Patents

Literature

621results about How to "Maintain reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

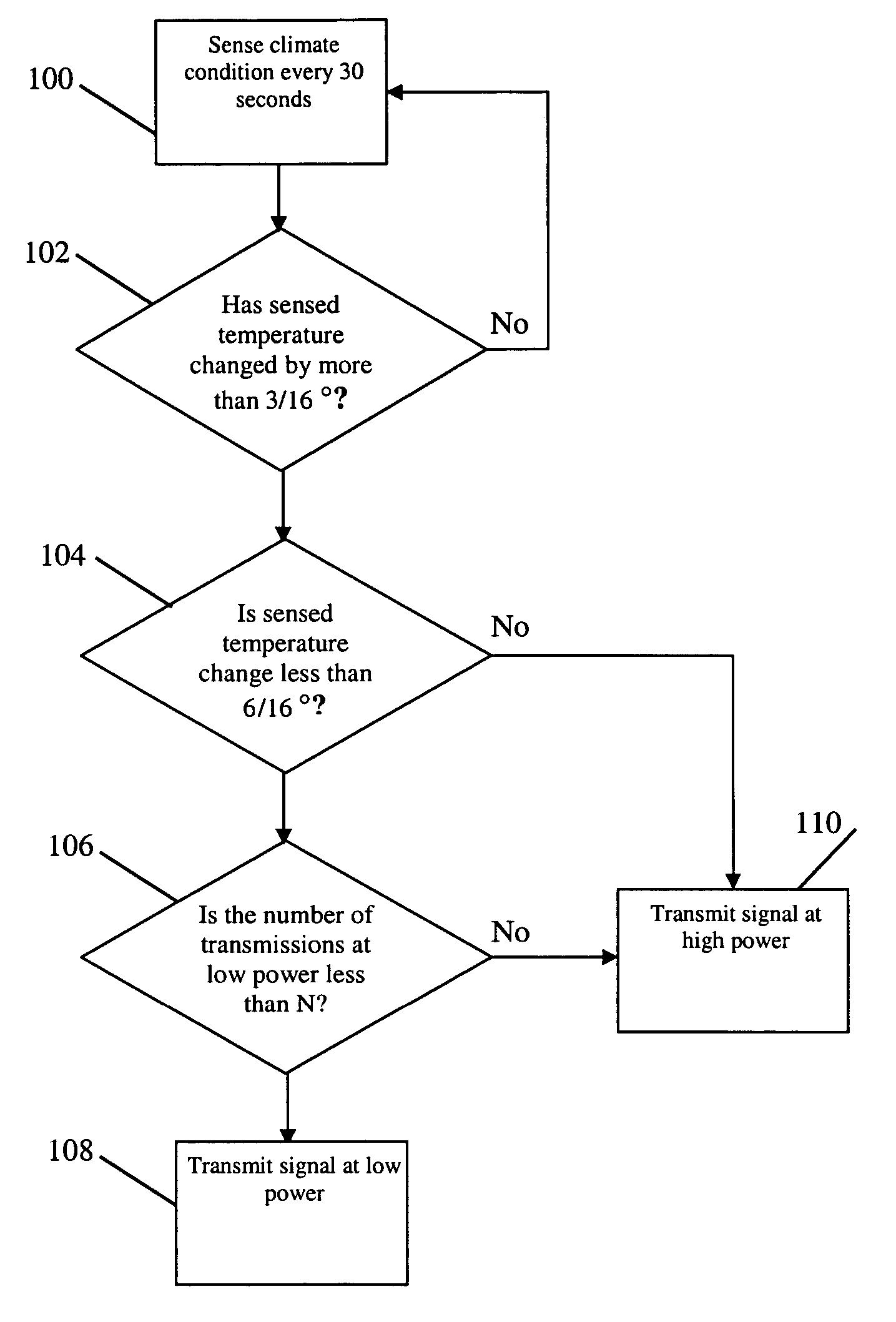

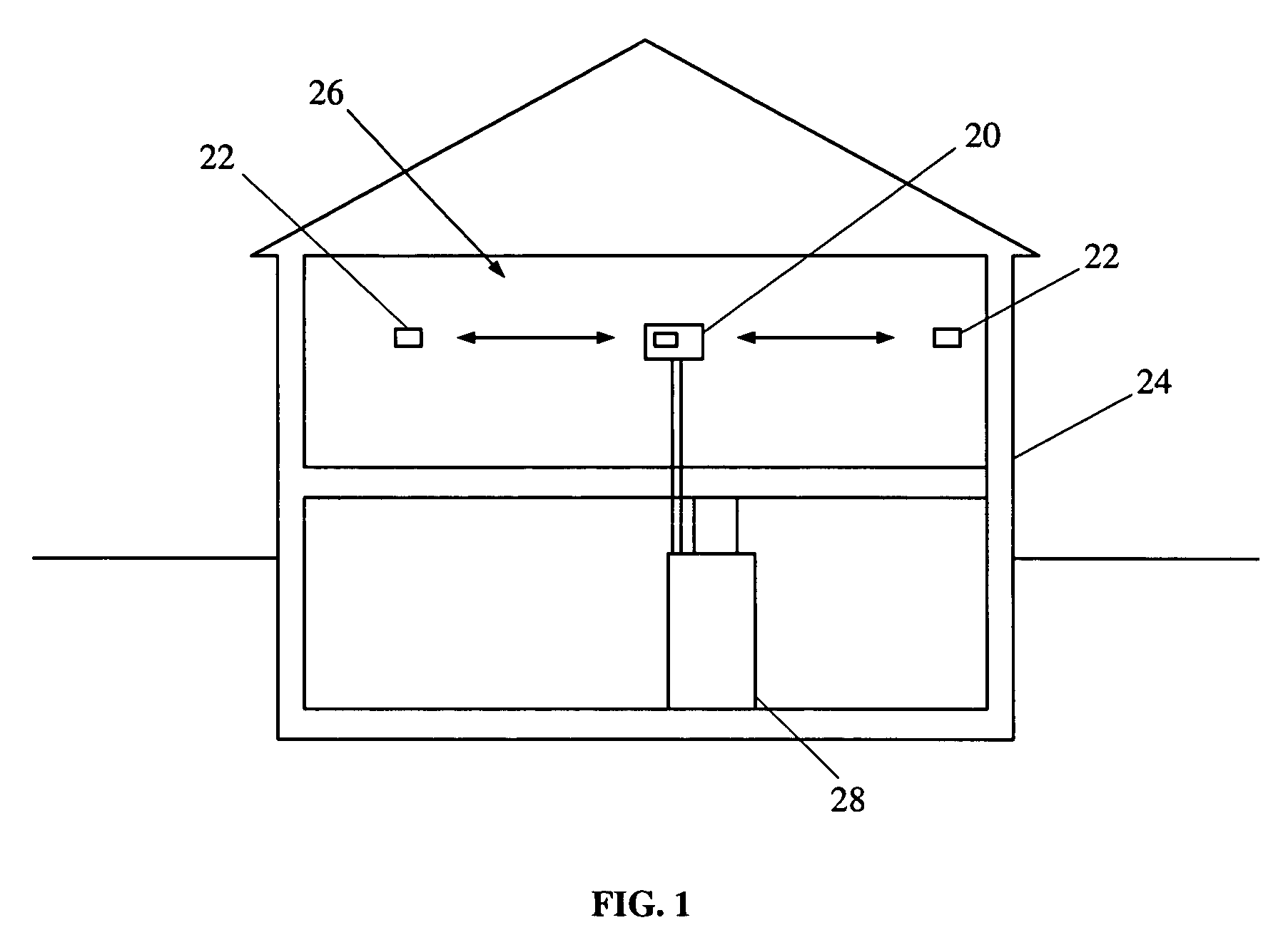

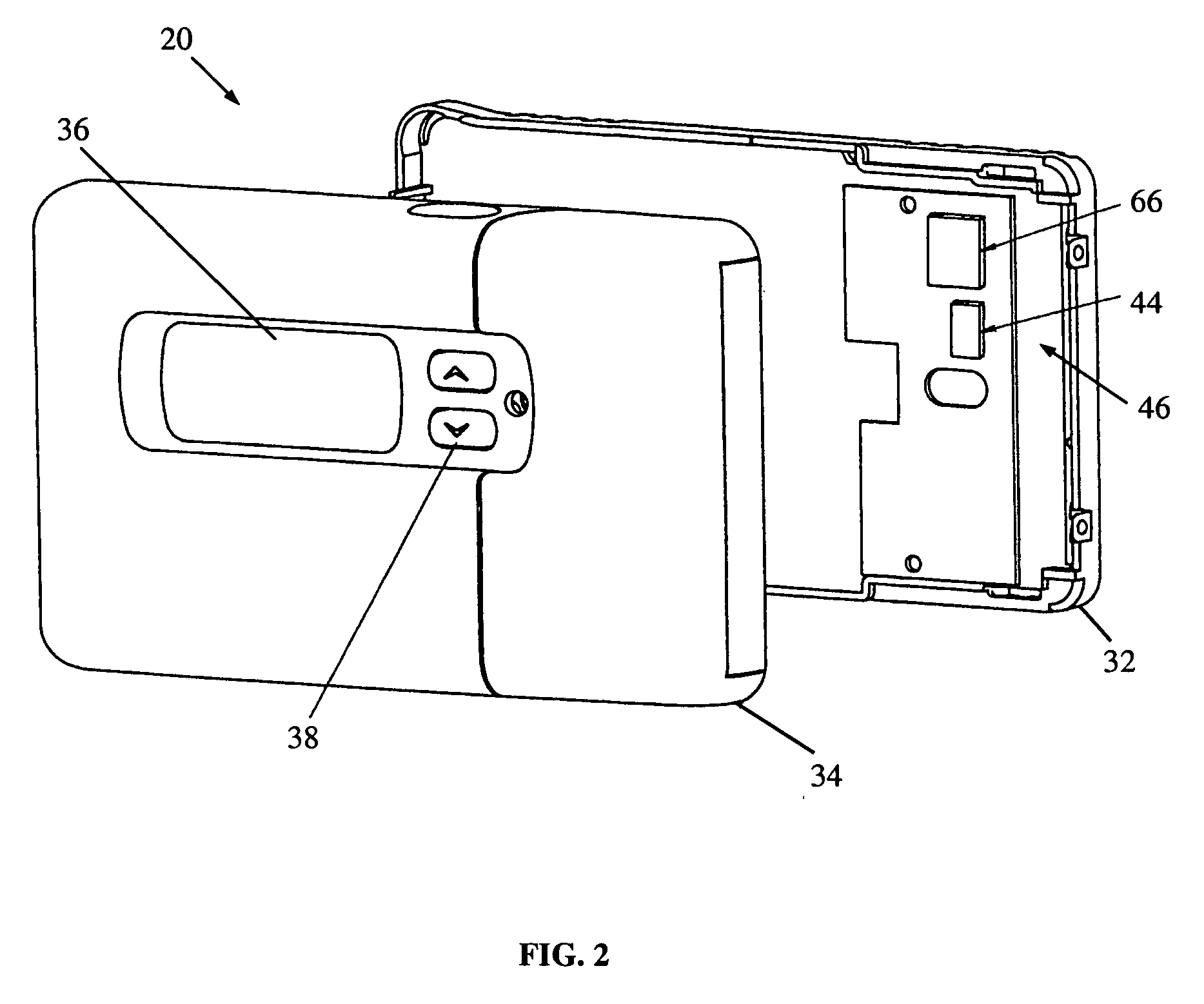

Thermostat control system providing power saving transmissions

ActiveUS7537171B2Reduce power consumptionMaintain reliabilityResonant long antennasTransmission systemsControl systemThermostat

A thermostat control system having remote devices and / or other internally powered devices provides transmissions at different power levels and at different data transfer rates to conserve power life. Thermostat control system components and devices may be powered by replaceable power supplies that are conserved by transmitting at a lower power level more often than at a higher power level. A higher power level transmission is provided at a lower data transfer rate, and a lower power level transmission is provided at a higher data transfer rate. A higher power transmission is provided periodically to ensure reliable communication of temperature information.

Owner:COPELAND COMFORT CONTROL LP

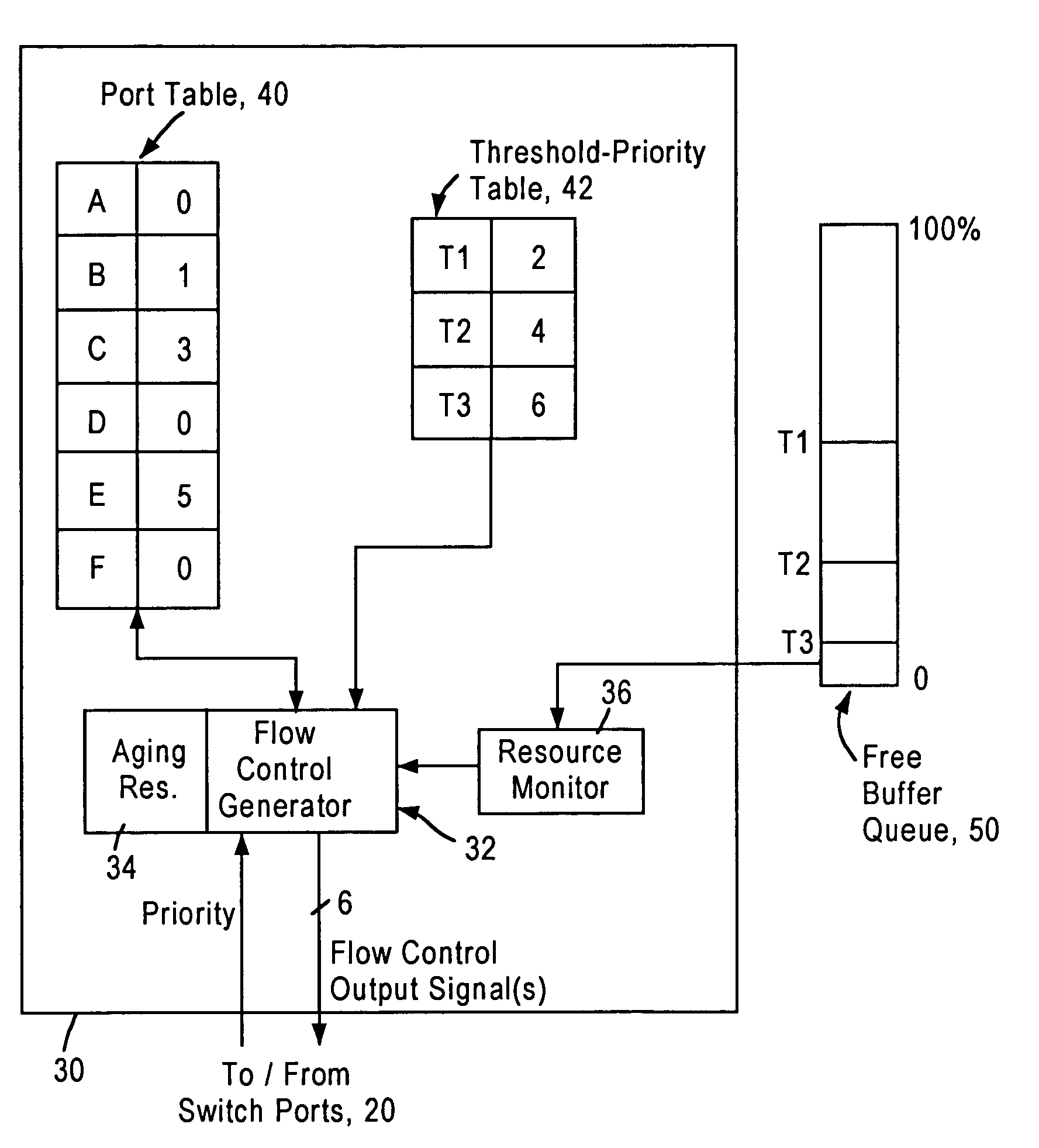

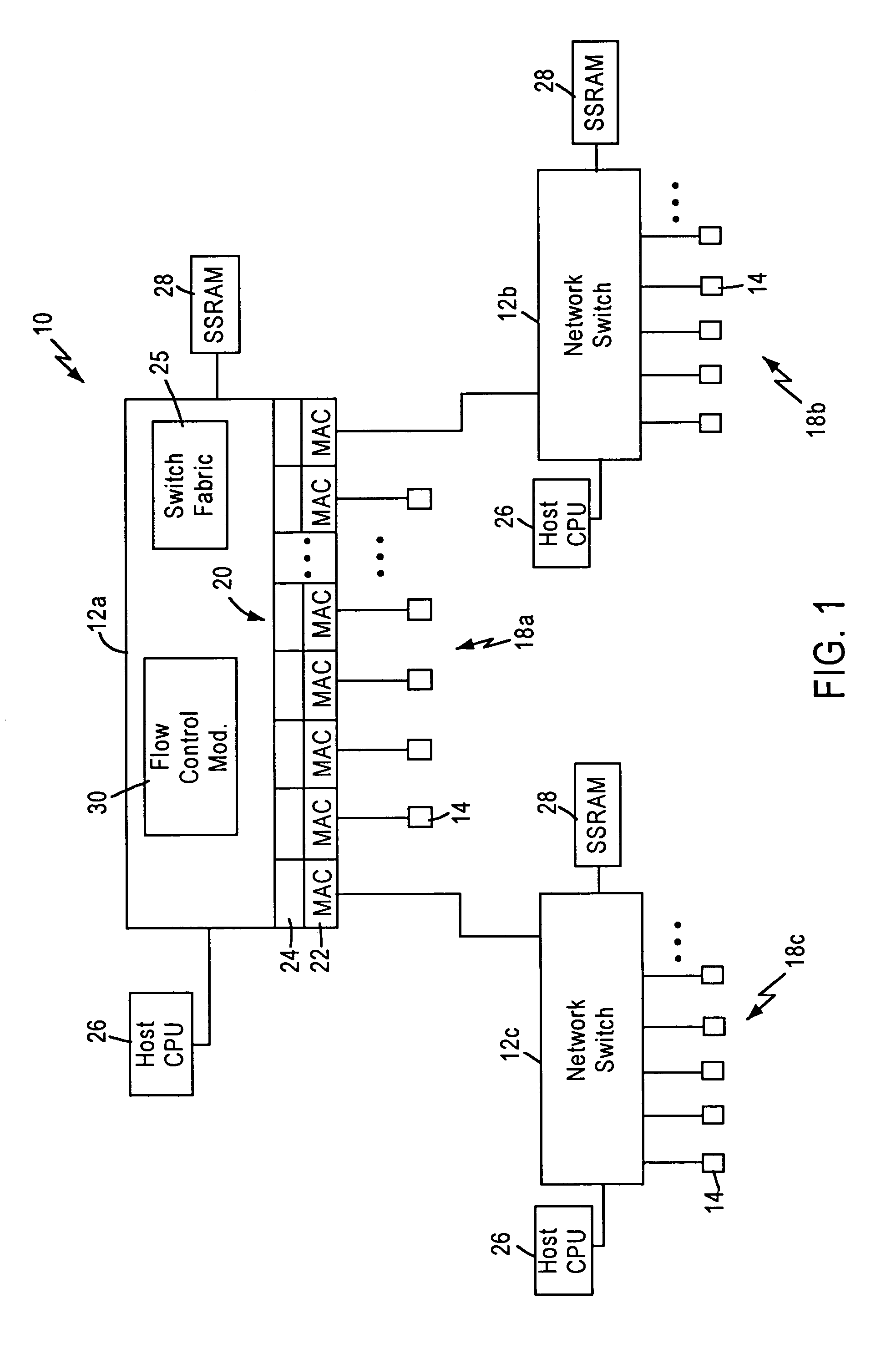

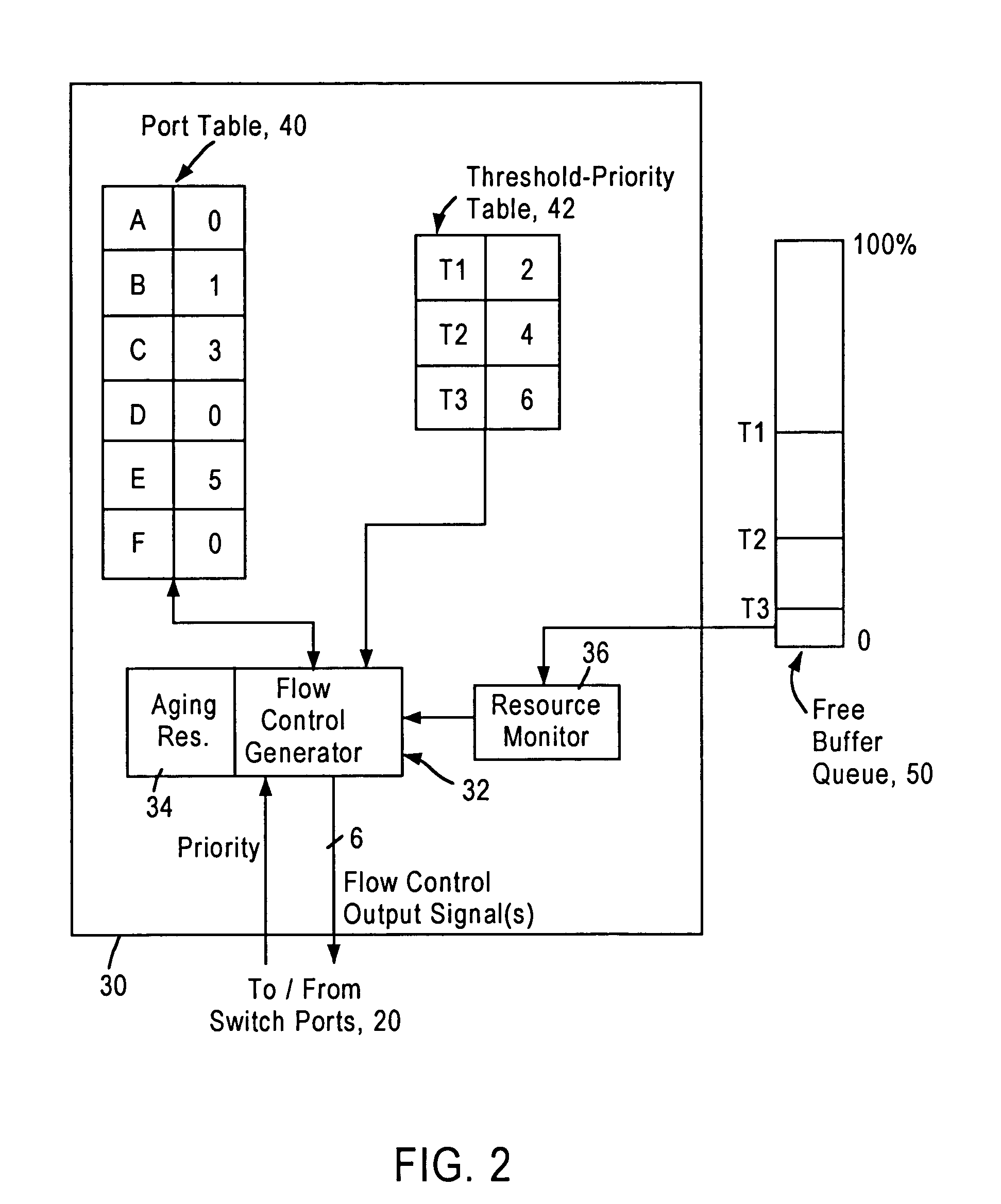

Flow control arrangement in a network switch based on priority traffic

InactiveUS6981054B1Avoid congestionMaintain reliabilityError preventionFrequency-division multiplex detailsTraffic capacityFrame based

A network switch includes network switch ports, each including a port filter configured for detecting user-selected attributes from a received layer 2 frame. Each port filter, upon detecting a user-selected attribute in a received layer 2 frame, sends a signal to a switching module indicating the determined presence of the user-selected attribute, for example whether the data packet has a prescribed priority value. The network switch includes a flow control module that determines which of the network switch ports should output a flow control frame based on the determined depletion of network switch resources and based on the corresponding priority value of the network traffic on each network switch port. Hence, any network switch port that receives high priority traffic does not output a flow control frame to the corresponding network station, enabling that network station to continue transmission of the high priority traffic. In most cases, the congestion and depletion of network switch resources can be alleviated by sending flow control frames on only those network switch ports that receive lower priority traffic, enabling the network switch to reduce congestion without interfering with high priority traffic.

Owner:GLOBALFOUNDRIES US INC

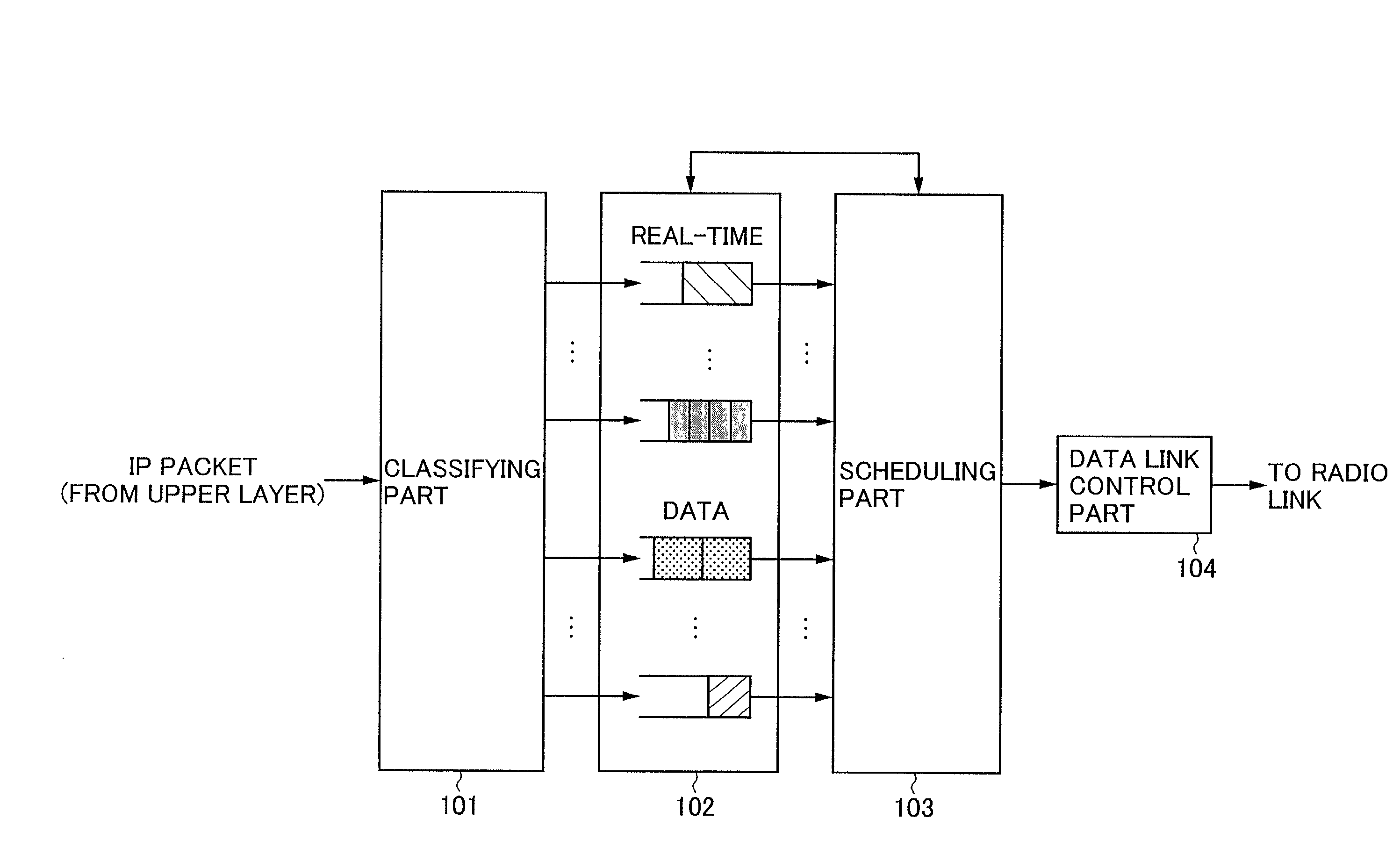

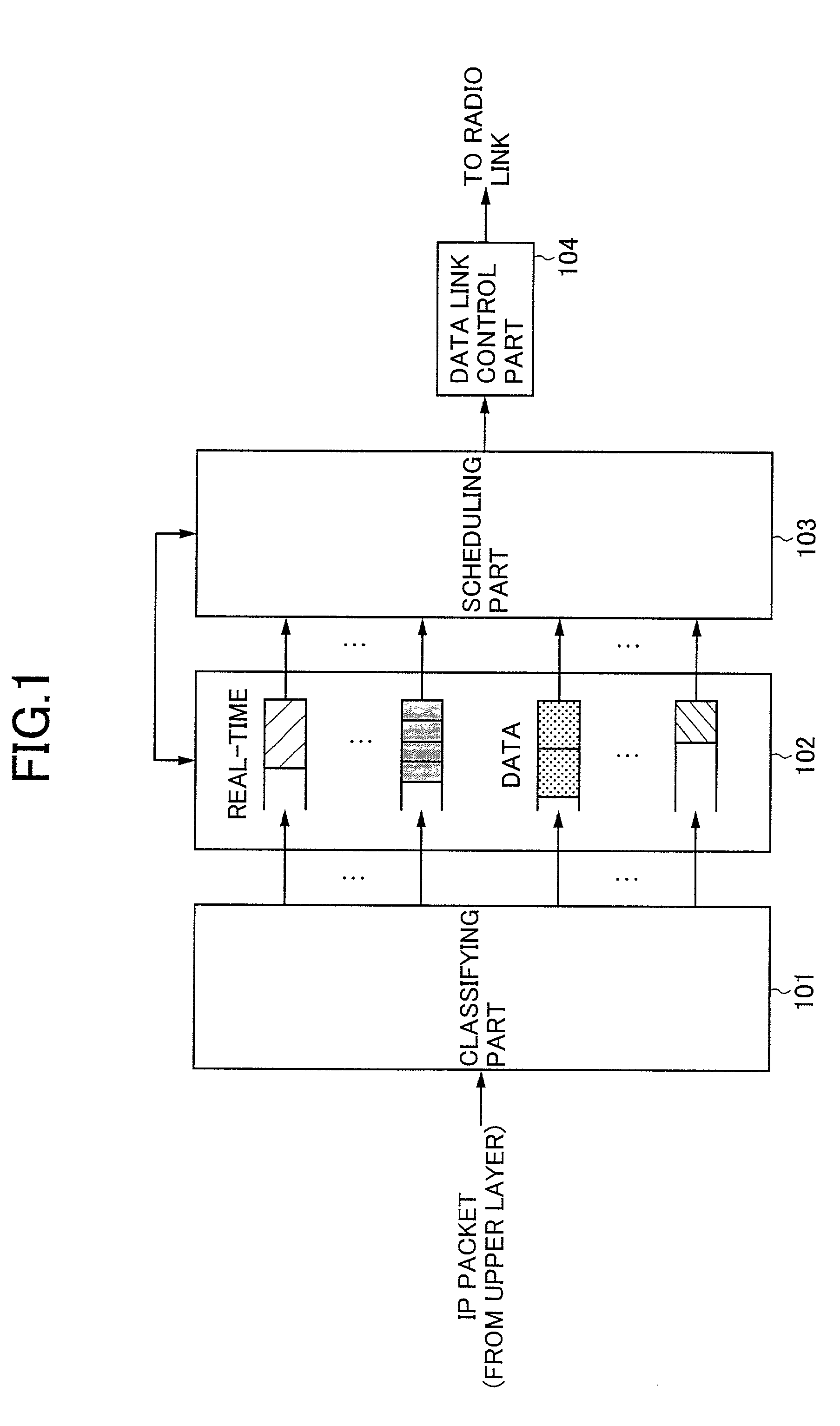

Packet transmission method and system, and packet transmitting apparatus, packet receiving apparatus, and packet transmitting/receiving apparatus

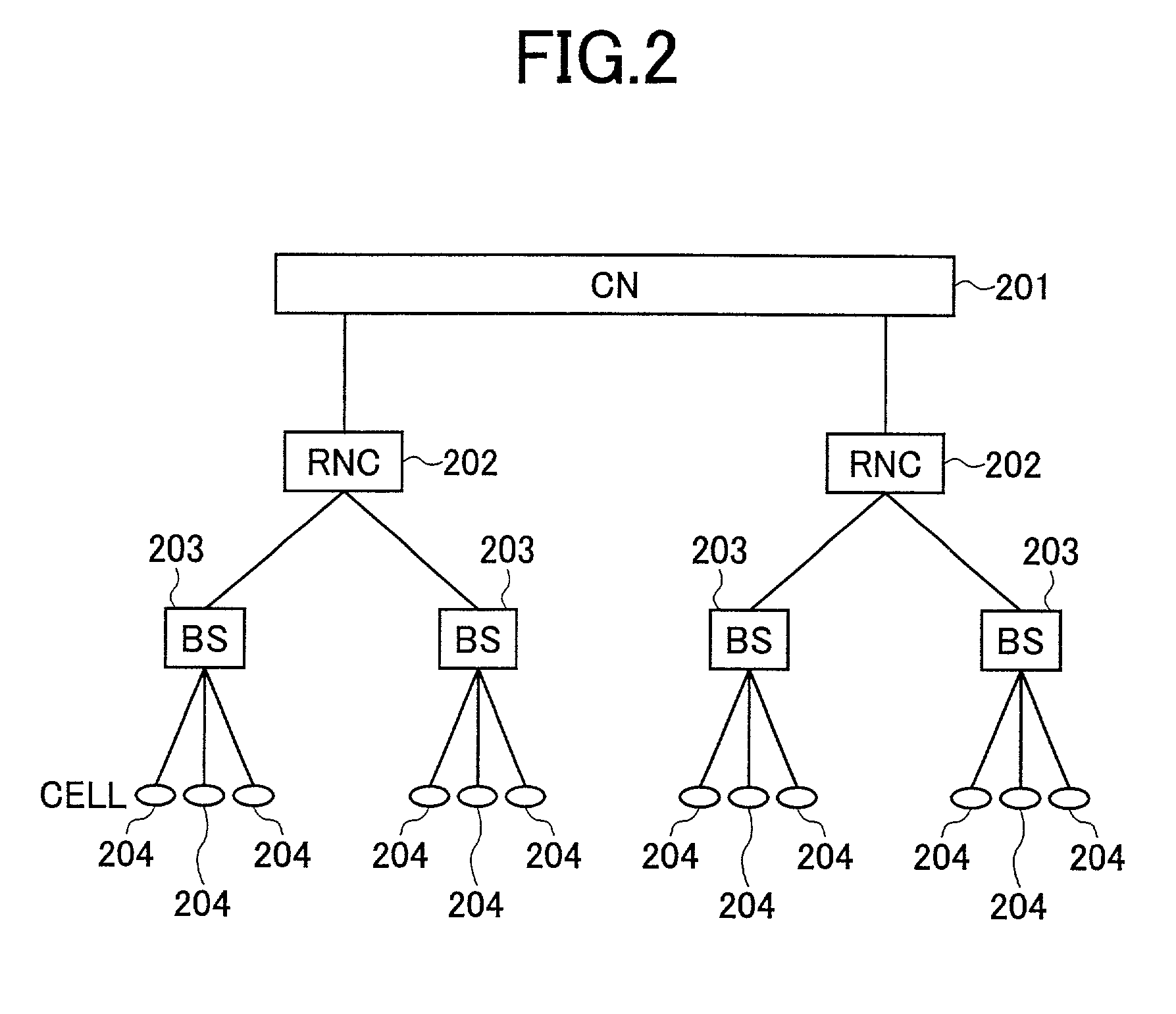

ActiveUS20020126675A1Minimum delayMaintain reliabilityError prevention/detection by using return channelNetwork traffic/resource managementQuality of serviceData type

A packet transmission method for transmitting packets classified according to a quality of service (QoS) requirement from a transmitting node to a receiving node is provided. In the transmitting node, the steps of: selecting sequentially a QoS class; dividing a queued packet to be transmitted belonging to the selected class into a plurality of predetermined data units, and transmitting one of the obtained predetermined data units; and applying a transmitter-side retransmission control process to the data unit to be transmitted when the selected class is a QoS class specified for data type packets are provided. In the receiving node, the steps of: receiving sequentially the data units transmitted from the transmitting node; assembling a plurality of received data units to decompress the original packet for each QoS class; and applying a receiver-side retransmission control process to the received data units to be assembled when the received data unit belongs to one of the QoS classes specified for the data type packets are provided.

