Temporary-storage mechanism of hollow-glass borders

A temporary storage mechanism and glass edge technology, which is applied in the field of packaging, can solve the problems of difficult handling of the glued frame, achieve the effect of solving the problem of placement and transmission, simple structure, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

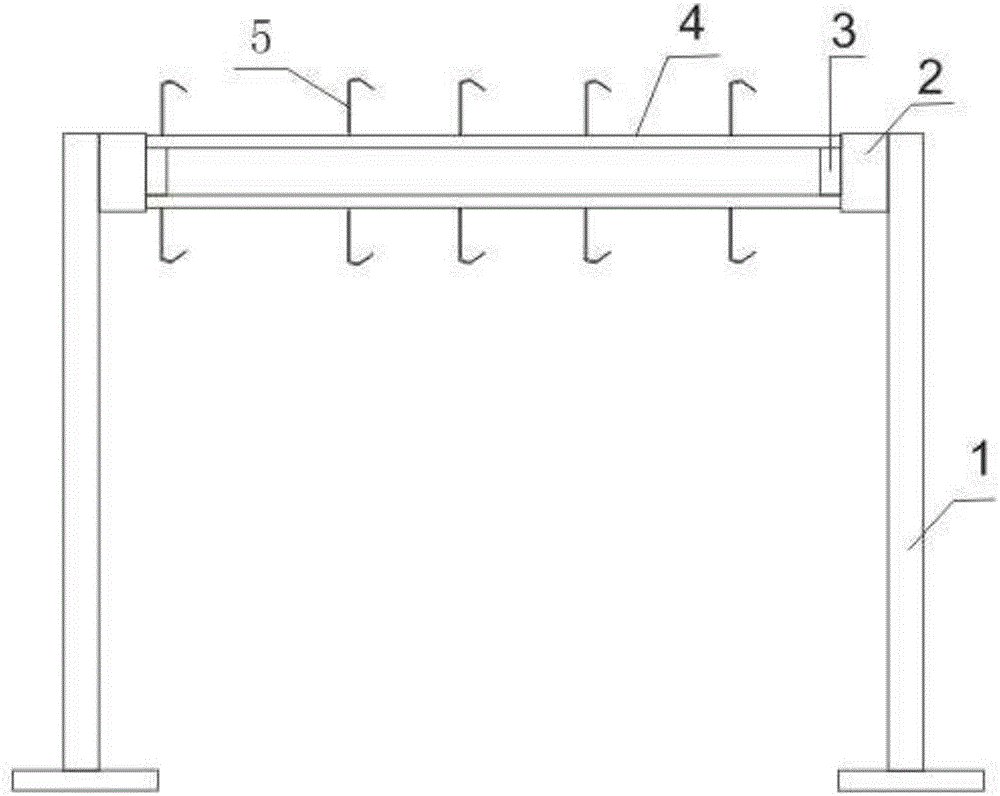

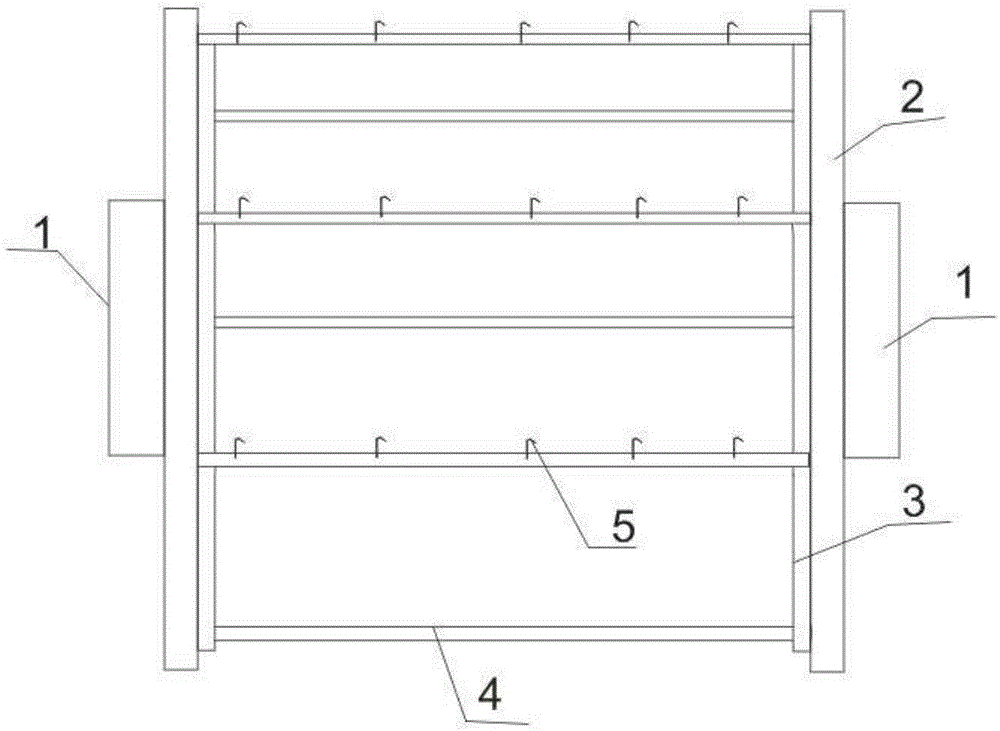

[0011] Example 1, such as figure 1 with 2 Shown: the hollow glass frame temporary storage mechanism of the present invention is made up of column 1, upper beam 2, conveying chain 3, steel pipe 4, frame hook 5.

[0012] There are two uprights 1, and the left and right sides are arranged oppositely. The lower end of the uprights 1 is provided with a mounting plate, and the uprights 1 are installed on the ground through the mounting plate. An upper beam 2 is arranged at the top of the two columns 1, and the upper beams 2 at the top of the two columns 1 are parallel to each other. The insides of the upper beams 2 on the left and right sides are provided with conveyor chains 3 extending along their lengths. The conveyor chains on both sides 3 are connected by a plurality of steel pipes 4, and a plurality of frame hooks 5 are distributed on each steel pipe 4. The conveying chain 3 can be controlled by a foot switch. The conveying device is installed between the gluing process and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com