Patents

Literature

171results about How to "Improve articulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

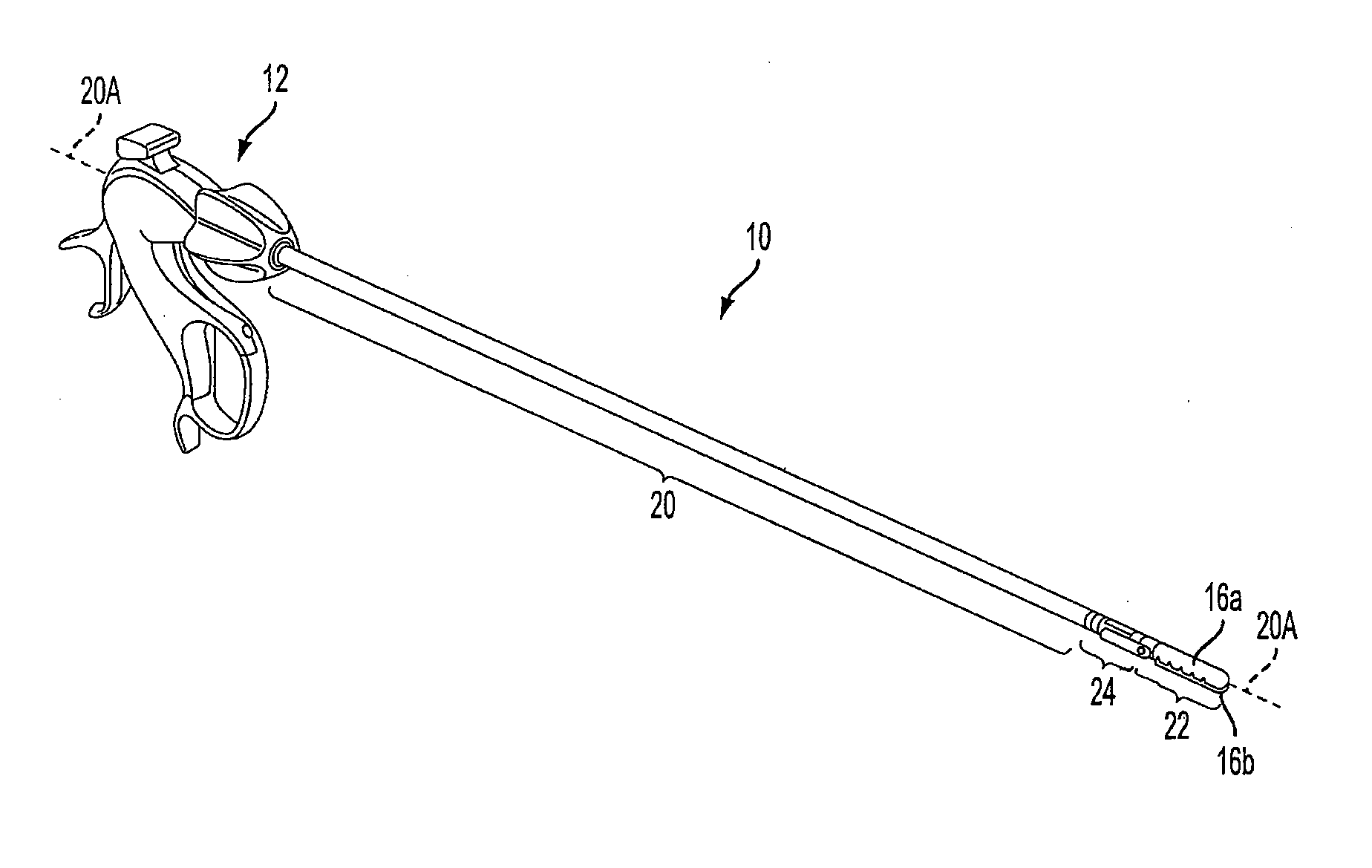

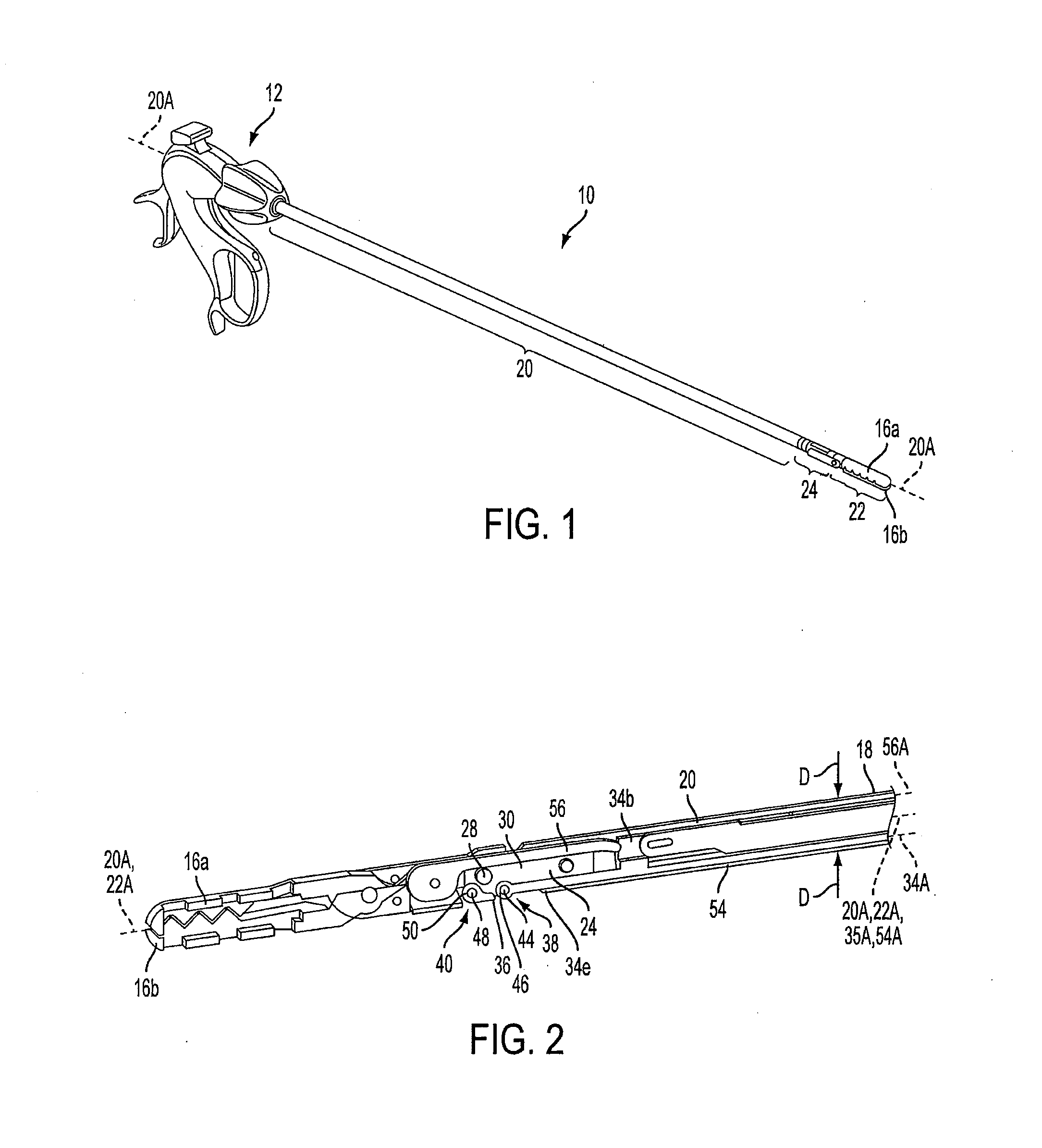

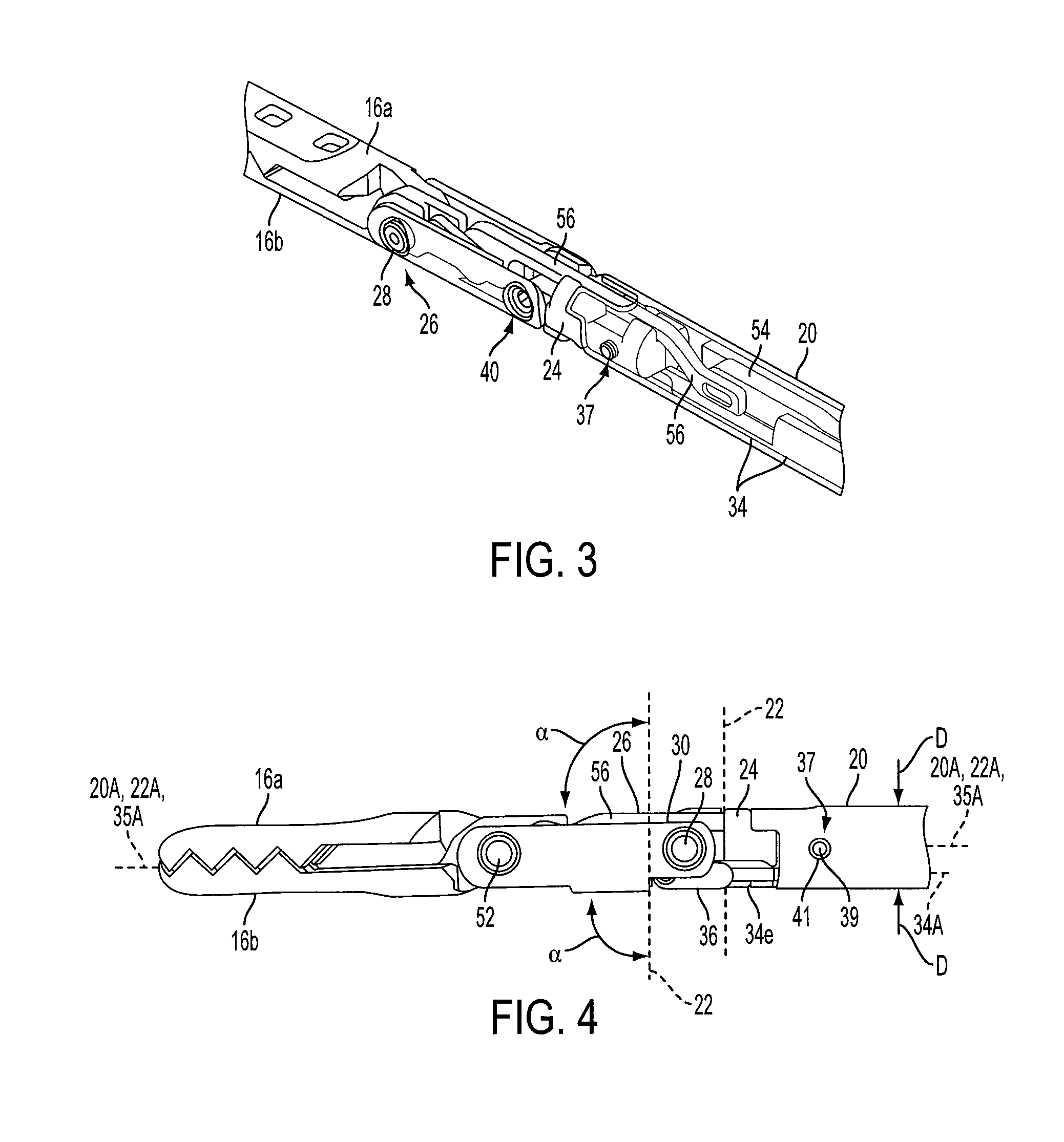

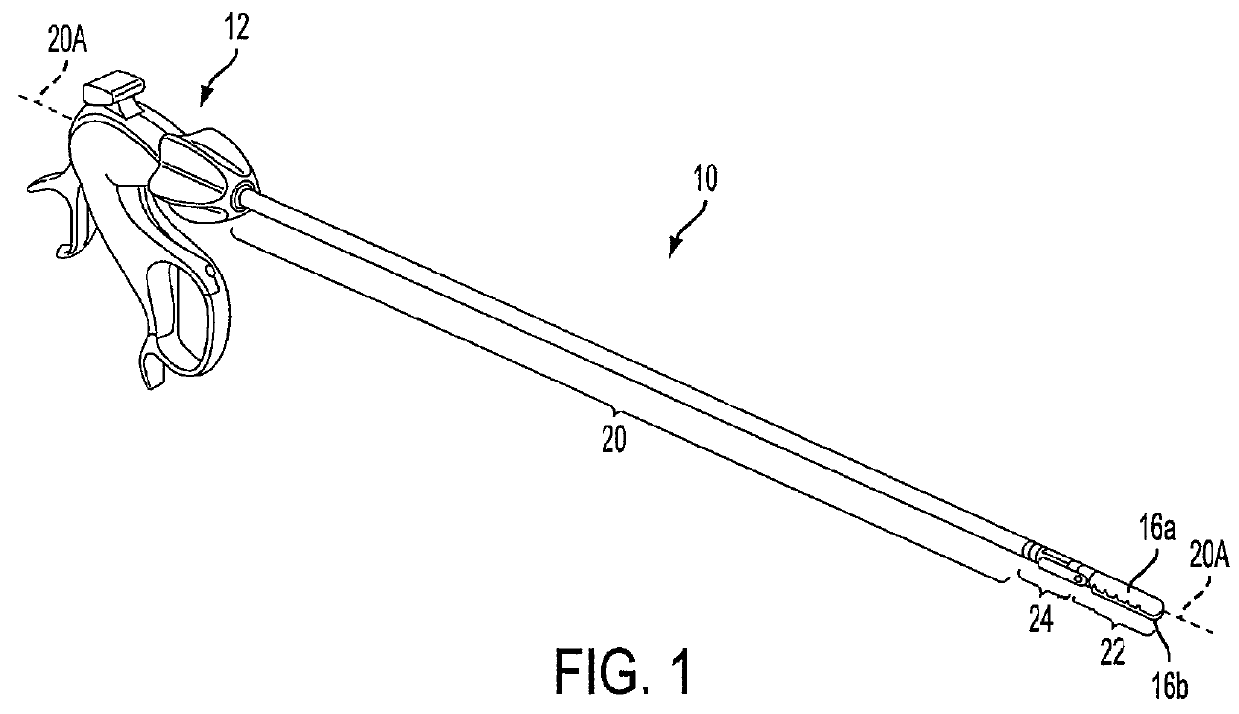

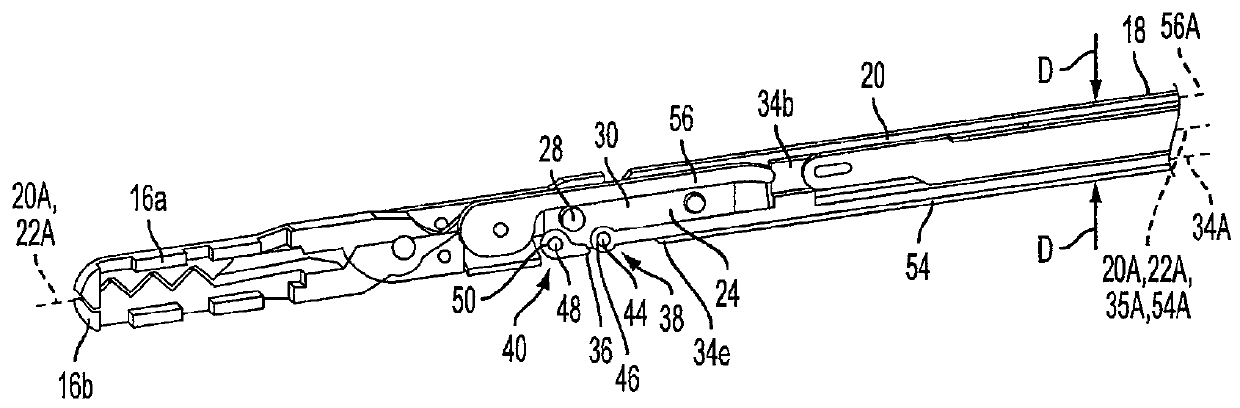

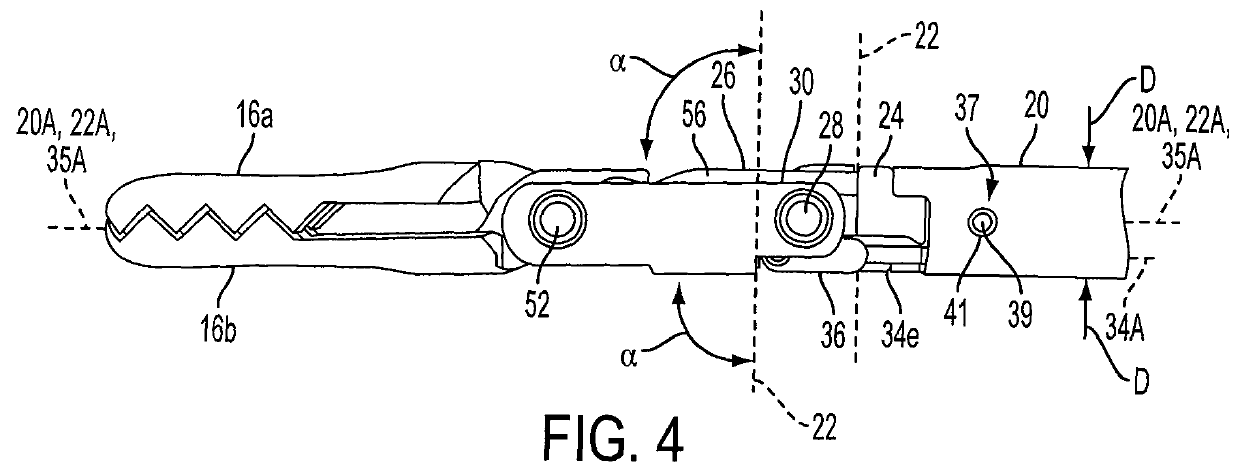

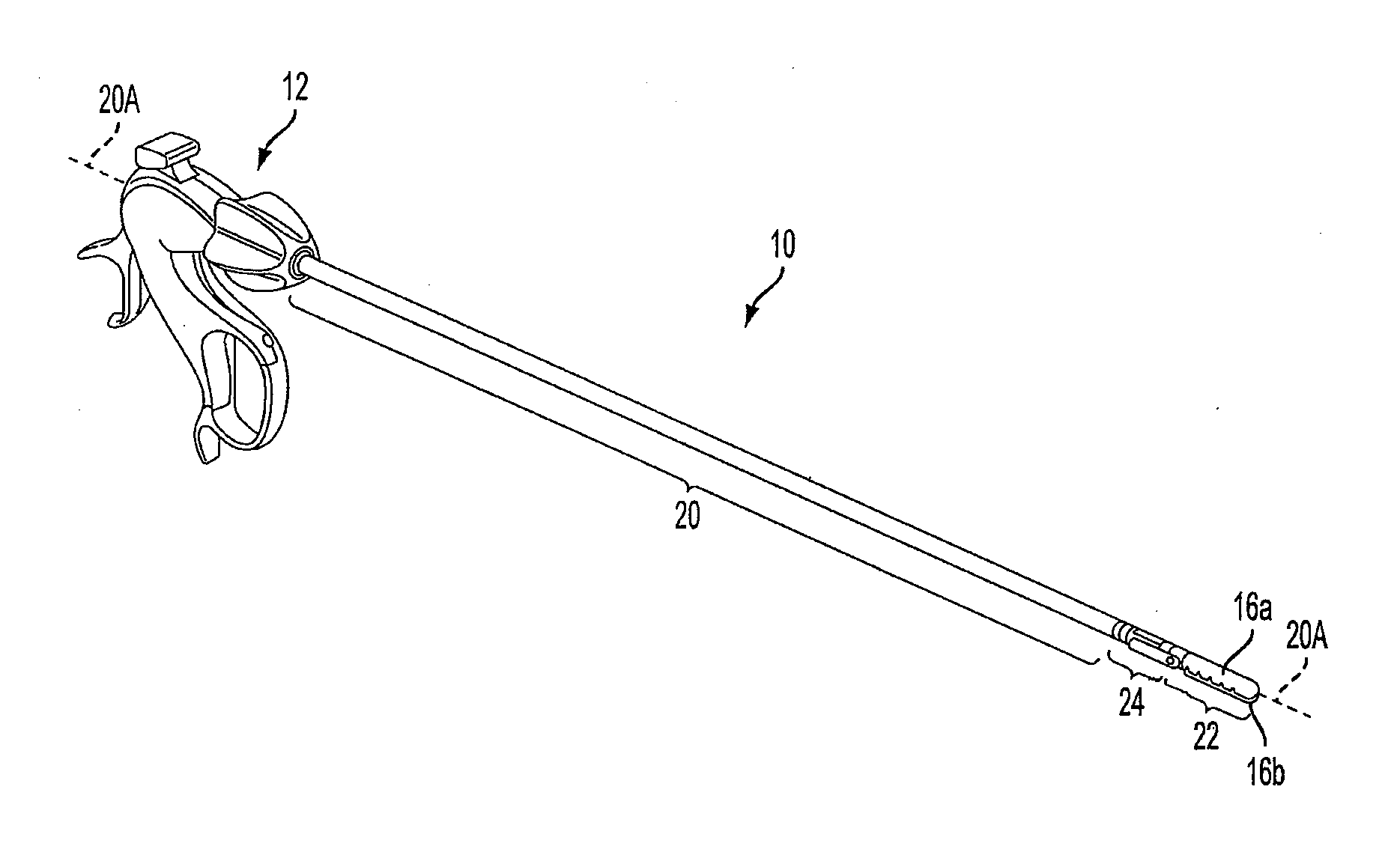

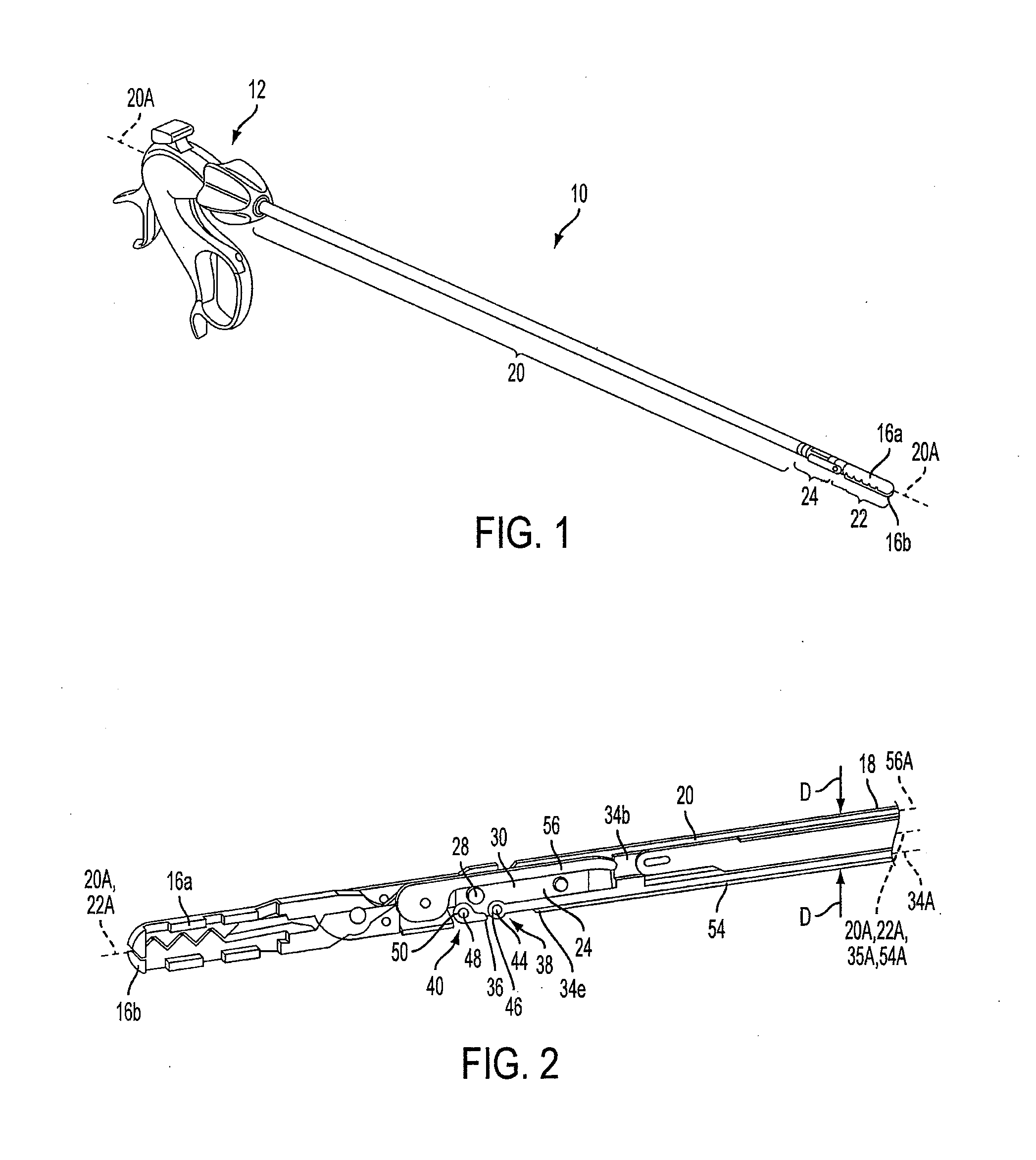

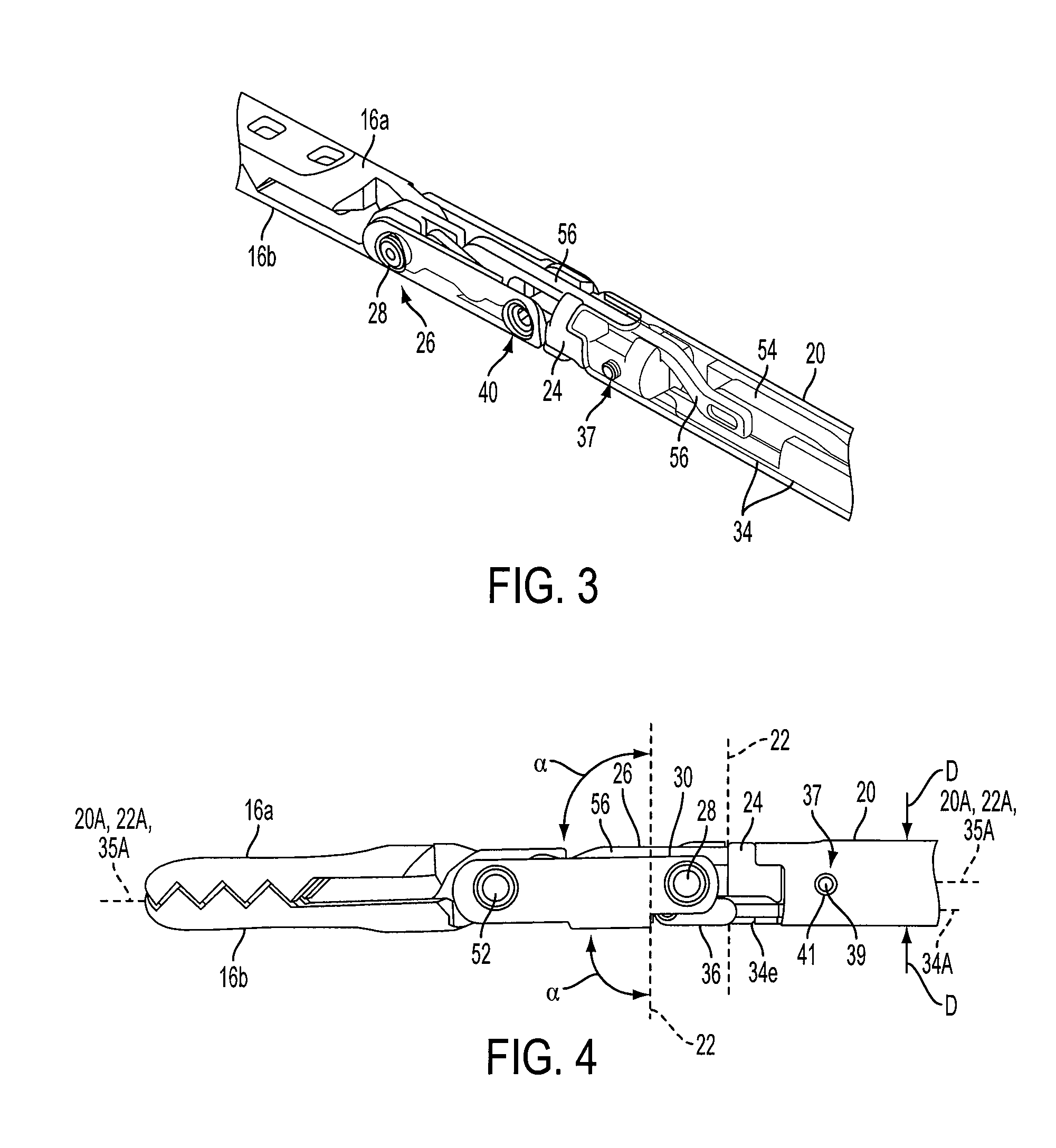

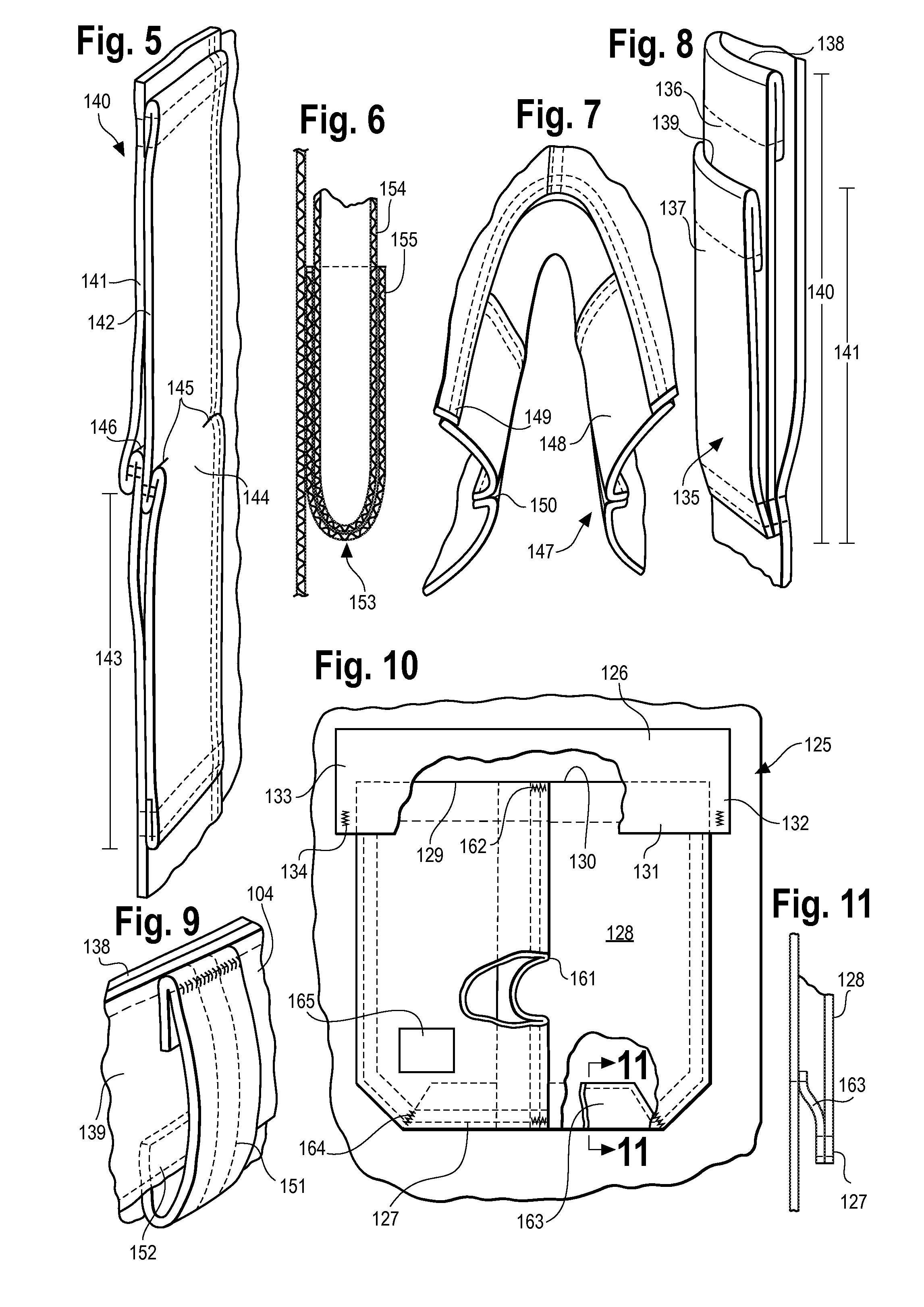

Laparoscopic devices with articulating end effectors

InactiveUS20110275901A1Improve articulationEffective movementCannulasSurgical scissorsPERITONEOSCOPERobot end effector

Methods and devices are provided for performing minimally invasive surgical procedures. In one embodiment, a surgical device is provided that includes an elongate shaft having an end effector at a distal end thereof. The end effector can be configured to be movable between a first configuration in which the end effector is longitudinally aligned with or linear relative to the shaft and a second configuration in which the end effector is articulated at an angle beyond 45 degrees relative to the shaft. With the end effector in the first configuration or in the second configuration, the device can be configured to allow selective actuation of the end effector.

