High-efficiency energy-saving high speed combustor of gas range

A high-efficiency energy-saving, burner technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of complex manufacturing process, limited thermal efficiency, high production cost, etc., and achieve low production cost, low power and wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

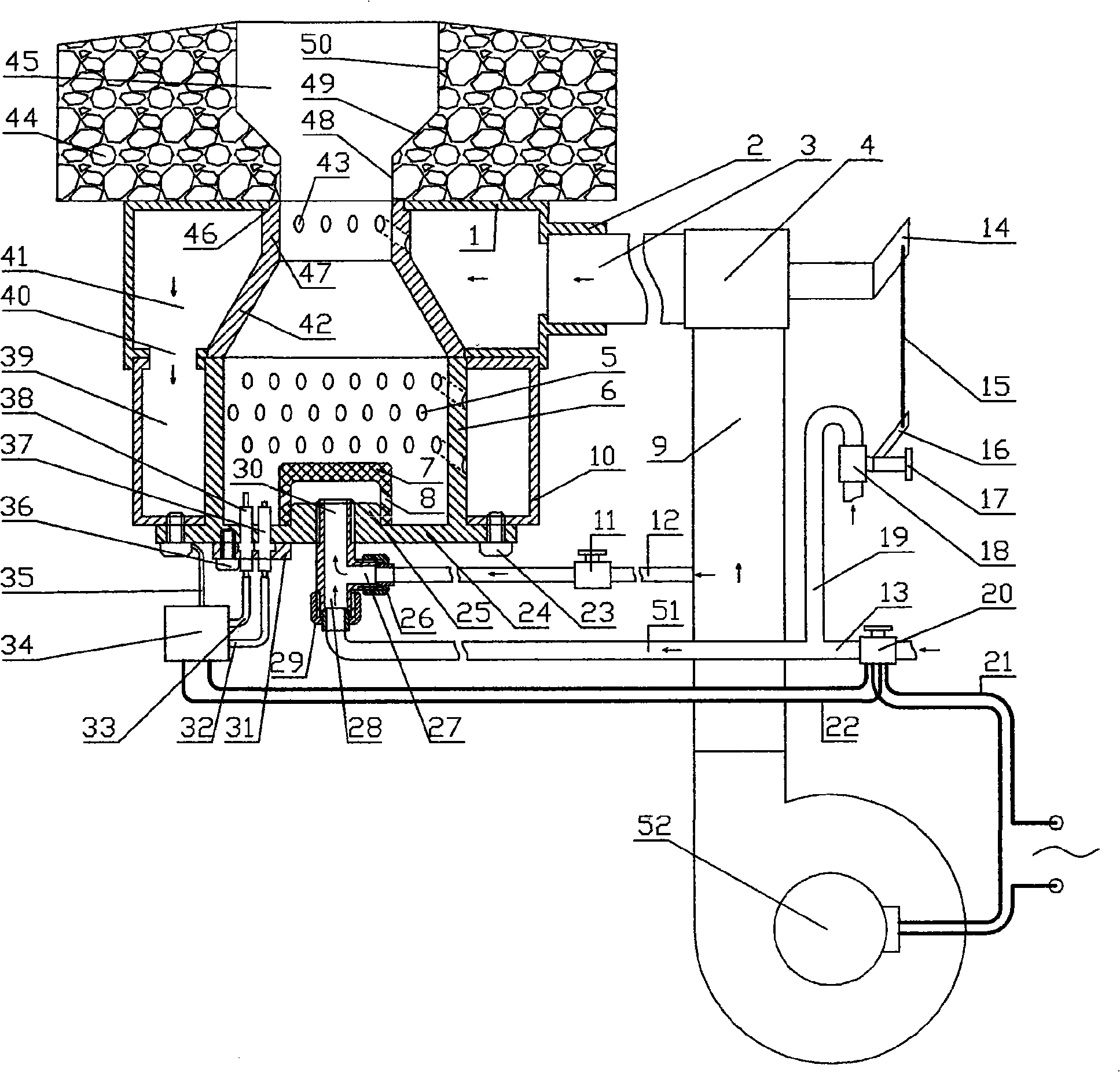

Embodiment 1

[0057] As shown in Figure 1, this embodiment is an inverted trumpet-shaped externally constricted preheater, a small trumpet-shaped refractory ring, a common forced premixed small fire under the burner cover, automatic electronic ignition, air disturbance mixing, two Secondary oxygen, gas-air linkage adjustment high-speed burner. The burner is composed of a burner casing 10 , an annular distributor 6 , and a burner lower cover 24 . The lower burner cover 24 and the annular distributor 6 are integral parts, the annular distributor 6 is sleeved into the burner casing 10, and the lower burner cover 24 is fixed on the burner casing 10 by bolts 23, and the bolts 23 are preferably different. The rusted material can be used for a long time and is easy to disassemble and assemble. This connection is convenient to take out the annular distributor 6 from the burner, so as to facilitate maintenance and remove the sundries falling into the burner. The burner casing 10 and the annular dis...

