputtering target stages arranged on the lower part of the sputtering and etching chamber, two sputtering ion source arranged on the middle part of the sputtering and etching chamber, an auxiliary washing ion source arranged on the middle part of the sputtering and etching chamber, and a set of X-ray photoelectron spectroscopy analysis system arranged in the physical property analyzing chamber. The sample exchange vacuum cavity is used for realizing the exchanging and transporting of the sample between thesputtering and etching chamber and the physical property analyzing chamber. The multiple functions are combined in the equipment. The equipment can be used in sputtering sedimentation, etching, polishing and thinning, heat treatment, and sample in-situ physical property analysis of high-quality multi-layer ultra-thin media and metal film materials.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

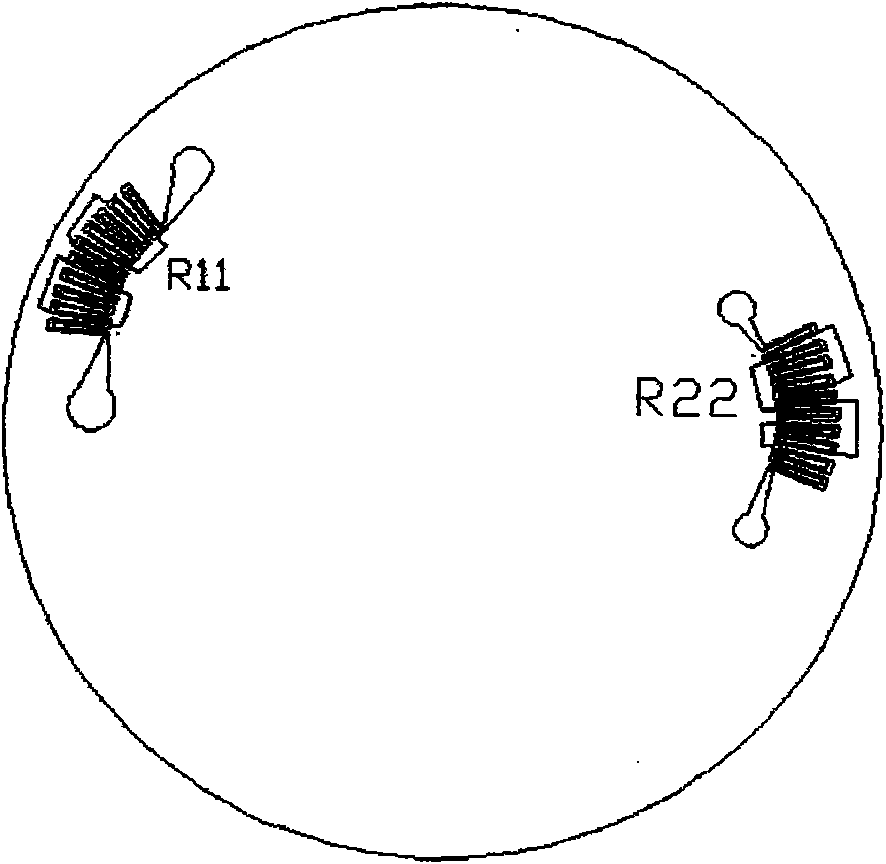

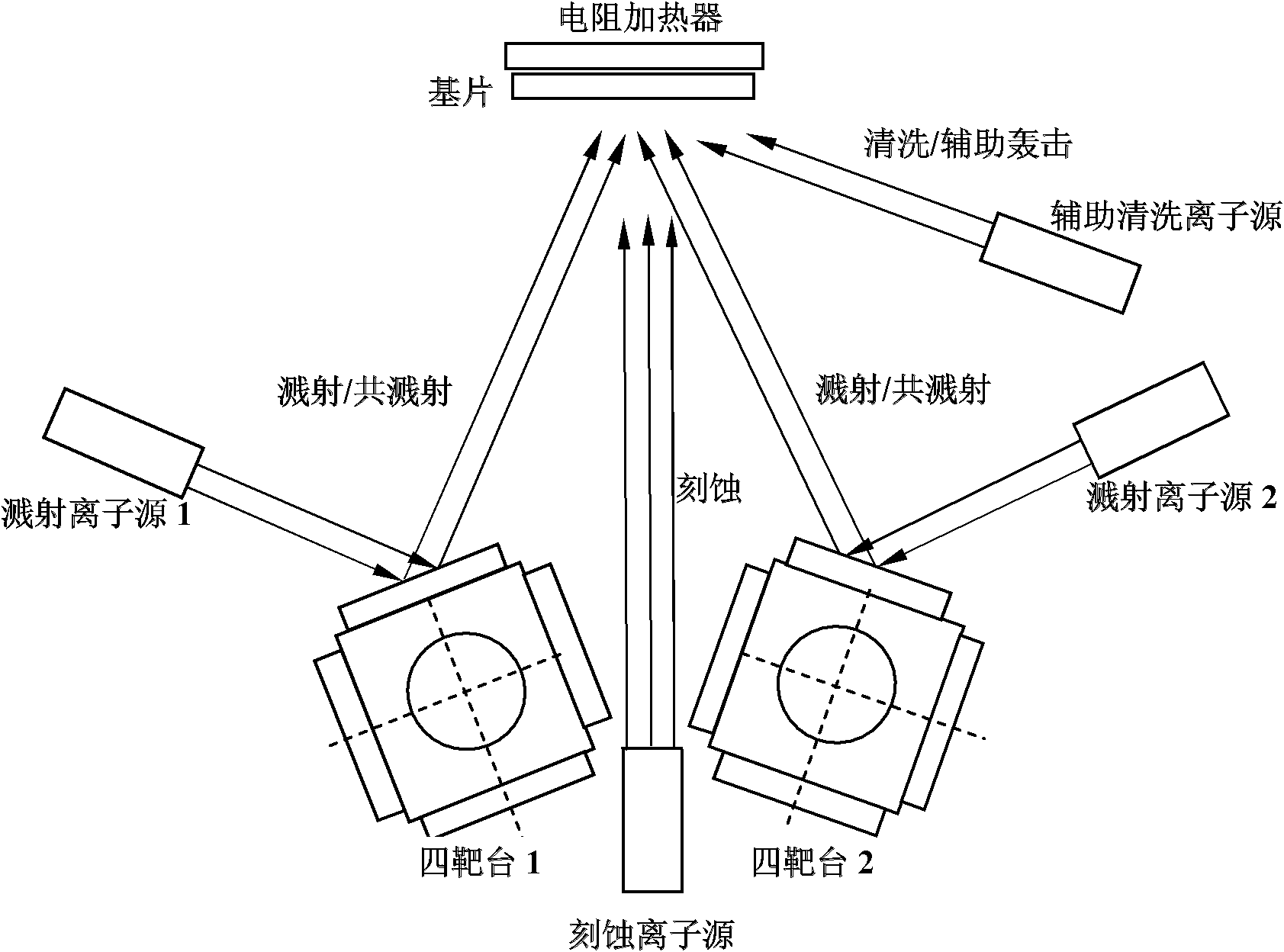

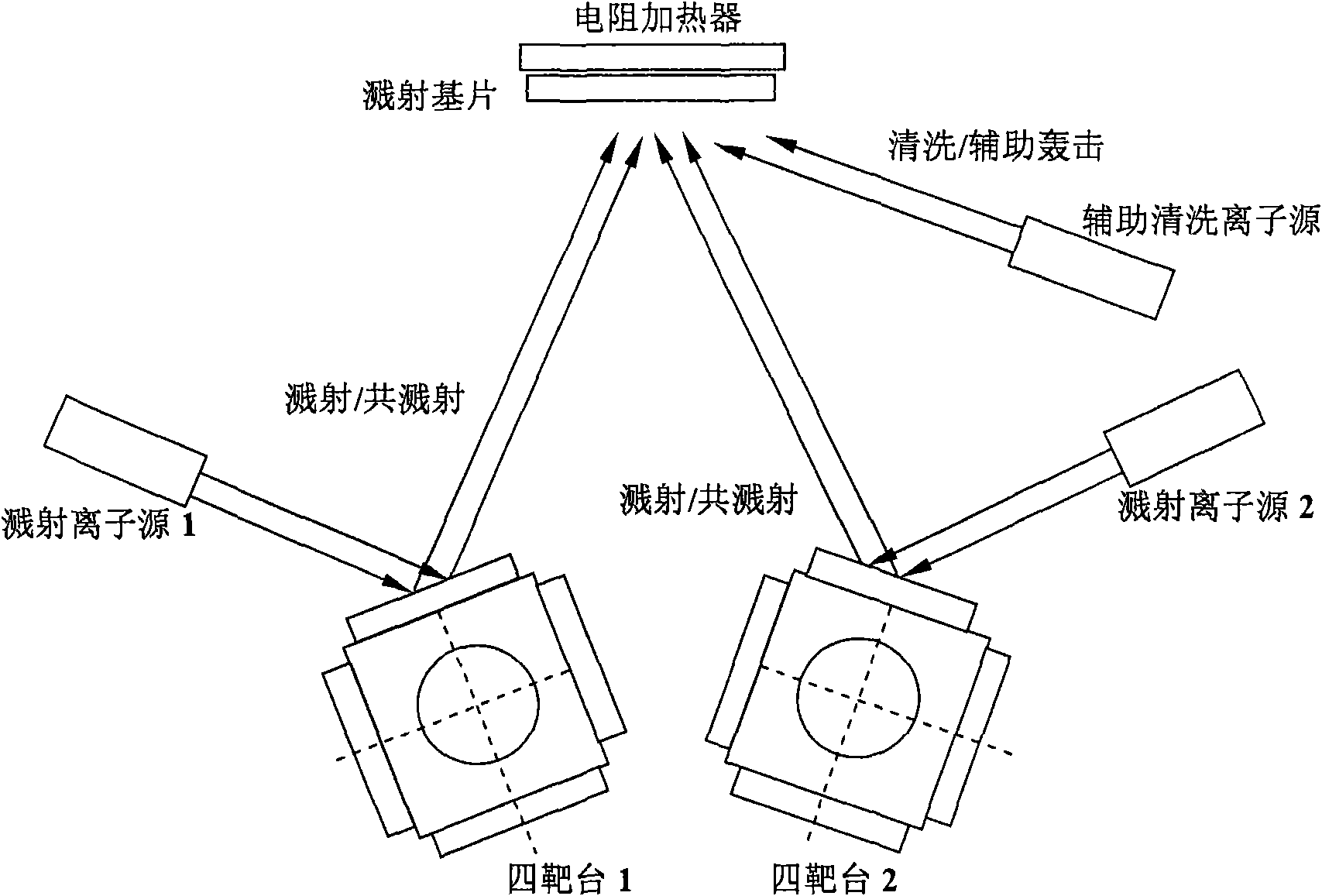

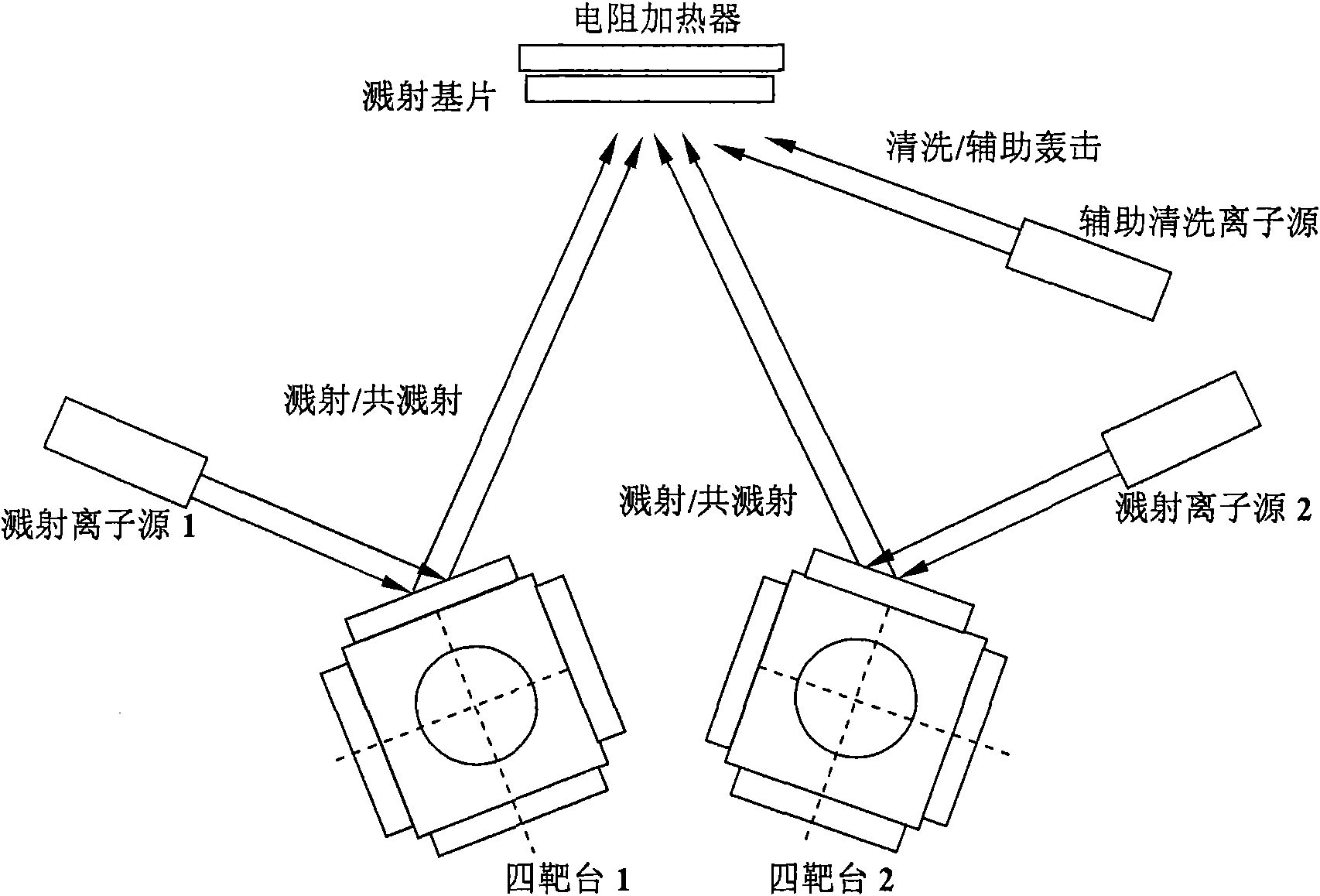

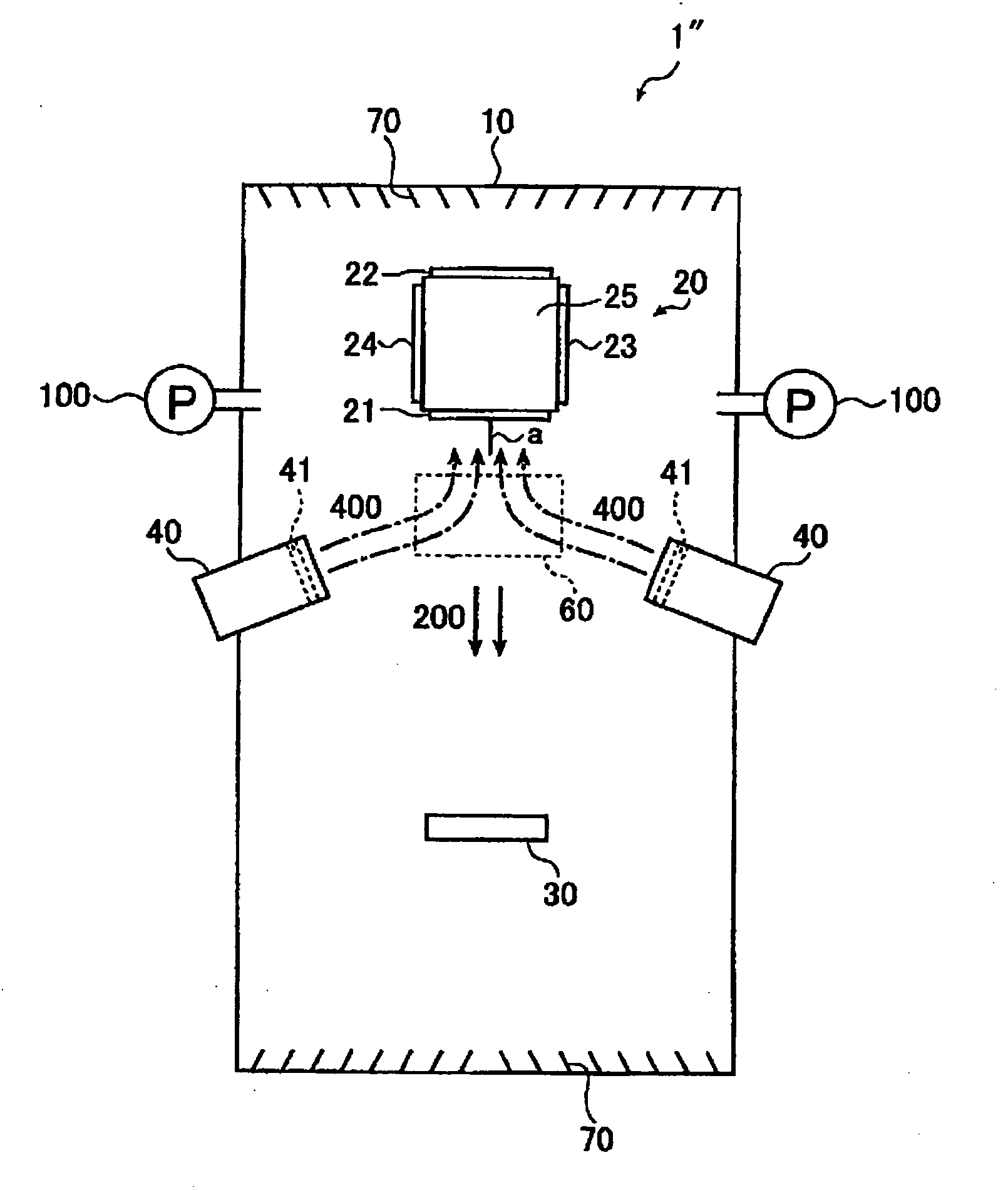

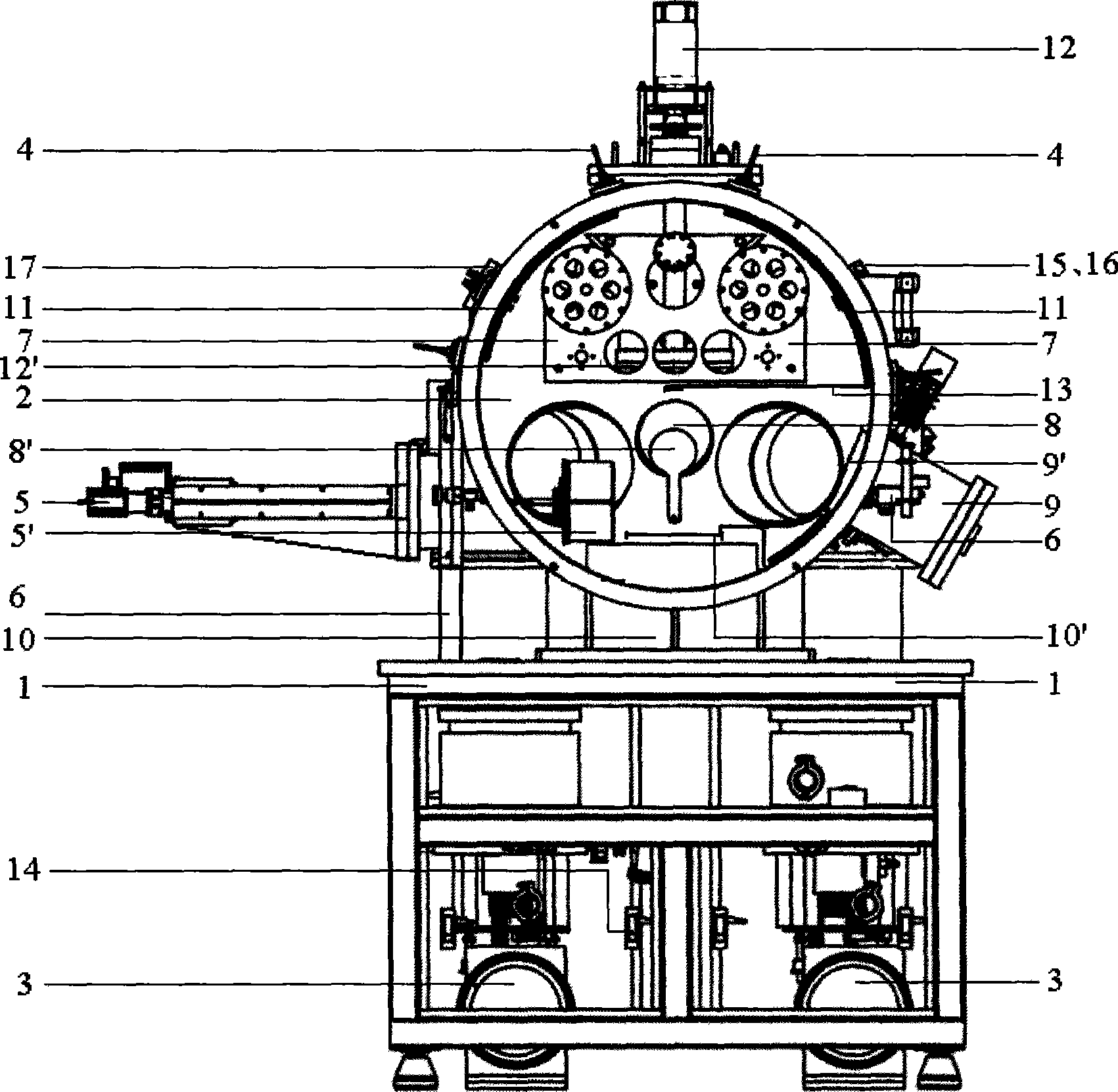

Multifunctional ion beam sputtering equipment

InactiveCN101880862AEasy to manufactureSimple structureVacuum evaporation coatingSputtering coatingTarget surfaceIon beam

The invention discloses multifunctional ion beam sputtering equipment which comprises a vacuum chamber, a sputtering workbench, two sputtering target platforms, two sputtering ion sources and an assistant cleaning ion source, wherein the sputtering workbench is arranged in