Patents

Literature

719results about "Load-engaging girders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

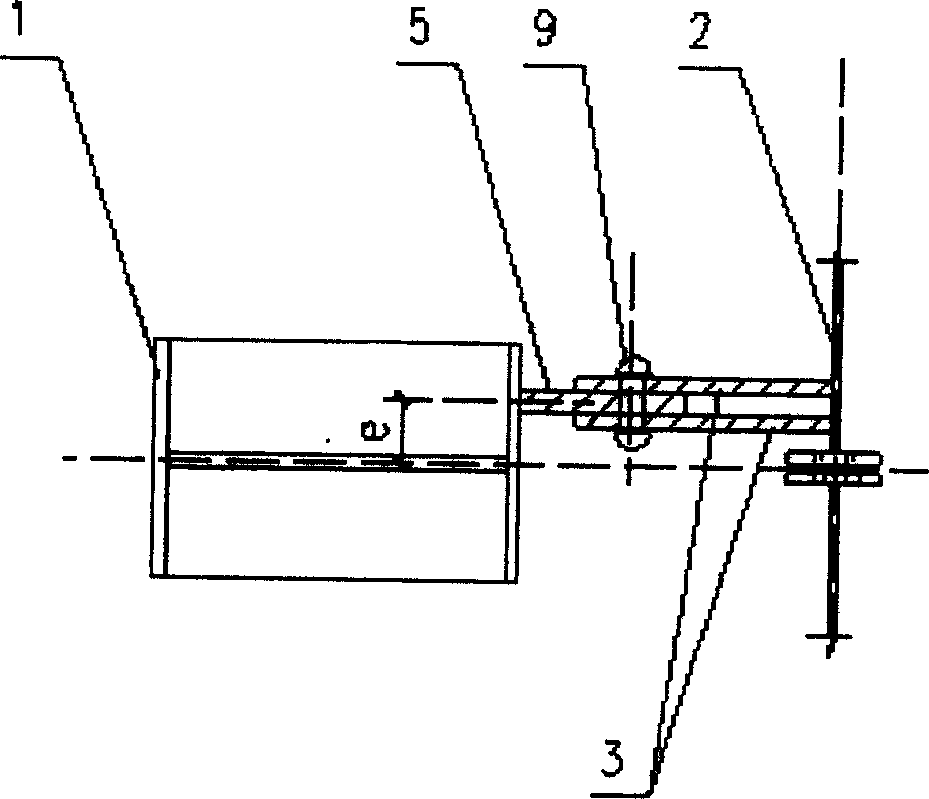

Hydraulic hoisting, slipping and emplacing method and equipment for large scale press components

ActiveCN102530732AConstruction safetyPrecise positioningLoad-engaging girdersTravelling cranesStructural engineering

