Patents

Literature

1546 results about "Double tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

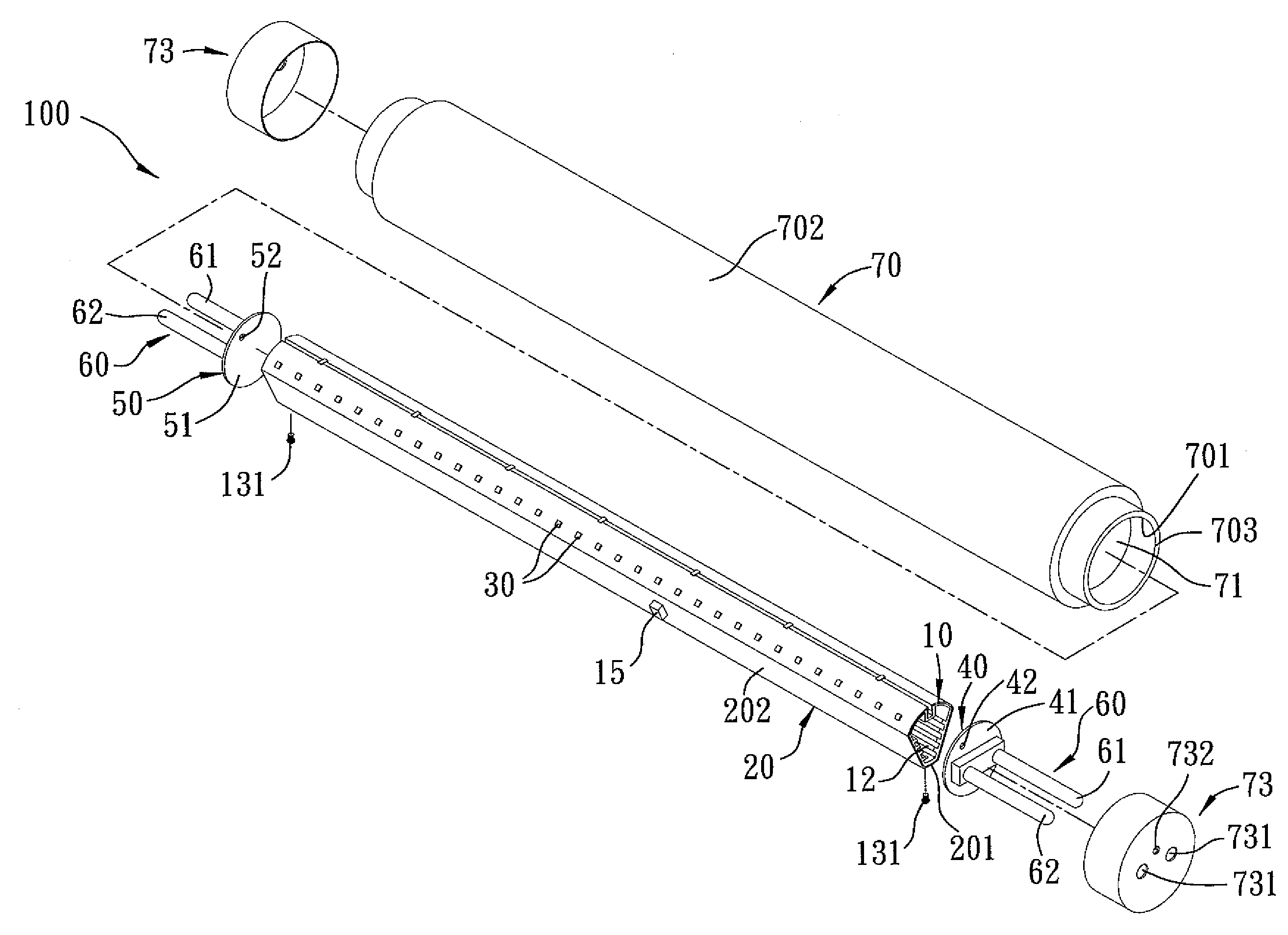

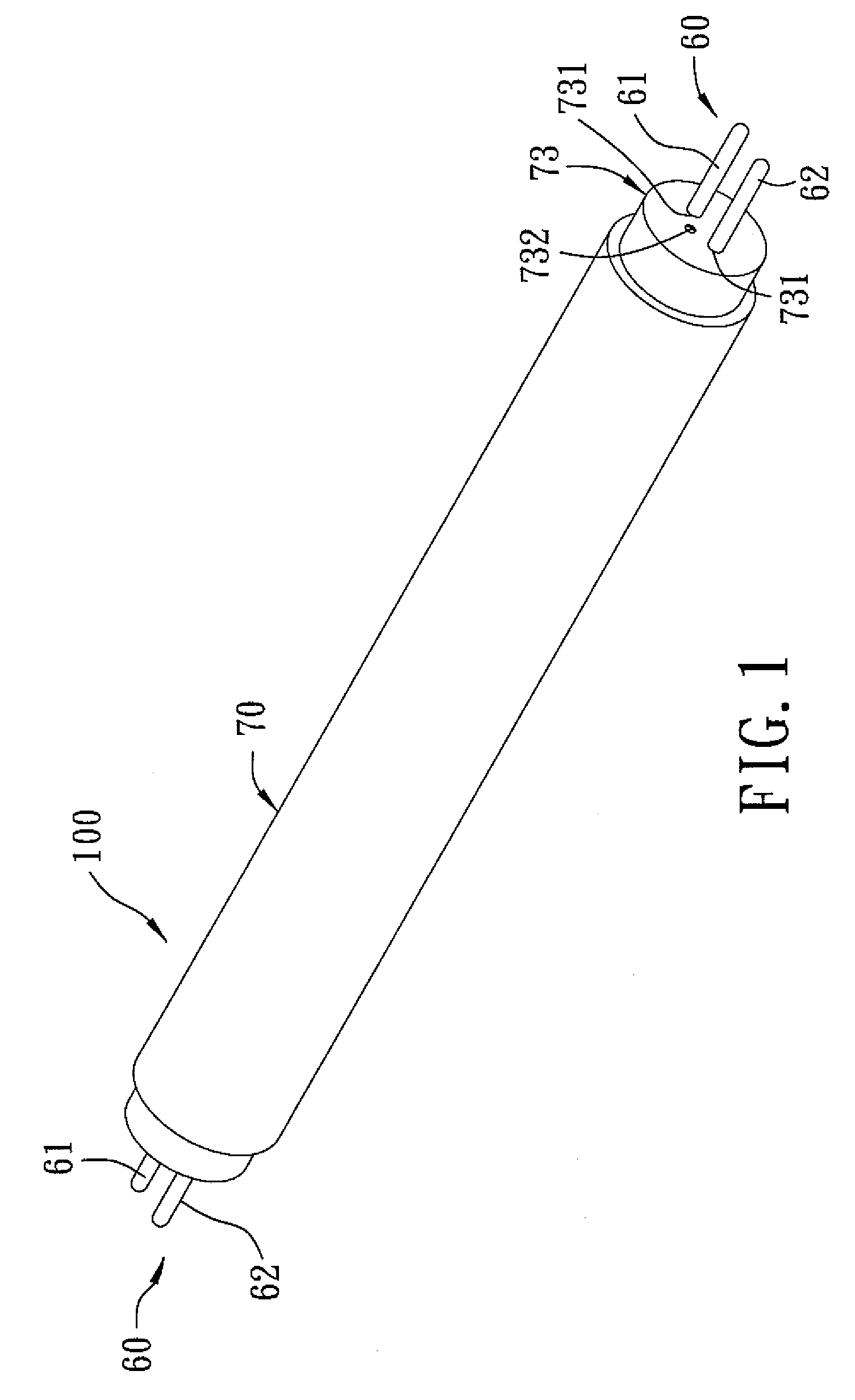

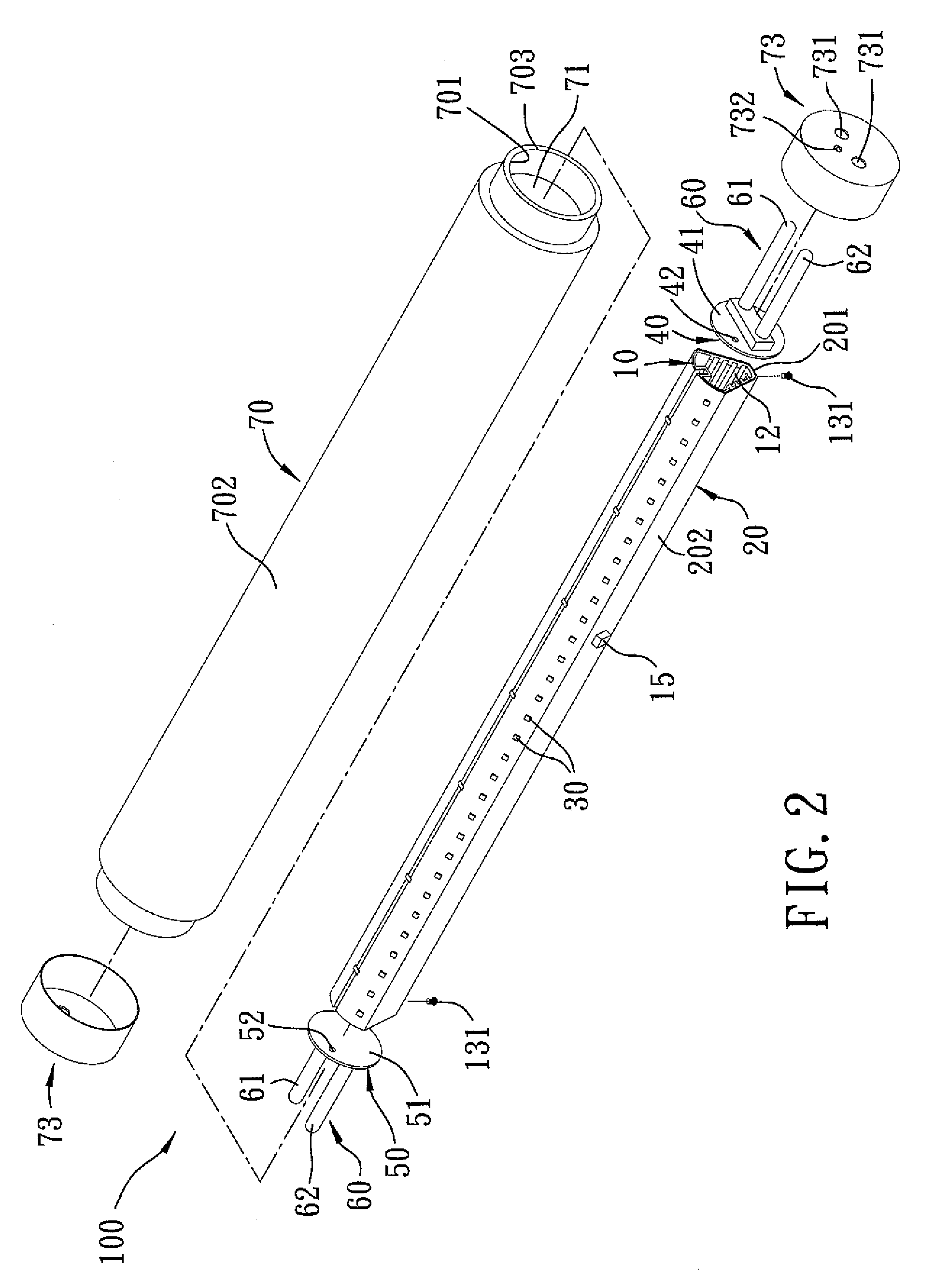

Energy-saving lighting fixture

InactiveUS20100253226A1Save energyLighting support devicesPoint-like light sourceDouble tubeEffect light

An energy-saving lighting fixture includes a light transmissive tubular enclosure including an inner tube defining an inner compartment therein, and an outer tube disposed around and spaced apart from the inner tube to define an outer compartment therebetween. As such, the tubular enclosure has a double-tube structure. A lamp assembly includes at least one lamp device disposed fixedly in the inner compartment of the tubular enclosure.

Owner:YADENT

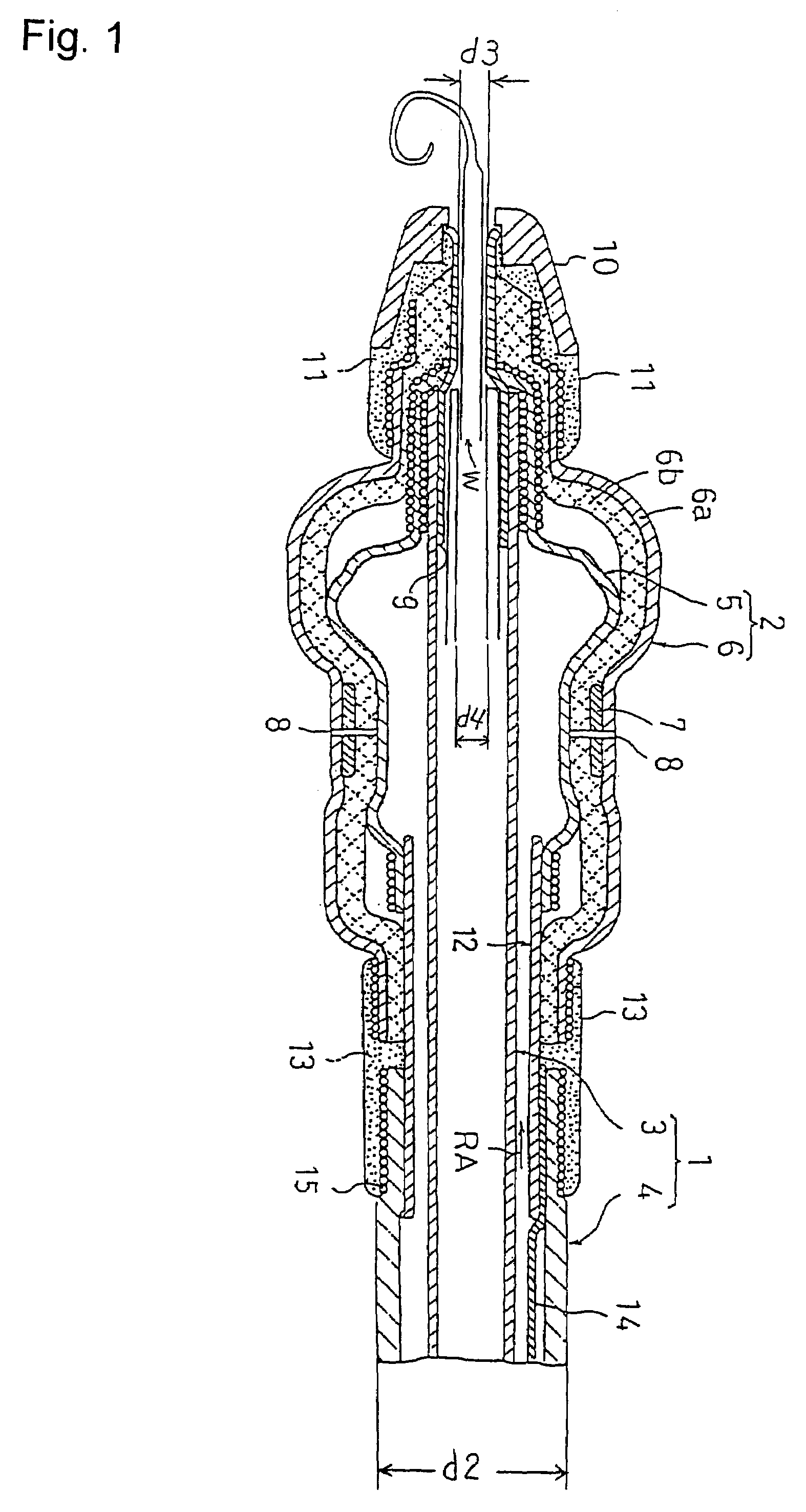

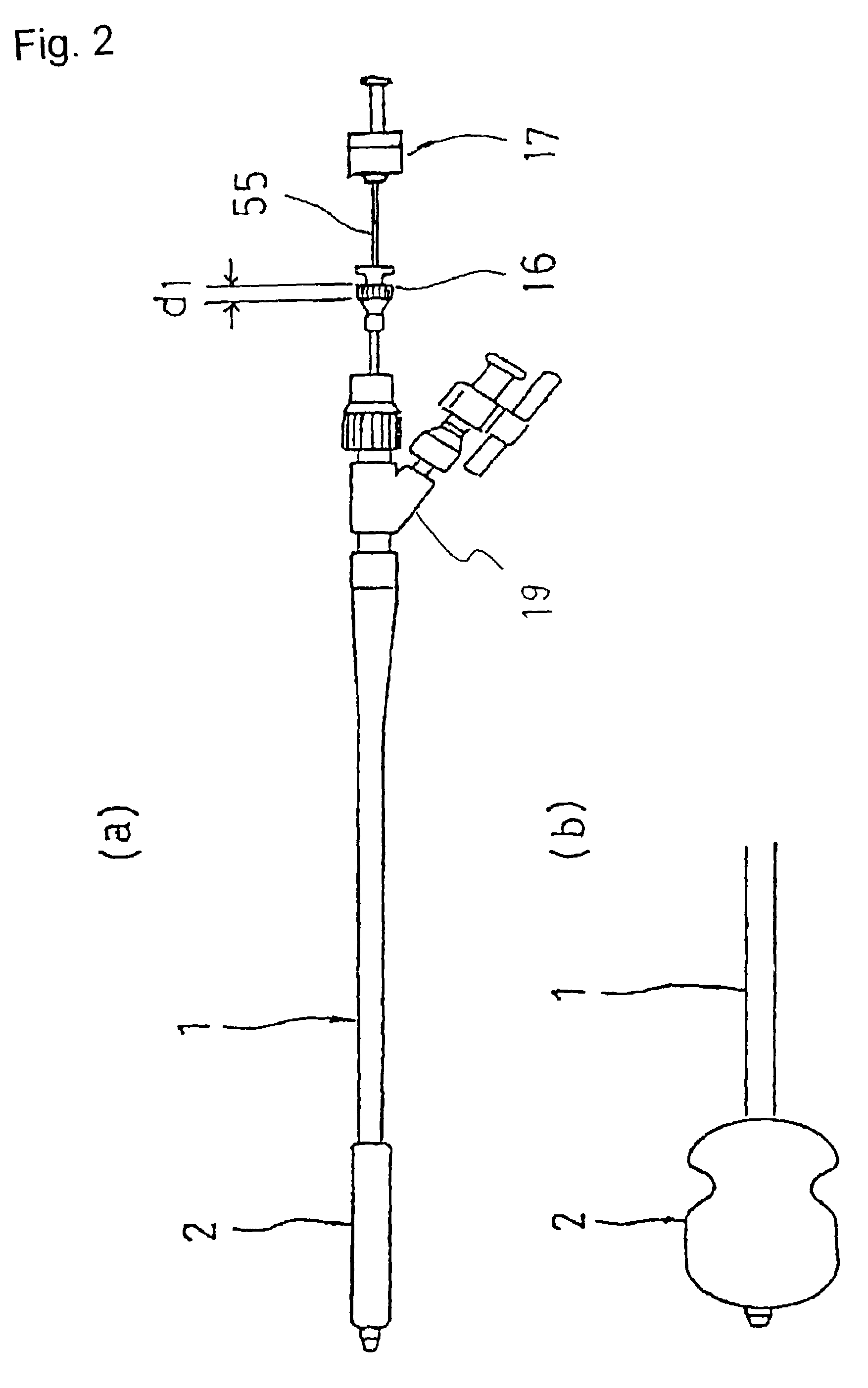

Catheter with balloon

A catheter with a balloon for mitral valve formative operation includes a double tube having an inner tube and an outer tube disposed concentrically. A balloon is fastened at one end to the inner tube and at the other end to the outer tube. A balloon-extending pipe stopper is disposed at the tip of the inner tube and includes an entry diameter at one end sized to receive a balloon-extending pipe with an allowance. An inner diameter of the balloon-extending pipe stopper at an opposite end is smaller than the entry diameter. The inner diameter of the extending pipe stopper is substantially equivalent to a diameter of the balloon-extending pipe. In use, the balloon-extending pipe is inserted into the inner tube and brought into contact with the balloon-extending pipe stopper for axially extending the balloon for contraction in diameter.

Owner:TORAY IND INC

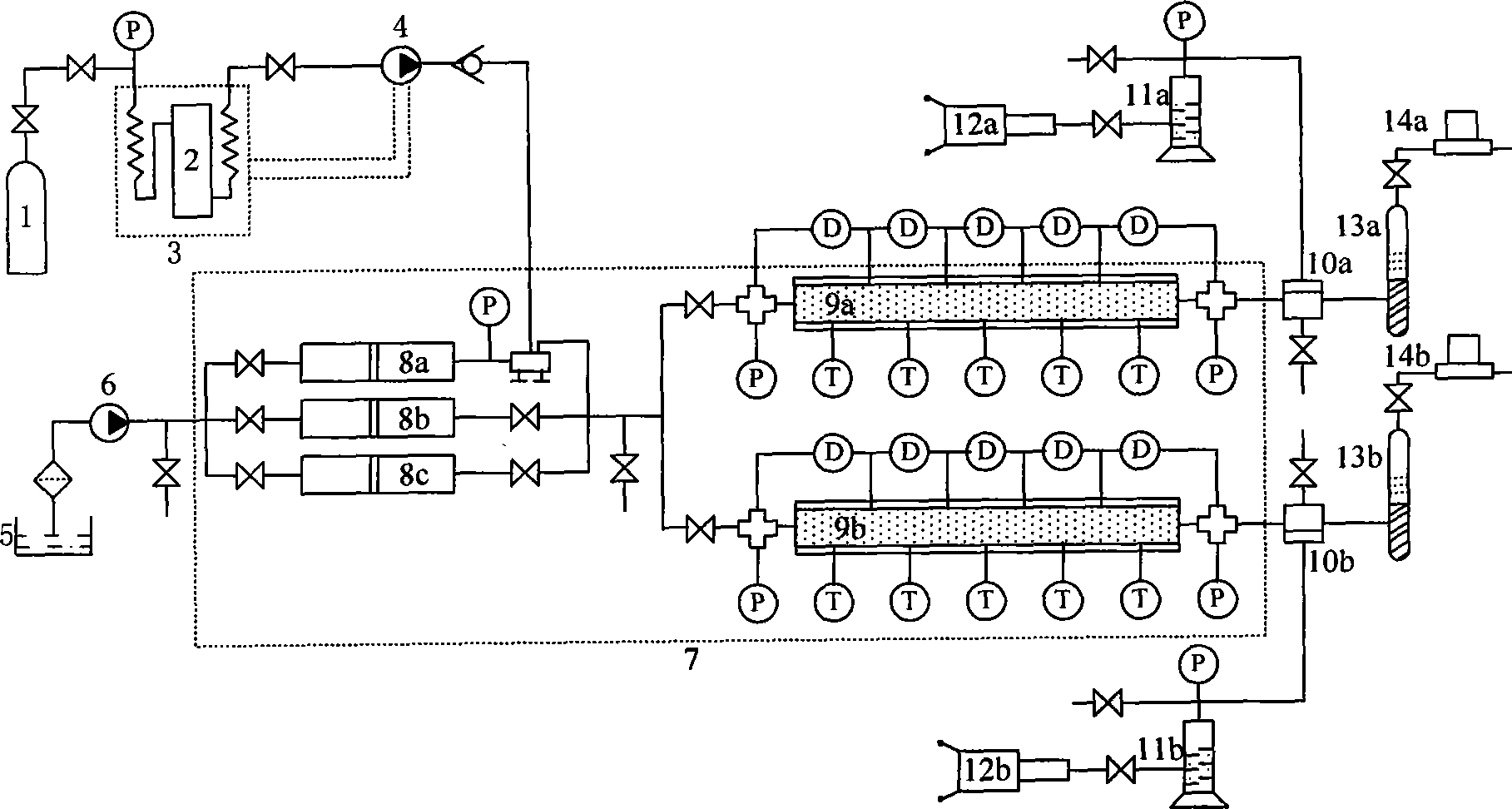

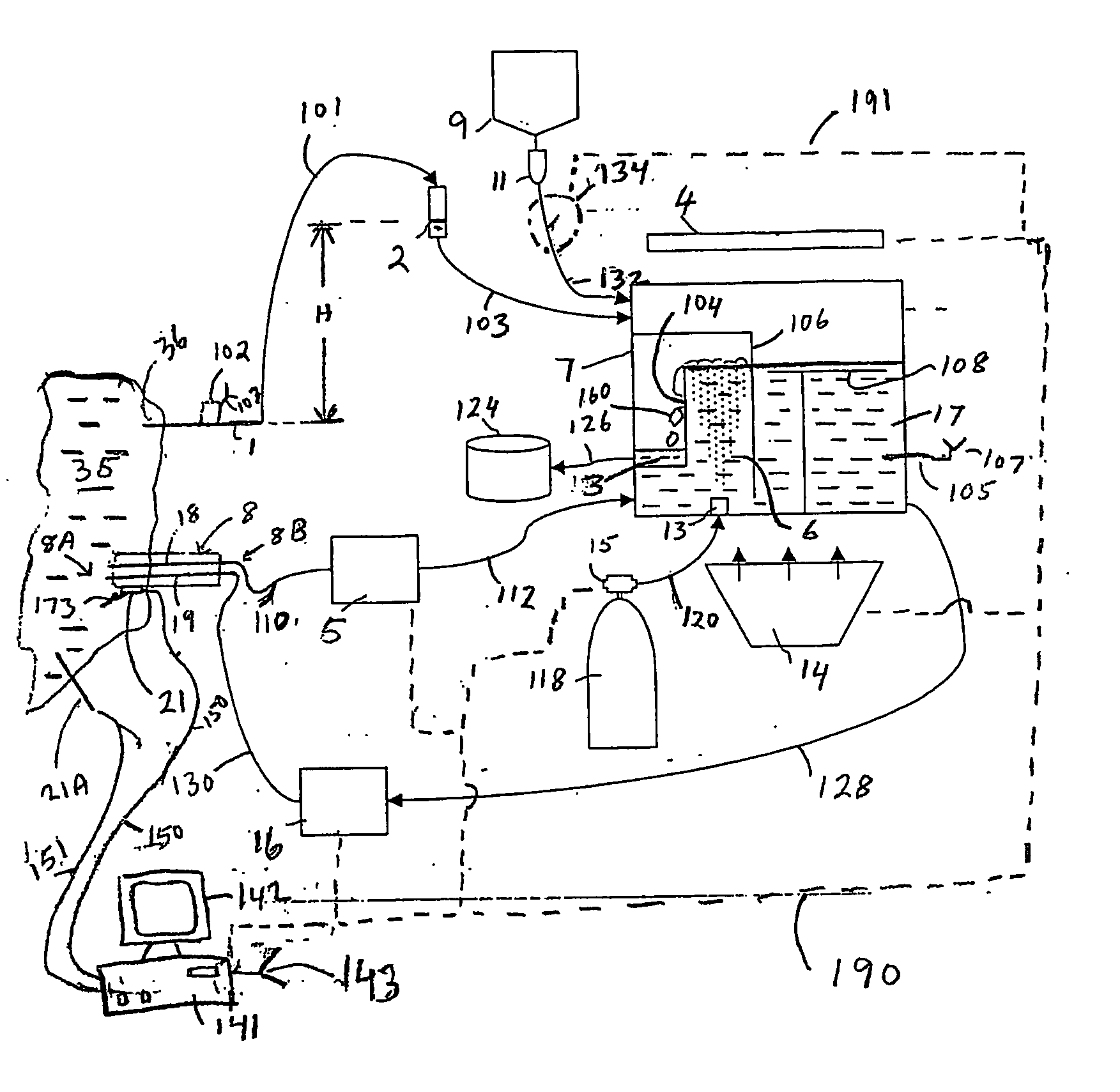

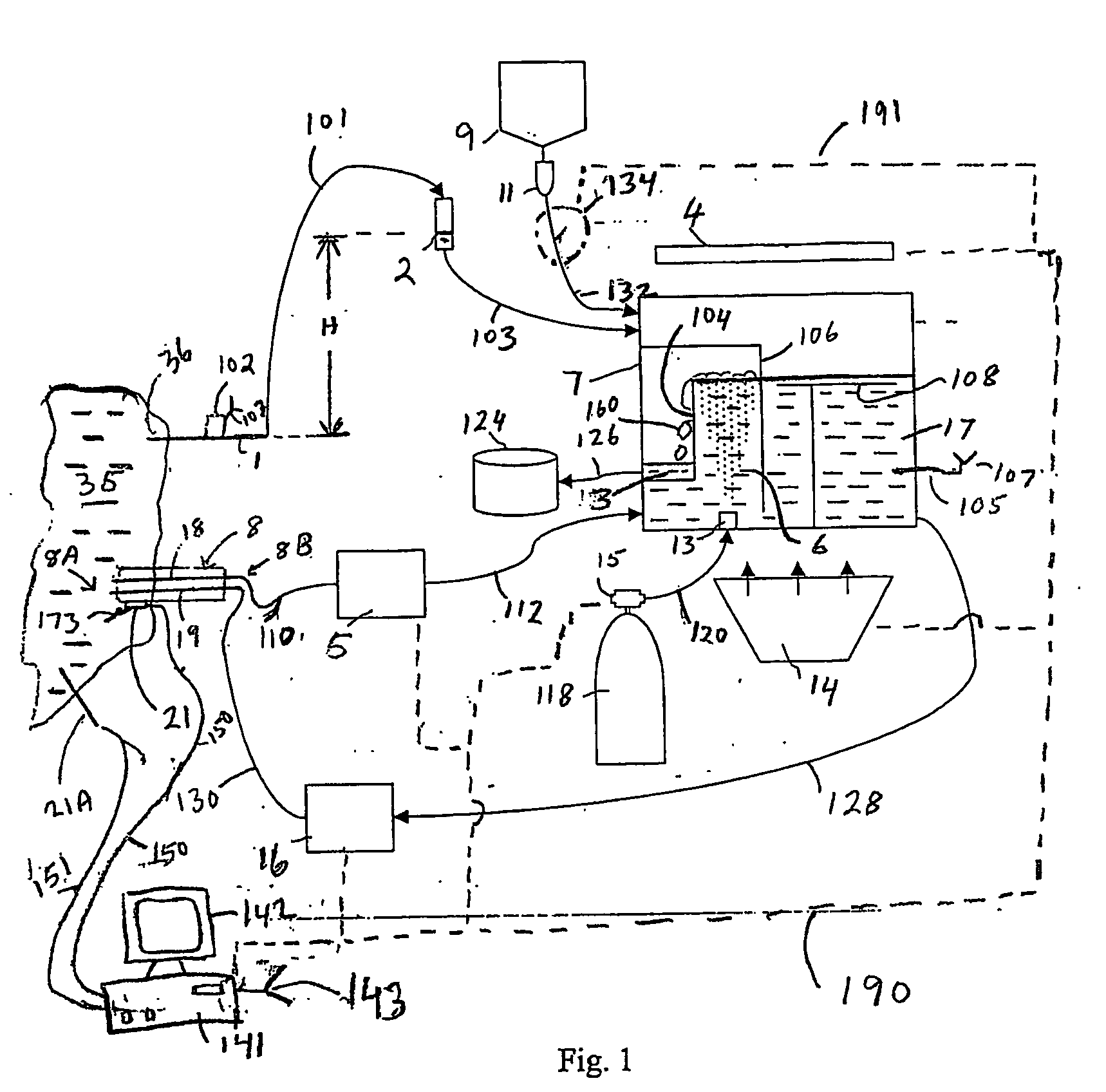

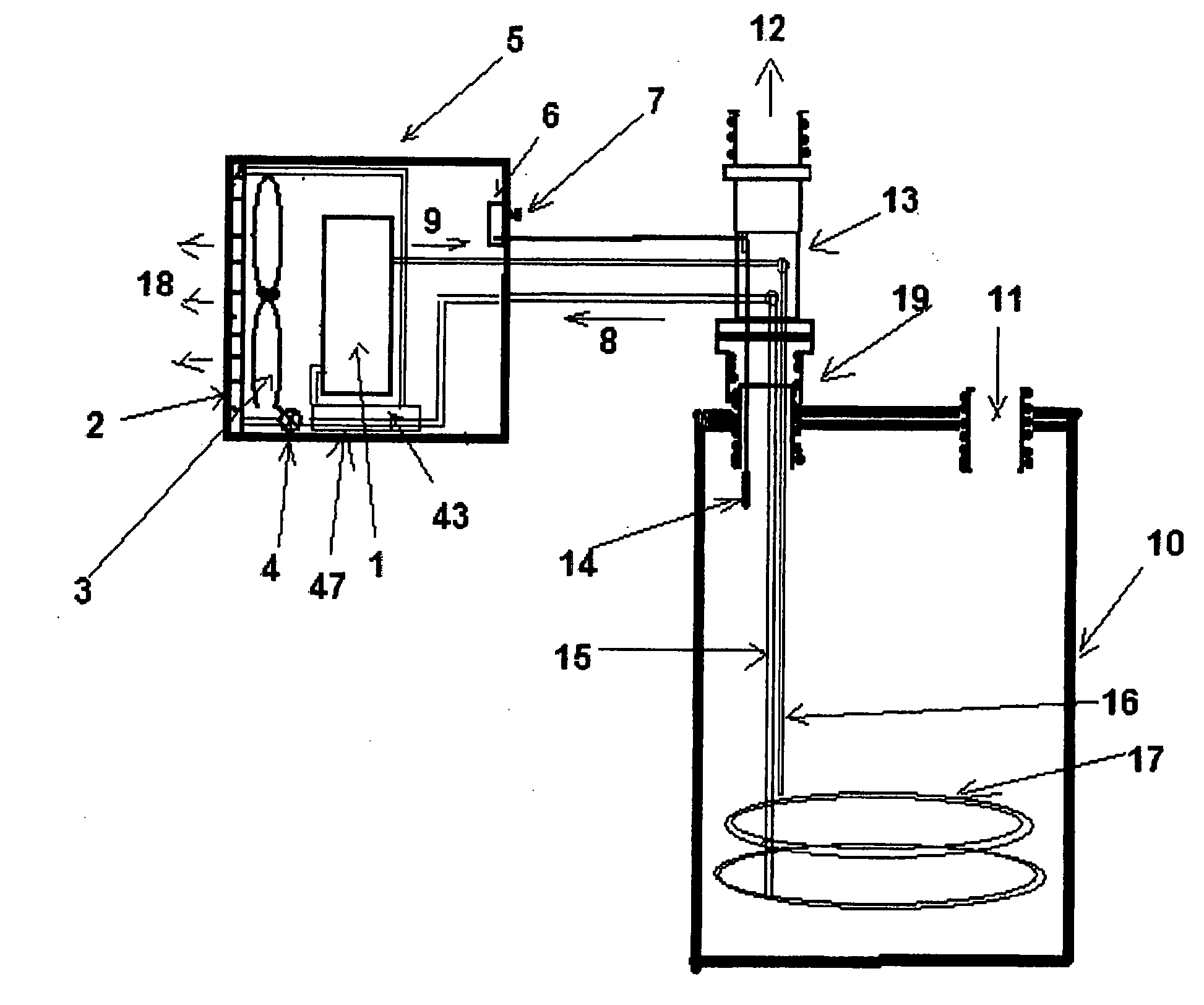

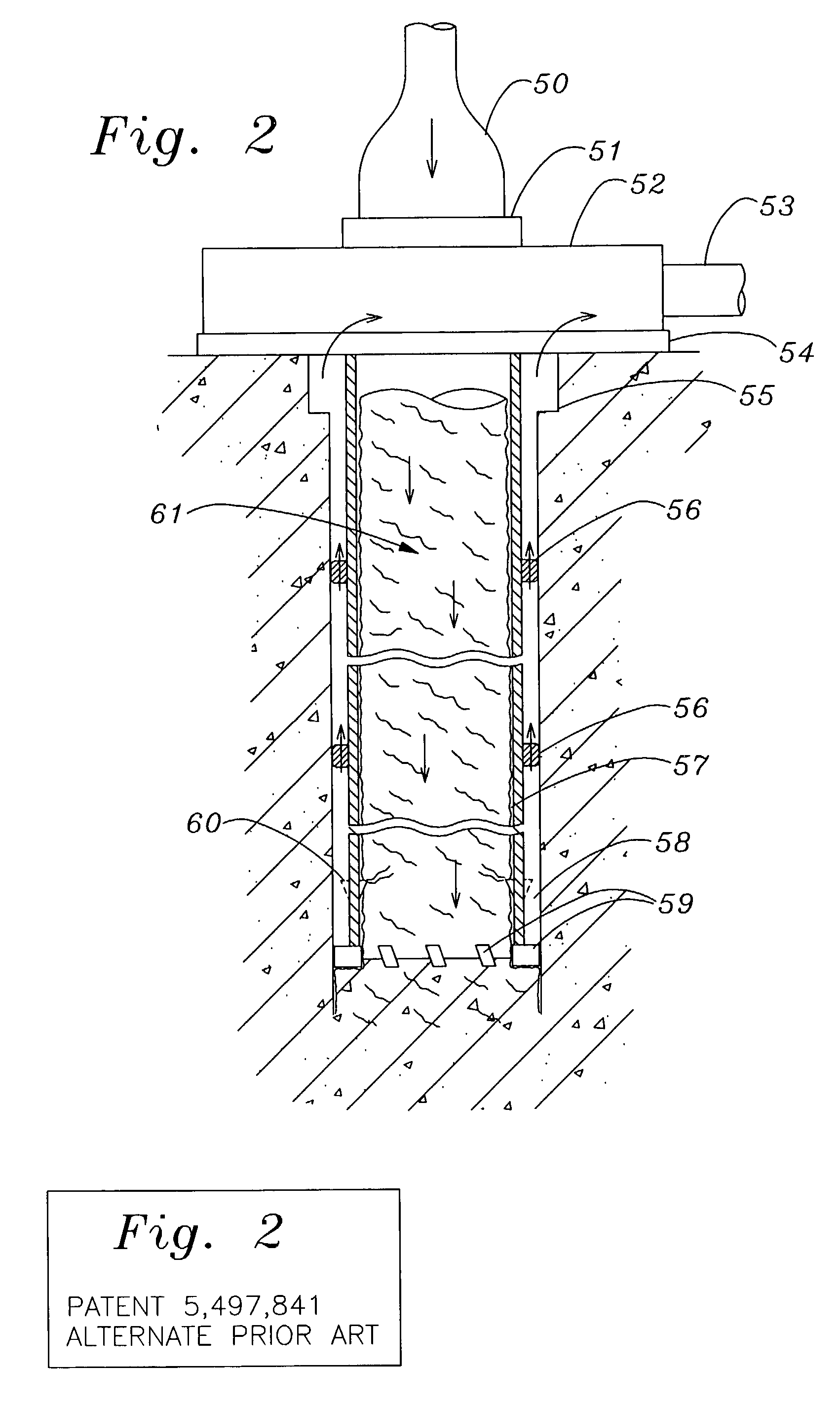

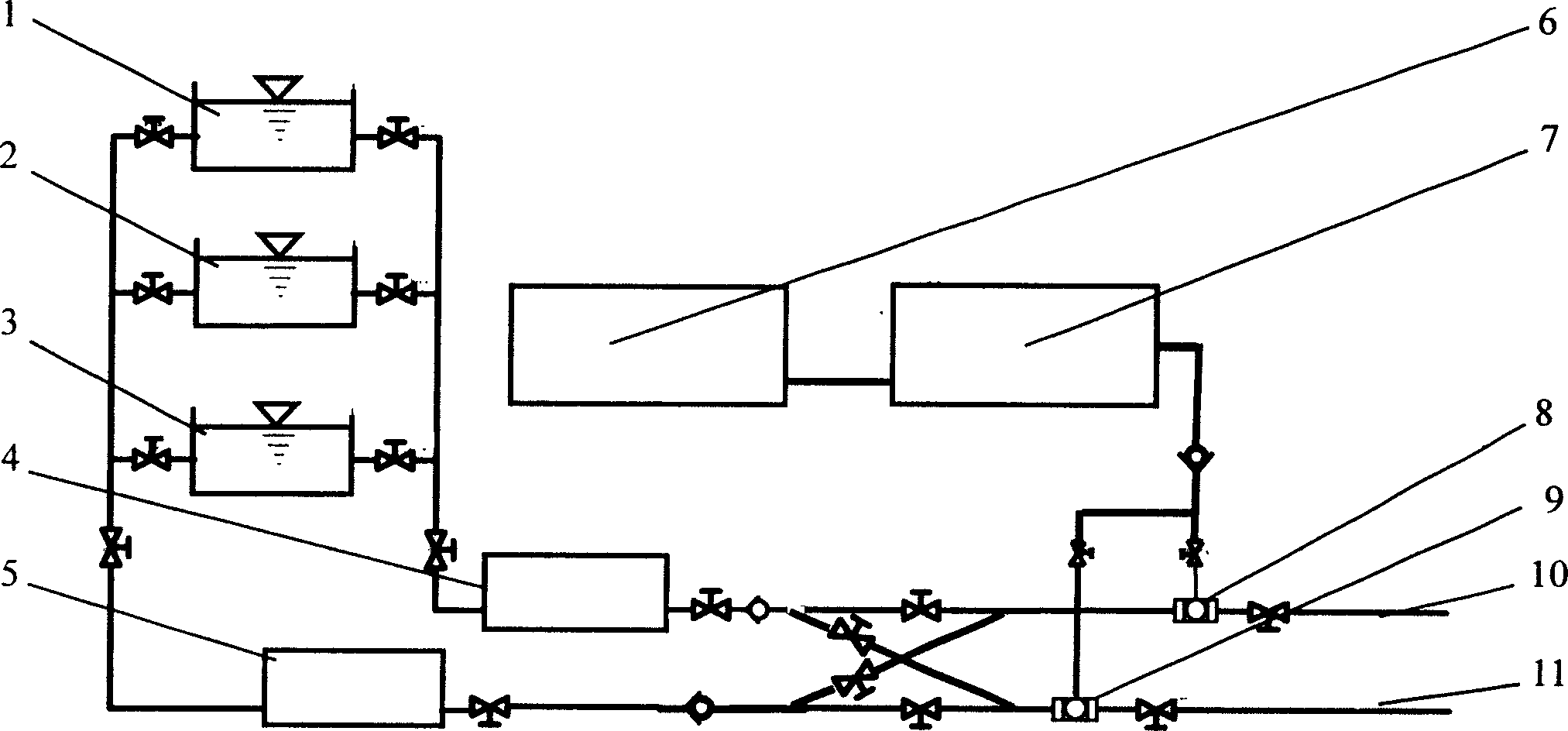

Supercritical carbon dioxide drive physical analogue device

InactiveCN101446189AEasy to achieve high temperature and high pressure supercritical stateOther gas emission reduction technologiesFluid removalRock coreDouble tube

