Patents

Literature

181 results about "Composite fabrication" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

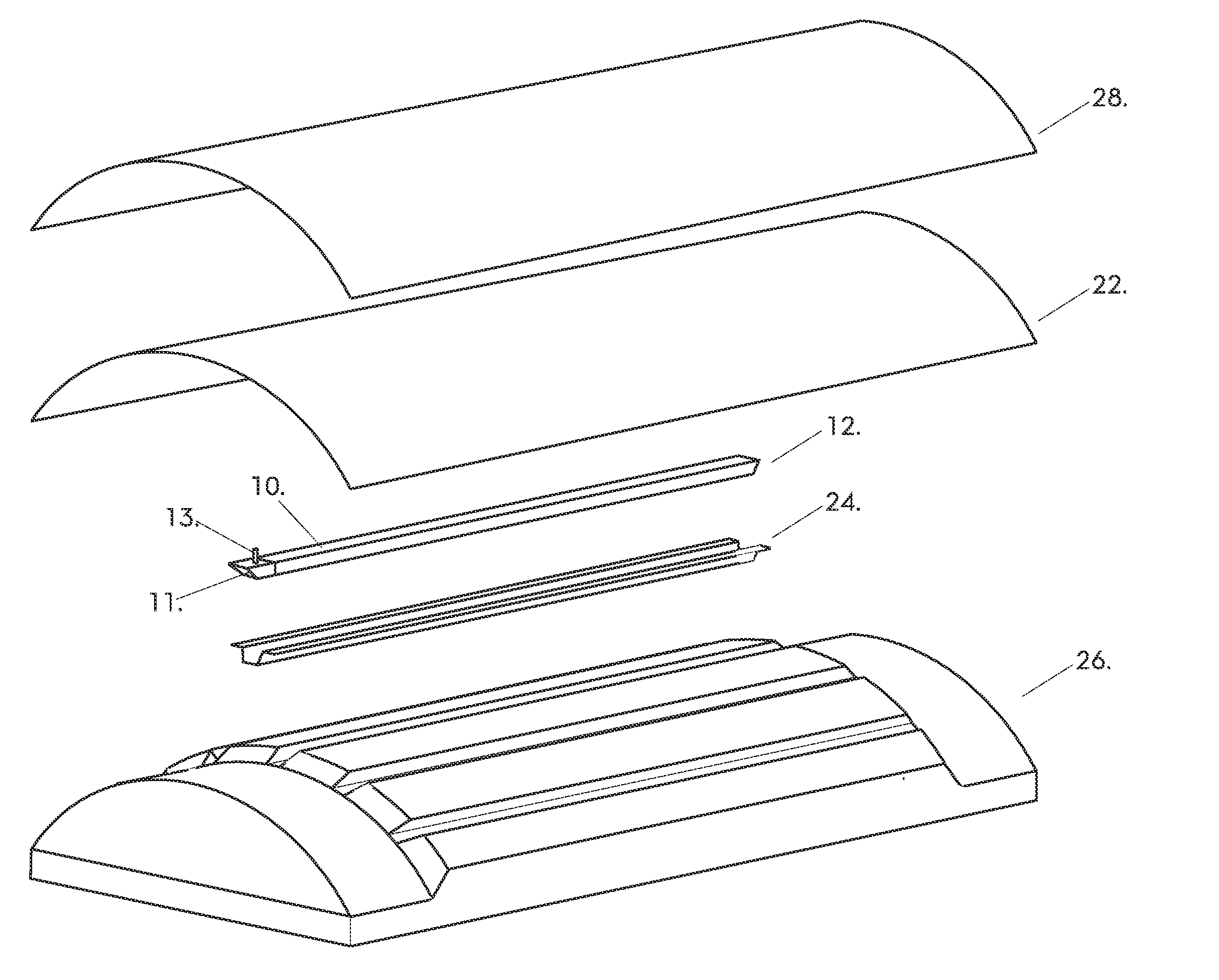

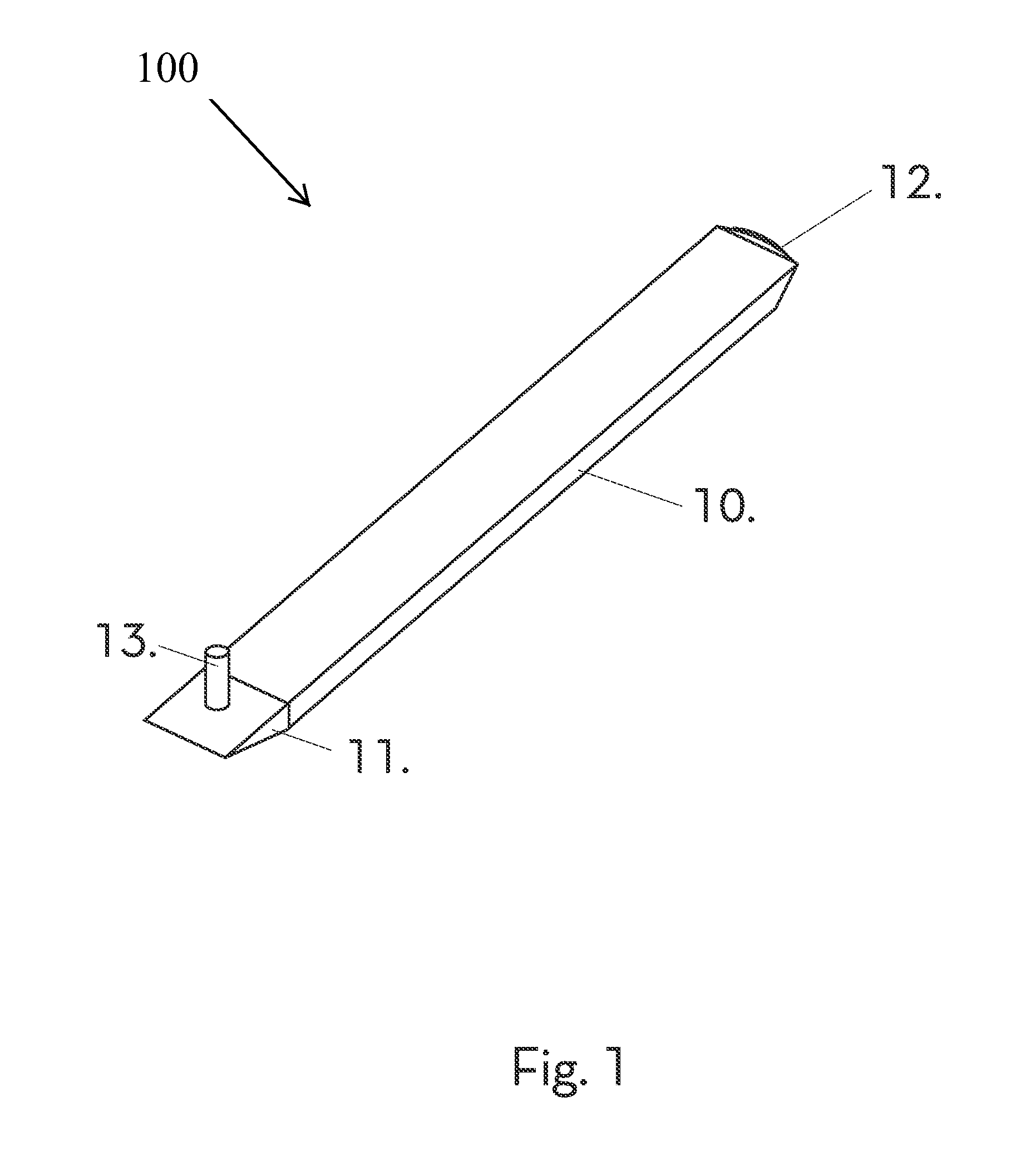

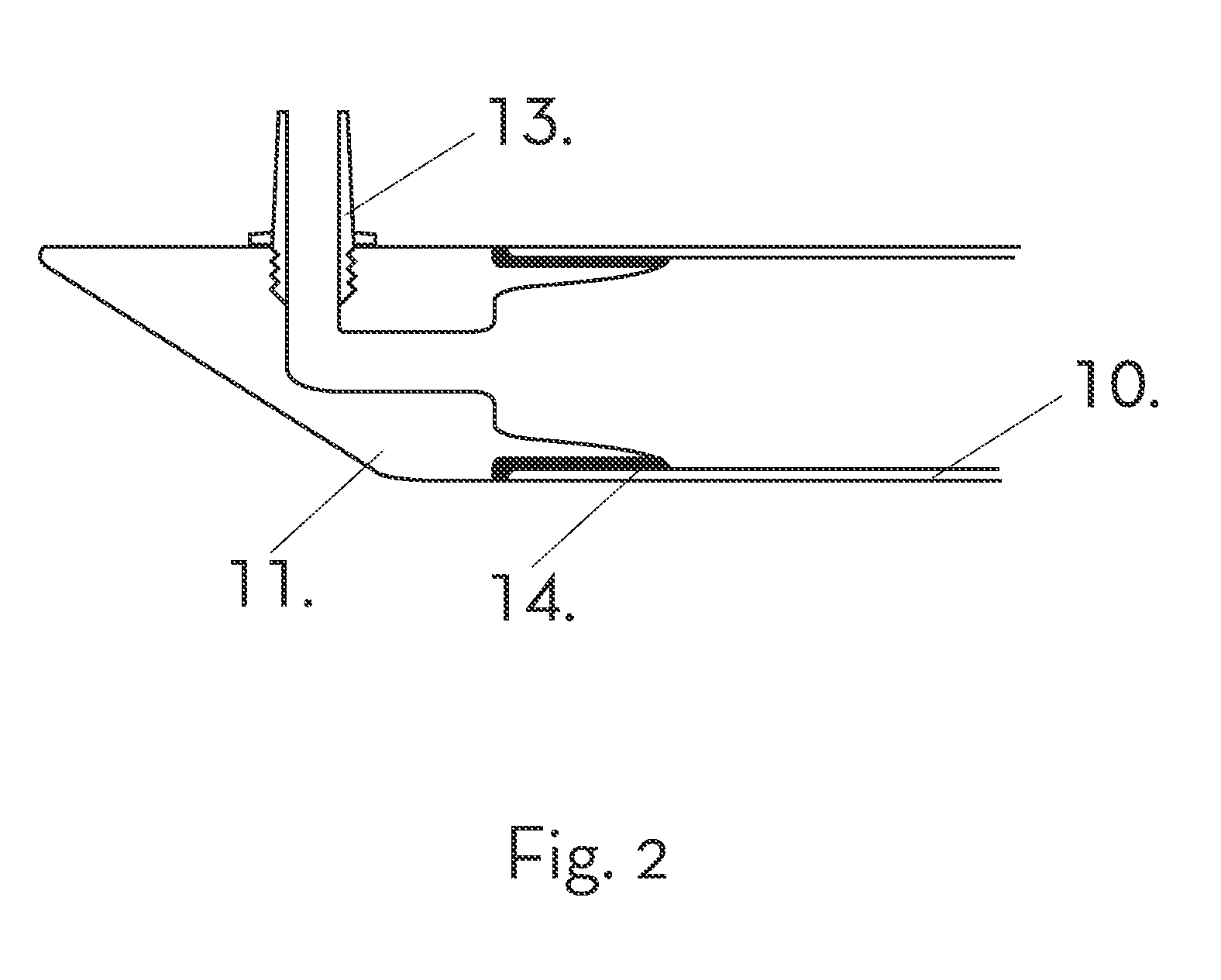

Thermoplastic mandrels for composite fabrication

InactiveUS20100186899A1Hollow filament manufactureFilament/thread formingEngineeringMechanical engineering

A mandrel assembly that includes an elongated hollow structure comprising a thermoplastic material that is extrudable having a first end and a second end. A first end cap attached to the first end. A vent tube attached to the first end cap, the vent tube extending from the first end cap. A second end cap attached to the second end. The mandrel assembly adapted to shape and form a composite structure in or outside an autoclave.

Owner:AIRTECH INT INC

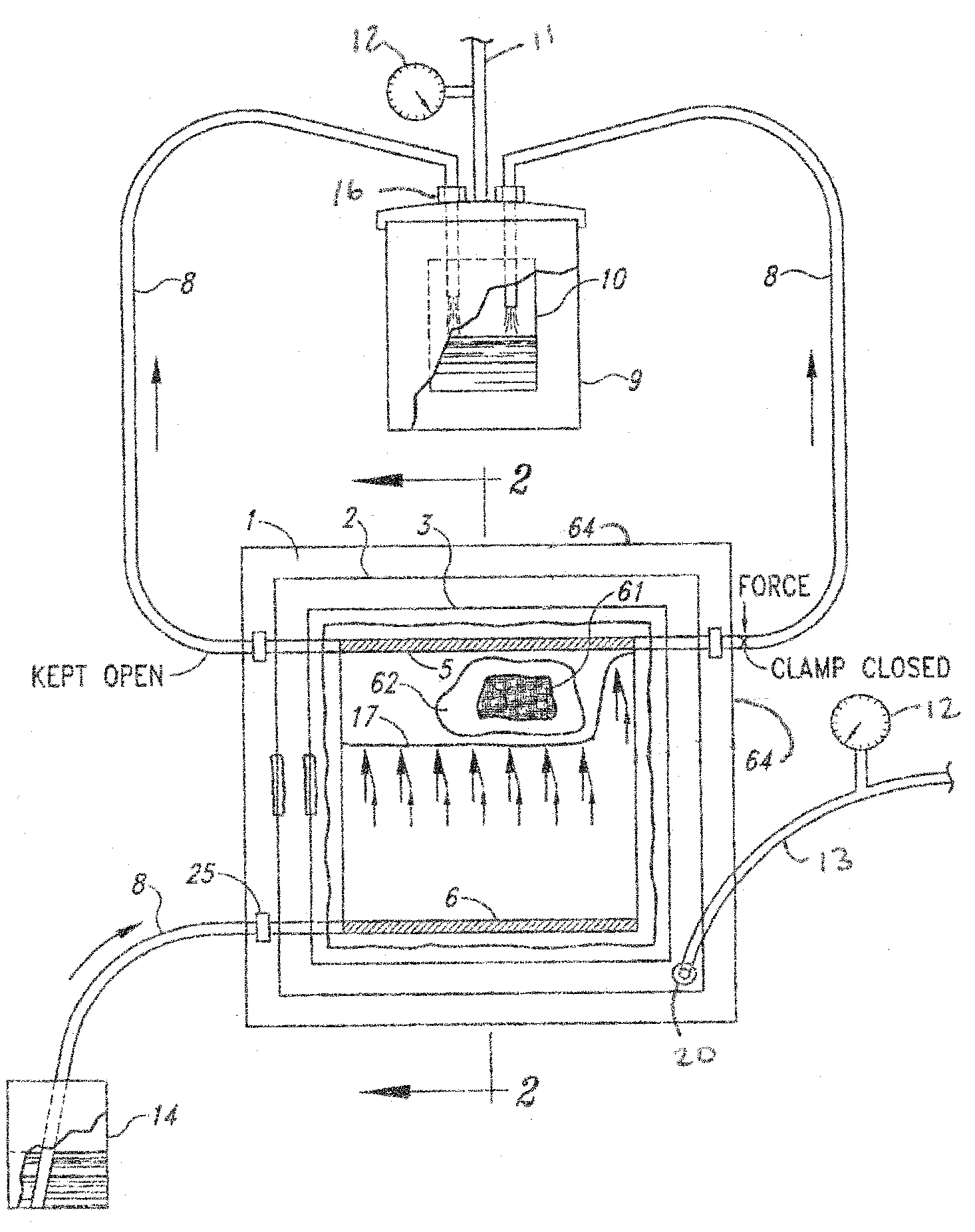

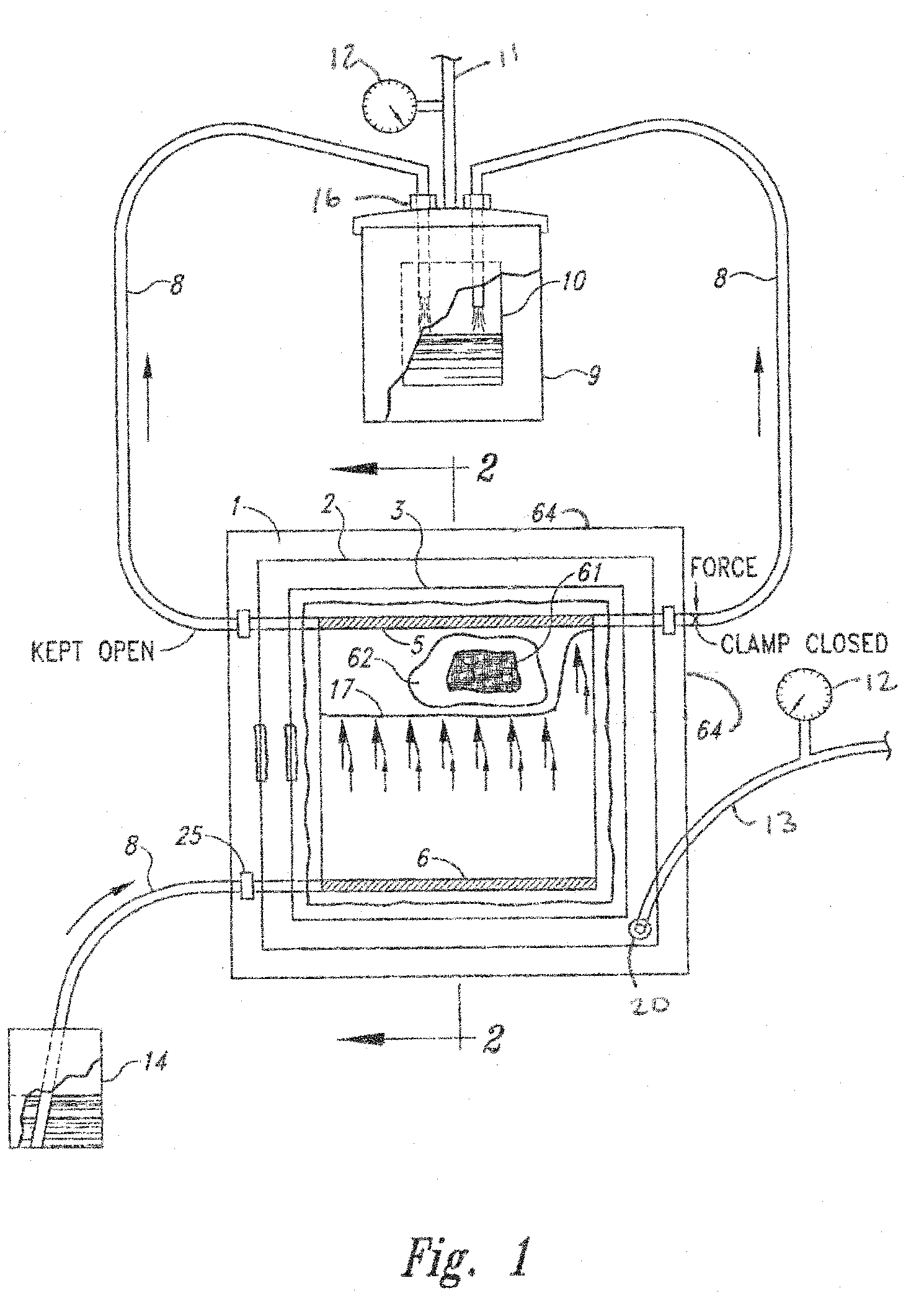

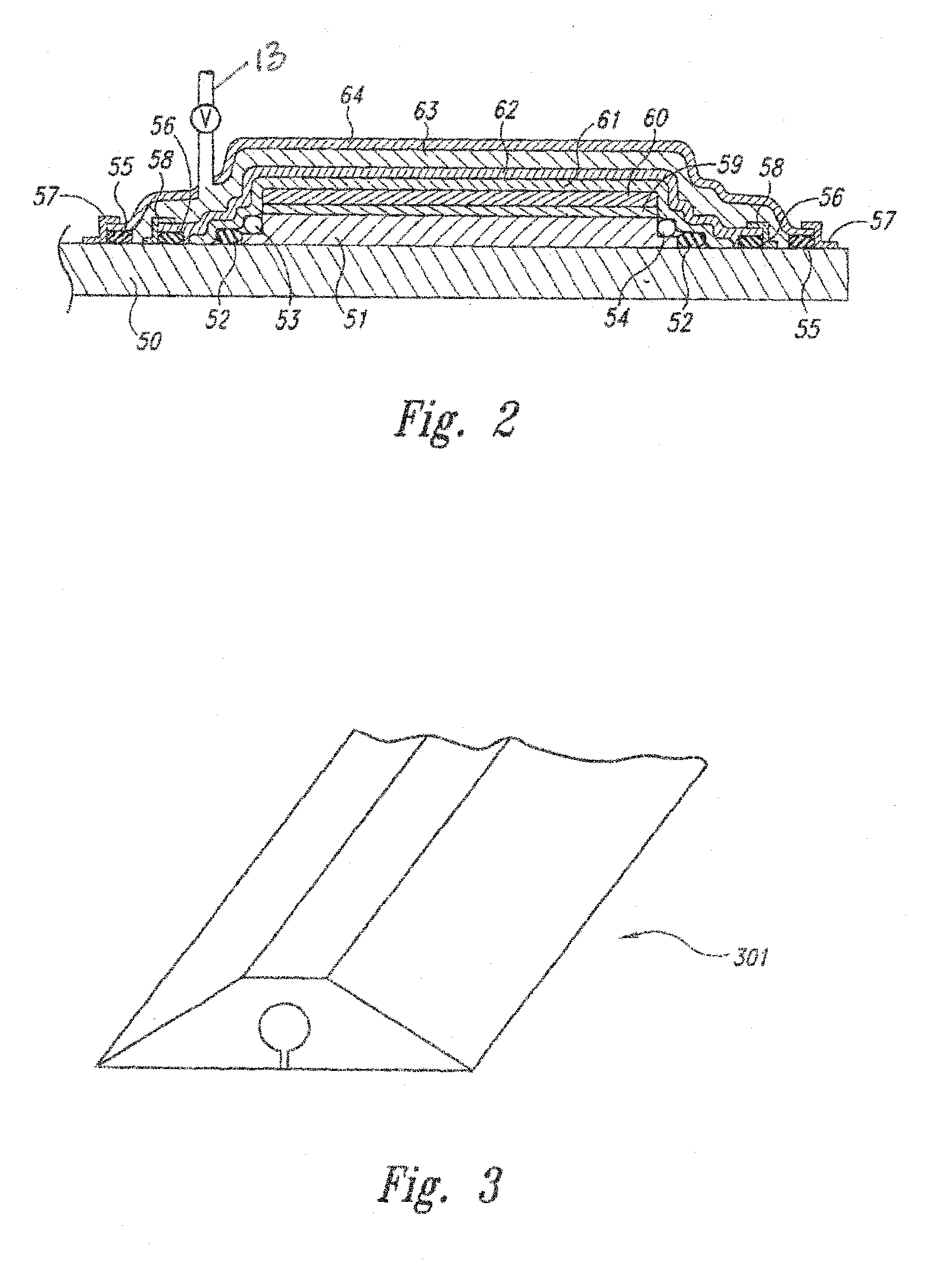

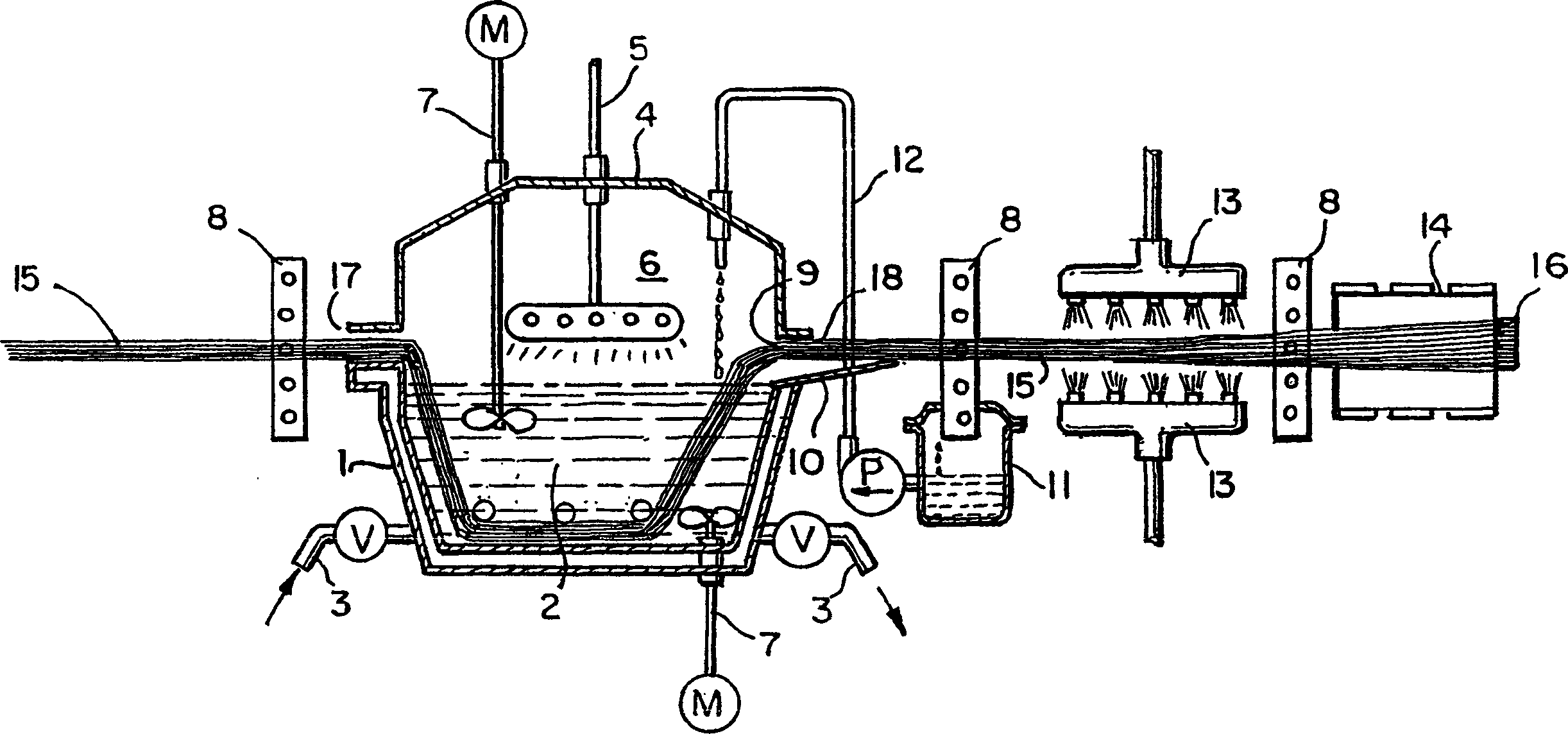

Double bag vacuum infusion process and system for low cost, advanced composite fabrication

Boeing is actively engaged in the production of lightweight composite airframes for both military and commercial applications. The double bag vacuum infusion process of the present invention provides a low cost, method for producing complex composite assemblies without an autoclave. It also enables the production of highly innovative structures. The quality of the composites produced using such an infusion process are comparable to composites made using prepregs, hand layup or fiber placement and autoclave curing.