Owner:中国机械工业建设集团有限公司 +1

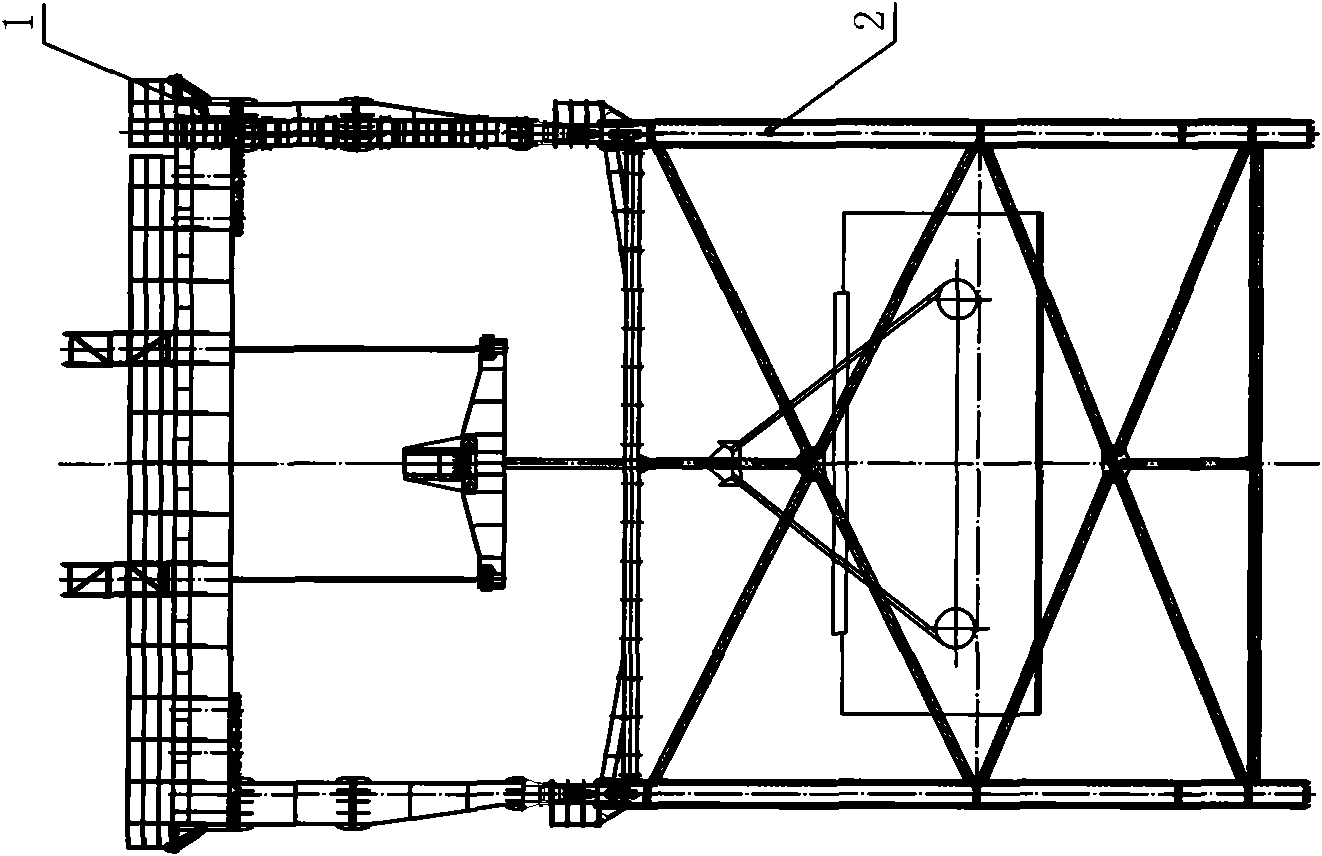

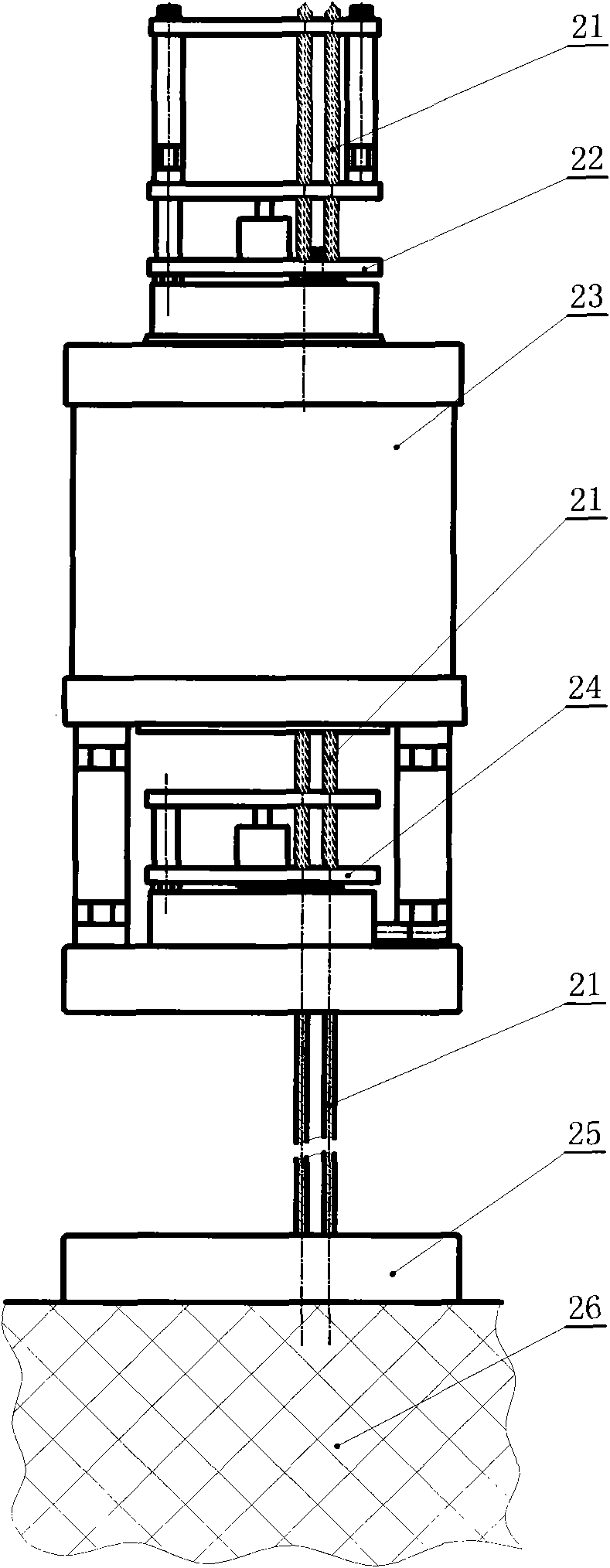

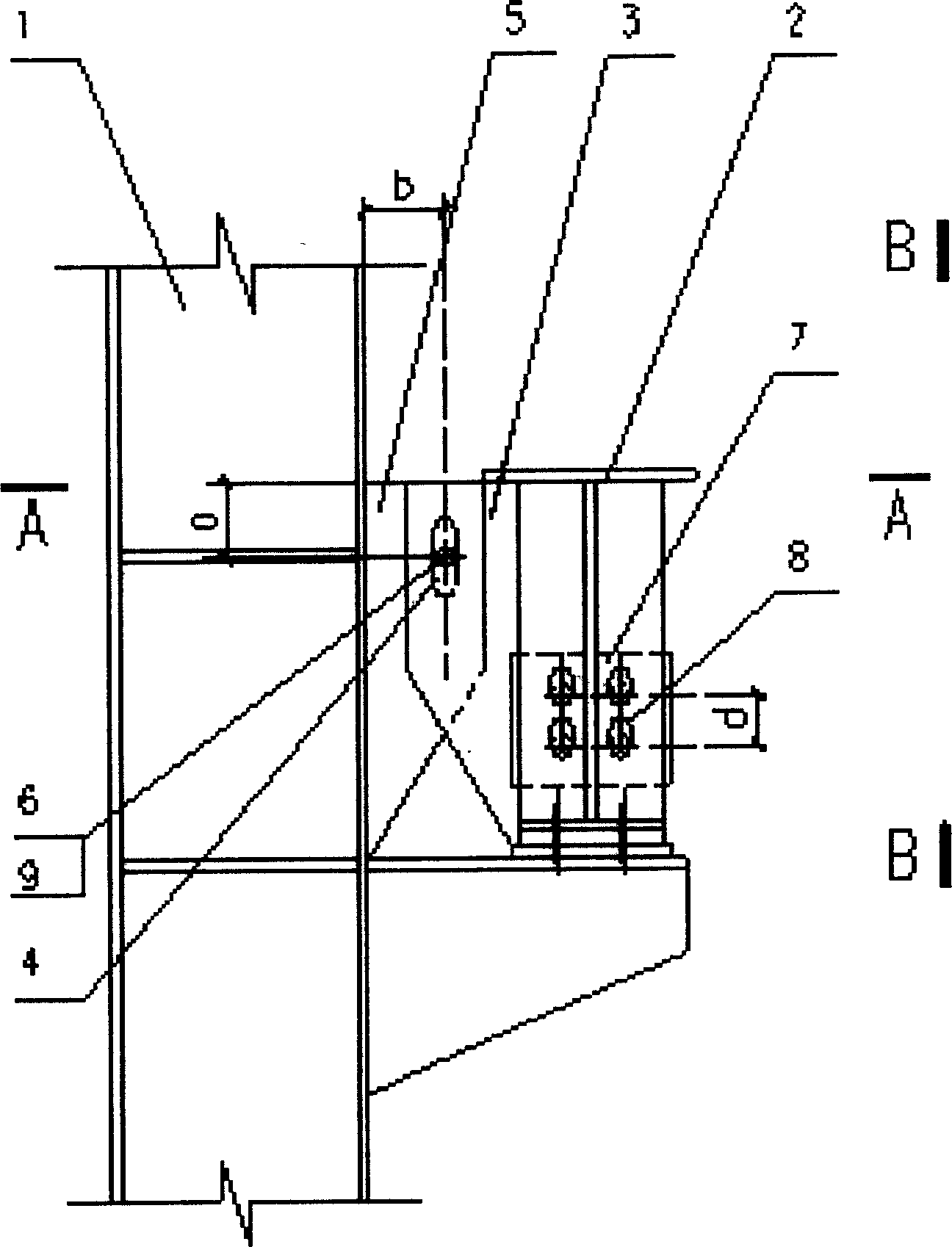

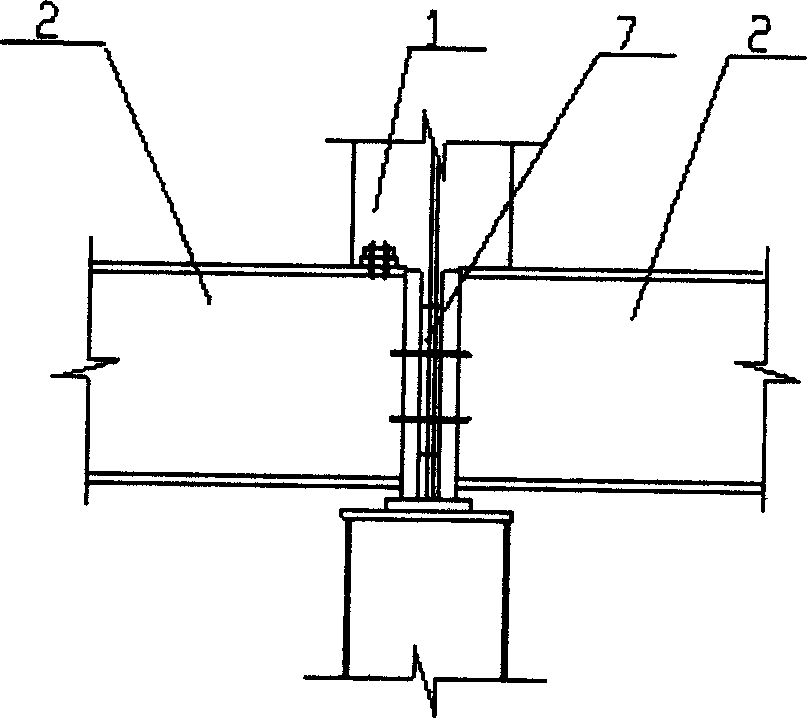

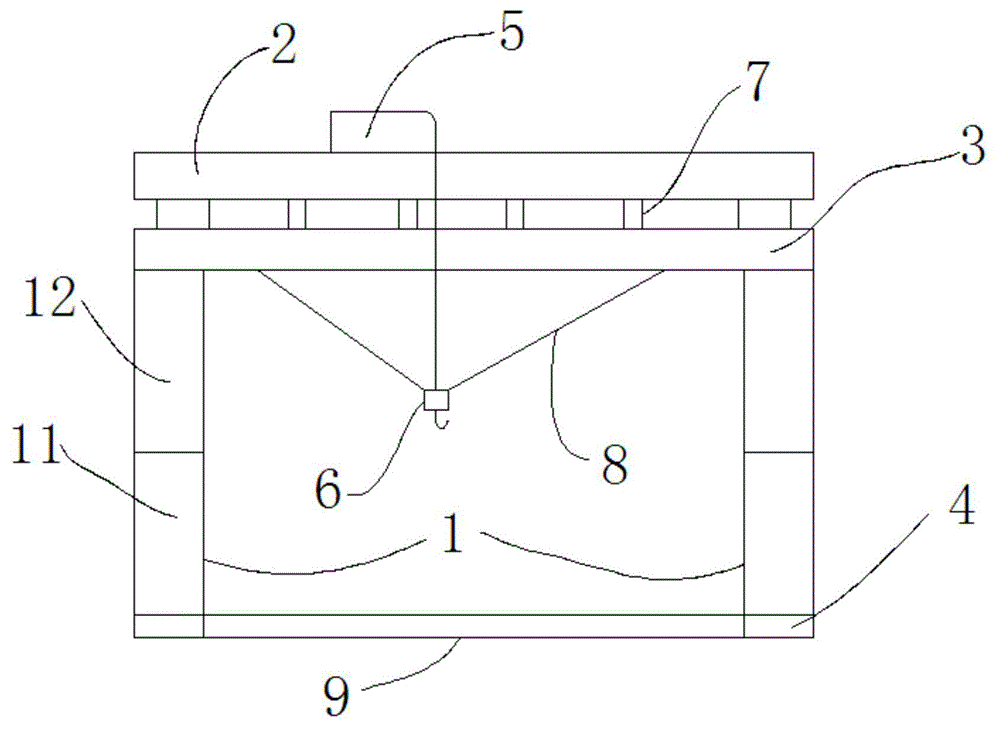

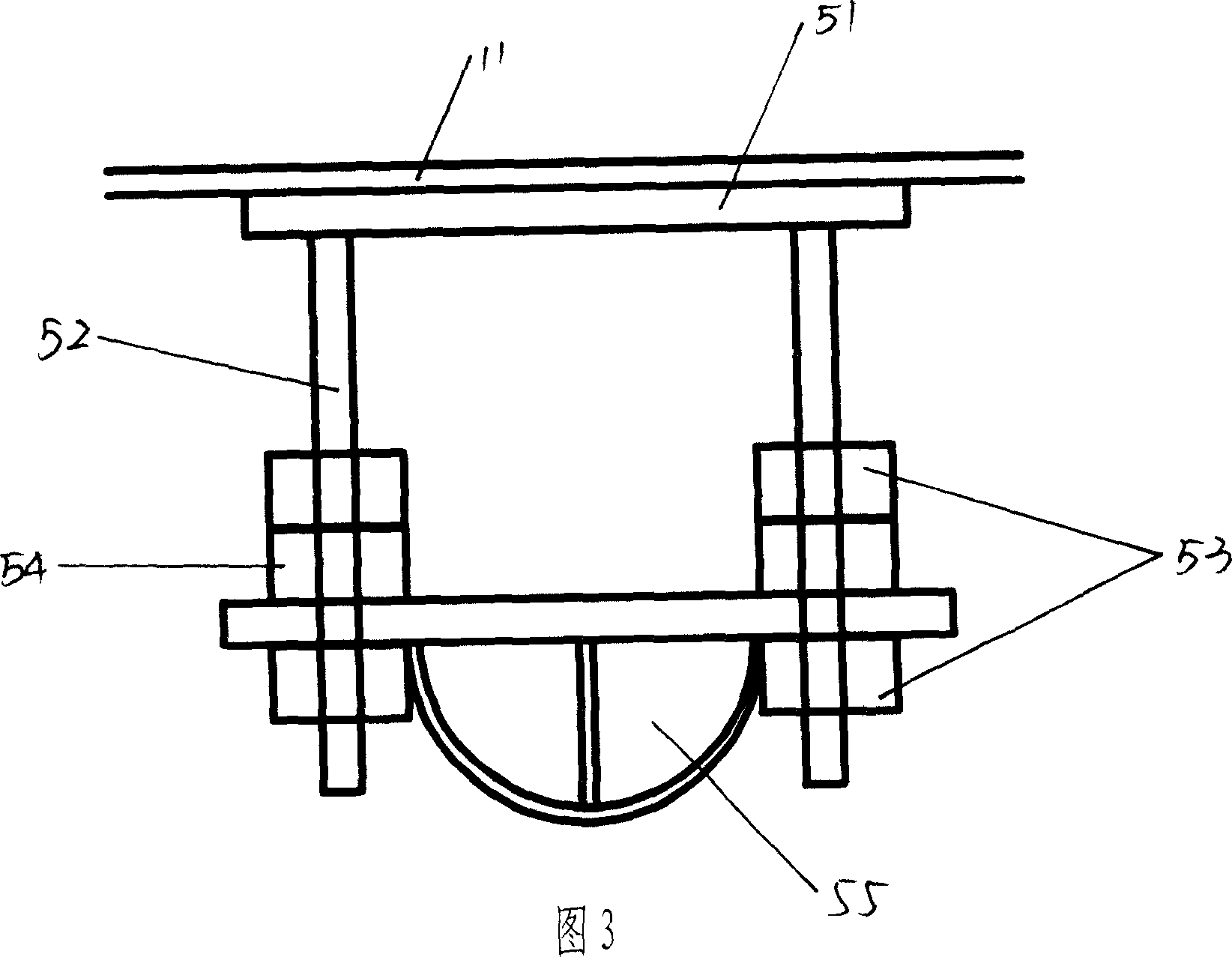

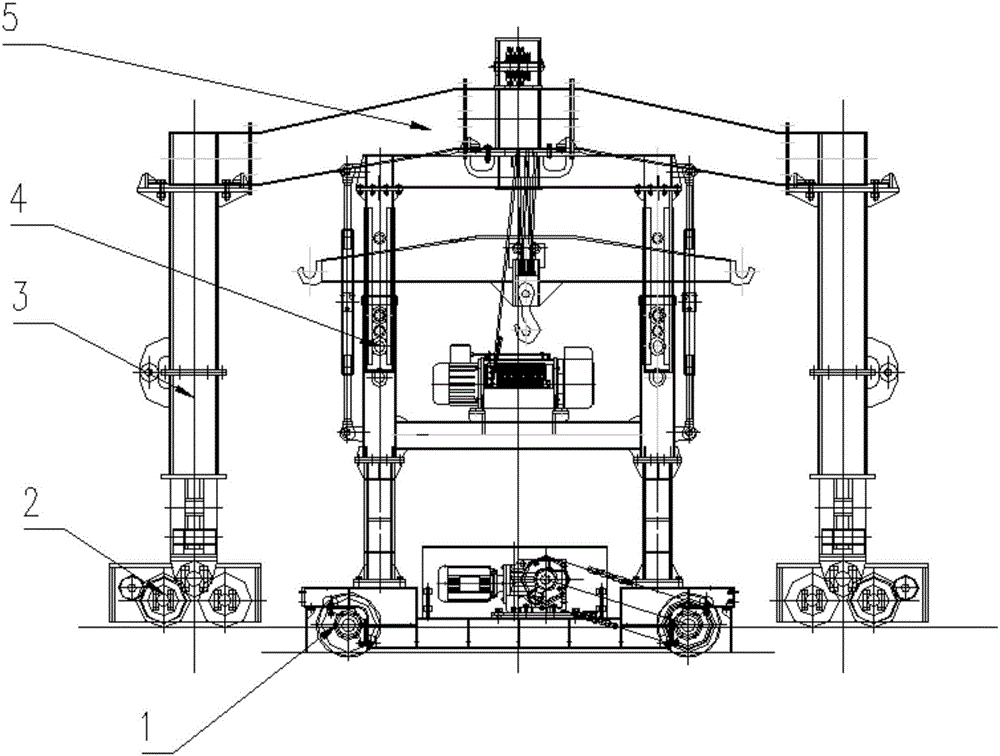

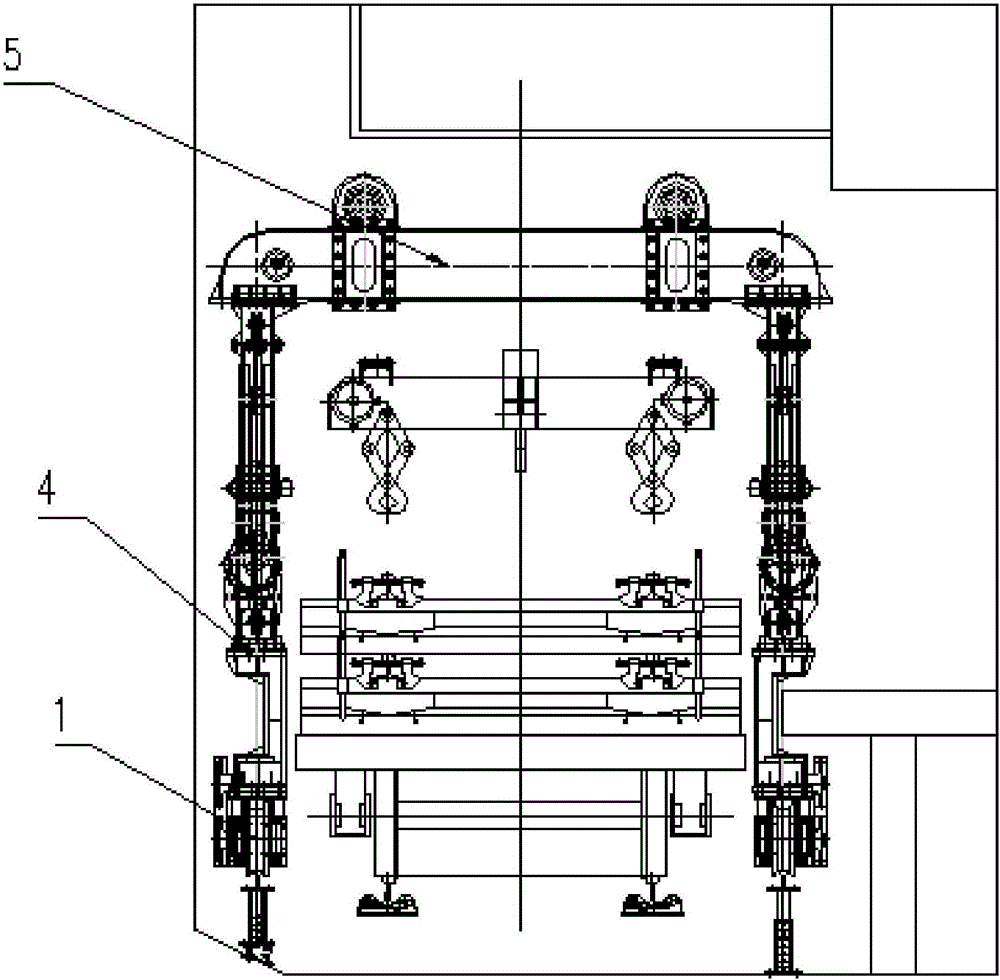

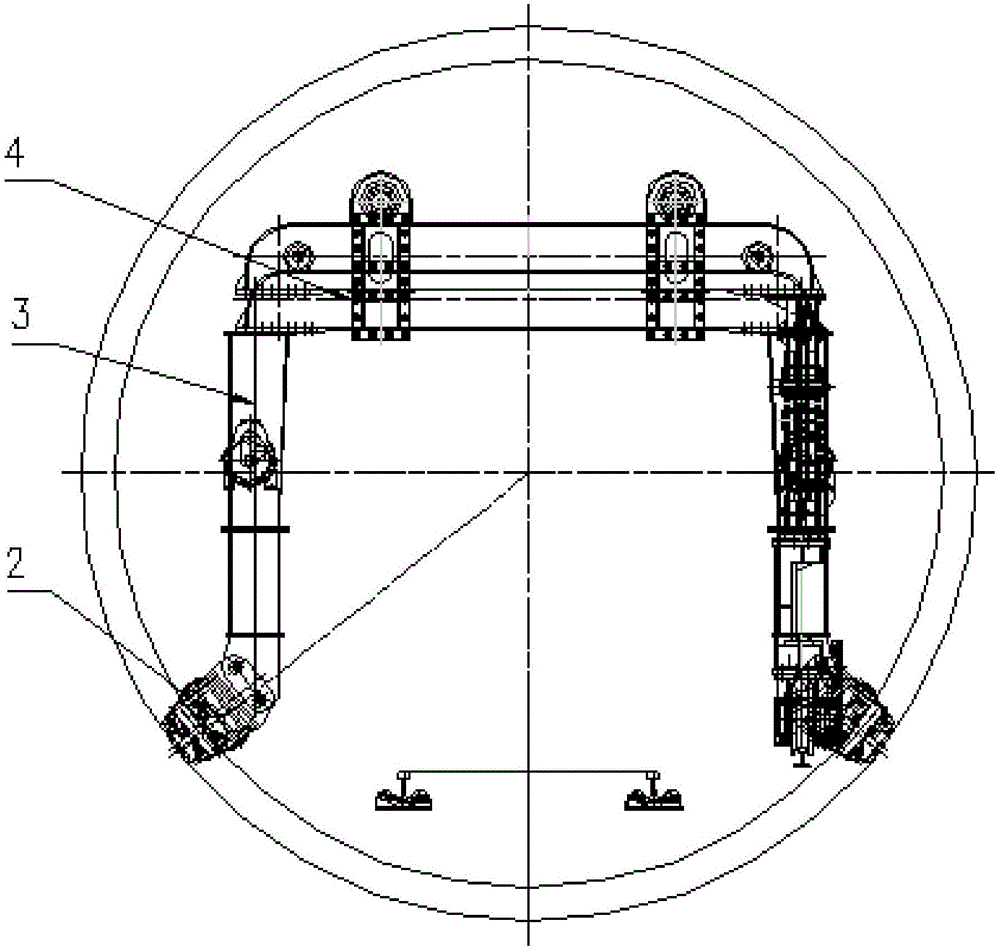

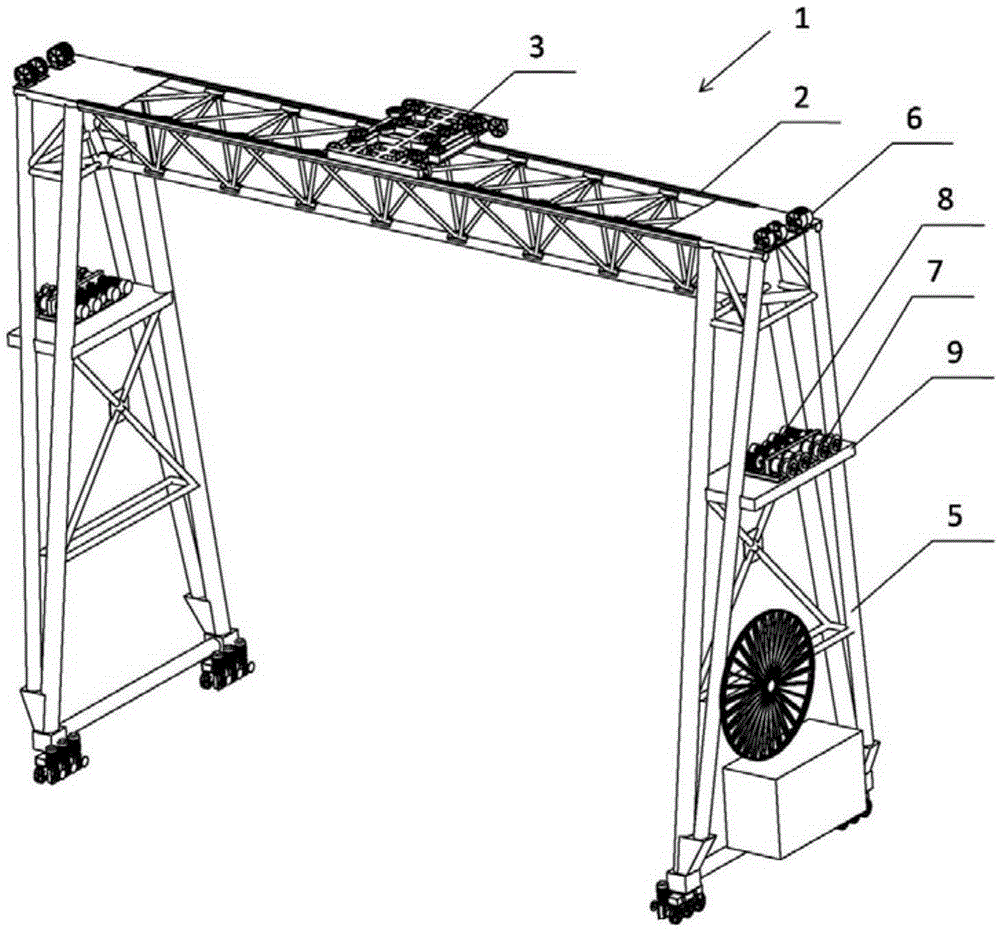

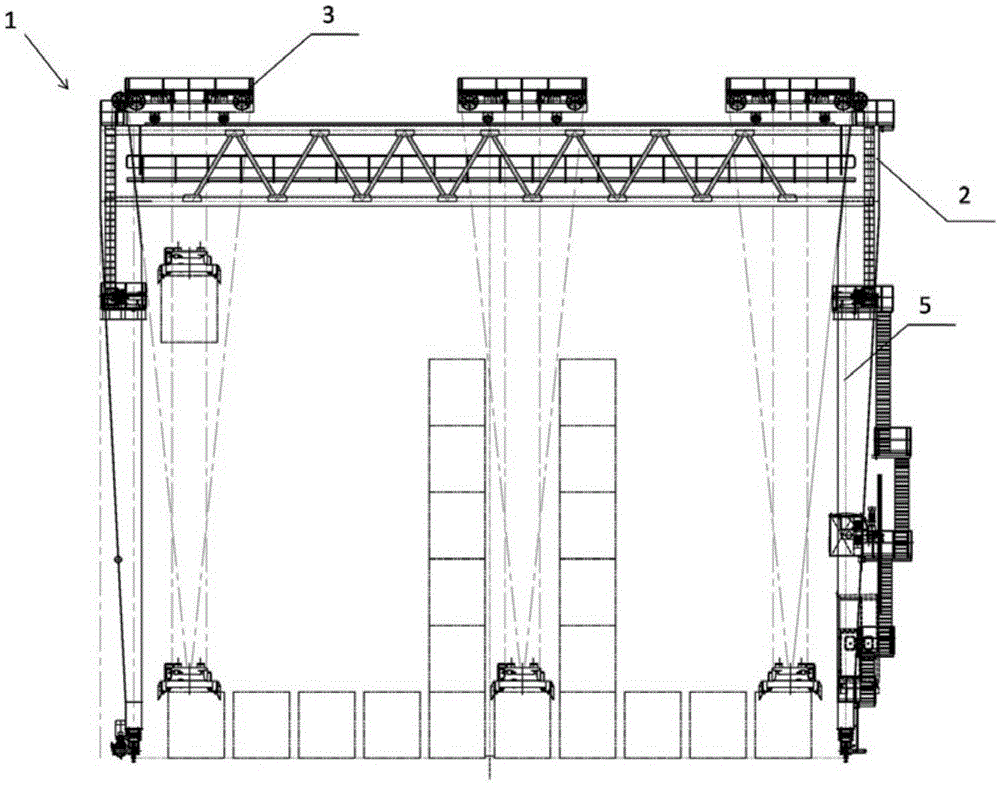

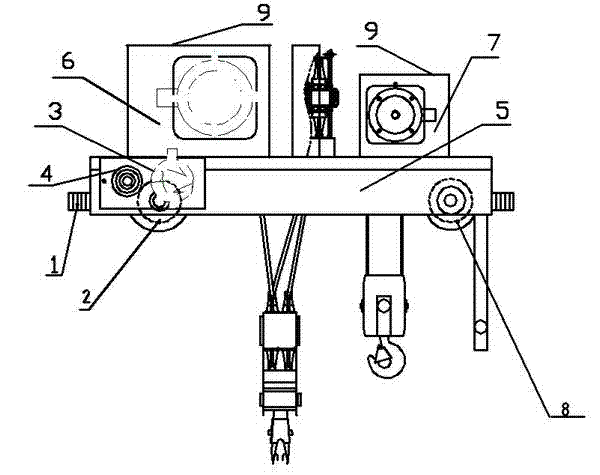

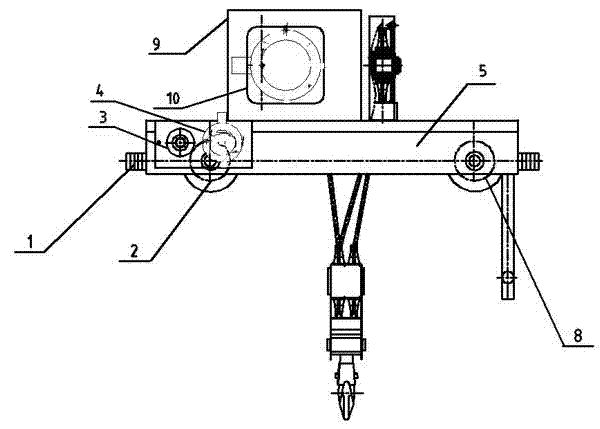

Multifunctional combined type lifting framework for installing large scale electrical power unit

ActiveCN101580211AMeet the needs of installation and constructionVarious combinationsLoad-engaging girdersTravelling cranesTransformerEngineering