Owner:NTT DOCOMO INC

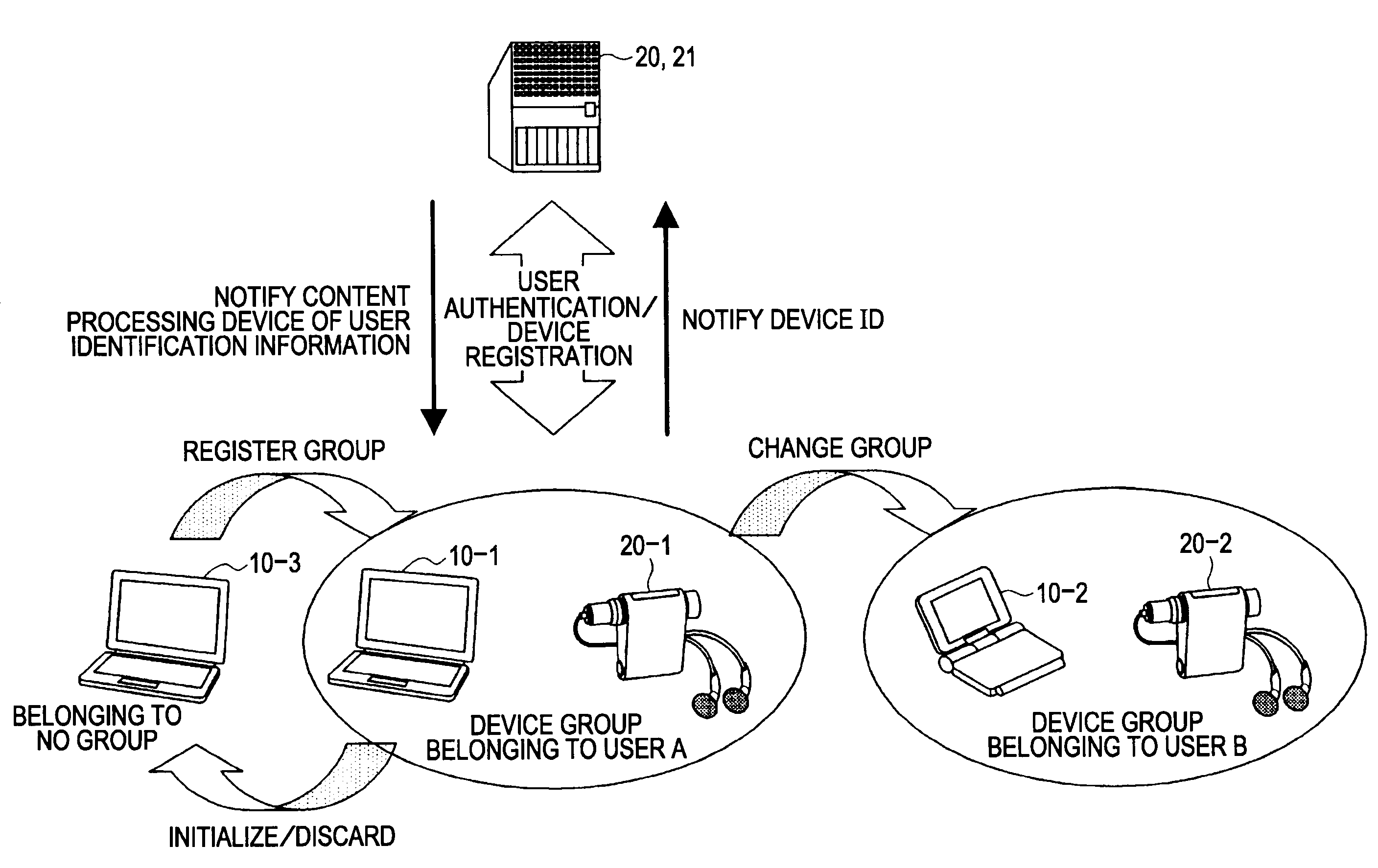

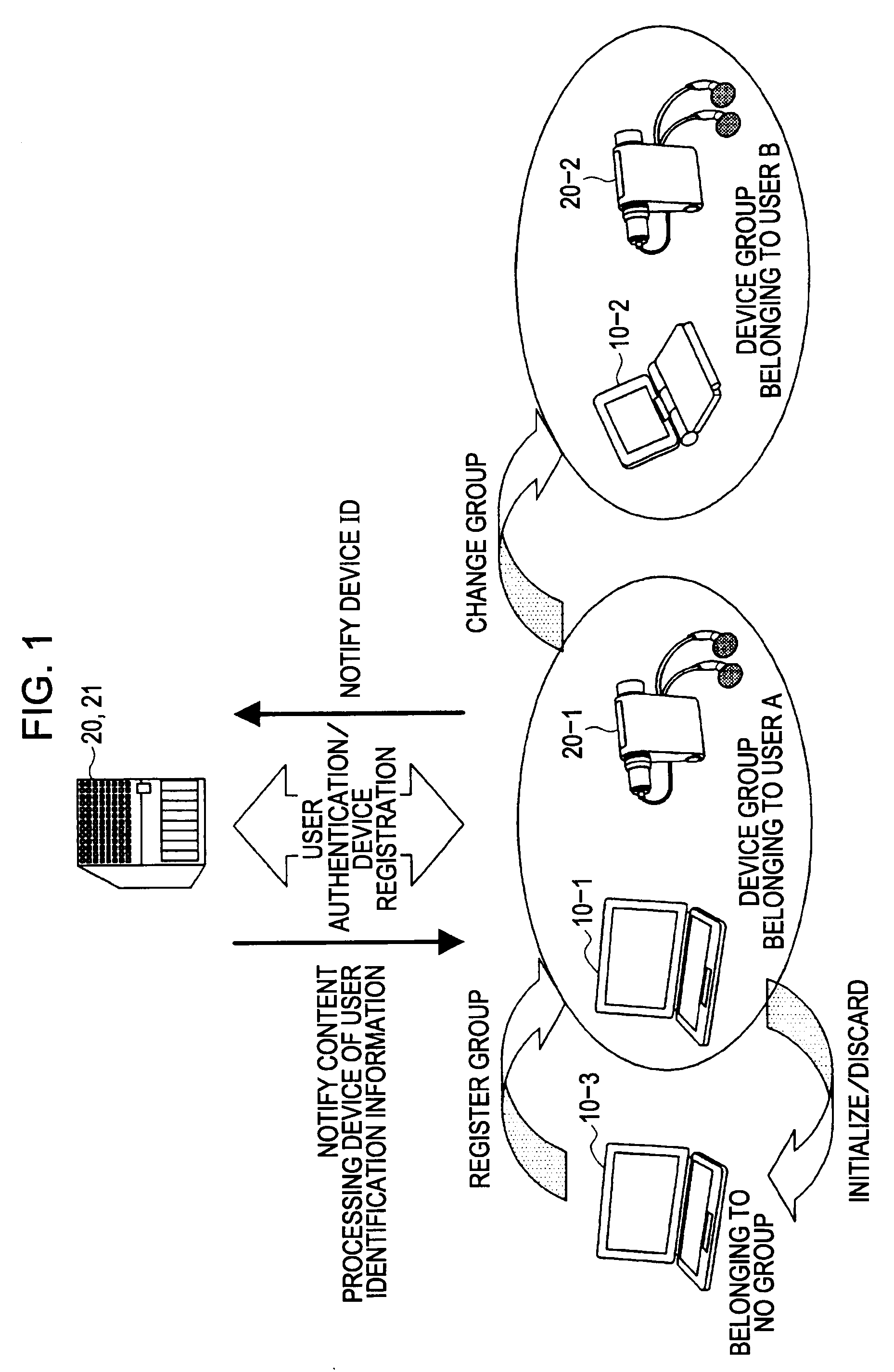

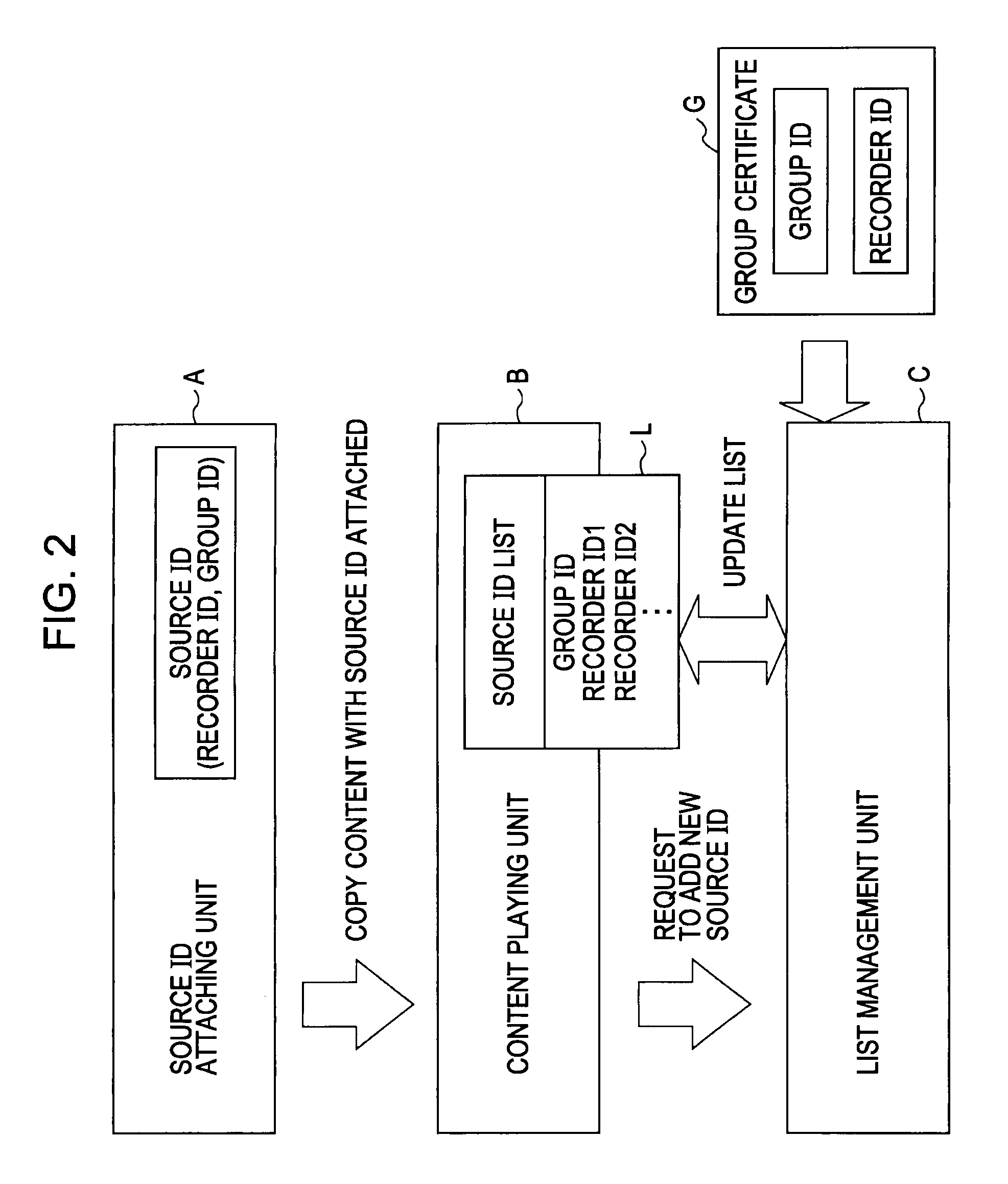

Group registration device, group registration release device, group registration method, license acquisition device, license acquisition method, time setting device, and time setting method

InactiveUS20090151006A1Simplify the registration processExecuted sufficientlyDigital data processing detailsUser identity/authority verificationDatabaseLicense

There is provided a group registration device or the like which is capable of simplifying registration processing to readily perform group registration while retaining secure registration processing.A group registration device 10 includes a registration request detecting unit, a session ID generating unit for generating a session ID, a registration request message sending unit, a registration reply message receiving unit, a verification unit 231 for verifying non-redundancy of a message, and a storage unit 241 for storing an ID list included in a registration reply message in a storage region so as to be associated with a group ID. Within the same registration session, the registration request message is sent once, the registration reply message is received once, and processing is restricted to sending of the registration request message and receiving of the registration reply message.

Owner:SONY CORP

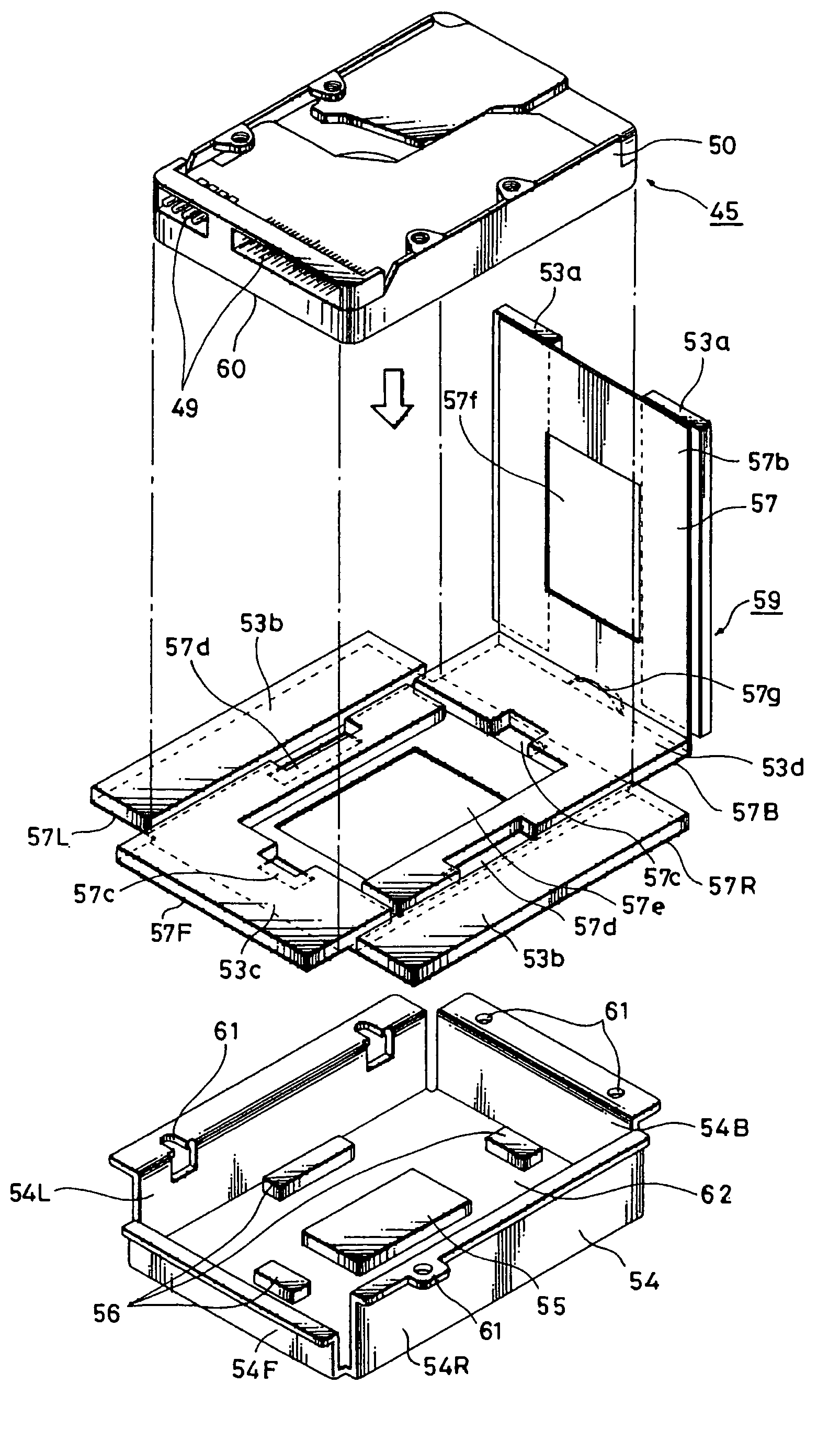

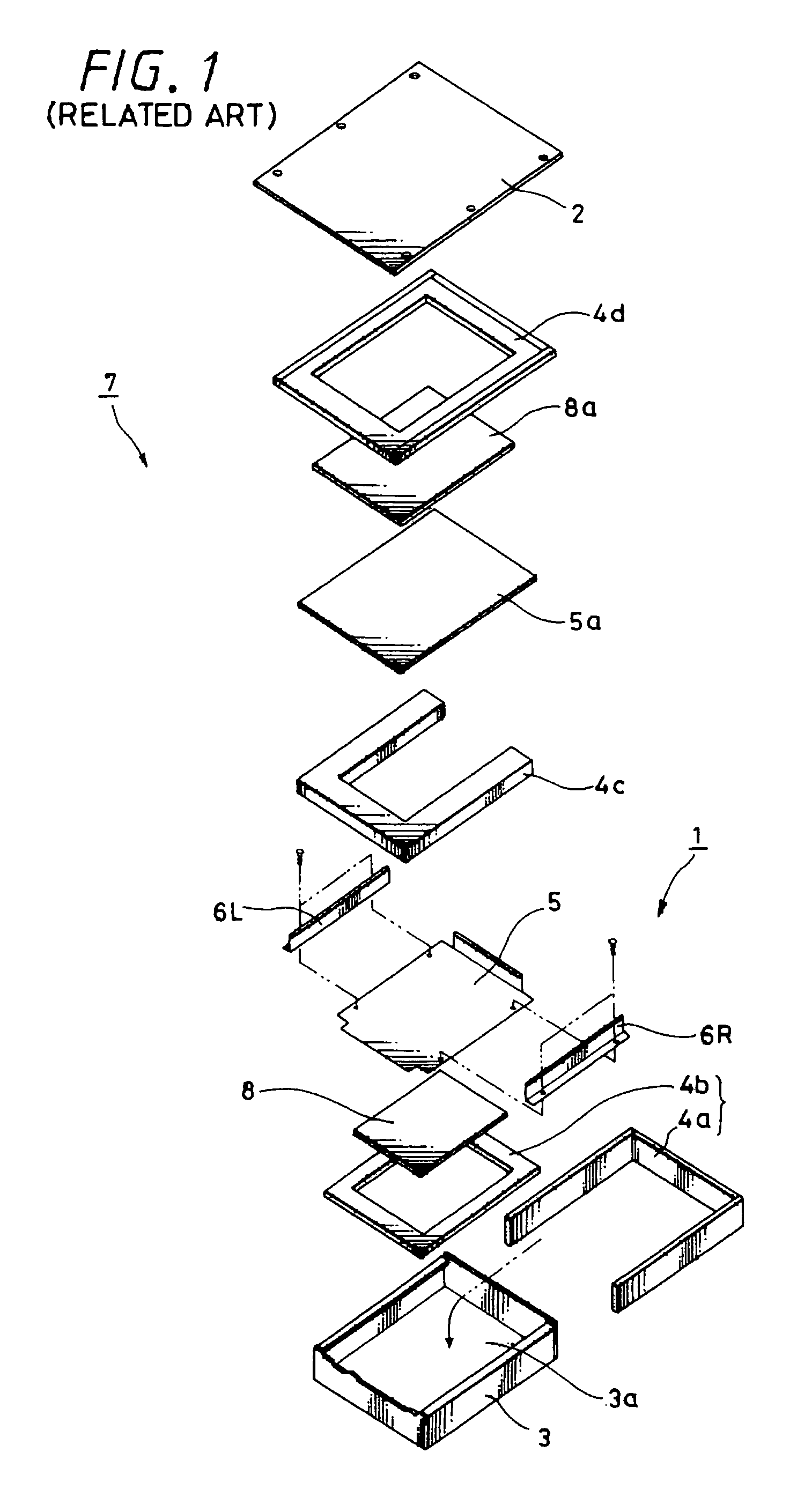

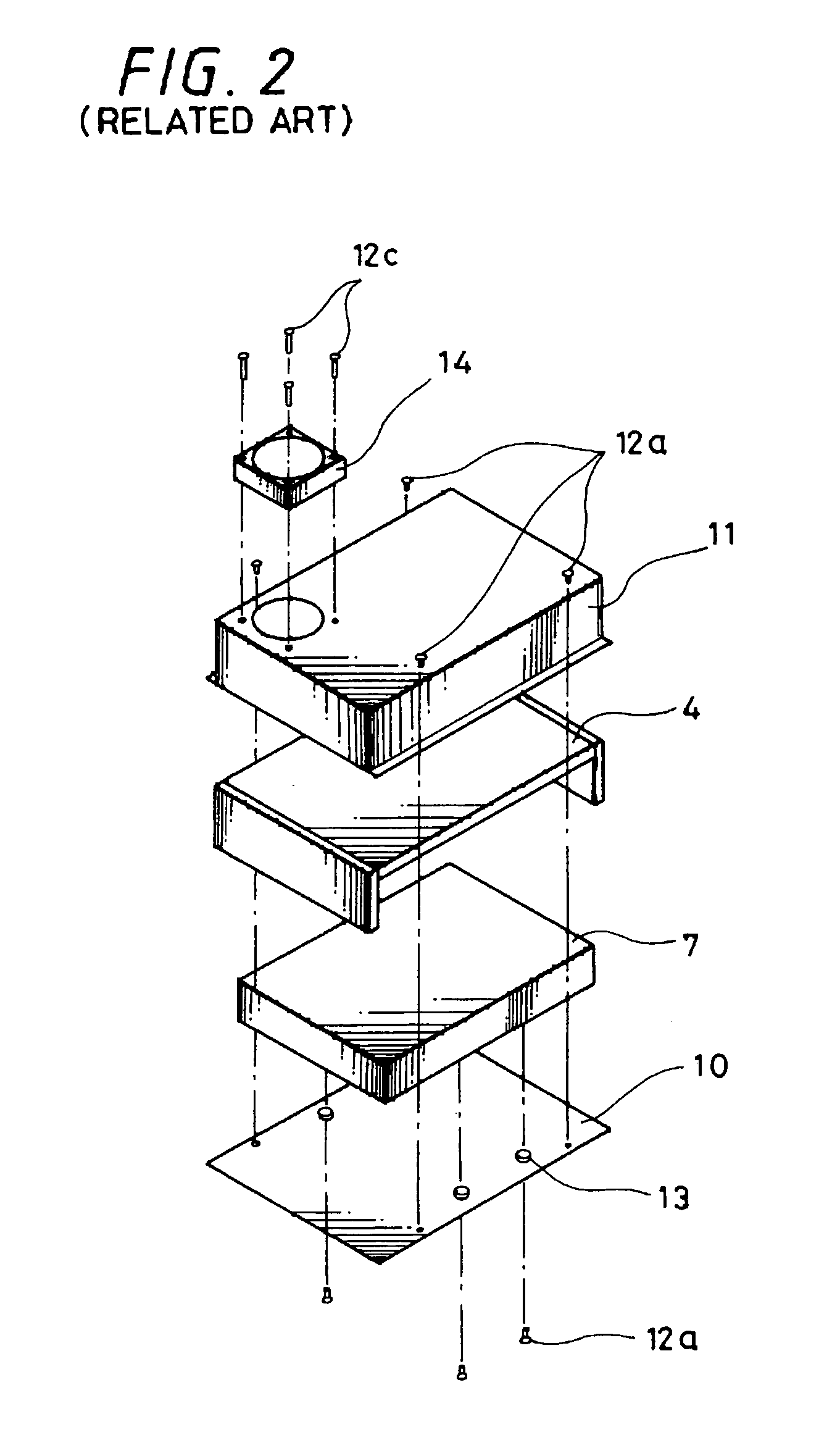

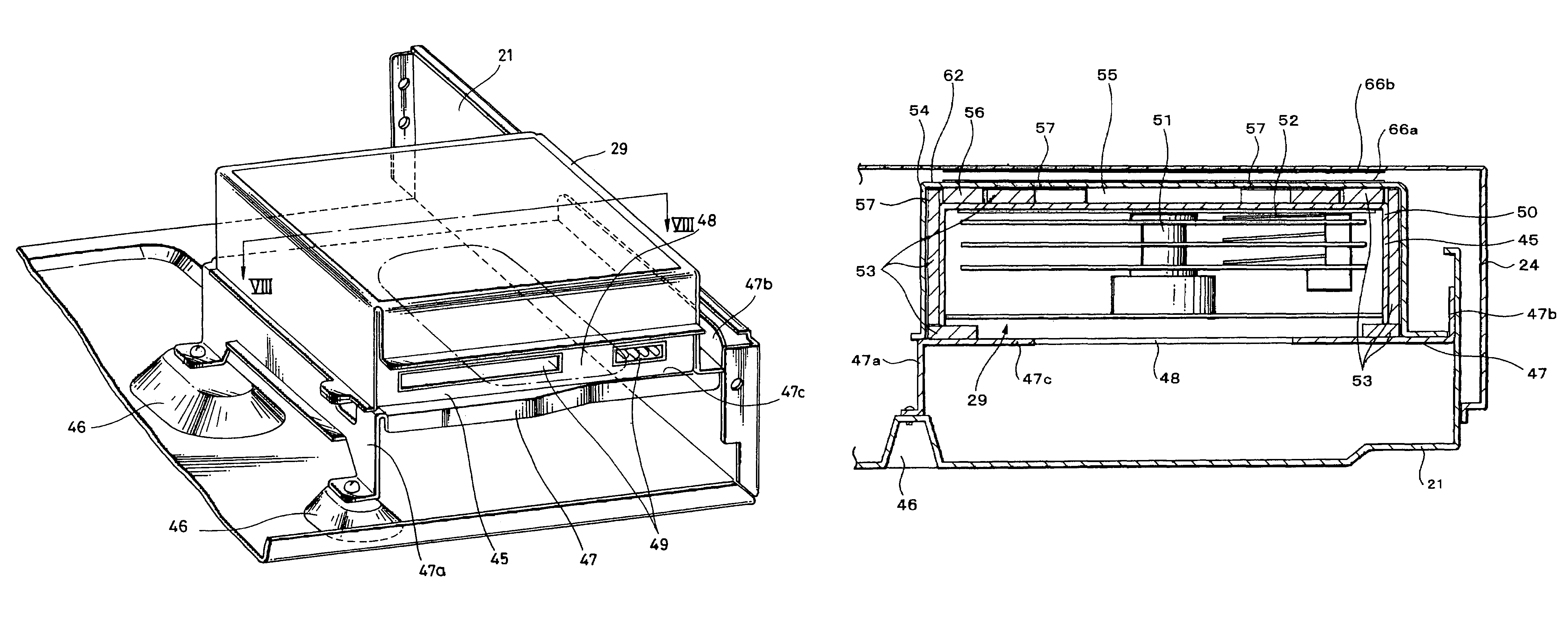

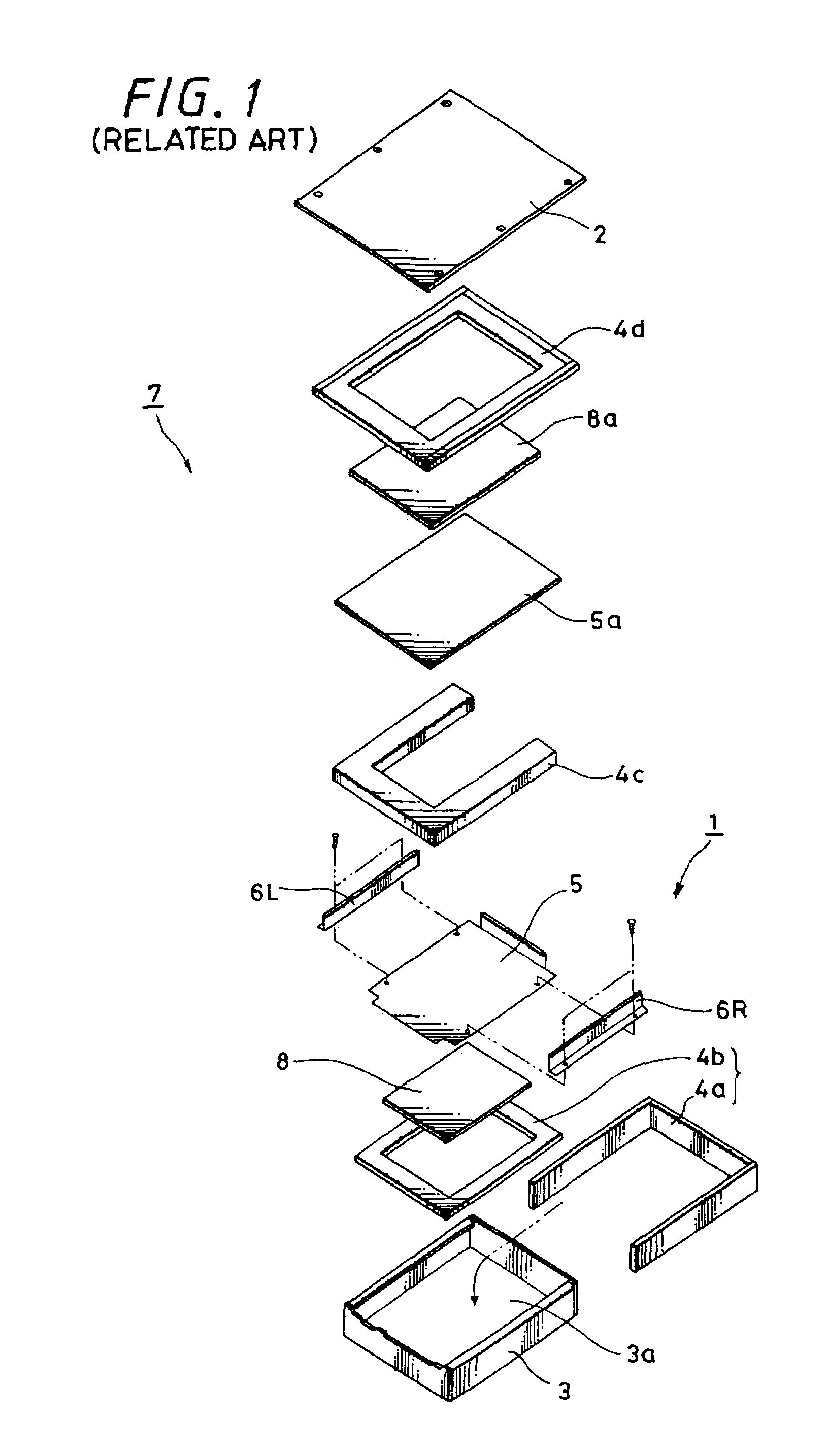

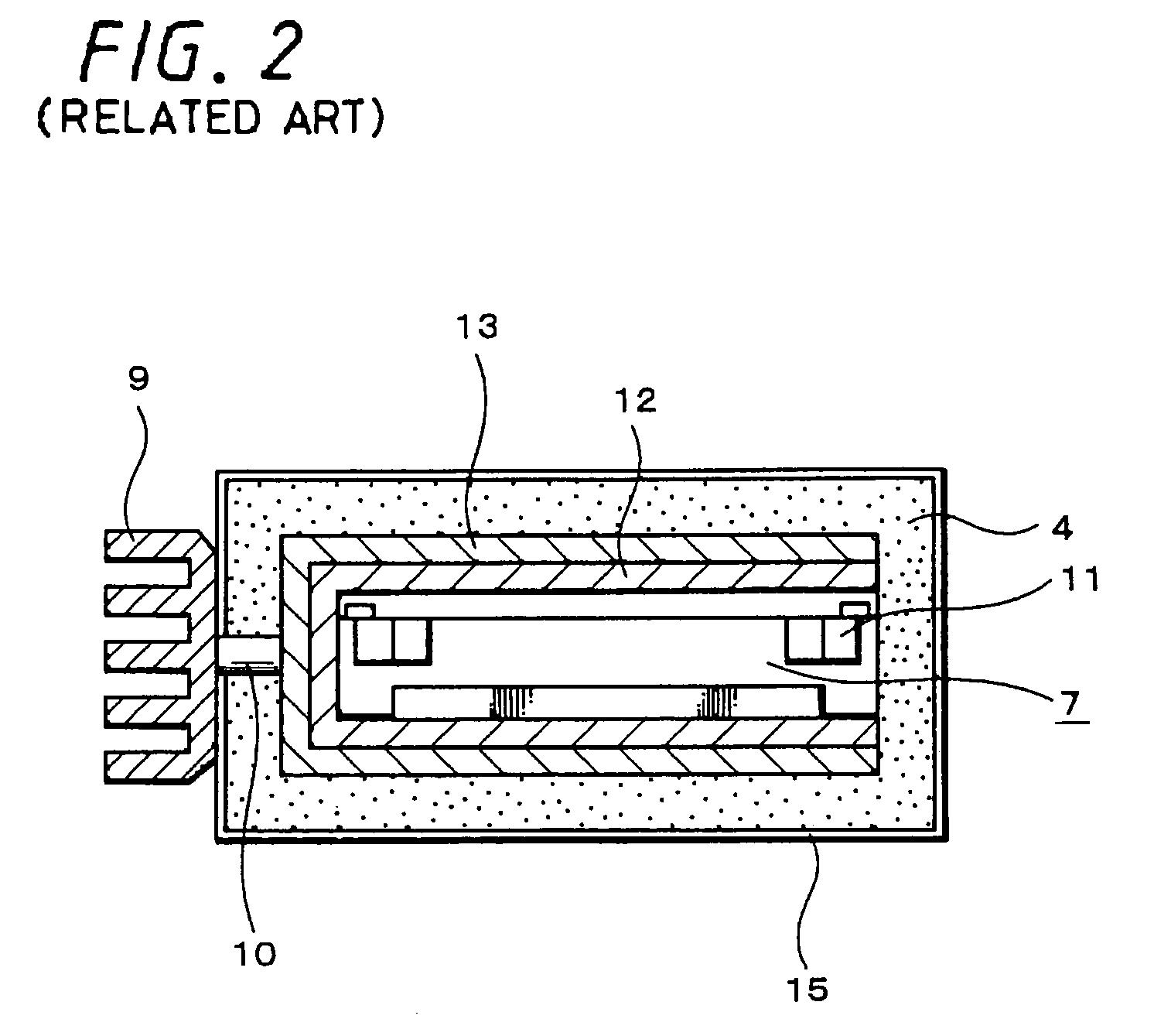

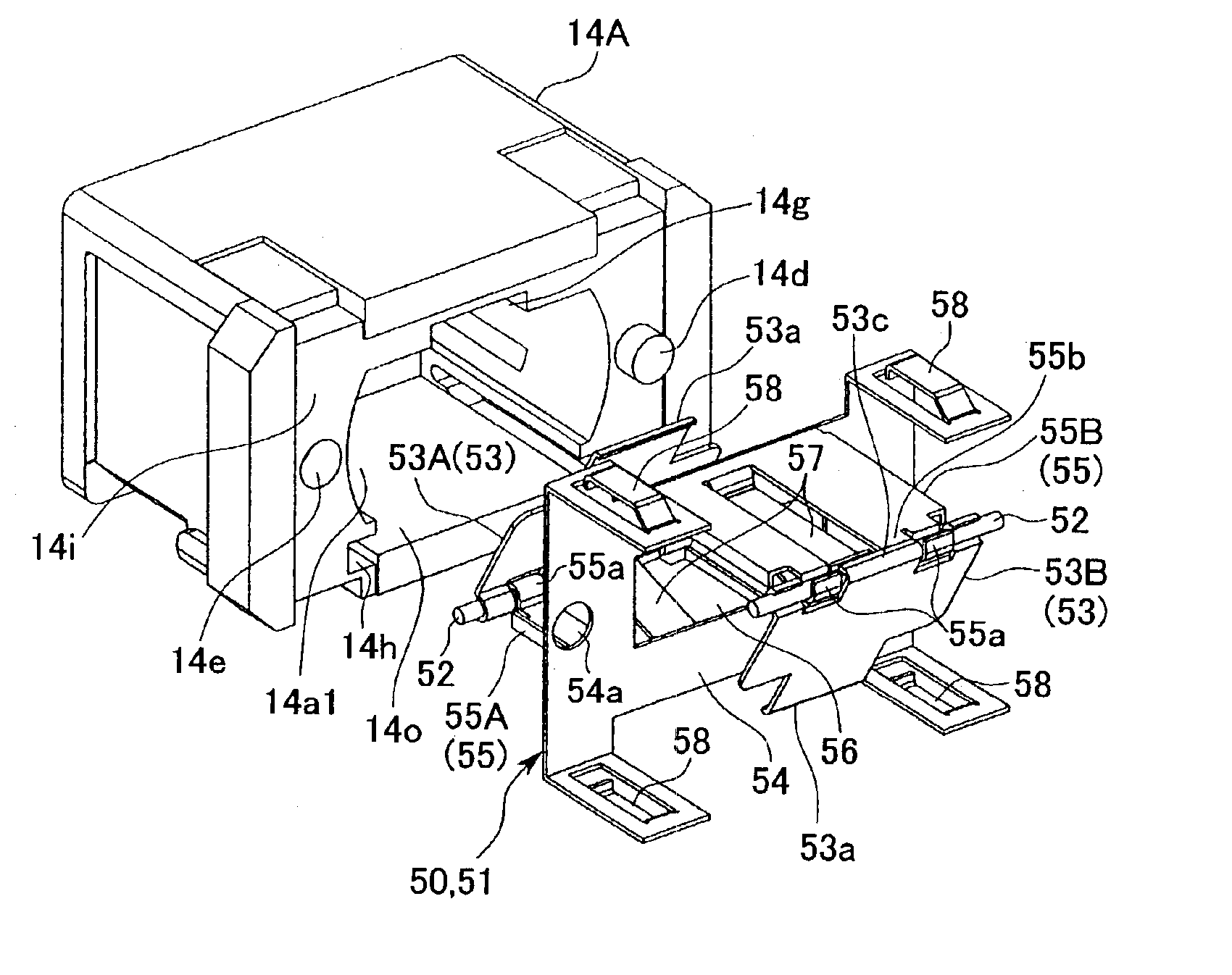

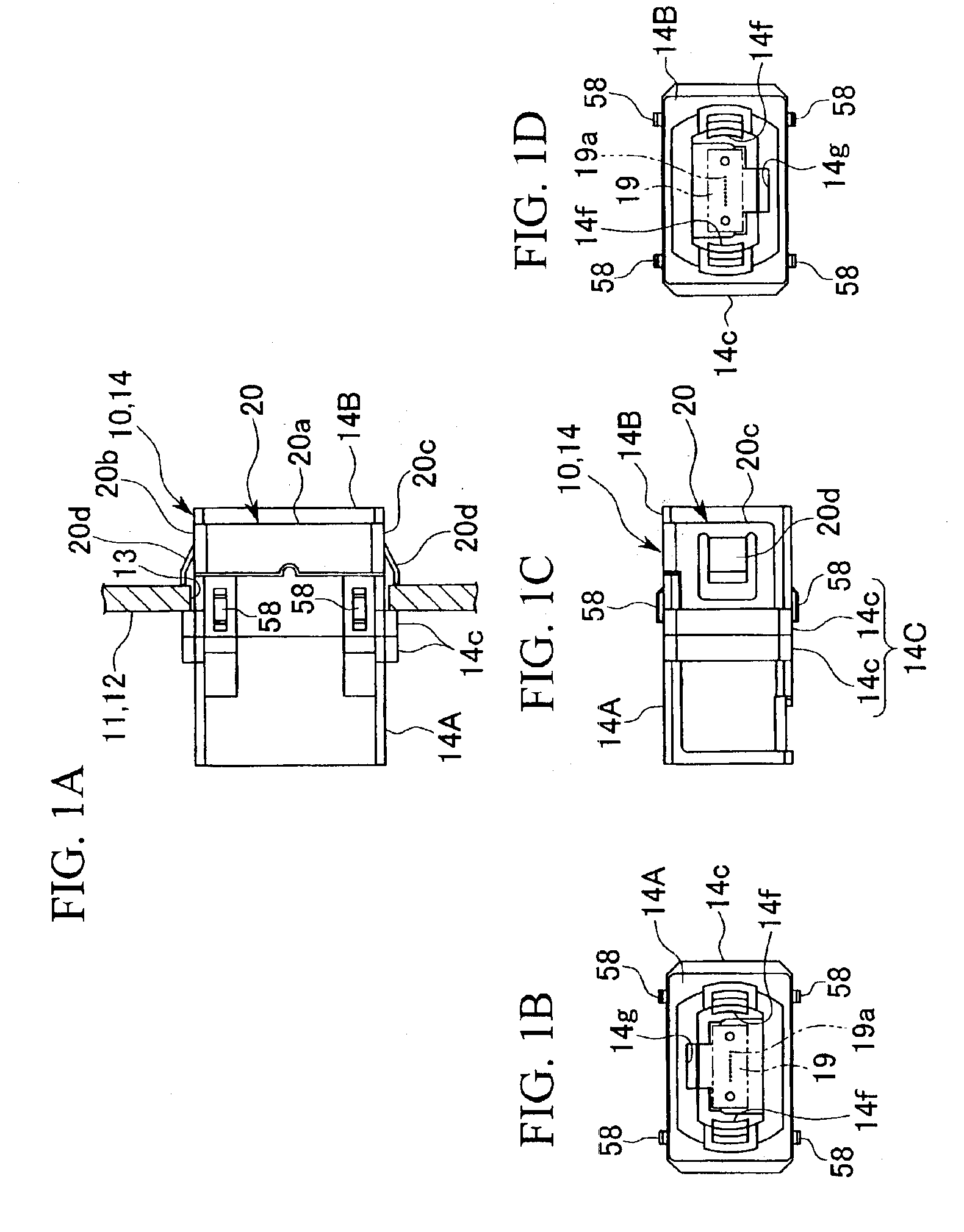

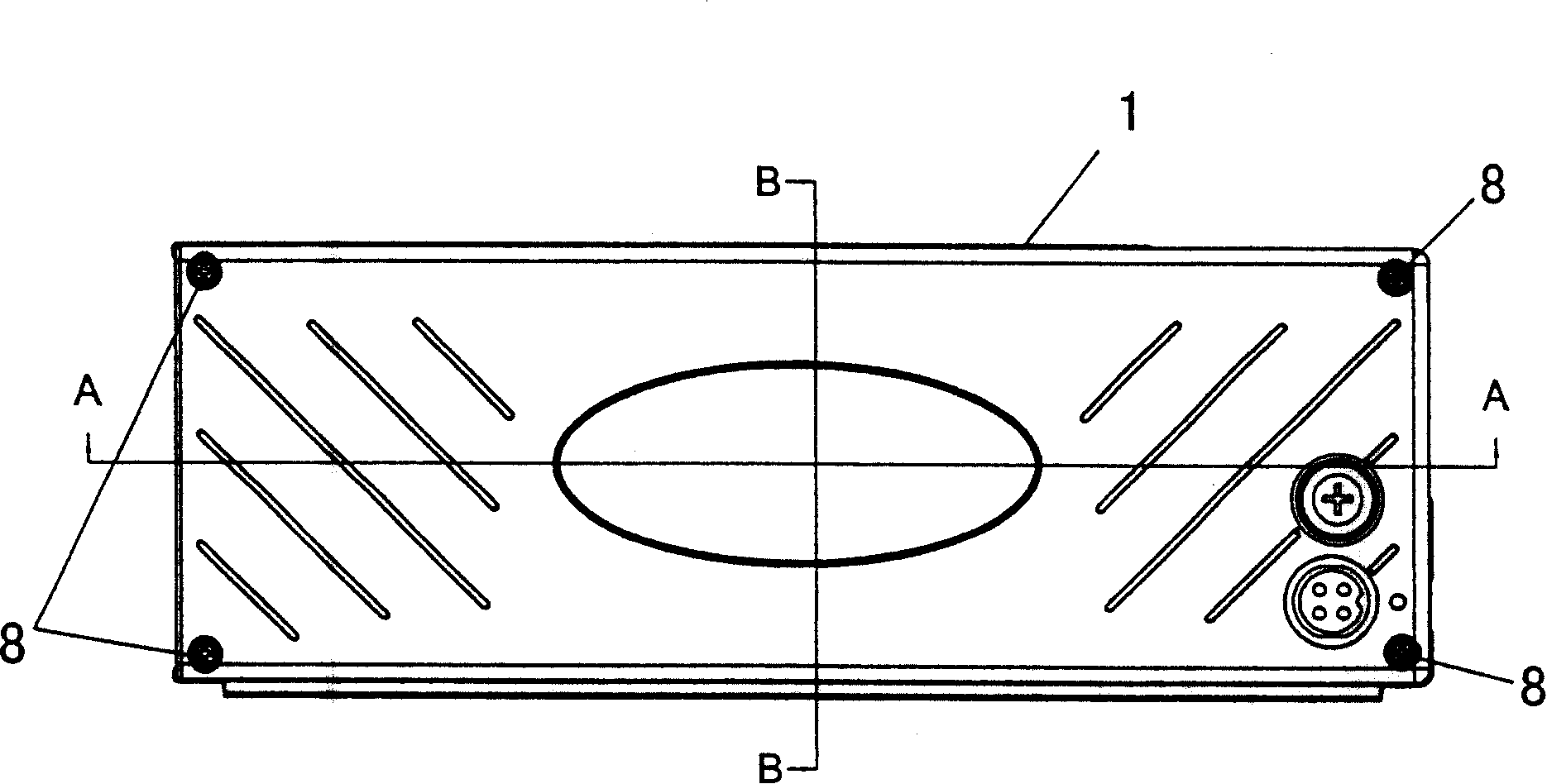

Hard disk drive housing apparatus and electronic apparatus

InactiveUS7167360B2Effective radiationMaintain reliabilityPortable framesDigital data processing detailsHard disc driveSurface mounting

In a hard disk drive (HDD) or an electronic apparatus in which the HDD is wrapped with a foam resin sheet with a noise absorption effect and a metal outer casing to thereby damp noise, a sub-assembly wrapping body incorporating therein the HDD wrapped with a wrapping body composed of a slippery film sheet with foam resin sheets attached thereto is mounted into the metal outer casing through the slippery surface of the slippery film sheet. In order to insulate a noise generated from a recording and reproducing drive apparatus such as the HDD, the system for use with the HDD and the electronic apparatus can simplify the assembly process required when the HDD is loaded into the outer casing serving as a noise insulation box through a noise absorption member.

Owner:SONY CORP

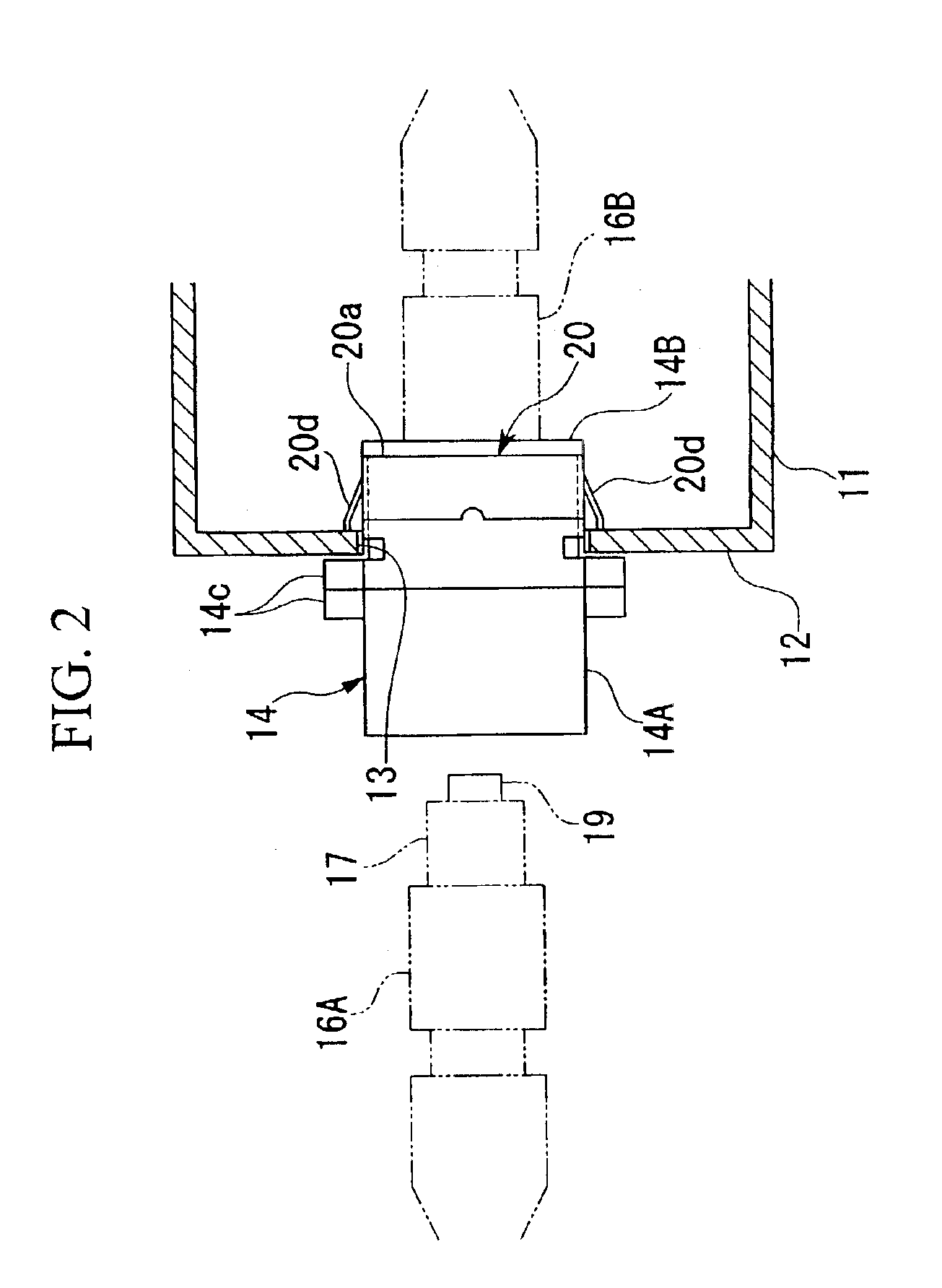

Electronic apparatus and hard disk drive housing apparatus

InactiveUS7315447B2Effective radiationImprove reliabilityApparatus for flat record carriersRecord information storageHard disc driveHeat transmission

A system for mounting a hard disk drive inside an electronic apparatus in such a way that the hard disk drive is isolated from vibration and noise and heat generated by the hard disk dive is radiated to a cover of the electronic apparatus to prevent overheating. A foam heat transmission sheet is placed between the hard disk drive cover and an outer casing that is mounted to the electronic apparatus and far-infrared ray transmitting and receiving sheets are attached to the outside of the outer casing and to the inside of the cover of the electronic apparatus to transmit heat from the hard disk drive to the exterior of the apparatus.