Owner:THE BOEING CO

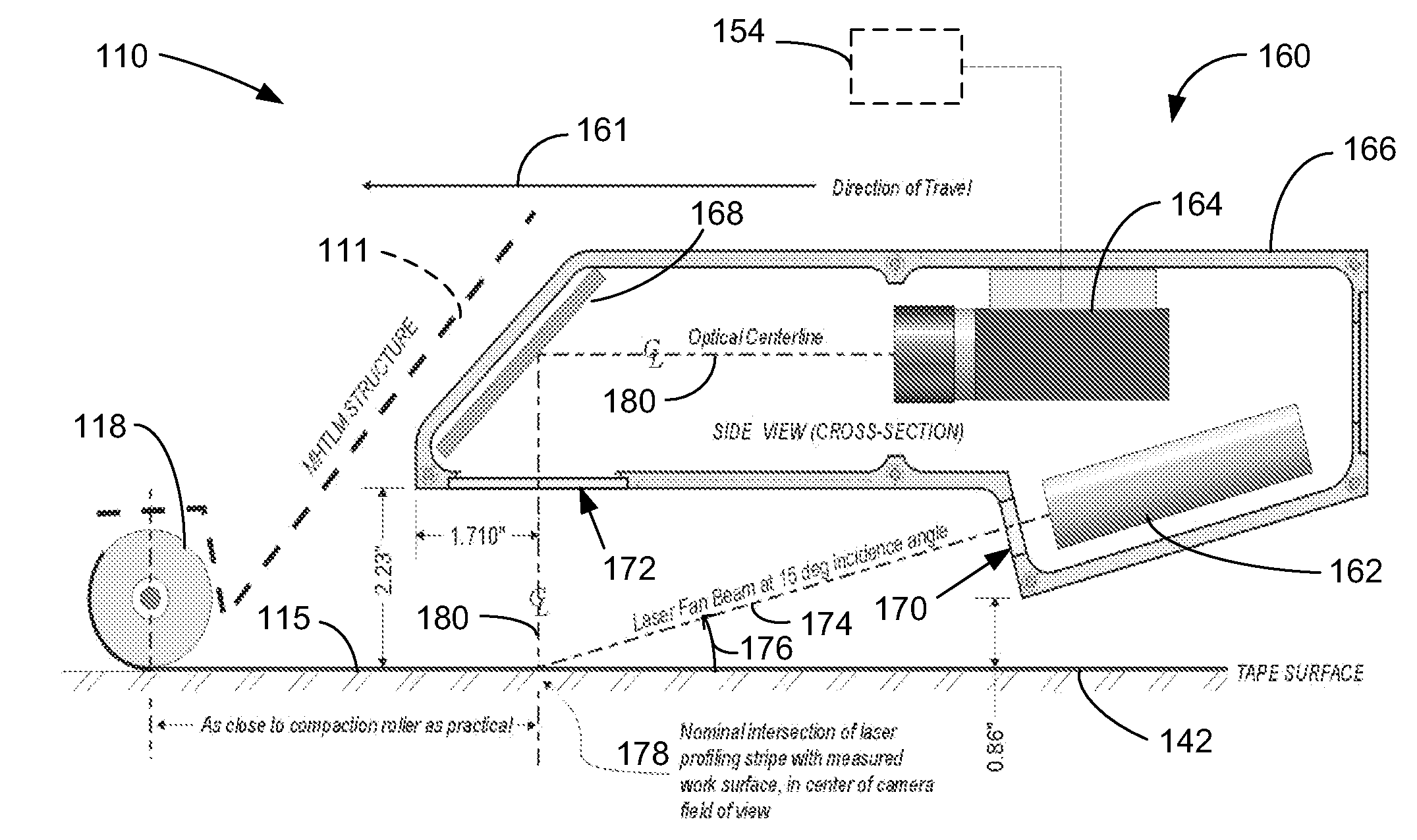

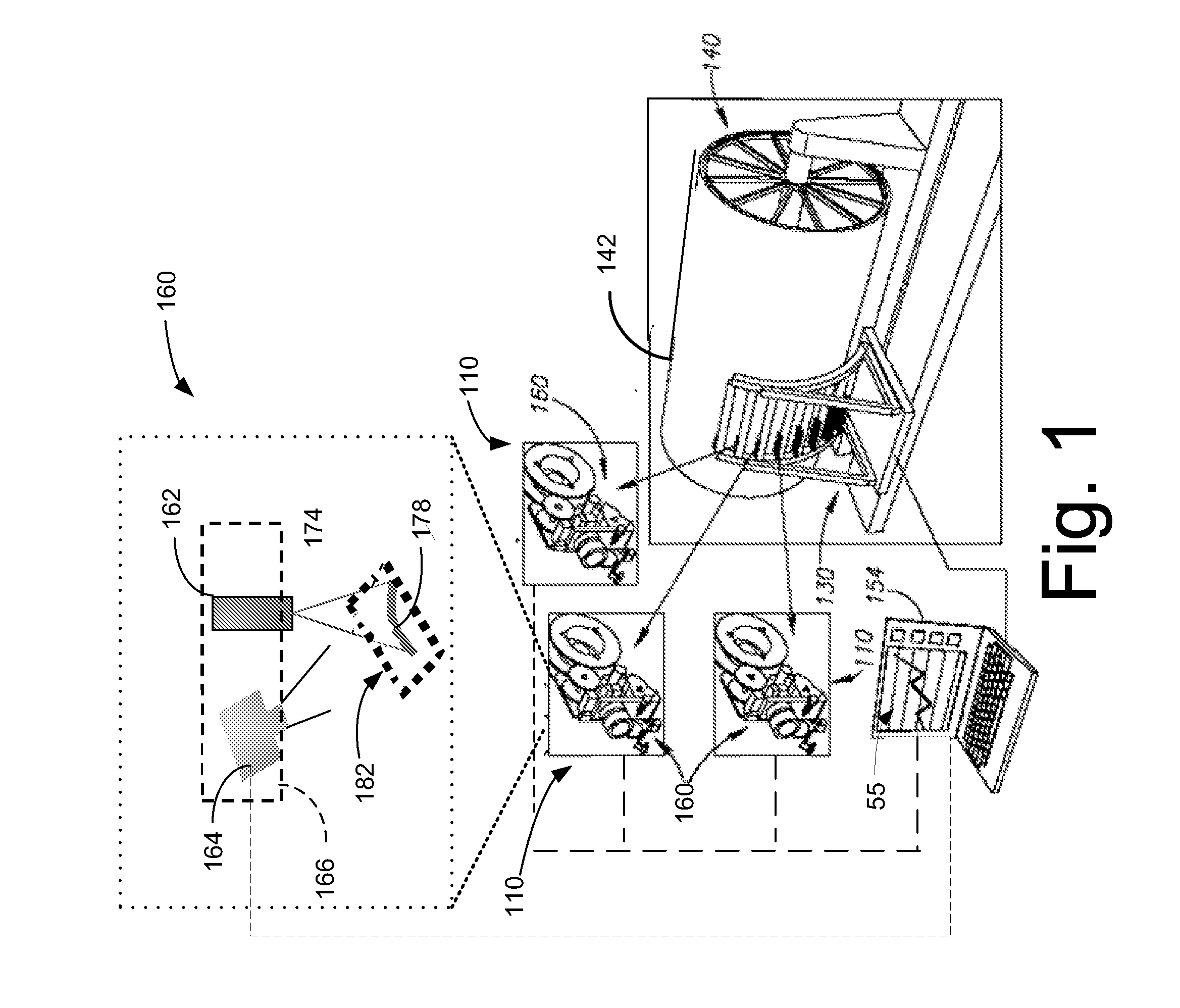

Systems and methods for monitoring automated composite manufacturing processes

InactiveUS20070277919A1Easy to detectImproved characterizationLamination ancillary operationsLaminationWrinkle skinProcess systems

Systems and methods for monitoring automated composite fabrication processes are disclosed. In one embodiment, a method includes performing a manufacturing operation on a portion of a workpiece using a tool moveable relative to the workpiece. Simultaneously with performing the manufacturing operation, the tool is translated relative to the workpiece, and a portion of the workpiece upon which the tool has performed the manufacturing operation is monitored. The monitoring includes illuminating an illuminated strip of the workpiece using a laser, and receiving a reflected beam reflected from the illuminated strip into a camera. Output signals from the camera may be analyzed to detect and characterize a feature of interest, wherein the feature of interest may include an edge, an overlap, a gap, a wrinkle, and foreign object debris (FOD).

Owner:THE BOEING CO

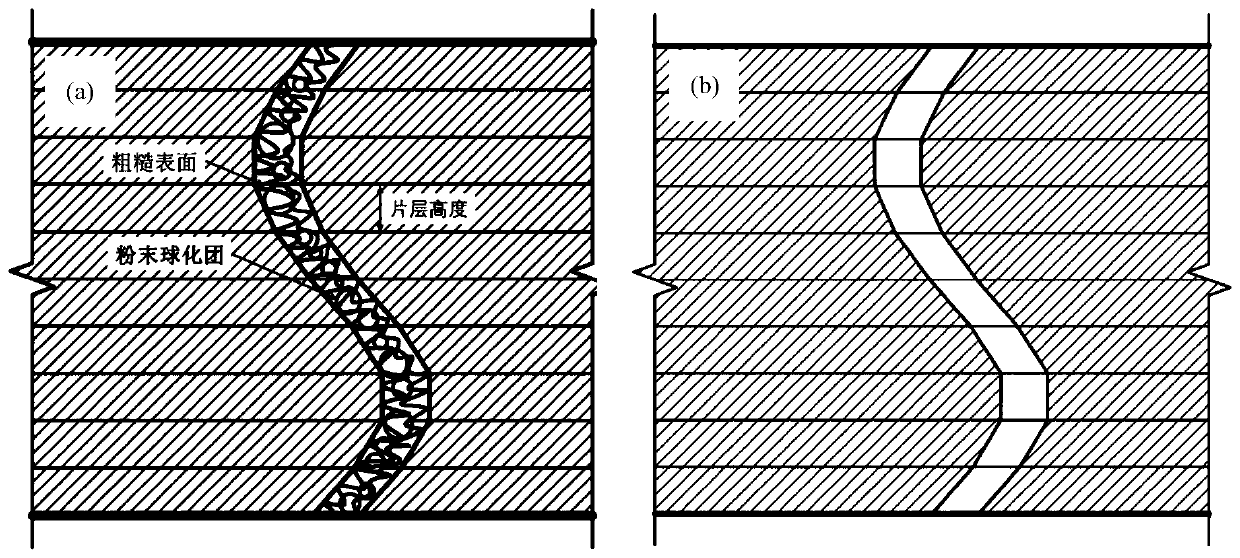

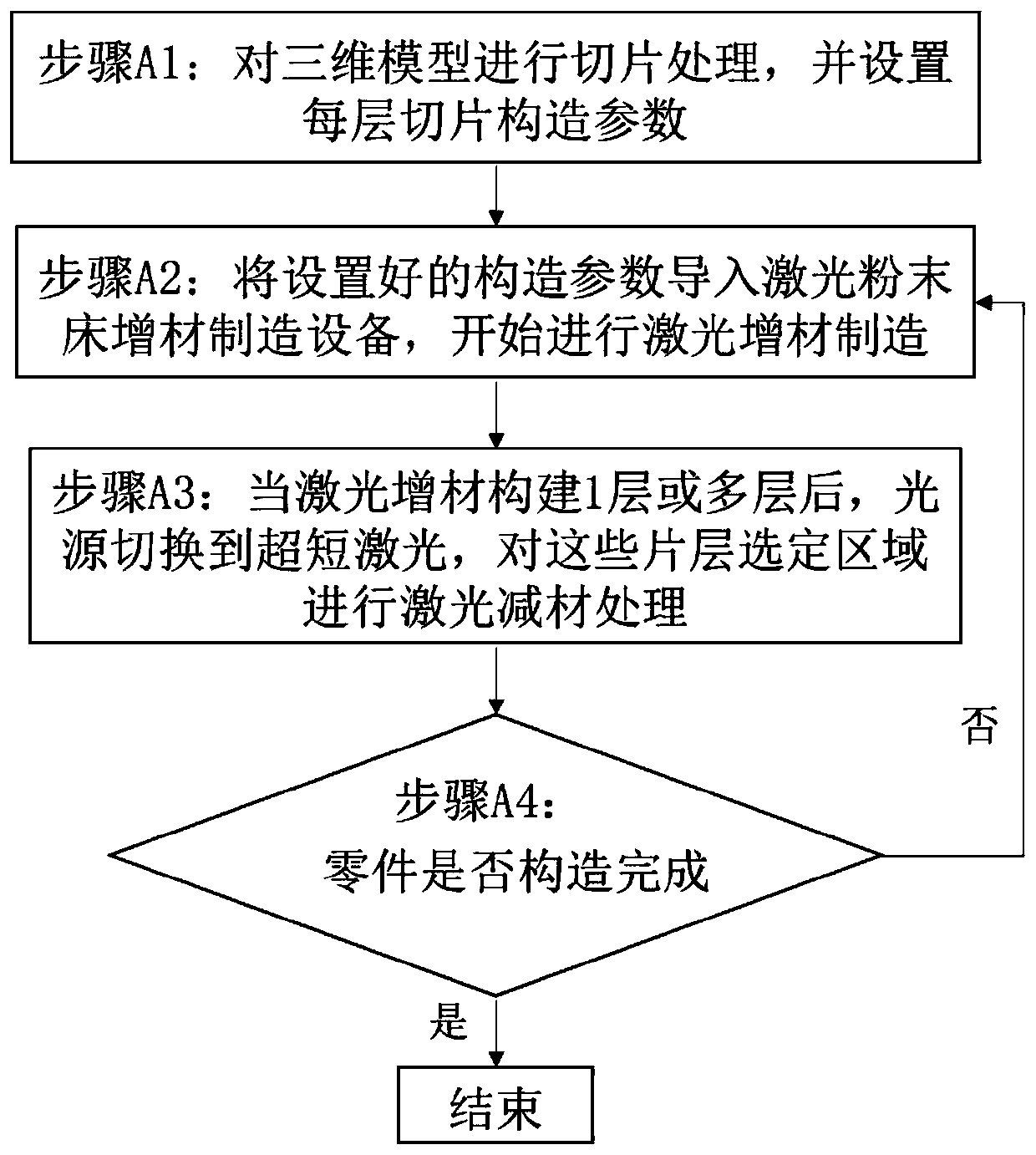

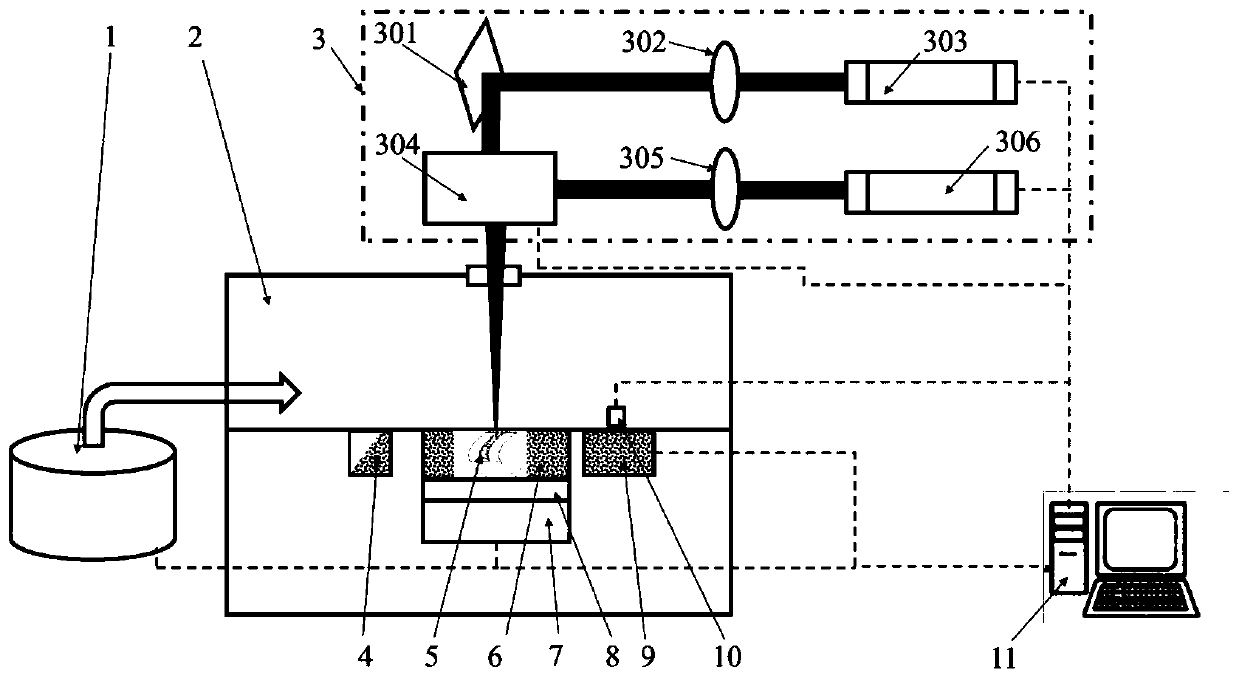

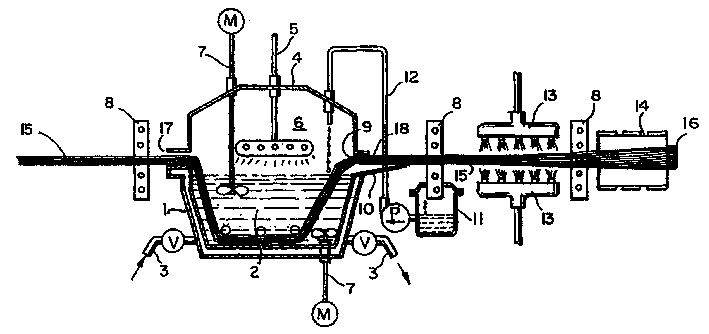

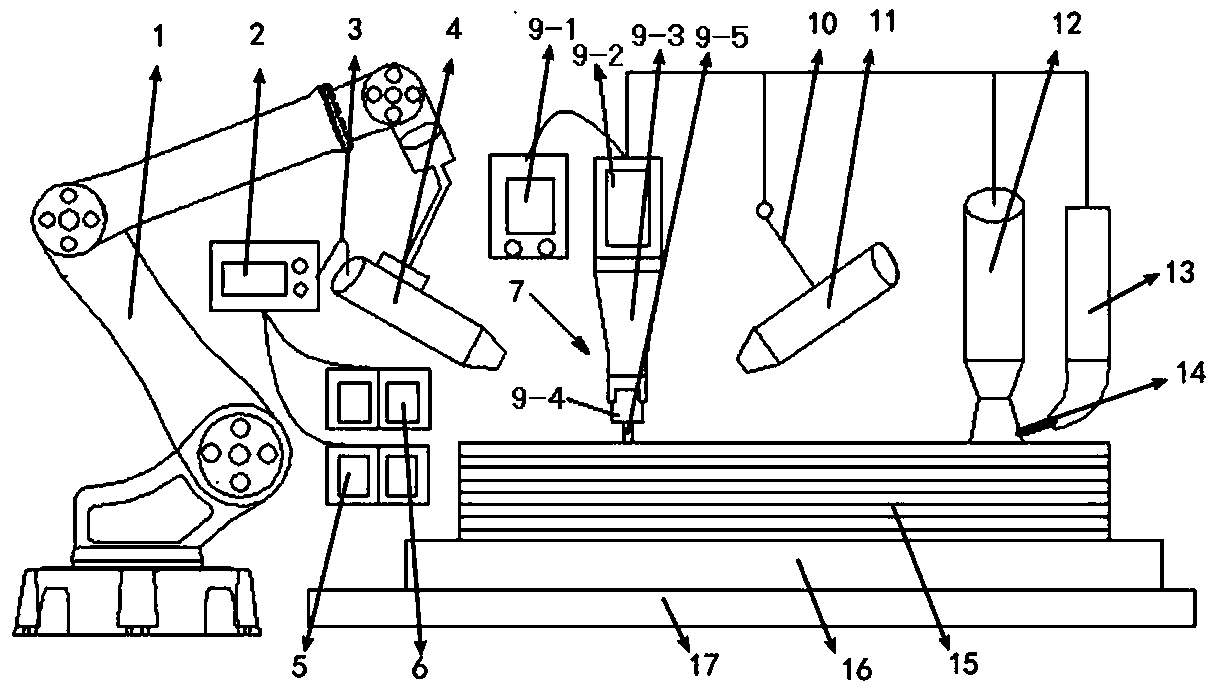

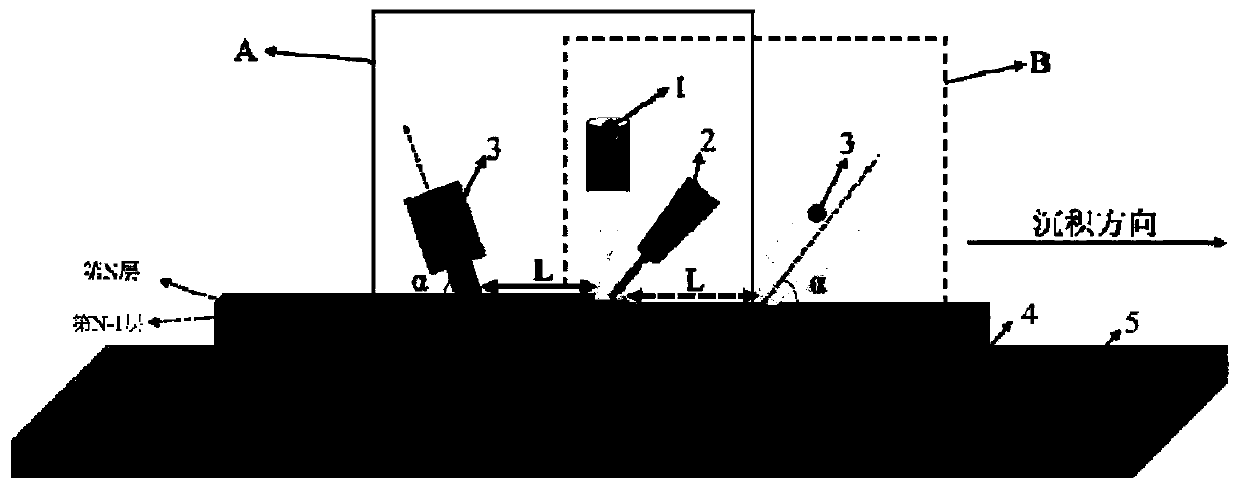

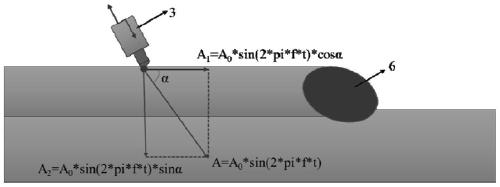

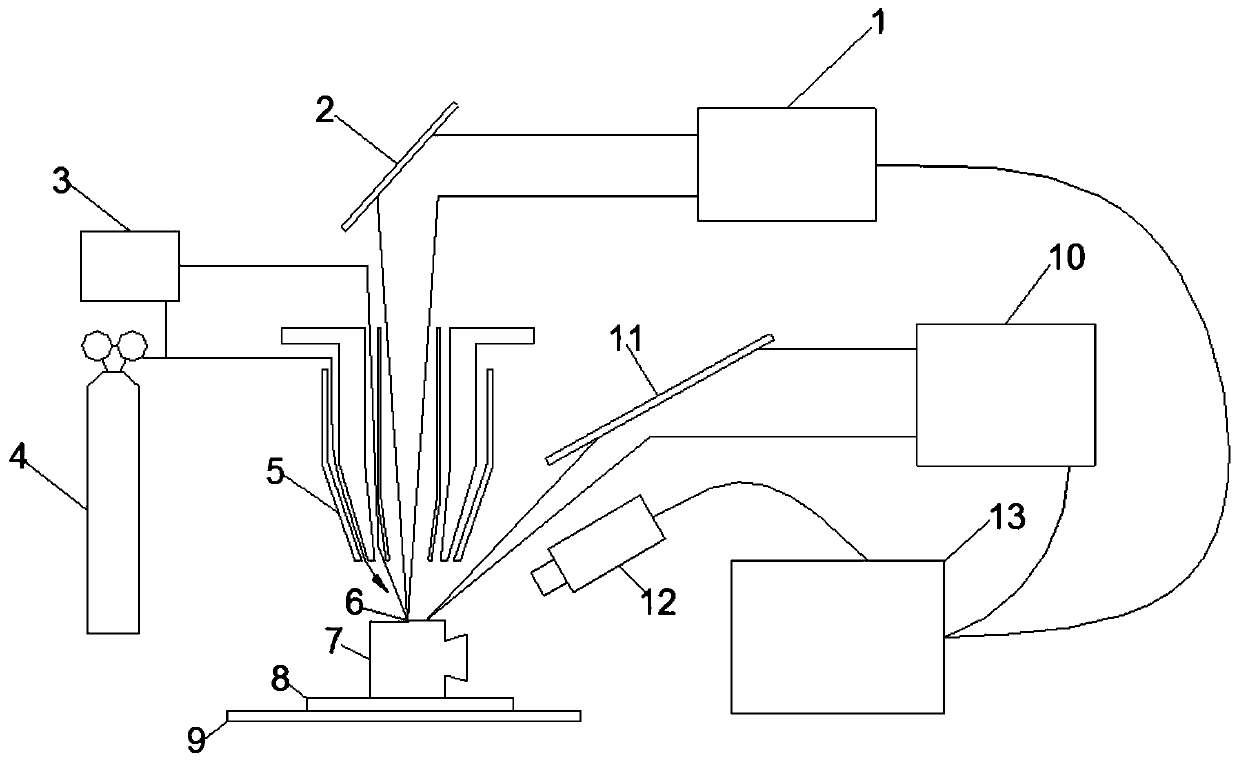

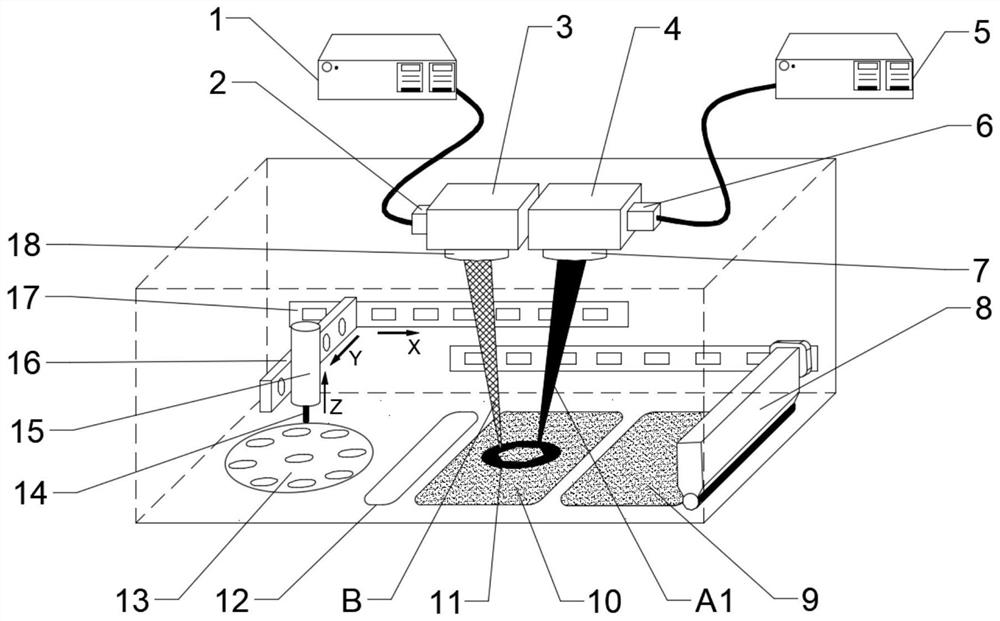

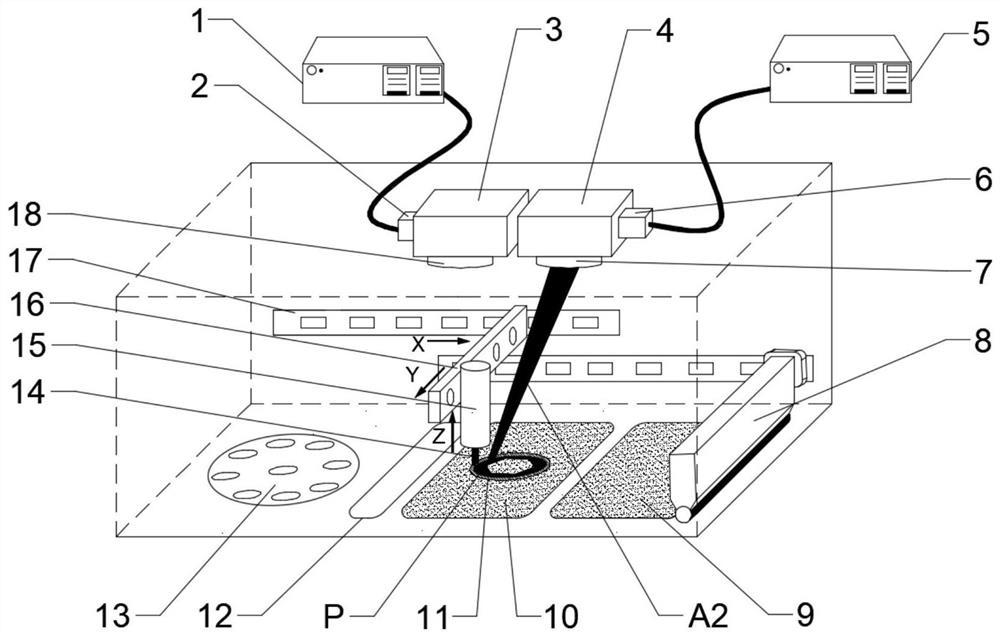

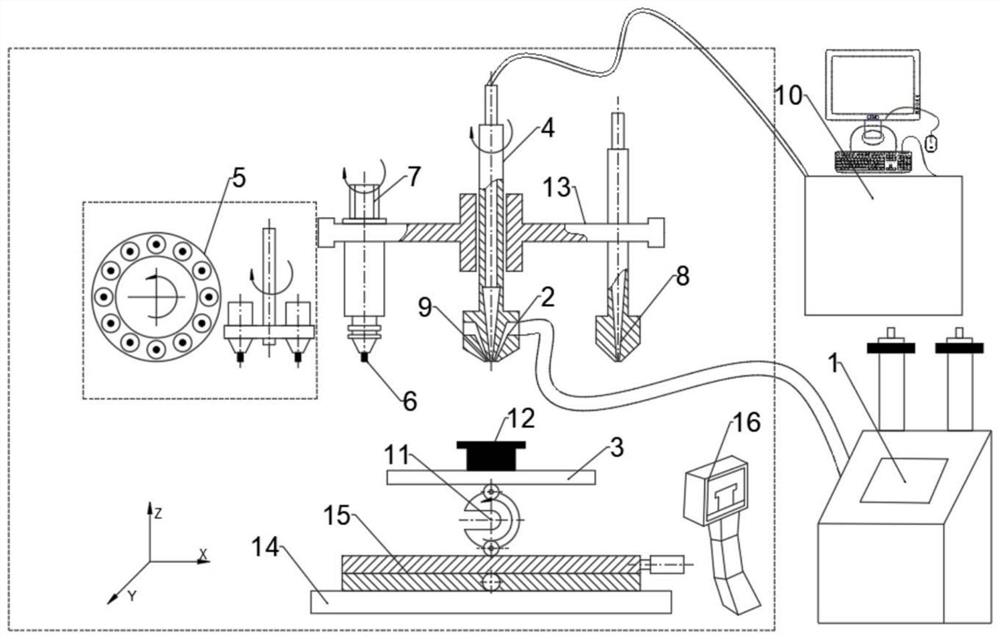

Near-net forming method and device for composite manufacturing fine workpiece based on laser additive manufacturing and subtractive manufacturing

PendingCN110369725AShort duration of actionChange the surface morphologyAdditive manufacturing apparatusIncreasing energy efficiencyFine structureLaser processing

The invention belongs to the field of laser processing, and relates to a near-net forming method and device for composite manufacturing a fine workpiece based on laser additive manufacturing and subtractive manufacturing. According to the method, the construction parameters of a three-dimensional digital-to-layer slicing layer are generated by utilizing software, laser additive manufacturing processing is carried out, and ultrafast pulse laser subtractive manufacturing processing is carried out alternately in the laser additive manufacturing processing process to form a three-dimensional entity. The device comprises a computer control device, a sealing molding chamber, a light path selecting system and an inert protection gas source; during additive manufacturing processing, the computer control device controls the light path selecting system to select the laser emitted by an additive manufacturing laser device and perform laser additive manufacturing processing; and during subtractivemanufacturing processing, the computer control device controls the light path selecting system to select ultrafast pulse lasers emitted by a subtractive manufacturing laser device and perform the ultrafast pulse laser subtractive manufacturing processing. According to the near-net forming method and device, the preparation of complex and fine-structure parts can be completed in a high-precision and integrated manner, the defects that traditional laser additive manufacturing is low in the forming precision, high in roughness and cannot be used for preparing a fine and complex inner cavity areovercome.

