Patents

Literature

6098 results about "Barium sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barium sulfate (or sulphate) is the inorganic compound with the chemical formula BaSO₄. It is a white crystalline solid that is odorless and insoluble in water. It occurs as the mineral barite, which is the main commercial source of barium and materials prepared from it. The white opaque appearance and its high density are exploited in its main applications.

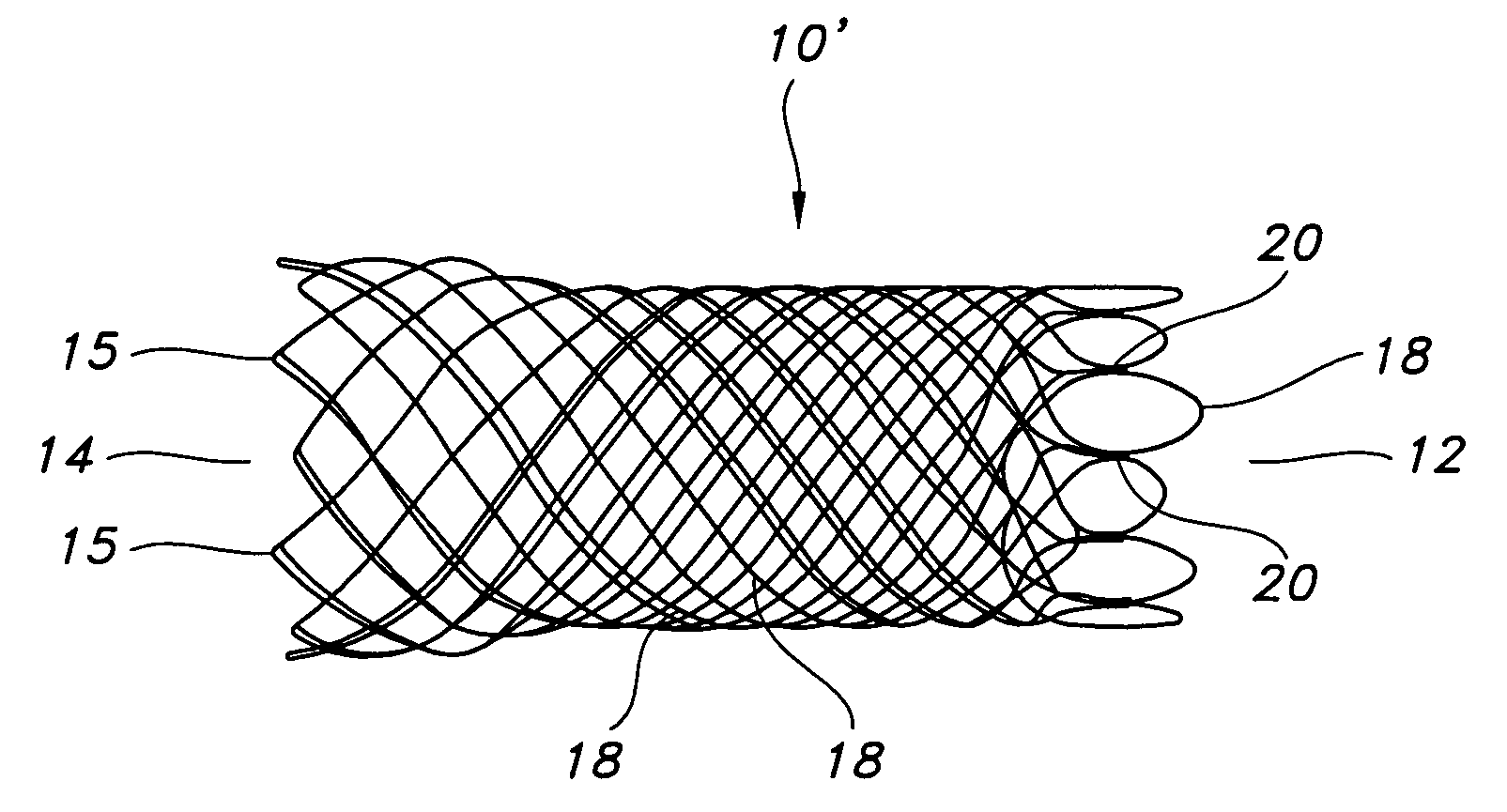

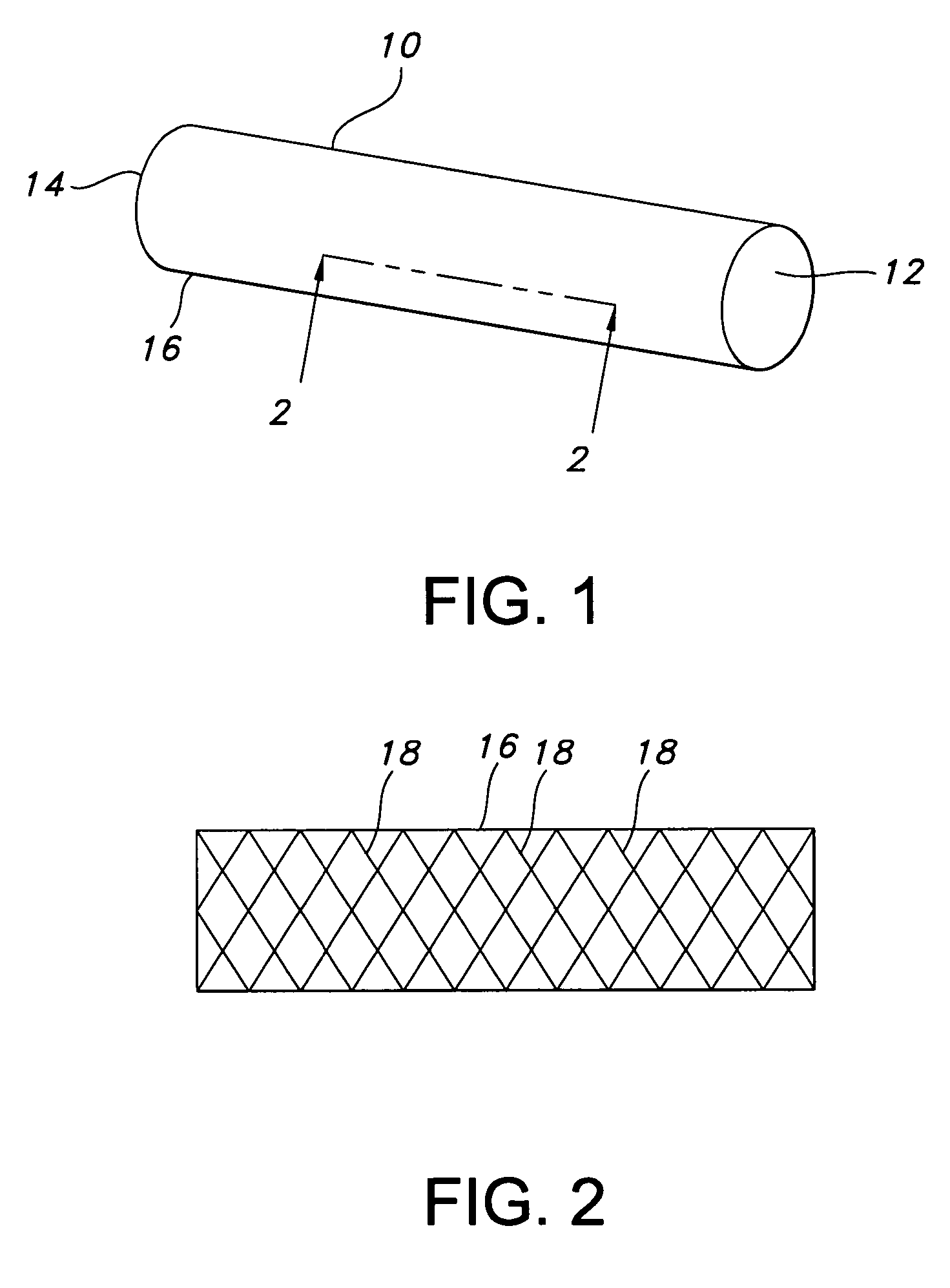

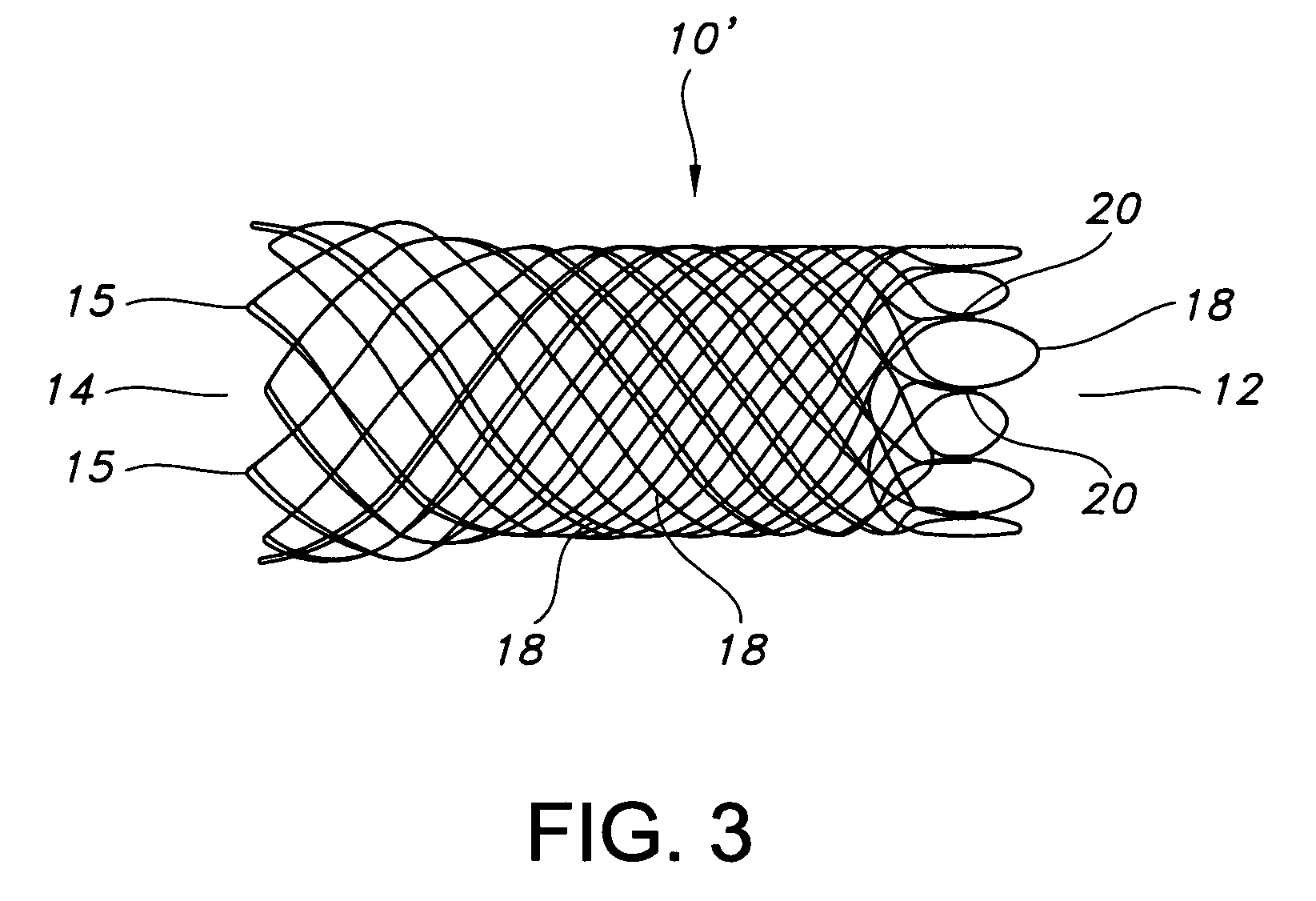

Atraumatic stent with reduced deployment force, method for making the same and method and apparatus for deploying and positioning the stent

An implantable stent includes a plurality of elongate wires braided to form a hollow tubular structure having a tubular wall to define an interior surface and an exterior surface and having opposed open first and second ends, wherein the opposed open first and second ends are atraumatic ends The atraumatic ends of the stent are desirably free of any loose wire ends. The wires include composite wires to enhance visibility of the wires to provide improved external imaging of the wires in the body. The elongate composite wires of the stent may be metallic wires having an outer metallic portion including a first metal, such as nitinol, and an inner metallic core portion including a second metal, which is a radiopaque material, such as gold, barium sulfate, ferritic particles, platinum, platinum-tungsten, palladium, platinum-iridium, rhodium, tantalum or combinations thereof.

Owner:BOSTON SCI SCIMED INC

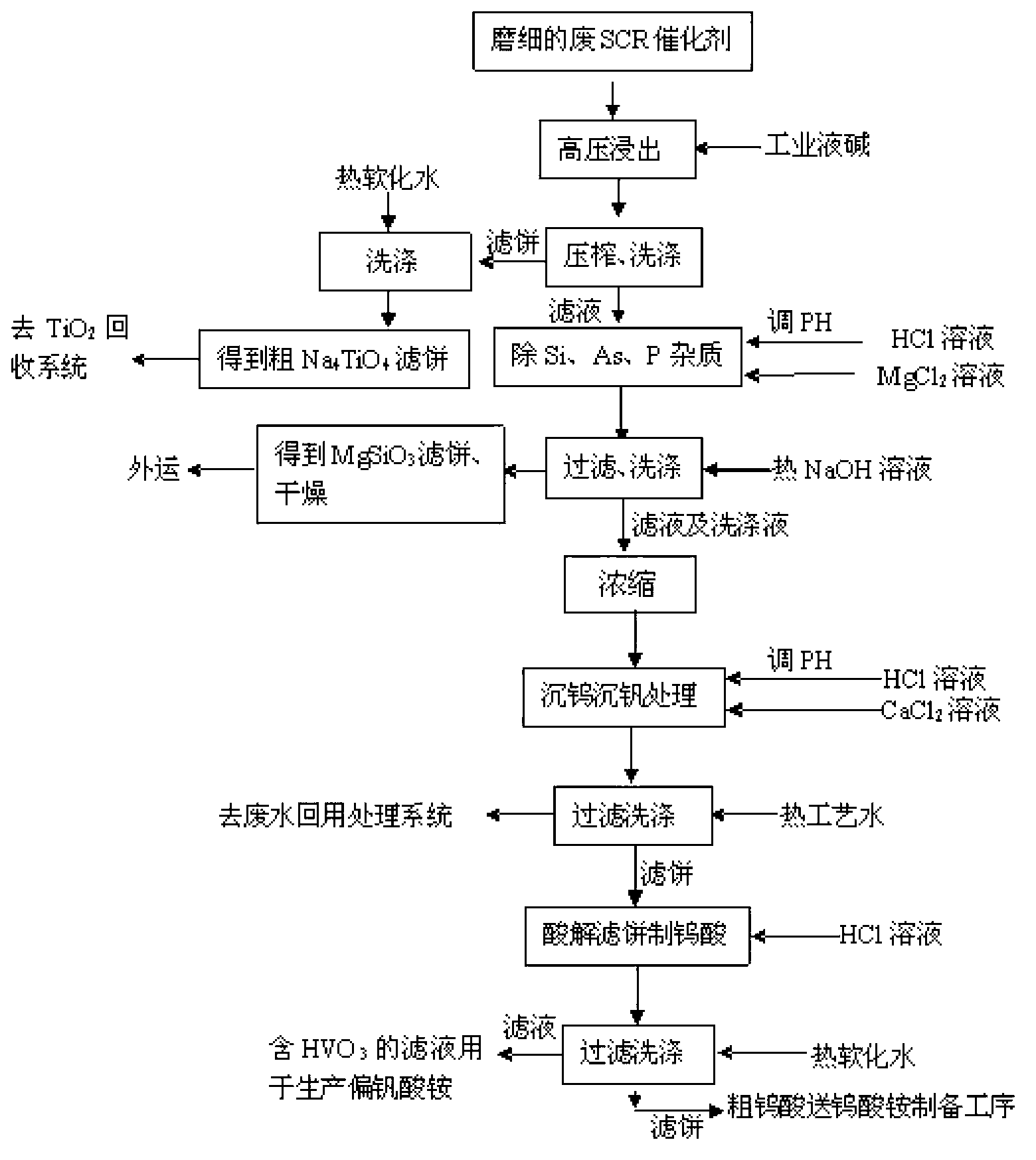

Recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst containing tungsten, vanadium and titanium

InactiveCN102936039AHigh purityHigh recovery rateTitanium dioxideVanadium compoundsHigh concentrationAmmonium paratungstate

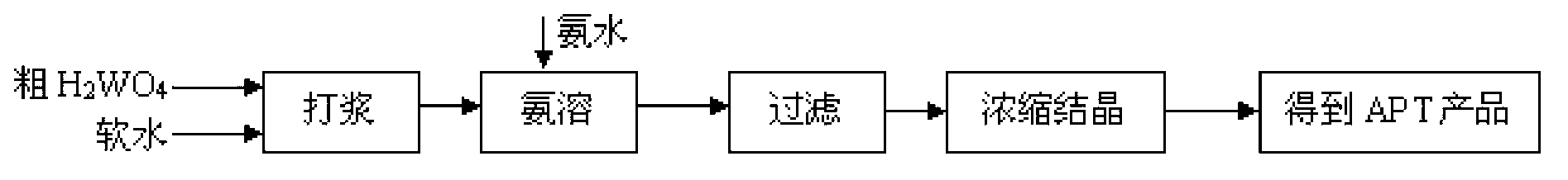

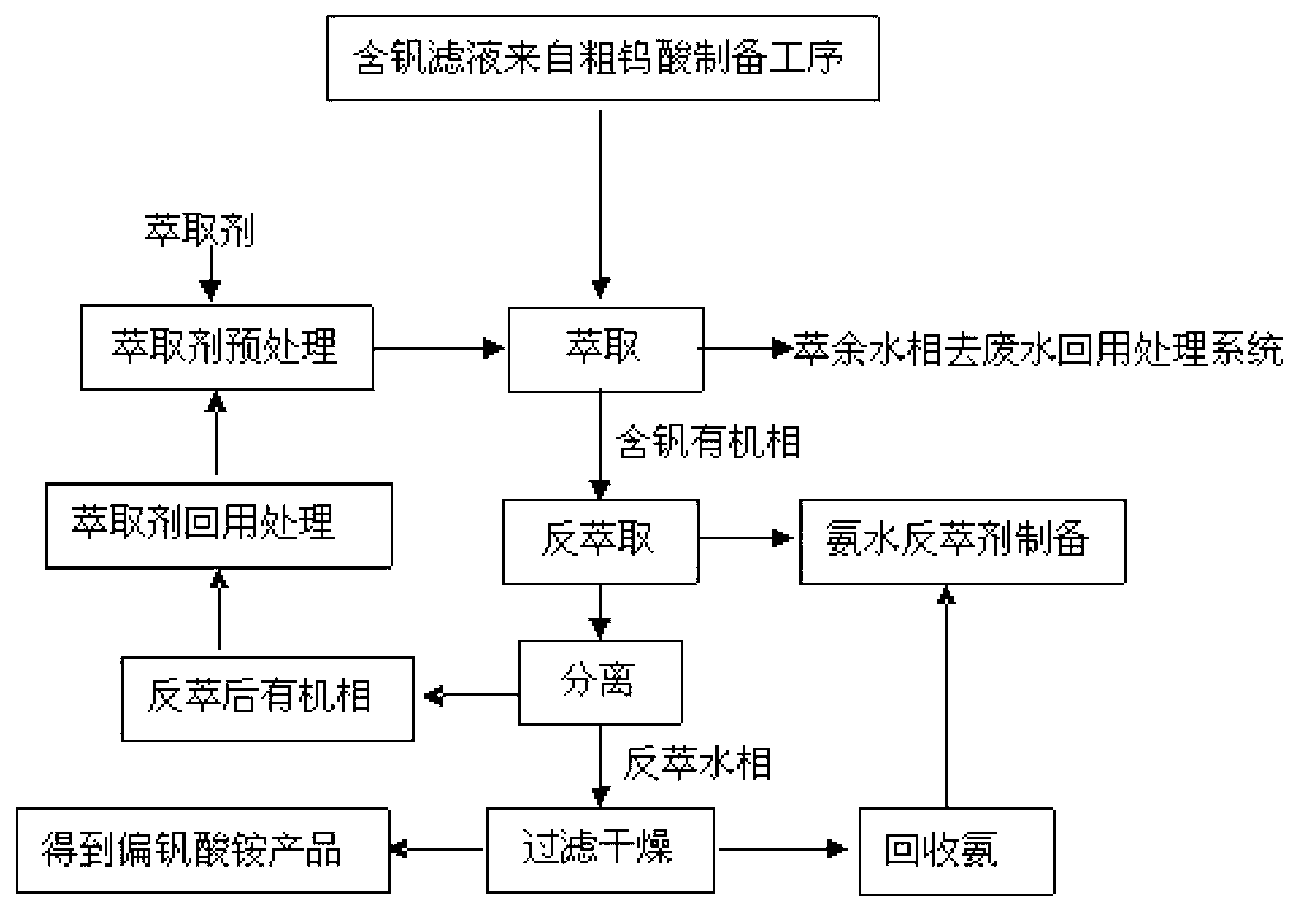

The invention discloses recovery process of honeycomb type selective catalytic reduction (SCR) waste catalyst. The process includes the following steps: a, preprocessing the SCR waste catalyst and leaching at the high temperature and under high pressure; b, adding hydrochloric acid into leaching liquid, adjusting pH, and removing impurities; c, adding hydrochloric acid into the leaching liquid, reacting, calcining and preparing rutile titanium dioxide; d, preparing ammonium paratungstate; e, preparing ammonium metavanadate; and f, recycling and treating waste water. Main products of ammonium paratungstate, ammonium metavanadate and rutile titanium dioxide obtained in the process are high in purity and recovery rate. By-products of silicon magnesium slags, salty mud, high-concentration sodium chloride liquid and barium sulfate dregs are high-purity harmless useful goods. The process is free of harmful secondary pollutant emission, environment-friendly and capable of circulating, has high economical and social benefit and is practicable.