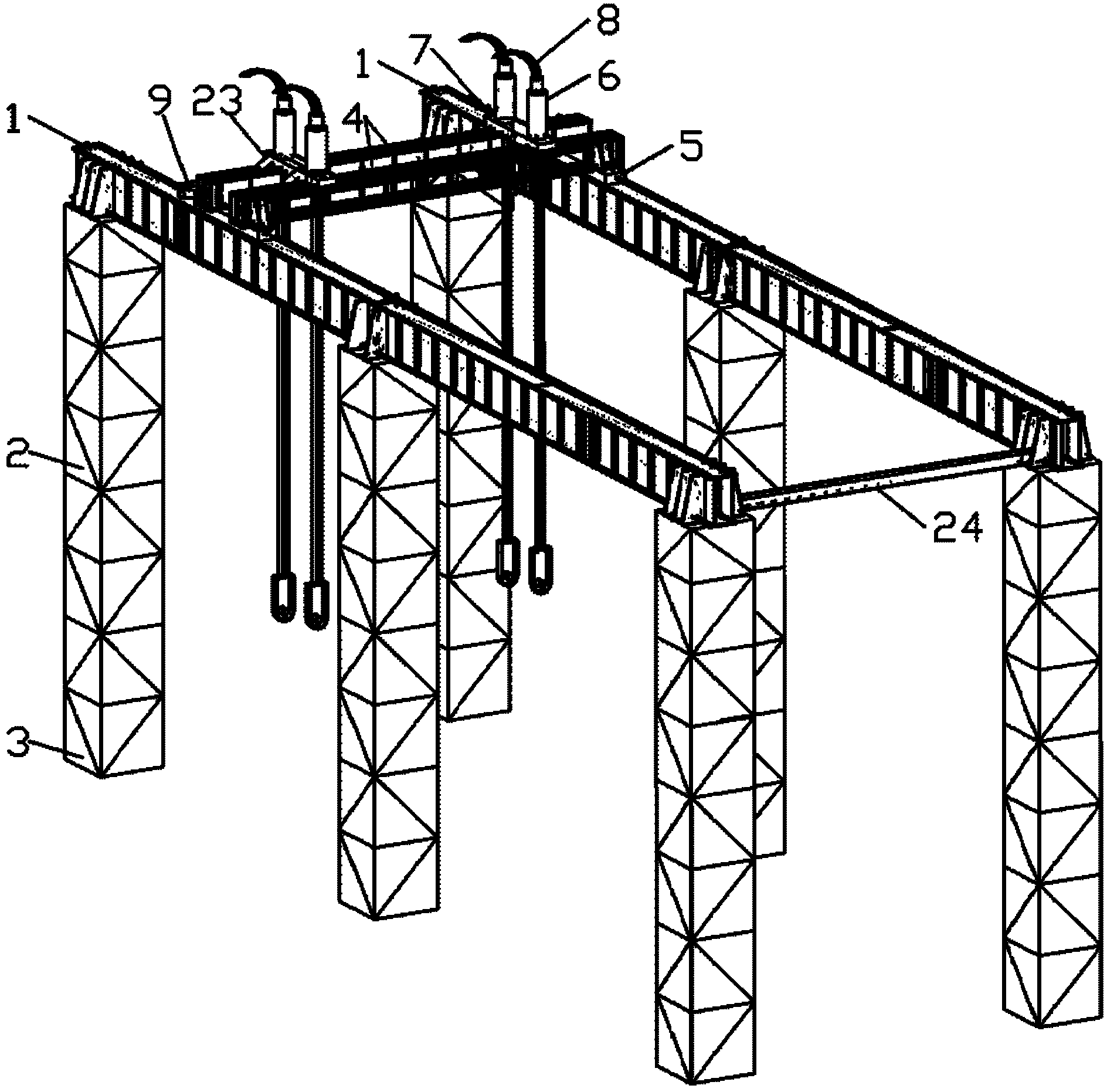

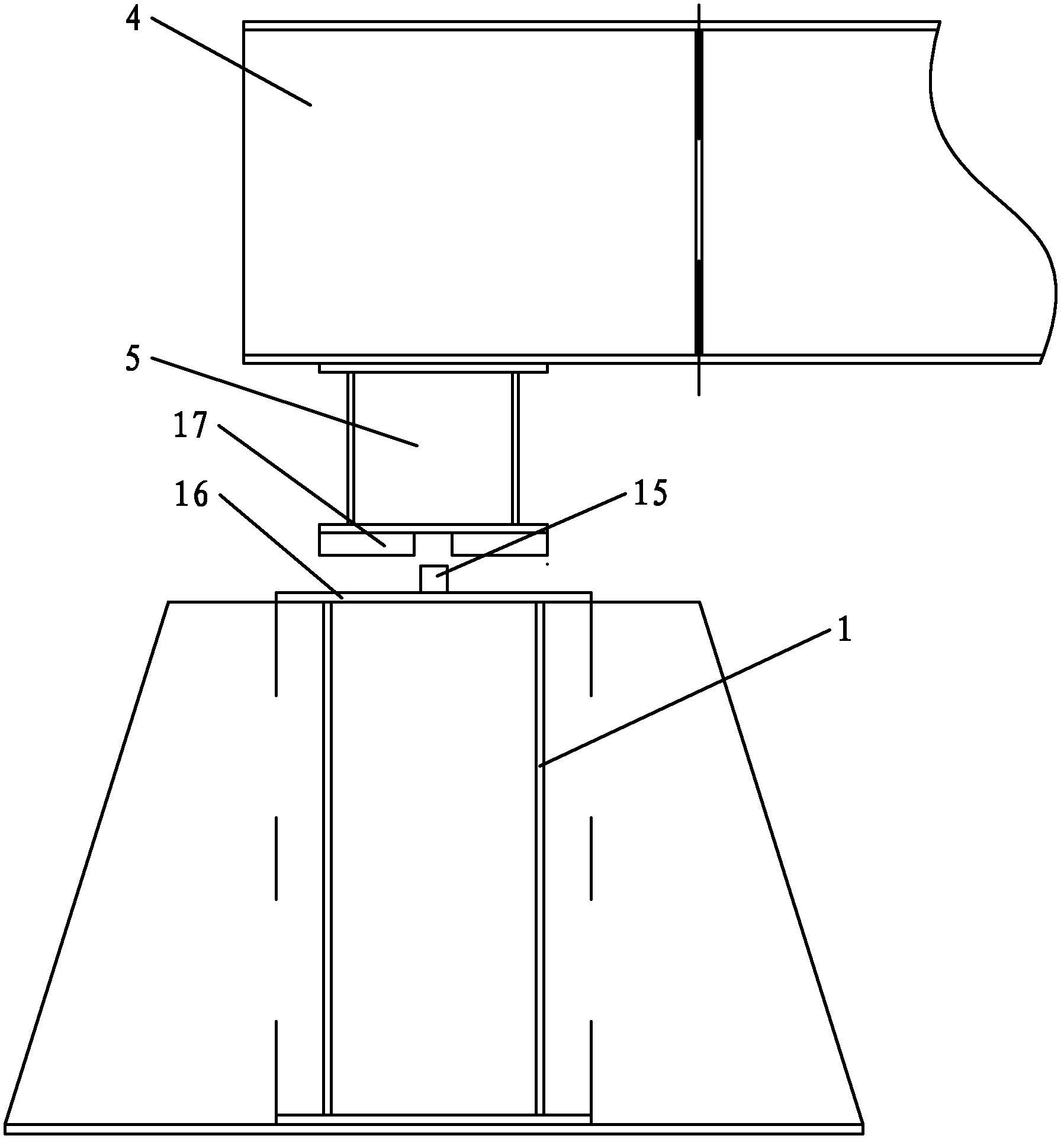

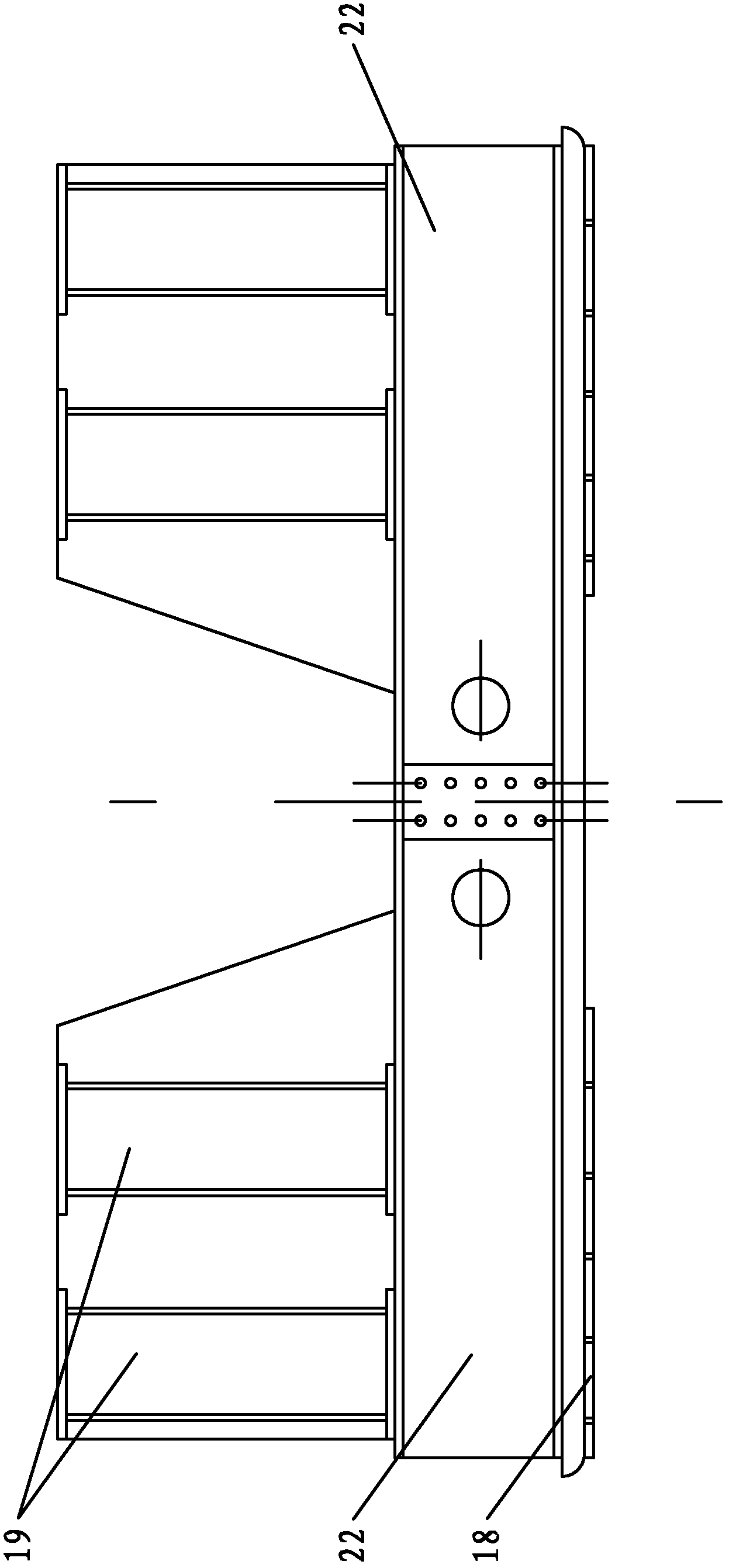

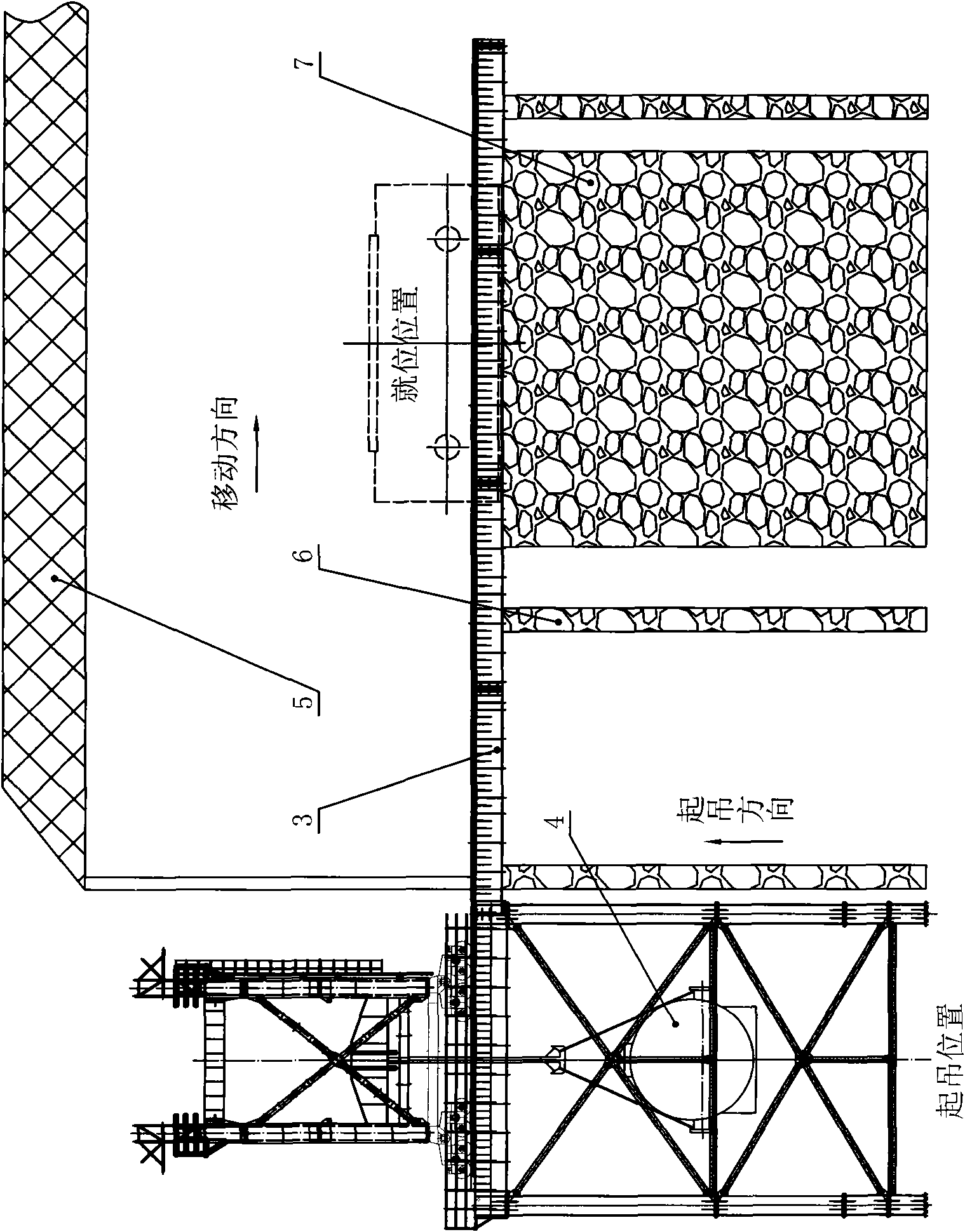

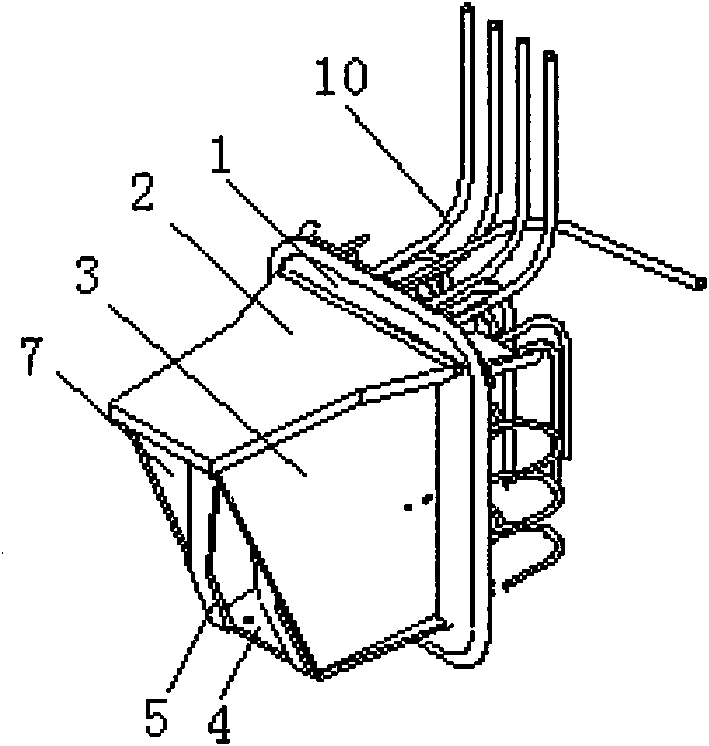

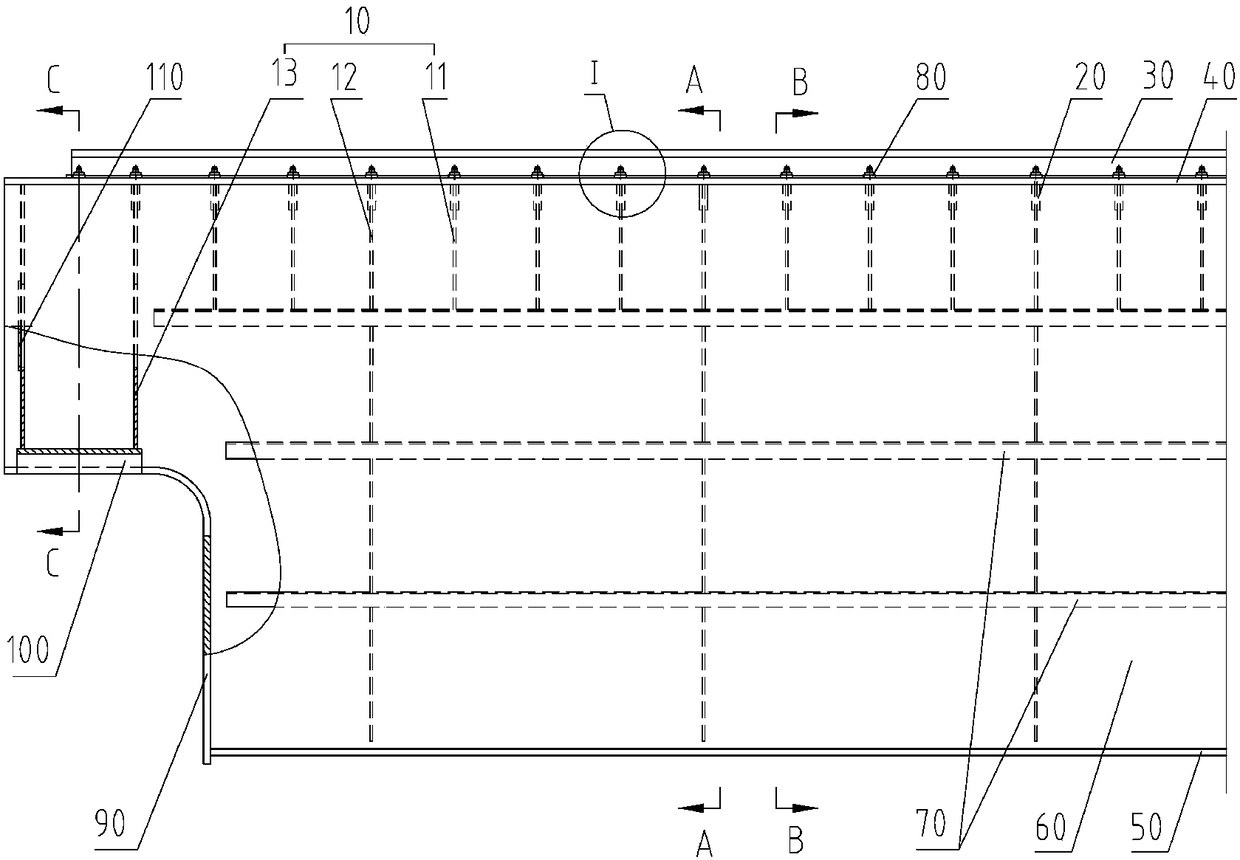

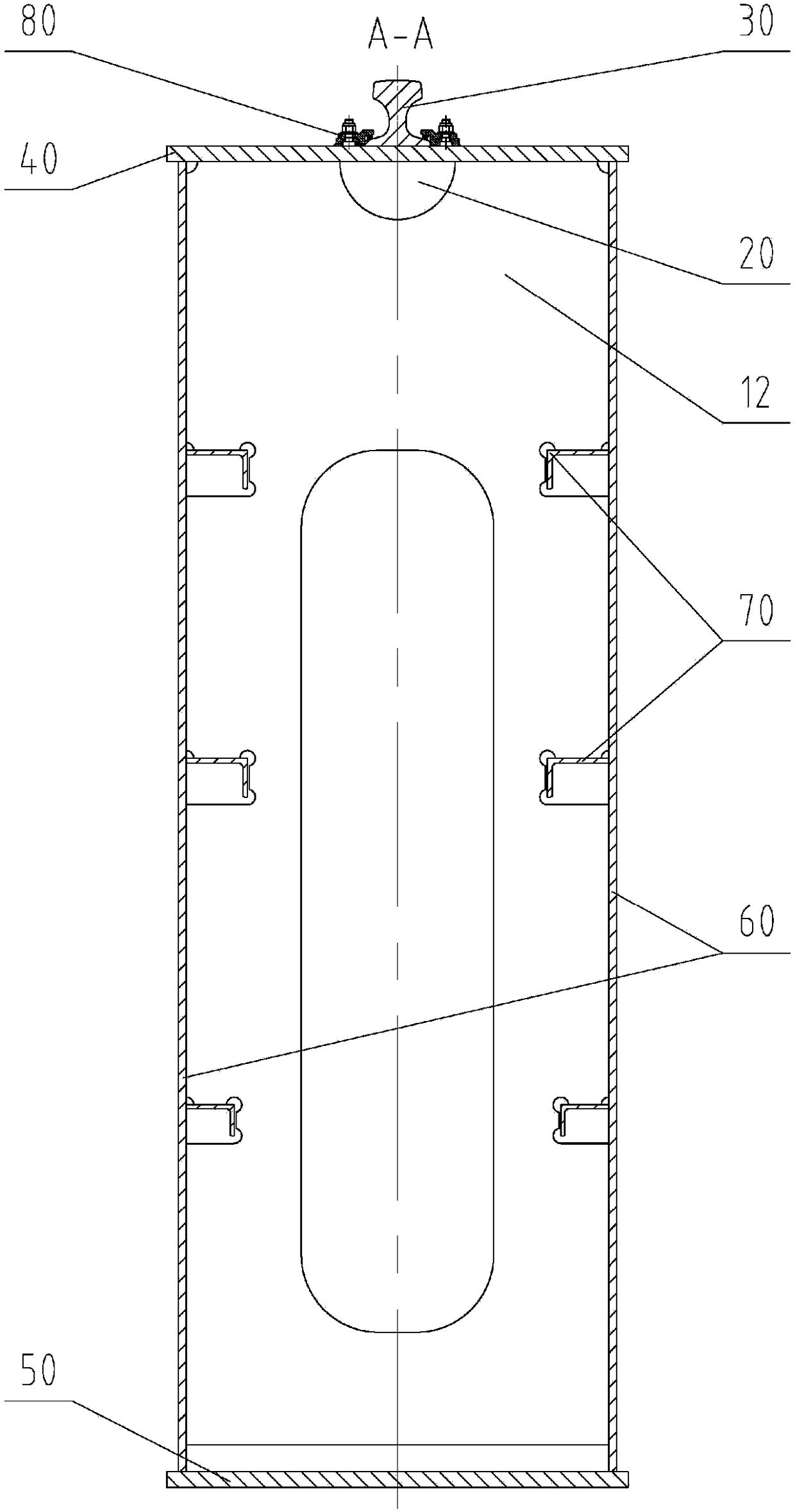

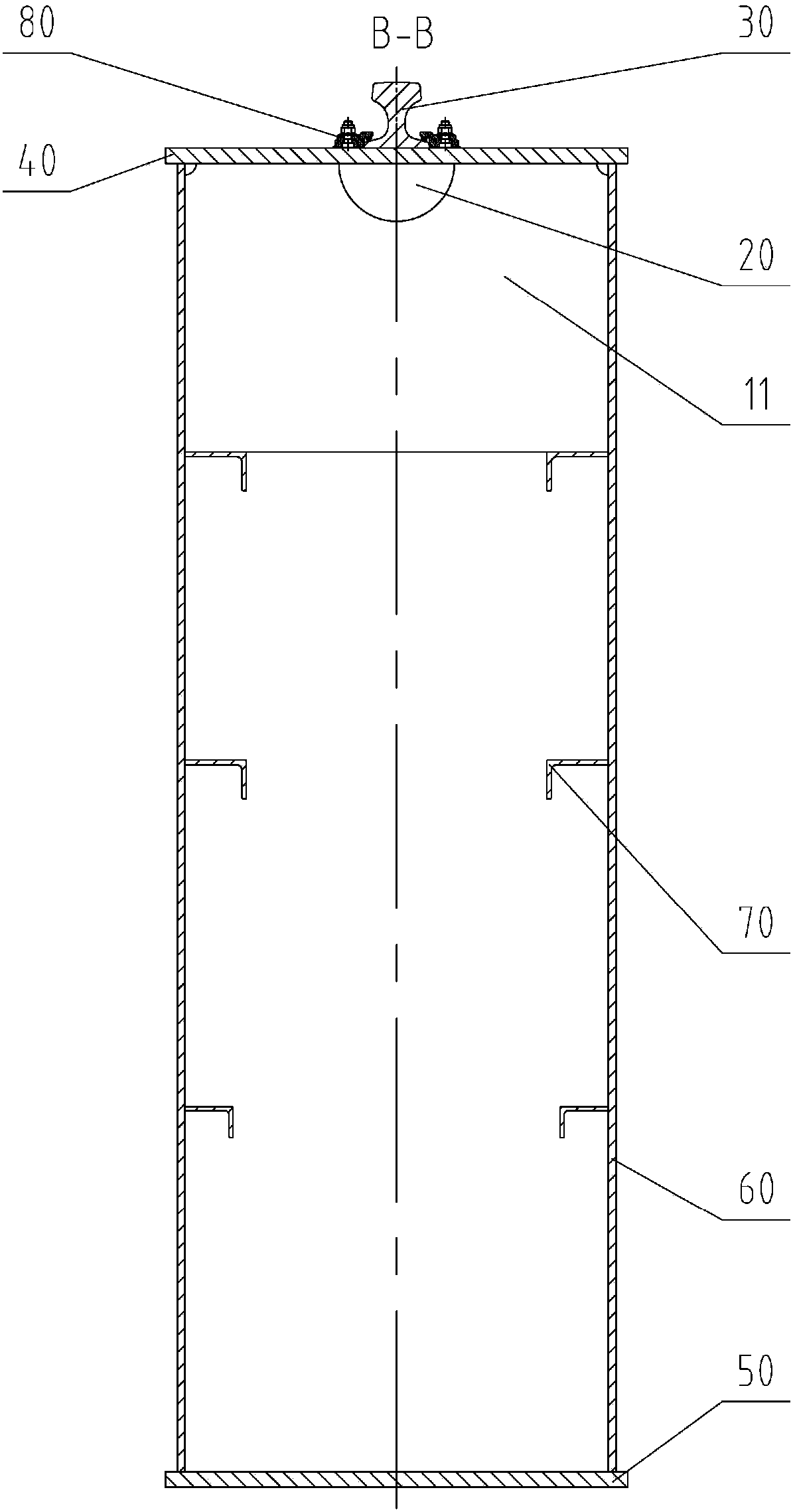

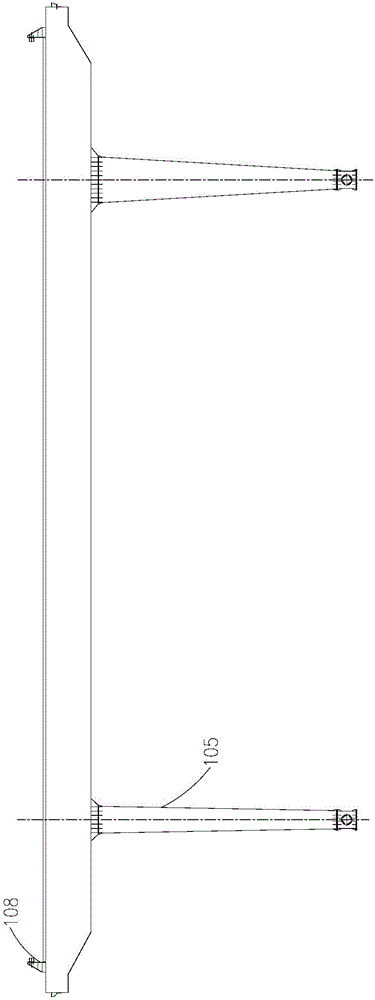

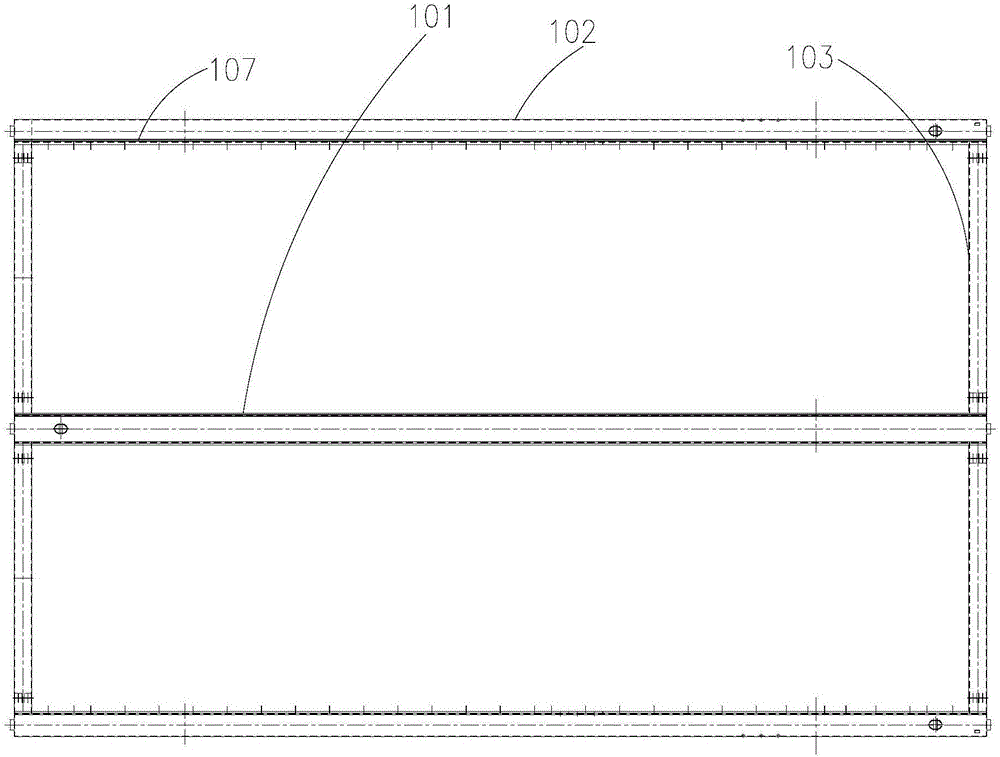

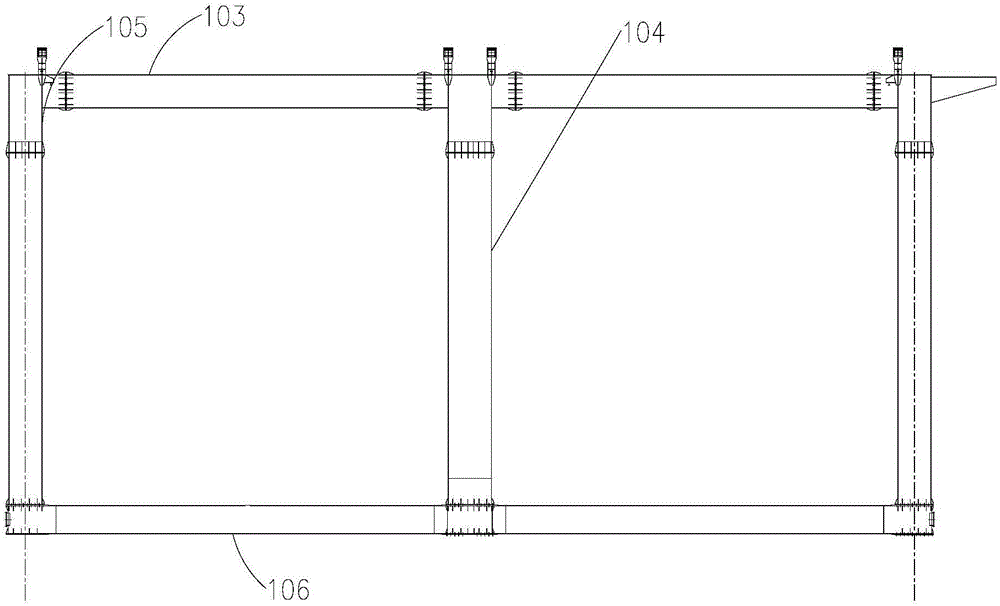

The invention relates to a multifunctional combined type lifting framework which is a heavy-duty hoisting steel structure designed by combining the installation and construction requirements of large scale equipment in power industry. The lifting framework mainly comprises a moving rack 1, a fixing rack 2, a track girder 3, auxiliary components, etc; wherein, the moving rack 1 is arranged at the installing position of a steel wire type hydraulic lifting device to realize horizontal shifting of a lifted part 4; the fixing rack 2 is installed at the outer side of the end part of a steam turbine building 5 to support the moving rack 1; the track girder 3 is installed on an upright post 6 of the steam turbine building for providing a travelling track for the moving rack 1; the auxiliary components are used for installing steam drums, main transformers, etc. The multifunctional combined type lifting framework has the characteristics of multiple functions, various combining forms and the like, can meet the installing needs of stators, the steam drums, the main transformers and the like of all levels of thermal generator sets with of 1000MW and below when being matched with the steel wire type hydraulic lifting device, and has the advantages of safety and reliability, convenient assembly and transportation, high construction efficiency and the like, thus providing a brand-new solution for the installation of the large scale electrical power units.

Owner:CHINA ELECTRIC POWER RES INST +1

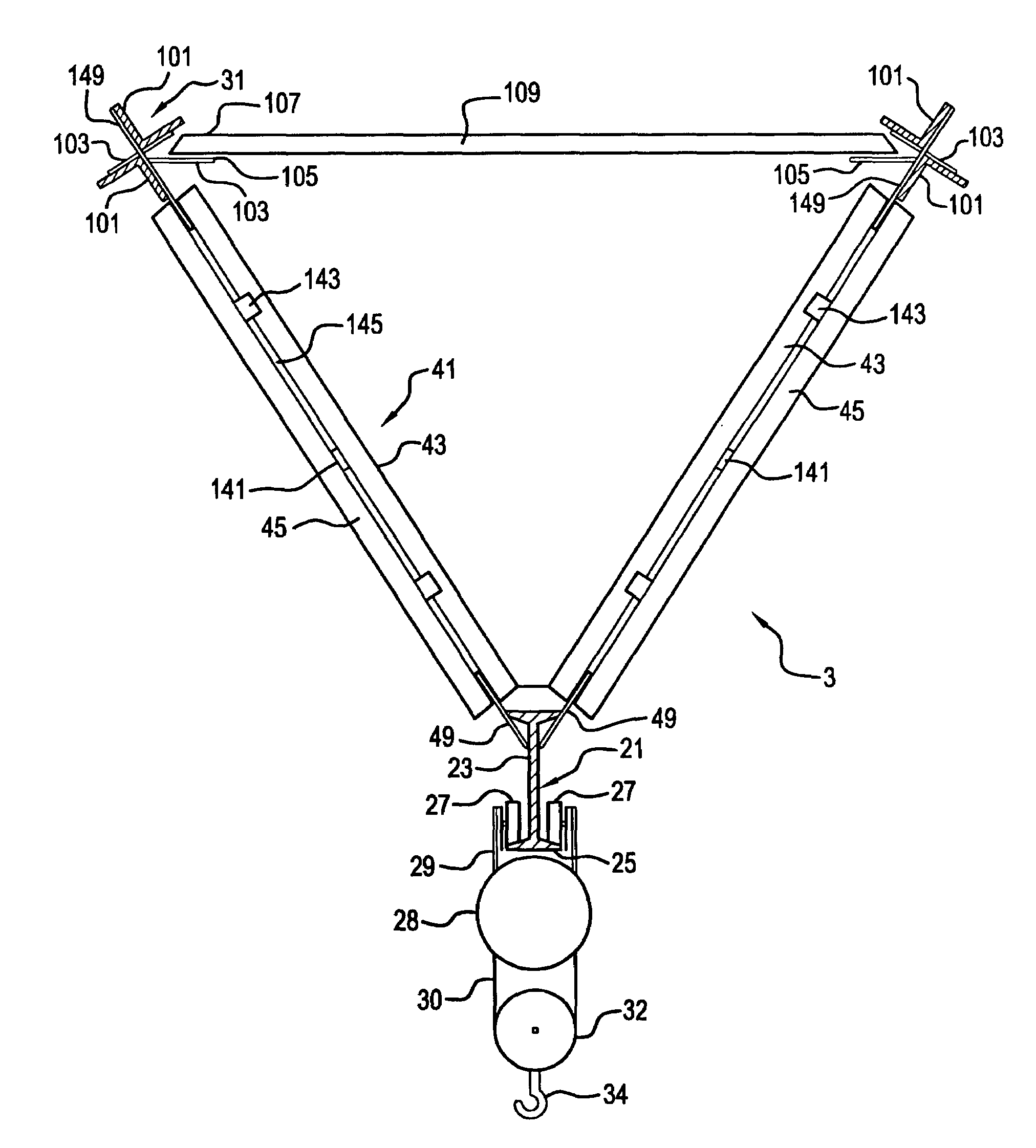

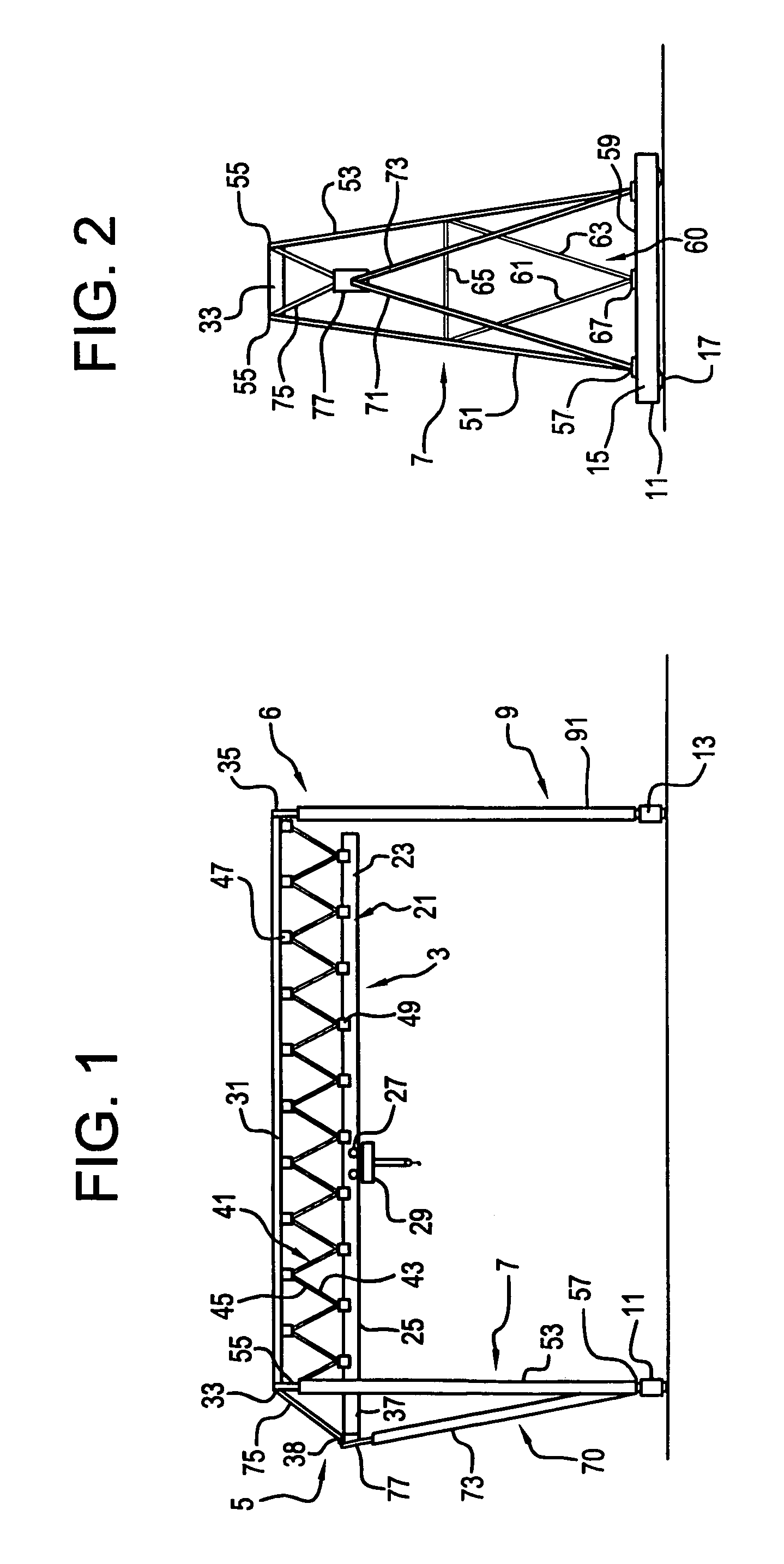

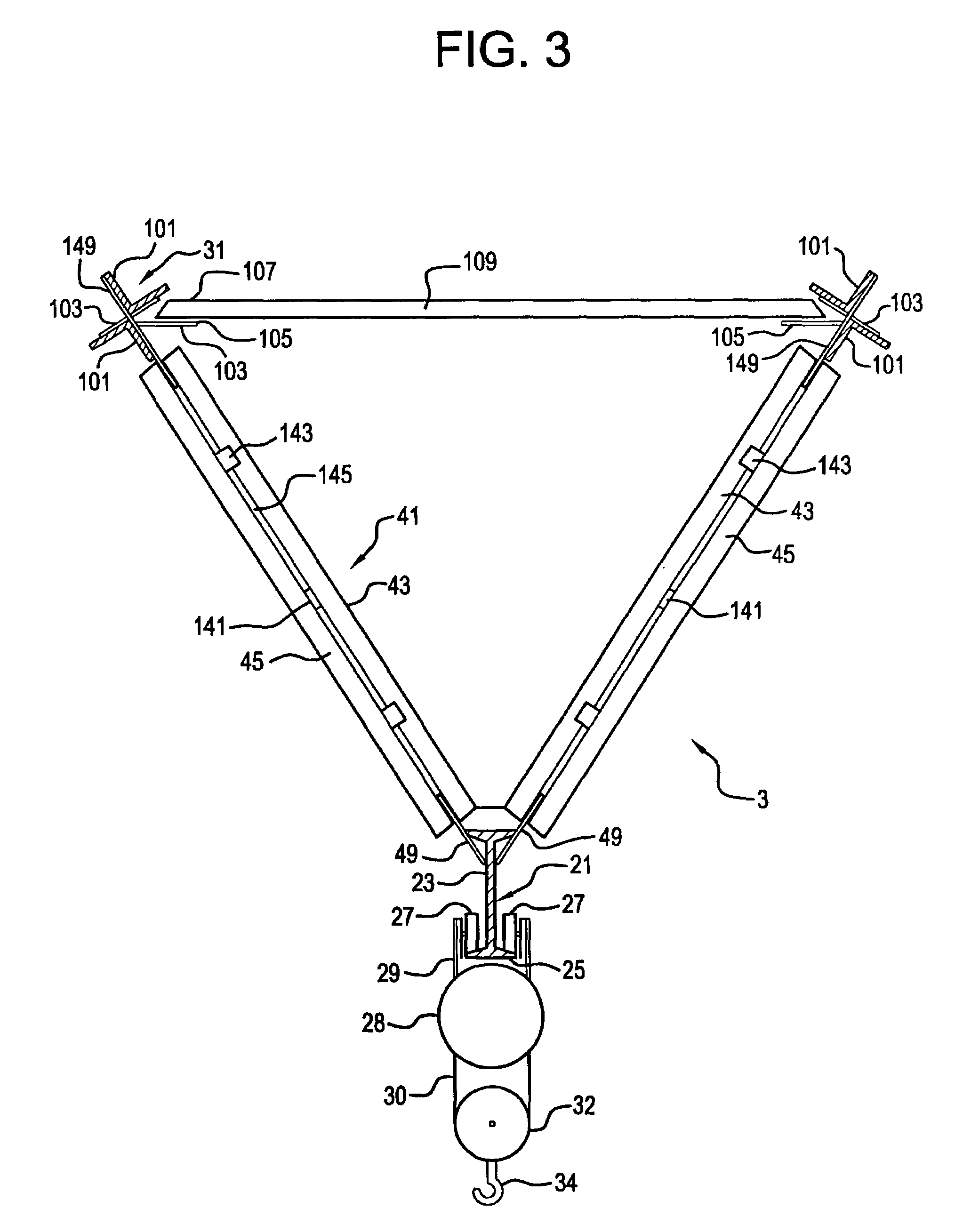

Gantry crane

InactiveUS7503460B1Easy erectionReduced flexibilityLoad-engaging girdersBase supporting structuresGusset plateMechanical engineering

A gantry crane has a rigid open three-dimensional truss cross-beam. A lower I-beam and parallel upper X-beams are interconnected with angular gussets and angle irons forming a triangular open beam bounded by three trusses. Angular gussets on the sides are as parallel members to provide maximum strength. One end support is rigid, with upper ends of legs having plates bolted to one end plate extending between the X-beams. Outrigger legs have an upper plate bolted to a sloped plate at an extended end of the I-beam. Vertical support legs at the other end have a strengthening cross-member and upper vertical plates which are bolted to the end plate on the X-beams. The unusual cross-beam structure and the unusual rigid leg structure and rigid interconnection provide rigidity of the entire crane. The vertical support legs accommodate variations in tracks.

Owner:PETRICIO YAKSIC DAVOR

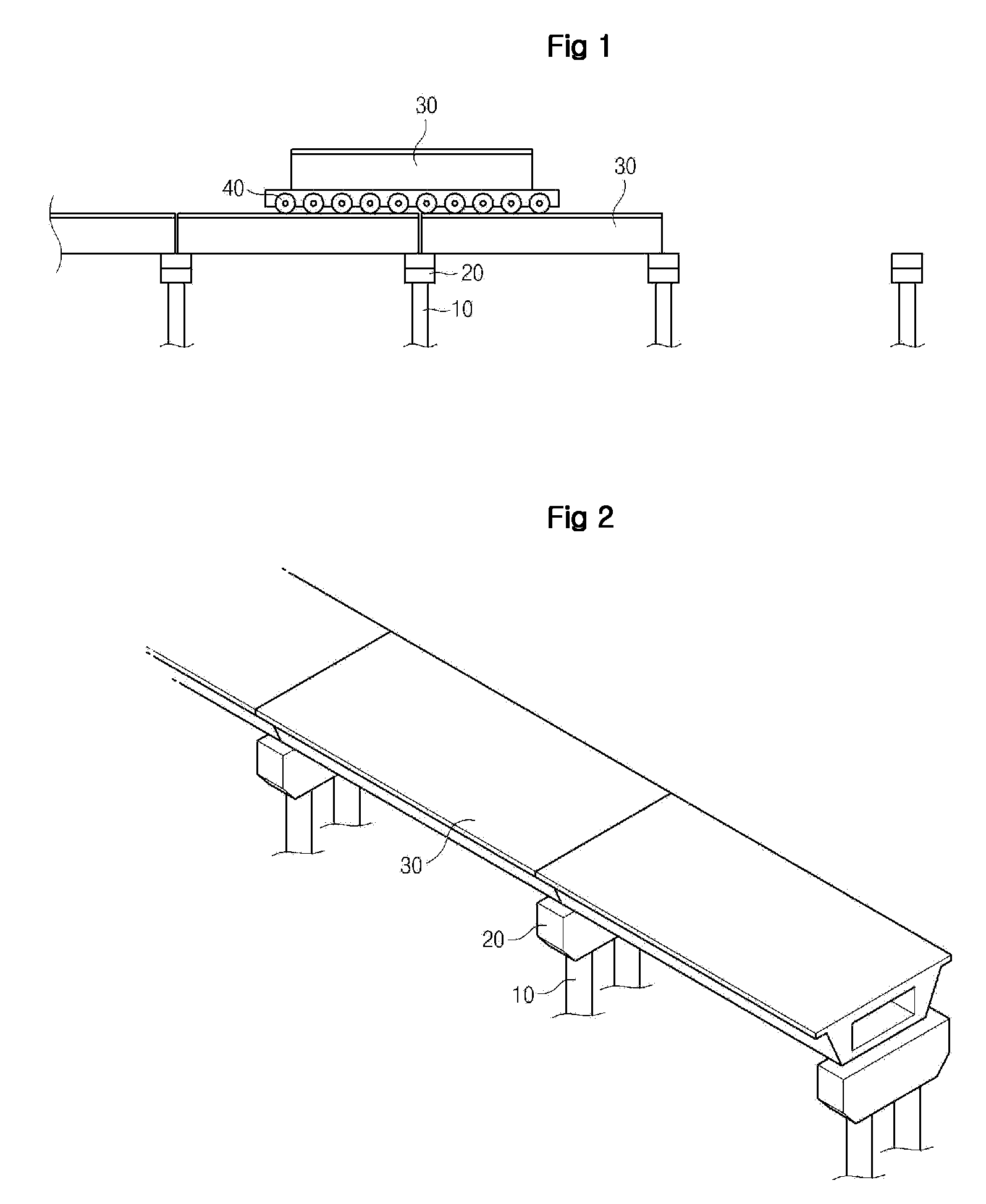

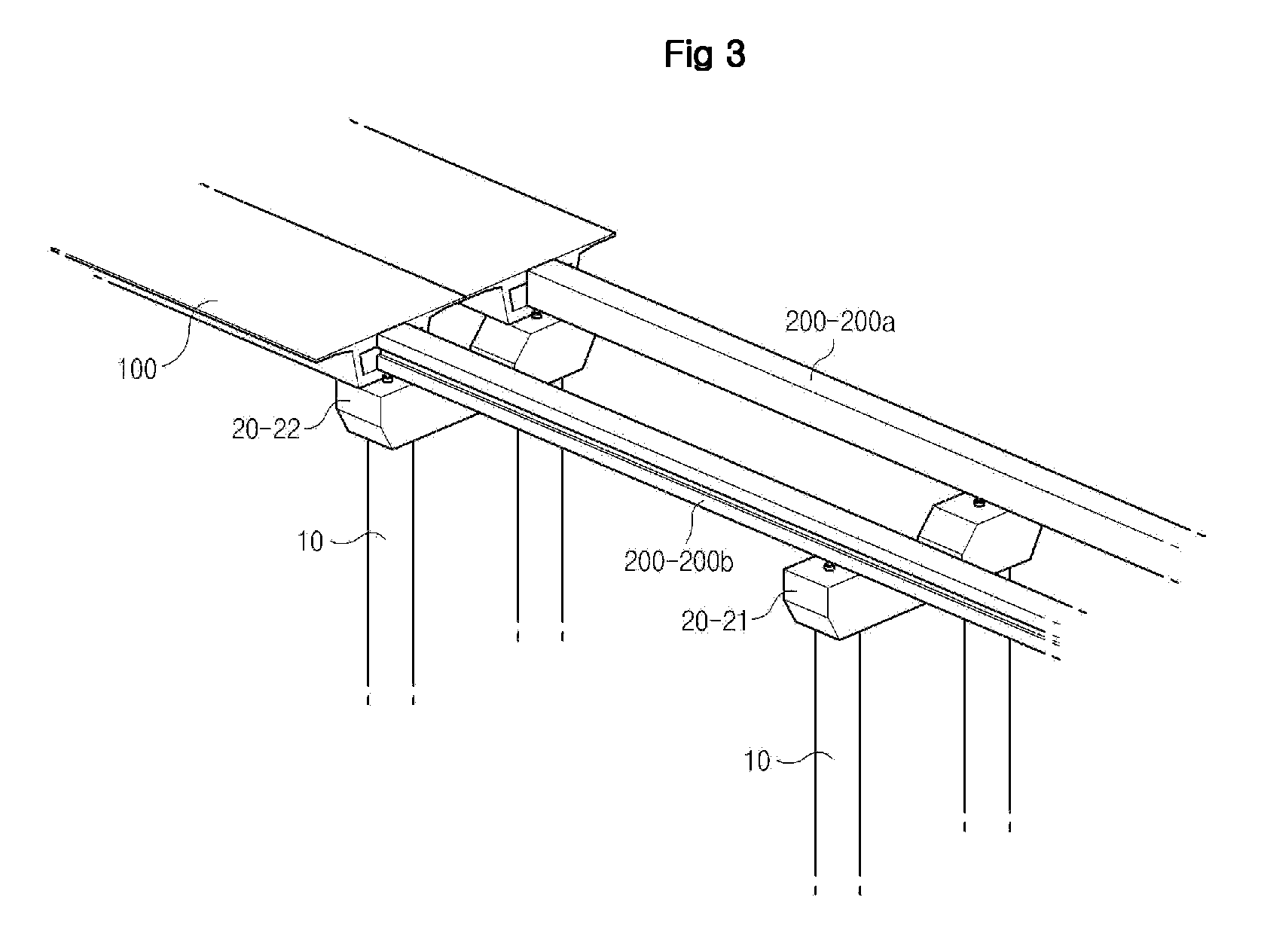

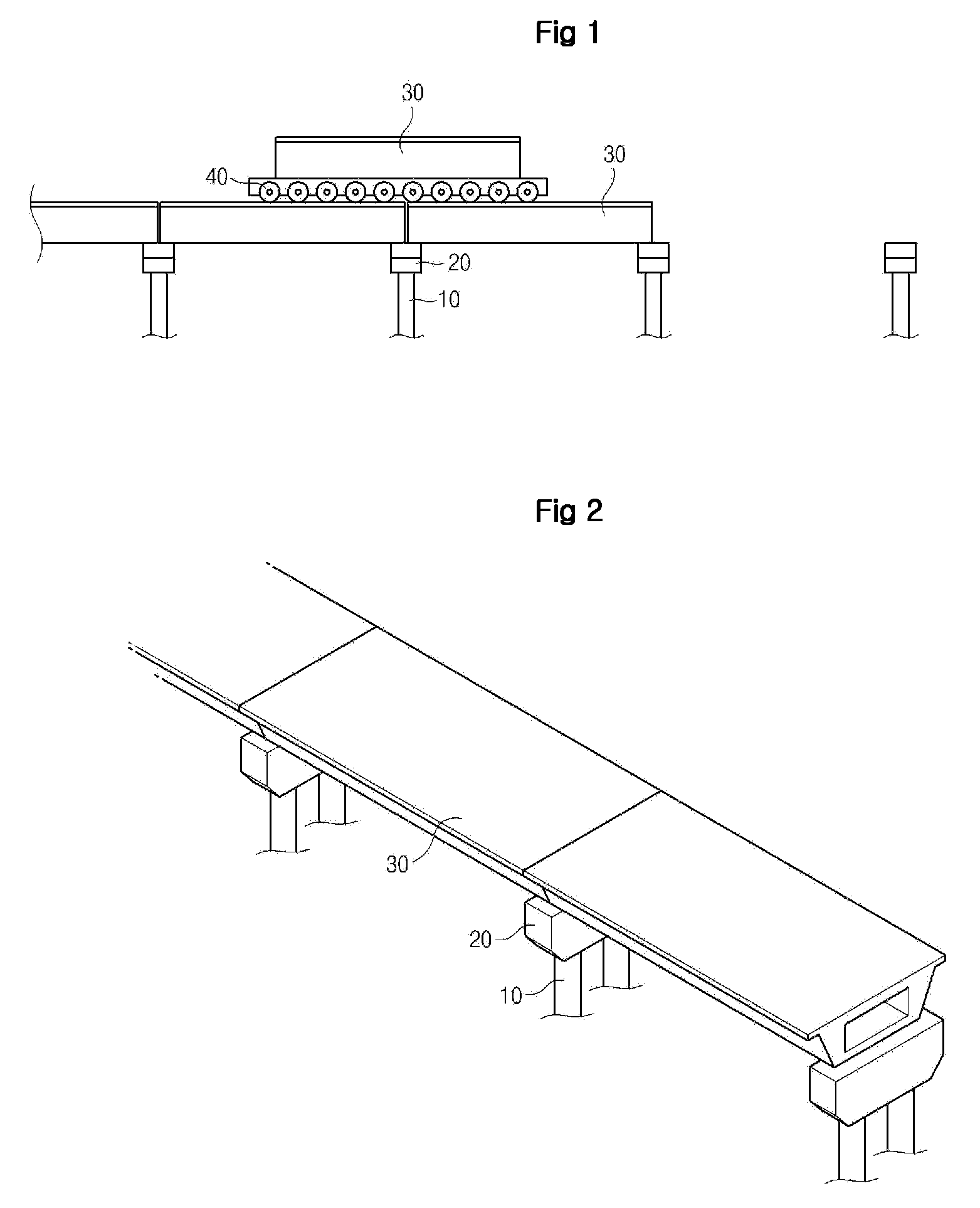

Construction method for girder in bridge, crane for pulling up girder, vehicle for carring girder, and girder used for the same

InactiveUS20080301889A1Prevent downward deformationAvoid interferenceLoad-engaging girdersTravelling cranesEngineeringStructural engineering

A construction method for a girder in a bridge which a plurality of piers are installed in an interval in a longitudinal direction of the bridge, a plurality of copings are installed on the piers, and a plurality of girders respectively installed between the piers are installed on the copings, the method comprising the steps of: installing at least one temporary girder on a front coping of the copings and a rear coping adjacent to the rear coping of the copings; installing a crane for pulling up a girder having a girder pulling up space therein guided by the temporary girder; providing with a girder by a pre-cast method so as to install a girder on the front coping and the rear coping; providing with a vehicle for carrying a girder, the vehicle being constituted so that load of a girder to the piers carried by the vehicle is distributed to the piers through the upper surface of the girders installed in advance; introducing the vehicle carrying a first girder moving along a guide of the temporary girder to a girder pulling up space of the crane; pulling up the first girder by the crane; drawing out the vehicle backward from the girder pulling up space; moving a first temporary girder of the temporary girders from a position where the first girder is to be installed to a front of the front coping of the one of the copings and installing the first temporary girder on a next front coping installed in a next front of the front coping and the front coping; and settling the first girder on the front coping and the rear coping by the crane is disclosed.

