Film packaging method of organic light-emitting device

An organic light-emitting device and thin-film packaging technology, which is applied in the manufacture of electric solid-state devices, semiconductor devices, and semiconductor/solid-state devices, etc., can solve the problems of unsatisfactory sealing effect, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

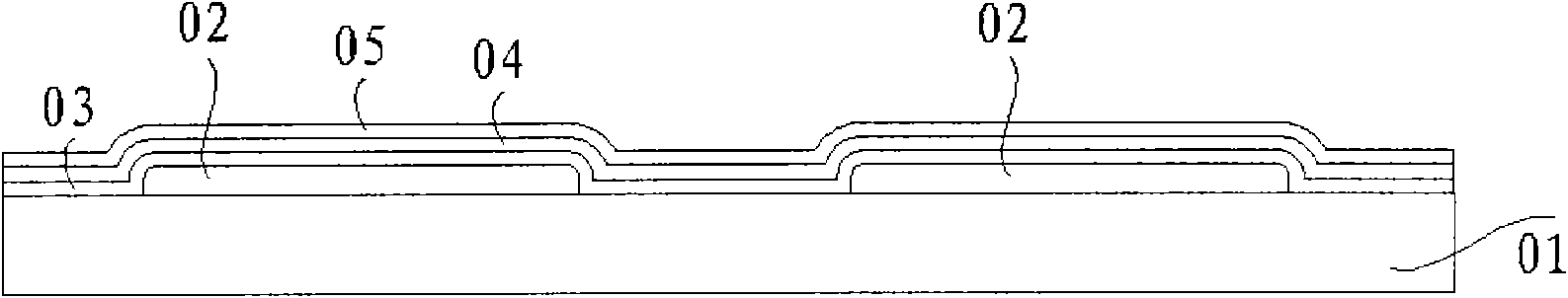

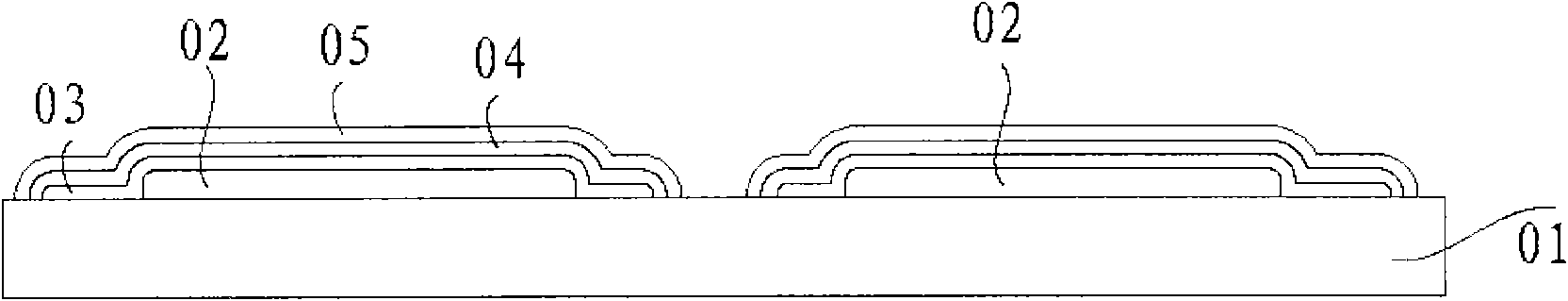

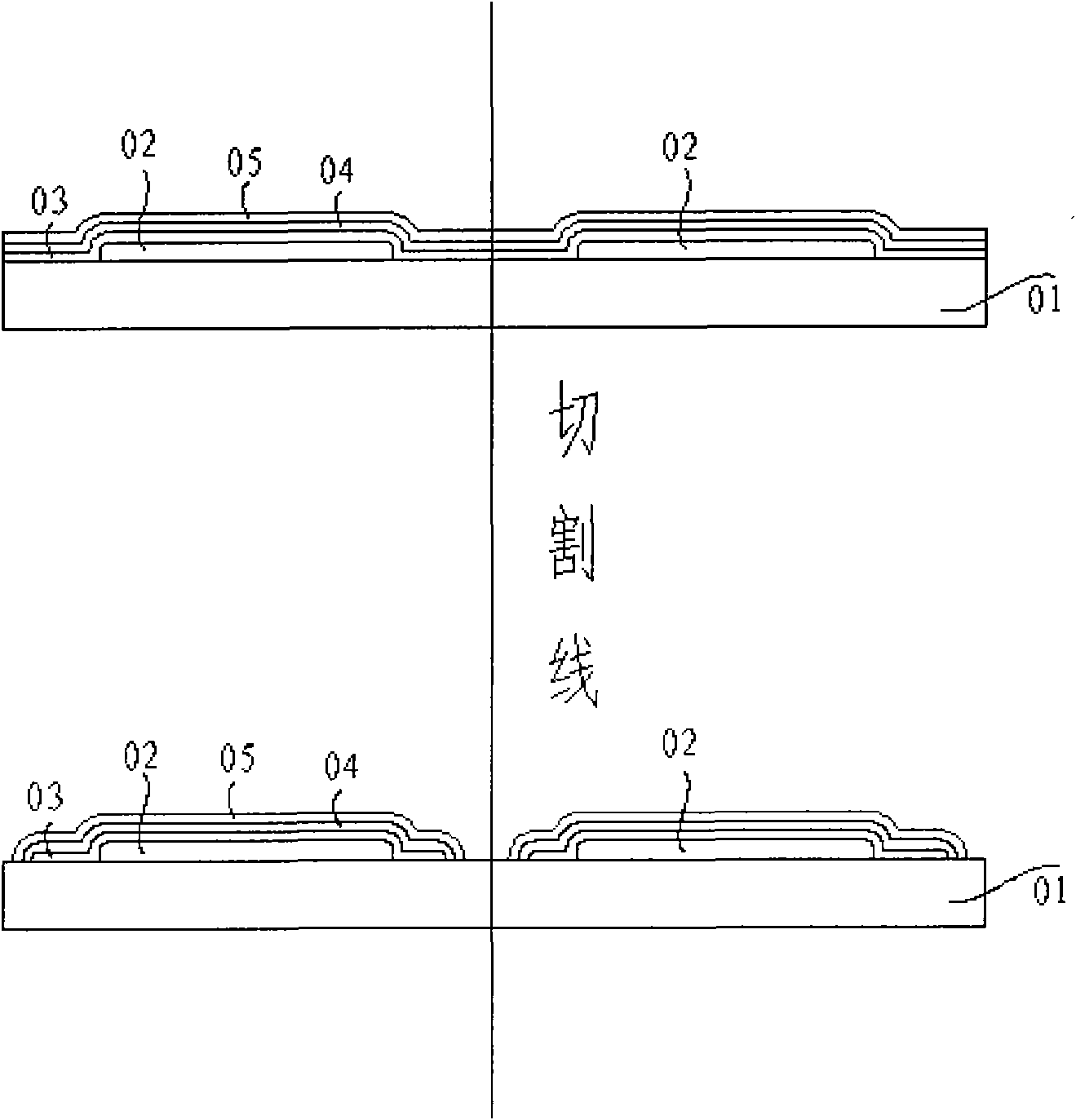

[0021] The present invention utilizes mask plate technology in the process of depositing thin film, makes deposited thin film produce such as figure 2 The sealing effect shown is that the upper sealing layer completely wraps the edge of the lower sealing layer to form individual sealing units. The mask plate is made of nickel steel, the pattern of the mask plate is consistent with the pattern of a single organic light-emitting device, and the size of the mask plate used for the thin film sealing layer 03 / 04 / 05 is increased by 50 microns sequentially.

[0022] The first step: Deposit the inorganic thin film sealing layer 03, this layer is deposited by ion beam sputtering, and the sealing material is Al 2 o 3 , the deposition chamber is 10 -6 The vacuum degree is Pa, the deposition time is 3min, and the deposition thickness is 15nm.

[0023] Put the substrate 01 into the deposition chamber, place the first mask on the corresponding position of the substrate 01, adjust the vac...

Embodiment 2

[0036] The first step: deposit the inorganic thin film sealing layer 03, this layer is deposited by magnetron sputtering, and the sealing material is Al 2 o 3 , the deposition chamber is 10 -6 The vacuum degree is Pa, the deposition time is 5min, and the deposition thickness is 50nm.