Owner:SONY CORP

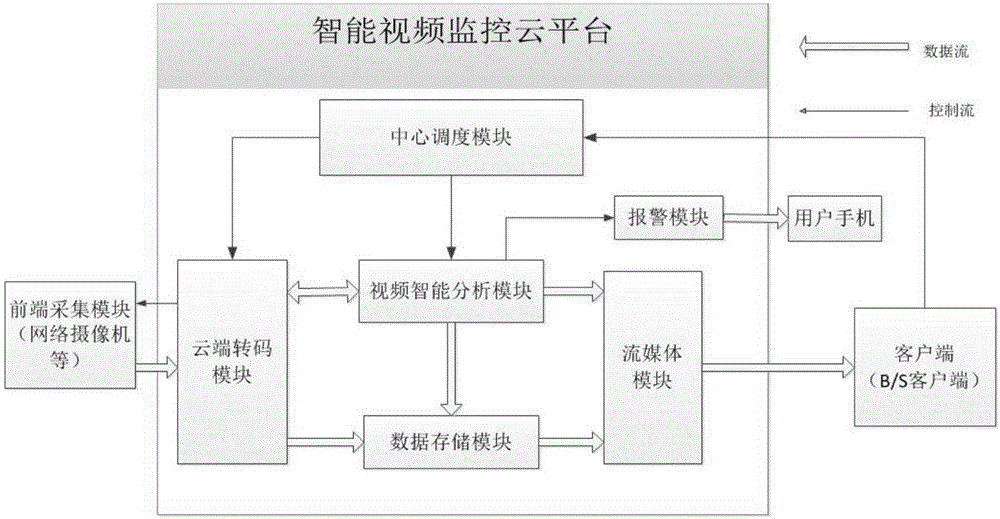

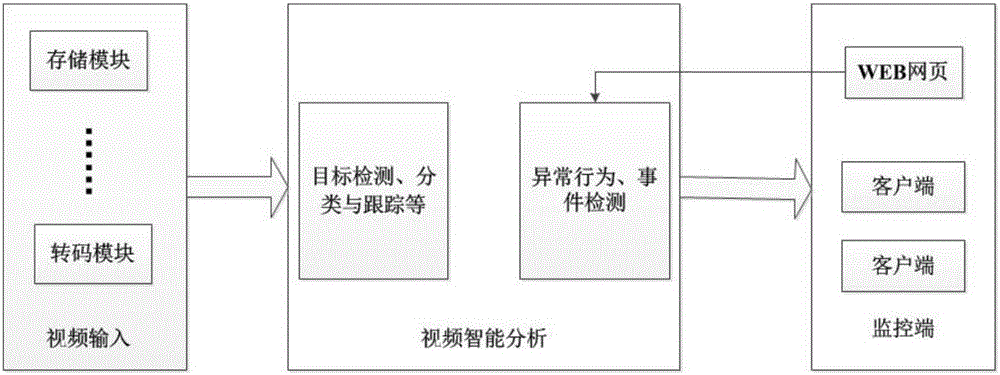

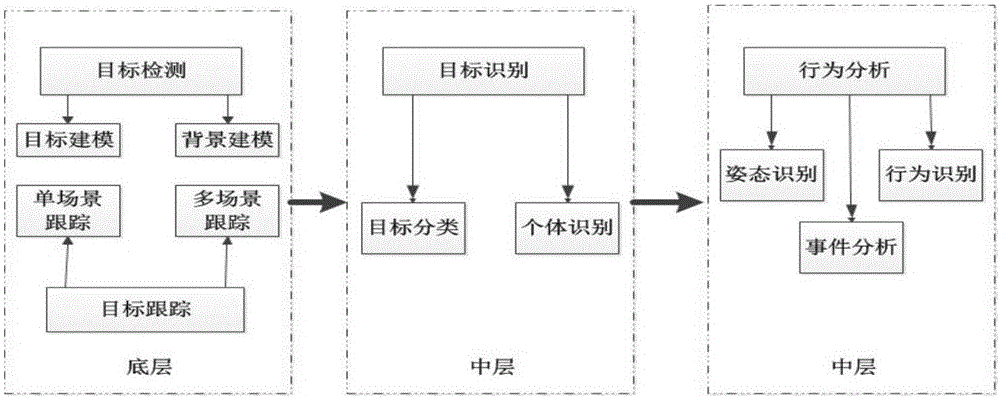

Smart video monitoring system based on cloud platform

InactiveCN106375721AImprove bindingQuality improvementClosed circuit television systemsTransmissionVideo monitoringTranscoding

The invention relates to a smart video monitoring system based on a cloud platform, and belongs to the technical field of remote smart monitoring. The system is characterized in that a video monitoring cloud platform is developed on a server cluster established on the basis of a Hadoop cloud computing platform, and video data acquired by front-end equipment are transmitted to a server in a stream way; through adoption of a massive distributed cloud computing technology, real-time tracking, processing, analysis and outputting of video streams are realized; and a service is provided externally, so that a terminal user can perform checking and calling conveniently. In the system, the characteristics of distributed high-concurrence access storage, high availability, rapid response, easiness in management and maintenance and the like are integrated. Video acquisition, video encoding and transcoding, video data storage, a streaming media distributed server and a client are all distributed on a physical host node in an access network. Compared with a conventional video monitoring system, the smart video monitoring system has the advantages that video real-time processing and transcoding efficiency and video data storage capacity are increased greatly; the requirement of people on the video monitoring system in a big data era is met; and a relatively large commercial value is achieved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

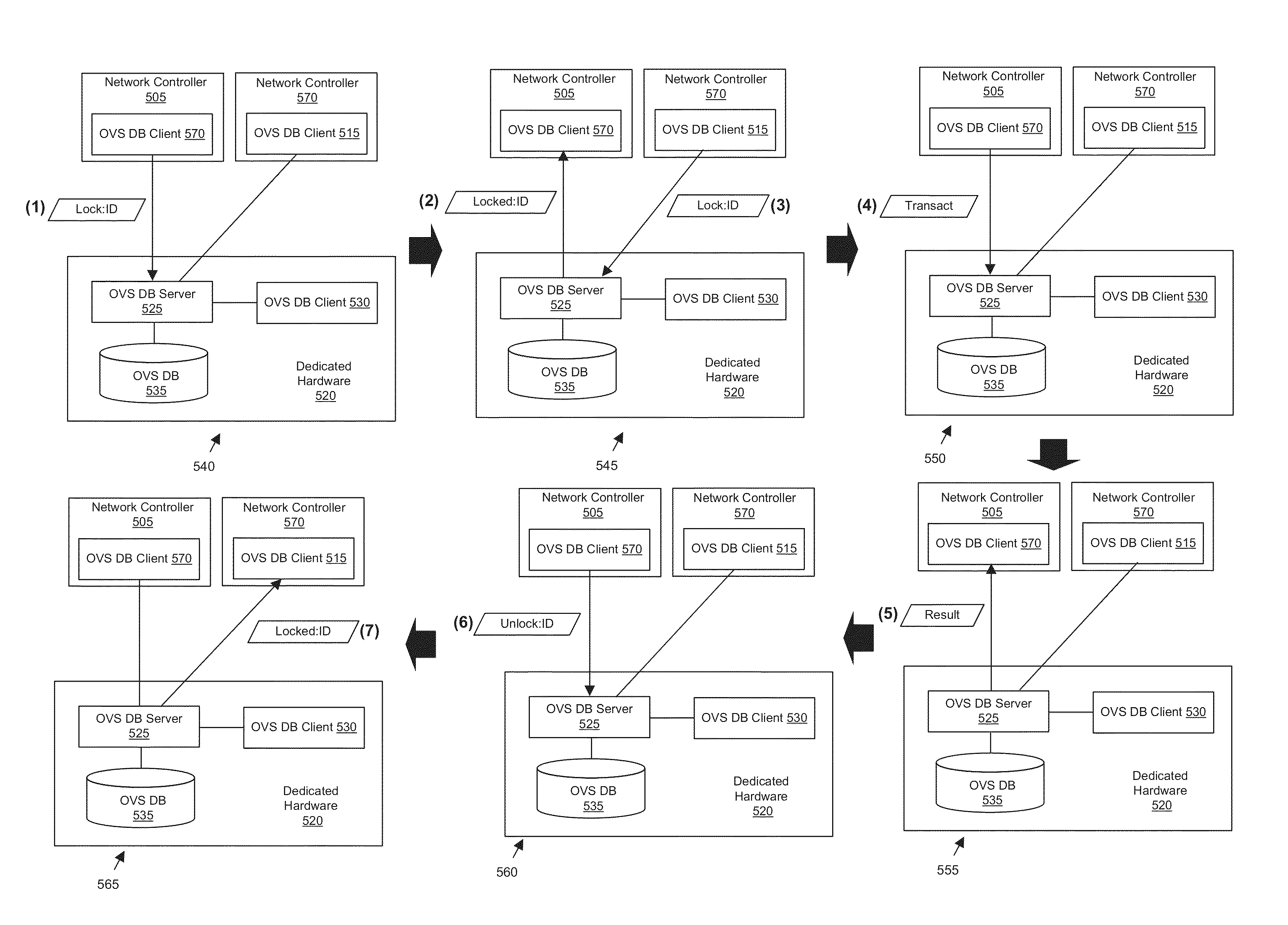

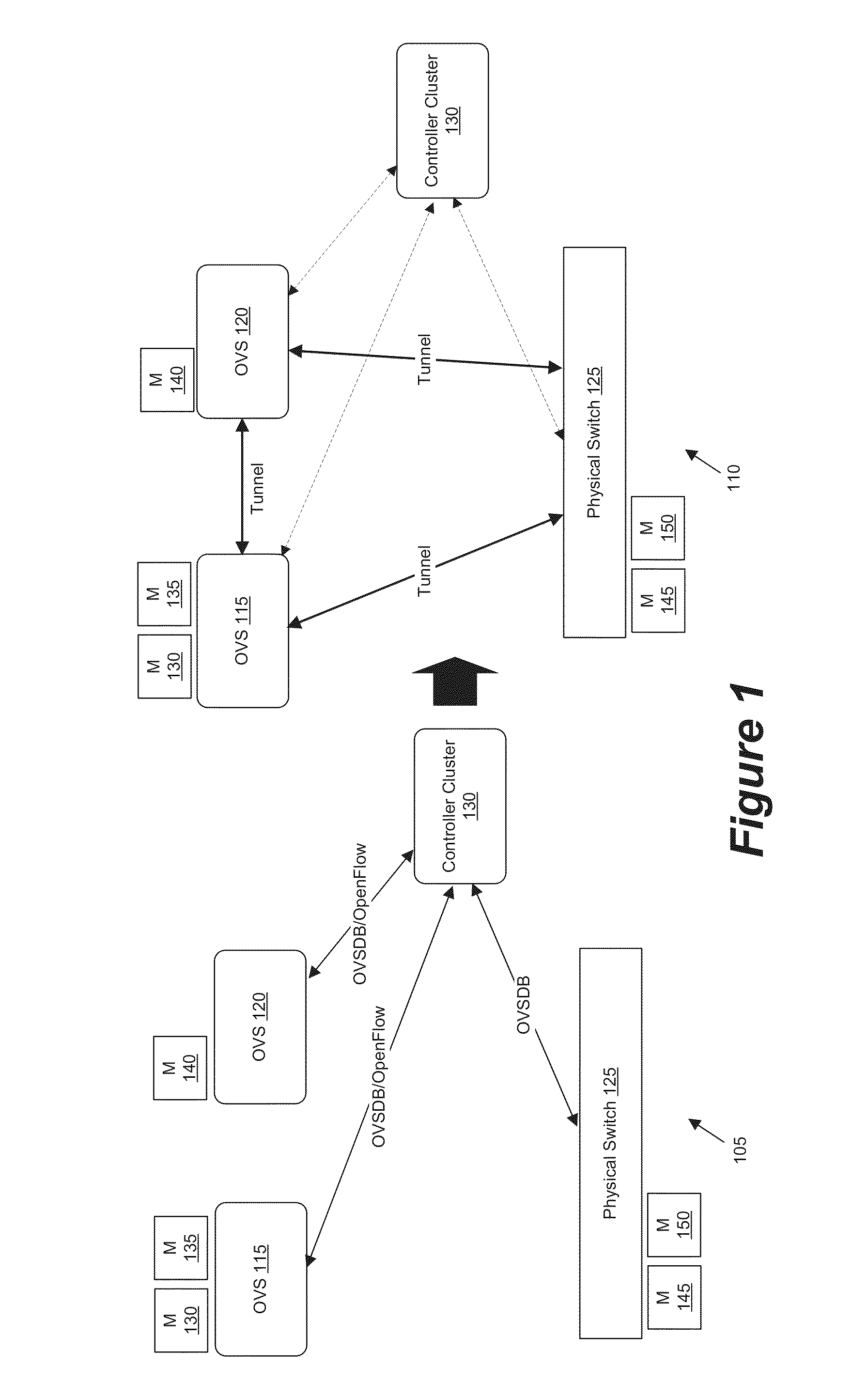

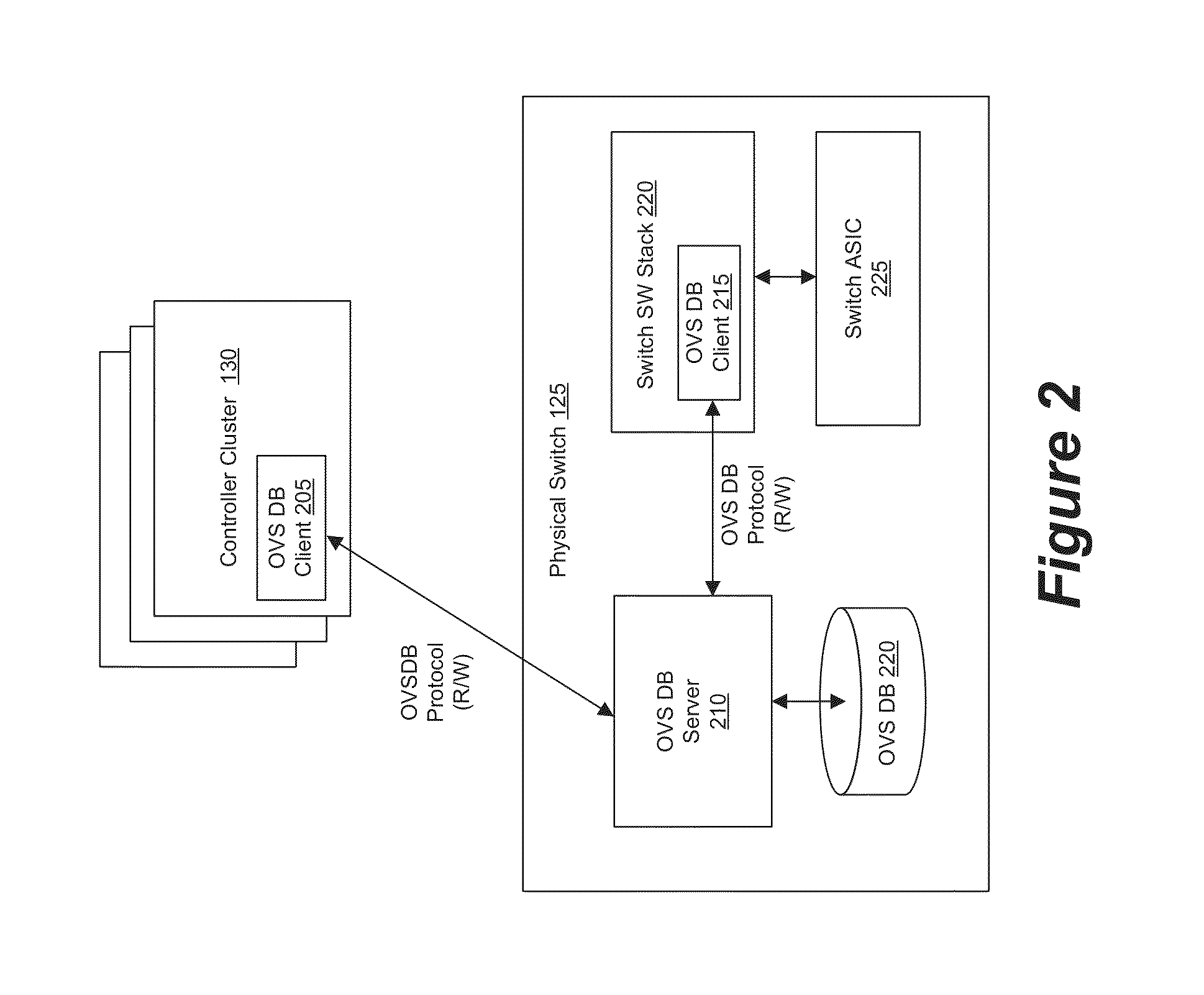

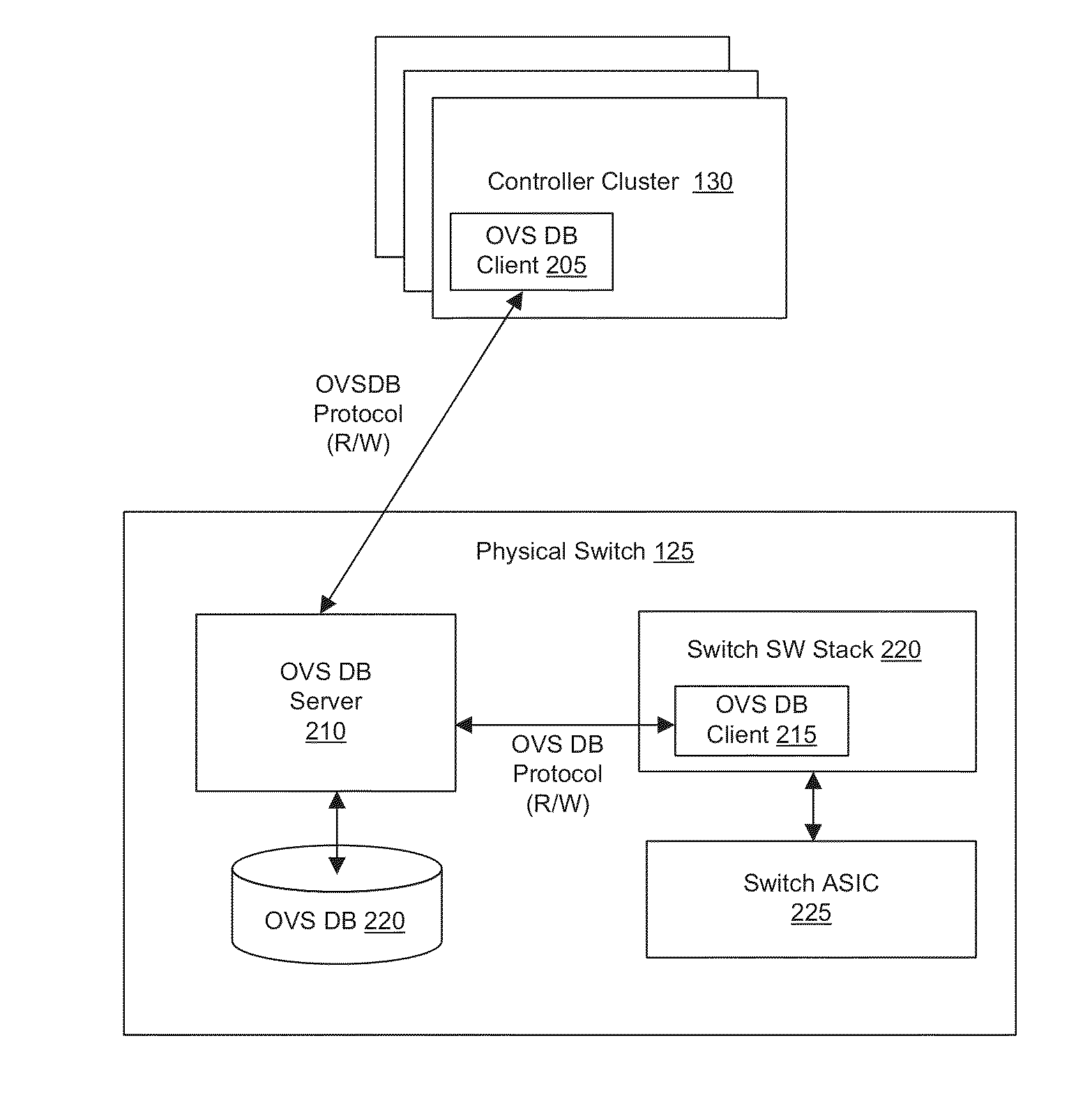

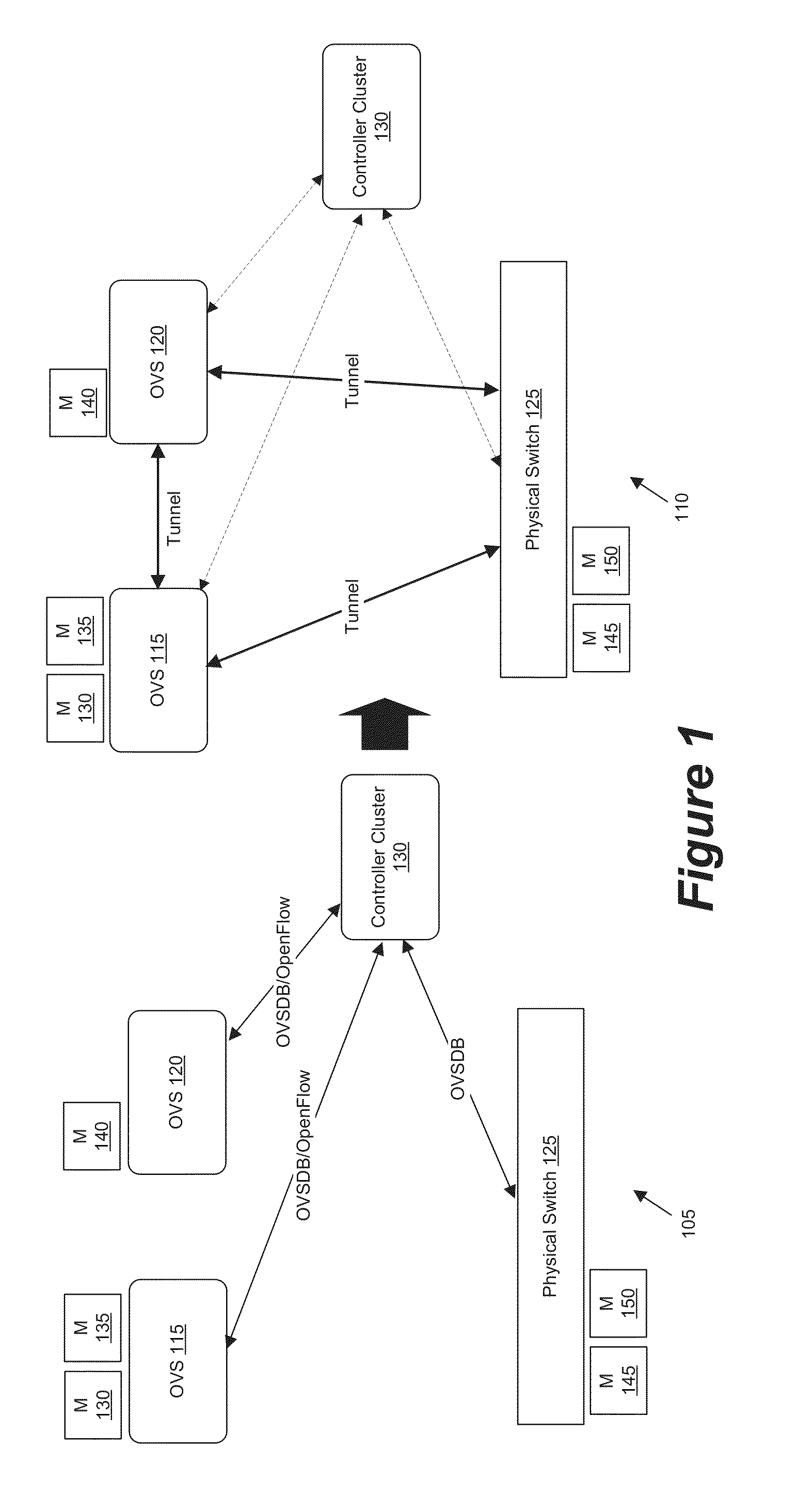

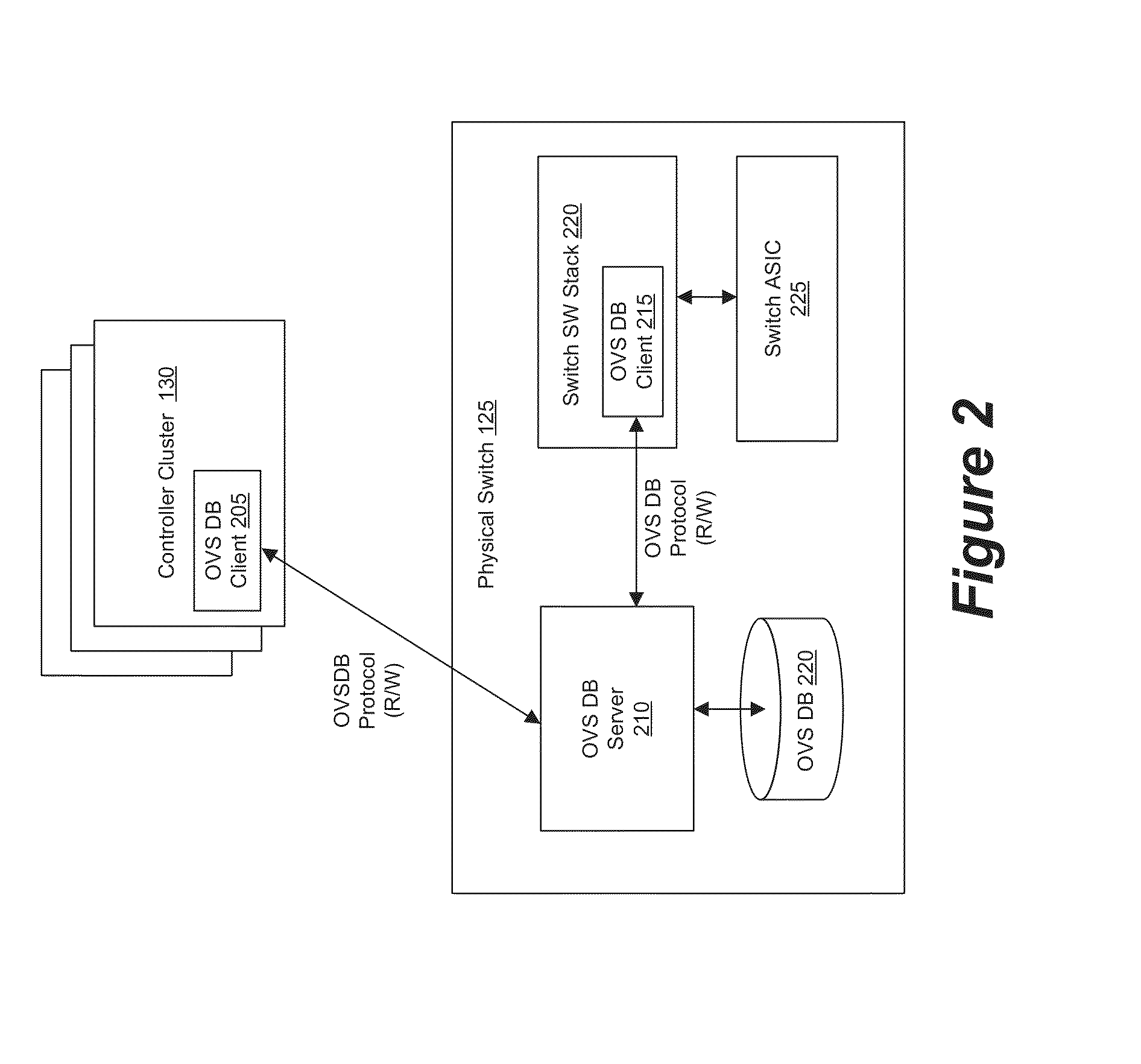

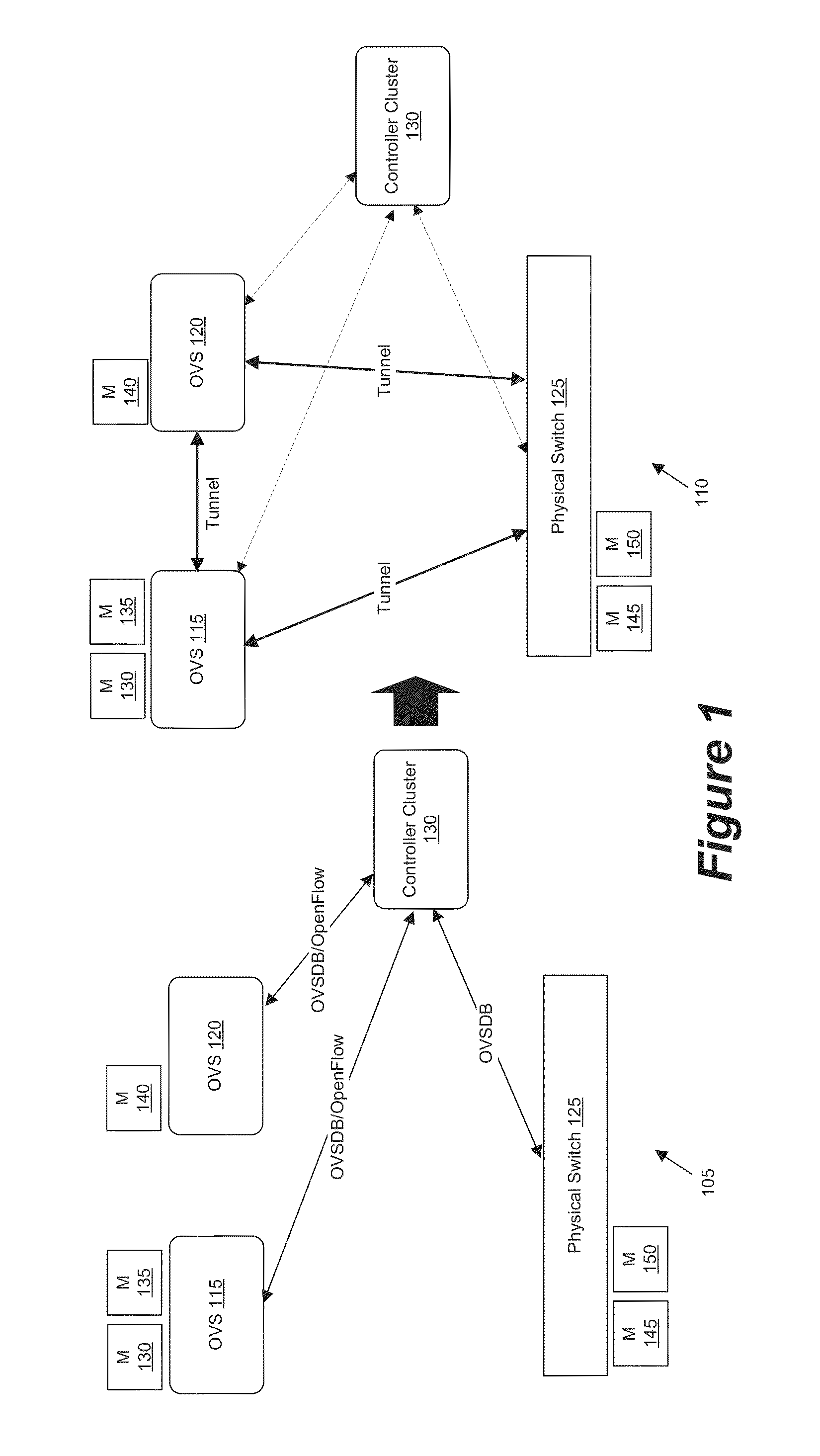

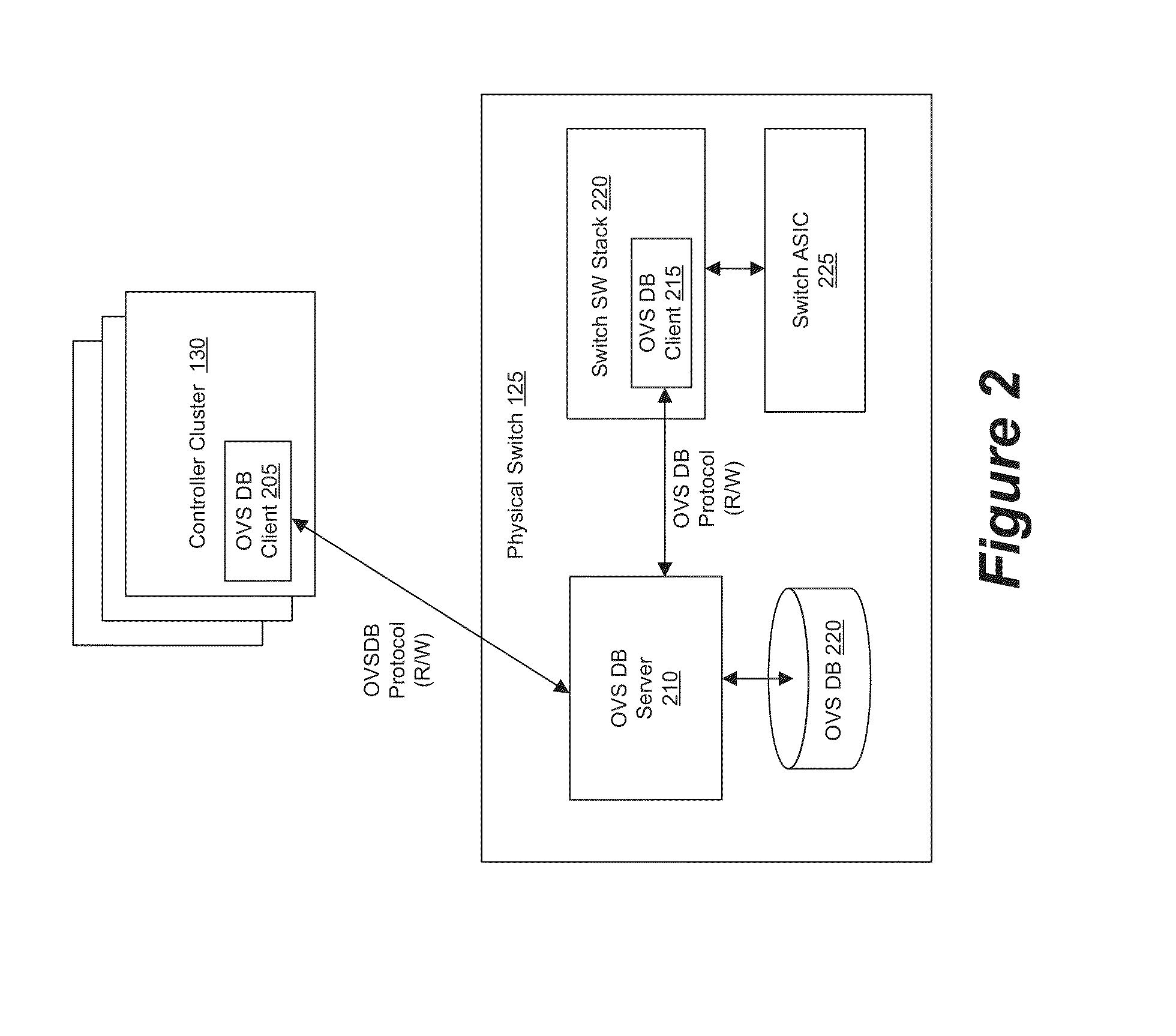

Managing Software and Hardware Forwarding Elements to Define Virtual Networks

ActiveUS20150100704A1Easy to implementMaintain reliabilityDigital computer detailsNetworks interconnectionLoad SheddingSoftware network

Some embodiments provide a set of one or more network controllers that communicates with a wide range of devices, ranging from switches to appliances such as firewalls, load balancers, etc. The set of network controllers communicates with such devices to connect them to its managed virtual networks. The set of network controllers can define each virtual network through software switches and / or software appliances. To extend the control beyond software network elements, some embodiments implement a database server on each dedicated hardware. The set of network controllers accesses the database server to send management data. The hardware then translates the management data to connect to a managed virtual network.

