Patents

Literature

767results about "Calcium/strontium/barium chlorides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

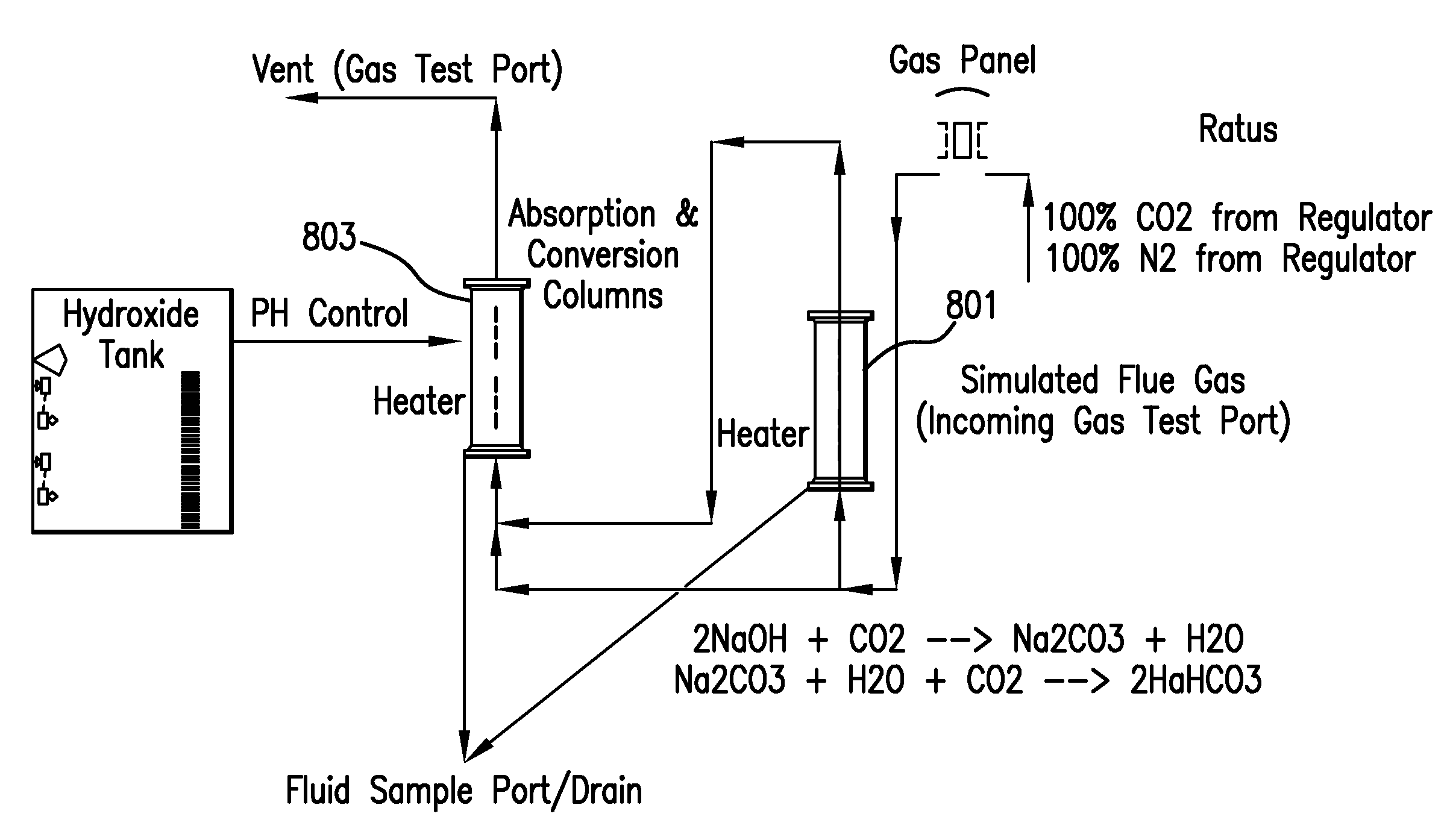

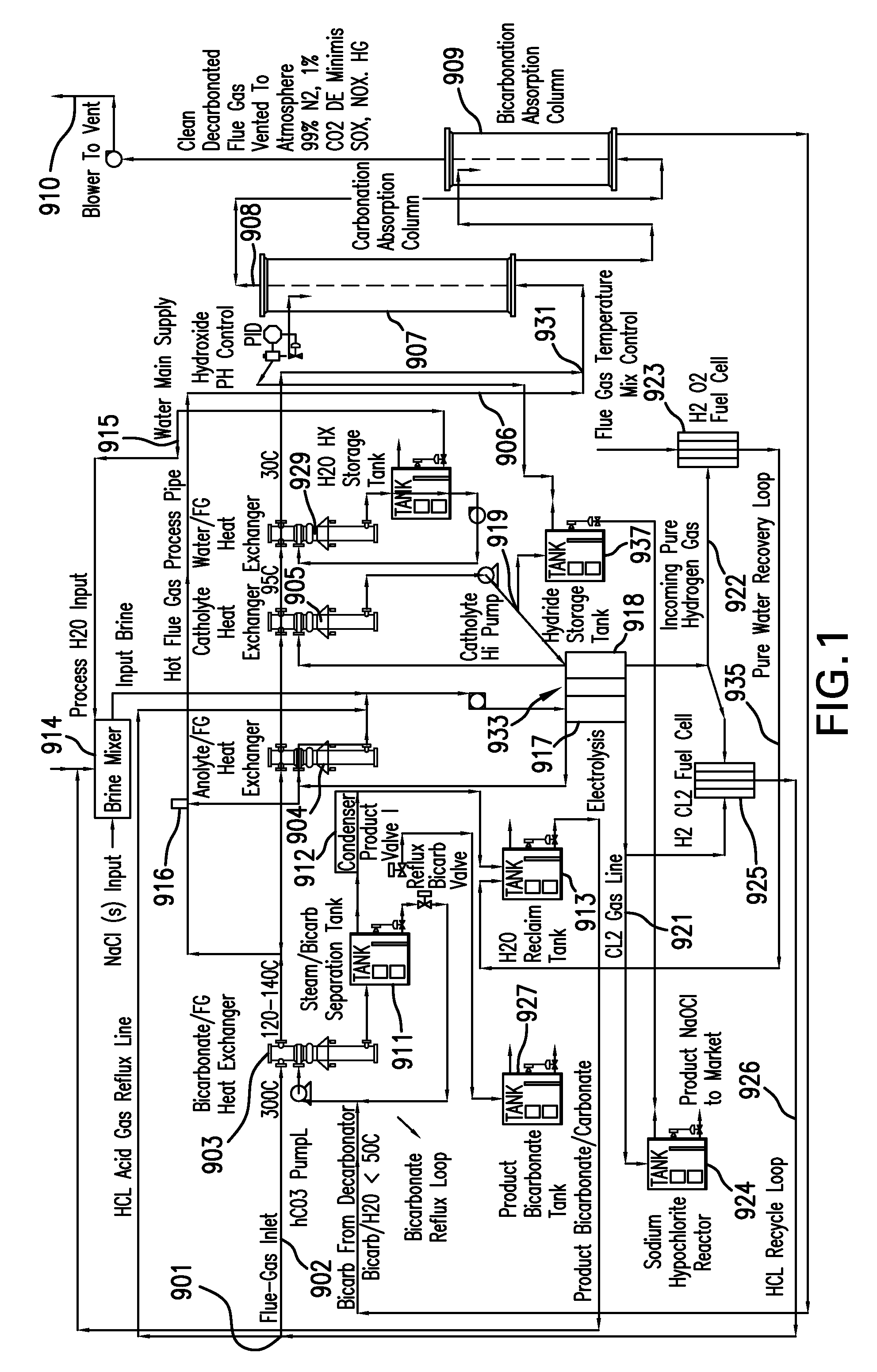

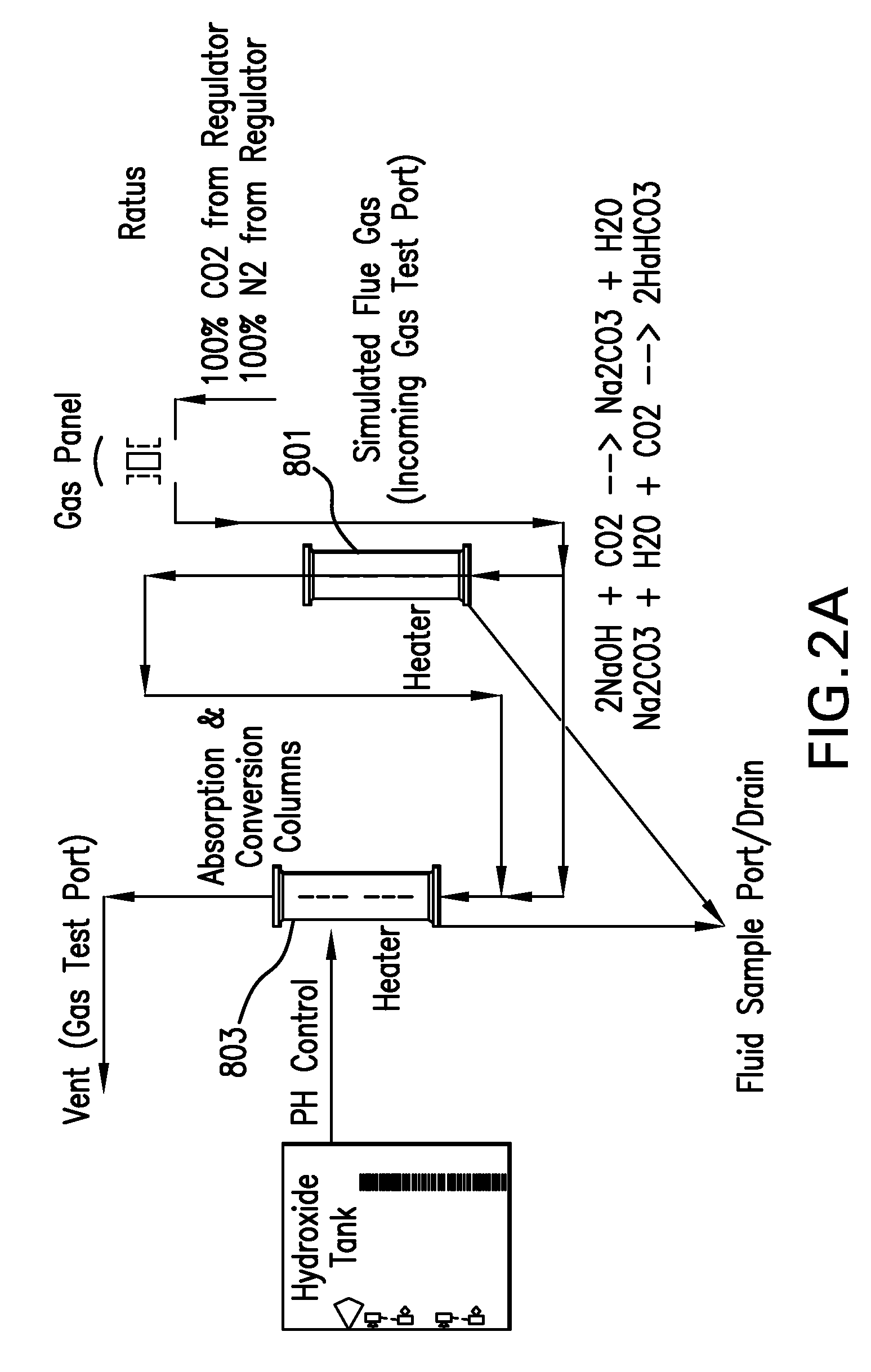

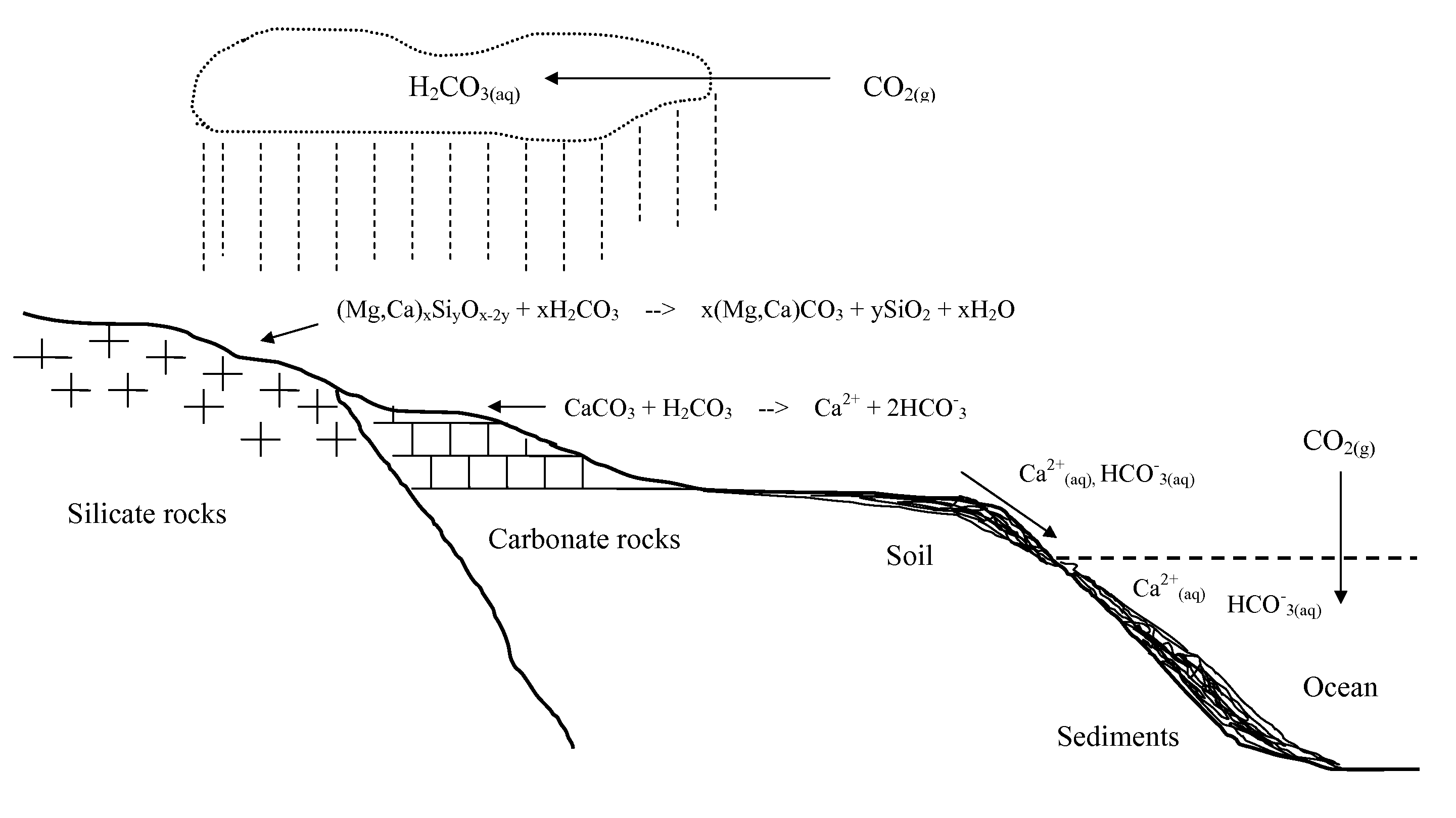

Removing Carbon Dioxide From Waste Streams Through Co-Generation of Carbonate and/or Bicarbonate Minerals

ActiveUS20090127127A1Prevent returnChloride preparationCalcium/strontium/barium chloridesDicarbonateElectrolysis

Apparatuses and methods for removing carbon dioxide and other pollutants from a gas stream are provided. The methods include obtaining hydroxide in an aqueous mixture, and mixing the hydroxide with the gas stream to produce carbonate and / or bicarbonate. Some of the apparatuses of the present invention comprise an electrolysis chamber for providing hydroxide and mixing equipment for mixing the hydroxide with a gas stream including carbon dioxide to form an admixture including carbonate and / or bicarbonate.

Owner:CARBONFREE CHEM HLDG LLC

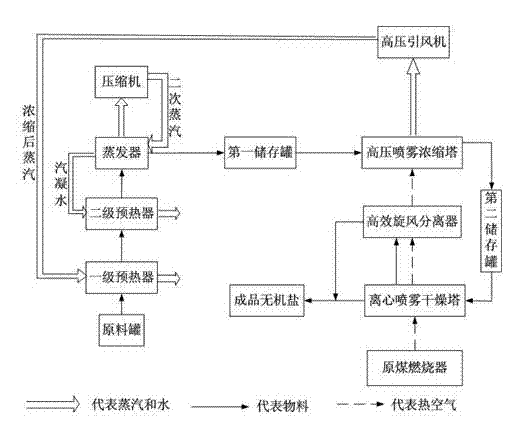

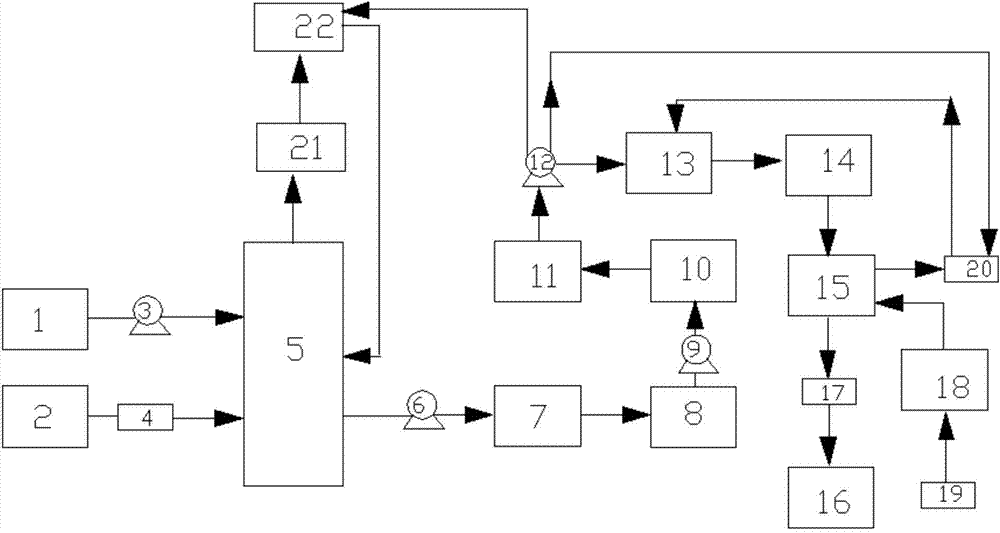

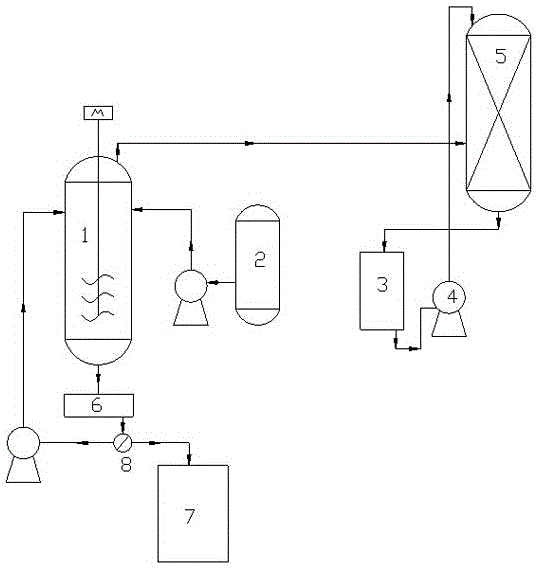

Energy-saving evaporation treatment process of high-salinity wastewater

ActiveCN102964019AStrong adsorption and removal abilityHigh purityCalcium/strontium/barium chloridesMultistage water/sewage treatmentInorganic saltsIndustrial effluent

The invention provides an energy-saving evaporation treatment process of high-salinity wastewater. The energy-saving evaporation treatment process comprises an evaporating system, a concentrating system, a drying system and a heat circulating system. Grading preheating, heating evaporation, adsorption purification, concentration, adsorption purification and high-temperature drying are successively carried out on the high-salinity wastewater treated by a wastewater treatment system to obtain the finished product of inorganic salt, heat exhausted in the evaporation, concentration and drying processes is recycled, and wastewater is discharged. By adopting the technical scheme, wastewater discharged finally meets the national industrial wastewater discharge standard, the purity of the obtained inorganic salt is as high as 99.3%, and the energy-saving effect is remarkable.