Owner:CILAG GMBH INT

Laparoscopic devices with flexible actuation mechanisms

ActiveUS9226760B2Improve articulationEffective movementSurgical forcepsEngineeringRobot end effector

Owner:CILAG GMBH INT

Laparoscopic devices with flexible actuation mechanisms

ActiveUS20110276084A1Improve articulationEffective movementSurgical forcepsRobot end effectorEngineering

Methods and devices are provided for performing minimally invasive surgical procedures. In one embodiment, a surgical device is provided that includes an elongate shaft having an end effector at a distal end thereof. The end effector can be configured to be movable between a first configuration in which the end effector is longitudinally aligned with or linear relative to the shaft and a second configuration in which the end effector is articulated at an angle beyond 45 degrees relative to the shaft. With the end effector in the first configuration or in the second configuration, the device can be configured to allow selective actuation of the end effector.

Owner:CILAG GMBH INT

Chopped glass fiber sizing agent for bulk molding compounds (BMC) for reinforcing thermosetting resin

The invention discloses a chopped glass fiber sizing agent for reinforcing thermosetting resin, which is prepared by the components by weight percent: (1) 0.2-1.5% of coupling agent; (2) 3.0-20.0% of binding agent that is cross-linked polyurethane emulsion or the mixture of the cross-linked polyurethane emulsion and medium and high molecular weight epoxy emulsion, wherein the contents of the cross-linked polyurethane emulsion and the medium and high molecular weight elastic epoxy ester emulsion are based on the respective solid content; (3) 0.0-1.2% of lubricating agent; (4) 0.05-0.8% of antistatic agent; (5) 0.1-2% of pH value conditioning agent; and (6) the balance of deionized water, wherein the total weight of all the components is 100%. The chopped glass fiber sizing agent improves the bundling property of chopped glass fiber, reduces the broken filament, improves the mixing uniformity and the fluidity of the glass fiber and the BMC resin paste, and improves the mechanical strength and the appearance performance of BMC products.

Owner:JUSHI GRP CO

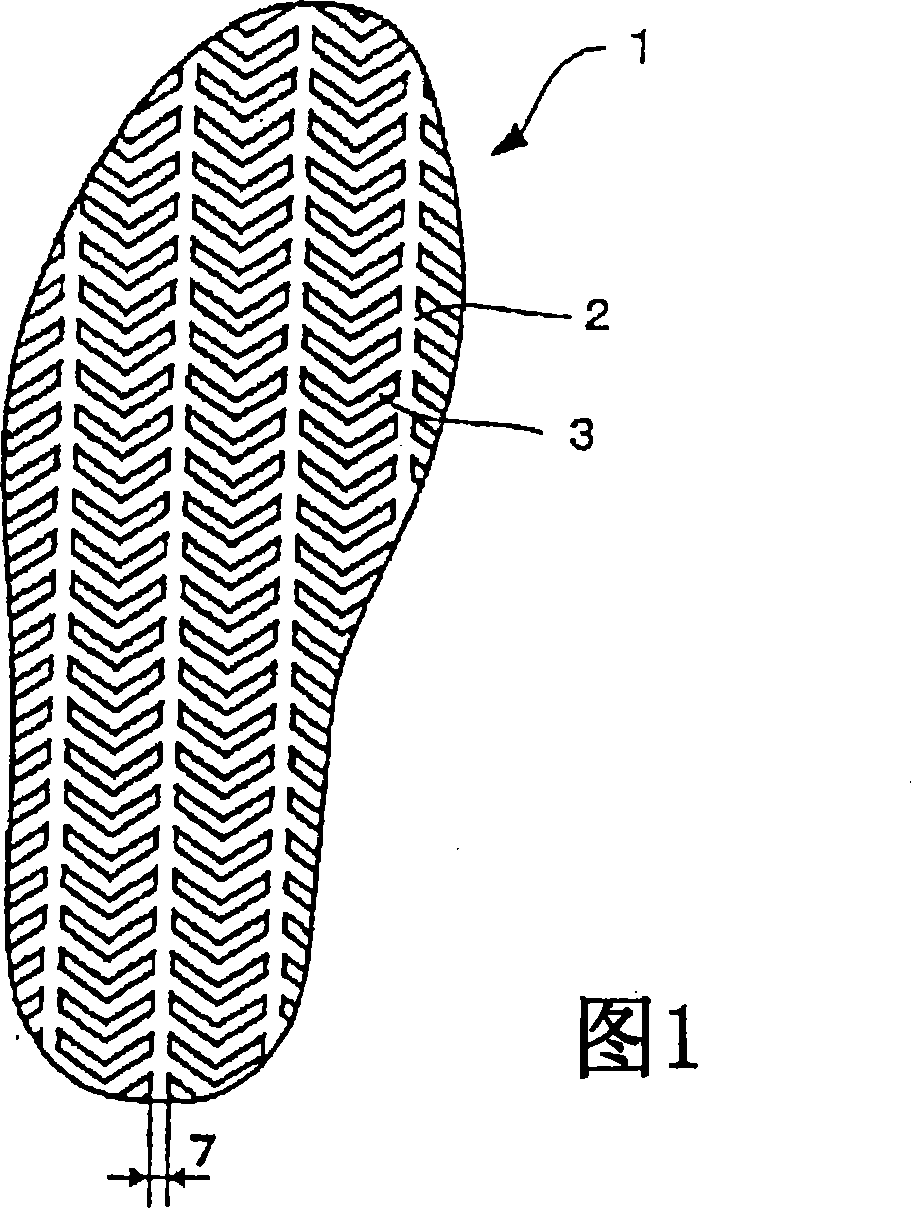

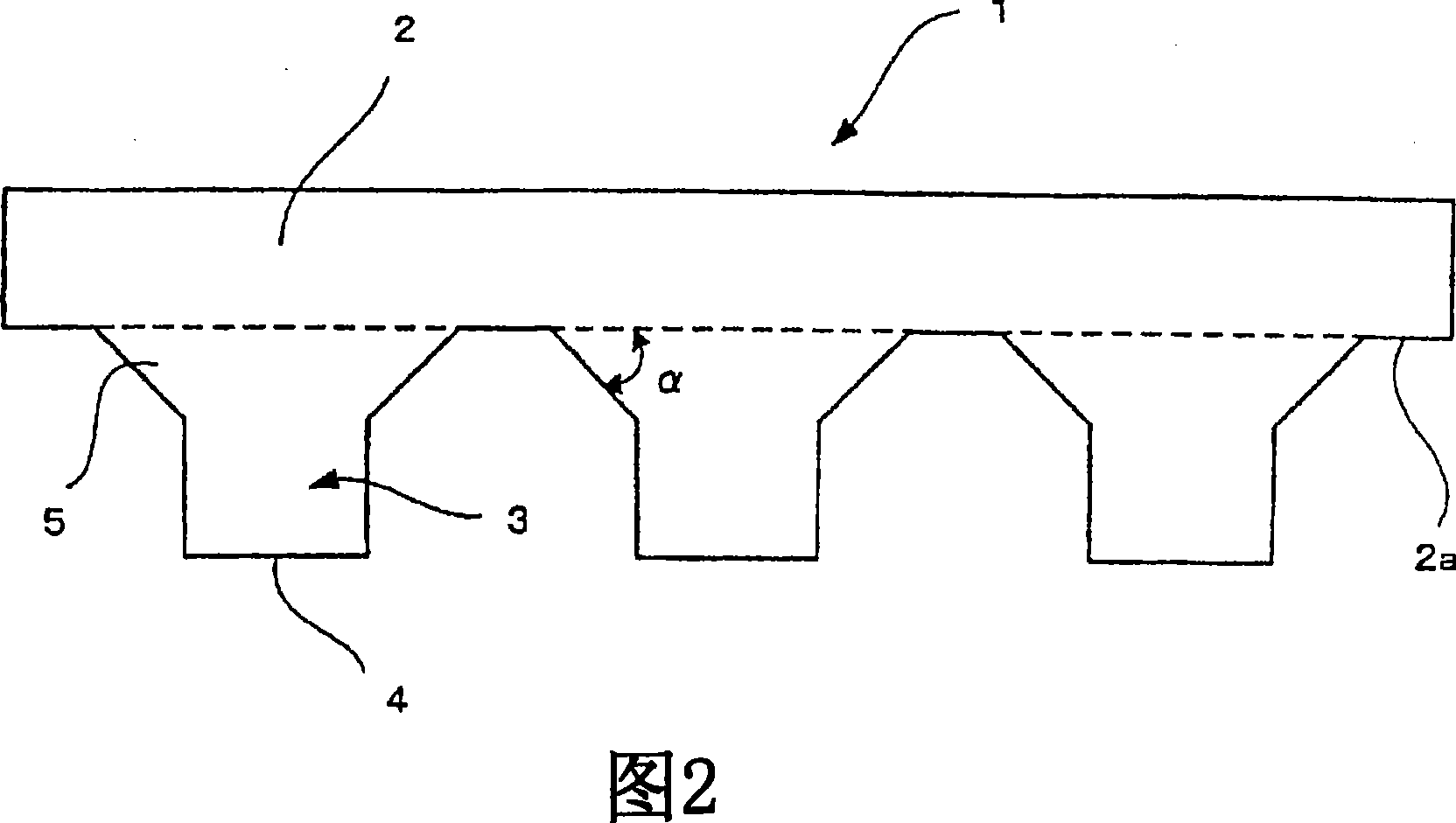

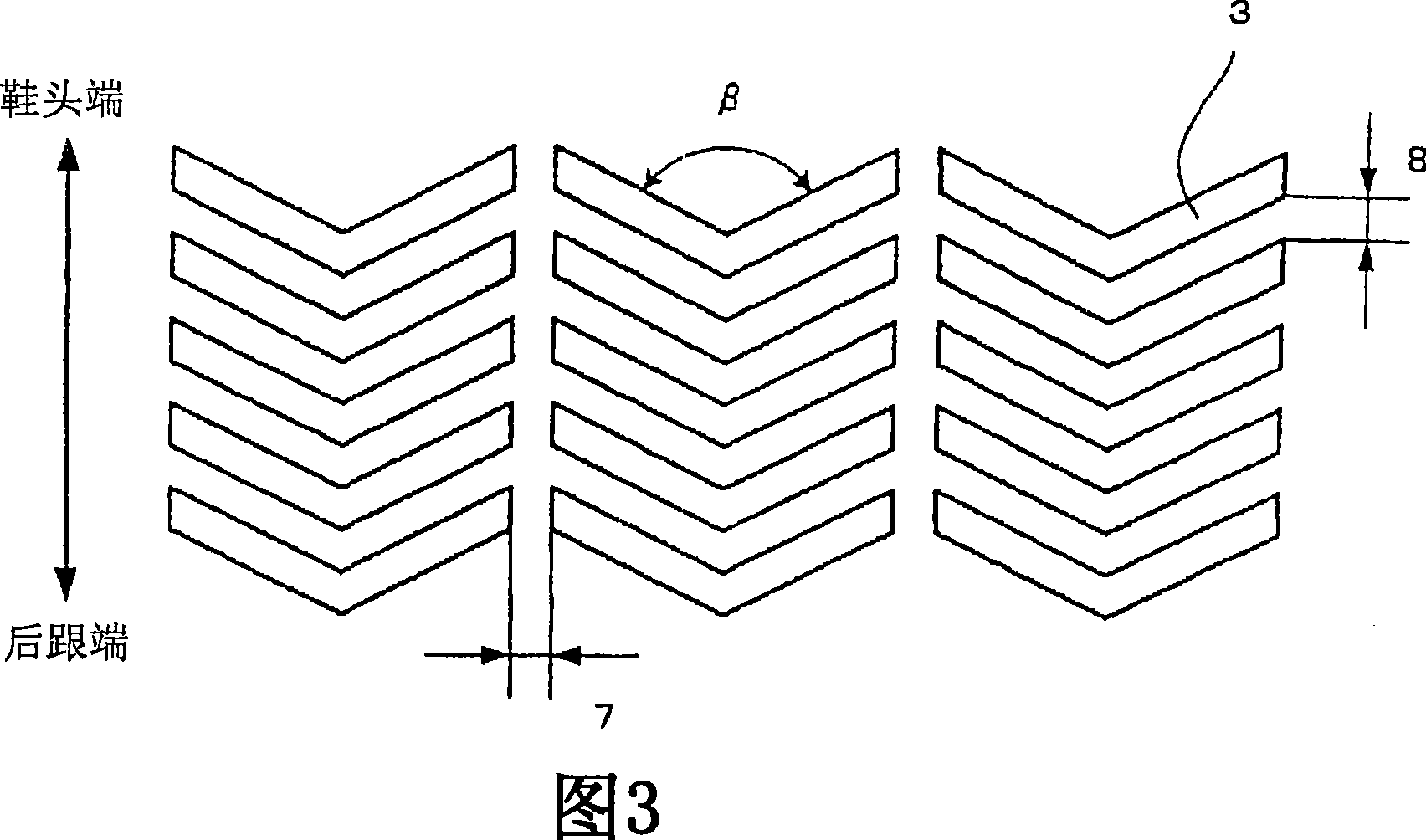

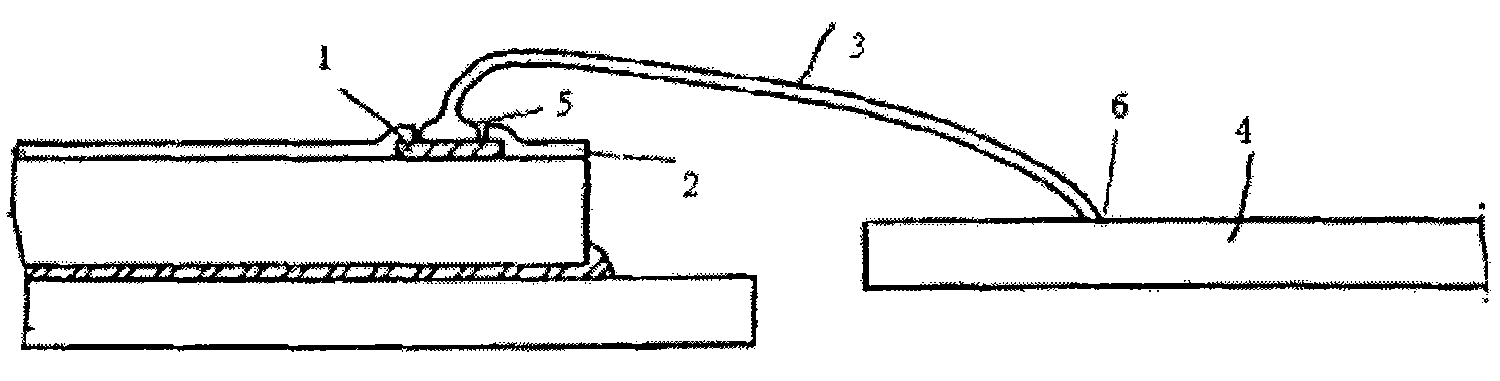

Slip-resistant shoe sole

The slip resistant shoe sole 1 of the invention comprises a plurality of ground contact projections 3 formed on the ground contact side of the sole base 2 with a predetermined gap between adjacent ground contact projections 3 in the longitudinal direction of the base 2, the ground contact projections 3 having a V-shaped horizontal cross section, having inclined reinforcements 5 provided at the roots of the ground contact projections 3 on the base 2, and being formed using an elastomeric polymer with a JIS-A hardness of 45 to 80 as measured at 20 DEG C.

Owner:NISSHIN RUBBER

Glass fiber soakage agent and preparation method and application thereof

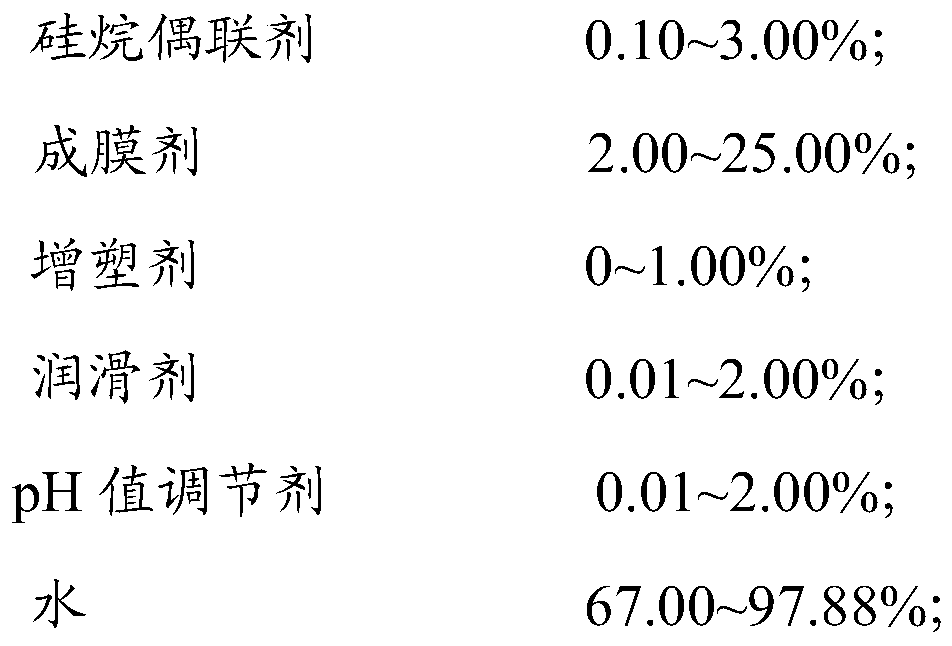

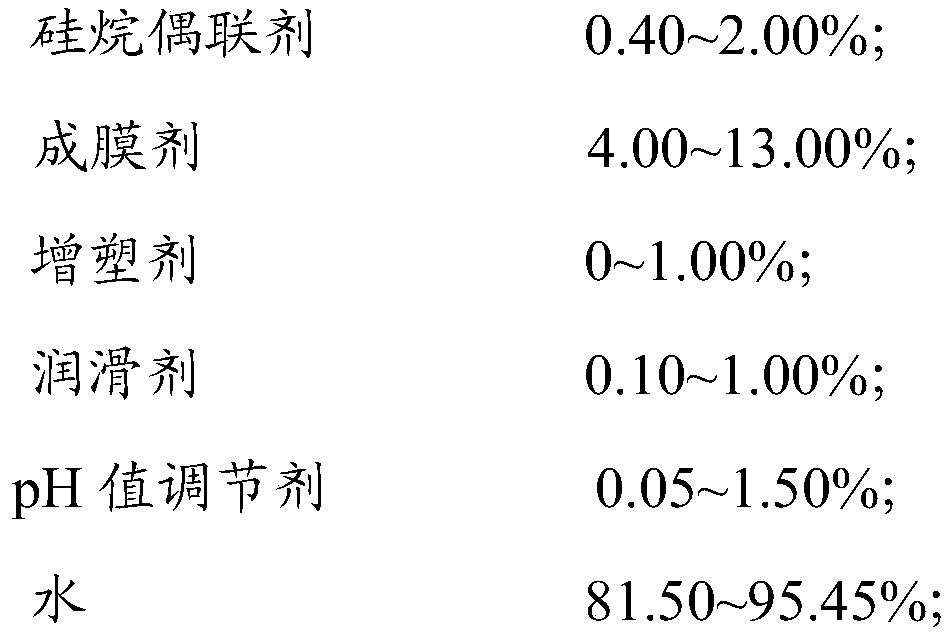

The invention provides a glass fiber soakage agent. The glass fiber soakage agent is suitable for an extrusion and injection moulding process. The glass fiber soakage agent is prepared from, by mass,0.10-3.00% of a silane coupling agent, 2.00-25.00% of a film forming agent, 0-1.00% of a plasticizer, 0.01-2.00% of a lubricating agent, 0.01-2.00% of a pH regulating agent and 67.00-97.88% of water;the film forming agent is a mixture of a first film forming agent and a second film forming agent, and the mass ratio of the first film forming agent to the second film forming agent is 10:1-1:8. Produced glass fiber twistless roving coated with the soakage agent is suitable for production of glass fiber reinforcement thermoplastic plastic.