The invention relates to a supercritical carbon dioxide drive physical analogue device, which belongs to the technical field of petroleum engineering and technology. The device adopts two paratactic simulation core devices to be connected with an injecting system, and each simulation core device is provided with an outlet measuring system; the injecting system injects formation water, crude oil and supercritical carbon dioxide to the simulation core devices, and a temperature and pressure measuring and controlling system is adopted to control the temperature set value and the pressure value of the whole system, and the outlet measuring system is adopted to measure the volumes of the carbon dioxide, the formation water and the crude oil which pass through the simulation core devices. After the CO2 gas is cooled and liquefied, the CO2 gas is pressurized and heated up to the supercriticality, and the difficulty of the accurate measurement of the injected CO2 flow; by adopting a double-tube model, the fingering and cross flow phenomenon during the driving process of the heterogeneous reservoir CO2 can be simulated; the design pressure of the device is 0 to 40 MPa, the design temperature is 0 to 180 DEG C, and the device is mainly applied to the research on supercritical CO2 miscible drive, non-miscible drive, continues gas drive or water and gas alternate drive.

Owner:DALIAN UNIV OF TECH

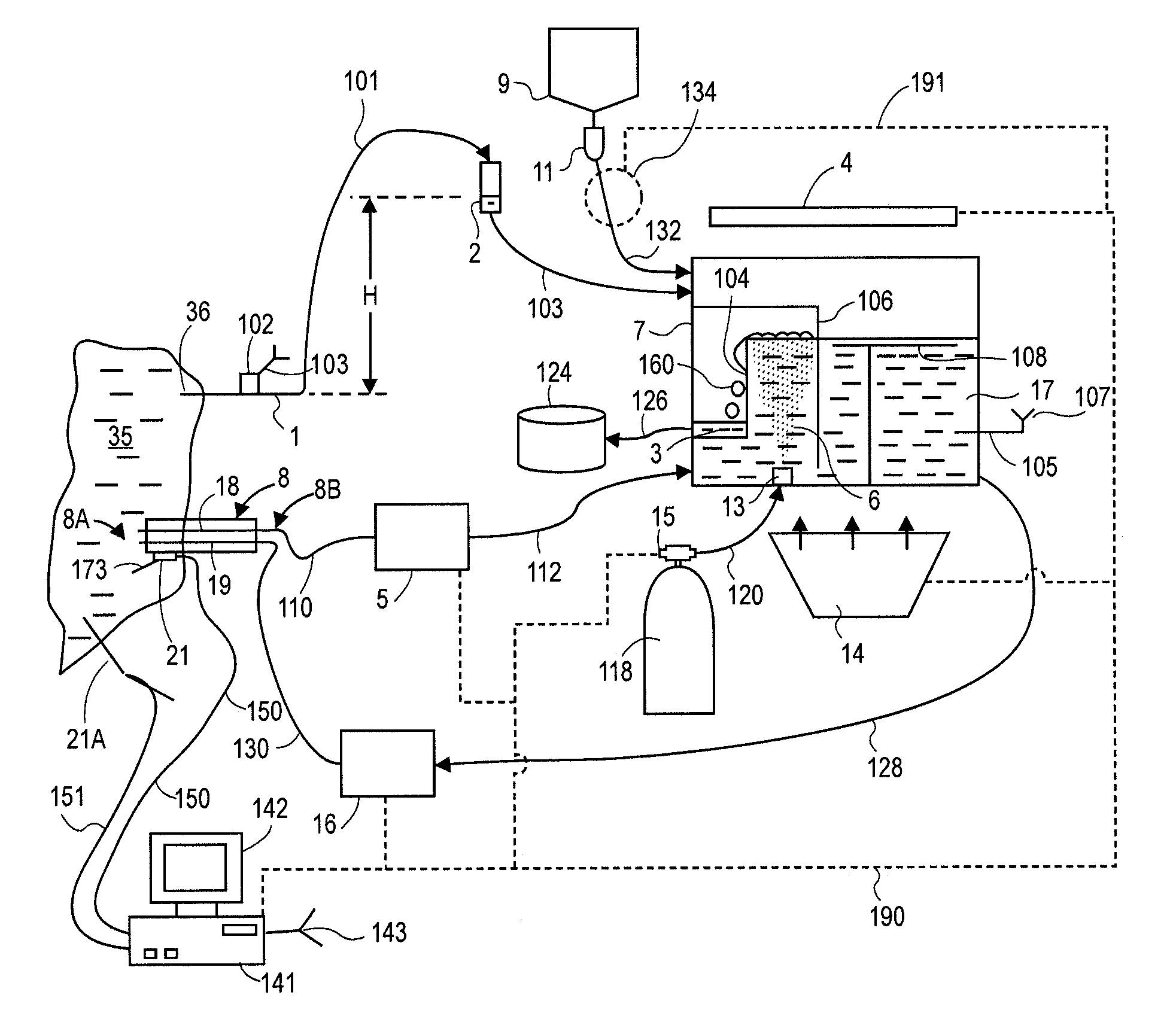

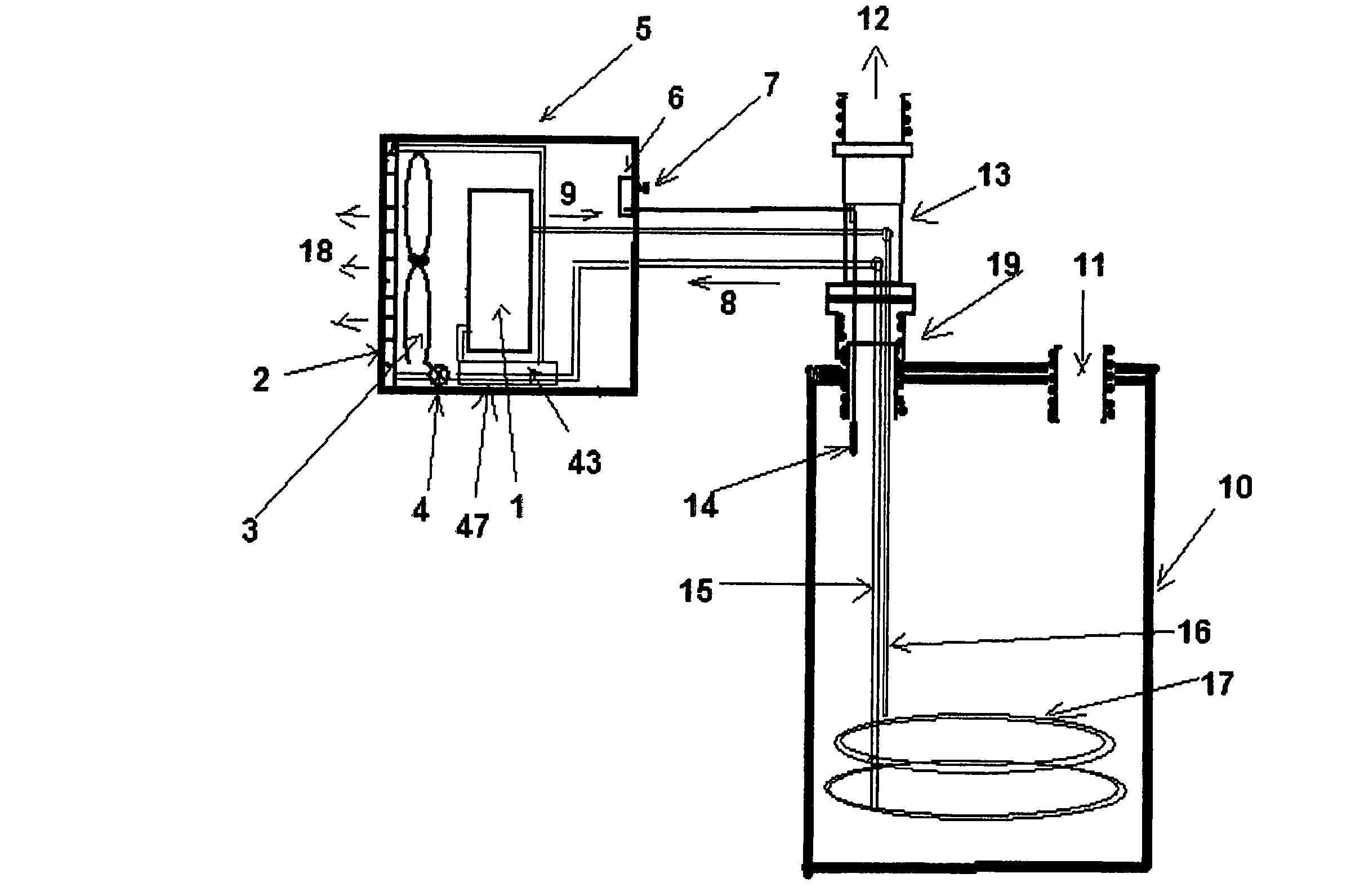

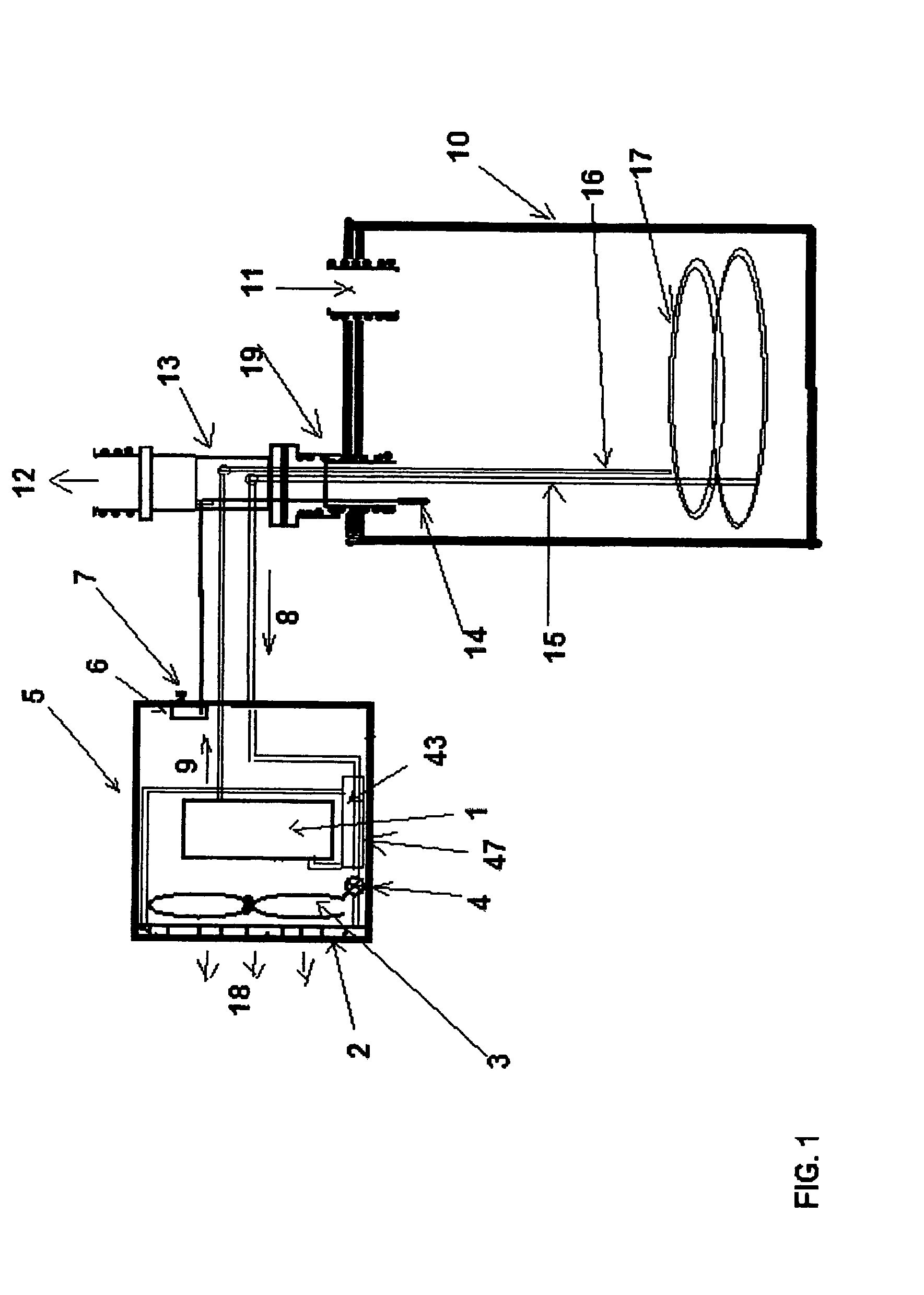

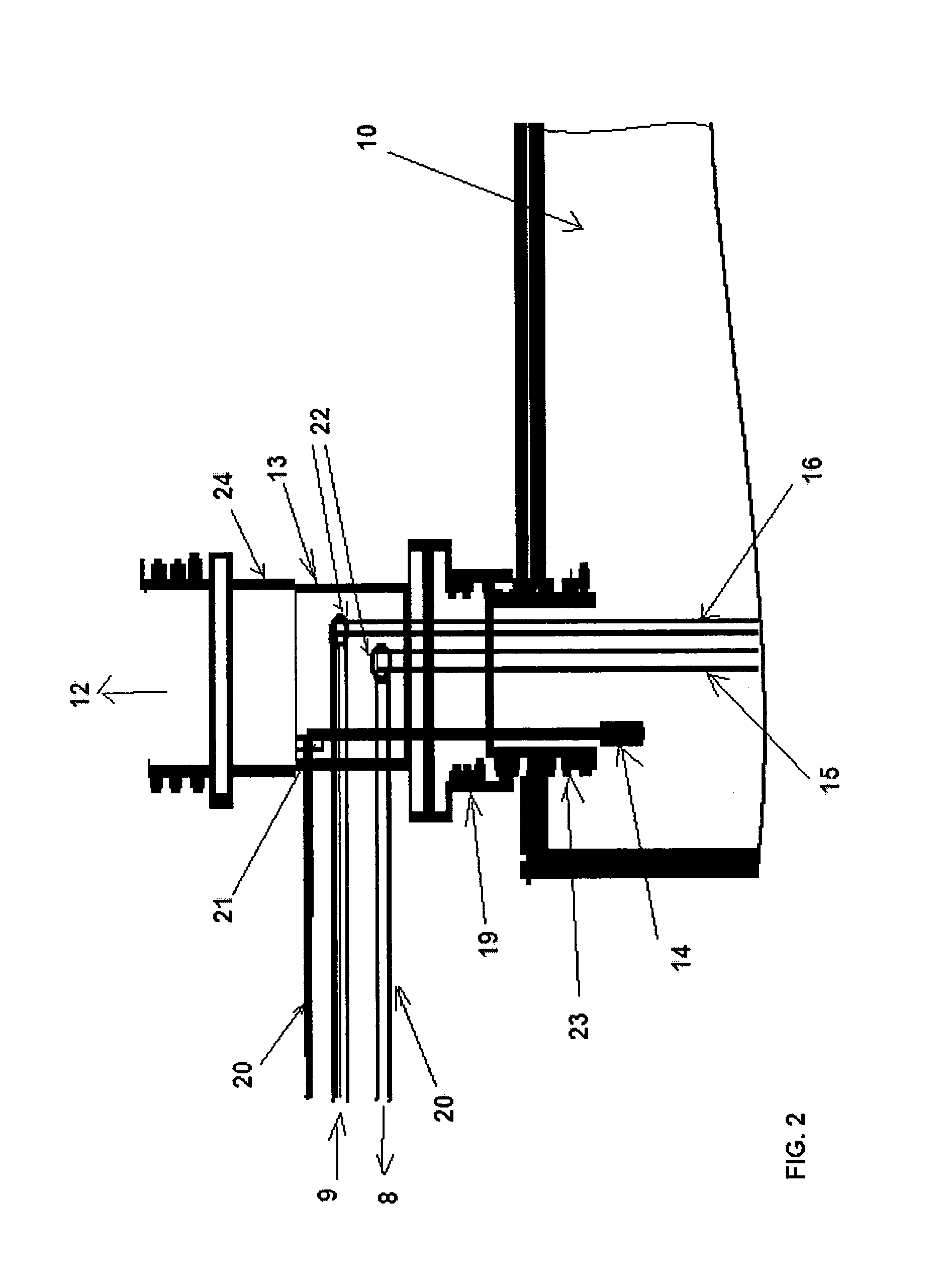

Device for the extravascular recirculation of liquid in body cavities

InactiveUS7842002B2Improves liquid distributionOptimize allocationMulti-lumen catheterOther blood circulation devicesSubarachnoid spaceDouble tube

Owner:THERANOVA LLC

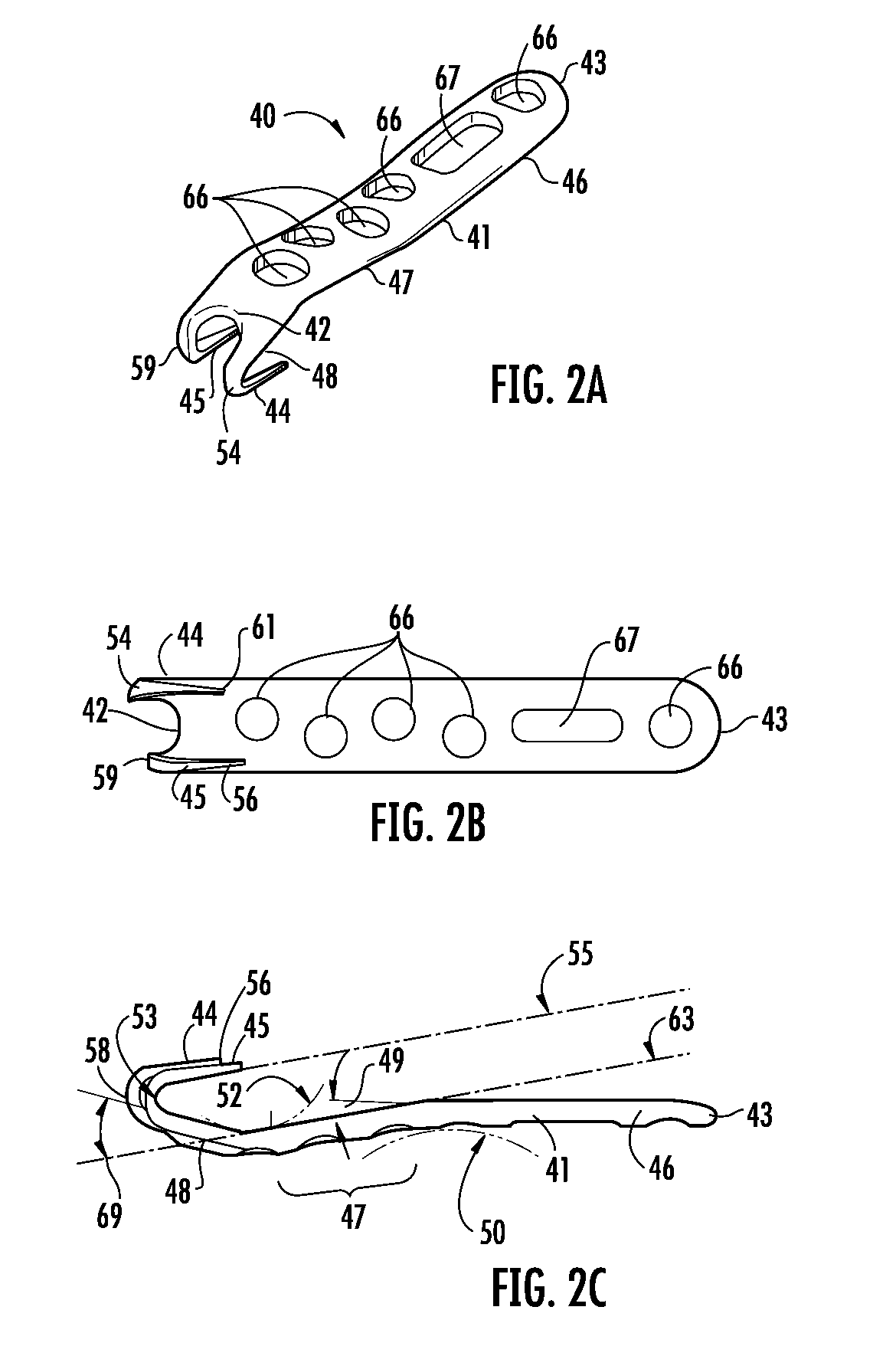

Contoured bone plate for fracture fixation having hook members and drill guide for same

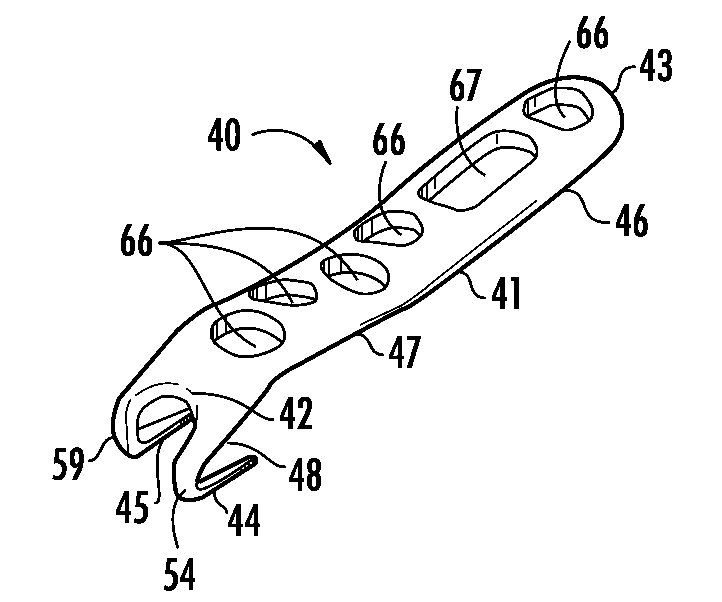

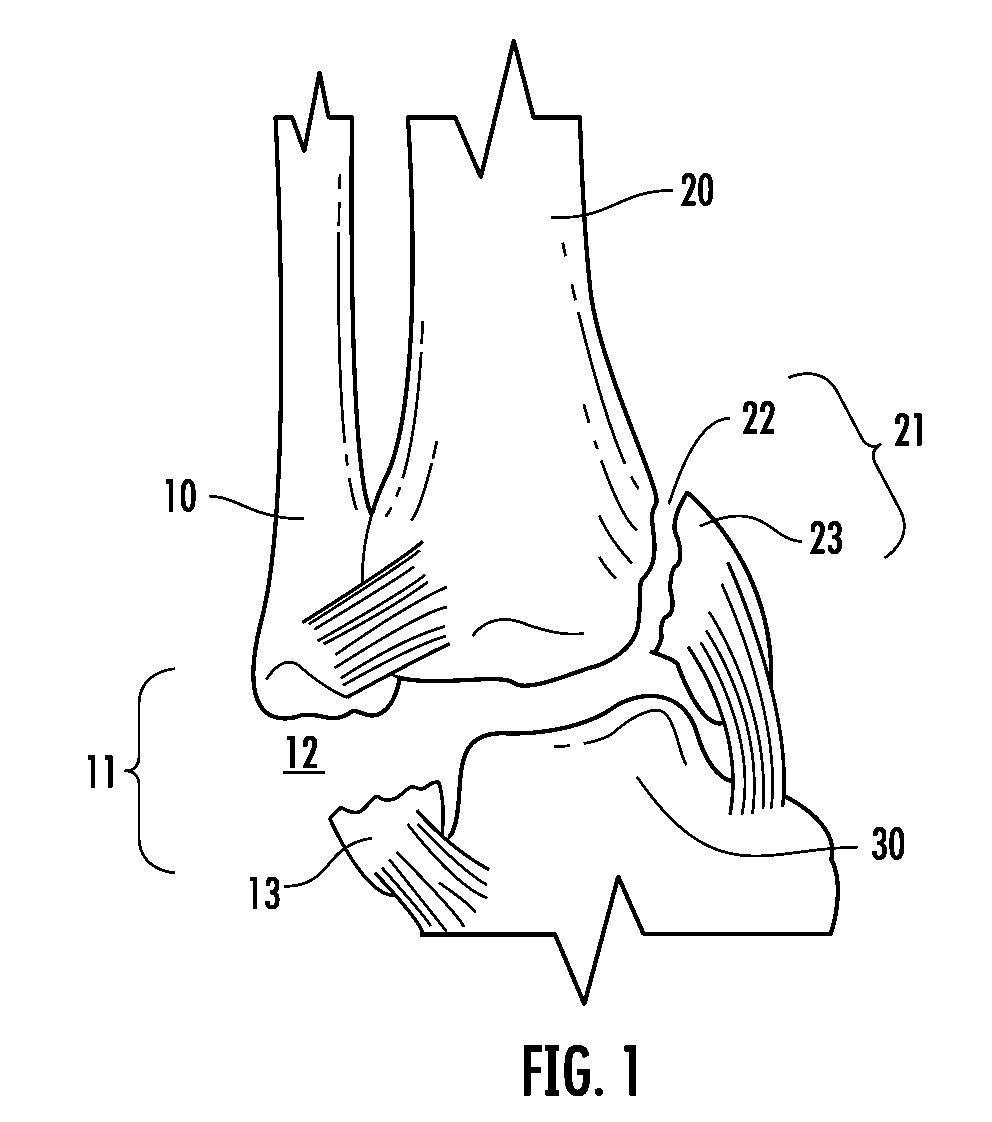

A bone fixation plate for fixation of fractures having a small terminal bone fragment, such as fractures of the lateral malleolus. The bone fixation plate includes an elongated body, and two hook members extending from a first end of the elongated body. Each hook member curves back upon a bottom surface of the elongated body, back towards a second end of the elongated body, and terminating in a pointed prong region. The elongated body includes a first region, a second region, and an angled region disposed between the first and second region. The prong region has a longitudinal axis that is substantially parallel to a longitudinal axis of the angled region of the elongated body of the bone plate. A double barreled drill guide and associated interchangeable cooperating inner drill guides and gauges are provided to facilitate the drilling of pilot holes in a terminal bone fragment for axial insertion of the pointed prong regions of the hook members.

Owner:TRIMED

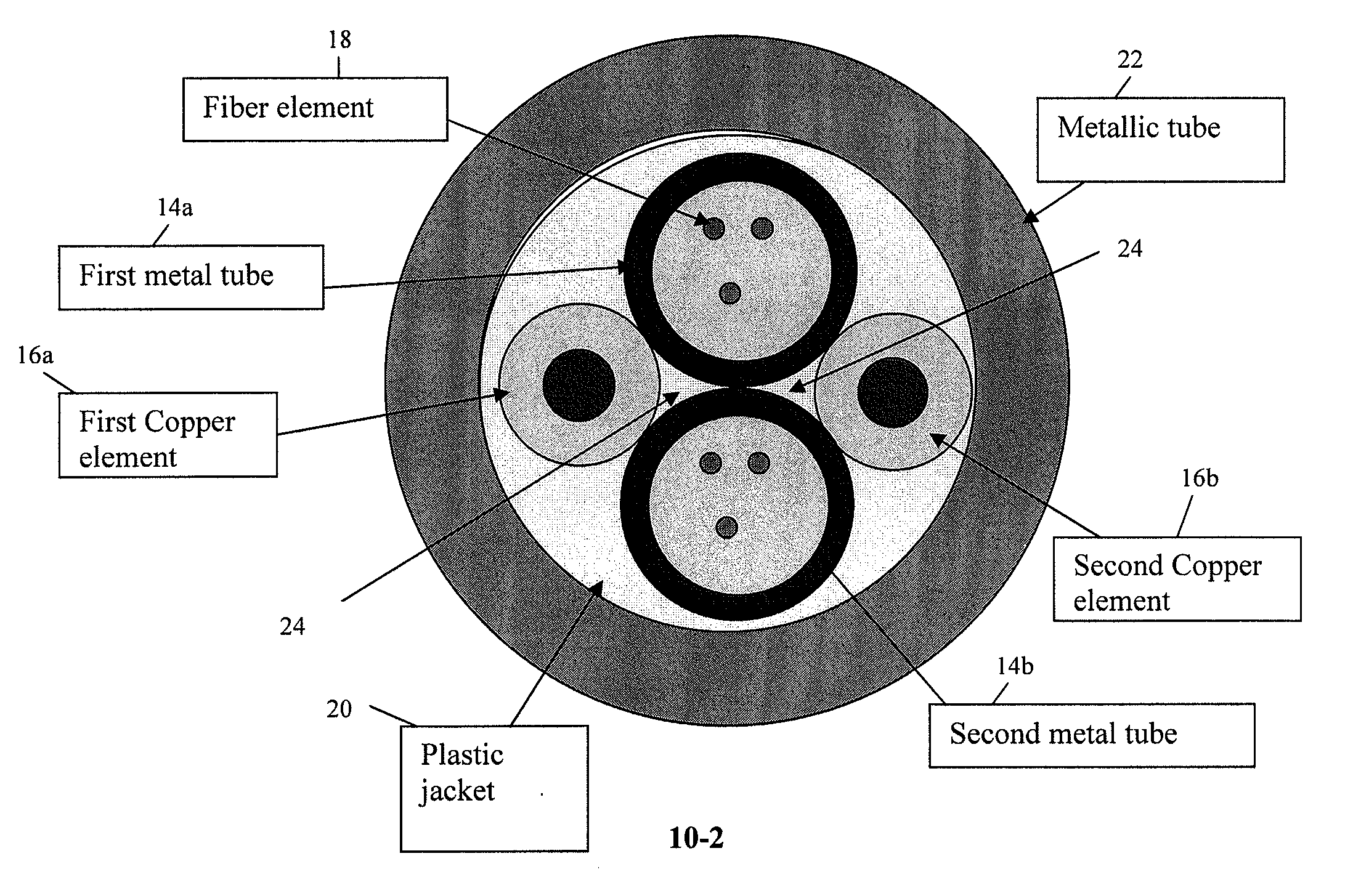

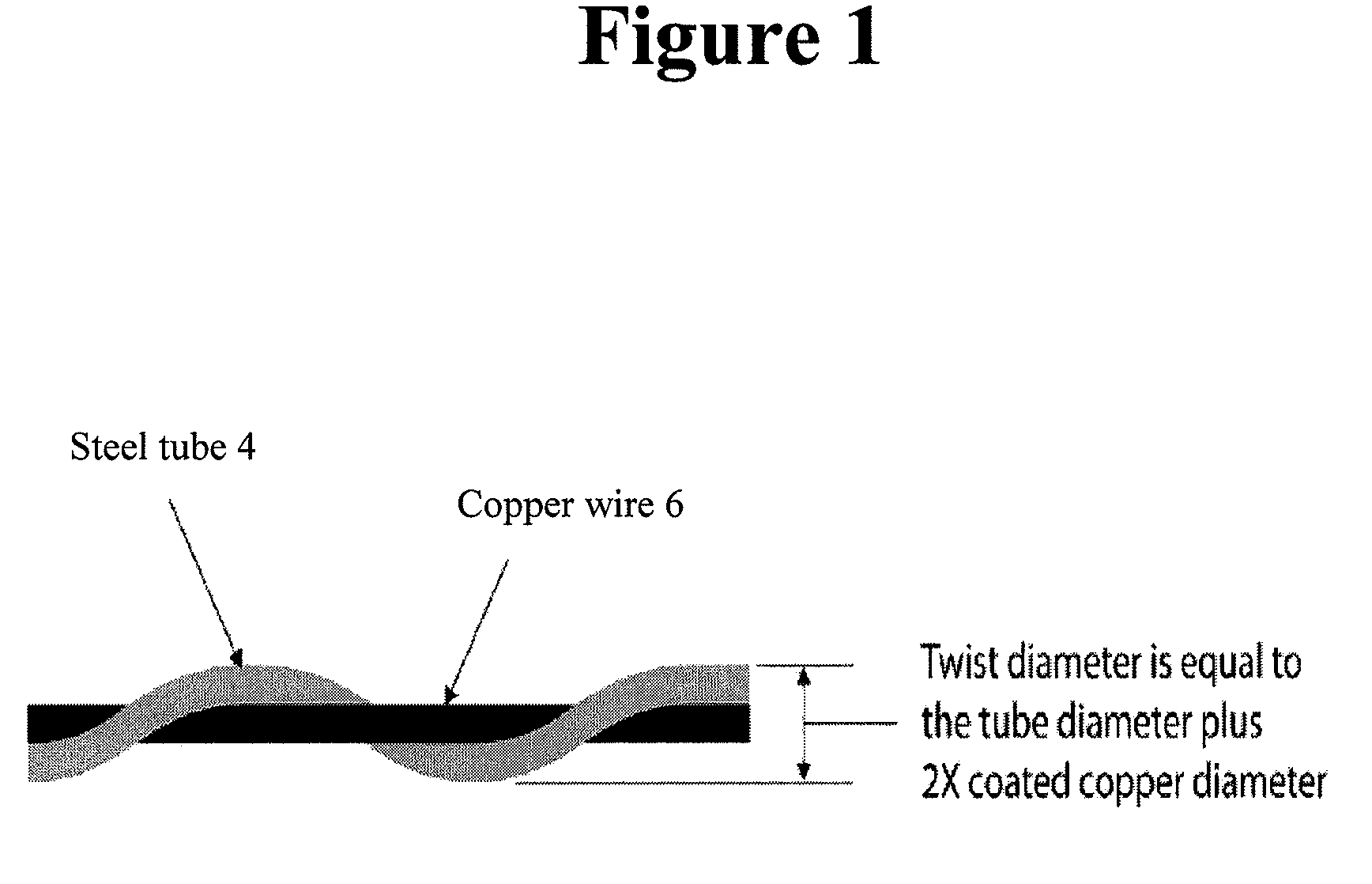

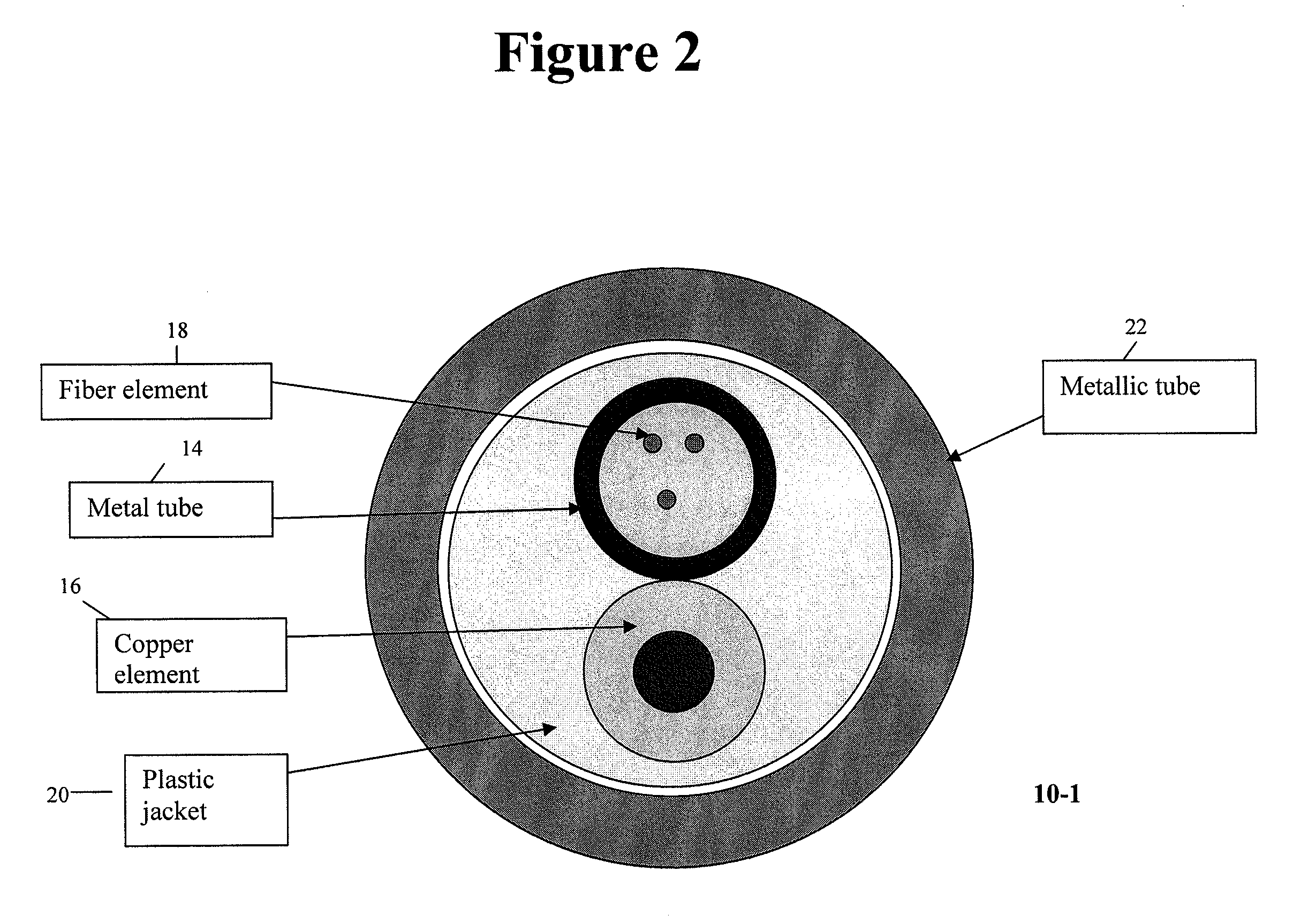

Downhole cables with both fiber and copper elements

ActiveUS20100008631A1Increase strainExcessively strainingLine/current collector detailsConductive materialFiberDouble tube

