Patents

Literature

3967 results about "Saponification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Saponification is a process that involves conversion of fat or oil into soap and alcohol by the action of heat in the presence of aqueous alkali (e.g. NaOH). Soaps are salts of fatty acids whereas fatty acids are saturated monocarboxylic acids that have long carbon chains (at least 10) e.g. CH₃(CH₂)₁₄COOH.

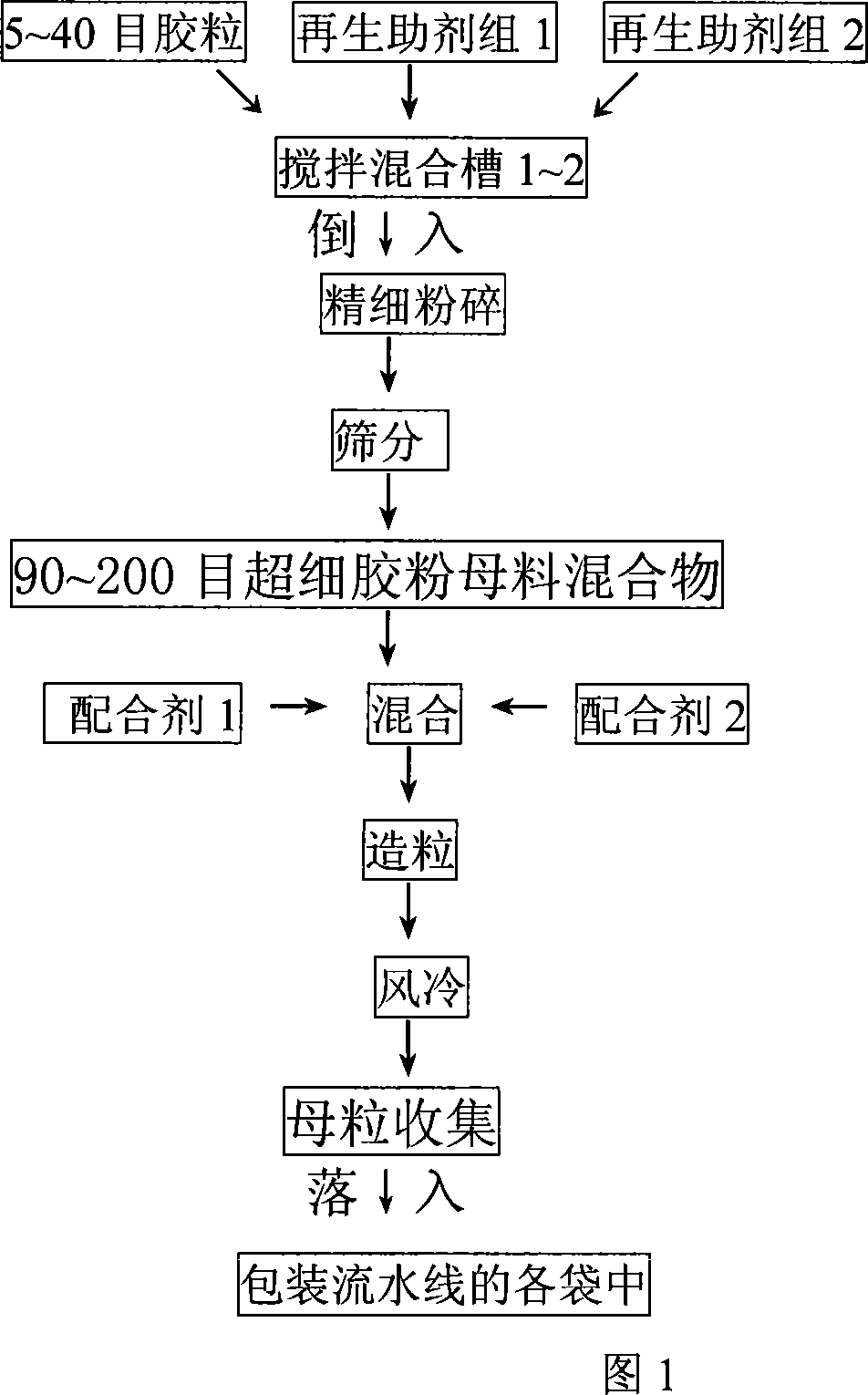

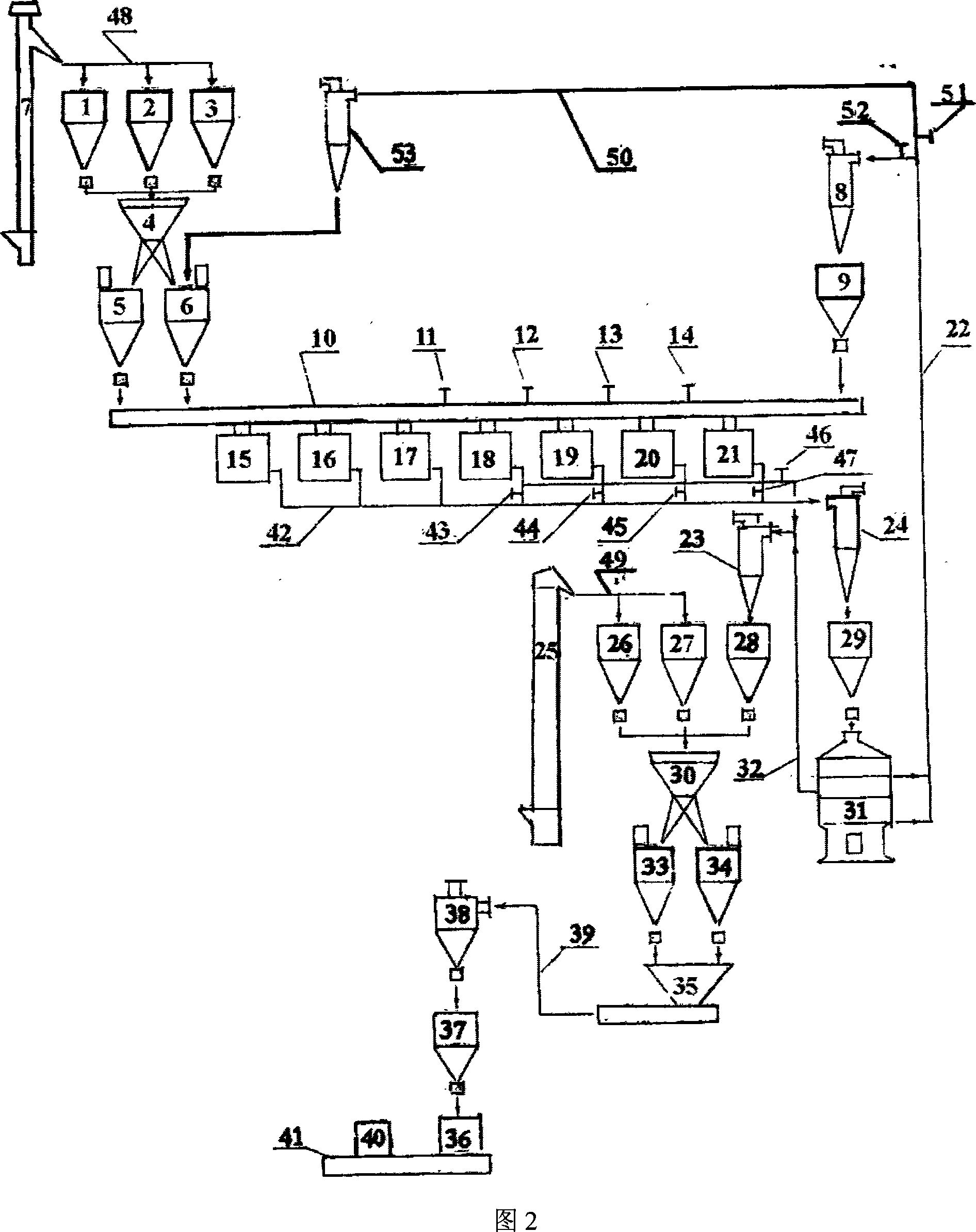

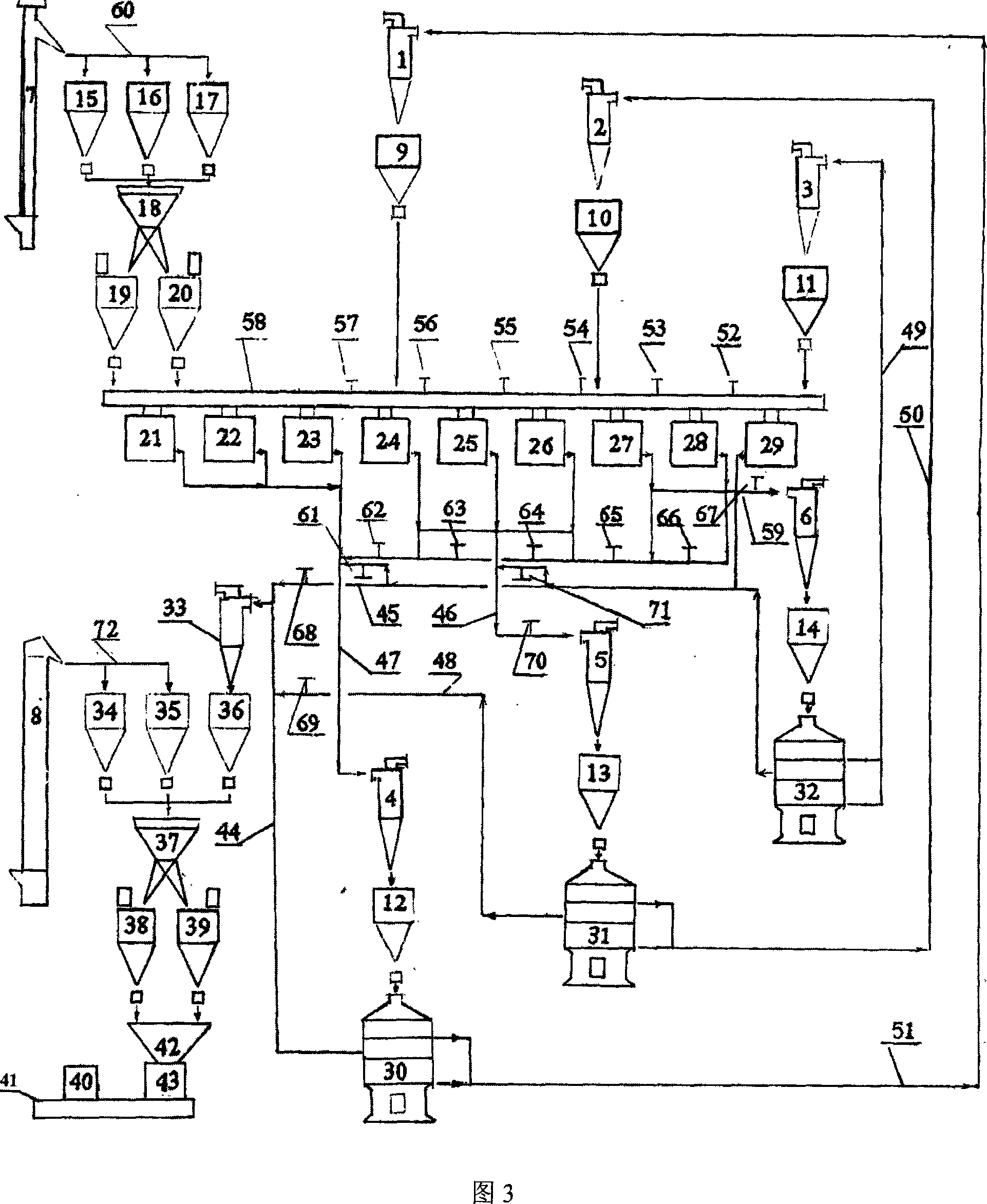

Reproduction new method for waste elastomer and plastic

InactiveCN101041725AThe ratio is roughly constantReduce or eliminate the impact of flow fluctuationsPlastic recyclingElastomerEngineering

The invention discloses a new regenerating method of waste elastics and plastic, which comprises the following steps: 1. blending waste elastics or / and plastic with grain size between 5 and 80 order and non-polluted regenerative adjuvant according to proportion; placing into the manufacturing machine; grinding; sieving; heating to desulfurize; bulking; soaping; emulsifying; kneading; pressing; graining; obtaining composite product 1 with mother material or mother particle or mother gel of plastic elastic powder; 2. weighing product 1 and non-polluted mating agent into mixing machine according to proportion; kneading; blending evenly; pressing; graining; obtaining the product 2 of mother material or mother particle or mother gel with 5-95% waste elastic or / and plastic.

Owner:陈书怡 +1

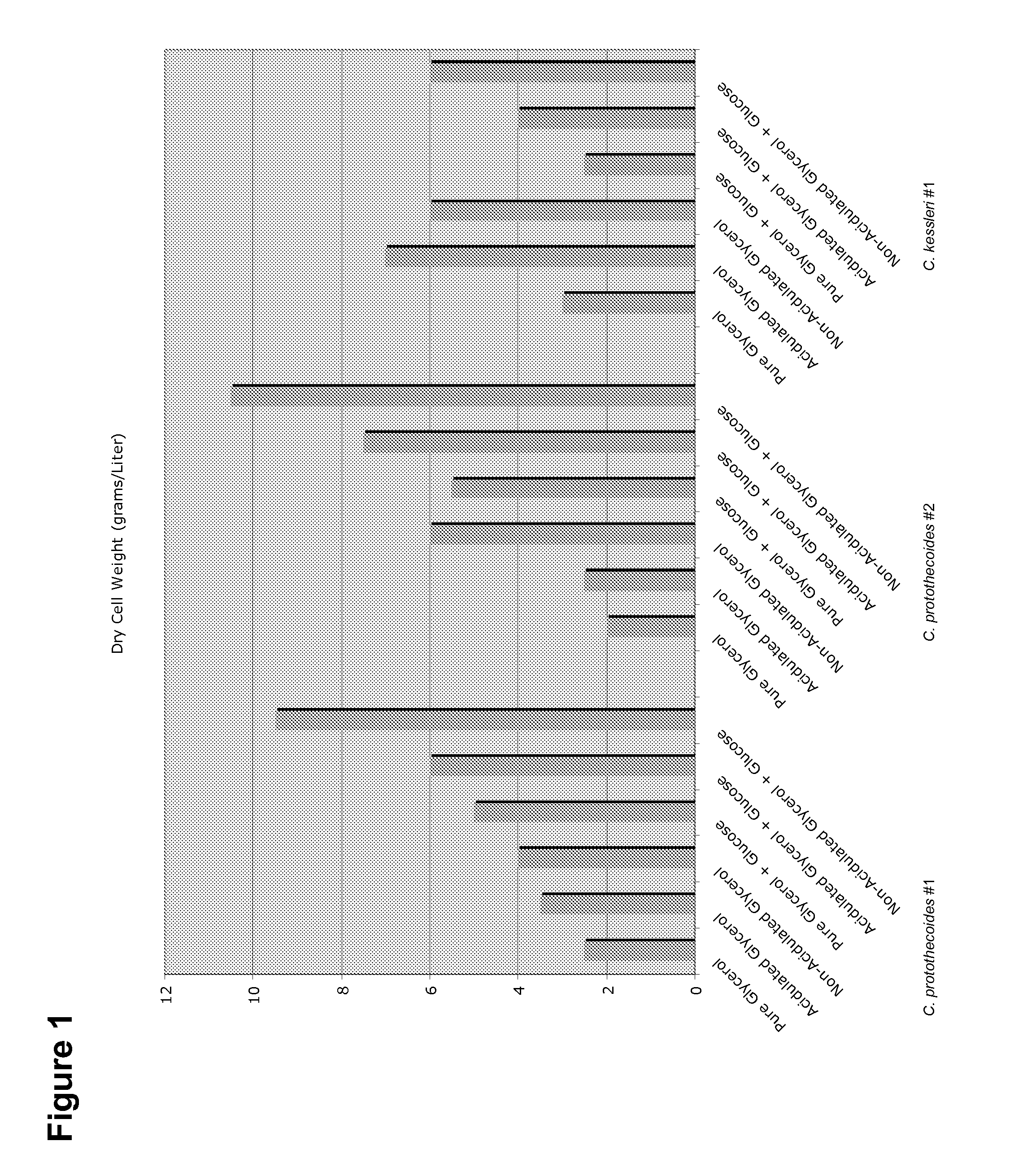

Soaps Produced from Oil-Bearing Microbial Biomass and Oils

ActiveUS20090305942A1Improve efficiencyLow costSoap detergents with organic compounding agentsBiofuelsMicroorganismMicrobial oil

