Method for processing wastewater produced in saponification cyclization step in epoxy chloropropane production method

A technology of epichlorohydrin and treatment method, which is applied in the fields of water/sewage multi-stage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as environmental pollution and impact on technical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

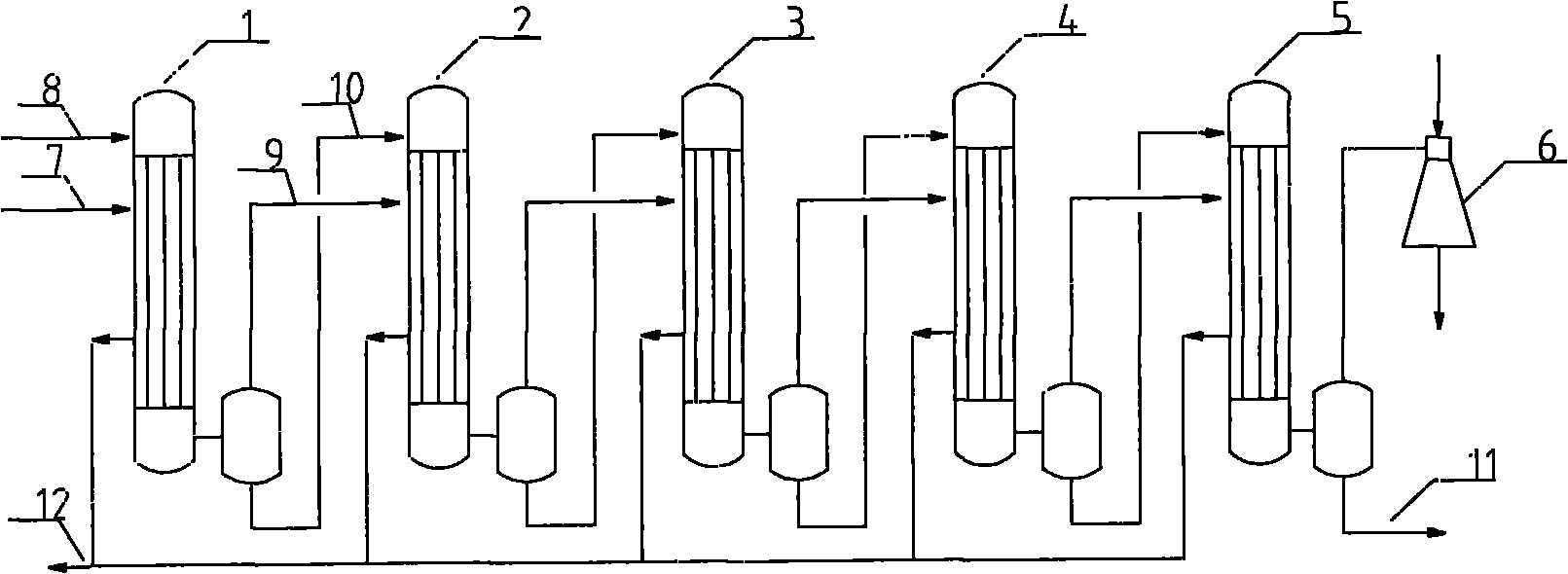

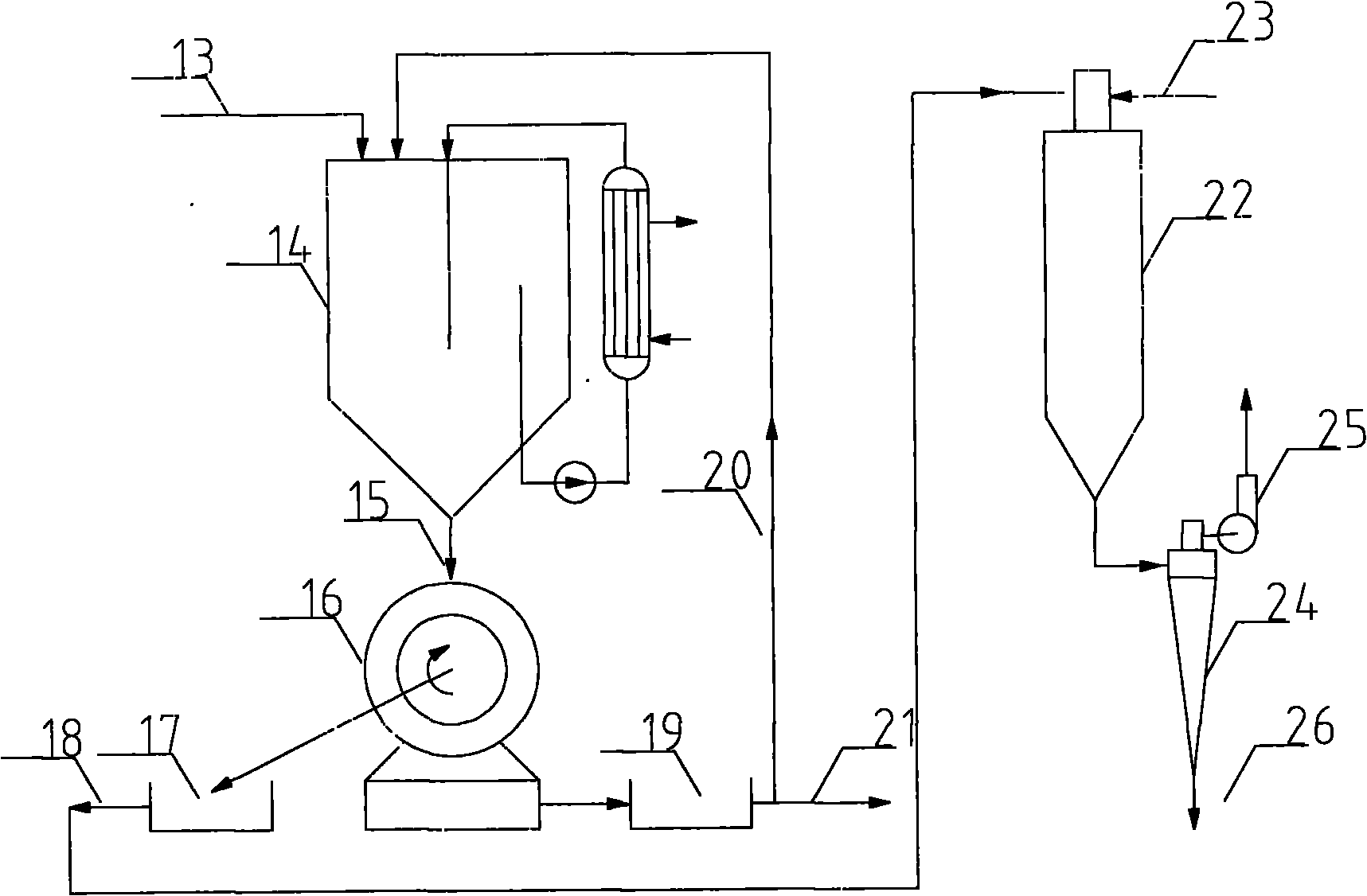

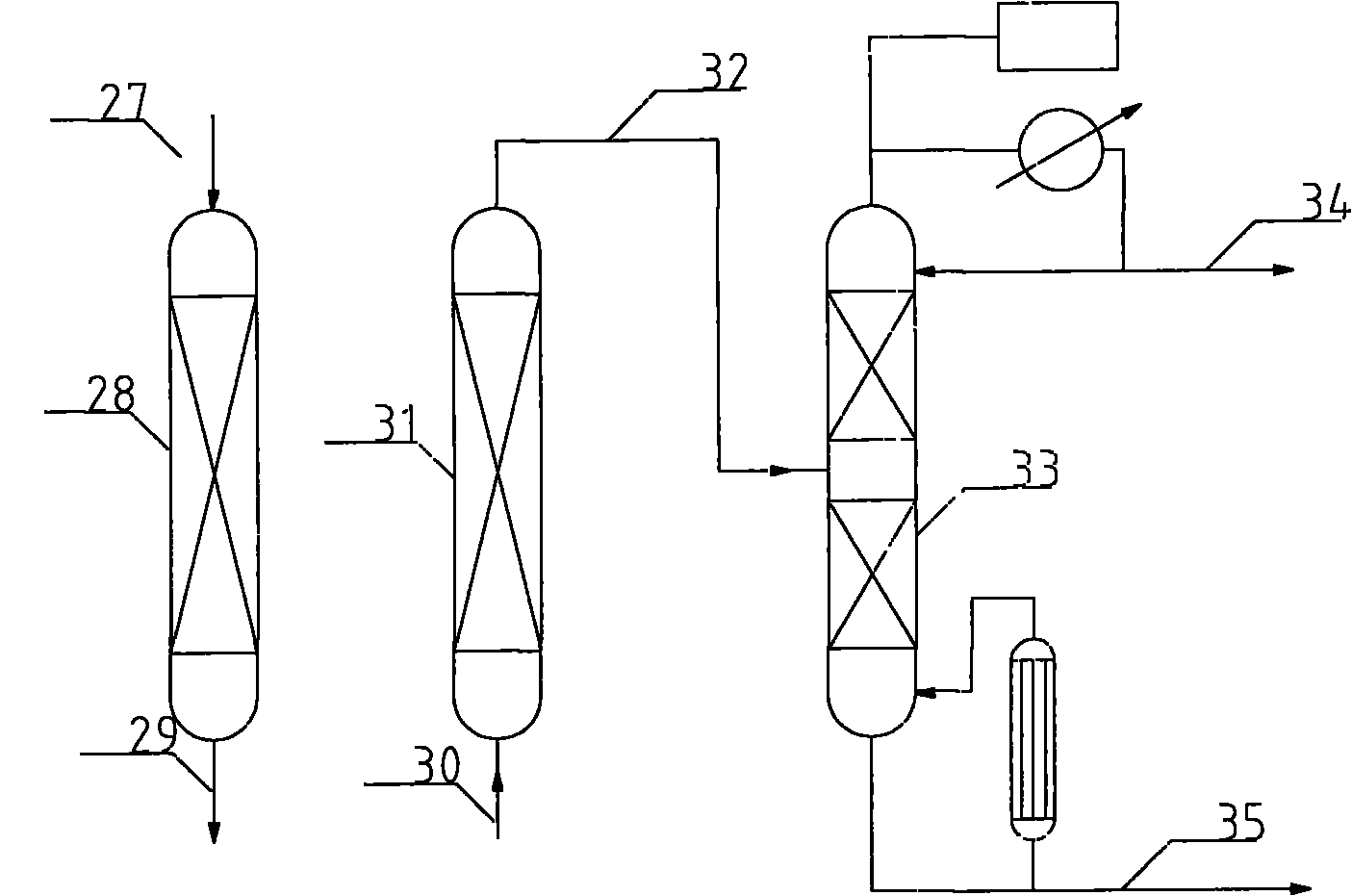

Image

Examples

Embodiment 1

[0117] Concentrate dichloropropanol dehydrochlorination saponification cyclization waste water, the composition of solution after concentration is 100gCaCl 2 / 100gH 2 O and 3.1g glycerol / 100g H 2 O. Get the solution 131.3g of this composition, be divided into two parts, one part is about 1 / 3 of the total weight of