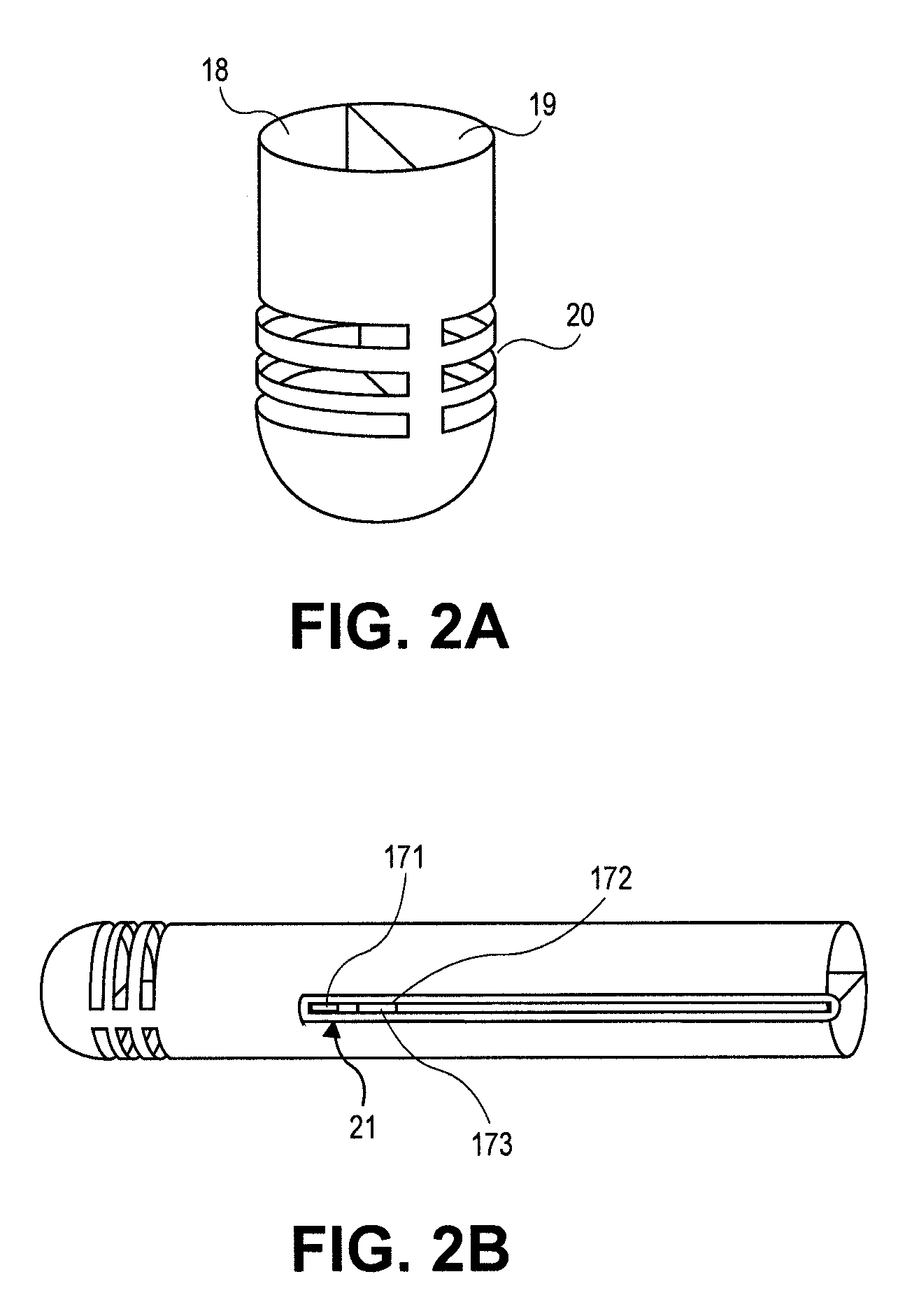

Provided is a method of manufacturing a downhole cable, the method including, forming a helical shape in an outer circumferential surface of a metal tube, the metal tube having a fiber element housed therein, and stranding a copper element in a helical space formed by the metallic tube. Also provided is a downhole cable including, a metallic tube having a helical space in an outer circumferential surface thereof, wherein the metallic tube has a fiber element housed therein, and a copper element disposed in a helical space formed by the steel tube. Double-tube and multi-tube configurations of the downhole cable are also provided.

Owner:AFL COMM LLC

Device for the extravascular recirculation of liquid in body cavities

InactiveUS20060161107A1Improves liquid distributionOptimize allocationMulti-lumen catheterOther blood circulation devicesSubarachnoid spaceDouble tube

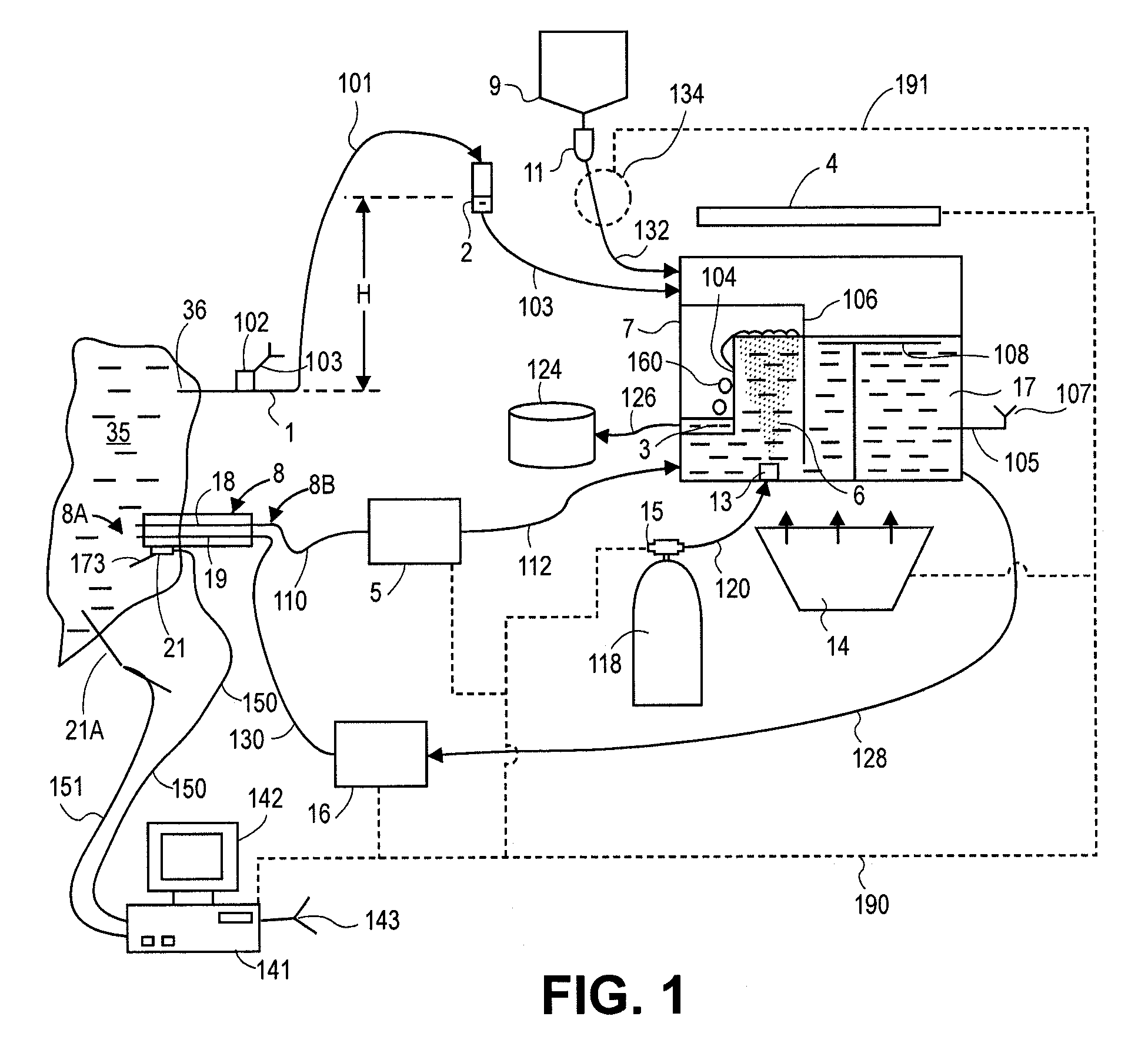

Biocompatible liquid is pumped into a body cavity (eg. subarachnoid space, peritoneum, mediastinum, pleural space) by means of one pump and removed from it by means a second pump, preferably via a double-barreled catheter is used for insertion and removal of the liquid. An optional secondary catheter removes liquid from a distal area of the body cavity. Temperature and pressure are sensed within the cavity and can be controlled by adjusting liquid flow rates. While outside the body, the liquid can be ultraviolet-sterilized, foam fractionated to remove contaminants, oxygenated and pH balanced, cooled or warmed, and augmented with exogenous liquid that may contain drugs.

Owner:THERANOVA LLC

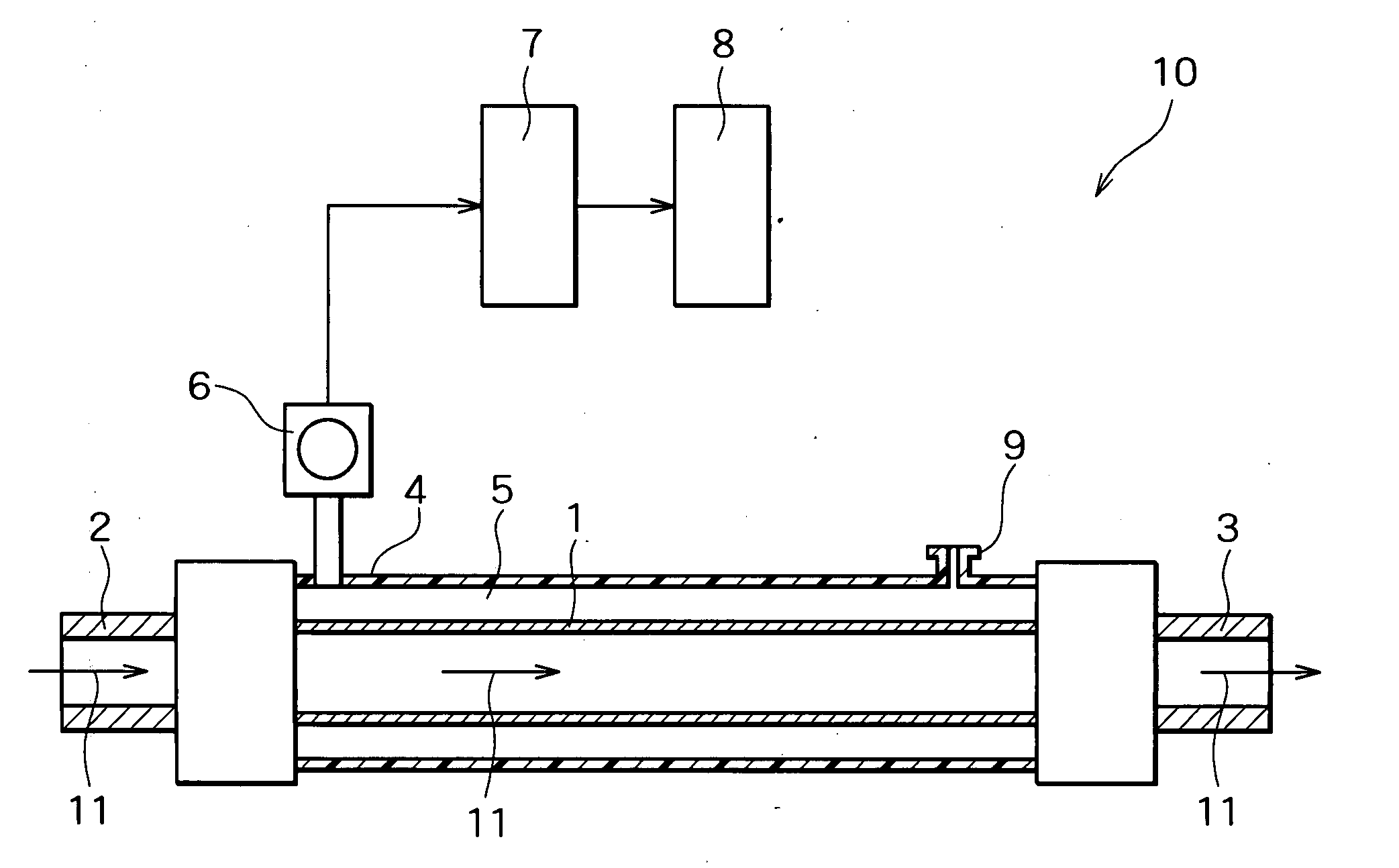

Piping structure having leak detection function and leak detector

InactiveUS20050166666A1Minimize impactIncrease pressureDetection of fluid at leakage pointMeasurement of fluid loss/gain rateDouble tubePipe fitting

A covering member having a valve encloses a flexible hose to form a double pipe. Gas supply pipe fittings are attached to respective ends of the double pipe to form a hermetic space between the flexible hose and covering member. The covering member also has a pressure-measuring device to which a decision unit equipped with an alarm device is connected. The same gas or liquid as the one flowing through the flexible hose is introduced to the hermetic space from the valve provided in the covering member, and sealed in the hermetic space by closing the valve. The pressure in the hermetic space is set so as to be higher than the pressure produced in the flexible hose when the gas or liquid is flowing. The pressure-measuring device measures the pressure in the hermetic space while the gas or liquid flows in the flexible hose, and the decision unit compares the measured value with a reference value. As a result, if the value measured by the pressure-measuring device is lower than the reference value, the decision unit decides that a breakage has occurred and then the alarm device activates an alarm.

Owner:LASERFRONT TECH

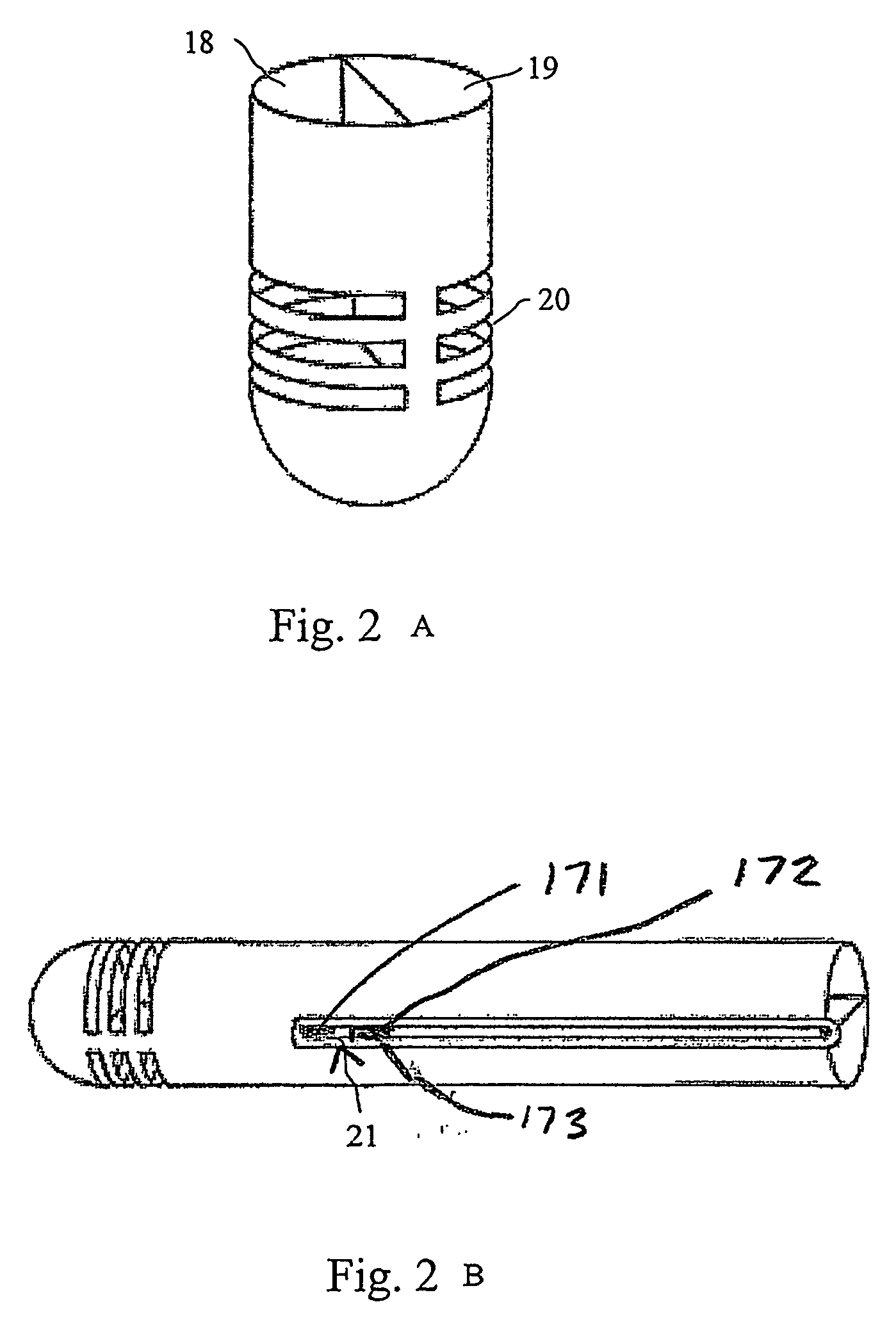

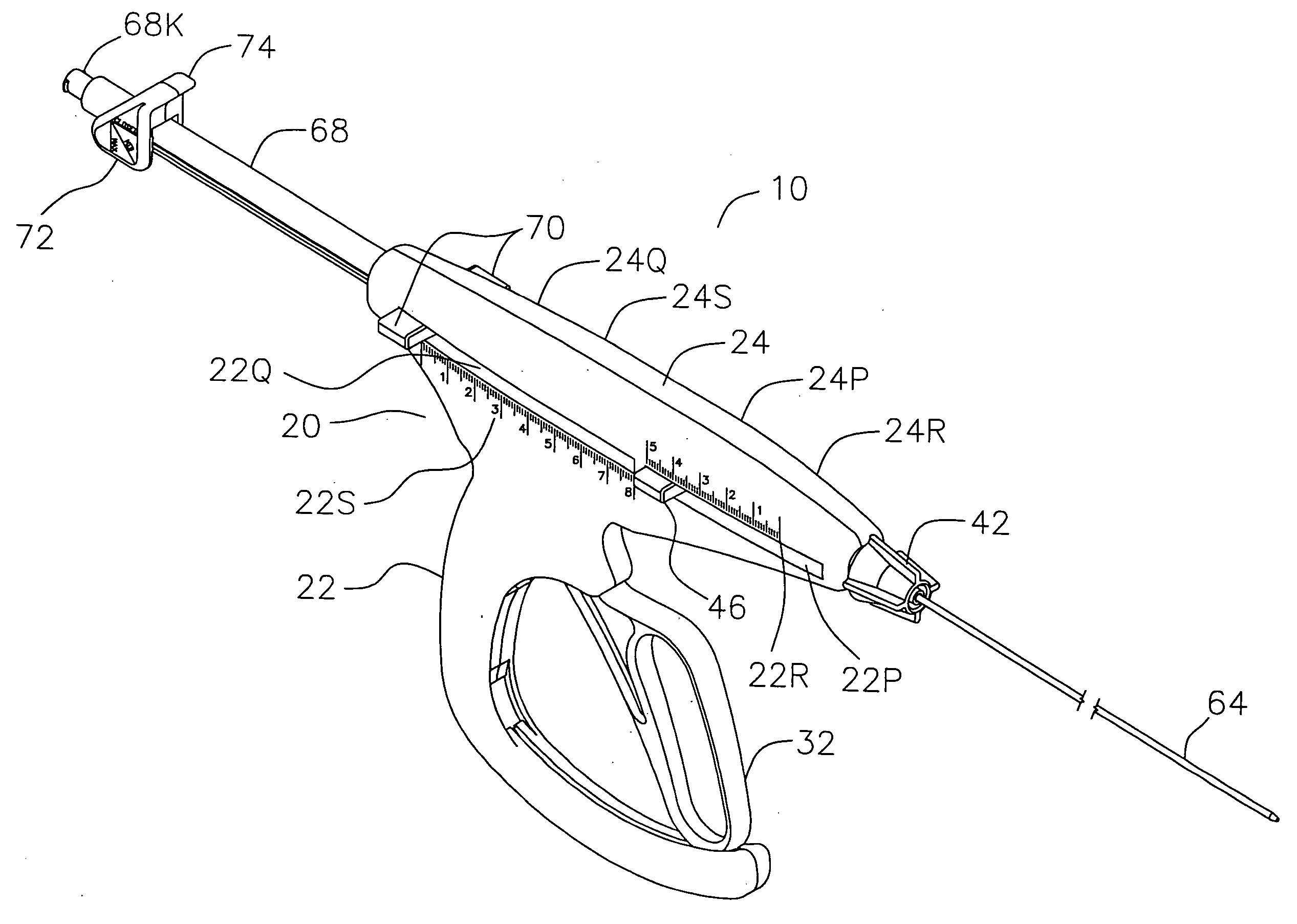

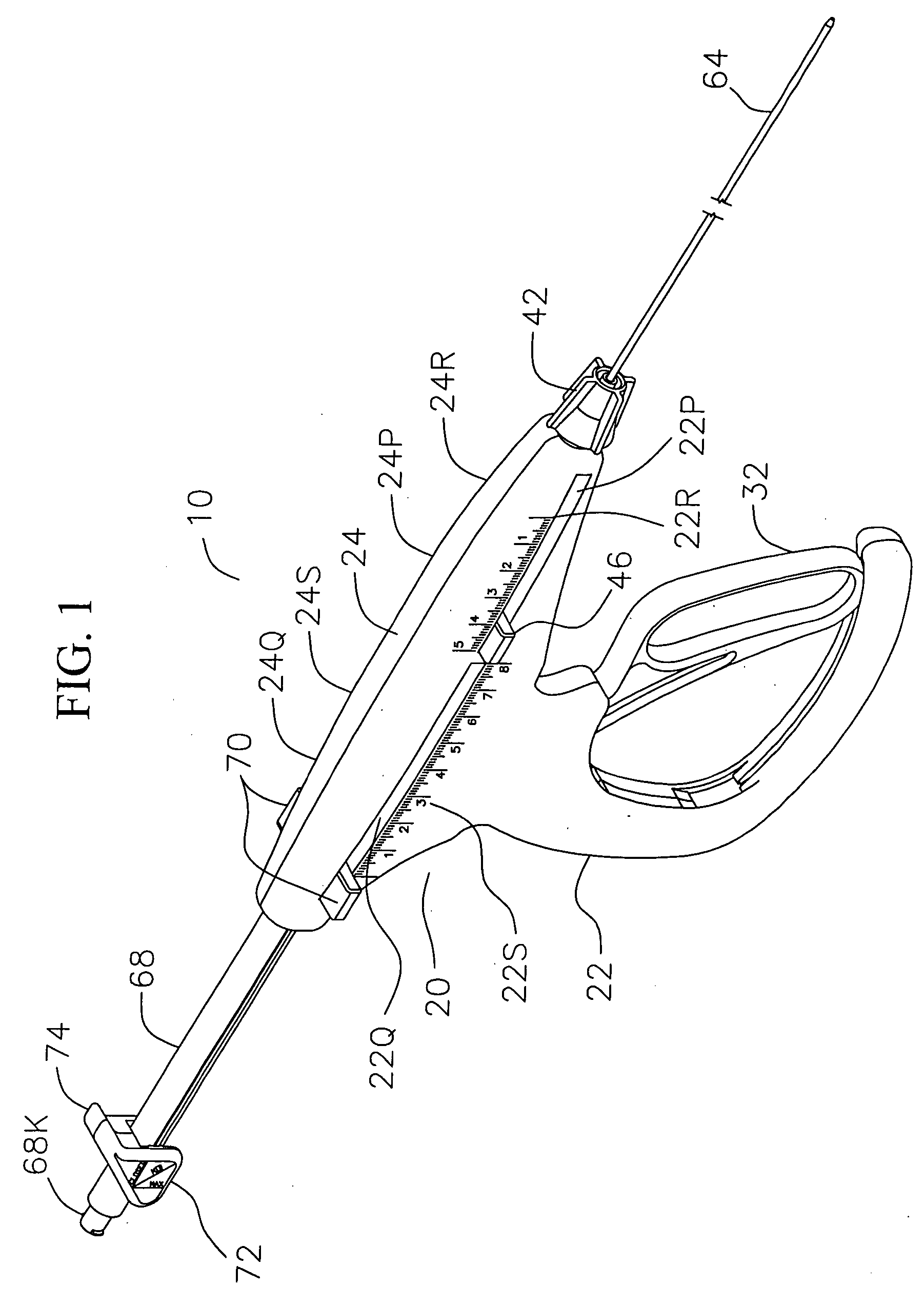

Ergonomic needle tissue harvesting instrument not requiring a stylet

A medical diagnostic instrument for the ergonomic effective and safe harvesting of specimen at targeted remote tissue sites includes a pistol grip style handle with a hand activated lever and a specialized elongated flexible double tube needle shaft inside of a protective sheath for use, in a preferred embodiment, within an endoscope. The length of needle shaft is adjusted using locking buttons. Moving another set of buttons sets the needle penetration depth. With a squeeze of the lever, a novel thin band drive mechanism advances the needle shaft out of its sheath, through adjacent tissue and into the targeted site. The double tube needle shaft incorporates a pointed distal tip attached to an innermost “grater” needle, which has sharp edged tissue cutting holes or “grating” features that are exposed by retracting back an overlying cover tube. Sliding back the cover tube is achieved via a cam. The sharp cutting surfaces of the grater tube communicate directly with a vacuum source attached near the handle. Oscillation of the vacuum augmented grater tube back and forth within the targeted tissue yields small pieces of tissue for harvest. When adequate amounts of tissue are drawn into the grater tube, the cover tube is re-advanced over the distal grater tube, the needle shaft is retracted back into the sheath and the instrument along with the harvested specimen are removed from the patient.

Owner:LSI SOLUTIONS

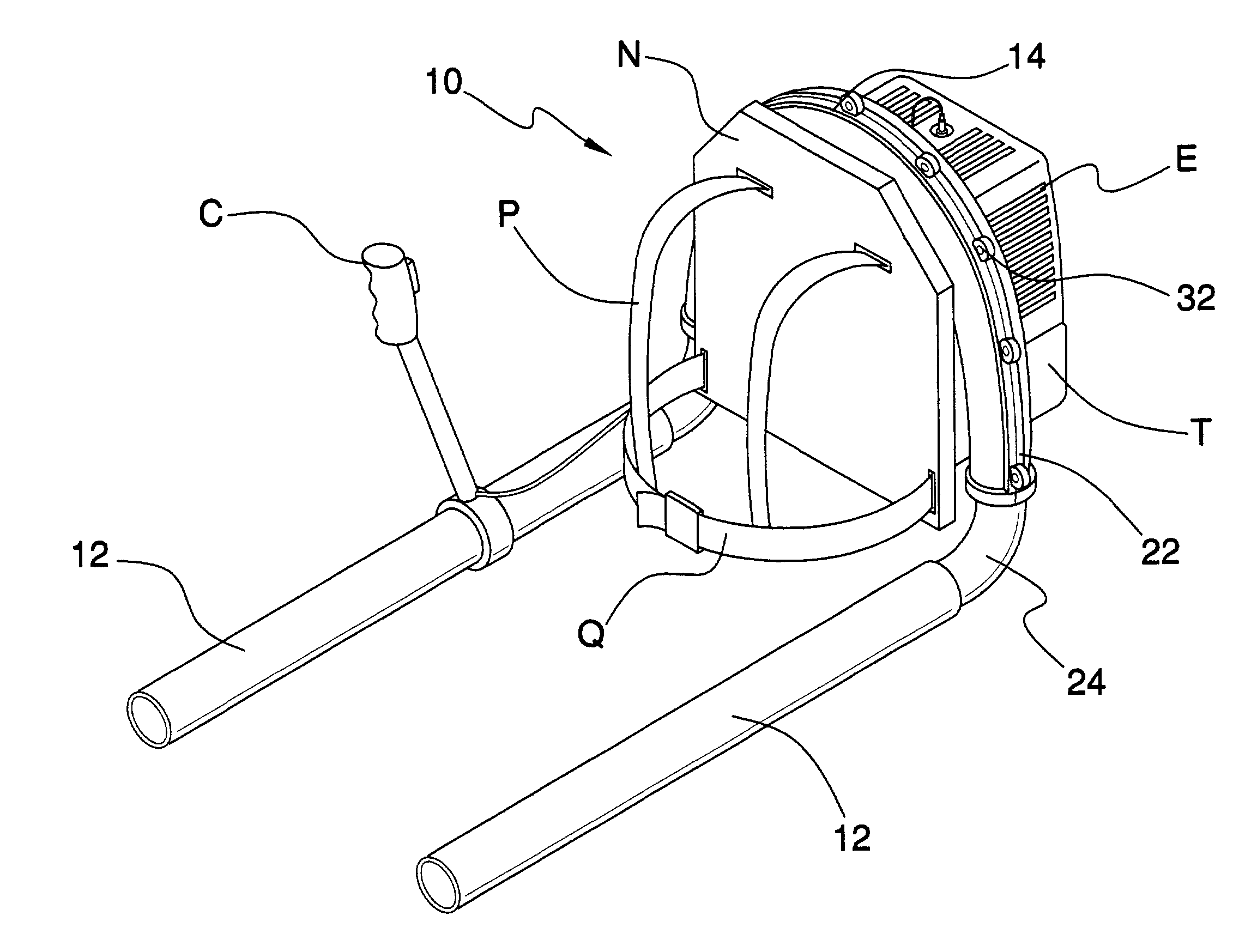

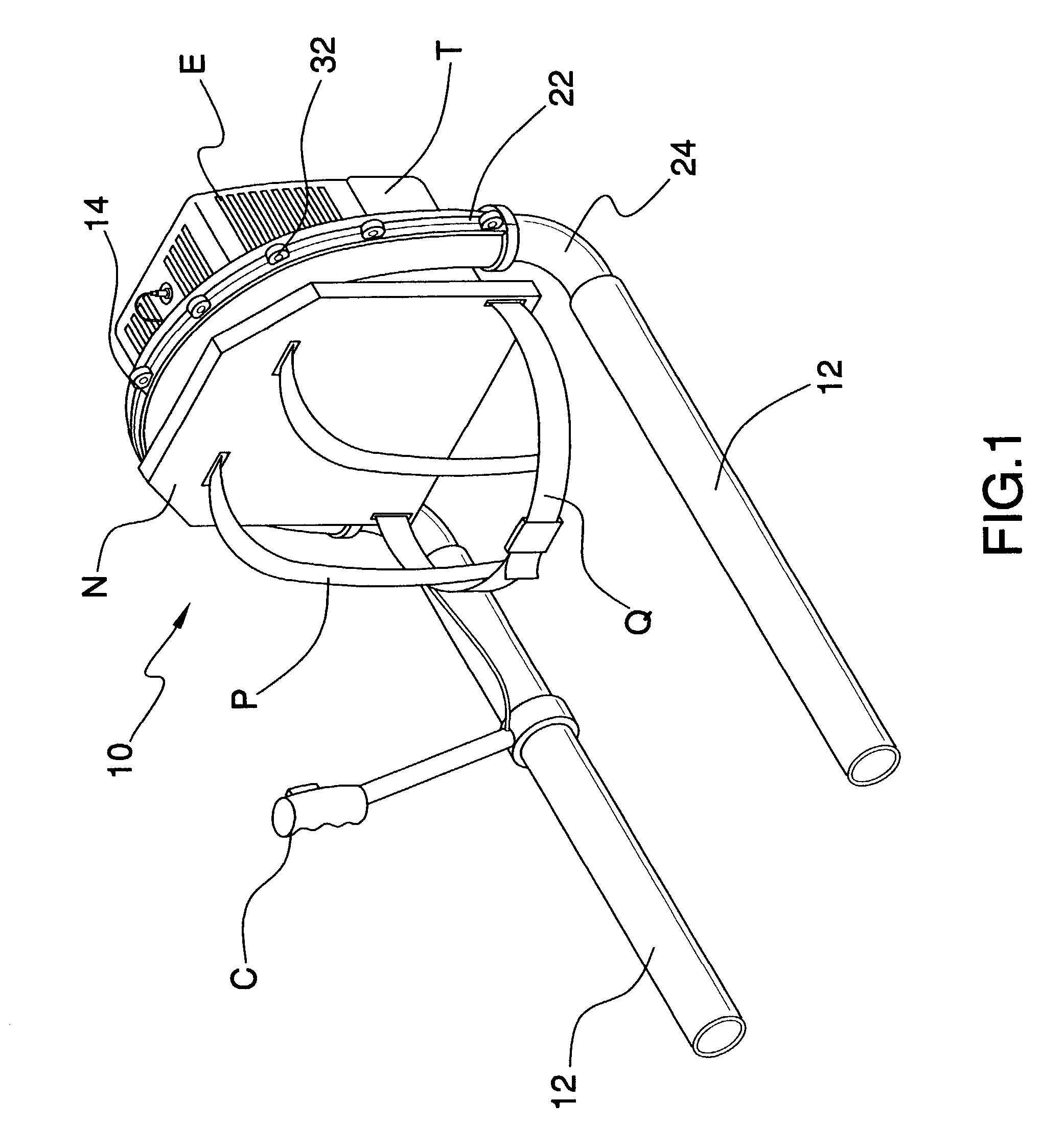

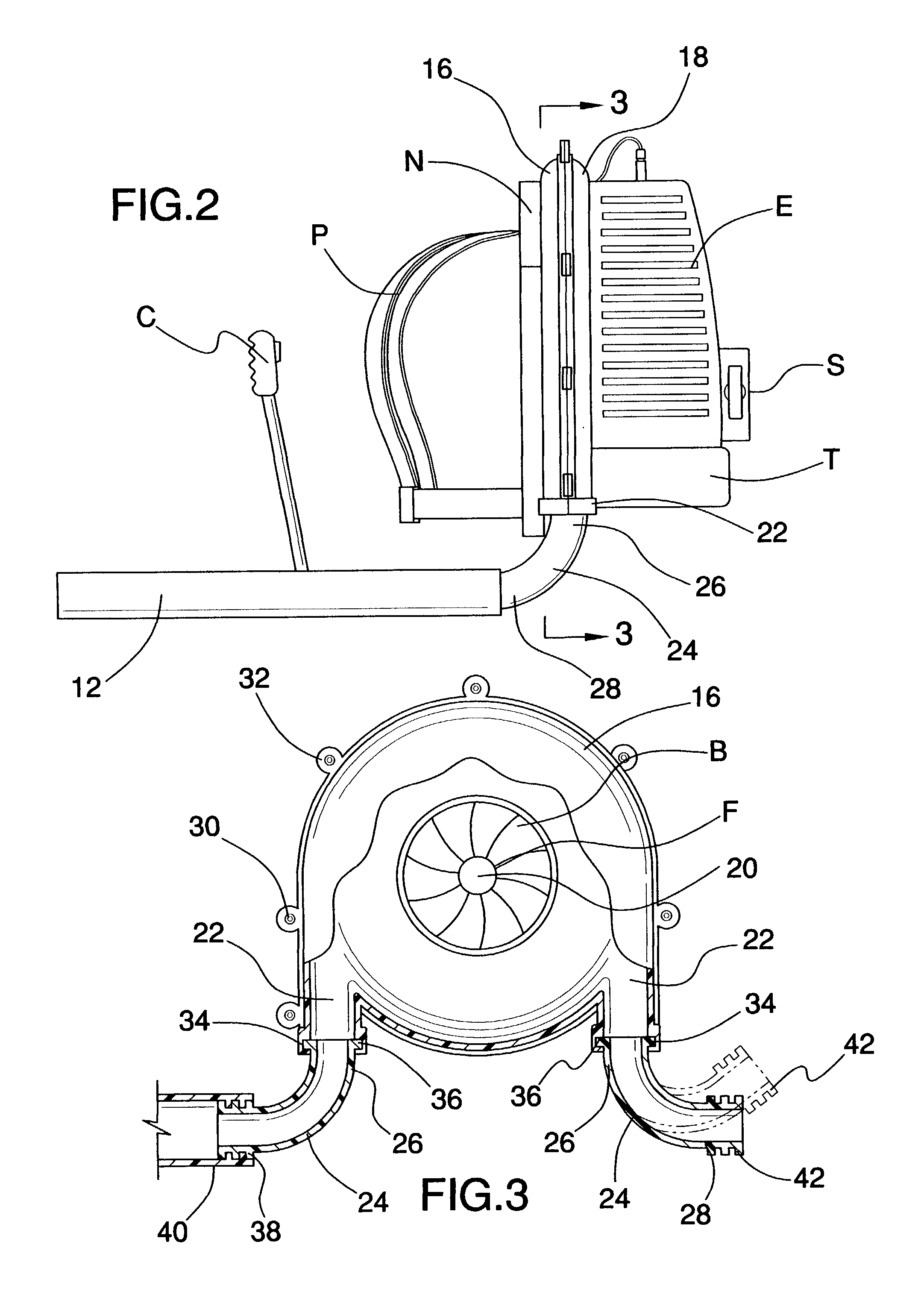

Blower with dual tubes

InactiveUS6928693B1Easily and efficiently manufactured and marketedReduce manufacturing costHops/wine cultivationSuction cleanersDouble tubeFuel tank

A backpack blower has a lightweight engine, a starter, a fuel tank, a fan, a frame for the engine, two hollow tubes, and a control mechanism upon one tube. The blower improvement comes from a housing and two elbows. The round housing contains the fan and has two tangential outlets. The two elbows have a generally round cross section and a generally right angle shape. On each elbow, the first end connects with an outlet and the second end joins a tube. The elbows rotate and bend, directing leaves and debris with airflow from the tubes.

