Patents

Literature

71 results about "Stress induction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Induction stress relieving is a process by which stress from the metal is removed by localized heating without weakening or softening it. Induction shrink fitting and stress relieving equipment is used by many industries. Railroads use it in the production of gearboxes, wheels, transmissions.

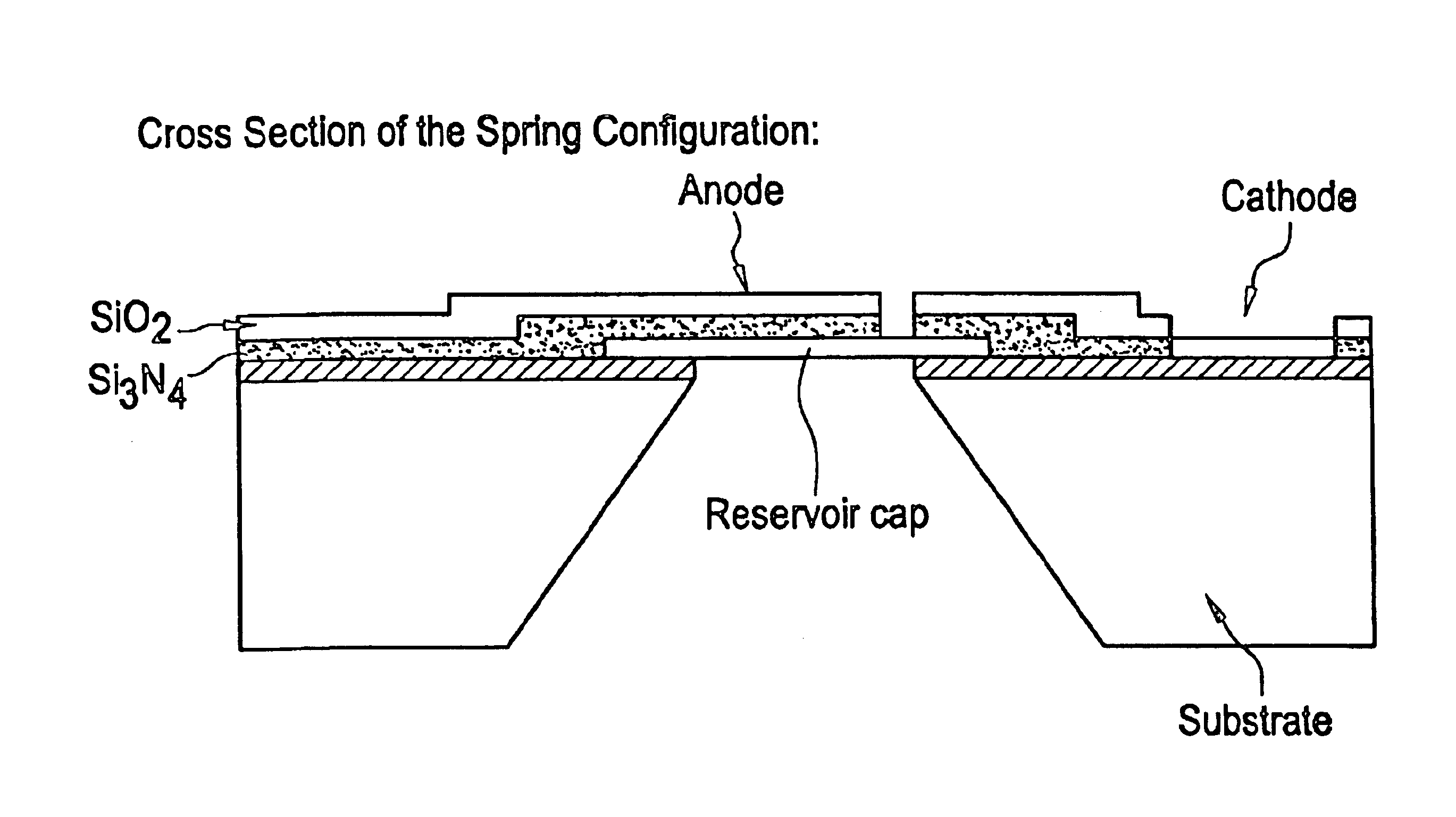

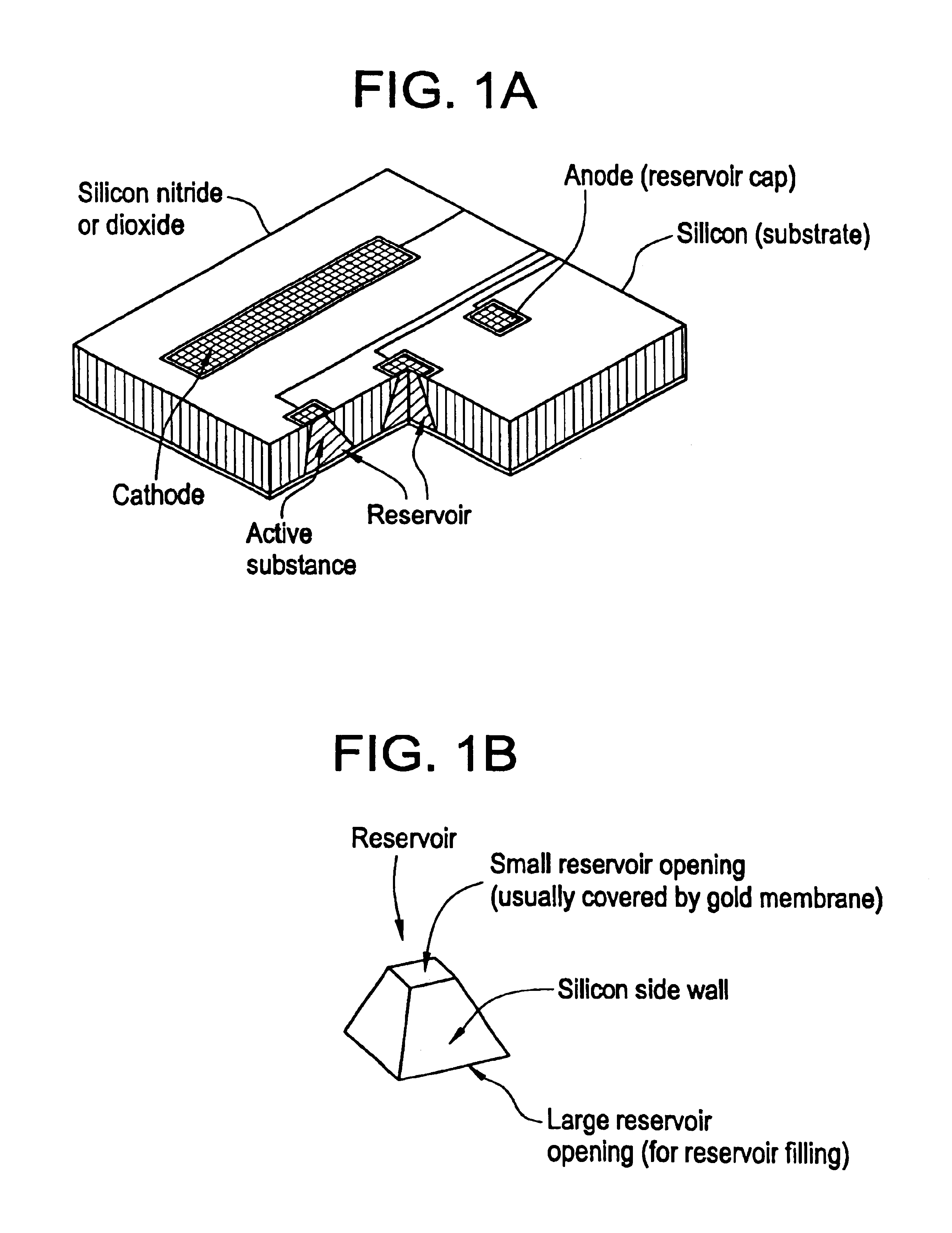

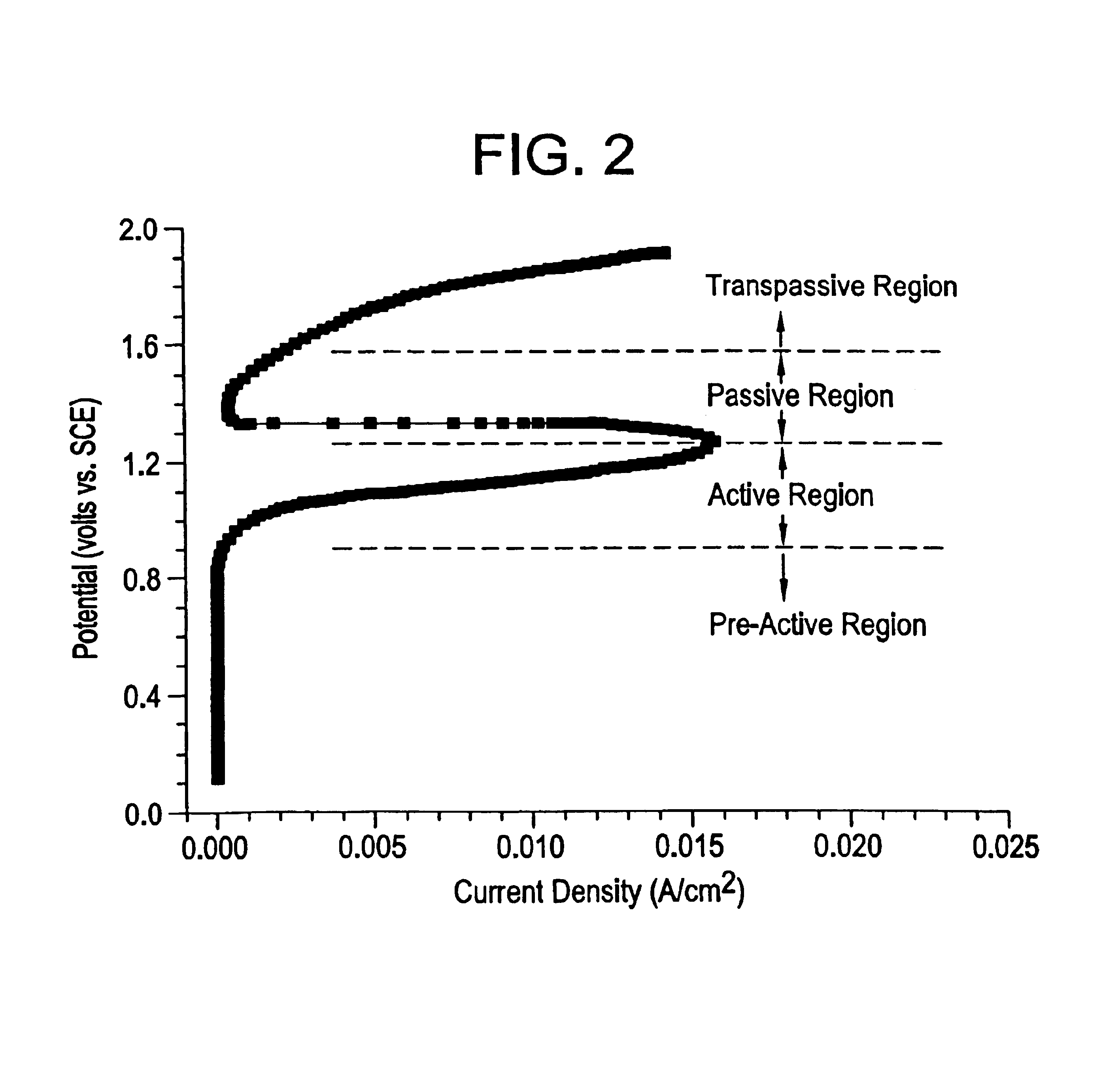

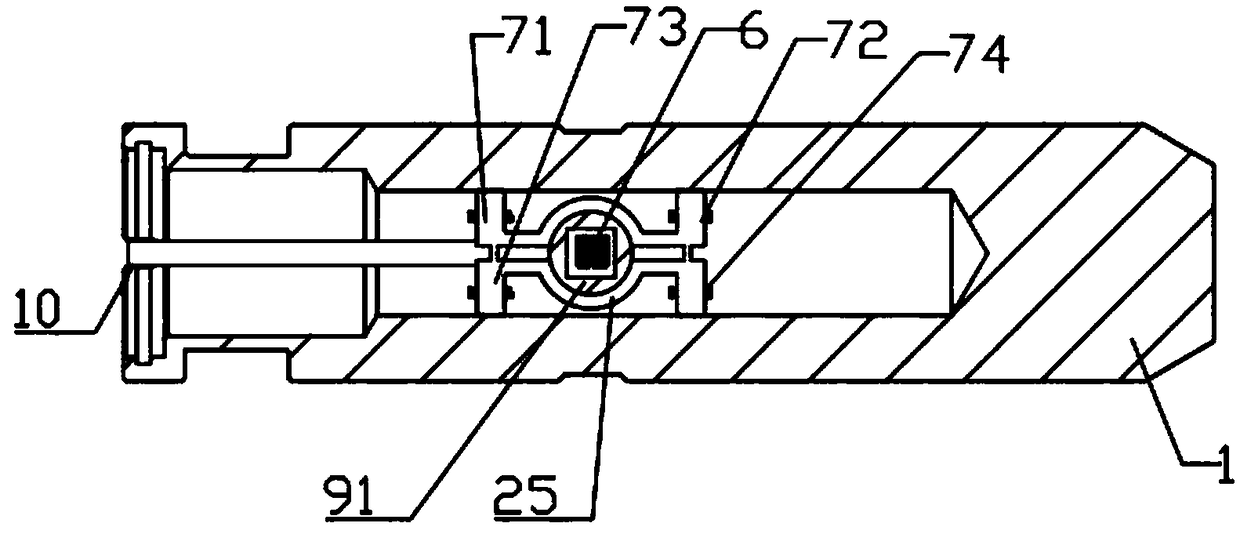

Microchip devices with improved reservoir opening

InactiveUS6875208B2Improve uniformityImprove reliabilityMedical devicesMicromachined deliveryControlled releaseCurrent distribution

Microchip devices and methods of manufacture thereof are provided to increase the uniformity and reliability of active exposure and release of microchip reservoir contents. In one embodiment, the microchip device for the controlled release or exposure of molecules or secondary devices comprises: (1) a substrate having a plurality of reservoirs; (2) reservoir contents comprising molecules, a secondary device, or both, located in the reservoirs; (3) reservoir caps positioned on the reservoirs over the reservoir contents; (4) electrical activation means for disintegrating the reservoir cap to initiate exposure or release of the reservoir contents in selected reservoirs; and (5) a current distribution means, a stress induction means, or both, operably engaged with or integrated into the reservoir cap, to enhance reservoir cap disintegration.

Owner:MASSACHUSETTS INST OF TECH

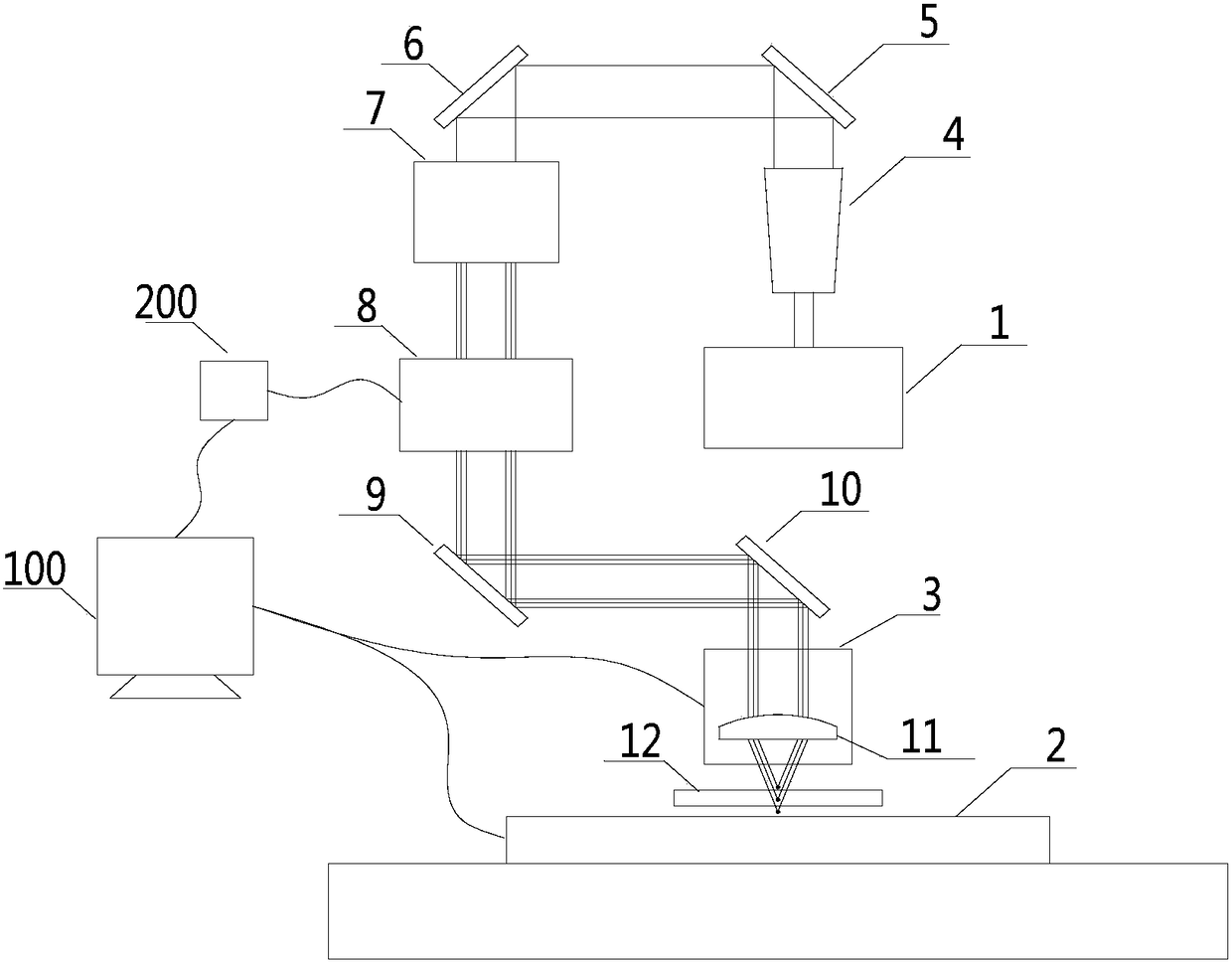

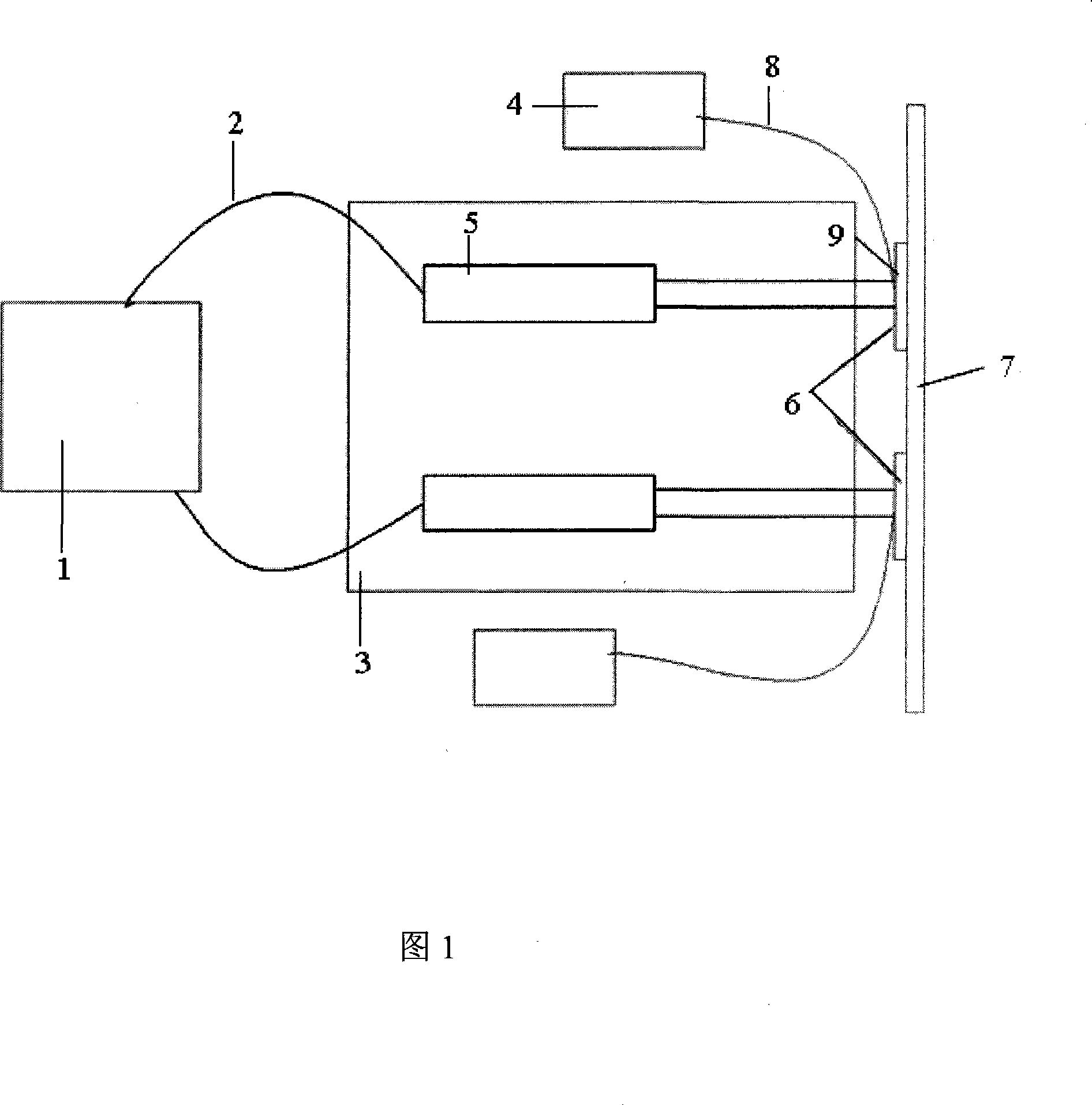

Method and device for machining brittle transparent materials through lasers with multiple focal points distributed dynamically

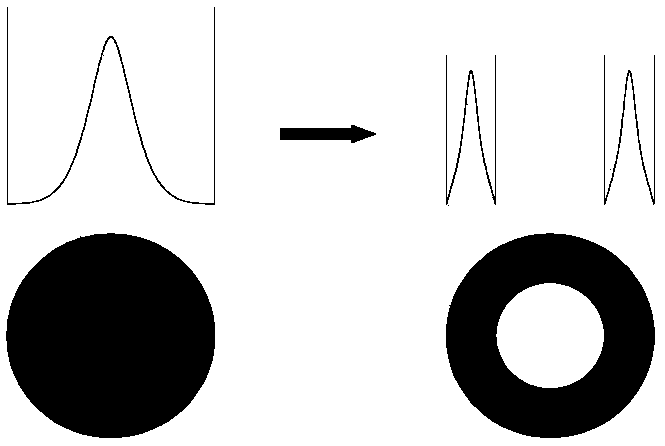

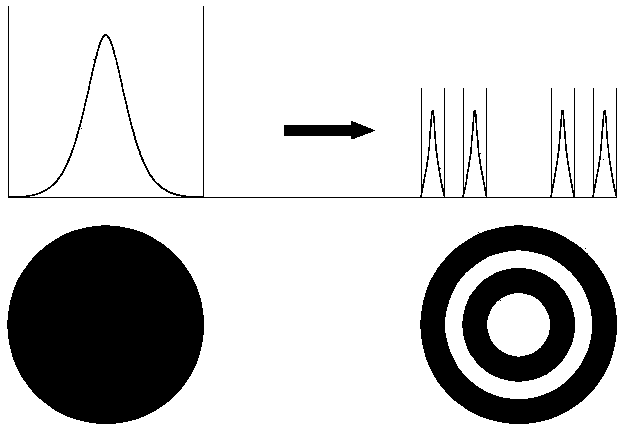

PendingCN108161250AAchieve segmentationImproving Some Drawbacks of Laser Stress-Induced MachiningLaser beam welding apparatusBeam expanderOptical axis

The invention relates to a method and a device for machining brittle transparent materials through lasers with multiple focal points distributed dynamically. A laser outputs a light beam, a beam expander is used for continuously adjusting a diameter and a divergence angle of the light beam, a first reflection unit reflects the light beams to a laser beam primary shaping device, the laser beam primary shaping device is used for carrying out the light beam shaping on the laser beams with a gaussian distribution appeared on energy, the shaped light beam energy is distributed in one or more annular regions, a light beam secondary shaping device is used for shaping the light beam again, the energy distribution and the size of the laser beam are adjusted, the distribution range of the focal point is dynamically controlled, a second reflection unit reflects the light beam to a focus lens, the light beam is focused, the light beam forms the multi-focal points distributed in a limited range, the focal point distribution range includes a machined object; and a X-Y axis motion platform carries the machined object and moves relative to the focus lens. According to the method and the device, the machining of the brittle transparent material is realized by increasing the number of focal points in the optical axis direction through an extension technology based on a laser stress induction cutting technology.

