Patents

Literature

306results about How to "High flame temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

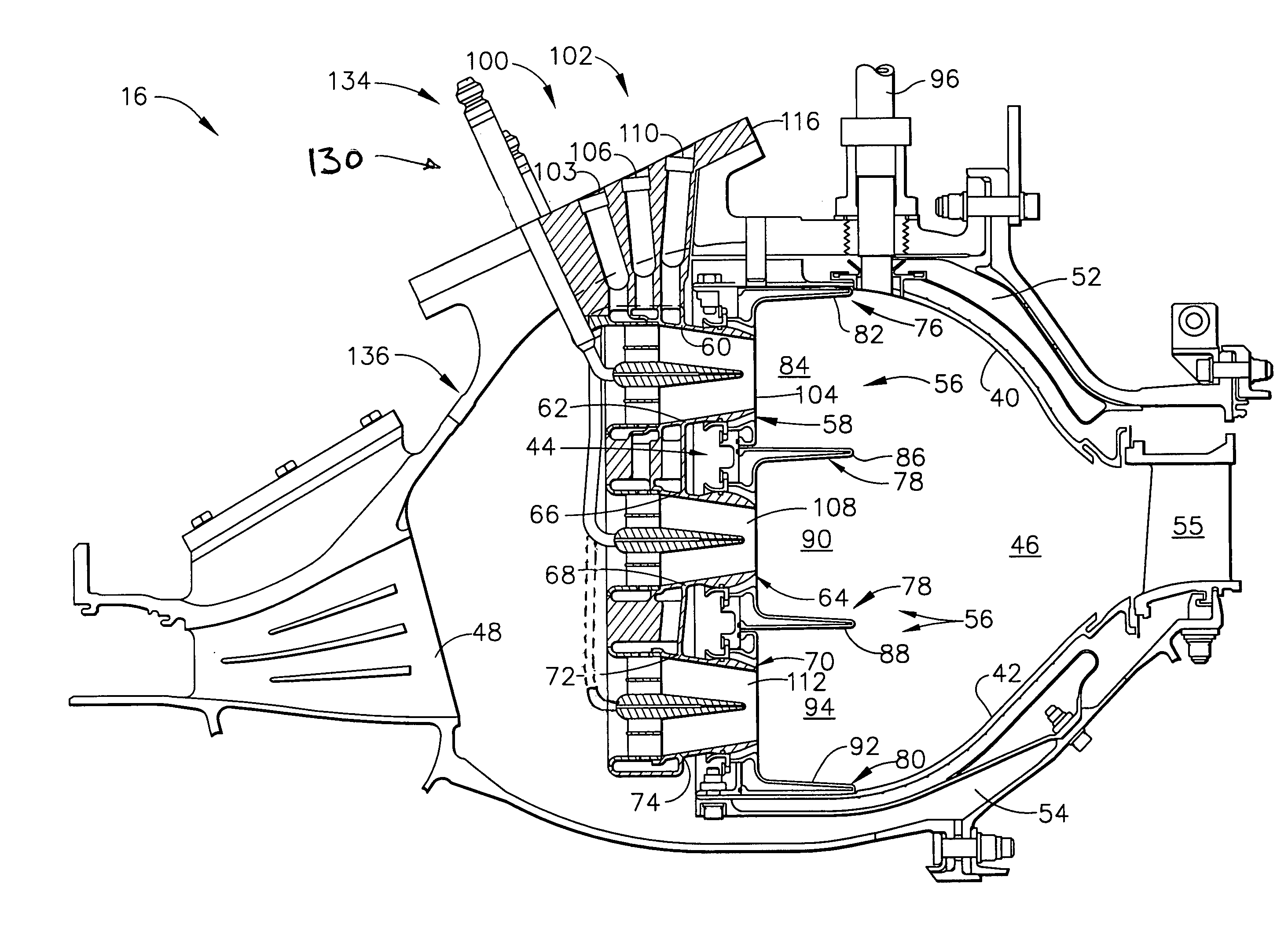

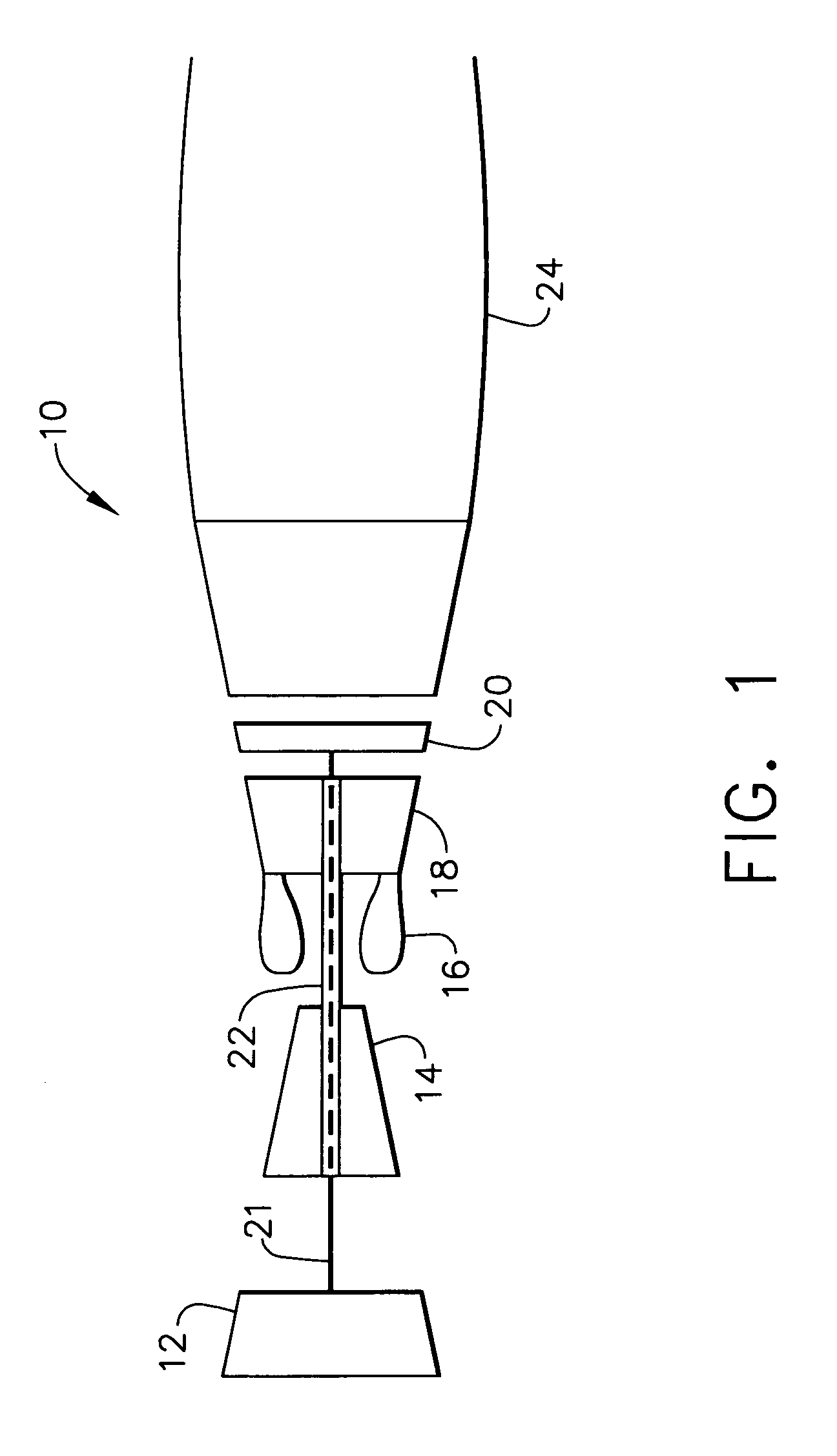

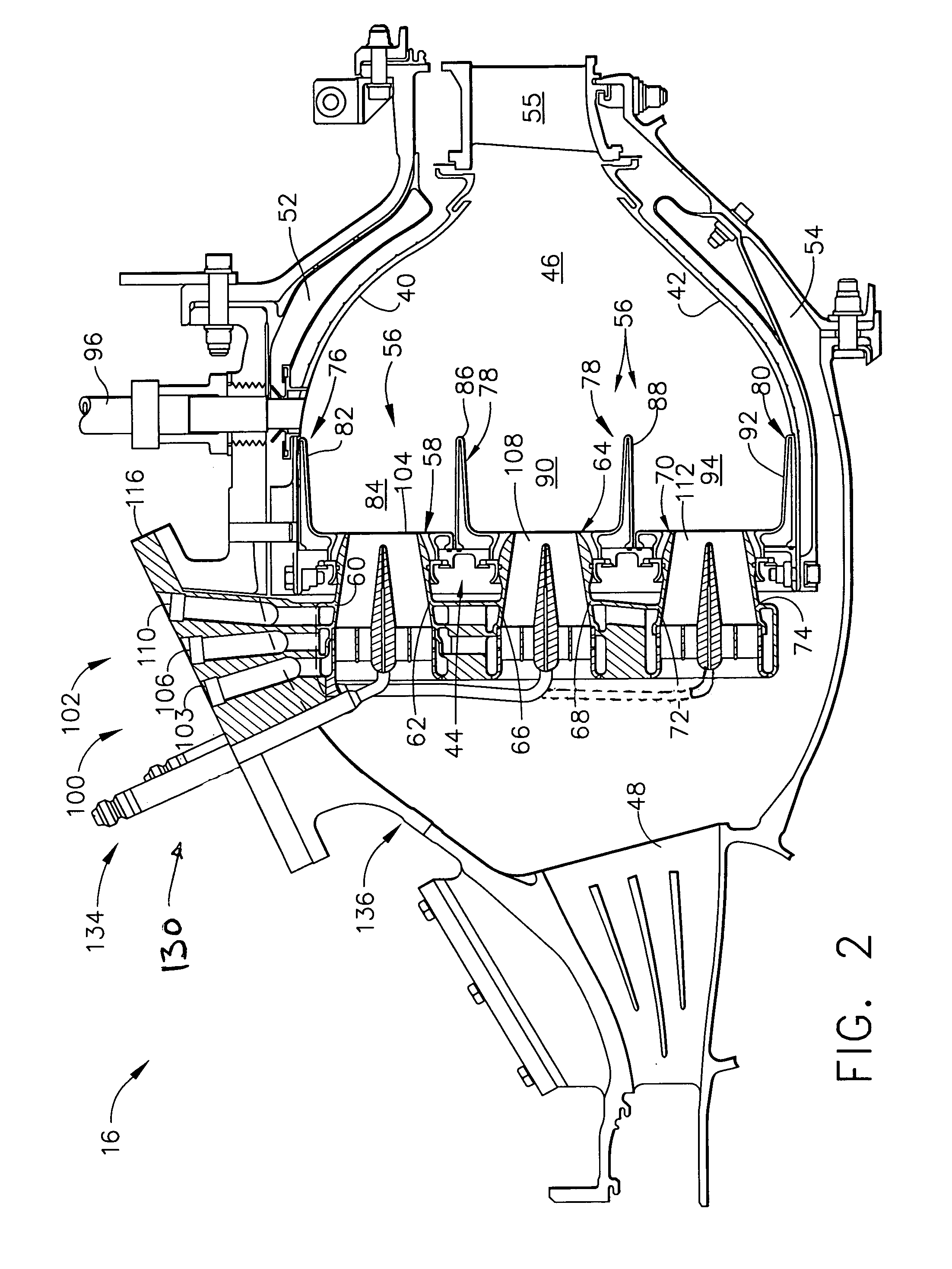

Methods and apparatus for reducing gas turbine engine emissions

InactiveUS6983605B1Increase resultReduce emissionContinuous combustion chamberGas turbine plantsWater deliveryAutomotive engineering

A gas turbine engine includes a combustor system including a lean premix combustor and a water delivery system. The combustor is operable with a fuel / air mixture equivalence ratio less than one and the water delivery system is configured to supply at least one of water or steam to the gas turbine engine such that either the water or the steam is injected into the combustor to control emissions generated by the combustor. As a result, nitrous oxide emissions for specified turbine operating power levels are lowered.

Owner:GENERAL ELECTRIC CO

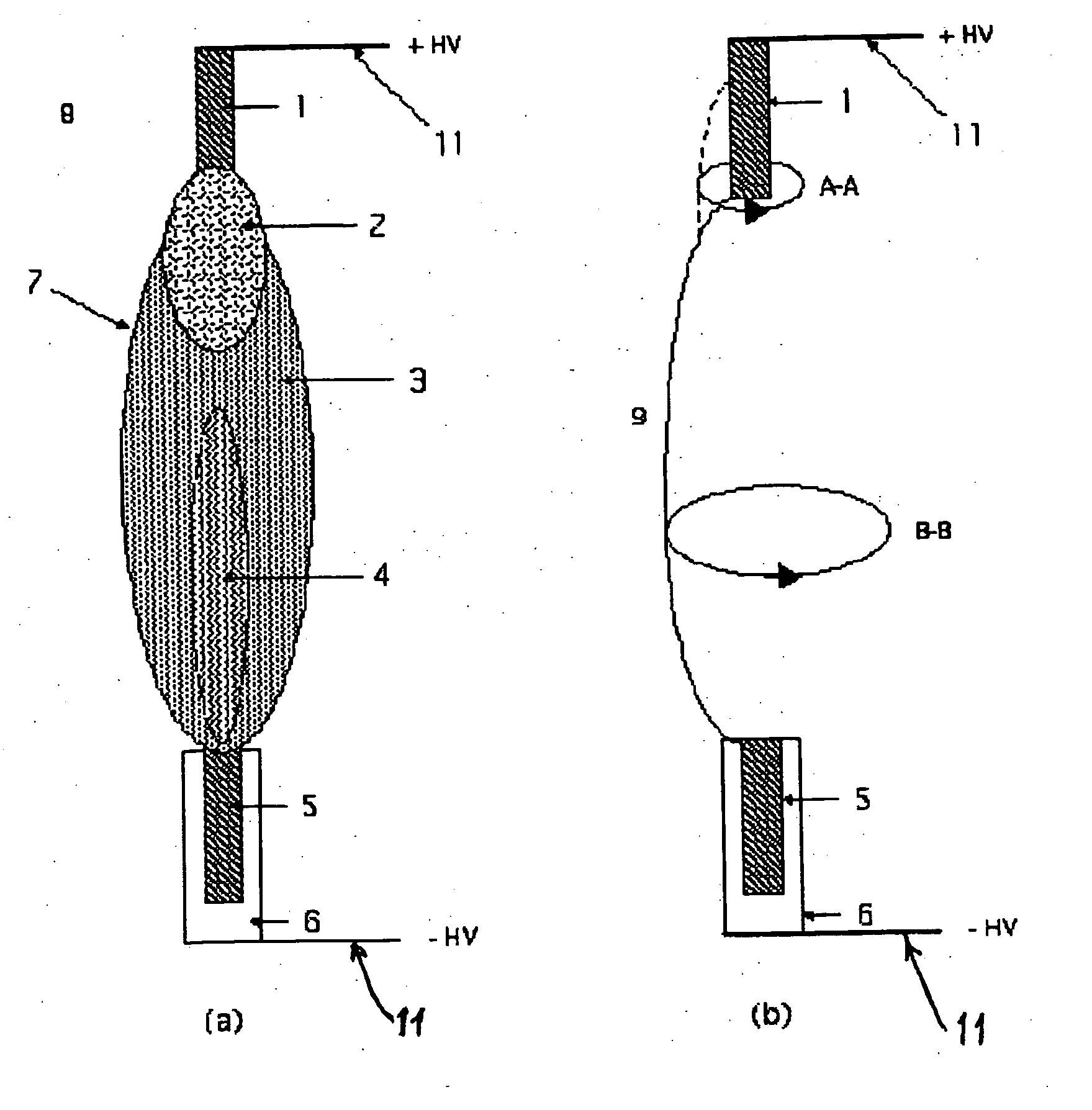

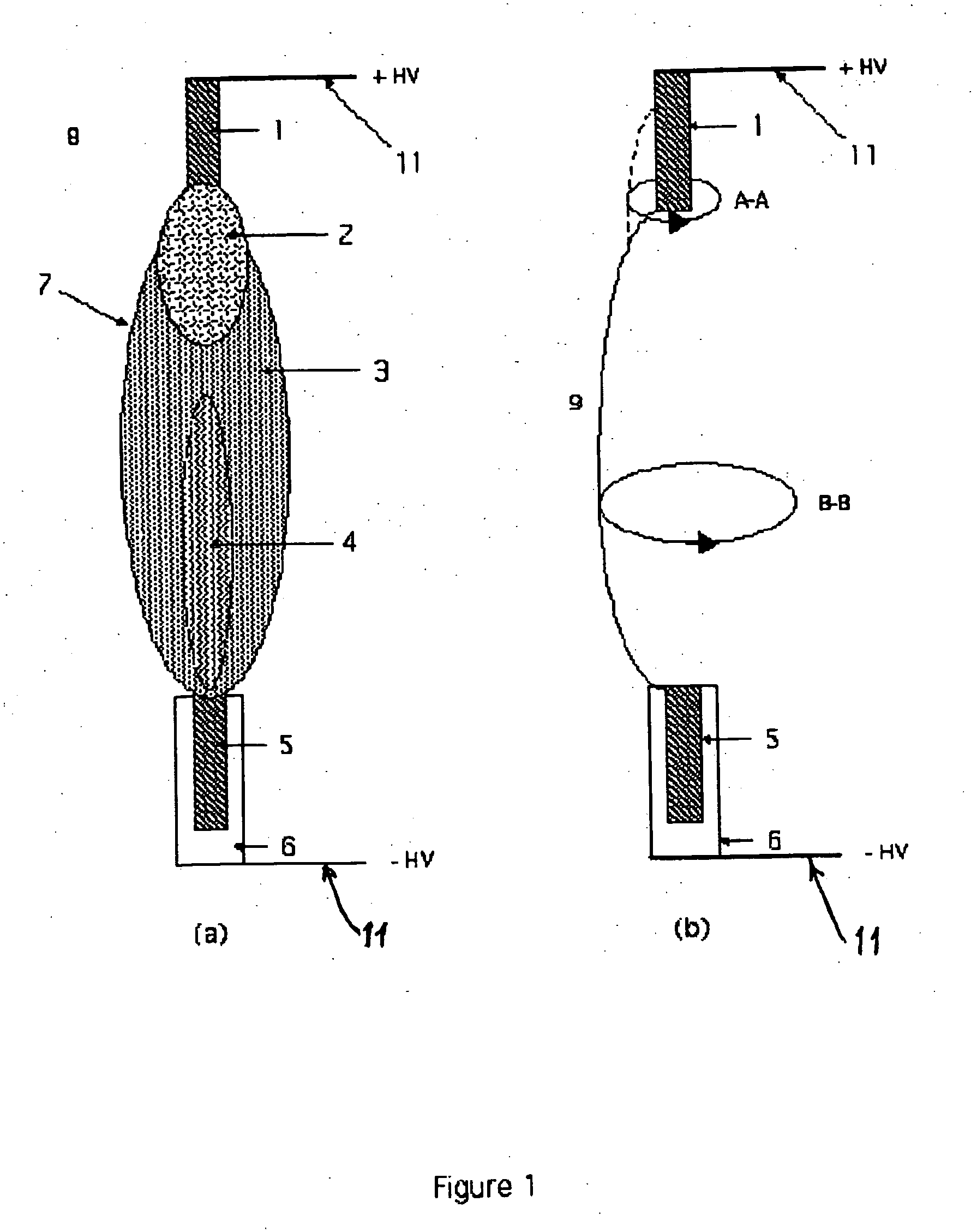

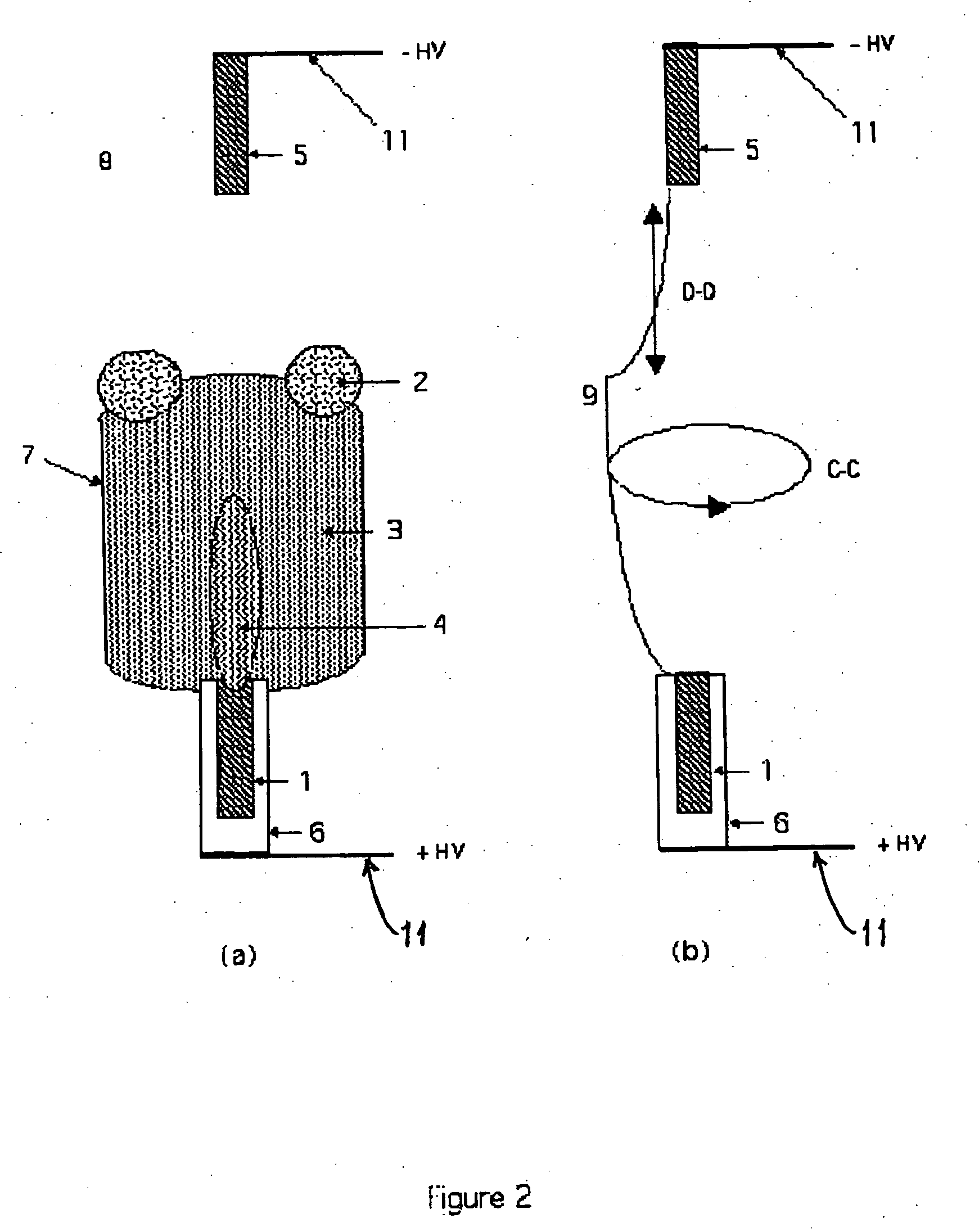

System, method, and apparatus for an intense ultraviolet radiation source

InactiveUS20060165555A1Increased energy inputImprove efficiencyNitrous oxide captureHydrogenThermal energyElectromagnetic radiation

An intense ultraviolet radiation source is disclosed that may be operated in substantially any arbitrary gas environment, without regard to a containment envelope for the ultraviolet radiation source. The intense ultraviolet radiation source can be generated by applying a pulsed or continuous electrical discharge to a partially ionized combustion flame via two electrodes. The combustion flame and electrical discharge can be focused, contained, or confined by gas pressure, electric fields, and / or magnetic fields. Optionally, the thermal energy in the flame and the electrical discharge power input may be augmented with an electromagnetic radiation source, such as a radio-frequency induction heater, a laser, or a microwave generator. Impurities may be placed in contact with or added to the fuel and / or the oxidizer to further alter the emitted ultraviolet radiation spectral brightness as needed. The ultraviolet source may be applied to the molecular dissociation of pollutants in exhaust gas streams of combustion systems. The efficient dissociation of such pollutants requires UV in the wavelength ranges of the vacuum ultraviolet band (100 nm-180 nm) and the UV-C band (180 nm-280 nm).

Owner:ABQ ULTRAVIOLET POLLUTION SOLUTIONS

Method for dyeing and finishing pure-cotton high-count high-density fabric

ActiveCN101532230AReduce trafficEmission reductionTextile storage in superimposed formSingeingHigh densityMoisture absorption

The invention discloses a method for dyeing and finishing pure-cotton high-count high-density fabric, which includes steps of singeing, cold dome, desizing and boiling-off, bleaching, mercerization, dyeing, moisture absorption and breath, no-iron sorting, tentering, pre-shrinking and packaging. The fabric dyed and finished by the present invention has advantages of high rebound, moisture absorption and breath, crease-resistance and soft feel.

