Patents

Literature

71results about How to "Easy to catch fire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production process of environmental-protection plant energy particle fuel

InactiveCN101892108AReduce pollutionMeet the requirements of energy saving and emission reductionBiofuelsSolid fuelsEnergy particleSolid fuel

The invention relates to a production process of an environmental-protection plant energy particle fuel, which is characterized by collecting combustible plant materials as raw materials and then sequentially processing the raw materials by the following steps of: (1) pulverizing: the raw materials are pulverized into powdery particle materials with the particle size less than 2 mm; (2) drying: the pulverized materials are dried so that the water content of the materials is 12%-20% by drying; and (3) extrusion molding: extrusion molding is carried out to the dried materials so that the materials form a solid particle fuel with the density of 1.0-1.4 g / cm<3> through extrusion molding. The invention can be used for processing various combustible plant materials comprising agricultural or forestall wastes and the like into high-efficiency combustible solid fuel particles, thereby solving the problem of considerably increased agricultural (forestall) wastes at present, also relieving the current situation of increasing energy shortage at present and being beneficial to environmental protection and energy saving.

Owner:福建泰和生物质能源科技有限公司 +2

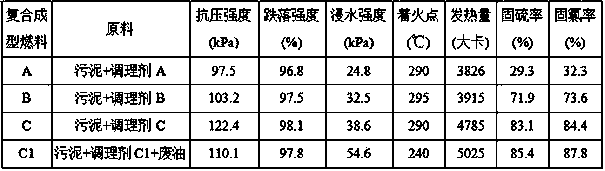

Environment-friendly sludge compound briquette fuel and preparation method thereof

The invention discloses an environment-friendly sludge compound briquette fuel and a preparation method thereof. The method comprises the steps of firstly, carrying out sludge dewatering pretreatment; uniformly mixing shell powder, aluminum powder and biomass powder to obtain a conditioner; then, cutting the dewatered sludge, mixing the dewatered sludge and the conditioner, pressing the mixture to form a granular material, drying, then, immersing the granular material into a layer of waste oil, and airing to obtain the environment-friendly sludge compound briquette fuel. The environment-friendly sludge compound briquette fuel is high in compressive strength larger than 95kPa and drop strength larger than 95% which are both far higher than the mechanical performance of briquette coal; the sulfur and chlorine fixation effects are good and can be respectively up to 85.4% and 87.8%; the calorific value can be up to 5025 kilocalories; the wet strength is up to 54.6kPa, the ignition point is reduced to 240 DEG C, the moisture resistance and waterproofness are remarkably improved, and the inflammability is enhanced; aluminum powder and combusting metal oxides can be subjected to reaction similar to aluminothermic reaction, so that the complete combustion of carbon granules is accelerated, reductive pollution gases are prevented from being generated, and the combustion activity is high; and in addition, the preparation method has the advantages of simplicity in operation, easiness for obtaining raw materials, low cost, little environment pollution and the like.

Owner:广州福之源环保科技有限公司

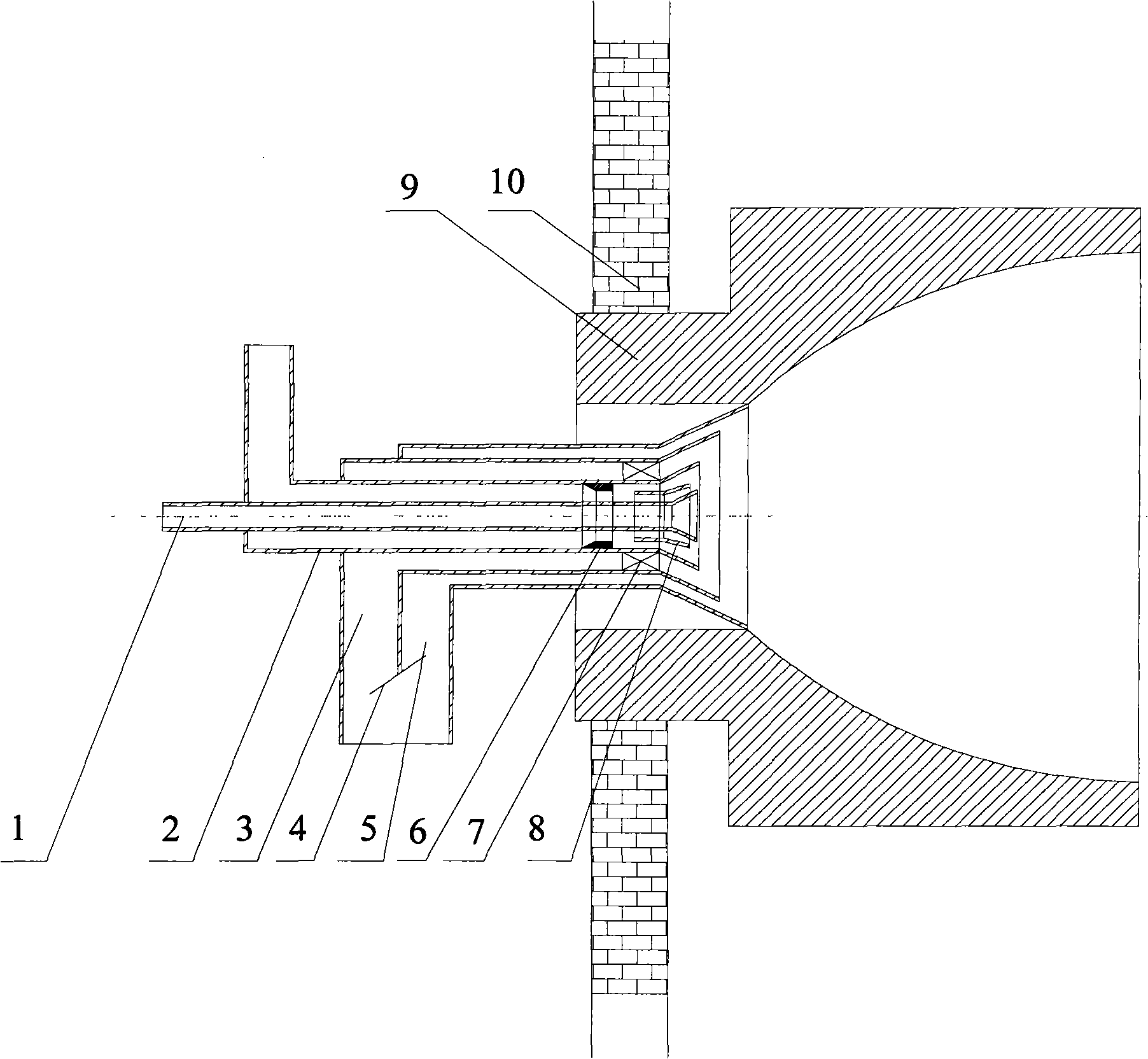

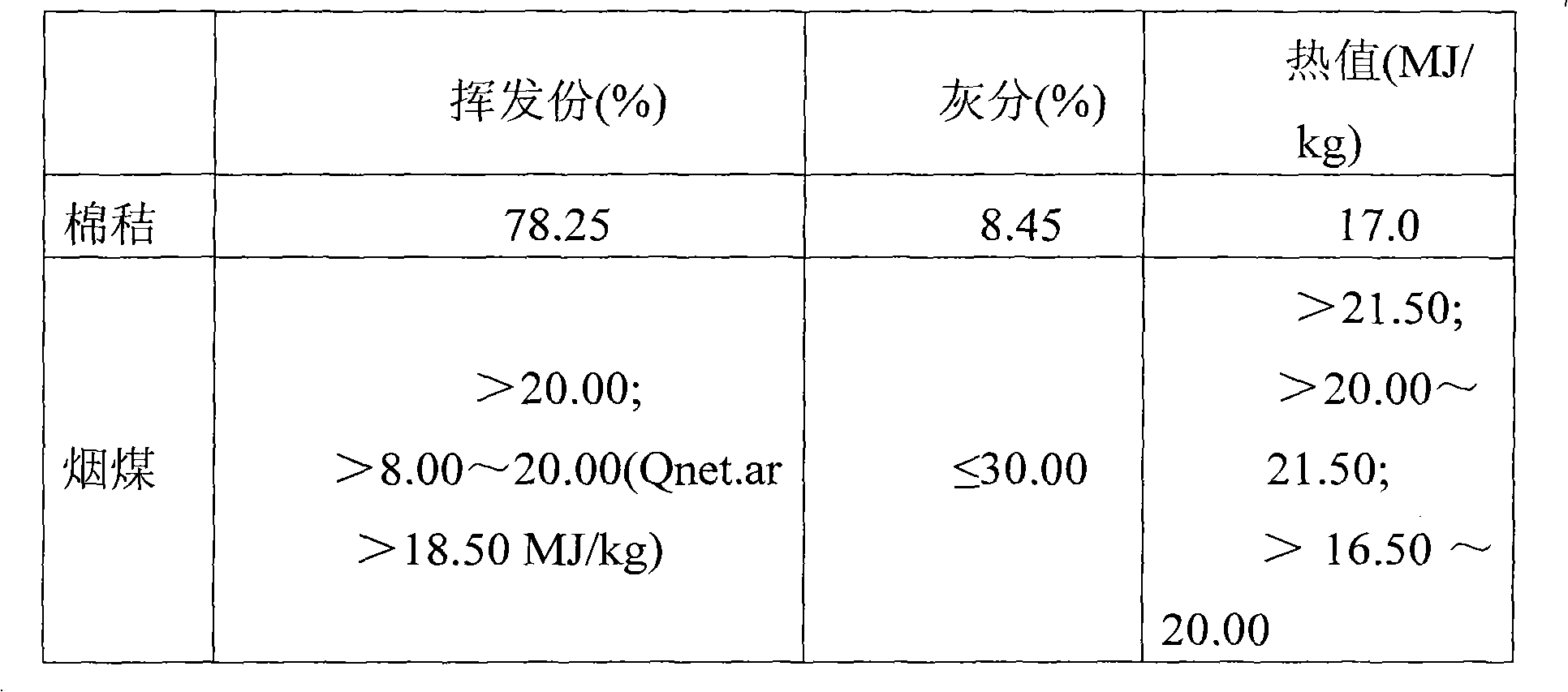

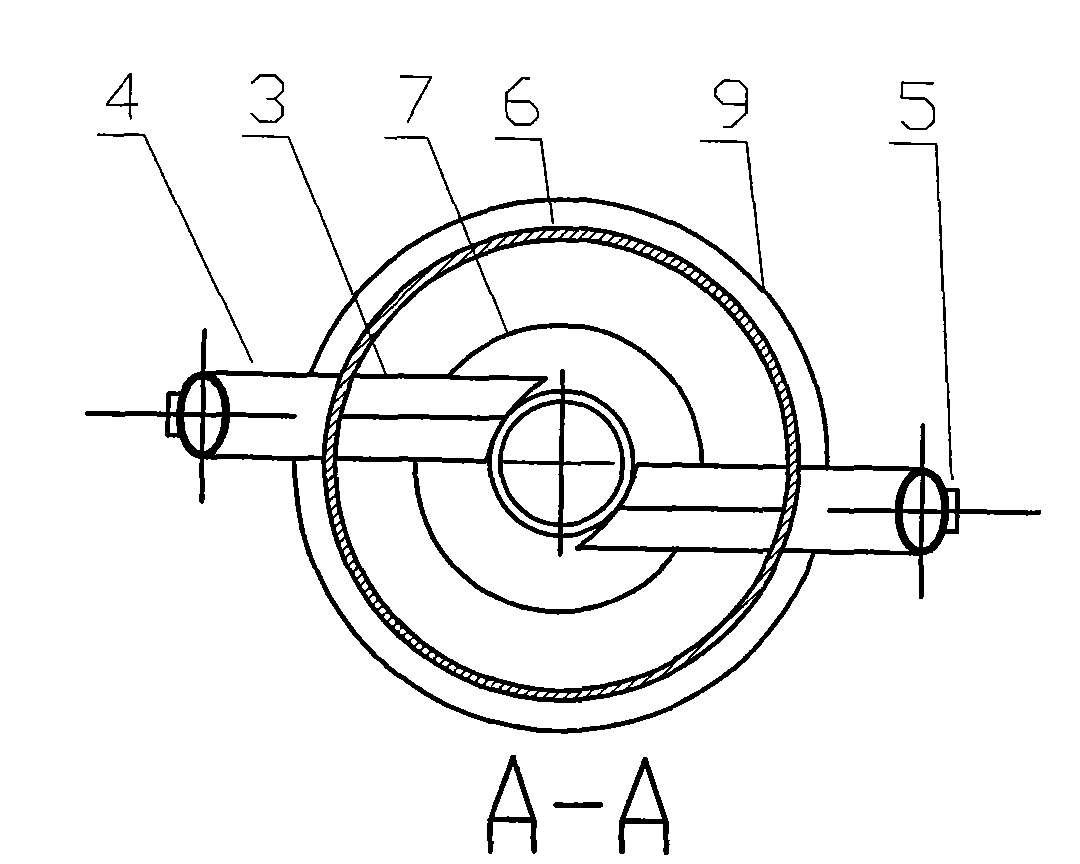

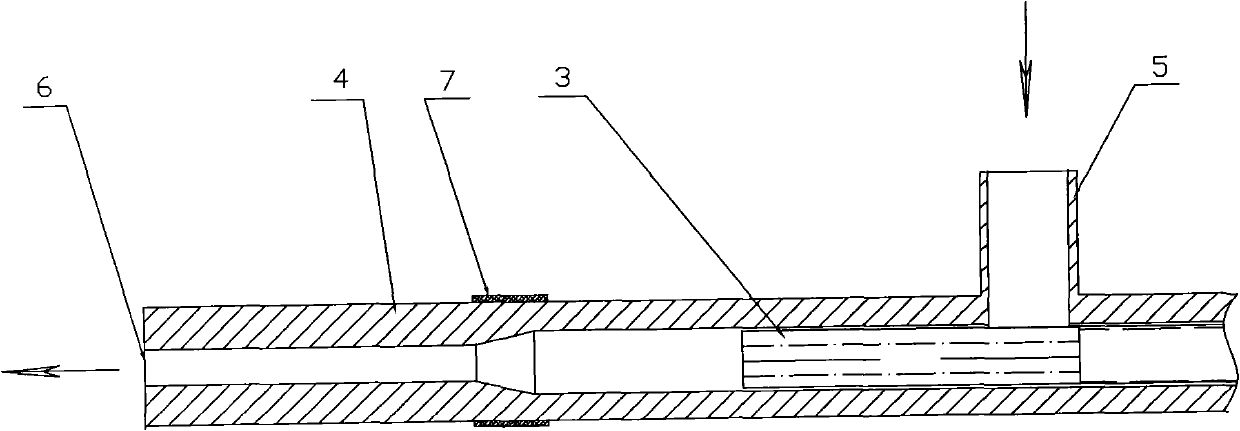

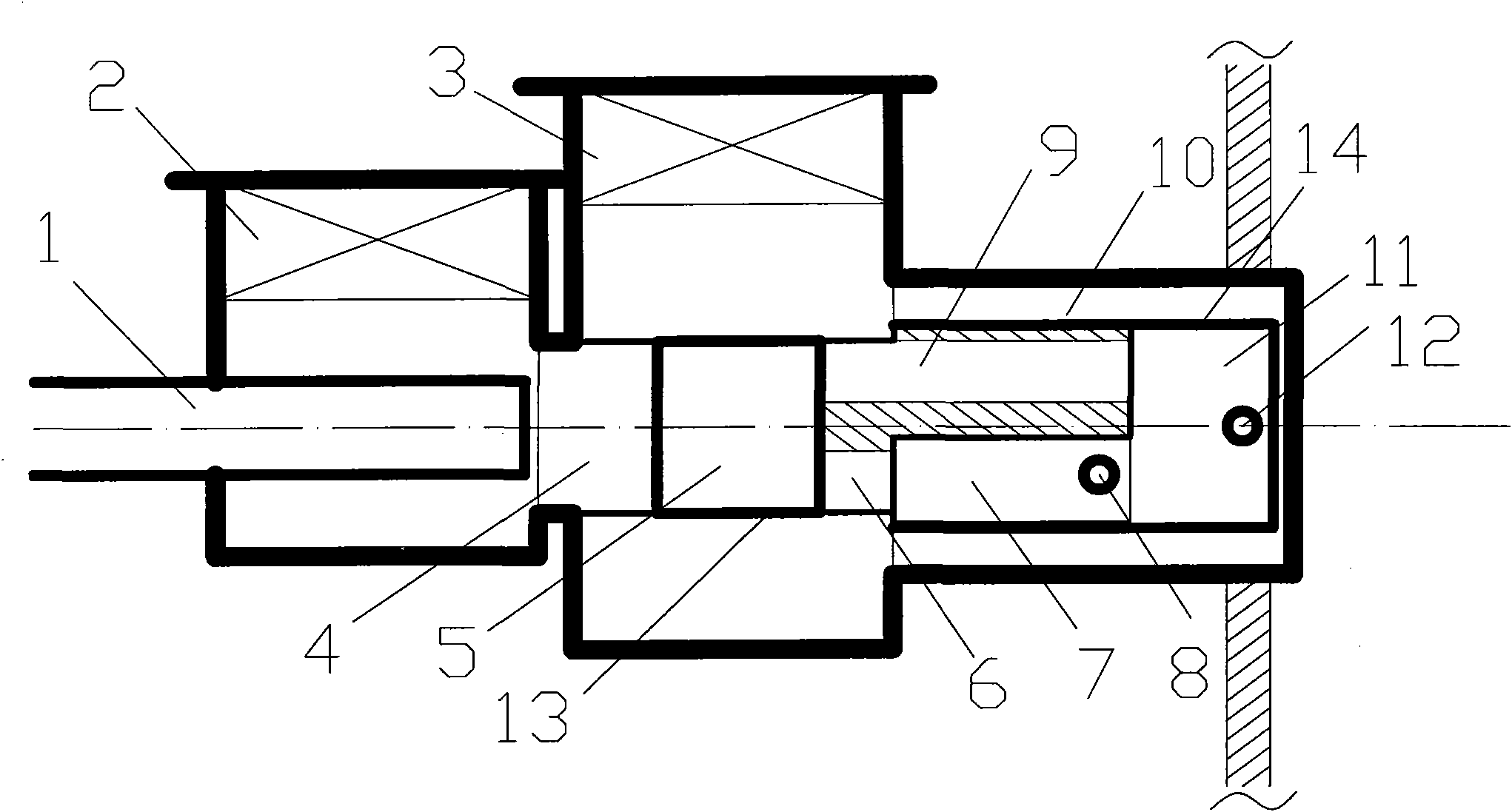

Adjustable type petroleum coke powder strengthening and burning device

InactiveCN101539292ACatch fire quicklyEasy to catch firePulverulent fuel combustion burnersCombustorMature technology

The invention relates to an adjustable type petroleum coke powder strengthening and burning device which comprises a high-temperature heat storage cavity and an adjustable type multi-stage burner. Aiming at the characteristics of low volatile component content and high burning NOx content of the petroleum coke powder, the device adopts a method for combining techniques of strengthening the heating-up speed of the petroleum coke powder, reducing the ignition heat, and the like so as to achieve the stable ignition and low-pollution burning of the petroleum coke powder. The depth of both the high-temperature heat storage cavity and a flaring structure of a central pipe for inserting in a hearth can be adjusted so as to adapt to the influence of the load change of a burning device. The device has strong pertinence and has the characteristics of convenience, adjustment, mature technology, high burning efficiency and convenient processing and manufacturing.