Owner:JUSHI GRP CO

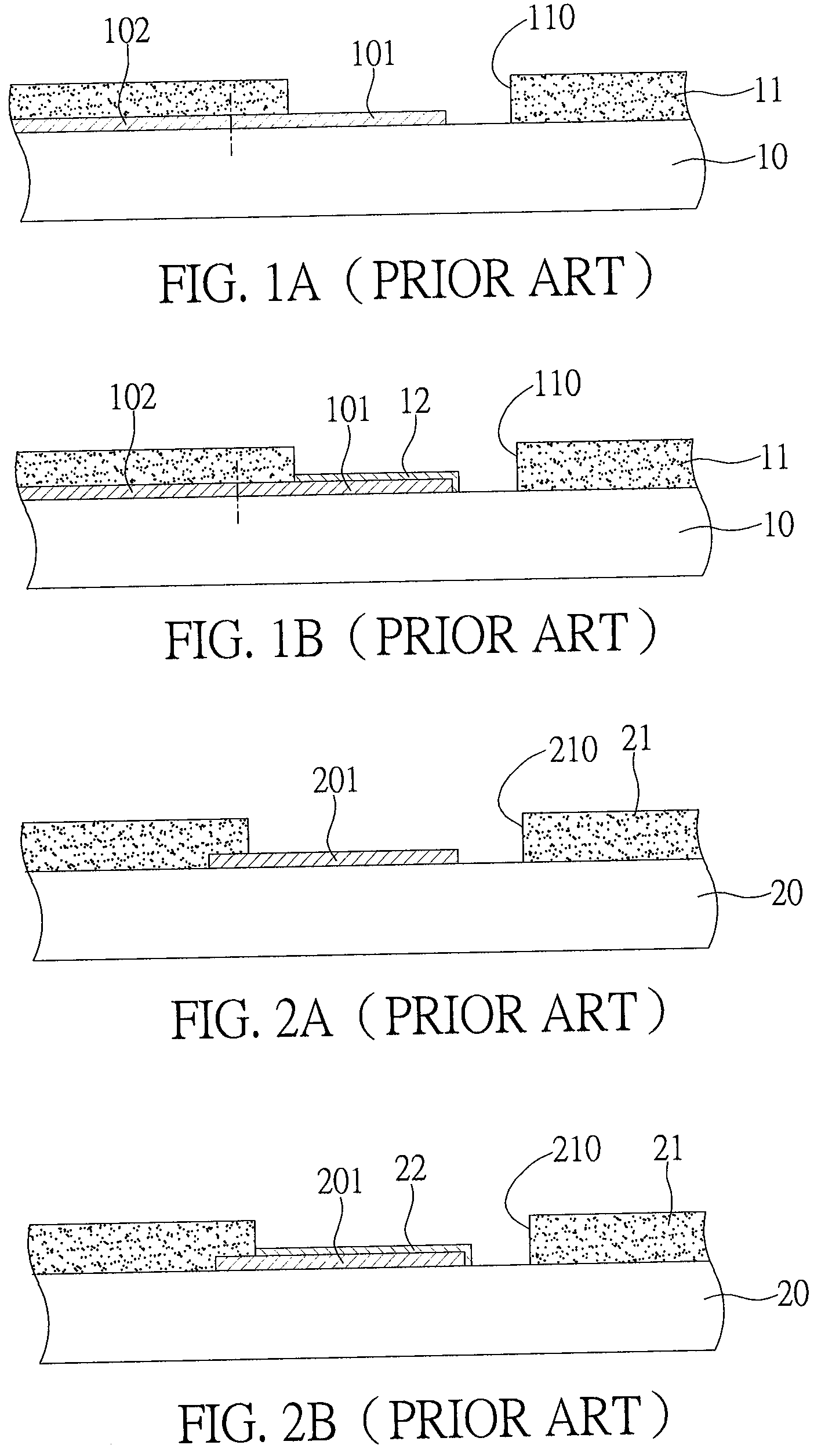

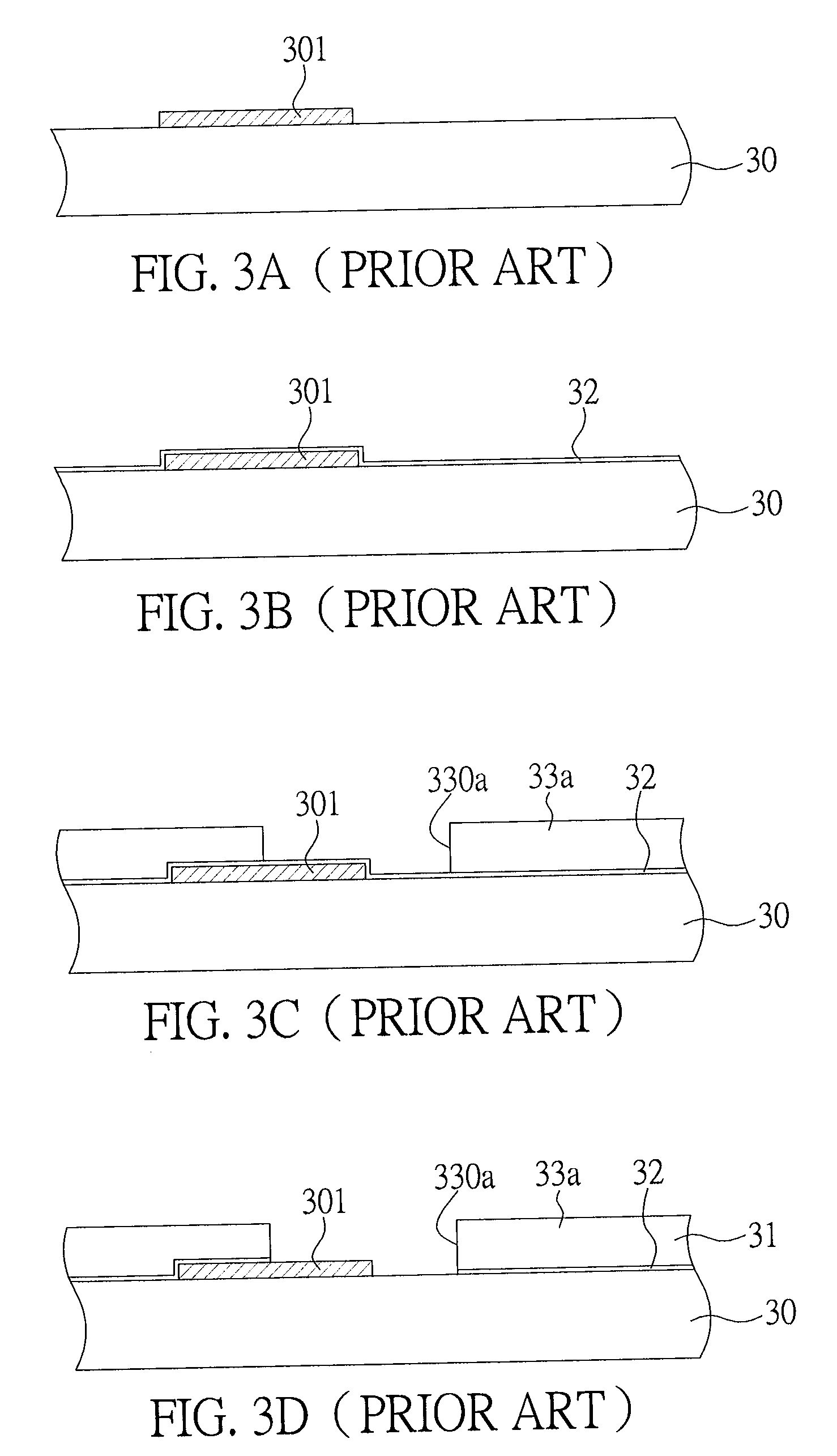

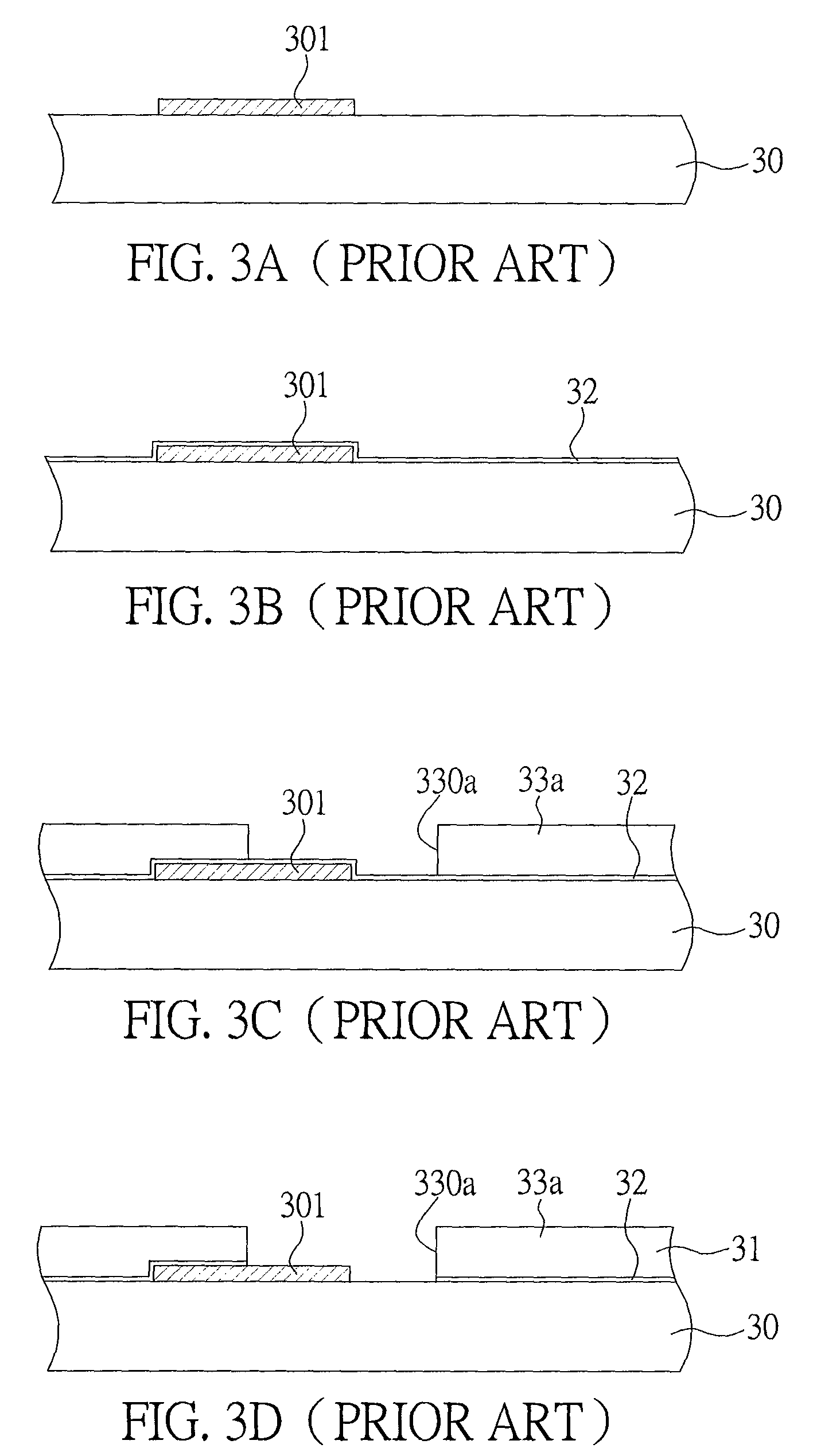

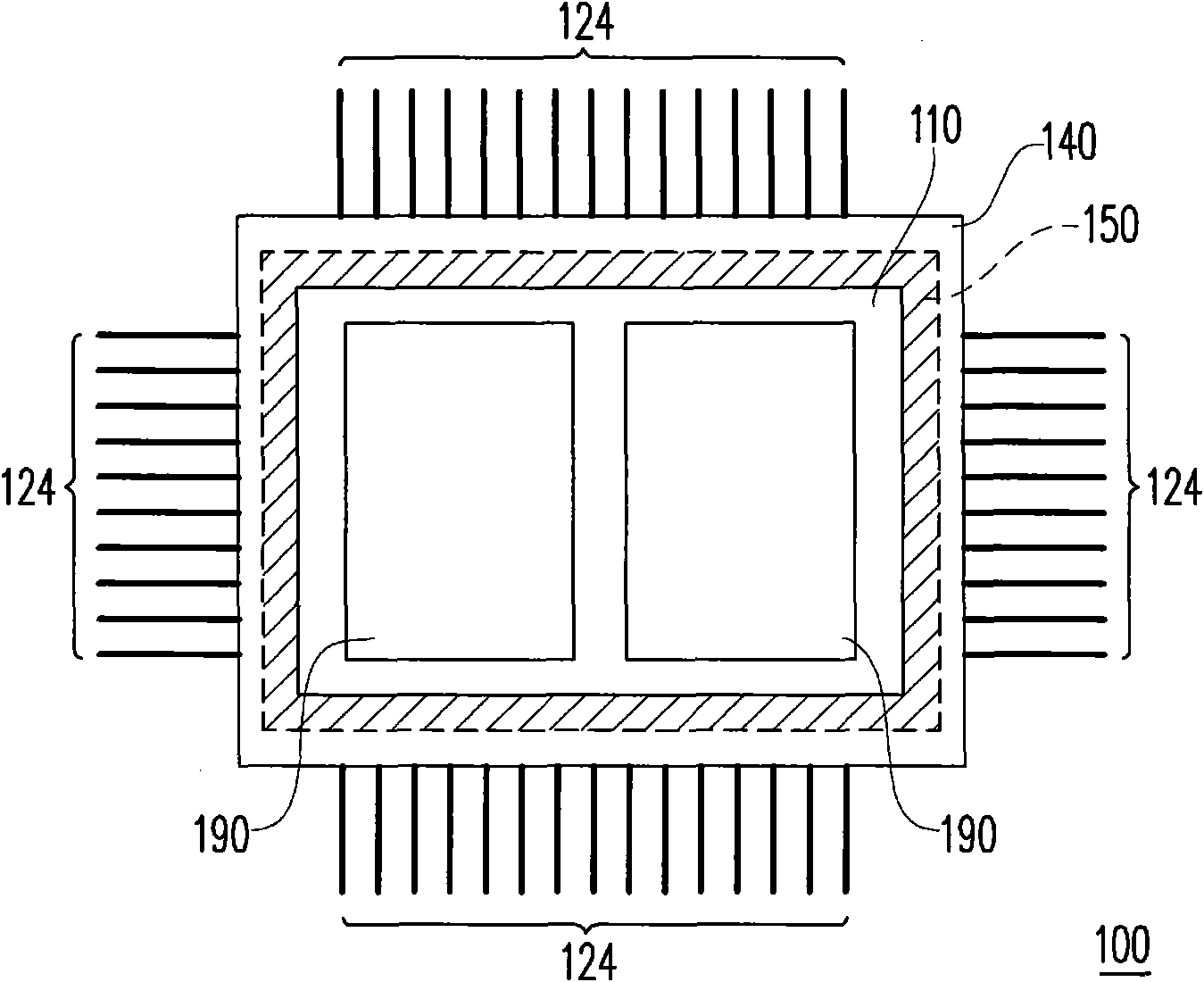

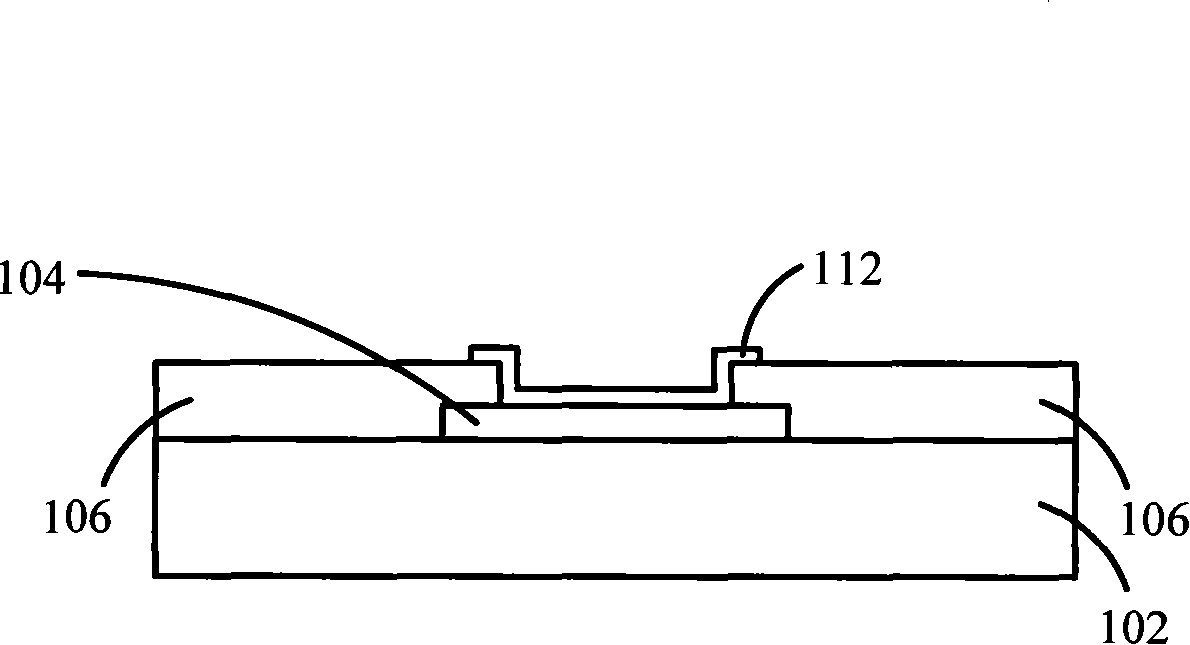

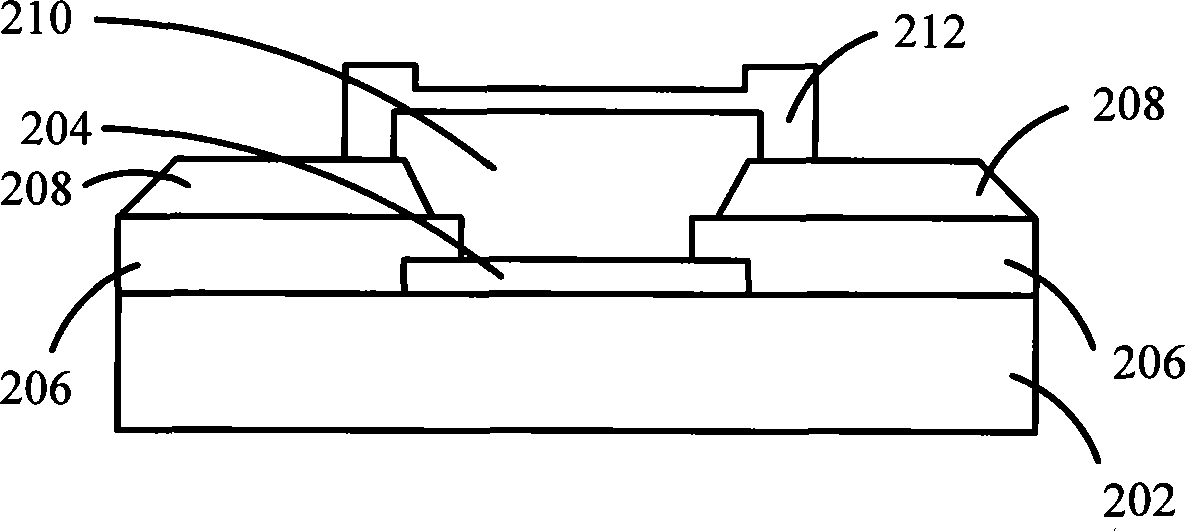

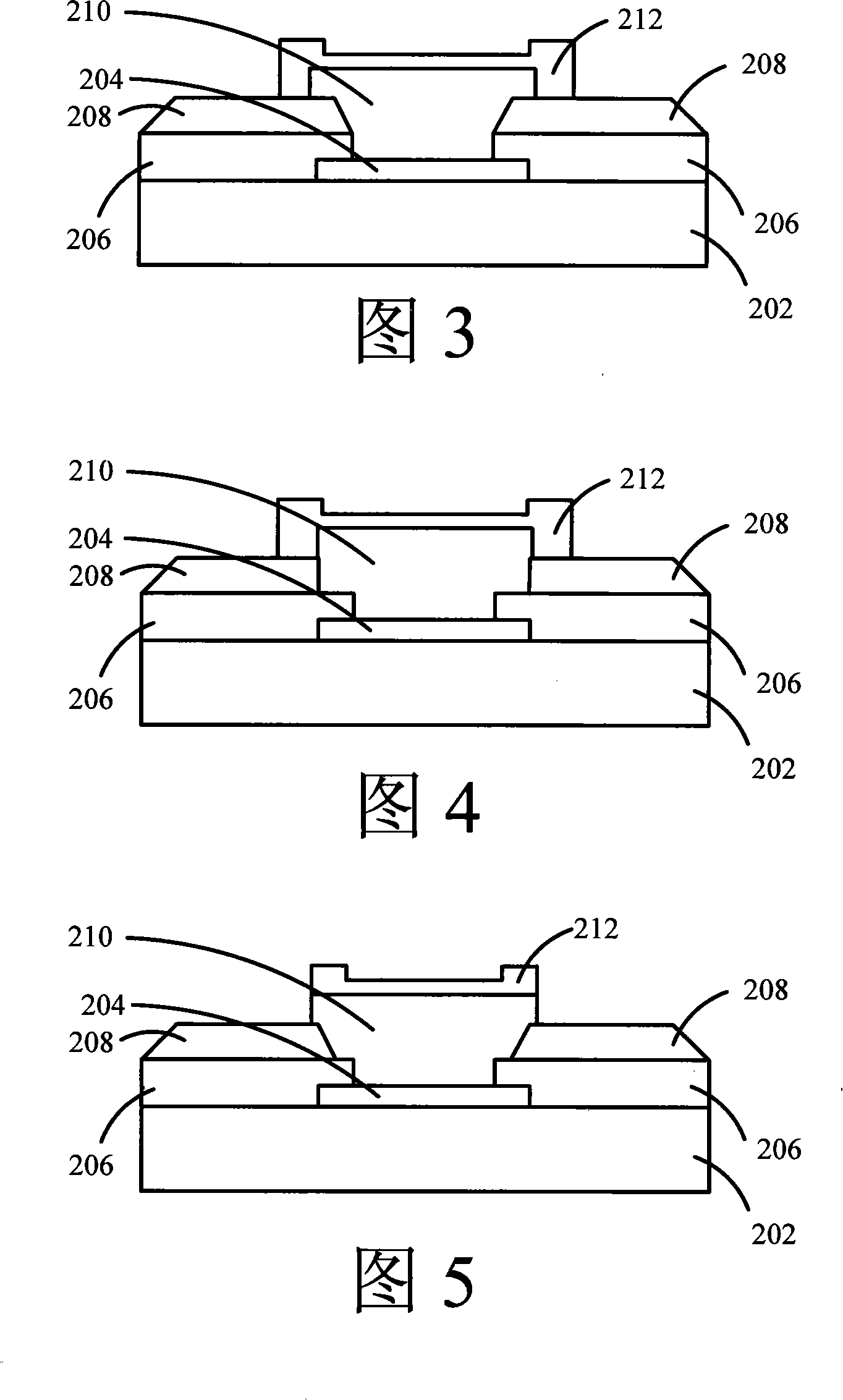

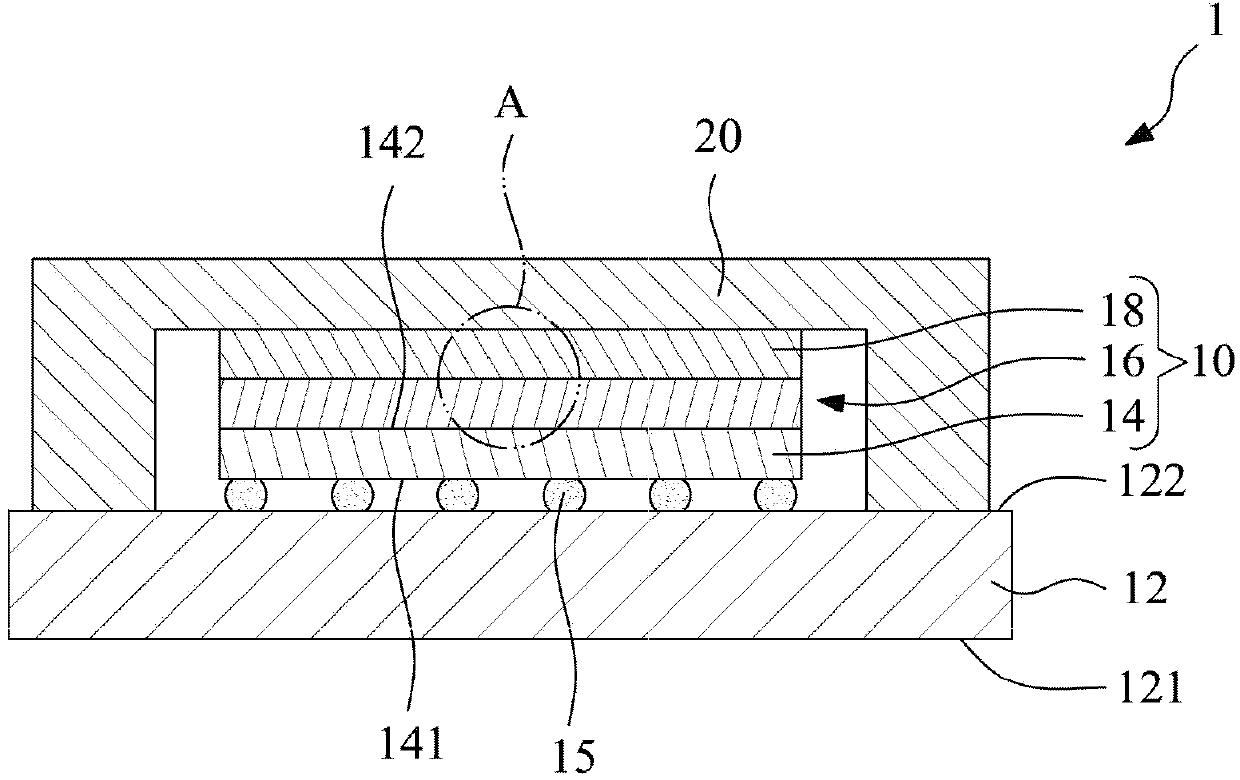

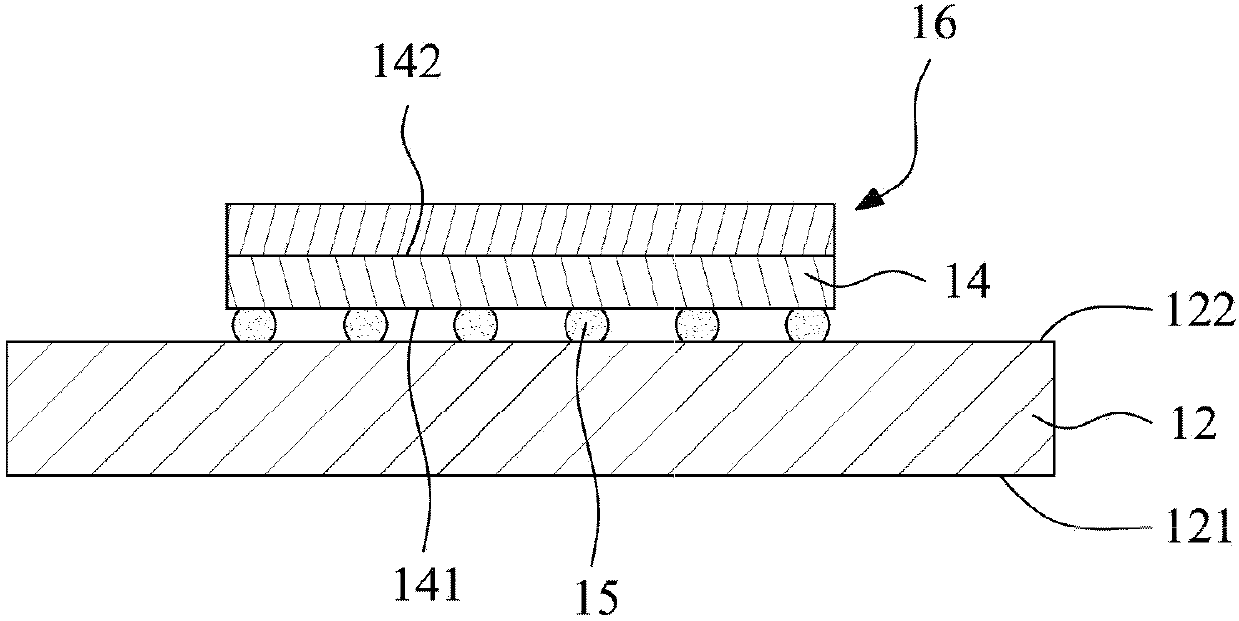

Package substrate and method for fabricating the same

ActiveUS20090096099A1Hard textureImprove bindingSemiconductor/solid-state device detailsStacked resist layersChemical platingLead bonding

A package substrate and a method for fabricating the same are provided according to the present invention. The package substrate includes: a substrate body with a die attaching side and a ball implanting side lying opposite each other, having a plurality of wire bonding pads and a plurality of solder ball pads respectively, and having a first insulating passivation layer and a second insulating passivation layer respectively, wherein a plurality of first apertures and a plurality of second apertures are formed in the first insulating passivation layer and the second insulation passivation layer respectively to corresponding expose the wire bonding pads and the solder ball pads; a chemical plating metal layer formed on the wire bonding pads and solder ball pads respectively; and a wire bonding metal layer formed on a surface of the chemical plating metal layer of the wire bonding metal layer.

Owner:PHOENIX PRECISION TECH CORP

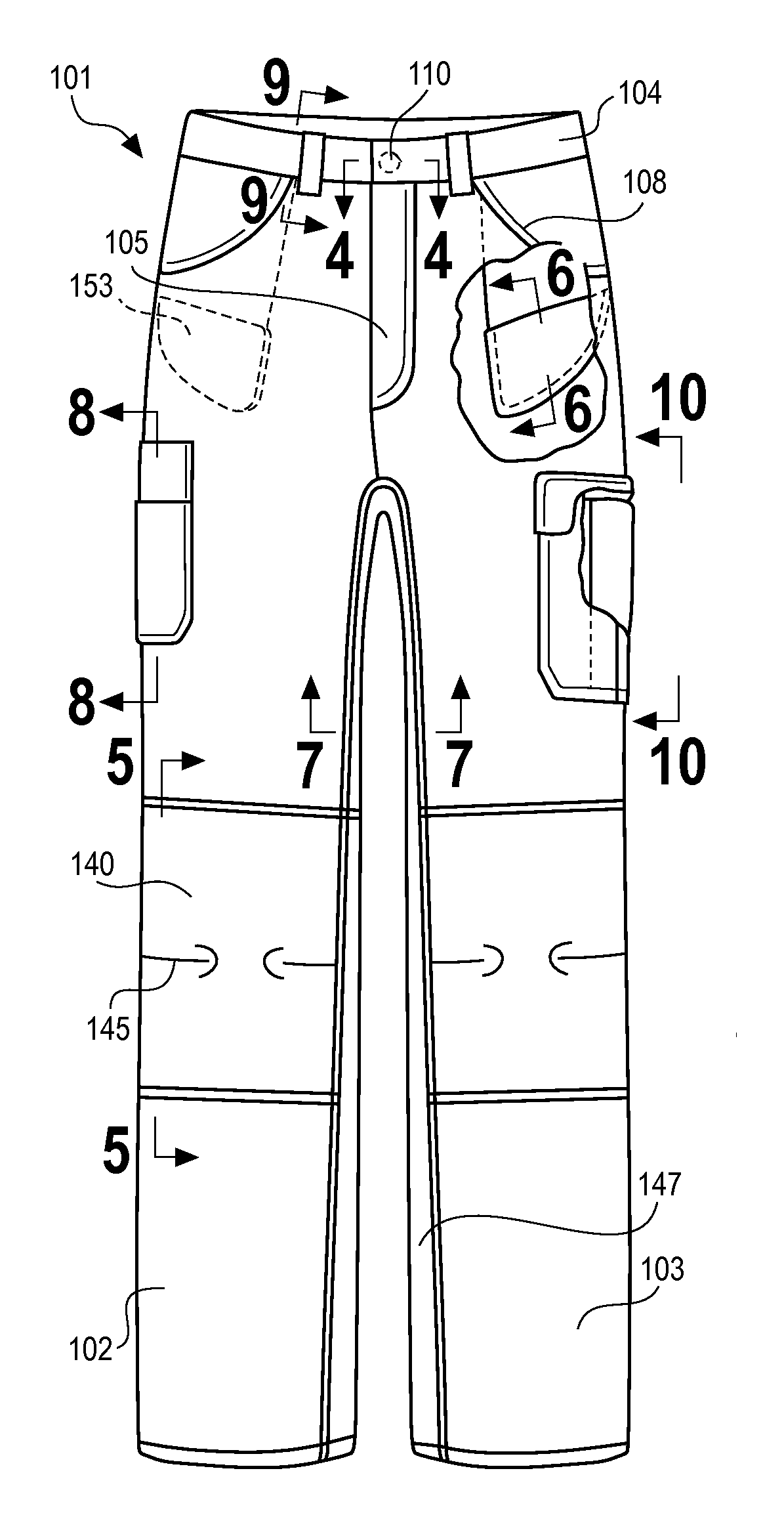

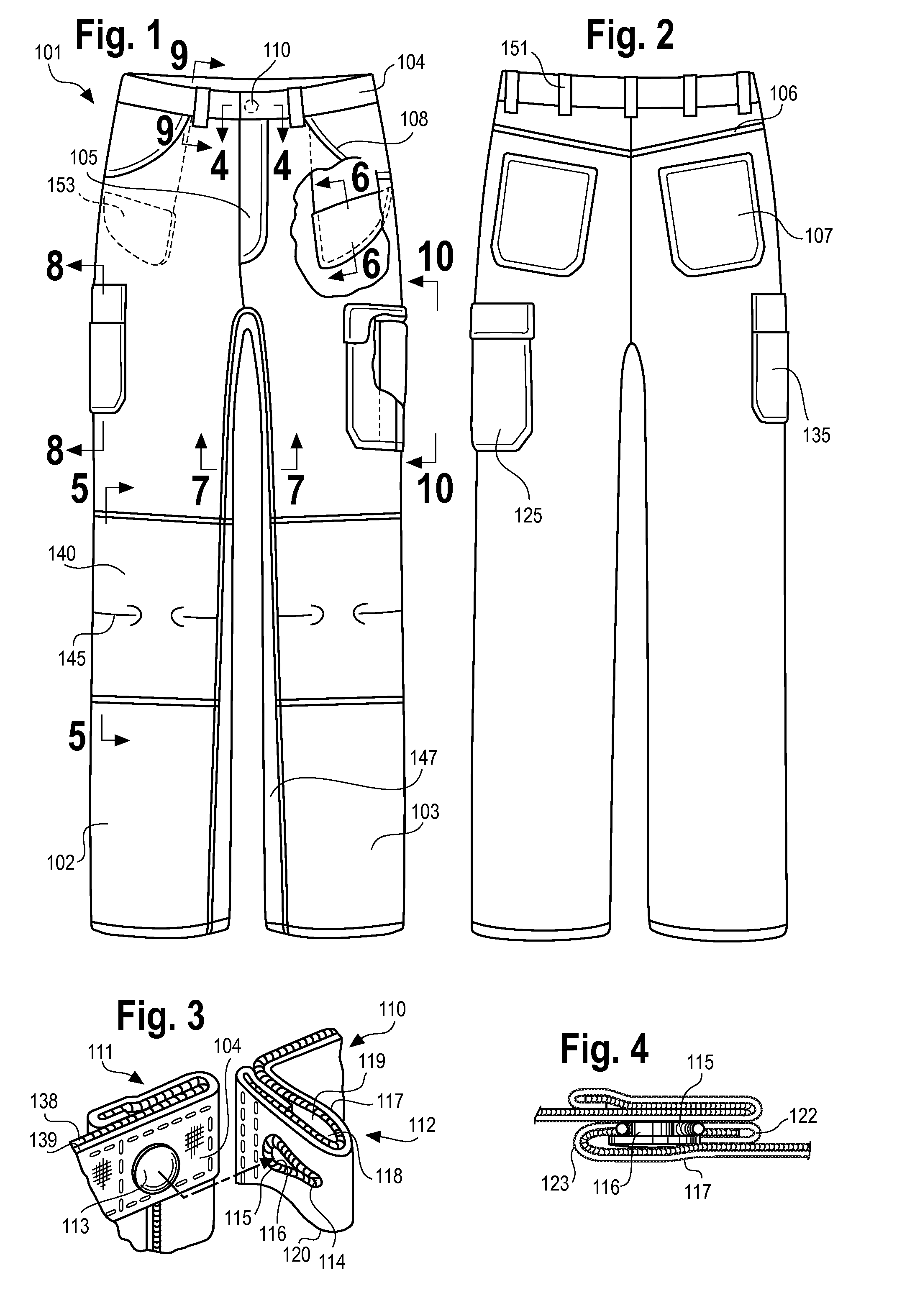

Pants configured for motor vehicle workers

ActiveUS20150282535A1Improve mobilityImprove comfortTrousersGarment beltsEngineeringMotorized vehicle

The pant of the present invention is specifically inspired and configured for use in the motor vehicle industry. The pant may be scratchless, meaning that the pant does not have any exposed features that are capable of scratching the finish on a motor vehicle. For example, the pant may comprise a concealed waistband closure mechanism. The pant may also comprise a scratchless security pocket, which is predisposed toward a closed position and thus does not require the use of buttons or the like. The pant may also be configured to provide enhanced mobility and comfort, allowing a wearer a range of movements without interference from his or her clothing. For example, the pant may be manufactured from a stretchable material and / or may comprise a waistband that is configured to stretch so as to provide increased mobility and comfort. The pant may also include an articulating, reinforcing knee feature, which provides additional strength to the knee portion of the pant while also providing for a more comfortable bend at the knee. Additionally, the pant may have reinforcement features, such as reinforced pockets or belt loops, which are particularly suitable for use by motor vehicle workers.

Owner:WORKWEAR OUTFITTERS LLC

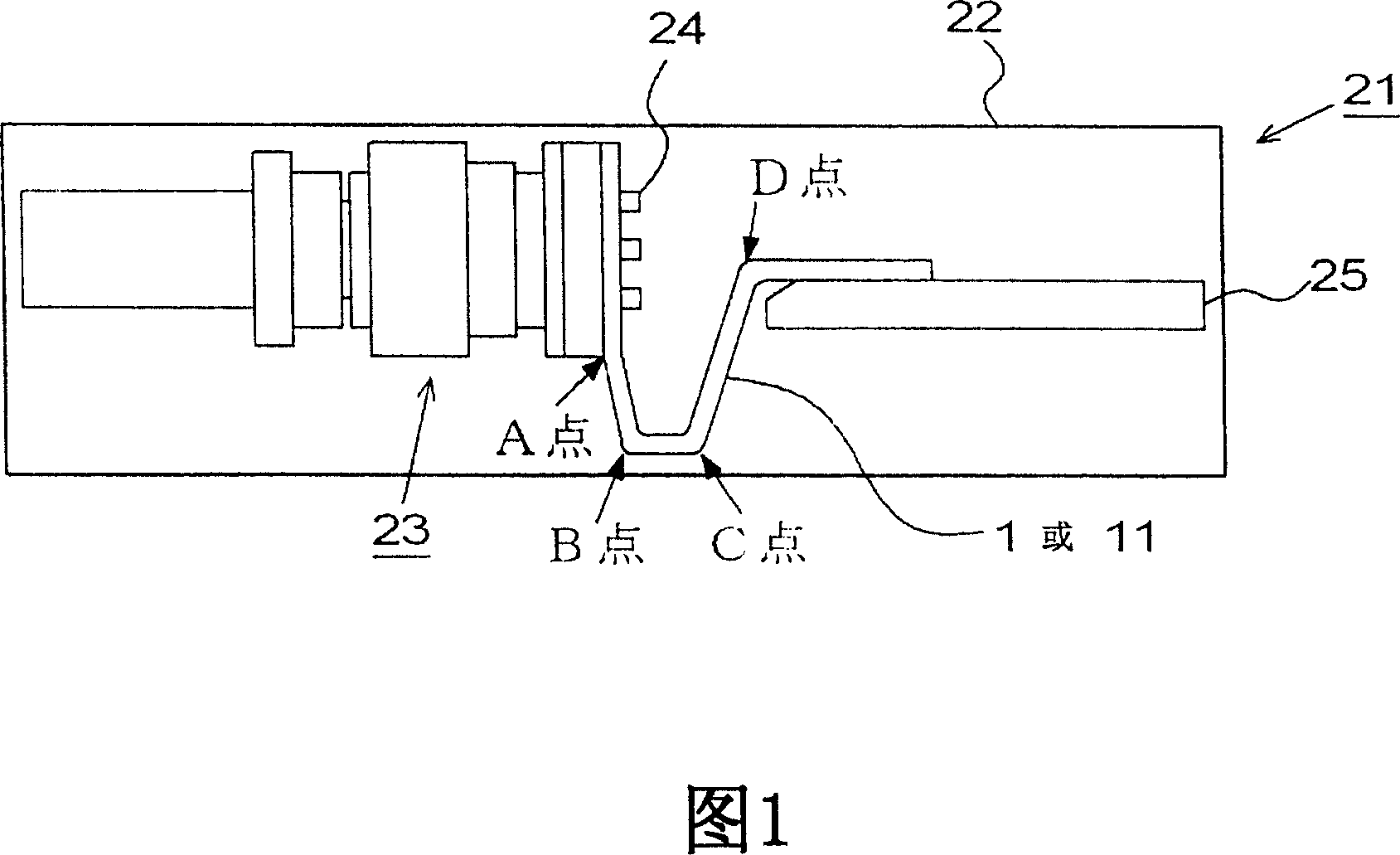

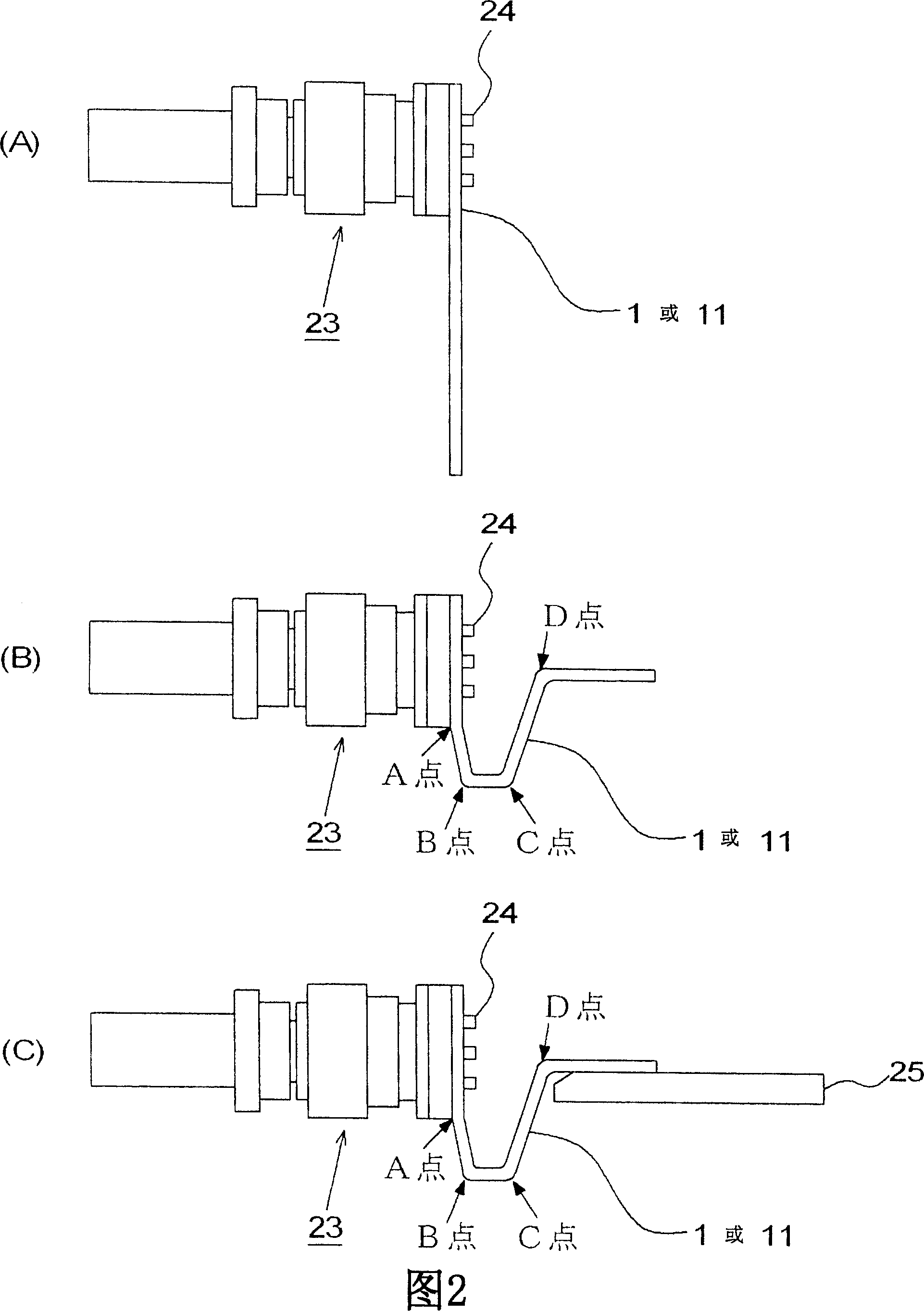

Alloy wire for connecting semiconductor components

InactiveCN102154574AImprove articulationHigh peel strengthSemiconductor/solid-state device detailsSolid-state devicesSemiconductor componentsPalladium

The invention discloses an alloy wire for connecting semiconductor components, which is characterized in that the alloy contains the following contents according to the weight percentage: 0.4 to 15% of gold, 0.2 to 5% of at least one of palladium and platinum, 0.0001 to 0.05% of at least one of Y, La, Ru, Ir, Eu, Yb, Gb and Be, and the rest of silver and inevitable impurities. The alloy wire can increase connectivity, peel strength and vibration fracture of a second side edge.