the top middle position of the vacuum chamber; the lower surface of the sputtering workbench is parallel to the horizontal plane; the two sputtering target platforms are arranged at the lower part of the vacuum chamber and symmetrical bilaterally with respect to the direction of the perpendicular bisector of the sputtering workbench; the two sputtering ion sources are arranged in the middle of the vacuum chamber and symmetrical bilaterally arranged in the direction of the perpendicular bisector of the sputtering workbench; an emitted ion beam and a target surface loaded on the sputtering target platforms form an angle of 45 DEG; the assistant cleaning ion source is arranged in the middle of the vacuum chamber; and the emitted ion beam and the lower surface of the sputtering workbench form an angle of 30 DEG. The equipment has various functions and can be used for sputtering deposition, etching, polishing thinning and heat treatment of high-quality multilayer ultrathin media and metal film materials.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

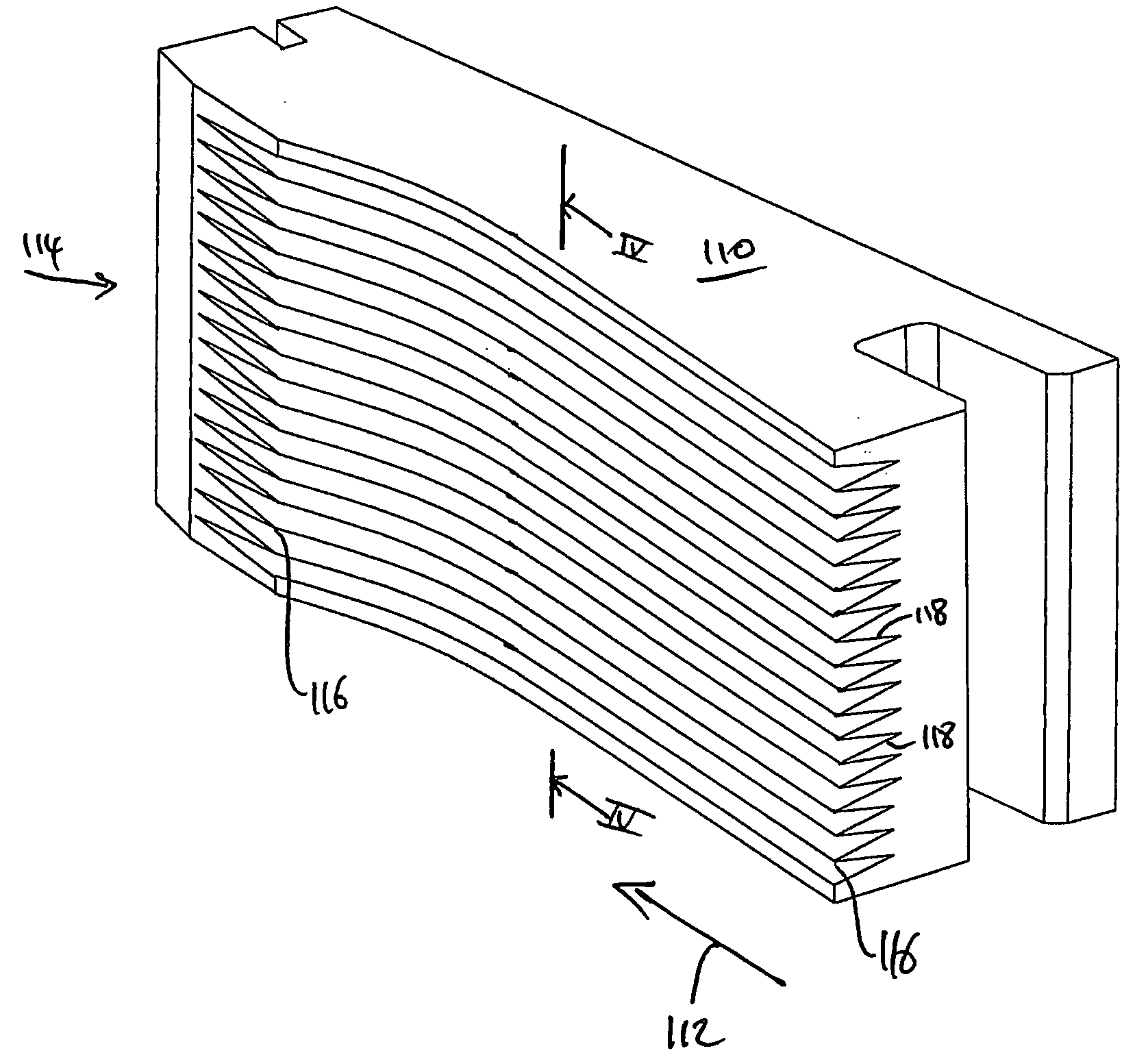

Ion implanters

The present invention relates to components in ion implanters having surfaces, such as graphite surfaces, adjacent to the path of the ion beam through the ion implanter. Such surfaces will be prone to sputtering, and sputtered material may become entrained in the ion beam. The present invention sees the use of surfaces that are formed so as to present a series of angled faces that meet at sharp intersections. In this way, any material will be sputtered away from the ion beam.