Owner:XI AN JIAOTONG UNIV

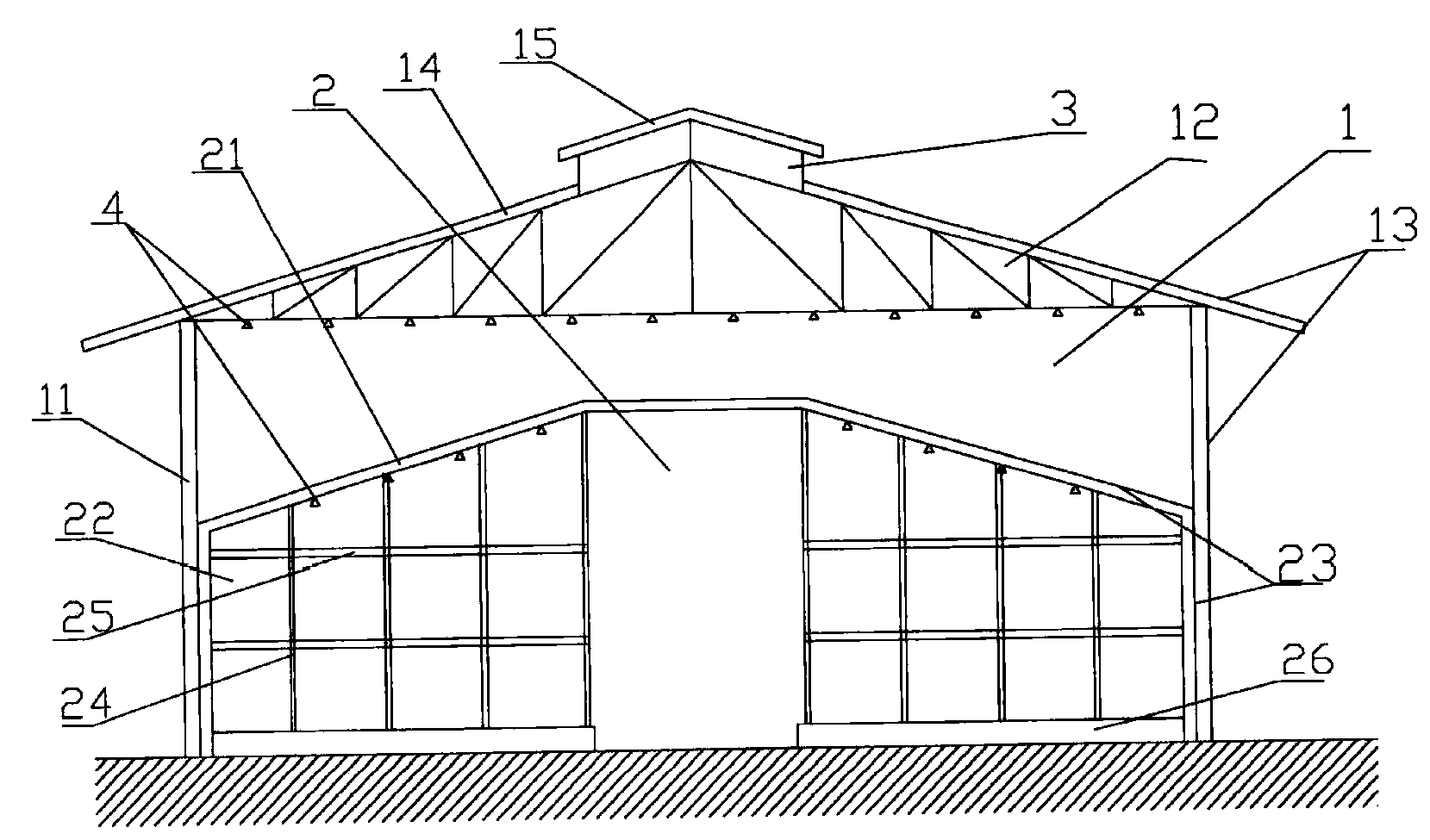

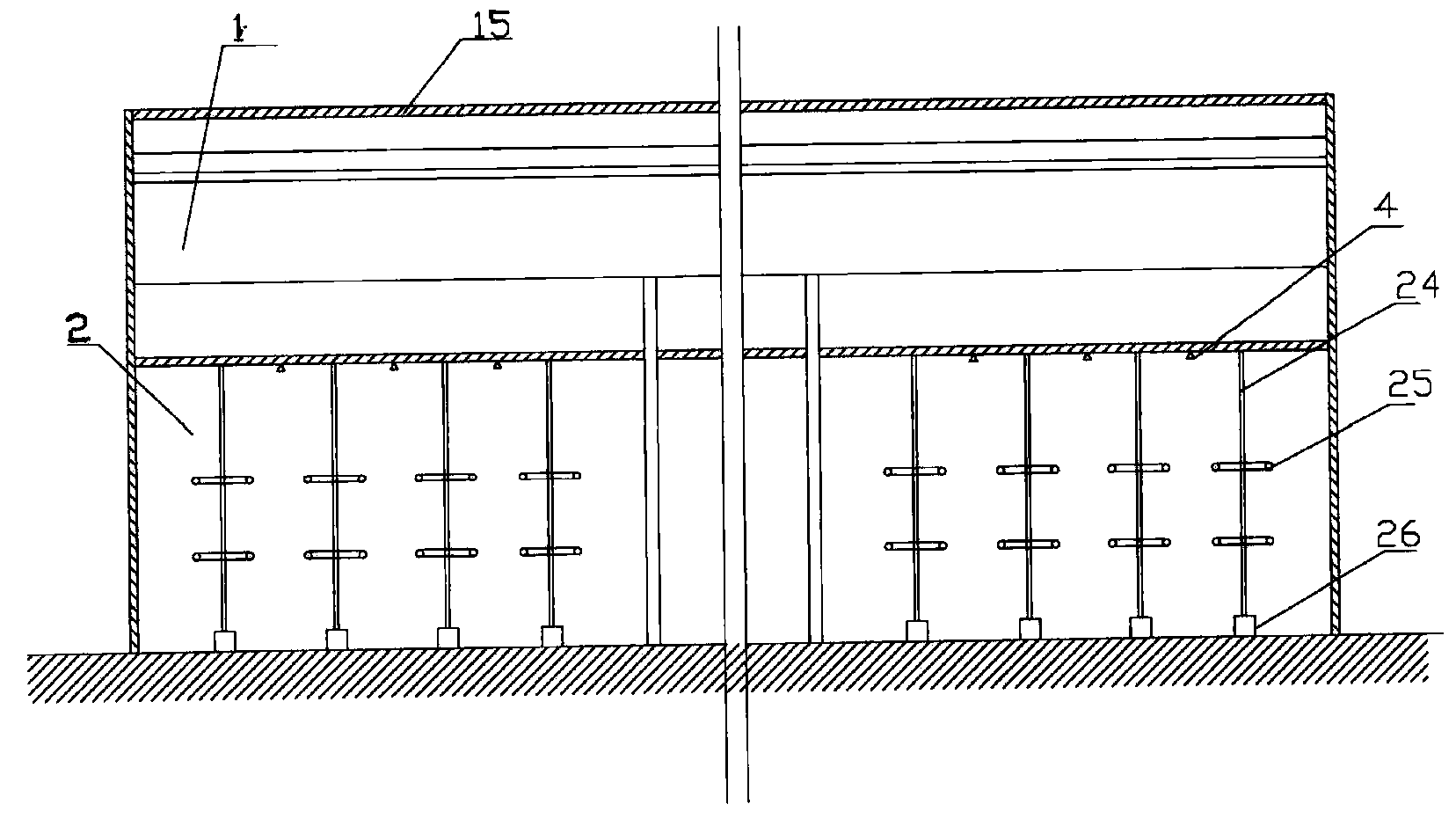

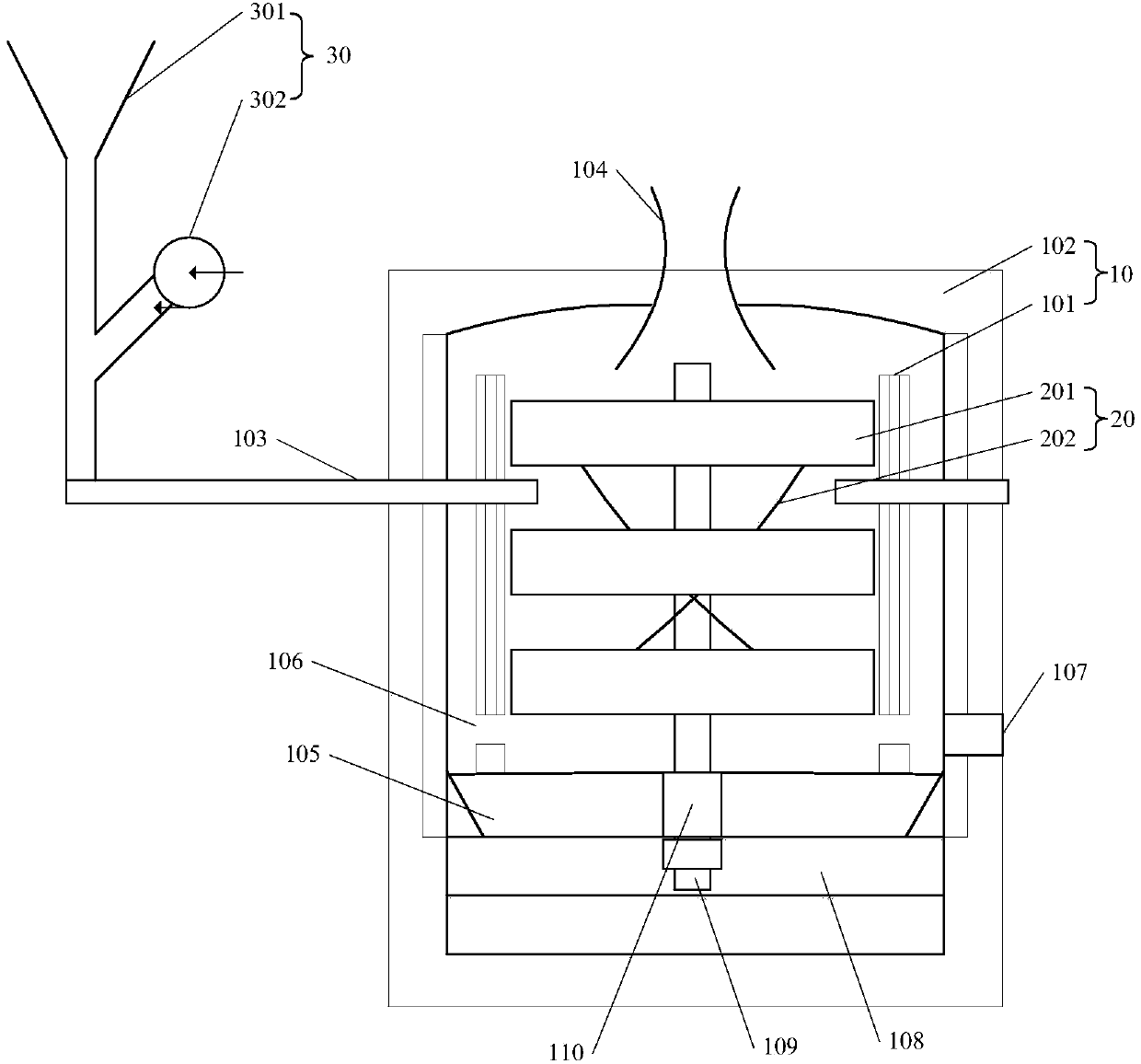

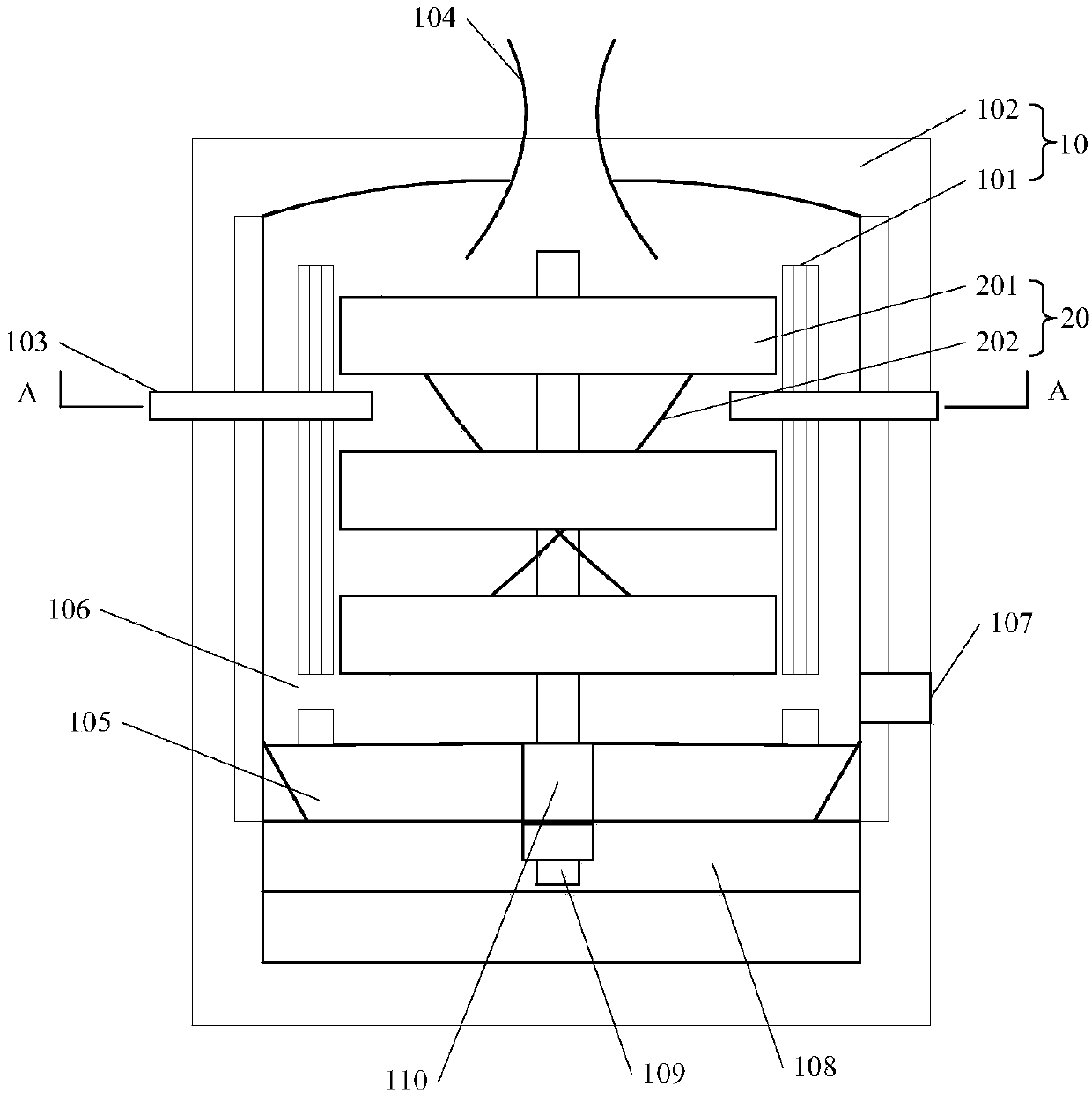

Special double-layer temperature-controllable steel frame pleurotus geesteranus greenhouse and thermoregulation fruiting stimulating cultivation method thereof

ActiveCN104335821AIncrease productionImprove qualityClimate change adaptationGreenhouse cultivationGreenhouseSteel frame

The invention provides a special double-layer temperature-controllable steel frame pleurotus geesteranus greenhouse and a thermoregulation fruiting stimulating cultivation method thereof. The special double-layer temperature-controllable steel frame pleurotus geesteranus greenhouse comprises an outer bracket canopy used as an outer layer and an inner shelf canopy used as an inner layer, wherein the outer bracket canopy comprises a canopy frame, a roof and a canopy frame outer surface covering, the outer bracket canopy and the inner shelf canopy positioned in the inner layer are two sealed canopy frames independent from each other, and the inner shelf canopy is wrapped in the outer bracket canopy; a ventilation opening is formed in the roof of the outer bracket canopy; the inner shelf canopy comprises a shelf canopy roof, a shelf and a shelf canopy outer surface covering, and cooling and humidifying devices are arranged in both the outer bracket canopy and the inner shelf canopy. The special double-layer temperature-controllable steel frame pleurotus geesteranus greenhouse has the characteristics that thermoregulation, humidification, heat insulation and ventilation can be achieved, the convenient regulation of whole micro-climate environment in the pleurotus geesteranus greenhouse can be realized, and pleurotus geesteranus fungus bags can be effectively and conveniently stimulated by temperature differences on site, so that labor cost can be reduced, and both the yield and quality of edible fungi can be improved.

Owner:吴泽英

Biomass carbon-based briquetted coal for replacing fossil fuel and production process thereof

InactiveCN102161926AWide variety of sourcesNo pollution in the processBiofuelsSolid fuelsMoisture regainCarbon-based fuel

The invention discloses biomass carbon-based briquetted coal for replacing fossil fuel. The biomass carbon-based briquetted coal for replacing fossil fuel, based on 100 mass parts of agricultural and forest biomass raw material, comprises the following auxiliary materials: 0.01 to 0.05 mass percent of swelling agent, 0.001 to 0.005 mass percent of potassium permanganate oxidizer and 0.1 to 0.5 percent of calcium lignosulphonate organic binder. The production process comprises: crushing, drying, mixing and stirring the raw materials; subjecting the stirred raw materials to primary prepressing and secondary compression forming, and performing moisture regain preventing treatment; and finally, packaging finished product. Besides high density, convenience for storage and transport, high combustibility, high combustion performance, high heat efficiency, the biomass carbon-based briquetted coal produced by the process also has the advantages of generating less ash, hardly generating SO2 andNOx during combustion, avoiding environment pollution and the like. The carbon-based fuel disclosed by the invention is prepared from widely available raw materials and is environment-friendly, and the environmental-protection benefit of the carbon-based fuel is very obvious.

Owner:周之海

Dehydrating combustion treating method for living refuse

InactiveCN1644986AHigh calorific valueImprove burnout rateIncinerator apparatusGrain treatmentsPretreatment methodCombustion

This invention is a dewatering burning treatment method of household garbage. Mechanical dewatering pretreatment method is adopted to replace the heat drying pretreatment method, household garage is broken up at first then efficient deep dewatering process is carried out by high speed centrifuge after removing water by filtering, the garbage dewatered is sent into the furnace to burning, the amount of the calorific power generated is increased by burning garbage through controlling the burning temperature and residence time of flue gas, the amount of generating dioxin is reduced too. The fluw gas generated by burning will be discharged after spray damp dry acid stripping and dsting. This invention can raise the burning temperature of garbage, and reduce the cost for flue gas treatment and environment pollution.

Owner:SHANGHAI JIAO TONG UNIV

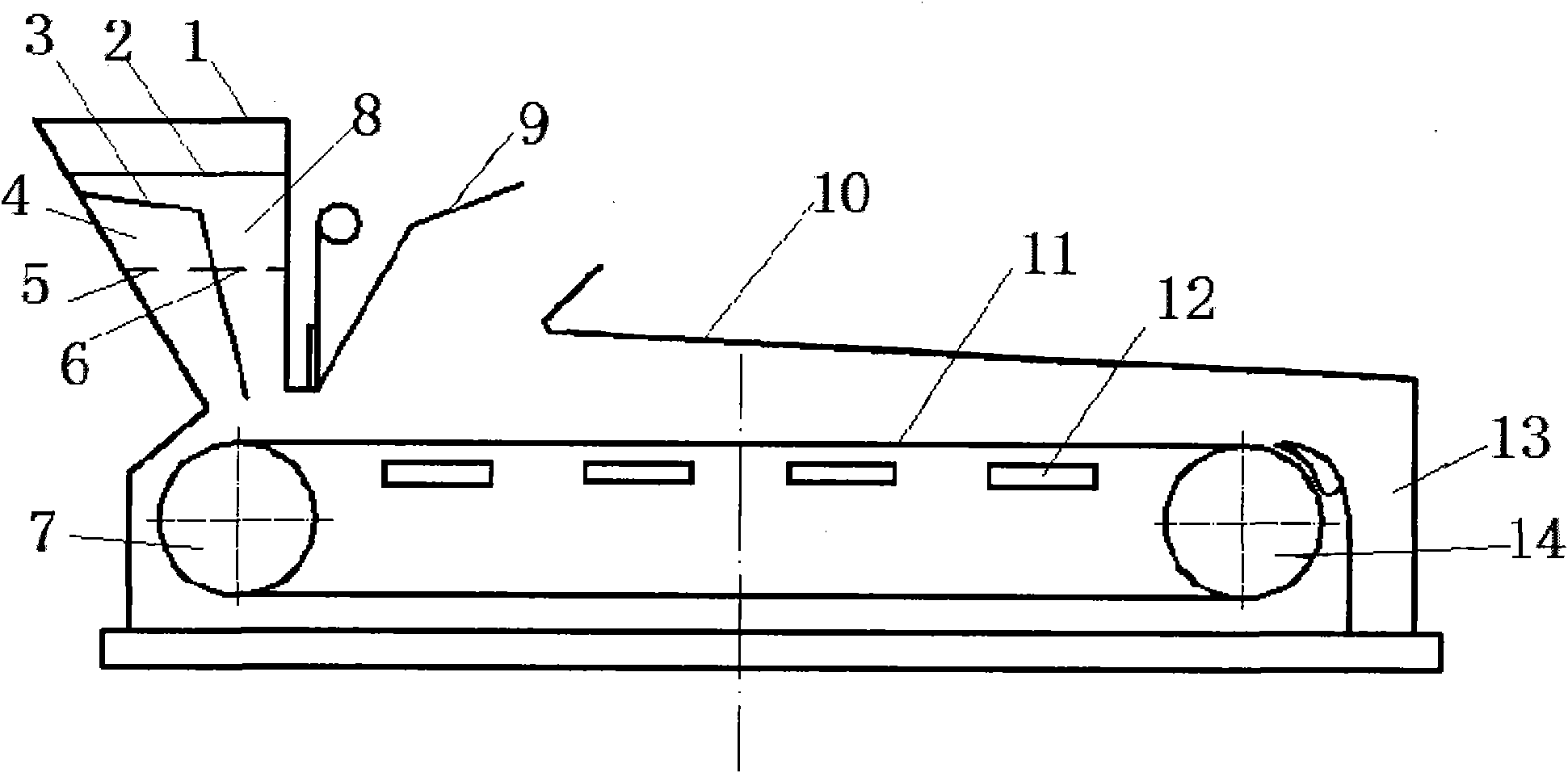

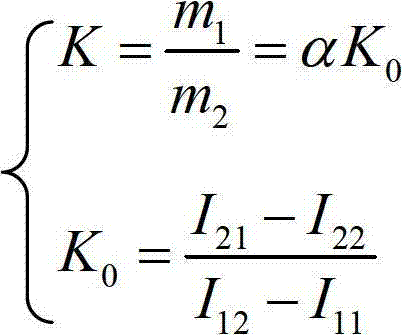

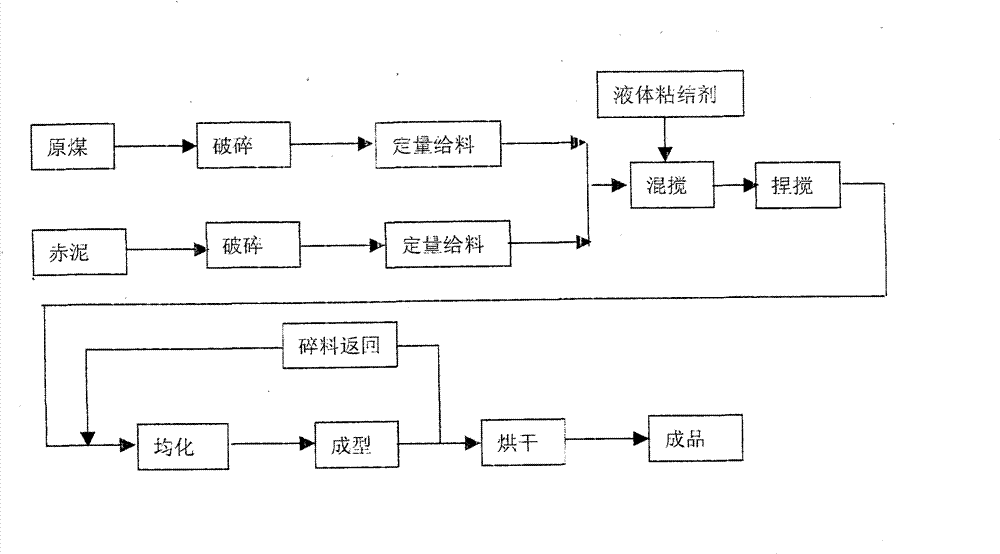

Inferior coal micro-oil ignition combustor

InactiveCN101603683AExtended service lifeSolve easy burnsPilot flame ignitersPulverulent fuel combustion burnersCycloneCombustion chamber

An inferior coal micro-oil ignition combustor comprises a streamlined air powder separation ring, a bidirectional cyclone oil combustor, a wing-shaped anti-friction block, a primary dense-phase coal powder combustion chamber, a secondary dilute-phase coal powder combustion chamber, a V-shaped cavity backflow blunt body, a circumferential cooling bellows and the like, employs a principle of gas-solid two phase flow separation, a principle of oil flame two-way cyclone ignition, backflow high-temperature flue gas of a blunt body, a principle of energy repeated utilization, a principle of coal powder graded ignition and energy gradual enlargement, forms a power field with low air speed, high density, strong eddy flow, strong backflow in the combustor, and creates favorable condition for firing coal powder, so as to effectively solve the problems of firing difficulty and low burn-out ratio of inferior coal. The combustor is capable of igniting inferior coal of 4 to 10 tons by using oil capacity of 150kg / h, which has an oil-saving ratio more than 80%, service life more than 4 years, and is beneficial for popularization in related industries.