Owner:ERICSON WILLIAM A

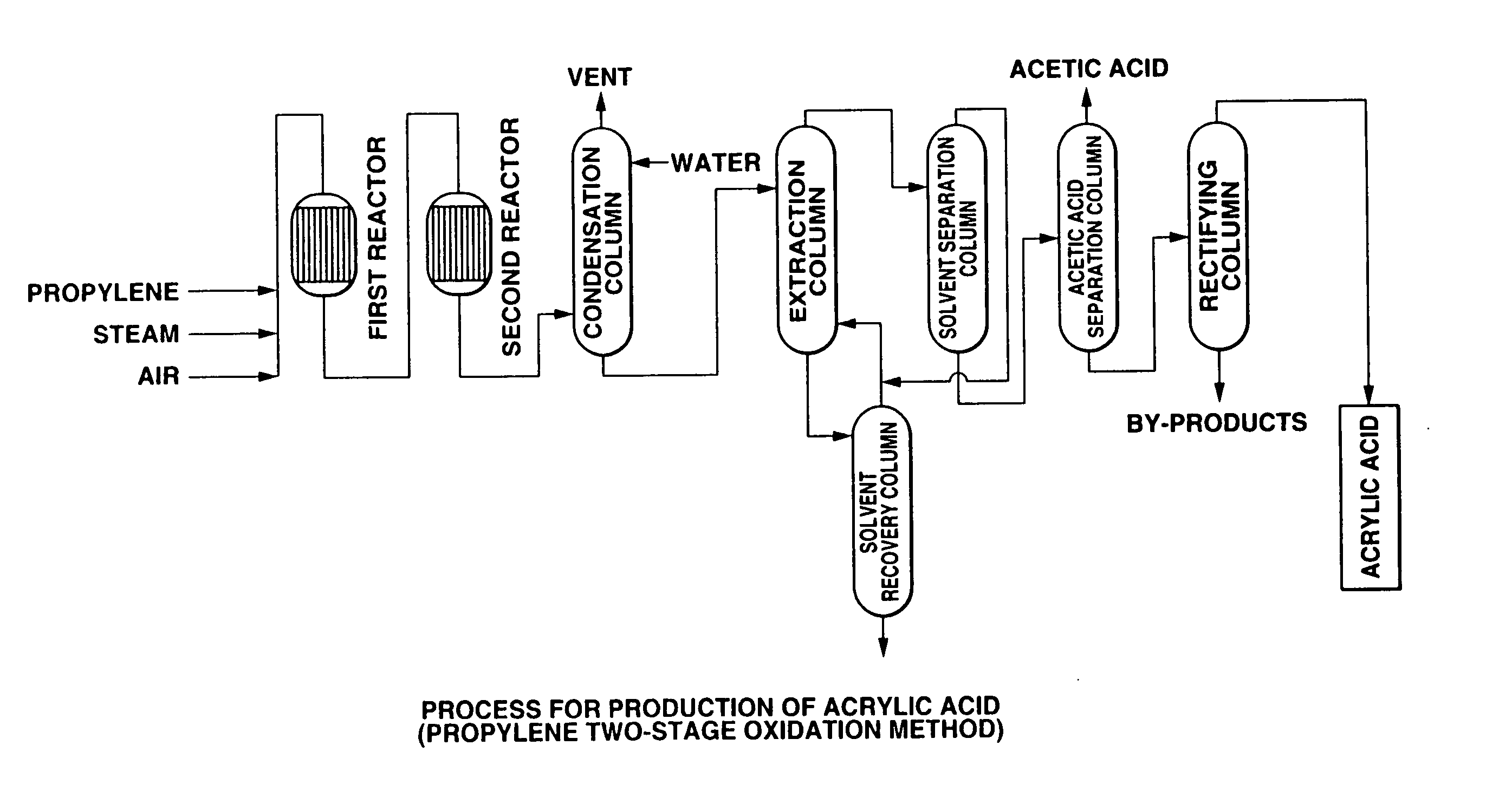

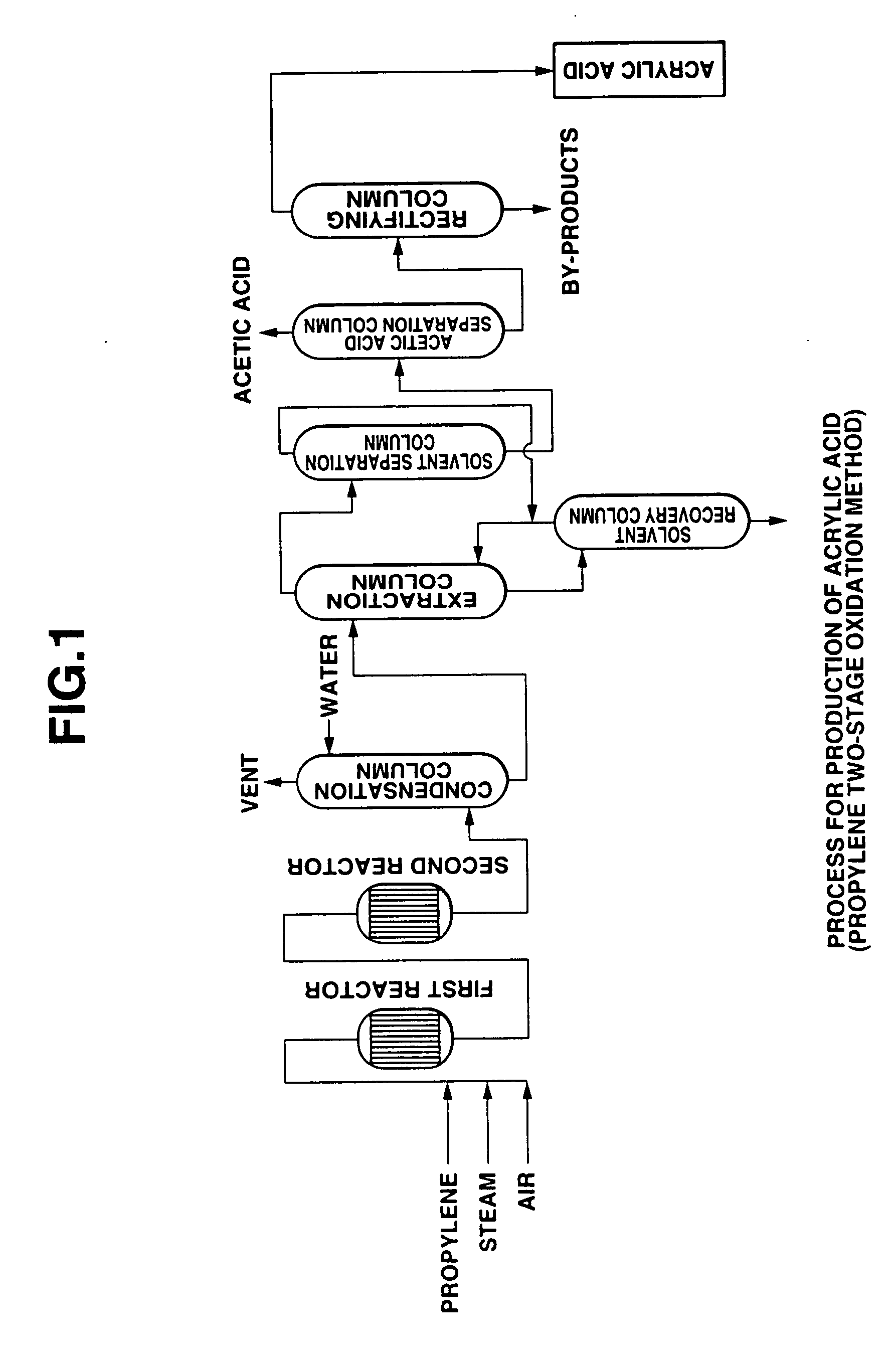

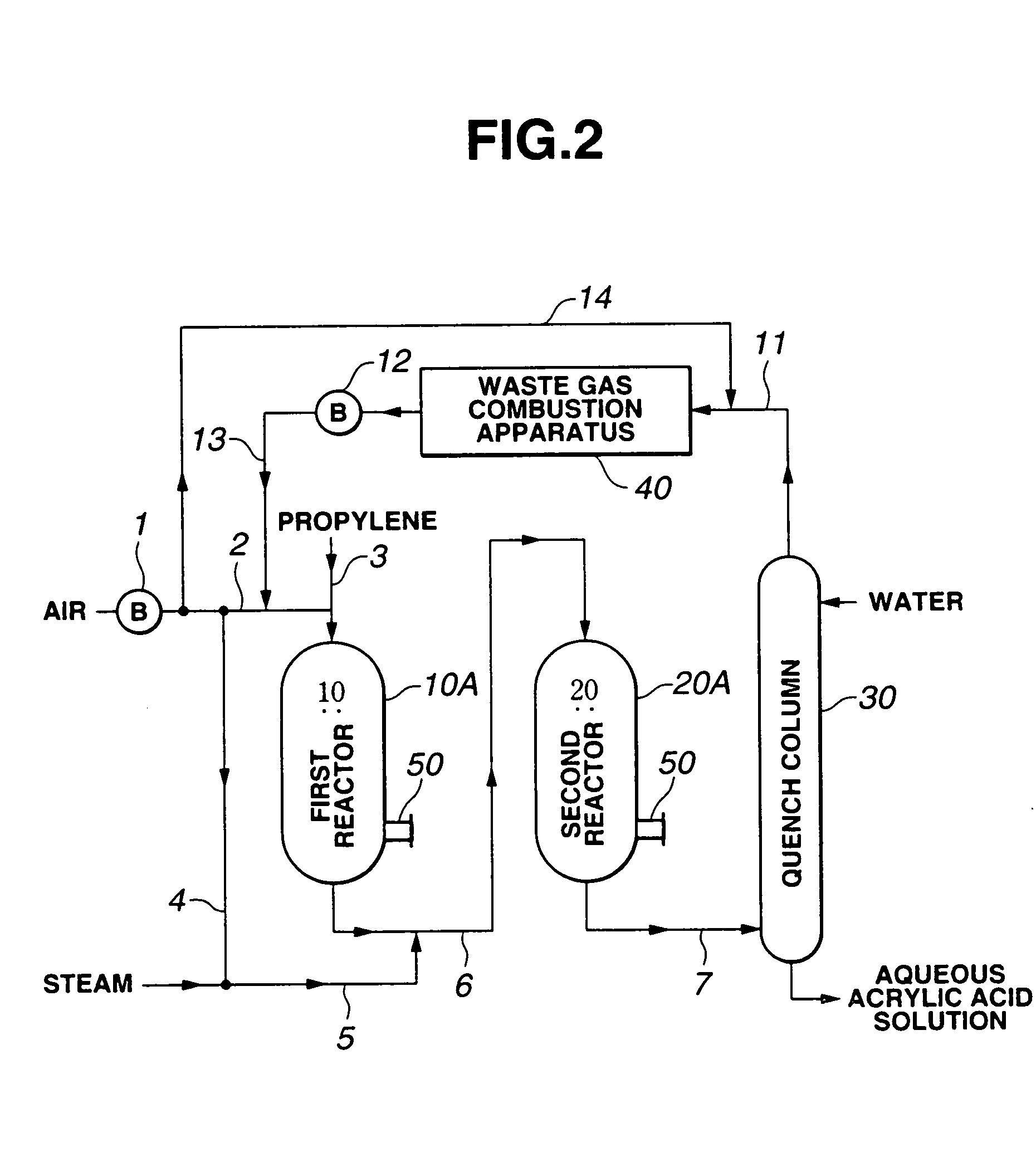

Oxidation reactor, process for producing (meth) acrylic acids, and method for analyzing easily-polymerizable compounds

ActiveUS20050143602A1Prevent auto-oxidationAvoid accumulationDisinfectionFeed devicesDouble tubeMeth-

An oxidation reactor includes a reactor body, a manhole nozzle projecting from the reactor body, and a partition plate separating an inside of the manhole nozzle and an inside of the reactor body from each other. In an oxidation reactor including the reactor body and a nozzle projecting from the reactor body, there is provided a means for feeding an inert gas into the nozzle. In a process for producing (meth)acrylic acids by subjecting propane, propylene or isobutylene to catalytic gas-phase oxidation reaction in an oxidation reactor for producing (meth)acrolein or (meth)acrylic acid, the above oxidation reactor is used as the oxidation reactor. In a method for analyzing an easily-polymerizable compound by introducing a gas containing the easily-polymerizable compound into an analyzing apparatus through a sampling tube, a double tube is used as the sampling tube, and a heating medium is fed into an outer tube of the double tube. According to these methods, the oxidation reaction can be stably conducted, and the reaction product gas can be prevented from being condensed and polymerized in the sampling tube, so that an on-line analysis can be performed at a high accuracy for a long period of time.

Owner:MITSUBISHI CHEM CORP

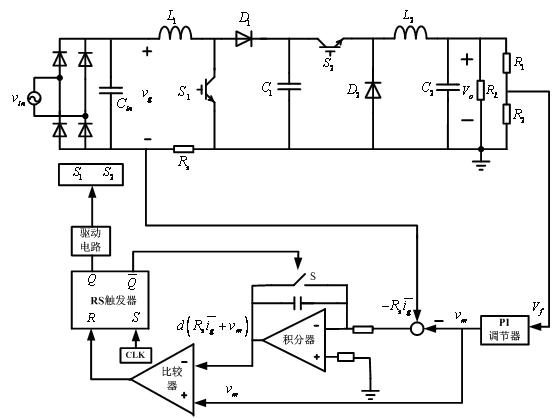

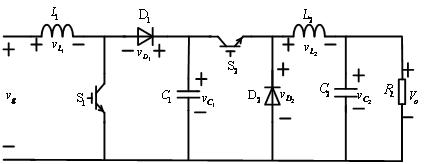

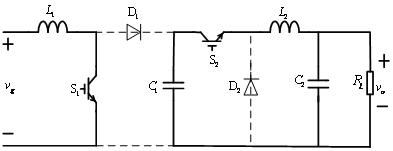

Double-tube Buck-Boost type PFC (Power Factor Correction) converter based on one-cycle control

InactiveCN102355130AReduce complexityReduce current distortionEfficient power electronics conversionDc-dc conversionIntegratorDouble tube

The invention discloses a double-tube Buck-Boost type PFC (Power Factor Correction) converter based on one-cycle control, a bridge rectification circuit is then connected with a BOCBB type double-tube Buck-Boost converter; one path of output signal of a PI (proportion integral) adjuster is sent to a noninverting input end of a comparator, the other path of output signal is superposed with a sampling signal of input current and then is sent to a resettable integrator, an output end of the resettable integrator is connected with an inverting input end of the comparator, an output end of the comparator is connected with an RS (remote sensing) trigger, one end of the RS trigger is connected with a reset switch of the resettable integrator, and a Q-end output signal of the RS trigger simultaneously drives two switching tubes of the BOCBB type double-tube Buck-Boost converter after passing by a driving circuit. The converter disclosed by the invention not only can realize output voltage raising and reducing control, but also can improve a network side power factor, reduces the distortion factor of network entry current, has the advantages of simple structure, high system efficiency and the like and is convenient to control.

Owner:NANTONG UNIVERSITY

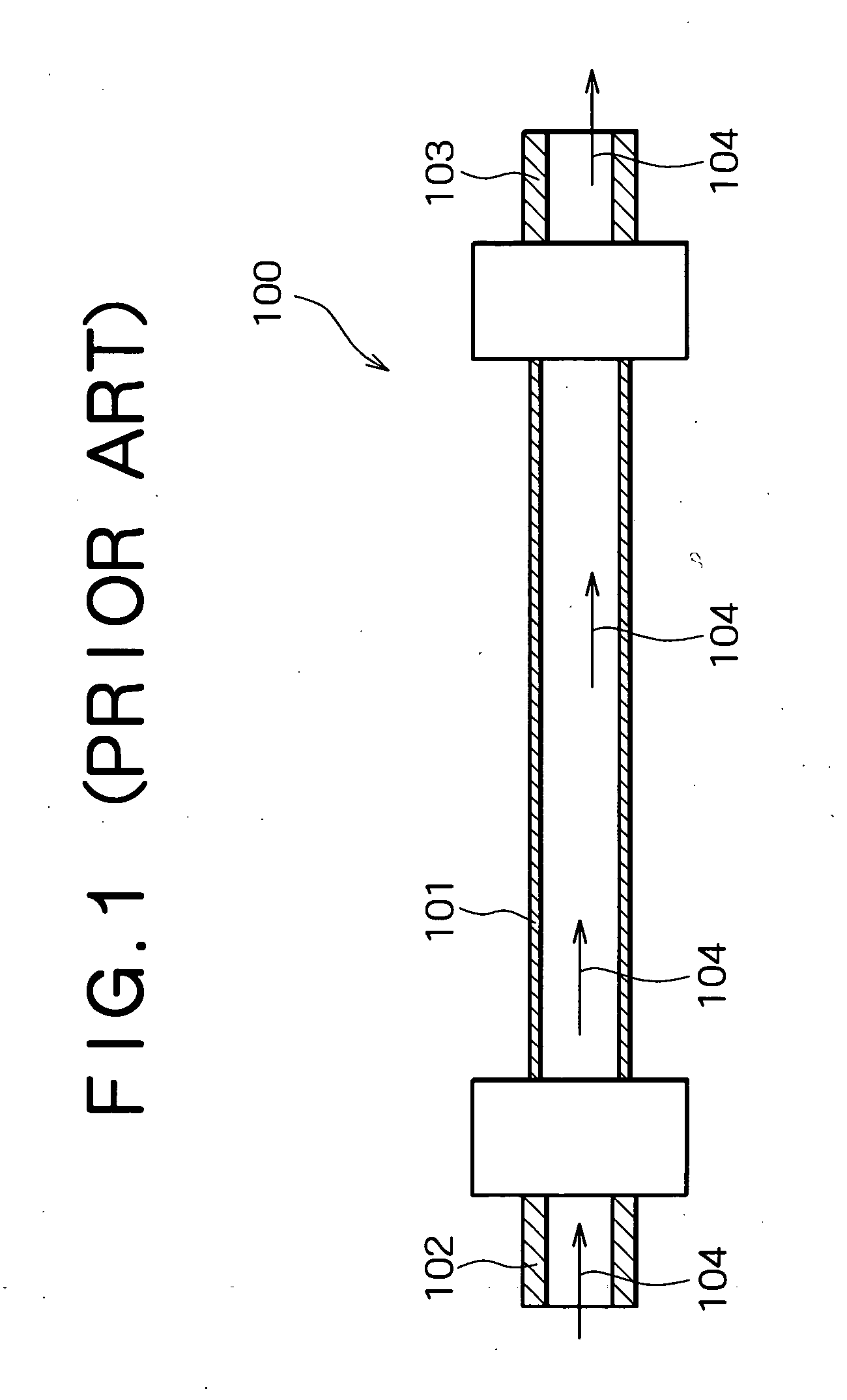

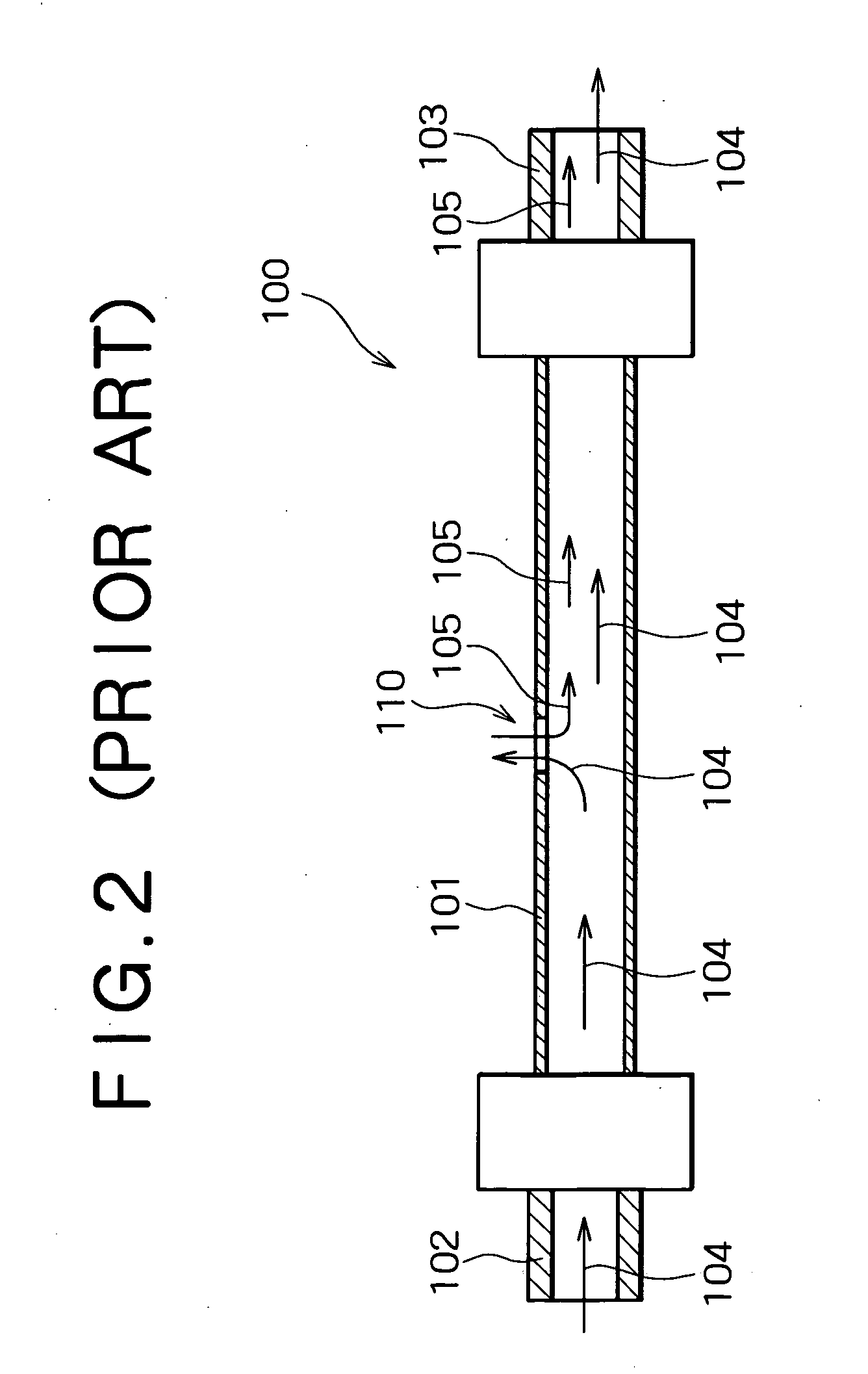

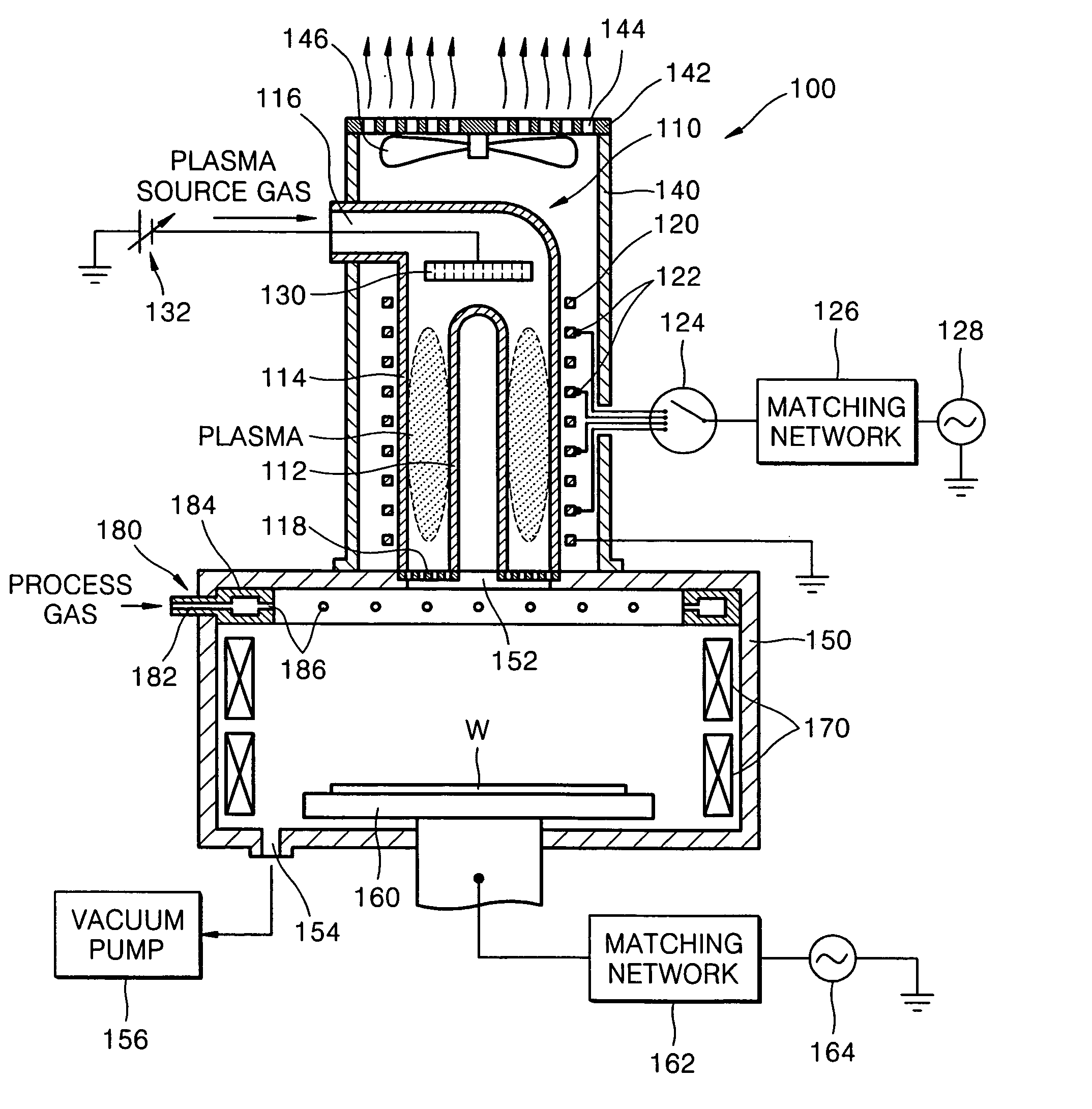

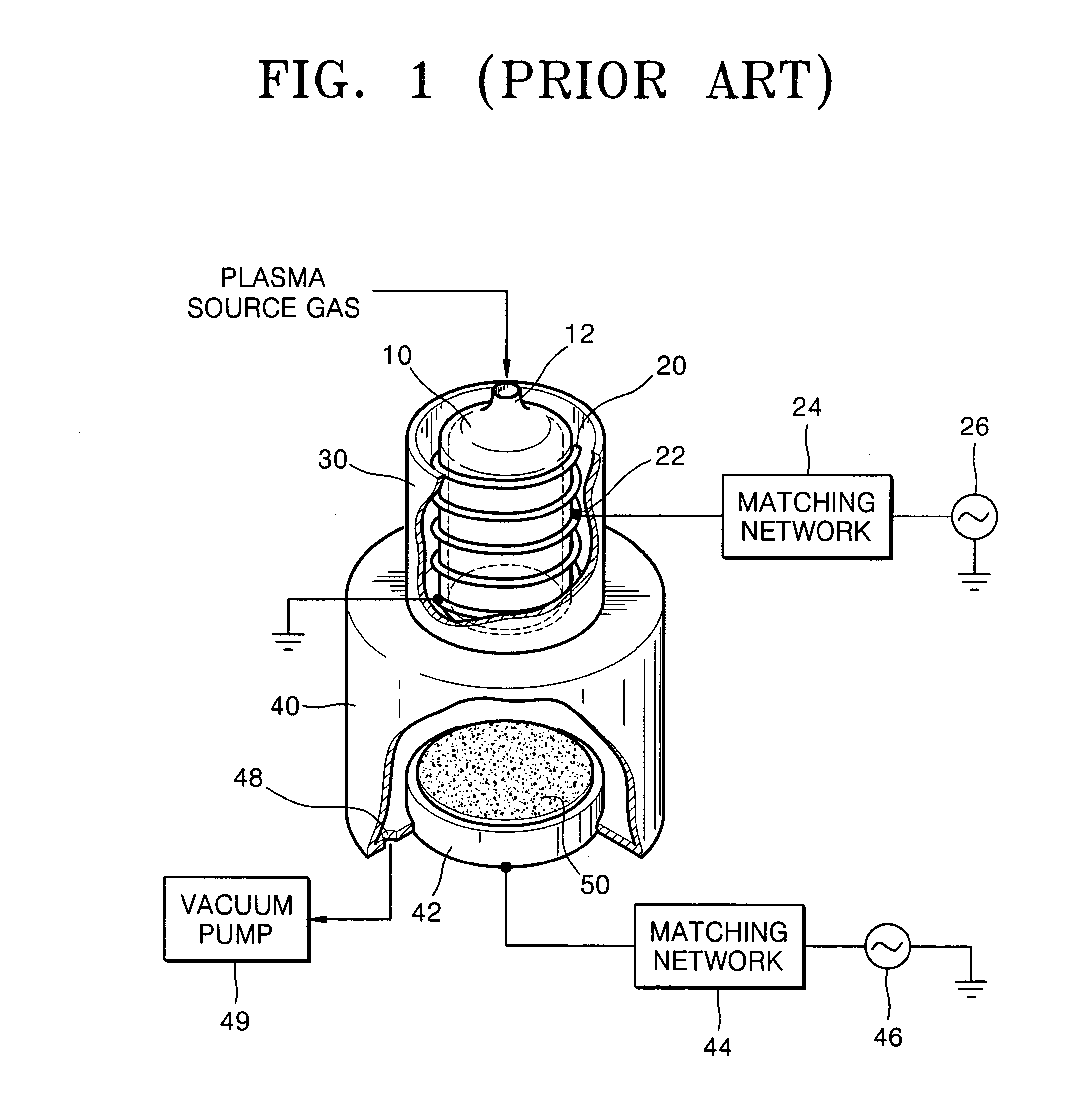

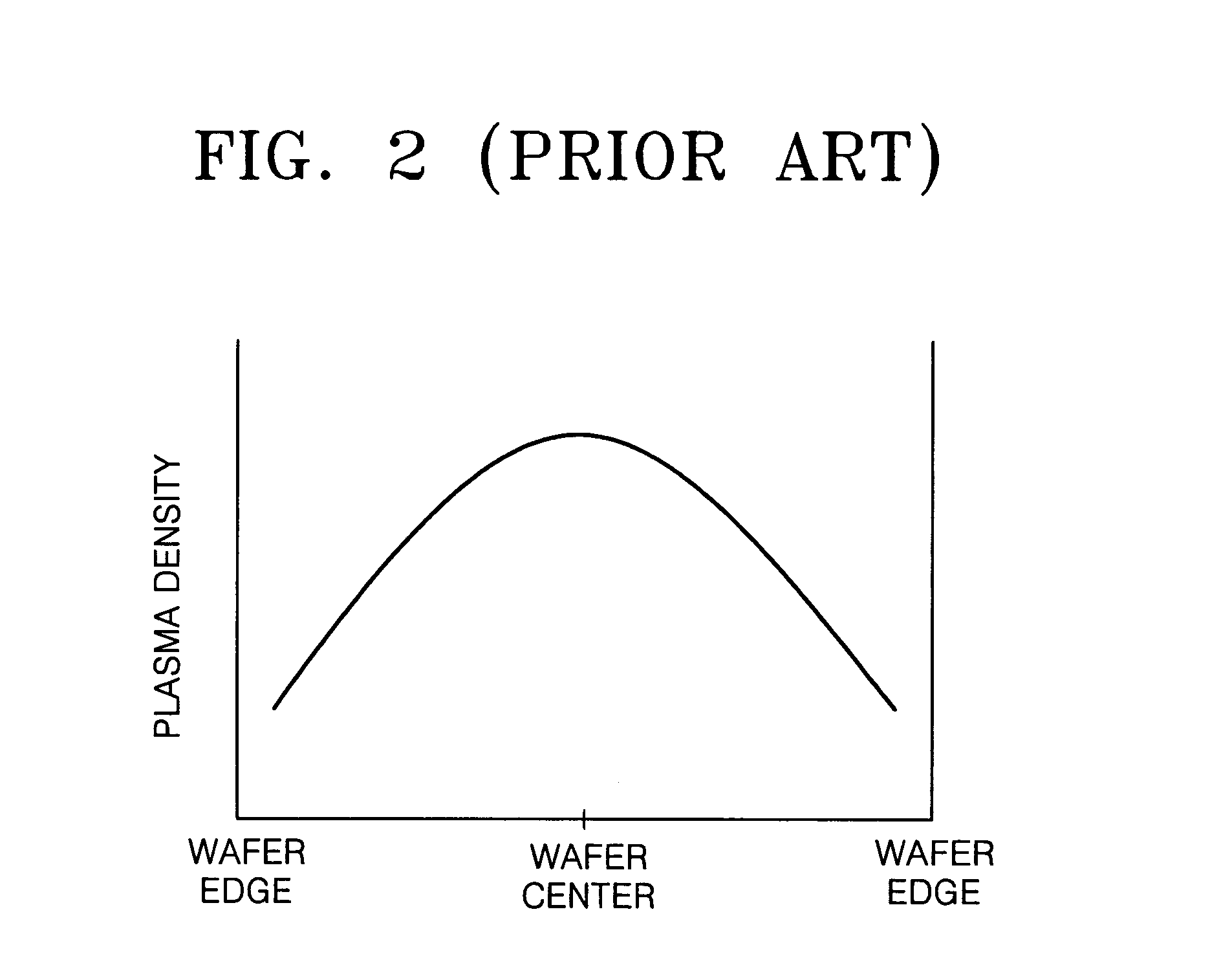

Helical resonator type plasma processing apparatus

InactiveUS20050093460A1Improve density uniformityEasy to controlElectric discharge tubesElectric arc lampsDouble tubeHelical resonator