Owner:山东大明消毒科技有限公司

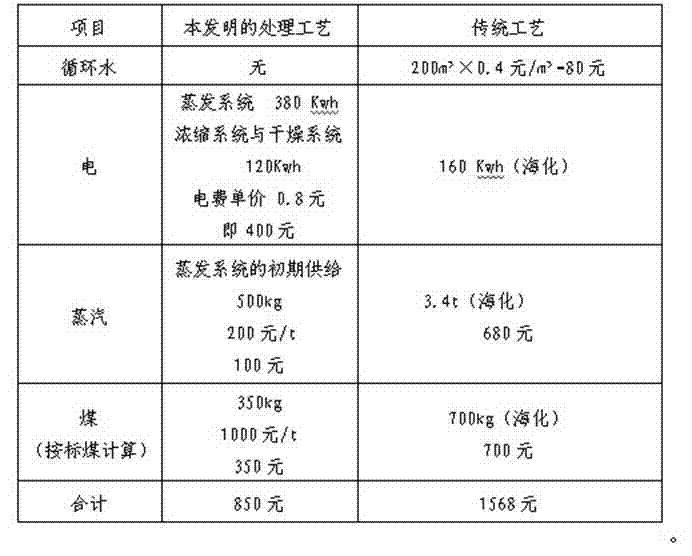

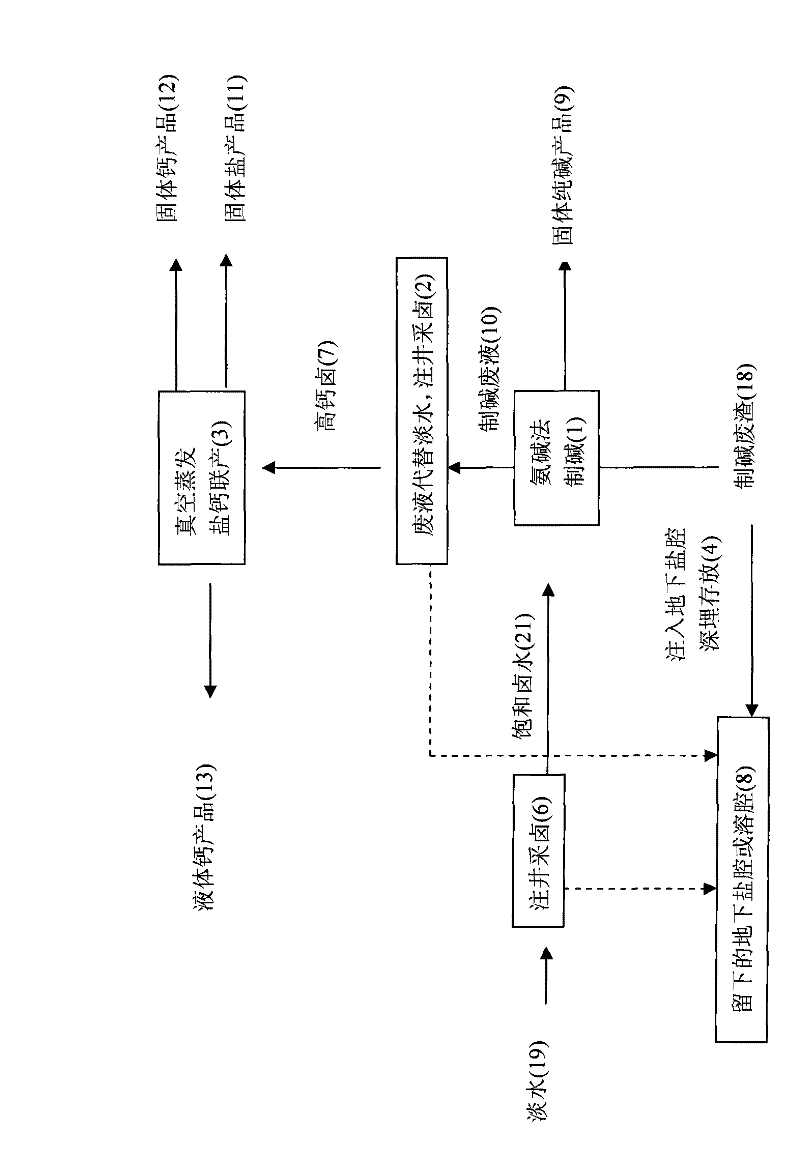

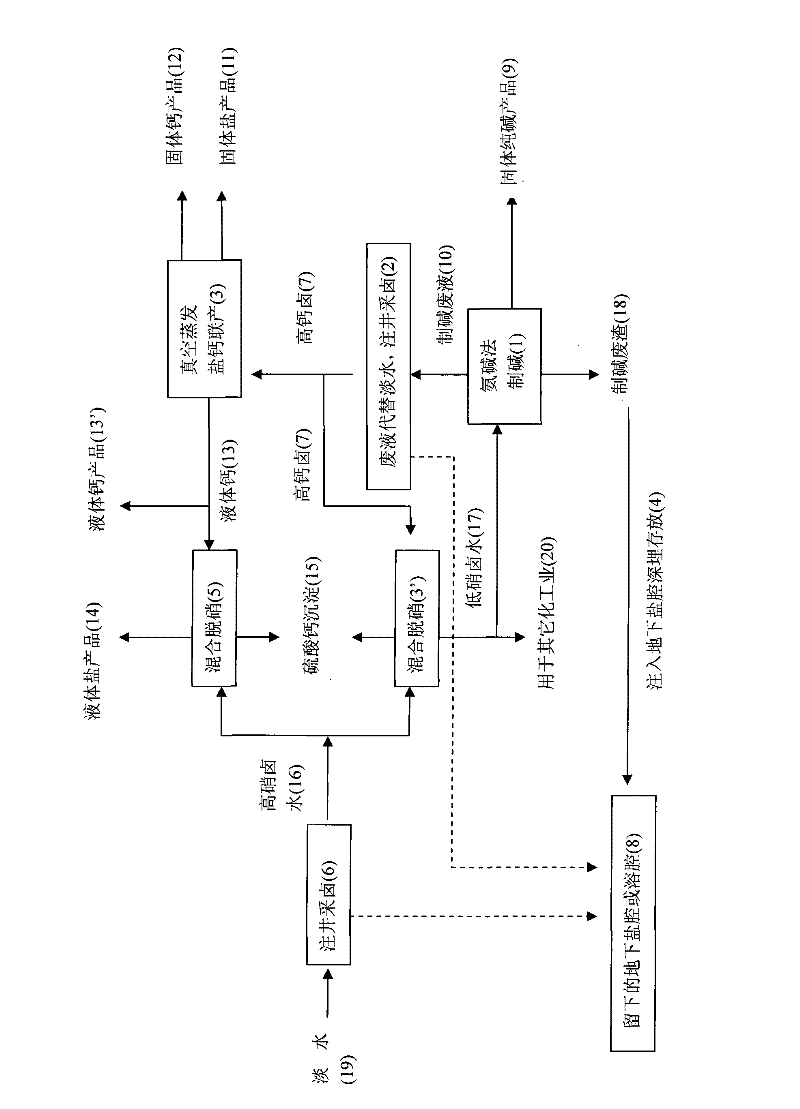

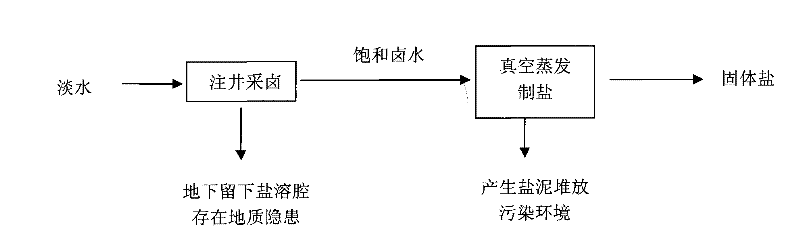

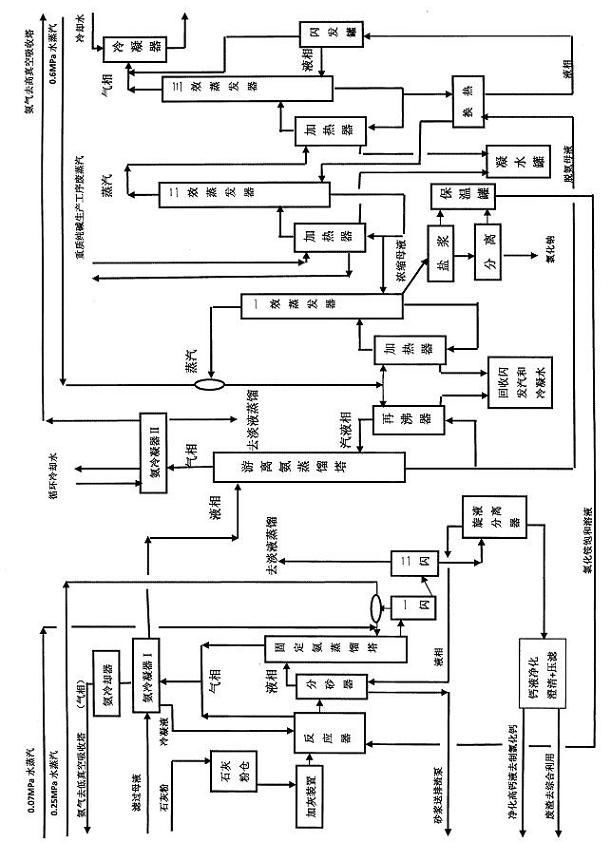

Salt, alkali and calcium combined cycle production technology by the use of well mineral salt

ActiveCN102205979ASolve processing problemsRealize energy saving and consumption reductionCalcium/strontium/barium chloridesAlkali metal chloridesDissolutionCalcium EDTA

The invention relates to a salt, alkali and calcium combined cycle production technology by the use of well mineral salt. Based on the exploitation of brine from well mineral salt, the salt, alkali and calcium combined cycle production technology by the use of well mineral salt is a cycle production technology, which focuses on the technology for making alkali from brine by the ammonia-soda process and takes account of the vacuum salt-making (including the brine refinement) and calcium-making technologies. Alkali-making wastewater replaces most fresh water to be injected into a salt mine well to collect brine, and the obtained high-calcium brine is taken as the raw material of the salt and calcium (including liquid calcium) co-production as well as the raw material for preparing alkali and other chemical production raw materials, wherein the liquid calcium can be used to produce liquid salt; alkali-making waste residues are injected into an underground dissolution cavern, namely a salt cavern which is formed by the exploitation of brine from well mineral salt, thus accomplishing the combined cycle production technology in which alkali-making and salt-making technologies are closely related with materials. The produced wastes are used as resources or undergo a harmless treatment, thus protecting the environment. In addition, the utilization rate of sodium chloride in rock salt reaches 100%, achieving maximum efficiency.

Owner:江苏苏盐井神股份有限公司 +1

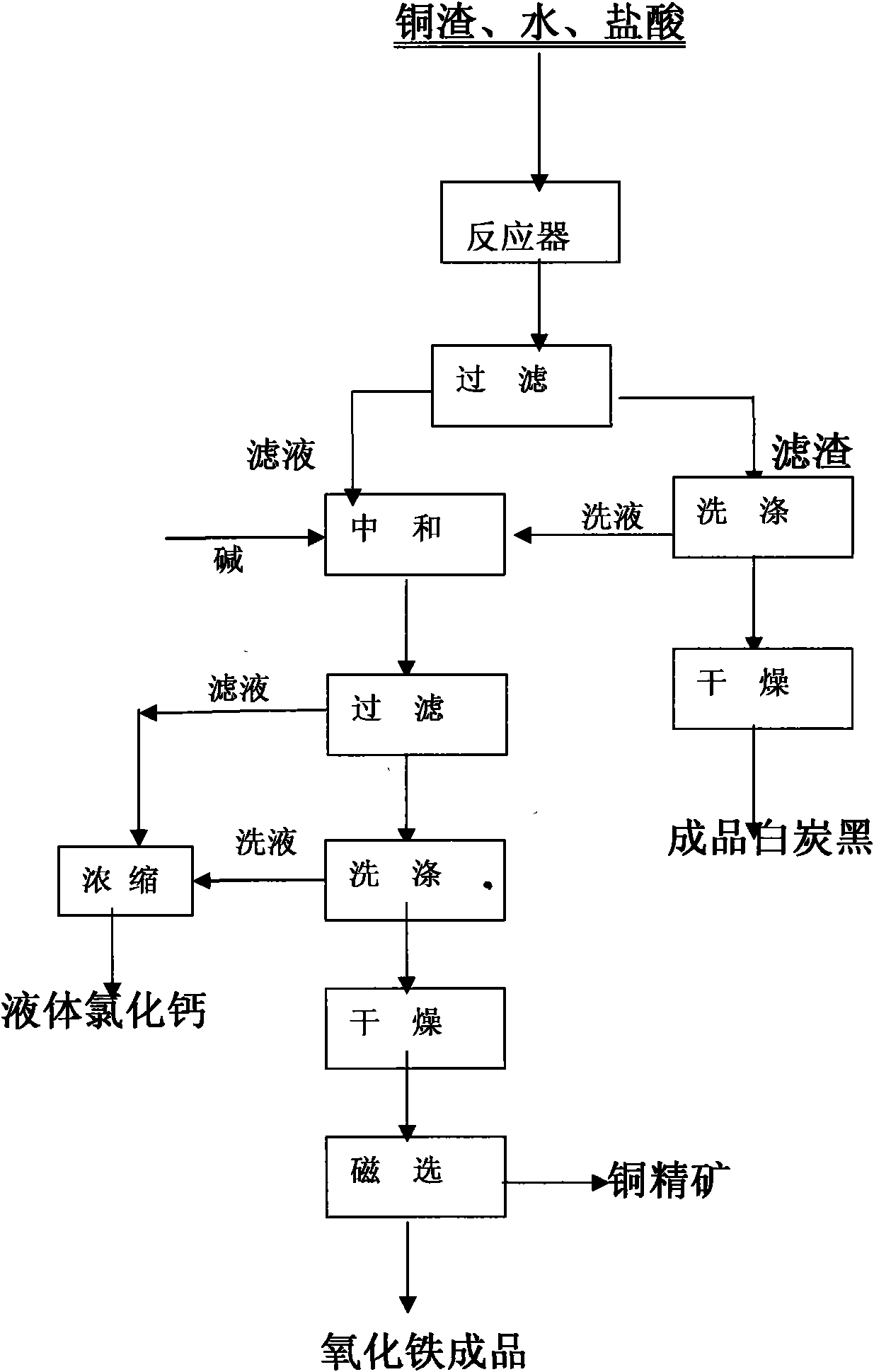

Method for comprehensively recovering Fe, Cu and Si from copper smelting slag

InactiveCN101555551AImprove resource utilizationImprove product added valueSilicaCalcium/strontium/barium chloridesSilicon dioxideMaterials science

The invention discloses a method for comprehensively recovering iron, copper and silicon dioxide from copper smelting slag. The method takes copper smelting slag as a raw material, and comprehensively recovers Fe, Cu and Si in copper slag by adopting wet chemistry metallurgical technology. A muriatic acid and an inorganic acid are mainly adopted for leaching the copper smelting slag, the leaching acid concentration, the solid to liquid ratio, the leaching temperature and the leaching time are selected according to the quality requirement of silicon dioxide products under certain conditions, and silicon dioxide is firstly separated through filtering and drying to prepare silica pigment; the leaching filtered liquid is counteracted, settled, filtered, dried and ground, and ferric oxide phase and copper-bearing phase are selectively separated by adopting a conventional mineral processing method.

Owner:KUNMING UNIV OF SCI & TECH

Method for Sequestering Carbon Dioxide

InactiveUS20110038774A1Enhance CO dissolutionMitigate local ocean acidificationCalcium/strontium/barium carbonatesProductsSodium bicarbonateSlag

