Method for manufacturing metallic pellets by direct reduction of oxygen-enriched combustion in rotary furnace

A technology of metallized pellets and oxygen-enriched combustion, applied in the direction of improving process efficiency, can solve the problems of gas and air consumption, high smoke exhaust, larger equipment specifications, equipment investment costs, high operating costs, etc., to achieve Effects of improving utilization factor, reducing air consumption, and reducing gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

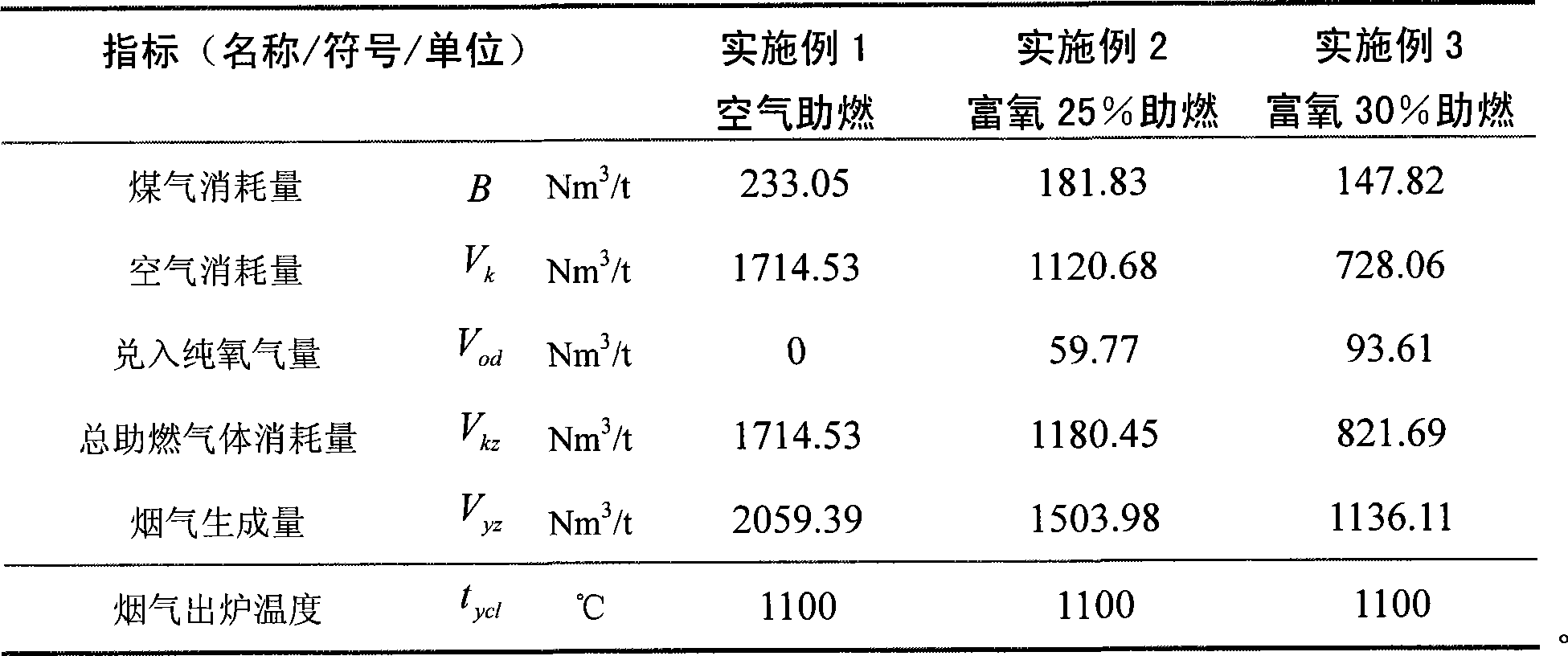

[0031] When air is used as the combustion gas, the air enters the heat exchanger through the blower, and after the heat exchange between the air and the high-temperature flue gas, the air temperature rises to 500°C, and then enters the rotary hearth furnace to participate in the combustion reaction. O in gas and air 2 Mixed combustion in the burner, the heat released by the combustion reaction is transferred to the pellets in the form of radiant heat, which is used for the reduction of iron, lead, zinc and other oxides in the pellets. The generated metal zinc, lead, etc. are separated from the pellets and enter the flue gas, and most of the iron oxides inside the pellets are reduced to metallic iron. The metallized pellets produced by direct reduction in the rotary hearth furnace have a grade of more than 65%, a metallization rate of more than 70%, and broken balls and powders less than 5mm not more than 3%, which can be directly used in the blast furnace.

