Patents

Literature

104 results about "Strontium hydroxide octahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Strontium hydroxide, Sr(OH)2, is a caustic alkali composed of one strontium ion and two hydroxide ions. It is synthesized by combining a strontium salt with a strong base. Sr(OH)2 exists in anhydrous, monohydrate, or octahydrate form.

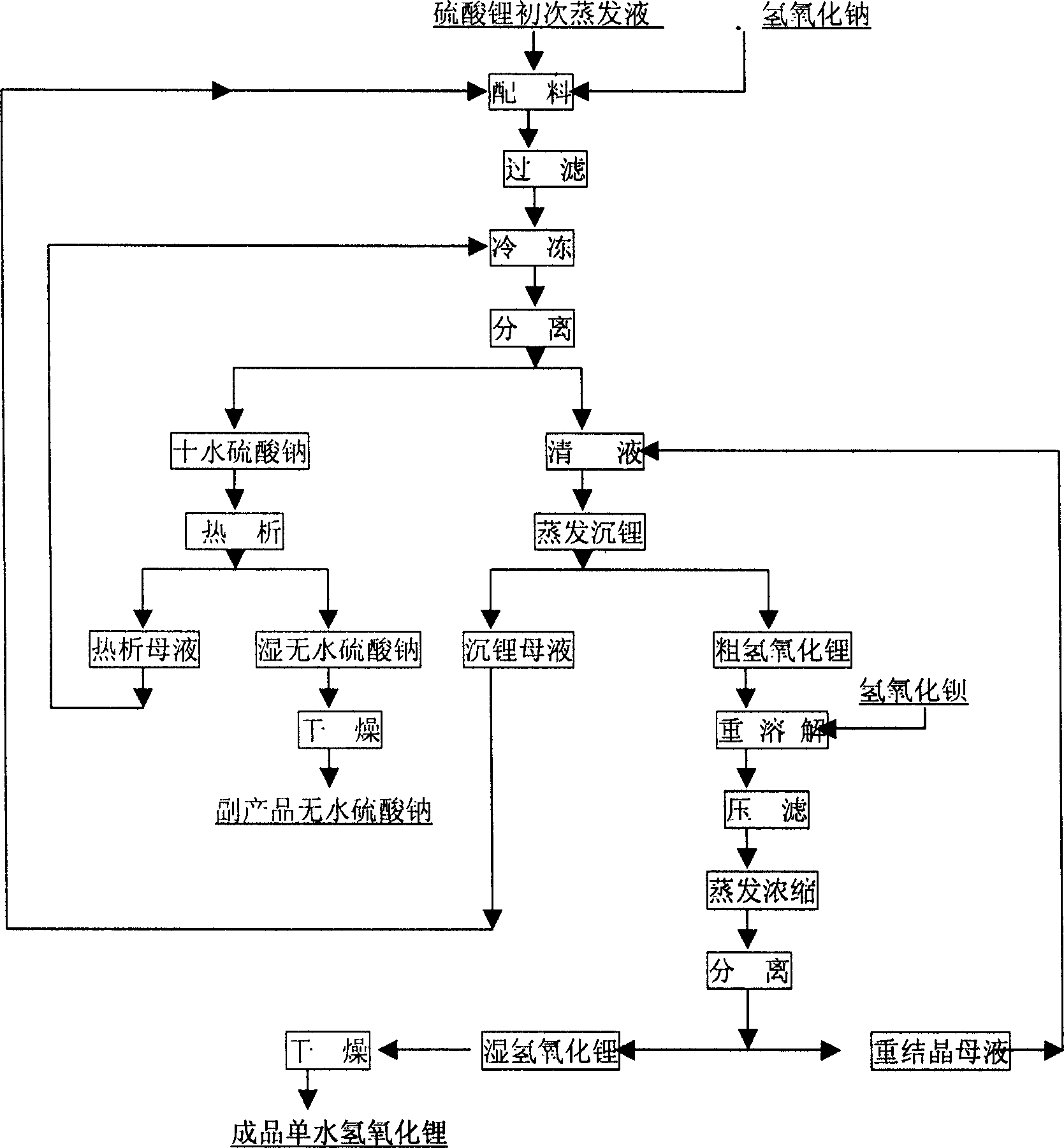

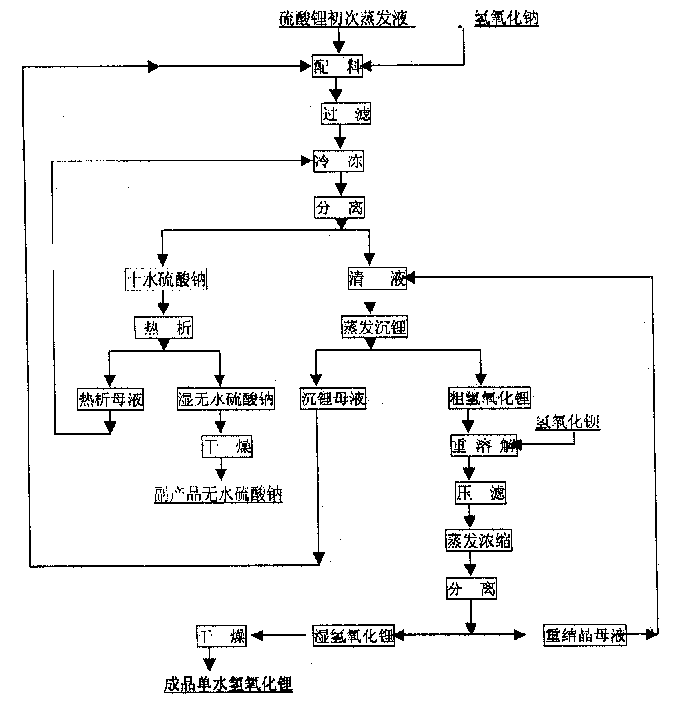

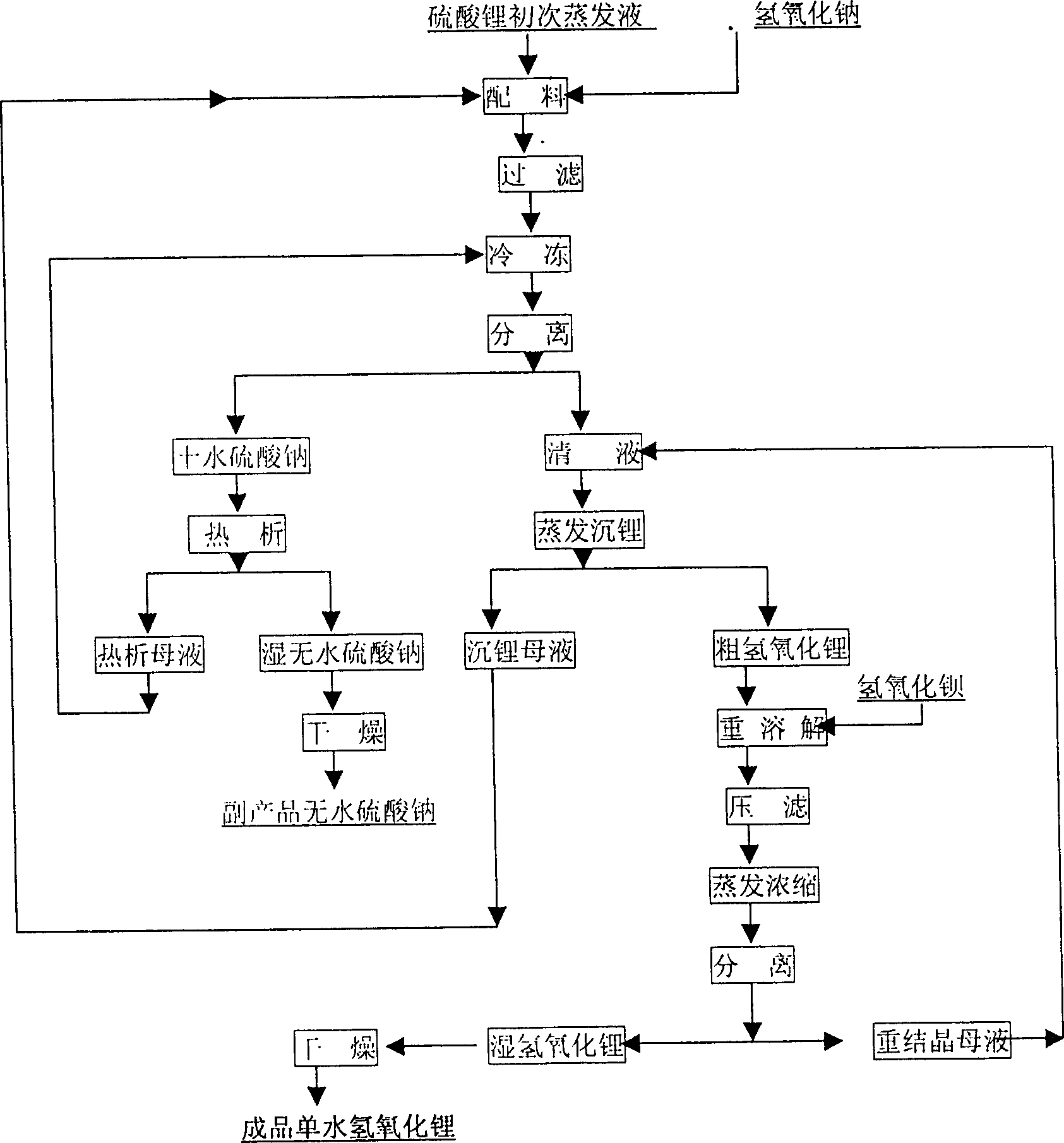

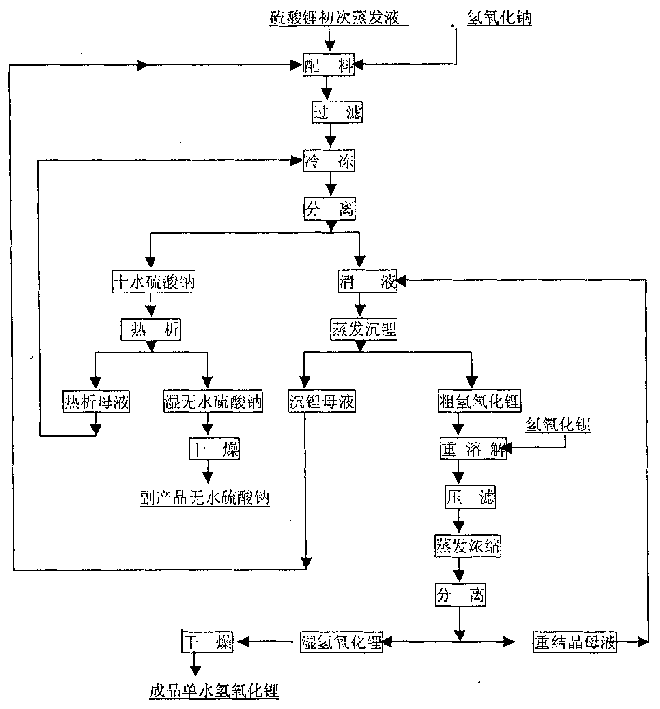

Production process of lithium hydroxide monohydrate

InactiveCN1486931AShort process routeHigh yieldSulfate/bisulfate preparationLithium oxides/hydroxidesSolubilityStrontium hydroxide octahydrate

In the production process of lithium hydroxide monohydrate, lithium sulfate solution and caustic soda are made to produce metathetic reaction to form mixture solution of sodium sulfate and lithium hydroxide, and sodium sulfate and lithium hydroxide monohydrate are then separated by means of the obvious difference in low temperature solubility. The production process includes the following steps: adding sodium hydroxide into lithium sulfate solution obtained through serial production steps to obtain mixture solution of sodium sulfate and lithium hydroxide; cooling to minus 10 deg.c to 5 deg.c for the crystallization and separation of sodium sulfate; heating to concentrate the separated clear liquid; crystallization and separation to obtain coarse lithium hydroxide monohydrate product; water dissolving coarse lithium hydroxide monohydrate, adding barium hydroxide to form insoluble barium sulfate, filtering, concentrating filtrate, crystallizing to separate wet lithium hydroxide monohydrate; and drying.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

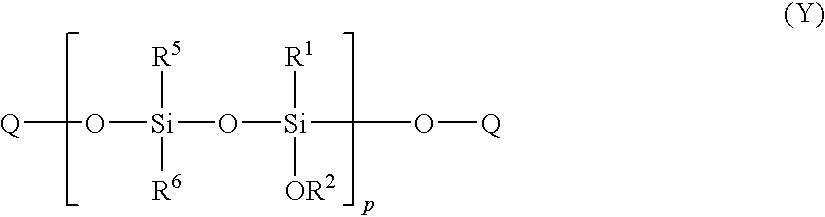

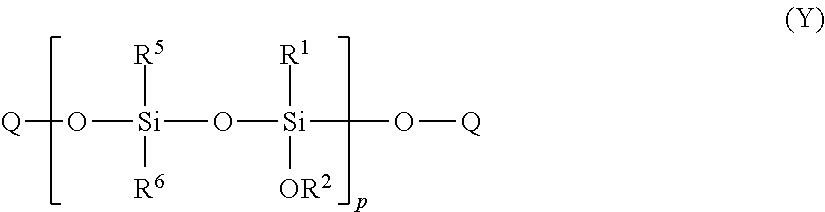

Process for producing polysiloxanes and use of the same

A process for the preparation of an organosilicon condensate which comprises reacting together a silicon containing compound having at least one silanol group and a silicon containing compound having at least one —OR group or at least one silanol group (or a compound having both groups) in the presence of strontium oxide, barium oxide, strontium hydroxide or barium hydroxide and optionally a solvent such as water, methanol, ethanol, 1-propanol, 2-propanol, 1-butanol and 2-butanol, acetone or toluene.

