Method monitoring fatigue service life of crane beam

A crane beam and crane technology, applied in the field of inspection, can solve the problems of high construction difficulty and high cost, and achieve the effect of increasing construction difficulty and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

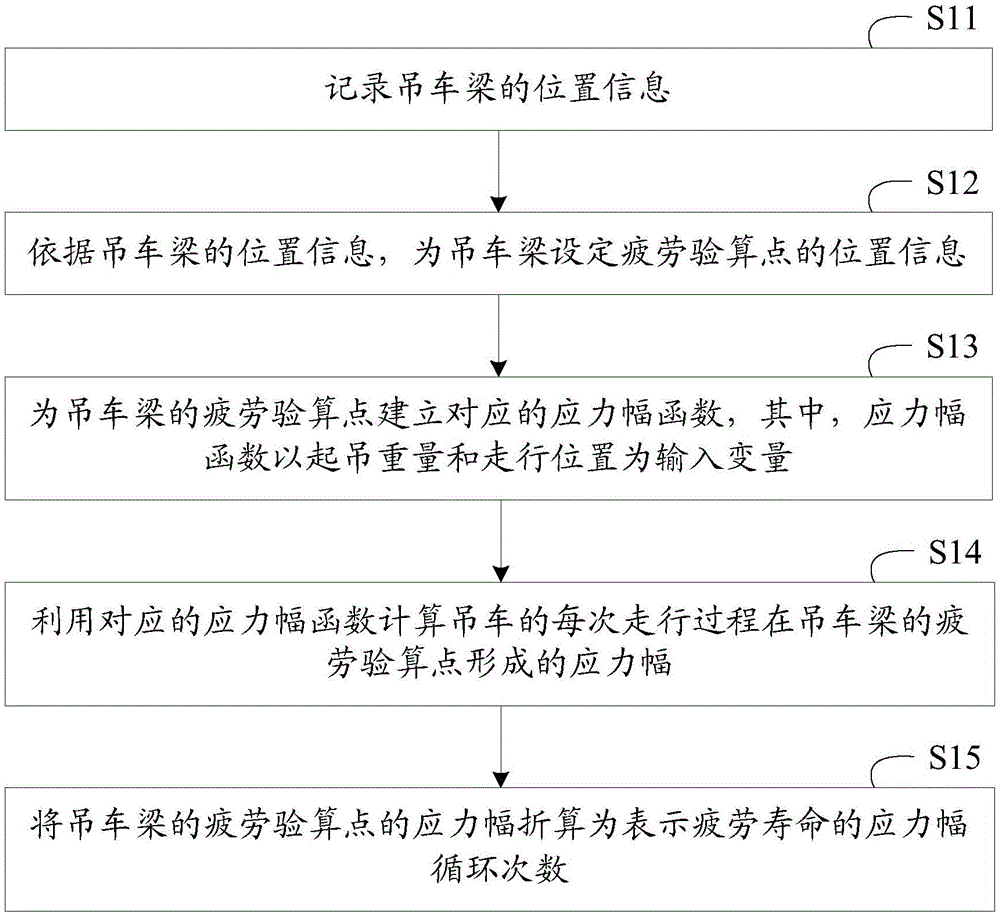

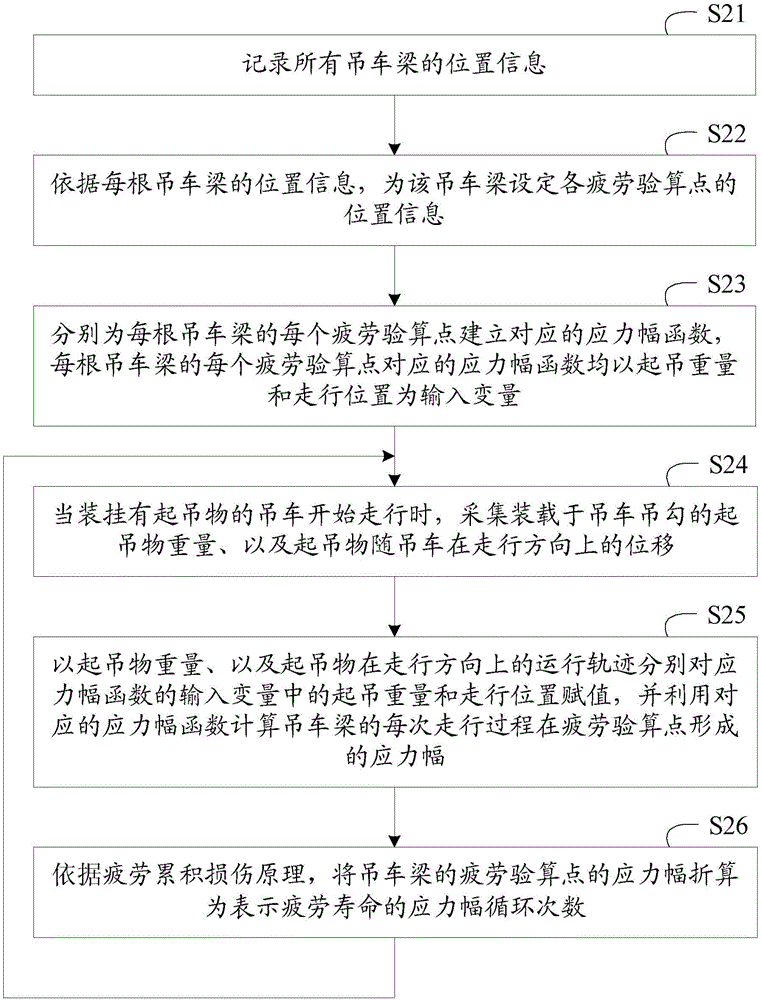

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

[0022] The monitoring cost and construction difficulty increase with the increase of the number of crane girders and fatigue checking points, mainly because the monitoring must rely on the installation of stress-sensing sheets at each fatigue checking point of each crane girder. Thus, in one embodiment, this is avoided by eliminating the dependency of monitoring on the stress-sensitive sheet.

[0023] That is, this embodiment pre-establishes the functional relationship between the lifting weight, the running position and the stress amplitude for each fatigue checking point of each crane girder, because such a functional relationship can reflect that when the crane girder bears different load weights at different stress positions The stress amplitude for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com