Owner:DONGGUAN ZHENGQI ELECTRONICS

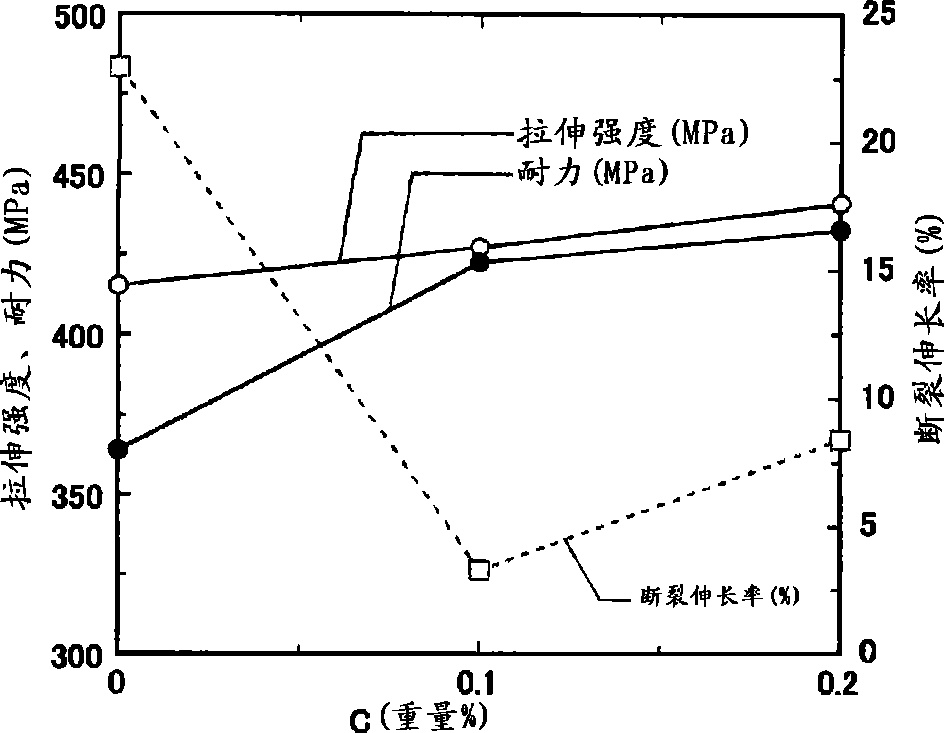

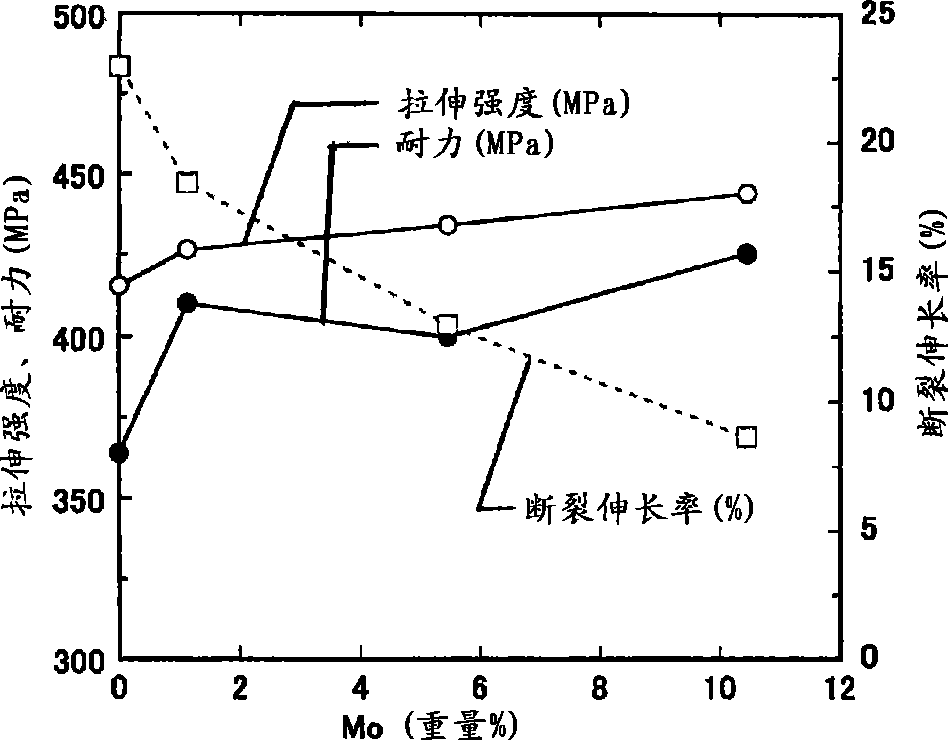

High-strength flame resistant magnesium alloy

A high-strength flame resistant magnesium alloy produced by adding, as a supplement additive, at least one member selected from among carbon (C), molybdenum (Mo), niobium (Nb), silicon (Si), tungsten (W), alumina (Al2O3), magnesium silicide (Mg2Si) and silicon carbide (SiC) to a small-piece block of flame resistant magnesium alloy resulting from addition of 0.5 to 5.0 mass% of calcium to a magnesium alloy, and subjecting the resultant matter to crushing, molding, sintering and plastic working. As the high-strength flame resistant magnesium alloy excels in joining capability, when it is applied to a filler metal, there can be attained an enhancement of weldability.

Owner:NAT INST OF ADVANCED IND SCI & TECH

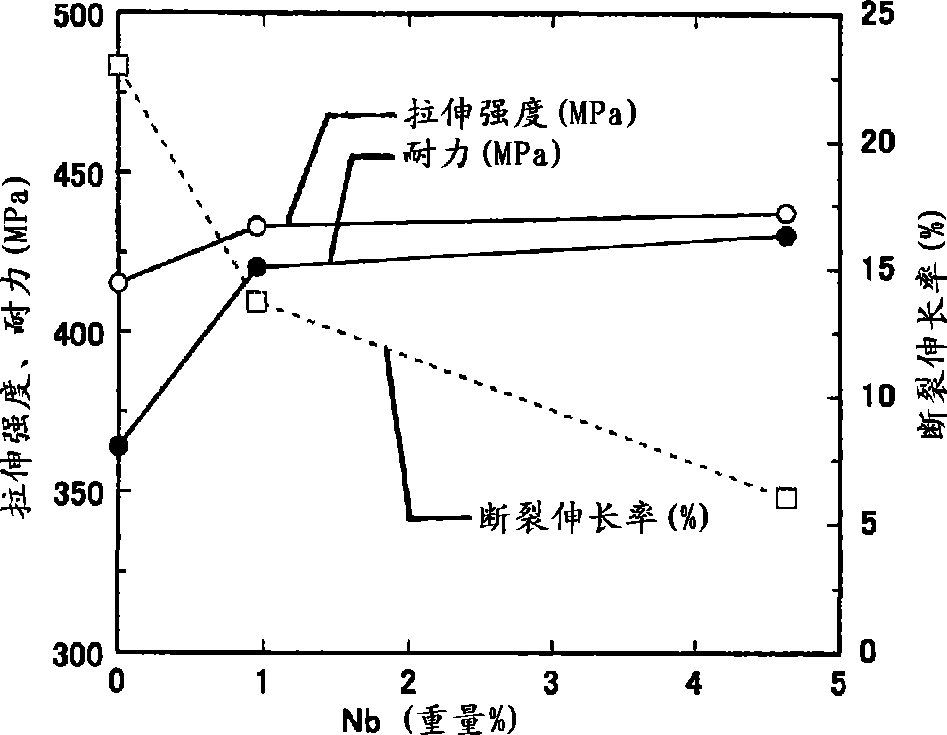

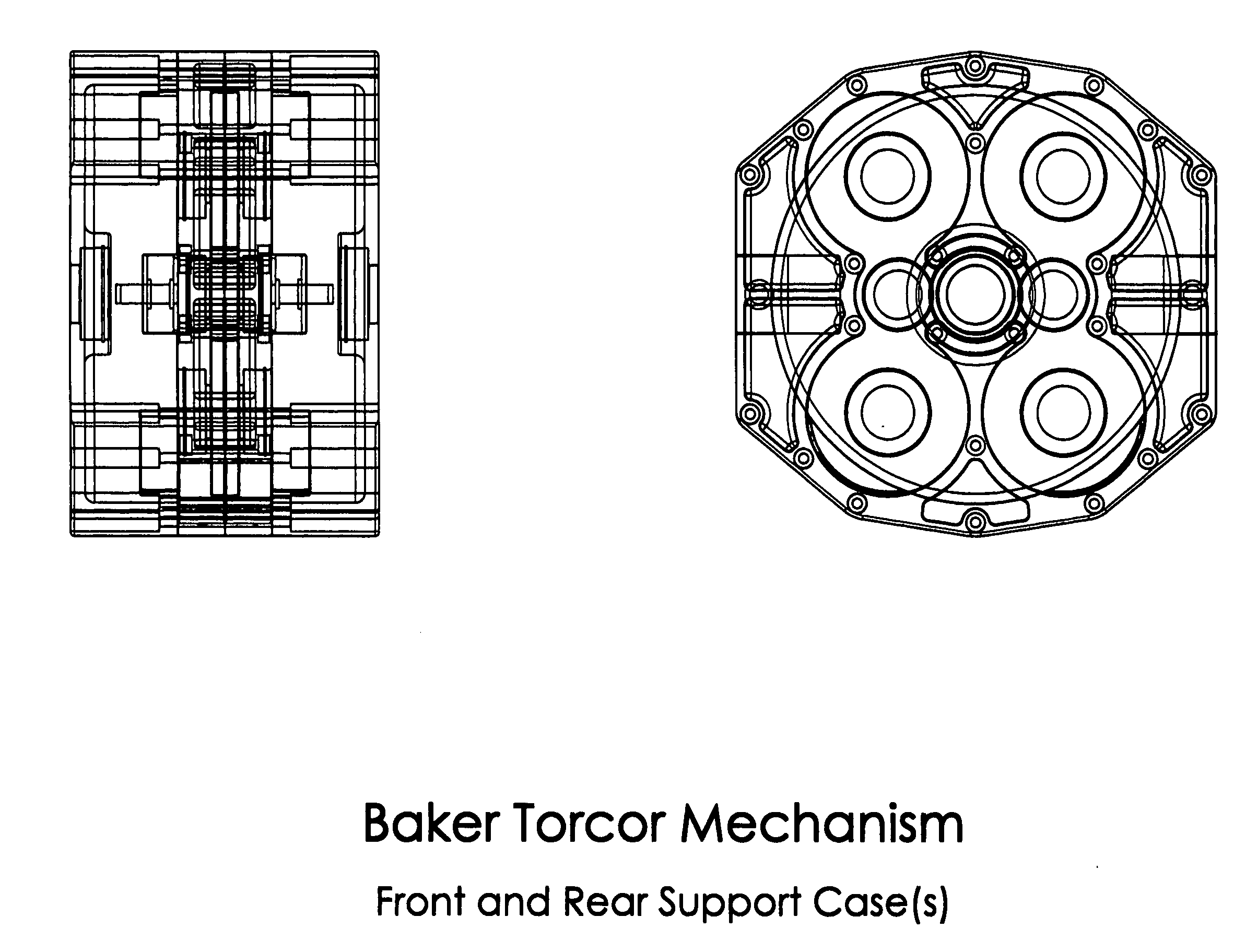

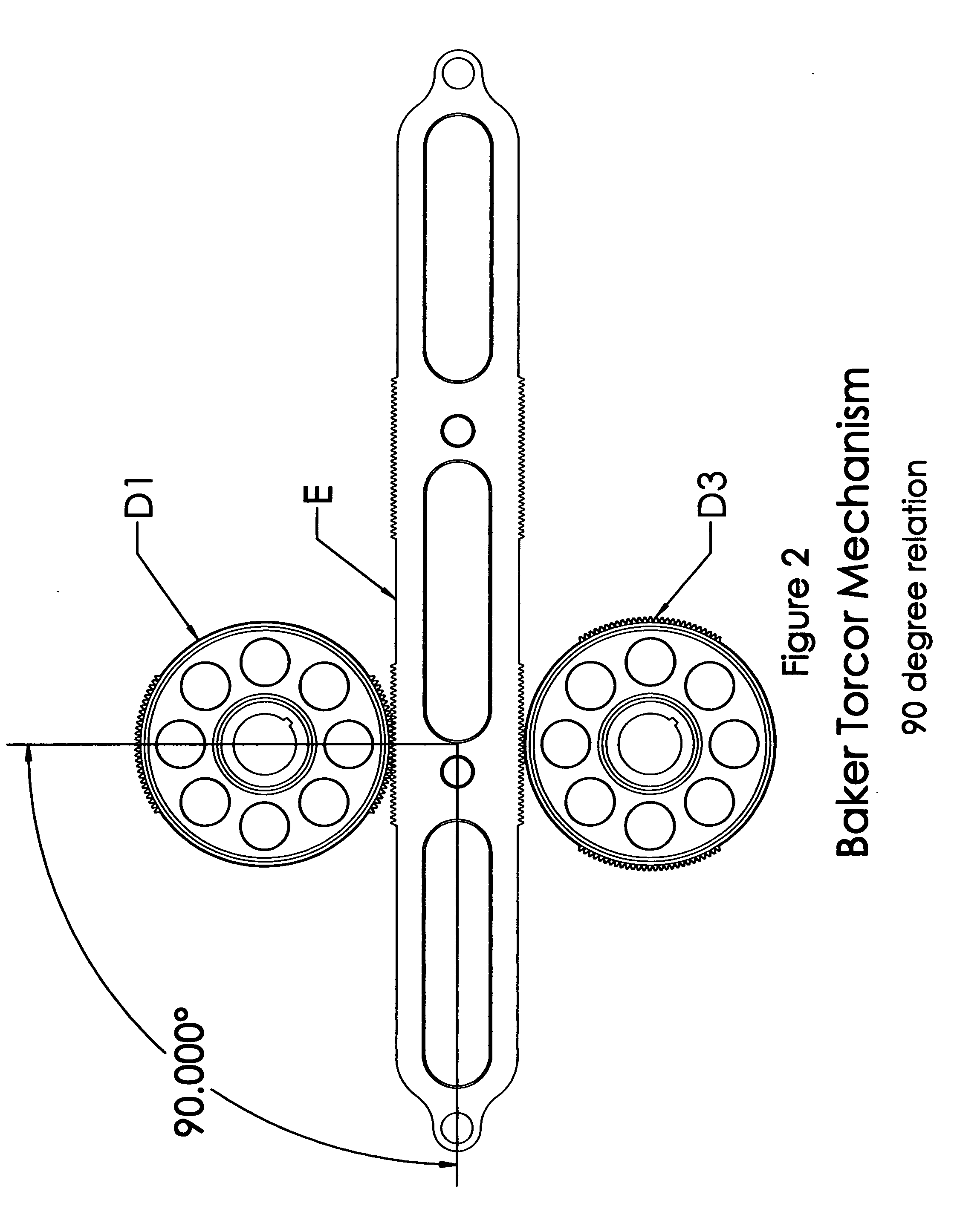

Baker Torcor motion conversion mechanism

InactiveUS20120291572A1Reduce energy consumptionEasy to operateVibration dampersSpringsLinear motionAngular degrees

The present invention utilizes a series of uniquely timed gears and flywheel(s) to convert a linear motion into a rotary motion or a rotary motion into a linear motion. The movement of the drive component (linear or rotary) results in an exact mathematical movement of the driven component (rotary or linear), divided by or multiplied by its gear ratio and can be measured at any point of the stroke or angle of rotation. The present invention achieves and maintains the mathematically and mechanically optimum 90 degree relationship between the linear and rotary components through the entire linear stroke and rotary motion, thereby eliminating the inefficient geometric constraints of a variable vector, crankshaft based motion conversion mechanism.

Owner:BAKER JAMES MICHAEL +3

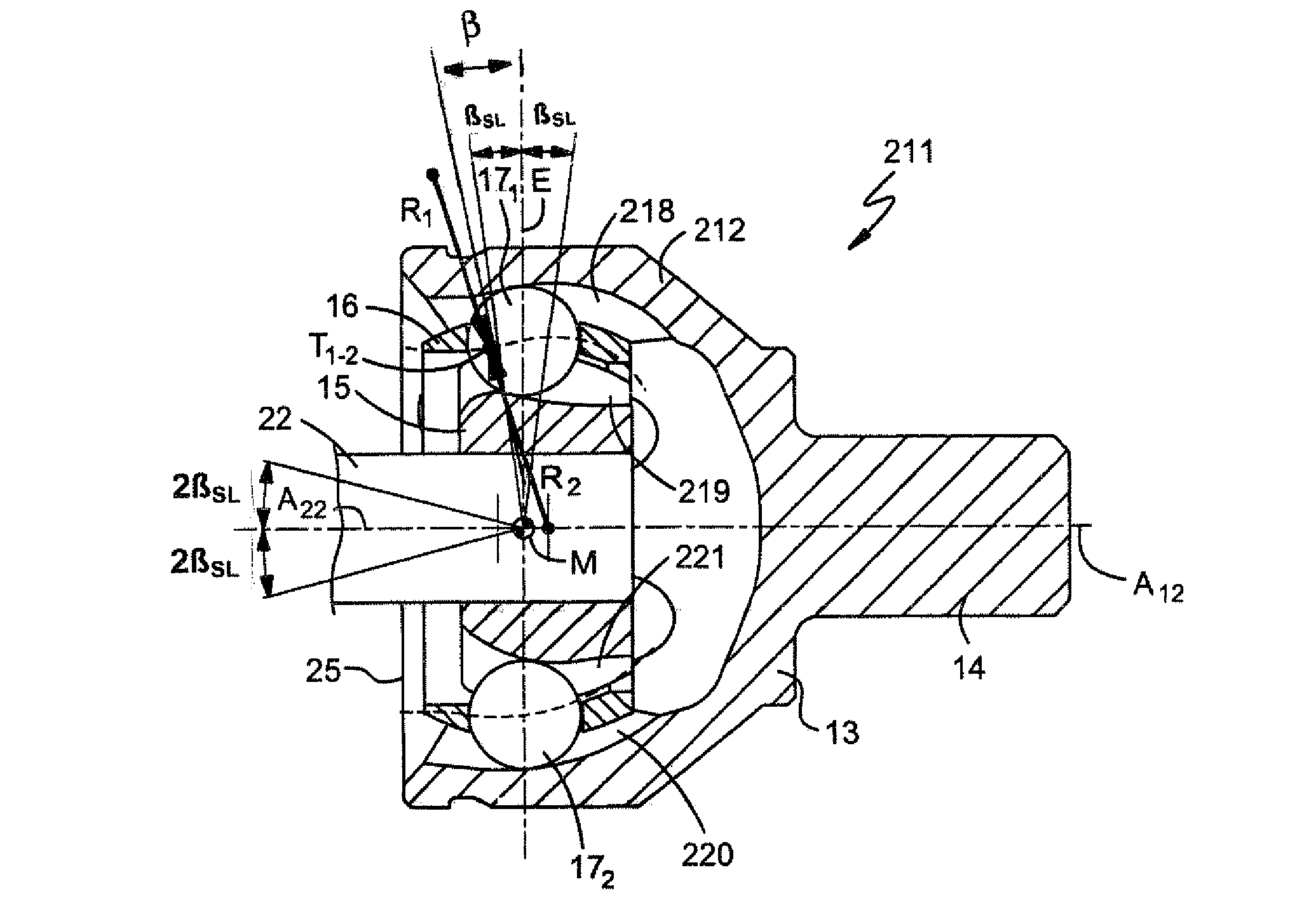

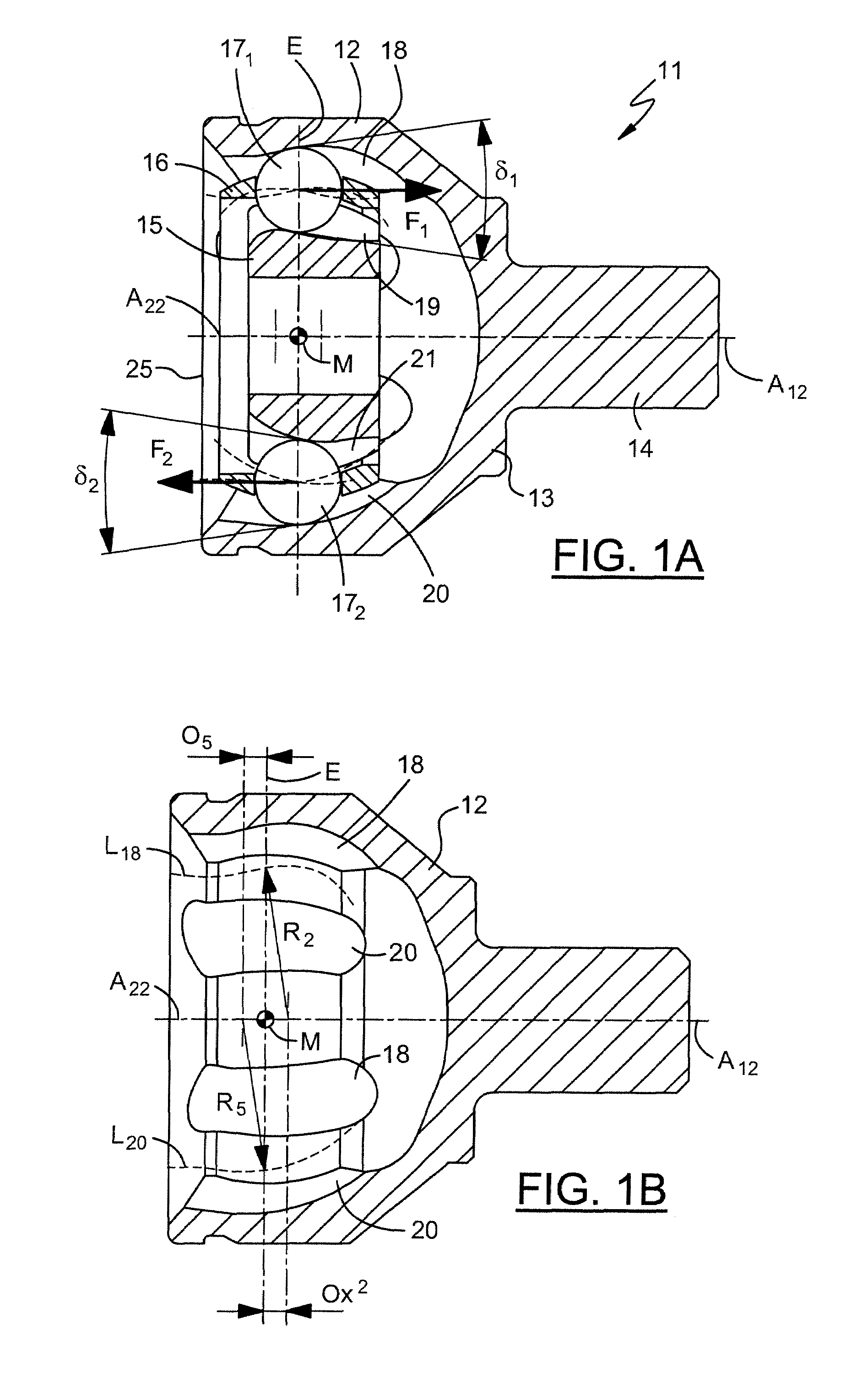

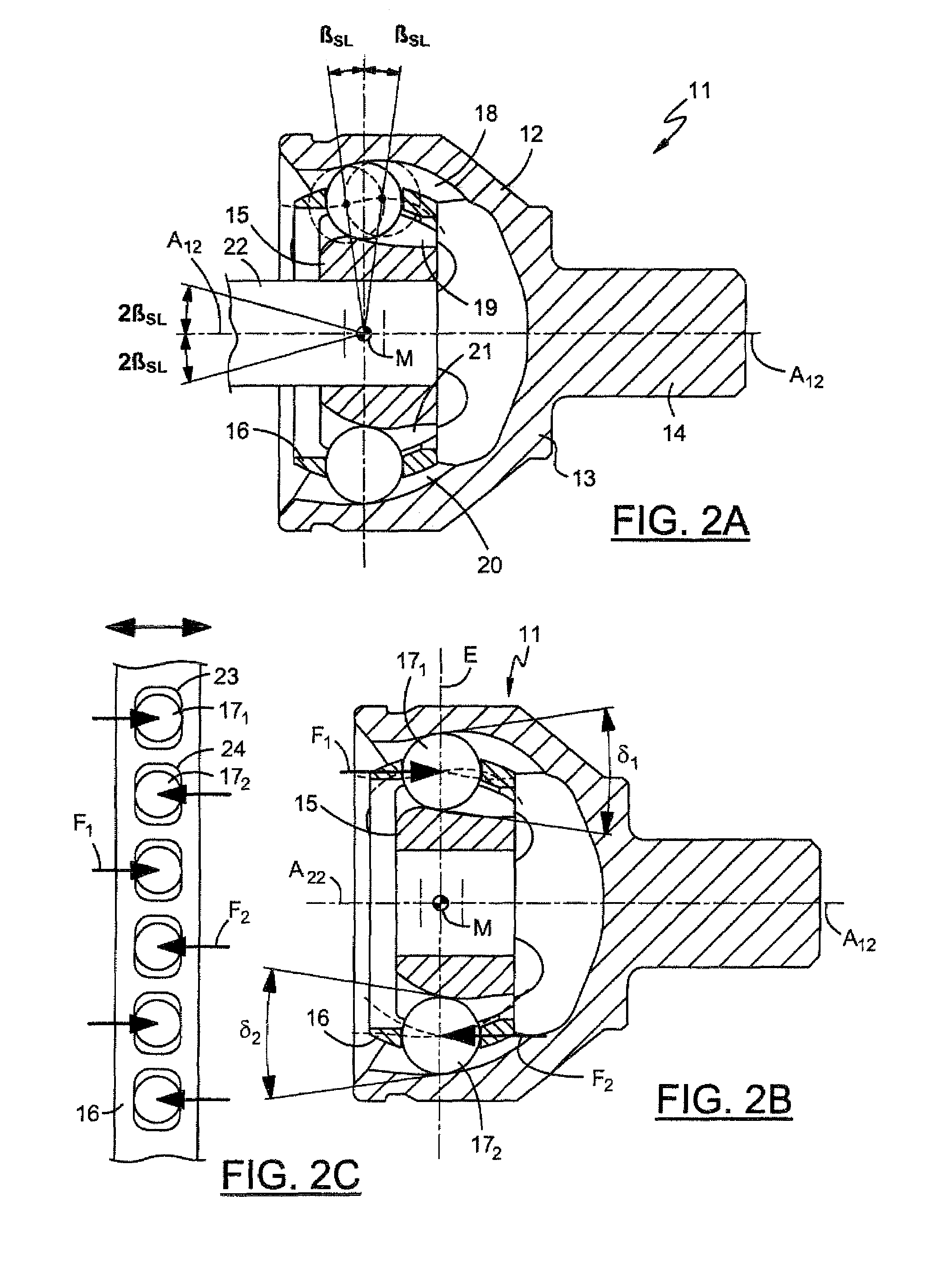

Counter track joint with track turning point

ActiveUS7396285B2Increased articulation angleExtended service lifeYielding couplingRotary machine partsControl theorySacroiliac joint

A constant velocity counter track joint (11) having an outer joint part with first outer ball tracks (18) and second outer ball tracks (20), an inner joint part with first inner ball tracks (19) and second inner ball tracks (21). A ball cage (16) is positioned between the outer joint part and the inner joint part with cage windows which each accommodate at least one of the balls. When the joint is in the aligned condition, the aperture angle (δ1) of the pairs of first tracks opens in the central joint plane (E) from the aperture end to the attaching end of the outer joint part (12), and the aperture angle (δ2) of the pairs of second tracks opens in the opposite direction. The central track lines (L18, L19) of the first pairs of tracks each have a turning point (T1-2), and the center angle (β) from the joint center to the turning point (T1-2), is greater than 4°.