Owner:范昌 +2

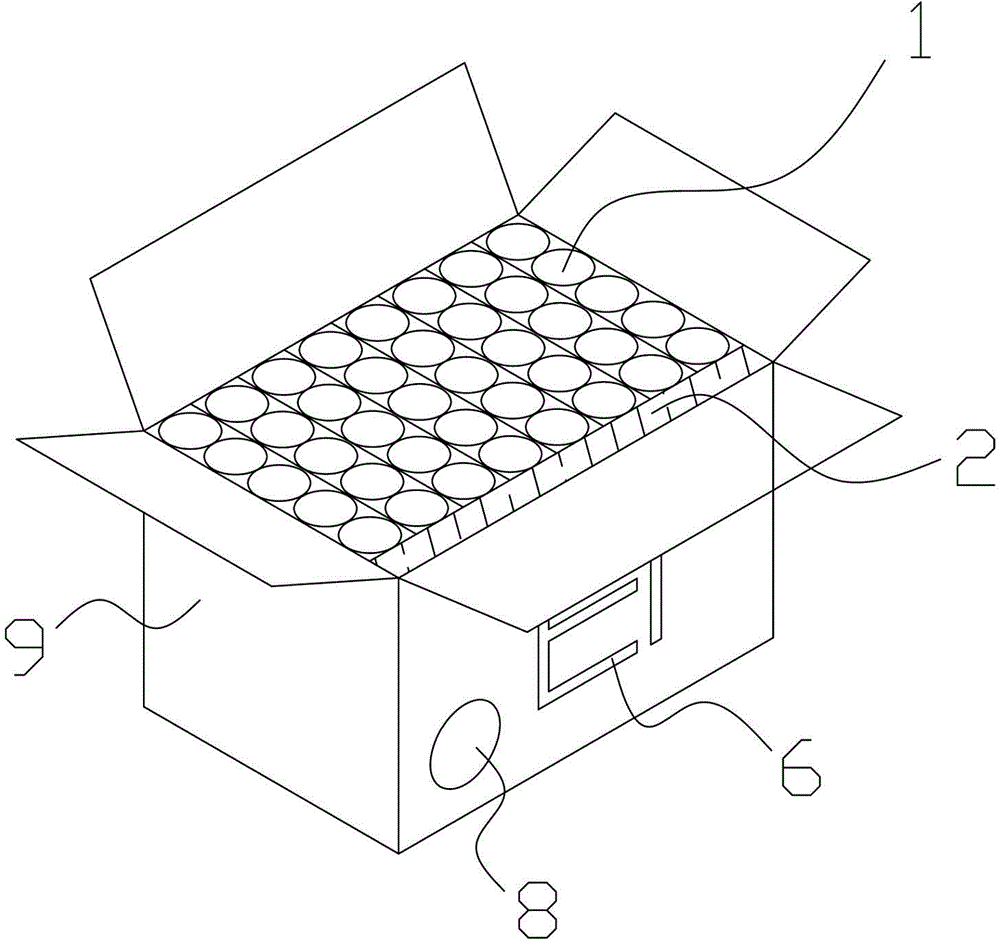

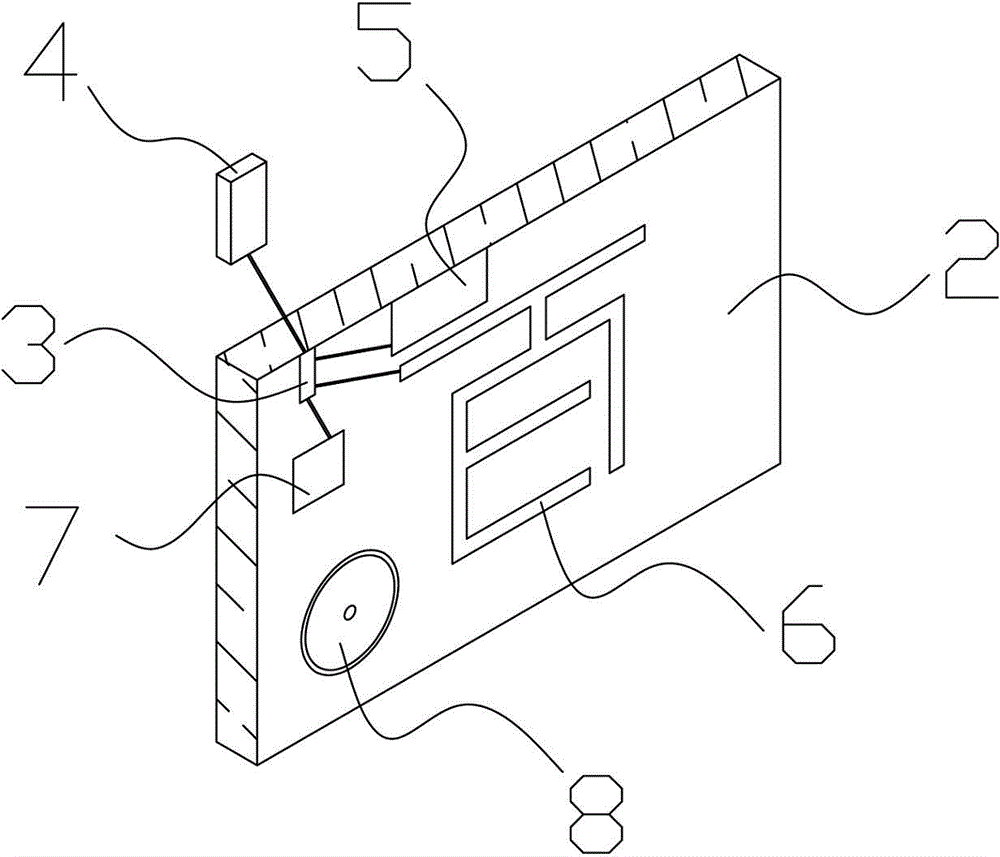

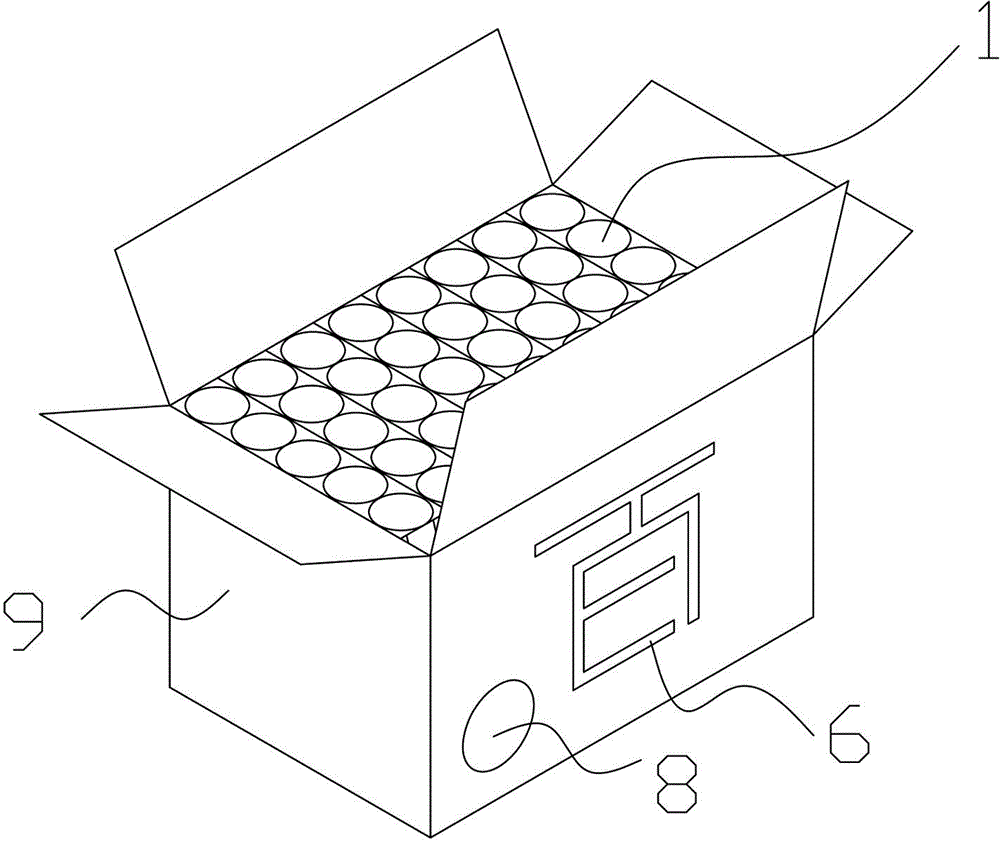

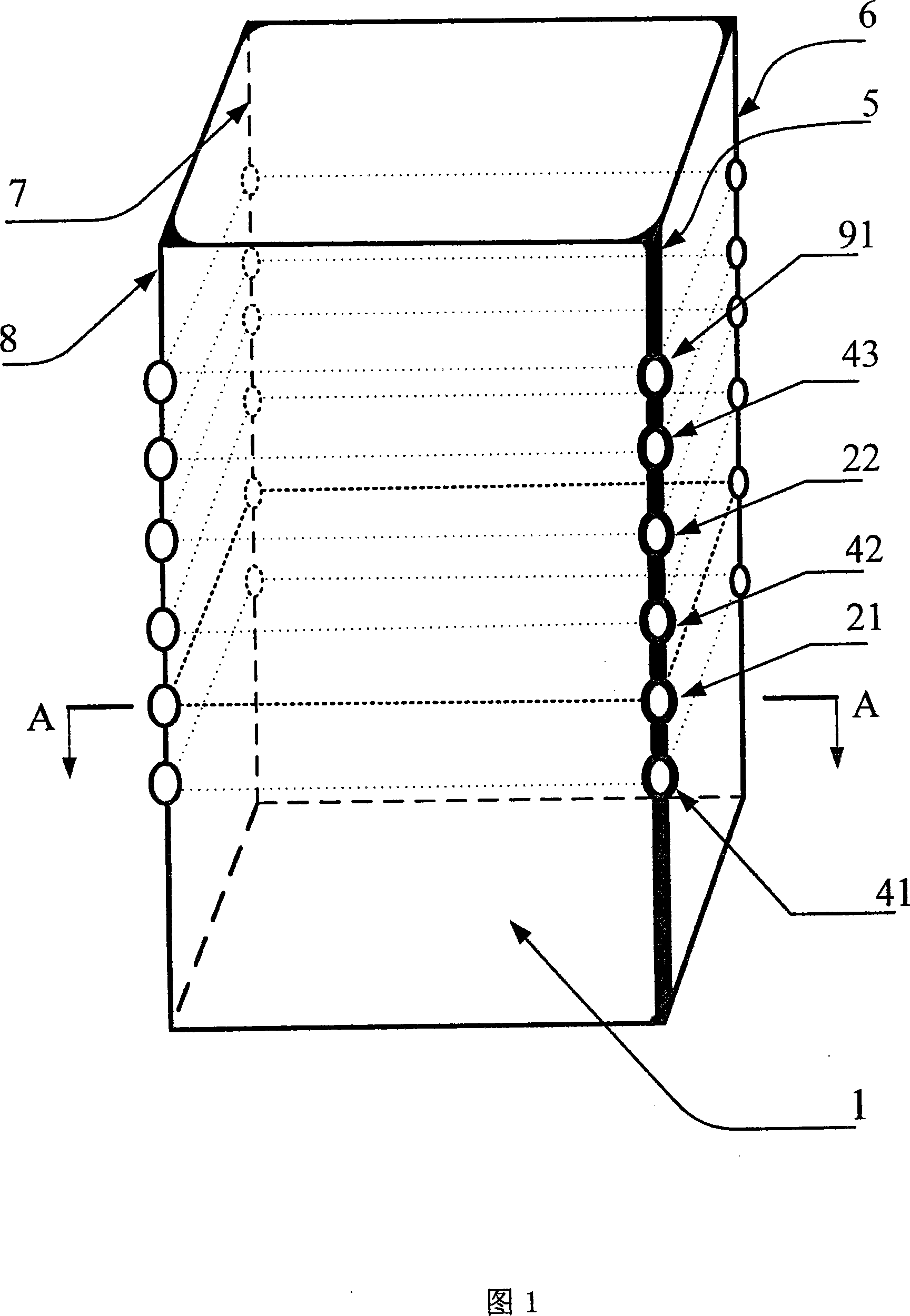

Battery box system with temperature automatically adjusted

ActiveCN108270047AAutomatic pressure adjustmentGuarantee the safety of useCells structural combinationElectric vehicle charging technologyLithiumPower battery

The invention provides a battery box system with the temperature automatically adjusted. The system comprises a cooling loop and a heating loop; a vehicle controller adjusts the temperature of a battery box through a low temperature controller and a high temperature controller according to the actual temperature of the battery box so that the temperature of the battery box can be kept within a settemperature range; meanwhile, the system monitors the working state of each component and reminds related personnel in time when an abnormality or fault occurs, so that it is guranateed that a battery pack, especially an electric vehicle lithium power battery pack, can work safely and reliably, and the service life of the battery pack can be prolonged.

Owner:北京科凌电动车辆股份有限公司

Additive for low-volatile coal and preparation method thereof

InactiveCN101899352AImprove combustion efficiencyEasy to catch fireSolid fuelsCombustionPotassium chlorate

The invention belongs to the field of resources and environmental technologies, in particular to an additive for low-volatile coal and a preparation method thereof. The additive for the low-volatile coal is characterized by comprising the following raw materials by weight percentage: 86-92% of oil shale, 3-4% of sodium chloride, 2-5% of potassium permanganate, 1-2% of sodium nitrate and 2-3% of potassium chlorate. The invention can improve the combustion efficiency of the low-volatile coal and have simple process and low cost.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Low-sulfur ester-based composite fuel oil

InactiveCN101812331AEasy to catch fireIncrease cetane numberBiofuelsLiquid carbonaceous fuelsBiodieselSulfur

The invention relates to low-sulfur ester-based composite fuel oil which can be used by automobile engines, various boilers and industrial furnaces. The ester-based composite fuel oil comprises biological diesel oil, dimethyl ether and an antioxidative stabilizer, wherein the biological diesel oil accounts for 51 to 99 weight percent of the ester-based composite fuel oil, the dimethyl ether accounts for 1 to 49 weight percent of the ester-based composite fuel oil, and the antioxidative stabilizer accounts for 0.0001 to 2 weight percent of the ester-based composite fuel oil. The fuel oil replaces high-price fossil fuel resources by low-cost renewable resources, belongs to oxygen-enriched fuel, has little theoretical air quantity required by combustion and sufficient combustion, can reduce the discharge quantity of flue gas, lowers the loss of the heat value of the discharge of the flue gas, lowers the concentration of sulfur and nitrogen compounds and granular dust in the discharged flue gas greatly and is beneficial to environmental protection, energy saving and discharge reduction.

Owner:KUNMING UNIV OF SCI & TECH

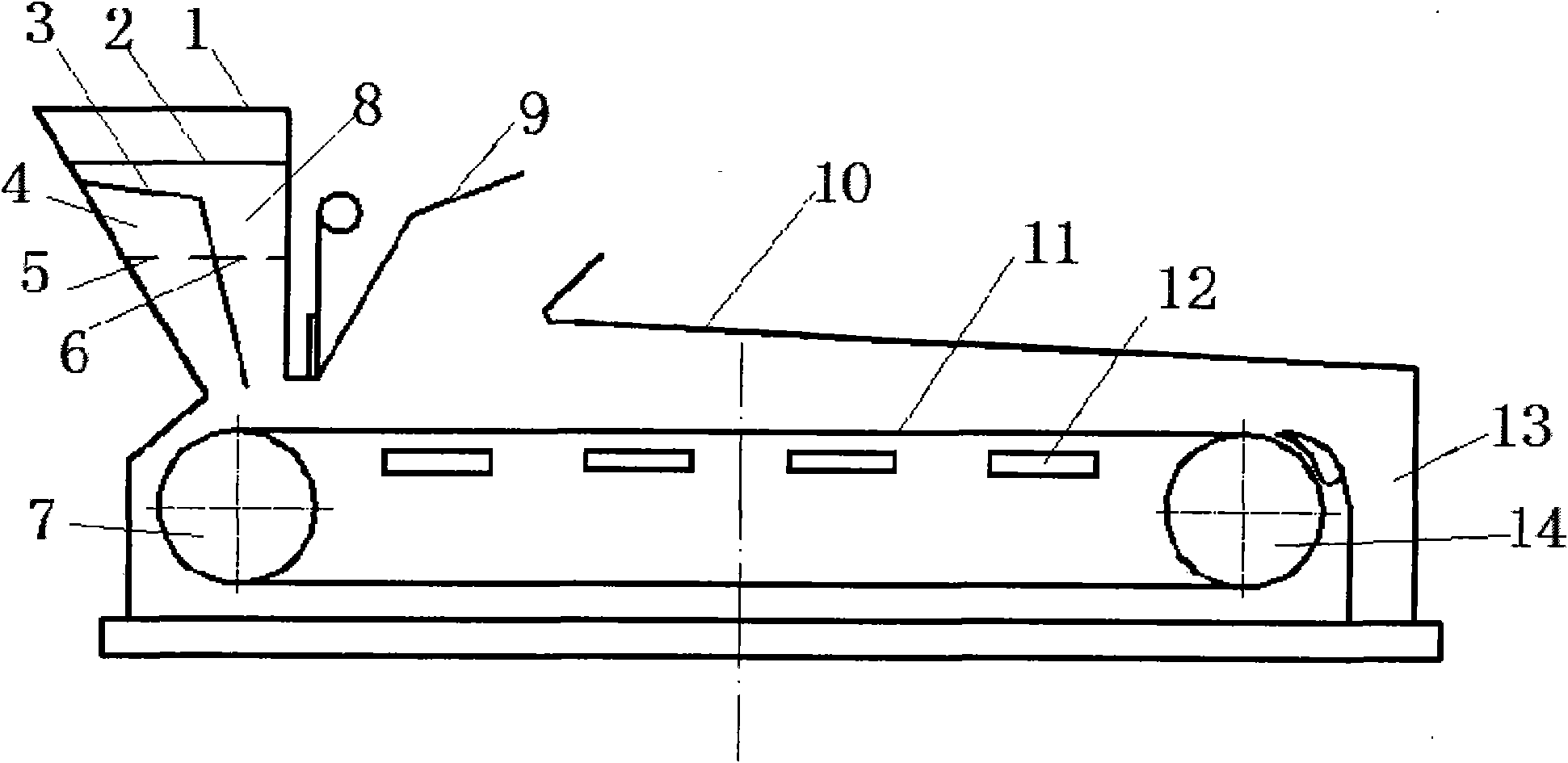

Petroleum coke direct burner

InactiveCN101852427AEasy to burnBurn quicklySolid fuel combustionIndirect carbon-dioxide mitigationAir preheaterCombustor

The invention discloses a petroleum coke direct burner, comprising a hopper, a fire grate, air chambers and a deslagging channel, wherein, the fire grate is driven by a driving shaft and a driven shaft to rotate; a front arch is arranged on an upper front wall, and a rear arch is arranged on a rear wall; the deslagging channel is arranged between the fire grate and the rear wall; a plurality of the air chambers are arranged under the fire grate; the hopper is arranged outside the front wall and is internally provided with a sizing screen; the lower space of a separating baffle plate is divided into a coarse material box and a fine material box, the coarse material box is provided with a coarse material gate for controlling discharge speed, and the fine material box is provided with a fine material gate for controlling discharge speed; and the air supply system of the air chamber is provided with an air preheater. The petroleum coke direct burner can be widely applied in the field of boiler combustion equipment, and has the advantages of simple structure, easy ignition and high combustion efficiency.

