Patents

Literature

814results about How to "Burn faster" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fuel for firing into rotary kiln cement clinker

A fuel which is used for rotary kiln cement clinker firing is composed of raw materials with the following weight percentage: coal 3-80, straw substances 0-90, forest products wastes 0-95 and food industry by-product residues 0-70. The straw substances refer to rice straws, wheat straws, cotton stalks, sesame stalks, soybean straws, corn stalks, sorghum stalks, rice husks, peanut shells, soybean shells and corn sticks, the forest products wastes refer to defective bamboo, wood, tree branches, leaves, shrubs, faggot straws and sawdust and wood wool corner scrap materials in the bamboo and wood-processing industry, the food industry by-product residues refer to bran, wheat skin, squeezing meal cake, bean dregs and wine lees, and the coal refers to bituminite, anthracite and coke coal powder. The flue raw materials which are used for the rotary kiln cement clinker firing have wide selecting range, simple preparation, convenient use and rapid burning speed and are beneficial for protecting atmosphere circumstances.

Owner:吴飞龙

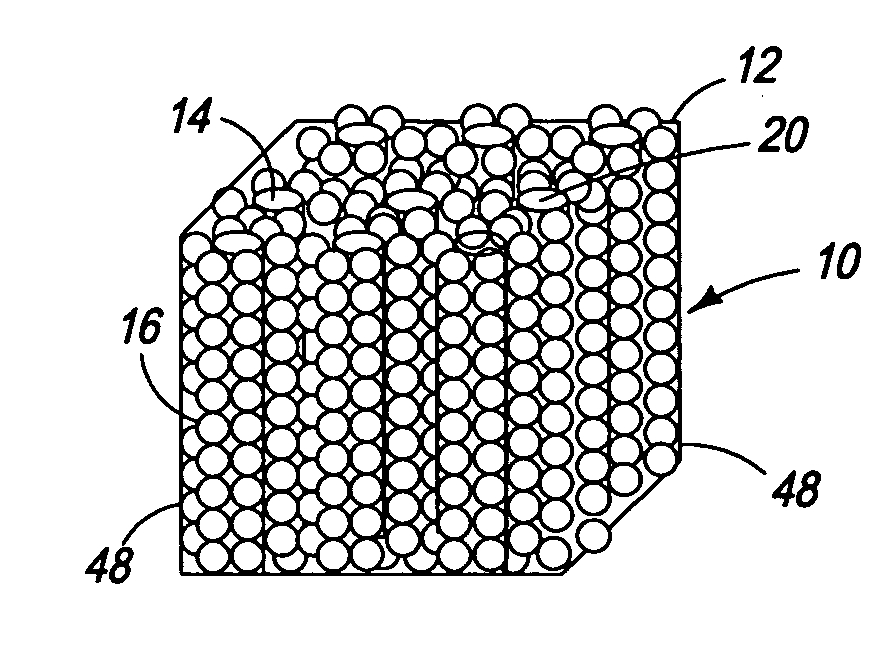

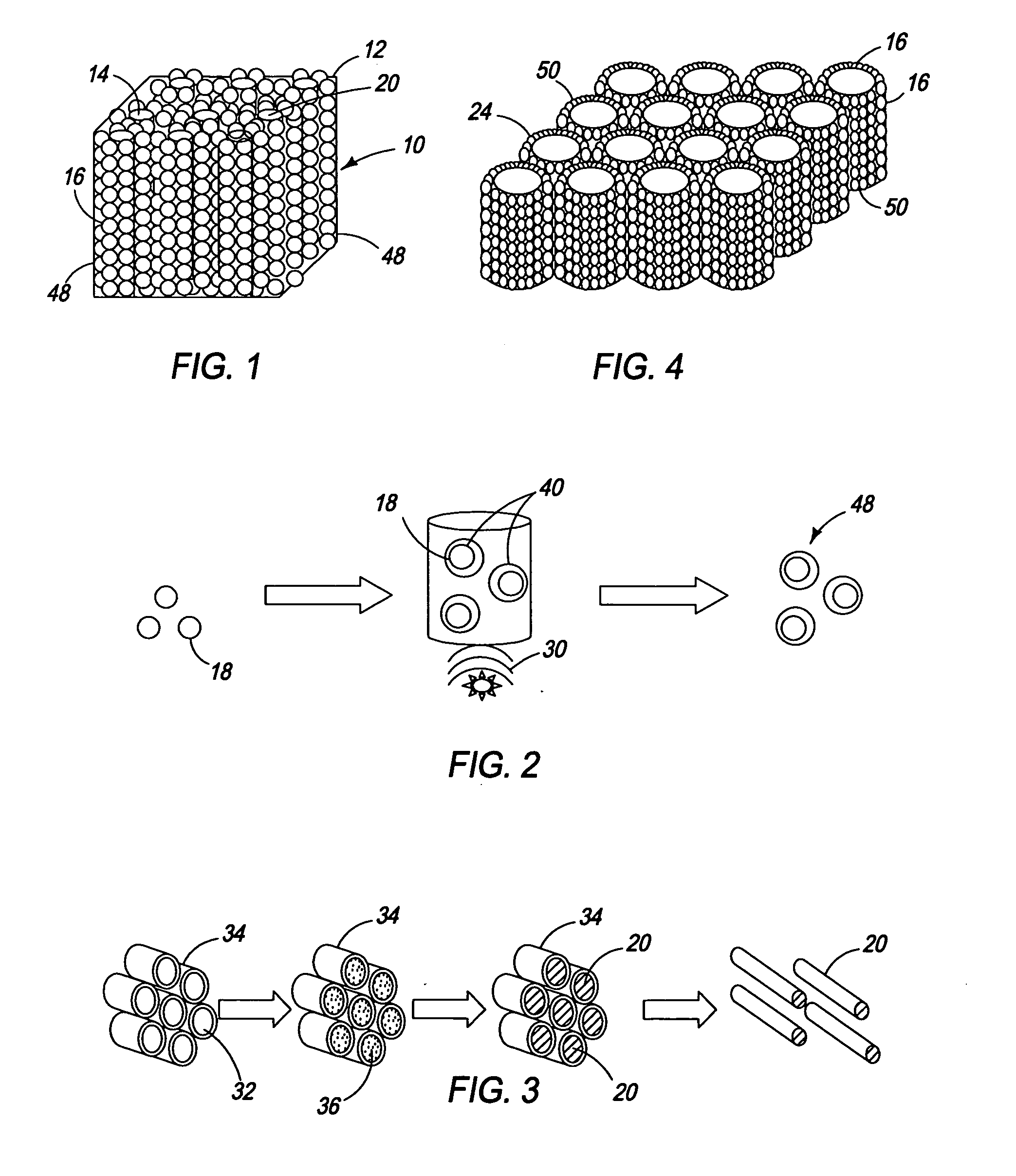

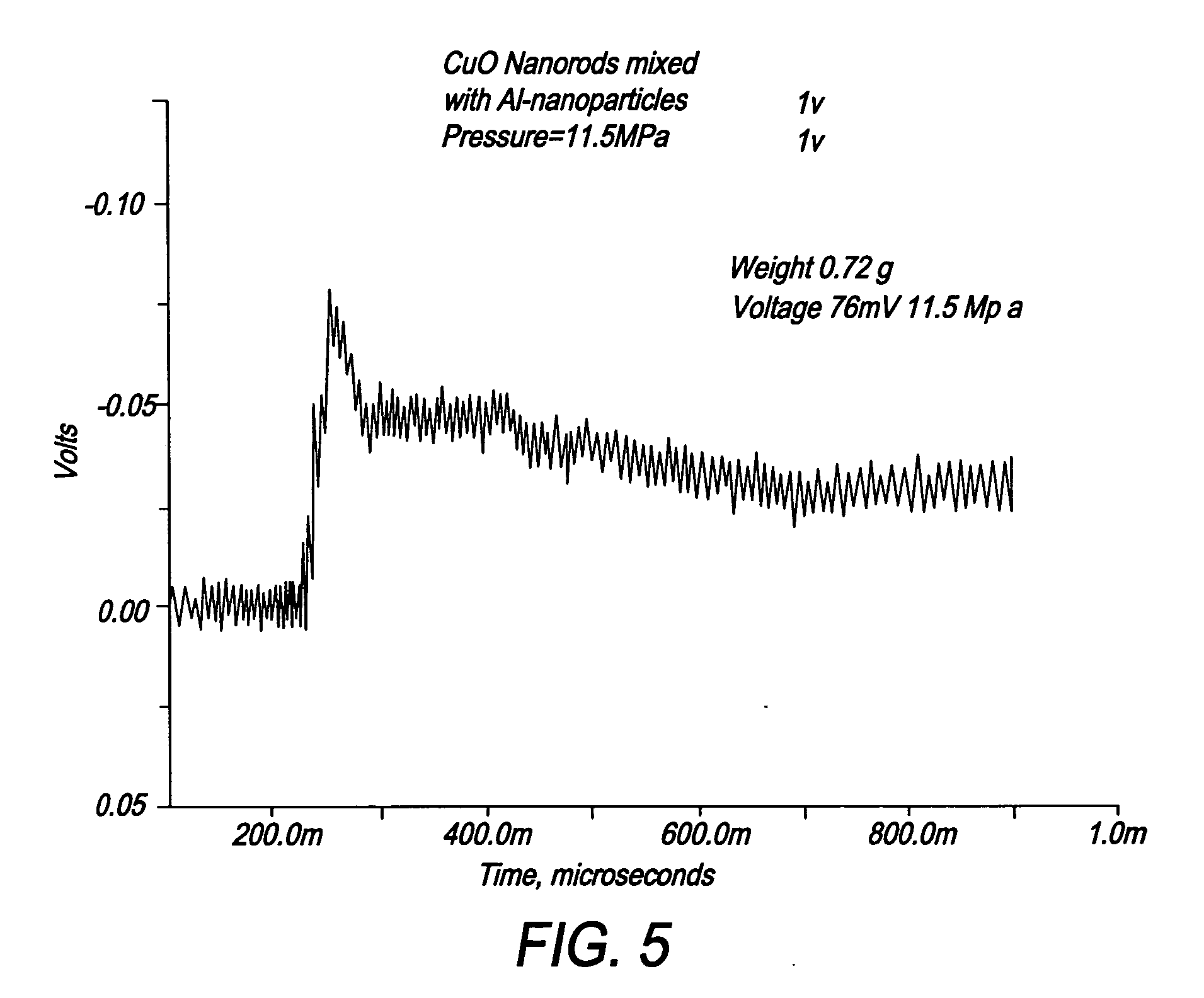

Ordered nanoenergetic composites and synthesis method

A structured, self-assembled nanoenergetic material is disclosed that includes a nanostructure comprising at least one of the group consisting of a fuel and an oxidizer and a plurality of substantially spherical nanoparticles comprising at least the other of the group consisting of a fuel and an oxidizer. The spherical particles are arranged around the exterior surface area of said nanorod. This structured particle assures that the oxidizer and the fuel have a high interfacial surface area between them. Preferably, the nanostructure is at least one of a nanorod, nanowire and a nanowell, and the second shaped nanoparticle is a nanosphere.

Owner:UNIVERSITY OF MISSOURI

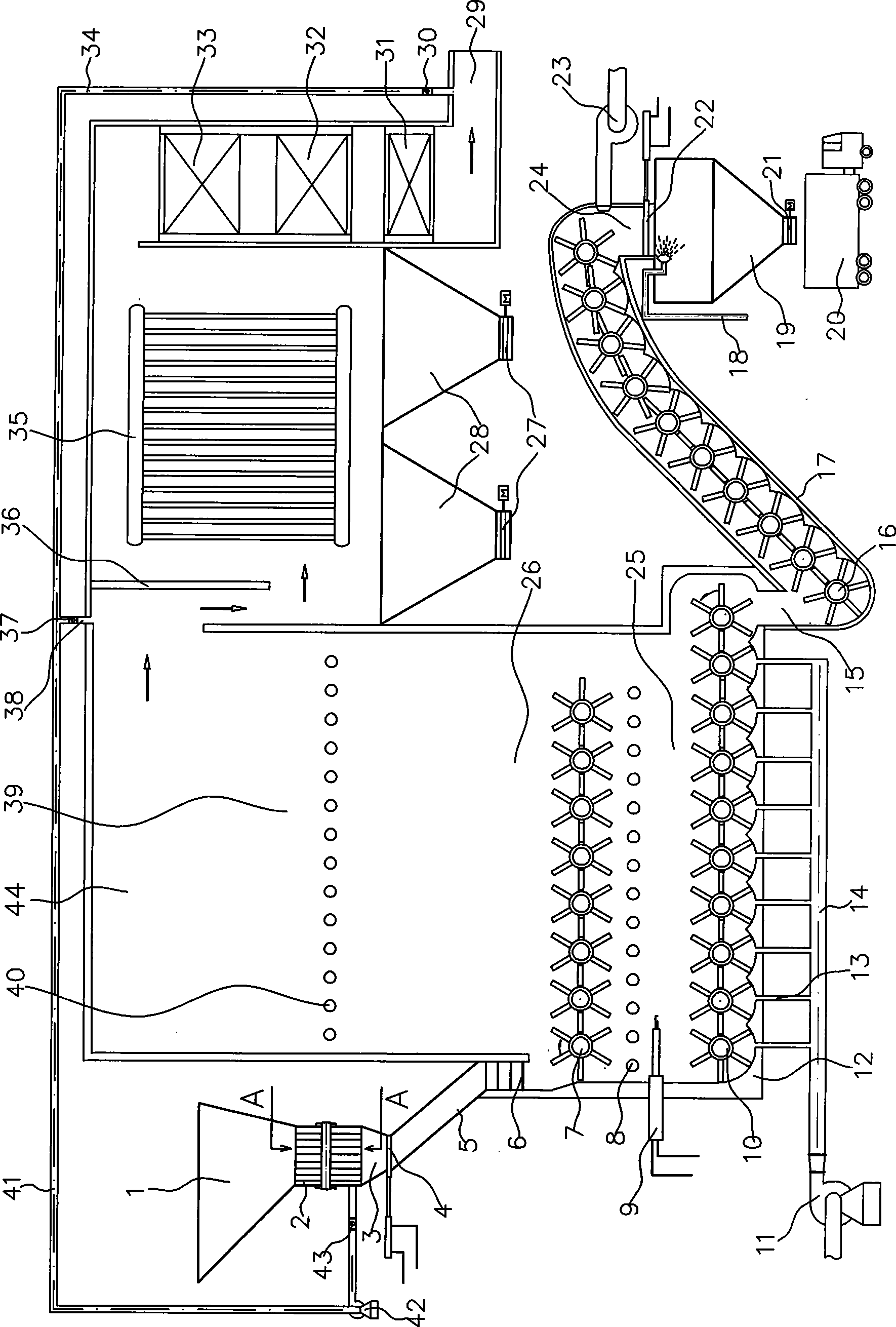

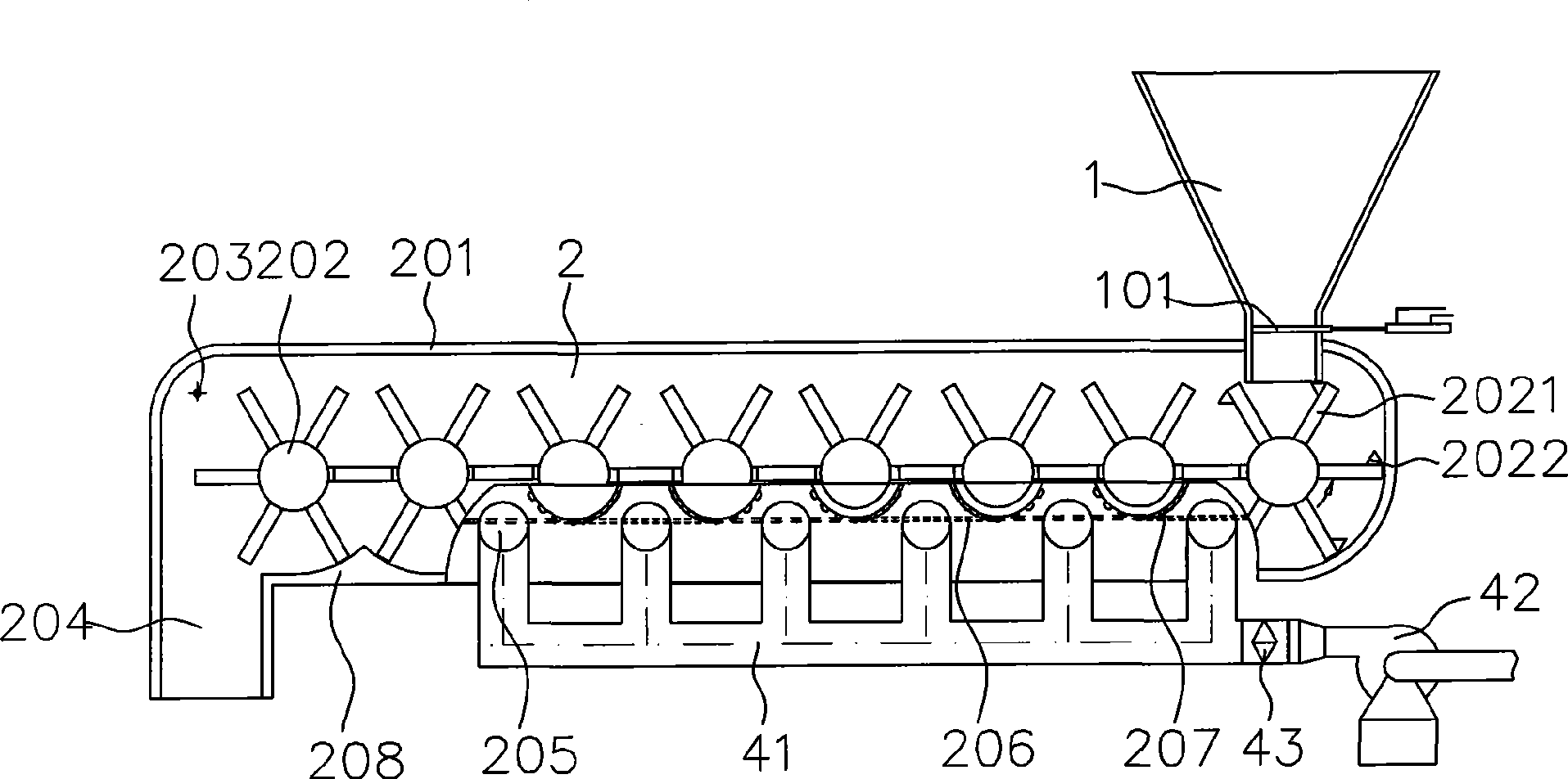

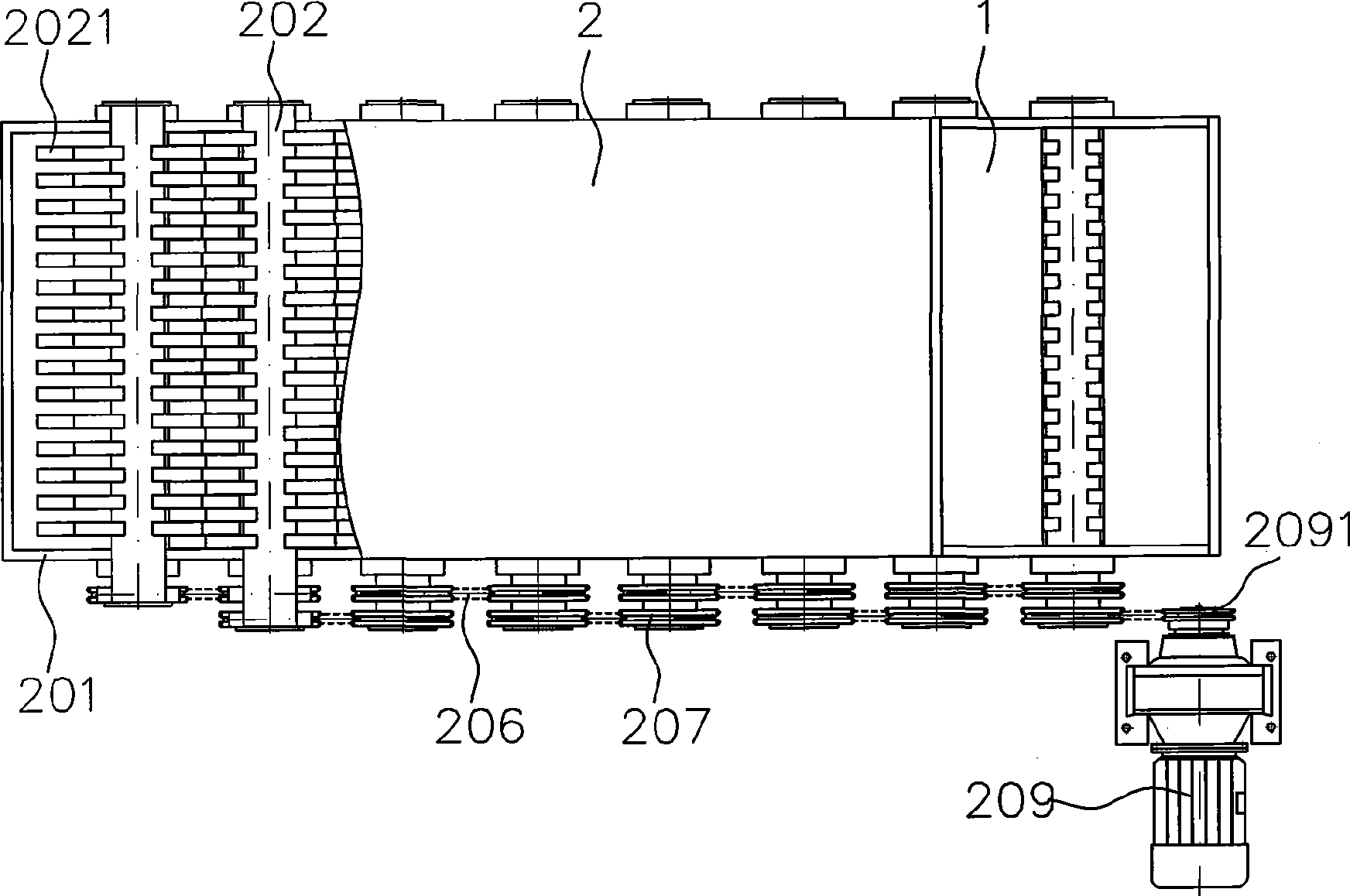

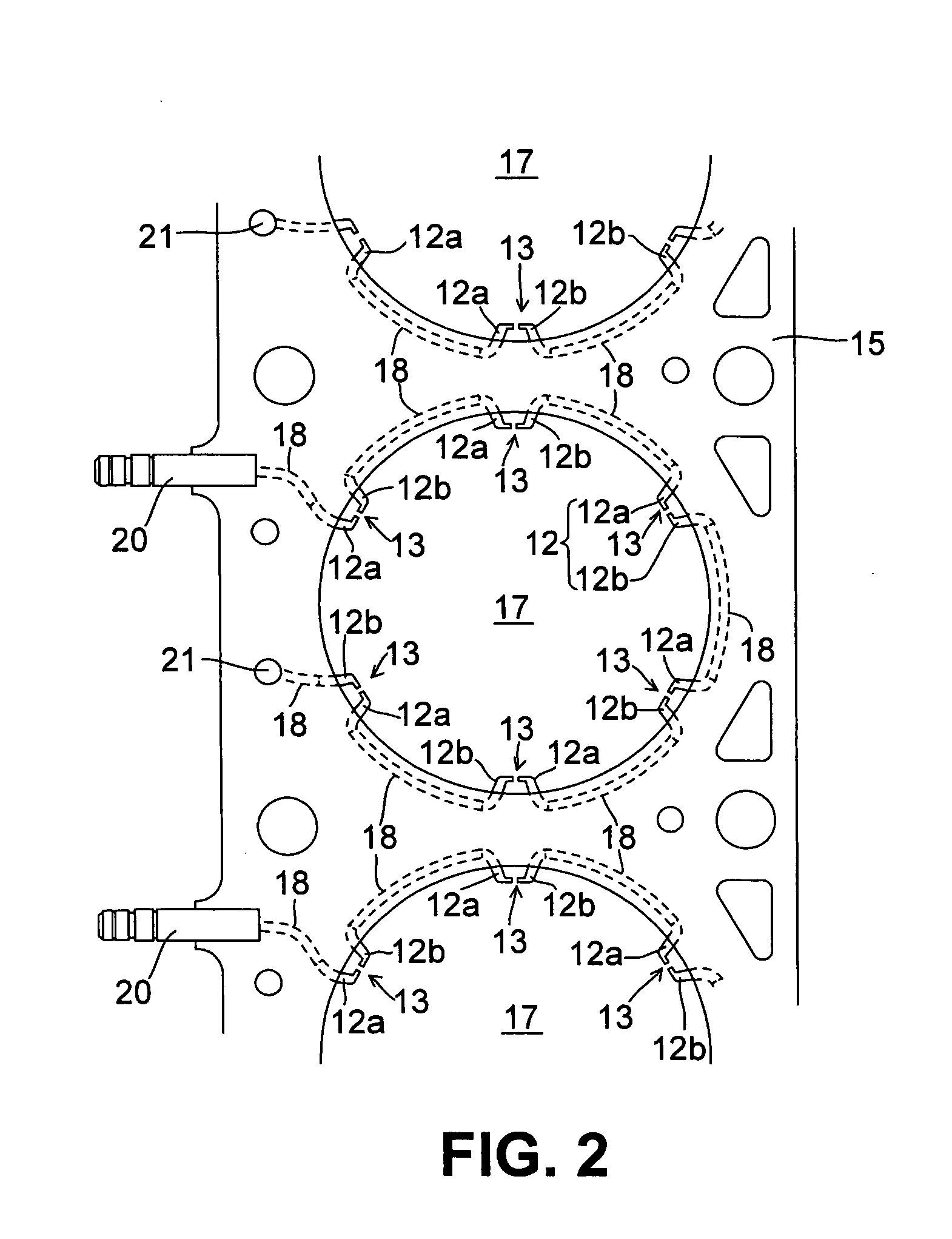

Efficient burning furnace with rotary fluidization grate

InactiveCN101532667ATurn overWith self-cleaning functionRevolving grateRocking grateCombustion systemFlue gas

The invention relates to an efficient burning furnace with a rotary fluidization grate. The burning furnace with the rotary fluidization grate consists of a feeding system, a burning system and a slagging system; moreover, a waste heat boiler and a flue gas treatment system are connected with the burning furnace to form a complete garbage burning and generating system. The feeding system consists of a feeding hopper, a pre-drying conveying device, an aggregate bin, a chute and a charge distributor. The feeding hopper is a receiving opening for feeding garbage into the burning furnace and is arranged in a garbage storage pit close to one side of the burning furnace. An outlet of the feeding hopper is connected with an inlet of the pre-drying conveying device. A material level switch is arranged in the feeding hopper, and gives an alarm to prompt an operator to feed materials when the material level is lower than a set value so as to ensure that the hopper is not empty. The outlet of the hopper can be selectively provided with a feeding device. The burning furnace has the advantages of high burning speed, high burning efficiency, high slag burning degree, easy control, lower energy consumption, low pollution, low cost and investment conservation, and is applicable to domestic garbage with low thermal value and high moisture; and the garbage does not need to be pretreated.

