Environmental-friendly machine-made charcoal and production method thereof

A technology of mechanism charcoal and production method, which is applied in the direction of biofuel, special dry distillation, petroleum industry, etc. It can solve the problems of large ash content, low calorific value, and environmental pollution, and achieve space saving, high drying efficiency, and energy saving energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

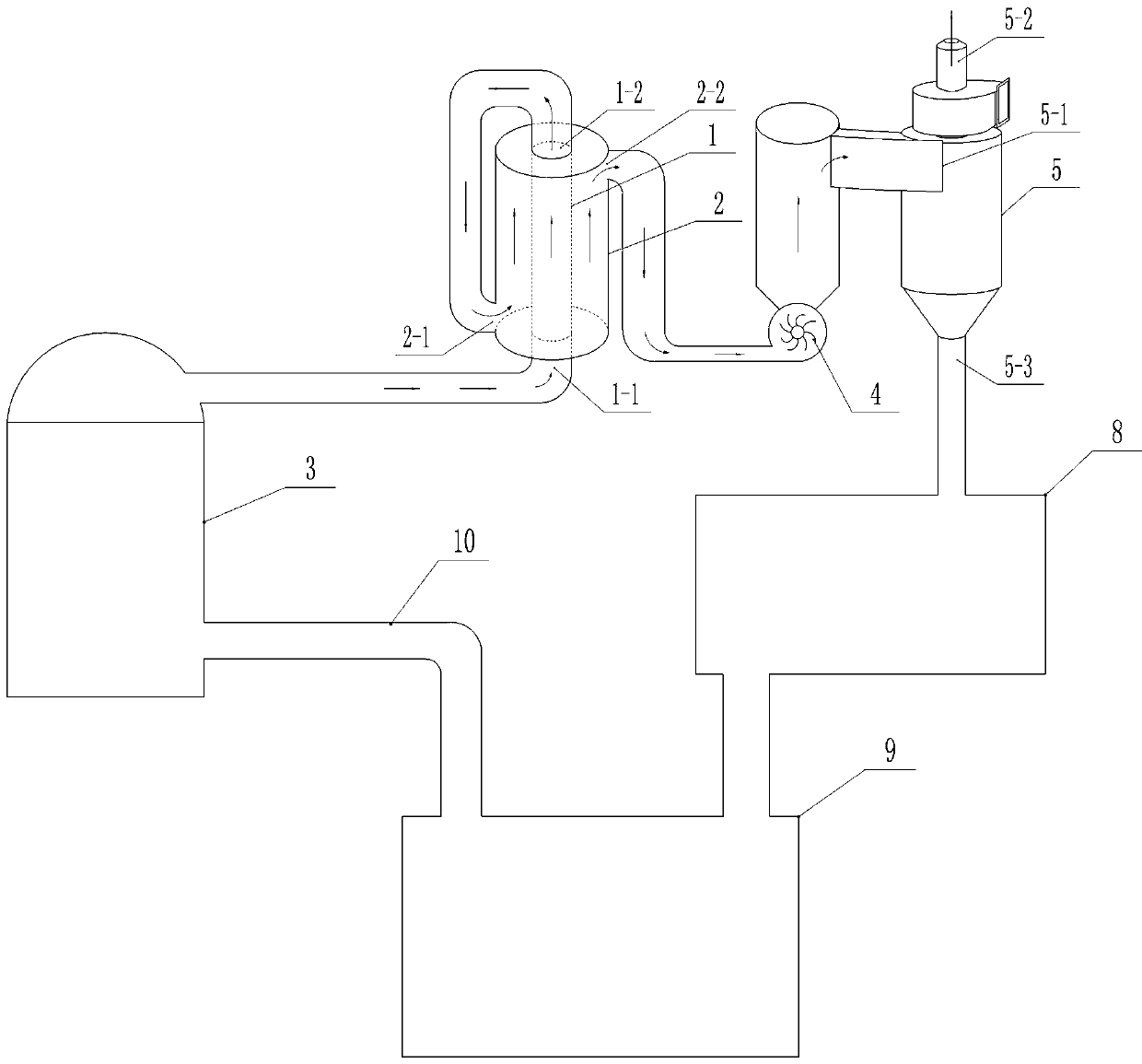

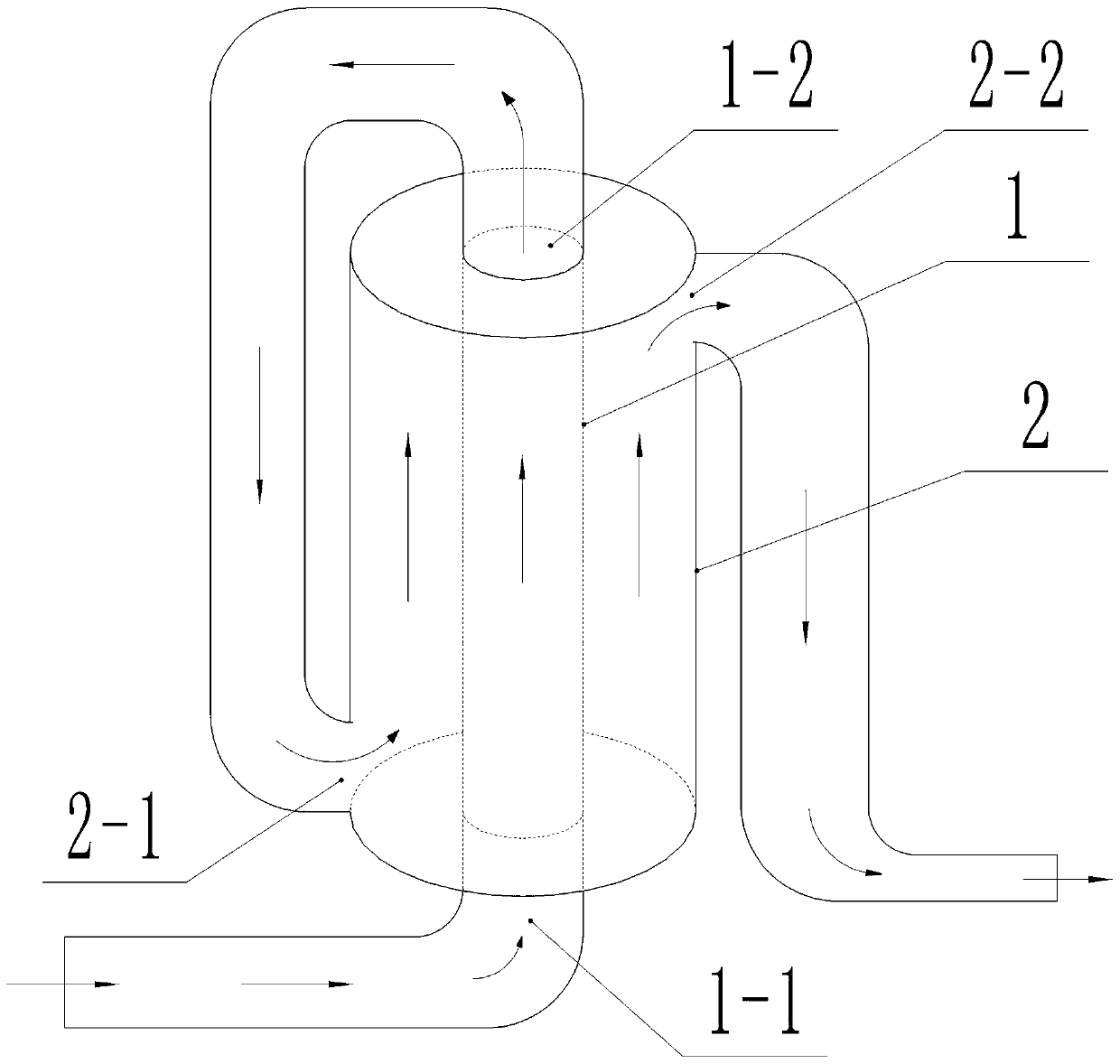