Owner:SOUTH CHINA UNIV OF TECH

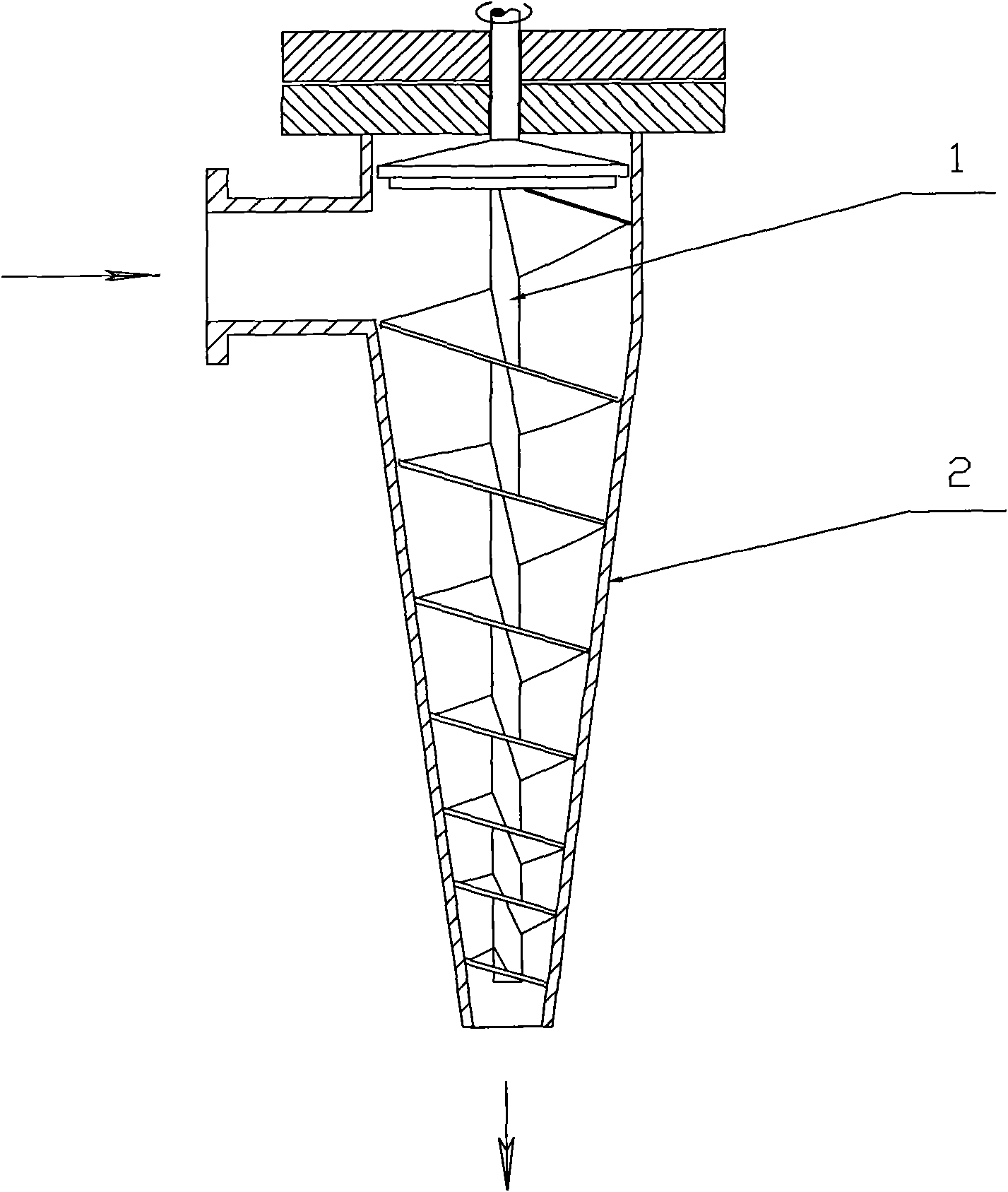

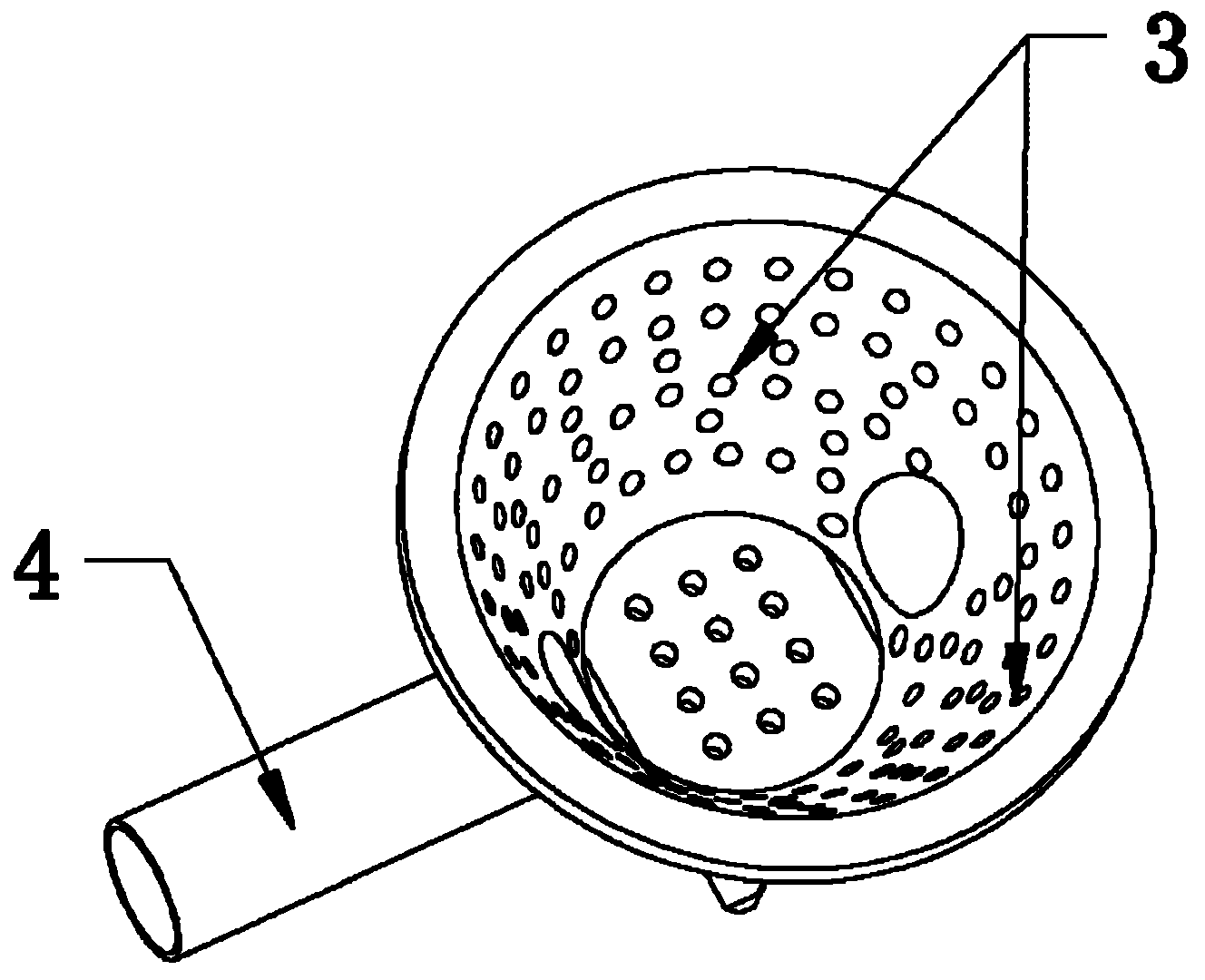

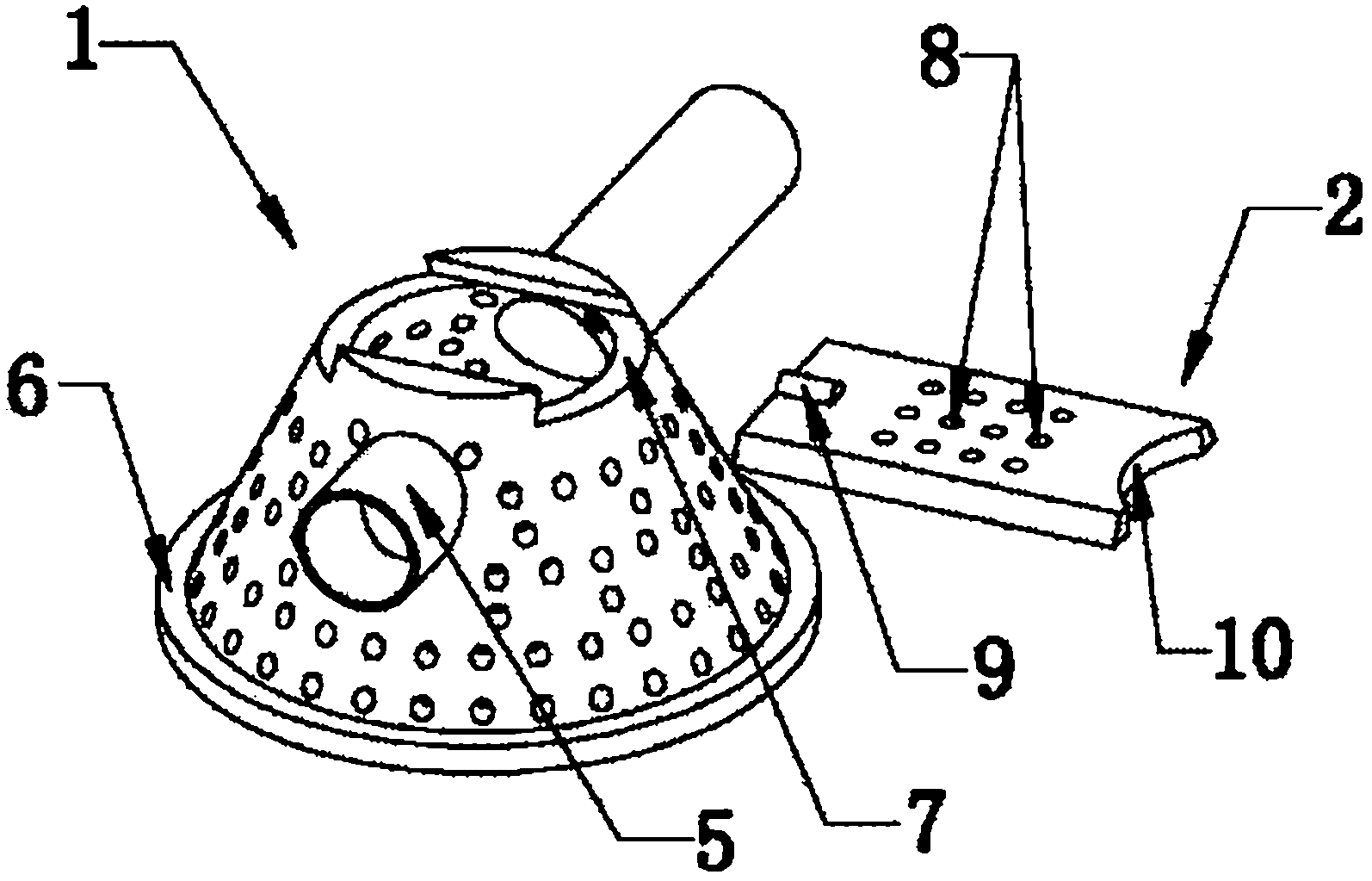

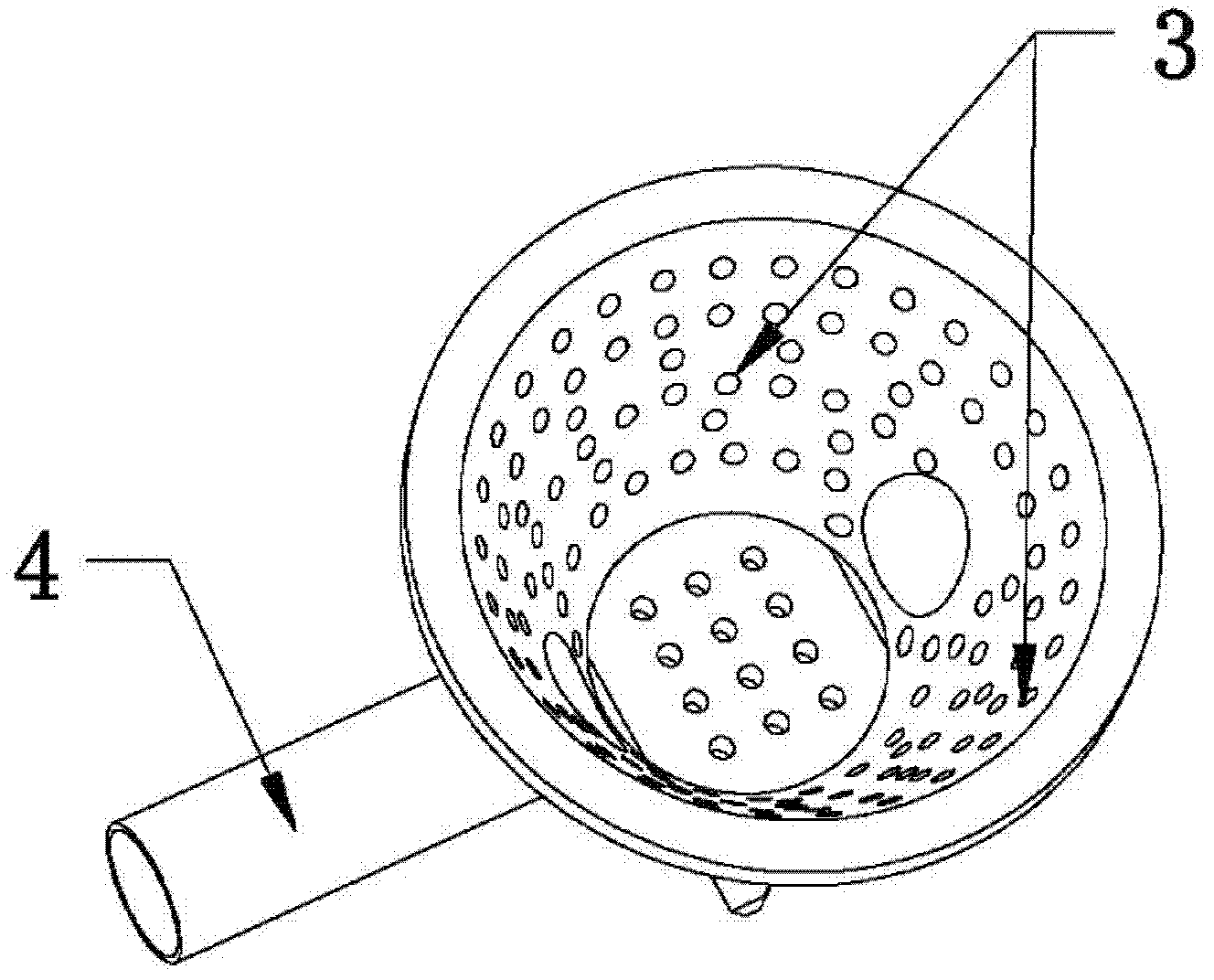

Grate for biomass particle environment-friendly boiler

The invention discloses a grate for a biomass particle environment-friendly boiler, which comprises a grate and a valve, wherein the grate body is movably connected with the valve; the grate body is in a taper shape and a plurality of vent holes A are uniformly distributed on the grate; one end of a side wall of the grate is provided with a long pipe for ignition and the other end of the side wall is symmetrically provided with a short pipe for ventilation; and a large orifice end of the grate body is circularly provided with a support block, a small orifice end is provided with a cavity of which the shape and the size are matched with the shape and the size of the valve, and a plurality of vent holes B are uniformly arranged on the valve. The problems that biomass particles in the prior art are hard to ignite and cannot burn fully, black smoke is easy to generate and fuel residue is inconvenient to remove and wash are effectively solved through the grate for the biomass particle environment-friendly boiler.

Owner:田和东

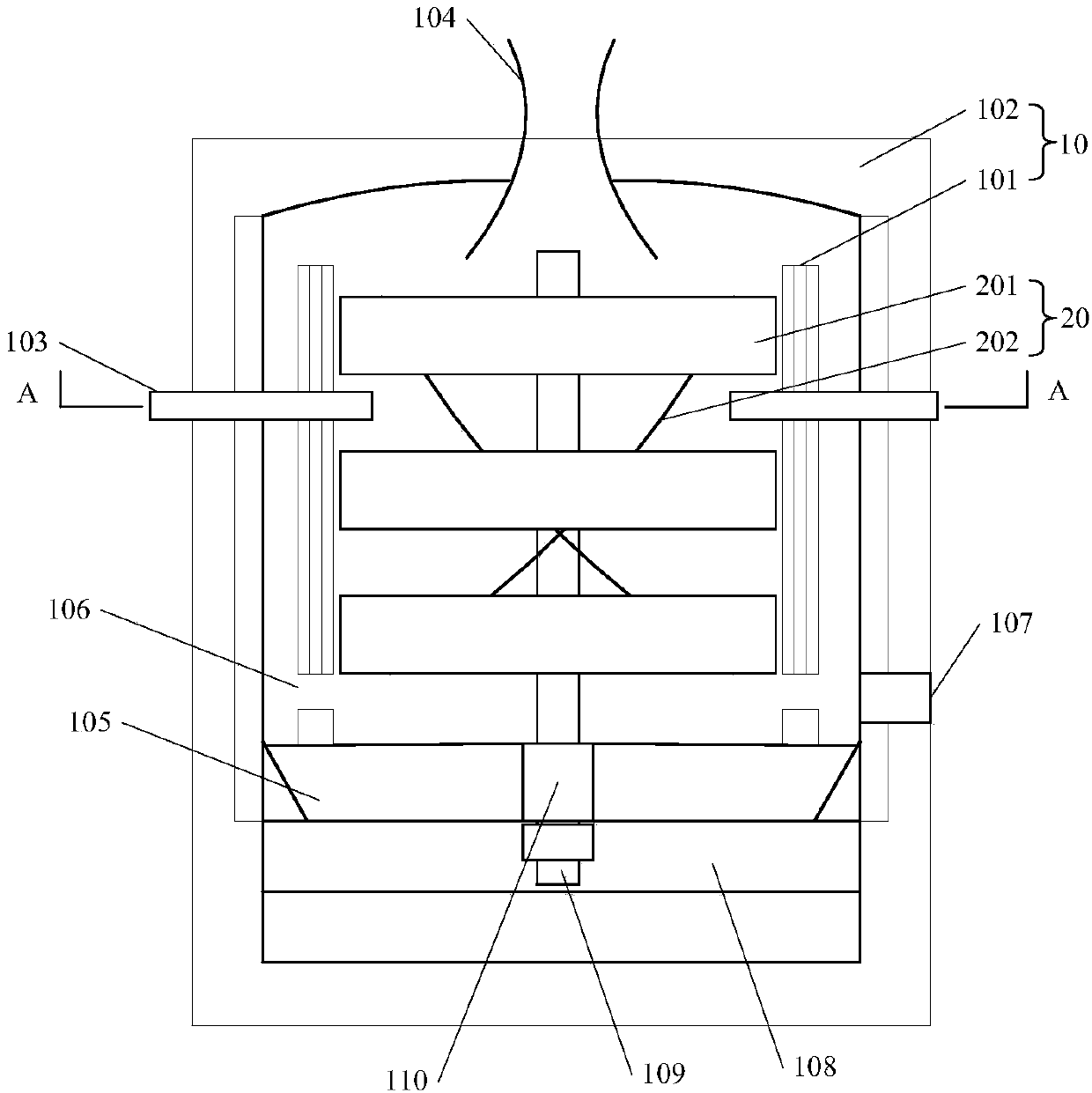

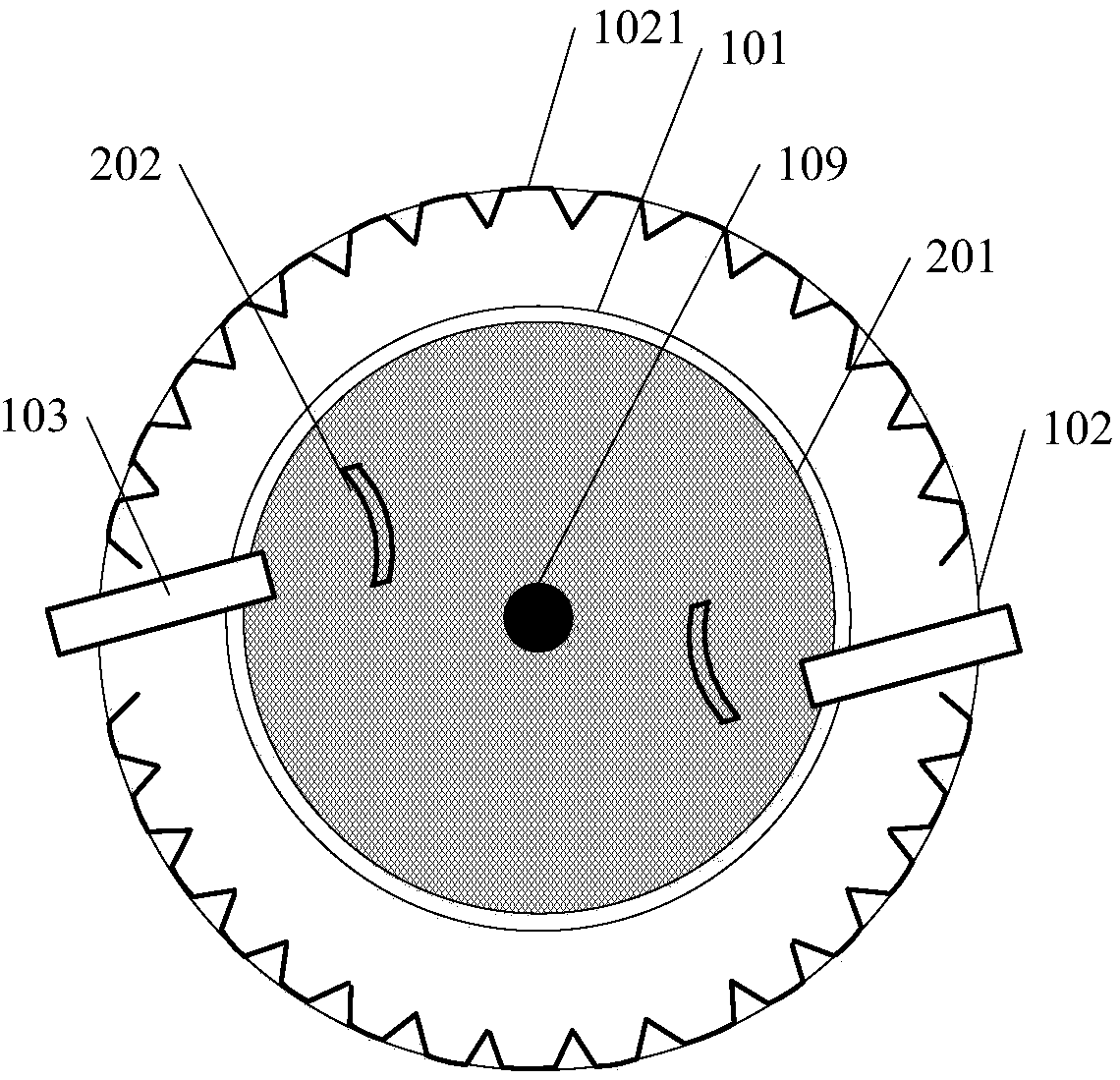

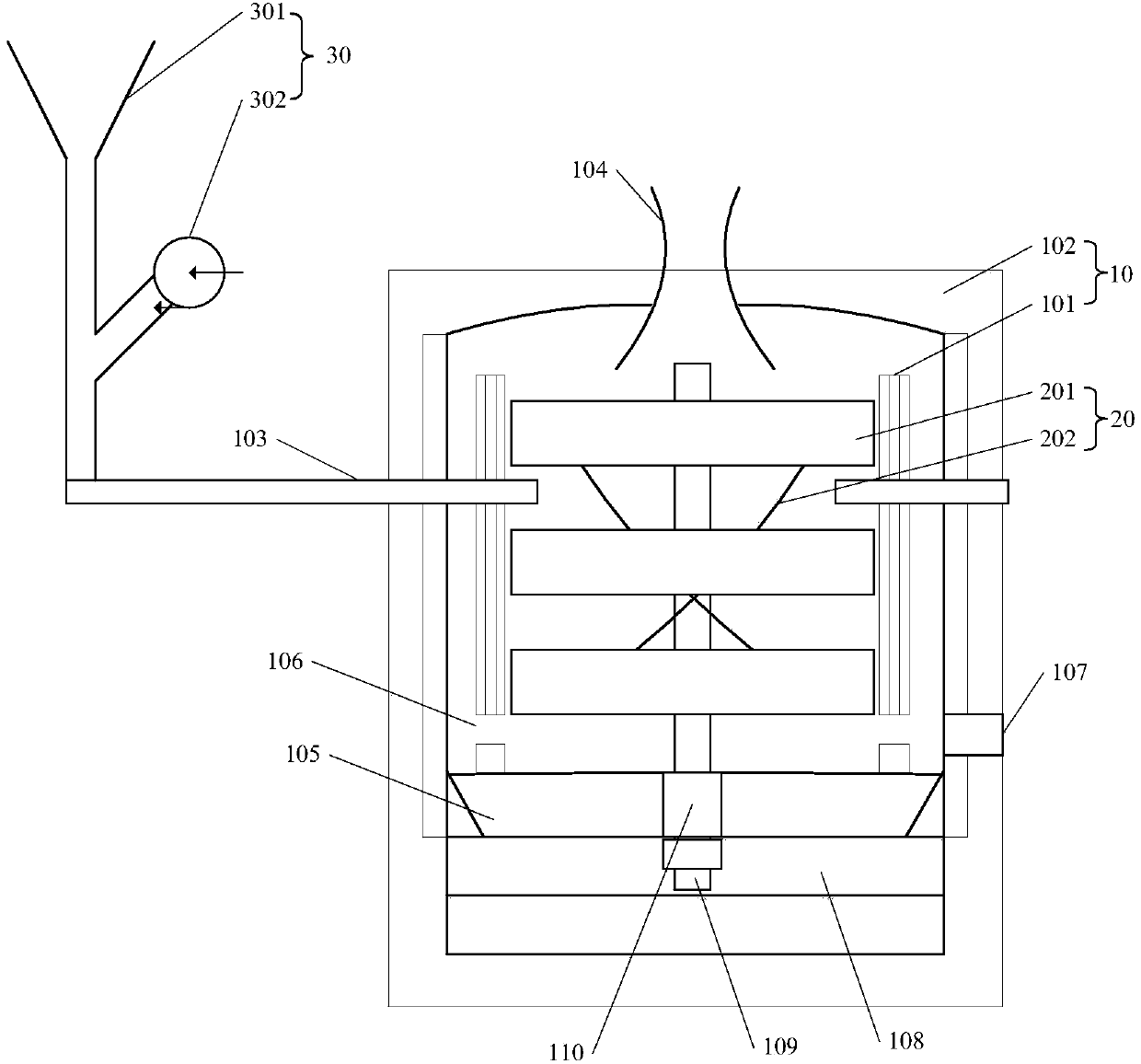

Biomass fuel boiler with rotatable fire grate

InactiveCN107741025APrevent fallingHeating up fastSolid fuel combustionWater heatersSlagMechanical engineering

The invention discloses a biomass fuel boiler with a rotatable fire grate. The biomass fuel boiler comprises a furnace body, wherein the furnace body comprises a first furnace body and a second furnace body which are arranged in a sleeved mode; the rotatable fire grate, wherein the rotatable fire grate is vertically arranged in the first furnace body in a rotating mode through a rotating shaft, the rotatable fire grate comprises multiple fuel trays, and the fuel trays are sequentially arranged in the axial direction of the rotating shaft at intervals; a pair of fins, wherein the pair of fins are spirally and symmetrically arranged on two sides of the rotating shaft, and sequentially penetrate through the multiple fuel trays; and pneumatic biomass powder feeding pipes, wherein one ends of the pneumatic biomass powder feeding pipes penetrate through the furnace body and extend to be opposite to the fins. A biomass particle feeding hole is formed in the top part of the furnace body; a mode water cooling wall is arranged on the side wall of the furnace body; a slag collecting tank is detachably arranged at the bottom part of the rotatable fire grate; multiple circulating ports are annularly and uniformly arranged on the side wall, close to the first furnace body, of the bottom of the second furnace body at intervals; and the biomass fuel boiler further comprises a smoke outlet anda base. According to the biomass fuel boiler, biomass powder and biomass particle fuel can be fully mixed and combusted, combustion is sufficient, the heat utilization rate is high, and energy-savingand environment-friendly effects are achieved.