Owner:ZETTA RES & DEV LLC RPO SERIES

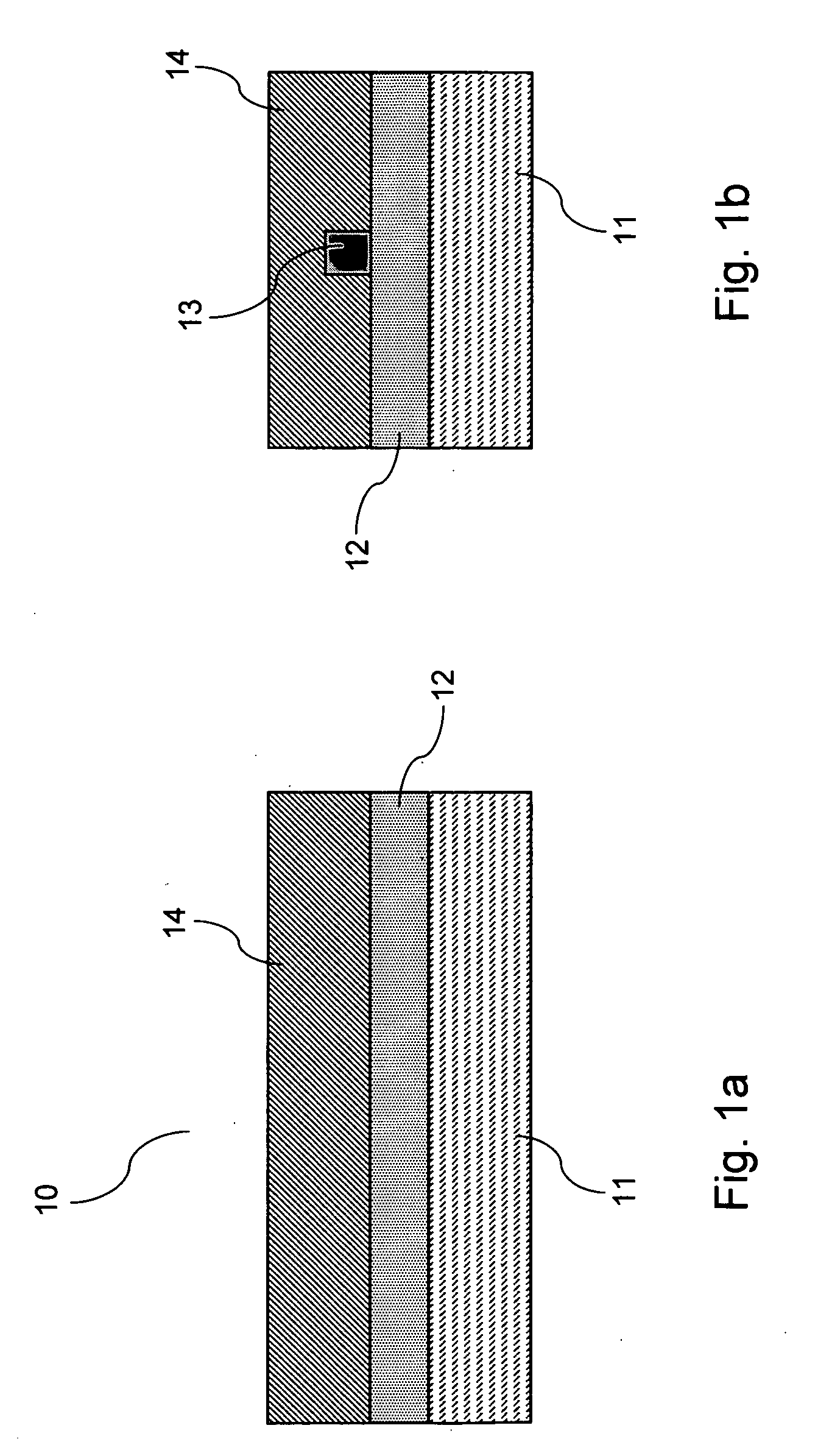

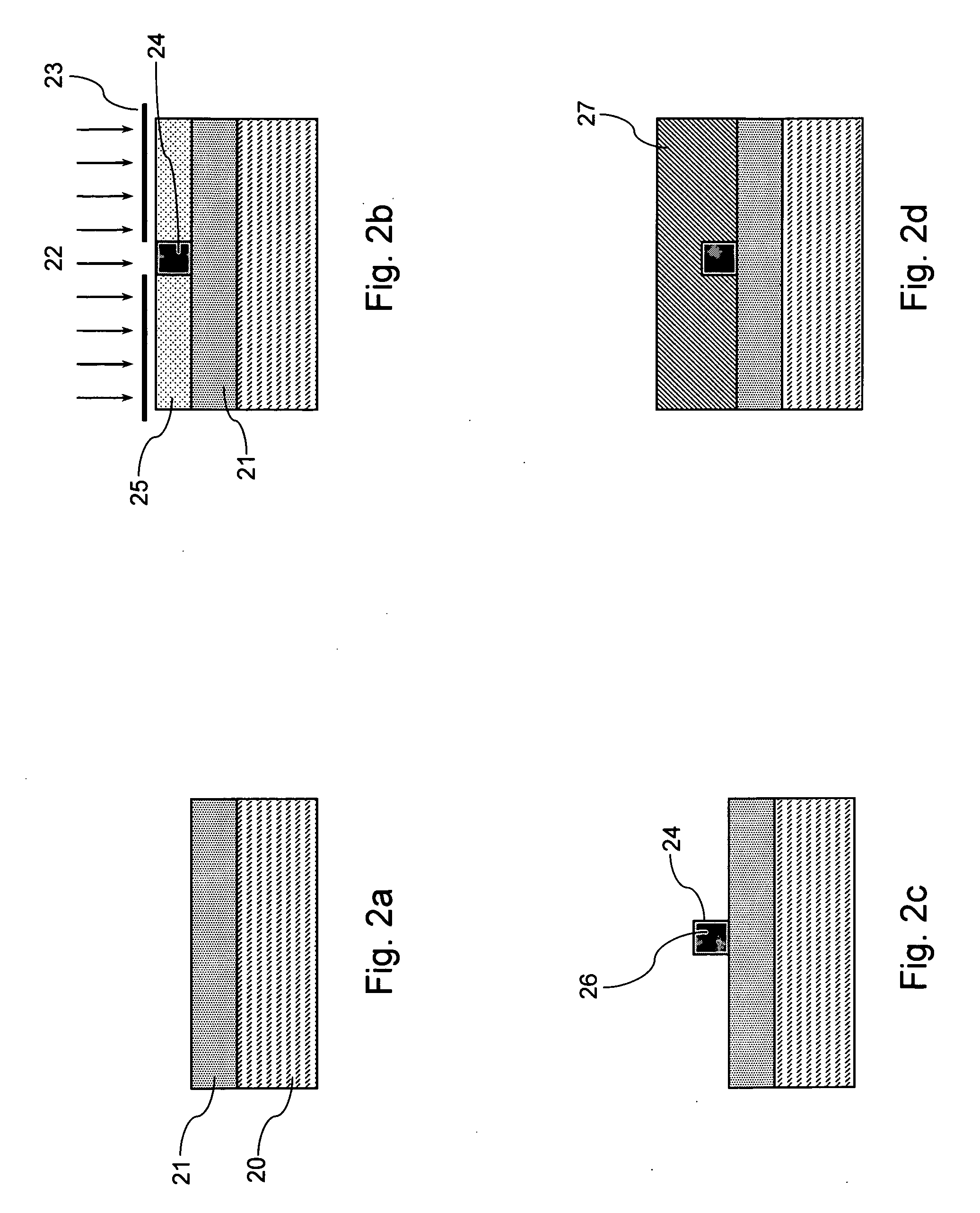

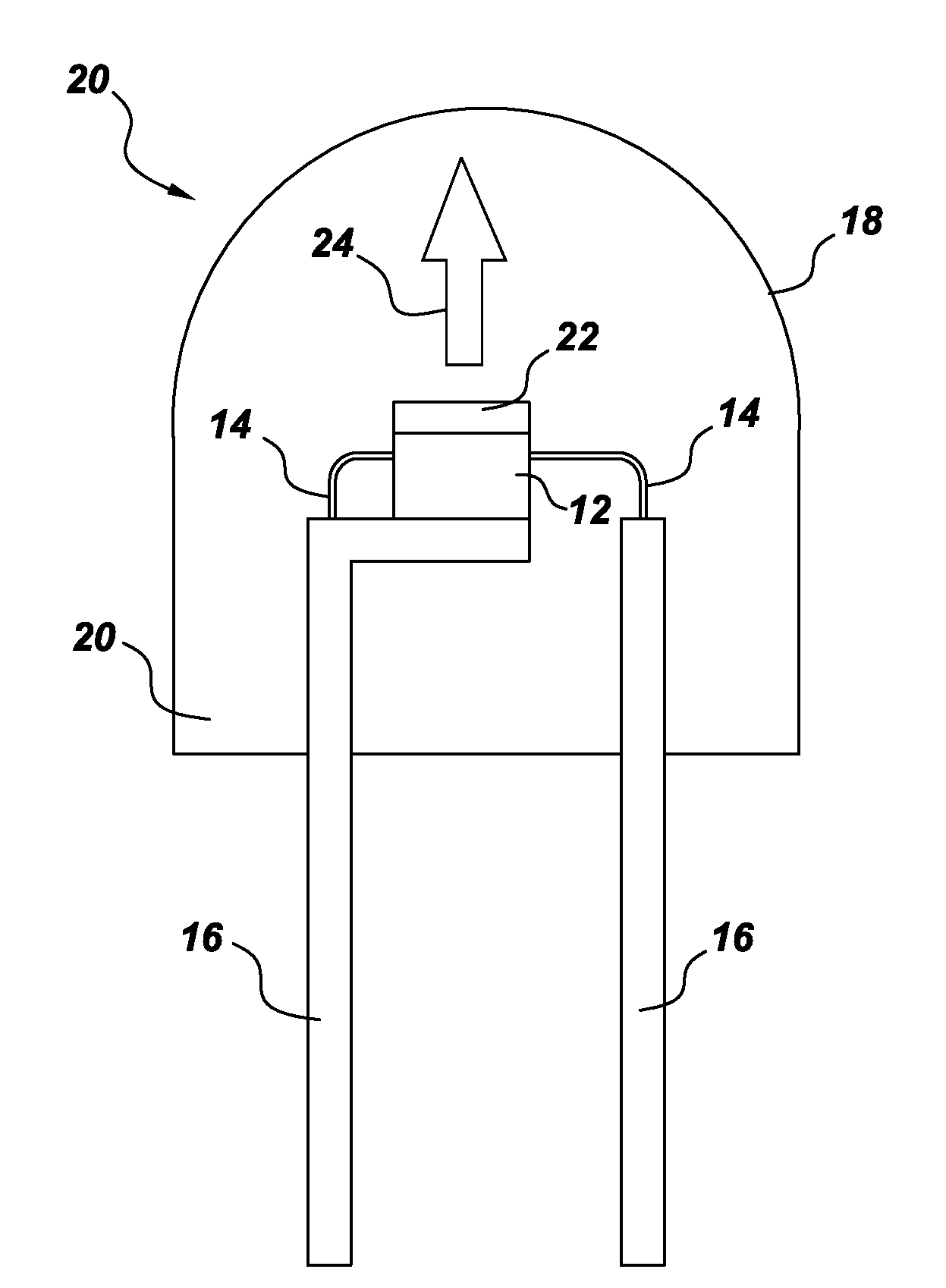

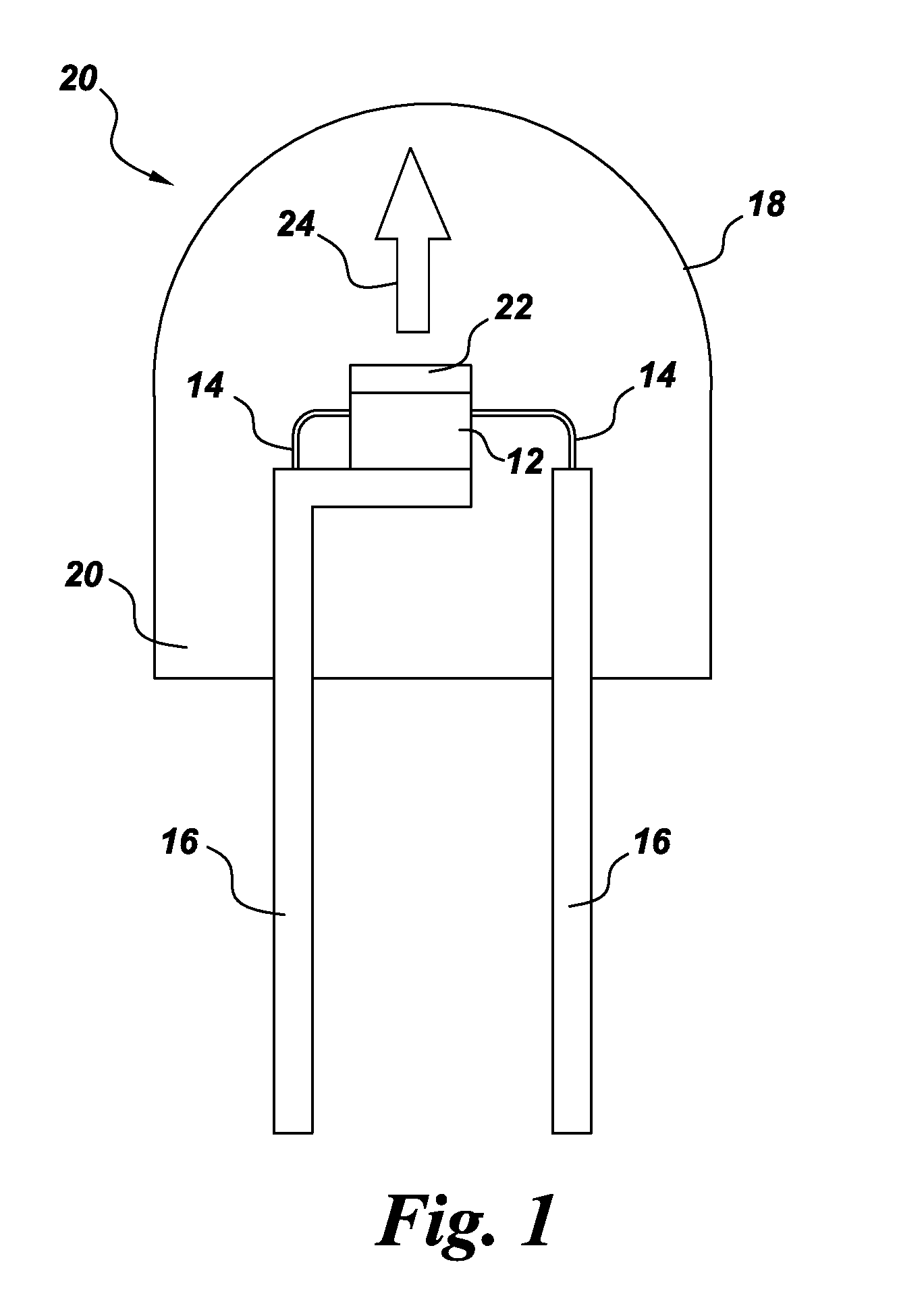

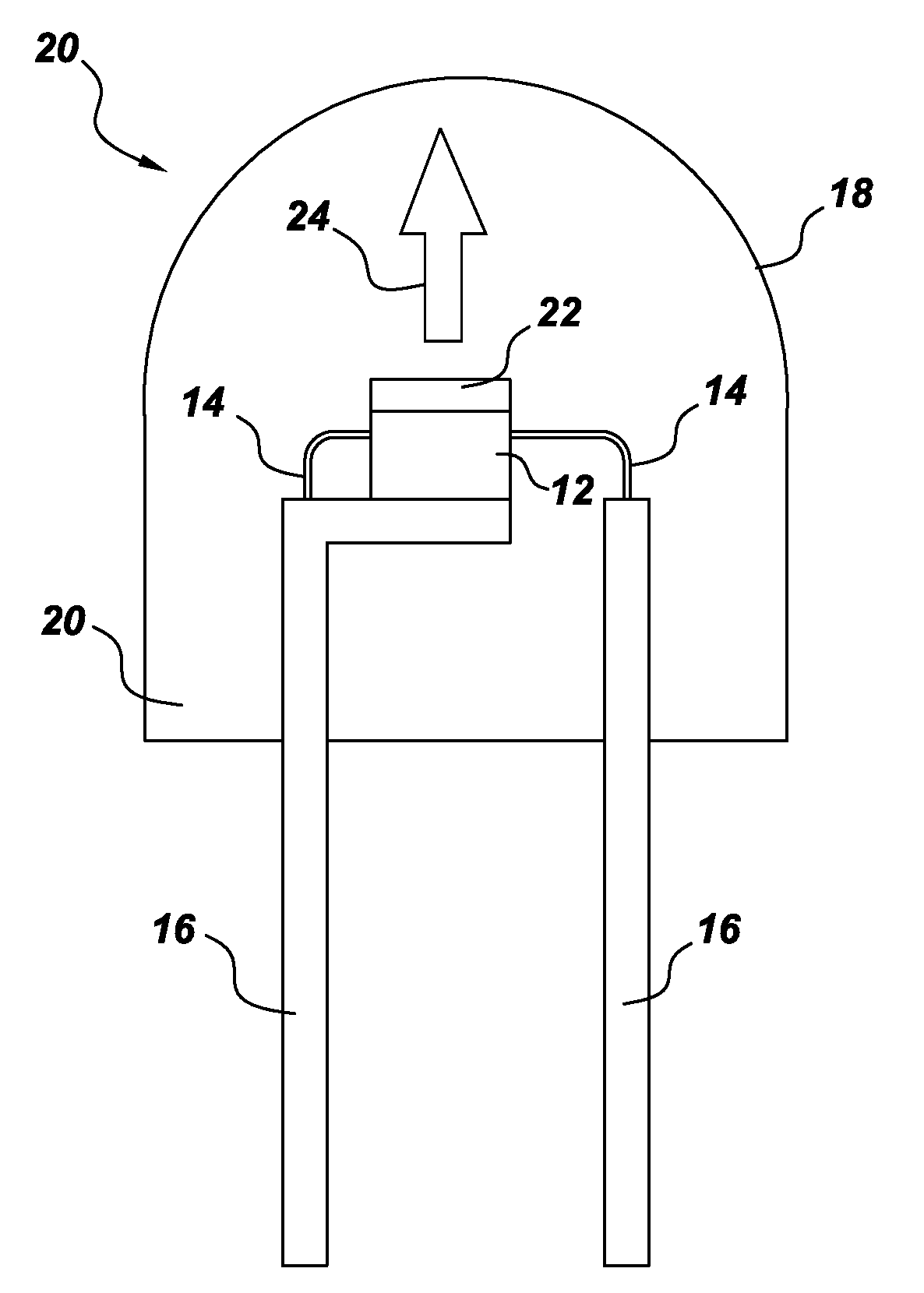

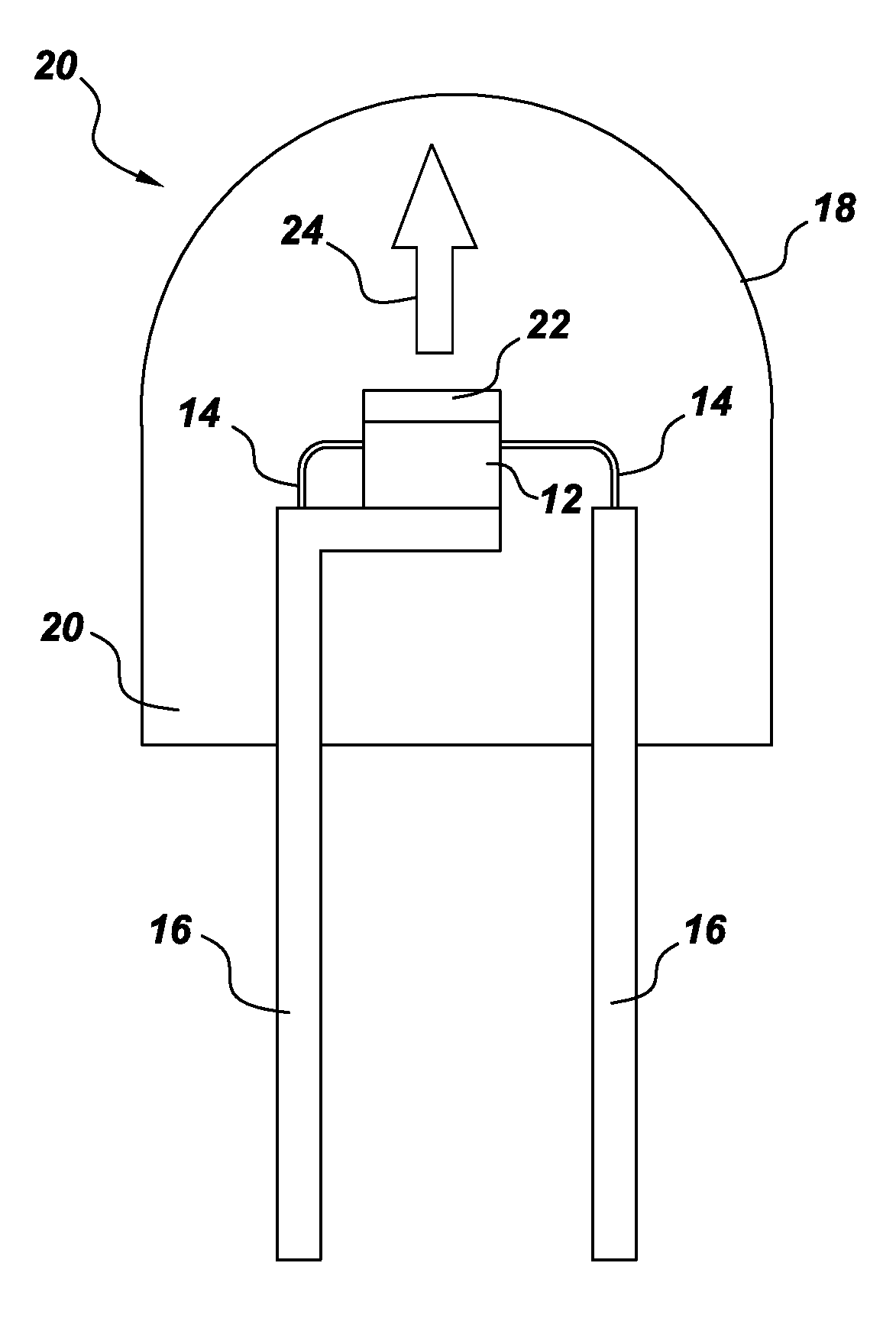

Color stable phosphors

ActiveUS20110279011A1Discharge tube luminescnet screensLamp detailsZinc hydroxideMagnesium phosphate

An LED lamp includes a light source configured to emit radiation with a peak intensity at a wavelength between about 250 nm and about 550 nm; and a phosphor composition configured to be radiationally coupled to the light source. The phosphor composition includes particles of a phosphor of formula I, said particles having a coating composition disposed on surfaces thereof;((Sr1−zMz)1−(x+w)AwCex)3(Al1−ySiy)O4+y+3(x−w)F1−y−3(x−w) Iwherein the coating composition comprises a material selected from aluminum oxide, magnesium oxide, calcium oxide, barium oxide, strontium oxide, zinc oxide, aluminum hydroxide, magnesium hydroxide, calcium hydroxide, barium hydroxide, strontium hydroxide, zinc hydroxide, aluminum phosphate, magnesium phosphate, calcium phosphate, barium phosphate, strontium phosphate, and combinations thereof; andA is Li, Na, K, or Rb, or a combination thereof;M is Ca, Ba, Mg, Zn, or a combination thereof; and0<x≦0.10, 0≦y≦0.5, 0≦z≦0.5, 0≦x≦x.