Owner:曾瑞

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

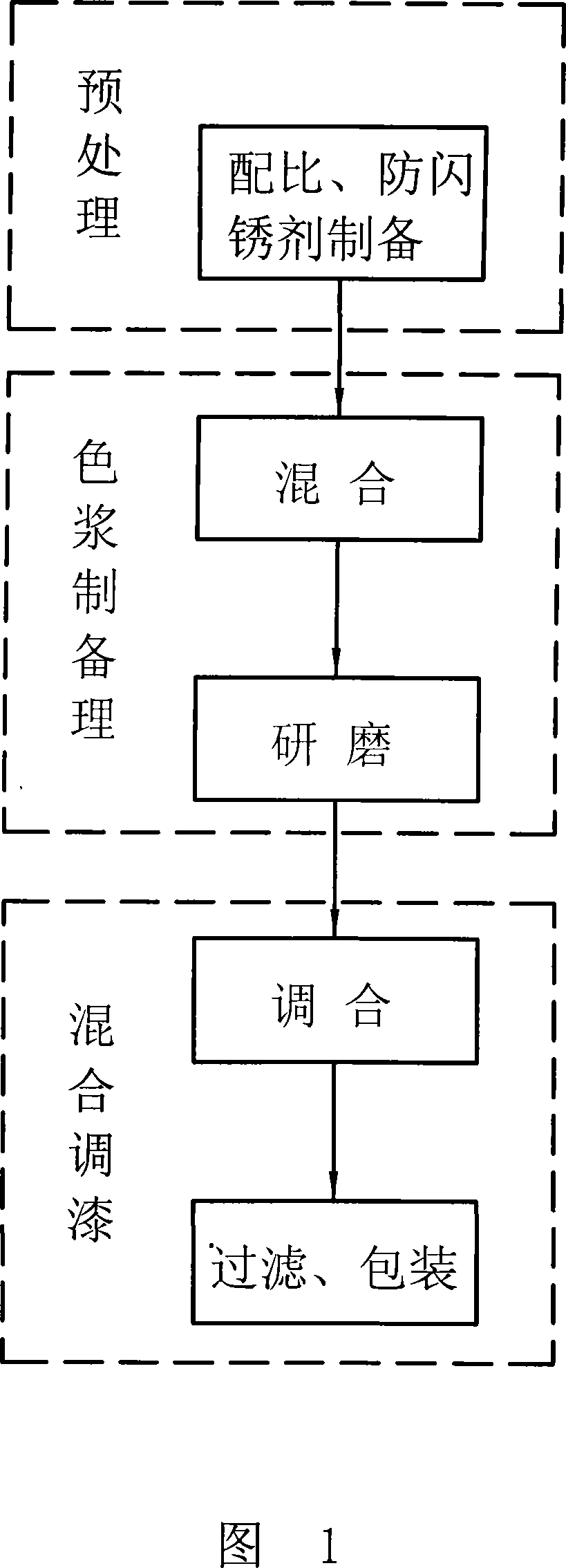

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

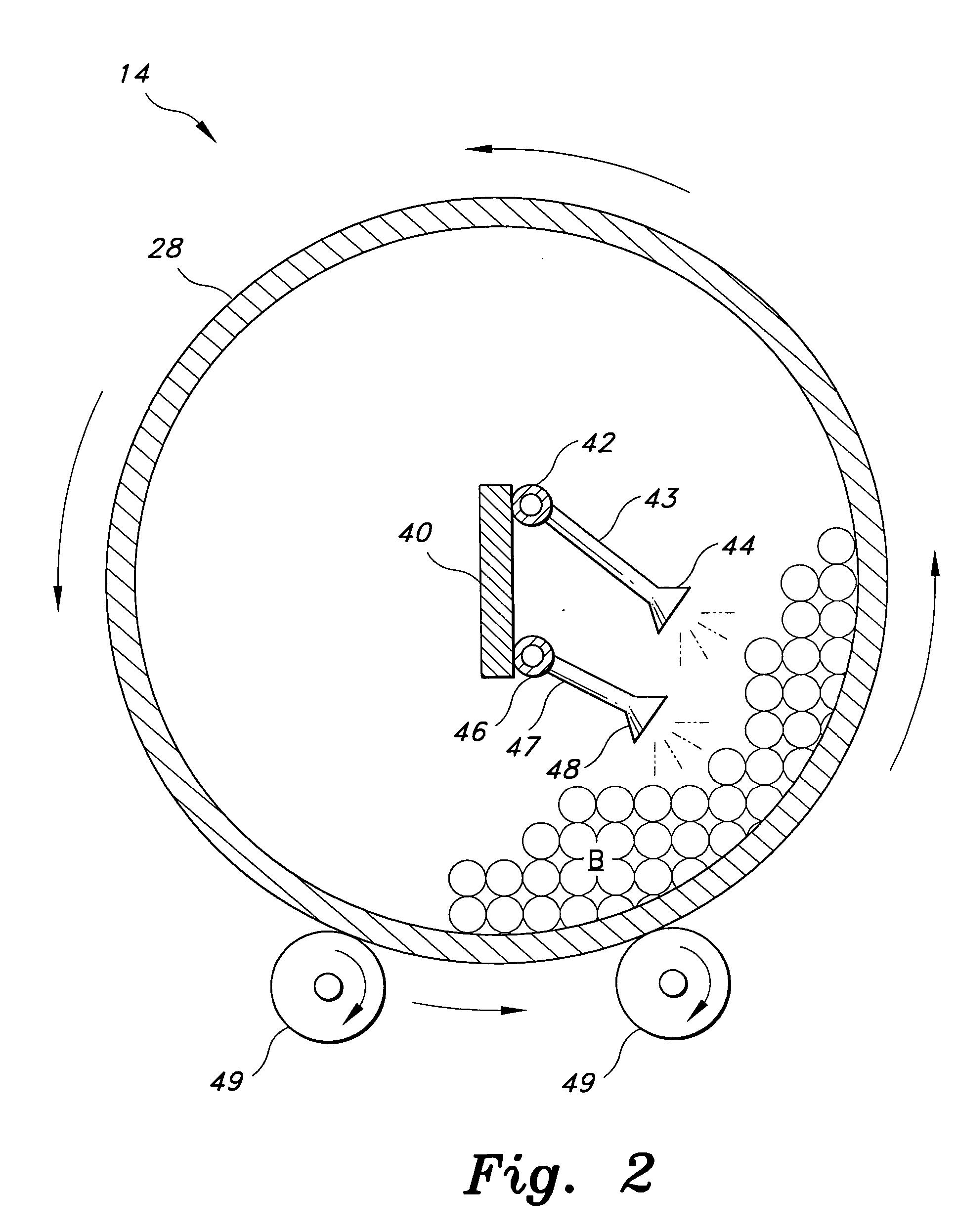

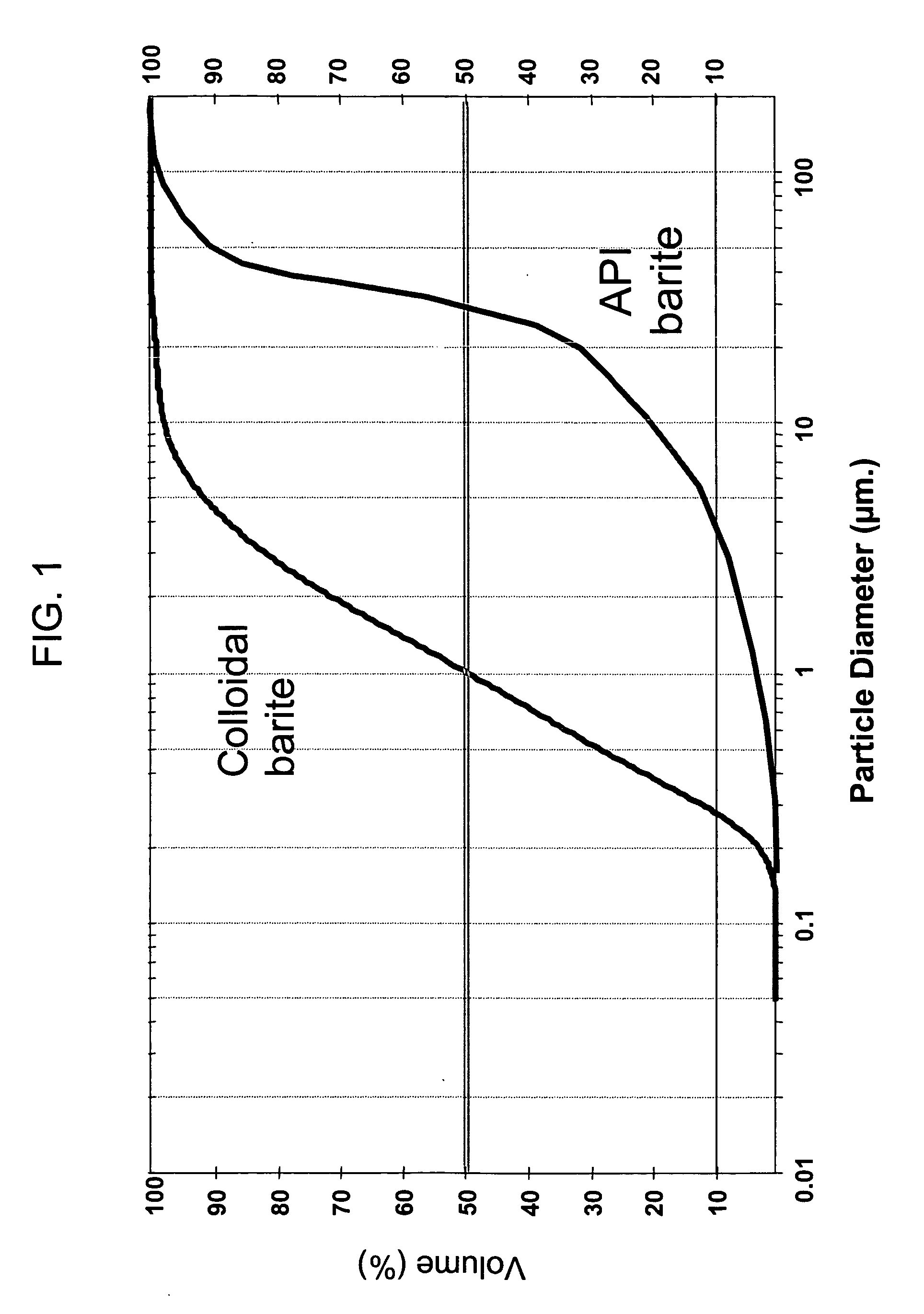

Additive for increasing the density of a fluid for casing annulus pressure control

InactiveUS20060188651A1Liquid surface applicatorsOther chemical processesVolumetric Mass DensitySolid particle

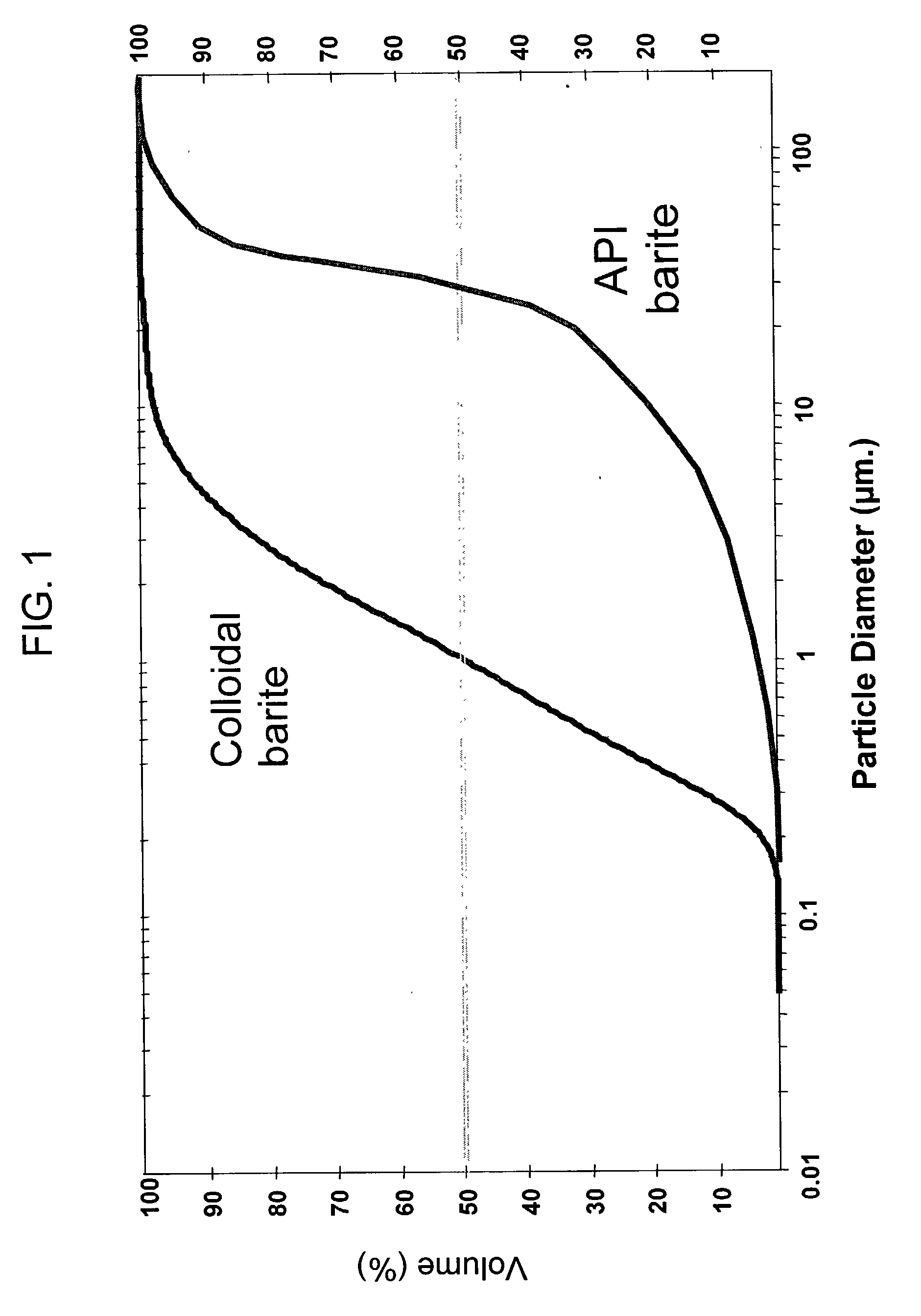

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:MI

Loadable polymeric particles for therapeutic and/or diagnostic applications and methods of preparing and using the same