Owner:GKN DRIVELINE INT GMBH

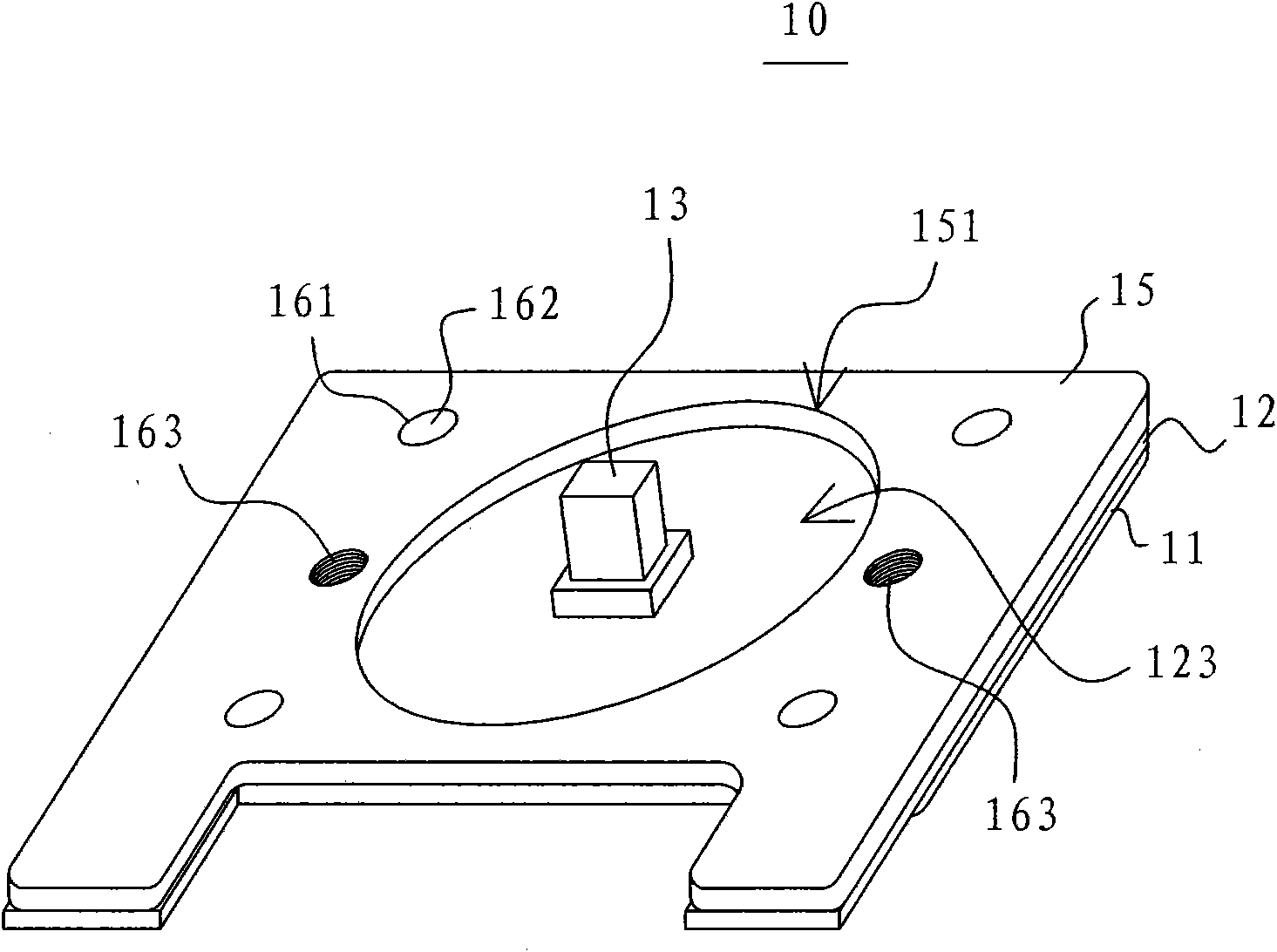

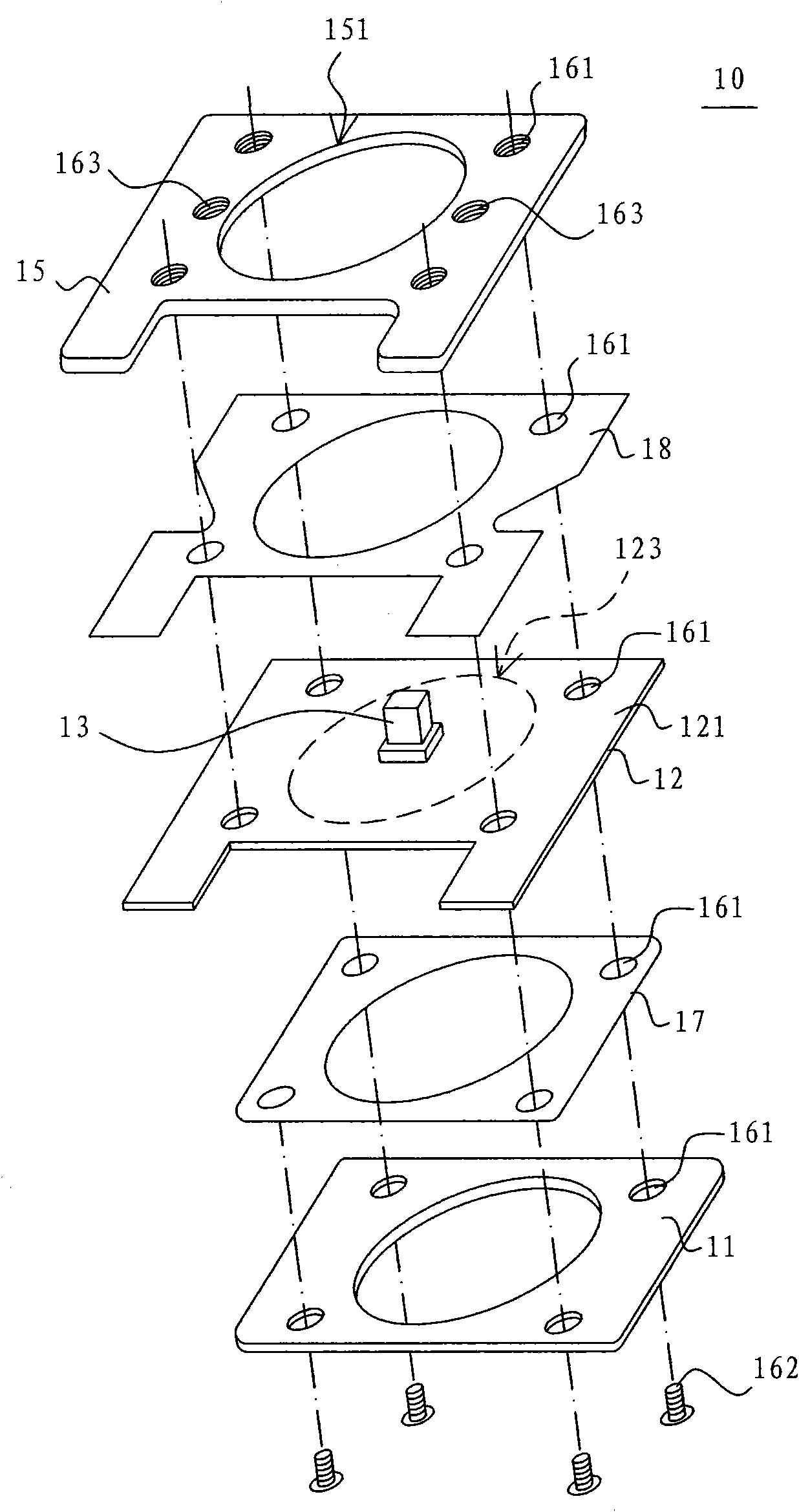

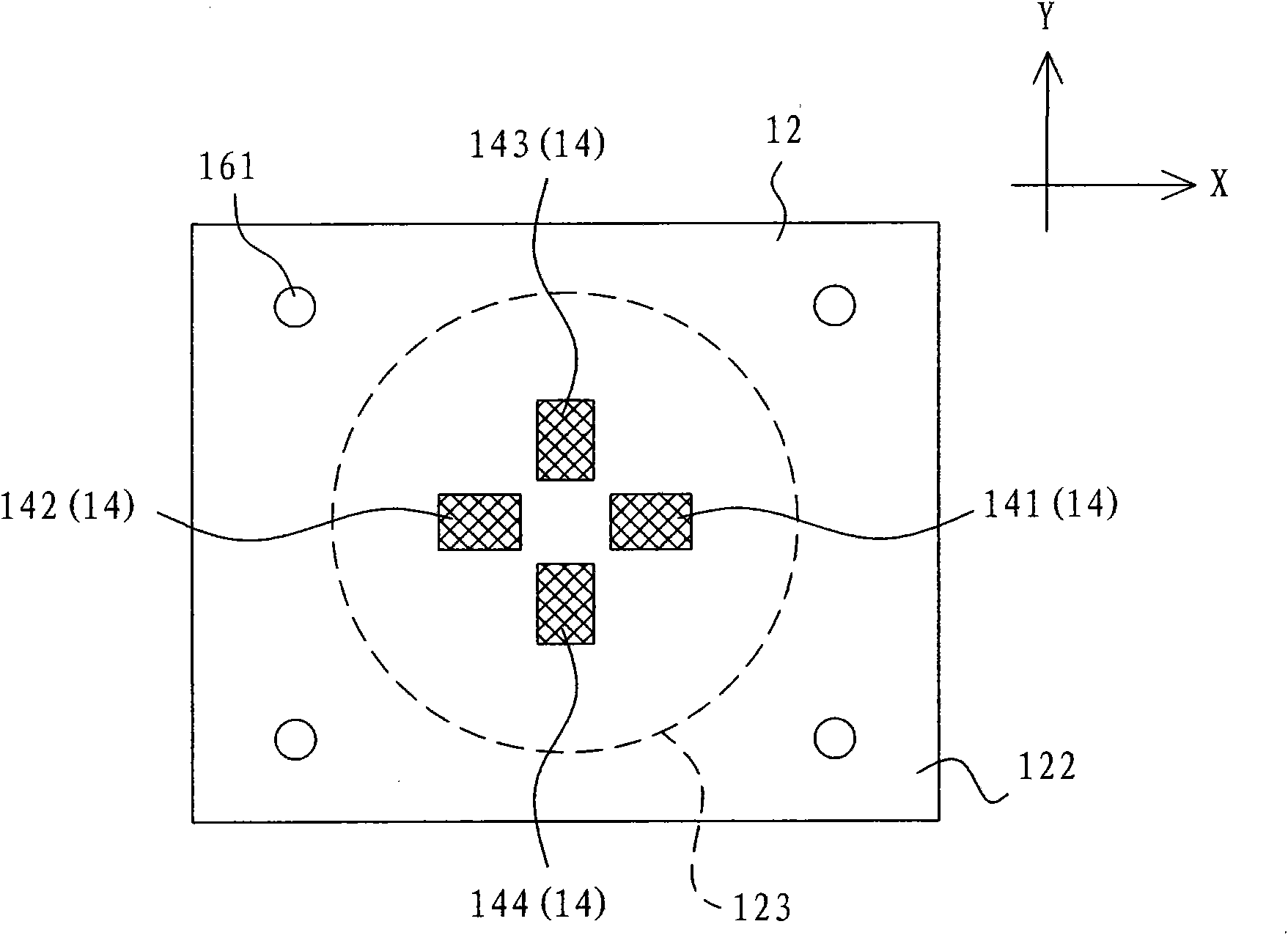

Stress inductor and assembly method thereof

The invention relates to a stress inductor and an assembly method thereof. The stress inductor comprises a circuit substrate, a pointing actuating part and a metal back plate, wherein the circuit substrate has a stress induction structure, and the stress induction structure comprises a stress deformation area and a plurality of stress induction resistors; the pointing actuating part is arranged on the top surface of the circuit substrate and connected with the stress induction structure; and the metal back plate is provided with at least one jointing material coating area, and a plurality of fixedly connected edges of the circuit substrate are fixedly connected in the jointing material coating area. The assembly method for the stress inductor is applied to the stress inductor and comprises the following steps of: combining the pointing actuating part to the top surface of the circuit substrate; and fixedly connecting the fixedly connected edges of the circuit substrate to the at least one jointing material coating area of the metal back plate. The stress inductor has a few elements, and has the advantages of small size and low cost; and because the circuit substrate is directly fixedly connected on the metal back plate, the assembly method for the stress inductor simplifies the assembly step and promotes the assembly efficiency.

Owner:ELAN MICROELECTRONICS CORPORATION

Carbon-silicon composite electrode material and preparation method thereof

ActiveCN104868095AImprove articulationImprove uniformityCell electrodesSecondary cellsDispersityComposite electrode

The invention discloses a carbon-silicon composite electrode material and a preparation method thereof. The carbon-silicon composite electrode material can improve the effective dispersity of silicon-containing particles on the surfaces of carbon-containing particles by coating the carbon-containing particles and the silicon-containing particles with organic high-molecular modified films. The carbon-silicon composite electrode material can comprise a carbon-containing conducting film coating the surface of the carbon-silicon composite electrode material to improve effective adhesion of the silicon-containing particles. The preparation method of the carbon-silicon composite electrode material can be completed in an aqueous-phase solution through dry mixing. Therefore, damage of volatile organic compounds to an operator and environment can be effectively avoided. According to the carbon-silicon composite electrode material and the preparation method, the carbon-silicon composite electrode material can effectively improve the electric capacity, the charging and discharging efficiency and the cycle life of a battery product using the carbon-silicon composite electrode material.

Owner:江门市荣炭电子材料有限公司

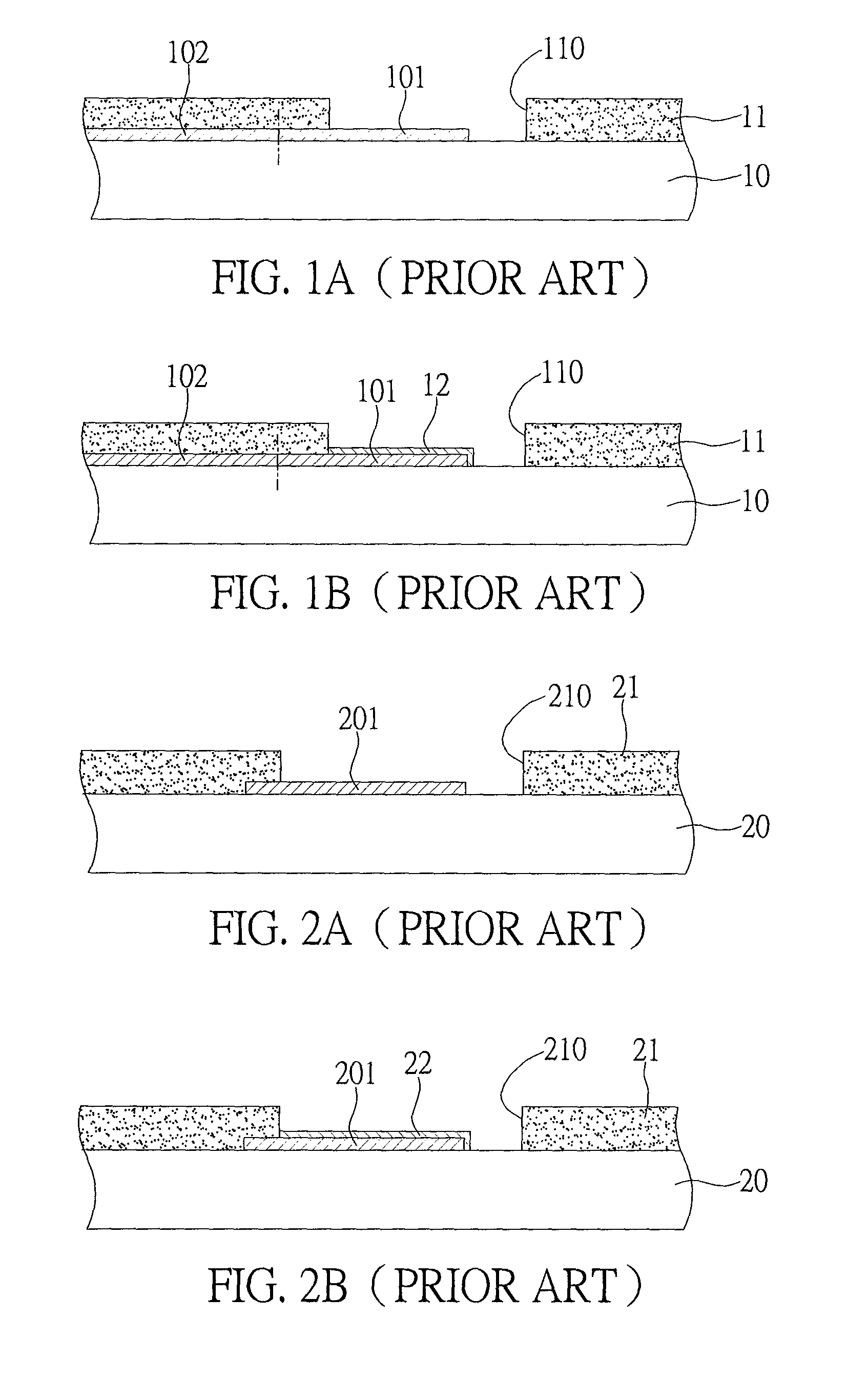

Package substrate and method for fabricating the same

ActiveUS7718470B2High densityLarge spacingSemiconductor/solid-state device detailsStacked resist layersChemical platingLead bonding

A package substrate and a method for fabricating the same are provided according to the present invention. The package substrate includes: a substrate body with a die attaching side and a ball implanting side lying opposite each other, having a plurality of wire bonding pads and a plurality of solder ball pads respectively, and having a first insulating passivation layer and a second insulating passivation layer respectively, wherein a plurality of first apertures and a plurality of second apertures are formed in the first insulating passivation layer and the second insulation passivation layer respectively to corresponding expose the wire bonding pads and the solder ball pads; a chemical plating metal layer formed on the wire bonding pads and solder ball pads respectively; and a wire bonding metal layer formed on a surface of the chemical plating metal layer of the wire bonding metal layer.

Owner:PHOENIX PRECISION TECH CORP

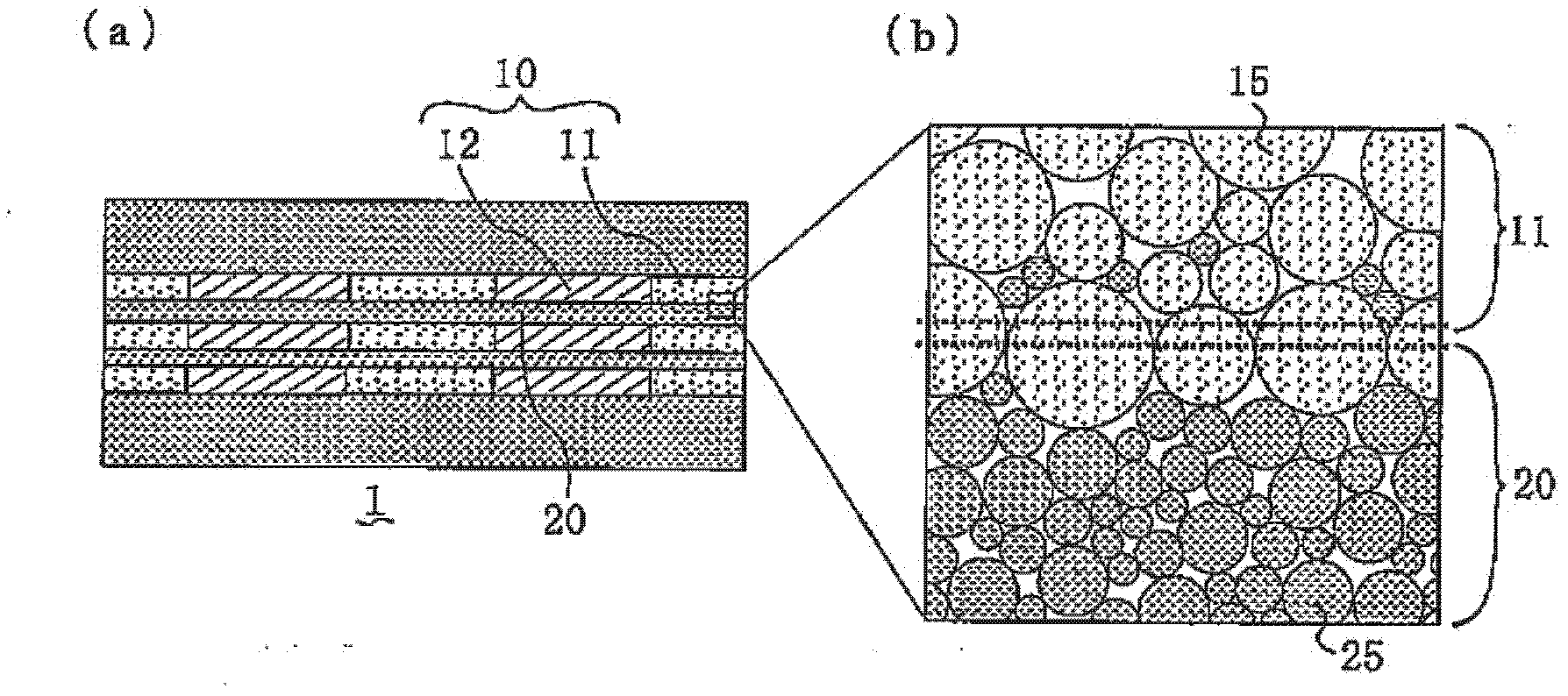

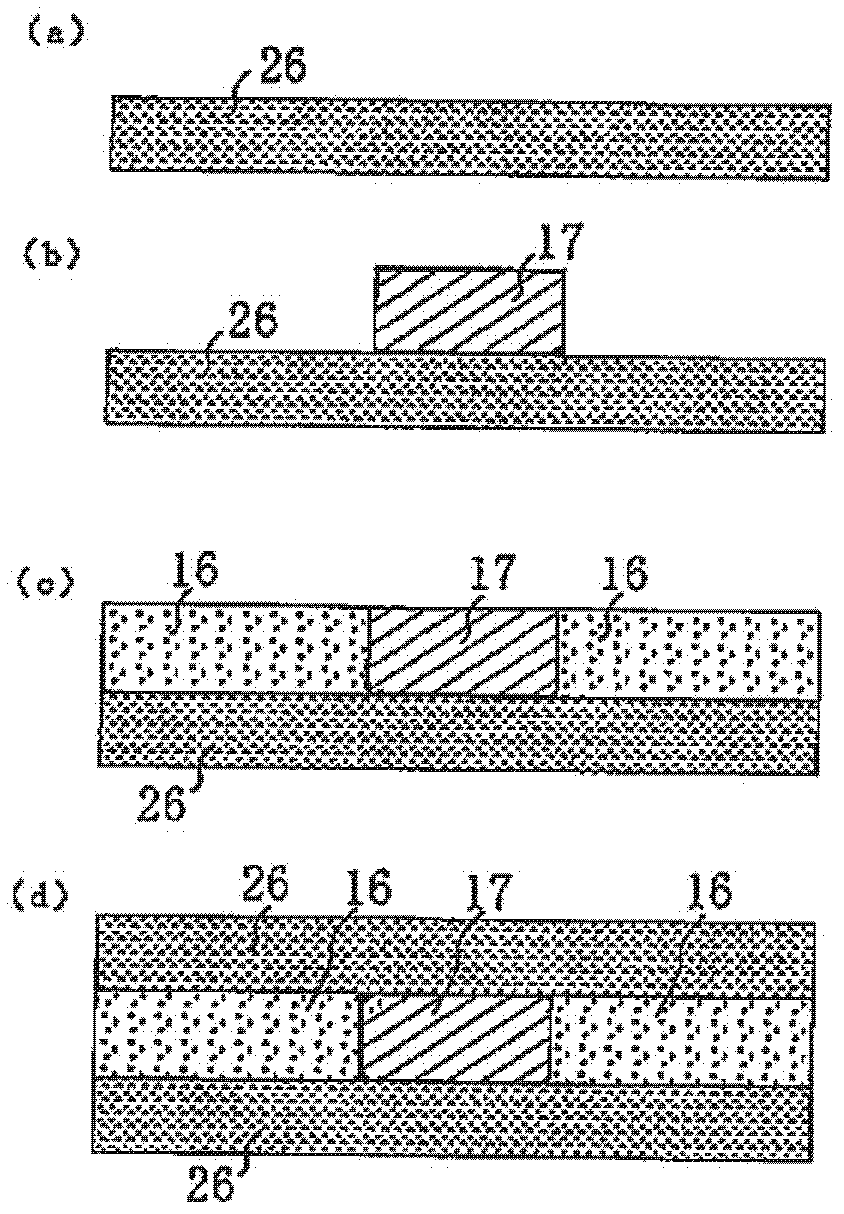

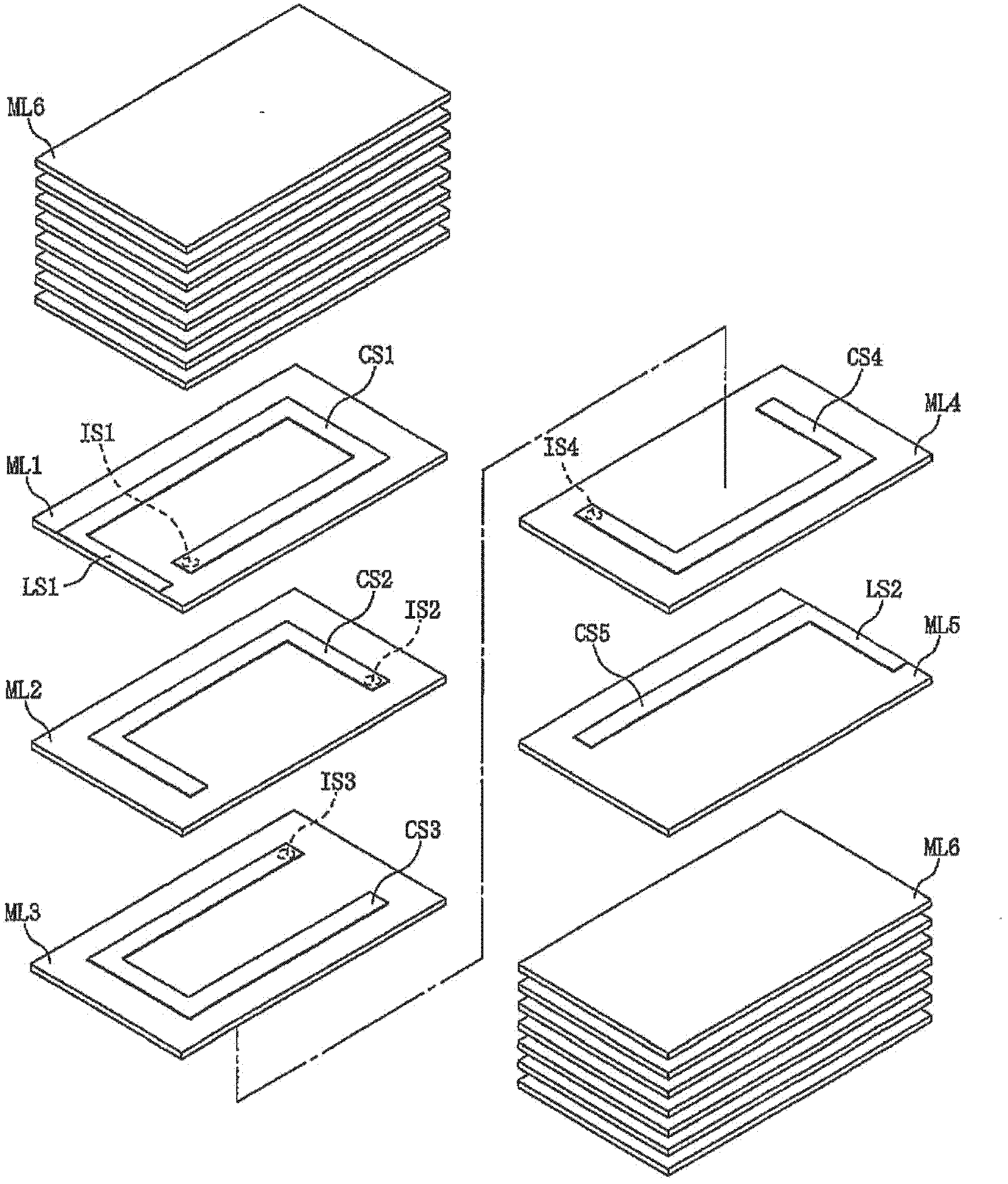

Laminated inductor

ActiveCN102930947AImprove permeabilityHigh strengthTransformers/inductances coils/windings/connectionsInorganic material magnetismMetallurgyInductor

A laminated inductor having a laminate structure constituted by magnetic layers and internal conductive wire-forming layers, wherein the magnetic layer is formed by soft magnetic alloy grains, the internal conductive wire-forming layer has an internal conductive wire and a reverse pattern portion around it, and the reverse pattern portion is formed by soft magnetic alloy grains whose constituent elements are of the same types as those of, and whose average grain size is greater than that of, the soft magnetic alloy grains constituting the magnetic layer.

Owner:TAIYO YUDEN KK

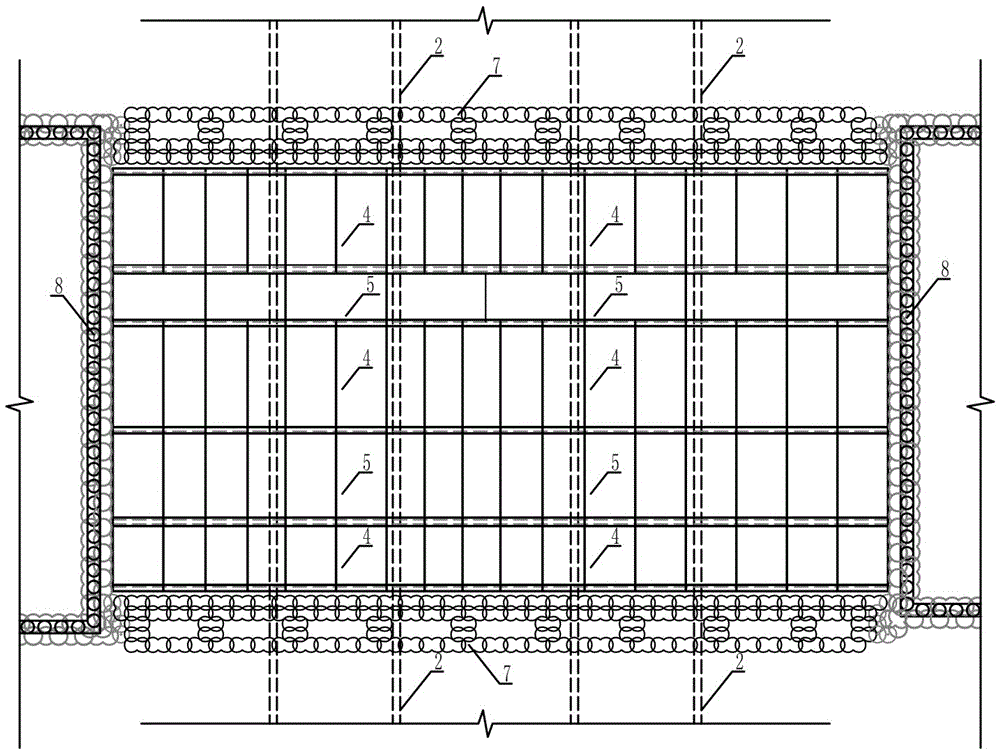

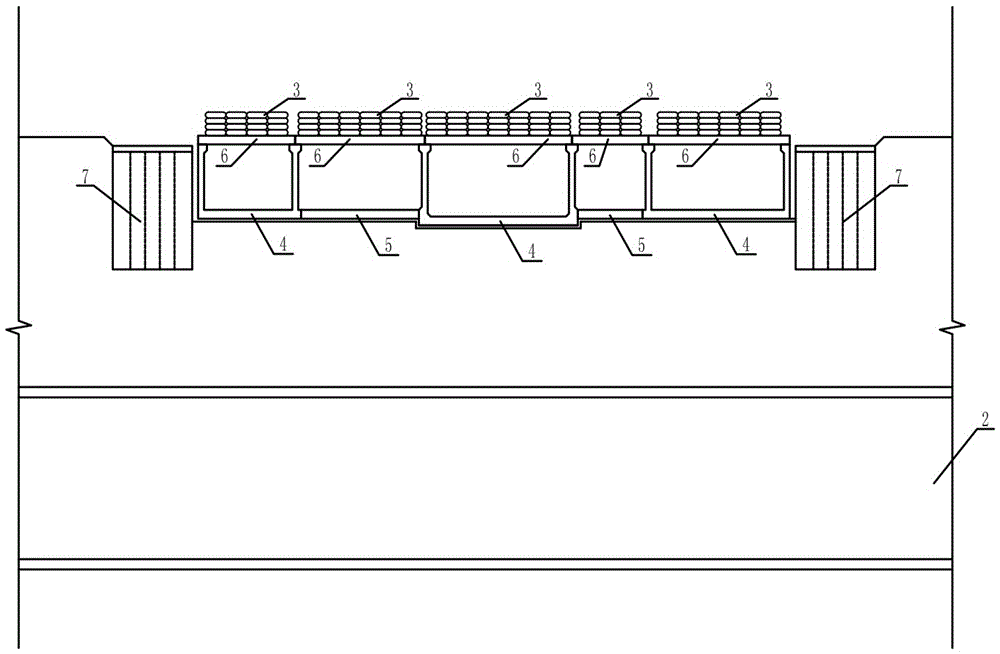

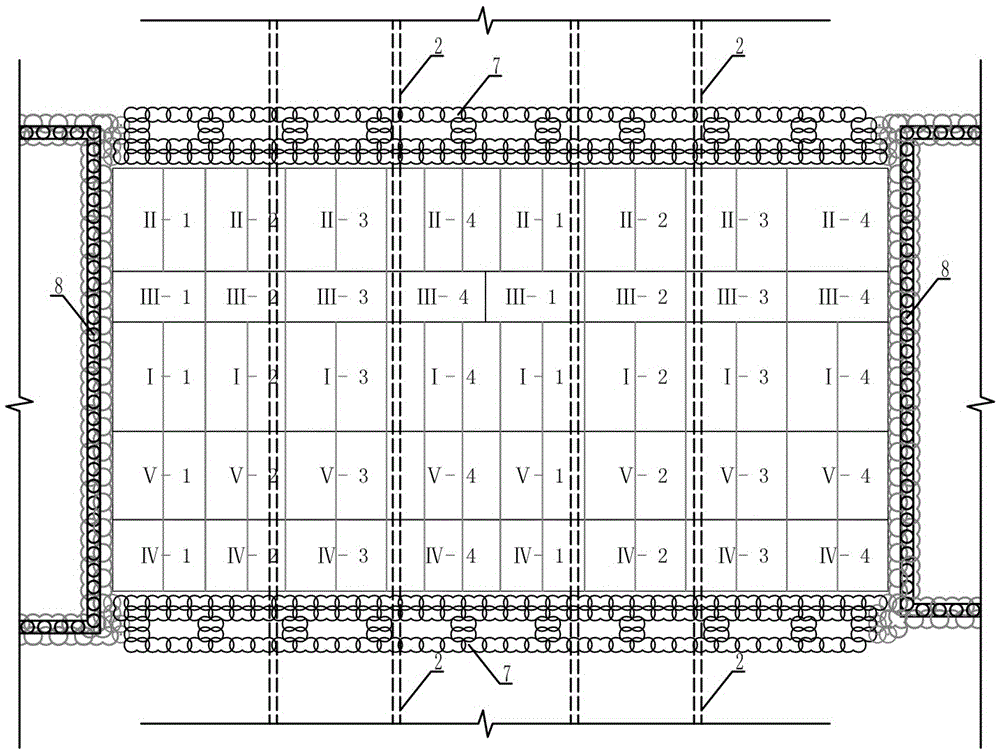

Underground structure of municipal pipeline group spanning tunnel and construction method for underground structure

ActiveCN105672356AEasy to installEasy to install, speed up the connection between various construction proceduresArtificial islandsUnderwater structuresReinforced concreteStructure of the Earth

The invention discloses an underground structure of a municipal pipeline group spanning tunnel and a construction method for the underground structure. The construction method is characterized in that the municipal pipeline group underground structure is excavated by adopting a construction method of strip-divided and block-divided pouring in a spacing manner, and a pipe section, which is assembled by a U-shaped slot prefabricated by reinforced concrete or a bottom plate and a cover plate, of a box-type structure is quickly hoisted, and bagged sand is piled up on the pipe section structure to compensate unloading caused by earth excavation, so that zero unloading during a pipeline mounting group construction period is realized, and heave deformation of an inferior subway tunnel is controlled. The specific construction of the construction method comprises the steps such as bracing of a foundation pit, earth excavation, pipeline mounting and the like. Compared with the prior art, the construction method controls the heave deformation of the pit bottom and the subway tunnel, has small influence on a surrounding environment, has high working efficiency and has low engineering risk, and is especially suitable for a soft soil area, so that environmental adverse effect caused by excavation of the foundation pit is reduced to be lowest, and the tunnel heave deformation caused by soil unloading is effectively controlled.