Provided is helical resonator plasma processing apparatus. The plasma processing apparatus comprises a process chamber having a substrate holder for supporting a substrate, a dielectric tube disposed on the process chamber to communicate with the process chamber, a helix coil wounded around the dielectric tube, and an RF power source to supply RF power to the helix coil. The dielectric tube has a double tube shape and comprises an inner tube and an outer tube, and a plasma source gas inlet port to supply plasma source gas into a space between the inner tube and the outer tube is disposed in the outer tube. A control electrode to control plasma potential is disposed in the dielectric tube. This plasma processing apparatus provides a uniform plasma density distribution along a radial direction of a wafer, and easy control of the plasma potential in the process chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

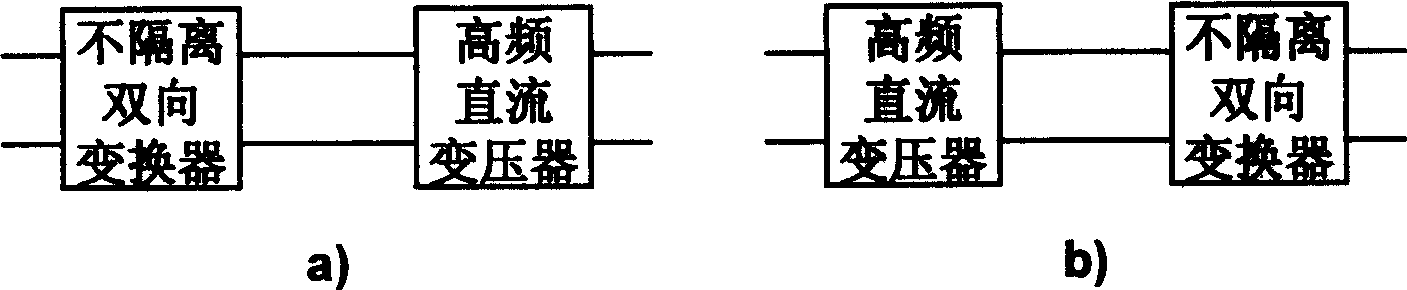

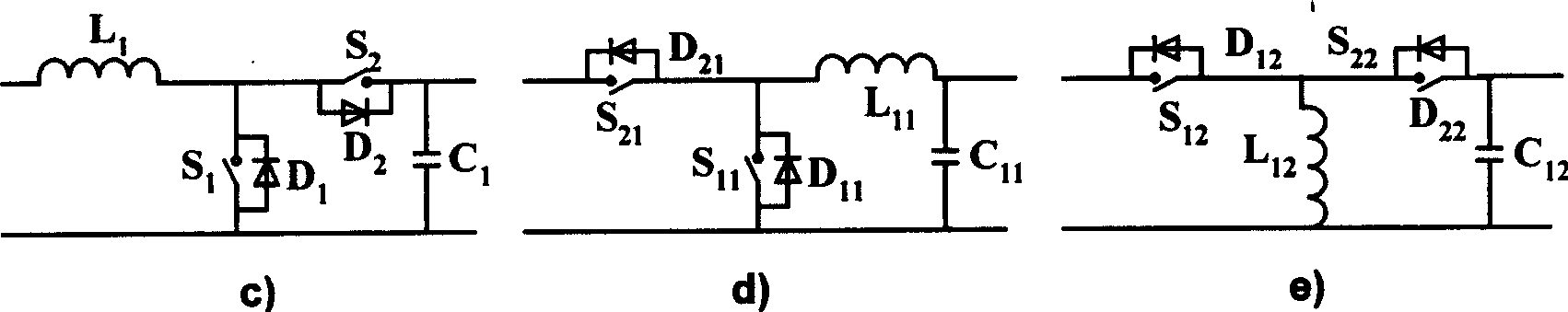

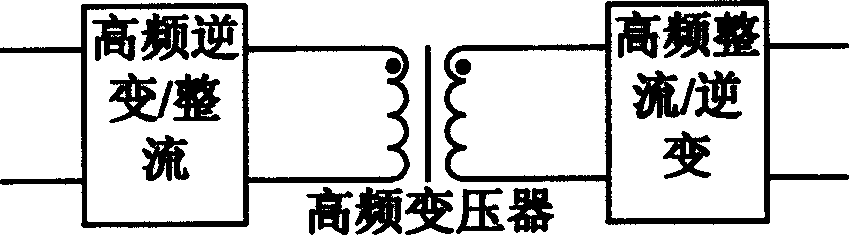

Cascading bidirectional DC-DC converter

InactiveCN1545194ASimple circuitAchieving Zero Voltage SwitchingEfficient power electronics conversionApparatus with intermediate ac conversionDouble tubeFull bridge

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

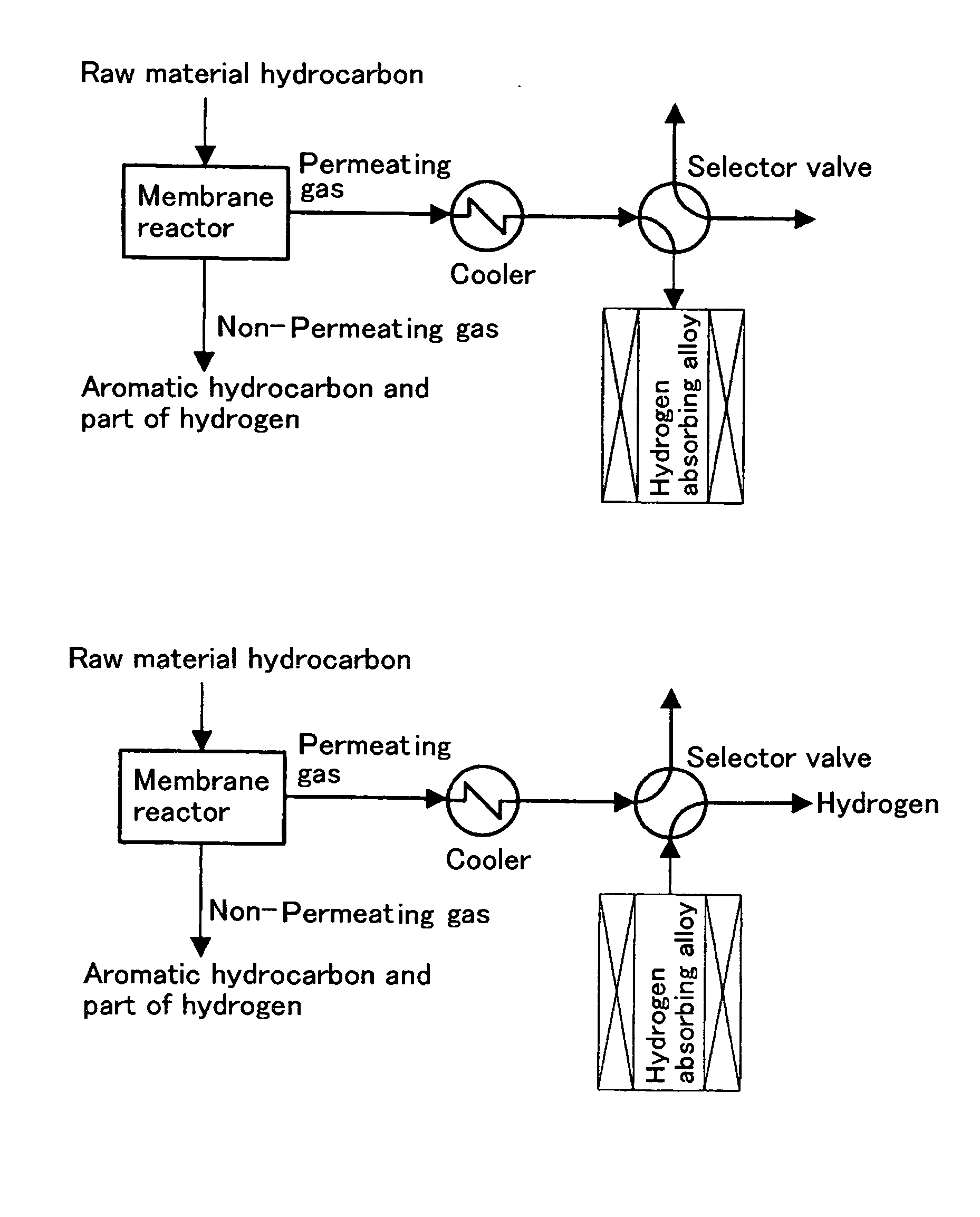

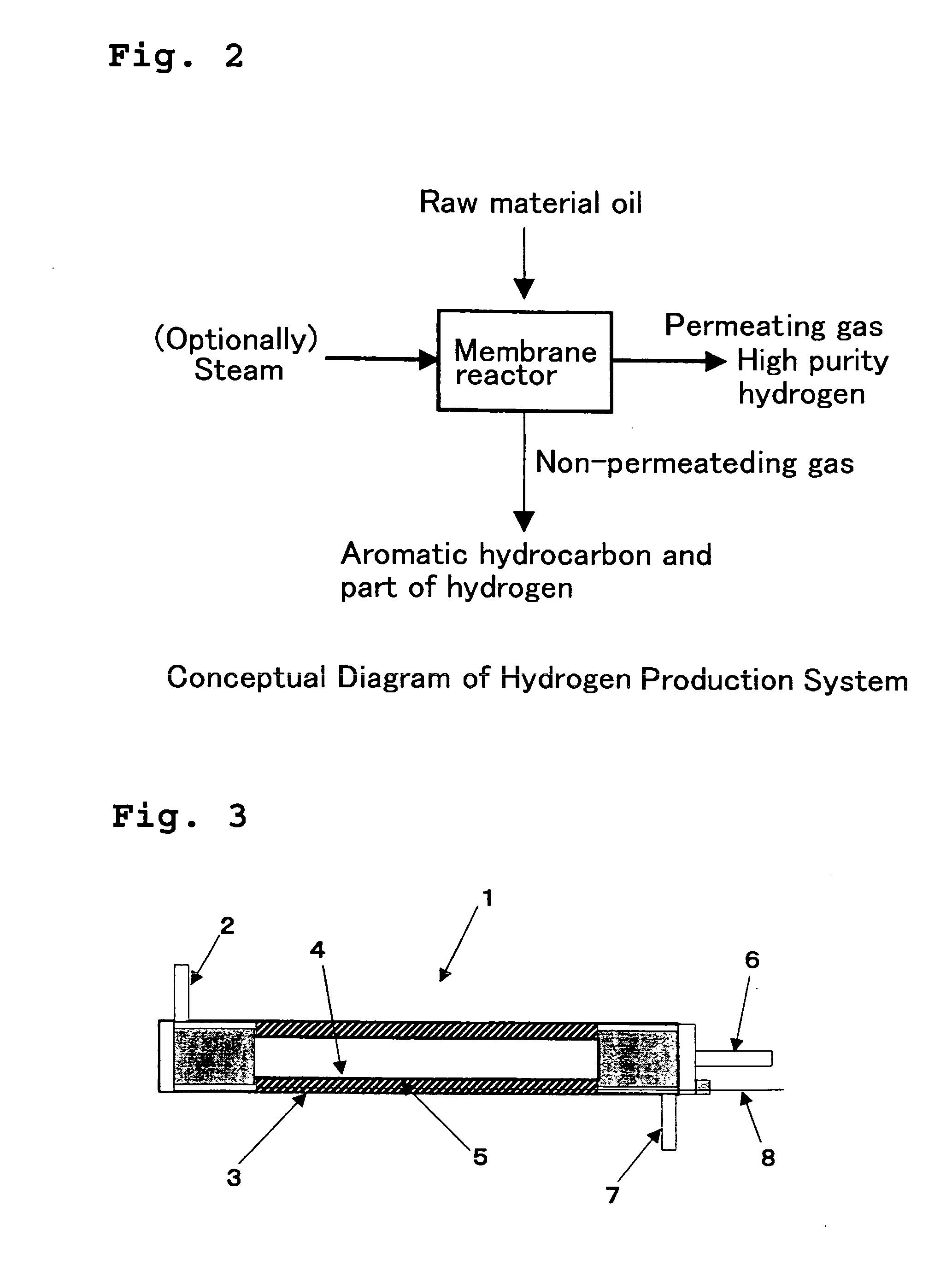

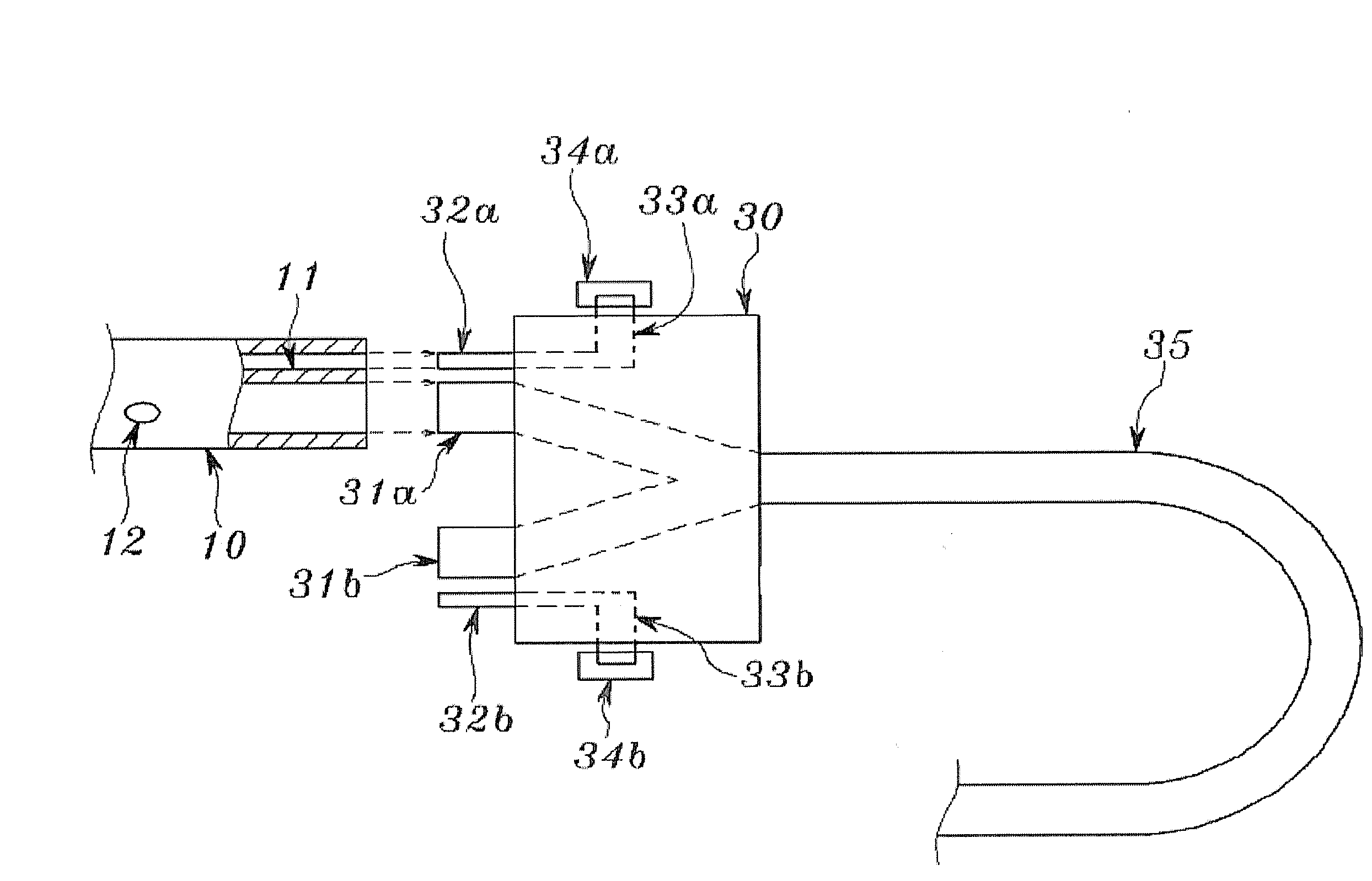

Method for Producing Hydrogen and System Therefor

InactiveUS20080234527A1Efficient productionReduce pressureOrganic chemistry methodsHydrogen/synthetic gas productionDouble tubeDehydrogenation

The present invention provides a hydrogen production method capable of producing hydrogen with good efficiency while solving problems such as separation, lower-temperature reaction and heat supply in production of hydrogen by dehydrogenation reaction of raw material oil. Within a reaction tube of a double-tube structure comprising an inner tube composed of a hydrogen separating membrane, a metallic outer tube having a plurality of internal fins, and a metal oxide layer and further a catalyst supported on the fins, hydrocarbon having cyclohexane ring is dehydrogenated to produce hydrogen and aromatic hydrocarbon, and selective membrane separating operation of hydrogen is performed within the reaction system while conducting the dehydrogenation to remove mainly the hydrogen on a permeating side and obtain mainly the aromatic hydrocarbon on a non-permeating side. The other method comprises absorbing at least part of the resulting hydrogen flow to a hydrogen absorbing (storing) alloy to make the pressure on the hydrogen permeating side of the hydrogen separating membrane lower than that on the non-permeating side.

Owner:NIPPON OIL CORP

Closed Suction Drainage Apparatus With Drainage Tube Having Anti-Clogging and Irrigating Functions

InactiveUS20080183156A1Efficient removalAvoid cloggingMulti-lumen catheterWound drainsDouble tubePositive pressure

The present invention relates to a closed suction drainage apparatus with a drainage tube having anti-clogging and irrigating functions. The closed suction drainage apparatus of the present invention have a double tube structure of the drainage tube and its connection unit. One tube of the drainage tube is used for drain blood and exudates from a dead space and the other tube is used for applying positive pressure to remove clotted substance in the drainage tube or irrigating a wound with liquid. The closed suction drainage apparatus according to the present invention can easily clear the clogged drainage tube or irrigate dead space when needed, even in the state that it is inserted in the body.

Owner:THE CATHOLIC UNIV OF KOREA IND ACADEMIC COOP FOUND

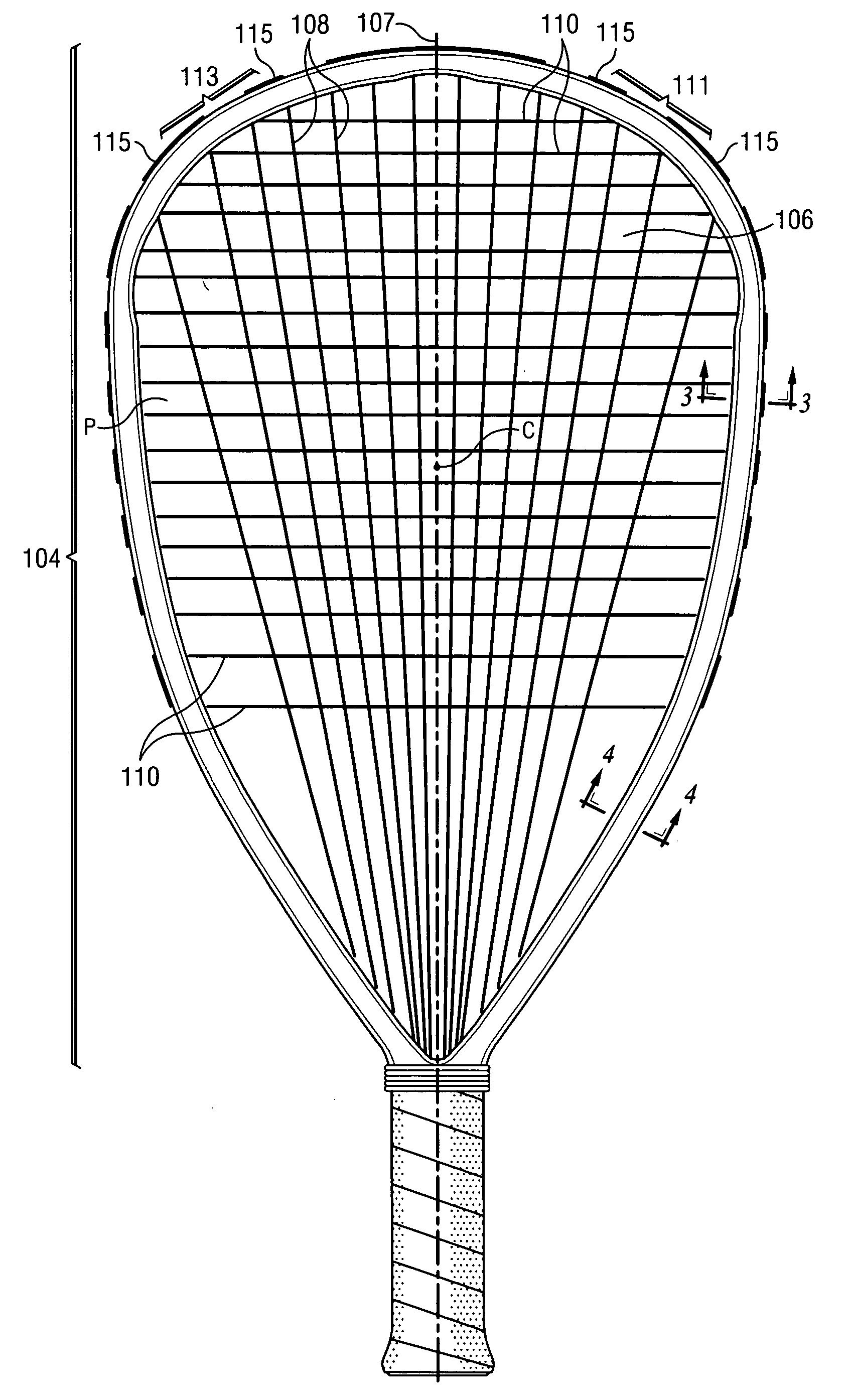

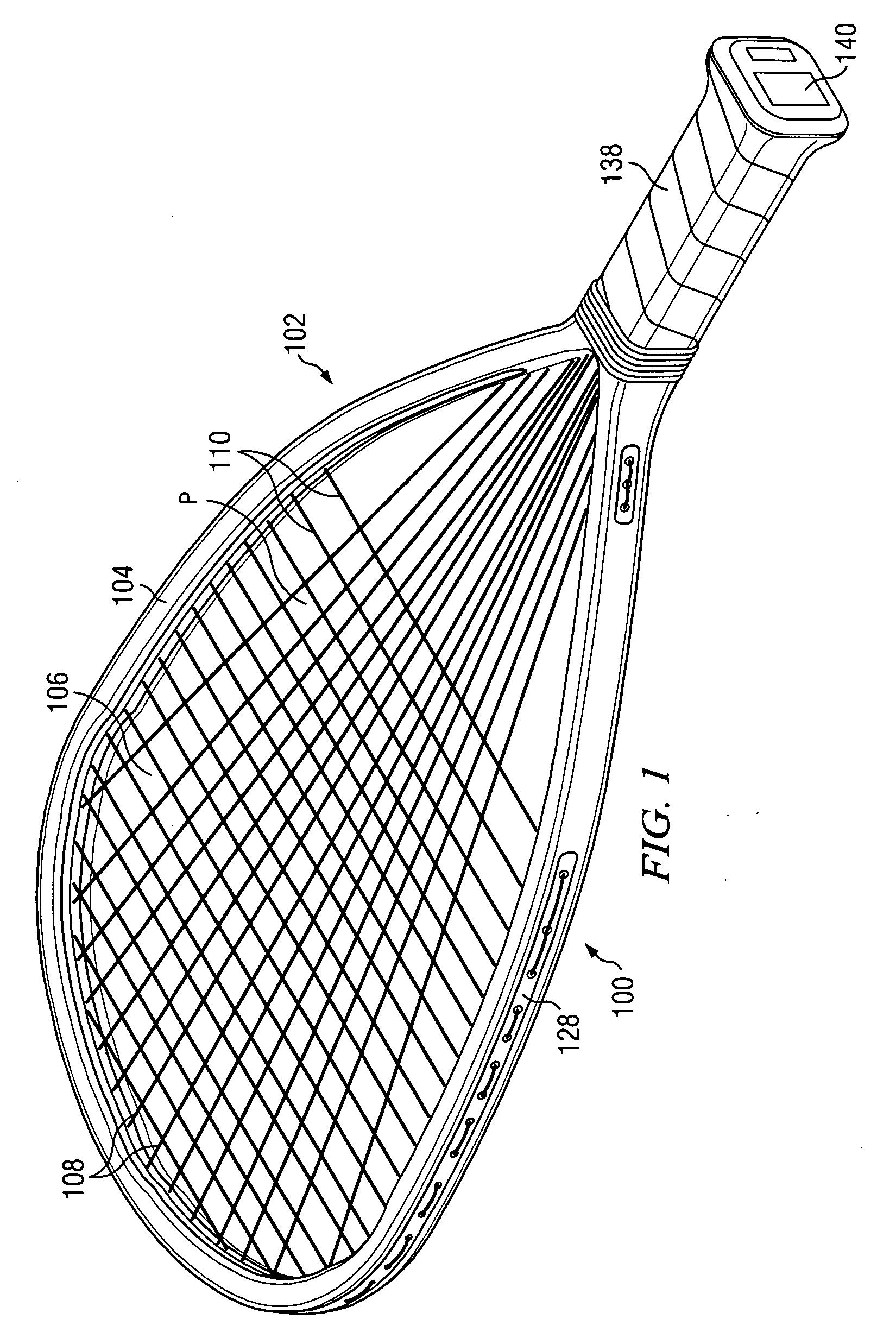

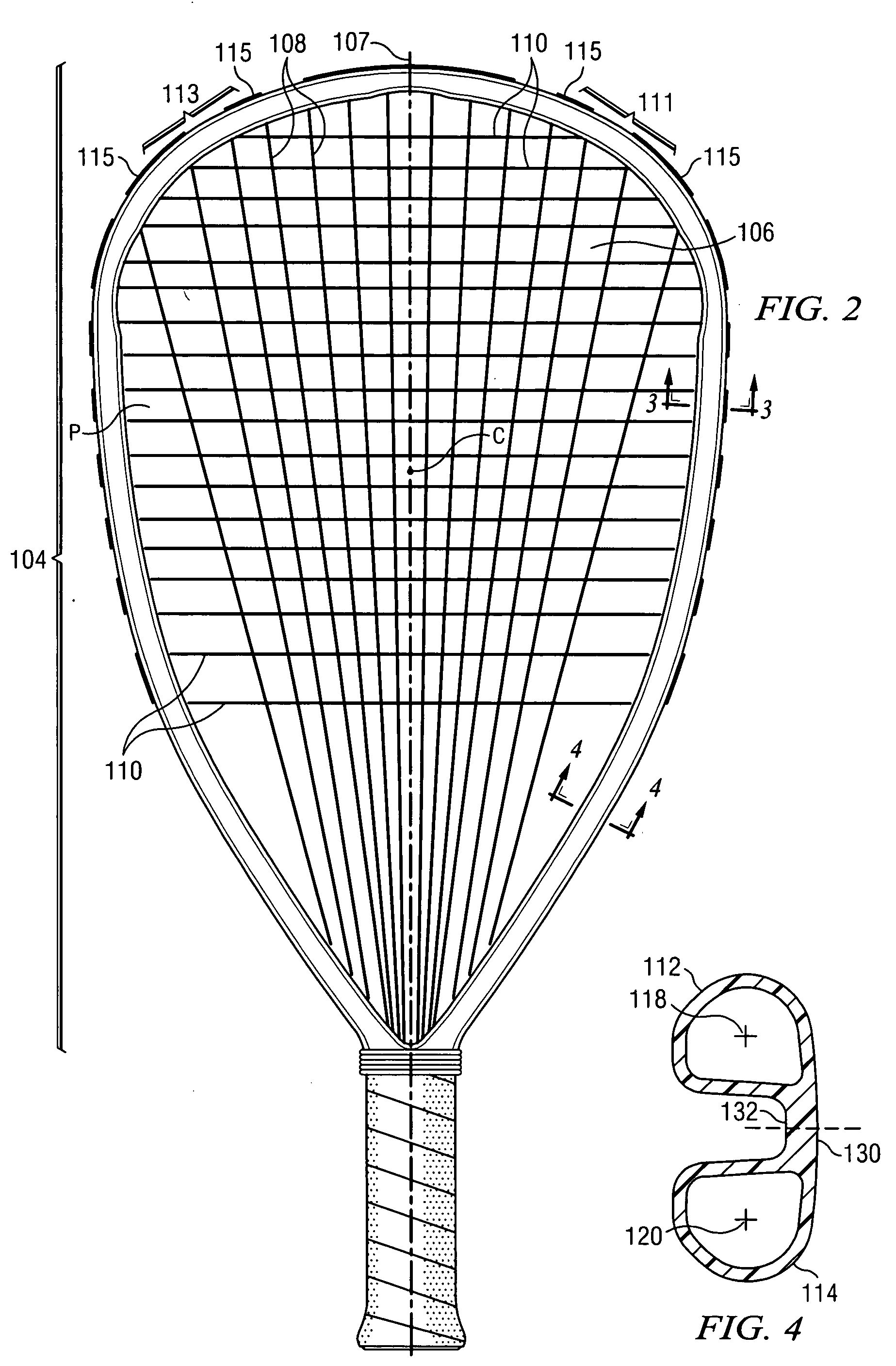

Composite racquet with double tube head frame

A sports racquet frame is built of a composite of laminations of fibrous material as impregnated by a thermosetting resin. The head section of the frame has an upper tube preferably disposed above the string bed plane and a lower tube preferably disposed below the string bed plane. A solid bridge of material integrally joins the upper tube to the lower tube. In a preferred embodiment the bridge is disposed radially exteriorly of the center line of the tubes, to maximize the length of string segments, which are strung to the bridge.

Owner:EF COMPOSITE TECH

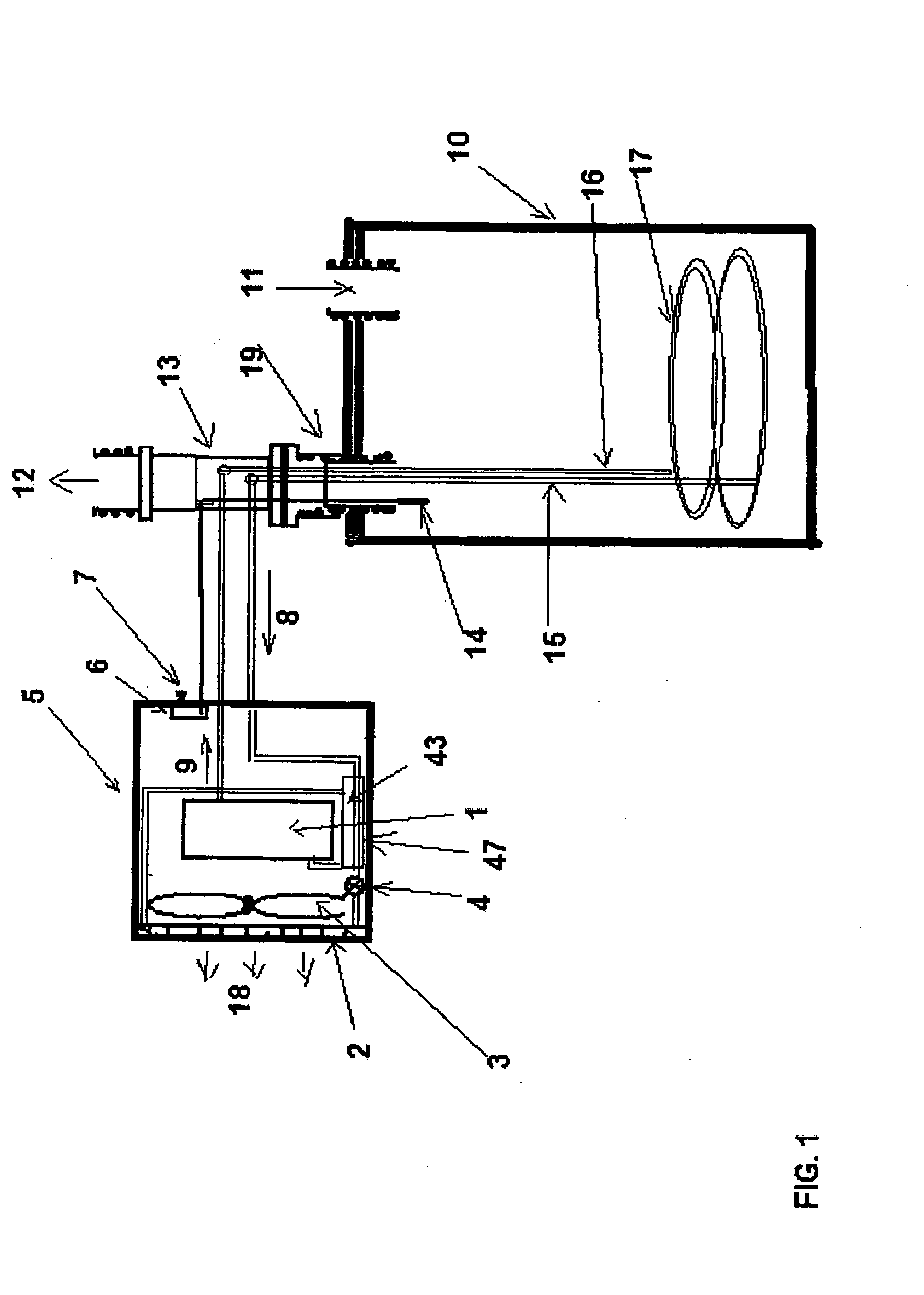

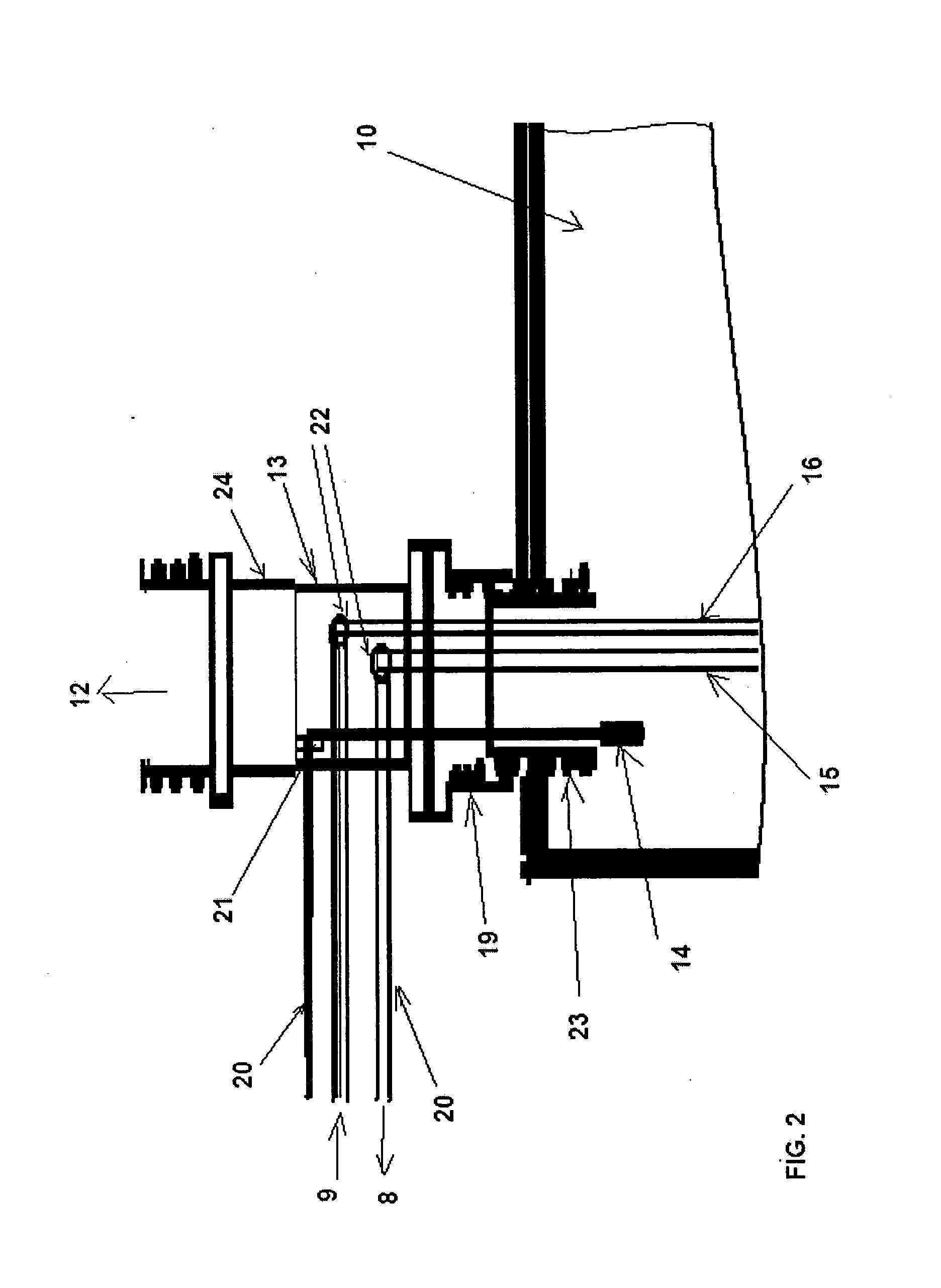

Heat pump liquid heater

InactiveUS20080000247A1Evaporators/condensersCombined heat and power systemsPlate heat exchangerRefrigerant reclamation

A heat pump liquid heater for heating a liquid comprising: a heat pump; a liquid tank in heat communication with the heat pump, wherein the liquid tank comprises the liquid; and at least one metal condenser tube immersed into the liquid, wherein the metal condenser tube forms at least one coil. The metal condenser tube has a flattened double-tube configuration and a cross-section defined by concentric ovals such that at least a portion of the concentric ovals is in contact with one another thereby minimizing space between the flattened double-tubes. The heat pump comprises a tube-in-tube heat exchanger and a compressor, wherein the tube-in-tube heat exchanger recovers heat from refrigerant returning from the liquid tank and transfers the recovered heat to refrigerant going to the compressor thereby superheating the refrigerant.