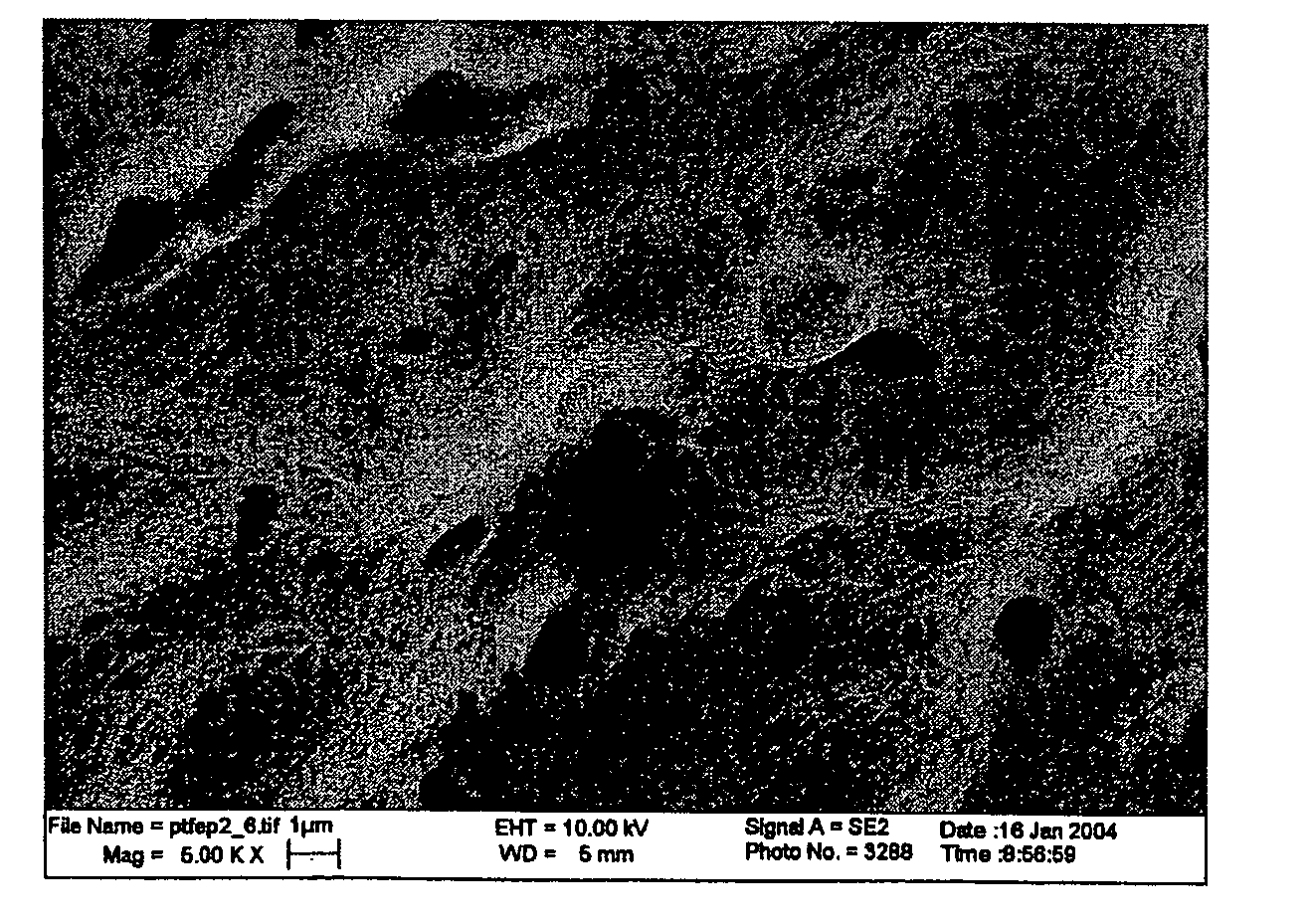

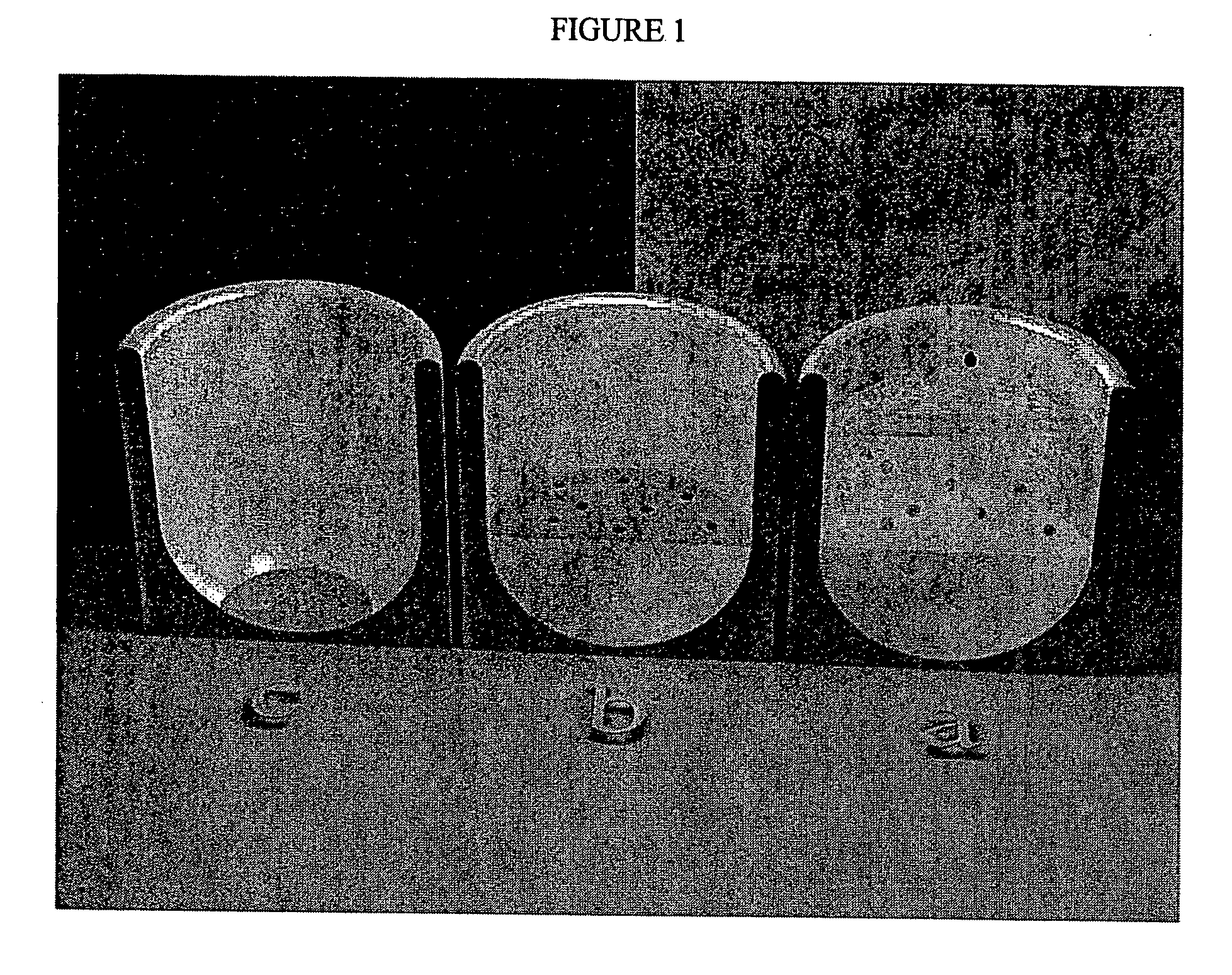

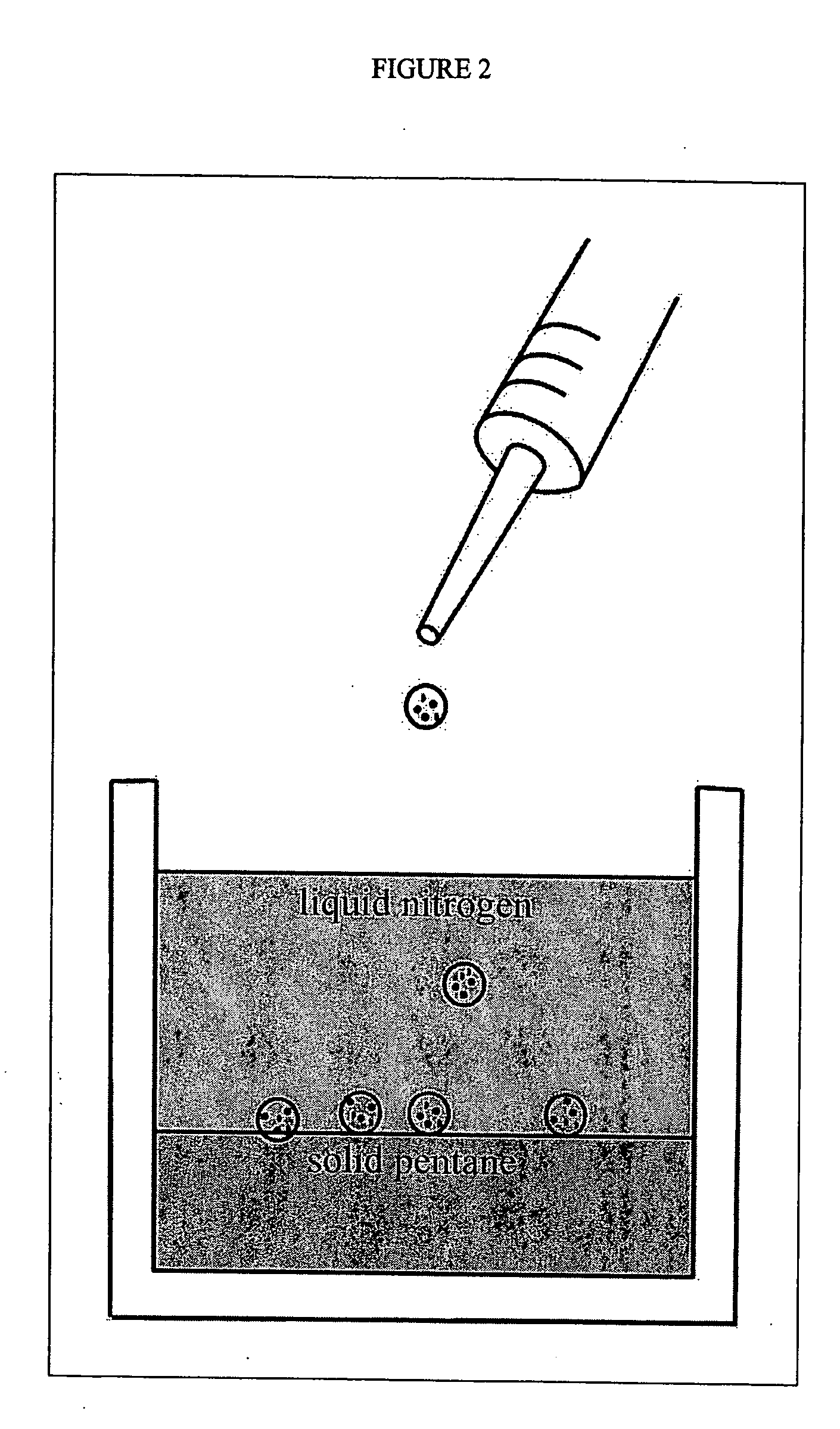

ActiveUS20060088476A1Minimize blood flowMinimizing agglomeration and aggregationPowder deliveryX-ray constrast preparationsActive agentVolumetric Mass Density

Particles are provided for use in therapeutic and / or diagnostic procedures. The particles include poly[bis(trifluoroethoxy) phosphazene] and / or a derivatives thereof which may be present throughout the particles or within an outer coating of the particles. The particles can also include a core having a hydrogel formed from an acrylic-based polymer. Barium sulfate may also be provided to the core of the particles as a coating or absorbed within the core of the particles. The particles can be used to minimize blood flow to mammalian tissues by occluding at least a portion of a blood vessel of the mammal, or to deliver an active agent to a localized area within a body of a mammal by contacting a localized area with at least one of the particles. Further, the particles are useful in sustained release formulations including active agent(s) for oral administration, as tracer particles for injection into the bloodstream of a mammal or for use in enhanced ultrasound imaging. The particles may include agents for increasing density for achieving useful buoyancy levels in suspension.

Owner:VARIAN MEDICAL SYSTEMS

Coating for fertilizer

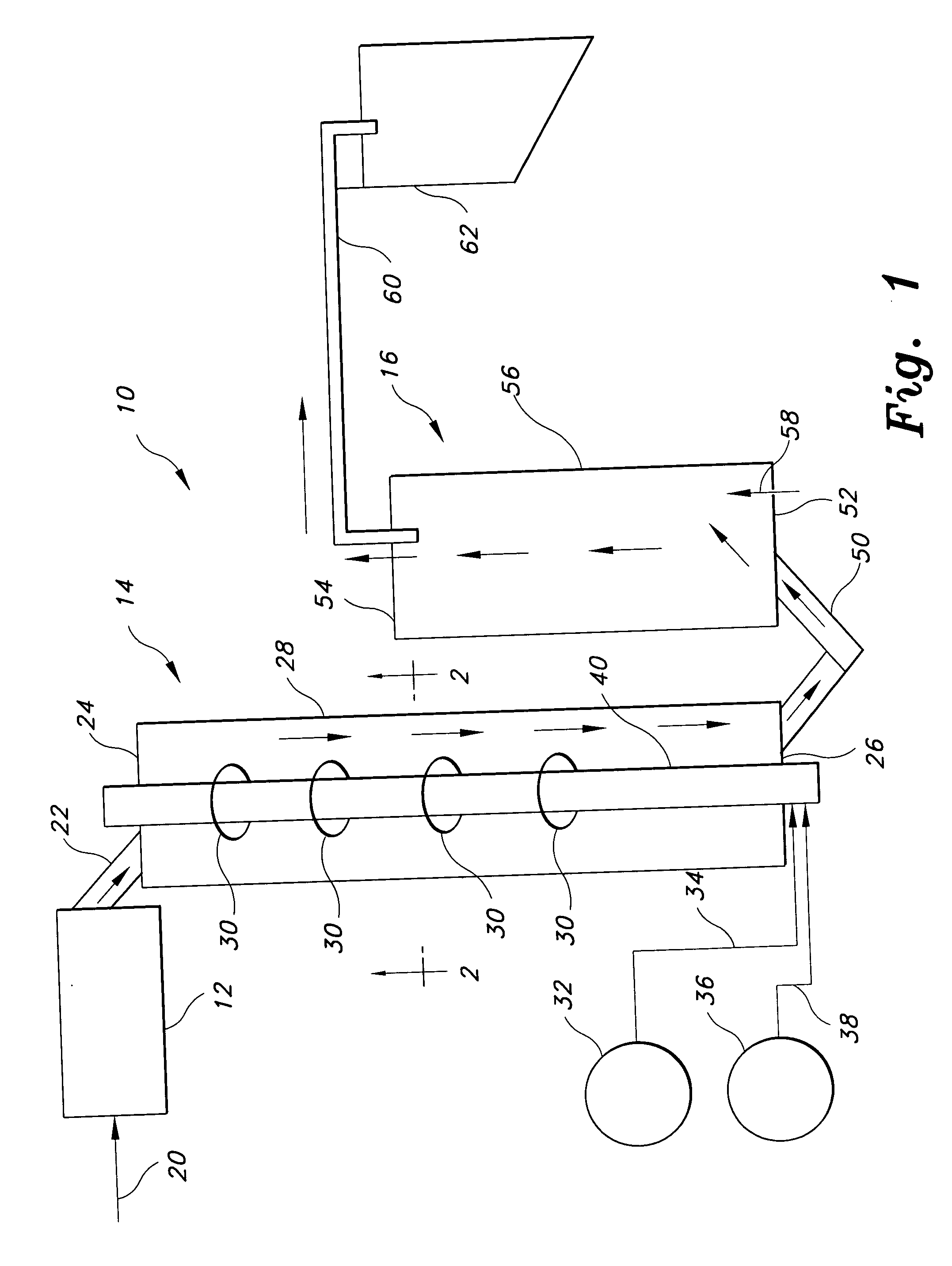

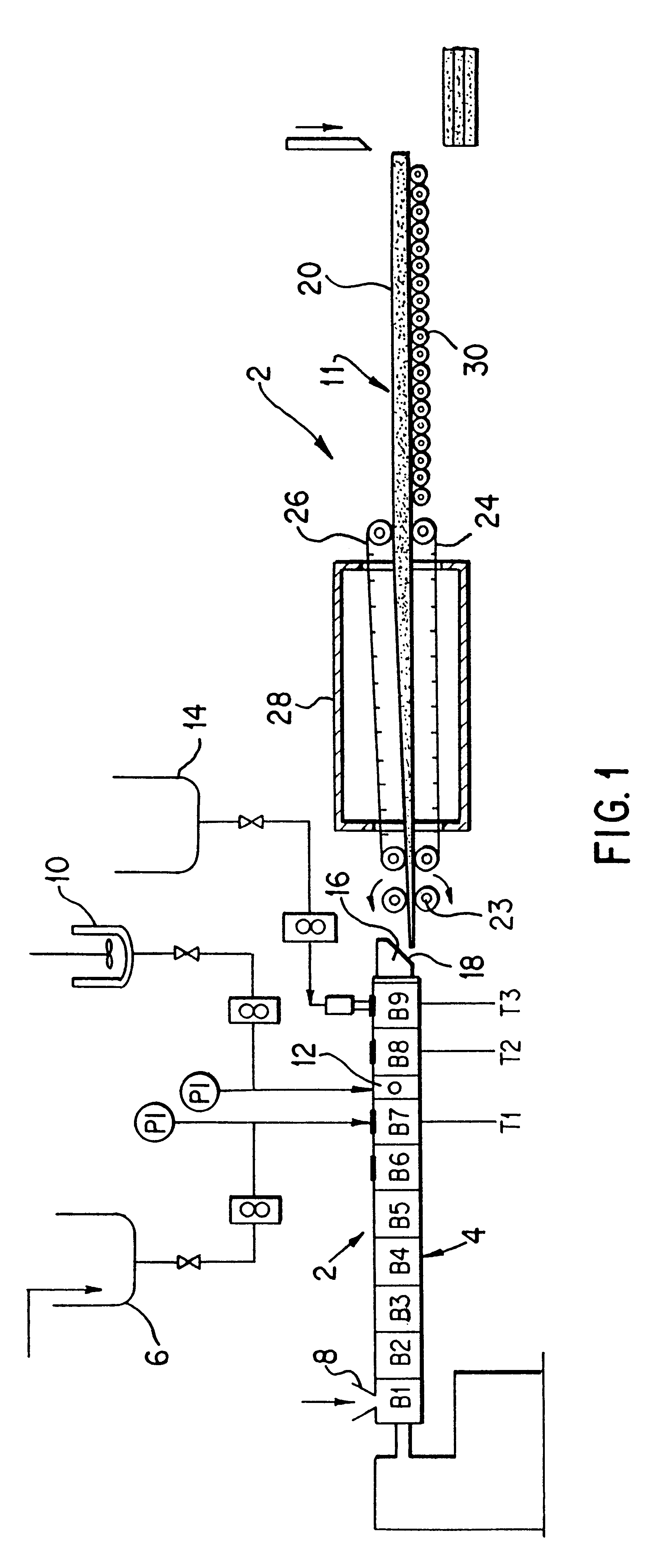

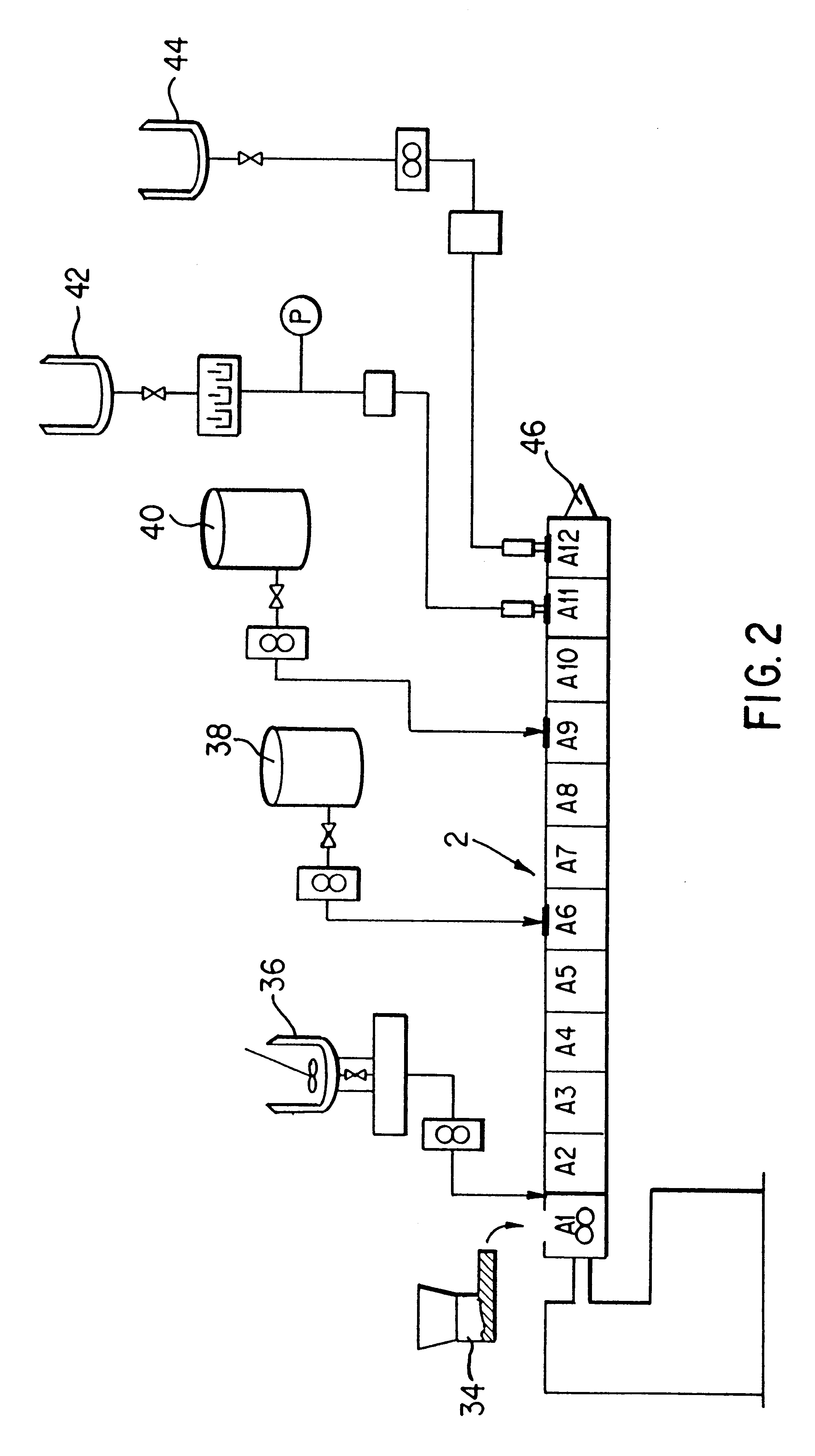

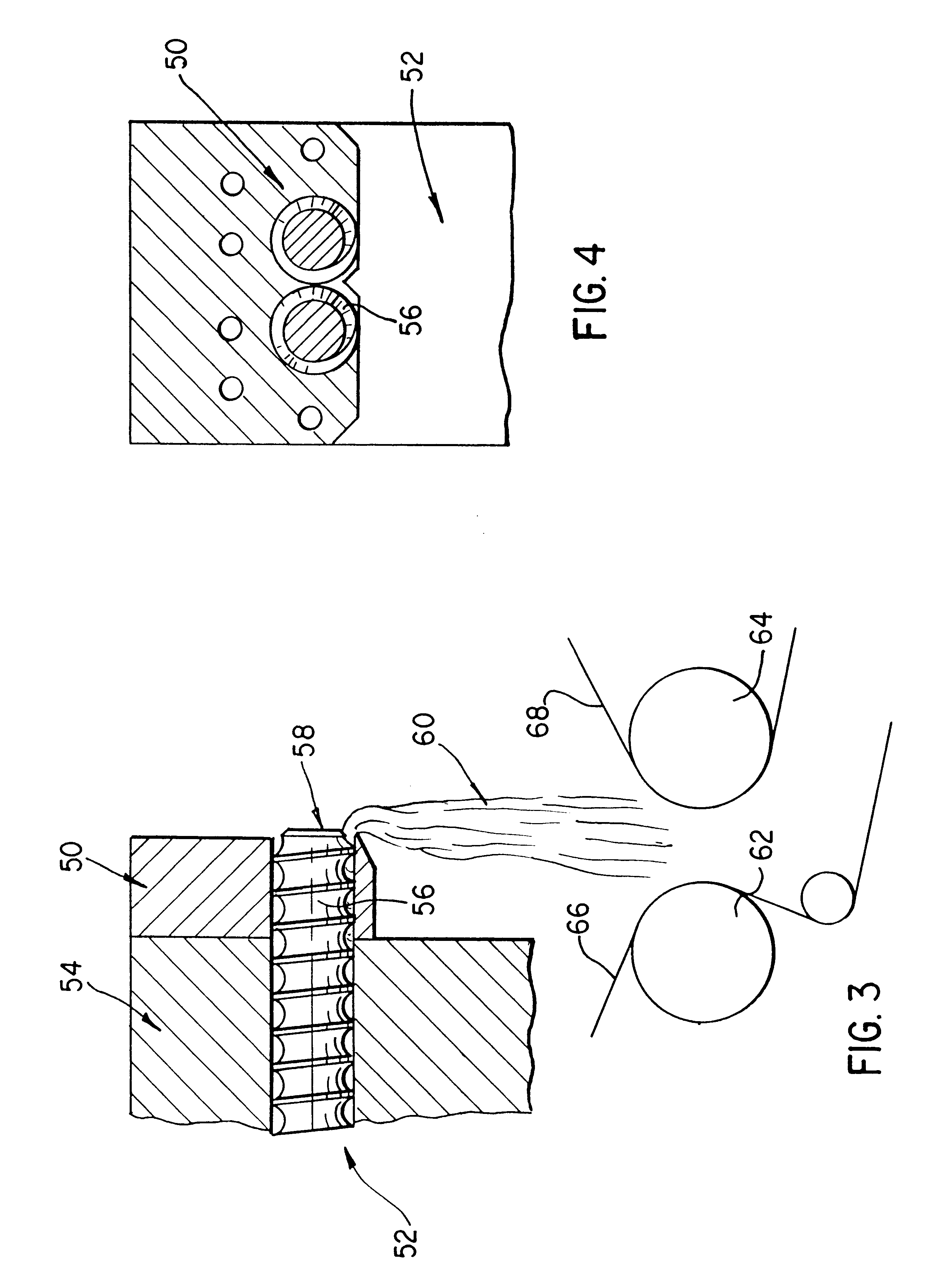

InactiveUS20050076687A1Maintain reaction temperatureImparts physical strengthBiocideGas treatmentVegetable oilPolymer chemistry

Method and apparatus for coating fertilizer in pellet or other form to impart time-release characteristics and the resulting coated pellet product. The polyurethane coating encapsulates fertilizer particles, forming a hydrophobic coating for slow-release qualities. The urethane polymer coating is formulated with an isocyanate and a combined fluid of a polyether polyol, a methyl ester derivative of plant or vegetable oil, a T-12 curing catalyst, barium sulfate, and an oil-based dye. The barium sulfate imparts physical strength to and enhances color quality of the polyurethane coating, and acts as a detackifier and maintains temperature in the coating reactor. The inventive formulation is effective in the practical polymer coating of sulfate-based or other fertilizer pellets in an inventive time-release fertilizer product. An apparatus is provided for carrying out the coating process.

