Multifunctional combined crane

A combined, crane technology, applied in the direction of cranes, trolley cranes, load hanging components, etc., can solve the problem that it cannot adapt to multi-function, multi-purpose, multi-working conditions, multi-lifting weight, bridge cranes cannot be used as gantry cranes, The door machine cannot be used as a bridge machine, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

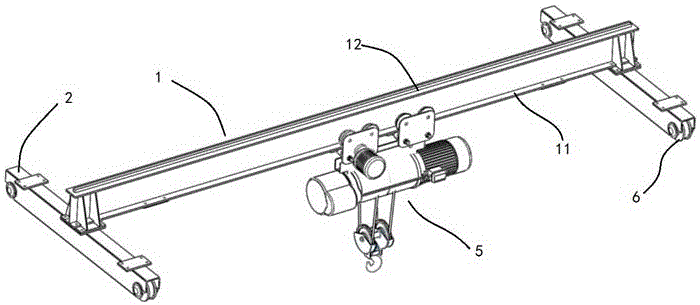

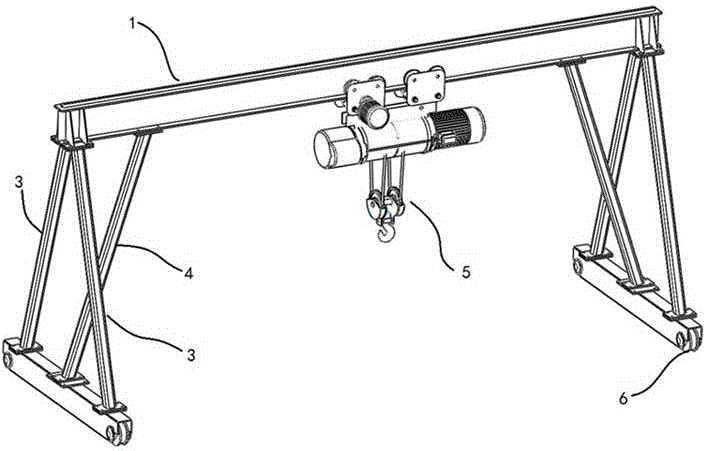

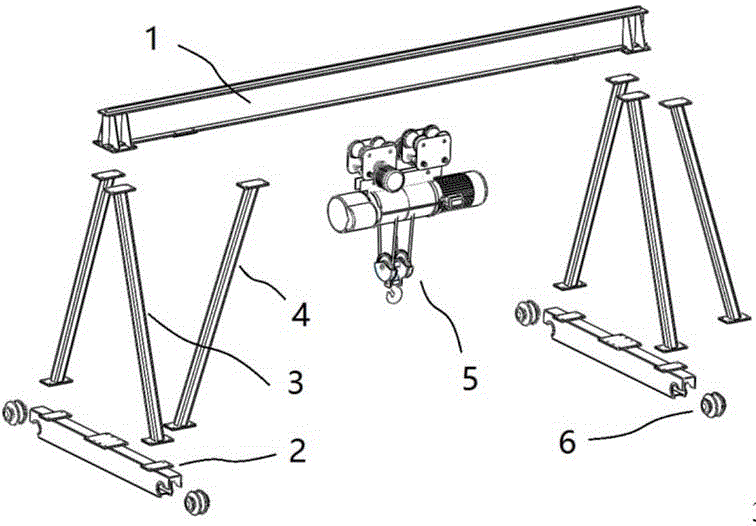

[0025] Such as Figure 1 to Figure 3 As shown, the present embodiment is a bridge-gate type conversion combined crane with a single girder, and the specific structure is:

[0026] A multifunctional combined crane, including a main beam 1 and a trolley for lifting heavy objects; the trolley is a lower trailer 5, and the main beam 1 is provided with a track I11 for the lower trailer 5 to travel and a trolley for the upper vehicle 8. The running track II12; the end of the main beam 1 is vertically provided with an end beam 2 for driving it to walk, and the front and rear ends of the end beam 2 are respectively provided with wheels 6 . The main beam 1 and the end beam 2 are detachably connected or / and connected by two legs A3 used to support the main beam 1, and the upper and lower ends of the legs A3 are connected to the main beam 1 and the end beam 2 There are detachable connections between them. In this field, such as figure 2 This arrangement position and arrangement manne...

Embodiment 2

[0031] Such as Figure 4 As shown, this embodiment is a single-girder gantry crane. On the basis of the single-girder bridge crane involved in Embodiment 1, the form of the outrigger changes after conversion: between the main girder 1 and the end girder 2 at its left end There are two outriggers B4 that are detachably connected inclined relative to the main beam 1, combined with Figure 4 , the two outriggers B4 are arranged in a V shape, and there is no outrigger B4 between the main beam 1 and the end beam 2 at its right end. With such a design, it can be used in occasions where the horizontal span of the door machine is larger.

Embodiment 3

[0033] Such as Figure 5 to Figure 9 As shown, the present embodiment is a double-girder bridge-gate conversion combined crane, and the specific structure is:

[0034] A multifunctional combined crane, including a main beam 1 and a trolley for lifting heavy objects; the trolley is an upper trolley 8, and the main beam 1 is provided with a track I11 for the lower trailer 5 to travel and a trolley for the upper trolley. 8. The track II12 for walking; the end of the main beam 1 is vertically provided with an end beam 2 for driving it to walk, and the front and rear ends of the end beam 2 are respectively provided with wheels 6; the main beam 1 and the end beam 2 are detachably connected or / and connected by two outriggers A3 for supporting the main beam 1, and the upper and lower ends of the outrigger A3 are detachably connected with the main beam 1 and the end beam 2 respectively.

[0035] In the above-mentioned multifunctional combined crane, there are two main girders 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com