Owner:新乡锅炉制造有限公司

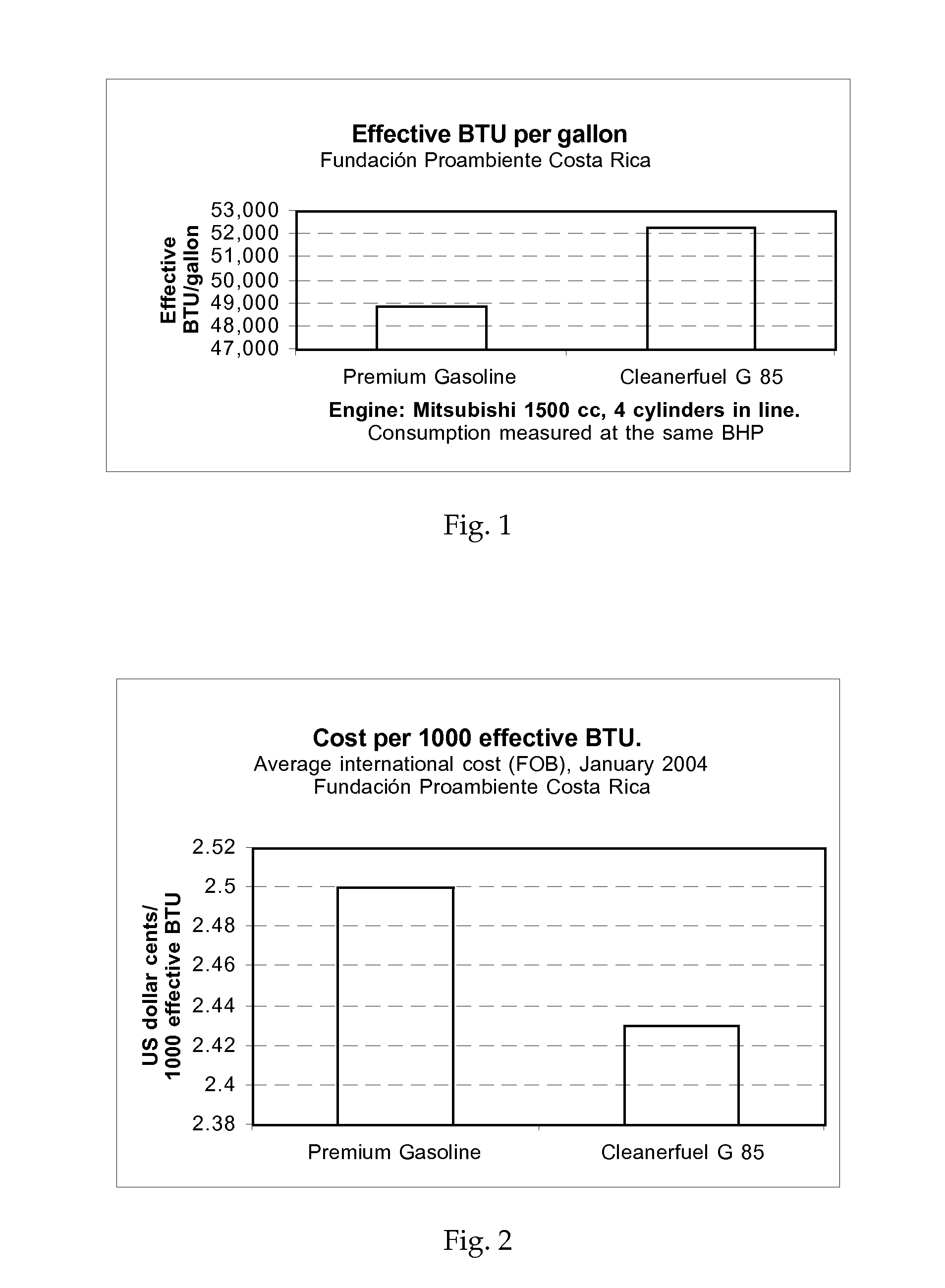

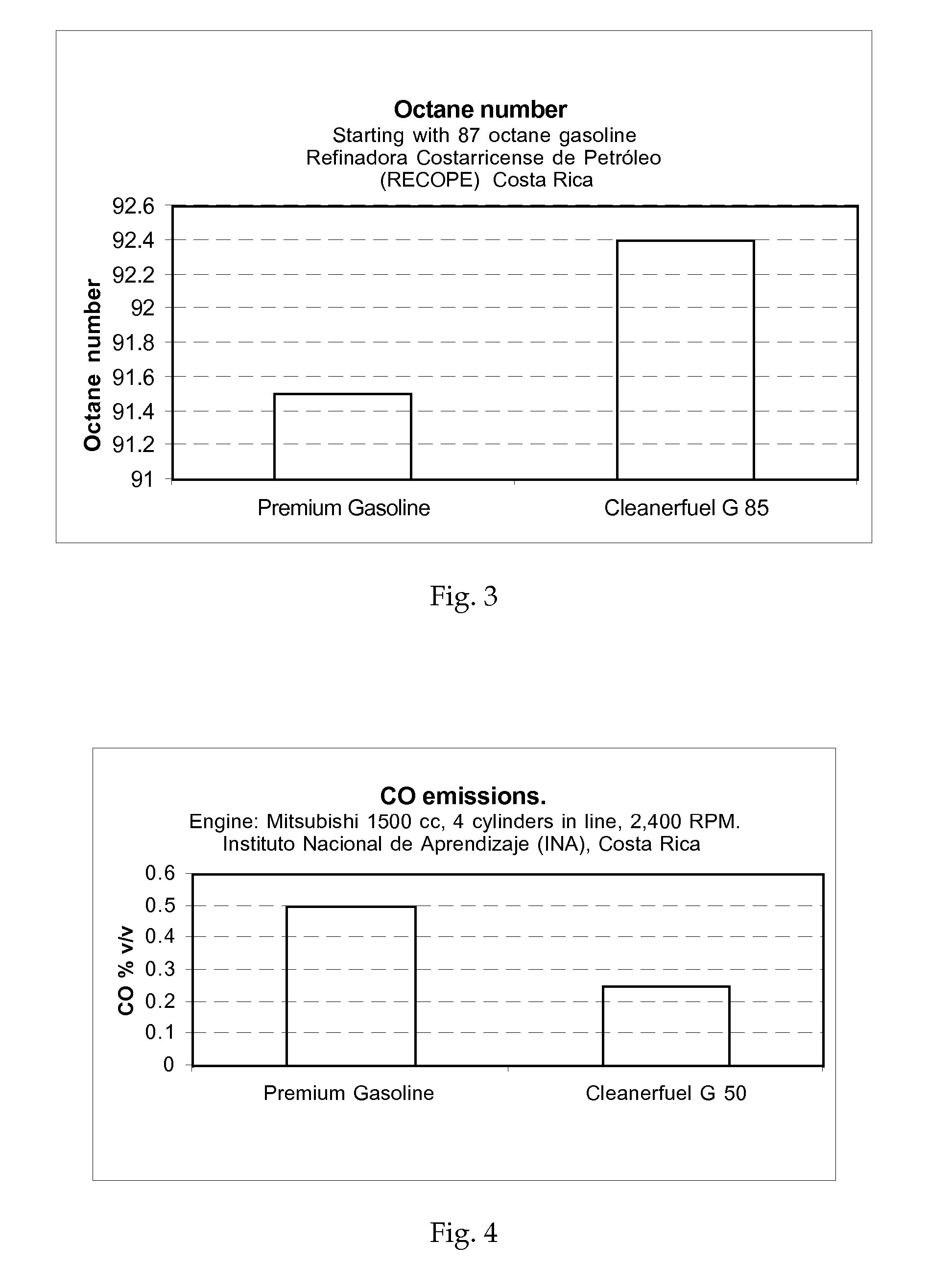

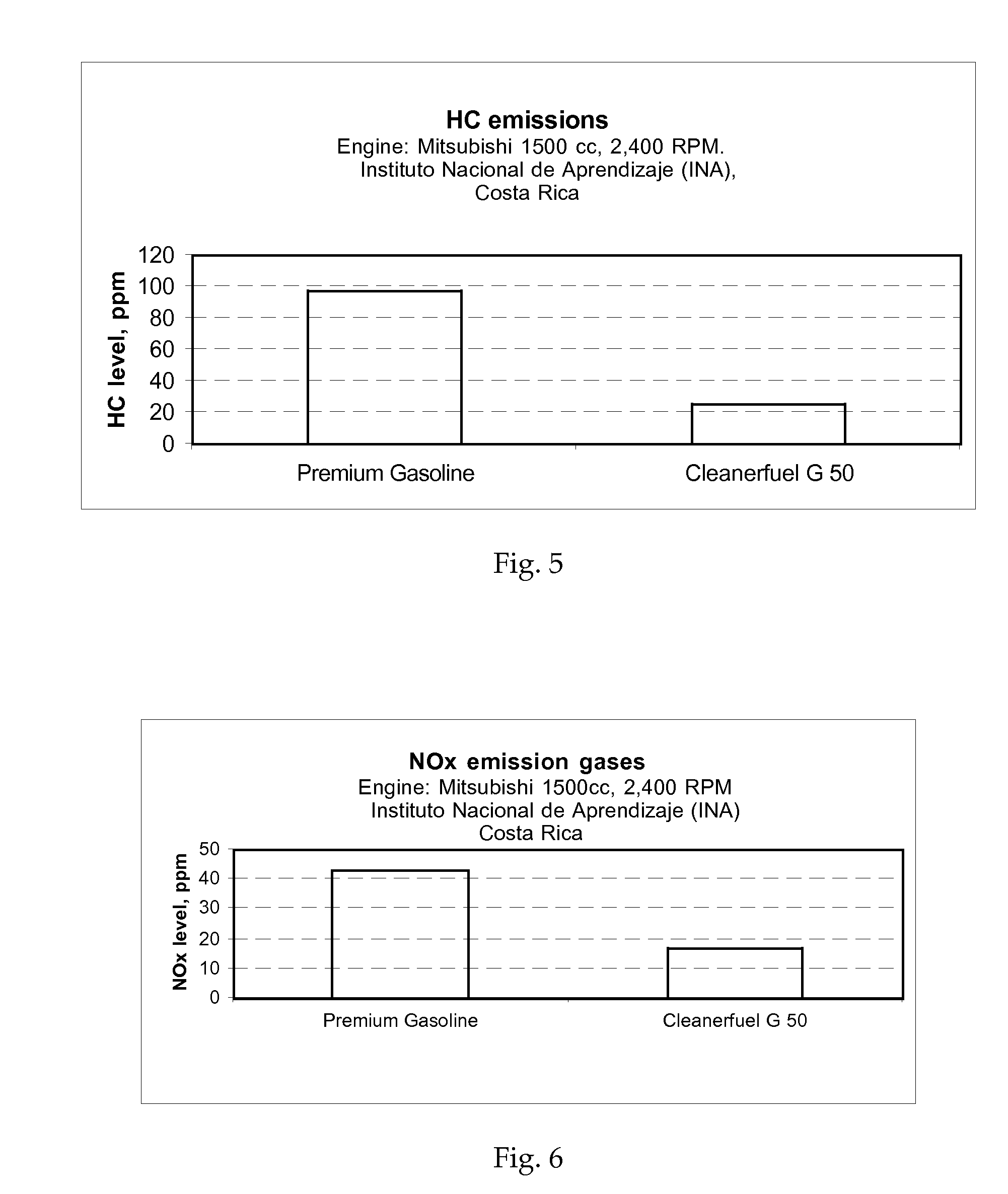

Alcohol based fuel and/or biofuel composition

InactiveUS20070130822A1Rapid expansionReduces available spaceBiofuelsLiquid carbonaceous fuelsAlcoholCombustion

Owner:ARAYA MARIO

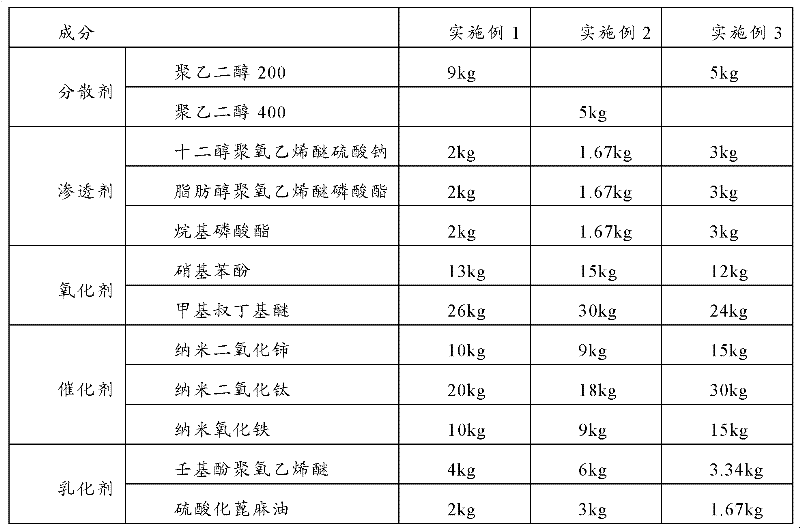

A kind of coal combustion accelerant

The invention provides a coal combustion improver which comprises 5 to 10 percent of dispersing agent, 5 to 10 percent of penetrant, 35 to 50 percent of oxidizing agent, 35 to 50 percent of catalyst and 5 to 10 percent of emulsifying agent, wherein the oxidizing agent is a mixture of nitrophenol and methyl tertiary butyl ether; and the catalyst is nano-scale metallic oxide. The coal combustion improver provided by the invention has high combustion improving efficiency and is safe and environmental-friendly. The invention also provides a method for preparing the coal combustion improver.