Owner:GE LIGHTING SOLUTIONS LLC

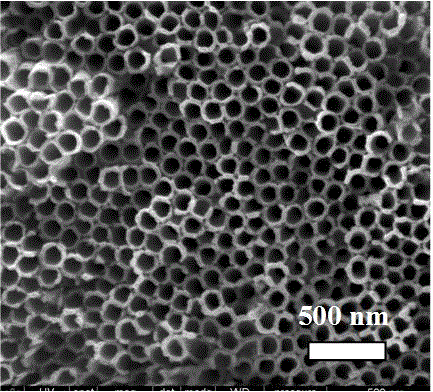

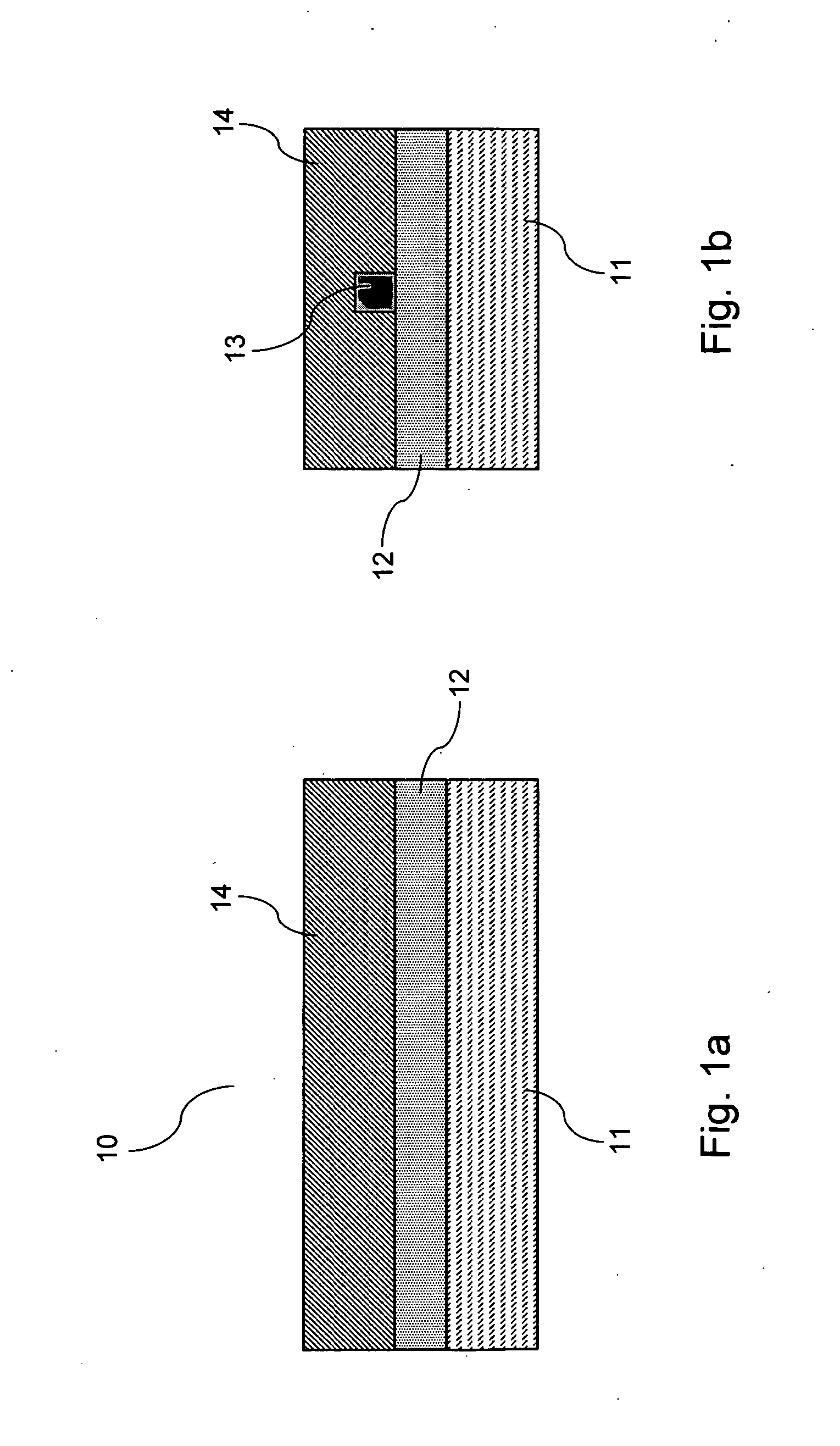

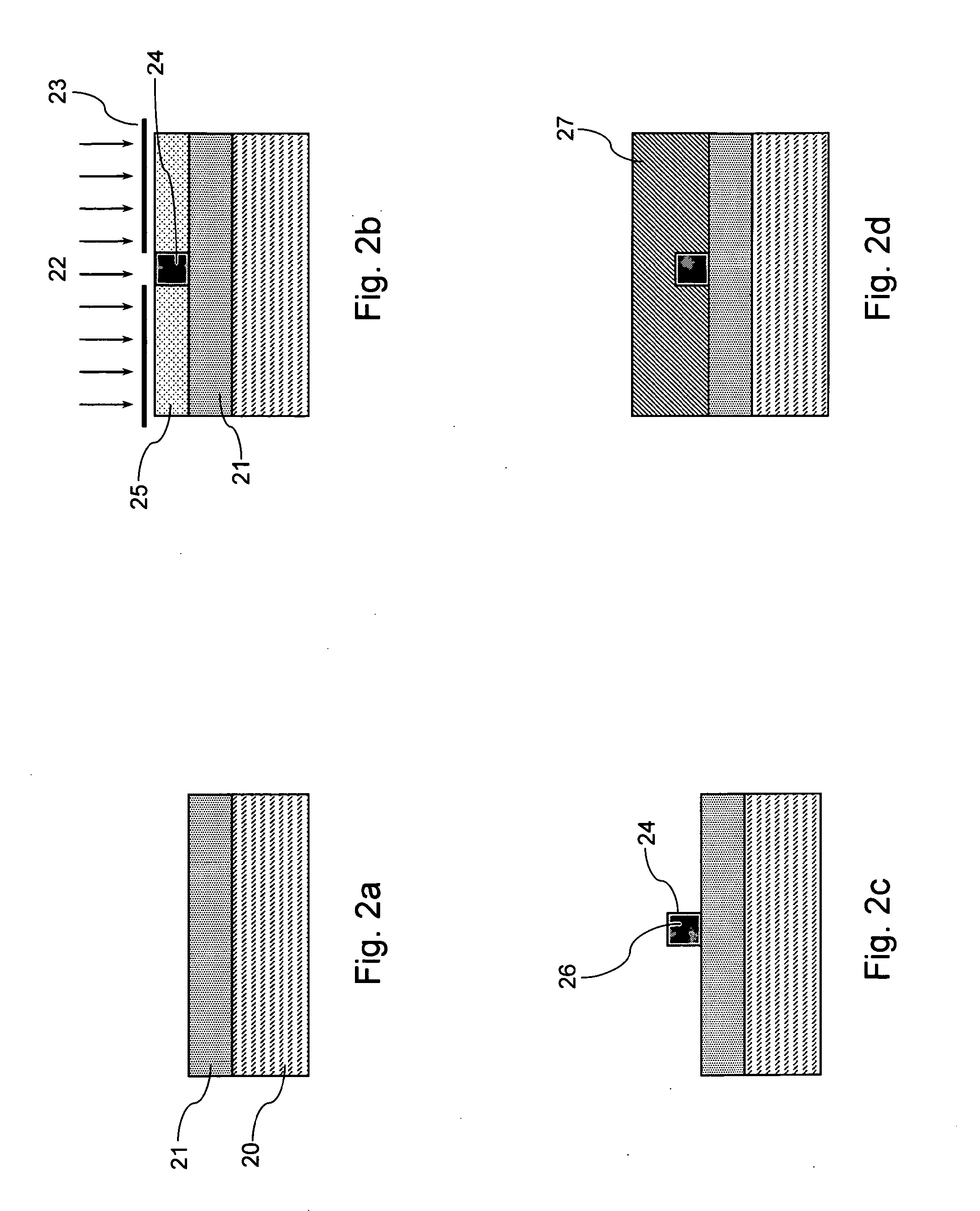

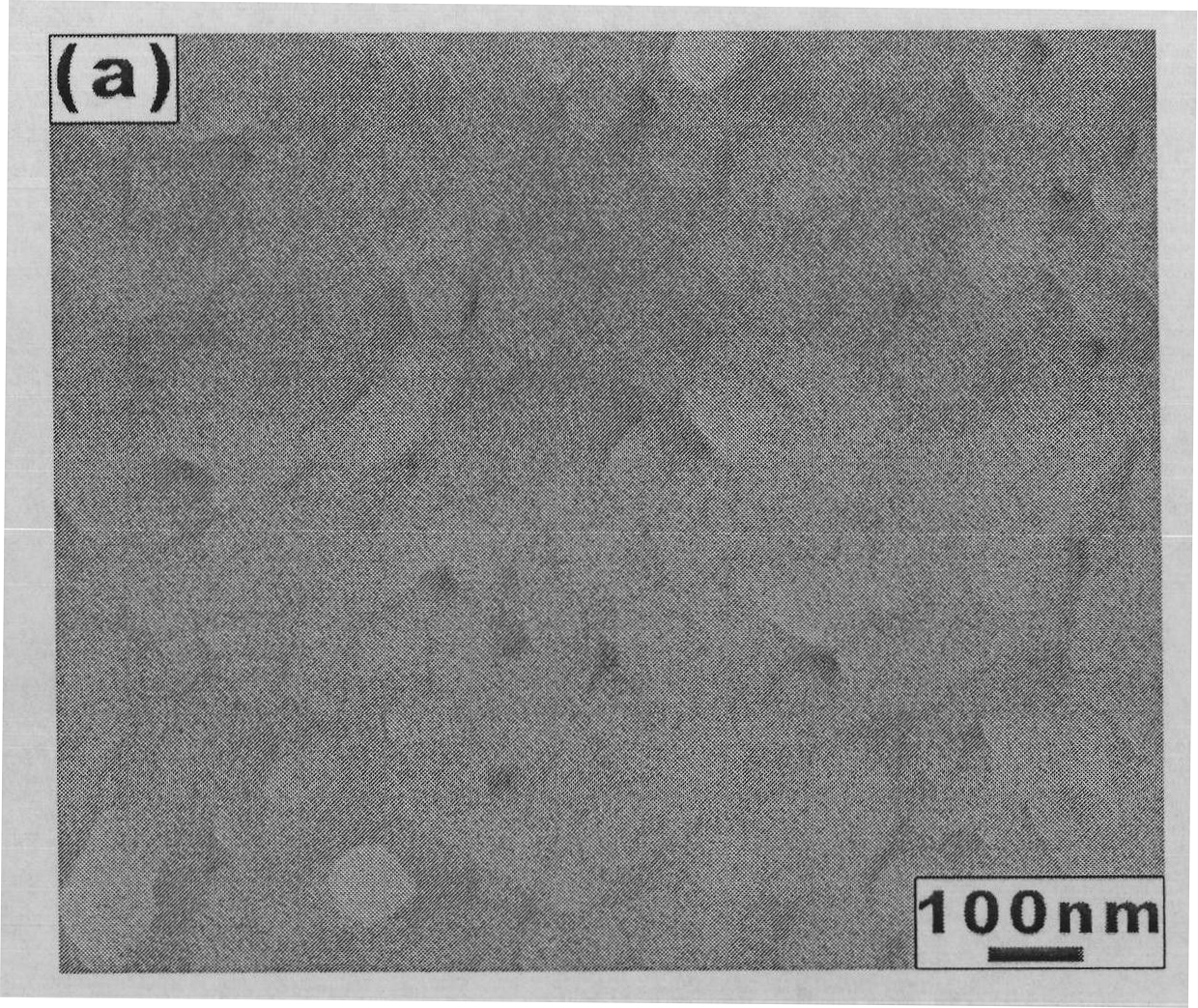

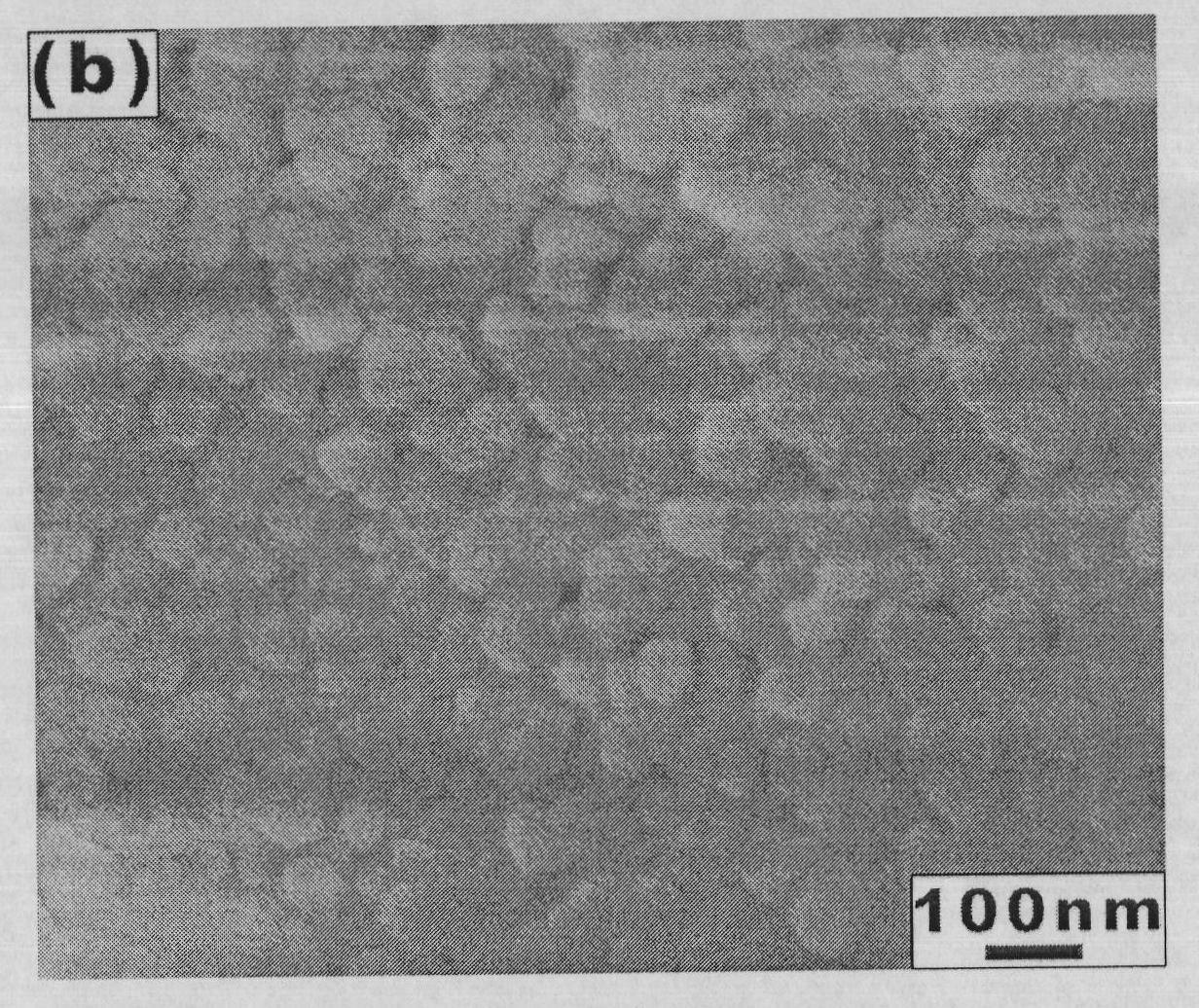

Medical titanium with a trace element slow-release function or titanium alloy implant material as well as preparation method and application of same

InactiveCN102908661AImprove biological activityIncrease success rateSurface reaction electrolytic coatingSuperimposed coating processElectrolytic agentTitanium metal

The invention relates to medical titanium with a trace element slow-release function or a titanium alloy implant material as well as a preparation method and an application of the medical titanium. The invention adopts the technical scheme that the preparation method comprises the following steps: putting a polished titanium-containing metal sheet into an electrolyte as an anode for anodic oxidation; flushing and drying the titanium-containing metal sheet subjected to anodic oxidation, carrying out heat treatment for 1-3 hours at a temperature of 100-500 DEG C, naturally cooling and ultrasonically cleaning and drying; and putting the dried titanium-containing metal sheet into one of or mixed solution of more than any two strontium hydroxide, strontium acetate, zinc acetate or magnesium acetate, carrying out hydrothermal reaction for 0.5-12 hours in a closed container at a temperature of 100-300 DEG C, naturally cooling, taking out, cleaning and drying, and carrying out heat treatment for 1-3 hours at a temperature of 450-550 DEG C to obtain the medical titanium with the trace element slow-release function or the titanium alloy implant material. The medical titanium or the titanium alloy implant material as well as the preparation method and the application thereof have the beneficial effects that the preparation method is simple and reliable, the loading quantity and the release amount of trace elements of the medical titanium in a nano tube are controllable, the medical titanium and the biological activity on the alloy surface can be better promoted, and the application prospect is good in the medical implant material.

Owner:WUHAN UNIV OF SCI & TECH

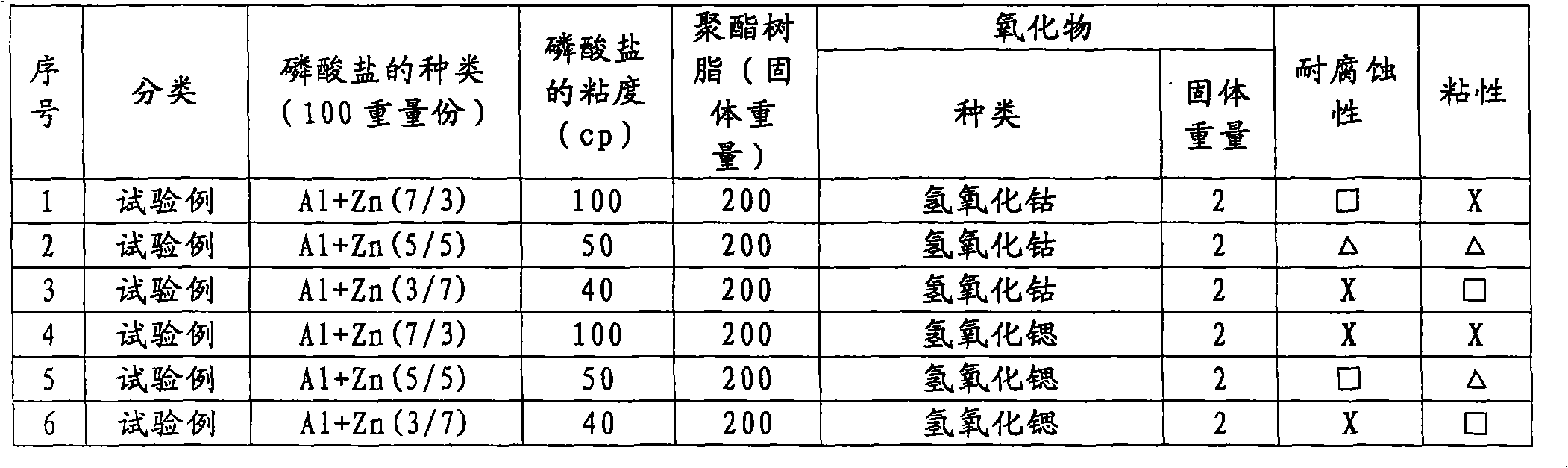

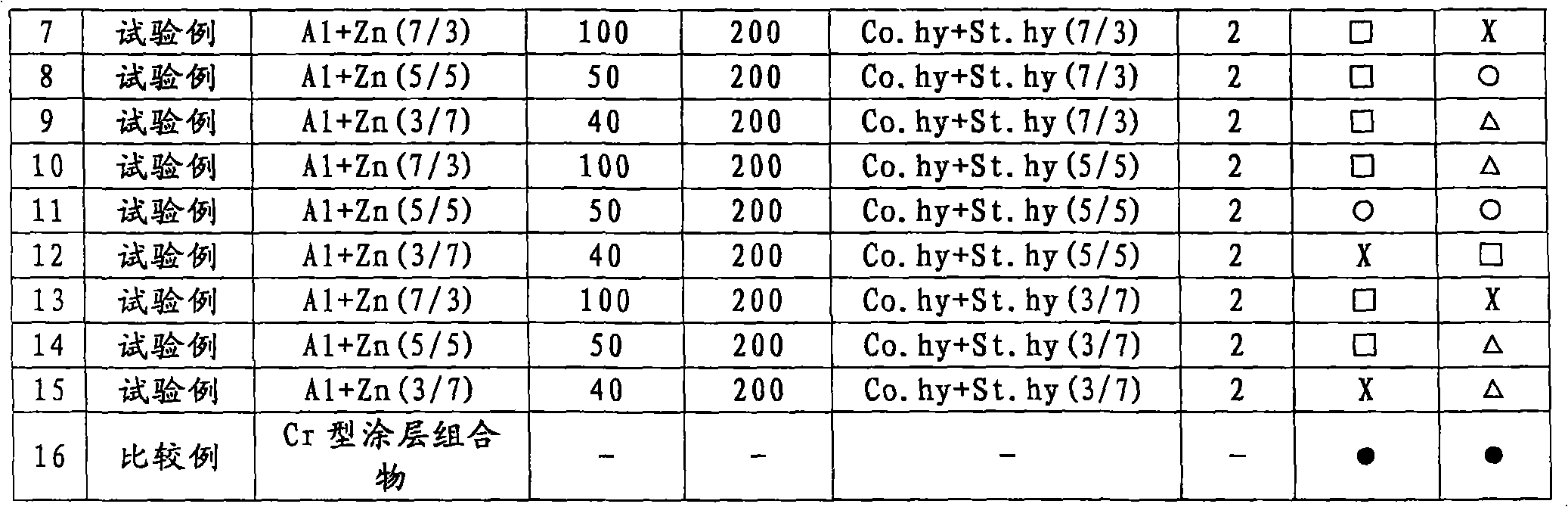

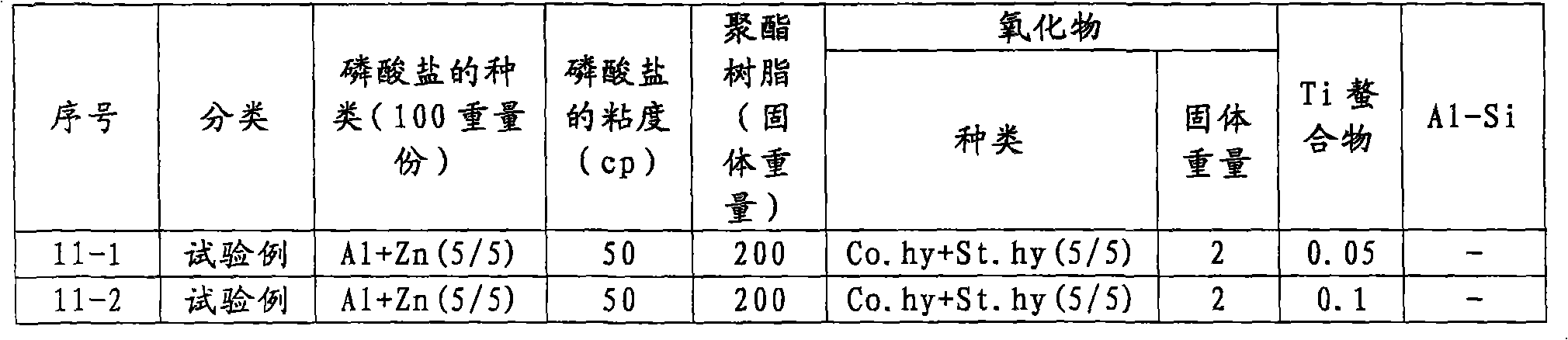

Coating solution for forming insulating film with excellent corrosion resistance property and film close adhesion property and film intensity without chrome and a method for making the insulation film

InactiveCN101517015AImprove corrosion resistanceImprove adhesionAnti-corrosive paintsMetallic material coating processesEpoxyChromium free

The invention provides a chromium-free coating composition for forming an insulation film, the composition having excellent corrosion resistance and excellent film adhesion and film strength after stress relief annealing (SRA), including, based on a lOOg phosphate solution having a solid content of 60% by weight, in which monoaluminum phosphate and monozinc phosphate are mixed at a 1 :1 ratio: 0.5-5g of a solid in which cobalt hydroxide and strontium hydroxide are mixed at a 1 :1 ratio: 100-300g of an emulsified polyester resin or an emulsified epoxy resin having a solid content of 20% by weight; 3-10g of aluminum silicate having a solid content of 20% by weight; and 0.1-6g of a titanium chelate.

Owner:POHANG IRON & STEEL CO LTD

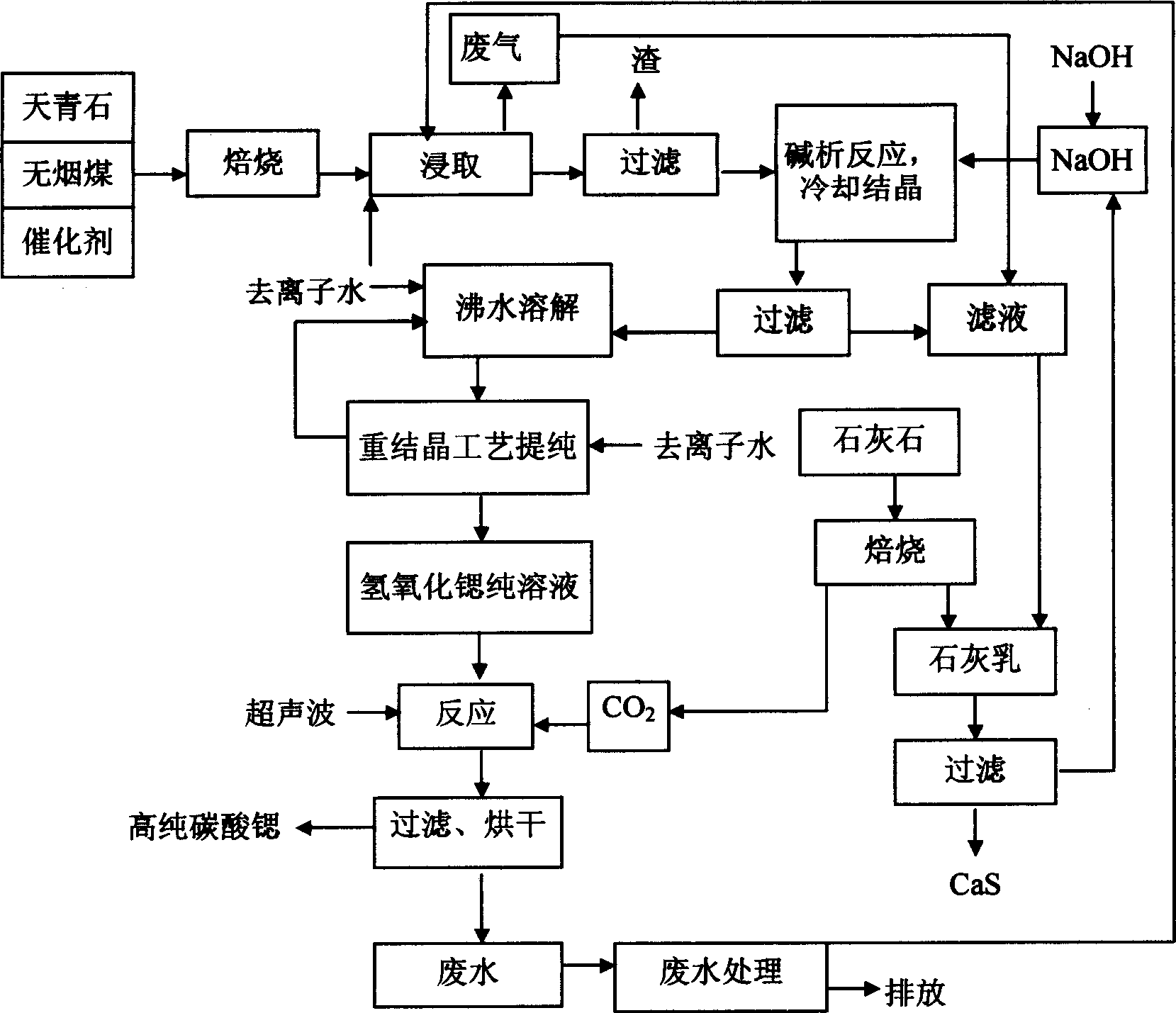

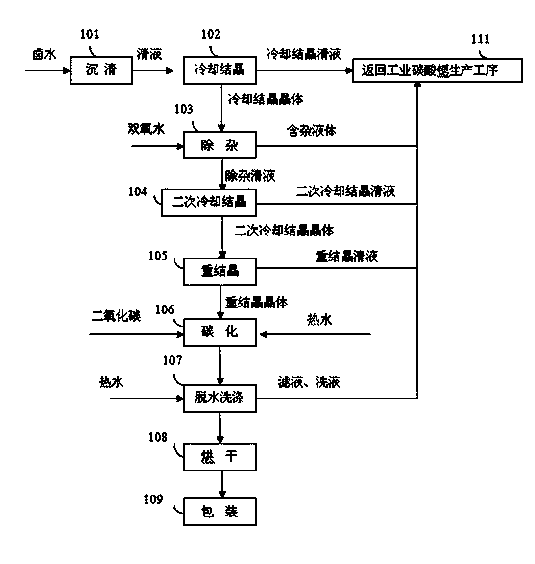

Process for preparing high purity strontium carbonate

InactiveCN1699178AImprove recovery rateImprove one-time yieldCalcium/strontium/barium carbonatesStrontium sulfideStrontium carbonate

Disclosed is a process for preparing high purity strontium carbonate, which comprises mixing celestite, anthracite coal, calcium chloride as catalyst, high-temperature roasting for deacidizing strontium sulfide, filtering strontium monosulfide through heat leaching, charging sodium-hydroxide and strontium monosulfide to result in alkali analysis reaction, producing strontium hydroxide crystalline body, the purifying strontium hydroxide through recrystallization process, finally reacting pure strontium hydroxide solution with let-in carbon dioxide at the presence of ultrasonic wave action, thus producing high purity strontium carbonate powder, and reacting lime cream with strontium monosulfide to obtain sodium-hydroxide and strontium monosulfide precipitate, wherein sodium-hydroxide can be circulated in the alkali analysis reaction.