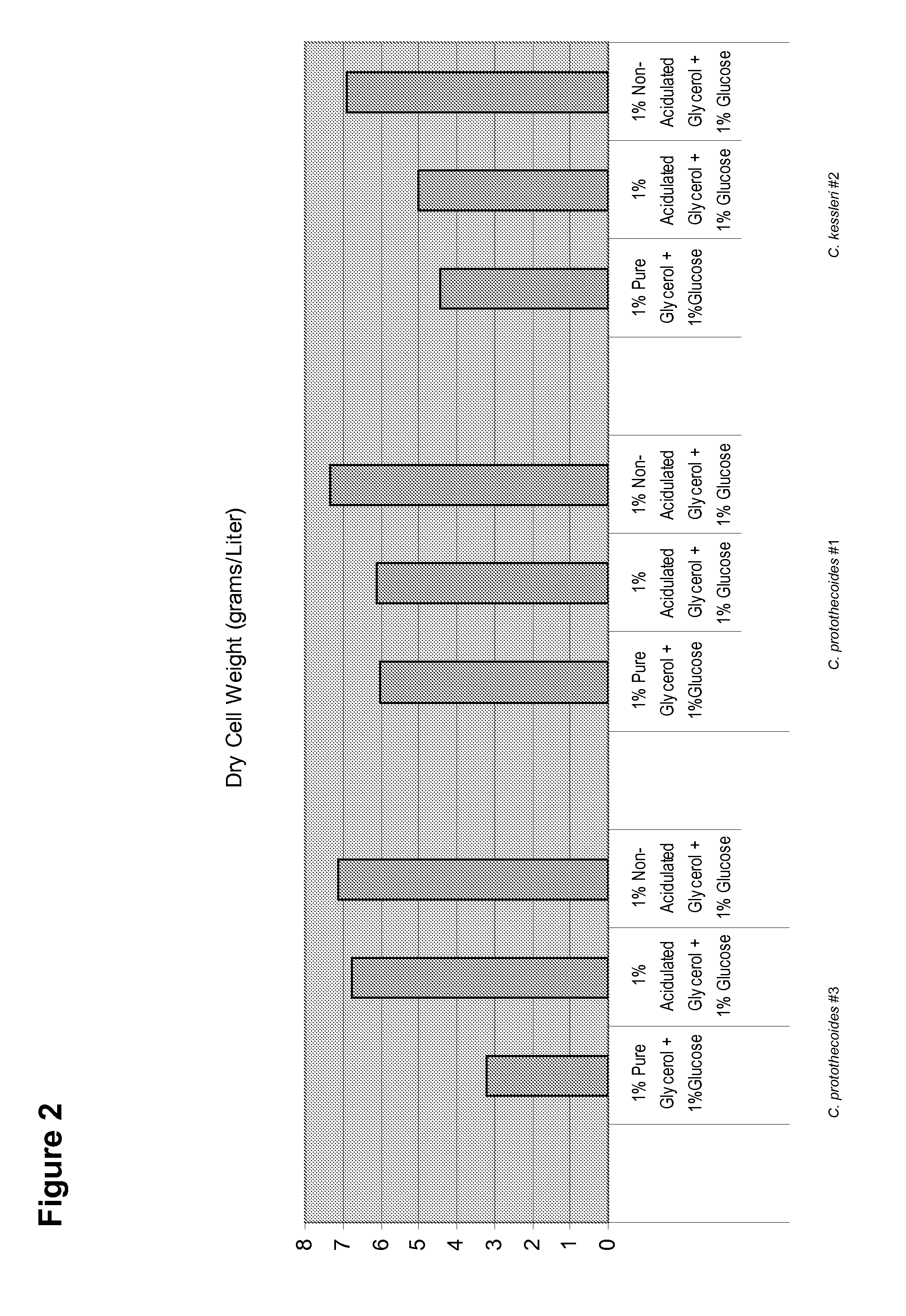

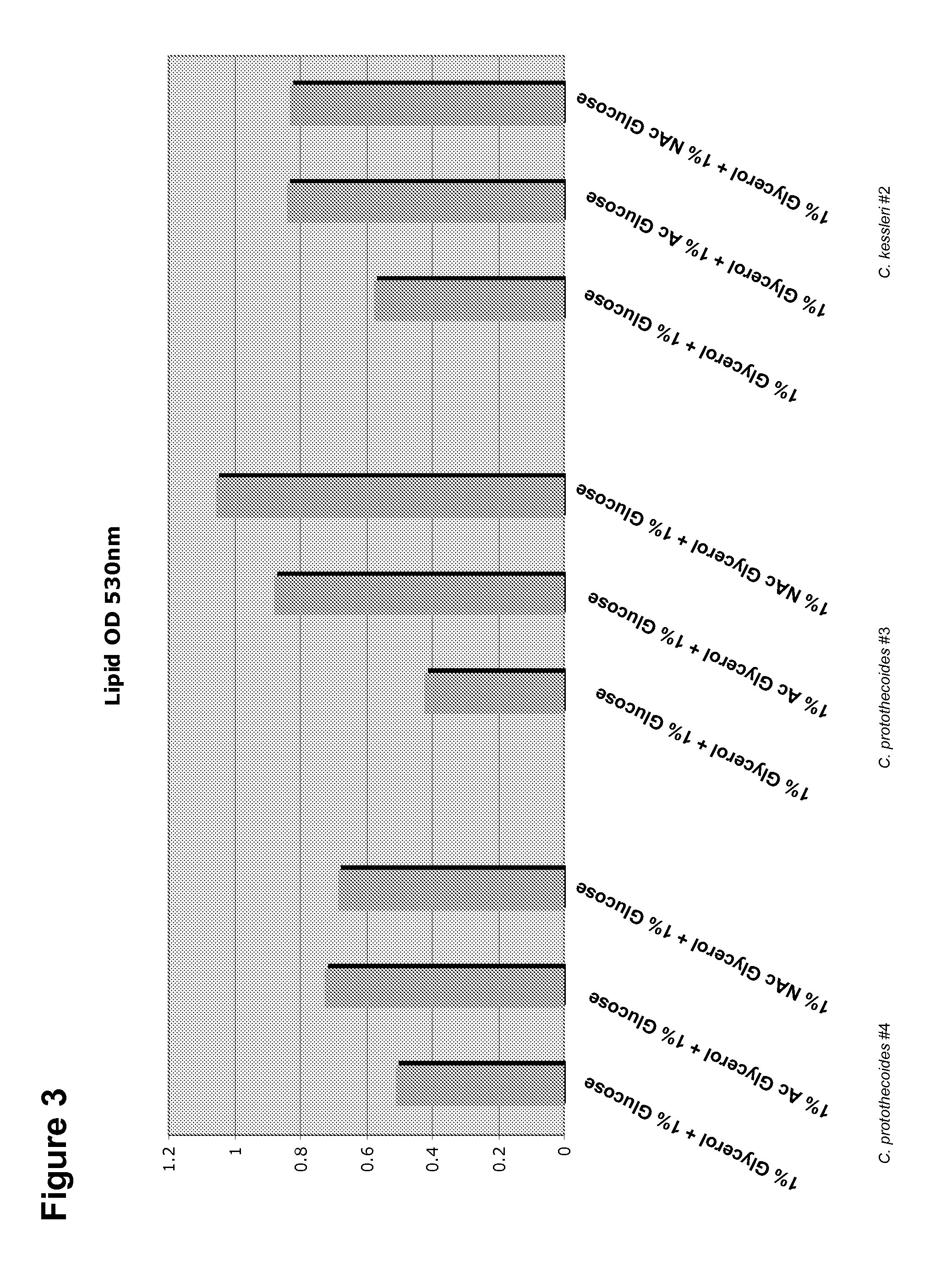

Soap and cosmetic products can be made from oil-bearing microbial biomass via the alkaline hydrolysis of glycerolipids and fatty acid esters to fatty acid salts. The saponified microbial oils / lipids can be combined with a variety of additives to produce compositions for use as soaps and other cosmetic products, which may also contain other constituents of the biomass, including unsaponified oils, glycerol and carotenoids, among others.

Owner:CORBION BIOTECH INC

Organ model

ActiveUS20120045743A1Suitable for operationSuitable for useSynthetic resin layered productsPretreated surfacesSilica particleSurface layer

A material for forming an organ model containing an aqueous gel, which comprises polyvinyl alcohol having an average degree of polymerization of 300 to 3500 and a degree of saponification of not less than 90% by mole, and silica particles; a method for producing a material for forming an organ model, comprising cooling an aqueous polyvinyl alcohol solution which contains polyvinyl alcohol having an average degree of polymerization of 300 to 3500 and a degree of saponification of not less than 90% by mole and silica particles, to a temperature of −10° C. or lower, and thawing the resulting formed aqueous gel; and an organ model at least provided with a surface layer comprising the material for forming an organ model. Thus, it is possible to provide: an organ model which has a hydrophilic property similar to an organ of a human body, gives such an incision feel that an incised portion spreads just similar to a living human organ and, therefore can be appropriately used in, for example, exercising surgical procedures; a material for forming an organ model appropriately usable for the organ model; and a method for producing the same.

Owner:YUUGENGAISHA SEIWADENTAL

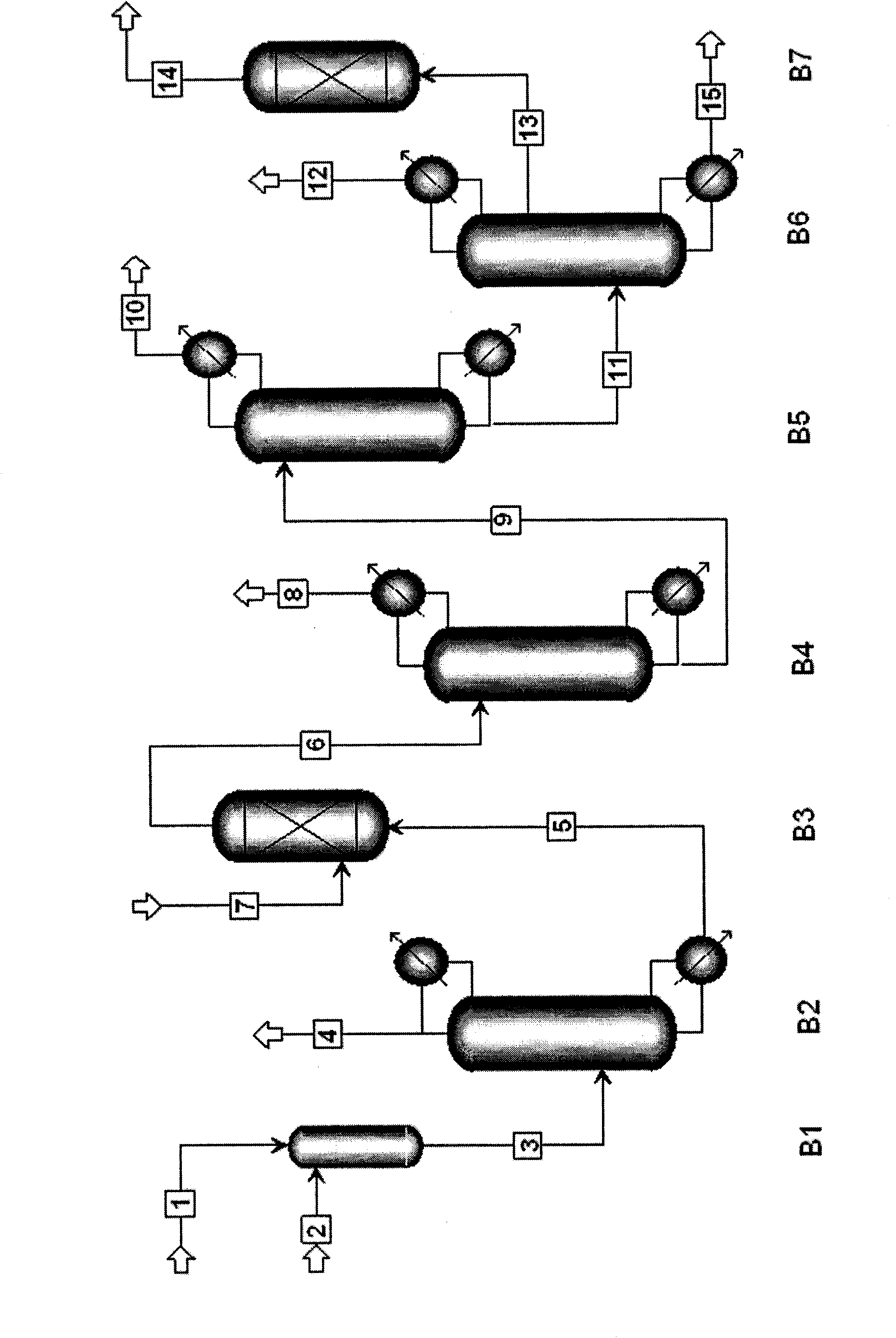

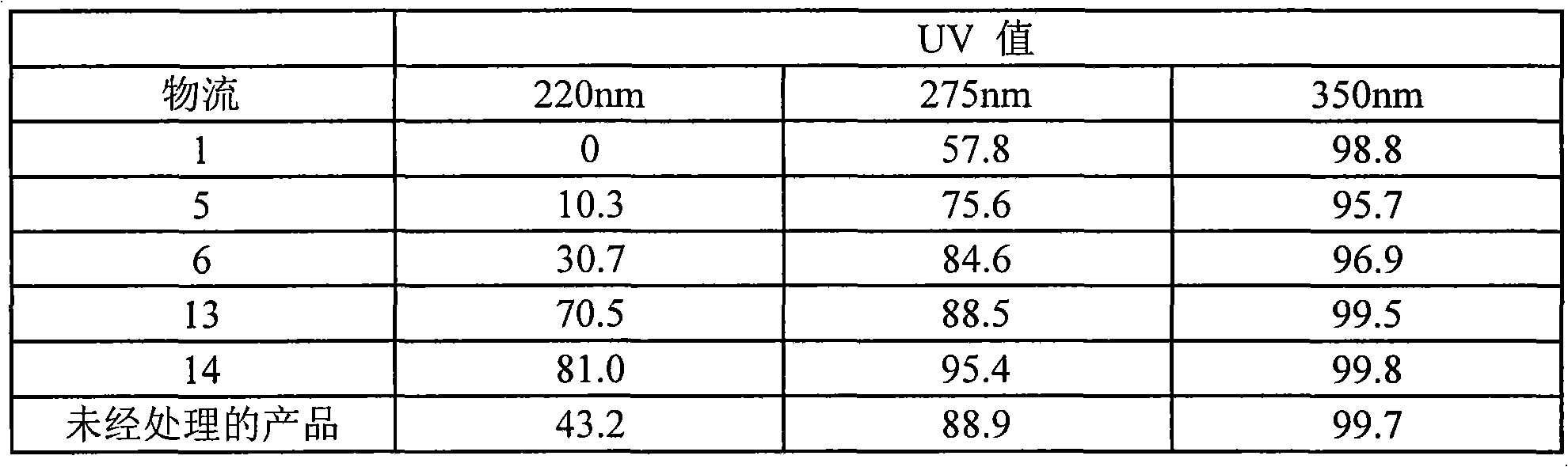

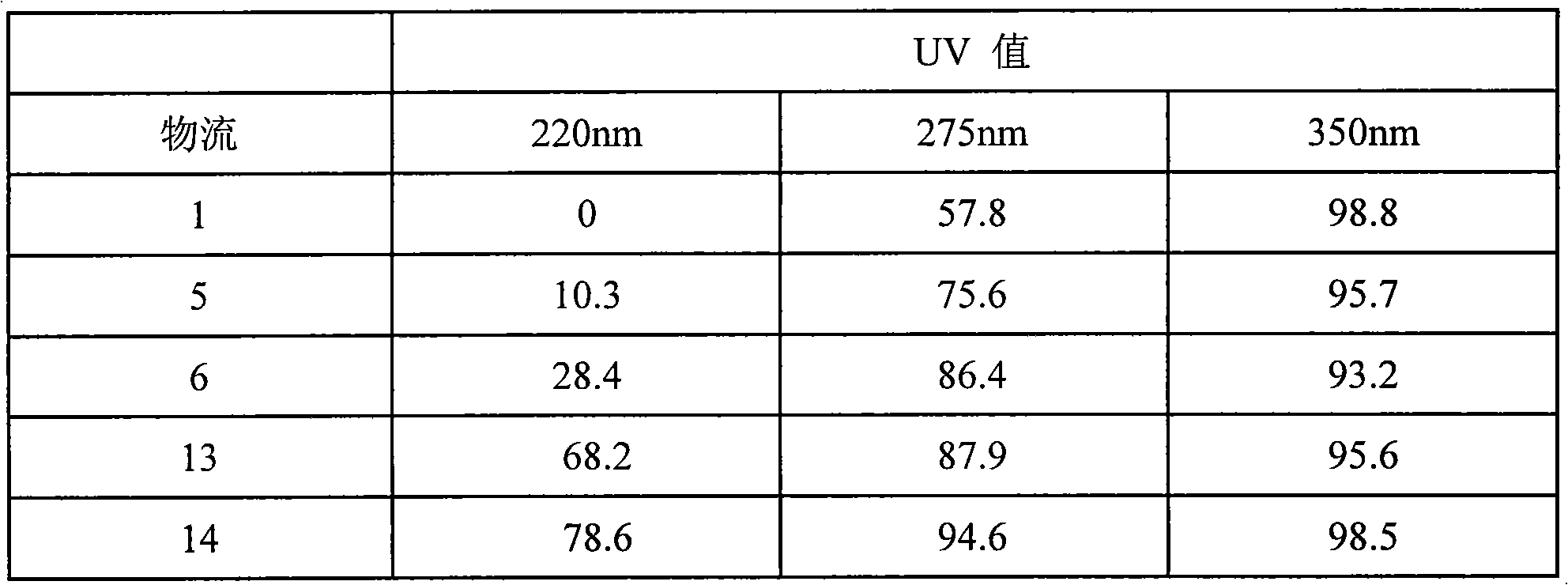

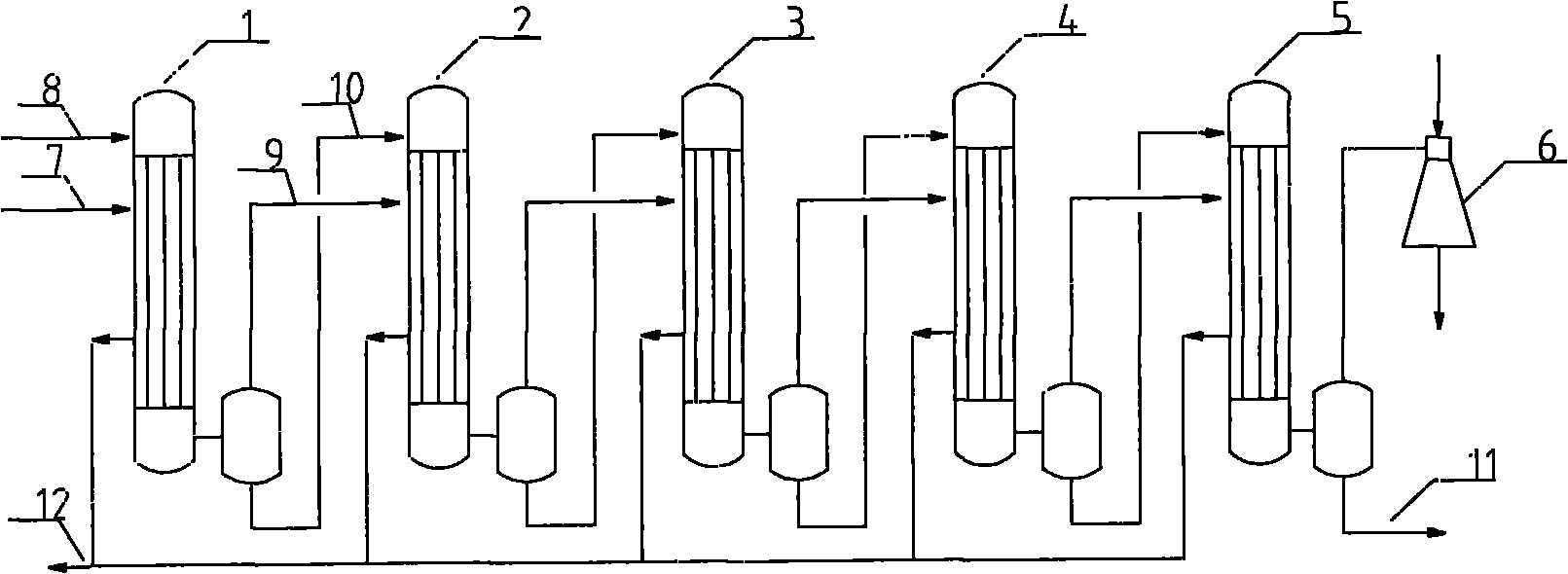

Purification technique for coal glycol rude products

ActiveCN101928201AHigh purityReduce energy consumptionOrganic compound preparationHydroxy compound separation/purificationChemical industryPolyester

The invention belongs to the technical field of chemical industry, in particular to a purification technique for coal glycol rude products. According to the technique, saponification, carbinol-removal, hydrogenation reaction, three-column distillation and absorption treatment are utilized to prepare the glycol with a mass percent more than 99.9% from the coal glycol rude products and the polyester glycol products having high transmissivity to the ultraviolet with wavelength between 220 and 350 mm. The purification technique for coal glycol rude products of the invention is characterized by low energy consumption, easy operation and high efficiency.