Owner:APPLIED MATERIALS INC

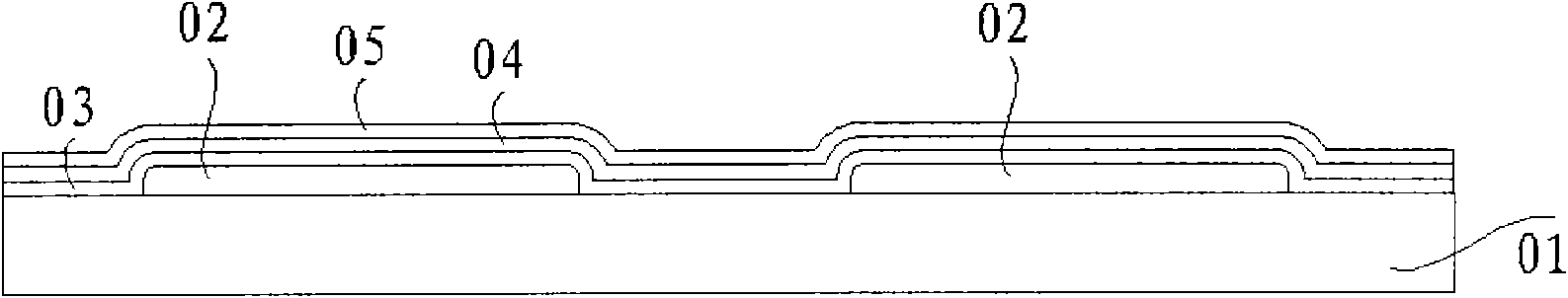

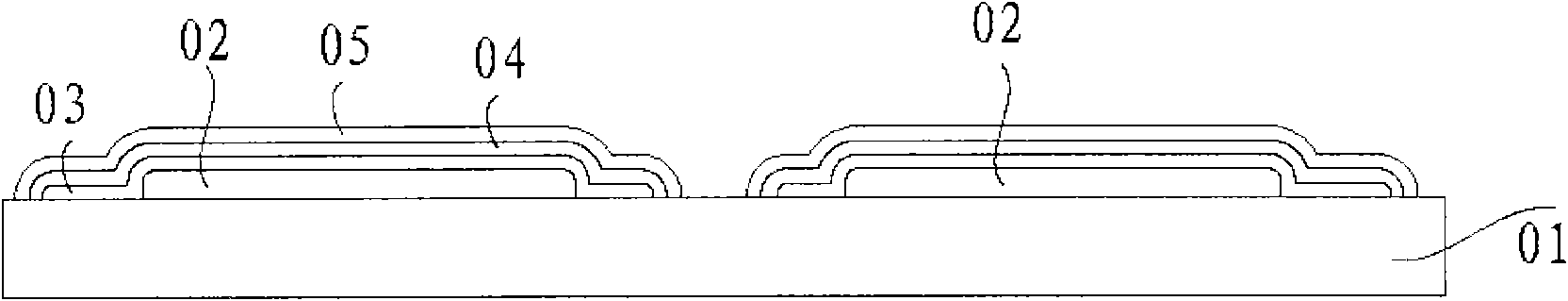

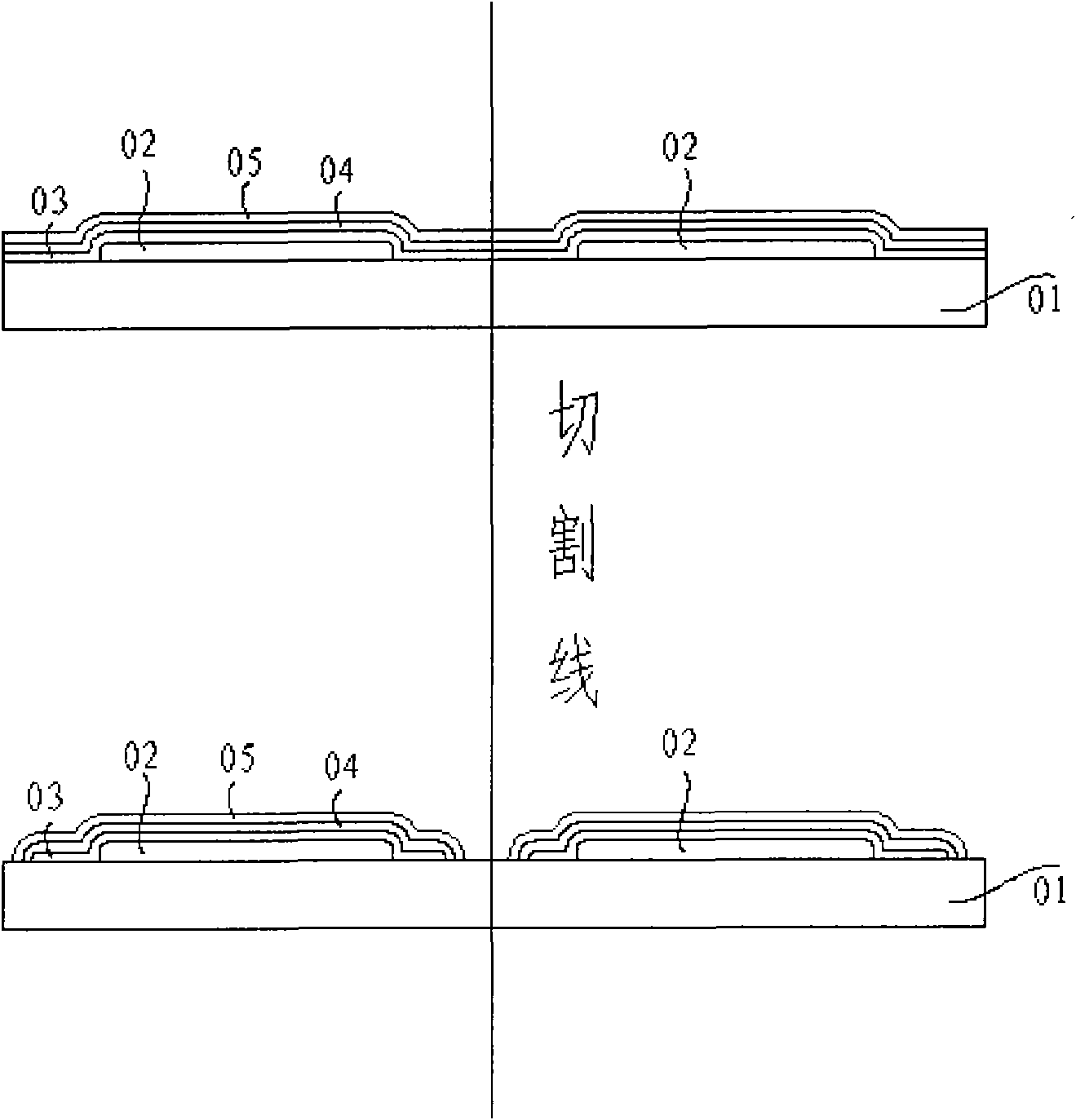

Film packaging method of organic light-emitting device

InactiveCN102610762AReduce crack phenomenonAvoid liftingSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmCrazing

The invention provides a film packaging method of an organic light-emitting device, at least three film sealing layers are deposited on a baseboard from bottom to top, wherein inorganic material and organic material are alternatively deposited on each film sealing layer; a chemical vapor deposition method is preferentially carried out on the organic film sealing layer, and an iron beam sputtering method or an atomic layer deposition method or an magnetron sputtering deposition can be carried out on the inorganic film sealing layer; the early deposited film sealing layer is thinner than the film sealing layer deposited latter; different mask plates are adopted to deposit each film sealing layer, the geometry sizes of the patterns of the mask plates of the first layer, the second layer and the third layer increase sequentially. According to the film packaging method of the organic light-emitting device, the crack caused by plate breaking can be effectively reduced, the space between the sealing layer and the baseboard can be prevented from tilting resulting in air leakage during cutting, and the service life of the device can be effectively prolonged.

Owner:IRICO DISPLAY DEVICES

Preparation method for tantalum oxide film with high laser damage threshold under high-temperature environment

InactiveCN102605333AImprove the characteristics of easy moisture absorptionImprove stabilityVacuum evaporation coatingSputtering coatingCombined methodRoom temperature

The invention relates to a preparation method for a tantalum oxide film with a high laser damage threshold under a high-temperature environment and belongs to the preparation method for an optical film. The preparation method comprises the following steps: plating a tantalum oxide film on a clean substrate according to a double ion beam sputtering method; performing post-processing on a prepared film in laser pre-processing and annealing manner, thereby achieving better functions of repairing film defect and relieving film stress; and preparing a laser film capable of being applied to high-temperature environment. The preparation method provided by the invention has the advantages that: 1) the film prepared according to the double ion beam sputtering method is compact, the characteristic of easiness in moisture absorption of a loosened film prepared according to an electronic beam preparation method is improved, and the stability is better; 2) the laser pre-processing and annealing combined method is adopted, thereby overcoming the limitation caused by traditionally adopting a single method, and being beneficial to greatly increasing the threshold; and 3) the film prepared according to the method can be used under a high-temperature environment with the highest temperature at 350 DEG C, and the problem of the prior art that only the laser film used under room temperature can be prepared is solved.