[0037] Put the substrate 01 into the deposition chamber, place the first layer of mask on the corresponding position of the substrate 01, adjust the vacuum degree in the deposition chamber and set the deposition time, complete the deposition after 5 minutes, and take out the first layer of mask Plate, replace the second mask plate.

[0038] This step completes the preparation of the inorganic thin film sealing layer 03 on the substrate 01 .

[0039] The second step: deposit organic thin film sealing layer 04, this layer adopts chemical vapor deposition (CVD), the sealing material adopts polyurea, and the deposition chamber is 10 -6 The vacuum degree is Pa, the deposition time is 10min, and t...

Embodiment 3

[0048] The first step: Deposit inorganic sealing layer 03, this layer is deposited by magnetron sputtering, the sealing material is SiN, and the vacuum degree in the deposition chamber is 10 -5 Pa, the deposition time is 3min, and the deposition thickness is 30nm.

[0049] Put the substrate 01 into the deposition chamber, place the first mask plate (10) on the corresponding position of the substrate 01, adjust the vacuum degree in the deposition chamber and set the deposition time, after 3 minutes to complete the deposition, take out the first Layer mask, replace with the second layer mask.

[0050] This step completes the preparation of the inorganic sealing layer 03 on the substrate 01 using SiN material.

[0051] The second step: deposit organic thin film sealing layer 04, this layer adopts chemical vapor deposition (CVD), the sealing material adopts C-type polychlorinated p-xylene, and the vacuum degree in the deposition chamber is 10 -5 Pa, the deposition time is 20min,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com