Owner:WHITTINGTON PATSIE A

Graphene anticorrosive powder paint and preparation method thereof

ActiveCN104109450AImprove corrosion resistanceIncrease resistanceAnti-corrosive paintsPowdery paintsEpoxyArray data structure

The invention relates to a graphene anticorrosive powder paint which is composed of the following components in parts by weight: 25-70 parts of epoxy resin, 25-70 parts of polyester resin, 5-40 parts of titanium white, 5-40 parts of barium sulfate, 3-10 parts of assistant, 0.5-10 parts of graphene and the balance of other pigments. The powder paint has excellent anticorrosive property and favorable powdering penetrating power, and the surface scratch resistance is up to 2H above. The preparation technique is simple; the application technique is convenient; and the paint has excellent comprehensive properties.

Owner:宁波派特勒新材料股份有限公司

Additive for increasing the density of a fluid for casing annulus pressure control

InactiveUS20050101493A1Photosensitive materialsScale removal and water softeningVolumetric Mass DensitySolid particle

A method of controlling the pressure of a casing annulus in a subterranean well that includes injecting into the casing annulus a composition including a base fluid and a polymer coated colloidal solid material. The polymer coated colloidal solid material includes: a solid particle having an weight average particle diameter (d50) of less than two microns, and a polymeric dispersing agent coated onto the surface of the solid particle during the cominution (i.e. grinding) process utilized to make the colloidal particles. The polymeric dispersing agent may be a water soluble polymer having a molecular weight of at least 2000 Daltons. The solid particulate material may be selected from materials having of specific gravity of at least 2.68 and preferably the solid particulate material may be selected from barium sulfate (barite), calcium carbonate, dolomite, ilmenite, hematite, olivine, siderite, strontium sulfate, combinations and mixtures of these and other similar solids that should be apparent to one of skill in the art.

Owner:MI

High and low-temperature resistant porcelain glaze for enamel

InactiveCN103274764AImprove smoothnessGood high and low temperature resistanceTemperature resistanceLead sulfate

The invention relates to porcelain glaze and in particular relates to high and low-temperature resistant porcelain glaze for enamel. According to the technical scheme, the highnd low-temperature resistant porcelain glaze for enamel is prepared from the following raw materials in parts by weight: 22-38 parts of sodium silicate with the modulus of 2-3.8, 11-19 parts of aluminum oxide, 10-20 parts of manganese dioxide, 6-9 parts of palladium oxide, 6-9 parts of high-boron calcium borate, 23-29 parts of lead sulfate, 2-4 parts of talc, 7-13 parts of calcium carbonate, 8-12 parts of barium sulfate, 12-19 parts of zinc sulfate and 2-9 parts of titanium oxide. The high and low-temperature resistant porcelain glaze has excellent ultralow-temperature resistance and high-temperature resistance.

Owner:XIANGFENG ZHEJIANG METAL PROD

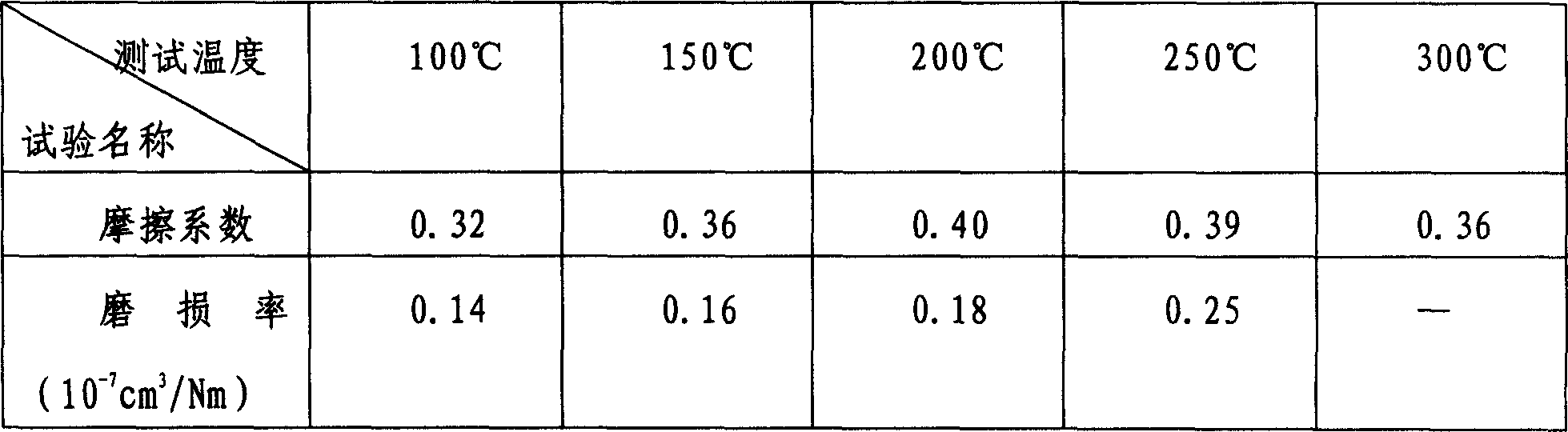

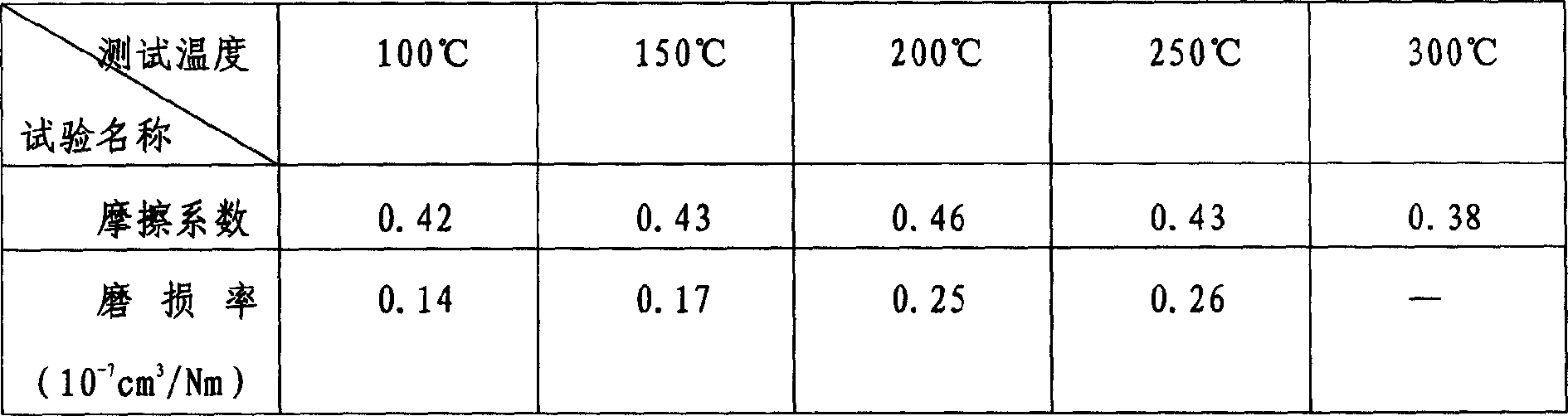

Automotiv non-asbestos high strength braking friction disk, and its prodn. method

InactiveCN1563735AImprove heat resistanceEnhancement effect is goodFriction liningHeat resistanceMetal fibers

The wearing piece of non-asbestos high srength material applies the high molecular compound, phenolic ressin as the agglomerant. The metal fiber or organic fiber is strengthen component. The stuffing applies regulator with frictional properties and barium sulfate, black lead, alumina as accessory ingredient. The production possesses excellent characteristic of physical chemical and mechanical and thermo-stability.

Owner:APPLIED PHYSICS INST OF GUANGXI ACADEMY OF SCI

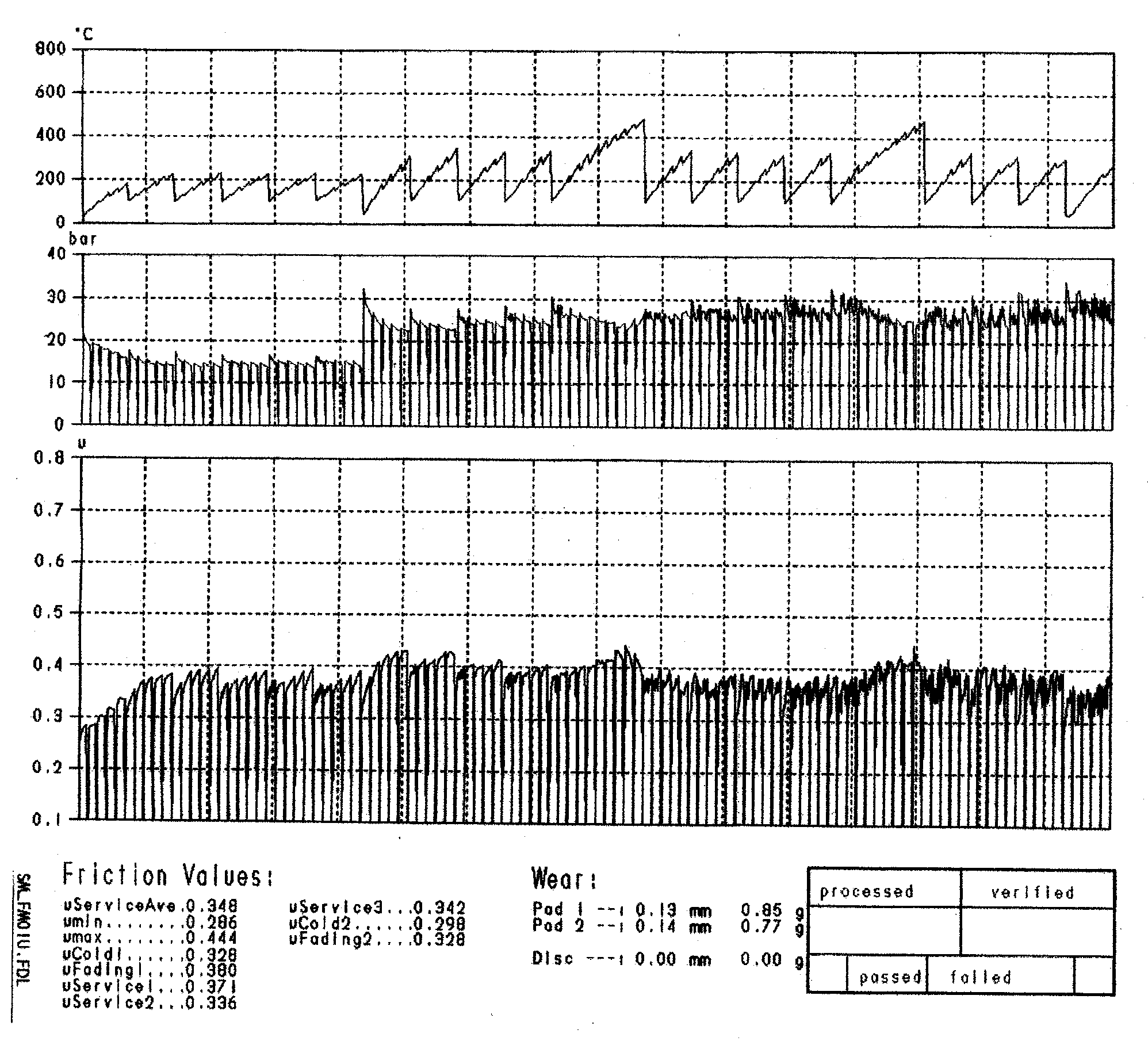

Ceramic base/NAO composite friction material and preparation method thereof

The invention relates to an oxide ceramic base / NAO composite friction material used in a brake of a medium or high-grade car and a preparation method thereof. In the composite friction material, mixed fibers comprise aramid fibers, potassium titanate fibers and silicon, magnesium and calcium oxide ceramic fibers; aedelforsite or mineral fibers and copper fibers are used as the enhancement and conduction fibers; phenolic resin is used as the organic bonding agent; pure oxide ceramics, such as Al2O3, ZrO2, MgO, CaO and the like, are used as the abrasives; solid lubricant, sulfide, graphite coke and the like are used as the abrasion resistant lubricants; and sodium bicarbonate is used as the blowing agent and pairing antioxidant, and barium sulfate inorganic filler is used as the function and toughening filler. The ceramic base / NAO organic friction material mainly maintains the unique performance of the asbestos friction material, remakably lowers the noise, reduces the abrasion possibility, and is beneficial to prolonging the service life of a brake disc, there by being a novel green (less-dust) low-noise environmentally-friendly friction material.

Owner:HUBEI CHIBI SALFER FRICTION MATERIAL

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

Cement oil-based mud spacer formulation

A spacer fluid made of a viscosity thinner, a weighting agent, an antifoaming agent, and a non-ionic surfactant in a base aqueous fluid. In some instances, the viscosity thinner is a sulfomethylated tannin, the weighting agent is barium sulfate, the antifoaming agent is a silicone, and the non-ionic surfactant is an ethoxylated alcohol. A method of treating a well bore annulus in preparation of introducing water-based cement slurry into a well bore using the spacer fluid. A method of using the spacer fluid to position a first fluid into a well bore annulus of a well bore containing a second fluid. A method for fluidly isolating at least a portion of a well bore annulus in a well bore containing an oil-based drilling fluid using water-based cement slurry and the spacer fluid.

Owner:SAUDI ARABIAN OIL CO

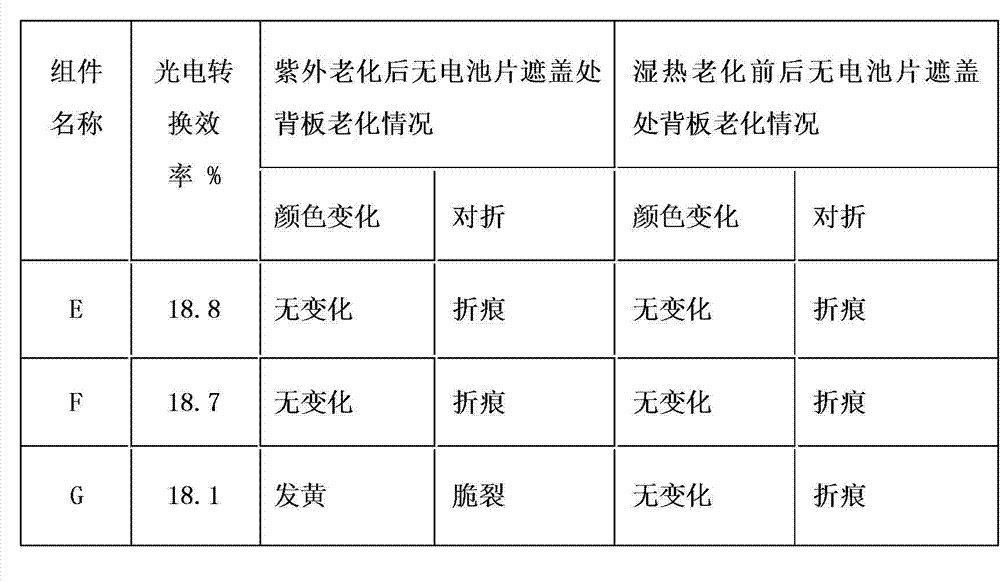

High-efficiency solar packaging film

ActiveCN102863918AAvoid damageLower requirementNon-macromolecular adhesive additivesFilm/foil adhesivesUltravioletPeroxide

The invention discloses a high-efficiency solar packaging film. The film comprises an upper layer film and a lower layer film, wherein the upper layer film comprises, by mass, 100 parts of ethylene-vinyl acetate (EVA) resin, 0.1-10 parts of peroxide, 0.1-5 parts of assistant crosslinkers, 0.1-5 parts of silane coupling agents and 0.1-15 parts of stable assistants; the lower layer film comprises, by mass, 100 parts of ethylene-vinyl acetate (EVA) resin, 0.1-10 parts of peroxide, 0.1-5 parts of assistant crosslinkers and 0.1-15 parts of stable assistants; and the lower layer film also comprises, by mass, one type or more types of titanium pigment, zinc oxide, calcium carbonate, barium sulfate, ferric oxide and carbon black. The film has good sunlight reflection capability and can prevent ultraviolet rays of sunlight effectively. The photoelectric conversion efficiency of solar assemblies is improved, the cost of solar assemblies is reduced and the service life of solar assemblies is prolonged.

Extruded polymer foam with filler particles and method

InactiveUSRE37095E1High quality dispersionAvoid reactionFlat articlesCalcium silicatePolyisocyanurate

A thermosetting foam, preferably polyisocyanurate or polyurethane foam, is prepared in an extruder which permits the incorporation of high levels of filler particles. The method includes introducing polyol, isocyanate and filler particles to an extruder screw for mixing. In conjunction with extruding, a catalyst is added. The catalyst may be added either in a last extruder barrel or with the extruder head. Foam with filler particle content in excess of 12% made be readily made. Filler particles, such as aluminum trihydrate, perlite, carbon black, diatomaceous earth, polyiso powders, ammonium phosphate, fly ash, barium sulfate, calcium silicate, and calcium carbonate, may be used. The process described is preferably used for making foam boards or bunstock.