Owner:SHANGHAI HUAYI ENERGY CHEM

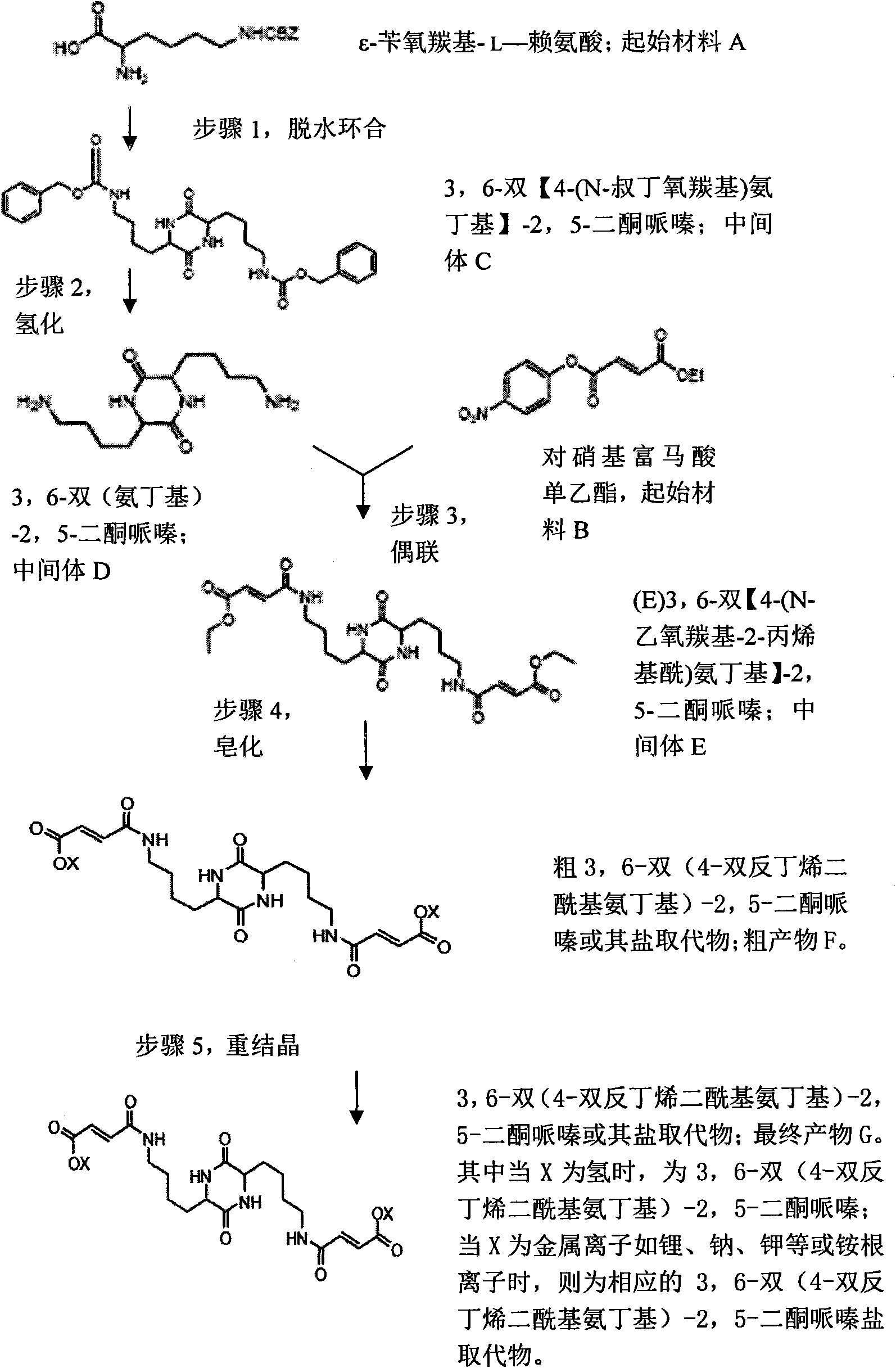

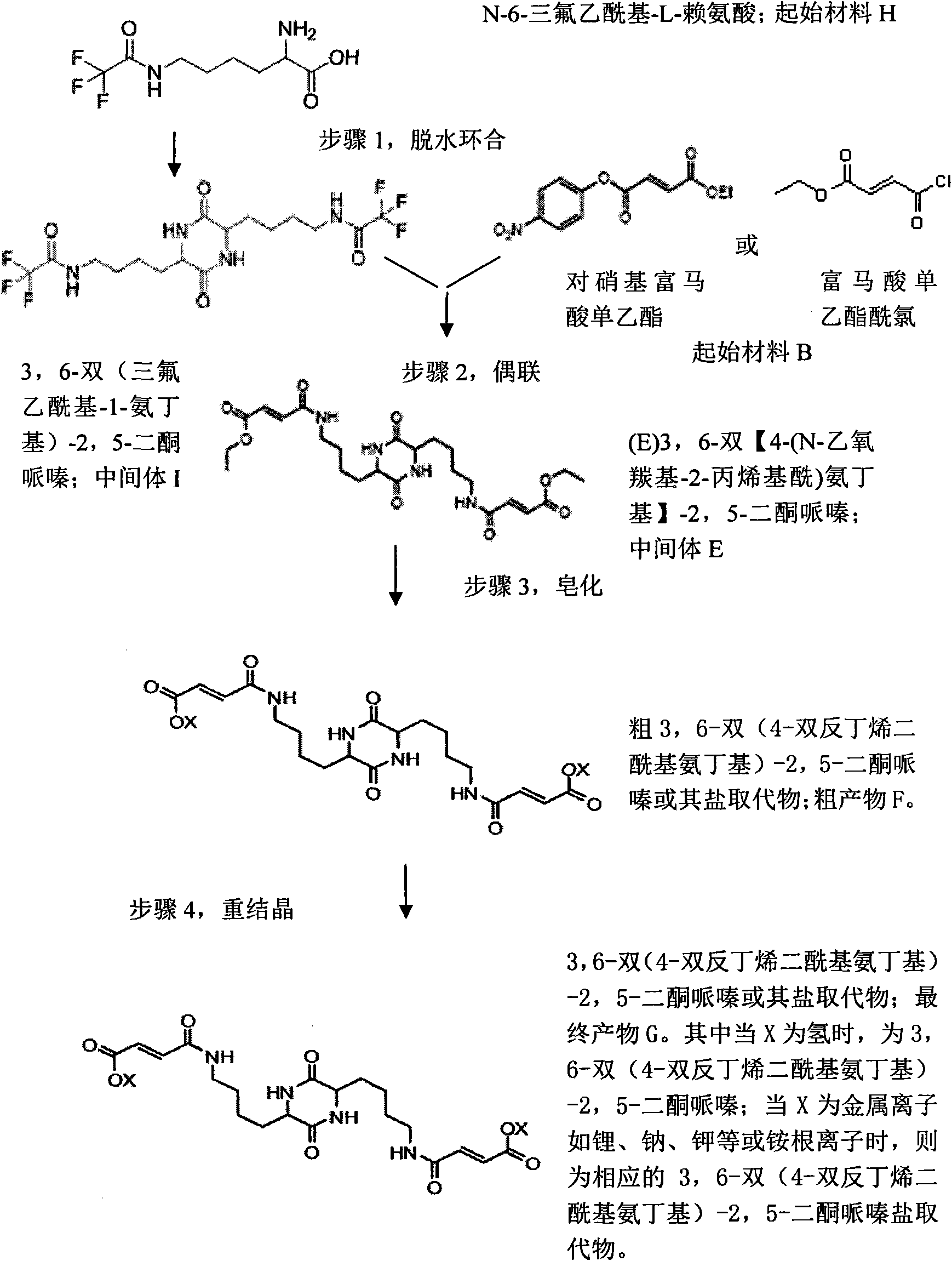

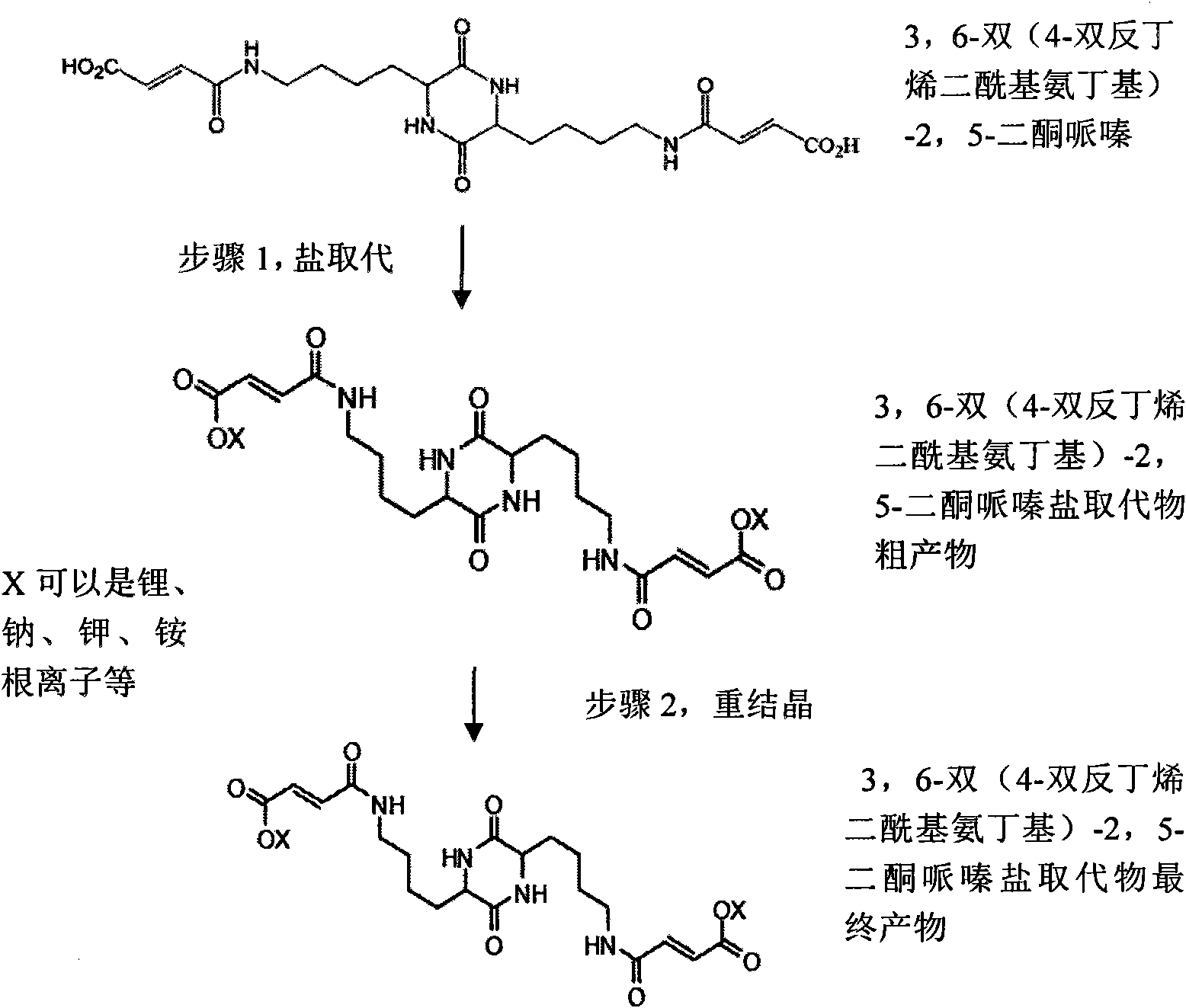

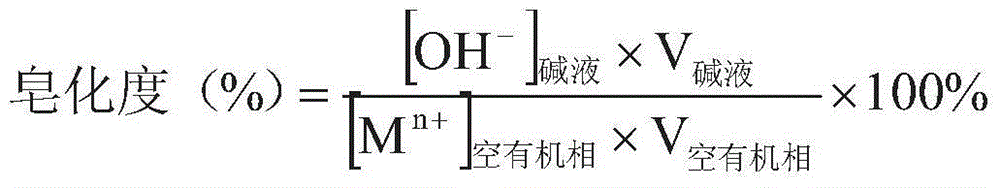

Synthetic methods of 3,6-bis(4-bisfumaroyl aminobutyl)-2,5-diketopiperazine and salt substitute thereof

The invention relates to two synthetic methods of 3,6-bis(4-bisfumaroyl aminobutyl)-2,5-diketopiperazine and a salt substitute thereof. The first synthetic method comprises the following steps of: obtaining a final product through the steps of cyclodehydration, hydrogenation, coupling, saponification, recrystallization and the like by using epsilon-benzoyloxycarbonyl-L-lysine and p-nitryl monoethyl fumarate as starting materials. The second synthetic method comprises the following steps of: obtaining the final product through the steps of cyclodehydration, coupling, saponification, recrystallization and the like by using N-6-trifluoroacetyl-L-lysine and the p-nitryl monoethyl fumarate (or p-nitryl monoethyl fumarate acyl chloride) as the starting materials. Meanwhile, the salt substitute of the 3,6-bis(4-bisfumaroyl aminobutyl)-2,5-diketopiperazine can also be generated by directly carrying out substitution reaction on the 3,6-bis(4-bisfumaroyl aminobutyl)-2,5-diketopiperazine as a reaction product and corresponding salt.

Owner:于清

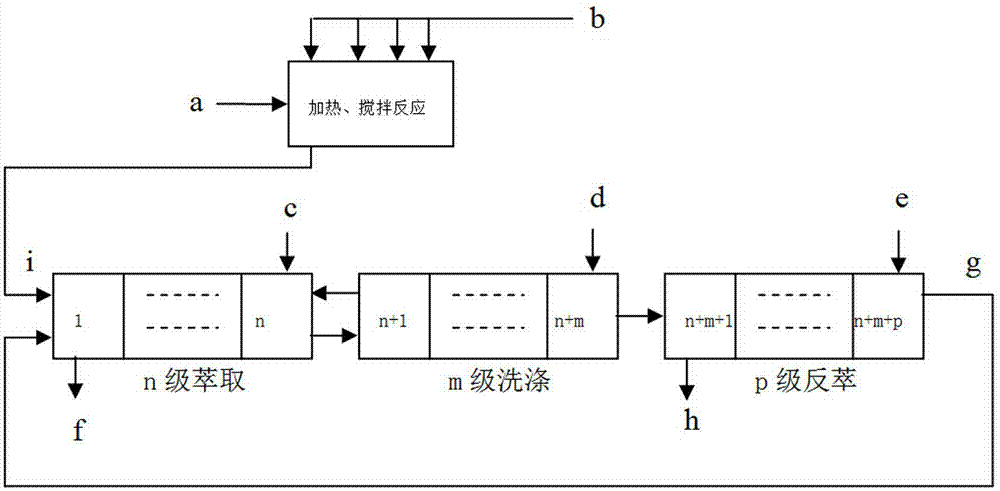

Regeneration method of lithium extraction system

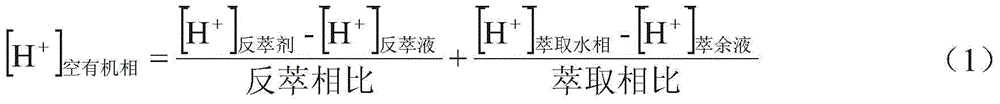

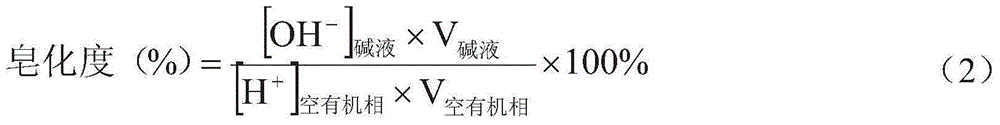

InactiveCN104388677AGuaranteed recyclingSimple regeneration methodProcess efficiency improvementLithiumDiluent

The invention discloses a regeneration method of a lithium extraction system. The lithium extraction system is regenerated by virtue of alkaline saponification and the regeneration method comprises the following steps of mixing empty-loading organic phases subjected to lithium extraction and reverse extraction and alkaline liquor, saponifying and standing for separating phases to obtain a clarified and transparent regenerated and extracted organic phase, wherein the empty-loading organic phases comprise an extractant, a synergistic extractant and a diluent which are involved in the lithium extraction and reverse extraction processes; the synergistic extractant is iron chloride; and the alkaline liquor is any one of sodium hydroxide solution and potassium hydroxide solution. The regeneration method of the lithium extraction system disclosed by the invention has the advantages of simplicity in operation and good saponifying effect; when lithium is extracted by virtue of the saponified, regenerated and recycled extraction organic phase, the extraction efficiency of lithium is high and the extraction effect is good; and by the method, the recycling of the extraction organic phase for extracting lithium is achieved and the process flows of extracting, carrying out reverse extraction, regenerating and extracting for circularly extracting lithium are completed.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Easily Adhesive Polyester Film and Film for Protecting Back Side of Solar Cell Using the Same

InactiveUS20080050583A1Improve adhesionEasy to stickFilm/foil adhesivesSynthetic resin layered productsVitrificationPolyvinyl alcohol

An easily adhesive polyester film is provided which is used for protection of the back side of a solar cell, the adhesive polyester film comprising a polyester film and a resin film situated on a surface of the polyester film, the resin film comprising a crosslinking agent and a resin selected from the group consisting of a polyester resin having a glass transition point of 20 to 100° C., an acrylic resin having a glass transition point of 20 to 100° C., a combination of the resins and a combination of at least one of the resins and a polyvinyl alcohol having a saponification degree of 70 to 90 mol %. This film has excellent adhesion to EVA while having excellent mechanical properties, heat resistance and moisture resistance.

Owner:TEIJIN DUPONT FILMS JAPAN

Methods of using modified natural products as dewatering aids for fine particles

InactiveUS6375853B1Reduce moistureHigh degreeDrying solid materials without heatSolid fuelsNatural productTransesterification

Naturally occurring lipids of vegetable and animal origin are broken into smaller molecules, and used as dewatering aids. The process of breaking the molecules include transesterification, interesterification, and saponification followed by acidulation. The modified lipid molecules can adsorb on the surface of the particles to be dewatered and greatly enhance their hydrophobicity, which will help increase the rate of dewatering and hence reduce cake moisture. The modified lipids are more effective dewatering aids than the naturally occurring unmodified lipids, possibly because they can more readily form close-packed monolayers of hydrophobes on the surface of the particles.

Owner:YOON ROE HOAN

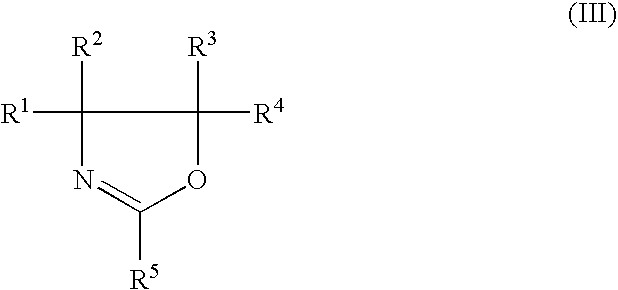

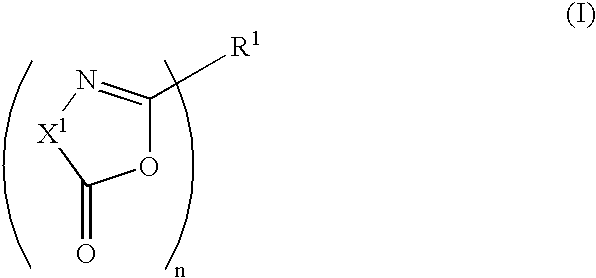

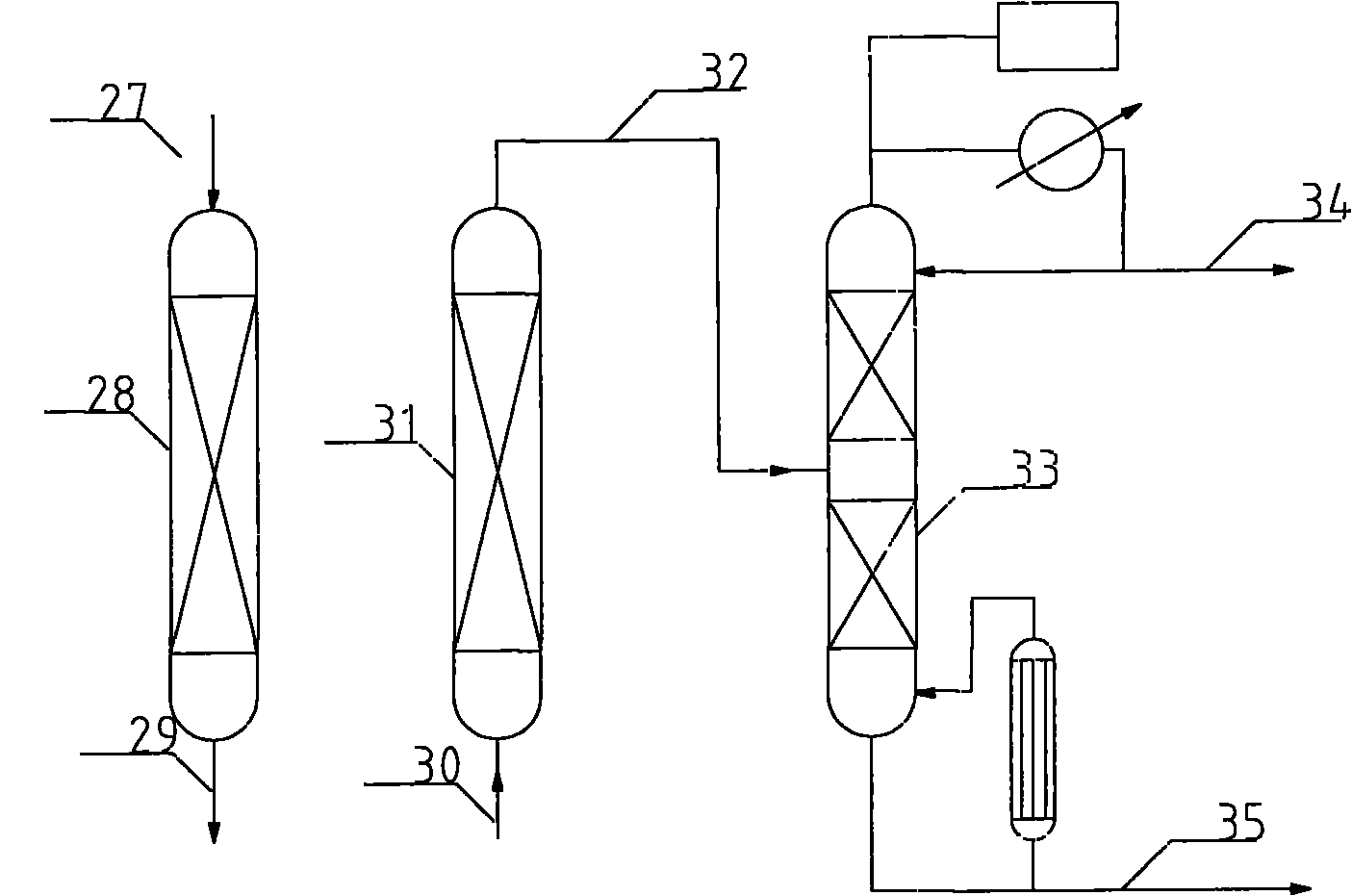

Method for non-saponification extraction and separation of light rare earth elements

ActiveCN104120258ALow viscosityImprove liquidityProcess efficiency improvementRare-earth elementPhosphate

The invention discloses a method for non-saponification extraction and separation of light rare earth elements. After a compound extraction agent consisting of acid phosphorus type extraction agent, alkaline amine type extraction agent and solvent oil is mixed with phosphate solvent or organic alcohol solvent at 30-70 DEG C, chlorinated light rare earth liquid is extracted and separated; and the water washing and the hydrochloric acid reverse extraction are performed to finally realize the separation of La, Ce, Pr and Nd; and a mixed organic phase after the reverse extraction is returned to an extraction tank for recycling. The method pretreats the mixed organic phase consisting of the compound extraction agent and the solvent, so that such defects as high viscosity, weak mobility, easy emulsification and long phase splitting time are overcome; the method has no need to saponify the acid phosphorus type extraction agent, so that no alkali liquor consumption and no waste water emission in the extraction process are realized, but the separation capacity of a saponification extracting agent system is achieved, and the extraction grade is reduced compared with that needed by the saponification extracting agent system; and the method is a rare earth element separation process with economy and high efficiency.