Owner:ZHONG SHAOJUN

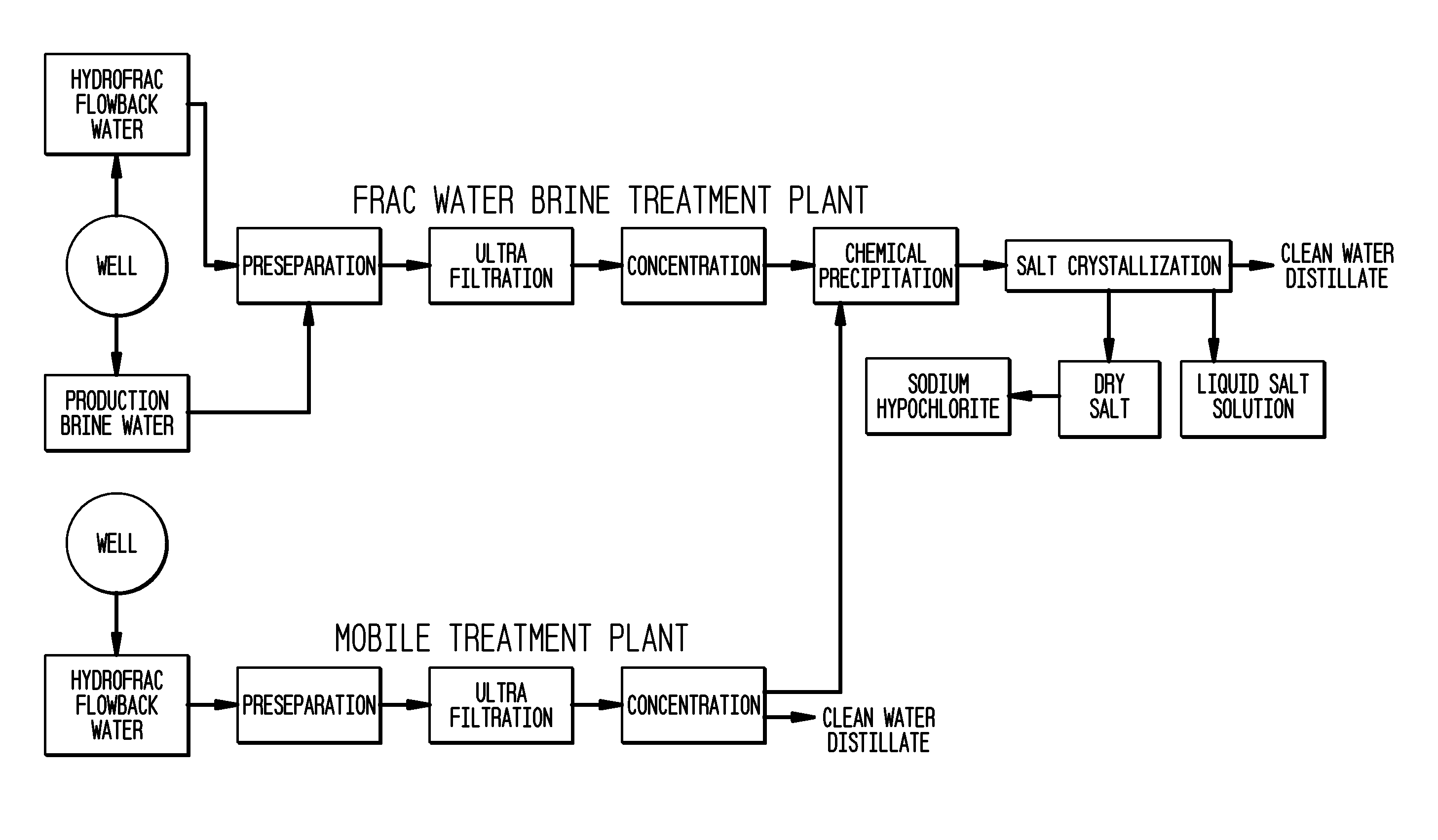

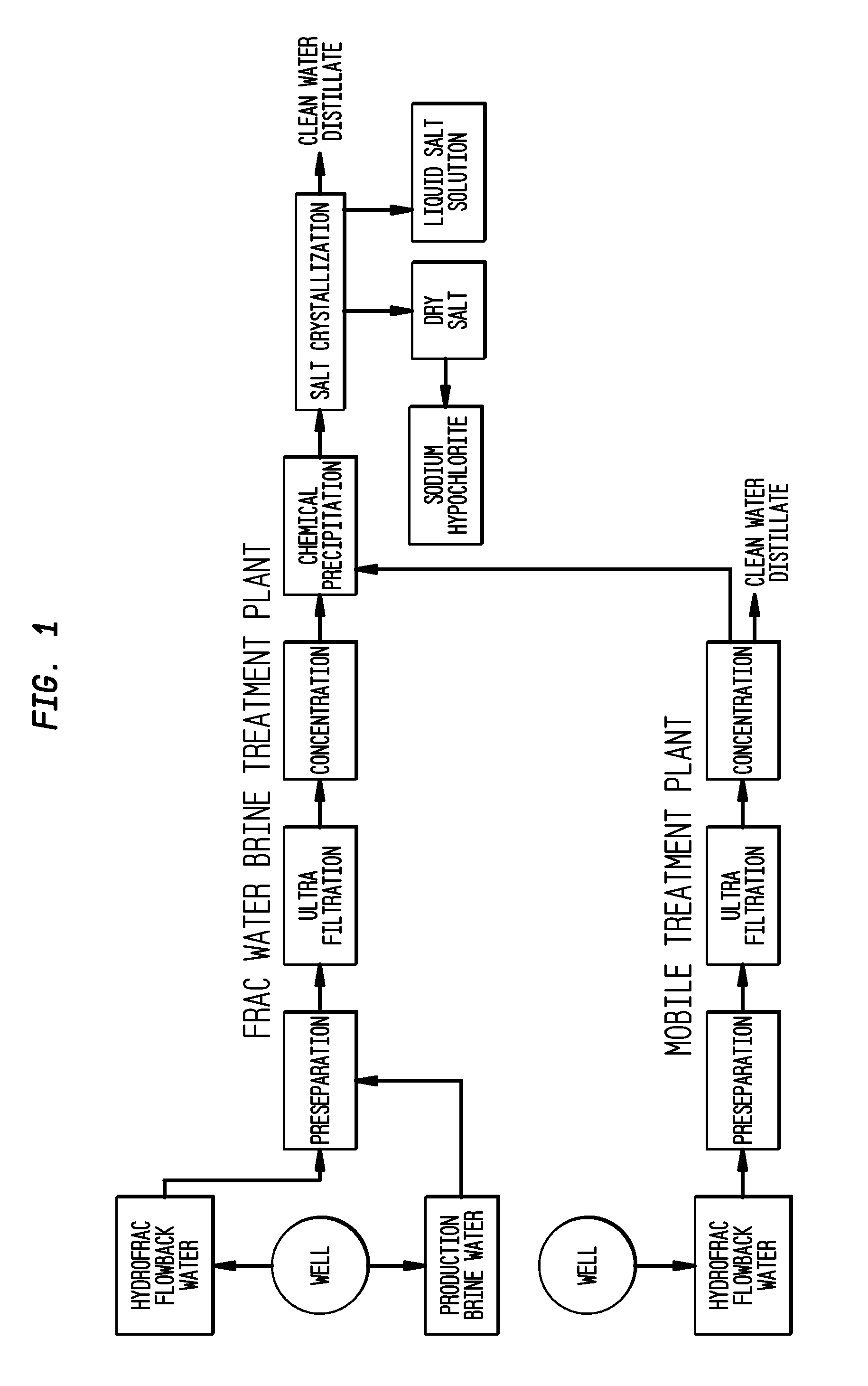

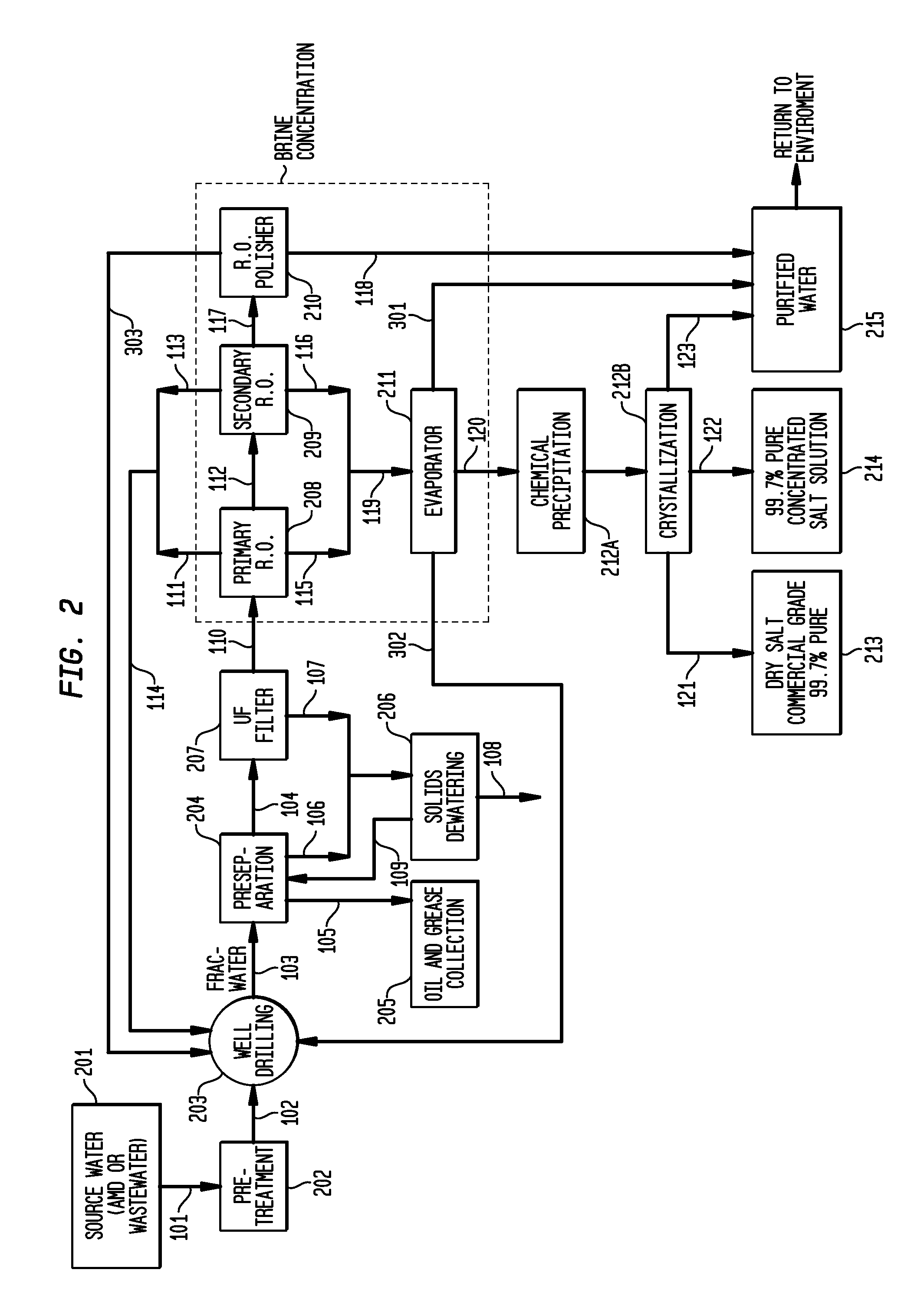

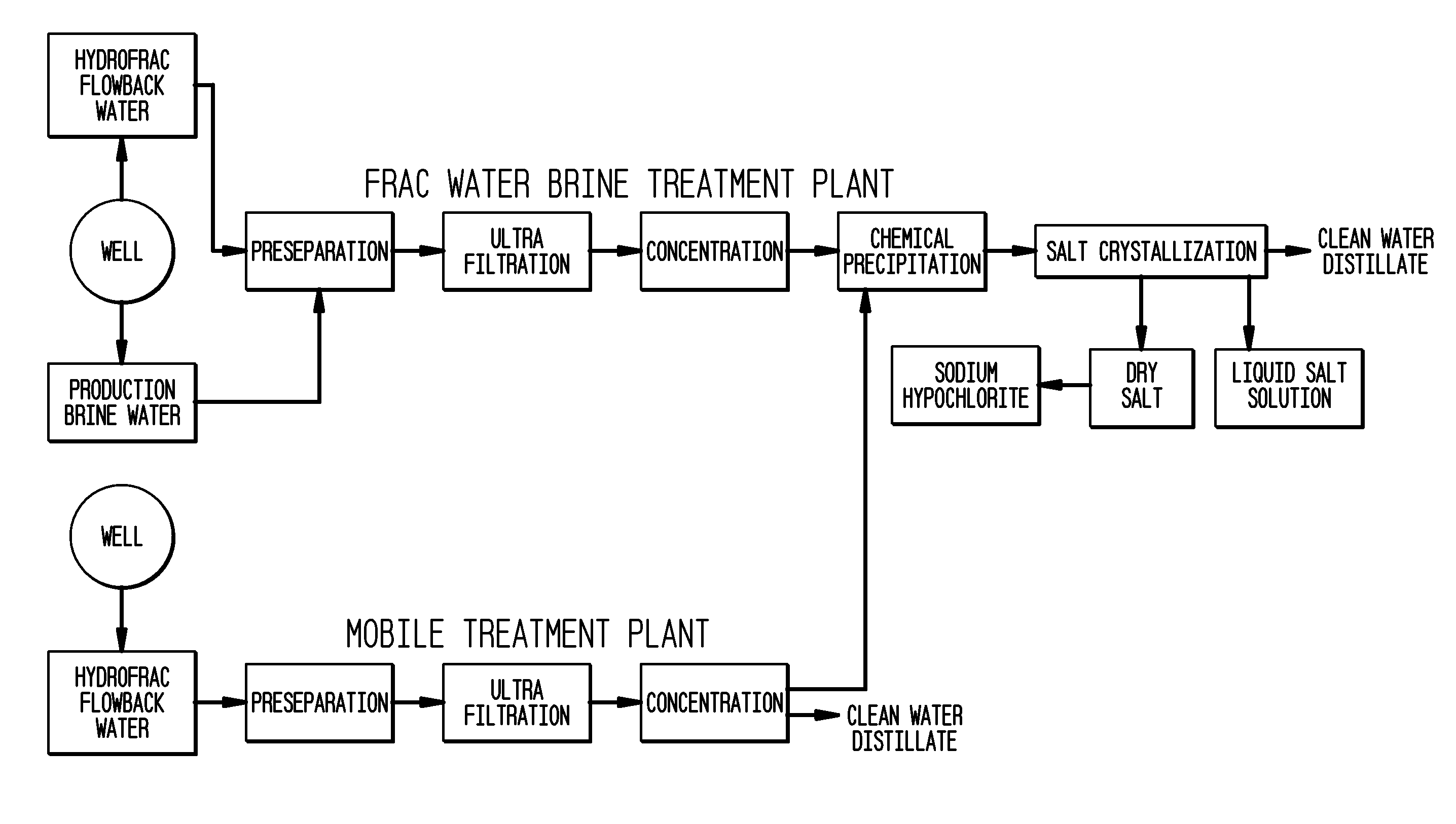

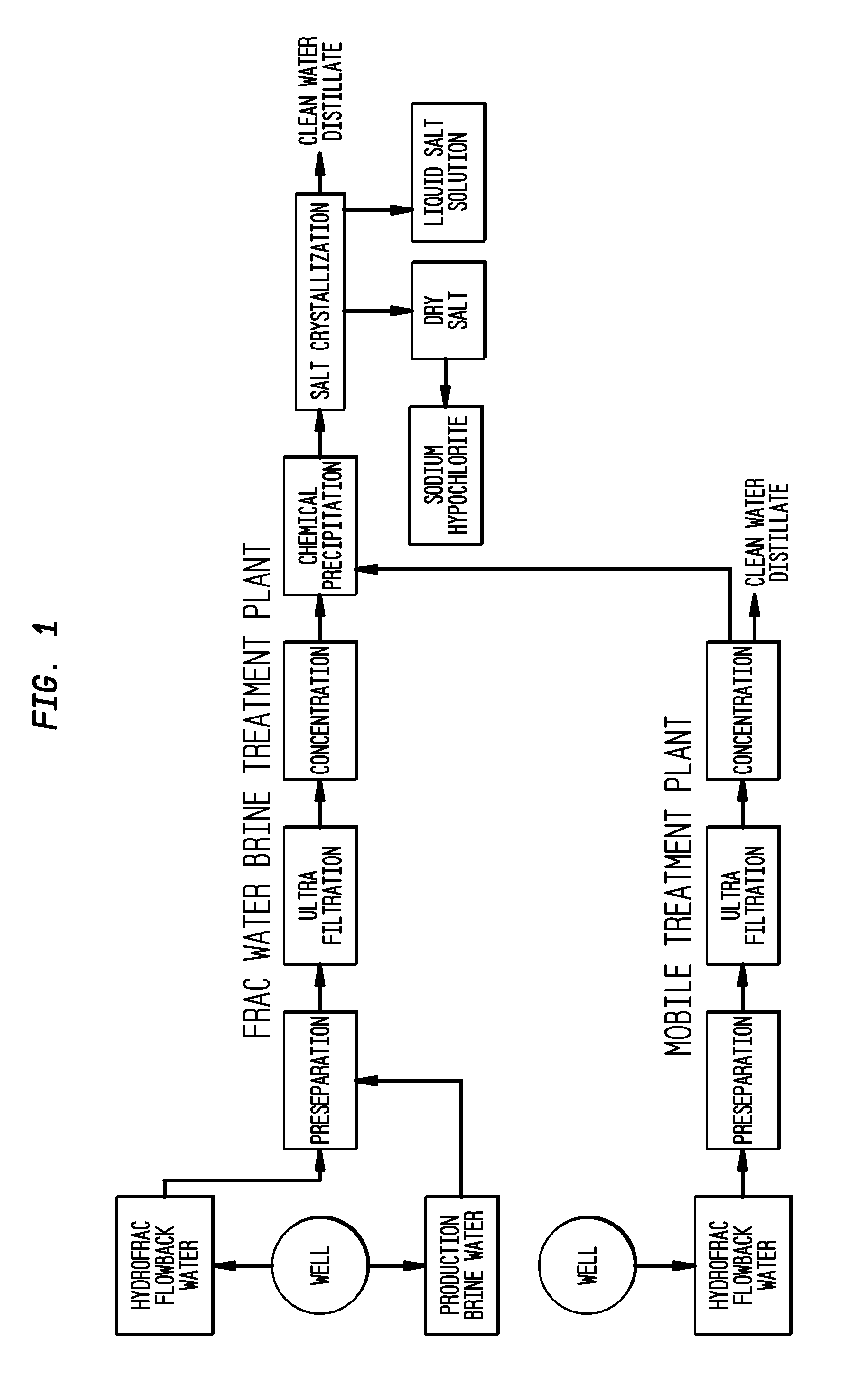

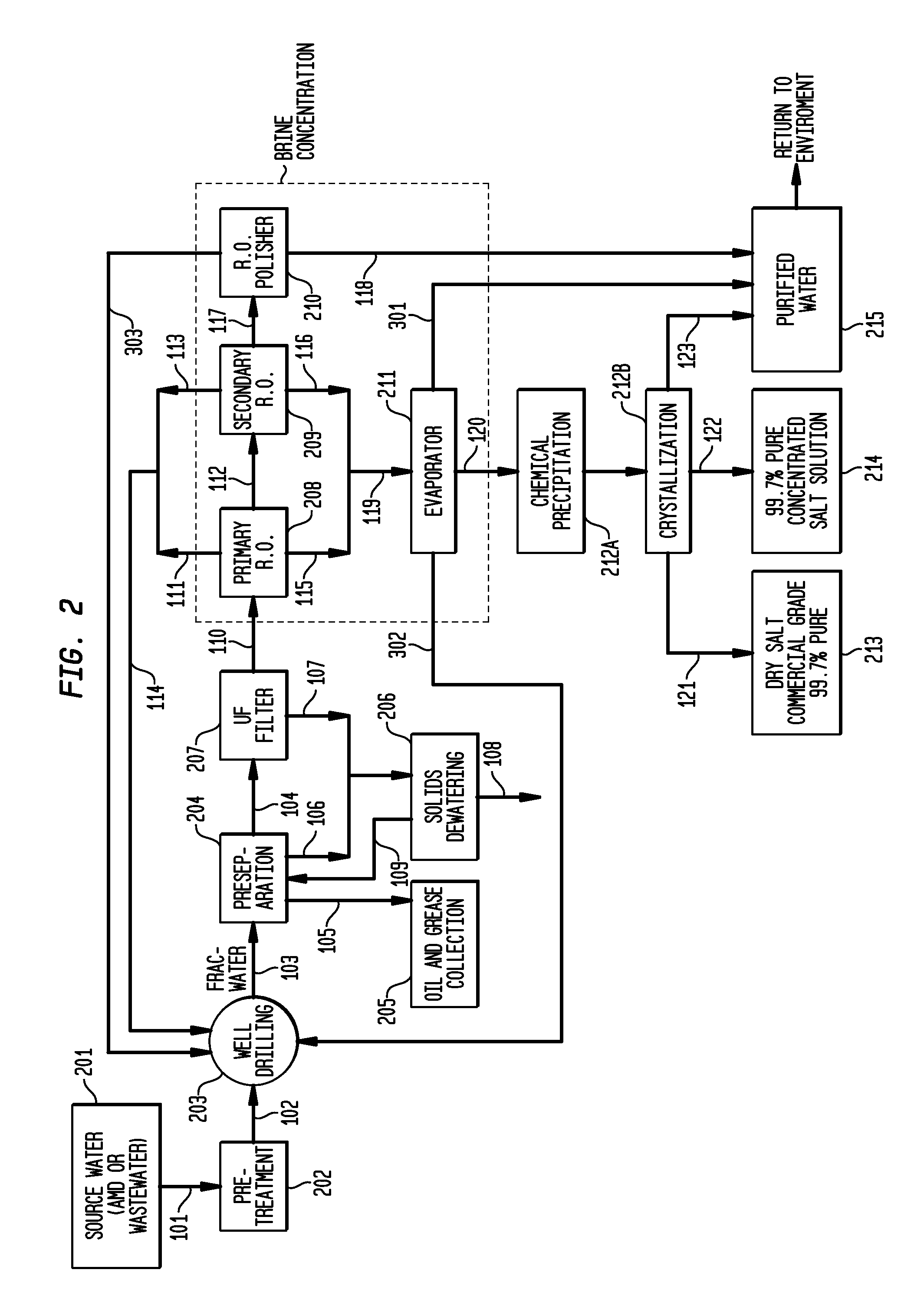

Method of making pure salt from FRAC-water/wastewater

ActiveUS8158097B2Yield maximizationQuality improvementCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesWater useParticulates

The present invention relates to a method for making pure salt comprises recapturing post-drilling flowback water from hydro-fracturing; removing oil from the flowback water; filtering the flowback water using an ultra filter with a pore size of about 0.1 microns or less to remove solid particulates and large organic molecules, such as benzene, ethylbenzene, toluene, and xylene, from the water; concentrating the flowback water to produce a brine that contains from about 15 wt % to about 40 wt % of salt relative to the total weight of the flowback brine; performing one or more chemical precipitation process using an effective amount of reagents to precipitate out the desired high quality commercial products, such as, barium sulfate, strontium carbonate, calcium carbonate; and crystallizing the chemically treated and concentrated flowback brine to produce greater than 99.5% pure salt products, such as sodium and calcium chloride.