Owner:IP RIGHTS

Formula and preparation method of high energy storage lead-acid battery lead paste

ActiveCN102354751AImprove charging efficiencyHigh initial capacityLead-acid accumulator electrodesFiberPolyester

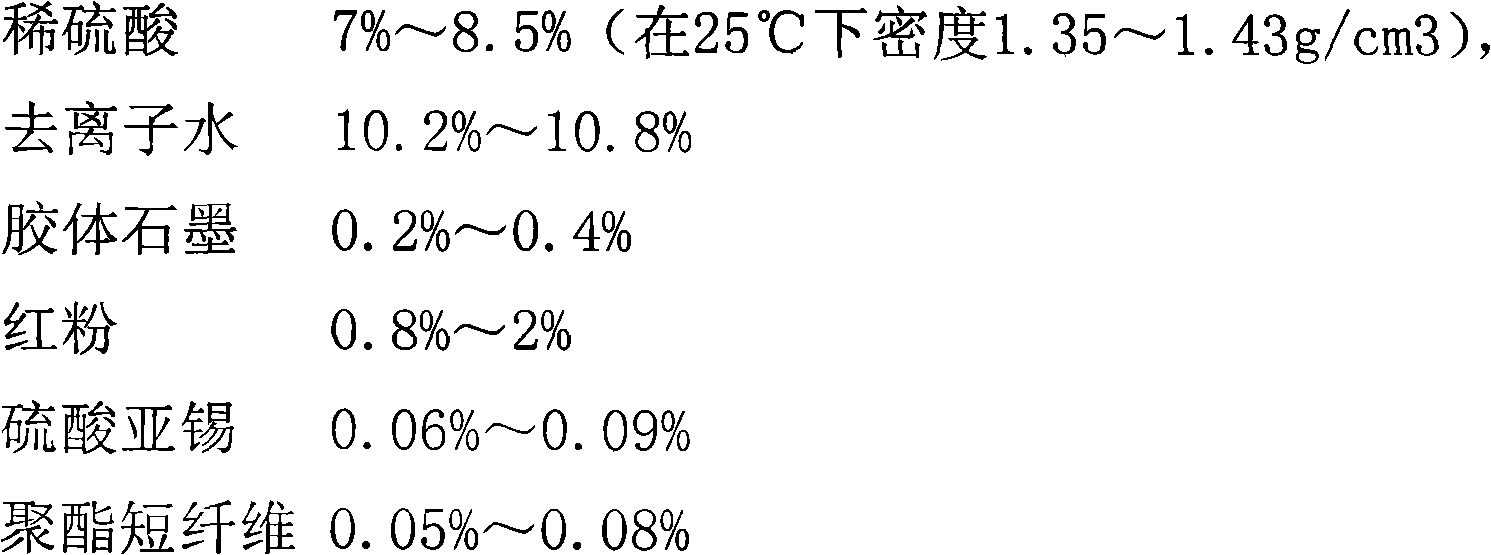

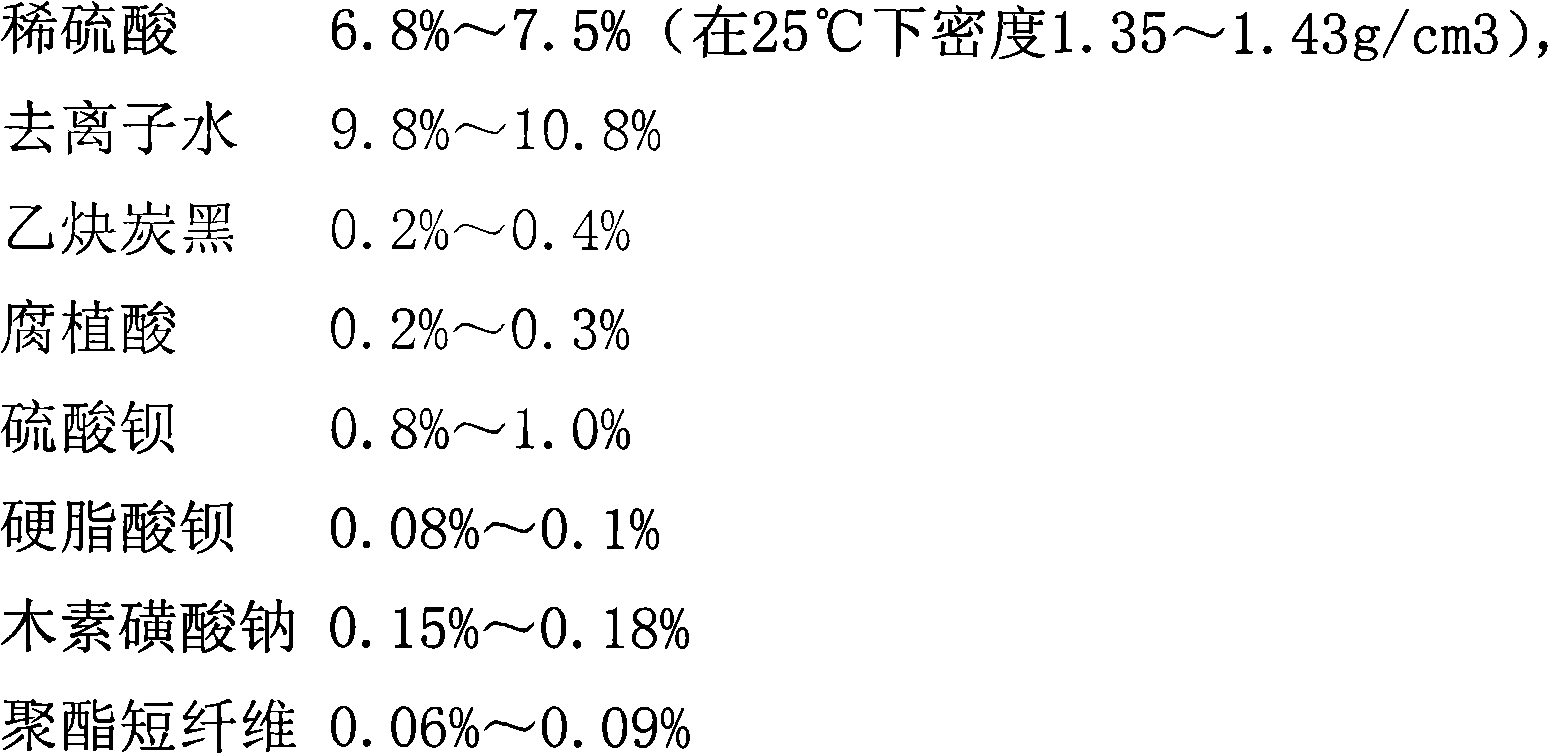

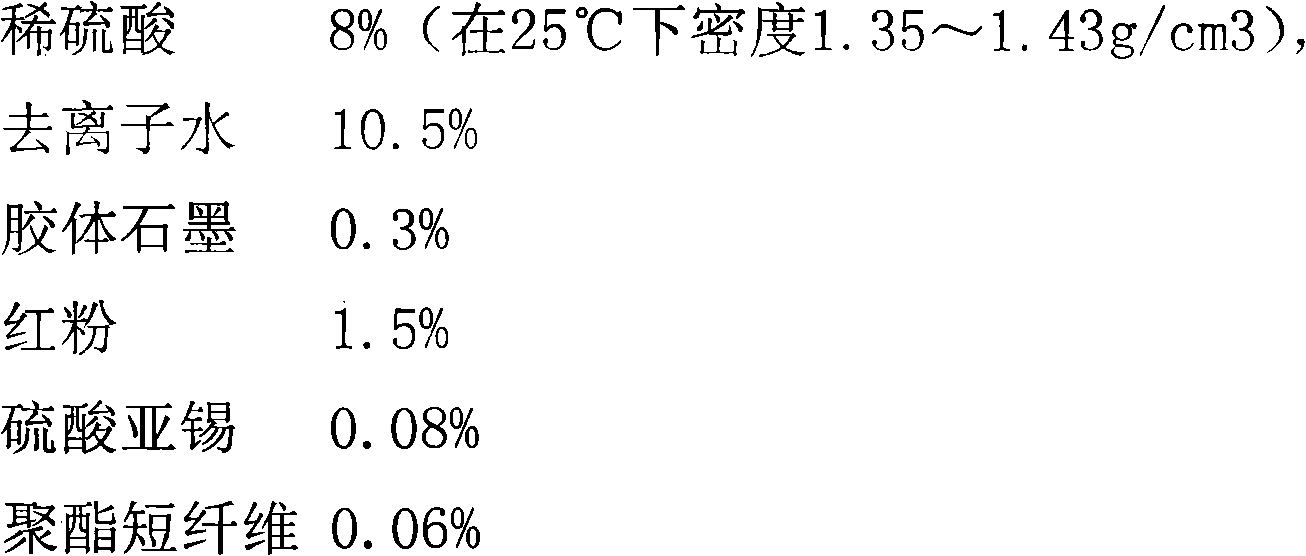

The invention provides a formula and preparation method of a high energy storage lead-acid battery lead paste and relates to the technical field of lead-acid batteries. The formula of a positive plate lead paste comprises the following raw materials: 7-8.5% of dilute sulphuric acid, 10.2-10.8% of deionized water, 0.2-0.4% of colloidal graphite, 0.8-2% of red powder, 0.06-0.09% of stannous sulfate, 0.05-0.08% of polyester staple fiber and the balance of lead powder; the formula of a negative plate lead paste comprises the following raw materials: 6.8-7.5% of dilute sulphuric acid, 9.8-10.8% of deionized water, 0.2-0.4% of acetylene black, 0.2-0.3% of humic acid, 0.8-1.0% of barium sulfate, 0.08-0.1% of barium stearate, 0.15-0.18% of sodium lignosulphonate, 0.06-0.09% of polyester staple fiber and the balance of lead powder. The battery prepared by the lead paste has the advantages of high initial capacity and long cycle life; and the overdischarge resistance and charge acceptance of the battery are higher than the standard requirements.

Owner:TIANNENG BATTERY GROUP +4

Non-asbestos static sealing materials and products thereof

InactiveCN1844291AEliminate micro gapsIncrease the compression ratioOther chemical processesFiberGraphite

The invention provides a packing material containing no asbestos and its preparing process, wherein the material is prepared from binders, mica, vermiculite, graphite, organic fiber and inorganic fiber, silicon dioxide, porcelain clay, barium sulfate, anti-aging agent, preservative agent and vulcanizing auxiliary agent through calendaring formation.

Owner:长春蓝天密封技术开发有限公司

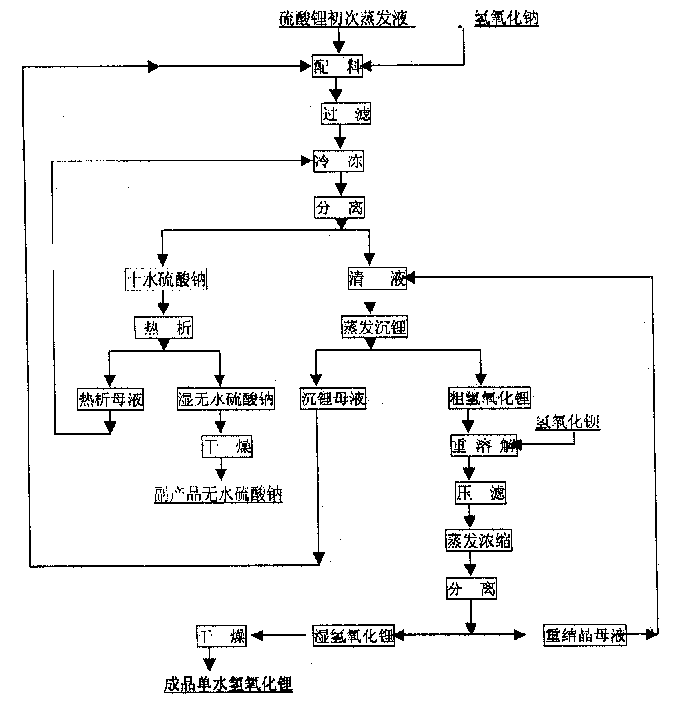

Production process of lithium hydroxide monohydrate

InactiveCN1486931AShort process routeHigh yieldSulfate/bisulfate preparationLithium oxides/hydroxidesSolubilityStrontium hydroxide octahydrate

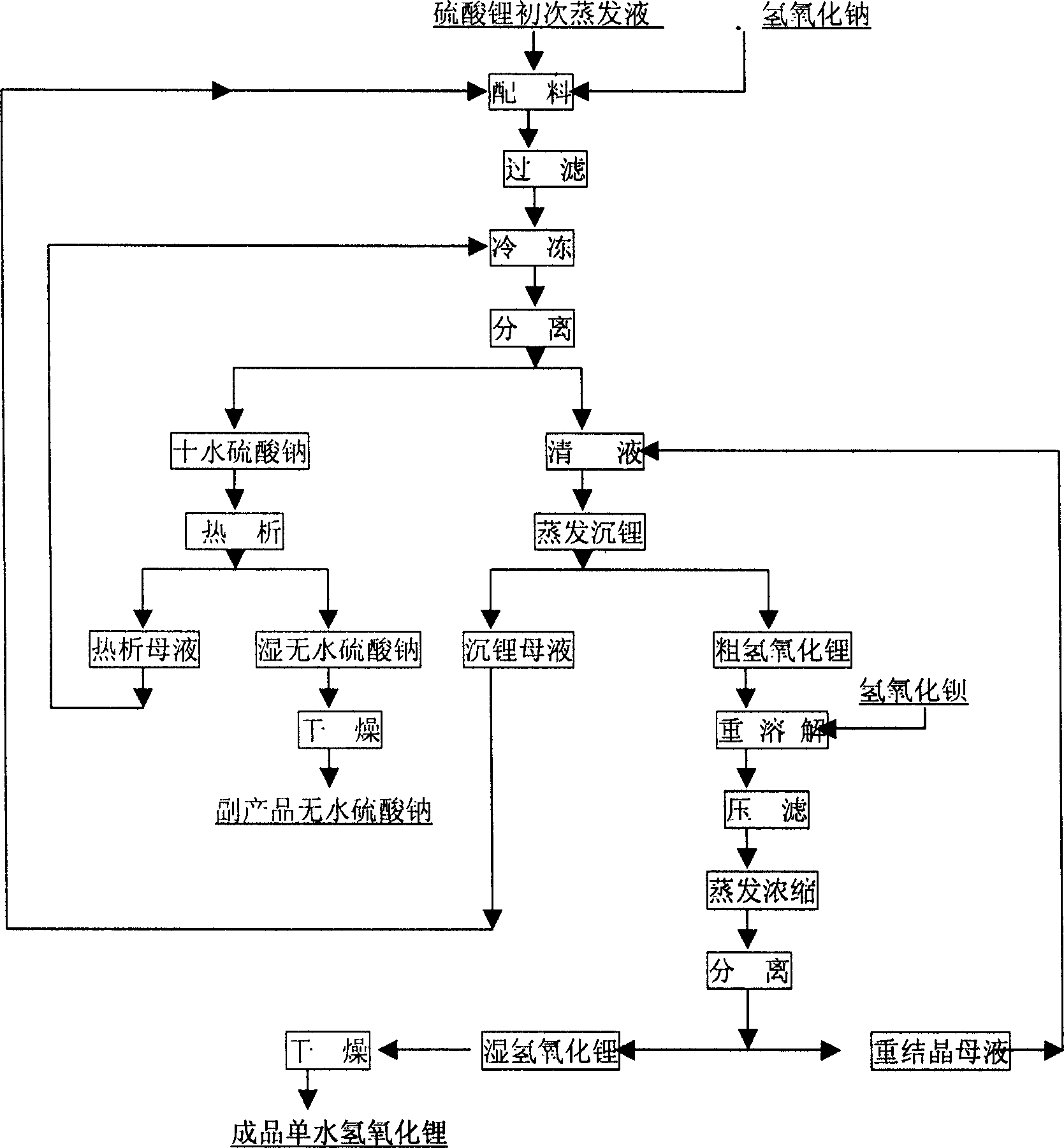

In the production process of lithium hydroxide monohydrate, lithium sulfate solution and caustic soda are made to produce metathetic reaction to form mixture solution of sodium sulfate and lithium hydroxide, and sodium sulfate and lithium hydroxide monohydrate are then separated by means of the obvious difference in low temperature solubility. The production process includes the following steps: adding sodium hydroxide into lithium sulfate solution obtained through serial production steps to obtain mixture solution of sodium sulfate and lithium hydroxide; cooling to minus 10 deg.c to 5 deg.c for the crystallization and separation of sodium sulfate; heating to concentrate the separated clear liquid; crystallization and separation to obtain coarse lithium hydroxide monohydrate product; water dissolving coarse lithium hydroxide monohydrate, adding barium hydroxide to form insoluble barium sulfate, filtering, concentrating filtrate, crystallizing to separate wet lithium hydroxide monohydrate; and drying.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

Electrically insulative powder coatings and compositions and methods for making them

InactiveUS20050065294A1Increased TgImprove adhesionPlastic/resin/waxes insulatorsInsulated cablesEpoxyAcrylic resin

The present invention provides powder compositions comprising from 20 to 90 phr of one or more than one silicone resin having a glass transition temperature (Tg) of at least 40° C., from 10 to 80 phr of one or more than one resin chosen from glycidyl functional acrylic resin, mixtures of aromatic epoxy resin or novolac resin with carboxyl functional acrylic resin carboxyl functional polyester resin or glycidyl functional acrylic resin, and one or more than one filler, such as wollastonite, barium sulfate, mica, talc, alumina, layered silicates like montmorillonite, and mixtures thereof. The one or more than one silicone resin may or may not be flaked and may or may not contain silanol groups. The compositions of the present invention provide single layer or multilayer powder coatings that are free of voids larger than 30 μm in diameter, and which may meet the UL Class H (180° C.) certification for electrical insulation applications. Further, the compositions may be used to provide powder coatings, films, moldings, electrical potting compounds and electrical encapsulation compounds.

