Method for preparing strontium chloride by using strontium slag

A strontium chloride and strontium slag technology, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., can solve the problems of strontium slag treatment difficulties, environmental pollution, etc., and achieve easy control of process parameters and equipment The effect of low requirements and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

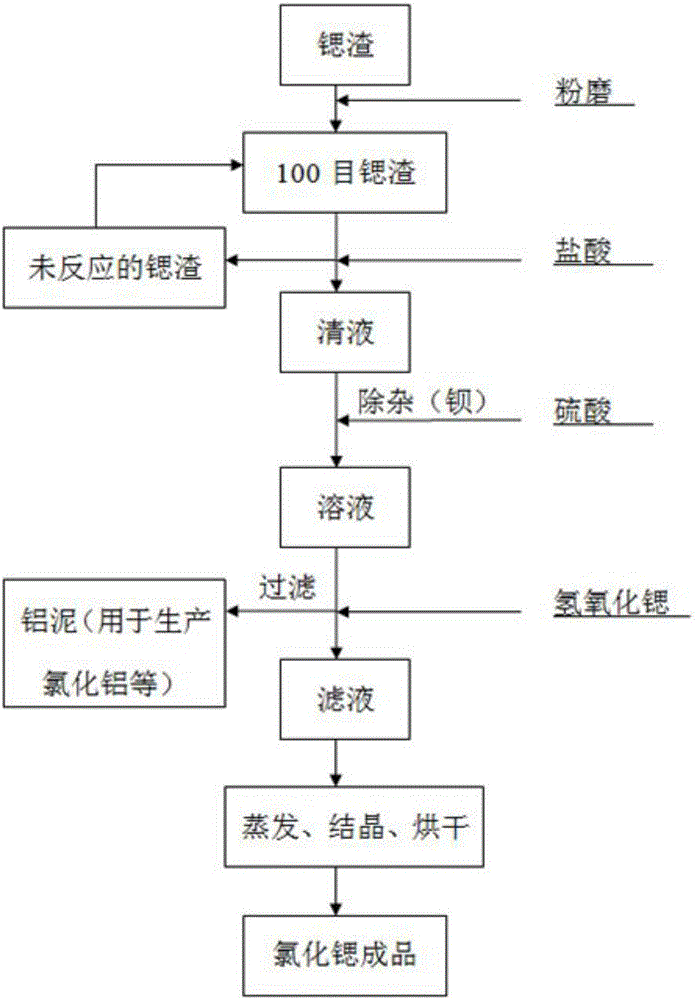

Image

Examples

Embodiment 1

[0024] (1) first strontium slag is ground, and then the ground strontium slag is passed through a 100-mesh sieve;

[0025] (2) adding hydrochloric acid to the sieved strontium slag powder, the addition of hydrochloric acid is 1.25 times of the weight of the strontium slag powder, then stirred, reacted for 2h, and filtered after the reaction to obtain clear liquid;

[0026] (3) add sulfuric acid to the clear liquid that step (2) makes, detect the barium content in the strontium slag, add sulfuric acid according to 1.2 times of the theoretical value of sulfuric acid for barium removal, then stir, and react for 1h;

[0027] (4) After the reaction is over, add strontium hydroxide to the solution, adjust the pH of the solution to 6.5, let it stand, and wait for complete precipitation, then filter to obtain the filtrate;

[0028] (5) Step (4) is heated, evaporated and crystallized to obtain strontium chloride.

Embodiment 2

[0030] (1) first strontium slag is ground, and then the ground strontium slag is passed through a 100-mesh sieve;

[0031] (2) Adding hydrochloric acid to the strontium slag powder after sieving, the addition of hydrochloric acid is 1.25 times of the weight of the strontium slag powder, then stir, react for 4h, filter after the reaction to obtain clear liquid;

[0032] (3) add sulfuric acid to the clear liquid that step (2) makes, detect the barium content in the strontium slag, add sulfuric acid according to 1.5 times of the theoretical value of sulfuric acid for barium removal, then stir, and react for 2h;

[0033] (4) After the reaction is over, add strontium hydroxide to the solution, adjust the pH of the solution to 7.5, let it stand, and wait for complete precipitation, then filter to obtain the filtrate;

[0034] (5) Step (4) is heated, evaporated and crystallized to obtain strontium chloride.

Embodiment 3

[0036] (1) first strontium slag is ground, and then the ground strontium slag is passed through a 100-mesh sieve;

[0037] (2) adding hydrochloric acid to the sieved strontium slag powder, the addition of hydrochloric acid is 1.25 times of the weight of the strontium slag powder, then stirred, reacted for 3h, and filtered after the reaction to obtain clear liquid;

[0038] (3) add sulfuric acid to the clear liquid that step (2) makes, detect the barium content in the strontium slag, add sulfuric acid according to 1.3 times of the theoretical value of sulfuric acid used for barium removal, then stir, and react for 1.5h;

[0039] (4) After the reaction is over, add strontium hydroxide to the solution, adjust the pH of the solution to 7.0, let it stand, and wait for complete precipitation, then filter to obtain the filtrate;

[0040] (5) Step (4) is heated, evaporated and crystallized to obtain strontium chloride.

[0041] According to the statistics of the company's preliminary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com