Owner:CHINA UNIV OF MINING & TECH

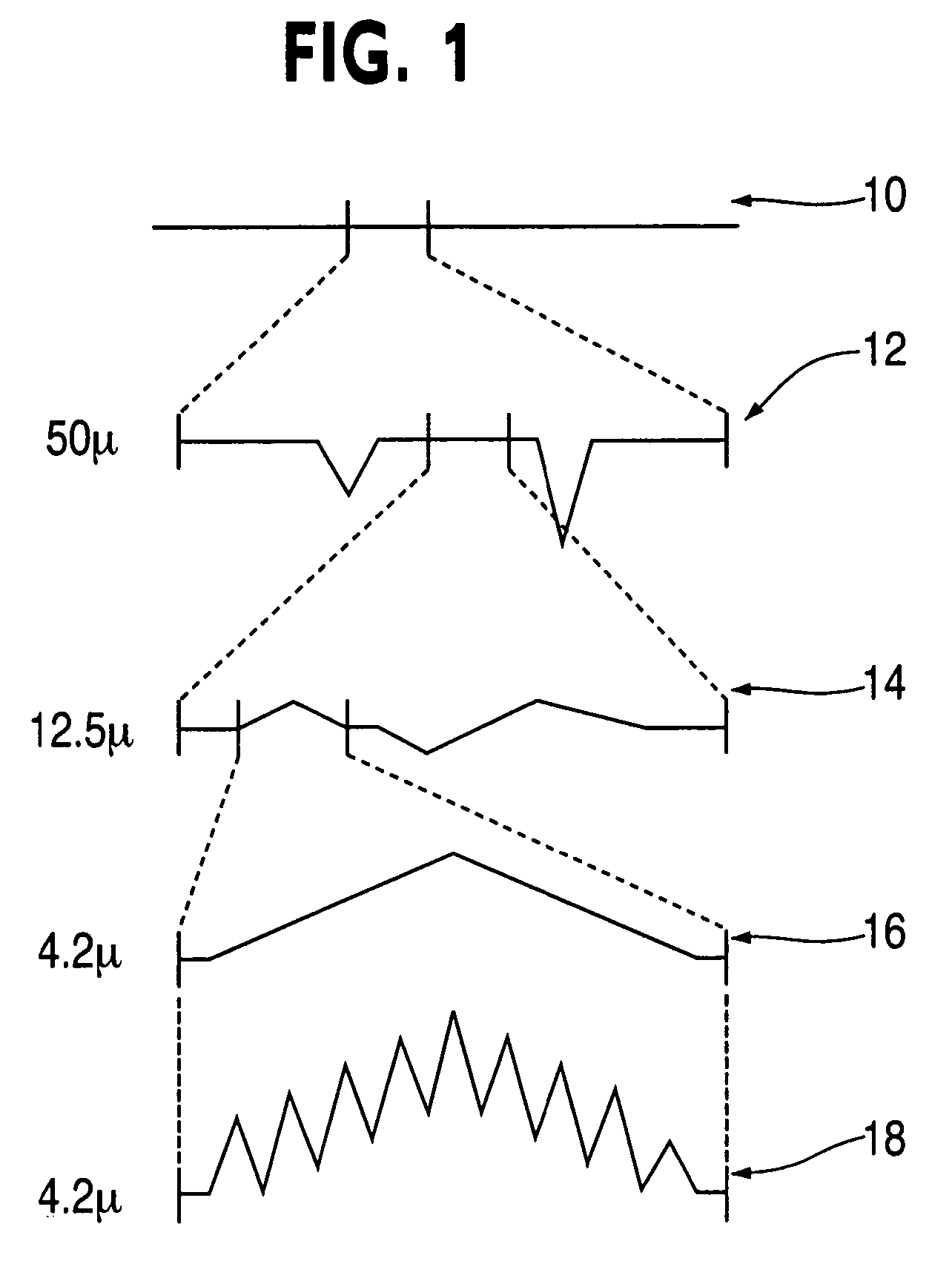

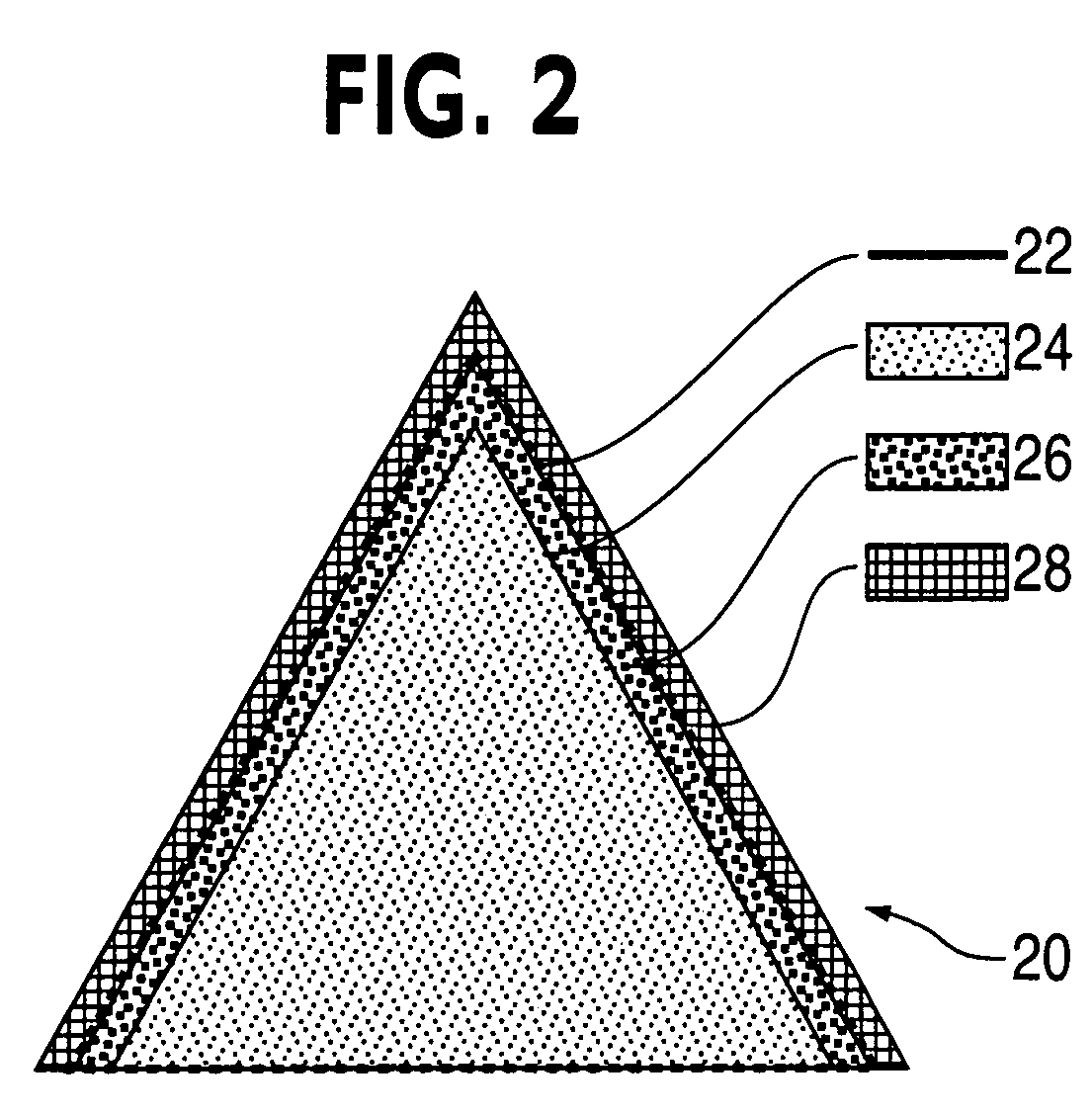

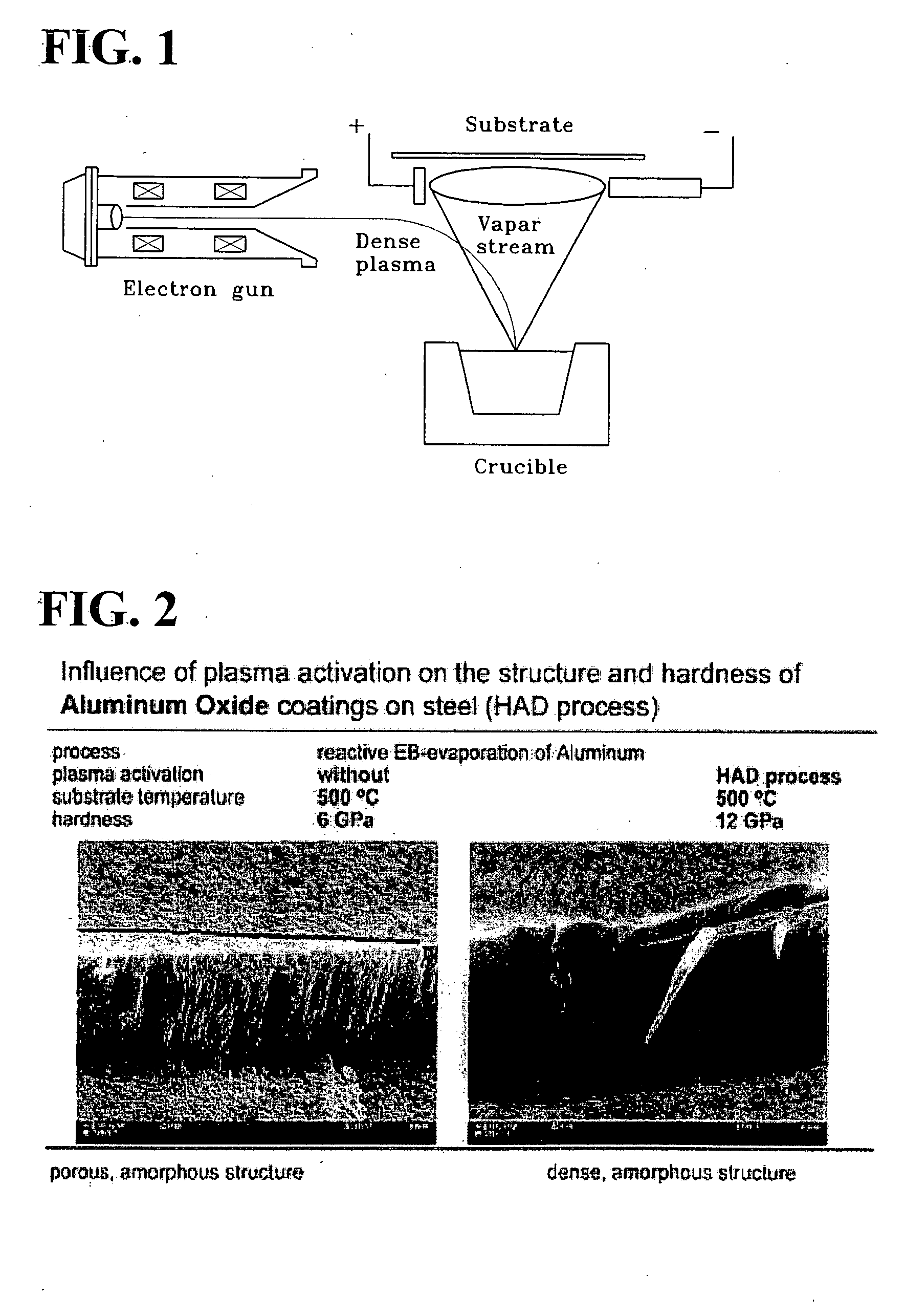

Treatment process for improving the mechanical, catalytic, chemical, and biological activity of surfaces and articles treated therewith

ActiveUS7374642B2High active site densityImprove performanceFurnaces without endless coreVacuum evaporation coatingEtchingMedical equipment

A continuous, uninterrupted two-step treatment process capable of forming nanometer scale physical structures on the surface of articles fabricated from metallic, ceramic, glass, or plastic materials, and then depositing a thin conformal coating on the nanostructured surface such that the physical structures previously produced are neither masked nor are the dimensions of the physical structures substantially altered. In an additional embodiment, a thicker coating can be grown from the thin conformal coating which itself can be nanostructured as it is deposited. In this case adhesion of the thicker coating is not dependent upon the use of conventional surface pretreatments such as machining, chemical etching, or abrasive blasting. Surface texturing may be performed by ion beam sputtering, and ion assisted coating forms the thin conformal coating, and thicker coating if desired. The treatment process is useful for improving the mechanical, catalytic, chemical, or biological activity of the surfaces so treated. The process thus has application on industrial machinery and equipment of all types, engines of all types, manufacturing tooling and wear parts of all types, and medical equipment and prostheses.

Owner:BEAMALLOY RECONSTRUCTIVE MEDICAL PRODS

Deposition method capable of enhancing preferred orientation growth of AlN film

ActiveCN101824592AEasy to operateReduce manufacturing costVacuum evaporation coatingSputtering coatingSurface roughnessSurface acoustic wave

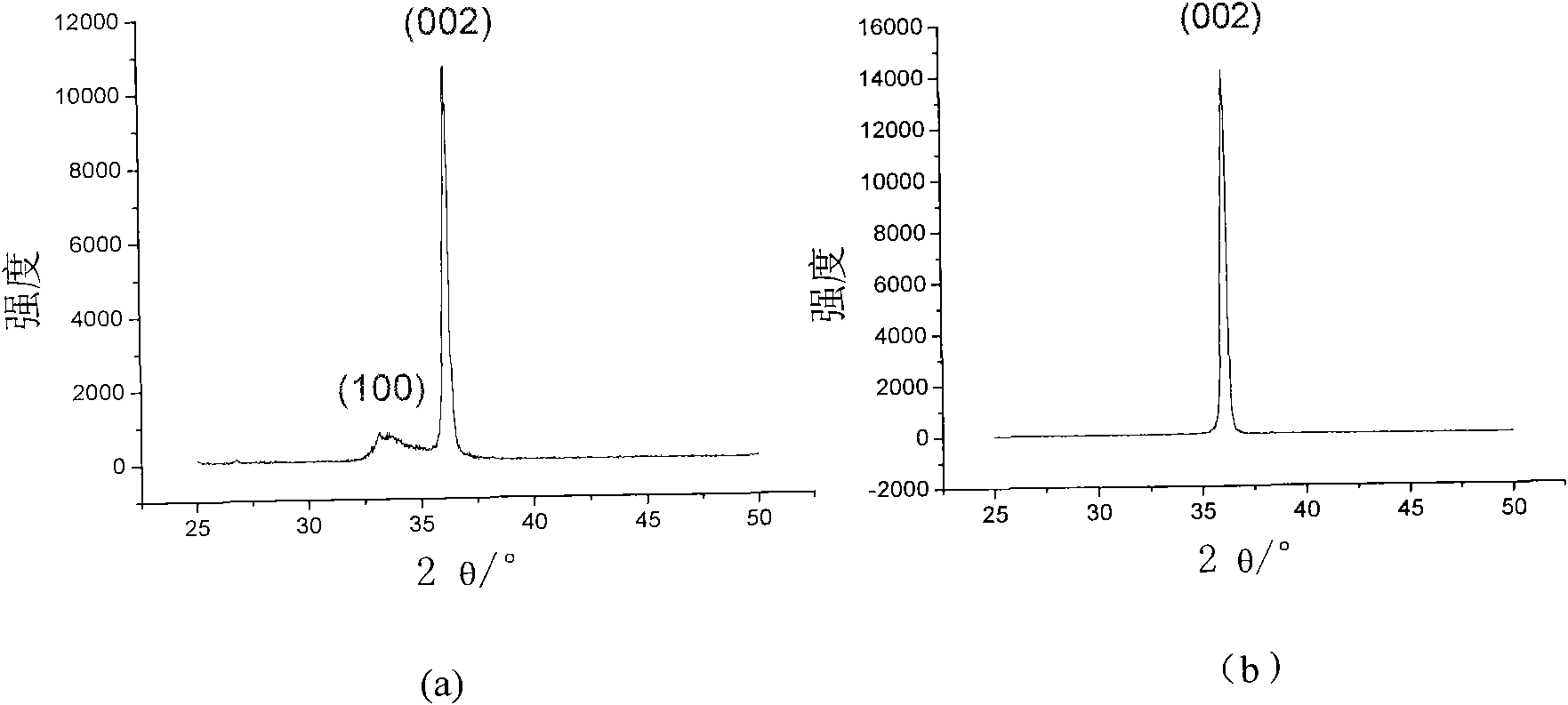

The invention relates to a deposition method capable of enhancing the preferred orientation growth of an AlN film. The deposition method comprises the following steps: adopting an ion beam-assisted deposition technique to prepare an AlN homogeneous transition layer: when using an Ar + ion beam of 2.0-2.5keV / 20-50mA for depositing an Al film in a sputtering way on a substrate, using a moderate-energy N+ ion beam of 20-35keV / 2-8mA for bombarding the Al film in an assisting way; and then depositing the AlN film by adopting magnetron sputtering, wherein base pressure is less than or equal to 5x10<-4>Pa, working air pressure is 0.5-10Pa and substrate temperature is 200 DEG C-500 DEG C. Through pre-depositing the homogeneous transition layer, the invention has the advantages that the internal stress between the film and the substrate can be effectively reduced, the full (002) orientation AlN film is formed, the surface roughness of the film is reduced, the bonding strength between the film and the substrate is increased and the film product can satisfy the requirements on the application in surface acoustic wave devices, acoustic bulk wave devices and other microelectronic devices and power devices.