Owner:CRAMER MICHELE LE +2

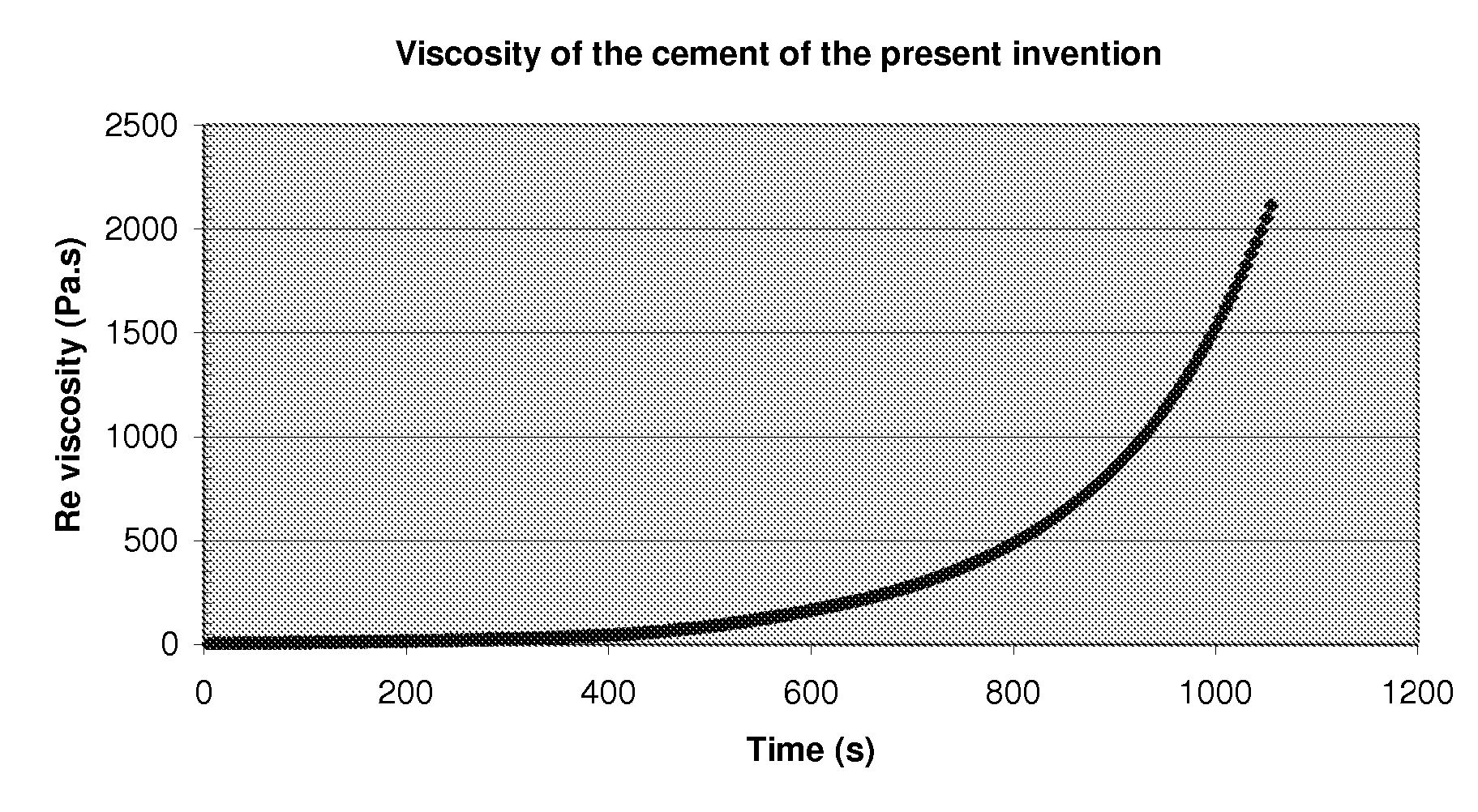

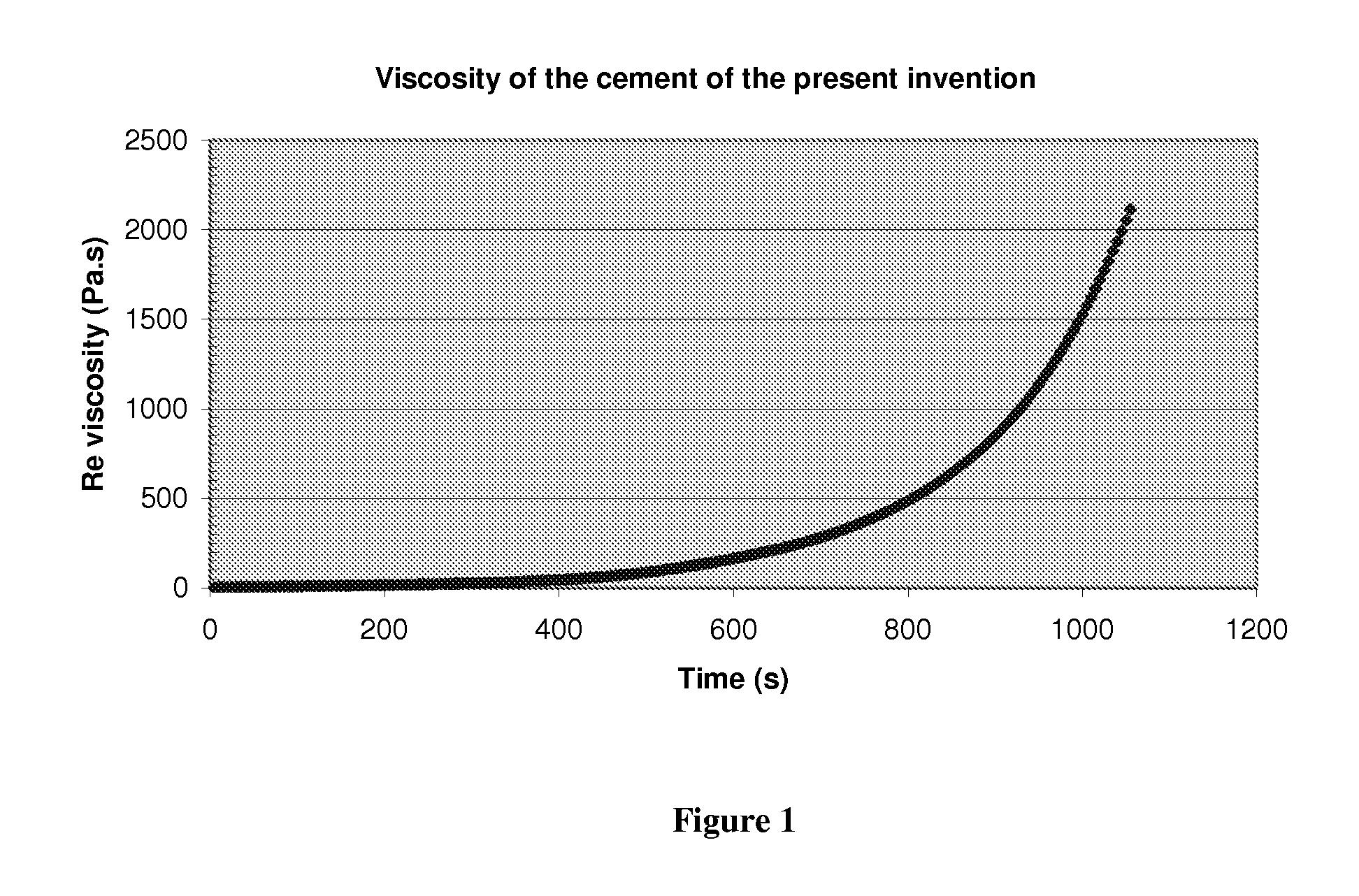

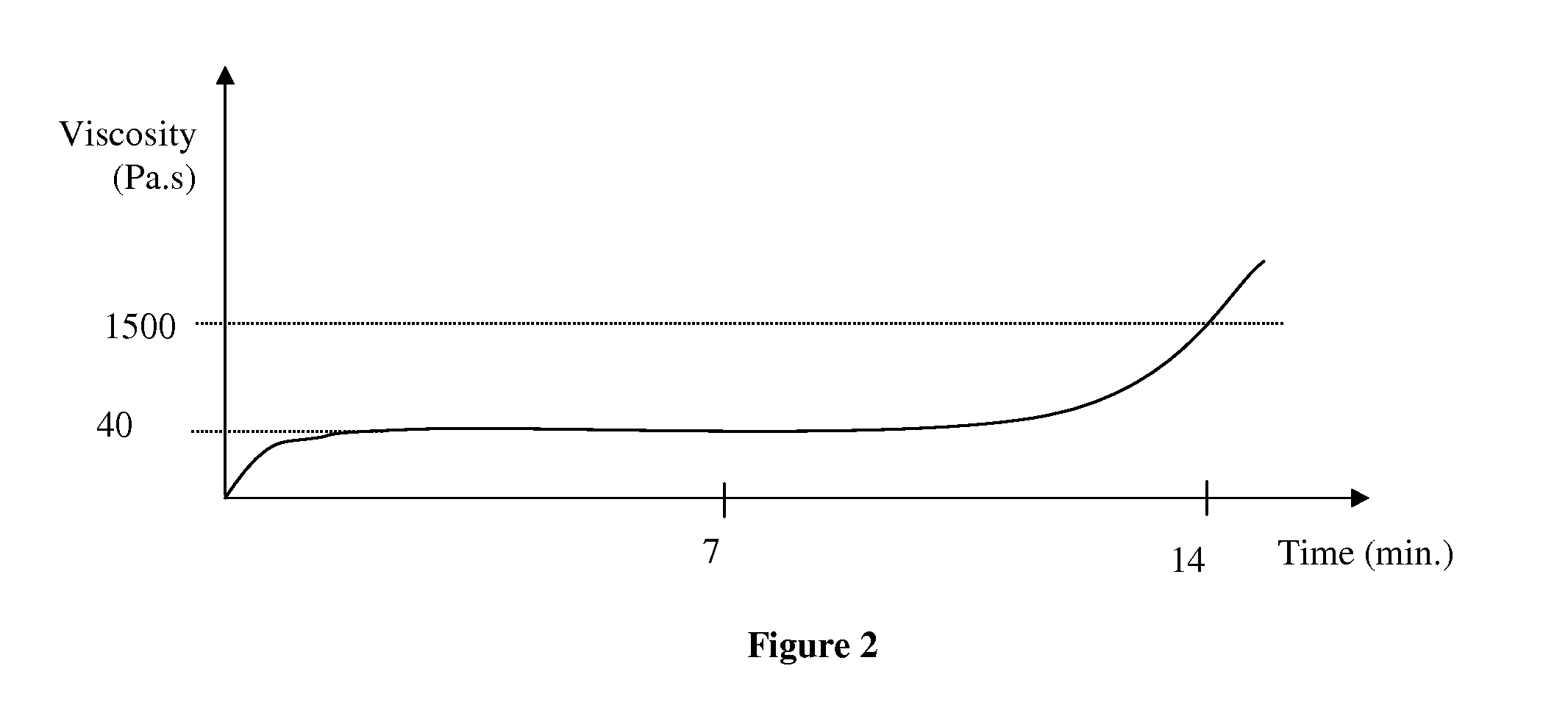

Polymer cement for percutaneous vertebroplasty and methods of using and making same

The invention provides a fluid cement for medical use for bone reconstruction, in particular for filling the vertebral body, and a binary composition which is intended for the preparation of such a cement. The invention also provides a device for conditioning the binary composition, and a method of preparing a bone cement from a binary composition. The fluid cement according to the invention comprises: a) approximately 60% to 85% by weight of a polymer comprising a polymethylmethacrylate and a methylmethacrylate monomer and b) approximately from 15 to 40% by weight of a radio-opaque composition. Preferably, the radio-opaque composition comprises a radio-opacifier, such as barium sulfate and zirconium dioxide, in a mixture with a calcium phosphate, for example apatite hydroxide.

Owner:TEKNIMED SAS

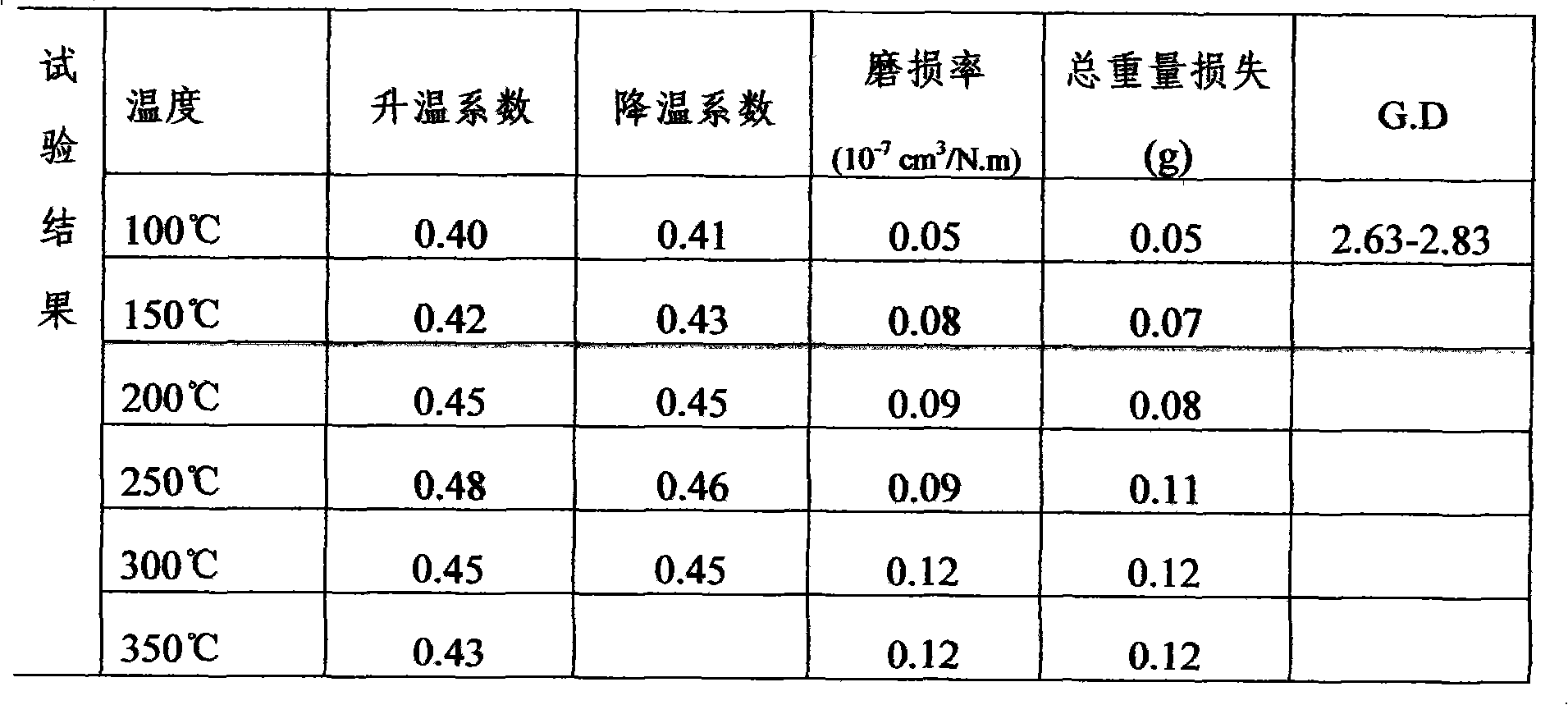

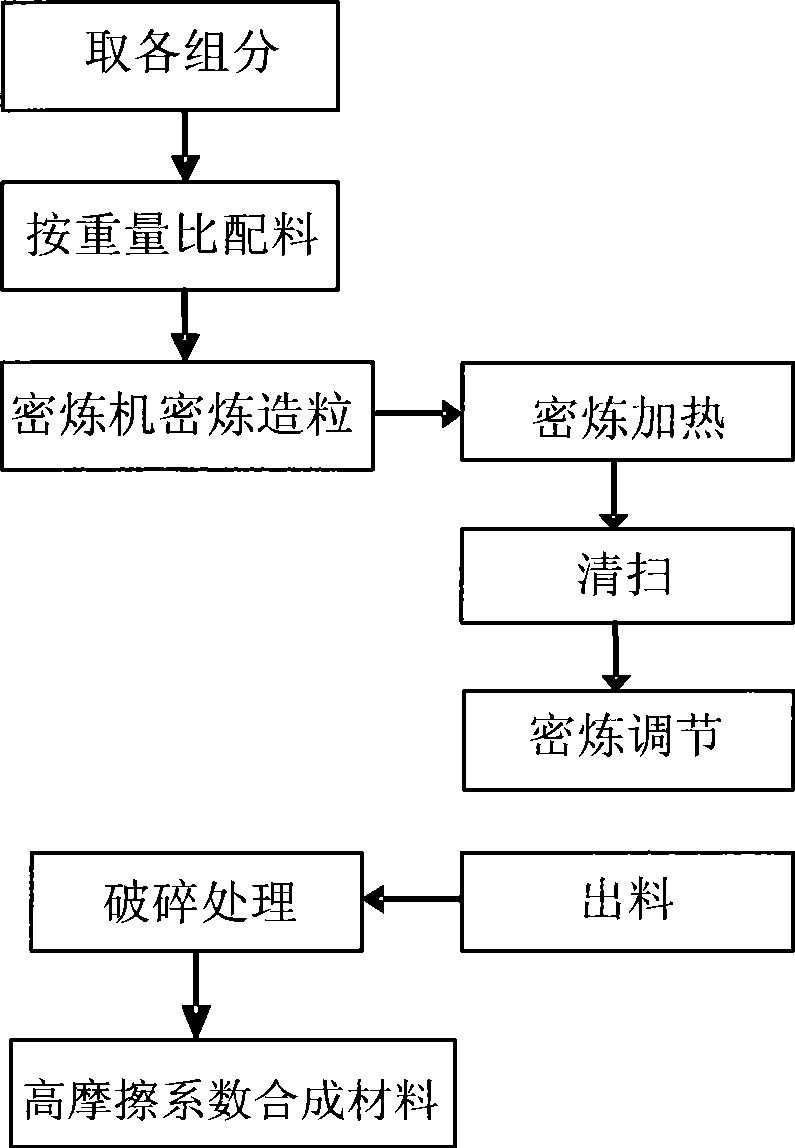

High friction coefficient synthetic materials and preparation method thereof

The invention discloses a high friction coefficient composite material and a manufacturing method thereof, wherein the material is prepared through material sealing and grain-making processing by the following compositions in weight percentage: 8 to 13 percent of butadiene-acrylonitrile rubber, 2 to 10 percent of styrene-butadiene rubber, 5 to 10 percent of cresol methyl-stage phenol-formaldehyde resin modified, 15 to 30 percent of steel fiber, 10 to 15 percent of magnesia, 5 to 10 percent of calcined petroleum coke, 2 to 5 percent of silicon carbide, 10 to 25 percent of mineral fiber, 5 to 10 percent of calcium hydroxide, 10 to 20 percent of barium sulfate, 5 to 10 percent of graphite, 1 to 5 percent of supramoly, 1 to 5 percent of carbon black, 1 to 3 percent of sulfur and 1 to 3 percent of accelerant. The material can be applied in a plurality of situations to prepare friction components, has stable friction performance and good abrasion resistance, effectively inhibits the phenomena of metal inlay, cracking, chip off-falling and so on, reduces the damage on vehicle wheels, has good impact resistance and good weathering resistance, can be used in the environment with large temperature variation for a long time, and has the application characteristics of wide application region and large difference of the regional environment.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