Owner:SAMSUNG C&T CORP

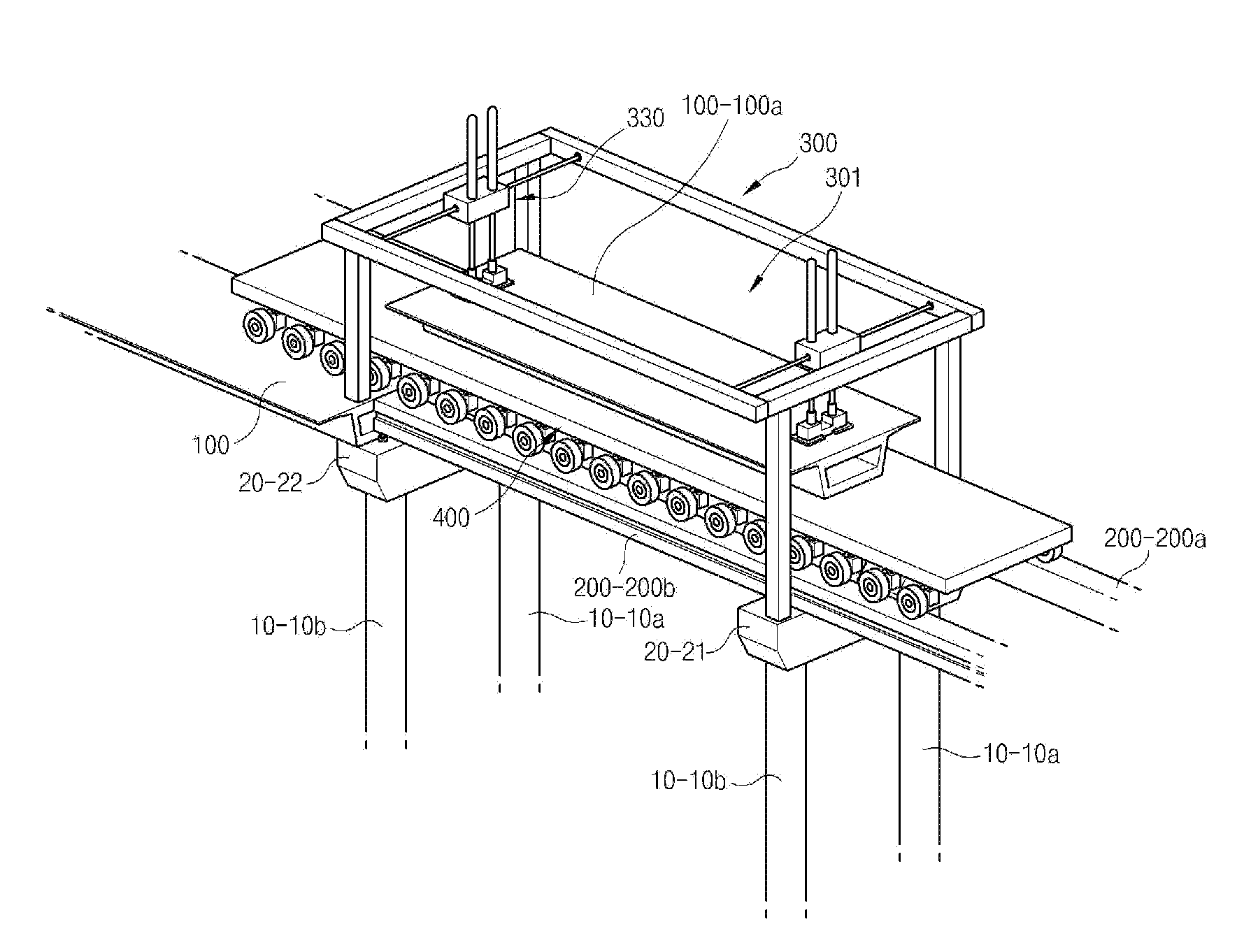

Propelled hydraulic cable carrying crane

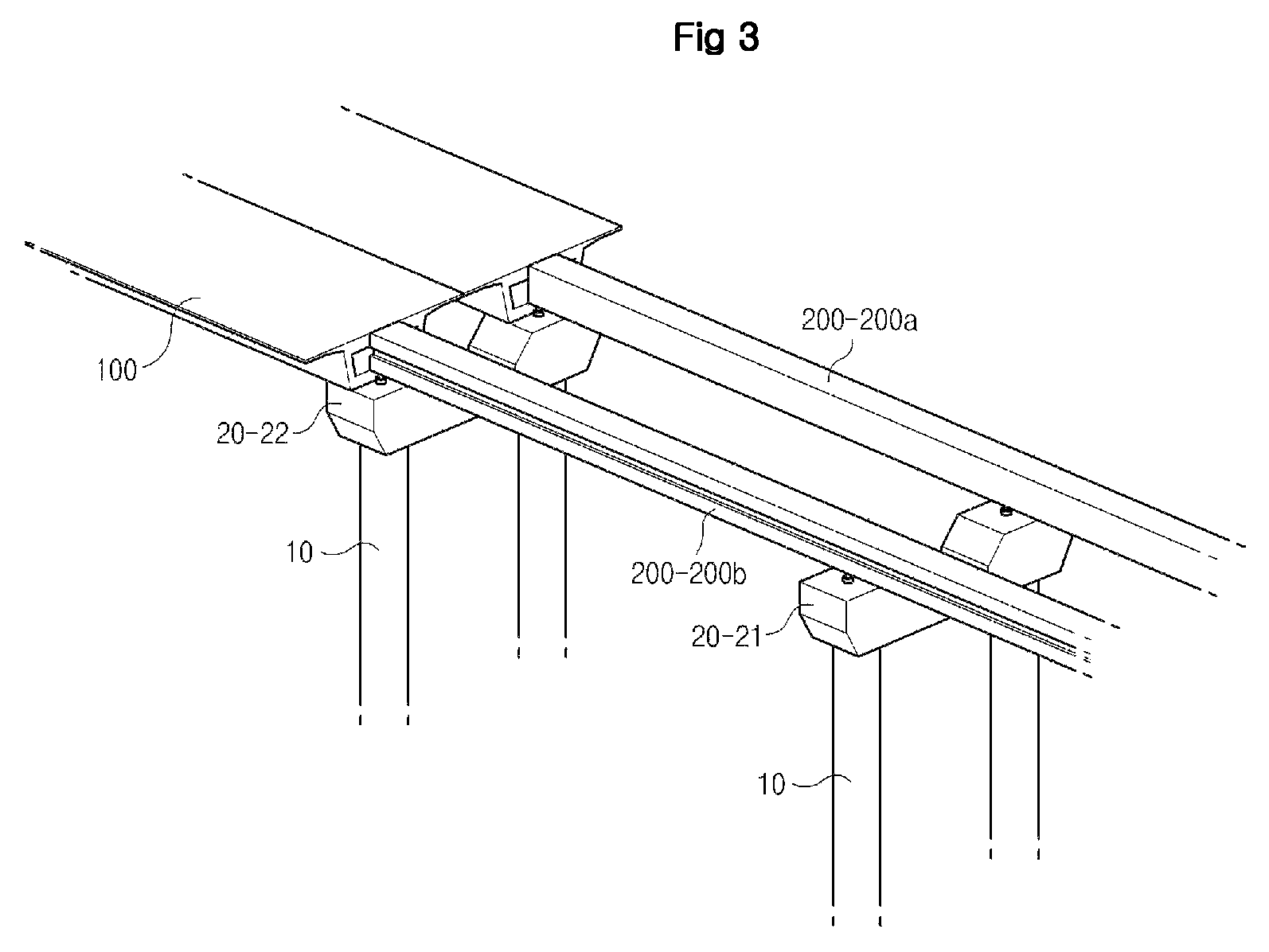

InactiveCN102153022AEnsure structural safetyWalk fastLoad-engaging girdersSuspension bridgeControl systemEngineering

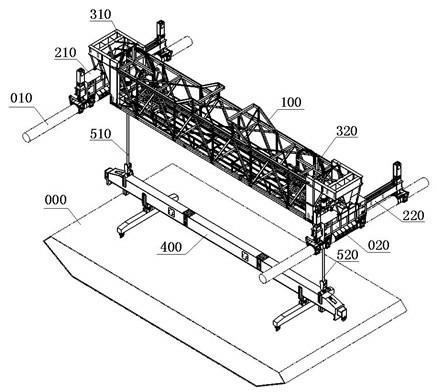

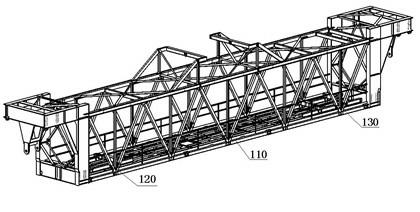

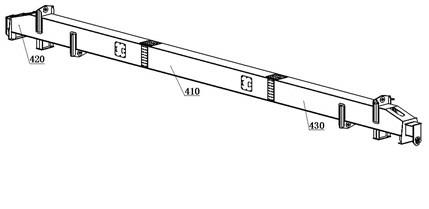

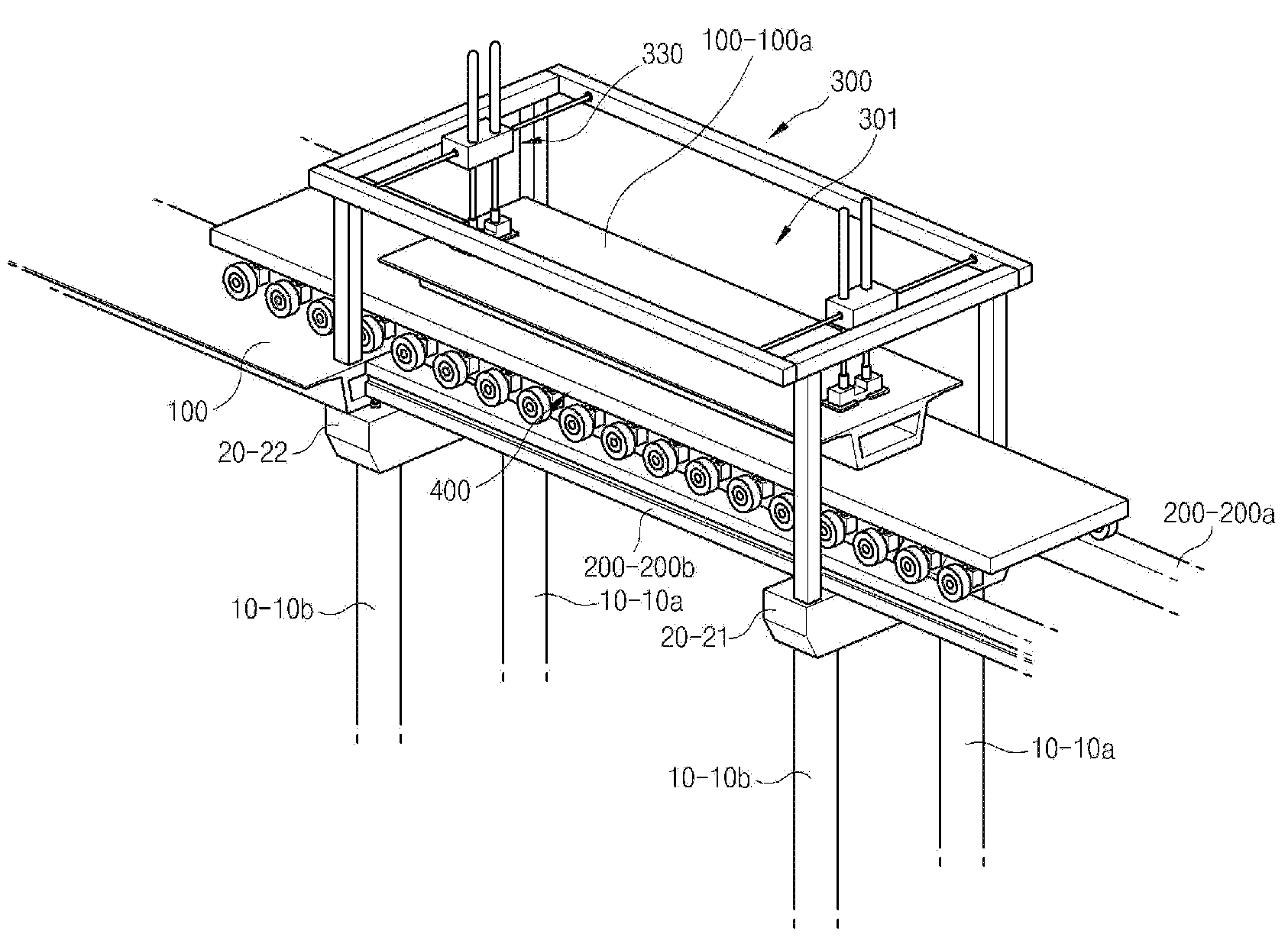

The invention discloses a propelled hydraulic cable carrying crane which comprises a power system, a control system and a mechanical executing mechanism, wherein the mechanical executing mechanism mainly comprises a main truss (100), walking type propelling systems (210 and 220) installed at both ends of the main truss, two sets of hydraulic lifting systems (310 and 320) installed on the main truss and a shoulder pole beam (400); the main truss and the shoulder pole beam both adopt length changeable structures; and the hydraulic lifting systems (310 and 320) comprise synchronous stepping continuous lifting jacks and continuous lifting steel strands (510 and 520). The whole crane realizes walking type propelling on a cable by controlling actions of a walking frame and a sliding end beam so as to alternately bear and alternately walk without additional traction equipment and manual disassembly, assembly and conveying of accessories at high altitude, such as clamping cables, hoops, and the like, and the invention has the advantages of high walking speed, high sliding resistance and high safety.

Owner:SOUTHWEST JIAOTONG UNIV +1

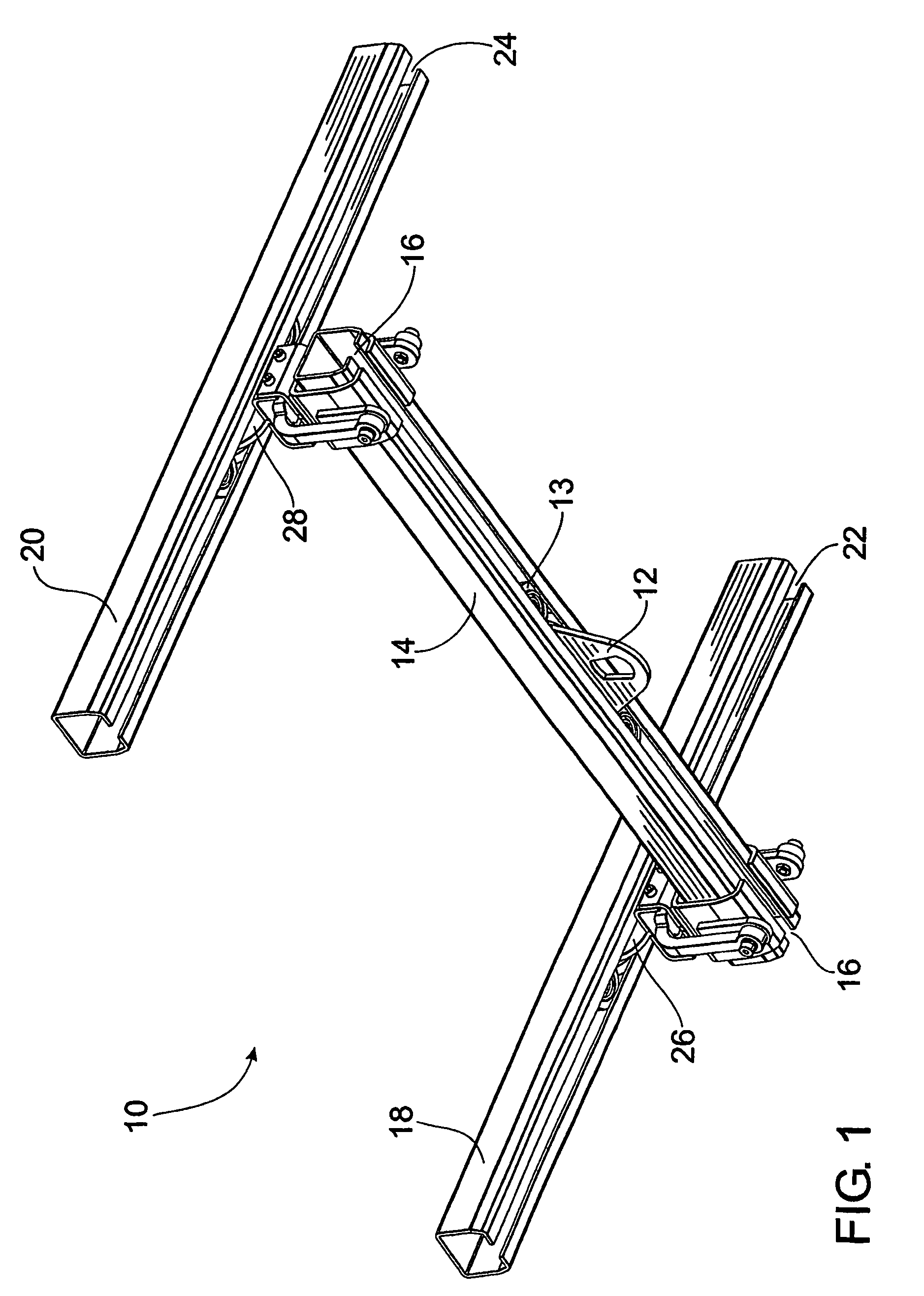

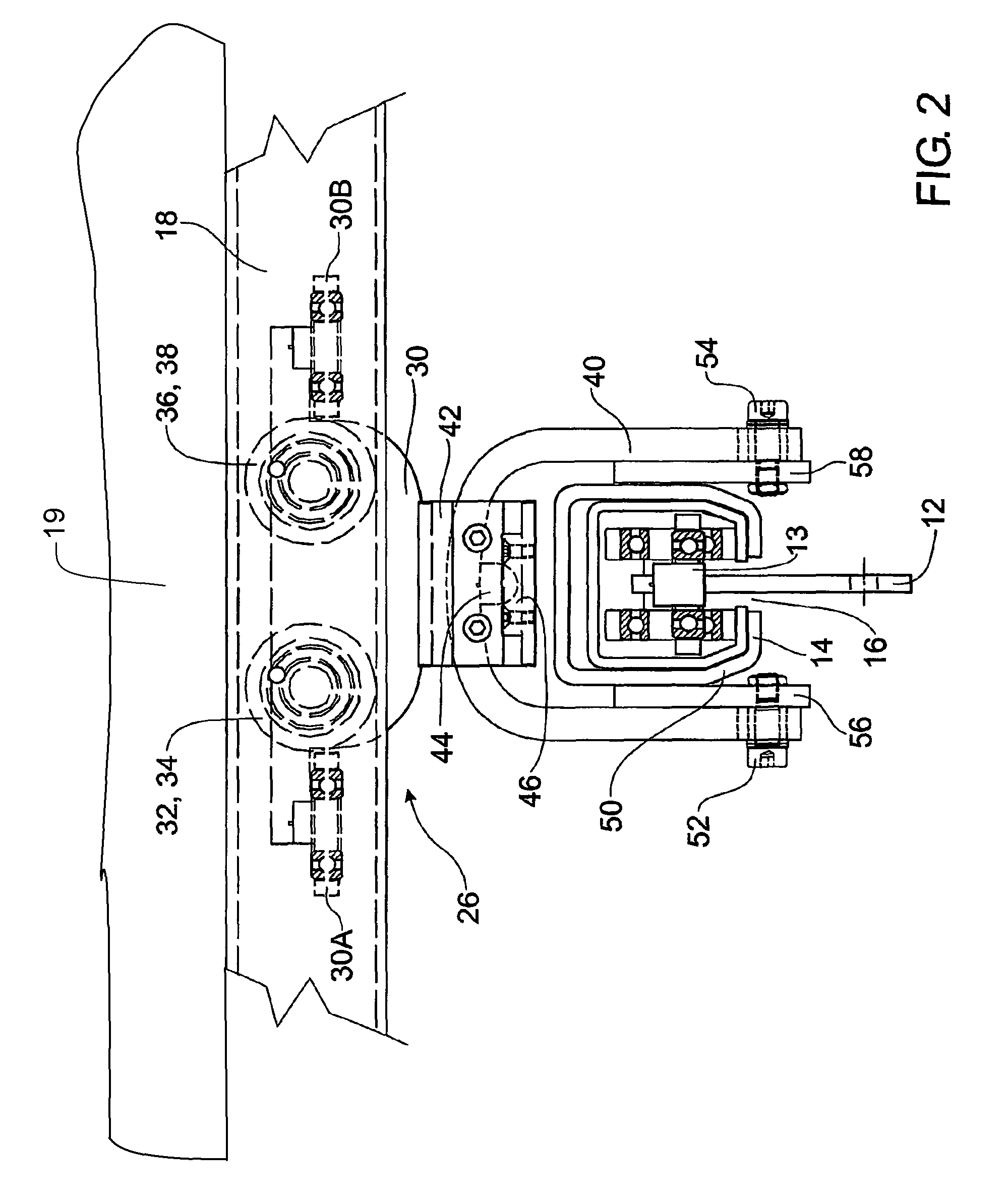

Crane assembly

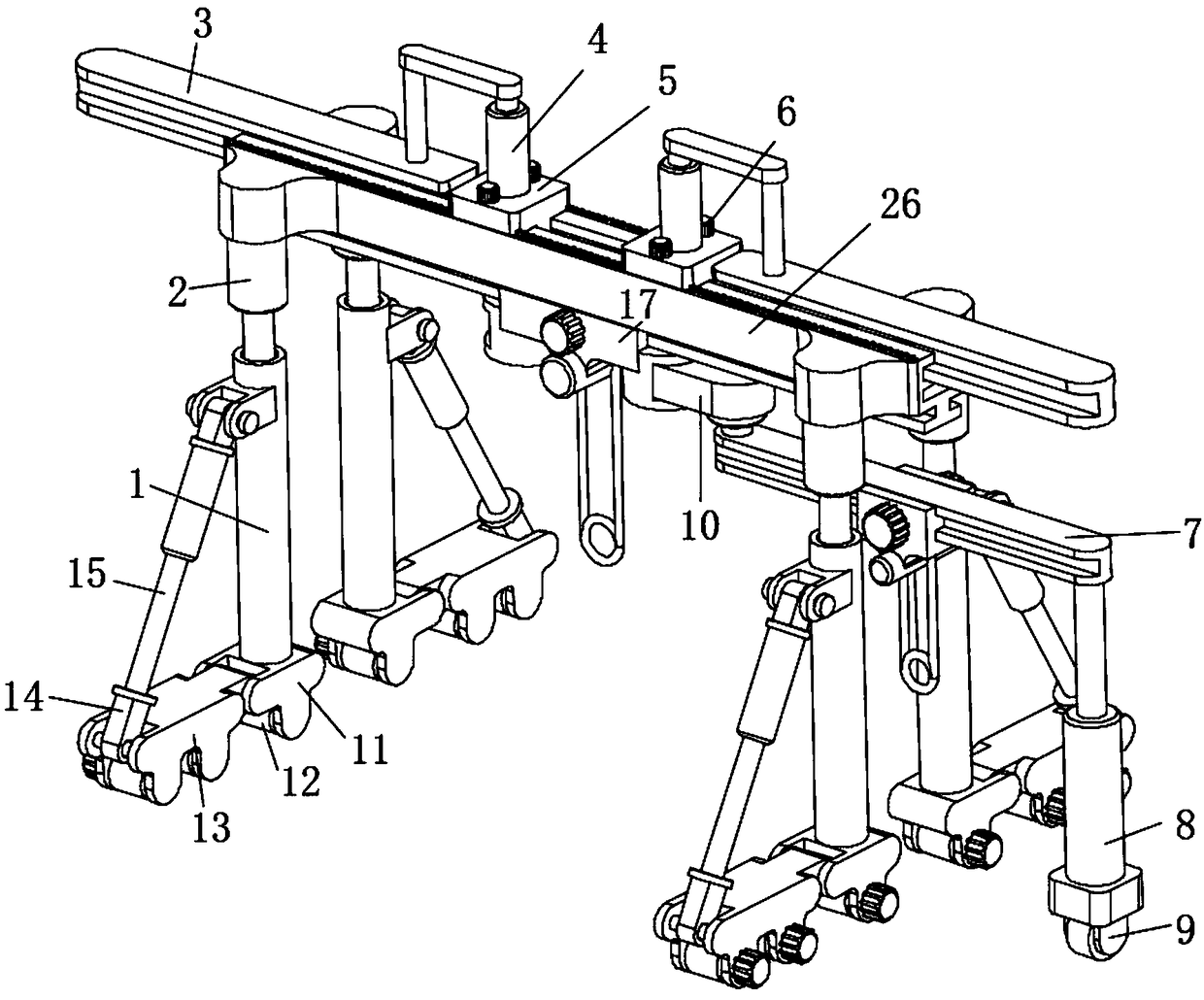

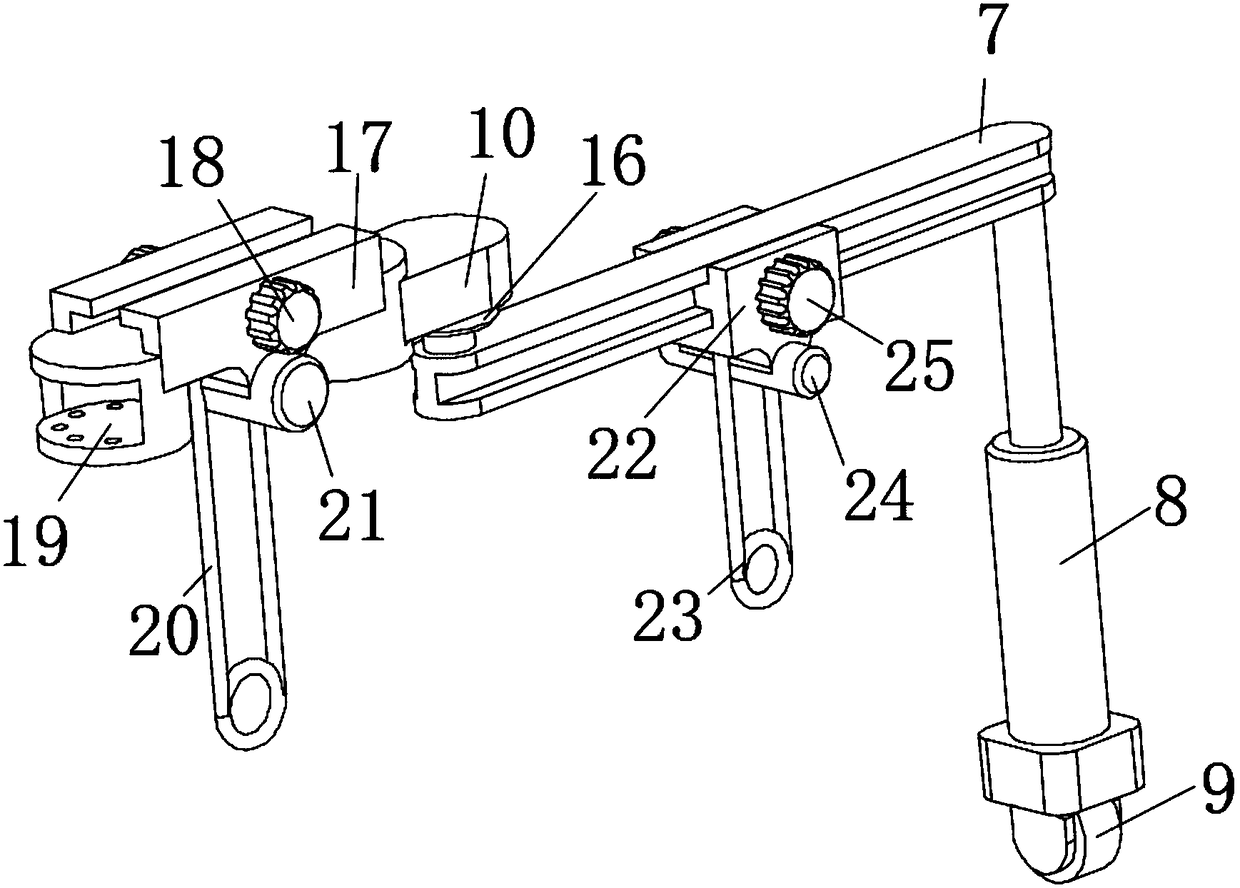

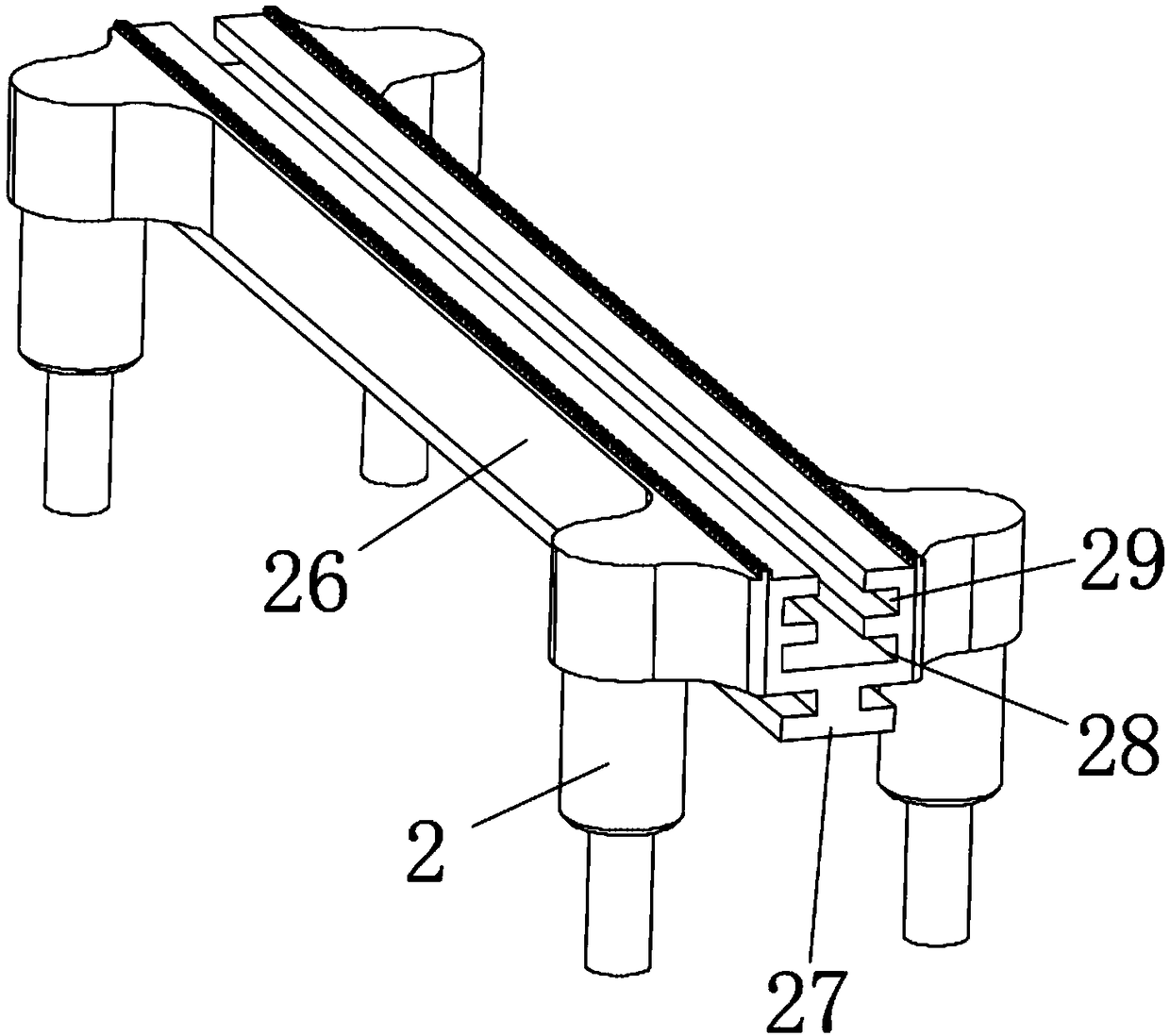

ActiveUS7850026B2Avoid interferenceReduce morbidityYielding couplingLoad-engaging girdersEngineeringMechanical engineering

