Synchronous desulphrization and denitration method of flue gas pyrolusite pulp for reclamation

A technology for coal-fired flue gas, desulfurization and denitrification, applied in chemical instruments and methods, separation methods, air quality improvement and other directions, can solve problems such as economic loss, inability to absorb nitrogen oxides, air pollution, etc. The effect of abundant reserves and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

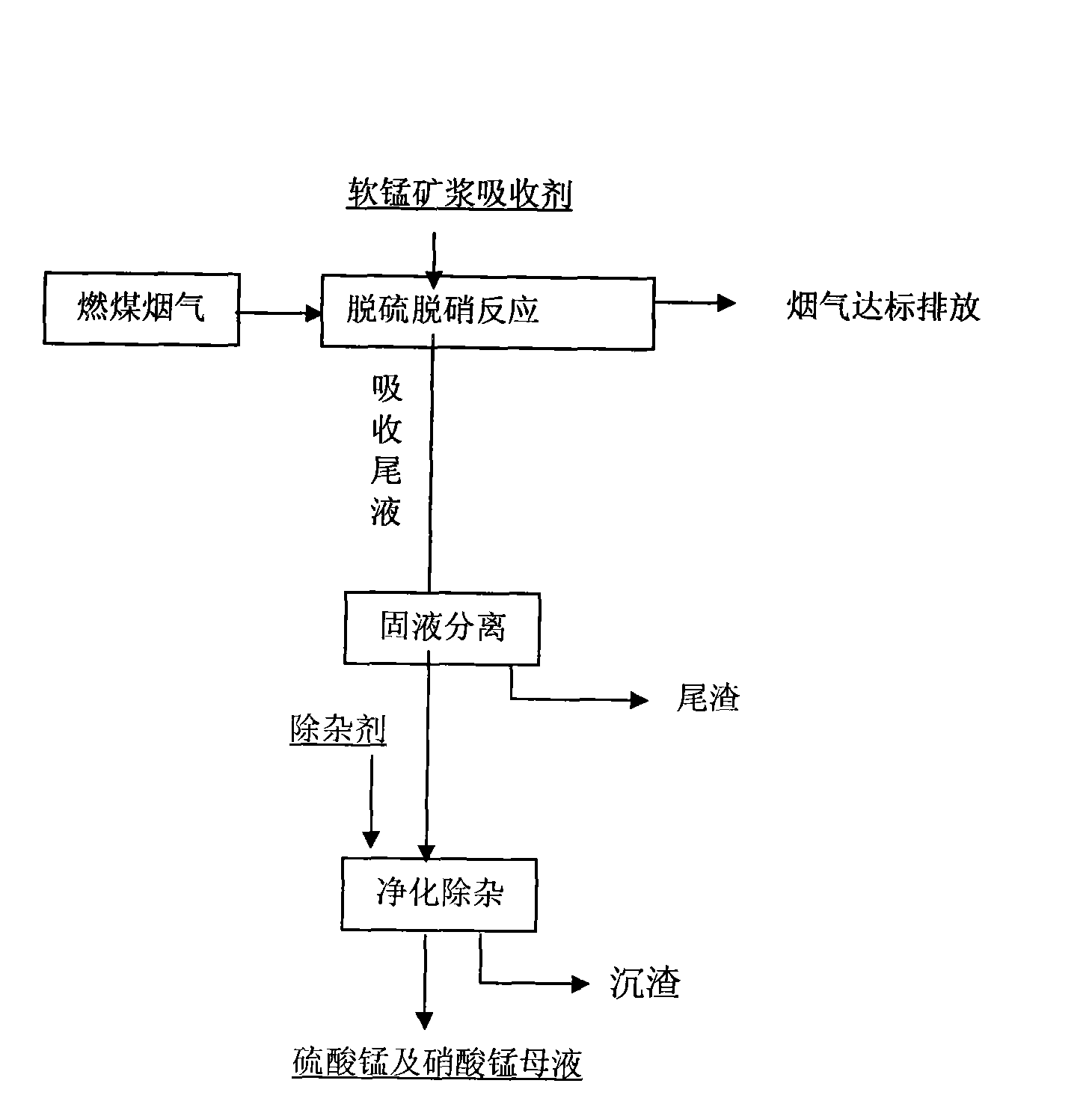

[0035] Take the treatment of a coal-fired boiler with a scale of 35t / h as an example. The amount of exhaust gas to be treated is 60000Nm 3 / h, SO in exhaust gas 2 The content is 3000ppm, NO X Content is 1500ppm, and the technological process of the present embodiment is as figure 1 shown. First crush the pyrolusite into pyrolusite powder of no more than 100 meshes, then put the pyrolusite powder, water and metal chelating agent polyacrylic acid into the pulp tank equipped with agitator, and prepare the pulp with a liquid-solid mass ratio of 3:1 , wherein the mass content of polyacrylic acid is 0.3% of the mass content of pyrolusite. Drive the slurry into the removal reactor through the slurry pump, containing SO 2 , NO X The flue gas first passes through the wet dust collector to cool and humidify, then enters the removal reactor, and is dispersed into the pulp by the gas dispersion device to be absorbed. SO in flue gas 2 , NO X Absorption reaction with pyrolusite pul...