Owner:SHANGHAI UNIV OF ENG SCI

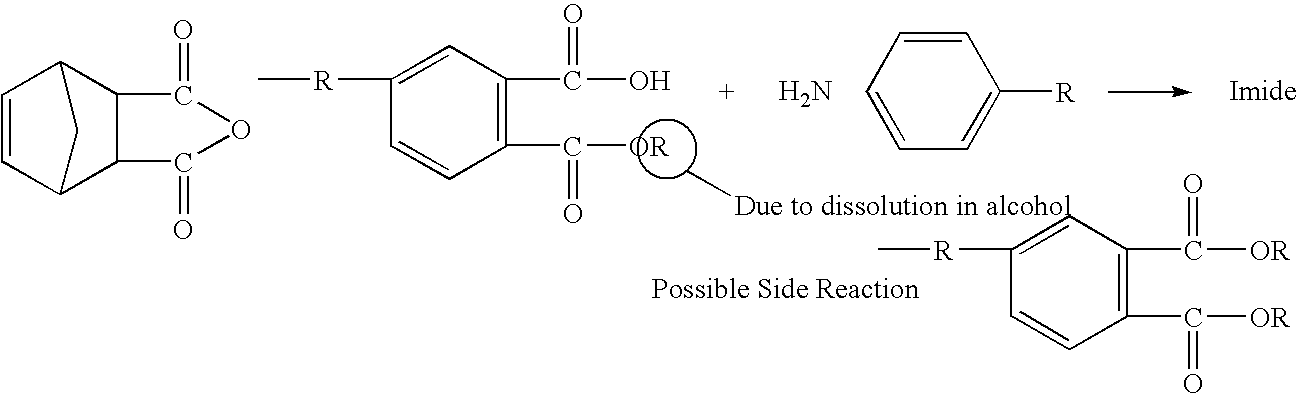

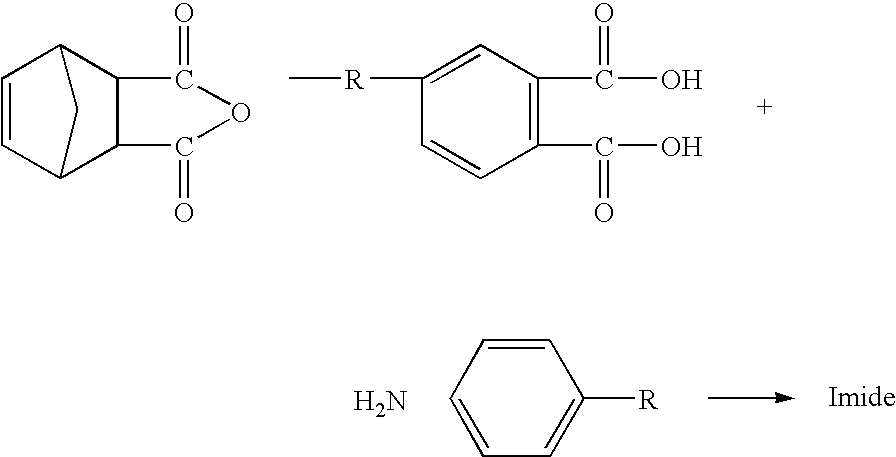

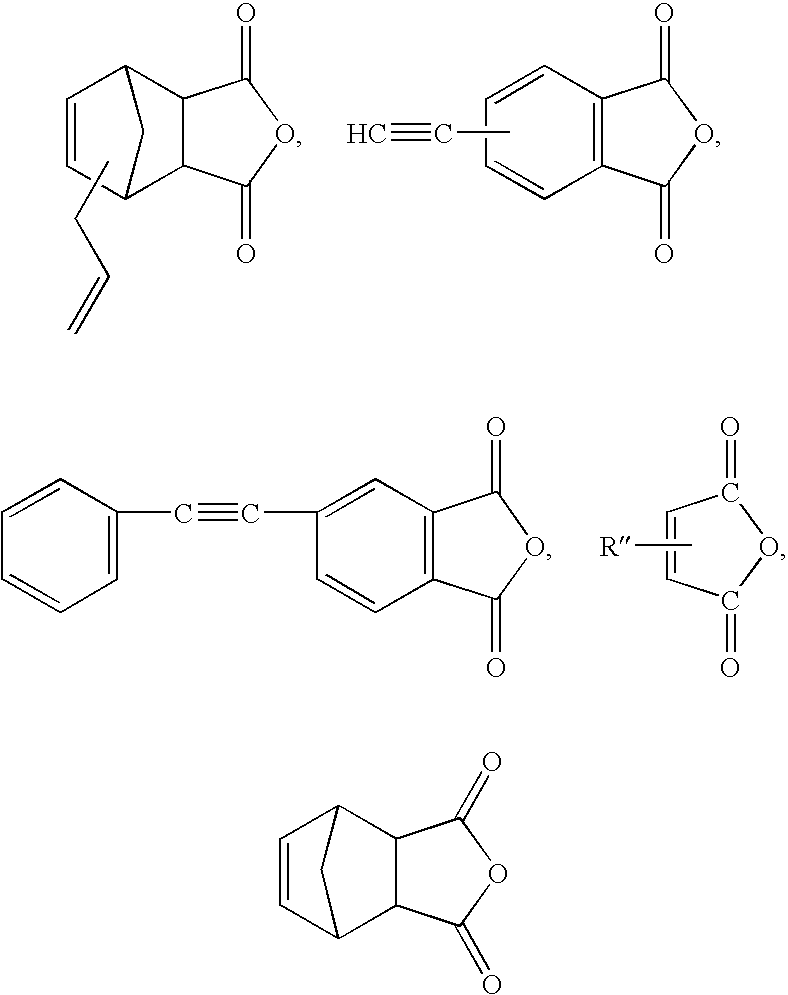

Water-entrained-polyimide chemical compositions for use in high-performance composite fabrication

ActiveUS20080300360A1Inhibit side effectsEliminate useCoatingsAdhesivesCoated surfaceChemical composition

Water-entrained compositions comprising colloidal or suspensoidal solutions comprising polyimide pre-polymers / oligomers are described. These compositions are obtained in water by initial dispersion of the resin constituents in water to from colloids or suspensoids. The water-entrained polyimide compositions can be applied to numerous surfaces or more beneficially used for composite fabrication. The coated surfaces or polyimide-pre-polymer impregnated reinforcing materials are subsequently cured and are ideal for providing thermal protection.

Owner:THE BOEING CO

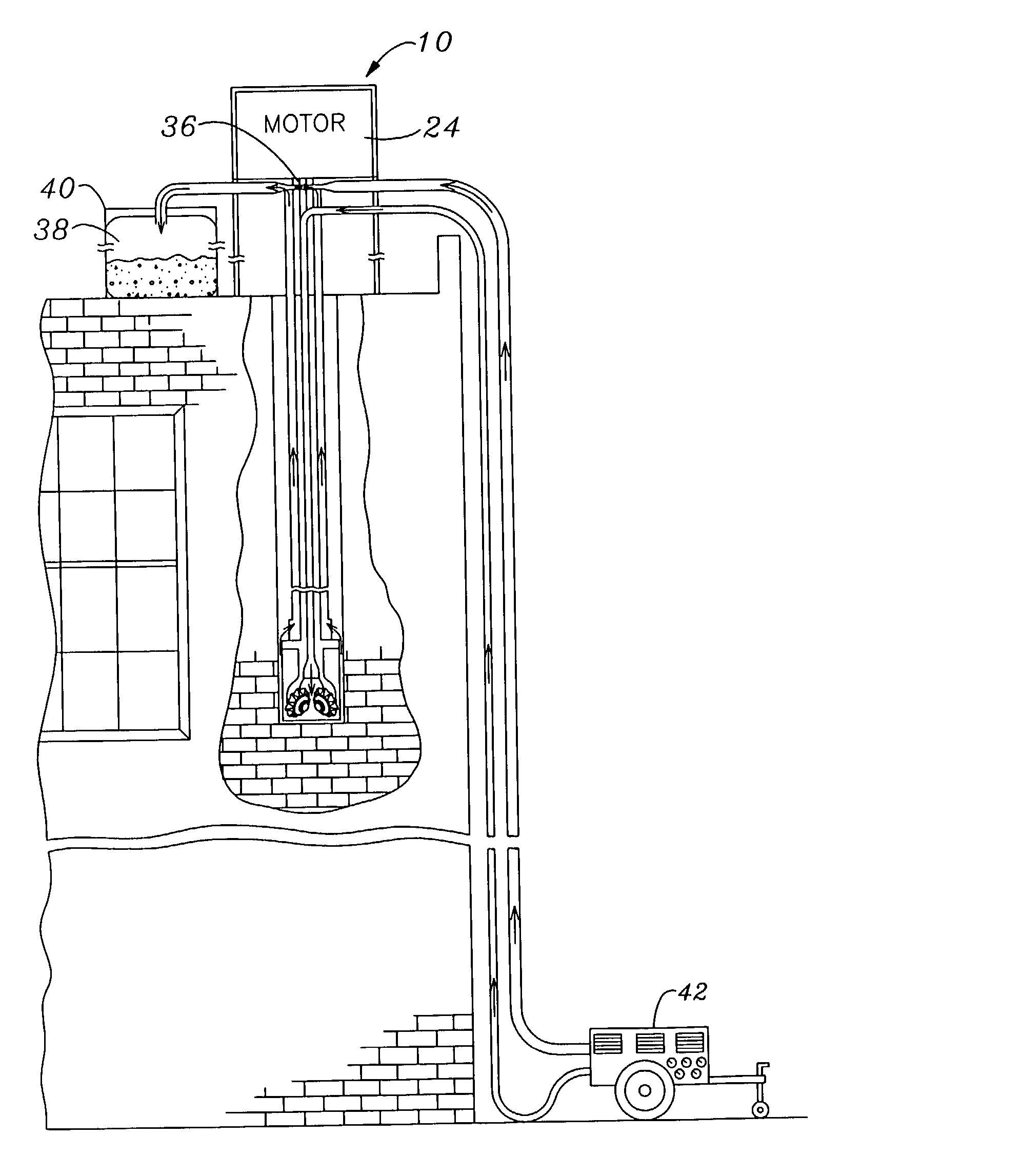

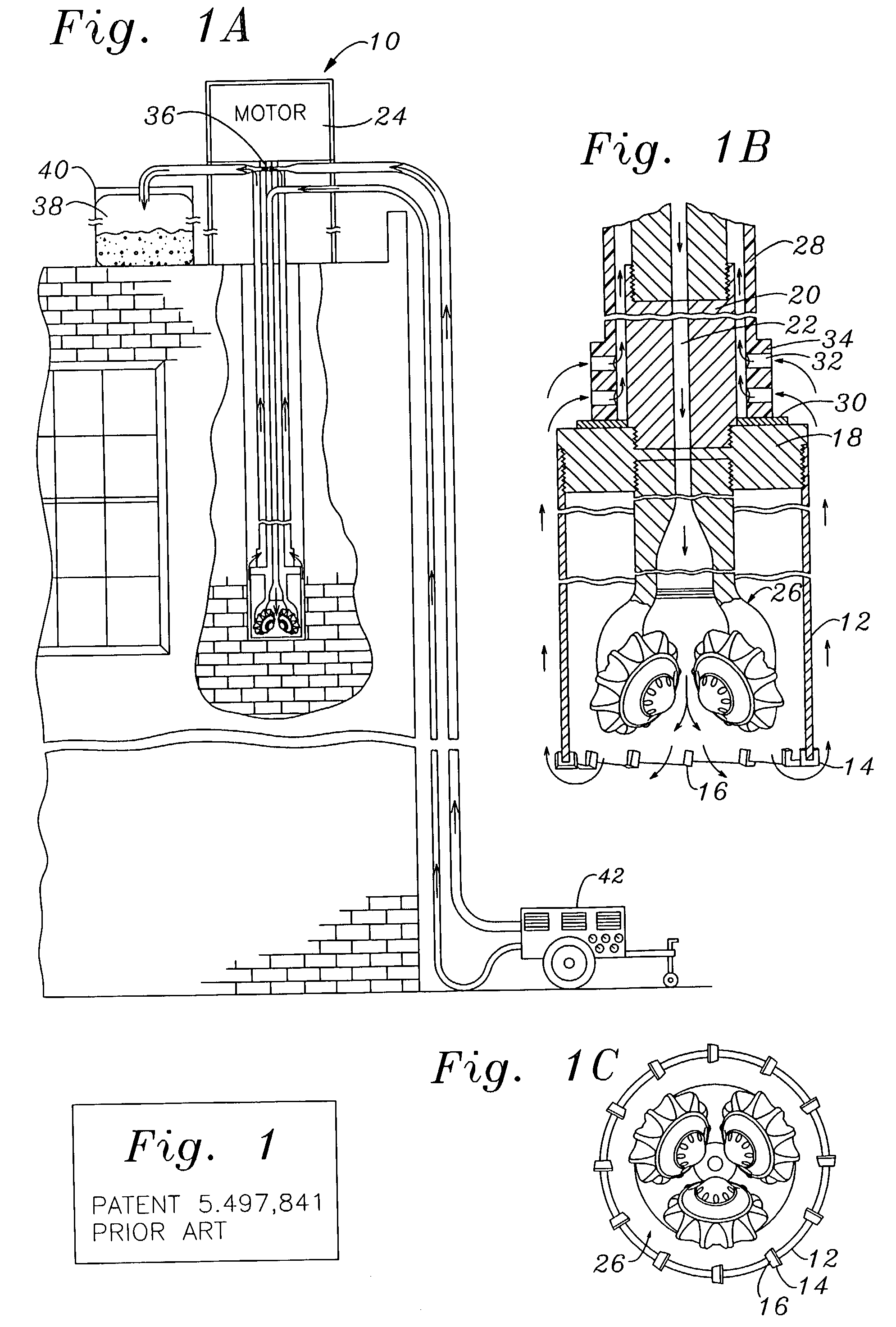

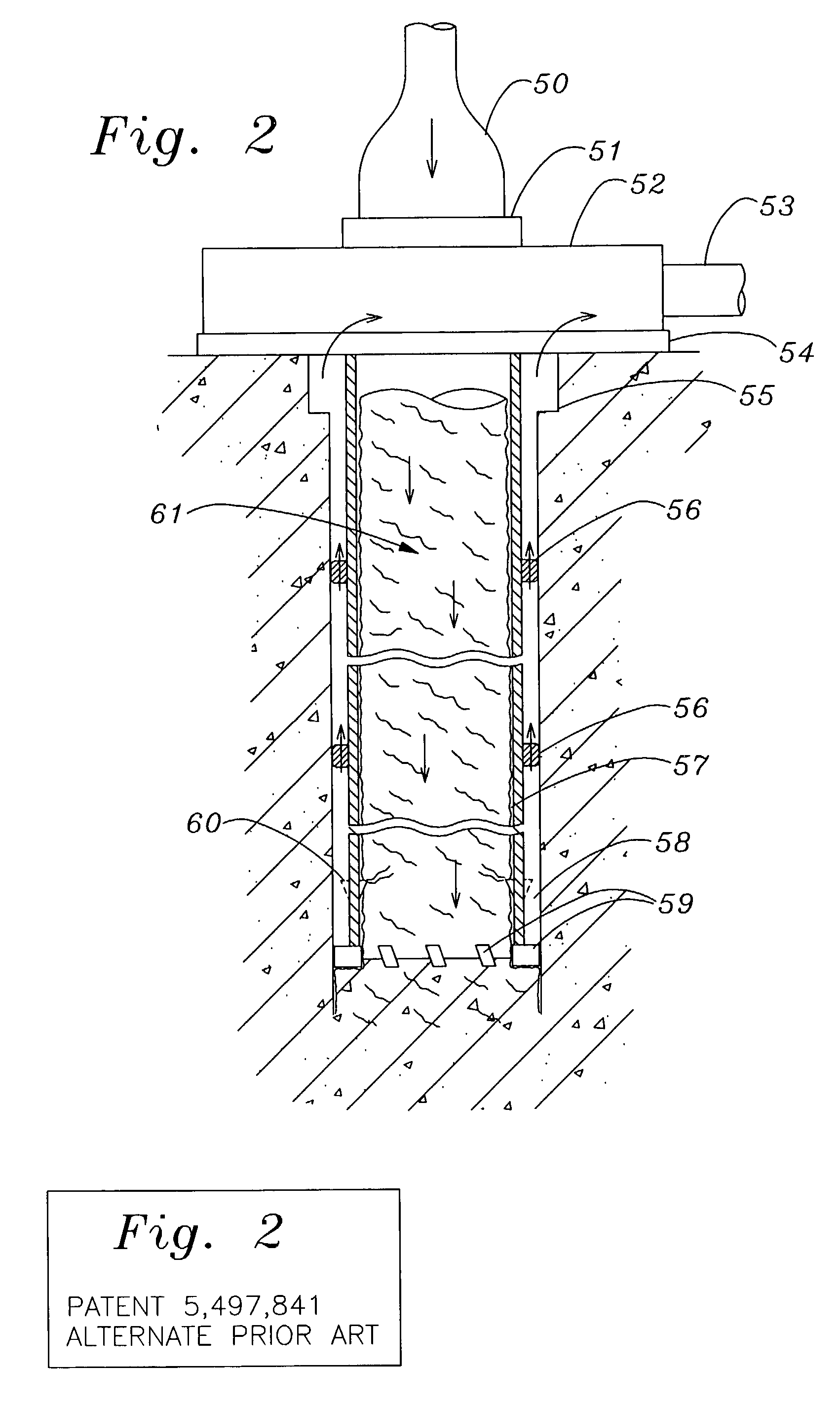

Advanced processes for coring and grouting masonry

Advanced masonry coring systems for coring and grouting masonry walls are disclosed in this patent. The systems include rotating machinery and a drill column in the form of a cylindrical double-piped string of pipe sections, rotating a cylindrical drill body. The drill body mounts cutting end faces having alternative means of employing carbide or diamond cutting and / or pulverizing elements. The double drill pipe weight is made workable through new aerospace composite fabrication. The double pipe permits more efficient routing of air and removal of drill cuttings. Advancement in various system components and means of placing reinforcement into walls is disclosed. Further disclosure is included of advanced means of optimizing resin grouting materials and procedures to fill the wall cavities created by the core drill, integrating the reinforcement into the walls.

Owner:MOHLENHOFF WILLIAM

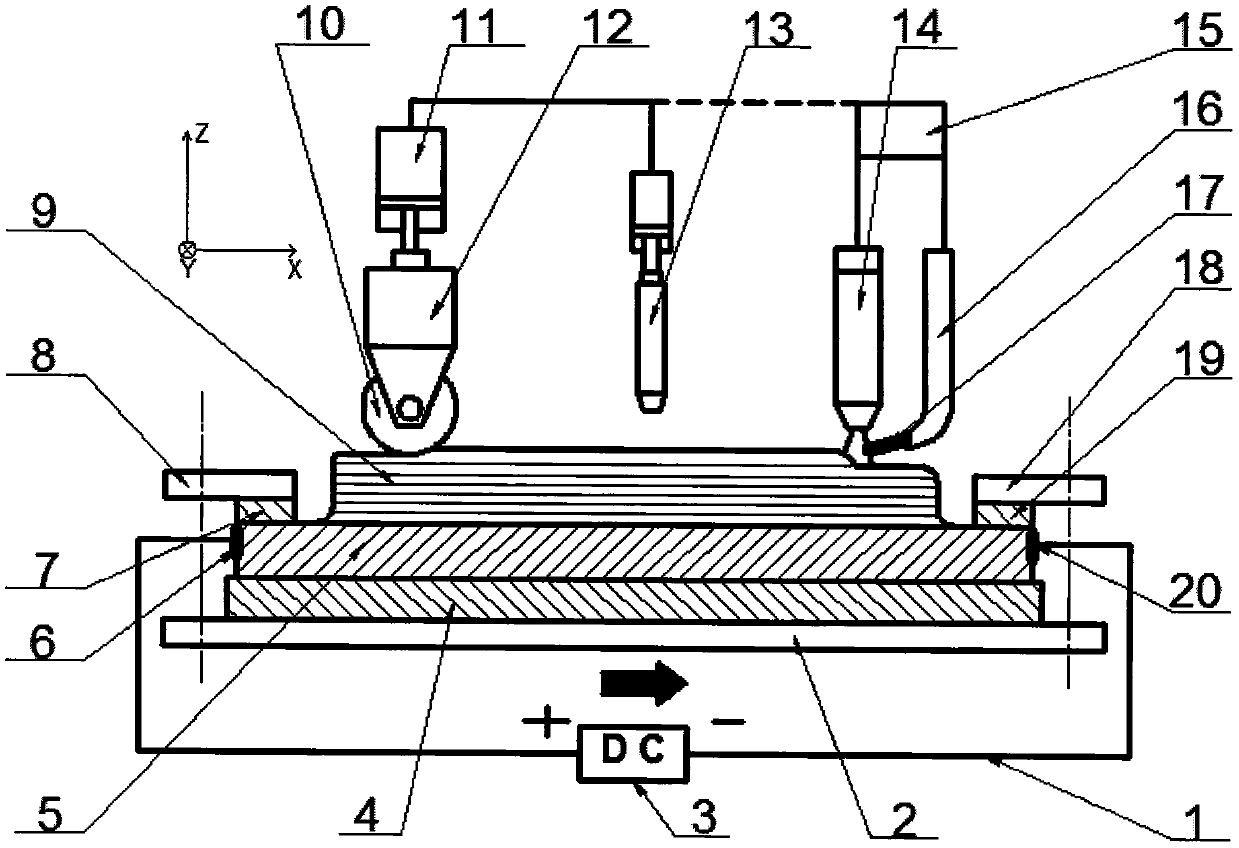

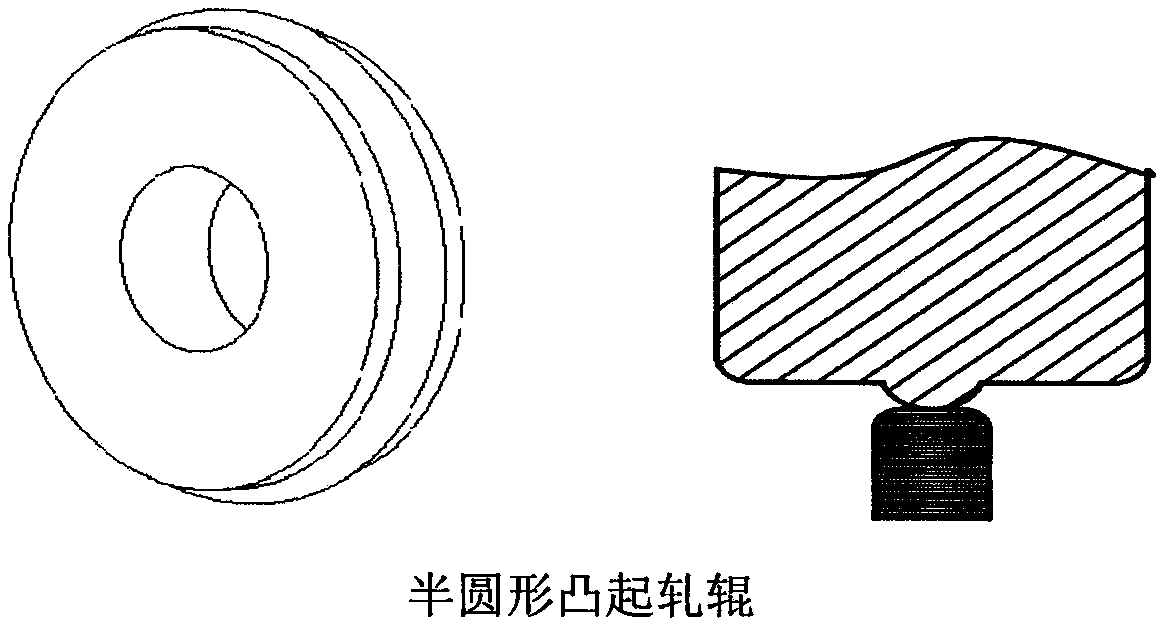

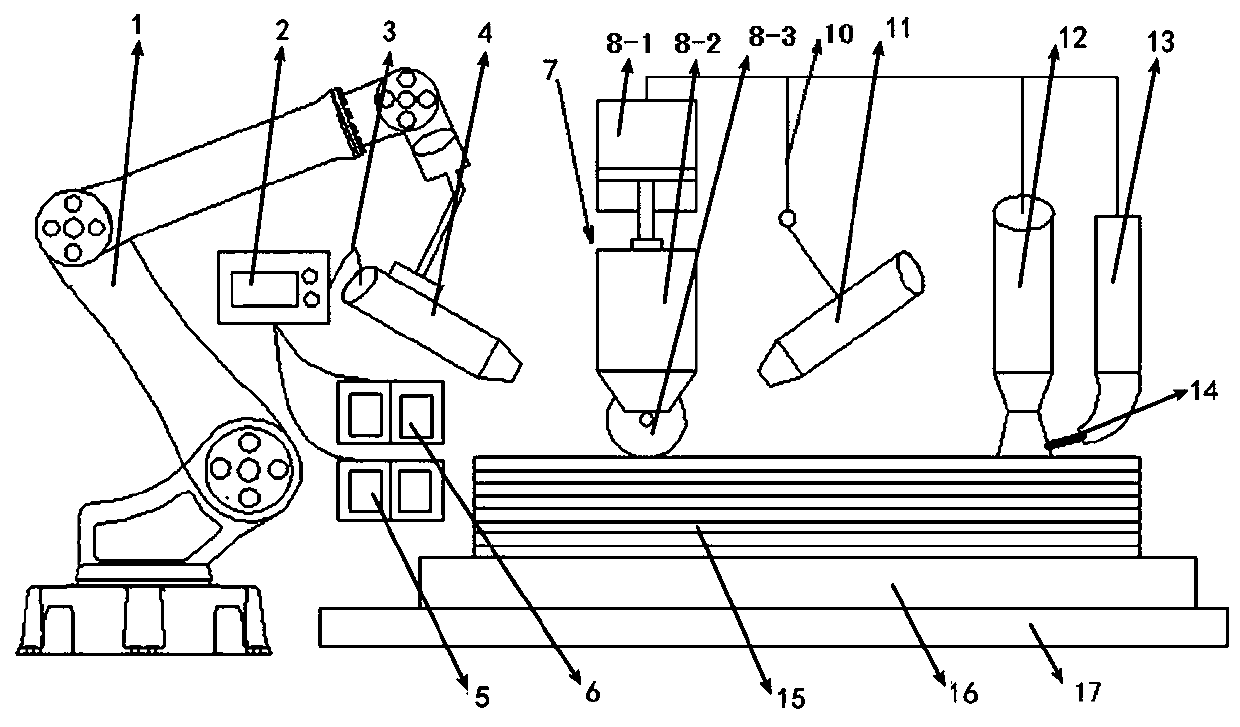

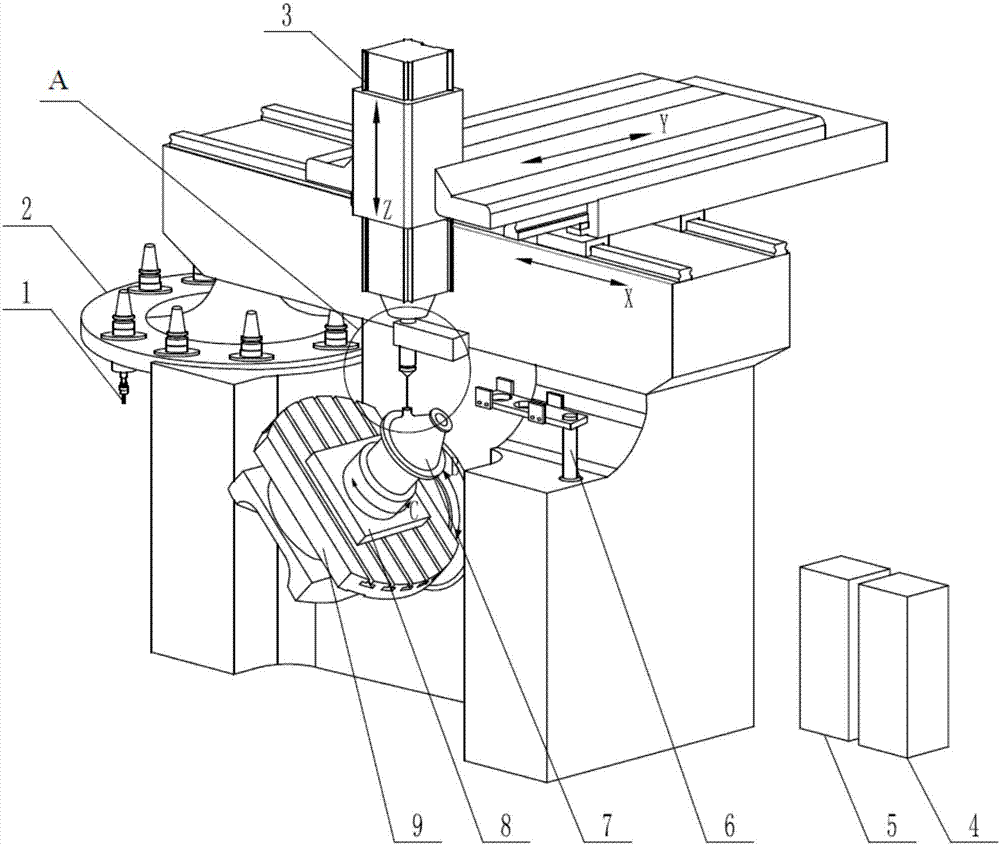

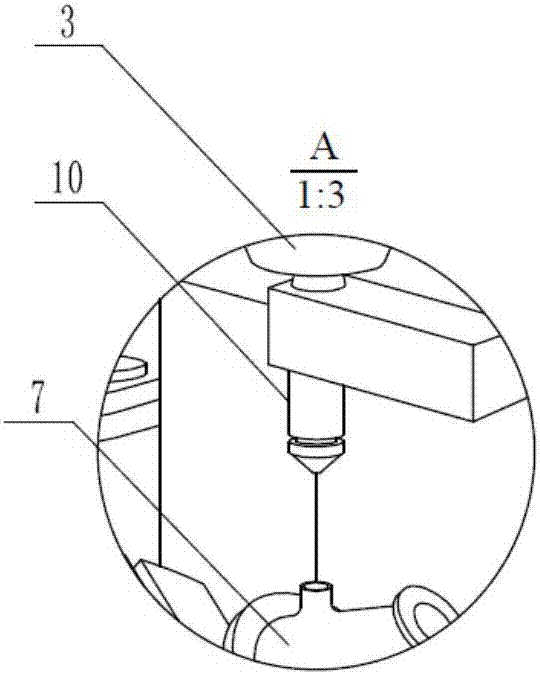

Electric arc material increasing and electrically aided hot rolling composite manufacturing method and device