Owner:ZHONGCHUAN NO 9 DESIGN & RES INST

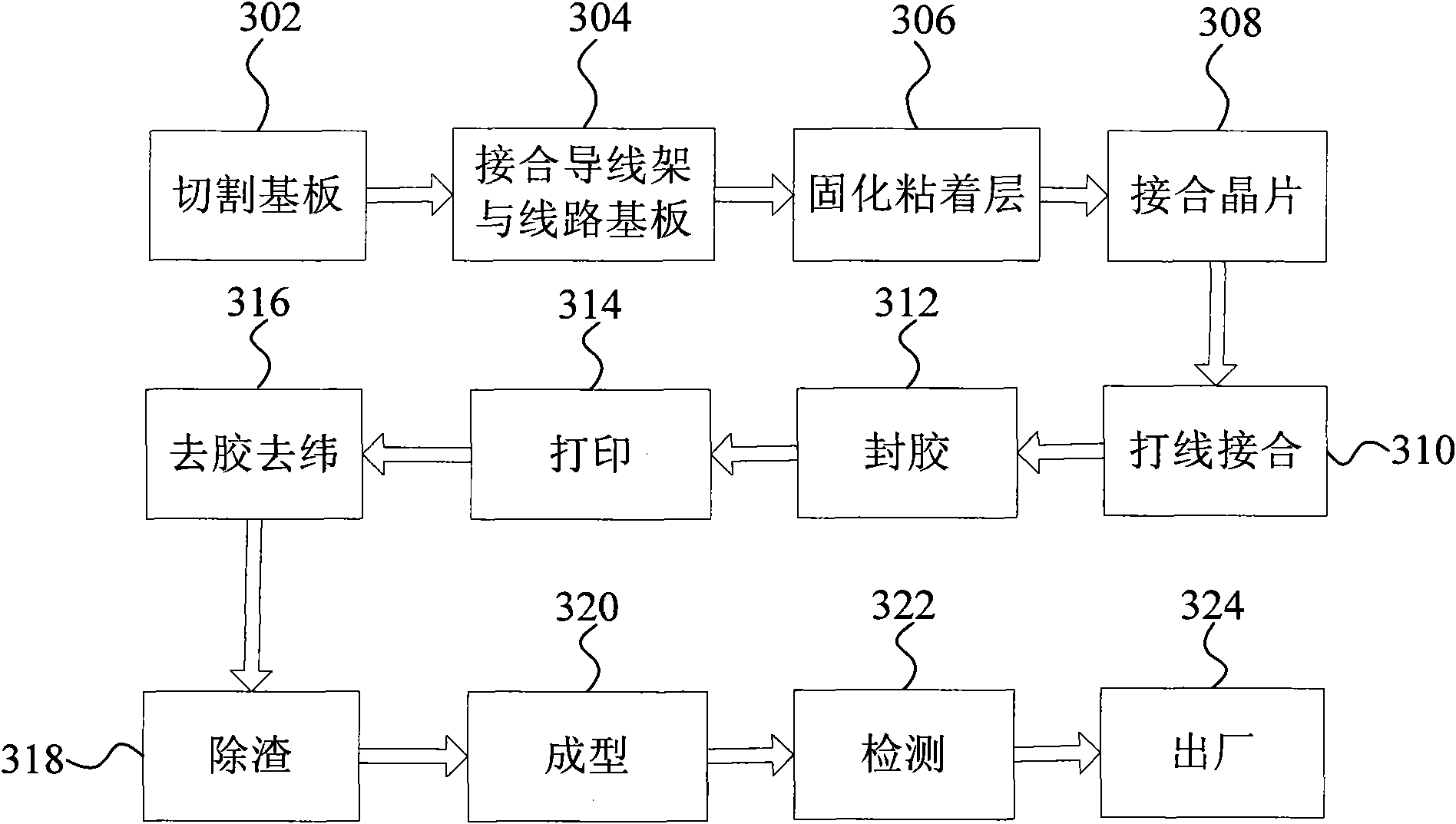

Packaging structure and packaging method

ActiveCN101989581AGood compatibilityGood system integration abilitySemiconductor/solid-state device detailsSolid-state devicesEngineeringColloid

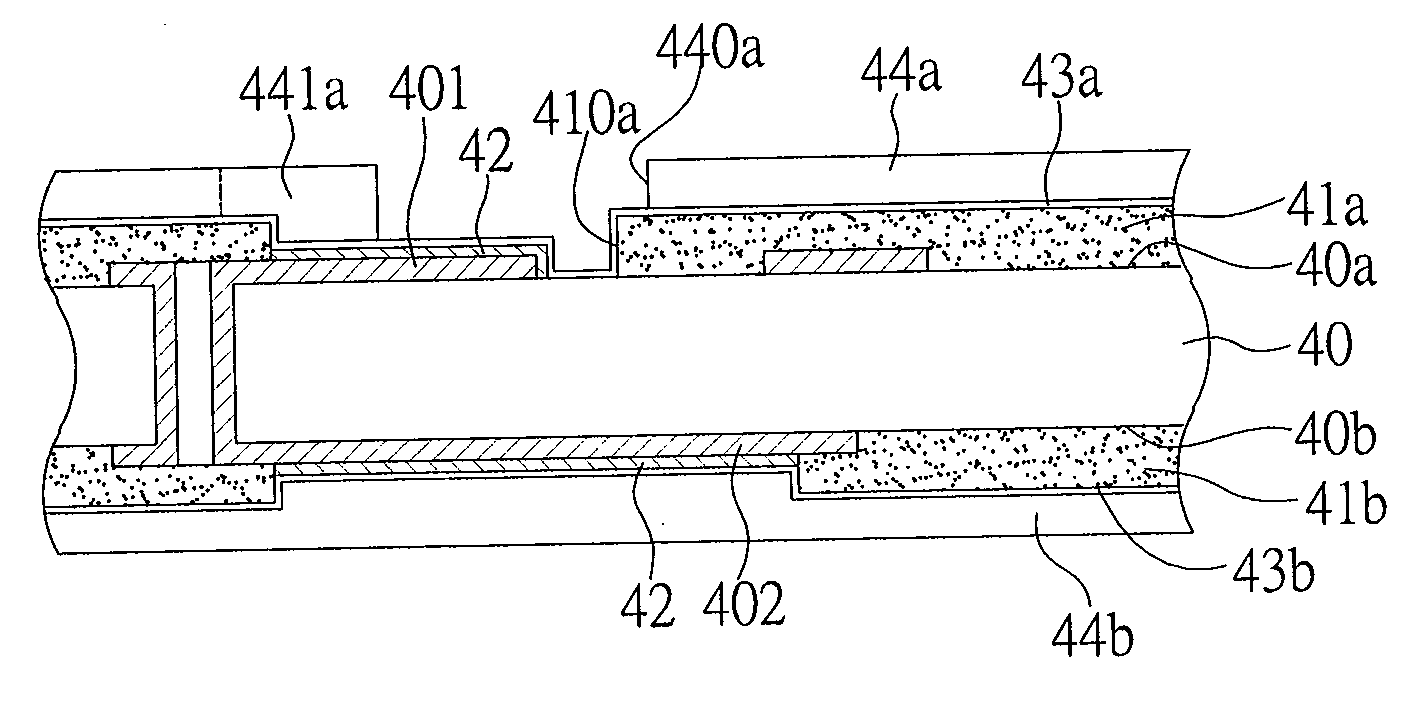

The invention provides a packaging structure and a packaging method. The packaging structure comprises a circuit substrate, at least one wafer, a plurality of pins and a packaging colloid. The circuit substrate is provided with a first surface and a second surface which are opposite, wherein the circuit substrate is provided with a plurality of contacts on the first surface. The wafer is arranged on the second surface of the circuit substrate and electrically connected with the circuit substrate. The plurality of pins are arranged on the periphery of the second surface of the circuit substrate to encircle the wafer. Each pin is provided with an inner pin part and an outer pin part, and each pin is electrically connected with the circuit substrate through the inner pin part thereof. The packaging colloid wraps the circuit substrate, the wafer and the inner pin part of each pin and exposes the first surface of the circuit substrate and the outer pin part of each pin, wherein the upper surface of the packaging colloid is coplanar with the first surface of the circuit substrate.

Owner:ADVANCED SEMICON ENG INC

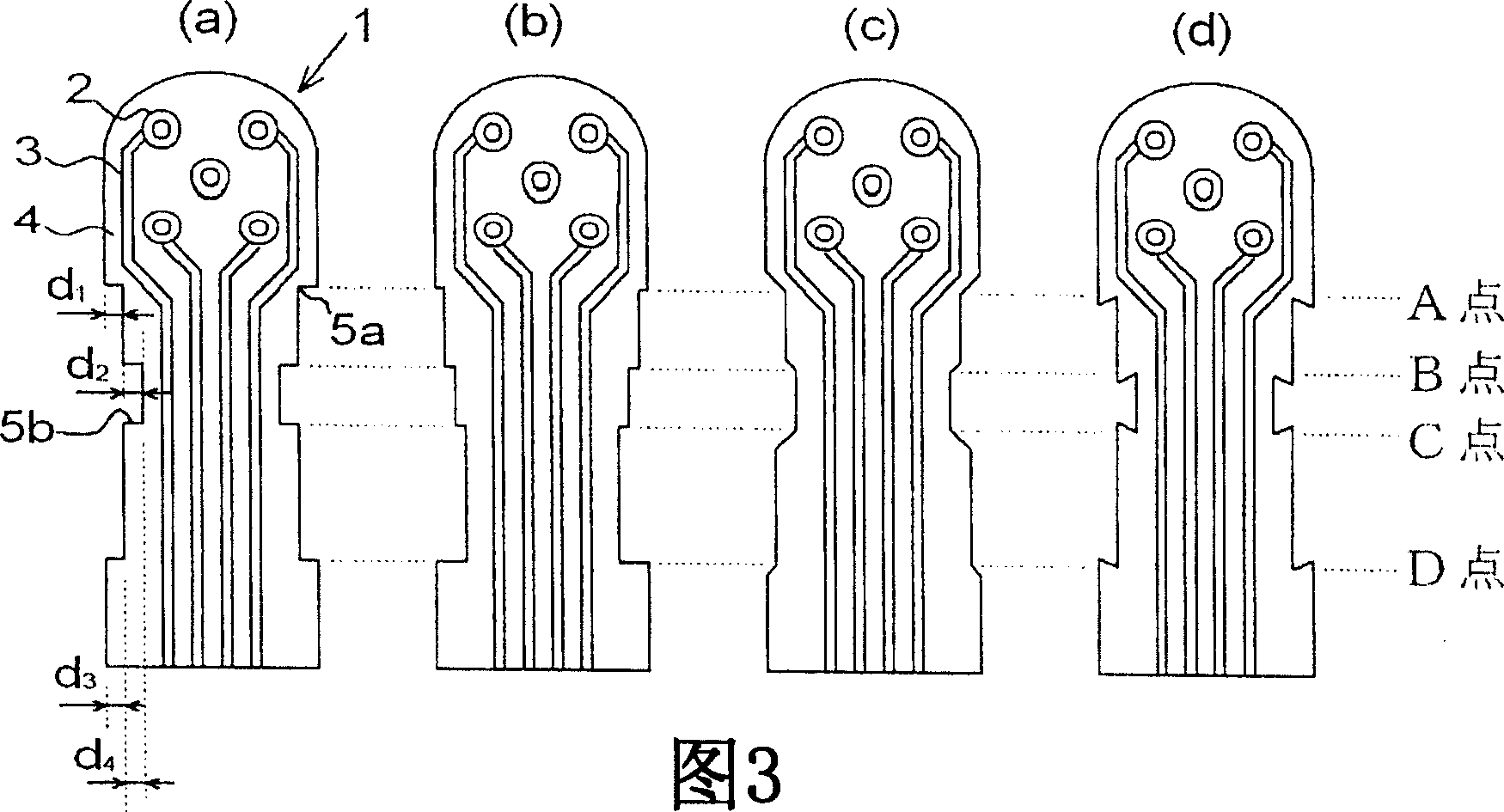

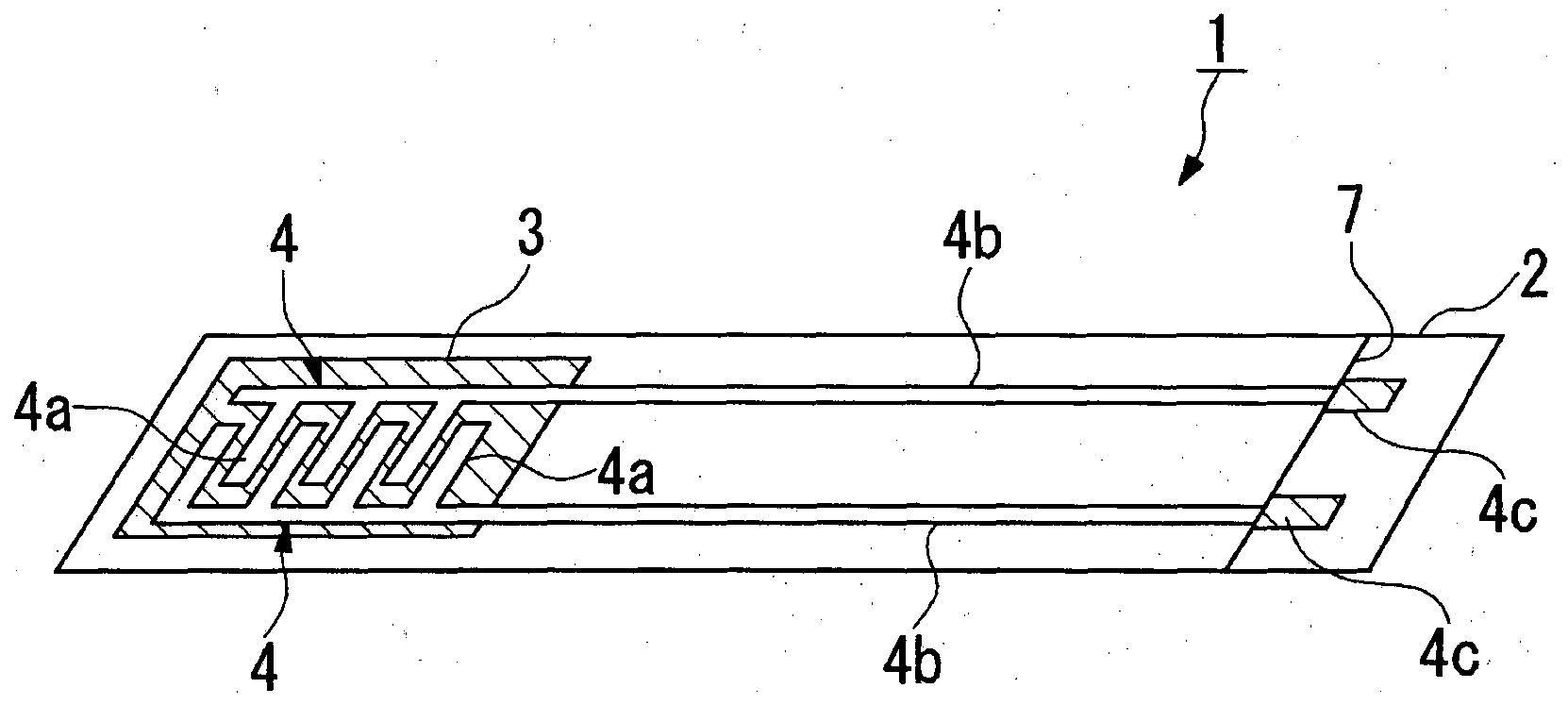

Flexible board

InactiveCN1956619AEasy to adjustWith configurationPrinted circuit aspectsElectrical connection printed elementsElectrical conductorEngineering

A flexible board capable of being bent easily and precisely a plurality of times at desired positions has insulating layer exhibiting flexibility, a conductor layer and recessed angular portions situated in both side edges of the board so as to oppose each other. Three of more of these angular portions are disposed on each side edge of the board. More specifically, the flexible board has at least one constricted portion that reduces the width of the board. The constricted portion is situated on both side edges of the board in such a manner that the constricted portions oppose each other, and has at least one of a step portion having a step-like shape and a cut-out portion having a V- or U-like shape. Three or more step-like portions and cut-out portions are situated together on each side edge the board.

Owner:NEC ELECTRONICS CORP

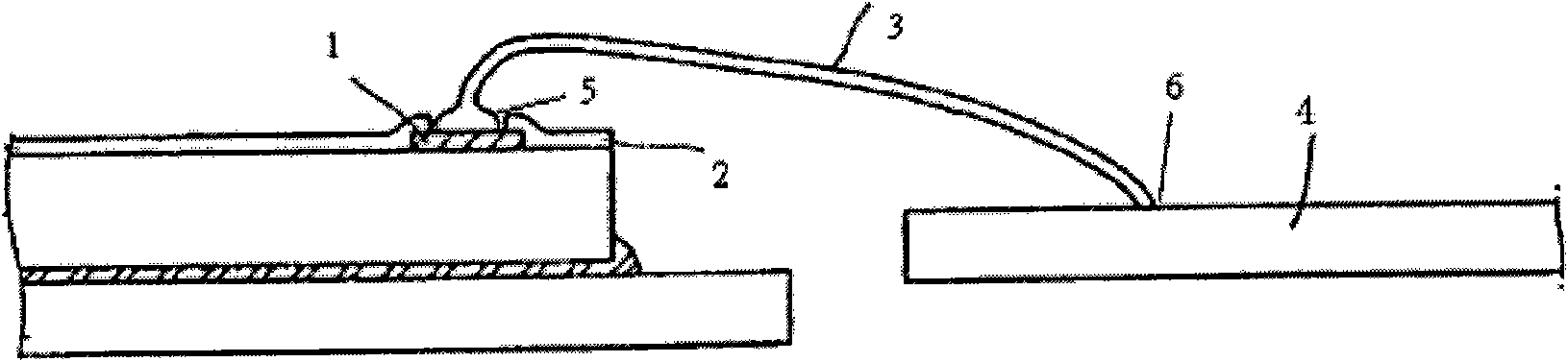

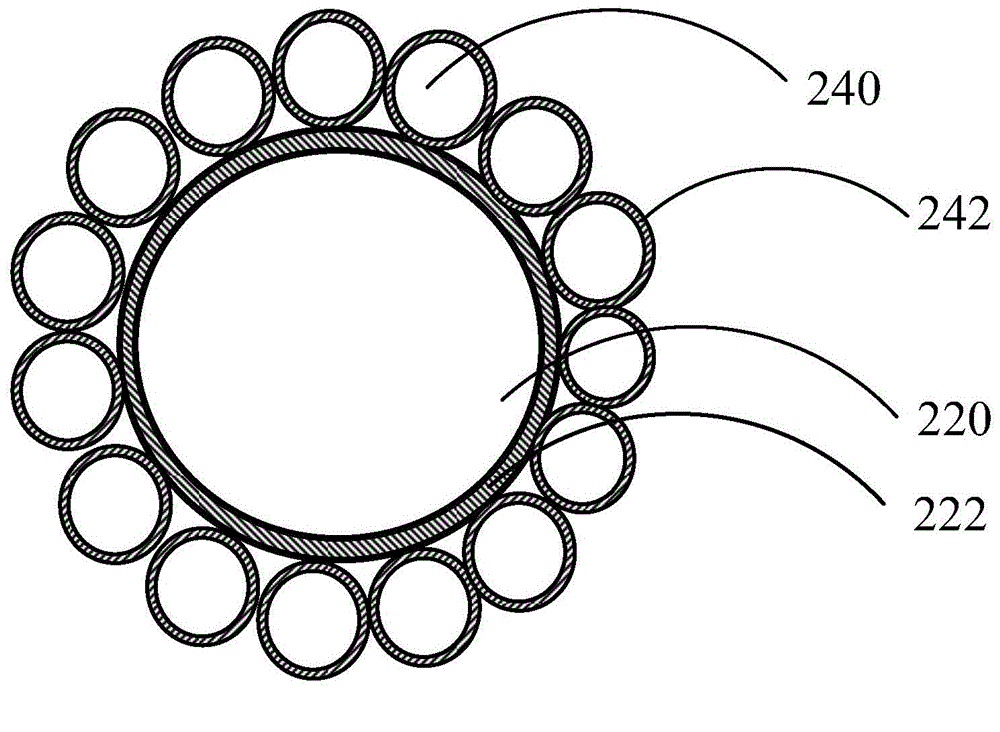

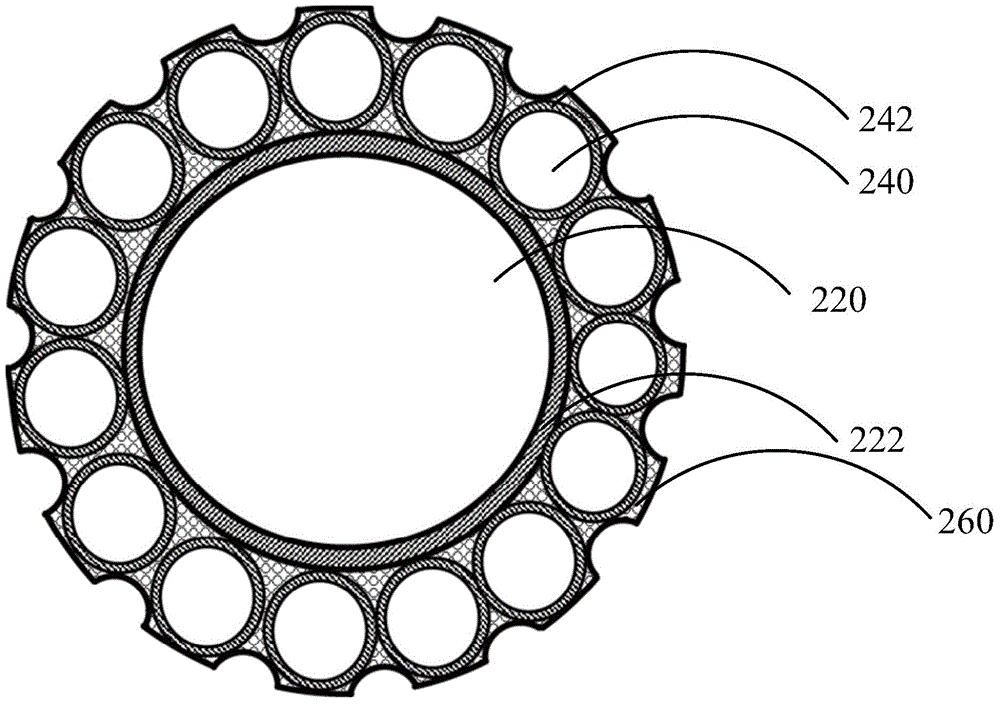

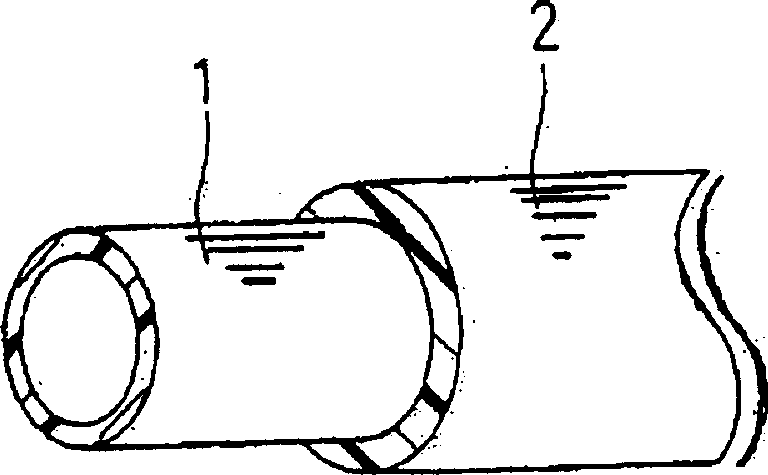

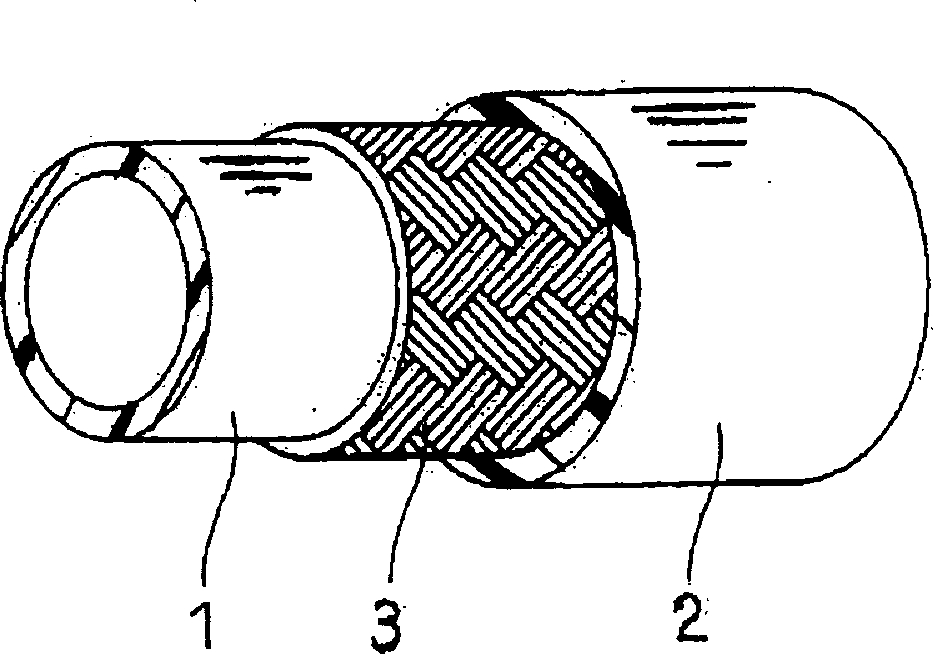

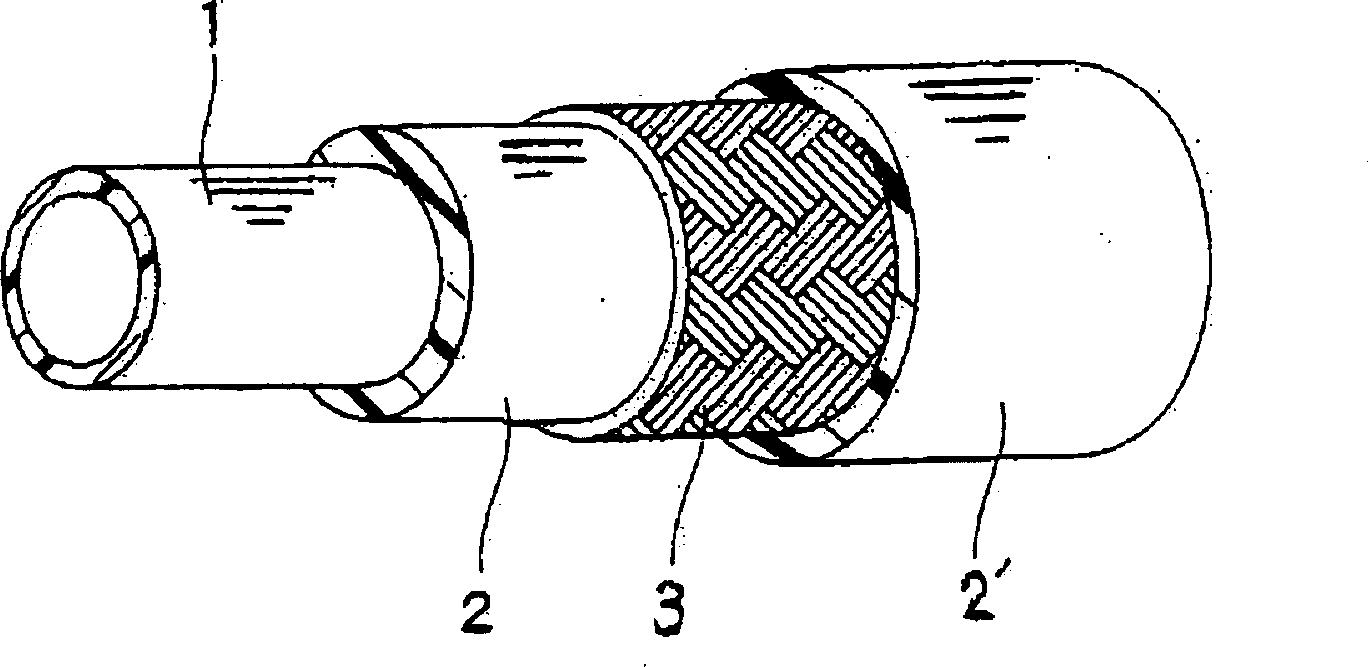

Heat-resistant hose

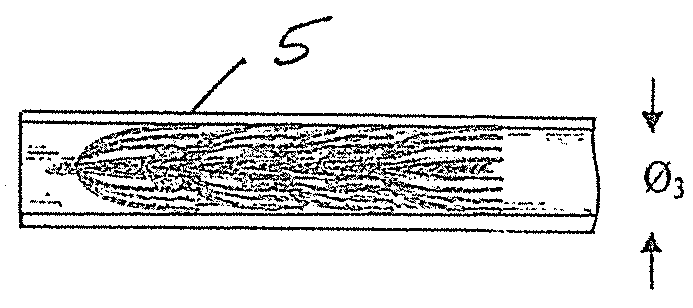

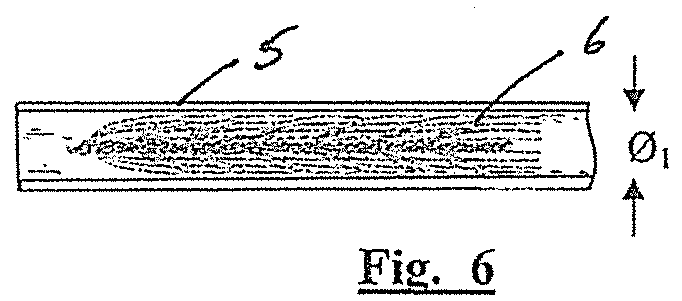

InactiveCN1661271AImprove heat resistanceImprove articulationMachines/enginesFlexible pipesElastomerPolymer science

A heat-resistant hose capable of exhibiting excellent interlaminar adhesion in a high-temperature environment. The heat-resistant hose has a laminar structure of an inner layer formed by fluorine-containing rubber (a fluorine-containing rubber layer 1) and an acrylic rubber layer 2 formed on an outer peripheral surface of the fluorine-containing rubber layer 1, wherein the acrylic rubber layer 2 is formed by a rubber composition comprising the following (A) to (D): (A) an acrylic elastomer; (B) a peroxide crosslinking agent; (C) phenothiazine; and (D) an acid receiver.