the solution, and the other part is 2 / 3 of the total weight of the solution, respectively put into a 150ml beaker, wherein the first Calcium chloride hexahydrate crystals are precipitated at low temperature. The beaker that has separated out the calcium chloride hexahydrate crystal and another part of the beaker that said solution is housed are put into a water bath, and the temperature of the water bath is controlled at 18°C, and the slurry of the calcium chloride hexahydrate crystal is slowly stirred with an agitator, and the Slowly pour another uncrystallized solution that has been cooled to 18°C into the slurry, keep the temperature of the slurry at 20°C for...

Embodiment 2

[0123] First, assemble a set of macroporous resin adsorption columns for laboratory use. DM130 macroporous adsorption resin is soaked in ethanol repeatedly for several times, and then pretreated by fully rinsing with clean water, and then the macroporous resin with a particle size of 50-20 mesh is screened. Use the natural sedimentation method to fill 150cm in the Φ29×500cm glass adsorption column 3 DM130 macroporous resin.

[0124] This example uses the filtrate obtained in Example 1, which contains 41% by weight of CaCl based on the total weight of the filtrate 2 and 9% by weight glycerin.

[0125] The filtrate was injected into the DM130 macroporous resin adsorption column at a flow rate of 0.2 m / min, and then the change of glycerol concentration in the effluent was detected by the method of GB / T13216.6-91. When the concentration of glycerol in the effluent reached 1.0% by weight, the injection of the original waste liquid was stopped.

[0126] The adsorption column sat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com