InactiveCN109605039AReduce peakLow densityOther manufacturing equipments/toolsElectricityHydraulic cylinder

The invention relates to an electric arc material increasing and electrically aided hot rolling composite manufacturing method and device. The method comprises the following steps that a substrate isfixed on a workbench, electric arc deposition is finished through welding gun movement and a wire feeding mechanism, a direct current pulse power supply is started to perform heating on the substrateand a deposition layer after deposition with one layer or more layers, and a roller is adopted to perfrom hot rolling on the surface of the deposition layer when heating is performed to a preset temperature. The device comprises the substrate, a clamp, the workbench, a welding gun, the wire feeding mechanism, a temperature sensor, the roller, a rolling loading unit, a hydraulic cylinder, an electrode, a wire, the direct current pulse power supply and an insulation gasket. For the method and the device, by organically combining exteranl electric field asistant heating, hot rolling plastic deformation with the electric arc material increasing process and adopting a pulse power supply for heating, the material deformation resistance can be lowered, and the plasticity of a material can be improved; and through the coupling effect of various fields including the electric field, a thermal field and a force field, crystalline grains at the deposition layer are fined, the defects of electric arc material increasing manufacturing is overcoem, the residual stress of the deposition layer is lowered, and the comprehensive mechanical properties of the material are improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Composite preparation method of vacuum sputtering coating and chemical coating for electromagnetic wave screen fabric and production thereof

InactiveCN101033546AWide electromagnetic wave shielding effectivenessVacuum evaporation coatingSputtering coatingSputteringLow temperature plasma

This invention relates to a complex manufacturing method and its product for vacuum sputter and chemical film-platings on industrial and household electromagnetic wave screen fabrics including one of the two methods: a, a fabric backing->plating a metal film by vacuum sputter->plating a metal film chemically->washing->exerting a protection layer->drying, b, factric backing->catalyzing->washing->activating->washing->plating metal film chemically->washing->drying->plating a metal film by vacuum sputter->enforcing a protection layer, in which, the fabrics can be processed with low temperature plasma before vacuum sputtering metal film characterizing in including a layer of tatted cloth or non-woven cloth , a layer of metal film deposited by a sputter film-plating method, an another metal film and a protection layer.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD +1

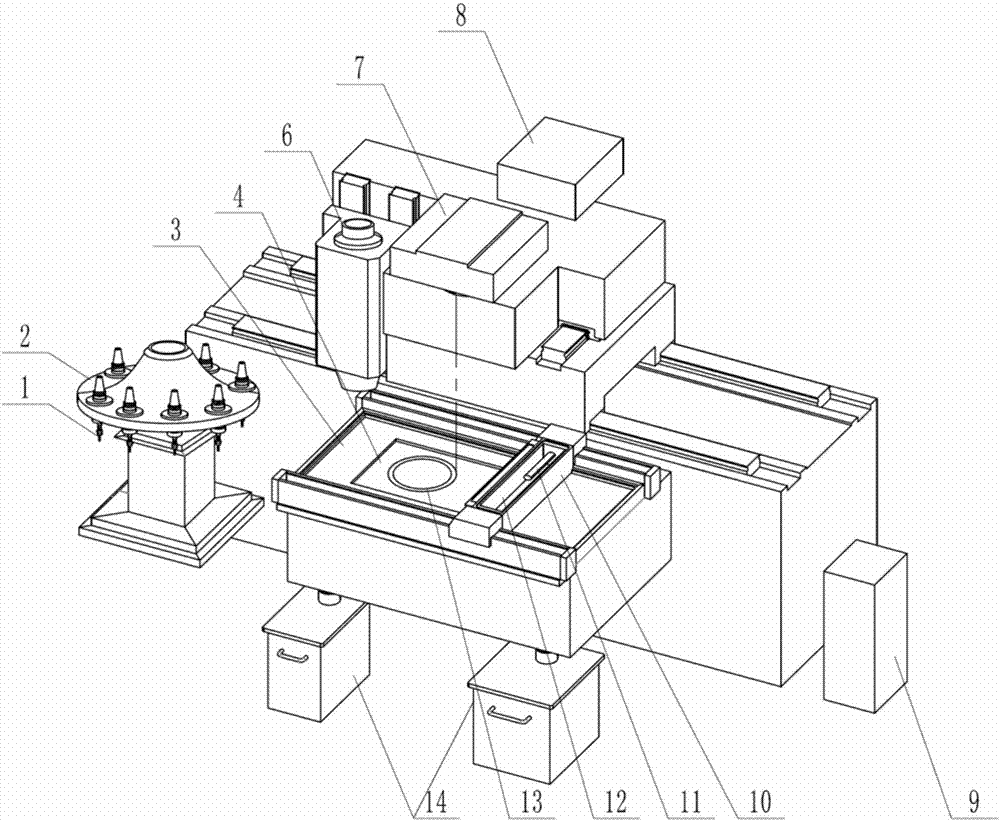

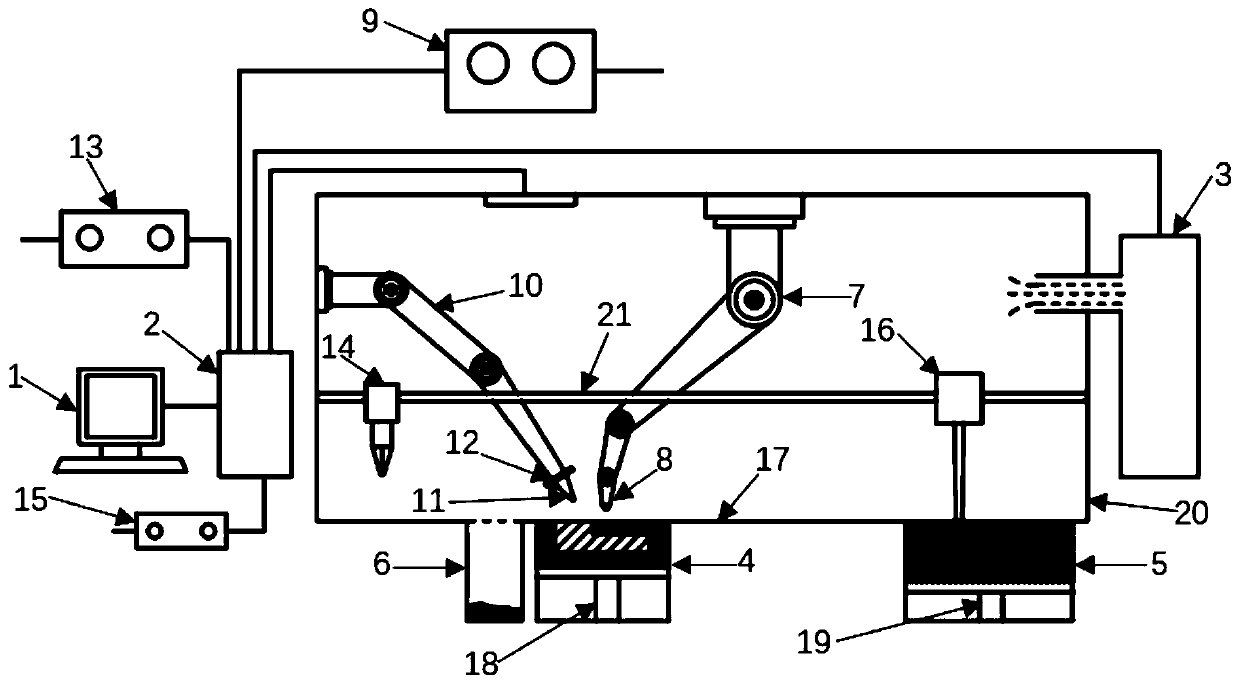

Equipment for applying ultrasonic cutting to powder laying type additional and subtractive composite manufacturing and machining method

InactiveCN107052340AExtended service lifeSolve the problem of longevityAdditive manufacturing apparatusIncreasing energy efficiencyLaser scanningEngineering

The invention relates to the field of additional and subtractive manufacturing, in particular to equipment for applying ultrasonic cutting to powder laying type additional and subtractive composite manufacturing and a machining method. A workbench is horizontally installed in the middle position of the front portion of a lathe bed. A molding cavity is formed in the workbench and can move up and down in the vertical direction. A base plate can be installed in the molding cavity. Additional and subtractive composite manufacturing is carried out on the base plate. A powder laying device is installed on the workbench and located at one end of the workbench. A laser generator and a laser screening system are fixed to the position over the front portion of the lathe bed. A powder supply device is located on the outer side of the lathe bed. A magazine tool is located on one side of the front portion of the lathe bed. A tool is installed in the magazine tool. A main shaft is installed on the front portion of the lathe body, and can slide along sliding rails in the X,Y and Z directions. During additional manufacturing, the main shaft is located at one end of the workbench. During subtractive machining, the main shaft moves to the position over the workbench. The tool is installed on the lower portion of the main shaft, and an ultrasonic cutting device is installed between the tool and the main shaft. A powder recycling device is arranged on the lower portion of the workbench.

Owner:DALIAN UNIV OF TECH

One component thermose polyurethane system

A process for the preparation of fiber reinforced composites in which the matrix polymer is derived from the catalyzed reaction of a liquid polyisocyanate containing material. The principle curing mechanism is the formation of urethane and / or isocyanurate linkages. At least a portion of the catalyst is applied onto the surface of the reinforcing fibers and / or onto the surface to the uncured resin impregnated reinforcing structure, under conditions such that the catalyst is not dispersed into the bulk of the isocyanate containing resin until cure. Curing is facilitated by a combination of mechanical and thermal action. The process is particularly well suited for the preparation of composites by pultrusion, using a one-component open-bath pultrusion machine. The process of the invention may be adapted to a much wider range of composite fabrication methods, including SMC and filament winding.

Owner:HUNTSMAN INT LLC

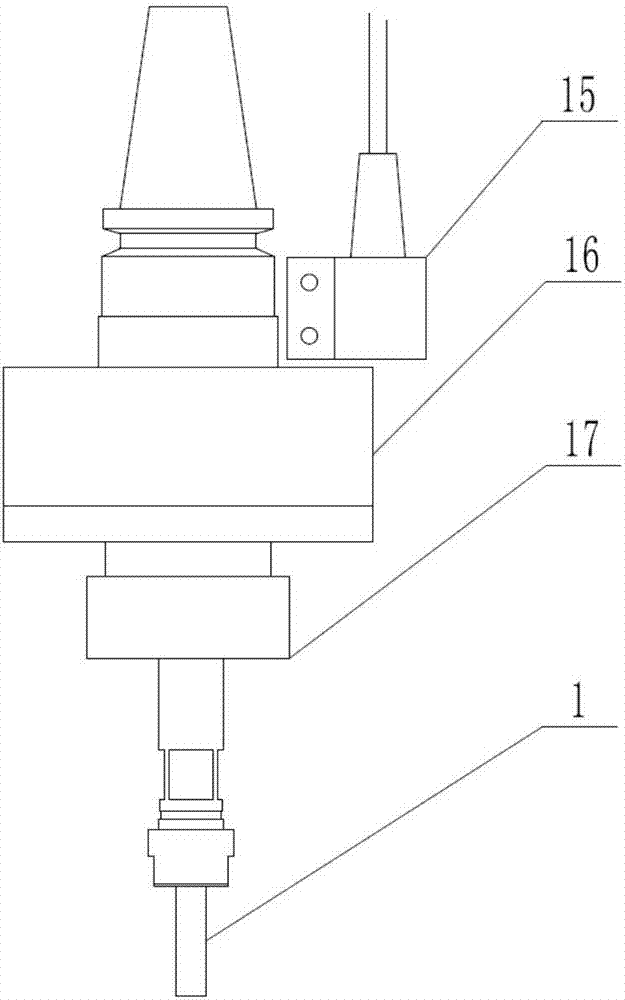

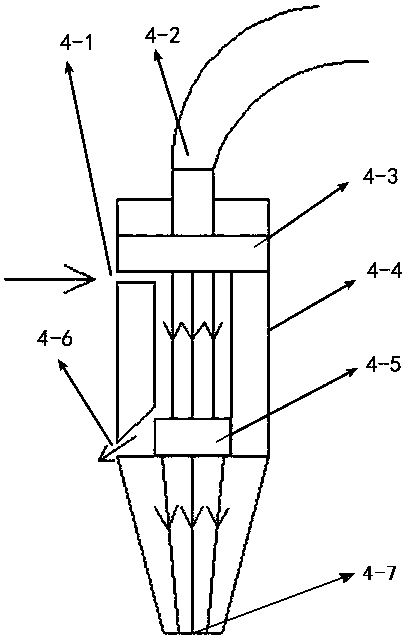

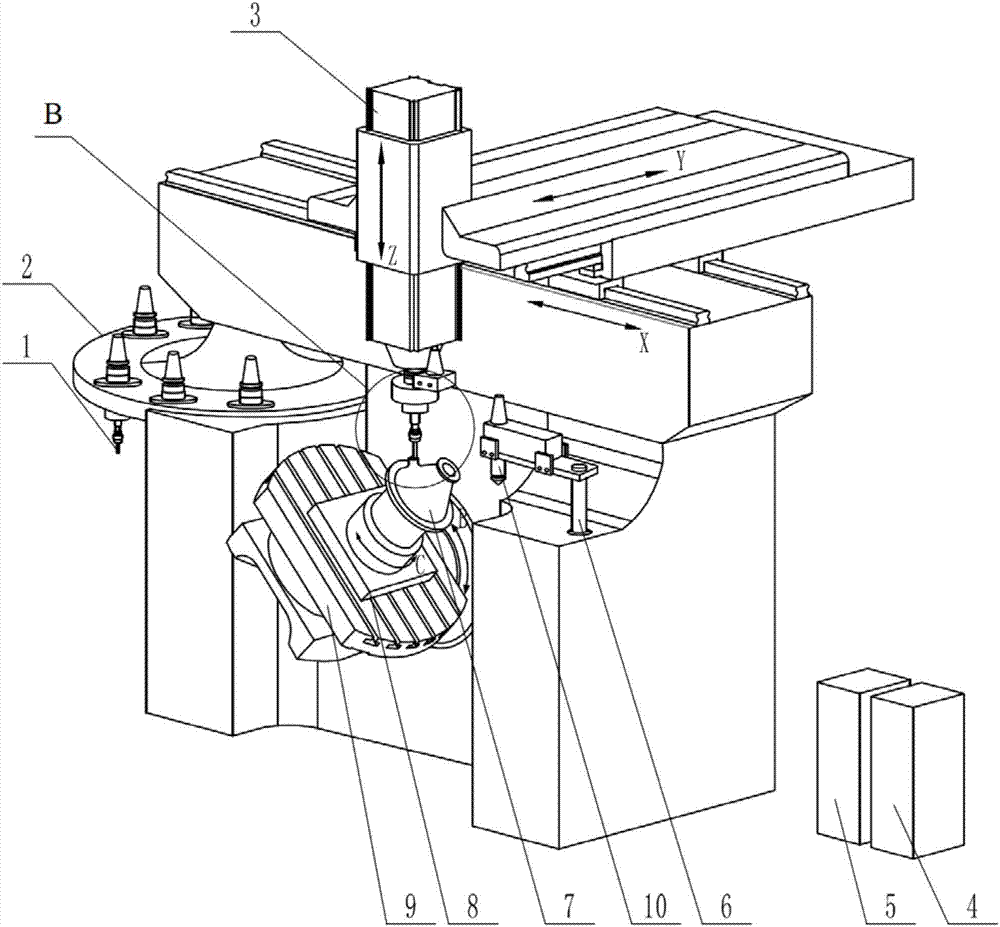

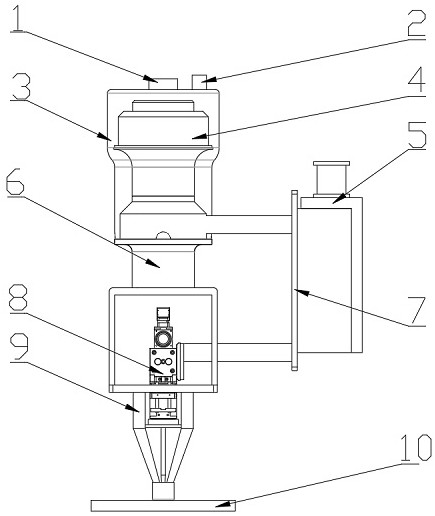

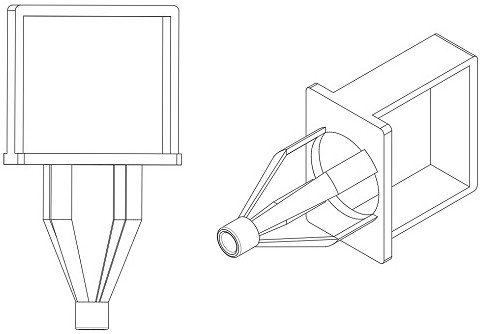

Arc additive and laser-assisted thermoplastic forming composite manufacturing device and method

InactiveCN110977172AImprove performanceReduce deformation resistanceAdditive manufacturing apparatusLaser beam welding apparatusLaser assistedLaser heating

The invention discloses an arc additive and laser-assisted thermoplastic forming composite manufacturing device and method. The arc additive and laser-assisted thermoplastic forming composite manufacturing device comprises a workbench and a base plate fixedly arranged on the workbench. A moving machine tool is arranged above the workbench; and an electric arc additive module and a plastic formingmodule which are connected to the moving machine tool are arranged above the base plate. The electric arc additive module comprises a welding gun and a wire feeder; the plastic forming module comprises a mechanism for carrying out plastic forming on a deposition layer on the surface of the base plate; a laser heating module for heating the deposition layer under the plastic forming mechanism is arranged at one side of the plastic forming module above the base plate; the laser heating module comprises a laser generator and a laser head connected with the laser generator through an optical fiber, the laser generator is connected with a stabilized voltage supply, the laser head comprises a housing, an optical fiber inlet is formed in one end of the housing, a laser outlet is formed in the other end of the housing, a collimating mirror and a focusing mirror are arranged in the housing, and the laser outlet faces the deposition layer under the plastic forming mechanism.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

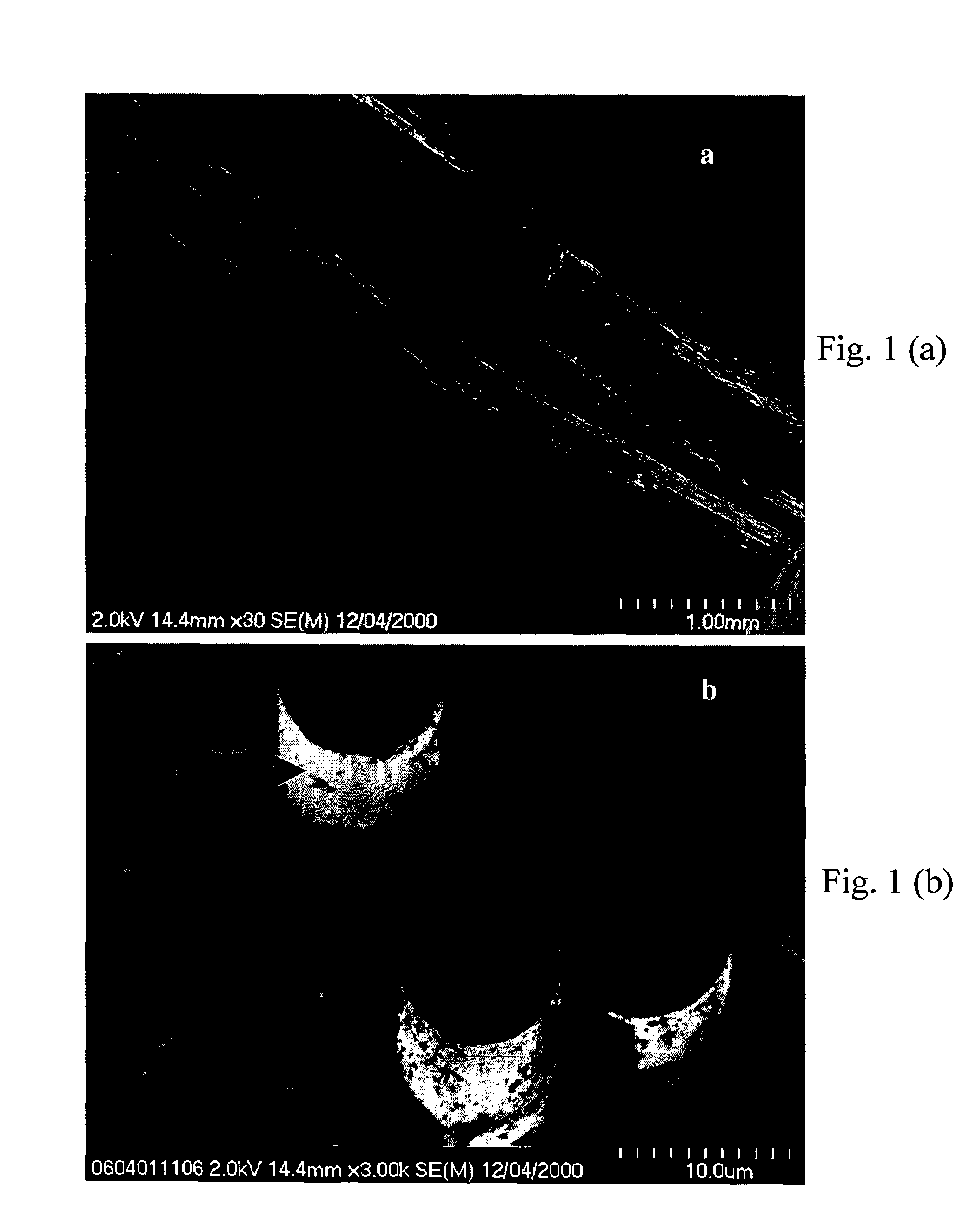

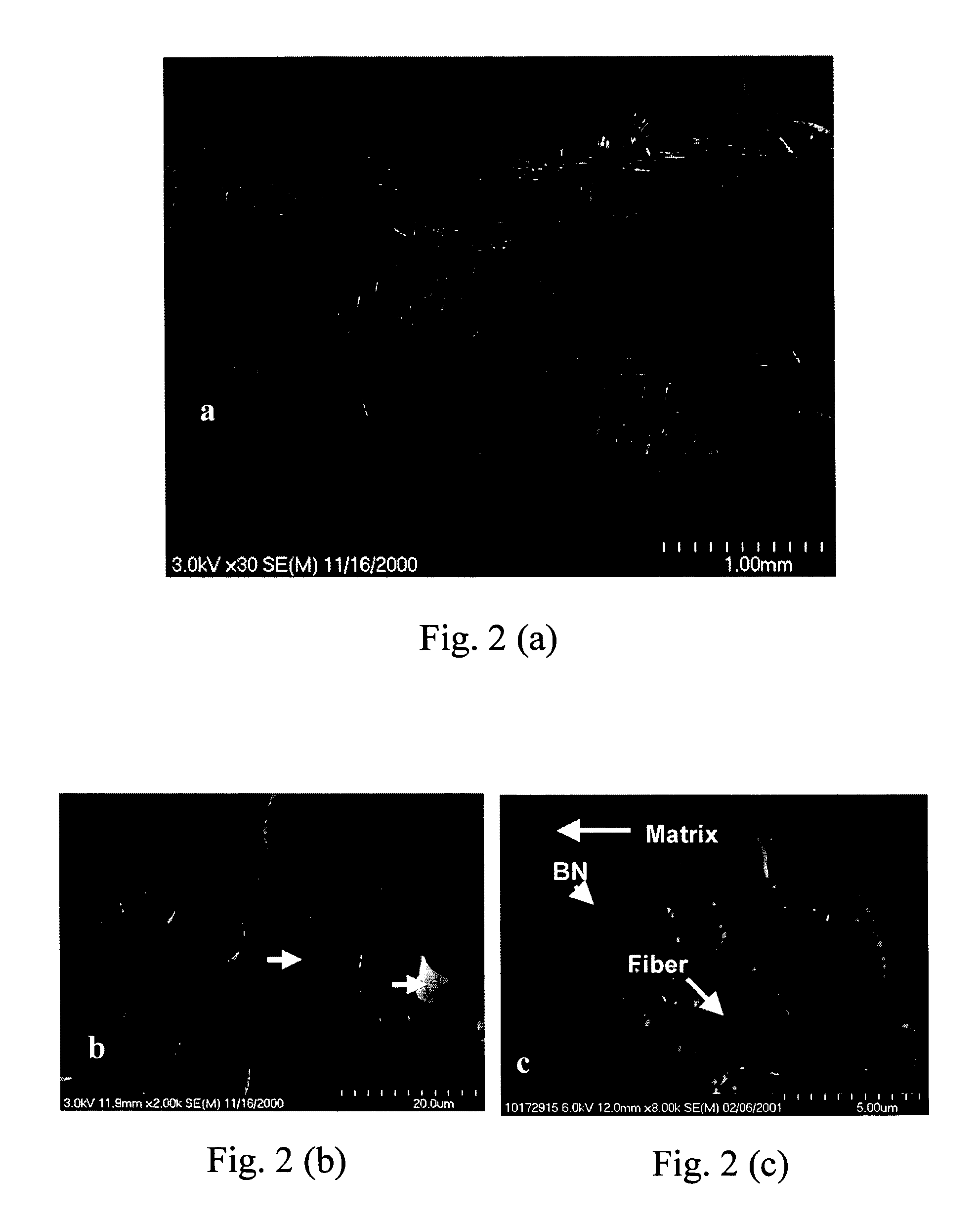

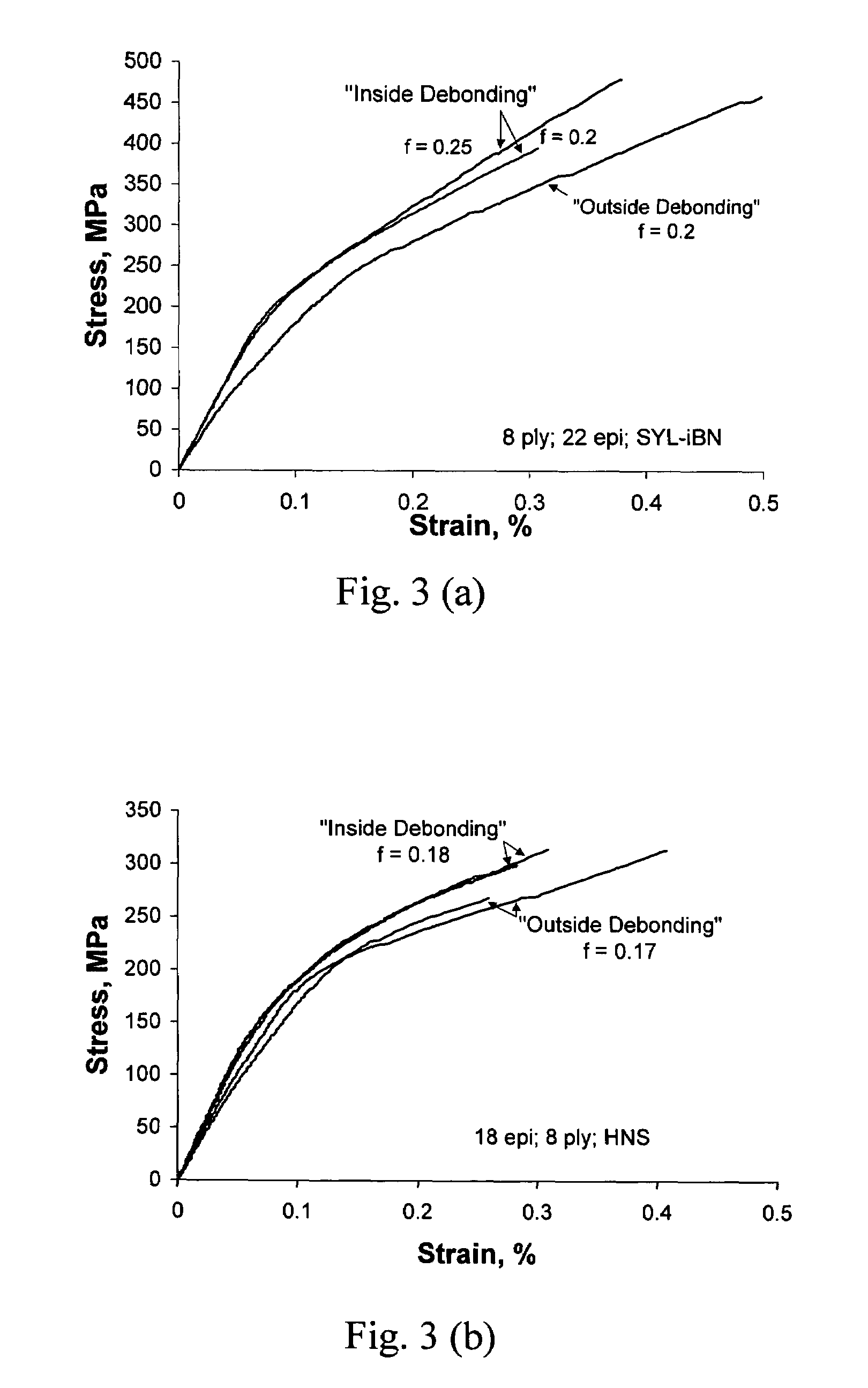

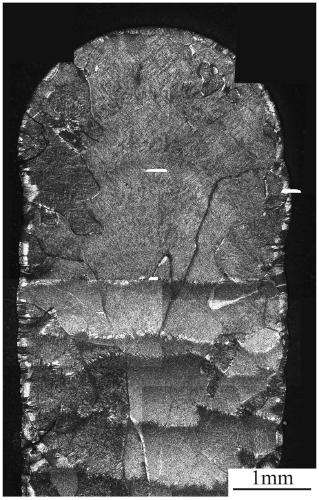

Interphase for ceramic matrix composites reinforced by non-oxide ceramic fibers

ActiveUS7427428B1Improve the oxidative durability of ceramic matrix composite materialsMaintain reliabilityLayered productsPretreated surfacesOxide ceramicNon oxide ceramics

A ceramic matrix composite material is disclosed having non-oxide ceramic fibers, which are formed in a complex fiber architecture by conventional textile processes; a thin mechanically weak interphase material, which is coated on the fibers; and a non-oxide or oxide ceramic matrix, which is formed within the interstices of the interphase-coated fiber architecture. During composite fabrication or post treatment, the interphase is allowed to debond from the matrix while still adhering to the fibers, thereby providing enhanced oxidative durability and damage tolerance to the fibers and the composite material.