Owner:安徽海螺材料科技股份有限公司

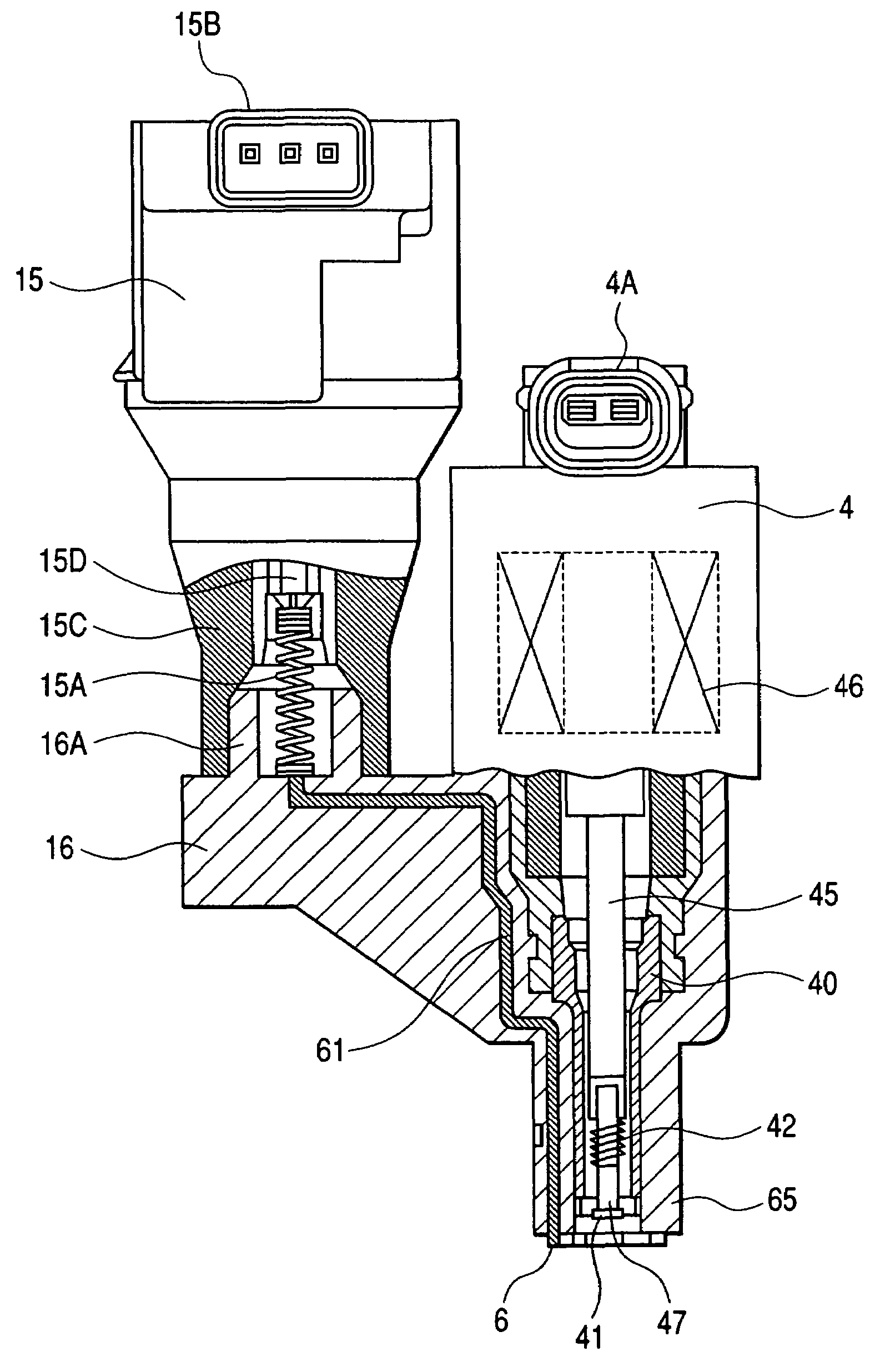

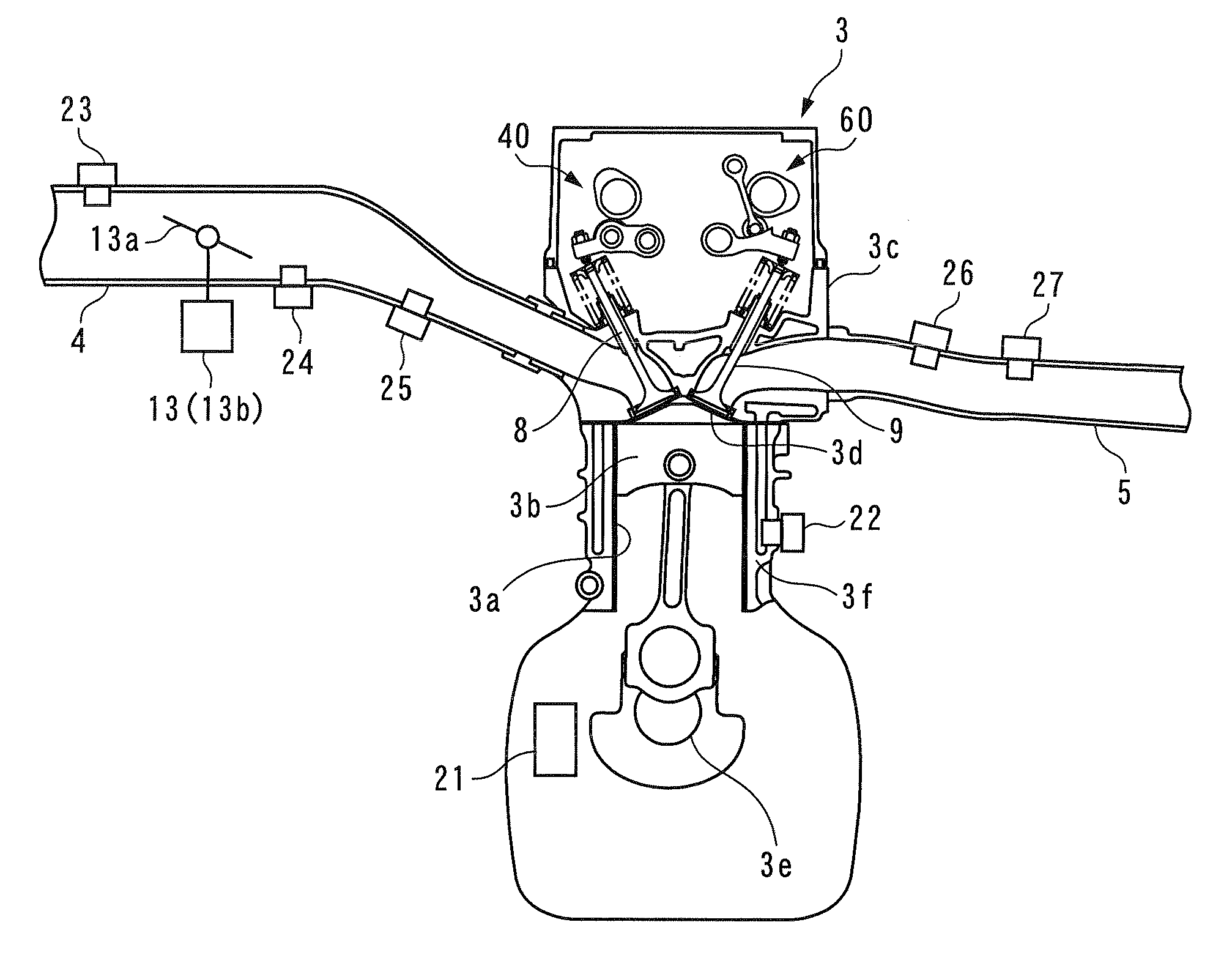

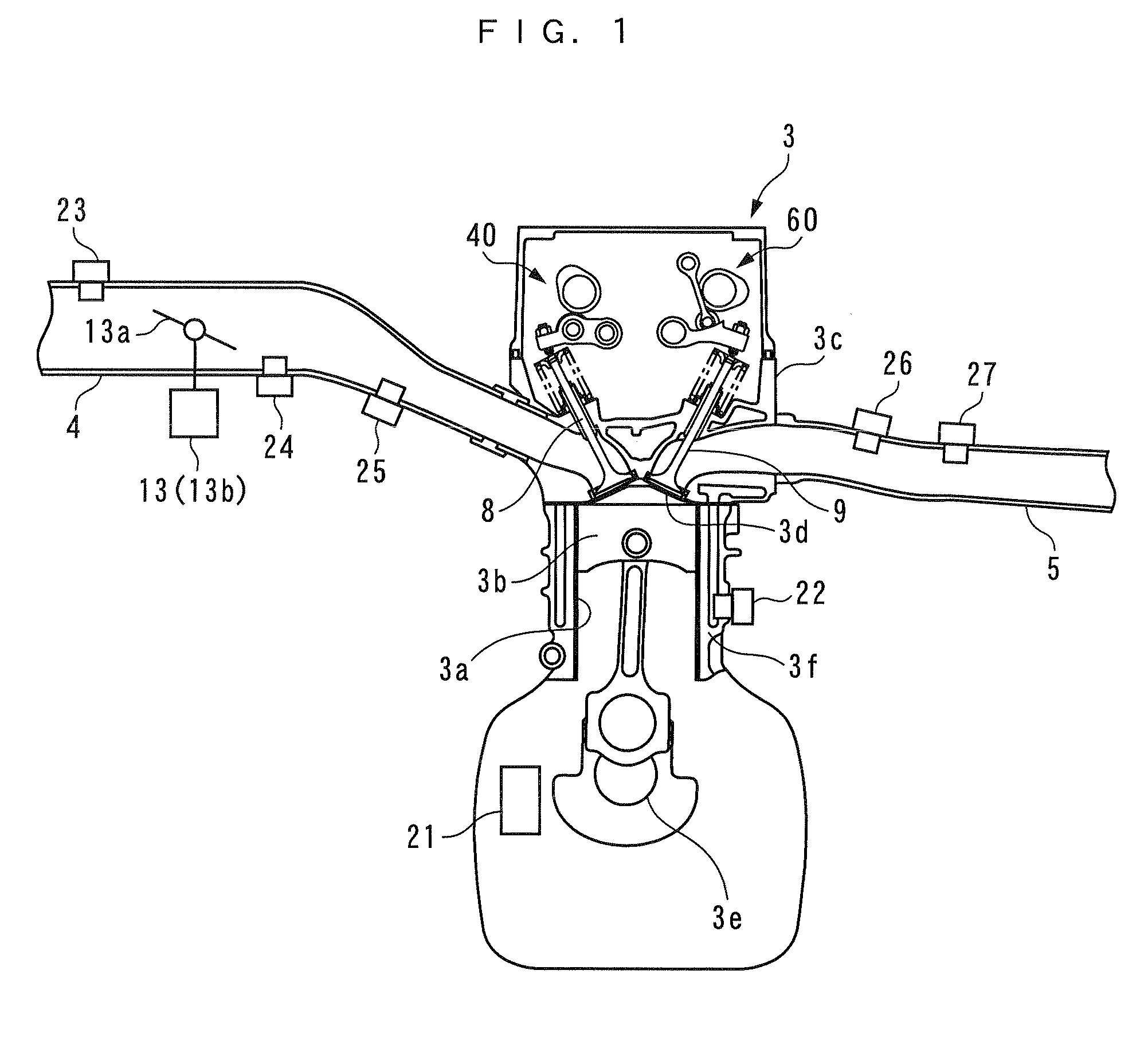

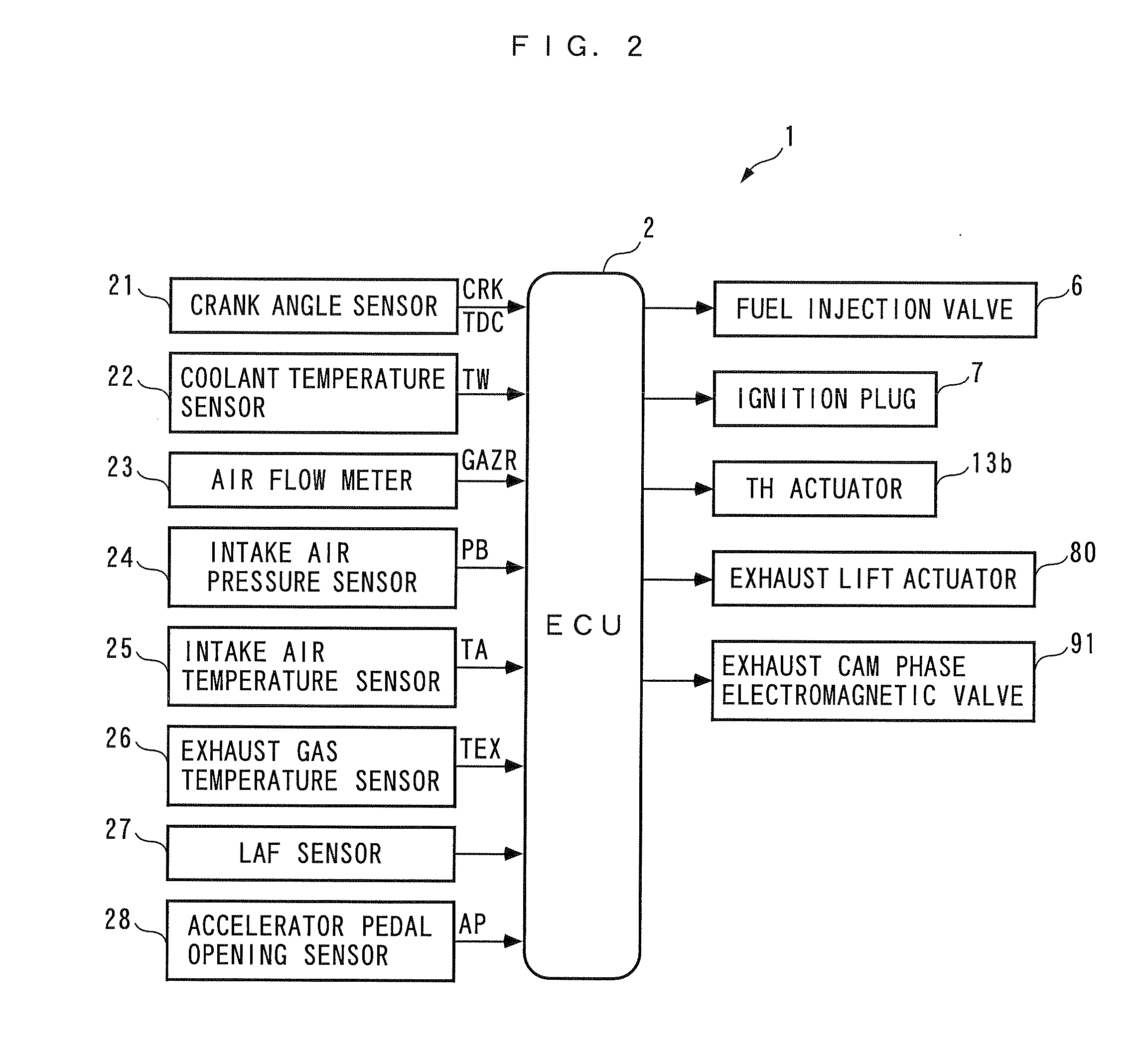

Spark ignition device and internal combustion engine with the same

InactiveUS20060102140A1Spread of fire be improveCombustion speed be increaseSparking plugsInternal combustion piston enginesIgnition coilInjector

A plurality of spark electrodes are disposed in an arc shape on the surface or so as to be projected from the surface of an insulating member formed on a part of the wall face of a combustion chamber, and are formed so as to be in series electrically via discharging gaps. A spark plug is provided integrally with an injector, and the spark plug and the ignition coil are integrated. The three members are constructed as an integral unit, thereby improving installability to an engine.