Owner:FRACPURE HLDG

System for producing anhydrous calcium chloride by using industrial waste hydrochloric acid, and technology thereof

ActiveCN104773750AExpand production scaleReduce energy consumptionCalcium/strontium/barium chloridesUsing liquid separation agentEvaporationLarge Calorie

The invention discloses a system for producing anhydrous calcium chloride by using industrial waste hydrochloric acid, and a technology thereof. The reaction system of the technology is connected to an evaporation system through a refined calcium chloride conveying device, and the evaporation system, a calcium chloride forming machine, a drying system, a finished calcium chloride conveying device and a finished calcium chloride bunker are sequentially connected; the reaction system is mutually connected with a reaction tail gas treatment system; and the refined calcium chloride conveying device is also connected with a dry tail gas washing device, and the gas outlet end of the drying system is connected to the inlet end of the evaporation system through the dry tail gas washing device. The reaction tail gas washing device adopts a clean calcium chloride solution as an absorbent, and the hydrogen chloride absorbed calcium chloride solution returns to a calcium chloride reactor, so the concentration of hydrochloric acid is not diluted, and the energy consumption of the evaporation system is reduced; and the calcium chloride solution is used to wash dust-containing tail gas with calories to make dusts not exist in vented tail gas, and a circulating absorption solution absorbing the calories in the tail gas returns to the evaporation system and is reused, so the energy consumption of the evaporation system is reduced.

Owner:LIAOCHENG LUXI CHEM ENG DESIGN

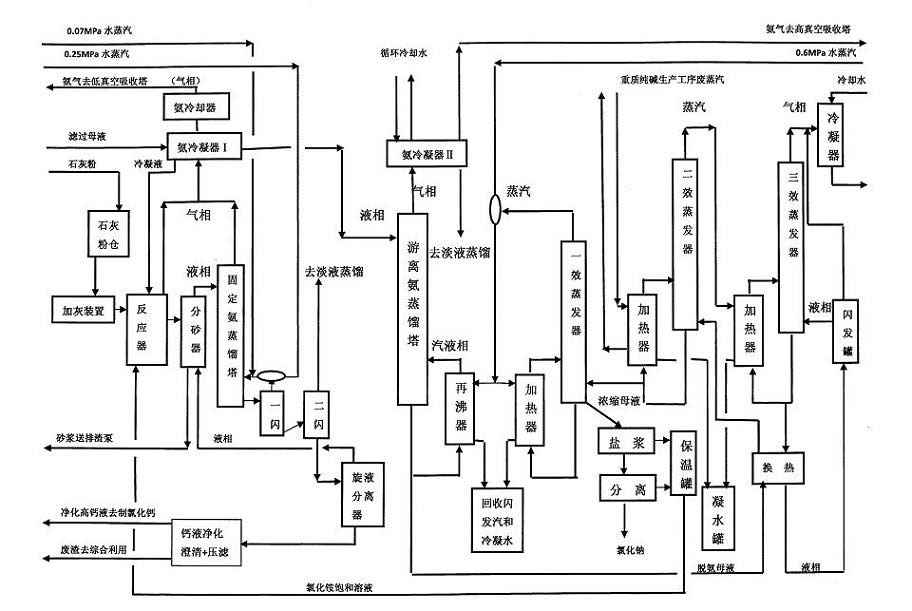

Process for preparing calcium chloride solution by utilizing ammonia soda filtration mother liquor

ActiveCN102145912AIncrease solute concentrationQuality improvementCalcium/strontium/barium chloridesEnergy inputFiltrationChloride

The invention discloses a process for preparing a calcium chloride solution by utilizing ammonia soda filtration mother liquor and relates to the field of the production method of calcium chloride. The process comprises the following steps: distilling the filtration mother liquor to obtain mother liquor without ammonia, performing triple effect evaporation and separation to the obtained mother liquor to obtain an ammonium chloride saturated solution, then using the ammonium chloride saturated solution to react with lime powder in a reactor and generate a calcium chloride solution, and finally purifying the calcium chloride solution to prepare the finished product-calcium chloride solution. By adopting the process, the soda-calcium production can be realized under the premise of ensuring the recovery and recycling of ammonia and carbon dioxide and the content of the calcium chloride solution is more than 30wt%.

Owner:大连大化工程设计有限公司 +1

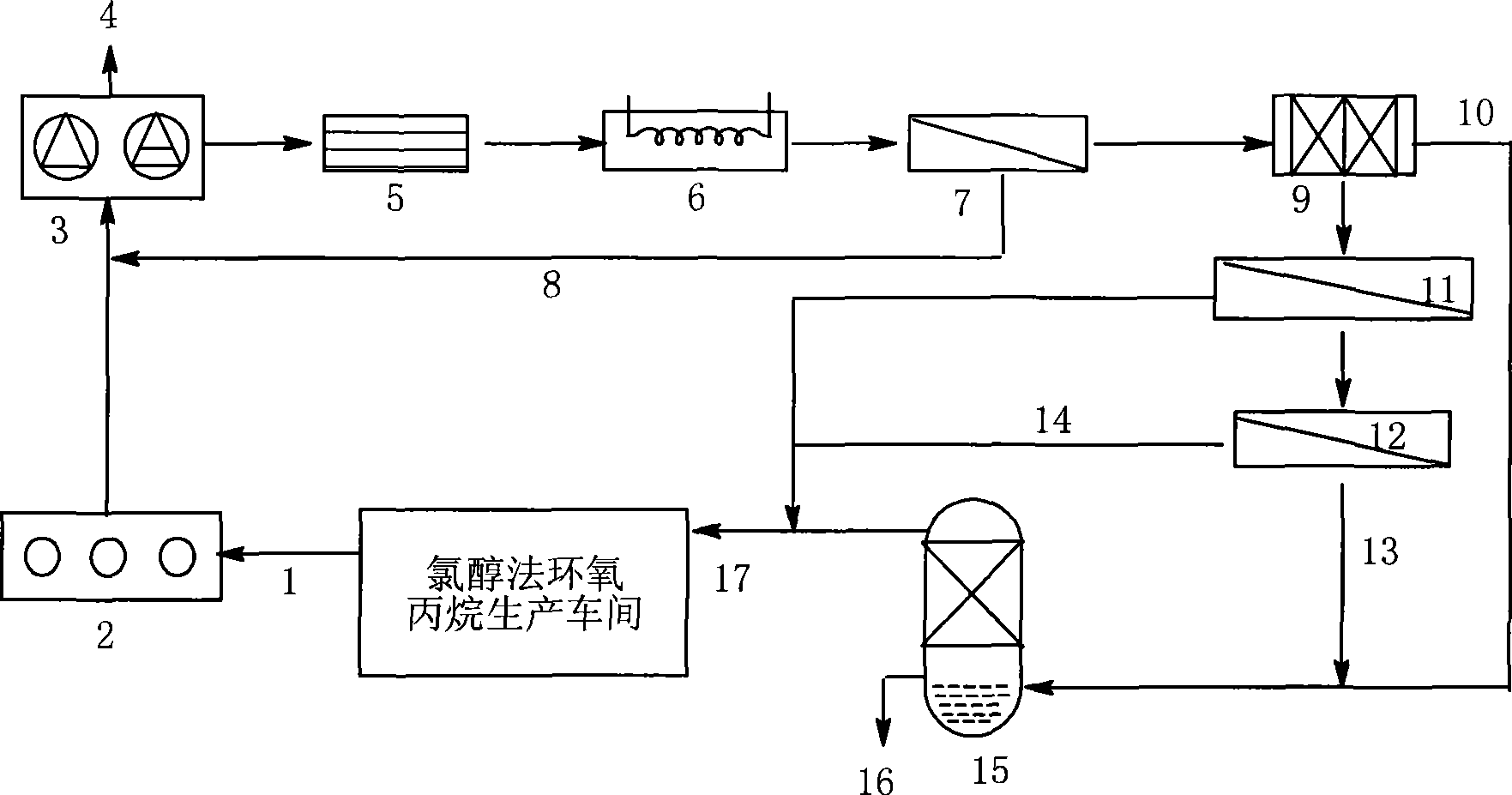

Process for treating saponification wastewater by chlorohydrination

ActiveCN101481190ASmooth cycle processingTroubleshoot placement issuesCalcium/strontium/barium chloridesDispersed particle separationChemical treatmentSocial benefits

The invention discloses a chemical processing method, and in particular discloses a method for recovering and reusing saponified waste water generated by a chlorohydrination method. The invention uses the novel film method and the salt and water recovering and reusing method to process the saponified waste water generated by a chlorohydrination method, and the technical designs, such as gas flotation, crystallizing prevention, ceramic film filtration, heat exchange, electrodialysis concentration, vaporizing recovery and the like are applied in the method. The invention has the advantages that the zero discharge of the waste water is basically realized, the salt and the water can be recovered, the small land area is occupied, the running expense is low, and the economic and social benefits are high. The invention can be widely used in the factories using the chlorohydrination method for producing propylene oxide.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Method of producing calcium chloride from industrial waste carbide slag

InactiveCN1923700ATake advantage ofReduce pollutionCalcium/strontium/barium chloridesSlagReaction temperature

The invention discloses a manufacturing method of calcium chloride through industrial waste carbide slag, which comprises the following steps: adding 20-40% industrial alcaine in the autoclave; adding carbide slag to react; controlling reacting temperature at 40-95 deg.c; terminating the reaction when the pH value is 5-8; filtering the product; adding activated carbon to discolor; adding barium chloride to remove sulfate ion; filtering; condensing the filtrate; crystallizing; drying to obtain calcium chloride.

Owner:游川北

A kind of treatment and reuse method of calcium chloride wastewater

InactiveCN102295392AAddress high pHSolve easy foulingCalcium/strontium/barium chloridesDispersed particle separationEvaporationReverse osmosis

The invention belongs to the technical field of sewage treatment, and in particular relates to a water treatment and reuse method of calcium chloride wastewater. The present invention basically achieves zero discharge of waste water and recyclable salt and water through the use of process design such as optimized pretreatment, biochemical treatment, reverse osmosis water recycling, electrodialysis concentration, and evaporation recovery. The invention has the advantages of small occupied area, low operation cost and good economic and social benefits. The invention can be widely used in enterprises producing calcium chloride wastewater.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

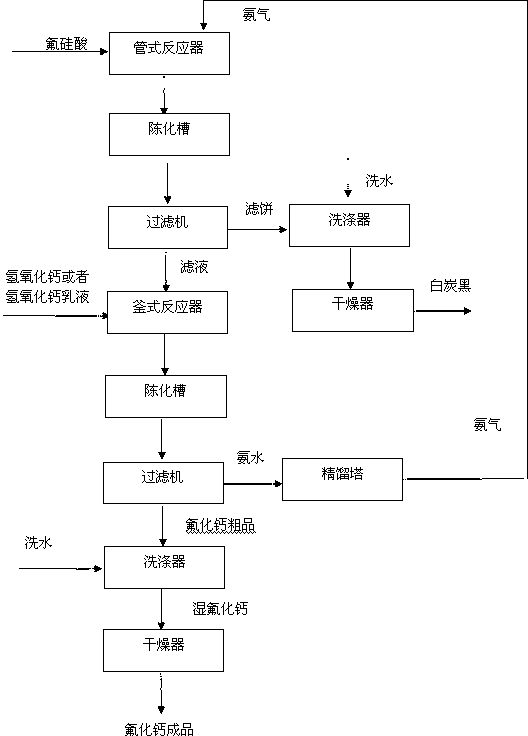

Producing method of calcium fluoride with white carbon black

ActiveCN103073040ALarge particle sizeFine particleSilicaCalcium/strontium/barium chloridesPhosphoric acidSlurry

The invention discloses a producing method of calcium fluoride with white carbon black. The producing method comprises the steps of allowing fluorosilicic acid (a wet-process phosphoric acid by-product) and ammonia to react continuously in a tubular reactor, ageing and filtering generated slurry to obtain an ammonium fluoride filtrate and a white carbon black filter cake, and washing and drying the white carbon black filter cake to obtain the white carbon black. Produced ammonium fluoride is good in quality and high in purity; the white carbon black is high in content, small in particle size, large in specific surface area and excellent in reinforcement performance, can be used for completely substituting the existing industrial water glass precipitation-process white carbon black; the ammonium fluoride filtrate and calcium hydroxide react to form a crude product of calcium fluoride and ammonia water; the crude product of calcium fluoride is washed and dried to form calcium fluoride; and the ammonia water is distilled into ammonia to serve as a raw material for ammoniation of fluorosilicic acid.

Owner:KUNMING DAOERSEN TECH

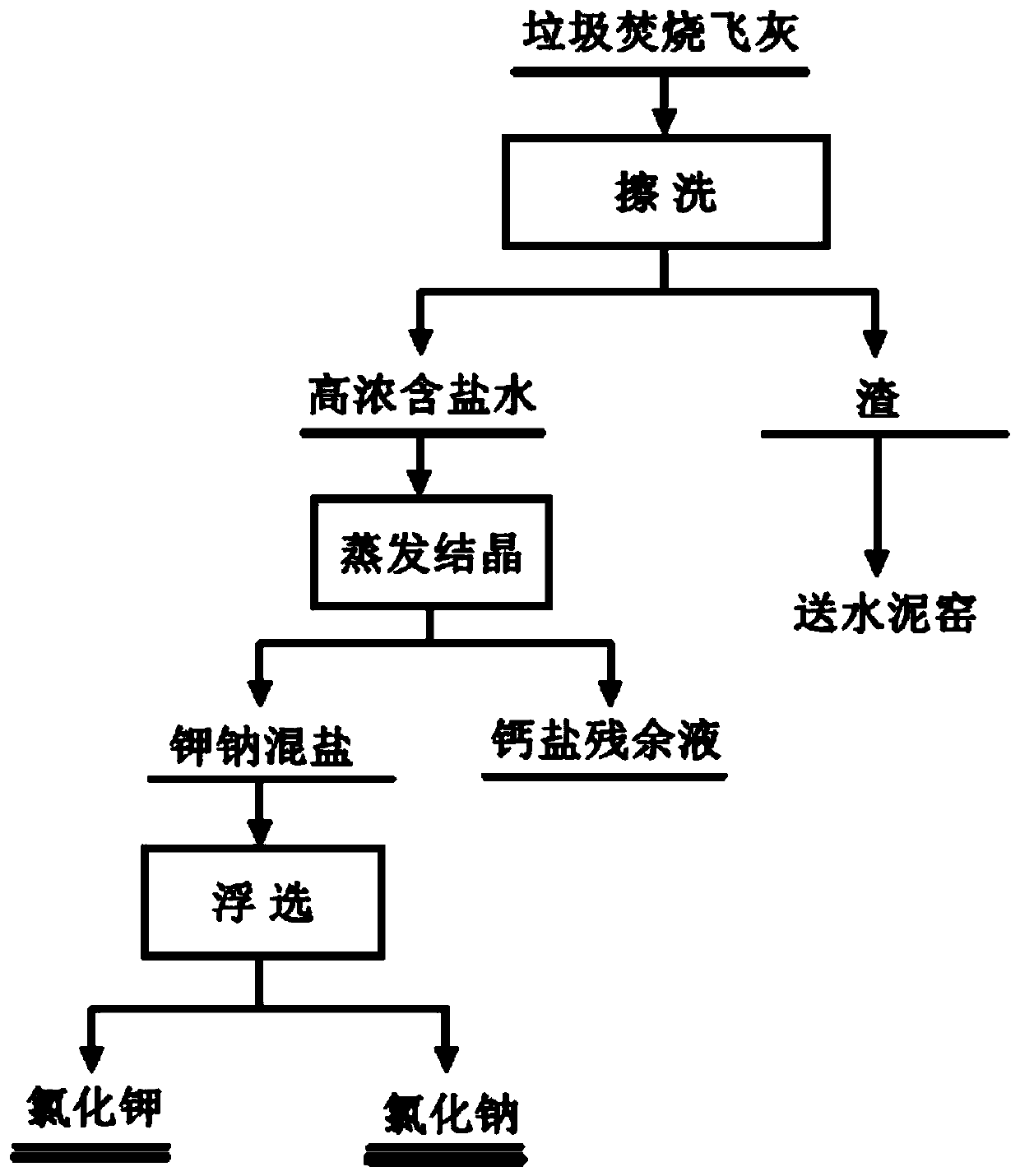

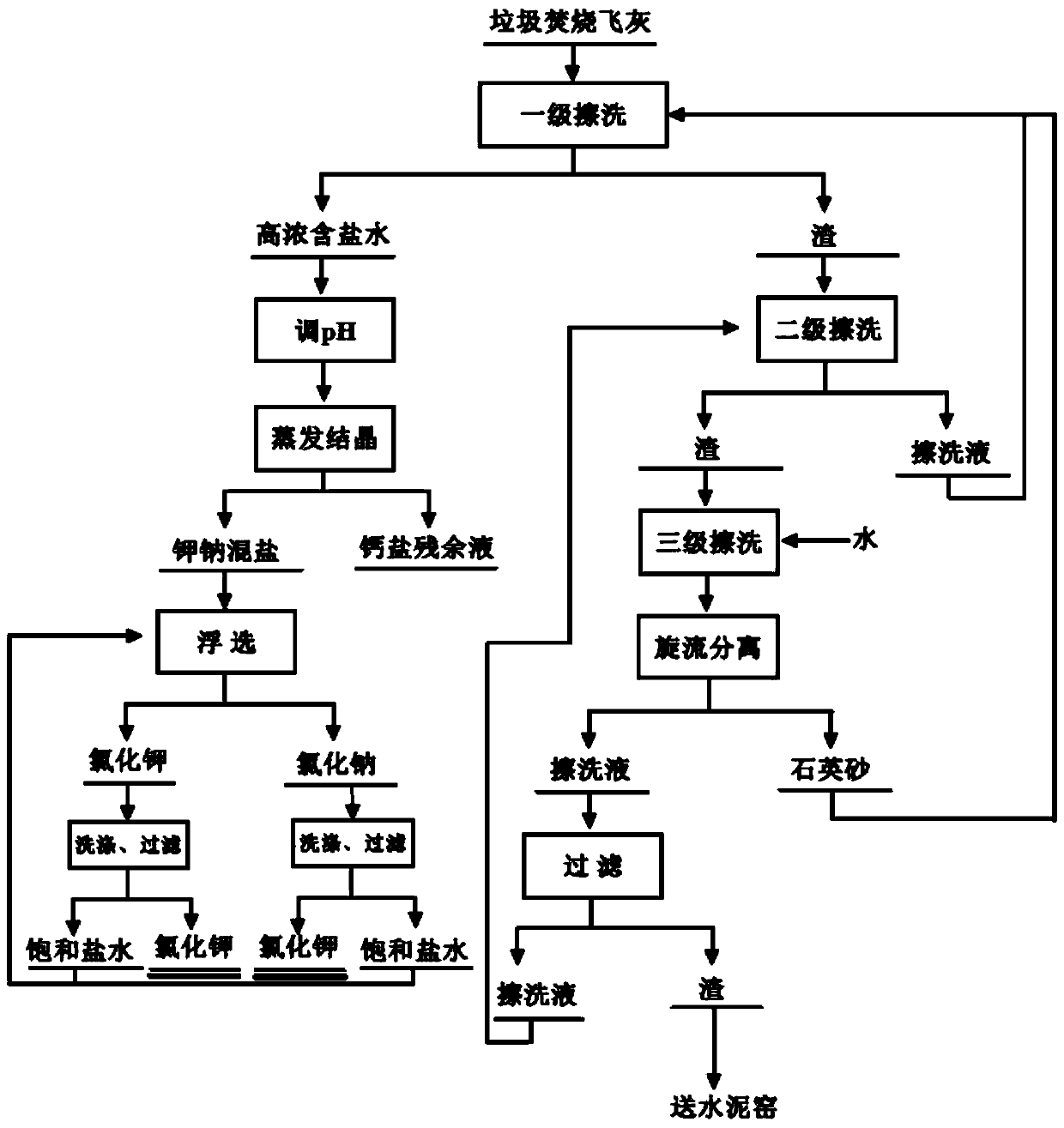

Method for recovering and separating potassium salt and sodium salt from waste incineration fly ash

InactiveCN110589856AImprove the dissolution rate of soluble saltsReduce consumptionCalcium/strontium/barium chloridesAlkali metal chloridesHigh concentrationFiltration