Owner:GUANGXI NORMAL UNIV

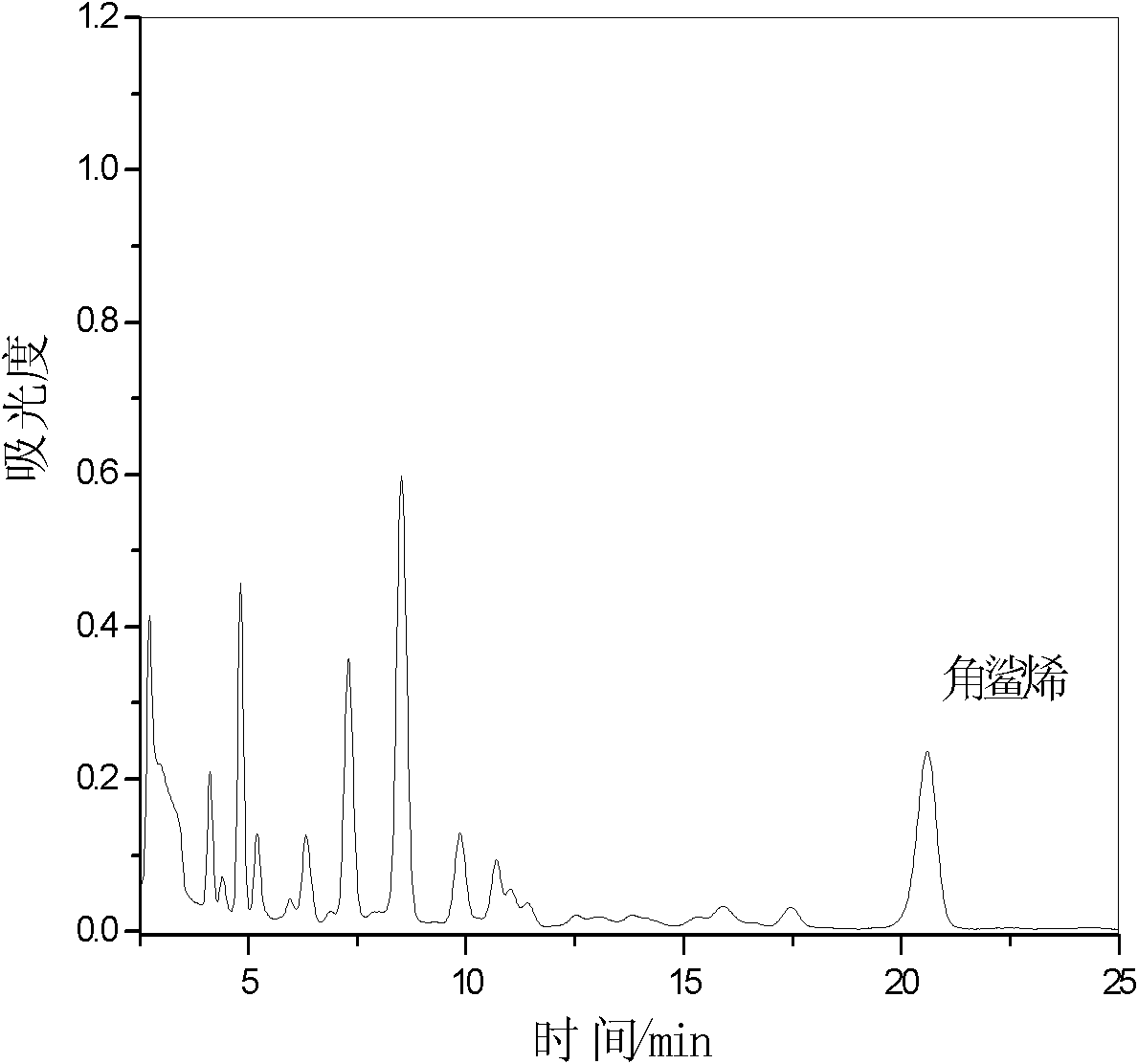

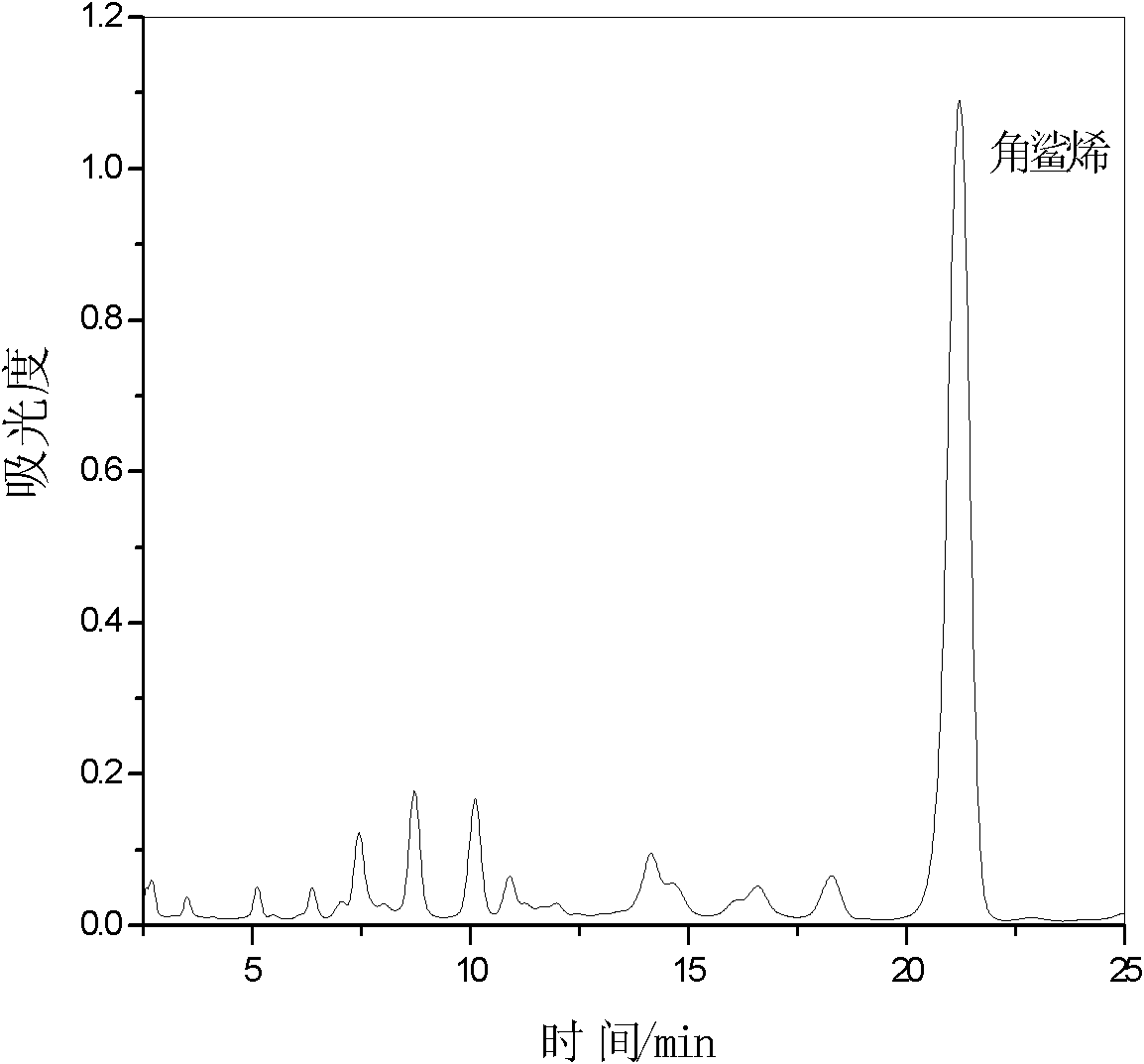

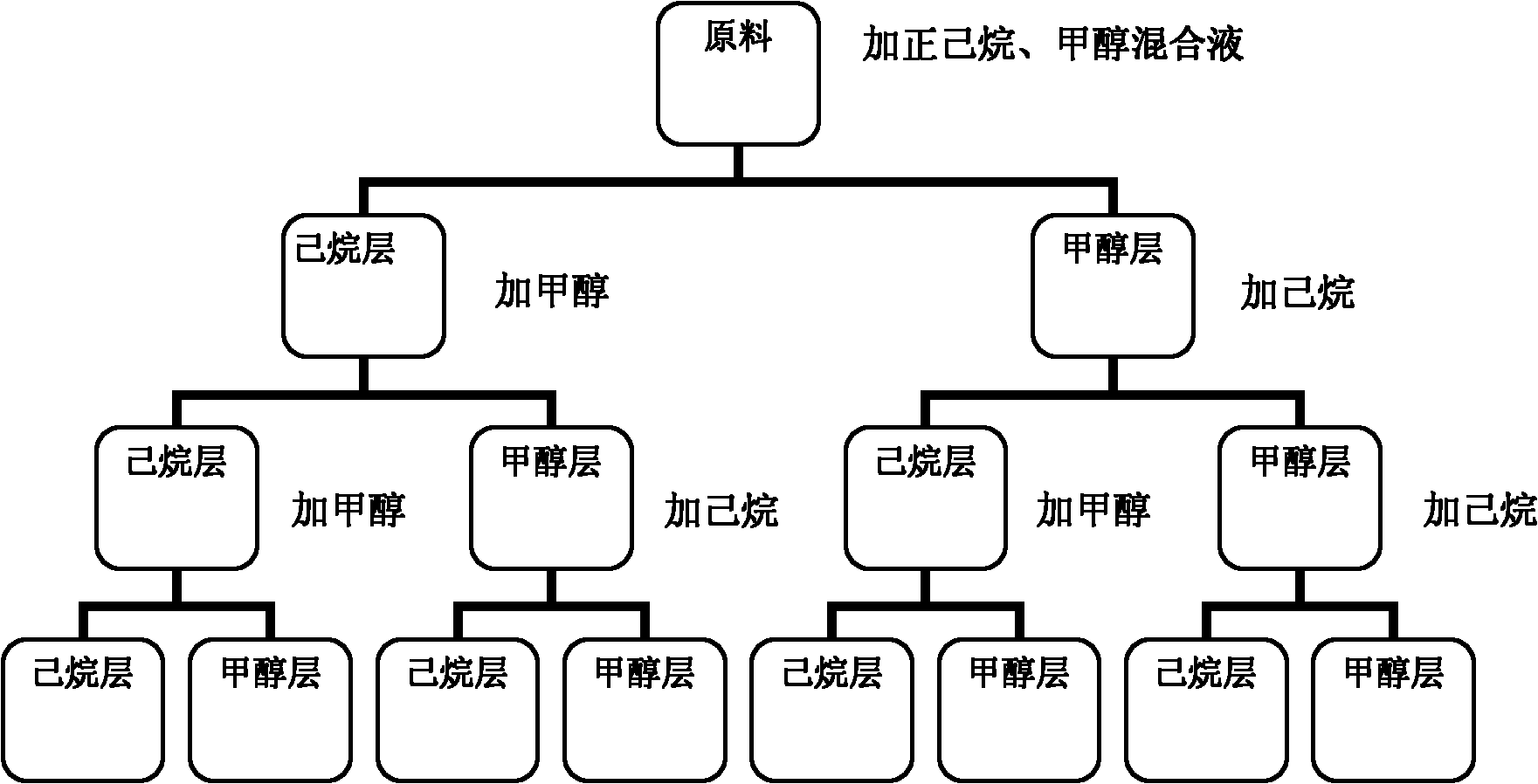

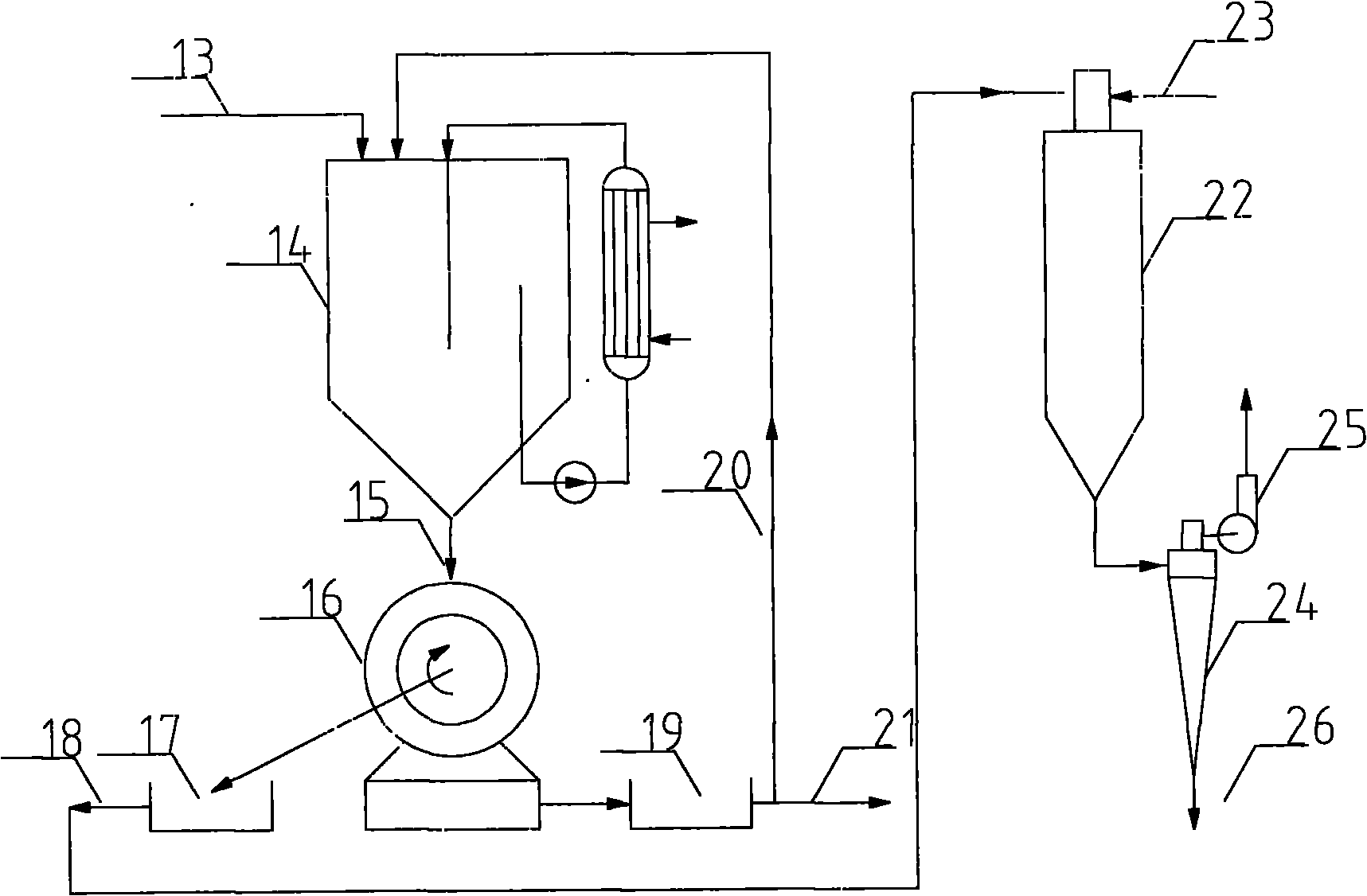

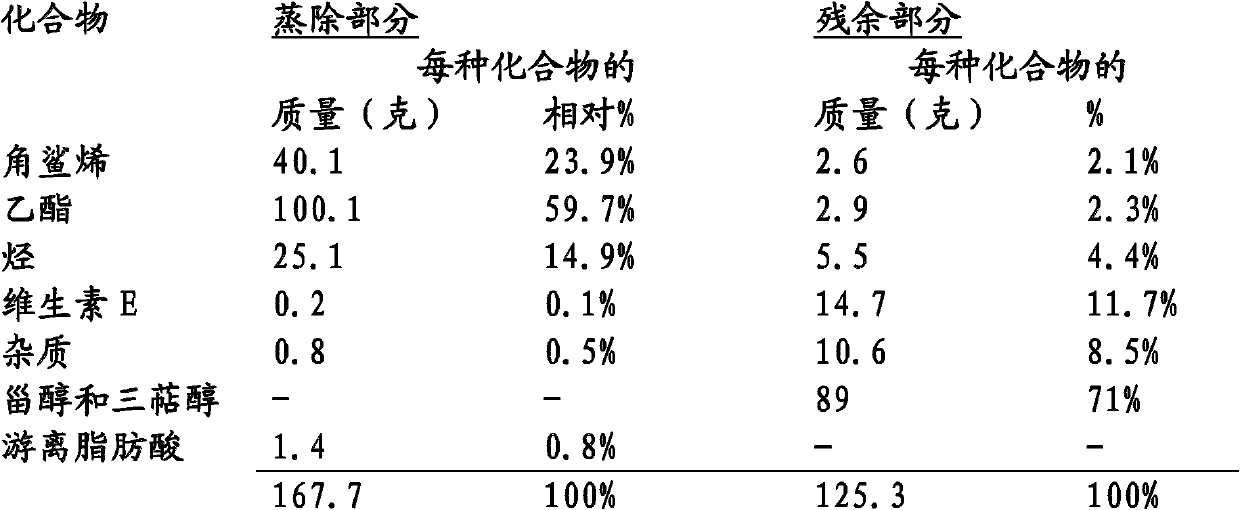

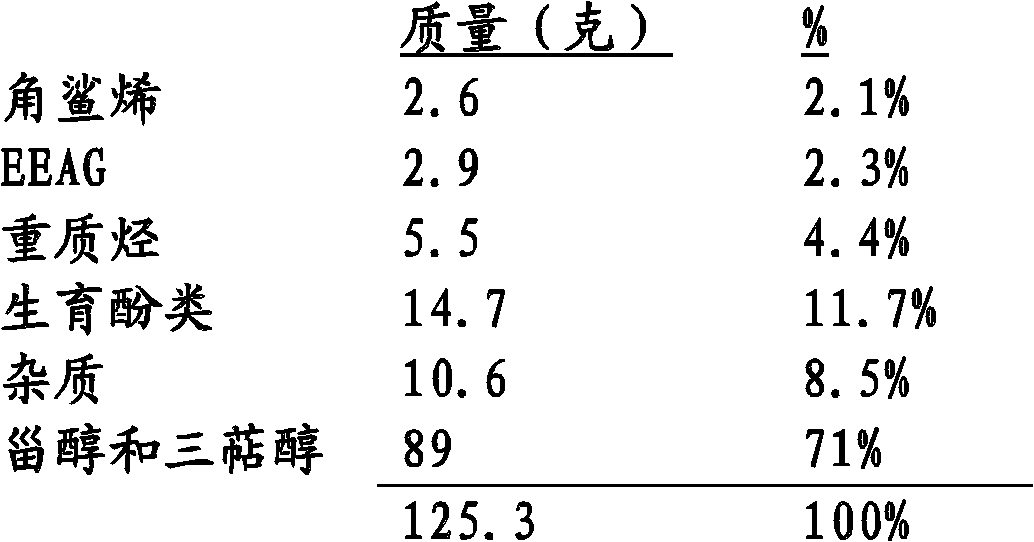

Method for extracting squalene from vegetable oil deodorized distillate

InactiveCN101830770AIdeal yieldIncrease contentDistillation purification/separationExtraction purification/separationHigh concentrationVegetable oil

The invention relates to a method for extracting squalene from vegetable oil deodorized distillate. A process method of combining molecular distillation with extraction and crystallization is used to extract high-concentration squalene and recover natural vitamin E and phytosterol with a certain purity from vegetable oil deodorized distillate. The method comprises the following steps of: carryingout a saponification reaction of the raw material; twice molecularly distilling unsaponifiable matter obtained by extraction; using the distillate obtained during the second distilling as a raw material for cold crystallization to obtain phytosterol; recovering squalene and mixed tocopherol from the filtrate; and extracting with multi-stage solvents to respectively enrich squalene and vitamin E in two phases. The process has simple flows, low-prices raw material and higher separation efficiency and recovery rate and comprehensively utilizes useful contents in the deodorized distillate.