Owner:HITACHI LTD

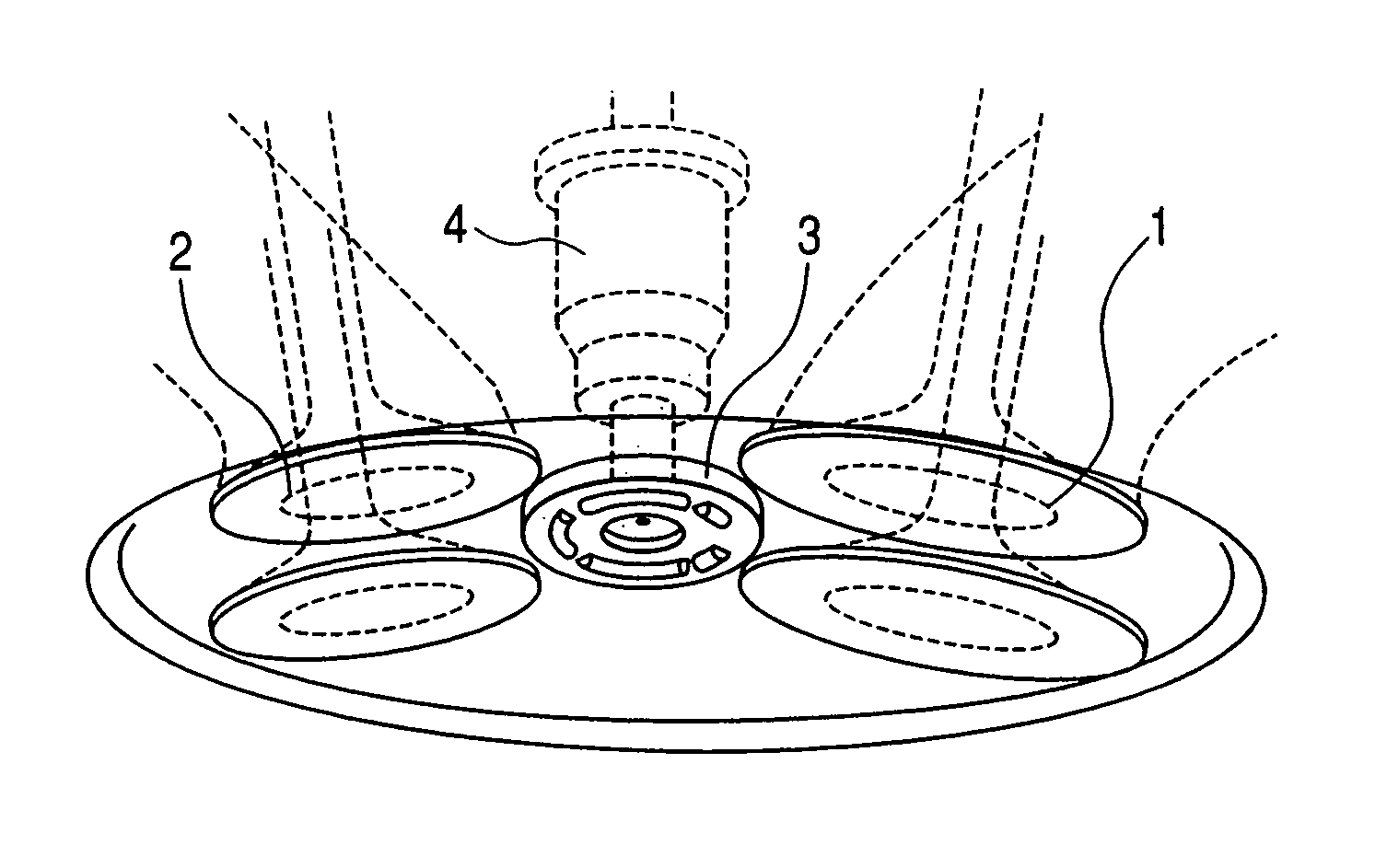

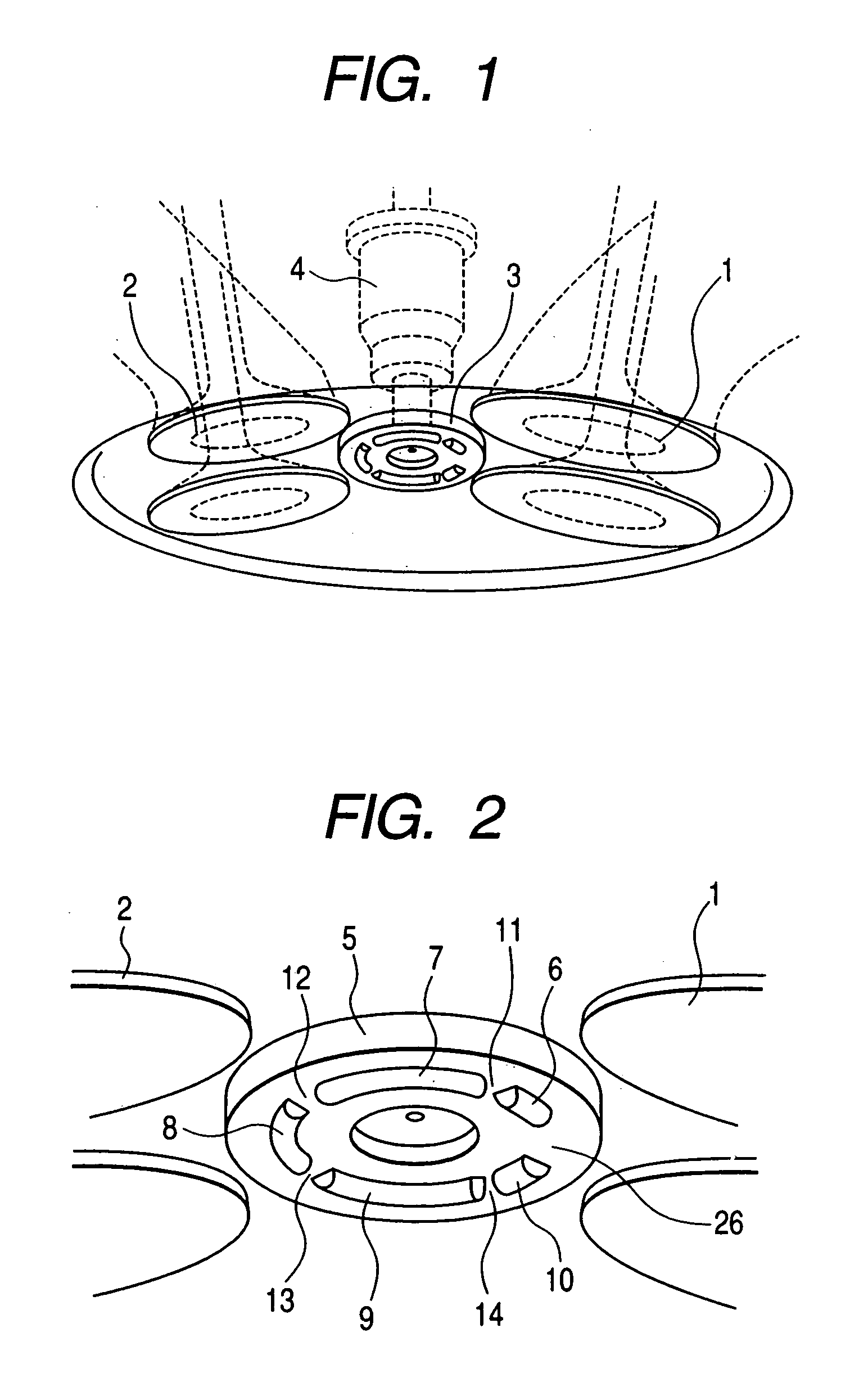

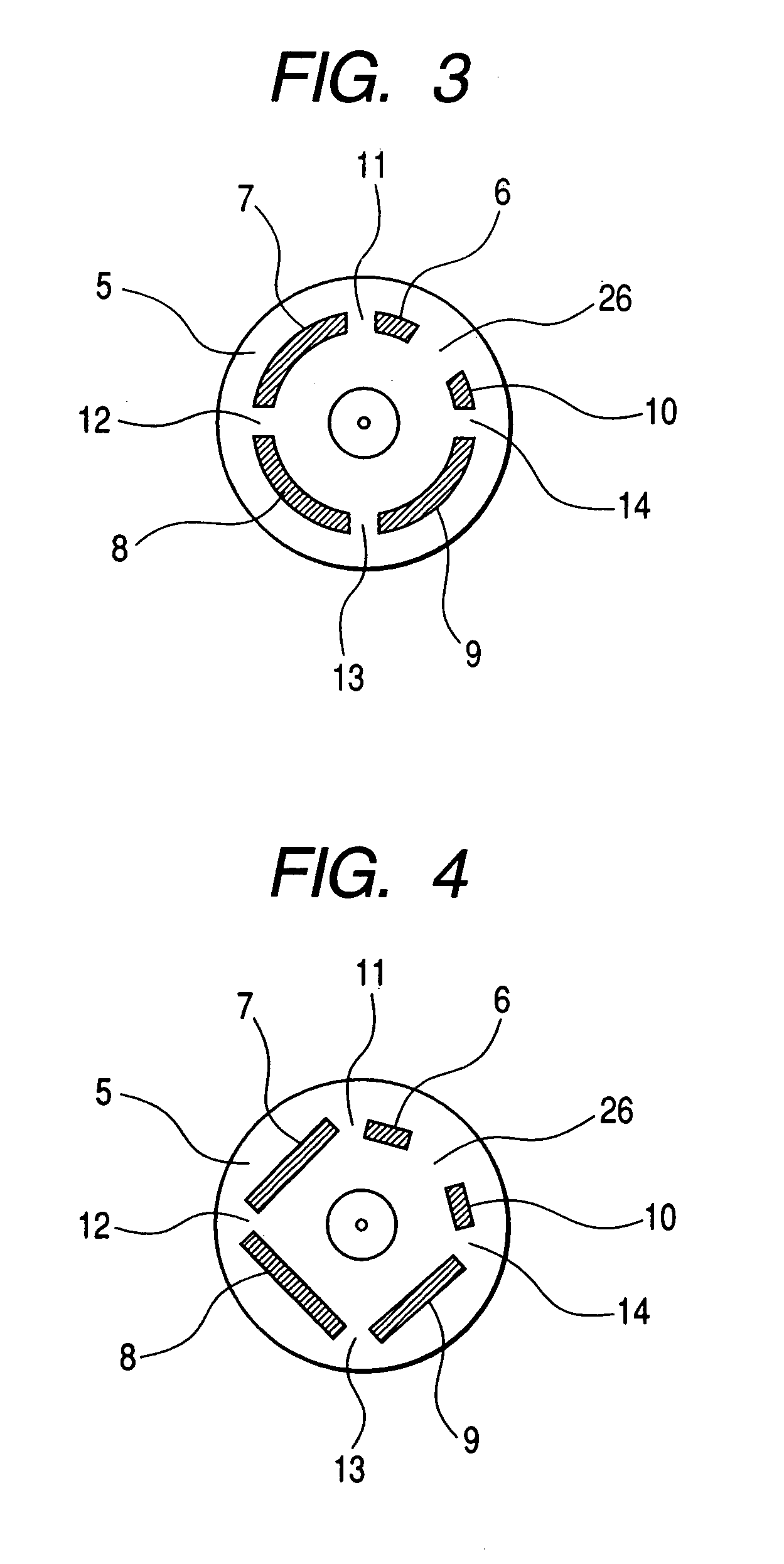

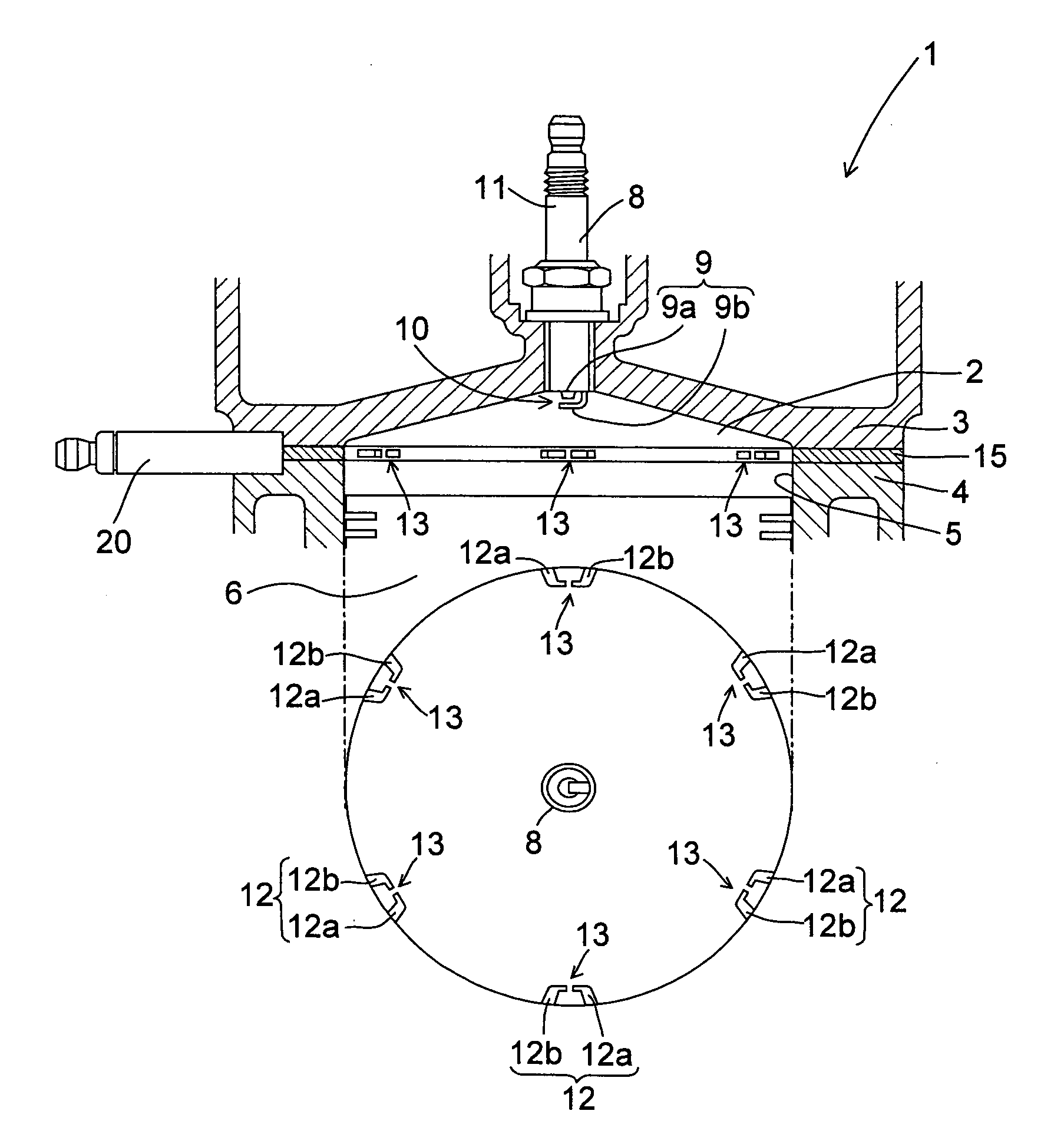

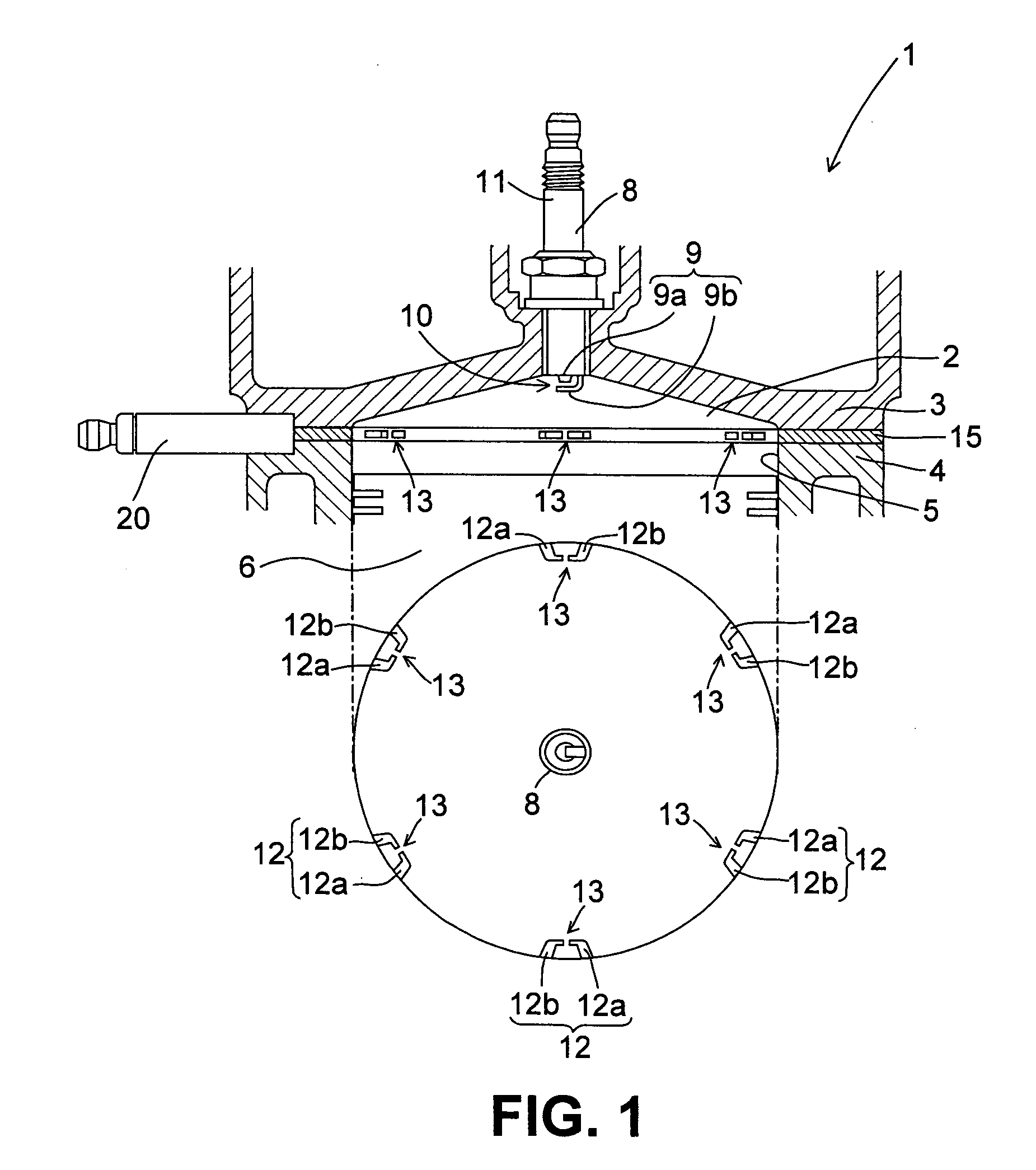

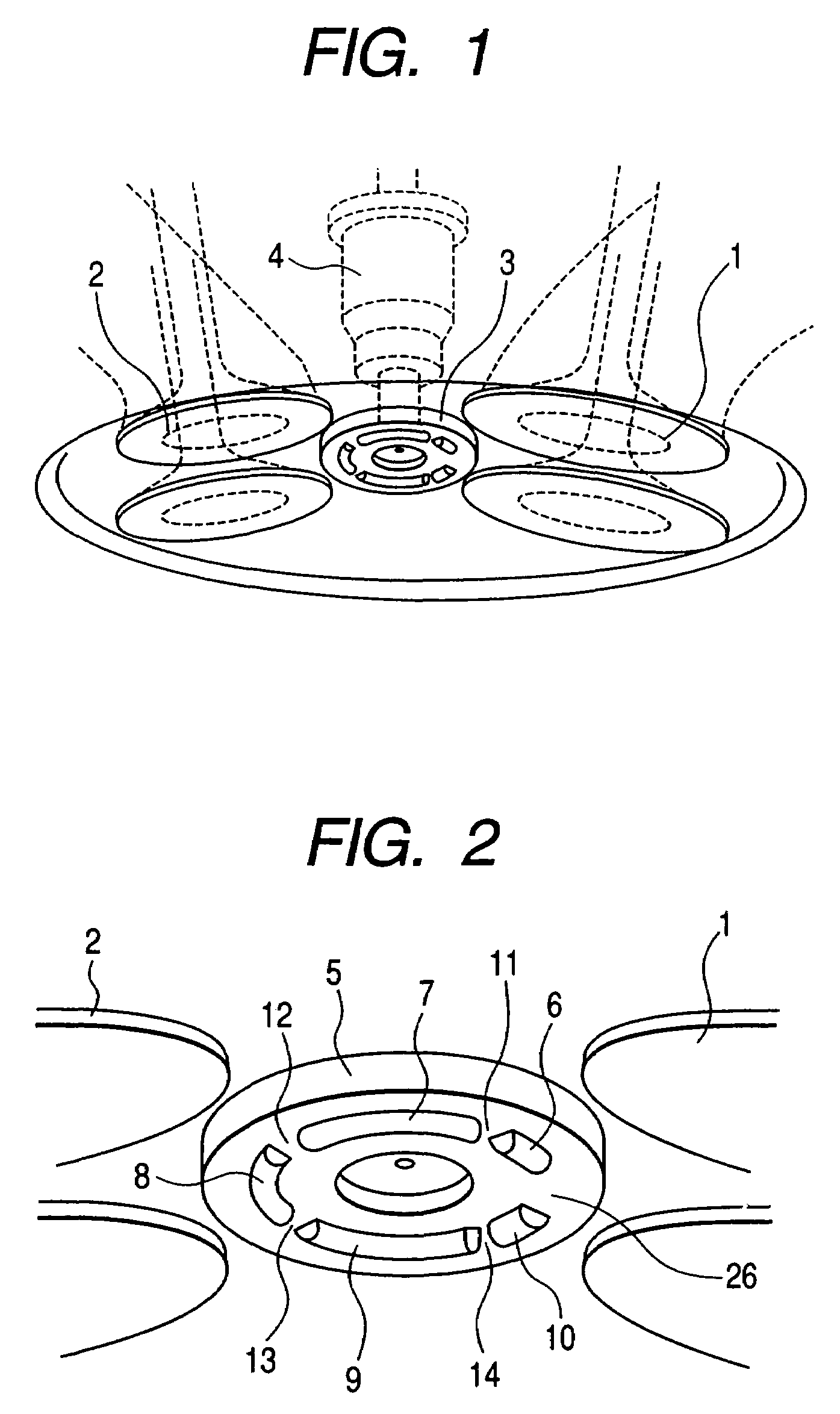

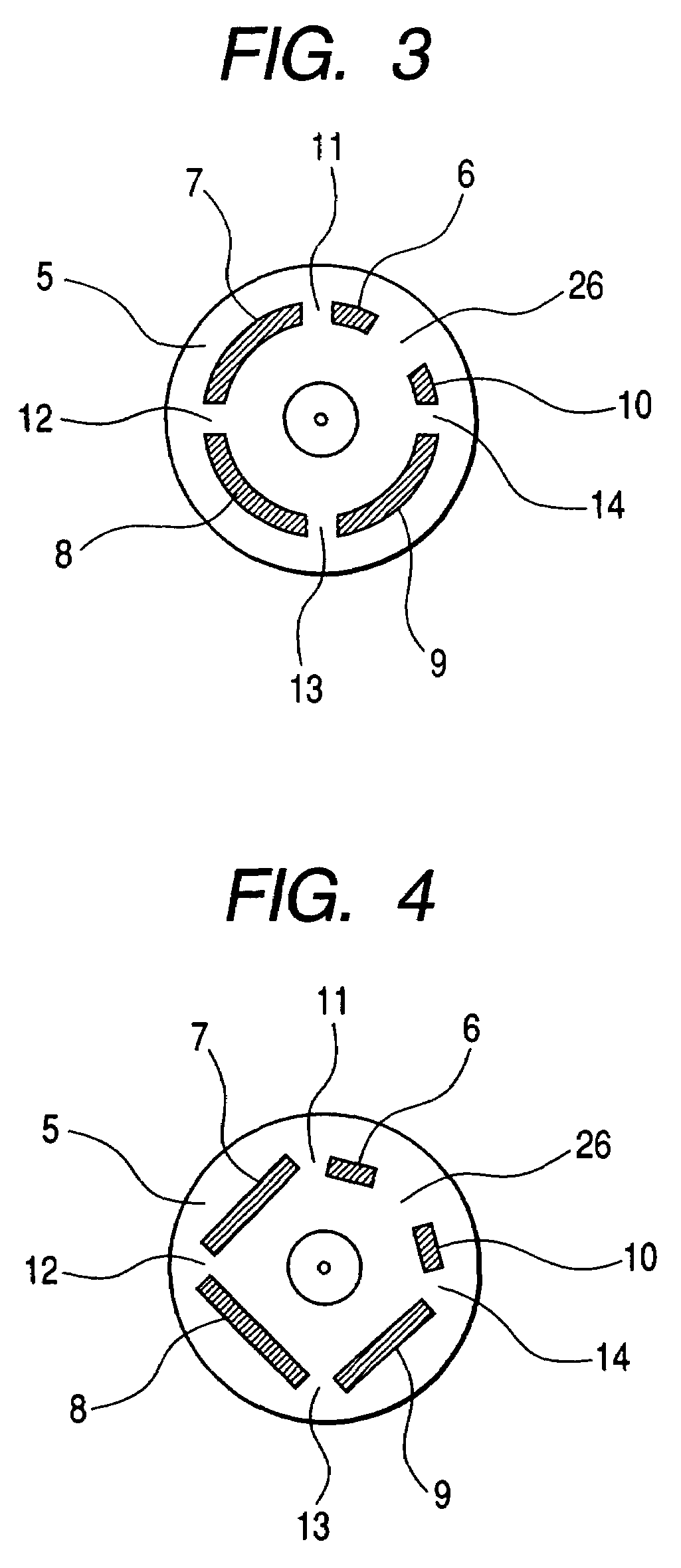

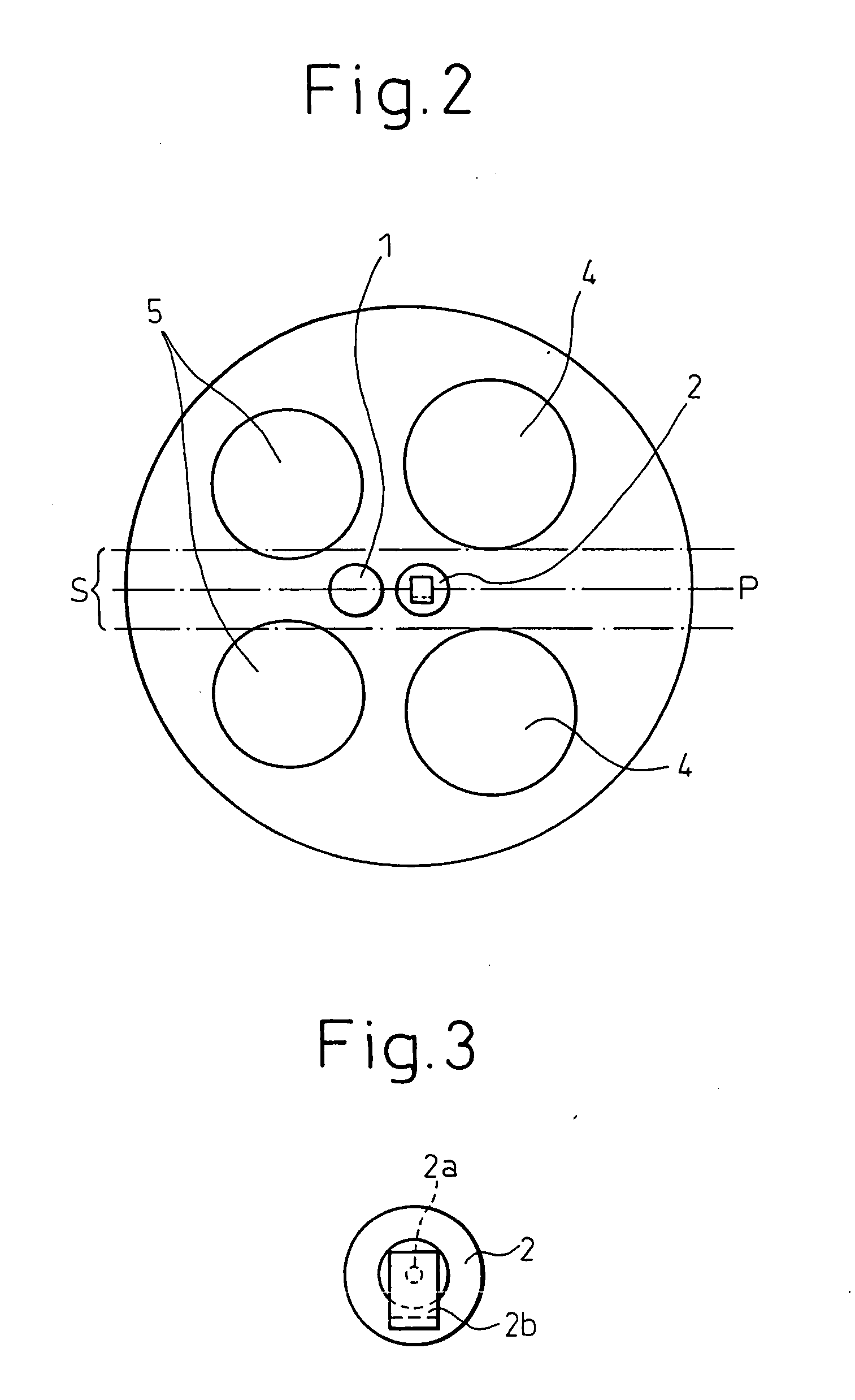

Multipoint ignition engine

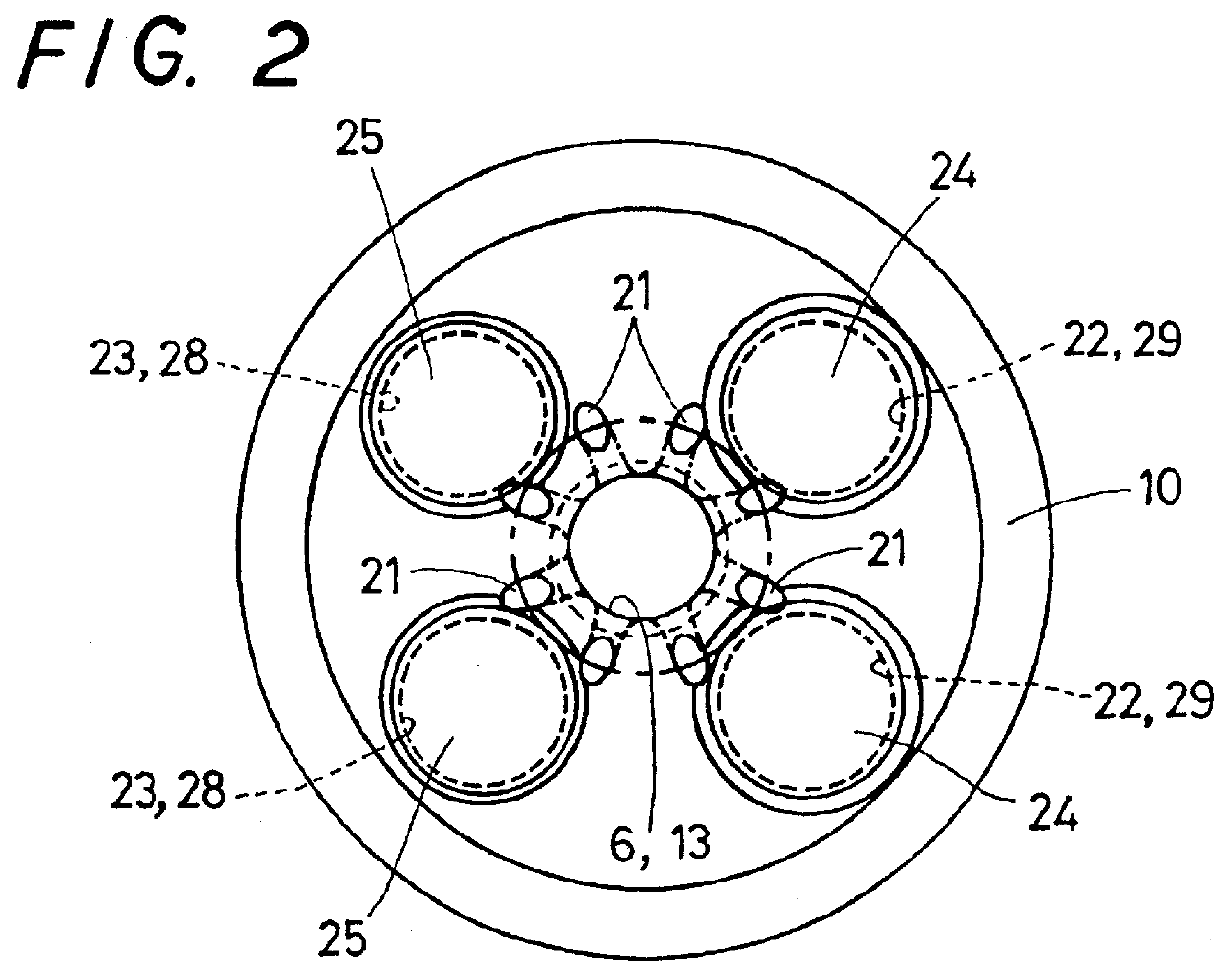

ActiveUS20070209634A1Burn fasterOutput and fuel efficiency can be improvedSparking plugsCombustion enginesHead gasketAir–fuel ratio

A multipoint ignition engine (1) includes a central electrode pair (9), disposed in the center of a combustion chamber (2), for forming a central spark gap (10), and a plurality of peripheral electrode pairs (12) held in a head gasket (15), which has an opening portion having a substantially identical diameter to an opening portion of a cylinder (5) in a position corresponding to the opening portion of the cylinder (5), for forming a plurality of peripheral spark gaps (13) around the inner periphery of the opening portion in the cylinder (5). An air-fuel mixture in the combustion chamber (2), which is obtained by mixing together fuel and air evenly to the stoichiometric air-fuel ratio or a richer / leaner air-fuel ratio than the stoichiometric air-fuel ratio, is ignited using both the central spark gap (10) and the plurality of peripheral spark gaps (13).

Owner:MIYAMA

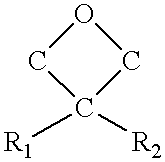

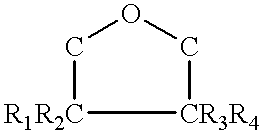

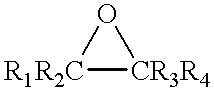

Chain-extended poly(bis-azidomethyloxetane), and combustible cartridge cases and ammunition comprising the same

InactiveUS6600002B2Efficient recyclingIntrinsically safeAmmunition projectilesShotgun ammunitionThermoplasticPolymer science

A combustible cartridge case is provided that includes at least one energetic thermoplastic homopolymer or copolymer derived from, at least in part, poly(bis-azidomethyloxetane) prepolymer blocks terminated with isocyanate-reactive groups, such as hydroxyl groups. Chain linking of the prepolymer blocks is performed with diisocyanates for end-capping the prepolymer blocks, and a difunctional linking compound for linking the end-capped prepolymer blocks. The energetic thermoplastic is preferably capable of being pressed, extruded, rotational molded, injection loaded, or otherwise shaped into a desired configuration. Also provided is a chain-extended poly(bis-azidomethyloxetane) homopolymer derived from bis-azidomethyloxetane prepolymer blocks, which are terminated with isocyanate-reactive groups and chain extended with at least one diisocyanate end-capping compound and at least one difunctional linking compound.

Owner:ORBITAL ATK INC

Spark ignition device and internal combustion engine with the same

InactiveUS7228840B2Reduce exhaustIncrease fuel consumptionSparking plugsInternal combustion piston enginesCombustion chamberIgnition coil

A plurality of spark electrodes are disposed in an arc shape on the surface or so as to be projected from the surface of an insulating member formed on a part of the wall face of a combustion chamber, and are formed so as to be in series electrically via discharging gaps.A spark plug is provided integrally with an injector, and the spark plug and the ignition coil are integrated. The three members are constructed as an integral unit, thereby improving installability to an engine.

Owner:HITACHI LTD

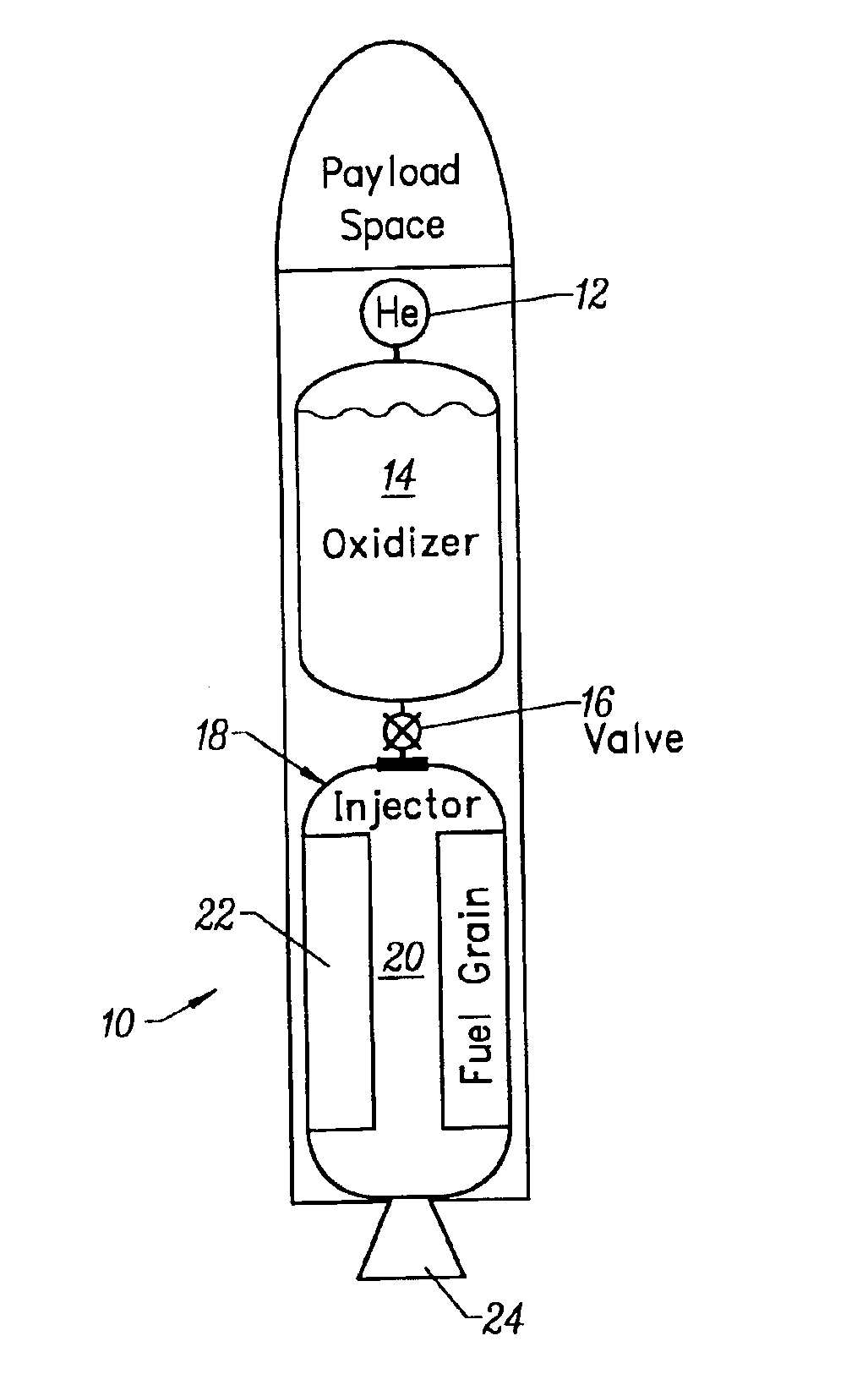

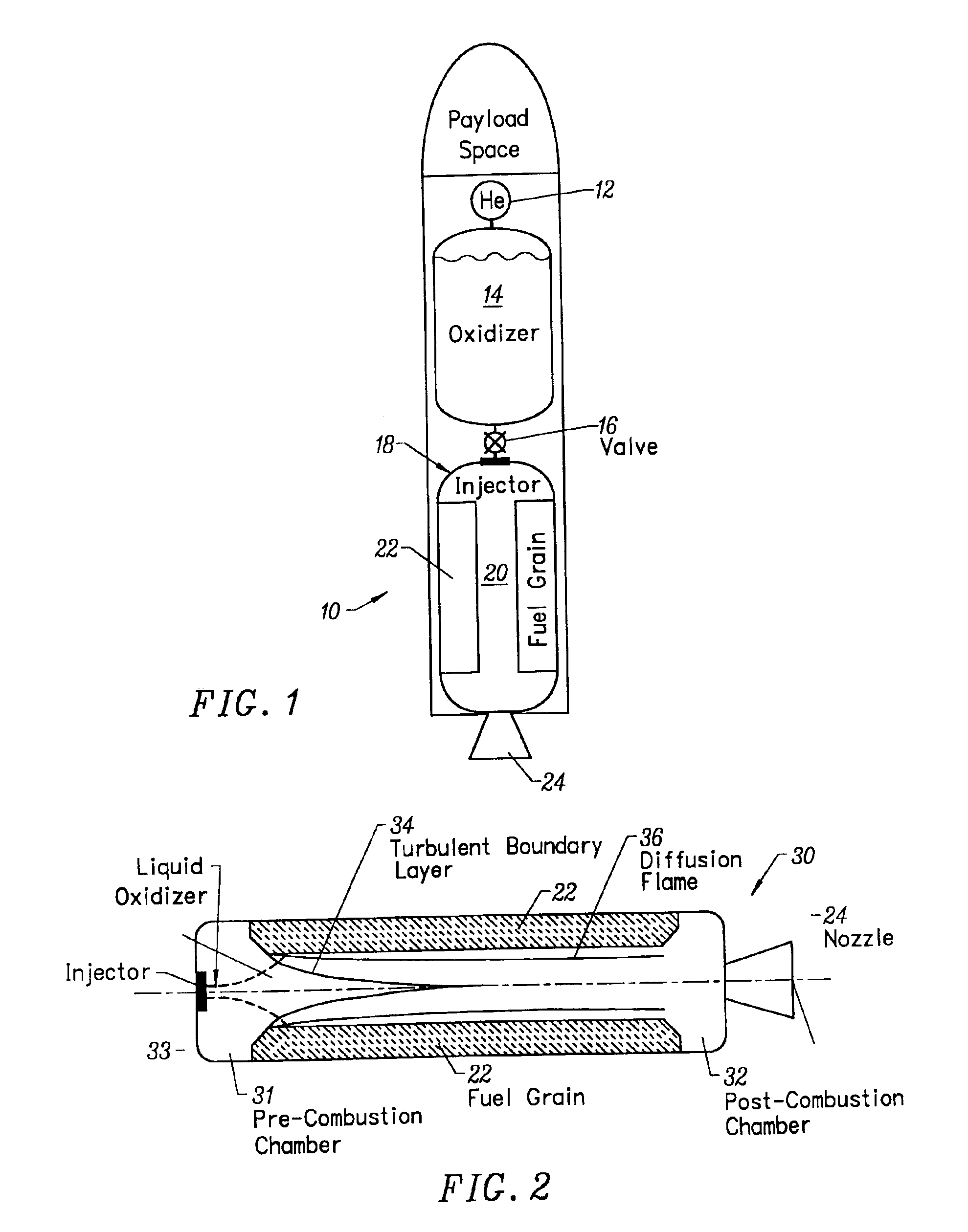

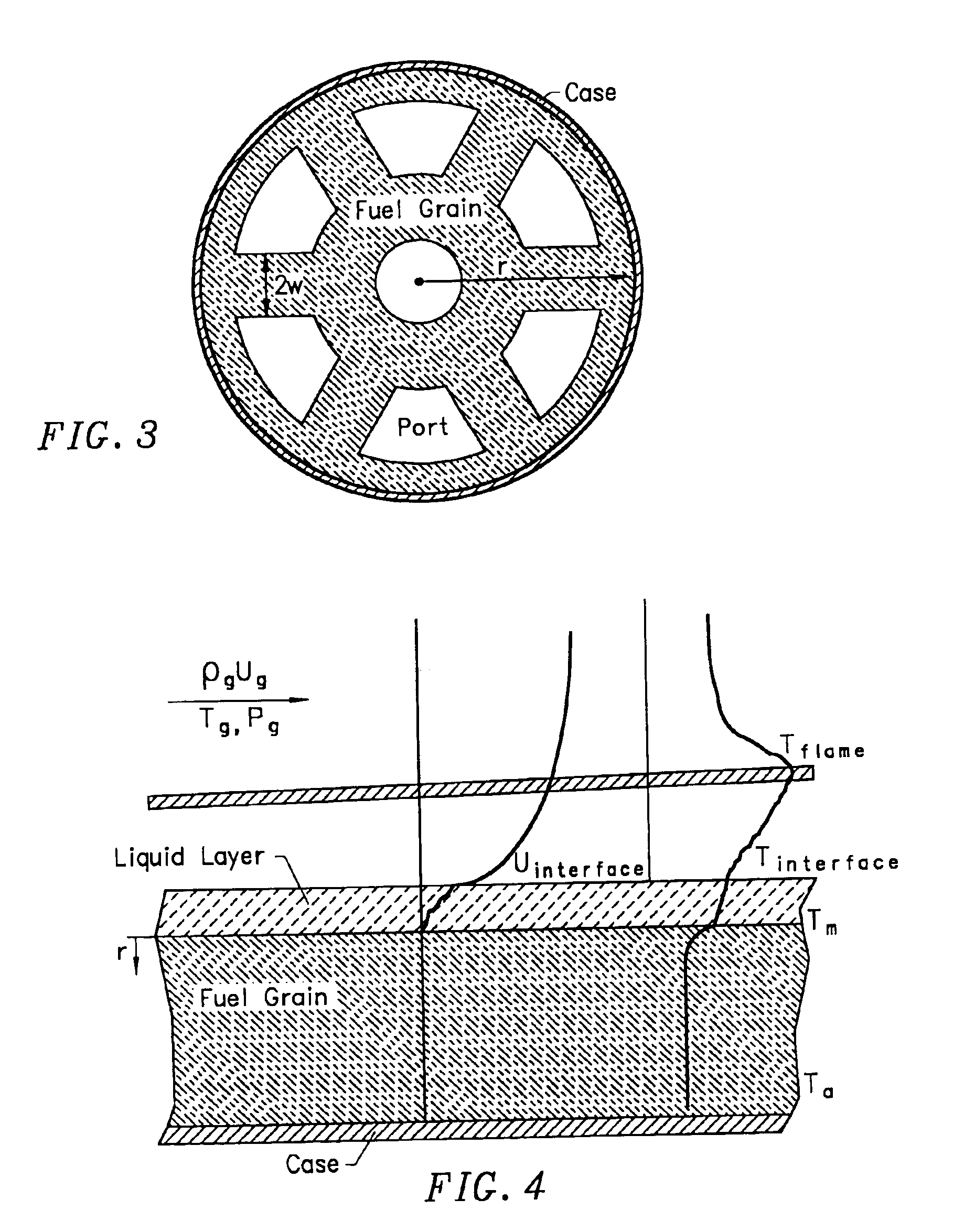

High regression rate hybrid rocket propellants and method of selecting

This invention comprises a new process for developing high regression rate propellants for application to hybrid rockets and solid fuel ramjets. The process involves the use of a criterion to identify propellants which form an unstable liquid layer on the melting surface of the propellant. Entrainment of droplets from the unstable liquid-gas interface can substantially increase propellant mass transfer leading to much higher surface regression rates over those that can be achieved with conventional hybrid propellants. The main reason is that entrainment is not limited by heat transfer to the propellant from the combustion zone. The process has been used to identify a new class of non-cryogenic hybrid fuels whose regression rate characteristics can be tailored for a given mission. The fuel can be used as the basis for a simpler hybrid rocket design with reduced cost, reduced complexity and increased performance.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

Energy-saving and high efficiency fuel coal combustion improver and preparation method thereof

The invention discloses an energy-saving and high efficiency fuel coal combustion improver and a preparation method thereof. The combustion improver comprises the following components by weight percentage: 40-60% of zinc oxide, 40-60% of manganese dioxide, preferably 50% of zinc oxide and 50% of manganese dioxide, wherein the manganese dioxide can be prepared by: weighing KMnO4 and MnC12.4H2O according to a weight ratio of 1:1, and fully grinding the materials in a container under room temperature for 20-50min to carry out solid phase reaction. The preparation method of the energy-saving and high efficiency fuel coal combustion improver includes the steps of: a. weighing the raw materials according to the following weight percentage: 40-60% of zinc oxide and 40-60% of manganese dioxide; b. grinding; c. dipping and drying; and d. roasting. The combustion improver provided by the invention reduces corrosion to boilers, improves the service life of boilers, significantly raises the flame temperature, improves the combustion activity and ignition performance of coal, improves the speed of ignition speed and combustion speed of coal, and has significant energy saving and environmental protection effects.