The invention relates to a method for recovering and separating a potassium salt and a sodium salt from waste incineration fly ash, which comprises the following steps of: extracting the potassium salt, the sodium salt and a calcium salt from the waste incineration fly ash by quartz sand and water to obtain high-concentration salt-containing water, separating the quartz sand from the fly ash, returning the quartz sand for continue use; adjusting the pH value of the high-concentration salt-containing water to 5-7 with an acid, and conducting evaporating and concentrating to obtain potassium andsodium mixed salts and a residual calcium chloride saturated solution; conducting flotation separation on the potassium and sodium mixed salts in saturated potassium chloride and sodium chloride solutions, and conducting filtration, so as to obtain a foam product, namely potassium chloride, and tailings slurry, namely sodium chloride; respectively conducting stirring washing on the potassium chloride and sodium chloride obtained by flotation through corresponding saturated salt water, and conducting filtering to obtain industrial grade potassium chloride and sodium chloride products, whereina washing solution is a saturated potassium chloride and sodium chloride mixed solution and is returned to the flotation procedure as a supplement solution of a flotation medium. The method effectively separates soluble salts in the fly ash: potassium chloride, sodium chloride and calcium chloride without decalcification to obtain high purity or industrial grade potassium chloride and sodium chloride products; and the efficiency-cost ratio of the treatment process is greatly improved.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

Processing method of titanium extraction tailings

InactiveCN104056841AReduce chlorine contentAchieve reuseCalcium/strontium/barium chloridesSolid waste disposalWater solubleChloride

The invention provides a processing method of titanium extraction tailings. The titanium extraction tailings contain a water soluble chloride; the method includes washing the titanium extraction tailings with water, so that the content of chlorine elements in the processed titanium extraction tailings is below 0.06 wt%. Through the processing method of the titanium extraction tailings, the titanium extraction tailings with the chlorine element content below 0.06% can be obtained.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

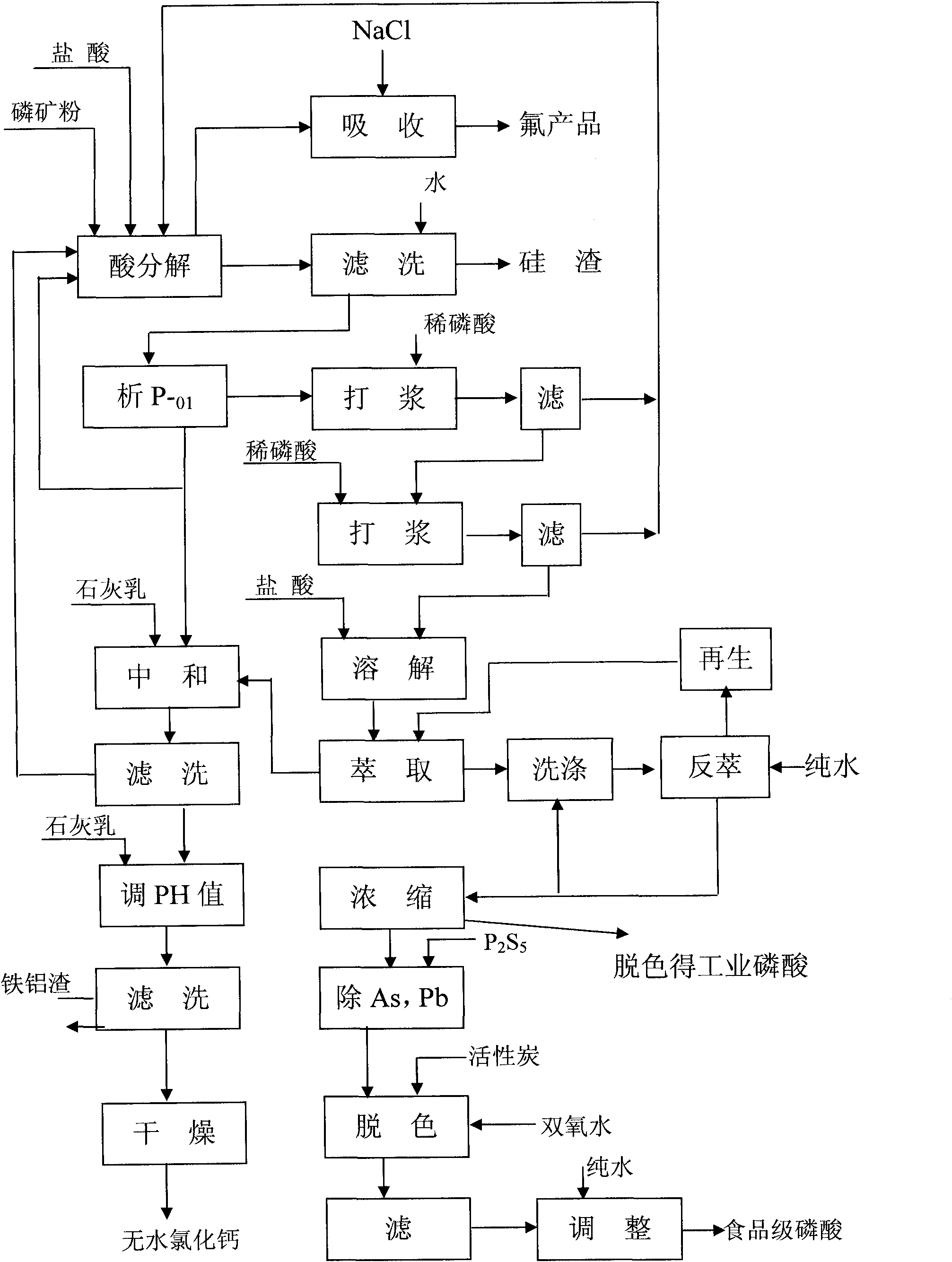

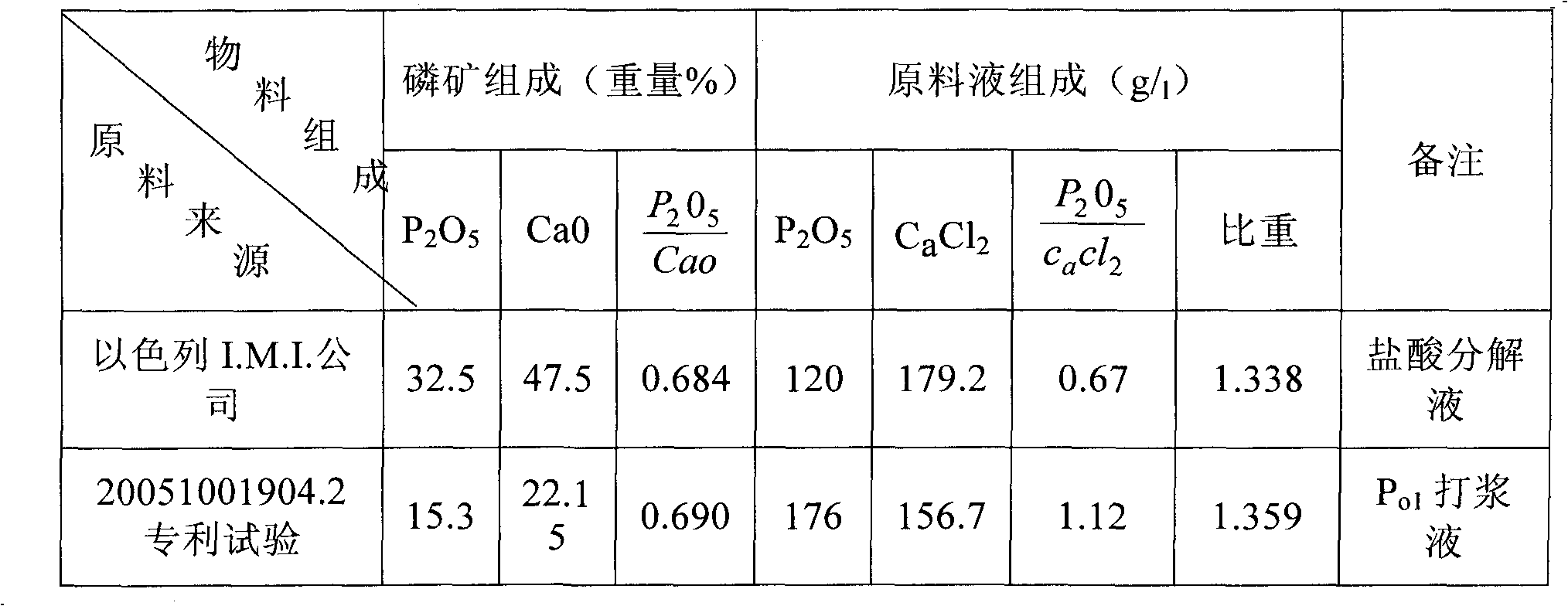

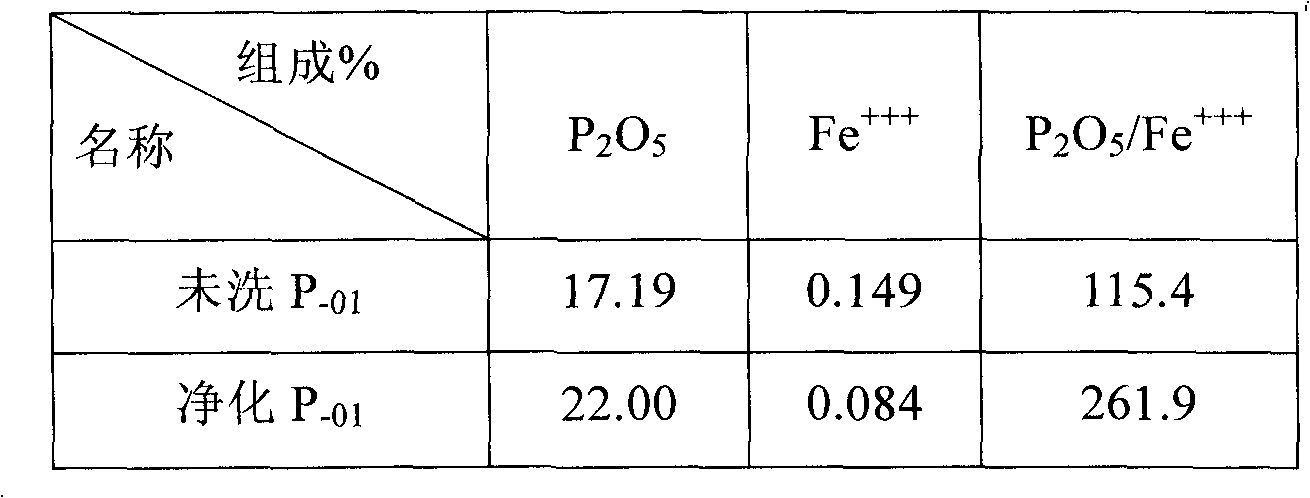

Method for manufacturing industrial phosphoric acid, industrial ammonium phosphate and food-grade phosphoric acid from medium and low-grade phosphorite by one-step extraction of hydrochloric acid method

InactiveCN102134063AHigh energy consumptionCalcareous fertilisersPhosphatesPhosphoric acidHydrogen peroxide

The invention discloses a method for manufacturing industrial phosphoric acid, industrial ammonium phosphate and food-grade phosphoric acid from medium and low-grade phosphorite by one-step extraction of a hydrochloric acid method. The method is characterized by comprising the following steps of: decomposing any phosphorite (the P2O5 of which is more than or equal to 6 weight percent) by using hydrochloric acid, preparing calcium chloride dihydrogen phosphate CaClH2PO4.H2O (P-01 for short), adding dilute phosphoric acid, pulping, filtering and purifying the P-01, pulping and dissolving the P-01 with hydrochloric acid, performing extraction by using tributyl phosphate, performing concentration and decolorization to obtain the industrial phosphoric acid, adding ammonia into the industrial phosphoric acid to obtain the industrial ammonium phosphate, or adding P2S5 into the concentrated industrial phosphoric acid to remove arsenic and heavy metal, performing decolorization by using active carbon and hydrogen peroxide and removing easily oxidized substances to reach the index requirement of the food-grade phosphoric acid.

Owner:上海协达精细化工研发有限公司

Method of making pure salt from frac-water/wastewater

ActiveUS20110104038A1Easy to produceQuality improvementCalcium/strontium/barium carbonatesCalcium/strontium/barium chloridesParticulatesWater use

The present invention relates to a method for making pure salt comprises recapturing post-drilling flowback water from hydro-fracturing; removing oil from the flowback water; filtering the flowback water using an ultra filter with a pore size of about 0.1 microns or less to remove solid particulates and large organic molecules, such as benzene, ethylbenzene, toluene, and xylene, from the water; concentrating the flowback water to produce a brine that contains from about 15 wt % to about 40 wt % of salt relative to the total weight of the flowback brine; performing one or more chemical precipitation process using an effective amount of reagents to precipitate out the desired high quality commercial products, such as, barium sulfate, strontium carbonate, calcium carbonate; and crystallizing the chemically treated and concentrated flowback brine to produce greater than 99.5% pure salt products, such as sodium and calcium chloride.

Owner:FRACPURE HLDG

Method for synchronously recovering mercuric chloride, metal salt and active carbon in spent catalyst

InactiveCN102962033AIncrease profitSolve the scarcityPhysical/chemical process catalystsCalcium/strontium/barium chloridesMetal saltsRaw material

The invention discloses a method for synchronously recovering mercuric chloride, metal salt and active carbon in a spent catalyst. The method is orderly implemented through the steps of spent catalyst drying, mercuric chloride recovery, complex perforation of active carbon and metal salt recovery, wherein mercuric chloride in the spent catalyst is recovered through destructive distillation in combination with condensation and aqueous solution absorption; deposits in the micropores of the active salt are displaced through hot water soaking in combination with bubbling by introducing air, thereby realizing the purpose of recovering the pores of the active carbon; and then the active carbon is recovered through drying and the metal salt is recovered through filtering; in the whole process, no pollutant is generated and discharged and the utilization rate of water is also extremely high; valuable elements in the spent catalyst are all recovered; and the valuable elements in the spent catalyst which is used in production previously and contains mercuric chloride, metal salt and active carbon are utilized, thereby achieving the purposes of solving the problems of scarce raw materials for new catalyst production and environmental pollution caused by inappropriate spent catalyst disposal; as a result, the method is obvious in economic benefit, environmental benefit and social benefit.

Owner:那风换

Tail-gas comprehensive utilization method in mercuric chloride catalyst

InactiveCN101455974AImprove protectionReduce energy consumptionCalcium/strontium/barium chloridesDispersed particle separationLiquid wasteActivated carbon

The invention discloses a comprehensive utilization method for tail gas in the production of a mercuric chloride catalyst. The method comprises the following steps: the temperature of tail gas coming from a dryer in the production of the mercuric chloride catalyst is between 90 and 105 DEG C; the discharge temperature of the tail gas of which the waste heat is recovered is controlled to be not higher than 45 DEG C through a heat exchange device serially connected with the back of the dryer; the tail gas of which the waste heat is recovered and the tail gas which comes from the other processes in the production of the mercuric chloride catalyst are mixed together, and enters from the lower part of a filler countercurrent gas-washing tower; mixture liquid of BaCl2 and Ba(OH)2 is continuously sprayed down from the top of the filler tower to perform countercurrent gas washing; liquid after washing flows into an anticorrosion circulation tank on the bottom of the tower; washing liquid is continuously circulated and sprayed under the action of a circulating anticorrosion pump; and the tail gas after washing is adsorbed to remove foam through dry activated carbon in an activated-carbon device for adsorbing and removing foam, so as to obtain the tail gas reaching discharge standard. The method can ensure that the tail gas after purification treatment reaches the discharge standard, and both solid waste and liquid waste generated can be directly used for producing the mercuric chloride catalyst, so as to save energy and reduce consumption.

Owner:WANSHAN HONGJING MERCURY

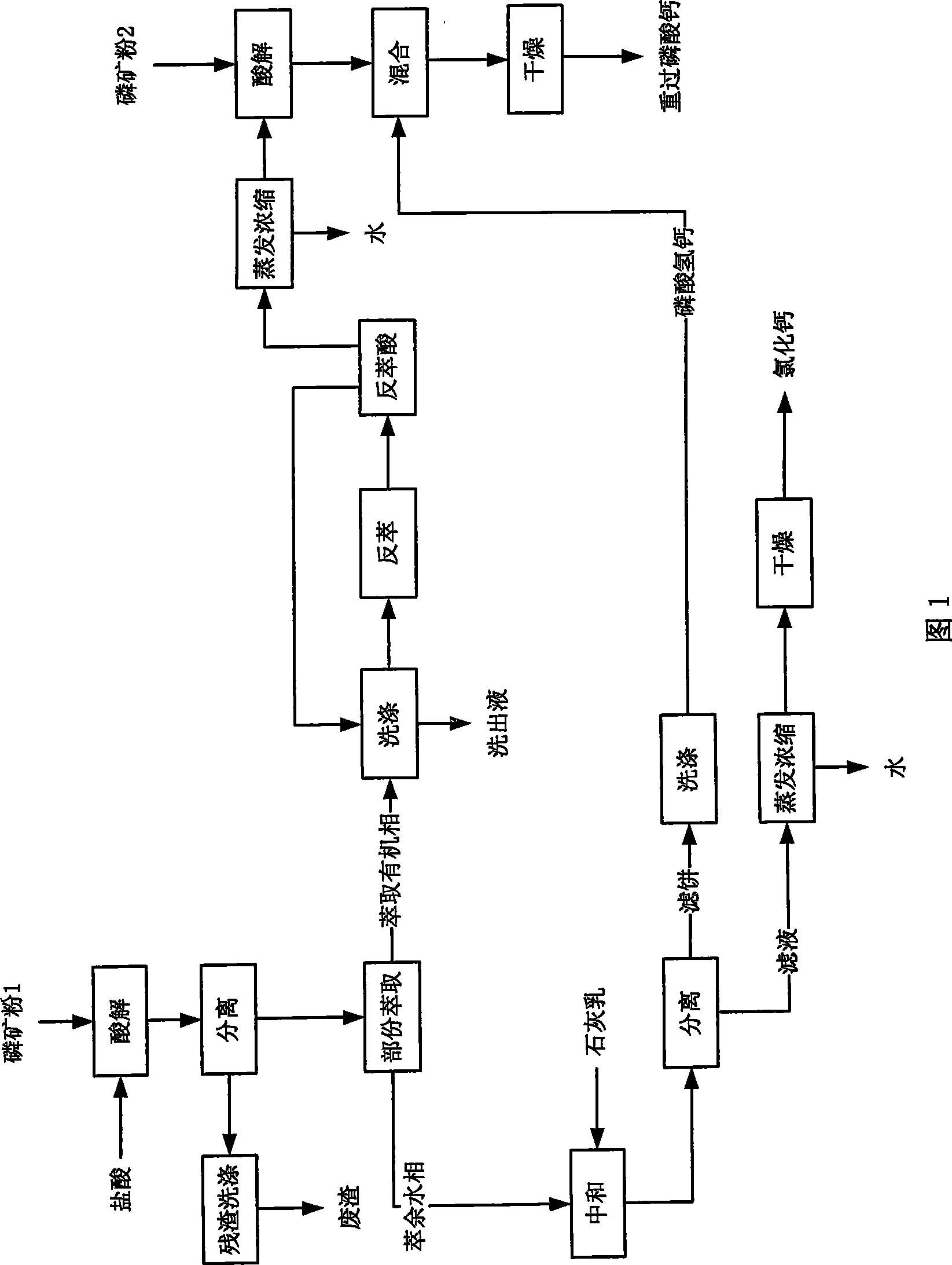

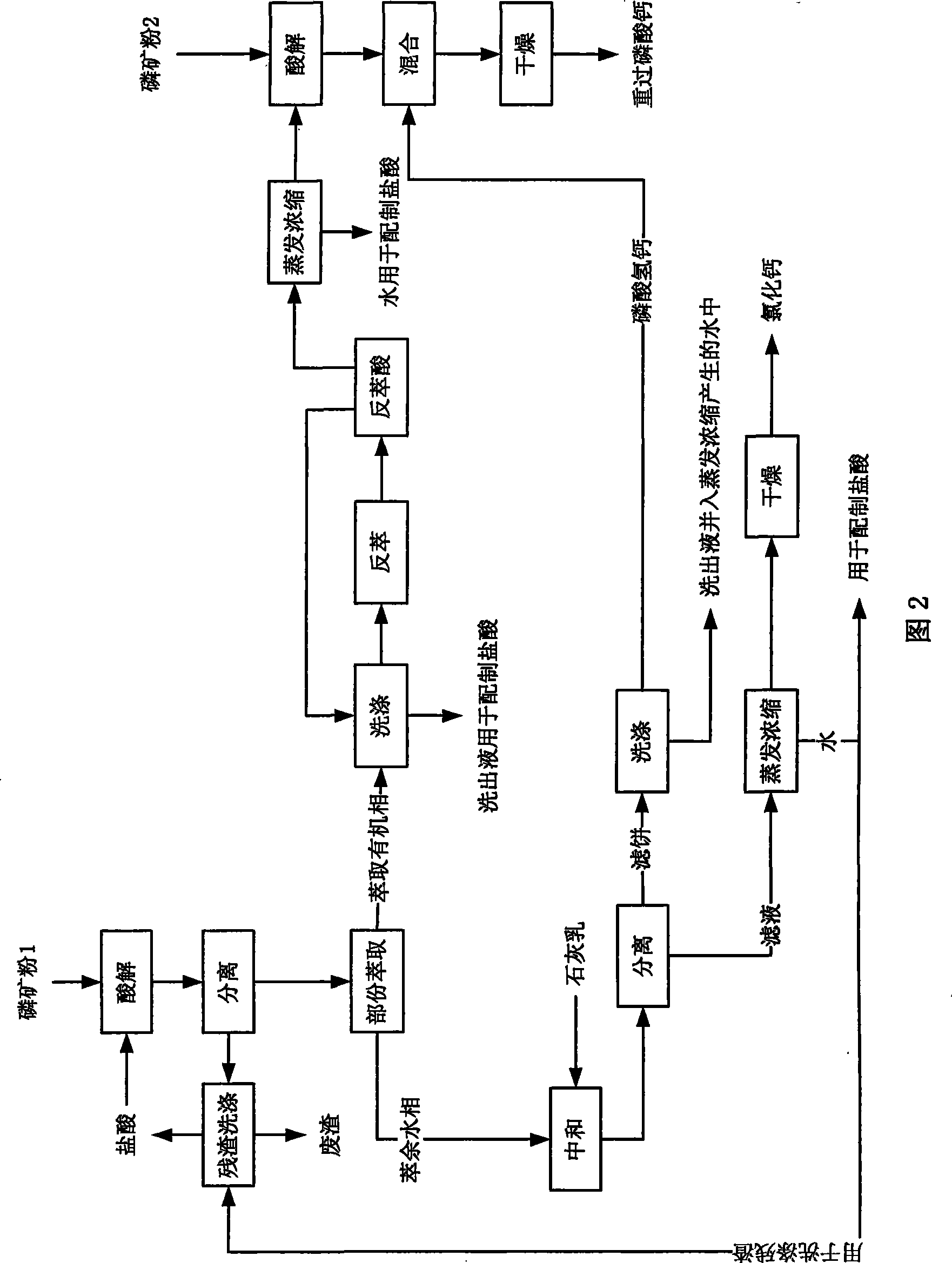

Method for producing triple superphosphate and co-producing calcium chloride by middle-low grade phosphate rock