Owner:NASA UNITED STATES OF AMERICA AS REPRESENTED BY THE ADMINISTATOR OF THE

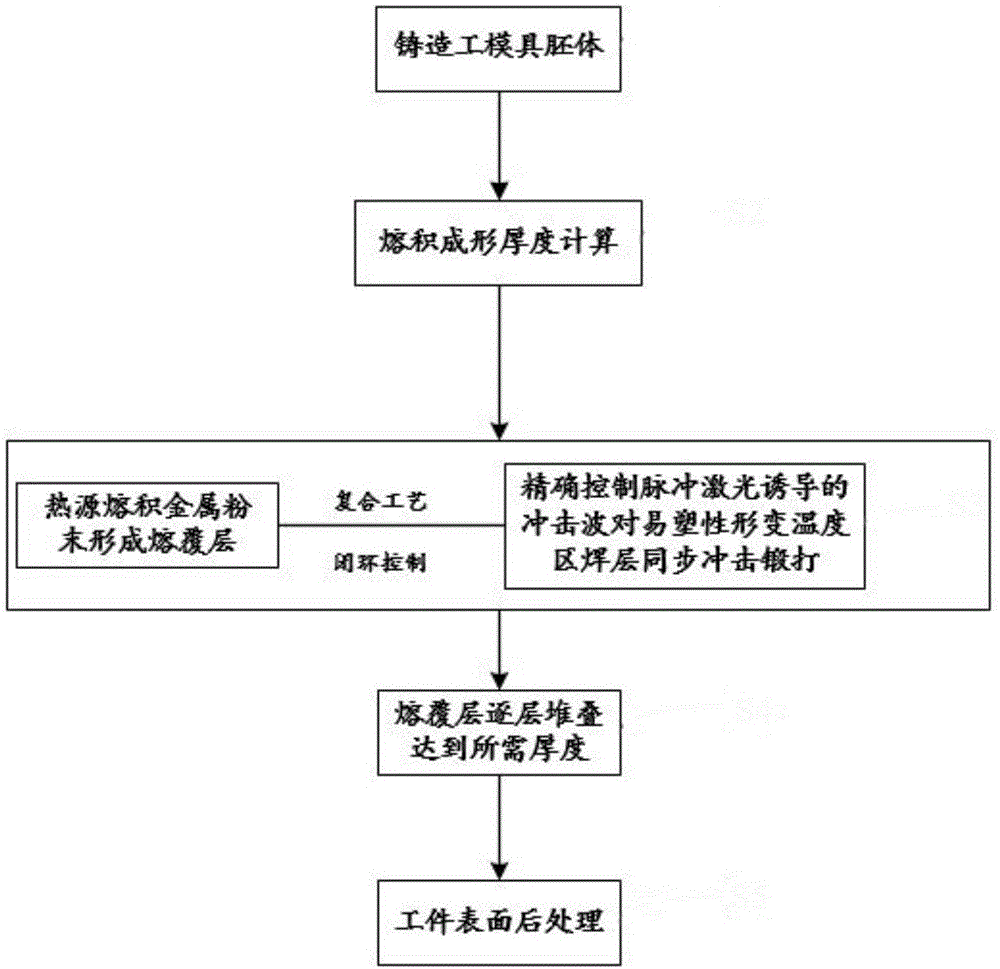

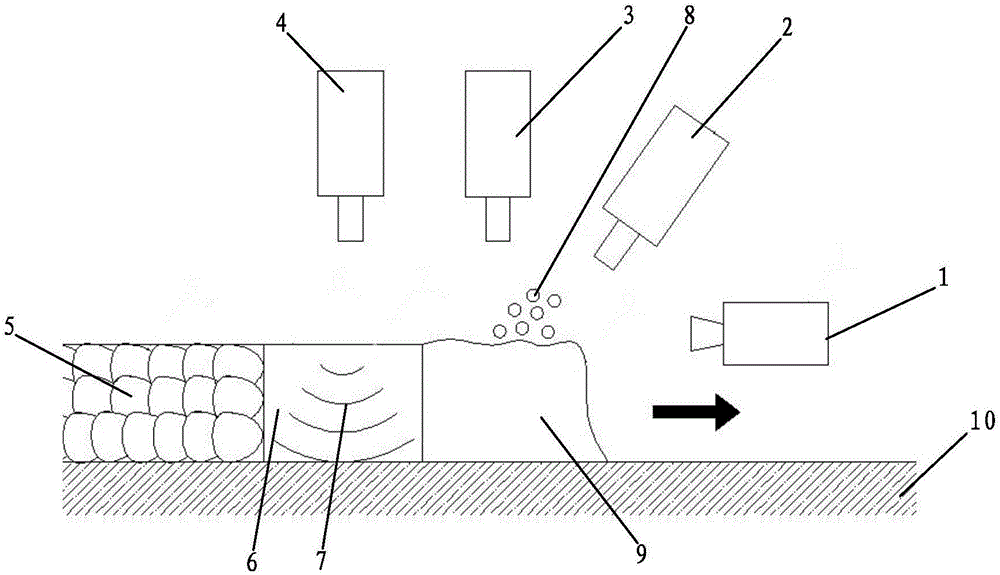

Mould melting-deposition forming and laser impact forging composite additive manufacturing method and device

InactiveCN107520449AQuality improvementImprove efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyMetal powderMetal mold

The invention discloses a mould melting-deposition forming and laser impact forging composite additive manufacturing method. The mould melting-deposition forming and laser impact forging composite additive manufacturing method comprises the following steps that (1) a mould blank body is cast; (2) the melting-deposition forming thickness is calculated; (3) metal powder is subjected to melting deposition through a heat source to form cladding layers, a controller controls a laser generator to conduct impact forging on a melting-deposition metal area at the plastic deformation temperature synchronously, the cladding layers are stacked layer by layer till the thickness of the cladding layers reach the thickness value in the step (2), and thus a workpiece is formed; and (4) the surface of the workpiece is treated. The invention further provides a mould melting-deposition forming and laser impact forging composite additive manufacturing device. The method adopts melting-deposition forming and laser impact forging composite manufacturing, melting-deposition forming and impact forging are conducted simultaneously, parameters are mutually coordinated and restrained in the process, thus, thermal stress, deformation and cracking can be avoided, the microstructure of a metal part is optimized, internal defects of pores, non-fusion, shrinkage porosity and the like are avoided, and the forming quality and efficiency of additive manufacturing of a metal mould are improved.

Owner:GUANGDONG UNIV OF TECH

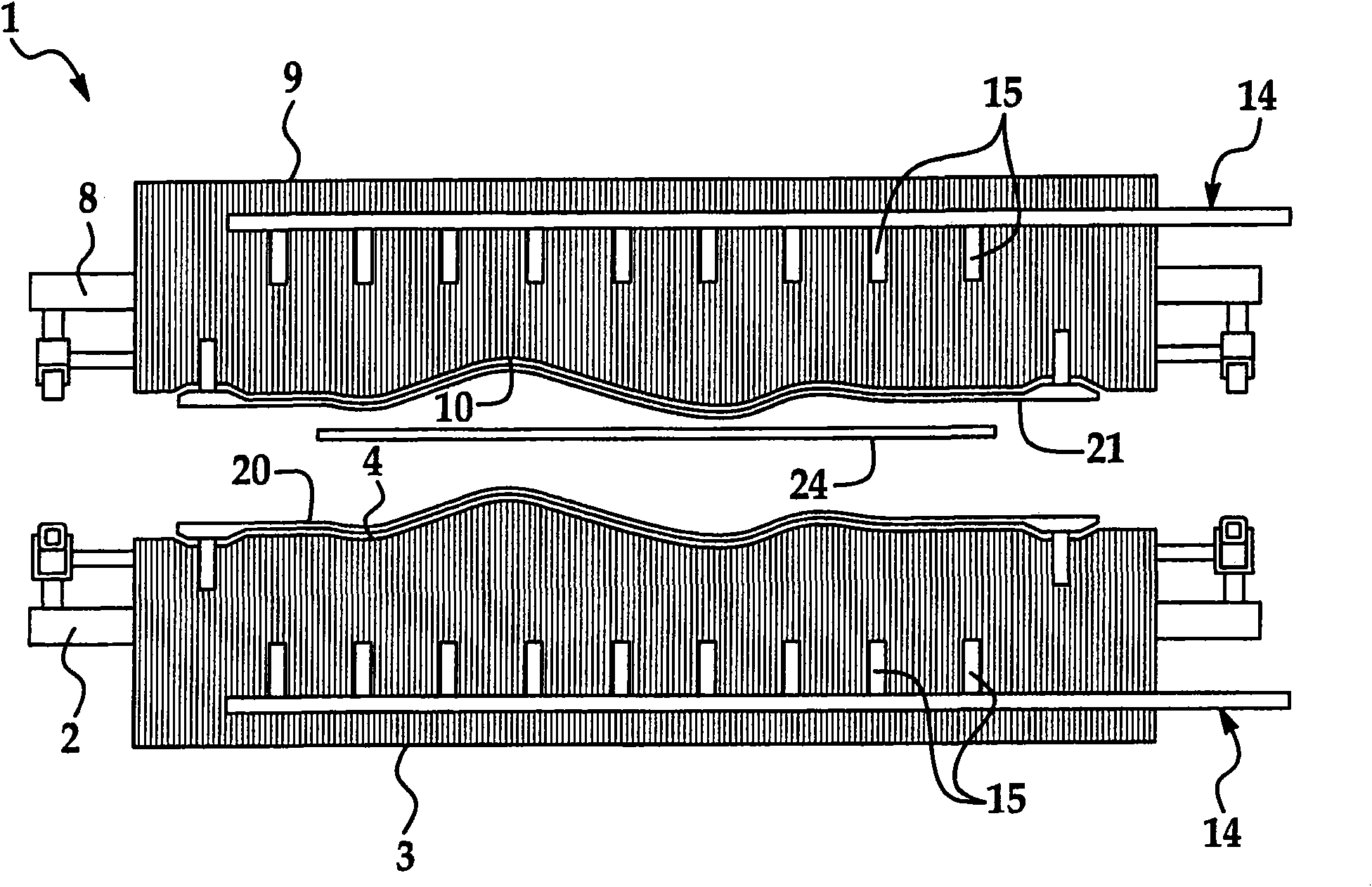

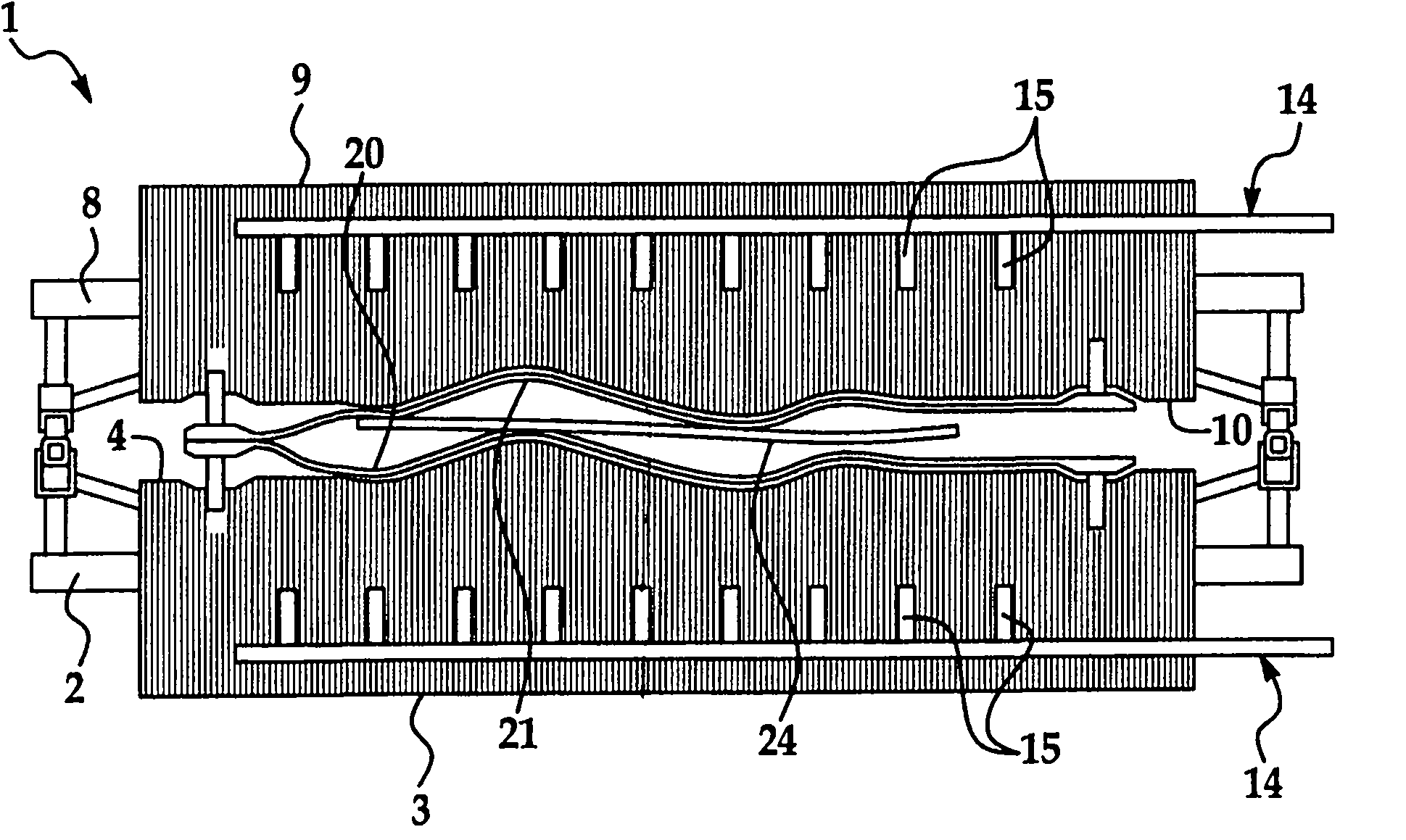

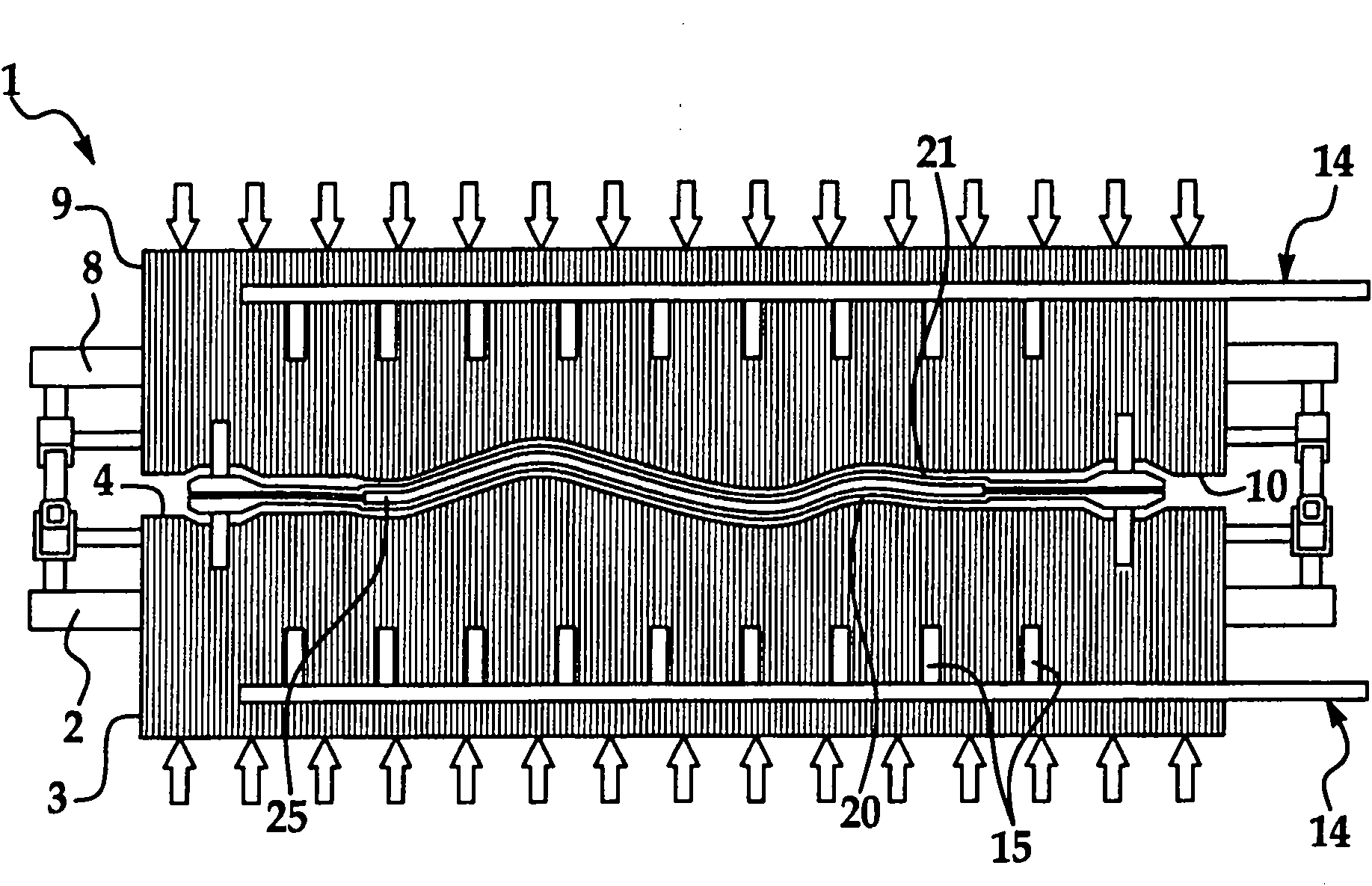

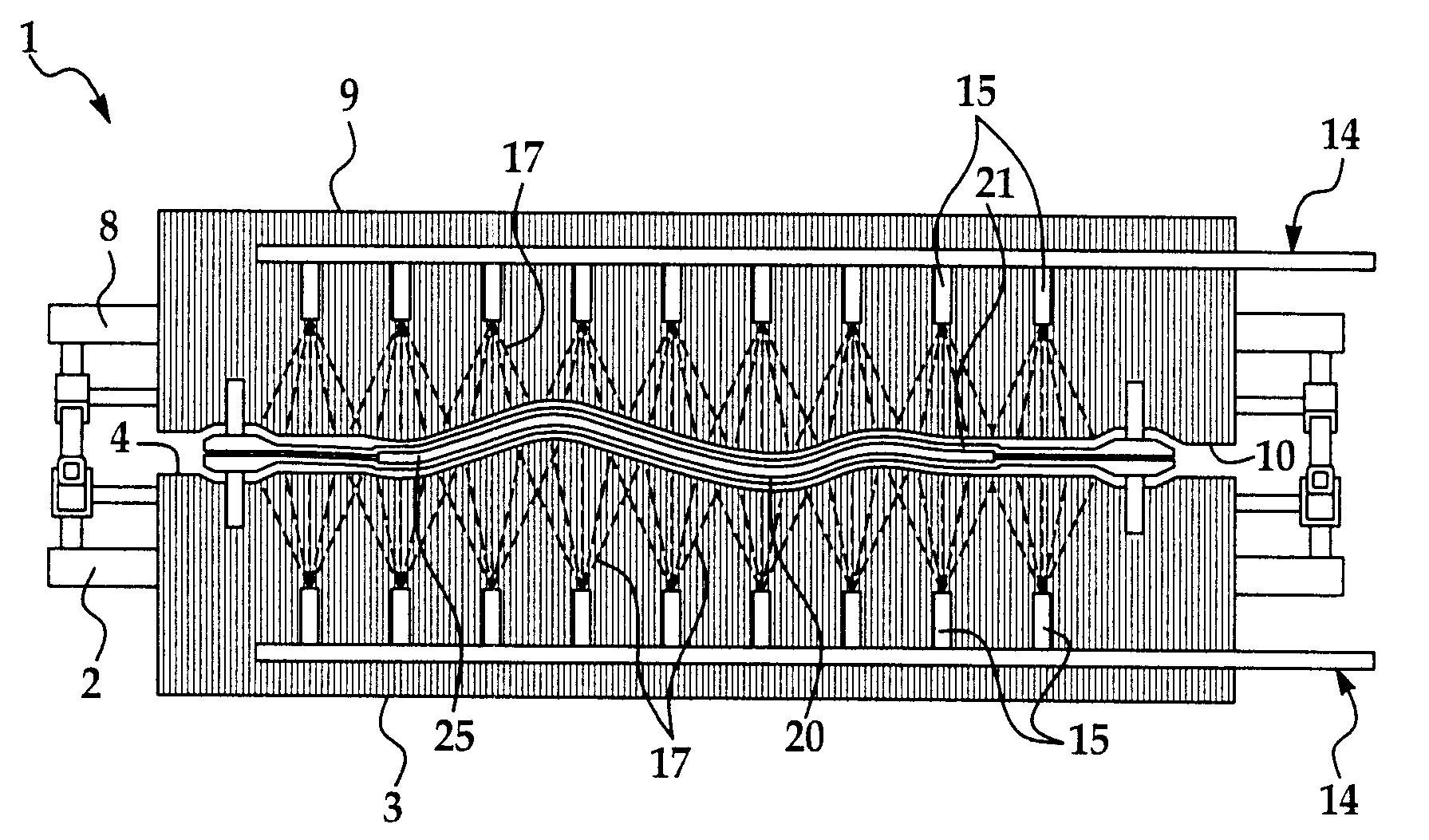

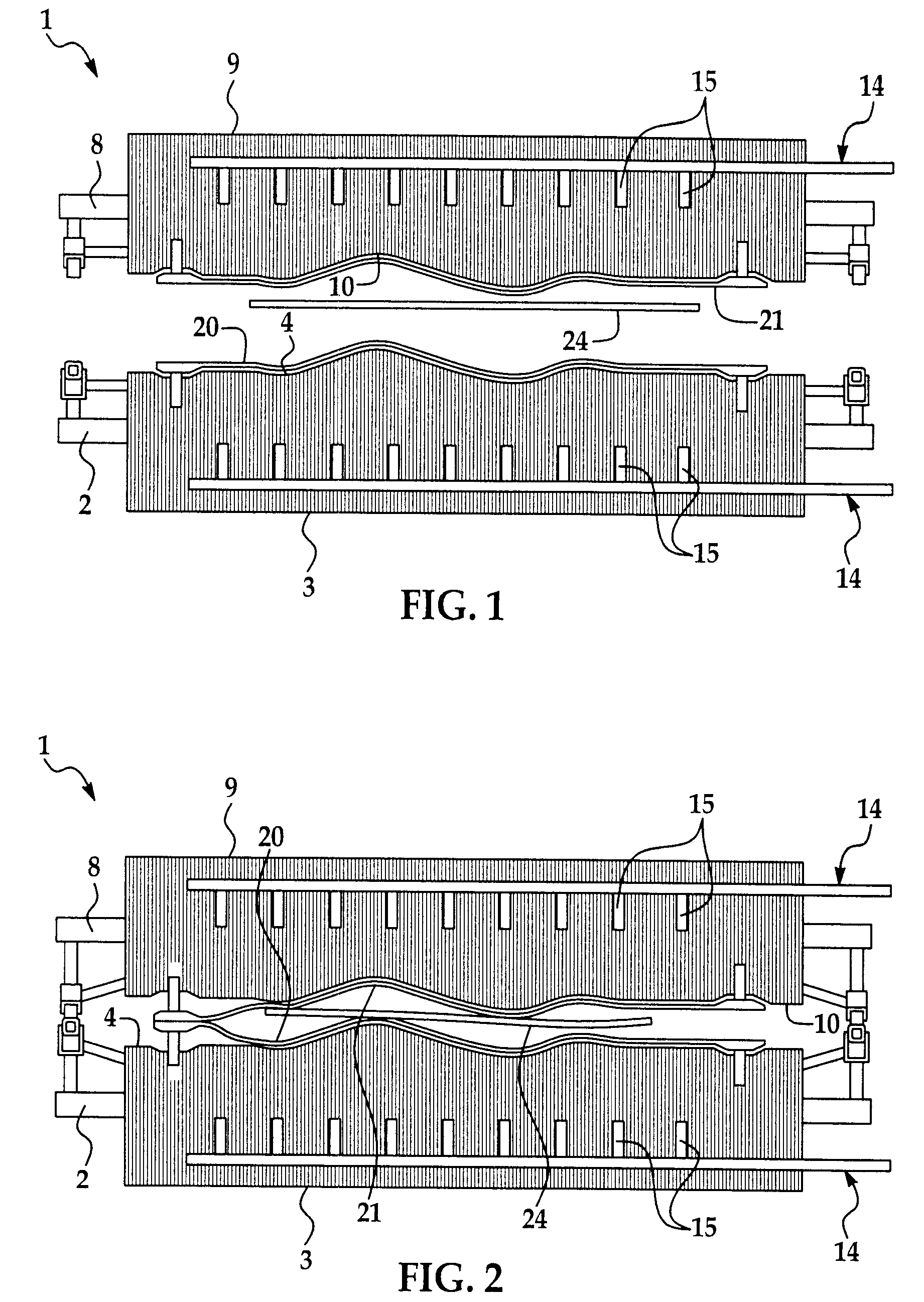

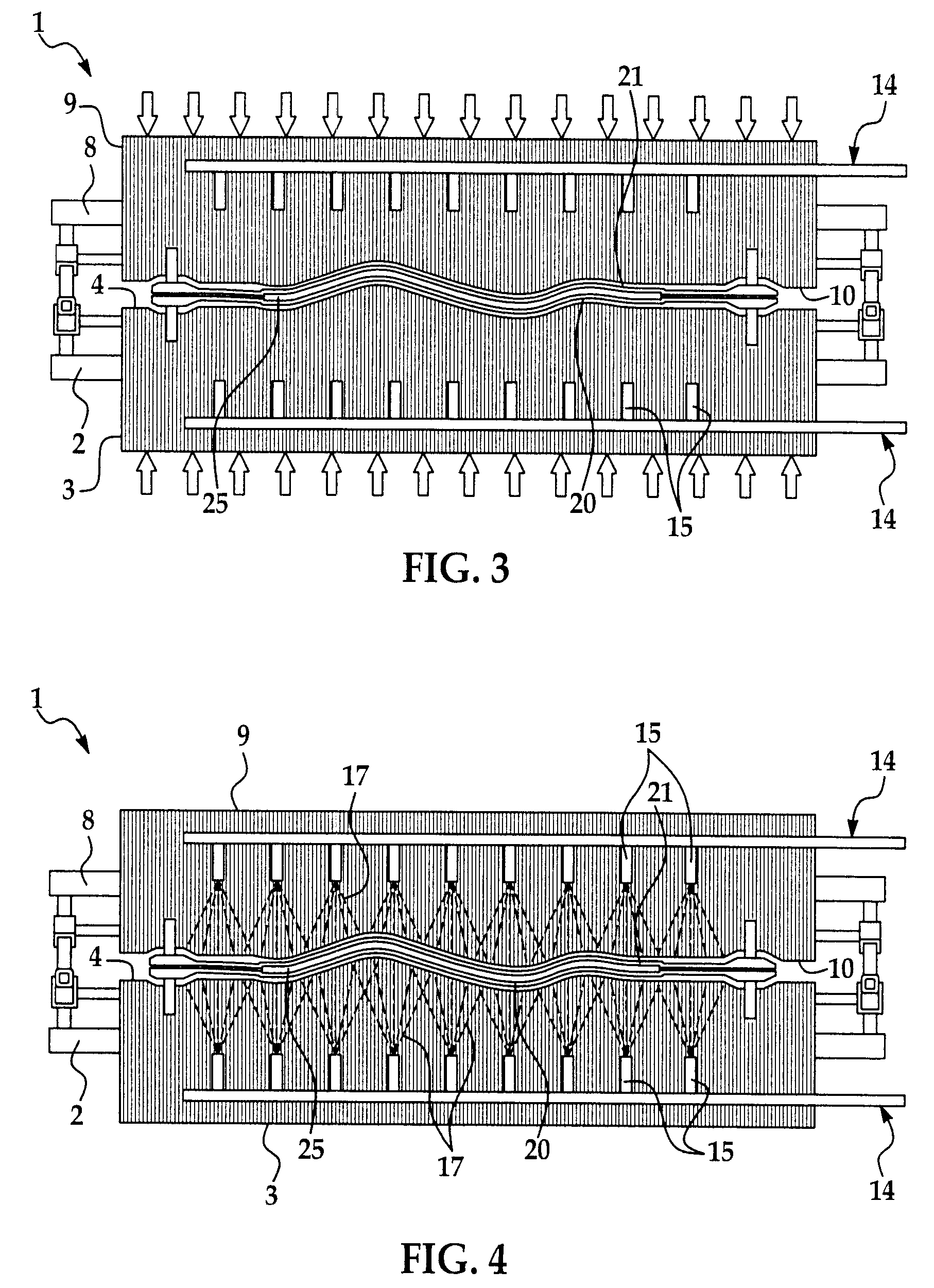

Method and apparatus for resin transfer molding composite parts

A composite fabrication apparatus (1) which may include a first tooling die (3) and a second tooling die (9) movable with respect to each other; a temperature control system (27) having induction coils (26) disposed in thermal contact with the first tooling die and the second tooling die; a first die susceptor (20) provided on the first tooling die and a second die susceptor (21) provided on the second tooling die and connected to the induction coils (26); and a cooling system (14) disposed in thermal contact with the first tooling die and the second tooling die. A resin transfer system (55) delivers resin from a resin source to the tooling dies to allow resin transfer molding. A composite fabrication method is also disclosed.