Owner:SUZHOU DELPHI LASER +1

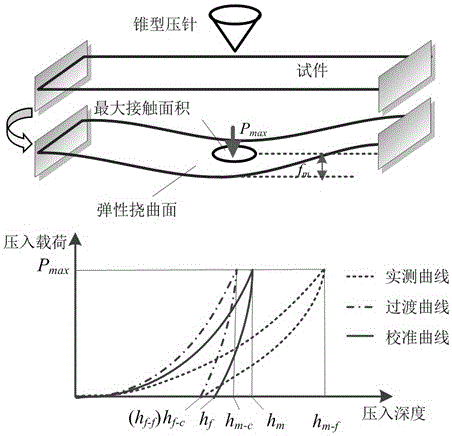

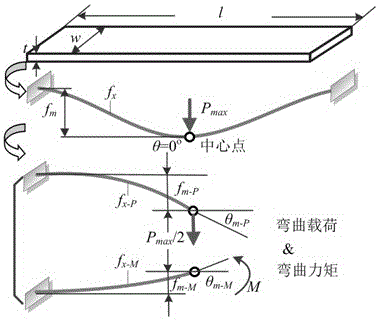

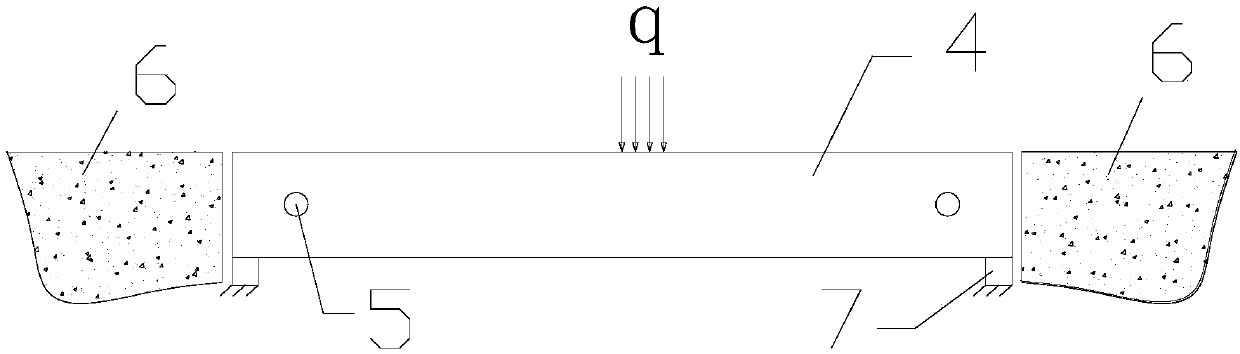

Calibration method for indention load-depth curve of micro-bridge of micro-electro-mechanical system

ActiveCN106501111AExact bending strengthExact yield strengthInvestigating material hardnessMaximum depthYoung's modulus

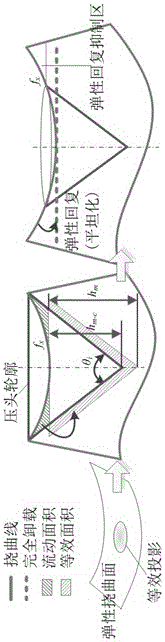

The invention relates to a calibration method for the indention load-depth curve of a micro-bridge of a micro-electro-mechanical system, belonging to the field of testing of the mechanical properties of materials. The bending load-deflection curve and the indention load-depth curve of a micro-bridge structure are synchronously acquired through a nanoindentation test on the micro-bridge structure, wherein the characteristic size of the micro-bridge structure is of a micron order, and two ends of the micro-bridge structure are fixed; and quantitative testing is carried out on the rigidity, Young modulus, hardness, yield stress and breaking strength of a bridge structure of a micro-electro-mechanical system device. Through analysis of a statically indeterminate structure of the micro-bridge, the actual maximum displacement of the tip end of an indenter is accurately parsed to be a sum of the maximum flexural deflection of the micro-bridge and the maximum indention depth of the indenter embedded into the surface of the micro-bridge; and a method for estimating a load-depth curve under the condition of elastic semi-infinite half-space by using the actually-measured indention load-depth curve is established on the basis of both the actual maximum displacement of the indenter and theoretical analysis of maximum depth of indentation by an elastic deflection surface and elastic deflection at the edge of an indentation micro-area; so a novel measuring method is provided for research on the mechanical behaviors of the micro-electro-mechanical system device under stress induction.

Owner:JILIN UNIV

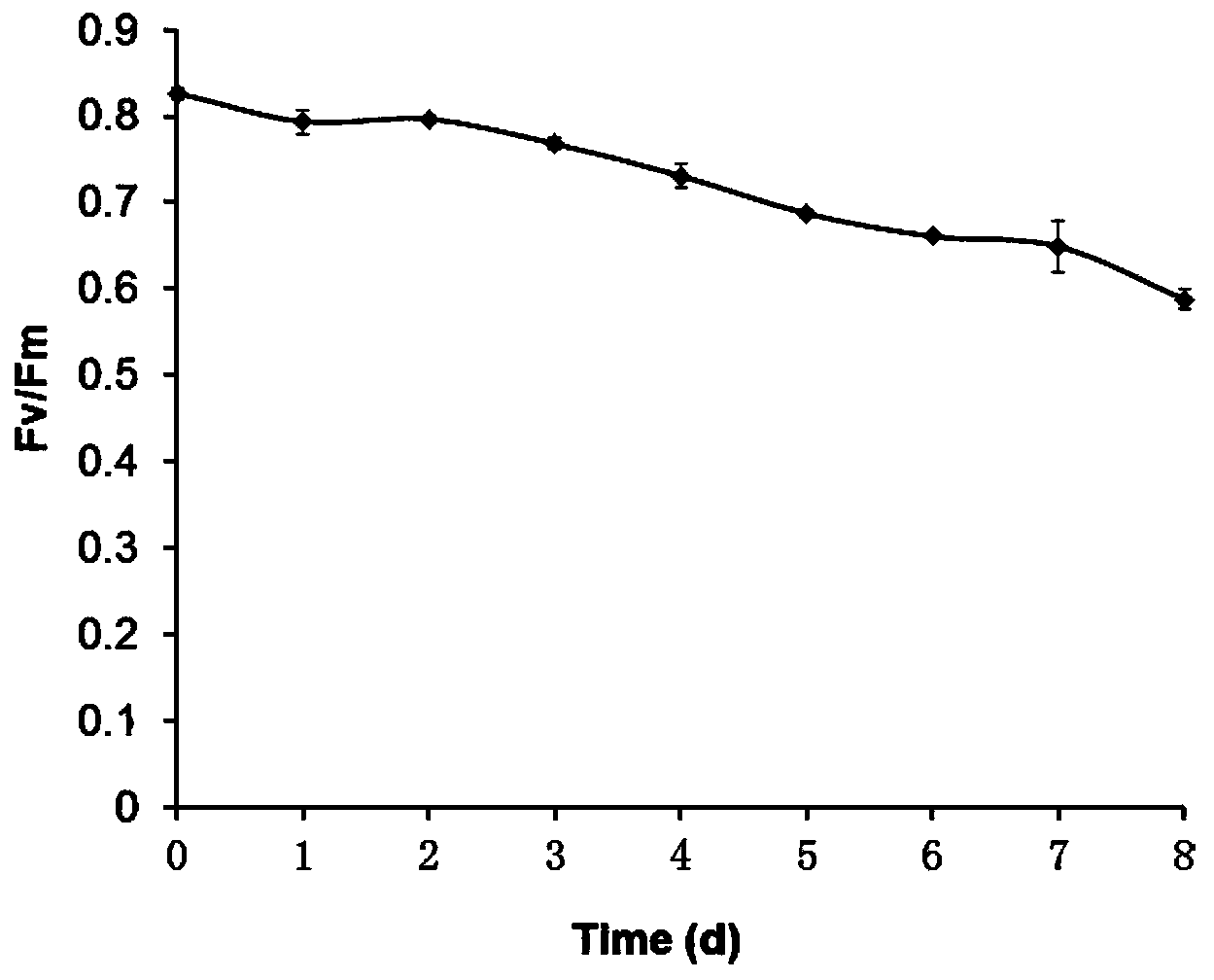

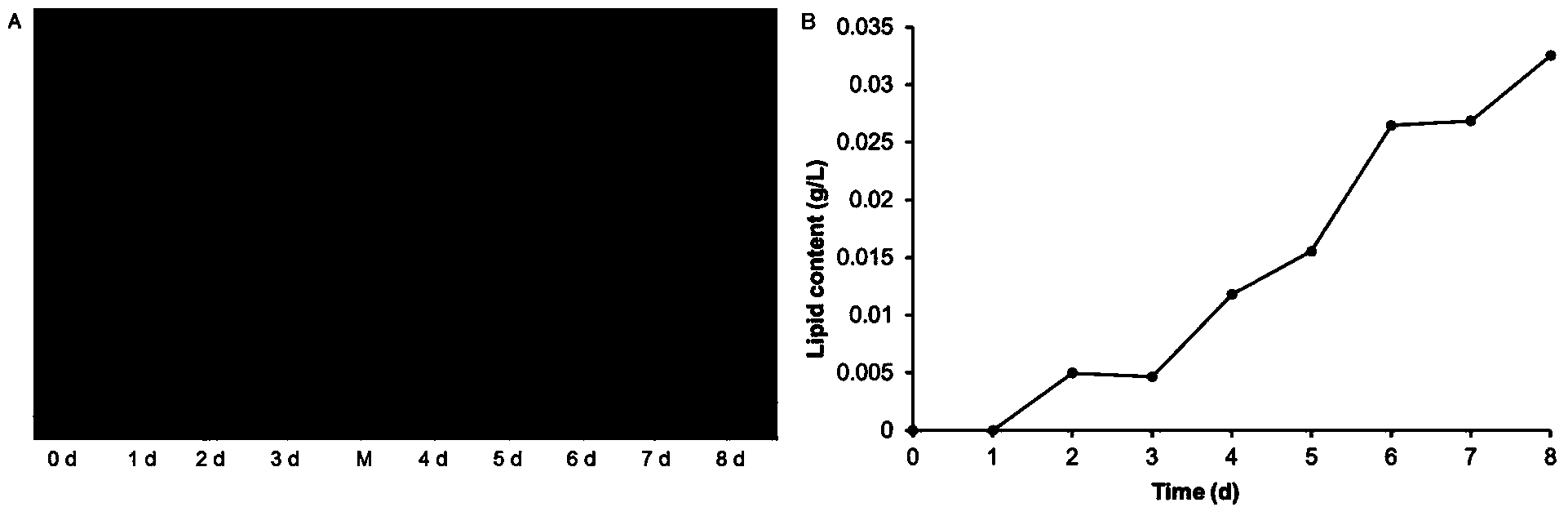

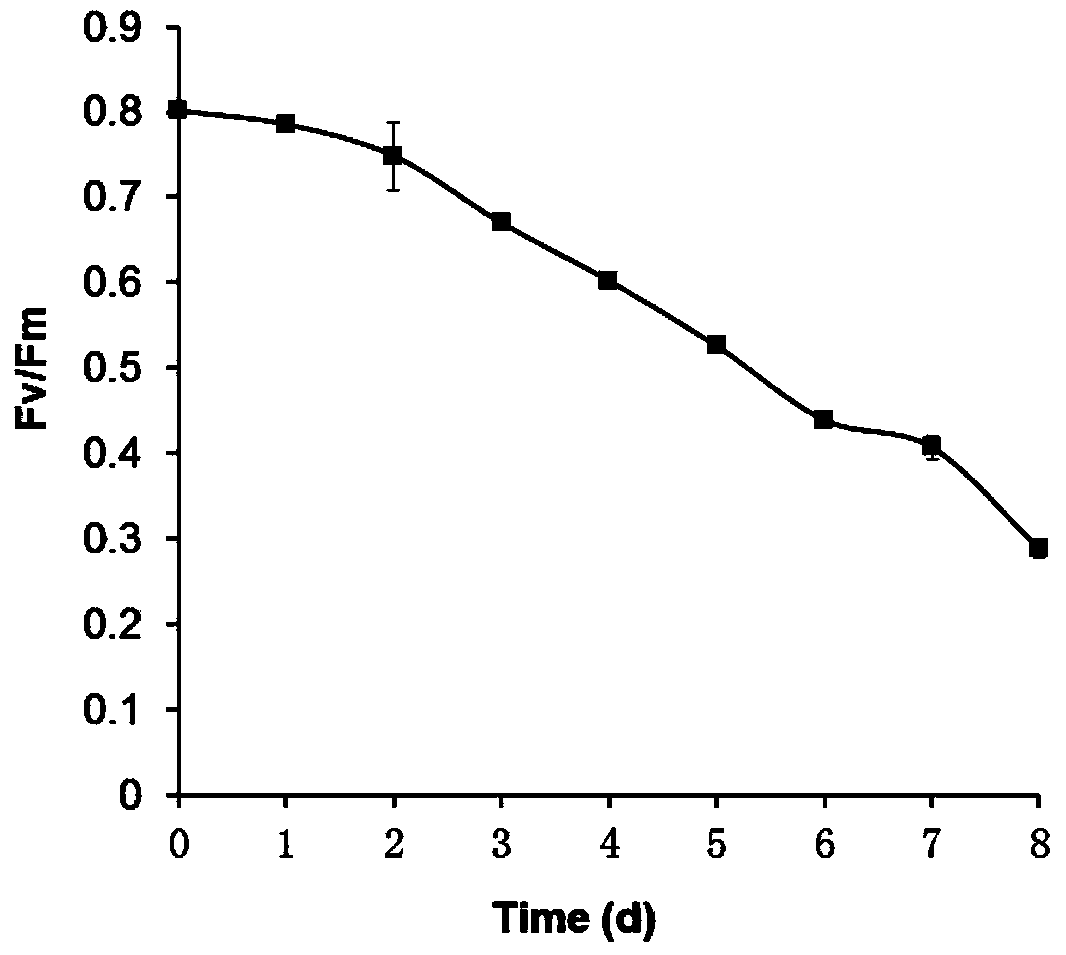

Method for determining oleaginous microalgae harvesting time by utilizing chlorophyll fluorescence parameter Pv/Fm

ActiveCN104374758ASimple detection operationFast detection operationFluorescence/phosphorescenceInterference factorOil production

The invention discloses a method for determining the oleaginous microalgae harvesting time by utilizing the chlorophyll fluorescence parameter Pv / Fm. The method comprises the following steps: (1) carrying out conventional culture and stress induction on oleaginous microalgae, namely carrying out conventional autotrophic culture on the oleaginous microalgae; culturing the oleaginous microalgae to mid-log phase, and inducing accumulation of neutral fat under a stress condition; (2) detecting the chlorophyll fluorescence parameter Fv / Fm, namely sampling in an oil-production inducing process, and detecting Fv / Fm; (3) detecting the content of neutral fat, namely extracting algae oil by chloroform / methanol, and detecting the content of the neutral fat by means of a thin layer chromatography method and image analysis software; (4) determining the harvesting time, namely harvesting microalgae after the neutral fat in cells starts to be remarkably accumulated for 1-2 days, determining the Fv / Fm range after the neutral fat starts to be remarkably accumulated for 1-2 days to be the Fv / Fm harvesting range if the detected Fv / Fm and the neutral fat content are remarkably related, and determining the harvesting time when the algae solution Fv / Fm reaches the harvesting range in induction of neutral fat production under the same stress induction. The method is simple and quick in the chlorophyll fluorescence parameter Pv / Fm detection operation, has few interference factors, and is accurate and stable.

