Patents

Literature

183results about How to "Low ignition point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy-saving and high efficiency fuel coal combustion improver and preparation method thereof

The invention discloses an energy-saving and high efficiency fuel coal combustion improver and a preparation method thereof. The combustion improver comprises the following components by weight percentage: 40-60% of zinc oxide, 40-60% of manganese dioxide, preferably 50% of zinc oxide and 50% of manganese dioxide, wherein the manganese dioxide can be prepared by: weighing KMnO4 and MnC12.4H2O according to a weight ratio of 1:1, and fully grinding the materials in a container under room temperature for 20-50min to carry out solid phase reaction. The preparation method of the energy-saving and high efficiency fuel coal combustion improver includes the steps of: a. weighing the raw materials according to the following weight percentage: 40-60% of zinc oxide and 40-60% of manganese dioxide; b. grinding; c. dipping and drying; and d. roasting. The combustion improver provided by the invention reduces corrosion to boilers, improves the service life of boilers, significantly raises the flame temperature, improves the combustion activity and ignition performance of coal, improves the speed of ignition speed and combustion speed of coal, and has significant energy saving and environmental protection effects.

Owner:HARBIN HONGTIAN RUIDA TECH

Biomass particle fuel

InactiveCN101955830AAvoid or reduce flowHigh calorific valueBiofuelsSolid fuelsEngineeringAnthracite

The invention discloses a biomass particle fuel. The biomass particle fuel comprises the following components in percentage by weight: 50 to 60 percent of plant straw, 2 to 5 percent of anthracite, 15 to 20 percent of coal slime, 2 to 5 percent of yellow mud, 2 to 5 percent of waste grease, 8 to 12 percent of food wastes, 8 to 12 percent of water and 10 to 15 percent of large animal manure. The fuel has the characteristics that: firstly, heat value is increased remarkably and unit heat value is up to 5,000 kilocalories; secondly, burning point is lowered greatly; thirdly, due to the addition of supporting materials such as the yellow mud and the like, air permeability is improved and heat utilization ratio is increased; fourthly, combustion time can be prolonged from 1.5 hours of a pure biomass fuel on average to over 3 hours; fifthly, a large number of food wastes are consumed, so that drainage oil and garbage pigs are reduced and prevented from being sold on the market; and sixthly, the pollution of the large animal manure on the environment is reduced.

Owner:王德明

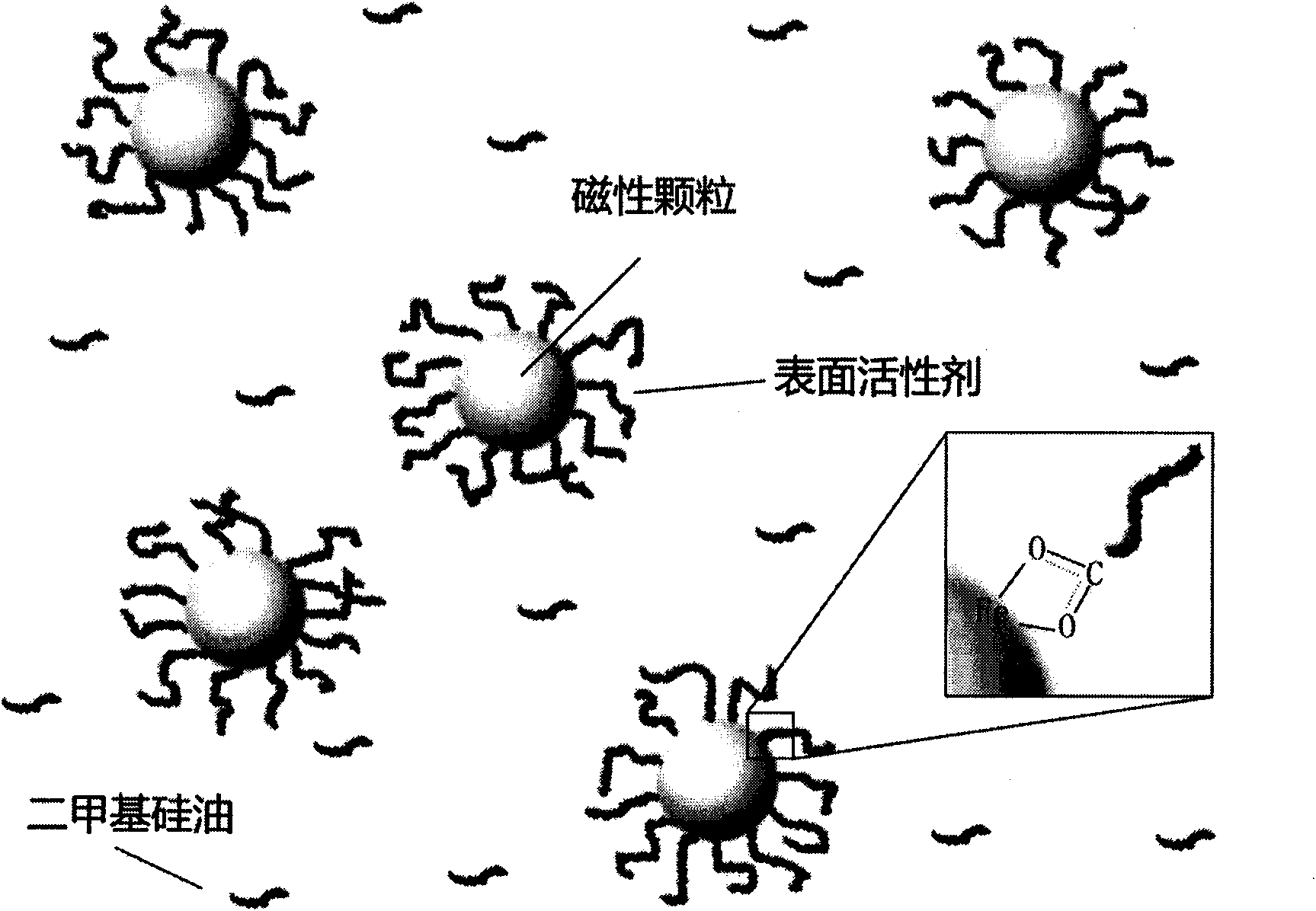

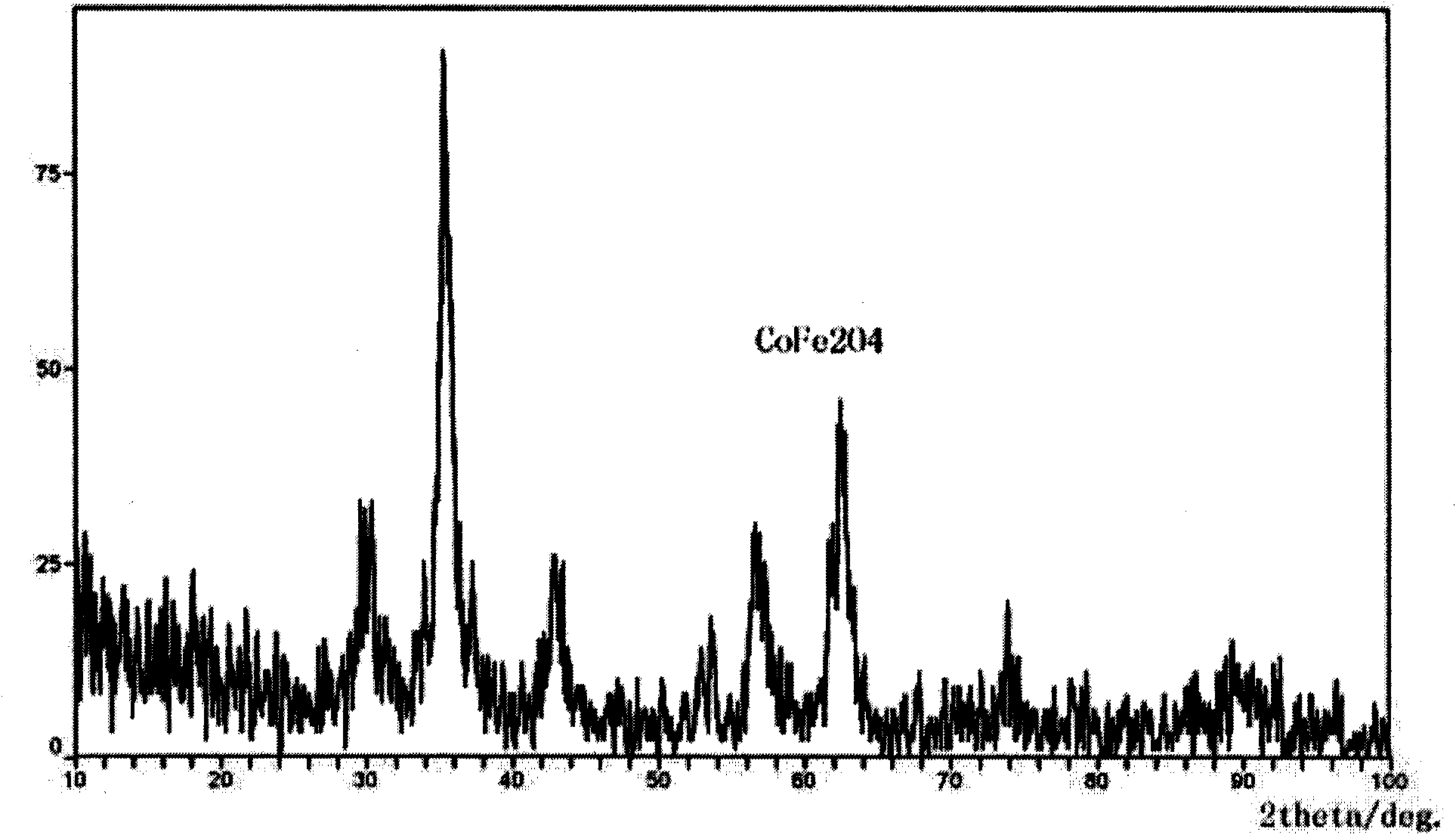

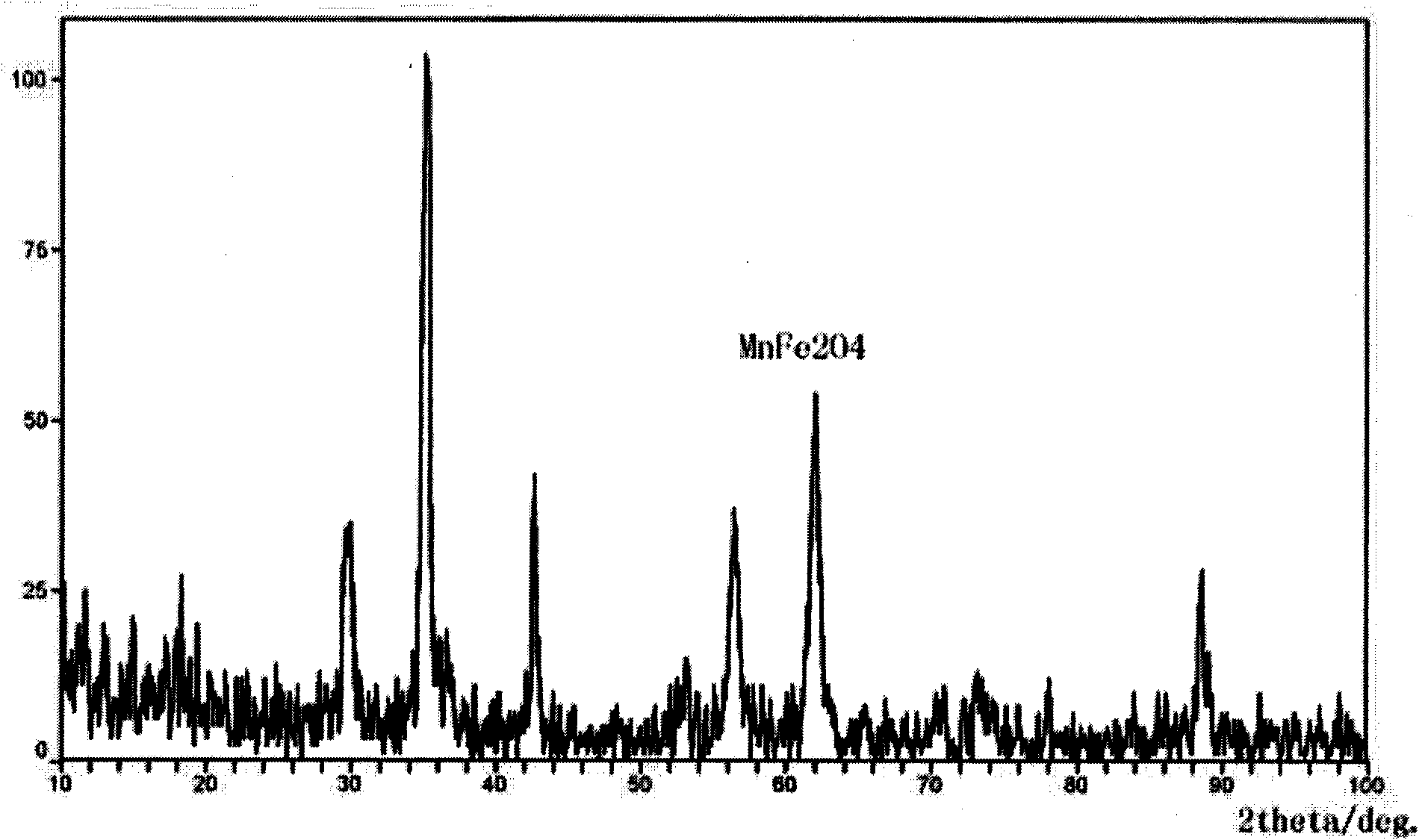

Oxidation resistant dimethyl silicon oil based magnetic fluid and preparation method thereof

InactiveCN101599335ASmall viscosity-temperature coefficientLow compression resistanceMagnetic liquidsOrganic/organic-metallic materials magnetismMethylene DichlorideMagnetic liquids

The invention provides oxidation resistant dimethyl silicon oil based magnetic fluid and a preparation method thereof; the dimethyl silicon oil based magnetic fluid is prepared by nano-magnetic particles, a surface modifier and carrier fluid, and the carrier fluid is the dimethyl silicon oil. The preparation method of the dimethyl silicon oil based magnetic fluid comprises the following steps: preparing the nano-magnetic particles; treating the nano-magnetic particles in an activated way; preparing the nano-magnetic particles which are modified by the surface modifier; adding the modified nano-magnetic particles which are purified into methylene dichloride, dispersing and filtering the mixture to obtain the methylene dichloride based magnetic fluid; adding the magnetic fluid into the dimethyl silicon oil to be stirred and dispersed, heating the mixture and maintaining the temperature between 50 and 90 DEG C, separating and precipitating the mixture to obtain the dimethyl silicon oil based magnetic fluid. The dimethyl silicon oil based magnetic fluid in the invention has the advantages of high stability, low temperature resistance and high temperature resistance. The preparation method is simple, high in efficiency and low in requirement on equipments, thus being easy to be applied in various fields and having wide application prospect.