Embodiment 2

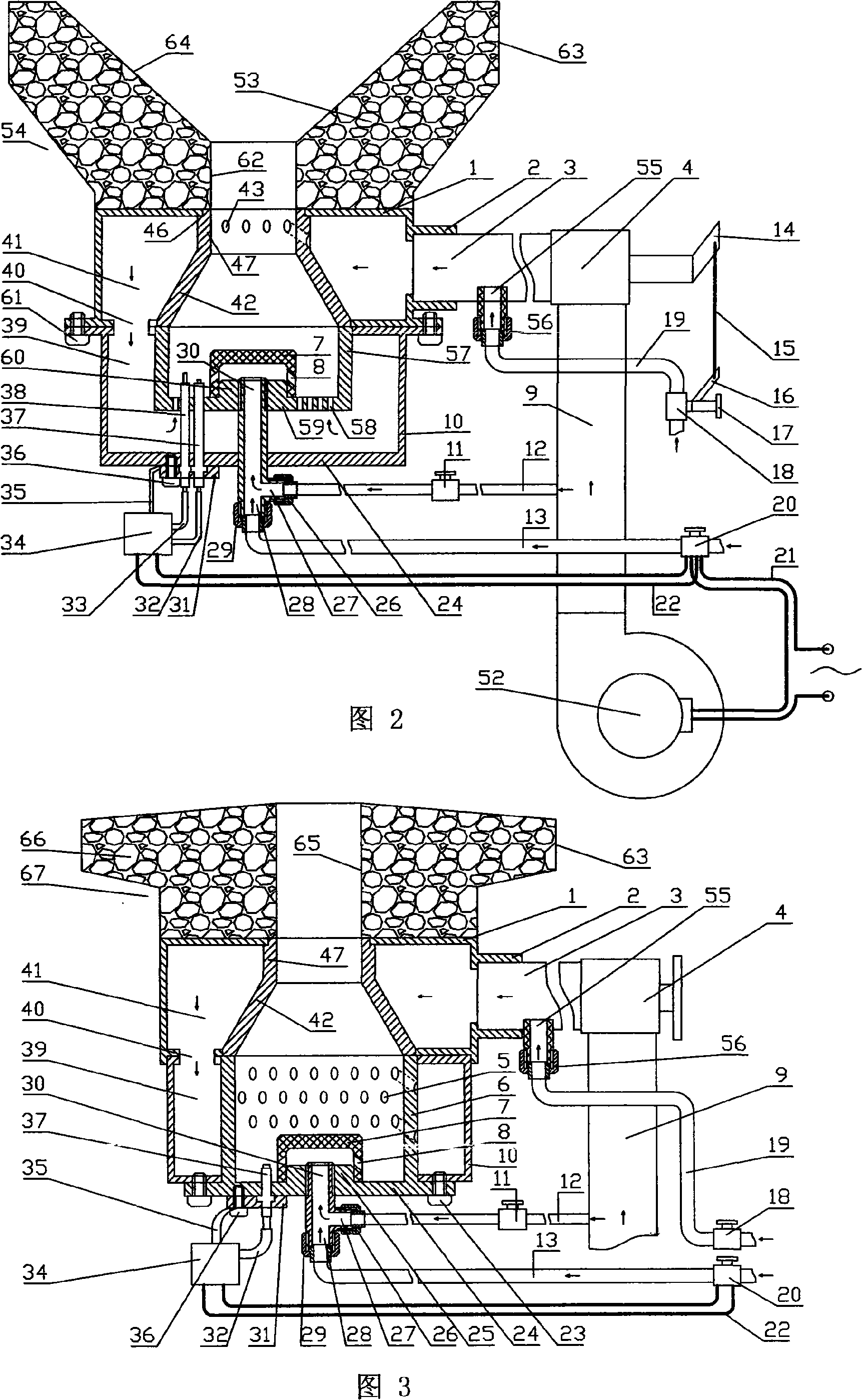

[0071] As shown in Figure 2, this embodiment is an inverted trumpet-shaped externally constricted preheater, a large trumpet-shaped refractory ring, a forced premixed small fire on the bottom of a drum-shaped mixer, a fully automatic electronic ignition, and an air premixed type. , Secondary supplementary combustion, gas-air linkage adjustment high-speed burner. The burner consists of the burner casing 10 , the drum mixer 57 and the burner lower cover 24 . The burner housing 10 and the lower burner cover 24 are one piece. The bottom surface 59 of the cylindrical mixer of the cylindrical mixer 57 has ventilation holes 58. The ventilation holes 58 are porous in any direction, preferably evenly arranged in a fan shape. The ejected gas is formed into a swirling gas. There is a cylindrical protrusion 60 in the center of the lower surface 59 of the drum-shaped mixer. The cylindrical protrusion 60 is sleeved or screwed with a fire distributor 7. The fire distributor 7 is provided w...