Owner:NICIRA

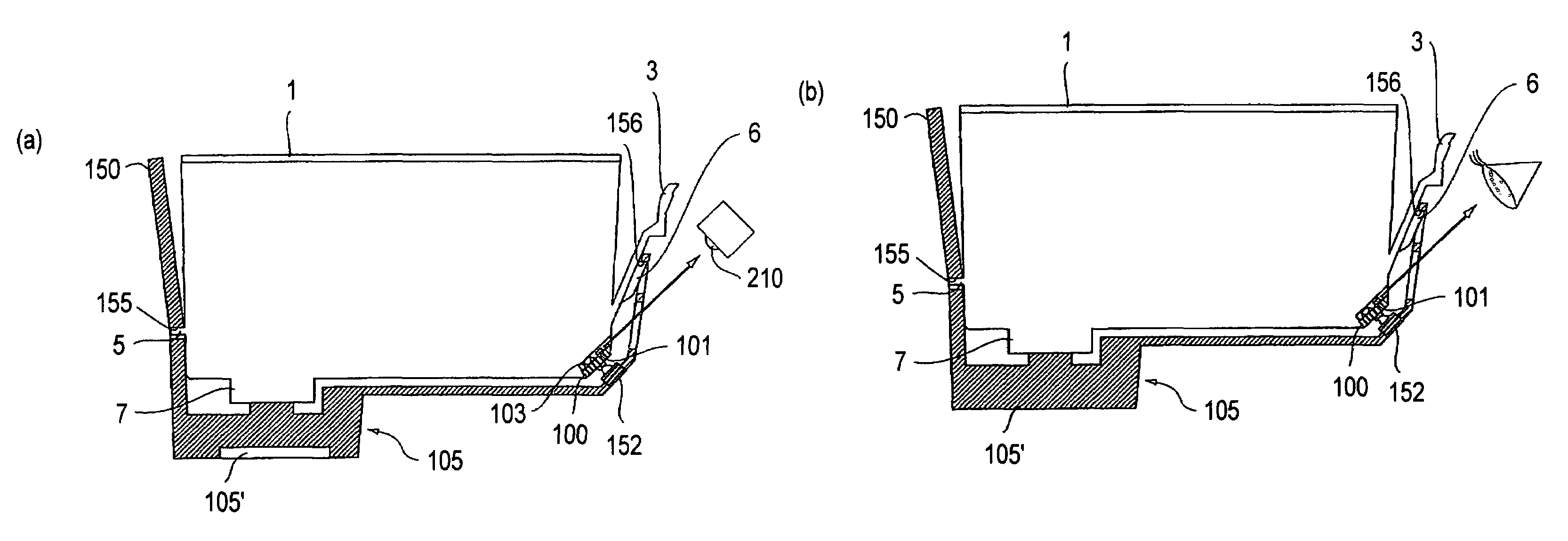

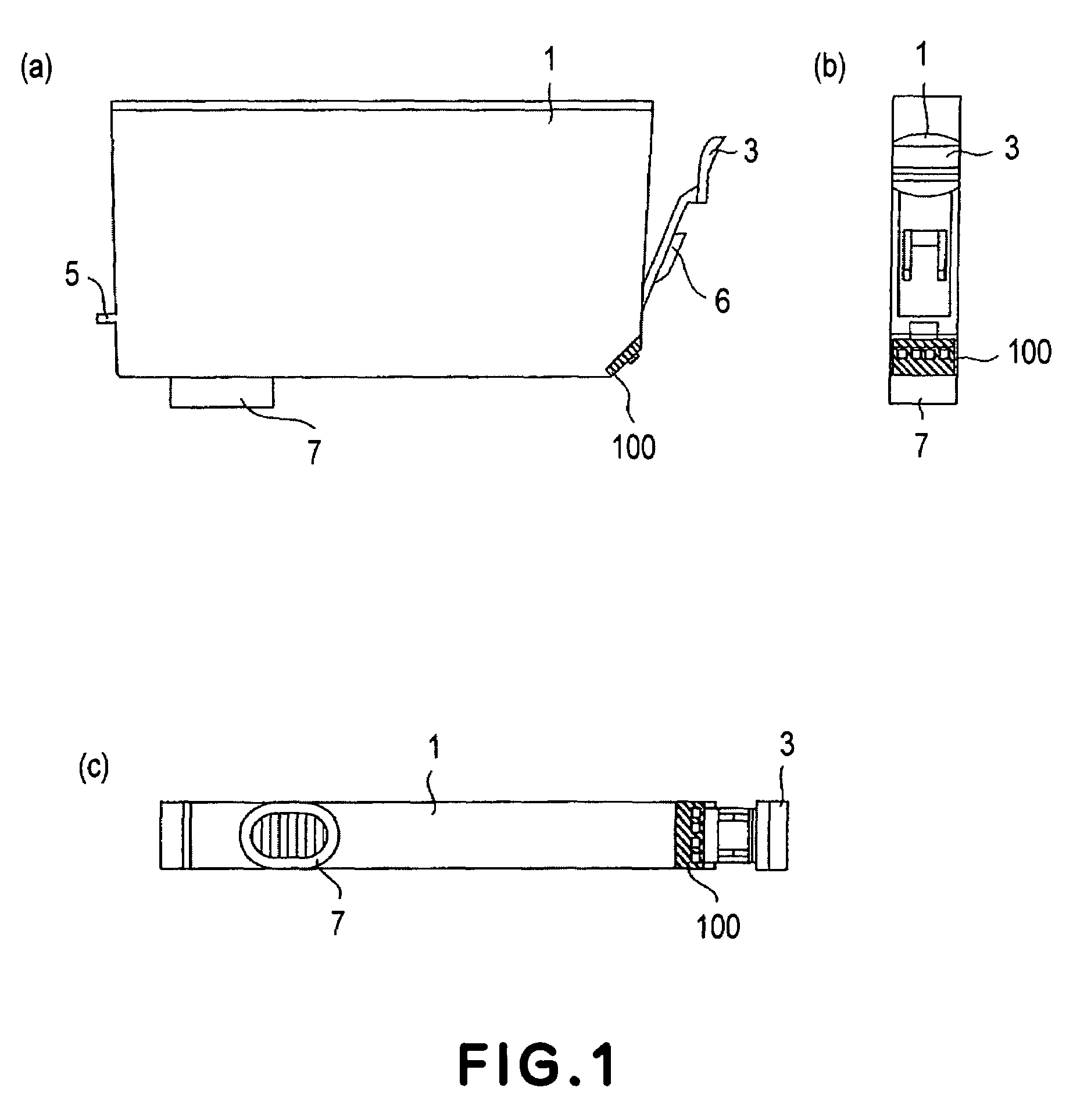

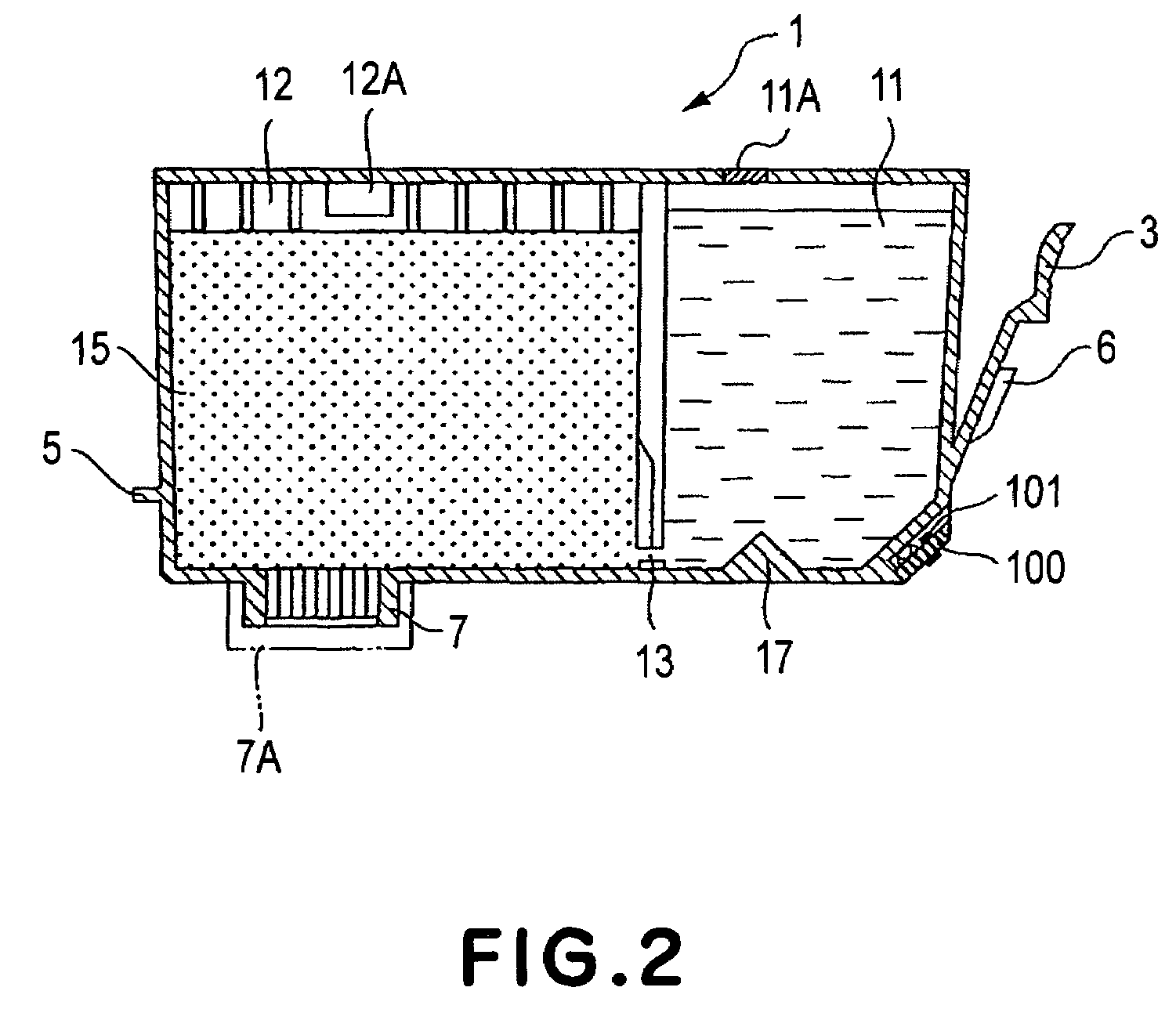

Liquid container, liquid supplying system, manufacturing method therefor, circuit board therefor and liquid containing cartridge

ActiveUS7237881B2Less expensiveIncrease the number ofOther printing apparatusElectricityElectrical contacts

A liquid container detachably mountable to a recording apparatus to which a plurality of liquid containers are detachably mountable, wherein the recording apparatus includes apparatus electrical contacts corresponding to the liquid containers, respectively, photoreceptor means for receiving light, and an electric circuit connected with a line which is commonly connected with the apparatus electrical contacts, the liquid container includes a container electrical contact electrically connectable with one of the apparatus contacts; an information storing portion capable of storing at least individual information relating to the liquid container; a light emitting portion; an actuating portion for actuating the light emitting portion; a controller for controlling access to the information storing portion and / or actuation of the light emitting portion by the driver in response to individual information supplied from the recording device and reception of a command from the recording device.

Owner:CANON KK

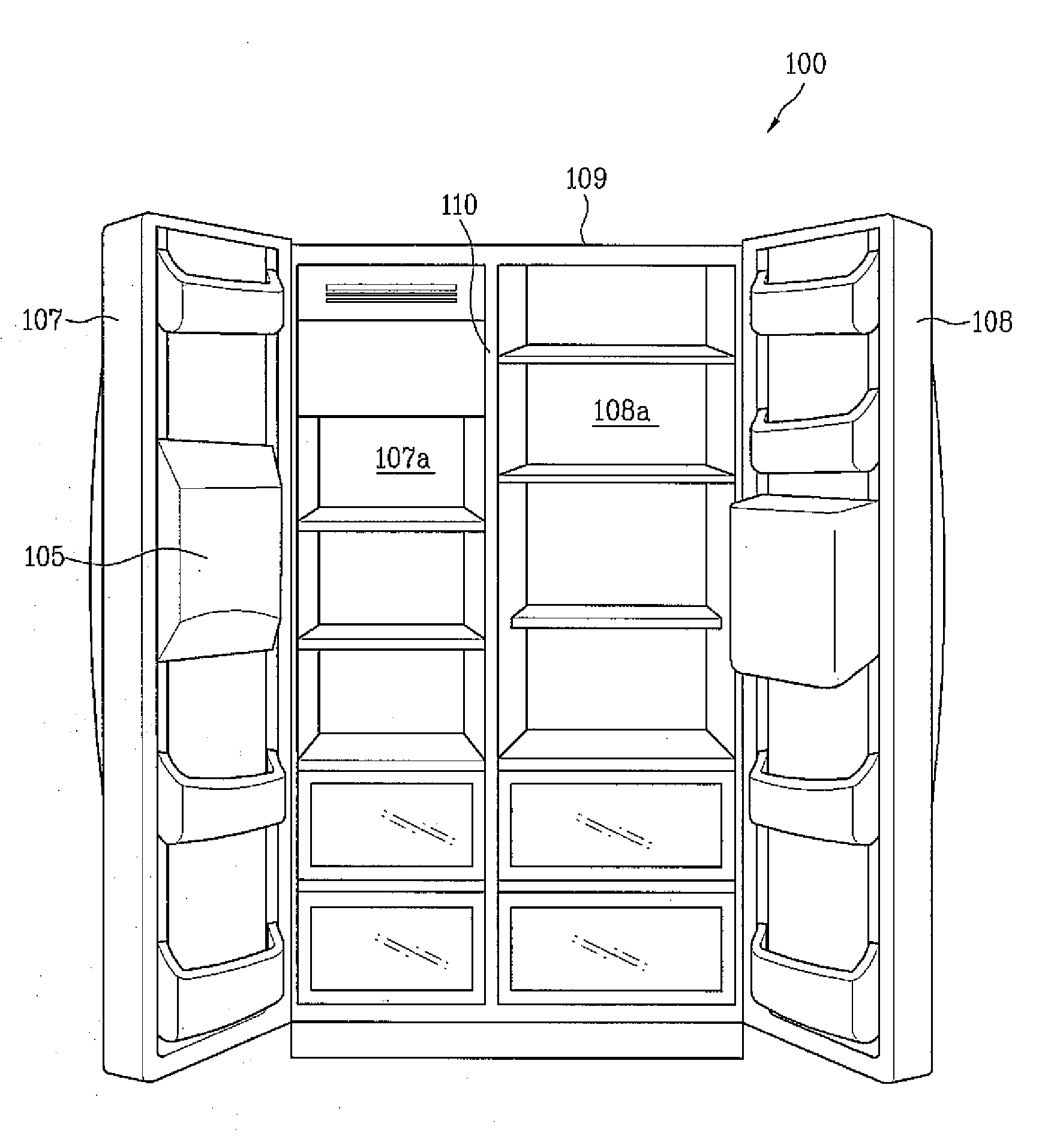

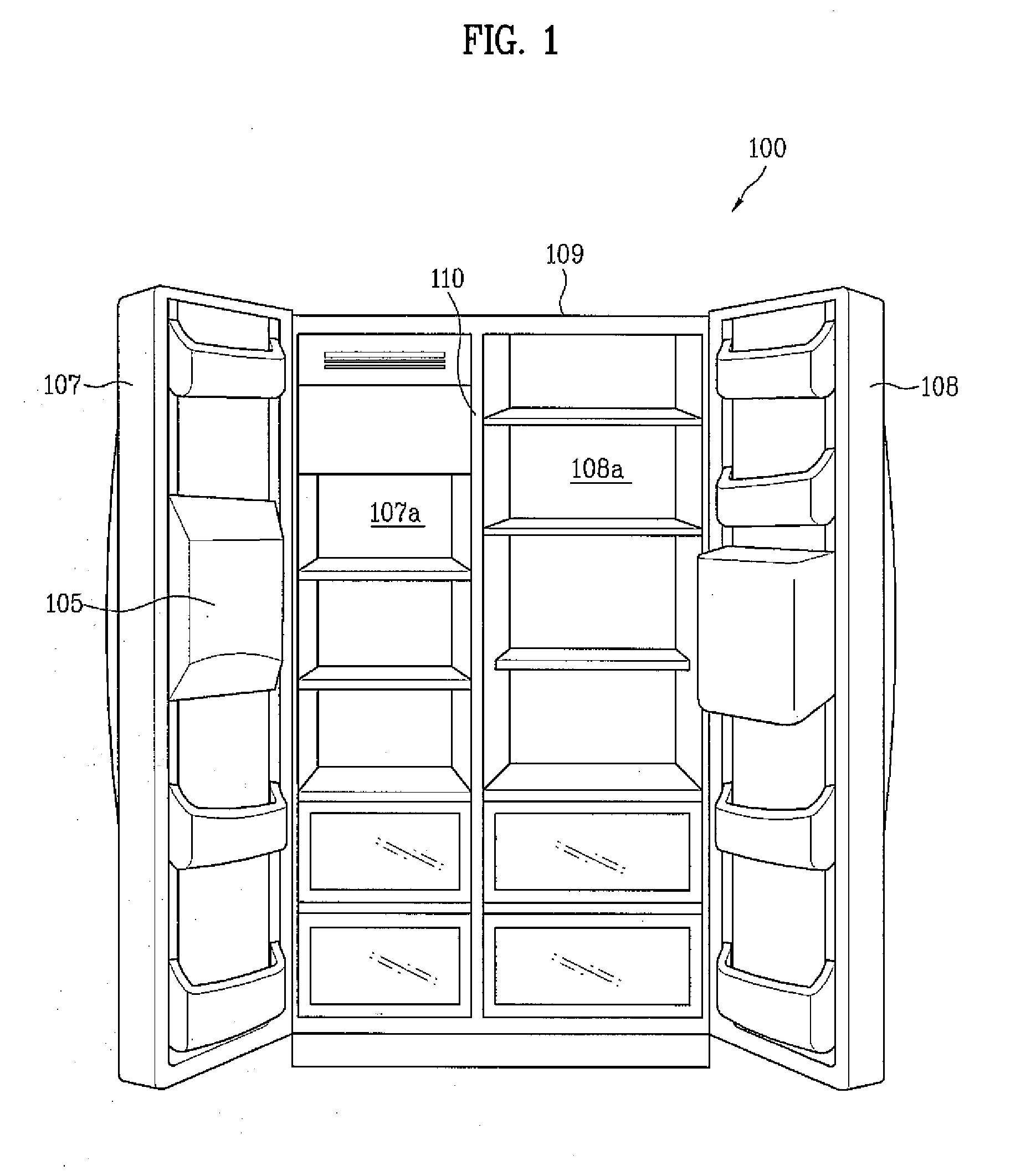

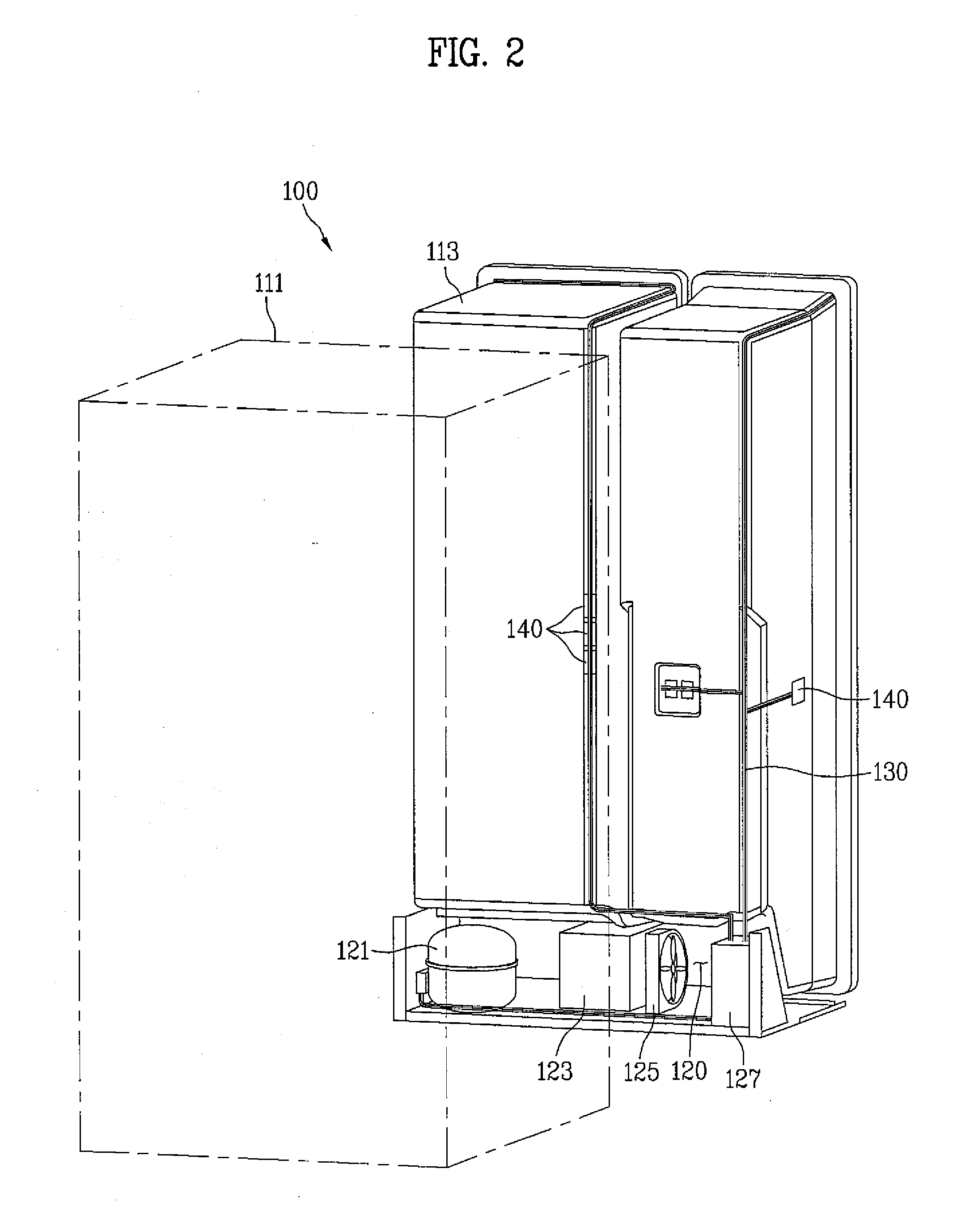

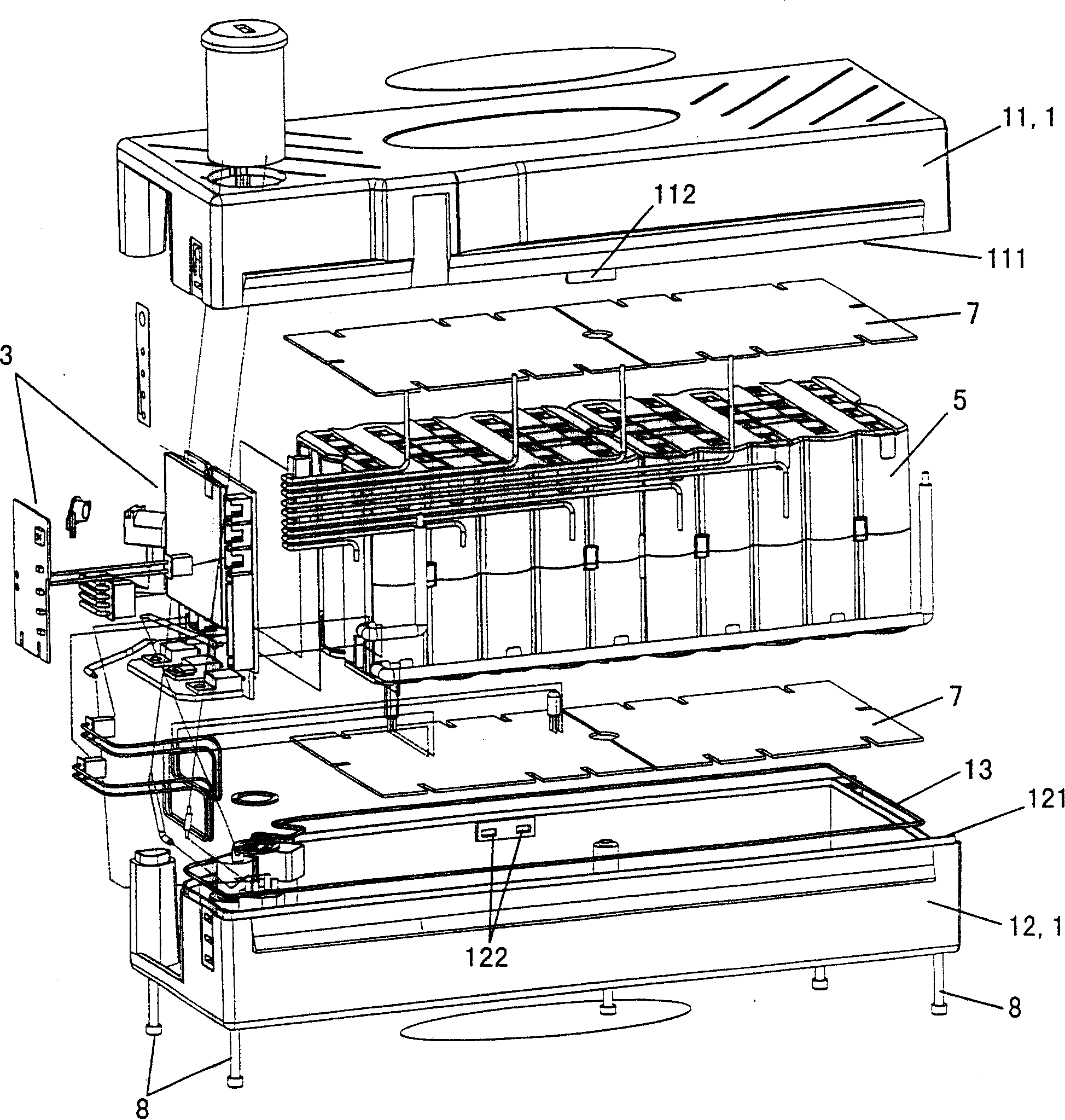

Refrigerator

InactiveUS20090058244A1Increasing the thicknessIndustrial applicabilityLighting and heating apparatusFurniture partsEngineeringElectric signal

A refrigerator including an outer case and an inner case arranged to define a body of a refrigerator; and an electric wire piping assembly to perform power supply and / or transmission of electric signals, the electric wire piping assembly provided along a predetermined path to prevent a thickness of a heat insulating material, that is filled between the inner case and the outer case, from being reduced. The electric wire piping assembly provided in the case of the refrigerator according to the present invention is disposed along the predetermined path not to reduce the thickness of the heat insulating material. As a result, the deterioration of heat insulation efficiency and the formation of drops on the refrigerator may be prevented.

Owner:LG ELECTRONICS INC

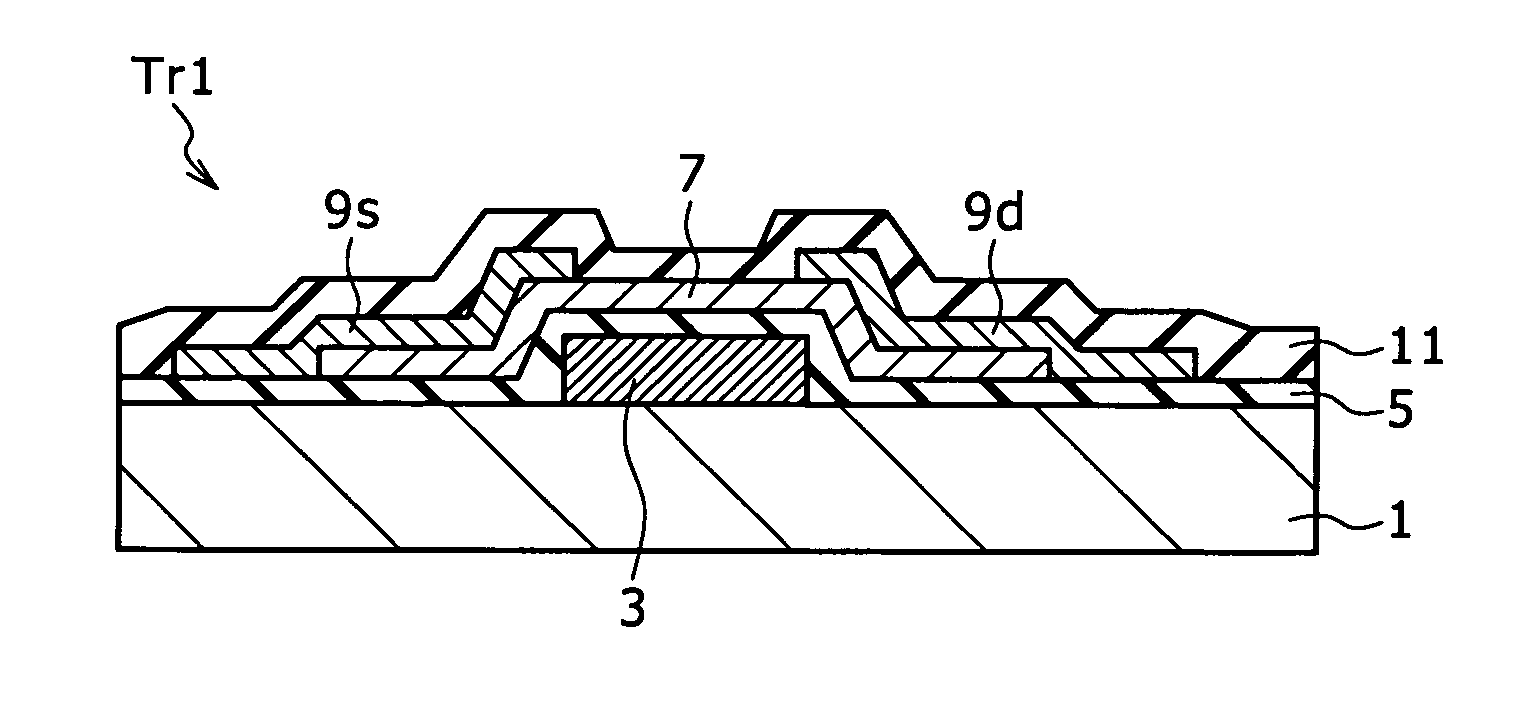

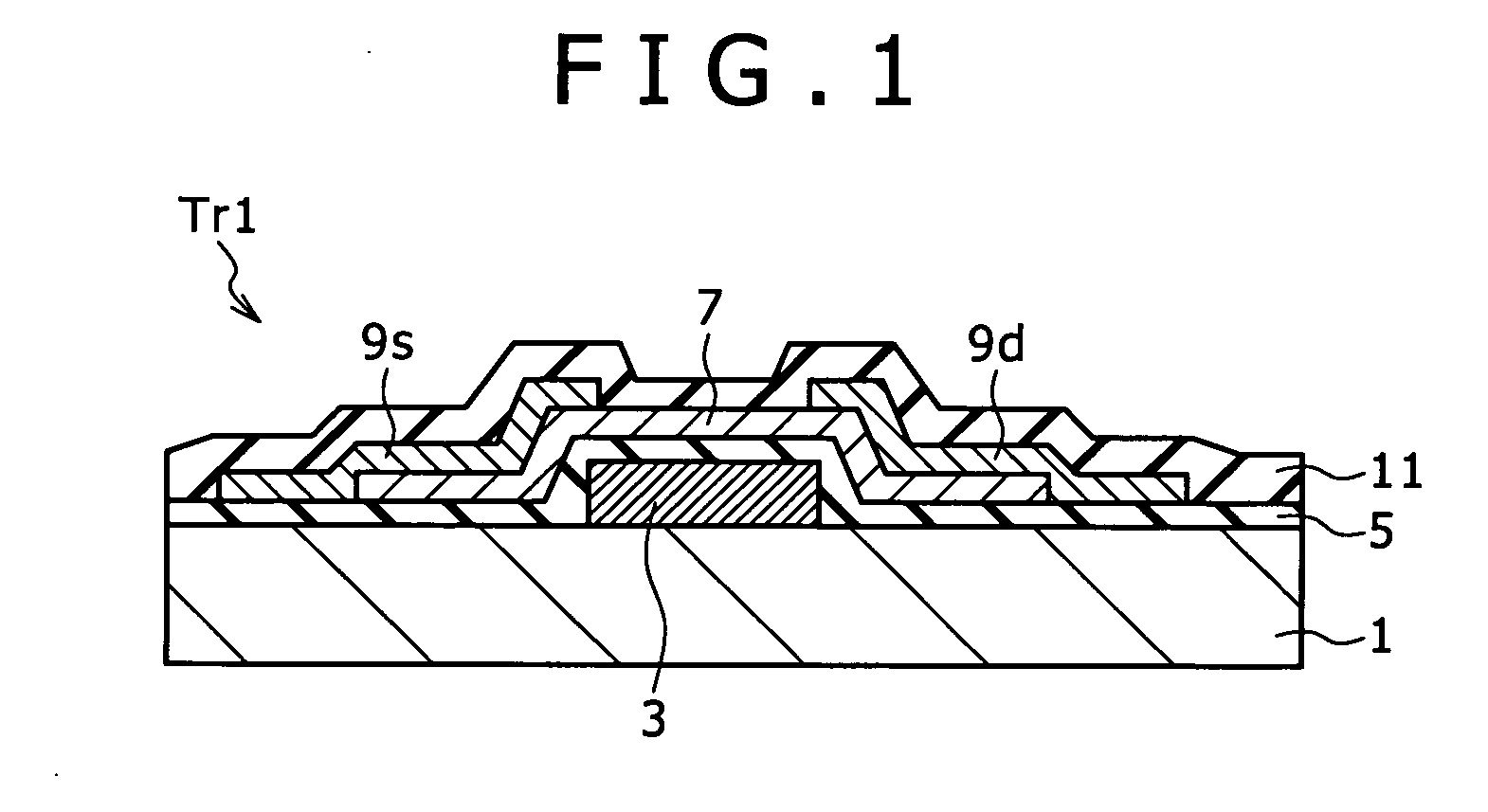

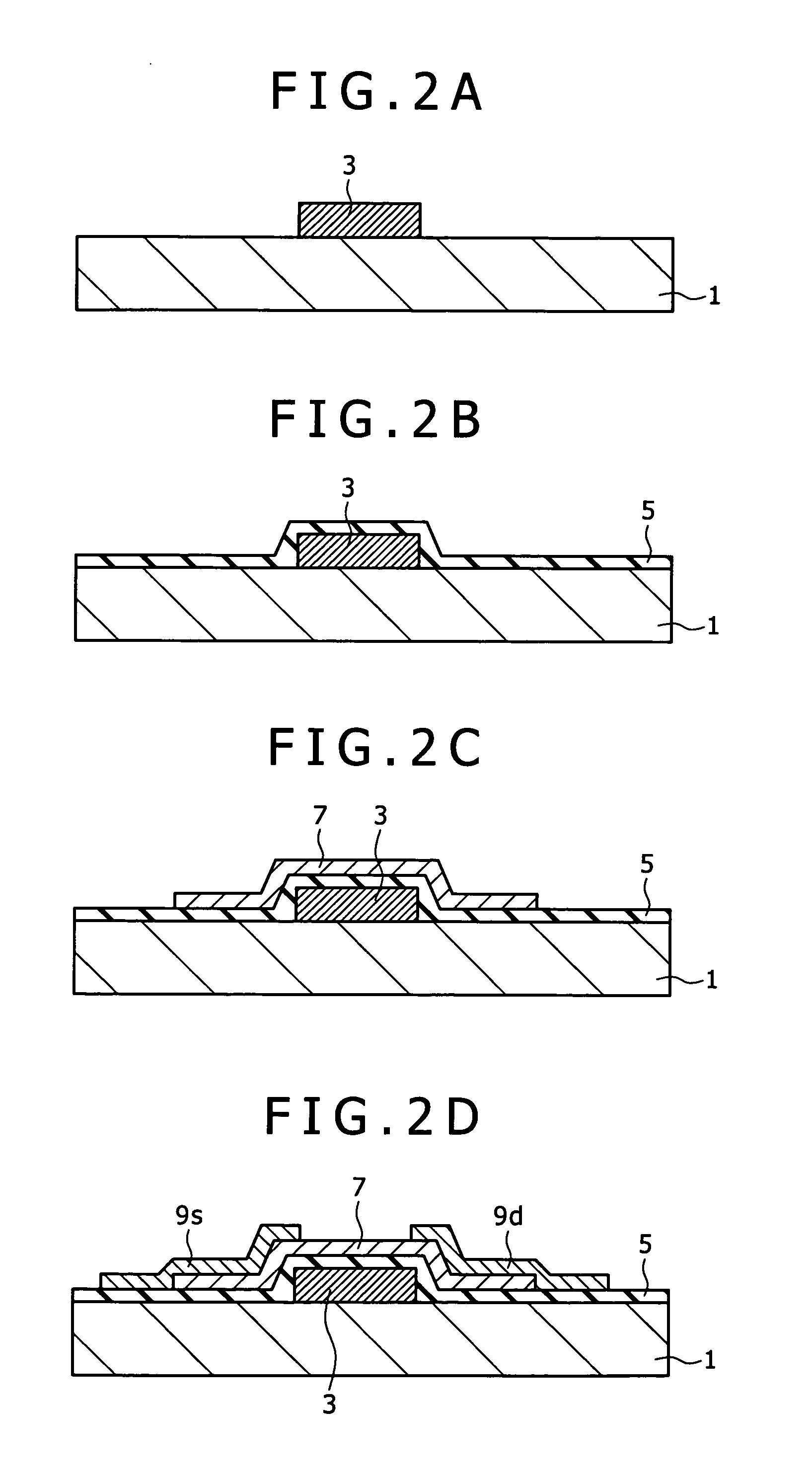

Thin film transistor, display, and electronic apparatus

InactiveUS20100295037A1Inhibit deteriorationMaintain stabilityTransistorSolid-state devicesIridiumDisplay device

Disclosed herein is a thin film transistor including: a semiconductor layer including an amorphous oxide, and a source electrode and a drain electrode which are provided in contact with the semiconductor layer. The source electrode and the drain electrode are formed by use of iridium or iridium oxide.

Owner:JOLED INC

Network Controller for Managing Software and Hardware Forwarding Elements

InactiveUS20150100560A1Easy to implementMaintain reliabilityDigital data information retrievalDigital data processing detailsSoftware networkDatabase server

Some embodiments provide a set of one or more network controllers that communicates with a wide range of devices, ranging from switches to appliances such as firewalls, load balancers, etc. The set of network controllers communicates with such devices to connect them to its managed virtual networks. The set of network controllers can define each virtual network through software switches and / or software appliances. To extend the control beyond software network elements, some embodiments implement a database server on each dedicated hardware. The set of network controllers accesses the database server to send management data. The hardware then translates the management data to connect to a managed virtual network.