Owner:SUN YAT SEN UNIV

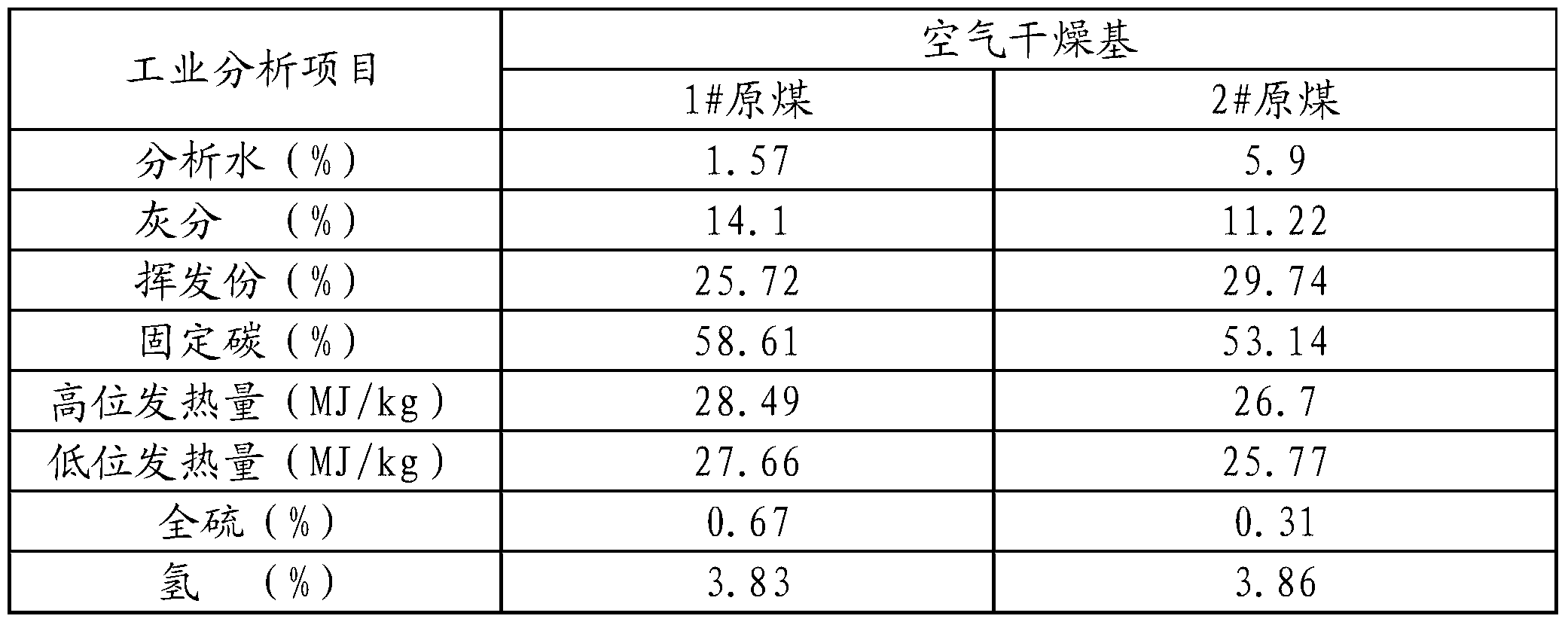

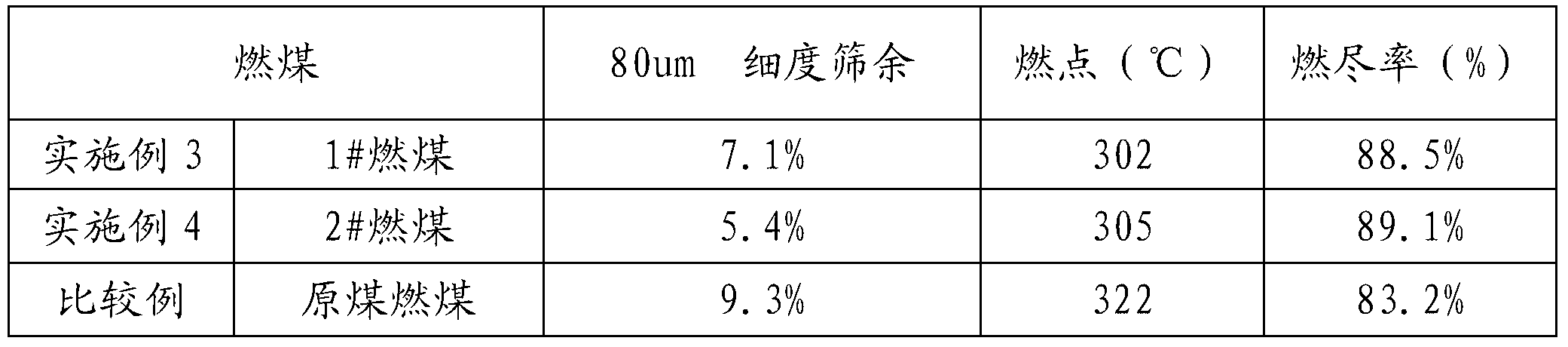

Pulverized coal combustion improver for thermal power plant

InactiveCN102559331ALow ignition pointImprove combustion effectSolid fuelsCombustionEconomic benefits

The invention discloses a pulverized coal combustion improver for a thermal power plant. The pulverized coal combustion improver comprises components with weight percentages as follows: 50 to 80 percent of manganese ore, 10 to 40 percent of chemical activator, 5 to 15 percent of clinker sintering agents and smaller than 2 percent of water, wherein the chemical activator is sodium aluminosilicate or potassium aluminum silicate. Raw materials of the chemical activator in the pulverized coal combustion improver are easy to obtain and an effect of saving more than 13 percent of coal can be achieved, so that the pulverized coal combustion improver has great economic benefits and is worthy of popularization.

Owner:洛阳大泽节能环保科技有限公司

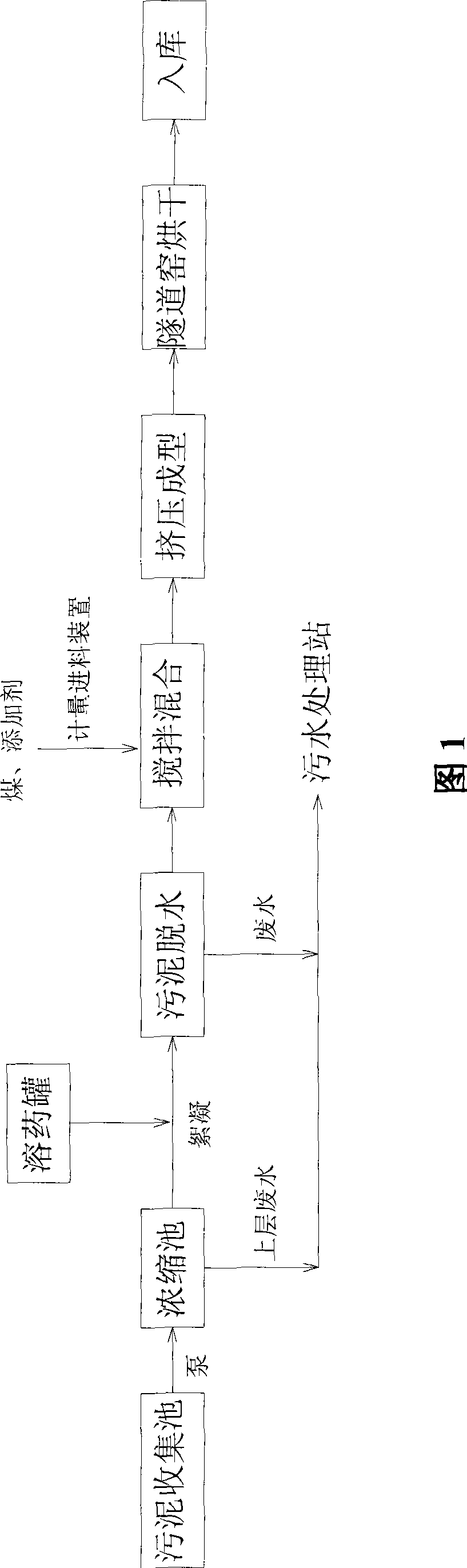

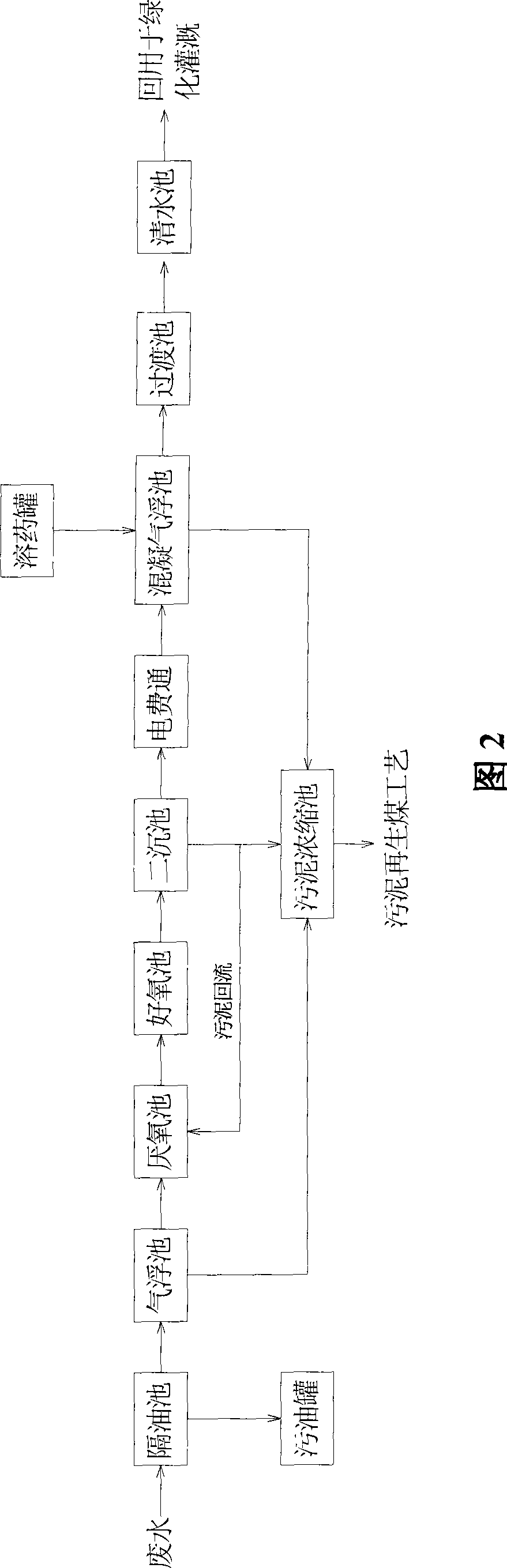

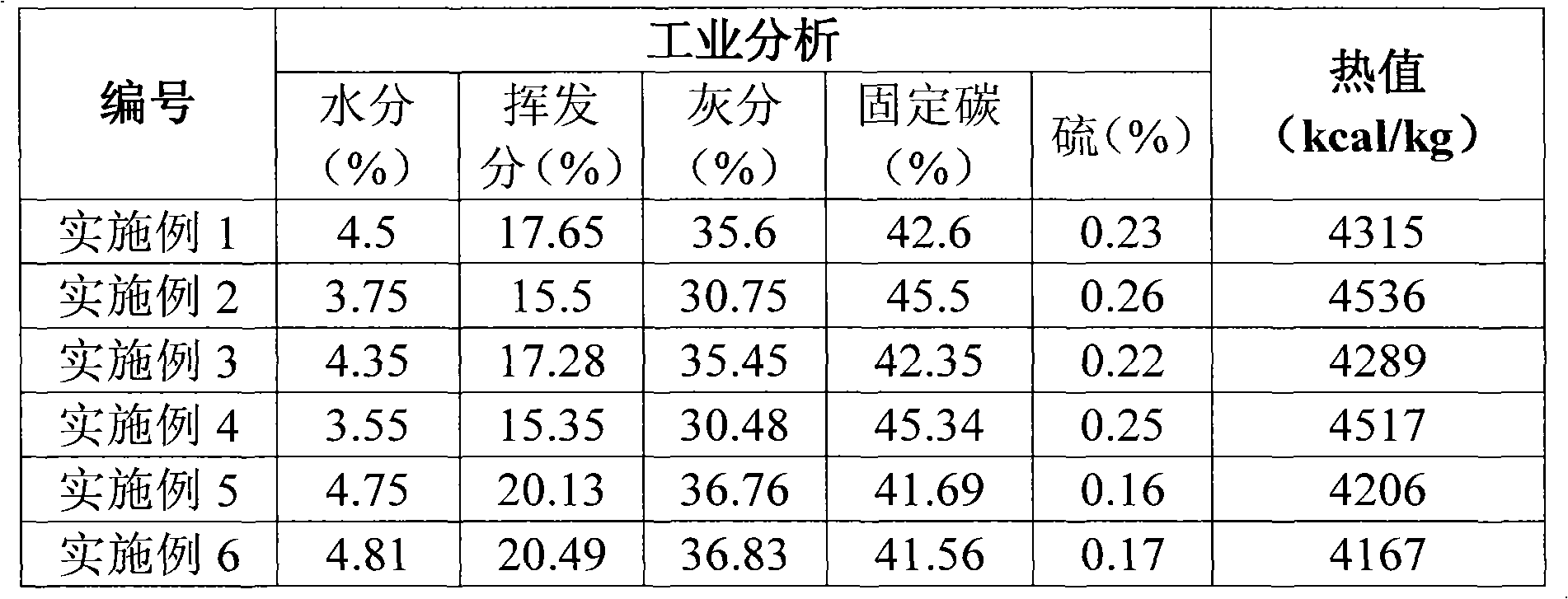

Regenerated coal prepared by oil-containing sludge from oil production field and oil-extraction plant and preparation technology thereof

The invention relates to an oily sludge renewable coal and a production technology thereof for an oil field and a refinery. The renewable coal composition is composed of 10 percent to 30 percent of oily sludge, 60 percent to 80 percent of coal, 3 percent to 6 percent of sulfur fixing matter and 1 percent to 5 percent of preservative according to the weight percentage. The production technology comprises the following steps: sludge thickening to flocculation reaction to sludge dehydration to stirring and mixing to extrusion forming and drying by a tunnel kiln. The production technology further comprises the disposal technology of wastewater containing oily sludge: wastewater to an oil separating tank to an air flotation tank to an anaerobic tank to an aerobic tank to a secondary sedimentation tank to a transition tank to an electricity charge payment device to a coagulation and air flotation tank to a clean water tank. The wastewater can achieve the national first level discharge standard after the treatment, and the outlet water is reused for green irrigation or car washing or toilet flushing. The oily sludge renewable coal has the advantages of high calorific value, low ignition point and low production cost, thereby truly realizing the purposes of reduction, harmlessness and resource utilization of the oily sludge.