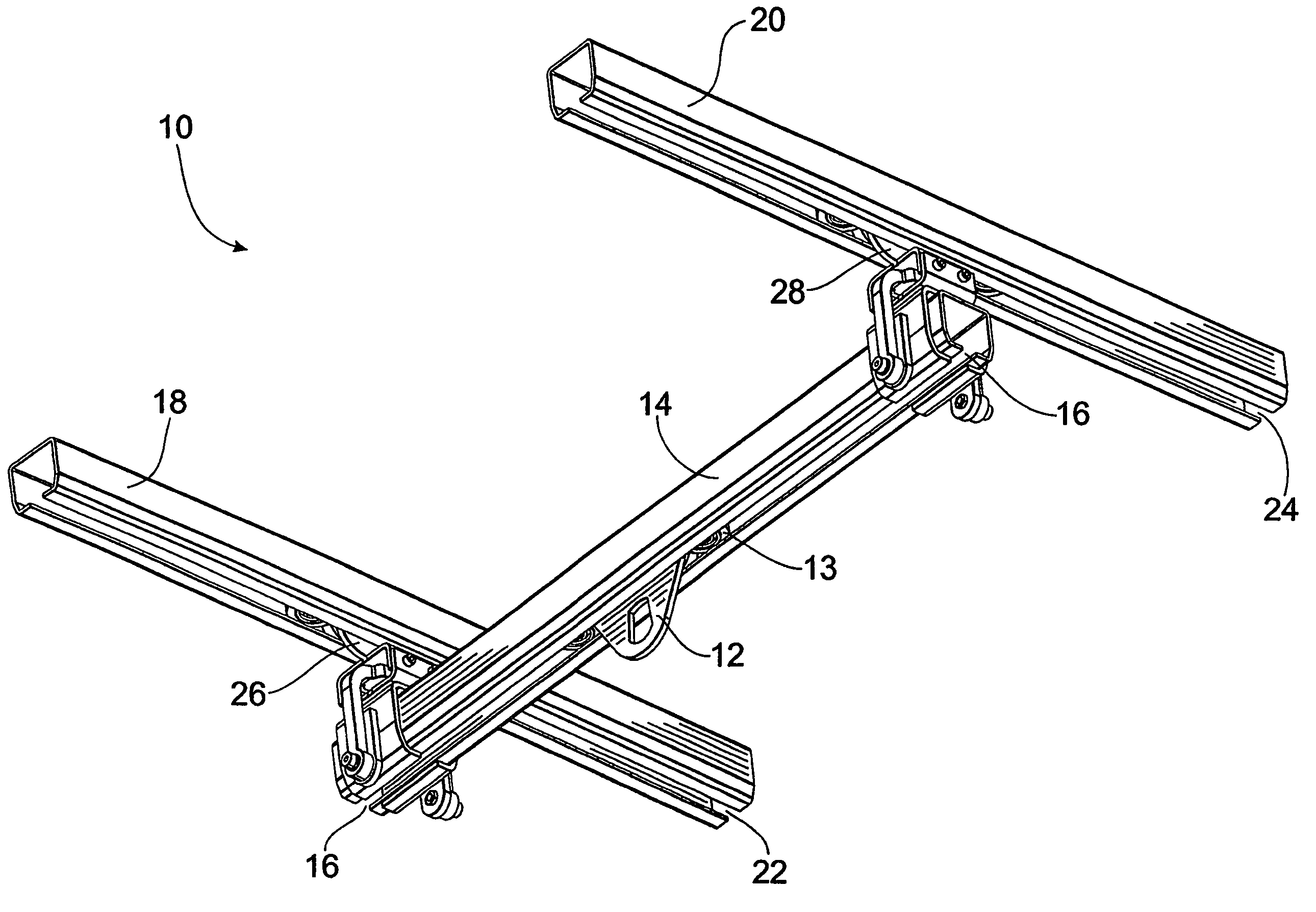

A lifting assembly comprising parallel guides (18, 20), a carriage (26, 28) associated with each parallel guide (18, 20) and movable along the length of the parallel guides, a displacement arm (40) pivotally connected to each carriage (26, 28) and pivotally supporting a bridge (14), preferably a trolley (13) located on the bridge (14) including attachment means (12) for supporting a lifting device.

Owner:THE MCKAY

Construction method for girder in bridge, crane for pulling up girder, vehicle for carring girder, and girder used for the same

InactiveUS8166596B2Prevent downward deformationAvoid interferenceLoad-engaging girdersTravelling cranesStructural engineering

Owner:SAMSUNG C&T CORP

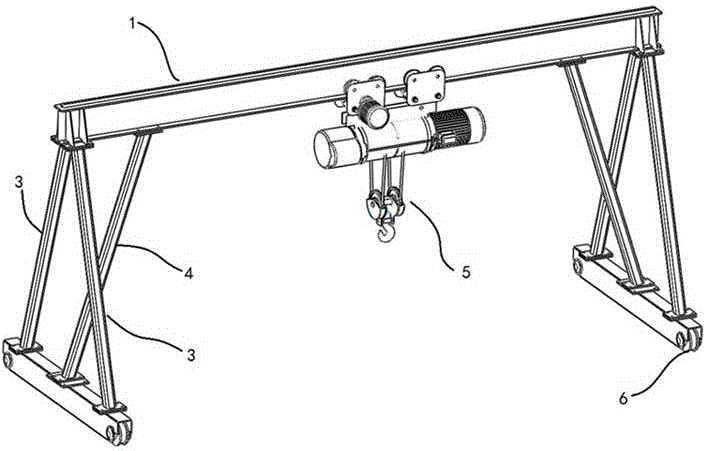

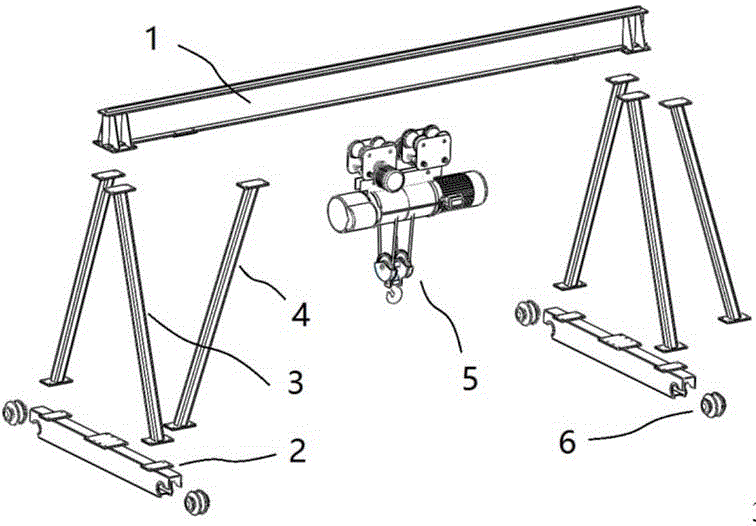

Expandable gantry crane frame

InactiveCN108502740AMeet the needs of transportationImprove stabilityLoad-engaging girdersBase supporting structuresEngineeringGantry crane

The invention discloses an expandable gantry crane frame. The expandable gantry crane frame comprises a main beam, wherein a pair of vertical pillars are arranged on two sides of the main beam respectively, a main lifting device is arranged at the lower end of the main beam, and a driving end of the main lifting device is fixedly connected with the upper ends of the vertical pillars; main supportsare arranged at the lower ends of the vertical pillars, and auxiliary supports are hinged and mounted on the outer sides of the main supports; connecting rods are hinged and mounted between the auxiliary supports and the vertical pillars, and auxiliary support resetting devices are arranged in the connecting rods. The mobile distance of a second mobile seat can be extended by use of extending auxiliary beams. According to the device, the support stability of the lower ends of the vertical pillars can be increased through the auxiliary supports, and during transportation, and space occupationof the auxiliary supports can be saved through folding. The device also can transport articles outside the device by use of a second lifting hook through matching of an auxiliary guide rail driving motor and a third mobile seat, so that the article transportation demand is better met, and the trouble of manual carrying is avoided.

Owner:丁瑞

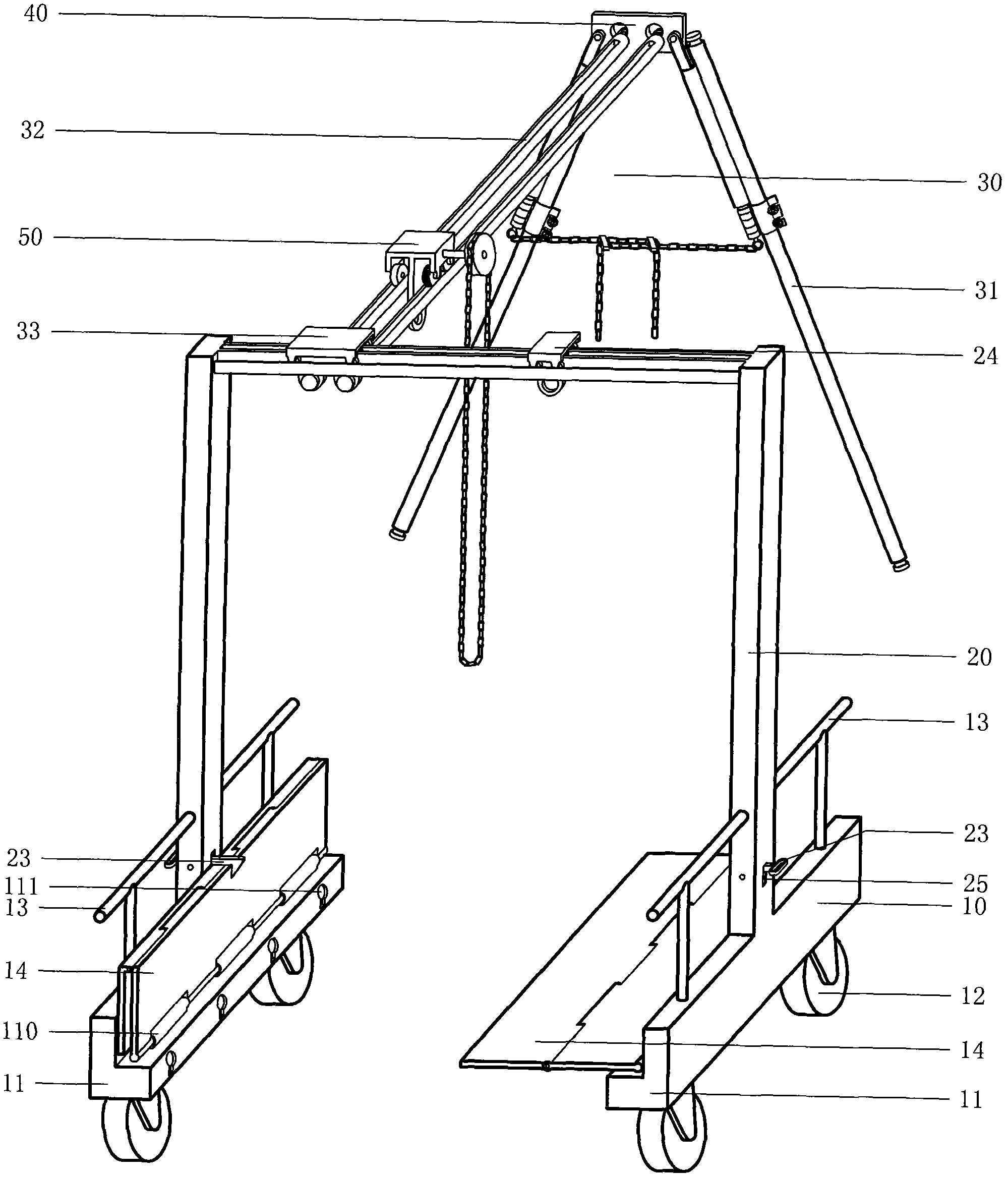

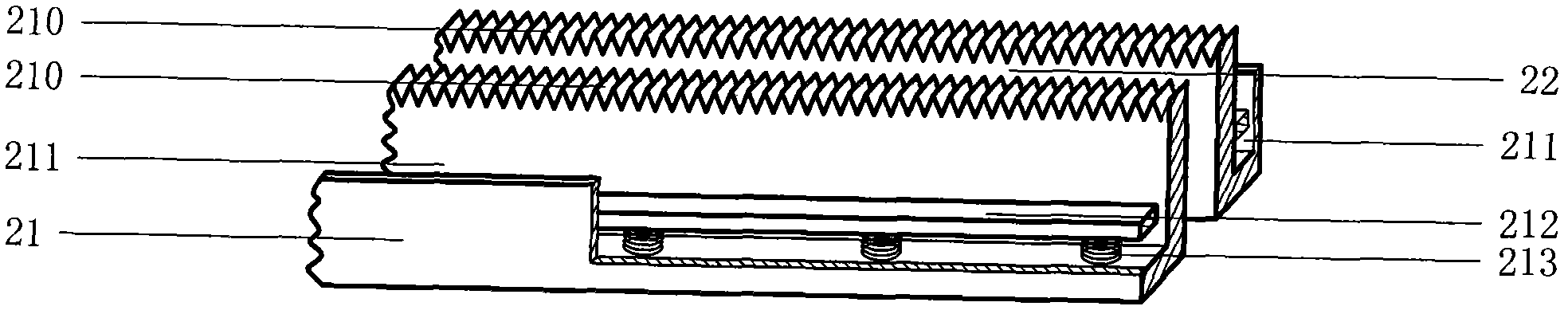

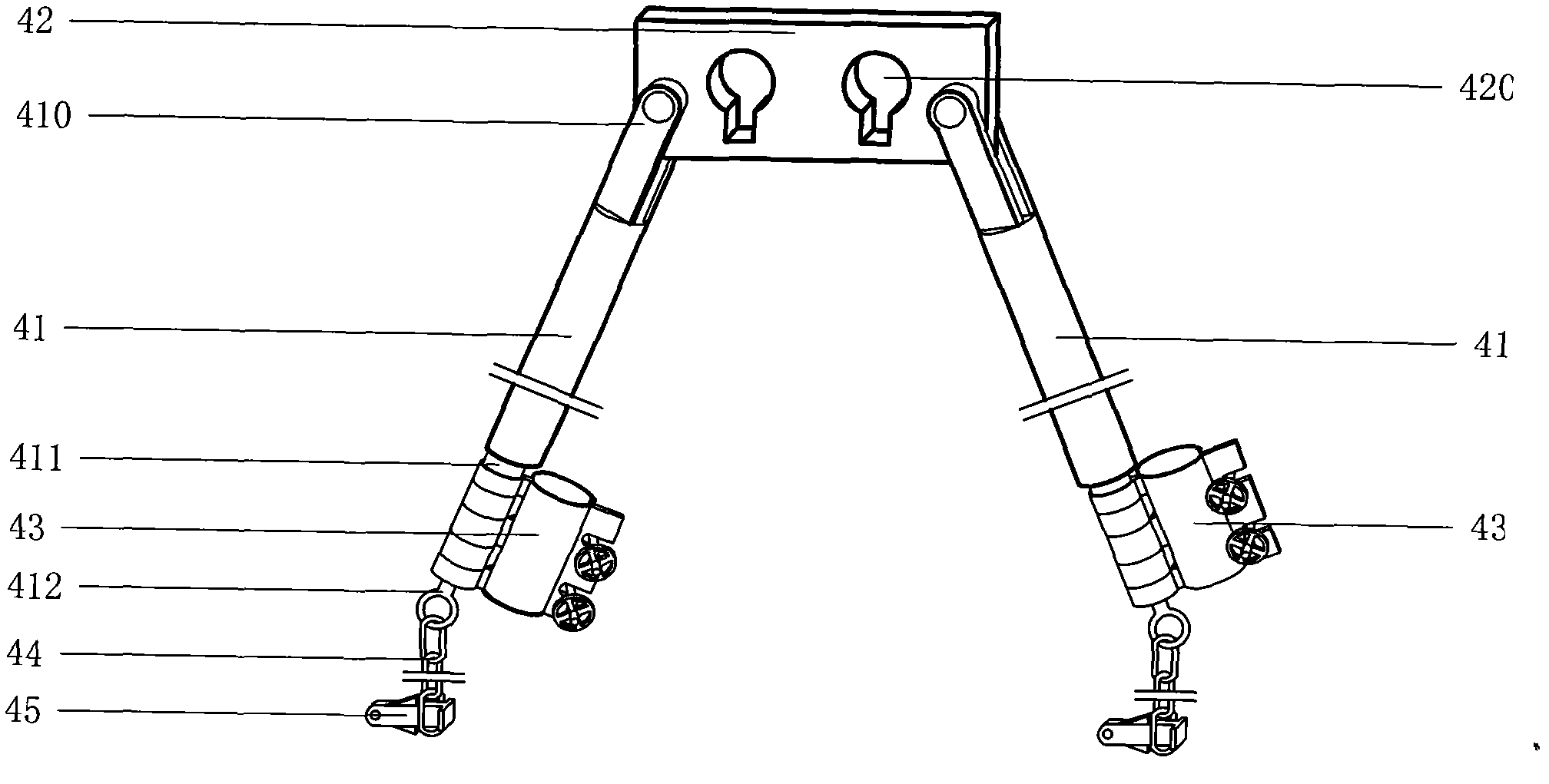

Combined type movable hanger

InactiveCN102659029AImprove work efficiencyIncrease job securityLoad-engaging girdersBase supporting structuresVehicle frameMachine maintenance

The invention provides a combined type movable hanger. The combined type movable hanger comprises a movable vehicle frame, a door type hanger and a fork type combination frame, and is characterized in that the movable vehicle frame comprises an angle form vehicle beam, carrying rollers, a push-pull handle and a carrying car plate, the door type hanger is installed on the movable vehicle frame, a top beam of the door type hanger comprises a groove type hanging beam and a rail hanger slideway, the fork type combination frame, the movable vehicle frame and the door type hanger are combined into a manual control carrier or a hoisting hanger, and the fork type combination frame comprises a comprehensive base frame, a fork frame vertical rod, a fork frame cross rod, a cross rod rail hanger and a chain driving rail hanger. According to the embodiment provided by the invention, an overhaul worker can conveniently and reasonably set a hoisting and hanging point at a production spot, without damaging a floor and affecting safety production of the whole device; moreover, equipment, hoisting tools and assembling / disassembling tools can be carried to the production spot or a machine maintenance plant together without needing other carriers; and therefore the combined type movable hanger has the advantages of reasonable structure and convenience for assembly, working efficiency of the overhaul worker can be effectively increased, and overhaul safety of the overhaul worker can be effectively improved.

Owner:QUZHOU YIKEDA ENERGY SAVING TECH

Connecting method and structure of crane beam for self adaptable column sedimentation

InactiveCN1613745AAdapt to vertical deformationLoad-engaging girdersSheet steelArchitectural engineering

A crane beam connecting method and structure adaptive to the settling of factory building columns features that the flexible connection able to move up or down is used between the said column and crane beam and between crane beams. A steel plate with vertical elliptical hole is fixed to the crane beam. A clamping plate with circular hole is fixed to the vertical column of factory building. Said steel plate and clamping plate are linked via pin.

Owner:GUIYANG AL-MG DESIGN & RES INST

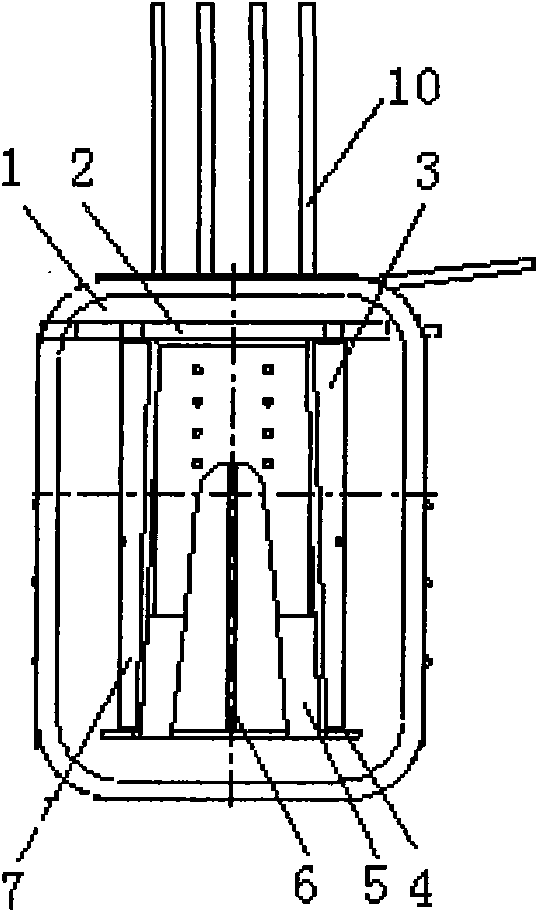

Ring crane corbel for nuclear power station and manufacturing method thereof

ActiveCN101875475AReasonable structureMeet support requirementsLoad-engaging girdersBuilding constructionsNuclear powerArchitectural engineering

The invention relates to a ring crane corbel for a nuclear power station and a manufacturing method thereof, belonging to the technical field of building construction facilities. In the ring crane corbel, a box-type frame main body comprises a rectangular main body plate, wherein an upper cover plate and a lower cover plate are respectively soldered and fixed on one side of the main body plate; a left lateral plate, a right lateral plate and a middle stiffened plate are soldered between the upper cover plate and the lower cover plate; the left lateral plate, the right lateral plate and the middle stiffened plate are soldered with the main body plate; the two ends of one side of the lower cover plate are soldered with the two bottom edges of an external baffle; the upper part of the external baffle extends between the left lateral plate and the right lateral plate after the upper part of the external baffle is bent; the two lateral edges of the upper part of the external baffle are respectively soldered with the inner surfaces of the left lateral plate and the right lateral plate; the other side of the main body plate is soldered with a bent bar; and horizontal and vertical stiffened plates are respectively soldered on corresponding positions on the main body plate, which are soldered with the upper cover plate, the lower cover plate, the left lateral plate, the right lateral plate and the middle stiffened plate. After the ring crane corbel is adopted, the use requirement can be met, and reasonable assembly and soldering sequence are adopted, so the final quality of the ring crane corbel component can be ensured.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

Middle rail box girder for large-tonnage bridge crane and manufacturing method of middle rail box girder

ActiveCN108382989ABreak through the technical bottleneck of limited useEasy to prepareLoad-engaging girdersRunwaysBox girderFlange

Disclosed are a middle rail box girder for a large-tonnage bridge crane and a manufacturing method of the middle rail box girder. Two semicircular reinforcing plates are welded to each of the two sides of a large transverse rib plate and a small transverse rib plate of the box girder, the upper end is machined overall, thus a smooth plane is formed, and the part, within a certain range at the bottom of a rail, of the plane is not welded to an upper flange plate and is only in close contact with the upper flange plate. The magnitude of extrusion stress between the upper flange plate and the transverse rib plates can be achieved by changing the thickness of the semicircular reinforcing plates, therefore, the technical bottleneck of use limitation of the middle rail box girder is broken through, the use range of the middle rail box girder is widened, thus the middle rail box girder is suitable for all elevating capacity types, the manufacturing method is simple, meanwhile, the condition that a large bent plate structural style with a half shaft sleeve is adopted for the end of the box girder is suggested for the first time, and economic low-height column hinge connection of the box girder and a trolley is achieved.