Owner:INST OF AQUATIC LIFE ACAD SINICA

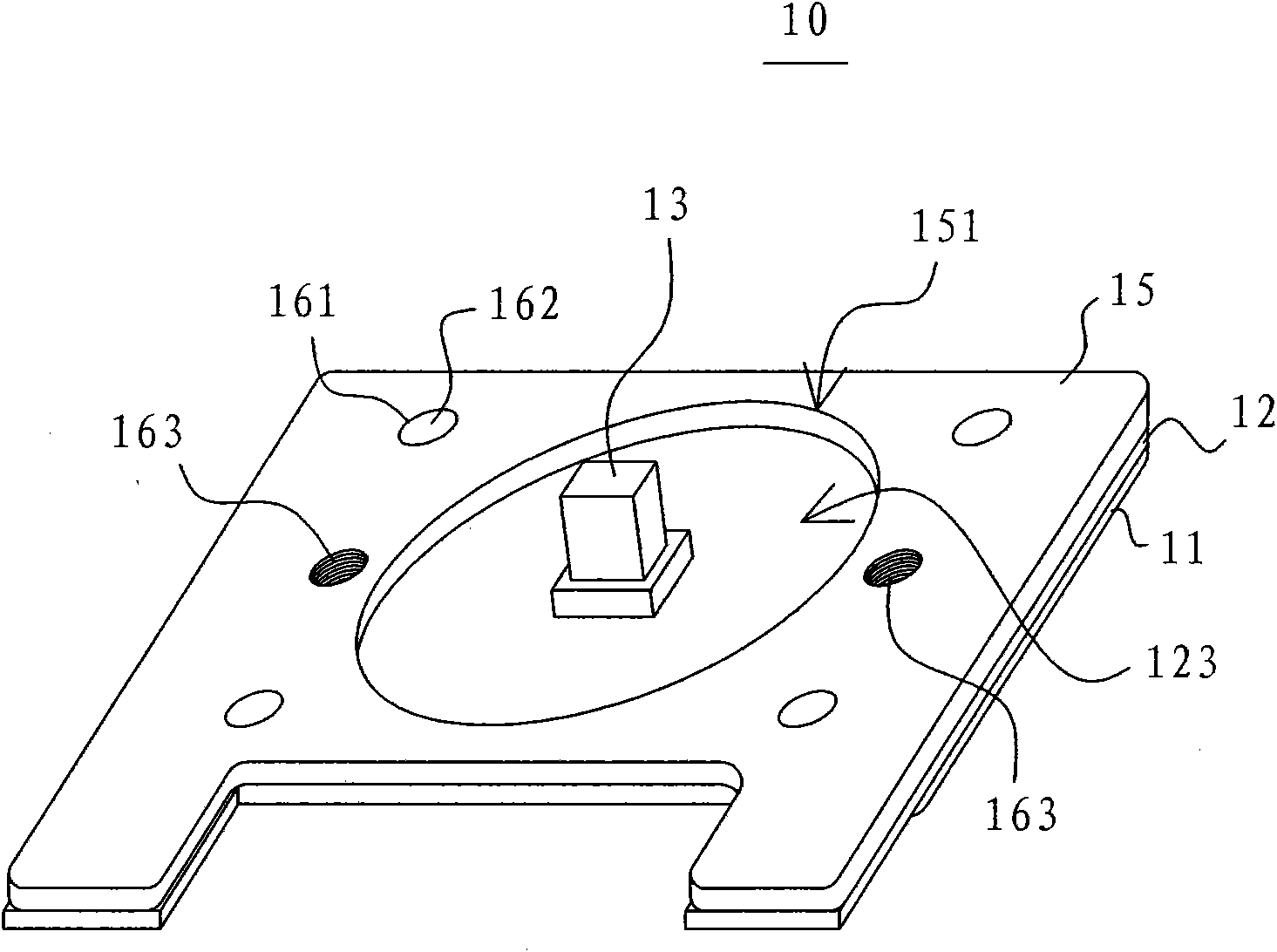

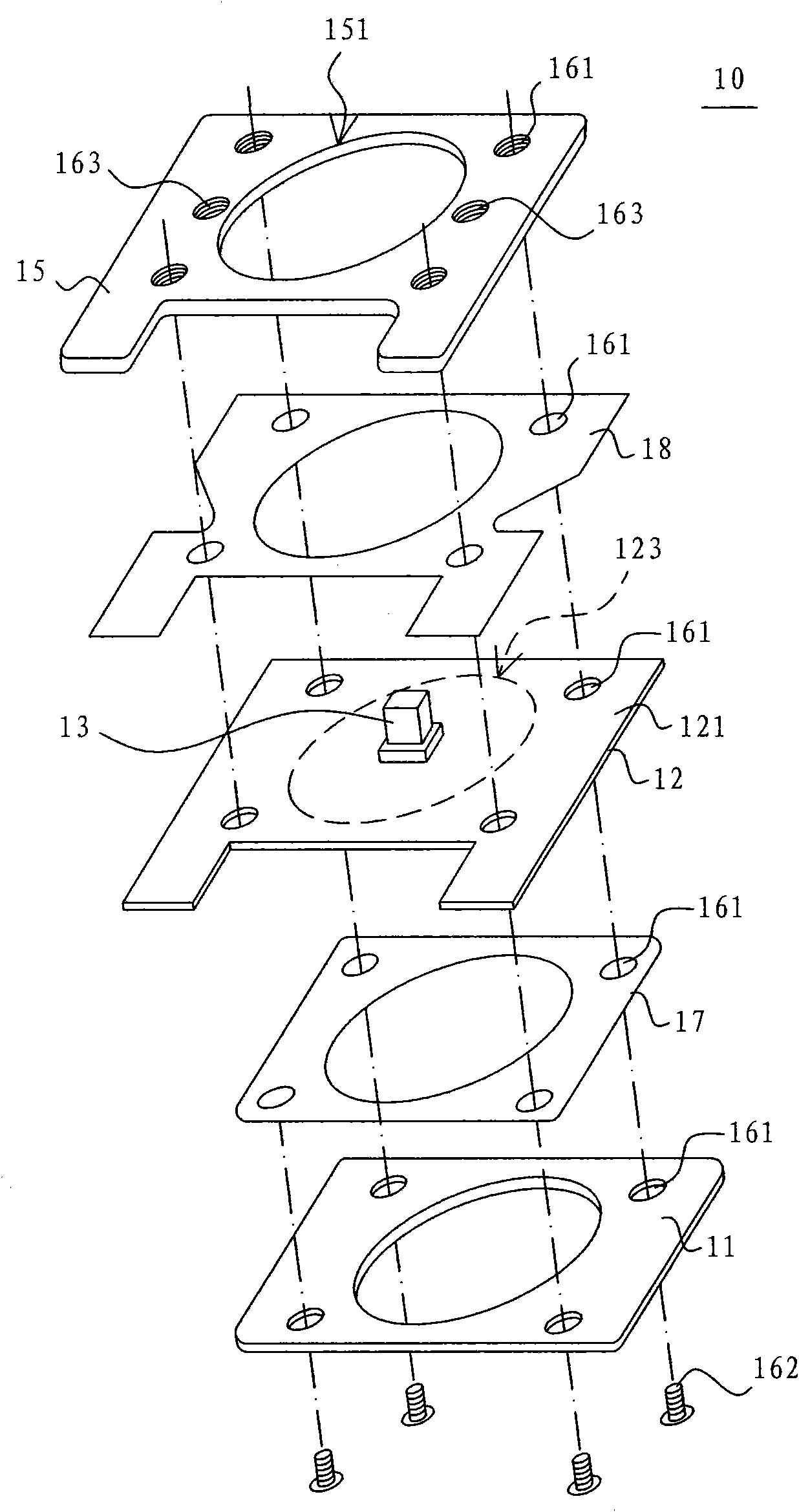

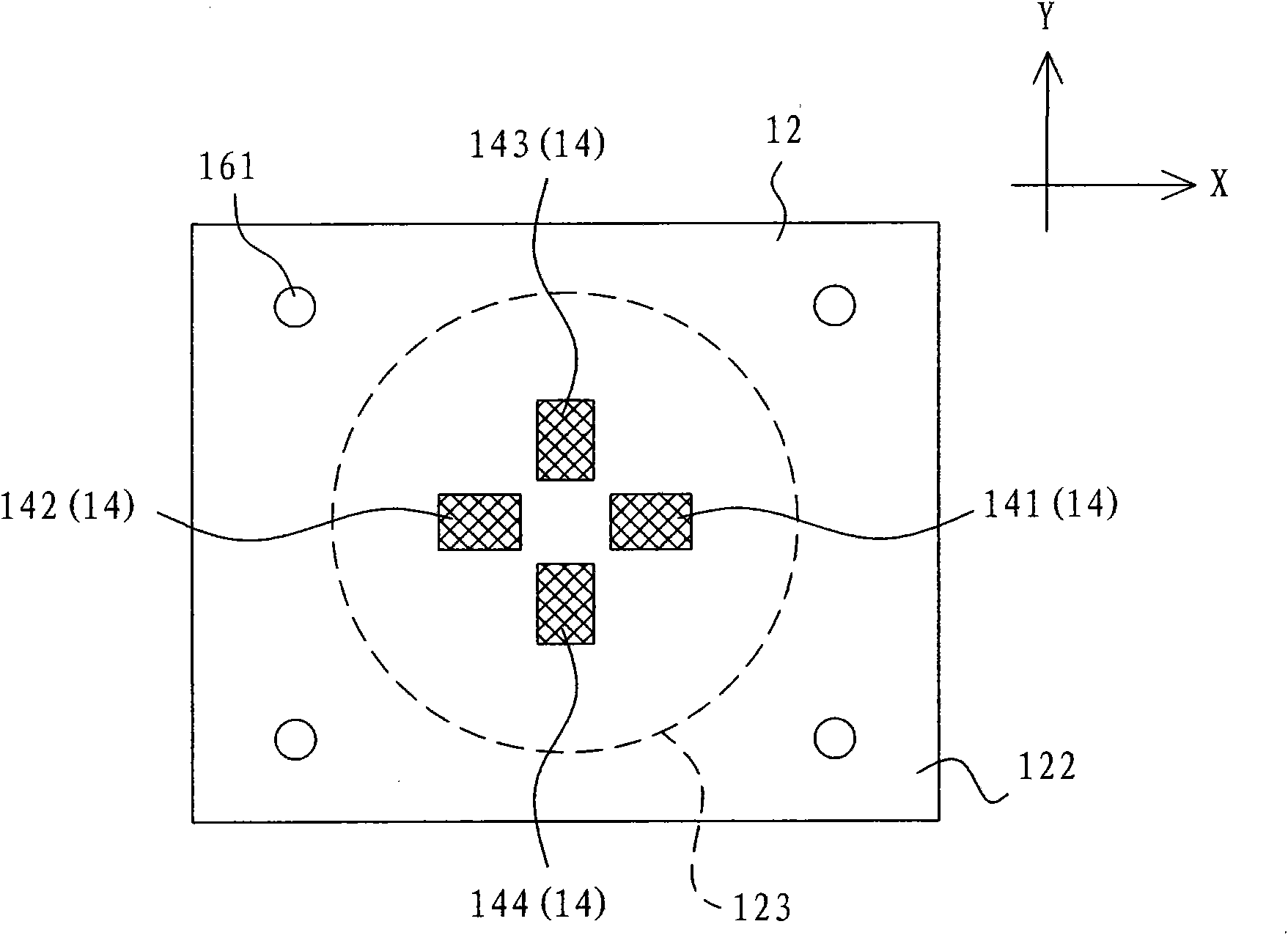

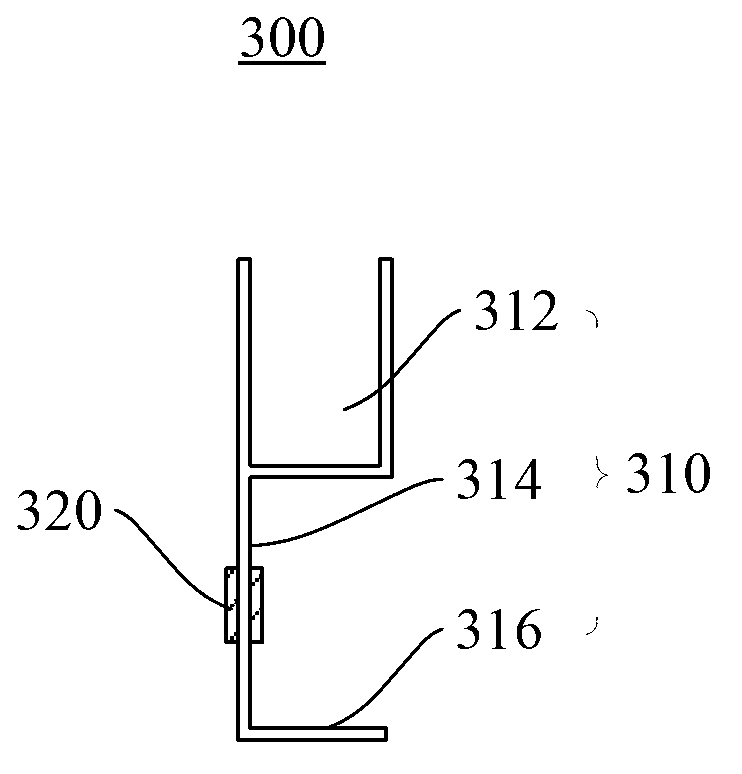

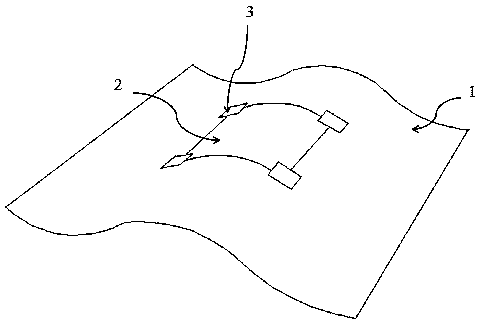

Stress inductor and assembly method thereof

The invention relates to a stress inductor and an assembly method thereof. The stress inductor comprises a circuit substrate, a pointing actuating part and a metal back plate, wherein the circuit substrate has a stress induction structure, and the stress induction structure comprises a stress deformation area and a plurality of stress induction resistors; the pointing actuating part is arranged on the top surface of the circuit substrate and connected with the stress induction structure; and the metal back plate is provided with at least one jointing material coating area, and a plurality of fixedly connected edges of the circuit substrate are fixedly connected in the jointing material coating area. The assembly method for the stress inductor is applied to the stress inductor and comprises the following steps of: combining the pointing actuating part to the top surface of the circuit substrate; and fixedly connecting the fixedly connected edges of the circuit substrate to the at least one jointing material coating area of the metal back plate. The stress inductor has a few elements, and has the advantages of small size and low cost; and because the circuit substrate is directly fixedly connected on the metal back plate, the assembly method for the stress inductor simplifies the assembly step and promotes the assembly efficiency.

Owner:ELAN MICROELECTRONICS CORPORATION

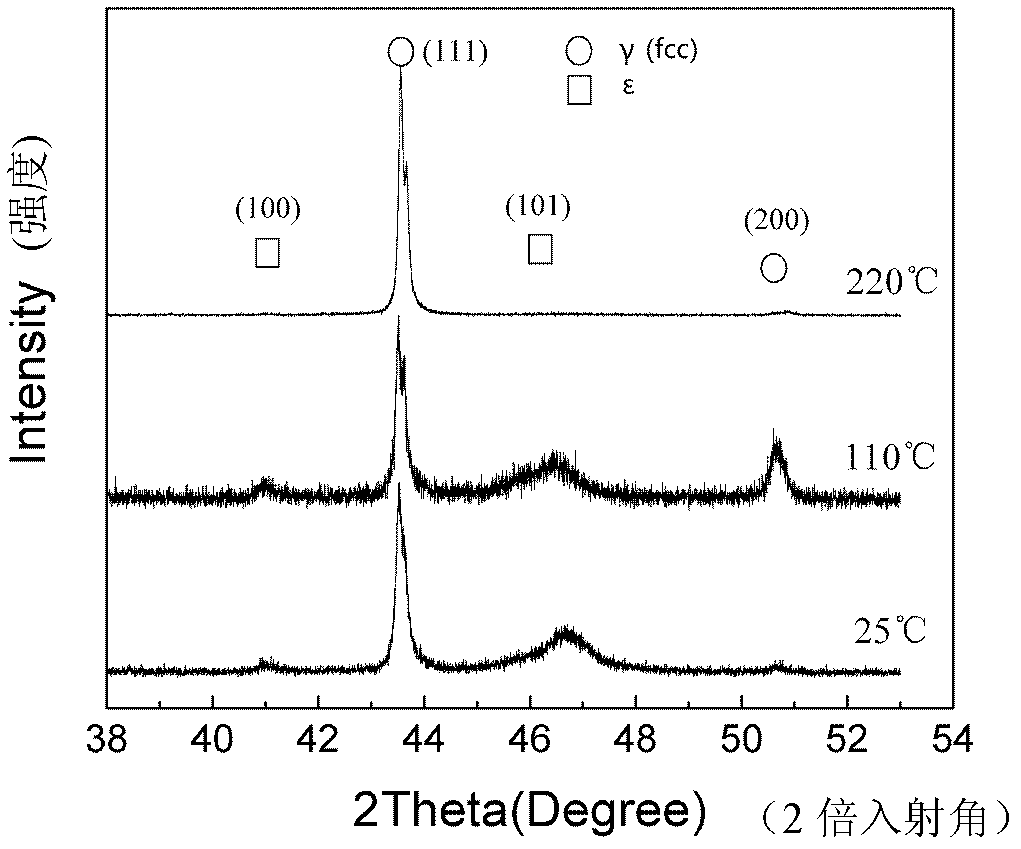

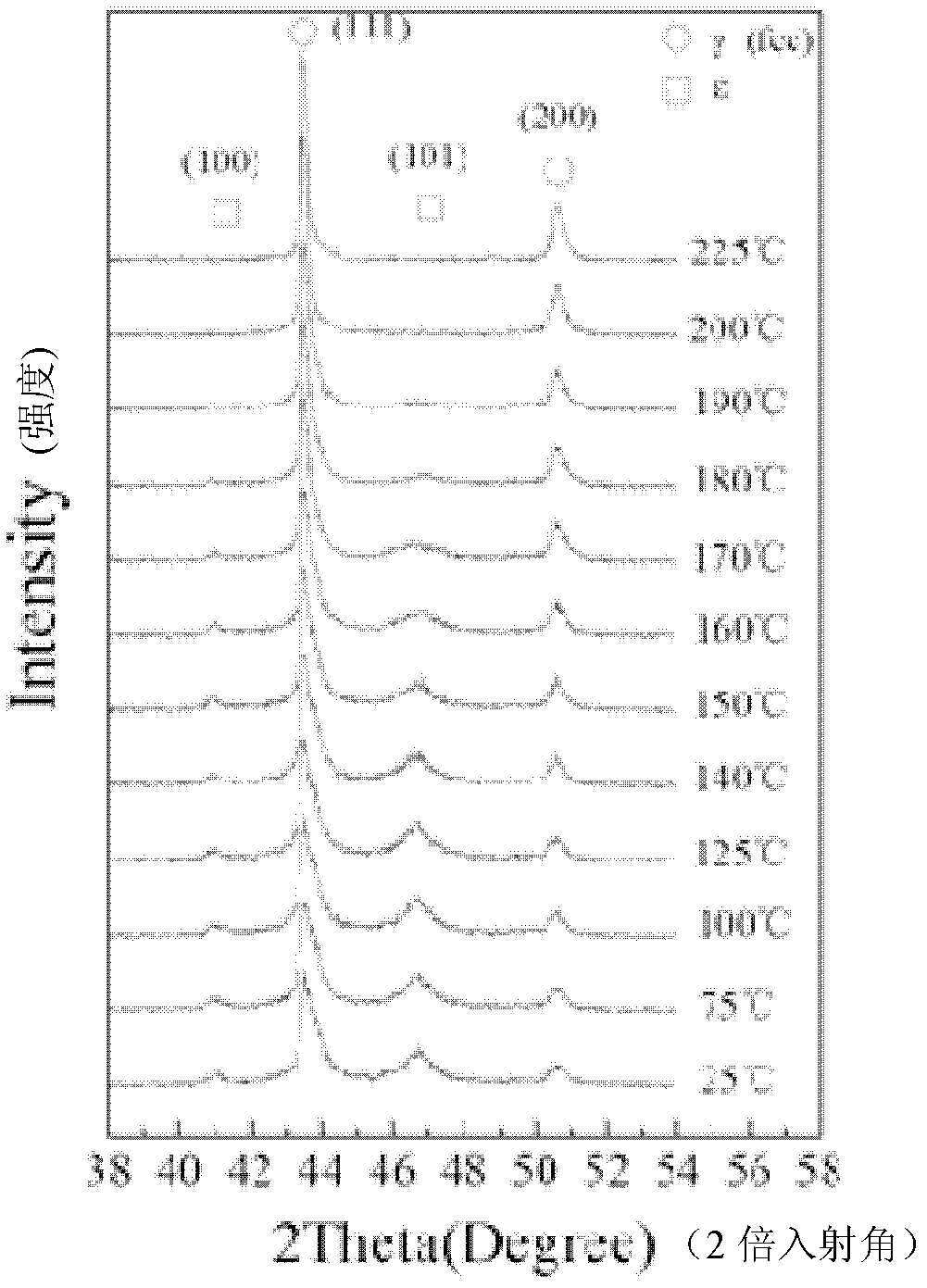

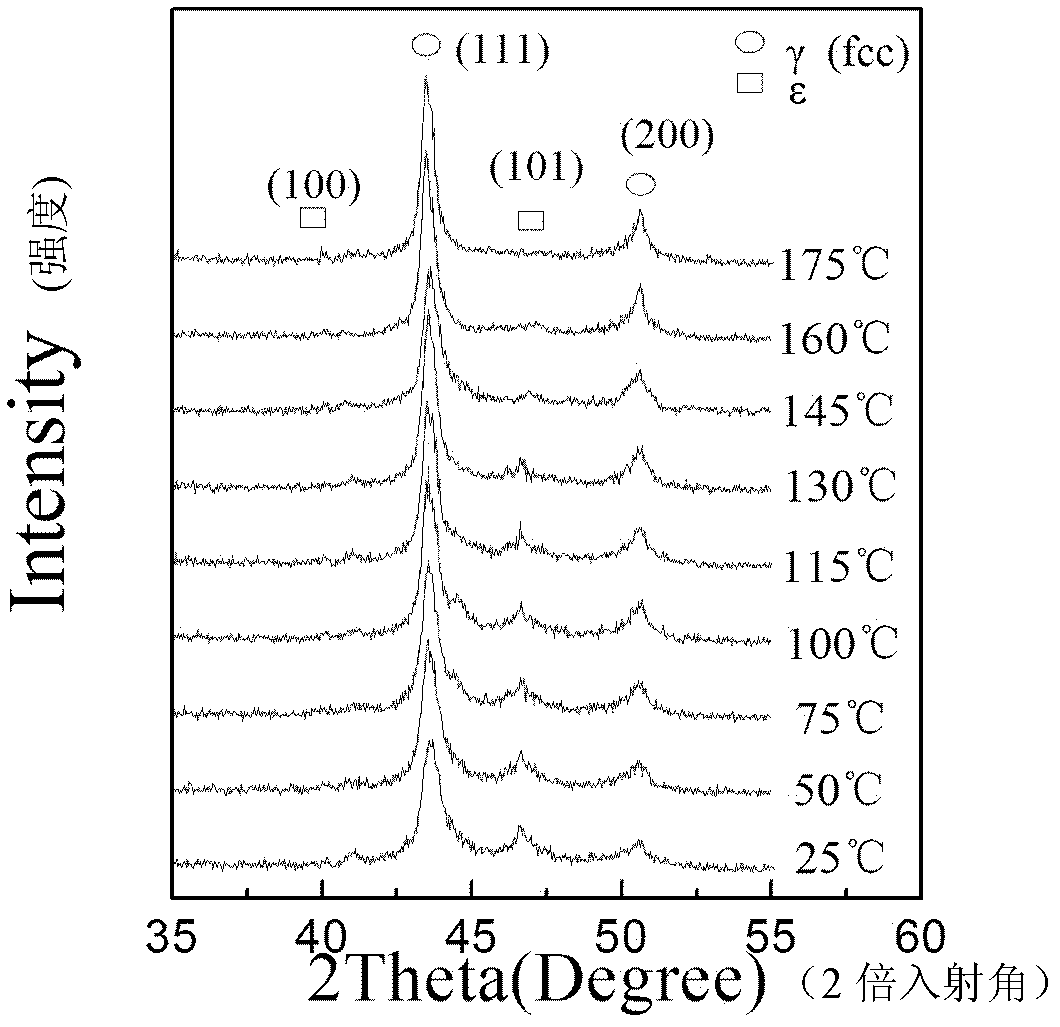

Method for representing recovery characteristics of Fe-Mn-Si-based memory alloy by in-situ X-ray diffraction

InactiveCN102435624AWill not characterize outcome effectsReduce measurement errorPreparing sample for investigationMaterial analysis using radiation diffractionX-rayAlloy

The invention discloses a method for representing recovery characteristics of a Fe-Mn-Si-based memory alloy by in-situ X-ray diffraction. In the method, in-situ X-ray diffraction analysis is introduced to the inverse phase change process of the Fe-Mn-Si-based memory alloy, thus phase change characteristics of conversion from martensite to austenite under stress induction in the heating shape recovery process of the Fe-Mn-Si-based memory alloy can be represented synchronously in real time through high-temperature in-situ X-ray diffraction. The method mainly comprises the steps of: pretreating a sample and carrying out X-ray diffraction on the pretreated sample by utilizing a high-temperature in-situ sample platform so as to obtain an in-situ X-ray diffractogram representing the shape memory recovery characteristics of the Fe-Mn-Si-based memory alloy. By using the method disclosed by the invention, phase change characteristics of the Fe-Mn-Si-based memory alloy can be presented from a macroscopic perspective, and the change of structure in the recovery process is synchronously, in situ and visually researched through diffraction pattern analysis.

Owner:TIANJIN UNIV

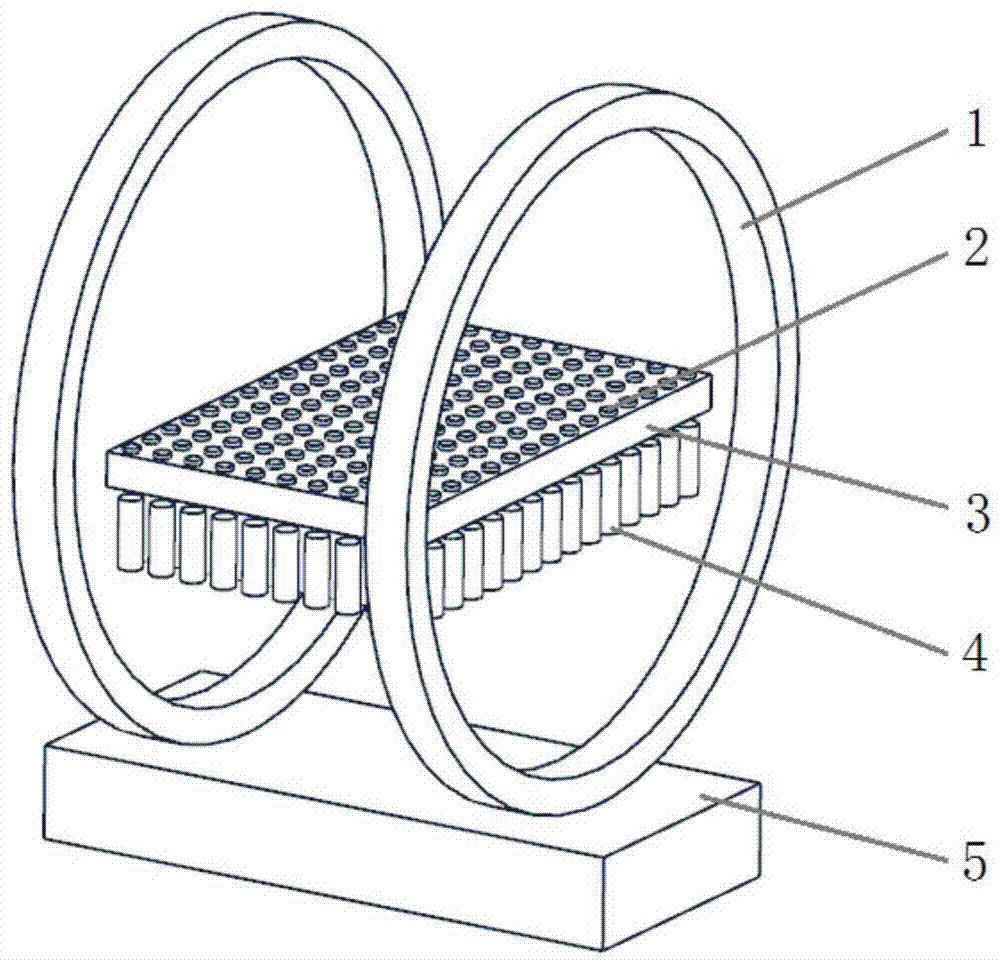

Device for testing contact stress between tire and road surface based on magnetic manometer heat image

The invention relates to a device for testing the contact stress between a tire and a road surface based on a magnetic manometer heat image and is applied to the field of road stress testing. The device comprises a stress induction panel, an outer magnetic field exciting system and an induction magnetic field testing system. The stress induction panel is made of non-ferromagnetic metal materials and is in a rectangular panel shape, and magnetic nano-particles with superparamagnetism are welded or bonded to the upper surface of the panel. The outer magnetic field exciting system is used for applying a constant or alternating magnetic field to the induction panel, and the induction magnetic field testing system is used for measuring the magnetization intensity of the magnetic nano-particles under the excitation of an outer magnetic field. Compared with a traditional tire ground pressure measuring method and device, the device can test the tire ground pressure under a running state, the stress distribution state of the contact between the tire and the ground can be directly reflected, and the accurate degree is high.

Owner:WUHAN UNIV OF SCI & TECH

Vehicle sideslip door propulsion experimental rig as well as testing method thereof

InactiveCN101251443AReduce construction costsAccurately assess the ability to resist lateral forcesVehicle testingEngineeringStress induction

The invention discloses a device for testing the thrust force of an automobile side sliding door, which comprises a test bench, a pressure adjusting device, a connecting device, a forcing device and a forcing piece; the pressure adjusting device, the connecting device, the forcing device and a forcing rack or a forcing block are connected in turn; the forcing device is fixed on the test bench. The device for testing the thrust force of the automobile side sliding door also comprises a display screen, a stress induction device and a data connecting wire; the forcing rack or the forcing block which is provided with the stress induction device is connected with the display screen through the data connecting wire. The building cost of the tester and the test bench is low; with small cost input, a simulation test bench set which can accurately evaluate the capacity of resisting lateral force by the automobile side sliding door and a retaining element can be built up.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Automatic adjustment human pile and pace analysis device used for wushu training

The invention relates to an automatic adjustment human pile and pace analysis device used for wushu training, belongs to the technical field of medical instruments. The technical scheme of the invention is that the automatic adjustment human pile and pace analysis device used for wushu training comprises a pace training analysis device base body, and the pace training analysis device base body is provided with a pace analysis sensing pad; the pace analysis sensing pad is provided with stress induction lines, the right side of the pace analysis sensing pad is provided with a light blocking register hole, the upper side of the pace training analysis device base body is provided with a fixed supporting angle iron. The automatic adjustment human pile and pace analysis device used for wushu training is complete in function and convenient to use, the operation is simple when wushu stake training and pace analysis guidance are performed, time and labor are saved, the device is safe and practical, high-efficient and rapid, scientific and accurate, and the training intensity of a wushu trainer is relieved.