Owner:深圳市宇力科技有限公司

Biomass moulded coal and preparation method thereof

InactiveCN101985575ALow calorific valueLow volatileBiofuelsSolid fuelsFixation agentSodium hydroxide

The invention provides a method for preparing biomass moulded coal by using biomass and inferior smokeless pulverized coal as raw materials. The biomass moulded coal is prepared by uniformly mixing the biomass, the inferior smokeless pulverized coal and additives (a sulfur fixation agent, a biomass binder, an oxidant and a waterproofing agent), and performing low-pressure compression moulding by a wet method, wherein the sulfur fixation agent is calcined lime CaO; the biomass binder is light yellow dope prepared by treating bagasse by using 1 to 2 percent sodium hydroxide solution; the oxidant is potassium permanganate; and the waterproofing agent is tar or a binder. The biomass moulded coal comprises following raw materials in part by mass: 40 to 65 parts of inferior smokeless pulverized coal, 25 to 55 parts of biomass and 5 to 10 parts of additive. The biomass moulded coal has the advantages of low cost, low ignition point, high burn-off rate and integrative desulfurization and water proofing performance, and has great significance of energy conservation and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

Biomass fuel and production method thereof

The invention relates to the technical field of biomass fuels, in particular to biomass fuel and a production method thereof. According to the production method, the materials, such as biogas residue, crop stalks, marshal sludge and sawdust, are mixed prior to being treated via a fermentation process; thus, organics are biologically react microscopically, the materials act with one another, the structure of biomass is enhanced, crushing and compressing treatment of the materials is easier, the difficulty and energy consumption of the biomass fuel is lowered, and the cost of biomass fuel production is lowered. In addition, pulverized coal is subjected to crushing treatment and added with illegal cooking oil and gasoline; thus, the waste, the illegal cooking oil and the gasoline are made full use, the ignition point of the biomass fuel is lowered, and the ignition cost of the biomass fuel in applications is lowered.

Owner:玉林市新滔环保科技有限公司

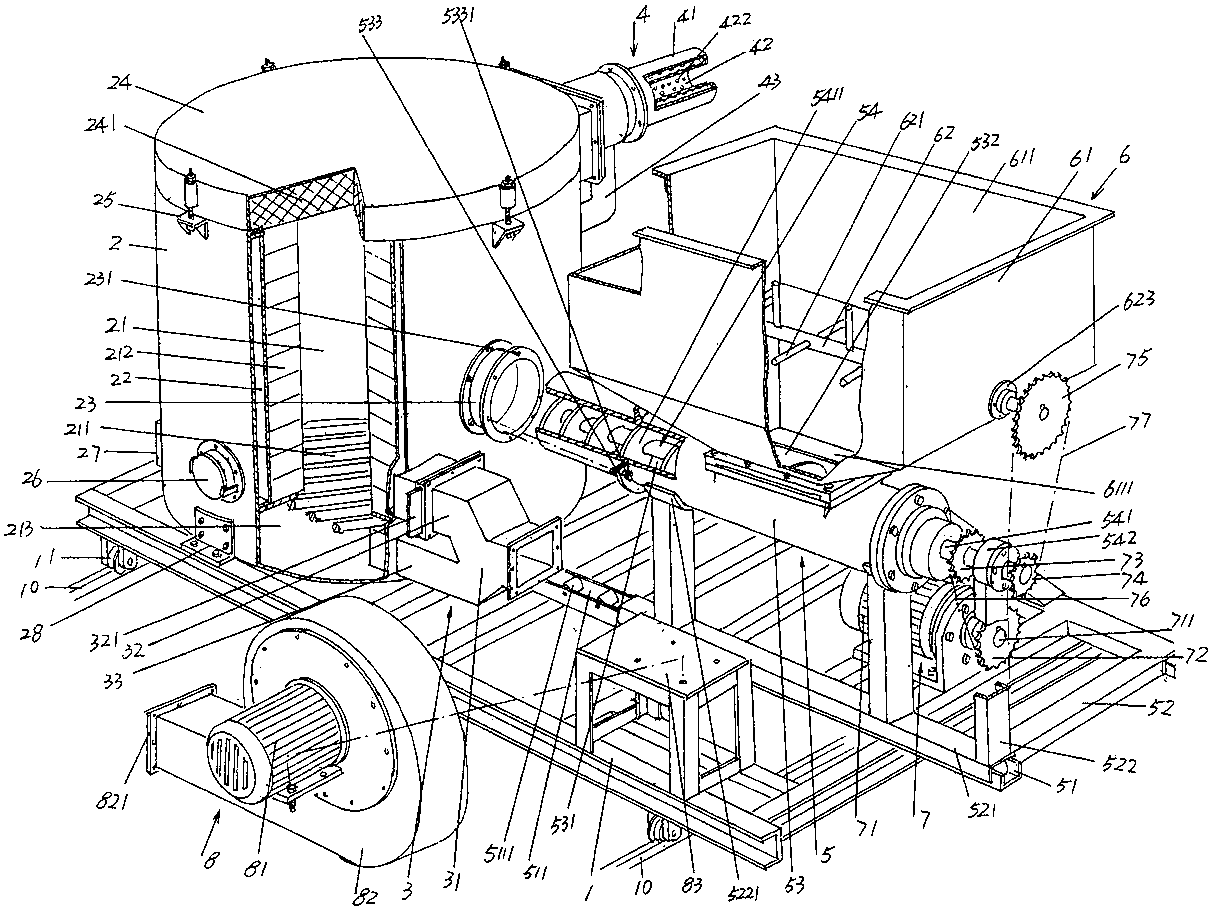

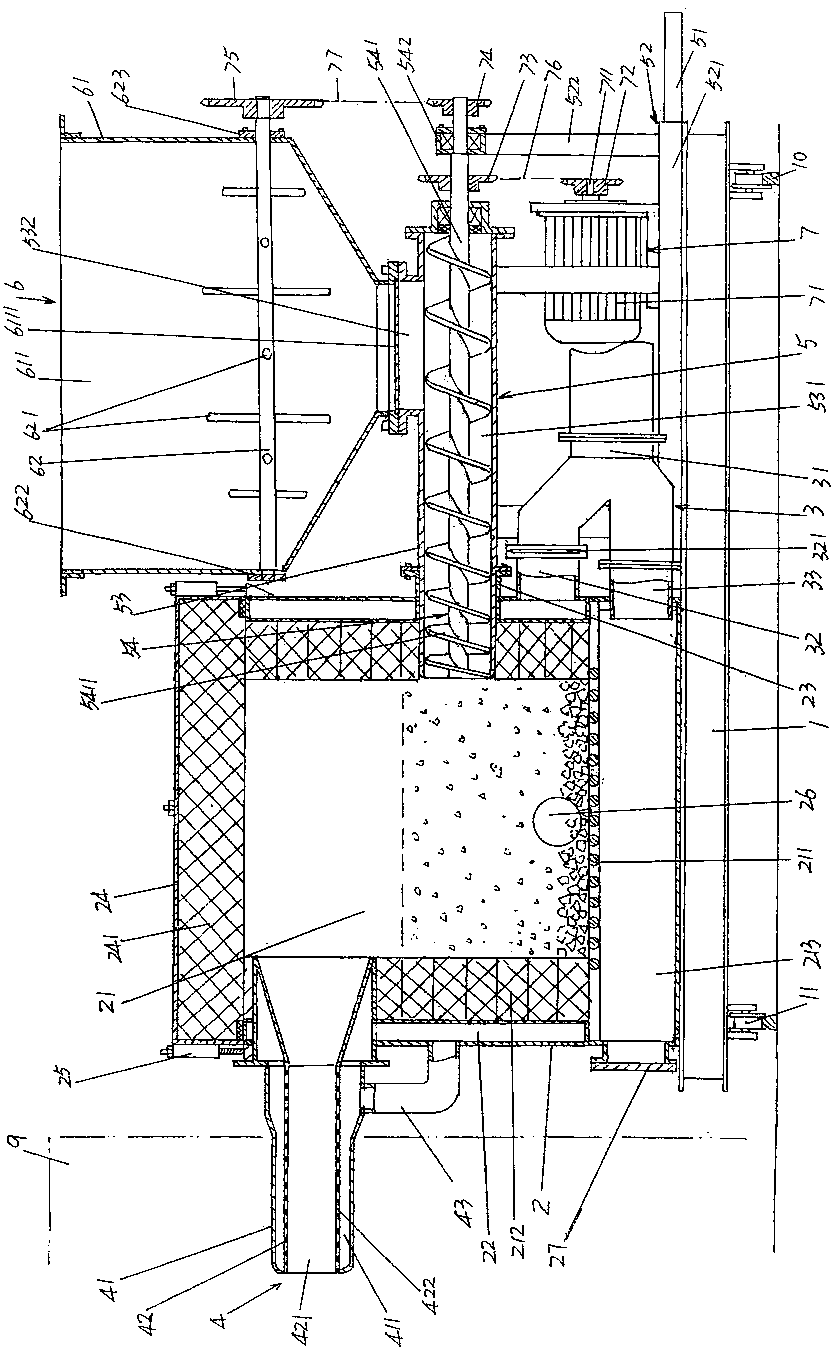

Biomass sawdust fuel burning furnace

InactiveCN103017143AImprove protectionWide variety of sourcesSolid fuel combustionNon-combustible gases/liquids supplyCombustionProcess engineering

The invention relates to a biomass sawdust fuel burning furnace, comprising a chassis frame, an incinerator, a spitfire mechanism, a fuel supply mechanism, a fuel supply box, a power transmission mechanism and an oxygen supply mechanism, wherein the chassis frame is arranged on floor; the incinerator is fixed at one end of the chassis frame, the outer wall of the incinerator constitutes a jacket and is provided with a feeding hole and a combustion-supporting air introduction mechanism, and a cover is arranged on the top of the incinerator in a matching manner; the spitfire mechanism is connected with the upper side part of the incinerator in a matching manner; the fuel supply mechanism is arranged on the other end of the chassis frame, and comprises a pair of guide rails, a moving frame, a screw rod cylinder and an extrusion screw rod; the fuel supply box is arranged on the fuel supply mechanism; the power transmission mechanism is arranged on the other end of the chassis frame; and the oxygen supply mechanism is arranged on the other end of a stand. The biomass sawdust fuel burning furnace disclosed by the invention has the advantages of high combustion efficiency, large heating quantity, low ignition point and high heating property, is friendly to the environment, good for protecting non-renewable natural resources such as petroleum and coal to embody the circular sustainable development of economy, concise in structure and convenient and safe to use; and a combustion effect can be guaranteed by introducing dense biomass sawdust into a hearth.

Owner:杭州华政新能源科技有限公司

Fire coal liquid oxidizer for cement production and preparation method thereof

ActiveCN103320196AImprove combustion effectIncrease burn rateSolid fuelsSocial benefitsMetal catalyst

The invention provides a fire coal liquid oxidizer for cement production. The fire coal liquid oxidizer comprises the following ingredients: by weight, 20-40% of mineral oil, 25-35% of plant oil, 6-16% of an emulsifier, 4-8% of metal catalyst salt, and the balance water. In comparison with the prior art, the fire coal liquid oxidizer for cement production has the following beneficial effects: on the basis of not changing original equipment and technology, burning point of prepared coal dust is reduced, burning rate is raised and burnout rate is improved; coal consumption per cement clinker is decreased, discharge capacity is minimized, energy is greatly saved, sintering of cement clinker is promoted, quality of cement clinker is raised, and economic and social benefits of cement clinker production are enhanced; and the fire coal liquid oxidizer is beneficial to environmental protection. The invention also provides a preparation method of the fire coal liquid oxidizer.