Owner:CHONGQING UNIV

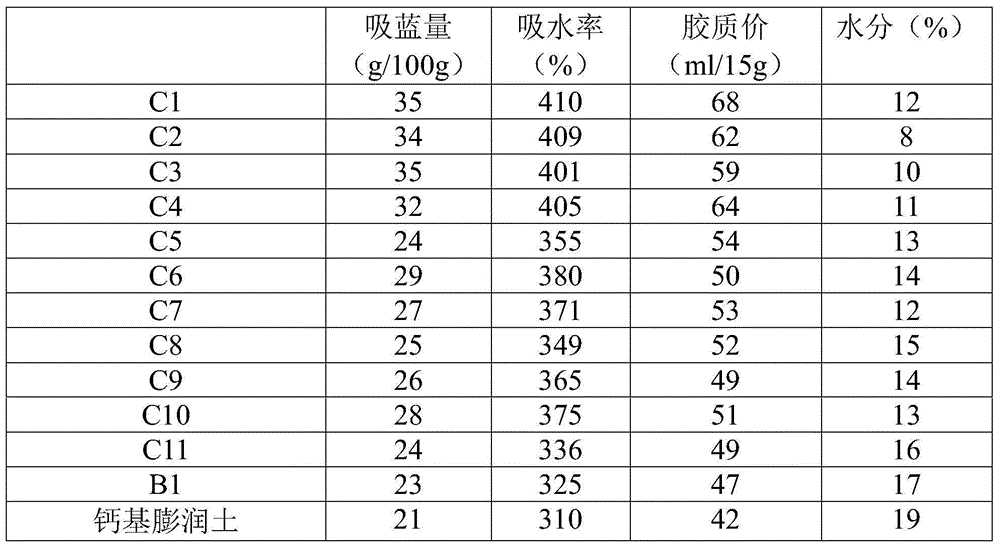

Sodium bentonite and double sodium modifying method for sodium bentonite

ActiveCN104986778ARaise the degree of sodiumImprove sodium effectSilicon compoundsSodium acetateSodium phosphates

The invention discloses sodium bentonite and a double sodium modifying method for the sodium bentonite. The method comprises the steps that 1, calcium bentonite and a sodium salt are mixed and modified in a sodium mode to manufacture first-class sodium bentonite; 2, the first-class sodium bentonite and an addition agent are mixed and inoculated to manufacture second-class sodium bentonite, wherein the addition agent comprises microcrystalline cellulose, silica gel modified by a sodium salt, expanded vermiculite, boric acid, a thickening agent and polyacrylamide; the sodium salt and the sodium salt in the silica gel modified by the sodium salt are independently selected from one or more of sodium carbonate, sodium silicate, sodium fluoride, sodium oxalate, sodium acetate, sodium phosphate, sodium polyacrylate, sodium hydroxide, sodium chloride, sodium thiosulfate and sodium cellulose; the thickening agent is selected from magnesium oxide and / or magnesium hydrate. According to the method, the calcium bentonite is fully modified into the sodium bentonite in the sodium mode, moreover, the sodium bentonite has excellent blue absorption power, a high water absorption rate and large colloid indexes, the steps are simple, and the raw materials are easy to obtain.

Owner:芜湖恒杰膨润土科技有限公司

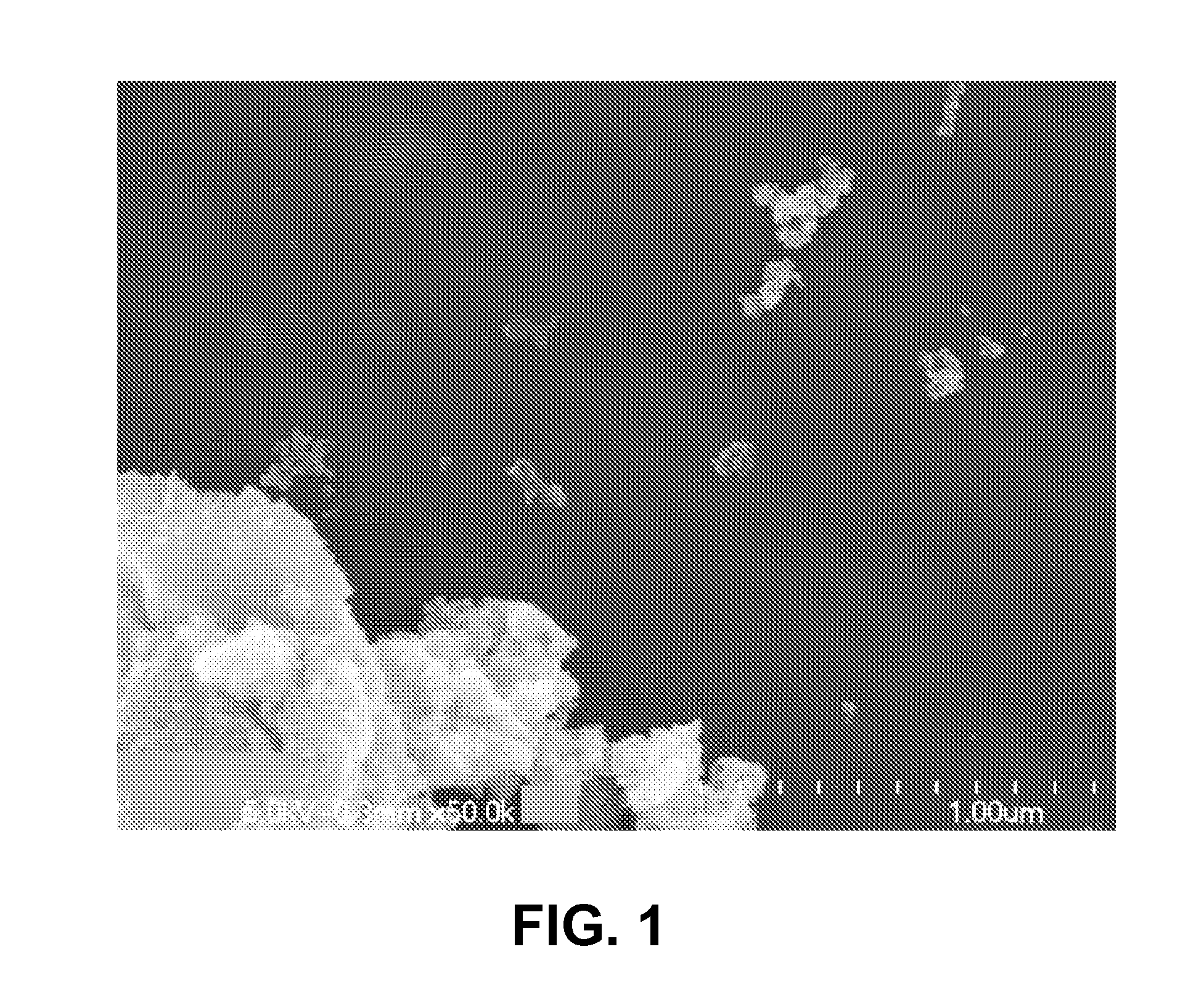

Color stable phosphors for LED lamps and methods for preparing them

ActiveUS8593062B2Discharge tube luminescnet screensElectroluminescent light sourcesZinc hydroxideMagnesium phosphate

An LED lamp includes a light source configured to emit radiation with a peak intensity at a wavelength between about 250 nm and about 550 nm; and a phosphor composition configured to be radiationally coupled to the light source. The phosphor composition includes particles of a phosphor of formula I, said particles having a coating composition disposed on surfaces thereof;((Sr1-zMz)1-(x+w)AwCex)3(Al1-ySiy)O4+y+3(x−w)F1-y-3(x−w) Iwherein the coating composition comprises a material selected from aluminum oxide, magnesium oxide, calcium oxide, barium oxide, strontium oxide, zinc oxide, aluminum hydroxide, magnesium hydroxide, calcium hydroxide, barium hydroxide, strontium hydroxide, zinc hydroxide, aluminum phosphate, magnesium phosphate, calcium phosphate, barium phosphate, strontium phosphate, and combinations thereof; andA is Li, Na, K, or Rb, or a combination thereof;M is Ca, Ba, Mg, Zn, or a combination thereof; and0<x≦0.10, 0≦y≦0.5, 0≦z≦0.5, 0≦x≦x.

Owner:GE LIGHTING SOLUTIONS LLC

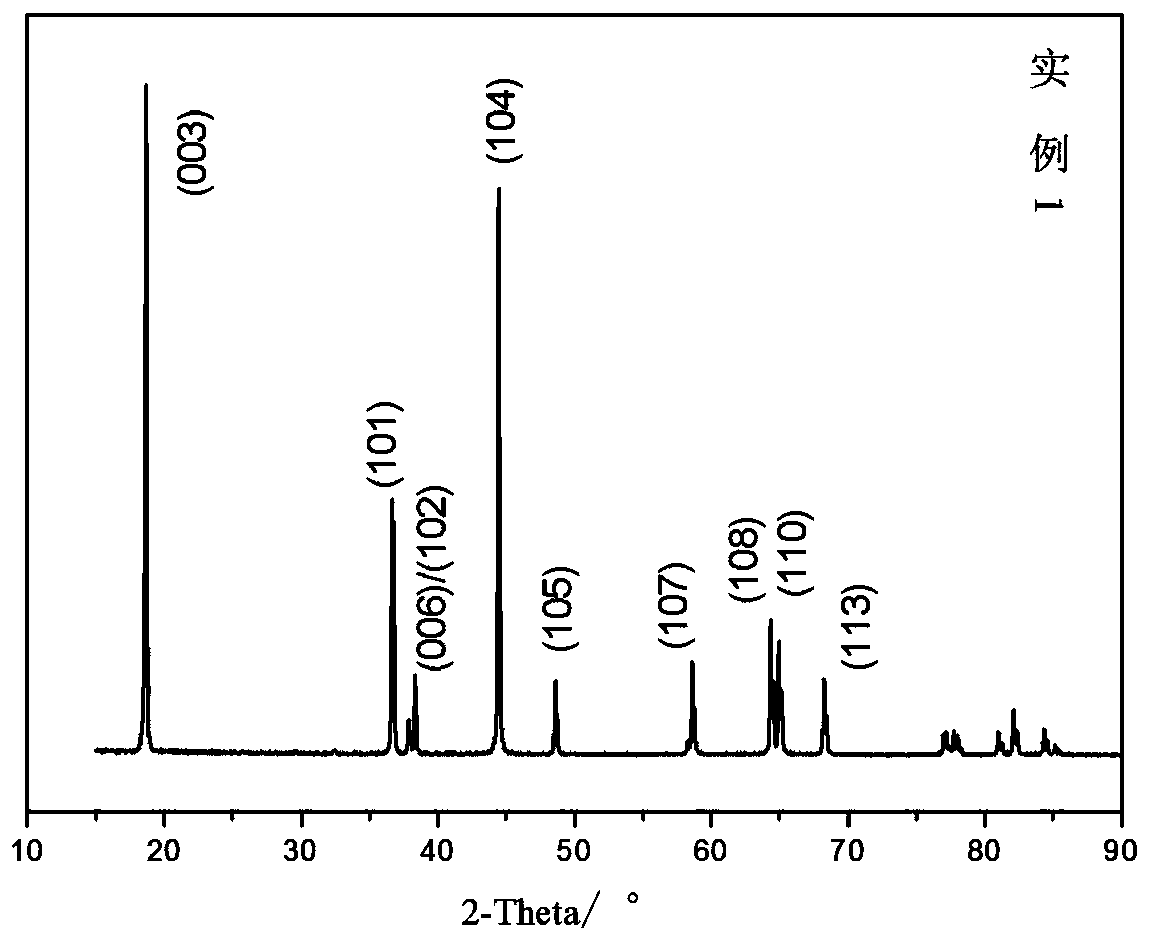

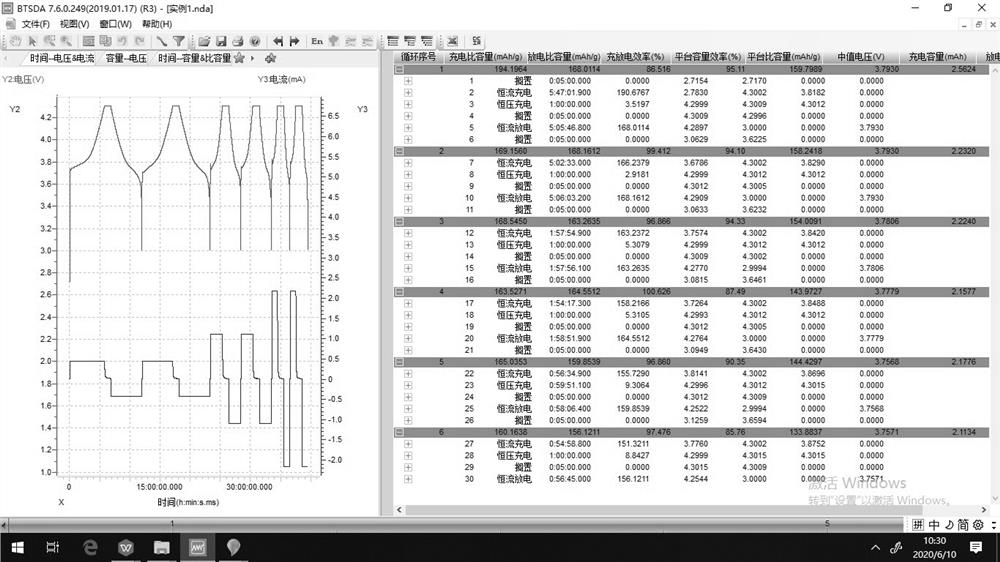

Method for preparing nickel-cobalt lithium manganate monocrystal cathode material by doping strontium

InactiveCN110867580AHigh mechanical strengthIncrease compaction densityPolycrystalline material growthCell electrodesLithium carbonateManganate

The invention discloses a method for preparing a nickel-cobalt lithium manganate monocrystal cathode material by doping strontium, comprising the following steps: uniformly mixing ternary cathode material precursor powders, lithium carbonate powders, and a fluxing agent in proportion to obtain mixed powders; calcining the mixed powder for the first time at a temperature of 910 to 970 degrees centigrade to obtain a primary calcined product; calcining the primary powders at a temperature of 780 to 880 degrees centigrade to obtain a nickel-cobalt lithium manganate cathode material, wherein the ternary cathode material precursor is Ni0.5Co0.2Mn0.3(OH)2, and the fluxing agent is strontium hydroxide. The cathode material provided by the present invention effectively improves the electrochemicalperformance of the ternary material under a high voltage by improving the structural integrity and surface properties of the cathode material, and exhibits high specific capacity and good cycle performance, can effectively improve high-temperature cycling and gas production of polycrystalline materials.

Owner:四川新锂想能源科技有限责任公司

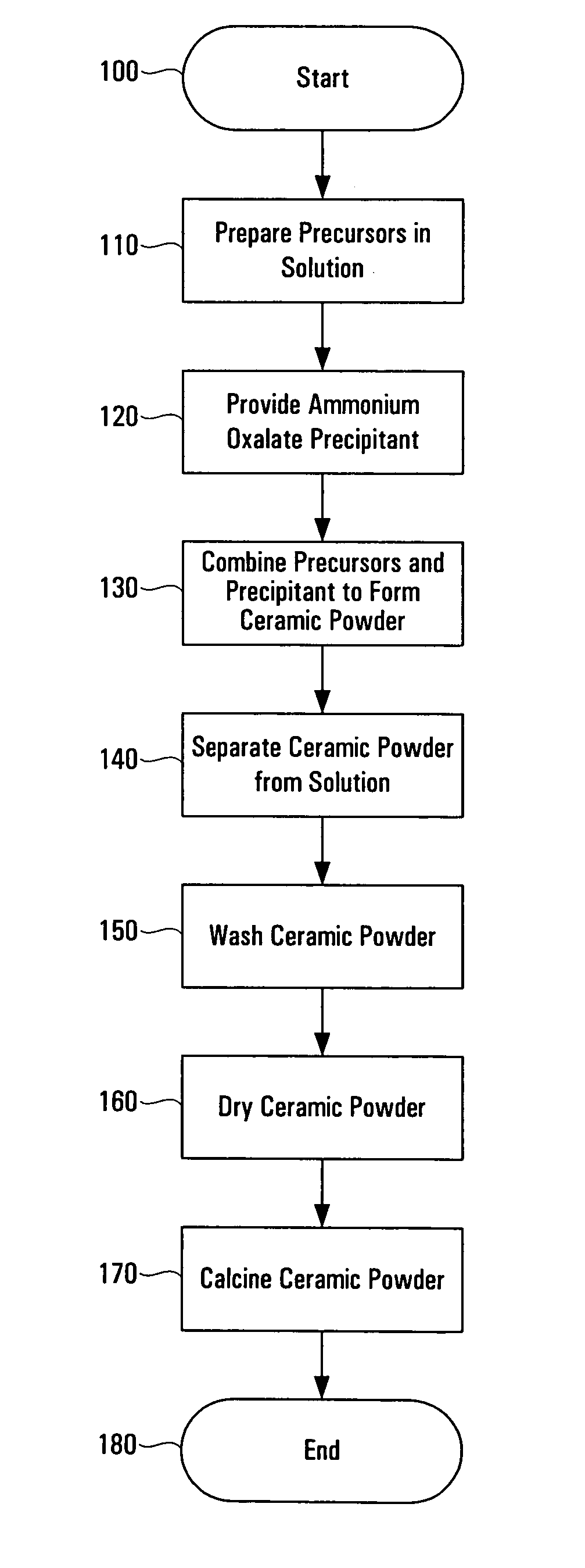

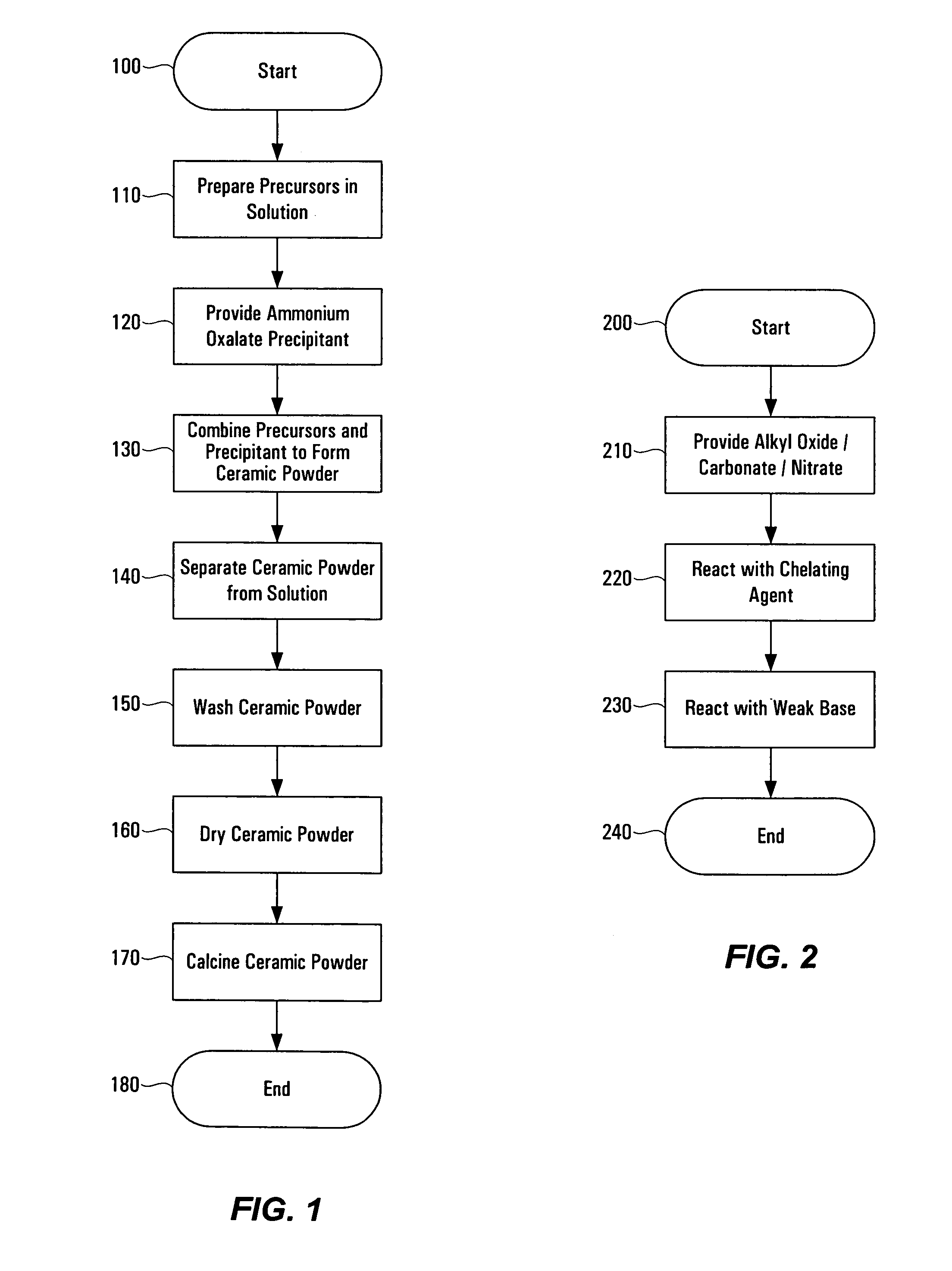

Method of preparing ceramic powders using ammonium oxalate

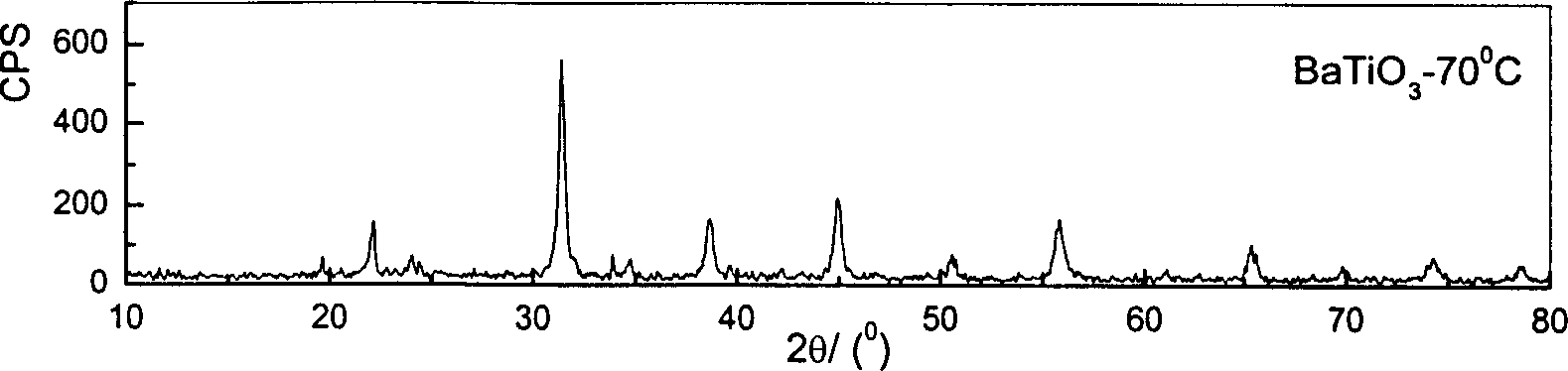

ActiveUS7993611B2Alkaline earth titanatesOxide/hydroxide preparationBarium titanateStrontium hydroxide octahydrate

