Connection structure of steel structure straw composite building components

A technology for building components and connecting structures, applied in building structures, buildings, etc., can solve the problems of self-heavy filling materials, poor construction environment, low thermal insulation performance, etc., and achieve high strength, reduce self-weight, and improve thermal insulation effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

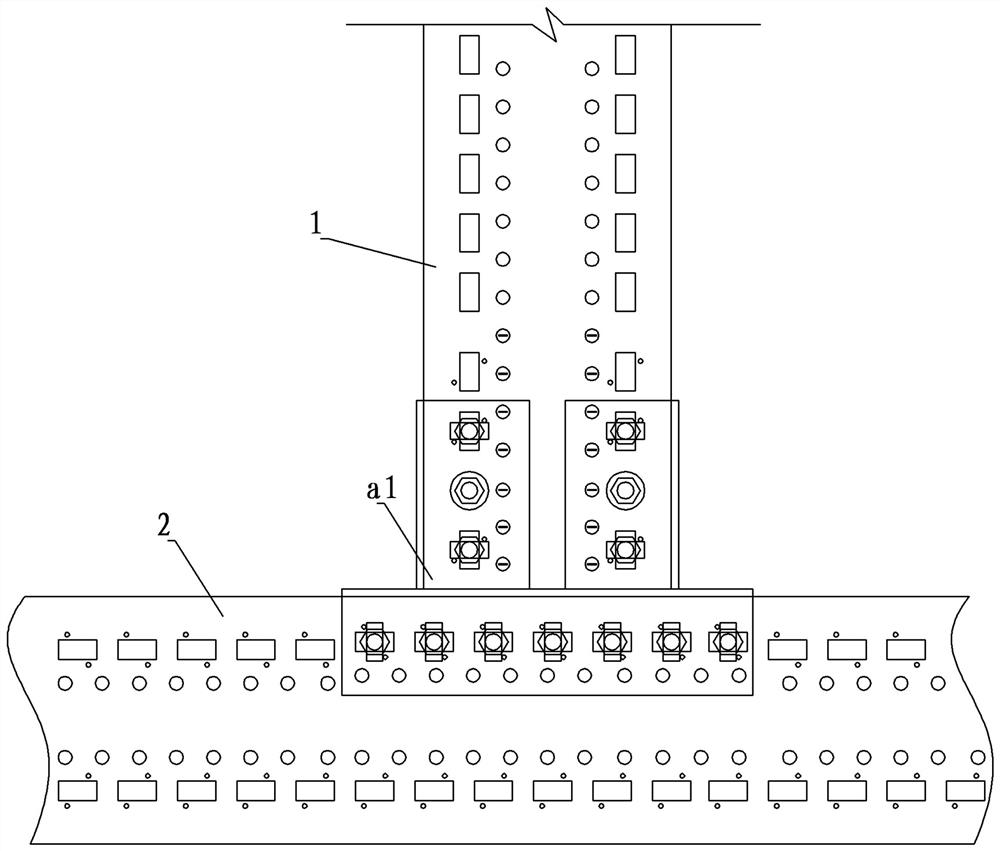

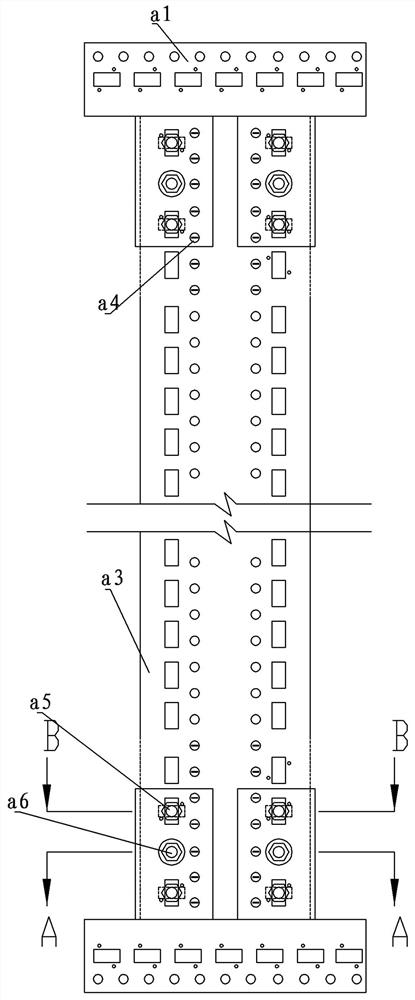

[0035] Embodiment one: see figure 1 , 3 -12, a connection structure of steel structure straw composite building components in the figure, including at least two cross-connected steel structure straw composite building components, at least one of which is a column and one beam, and a connecting piece, the characteristics of which are:

[0036] Both the columns and the beams include two channel-shaped steels with the same length and arranged opposite to each other. The channel-shaped steels include side plates on both sides and webs connected between the side plates, and the edges of the side plates face inwardly The flanging, the flanging part is parallel to the side plate and there is a gap, and the straw compression core is arranged inside the two channel-shaped steels, and the cross-sectional shape of the core matches the cross-sectional shape inside the two channel-shaped steels,

[0037] There is an end connector at the end of the channel-shaped steel. The end connector i...

Embodiment 2

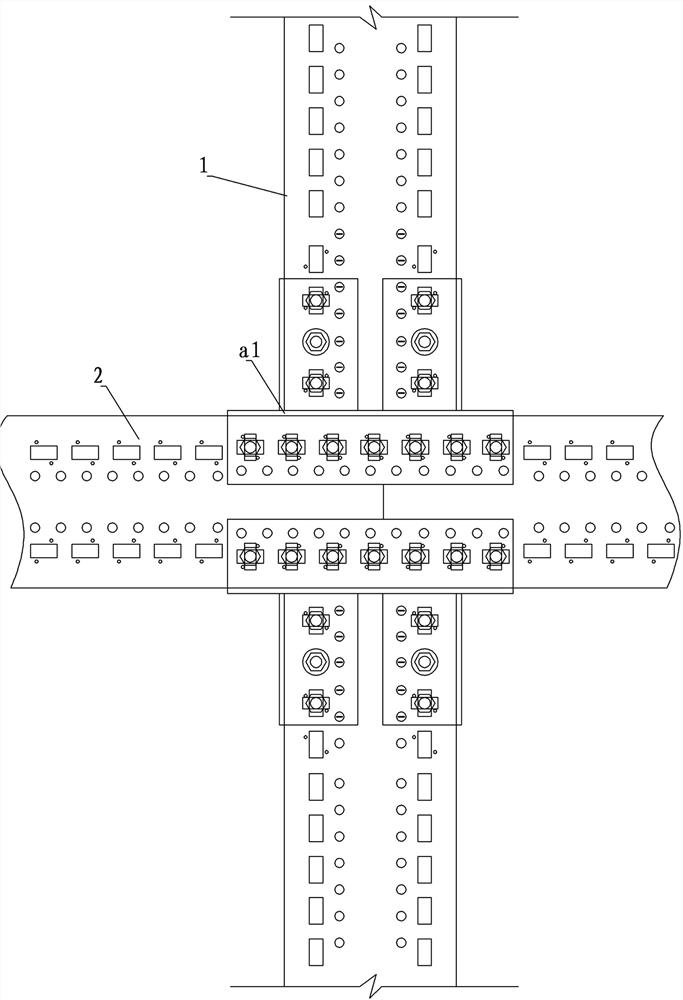

[0049] Embodiment two: see figure 2 , Embodiment 2 is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that there are four beams described in Embodiment 2, which are connected to the four sides of the column in a "cross" shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com