Owner:NICIRA

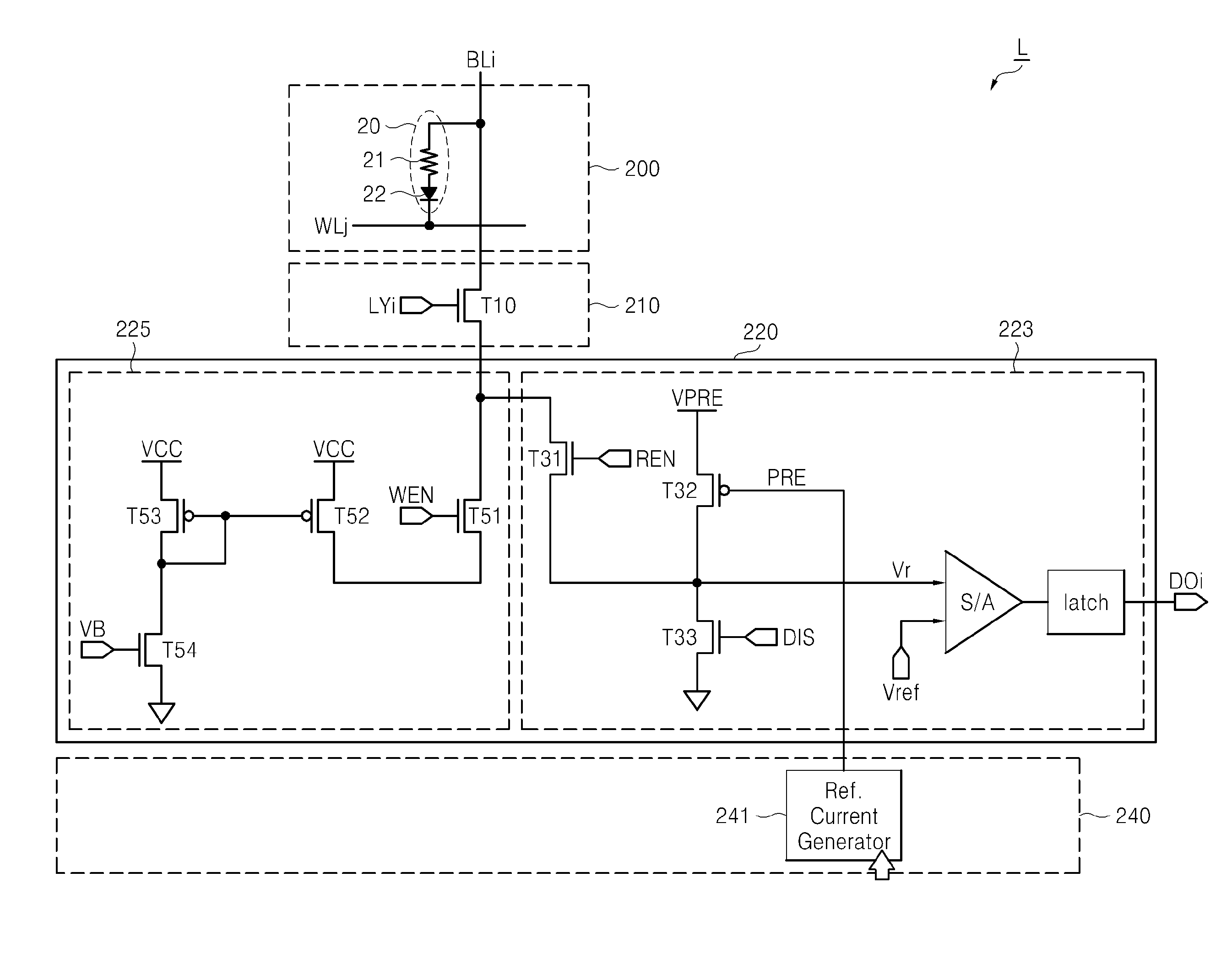

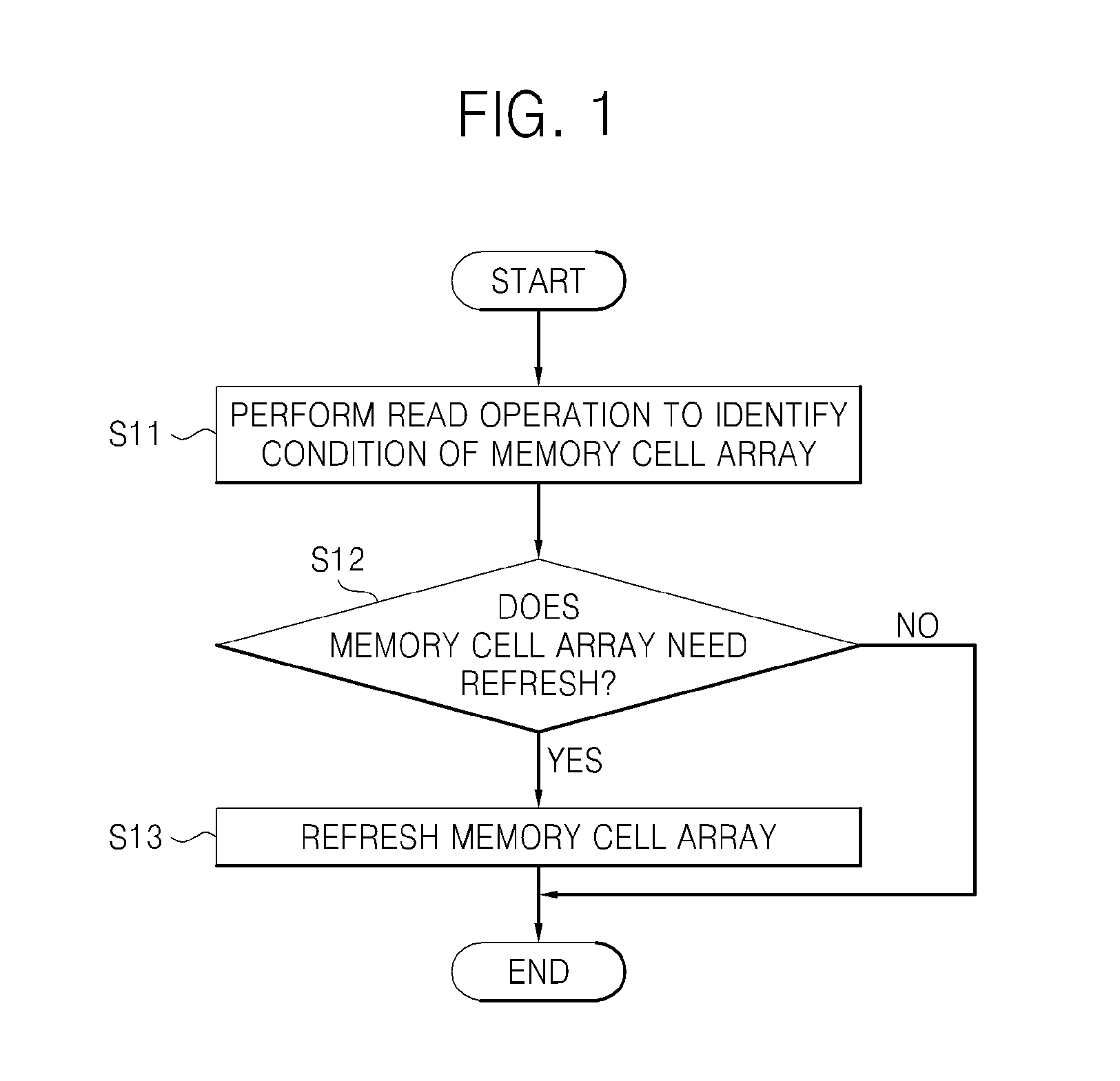

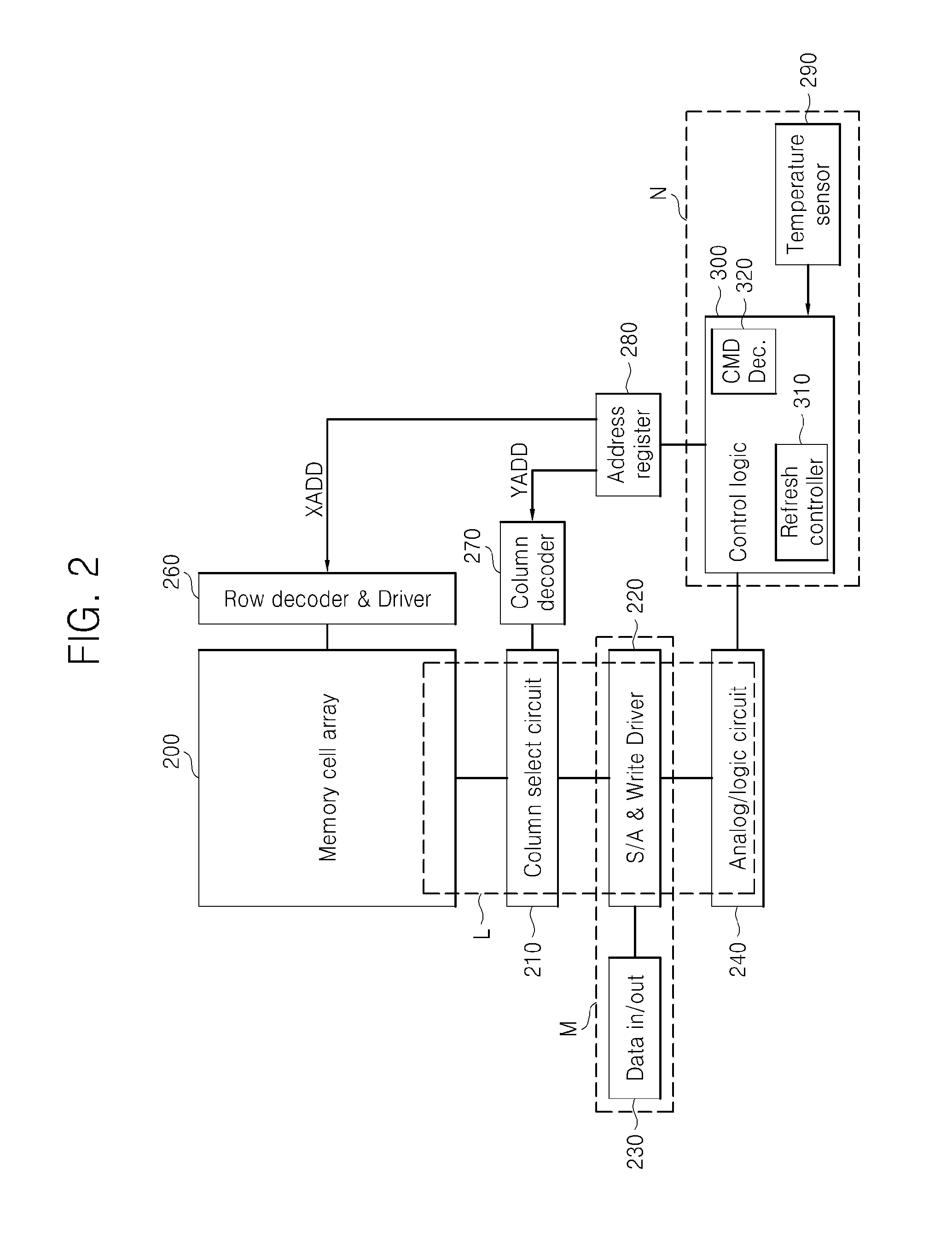

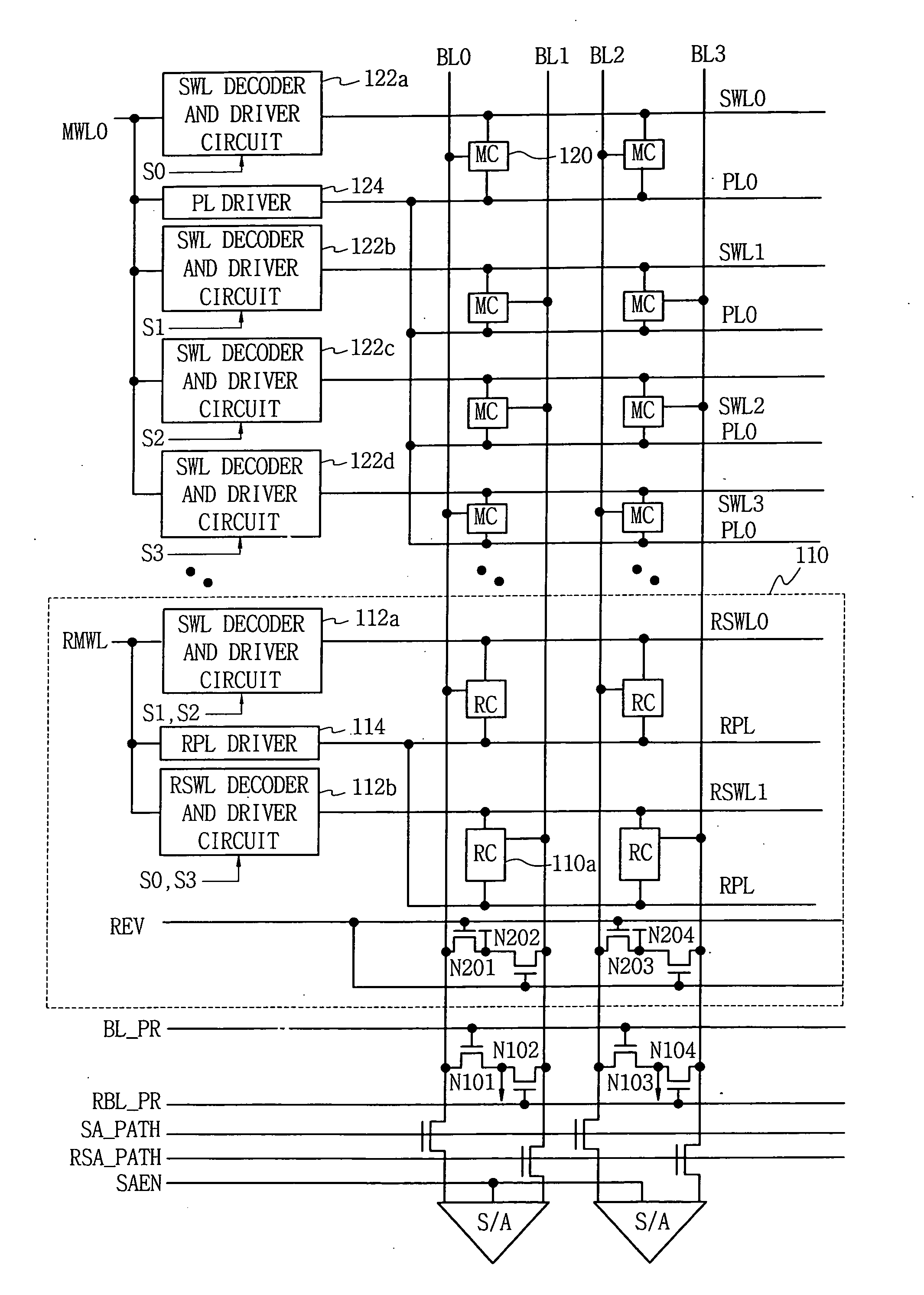

Resistive memory device and method of controlling refresh operation of resistive memory device

ActiveUS20120063196A1Maintain reliabilityAmount of timeRead-only memoriesDigital storageComputer hardware

A resistive memory device comprises a memory cell array comprising a plurality of memory units. The memory device performs a refresh read operation to check a condition of each of the memory units. Then, it determines whether to refresh each memory unit based on data read by performing the refresh read operation, and refreshes the memory unit according to a result of the determination. The refresh read operation uses a reference resistance with a smaller margin from a resistance distribution than a normal read operation.

Owner:SAMSUNG ELECTRONICS CO LTD

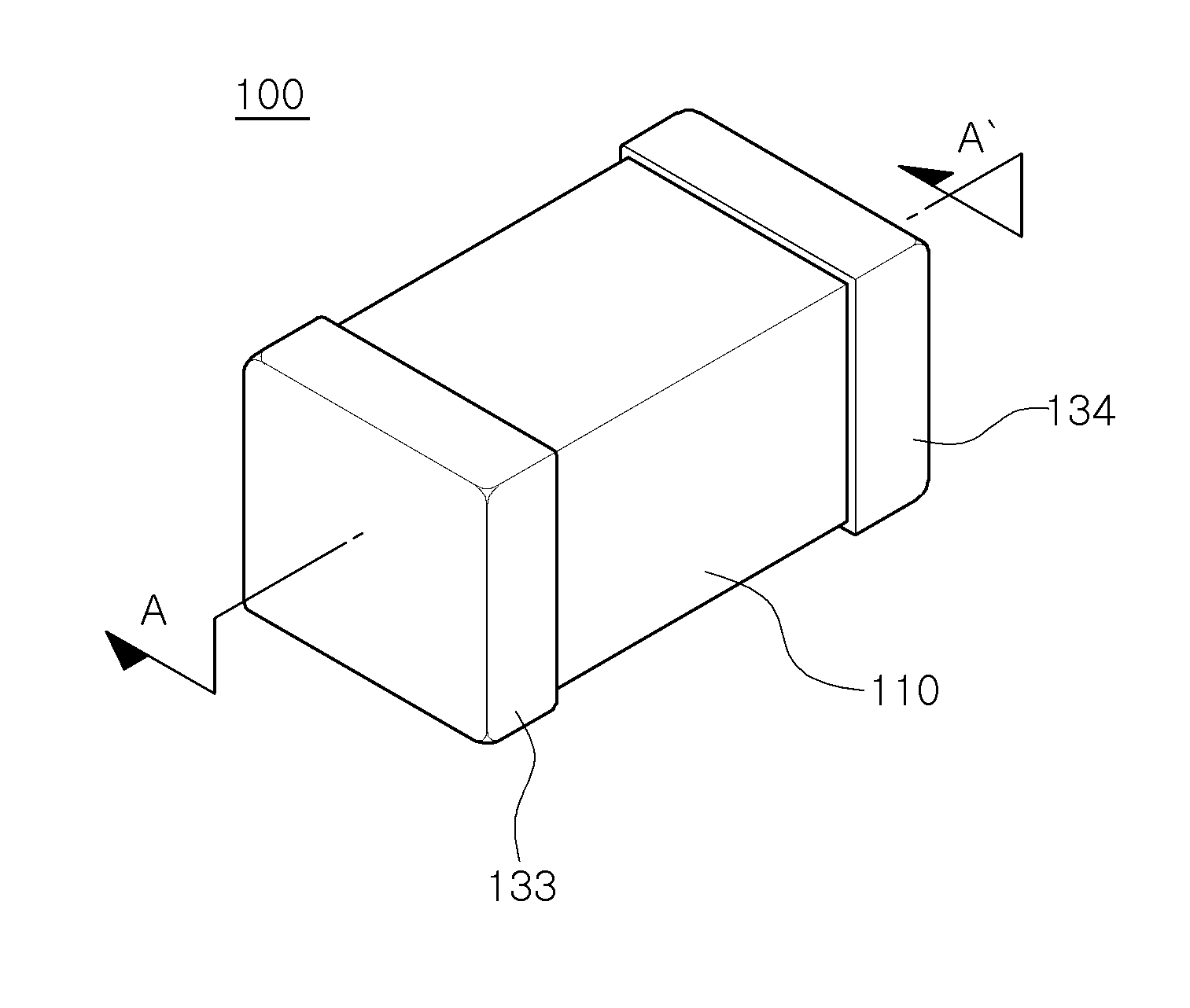

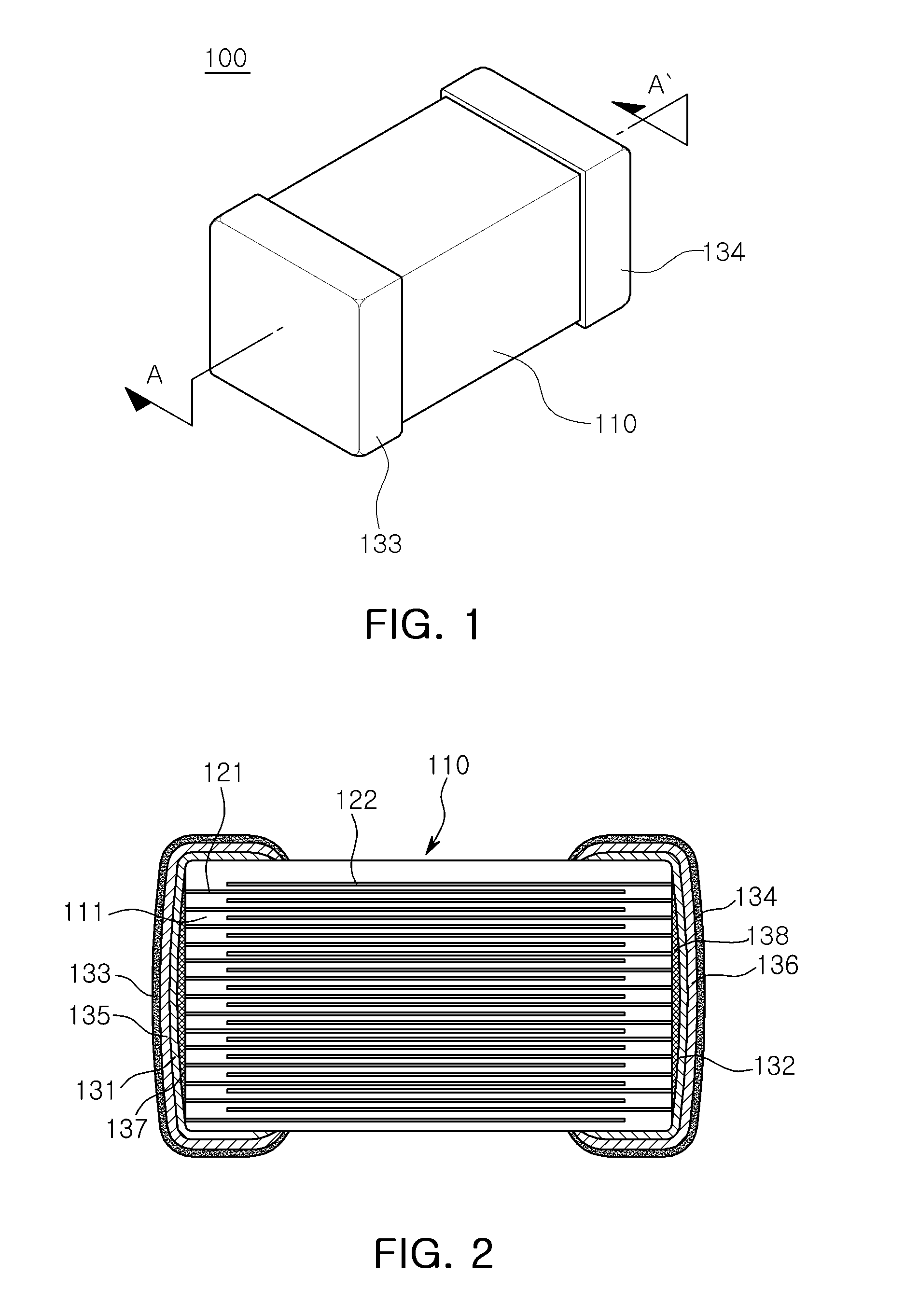

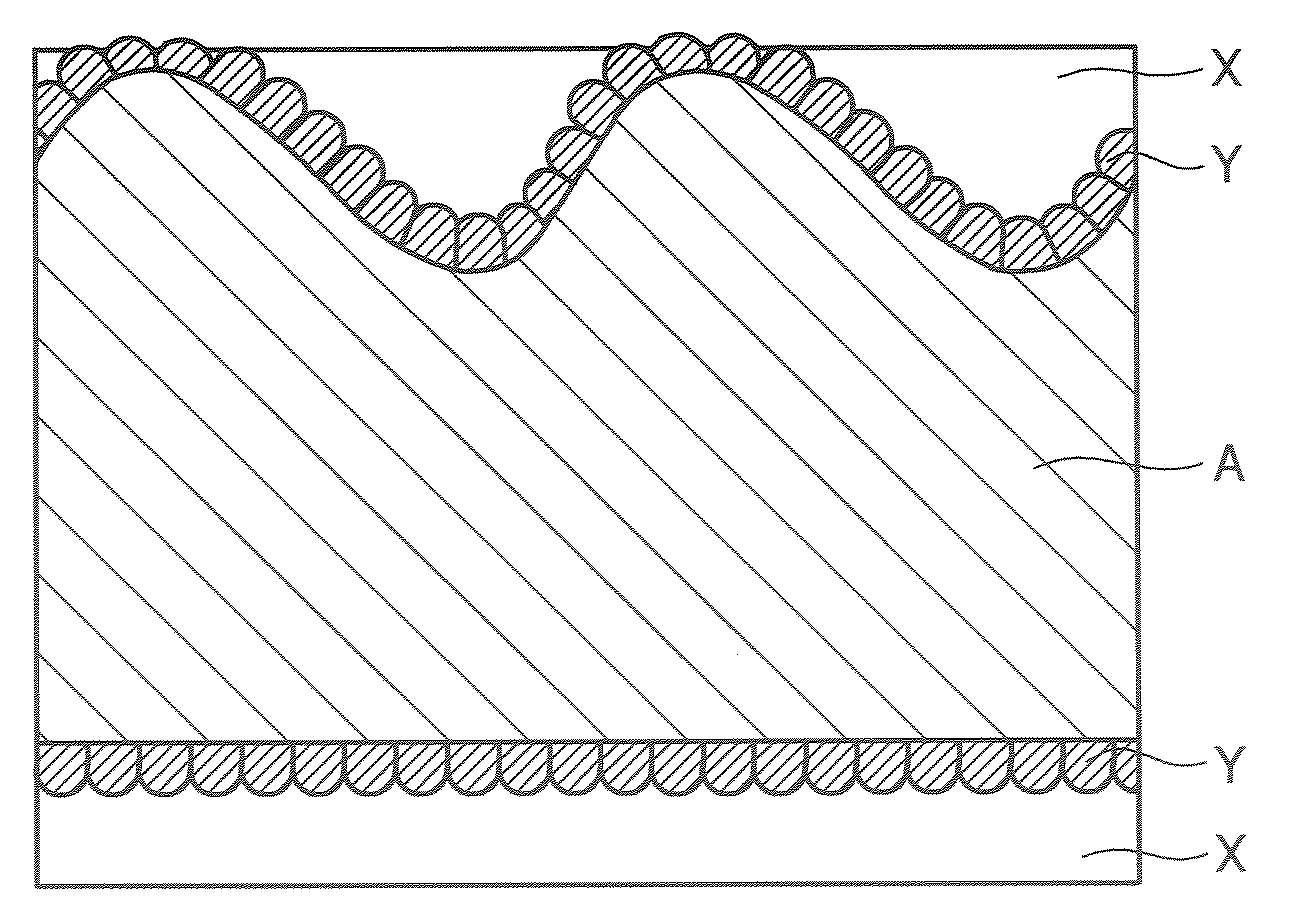

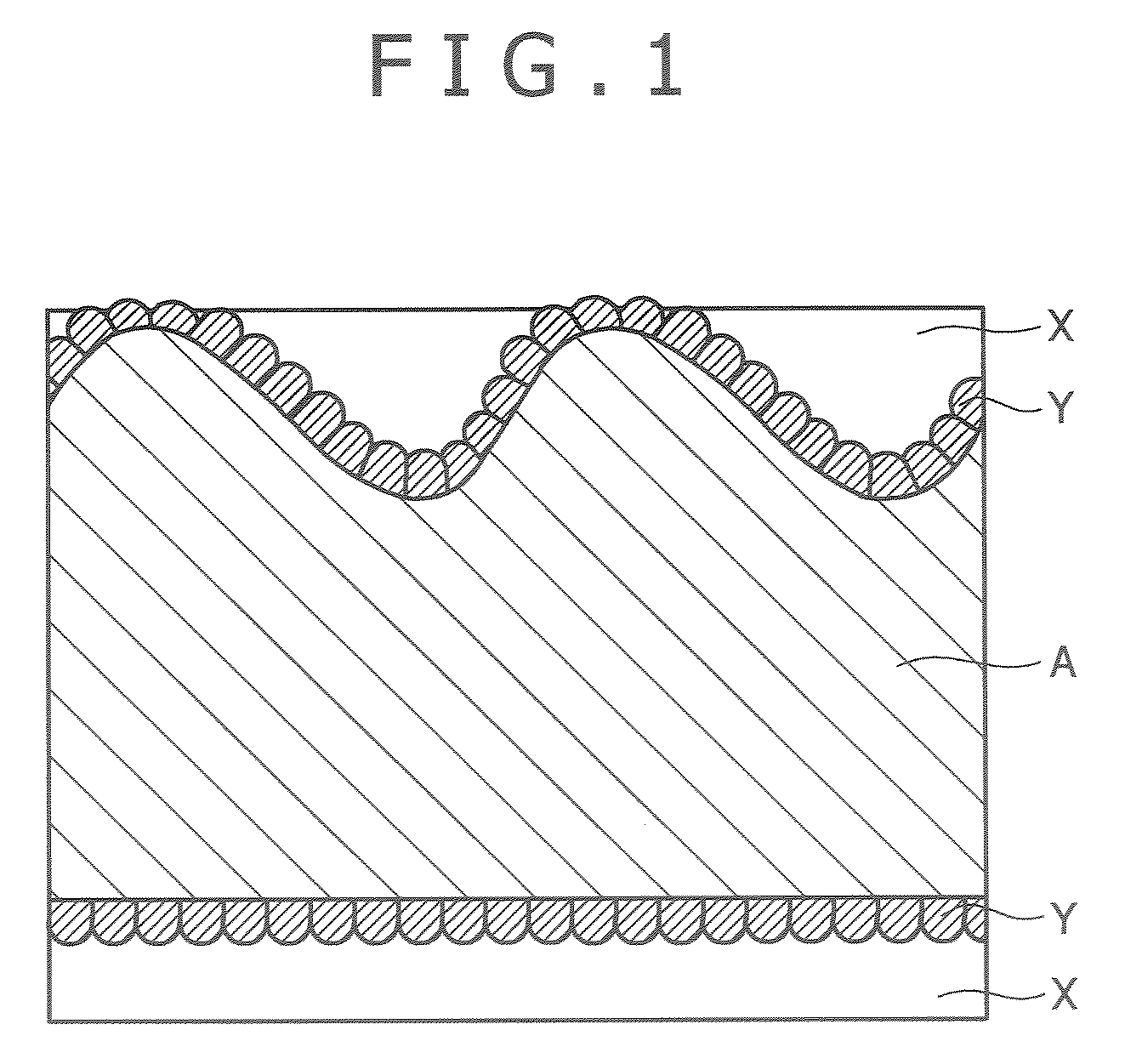

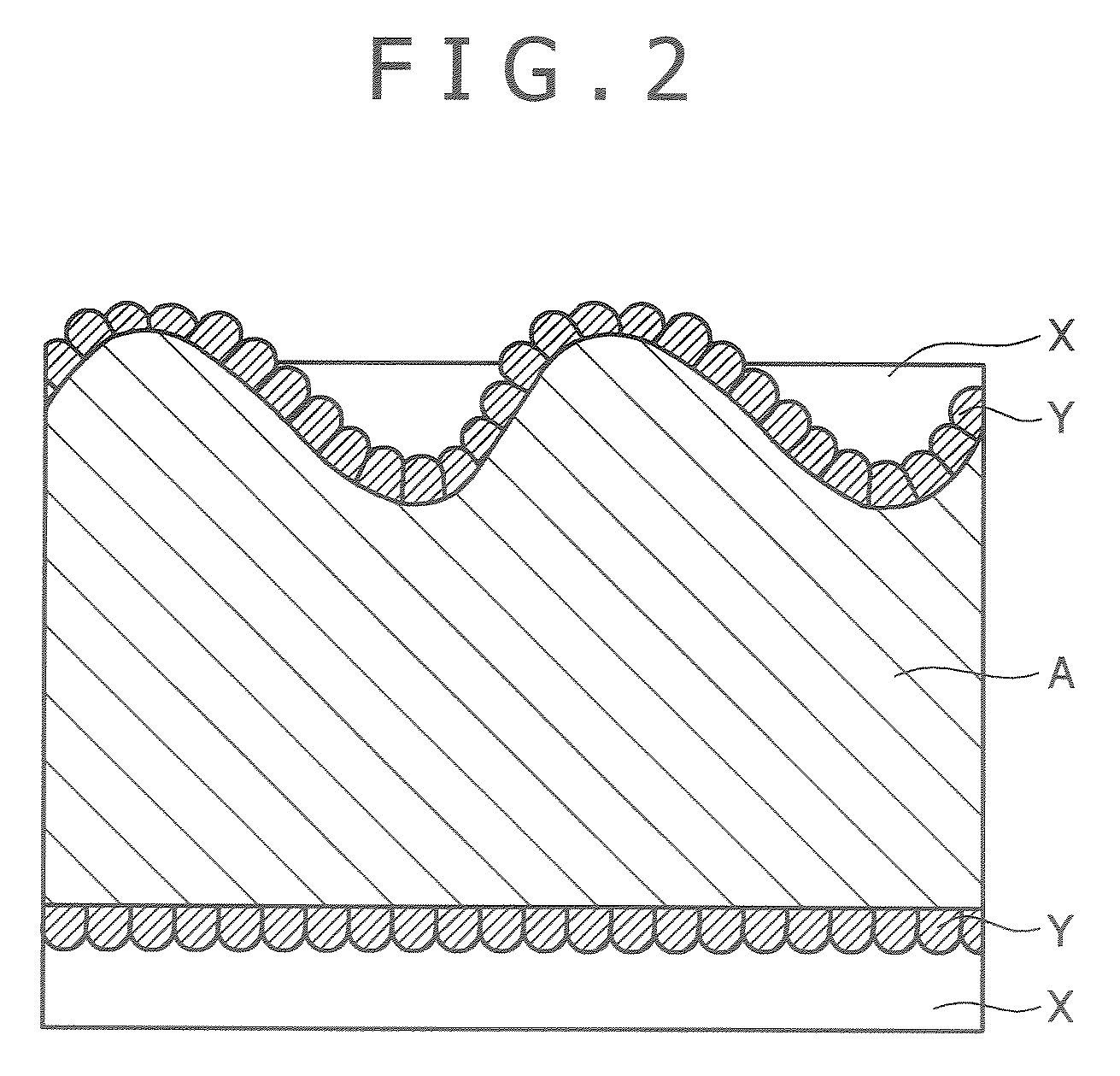

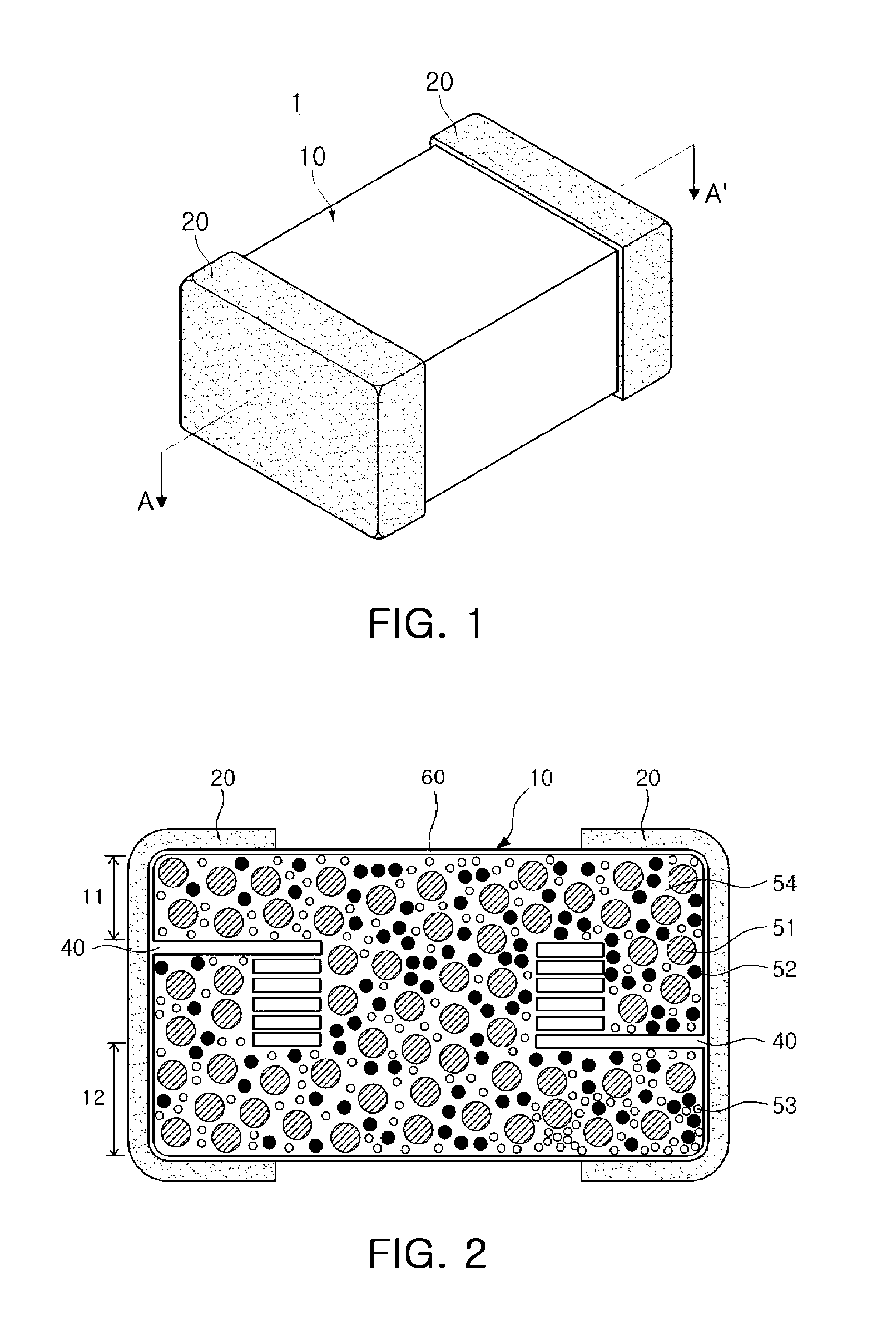

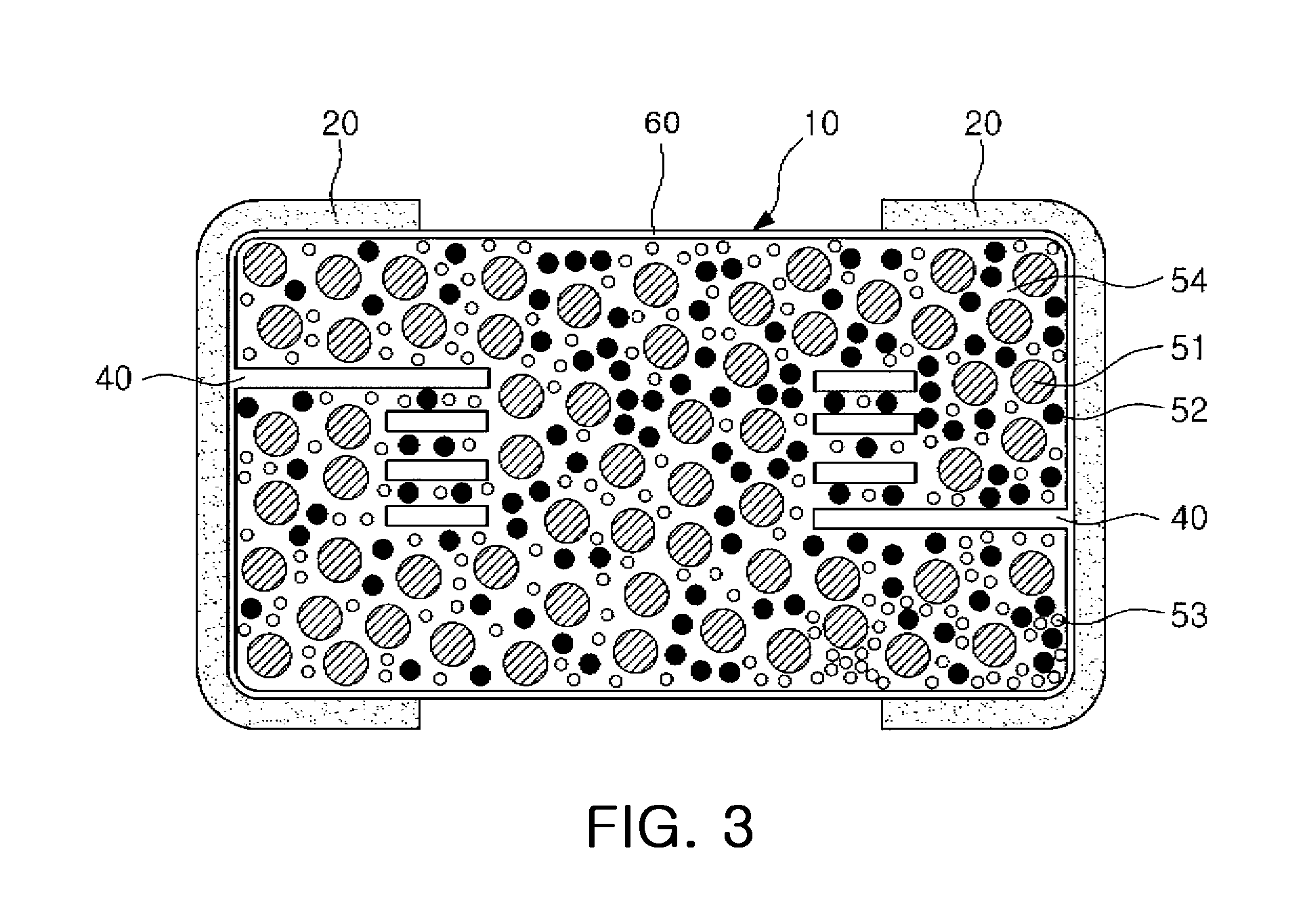

Conductive resin composition, multilayer ceramic capacitor having the same and method of manufacturing the same

ActiveUS20130294006A1Reduce product manufacturing costsMaintain reliabilityMaterial nanotechnologyFixed capacitor electrodesNitrogenCopper

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

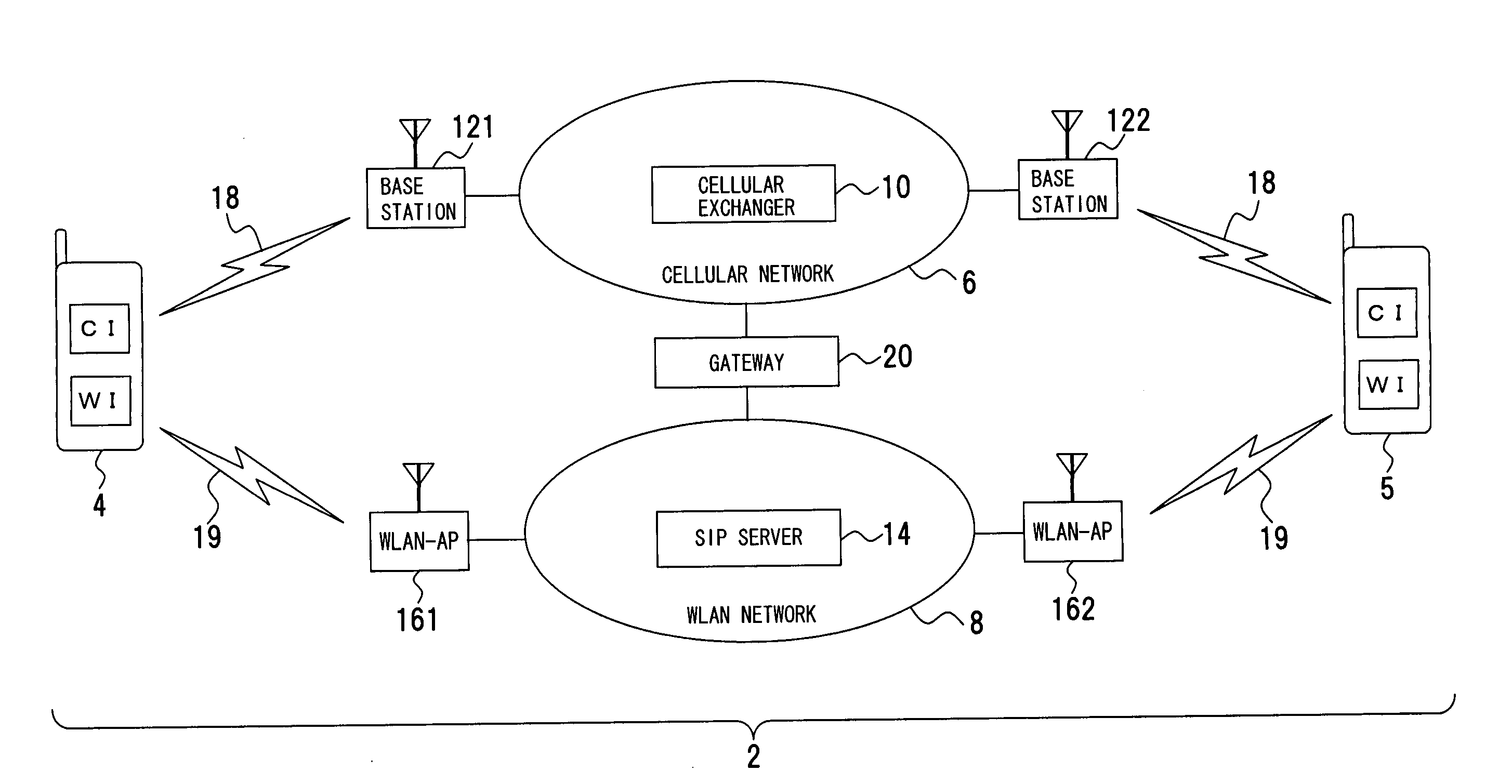

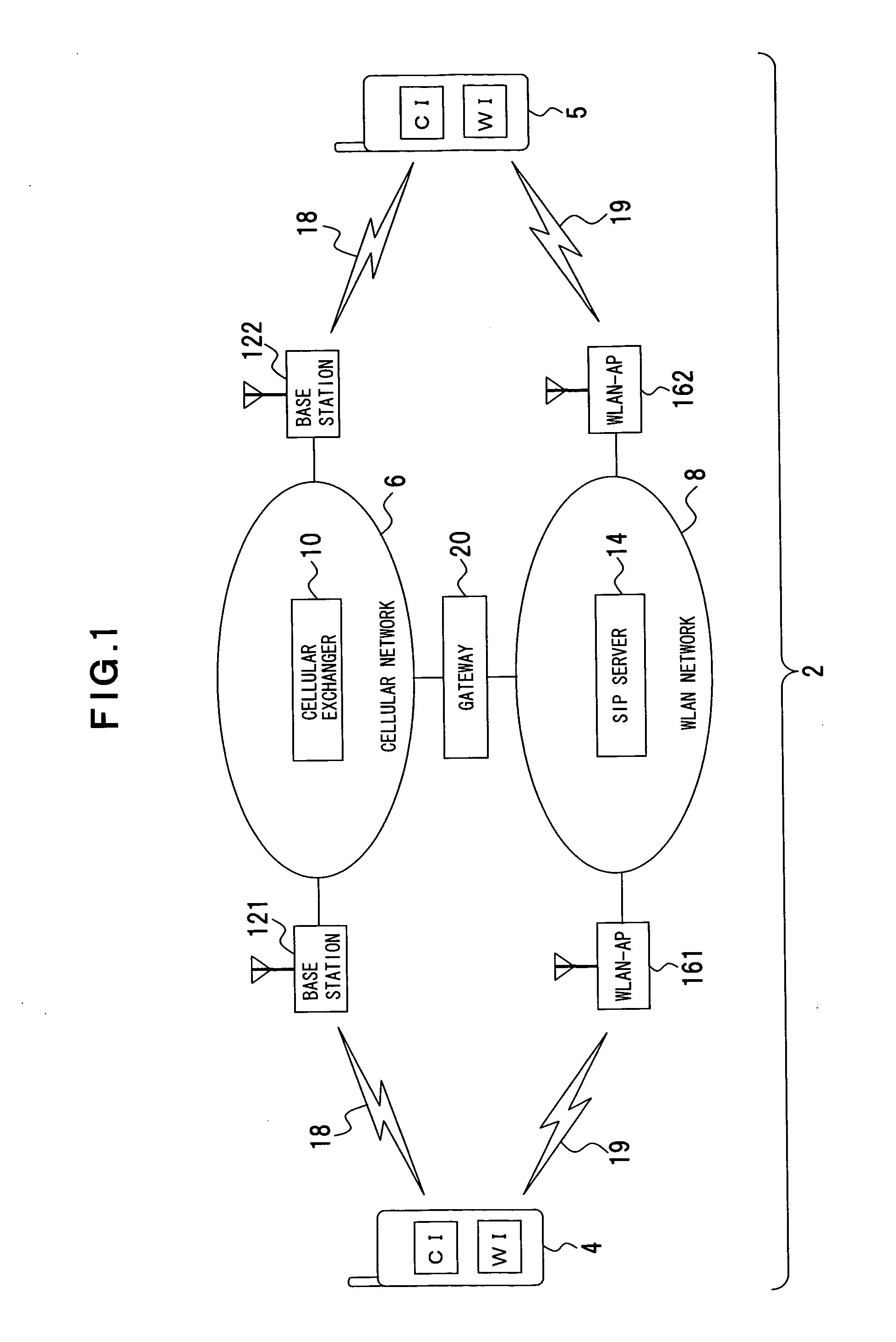

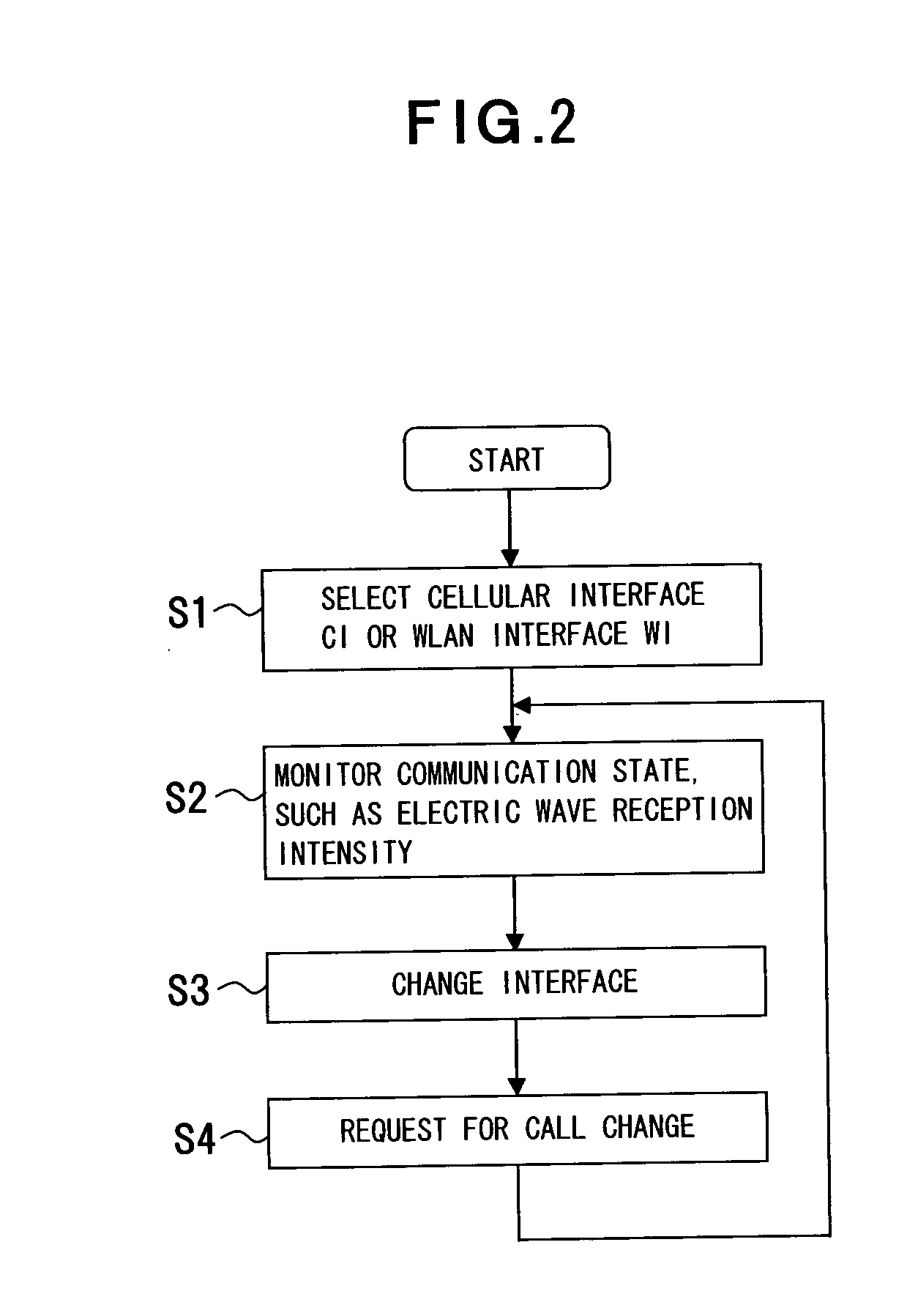

Communication apparatus, relay apparatus, communication system, communication method, and communication program

InactiveUS20080046542A1Reduce power consumptionReliable maintenancePower managementEnergy efficient ICTCommunications systemTerminal equipment

A communication apparatus has a plurality of interfaces serving a plurality of networks. The communication apparatus selects an interface according to electric wave reception intensity to reduce power consumption and contribute to the maintenance of reliability in communication. The communication apparatus (communication terminal apparatus, the other party's communication terminal apparatus) is used for communication in such a way that the communication apparatuses are connected to the plurality of networks wirelessly to carry out communication through each network. The communication apparatus has the plurality of interfaces (cellular interface CI, WLAN interface WI) responding to the networks. The communication apparatus also has controlling unit (power supply controlling unit) that connects any one of the interfaces to the power supply to actuate the connected interface, and that connects an interface on rest to the power supply in response to a communication state of an interface on communication to change communication connection from the interface on communication to the other interface on rest. The communication apparatus changes the interfaces while maintaining communication with the other party's communication apparatus.