Owner:HARBIN INST OF PHYSICAL EDUCATION

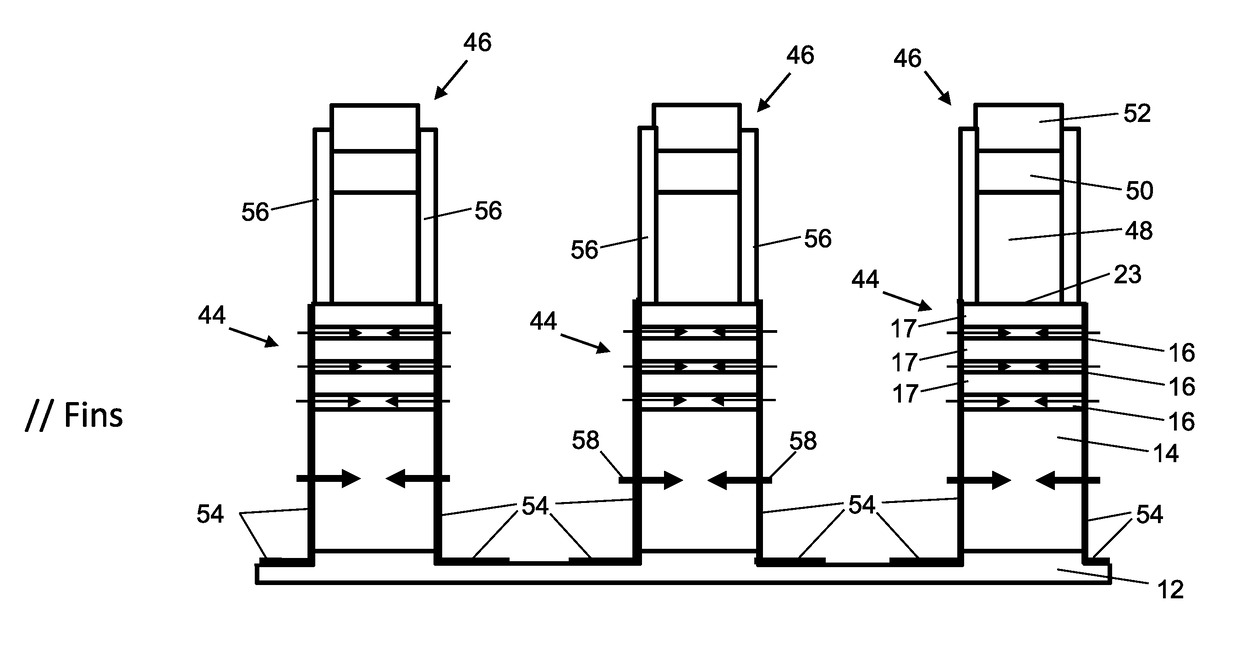

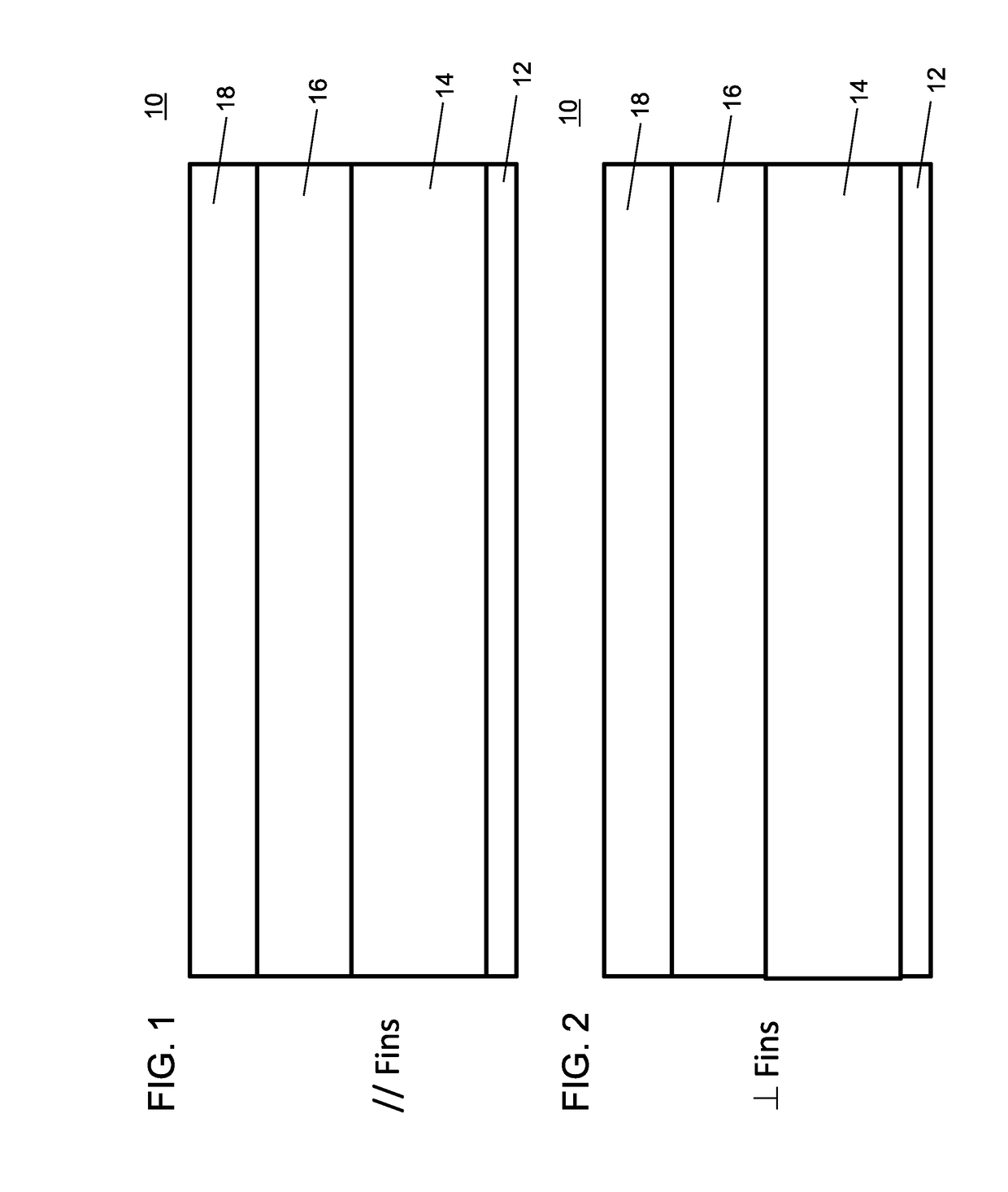

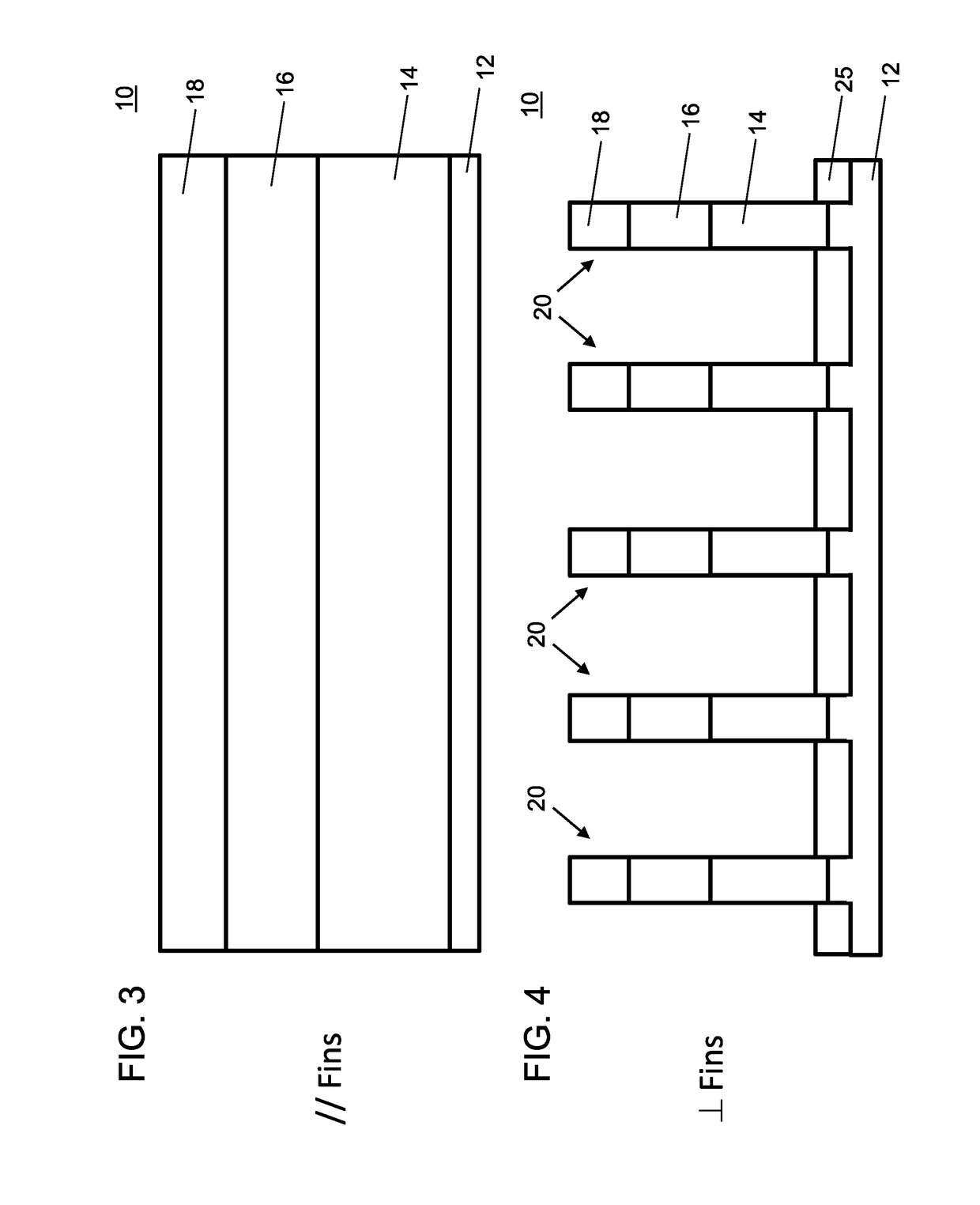

Stress induction in 3D device channel using elastic relaxation of high stress material

A method for inducing stress in a device channel includes forming a stress adjustment layer on a substrate, the stress adjustment layer including an as deposited stress due to crystal lattice differences with the substrate. A device channel layer is formed on the stress adjustment layer. Cuts are etched through the device channel layer and the stress adjustment layer to release the stress adjustment layer to induce stress in the device channel layer. Source / drain regions are formed adjacent to the device channel layer.

Owner:IBM CORP

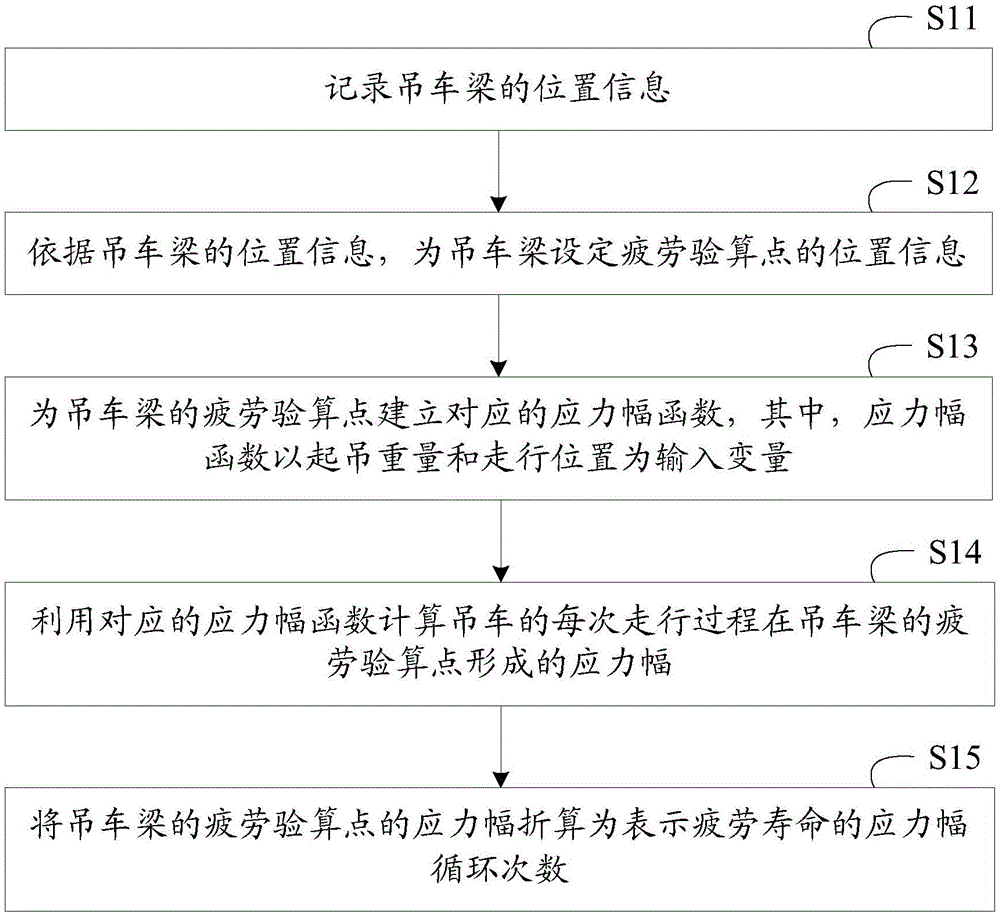

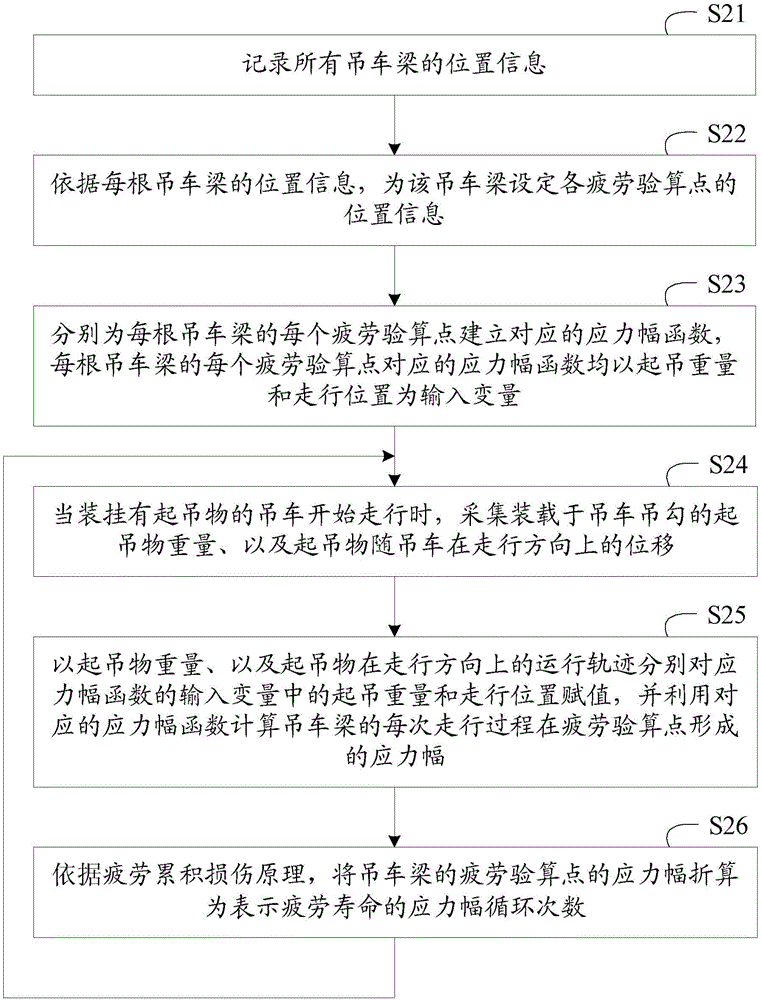

Method monitoring fatigue service life of crane beam

ActiveCN105069182AIncrease costIncrease the difficulty of constructionLoad-engaging girdersSpecial data processing applicationsAmplitude functionStress induction

The invention discloses a method monitoring fatigue service life of a crane beam; the method comprises the following steps: recording position information of the crane beam; setting position information of fatigue checking computation points for the crane beam; setting up a corresponding stress amplitude function for each the fatigue checking computation point of the crane beam, wherein the stress amplitude function uses hoisting weight and walking position as input variables; using the corresponding stress amplitude function to calculate a stress amplitude formed on the fatigue checking computation point by a hoisting object in each walking process of the crane beam; converting the stress amplitude of the fatigue checking computation point of the crane beam into a stress amplitude cycle index indicating fatigue life. The method can monitor the fatigue service life of the crane beam without needing a stress induction sheet, so monitoring cost and construction difficulty cannot be obviously improved by increasing number of the crane beams and fatigue checking computation points.