Owner:SUMITOMO RIKO CO LTD

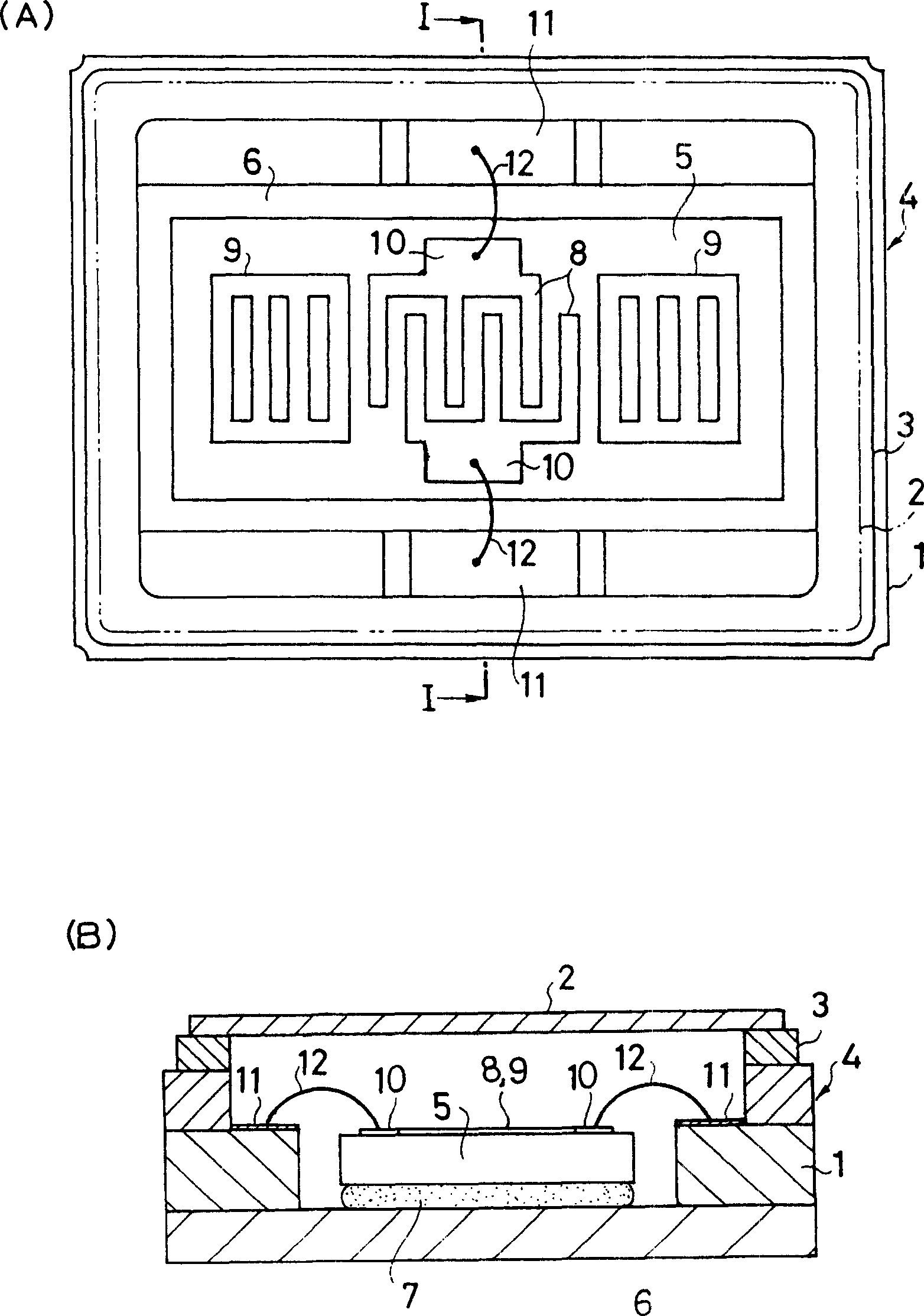

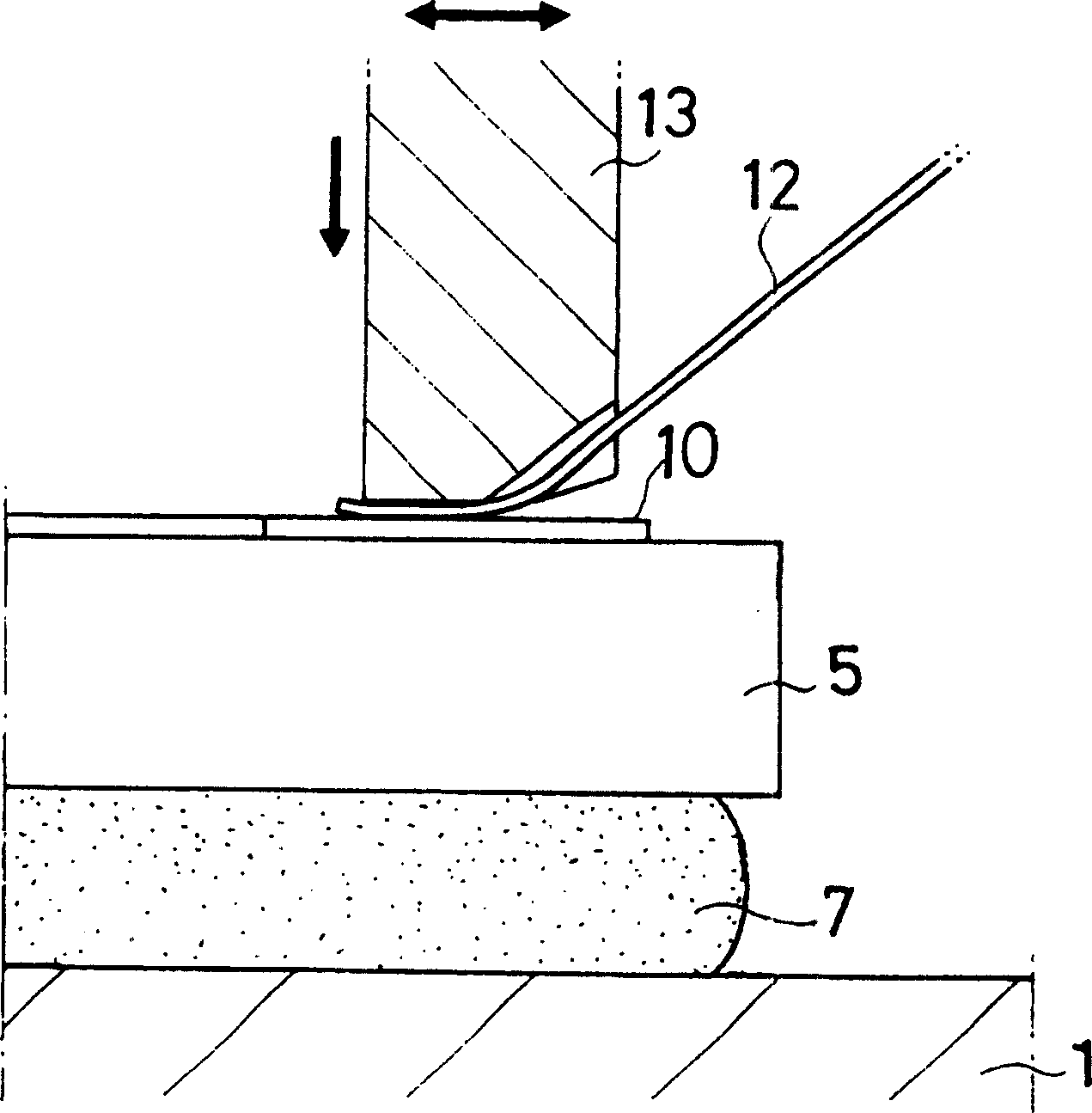

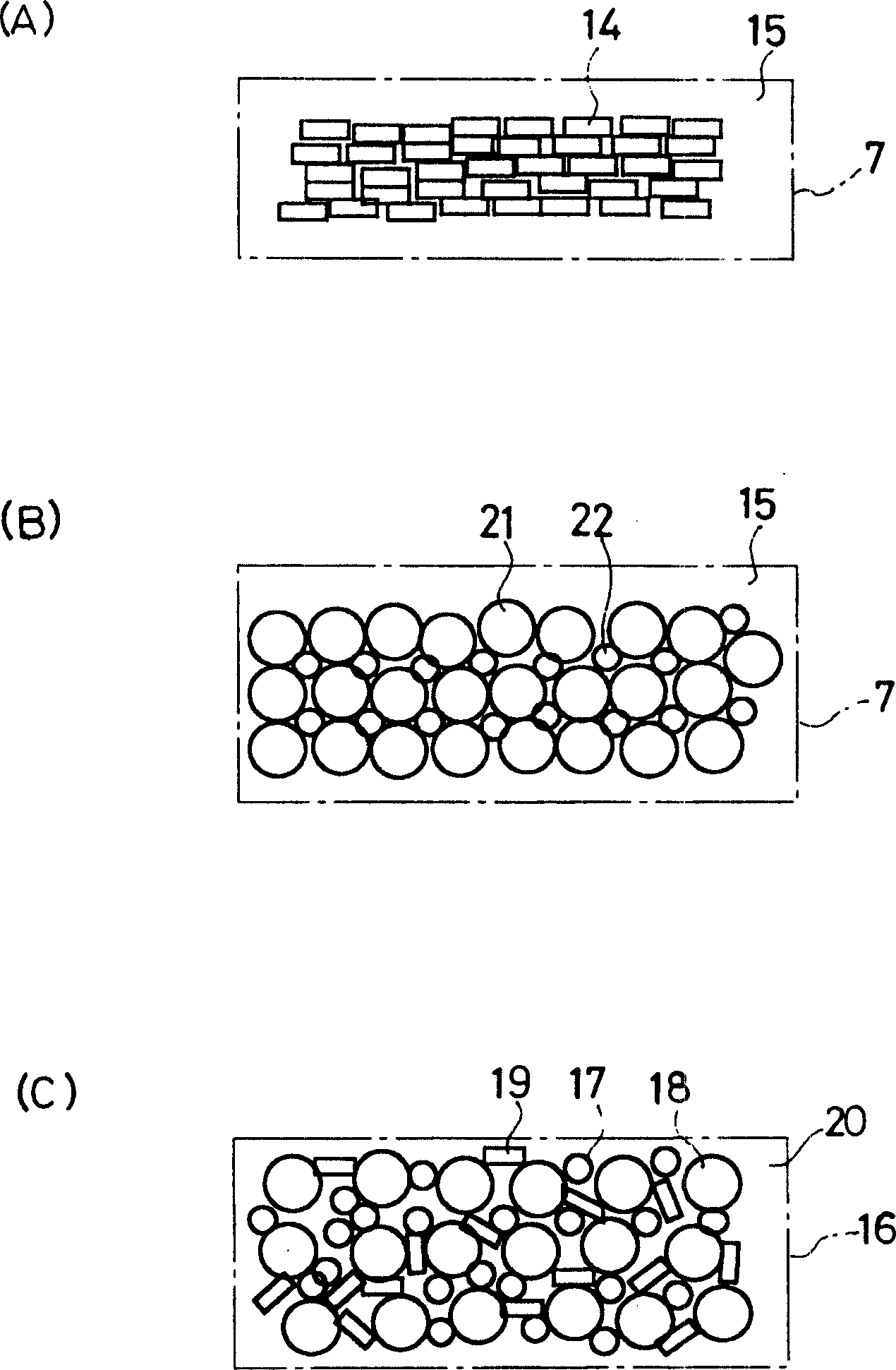

Conductive adhesive and piezoelectric device using it

InactiveCN1581686AQuality improvementImprove reliabilityNon-macromolecular adhesive additivesImpedence networksParticulatesAdhesive

In an SAW device in which an SAW element (5) is mounted on a base (1) of a package (4) with its bonding pads (10) and connection terminals (11) of the package connected by bonding wires, a lid (2) is joined to the base (1) by seam welding to be hermetically sealed. The SAW element (5) is bonded and affixed to a mounting surface (6) of the base (1) by using a conductive adhesive (7) which contains 80 to 85 wt.% of a resin material and 20 to 15 wt.% of a flaky conductive filler, or a conductive adhesive which contains an 82.5 to 85 wt.% of a resin material and 17.5 to 15 wt.% of a conductive filler, the conductive filler comprising 30 wt.% of a small particulate conductive filler and 70 wt.% of a large particulate conductive filler.

Owner:SEIKO EPSON CORP

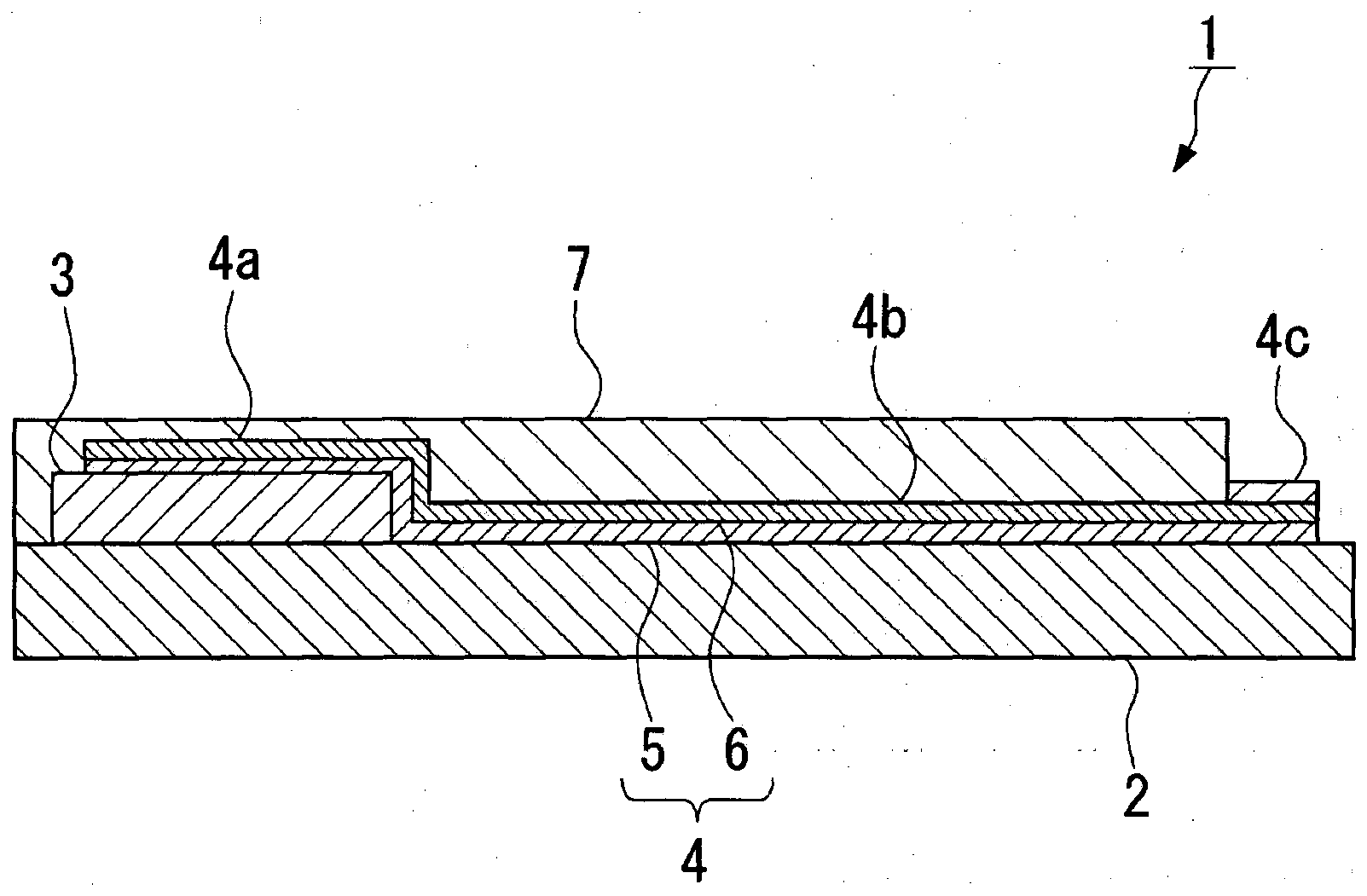

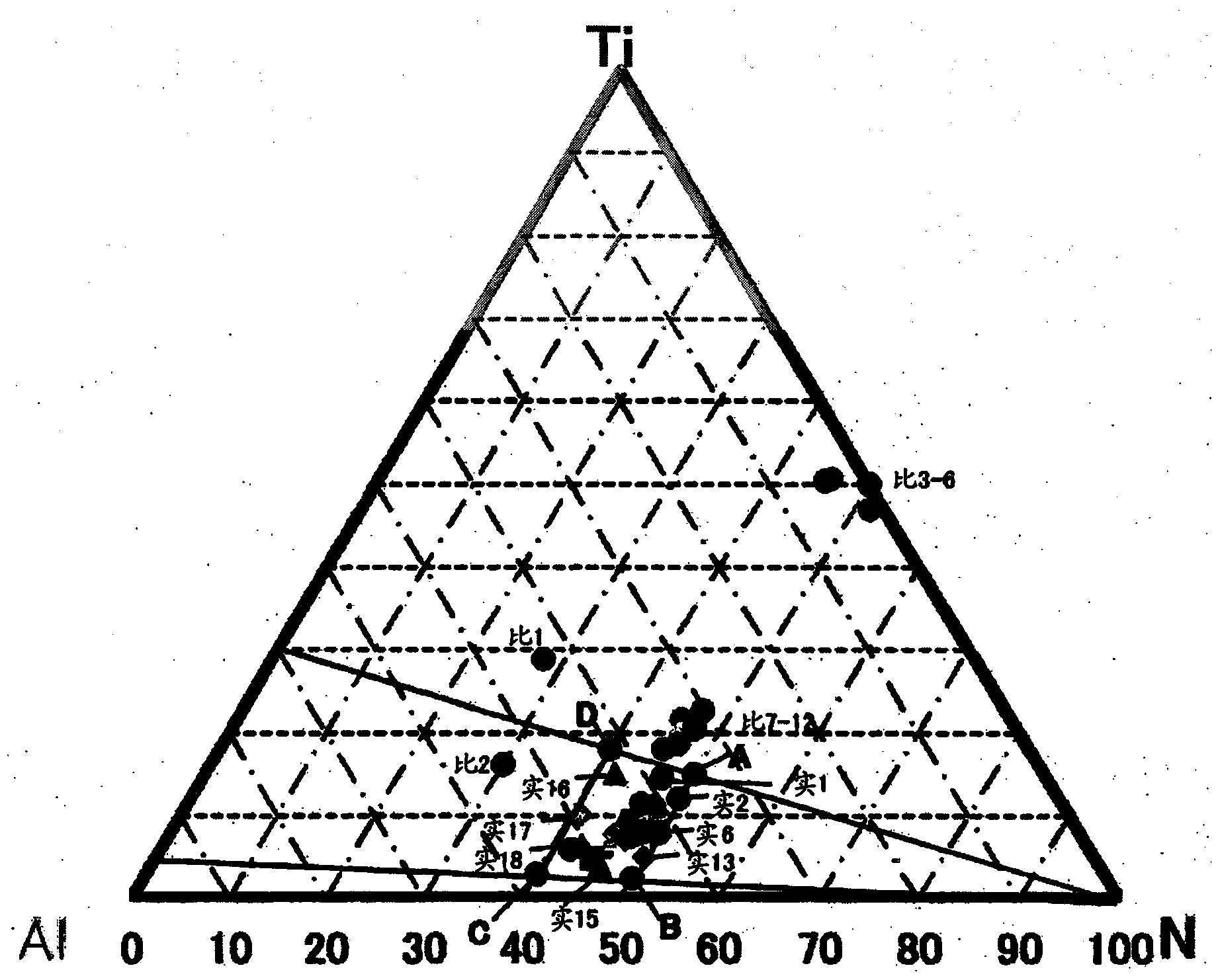

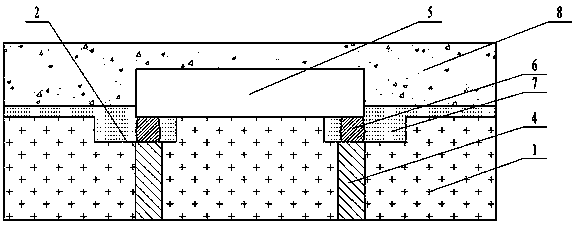

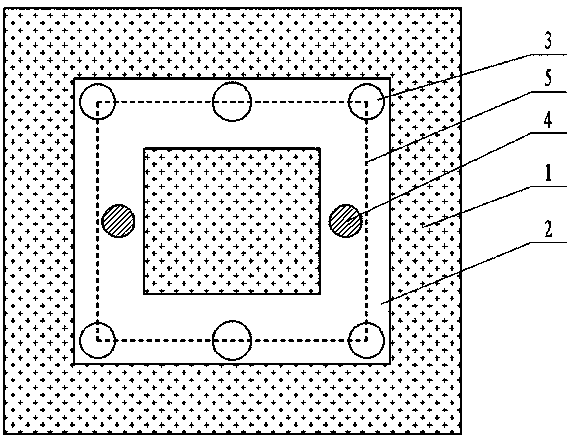

Temperature sensor and method for producing same

ActiveCN104169699AFlexibleNot easily oxidizedThermometers using electric/magnetic elementsUsing electrical meansElectrical resistance and conductanceOptoelectronics

Provided is a temperature sensor that: is not susceptible to an increase in resistance in an electrode structure with respect to a TiAlN thermistor material layer, even in a high-temperature environment; can be directly formed on a film, or the like, without baking; and is highly reliable due to having high heat resistance. Further provided is a method for producing the temperature sensor. The temperature sensor is provided with: an insulating substrate (2); a thin-film thermistor part (3) formed on top of the insulating substrate (2); and a pair of pattern electrodes(4) that has a pair of counter electrode parts (4a), which face each other, disposed on the thin-film thermistor part, and that is formed on the insulating substrate. The thin-film thermistor part is formed by a TiAlN thermistor material, and the pattern electrodes comprise a TiN joining layer (5) formed on the thin-film thermistor, and an electrode layer (6) formed by a precious metal on the joining layer.

Owner:MITSUBISHI MATERIALS CORP

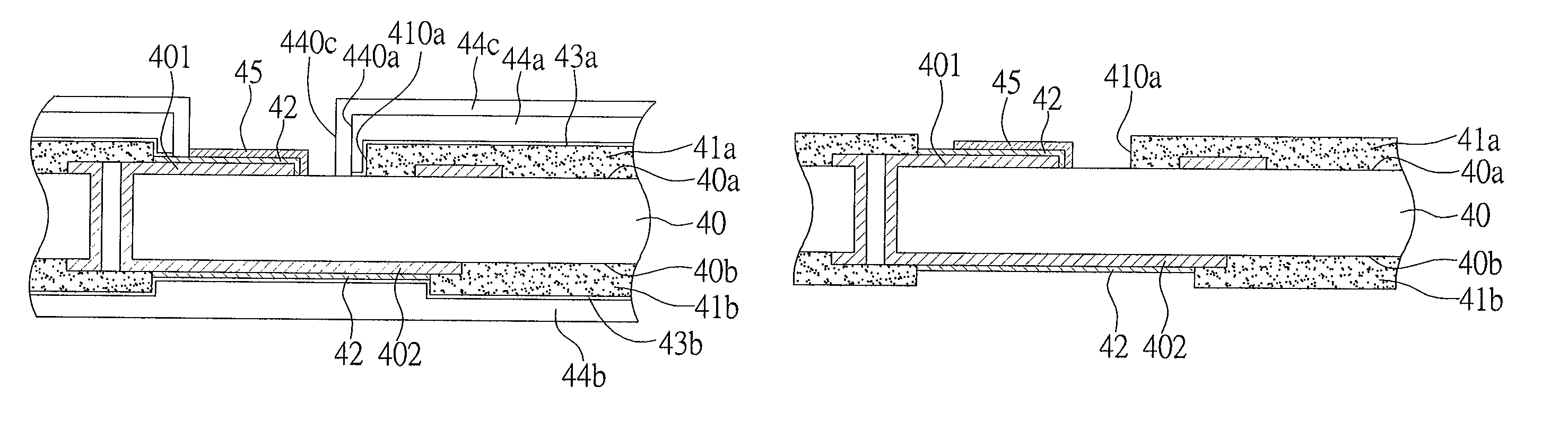

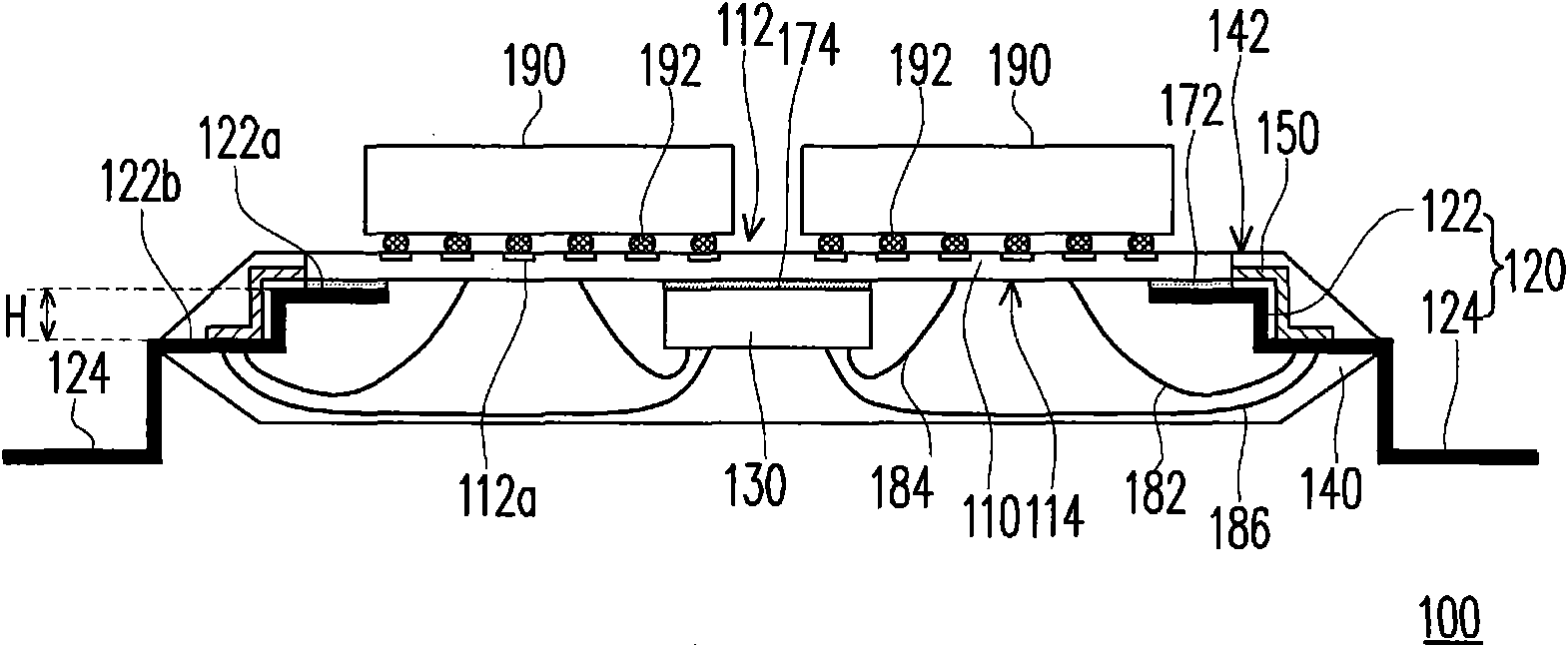

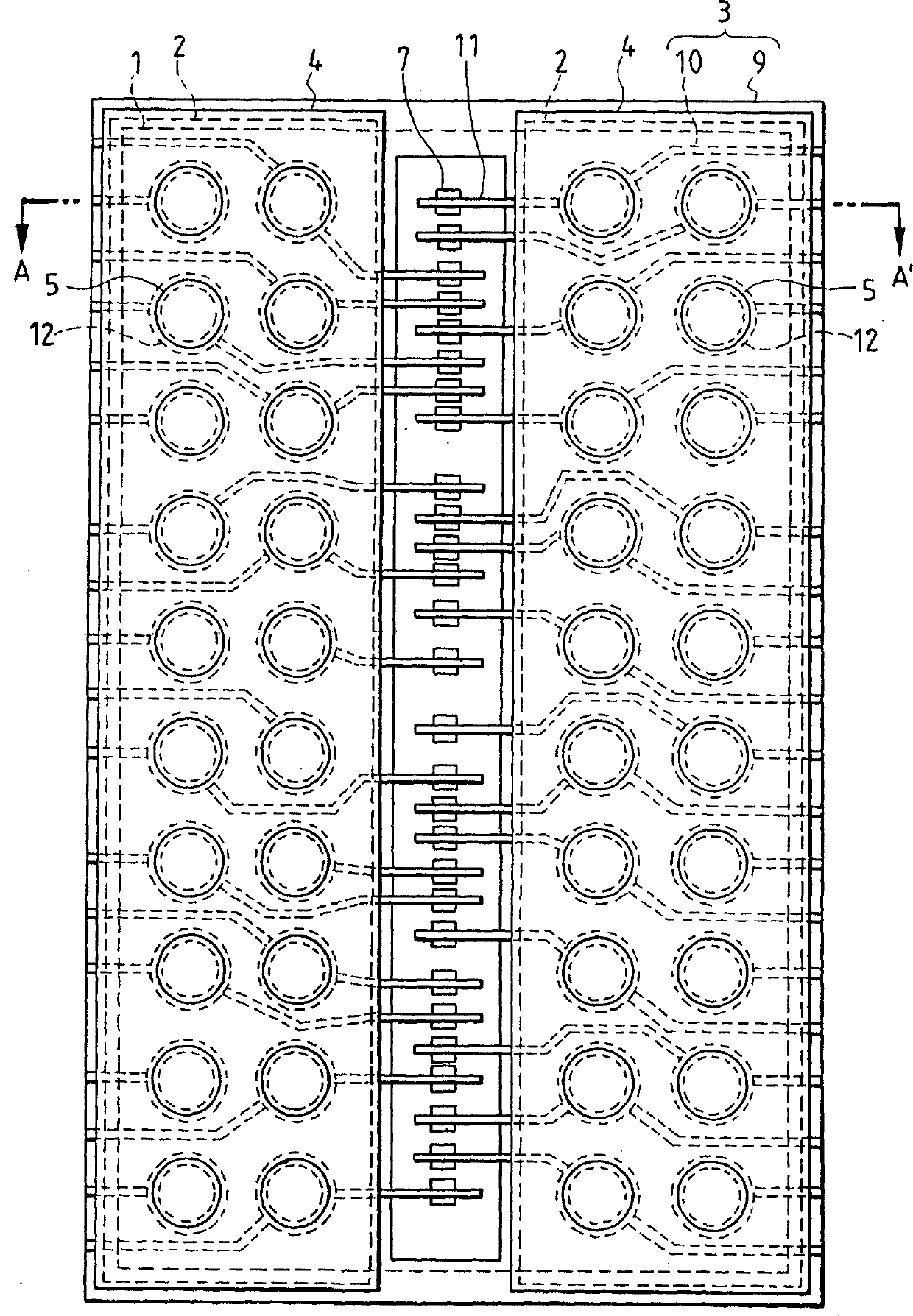

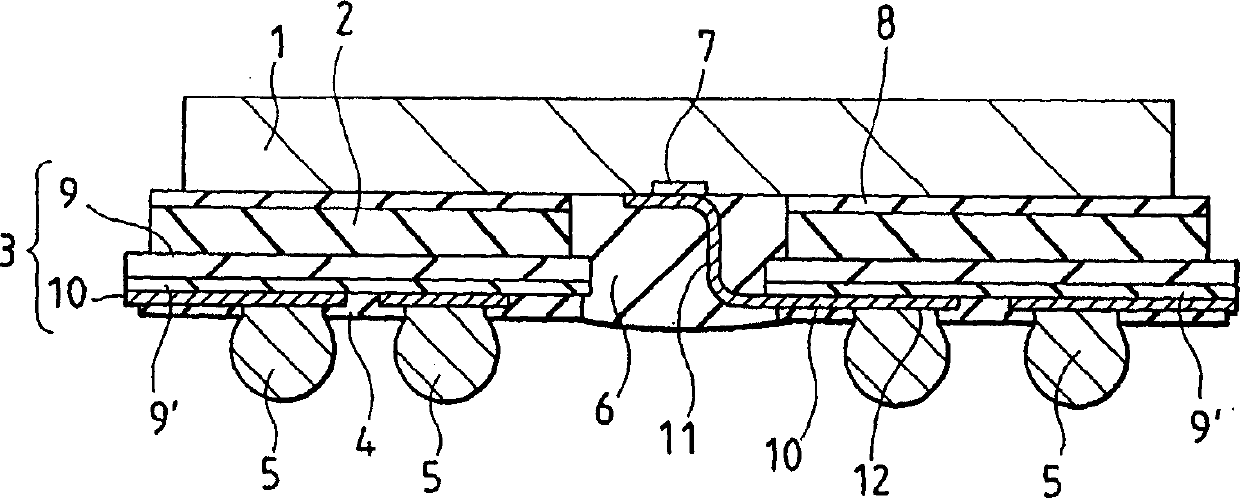

Semiconductor device

InactiveCN1728372AReduce flatnessReduce crackingSemiconductor/solid-state device detailsSolid-state devicesResistElastomer

A ball grid array type semiconductor package includes a semiconductor chip formed with bonding pads, an elastomer bonded to the semiconductor chip, a flexible wiring substrate bonded to the elastomer and formed with wirings connected at one end of the bonding pads of the semiconductor chip, a solder resist formed on the main surface of the flexible wiring substrate and solder bump electrodes connected to the other ends of the wirings. The elastomer is bonded to the flexible wiring substrate on the side of the tape, the solder resist is formed on the side of the wirings, and the solder bump electrodes are connected with the wirings by way of through holes formed in the solder resist.

