Method for preparing concrete pavement brick by using recycled aggregate of construction waste

A technology of concrete pavement and recycled aggregate, applied in the field of building materials, can solve the problems of less than 5% utilization rate of construction waste, inability to realize resource utilization of construction waste, high water absorption rate of unburned bricks, etc., and achieve low cost, Long service life and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

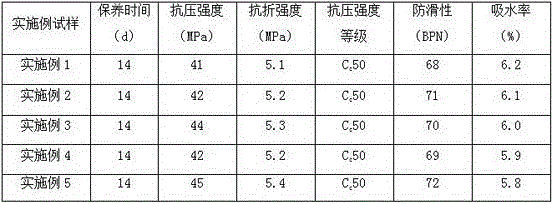

Examples

Embodiment 1

[0026] Raw materials for preparing concrete pavement bricks: 60 parts of recycled construction waste aggregate, 25 parts of superfine 52.5 Portland cement, 10 parts of gelling agent, 0.5 part of superplasticizer, 0.5 part of reinforcing agent, 0.1 part of dispersing agent, retarder 0.1 part of dose;

[0027] The preparation method of concrete pavement brick comprises the steps:

[0028] S1. First, add recycled construction waste aggregate, superfine 52.5 Portland cement, gelling agent, high-efficiency water reducer and appropriate amount of water into the mixer and stir for 3-5 minutes, then add reinforcing agent, dispersant and retarder to continue stirring After 5-10 minutes, adjust the consistency of the mixture with an appropriate amount of water, put the mixed material into the concrete pavement brick mould, vibrate and press to solidify, and demould after 15-20 hours to obtain a concrete pavement brick body with a vibration frequency of 4000-4500 times / min, vibration ti...

Embodiment 2

[0032] Raw materials for preparing concrete pavement bricks: 65 parts of recycled construction waste aggregate, 28 parts of superfine 52.5 Portland cement, 11 parts of gelling agent, 0.8 part of superplasticizer, 0.8 part of reinforcing agent, 0.2 part of dispersing agent, retarder 0.1-1 part of agent; the preparation method is the same as in Example 1.

Embodiment 3

[0034] Raw materials for preparing concrete pavement bricks: 70 parts of recycled construction waste aggregate, 30 parts of superfine 52.5 Portland cement, 12 parts of gelling agent, 1.5 parts of superplasticizer, 1.5 parts of reinforcing agent, 0.3 parts of dispersing agent, retarder 0.1-1 part of agent; the preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com