Owner:中冶检测认证(上海)有限公司 +2

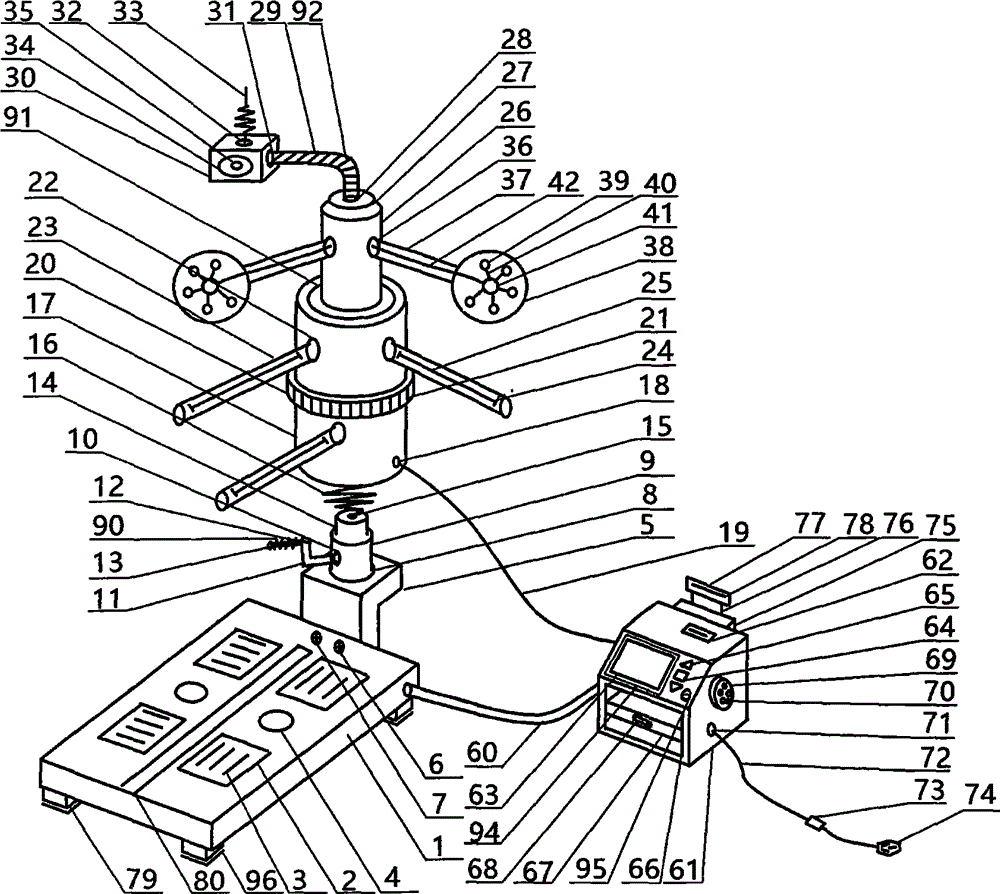

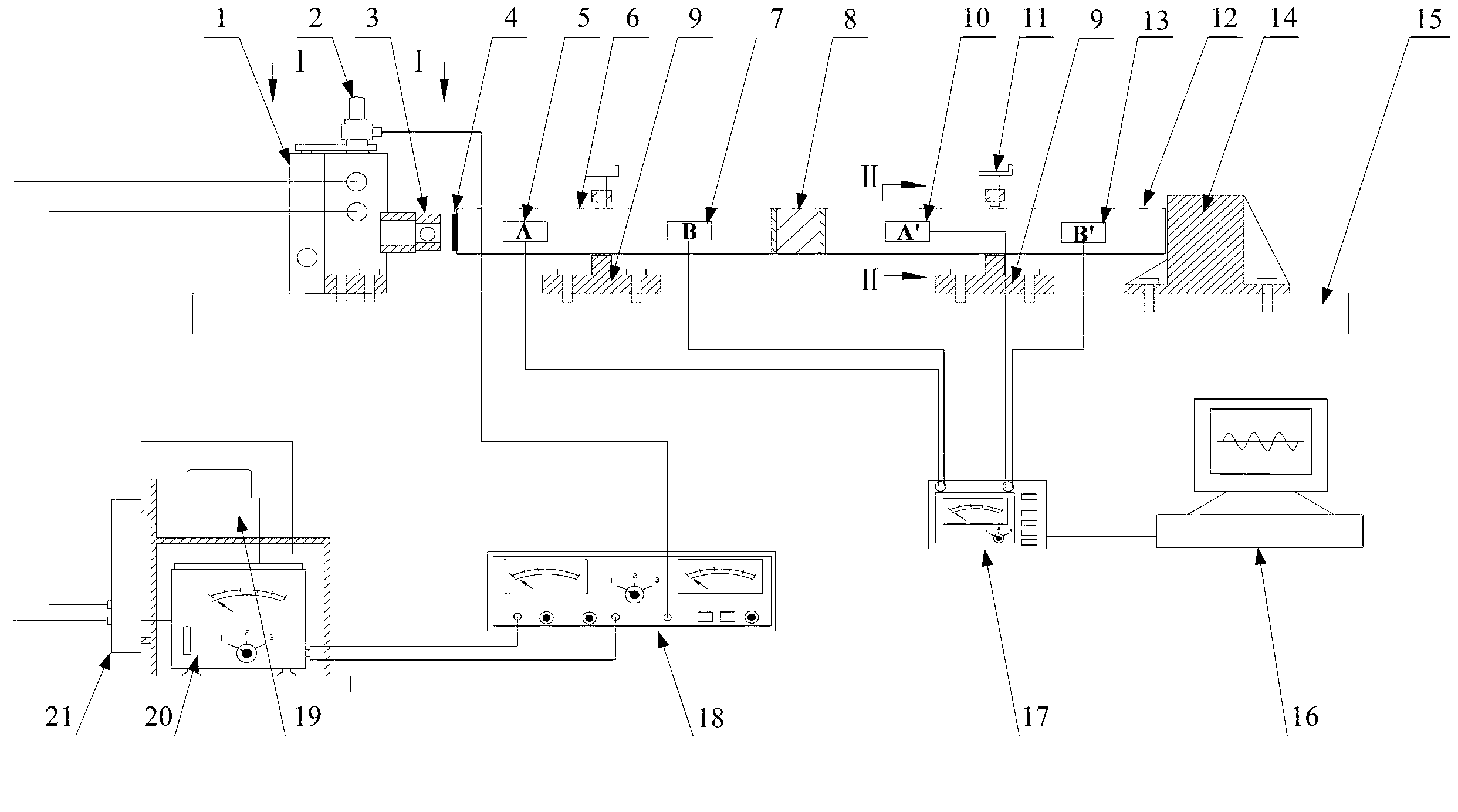

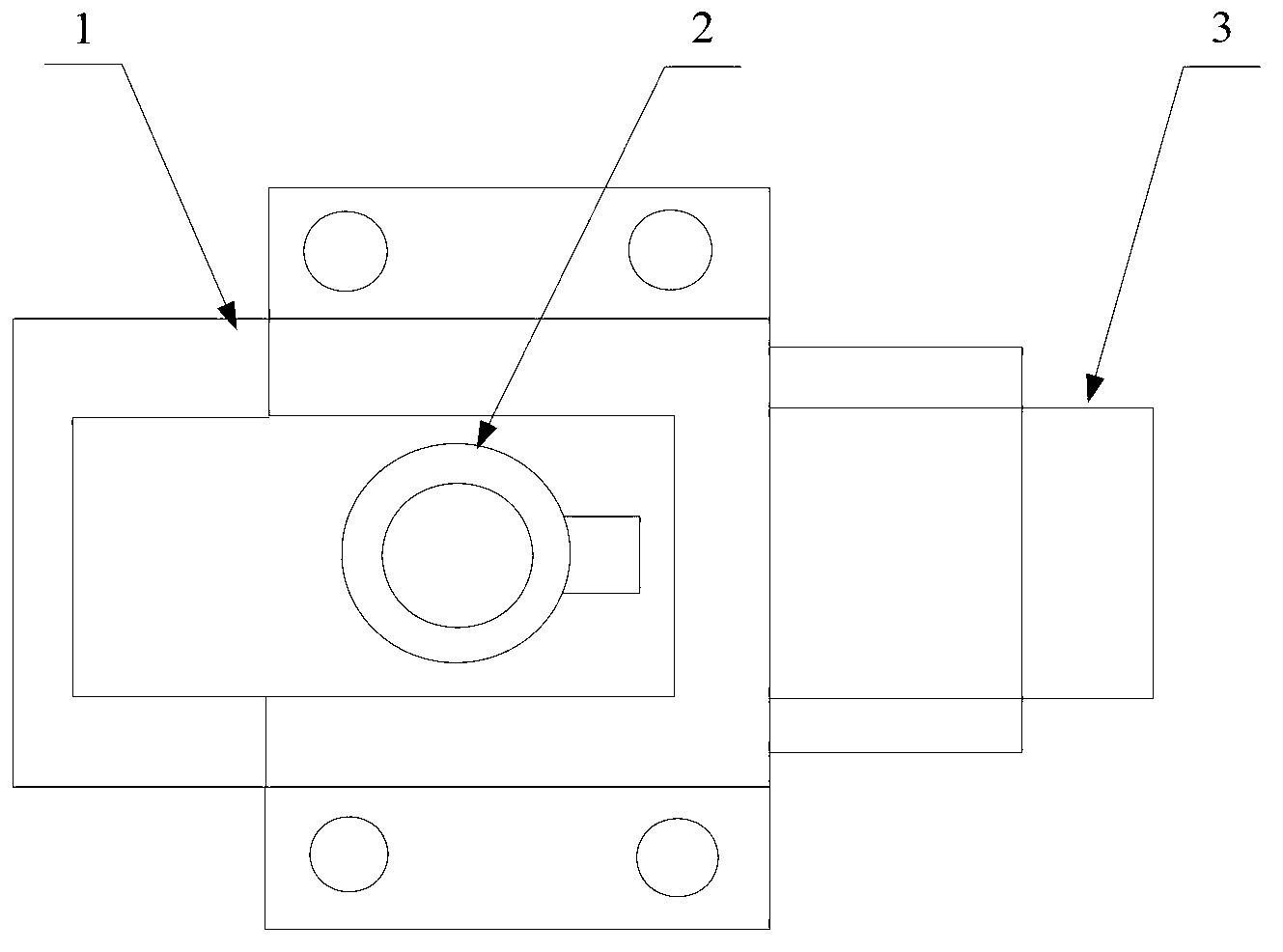

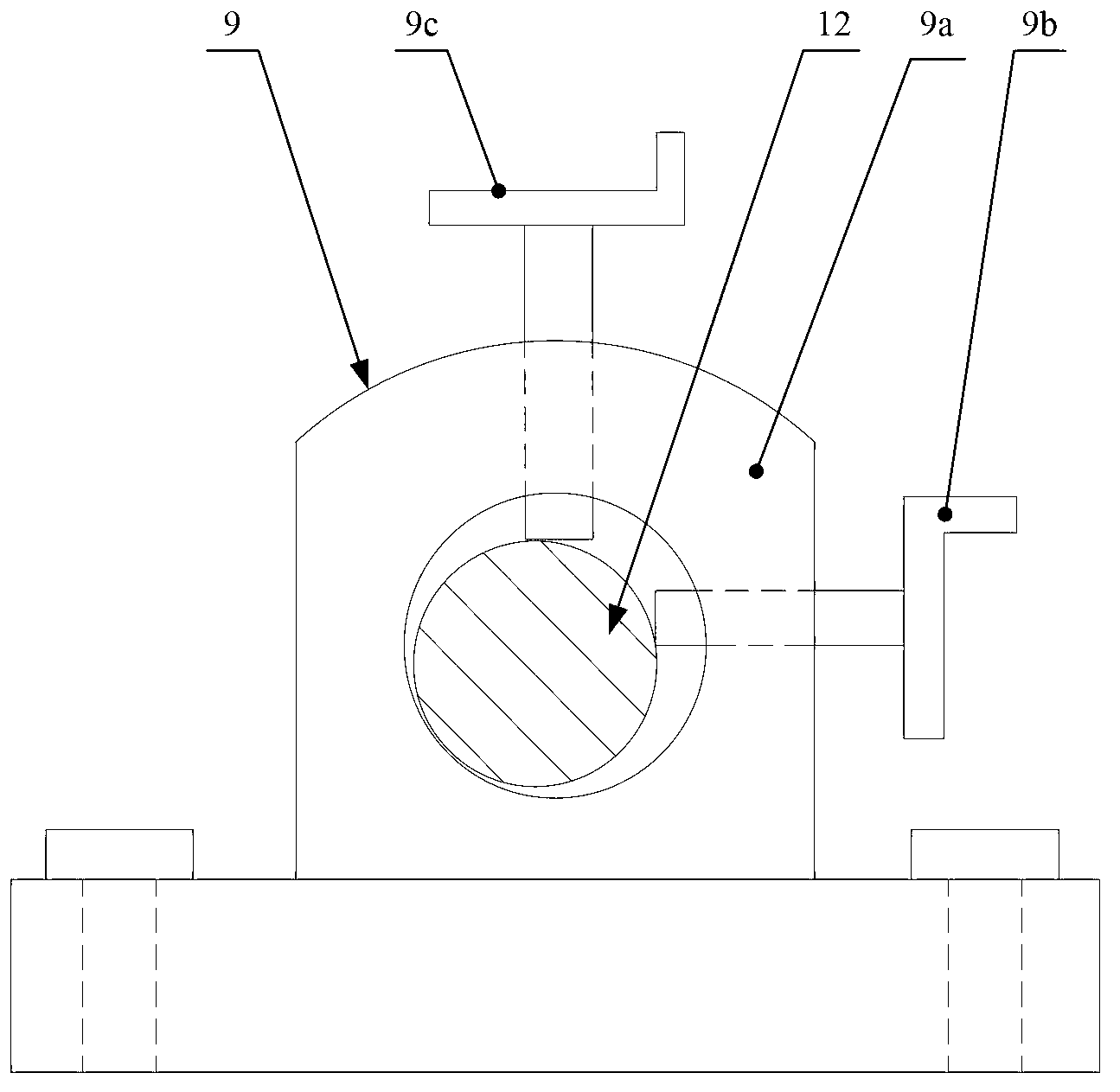

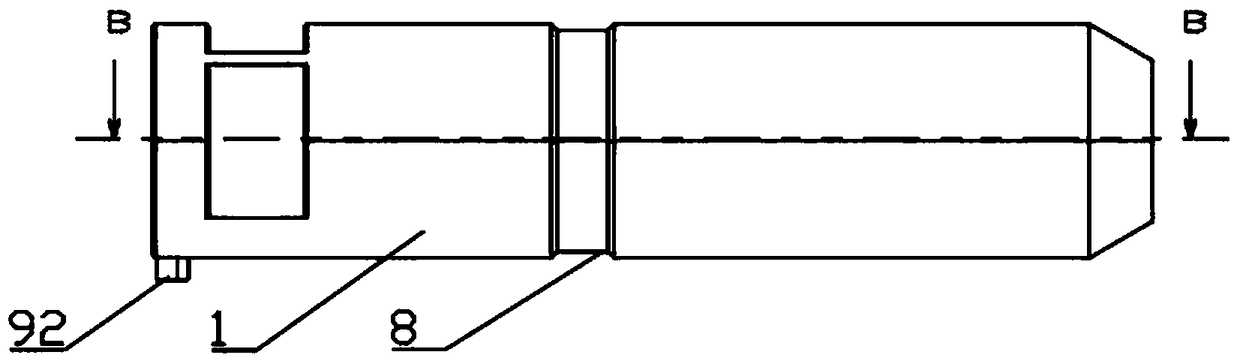

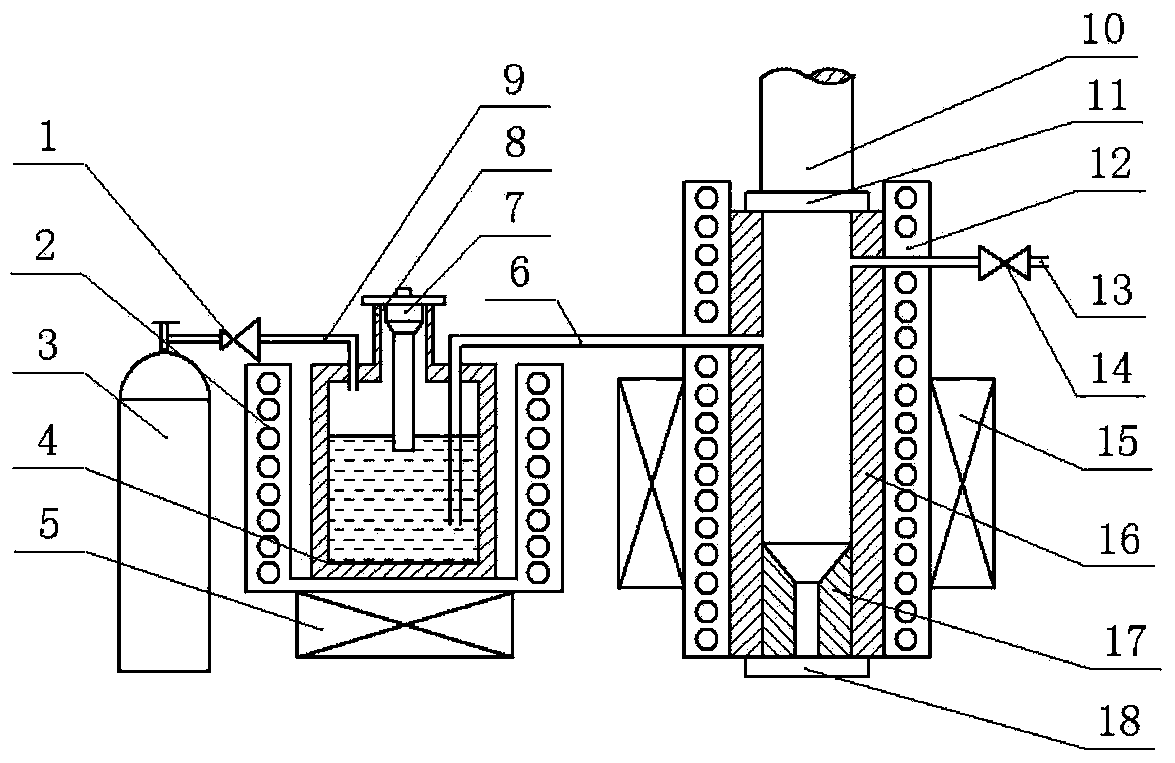

One-dimensional stress wave rock test piece dynamic tester

The invention discloses a one-dimensional stress wave rock test piece dynamic tester. The tester provided by the invention comprises a pedestal (15), an input bar (6) and an output bar (12) which are fixed on the pedestal (15), a stress wave output device for applying stress on the input bar (6) and a stress induction processing device for processing stress wave. The stress save output device comprises a vibration exciter (3) which is fixed on the pedestal (15) and used for applying impact force on the input bar (6), a servo control system connected with the vibration exciter (3), and a master controller (18) which is in communication connection with the servo control system and used for controlling impact signals applied on the vibration exciter (3) by the servo control system. The one-dimensional stress wave rock test piece dynamic tester provided by the invention is convenient for researches on interaction laws between one-dimensional controllable stress wave and a rock test piece at different loading rates.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

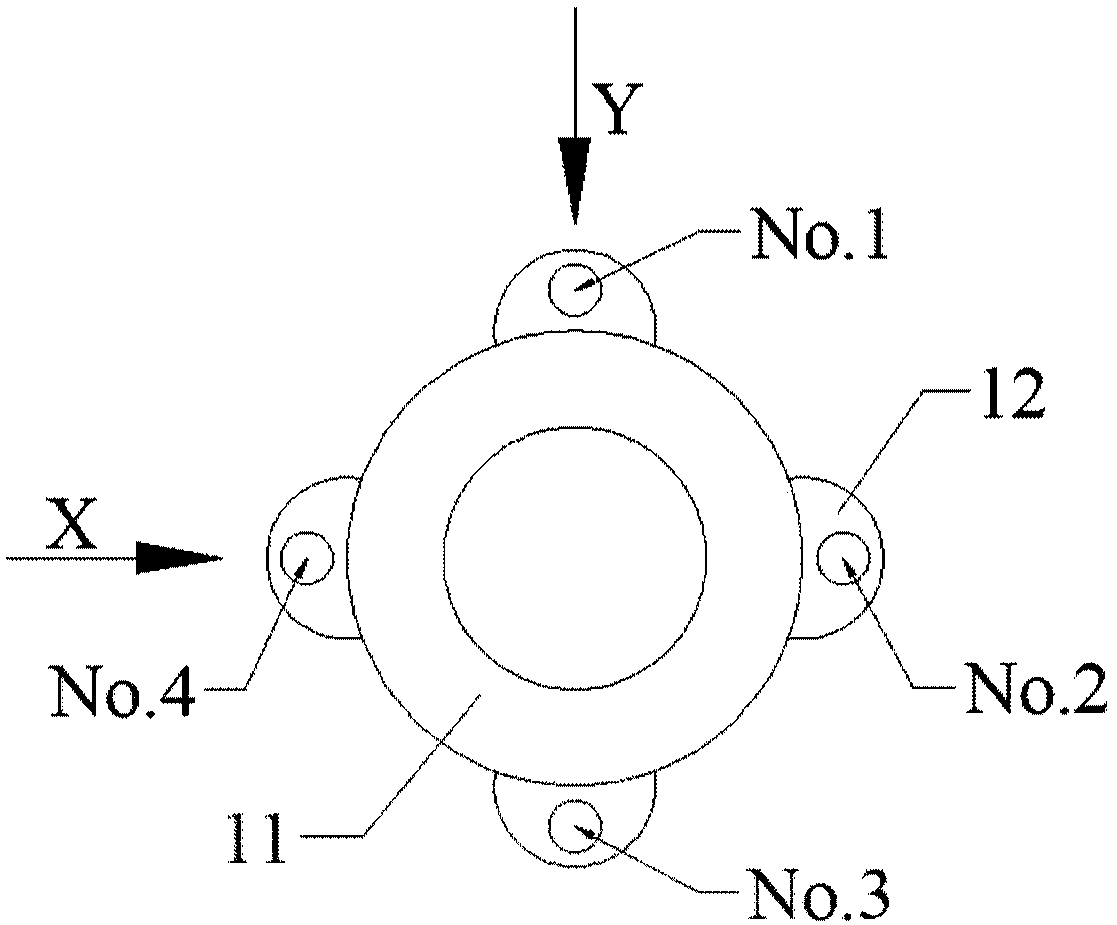

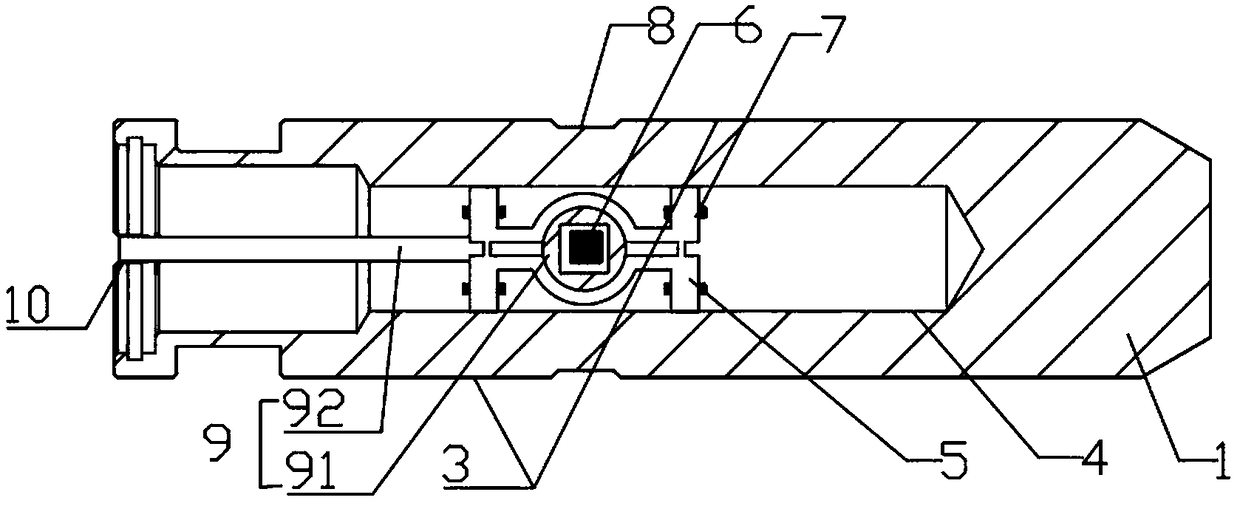

Vascular interventional catheter and device, and contact force detection method and detection device

ActiveCN108066881AContact force monitoringImprove securityMedical devicesCatheterContact forceCatheter

The invention provides a vascular interventional catheter and device, and a contact force detection method and detection device. The vascular interventional catheter includes a phase change material catheter, wherein the stiffness of the phase change material catheter changes according to a temperature change. The vascular interventional catheter includes a stress induction section and a stiffnessadjustment section, wherein the stress induction section is arranged at the top end of the phase change material catheter and intervenes into the blood vessel to acquire the contact force between thephase change material catheter and the blood vessel wall; and the stiffness adjustment section is connected with the stress induction section and used for adjusting the stiffness of the phase changematerial catheter. According to the vascular interventional catheter and device, and the contact force detection method and detection device, by arrangement of the stress induction section, the monitoring of the blood vessel wall contact force can be achieved, the stiffness of the vascular interventional catheter can be adjusted by arrangement of the stiffness adjustment section, and thus the safety in the intervention process is improved.

Owner:TIANJIN UNIV

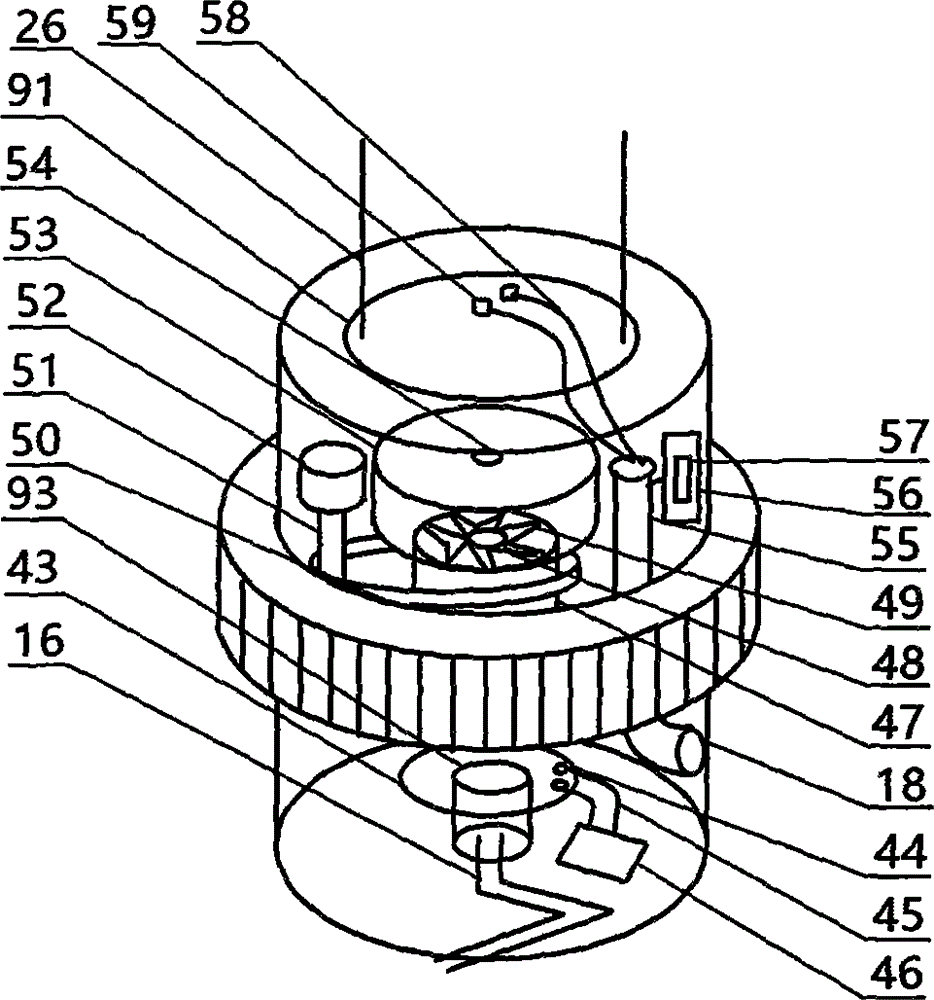

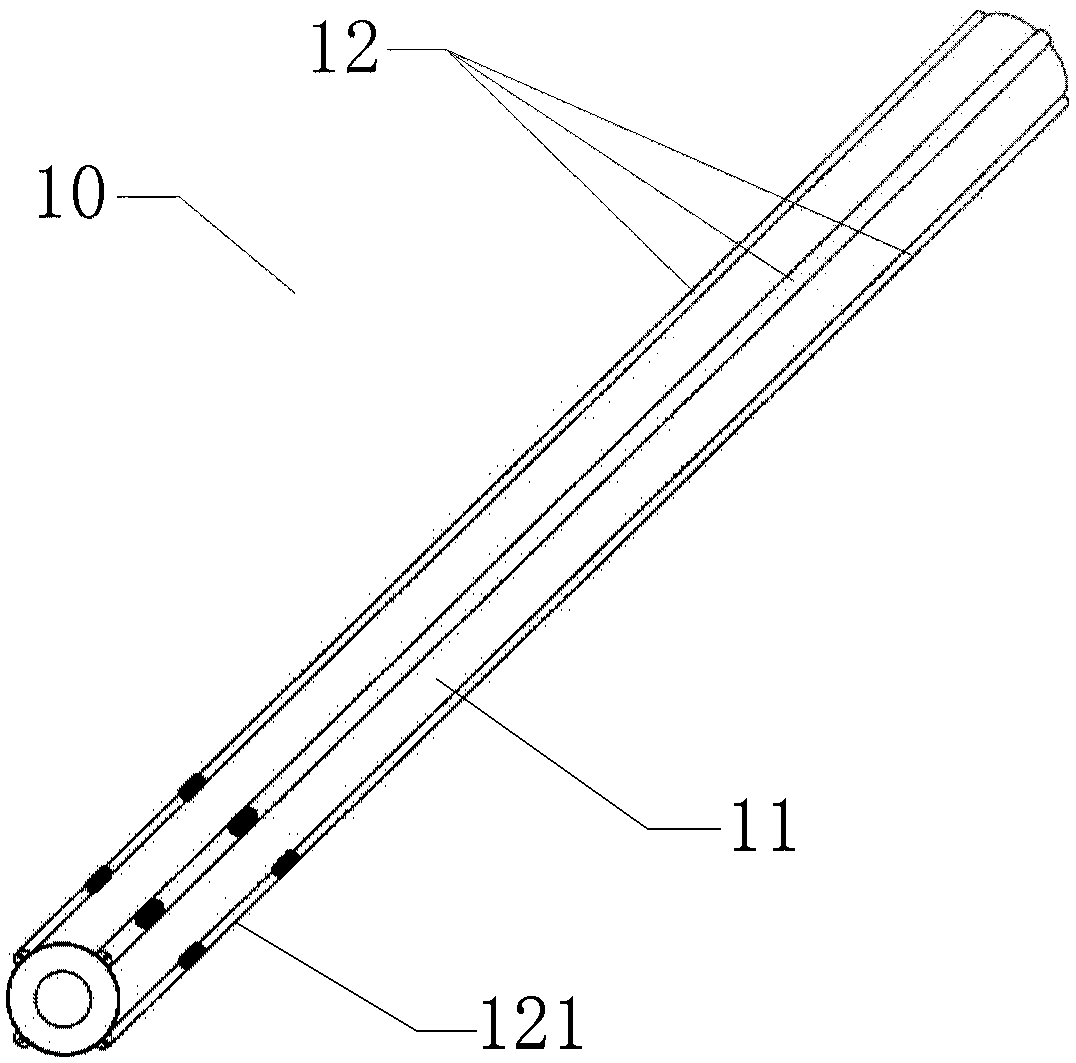

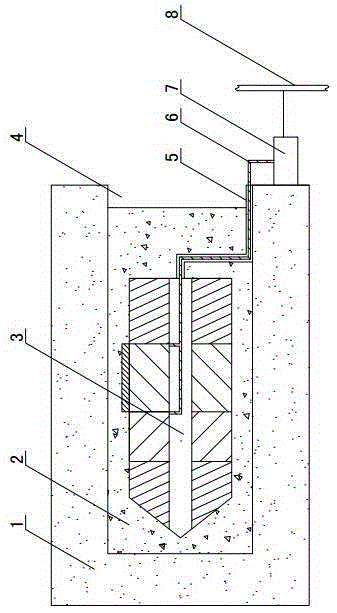

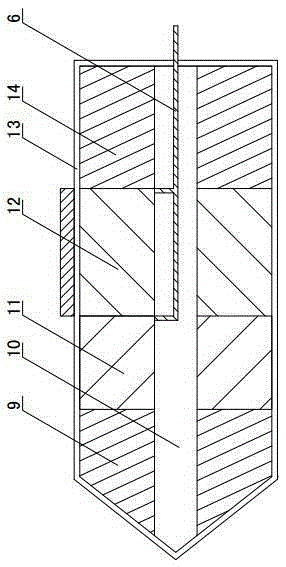

Spatial pre-embedded type three-dimensional stress monitoring system and method for underground coal and rock mass

InactiveCN105352635AImprove securityAccurate judgmentForce measurement using piezo-electric devicesMonitoring systemOutput device

The invention provides a spatial pre-embedded type three-dimensional stress monitoring system and method for underground coal and rock mass and belongs to the technical field of coal and rock mass safety. The system is characterized by comprising an inductive output device (3) fixed in the coal and rock mass (1), the inductive output device (3) at least comprises a stress induction module (12), a stress detection unit for detecting three-dimensional stress of the coal and rock mass (1) is arranged in the stress induction module (12), and output signals of the stress detection unit are led out by a signal line (6). The method comprises a stress monitoring process and a temperature compensation process performed before the stress monitoring process. According to the spatial pre-embedded type three-dimensional stress monitoring system for the underground coal and rock mass, the stress in three directions of the coal and rock mass can be detected, the pressure coming direction and the size of the stress of the coal and rock mass are judged more accurately, and accordingly, the safety of underground construction is improved.