Owner:NINGXIA TIANDI BENNIU YINQI EQUIP

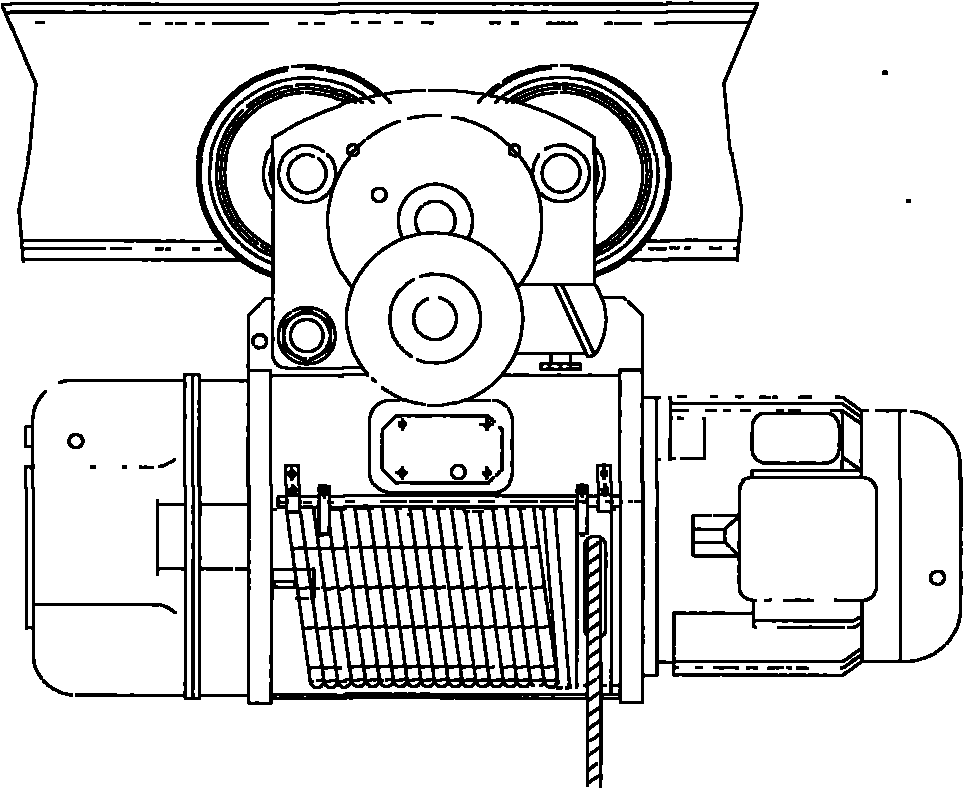

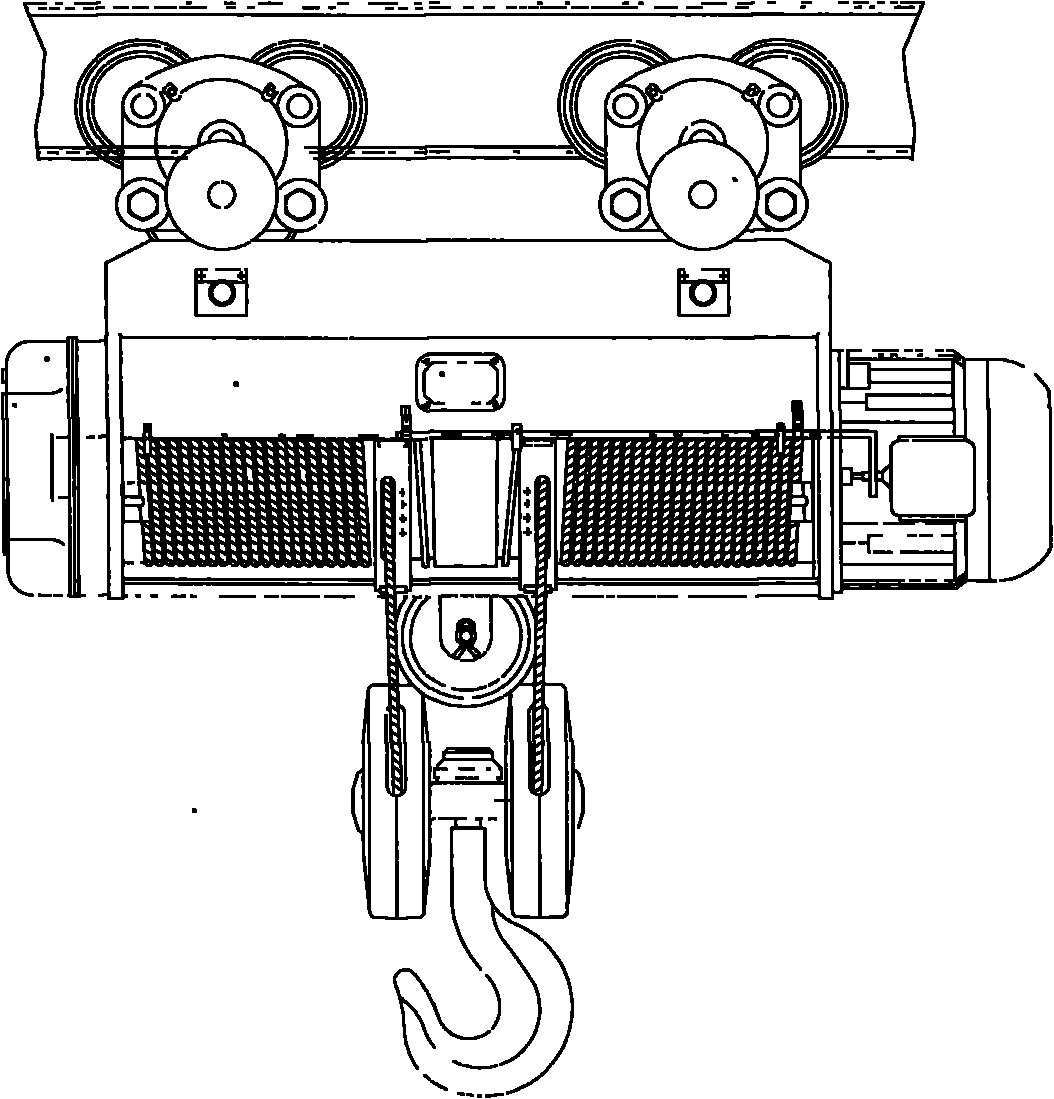

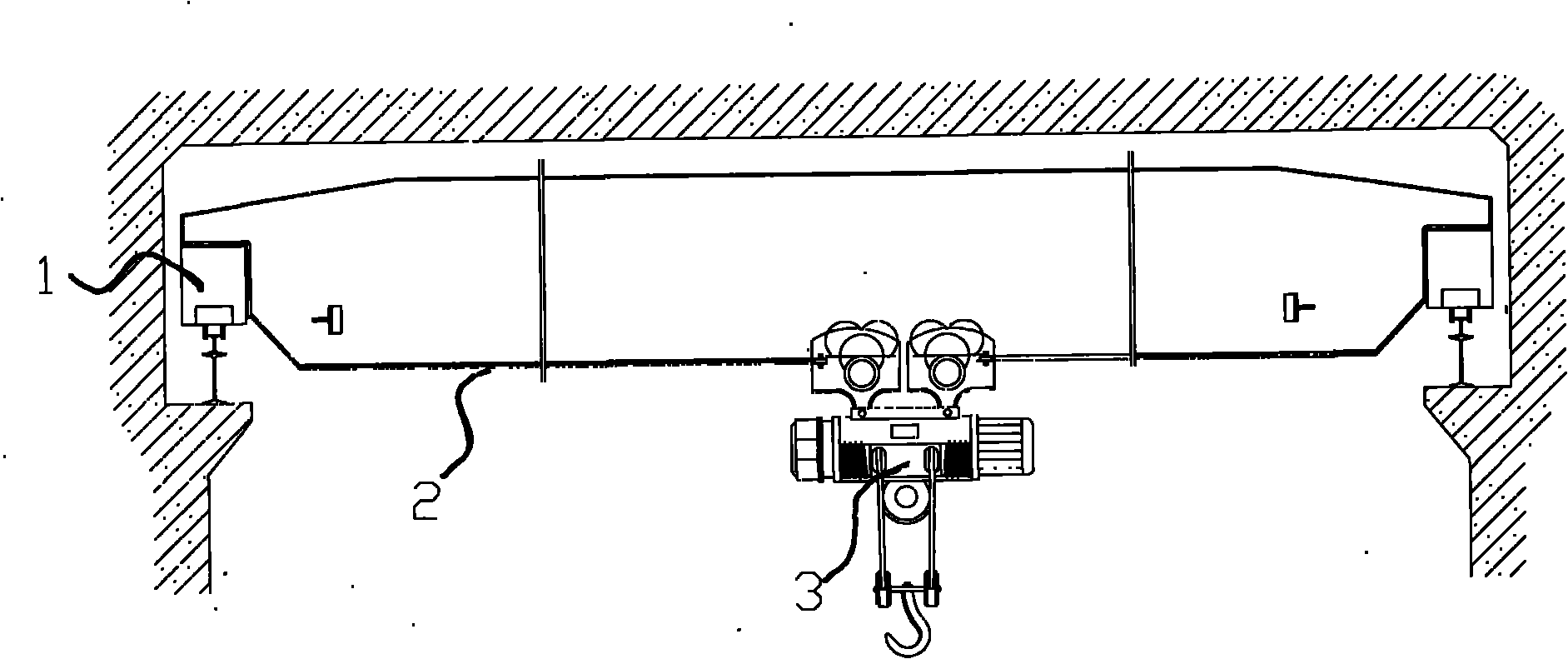

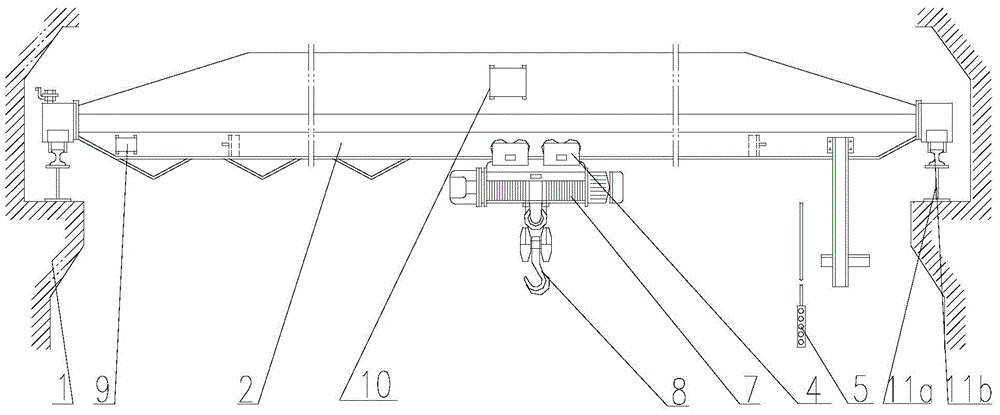

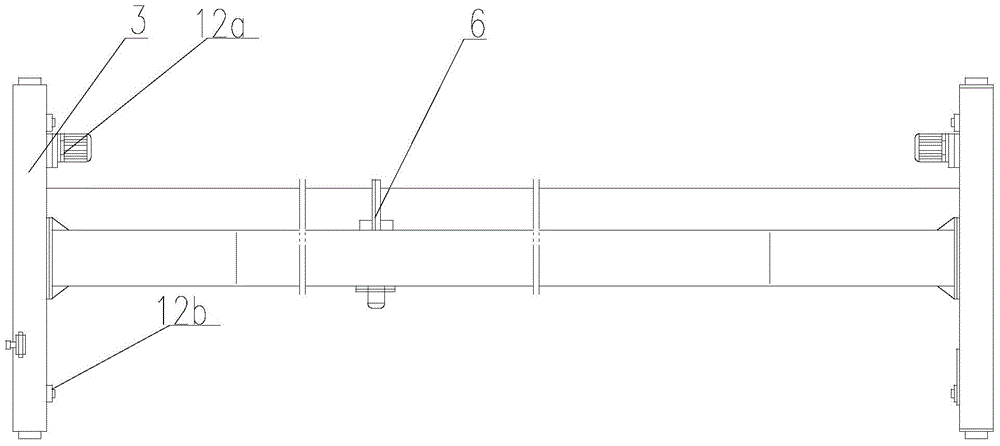

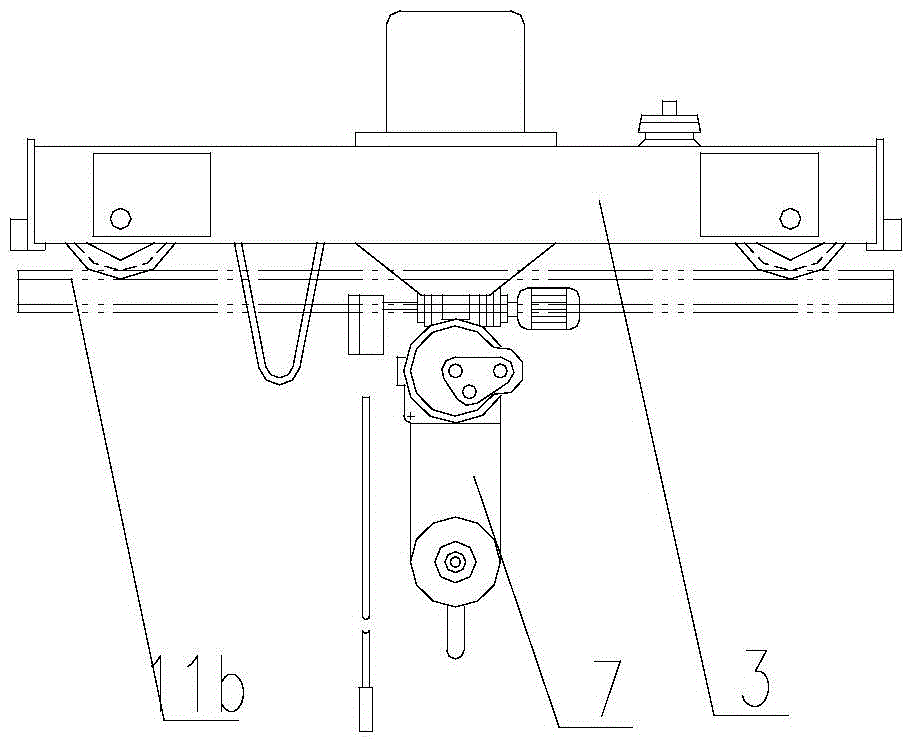

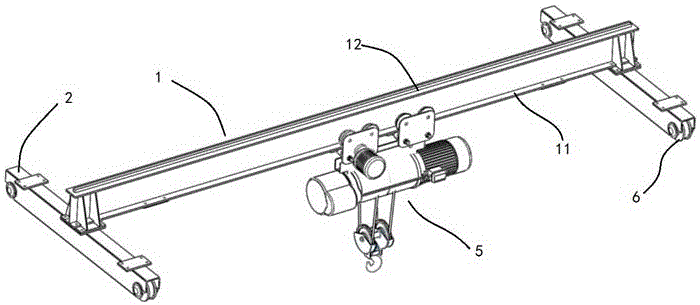

Novel electric hoist mono-beam bridge type crane

InactiveCN101973485AReasonable structureGood workmanshipLoad-engaging girdersRunwaysLow noiseDrive wheel

The invention relates to an electric hoist mono-beam bridge type crane, and relates to the field of cranes. The electric hoist mono-beam bridge type crane comprises end beams, main beams, an electric hoist running mechanism and an electrical apparatus mechanism, wherein the main beam is arranged between the end beams on both wings; the electric hoist running mechanism is arranged on the main beam and moves between the main beams under the control of the electrical apparatus mechanism; and a driving wheel set and a driven wheel set are arranged on the end beams. Due to the adoption of the novel electric hoist main beams and the novel electric hoist running mechanism and the design of a corresponding rectangular steel pipe end beam and a novel cart running mechanism, the electric hoist mono-beam bridge type crane has the advantages of reasonable structure, high manufacturability, light weight, low noise, low power consumption, long service life and accurate positioning, and is an environmental-friendly product with low energy consumption, and the weight of the complete machine can be reduced by 12 percent.

Owner:冯锡兴

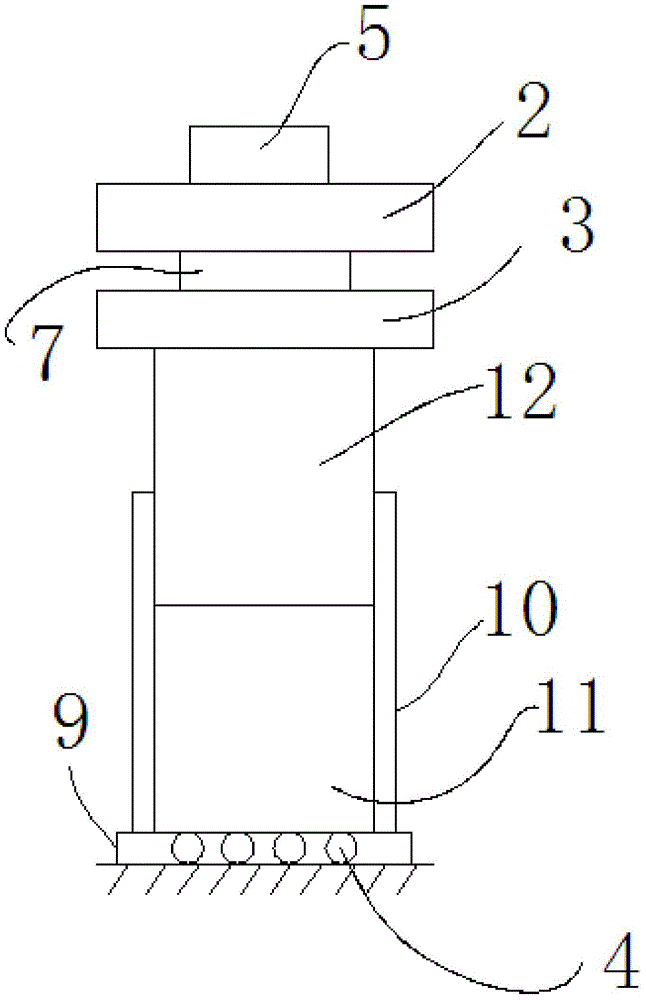

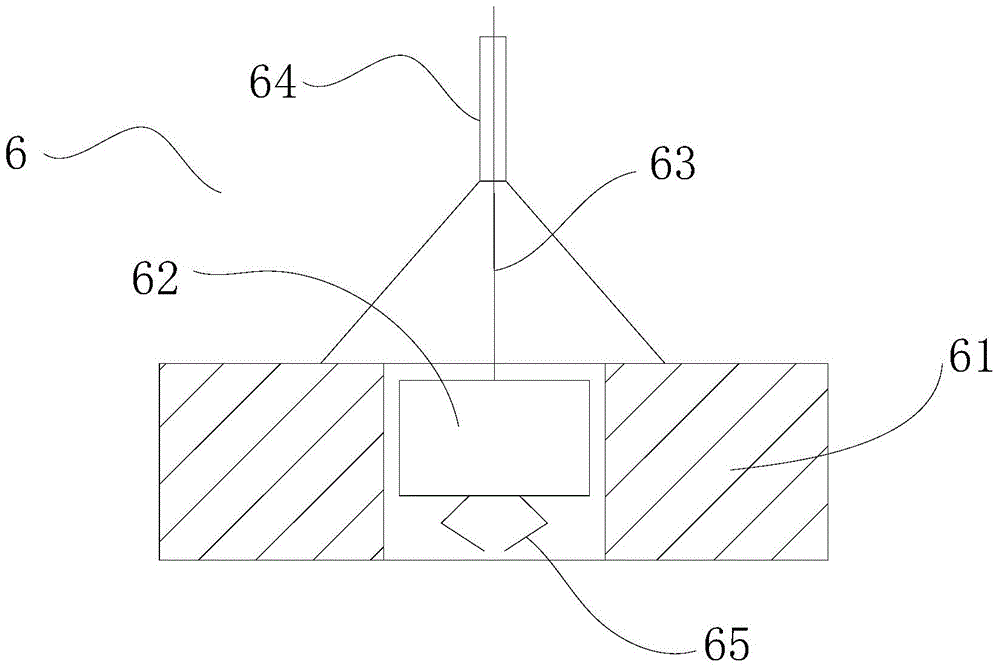

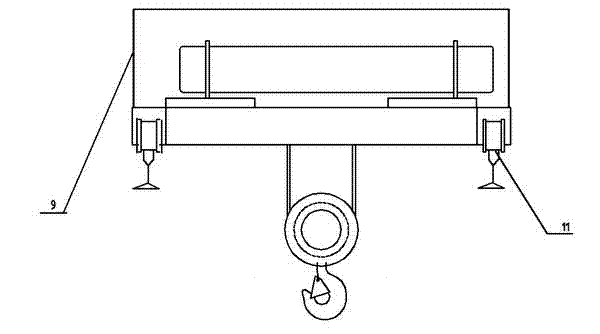

Liftable and movable gantry crane

InactiveCN104627848APrevent fallingSimple structureLoad-engaging girdersBase supporting structuresEngineeringMobile device

The invention discloses a liftable and movable gantry crane, which comprises a rack and a sling. The rack includes a pedestal, column located at both ends of the pedestal respectively and a crossbeam bridges the columns. Each column consists of a first column and a second column disposed on the pedestal, and the second column can do lifting sliding relative to the first column. Also mobile devices in contact with the ground are mounted at two ends or one end of the pedestal. A slide rail is disposed on the crossbeam, a sliding device is mounted on the slide rail, and the lower end of the sliding device is provided with the sling. A reinforcing bar is also arranged between the second column and the pedestal, one end of the reinforcing bar is rotatably connected to the second column, and the other end of the reinforcing bar is slidably disposed on the pedestal. The gantry crane provided by the invention has the characteristics of simple structure and strong practicability, and is liftable and movable at the same time.

Owner:SUZHOU KELIAN PRECISION MACHINERY

Beam crane and its downward bent beam repairing method

The present invention relates to beam crane, and is especially one kind of self-repaired pre-stressed beam crane and the method of applying external pre-stress to repair the downwards bent beam of beam crane. The method of the present invention includes the following steps: 1. fixing stretching bearing and fixed bearing separately on two ends below the lower cover of the crane beam; 2. stringing steel strands separately in the fixing anchor beside the fixed bearing and the stretching anchor beside the stretching bearing to anchor the fixed end and to pressing the stretching anchor to the outer side of the stretching bearing; 3. regulating the initial stress of each steel strand with jack for equalized stress; 4. fixing 1-4 staying devices on the lower cover of the crane beam and setting the steel strands; and 5. stretching the steel strand of the stretching anchor with jack for the beam to bend upwards, anchoring the stretching end and regulating the staying devices for proper stress.

Owner:王冠华

Single-beam overhead crane

InactiveCN104692257AGuaranteed uptimeRun quick stopLoad-engaging girdersTravelling cranesManufacturing cost reductionVehicle frame

The invention discloses a single-beam overhead crane in one embodiment. The single-beam overhead crane comprises a beam frame, a cart, a trolley, an electric block and a control mechanism; an end beam is composed of end beams on the two sides and a main beam connected with the end beams; the end beams are driven by the cart to travel on an end beam track; the electric block runs on a main beam track along with the trolley; a guide wheel device is mounted on the frame of the cart or the trolley or on both the frames of the cart and the trolley to keep the cart and / or the trolley run stably; the control mechanism is provided with an anti-crossing system to shut down a motor in case of a crossing fault. According to the single-beam overhead crane, the overall single-beam overhead crane and the auxiliary system thereof are improved, and therefore, the performance of the product can be improved in the aspects of manufacturing cost reduction, steady operation guarantee, safety performance improvement and the like.

Owner:周磊

Rail-mounted and wheel-mounted combined type tunnel track-laying crane and construction method thereof

ActiveCN106044576ASolve the problem of not being able to use bothAvoid damageLoad-engaging girdersTrolley cranesDual purposeTunnel construction

The invention relates to a crane and a construction method, belongs to the field of engineering equipment, and especially relates to a rail-mounted and wheel-mounted combined type tunnel track-laying crane and a construction method thereof. The crane provided by the invention comprises a rail-mounted wheel set and a wheel-mounted wheel set, wherein the top of the rail-mounted wheel set is movably provided with a connecting beam; and both ends of the connecting beam are provided with support-angle-adjustable wheel-mounted wheel set. Therefore, the invention has the following advantages: the design structure is simple; by the double walking modes of rail walking and wheel walking, the problem that different cross-sections of tunnel construction cannot be dual-purpose can be solved; and different walking modes can be rapidly switched, thus improving production efficiency and reducing damage to duct pieces.

Owner:CHINA RAILWAY ENG MASCH RES & DESIGN INST CO LTD

Multifunctional combined crane

ActiveCN105800476AAny combination of changesMeet different needsLoad-engaging girdersTrolley cranesMarine engineeringStructural engineering

The invention relates to a multifunctional combined crane capable of performing conversion between a bridge crane and a gantry crane and conversion between a single-beam crane and a double-beam crane, and belongs to the field of lifting machinery. The multifunctional combined crane comprises a main beam and a trolley for lifting a weight; the trolley is a lower trailer or / and an upper travelling crane; the main beam is provided with a rail I for the lower trailer to walk and a rail II for the upper travelling crane to walk; end beams for driving the main beam to walk are perpendicularly arranged at the end part of the main beam; wheels are arranged at the front and back ends of each end beam; the main beam and each end beam are detachably connected or / and through two support legs A for supporting the main beam; and the upper and lower ends of the support legs A are detachably connected with the main beam and each end beam.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

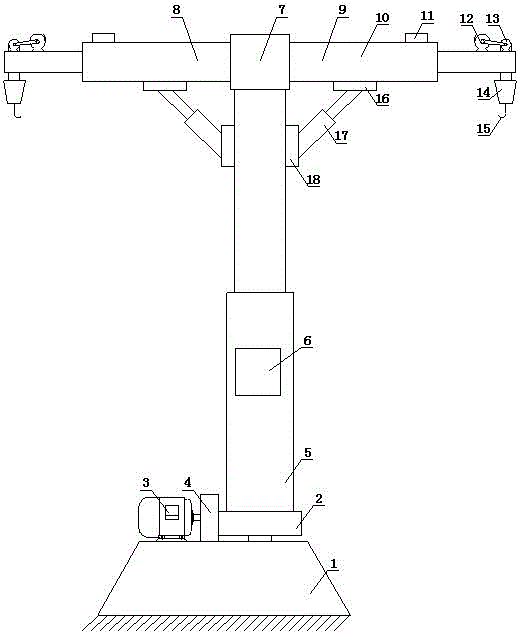

Double-beam cantilever crane

ActiveCN106006403ASimple structureGuaranteed uptimeLoad-engaging girdersCranesBlock and tackleEngineering

The invention relates to a double-beam cantilever crane. The double-beam cantilever crane comprises a fixing base. The fixing base is provided with a motor A and a gear. An output shaft of the motor A is connected to an input shaft of a reduction gearbox. The upper part of the gear is provided with a telescoping column. The lower part of the telescoping column is provided with a controller. The top of the telescoping column is provided with a fixing block. Left and right sides of the fixing block are symmetrically provided with a main beam A and a main beam B. The main beam B comprises a telescoping rod. The upper part of the telescoping rod is provided with a levelness tester. The tail end of the telescoping rod is provided with a motor B. The motor B is connected to a lifting pulley. The lifting pulley is connected to a pulley block. The lower part of the pulley block is provided with a suspension hook. The lower part of the telescoping rod is provided with a connection block A. The connection block A is connected to a hydraulic rod. The double-beam cantilever crane has the advantages of simple structure, reliable operation, low cost and good economy.

Owner:HENAN SINOKO CRANES

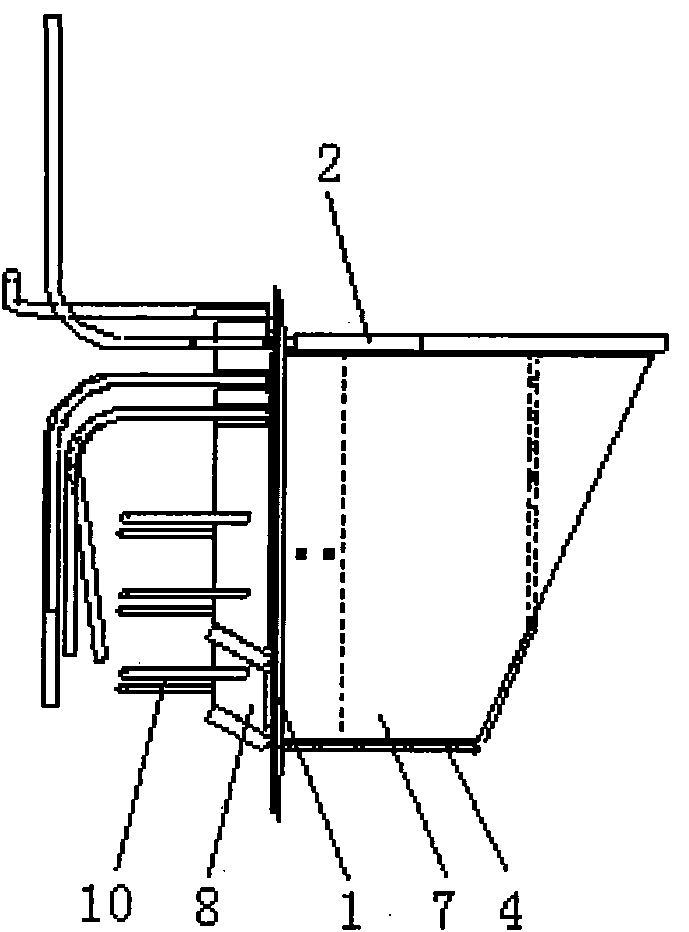

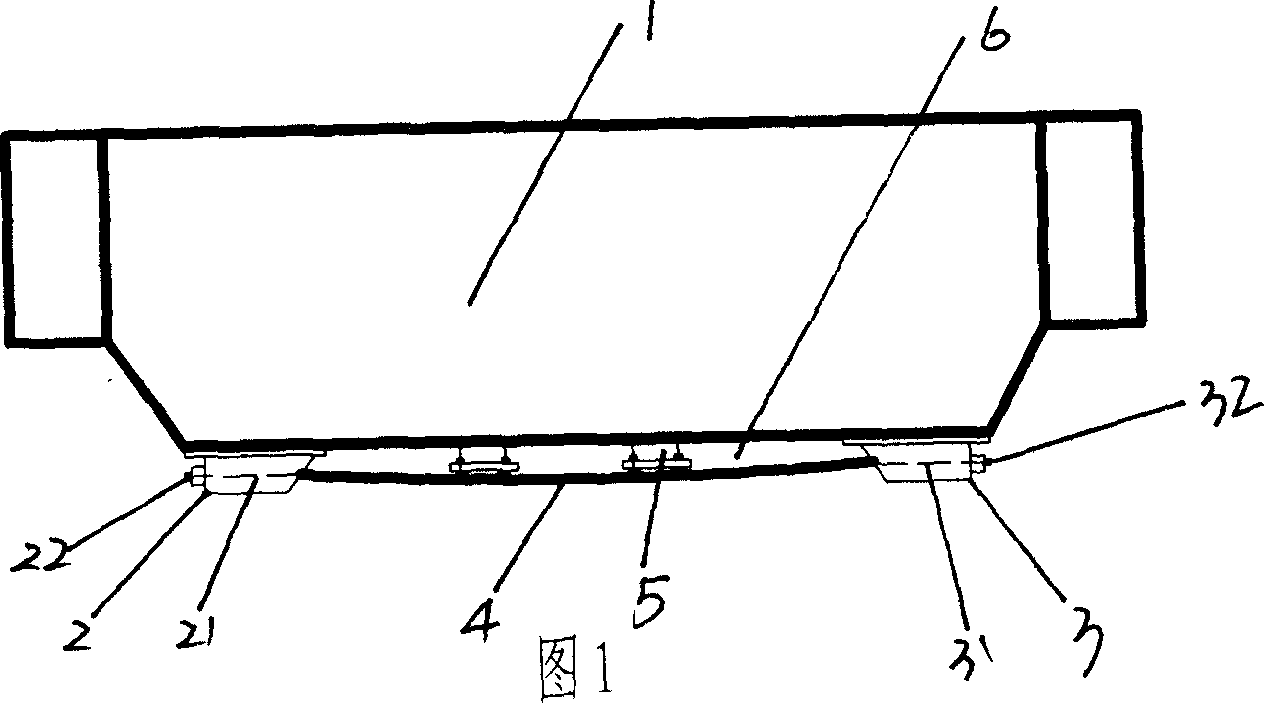

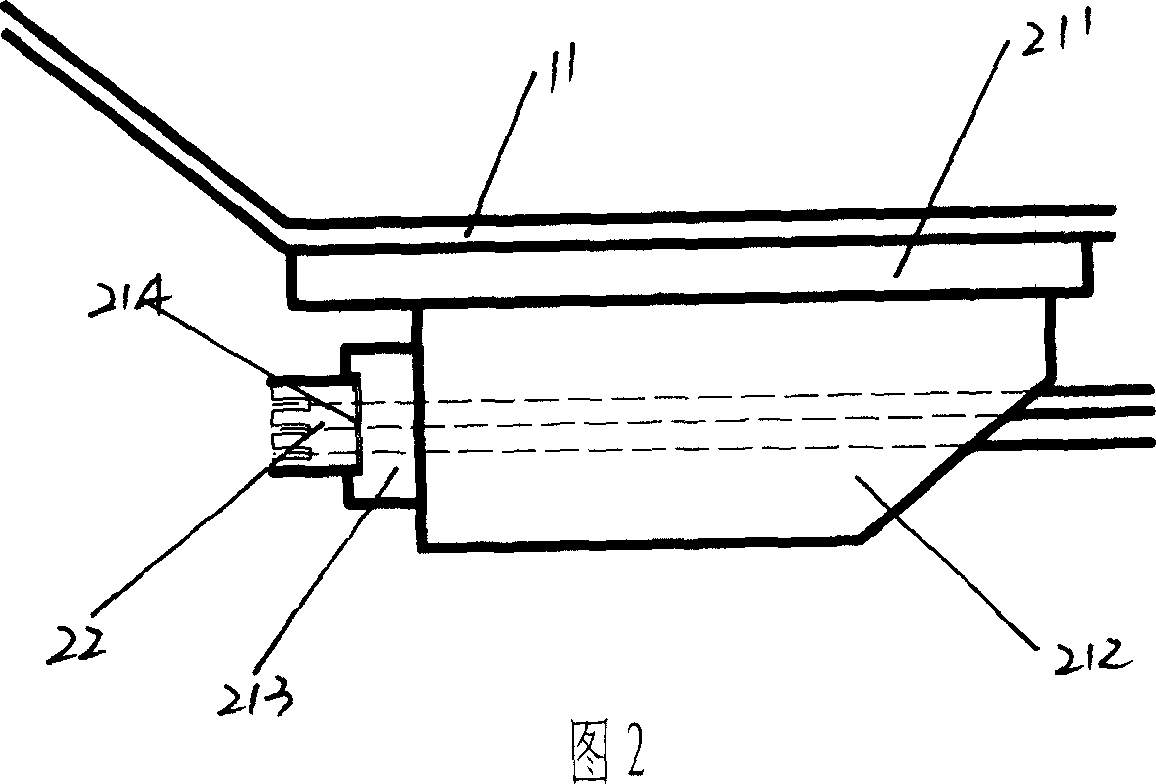

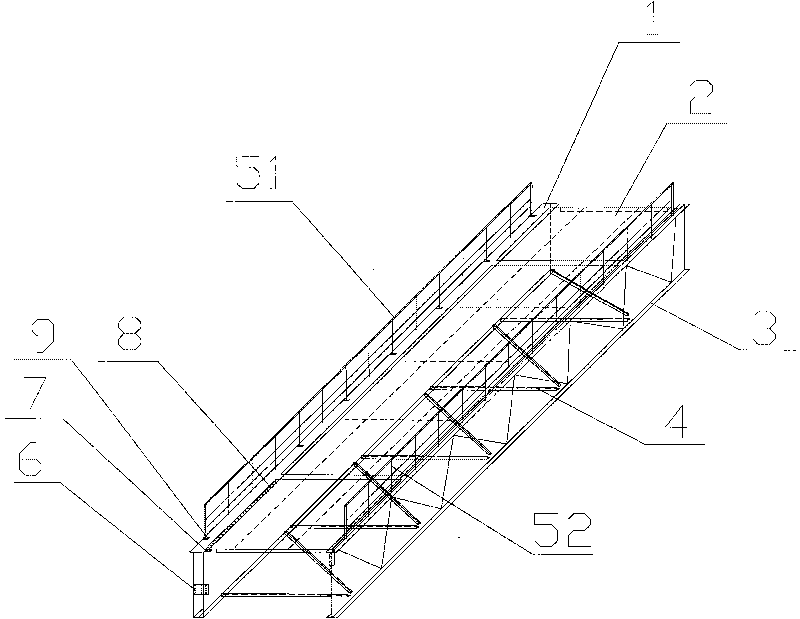

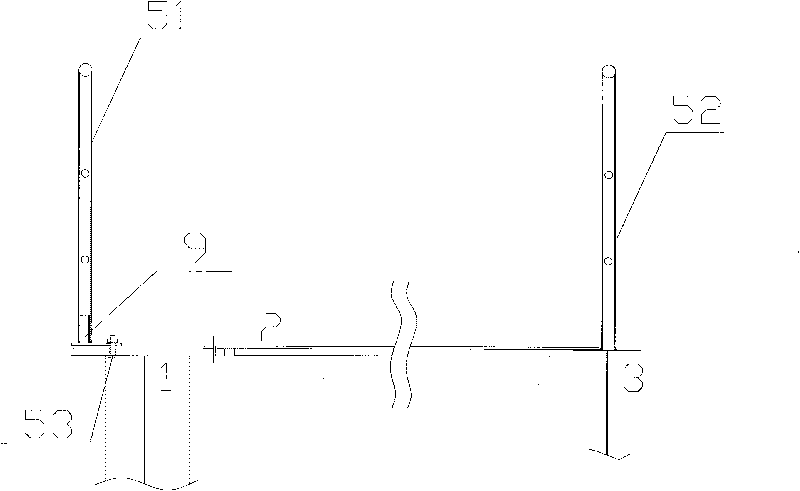

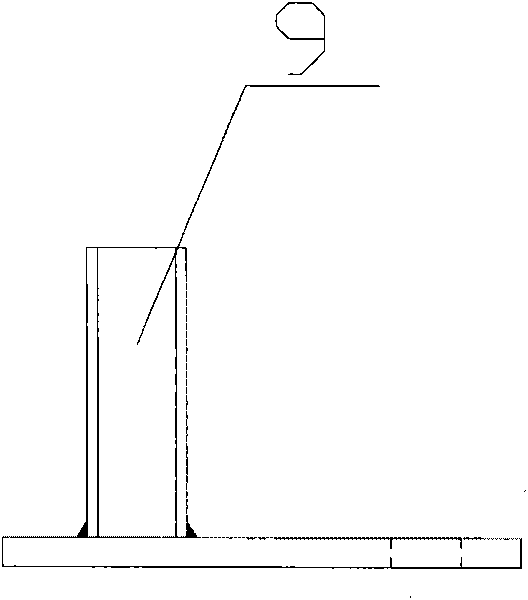

Crane beam frame construction method

ActiveCN101759098AReduce the amount of work at heightsReduce investmentLoad-engaging girdersSupport planeBeam system