Owner:THE BOEING CO

Composite fabrication process for tooth blank of automobile gear shifting box combining tooth

The invention is a compound making technique of automobile gear-box combined gear blanks, adopting finely forge-molding processing method. It heats the blank material to 1000-1200 deg.C, premolding the blank material on a hot mold forging press, after constant-temperature normalizing, eliminating oxide debris by impeller cleaning, and surface bonderizing and phosphatization, making cold-refining on tooth form, and finally making cone molding on the tooth by radial extruding method. It instantaneously completes hot mold forging premolding, refining, and cone molding on the press without cutting, saving material, saving labor, low-cost, high-efficiency, long-service life. The combined tooth root has no escrape, it has no stress concentration phenomenon and the tooth has high strength; the extrusion molding of the gear blank does not destroy metallic streamlines, it heightens the synthetic performance, the product quality is stable and can meet use and industrialized production requirements of top-grade autocars.

Owner:夏汉关 +1

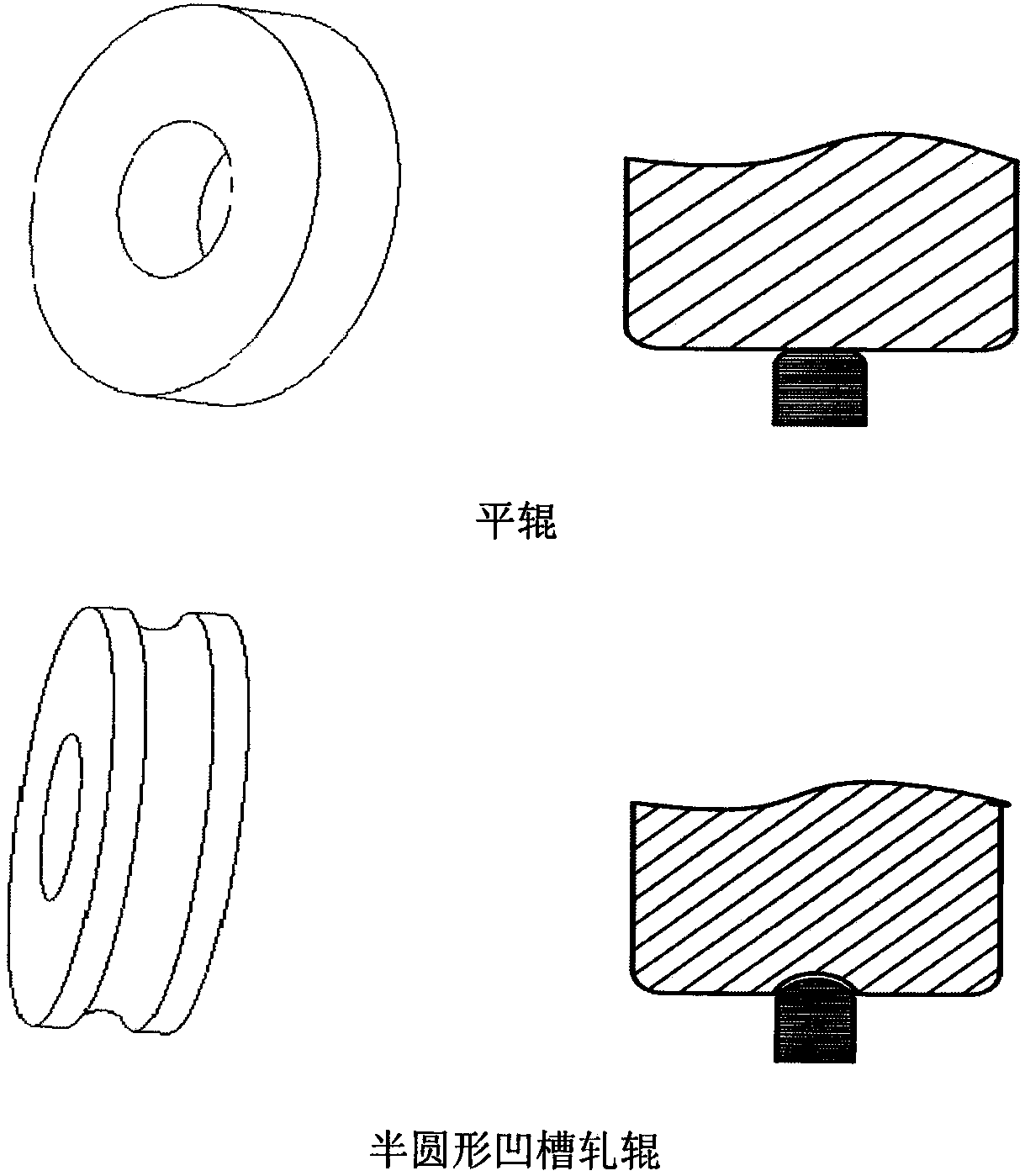

Manufacturing process of hot-rolled composite corrosion-resistant bimetallic steel pipe

InactiveCN102274853AReduce consumptionReduce manufacturing costMetal rolling arrangementsCost savingsCorrosion resistant

The invention discloses a hot-rolled composite corrosion-resistant bimetallic steel pipe manufacturing process, which includes the following steps: (1) tube blank preparation; (2) mechanical compounding; (3) welding edge sealing; (4) tube blank heating; 5) hot rolling composite; (6) heat treatment; (7) post-finishing. The invention provides a manufacturing process of hot-rolled composite corrosion-resistant bimetallic steel pipes. Two or more steel pipes of different materials and specifications are made into composite pipe blanks, and the composite pipe blanks are rolled into composite pipes meeting the requirements. The relative deformation of the finished product is not less than 60% during hot rolling and compounding, which avoids the problems of high cost and difficulty in the traditional metallurgical compounding process, and has the advantages of low raw material cost, saving metal raw material consumption, low production cost, and compounding The effect is good, and the maximum outer diameter of the product can reach 610mm.

Owner:SICHUAN SANZHOU SPECIAL STEEL PIPE

Laser wire fusing additive manufacturing titanium alloy component structure refining and isometric crystal converting method

ActiveCN111451504AEffectively compatibleRelease residual stressAdditive manufacturing apparatusIncreasing energy efficiencyManufacturing technologyMetallurgy

Owner:HARBIN ENG UNIV

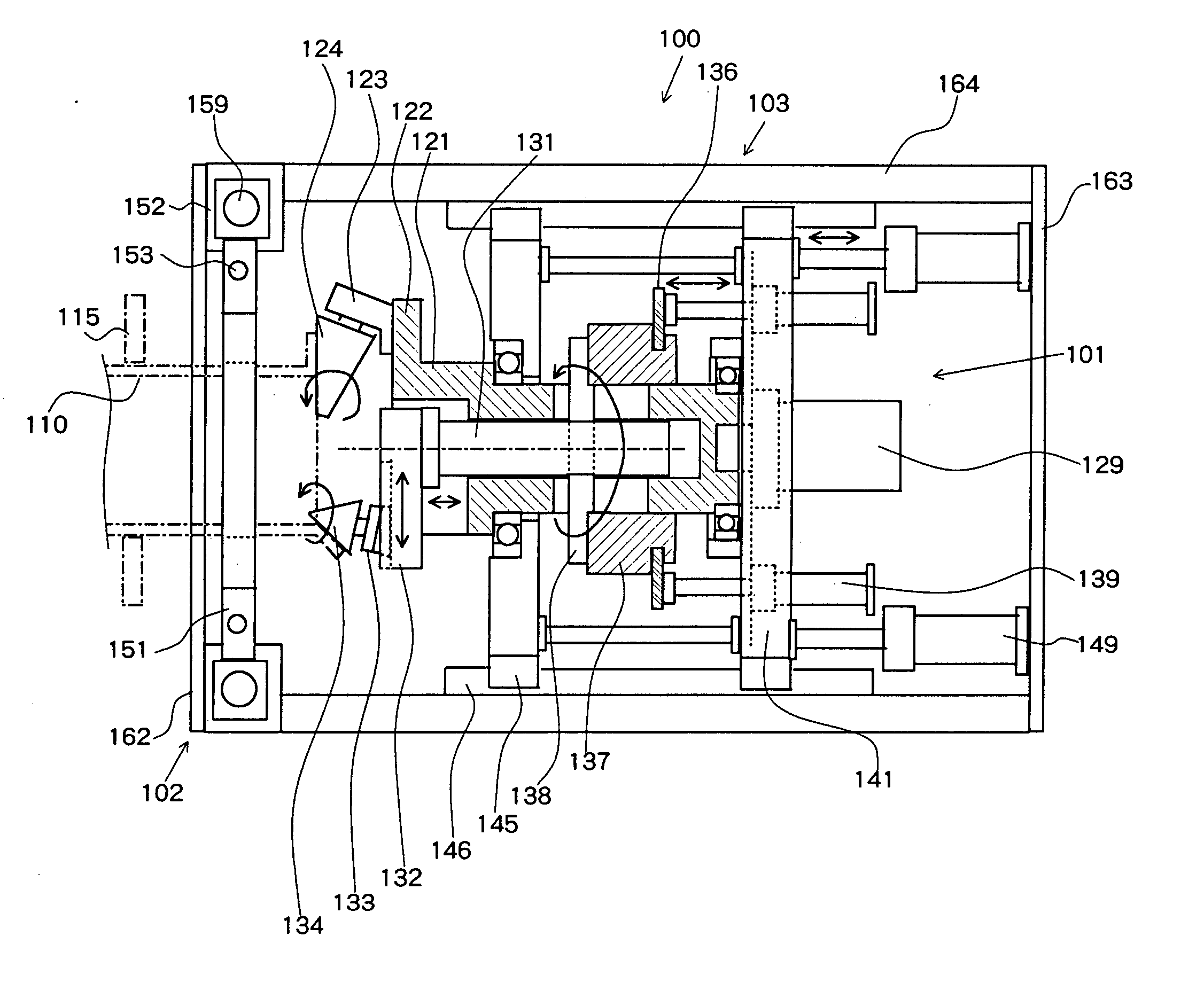

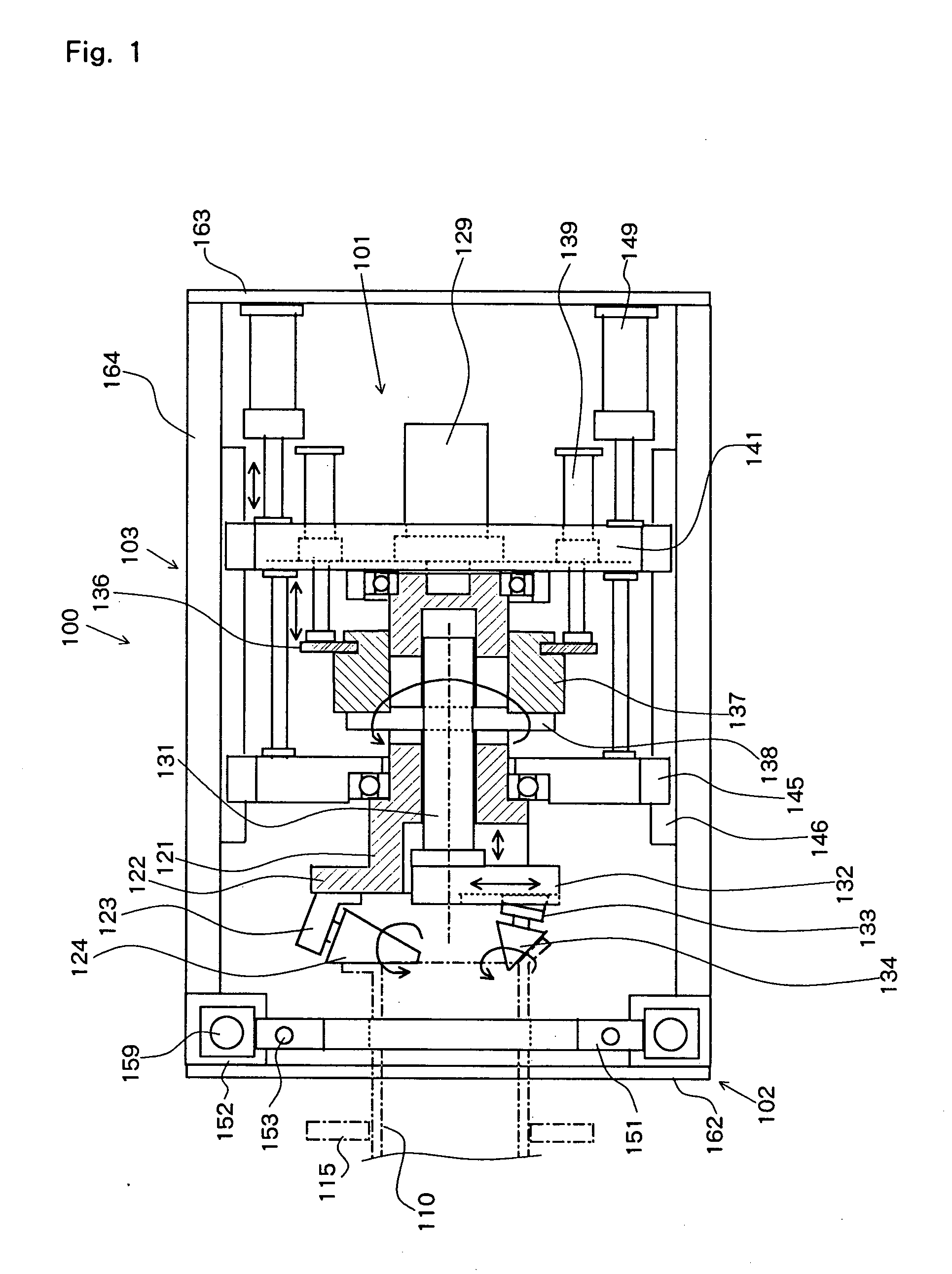

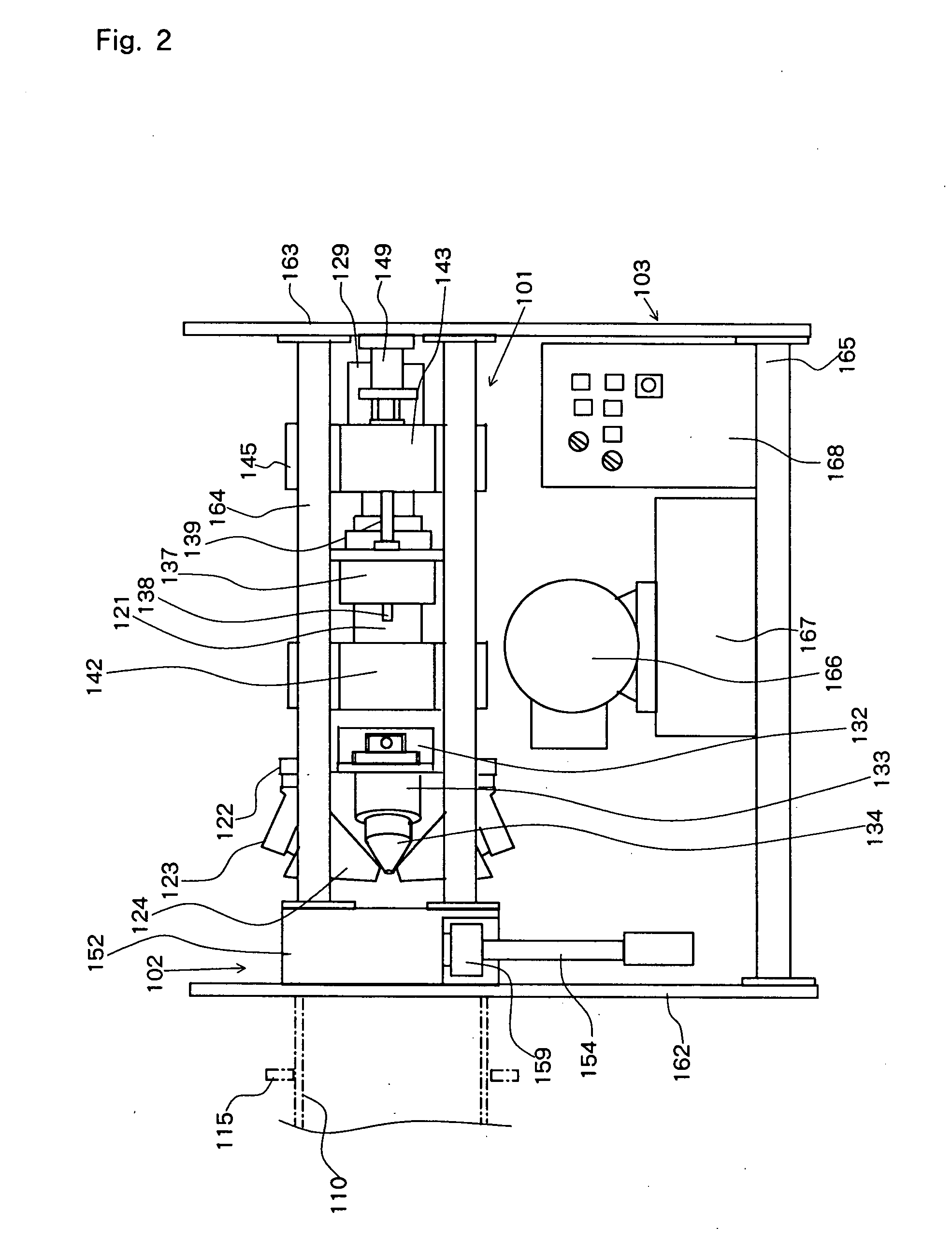

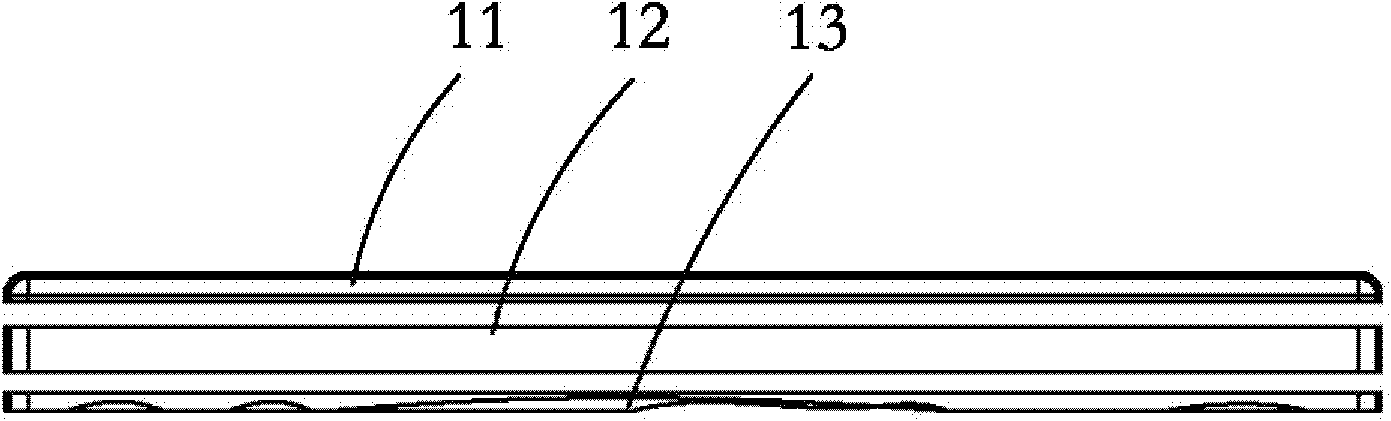

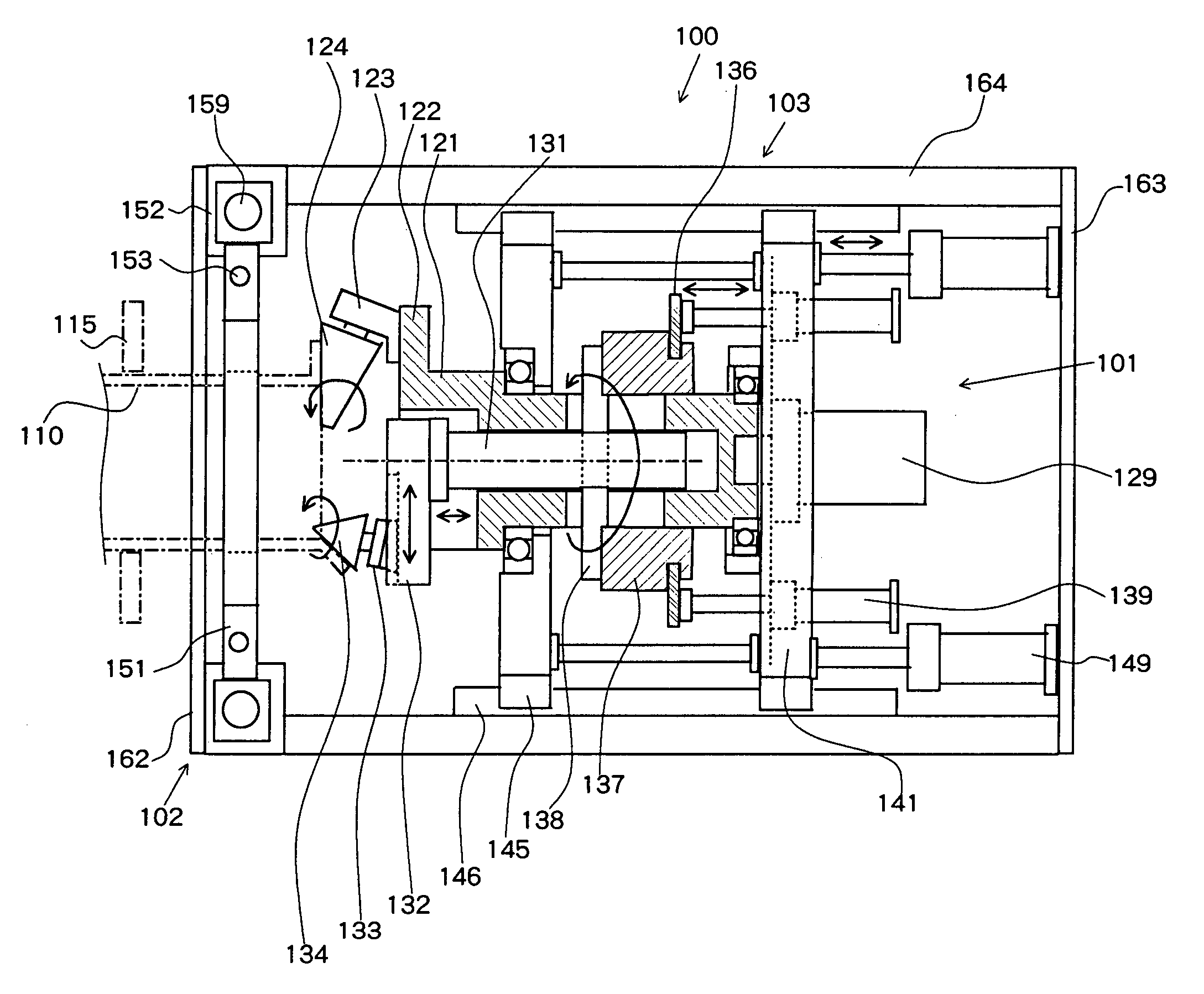

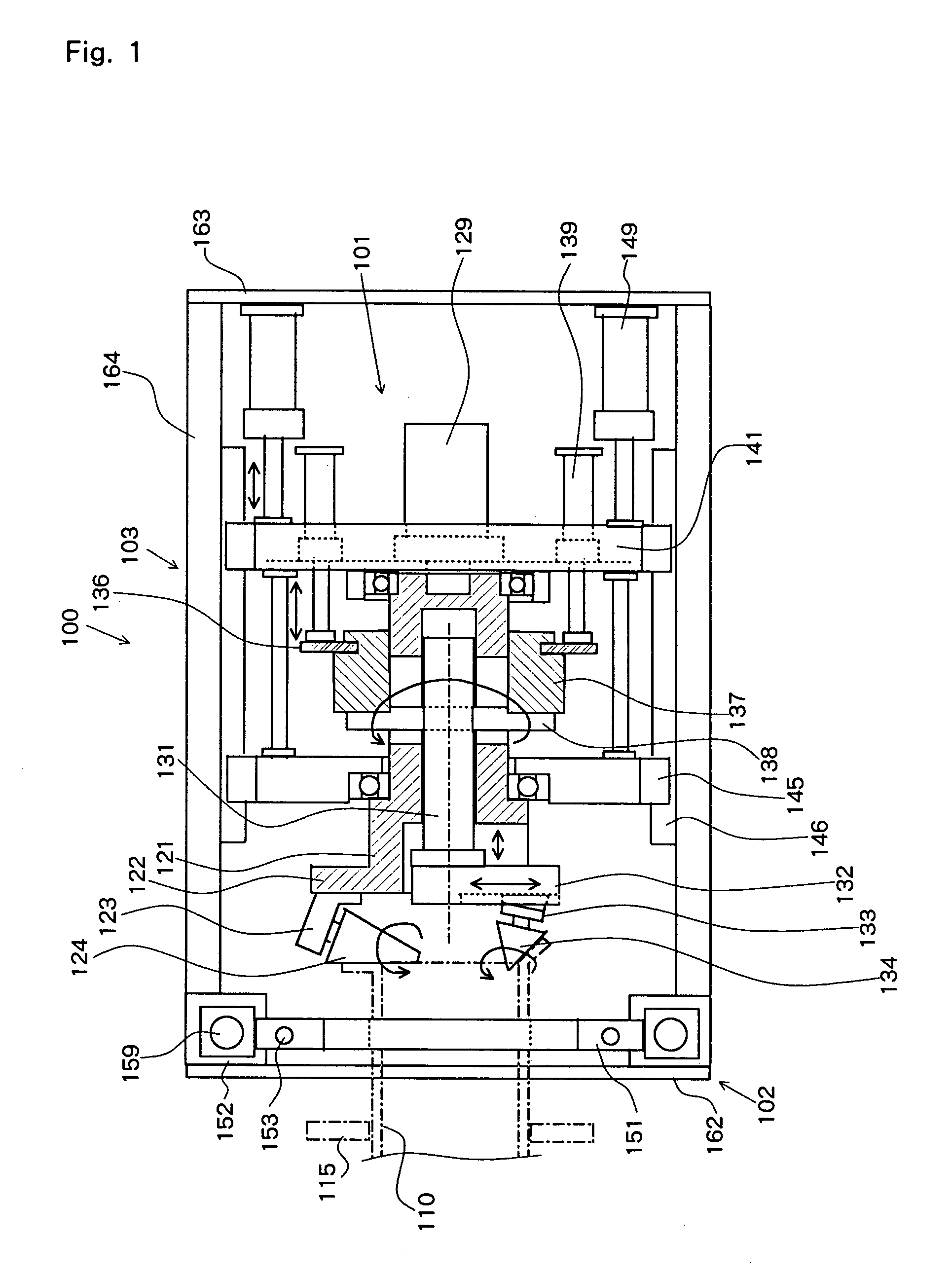

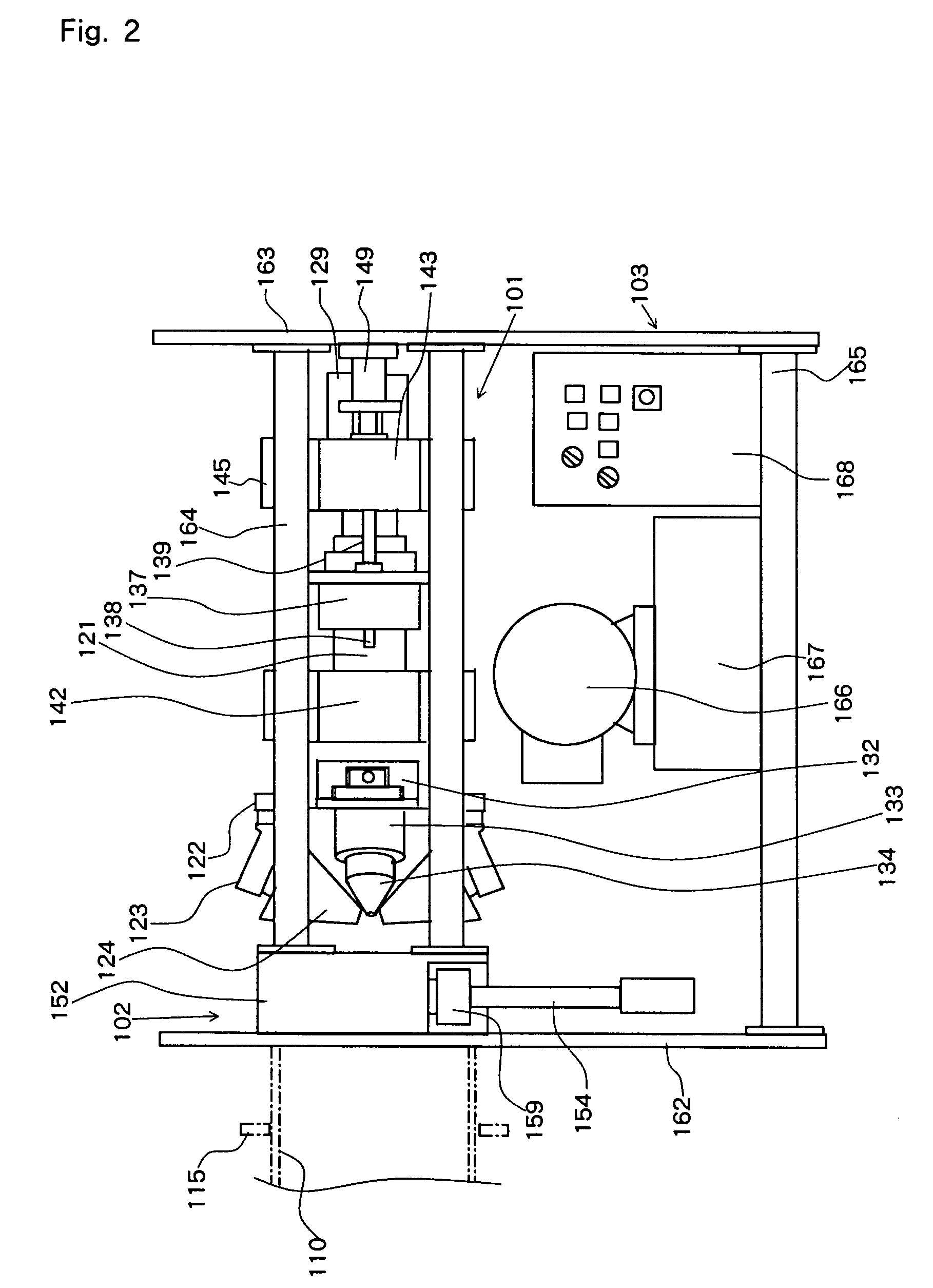

Composite fabrication facility of steel tube and fabrication method of steel tube

InactiveUS20060162410A1Small sizeEasy to moveEdge grinding machinesOther manufacturing equipments/toolsMachiningSteel tube

The present invention pertains to a combined machining equipment for steel tubes, and a machining method is of a small size, can easily be moved, and is capable of not only flaring a steel tube, but also grinding a flared surface, forming a groove, and peeling off a lining. A main shaft (121) is rotatably mounted on a slide frame (141) slidable with respect to a common mount (103), and a second machining head (124) is mounted on a flange on the distal end of the main shaft (121). An auxiliary shaft (131) is slidably disposed in the main shaft (121) for rotation therewith. A first machining head (134) is mounted on a mount base (132) on the distal end of the auxiliary shaft (131). When the main shaft (121) is rotated and moved back and forth and the auxiliary shaft (131) is moved back and forth with respect to the main shaft (121), the first machining head (134) spreads the tip end of a steel tube (110) held by a steel tube holding apparatus (102) to a first position, and the second machining head (124) spreads the tip end of the steel tube (110) to a predetermined flanged position, thus flaring the tip end of the steel tube (110).