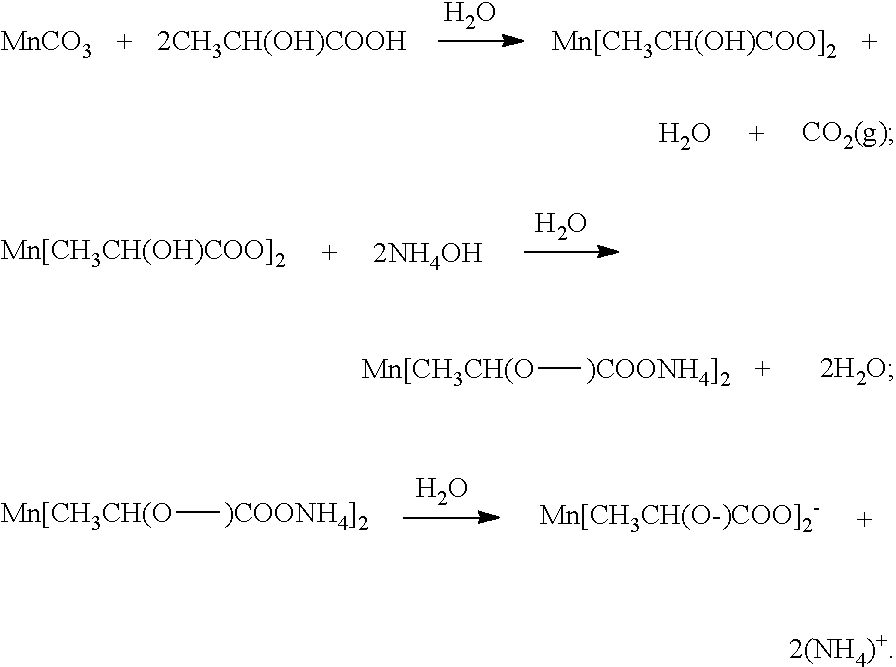

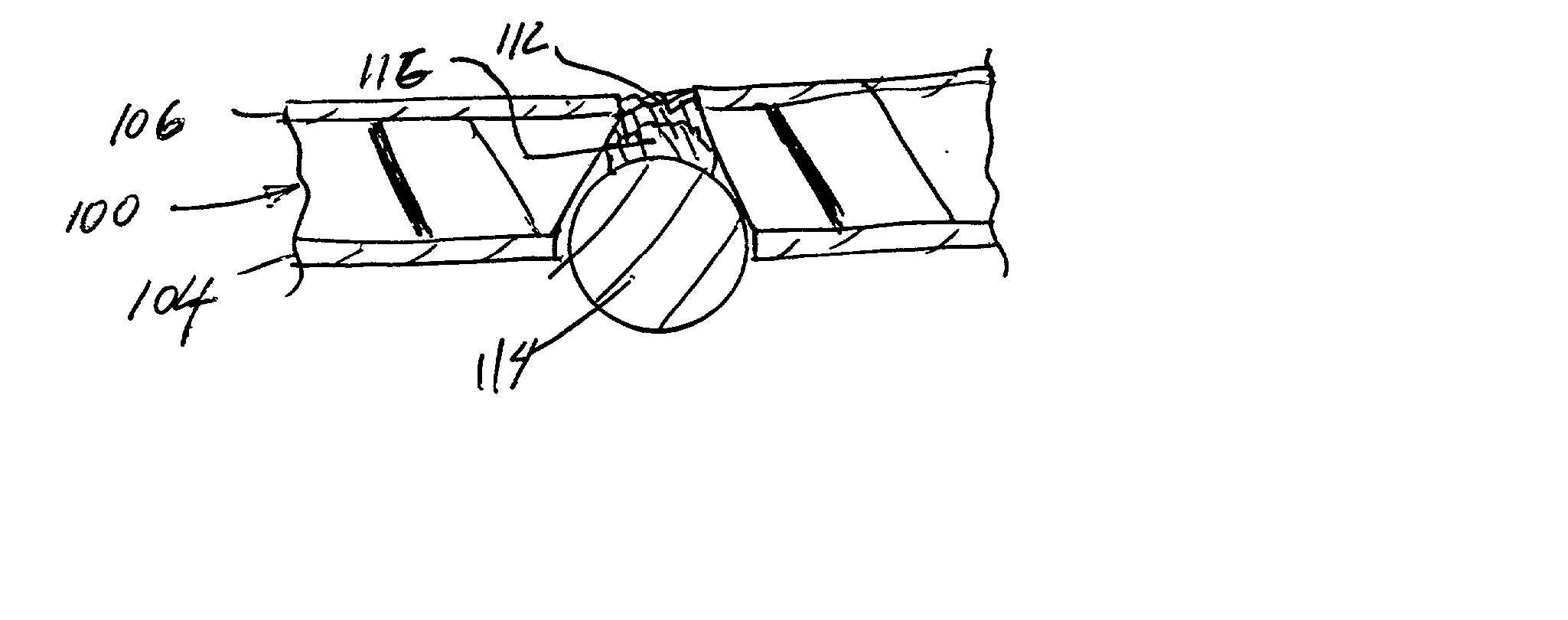

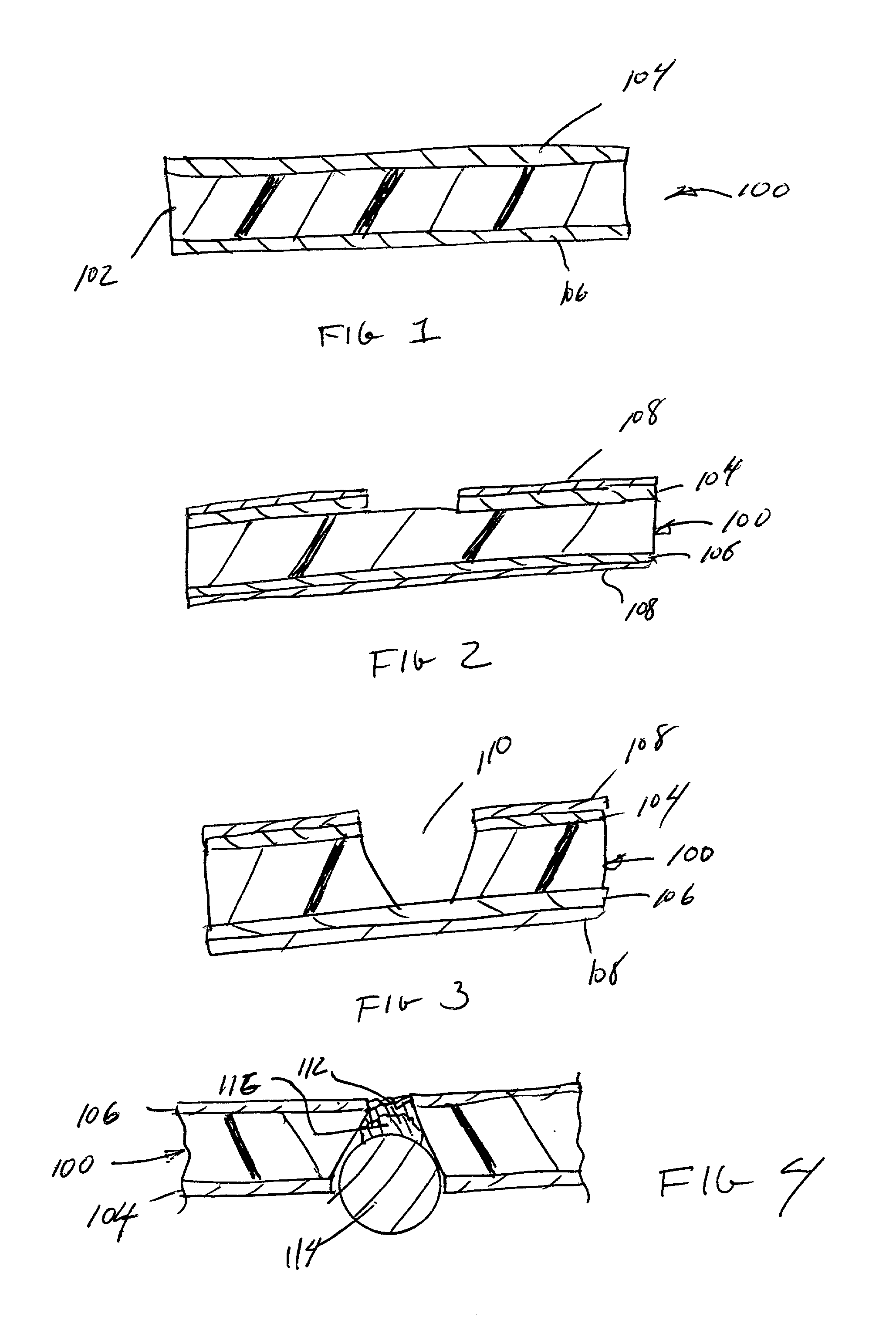

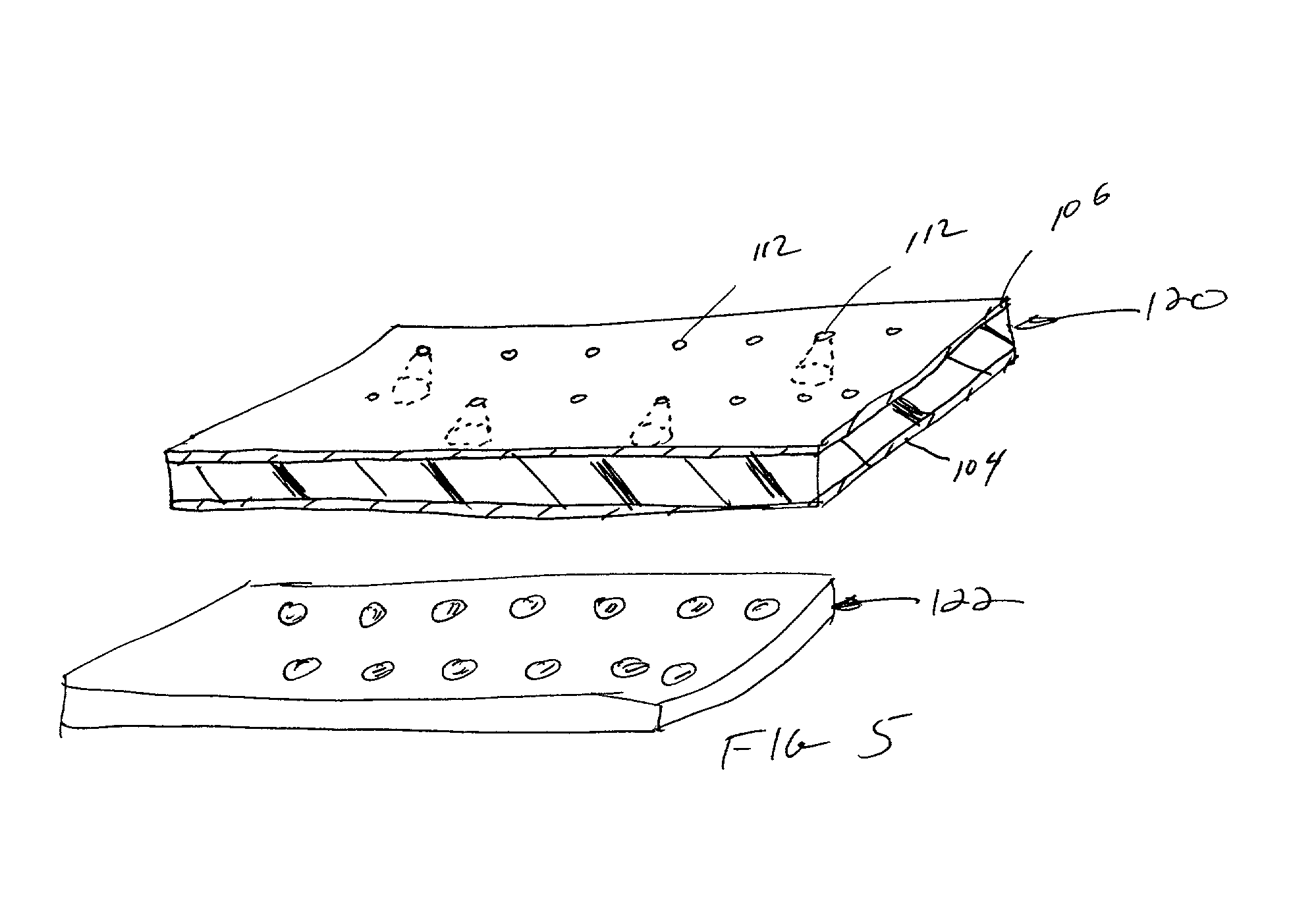

Wet-chemical methods involving the use of water-soluble hydrolytically stable metal-ion chelate precursors and an ammonium oxalate precipitant can be used in a coprecipitation procedure for the preparation of ceramic powders. Both the precursor solution and the ammonium oxalate precipitant solution are at neutral or near-neutral pH. A composition-modified barium titanate is one of the ceramic powders that can be produced. Certain metal-ion chelates can be prepared from 2-hydroxypropanoic acid and ammonium hydroxide.

Owner:EESTOR

Process for producing superfine barium carbonate and strontium carbonate

InactiveCN1504411ALow costIncrease productivityCalcium/strontium/barium carbonatesStrontium carbonateStrontium sulfide

A novel process for preparing ultra-fine barium carbonate and strontium carbonate, wherein barium sulphide solution or barium hydrate solution are used as raw material to be carbonized by carbon dioxide in helical channel type revolving bed, obtaining precipitate, then ultramicro fine barium carbonate is obtained through washing, dewatering and drying, and strontium sulfide solution or strontium hydroxide solution are used as raw material to be carbonized by carbon dioxide in helical channel type revolving bed, obtaining precipitate, then ultramicro fine strontium carbonate is obtained through washing, dewatering and drying.

Owner:HENGYANG JINYUAN NANO TECH

Wet etch process and composition for forming openings in a polymer substrate

InactiveUS20020084248A1Easy to controlPoint becomes highDecorative surface effectsPrinted circuit aspectsLithium hydroxidePotassium hydroxide

A composition and method for etching a polymer substrate in particular for forming micro vias includes a dihydric alcohol having from two to five carbon atoms, a hydroxide compound selected from the group of lithium hydroxide, sodium hydroxide, potassium hydroxide, calcium hydroxide, barium hydroxide, strontium hydroxide and mixtures thereof, and water. In one embodiment the composition includes glycol, potassium hydroxide and deionized water, wherein the glycol and the water are present in a ratio of from about 0.5:1 to about 8.5:1 and the potassium hydroxide is present in an amount of from about 40 to about 80 grams per 100 ml of glycol and water solution.

Owner:TESSERA INC

Environmentally-friendly energy-saving combustion improver for coal

The invention relates to an environmentally-friendly energy-saving combustion improver for coal, comprising the following components in parts by weight: 1-50 parts of sodium chloride, 20-60 parts of sodium hydroxide, 20-60 parts of sodium carbonate, 20-50 parts of potassium carbonate, 20-40 parts of potassium nitrate, 15-60 parts of manganese dioxide, 25-75 parts of barium hydroxide, 30-80 parts of nickel oxide, 20-60 parts of magnesium sulphate, 50-100 parts of magnesium nitrate, 30-80 parts of strontium hydroxide and 30-50 parts of calcium carbonate. Multiple tests show that: combustion time of coal is prolonged, the coal can be completely combusted, and ignition temperature is reduced, thus the coal is difficult to coke, coked substances in a container are eliminated, and dust and smoke are eliminated and desulphurization is carried out, thus the coal is fully burned, the thermal efficiency is improved, non-metallic elements such as sulphur in the coal burning are effectively deposited into the coal, emission of harmful gas in acid gases such as nitric oxide and sulphur dioxide and the dust is reduced, and environmental pollution is reduced. Thus the aims of protecting the environment and saving energy sources are achieved. The environmentally-friendly energy-saving combustion improver is convenient, safe and reliable to use and has obvious economic benefit and social benefit.