Owner:湖南特瑞精密医疗器械有限公司

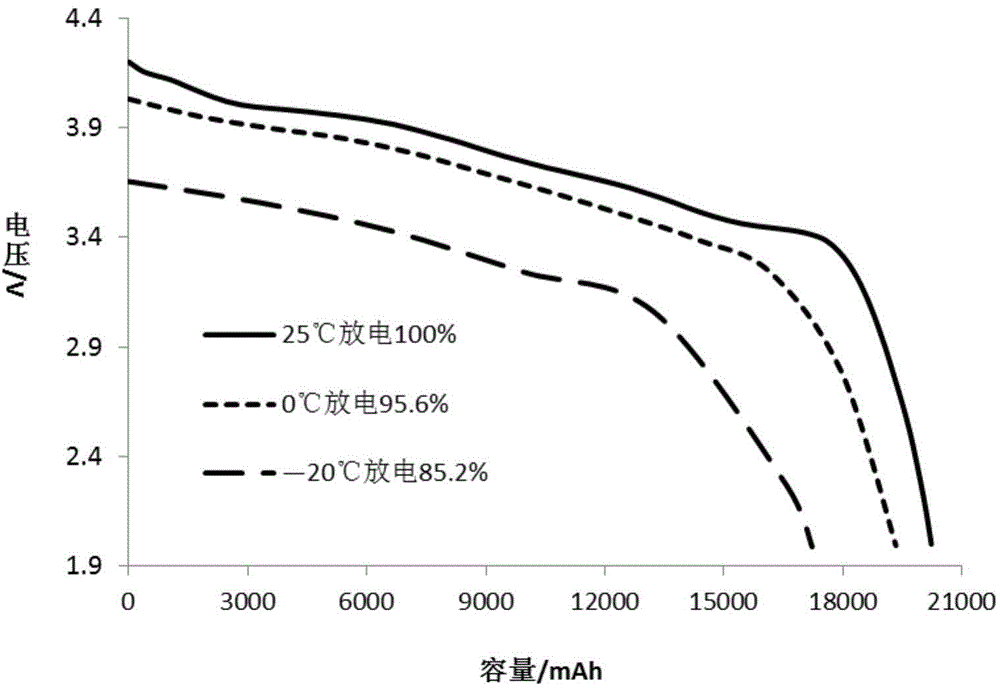

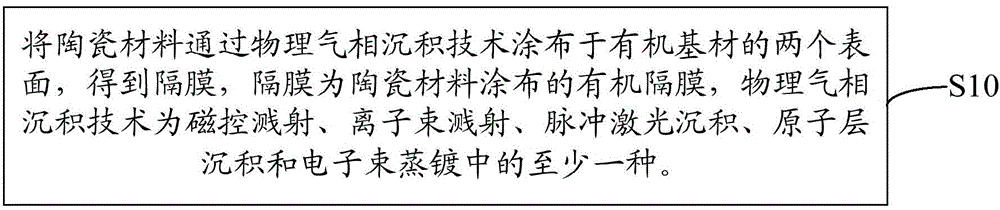

Preparation method of diaphragm and lithium ion battery

The invention relates to a preparation method of a diaphragm and a lithium ion battery with the diaphragm prepared through the preparation method of the diaphragm. The preparation method of the diaphragm includes the following steps that the two surfaces of an organic base material are coated with a ceramic material through the physical vapor deposition technology, the diaphragm is obtained, the diaphragm is an organic diaphragm coated with the ceramic material, and the physical vapor deposition technology is at least one of magnetron sputtering, ion beam sputtering, pulsed laser deposition, atomic layer deposition and electronic beam evaporation. The technological process of the physical vapor deposition technology is simple, the environment is improved, no pollution is caused, fewer consumables are adopted, and a formed film is uniform and dense; the binding force of the ceramic material and the organic base body is high, the mechanical adhesion of the ceramic material layer and the base material in the prepared diaphragm is high, and application is promoted. In addition, the lithium ion battery is designed and comprises the diaphragm prepared through the preparation method of the diaphragm.

Owner:LONG POWER SYST SUZHOU

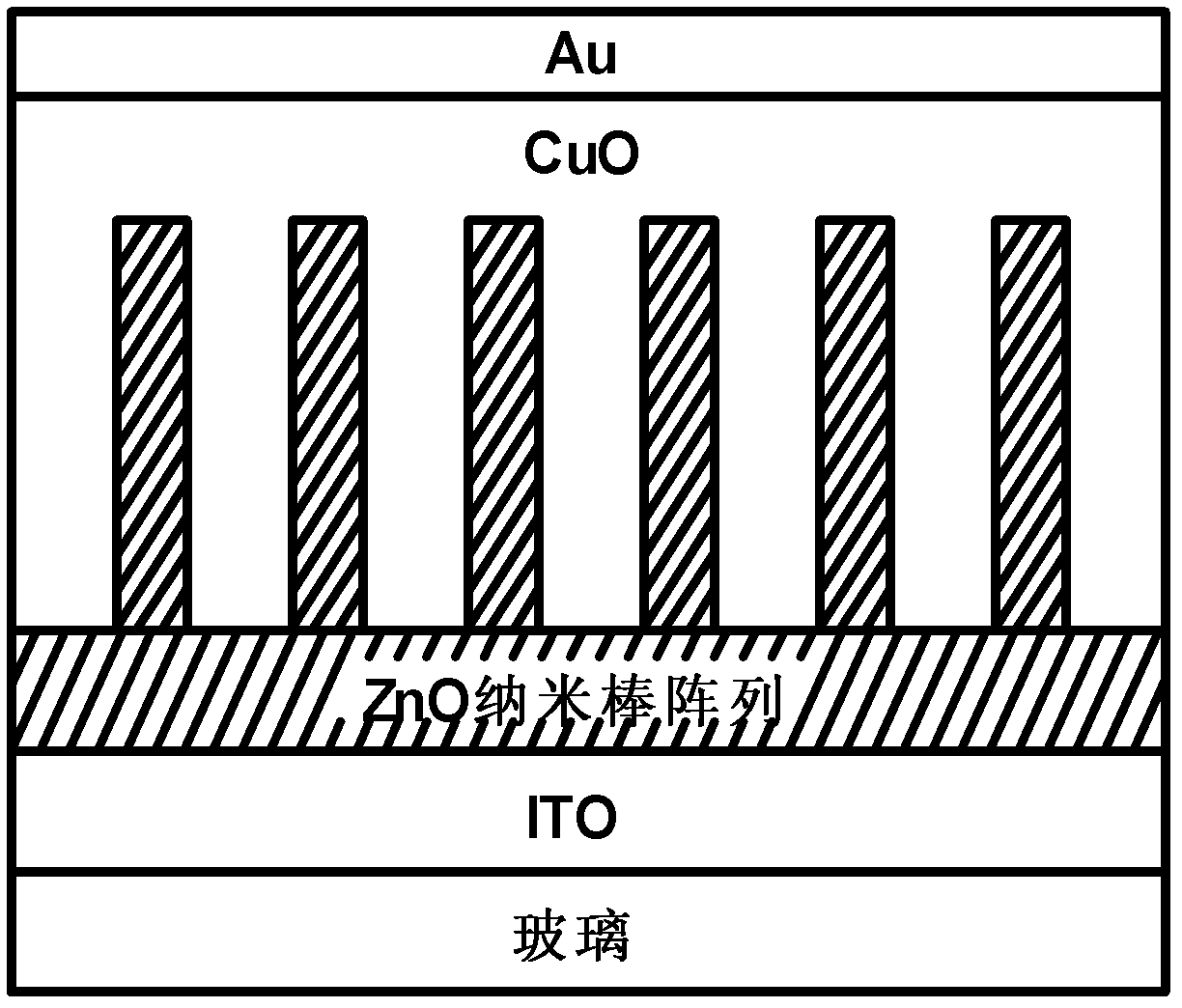

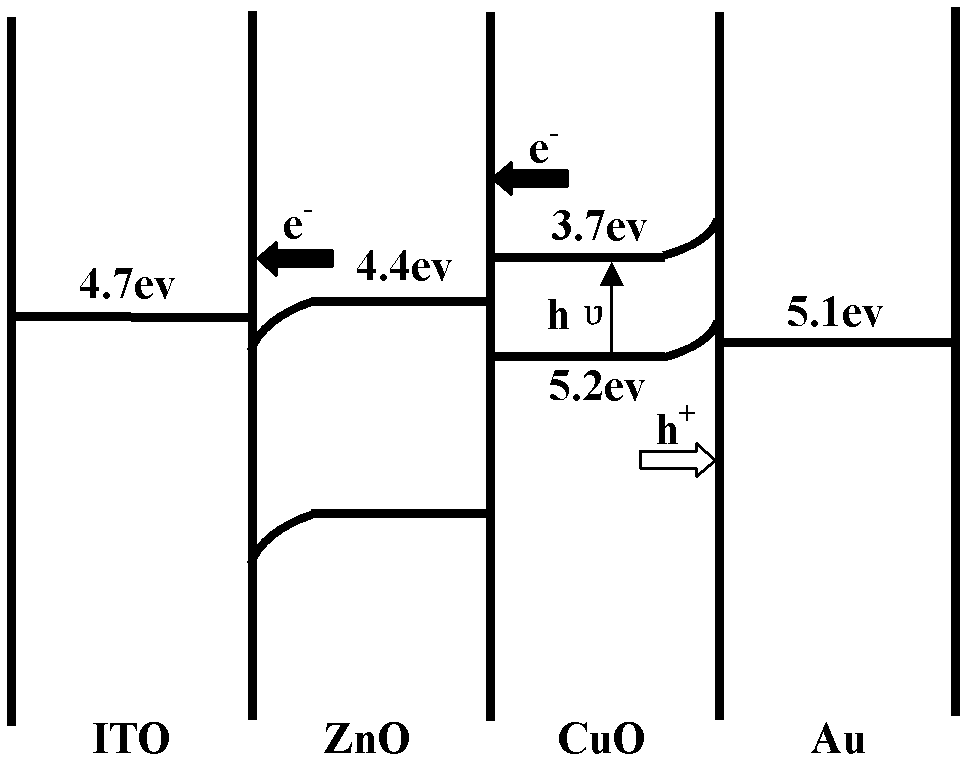

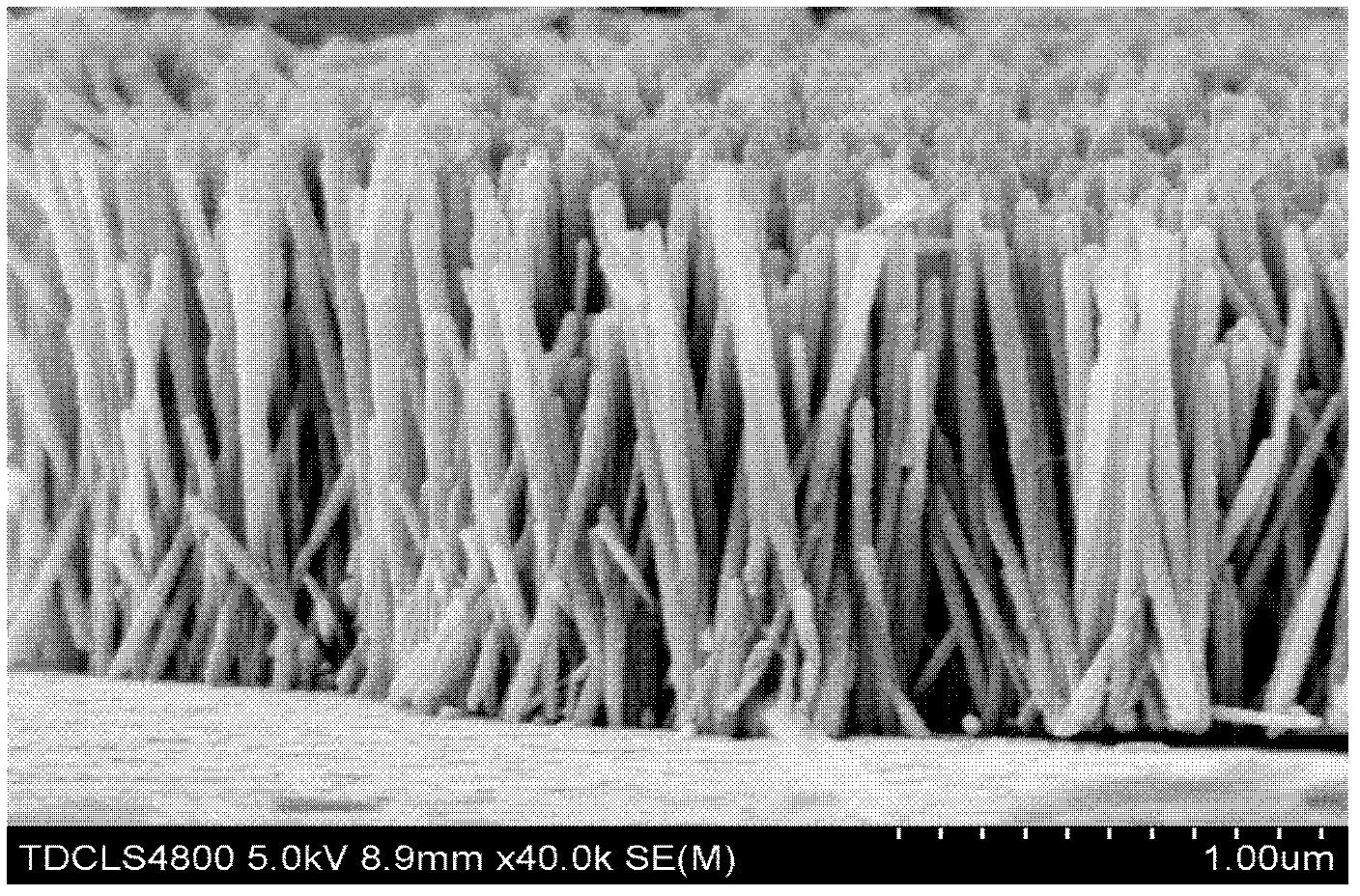

p-CuO-n-ZnO solar cell and preparation method of p-CuO-n-ZnO solar cell

InactiveCN102610687AImprove photoelectric conversion efficiencyLow costFinal product manufacturePhotovoltaic energy generationHole transport layerZinc oxide nanorod