Owner:江苏东方电力锅炉配件有限公司

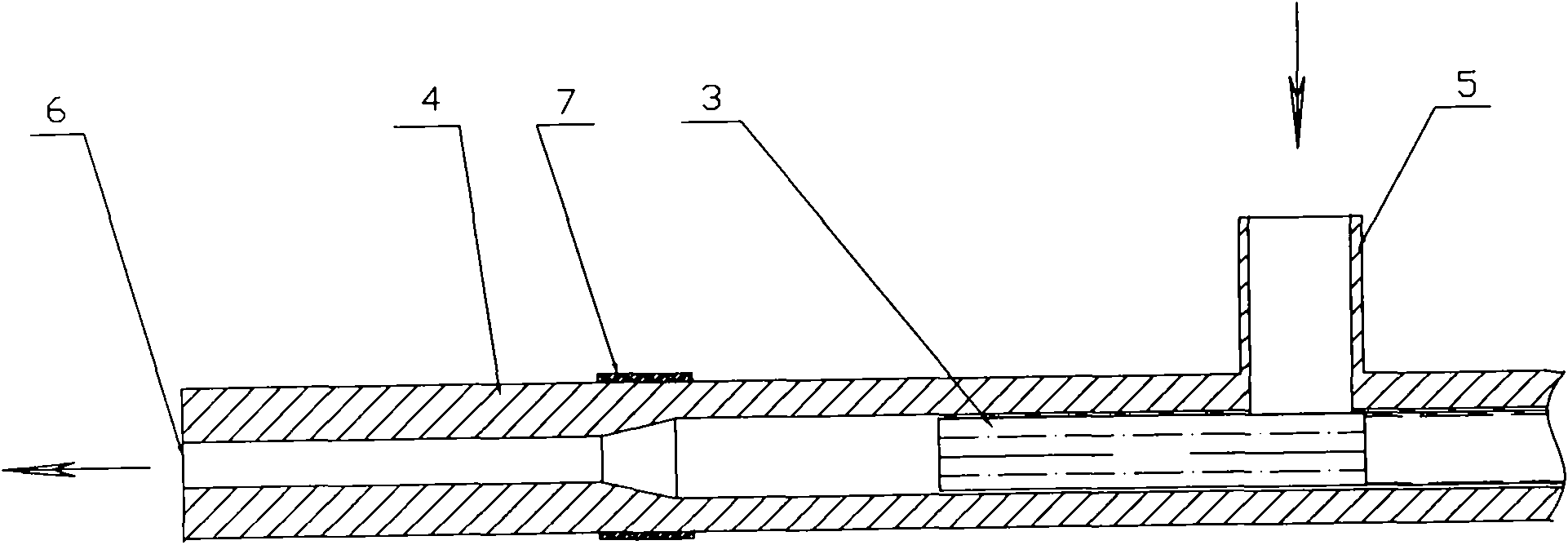

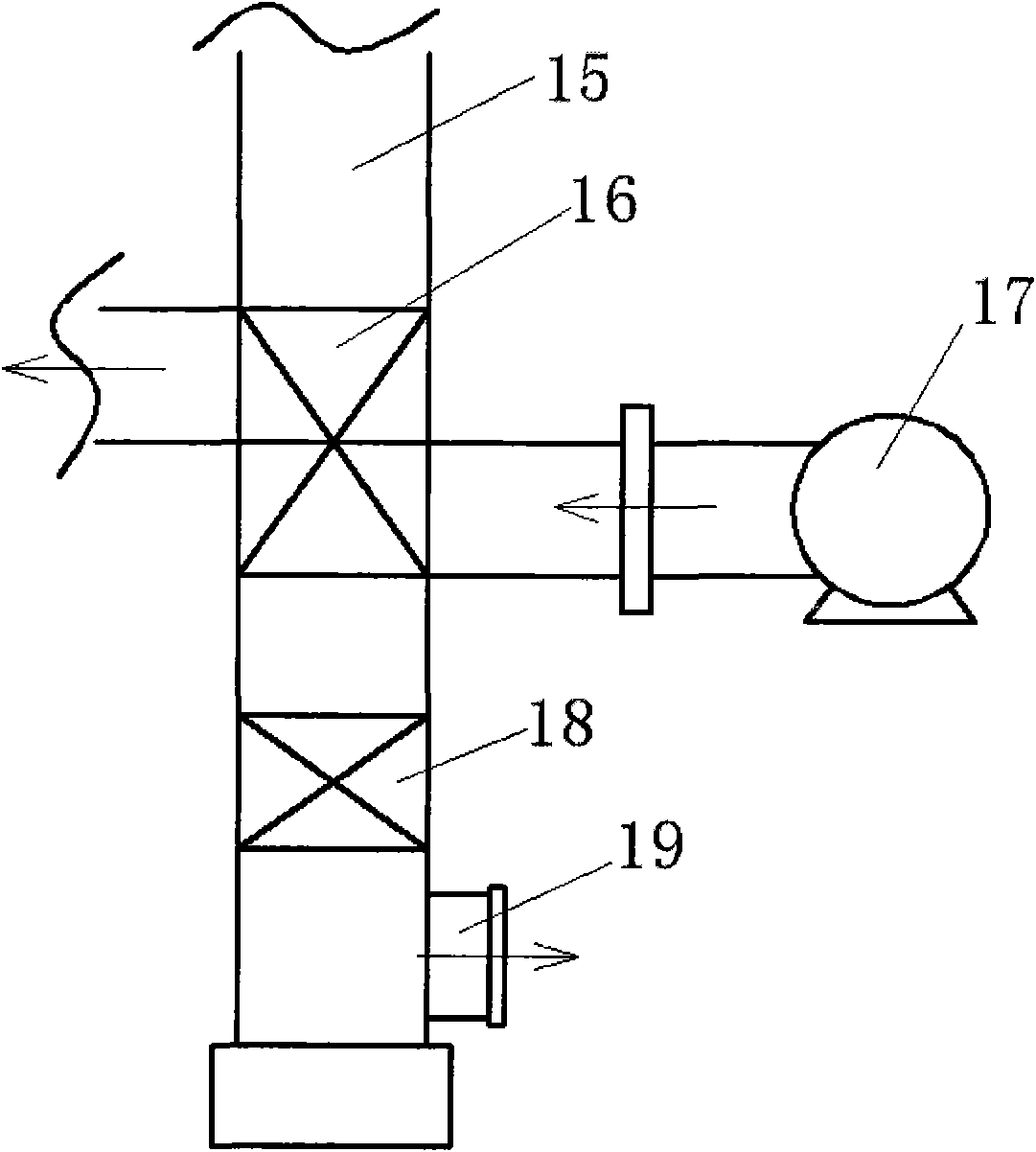

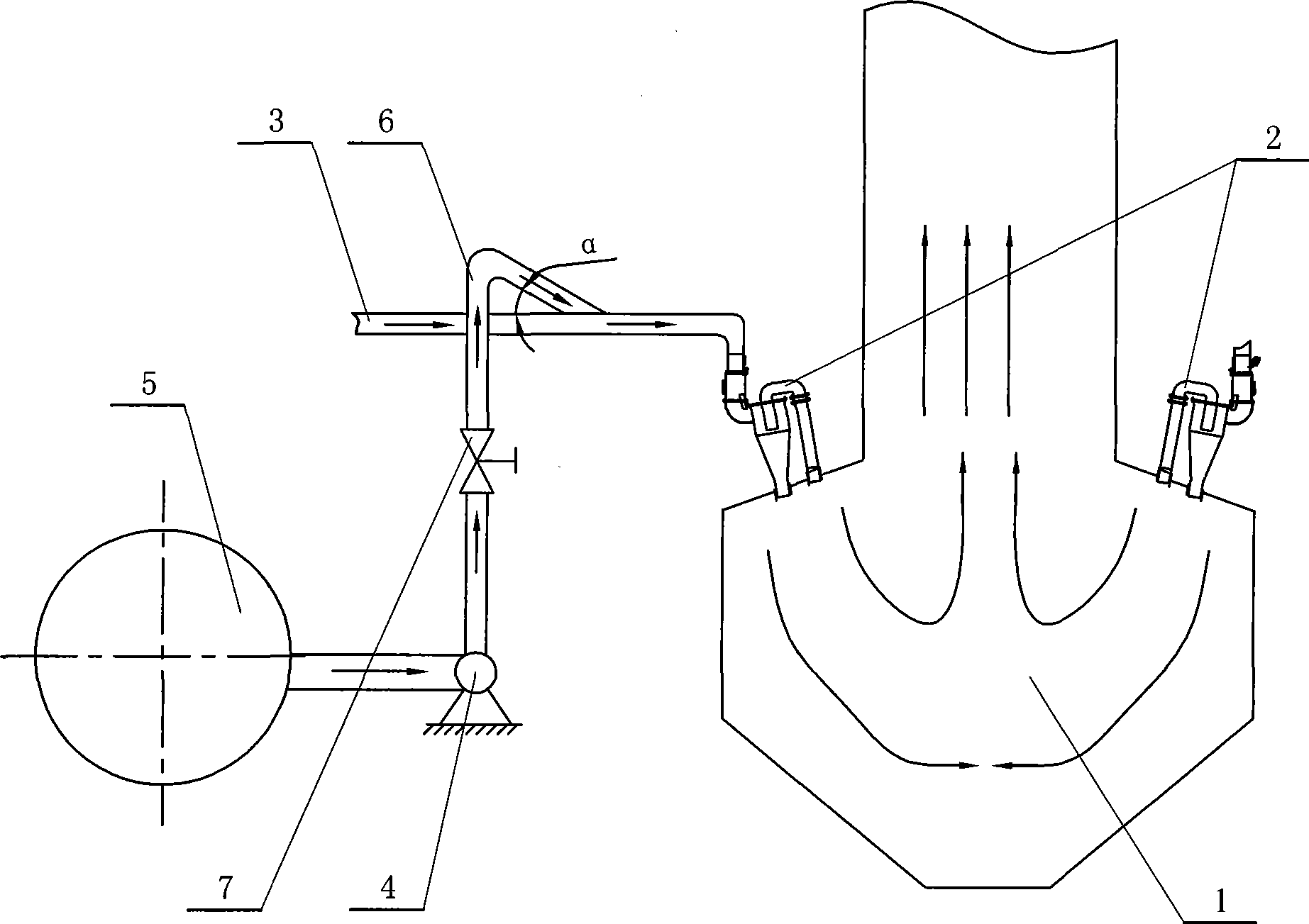

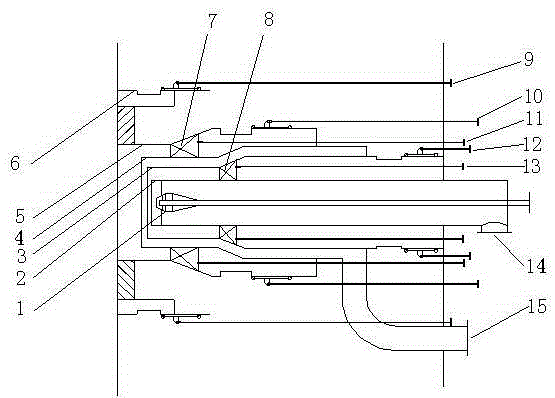

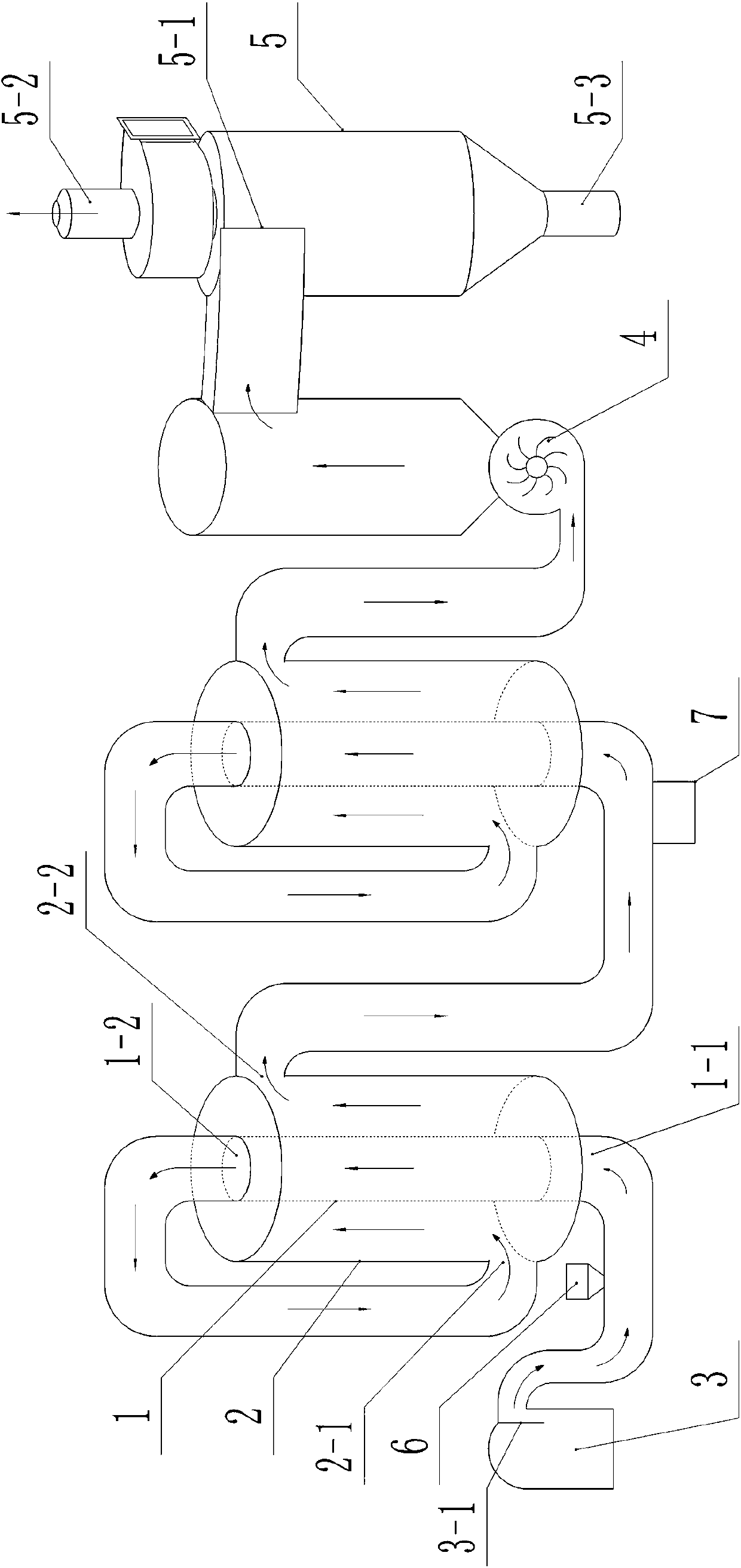

Method and apparatus for improving primary air breeze gas flow temperature of W-shaped flame boiler

ActiveCN101430098APromote precipitationSimple methodCombustion processIndirect carbon-dioxide mitigationAir volumeCombustor

A method and a device for improving the primary air pulverized coal airflow temperature of a W-shaped flame boiler relate to the method and the device for improving primary air auxiliary hot air of the W-shaped flame boiler. The method and the device are designed against the problems of poor combustion stability and poor ignition capacity of the W-shaped flame combustion technology. The method is as follows: auxiliary air is led out by a hot air pipe, the air temperature is 320-370 DEG C, the auxiliary air is introduced into a primary air pipe before entering a burner and mixed with primary air with the air temperature of 100-110 DEG C and the air speed of 22.0-23.0m / s, the amount of the auxiliary air which is introduced into the primary air pipe accounts for 19-21 percent of the amount of the primary air, the air temperature of the primary air which enters the burner is 140-160 DEG C, and the air speed is 32.0-33.0m / s. The device is as follows: the hot air pipe is communicated with the primary air pipe by an induced draft fan and an auxiliary air pipe, the primary air pipe is communicated with the burner, and an included angle alpha between the direction of the auxiliary air which is introduced into the primary air pipe from the auxiliary air pipe in the method and the device and the flow direction of pulverized coal in the primary air pipe is 25-35 degrees. The method and the device reduce the heat needed by ignition and realize the purposes of easy ignition and stable combustion.

Owner:HARBIN INST OF TECH

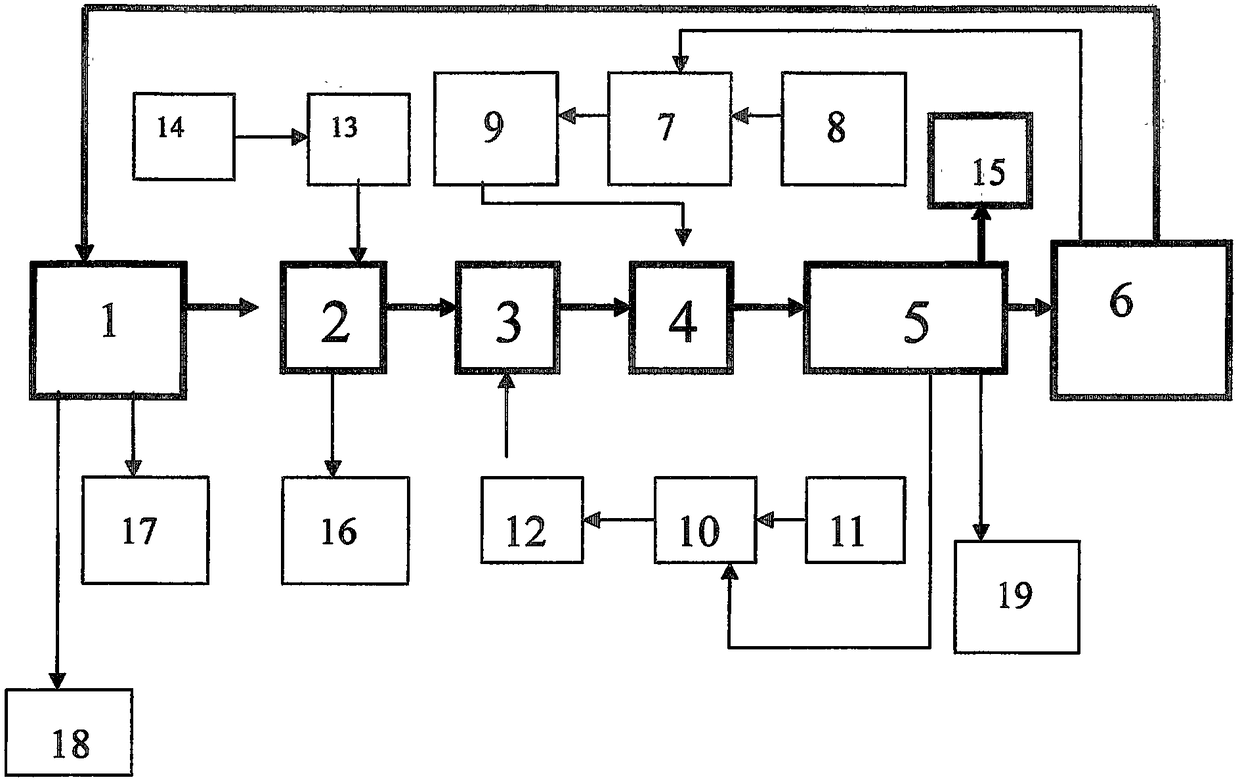

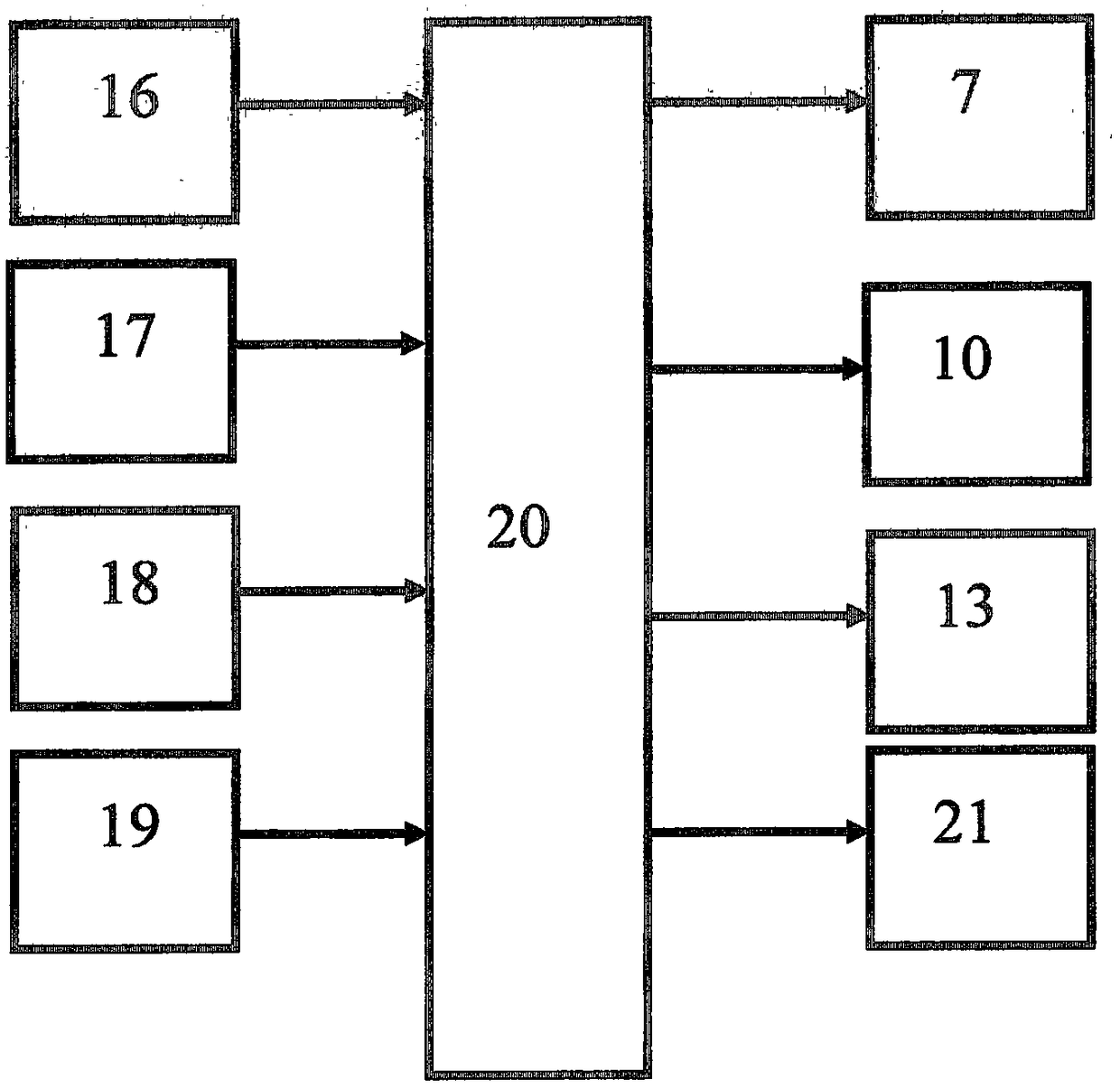

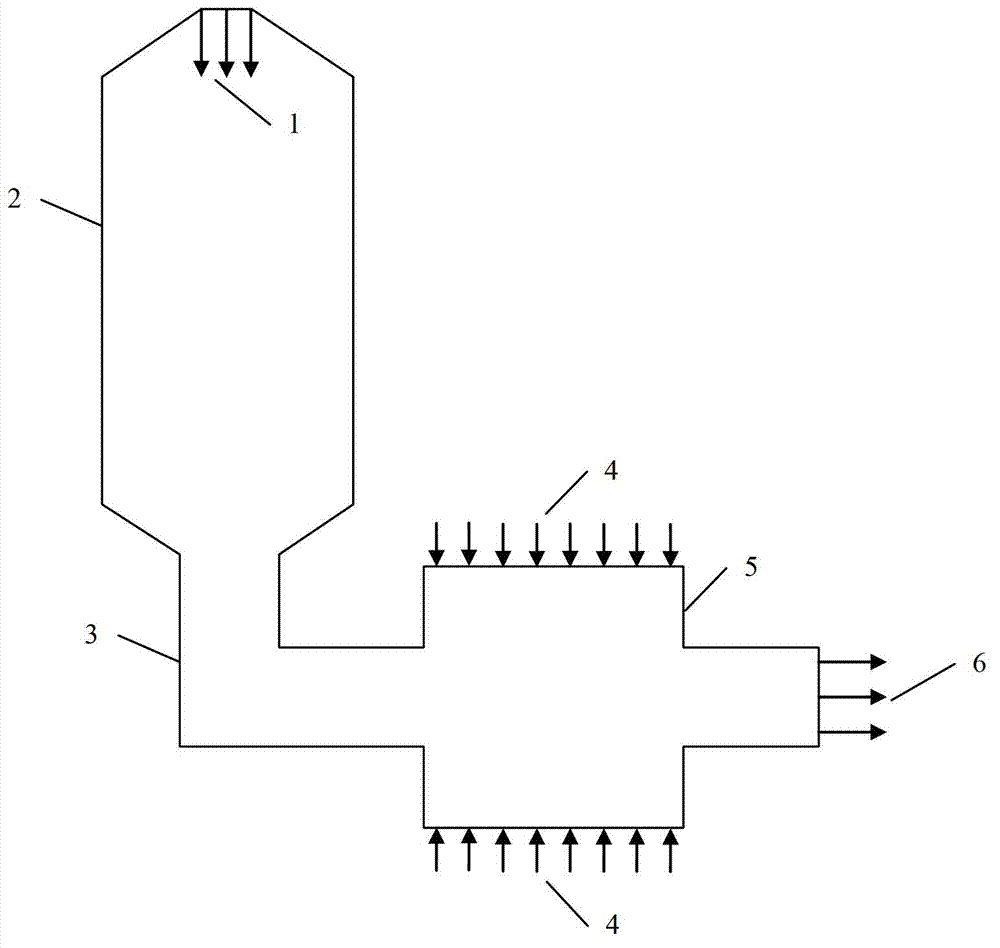

Steam-flue gas mixing fluid generation method for thickened oil thermal recovery

InactiveCN102900414AEasy to catch fireBurn out fastSteam generation heating methodsFluid removalFlue gasHearth

A steam-flue gas mixing fluid generation method for thickened oil thermal recovery belongs to the technical field of thickened oil thermal recovery and boiler equipment. A generation system comprises a boiler, a transition gas flue and a mixing chamber. The steam-flue gas mixing fluid generation method comprises the following steps of: feeding pressurized gas or liquid fuel and air into the hearth of the boiler, mixing and burning in the hearth to generate high-temperature and high-pressure flue gas, and feeding the flue gas into the mixing chamber through the transition gas flue; spraying purified water into the mixing chamber through an atomization plant to form tiny liquid drops, mixing the tiny liquid drops with the high-temperature and high-pressure flue gas in the mixing chamber, heating the mixture by the flue gas to turn into water vapor after being vaporized, and further generating the high-temperature and high-pressure steam-flue gas mixing fluid; and finally, leading the high-temperature and high-pressure steam-flue gas mixing fluid out to a steam injection pipeline. The steam-flue gas mixing fluid generation method has the advantages of reducing flue gas purification and compression links, effectively saving investment and running costs and water resources and obviously reducing the cost of water treatment.