Owner:OGAWA KIYOSHI

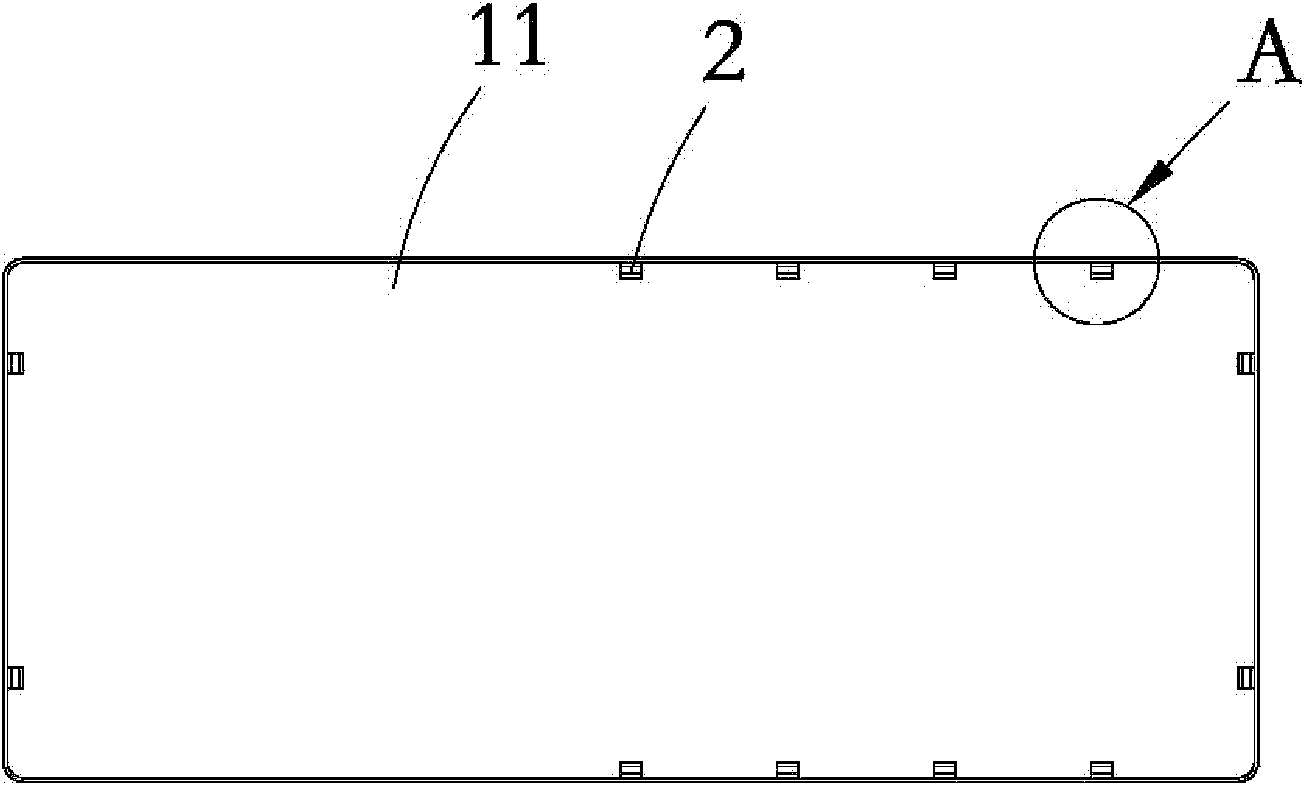

Composite manufacturing process for handy terminal exterior piece, and product thereof

The invention is suitable for the technical field of handy terminal production, and provides a composite manufacturing process for a handy terminal exterior piece, and a product thereof. The process comprises the following steps of: 1, performing impact molding to obtain a titanium / titanium alloy / gold / silver shell panel; 2, manufacturing a titanium / titanium alloy / gold / silver clamp hook, or punching a plurality of micropores on the inner surface of the titanium / titanium alloy / gold / silver shell panel, wherein the titanium / titanium alloy / gold / silver shell panel and a die casting aluminum alloy / zinc alloy internal are connected through the clamp hook or in a micropore penetration mode; and 3, performing surface treatment on the outer surface of the shell panel. The provided composite manufacturing process can save the titanium / titanium alloy / gold / silver material, and reduces the production cost of the handy terminal exterior piece. The invention also provides the handy terminal exterior piece which is produced by the process, and the exterior piece has low production cost, high corrosion resistance, light weight, and high intensity and beauty.

Owner:深圳市华欣永业科技有限公司

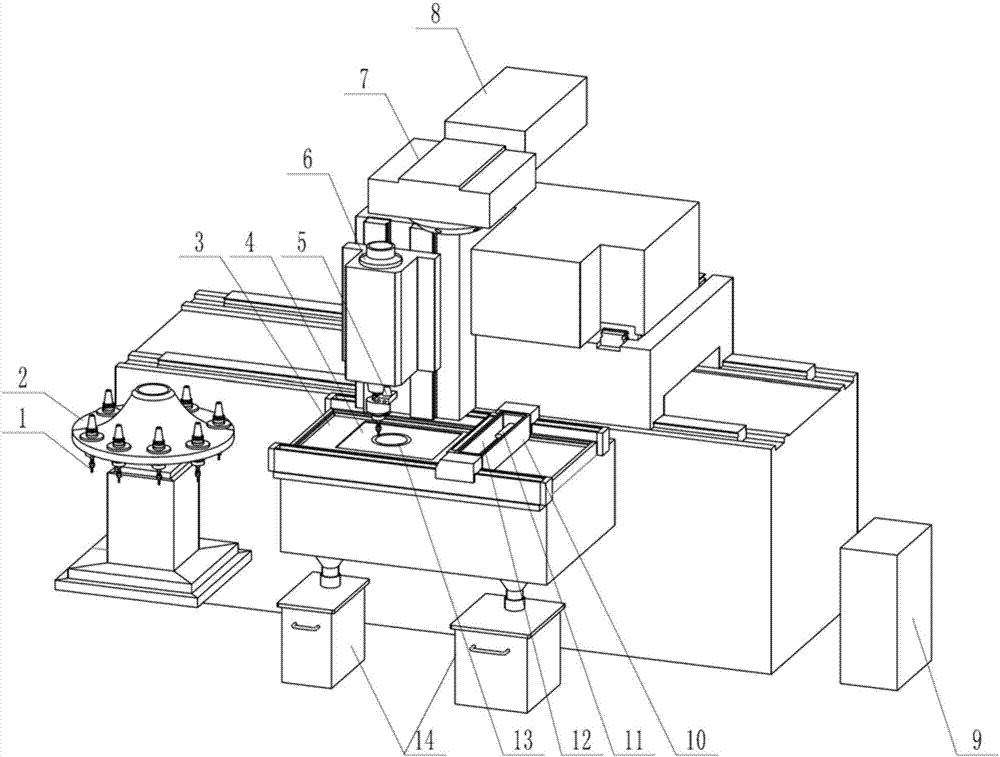

Equipment for applying ultrasonic cutting to powder feeding type material increase and removal composite manufacturing and machining method

InactiveCN107127583AExtended service lifeSolve the problem of longevityOther manufacturing equipments/toolsMaterial removalHorizontal axis

The invention relates to the field of material increase and removal manufacturing, in particular to equipment for applying ultrasonic cutting to powder feeding type material increase and removal composite manufacturing and a machining method. The equipment comprises a tool, a tool magazine, a main shaft, a lathe bed, a laser generator, a powder feeding device, a nozzle bracket, a base plate, a working table and a cladding spray head. The main shaft is installed on the upper portion of the lathe bed. In the material increase manufacturing process, the cladding spray head is installed on the lower portion of the main shaft. In the material removal machining process, the tool is installed on the lower portion of the main shaft, and an ultrasonic cutting device is installed between the main shaft and the tool. A cradle type working table capable of rotating around the horizontal axis and the vertical axis is installed on the portion, below the main shaft, of the lathe bed. The base plate is installed on the working table. Workpiece material increase composite manufacturing is carried out on the base plate. The nozzle bracket is installed on the lathe bed and located on one side of the main shaft working table. The nozzle bracket is used for storing the cladding spray head. The cladding spray head is connected with the external laser generator and the powder feeding device. The tool magazine is installed on the other side of the working table, and the tool is installed in the tool magazine. The equipment has the beneficial effects of being novel in structure, easy to machine, high in stability and applicable to various kinds of high-difficulty workpiece machining, prolonging the service life of the tool and improving workpiece machining precision.

Owner:DALIAN UNIV OF TECH

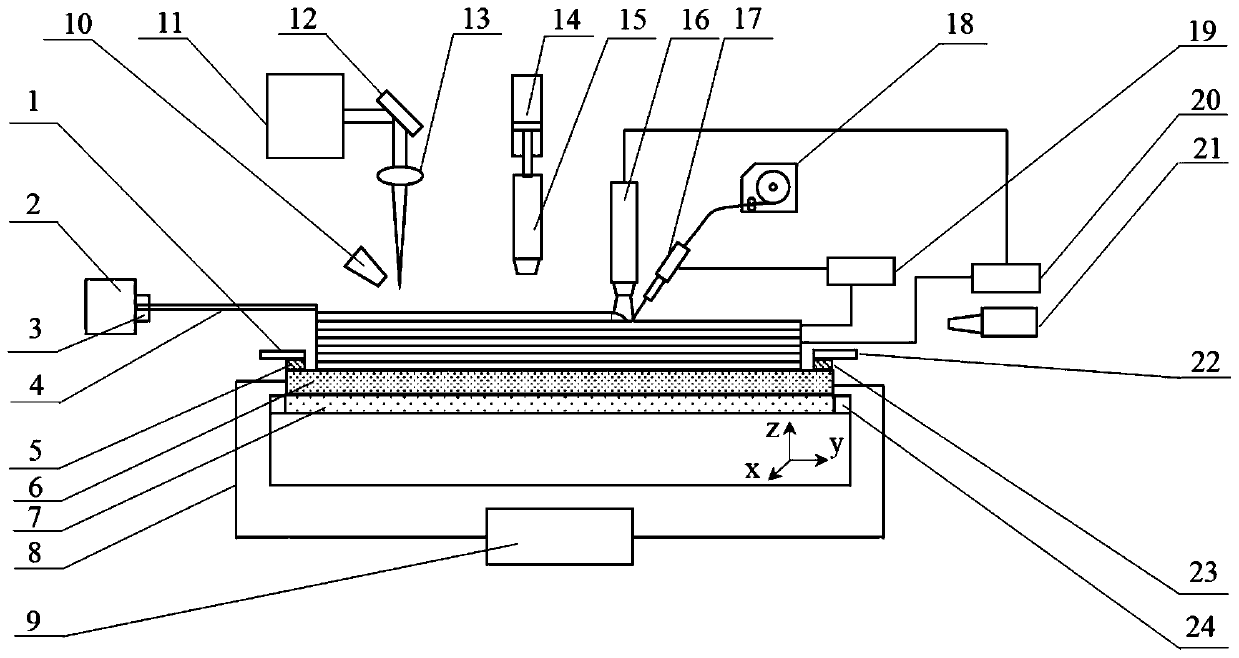

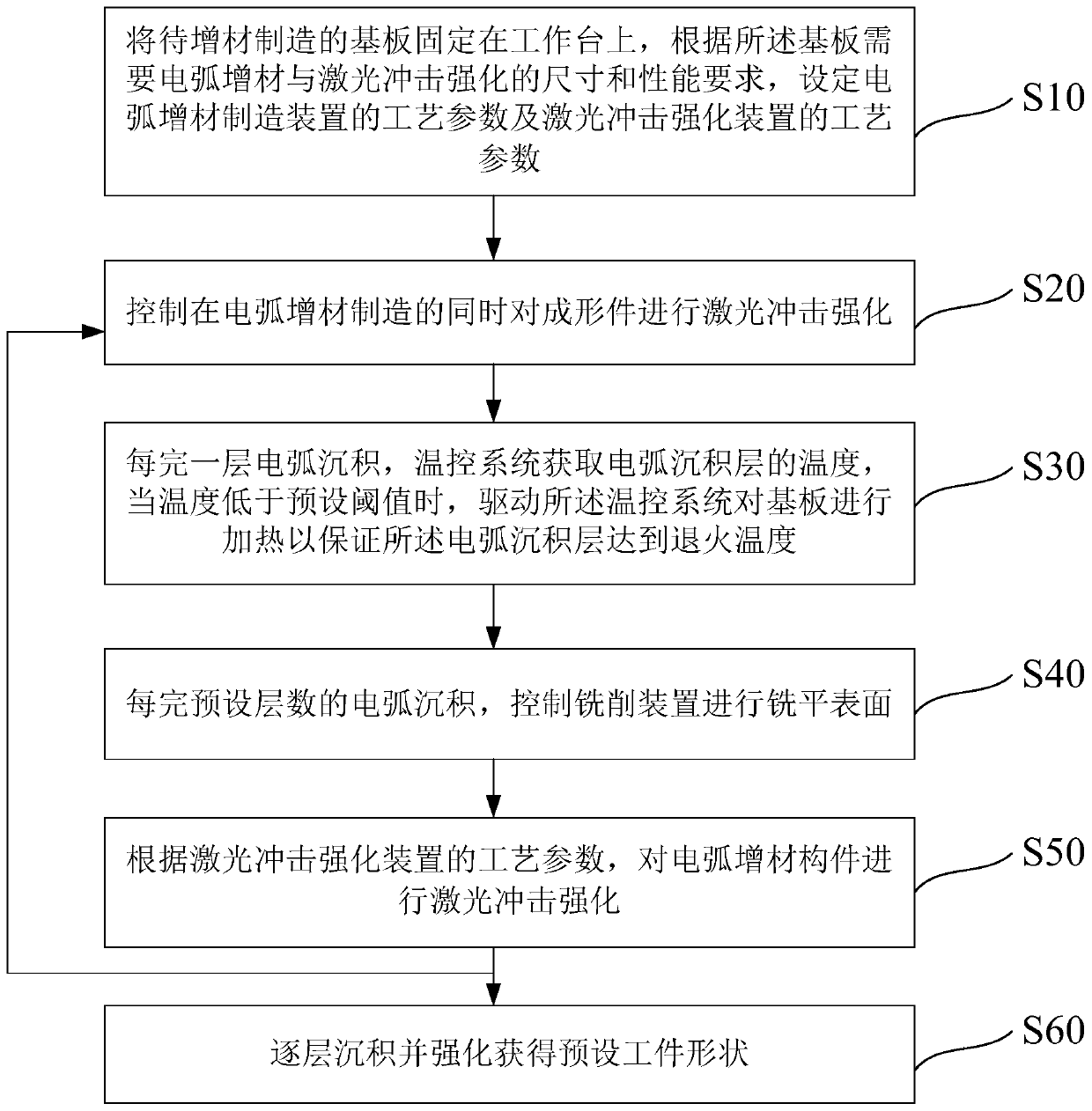

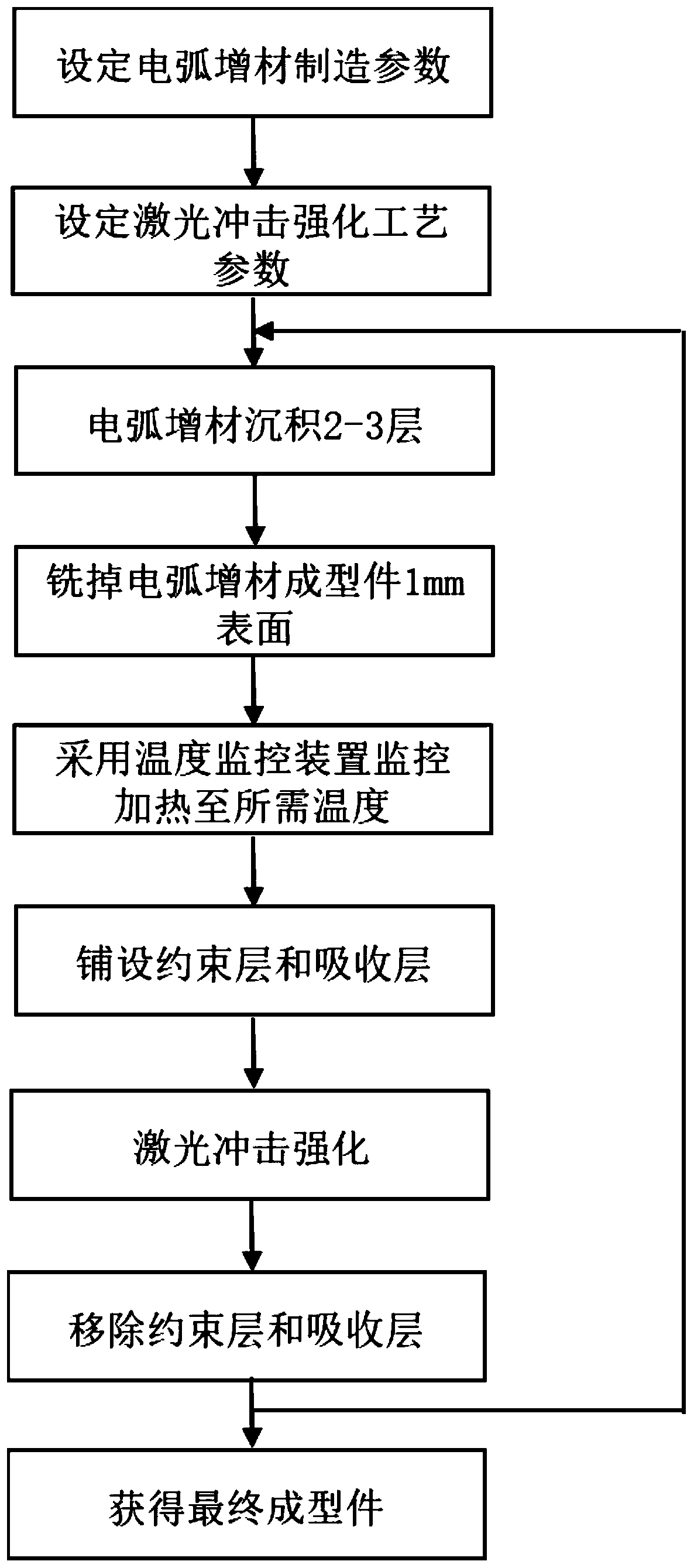

Wire and arc additive and laser shock peening composited manufacturing device and method

ActiveCN111545916AImprove applicabilityCompact structureAdditive manufacturing apparatusLaser beam welding apparatusTemperature controlControl system

The invention discloses a wire and arc additive and laser shock peening composited manufacturing device and method. The wire and arc additive and laser shock peening composited manufacturing device comprises a clamping device, a wire and arc additive manufacturing device, a laser shock peening device, a milling device, a constraint layer laying device, a temperature control system and a control system; and the control system is respectively and controllably connected with the wire and arc additive manufacturing device, the laser shock peening device, the milling device, the constraint layer laying device and the temperature control system. According to the wire and arc additive and laser shock peening composited manufacturing device and method, the wire and arc additive manufacturing device and the laser shock peening device are combined, so that reasonable structure design, simple operation and high applicability are achieved; and the uneven residual tensile stress caused by an even temperature field and a cooling contraction effect after forming in the manufacturing process of a wire and arc additive can be effectively eliminated, thick columnar crystal structures of components of the additive can be refined, and the microstructure and the mechanical property of the manufactured components of the additive can be further effectively improved.

Owner:BEIHANG UNIV +1

Laser melting deposition and laser shock strengthening combined manufacturing device and method

PendingCN110802226AIncrease stressImprove performanceAdditive manufacturing apparatusIncreasing energy efficiencyControl systemMonitoring system

The invention provides a laser melting deposition and laser shock strengthening combined manufacturing device. The device comprises a melting deposition system, a shock strengthening system and an online monitoring system which are connected by leads; the melting deposition system includes a melting laser device, a laser path assembly, a powder feeder, a melting deposition head and a three-dimensional processing platform; after being guided by the laser path assembly, a laser beam emitted from the melting laser device passes through the melting deposition head and reaches the three-dimensionalprocessing platform to form a laser spot; the shock strengthening system includes a shock strengthening laser device and a laser guide assembly; and the online monitoring system includes an online monitoring sensor and an information collection control system which are connected by leads. The combined manufacturing device can further overcome the problem of combined manufacturing of complex curved surface parts while solving the thermal stress problem in the process of laser melting deposition, and in addition, laser shock control is employed, the combined manufacturing device has the advantages of fast response, no contact, high controllability and the like.

Owner:西安空天机电智能制造有限公司

Part additive composite manufacturing device and method

InactiveCN110976869AAvoid processing powerIncreased efficiency in high-quality molding processesAdditive manufacturing apparatusIncreasing energy efficiencyLaser transmitterFemto second laser

The invention discloses a part additive composite manufacturing device and method. The part additive composite manufacturing device comprises a forming chamber, a controlling device, a laser melting mechanical arm, a laser shot blasting mechanical arm, a femtosecond laser transmitter and a forming cylinder, wherein the bottom face of an inner cavity of the forming chamber serves as a working tabletop, the top of the forming cylinder is connected with the bottom of the working table top, a bottom plate of the forming cylinder is connected with a first lifting device, the laser melting mechanical arm and the laser shot blasting mechanical arm are both arranged on the inner wall of the forming chamber, a laser melting nozzle is arranged at the tail end of the laser melting mechanical arm, alaser shot blasting nozzle is arranged at the tail end of the laser shot blasting mechanical arm, an electric linear reciprocating mechanism is arranged in the inner cavity of the forming chamber, thefemtosecond laser transmitter is connected to the electric linear reciprocating mechanism, and the movement direction of the electric linear reciprocating mechanism is parallel to the working table top. The effect that three machining devices do not affect one another is realized, the comprehensive performance of produced parts is greatly improved, and meanwhile secondary machining is avoided.