Owner:TIANJIN UNIV

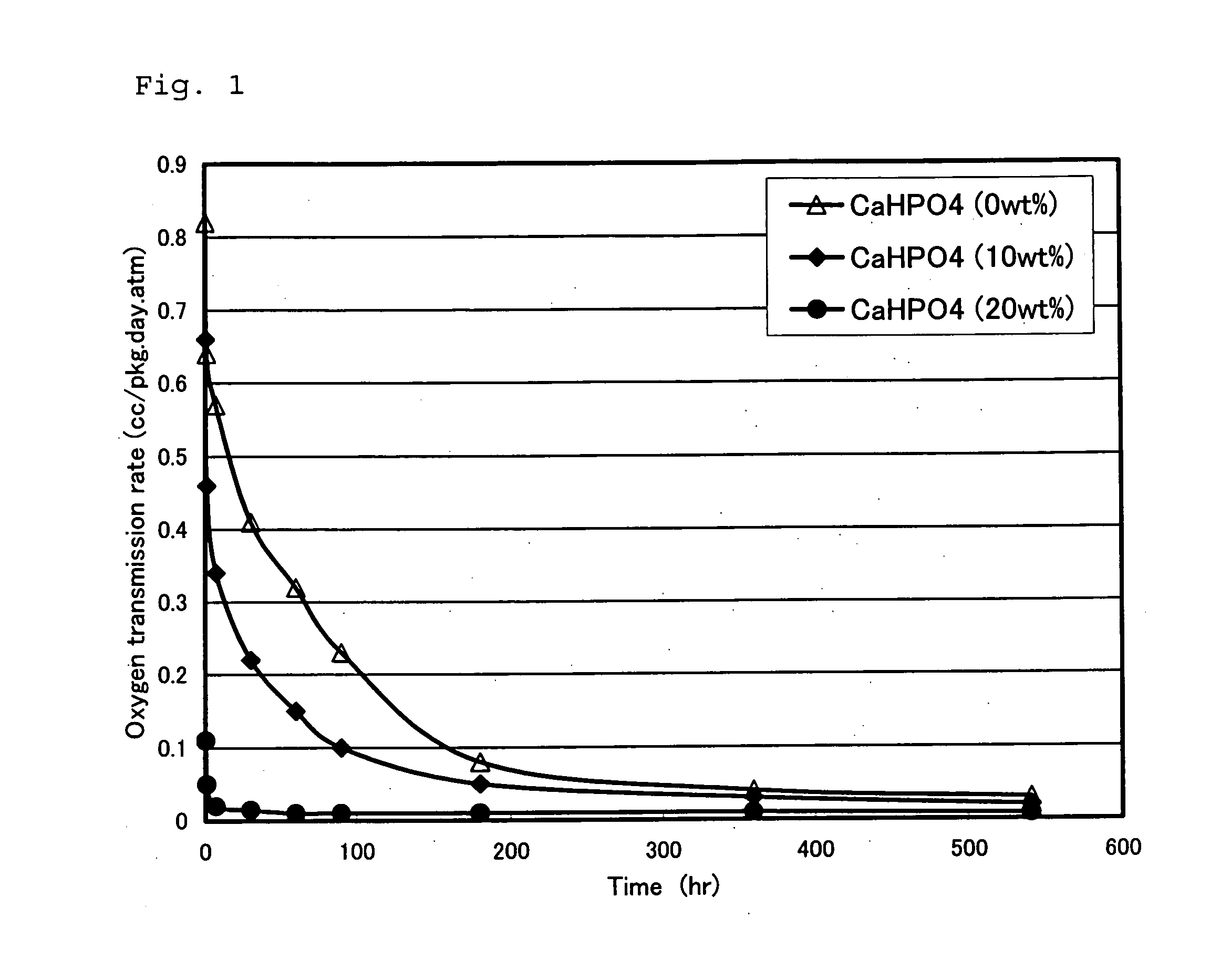

Resin composition, process for preparing the same, and laminate containing layer of said resin composition

InactiveUS6174949B1Dispersed uniformly and efficientlyBottlesSynthetic resin layered productsAcetic acidPolymer science

A resin composition is provided which comprises (A) a saponified ethylene-vinyl acetate copolymer (referred to as EVOH for short) with an ethylene content of 20 to 60 mole percent and a saponification degree of not less than 90 mole percent, and contains therein (B) a boron compound as an essential component, (C) acetic acid as an optional component, and at least one compound selected from among (D) an acetic acid salt and (E) a phosphoric acid compound as an essential component, the contents of the respective additive components per 100 parts by weight of EVOH (A) being as follows:boron compound (B): 0.001 to 1 part by weight on the boron basis;acetic acid (C): 0 to 0.05 part by weight;acetic acid salt (D): 0.001 to 0.05 part by weight on the metal basis; andphosphoric acid compound (E): 0.0005 to 0.05 part by weight on the phosphate radical basis.This resin composition is typically produced by bringing EVOH (A) with a water content of 20 to 80% by weight into contact with an aqueous solution containing the respective additive components mentioned above and then subjecting the thus-treated EVOH to fluidized state drying and then to stationary state drying.

Owner:THE NIPPON SYNTHETIC CHEM IND CO LTD

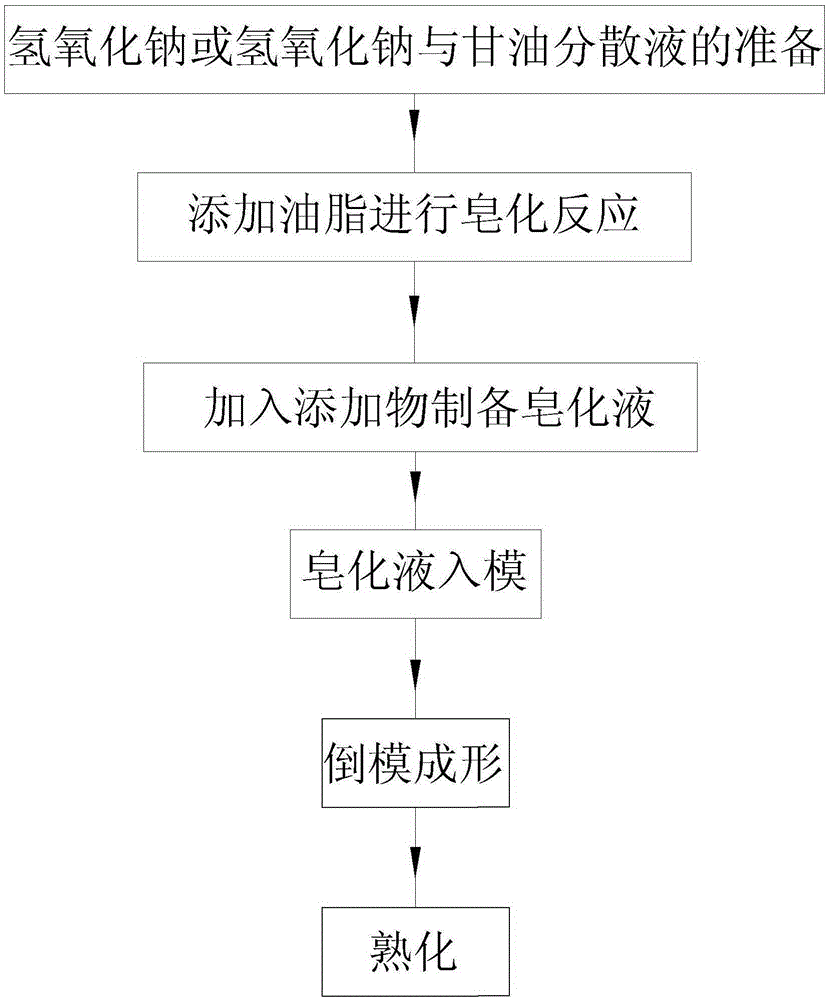

Preparation method of cold-formed soap

ActiveCN105400617AAvoid contact reactionsGive full play to effective functionsShaping soapAlkali/ammonium soap compositionsCold formedReaction rate

The invention relates to a preparation method of a cold-formed soap. The method has simple process steps, and substitutes traditional aqueous solution of sodium hydroxide with sodium hydroxide or a dispersion of sodium hydroxide and glycerol; sodium hydroxide is completely soluble in glycerol but disperses in glycerol, so as to avoid fast reaction after mixing of sodium hydroxide solution with oil too, reduce the initial reaction rate of saponification, and effectively control saponification reaction rate; along with the saponification reaction, the reaction product of glycerol continuously increases to help more fully dispersion of sodium hydroxide, accelerate the reaction rate of sodium hydroxide and the remaining oil. Since the method employs an anhydrous formula, water evaporation process is not needed after soap formation by liquid soap, and the production cycle is significantly shortened; and the nutrition substances are added in solid form powder to effectively prevent the contact reaction of non-alkali-resistant nutrients and alkali hydroxide molecules, so as to retain the active nutrient ingredients in the soap and give full play to the role of skin care of the nutrients.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Special release agent for concrete and preparation method thereof

ActiveCN103103011AGood compatibilityGood antirust effectCeramic shaping apparatusAdditivesFatty acidSaponification

The invention relates to a special release agent for concrete, which comprises the following materials in parts by weight: 80-90 parts of mineral substance oil, 1-5 parts of an emulgator, 1-5 parts of a defoaming agent, 0.01-0.4 part of a corrosion inhibitor, and 1-10 parts of fatty acid. The invention also relates to a preparation method for the release agent. The special release agent for concrete adopts two substances, namely, a fatty acid active substance and the emulgator, the adhesive strength of the surface of the concrete is reduced when surface saponification is formed, so that demoulding is easier and the surface is smooth and has no defects. The product prepared by the method can be stored at temperature of wide range, is convenient to store and can be stored for a long time, has small relative density, can be diluted for use by adding 2-6 times of water, and lowers the transportation cost of the release agent.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

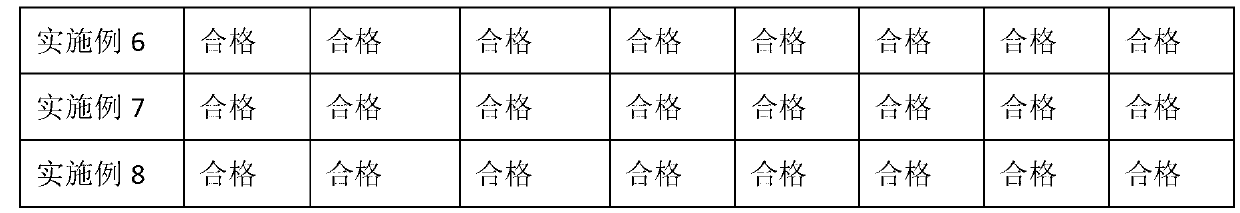

Synthetic process of herbicide dicamba

ActiveCN102942474AImprove one-way yieldImprove quality and efficiencyOrganic compound preparationCarboxylic compound preparationMethoxylaricinolic acidFixed bed

The invention relates to a preparation method of herbicide dicamba. The preparation method includes: (1) liquid potassium hydroxide and 2, 5-dichlorophenol are reacted according to molar ratio of 0.95:1-1:1 to obtain 2, 5-dichlorophenol potassium; (2) at the presence of anhydrous potassium carbonate and catalyst, the 2, 5-dichlorophenol potassium obtained in the step (1) is reacted with CO2 to generate 3, 6-dichlorosalicylic acid, pressure of CO2 is controlled to be 4-6MPa, reaction temperature ranges from 100 DEG C to 160 DEG C, and molar ratio of anhydrous potassium carbonate and 2, 5-dichlorophenol potassium is 1-2:1; and (3) in alkaline condition, at the temperature of 70-100 DEG C, the 3, 6-dichlorosalicylic acid obtained in the step (2) and chloromethane are reacted under the action of the catalyst through a tube fixed-bed reactor according to molar ratio 1:1-3.5, saponification and acidification are performed to obtain 3, 6-dichloro-2-methoxysalicylic acid, namely the dicamba. The process is high in reaction yield, simple in reaction condition, good in product quality, small in three wastes and low in energy consumption.