The invention discloses a p-CuO-n-ZnO solar cell. An indium-tin-oxide (ITO) substrate, a vertically oriented ZnO nanorod array, a CuO film and an Au electrode are superposed in sequence from the bottom layer to the top layer, wherein the vertically oriented ZnO nanorod array is used as an n-type semiconductor absorption layer, and the CuO film is used as a p-type semiconductor light absorption layer and a hole transporting layer. The preparation method of the p-CuO-n-ZnO solar cell comprises the following steps of: preparing a ZnO seed crystal layer on ITO by utilizing a sol-gel method; preparing the vertically oriented ZnO nanorod array by utilizing a chemical bath deposition method; preparing the CuO film on the ZnO nanorod array by utilizing an in-situ growth method; and sputtering the Au electrode by using an ion beam sputtering system. The invention has the advantages that the equipment adopted by the preparation method is simple, and the cost is low; as CuO is adopted to serve as the light absorption layer and the hole transporting layer, compared with organic materials, the CuO has higher electromigration capacity; and by combining with the electrical conduction characteristic of inorganic ZnO with high light absorption and low thermal emittance of the CuO, the photoelectric conversion efficiency of the solar cell can be effectively increased.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Method for preparing germanium quantum dot doped nano-titanium dioxide composite film

InactiveCN102071396AFree adjustment of light absorption characteristicsOvercome the disadvantages of easy reunionFinal product manufactureVacuum evaporation coatingComposite filmQuantum dot

The invention relates to a method for preparing a germanium quantum dot doped nano-titanium dioxide composite film through ion beam sputtering. The method comprises the following steps of: cleaning a substrate and a target, placing the substrate and the target into a sputtering chamber, and performing pre-sputtering cleaning on the substrate and the target under vacuum and under protection of argon; performing alternate sputtering on titanium dioxide and the germanium target by argon ion beams with certain projected current and voltage to deposit a titanium dioxide film and a germanium film on the substrate to obtain a germanium-doped nano-titanium dioxide composite film in which the titanium dioxide film is taken as a covering layer; and annealing to obtain the germanium quantum dot doped nano-titanium dioxide composite film. The invention has the advantages that: the method is simple, conditions are mild, the content, scale, morphology and distribution of germanium quantum dots can be freely adjusted in the process, and the disadvantage that the quantum dots are easy to aggregate when prepared by a solution method is overcome so as to adjust the optical absorption characteristics of doped titanium dioxide films.