Owner:SUNTEX

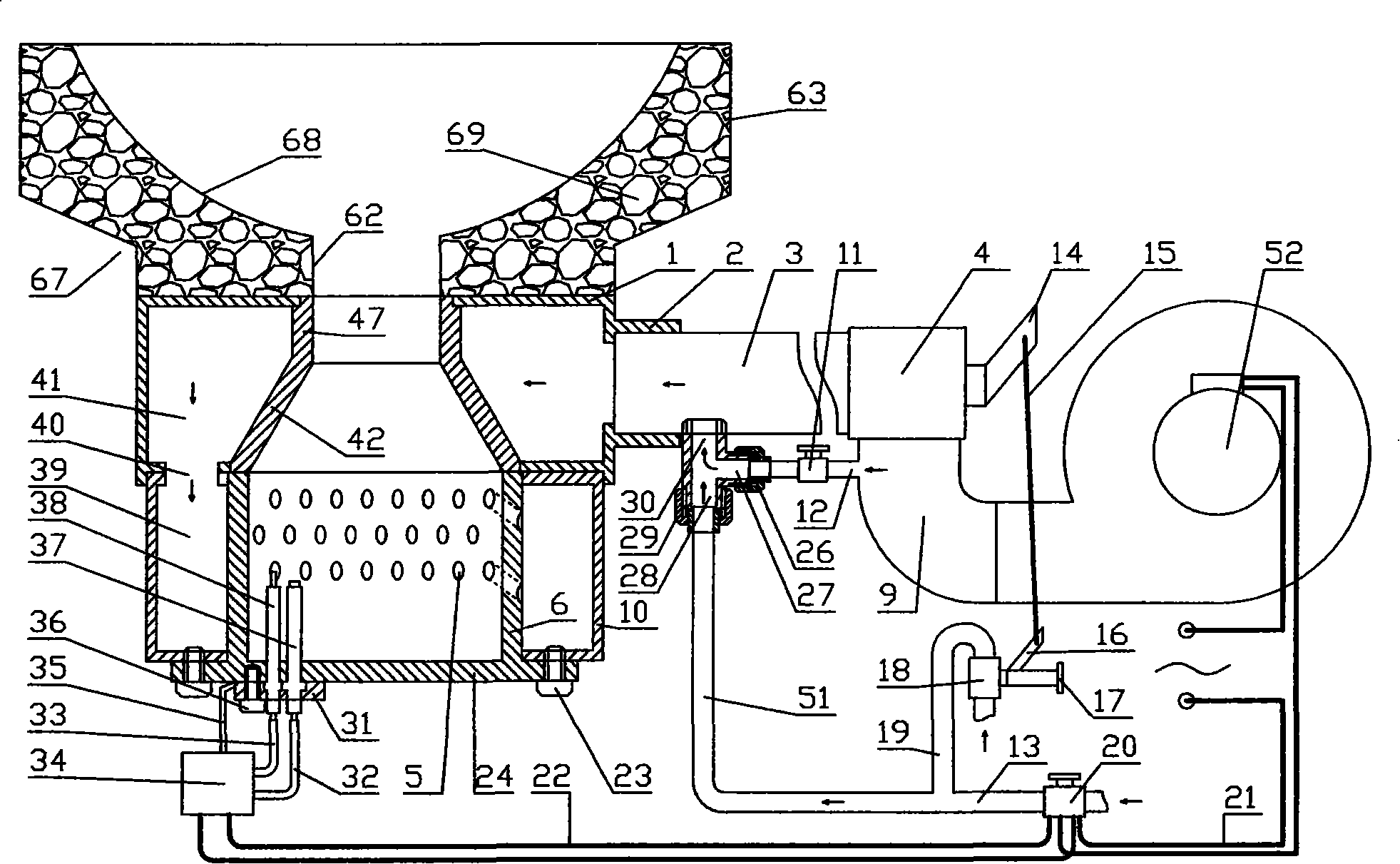

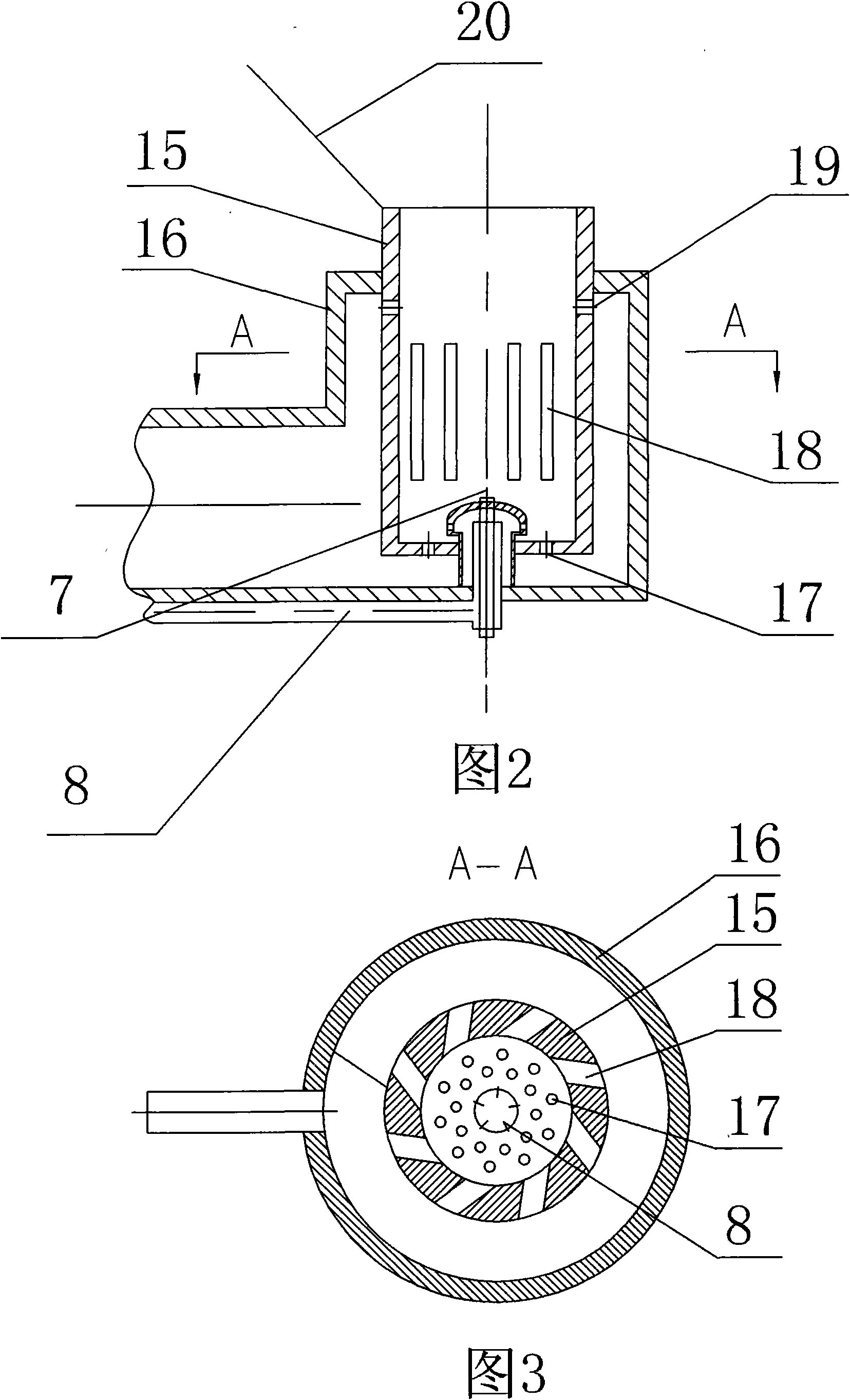

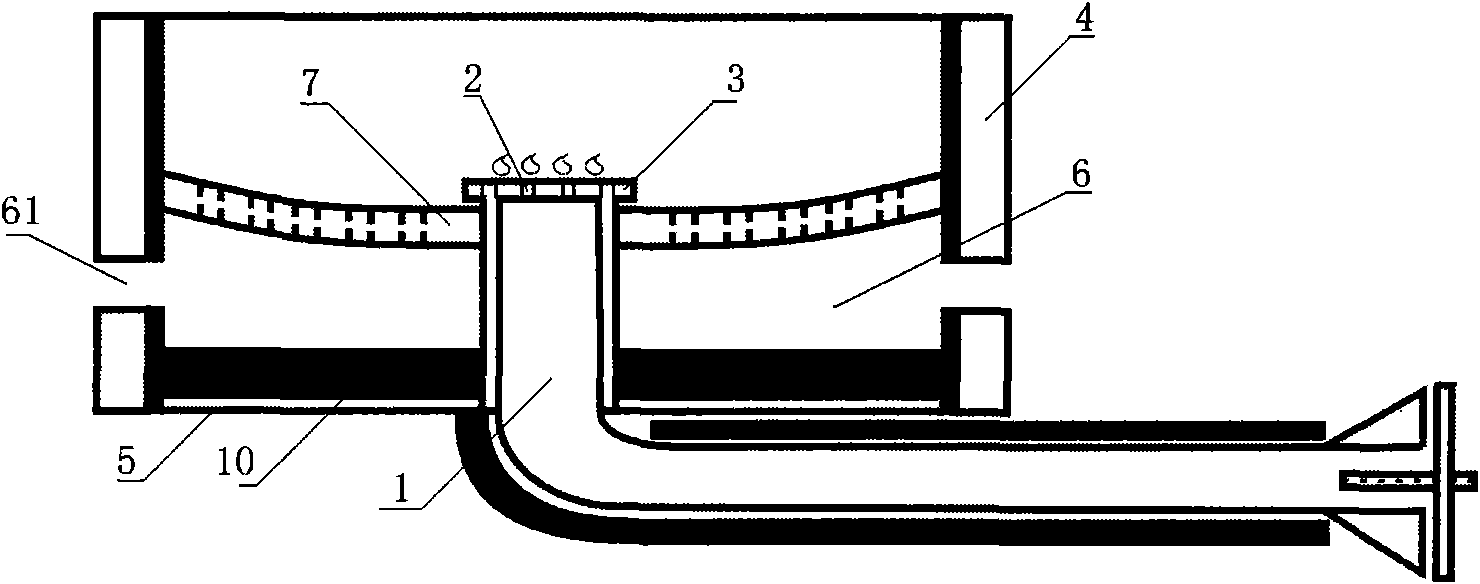

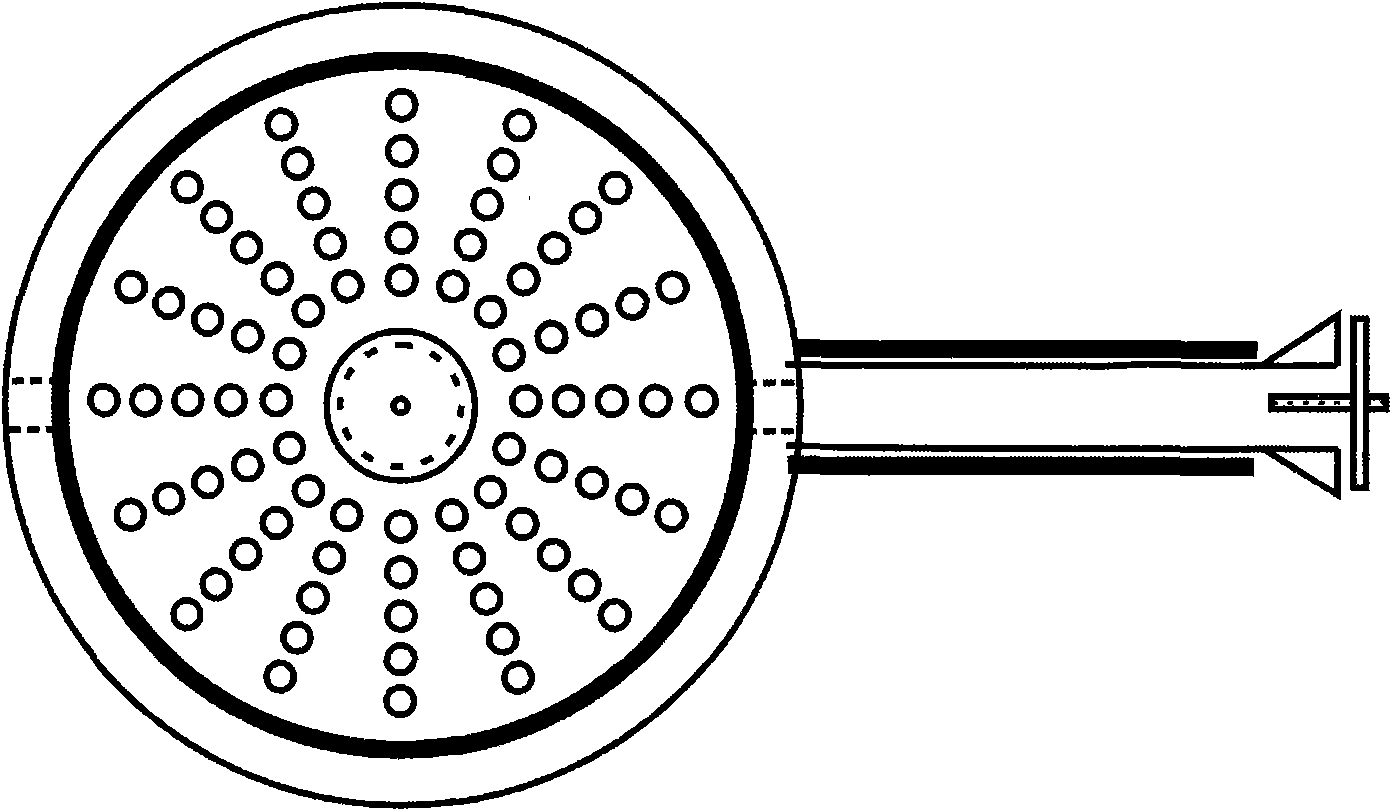

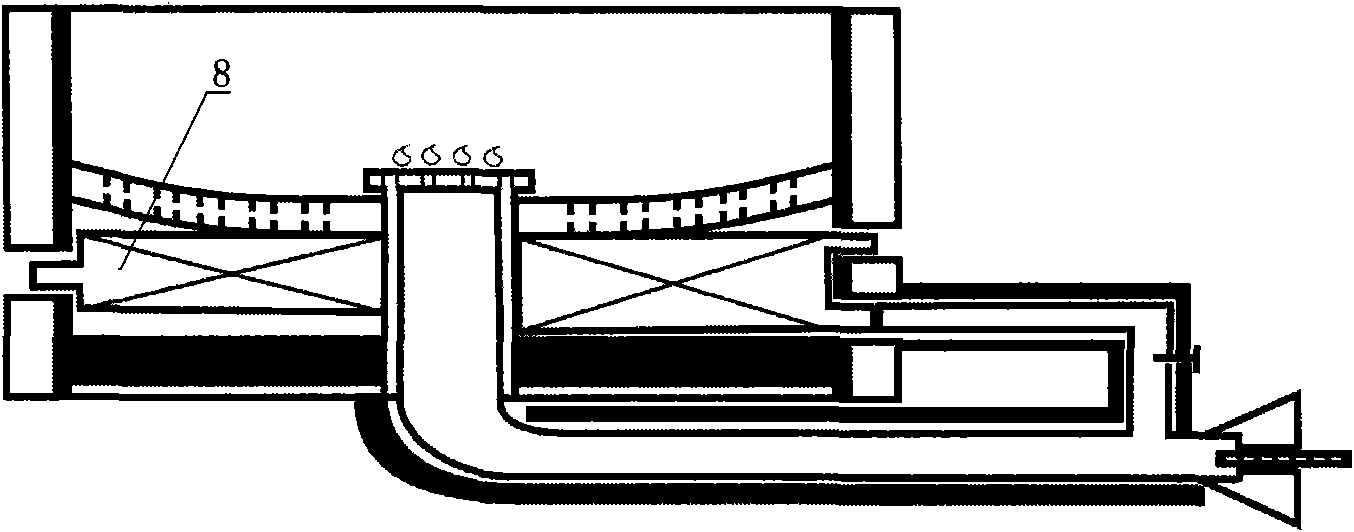

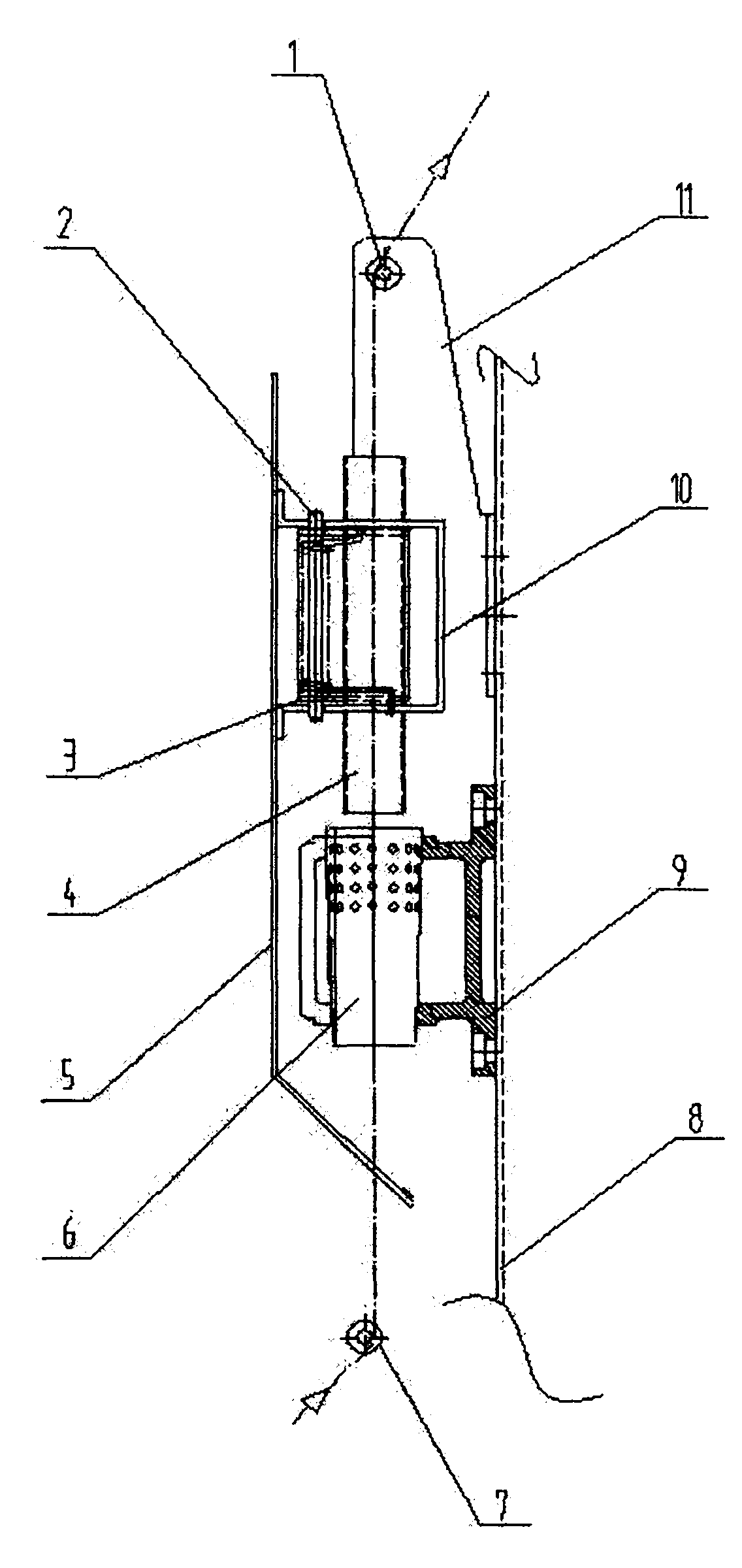

High-efficiency energy-saving high speed combustor of gas range

The invention is a high-efficiency, energy-saving and high-speed burner for a gas cooker used in catering industry and includes a burner, a pre-heater, a pre-mixing small fire burner, a fireproof fire ring, an electronic ignition system and a regulating device. After being necked down, the burning flame is ejected with high speed rotation to form the rotary rapid ejection burning flame, thereby realizing sufficient burning, facilitating boiler heating, and increasing the heating speed with low burning noise and high heat efficiency. The high-efficiency, energy-saving and high-speed burner for the gas cooker has the advantages of simple manufacture, easy maintenance, sufficient burning, high flame temperature, convenient boiler heating, improved heating speed, low power of the equipped blower fan, low burning noise, high thermal efficiency, convenient regulation, full-automatic ignition, concentrative firepower, intensive fire, energy conservation, strong adaptability, capability of meeting different requirements, wide application, easy processing, low manufacture cost and suitability for mass production.

Owner:尹华金

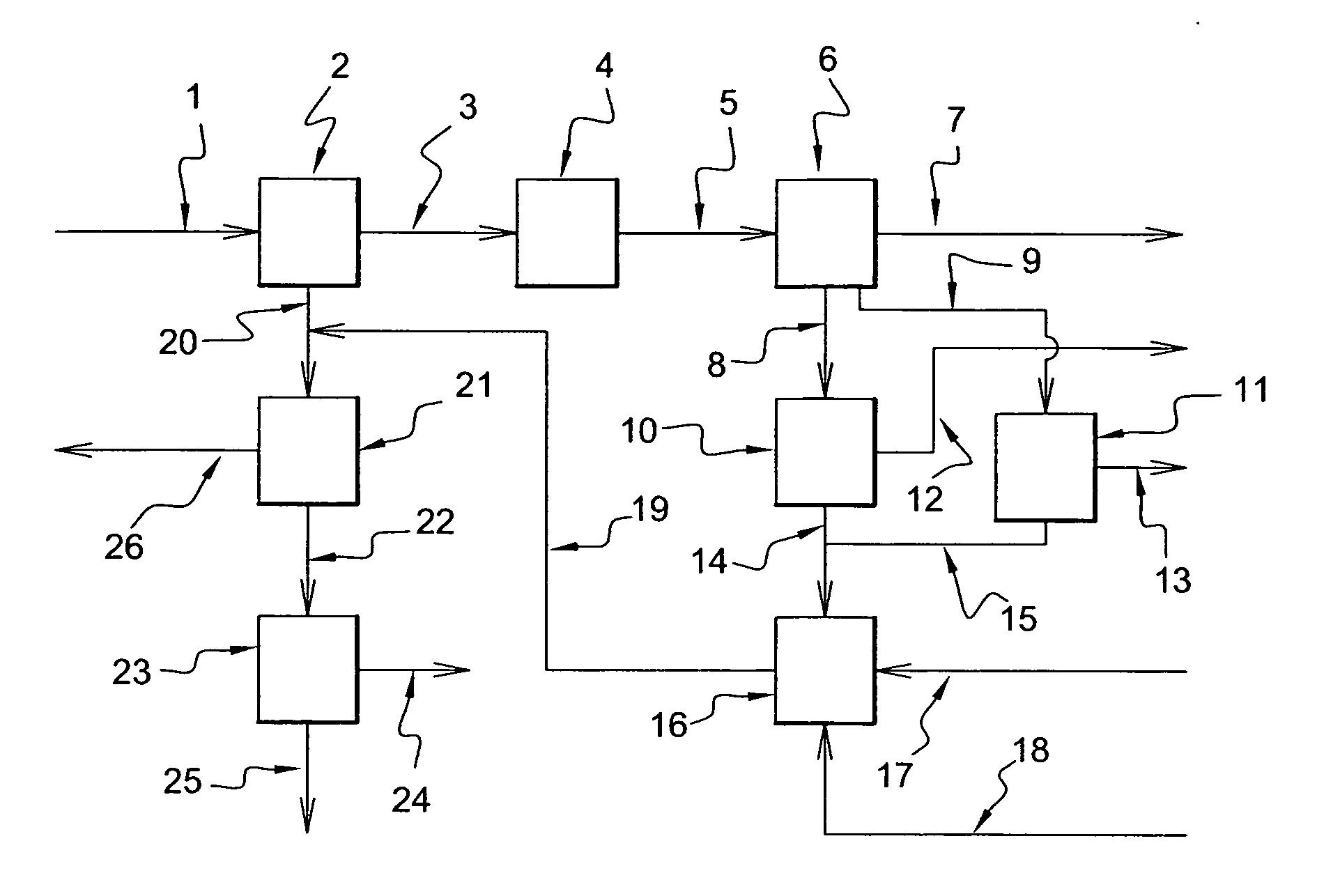

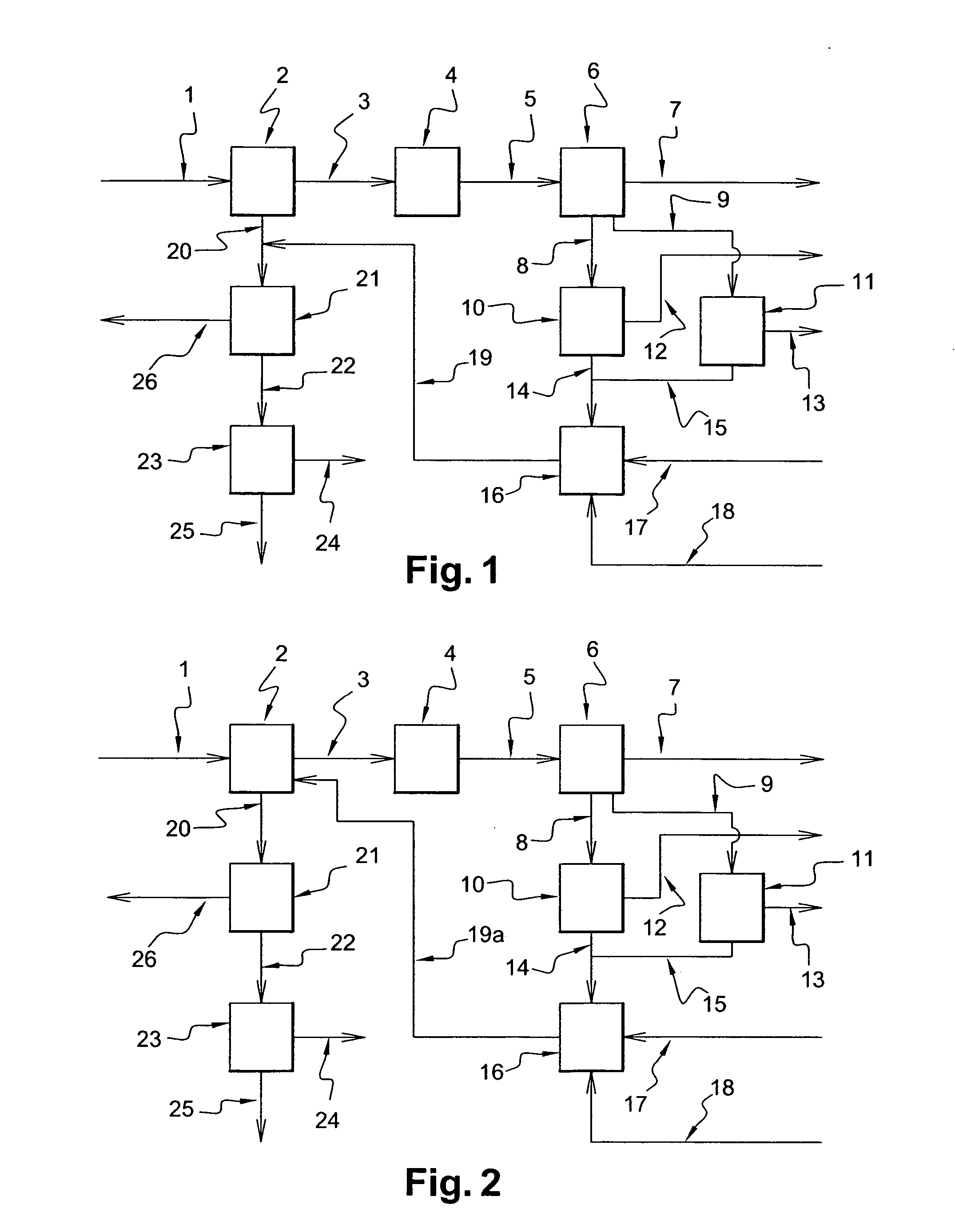

Process and installation for the treatment of DSO

The invention relates to a process for the treatment of gas containing mercaptans and acid gases, comprising the following steps: (1) separating the acid gases from the said gas and obtaining a sweetened gas and the flow of acid gases containing H2S; (2) reacting the H2S thus obtained in step (1) according to the Claus reaction; (3) concentrating themercaptans in at least one cut of the said sweetened gas; (4) extracting the mercaptans of the said cut; and further comprising: (5) transforming the mercaptans into dialkyl-disulfide (DSO); (6) hydrogenating DSO into H2S; and (7) reacting the H2S thus obtained at step (6) according to the Claus reaction. The invention also relates to an installation for carrying out this procedure.