Owner:JIANGSU YOUJIA CHEM +2

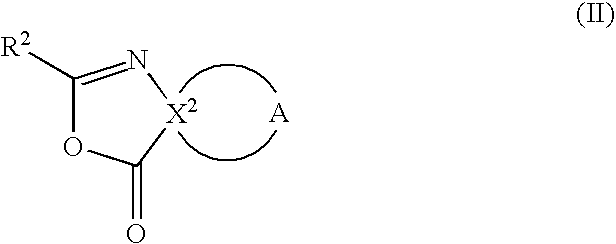

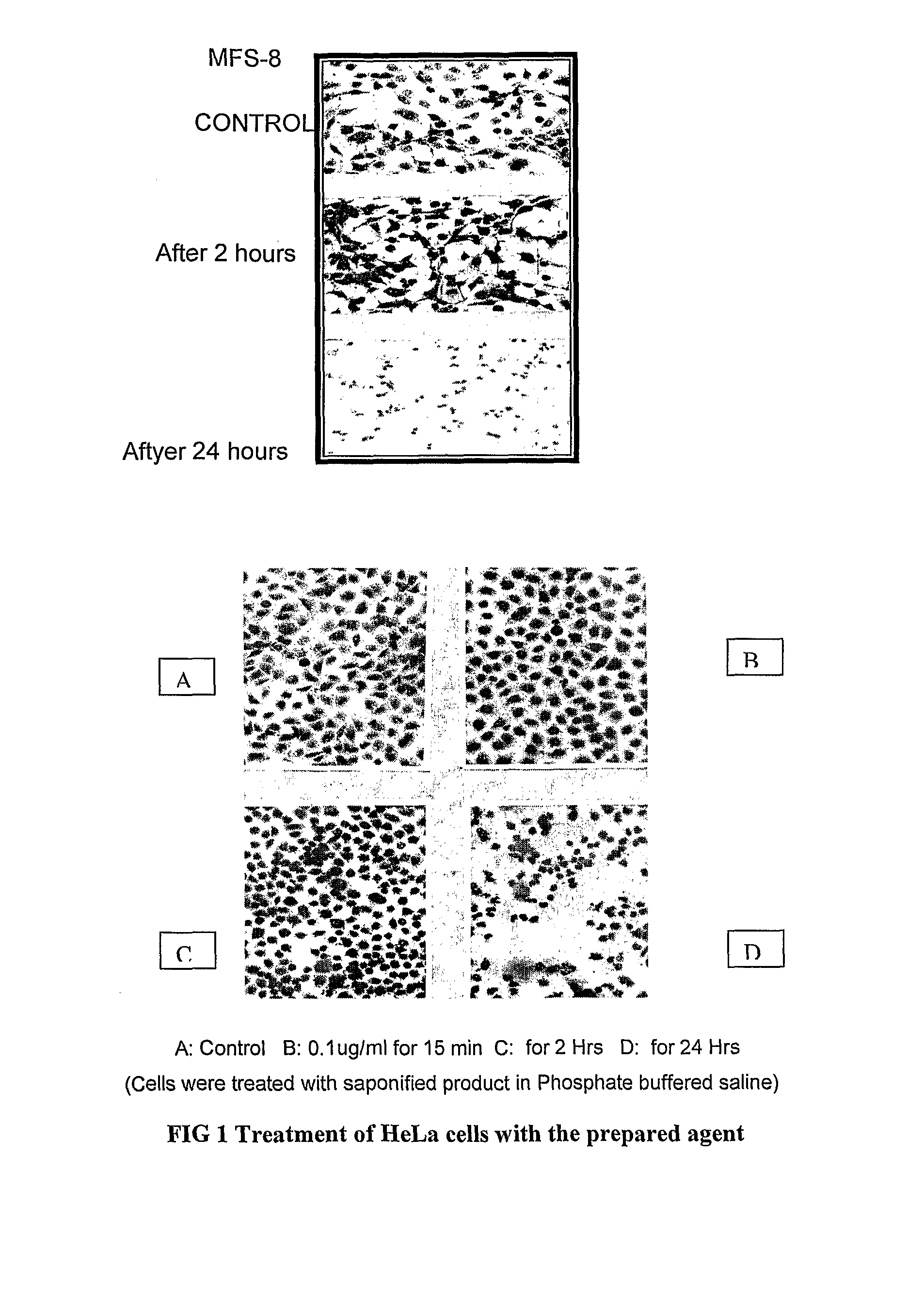

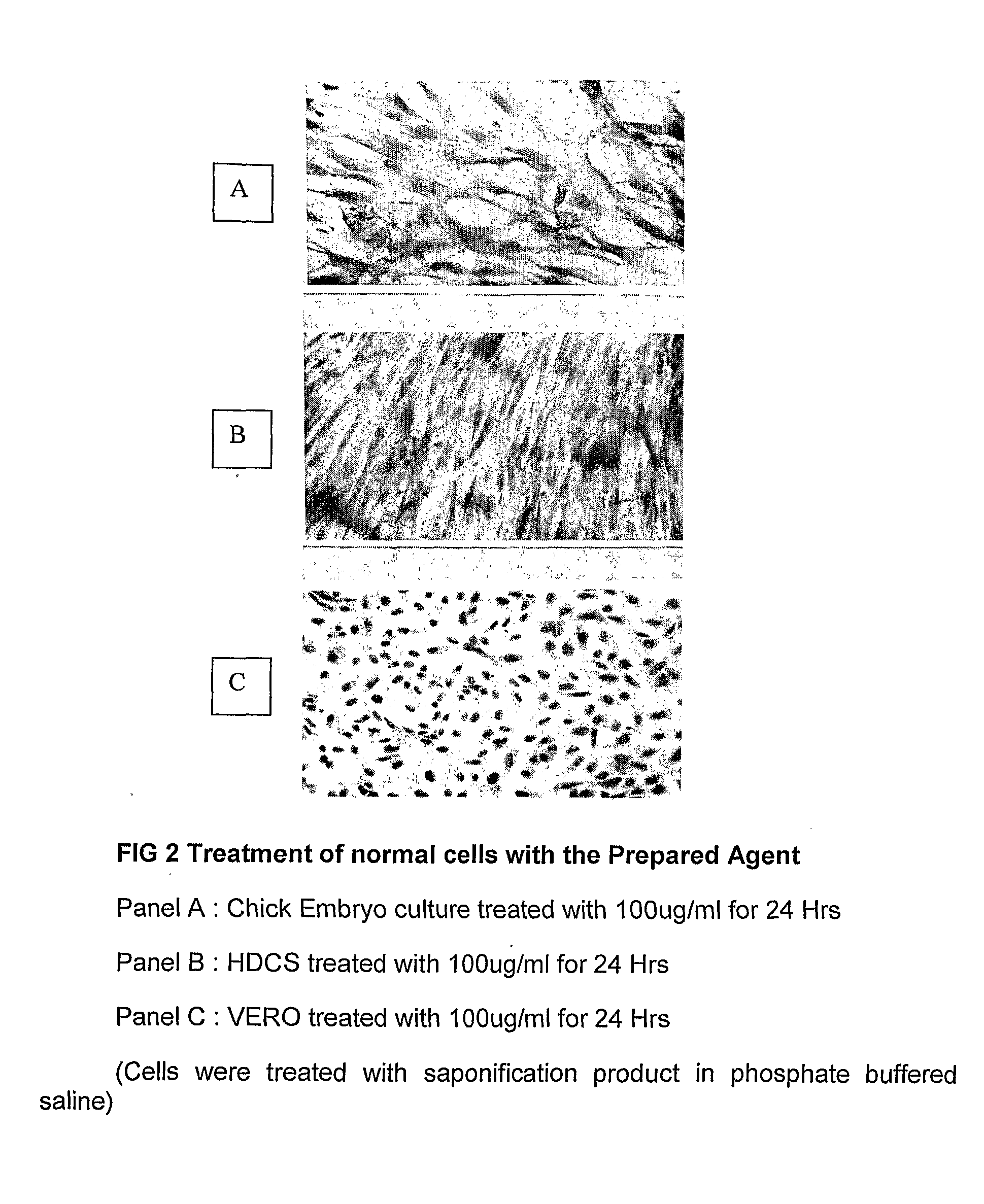

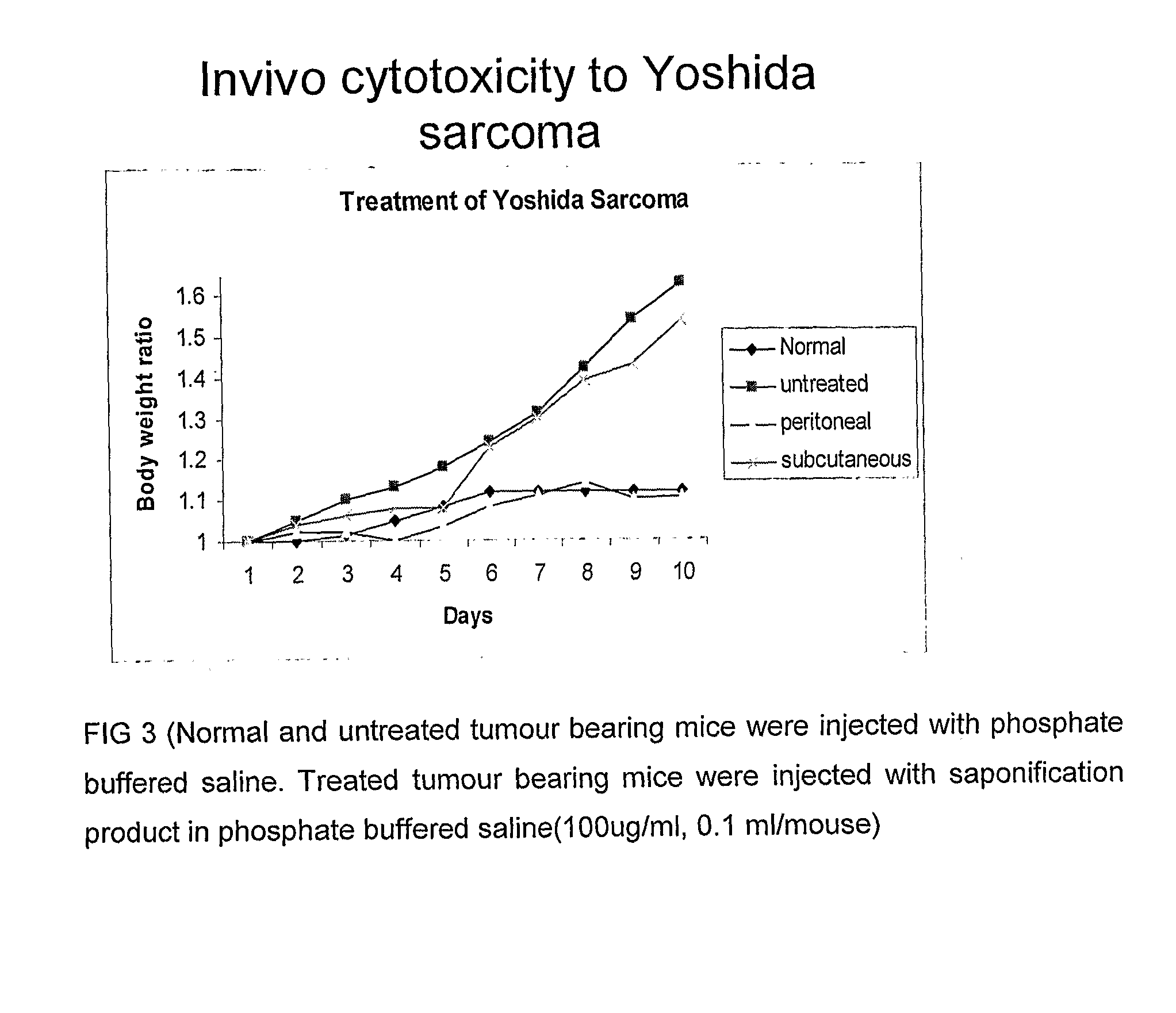

Novel agents for treatment of ailments and dysfunctions

The present invention is related to the use of novel agents effective for differential killing of abnormal cells such as cancer cells without damaging or being toxic to normal cells. Further these agents may be used for treating a host of ailments including various types of cancers, skin diseases, prevention and reversal of ageing process, prevention of inflammatory reactions, cure of bacterial infections, cure of fungal infections, etc. The agents are prepared by air oxidation of natural oils optionally in the presence of a catalyst wherein the isolated agents have Iodine value 40-60% of the starting oil, Saponification value 20-60 higher than that of the starting oil, Peroxide value 2-3 times that of the starting oil. These agents on saponification and acidification yield free fatty acids and ether linked fatty acid dimmer wherein the dimmer also acts as an active.

Owner:REGAIN BIOTECH PVT

Inkjet recording medium

InactiveUS20080241436A1High glossMaintaining film propertyDuplicating/marking methodsCross-linkAlumina hydrate

An inkjet recording medium including a water-resistant support, and on the water-resistant support, two or more ink receiving layers including an upper ink receiving layer and a lower ink receiving layer, each of the two or more ink receiving layers containing a pseudo boehmite alumina hydrate, wherein the upper ink receiving layer further contains a polyvinyl alcohol having a saponification degree of 90% or higher and at least one crosslinking agent selected from the group consisting of boric acid and boric acid salts, and the lower ink receiving layer further contains a polyvinyl alcohol having a saponification degree of less than 90% and at least one cross-linking agent selected from the group consisting of boric acid and boric acid salts.

Owner:FUJIFILM CORP

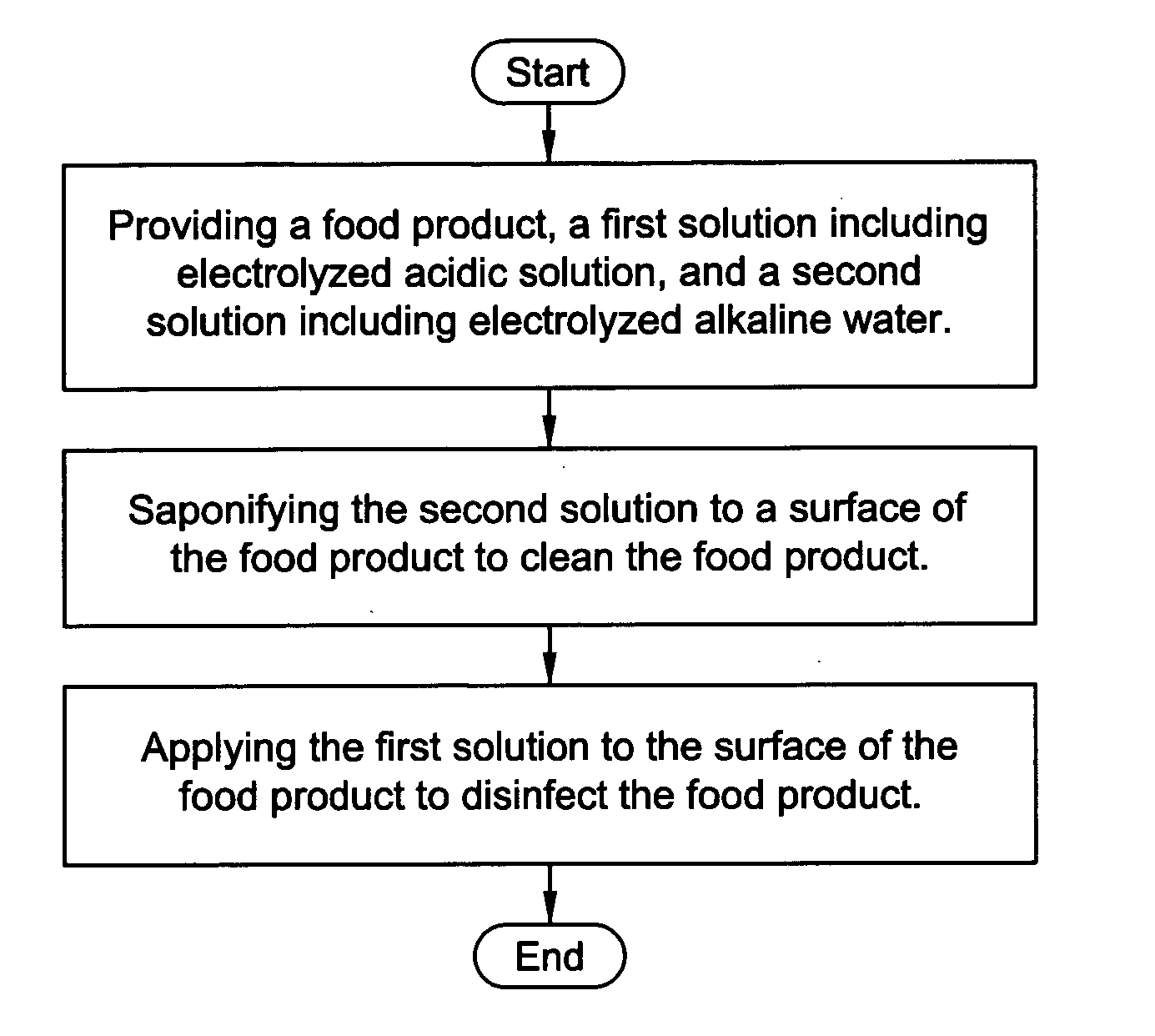

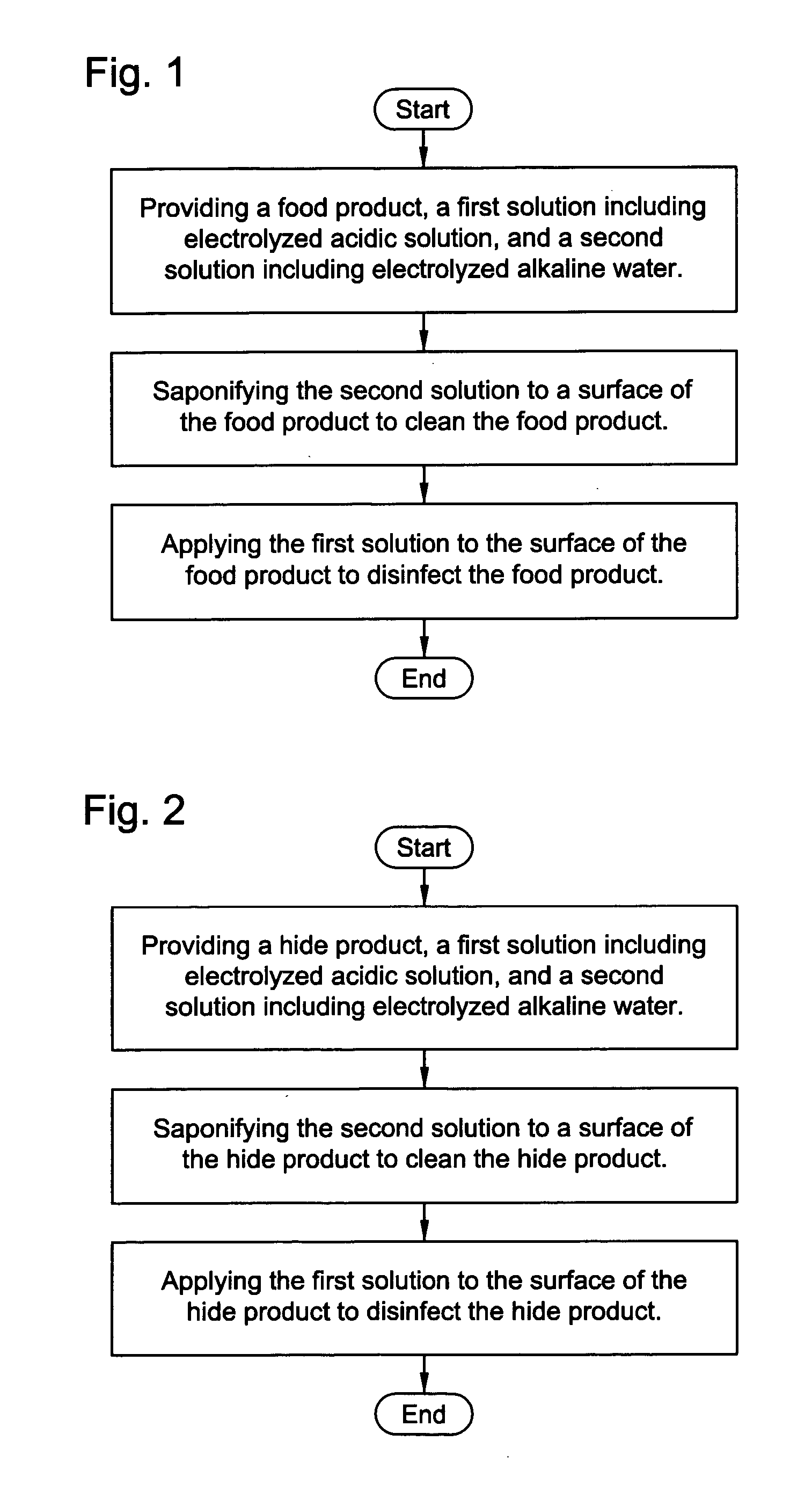

Electrolyzed water treatment for meat and hide

InactiveUS20050244556A1Electrolysis componentsLiquid separation by electricityElectrolysisIndividual animal

Owner:ELECTRIC AQUAGENICS UNLMITED

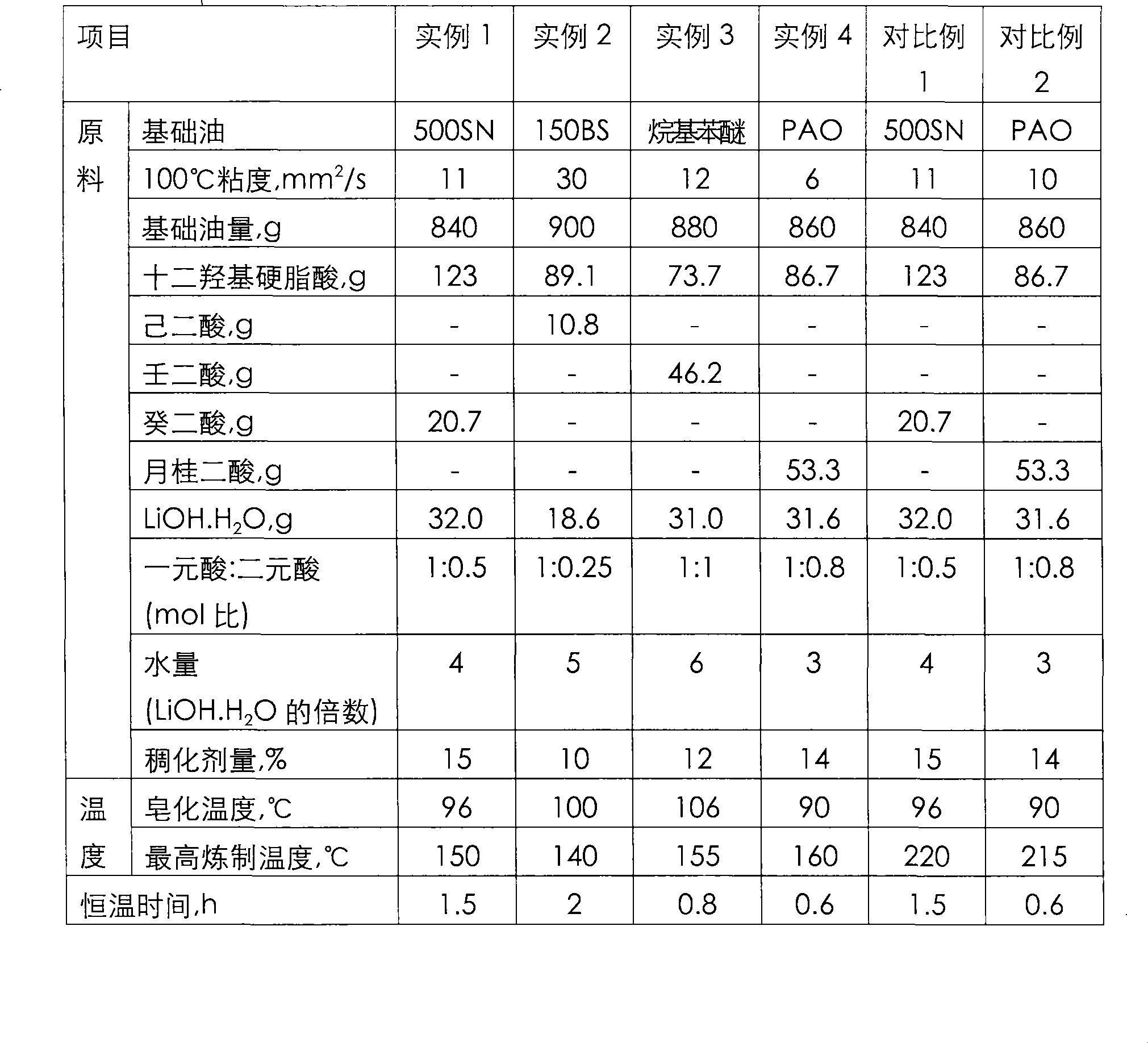

Process for preparing composite lithium base grease

ActiveCN101481637AReduce oxidationImprove Oxidation StabilityThickenersBase-materialsOrganic acidLithium hydroxide

The invention provides a method for preparing complex lithium grease, comprising: part of base oil is mixed with C12-C24 monobasic organic acid and at least one C4-C18 binary organic acid; the mixture is heated up to 80-120 DEG C and then added with lithium hydroxide aqueous solution for saponification reaction, and then moisture is removed; the temperature is risen to 130-180 DEG C for refining at the constant temperature, the rest base oil is added into the mixture to reduce the temperature, and the mixture is ground. The invention adopts lower refining temperature to prepare the complex lithium grease with high dropping point, so as to not only save the power resource, but also have the equivalent performances compared with the grease prepared by the prior art. Meanwhile, the method reduces the oxidation of lubricating oil when in the preparation process and improves the oxidation stability of the grease.

Owner:CHINA PETROLEUM & CHEM CORP +1

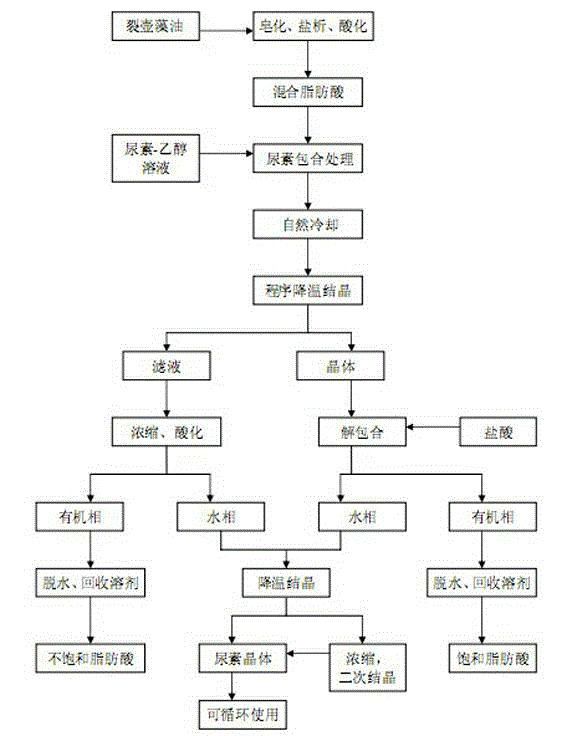

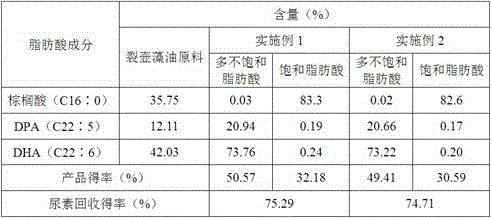

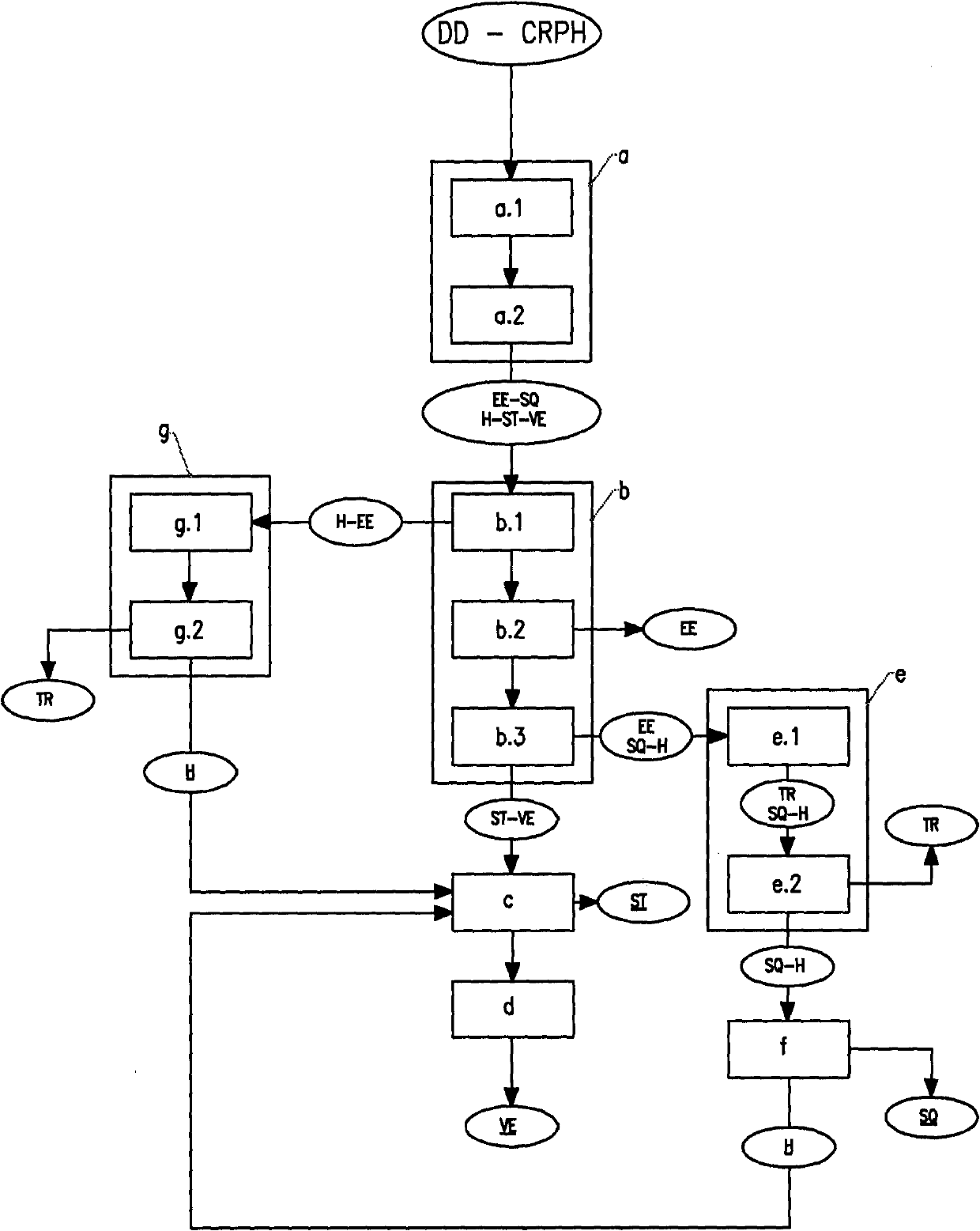

Method for separating and purifying DHA (docosahexaenoic acid) and saturated fatty acid from schizochytrium limacinum oil