InactiveCN101456545AOvercoming the Prejudice of Not being able to Produce TSPLow grade requirementsCalcium/strontium/barium chloridesPhosphorus compoundsPhosphoric acidEvaporation

The invention relates to a method for producing concentrated superphosphate and coproducing calcium chloride through medium and low grade phosphorite, which comprises: firstly, using hydrochloric acid to perform acidolysis on powdered rock phosphate 1 which is medium and low grade powdered rock phosphate with the particle diameter of less than or equal to 1,165 mu m; secondly, performing partial extraction, namely performing countercurrent extraction on an acidolysis solution obtained in the first step, wherein P2O5 entering an organic phase accounts for 50 to 90 percent of the total mass of P2O5; thirdly, performing washing and back-extraction on the organic phase in the second step, and concentrating a back extract acid to prepare concentrated phosphoric acid; fourthly, performing neutralization reaction on a residual aqueous phase in the second step and lime cream, performing solid-liquid separation after the reaction is over, washing filter cakes to obtain calcium hydrophosphate, and performing evaporation, concentration and drying on filtrate to obtain the calcium chloride; and fifthly, using the concentrated phosphoric acid obtained in the third step to perform acidolysis on powdered rock phosphate 2 which is medium and low grade powdered rock phosphate with the particle diameter of less than or equal to 74 mu m, adding the calcium hydrophosphate prepared in the fourth step for reaction after the acidolysis reaction is over, and drying reaction products to obtain the concentrated superphosphate after the reaction is over.

Owner:SICHUAN UNIV

Method for combined production of ammonia and basic calcium chloride by decomposing ammonium chloride

InactiveCN101941719AReduce energy consumptionLess investmentCalcium/strontium/barium chloridesAmmonia preparation/separationChemical reactionSolvay process

The invention provides a method for the combined production of ammonia and basic calcium chloride by decomposing ammonium chloride, which comprises the following steps: grinding or crushing calcareous materials and ammonium chloride according to a mol ratio of 1:0.5-2 in a ball grinder or a crusher at -20-200 DEG C, enabling the calcareous materials and the ammonium chloride to be subject to a chemical reaction to decompose the ammonium chloride so as to release ammonia gas and generate basic calcium chloride. The invention fully uses the large amount of ammonium chloride as the byproducts of the combined soda process and the ammonia soda process, realizes the recycling of ammonia and generates the basic calcium chloride as the byproduct. The invention has the characteristics of simple process, low investment, high conversion rate, no pollution and low energy consumption, is applicable to industrial production and meets the requirements green chemical development in the present society.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for separatingcalcium chloride and sodium chloride in ammonia distillation waste clear solution with nanofiltration technology and application of production by the method

InactiveCN101219797AIncrease concentrationReduce consumptionCalcium/strontium/barium chloridesWater/sewage treatment bu osmosis/dialysisHigh concentrationDistillation

The invention discloses a method for separating calcium chloride and sodium chloride in ammonia distillation waste clear liquid by using nanofiltration membrane technology and application of product thereof, relating to a chemical field of preparing calcined soda by using an ammonia-soda process or a union alkali method; the method comprises that the ammonia distillation waste clear liquid is separated through a nanofiltration membrane filtering equipment to obtain concentrated solution mainly containing calcium chloride solution and penetrant mainly containing sodium chloride solution. The penetrant can be recycled for salt dissolving technology. The concentrated solution containing high-concentration calcium chloride can be used for producing calcium chloride product by adopting methods of evaporation and crystallization. The method leaves out processes of repeated sunning, heating and vacuum pumping, and most moisture can be reused; the invention reduces energy consumption and area occupation, saves a large amount of water resource, which create good condition for technology of subsequent salt dissolving and the calcium chloride production.

Owner:王晓璐

Combination production method for obtaining multi-products using high iron bauxite as raw material

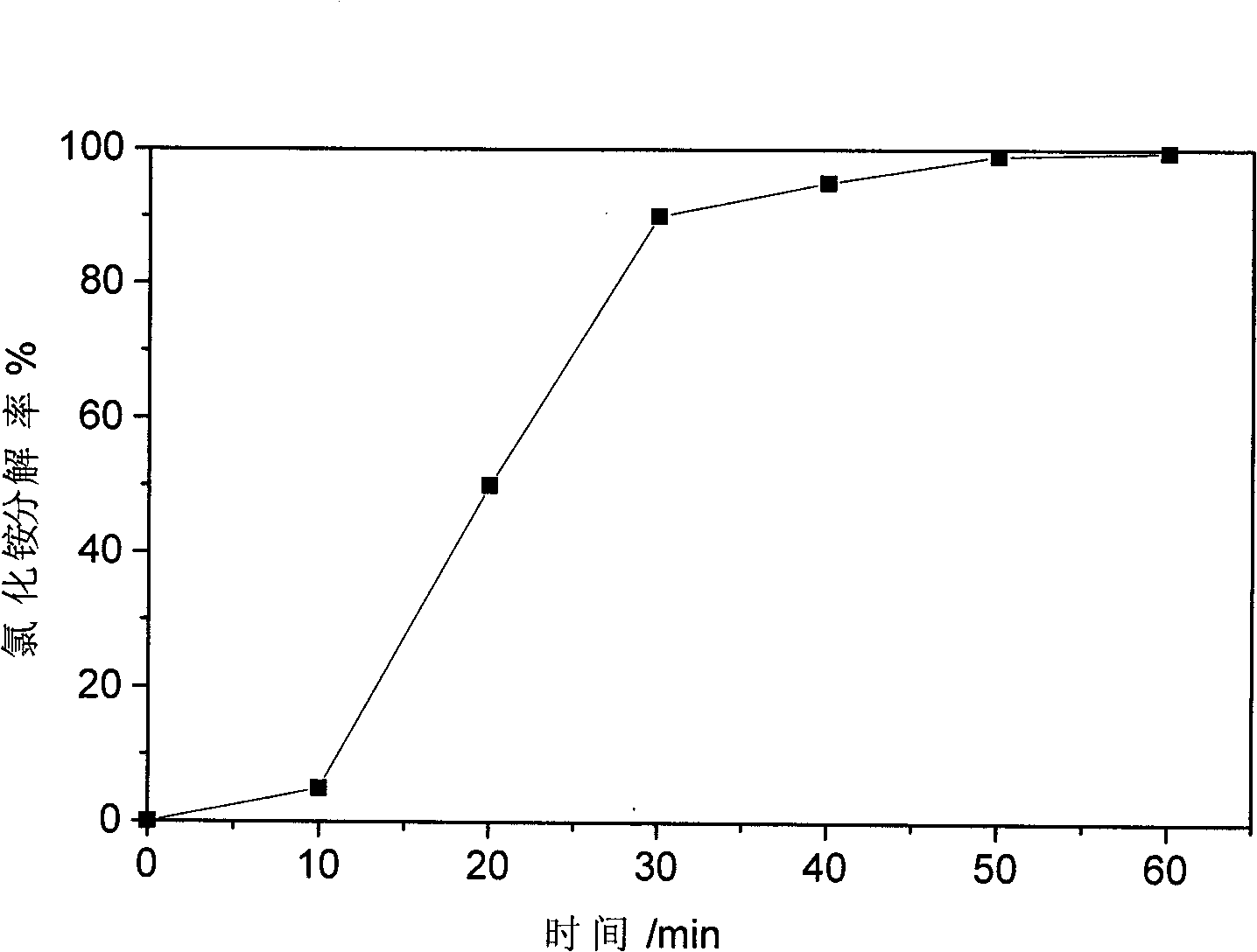

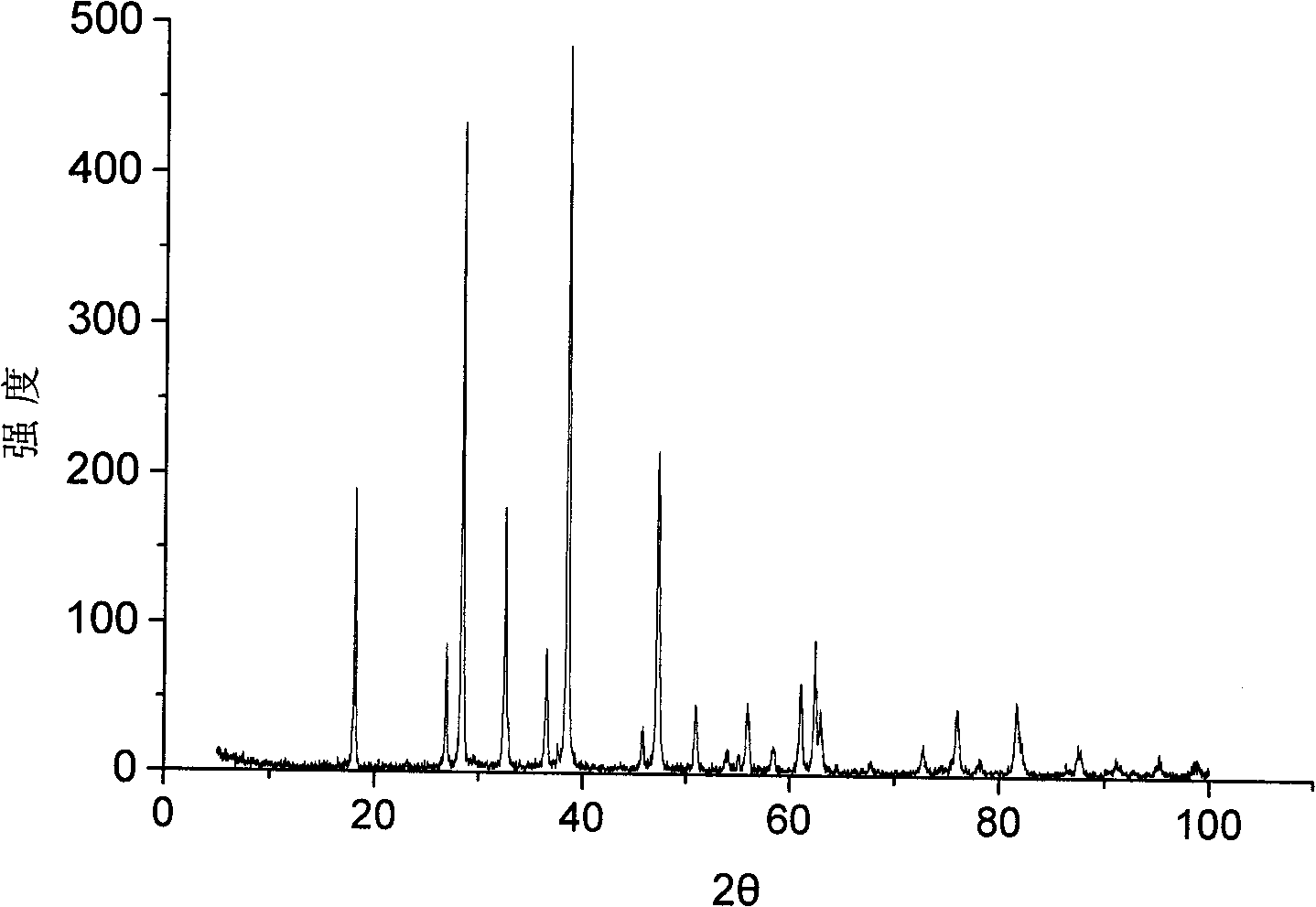

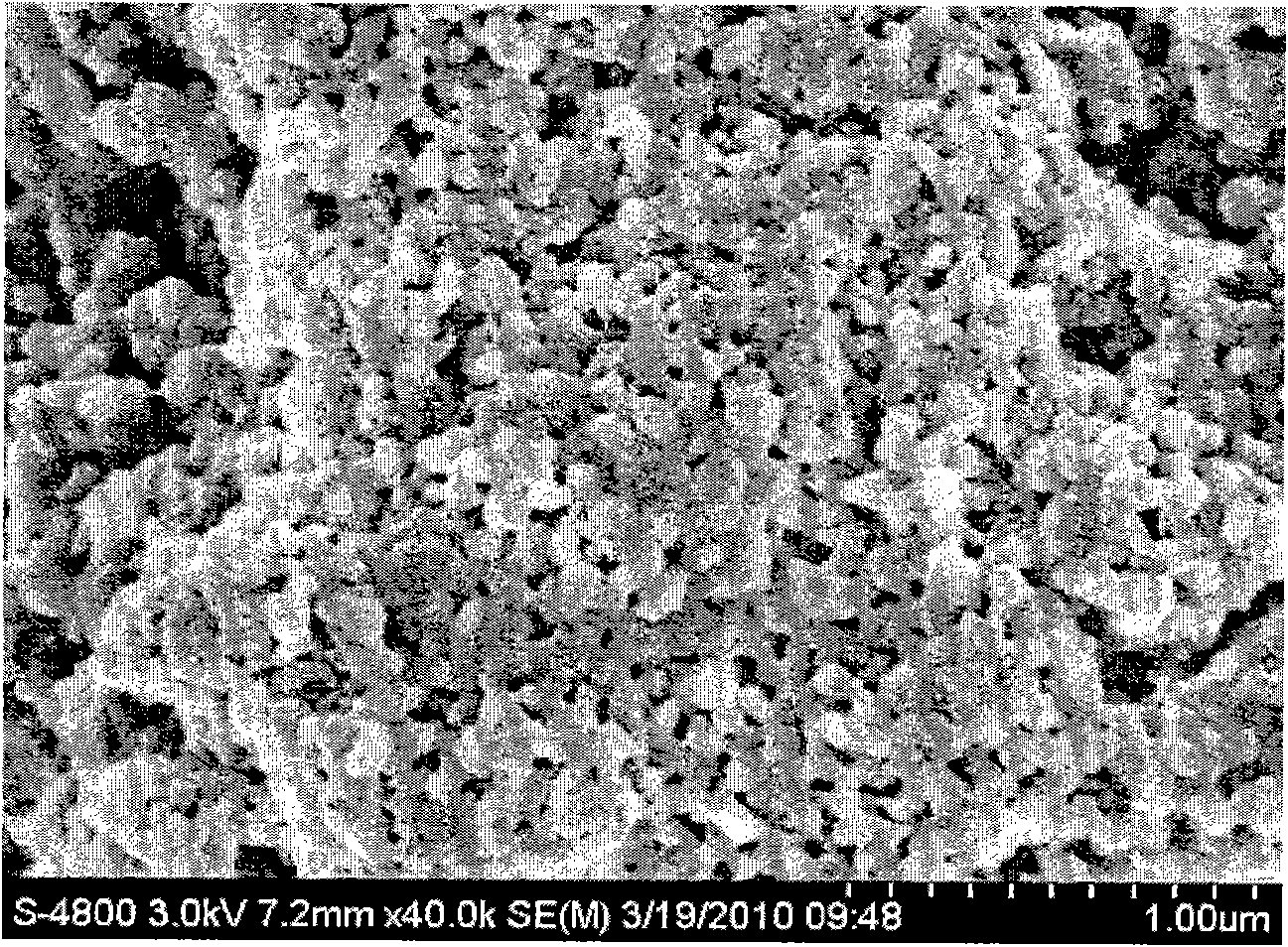

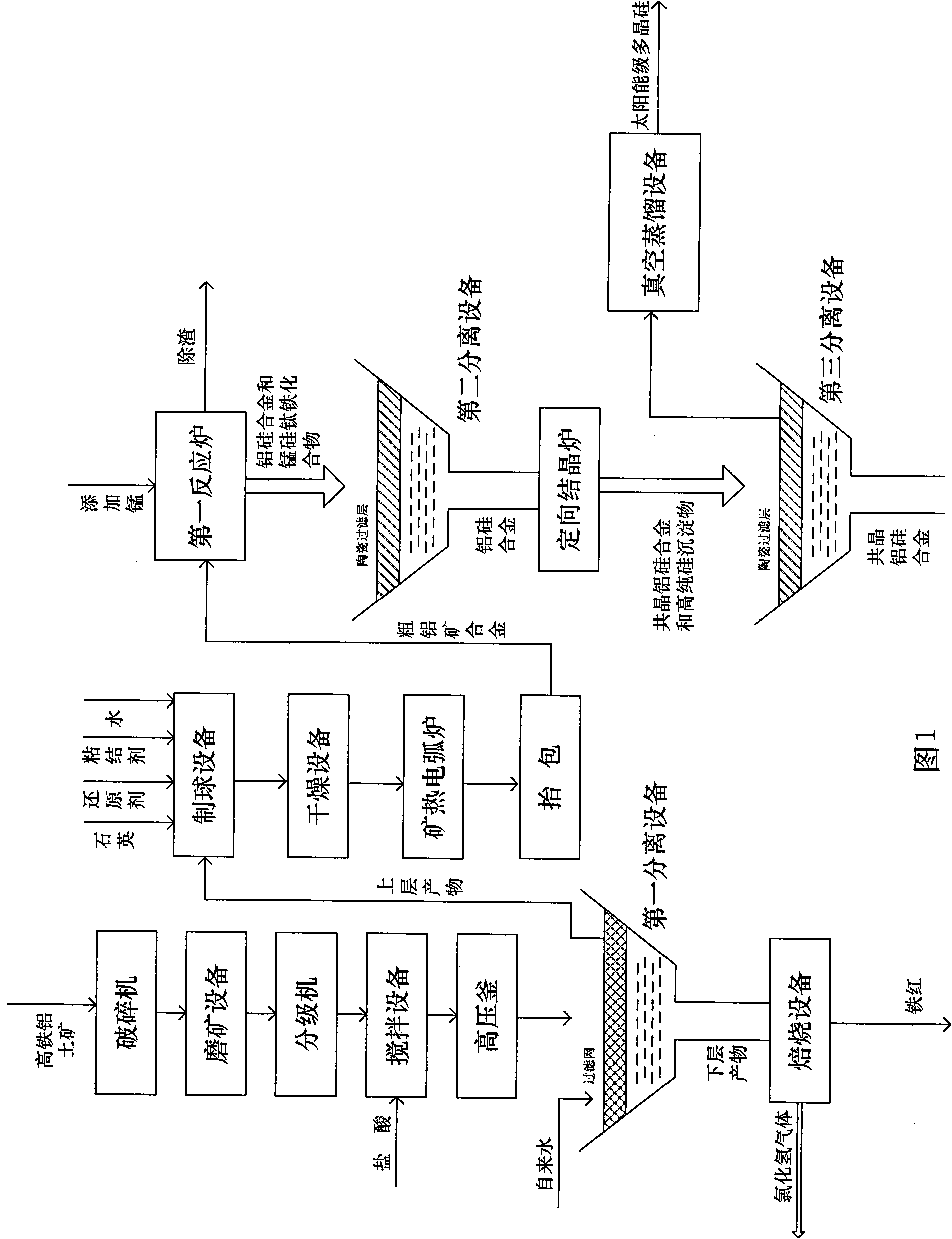

The invention discloses a combination production method for industrially producing a plurality of products by using high-iron alumyte as a material. The combination production method comprises the steps of performing pressure-leaching the high-iron alumyte by using hydrochloric acid as a leaching medium, iron enters the hydrochloric acid in the form of ion to form the chloride of iron, aluminum is left in solid alumyte, thereby separating iron from aluminum; roasting a hydrochloric acid leaching fluid to obtain iron oxide red and a chlorine hydride gas, wherein the chloride hydride gas is absorbed by washing water and becomes hydrochloric acid, which can be recycled; and melting the upper layer of products, conducting directional crystallization to prepare a cocrystallized Al-Si alloy with silica content below 14wt%. Therefore, the high-iron alumyte which cannot be utilized currently, can be comprehensively utilized.