Owner:TIANJIN UNIV

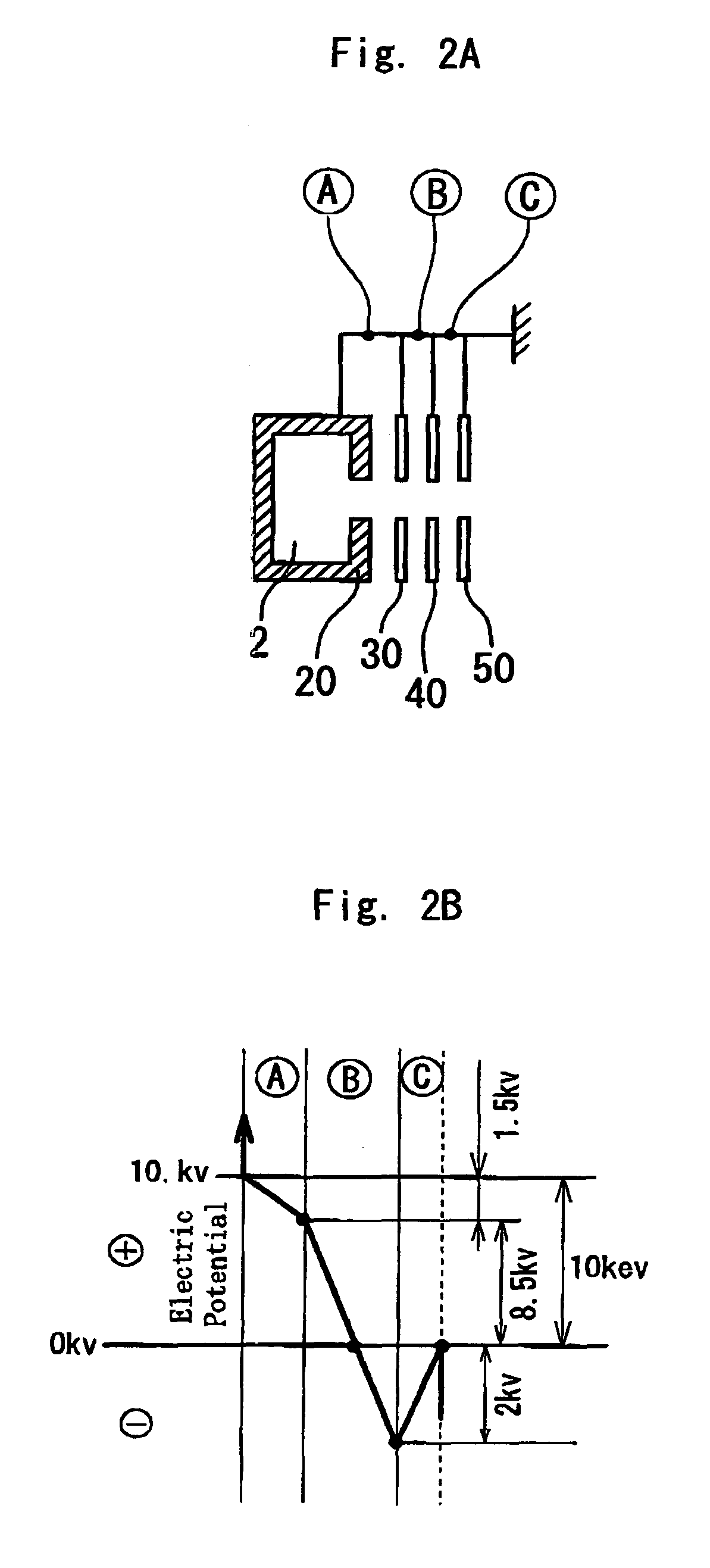

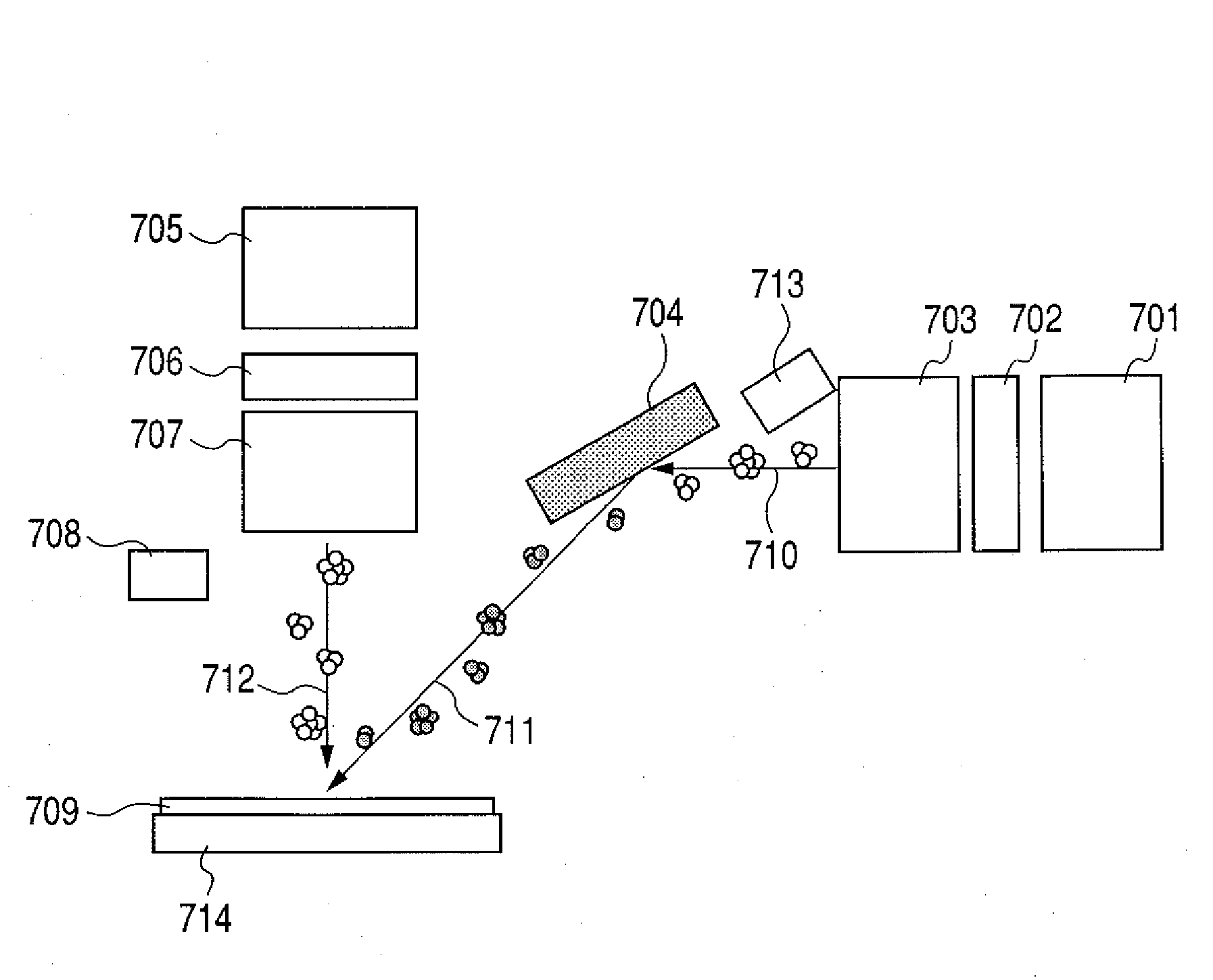

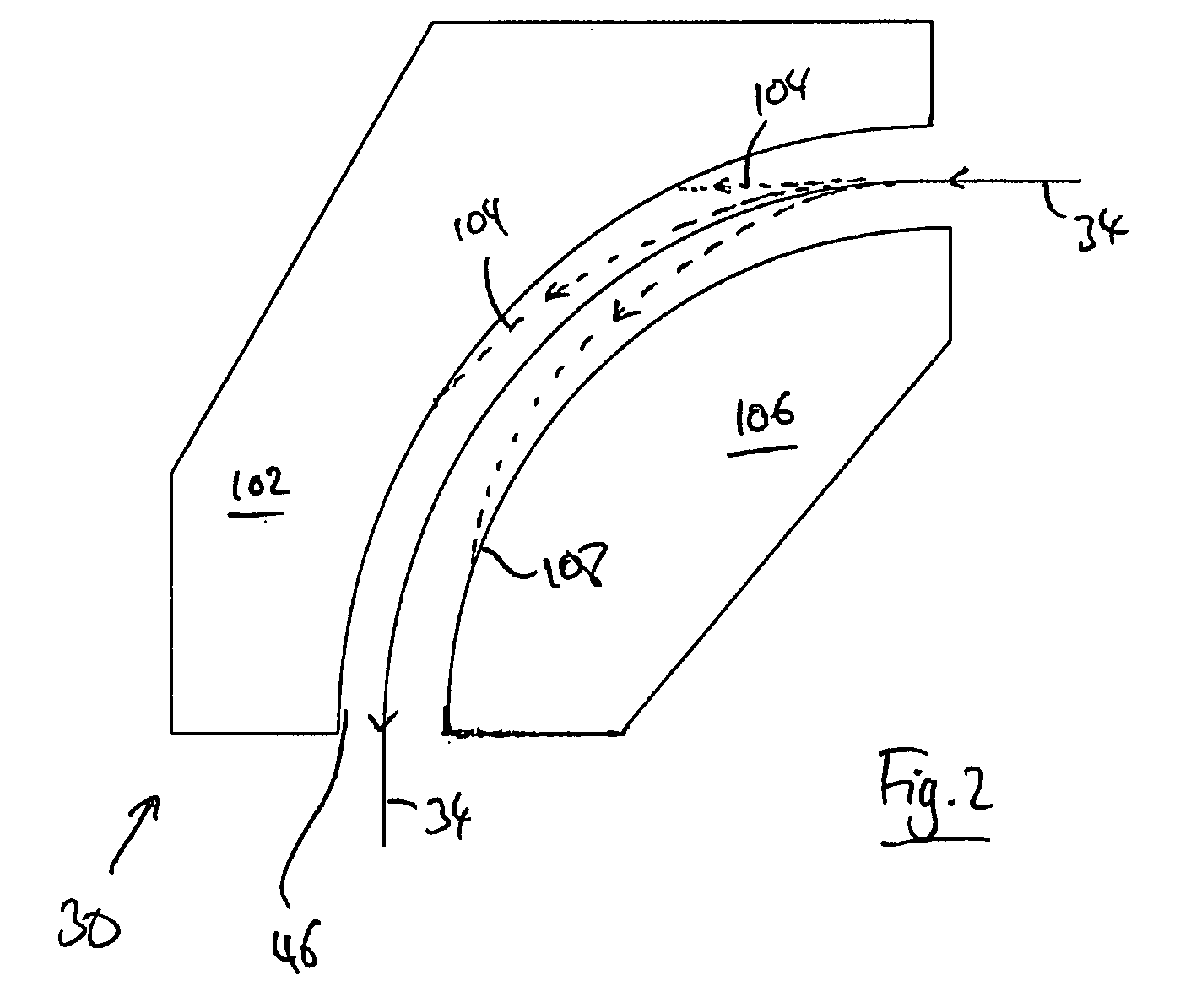

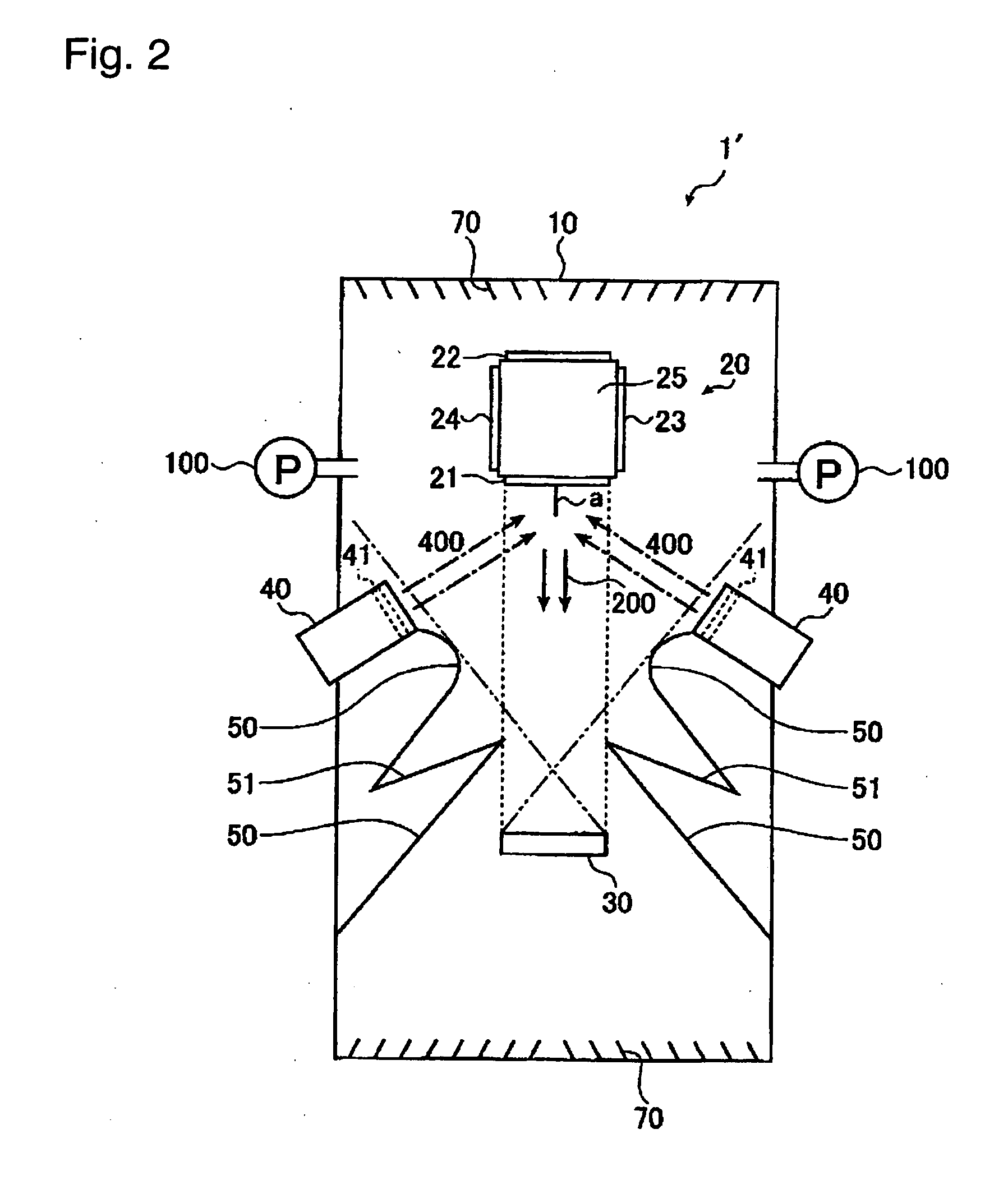

Ion beam sputtering apparatus and film deposition method for a multilayer for a reflective-type mask blank for EUV lithography

InactiveUS20070087578A1Reduce the likelihood of occurrenceReduce the possibilityNanoinformaticsVacuum evaporation coatingLithographic artistIon beam

A film deposition method for a multilayer for a EUV mask blank by which a defect caused by the mixing of a particle in the layer during film formation can be prevented and an ion beam sputtering apparatus suitable for the method are presented. A film deposition method for forming a multilayer for a reflective-type mask blank for EUV lithography on a film deposition substrate by using an ion beam sputtering method, the film deposition method being characterized in that a sputtering target and a film deposition substrate are disposed at opposed positions with a predetermined space, and ion beams are injected to the sputtering target from an ion source which is disposed at a position out of the region where particles move linearly from the film deposition substrate toward the sputtering target.

Owner:ASAHI GLASS CO LTD

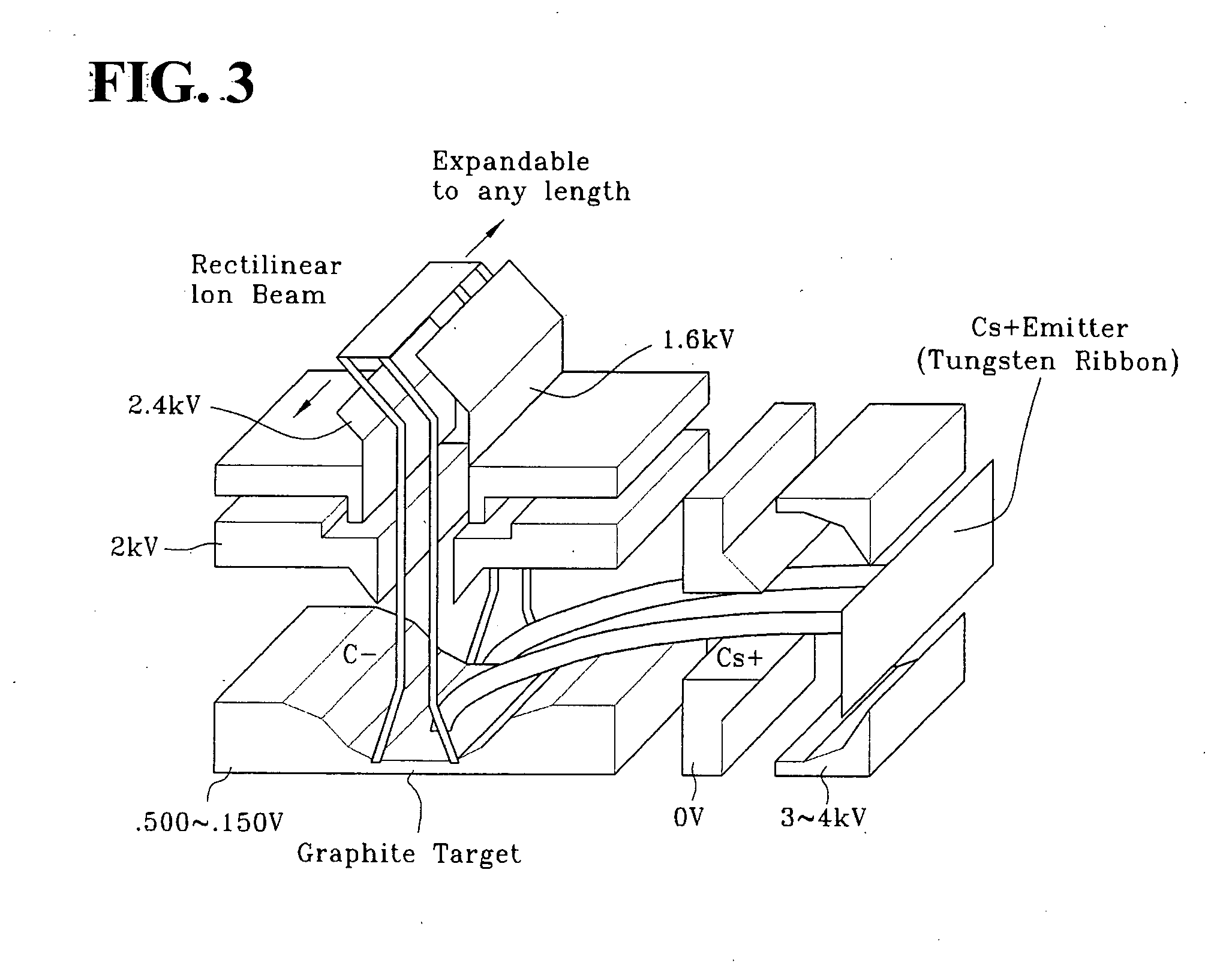

Direct ion beam deposition method and system

InactiveUS20060225998A1Avoid overall overheatingFacilitating ion emission of the deposit materialCellsElectric discharge tubesIonizationElectron

Disclosed herein is a direct ion beam deposition method through ion beam sputtering. The method comprises the steps of: a) providing a workpiece on which a certain material is to be deposited with a certain desired thickness; b) providing a deposit material having a certain area from which the deposit material is discharged into a certain working gas atmosphere; c) transforming the working gas atmosphere into a plasma atmosphere by bombarding electrons widely to the working gas atmosphere; d) emitting a surface material by means of a sputter from the deposit material exposed in the plasma atmosphere; e) exposing the emitted deposit material to an ionization environment; f) and providing energy to the deposit material by applying an electric potential to the step e) to thereby be radiated on a corresponding face of the workpiece. A direct ion beam deposition system is also disclosed.

Owner:SONG SEOK KYUN

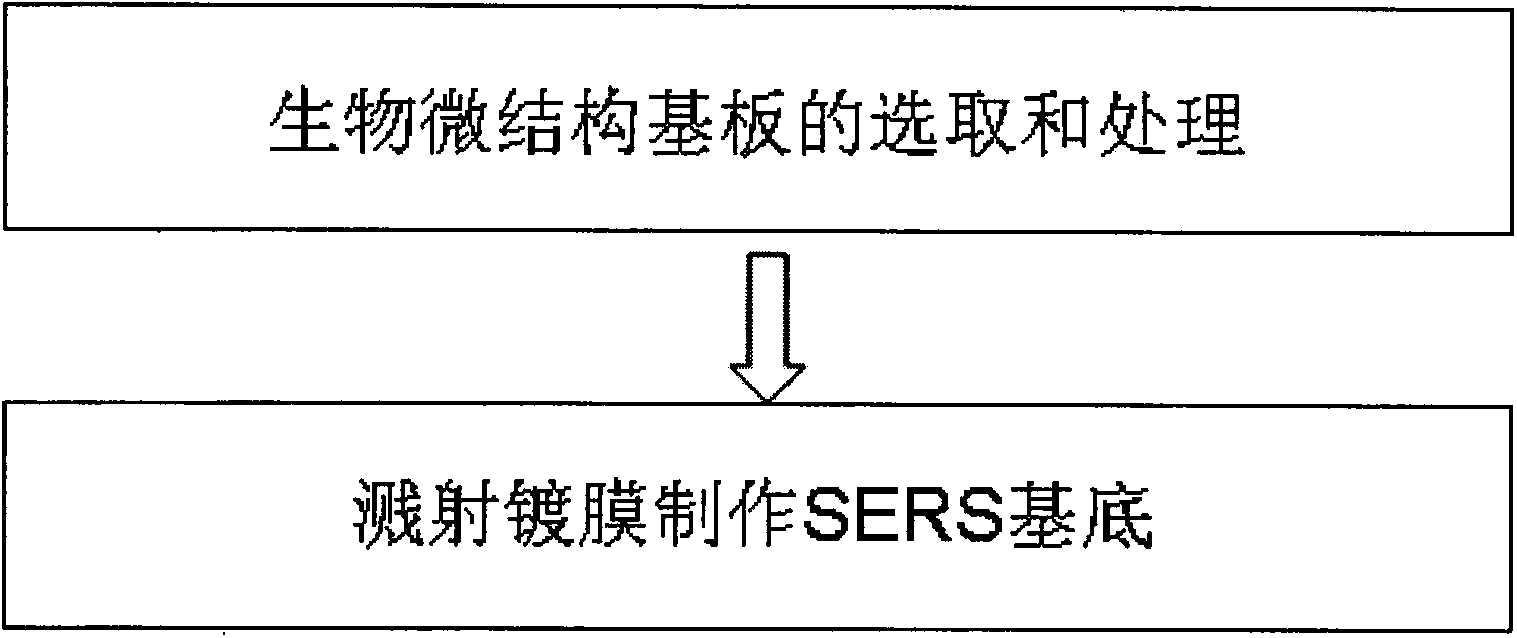

Method for manufacturing surface enhancement Raman scatting substrate

InactiveCN103361601ALow costSimple methodVacuum evaporation coatingSputtering coatingEnvironmental resistanceMicro nano