Owner:张云佳 +1

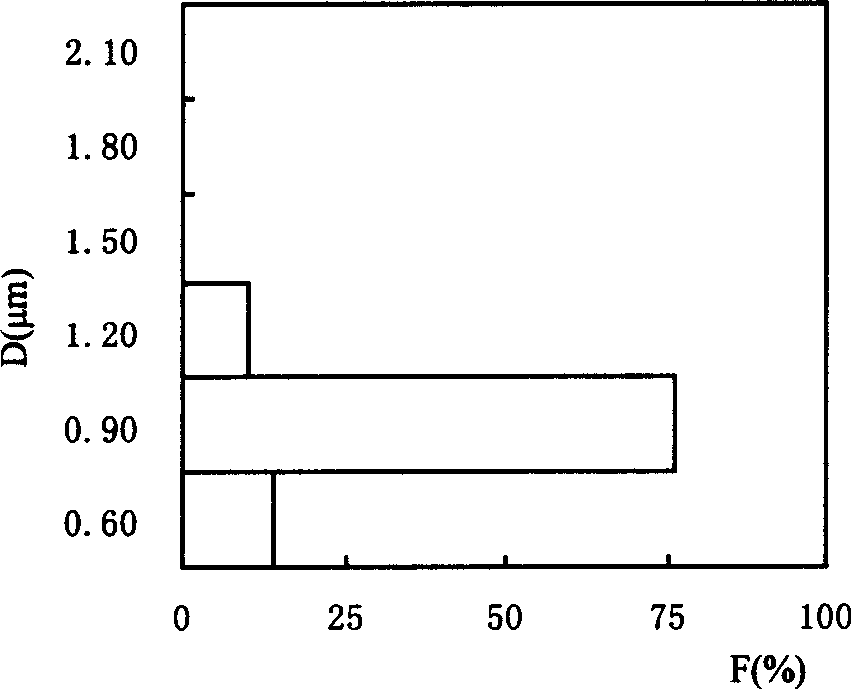

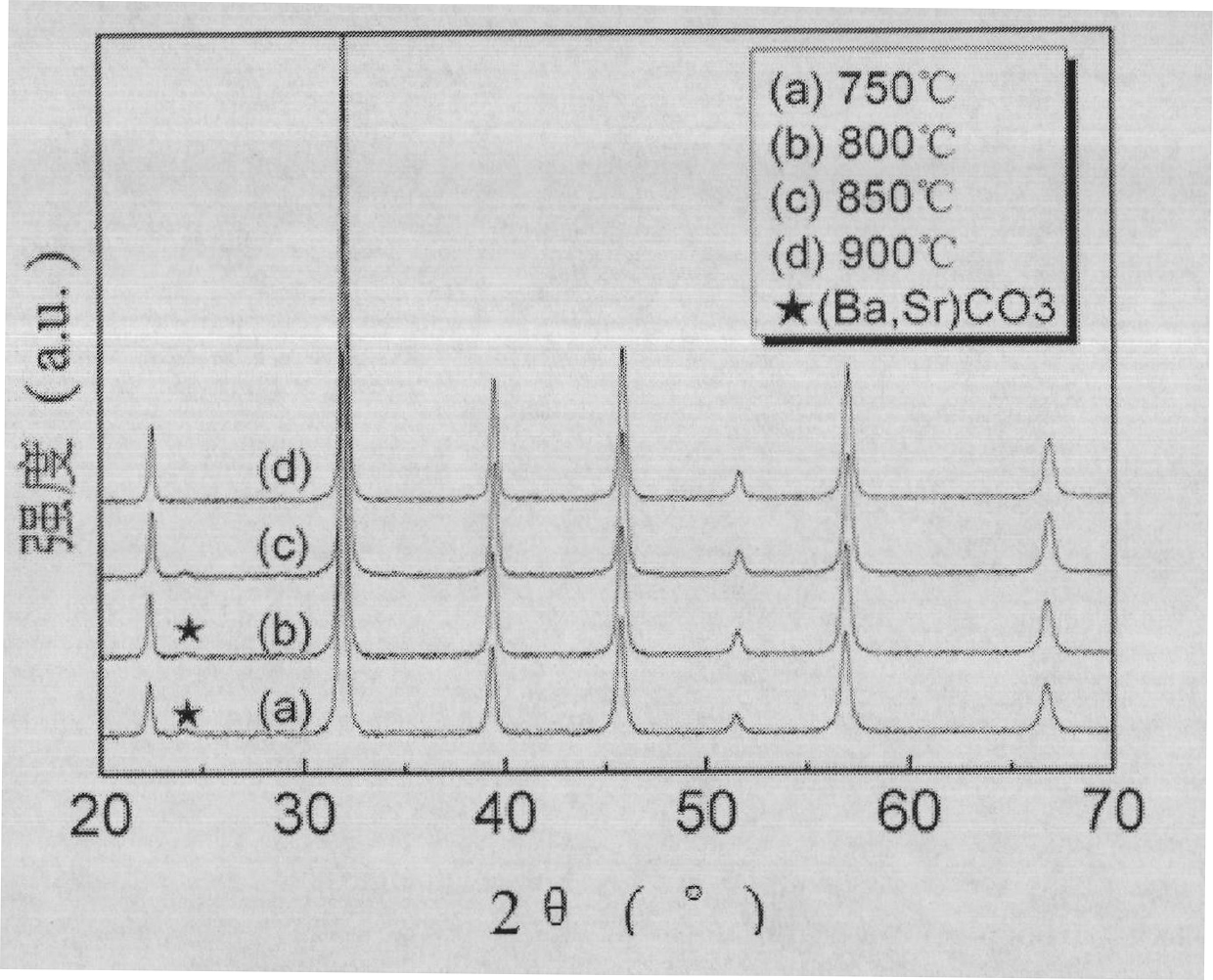

Preparation method for barium strontium titanate (BST) thick film material

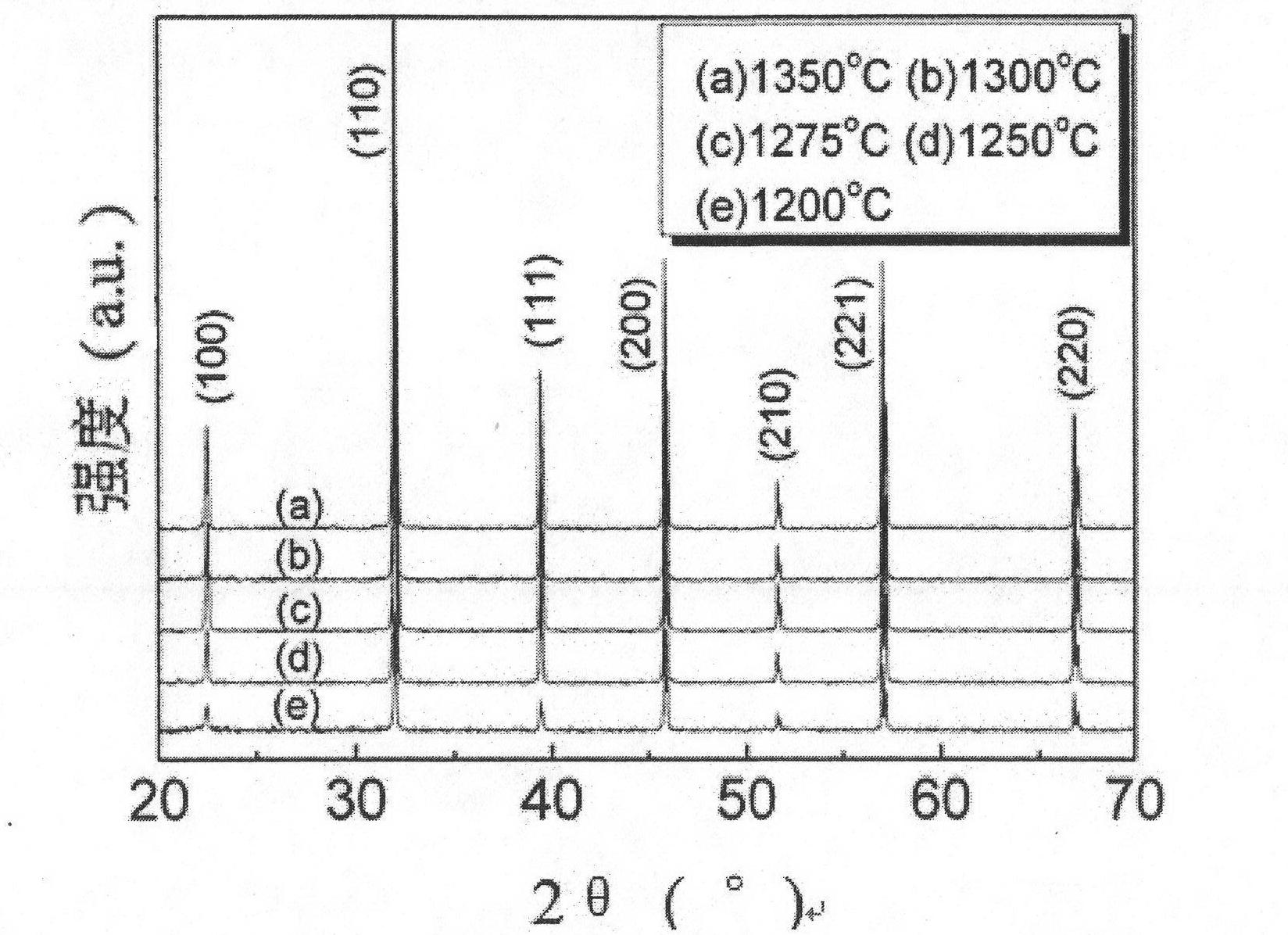

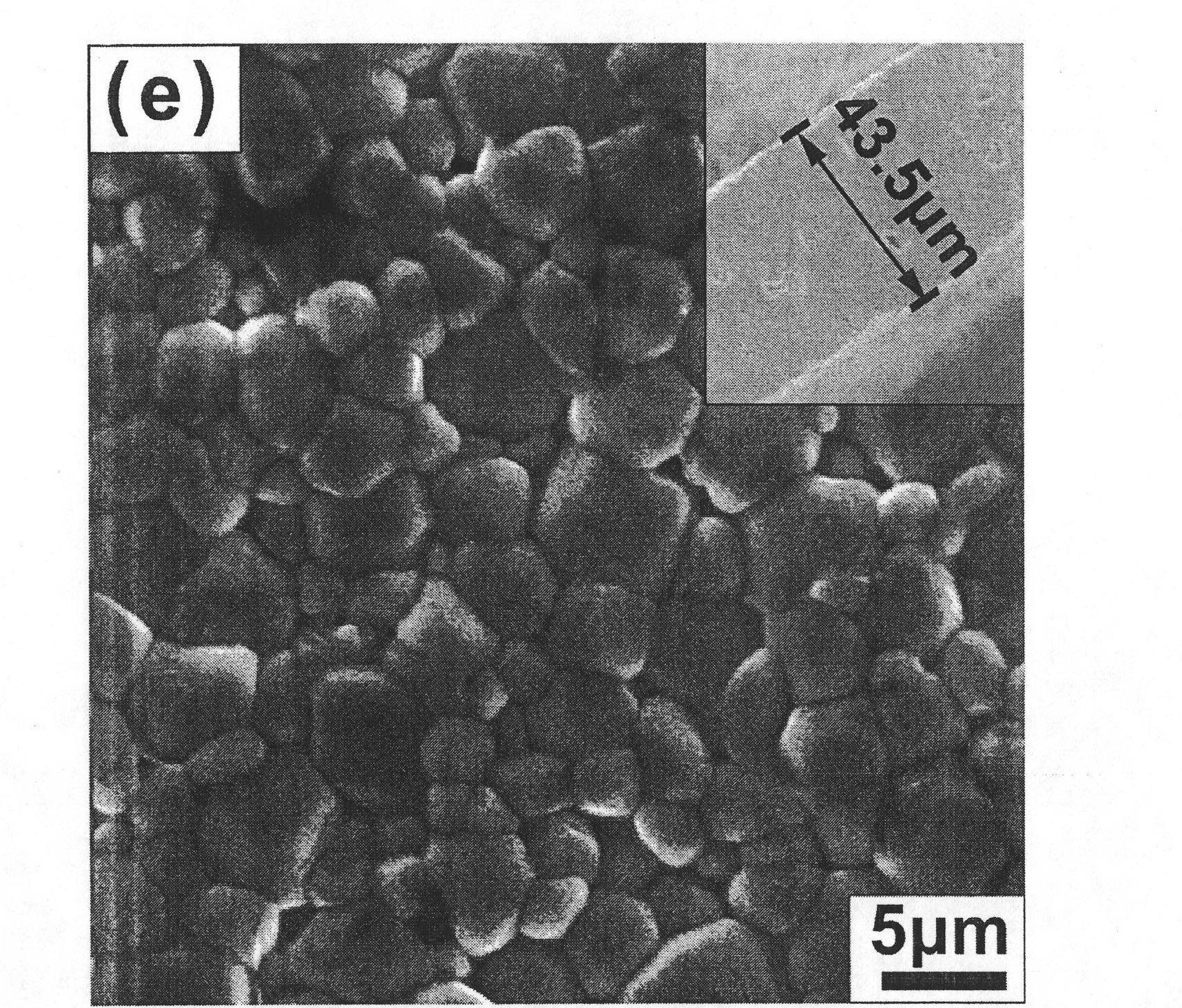

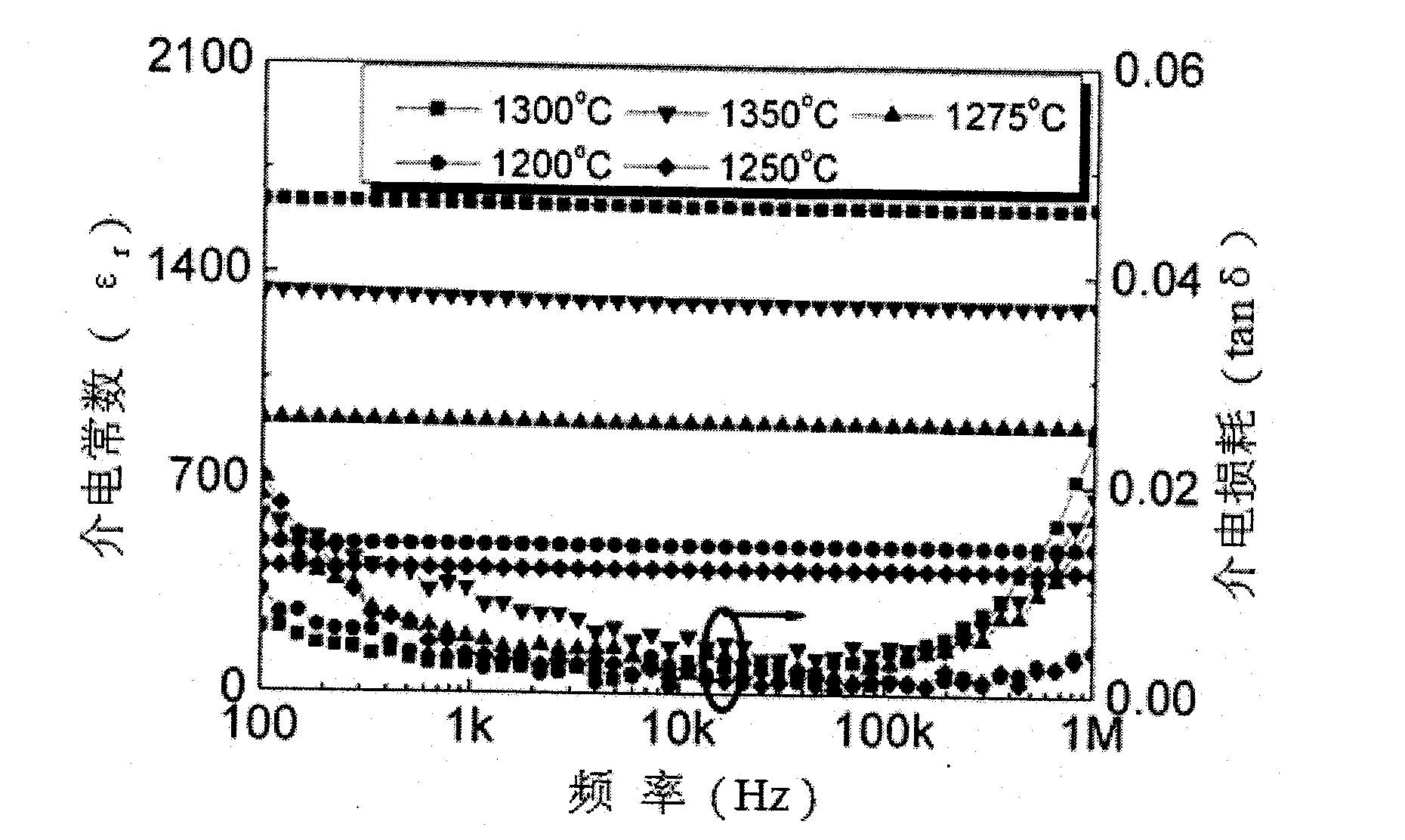

InactiveCN101805179ALow dielectric lossImprove electrical performanceBarium strontium titanateStrontium hydroxide octahydrate

The invention discloses a preparation method for a barium strontium titanate thick (BST) film material, which is used for solving the technical problem that the barium strontium titanate (BST) thick film material with a substrate prepared by a conventional preparation method has poor electrical property. The technical scheme comprises the following steps: preparing a BST colloid from barium acetate, strontium hydroxide, tetrabutyl titanate, glacial acetic acid, ethylene glycol monomethyl ether and acetylacetone; and tape-casting the BST colloid and then sintering the colloid at the high temperature so as to obtain the barium strontium titanate thick film material. Because the barium strontium titanate thick film material with substrate is prepared by the tape-casting method, the dielectric loss of the barium strontium titanate thick film material is reduced from about 0.02 to below 0.02 so as to improve the electrical property of the barium strontium titanate thick film material; and the barium strontium titanate thick film material has high compactness and uniform granularity.