Owner:CHINA UNIV OF MINING & TECH

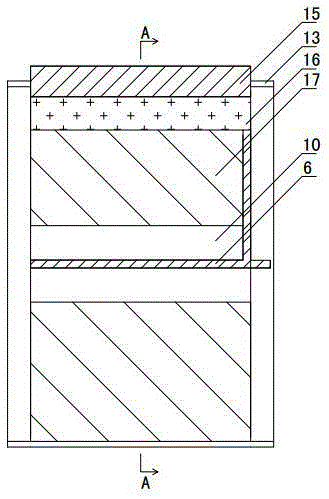

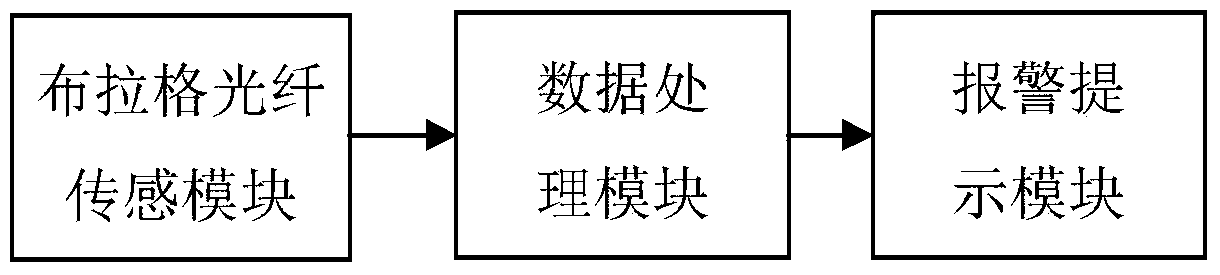

Underground pipeline safety monitoring device based on stress induction technology

InactiveCN103900743AAvoid catastrophic accidentsRealize monitoringForce measurement by measuring optical property variationFiberStress conditions

An underground pipeline safety monitoring device based on the stress induction technology comprises a Bragg fiber sensing module, a data processing module and an alarm prompting module. The data output end of the Bragg fiber sensing module is connected with the data input end of the data processing module, and the data output end of the data processing module is connected with the data input end of the alarm prompting module. According to the underground pipeline safety monitoring device, Bragg fibers and gratings are applied, the stress condition of a pipeline is judged through remote stress induction, the stress condition of the pipeline is monitored in real time, and therefore when the stress exceeds the limiting value, the device can give an alarm in time, and the disastrous accidents are avoided.

Owner:TIANJIN SIBOKE TECH DEV

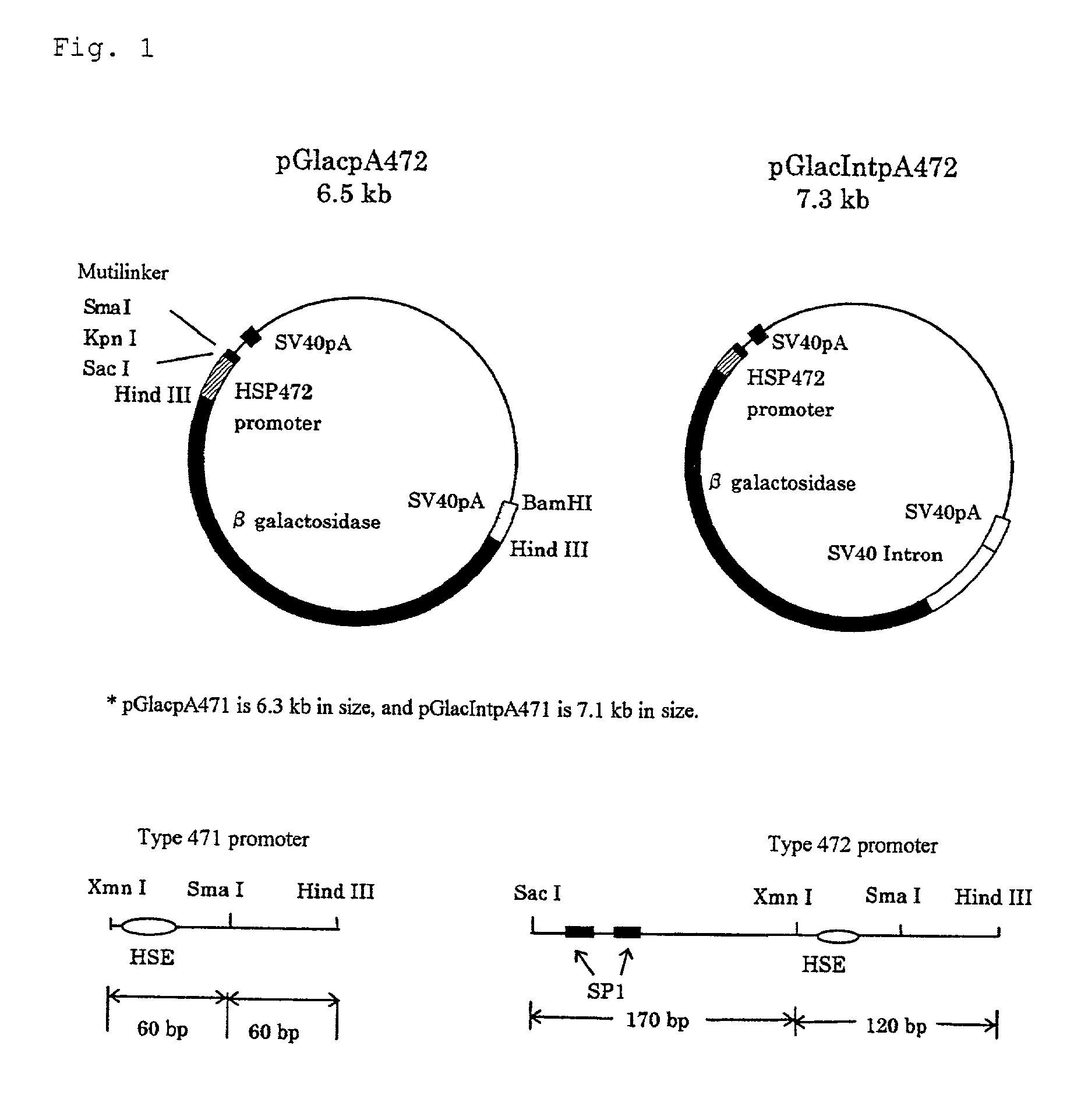

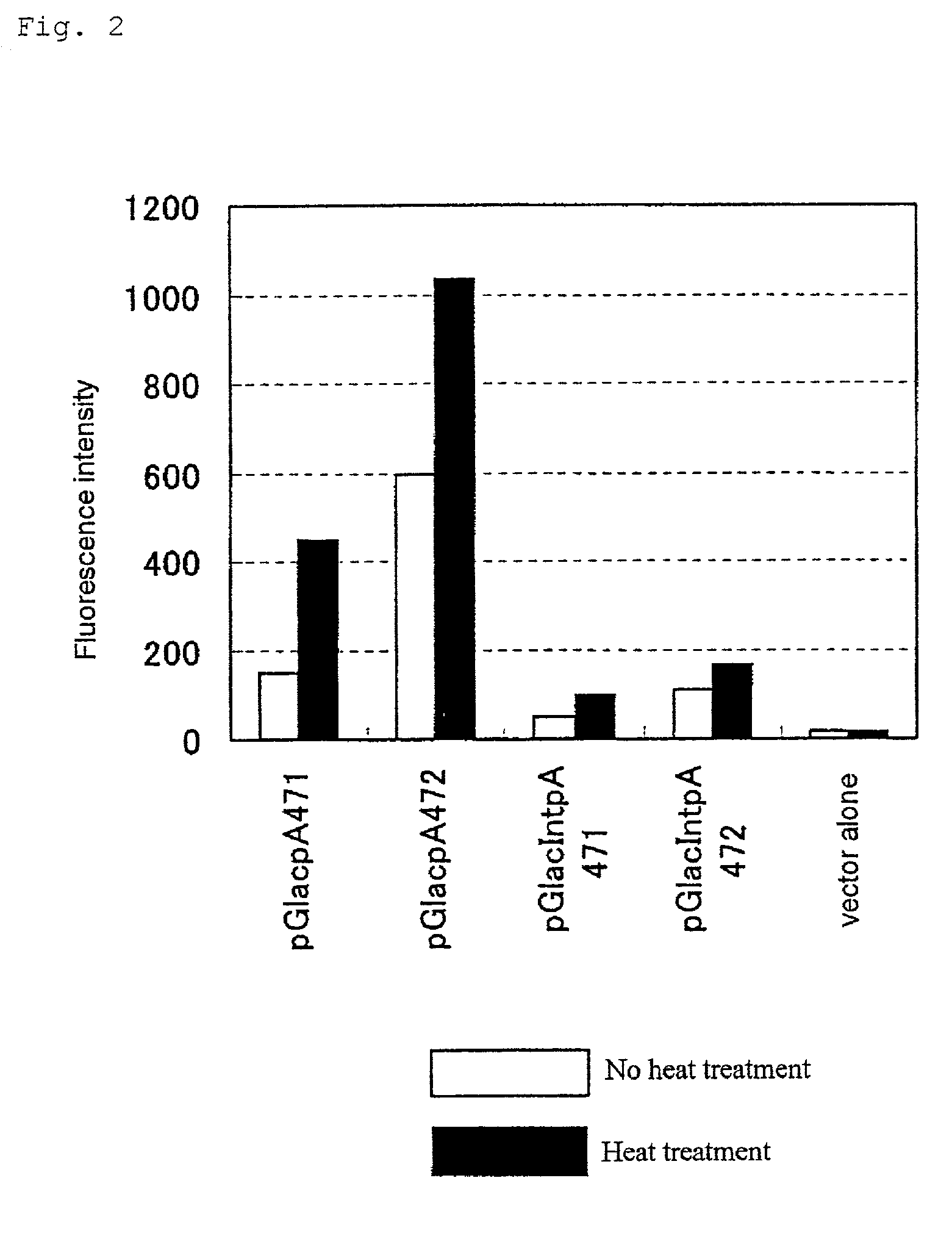

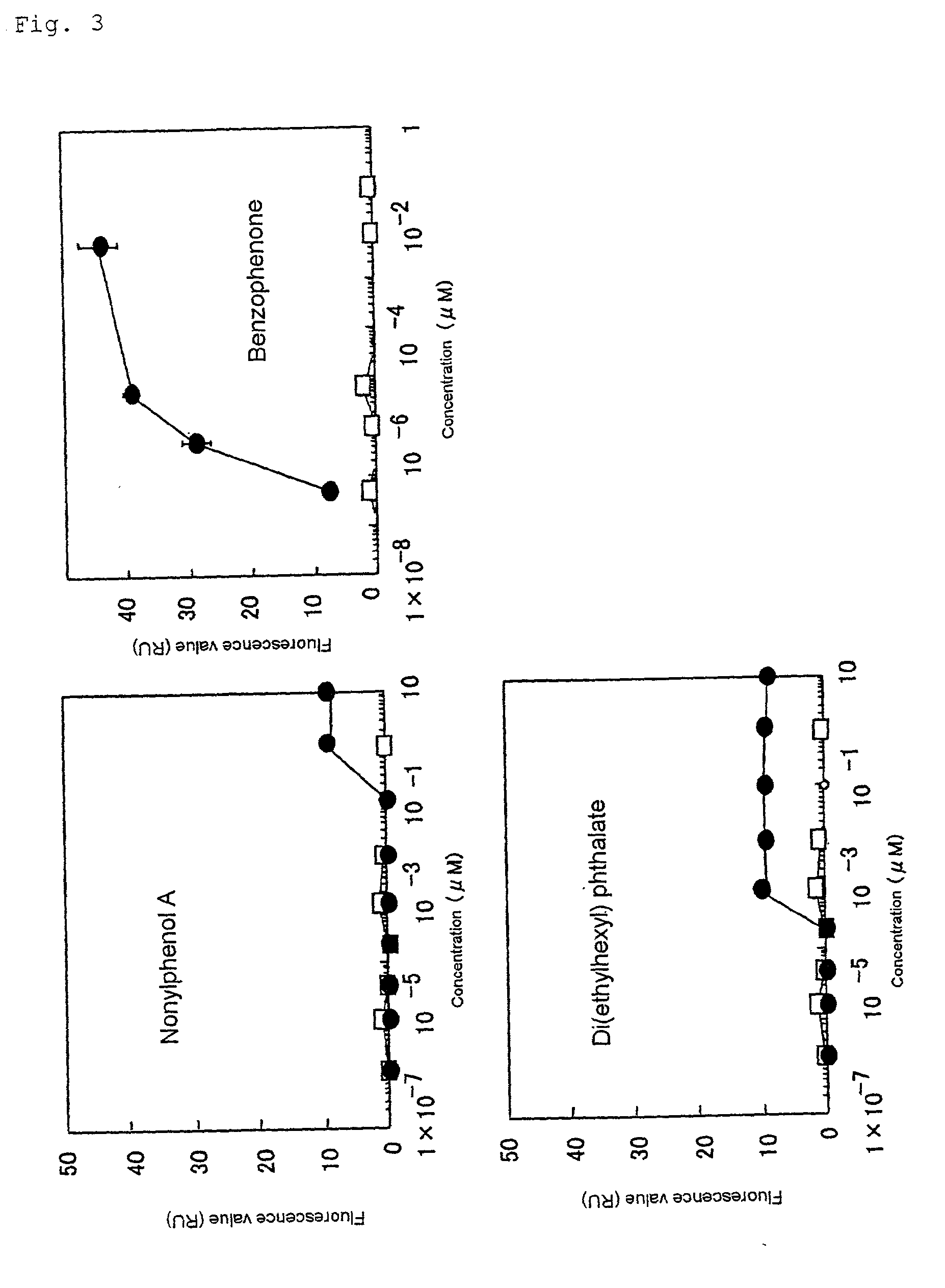

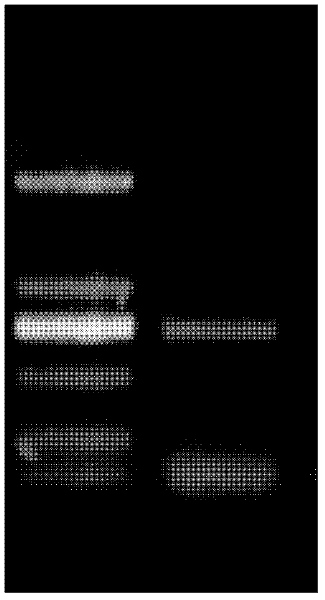

High-sensitive detection of environmental pollutants

The present invention is aimed to provide a bioassay system that can detect hazardous chemical substances or natural toxic substances in the environment, inclusive of the unknown homologs, with high sensitivity, simplicity and speed. The present invention is a method for detecting a hazardous chemical substance or a natural toxic substance, which comprises culturing a cell in a test sample-containing medium and then measuring a reporter gene protein inducing activity. Said cell is obtained by transferring a promoter containing a heat shock factor binding DNA sequence and a transcriptional regulatory sequence necessary on an occasion of stress induction as a transcriptional regulatory factor binding site, as well as a reporter gene under the control of said promoter into a chromosome, said reporter gene being connected, on the downstream side thereof, to the SV40pA signal without any intervening intron.

Owner:NAT INST OF ADVANCED IND SCI & TECHNOLGOY AIST ADMINISTATIVE INSTION IAI UNDER MINIST OF ECONOMY TRADE & IND +1

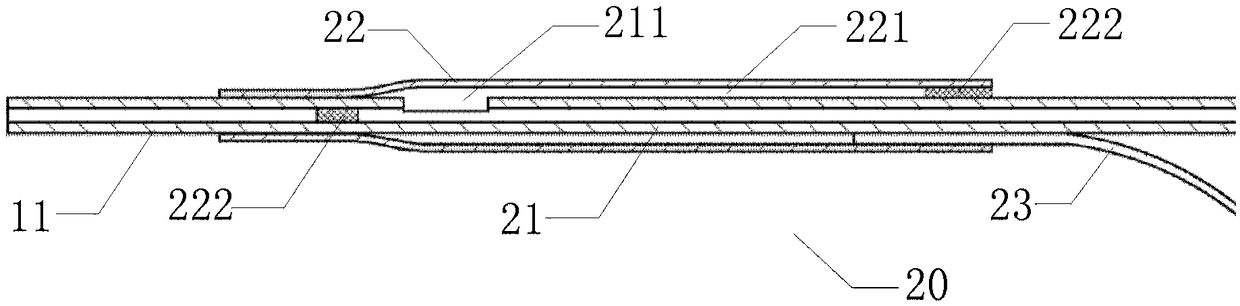

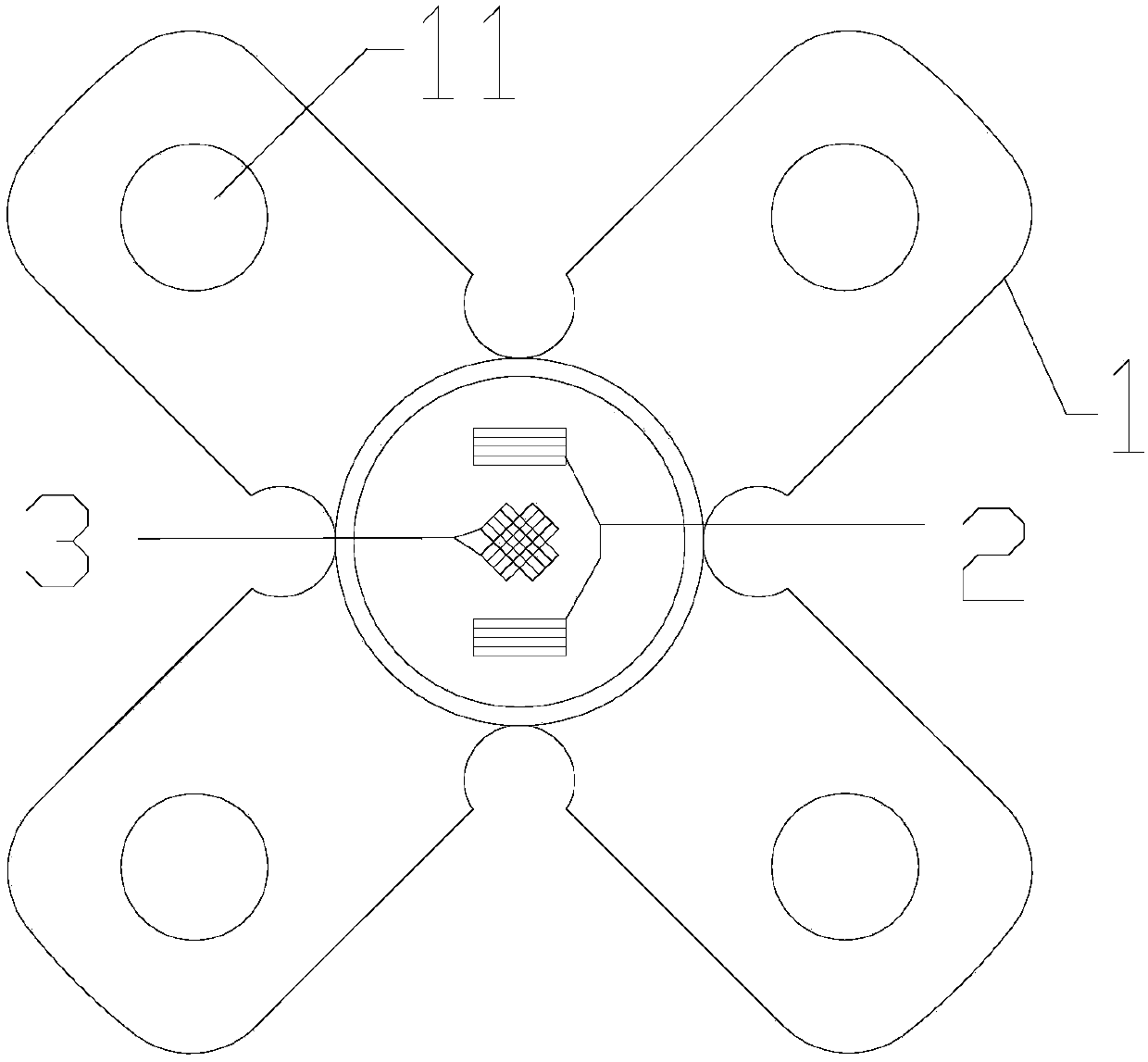

Method for achieving tractor shearing stress sensing by using magnetic induction

InactiveCN108645555APrecise Sensing ResistancePrecise and sensitive controlForce measurement by measuring magnetic property varationApparatus for force/torque/work measurementShear stressMagnetic poles

The invention discloses a method for achieving tractor shearing stress sensing by using magnetic induction. The method comprises the following steps that (1) an excitation magnetic core is arranged sothat a magnetic induction line of the excitation magnetic core is fixedly perpendicular to a paper surface and diverges outwards; (2) the left and right edges of the excitation magnetic core are respectively provided with a first induction magnetic core,a second induction magnetic core,a third induction magnetic core and a fourth induction magnetic core of which the induction surfaces are parallel to a paper surface so that an included angle between the longitudinal profile where the a magnetic pole of the excitation magnetic core is located and the longitudinal profile where magnetic poles of the induction magnetic cores are located is 90 degrees; (3) induction coils with the same number of turns wind the first induction magnetic core,the second induction magnetic core,the third induction magnetic core and the fourth induction magnetic core respectively; and (4) the first induction magnetic core,the second induction magnetic core,the third induction magnetic core,the fourth inductionmagnetic core and the excitation magnetic core are placed on a shearing stress induction area so that the side surfaces of the first induction magnetic core,second induction magnetic core,third induction magnetic core and fourth induction magnetic core can receive induction forces. The method for achieving the tractor shearing stress sensing by using the magnetic induction has the advantages thatthe shearing stress detection during the tractor operation can be can precisely achieved so that the resistance suffered by the tractor can be precisely induced.