Owner:TOTAL PUTEAUX FR

Energy-saving and high efficiency fuel coal combustion improver and preparation method thereof

The invention discloses an energy-saving and high efficiency fuel coal combustion improver and a preparation method thereof. The combustion improver comprises the following components by weight percentage: 40-60% of zinc oxide, 40-60% of manganese dioxide, preferably 50% of zinc oxide and 50% of manganese dioxide, wherein the manganese dioxide can be prepared by: weighing KMnO4 and MnC12.4H2O according to a weight ratio of 1:1, and fully grinding the materials in a container under room temperature for 20-50min to carry out solid phase reaction. The preparation method of the energy-saving and high efficiency fuel coal combustion improver includes the steps of: a. weighing the raw materials according to the following weight percentage: 40-60% of zinc oxide and 40-60% of manganese dioxide; b. grinding; c. dipping and drying; and d. roasting. The combustion improver provided by the invention reduces corrosion to boilers, improves the service life of boilers, significantly raises the flame temperature, improves the combustion activity and ignition performance of coal, improves the speed of ignition speed and combustion speed of coal, and has significant energy saving and environmental protection effects.

Owner:HARBIN HONGTIAN RUIDA TECH

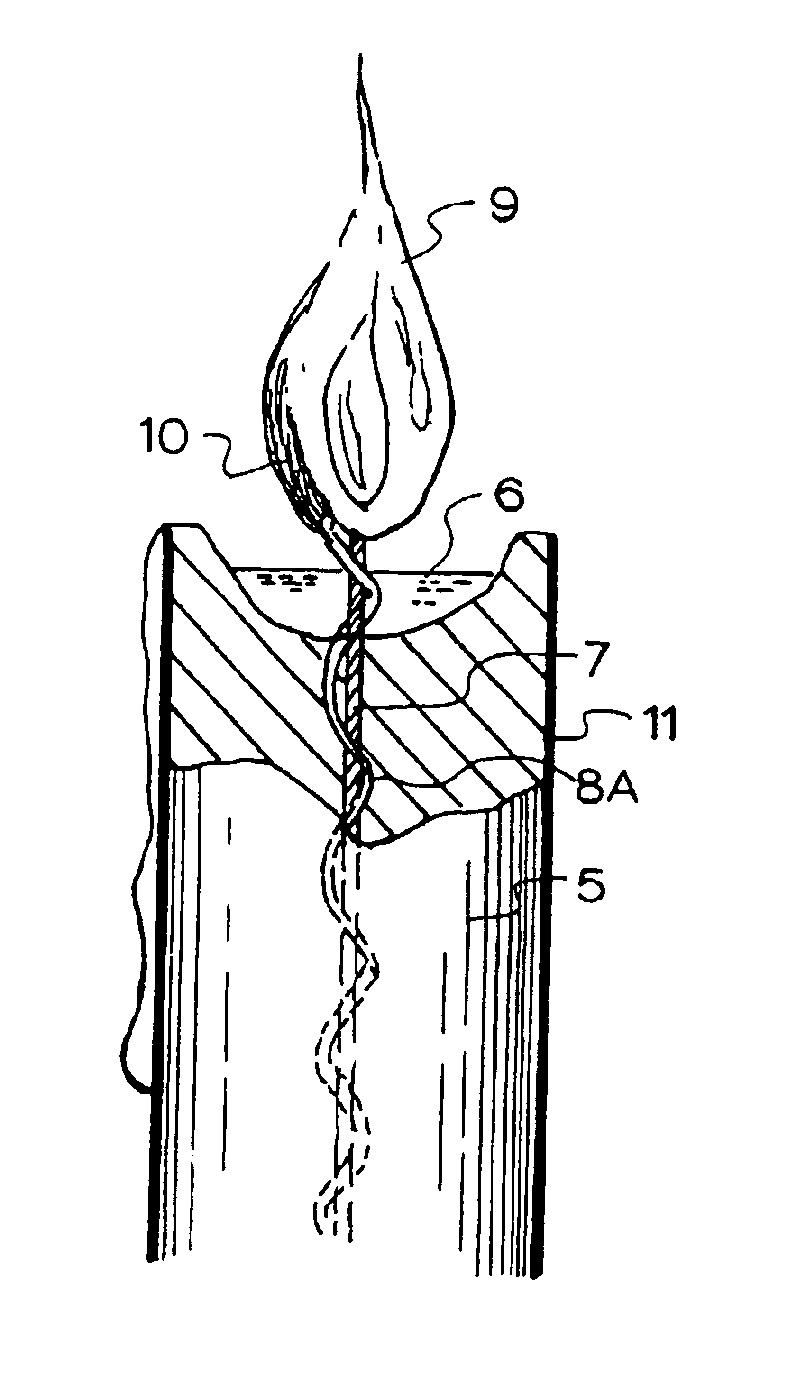

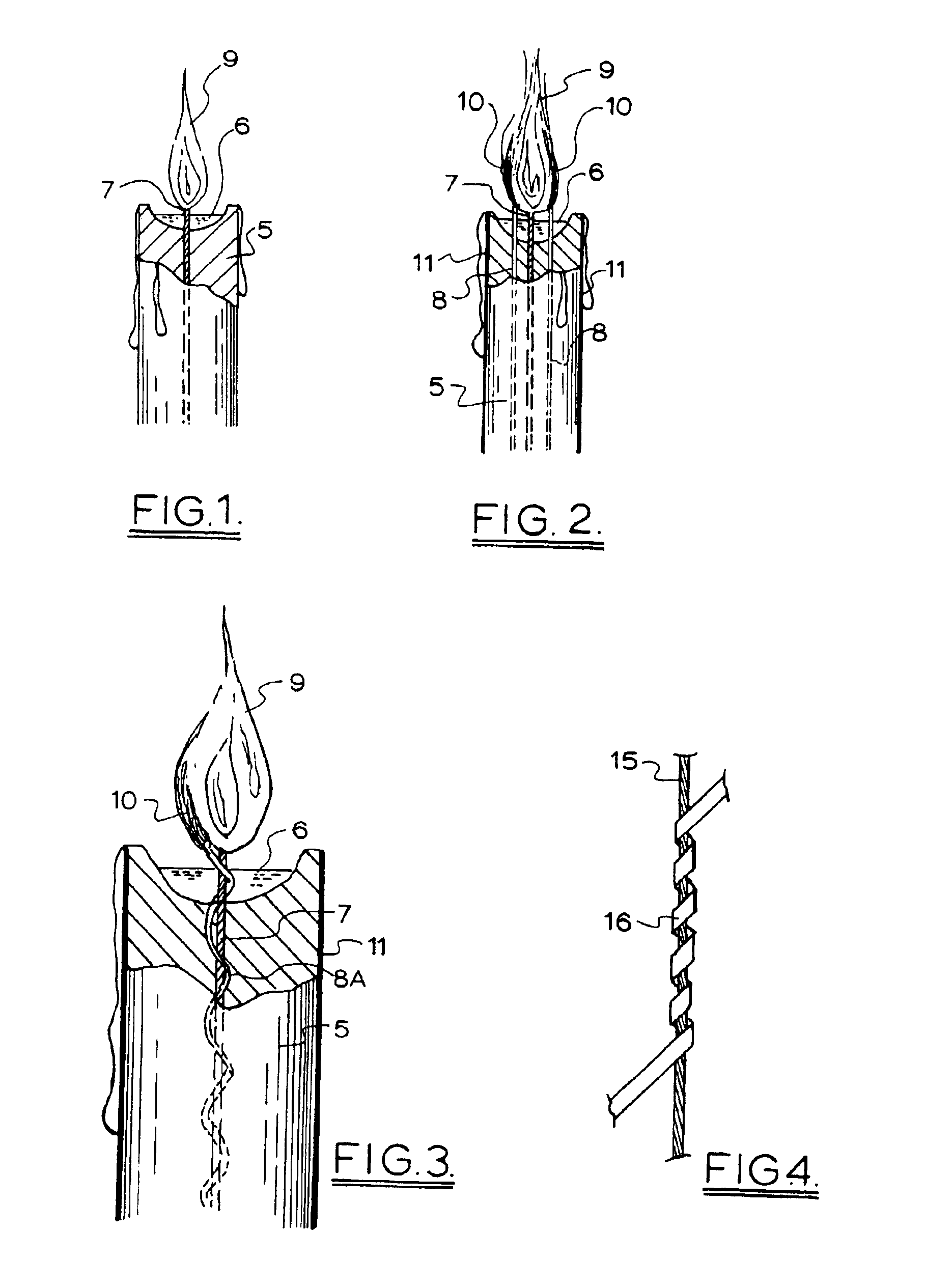

Candles with colored flames

A candle with transparent flame and flame temperature higher than paraffin candles consists of a fuel mix consisting of sorbitol, ethane diol and glycerol with a polyaramid wick. The candle can be used in catering and for the production of colored flames. For colored flames a colorant wick delivers the colorant to the portion of the flame that maximises the temperature and the residence time of the colorant in the flame. The colorant wick may be spirally wound around a former, heat set and then threaded with the combustion wick so that when alight the free end of the colorant wick relaxes to lie in the hottest portion of the flame.

Owner:NOVAFLAME

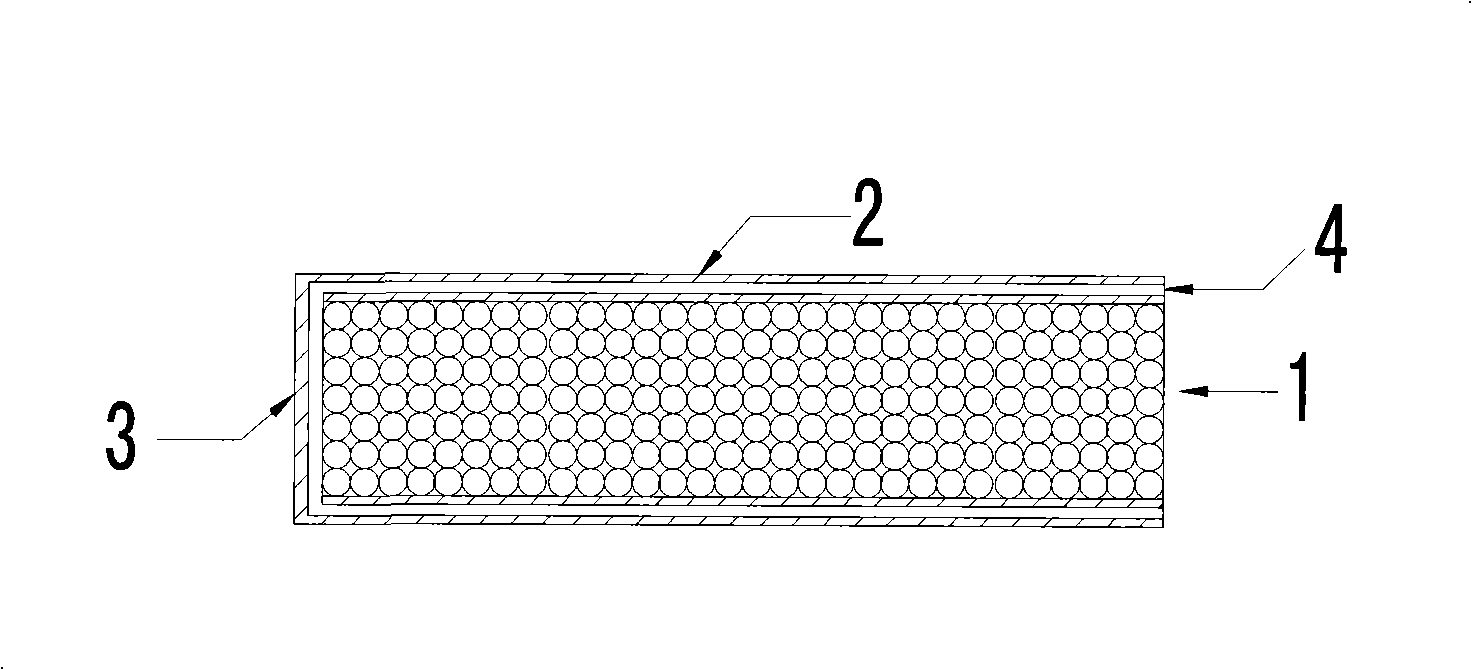

High-efficiency porous media combustor for minitype heat optoelectronic system

InactiveCN101354132AImprove temperature distributionStable and efficient workGaseous fuel burnerExhaust gasProduct gas

The invention provides a high-efficiency porous medium burner used in a micro thermo photovoltaic system, relating to the technical field of combined combustion of a two-phrase gas. SiC ceramic spherules with diameter of 0.3mm to 0.35mm are filled in a shell of the burner in the form of oblique parallelepiped and then sintered with the shell to form a porous medium structure with porosity epsilon equal to 26 percent to 27 percent and a tail gas discharging channel is arranged on the external wall of the burner. The shell of the burner is processed first and then a bottom cover (3) of the burner is processed and sintered with the shell, and finally, in the interior of which the screened SiC ceramic spherules with diameter of 0.34mm are filled, after sintering, the porous medium structure is formed and the tail gas discharging channel is arranged in the interior of the shell (2) of the burner. The porous medium burner reduces the heat loss brought by increase of surface to volume ratio due to microscale, greatly improves the temperature distribution on the external wall of the burner, promotes combustion efficiency and combustion stability, lowers gas discharging temperature and heightens the temperature of the external wall, thus greatly advancing the efficiency of the whole micro thermo photovoltaic system.

Owner:JIANGSU UNIV

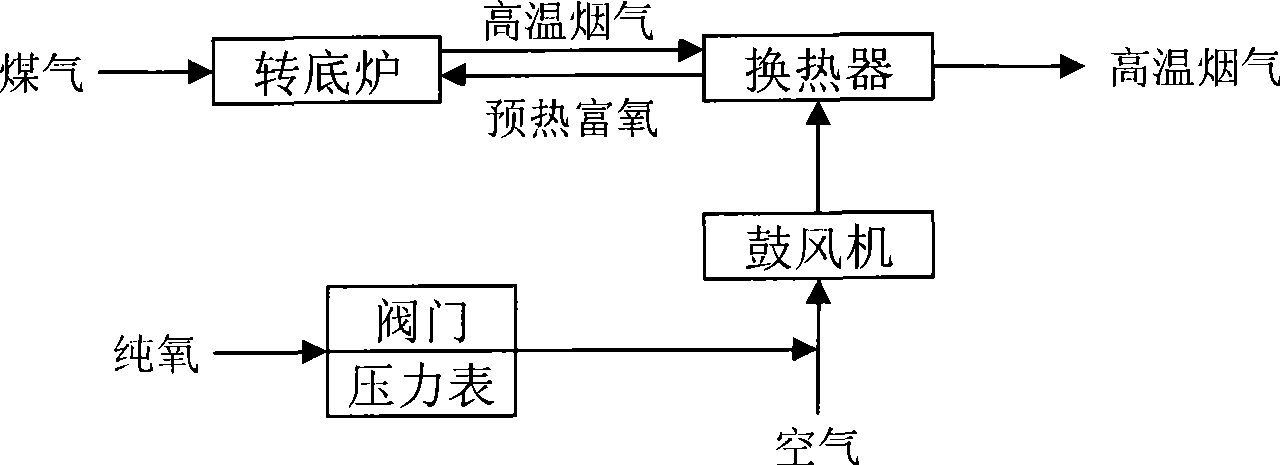

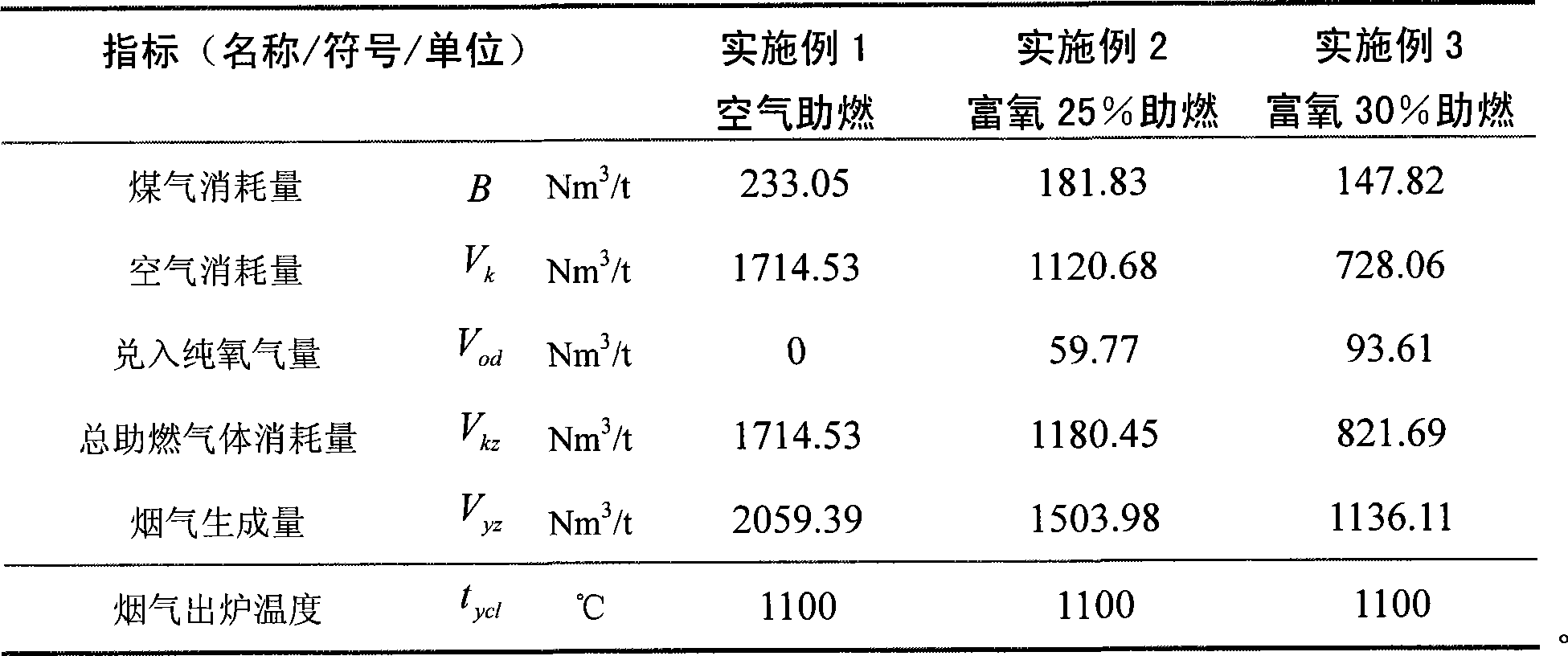

Method for manufacturing metallic pellets by direct reduction of oxygen-enriched combustion in rotary furnace

InactiveCN101445869AReduce consumptionReach the remarkable effect of saving energy and reducing consumptionProcess efficiency improvementAir blowerRotary furnace

The invention provides a method for manufacturing metallic pellets by direct reduction of oxygen-enriched combustion in a rotary furnace, which belongs to the technical field of steel industry for manufacturing metallic pellets (or direct reduction iron). The method is characterized in that oxygen enriched air is adopted as an auxiliary fuel gas; the oxygen enriched air enters a heat exchanger through a blower; and after the heat exchange between the oxygen enriched air and high temperature flue gas is performed, the temperature rises to 400 DEG C to 600 DEG C, and then the oxygen enriched air enters the rotary furnace. The invention breaks through the limitation of the prior air taking as a combustion medium and fixing the oxygen content, realizes the actual demand that the oxygen content in the combustion medium is controllable, further enhances the heat efficiency of the rotary furnace, reduces over 35% of air consumption amount, reduces over 31% of total consumption amount of the auxiliary fuel gas; and the coal gas consumption, the flue gas discharge capacity and the investment cost are reduced, and conforms to the national policy requirements of energy conservation, emission reduction and circulation economy.

Owner:LAIWU IRON & STEEL GRP

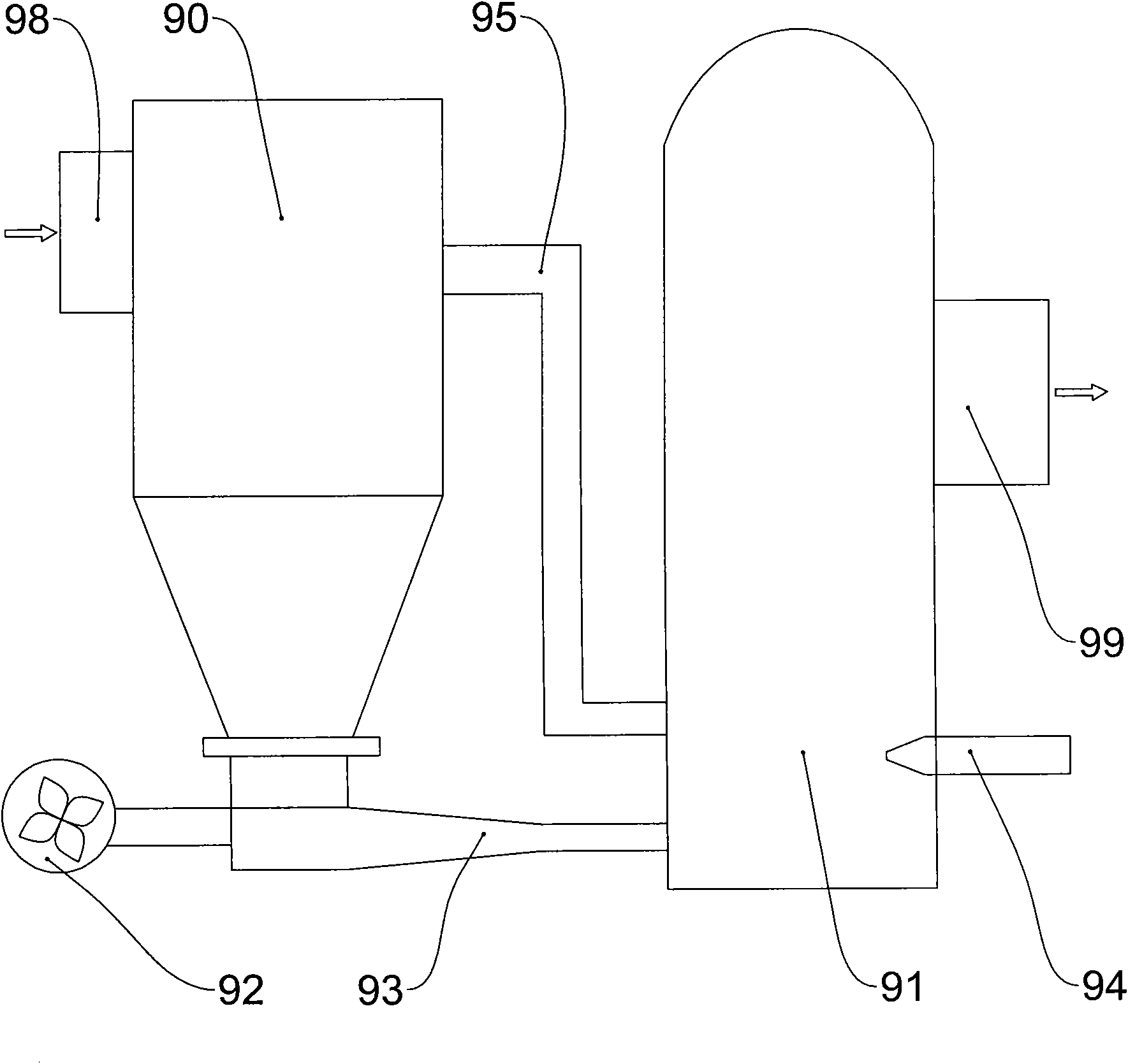

Oxygen-enriched combustion transformation method and device for garbage incineration grate furnace

InactiveCN104100979ABurn fullyAdjustable temperatureIndirect carbon-dioxide mitigationIncinerator apparatusBaghouseEngineering

The invention discloses an oxygen-enriched combustion transformation method for a garbage incineration grate furnace. The method comprises the steps that an oxygen injecting step is added before the primary air of a combustion section, namely, oxygen obtained by gasifying and pressure regulating is injected into a primary air pipeline of the combustion section, so the air is fully mixed with the normal air of the combustion section and is then injected into a hearth; injection of normal secondary air is stopped, a draught fan behind a cloth bag deduster is connected with a secondary fan by a pipeline, so circulated smoke is guided into a secondary air pipeline by the secondary draught fan, and is injected into the hearth by a secondary air opening. The invention discloses a corresponding oxygen-enriched combustion device. The excess air coefficient is reduced, the flame temperature in the furnace is improved, the combustion condition is optimized, the generation of pollutants such as dioxin is effectively inhibited, the efficient, stable and safe operation of the incineration equipment is ensured, the smoke exhaust is reduced, the smoke heat loss and output of the draught fan are reduced, the combustion efficiency is improved, and the investment and operation cost of smoke purifying equipment are favorably reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