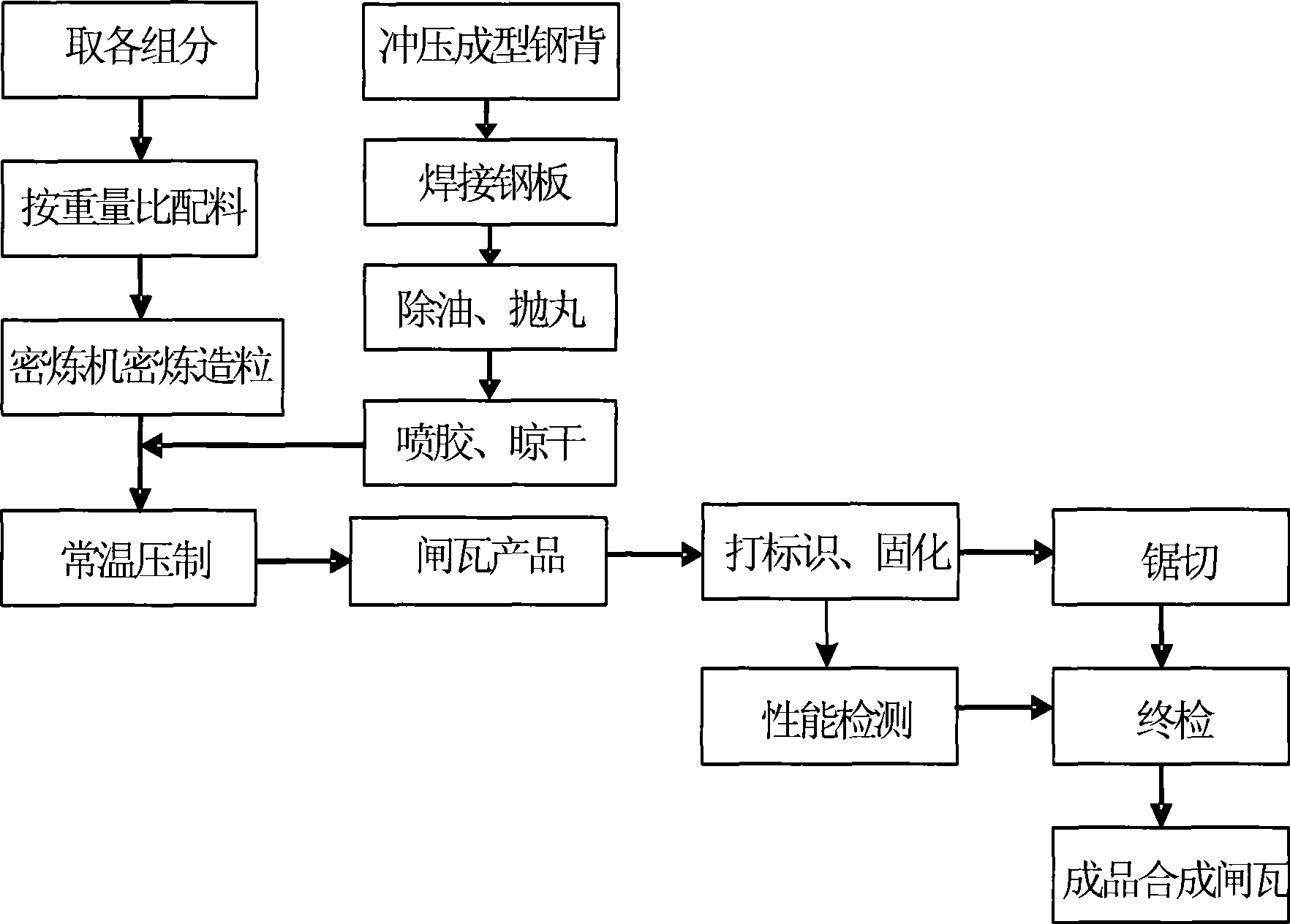

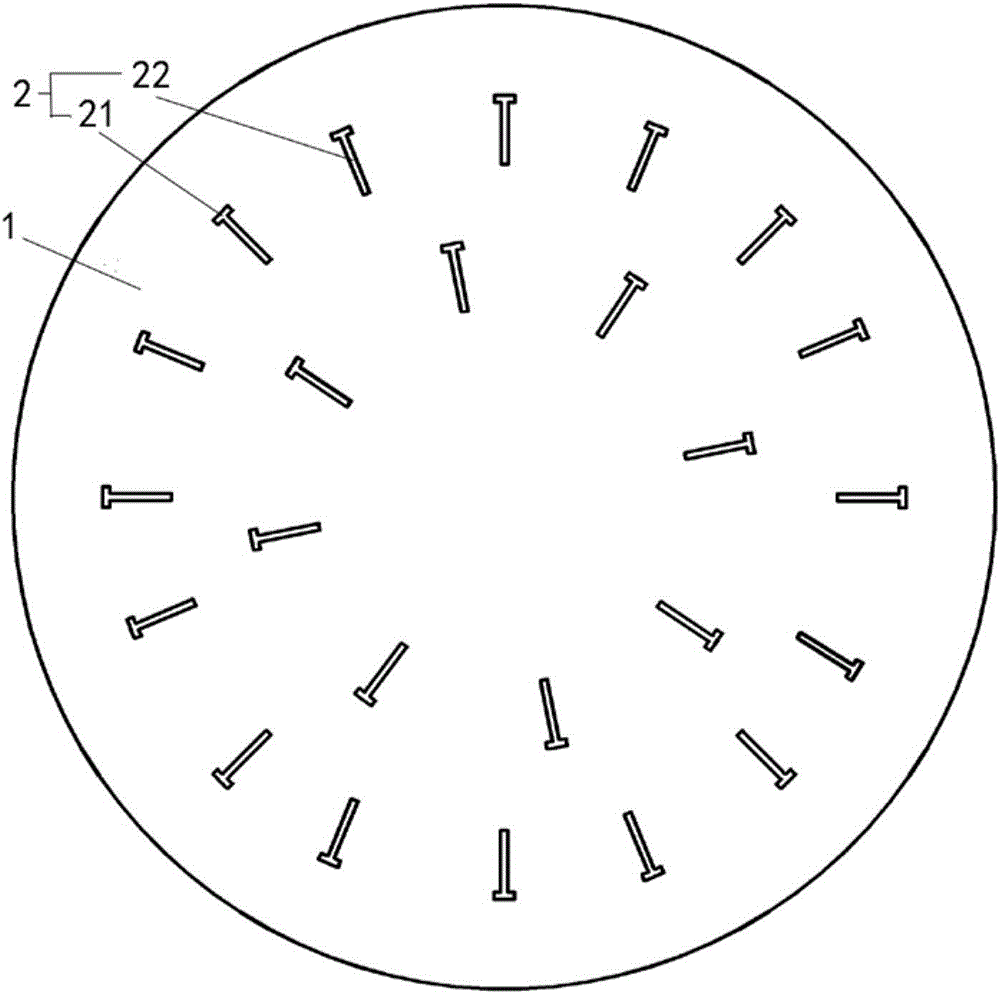

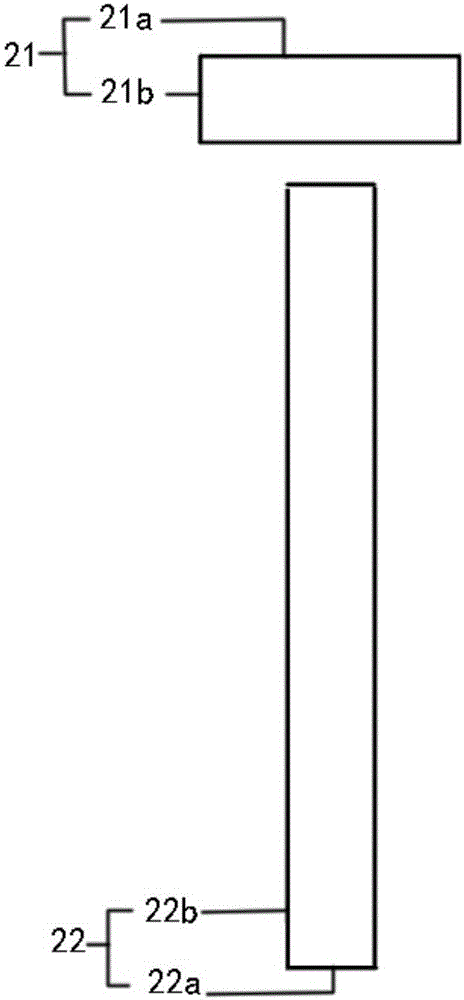

High friction composite brake shoe for railway freight car and manufacture method thereof

ActiveCN101391611AHigh compressive strengthHigh impact strengthBraking membersBrake arrangement with braking memberFiberEngineering

The invention discloses a high friction composite brake shoe for a railway wagon and a manufacturing method thereof. The composite brake shoe comprises: a steel back and a brake shoe body which is fixed on the steel back, wherein, the brake shoe body is prepared by materials which are synthesized by various components with the following weight ratio: 8 to13 parts of nitrile butadiene rubber, 2 to10 parts of styrene butasiene rubber, 5 to10 parts of cresol modified A-stage phenolic resin, 15 to 30 parts of steel fiber, 10 to 15 parts of magnesium oxide, 5 to 10 parts of calcined petroleum coke, 2 to 5 parts of silicon carbide, 10 to25 parts of mineral fiber, 5 to 10 parts of calcium hydride, 10 to 20 parts of barium sulfate, 5 to 10 parts of graphite, 1 to 5 parts of molybdenum disulfide, 1 to 5 parts of carbon black, 1 to 3 parts of sulfur and 1 to 3 parts of enhancer. The brake shoe can be used in the railway heavy-duty high-speed wagon and has stable friction performance and better wear resistance; the brake shoe can effectively inhibit the phenomena of metal inlay, cracks, dropping blocks and the like and reduce the damages on wheels; and the brake shoe is characterized by better impact resistance performance and good weatherability.

Owner:BEIJING RAILWAY STAR FORTUNE HIGH TECH

Preparation method of lodging-resistant multi-difference polyester low-elastic filament

ActiveCN106400179AImprove heat resistanceEasy to processMelt spinning methodsMonocomponent polyesters artificial filamentFiberPolyethylene glycol

The invention relates to a preparation method of a lodging-resistant multi-difference polyester low elastic filament. The preparation method comprises the following steps: firstly, mixing nano sepiolite fibers, organic magnesium hydroxide whisker, organic barium sulfate nano powder, ethylene glycol, propylene glycol, p-hydroxybenzoic acid and sodium germanate to obtain a high-modulus composite alcohol solution; secondly, mixing organic wollastonite nano needle-like fibers, mica powder, polyethylene glycol, the propylene glycol, an antioxidant 1010, ethylene glycol antimony and protonated agent phosphoric acid to obtain a high-modulus composite promoter; thirdly, co-polycondensing the high-modulus composite multifunctional alcohol solution and the high-modulus composite promoter with purified terephthalic acid and the ethylene glycol to obtain high-modulus modified polyester; a melt of the high-modulus modified polyester is sprayed from a T-shaped spinneret orifice in a spinneret plate; the lodging-resistant multi-difference polyester low elastic filament is prepared by a special cooling mode and a low-temperature texturing process. The fiber prepared by the preparation method has multiple different properties of different crystallization, different orientation and different shrinkage; after different shrinkage, the appearance is good, and a brushed fabric prepared from the lodging-resistant multi-difference polyester low elastic filament is not easy to lodge.

Owner:荣翔化纤有限公司

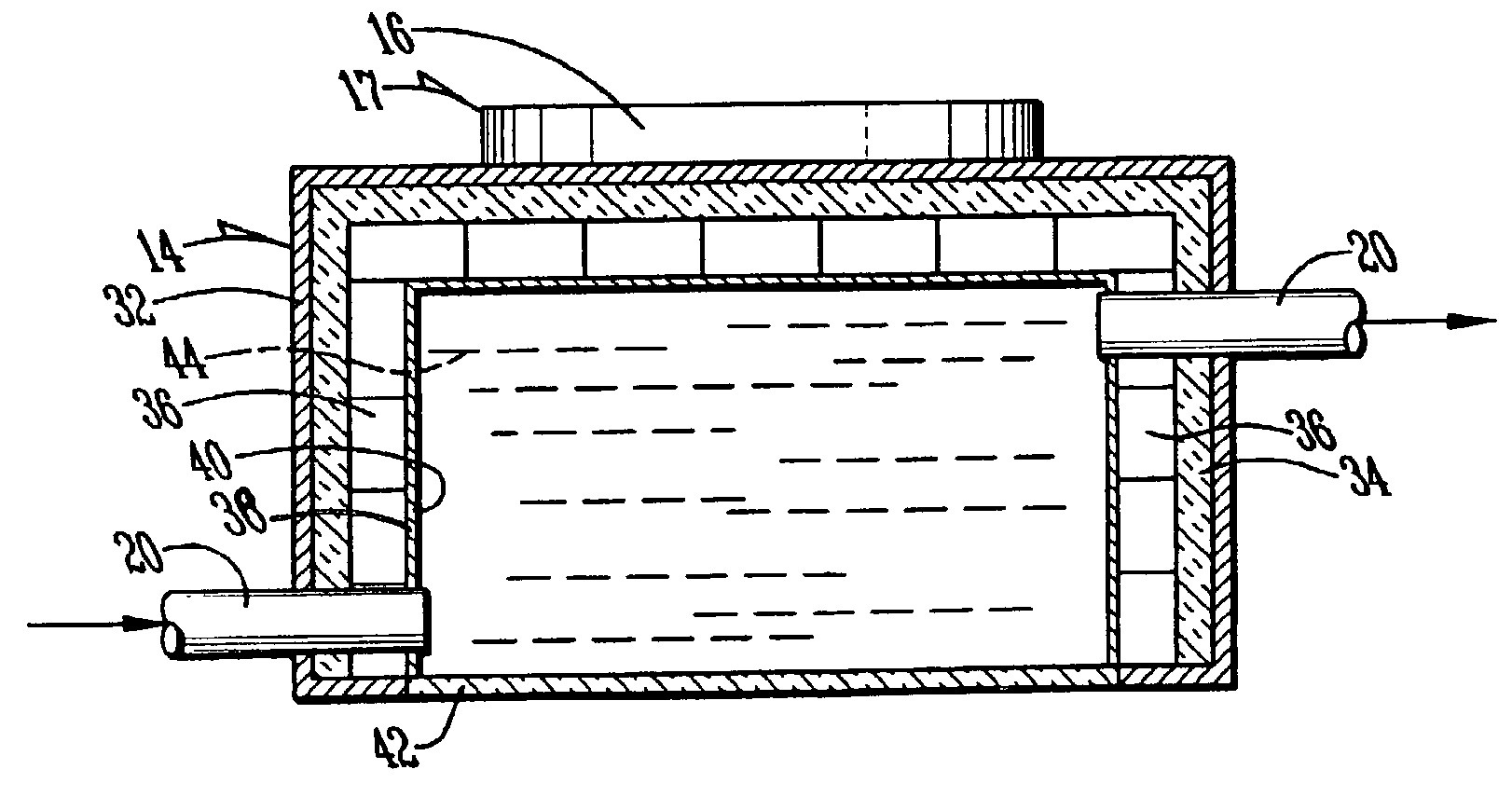

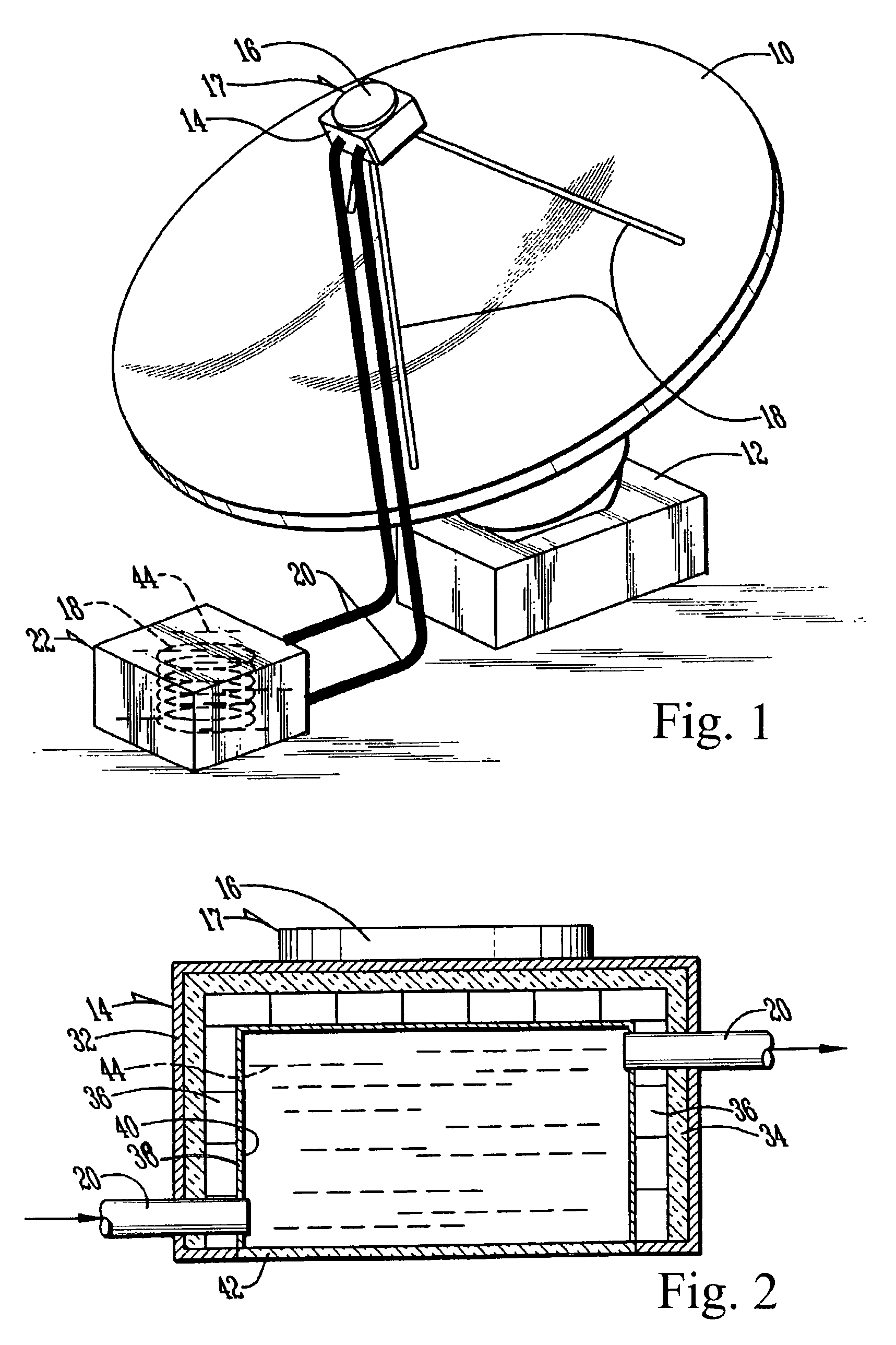

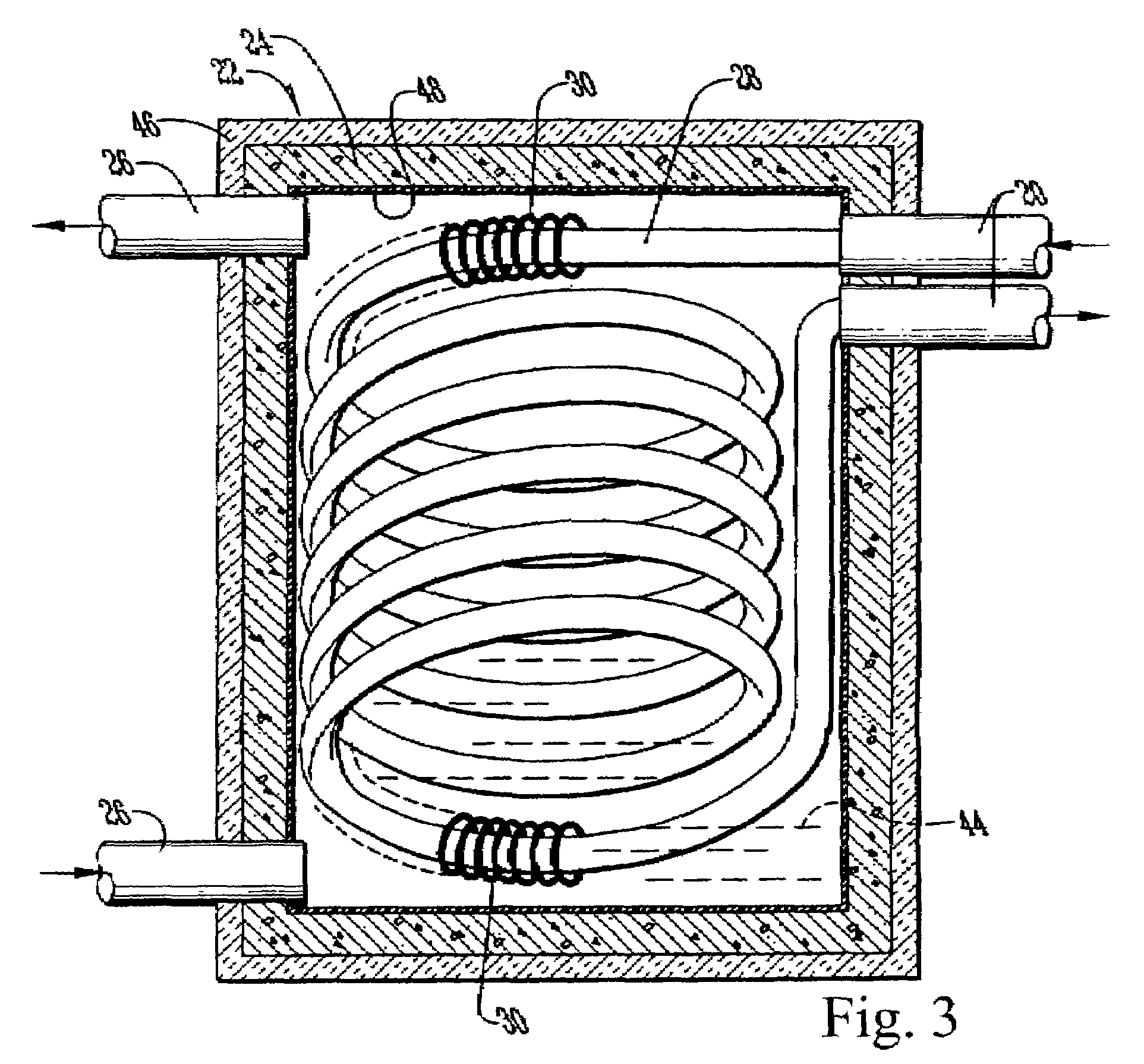

Solar co-generator

InactiveUS7173179B2Improve energy conversion efficiencyImprove photovoltaic efficiencySolar heating energySolar heat devicesThermal energyAnti-reflective coating

A solar co-generator for producing both heat energy and electricity is disclosed. A solar concentrator directs sunlight into a container lined with solar cells and filled with a thermal transfer fluid. The fluid is transparent with respect to certain wavelengths of light that may be converted to electricity by the solar cell, but is opaque with respect to longer wavelengths, particular the infrared band. The infrared portion of the sunlight heats the thermal transfer fluid, which then transfer that heat through a storage facility using a heat exchange mechanism. The thermal transfer fluid increases the efficiency of photovoltaic generation by preventing heating of the solar cells due to infrared radiation. The thermal transfer fluid may be a mixture containing barium sulfate and a suspension of zinc sulfide phosphors. A fluorescing anti-reflective coating may be applied to the solar cells to further increase efficiency.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ARKANSAS

Fiducial marker

InactiveUS20080234532A1Minimise patients' discomfortImprove radiopacitySurgeryDiagnostic markersImaging techniqueNuclear medicine

A fiducial marker which is visible to a wide range of imaging techniques, comprises a radiopaque material, such as barium sulphate or a metal wire, encapsulated in a biocompatible polymeric material, for example a polyaryletherketone such as polyetheretherketone.

Owner:INVIBIO

Fracturing fluids for delayed flow back operations

InactiveUS7256160B2Prevents oil wettingAvoid damageFlushingDrilling compositionSulfate-reducing bacteriaBiopolymer

It has been discovered that certain fracturing fluid compositions can be used to fracture a subterranean formation and be permitted to stay within the formation for a relatively extended period of time, for example 28 days or more, before being flowed back or produced. At least two embodiments are envisioned, a bacteria-containing formulation and an anti-bacterial formulation. Both systems would be expected to prevent the potential of the fluid to oil wet the formulation (water block condition) by keeping the formation water wet through the use of water wetting surfactants or solvents. Additionally, both formulations would control reservoir crude souring (H2S generation by in situ sulfate-reducing bacteria), reservoir plugging (via slime biopolymers generated by in situ microbes, inorganic scale deposition like calcium carbonate or barium sulfate, and clay fines migration).