Owner:FUJITSU LTD

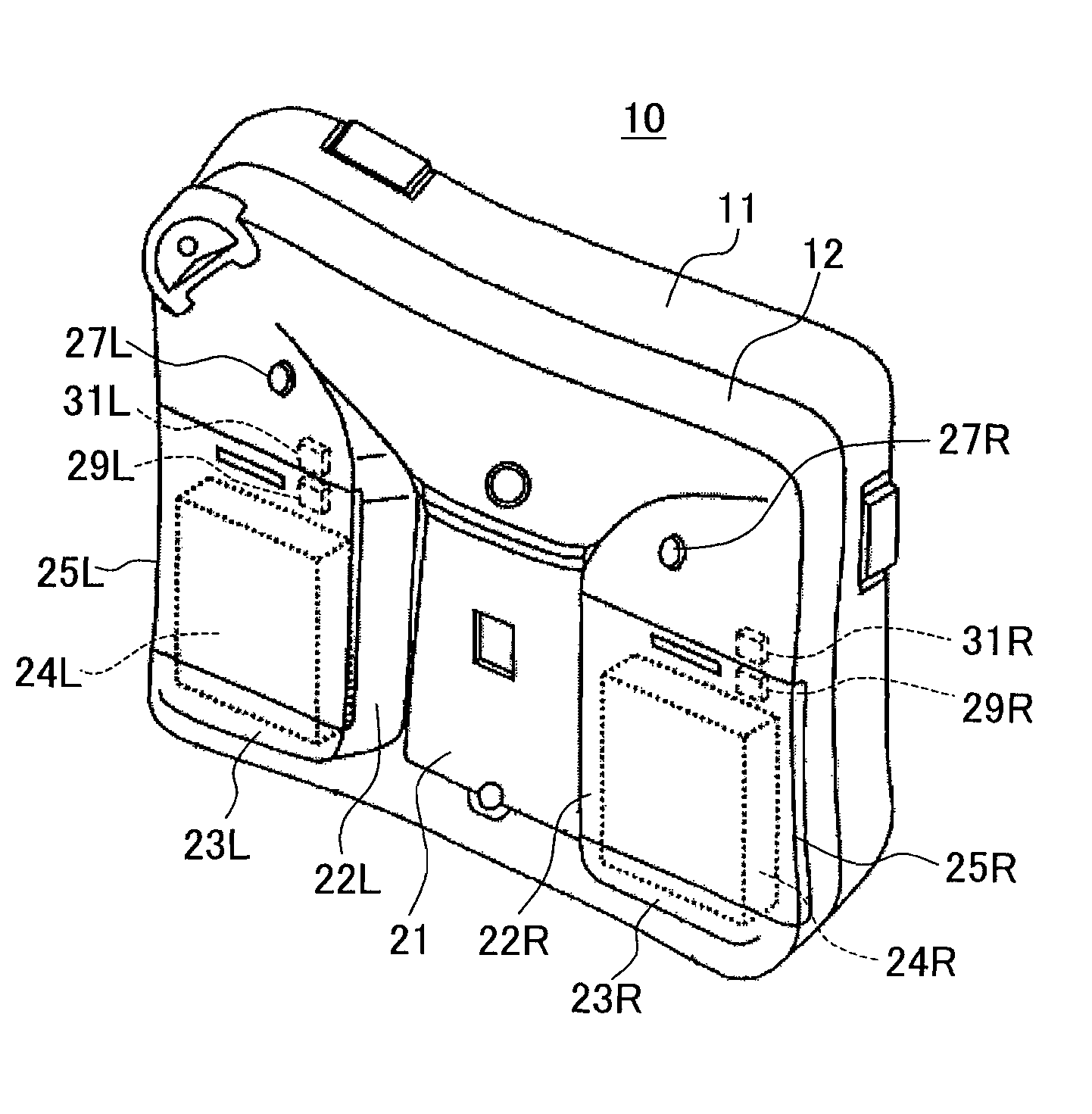

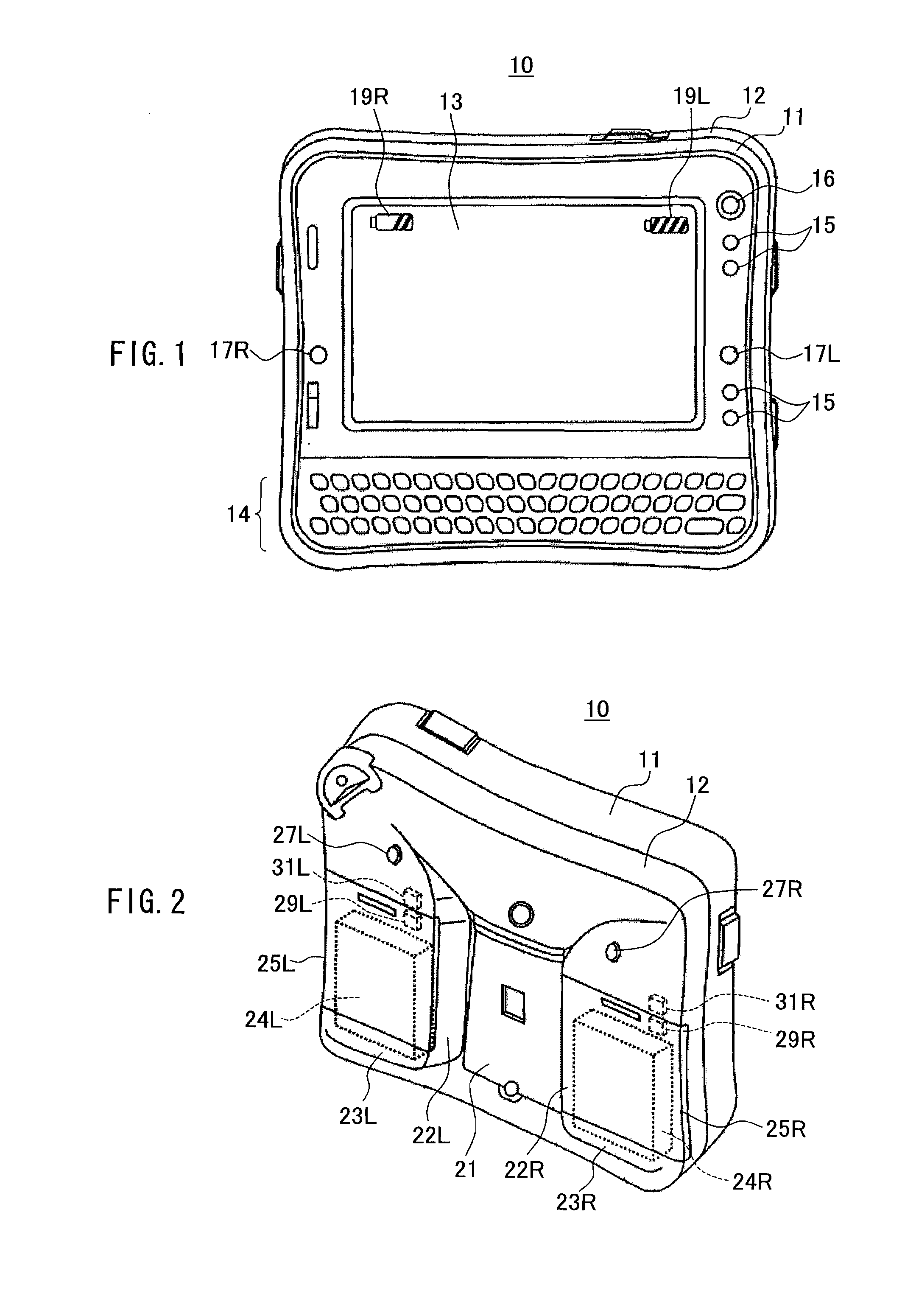

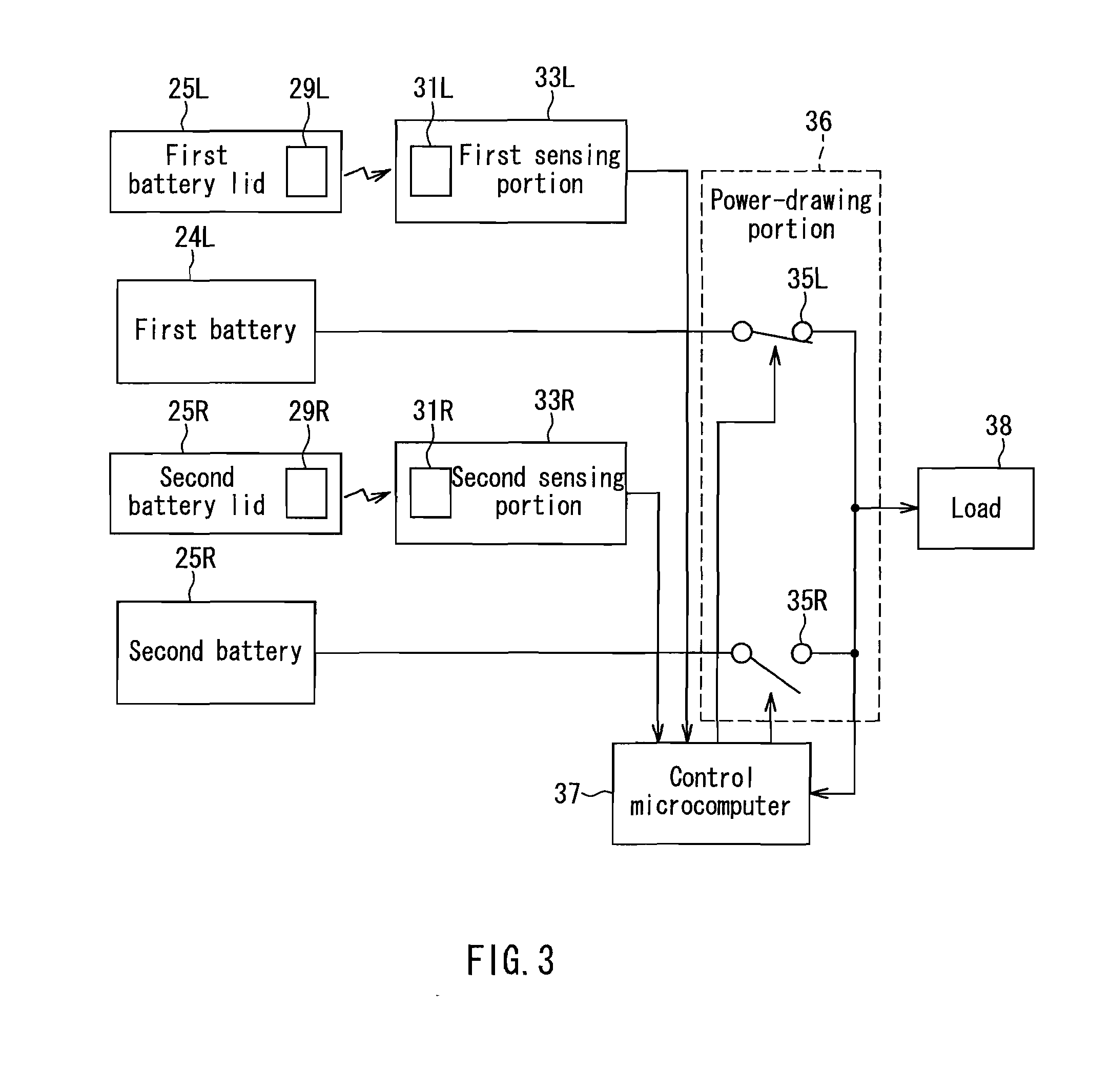

Information processing equipment and the integrated circuit

InactiveUS20090284225A1Size and cost reductionMaintain reliabilityDc network circuit arrangementsCharge equalisation circuitElectrical batteryIntegrated circuit

Information processing equipment is provided that can be operated continuously and stably for a long time due to improved stability during alternately switching between the batteries being used and, therefore, can maintain the reliability of the operation of switching the batteries being used over a long period. The information processing equipment includes battery housing portions configured to individually house a plurality of batteries; battery lids that are provided corresponding respectively to the plurality of batteries, that are opened and closed independently during attachment or removal of the batteries, and that are provided with magnets serving as magnetic-field-generating portions; magnetic-field-detecting elements that detect the strength of a magnetic field from the magnetic-field-generating portions; and a control microcomputer that controls a power-drawing portion based on a detection result obtained by the magnetic-field-detecting elements so as to change the switch.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

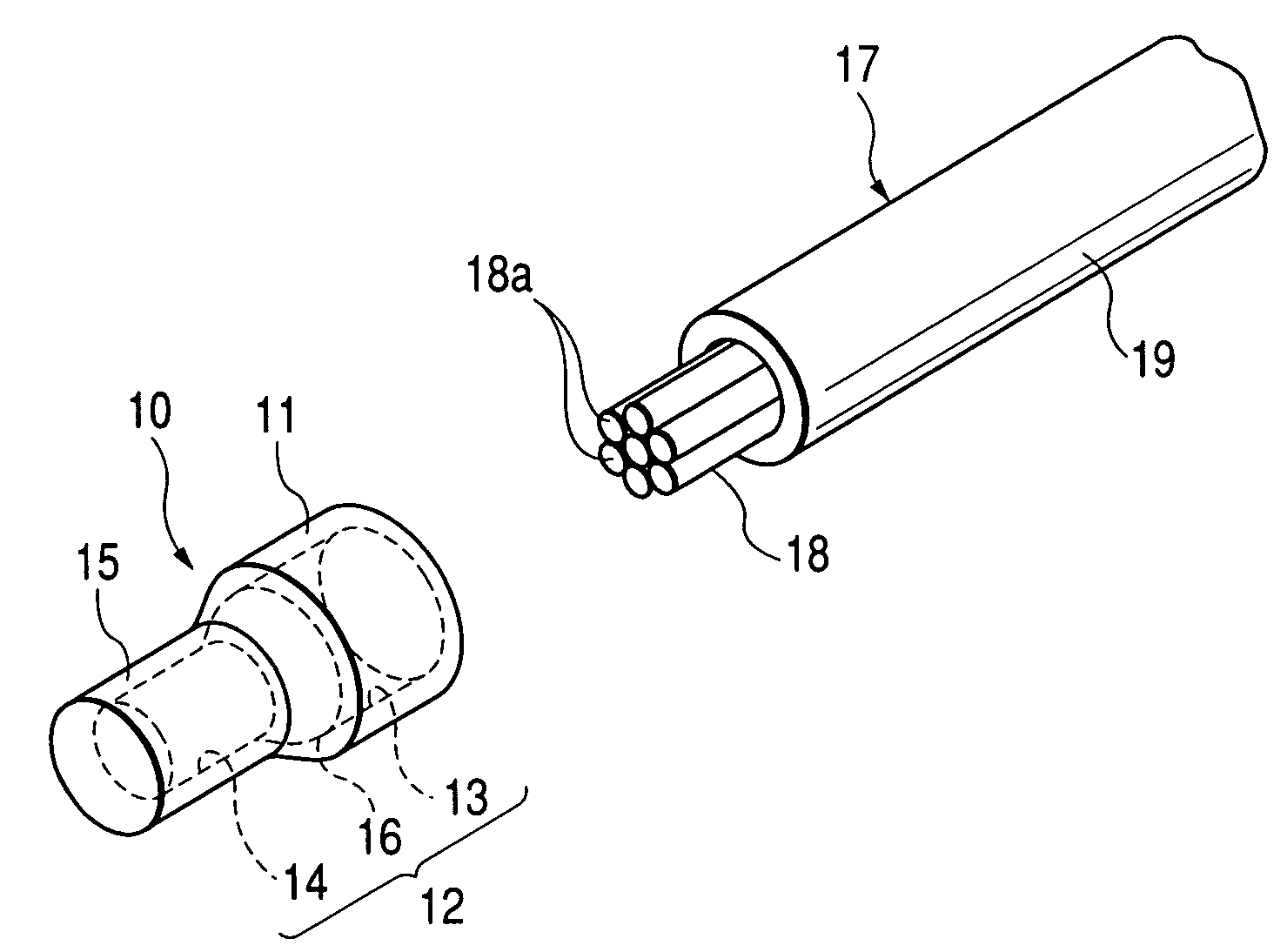

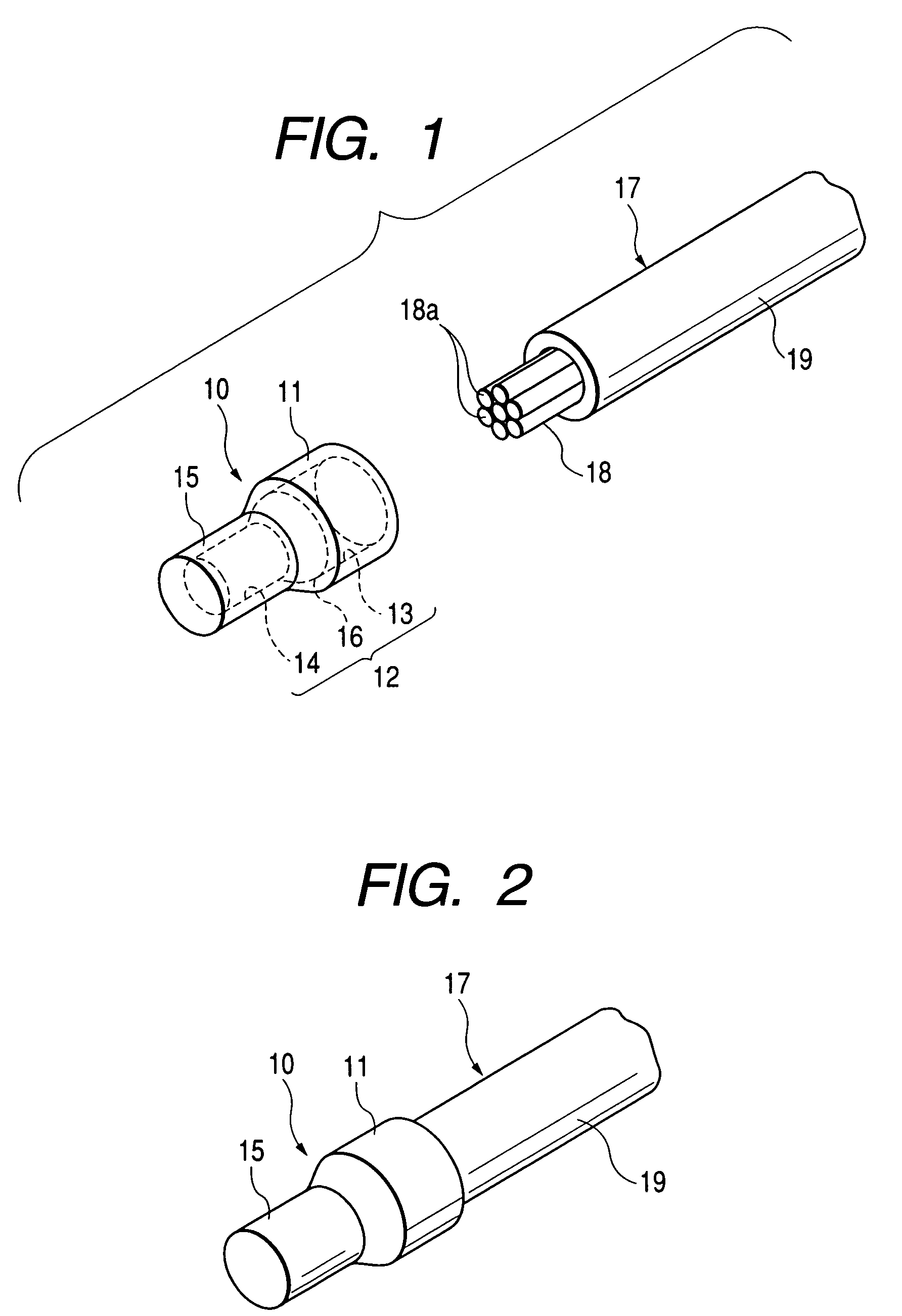

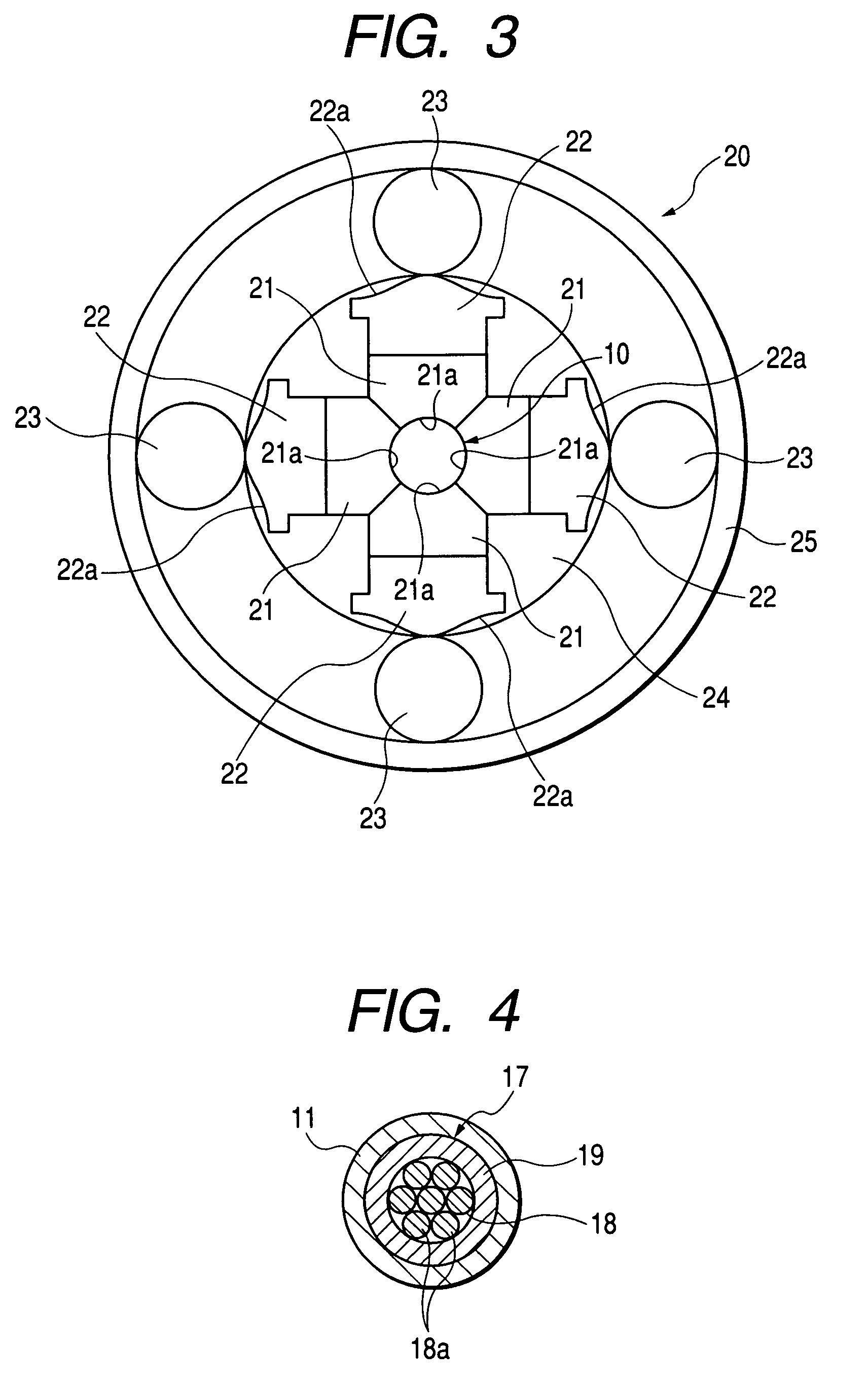

Method of connecting wire and terminal fitting

InactiveUS7374466B2Treatment effectAvoid damageSoldered/welded conductive connectionsCoupling contact membersElectric wireElectrical and Electronics engineering

A method of connecting a terminal fitting and an electric wire, includes the steps of: providing a terminal fitting; providing an electric wire in which a core wire is covered with an insulating sheath; providing a conductive connecting member formed with an insertion hole; inserting the electric wire into the insertion hole of the connecting member; compressing the connecting member radially inwardly so as to caulk an inserted portion of the electric wire uniformly over a whole periphery thereof; and welding the connecting member and the terminal fitting by applying ultrasonic wave.

Owner:YAZAKI CORP

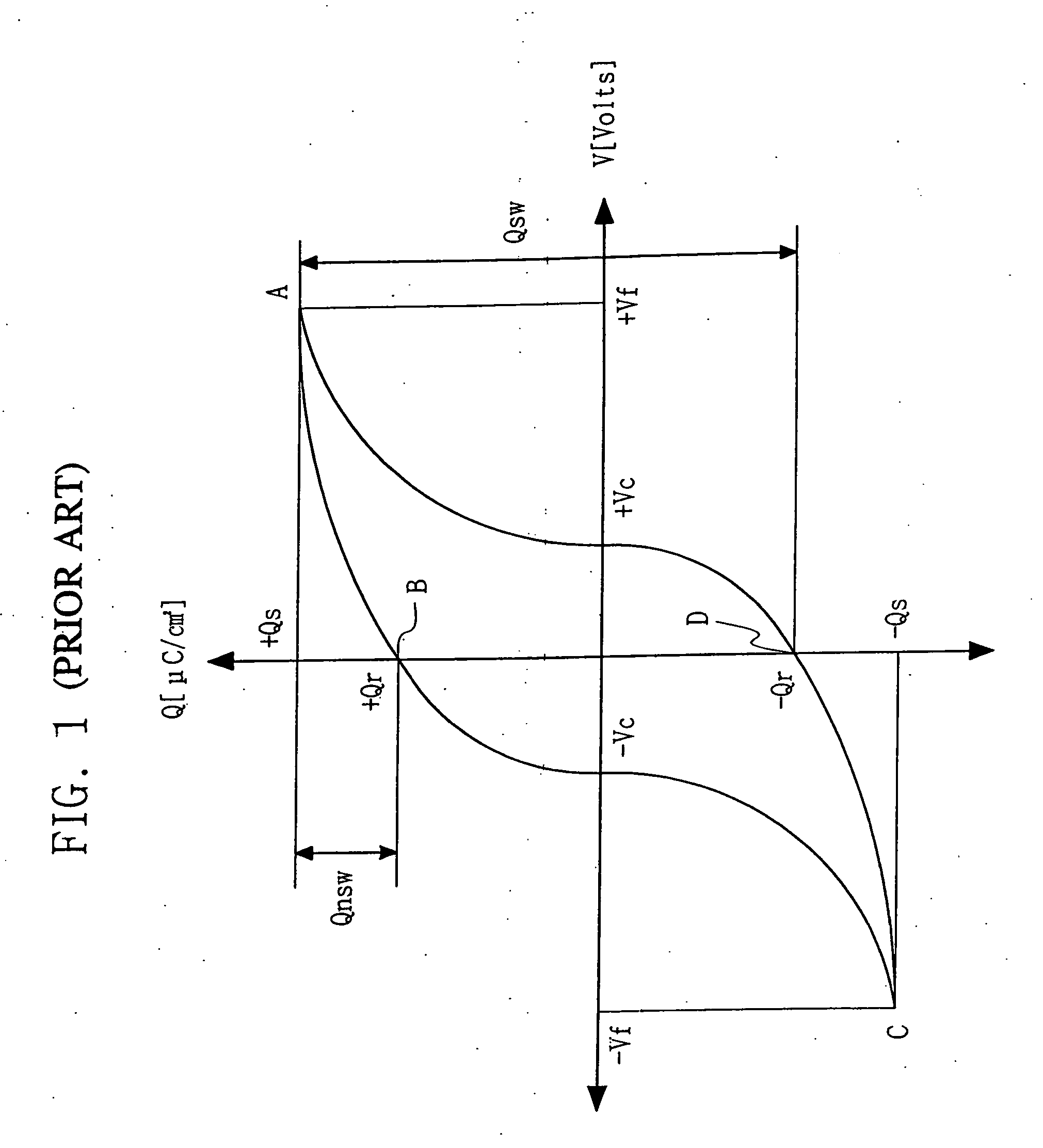

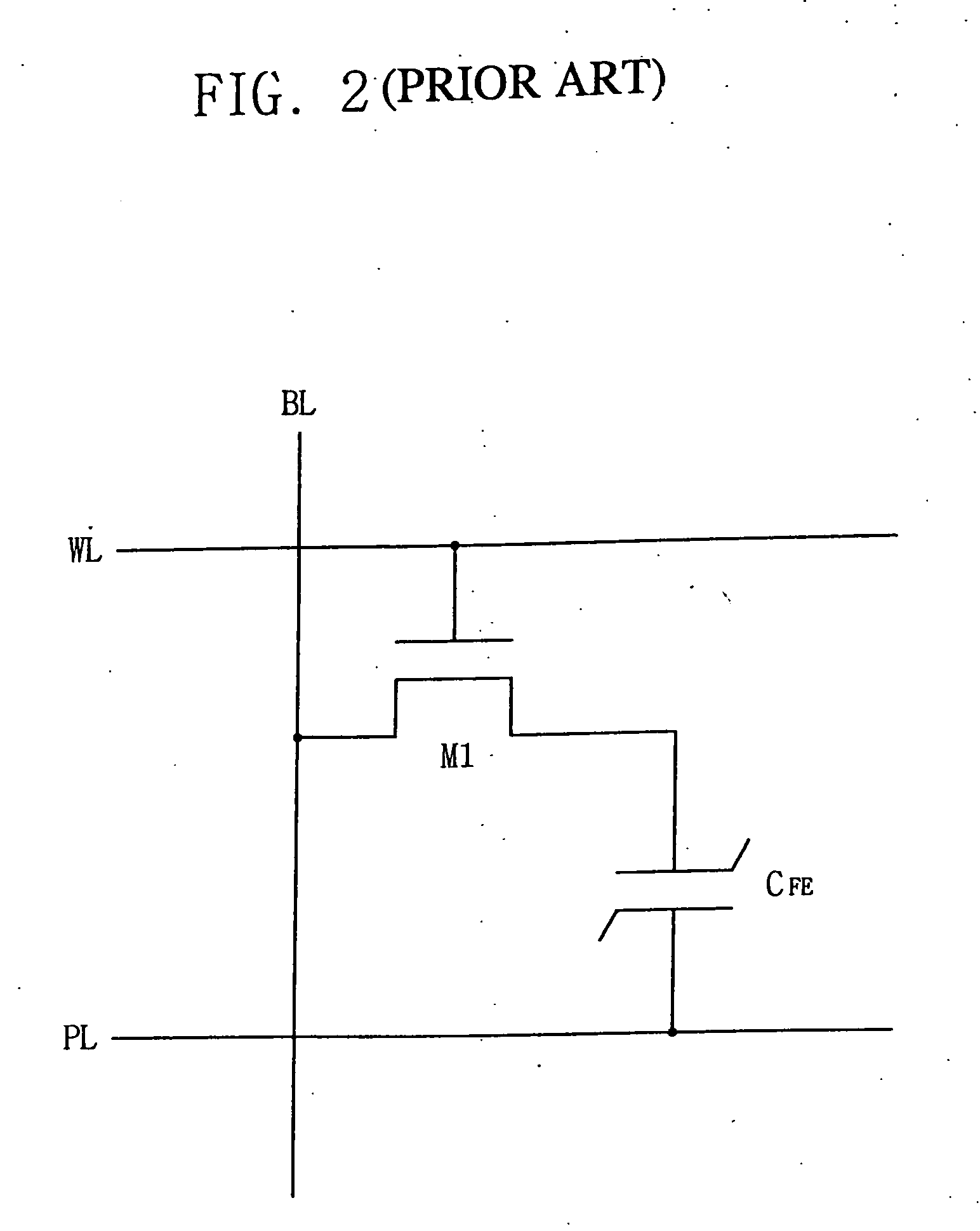

Apparatus and method for generating an imprint-stabilized reference voltage for use in a ferroelectric memory device

A reference voltage supply apparatus and a driving method thereof in a ferroelectric memory device provide a reference voltage stabilized against the imprint effect thus maintaining reading reliability of the device. In the reference voltage supply apparatus (e.g., using a non-switching capacitance of a ferroelectric capacitor), a reference cell is constructed of a ferroelectric capacitor and an access switch, and provides a reference voltage to read data from a memory cell. In an active mode, the reference cell stores data of a first logic state (e.g., corresponding to the non-switching capacitance of the ferroelectric capacitor), in the reference cell, and then supplies, as a reference voltage, the voltage corresponding to the data of the first logic state to a bit line; and in a stand-by mode, a reference voltage controller stores (writes) data of a second logic state (opposite to the first logic state), into the reference cell.

Owner:SAMSUNG ELECTRONICS CO LTD

Optical connector with shutter

InactiveUS6866424B2Reduce the amount requiredDeterioration can be suppressedCoupling light guidesEngineeringElectromagnetic shielding

This optical connector with a shutter is for blocking emitted light from the connected optical connector, such as an optical connector adaptor, provided in a connector hole of a connector housing by using a shutter. In this optical connector with a shutter, the shutter unit is assembled in the center part of the connector housing, and the emitted light in the connector hole from the connected optical connector is blocked by shutter pieces of the shutter unit. Furthermore, an electromagnetic shielding capacity can be obtained without enlarging the optical connector by making the shutter unit from electrically conducting members.

Owner:FUJIKURA LTD

Conductive Material For Connecting Part And Method For Manufacturing The Conductive Material

ActiveUS20080090096A1Excellent propertyLow coefficient of frictionHot-dipping/immersion processesElectrically conductive connectionsConductive materialsAlloy

There is provided a conductive material comprising a base material made up of a Cu strip, a Cu—Sn alloy covering layer formed over a surface of the base material, containing Cu in a range of 20 to 70 at.%, and having an average thickness in a range of 0.1 to 3.0 μm, and an Sn covering layer formed over the Cu—Sn alloy covering layer having an average thickness in a range of 0.2 to 5.0 μm, disposed in that order, such that portions of the Cu—Sn alloy covering layer are exposed the surface of the Sn covering layer, and a ratio of an exposed area of the Cu—Sn alloy covering layer to the surface of the Sn covering layer is in a range of 3 to 75%. The surface of the conductive material is subjected to a reflow process and preferably, an arithmetic mean roughness Ra of the surface of the material in at least one direction, is not less than 0.15 μm while the arithmetic mean roughness Ra thereof, in all directions, is not more than 3.0 μm and the average thickness of the Cu—Sn alloy covering layer is preferably not less than 0.2 μm. The conductive material is fabricated by a method whereby the surface of the base material is subjected to roughening treatment, an Ni plating layer, a Cu plating layer and an Sn plating layer are formed, as necessary, over the surface of the base material, and subsequently, a reflow process is applied.