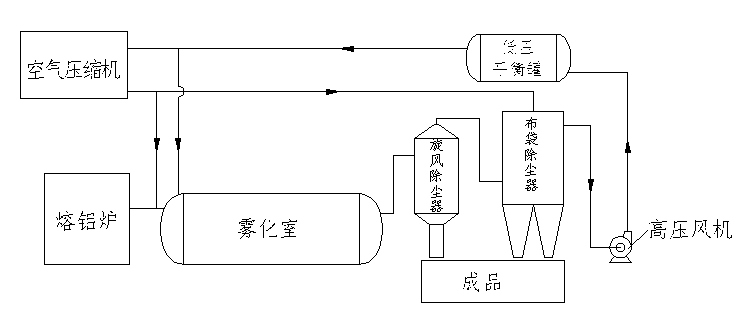

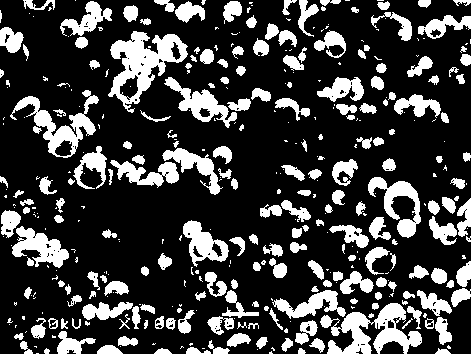

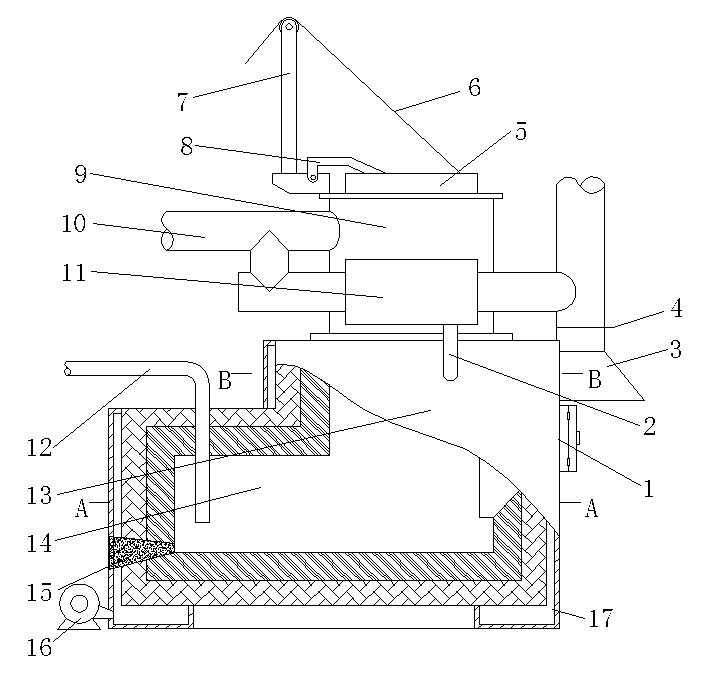

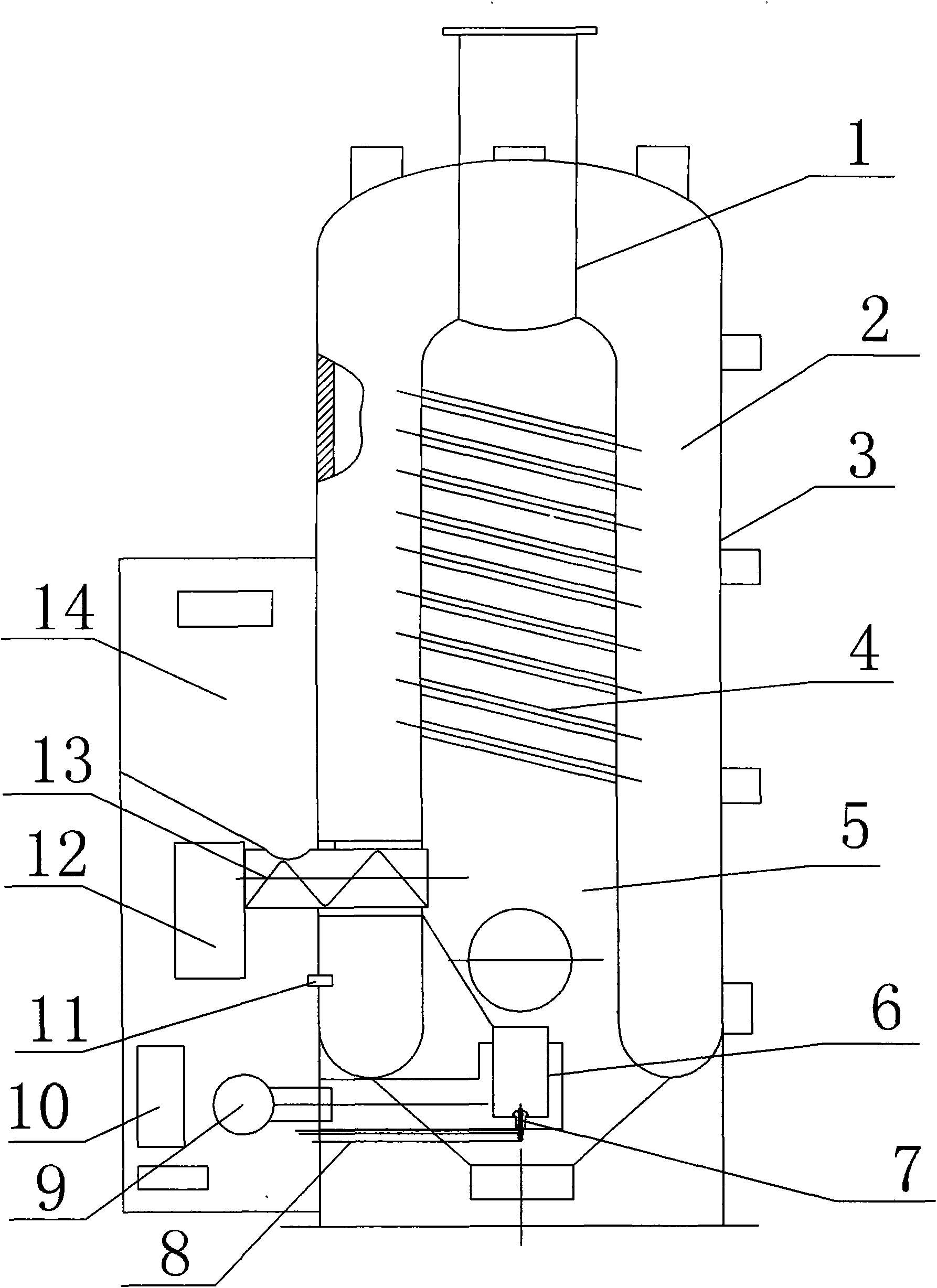

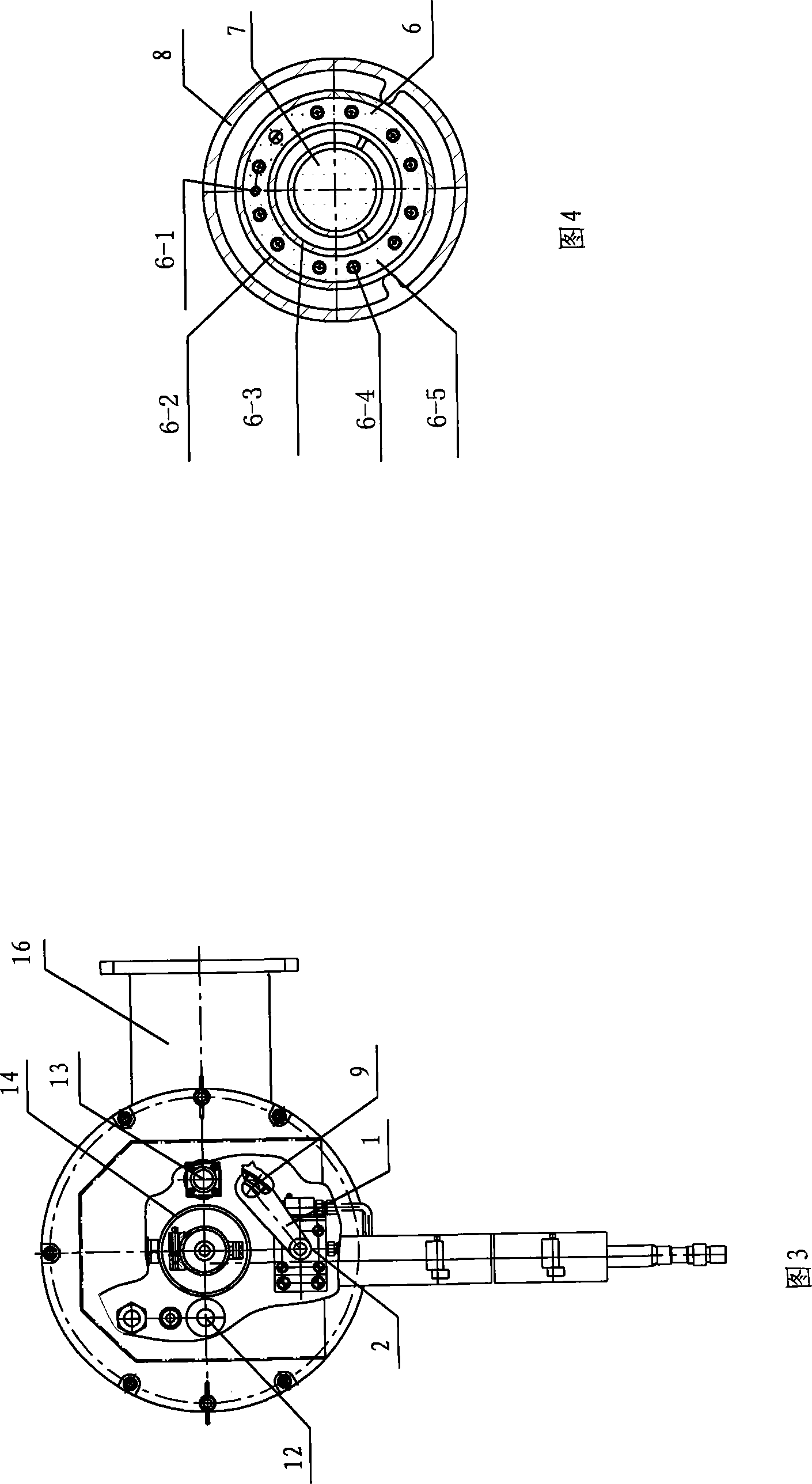

High-activity ultrafine aluminum powder preparing process and device

The invention relates to a high-activity ultrafine aluminum powder preparing process and a high-activity ultrafine aluminum powder preparing device. The high-activity ultrafine aluminum powder preparing process comprises melting, atomizing and classifying steps. The high-activity ultrafine aluminum powder preparing device relates to a special aluminum melting furnace and a gas atomizing nozzle, wherein the aluminum melting furnace comprises an aluminum melting furnace body with a circular furnace bottom, a burner nozzle installed in the aluminum melting furnace body, and a furnace door installed on the aluminum melting furnace body; a vertical furnace body is installed at the upper end of the aluminum melting furnace body; a feed port is formed in the upper end surface of the vertical furnace body; the high-activity ultrafine aluminum powder preparing device is characterized in that an aluminum liquid heat-preserving area is arranged on one side inside the aluminum melting furnace body with the circular furnace bottom; one end of an aluminum liquid suction pipe is communicated with the aluminum liquid heat-preserving area; the other end of the aluminum liquid suction pipe is connected with aluminum powder producing equipment; a flue gas recycling hood is installed at the upper end of the furnace door; an air preheater is communicated with the flue gas recycling hood and the vertical furnace body; and an air inlet of the burner nozzle is connected with the air preheater. The high-activity ultrafine aluminum powder preparing process and the high-activity ultrafine aluminum powder preparing device have the characteristics of simple process, low production cost, recyclability of a mixed gas, reasonable structures of the aluminum melting furnace and the gas atomizing nozzle, high production efficiency and the like.

Owner:宁夏新和新材科技有限公司

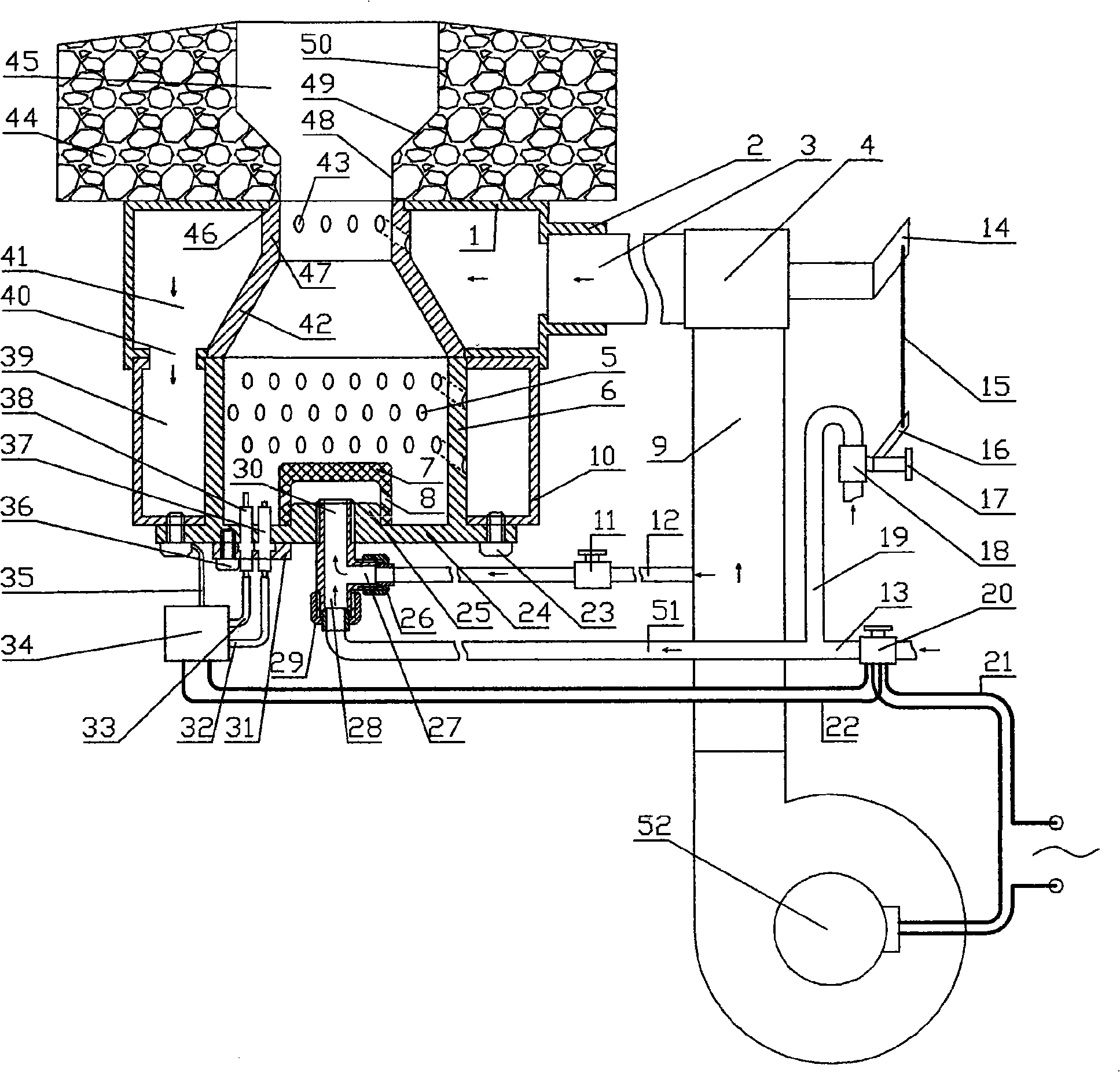

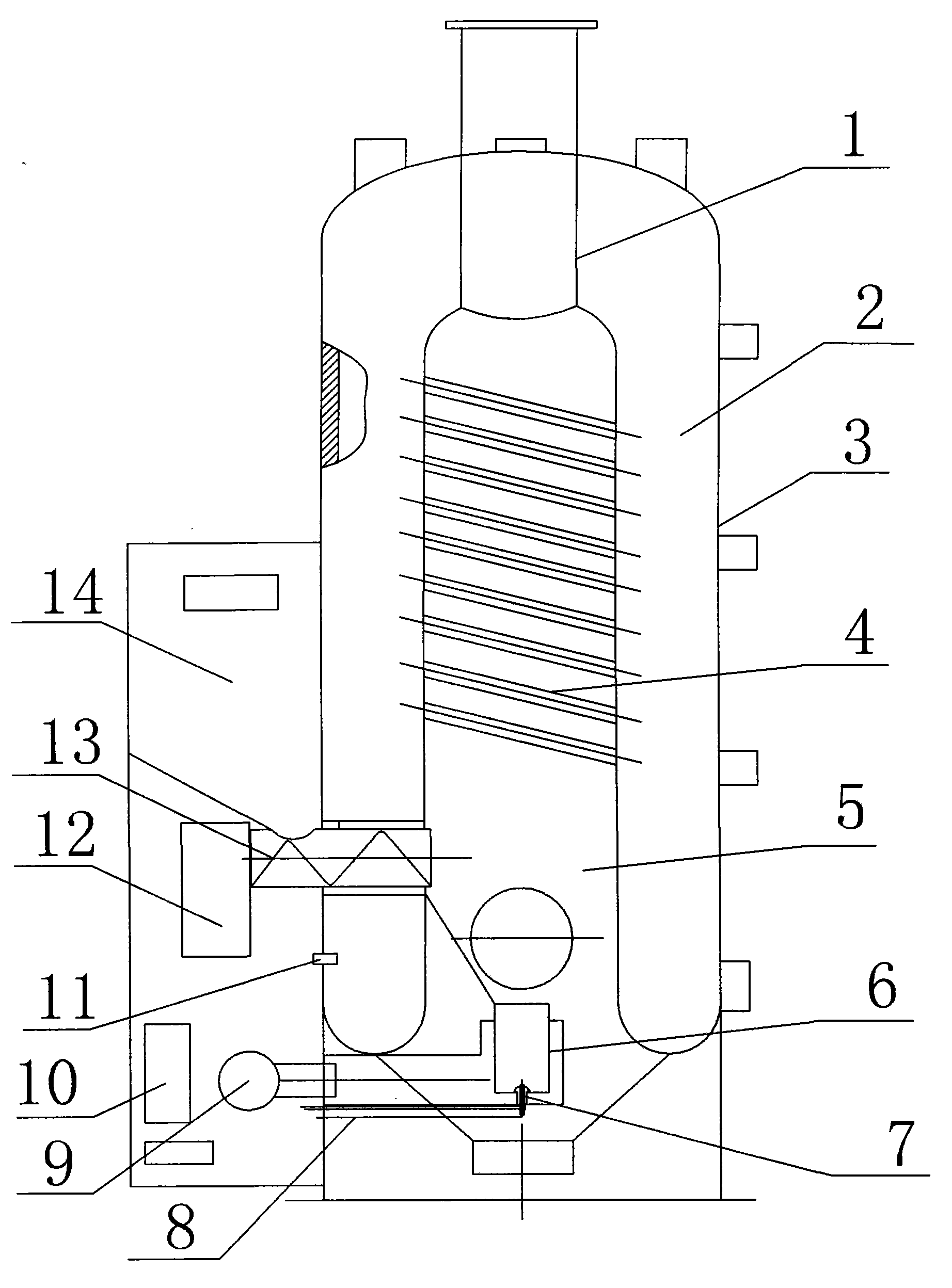

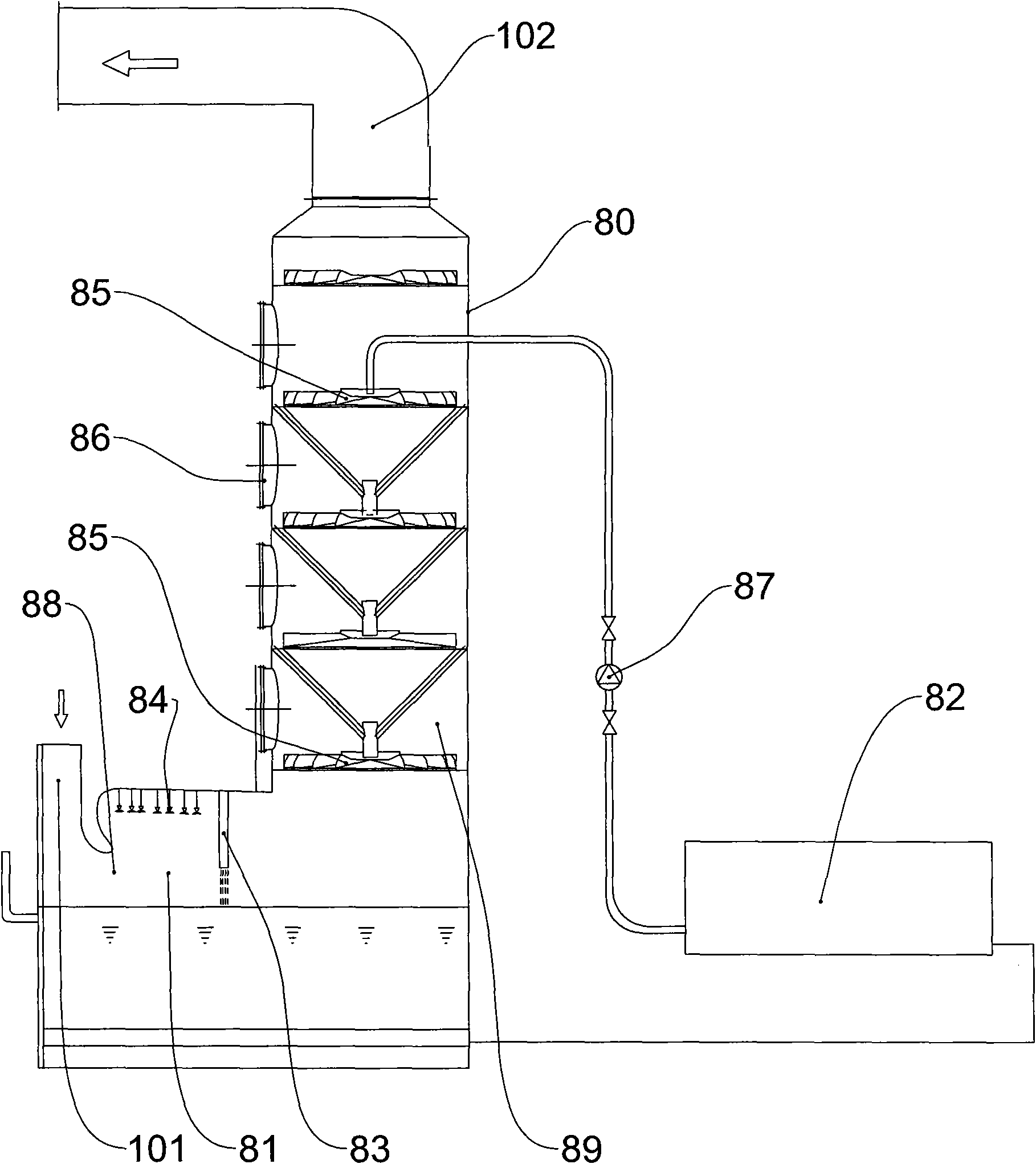

Biomass fuel boiler

InactiveCN101846386ABurn fullySolve the problem of stickingSteam generation plantsWater heatersCombustion chamberCombustor

The invention discloses a biomass fuel boiler which is equipped with an outer shell and an inner combustion chamber, wherein, a water storage room is arranged between a barrel and the combustion chamber, and a burner is arranged at the lower part of the combustion chamber. The biomass fuel boiler is characterized in that the burner is of a double-layer sleeve structure, wherein, the inner layer thereof is a cylinder with an open on the upper surface, and an ignition device is arranged in the middle of the bottom; an outer layer is a closed body which is communicated with a fan and is used for enclosing the inner-layer cylinder besides an open mouth; and air intakes are arranged at the middle part and the upper part of the bottom and the side of the inner-layer cylinder; and a particle fuel tank is arranged at the side of the shell, and particle fuel is connected to the burner through a twisting cage. In the invention, three types of combustion air such as upper straight air, middle spiral air and bottom raising air are formed in the burner by changing the mode of air supply, wherein, the bottom raising air enables biomass particles to suspend in the burner; the middle spiral air enables biomass fuel more dispersed and more fully burned; and the upper straight air performs secondary oxygen supply to achieve more thorough combustion and improve thermal efficiency.

Owner:范家文

Two-stage flame generator

The present invention discloses a double stage flame generator, comprising a housing, a first stage flame generator consisting of an ignition gun, an oil inlet tube and a carburetor, a second stage flame generator axially and concentrically sleeved inside a central ventilation chimney of the first stage flame generator. A vaporizer of the first stage flame generator is fixed inside an air distribution cylinder. The air distribution cylinder at the far end of the vaporizer is provided with a comparative long precombustion chamber. The axial center of the vaporizer of the first stage flame generator is provided with a guiding cylinder formed by circular holes. The guiding cylinder is used for placing the second stage flame generator, and is an air inlet path of part combustion promoting air. The second stage flame generator is positioned inside the guiding cylinder when the first stage flame generator is ignited, and stretches out to a coal powder combustor spout of the housing after the ignition. The flame generator has large power adjusting ratio, and is capable of realizing cooling furnace curve ignition. The temperature of flame is higher, and the rigidity of the flame is larger. The flame does not vie with the coal powder for air. The flame generator has further advantages of 100 percent gasification combustion, high combustion efficiency, low working pressure and large safety factor.