Owner:SUPERIOR ENERGY SERVICES LLC

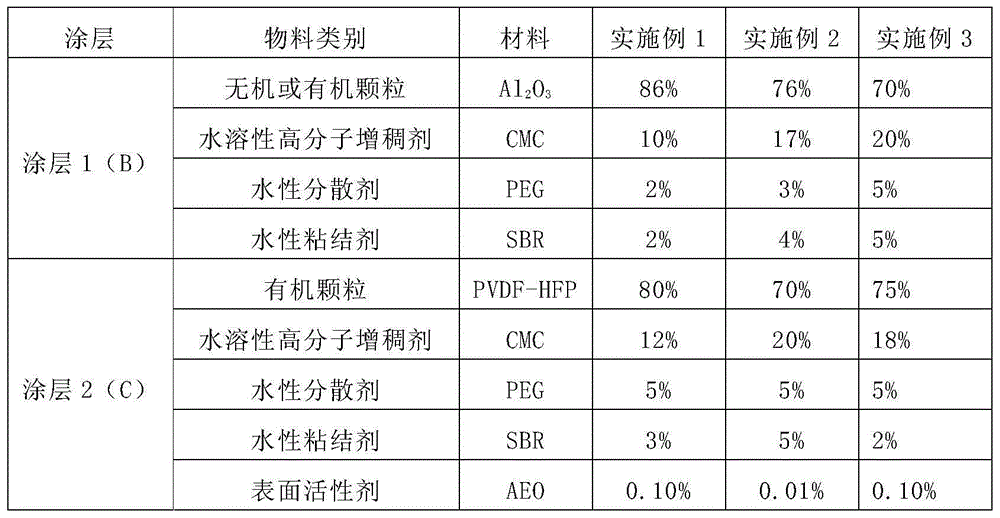

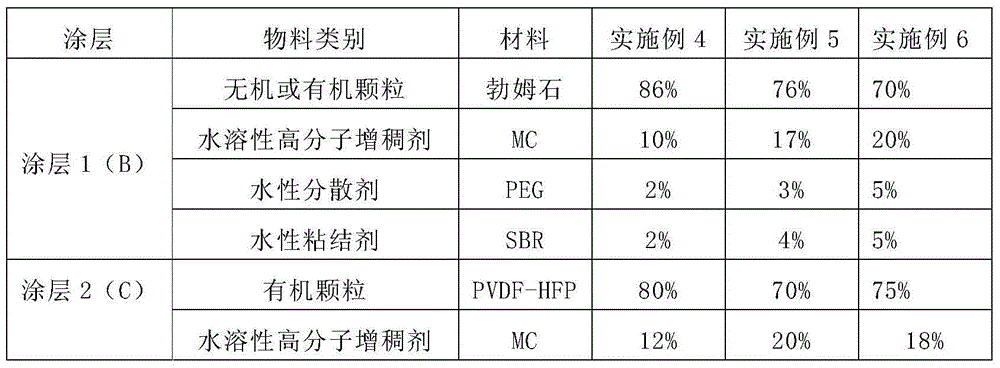

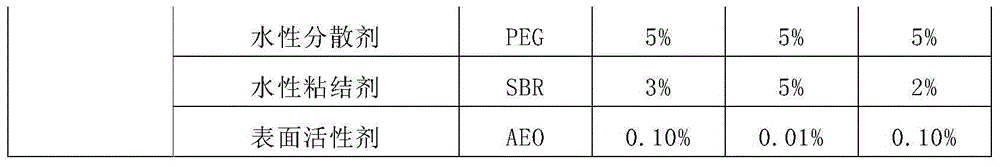

Water-based multi-layer membrane for lithium ion battery

InactiveCN104868081ACell seperators/membranes/diaphragms/spacersSecondary cellsWater basedElectrical battery

The invention provides a water-based multi-layer membrane for a lithium ion battery. The water-based multi-layer membrane comprises a polymer membrane substrate (A), an inorganic or organic particle coating (B) coating one or two sides of the polymer membrane substrate (A), and an organic particle coating (C) coating the inorganic or organic particle coating (B), wherein the inorganic or organic particle coating (B) is formed by a composition which comprises 15-70wt% of inorganic or organic particles and 30-85wt% of water; the inorganic or organic particles are selected from aluminum oxide, silica, barium sulfate, boehmite or polyimide; the organic particle coating (C) is formed by a composition which comprises 5-30wt% of organic particles and 70-95wt% of water; and the organic particles are selected from polyvinylidene fluoride-hexafluoropropylene, polyacrylonitrile, polyoxyethylene or polymethyl methacrylate.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

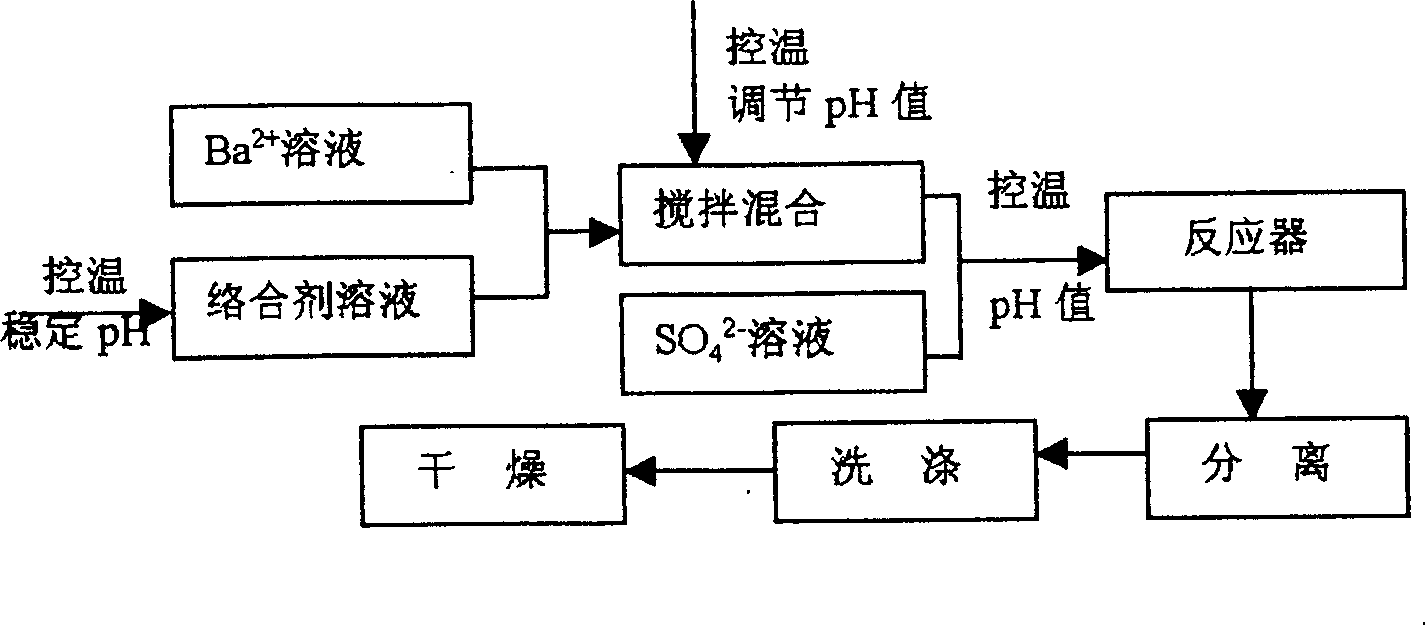

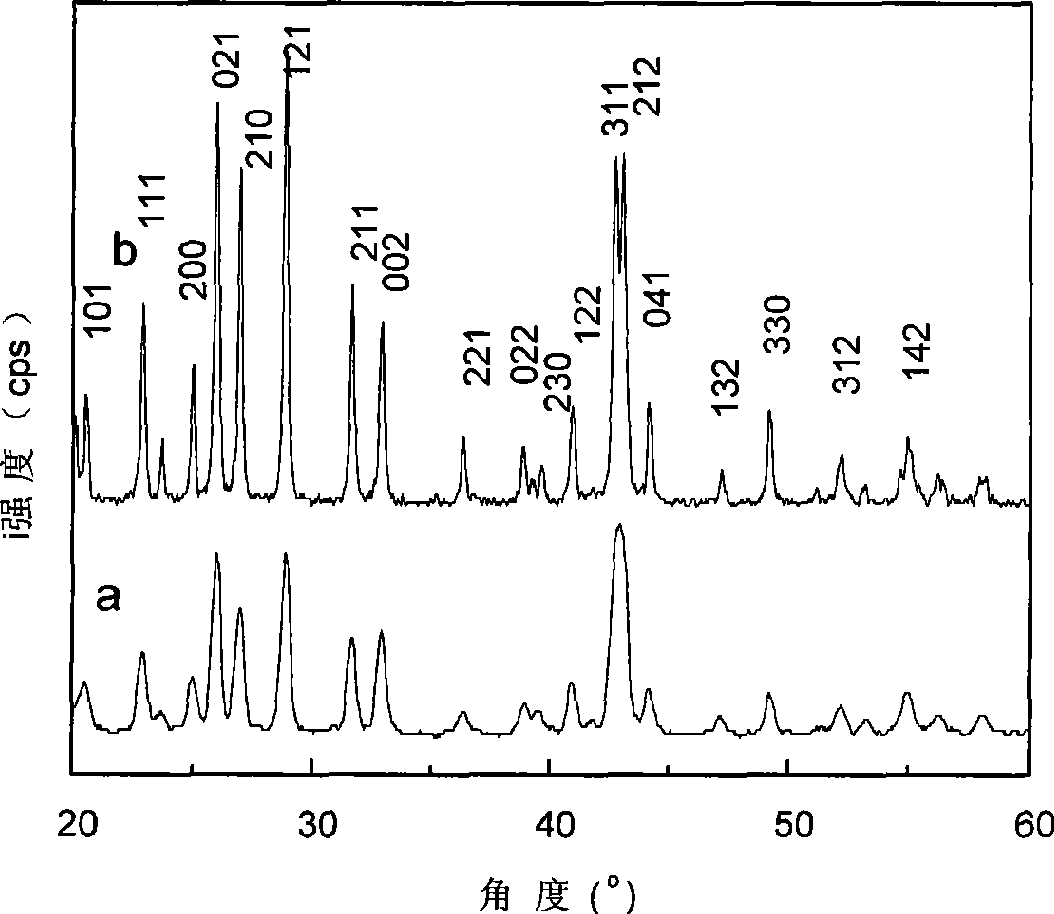

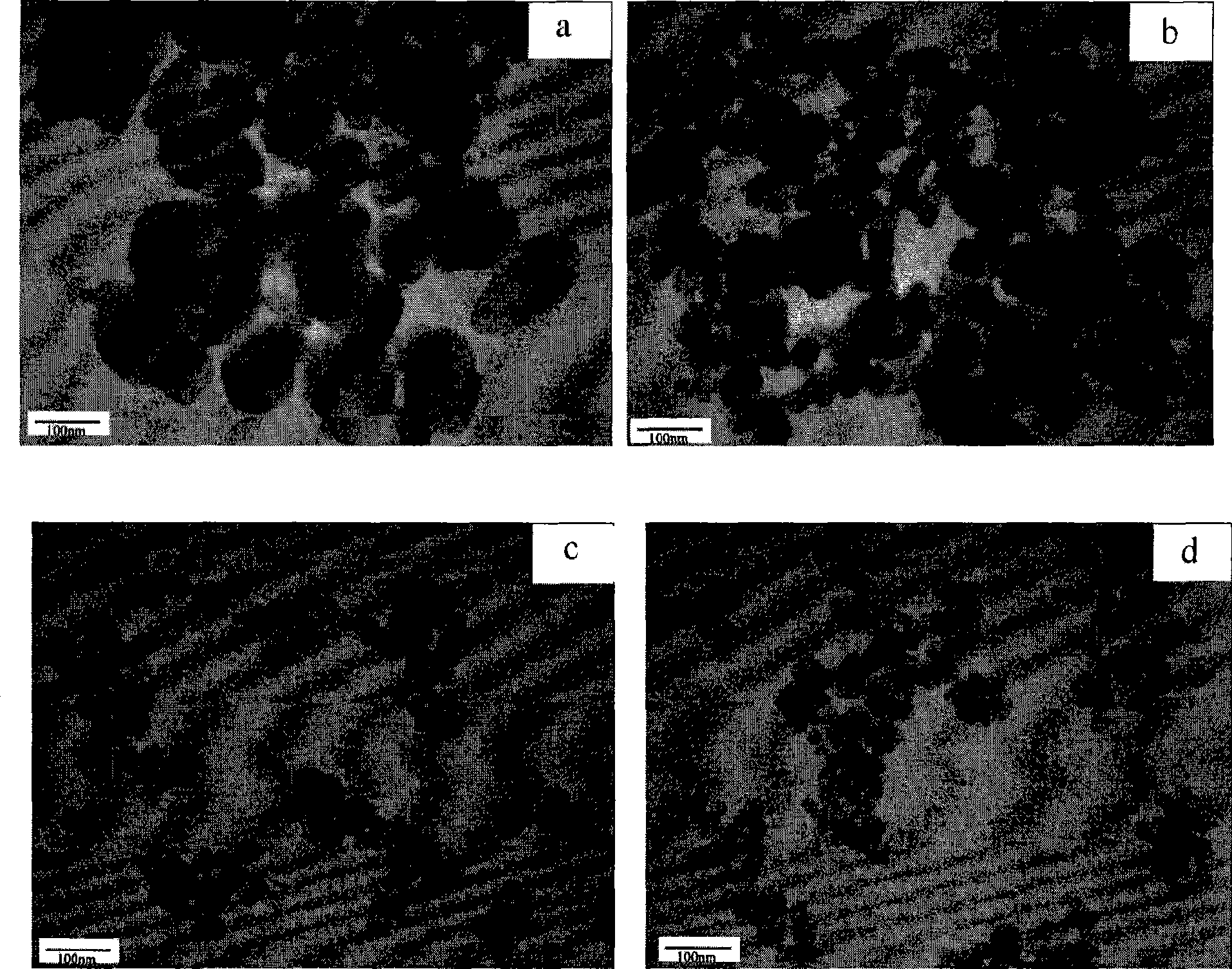

Prepn of nano barium sulfate

InactiveCN1398789AStable operating conditionsGood resolubility and dispersibilityMaterial nanotechnologyCalcium/strontium/barium sulfatesSal ammoniacSulfate radicals

The present invention belongs to the field of chemical technology and is especially a complexing process of preparing nanometer BaSO4. The process includes two main steps of complexing reaction and deposition reaction. Specifically. Ba2+ ion solution and EDTA complexing agent solution produce complexing reaction in a reactor to produce complex solution with certain stability and ammonia water being used for regulating system pH value. The complex solution is made to react with sulfate radical solution while stirring to prepare nanometer level BaSO4 particles as precipitate. The nanometer level BaSO4 product is hexagonal crystal and blue in color, and has grain size of 20-40 nm and average grain size of 25 nm. The process is stable in operation, and the product has high quality and dispersivity.

Owner:ZHONGBEI UNIV

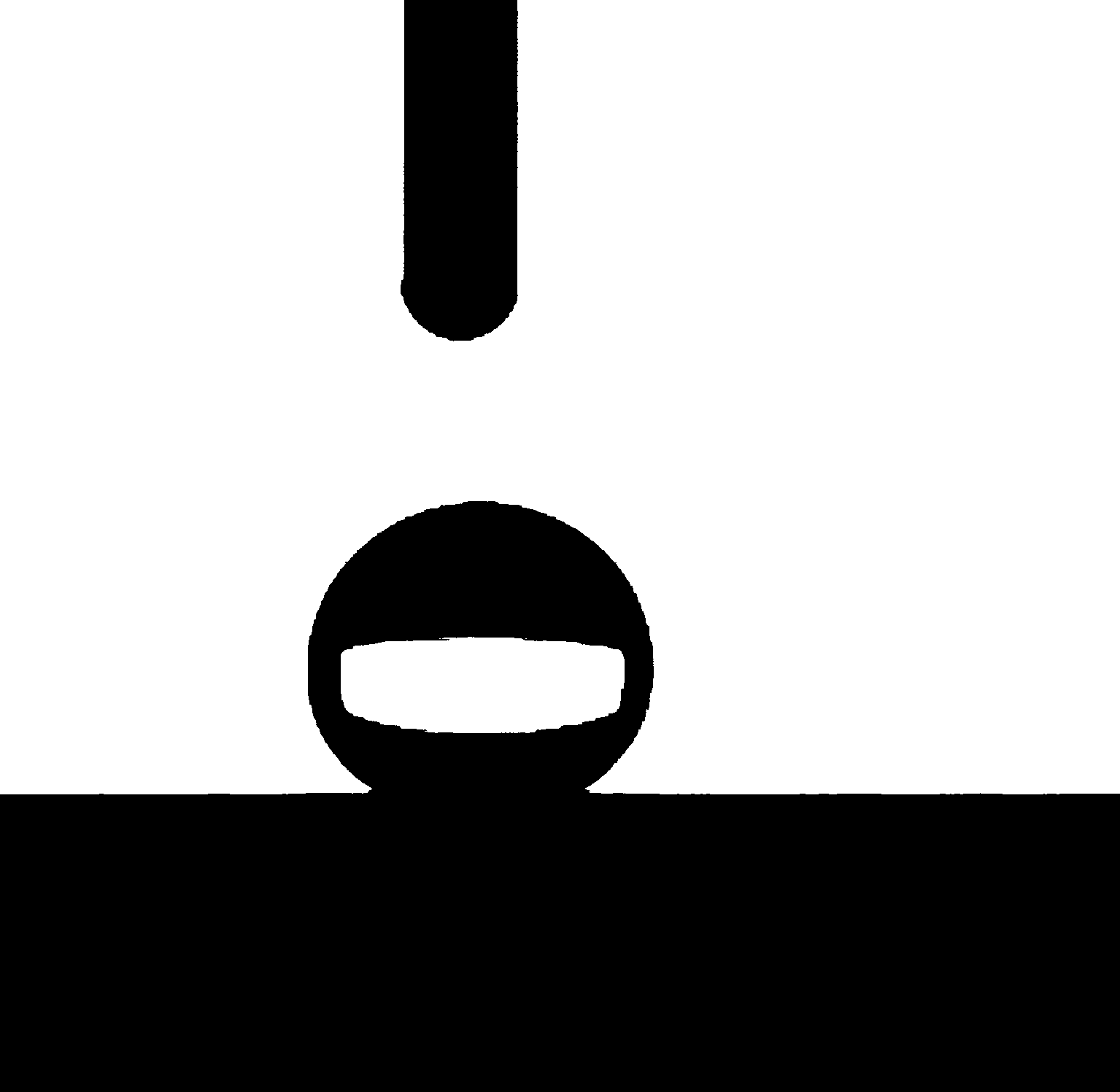

Super-hydrophobic nano coating and preparation method thereof

The invention provides a super-hydrophobic nano coating. The super-hydrophobic nano coating is characterized by consisting of the following components in percentage by weight: 0.5-1.5% of nano dioxide, 0.5-1.5% of nano silicon dioxide, 0-20% of barium sulfate, 0-20% of talcum powder, 40-70% of a thinner and 20-50% of organic silicon resin. The preparation method comprises steps of preparing a dispersion solution from filler particles, the thinner and a dispersing agent in a certain proportion, mixing with the organic silicon resin, adding a curing agent, uniformly stirring, coating on a substrate in a spin-coating or dip-coating way, and drying at 50-80 DEG C. The prepared coating has a contact angle of 145-160 degrees with water drops on the surface of the substrate, and a rolling angle is lower than 10 degrees. The method is wide in raw material resource, simple in process, convenient to use, low in cost, suitable for industrial production, and applicable to surface self-cleaning, icing resistance, water and fog resistance, fluid drag reducing and other situations.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method for preparing nano barium sulfate with controllable particle size distribution

InactiveCN101423239APrecise control of particle sizeInhibit growthCalcium/strontium/barium sulfatesEmulsionSlurry

The invention provides a preparation method of nano barium sulfate with the controllable particle size distribution. The preparation method takes BaCl2 and Na2SO4 as raw materials, respectively prepares two types of solution and then simultaneously adds the two types of solution into a rotary liquid membrane reactor with the high-speed rotation at the same flow rate for carrying out nucleation reaction, and centrifugal washing and drying are carried out to the obtained slurry to obtain the nano BaSO4 with the particle size of 30-120nm and the narrower particle size distribution. The purpose of precisely controlling the particle size of the product can be achieved by regulating and controlling the rotational speed, the gap and other operation parameters of the reactor, thereby being capable of preparing the BaSO4 with the particle size of 30-40nm. The method combines the advantages of a micro-reactor and a high gravity reactor and simultaneously avoids the shortcomings of the micro-emulsion method, the complex method and the like, thereby having small reaction space and high preparation speed and being capable of meeting the requirements on the industrial preparation of the nano BaSO4.

Owner:BEIJING UNIV OF CHEM TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com