Embodiment 2

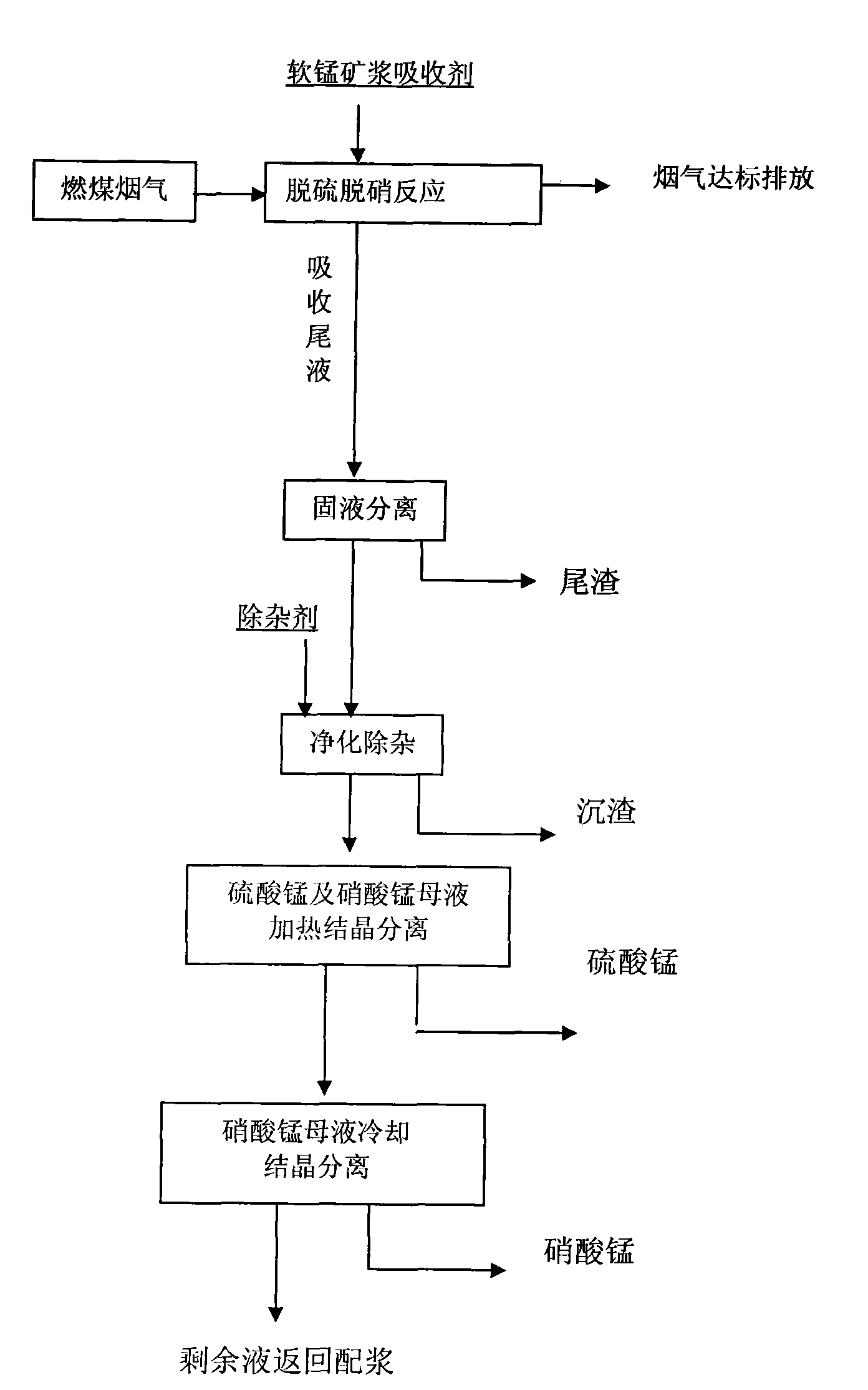

[0037] The technological process of this embodiment is as figure 2 shown. In this embodiment, the technological process from preparing pyrolusite pulp to preparing the primary product of the mixed mother solution of manganese sulfate and manganese nitrate is the same as that of embodiment 1. This embodiment follows embodiment 1 to produce manganese sulfate and manganese nitrate finished products. Heat the mixed mother liquor of relatively pure manganese sulfate and manganese nitrate to about 100°C to evaporate and concentrate it, so that the manganese sulfate contained in it undergoes a crystallization reaction. Manganese crystals are dried at 150°C to 200°C for two hours to obtain the product manganese sulfate. Cool the remaining liquid after heating crystallization and solid-liquid separation to about 20°C. The manganese nitrate contained in the liquid undergoes a crystallization reaction. The manganese nitrate crystals are dried at 100°C to 110°C for two hours to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com