Owner:AIRGENERATE LLC

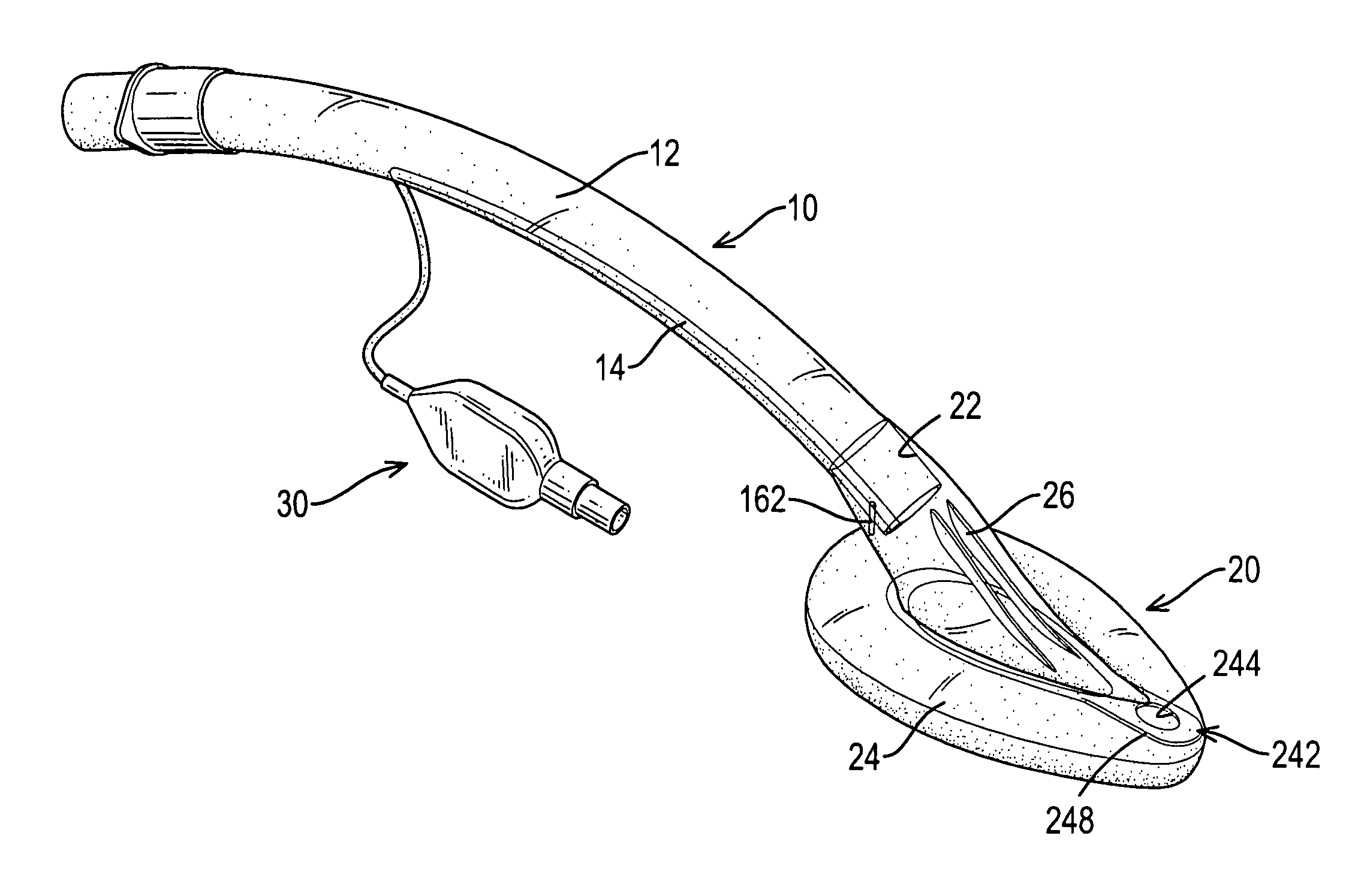

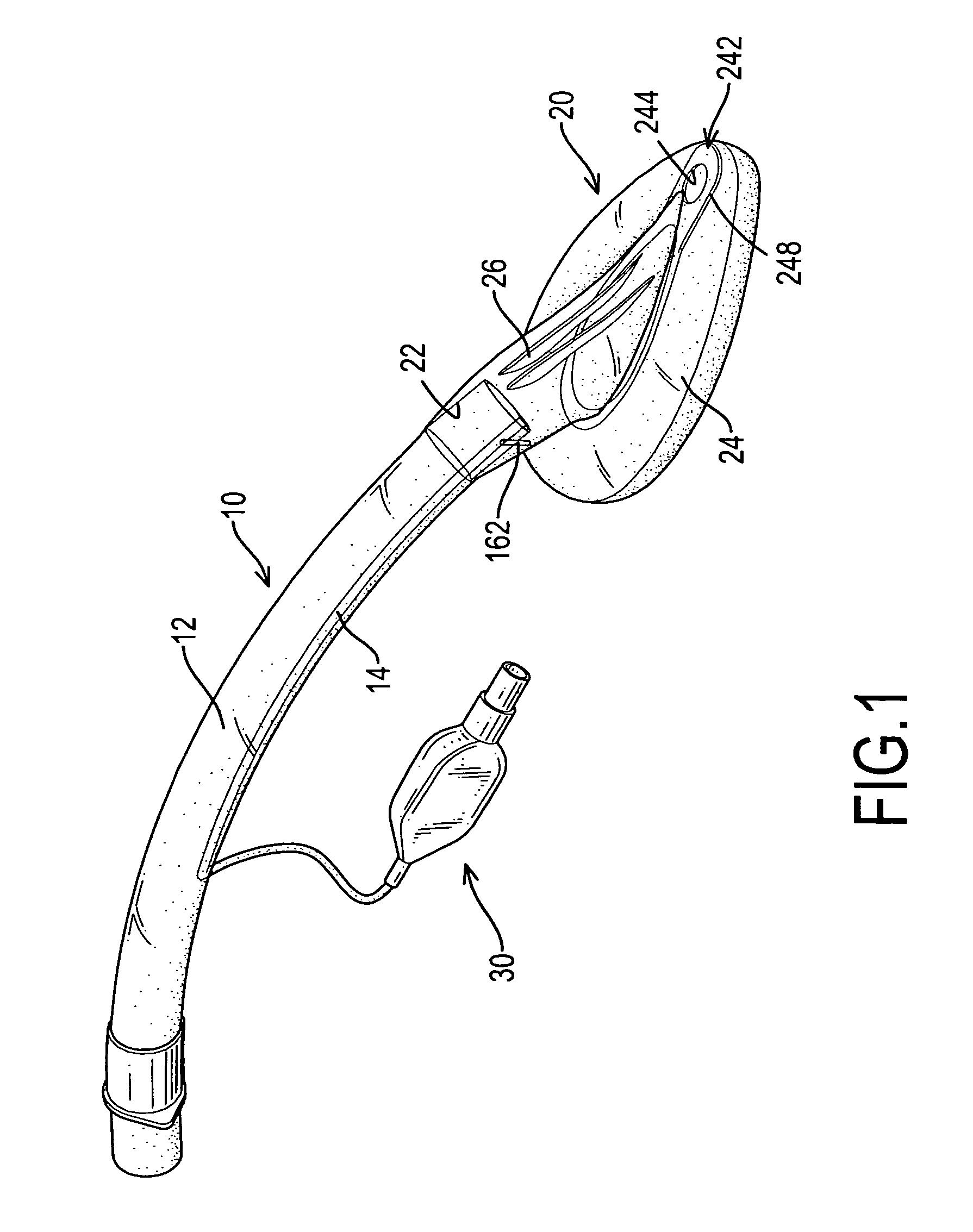

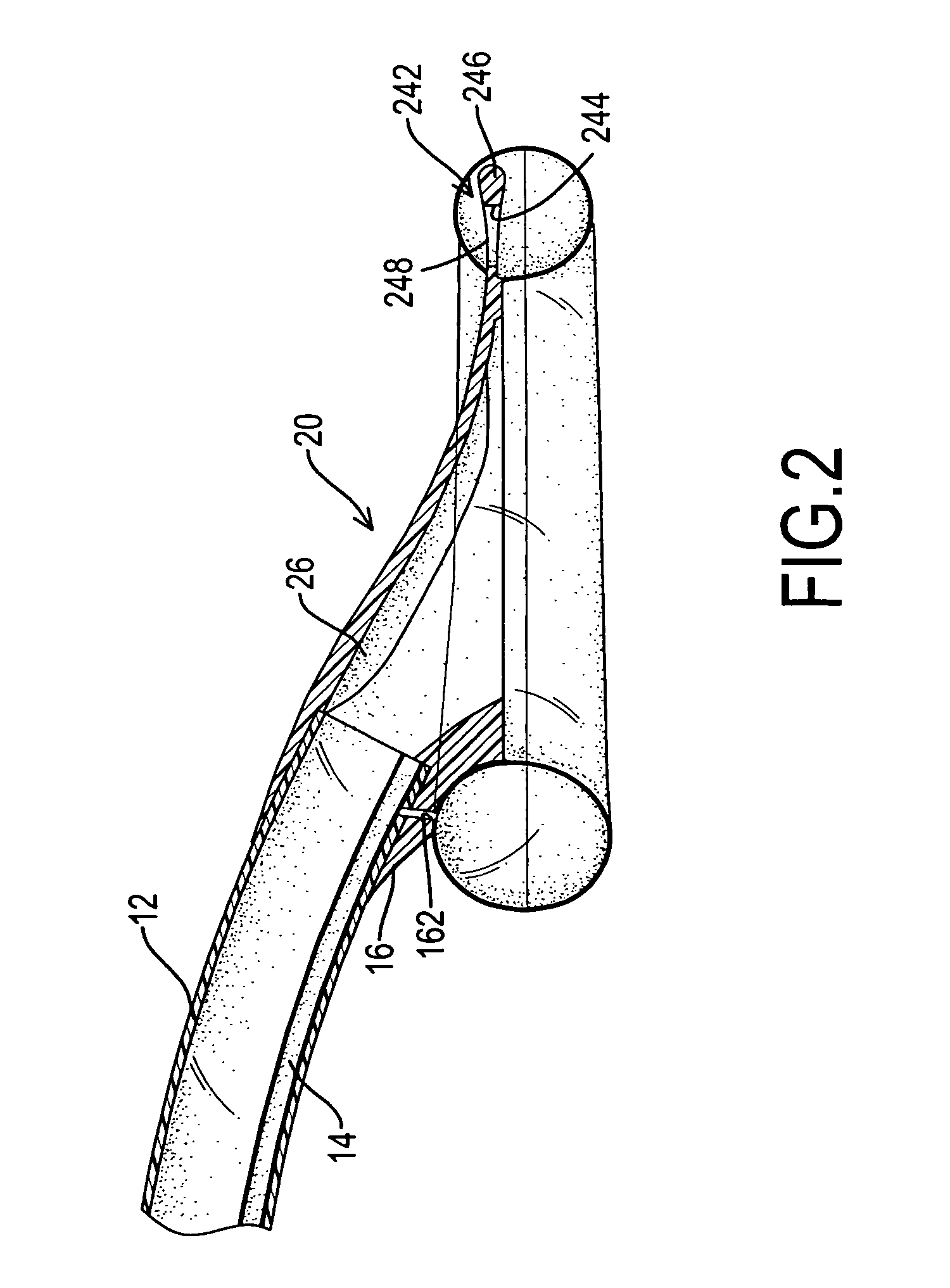

Laryngeal mask airway

InactiveUS7047973B2Easy to operateComfortable and durable in useTracheal tubesSurgeryLaryngeal airwayDouble tube

A laryngeal mask tube has of a dual-airway tube, a mask with an inflatable bladder and an inflation indicator device. The dual-airway tube has a primary tube communicated with the mask to guide gas into the body of a patient and a secondary tube communicated between with the bladder and the inflation indicator device. Two ribs are formed in the mask to prevent blockage of the primary tube and a tongue is formed inside the bladder to prevent the bladder from folding. Improvements of the laryngeal mask are that the tongue further has an easing hole to reduce rigidity of the tongue and the mask further has a fusing portion to integrally combine the dual-tube and the bladder together to avoid breakage at the bladder. Whereby, the laryngeal mask airway eliminates feelings of discomfort to patients and is durable in use.

Owner:CHANG TI LI

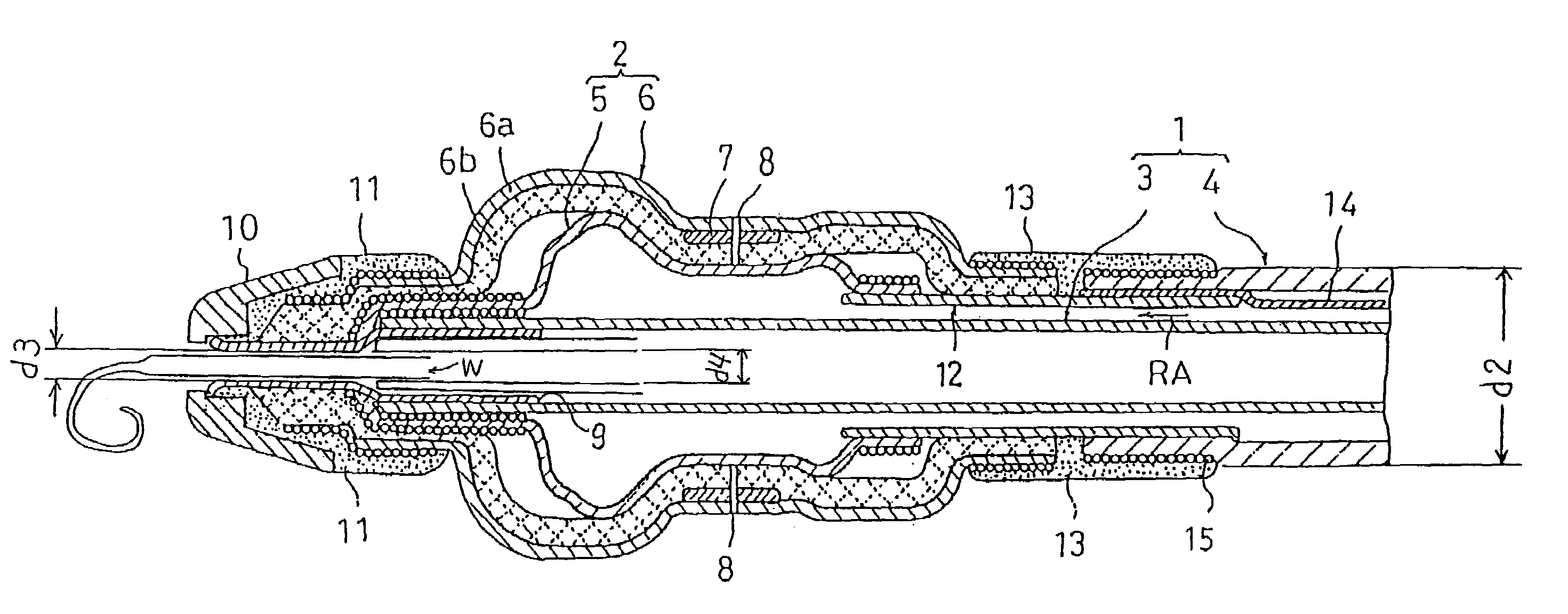

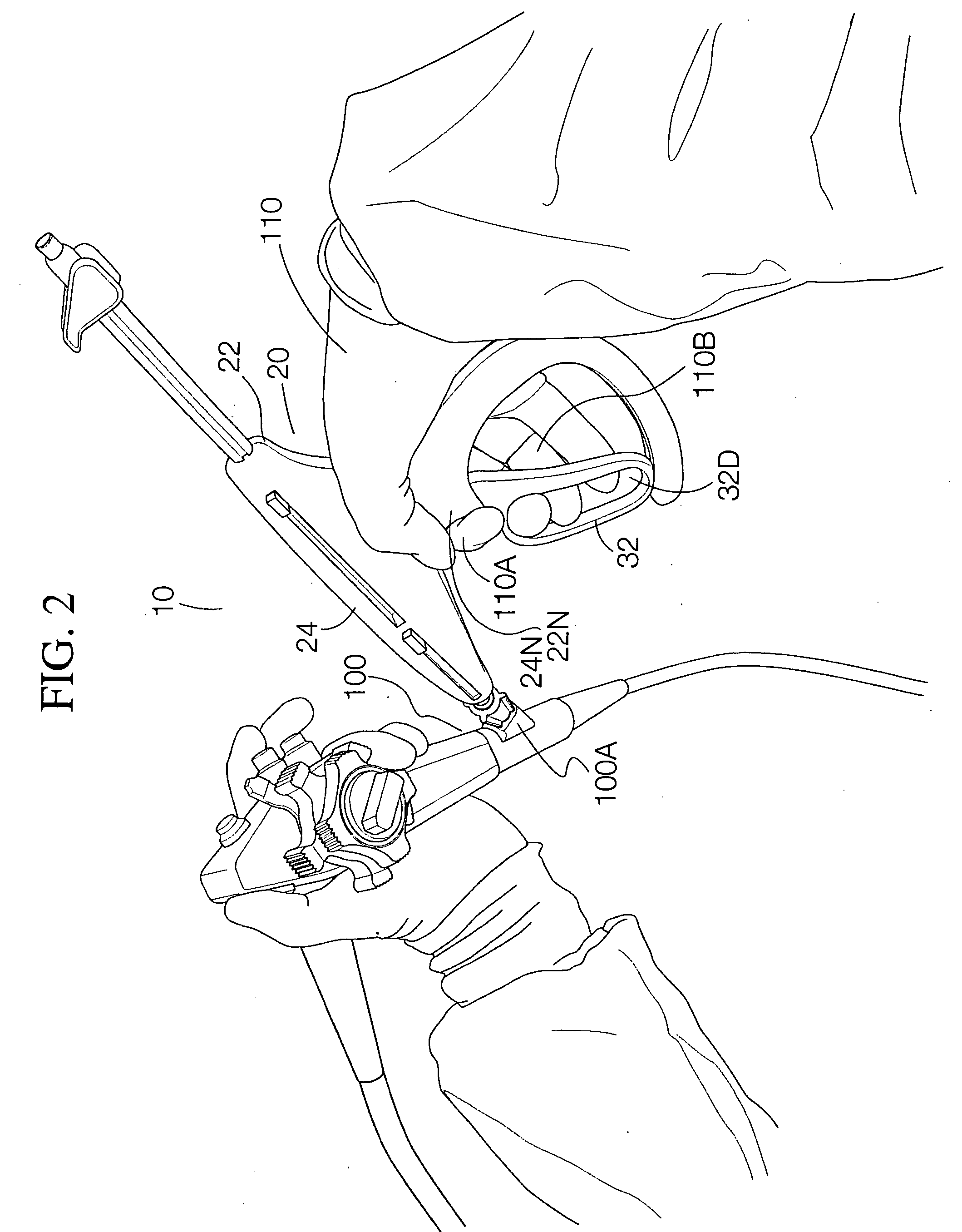

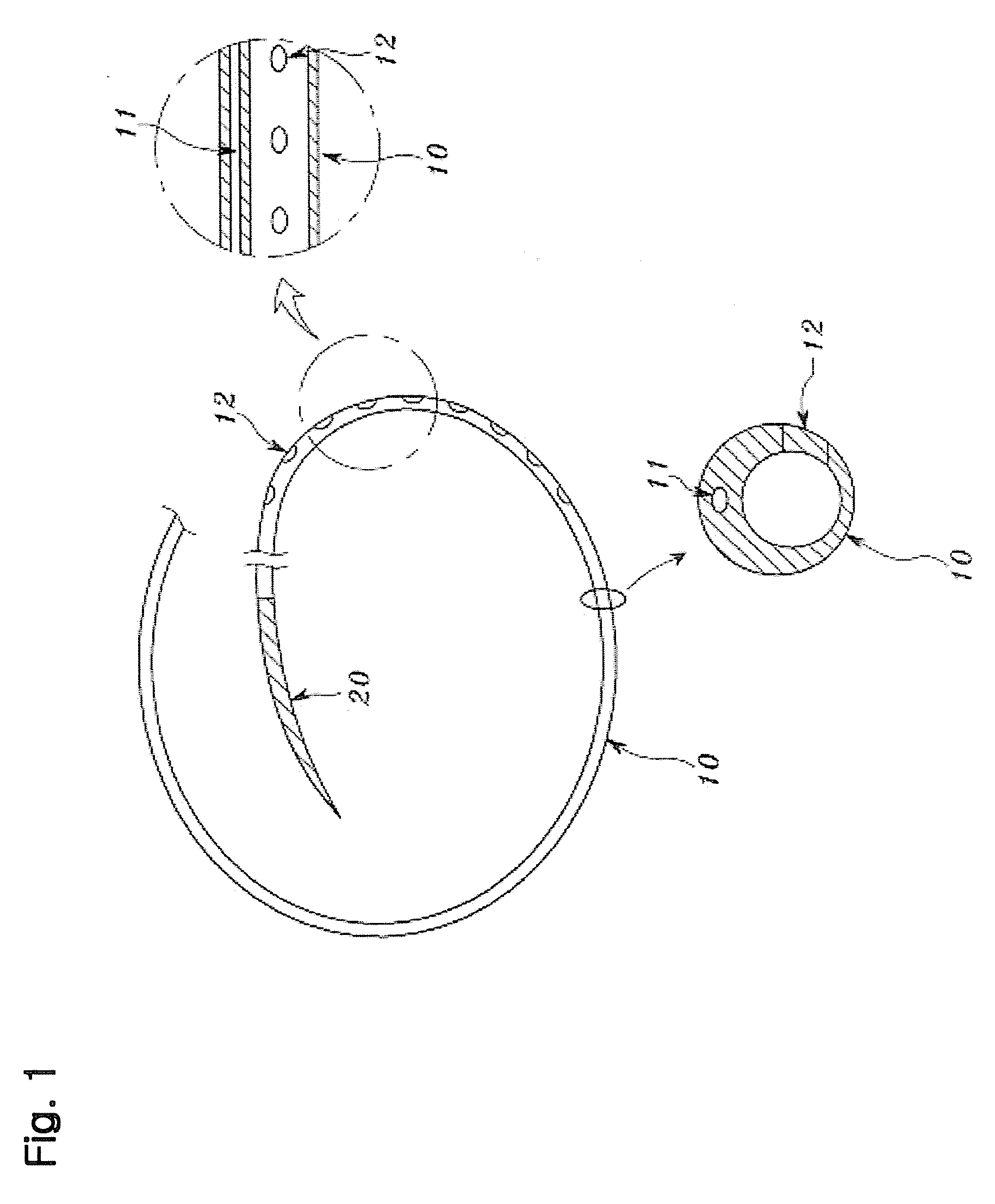

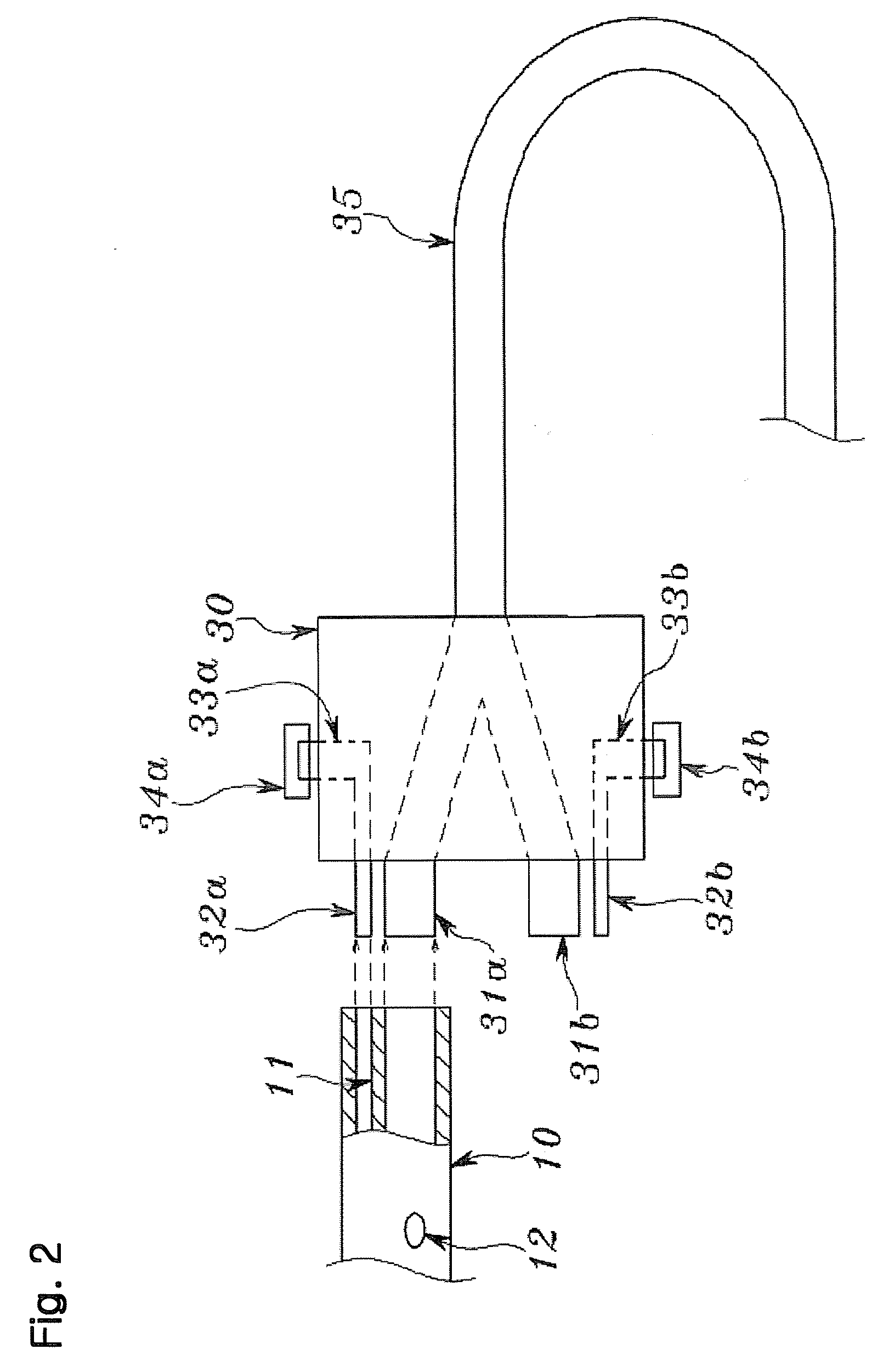

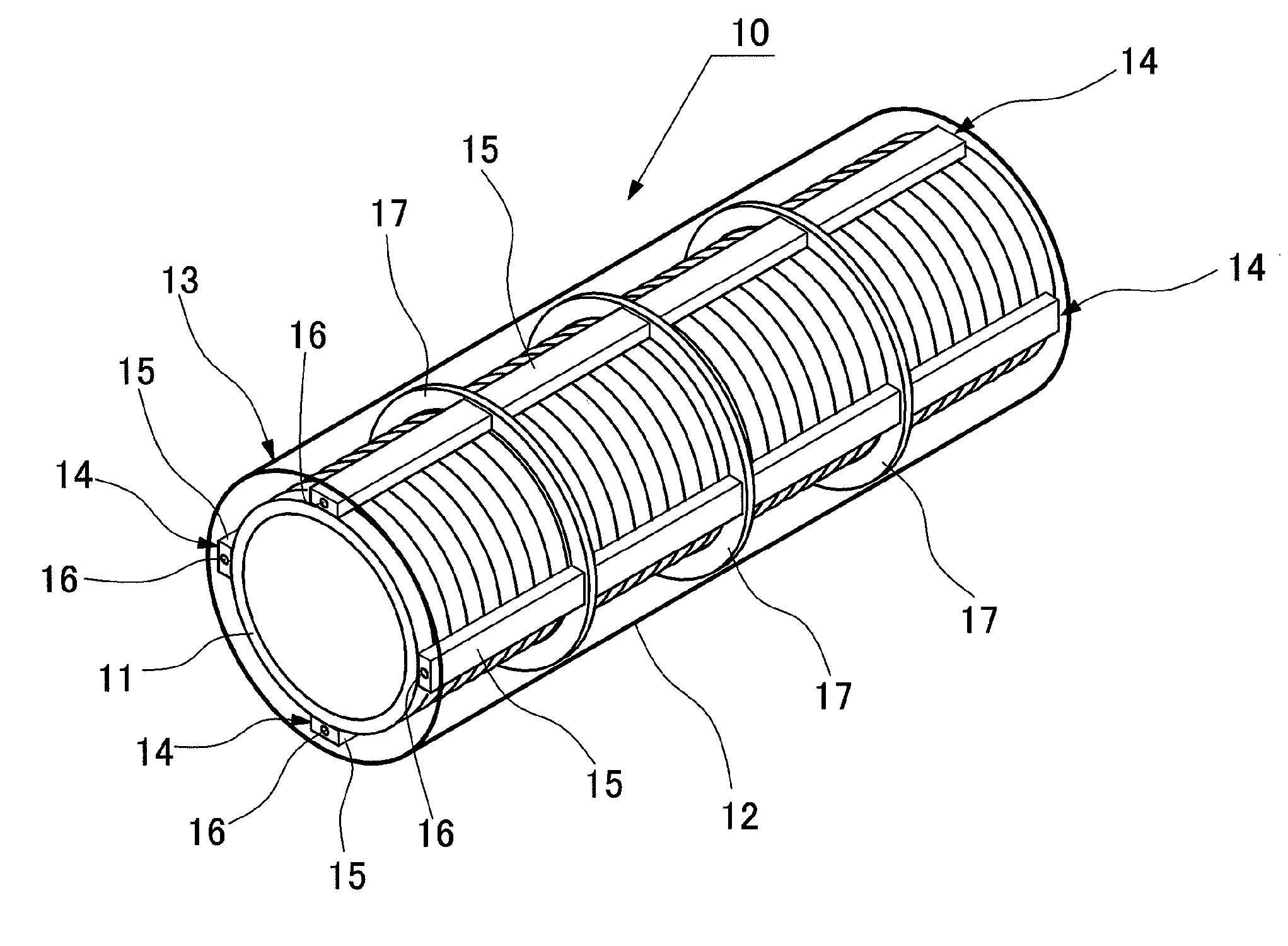

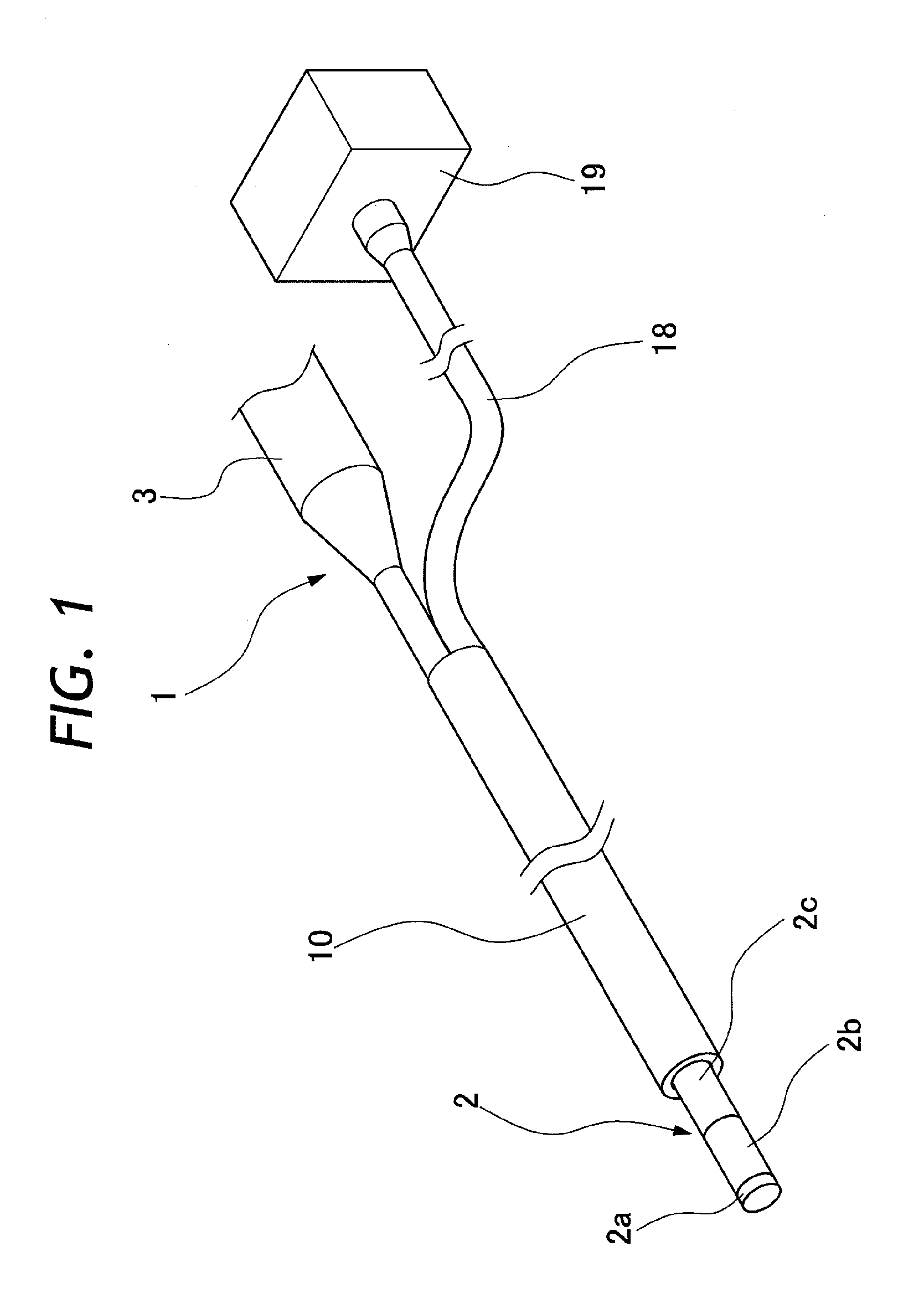

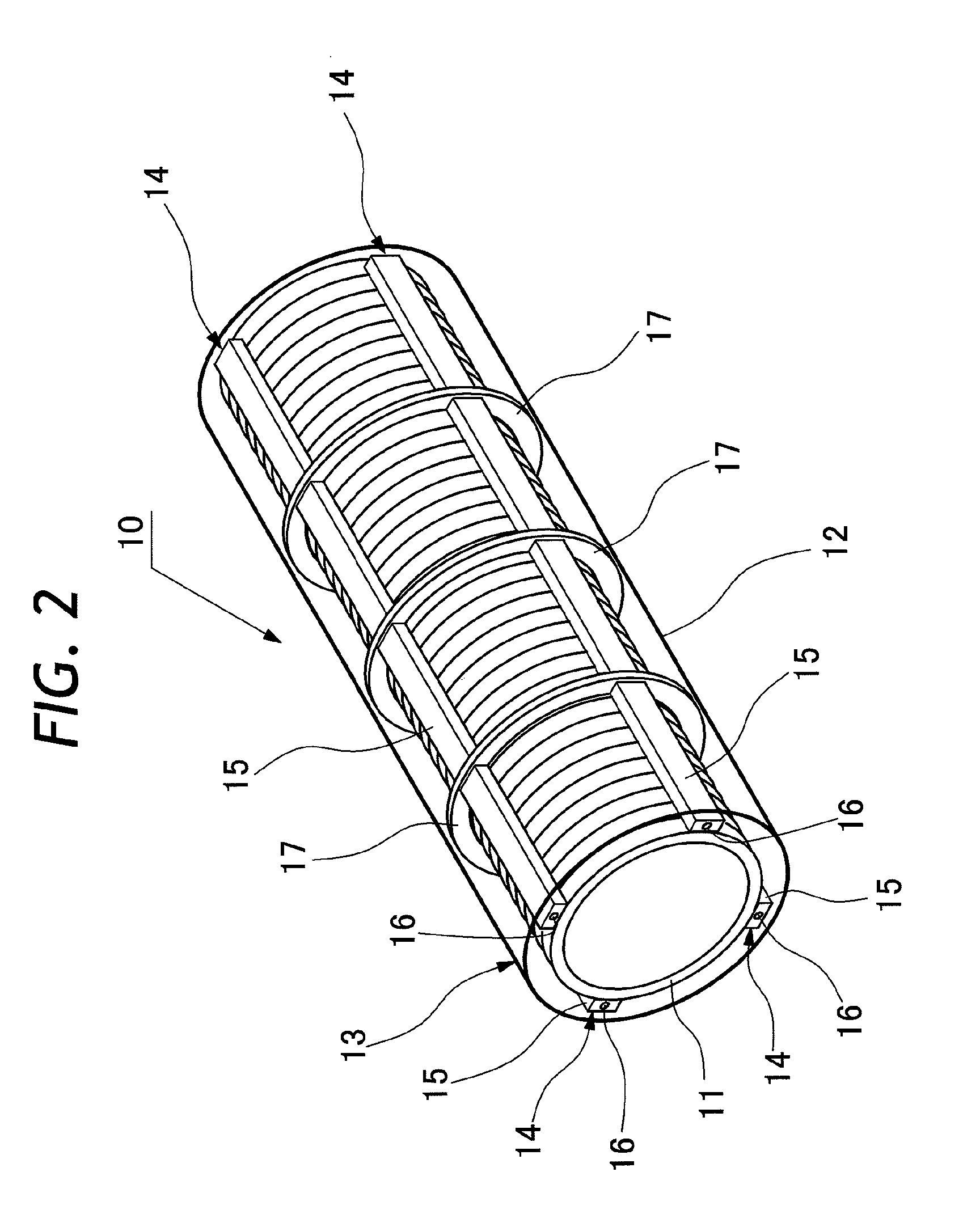

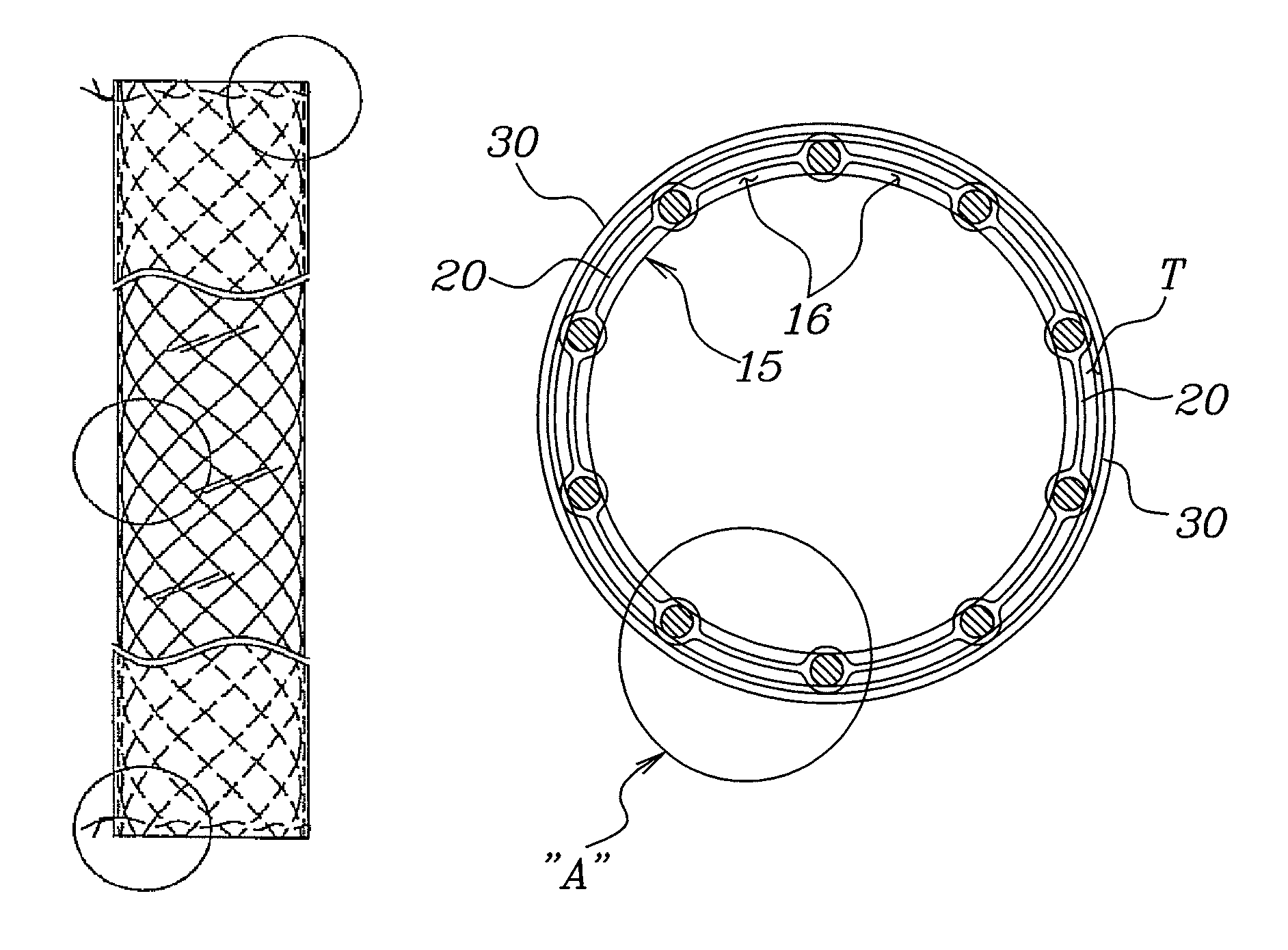

Guide tube for guiding endoscope or surgical tool in or into body cavity

In order to secure a path of insertion for an insertion rod 2 of an endoscope 1 and for transformation from a flexible structure to a rigid structure, a guide tube is constituted by a flexible double tube 13 having flexible inner and outer tubes 11 and 12 which are flexible in bending directions and fitted one on the other to define a hermetically closed space therebetween. Muscle members 14, each composed of a friction strip 15 and attached with a metal wire 16, are provided at predetermined angular positions between the inner and outer tubes. Dislodgements of the muscle members 14 from the respective angular positions are prevented by restraint rings 17. A suction tube 18 of a pump unit 19 is connected to the double tube 13 to evacuate a fluid from the closed space between the inner and outer tubes 11 and 12.