The invention relates to the crane beam system construction field, in particular to a crane beam frame construction method. The method comprises three steps of assembling on the ground, integral-hoisting and commissioning of formal railings. The crane beam frame comprises a crane beam (1), a brake board (2), a truss (3), a horizontal support frame (4), a connection plate (6), a hinge plate (7) and stopping plate bolts (8). The crane beam frame is characterized in that the crane beam frame also comprises temporary railings (51), formal railings (52), railing bolts (53) and connection members (9), the upper part of the crane beam (1) is fixed with the temporary railings (51) through the connection members (9) and the railing bolts (53), the upper part of the auxiliary truss (3) is welded and fixed with the formal railings (52); and the integral-hoisting and the commissioning of the formal railings are performed in turn after the crane beam frame is assembled on the ground. The invention reduces the quantity of works at heights, the operation is safe, the working efficiency and quality are high, the investment is little and the applicability is high.

Owner:MCC5 GROUP CORP SHANGHAI

Differential type track container crane

InactiveCN105384079AReduce weightReduced activityLoad-engaging girdersTrolley cranesContainer craneEngineering

The invention provides a differential type track container crane. The differential type track container crane comprises a portal structure, a trolley used for moving a container, and a drive mechanism driving the trolley to walk. The drive mechanism is arranged on the portal structure and not arranged on the trolley. The drive mechanism comprises eight differential reduction boxes with two freedom degrees. Container ascending and trolley walking are achieved through the same set of steel wire ropes, in other words, the eight differential reduction boxes can be connected with corresponding steel wire rope drums respectively, the first freedom degree that eight steel wire ropes are driven to achieve adjustment on ascending or descending or transportation of the container is adopted, the second freedom degree that eight steel wire ropes drag the trolley to walk in a combined movement manner at the same time is adopted, and therefore trolley walking and container ascending are integrally driven, the weight of the trolley is reduced, the movable load and the ascending or braking inertia of the trolley are reduced, and the dead load and the bearing condition of the portal structure are improved. Slipping, rail gnawing and other faults of the trolley can be avoided through dragging walking.

Owner:TONGJI UNIV +1

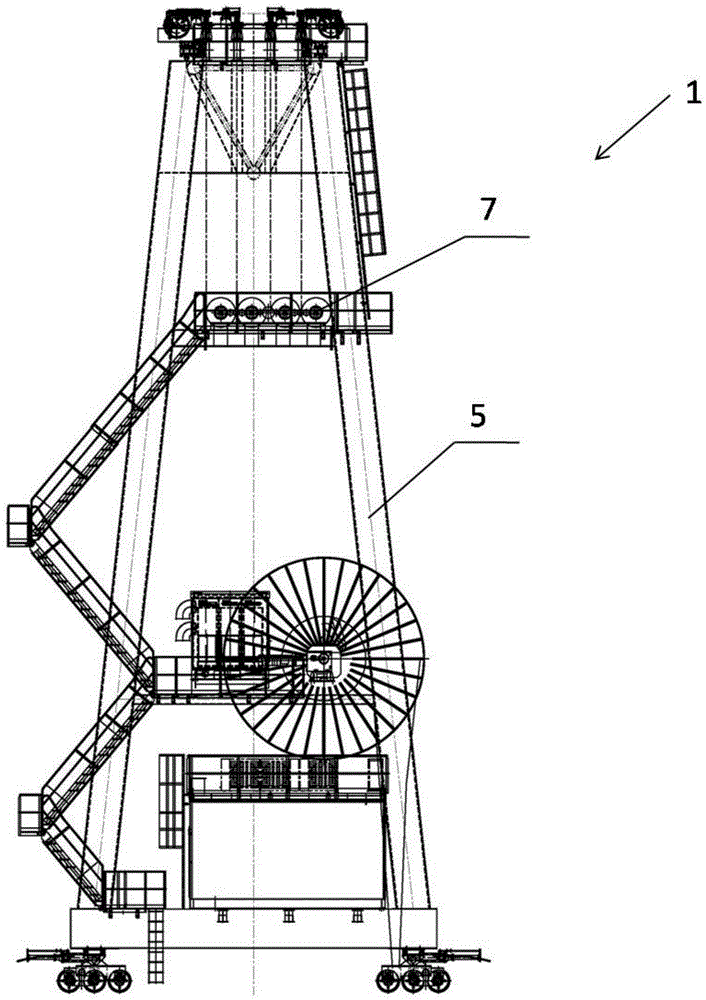

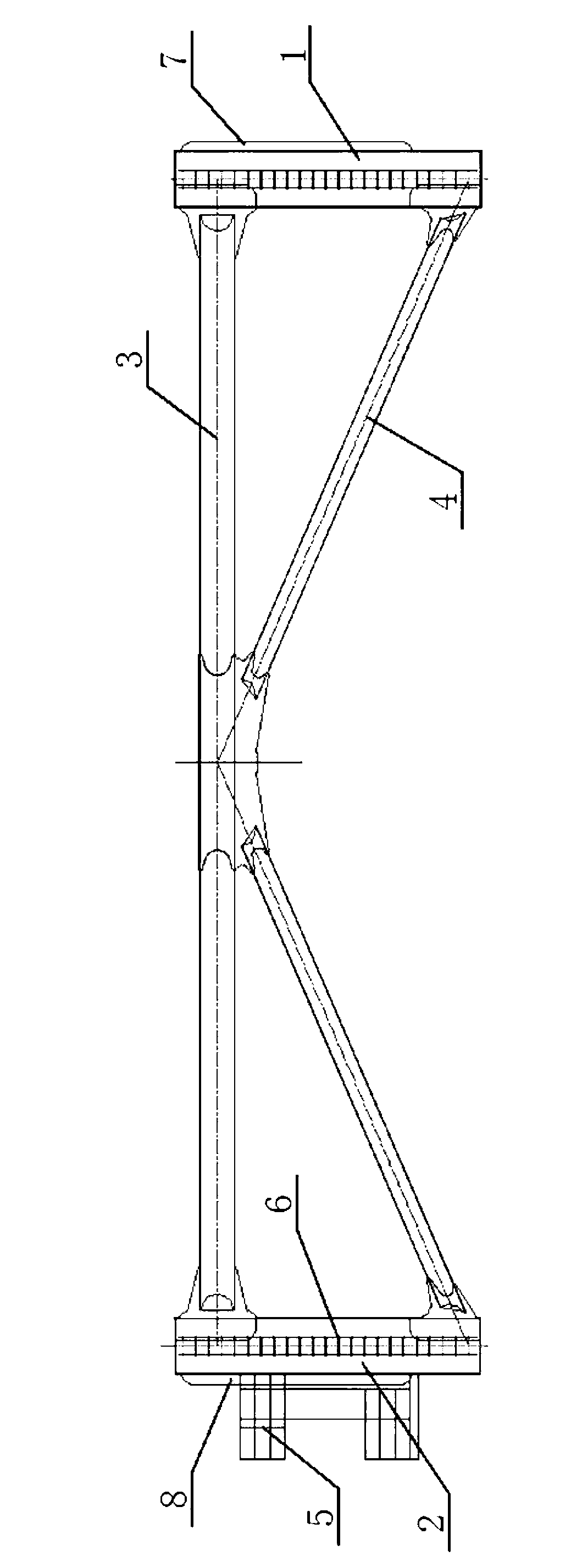

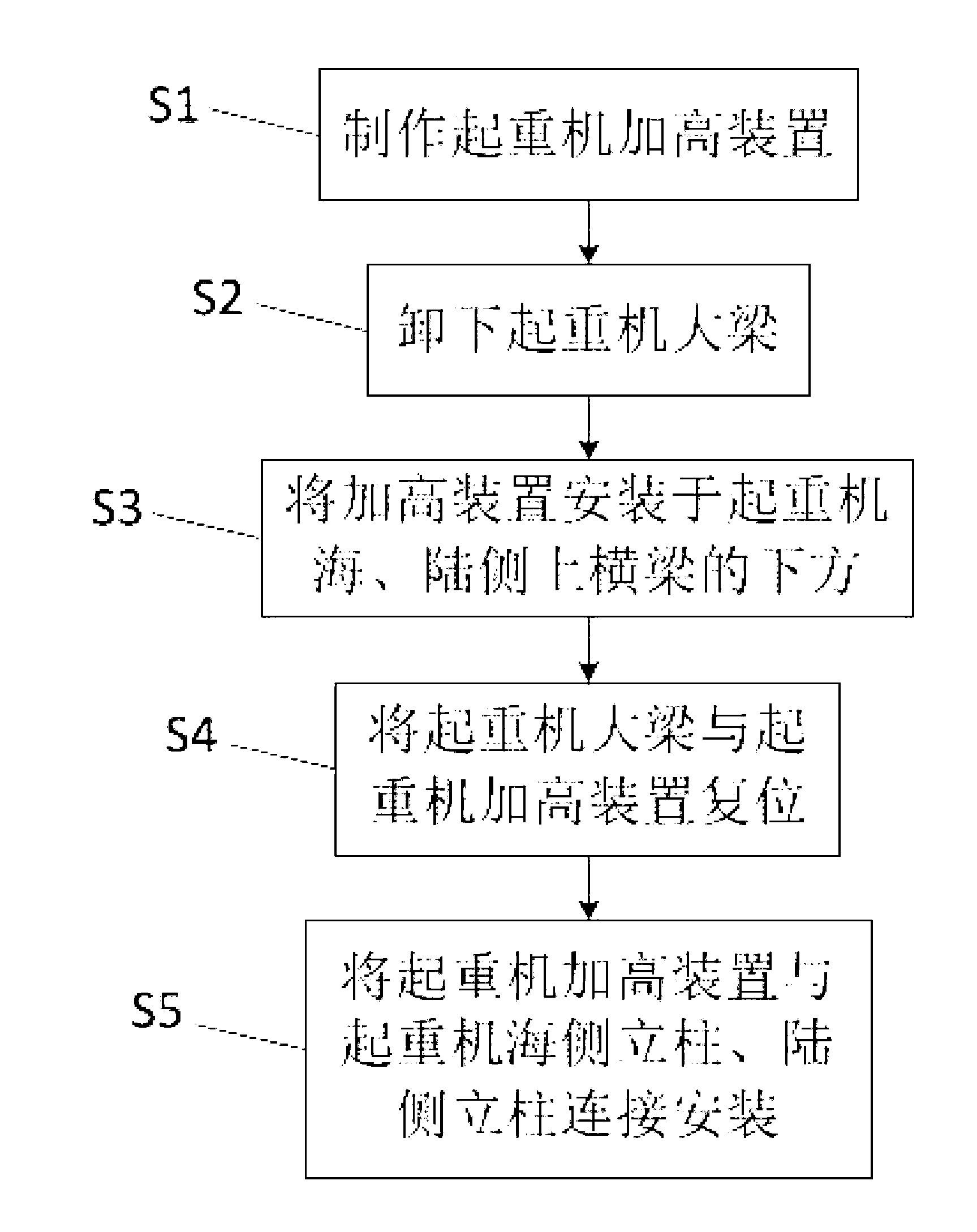

Crane heightening device and method

ActiveCN103193162AMaximize utilizationSimple structureLoad-engaging girdersTravelling cranesEngineeringCrane Equipment

The invention discloses a crane heightening device and a crane heightening method. A crane comprises a large front beam, a large rear beam, an upper cross beam at the sea side, an upper cross beam at the land side, a vertical column at the sea side, a vertical column at the land side and the like; the heightening device comprises a heightening section of the vertical column at the sea side, a heightening section at the vertical column at the land side, a horizontal support rod, a door frame diagonal bracing, a door frame diagonal bracing at the sea side and a door frame diagonal bracing at the land side. The method comprises the following steps of: step 1, manufacturing the crane heightening device; step 2, dismounting the large front beam and the large rear beam of the crane; step 3, installing the heightening device on the ground below the upper cross beam at the sea side and the upper cross beam at the land side; step 4, resetting the large front beam and the large rear beam of the crane and a heightening device assembly; and step 5, connecting and installing the crane heightening device and the top ends of the vertical columns at the sea side and the land side of the crane. By adopting the technical scheme provided by the invention, the existing crane equipment can be utilized to the maximum, and the structure of the heightening device is simplified, so that the heightening method is convenient and rapid, and the cost is saved.

Owner:SHANGHAI ZHENHUA HEAVY IND

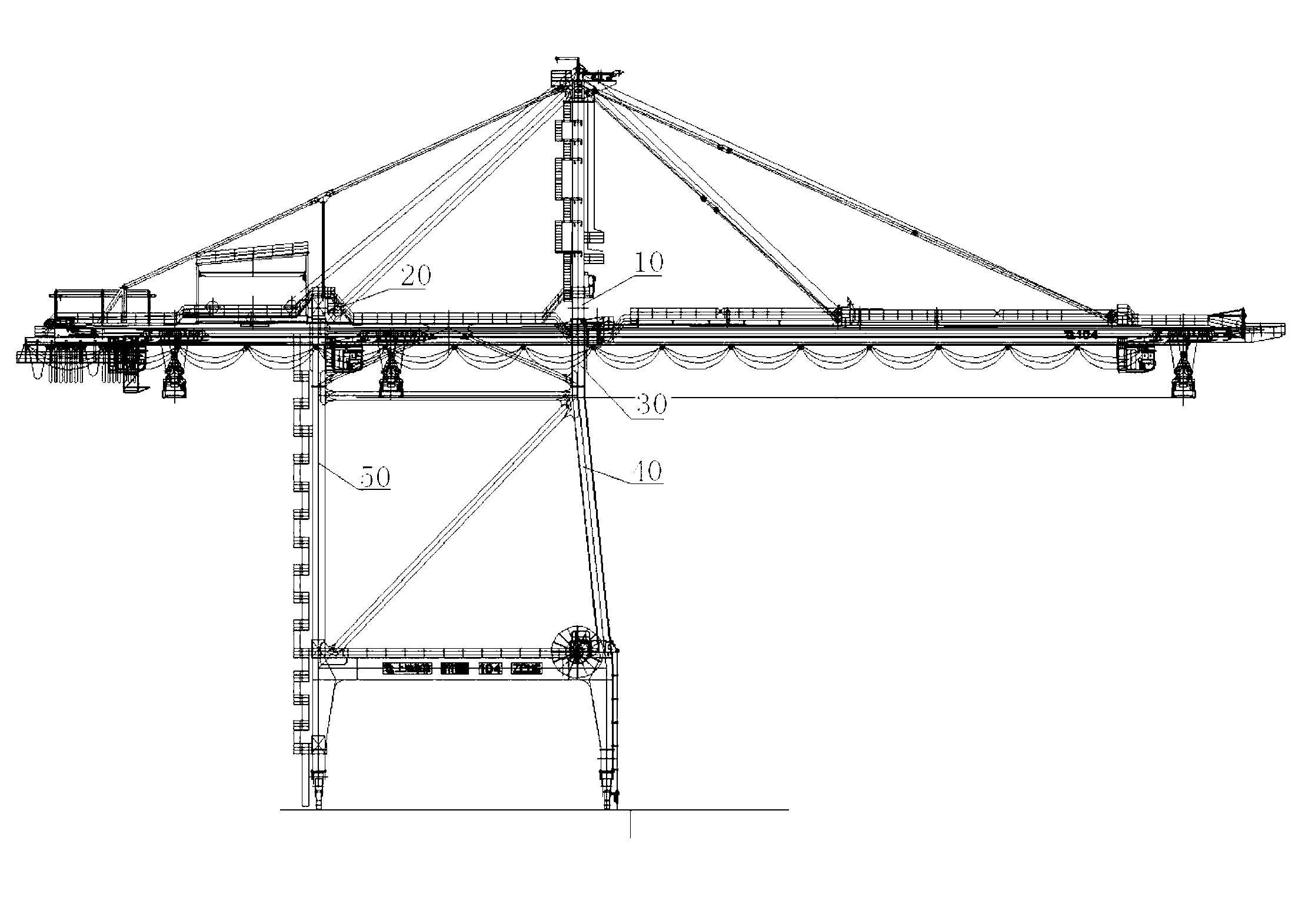

Three-beam double-trolley rail type container portal crane

ActiveCN105110200AIncrease floor spaceImprove efficiencyLoad-engaging girdersTrolley cranesElectronic control systemEngineering

The invention provides a three-beam double-cart rail type container portal crane and belongs to the field of lifting equipment. The crane comprises a three-beam portal, a large trolley travelling mechanism, a small trolley assembly, a container sling and an electronic control system. The crane comprises three main beams and two trolley assemblies; during operation, the trolley assemblies are suitable for independent operation; meanwhile, operation efficiency of container handling is greatly improved on the basis of slightly increasing floor area and equipment cost; compared with a traditional way of co-use of multiple cranes, the crane is beyond comparison, input can be greatly saved, cost can be greatly lowered, and benefit can be greatly improved.

Owner:湖南中铁五新重工有限公司

Production technology of box girder of crane

InactiveCN104400351AIncrease stiffnessExtended service lifeLoad-engaging girdersArc welding apparatusButt weldingEconomic benefits

The invention discloses a production technology of a box girder of a crane. The production technology is characterized by comprising the following steps of (1) delivering raw material into a warehouse for standby; (2) scribing; (3) blanking; (4) cleaning and correcting; (5) butt welding; (6) assembling and welding separating plates; (7) assembling and welding a lower cover plate; (8) correcting and checking. By adopting the scheme, the production technology has the advantages that the technology is simple and reasonable; the rigidity of the girder is greatly improved; the submerged arc automatic welding technology is adopted for welding, so the welding deformation is small, the strength of welding seams is high, the residual stress is small, the bearing capability is improved, the service life of the girder is prolonged, the manufacturing cost is reduced, and the economic benefits of enterprises are increased.

Owner:ANHUI WEISA HEAVY MACHINERY

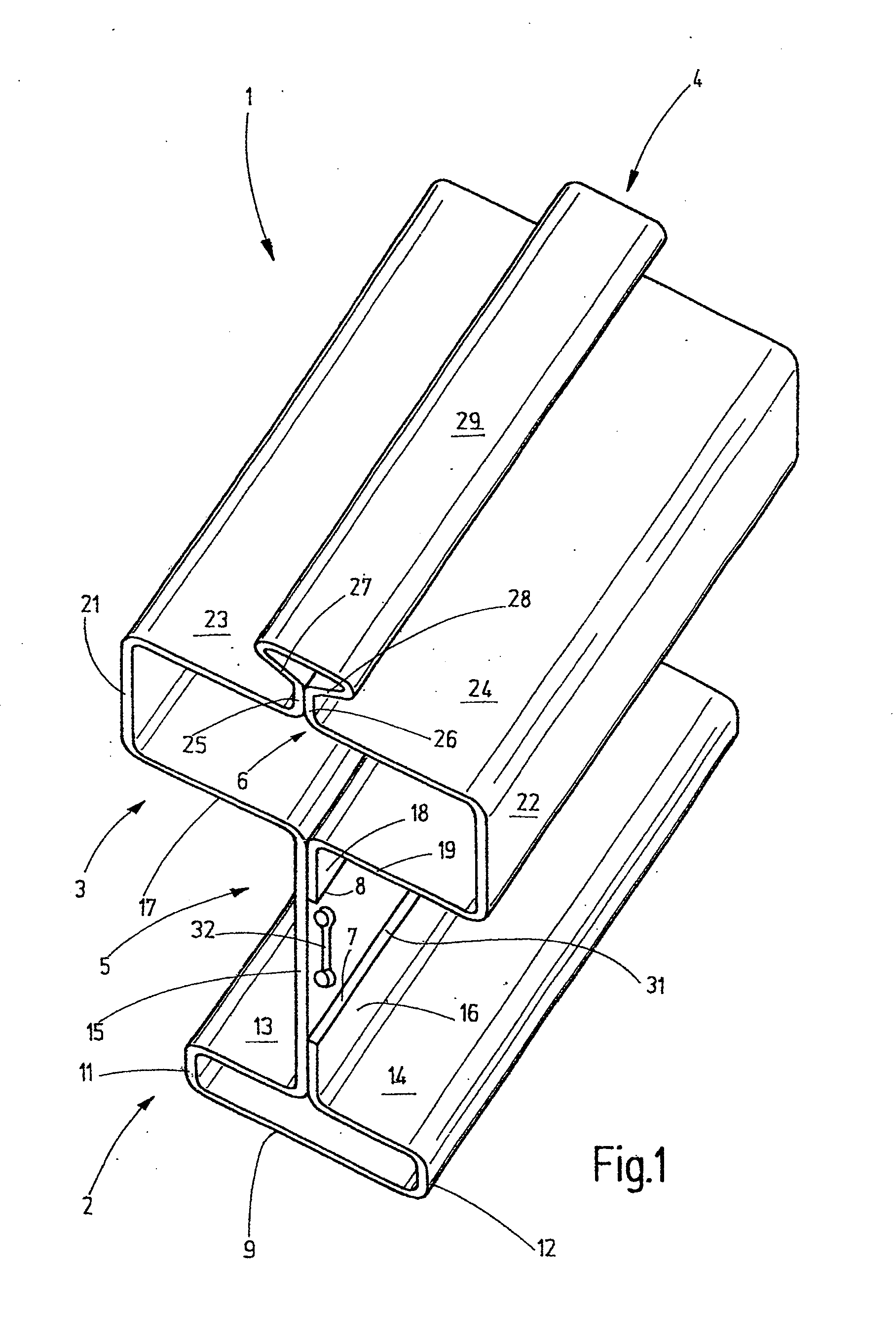

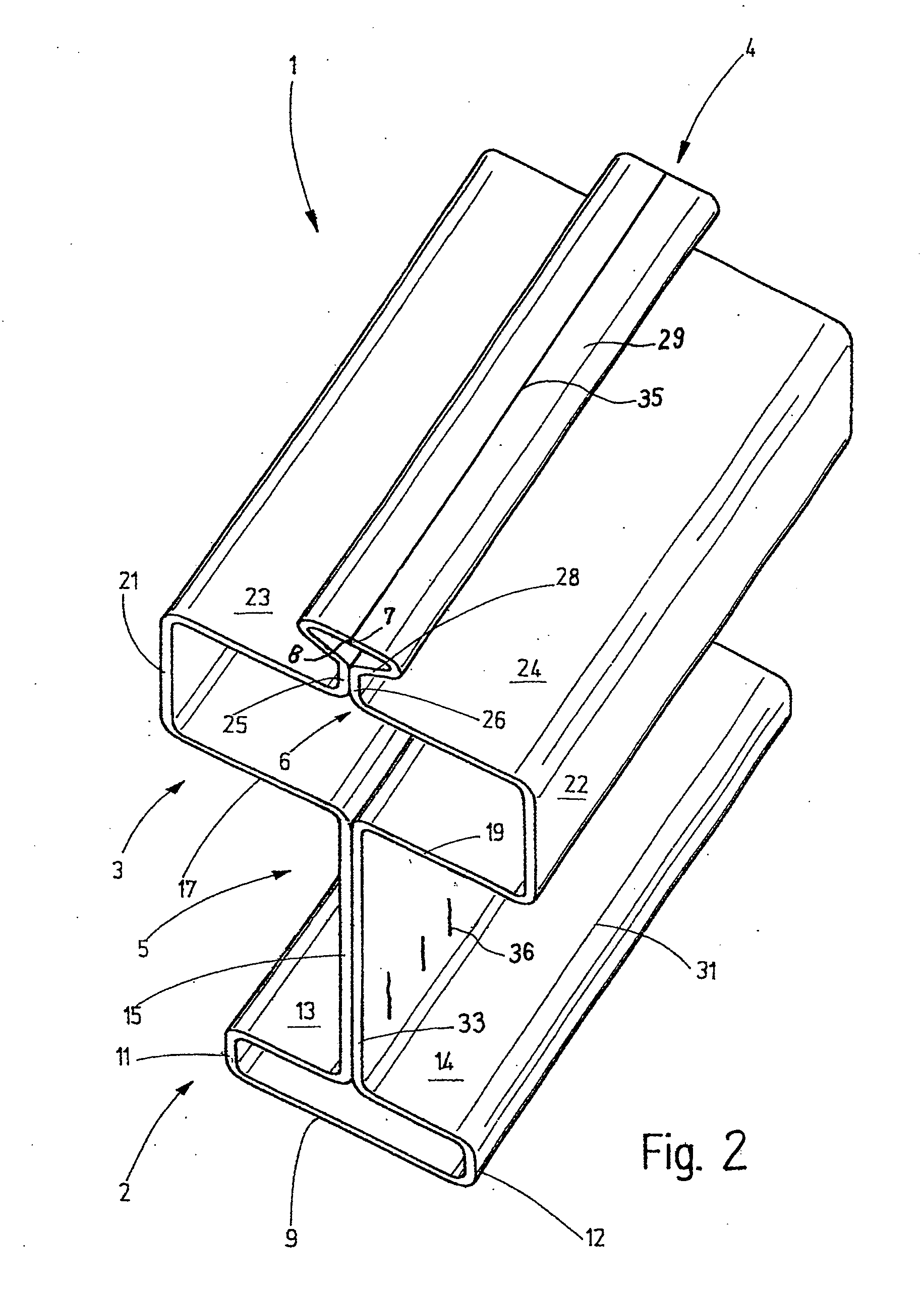

Laser-welded crane rail for suspended crabs

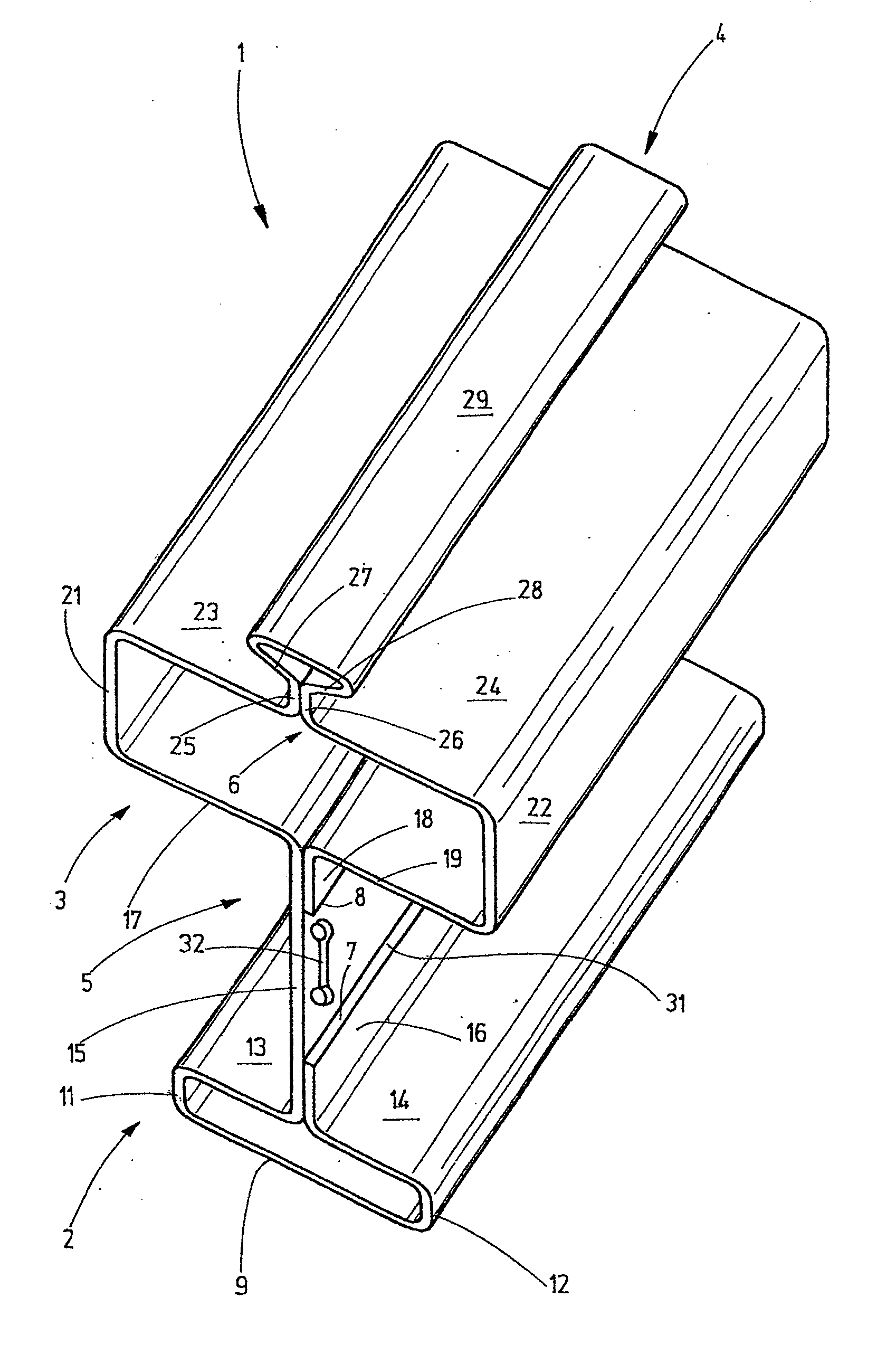

InactiveUS20100107918A1Maintain good propertiesEasy to makeCandle holdersLoad-engaging girdersEngineeringSteel belt