The invention discloses a method for manufacturing a surface enhancement Raman scatting (SERS) substrate having ultra high performance. The method comprises the steps: firstly, selecting a cicada wing, a butterfly wing, a scarlet macaw feather or other biological micro structures as a basal plate, and simply cleaning, drying and shaping the biological micro structure basal plate; and then plating gold, silver or other precious metals on the biological micro structure basal plate by magnetron sputtering or ion beam sputtering or other precise film plating methods to produce the SERS substrate. The gap size of a micro-nano structure is precisely controlled by controlling the thickness of the plating film, and the micro-nano gap size can be controlled to be less than 10 nm. The manufactured SERS substrate has the outstanding advantages of large area, low cost, uniformity, environmental protection, ultra sensitivity, precisely controllable gap and the like. The environmental protection material is selected as the basal plate, the quite simple, mature and low-cost method is used for manufacturing the high performance SERS substrate which meets the needs of practical applications and theoretical researches, so that a powerful tool and a solid foundation are provided for the theoretical researches and the practical applications of an SERS effect.

Owner:NANKAI UNIV

Preparation device and preparation method of high-flux combined material

InactiveCN104404468AImprove qualityAvoid pollutionVacuum evaporation coatingSputtering coatingHigh fluxIon beam

The invention discloses a preparation device and a preparation method of high-flux combined material. The preparation device comprises a target storage cavity, a preparation cavity and a target change cavity, wherein the target storage cavity is used for storing spare targets; the preparation cavity is sputtered on surfaces of the targets through ion beam and is re-sputtered on the surface of a substrate to deposit a plurality of film materials, so as to form a combined target chip precursor; the target change cavity transfers and stores the targets between the preparation cavity and the target storage cavity; interiors of the target storage cavity, the preparation cavity and the target change cavity are at vacuum state. The preparation device and the preparation method of the high-flux combined material avoid target pollution, and reduce the pollution to films by pollution sources of oxygen and the like in the preparation device, so that high-quality high-flux combined material chips can be obtained.

Owner:INFINITE MATERIALS TECH

Vacuum multifunctional continuous film coating apparatus

InactiveCN101413109AIncrease profitReduce manufacturing costVacuum evaporation coatingSputtering coatingComposite filmEvaporation

The invention belongs to the technical field of electronic mechanical technology and relates to a high-vacuum multifunctional ion beam sputtering and electron beam evaporation continuous film plating device. A vacuum film plating chamber of the device has a single chamber structure; a generator of an ion beam sputtering source and a generator of an electron beam evaporation plating source are arranged outside the vacuum film plating chamber; inlets of two generators conducting to the vacuum film plating chamber are correspondingly provided with an ion beam sputtering source baffle plate and an electron beam evaporation plating source baffle plate; constant tensile force can reverse a furling and stretching reel of a winding unit, follow a transition shaft and is fixed on a connecting and supporting device of the vacuum film plating chamber; and corresponding sensing, driving and controlling are arranged outside the vacuum film plating chamber. The device has a compact structure, various film plating and continuous film plating functions in the single vacuum chamber, can realize the auxiliary enhanced deposition of ion beams in the discontinuous or full film plating process, can improve the utilization rate of a sputtering target material by 60 to 100 percent, in particular a noble metal target material and a class of a target material which is difficult to machine, and can also obtain a coating-type composite film product with special functions through an inlaid-type target.

Owner:KUNMING UNIV OF SCI & TECH

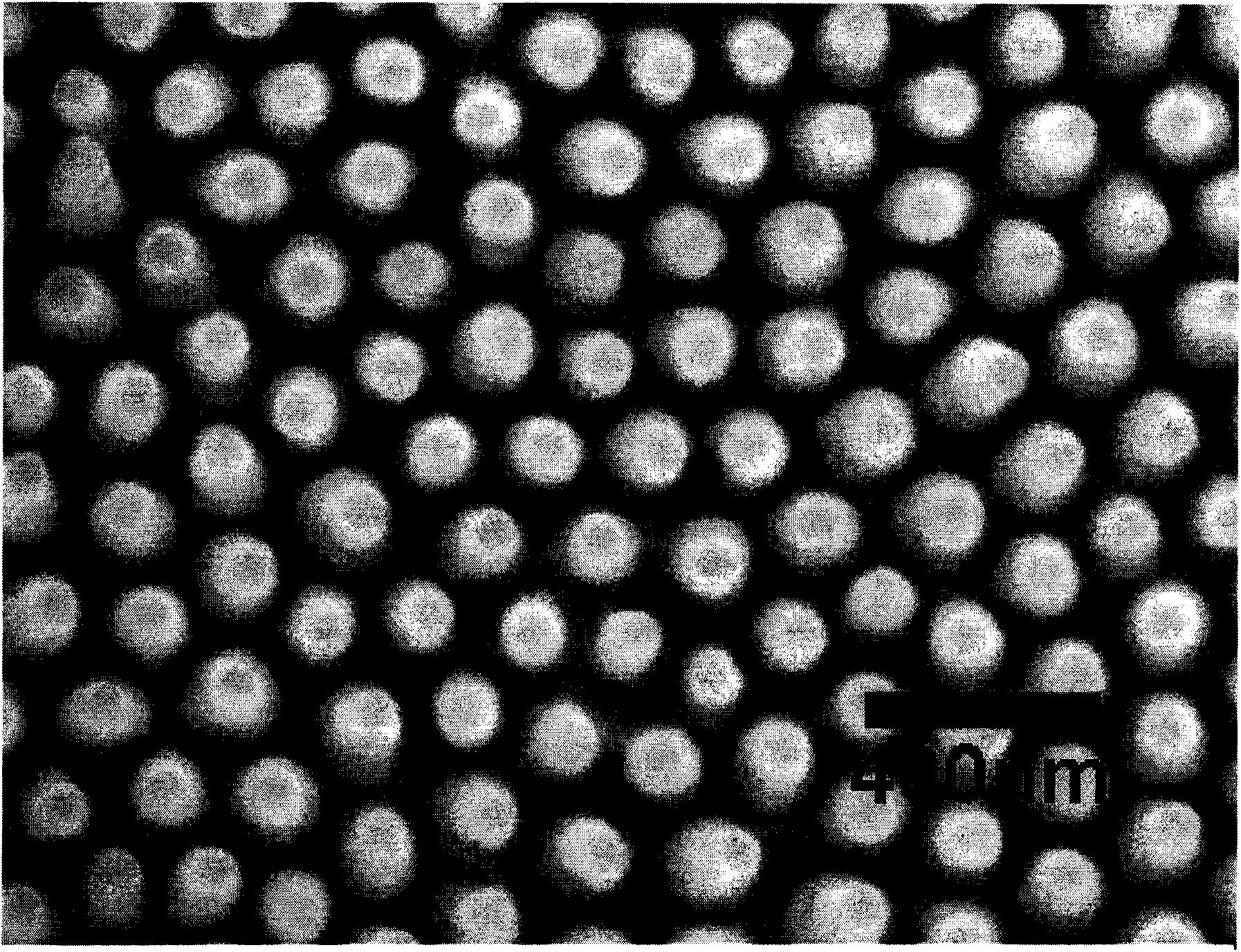

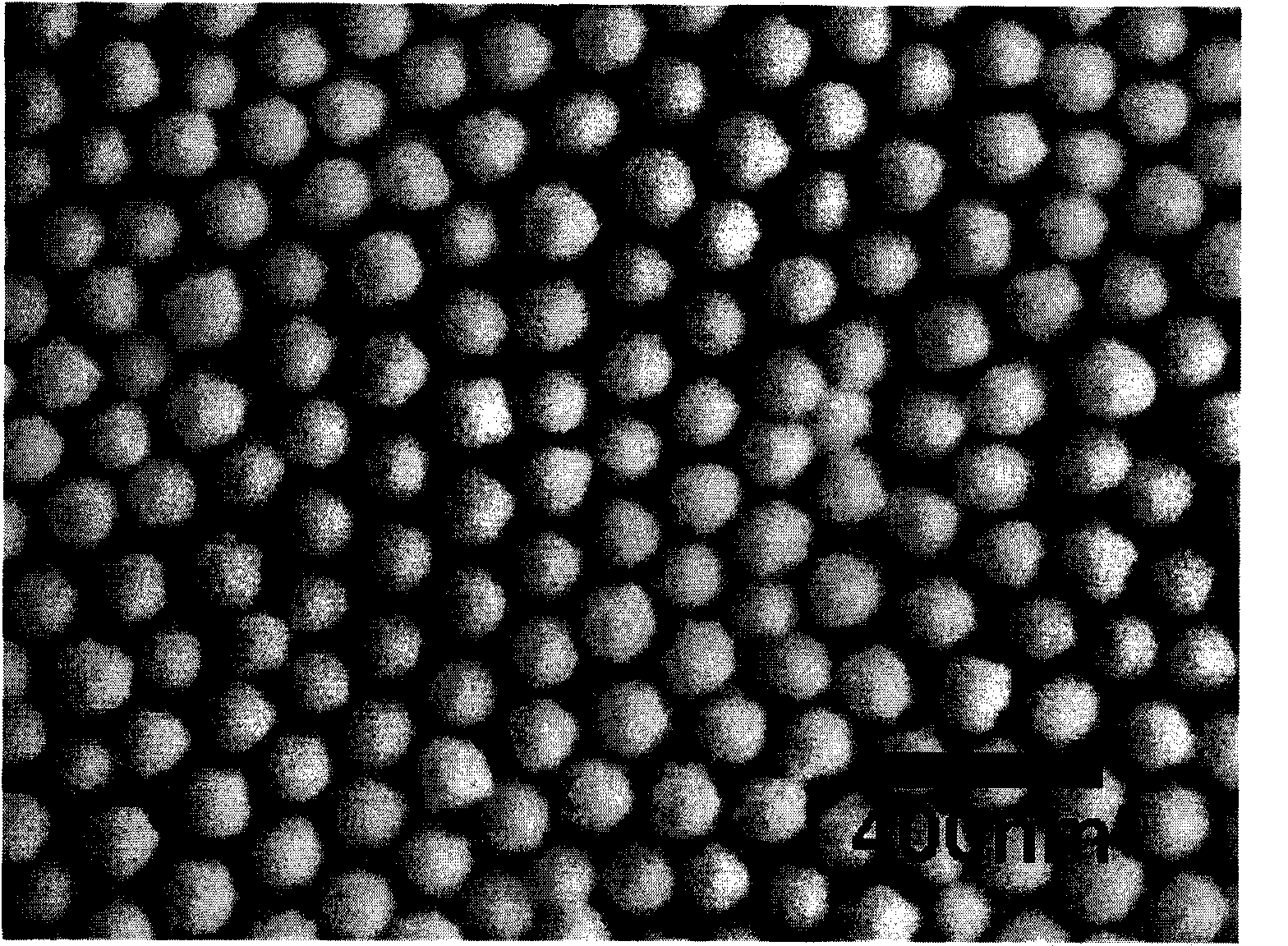

Large-area metal nano-structural substrate for surface-enhanced Raman and preparation method thereof

InactiveCN101716839AUniform shapeEnhanced Raman activityVacuum evaporation coatingSputtering coatingMetallic materialsAlloy

The invention discloses a large-area metal nano-structural substrate for surface-enhanced Raman and a preparation method thereof. The large-area metal nano-structural substrate for the surface-enhanced Raman consists of a nano-scale structural substrate consisting of different phase alloy materials and a nano-thickness metal material deposited on the substrate. The metal nano-structural substrateprovided by the invention has good Raman enhancing effect, and can be widely applied in the fields of physics, chemistry, materials science, biomedicine and the like. The preparation method for the large-area metal nano-structural substrate for the surface-enhanced Raman uses an alloy material consisting of different phases as a primary template, adopts a selective plasma etching method to etch the nano-structural substrate, and then adopts an ion beam sputtering method to deposit the nano-thickness metal material on the nano-structural substrate so as to form the surface-enhanced Raman substrate based on different phase metal materials; and the preparation method has mature industrial technology and low production cost, and can implement industrialized mass production.

Owner:NANJING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com