High-strength spoke manufacturing process

A manufacturing process and high-strength technology, applied in spoke-type wheels, metal material coating technology, wheel manufacturing, etc., can solve the problems of easy bending and breaking, difficult to store for a long time, and easy to corrode the spokes, and reduce cracks. , the effect of prolonging the storage time and improving the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

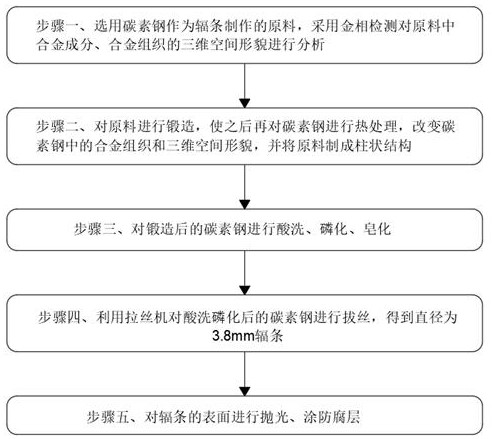

[0024] refer to figure 1 , a high-strength spoke manufacturing process, comprising the following steps:

[0025] Step 1. Selecting carbon steel as the raw material for making the spokes, and using metallographic detection to analyze the three-dimensional spatial morphology of the alloy composition and alloy structure in the raw material;

[0026] Step 2, forging the raw material, so that the carbon steel is then heat-treated to change the alloy structure and three-dimensional space morphology in the carbon steel, and make the raw material into a columnar structure;

[0027] Step 3, pickling, phosphating and saponifying the forged carbon steel;

[0028] Step 4, using a wire drawing machine to draw wires on the carbon steel after pickling and phosphating to obtain spokes with a diameter of 3.8 mm;

[0029] Step 5, polishing and coating the surface of the spokes with an anti-corrosion layer.

[0030] Further, in step 2, the forging adopts hot forging, the forging temperature i...

Embodiment 2

[0038] refer to figure 1 , a high-strength spoke manufacturing process, comprising the following steps:

[0039] Step 1. Selecting carbon steel as the raw material for making the spokes, and using metallographic detection to analyze the three-dimensional spatial morphology of the alloy composition and alloy structure in the raw material;

[0040] Step 2, forging the raw material, so that the carbon steel is then heat-treated to change the alloy structure and three-dimensional space morphology in the carbon steel, and make the raw material into a columnar structure;

[0041] Step 3, pickling, phosphating and saponifying the forged carbon steel;

[0042] Step 4, using a wire drawing machine to draw wires on the carbon steel after pickling and phosphating to obtain spokes with a diameter of 3.8 mm;

[0043] Step 5, polishing and coating the surface of the spokes with an anti-corrosion layer.

[0044] Further, in step 2, the forging adopts hot forging, the forging temperature i...

Embodiment 3

[0052] refer to figure 1 , a high-strength spoke manufacturing process, comprising the following steps:

[0053] Step 1. Selecting carbon steel as the raw material for making the spokes, and using metallographic detection to analyze the three-dimensional spatial morphology of the alloy composition and alloy structure in the raw material;

[0054] Step 2, forging the raw material, so that the carbon steel is then heat-treated to change the alloy structure and three-dimensional space morphology in the carbon steel, and make the raw material into a columnar structure;

[0055] Step 3, pickling, phosphating and saponifying the forged carbon steel;

[0056] Step 4, using a wire drawing machine to draw wires on the carbon steel after pickling and phosphating to obtain spokes with a diameter of 3.8 mm;

[0057] Step 5, polishing and coating the surface of the spokes with an anti-corrosion layer.

[0058] Further, in step 2, the forging is hot forging, the temperature of the forgin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com