Cascading bidirectional DC-DC converter

A DC-DC and converter technology, applied in the field of cascaded bidirectional DC-DC converters, can solve problems such as restricting applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

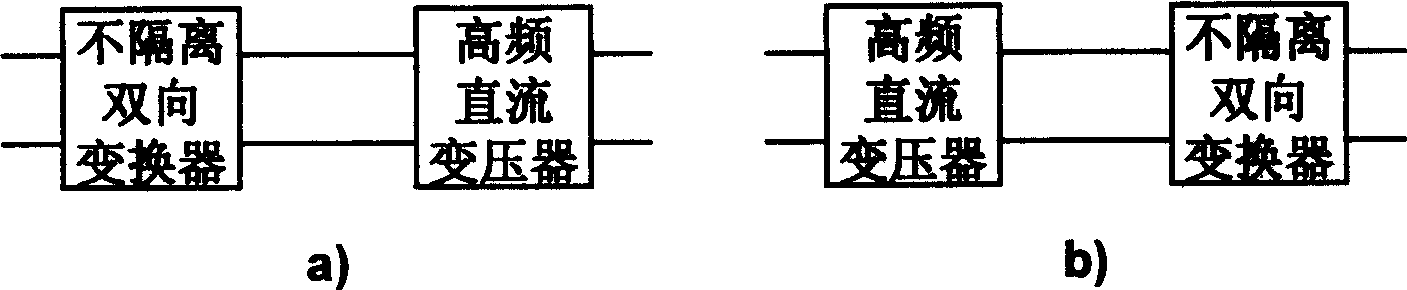

[0022] figure 1 Is the structural block diagram of the cascaded bidirectional DC-DC converter, composed of figure 1 It can be seen that the cascaded bidirectional DC-DC converter is formed by interconnecting a non-isolated bidirectional DC-DC converter and a high-frequency DC transformer. That is, the non-isolated bidirectional converter is cascaded with the high-frequency DC transformer, or conversely, the high-frequency DC transformer is cascaded with the non-isolated bidirectional converter.

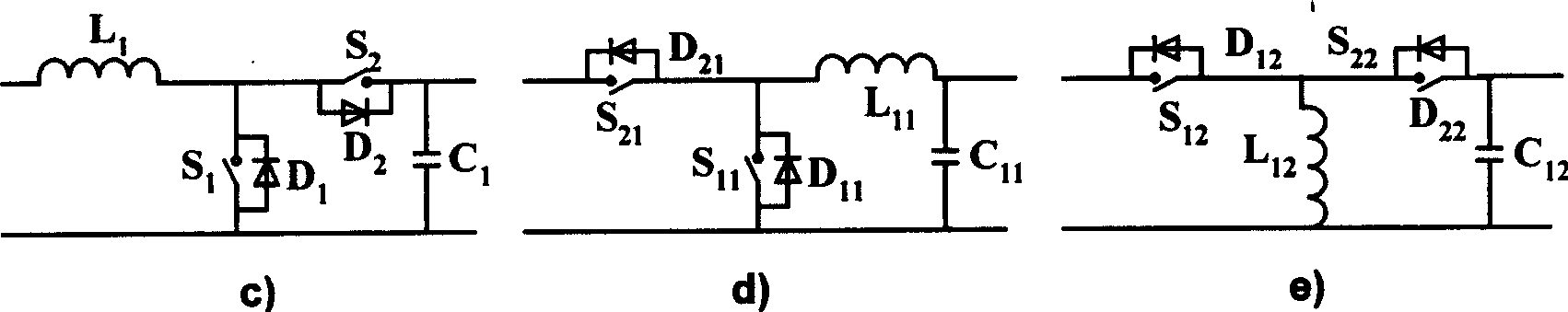

[0023] Non-isolated bidirectional DC-DC converters can be figure 2 The bidirectional boost converter shown in figure (c), the bidirectional buck converter circuit shown in figure (d), and the bidirectional buck-boost converter circuit shown in figure (e) are bidirectional conversion topologies.

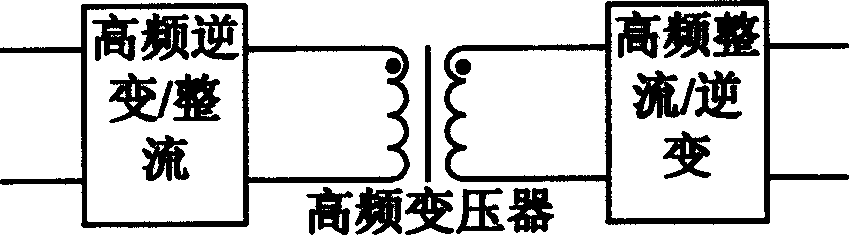

[0024] The composition of high frequency DC transformer is as follows: image 3 As shown, the high-frequency inverter / rectifier circuit is connected to the primary side of the high-freque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com