Owner:STAHL CRANESYSTEMS GMBH

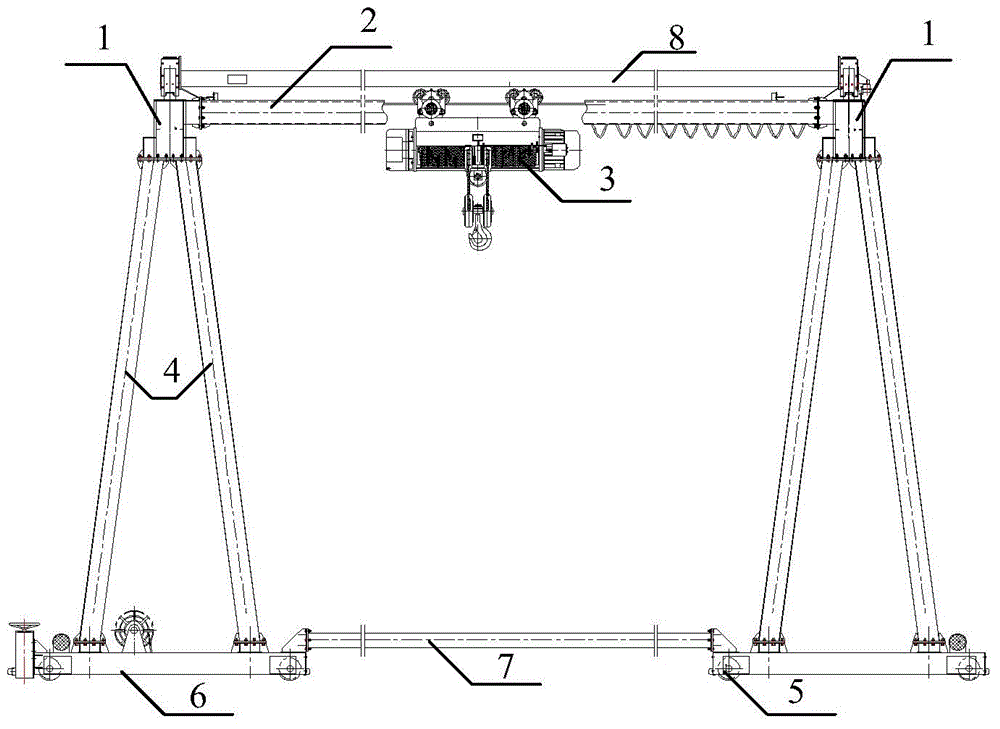

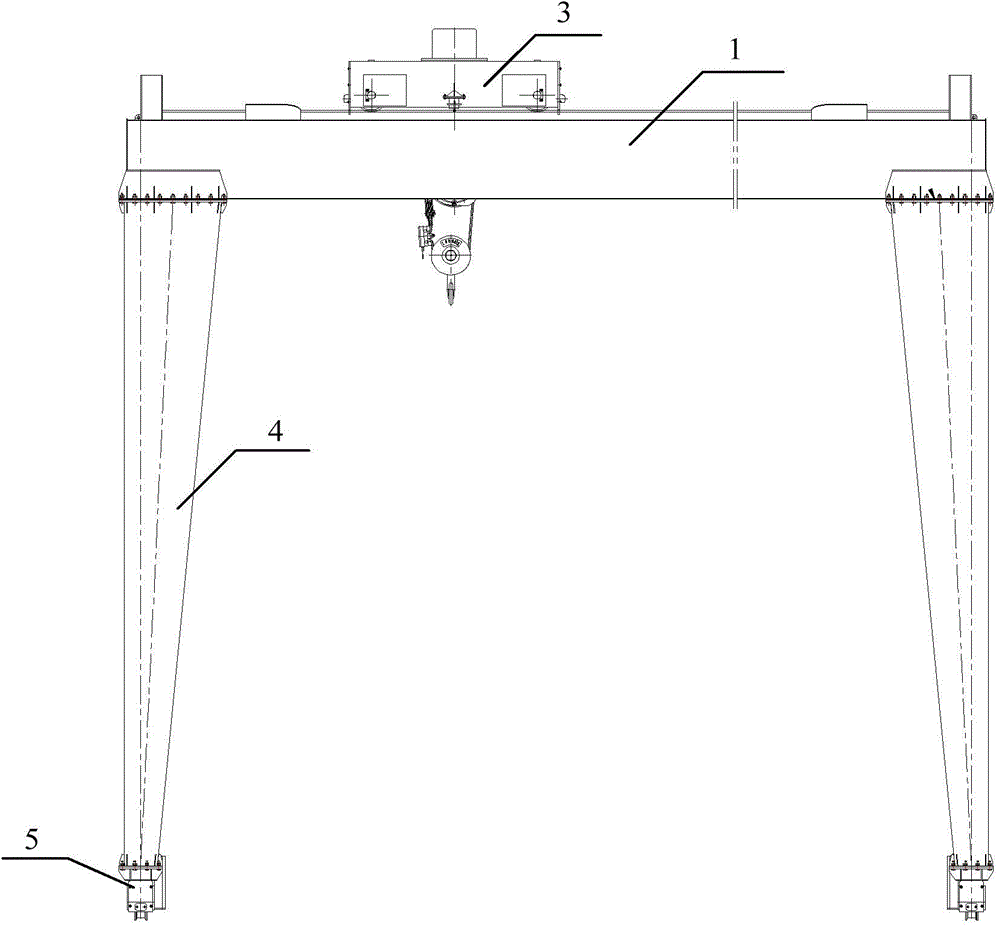

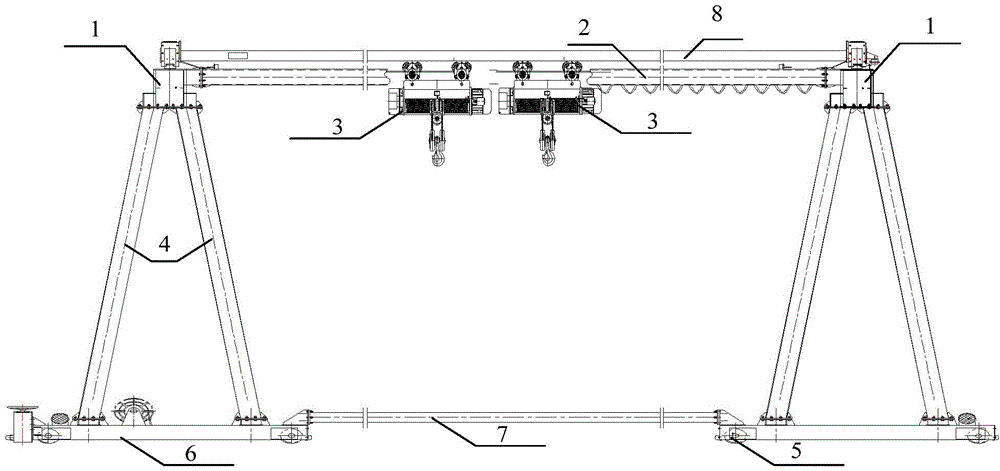

Electric hoist portal crane

InactiveCN102689841AReasonable structurePractical, flexible and convenientLoad-engaging girdersTrolley cranesStructural engineeringControl theory

The invention relates to the field of cranes, specifically to an electric hoist portal crane. The electric hoist portal crane provided by the invention is composed of buffers, active wheel assemblies, decelerators, motors, trolley frames, a 20-ton electric hoist, a 5-ton electric hoist, passive wheel assemblies, trolley protective covers, a 40-ton electric hoist, a track, a winding leg and a main beam. The winding leg is fixedly connected with the main beam. The track is laid on the main beam. Two trolleys are disposed on the track. The active wheel assembly and the passive wheel assembly of each trolley are arranged on the track of the main beam. The active wheel assembly and the passive wheel assembly of each trolley are fixed on the trolley frame through wheel shafts. Two ends of each trolley frame on the track are provided with buffers. Each motor and each decelerator are disposed at the inner side of one end of each trolley frame. The motors are connected with the decelerators. The 20-ton electric hoist and the 5-ton electric hoist are mounted in one trolley frame and the 40-ton electric hoist is mounted in the other trolley frame. The trolley protective cover is arranged on each electric hoist.

Owner:DALIAN DAQI IND DEV

Welded-railway-type crane main beam

The invention discloses a welded-railway-type crane main beam. A crane trolley running railway is welded with a top flange plate of a box-type main beam or an upper chord of a truss-type main beam, so that intervals among stiffening ribs of the box-type main beam increase from 0.5m to 0.75m, thereby reducing the steel using quantity of the top flange plate and the stiffening ribs of the box-type main beam of a crane, and reducing the steel using quantity of the upper chord of the truss-type main beam; because a railway is welded with the main beam of the crane, railway pressing plates are saved, and the railway is prevented from being loosened, thereby reducing the repairing and maintaining workload of the crane railway.

Owner:谢合清

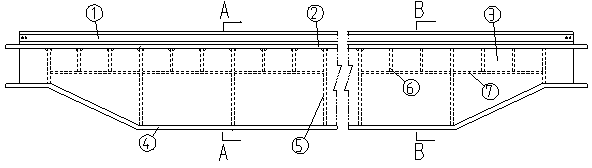

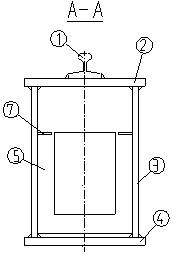

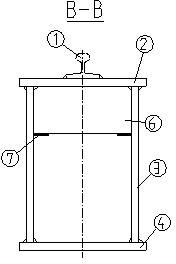

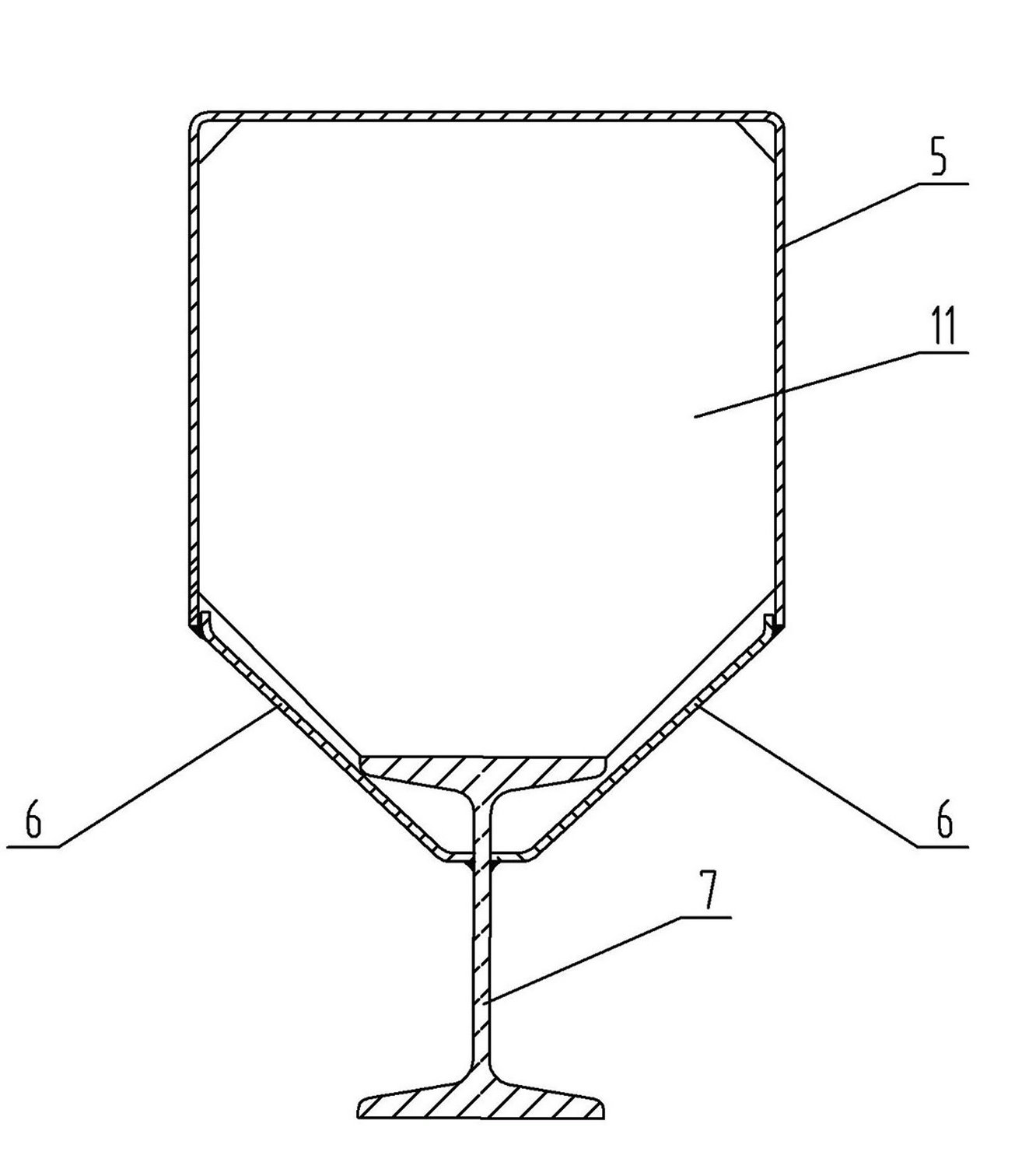

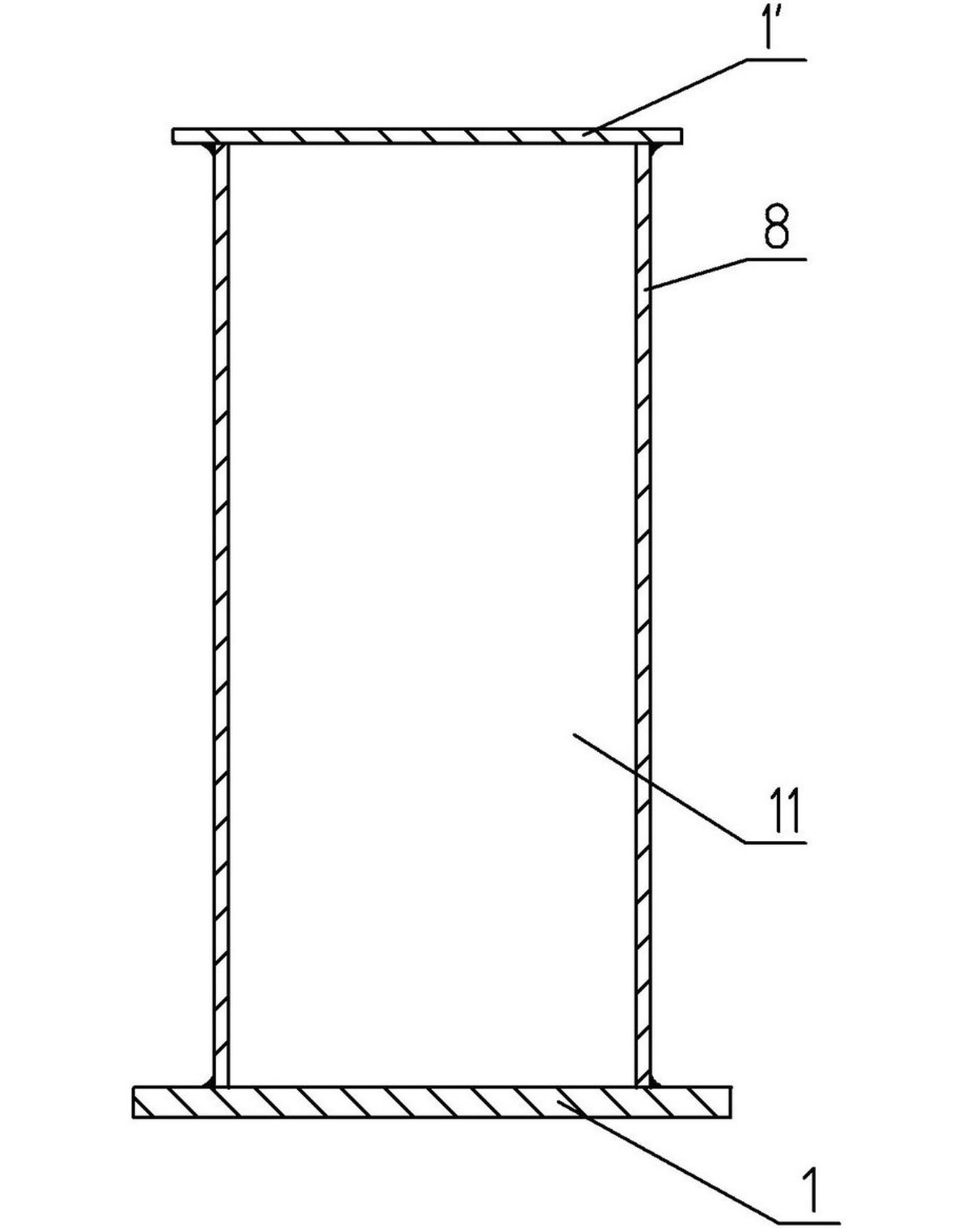

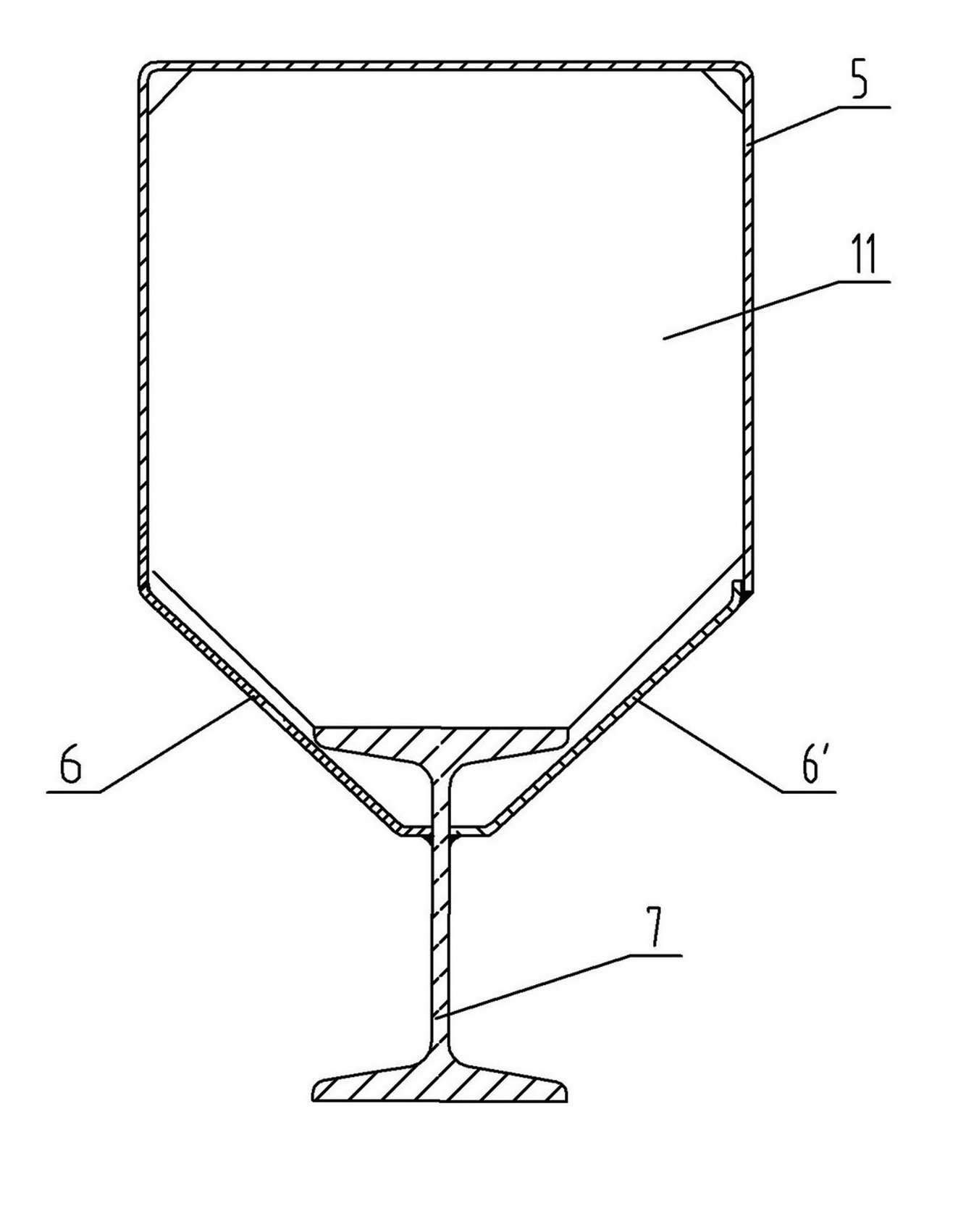

Main girder of single-girder crane

The invention relates to an improved structure of a main girder of a crane and especially to a main girder of a single-girder crane. The main girder comprises an upper bearing plate, a lower bearing plate and two symmetrical special-shaped side plates; reinforcing plates are fixed in an inner cavity of a main girder body along a transverse direction at intervals; the cross section of the main girder is an approximate combined section, the upper part of the section is a rectangle with a bottom opening, the middle part of the section is a reversed isosceles trapezoid with a top opening and a bottom opening, the lower part of the section is a rectangle with a top opening, and the length and the width of the rectangle with a bottom opening at the upper part are respectively greater than the length and the width of the rectangle with a top opening at the lower part; the width of the upper bearing plate is greater than the maximum width between the two side plates, the width of the lower bearing plate is greater than the minimum width between the two side plates but smaller than the maximum width between the two side plates, the thickness of the upper bearing plate is greater than or equal to the thickness of the two side plates, and the thickness of the lower bearing plate is greater than the thickness of the two side plates. The main girder provided in the invention has a simple structure, is easy to manufacture and process, enables manufacture cost to be reduced and production efficiency to be improved and is especially applicable to flow line production; in the process of manufacturing the main girder, the problem of camber of the main girder of a crane is easily overcome, and the service life of the crane is prolonged, so the main girder can be easily popularized and applied.

Owner:王松江

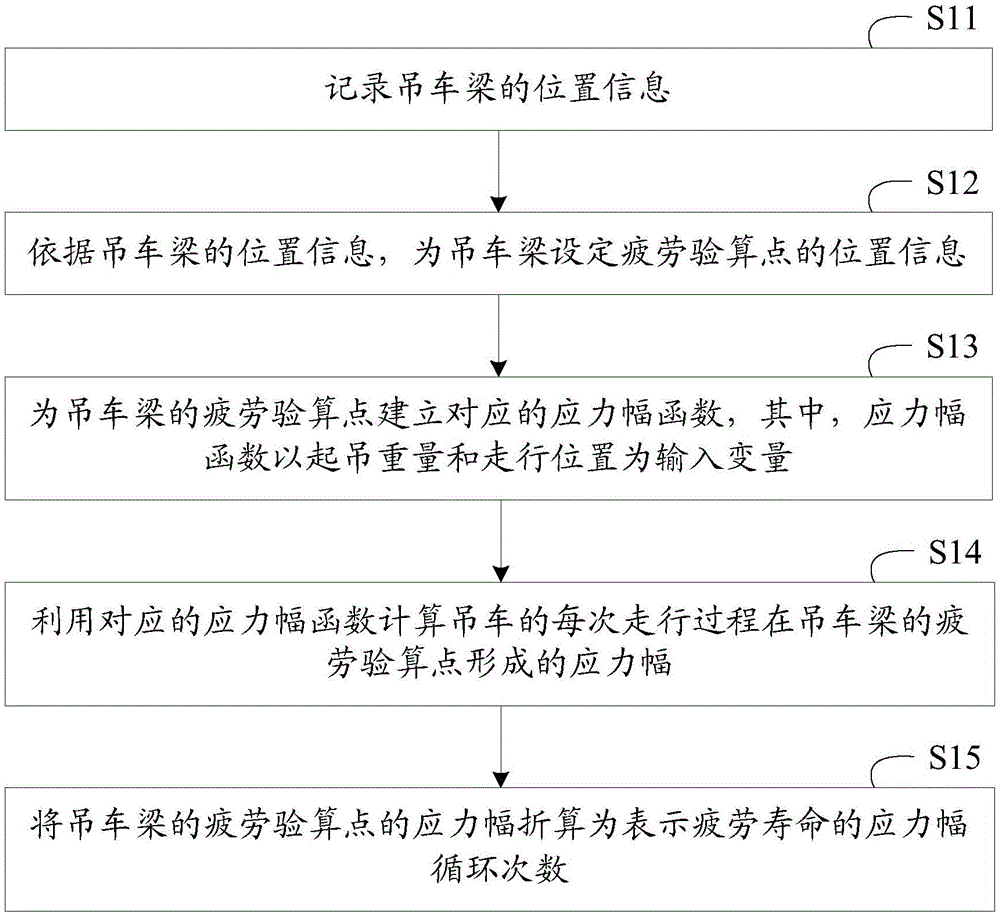

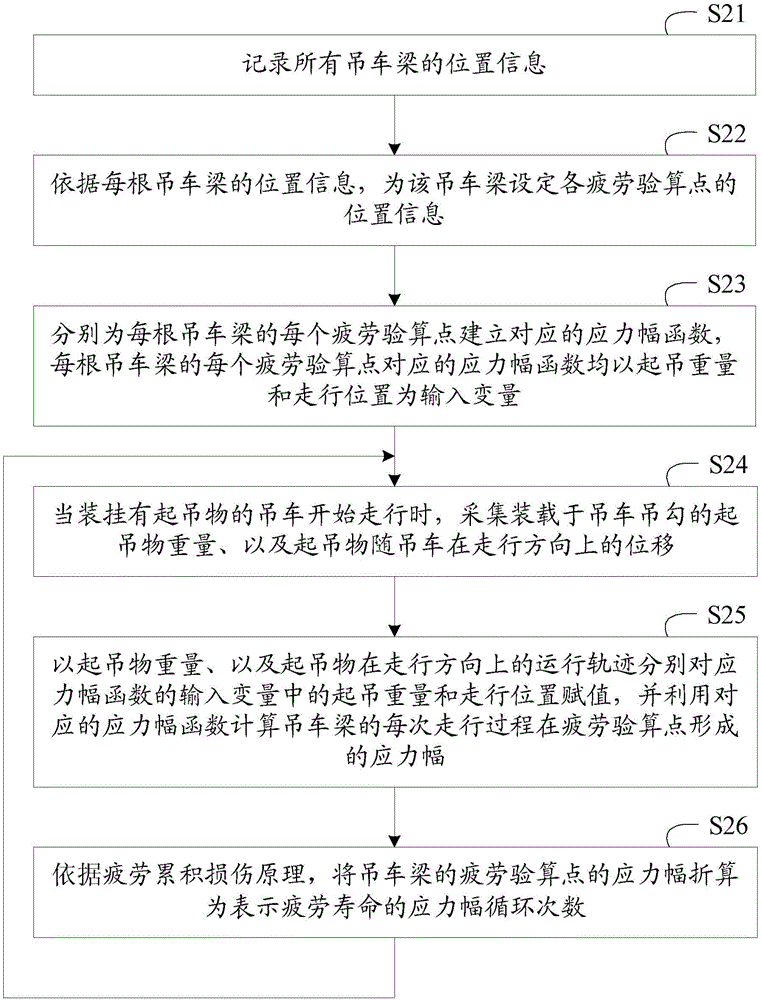

Method monitoring fatigue service life of crane beam

ActiveCN105069182AIncrease costIncrease the difficulty of constructionLoad-engaging girdersSpecial data processing applicationsAmplitude functionStress induction

The invention discloses a method monitoring fatigue service life of a crane beam; the method comprises the following steps: recording position information of the crane beam; setting position information of fatigue checking computation points for the crane beam; setting up a corresponding stress amplitude function for each the fatigue checking computation point of the crane beam, wherein the stress amplitude function uses hoisting weight and walking position as input variables; using the corresponding stress amplitude function to calculate a stress amplitude formed on the fatigue checking computation point by a hoisting object in each walking process of the crane beam; converting the stress amplitude of the fatigue checking computation point of the crane beam into a stress amplitude cycle index indicating fatigue life. The method can monitor the fatigue service life of the crane beam without needing a stress induction sheet, so monitoring cost and construction difficulty cannot be obviously improved by increasing number of the crane beams and fatigue checking computation points.

Owner:中冶检测认证(上海)有限公司 +2

Frame type lifting device

InactiveCN104150370ALarge structural spanMany fulcrumsLoad-engaging girdersBase supporting structuresEngineeringSupport point

The invention discloses a frame type lifting device. The device comprises two main beams which are mutually parallel and are vertical to a walking guide rail, a walking vehicle which is arranged on the main beams and can walk along the main beam, and a crane which is arranged on the walking vehicle, wherein two supporting legs which are used for supporting the main beams and are formed into a certain included angle are respectively arranged at each end head of the main beams, the plane formed by the two supporting legs is parallel to the walking guide rail, and walking wheels are arranged at the bottom part of the supporting legs. Compared with the prior art, the device has the advantages that a frame type structure with large span and multiple supporting points belongs to a stable structure, and structure stability of the frame type lifting device is obviously improved; the overturn is difficult to generate, and the accident of the overturn can be effectively avoided when the lifting operation is carried out during assembly and molding.

Owner:STATE GRID CORP OF CHINA +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com