Owner:北京金隅节能科技有限公司

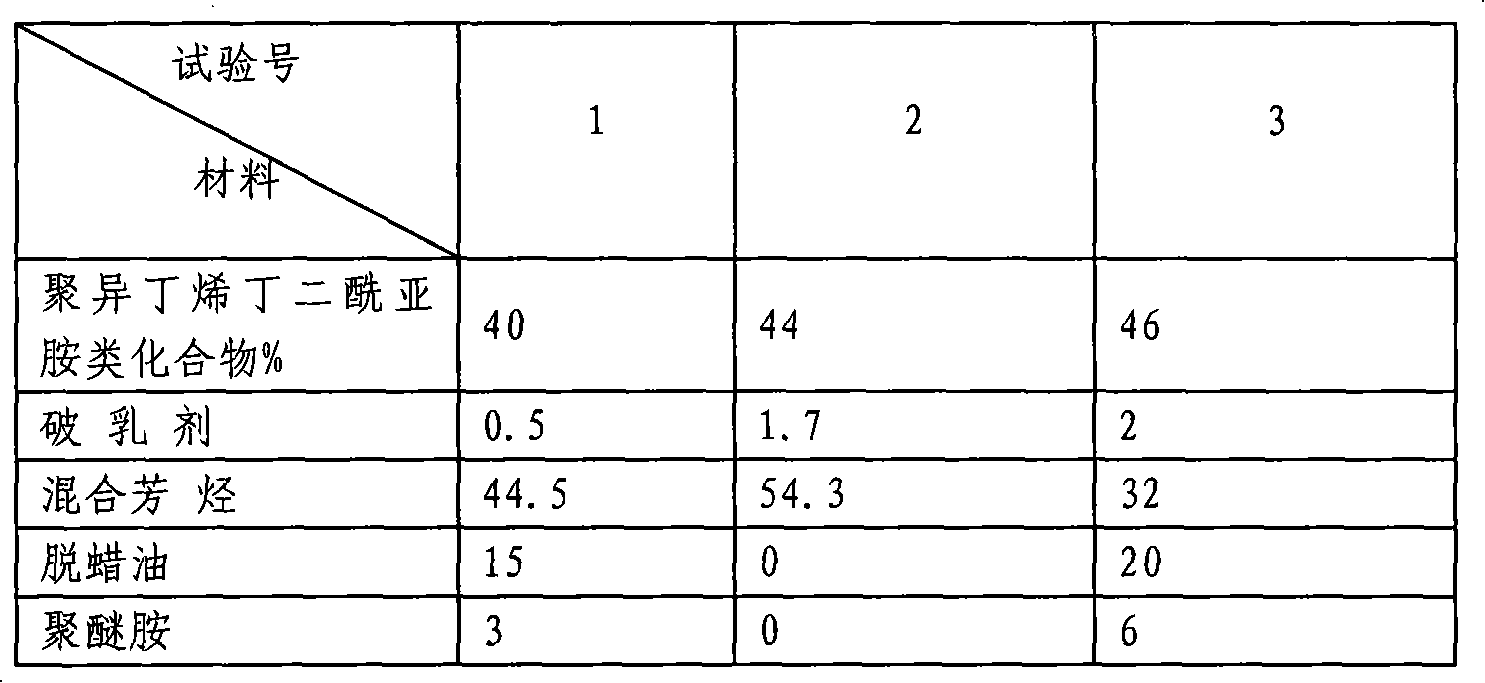

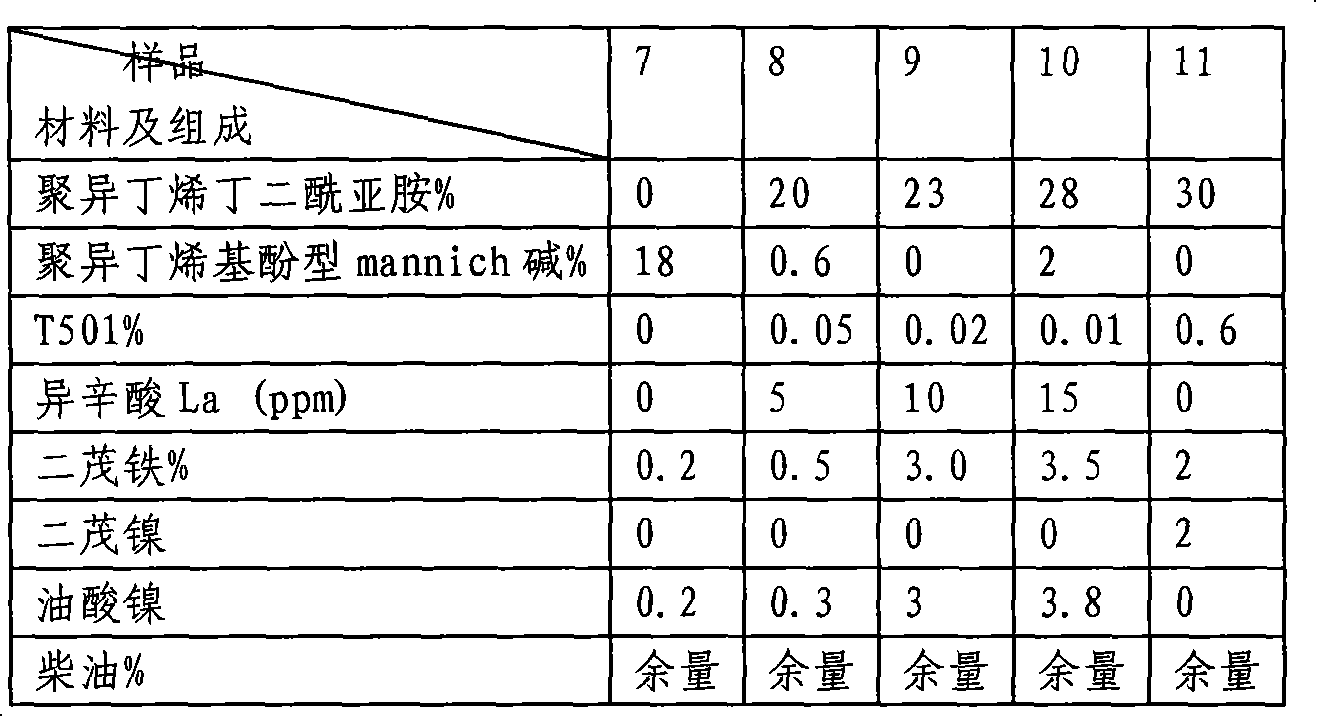

Fuel system carbon deposit undisassembly abluent of diesel engine

InactiveCN101602969APower recoveryExtended service lifeLiquid carbonaceous fuelsMachines/enginesInternal combustion engineCarbon deposit

The invention relates to a fuel system carbon deposit undisassembly abluent of a diesel engine. The abluent can effectively moisten and disperse oil dirt, colloid substance and carbon deposit which are attached to a fuel system of a gas engine when the gas engine starts up, and also can reduce the burning point of the carbon deposit to enable the carbon deposit to burn. When in use, the abluent can be added in the fuel according to a certain proportion. The abluent has the functions of saving fuel, reducing consumption, purifying tail gas, enhancing power and preventing attachment of dirt andlong-time maintenance. The component of the formula of the abluent is a compound taking organic polymer as a base solution, and the abluent is prepared by mixing a dispersant agent, a decarbonizer, an oxygenate, a carbon burning accelerant and a carbon burning point depressant in a compound way.

Owner:海军后勤技术装备研究所

Catalyst of low-temperature catalytic burning integral type and preparation method thereof

ActiveCN101612579AActiveLow ignition pointCell electrodesMetal/metal-oxides/metal-hydroxide catalystsChemistryOxide

The invention discloses a catalyst of a low-temperature catalytic burning integral type and a preparation method thereof. The catalyst comprises the following materials in percentage by weight: 0.1-5 active component Pt, 0.1-5 transition metal oxide as a catalyst additive by metal elements, 2-10 alumina gel, and the balance of porous material substrate, wherein the alumina gel is coated on the porous material substrate, and a mol ratio of a metal element in the Pt to the metal element in the transition metal oxide is 1: (1-20). The catalyst has good activity, high selectivity to methanol, methane, hydrogen, and the like, and has the advantages of low gas firing point, high burning efficiency, low oxygen consumption, good mass and heat transfer performance, reduced resistance, and the like. The preparation method is simple and has lower cost.

Owner:HANERGY TECH

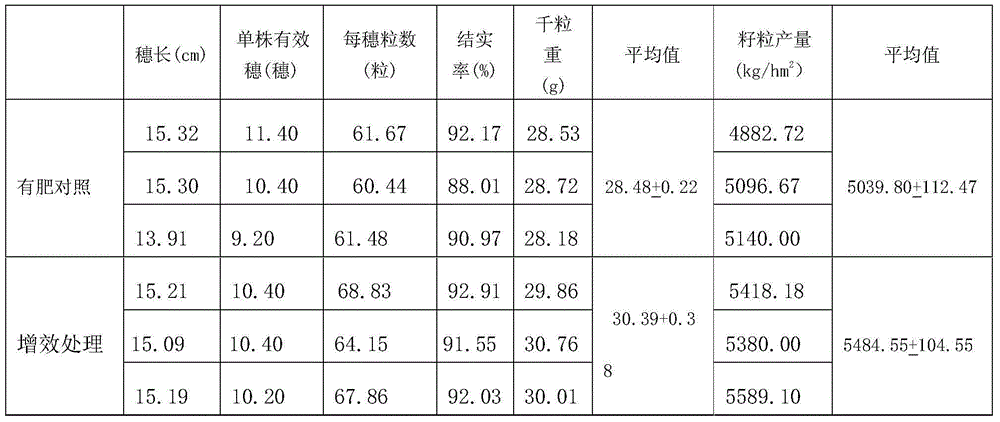

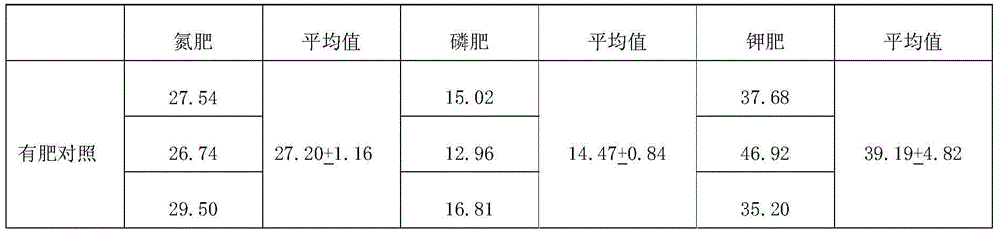

Mixing synergist capable of improving utilization rate of rice fertilizer, and use method of mixing synergist

InactiveCN104529630ALow ignition pointEnhance the ability to absorb and retain nutrientsMatrix fertilisersFertilizer mixturesBiologyAgricultural nonpoint source pollution

The invention discloses a mixing synergist capable of improving the utilization rate of a rice fertilizer, and a use method of the mixing synergist, relating to the technical field of fertilizers used by rice planting. The mixing synergist is prepared by the following raw materials in parts by weight: 1-3 parts of a urease inhibitor, 1-2 parts of a long-acting compound fertilizer additive, 0.5-1.2 parts of a synergist, and 0.5-1 part of nano carbon. The mixing synergist has the characteristics of improving the utilization rate of the rice fertilizer and the grain yield, reducing the flow rate of nitrogen and phosphorus of a farmland to a water body and soil, and controlling the agricultural non-point source pollution generated by the farmland from the source and the like. The mixing synergist capable of improving the utilization rate of the rice fertilizer provided by the invention is a mixing synergist capable of improving the utilization rate of the rice fertilizer and reducing the nitrogen and phosphorus loss, and is suitable for being applied in early and late rice planting.

Owner:HUNAN ANBANG NEW AGRI SCI & TECH +2

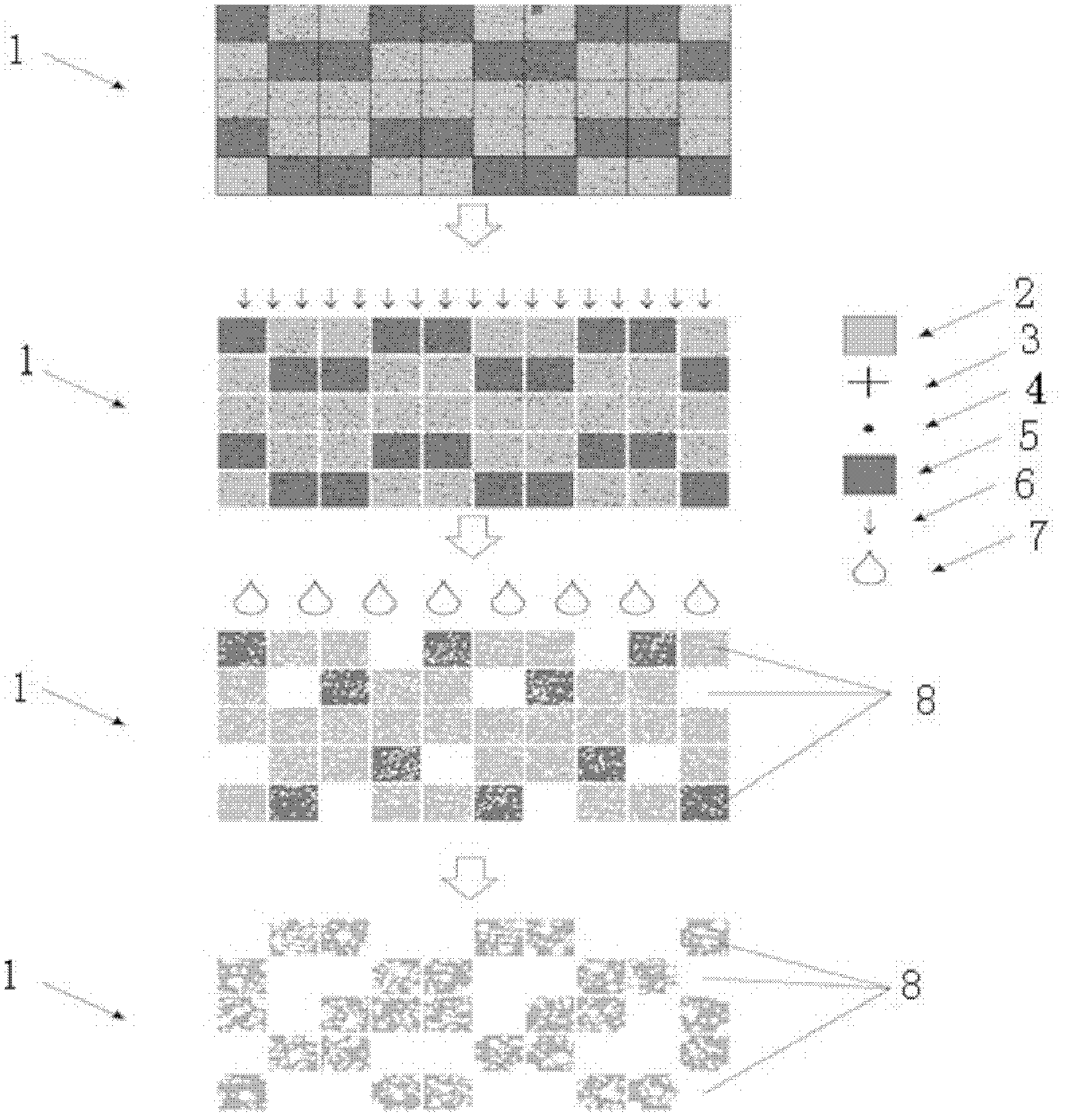

Light-biological double-degradation agricultural film

InactiveCN102492203ALow costLow ignition pointClimate change adaptationPlant protective coveringsBacillus nattoChemical structure

The invention discloses a light-biological double-degradation agricultural film, which comprises the following ingredients in percentage by weight: 81%-86% of plastic materials, 1%-3% of photosensitizer, 0.1%-0.3% of natto bacillus powder, 11%-13% of ore powder and 1%-3% of additive. The light-biological double-degradation agricultural film has the beneficial effects that: the photosensitizer, the natto bacillus powder and the ore powder are added in a polyethylene raw material for producing the agricultural film, so that the chemical structure of the agricultural film on an agricultural land can be changed (molecular weight is decreased) due to the action of natural daylight on the photosensitizer, the material strength is lowered, the phenomena of breakage and crushing occur, and the agricultural film can be quickly and effectively degraded in soil naturally after the natto bacillus powder and the ore powder are in contact with moisture in the soil.