Owner:CHANGAN UNIV +1

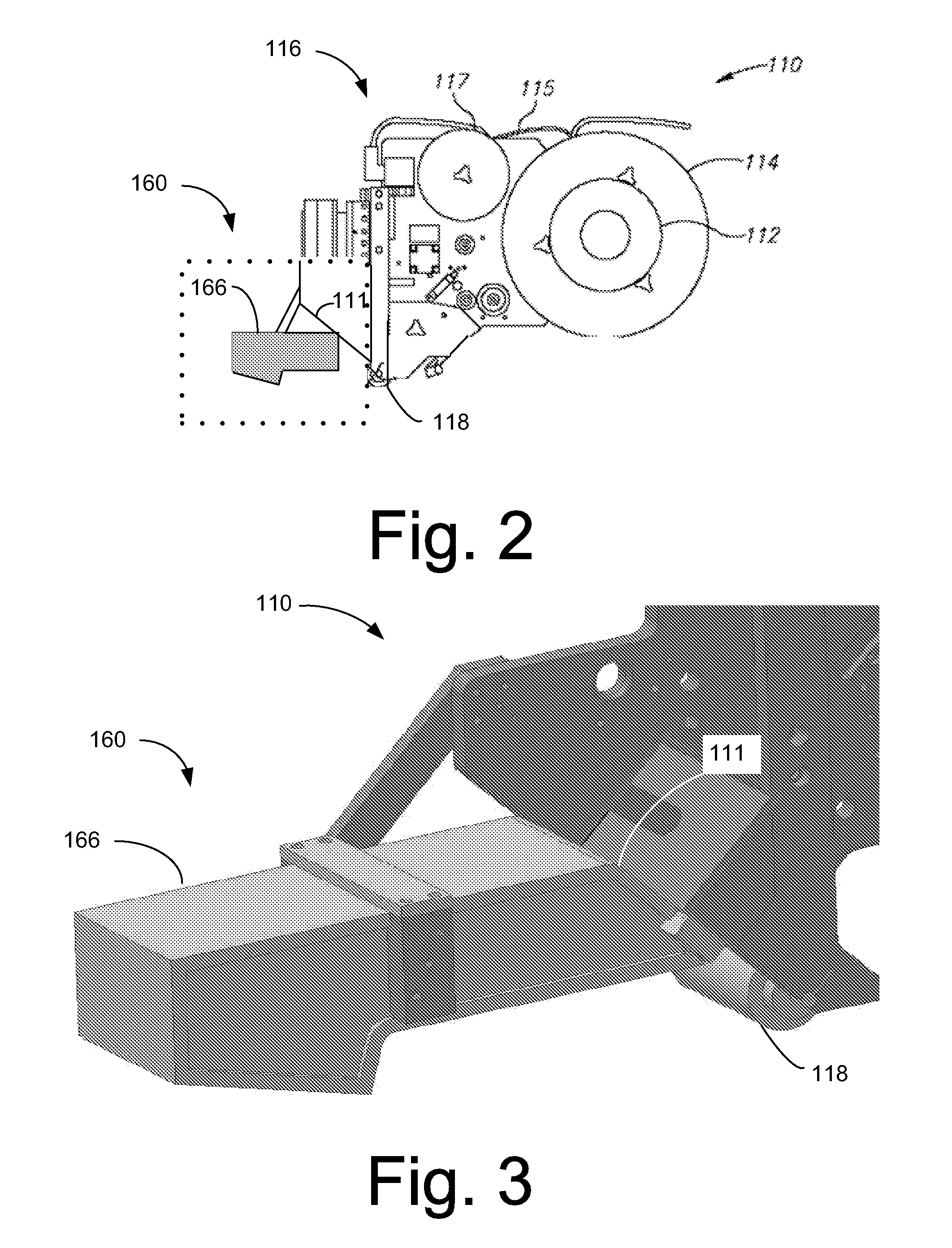

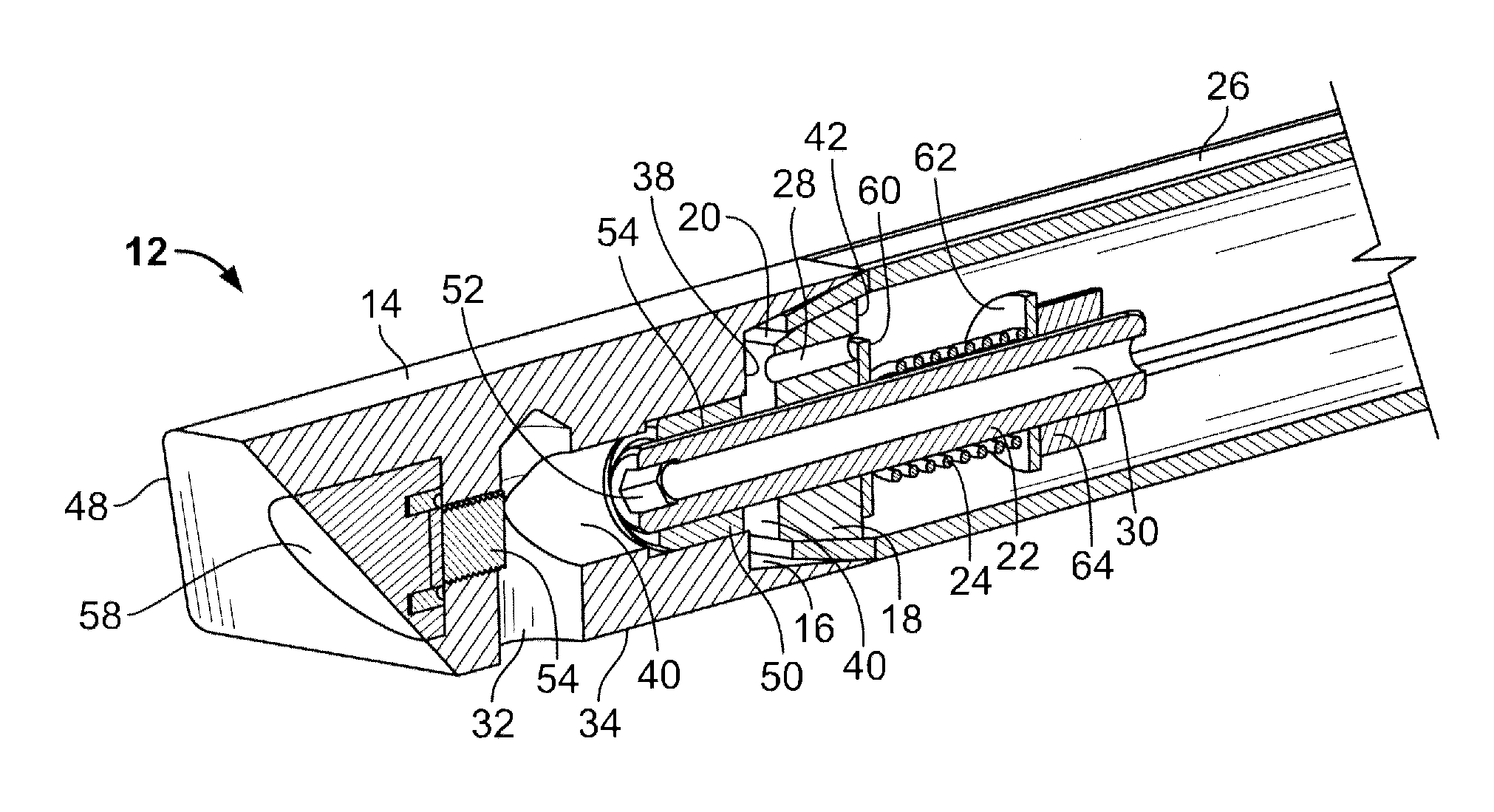

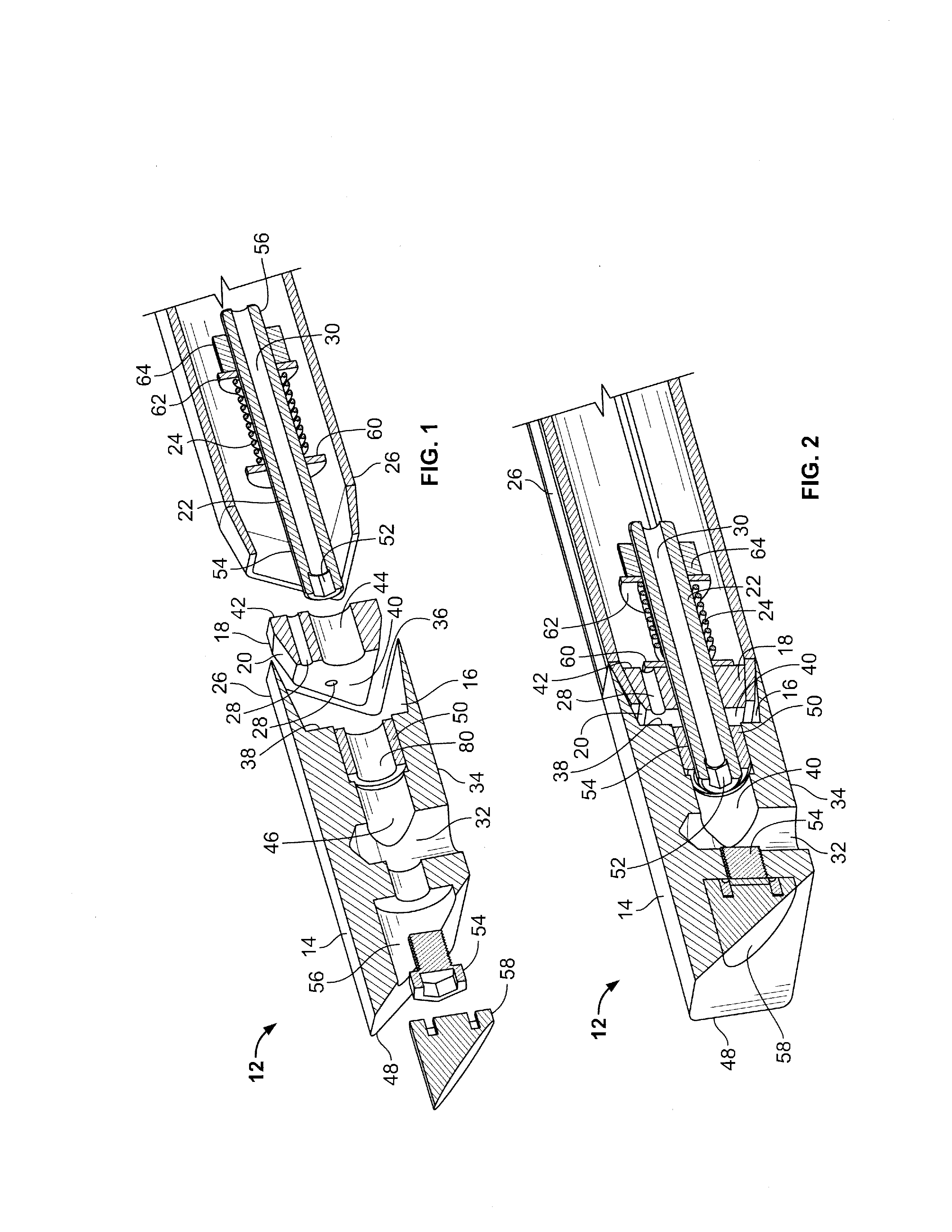

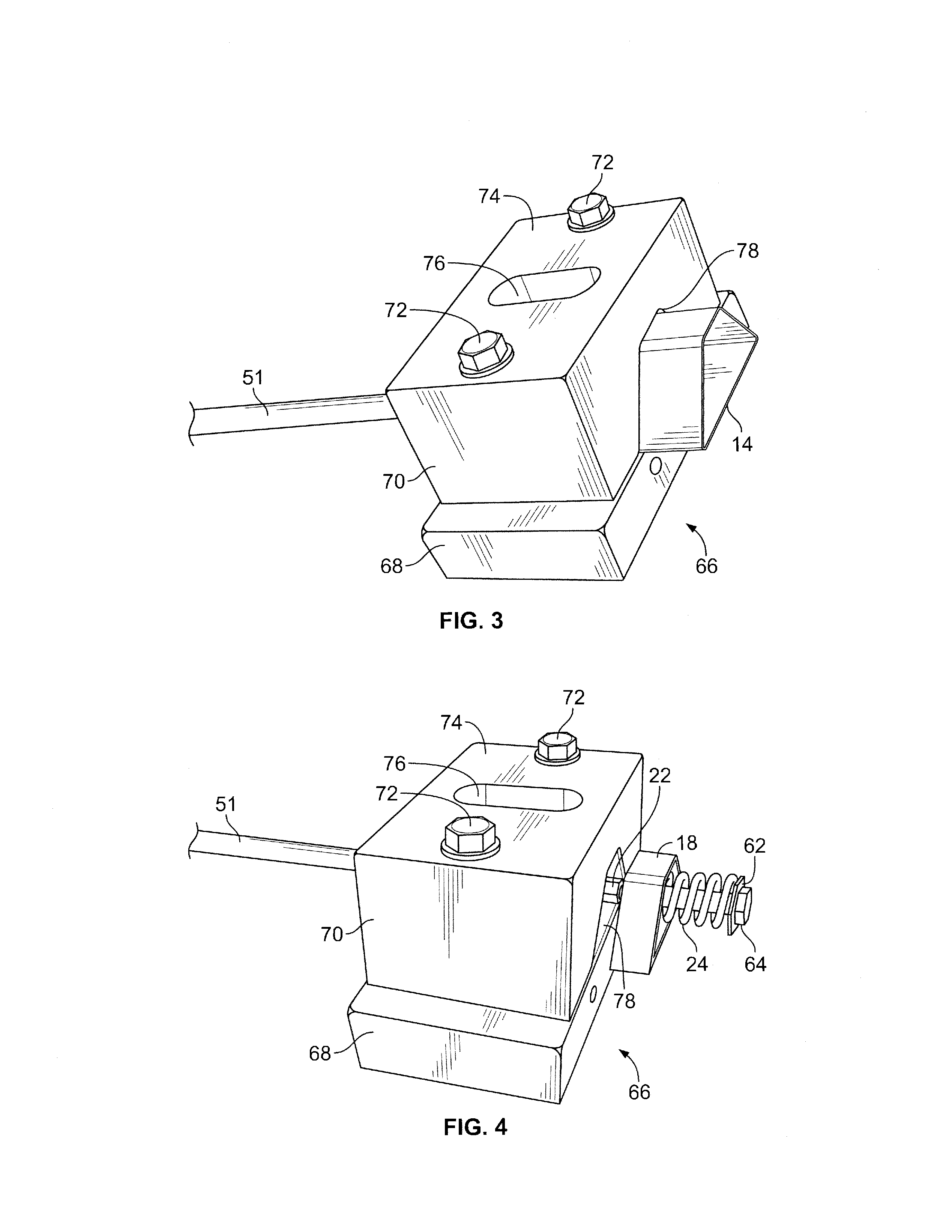

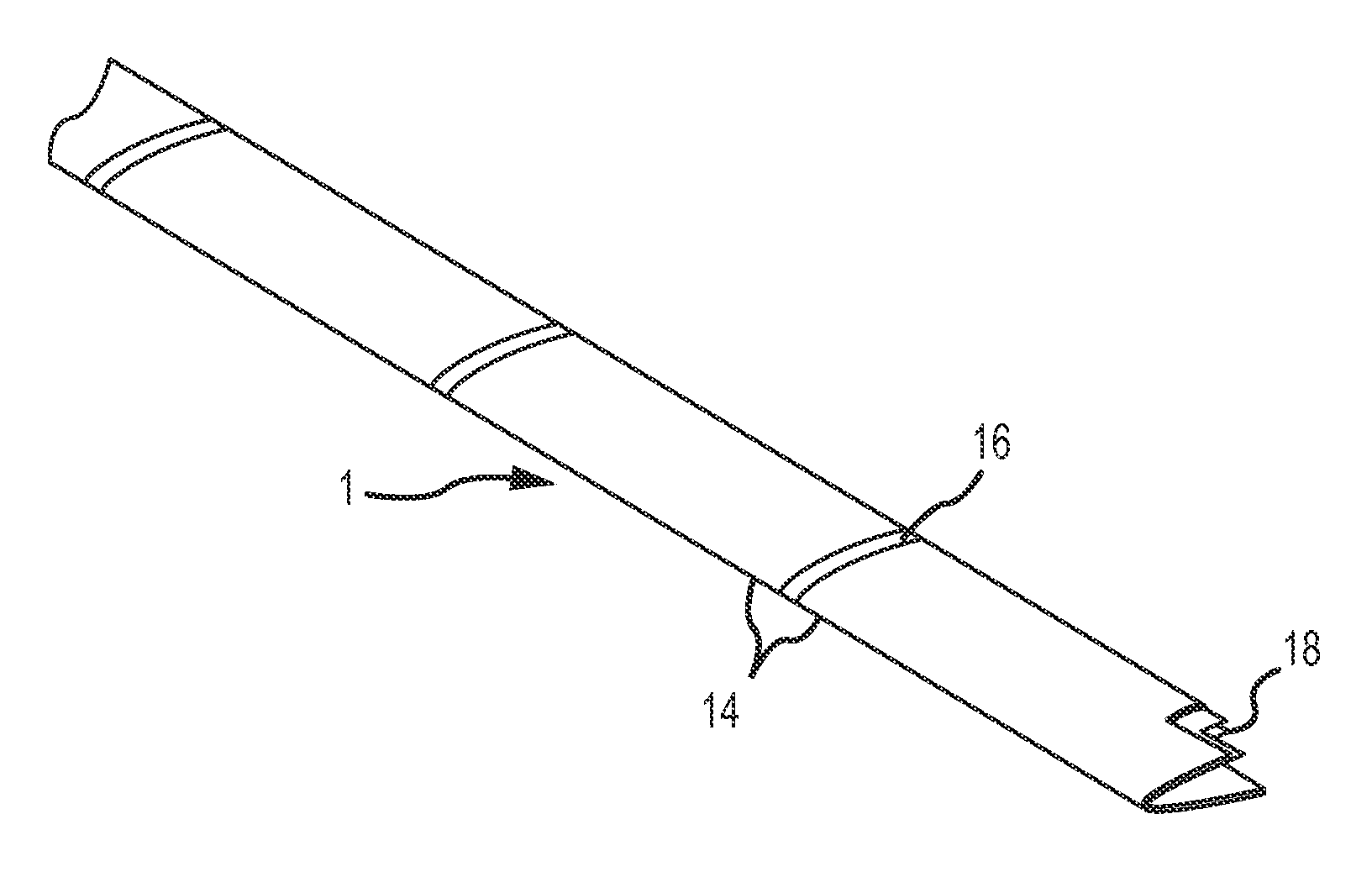

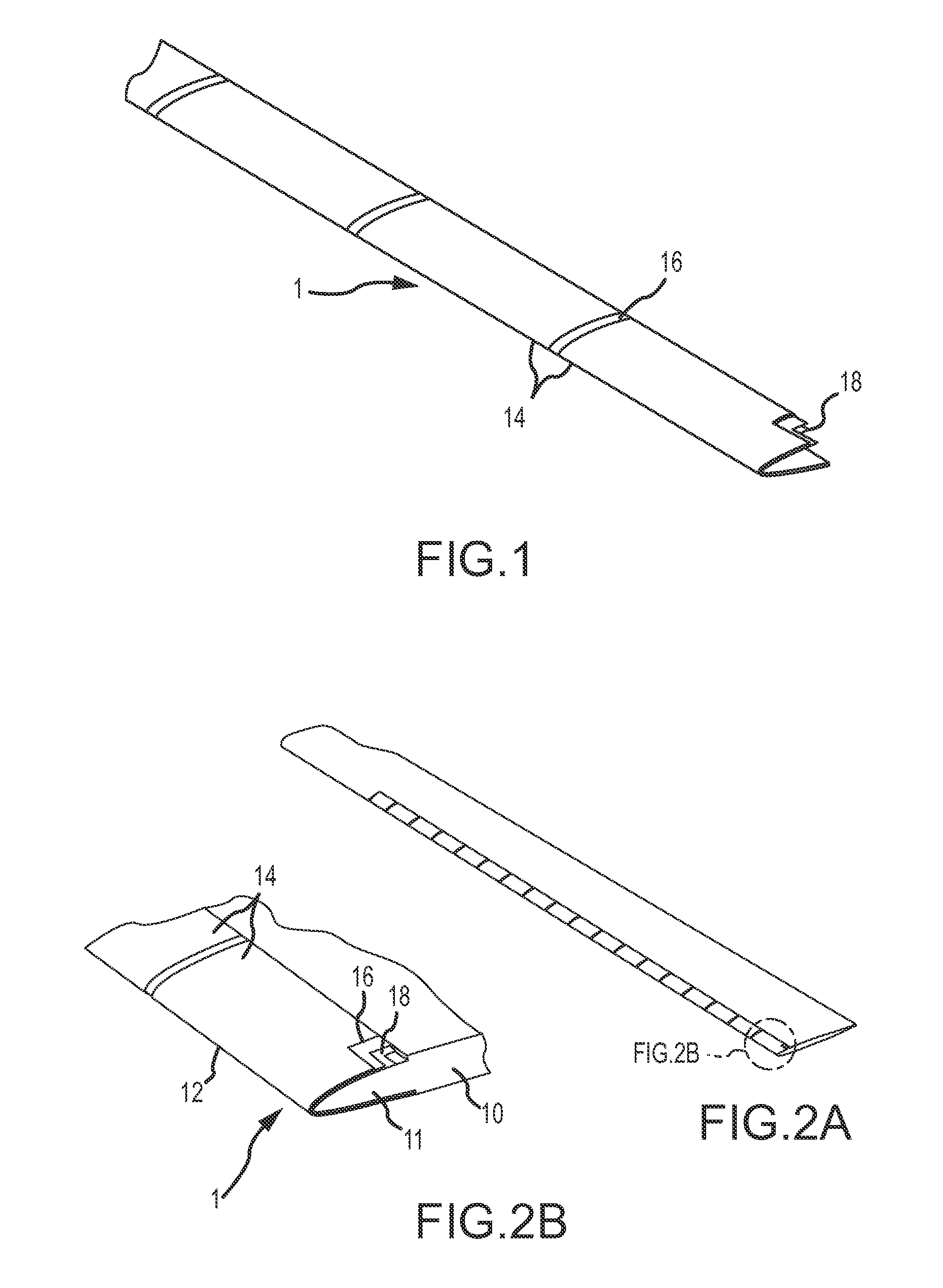

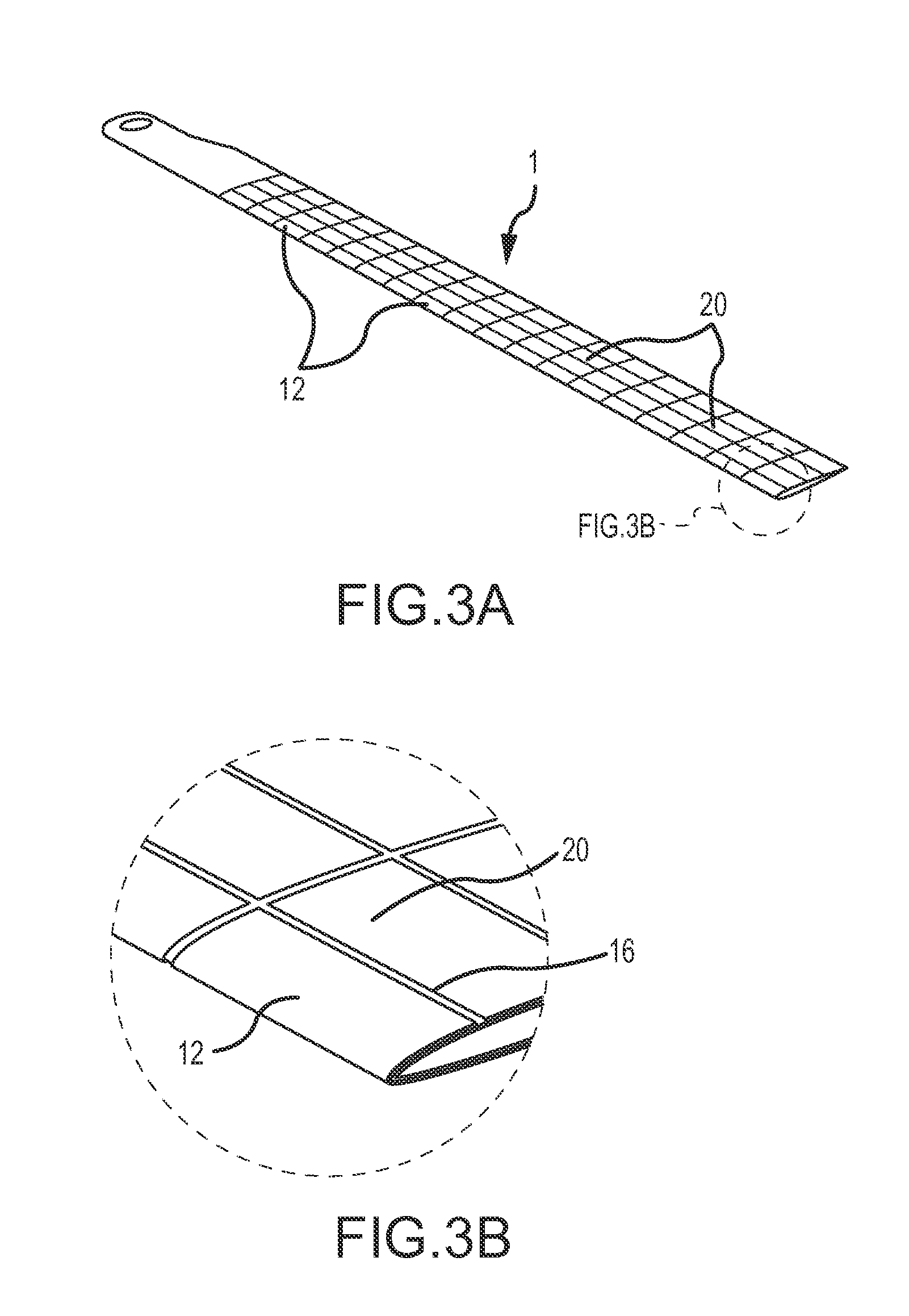

Composite fabrication vent assembly and method

ActiveUS20130175749A1Avoid insufficient clamping forceMaintain pressureSleeve/socket jointsPipe supportsControl mannerEngineering

A composite fabrication vent assembly for connection to an inflatable bladder, the combination of a vent assembly and an inflatable bladder, and a method of mechanically connecting a vent assembly and a bladder. The vent assembly comprises a body member having a first clamping surface, a clamping member having a second clamping surface, and a carriage member interconnecting the body member and the clamping member, with the first and second clamping surfaces in opposing relationship. With the open end of an inflatable bladder inserted between the opposed clamping surfaces, the carriage member is adapted to translate the body member and clamping member toward one another to form an airtight seal with the inflatable bladder. A controlled source of pressurized gas, connected to a gas inlet of the vent assembly, can then inflate and deflate the bladder in a controlled manner through one or more passageways in the vent assembly.

Owner:RUBBERCRAFT OF CALIFORNIA

Composite fabrication facility of steel tube and fabrication method of steel tube

InactiveUS7216521B2Small sizeEasy to moveEdge grinding machinesOther manufacturing equipments/toolsMachiningSteel tube

The present invention pertains to a combined machining equipment for steel tubes, and a machining method is of a small size, can easily be moved, and is capable of not only flaring a steel tube, but also grinding a flared surface, forming a groove, and peeling off a lining. A main shaft (121) is rotatably mounted on a slide frame (141) slidable with respect to a common mount (103), and a second machining head (124) is mounted on a flange on the distal end of the main shaft (121). An auxiliary shaft (131) is slidably disposed in the main shaft (121) for rotation therewith. A first machining head (134) is mounted on a mount base (132) on the distal end of the auxiliary shaft (131). When the main shaft (121) is rotated and moved back and forth and the auxiliary shaft (131) is moved back and forth with respect to the main shaft (121), the first machining head (134) spreads the tip end of a steel tube (110) held by a steel tube holding apparatus (102) to a first position, and the second machining head (124) spreads the tip end of the steel tube (110) to a predetermined flanged position, thus flaring the tip end of the steel tube (110).

Owner:OGAWA KIYOSHI

Hybrid composite for erosion resistant helicopter blades

A protective hybrid composite for a rotor blade is based on the use of tape cast ceramic layers densified by pre-ceramic polymer infiltration methods and laminated together with polymer matrix composite prepregs, with or without an embedded metallic mesh, to form a conforming helicopter blade cladding that is laminated to the blade surface for added erosion protection. The hybrid composite is fabricated to net shape and laminated to the blade using either an adhesive or a polymer composite prepreg inner layer. Installation is accomplished by a standard composite fabrication method of vacuum bagging the blade while the system is laminated to its surface. Repair methods based on removal of ceramic tiles is facilitated by incorporation of a metallic mesh element laminated beneath the ceramic tiles that can be used to heat the tile and decrease its adhesion strength.

Owner:TELEDYNE SCI & IMAGING

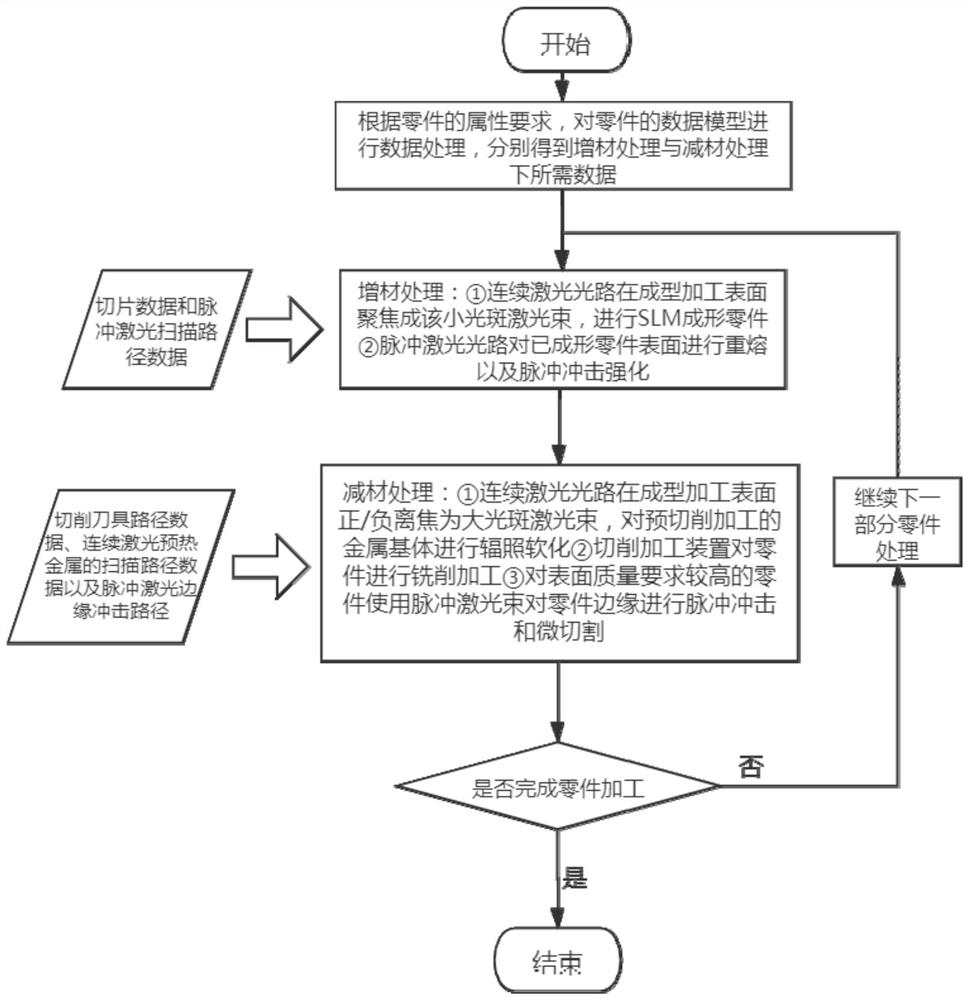

Additive and subtractive composite manufacturing device and method based on in-situ multi-laser regulation and control

PendingCN111974997AReal-time adjustment of stress distributionReduce distortionAdditive manufacturing apparatusIncreasing energy efficiencyPulsed laser beamFacula

The invention discloses an additive and subtractive composite manufacturing device and method based on in-situ multi-laser regulation and control. The method comprises the following steps: carrying out data processing on a data model of a part; carrying out additive treatment, specifically, forming the part through a small-light-spot continuous laser beam SLM, and carrying out remelting and laserimpact strengthening on the surface of the formed part through a pulse laser beam; carrying out subtractive treatment, specifically, carrying out irradiation softening on the part to be machined through a large-light-spot continuous laser beam, and milling the part through a cutting tool device; switching the mode into an additive manufacturing mode, and continuing additive stacking forming of thenext portion of the part; and repeating the additive treatment step and the subtractive treatment step until forming machining of the whole part is completed. According to the device and the method,multi-laser in-situ regulation and control is utilized, multi-wavelength laser additive, subtractive and tool milling integrated collaborative forming is carried out, and efficient and integrated additive and subtractive composite manufacturing of the low-defect, high-precision and high-performance part is realized.

Owner:SOUTH CHINA UNIV OF TECH +1

Ultrasonic impact and deposition forming integrated device and technology for improving structure and performance of additive manufacturing metal component

InactiveCN112342366AImprove cooling efficiencyGuaranteed concentrationAdditive manufacturing apparatusIncreasing energy efficiencyMaterial defectMetallic materials

The invention provides an ultrasonic impact and deposition forming integrated device and technology for improving the structure and performance of an additive manufacturing metal component, and belongs to the field of metal material additive manufacturing. A deposition forming device and an ultrasonic impact tool head are coaxially assembled, the impact path can be synchronously changed along withany machining path, an annular ultrasonic micro-forging tool head carries out synchronous impact forging along with a deposition layer in the metal deposition process, on the basis that plastic deformation happens to the deposition layer, the novel integrated impact device can promote dynamic recrystallization happening in a high-temperature area above the recrystallization temperature, and therefore grains are refined, material defects are reduced, and residual stress is eliminated. Compared with an existing device, according to the integrated device, the acting depth and the impact effect can be greatly improved, meanwhile, complex workpiece forming path planning and the ultrasonic impact path can be combined into one, the machining procedure of the complex metal component is greatly simplified, and design and manufacturing of a high-end machining center for forging increasing and reducing composite manufacturing are facilitated.

Owner:哈船制造科学研究院(烟台)有限公司 +2

Composite fabrication apparatus

Owner:THE BOEING CO

Composite manufacturing system and method of additive manufacturing and laser preheating assisted subtractive cutting

PendingCN111702322AImprove surface cutting qualityHigh geometric accuracyOther manufacturing equipments/toolsLaser beam welding apparatusControl cellProcess engineering

The invention discloses a composite manufacturing system and method of additive manufacturing and laser preheating auxiliary subtractive cutting. The system comprises an additive manufacturing module,a subtractive cutting module, a laser preheating module, a module switching unit, a control unit and a workbench. The additive manufacturing module, the laser preheating module and the subtractive cutting module are all mounted on the module switching unit. The additive manufacturing module, the subtractive cutting module, the laser preheating module, the module switching unit and the workbench are all connected with the control unit. The workbench is used for containing a part to be formed. According to the composite manufacturing system and method, by means of the online laser preheating module, the cutting performance of the material can be effectively improved, the service life of cutters is prolonged, and the requirement of a traditional additive and subtractive manufacturing processon an additional annealing heat treatment process is completely eliminated. The additive and subtractive composite manufacturing system including a laser assisted cutting module can produce parts with high complexity and high precision.

Owner:PERA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com