Owner:KOBE STEEL LTD

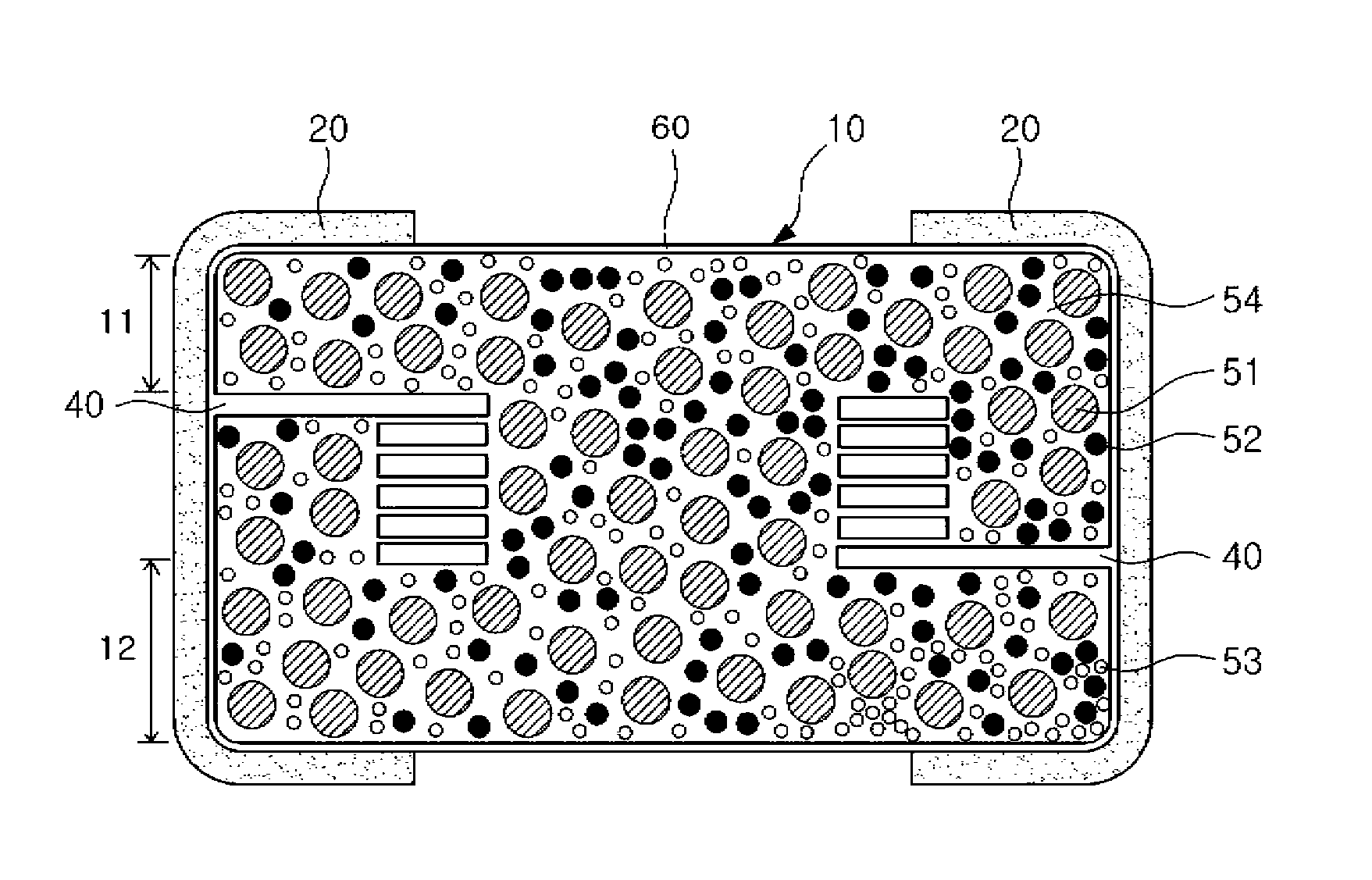

Multilayer inductor and method of manufacturing the same

InactiveUS20130293334A1Increase the inductance valueHigh currentTransformers/inductances coils/windings/connectionsInorganic material magnetismPolymer resinInductor

There is provided a multilayer inductor including: an inductor body formed of a material including metal powder particles, a ferrite, and a polymer resin; a coil part having a conductive circuit and a conductive via formed in the inductor body; and external electrodes formed on ends of the inductor body.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

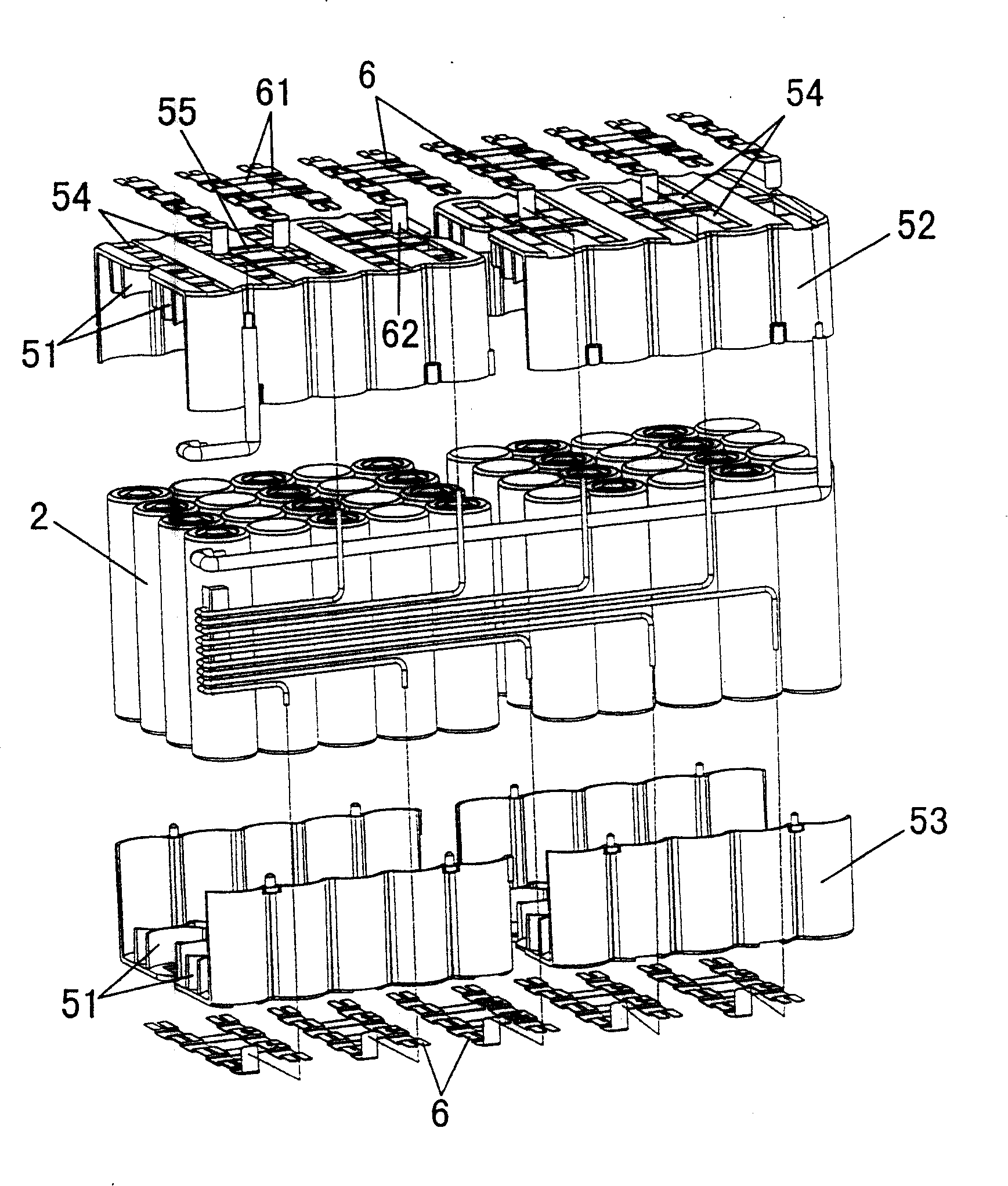

Shakeproof and dampproof dynamic battery unit

InactiveCN101237033AGood shock resistanceGood waterproof functionBattery isolationSecondary cellsEngineeringPower battery

The invention relates to a shock-resistant and damp-proof power battery set which comprises an outer shell (1), a plurality of cells (2) arranged inside the outer shell (1) and a charging / discharging protection circuit board (3) in electric connection with the plurality of cells (2), wherein a support structure (5) constraining the positions of the plurality of cells (2) axially and radically is fixed in the outer shell (1), the plurality of cells (2) constrained in the support structure (5) are arranged with a clearance in between. The cells in the battery set can be positioned reliably to keep a sound electric contact, has very good shock-resistant performance and heat dispersion performance and is very suitable to be used on various power battery sets in shaking circumstances.

Owner:GUANGZHOU ZHANHUI ELECTRONICS

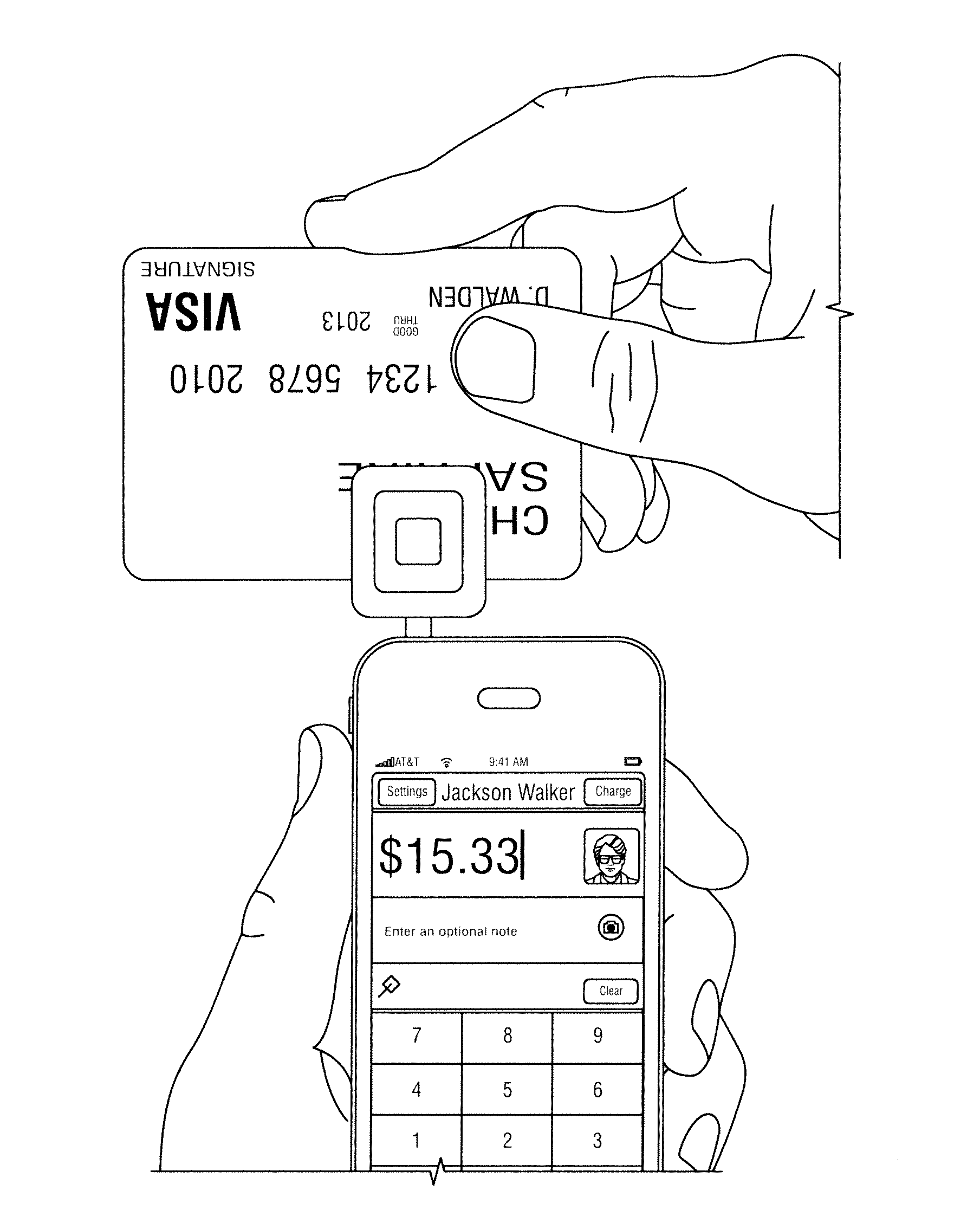

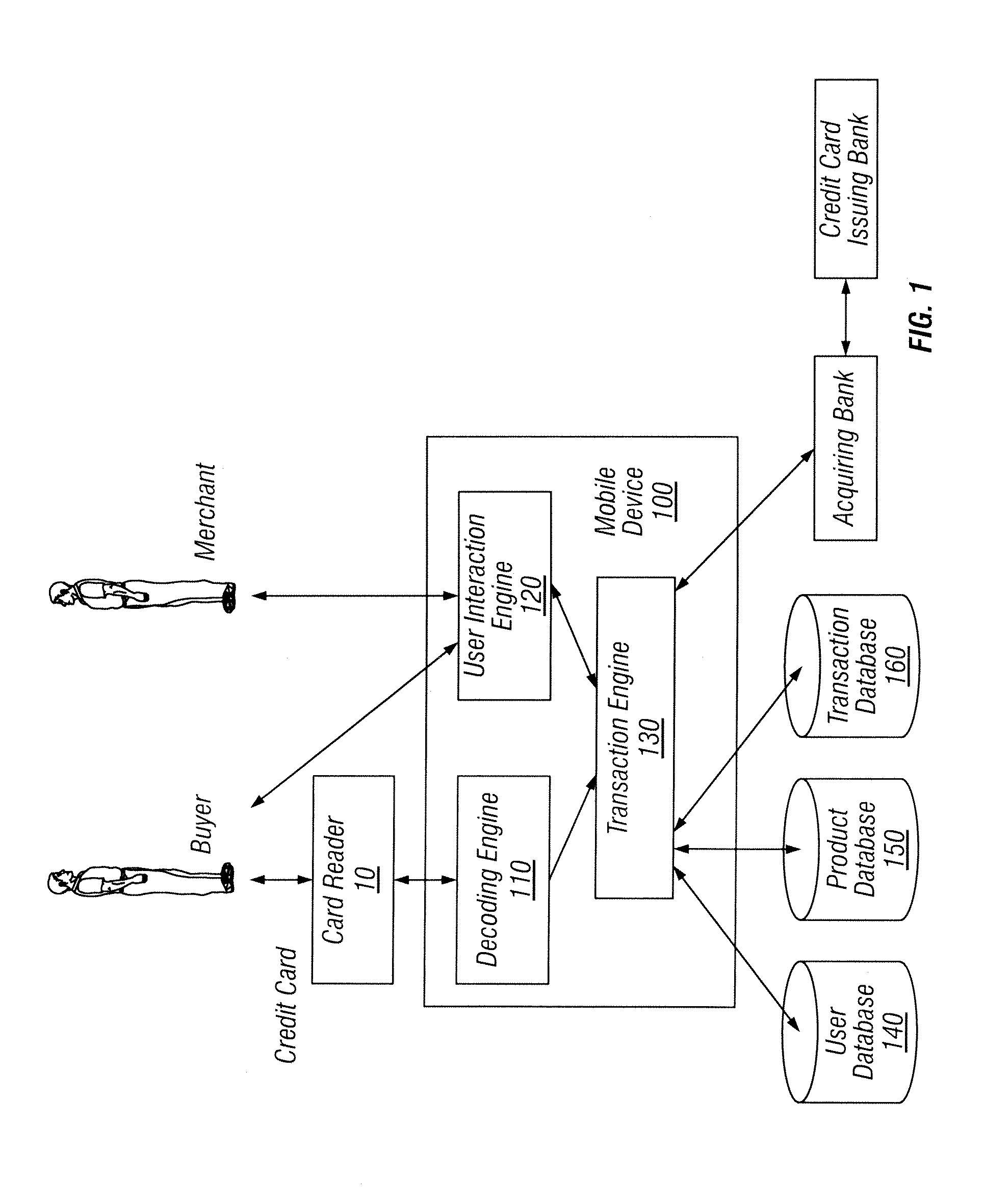

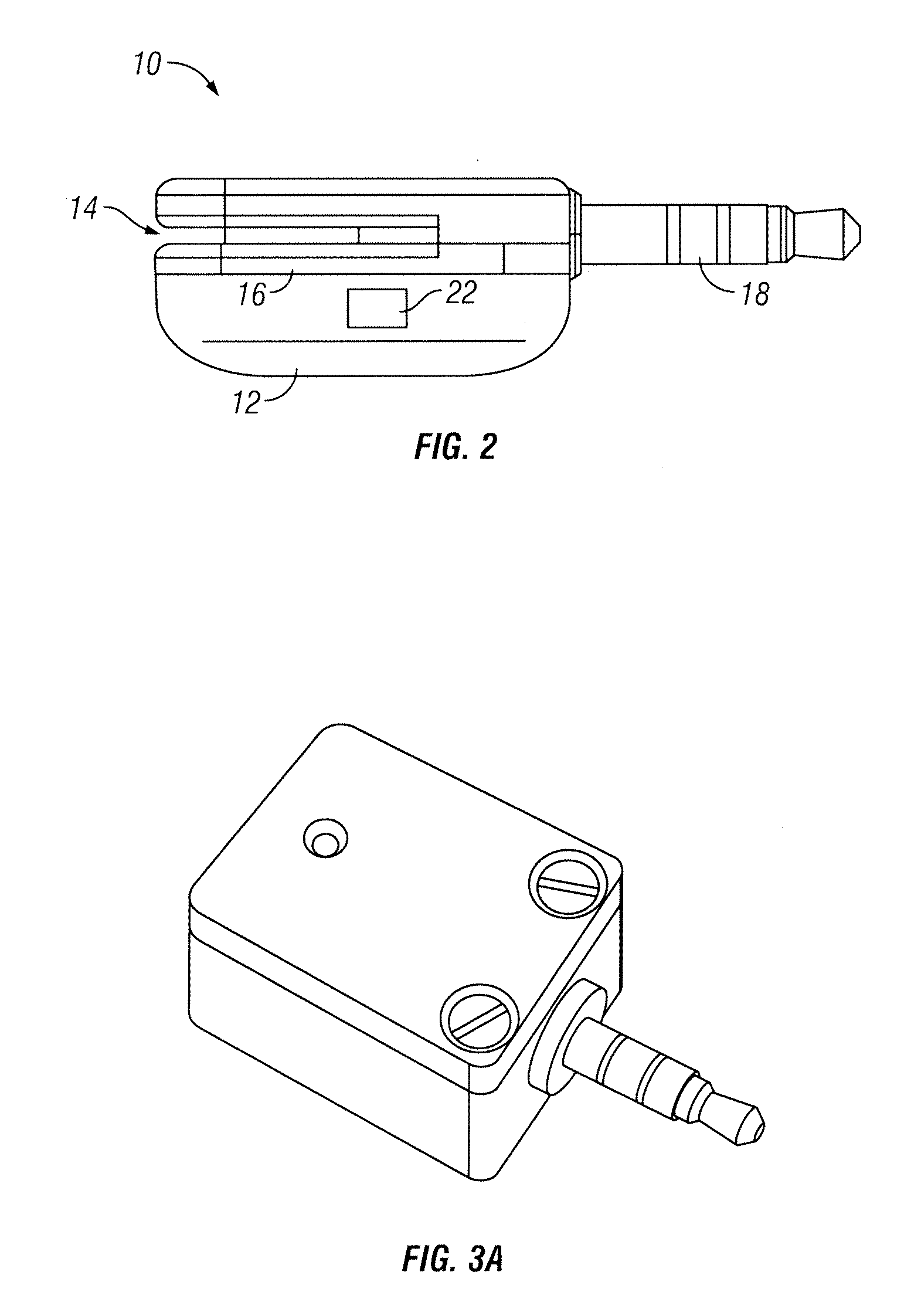

Read head device with slot configured to reduce torque

ActiveUS20120095870A1Reduce torqueMaintain accuracyComplete banking machinesAcutation objectsFinancial transactionMobile device

A read head system has a housing and a read positioned in the housing with a slot for swiping a magnetic stripe of a financial transaction card with the slot utilized to enable a financial transaction between a buyer and seller. The read head reads data on the magnetic stripe and produces a signal indicative of data stored on the magnetic stripe. The read head includes an output jack configured to be coupled to at least one of a audio jack or microphone port of a mobile device. The read head provides the signal to the mobile device. The slot is oriented and sized to reduce torque applied on the read head as the financial transaction card is swiped through slot in order to maintain accuracy and reliability of the data read by the read head. Decoding of the signal is performed in the mobile device. The decoding includes determining pulses in the signal and converting at least some of the pulses to characters.

Owner:BLOCK INC

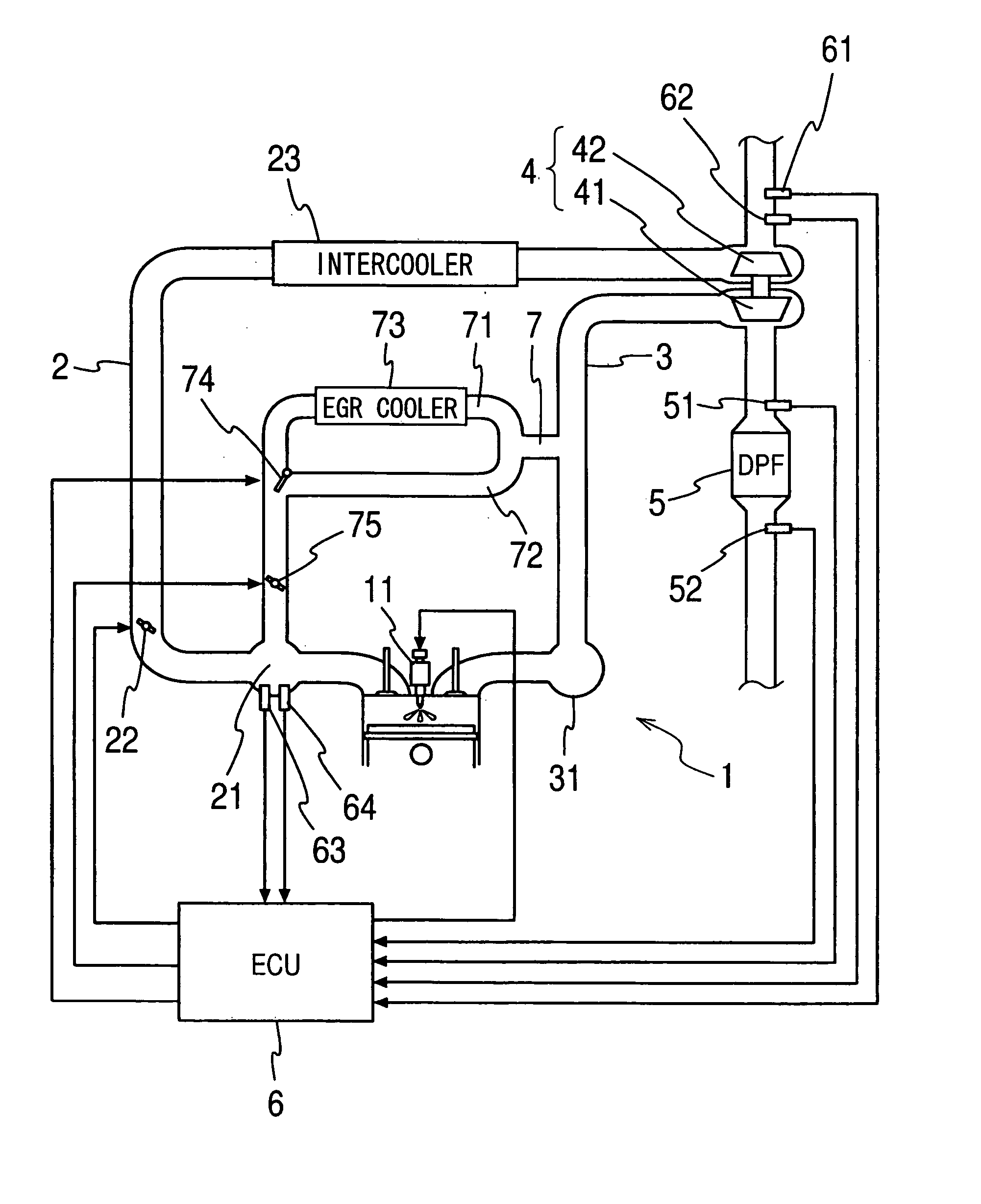

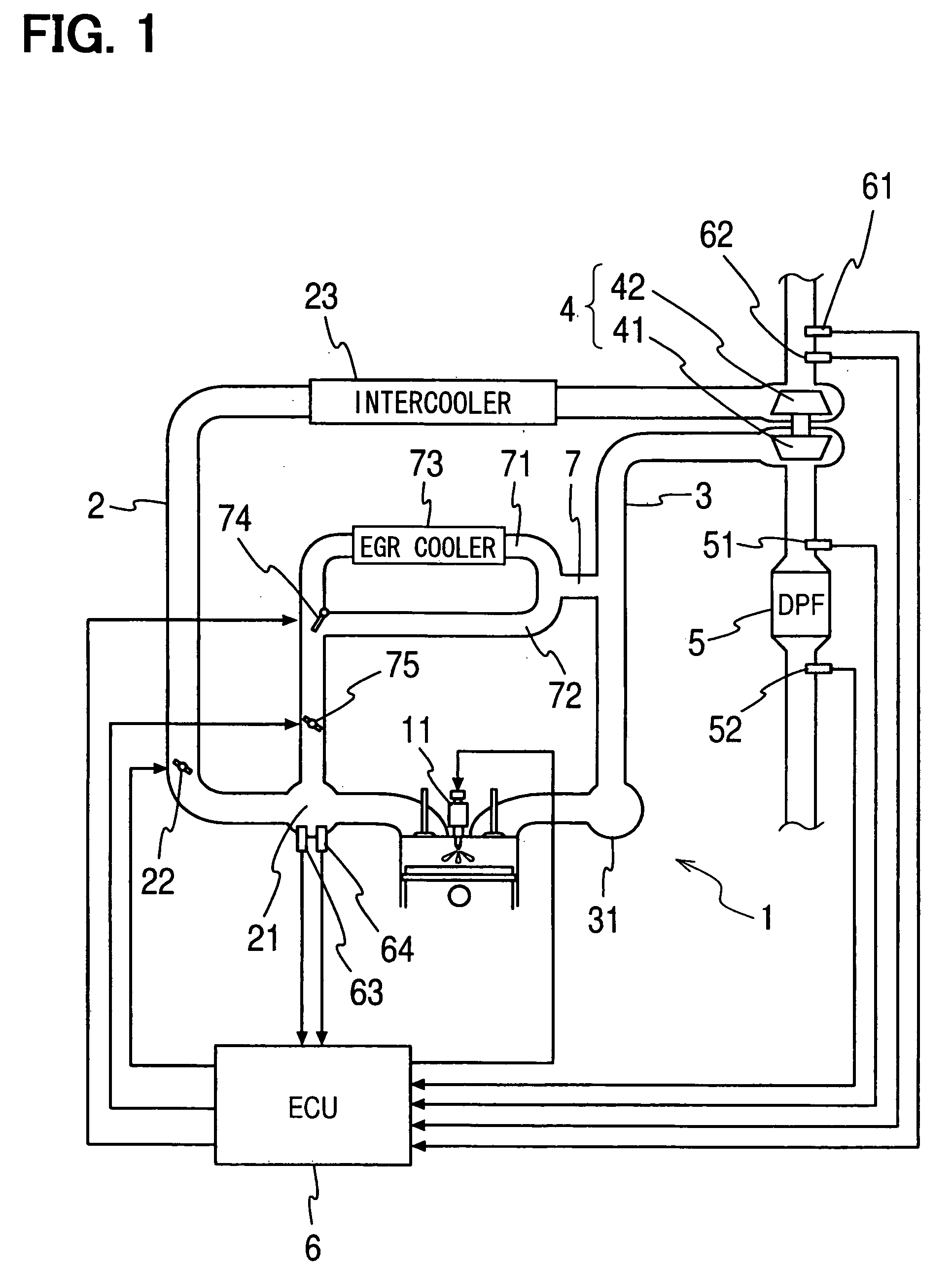

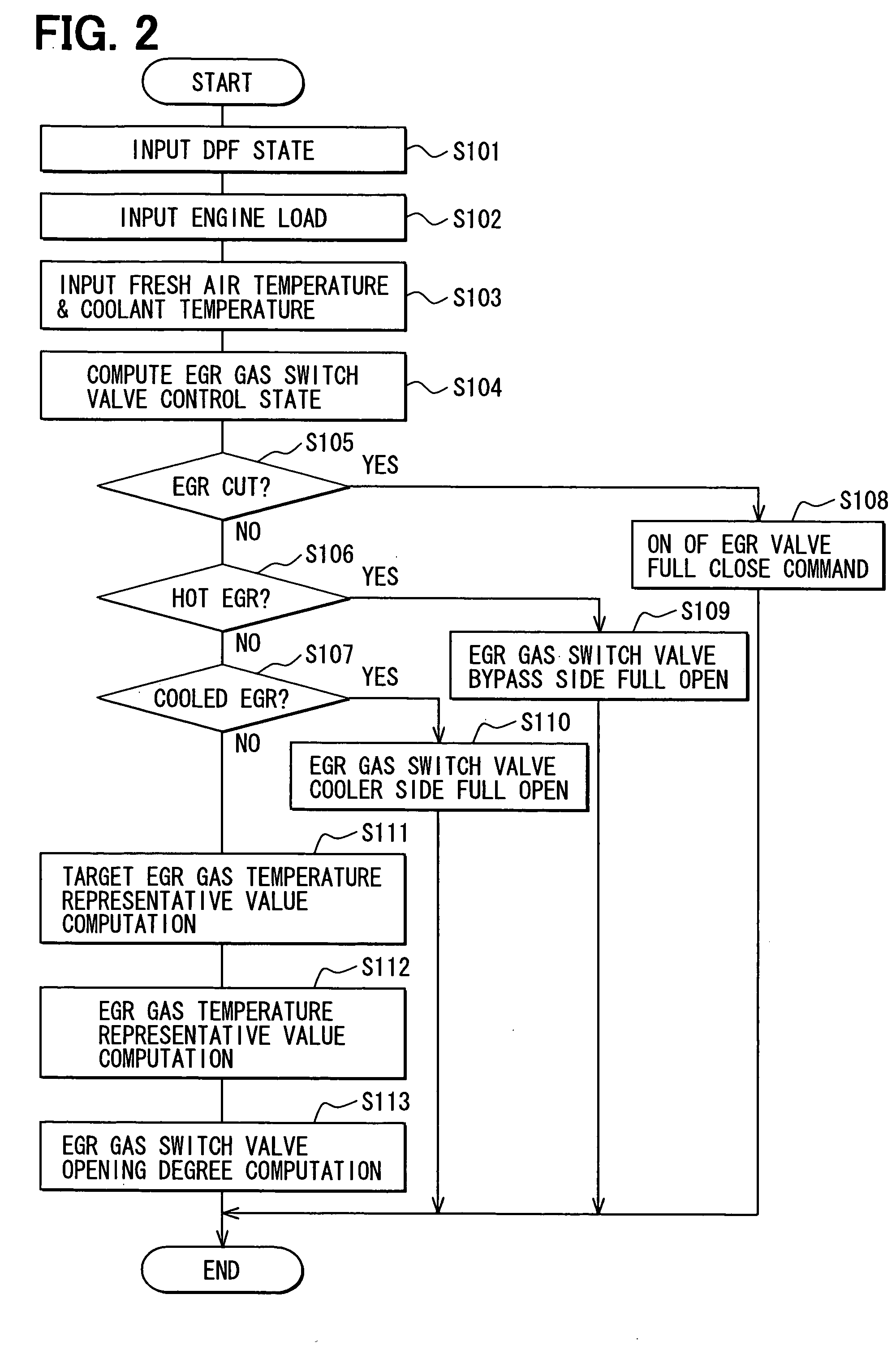

Exhaust gas purifying apparatus

InactiveUS20060112679A1Maintain reliabilityElectrical controlNon-fuel substance addition to fuelExhaust gasExhaust fumes

An ECU controls an opening degree of an EGR gas switch valve based on a temperature of intake air and a load state of an engine in such a manner that a temperature of exhaust gas becomes a suitable temperature, which is suitable for regeneration of a particulate filter arranged in an exhaust gas passage. In this way, cooled EGR gas, which passes a main passage, and hot EGR gas, which passes a bypass passage, are appropriately mixed. In a case, where reliability of an EGR valve cannot be maintained, EGR cut is performed.

Owner:DENSO CORP

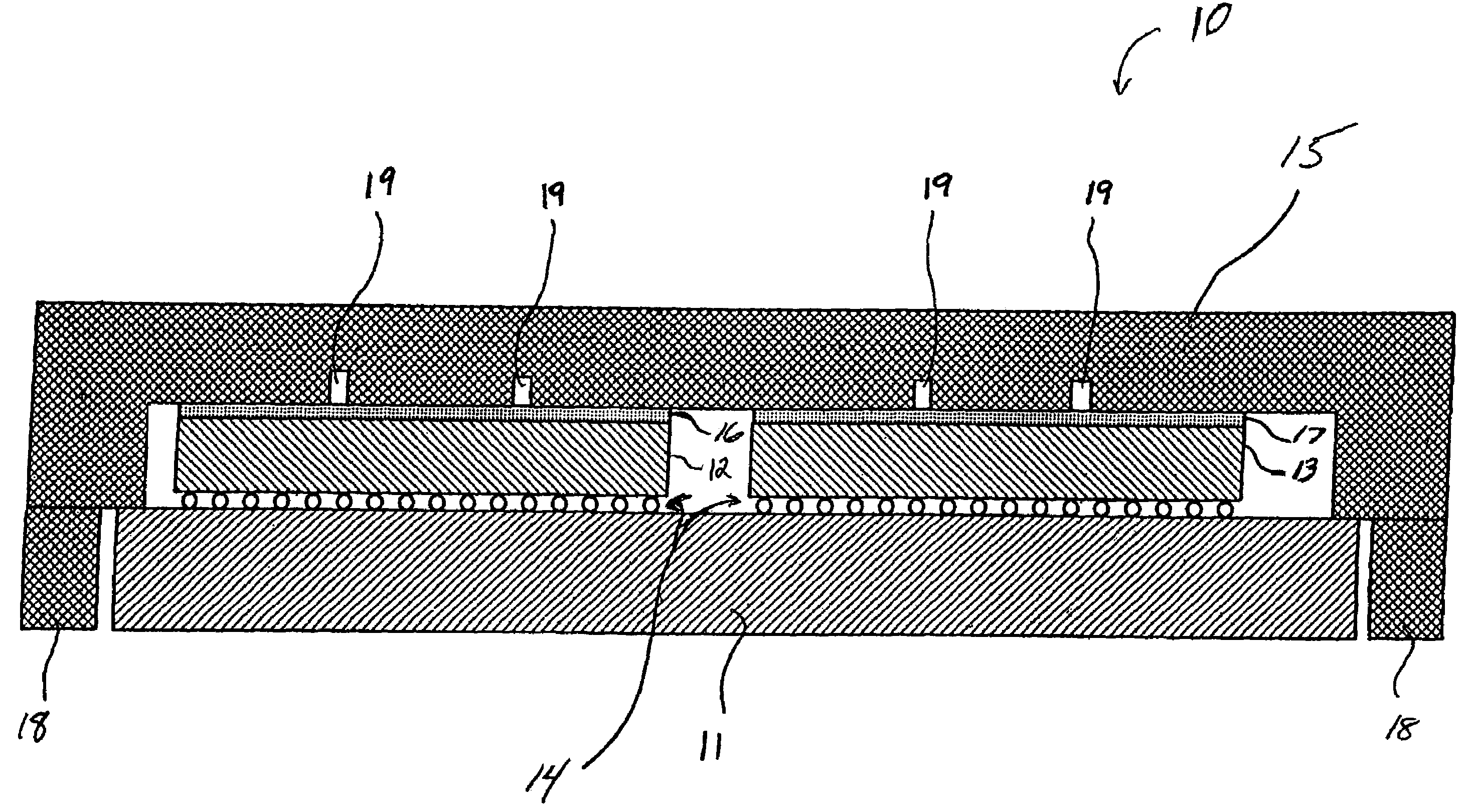

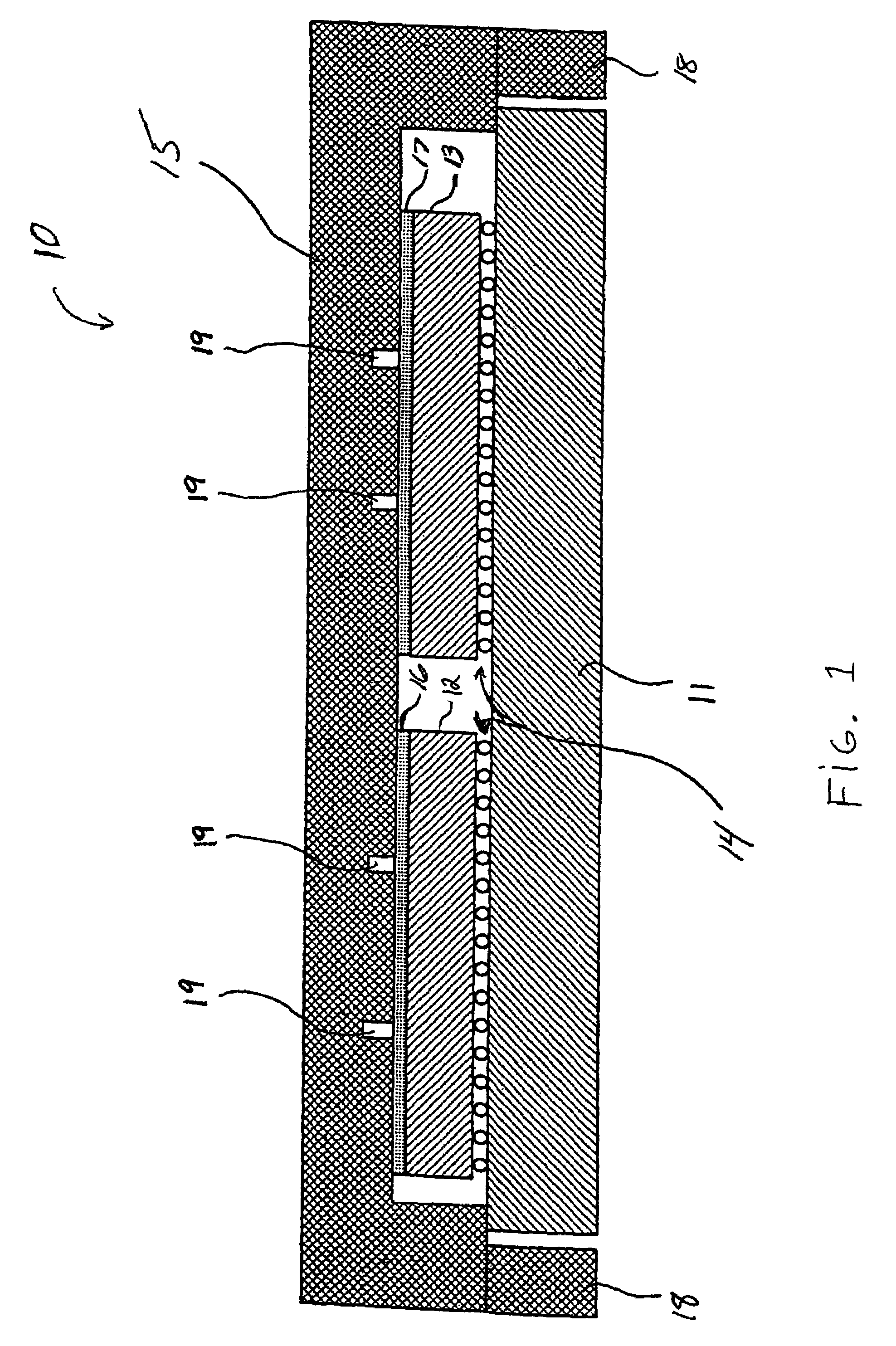

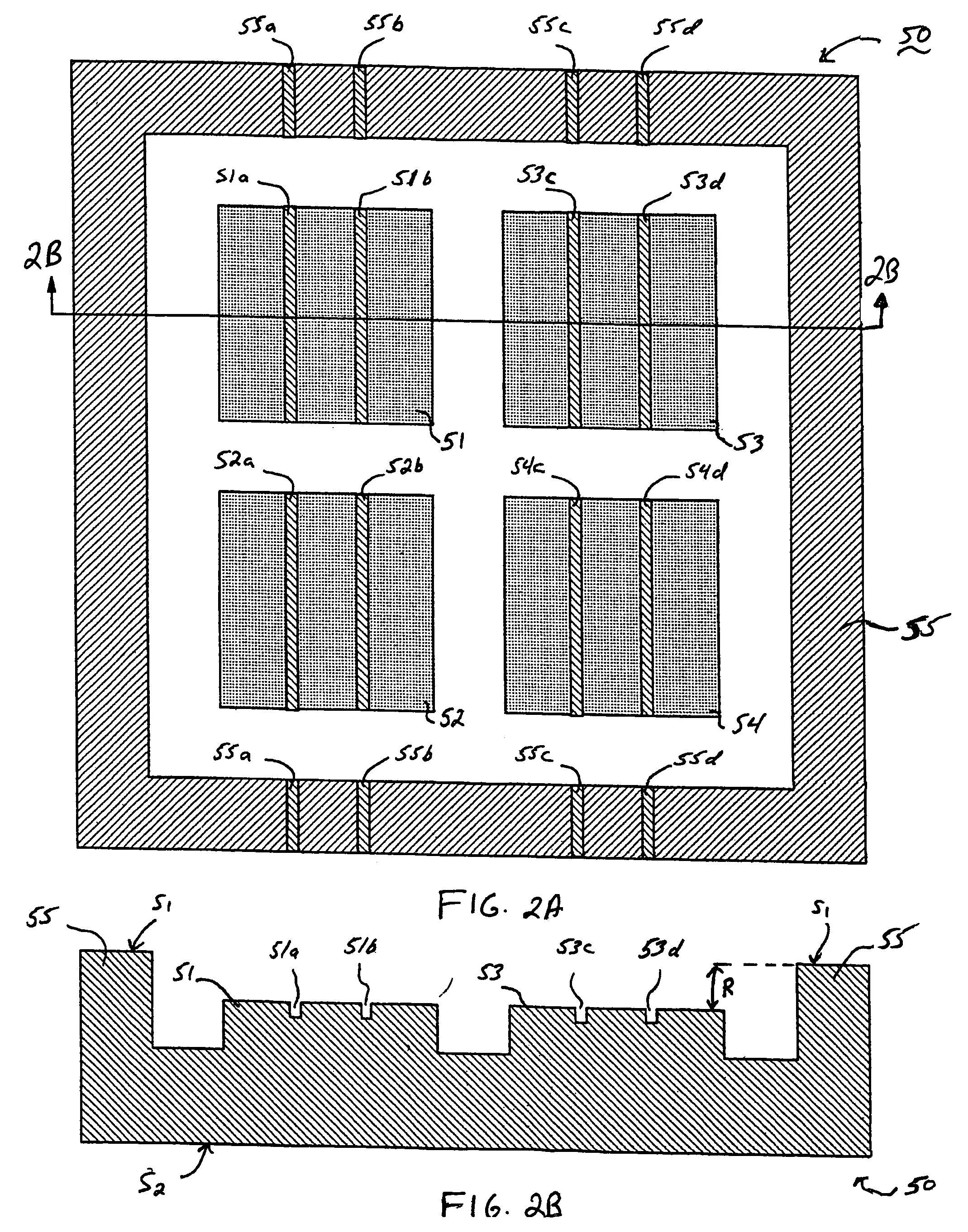

Apparatus and methods for cooling semiconductor integrated circuit package structures

ActiveUS7394659B2Maintain reliabilityHigh retention rateSemiconductor/solid-state device detailsSolid-state devicesHeat conductingSemiconductor chip

The present invention relates generally to apparatus and methods for cooling semiconductor integrated circuit (IC) chip package structures. More specifically, the present invention relates to apparatus and methods for thermally coupling semiconductor chips to a heat conducting device (e.g., copper thermal hat or lid) using a compliant thermally conductive material (e.g., thermal paste), wherein a thermal interface is designed to prevent / inhibit the formation of voids in the compliant thermally conductive material due to the flow of such material in and out from between the chips and the heat conducting device due to thermal cycling.