Owner:HARBIN HONGTIAN RUIDA TECH

Macroporous composite metal oxide catalyst for purifying soot of diesel and preparation method thereof

InactiveCN101683616AReduce the temperatureFacilitated DiffusionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMischmetalPtru catalyst

The invention relates to a macroporous composite metal oxide catalyst for purifying the soot of diesel and a preparation method thereof. The invention firstly provides an oxidation catalyst for the combustion of soot particulates discharged by diesel engine road vehicles, and the catalyst is perovskite type, perovskite-like type or spinel type composite metal oxide which takes more than two elements of rare earth metal, transition metal and basic metal as active components and has a macroporous structure, wherein the average aperture of the composite metal oxide is more than 50nm. The catalyst can reduce the temperature that the soot particulates are combusted into CO2 within an exhaust temperature range of tail gas of the diesel engine road vehicles; and the catalyst has the honeycomb macroporous structure, is favorable for the diffusion of the soot particulates in pore canals, improves the utilization rate of active surface area of the catalyst, and greatly reduces the combustion temperature of the soot particulates. The invention also provides a method for preparing the catalyst, which combines organic complexation with in-situ combustion to prepare the catalyst.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

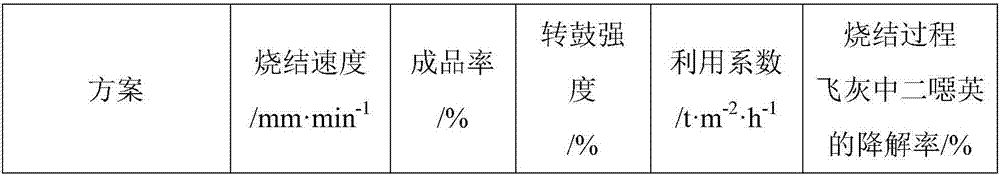

Dioxin control method for iron ore sintering garbage fly ash coprocessing process

ActiveCN107159678ARealize normal sinteringEffectively fixedTransportation and packagingSolid waste disposalSludgeLitter

The invention discloses a dioxin control method for the iron ore sintering garbage fly ash coprocessing process. According to the method, garbage fly ash, lime milk, flammable solid fuel and sludge are subject to mixed granulation and drying, and small balls containing garbage fly ash are obtained; iron core sintering raw materials are granulated and then are mixed with the small balls of the garbage fly ash, and after distribution, ignition and sintering are carried out. According to the method, on the premise that the iron ore sintering is not affected, efficient decomposing of dioxin contained in the fly ash can be achieved, dioxin secondarily formed in the garbage fly ash sintering process is prevented, according to the method, the decomposing rate of the garbage fly ash dioxin reaches 90% or above, meanwhile, effective solidifying of the garbage fly ash can be ensured, and in the sintering process, the aim of cleaning the garbage fly ash is achieved.

Owner:CENT SOUTH UNIV +1

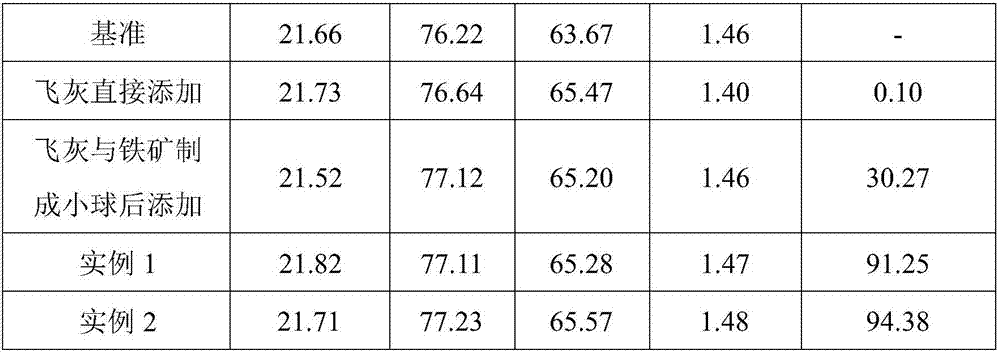

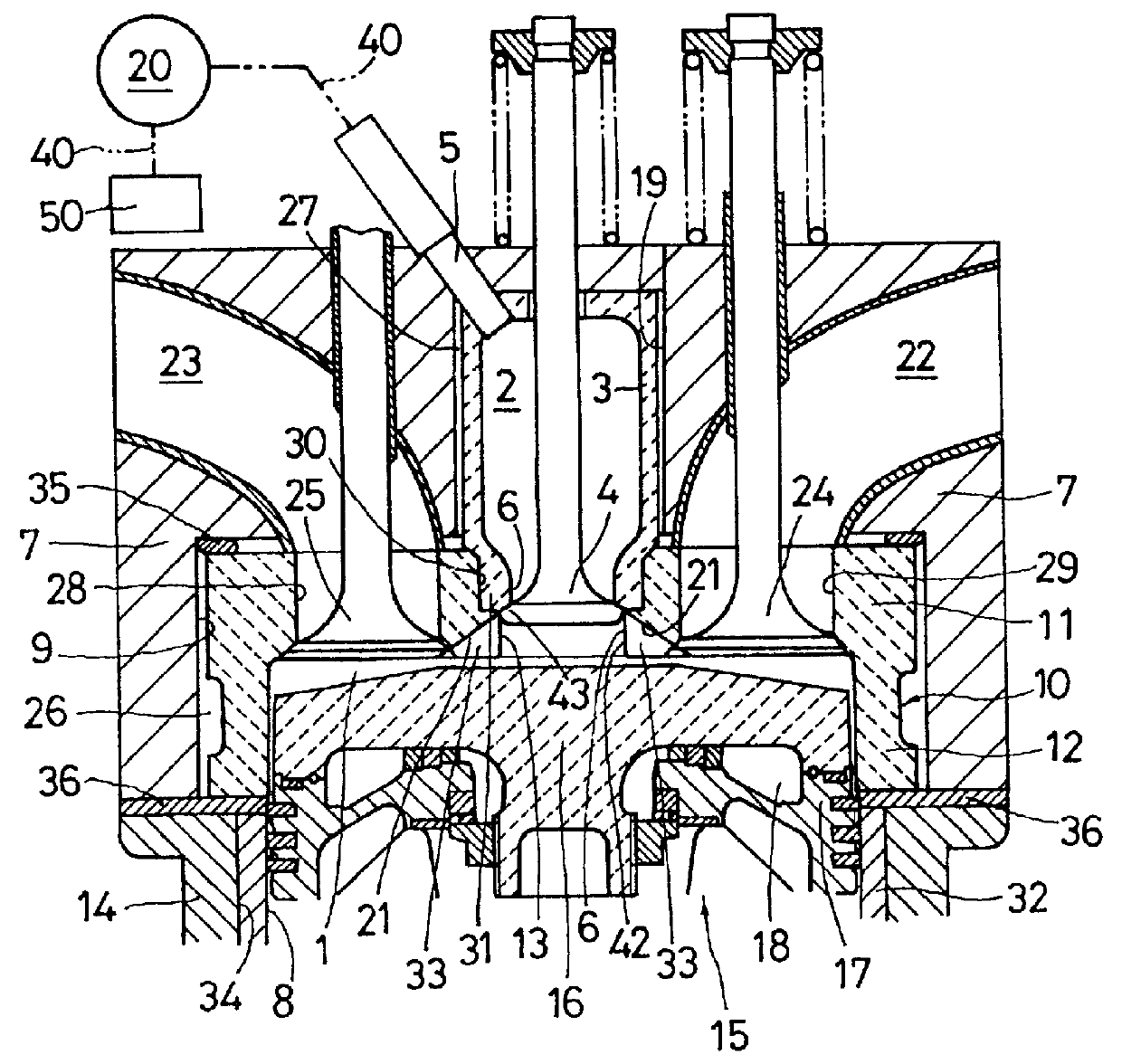

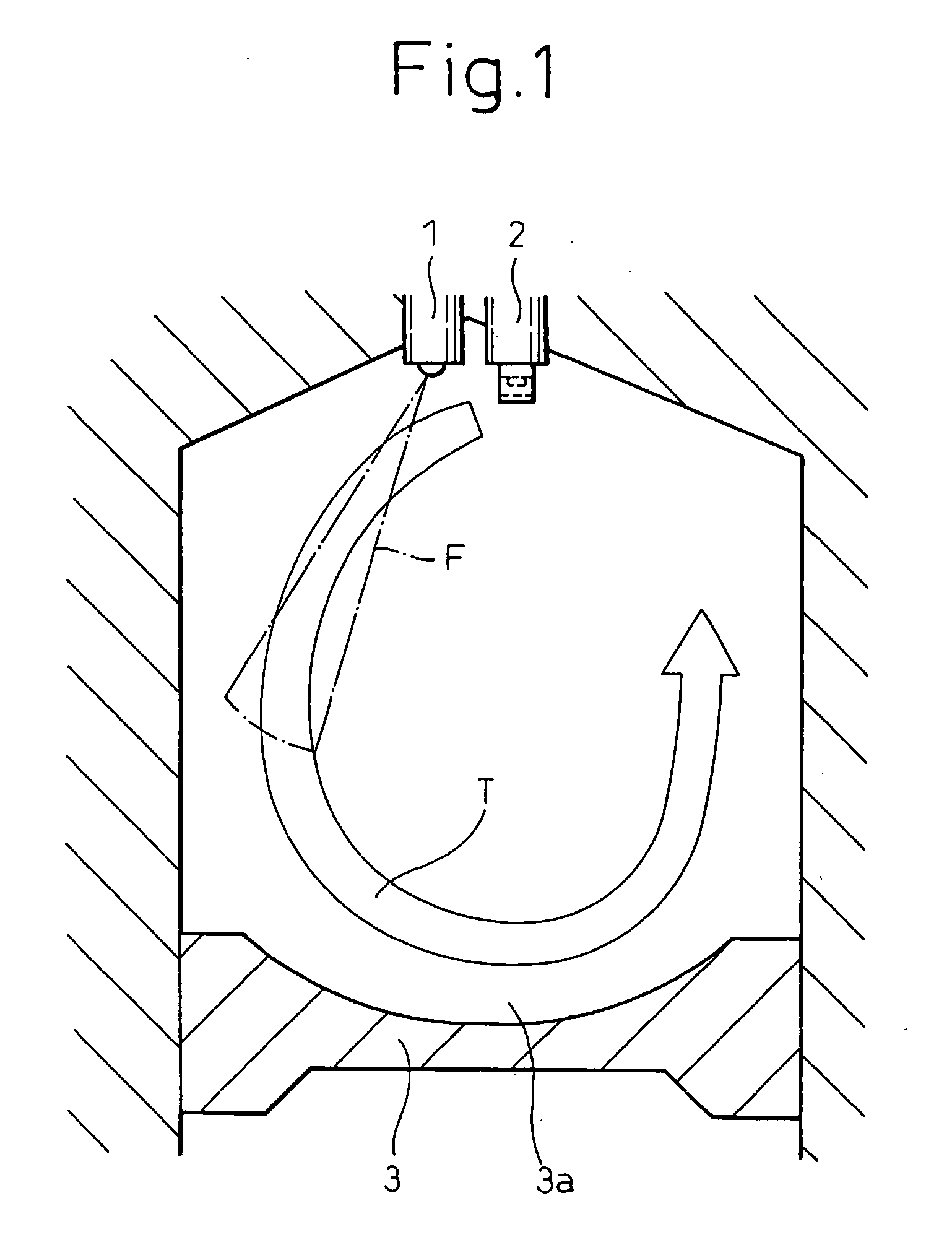

Gas engine with pre-combustion chamber

InactiveUS6073605AImprove performanceIncrease speedInternal combustion piston enginesFuel supply apparatusCombustion chamberCylinder head

This gas engine with pre-combustion chambers. effectively uses ejection energy of flames and air-fuel mixtures ejected from the pre-combustion chambers into the main combustion chambers to shorten the combustion duration and thereby enhance performance. Installed in the cylinder head at the central part of the cylinders are pre-combustion chamber structures. that form pre-combustion chambers; Combustion chamber structures are formed with communication port that communicate the pre-combustion chambers with the main combustion chambers. Control valves are provided to open and close the communication ports. The communication ports comprise main communication ports and sub-communication ports formed around the main communication ports. The sub-communication ports are formed in the combustion chamber structures so that they extend radially toward the cylinder periphery.

Owner:ISUZU MOTORS LTD

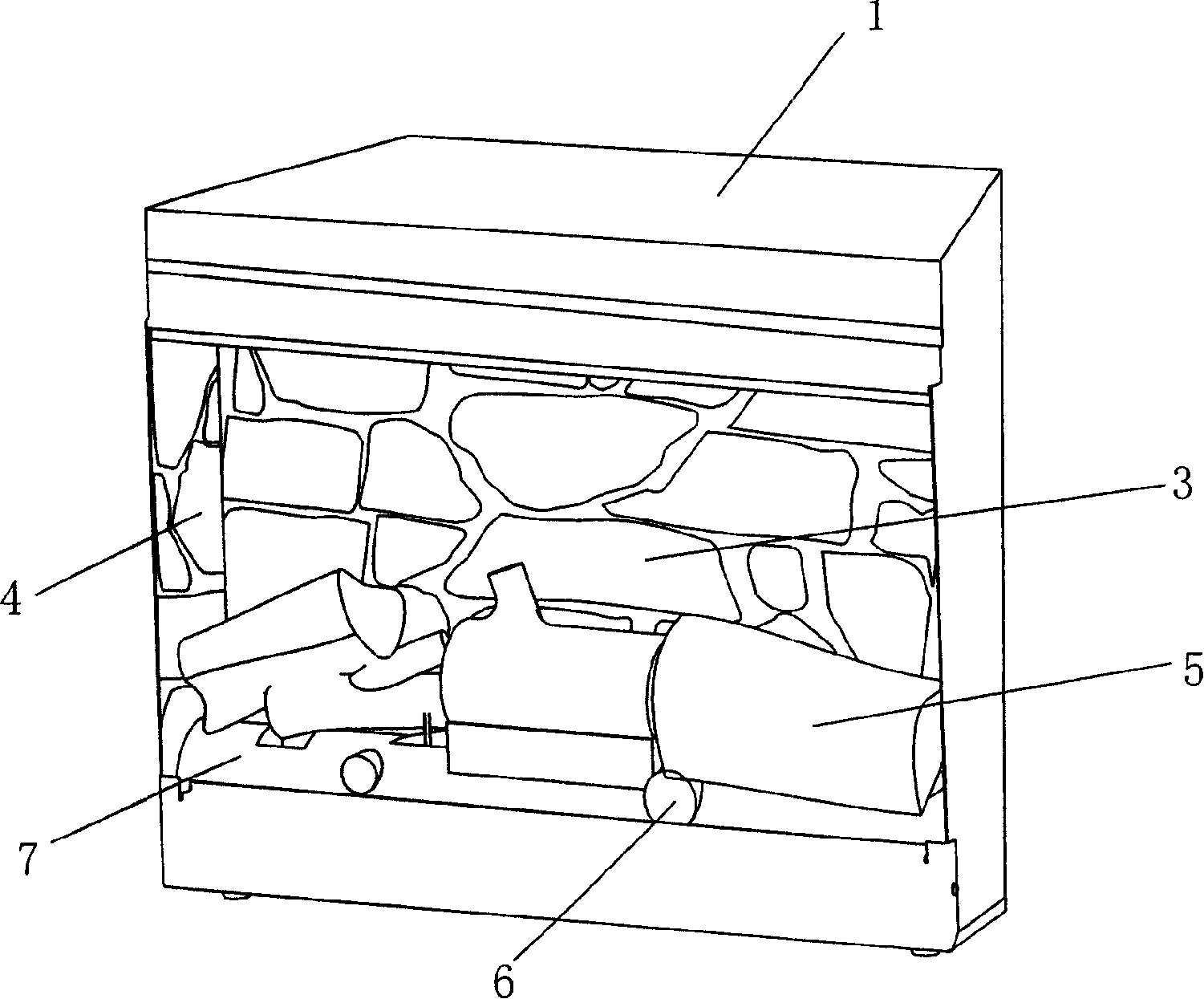

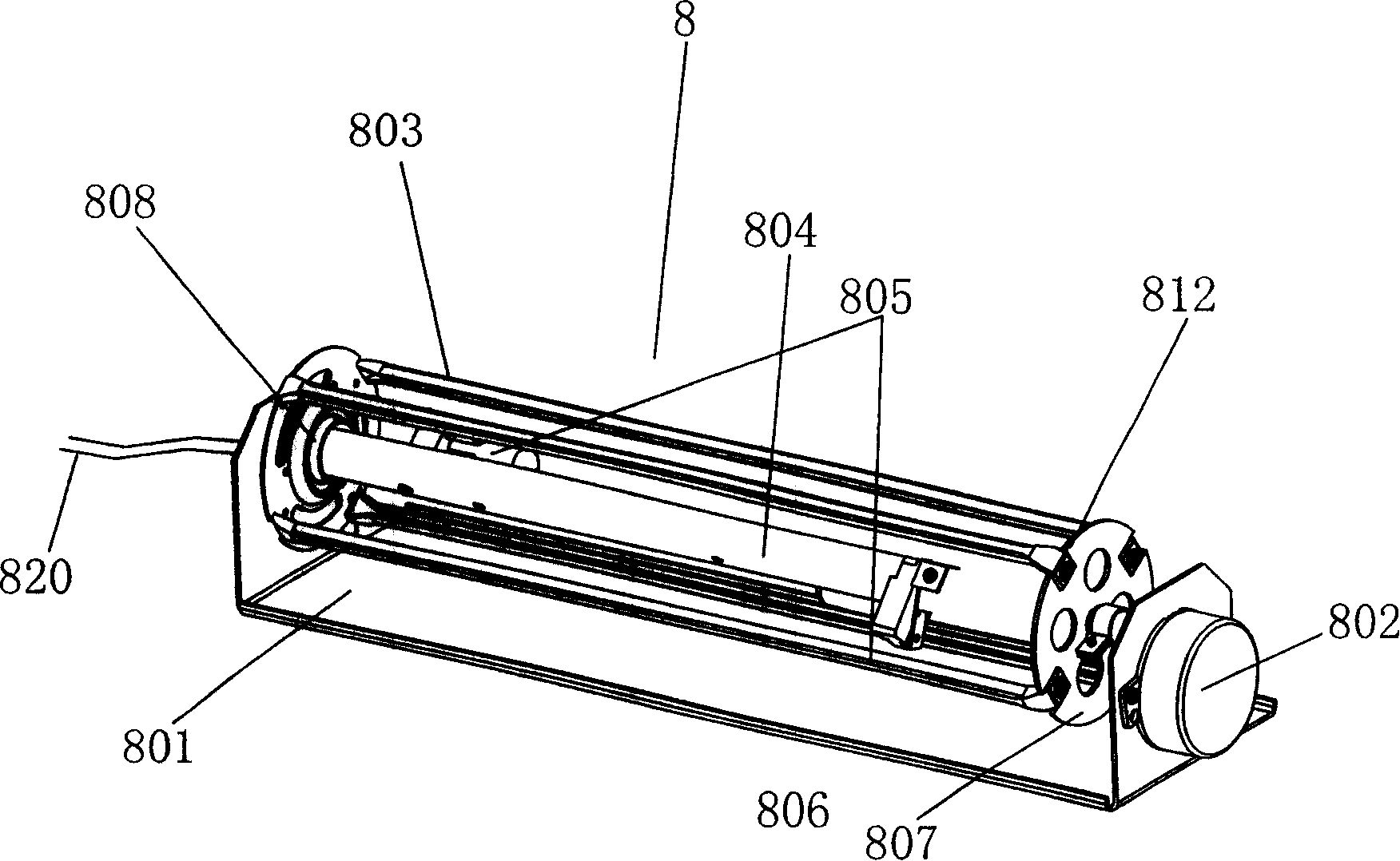

Flame simulating system

The invention discloses a flame imitation system, relating to electric stove technique used in electric fireplace, comprising a crate with a fireplace, a simulation furnace of the fireplace, a simulation fuel bed, a dynamic light source device, a flame shape filter plate and an imaging screen producing the dynamic flame effect. The flame imitation system is characterized in that the simulation furnace is composed of the posterior wall of the furnace formed by the imaging screen, the simulation fuel bed and the simulation fuel; the dynamic light source with a basic flame shape is projected onto the imaging screen by the flame shape filter plate, producing a dynamic flame and a dynamic flame image formed when the fuel with a corresponding shape to the imitation combustion of the simulation fuel combusts; the dynamic light source device adopts a flexible shaft to eliminate noise. The imaging screen, the watching screen and the posterior wall of the furnace are integrated on a base plate; the imitation flame is bright and vivid; a color ember block and an optical fiber make the combustion effect more vivid.

Owner:宁波高博科技有限公司

Coal-saving devulcanized coke cleaning clean synergistic agent and preparation technique thereof

InactiveCN101348743ALower ignition pointImprove oxidation effectSolid fuelsStrontium carbonateFerrosilicon

The invention relates to a process for preparing a clean synergist for saving coal, desulfurization and cleaning coke. Active calcium oxide and magnesium hydrate are mixed and added with sodium carbonate, ferrosilicon powders, manganese dioxide, strontium carbonate and barium hydroxide in turn and finally added with active carbon and evenly mixed to prepare the clean synergist which comprises the following compositions in percentage by weight: 20 to 30 percent of the active calcium oxide, 9 to 12 percent of the magnesium hydrate, 12 to 20 percent of the sodium carbonate, 8 to 10 percent of active carbon, 12 to 15 percent of the ferrosilicon powders, 8 to 12 percent of the manganese dioxide, 3 to 5 percent of the strontium carbonate and 5 to 7 percent of the barium hydroxide. on the premise of unchanging the prior coal burning process and equipment of various boilers and the prior smoke exhaust process and equipment, the clean synergist of the process is only needed to add according to the physicochemical index of coal used by customers, thereby achieving the functions of saving the coal, the desulfurization and cleaning the coke.