Owner:GUANGDONG HAIRONG ENVIRONMENTAL PROTECTION TECH CO LTD

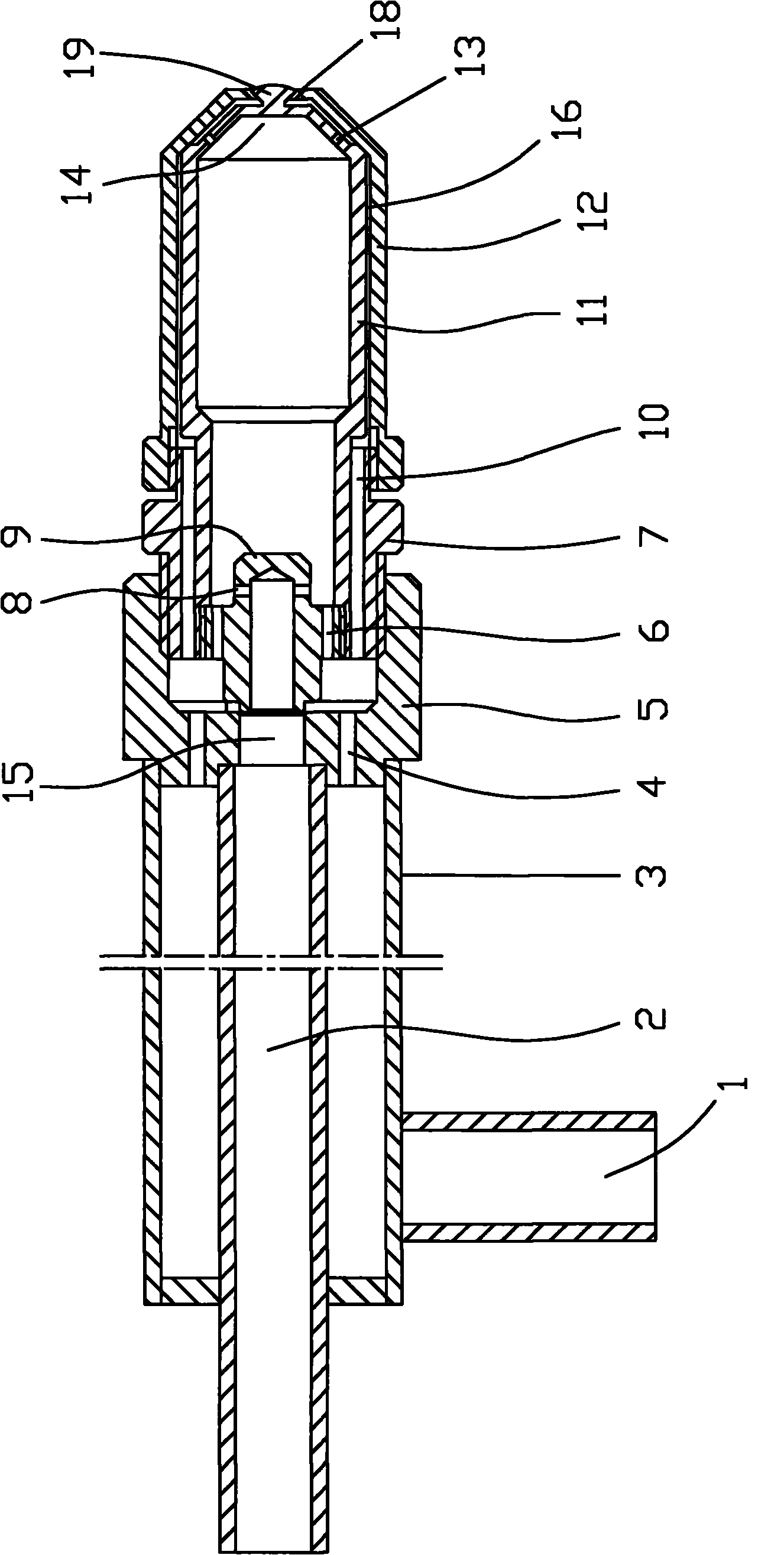

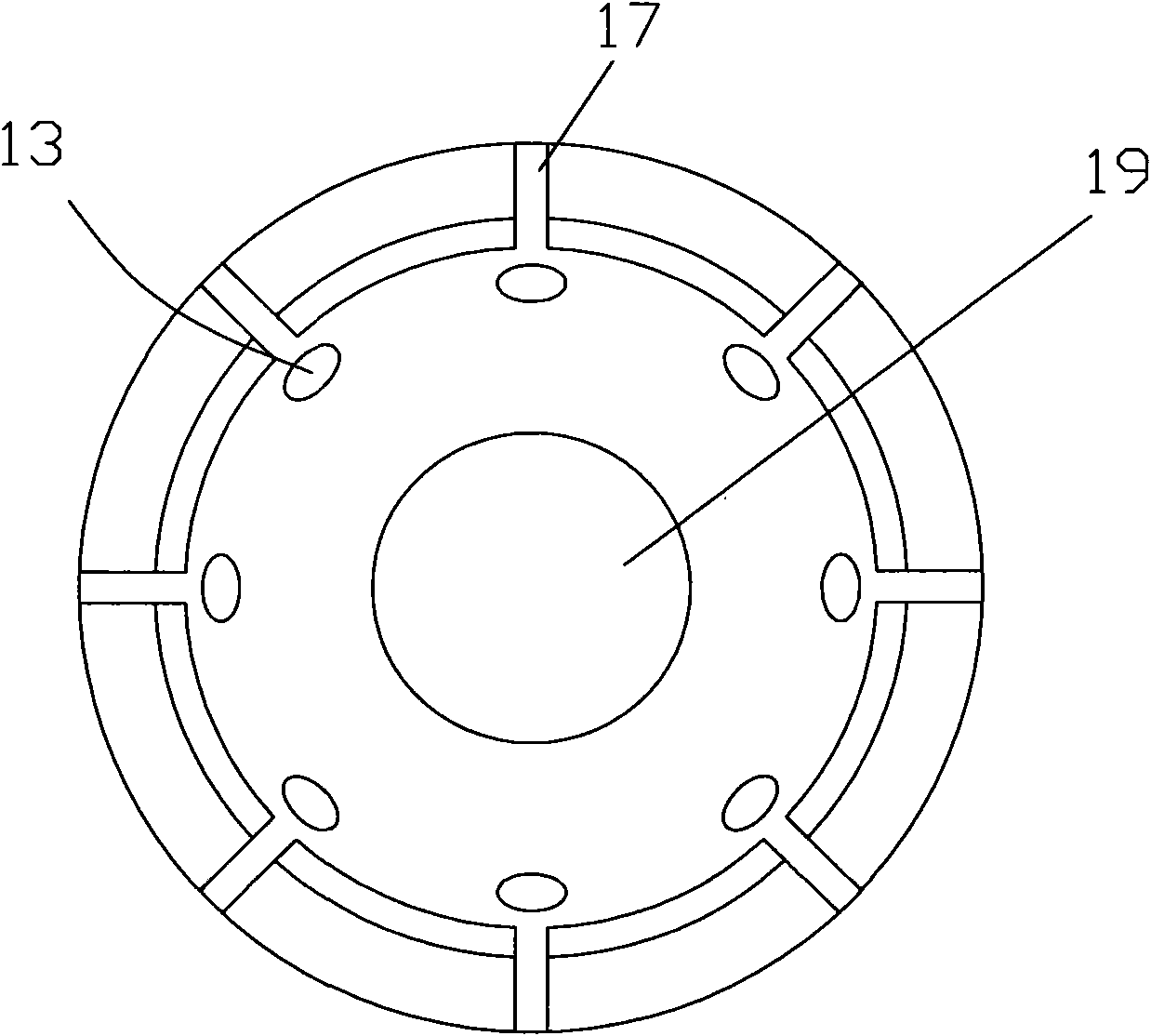

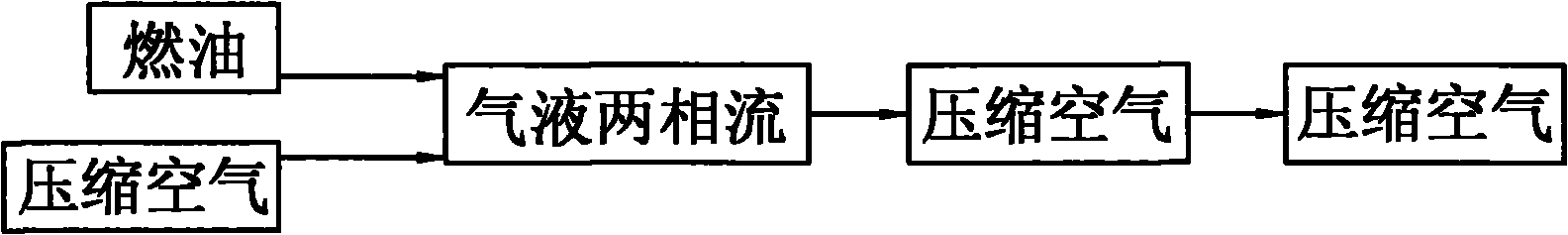

Low-pressure oil film breaking and atomizing technology and device thereof

The invention discloses low-pressure oil film breaking and atomizing technology and device thereof. The low-pressure oil film breaking and atomizing technology is characterized in that fuel oil and an auxiliary gas are formed into gas-liquid two-phase fluids, the gas-liquid two-phase fluids are jetted into a furnace cavity through an oil gun, and the jetted gas-phase fluids enable a formed oil film to be broken by overcoming the surface tension of the jetted gas-phase fluids so as to realize the superfine atomization of the fuel oil; the outlet of a circular jet hole is provided with a secondary transverse ultrasonic air flow, the jet direction of the secondary transverse ultrasonic air flow is perpendicular to that of the circular jet hole, and the secondary transverse ultrasonic air flow further impacts initially-atomized fuel oil jetted from the circular jet hole to carry out secondary breakage and atomization on the fuel oil. The invention has the advantages of smaller average diameter of an oil drop, high penetrating capability of oil mist, good adjustability of an atomized taper angle and very little change of the average dimension of the oil drop when the viscidity of the fuel oil is enhanced or the ejection force of the oil gun is smaller; and in addition, the invention only needs lower fuel oil pressure of 0.4-0.5 MPa, thereby lowering the pressure of a fuel oil system, reducing the electricity consumption of an oil pump and saving the plant electrical consumption.

Owner:艾佩克斯科技(北京)有限公司

High efficiency, environmental protection type coal-saving agent, and its prodn. art

An environment protection type coal saving agent is proportionally prepared from sulfur fixating agent, combustion promoter, oxidant, puffing agent, catalyst and water. Its advantages are high effect to decrease consumption of coal and increase thermal efficiency of boiler, and no secondary pollution.

Owner:田立军

High temperature resistant thermal insulation coating

InactiveCN102241936AImprove high temperature resistanceReduce surface temperatureCoatingsEmulsionThermal insulation

The invention discloses a high temperature resistant thermal insulation coating, containing acrylic emulsion, fluorinated silicone rubber, film forming aid, a dispersing agent, pigment filler, water, and the like. The coating has the advantage of excellent high-temperature resistance so that the coating can be used on the surface of an object at a temperature of -80 DEG C to 1100 DEG C; meanwhile, the coating has the advantage of excellent thermal insulation effect so that the temperature of the surface of the object can be obviously reduced and more than 30% of heat loss can be decreased. The coating can be applied to inside and outside surfaces of all kinds of high temperature pipelines, furnaces and kilns.

Owner:开平市日固力涂料有限公司

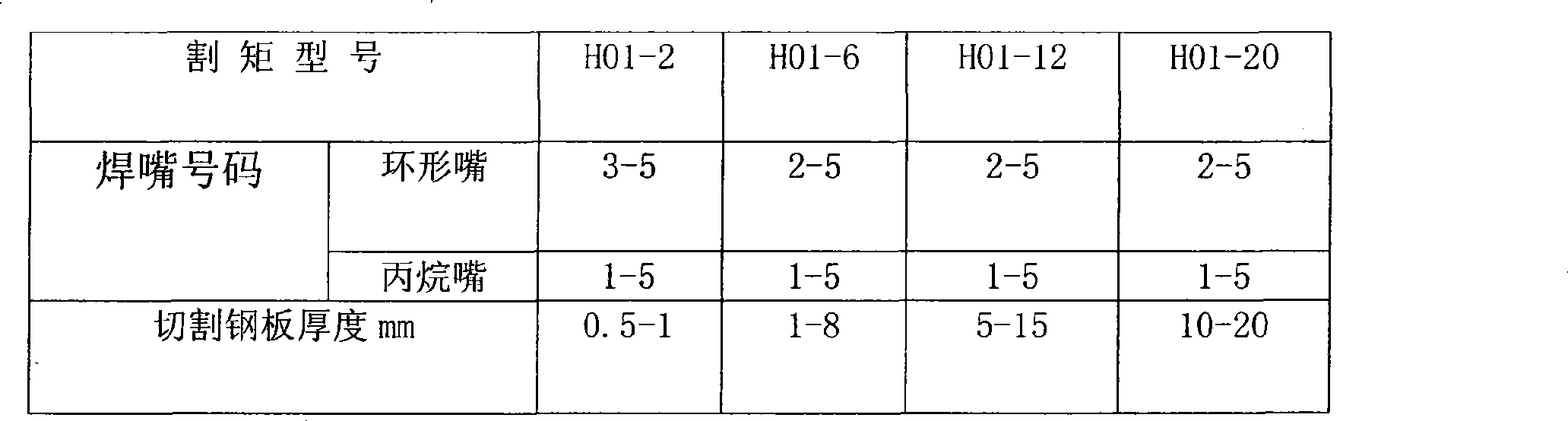

Solar nuclear active ion welding gas and preparation method thereof

InactiveCN101451084AChange frequencyImprove combustion effectGaseous fuelsContainer filling under pressureOxygenBiological activation

The invention relates to solar nuclear active ion scarfing gas and a preparation method thereof. The invention provides modified scarfing gas, which is prepared from the following raw materials: 1, 20 milliliters of dimethylbenzene; 2, 40 milliliters of petroleum ether or dimethyl ether; 3, 20 milliliters of acetone; 4, 1 gram of colophony; 5, 0.5 gram of ferrocene; 6, 3 kilograms of liquefied petroleum gas; 7, 10 grams of lead or 0.5 gram of potassium permanganate; and 8, 70 milliliters of hydrogen peroxide. Moreover, proper antifreezing agent can also be added according to air temperature conditions. The invention also provides a method for preparing a scarfing gas additive. The additive is added into the liquefied petroleum gas or propane to modify mother liquor, can effectively improve the gasification performance and the activation performance of the mother liquor, change the combustion wavelength and the combustion frequency of the mother liquor in oxygen, improve the combustion performance, and increase the flame temperature, so as to replace acetylene gas to cut and weld metals.

Owner:周文虎

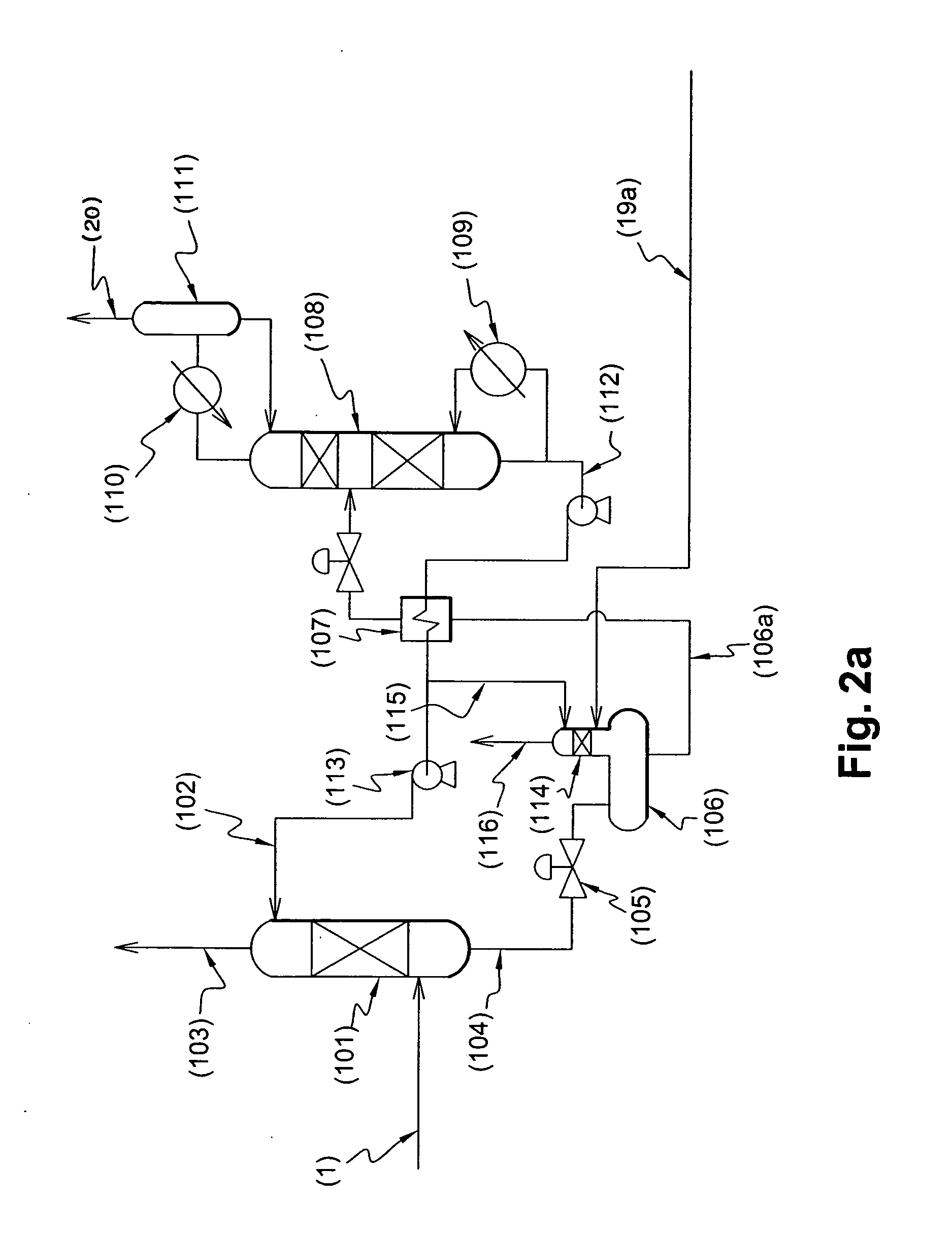

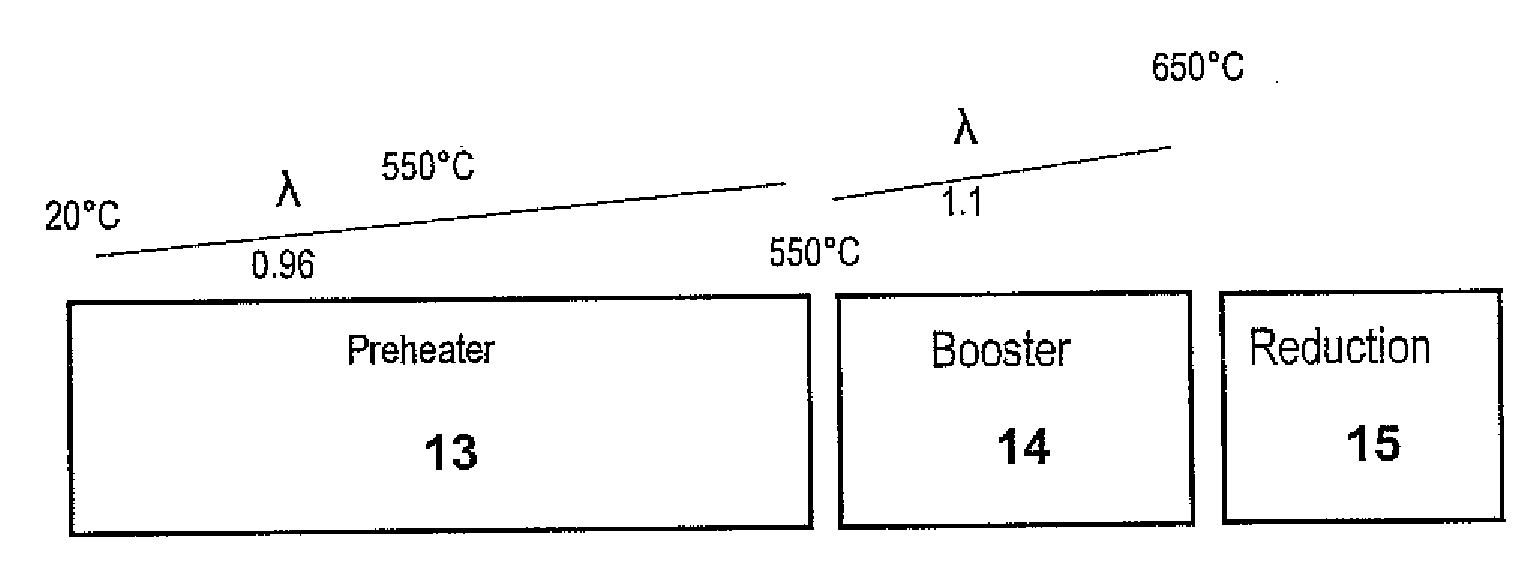

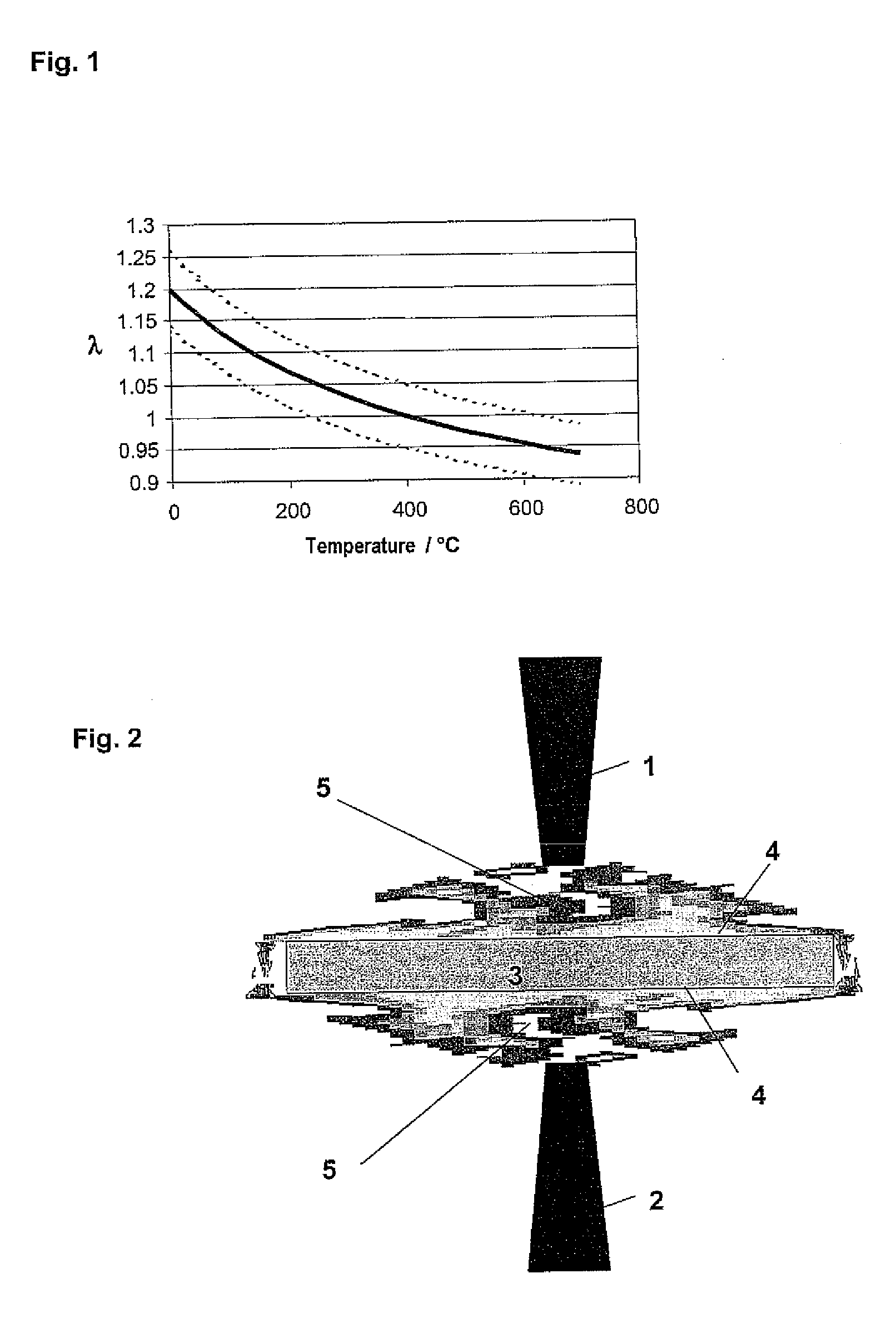

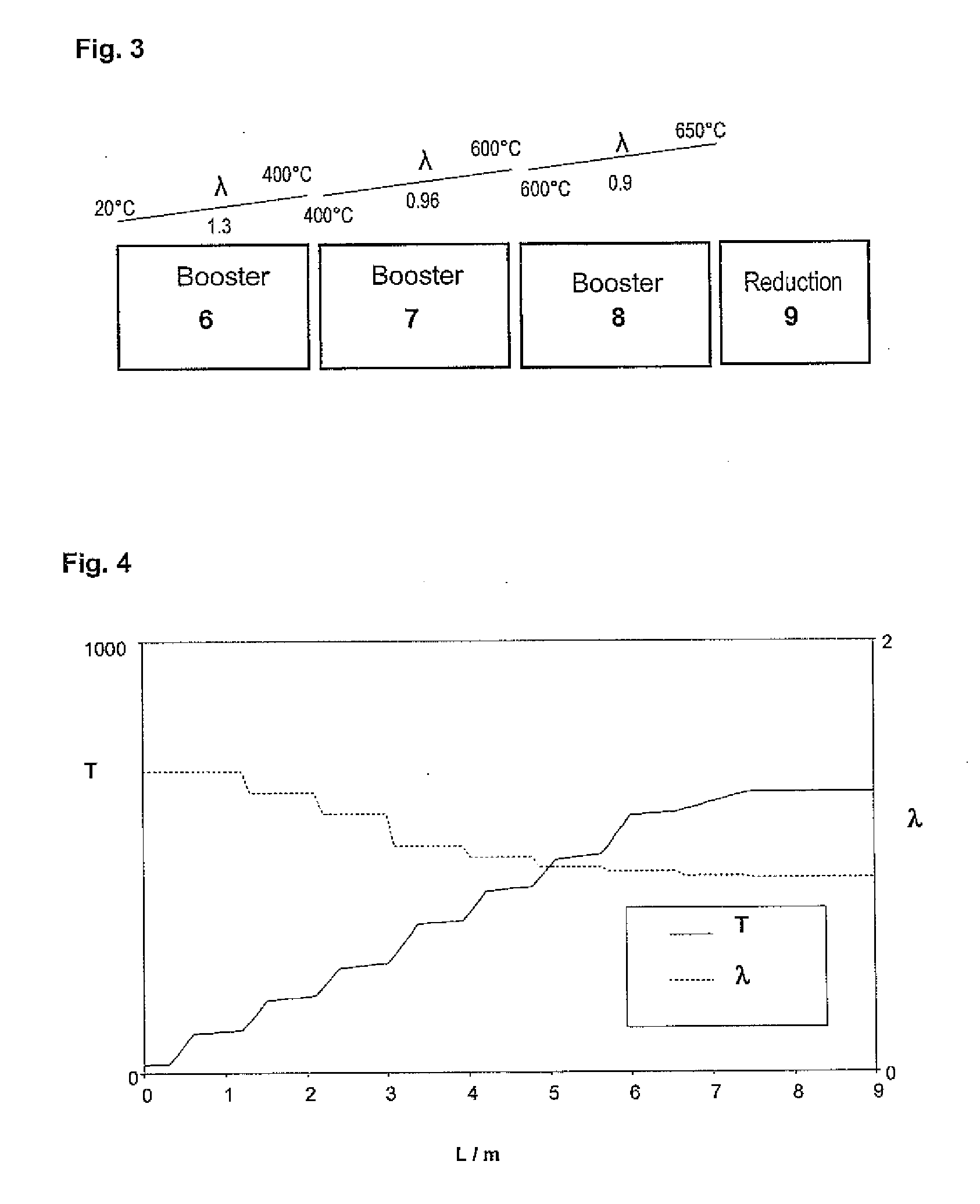

Process for the heat treatment of steel products

ActiveUS20090188591A1Heating fastHigh flame temperatureFurnace typesDrying machines with progressive movementsSheet steelProduct gas

The invention provides a process for the heat treatment of steel products, in particular of steel strips or sheets, in which the product is brought from a starting temperature to a target temperature in a booster zone having at least one burner; the burner is operated with a fuel, in particular a fuel gas, and an oxygen-containing gas which contains more than 21% oxygen; and the product is brought into direct contact with the flame generated by the burner, the air ratio λ within the flame being set as a function of the starting temperature and / or the target temperature.