Owner:辽宁建元投资发展有限公司 +1

Production method of calcium chloride snow melting agent

InactiveCN101045546AReduce pollutionTake advantage ofCalcium/strontium/barium chloridesCalcium hydroxideSnow melting

A process for preparing the calcium chloride as snowmelt agent with low environmental pollution includes such steps as loading the hydrochloric acid as a by-product into a reactor with stirrer, continuous stirring while slowly adding the rejected calcium carbide dregs containing calcium hydroxide, reacting while stirring until pH=7-8, vacuum filtering, taking clear liquid, evaporating, and drying.

Owner:SHENYANG CHEM IND CO LTD

System and method for treating chlor-alkali production byproduct salt mud

ActiveCN105129822AHarden fastImprove cold resistanceCalcium/strontium/barium chloridesIron oxides/hydroxidesFiltrationCalcination

The present invention discloses a system and a method for treating a chlor-alkali production byproduct salt mud. According to the present invention, through the system, chlor-alkali calcium carbonate salt mud is treated with hydrochloric acid to remove carbonate ions, the generated carbon dioxide is conveyed into an absorption tower and reacts with caustic soda to generate soda ash for salt water refining, the pH value of the solution can be adjusted by adding the caustic soda, acid insoluble substances and magnesium ions are precipitated, pressure filtration is performed to obtain a calcium chloride clear liquid, the calcium chloride clear liquid can be used as the refrigerant of the membrane method nitrate removal refrigeration unit and can be used for export, and in the waste residue obtained after the pressure filtration, the acid insoluble substance residue is conveyed to the cement plant, and the magnesium hydroxide is subjected to high temperature calcination to obtain magnesium oxide so as to achieve the zero emission of pollutants.

Owner:YIBIN HAIFENG HERUI

Method for preparing ammonia water and calcium chloride solution through decomposition recovery of ammonium chloride waste liquor

InactiveCN104876383ASimple processEmission reductionCalcium/strontium/barium chloridesWater contaminantsHigh concentrationLiquid waste

The invention discloses a method for preparing ammonia water and calcium chloride solution through the decomposition recovery of ammonium chloride waste liquor. The method comprises the following steps: the waste liquor is pretreated, and ammonium chloride and calcium oxide or calcium hydroxide powder is added into the pretreated ammonium chloride waste liquor; ammonia is distilled from the treated ammonium chloride waste liquor and is transferred into an ammonia absorption tower after being condensed, and a reaction liquid flows out from the bottom of a distillation tower; ammonia is absorbed from the condensed ammonia in the absorption tower by using desalted water, and the tail gas is exhausted after residual ammonia is washed by a tail gas washing tower; reaction liquid out of the bottom of the distillation tower is subjected to flash vaporization for recycling the energy and then is transferred into a clarifying barrel, and the clarified calcium chloride supernatant is used as the target product. According to the invention, the method is particularly suitable for the transformation of ammonium chloride wastewater treatment technology of enterprises in the existing rare earth industry, potassium carbonate industry and baking soda industry, and is simple in process; the ammonia is recycled by using desalted water through multi-stage absorption, and the recovery rate is up to 99%; the high-concentration calcium chloride solution can be used for producing calcium chloride products and the products can be recycled so as to have better economic benefits.

Owner:江苏大江干燥设备有限公司

Method for Recycling Ammonia from Low-Concentration Ammonium Chloride Wastewater

InactiveUS20170101326A1Reduce power consumptionEasy to processCalcium/strontium/barium chloridesTreatment involving filtrationLiquid wasteSlag

A method for comprehensively treating low-concentration ammonia-nitrogen wastewater by completely recycling is disclosed. The low-concentration ammonia-nitrogen wastewater and carbide slag or quick lime are mixed and reacted to obtain a mixed solution containing ammonia water and ammonium chloride. The mixed solution is transferred into an ammonia-water evaporative concentration tower to separate the ammonia water and thus obtain an ammonia vapor and a calcium chloride waste solution. The ammonia vapor is transferred into an ammonia-water cooler, and the calcium chloride waste solution is introduced into an aging pool for aging, and then filtered to obtain a purified calcium chloride solution; and the purified calcium chloride solution is introduced into an MVR triple-effect evaporator for evaporation, so as to obtain distilled water and a concentrated calcium chloride solution. The concentrated calcium chloride solution is introduced into a fluidized bed for spray granulation, so as to obtain an anhydrous calcium chloride product.

Owner:BAOTOU CITY XIJUN ENVIRONMENTAL SCI & TECH CO LTD

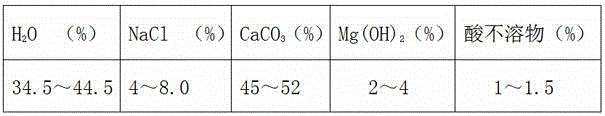

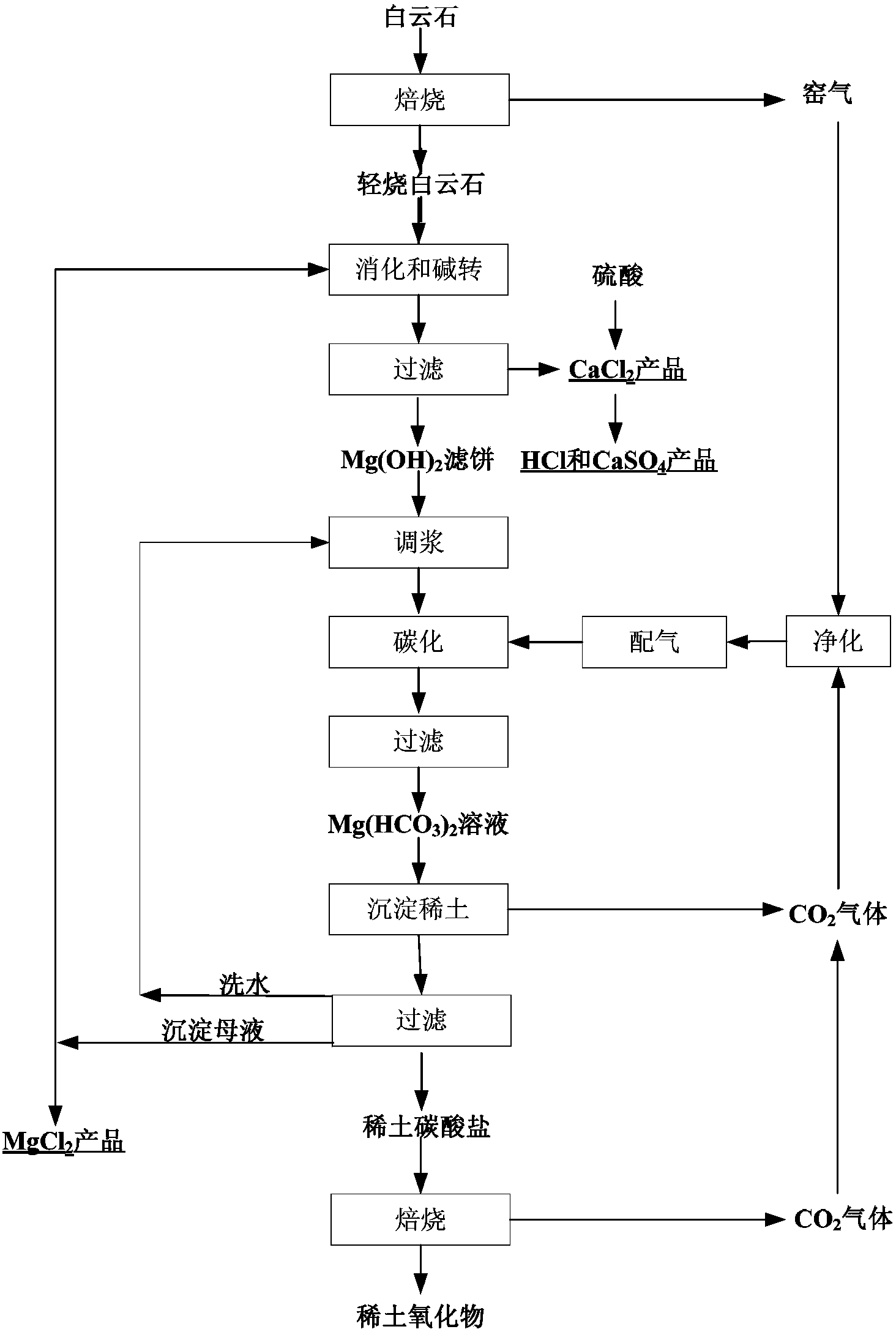

Preparation and comprehensive utilization method of magnesium bicarbonate solution

ActiveCN103382034ARealize comprehensive utilizationAchieve emissionsChlorine/hydrogen-chlorideCalcium/strontium/barium chloridesCarbonizationSlurry

The invention relates to a preparation and comprehensive utilization method of a magnesium bicarbonate solution. The method is used to prepare the magnesium bicarbonate solution used for deposition, crystallization and recovery of rare earth ions, and comprehensive recovery of calcium-compound products and magnesium-compound products by taking dolomite as a raw material. The method specifically comprises: roasting dolomite to obtain a powder containing calcium oxide and magnesium oxide, directly mixing with a magnesium chloride solution for digestion and alkali transformation at the same time to prepare a magnesium hydroxide secondary-product and a calcium compound secondary-product, and further to realize effective separation of calcium and magnesium; performing slurry mixing on magnesium hydroxide, introducing carbon dioxide gas for a carbonization reaction to prepare the magnesium bicarbonate solution; applying obtained magnesium bicarbonate to deposition and crystallization of the rare earth ions to produce rare-earth carbonate or rare-earth oxide products; and recycling one part of the filtrate to prepare magnesium bicarbonate, and evaporating one part of the filtrate for crystallization to produce the magnesium compound product.

Owner:GRIREM ADVANCED MATERIALS CO LTD

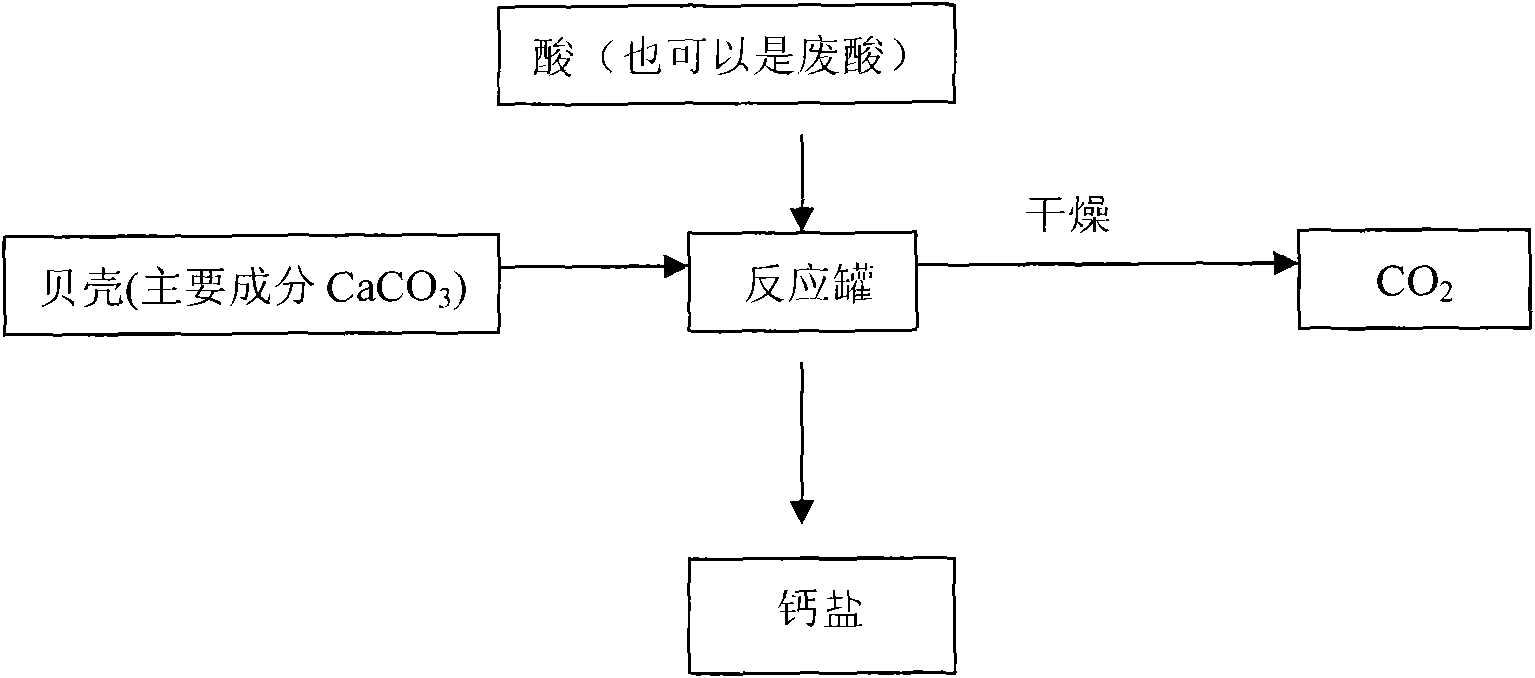

Method for manufacturing snowmelt agent by using shells

InactiveCN101654611AReduce leakageHigh economic valueCalcium/strontium/barium chloridesOther chemical processesLow leakagePollution

The invention relates to a method for manufacturing snowmelt agent, also is a method for manufacturing snowmelt agent by using shells, which uses shells and muriatic acid or acetic acid as raw materials for reaction and obtains the snowmelt agent after filteration, concentration and crystallization. The invention has simple synthesized route, and the production process has the advantages of no pollution, comprehensive recycled utilization, less secondary pollution in the production process, greatly lowered noise, low leakage of dust and controllable and environment-friendly production process.As the main ingredient of the shells is calcium carbonate, marine products for processing waste shells are taken as raw materials to manufacture environment-friendly calcium chloride or calcium acetate snowmelt agent, so that the environment pollution problem of processing waste shells by using marine products can be solved, the economic value of the marine product for processing waste shells isgreatly enhanced, and byproduct carbon dioxide is obtained. If shells and waste acid are used for reaction to manufacture snowmelt agent, the economic value of the waste acid can be improved.

Owner:ZHANGZIDAO GRP +1

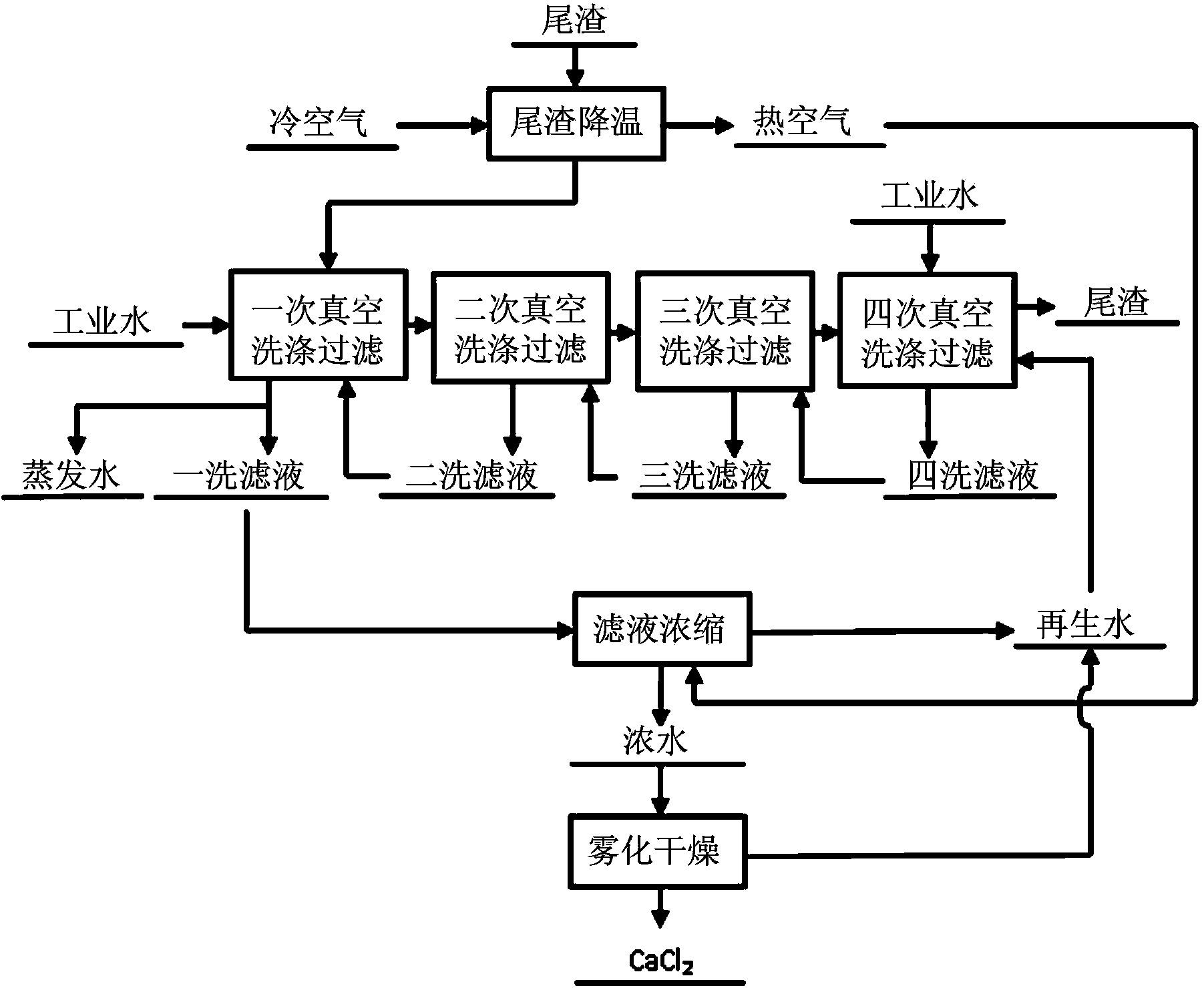

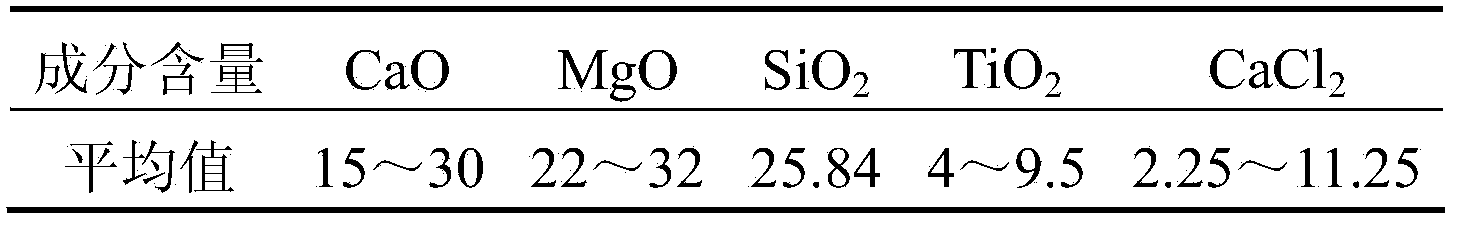

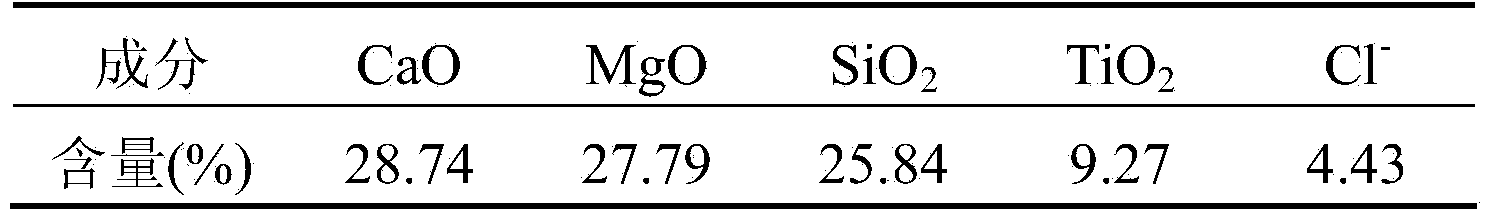

Pollution-free processing method and system for tailings generated by chlorination-process titanium extraction