ActiveCN102746947AIncrease contentPrevent oxidationPreparation from carboxylic acid saltsFatty acids production/refiningMixed fatty acidSalting out

The invention discloses a method for separating and purifying DHA (docosahexaenoic acid) and saturated fatty acid from schizochytrium limacinum oil. The method includes: firstly, saponifying, salting out and acidizing the schizochytrium limacinum oil under protection of nitrogen so as to obtain free mixed fatty acid, and separating the fatty acid different in degree of saturation by urea adduction fractionation so as to obtain filtrate and solids after filtration; concentrating and extracting the filtrate so as to obtain polyunsaturated fatty acid rich in DHA and DPA (docosapentenoic acid); and allowing the solids to leach by means of acidolysis, extracting the saturated fatty acid (mainly comprising palmic acid) and recovering urea, wherein the urea is recyclable. The method is performedat a low temperature, oxidization of the unsaturated fatty acid is avoided, biological activity and nutrition of the unsaturated fatty acid are kept intact, and the problem of residual solvent is avoided. Products are high in purity, and the obtained polyunsaturated fatty acid mainly comprises the DHA and the DPA and hardly comprises EPA (eicosapentaenoic acid), the content of the DHA and the DPAis higher than 93%, and the content of the palmic acid of the saturated fatty acid is higher than 82%.

Owner:福建华尔康生物科技有限公司

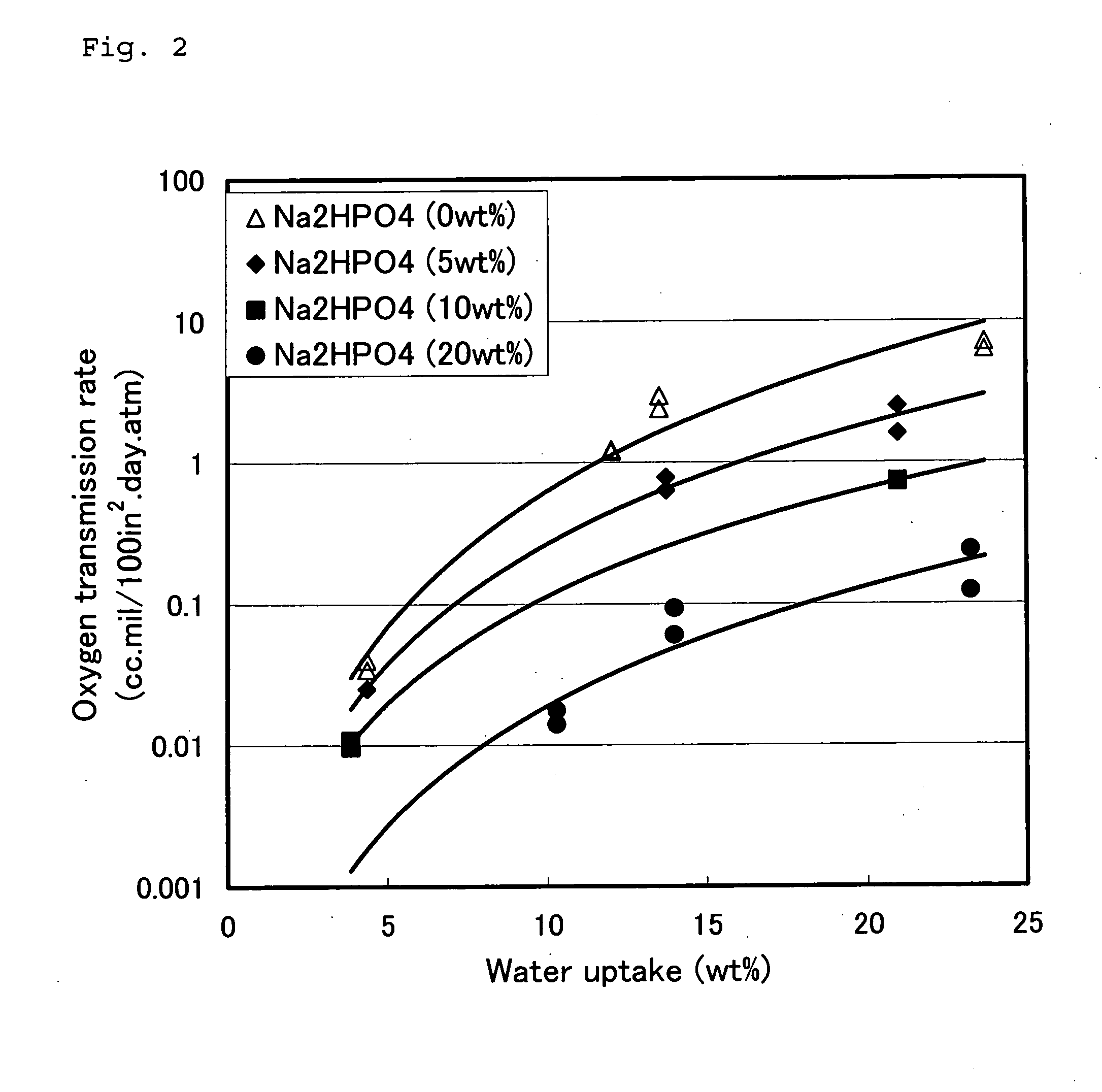

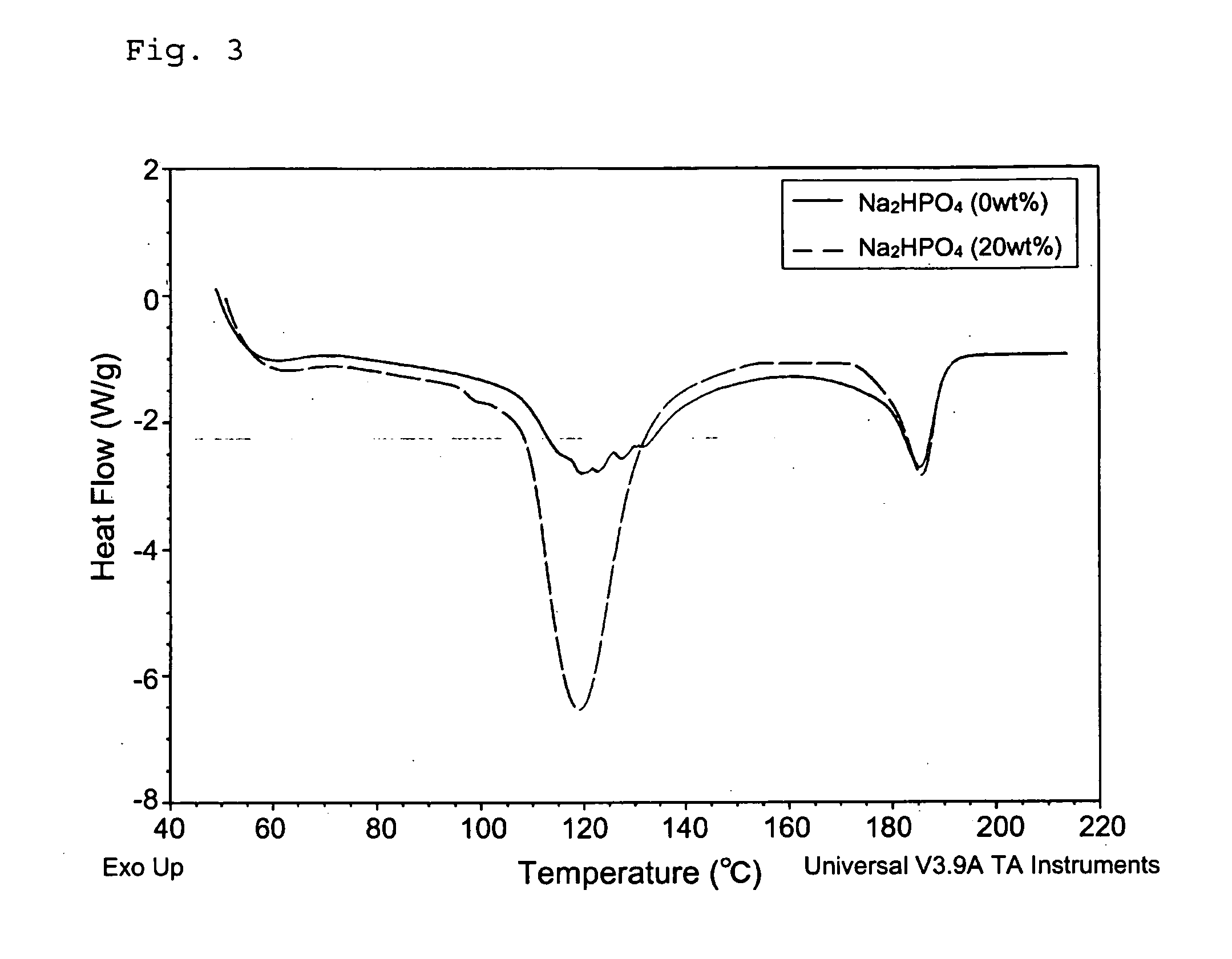

Resin composition and multilayer structure

InactiveUS20070275197A1Excels in gas barrier property and moisture resistanceMultilayer structure being prevented from deterioration in gas barrier propertiesSynthetic resin layered productsOrganic dyesPhosphoric acidMoisture resistance

To provide a resin composition including: an ethylene-vinyl alcohol copolymer (A) having an ethylene content of from 15 to 65 mol % and a saponification degree of at least 95 mol %, a phosphoric acid salt (B) which can form a hydrate, and a conjugated polyene compound (C) having a boiling point of at least 150° C., wherein the resin composition comprises from 50 to 99 parts by weight of (A), from 1 to 50 parts by weight of (B) and from 0.00001 to 1 parts by weight of (C), based on 100 parts by weight of the total amounts of (A) and (B). This resin composition excels in gas barrier property and also in moisture resistance at high temperatures and high humidities. Therefore, it is suitable for food packaging containers to be retorted.

Owner:KURARAY CO LTD

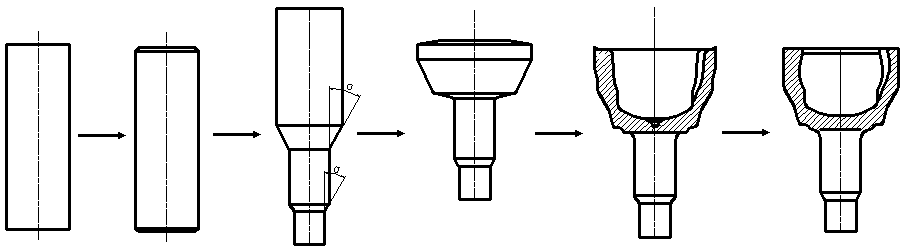

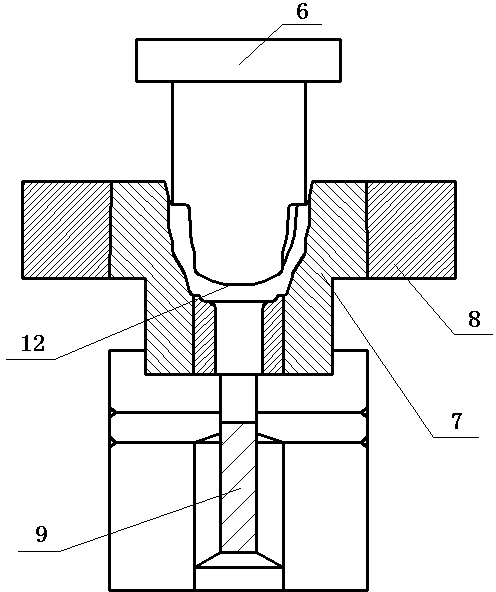

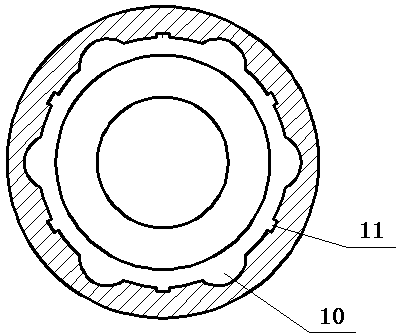

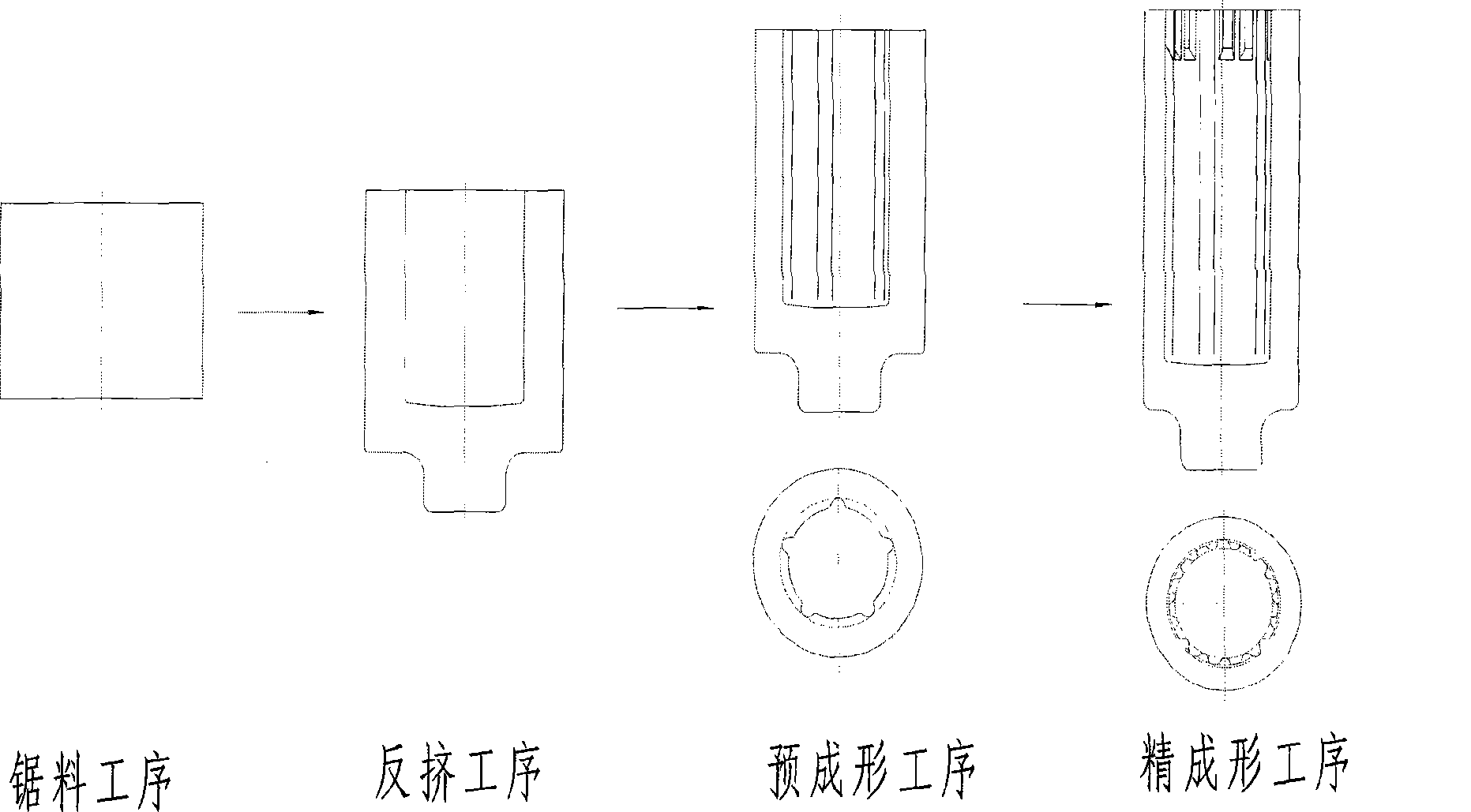

Precision-forging plastic molding technology of bell shell of ball-cage type universal joint

InactiveCN102861861AReduce workloadImprove product qualityRailway componentsForging/hammering/pressing machinesSand blastingUniversal joint

The invention discloses a precision-forging plastic molding technology of a bell shell of a ball-cage type universal joint, comprising steps of warm-forging plastic molding and cold-forging plastic molding. The warm-forging plastic molding technology comprises the following steps: a. blanking; b. manufacturing a blank; c. coating; d. heating; e. directly extruding; f. upsetting; g. extruding reversely; h. normalizing, shaping, sand blasting, parkerising, and treating the surface by a manner of saponification; and adopting the forging plastic molding technology of combining the warm-forging plastic molding technology with the cold-forging plastic molding technology, firstly upsetting to obtain the pre-molding blanking material, secondly, extruding reversely in the chamber of the molding mold to form a ball channel and finally forming the inner spherical surface by using the cold-forging plastic molding technology. The product quality is steady, the production efficiency is improved, the production period is short, the method for adopting the machine tool after the hot-forging is replaced, the workload of the machine tool process is reduced, the precision requirements are met, the manufacturing cost and the period are reduced, and the development trend of the manufacturing field in the world is met.

Owner:张太良

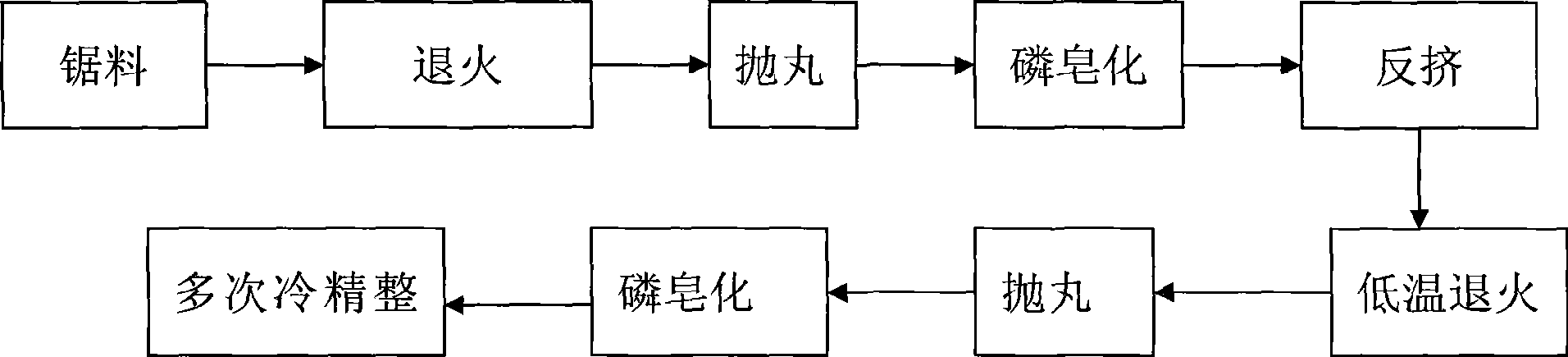

Accurate forming method of special-shape deep-hole type parts

ActiveCN101422861ADense internal organizationQuality improvementFurnace typesHeat treatment furnacesStructure propertyMetal machining

The invention provides a precision forming method of special-shaped parts with deep holes, which relates to the metal machining field with almost no cutting, especially a precision cold forging forming technology of special-shaped parts with deep holes. The invention comprises the process of saw-setting, annealing, shot blasting and phosphorus-saponification of part blank, and back extrusion with tremendous deformation of the part blank; thus, the preformed body with deep holes is completed; then the process of low temperature annealing, shot blasting, phosphorus-saponification is repeated; and subsequently by a plurality of cold finishing, the final product which meets the requirements of structure property and dimension precision is obtained. The method has the beneficial effect that by back extrusion, the preformed body is once completed. The metal streamlines inside the product are continuously distributed according to the shape, and the product has compact microstructure and stable quality, thereby prolonging the service life of the product.