Owner:陈宏谋 +1

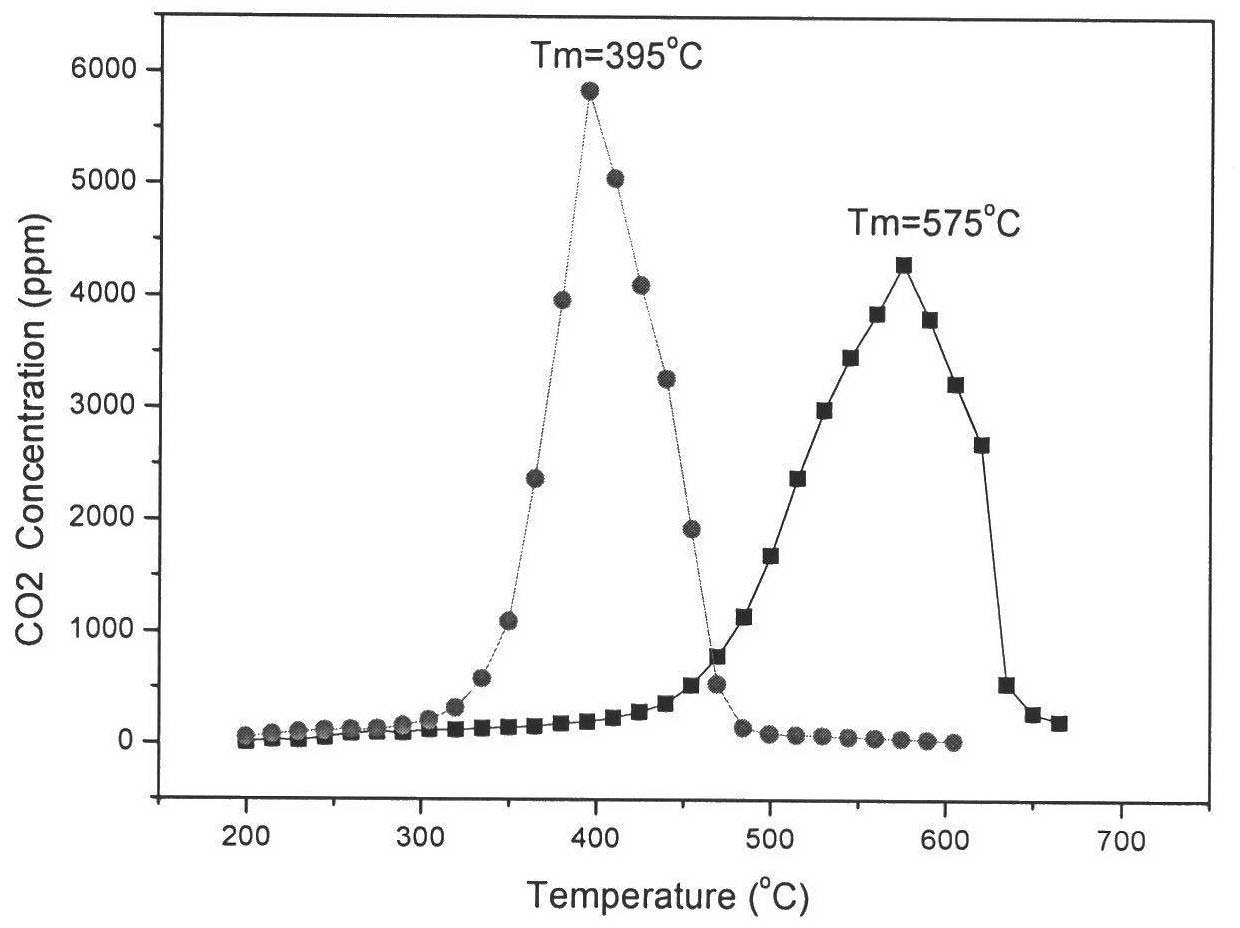

Catalyst for combustion of soot particles in diesel vehicle exhaust, and preparation method thereof

InactiveCN102658122AMeet the low temperature requirements of the exhaust gasPromote regenerationMetal/metal-oxides/metal-hydroxide catalystsRare earthSoot particles

The invention provides a rare earth oxide and transition metal oxide-supported alkali metal catalyst for reducing the combustion temperature of soot particles in diesel vehicle exhaust, and a preparation method thereof. The preparation method is characterized in that non-noble metal salts are taken as raw materials, the sol-gel method is employed as the preparation technology, and the preparation process is easy to control. Soluble salts of rare earth Ce, transition metal Mn and alkali metal K are taken as precursors and the mass percents of Ce, Mn and K are adjusted to obtain the K / CeO2-MnO2 catalyst. In a bulk contact condition, the combustion temperature of the soot can be reduced from 575 DEG C in absent of a catalyst to 395 DEG C in present of the catalyst, thereby meeting the temperature range of the diesel vehicle exhaust. The catalyst is a catalyst which is capable of removing the soot in the diesel vehicle exhaust effectively.

Owner:EAST CHINA UNIV OF SCI & TECH

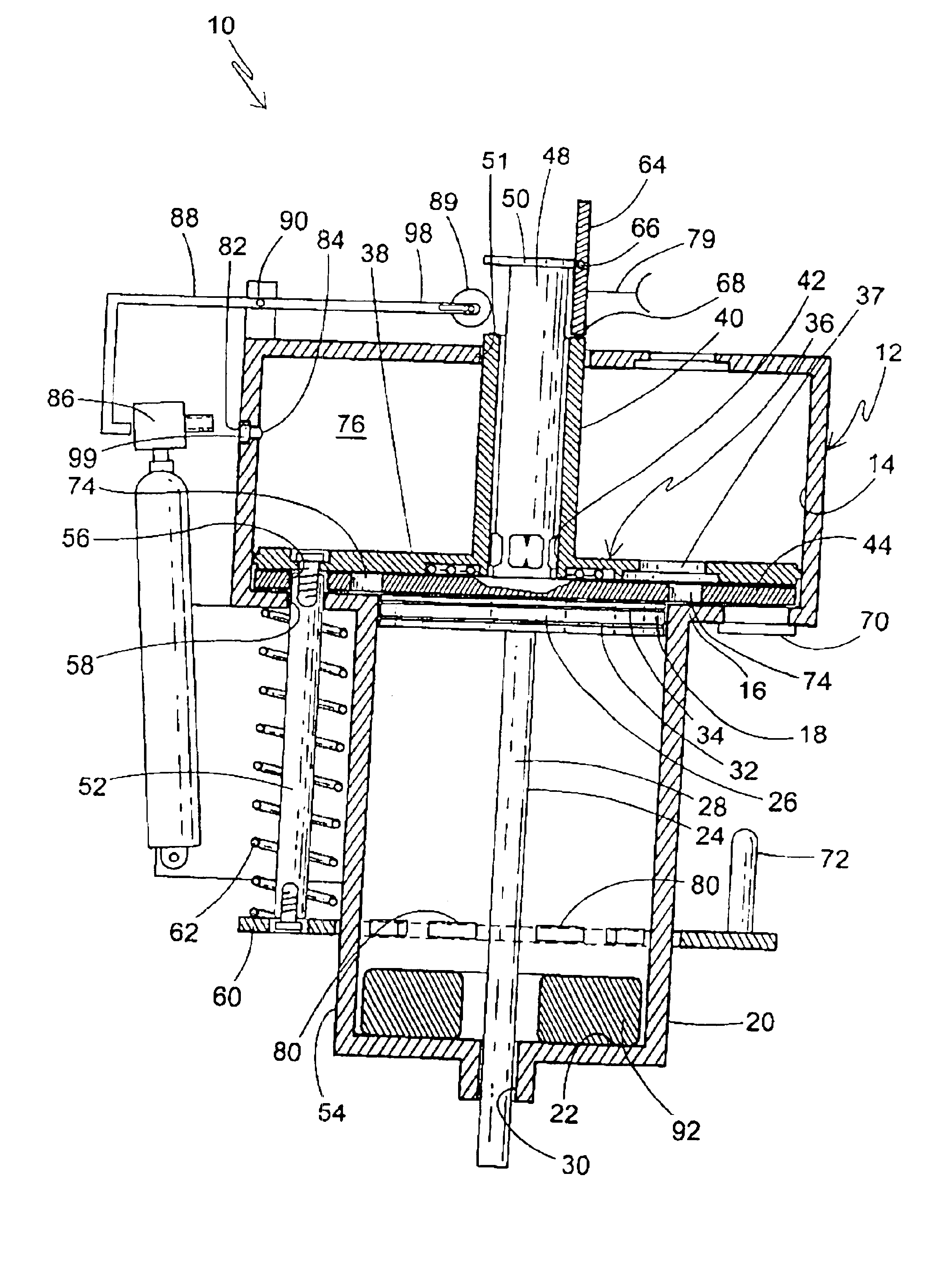

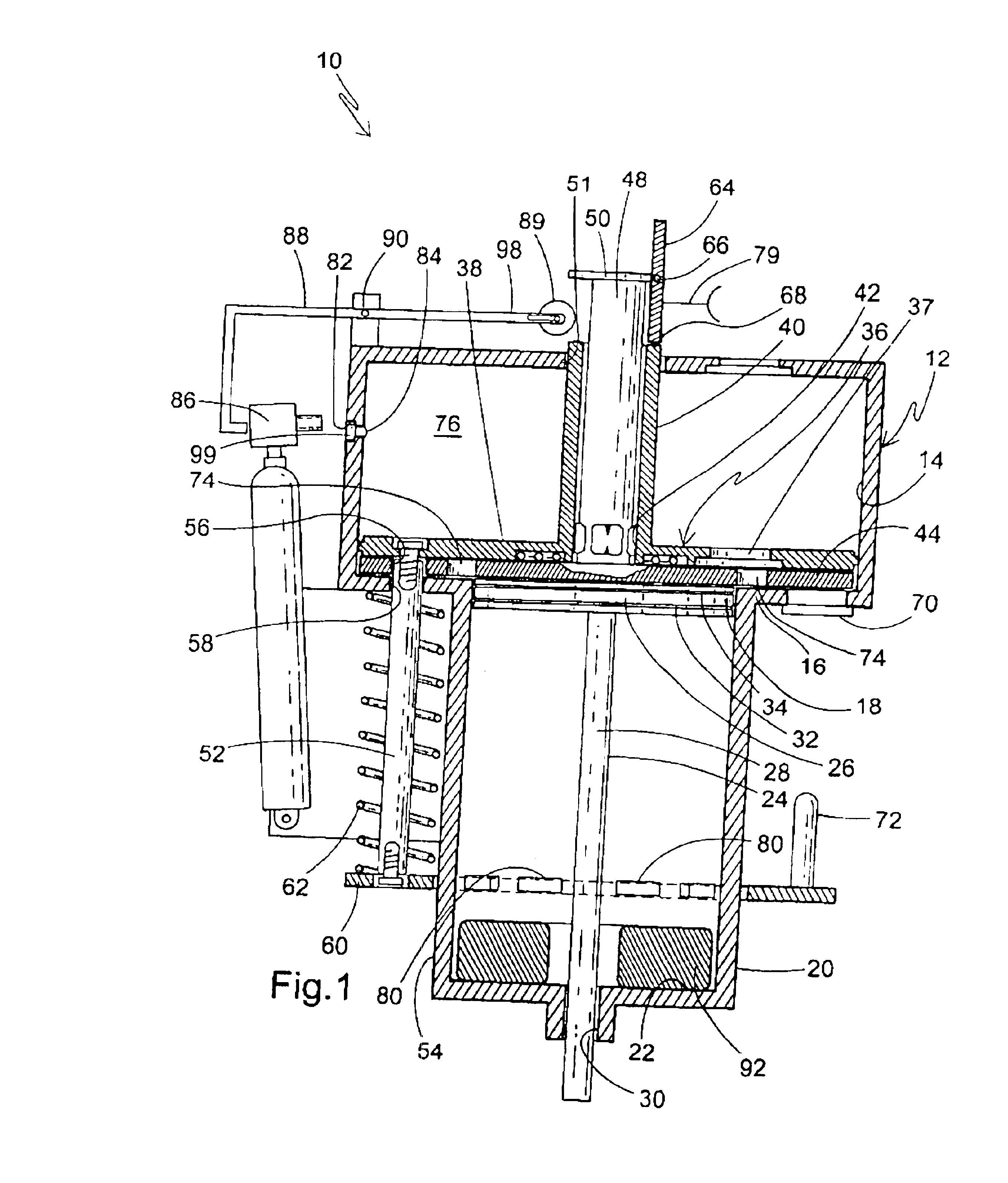

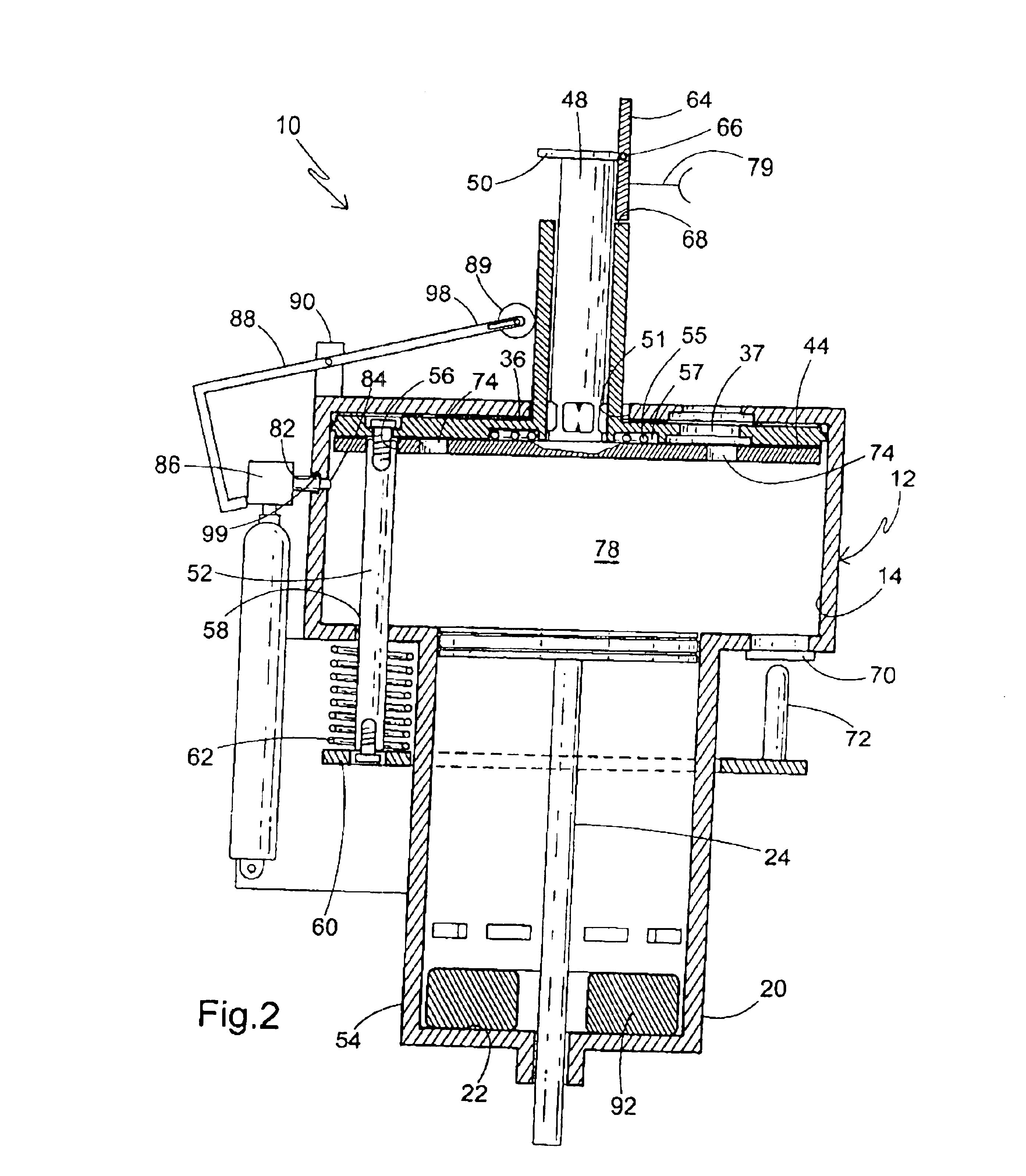

Latching mechanism for combustion chamber plate of a fastener driving tool

InactiveUS6892524B1Less-expensive to manufactureLess-expensive to repairCombustion enginesGas turbine plantsCombustion chamberReciprocating motion

Owner:ILLINOIS TOOL WORKS INC

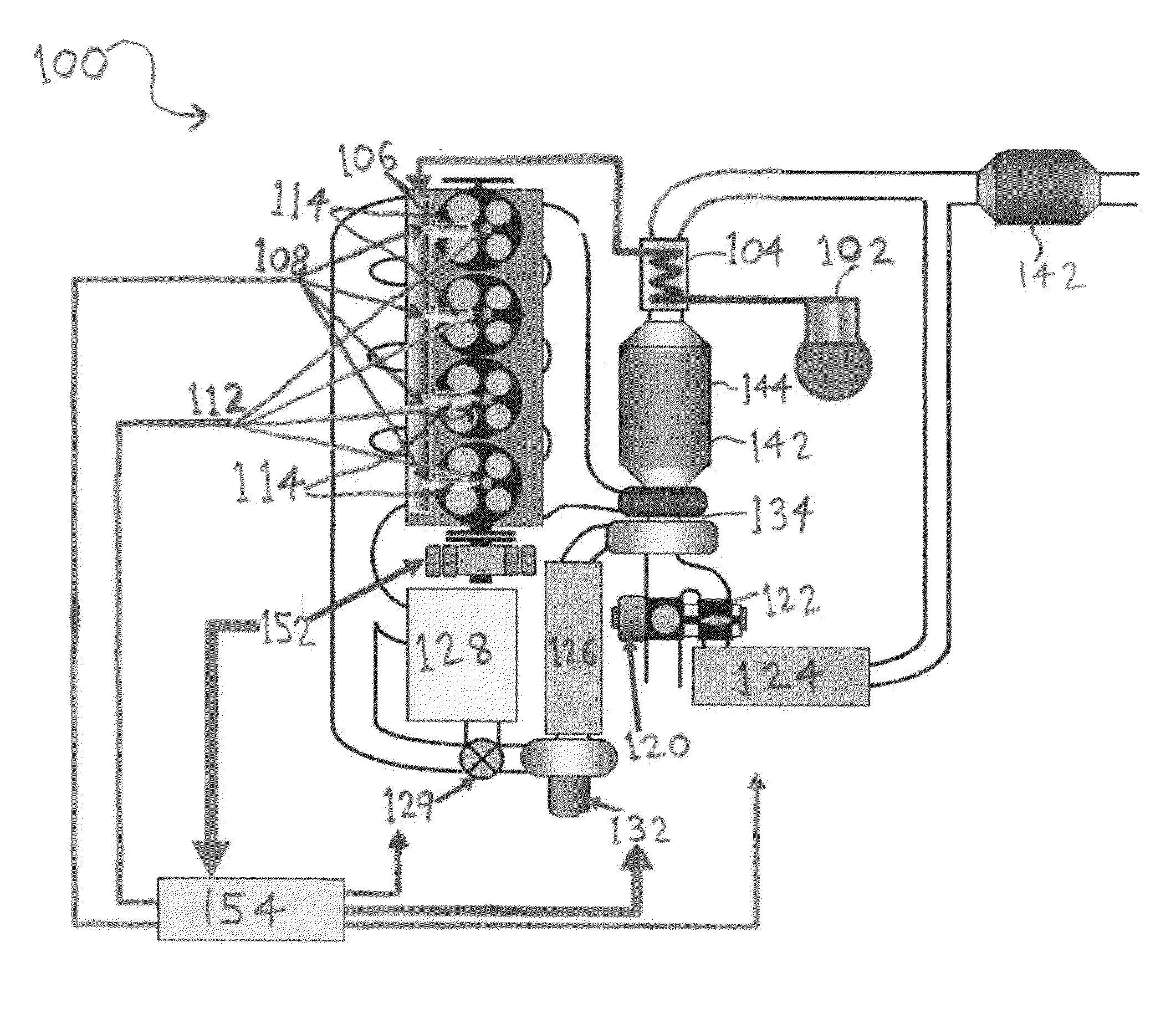

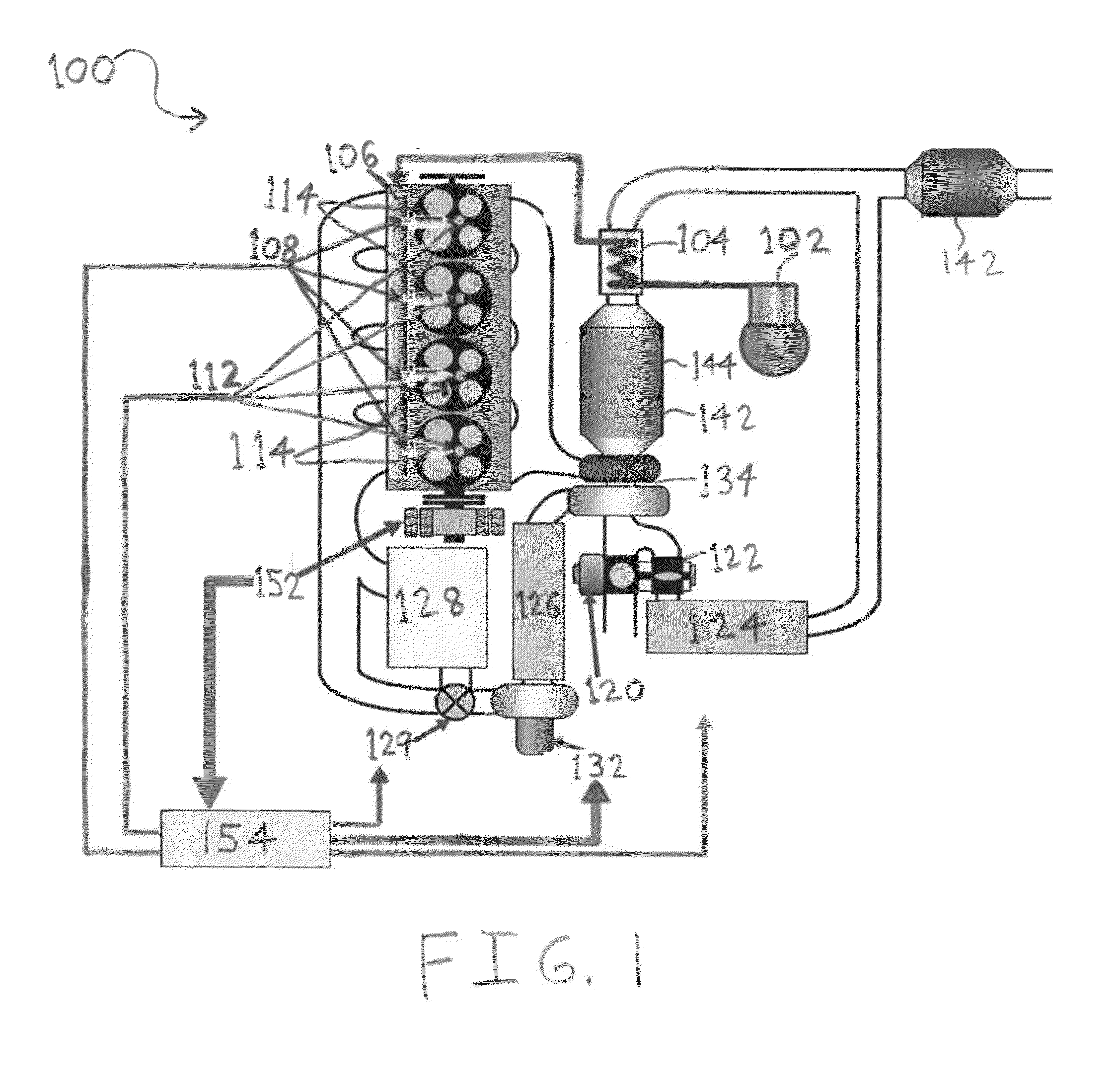

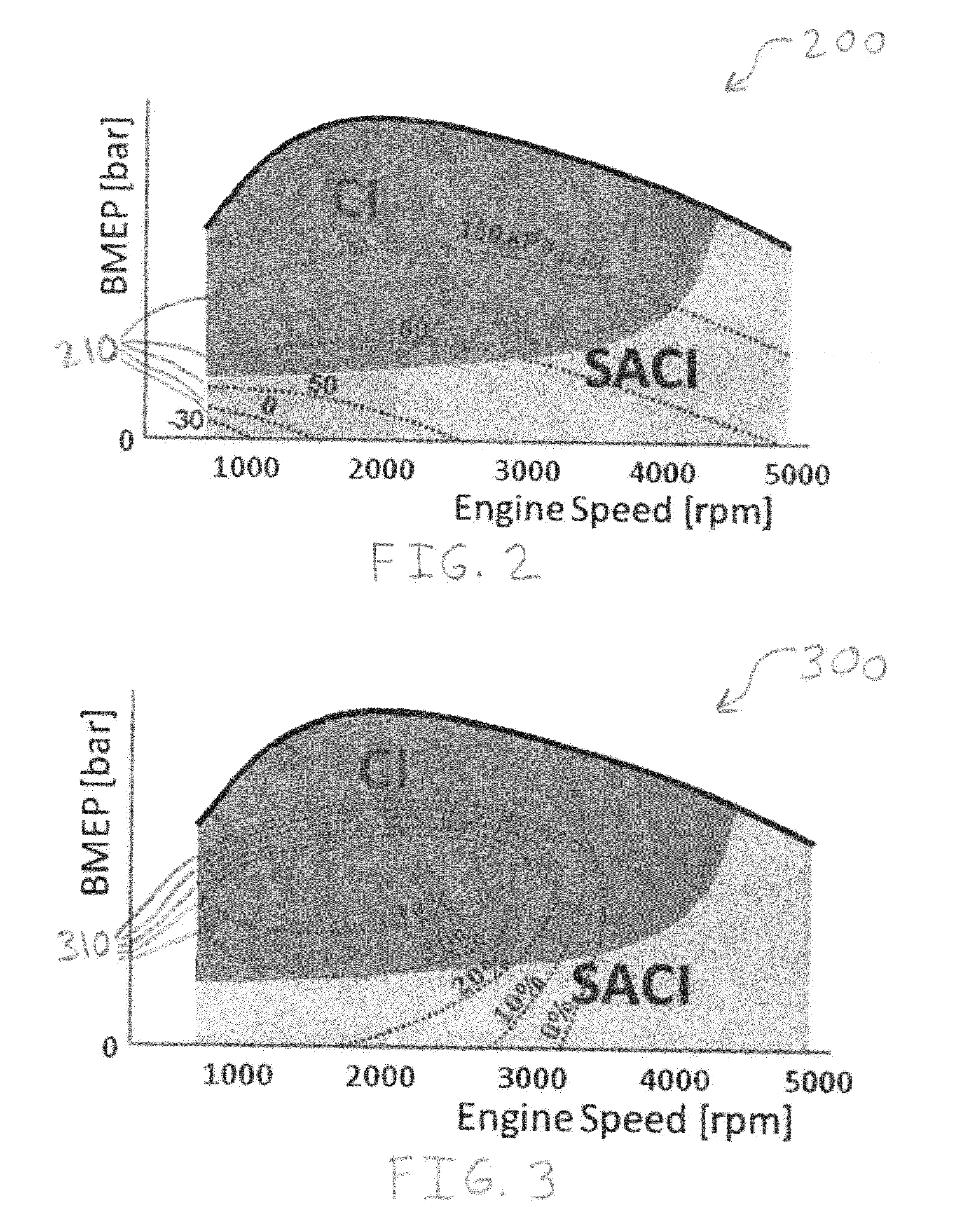

Internal combustion engine with high temperature fuel injection

InactiveUS20150053171A1High exhaust gas recirculation (EGR) toleranceIncrease rangeElectrical controlInternal combustion piston enginesCombustion systemExhaust gas recirculation

Set forth herein are apparatuses and systems that utilize high temperature fuel injection to eliminate knocking within a combustion systems, and more particularly internal combustion engines. In some embodiments, the combustion system of the present invention can eliminate knocking through the use of high compression ratios and high intake boost pressures. The combustion system can have a high exhaust gas recirculation (EGR) tolerance, as well as an increased range of fuel-air ratio with improved ignitability and increased combustion speed of the system. In some embodiments, combustion in the present invention takes place using a compression ignition process, a spark assisted compression ignition process or a combination thereof.