Owner:海安远东新材料有限公司 +1

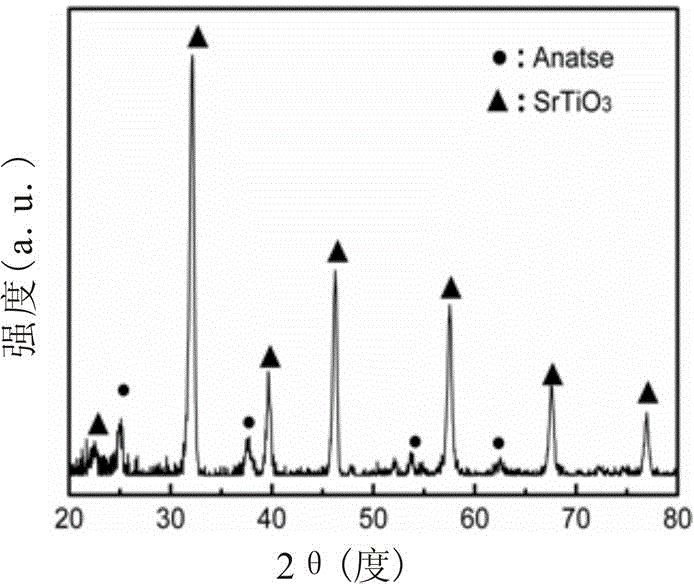

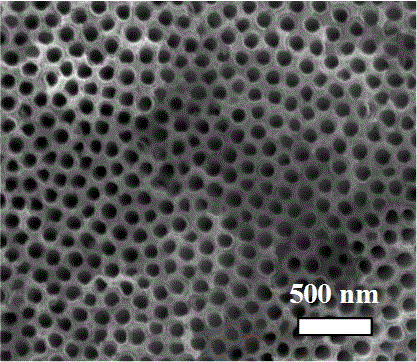

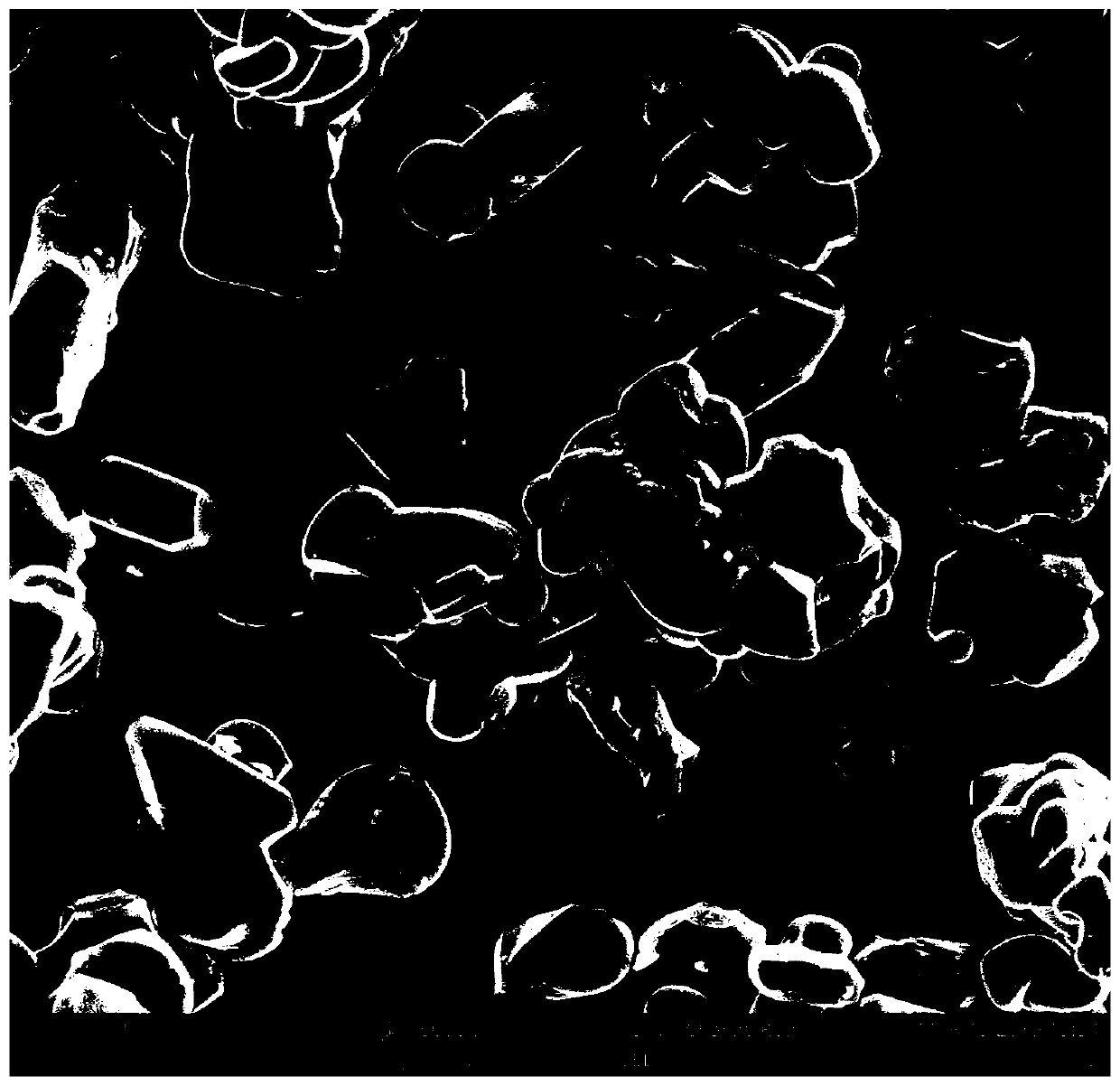

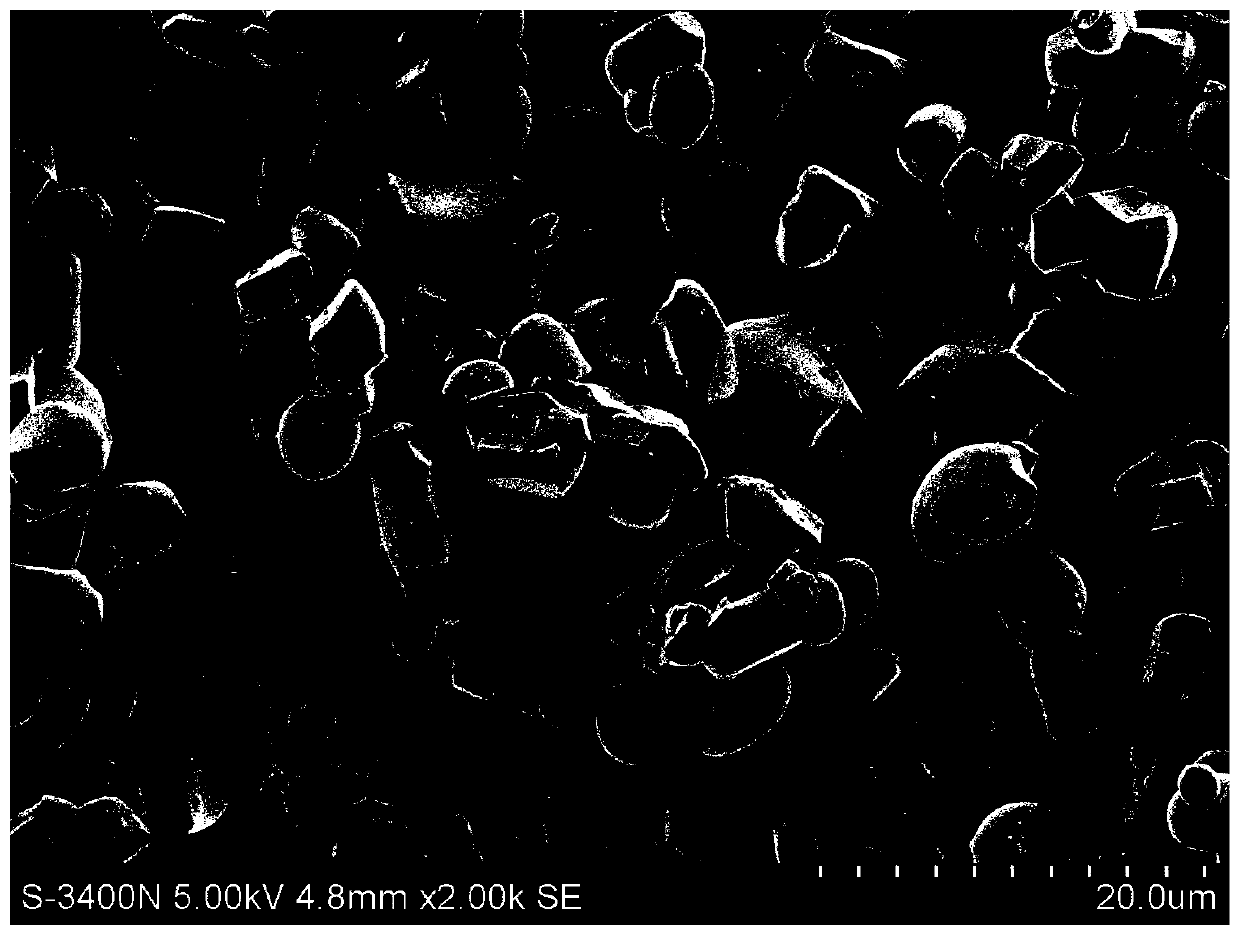

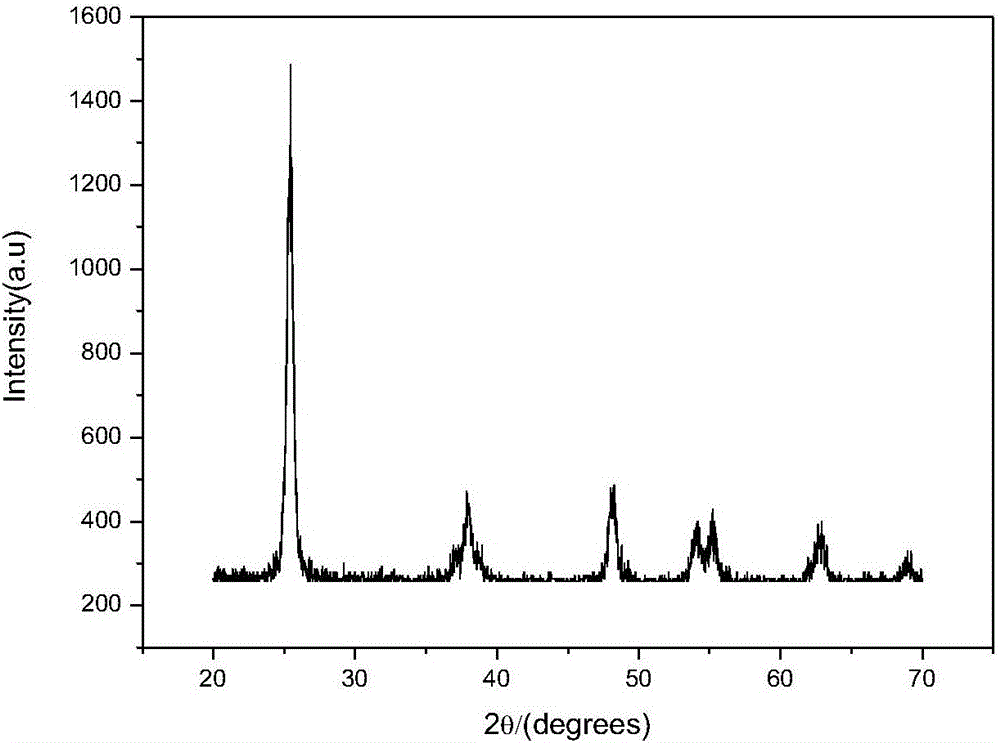

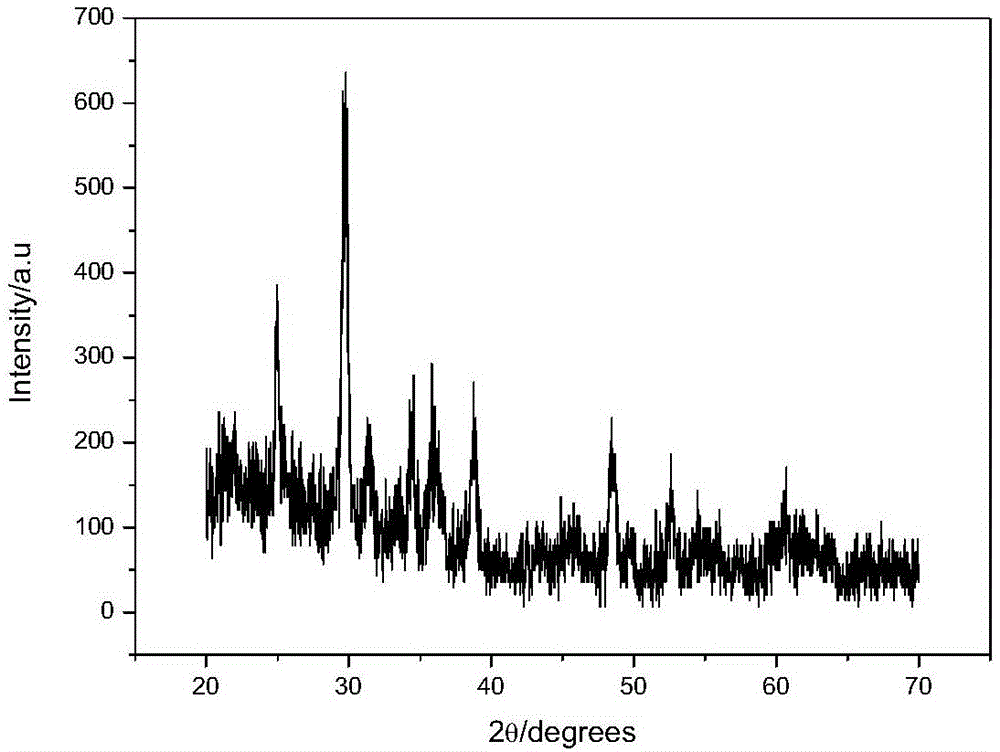

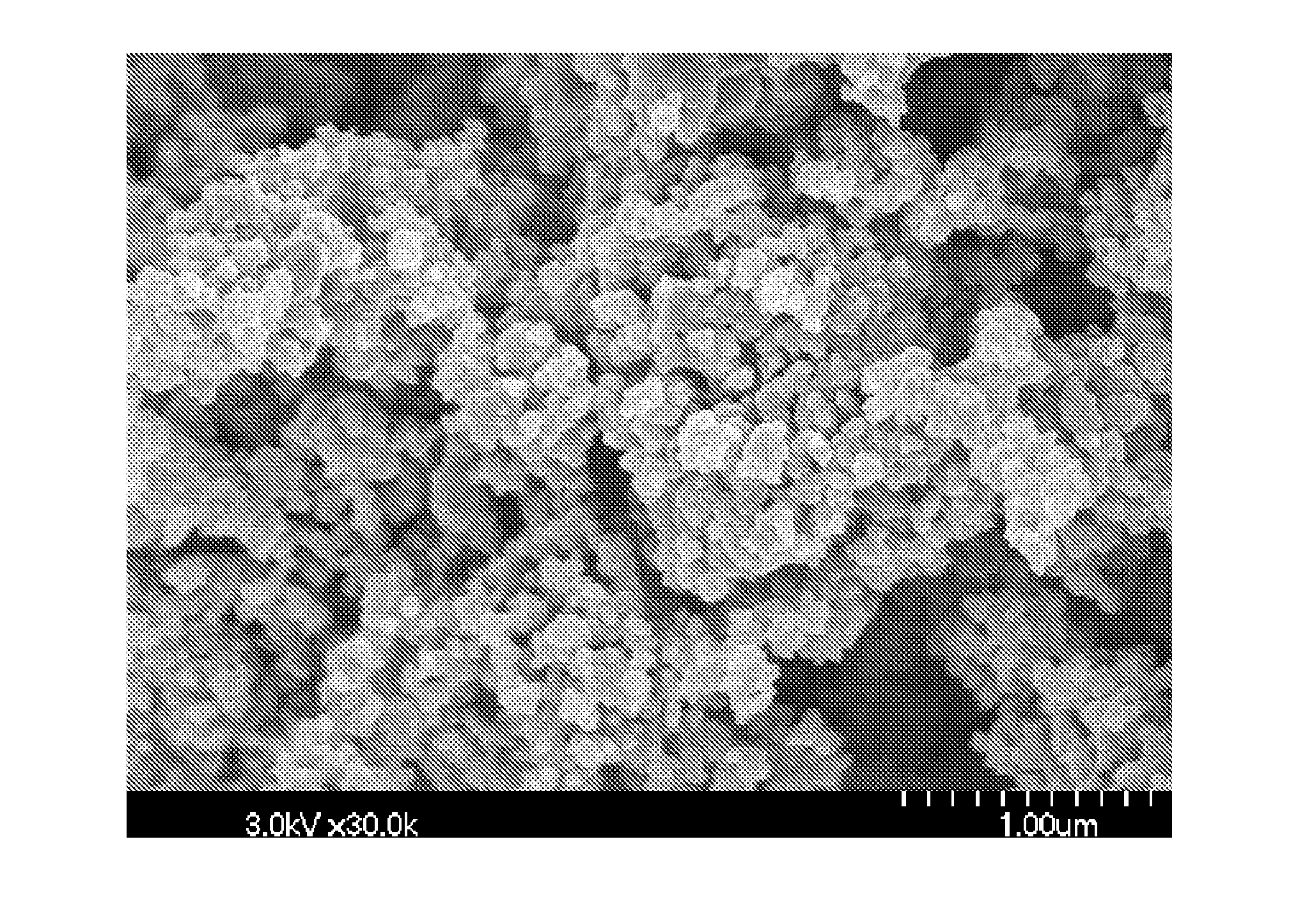

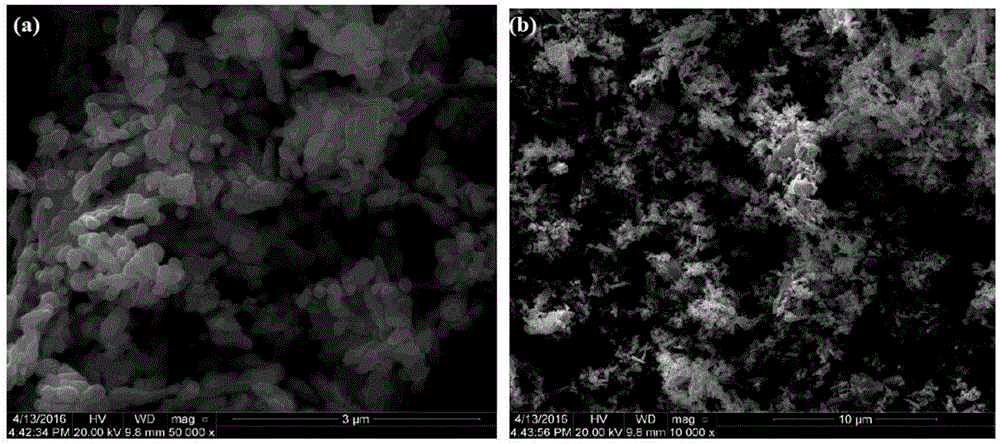

Synthesis method of rodlike Mg<2+>-doped SrTiO3

ActiveCN106745205AExcellent dielectric propertiesEasy to prepareAlkaline earth titanatesStrontium titanateSynthesis methods

The invention discloses a synthesis method of rodlike Mg<2+>-doped SrTiO3. Firstly, a precursor Na2Ti3O7 is prepared from titanium dioxide and sodium hydroxide as raw materials under a hydrothermal condition of 200 DEG C; and secondly, rodlike Mg<2+>-doped SrTiO3 powder is prepared from Na2Ti3O7, strontium hydroxide and magnesium nitrate as raw materials. A product does not contain other impurities and is a pure substance through FT-IR analysis. The internal structure and surface of the final product SMT are discussed separately through XRD, ICP, SEM and CA. The method is mild in reaction conditions, friendly to environment and high in yield; and meanwhile, the form, crystallinity and size of strontium titanate can be effectively controlled. The method is simple in step, convenient to operate and high in practicability.

Owner:LULIANG UNIV

Method for preparing strontium carbonate salt from metal strontium slag

ActiveCN101100308ASimple production processReduce manufacturing costCalcium/strontium/barium carbonatesAnthracene dyesStrontium carbonateSlag

This invention relates to production of strontium carbonate salt by using strontium slag as raw material. The procedures are: (1), crashing the slag into powder; (2), putting said powder into boiling water and agitating thoroughly, to produce soluble strontium hydroxide during reaction; (3), obtaining the solution after centrifuging or filtering; (4), adding carbonate or bicarbonate, together with agitation to make through reaction; (5), obtaining precipitate of strontium carbonate by filtering or centrifuging, (6), drying said precipitate to obtain the inventive product. In this invention, due to the use of boiling water as a substitute for inorganic acid, the production cost is reduced and the production process is simplified.

Owner:山东云信铝业科技有限公司

Process for producing polysiloxanes and use of the same

Owner:ZETTA RES & DEV LLC RPO SERIES

Preparation method for high-purity strontium carbonate

InactiveCN103787397AAvoid problemsImprove uniformityCalcium/strontium/barium carbonatesDigestionImpurity

The invention discloses a preparation method for high-purity strontium carbonate. The preparation method comprises the steps of adding a bicarbonate solution into a solution in which strontium hydroxide and a surfactant are dissolved through a multi-region material feeding type reaction kettle, performing stirring reaction for certain time, centrifugating products obtained in the reaction, leaching solids with a detergent, and roasting the solids by adopting an on-line temperature gradient control dynamic roasting technology to obtain the high-purity strontium carbonate. According to the preparation method disclosed by the invention, the strontium hydroxide and bicarbonate which do not contain chlorides are used as raw materials, so that the existence of the chlorides in the reaction products is avoided; meanwhile, due to the action of the surfactant which is added before precipitates are produced, a multi-point material feeding reaction mode and the on-line temperature gradient control technology of a roasting furnace, the problem of aggregation of the precipitates can be solved, and the digestion time of the precipitates is fully shortened; crystal residues and impurity residues are prevented in the precipitate crystallization process; the conversion of the products from rod-type structures into spherical crystal structures is realized; the uniformity of the particle sizes of the products is improved.

Owner:MIANYANG YUANDA NEW MATERIALS

Preparation method of high-purity strontium carbonate

InactiveCN103351015AMeet environmental protection requirementsCalcium/strontium/barium carbonatesStrontium carbonateWastewater

The invention provides a method for preparing high-purity strontium carbonate. According to the invention, bittern is adopted as a raw material, and refined strontium hydroxide is prepared; and carbon dioxide is adopted as a synthesis agent, such that high-purity strontium carbonate is prepared. All wastewater produced during a processing process is returned to industrial strontium carbonate production, and no wastewater is discharged outside.

Owner:NANJING JINYAN STRONTIUM IND

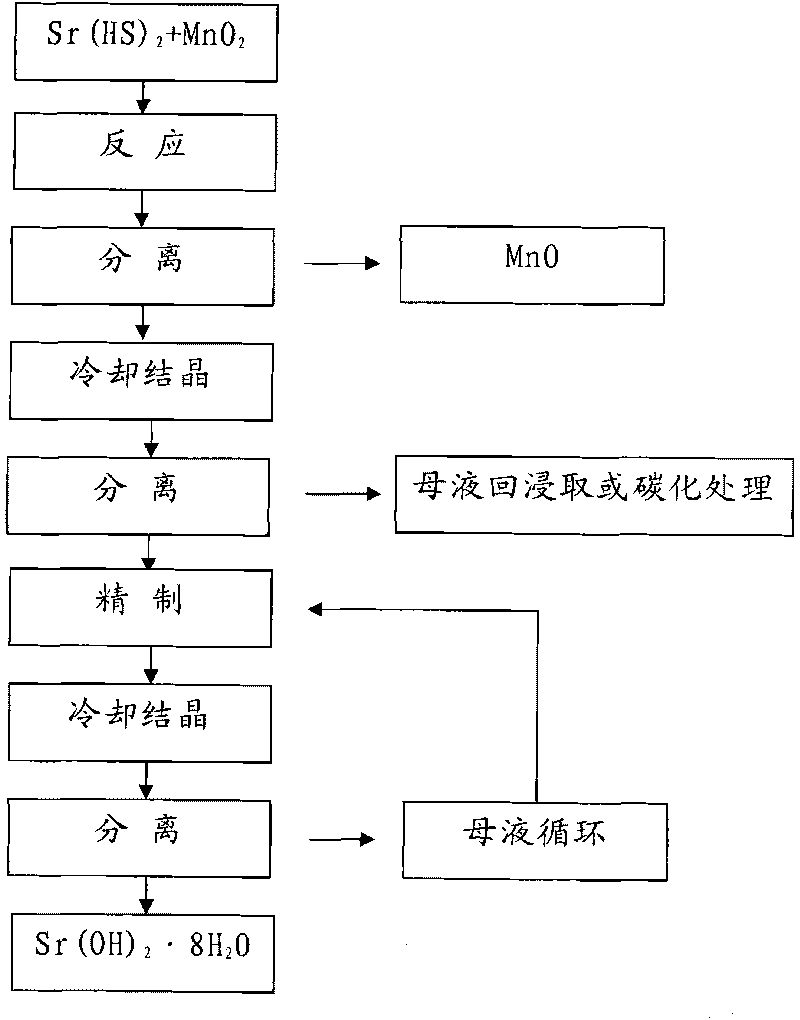

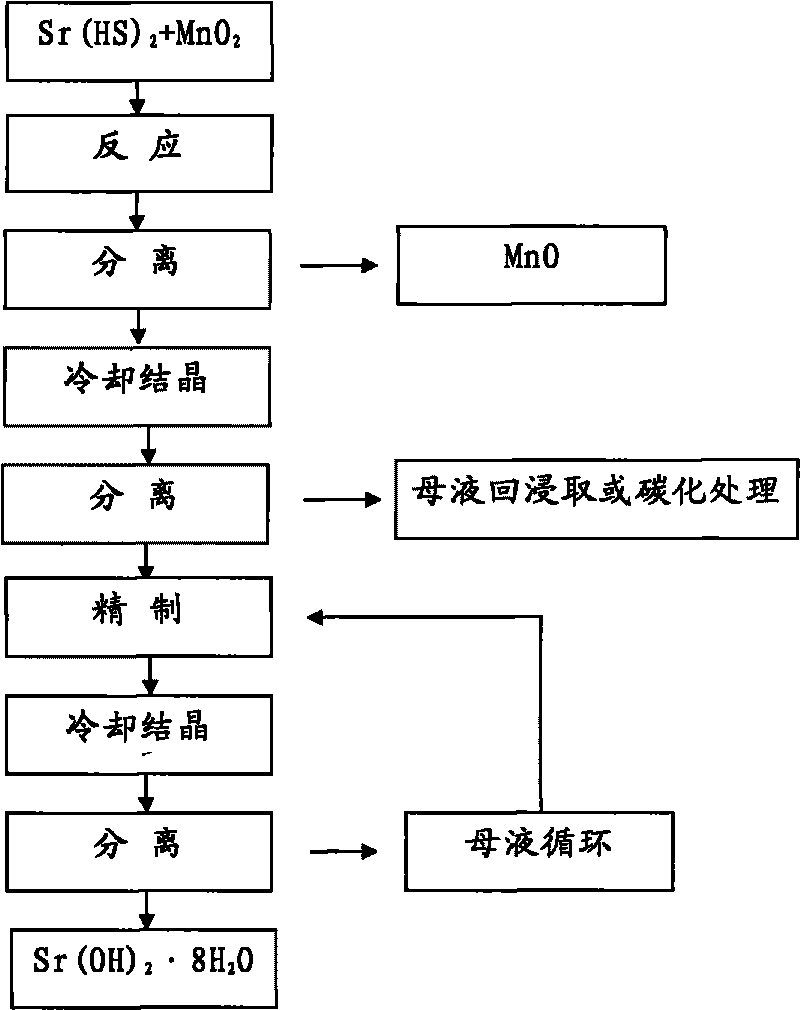

Preparing method of Sr(0H)2.8H2O

InactiveCN101759219AReduce manufacturing costCalcium/strontium/barium oxides/hydroxidesReaction temperatureStrontium hydroxide octahydrate

The present invention relates to a preparing method of strontium hydroxide. In the method, quantitative manganese oxide powdered ore is added into Sr(HS)2 solution of which the concentration is 0.20 to 0.55 mol / L, and the reaction temperature is maintained within 60 DEG C to 85 DEG C ; the mixture is stirred closely for 1.5 to 3 hours to be separated in a solid-liquid way; filtered liquid is cooled closely to 25 DEG C to 35 DEG C, and is separated in the solid-liquid way to obtain crude Sr(0H)2.8H2O; the obtained solid is dissolved by de-ionized water according to concentration of 0.5 to 0.8 mol / L [Sr2+]; 27.5% of H2O2 is added according to the proportion of 2 to 5mol / L to be heated and boiled for 15 to 30 minutes, and the solution is filtered and separated; the obtained filtered liquid is closely cooled and crystallized to 35 DEG C to 45 DEG C, and is separated in a centrifugal way; and solid is dried to obtain the final product of Sr(0H)2.8H2O. The Sr(HS)2 solution generated by hydrolyzing SrS is extracted twice, which can obtain strontium hydroxide with low cost.

Owner:GUIZHOU REDSTAR DEVING +1

Production process of lithium hydroxide monohydrate

InactiveCN1214981CShort process routeHigh yieldSulfate/bisulfate preparationLithium oxides/hydroxidesSolubilityStrontium hydroxide octahydrate

In the production process of lithium hydroxide monohydrate, lithium sulfate solution and caustic soda are made to produce metathetic reaction to form mixture solution of sodium sulfate and lithium hydroxide, and sodium sulfate and lithium hydroxide monohydrate are then separated by means of the obvious difference in low temperature solubility. The production process includes the following steps: adding sodium hydroxide into lithium sulfate solution obtained through serial production steps to obtain mixture solution of sodium sulfate and lithium hydroxide; cooling to minus 10 deg.c to 5 deg.c for the crystallization and separation of sodium sulfate; heating to concentrate the separated clear liquid; crystallization and separation to obtain coarse lithium hydroxide monohydrate product; water dissolving coarse lithium hydroxide monohydrate, adding barium hydroxide to form insoluble barium sulfate, filtering, concentrating filtrate, crystallizing to separate wet lithium hydroxide monohydrate; and drying.

Owner:JIANGSU RONGHUI GENERAL LITHIUM IND CO LTD

High temperature stable anatase titanium dioxide

InactiveUS20100266487A1Improve stabilityMaterial nanotechnologyTitanium dioxideTetramethylammonium hydroxideStrontium hydroxide octahydrate

This disclosure relates to a process for making titanium dioxide in an anatase crystalline form which is stable at temperatures above 1000° C., comprising: precipitating a halide salt and a hydrolyzed compound comprising titanium from a reaction mixture comprising a titanium starting material selected from the group consisting of titanium tetrachloride, titanium oxychloride, and mixtures thereof, a base selected from the group consisting of ammonium hydroxide, ammonium carbonate, ammonium bicarbonate, tetramethyl ammonium hydroxide or tetraethyl ammonium hydroxide or mixture thereof, a solvent selected from the group consisting of ethanol, n-propanol, i-propanol, dimethyl acetamide, alcoholic ammonium halide and aqueous ammonium halide and mixtures thereof, a source of aluminum and a source of silicon to form a precipitate; and removing the halide salt from the precipitate to recover a oxide of titanium in a predominantly anatase crystalline form. The disclosure additionally relates to anatase which is stable at temperatures above 1000° C.

Owner:EI DU PONT DE NEMOURS & CO

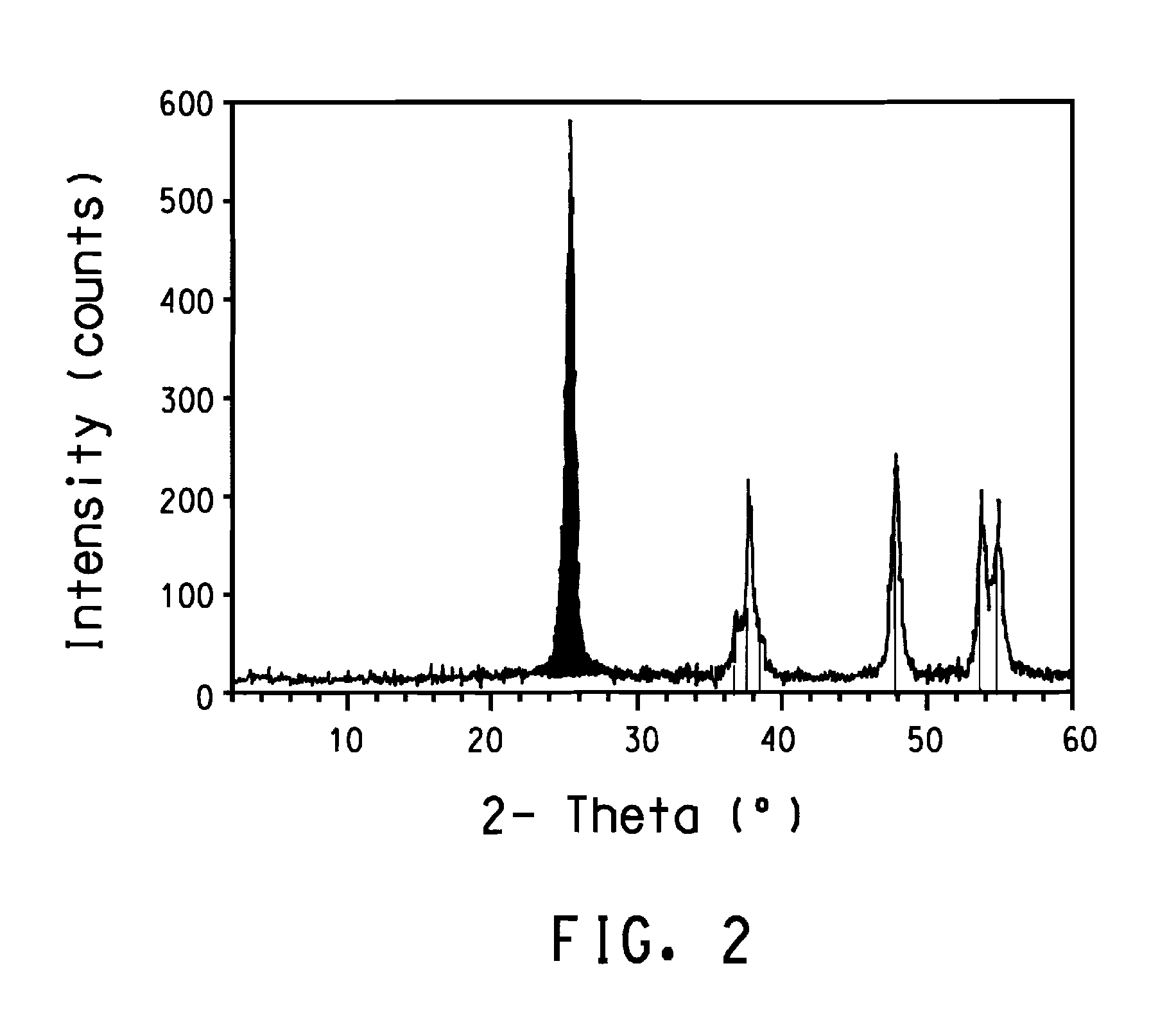

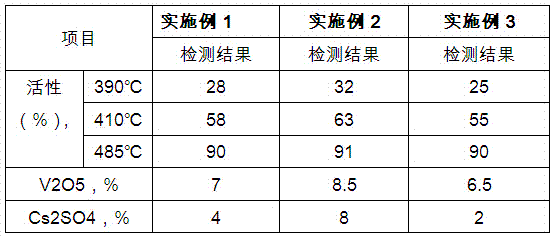

Catalyst containing caesium and vanadium and preparation method thereof

InactiveCN105435772AExtended service lifeQuality improvementSulfur compoundsMetal/metal-oxides/metal-hydroxide catalystsSulfite saltPotassium hydroxide

The invention discloses a catalyst containing caesium and vanadium and a preparation method thereof. With the total mass of the catalyst components as 100% parts, the content of vanadium pentoxide is 5-10%, the content of cesium oxide is 2-14%, the content of potassium oxide is 6-14%, the content of sodium oxide is 1-9%, and the balance is diatomaceous earth. A raw material of the cesium oxide is salt or alkali containing the cesium, such as cesium sulfate (Cs2SO4), cesium carbonate (Cs2CO3) or cesium hydroxide (CsOH). A raw material of the potassium oxide is salt or alkali containing potassium like potassium sulfate, potassium sulfite or potassium hydroxide. A raw material of the sodium oxide is salt or alkali containing sodium like sodium sulfate, sodium sulfite or sodium hydroxide. The catalyst is stable in performance, low in operating temperature, wide in areas, slow in heat fading and high in catalytic efficiency.