Owner:JIANGSU SUNWAY PRECISION FORGING

Dispersion stabilizer for suspension polymerization of vinyl compound and method of producing the same

ActiveUS7070731B2Less polymer scale adhesionHigh bulk densityColloidal chemistry detailsAcetic acidPolymer science

The present invention provides a new dispersion stabilizer that satisfies, at a high level, the performances required for a dispersion stabilizer used for suspension polymerization. A method of producing a dispersion stabilizer that is useable for suspension polymerization of a vinyl compound and contains a vinyl alcohol polymer (A) includes producing the vinyl alcohol polymer (A) by heat-treating a vinyl alcohol polymer (B) at a temperature of 90 to 180° C. for 0.5 to 20 hours in an atmosphere in which an oxygen concentration is 8000 ppm or lower. The vinyl alcohol polymer (B) has a saponification degree of at least 60 mol % and contains a residual acetic acid group whose block character is in the range of 0.3 to 0.6.

Owner:KURARAY CO LTD

Method for processing wastewater produced in saponification cyclization step in epoxy chloropropane production method

ActiveCN101798154ARealize resourcesOptimize process flowWater contaminantsMultistage water/sewage treatmentEpoxyWastewater

The invention relates to a method for processing organic saponification high-salinity wastewater produced in the production processes of epoxy chloropropane and epoxy-propane. The processing method comprises the steps of concentration of organic high-salinity wastewater, crystallization of calcium chloride, purification and recycling, innocent treatment of mother liquid and the like. The method has simple and convenient technical process, easy operation and control, obvious economic benefit, and environmental protection; the recovery rate of calcium chloride can reach 98%, and the recovery rate of glycerine can reach 88%, thereby changing pollutant into resources.

Owner:NINGBO HUANYANG CHEM

Non-saponification rare earth extraction separation process

ActiveCN102766766ASolve the emission problemEmission reductionProcess efficiency improvementRare earthWastewater

The invention belongs to the field of metallurgy chemical engineering and relates to a novel non-saponification rare earth extraction separation process by using a composite type extracting agent. According to the non-saponification rare earth extraction separation process, a composite solvent which is formed by mixing a P507 or P204 acidic phosphorous extracting agent and an amine extracting agent such as an N235 amine extracting agent is used as the composite type extracting agent, and the extracting agent is not required to be saponified and can be directly used for extracting rare earth, so that the problem that a large amount of ammonia containing waste water is generated during an extraction process due to the fact that ammonia is used for saponifying the extracting agent is thoroughly solved, simultaneously, the usage of ammonia alkali and acid is greatly reduced, and production costs are reduced.

Owner:宁夏同乐新材料科技有限责任公司

Process for the extraction of squalene, sterols and vitamin e contained in condensates of physical refining and/or in distillates of deodorization of plant oils

InactiveCN102089263AHigh priceEfficient use ofFatty acid esterificationMetabolism disorderSterolVegetable oil

The invention describes an overall process for the extraction of sterols, vitamin E, squalene and other plant-based hydrocarbons from deodorization distillates of plant oils. After an esterification of the free fatty acids, then a transesterification of the combined fatty acids (glycerides and sterides) by the same short alcohol, three successive distillations make it possible to successively recover a first fraction of hydrocarbons, the main fraction of alkyl esters, then the heaviest alkyl esters with squalene. The third distillate will be used for the production of squalene and a second fraction of hydrocarbons. The residue of the third distillation will be used for the production of sterols and vitamin E. By using bioethanol, plant-based glycerol and the plant-based hydrocarbons of the process, the process makes it possible to extract each of the four unsaponifiable substances without any solvent of oil-based origin and to claim the seals of approval for products obtained by natural physical and chemical processes.

Owner:SOPHIM

Process for the preparation of a crystalline l-mgda trialkali metal salt

ActiveUS20120283473A1Organic compound preparationAmino-carboxyl compound preparationAqueous solutionL-α-alanine

A process is proposed for the preparation of a crystalline L-MGDA trialkali metal salt by crystallization from an aqueous solution thereof which has been obtained by Strecker synthesis, starting from L-α-alanine, by reaction with formaldehyde and hydrocyanic acid to give L-α-alanine-N,N-diacetonitrile and subsequent alkaline saponification of the L-α-alanine-N,N-diacetonitrile to give the L-MGDA trialkali metal salt, wherein a temperature of 150° C. is not exceeded during the alkaline saponification.

Owner:BASF AG

Polyvinyl acetal resin composition

ActiveUS20110049434A1Sufficient flexibilityNot easy to damageConductive materialOrganic conductorsConductive pastePolyvinyl acetate

It is an object of the present invention to provide a polyvinyl acetal resin composition capable of giving a ceramic green sheet which has sufficient flexibility and is hardly damaged even when being formed into a thin film, when the polyvinyl acetal resin composition is used as a binder for a ceramic green sheet. It is another object of the present invention to provide a ceramic slurry, a ceramic paste, a ceramic green sheet, a conductive paste and an interlayer film for laminated glass for automobiles, each produced by using the polyvinyl acetal resin composition.The present invention pertains to a polyvinyl acetal resin composition containing a polyvinyl acetal resin A and a polyvinyl acetal resin B incompatible with the polyvinyl acetal resin A, which is formed by acetalizing a mixed polyvinyl alcohol containing two or more kinds of polyvinyl alcohols having different saponification degrees, and wherein the mixed polyvinyl alcohol contains main two kinds of polyvinyl alcohols in which X and Y satisfy the relationship of the following equation (1):[Formula 1]|X−Y|≧10 (1)in which X represents the saponification degree of any one polyvinyl alcohol a of the polyvinyl alcohols contained in the mixed polyvinyl alcohol and Y represents the saponification degree of a polyvinyl alcohol b other than the polyvinyl alcohol a, andwherein in denoting, by M, the polymerization degree of one polyvinyl alcohol having a higher polymerization degree of the main two kinds of polyvinyl alcohols and denoting the polymerization degree of the other polyvinyl alcohol by N, M and N have the relationship of the following equation (2):[Formula 2]M / N≦3 (2)and a phase composed of the polyvinyl acetal resin A and a phase composed of the polyvinyl acetal resin B form a sea-island structure.

Owner:SEKISUI CHEM CO LTD

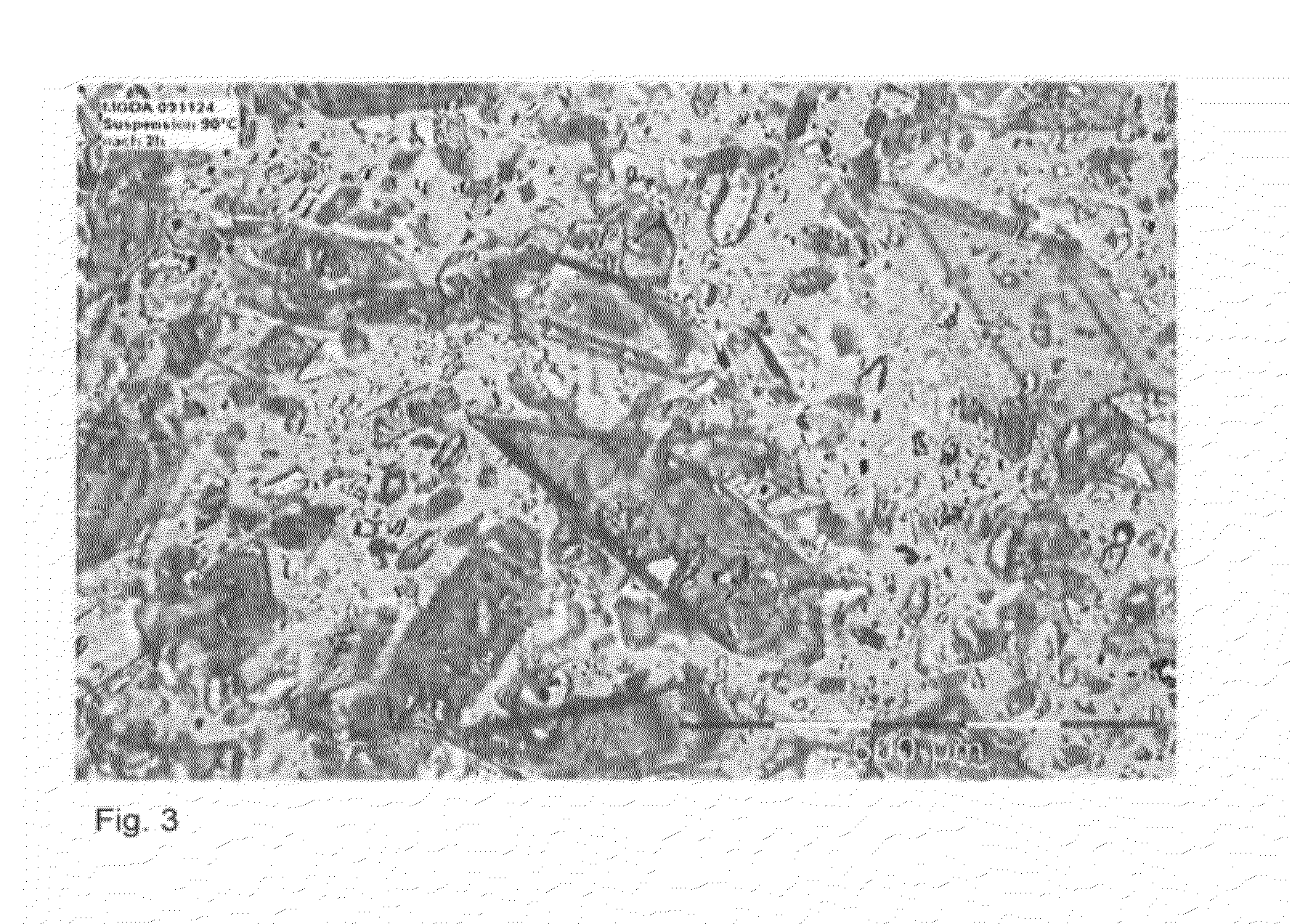

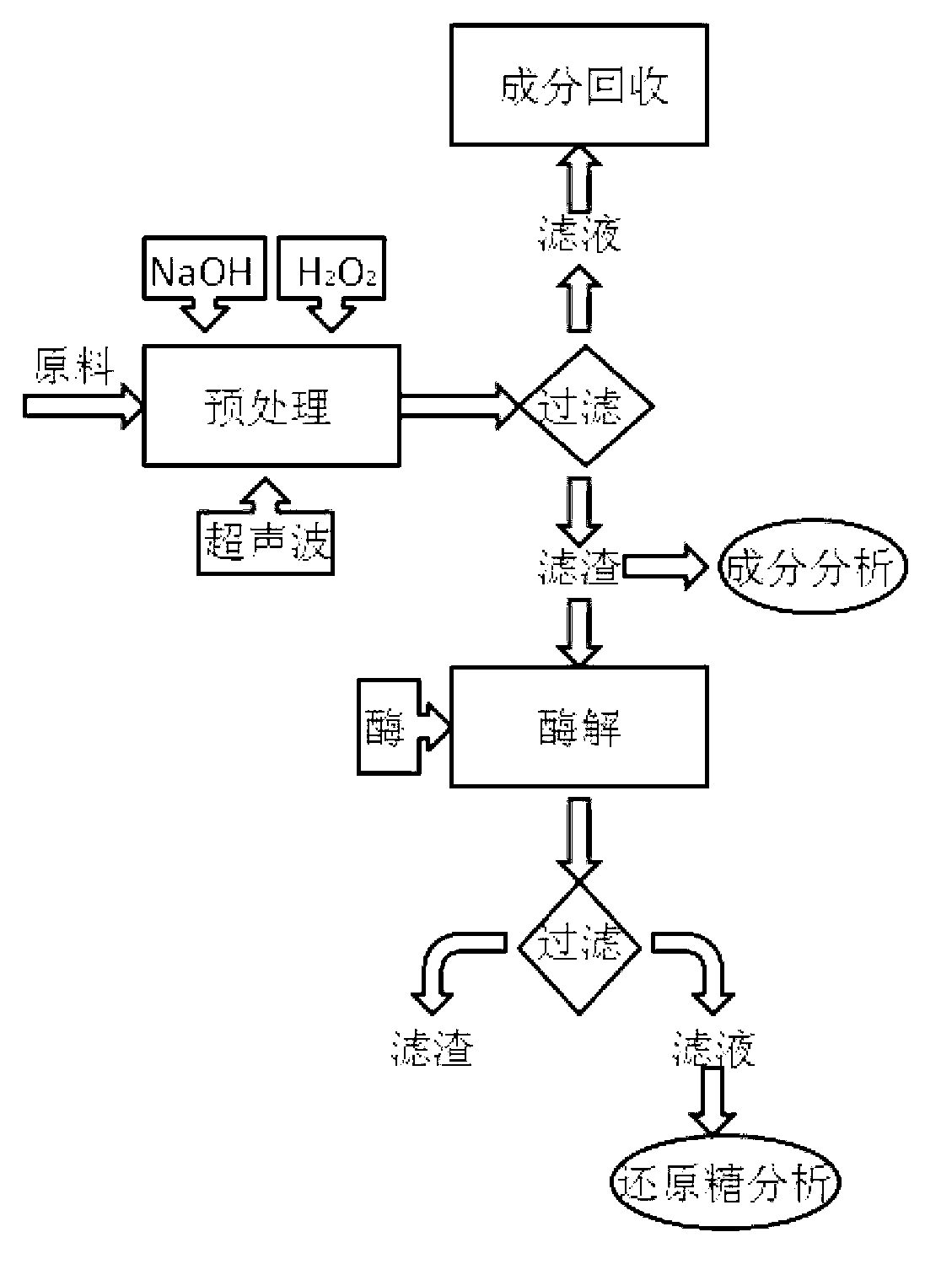

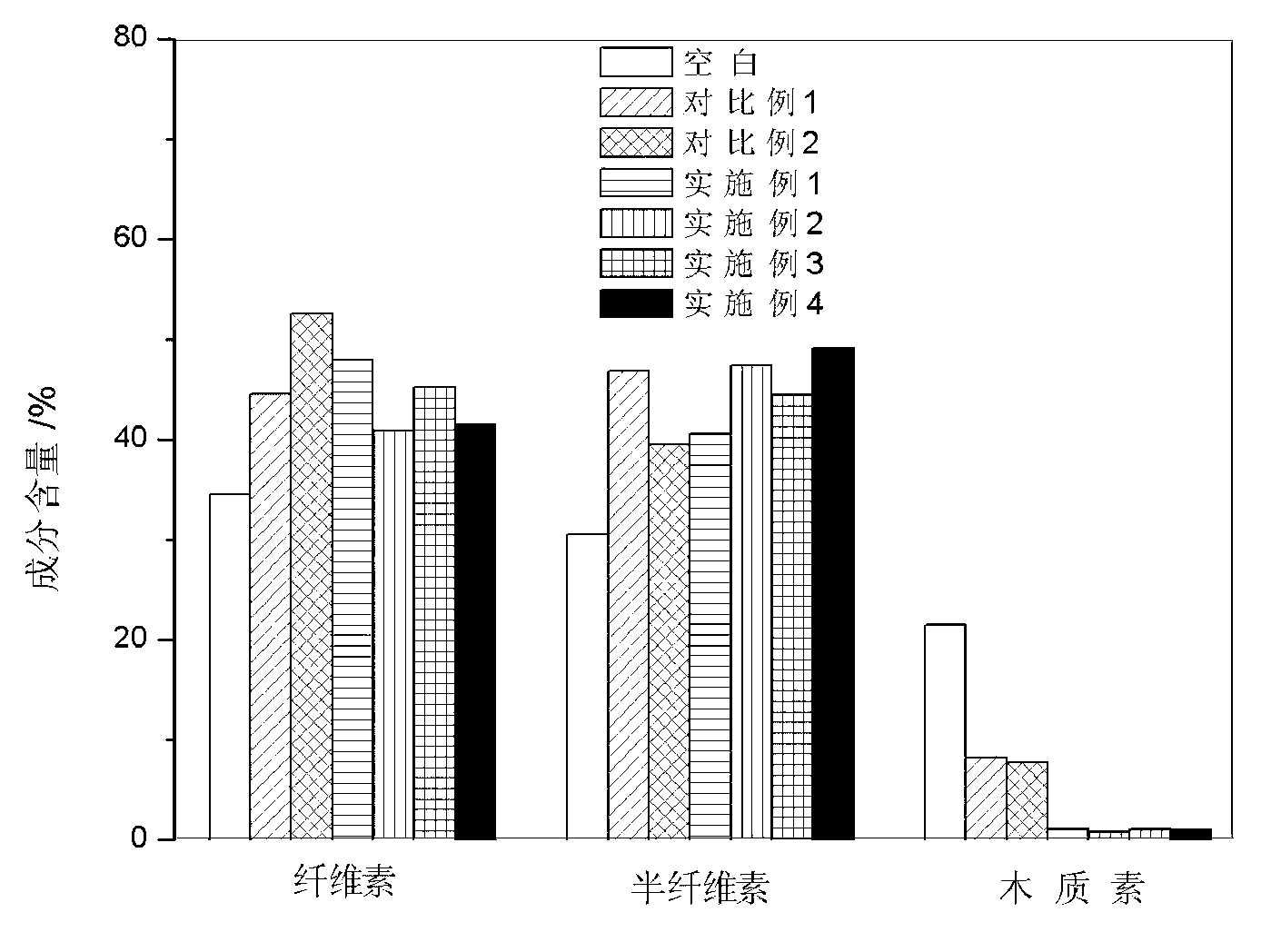

Method for enhancing alkaline hydrogen peroxide to pretreat lignocellulose by ultrasonic wave

InactiveCN102839198AReduce hindranceHigh yield of enzymatic hydrolysisBiofuelsFermentationCellulaseHemicellulose

The invention relates to a method for enhancing alkaline hydrogen peroxide to pretreat lignocellulose by an ultrasonic wave, and the method comprises the steps that when the lignocellulose is subjected to alkali treatment, the enhancing effect of the ultrasonic wave is conducted; after a period of time, the hydrogen peroxide is added for strong oxidization; and after the pretreatment is finished, a raw material is subjected to solid-liquid separation, wherein after a solid component in the raw material is dried, cellulase enzymolysis and composition analysis are conducted, and a liquid component is used for recovering hemicellulose and lignin components. The method aims at enhancing saponification and the strong oxidization of the alkaline hydrogen peroxide on the lignin component by fierce cavitation of the ultrasonic wave, so that the content of the lignin hindering the enzymolysis of a lignocellulose raw material is reduced greatly, most cellulose and hemicellulose are degraded to be fermentable monosaccharide, and the raw material utilization ratio of the lignocellulose is increased to the greatest extent. In addition, the hemicellulose and the lignin in pretreatment liquid are recovered by an acidulation method, and the green process without wasting of resources is realized.

Owner:SOUTHEAST UNIV

Lutein crystal preparing process from marigold flower

The present invention is the lutein crystal preparing process from marigold flower. Lutein ester is first extracted from marigold flower with non-polar solvent under heating condition and then saponified with alkali solution in stirring and heating condition; and the saponified product is diluted with deionized water and separated, washed and vacuum dried. After that, the obtained lutein crystal is re-crystallized in three-component solvent of tetrahydrofuran, deionized water and normal hexane or petroleum ether; and the lutein crystal is suction filtered, washed and vacuum dried. The present invention has low-toxicity solvent in small amount used, simple technological process, high extraction, rate, and high product purity. The product of the present invention may be used widely as feed coloring additive and food coloring agent and in medicine and health care article.

Owner:海宁凤鸣叶绿素有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com