Owner:TSINGHUA UNIV

Novel firework with LED display and music play

InactiveCN104101260ASafe and reliable controlRealize electrification effectFireworksTemperature controlControl power

The invention relates to a novel firework with LED display and music play. The novel firework comprises a high-altitude set-off firework, an on-site LED caption firework, and an automatic sensing electrifying device that is connected with the high-altitude set-off firework and the on-site LED caption firework through circuits; the automatic sensing electrifying device comprises a control chip, a temperature control switch, a power supply, an LED caption display screen and a sound box, wherein the temperature control switch, the power supply, the LED caption display screen and the sound box are connected with the control chip; the temperature control switch is connected with a firing line on the high-altitude set-off firework; the temperature control switch is used to connect the power supply according to the sensed temperature of the firing line and synchronously control the LED caption display screen to light as well as control the sound box to produce music. According to the novel firework with the LED display and music play, the temperature control device controls the connection or disconnection of a circuit control power supply, thus the safety in firework control is ensured; the LED caption firework does not produce any smoke, is long in lighting time, low in temperature, safe and recyclable.

Owner:彭健

Treatment process of agricultural and forest waste

InactiveCN109022092AAbundant resourcesSimple methodBiofuelsSolid fuelsMaterial resourcesEnergy conservation

The invention discloses a treatment process of agricultural and forest waste. The process comprises the following steps of S1, performing coarse crushing on agricultural and forest waste; crushing theagricultural and forest waste to the particle diameter being below 2mm; S3, soaking the materials crushed to the state with the particle diameter being smaller than 2mm into hot water being 60 to 70DEG C for 10 to 12h; performing press filtering by a plate-and-frame filter press; putting the materials into a fermentation pool; S3, adding biomass carbon powder into materials subjected to anaerobic fermentation treatment in the step S2; after the uniform stirring, isolating the air for continuous fermentation for 10 to 20 days; performing deodorization and drying to obtain a mixture A; S4, adding additives, bentonite and anti-coking additives into the mixture A; then, performing uniform mixing to obtain a mixture B; ensuring the water content of the mixture B to be within 15 percent; performing extrusion shaping by using an extrusion shaping machine; performing drying to obtain biomass fuel. The agricultural and forest waste is a resource capable of being regenerated and utilized; theraw material resources are rich; the energy source saving is facilitated by using the agricultural and forest waste solid type regeneration clean fuel; the problem of energy source shortage is solved.

Owner:滁州三丰科技有限公司

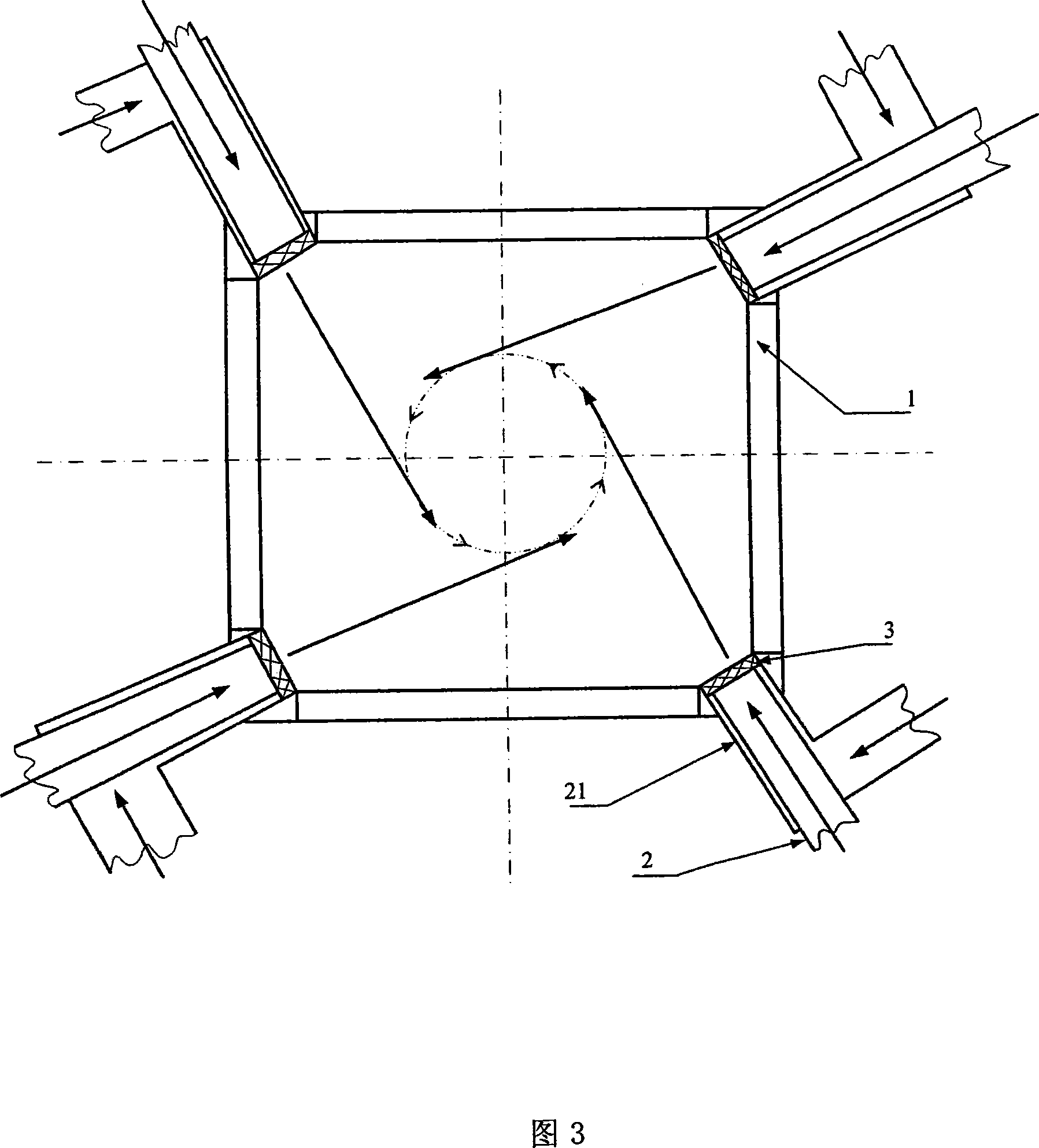

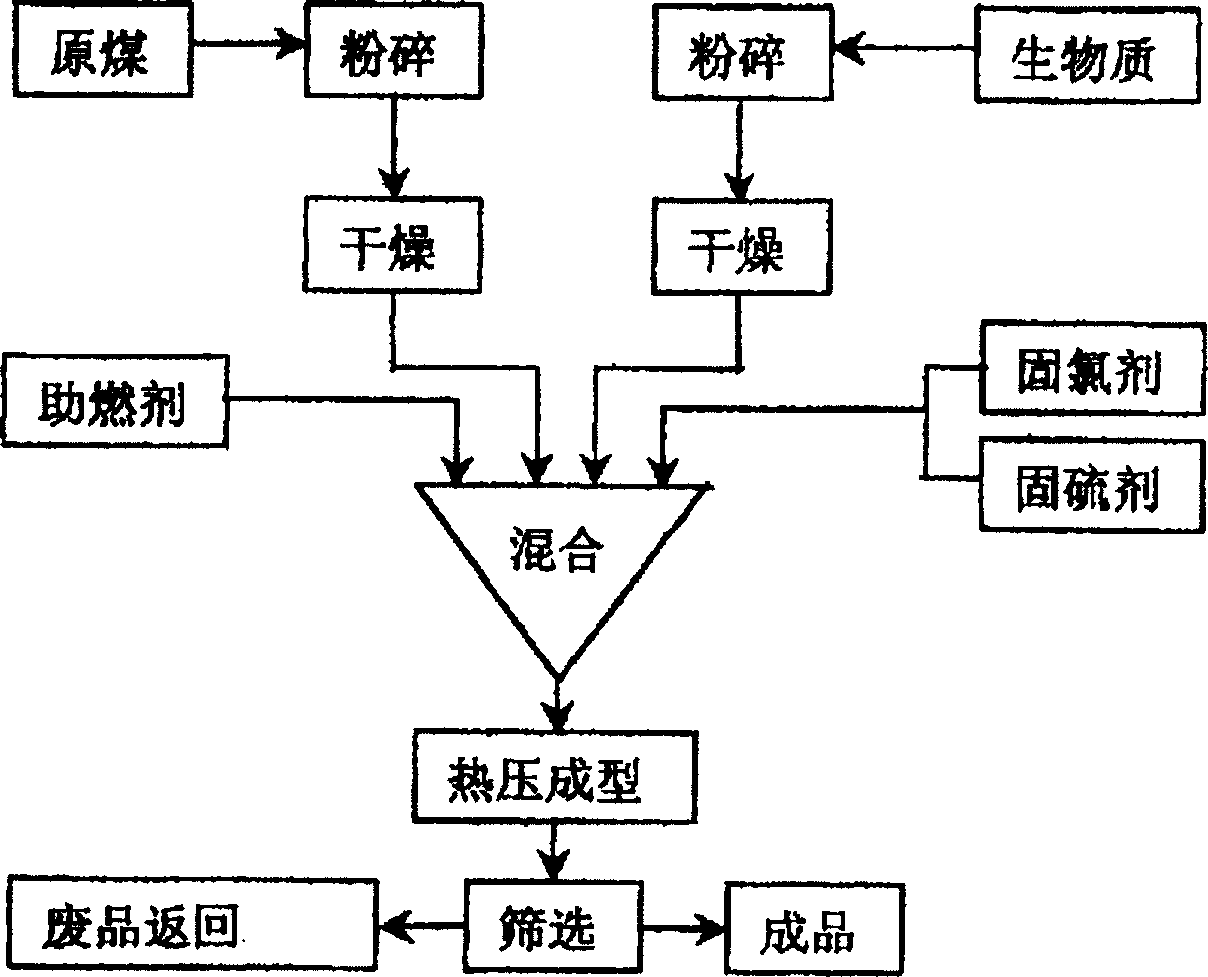

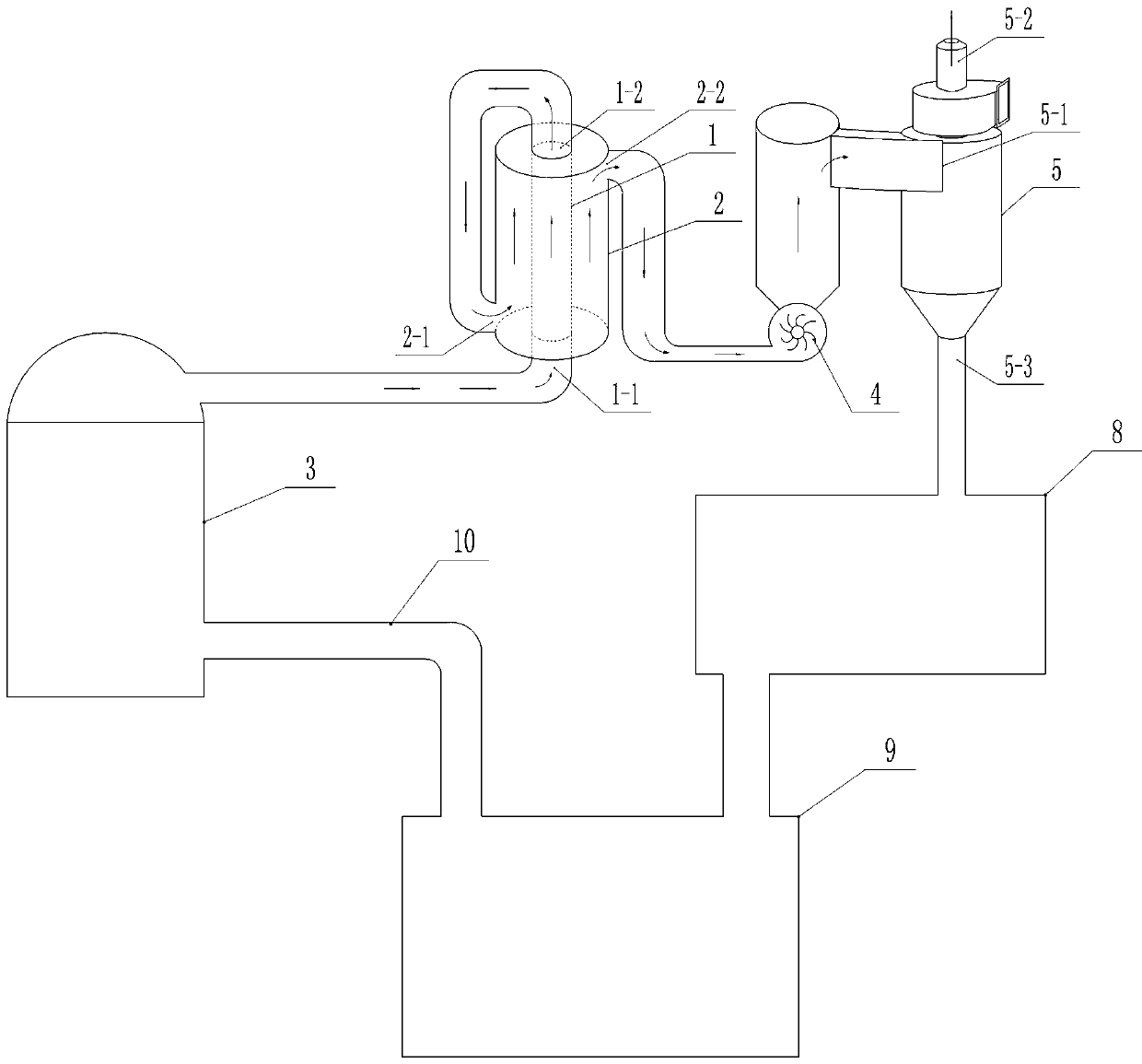

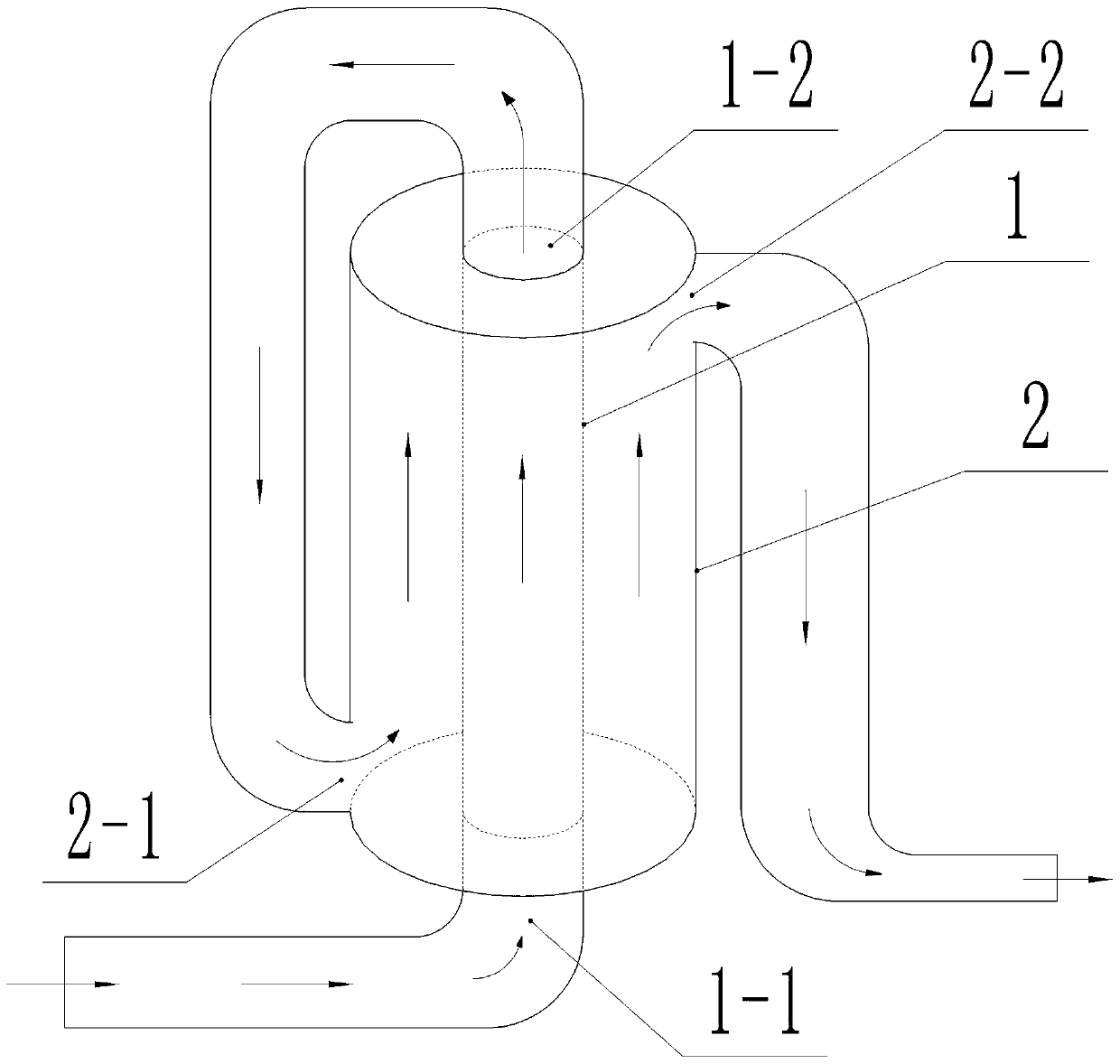

Petroleum water coke slurry combustion apparatus and burning method thereof

InactiveCN101135440AAvoid cokingControllable combustion processCombustion using gaseous and pulverulent fuelBurnersCombustion chamberExhaust fumes

This invention relates to a burning device and process of petroleum coke water slurry which is applicable for industrial boiler and furnace using the petroleum coke water slurry as fuel. In this burning device the boiler body has the multiply positioned inlet of the straight flow triple fuel burner in which each array includes the independent inlet, the inlet adaptable for refinery off-gas lance and the inlet adaptable for slurry and oil lance, and each level has identical inlets. The burning process uses petroleum coke water slurry as the primary fuel and refinery off-gas, fuel oil as assistant fuel, it first combusts refinery off-gas, petroleum residual slurry or fuel oil to raise the temperature of the combustion chamber to 680-700deg.C and the boiler load to 60-70%, and then switches to petroleum coke water slurry gradually.

Owner:GUANGDONG TIANYI GROUP

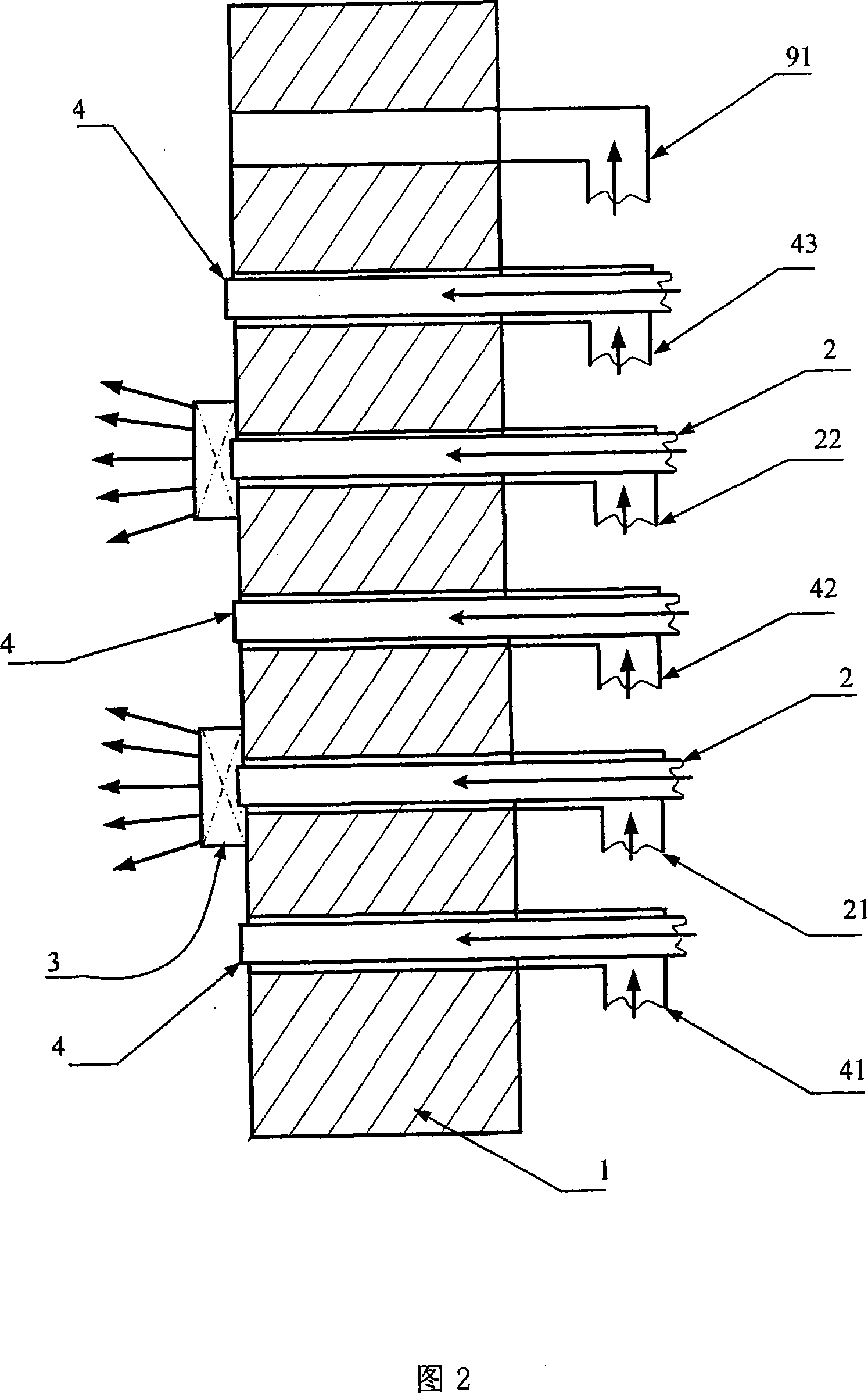

Process for preparing composite biomass briquettes

InactiveCN1236027CHigh compressive strengthSuitable for long distance transportationBiofuelsSolid fuelsForest industryCombustion

A composite biomass briquette is made up of biomass including stalk or straw, wood leftover, city household garbage and raw coal through crushing, mixing with chlorine fixating agent, sulfur fixating agent and combustion promoter, and hot die pressing. Its advnatages are high compression strength, low combustion point, high combustion efficiency and less environmental pollution.