Owner:ECOMOTORS

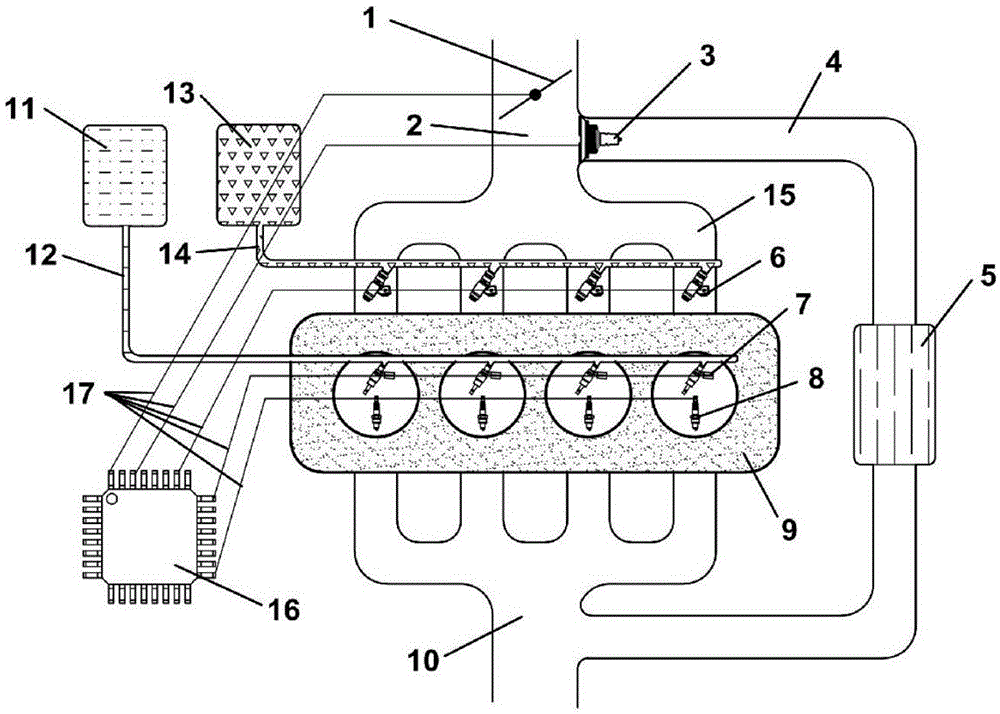

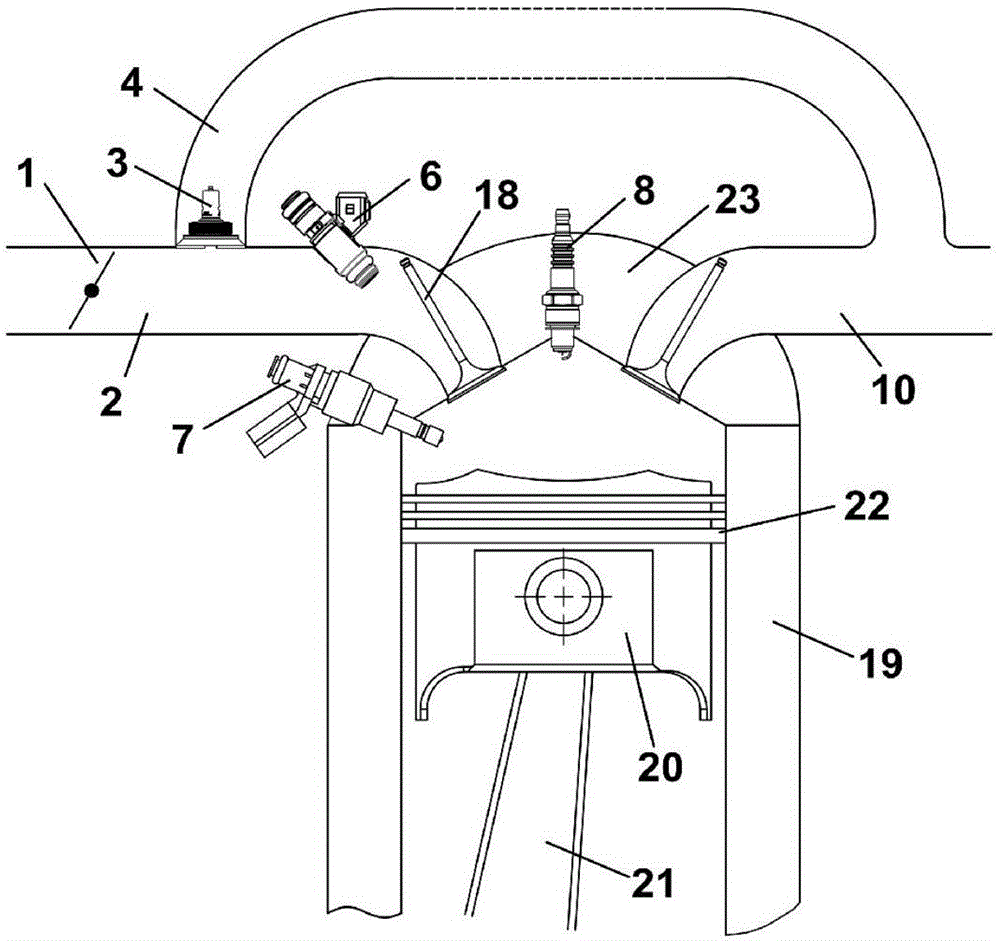

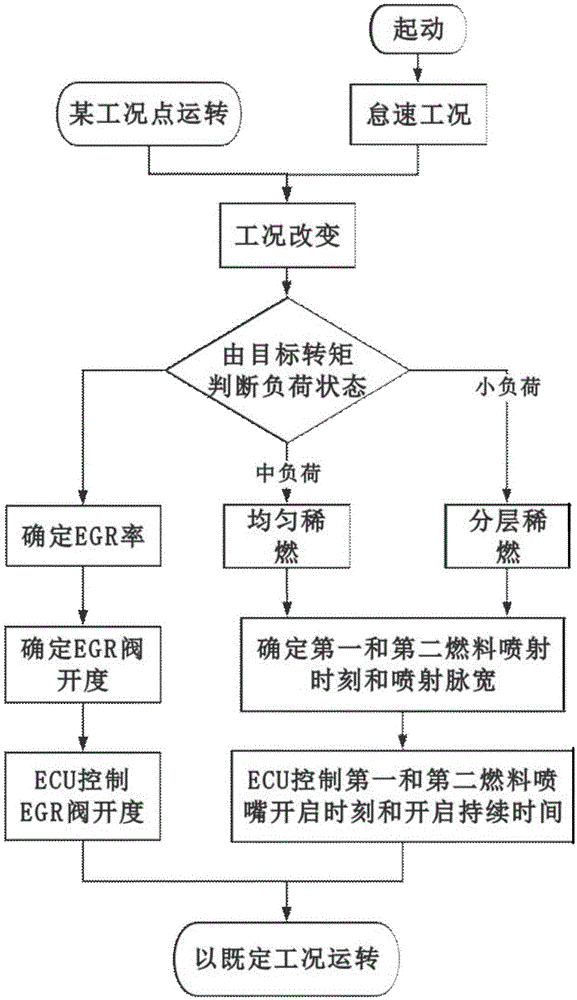

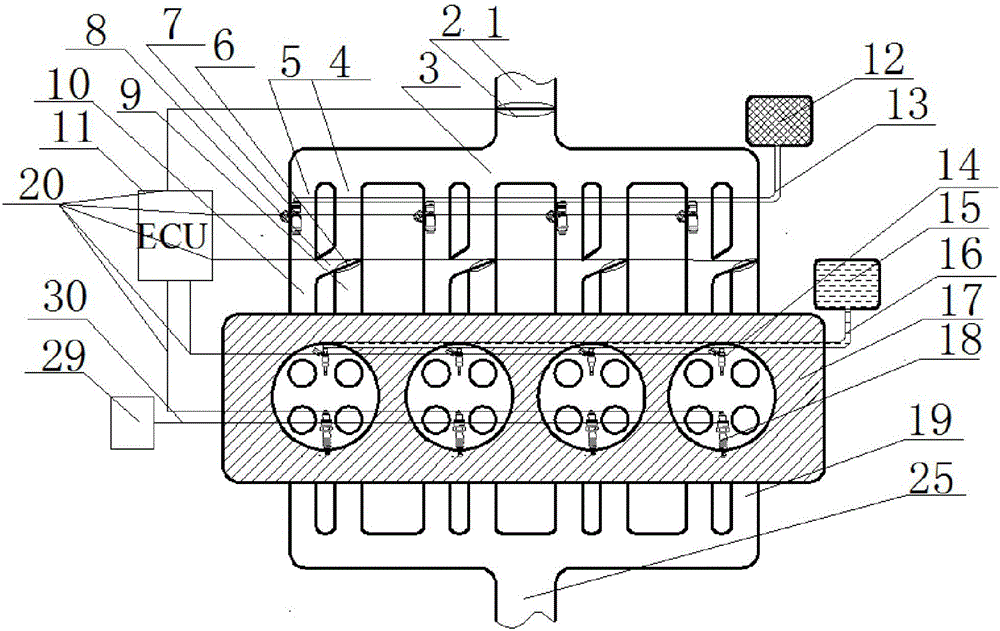

Lean-burn gas duel-fuel spark-ignition-type internal combustion engine based on EGR system and control method

InactiveCN105114174AReduce lossesCurb emissionsElectrical controlNon-fuel substance addition to fuelExternal combustion engineExhaust gas recirculation

The invention relates to a lean-burn gas duel-fuel spark-ignition-type internal combustion engine based on EGR (Exhaust Gas Recirculation) system and a control method, and can solve the problems of unstable combustion, high NOx emission and the like of a gas fuel spark-ignition-type internal combustion engine caused during lean burn. Based on the in-fuel-gas-cylinder direct injection and inlet duct spray combined duel-fuel spark-ignition-type internal combustion engine technology and the EGR technology, the internal combustion engine and the control method ensure that the duel-fuel spark-ignition-type internal combustion engine can realize stable and efficient lean burn and reduce the phenomena of cyclical variation and fire accident at a high compression ratio; meanwhile, part of exhaust gas is re-guided into the cylinder to participate in combustion, the EGR ratio is changed according to the requirements of working conditions, the in-cylinder combustion temperature is lowered, and the generation of NOx is inhibited; and besides, as lean burn and EGR co-exist, the opening degree of a throttle valve can be increased and the pumping loss is reduced. In conclusion, reduction of energy consumption and super-low emission of pollutants can be fundamentally realized.

Owner:JILIN UNIV

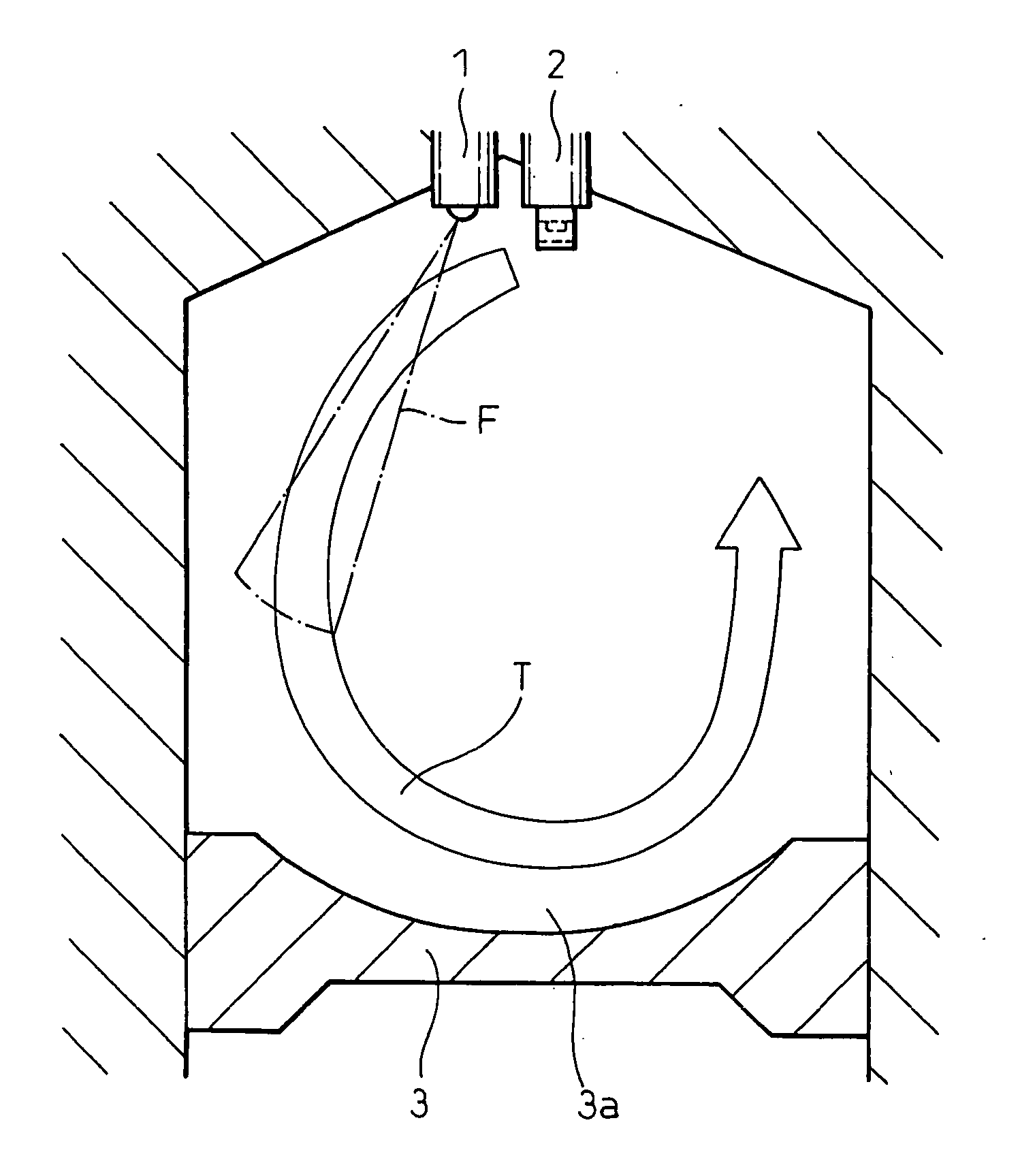

Direct Fuel Injection-Type Spark Ignition Internal Combustion Engine

InactiveUS20080135016A1Increase intensityTumbling flow can be favorablyElectrical controlInternal combustion piston enginesExhaust valveInlet valve

When a homogeneous combustion is to be executed at a lean air-fuel ratio, a tumbling flow that whirls in the cylinder descending in the cylinder bore on the exhaust valve side and ascending in the cylinder bore on the intake valve side, is intensified by the fuel that is injected from the fuel injection valve toward the exhaust valve side in the cylinder bore in the last stage of the intake stroke.

Owner:TOYOTA JIDOSHA KK

Method for extracting germanium from brown coal

The invention provides a process of germanium extraction from brown coal, which is germanium extraction by employing a cyclone furnace. The process includes that the brown coal is added in the cyclone furnace to mix with hot wind which is sent into the cyclone furnace, the brown coal is burned, the CO content inside the cyclone furnace is controlled within the range of 0.5-1%, germanium in the brown coal is reduced and volatilized into flue gas, and flue dust is collected as raw material of the germanium. The process can achieve the purposes that the flour shaped brown coal is fully used to enlarge the productivity of the germanium, the recovery ratio of the germanium is increased, and the excess energy is effectively recovered.

Owner:锡林郭勒通力锗业有限责任公司

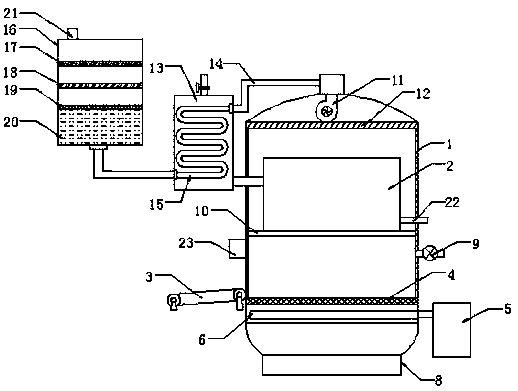

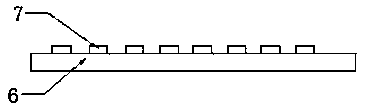

Environment friendly type industrial smoke overall treatment boiler and using method thereof

InactiveCN108645021ABurn evenlyBurn fullySolid fuel combustionCombustion technology mitigationCoalEngineering

The invention discloses an environment friendly type industrial smoke overall treatment boiler which comprises a boiler body, a heat exchange box and a purification box. A base is arranged at the bottom end of the boiler body, a burning cavity is arranged inside the boiler body, a burning separating plate is arranged at the lower end of the burning cavity, a fuel gas pipe is arranged below the burning separating plate, one end of the fuel gas pipe is connected with a fuel gas device, a feeding opening is formed in one side of the burning cavity, a conveying belt is arranged on the outer side of the feeding opening, a combustion-supporting pump is arranged on one side of the burning cavity, a supporting plate is arranged above the burning cavity and supports a water tank, and water in the water tank is heated to be discharged through a water discharging pipe; and the heat exchange box is arranged, heat of smoke in a smoke pipe is transferred to water in the heat exchange box, the waterin the heat exchange box is preheated, the water heating speed is increased, the heat energy is sufficiently used, the using amount of fire coal can be reduced, and energy conservation and emission reduction are achieved. The environment friendly type industrial smoke overall treatment boiler is reasonable in design, practical, feasible, more user-friendly and suitable for application and popularization.

Owner:王连会

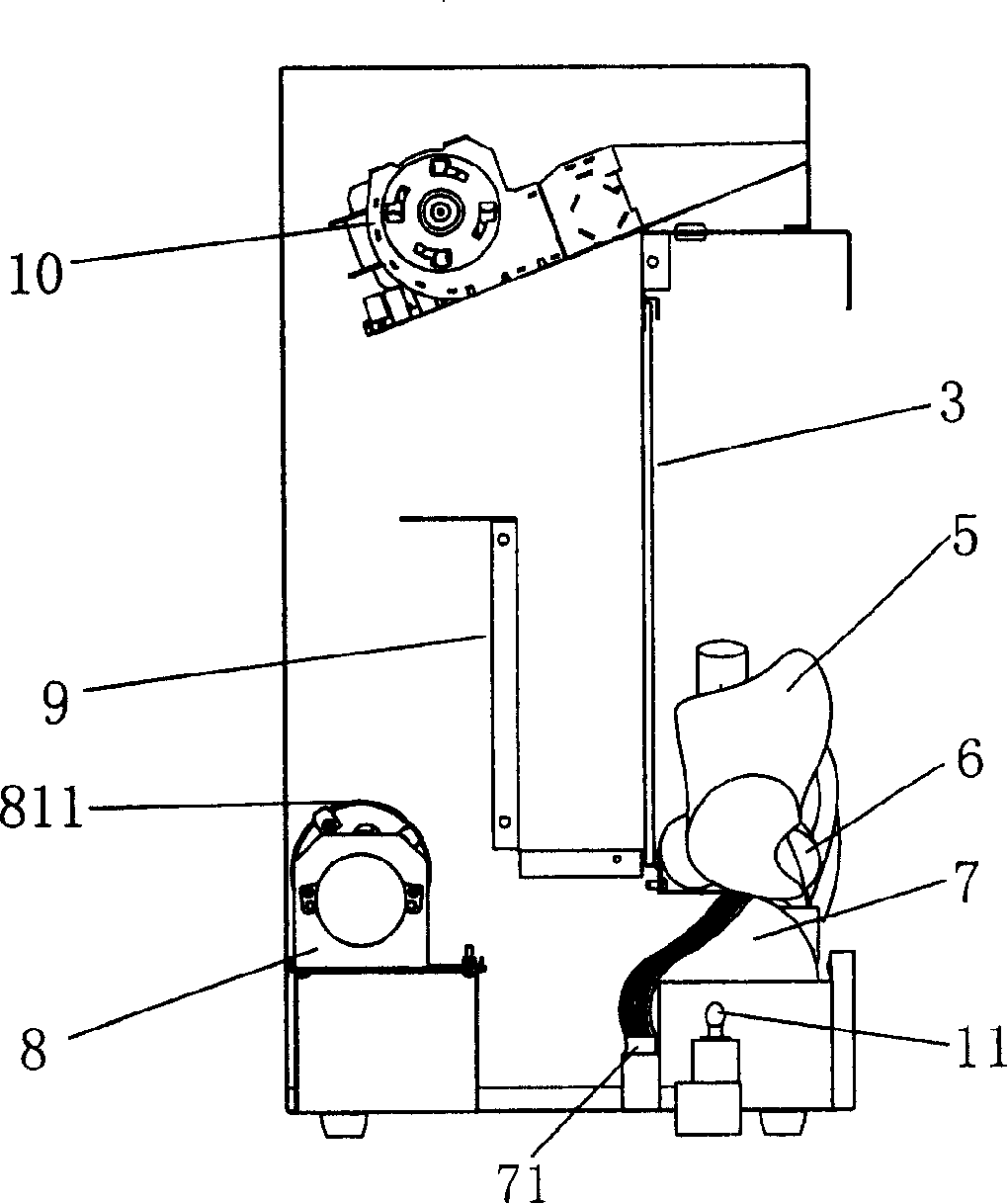

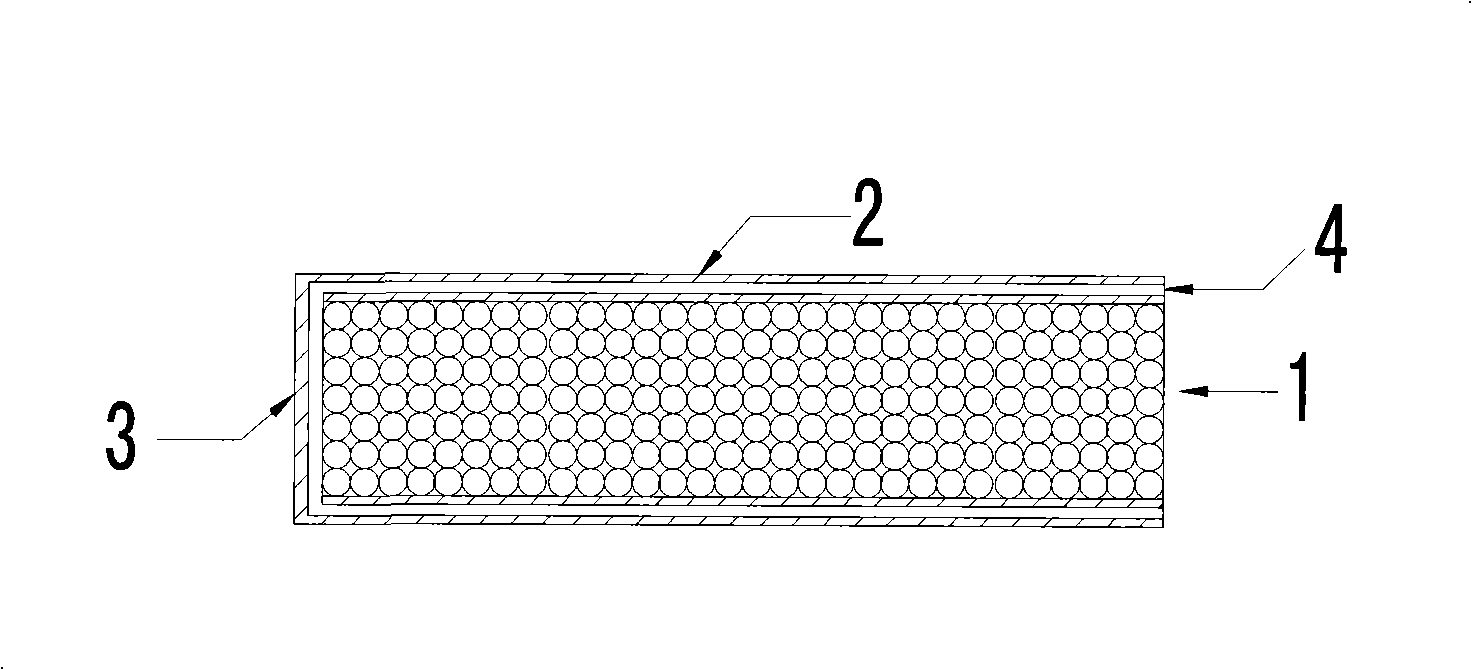

High-efficiency porous media combustor for minitype heat optoelectronic system

InactiveCN101354132AImprove temperature distributionStable and efficient workGaseous fuel burnerExhaust gasProduct gas

The invention provides a high-efficiency porous medium burner used in a micro thermo photovoltaic system, relating to the technical field of combined combustion of a two-phrase gas. SiC ceramic spherules with diameter of 0.3mm to 0.35mm are filled in a shell of the burner in the form of oblique parallelepiped and then sintered with the shell to form a porous medium structure with porosity epsilon equal to 26 percent to 27 percent and a tail gas discharging channel is arranged on the external wall of the burner. The shell of the burner is processed first and then a bottom cover (3) of the burner is processed and sintered with the shell, and finally, in the interior of which the screened SiC ceramic spherules with diameter of 0.34mm are filled, after sintering, the porous medium structure is formed and the tail gas discharging channel is arranged in the interior of the shell (2) of the burner. The porous medium burner reduces the heat loss brought by increase of surface to volume ratio due to microscale, greatly improves the temperature distribution on the external wall of the burner, promotes combustion efficiency and combustion stability, lowers gas discharging temperature and heightens the temperature of the external wall, thus greatly advancing the efficiency of the whole micro thermo photovoltaic system.