Owner:SOUTHWEST UNIVERSITY

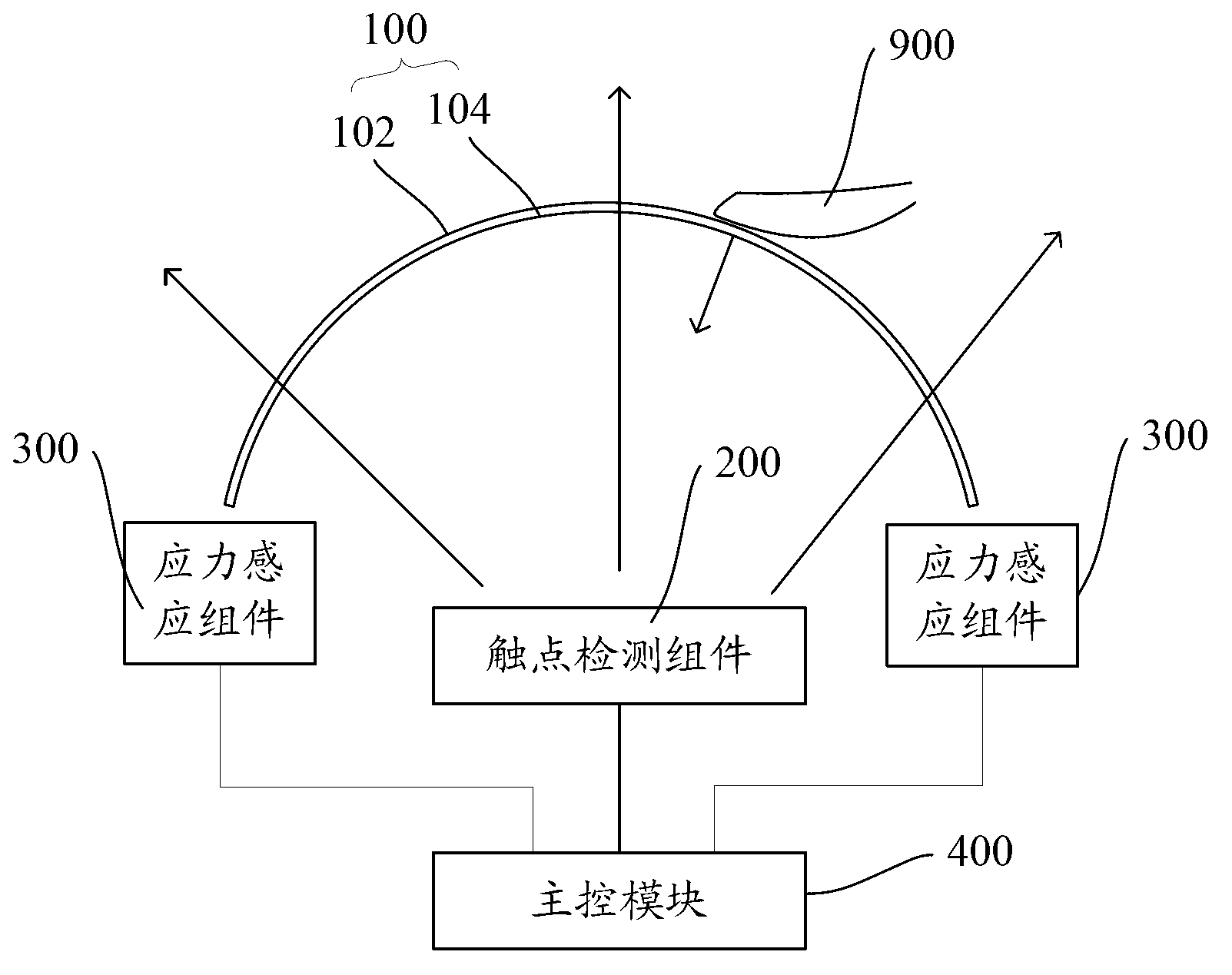

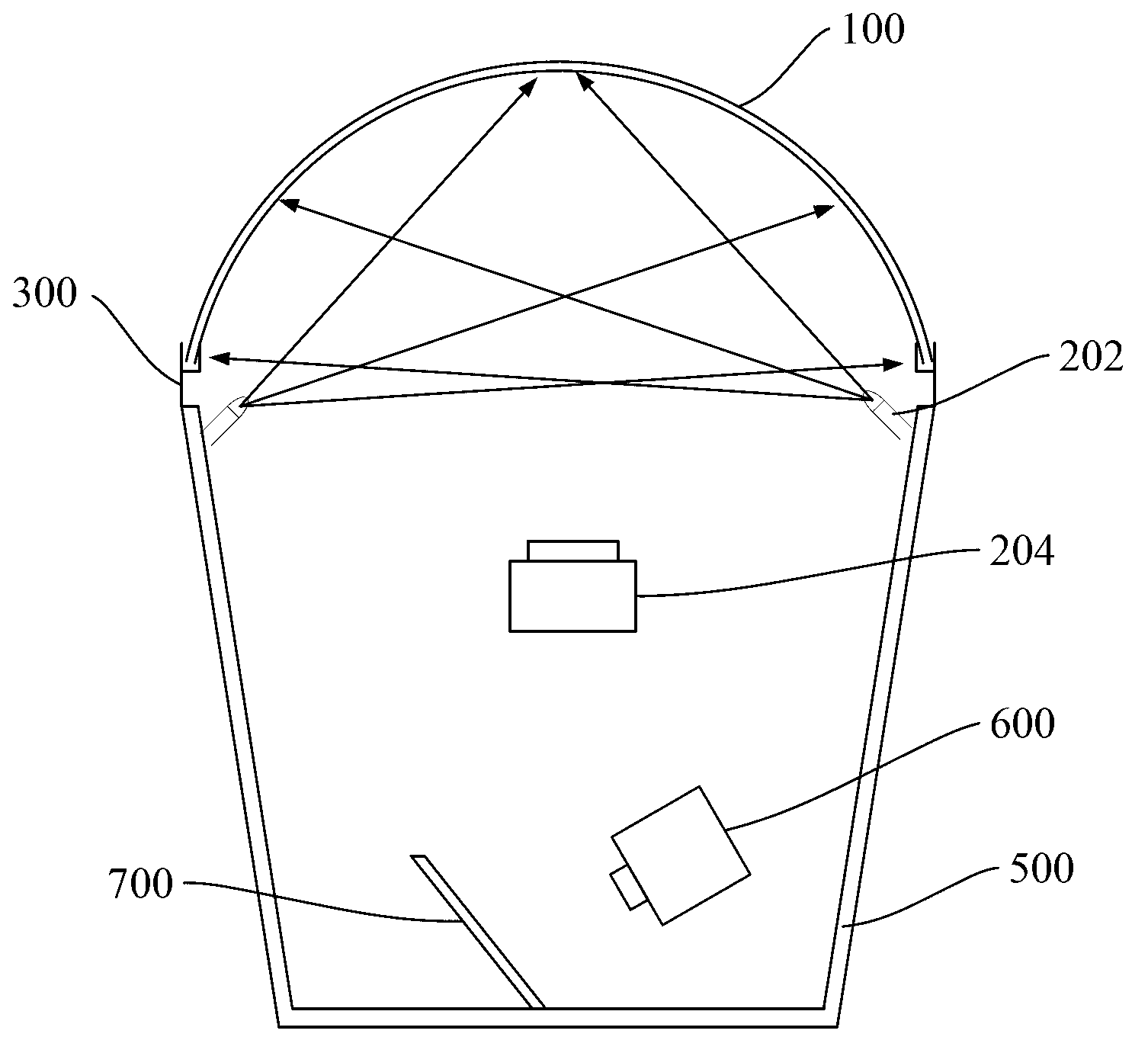

Touch control device and touch control detection method based on curved face display

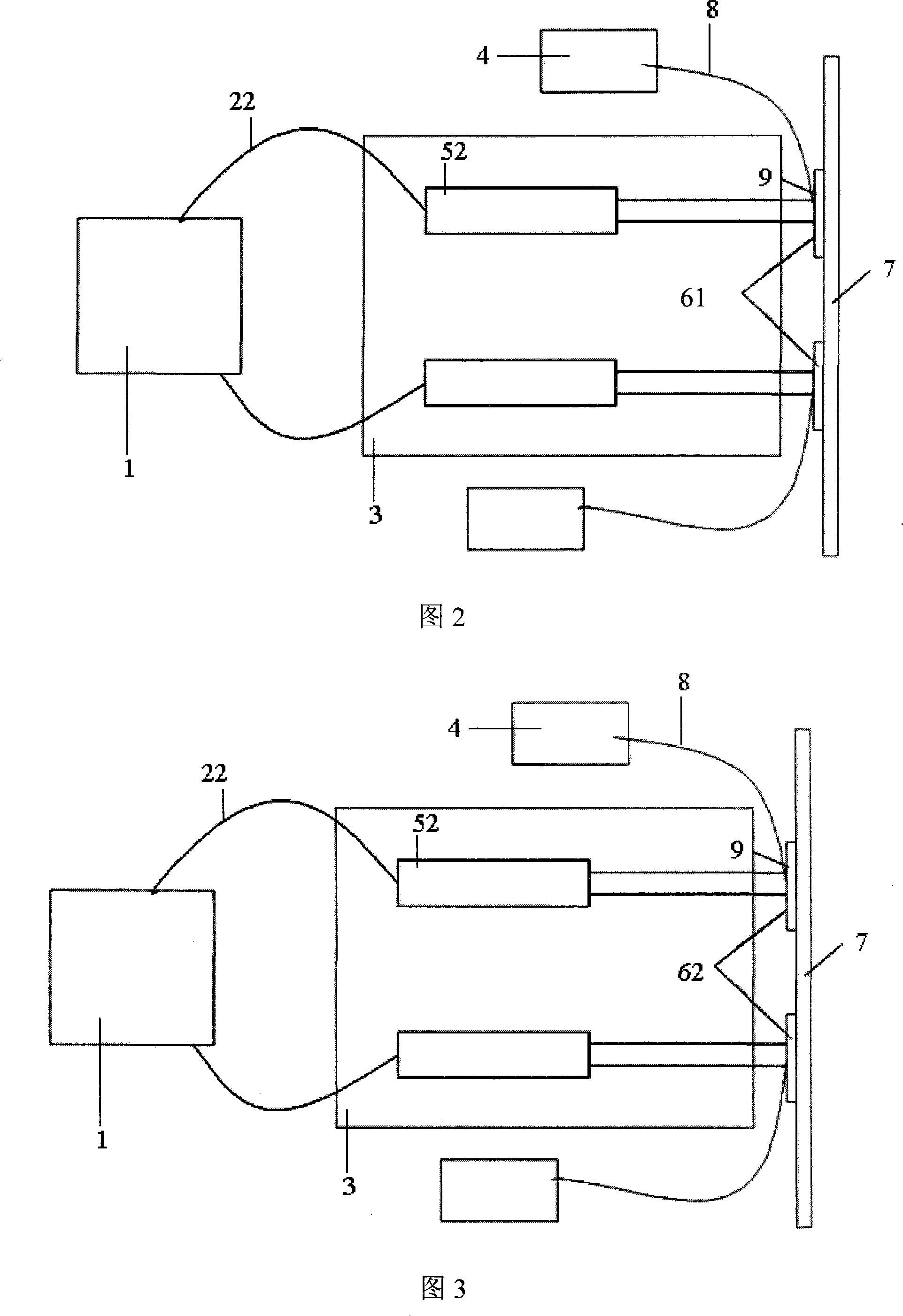

ActiveCN103019478AEnsure full implementationAvoid misuseInput/output processes for data processingProjection screenStress induction

The invention discloses a touch control device based on curved face display. The touch control device based on the curved face display comprises a curved face type projection screen, a touch spot detection component, stress induction components and a main control module, wherein the curved face type projection screen is provided with an outward bulgy touch control face and a projection face opposite to the touch control face; the touch spot detection component is located on one side of the projection face and detects touch spot position data by emitting infrared light to the curved face type projection screen and further receiving the infrared light reflected by a touch object on one side of the touch control face; each stress induction component is used for generating stress data by the time the curved face type projection screen is touched; and the main control module obtains the touch spot position data and the stress data and judges whether the touch control occurs or not. The invention also discloses a touch control detection method applied to the device. With the adoption of the device and the method, the execution of a touch control instruction in the actual occurrence of touch control is guaranteed, so that a contactless type misoperation is prevented.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Cluster magnetorheological polishing pad performance test device and method

ActiveCN104191369AAccurate measurementQuick testGrinding feed controlInvestigating material hardnessPositive pressureEngineering

The invention discloses a cluster magnetorheological polishing pad performance test device and method. The test device comprises a CNC machine tool spindle, a piezoelectric sensor, a point gauge, a polishing disk, a magnetic body and a cluster magnetorheological polishing pad, wherein the point gauge is installed on the micro piezoelectric sensor, the piezoelectric sensor is installed on the CNC machine tool spindle, the stress induction face of the piezoelectric sensor is perpendicular to the direction of force measured by the polishing disk, a magnetic field generator is embedded in the polishing disk, magnetorheological polishing working solution is sprayed onto the polishing face of the polishing disk, and the output end of the piezoelectric sensor is connected with a computer through an A / D converter. Due to the test device and method, positive pressure and shearing force of the cluster magnetorheological polishing pad on the point gauge can be accurately measured, the relative positions of the point gauge and the polishing disk are controlled through a CNC system, rotating speed of the polishing disk is adjusted, distribution of polishing force of the cluster magnetorheological polishing pad at different positions and under different states can be measured, changes of the positive pressure and the shearing force in the radial direction and the normal direction are obtained, and performance of the cluster magnetorheological polishing pad can be detected quantitatively.

Owner:GUANGDONG UNIV OF TECH

Transcription factor ERF related to soybean stress, coding gene thereof and application of coding gene

InactiveCN102336826AImprove drought resistancePlant peptidesGenetic engineeringAgricultural scienceNucleotide

The invention relates to a transcription factor ERF related to soybean stress, a coding gene thereof, and application of the coding gene, and belongs to the field of plant gene engineering. The amino acid sequence of the transcription factor ERF related to soybean stress is shown as a Sequence No.2, and the nucleotide sequence of the coding gene of the transcription factor is shown as a Sequence No.1. A soybean GmERF6 transcription factor gene related to stress induction is cloned, the expression mode and transcription regulator activity of the gene are researched, the drought resistance of wild arabidopsis is compared with that of a GmERF6 gene-transformed arabidopsis, a basis is provided for effectively applying the GmERF6 gene, and the GmERF6 gene has important significance for improving the stress resistance of plants, particularly breeding drought-resistant soybean varieties.

Owner:JILIN UNIV

Polyolefin material melted extrusion functionalization stress induction method

The invention relates to a new technology for functionalization reaction by fusing ANF squeezing polyolefin material, belonging to field of modifying polymer material. It comprises following steps: dissolving ethylene monomer into solvent and mixing it with polyolefin material, stewing, adding lubricant after solvent volatilization, filling them into parallel spin reverse-flighted screw extrusion machine with high rotation speed and high cutting, the squeezing temperature is between 160 to 350 Deg. C, the rotation speed of main bolt is between 350 to 1200 rmp, cooling, grain cutting and drying and getting final product. The method can inhibit or avoid cross bonding secondary reaction during functionalization reaction, increase grafting rate for function product and flux flowing speed, and is characterized by simple, high effective and easiness for industrialization.

Owner:NANJING UNIV OF TECH

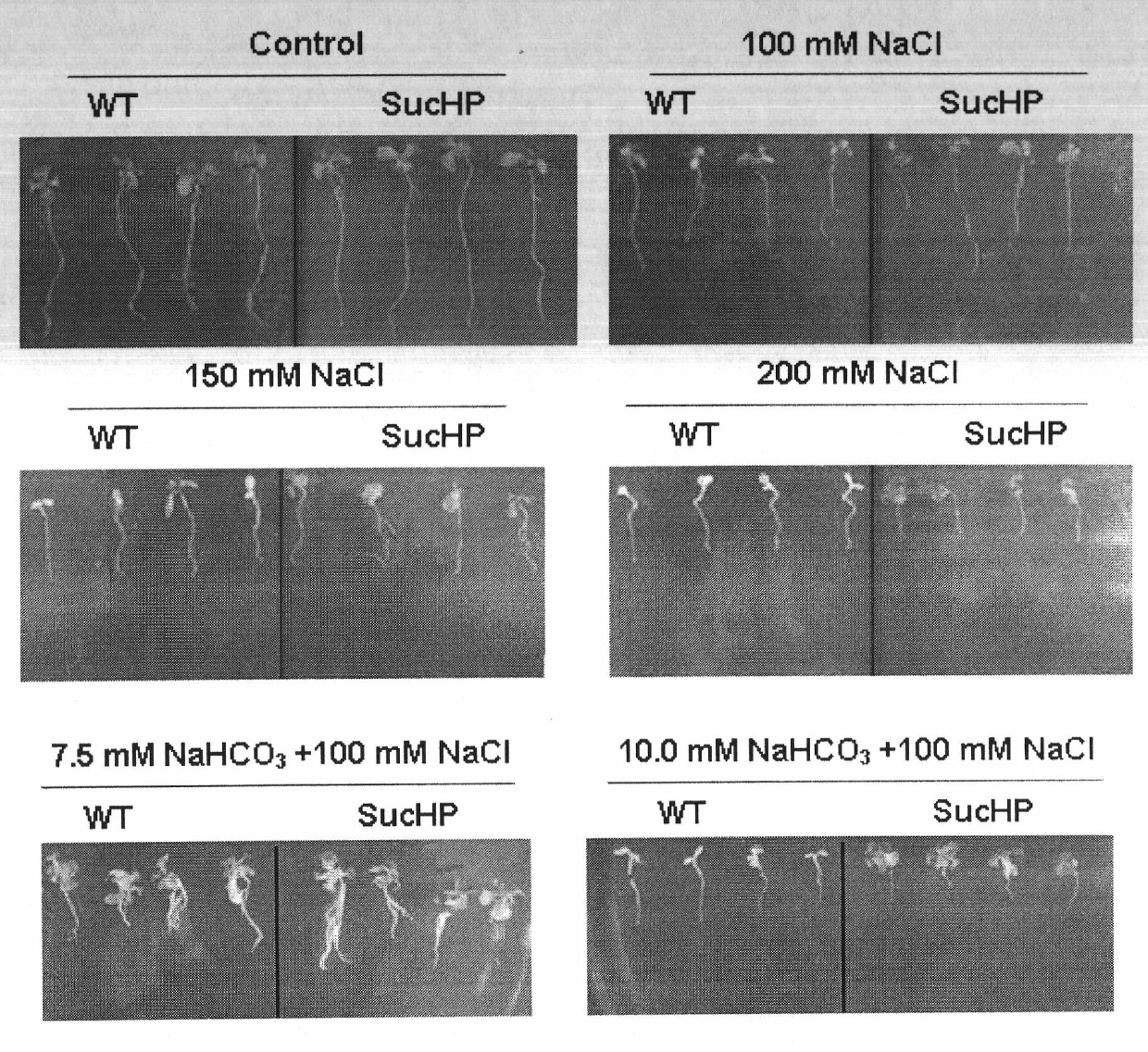

Plant high-pH saline-alkaline tolerance gene SucHP and application thereof

InactiveCN102002505AImprove salt and alkali resistanceHigh resistance to high pH saline alkaliPlant peptidesFermentationHigh densityNormal growth

The invention discloses a plant high-pH saline-alkaline tolerance gene SucHP and researches the expression of a high-pH saline and alkaline stress induction gene in a common seepweed herb seedling period by using suppression subtractive hybridization and high-density lattice film technology. The plant high-pH saline-alkaline tolerance gene SucHP can be prepared by the following steps of: firstly separating a gene of a coding tonoplast proton pump from common seepweed herbs; constructing a sense expression vector of the gene; and converting Arabidopsis. A transgenic plant has high high-pH saline-alkaline tolerance and can normally grow under the conditions of 100mM NaHCO3+200mM NaCl and 8.5 of pH. The plant high-pH saline-alkaline tolerance gene SucHP can be used for plant genetic transformation and increases plant saline and alkaline resistance.

Owner:JILIN AGRICULTURAL UNIV

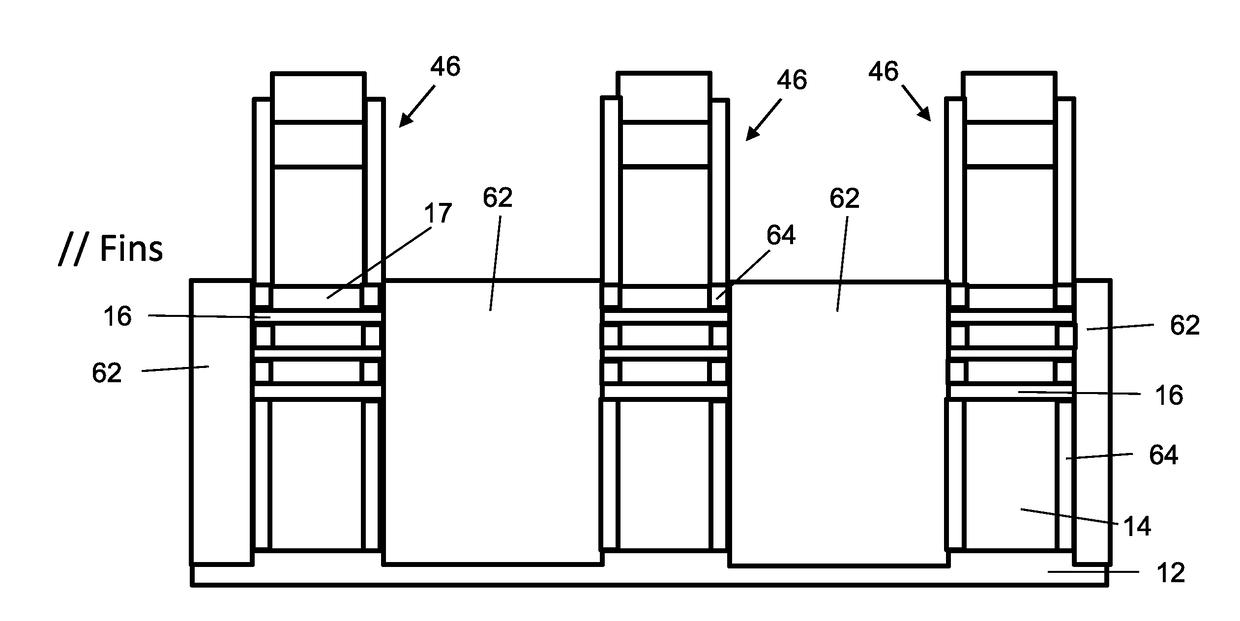

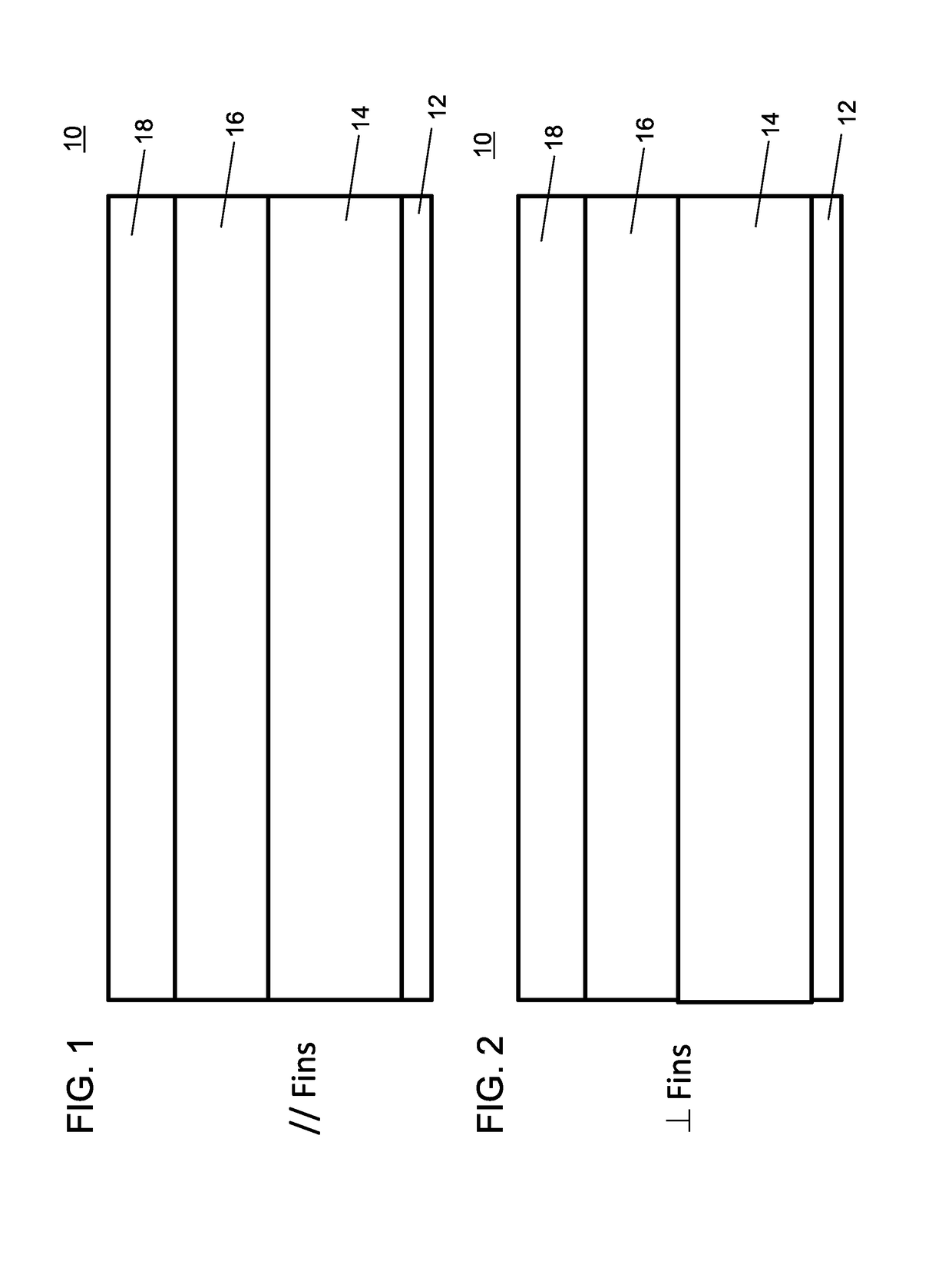

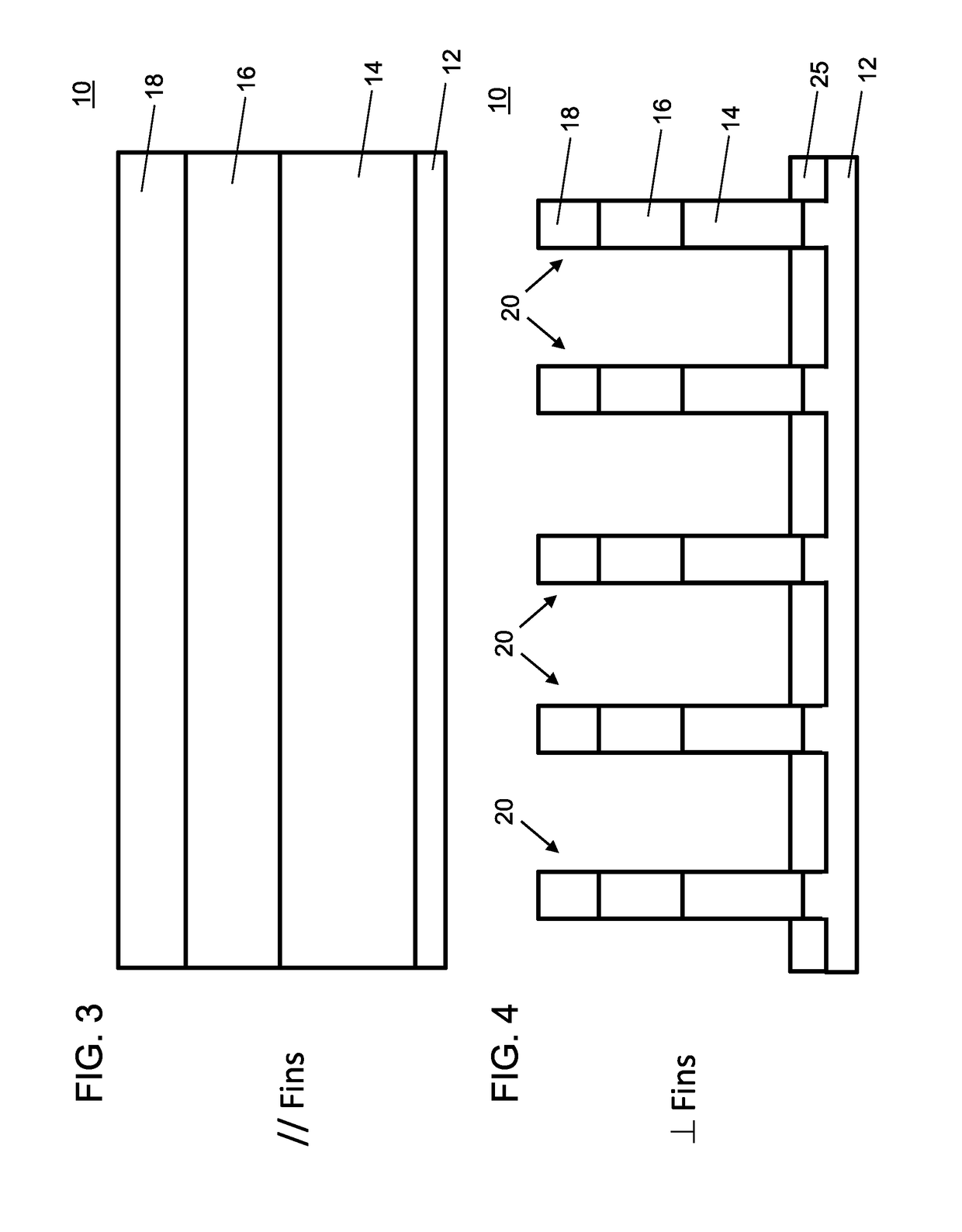

Stress induction in 3D device channel using elastic relaxation of high stress material

ActiveUS20180197992A1NanoinformaticsSemiconductor/solid-state device manufacturingStress inductionHigh stress

A method for inducing stress in a device channel includes forming a stress adjustment layer on a substrate, the stress adjustment layer including an as deposited stress due to crystal lattice differences with the substrate. A device channel layer is formed on the stress adjustment layer. Cuts are etched through the device channel layer and the stress adjustment layer to release the stress adjustment layer to induce stress in the device channel layer. Source / drain regions are formed adjacent to the device channel layer.