Owner:KUNMING UNIV OF SCI & TECH

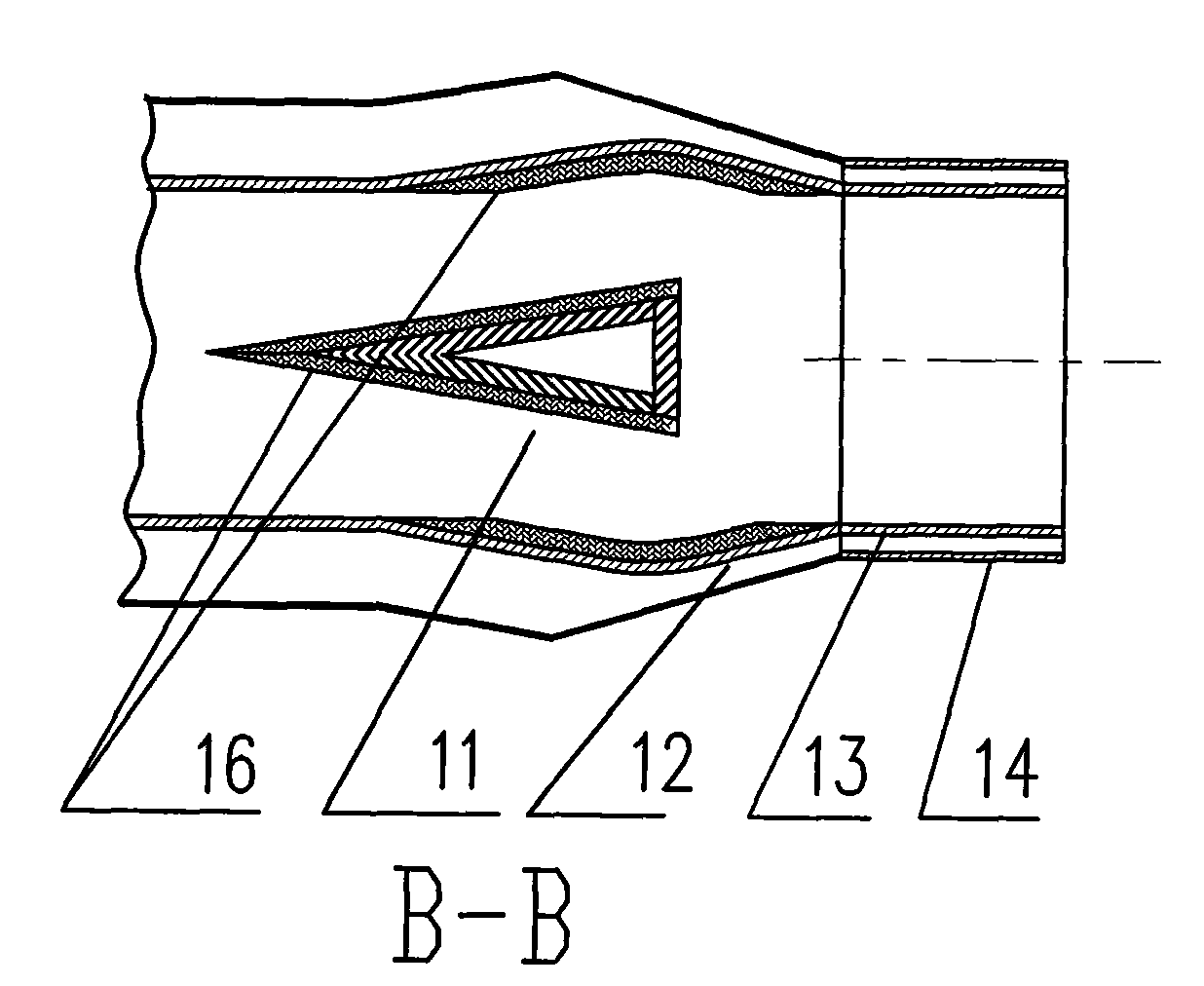

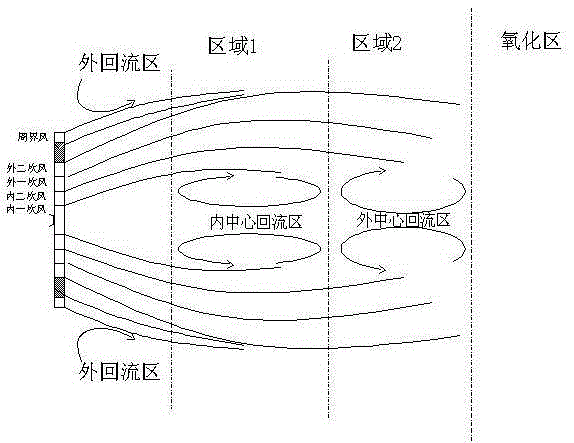

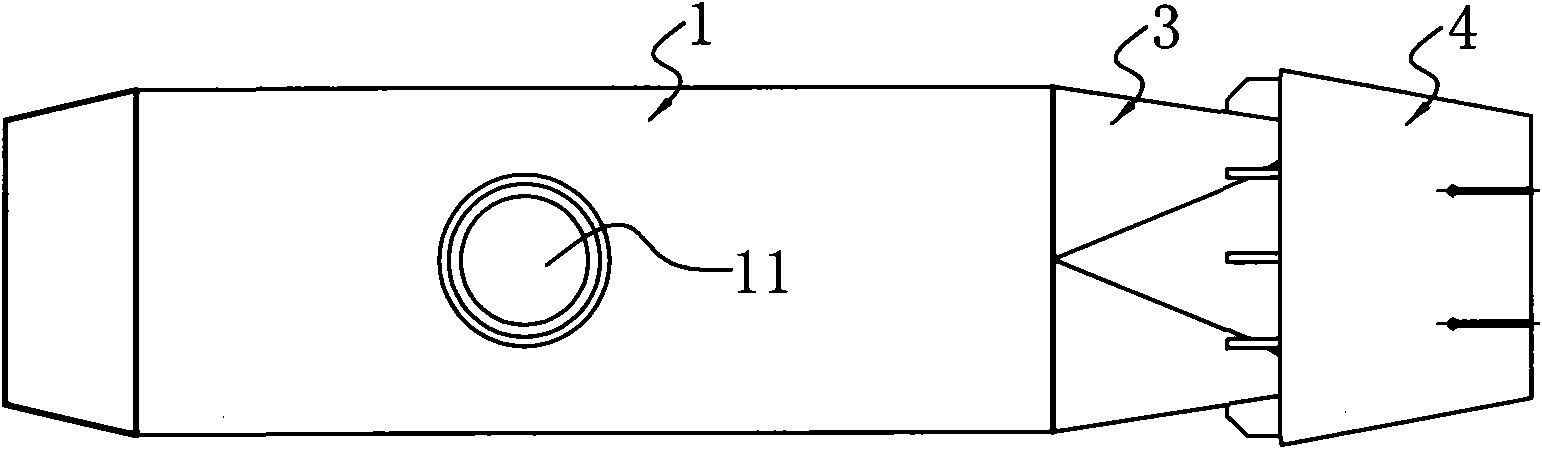

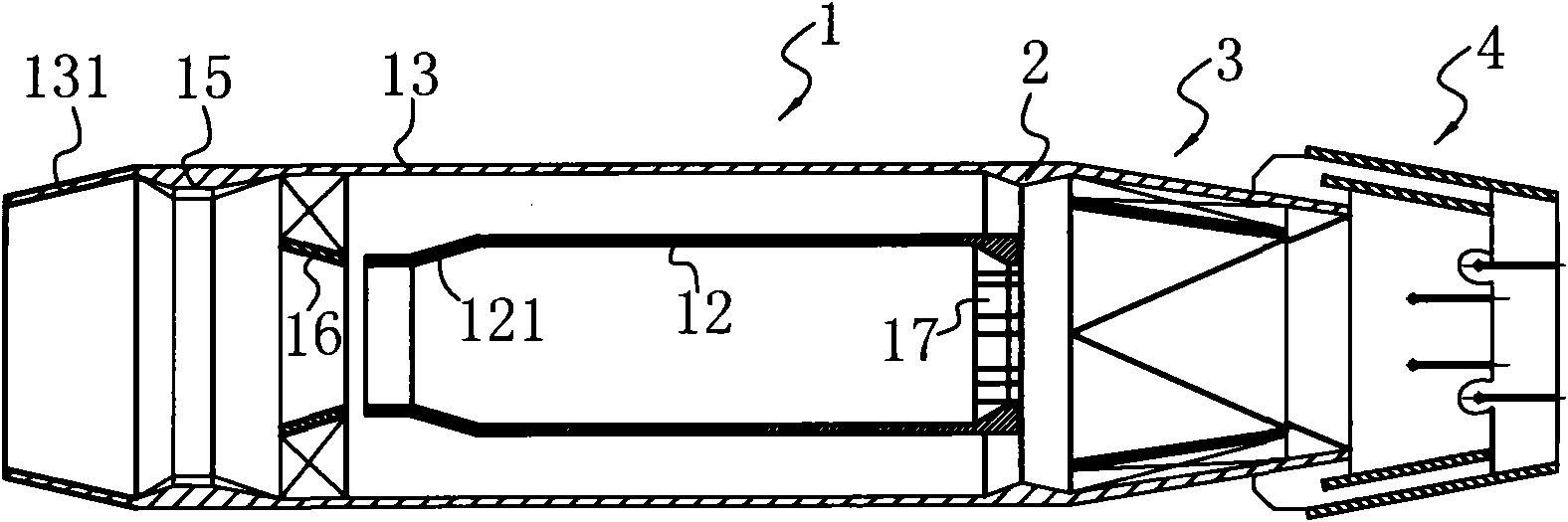

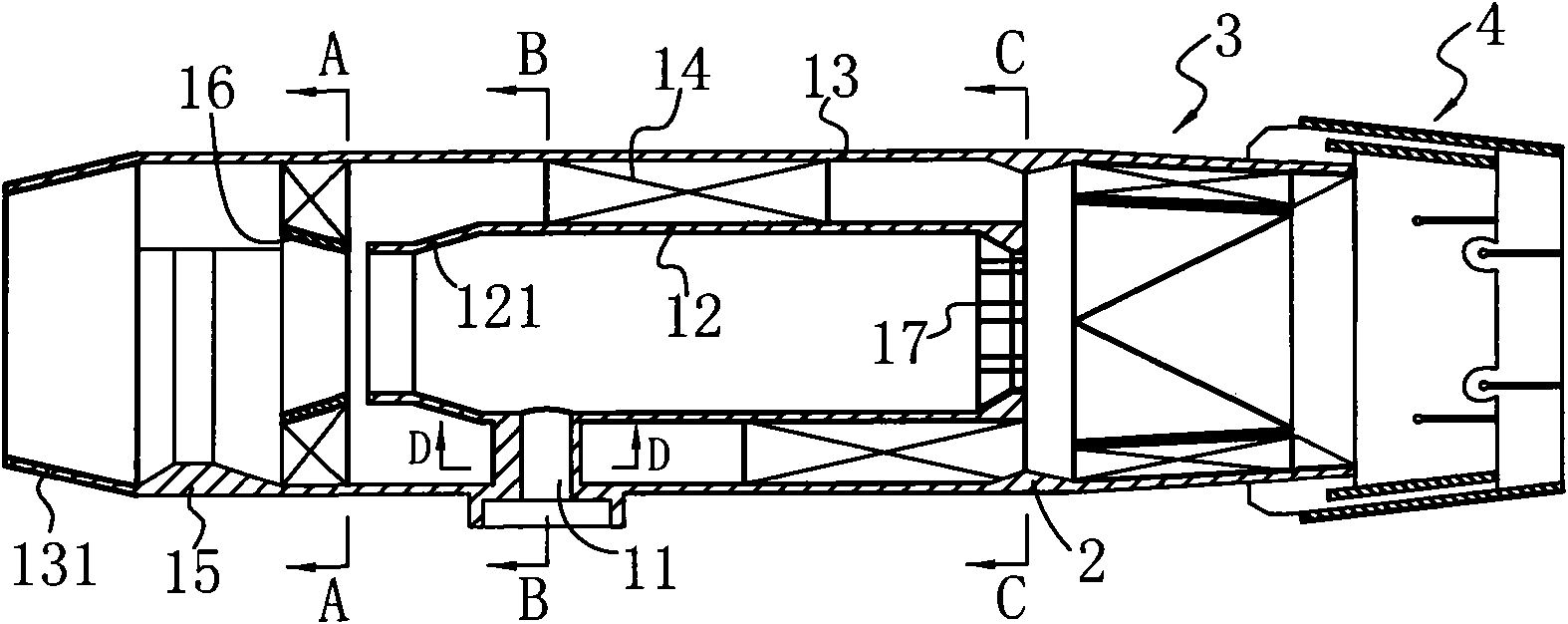

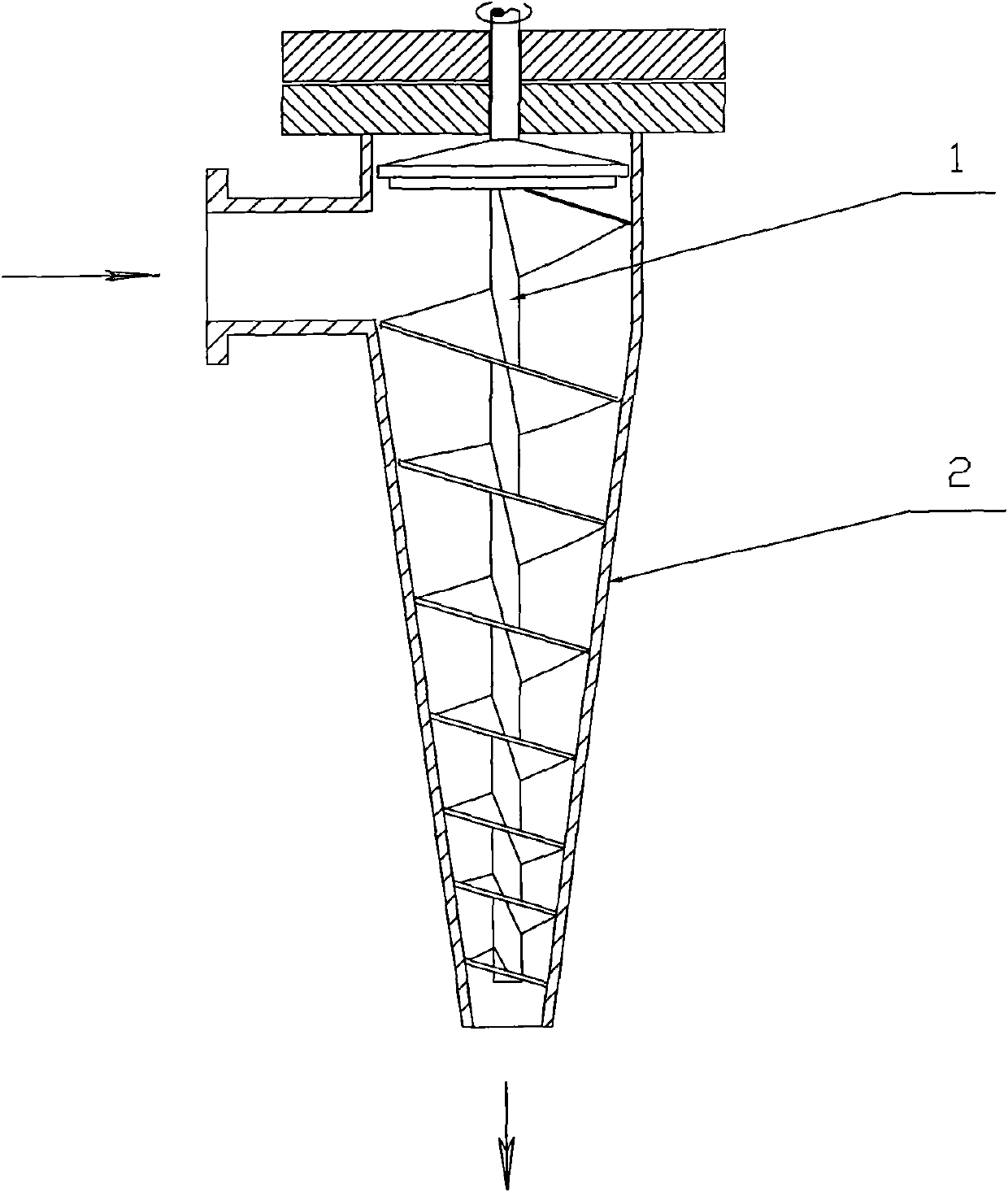

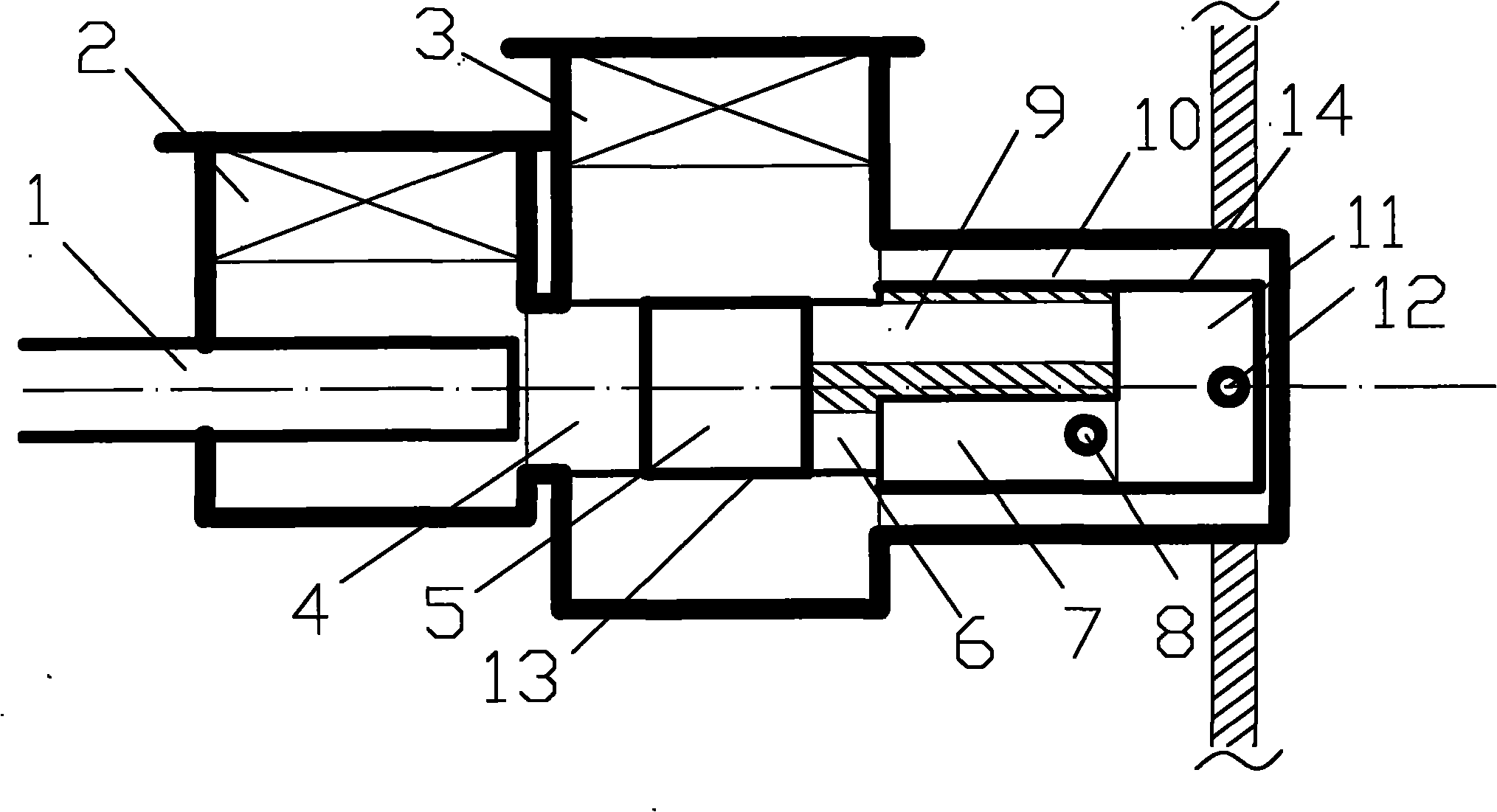

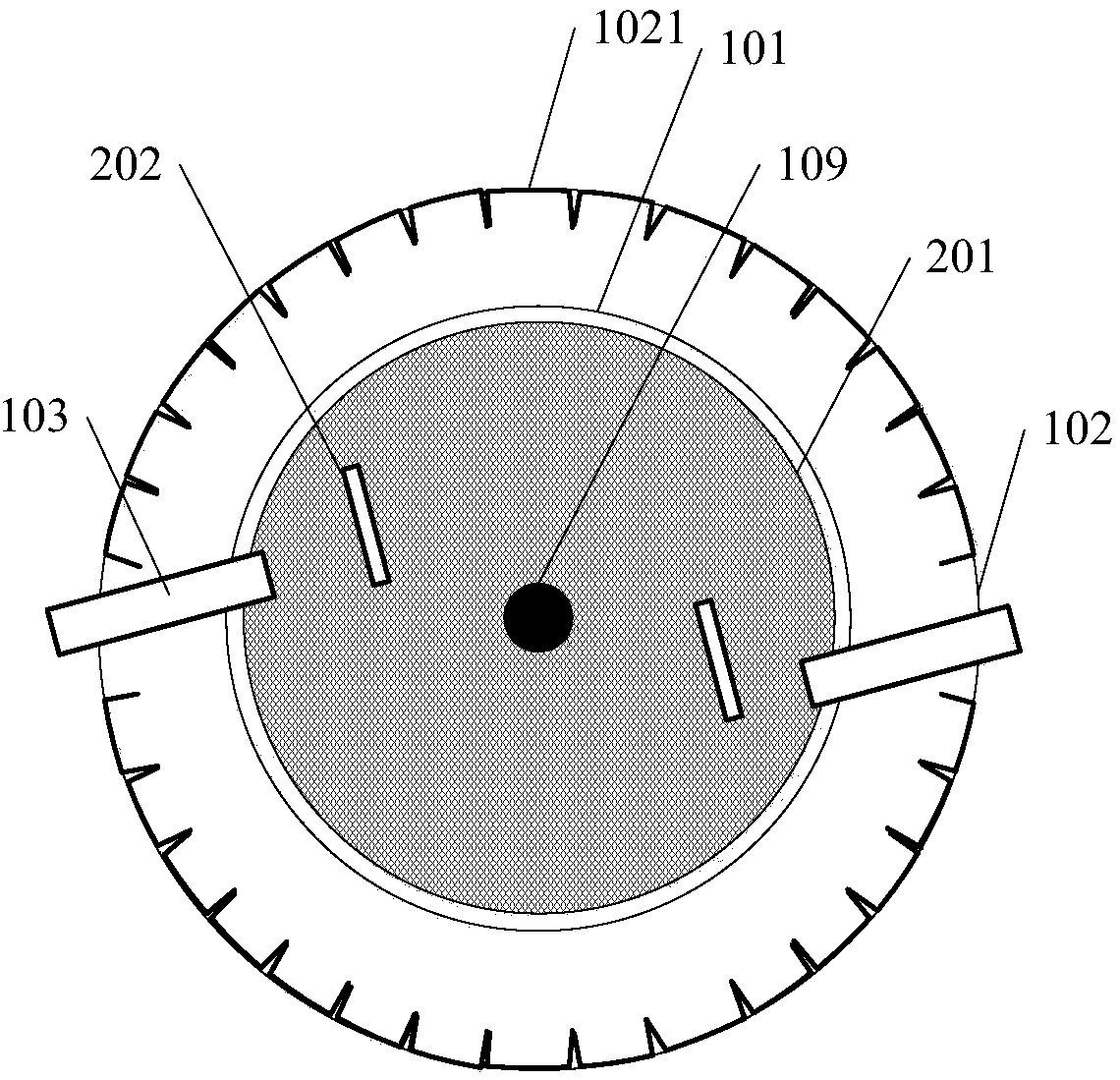

Coal-fired power plant turbulent burner suitable for low-order mixed coal combustion

ActiveCN105402723AAvoid rushingReduce generationPulverulent fuel combustion burnersCombustionCoal fired

The invention discloses a coal-fired power plant turbulent burner suitable for low-order mixed coal combustion. The coal-fired power plant turbulent burner comprises a cone, an inner primary air shell, an inner secondary air shell, an outer primary air shell, an outer secondary air shell and a surrounding air shell, wherein the center cone is sleeved with the inner primary air shell, the inner primary air shell is sleeved with the inner secondary air shell, the inner secondary air shell is sleeved with the outer primary air shell, the outer primary air shell is sleeved with the outer secondary air shell, and the surrounding air shell is arranged on the outer side of the outer secondary air shell. An inner primary air channel is defined by the inner primary air shell, an inner secondary air channel is defined by the inner secondary air shell and the inner primary air shell, an outer primary air channel is defined by the inner secondary air shell and the outer primary air shell, an outer secondary air channel is defined by the outer primary air shell and the outer secondary air shell, and a surrounding air channel is formed outside the turbulent burner. By the adoption of the coal-fired power plant turbulent burner, the problem that air is insufficient when different types of coal of the large combustion difficulty characteristic difference are mixed and burned at a single primary air nozzle of a traditional turbulent burner is solved, and ignition and combustion of the types of coal difficult to burn can be promoted.