Owner:贵州威顿催化技术有限公司

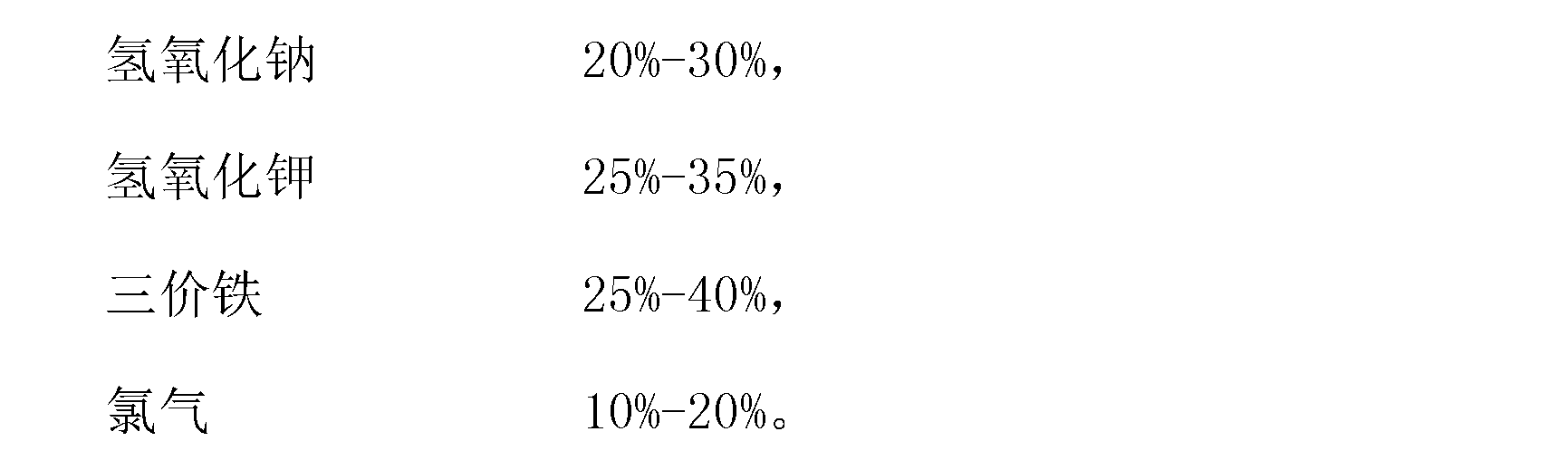

Potassium ferrate disinfectant and preparation method thereof

The invention provides a potassium ferrate disinfectant and a preparation method of the potassium ferrate disinfectant, and relates to the technical field of a disinfectant, wherein the potassium ferrate disinfectant consists of raw material components with a certain quantity such as sodium hydroxide, potassium hydroxide, ferric iron and chlorine. The preparation method comprises the following steps of: leading 40% sodium hydroxide solution to have reaction with the chlorine to generate sodium hypochlorite, when the reaction stops, adding the sodium hydroxide, to prepare saturated sodium hypochlorite, and filtering for later use; leading the saturated sodium hypochlorite to have reaction with the ferric iron to generate sodium ferrate; carrying out replacement reaction between the potassium hydroxide and the sodium ferrate, and filtering to obtain a potassium ferrate crude product; washing the potassium ferrate crude product by absolute ethyl alcohol to obtain a potassium ferrate refined product, and drying at low temperature in a leaching way to obtain the dried potassium ferrate refined product. According to the invention, the chlorine is charged into the sodium hydroxide to prepare the sodium hypochlorite firstly, the sodium ferrate can be further prepared, and the potassium hydroxide is used for replacing to generate the potassium ferrate, so that the potassium hydroxide can be saved by 30%-40%, and the cost can be reduced by 25%-30%, and the more than 98% potassium ferrate refined product can be continuously and stably produced due to the proportioning of the raw materials.

Owner:ANHUI HUANGHUAI VETERINARY MEDICINE

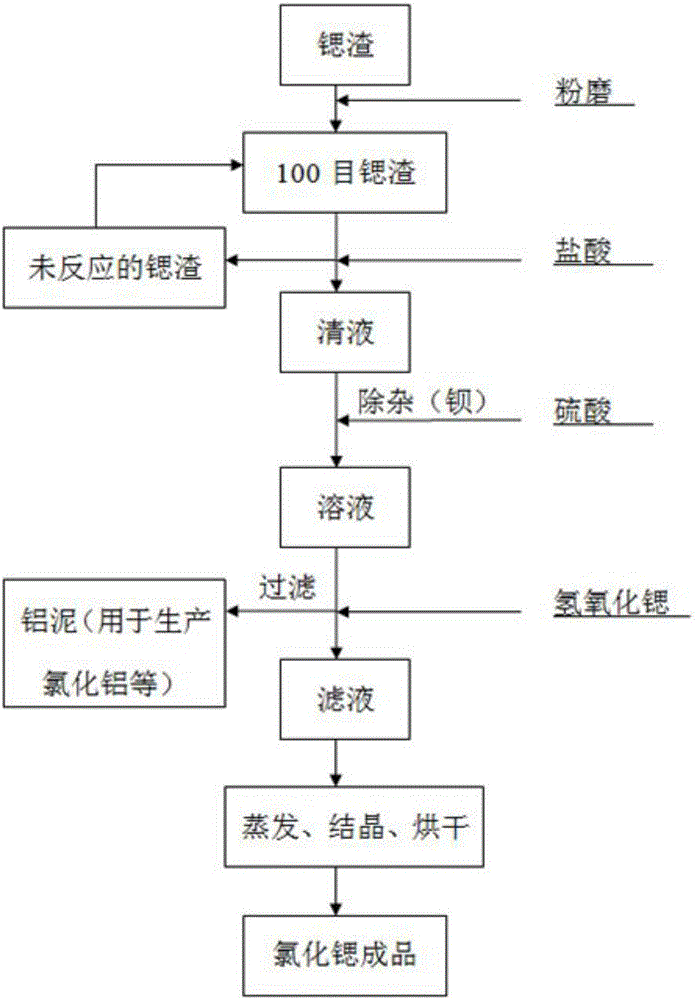

Method for preparing strontium chloride by using strontium slag

InactiveCN104058444AEmission reductionNothing producedCalcium/strontium/barium chloridesStrontium hydroxideSlag

The invention discloses a method for preparing strontium chloride by using strontium slag. The method specifically comprises the following steps: (1), firstly grinding the strontium slag into powder, then sieving the ground strontium slag through a 100-mesh sieve; (2), adding hydrochloric acid in the sieved strontium slag powder, wherein the weight ratio of hydrochloric acid to the strontium slag powder is 1.25:1; then stirring, reacting for 2-4h, filtering to obtain supernate after the reaction is ended; (3), adding sulfuric acid in the supernate prepared in the step (2), stirring, and reacting for 1-2h; (4), after the reaction is ended, adding strontium hydroxide in the solution, regulating pH of the solution to 6.5-7.5, standing, and filtering to obtain filtrate after completely settling; and (5), heating, evaporating and crystallizing the filtrate obtained in the step (4) to obtain the strontium chloride. The method provided by the invention has the advantages of simplicity, low requirement on equipment, safety, environment friendliness, high yield, and the like.

Owner:MINLE FUYUAN CHEM

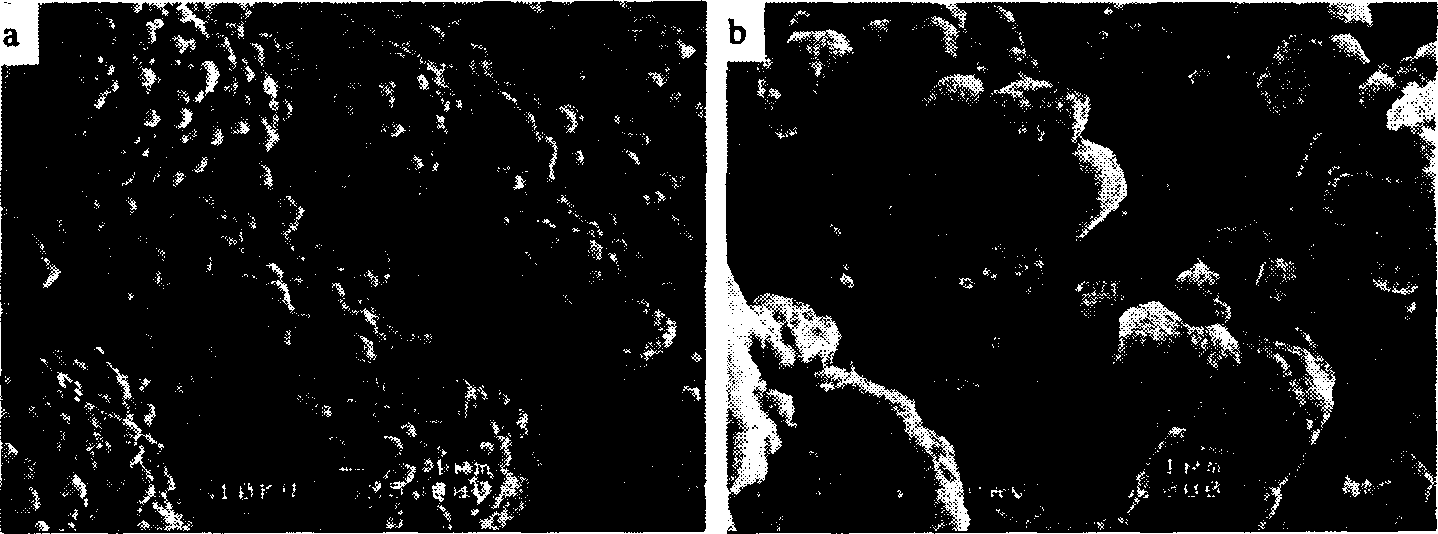

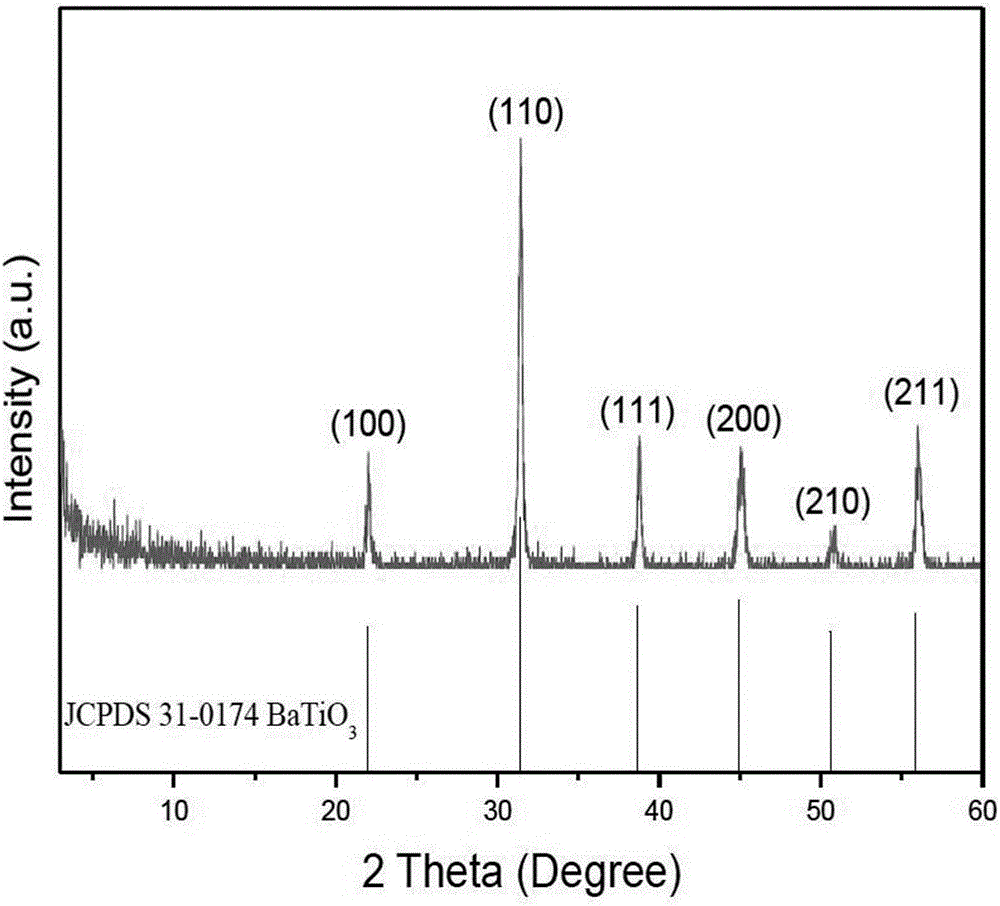

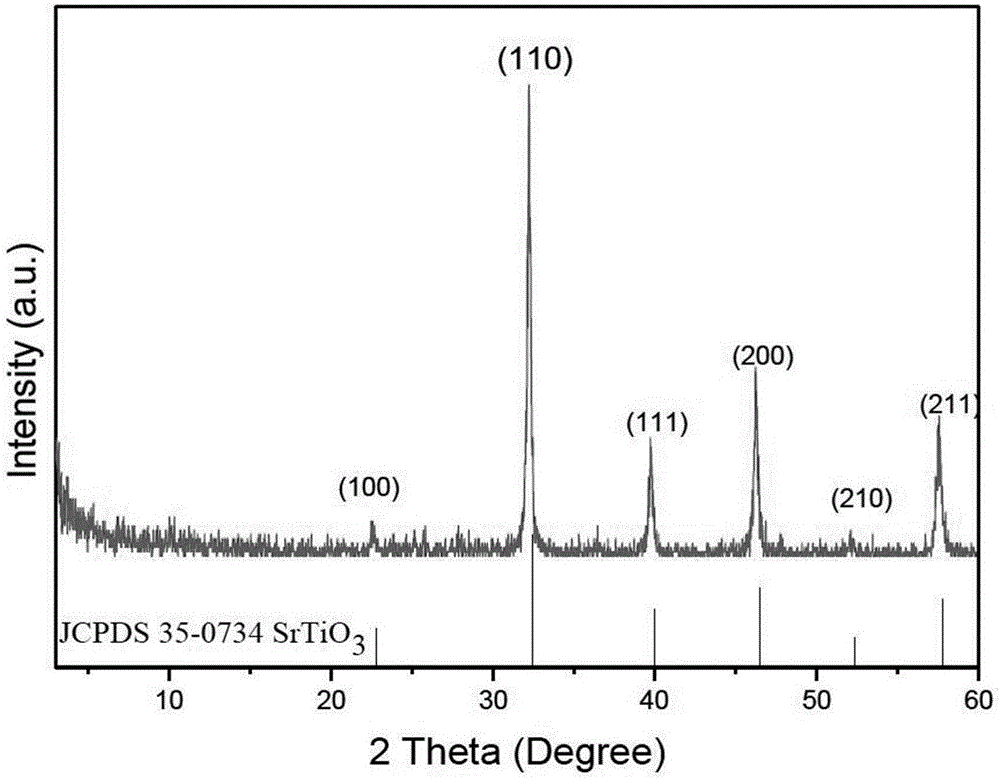

Preparation method of preferred orientation BaTiO3/SrTiO3 nano composite ceramic

ActiveCN106478089AHigh piezoelectric constantAlkaline earth titanatesComposite ceramicStrontium hydroxide octahydrate

The invention discloses a preparation method of preferred orientation BaTiO3 / SrTiO3 nano composite ceramic. The method includes that titanic acid, barium hydroxide and strontium hydroxide are taken as raw materials, a hydrothermal method is used to optimize technical parameters, and BT and ST ceramic powder is synthesized; through testing result analysis of a scanning electron microscope, all the prepared powder is nanoscale, a green structure is formed by tape-casting lamination according to a template grain growth method, and the composite ceramic is obtained by sintering according to a specific process. Calculation results show that the ceramic has a certain orientation; the piezoelectric constant (d33) of the polarized ceramic is big, and the preferred orientation BaTiO3 / SrTiO3 nano composite ceramic can be used as a leadless piezoelectric ceramic material.

Owner:BAOJI UNIV OF ARTS & SCI

Method of synthesizing nano grade calcium titanium ceramic powder

Owner:TSINGHUA UNIV

Nano-isolation agent for preventing high-temperature surface oxidation of stainless steel

The invention relates to a nano-isolation agent for preventing high-temperature surface oxidation of stainless steel. The nano-isolation agent comprises, by weight, 40 to 70% of zircon, 20 to 40% of blast furnace slag, 5 to 30% of nano-silica, 1 to 20% of borax, 0.1 to 5% of nano-strontium hydroxide, 1 to 15% of silica sol, 1 to 3% of sodium alginate and water, wherein the weight of the water is 50 to 70% of the total weight of the above materials. The nano-isolation agent is prepared by a mechanical mixing method. The nano-isolation agent is suitable for preventing oxidation of a stainless steel blank heated at a temperature of 1200 to 1400 DEG C for 1 to 10h, and is spray-coated or brush-coated on the stainless steel surface in a range of a normal temperature to 800 DEG C to form an isolation agent layer having the thickness of 20 to 100 microns. Drying time of the nano-isolation agent in air at a normal temperature of 25 DEG C is in a range 0.5 to 1h. The nano-isolation agent can form compact molten glass thereby preventing diffusion of oxygen atoms to a stainless steel matrix. The nano-isolation agent for preventing oxidation comprises a large amount of zircon and blast furnace slag so that an isolation agent cost and resource consumption are reduced.

Owner:上海钫淦冶金科技有限公司

Method for preparing nano barium strontium titanate powder by adopting sol-gel method

InactiveCN101792177AUniform particle size distributionPrecise control of preparation parametersNanostructure manufactureTitanium compoundsAcetic acidBarium strontium titanate

The invention discloses a method for preparing nano barium strontium titanate powder by adopting a sol-gel method, which is mainly used for solving the technical problem that barium strontium titanate powder prepared by a traditional preparation method has uneven particle size distribution. In a technical scheme, the nano barium strontium titanate powder is prepared from barium acetate, strontium hydroxide, tetra-n-butyl titanate, glacial acetic acid, ethylene glycol monomethyl ether and acetylacetone by adopting the sol-gel method. Because the traditional sol-gel method is improved and preparation parameters are accurately controlled, the barium strontium titanate (BST) nano-powder with even particle size distribution is obtained.

Owner:JIANGSU JUXIN MAGNET +1

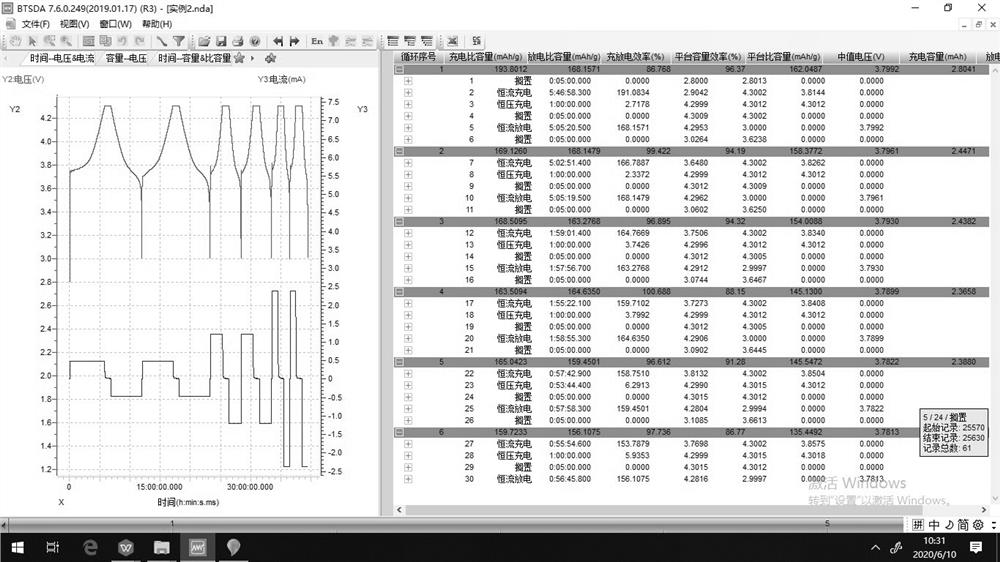

Manufacturing method of high-compaction lithium battery positive electrode material nickel cobalt lithium manganate

PendingCN111710843AGood value for moneyImprove compactnessSecondary cellsPositive electrodesManganateManganese

The invention discloses a manufacturing method of a high-compaction lithium battery positive electrode material nickel cobalt lithium manganate, which belongs to the technical field of lithium ion battery positive electrode material nickel cobalt lithium manganate, and comprises the following steps of (1) material preparation: selecting nickel cobalt manganese hydroxide, battery grade lithium carbonate and strontium hydroxide, (2) lithiation mixing: uniformly mixing the three raw materials, (3) high-temperature calcination: calcining the mixed product in a high-temperature kiln, and (4) crushing and crushing the calcined product to obtain a finished product. The invention provides a method for doping strontium hydroxide and improving compaction of nickel cobalt lithium manganate in a conventional production process, and the method is combined with a high-temperature solid-phase reaction in the production process of nickel cobaltlithium manganate, so that the particle size of a productsingle crystal is increased, the combination tightness of each single crystal is enhanced, and the method has relatively high economic usability and safety.

Owner:HENAN FUSEN NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com