Owner:东莞市川森环保塑料有限公司

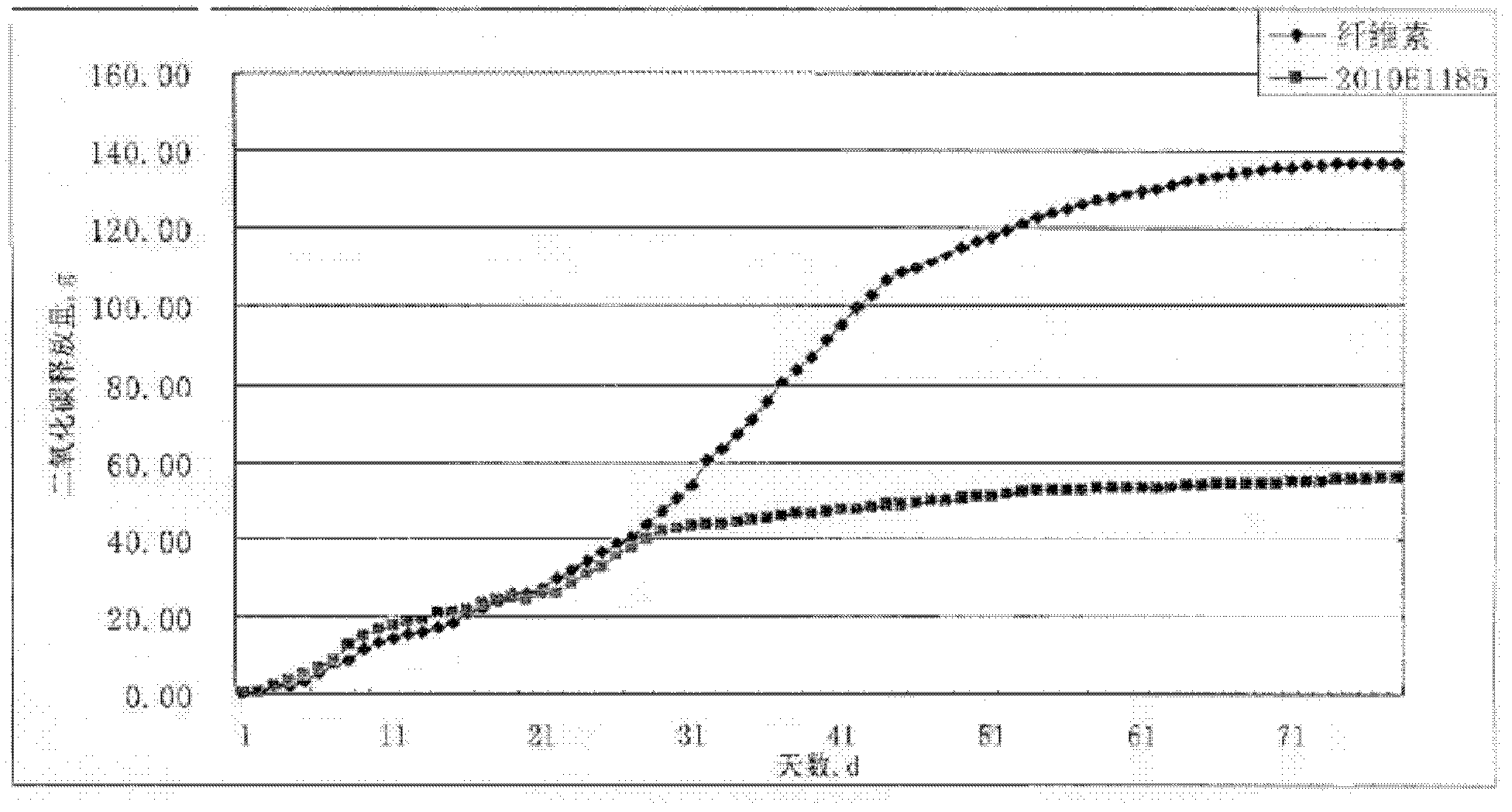

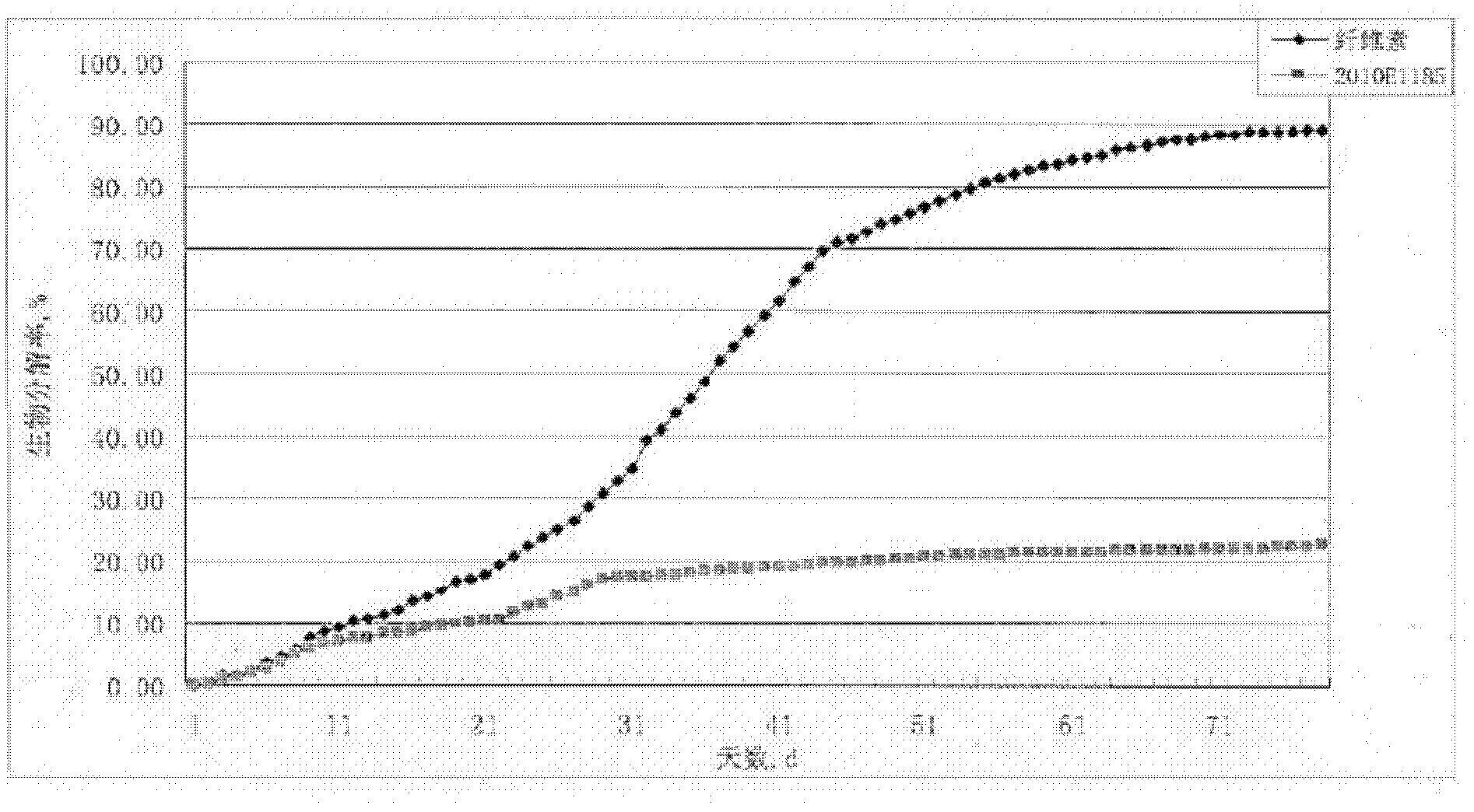

Method for preparing biomass fuel mainly from fresh chicken manure

ActiveCN106244278AWith water absorption and heat releaseReduce moisture contentBiofuelsSolid fuelsMicroorganismMushroom

The invention belongs to the technical field of environmental protection, and particularly relates to a method for preparing a biomass fuel mainly from fresh chicken manure. The method comprises the following steps: 1) pretreating raw materials; 2) fermentation: mixing fresh chicken manure, mushroom sticks and calcined shell powder, inoculating deodorizing composite microbes and nitrogen fixation-desulfurization composite microbes, and carrying out pile fermentation; 3) naturally drying the fermentation material; and 4) adding tea stems, and carrying out extrusion granulation. The fresh chicken manure is used as the main raw material, the waste mushroom sticks, calcined shell powder and tea stems are used as the auxiliary raw materials, the deodorizing composite microbes and nitrogen fixation-desulfurization composite microbes are added, and the flammability and comprehensive combustion characteristics of the reinforcing material of the composite microbes are fully utilized, thereby preparing the biomass granular fuel which has the advantages of low ignition point, high combustion heat value and high combustion rate. The method can greatly consume chicken manure, and solves the problem of environmental pollution caused by chicken manure. The method provides direction for the recycling of the waste mushroom sticks, shells and tea stems.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

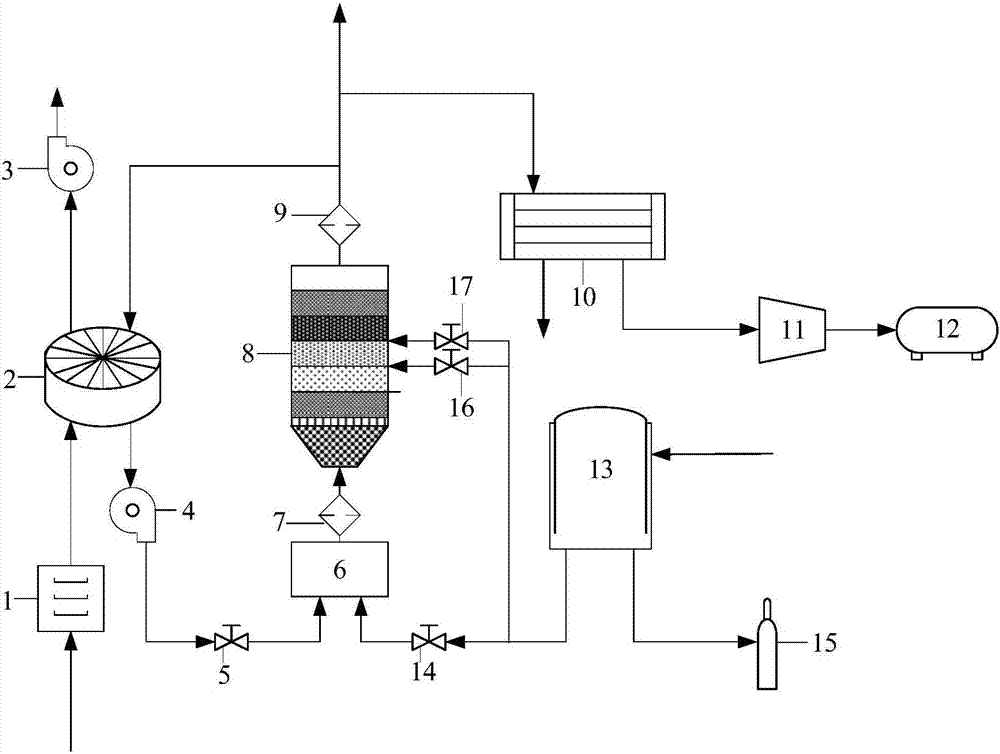

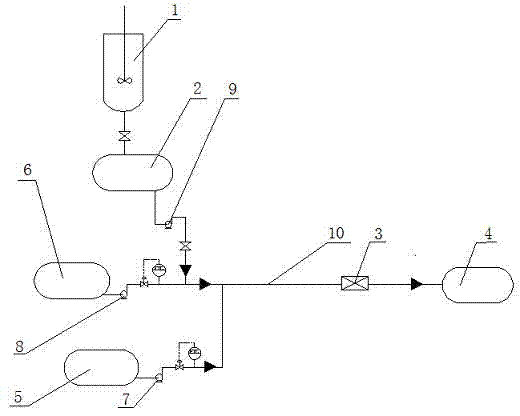

Organic exhaust gas treatment system and method

PendingCN107051033AReduce burn timeBurn fasterDispersed particle filtrationIncinerator apparatusExhaust gasCombustion chamber

The invention discloses an organic exhaust gas treatment system and method. The organic exhaust gas treatment system comprises a dust remover, an adsorber, a combustor and an oxygen source, wherein an inlet of the dust remover is connected with an organic exhaust gas source, an outlet of the dust remover is connected with an adsorption inlet of the adsorber, a desorption outlet of the adsorber is connected with an inlet of the combustor, an outlet of the combustor is connected with a desorption inlet of the adsorber, and the oxygen source is connected with an inlet of the combustor. The combustor is sequentially provided with a mixing chamber, a gas distributor and a uniform combustion chamber from bottom to top. The mixing chamber is provided with an organic exhaust gas pipeline and an oxygen pipeline. The combustion chamber is filled with a nonuniform honeycomb structure, the honeycomb structure comprises an upper layer, a middle layer and an upper layer, the middle layer is a combustion zone, the lower layer and the upper layer are smaller than the middle layer in hole diameter, and the hole diameter and porosity of the middle layer are progressively increased from bottom to top. The problems of high device requirement, easily produced secondary pollution, low combustion smoke heat utilization rate and the like of an organic exhaust gas treatment method in the prior art can be solved.

