Method for preparing barium sulfate and zinc sulfide

A technology of zinc sulfide and barium sulfate, which is applied in the direction of zinc sulfide, calcium/strontium/barium sulfate, etc., can solve the problems of low utilization rate, uneconomical economy, and poor benefit, and achieve favorable environmental protection and convenient and easy access to raw materials , good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

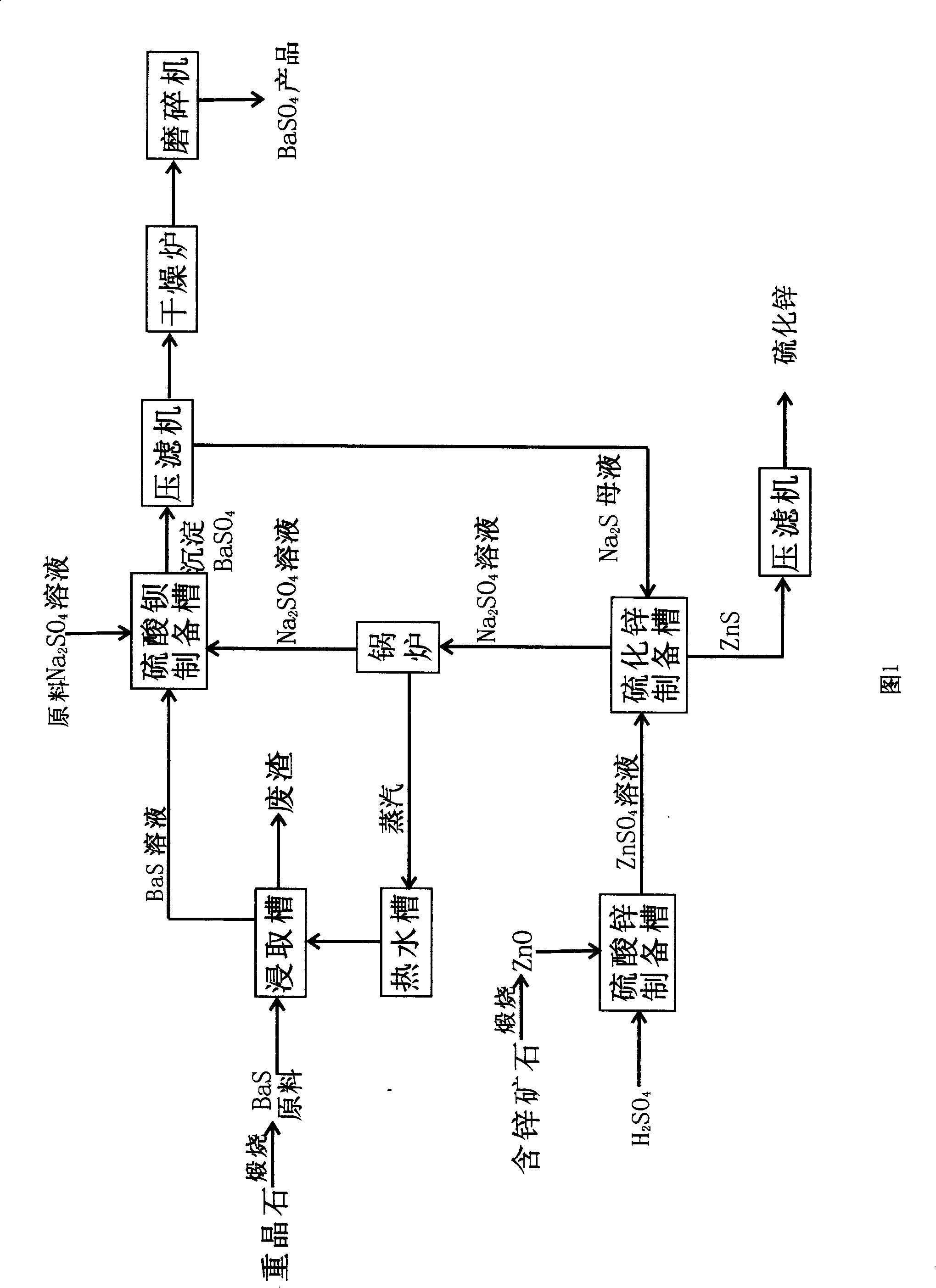

[0020] As shown in Figure 1, this method for preparing barium sulfate and zinc sulfide, it is main raw material with barite and zinc-containing ore, and technological process is:

[0021] 1) Calcining barite and coal at a ratio of 3:1 and controlling the temperature at 1100°C to 1200°C for 2 hours, and the obtained barium sulfide is soaked in hot water in a hot water tank to obtain clarified barium sulfide. Barium sulfide solution, the waste residue after leaching barium sulfide is used as refractory material after acidification and neutralization;

[0022] 2), in the precipitated barium sulfate preparation tank, the barium sulfide BaS solution and Glauber's salt Na 2 SO 4 Solution reaction, the reaction product is filtered and separated by a filter press, dried in a drying oven, and ground by a grinder to obtain barium sulfate BaSO with a content of more than 98%. 4 Product, containing alkali sulfide Na after separation of barium sulfate 2 S mother liquor is sent in the zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com