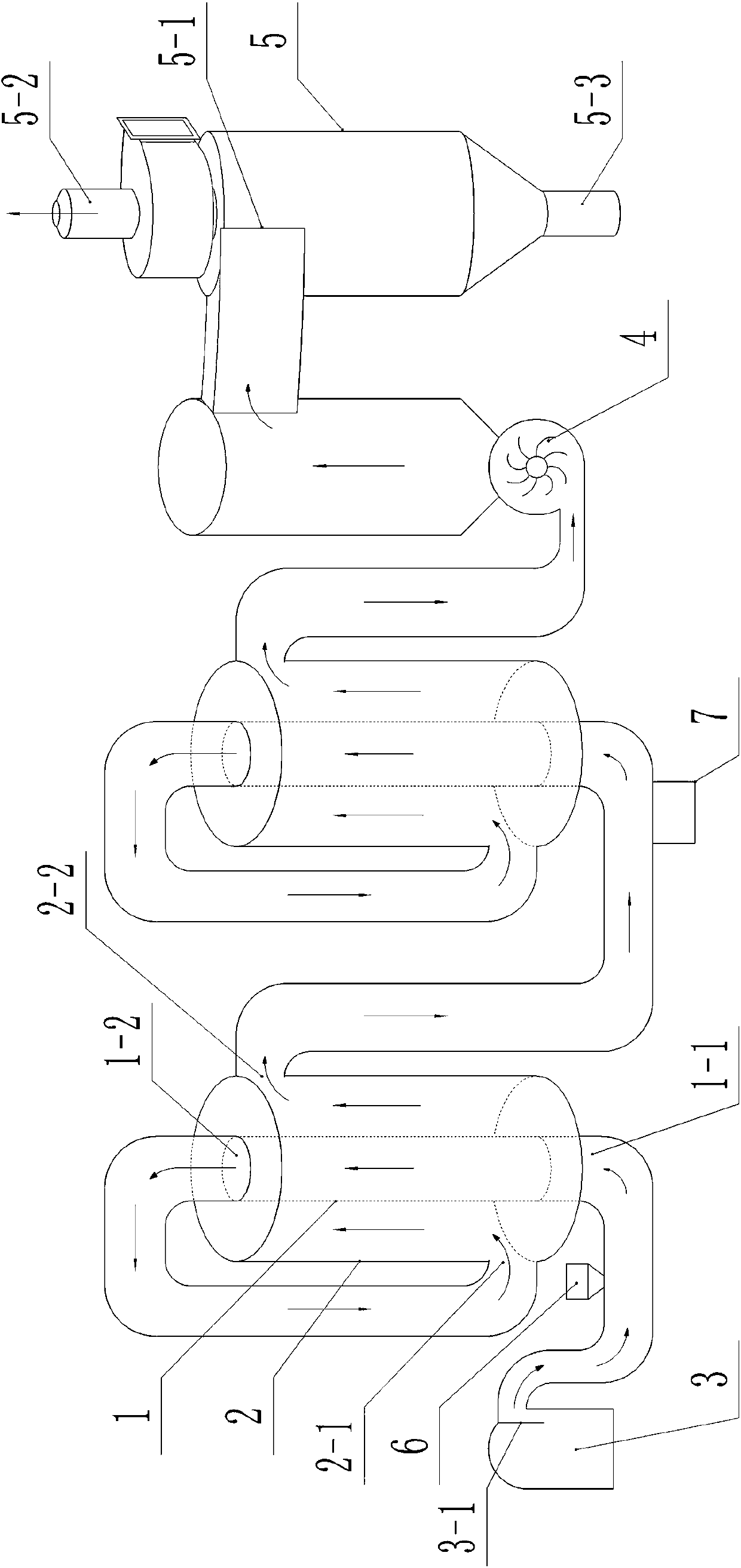

[0038] refer to Figure 1-Figure 3 , a production method of environment-friendly machine-made charcoal, comprising a machine-made charcoal smoke-free production system, the machine-made charcoal smoke-free production system comprising a hot air source 3, a drying tank, an induced draft fan 4, a gas-solid separator 5, a rod-making machine 8 and carbonization furnace 9, the oven includes an inner tube 1 and an outer tube 2, one end of the inner tube 1 is an inner tube inlet 1-1, and the other end is an inner tube outlet 1-2; the outer tube 2 One end of the outer tube is the inlet 2-1, and the other end is the outlet 2-2 of the outer tube; the inner tube 1 is arranged inside the outer tube 2, and the inner tube outlet 1-2 communicates with the outer tube inlet 2-1; The inner pipe inlet 1-1 is the feed inlet and the drying air inlet, and the outer pipe outlet 2-2 is the material outlet and air outlet;

[0039] The air outlet of the hot air source 3 communicates with the inner tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com