Owner:MESSER IND USA INC

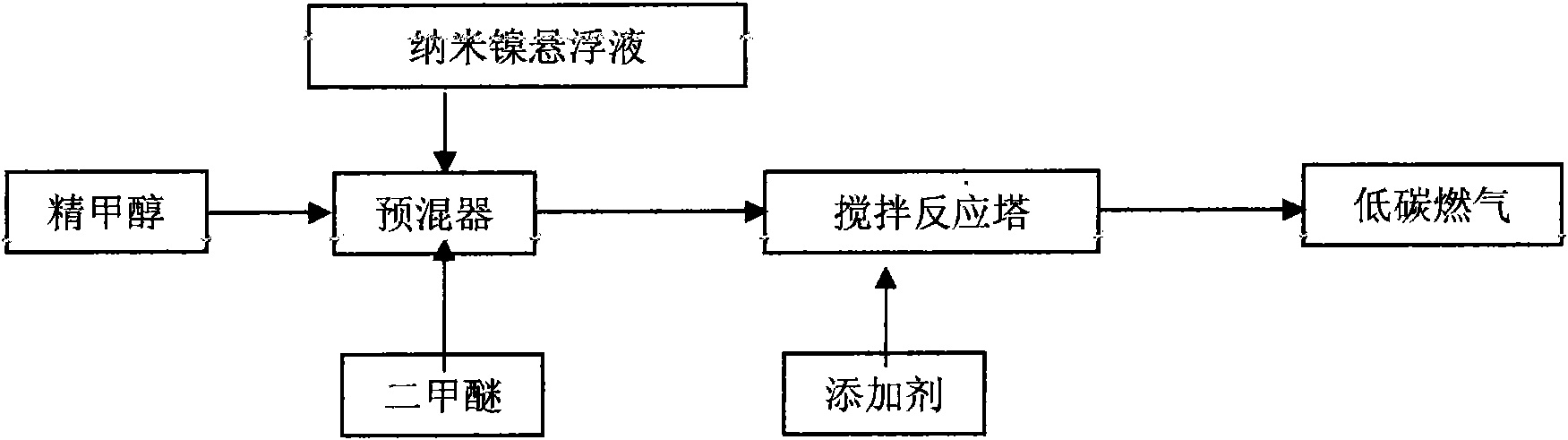

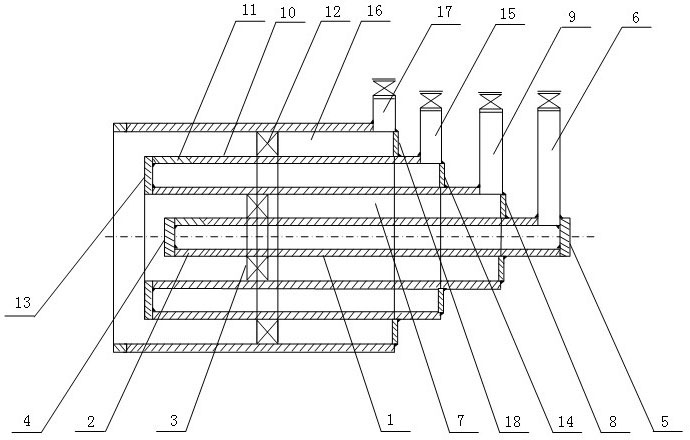

Low-carbon energy-saving gas

The invention discloses a low-carbon energy-saving gas, relating to a gas fuel, in particular to an industrial or civil gas fuel. The low-carbon energy-saving gas comprises the following components in proportion by weight: 60-80 of dimethyl ether, 20-36 of methanol, 1-3 of additive and 0-0.2 of nano nickel liquid suspension; wherein the additive comprises the following raw materials in proportion by weight: 15-25 of propyl ether, 0.3-0.7 of dicyclopentadienyl iron, 1-2 of naphthenate, 1-3 of anti-livering agent, 1-2 of preservative, 1.5-2.5 of dispersing agent, 8-12 of stabilizing agent, 1.5-2.5 of inhibiting agent, 1-1.4 of lanthanum(III) 2-ethylhexanoate and 0.2-0.4 of nano nickel liquid suspension. The invention solves the problems of overhigh cost, environment pollution and potential safety hazard in the prior art.

Owner:蓝冰 +3

Gas burner capable of adjusting premix

InactiveCN102353054ADoes not affect the heating curveBurn fasterGaseous fuel burnerGas burnerAir volume

The invention relates to a gas burner capable of adjusting premix, and the gas burner is provided with a small nozzle gas pipe and a large nozzle gas pipe, wherein the small nozzle gas pipe is located in the center of the burner; the large nozzle gas pipe is sleeved at the outer side of the small nozzle gas center; air passages are respectively arranged between the small nozzle gas pipe and the large nozzle gas pipe and between the large nozzle gas pipe and the outer wall of the burner; gas orifices are respectively arranged at the front end faces of the small nozzle gas pipe and the large nozzle gas pipe; the front and rear ends of the small nozzle gas pipe and the large nozzle gas pipe are respectively provided with a baffle, the rear ends of the small nozzle gas pipe and the large nozzle gas pipe are communicated with gas through a gas inlet pipe and a gas control valve; and the air passages are respectively internally provided with an air swirl plate and the rear ends of the air passages are respectively provided with a baffle, the rear ends of the air passages are communicated with compressed air through the air inlet pipe and the air control valve. Gas quantity and combustion air rate ejected by the burner are both adjustable, and the gas burner has the advantages of fast burning velocity, high flame temperature, improved heat efficiency, decreased gas volume and low cost.

Owner:金艺

Energy-saving stove

InactiveCN101581455AAvoid performance lossHigh flame temperatureDomestic stoves or rangesLiquid heating fuelCombustionHeat losses

The invention provides an energy-saving stove. The stove comprises a mixing chamber of fuel and air, the mixing chamber is communicated with a jet hole on a combustion head; the combustion head is arranged in a furnace tank circled by a stove ring and a stove bottom; the closed furnace is provided with a smoke gas outlet; a smoke gas flow passage is formed between the combustion head and the smoke gas outlet; the smoke gas flow passage is provided with porous thermal storage radiant panels for stopping. The energy-saving stove has the advantages of small heat loss and high heat efficiency.

Owner:ZHEJIANG UNIV OF TECH

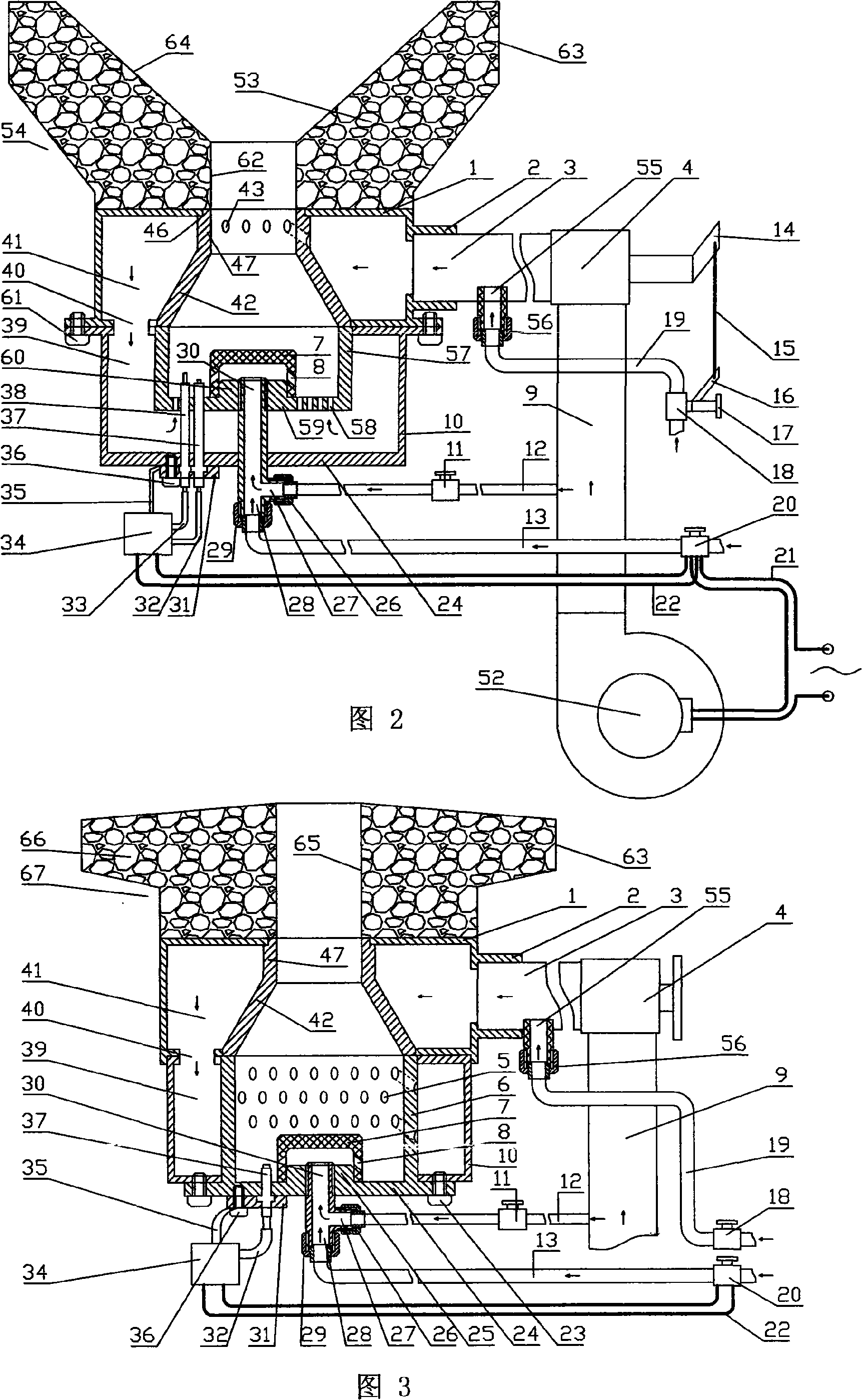

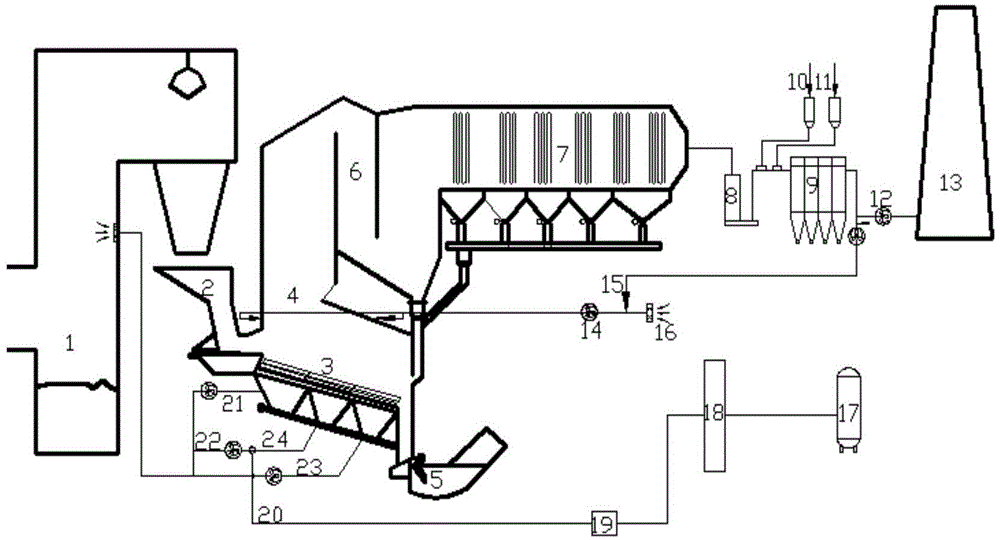

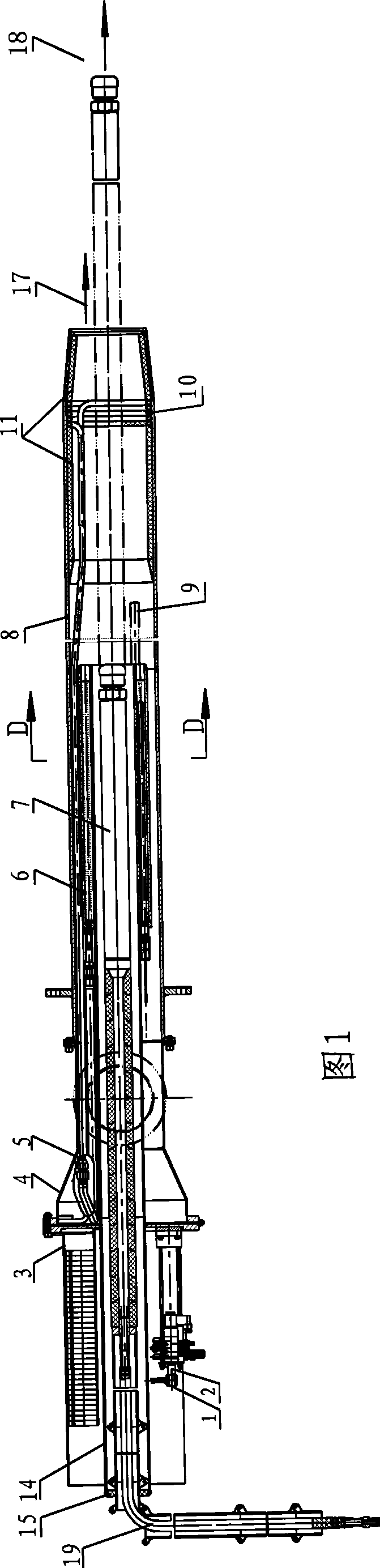

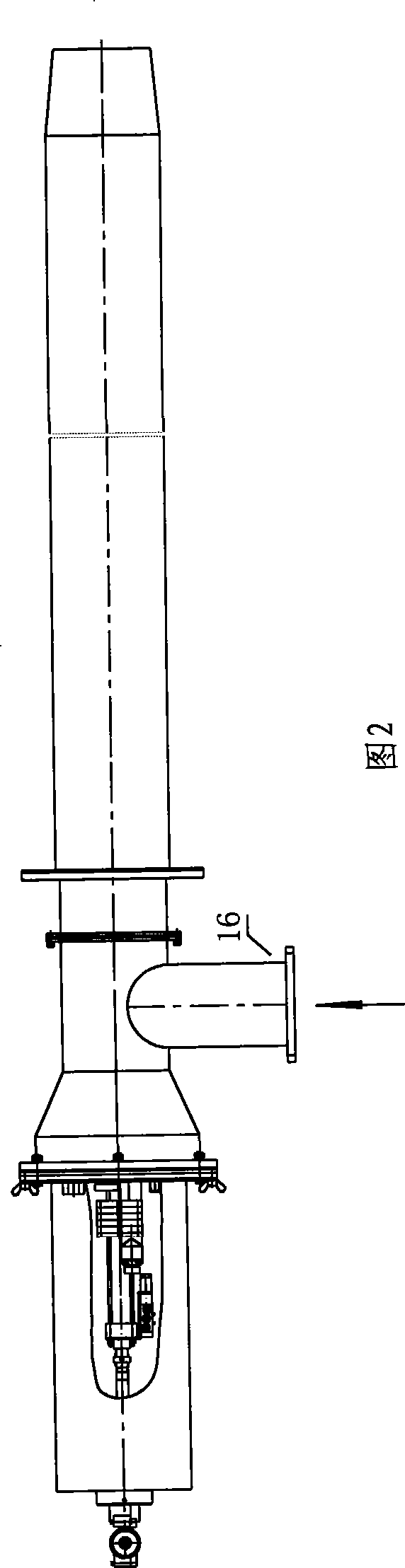

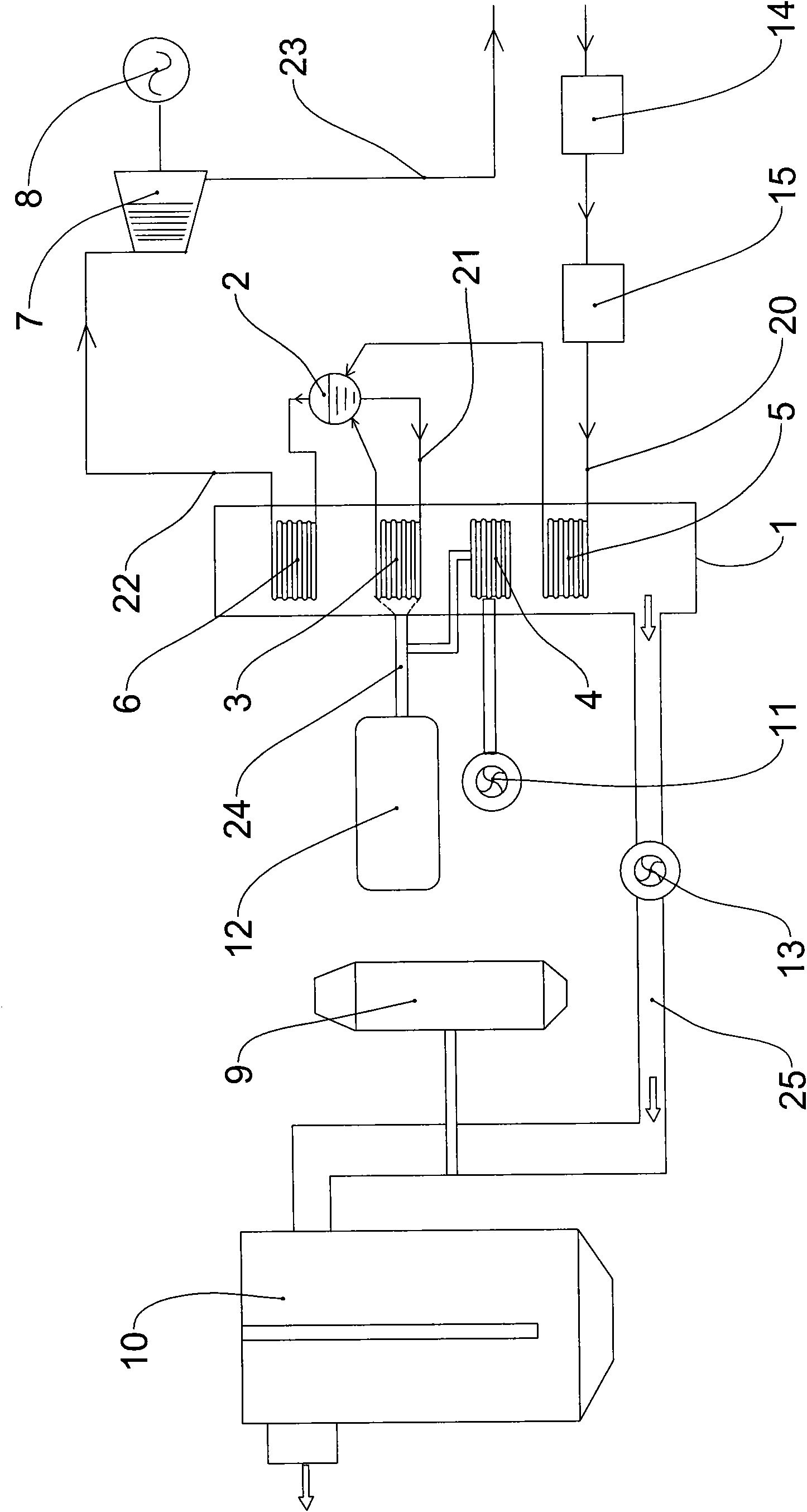

Integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system

ActiveCN101986025AObvious superiorityLower discharge temperatureSteam generation plantsIndirect carbon-dioxide mitigationCombustionEngineering

The invention discloses an integrated low-carbon micro-discharge energy-saving and emission-reduction boiler system. The system comprises a boiler body (1), a steam drum (2), a heat exchanger (3), a preheater (4), an economizer (5), a superheater (6), a steam turbine (7), a generator (8), a secondary smoke combustion device (9), a desulfuration and dust collect unit (10), an air blower (11) and a smoke exhauster (13), wherein the steam drum (2) and the heat exchanger (3) constitute a hot-water heating circulation loop, the economizer (5) is connected with the steam drum (2), and the air blower (11) feeds air to the preheater (4); the steam drum (2) is connected with the superheater (6), and then connected with the steam turbine (7) by a superheated steam pipe (22); the steam turbine (7) is connected with a low-pressure steam pipe (23), and the generator (8) is linked with the steam turbine (7); and the outlet of a gas duct of the boiler body (1) is connected with a smoke pipe (25), and the smoke exhauster (13) is arranged on the smoke pipe (25), and sequentially feeds smoke into the secondary smoke combustion device (9) and the desulfuration and dust collect unit (10) so as to process and discharge the smoke.