Embodiment 3

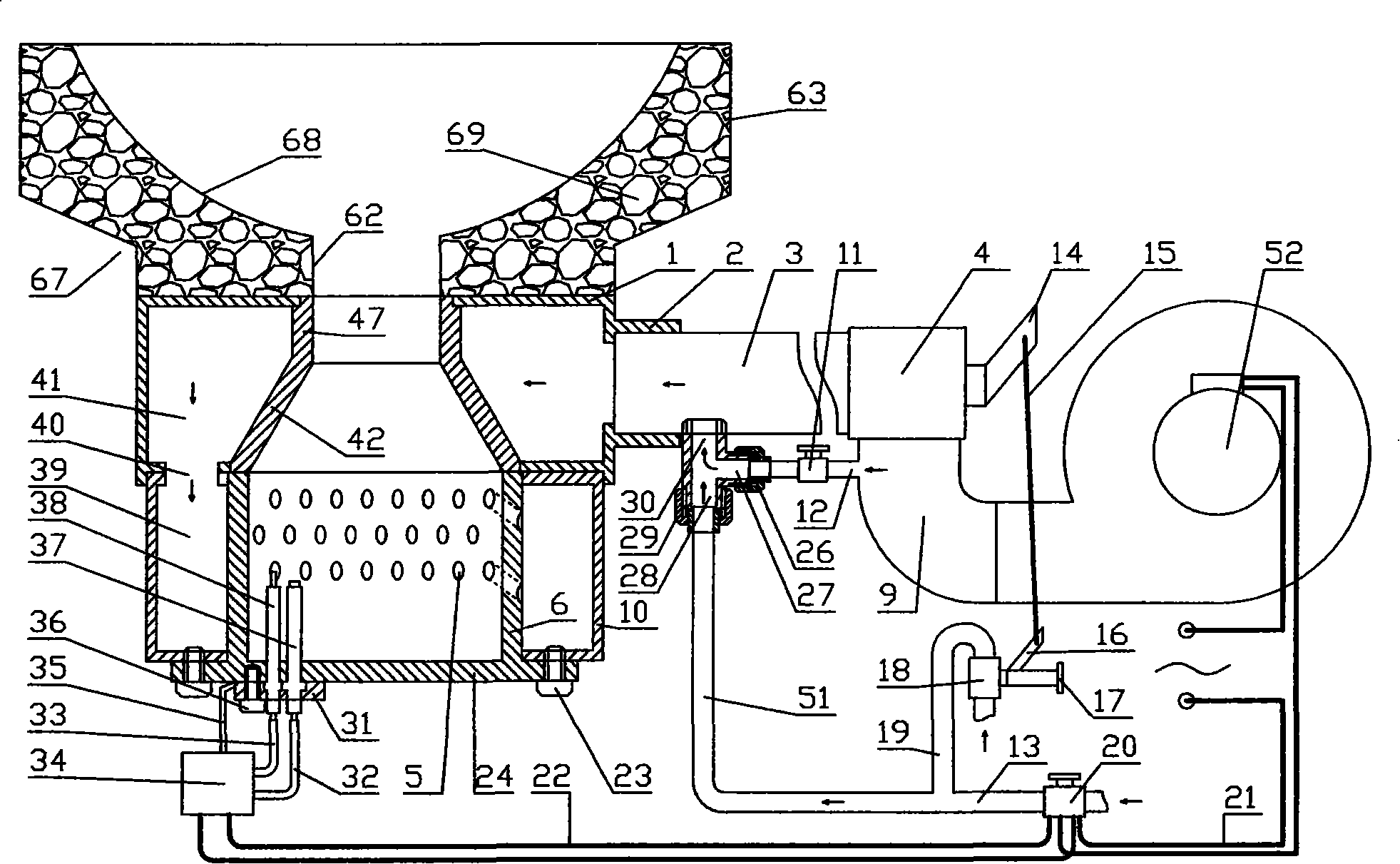

[0076] As shown in Figure 3, this embodiment is an inverted trumpet-shaped externally constricted preheater, cylindrical refractory ring, forced premixed small fire under the burner cover, semi-automatic electronic ignition, and air premixed high-speed burner. A gas nozzle 55 is fixed on the intake pipe 3 of the first embodiment, and the lower end of the gas nozzle 55 is connected to the main fire gas pipe 19 through a gas swivel head 56 . The electronic ignition is semi-automatic electronic ignition, and the electronic ignition controller 34 is a pulse controller. As shown in Figure 28, rotate and press the handle of the small fire gas valve 20, the electronic ignition control line 22 can be connected through the electronic ignition controller switch contact 136, the electric needle 37 is discharged, and after the small fire is ignited, the small fire is released. Fire the handle of the gas valve 20, and the electric needle 37 stops discharging. This ignition method is simpl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com