Process for treating saponification wastewater by chlorohydrination

A technology of wastewater treatment and treatment method, applied in the field of chemical treatment, can solve the problems of easy local crystallization, pipeline blockage, crystallization scaling, etc., to achieve good social and economic benefits, and the effect of increasing concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

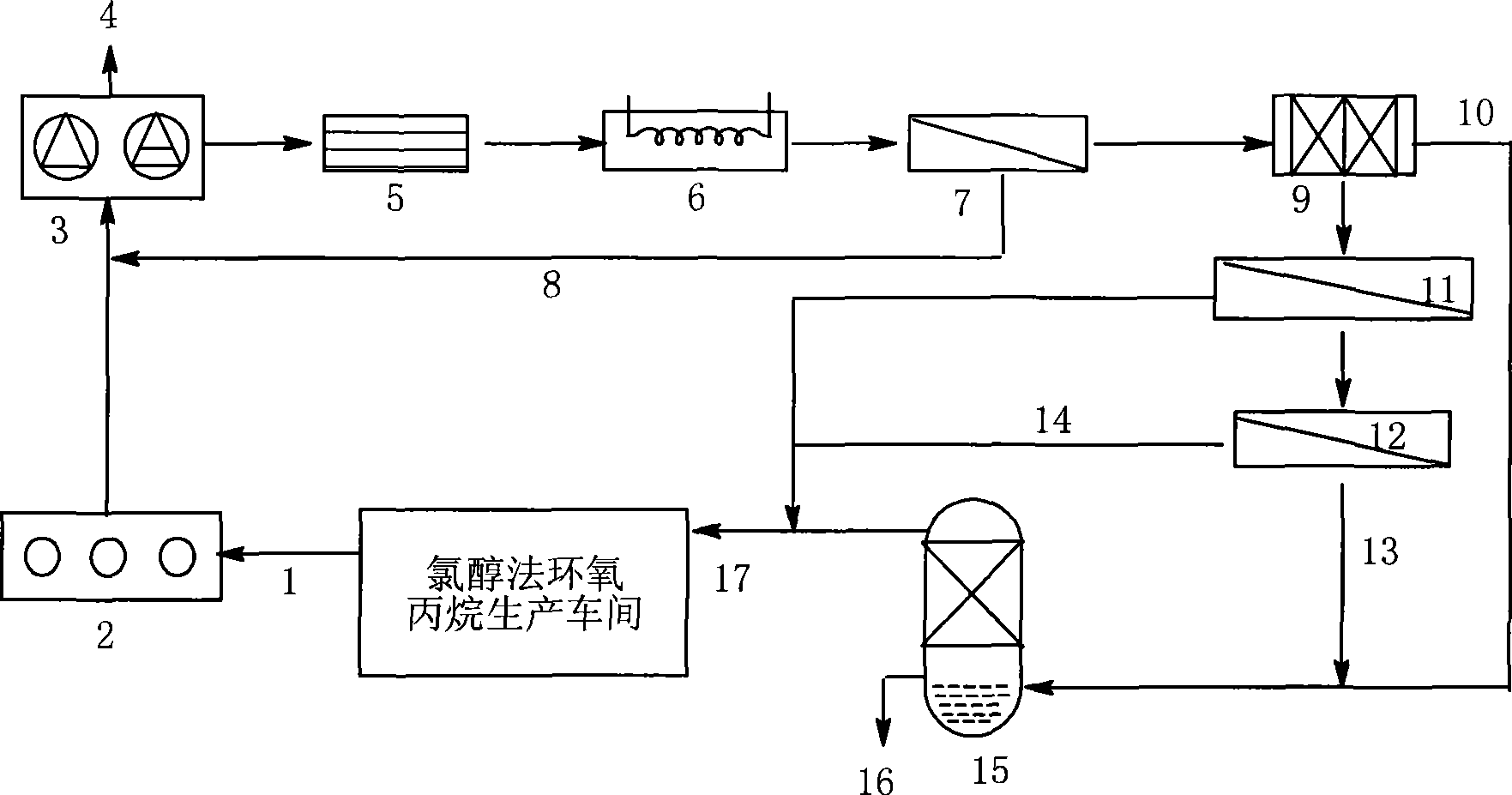

Method used

Image

Examples

Embodiment 1

[0044] Design, install and debug each treatment device of the whole process with a treatment capacity of 2 tons per hour, and finally conduct a field test on the saponification wastewater of a propylene oxide plant:

[0045] It has been determined that the discharge of saponification wastewater is about 10,000 tons / day, the pH of saponification wastewater is 11.8, the salt content is 2.9%wt, COD Cr 1800mg / L, suspended solids SS 2800mg / L, water temperature 81°C; follow the steps below:

[0046] 1. The saponification wastewater is pumped into the thickening tank 2 through the sludge pump to recover the gray milk. The SS value of the supernatant is determined to be 850mg / L, and the supernatant enters the turbine type air flotation sedimentation combined tank 3 to remove some small particles Suspended matter and large particle suspended matter, the settling time is 1.5 hours, and the sediment is pressed into a filter cake with a filter press and shipped out. After air flotation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com