Owner:慧生能源科技有限公司

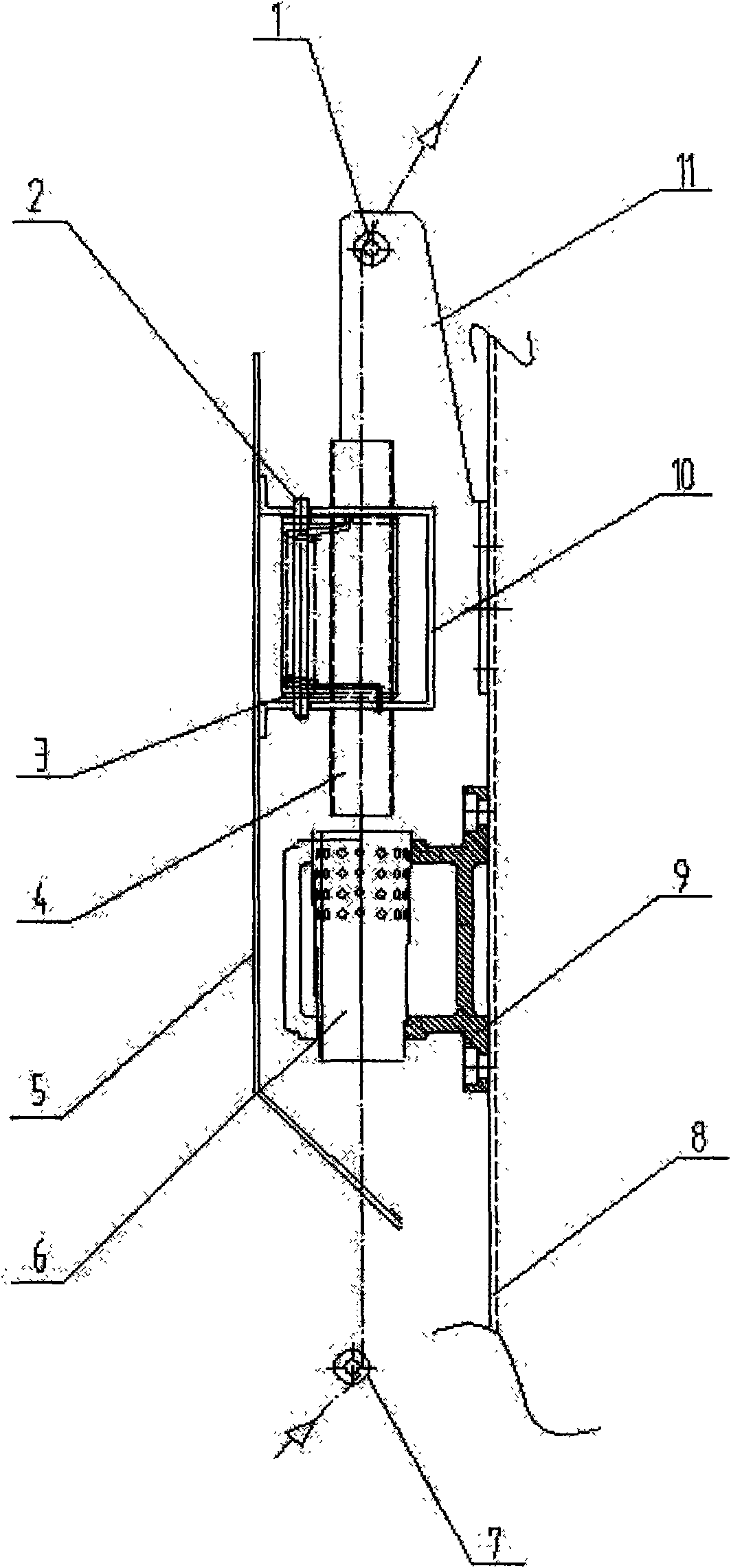

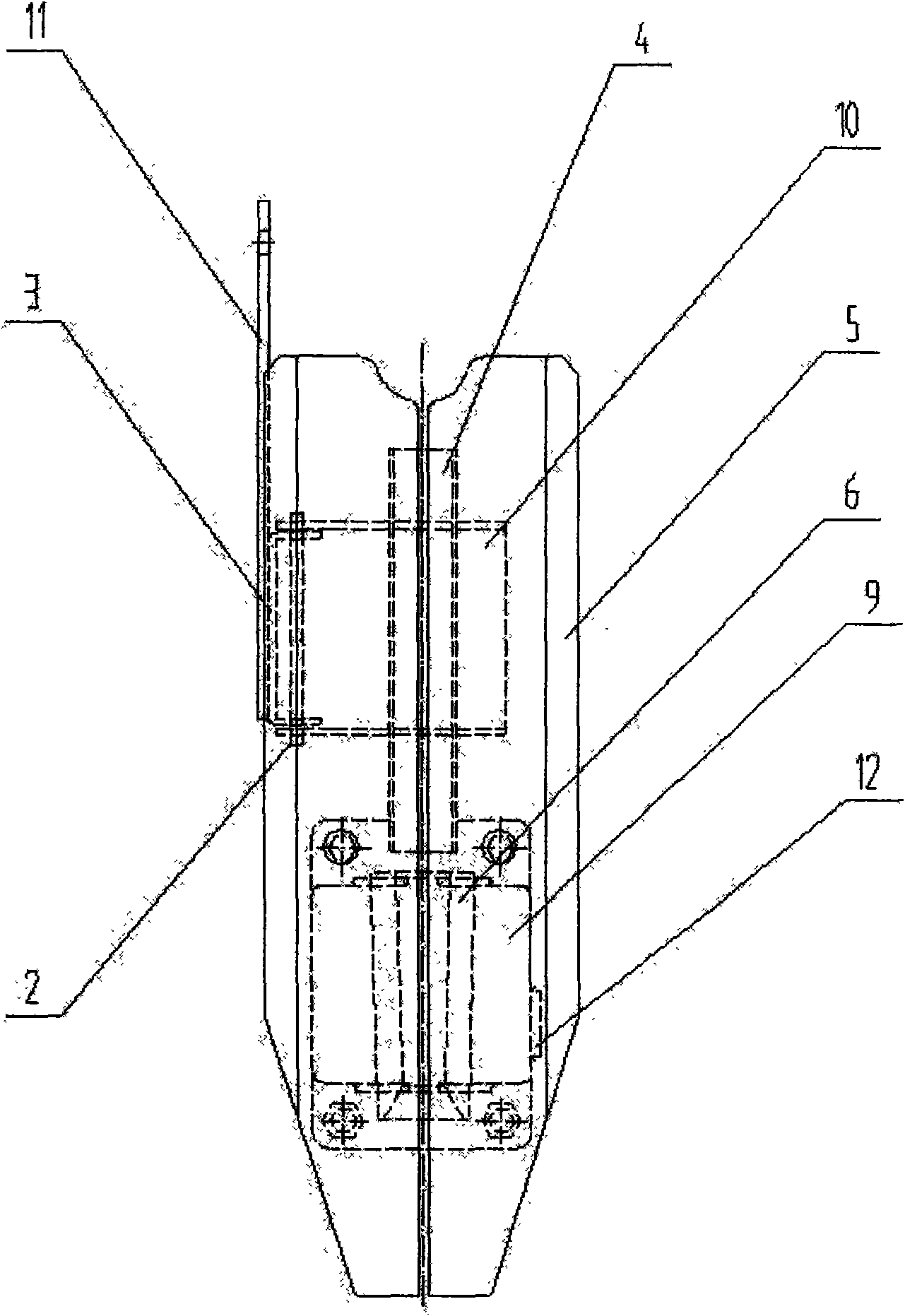

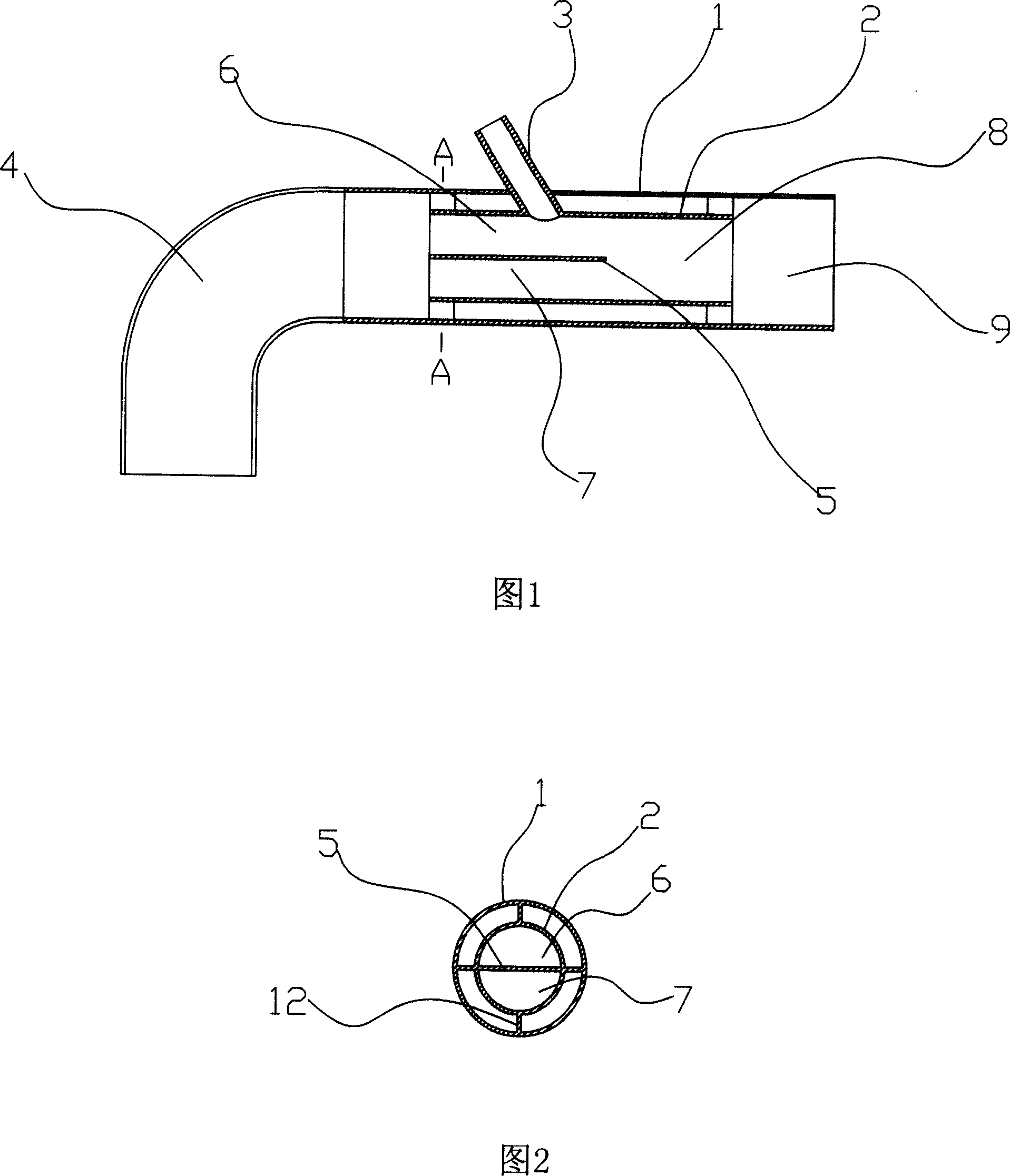

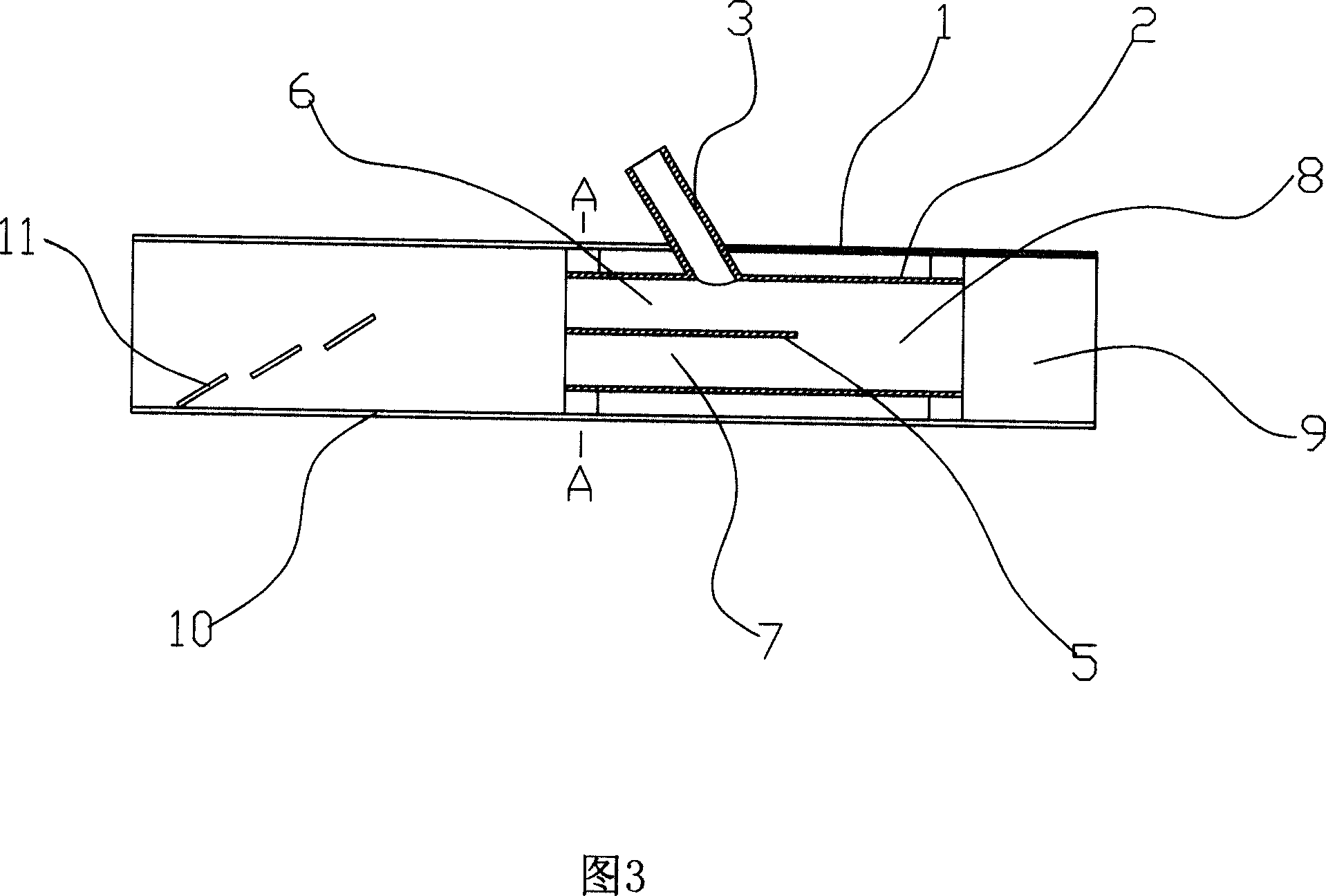

Jet combustion device for yarn singeing machine

The invention discloses a jet combustion device for a yarn singeing machine, and aims to solve the problems of insufficient combustion, a low flame temperature and short and instable flames of the conventional combustion device. The center of a fire distributor in the middle of an air supply support of the device is provided with a combustion channel for yarn singeing; the front surface of the air supply support and the circumferential wall of the fire distributor are provided with a vertically through yarn feeding and discharging channel; the circumferential wall of the fire distributor is provided with ventilation combustion holes which are formed radially and are communicated with a mixed gas inlet through the air supply support; the wall of a flame guiding pipe which is arranged over and adjacent to the fire distributor is provided with a vertically corresponding yarn feeding and discharging channel and a ventilation hole; the flame guiding pipe is fixed at the back of a protective mask; the middle of the protective mask is provided with a corresponding yarn feeding and discharging channel; the edge of the protective mask is provided with a hinge for resetting the protective mask; an upper yarn guiding ring and a lower yarn guiding pipe are arranged on the axis lines of the fire distributor and the flame guiding pipe; and the inside of the air supply support has a cavity structure, and the air supply support is in Morse taper fit with the fire distributor.

Owner:SHANDONG TONGJI ELECTROMECHANICAL

Hydrocarbon fuel compositions

InactiveUS20100115829A1Readily availableImprove economyGaseous fuelsLiquid carbonaceous fuelsTorchProduct gas

The present invention relates to a hydrocarbon fuel composition comprising (i) at least 99% by weight of a base gas; and (ii) additives comprising (a) 2 to 50 ppm organometallic compound; and (b) 100 to 5000 ppm aniline or substituted aniline and 100 to 5000 ppm toluidine. The present invention discloses addition of an additive or additive mixture to base fuel preferably, liquefied petroleum gas. The addition of additive mixture not only improves the properties of the base fuel for use as torch gas for cutting and welding application, but also reduces the consumption of both fuel and oxygen for cutting applications.

Owner:BHARAT PETROLEUM CORP LTD

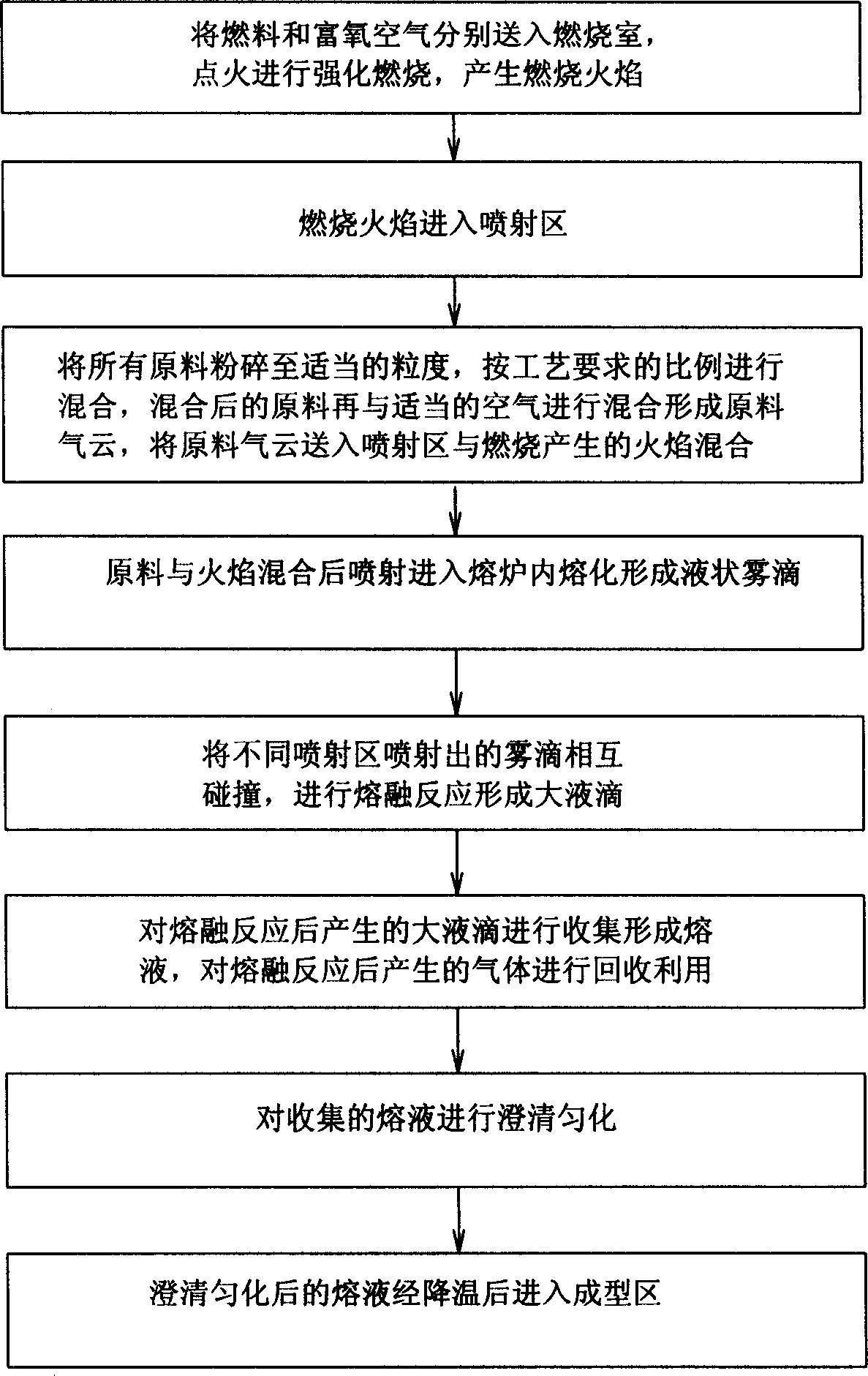

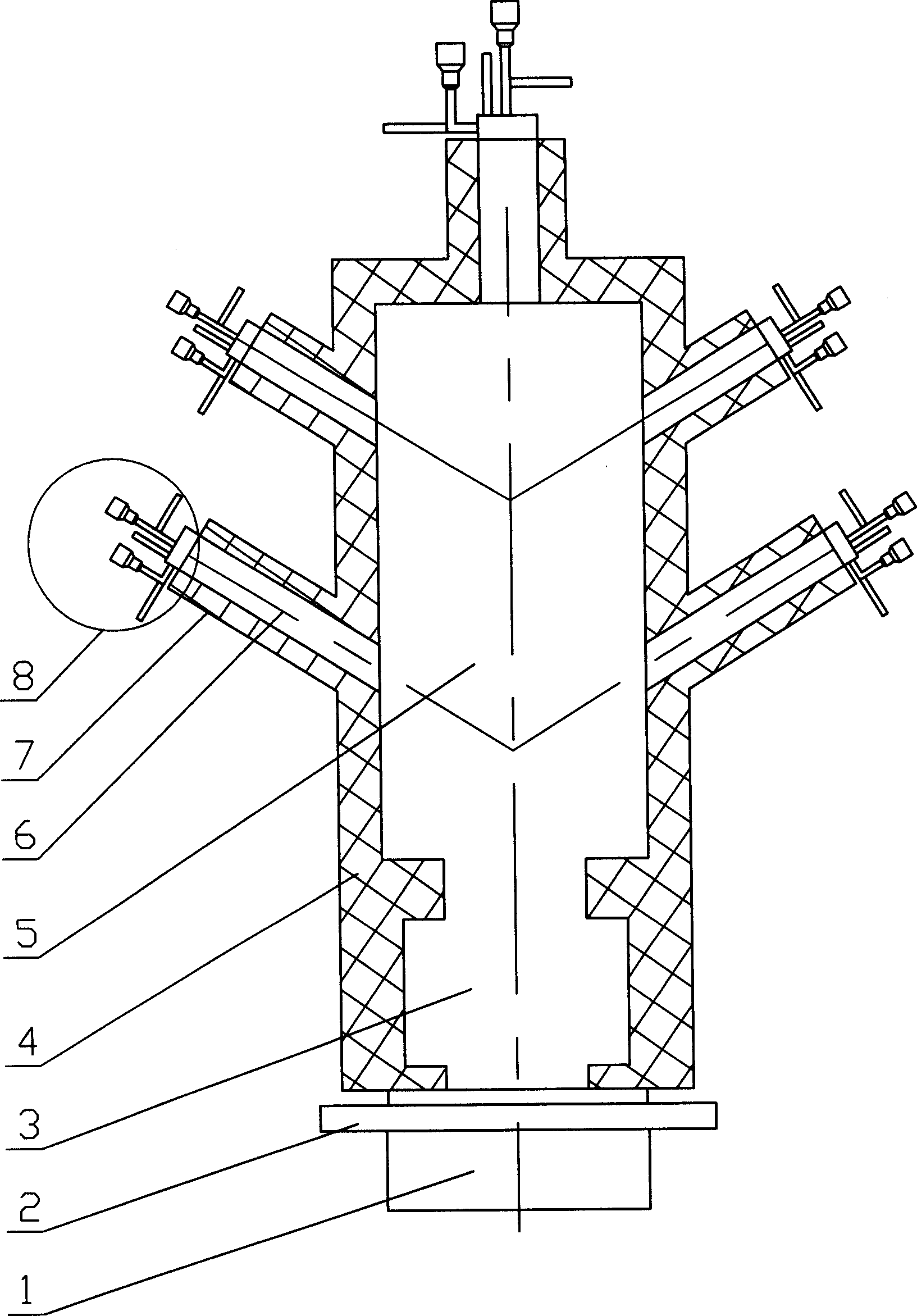

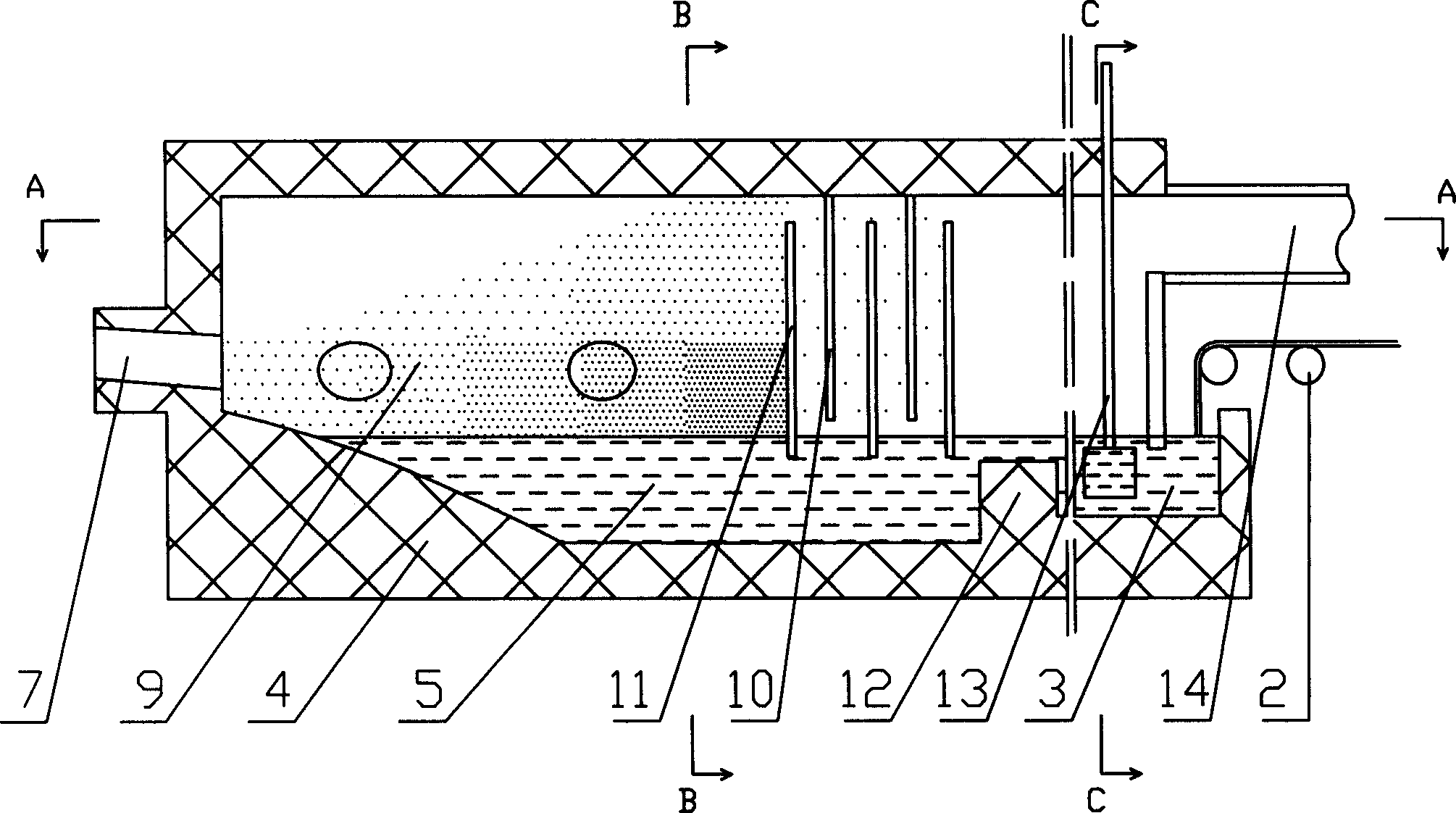

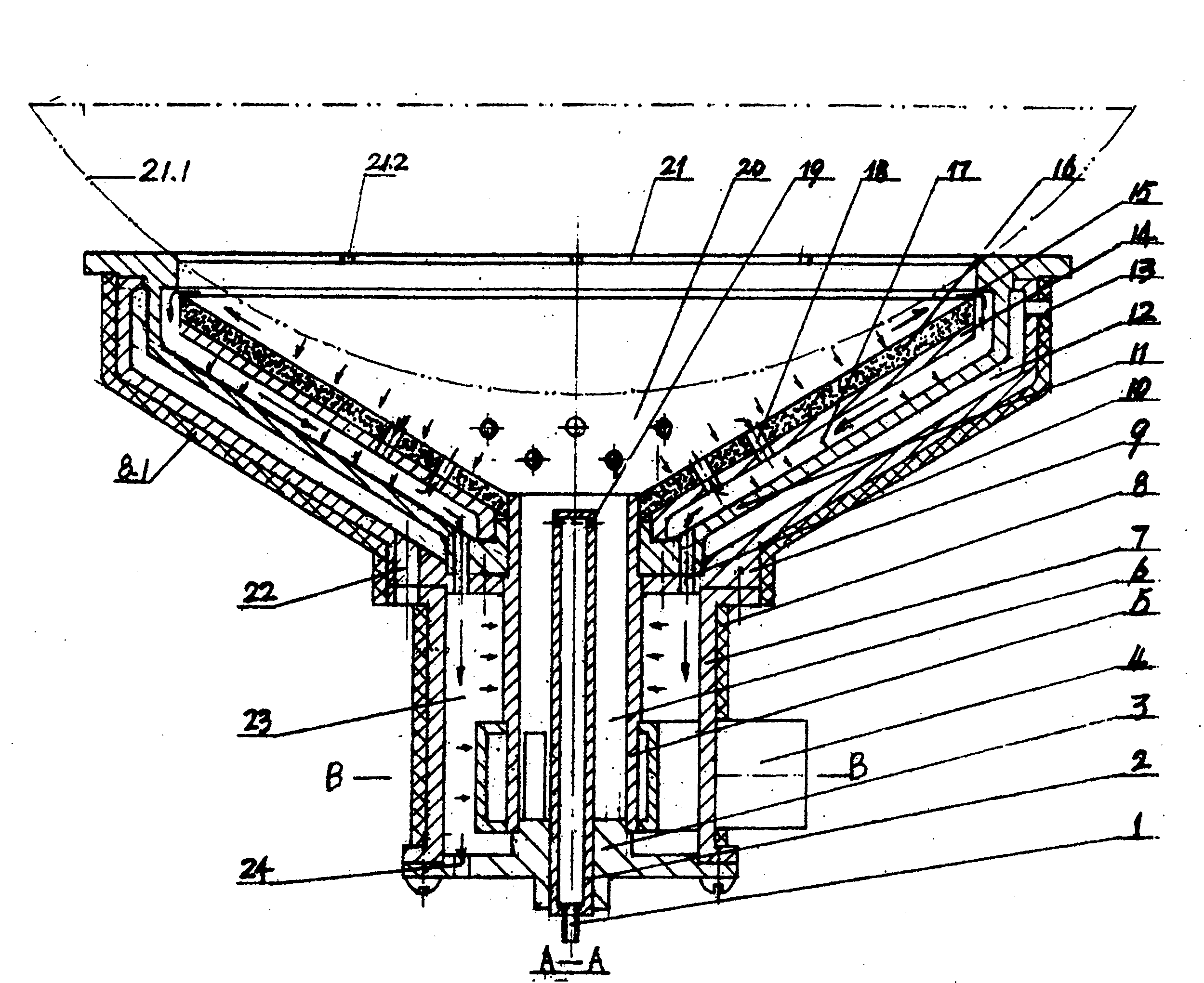

Full premixed combustion smelting method and smelting furnace for producing glass using the method

InactiveCN1594149AAvoid wastingSolve pollutionCharging furnaceGlass furnace apparatusCombustionHeat energy

The invention relates to a full premixed combustion smelting method and smelting furnace for producing glass using the method, wherein the method consists of disintegrating the raw materials, mixing and loading into flame for full contact with the flame, thus realizing completely premixed combustion and smelting, the droplets formed in smelting fall into the smelting pool through colliding each other and forming shaped liquid. The disclosed method can increase utilization factor of heat energy substantially.