InactiveCN103936050AReduce Chloride ContentAchieve recyclingCalcium/strontium/barium chloridesCold airChloride

The invention provides a pollution-free processing method and system for tailings generated by chlorination-process titanium extraction. The method comprises the following steps: cooling high-temperature tailings generated by chlorination-process titanium extraction by using cold air to obtain hot air and hot tailings with temperature of 120-150 DEG C; orderly carrying out vacuum washing and filtering on the hot tailings for more than twice, wherein every time vacuum washing and filtering is carried out, the tailings are mixed and soaked with a scrubbing solution and then filtrate and washed tailings can be obtained through filtering, and in addition the filtrate in the last vacuum washing and filtering process is used as the scrubbing solution in the previous vacuum washing and filtering process; concentrating the filtrate obtained in the first vacuum washing and filtering process by using hot air, so as to obtain a concentrated solution; and carrying out spray drying on the concentrated solution to obtain calcium chloride. The system comprises a cooling unit, a vacuum washing and filtering unit, a concentrating unit, a spray drying unit and a cold air supply unit. The tailings which can be applied to the industries such as building materials and can meet the pollution-free requirements can be obtained and cyclic utilization of the scrubbing solution can be achieved; moreover, the pollution-free processing method and system can be effectively connected with the process of preparing titanium tetrachloride by the chlorination process.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

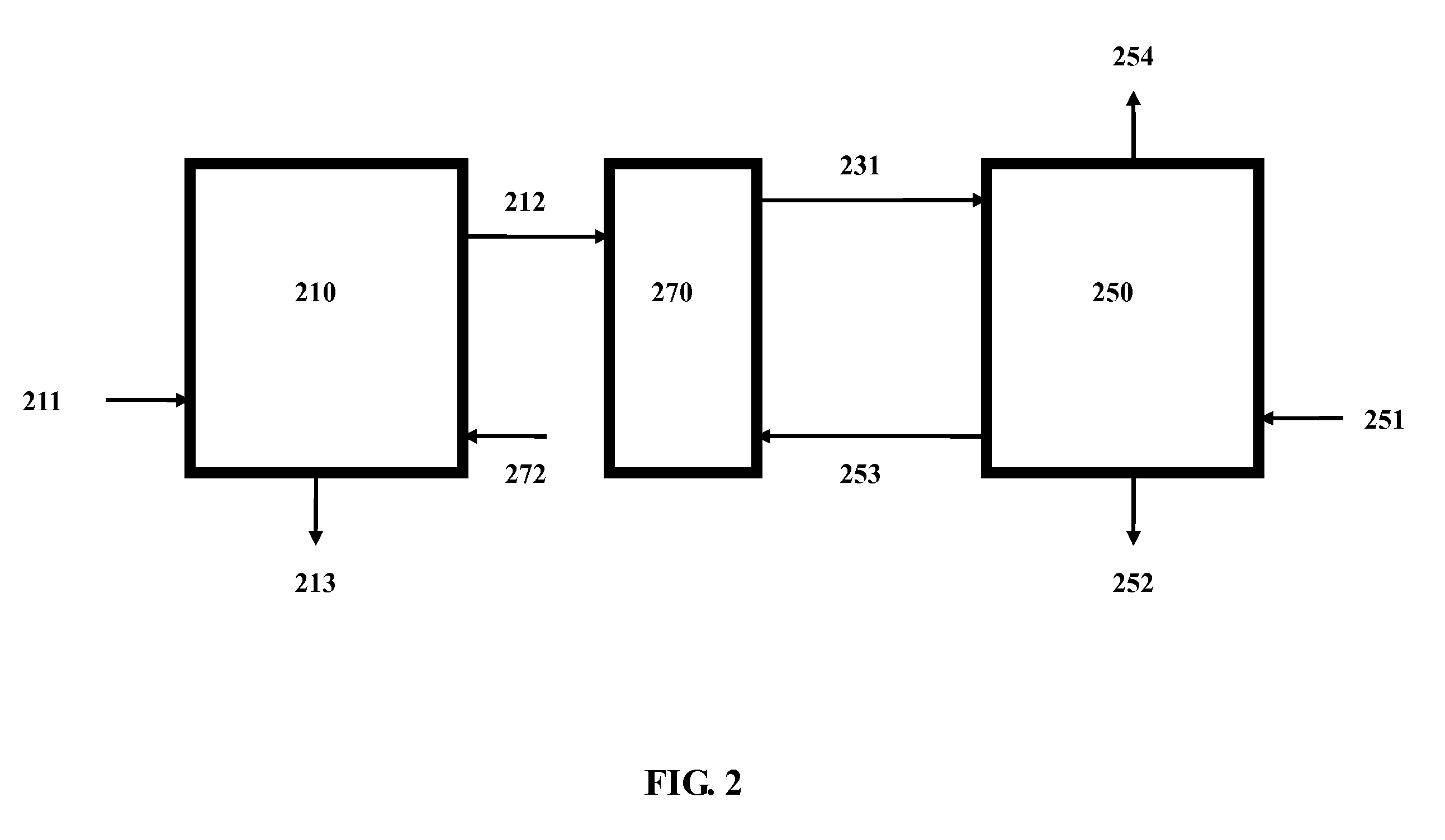

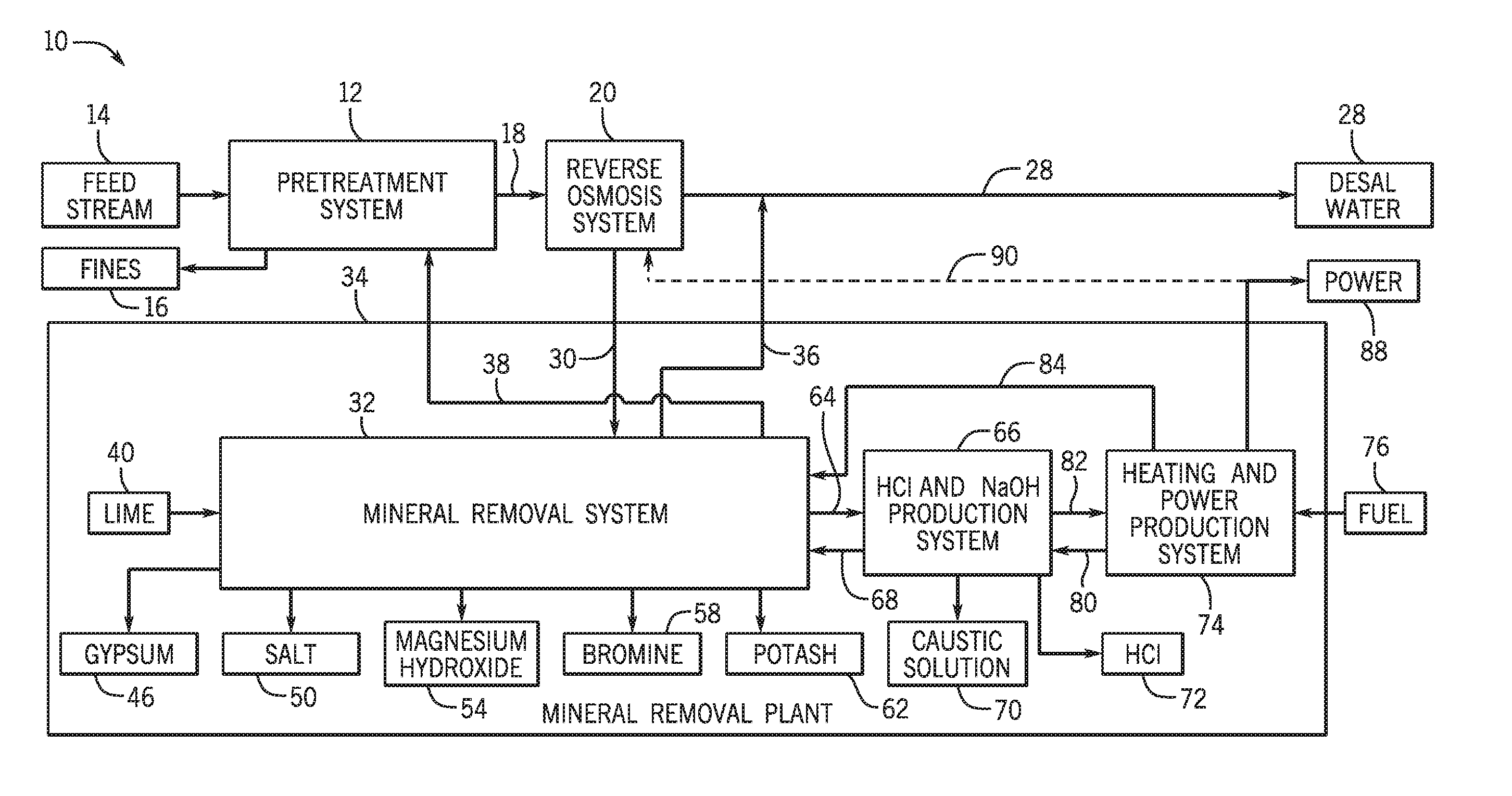

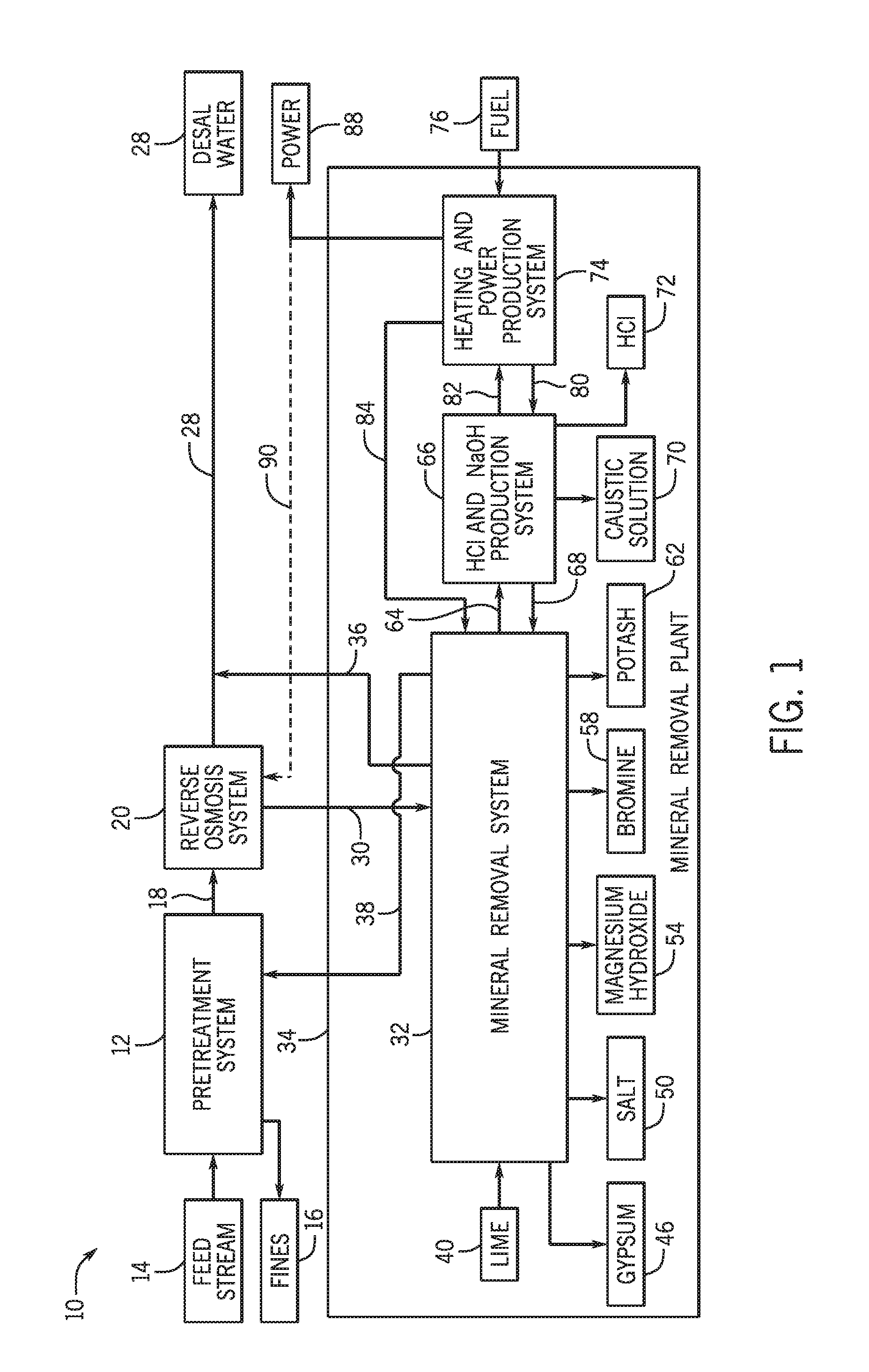

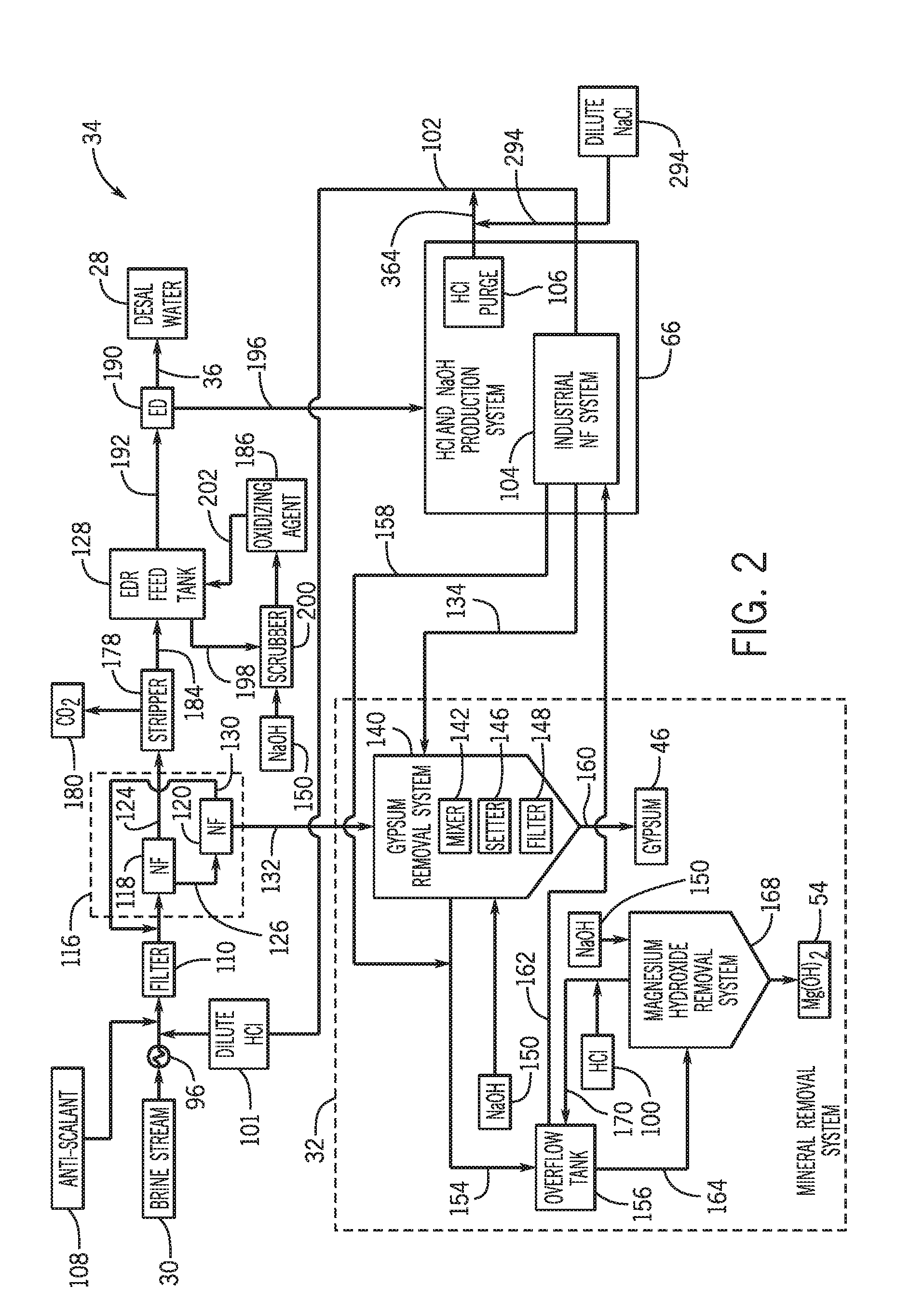

System and methods for removing minerals from a brine using electrodialysis

ActiveUS20160289099A1Chlorine/hydrogen-chloride purificationCalcium/strontium/barium chloridesSaline waterNanofiltration

A method includes treating a first brine stream including a plurality of minerals with an anti-scalant to produce a treated brine. The first brine stream is provided by a wastewater treatment system. The method also includes directing the treated brine to a first nanofiltration (NF) system disposed downstream from and fluidly coupled to the wastewater treatment system, generating a first NF permeate stream and a first NF non-permeate stream from the treated brine in the first NF system, directing the first NF non-permeate stream to a mineral removal system disposed downstream from and fluidly coupled to the first NF system, and removing the plurality of minerals from the first NF non-permeate stream to generate a first overflow stream in the mineral removal system. The first overflow stream comprises at least a portion of the plurality of minerals. The method also includes routing a first portion of the first overflow stream to a hydrochloric acid (HCl) and sodium hydroxide (NaOH) production system disposed downstream from and fluidly coupled to the mineral removal system. The HCl and NaOH production system includes a second NF system that may receive the first portion of the first overflow stream and may generate a second brine stream from the first portion of the first overflow stream. The method further includes directing the second brine stream to a first electrodialysis (ED) system disposed within the HCl and NaOH production system and fluidly coupled to the second NF system. The first ED system may generate HCl and NaOH from the second brine stream.

Owner:ENVIRO WATER MINERALS COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com