Owner:SHANDONG UNIV

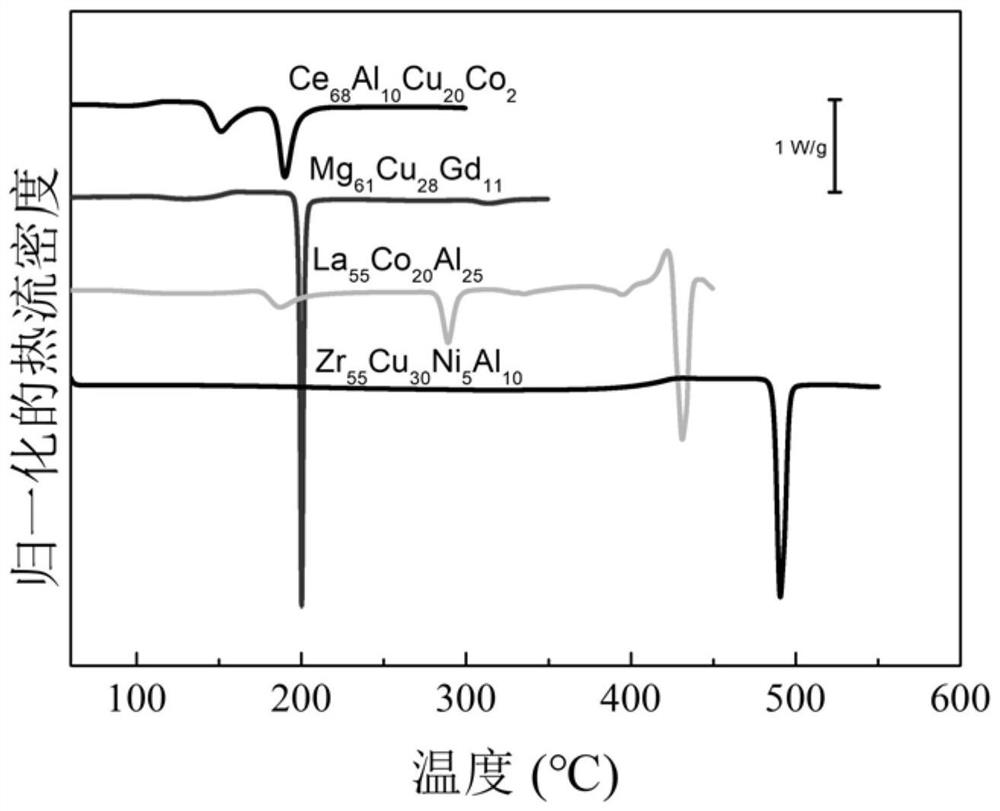

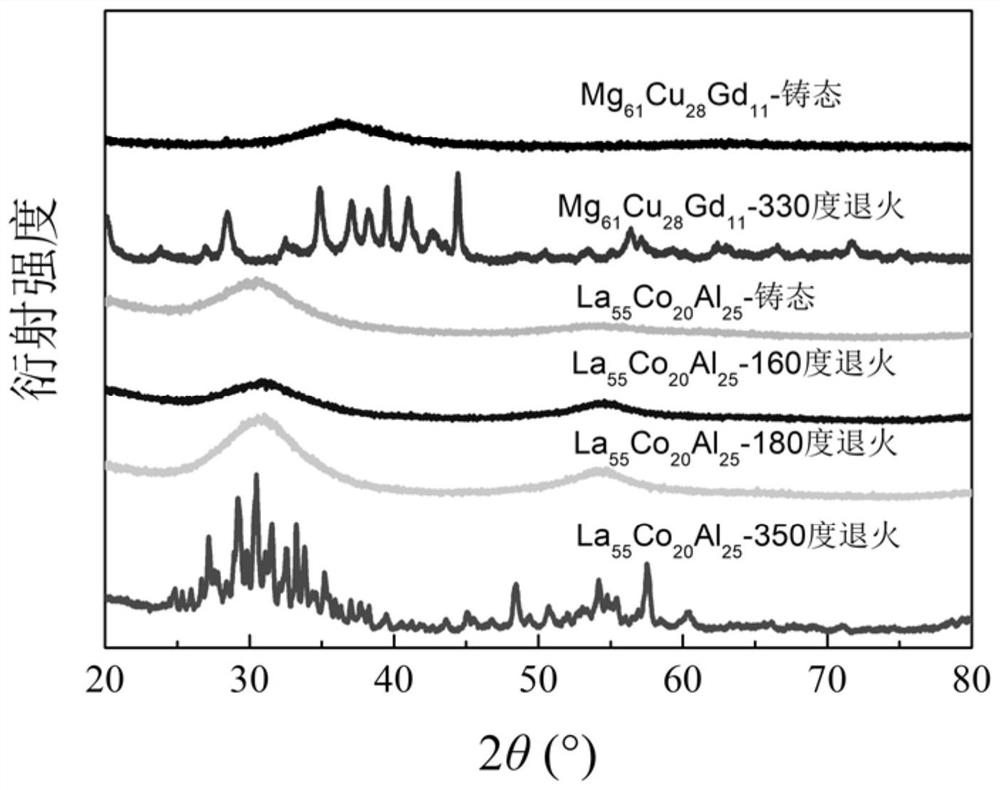

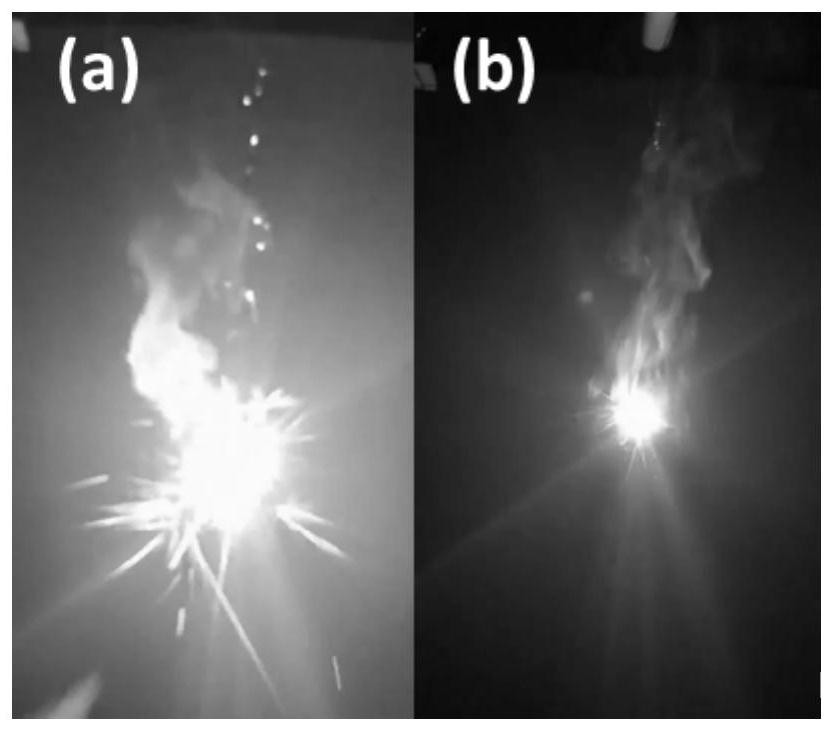

High-energy-content amorphous alloy material and preparation method and application thereof

PendingCN112981278AIncrease the calorific value of combustionNo chemical changeExplosive AgentsFireworks

The invention provides a high-energy-content amorphous alloy material. The high-energy-content amorphous alloy material contains one or more of the following elements of Mg, Al, La, Ce and Zr, the heat value of the high-energy-content amorphous alloy material ranges from 0.7 kJ / g to 30 kJ / g, and preferably ranges from 10 kJ / g to 25 kJ / g. The amorphous alloy high-energy-content material not only has a lower ignition point, but also keeps a higher combustion heat value, and is safer, lower in cost and higher in yield compared with crystalline alloy nano powder. The amorphous alloy high-energy-content material can be applied to the fields of explosives, leads, fireworks, solid propellants and the like.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Inflammable alloy and preparation method thereof

The invention discloses an inflammable alloy and a preparation method thereof. The inflammable alloy contains 35 to 45 percent of cerium, 5 to 15 percent of tin, 35 to 45 percent of zinc, 1 to 5 percent of magnesium and 5 to 10 percent of iron. The preparation method sequentially comprises the following steps of: (1) weighing cerium, tin, zinc, iron and magnesium serving as raw materials according to the mass percentage of each component in the inflammable alloy, and cutting each component into small blocks; (2) putting the components into a smelting furnace together, and performing high-temperature smelting in a state of isolated oxygen; and (3) performing electromagnetic stirring and uniform mixing after the components are smelted, discharging, cooling ingots in the state of isolated oxygen, and thus obtaining the finished inflammable alloy product. The inflammable alloy product is stable in performance, low in ignition point and strong in abrasion resistance.

Owner:李宏伟 +2

Solid biological granular fuel

The invention discloses a solid biological granular fuel. The solid biological granular fuel is characterized by containing the following substances in parts by weight: 11-19 parts of rice straw powder, 100-120 parts of corn stalk powder, 20-35 parts of sunflower stalk powder, 25-32 parts of coal slurry, 50-60 parts of soybean straw powder, 14-20 parts of pigweed cake, 14-23 parts of rice bran, 6-9 parts of camphor tree limb, 20-30 parts of rice hull powder, 10-15 parts of chicken manure and 5-10 parts of grass charcoal. The solid biological granular fuel has the advantages that the calorific value is high, the unit calorific value can reach 5,000 kilocalories, the burning point is greatly lowered, the air permeability is good, the heat energy utilization ratio is high, and the burning time can be prolonged to be longer than 3 hours from the average 1.5 hours of pure biomass fuels.

Owner:QINGDAO JINXIU SHUIYUAN COMMERCE & TRADE

Pyrethroid pesticide aqueous emulsion and method for preparing the same

InactiveCN101438700AReduce pollutionSuitable for productionBiocideArthropodicidesVegetable oilOrganic solvent

The invention discloses a synthetic pyrethroid type pesticide aqueous emulsion. Synthetic pyrethroid, vegetable oil, phosphate polyoxyethylene nonyl phenol, stabilizer, antifreezer, thickener, preservative agent and water are mixed, the shearing at high speed is carried out by using a high-shearing emulsion machine, and then the oil phase and the water phase are fully mixed into even milky milk-shaped even and stable aqueous emulsion. The pesticide aqueous emulsion utilizes the vegetable oil as the solvent of the technical grade of the synthetic pyrethroid, therefore, compared with the chemical organic solvent, the pesticide aqueous emulsion is more natural, is easier to be decomposed and more environmental-friendly, has low burning point, is non-toxic and safer, and is particularly suitable for the green nuisance-free vegetable production.

Owner:西安鼎盛生物化工有限公司

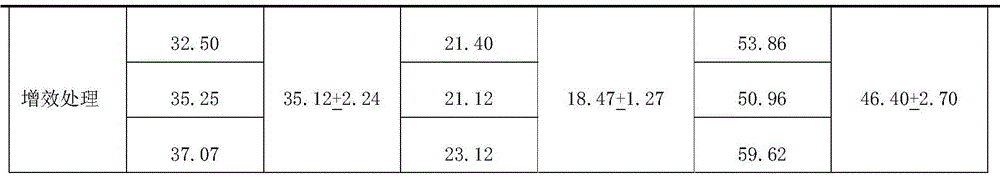

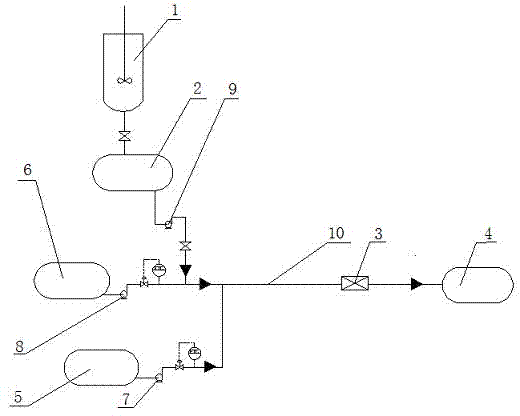

A production device and preparation method of clean dimethoxymethane diesel oil

InactiveCN102268304ALow costLow ignition pointLiquid carbonaceous fuelsFuel additivesBenzotriazoleProcess engineering

The invention discloses clean dimethoxymethane diesel oil, which is characterized in that the diesel oil is prepared by the following raw materials: dimethoxymethane, diesel oil and dimethoxymethane solution I, wherein the dimethoxymethane solution I is prepared by dissolving benzotriazole, dilinoleic acid, 2,6-tert-butyl-4-methylphenol, LD-r01 diesel lubricity improver, isooctyl nitrate(amyl nitrate) in the dimethoxymethane. A preparation method of the clean dimethoxymethane diesel oil comprises the following steps: A, mixing the dimethoxymethane, the diesel oil and the dimethoxymethane diesel oil solution I according to a ratio of 14.00:85.00:1.00, preparing D15 dimethoxymethane diesel oil; B, mixing the dimethoxymethane, the diesel oil and the dimethoxymethane diesel oil solution I according to the ratio of 29.00:70.00:1.00, and preparing the D30 dimethoxymethane diesel oil. Compared with the methanol diesel oil, the unique dimethoxymethane diesel oil in the invention has the advantages that the fire point of dimethoxymethane is low, cetane number is high and the like, and the dimethoxymethane diesel oil can be miscible with diesel oil in any proportion and has low cost and strong competitiveness.

Owner:HENAN COAL CHEM IND GROUP INST

Formula and processing technique of biomass type coal

InactiveCN102115686ASolve wasteSolve environmental problemsSolid fuelsWaste based fuelNatural resourceEngineering

The invention relates to a biomass type coal and a processing technique thereof. All the coal used at present is the naturally formed resources. The natural resources in China and even the world are limited, and the current situation of China is more worrying. At present, the task of energy saving and emission reduction in China is very arduous, the energy structure is not rational, and the raw coal accounts for more than 70% of the energy structure, occupying the first place in the world. China is a large country lacking in energy sources, and too much available waste is discarded. The biomass type coal comprises the following components in parts by weight: 40-50 parts of coal slurry, 20-30 parts of high-quality blind coal, 10-20 parts of biomass straw, 5 parts of turfy soil and 5 parts of lime. The invention is used for producing biomass type coal.