Owner:谢西平

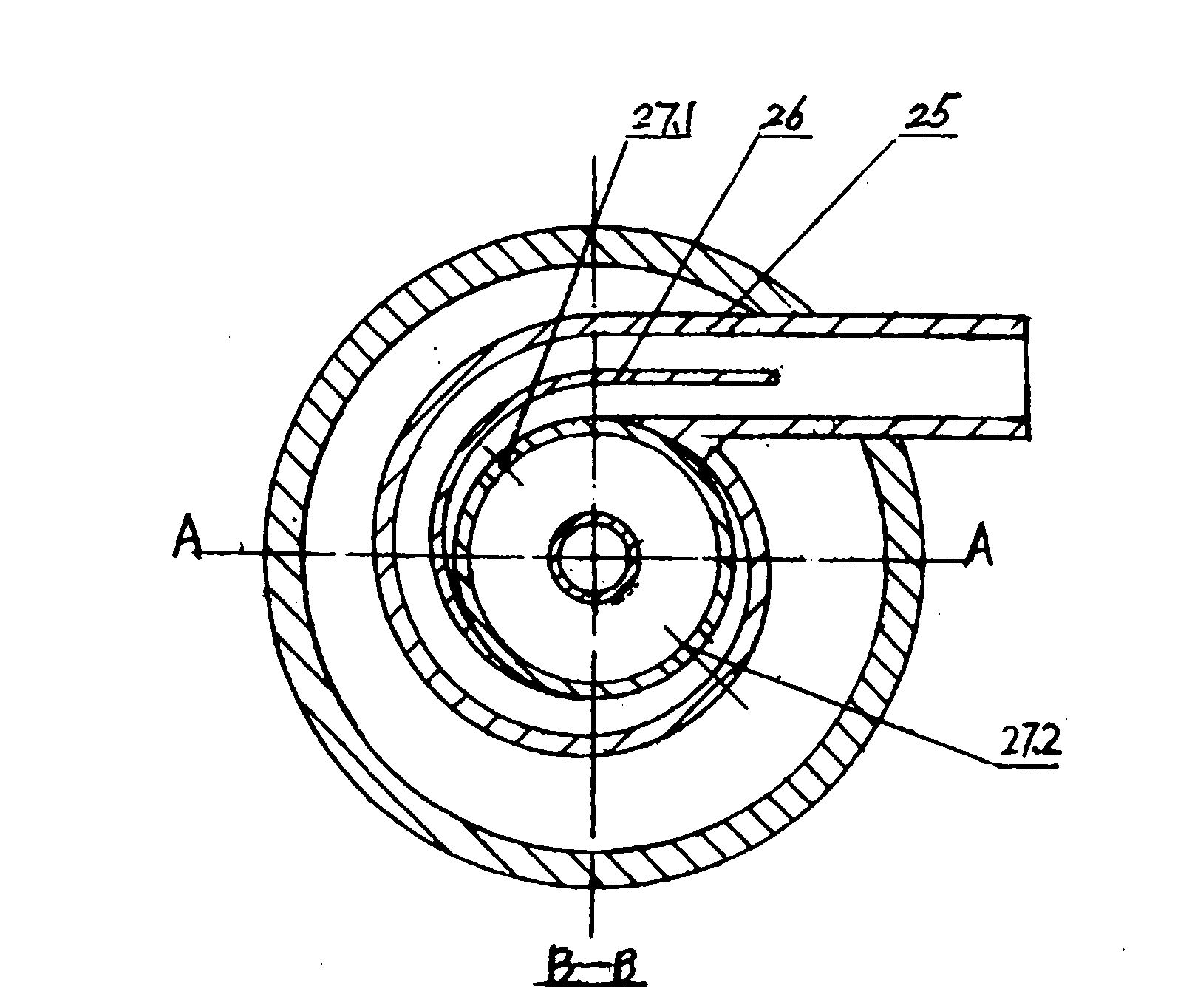

Spiral-flow type fishtail high-efficiency energy-saving burner

ActiveCN103629705AHeating up fastHeat up fastDomestic stoves or rangesStoves/ranges topsAir preheaterEngineering

The invention discloses a spiral-flow type fishtail high-efficiency energy-saving burner. The spiral-flow type fishtail high-efficiency energy-saving burner comprises a burner and a hearth. The burner comprises a spiral-flow type air register, a cylindrical channel, a return pipe, combustion gas holes and an air preheater. The hearth comprises a furnace ring and an expansion cover. The expansion cover is a hollow interlayer and comprises an inner expansion cover, a middle expansion cover and a flue gas chamber between the inner expansion cover and the middle expansion cover. An upper opening of the inner expansion cover and a lower opening of the furnace ring form an annular flue gas shunting opening and the annular flue gas shunting opening is communicated with the flue gas chamber, flue gas holes, the air preheater and a gas outlet hole. The outer wall of the middle expansion cover is provided with a hot water sleeve. The hot water sleeve is provided with a water inlet and a water outlet. A temperature-resistant heat-collection corrosion-resistant sleeve is arranged in the inner expansion cover and the lower periphery of the temperature-resistant heat-collection corrosion-resistant sleeve is provided with a flue gas backflow hole communicated with the flue gas chamber. When the spiral-flow type fishtail high-efficiency energy-saving burner burns, the flame in a fishtail shape radially burns closely to the surface of the inner expansion cover, a pan clings to the furnace ring and is closely heated and high-temperature flue gas goes through the flue gas chamber from the annular flue gas shunting opening and then enters into the air preheater to heat air so that the hearth has a high temperature, foods can be heated fast and work efficiency is high. The spiral-flow type fishtail high-efficiency energy-saving burner is environmentally friendly, saves energy, can supply hot water and can effectively improve a kitchen environment.

Owner:湖北满天星节能环保科技有限公司

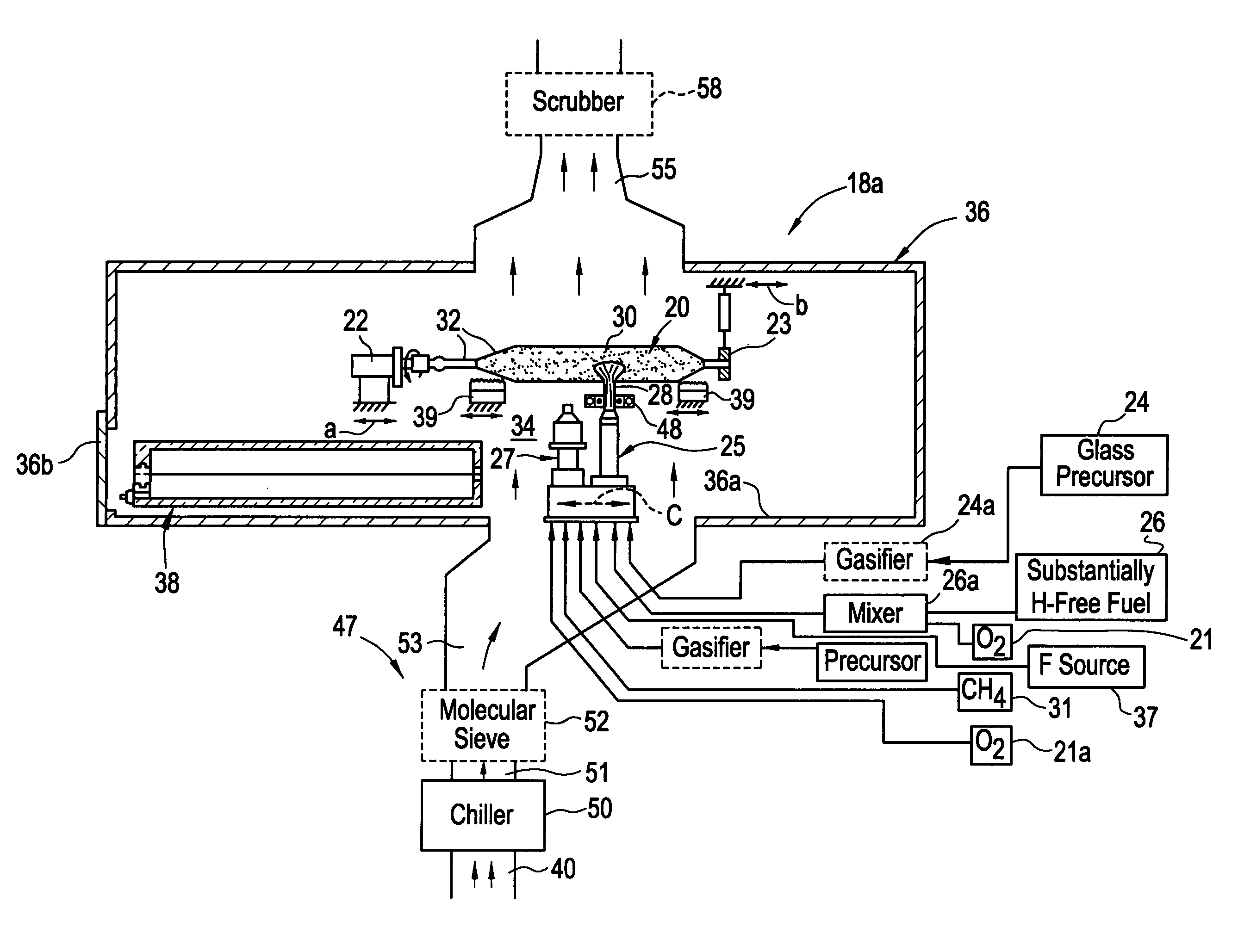

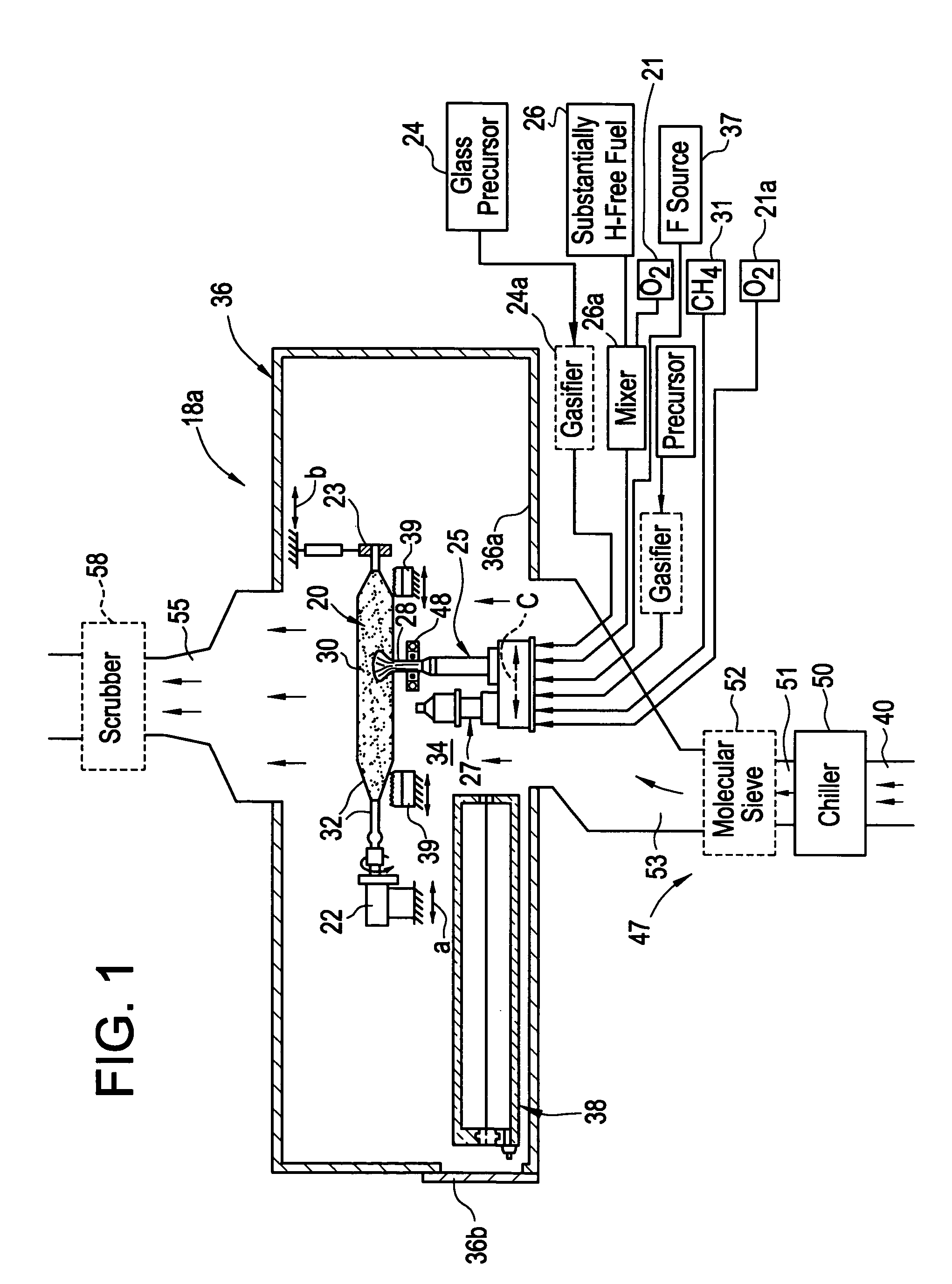

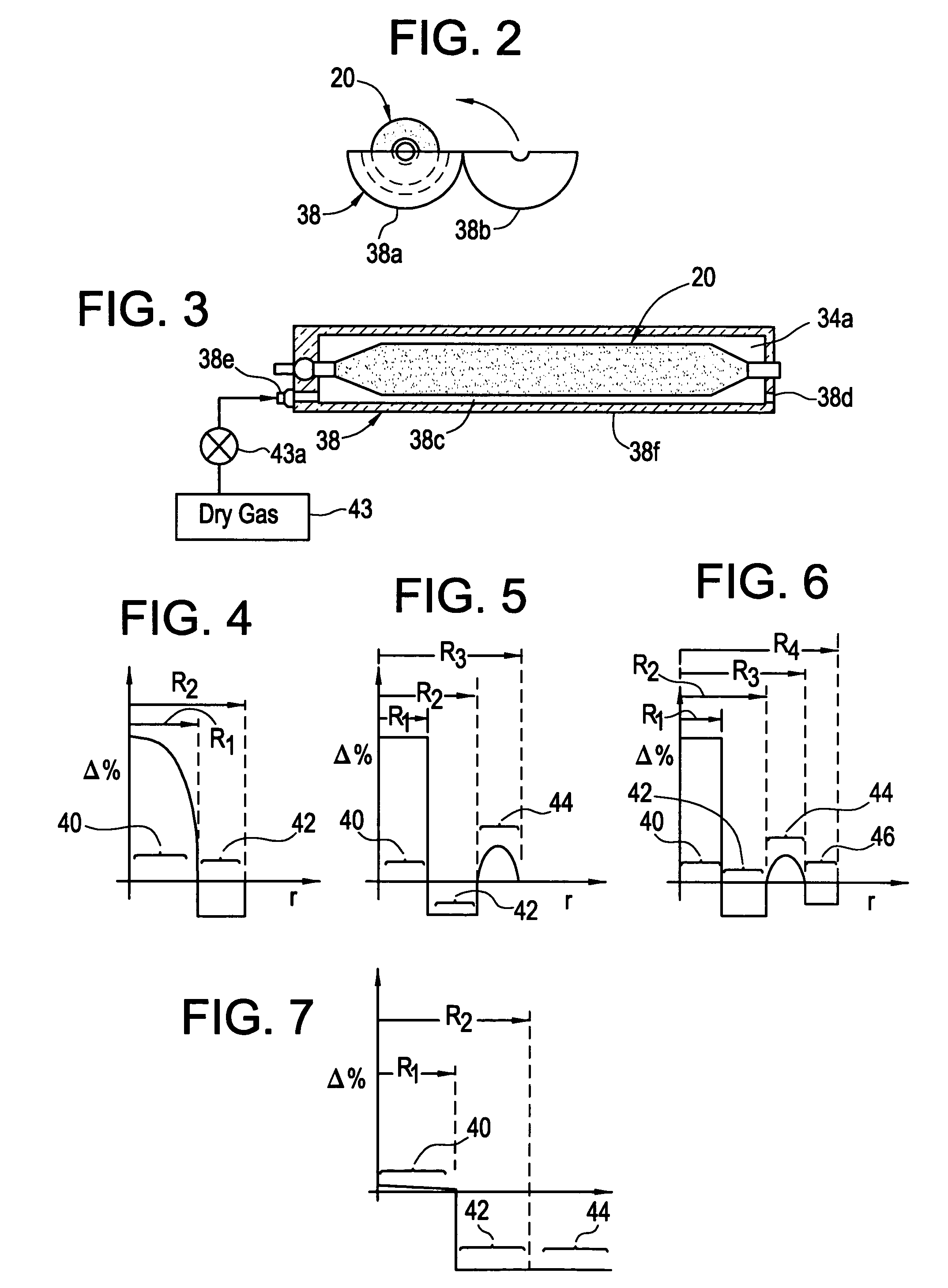

Substantially dry, silica-containing soot, fused silica and optical fiber soot preforms, apparatus, methods and burners for manufacturing same

InactiveUS20050155388A1Burn fasterImproves flame 's burning rateGlass shaping apparatusGlass deposition burnersWater productionSilicon dioxide

Methods, apparatus and precursors for producing substantially water-free silica soot, preforms and glass. The methods and apparatus make substantially water-free fused silica preforms or glass by removing water as a reaction product, removing water from the atmosphere, removing water from the transport process, or combinations thereof. In a first embodiment, substantially water-free soot, preforms or glass are achieved by using a hydrogen-free fuel, such as carbon monoxide, in the deposition process. In another embodiment, a soot producing burner has parameters that enable operation on a substantially hydrogen-free fuel. End burners, which minimize water production, are also described. Such water-free methods are useful in depositing fluorine-doped soot because of the low water present and the efficiency in which fluorine is incorporated. In another embodiment, glassy barrier layer methods and apparatus are described for minimizing dopant migration, especially fluorine. Laser and induction methods and apparatus for forming the barrier layer are depicted. A chlorine, fluorine and silica precursor, such as chlorofluorosilane, may be utilized to form fluorinated soot. Other methods and apparatus are directed to combinations of conventional and substantially water-free processes. One embodiment is directed to combustion enhancing additives for addition to the substantially hydrogen-free fuels. The methods and apparatus in accordance with the invention are particularly useful for producing photomask substrates and optical fiber preforms.

Owner:BURKE GERALD E +3

Metal welding and cutting ether-hydrocarbon gas

InactiveCN1468942AHigh flame temperatureCan be welded and cut thickGaseous fuelsMetallic materialsPetroleum

The ether-hydrocarbon gas for welding and cutting metal consists of dimethyl ether 40-58 wt%, liquefied petroleum gas 23-40 wt%, pentane 15-20 wt% and additive 1-5 wt%. The ether-hydrocarbon gas for welding and cutting metal is compounded by utilizing the physical and chemical properties of dimethyl ether and the features of pentane, and has the features of low cost, less pollution and low toxicity, and may be used in replacing acetylene for welding and cutting metal. Owing to dimethyl ether containing oxygen in 35 %, using the ether-hydrocarbon gas in welding and cutting metal has 20 % lowered oxygen consumption.

Owner:乐清市金佩克新能源有限公司

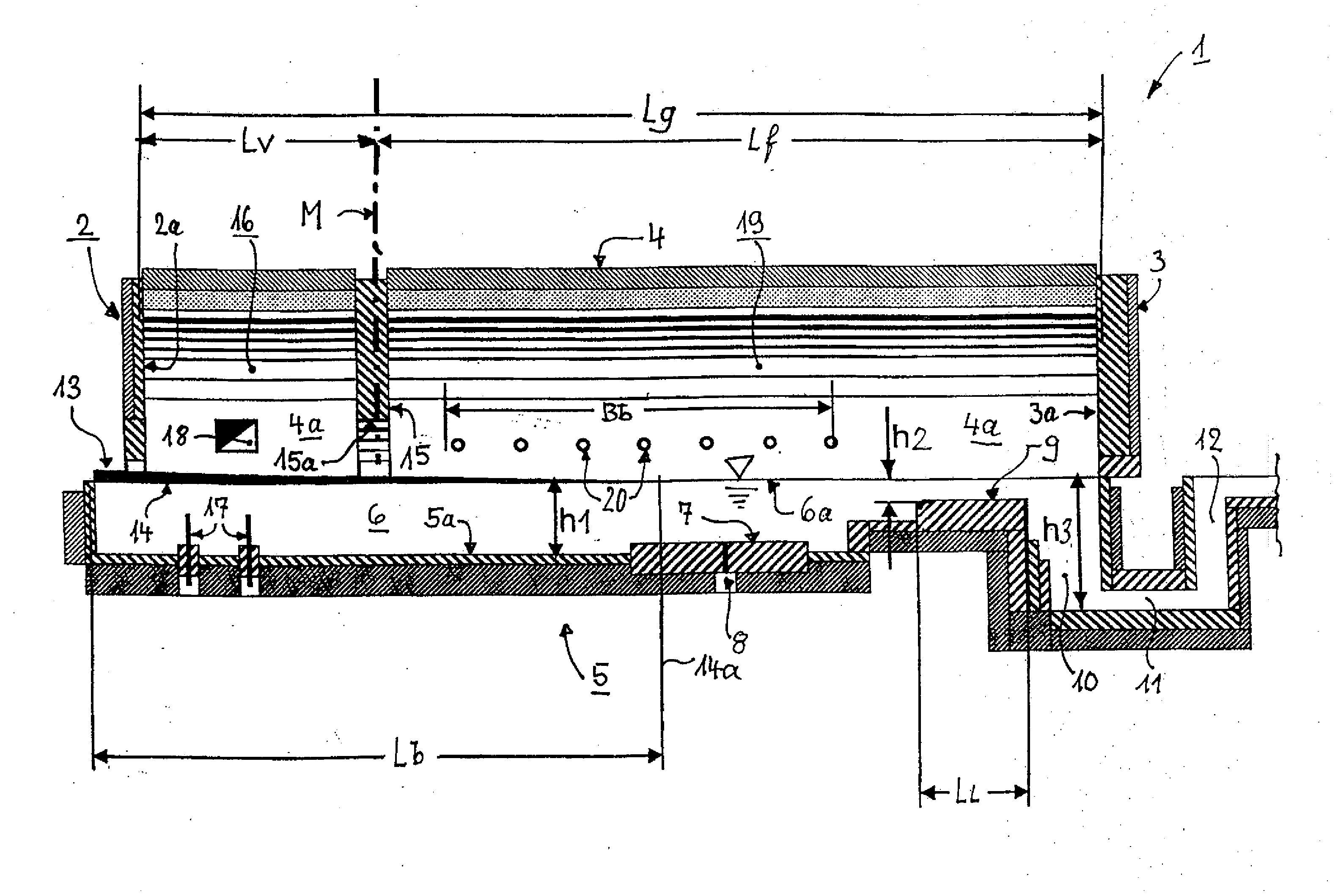

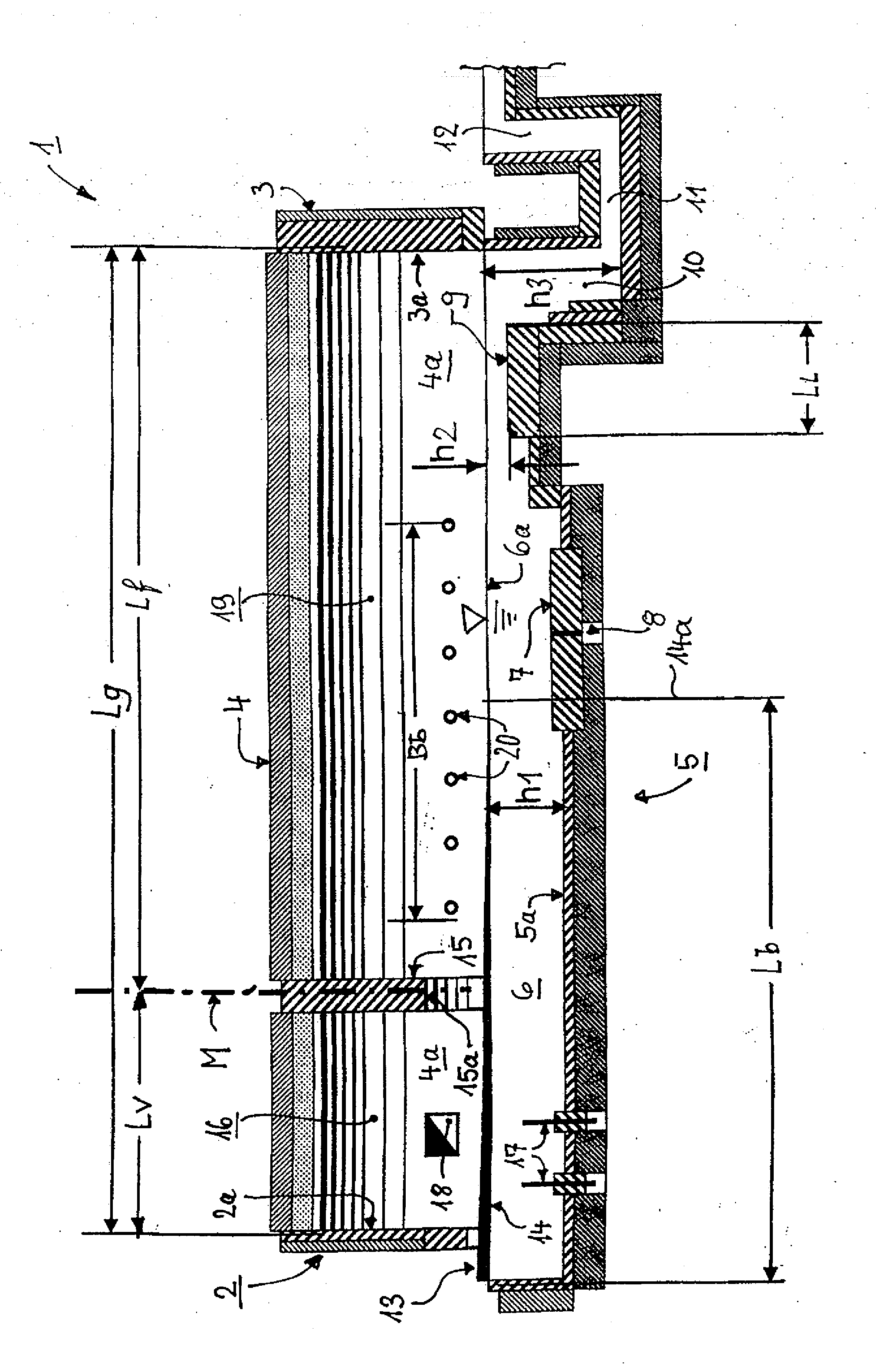

Glass melting furnace and method for melting glasses

InactiveUS20100175427A1Reduce nitrogen oxide emissionsReduce entrainmentGlass furnace apparatusTank furnacesCombustorAtmospheric air

A glass melting furnace with a tank and a superstructure with a furnace crown and a total internal length (“Lg”), with a preheating zone for charging material and a combustion zone with burners. A single radiation wall is located between the preheating zone and the combustion zone such that the length of the preheating zone is between 15 and 35% of the total internal length and the length of the combustion zone is between 65 and 85% of the total internal length. The preheating zone is designed for use solely with preheating of the charging material within the furnace. The oxidation gas supply contains at least 85 volume percent oxygen and at least one outlet for the waste gases from the preheating zone is connected to the atmosphere without a heat exchanger.

Owner:BETEILIGUNGEN SORG

Concentrated and thin fuel-saving igniting coal powder burner

InactiveCN101021319ASimple structureReduce manufacturing costPulverulent fuel combustion burnersLump/pulverulent fuel feeder/distributionCombustorCombustion chamber

The present invention relates to a dense-thin oil-saving ignition coal powder combustor. It includes combustor self-body, one-stage combustion chamber and ignition heat-source nozzle. It is characterized by that in the described combustor self-body that in the described combustor self-body inlet a dense-thin coal powder separation device is set, in the described one-stage combustion chamber interior two separation partition boards are set, said one-stage combustion chamber is divided into dense coal powder zone, thin coal powder zone and dense-thin coal powders mixing zone by means of partition boards, in the described dense coal powder zone an ignition heat-source nozzle is set. Said invention also provides the working principle of said coal powder combustor and its concrete operation method.

Owner:杭州意能节能技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com