Owner:FUJIFILM CORP

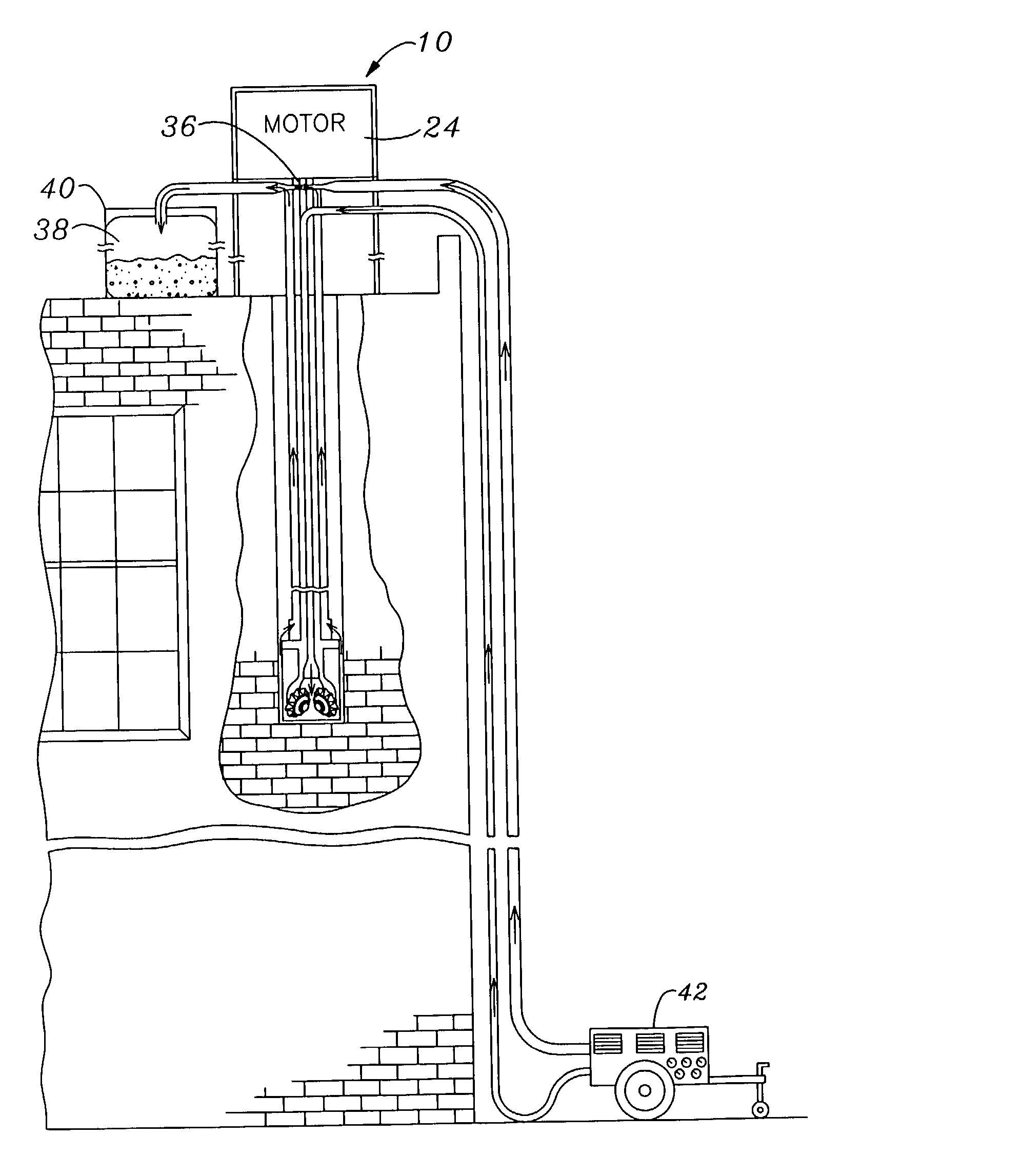

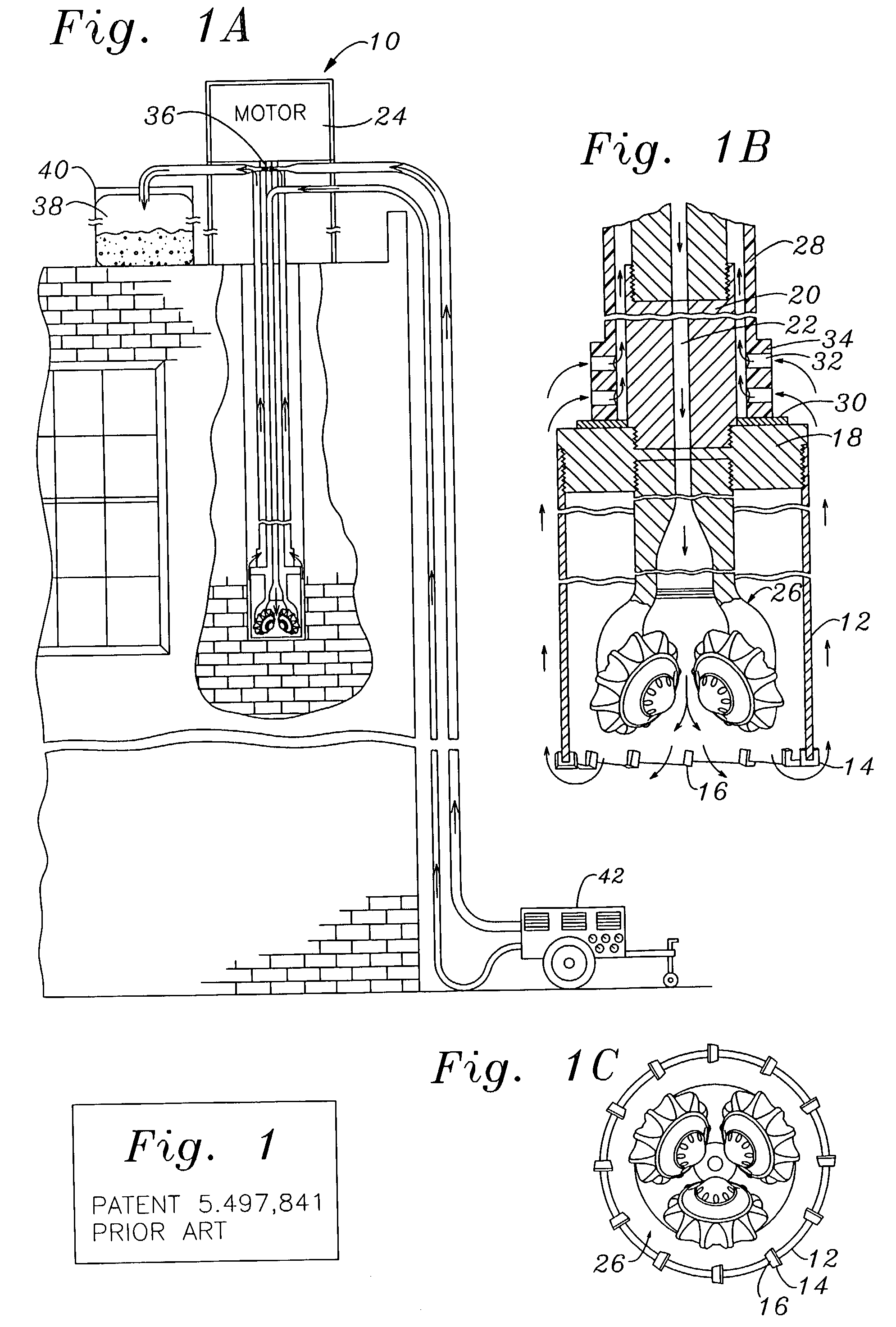

Advanced processes for coring and grouting masonry

Advanced masonry coring systems for coring and grouting masonry walls are disclosed in this patent. The systems include rotating machinery and a drill column in the form of a cylindrical double-piped string of pipe sections, rotating a cylindrical drill body. The drill body mounts cutting end faces having alternative means of employing carbide or diamond cutting and / or pulverizing elements. The double drill pipe weight is made workable through new aerospace composite fabrication. The double pipe permits more efficient routing of air and removal of drill cuttings. Advancement in various system components and means of placing reinforcement into walls is disclosed. Further disclosure is included of advanced means of optimizing resin grouting materials and procedures to fill the wall cavities created by the core drill, integrating the reinforcement into the walls.

Owner:MOHLENHOFF WILLIAM

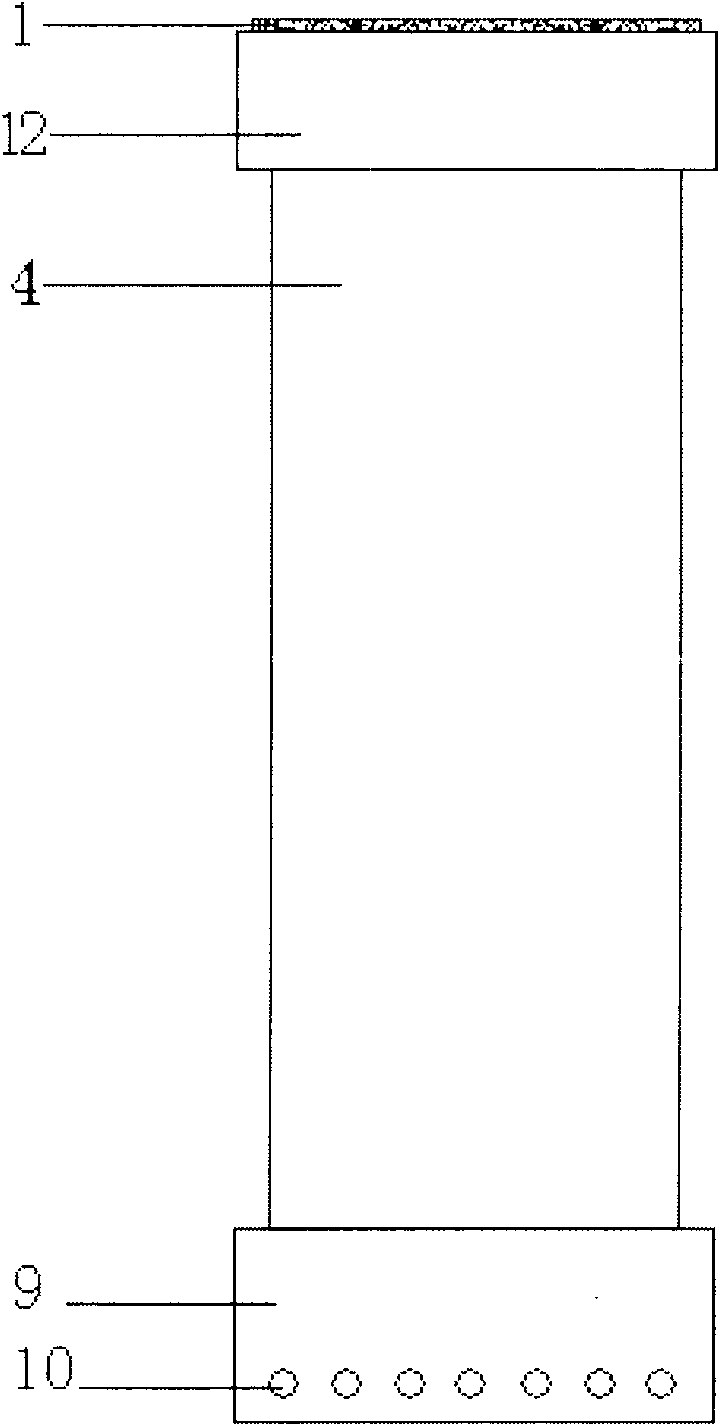

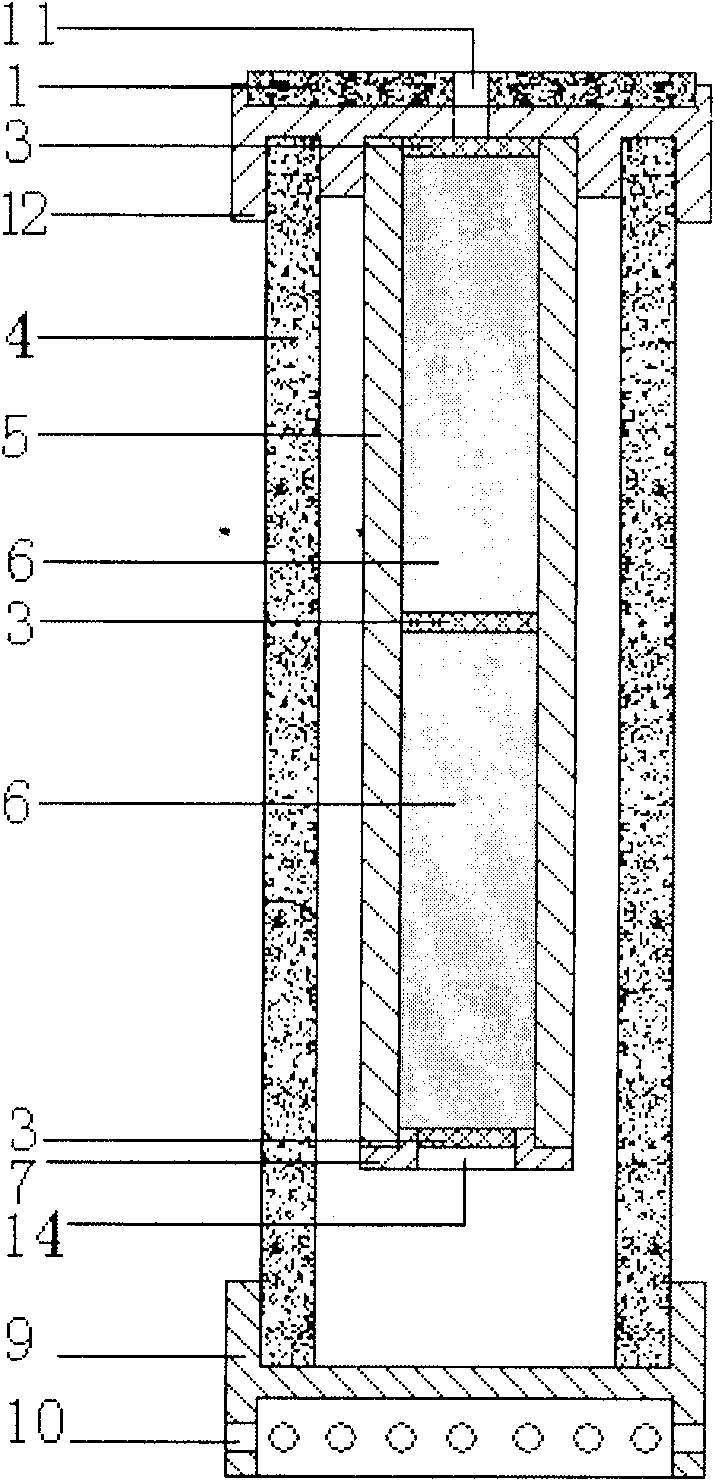

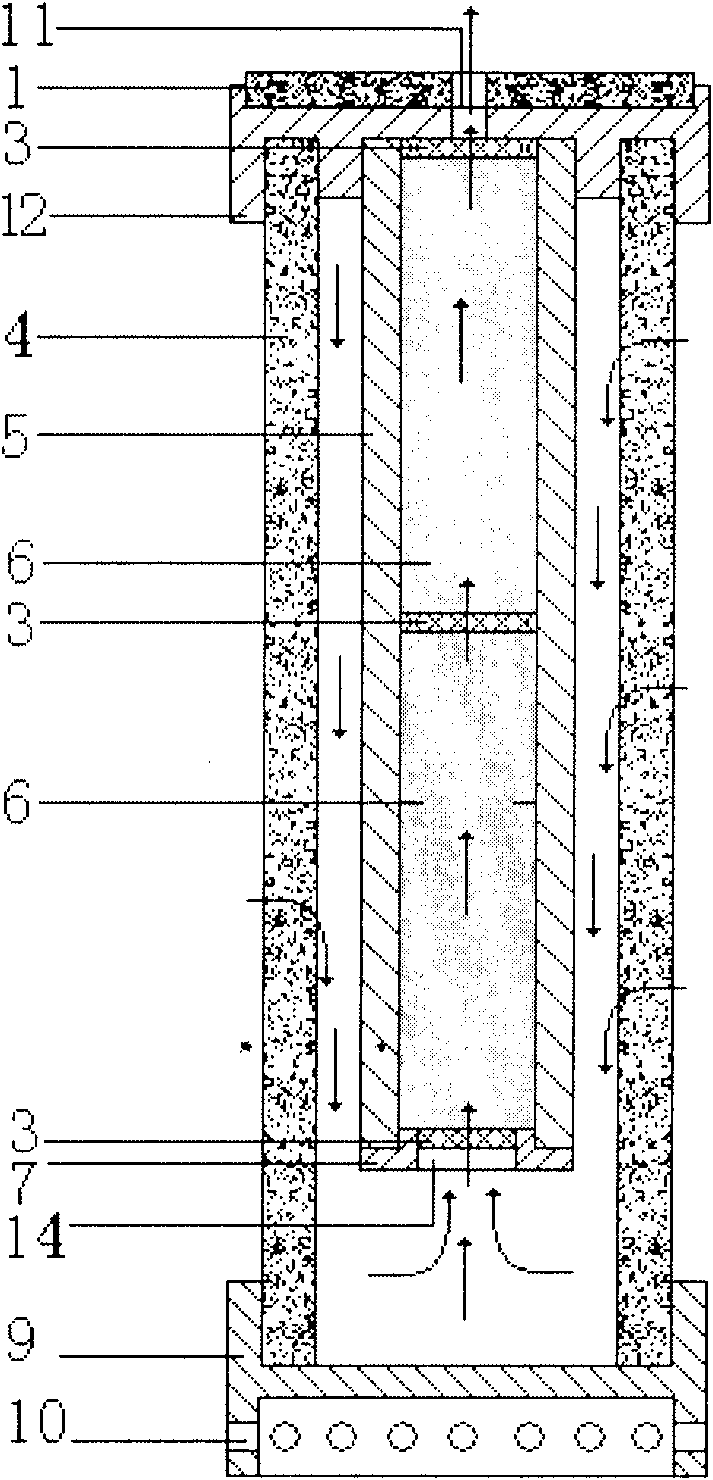

Double-tube combined filter element

InactiveCN101584949ASimple structureLow costStationary filtering element filtersDouble tubeWater flow

The present invention relates to a table-water purification technology field, especially a double-tube combined filter element, including an outer filtering layer, an inner tube, a lower cover of the inner tube, a special filtering material, an top cover of the outer filtering layer, a lower cover of the outer filtering layer and an insulation net. The advantage of the invention is that the double-tube combined filter element is small-sized, simple, convenient and practical. The double-tube combined filter element has same filtrating water stream paths, a simple structure and a low cost, and is capable of achieving a safe and stable water treatment effect.

Owner:庞剑

Heat pump liquid heater

InactiveUS7543456B2Evaporators/condensersCombined heat and power systemsPlate heat exchangerRefrigerant reclamation

Owner:AIRGENERATE LLC

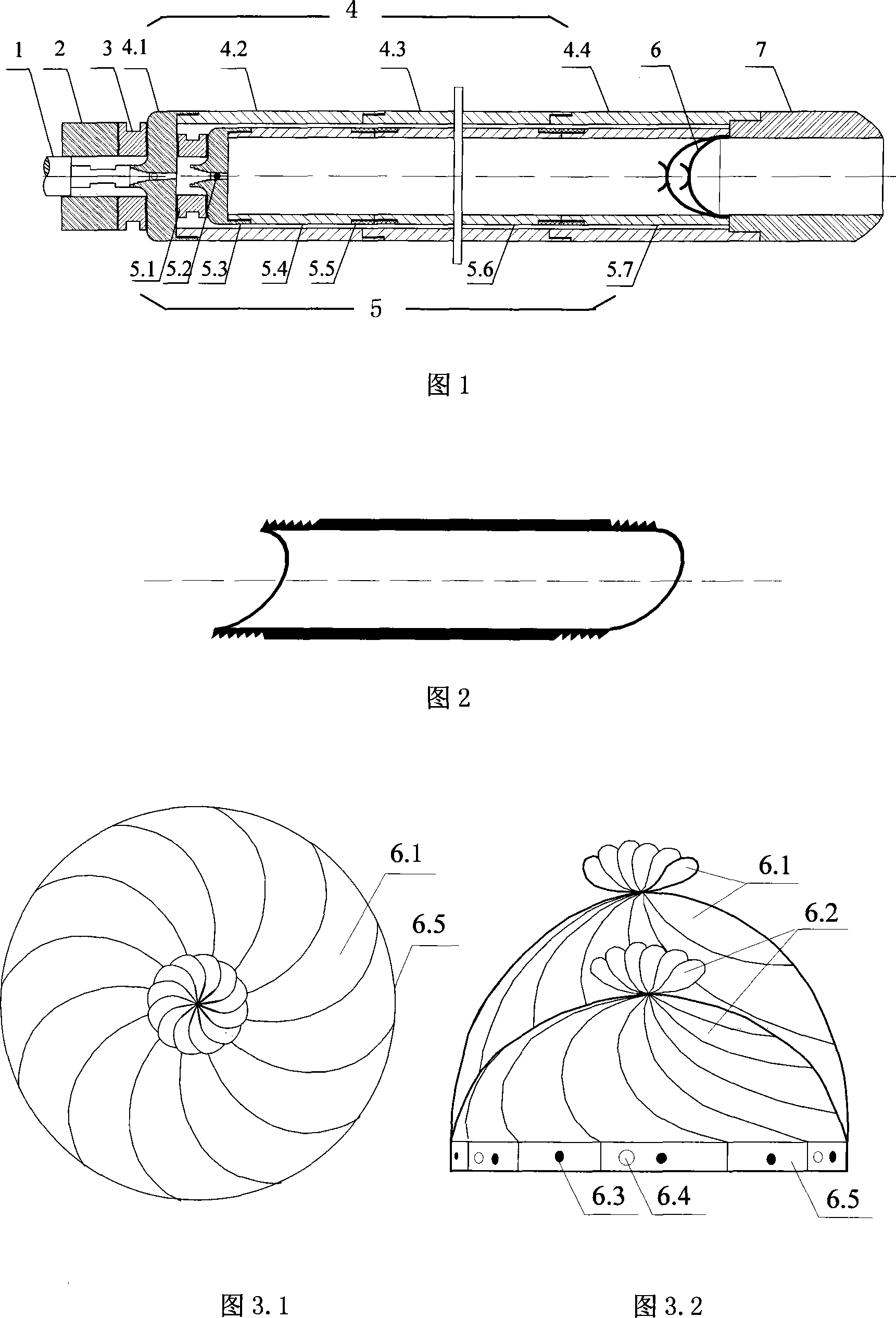

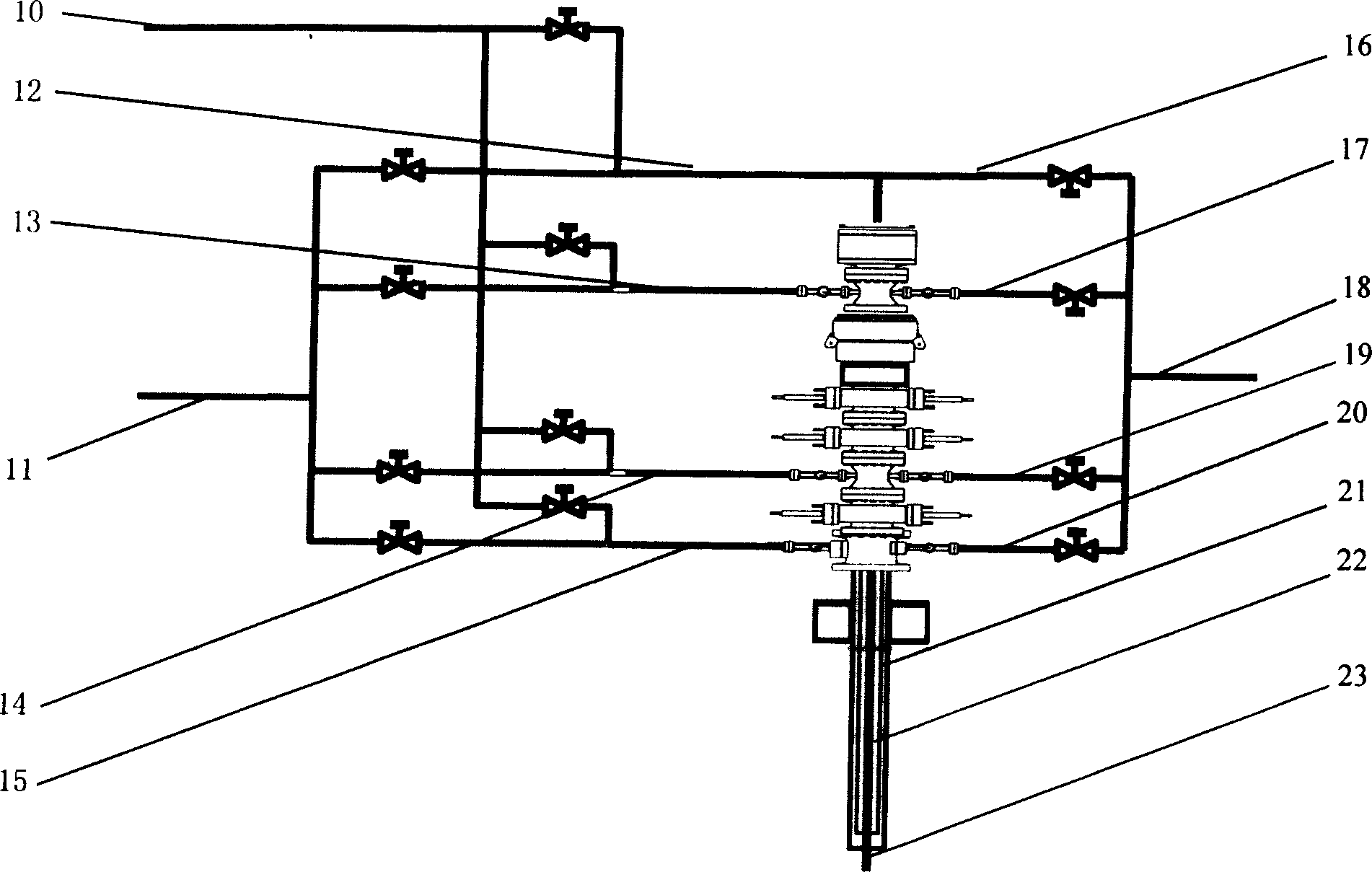

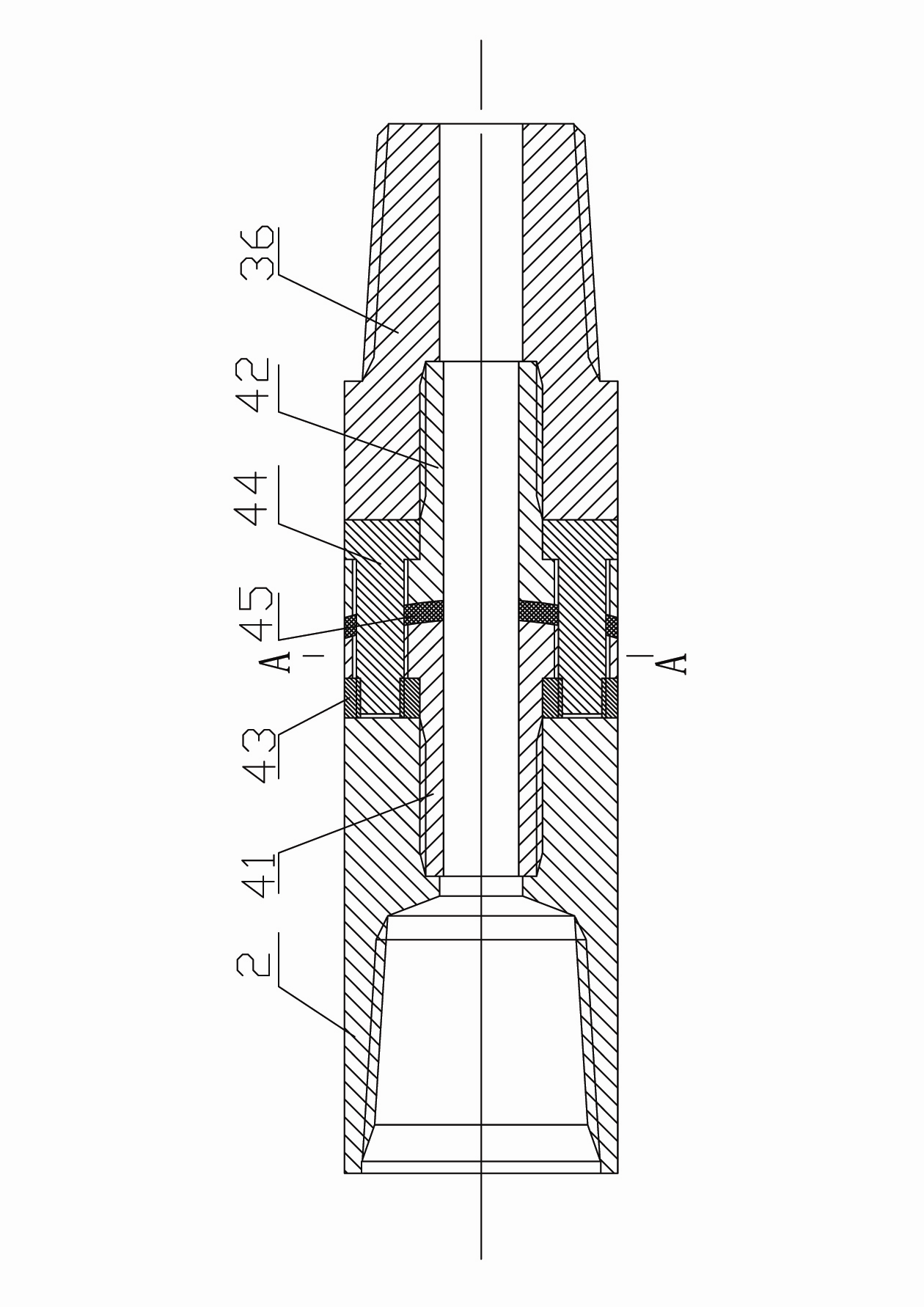

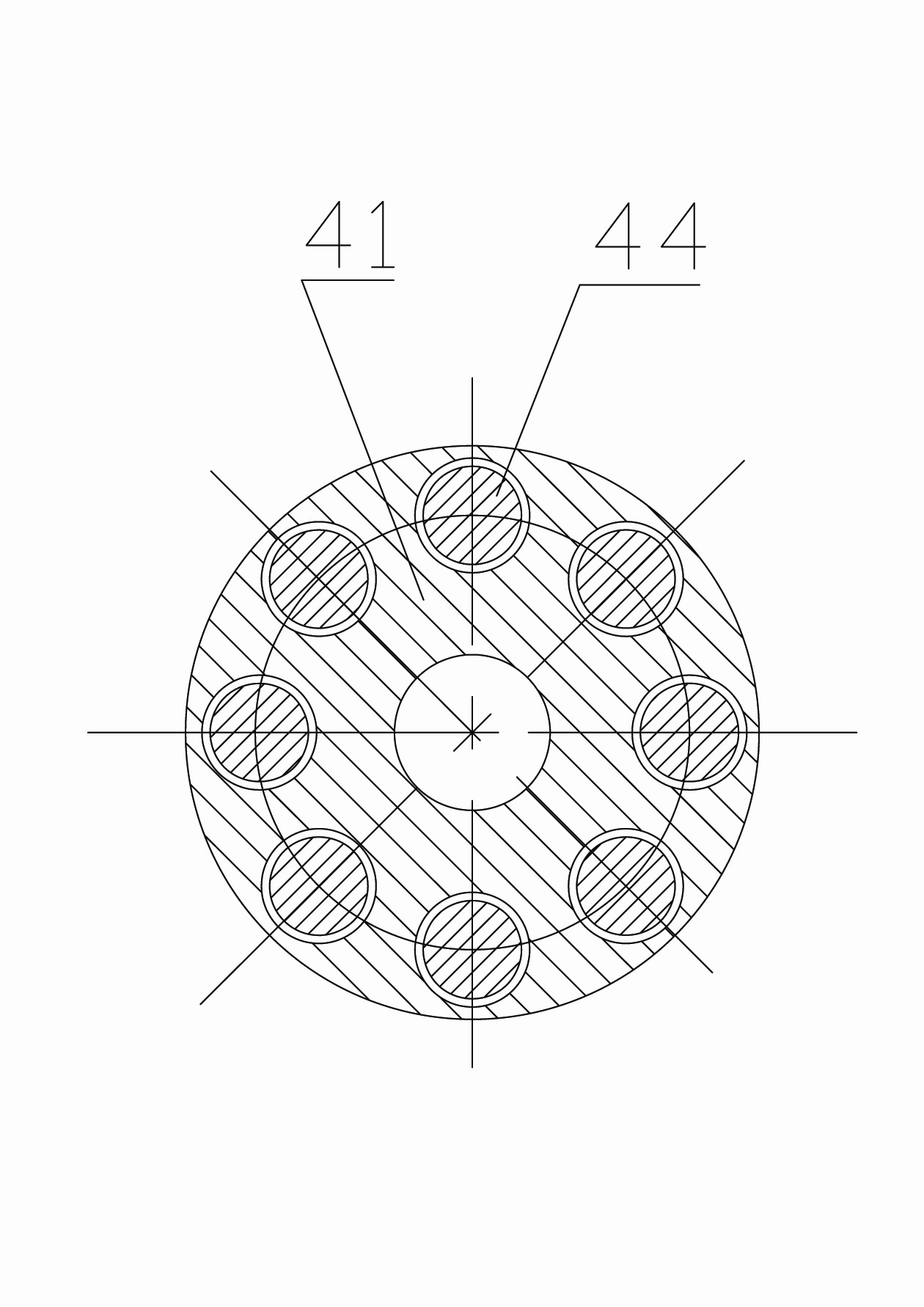

Impact type double tube double-motion coring device and its method

The invention particularly relates to an impulse type double-pipe double-acting core taking device and a method, which relates to a technique for geotechnical engineering to survey loose ground layer and sample. The structure of the device is that the upper end of a guide rod (1) is connected with a drill rod of a drilling machine, the lower end of the guide rod (1) is connected with an outer cannula (4) after passing through a cross-core jump bit (2) and an impacting disc (3) in turn, the lower end of the outer cannula (4) is connected with an impacting drill head (7), the cross-core jump bit (2) is connected with an automatic hammer dropping device of a hoisting rope of the drilling machine, which is arranged on the impacting disc (3), the inner wall of the outer cannula (4) is provided with a sampling inner pipe (5), the lower end of the sampling inner pipe (5) is connected with a double-layer loose-leaf flap spring plate (6). The impulse type double-pipe double-acting core taking device not only has obvious advantages to invest and sample under complex ground layer loose condition, which can also be used to do geological investigation and sample for the field such as underwater, sea engineering and the like.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