[0032] Based on 1...

Embodiment 2

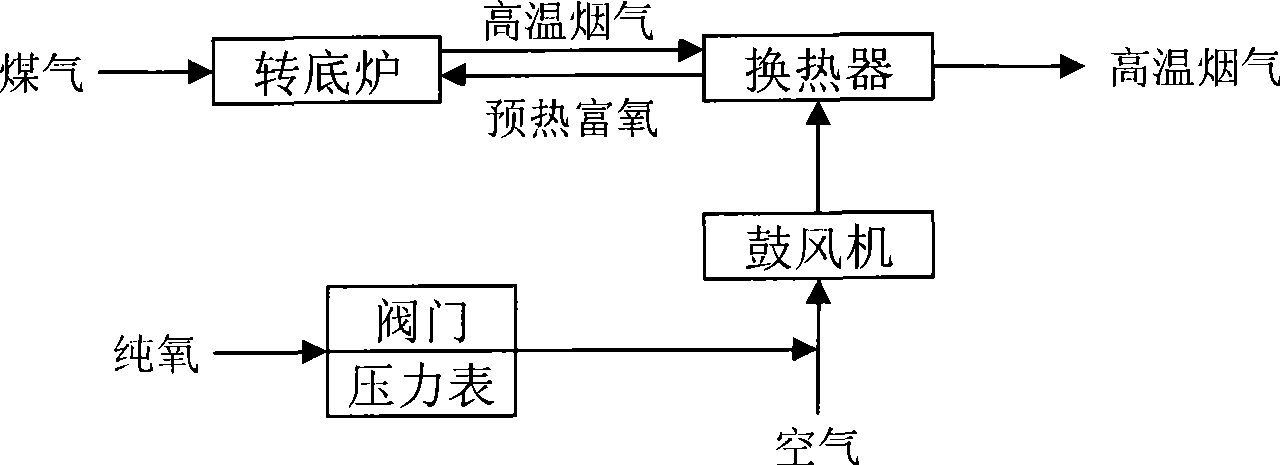

[0034] Oxygen-enriched combustion direct reduction of rotary hearth furnace equipment for producing metallized pellets, including: rotary hearth furnace, blower, heat exchanger, oxygen delivery pipe, air intake pipe; the oxygen delivery pipe is connected to the air delivery pipe, and the air delivery pipe passes through The blower is connected to the heat exchanger, which is connected to the burner of the rotary hearth furnace through pipes. A valve and a pressure detection gauge are left on the oxygen delivery pipe. The amount of oxygen dispensed is controlled by a valve and a pressure gauge on the oxygen delivery pipe.

[0035] The oxygen delivery pipe is connected to the air delivery pipe, and the amount of oxygen to be distributed is controlled by the valve on the oxygen delivery pipe and the pressure detection gauge. The oxygen-enriched mixed gas enters the heat exchanger for heat exchange and temperature rise by means of the blower. The heat source is the high-temperatu...

Embodiment 3

[0039] When 30% oxygen-enriched gas is used as the supporting gas, air and pure oxygen are mixed in a certain proportion to form oxygen-enriched oxygen, which enters the heat exchanger through the blower, and after heat exchange between the enriched oxygen and high-temperature flue gas, the temperature of the enriched oxygen rises to 600°C , and then enter the rotary hearth furnace to participate in the direct reduction reaction. Others are with embodiment 2. Based on 1 ton of metallized pellets, the gas consumption is 147.82Nm 3 / t, air consumption 728.06Nm 3 / t, pure oxygen consumption 93.61Nm 3 / t, total combustion gas consumption 821.69Nm 3 / t, smoke generation 1136.11Nm 3 / t, the flue gas outlet temperature is 1100°C.

[0040] Implementation case comparison:

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com