Owner:STATE GRID HEBEI ENERGY TECH SERVICE CO LTD

Preparation method of synthesizing biomass formed fuel by using pharmaceutical mushroom dregs

InactiveCN106675688AHigh calorific valueEasy to catch fireBiofuelsSolid fuelsWater contentSpecific gravity

The invention relates to a preparation method of synthesizing a biomass formed fuel by using pharmaceutical mushroom dregs. Antibiotic mushroom dregs are prepared into the biomass formed fuel by a raw material crushing and screening unit, a prilling and molding unit, and a conveying and air-drying unit. By making full use of the characteristics of the mushroom dregs that the content of organic matters is high (greater than 90%) and the heat value is high (3600-4000Kcal / kg, the water content is less than or equal to 20%), the mushroom dregs are compressed and molded to obtain the biomass fuel. Through the process, wastes (mushroom dregs) which are low in energy density are compressed to granular or bulky fuels which are large in specific gravity and hard in texture. The product processed by the steps has the characteristics of being easily on fire, low in ash content, clean and sanitary and the like, and the product meets the technical requirements of national biomass solid formed fuel so as to be further used as a raw material for a biomass power generation plant to replace part of straws for incineration power generation and heating, so that harmless treatment and resource utilization are realized and the fuel cost of a production enterprise is lowered.

Owner:河北银发瑞洁环境科技有限公司

Formula of environment-friendly biomass briquette

The invention discloses a formula of an environment-friendly biomass briquette. The formula comprises fuel and an additive, wherein the additive is water glass and the fuel is the mixture of biomass powdered carbon and fine anthracite. The concentration of the water glass is set to be 3.2 moduli. The water glass is 12-30% of the environment-friendly biomass briquette by weight and the fuel is 70-88% of the environment-friendly biomass briquette by weight. If the concentration of the water glass is less than 3.2 moduli, the proportion is correspondingly increased.

Owner:肖国雄

Two-stage speed-down pulverized coal burner

ActiveCN101639217AIncrease concentrationIncrease temperaturePulverulent fuel combustion burnersCombustion chamberHeating time

The invention discloses a two-stage speed-down pulverized coal burner, which comprises a speed-down ignition burning chamber, wherein the axial side wall of the speed-down ignition burning chamber isprovided with at least one inserting hole; and an ignition device for igniting pulverized coals passing through the speed-down ignition burning chamber is inserted in the inserting hole. Because the heating energy and the heating time of the pulverized coal are in direct proportion on the premise of other unchanged conditions, when the airflow speed reduces by one time, the heating energy of flameto the pulverized coals raises by one time. The ignition burning chamber is designed into the speed-down ignition burning chamber 1, namely the speed of the pulverized coals passing through the ignition burning chamber is reduced, so that the time of staying at high-temperature flame of the pulverized coals is prolonged, and the heating energy of the flame to the pulverized coals is raised so asto speed up heat chemical conversion to restore volatile matters and promote complete burning, thereby being favorable for ignition and stable burning.

Owner:BEIJING GUNGYAO ELECTRICITY EQUIP CO LTD

Environmental-friendly machine-made charcoal and production method thereof

ActiveCN107805516ASave energyImprove drying efficiencyBiofuelsSpecial form destructive distillationDouble tubeCarbonization

The invention discloses environmental-friendly machine-made charcoal and a production method thereof. The production method comprises the following steps: drying a raw material, and separating the dried raw material from hot air; making rods; performing carbonization, namely carbonizing the machine-made charcoal rod cores in a carbonization furnace so as to obtain machine-made charcoal; in carbonization, feeding combustion smoke discharged from the carbonization furnace into a carbonization furnace smoke discharge recycling pipeline, feeding the combustion smoke discharged from the carbonization furnace into a heat source stove under the action of a draft fan and the pressure inside the carbonization furnace, fusing the combustion smoke with existing heat of the heat source stove, feedinginto a double-tube type drying tank, dyeing the raw material, and repeating the operation in circulation. By adopting the production method, no-smoke production is achieved in the whole production process, no fume is discharged into the environment, the air is not polluted, and the environment can be protected; the environmental-friendly machine-made charcoal is relatively high in heat value, relatively small in ash amount, easy to combust, free of harmful gases such as sulfur oxide, potassium sulfide, nitric oxide and carbonic oxide when being combusted, free of flying dust or bursting phenomenon and free of influence on human body health.

Owner:刘沛龙

Production process of biomass carbon-based briquetted coal for replacing fossil fuel

The invention discloses biomass carbon-based briquetted coal for replacing fossil fuel. The biomass carbon-based briquetted coal for replacing fossil fuel, based on 100 mass parts of agricultural and forest biomass raw material, comprises the following auxiliary materials: 0.01 to 0.05 mass percent of swelling agent, 0.001 to 0.005 mass percent of potassium permanganate oxidizer and 0.1 to 0.5 percent of calcium lignosulphonate organic binder. The production process comprises: crushing, drying, mixing and stirring the raw materials; subjecting the stirred raw materials to primary prepressing and secondary compression forming, and performing moisture regain preventing treatment; and finally, packaging finished product. Besides high density, convenience for storage and transport, high combustibility, high combustion performance, high heat efficiency, the biomass carbon-based briquetted coal produced by the process also has the advantages of generating less ash, hardly generating SO2 andNOx during combustion, avoiding environment pollution and the like. The carbon-based fuel disclosed by the invention is prepared from widely available raw materials and is environment-friendly, and the environmental-protection benefit of the carbon-based fuel is very obvious.

Owner:周之海

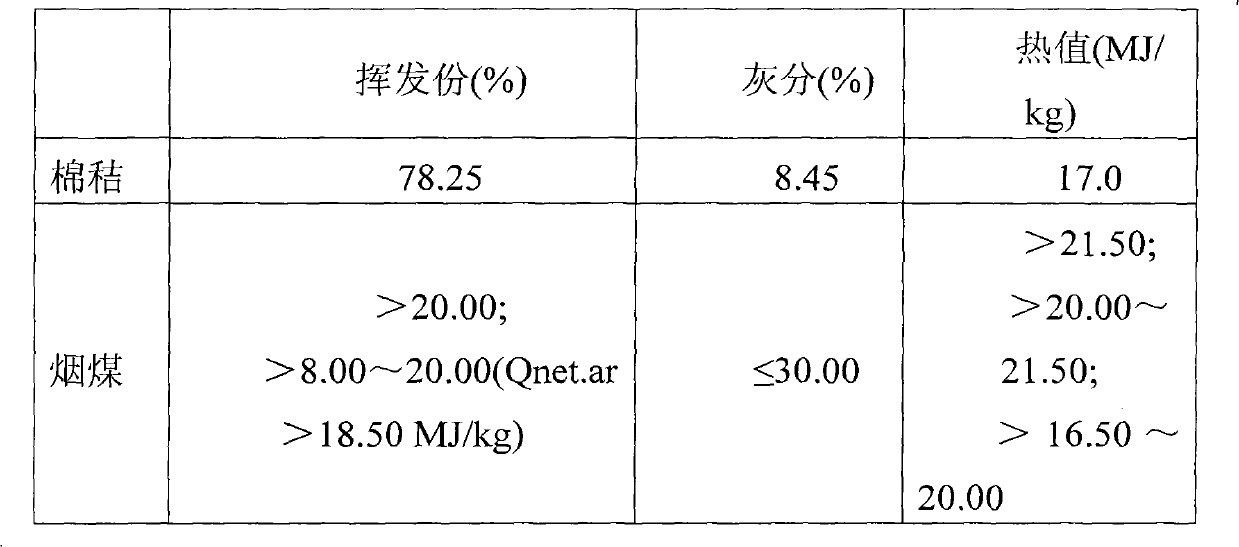

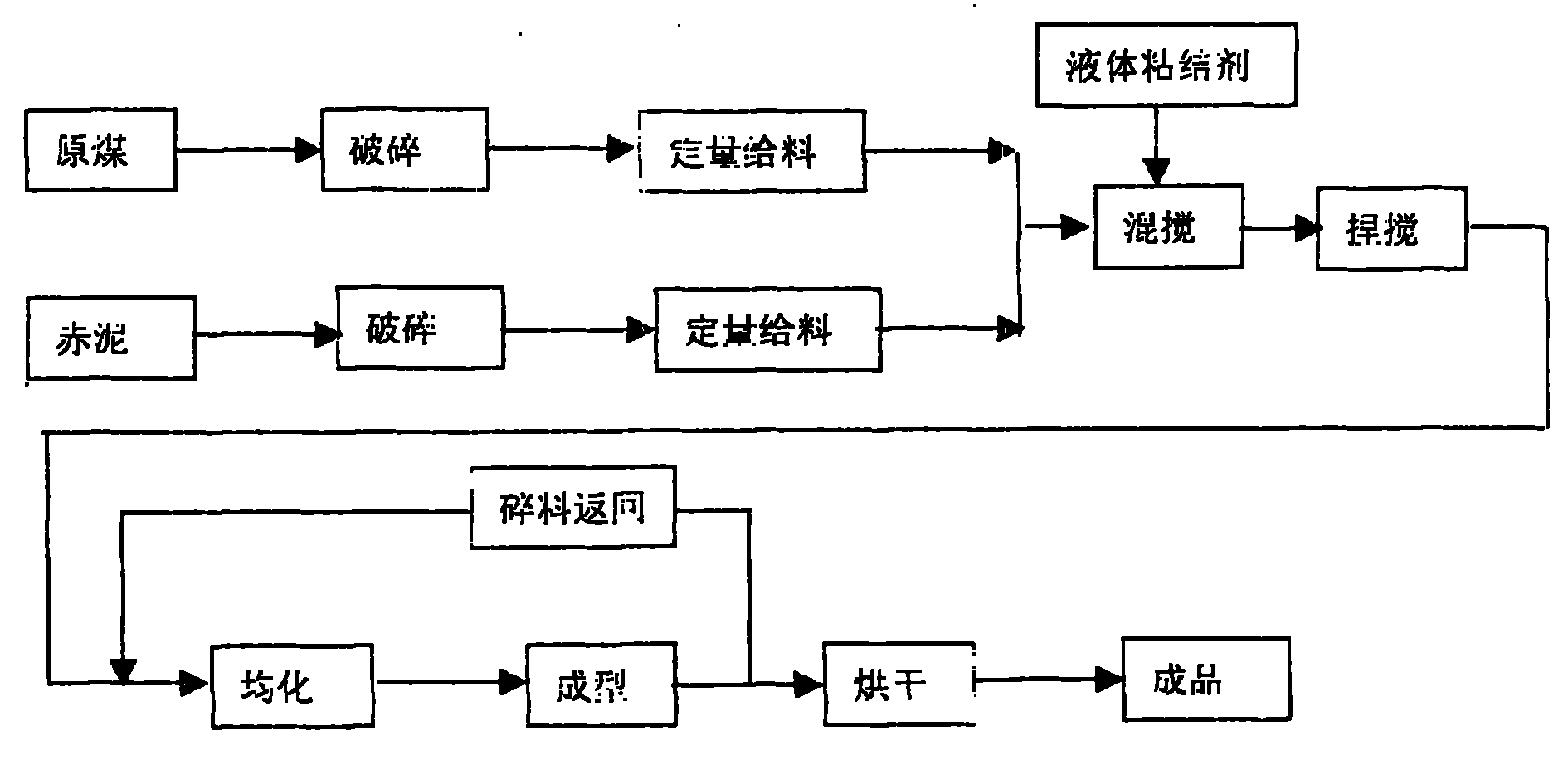

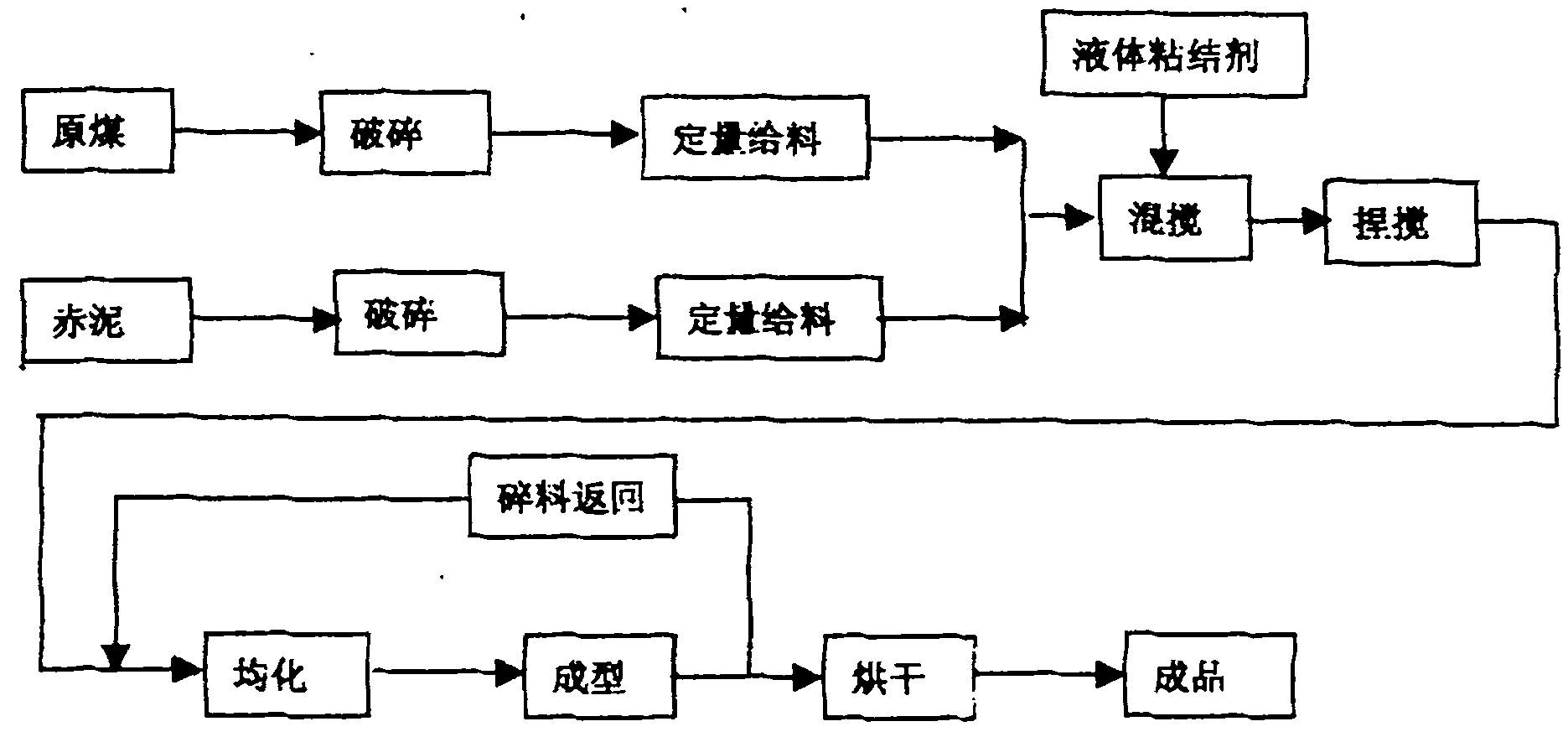

Water-soluble briquette adhesive and process applied to briquette production thereof

The invention discloses a water-soluble briquette adhesive and a process applied to briquette production thereof and relates to an adhesive for briquette for production industry and civilian use and application thereof. The water-soluble briquette adhesive is combined by organic water-soluble adhesive, inorganic water-soluble adhesive, water-soluble preservative, water-soluble combustion improverand water-soluble sulfur and fluorine removal agent, and the process flow for producing the briquette by utilizing the adhesive is as follows: A. raw material crushing; B. quantitative feeding; C. mixing and stirring; D. pinching and stirring; E. homogenizing; F. molding; and G. drying. The adhesive has little use amount in the briquette production, high adhesive strength, high content of fixed carbon and high fuel value, fire-leading is easy, the firepower is large, and soot smell is difficult to smell.

Owner:宋邦娟

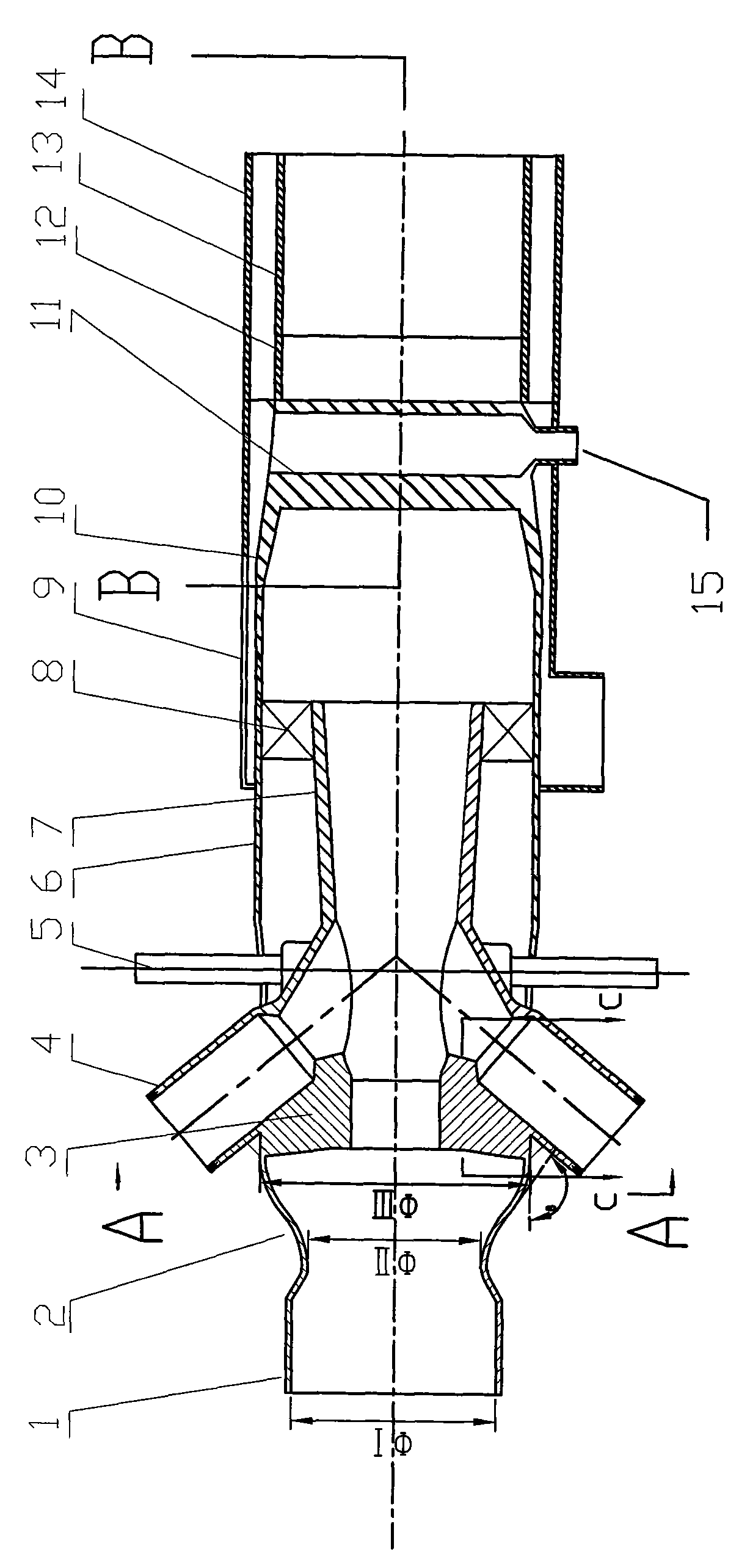

Petroleum coke power combustor

InactiveCN101865463AWell mixedPromote ignitionPulverulent fuel combustion burnersCombustion chamberCombustor

The invention discloses a petroleum coke powder combustor, which comprises a feeding pipe, a primary air turbine, a secondary air turbine, and a combustion cylinder coaxially arranged in turn. A primary air passage is provided with a petroleum coke powder concentrator inside; a secondary air passage is sleeved outside the combustion cylinder and is communicated with the secondary air turbine; the petroleum coke powder concentrator is respectively communicated with a thick petroleum coke powder passage and a thin petroleum coke powder passage; the thick petroleum coke powder passage and the thin petroleum coke powder passage are respectively communicated with a first-stage combustion chamber and a second-stage combustion chamber; the first-stage combustion chamber is communicated with the second-stage combustion chamber; and the second-stage combustion chamber and the secondary air passage are connected to a hearth. The two-stage combustion technology is adopted, so the space and time for combusting petroleum coke powder airflow are enlarged and prolonged. The primary air turbine feeds primary air to enhance the disturbance; simultaneously the secondary air turbine feeds secondary air to form rotary jet flow to entrain high-temperature flue gas, so that the petroleum coke powder is easy to fire.

Owner:SOUTH CHINA UNIV OF TECH

Water-soluble briquette adhesive and process applied to briquette production thereof

The invention discloses a water-soluble briquette adhesive and a process applied to briquette production thereof and relates to an adhesive for briquette for production industry and civilian use and application thereof. The water-soluble briquette adhesive is combined by organic water-soluble adhesive, inorganic water-soluble adhesive, water-soluble preservative, water-soluble combustion improver and water-soluble sulfur and fluorine removal agent, and the process flow for producing the briquette by utilizing the adhesive is as follows: A. raw material crushing; B. quantitative feeding; C. mixing and stirring; D. pinching and stirring; E. homogenizing; F. molding; and G. drying. The adhesive has little use amount in the briquette production, high adhesive strength, high content of fixed carbon and high fuel value, fire-leading is easy, the firepower is large, and soot smell is difficult to smell.

Owner:宋邦娟

Energy-saving type biomass fuel furnace

ActiveCN107726295AHeating up fastPrevent fallingSolid fuel combustionWater heatersEngineeringEnergy conservation

The invention discloses an energy-saving type biomass fuel furnace. The energy-saving type biomass fuel furnace comprises a furnace body. The furnace body comprises an inner furnace body and an outerfurnace body. The inner furnace body is arranged in the outer furnace body in a sleeving manner. A rotatable grate is rotatably and vertically arranged in the inner furnace body by a rotary shaft. Therotatable grate comprises a plurality of fuel pallets which are sequentially arranged on the rotary shaft at intervals along the axial direction. Pared fins are symmetrically arranged at two sides ofthe rotary shaft in a spiral-shaped manner and penetrate the fuel pallets in sequence. One end of a pneumatic biomass powder feeding pipe is arranged in the way of penetrating the furnace body, extending to the fins and exactly facing the fins. A biomass particle feeding port is arranged at the top of the furnace body. A mode water-cooling wall is arranged on the side wall of the furnace body. Aslag collecting groove is arranged at the bottom of the rotatable grate in a detachable manner. A plurality of circulation ports are uniformly arranged on the side wall which is closed to the bottom of the inner furnace body at intervals in an annular manner. The energy-saving type biomass fuel furnace further comprises a smoke exhausting port and a base. The energy-saving type biomass fuel furnace is capable of mixing and burning biomass powder and biomass particle fuel sufficiently, full in combustion, high in heat utilization rate and good in energy conservation and environment protection.

Owner:河北衡晓生物科技有限公司

Layered energy-saving and environmental-protection honeycomb briquette

The invention discloses a layered energy-saving and environmental-protection honeycomb briquette, and belongs to the energy field. The honeycomb briquette comprises plant stalk carbon, coal slag, coal, a combustion improver, a sulfur fixing agent and water, and is made through the following steps: carrying out layered weighing of all above components, respectively adding water, well mixing, sequentially adding the obtained mixtures into a die, and extruding. The raw materials comprising crop stalks and coal slag are cheap, and are changed into valuables, so the coal energy is saved; a golden section law and a layering technology are used, and the water content of all layers is similar, so no separation is realized after extrusion molding, and the honeycomb briquette is scientifically produced; and the honeycomb briquette has the advantages of easy energization, good combustion connection, high flare, full and stable combustion, no pollution, few damages to human bodies, and less pollution to environment.

Owner:吕晓娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com