Owner:IBM CORP

Chlorella-based metallothionein preparation method

InactiveCN104480173AReduce manufacturing costPromote growthMicroorganism based processesAnimal feeding stuffAlcoholMicrofiltration membrane

The invention provides a chlorella-based metallothionein preparation method. The method comprises the steps: respectively feeding zinc and copper ions to a chlorella reactor for culturing; concentrating through a microfiltration membrane; breaking the wall of chlorella at the normal pressure; extracting chlorophyll; and extracting metallothionein. According to the preparation method, algae can be used as the source of metallothionein, so that the production cost of metallothionein is obviously decreased; metallothionein extracted through the chlorella has outstanding advantages, can grow fast, and is high in accumulation and easily processed; dry chlorella powder with metallothionein extracted out can be used for preparing a feed of the animal husbandry; chlorophyll in the chlorella is extracted through ethyl alcohol, so that the influence of chlorophyll on extraction and separation of metallothionein can be reduced, and the quality of metallothionein can be improved; and then zinc and copper are utilized for alternative stress induction for preparing metallothionein; and therefore, the productive rate of the obtained metallothionein is up to 10g / 250kg, and the high-purity metallothionein can be obtained after purifying.

Owner:TIANKE HUIYANG TECH DEV TIANJIN CO LTD

Preparing device and method of directional carbon nano tube reinforced metal matrix composite material

The invention discloses a preparing device and method of directional carbon nano tube reinforced metal matrix composite material. The preparing device and method are used for solving the problem that an existing preparing device prepares the directional carbon nano tube reinforced metal matrix composite material difficultly. According to the technical scheme, the bottom of a crucible is provided with an electromagnetic stirrer, an opening of the crucible is provided with an ultrasonic amplitude rod, the crucible is communicated with a gas pressure tank through a gas conveying pipe provided with a reducing valve, and is communicated with a female die barrel through a liquid conveying pipe, an exhaust pipe provided with a valve is used for exhausting gas, the crucible and the female die barrel are placed in a first resistance furnace and a second resistance furnace to be heated, a coil is placed outside the second resistance furnace of the female die barrel, the upper portion of the female die barrel is sealed through a male die and an upper cushion block, and the lower portion of the female die barrel is sealed through a forming die and a lower cushion block. According to the preparing device and method, even dispersion of carbon nano tubes in metal liquid is achieved through an electromagnetic field and ultrasonic coupling, then the directional carbon nano tube reinforced metal matrix composite material is formed by means of the coupling function of magnetic filed induction and stress induction.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

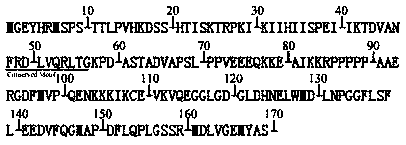

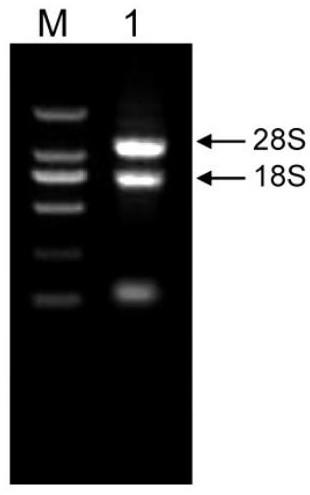

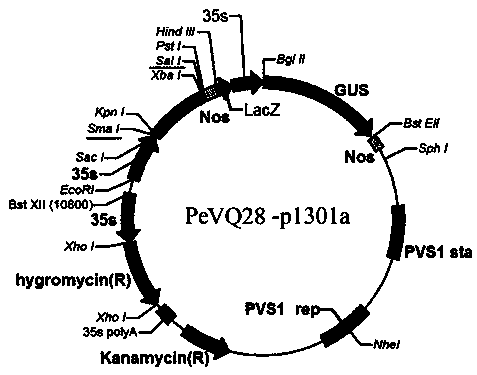

Phyllostachys heterocycle PeVQ28 protein and coding gene and application thereof

ActiveCN109081865AImprove salt resistanceAdaptableBacteriaPlant peptidesAgricultural scienceWild type

The invention discloses Phyllostachys heterocycle PeVQ28 protein and a coding gene and application thereof. The amino acid sequence of the protein is as shown in SEQ ID No. 1, coding DNA sequence (CDS) is as shown in SEQ ID No. 2, and the cDNA sequence overall length of the Phyllostachys heterocycle PeVQ28 gene is as shown in SEQ ID No. 3. The PeVQ28 gene has high expression under different-degreesalt stress induction. The fact that the salt resistance of transgenic wild arabidopsis obtained by using a agrobacterium tumefaciens mediated inflorescence impregnating method to transfer a PeVQ28 gene expression vector into wild Arabidopsis is evidently increased shows that the PeVQ28 gene can increase the salt resistance of the transgenic Arabidopsis. A plant material obtained by using the Phyllostachys heterocycle PeVQ28 gene expression vector has certain adaptability to an external salt stress environment, and promising application prospect is achieved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

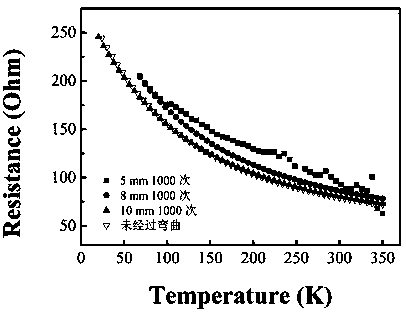

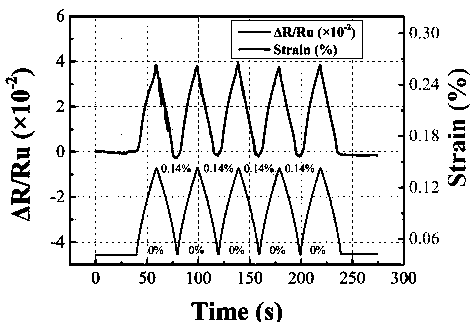

Electronic skin and preparation method and application thereof

The invention discloses an electronic skin and a preparation method thereof. The electronic skin includes a mica substrate, a 50% Nb-doped BaTiO3 semiconductor thin film layer covering the mica substrate, and a platinum electrode covering the semiconductor thin film layer, the thickness of the mica substrate is 0.02-20 [mu]m, the thickness of the semiconductor thin film layer is 5-200 nm, and thethickness of the metal electrode is 5-200 nm. The electronic skin can sense temperature, stress, deformation and light, has the advantages of flexible, low weight, low thickness, low power consumption, highly sensitive stress induction, low-temperature and organic solvent resistance and the like, and further has the characteristics of good low-temperature and flexural fatigue resistance; and the preparation process of electronic skin is simple, a mature coating process can be compatible with a semiconductor process, photoetching and ion etching can be realized, thus the efficiency is higher, device miniaturization and integration are more convenient, and industrialized promotion is easy.

Owner:INT ACAD OF OPTOELECTRONICS AT ZHAOQING SOUTH CHINA NORMAL UNIV

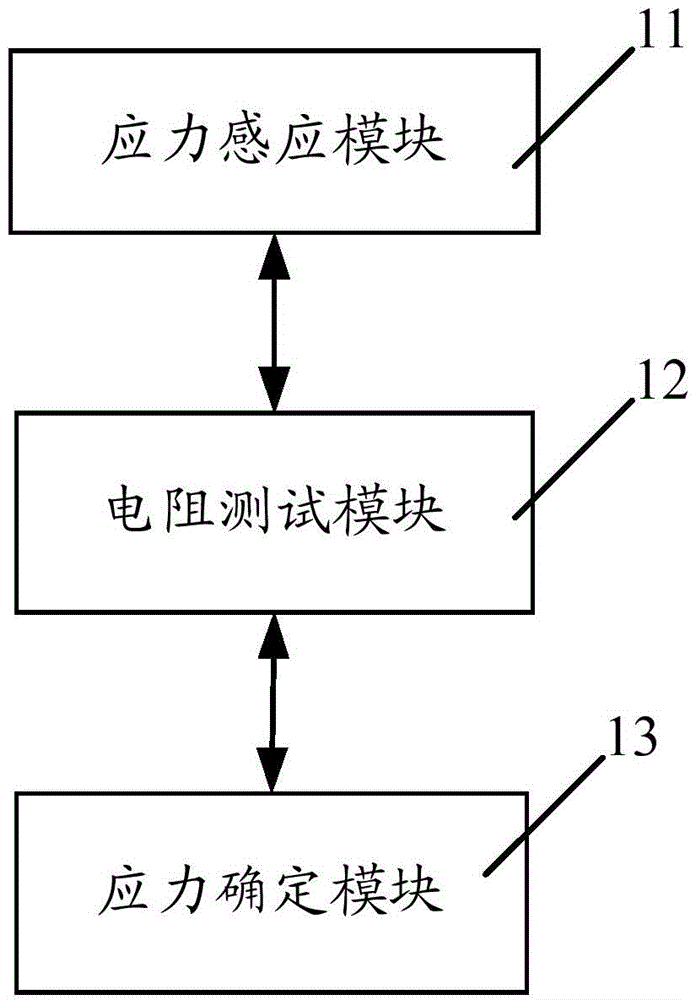

Stress testing apparatus and lingual orthodontic force measuring apparatus

InactiveCN104000667ACorrective force monitoringGood choiceOthrodonticsElectrical resistance and conductanceArch wires

The invention discloses a stress testing apparatus and a lingual orthodontic force measuring apparatus. The stress testing apparatus comprises: a stress induction module having a plurality of resistor modules; a resistance testing module connected with the stress induction module, and used for acquiring the electrical signals of the plurality of resistor modules and measuring the resistance of each of the resistor modules; and a stress determination module connected with the resistance testing modules and used for determining corresponding stress according to the resistance. The lingual orthodontic force measuring apparatus comprises a lingual orthodontic bracket, an orthodontic arch wire and the stress testing apparatus, wherein the lingual orthodontic bracket is bonded to the lingual side of teeth and is fixed to the orthodontic arch wire, and the stress induction module of the stress testing apparatus is bonded to the labial side of the teeth. The stress testing apparatus and the lingual orthodontic force measuring apparatus realize the real-time accurate monitoring of the orthodontic force of a lingual side appliance, and provides a reliable basis for the improvement of the scheme of tooth treatment, the selection of the orthodontic arch wire with excellent performances and the improvement of the efficiency of a lingual orthodontic technique.

Owner:BEIJING STOMATOLOGY HOSPITAL CAPITAL MEDICAL UNIV

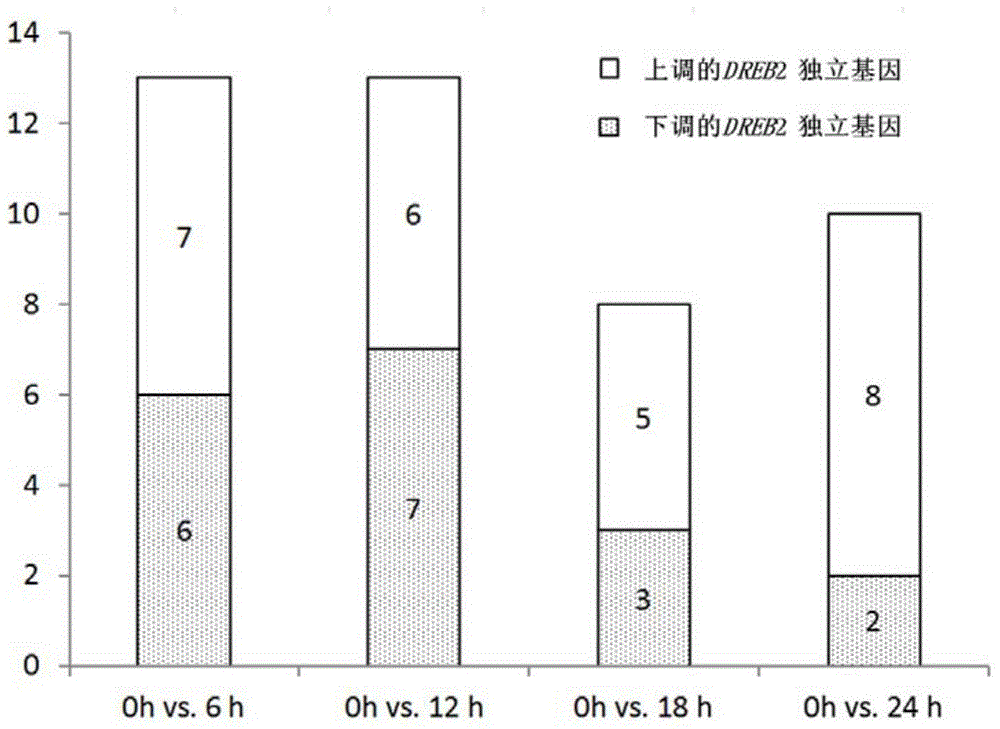

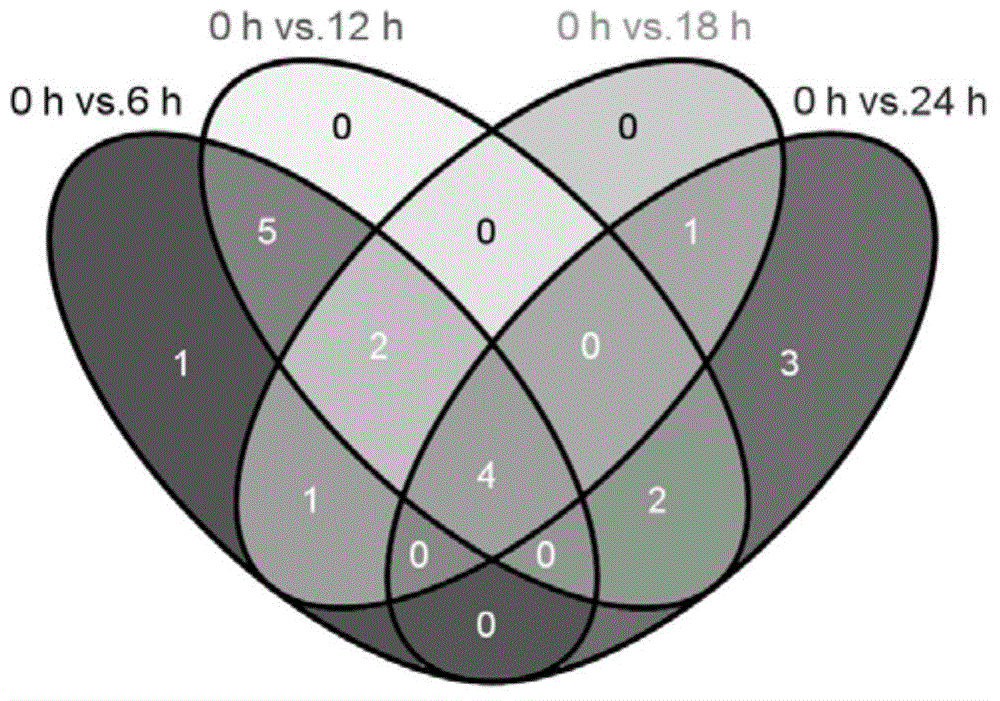

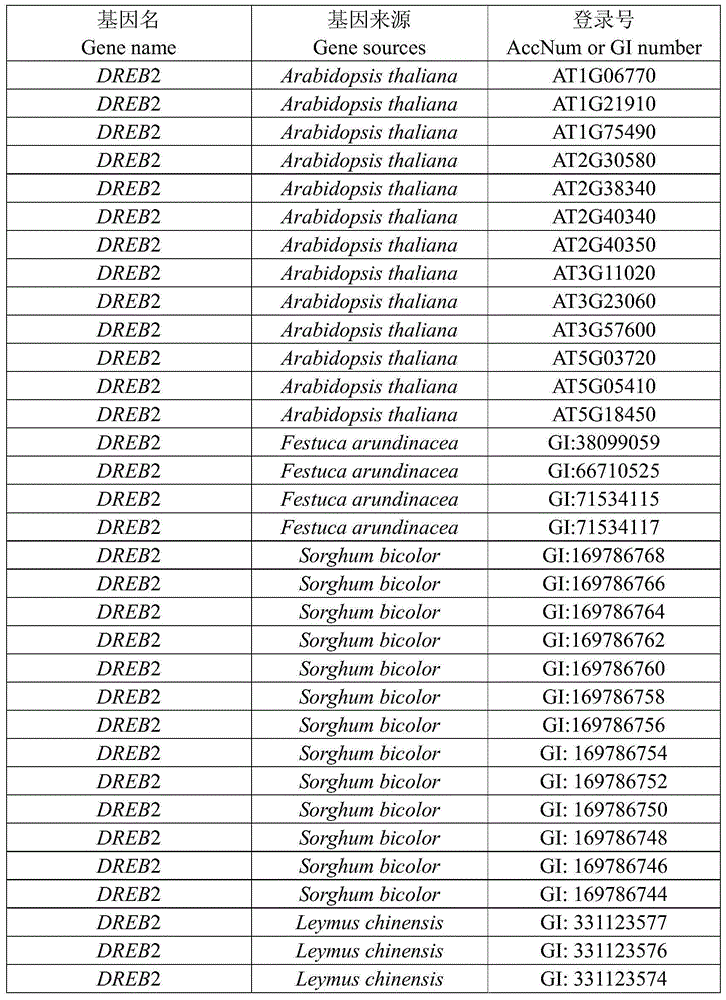

Screening kit and method for early drought stress induced festuca arundinacea DREB2 (dehydration responsive element binding protein 2) gene

The invention discloses a screening kit and a method for an early drought stress induced festuca arundinacea DREB2 (dehydration responsive element binding protein 2) gene. According to the method, PEG (polyethylene glycol) 6000 drought stress treated (0h, 6h, 12h, 18h and 24h) festuca arundinacea is used as an experimental material, mixed transcriptome sequencing analysis is performed by utilizing an RNA-seq (ribonucleic acid-sequencing) technology of an Illumina / Solexa sequencing platform, and a registered DREB2 gene sequence is used as a probe to perform Local Blast, so that the early drought stress induced festuca arundinacea DREB2 gene is screened. The method can be used for quickly and comprehensively screening the drought stress induced festuca arundinacea DREB2 candidate gene, and has an important guiding magnificence to drought-resistance mechanism researches and plant resistant breeding.

Owner:HUNAN AGRICULTURAL UNIV +1

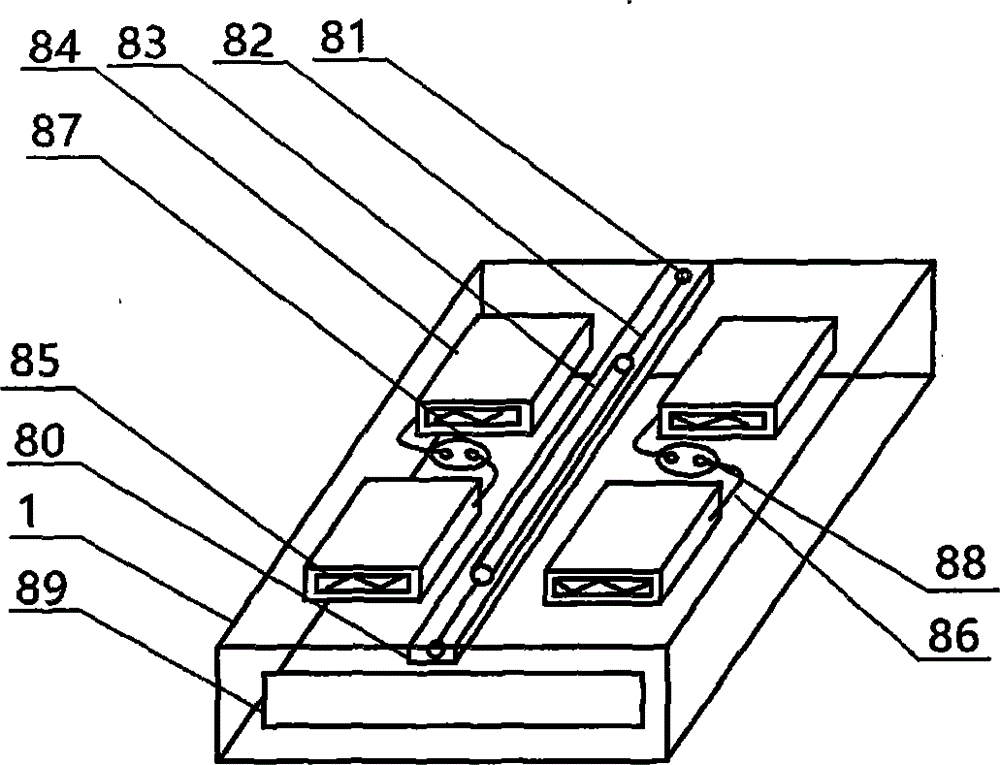

Weighing platform and weighing platform paving structure

PendingCN108020369ACorrect the error of load detectionReduce mistakesMeasurement of force componentsHorizontal forceEngineering

The invention provides a weighing platform and a weighing platform paving structure, a sensor is arranged in the weighing platform, and the sensor comprises two stress induction teeth that are mutually perpendicularly connected; parts, arranged in an overlapped manner, of the stress induction teeth are provided with strain gages that stretch or contract along with the stress induction teeth; the strain gages include two horizontal force strain gages that extend along a horizontal direction and a vertical force strain gage arranged between the two horizontal force strain gages. Via arrangementof the horizontal force strain gages and the vertical force strain gage, numeric values of braking force that a motor vehicle receives and real time weight of the motor vehicle can be measured, and achange relation between the two can be detected.

Owner:BEIJING PANTIAN NEW TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com