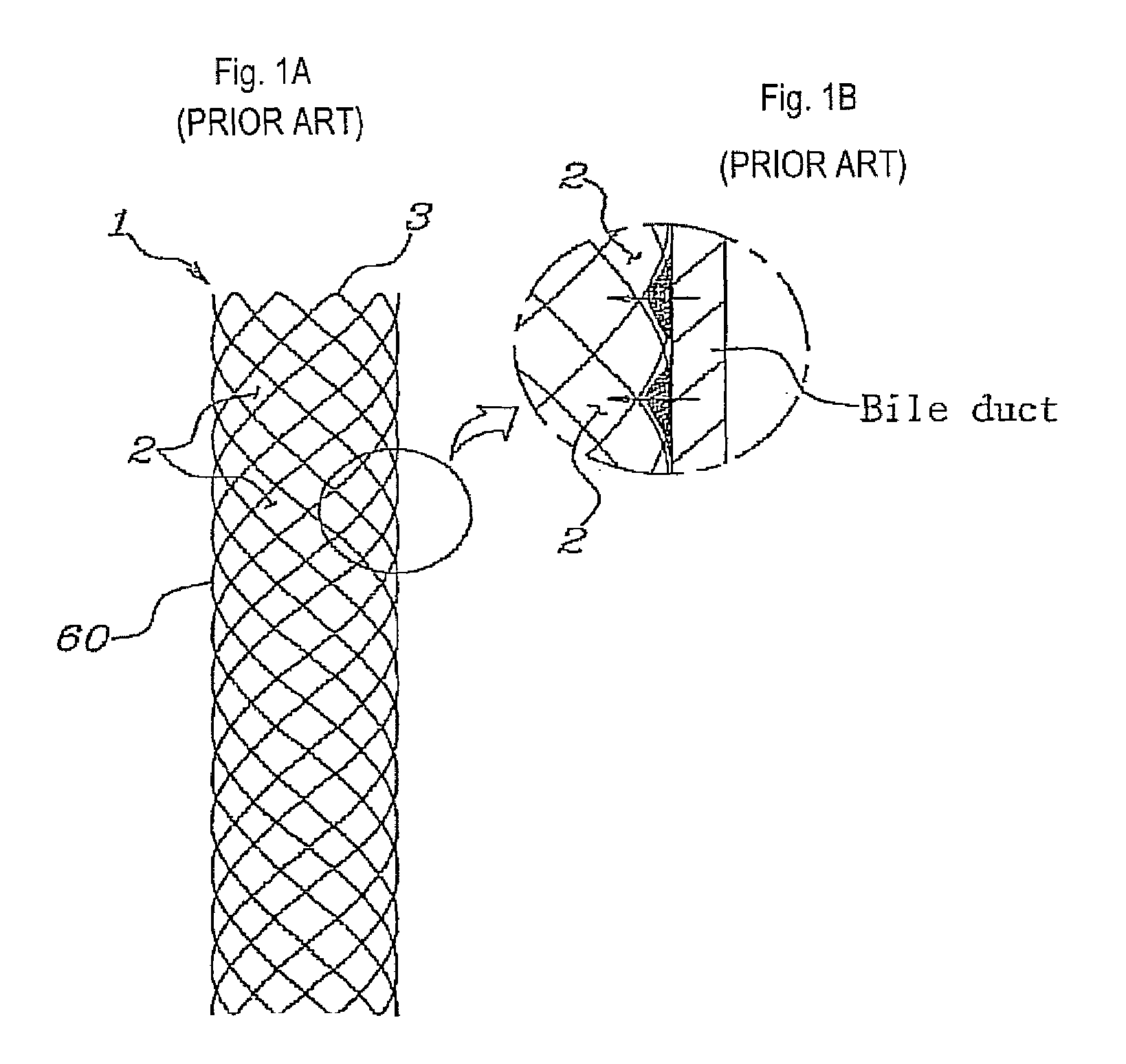

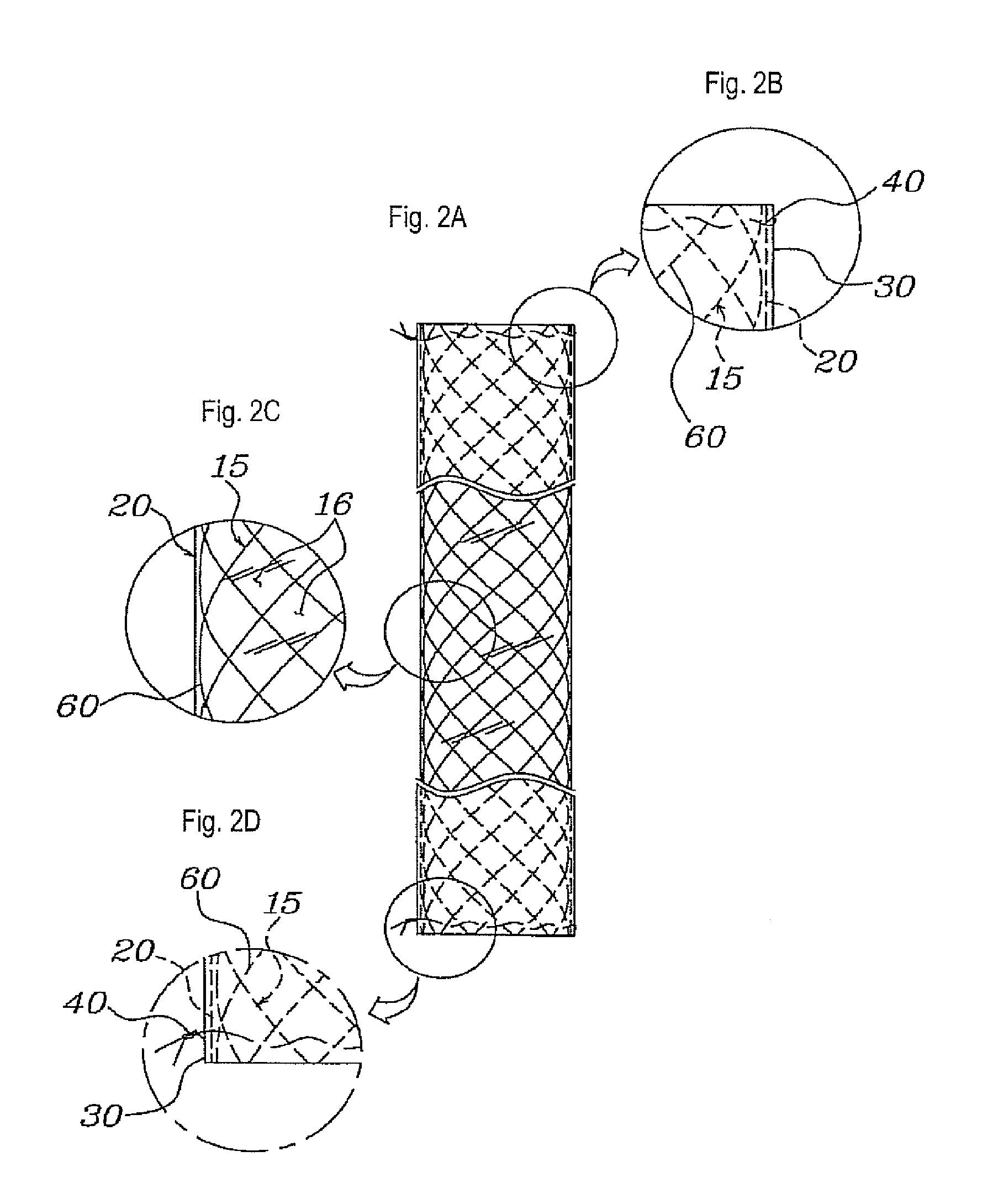

Double-tube type stent

A double-tube type stent is inserted into a hollow tubular organ such as a bile duct so as to relieve narrowing of the bile duct on, for instance, an anastomotic area of the intrahepatic bile duct of a liver transplant patient. A hollow cylindrical body has a plurality of rhombic spaces formed by weaving a superelastic shape-memory-alloy wire so as to be crossed. A silicon coating layer is coated on an outer surface of the cylindrical body using a silicon solution. A polytetrafluoroethylene (PTFE) tube is fixedly fitted around the cylindrical body having the silicon coating layer leaving a gap therebetween.

Owner:TAEWOONG MEDICAL CO LTD

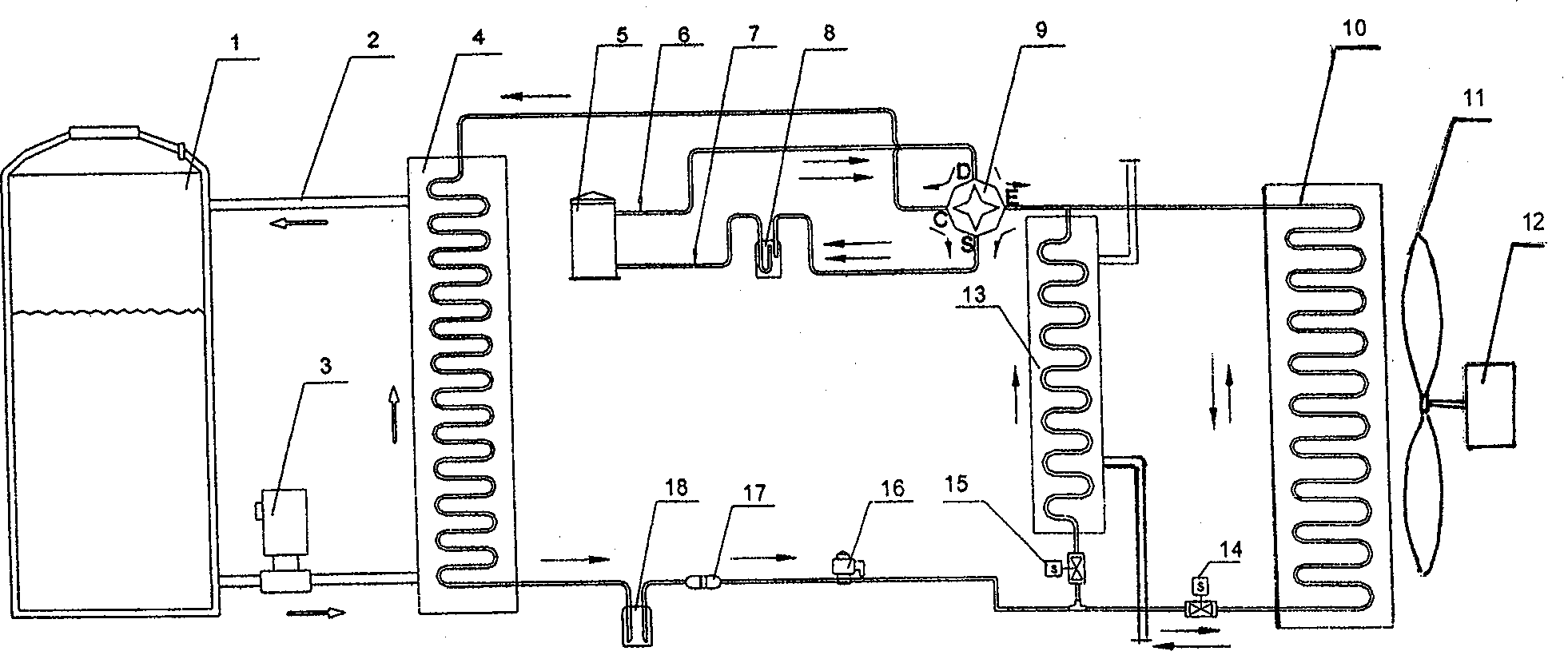

Double-heat source heat pump water heater with air source and water source

ActiveCN101476774AIncrease the COP valueAchieve water supplyFluid heatersHeat pumpsFour-way valveDouble tube

The invention discloses an air-water dual heat source heat pump water heater, which comprises a main machine, a heat-storage and preservation water tank, a controller, an environment temperature controller, a coil temperature sensor, a water tank temperature sensor, a high-water-level switch, a low-water-level switch, a target-flow switch, a water inflow electromagnetic valve, a circulating water pump, a compressor, a motor, an electronic expansion valve, a double-pipe evaporator circuit electromagnetic valve, a fin tube evaporator circuit electromagnetic valve, a circulating hot water pipe, a tube-in-tube condenser and a four-way valve, wherein the D port of the four-way valve is connected with the exhaust pipe of the compressor through a high-pressure switch, the C port of the four-way valve is connected with the upper part of a tube-in-tube condenser, the S port of the four-way valve is connected with the air intake of the compressor through a vapor liquid separator and a low-pressure switch, the E port of the four-way valve is connected with the upper part of a double-pipe evaporator and the upper part of a fin tube evaporator, and the tube-in-tube condenser forms a water cooled heat exchanger through a liquid container, a filter, the electronic expansion valve, an axial flow fan blade, a motor and the double-tube evaporator and forms a wind cooled heat exchanger through a fin tube evaporator. The water heater can be used for 24 hours each day all the year around in the north of China.

Owner:ZHEJIANG AMA & HIEN TECH

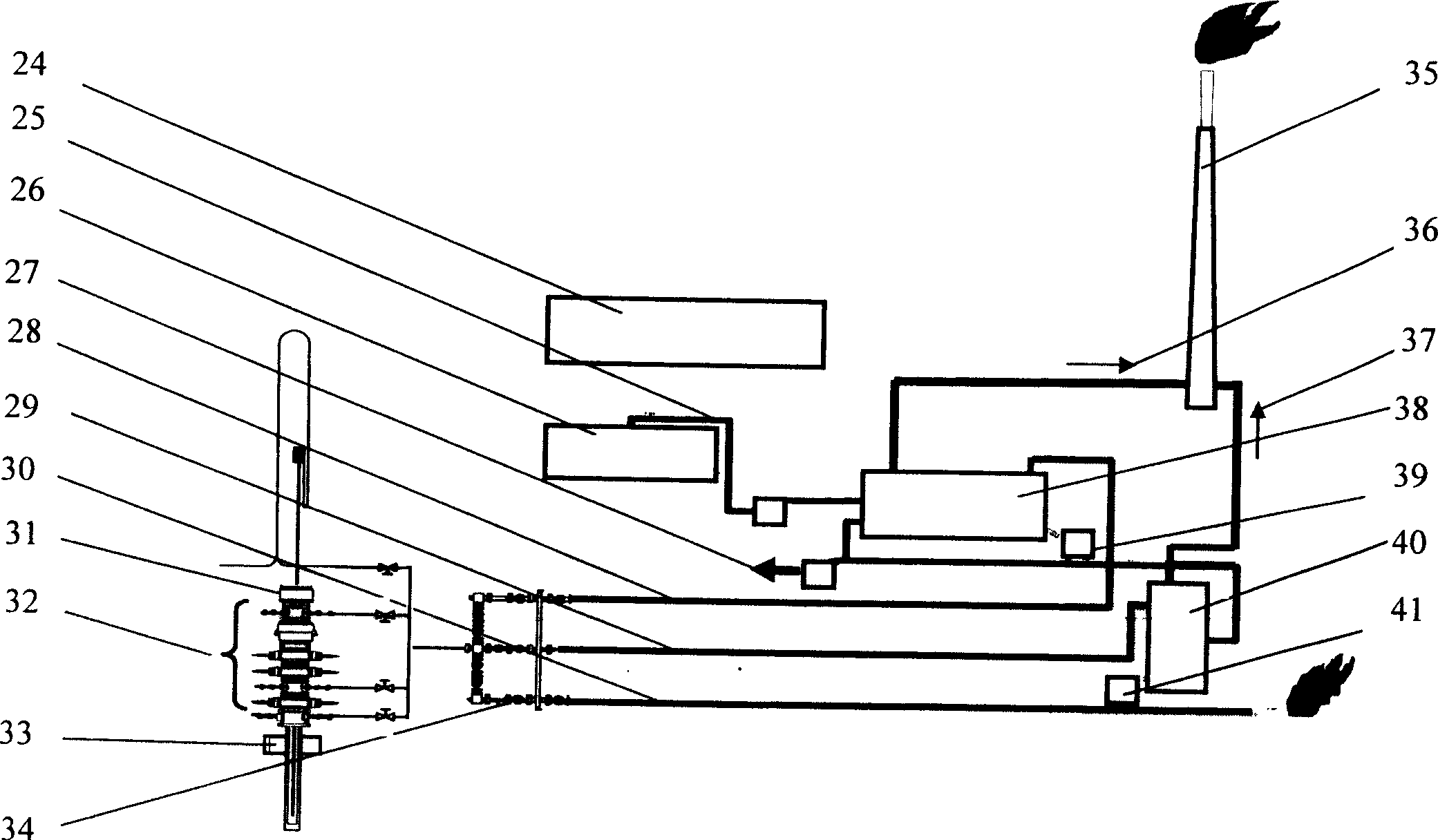

Continuous circulation system for oil and gas well and usage thereof

The invention relates to continuous circulation system that is constituted by multifunction injection system, in well circulation system and ground returning system. The injection system includes drilling fluid that has three densities, two or three mud pumps, and high pressure gas injection device. By the method of injecting two drilling fluids that have different density and fast mixing, or injecting high pressure gas, the in-well liquid column pressure would be adjusted fast and flexibly. The in-well circulation system includes double tube well structure and in-well drilling column, and supplies three flowing channels as the returning channel or injecting channel. The ground returning system includes well head control combination, casing head and gas-liquid-solid separating device. The continuous circulation system is constituted by eight purposes and improves the safety of the well.

Owner:SOUTHWEST PETROLEUM UNIV

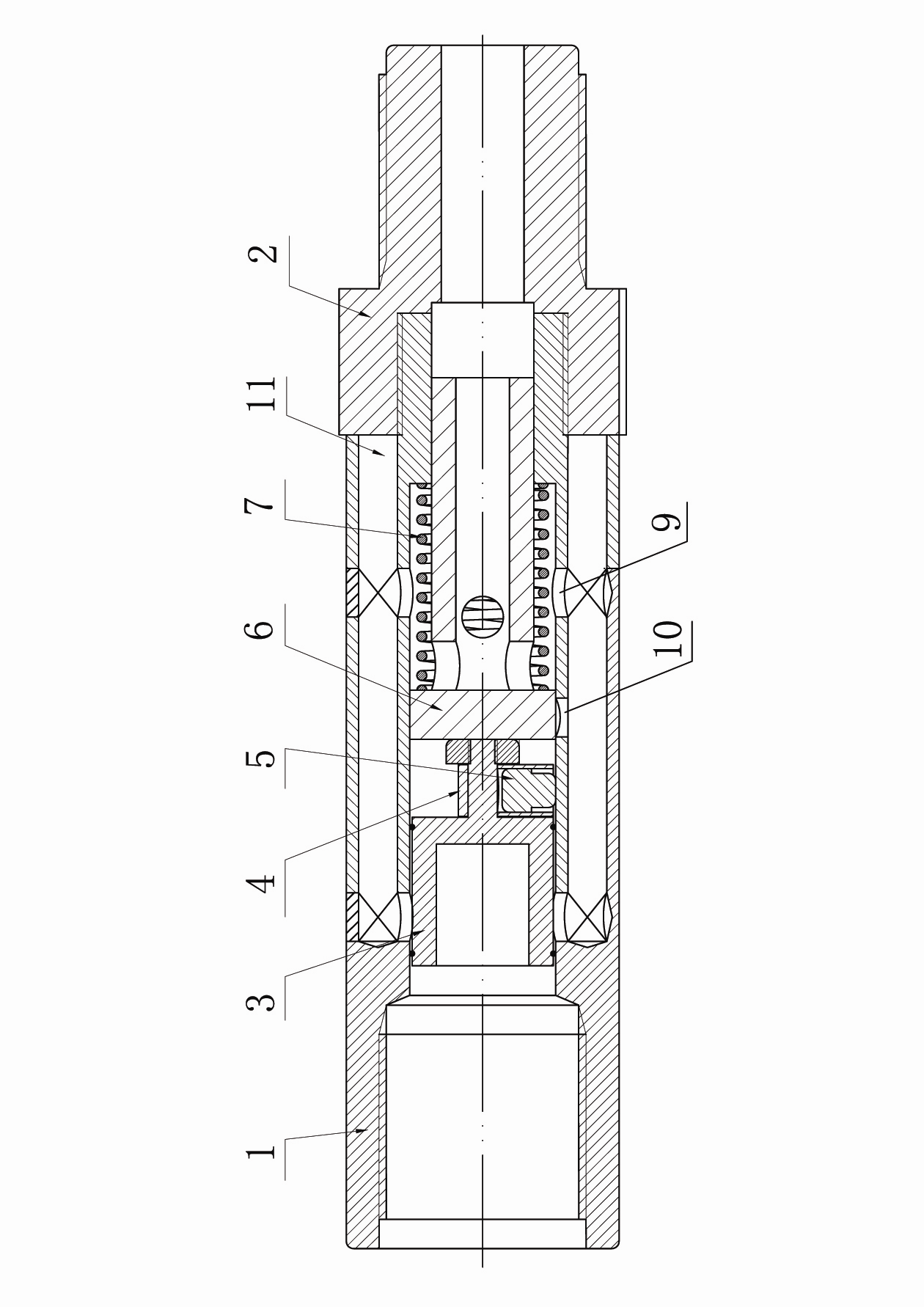

Continuous directional coring and deflecting machine tool with dual tubes for outer guiding and inner drilling and deflecting method thereof

ActiveCN102080503ASolve the technical problems of continuous coring and deflectionSurveyDrilling rodsEngineeringCoring

The invention discloses a continuous directional coring and deflecting machine tool with dual tubes for outer guiding and inner drilling and a deflecting method thereof, which belong to the technical field of continuous directional coring and deflecting. During the drilling in a directional drilling and deflecting segment, a drilling tool group special for continuous directional coring, deflecting and drilling is adopted, and the continuous directional coring, deflecting and drilling is performed by an inner tube coring drilling tool through the directional guiding deflection of an outer tube. The invention well solves the technical difficulty that the traditional domestic directional drilling and deflecting technique cannot perform coring, and provides a utility device and a deflecting method thereof for achieving the full-bore coring during the directional drilling in hydropower investigation projects. Meanwhile, the invention provides a reference for the directional drilling requiring continuous coring and deflecting in other industries of China.

Owner:POWERCHINA ZHONGNAN ENG +1

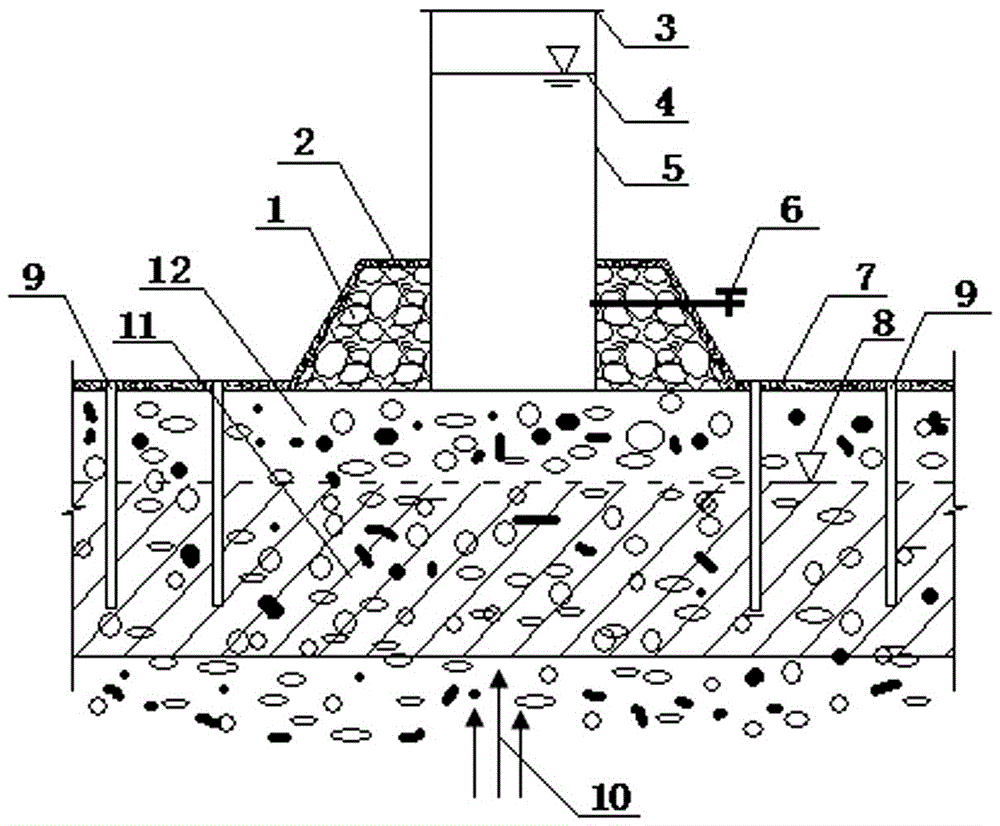

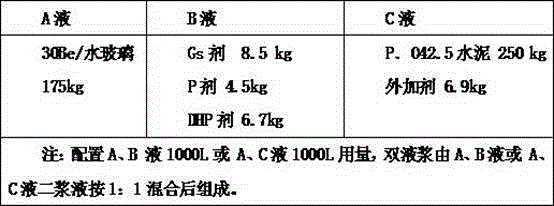

Emergency treatment method for sudden gushing of high confined water stratum foundation pit

ActiveCN105780793AReduce workloadConvenient sourceFoundation engineeringDouble tubeTherapeutic effect

The invention discloses an emergency treatment method for sudden gushing of a high confined water stratum foundation pit. The method is characterized by comprising the steps that the water gushing condition is proved, a steel casing is arranged on the water gushing point in a covering manner to serve as an energy-releasing relief well, a simple back pressure platform is arranged at the bottom of the steel casing, the height of the steel casing should be 1 m above the static water level, water gushing kinetic energy can be guided into the steel casing, then, the water head pressure is released, and the water level in the steel casing depends on the pressure difference to be balanced; and meanwhile, the top face of the casing is sealed, communication of internal gas pressure and external gas pressure of the casing is prevented, the backpressure backfilling sealing grouting condition is simulated, a WSS double-tube non-shrinkage two-fluid grouting technology is adopted for carrying out advancing type segmented grouting, and therefore the aims of rapidly controlling water gushing of the foundation pit and reducing the risks of the foundation pit are achieved. According to the method, the number of emergency treatment materials and machine tools is small, the source is convenient, a construction technology is simple, the workload is small, and the construction cost is low; the emergency treatment time is short, and the dangerous omen can be rapidly controlled; and the method is suitable for treating water gushing of the foundation pit in various foundation pit excavation processes, and is particularly best in sudden gushing treatment effect of the high confined water head stratum foundation pit.

Owner:CHINA CONSTR COMM ENG GRP UNITED

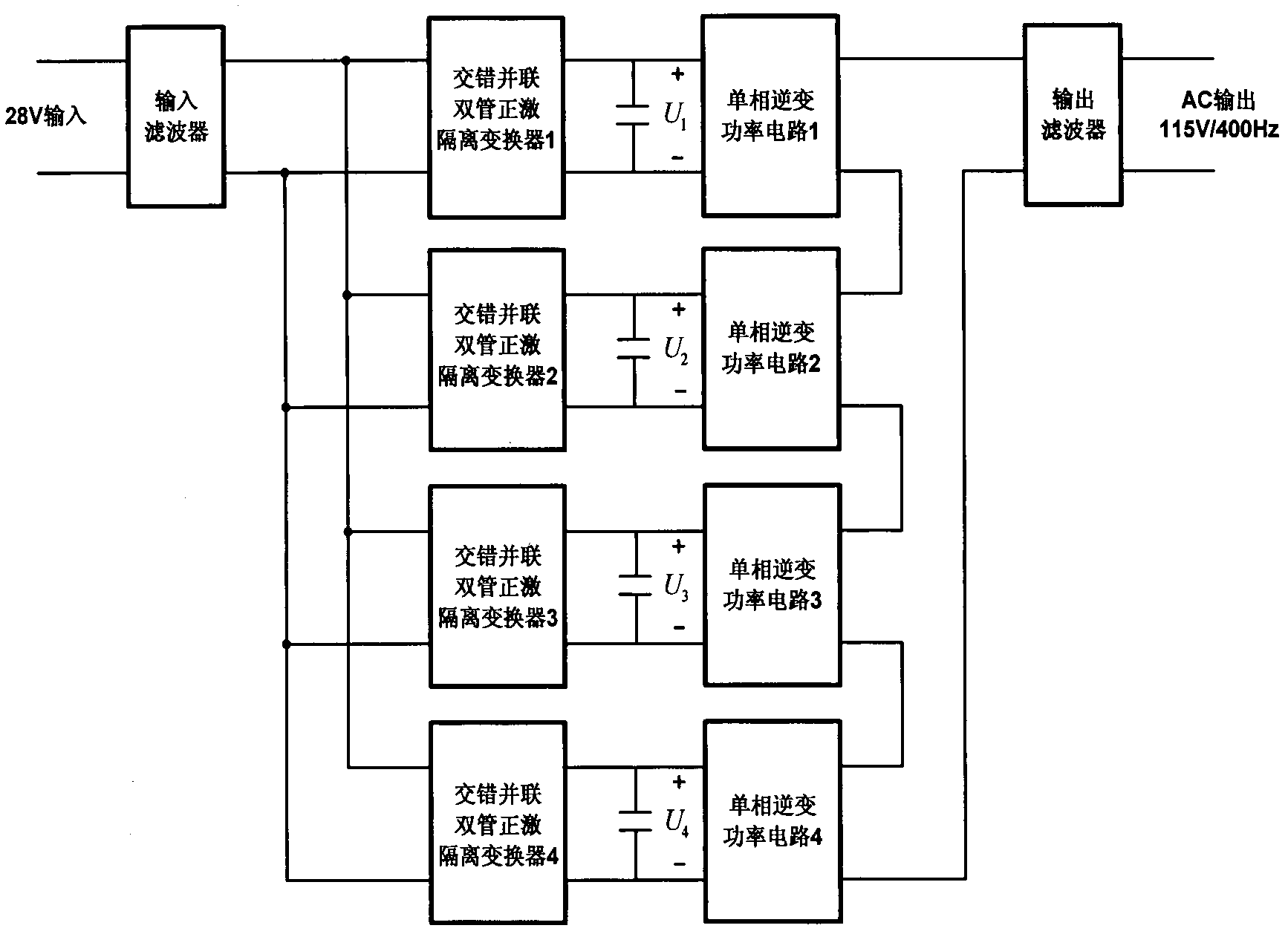

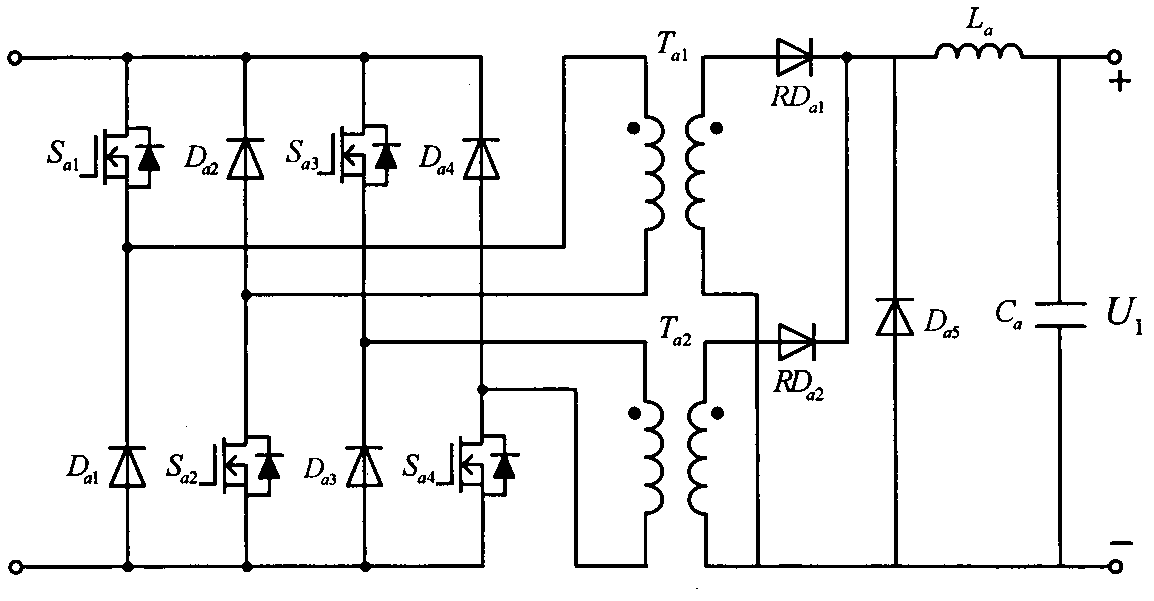

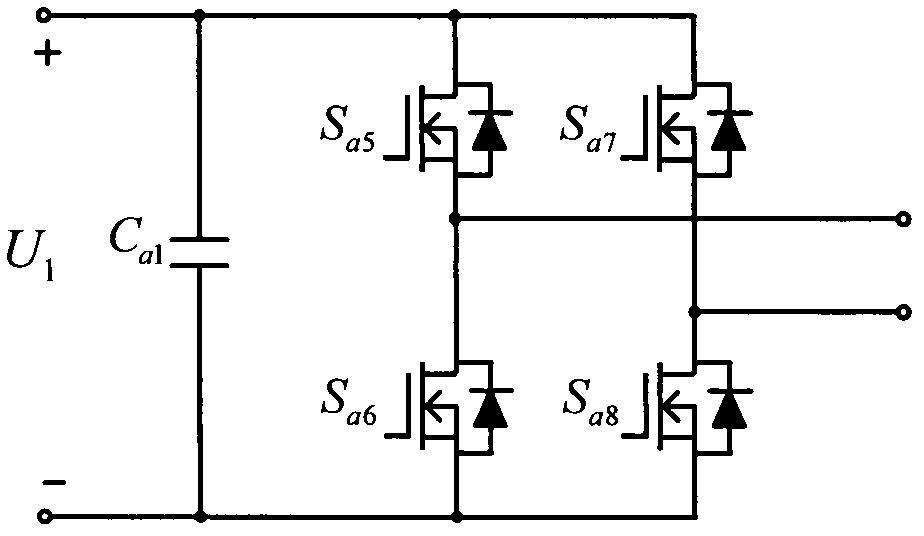

Cascade type time-interval variable-order multi-level static converter

InactiveCN102332839ASimple structureSimple modular structureDc-dc conversionElectric variable regulationDouble tubeTotal harmonic distortion

The invention provides a cascade type time-interval variable-order multi-level static converter, which can be modularized; a previous-stage four-way isolation DC-DC (Direct-Current-Direct-Current) converter (1) is connected to a subsequent-stage four-unit cascade inverter (2); a novel time-interval variable-order multi-level control circuit (3) is connected between the previous stage and the subsequent stage; the converter is characterized in that the previous stage is adopted with four ways of mutually independent, staggered and parallel double-tube forward direct-current converters; the subsequent stage is a cascade structure composed of four single-phase H bridges; a carrier phase-shifting frequency-doubling SPWM (Sinusoidal Pulse Width Modulation) technology is adopted; the time-interval variable-order multi-level control circuit is connected between the previous stage and the subsequent stage; the previous stage of the static converter is beneficial to reducing input current ripple and reducing the volume of a filter; the subsequent stage is low in voltage stress of a power switch device, high in circuit modularization degree and low in loss; and, by means of the time-interval variable-order multi-level control circuit, on the premise of not increasing the number of independent sources of the previous stage, the more level number of output can be realized, and the THD (Total Harmonic Distortion) of the harmonic wave is low.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com