Owner:JIANGSU UNIV

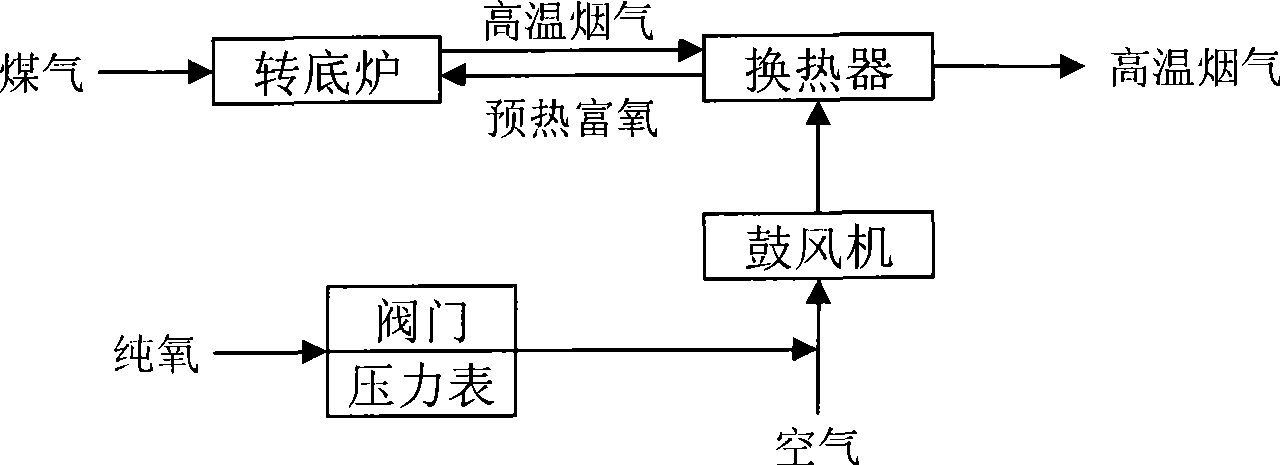

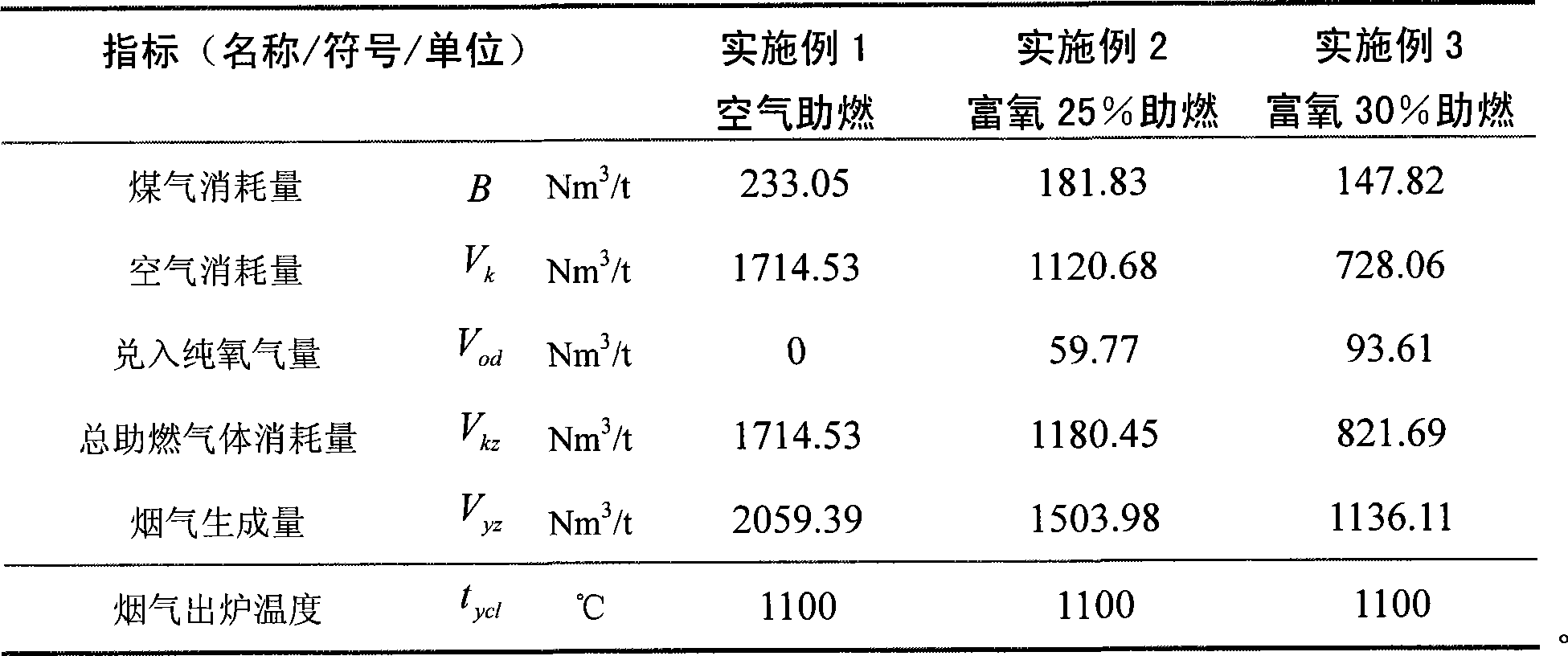

Method for manufacturing metallic pellets by direct reduction of oxygen-enriched combustion in rotary furnace

InactiveCN101445869AReduce consumptionReach the remarkable effect of saving energy and reducing consumptionProcess efficiency improvementAir blowerRotary furnace

The invention provides a method for manufacturing metallic pellets by direct reduction of oxygen-enriched combustion in a rotary furnace, which belongs to the technical field of steel industry for manufacturing metallic pellets (or direct reduction iron). The method is characterized in that oxygen enriched air is adopted as an auxiliary fuel gas; the oxygen enriched air enters a heat exchanger through a blower; and after the heat exchange between the oxygen enriched air and high temperature flue gas is performed, the temperature rises to 400 DEG C to 600 DEG C, and then the oxygen enriched air enters the rotary furnace. The invention breaks through the limitation of the prior air taking as a combustion medium and fixing the oxygen content, realizes the actual demand that the oxygen content in the combustion medium is controllable, further enhances the heat efficiency of the rotary furnace, reduces over 35% of air consumption amount, reduces over 31% of total consumption amount of the auxiliary fuel gas; and the coal gas consumption, the flue gas discharge capacity and the investment cost are reduced, and conforms to the national policy requirements of energy conservation, emission reduction and circulation economy.

Owner:LAIWU IRON & STEEL GRP

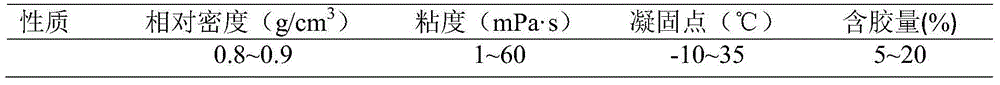

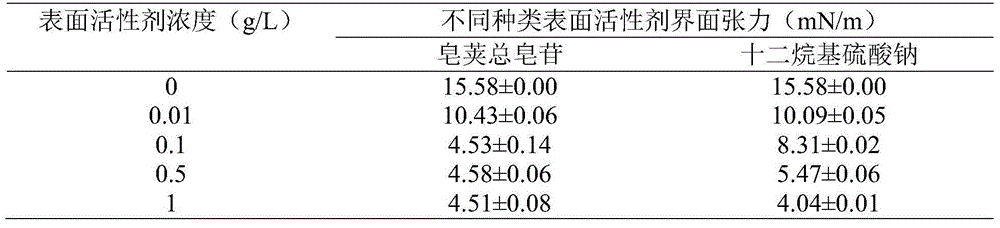

Application of plant source surface active agent

InactiveCN104874329AHas an activation effectIncrease gasification rateNon-ionic surface-active compoundsOther chemical processesEmulsionResource utilization

The invention relates to a total saponnis extraction technology of a honeylocust extract and an application field thereof. The total saponnis extraction technology is characterized in that the total saponnis is a plant source nonionic type surface active agent, and has the interfacial tension reduction property, emulsion activity, wetting property, temperature-resistant and salt-tolerant property, dispersant solubilizing and the like, so as to provide the applicability in the fields of recovery, storage and transportation of crude oil; the green surface active agent from the plant, namely the honeylocust, is applied to the bulk industrial purpose, so the resource utilization rate of the honeylocust is improved, the recovery rate of crude oil is improved, the storage and transportation cost of crude oil is reduced, and the pollution to the environment is reduced.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Ignition timing control system for internal combustion engine

InactiveUS20100274463A1Stable combustionImprove drivabilityAnalogue computers for vehiclesElectrical controlControl systemTime control

To provide an ignition timing control system for an internal combustion engine, which is capable of ensuring stable combustion without causing a misfire or knocking, by properly setting ignition timing in the compression stroke injection mode, thereby making it possible to improve drivability. The ignition timing control system for the engine 3 that directly injects fuel into cylinders 3a and is operated by switching the fuel injection mode between an intake stroke injection mode and a compression stroke injection mode comprises fuel injection timing-setting means 2 for setting a fuel injection timing INJOBJ according to an engine speed NE of the engine 3 and a fuel injection amount GFUEL, basic value-setting means 2 for setting a basic value IGBASE of ignition timing according to the engine speed NE of the engine 3 and the fuel injection timing INJOBJ, and ignition timing-setting means 2 for setting ignition timing IGCOMP in the compression stroke injection mode by correcting the basic value IGBASE according to a detected air-fuel ratio AF.

Owner:HONDA MOTOR CO LTD

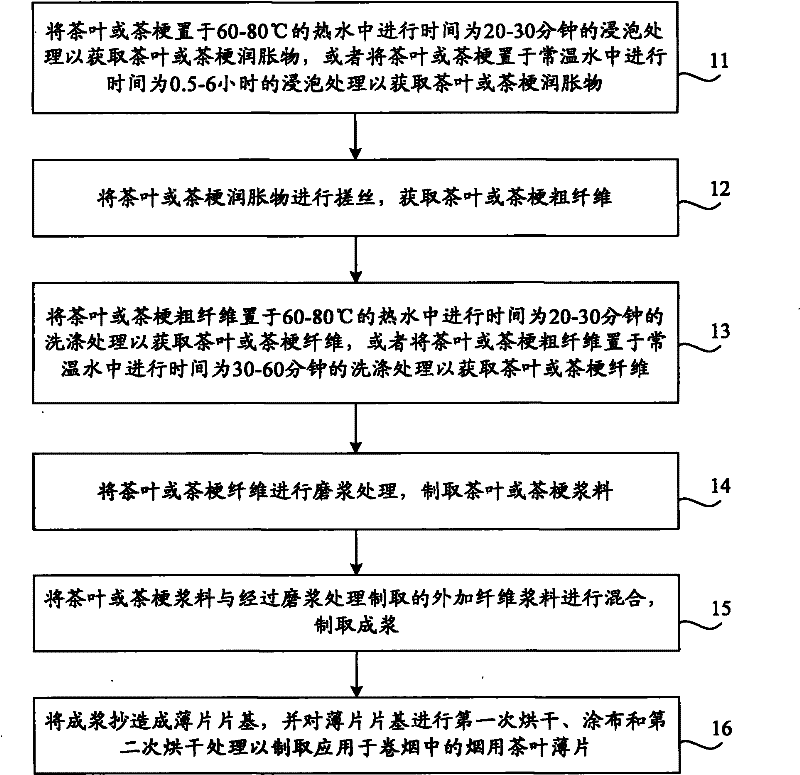

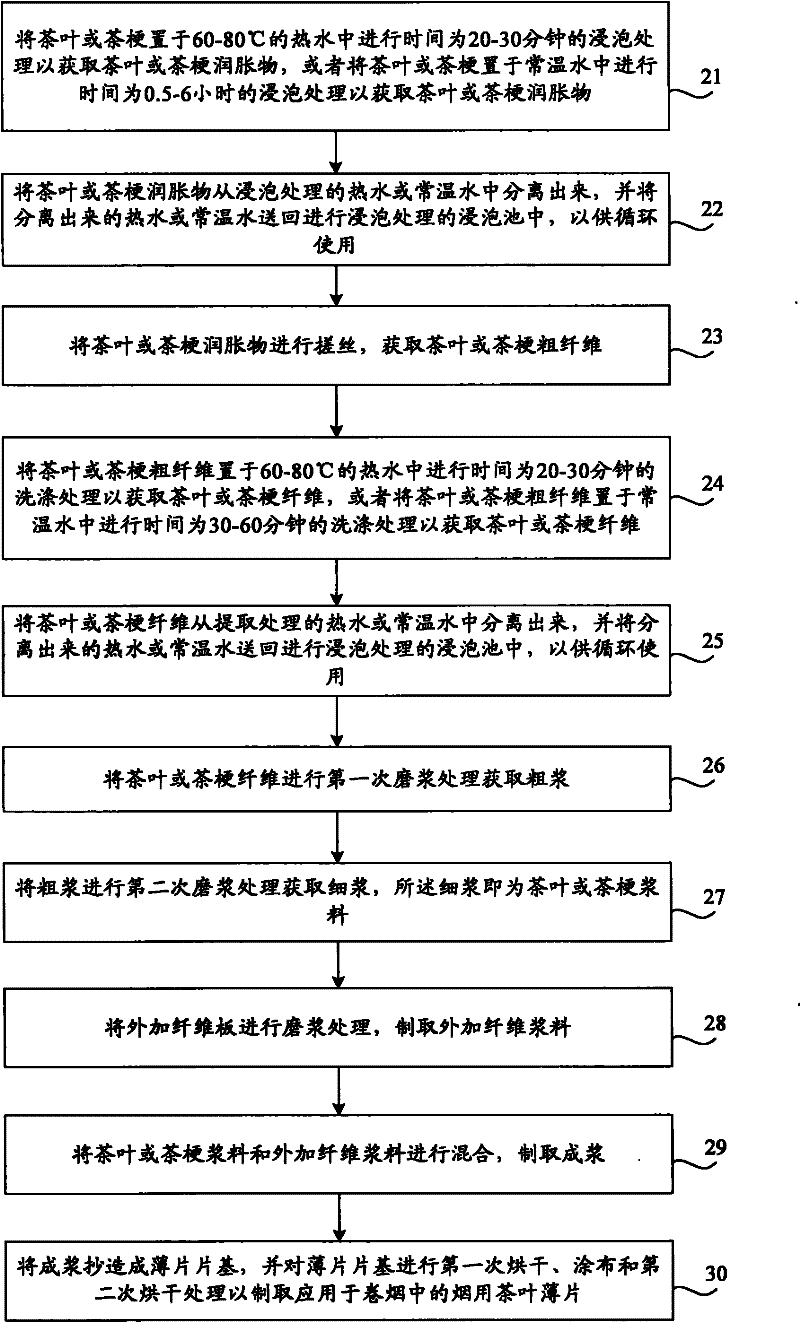

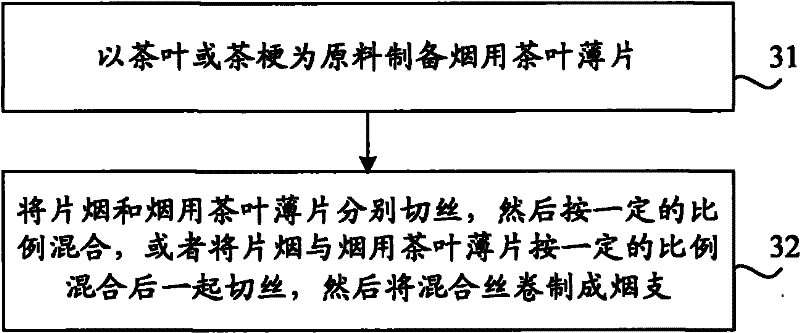

Tea leaf thin sheet for cigarette, preparation method thereof and cigarette

InactiveCN102217782ABurn fasterReduce releaseTobacco preparationTobacco treatmentFiberPulp treatment

The invention provides a tea leaf thin sheet for a cigarette, a preparation method thereof and the cigarette, wherein the tea leaf thin sheet for the cigarette takes tea leaves or tea stalks as raw material, and the preparation method comprises the following steps: placing the tea leaves or the tea stalks in hot water or normal temperature water for performing soaking treatment so as to get a swollen matter of the tea leaves or the tea stalks; performing thread rolling on the swollen matter of the tea leaves or the tea stalks to get crude fiber of the tea leaves or the tea stalks; placing the crude fiber of the tea leaves or the tea stalks into the hot water or the normal temperature water for performing washing treatment so as to get fiber of the tea leaves or the tea stalks; performing pulping treatment on the fiber of the tea leaves or the tea stalks to prepare pulp of the tea leaves or the tea stalks; and preparing the pulp of the tea leaves or the tea stalks and the additional fiber pulp prepared by the pulping treatment into finished pulp, further manufacturing paper with the pulp for making a thin sheet base, and performing primary drying, coating and secondary drying on the thin sheet base for getting the tea leaf thin sheet for the cigarette. The tea leaf thin sheet for the cigarette, which is prepared according to the preparation method, is applied in the cigarette, can solve the problems of limited harm-reducing effect and instability in the prior art and realizes the purpose of reducing harm.

Owner:北京中海钓台食品供应中心有限公司

Method for improving quality of high-chromium vanadium and titanium sinter

The invention provides a method for improving the quality of high-chromium vanadium and titanium sinter and belongs to the technical field of ferrous metallurgy. The method mainly comprises the steps that sintering return mines, high-chromium vanadium and titanium concentrate fines, ordinary iron ore concentrate powder, boron iron ore concentrate, metallurgical lime, magnesite, coke powder and other sintering raw materials are subjected to secondary atomization injection and blowing blending, wetting and pelletizing at a certain proportion; then distribution, ignition and sintering are conducted; and finally grain settlement and screening are conducted to obtain the high-chromium vanadium and titanium sinter good in metallurgical performance. The method has the characteristics of being simple in process, high in raw material adaptability, high in production efficiency, low in cost and the like. The quality of the high-chromium vanadium and titanium sinter and the sintering production efficiency can be improved remarkably; the method has important realistic significance for development and utilization of the high-chromium vanadium and titanium sinter and has wide application prospects.

Owner:NORTHEASTERN UNIV

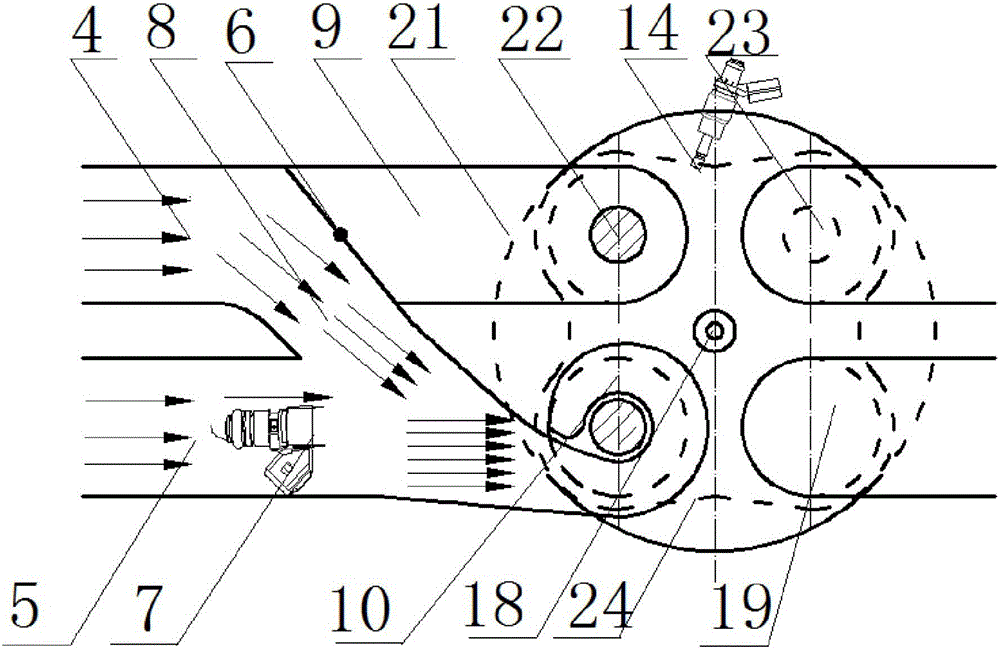

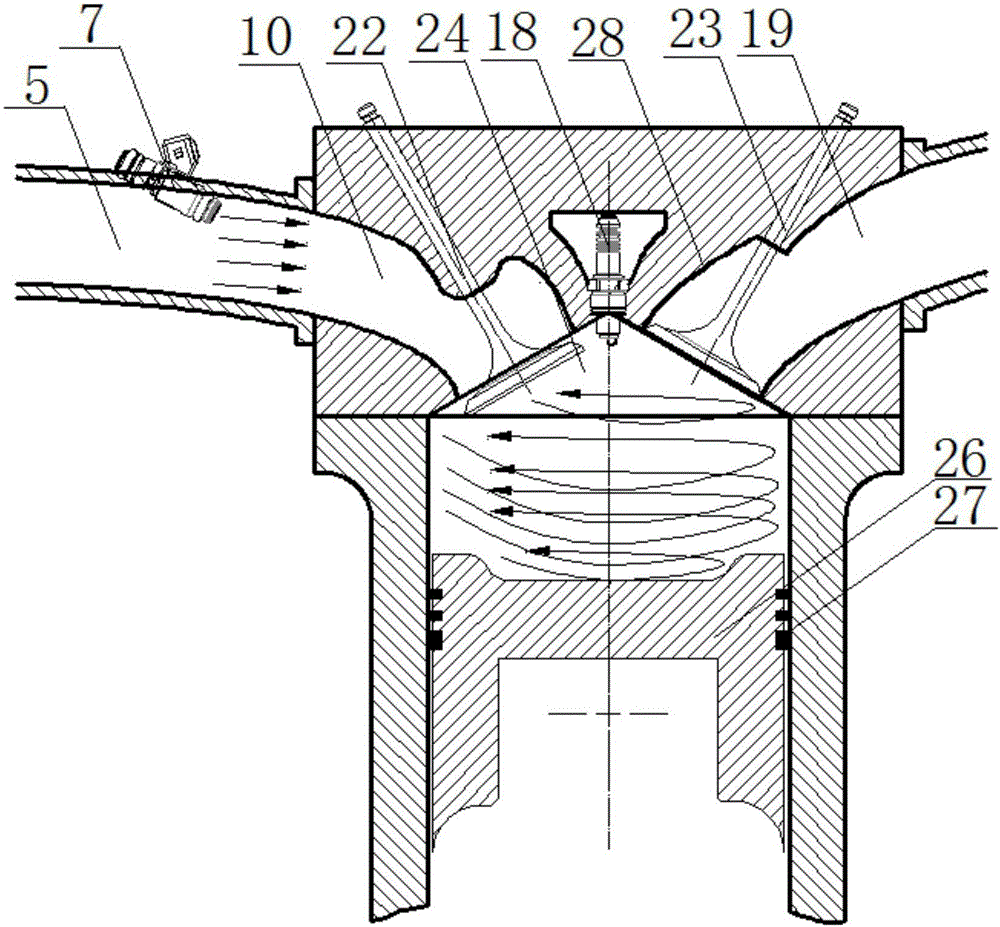

Dual-fuel spark-ignition internal combustion engine based on variable air channel, and control method

InactiveCN105715367ABurn fasterImprove economyInternal combustion piston enginesAir intakes for fuelCombustionInternal combustion engine

The invention designs a dual-fuel spark-ignition internal combustion engine based on a variable air channel, and a control method, aims at solving the problem that effective adjustment cannot be carried out on an intake flow and an airflow direction in an air channel, of an internal combustion engine adopting the traditional intake structure, and in particular, an internal combustion engine adopting a four-valve structure, and solving the problems of instable combustion, difficult ignition, fire and the like generated during lean combustion, and develops a dual-fuel spark-ignition internal combustion engine based on a variable air channel, and a control method. The invention provides a variable intake system. According to the variable intake system, the optimal airflow movement under different working conditions is obtained through control for the opening and closing of a swirl control valve, and in combination with a piston top surface with a special shape. The invention discloses a combined internal combustion engine technology for carrying out in-cylinder direct injection and intake channel injection respectively on the basis of two fuels. The different combustion modes of an in-cylinder mixed gas are realized through control for an injection time and an injection pulse width, and in combination with an airflow movement, and then the working efficiency of the internal combustion engine under different working conditions is improved, and oil consumption and emission are reduced.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com