Owner:BOLI HENGQI FURNACE MFG PLANT

A composite additive for coal-fired sulfur-fixing catalytic combustion and its preparation method

A composite additive for coal-burning sulfur-fixing catalytic combustion, which is composed of a main sulfur-fixing agent and an auxiliary additive. The main sulfur-fixing agent is composed of dolomite powder and slaked lime, and the auxiliary additive is one of alumina, cerium oxide, iron oxide and quartz sand. or a combination of two or more in arbitrary proportions; its preparation method is: firstly crush dolomite powder and slaked lime to 80-300 mesh respectively and mix them according to the mass percentage, and then mix the selected auxiliary additives uniformly according to the mass percentage to prepare compound additives. The invention has the advantages of: excellent sulfur fixation effect, catalytic combustion performance and coal-saving performance; the product generated by catalytic combustion contains CaO-Al2O3-SiO2 system substances, which can wrap glassy quartz fragments in fly ash, making the original sharp The edges and corners are reduced, which reduces the wear of the fly ash on the pipeline; the preparation method is simple and easy to implement, and can be widely used in coal-fired fields such as industry, civil boilers, casting, and metallurgical power generation.

Owner:力博(天津)节能环保科技有限公司

Low-sulfur ester-based composite fuel oil

InactiveCN101812331AEasy to catch fireIncrease cetane numberBiofuelsLiquid carbonaceous fuelsBiodieselSulfur

The invention relates to low-sulfur ester-based composite fuel oil which can be used by automobile engines, various boilers and industrial furnaces. The ester-based composite fuel oil comprises biological diesel oil, dimethyl ether and an antioxidative stabilizer, wherein the biological diesel oil accounts for 51 to 99 weight percent of the ester-based composite fuel oil, the dimethyl ether accounts for 1 to 49 weight percent of the ester-based composite fuel oil, and the antioxidative stabilizer accounts for 0.0001 to 2 weight percent of the ester-based composite fuel oil. The fuel oil replaces high-price fossil fuel resources by low-cost renewable resources, belongs to oxygen-enriched fuel, has little theoretical air quantity required by combustion and sufficient combustion, can reduce the discharge quantity of flue gas, lowers the loss of the heat value of the discharge of the flue gas, lowers the concentration of sulfur and nitrogen compounds and granular dust in the discharged flue gas greatly and is beneficial to environmental protection, energy saving and discharge reduction.

Owner:KUNMING UNIV OF SCI & TECH

Inflammable sparking alloy and preparation method thereof

The invention discloses an inflammable sparking alloy and a preparation method thereof. The inflammable sparking alloy contains 20 to 25 percent of lanthanum, 15 to 20 percent of cerium, 5 to 15 percent of tin, 35 to 45 percent of zinc, 1 to 5 percent of magnesium and 5 to 10 percent of iron. The preparation method sequentially comprises the following steps of: (1) weighing magnesium, cerium, tin, zinc, iron and magnesium serving as raw materials according to the mass percentage of each component in the inflammable sparking alloy, and cutting each component into small blocks; (2) putting the components into a smelting furnace together, and performing high-temperature smelting in a state of isolated oxygen; and (3) performing electromagnetic stirring and uniform mixing after the components are smelted, discharging, cooling ingots in the state of isolated oxygen, and thus obtaining the finished inflammable sparking alloy product. The inflammable sparking alloy product is stable in performance, low in ignition point and strong in abrasion resistance.

Owner:李宏伟 +2

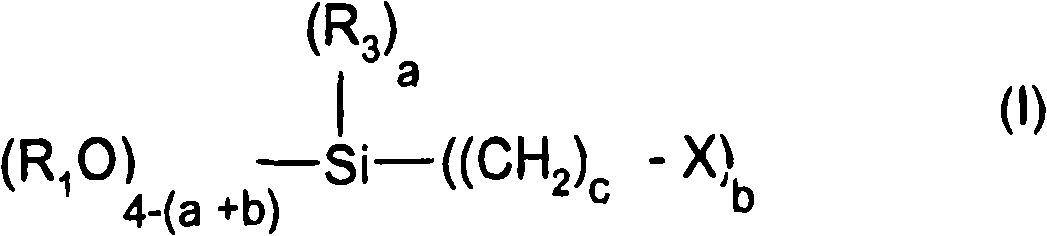

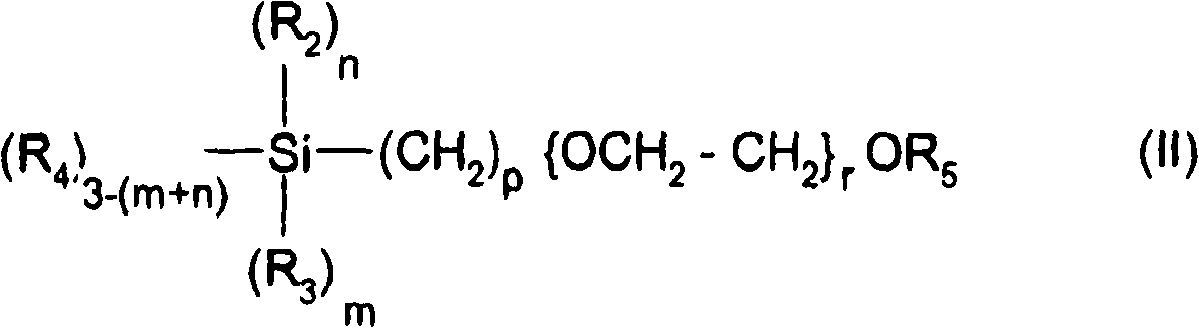

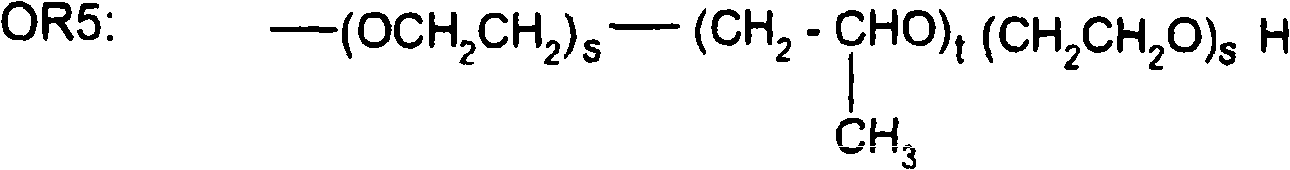

Aqueous emulsion containing organic silicon compound, preparation and use thereof in surface treatment

The invention provides a waterborne emulsion containing an organic silicon compound, and a preparation thereof and the application to surface treatment thereof. The invention discloses the waterborne emulsion containing the organic silicon compound which is used for surface treatment of inorganic base material, and also discloses a preparation thereof, a preparation of a specific organic silicon compound, and the application of the waterborne emulsion. On one hand, the invention relates to the waterborne emulsion containing the organic silicon compound, which is suitable for impregnating inorganic materials, especially for impregnating building materials, and also relates to the preparation of the special organic silicon compound such as the compound with the general formula II, and the application of the emulsion; on the other hand, the invention relates to a waterborne oil-in-water emulsion of functional alkoxy silane and siloxane oligomer, the preparation of the emulsion in a high-pressure emulsifying device, and the application of the emulsion to surface treatment of organic materials and inorganic materials. The size distribution of drops which is from 0.6 to 1.2 of the oil-in-water emulsion is preferably selected, and the size distribution is expressed by the value of Span.

Owner:GOLDSCHMIDT CHEM CORP

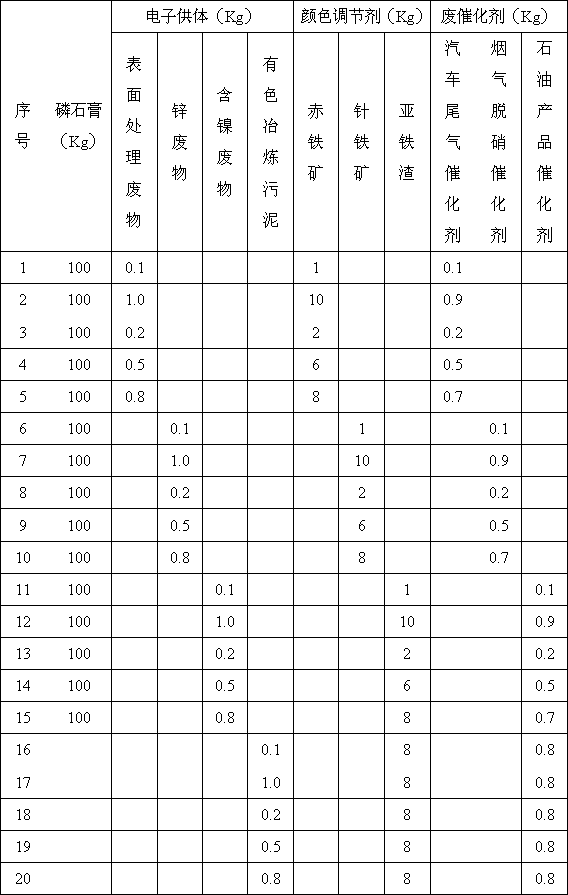

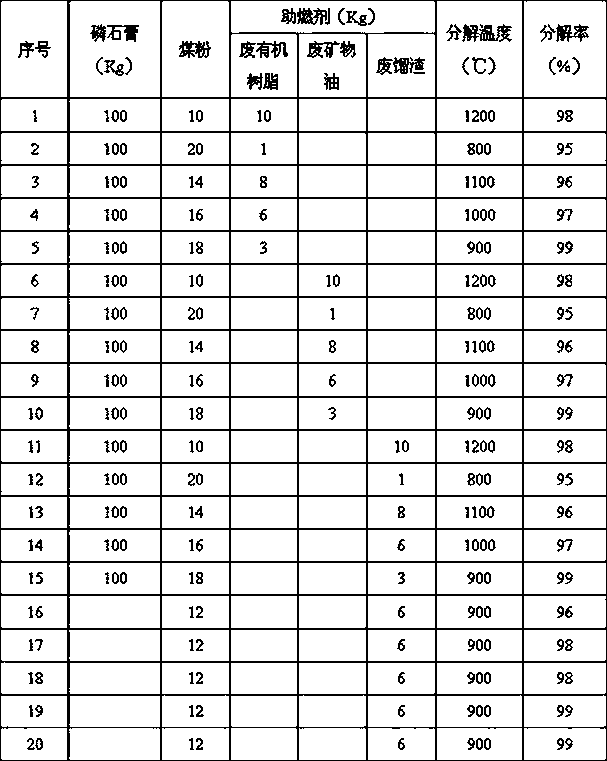

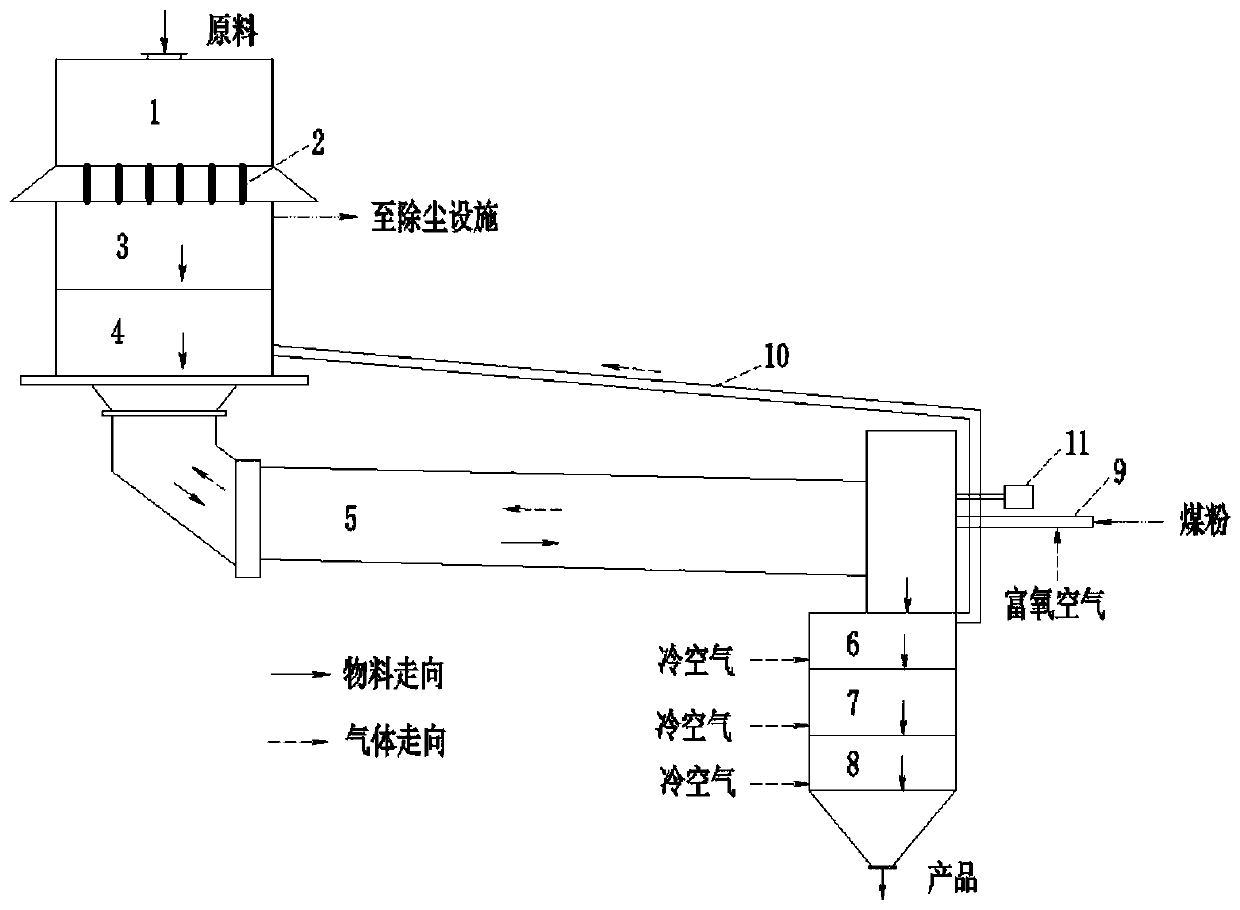

Method for utilizing sulfur and calcium resources in gypsum respectively

ActiveCN109650345ALower decomposition temperatureLow costSulfur compoundsCalcium/strontium/barium oxides/hydroxidesCombustionElectron donor

The invention discloses a method for utilizing sulfur and calcium resources in gypsum respectively, and the method is as follows: adding an electron donor, a color modifier, a waste catalyst and microorganisms into the gypsum, uniformly mixing, aging and drying to obtain a dry material; introducing coal powder and a combustion improver into a boiling furnace to decompose the dry material in the boiling furnace to obtain a sulfur oxide gas and calcium oxide with color. Compared with the prior art, the method has the advantages of low production cost, high production efficiency and thorough decomposition.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Process method for preparing active calcium oxide through oxygen-enriched calcination

InactiveCN110627384AHigh activityLow ignition pointCalcium/strontium/barium oxides/hydroxidesDecompositionHeat transfer efficiency

The invention discloses a process method for preparing active calcium oxide by oxygen-enriched calcination. The process method the following steps of firstly crushing and sieving raw limestone to enable the particle size of the raw limestone to be 10-55 mm, conveying the raw limestone into a stock bin with a circular cross section, wherein the stock bin is arranged at an upper part of a vertical preheater; then, uniformly conveying the raw materials in the stock bin into the vertical preheater through a blanking pipe, and preheating the raw materials by using high-temperature kiln gas and cooling gas of a vertical cooler; then, feeding the materials into a rotary kiln, and importing oxygen-enriched air from a kiln head to perform oxygen-enriched calcination; and then, feeding the calcium oxide obtained after calcination and decomposition into the vertical cooler to be cooled by air, namely, obtaining the active calcium oxide. According to the process method disclosed by the invention,through the integration of the processes of graded preheating, oxygen-enriched calcination, graded cooling, dynamic temperature monitoring and the like, and the raw materials are preheated by combining the high-temperature kiln gas and the high-temperature gas discharged from the cooler, the heat transfer efficiency of the system is greatly improved, the activity of calcium oxide is obviously improved, the energy consumption is reduced, and the energy conservation and emission reduction are realized.