Owner:HITACHI LTD +1

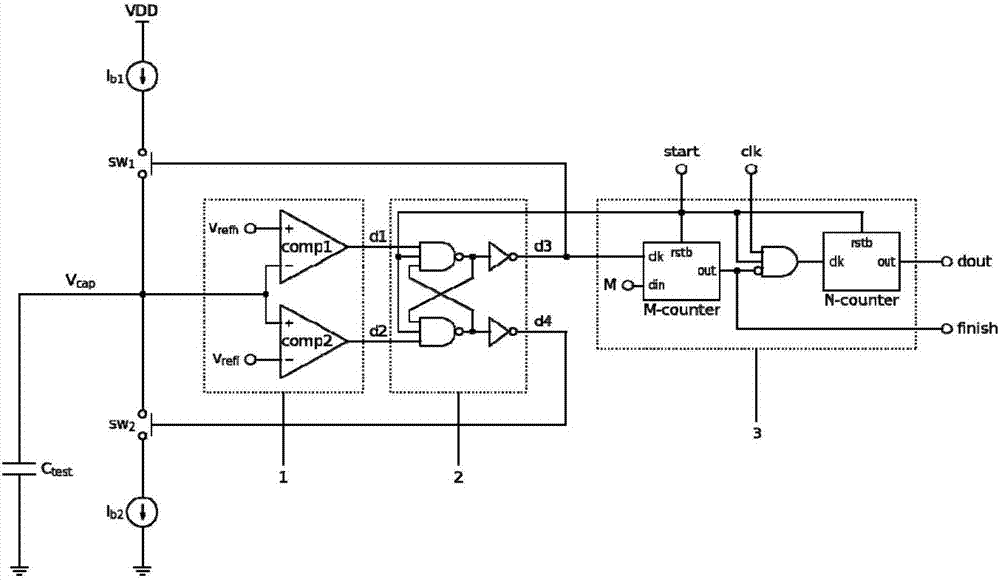

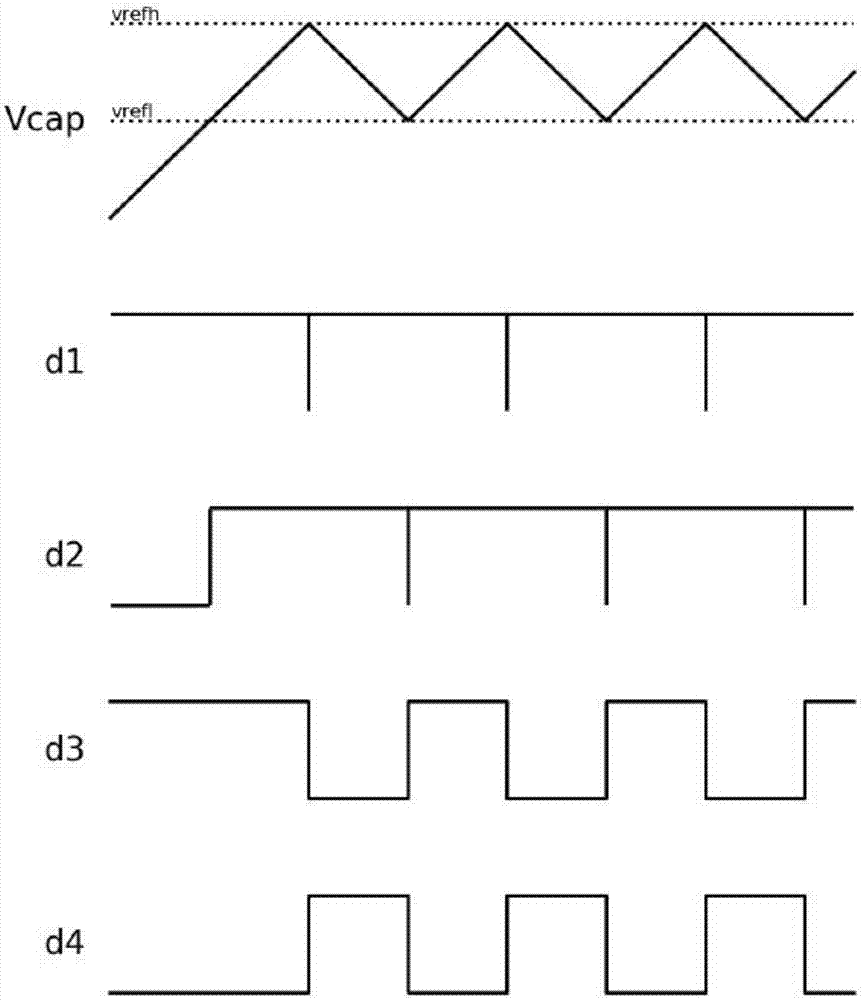

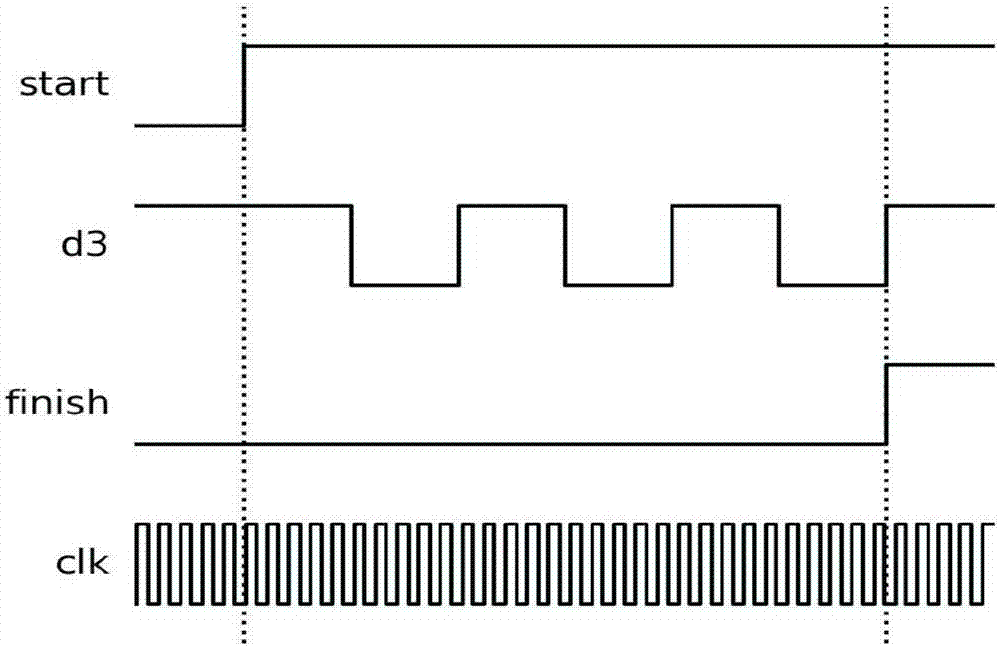

Capacitor measuring system and measuring method thereof

PendingCN107543972APromote accumulationImprove articulationResistance/reactance/impedenceCapacitanceMeasurement cost

The invention discloses a capacitor measuring system and a measuring method thereof. The system comprises a charging current source which charges a capacitor to be measured, a comparator group whose input end is connected to a first end of the capacitor to be measured, the capacitor to be measured which provides an initial comparison voltage value which is a voltage value Vcap of the capacitor tobe measured to the comparator group, a latch whose input end is electrically connected to an output end of the comparator group, and a counter group which is connected to the output end of the latch and is used for counting a period of a level signal outputted by the latch, wherein a first output end of the latch is correspondingly connected to a first control switch, a second output end of the latch is connected to a second control switch. The system and the method have the advantages of a simple circuit structure, a simple and convenient measurement method, low measurement cost and high measurement precision.

Owner:ESPRESSIF SYST SHANGHAI

Method for preparing powdery selective catalytic reduction denitration catalyst by using sol impregnation method

InactiveCN101695656AImprove thermal stabilityHigh activityDispersed particle separationCatalyst activation/preparationOxalateFlue gas

The invention discloses a method for preparing powdery selective catalytic reduction denitration catalyst by using a sol impregnation method, which is a method for preparing powdery SCR denitration catalyst by utilizing sol type meta-titanic acid as an impregnation carrier. The method comprises the following steps of: by taking the sol type meta-titanic acid as the carrier, carrying out first impregnation loading on the sol type meta-titanic acid and ammonium tungstate-oxalic acid solution; finishing secondary impregnation loading on a prepared composite powder and ammonium metavanadate-oxalic acid solution after procedures including calcining, grinding and screening; and finally, finishing a preparation process of the powdery SCR denitration catalyst through treatments including secondary calcining, secondary grinding and secondary screening. Compared with a traditional SCR denitration catalyst preparation technology, the method has the advantages of simple technology and low economic cost and is suitable for an integral production mode of a titanium dioxide preparation technology and an SCR denitration catalyst production technology. In addition, the catalyst prepared by the method has the advantages of large specific surface area, uniform and reasonable micro hole structure, favorable thermal stability, ideal catalytic conversion efficiency to Nox component in flue gas and the like.

Owner:SOUTHEAST UNIV

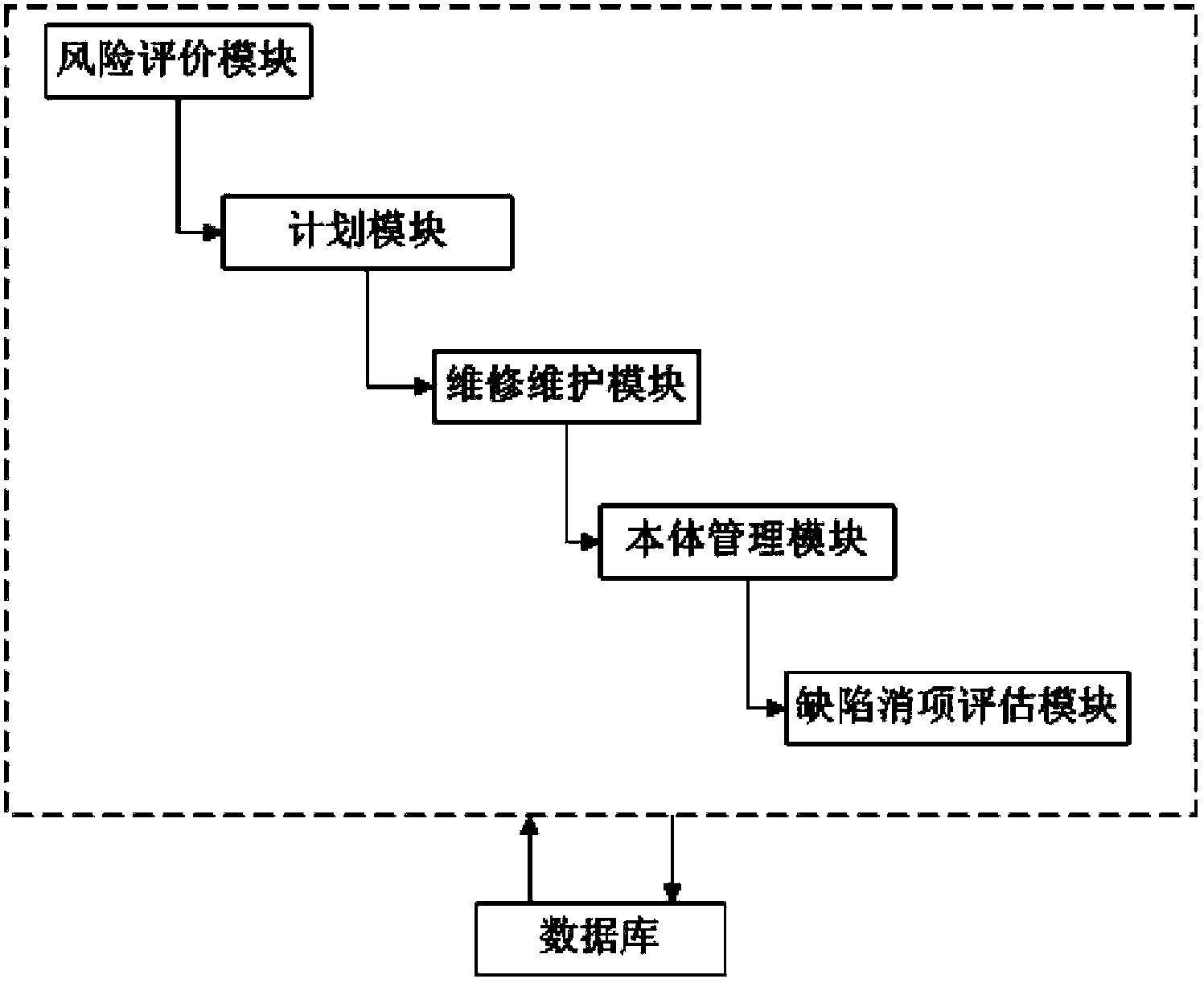

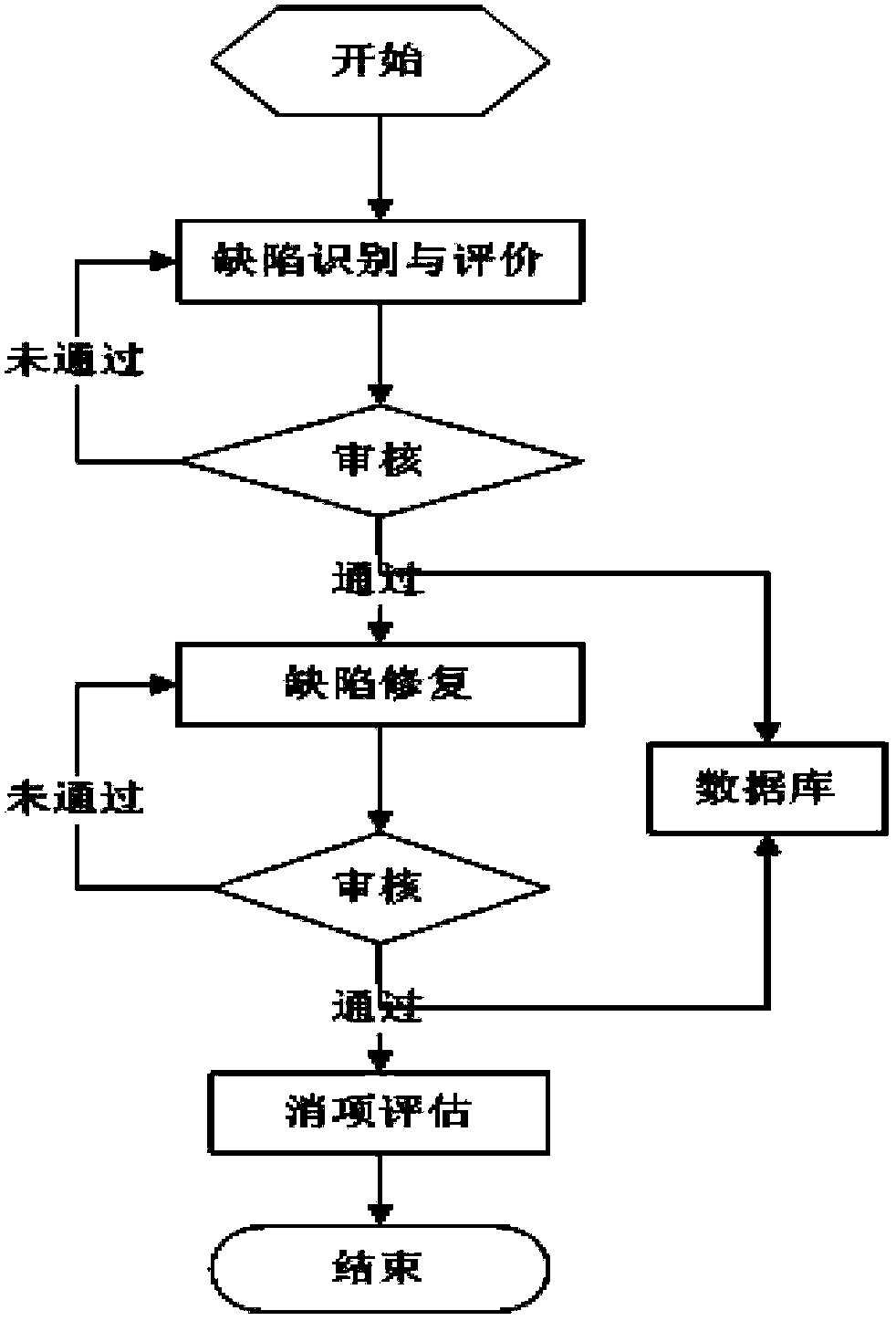

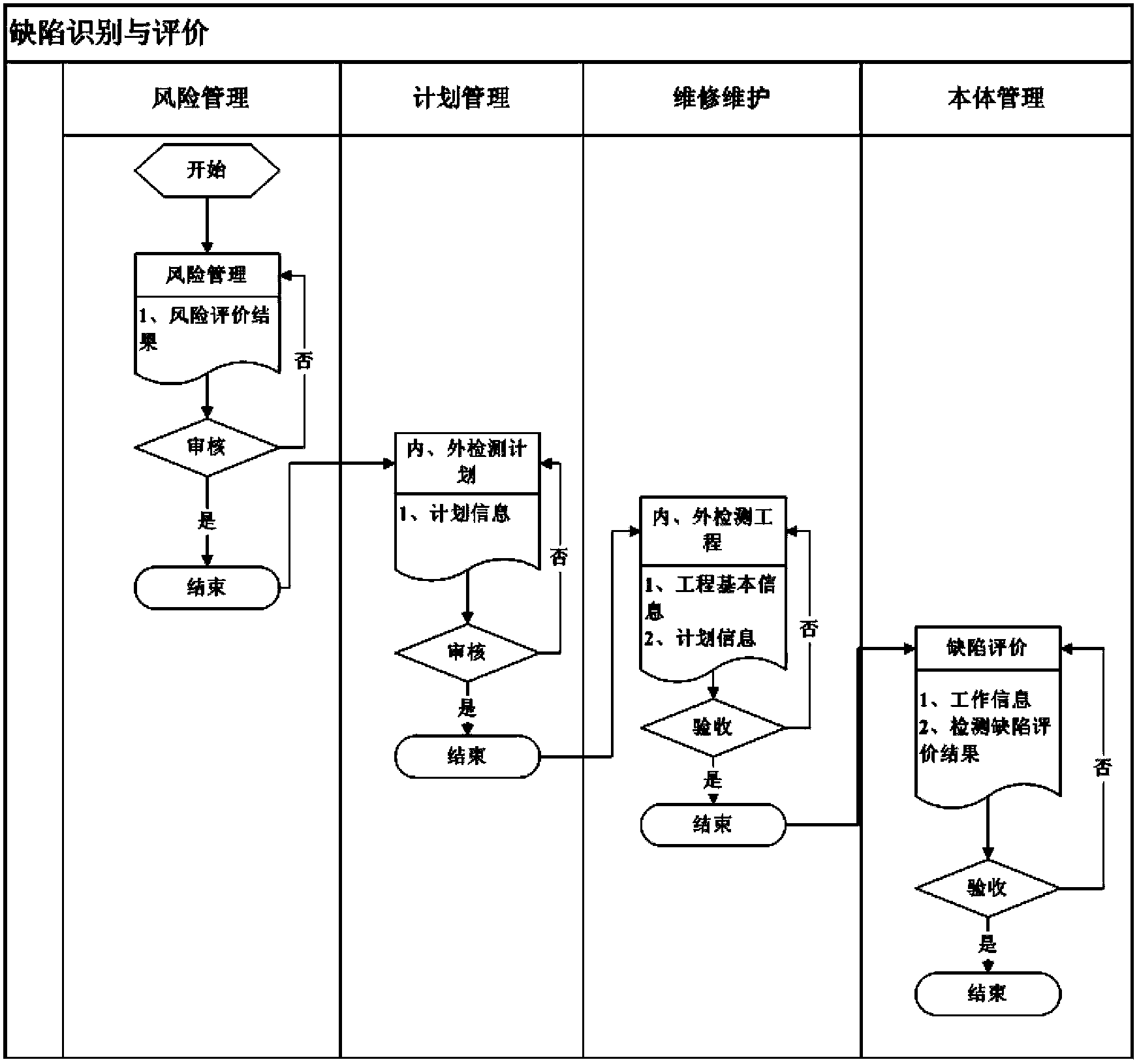

Method and system of closed loop assessment for pipe body defects of long-distance oil and gas pipeline

The invention discloses a method and system of closed loop assessment for pipe body defects of a long-distance oil and gas pipeline, and relates to the technical field of pipeline systems. The assessment method comprises the following steps: 1) beginning; 2) recognizing and assessing the pipe body defects; 3) examining and verifying; 4) if the examination and verification are not pass, returning to recognize and assess the pipe body defects, and if the examination and verification pass, moving to a database firstly and then conducting defect repairing; 5) examining and verifying; 6) if the examination and verification are not pass, returning to defect repairing, and if the examination and verification pass, moving to the database firstly and conducting item-removing assessment; 7) finishing. According to the invention, a closed loop monitoring of defect recognizing and assessing, defect repairing and defect item-removing assessment for a pipe body can be achieved, the operation process of the defect closed loop assessment is simplified, related service information is integrated, accurate and reliable data support is provided for service management and decision, and defect item removing effect is effectively assessed.

Owner:PIPECHINA SOUTH CHINA CO

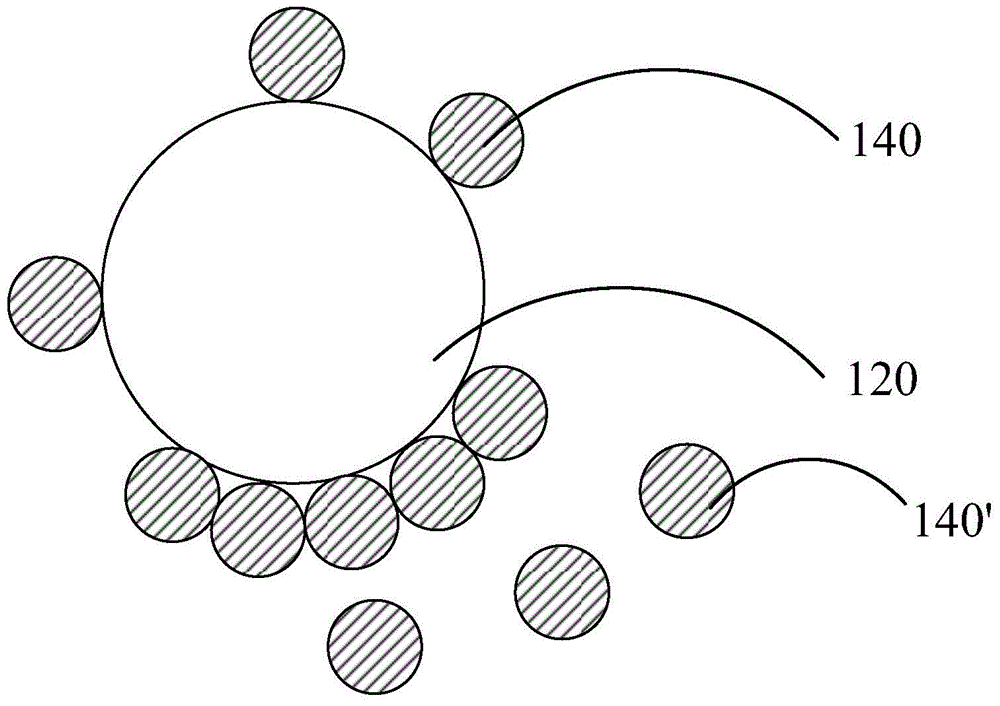

Embolisation systems

A bristle device (8) for delivery into a body lumen comprises a longitudinally extending stem and a plurality of bristles extending generally outwardly from the stem for anchoring the device in a body lumen. There may beat least two bristle segments (96) and there are flexible sections (95) between the segments (96). The flexible sections (95) articulate to enable the device to pass through a catheter placed in a tortuous anatomy or to be deployed in a curved vessel, or across a bifurcation. In some cases at least some of the bristle segments (96) are spaced-apart to accommodate bending of the bristles.

Owner:EMBO MEDICAL

LED packaging structure and method

The invention provides an LED packaging structure and method. The LED packaging structure comprises a polymer layer and a fluorescent resin layer covering the polymer layer and the LED chip; the polymer layer is a photo-curable and heat-curable polymer material; the fluorescent resin layer is a thermosetting resin material; and the final curing of the polymer layer is realized in the same heatingstep together with the curing of the fluorescent resin layer.

Owner:南通沃特光电科技有限公司

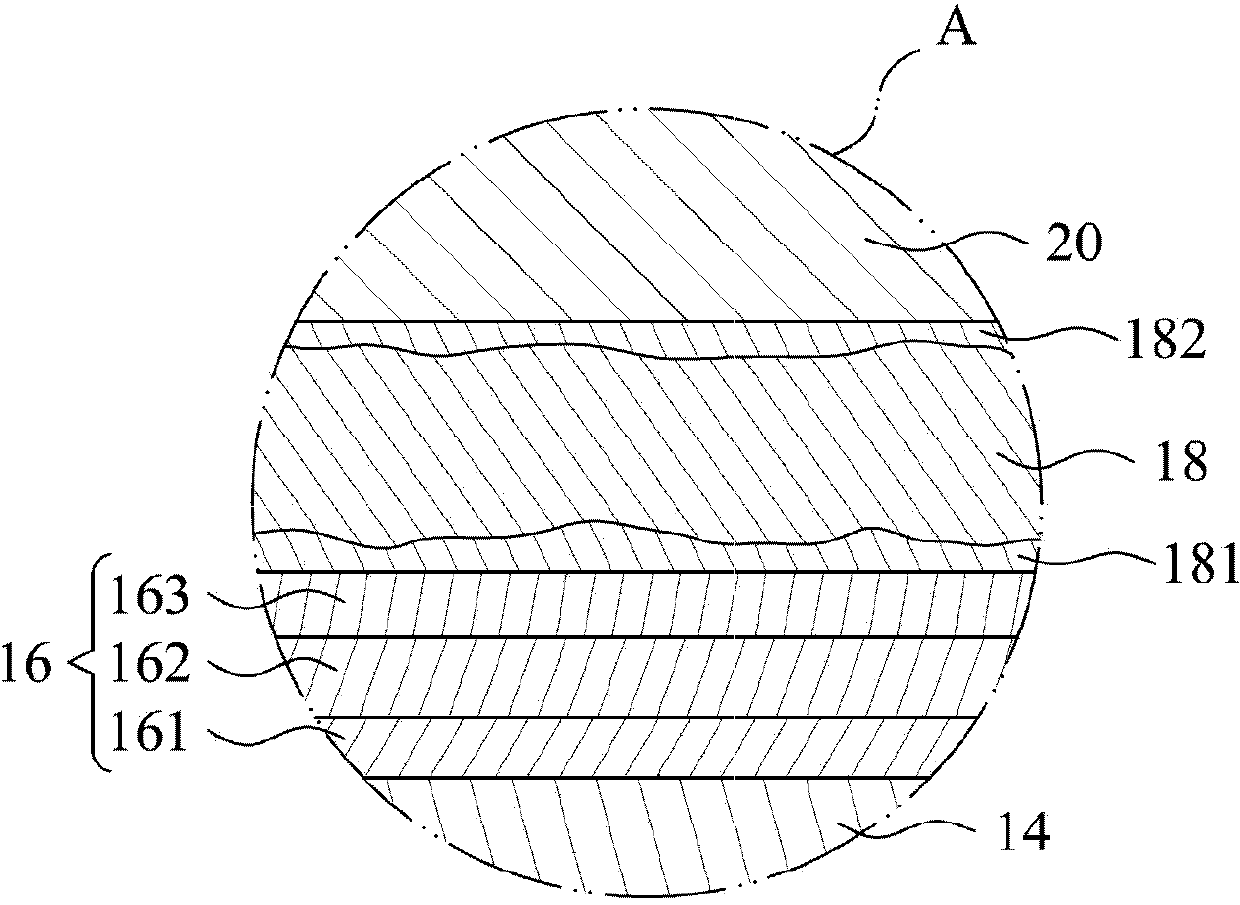

Wafer structure with buffer layer

ActiveCN101252106AImprove structural strengthImprove shock absorptionSemiconductor/solid-state device detailsSolid-state devicesProtection layerUnder bump metallurgy

The invention discloses a wafer structure provided with a buffer layer, comprising a wafer which is provided with at least one welded gasket, wherein, a passivation layer is arranged on the wafer and exposes the welded gasket; the buffer layer is arranged on the passivation layer and the welded gasket; an under bump metallurgy (UBM) layer is arranged on the buffer layer. The buffer layer comprises a thickened inner buffer layer which is made of aluminum materials and is formed between the UBM layer and the welded gasket so as to strengthen the damping capacity of the wafer during the process of a drop test, thereby the phenomenon that a conductive lug which is used for being coupled with a substrate is dropped off and broken is avoided and the coupling ability of the conductive lug and the UBM layer can be strengthened. Moreover, the buffer layer can also comprise an outer buffer layer which is made of polyamide materials, arranged on the passivation layer and partially positioned between the UBM layer and the passivation layer.

Owner:ADVANCED SEMICON ENG INC

Semiconductor element, semiconductor package structure and manufacturing method thereof

ActiveCN103441109AImprove articulationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesMetal coatingElectrical conductor

The invention relates to a semiconductor element, a semiconductor package structure and a manufacturing method thereof. The semiconductor device includes a semiconductor crystal, a back side metal coating, a thermal interface material and a first intermetallic compound. The back side metal coating is arranged on one surface of the semiconductor crystal. The thermal interface material is arranged on the back side metal coating and contains indium zinc alloy. The first intermetallic compound is arranged between the back side metal coating and the thermal interface material, contains indium and does not contain zinc. Therefore, during the reflow process, the bonding effect and heat radiating effect are increased.

Owner:ADVANCED SEMICON ENG INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com