Owner:HUBEI UNIV

Biomass compound coal for tobacco flue-curing and preparation method thereof

InactiveCN101899344AHigh volatile contentReduce carbon contentSolid fuelsWaste based fuelAdhesiveAnthracite

The invention discloses biomass compound coal for tobacco flue-curing, which is especially suitable for combustion requirements of bulk curing barn curing equipment. The invention also discloses a preparation method thereof. The invention adopts the following technical scheme to realize the aims: the biomass compound coal for tobacco flue-curing is prepared by the following components by weight percent: 57-95% of coal slime, 0-19% of soft coal with high heat productivity, 0-19% of anthracite, 2-3% of smashed plant straw and 2-2.5% of adhesive, wherein the compound coal also comprises a sulphur fixing agent; and the preparation method has the steps of weighting and mixing the components, and evenly pressing to obtain the product. Based on the scheme, the biomass compound coal for tobacco flue-curing can be obtained, which is especially suitable for combustion requirements of bulk curing barn curing equipment.

Owner:YUNNAN TOBACCO CORP QUJING BRANCH

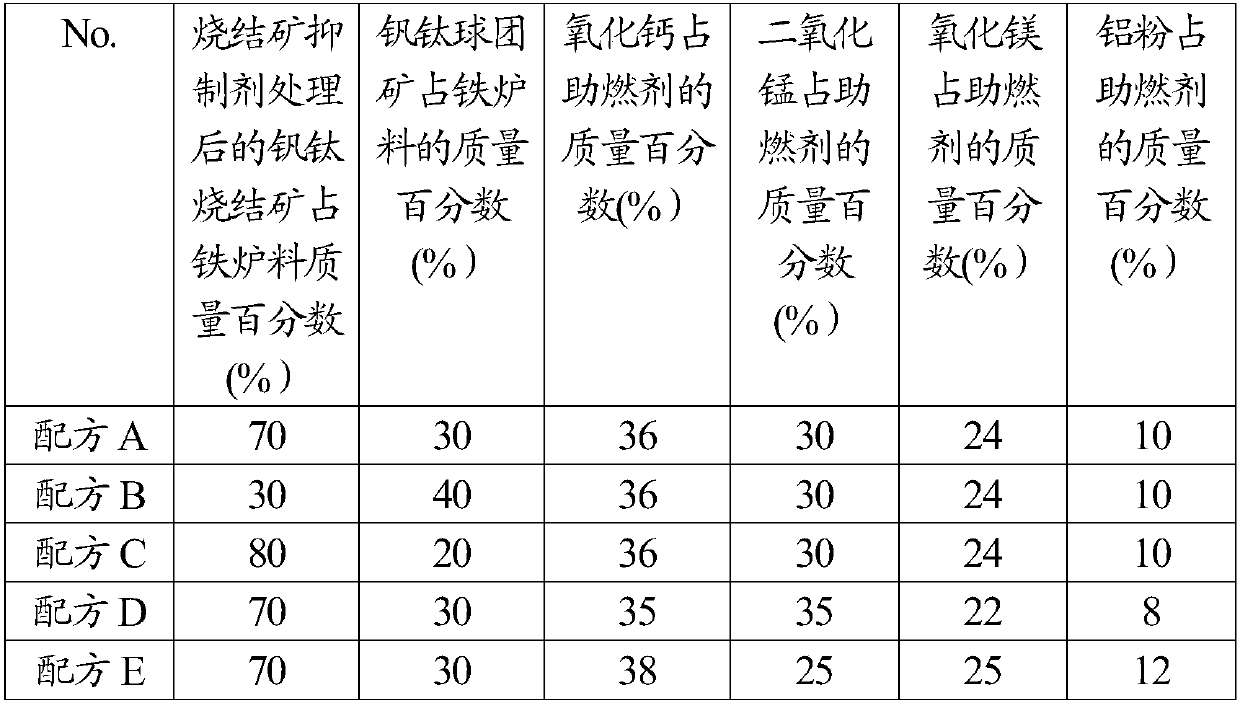

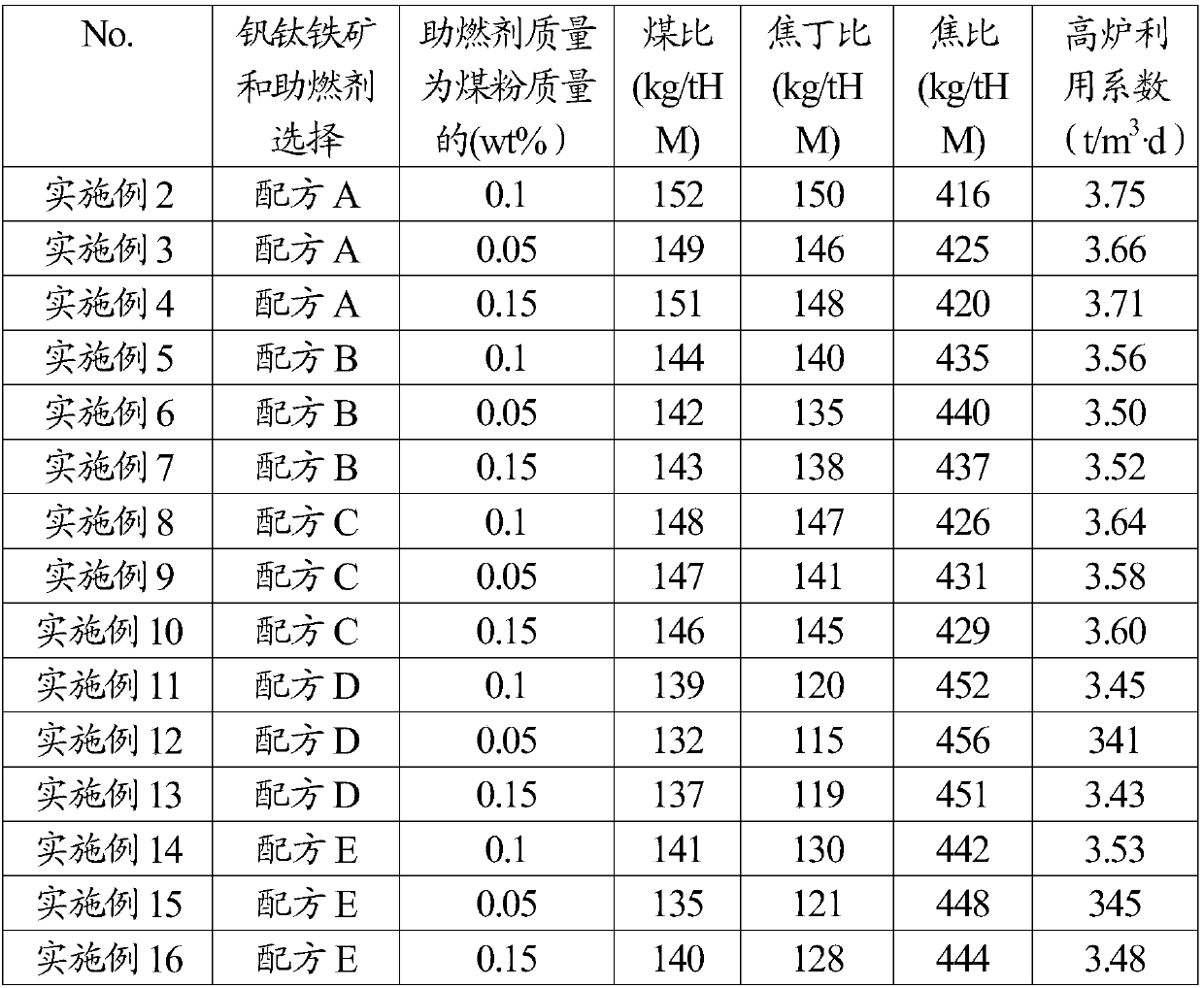

Blast furnace smelting method capable of lowering coke ratio and increasing coal ratio

InactiveCN107641670AEliminate internal stressReduce the pulverization rate of low temperature reductionBlast furnace detailsSmelting processBlast furnace smelting

The invention discloses a blast furnace smelting method capable of lowering coke ratio and increasing coal ratio. The blast furnace smelting method comprises the following steps: uniformly mixing vanadium-titanium sinter, vanadium-titanium pellets and coking ore processed by a sinter inhibitor to form an ore layer, wherein the vanadium-titanium sinter in the ore layer accounts for 60% to 80% of the total mass of iron furnace charge, and the vanadium-titanium pellets account for 20% to 40% of the total mass of the iron furnace charge; alternately distributing coke and the ore layer into a blastfurnace to form the alternate layer structure of the ore layer and the coke; mixing a combustion improver with pulverized coal to obtain a mixture; injecting the mixture into the blast furnace to becombusted; the combustion improver comprises 35% to 38% of calcium oxide, 25% to 35% of manganese dioxide, 22% to 25% of magnesium oxide and 8% to 12% of aluminum powder calculated in percentage by mass; the combustion improver accounts for 0.05 to 0.15% of the mass of coal calculated in percentage by mass; the technical indexes of the smelting process are that the coke ratio is 416 to 456 kg / tHM,the coking ratio is 115 to 150 kg / tHM, the coal ratio is 132 to 152kg / tHM, the blast temperature is 1150 to 1250 DEG C, and oxygen enrichment is greater than 2500m<3> / h; by adopting the blast furnacesmelting method, the coke ratio can be lowered, and the coal ratio and utilization coefficients of the blast furnace are increased.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

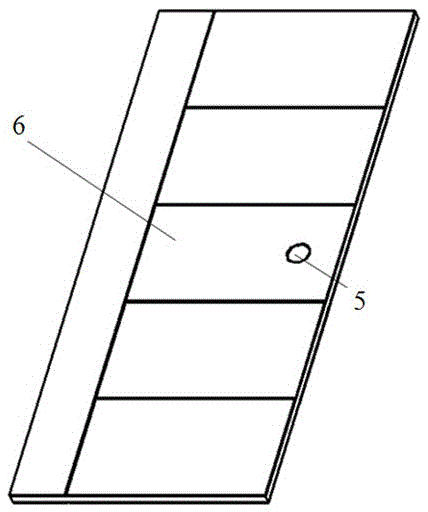

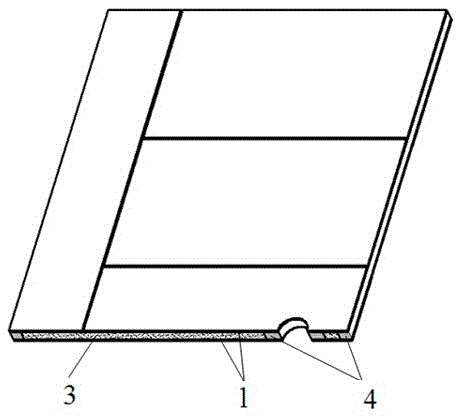

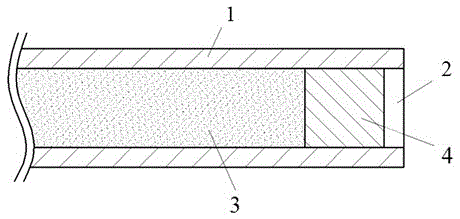

Novel composite luxury wood-like compression-molded door and manufacturing method

The invention relates to a novel composite luxury wood-like compression-molded door and a manufacturing method. According to the technical scheme, the novel composite luxury wood-like compression-molded door comprises a composite door skin plate and a supporting frame fixed to the periphery of the door skin plate, wherein the composite door skin plate is made of an SMC flake molding compound as a raw material; a cavity is formed in the door skin plate and filled with a polyurethane foamed high polymer material, a lock hole is formed in the door skin plate, a solid-wood block structure is embedded in the lock hole, and a wood-like texture structure is designed on the surface of the door skin plate. The novel composite luxury wood-like compression-molded door and the manufacturing method have the advantages that better permeability and mobility are achieved, and the oil absorption rate is lower; by improving the chemical molecular structure of a resin matrix, gaps among molecules are enlarged and can be filled with more aluminum hydroxide micro powder, and the flame retardant effect is more outstanding. Compared with other flame retardant type auxiliaries, water can be decomposed by aluminum hydroxide in the burning process so that the ignition point of inflammable materials can be effectively increased, the flame retardant effect is achieved, and the process is nontoxic and harmless.

Owner:SHENGLI OIL FIELD XINDA PIPE IND TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com