Owner:INT BUSINESS MASCH CORP

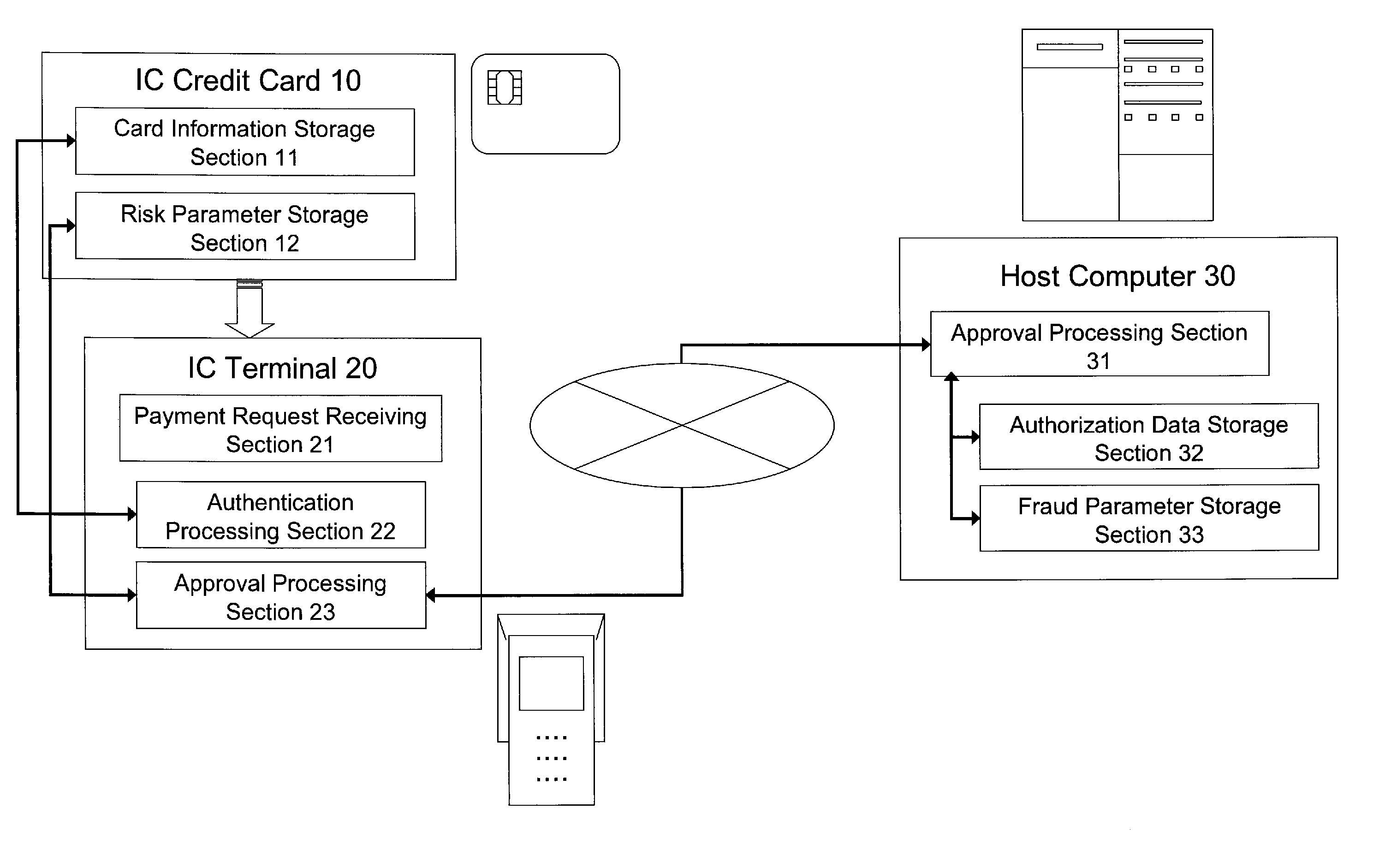

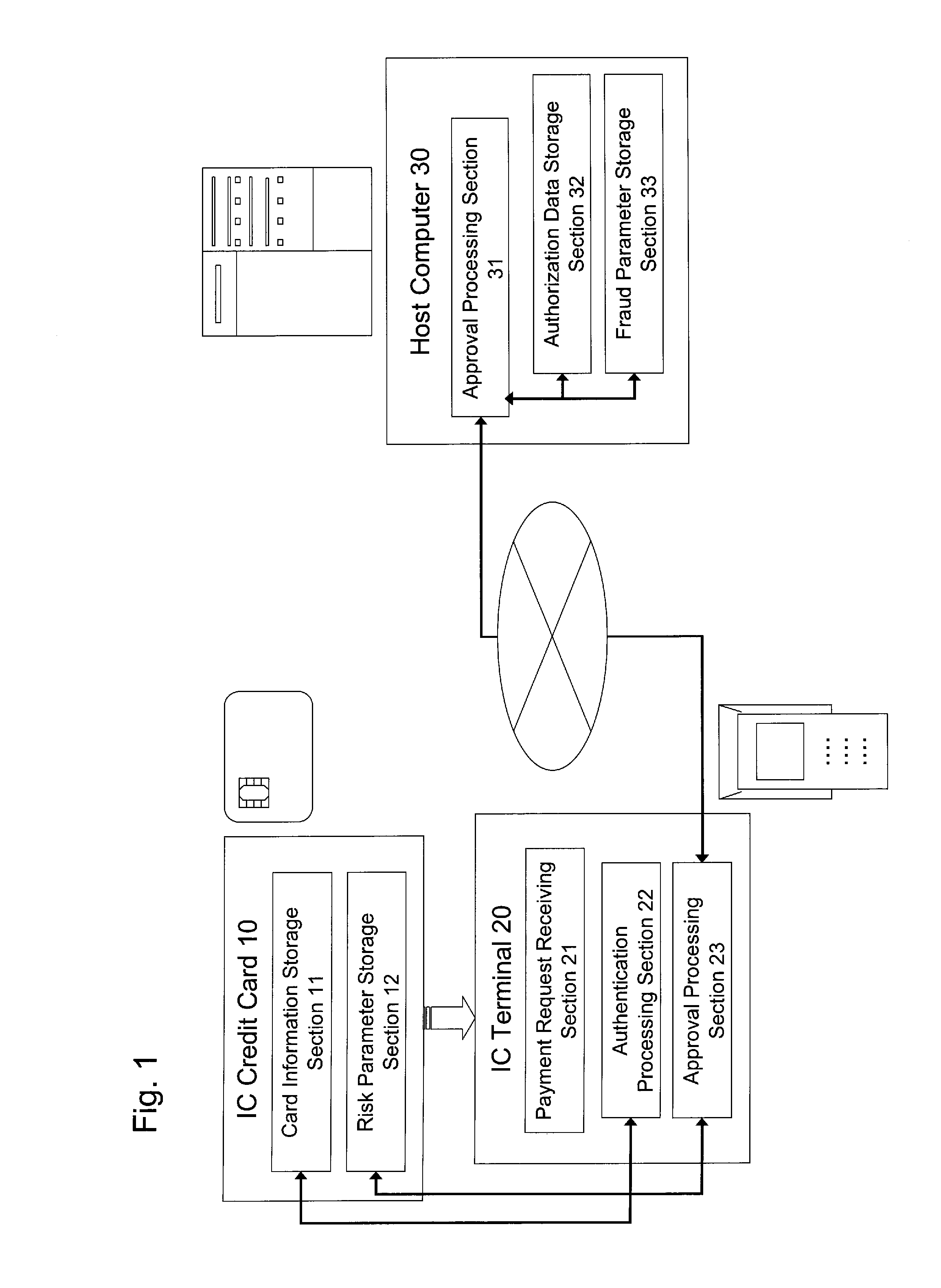

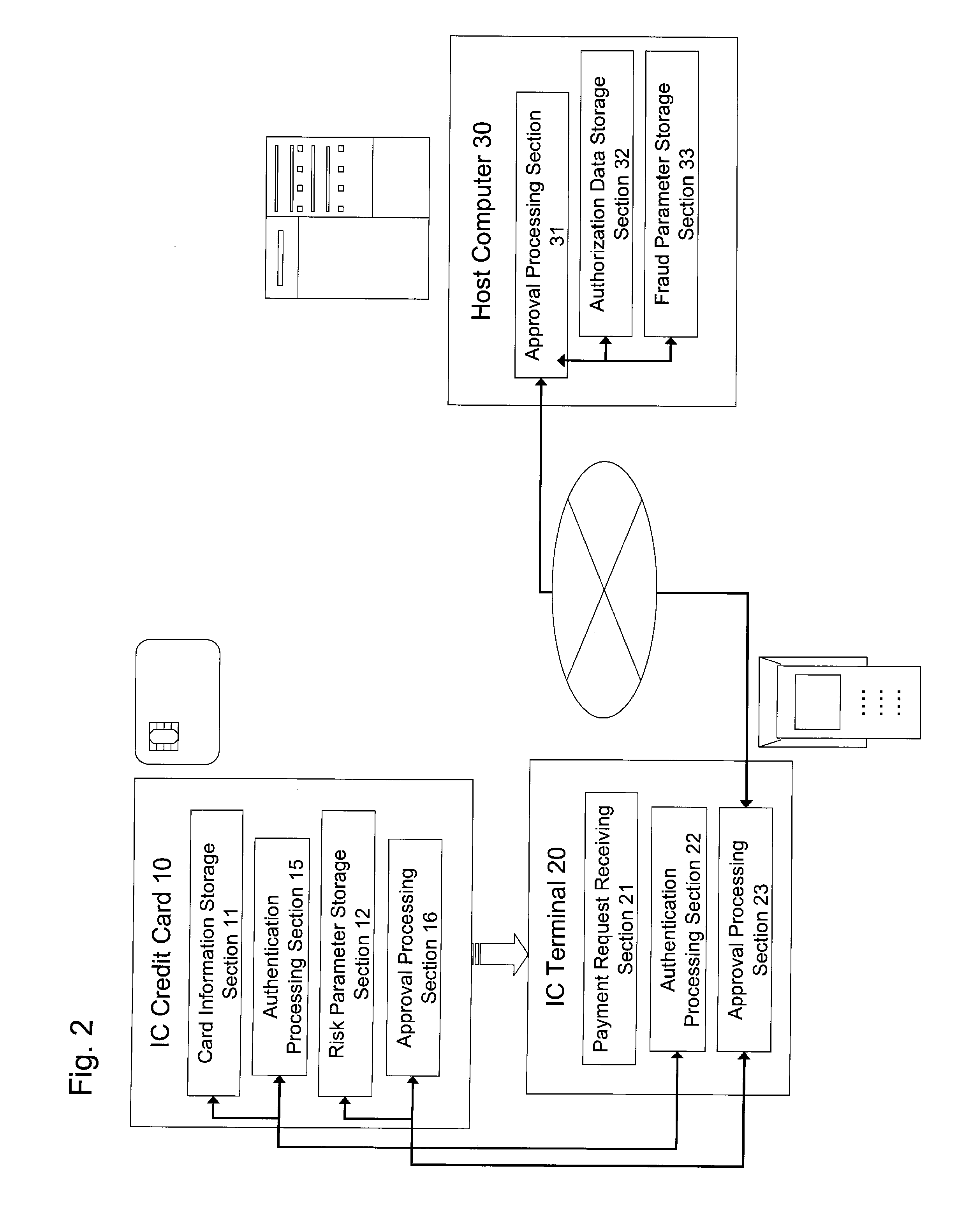

Payment approval system and method for approving payment for credit card

ActiveUS20100327056A1Improve reliabilityReduce in quantityOther printing matterCo-operative working arrangementsCredit cardComputer terminal

A payment approval system and a method for approving a payment for credit cards are provided for providing efficient processing while maintaining accuracy in detection of fraud usage of credit cards with an IC chip. Fraud parameters obtained by modeling a pattern of fraud usage is stored in the IC chip equipped in the IC credit card to use for payment approval to achieve improved reliability of offline approval. When offline approval process finds a possibility of fraud usage, online approval for more detailed statistical analysis processing is requested to a host computer. When update information of the fraud parameter used for the judgment is transmitted together with the request for approval and the newest fraud parameter created by analyzing the newest transaction trend etc. is confirmed to have been updated at the host computer, the newest fraud parameter along with the approval result from the host computer is transmitted to the IC terminal to update the fraud parameter in the IC chip to the up-to-date state.

Owner:INTELLIGENT WAVE INC

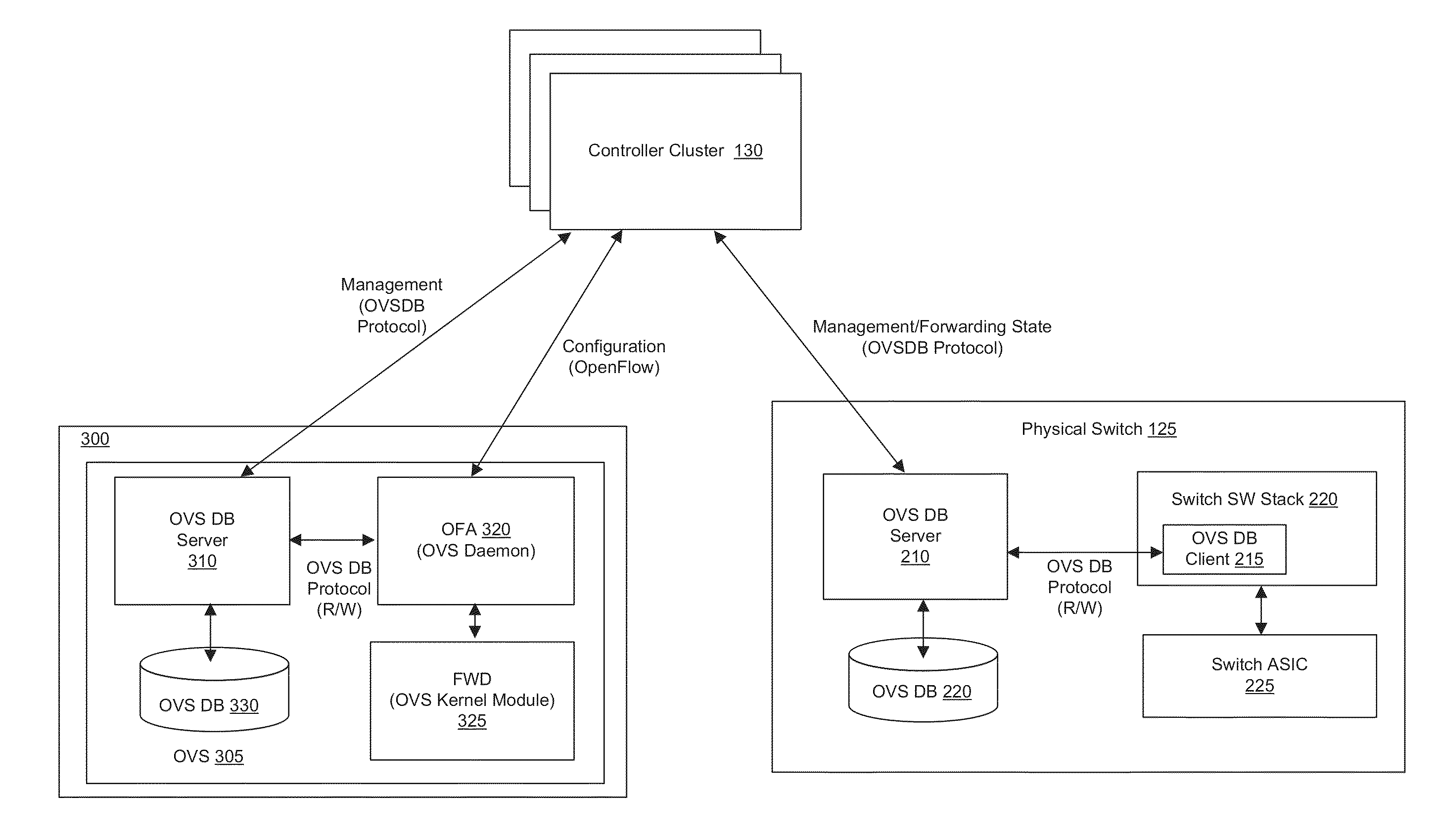

Database Protocol for Exchanging Forwarding State with Hardware Switches

ActiveUS20150100675A1Maintain reliabilityEasy to implementDigital computer detailsNetworks interconnectionSoftware networkDatabase server

Some embodiments provide a set of one or more network controllers that communicates with a wide range of devices, ranging from switches to appliances such as firewalls, load balancers, etc. The set of network controllers communicates with such devices to connect them to its managed virtual networks. The set of network controllers can define each virtual network through software switches and / or software appliances. To extend the control beyond software network elements, some embodiments implement a database server on each dedicated hardware. The set of network controllers accesses the database server to send management data. The hardware then translates the management data to connect to a managed virtual network.

Owner:NICIRA

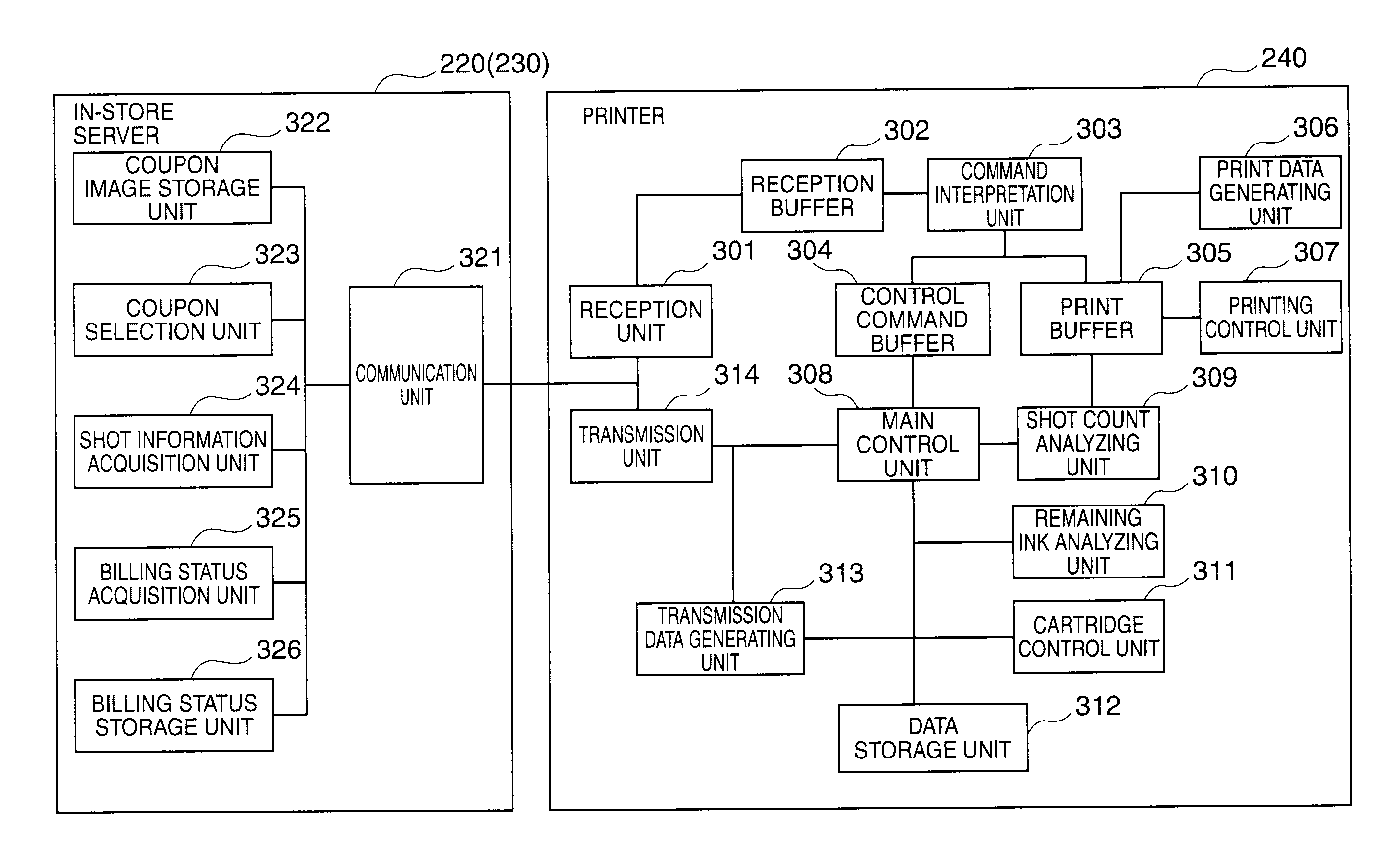

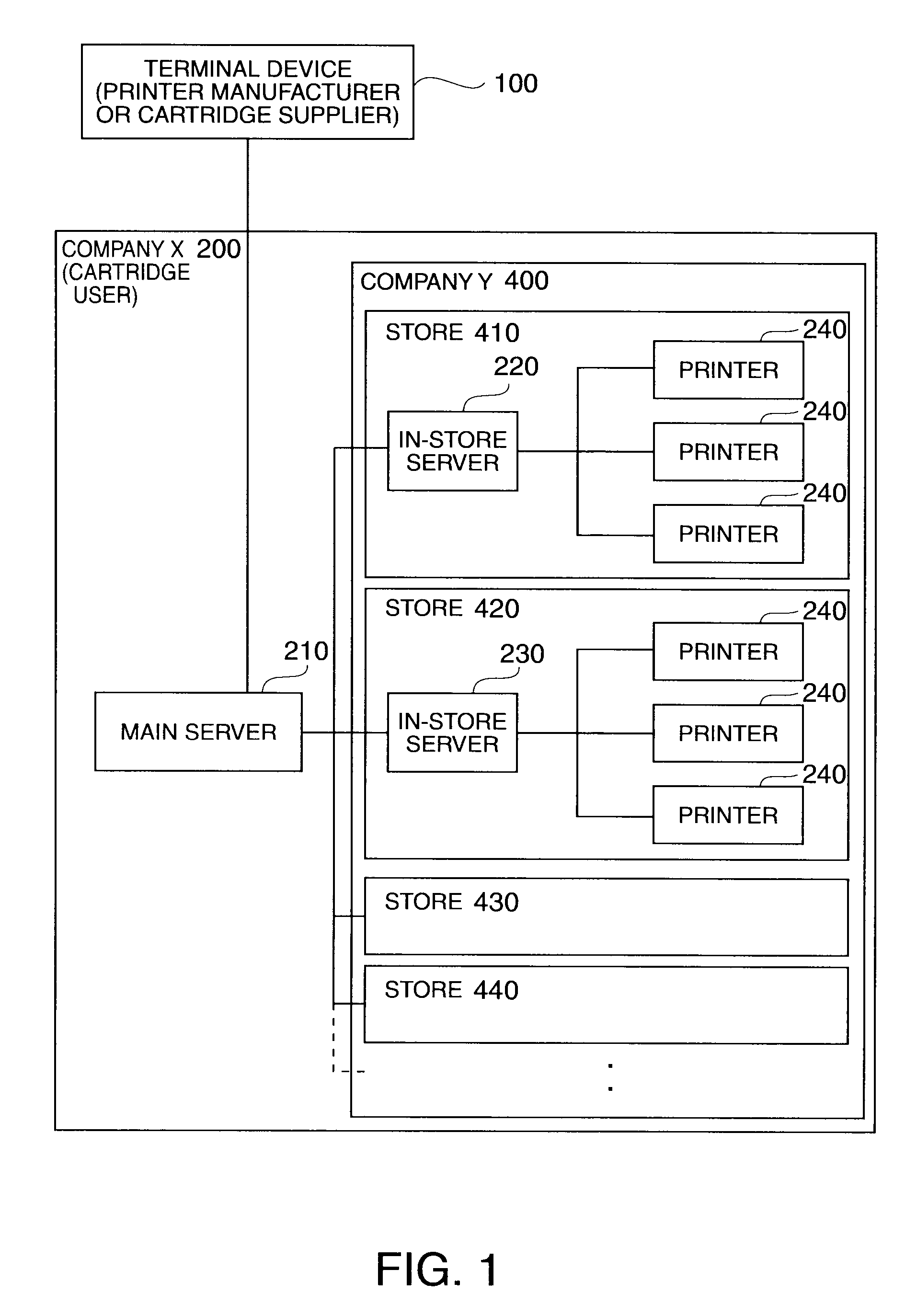

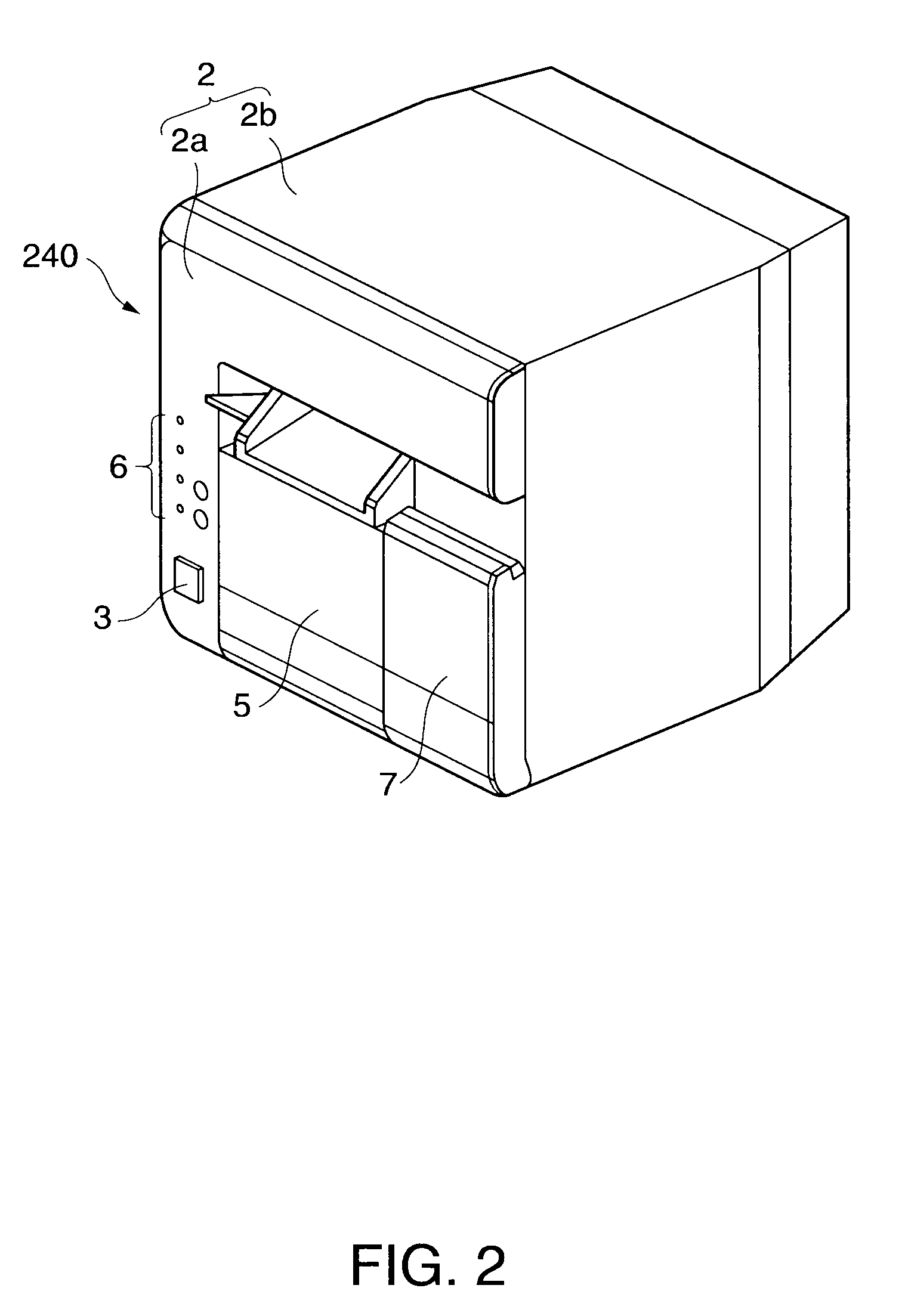

Printer and printing system

A printer 240 calculates the amount of ink used only for printing as a number of discharged ink shots, and sends this shot count with the printer serial number and ink cartridge ID to a server 220. The server 220 saves the shot count, printer serial number, ink cartridge ID, and an error correction code as status information. The server 220 or server upstream from the server 220 can reliably determine the number of ink shots used by the printer 240 only for printing from this status information.

Owner:SEIKO EPSON CORP

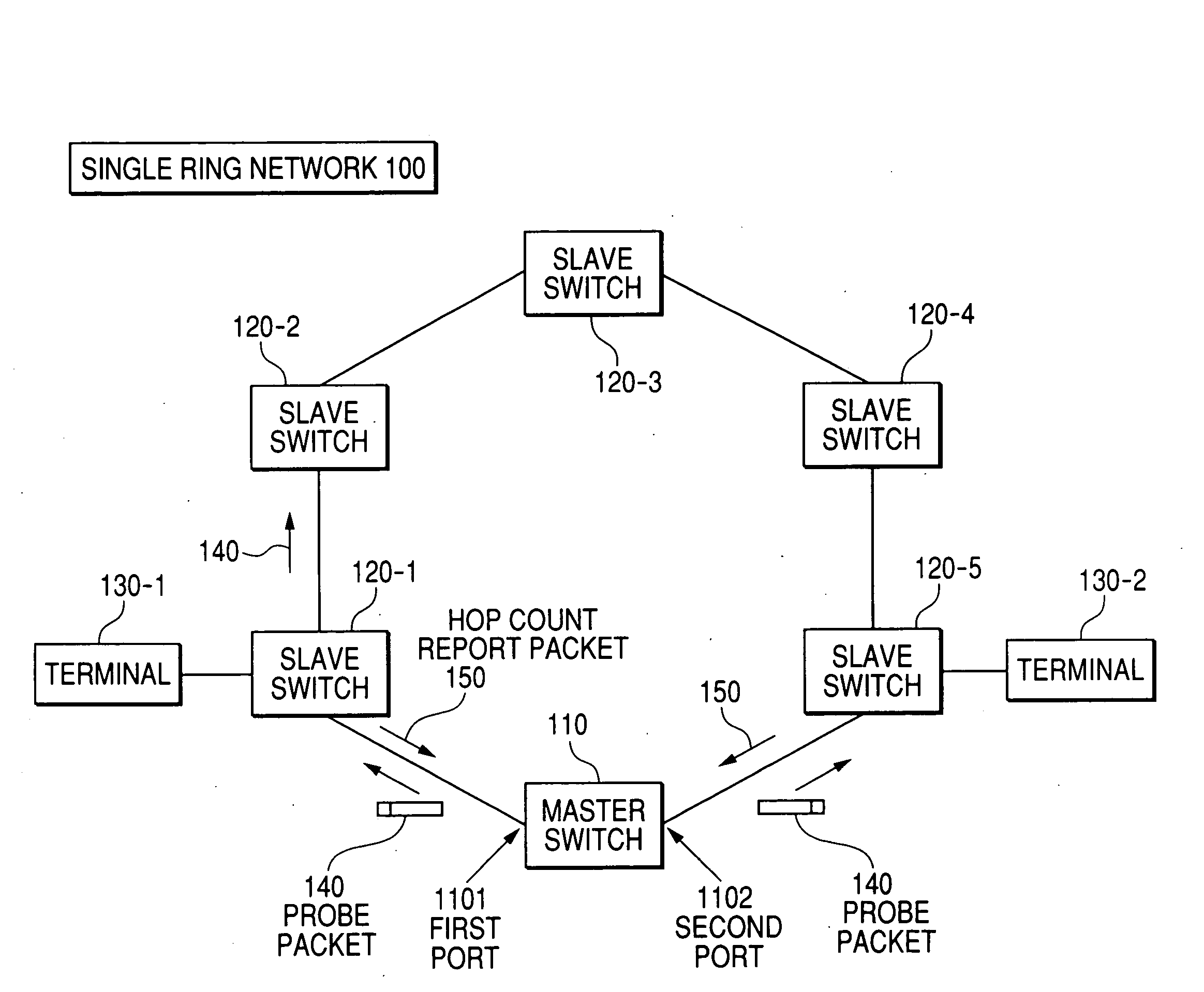

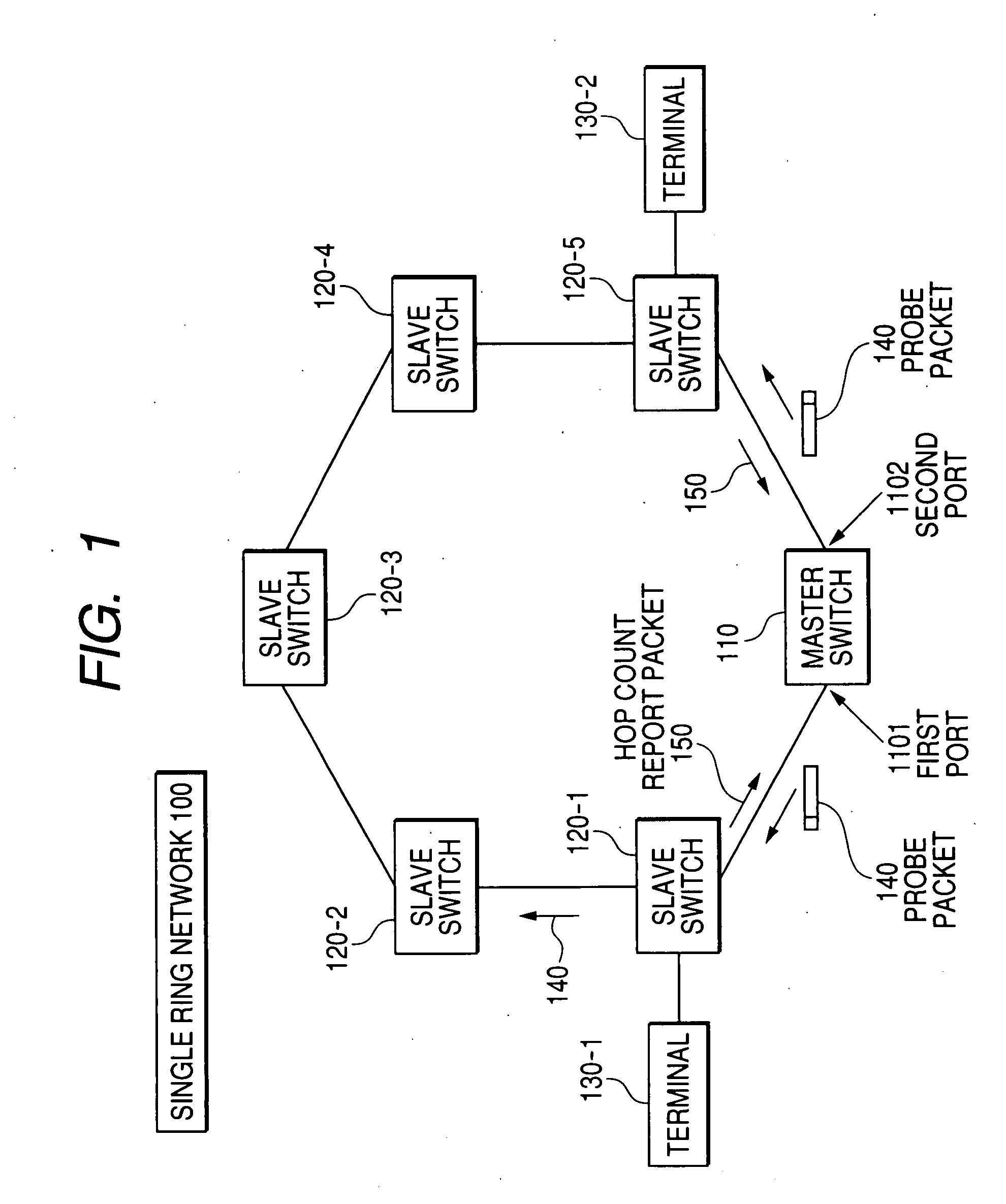

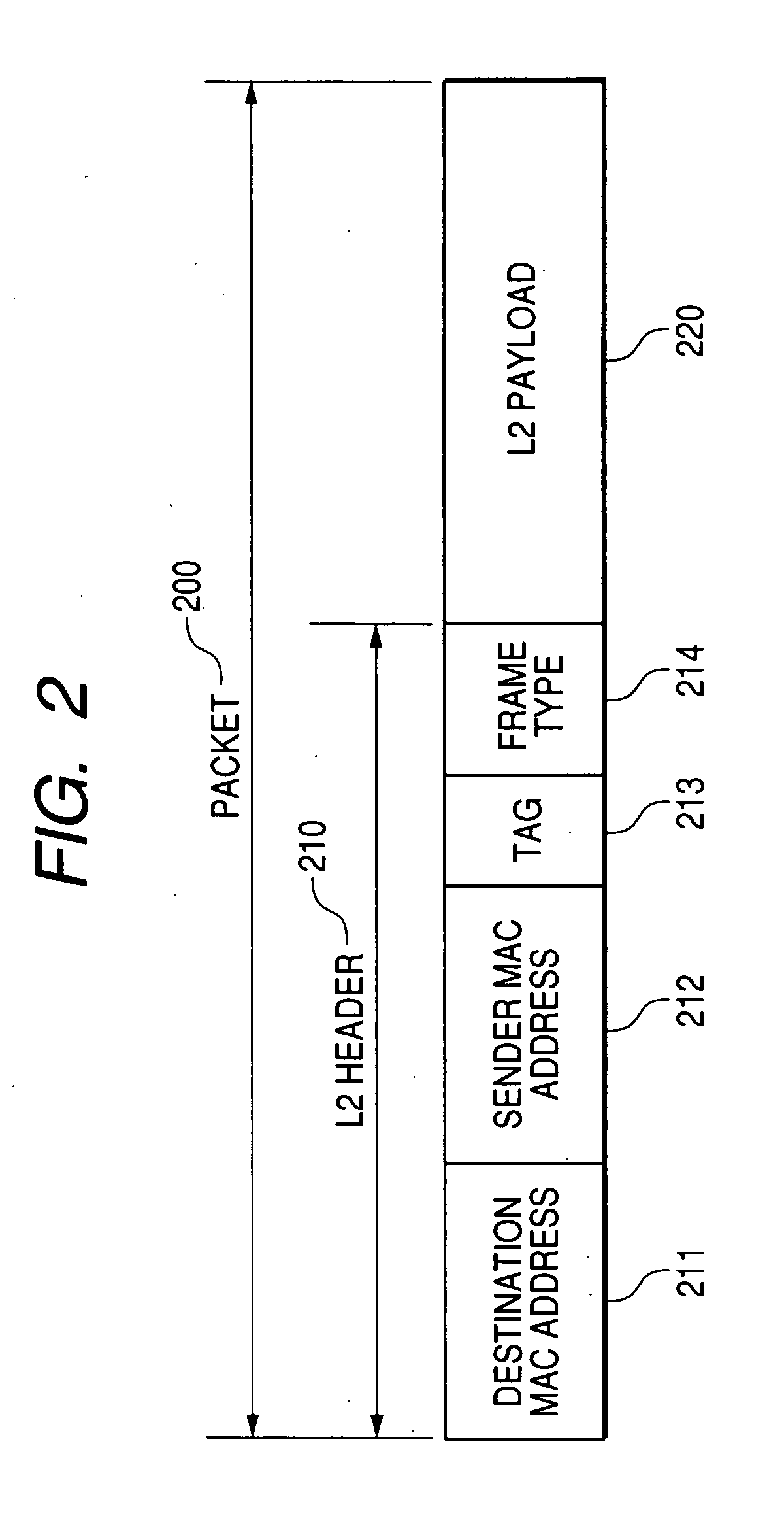

Ring network and master node

InactiveUS20070204068A1Improve communication reliabilityMaintain reliabilityError preventionFrequency-division multiplex detailsRing networkMultiple fault

A master node transmits a probe packet for checking a condition of a network in a ring in both directions thereof to detect the occurrence of a fault on the ring. A slave node increments a hop count included in the received probe packet, transmits it to an adjacent node configuring the ring, and transmits a hop count report packet to the master node. The master node detects a fault on the ring based upon a fact that the master node does not receive the probe packet transmitted by itself. Further, the master node detects the occurrence of multiple faults and the recovery of at least one of the multiple faults based upon the sum of maximum values of hop counts in the hop count report packets received from both directions of the ring and transmits a packet for prompting the update of the database for packet transfer.

Owner:ALAXALA NETWORKS

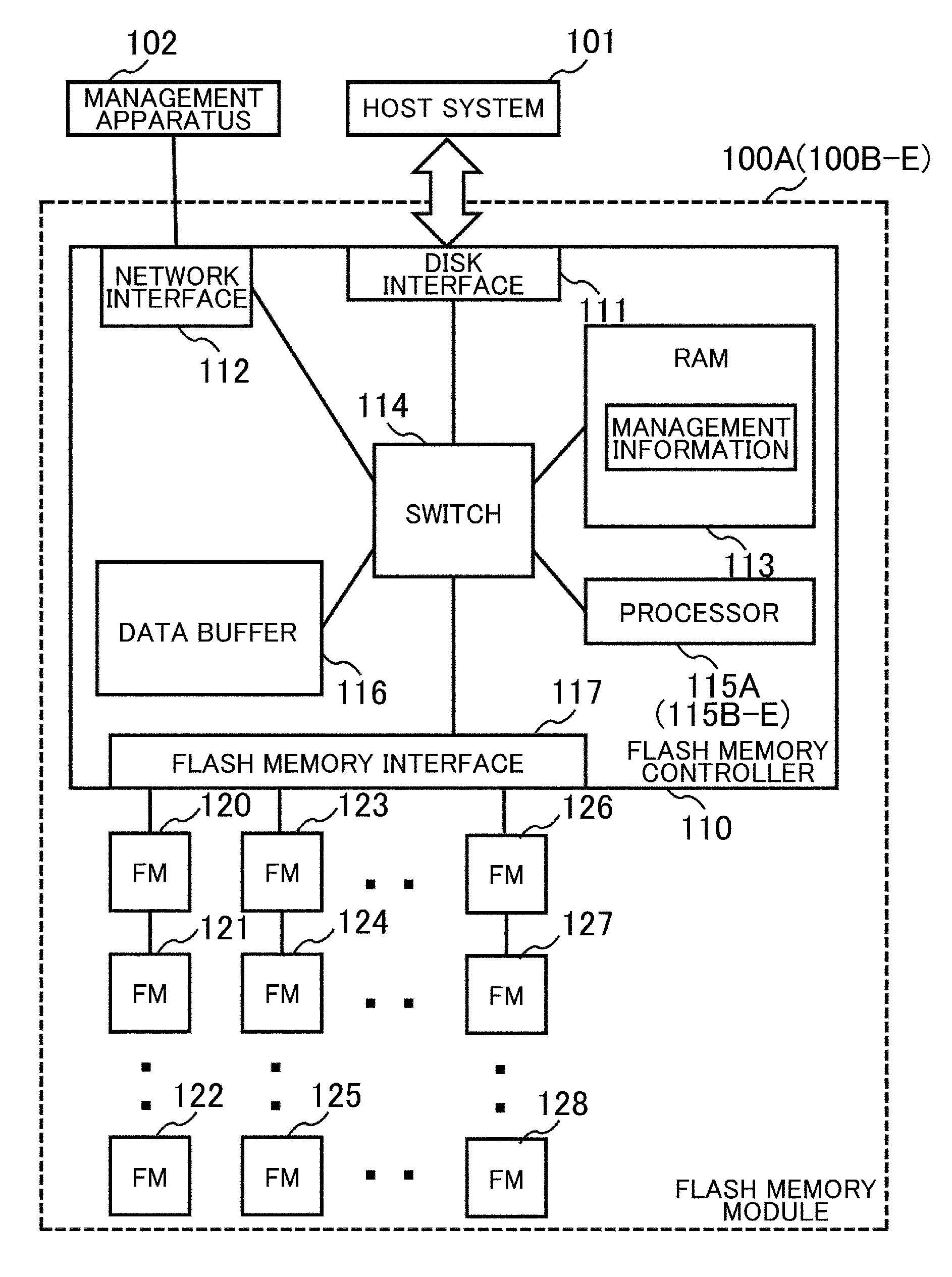

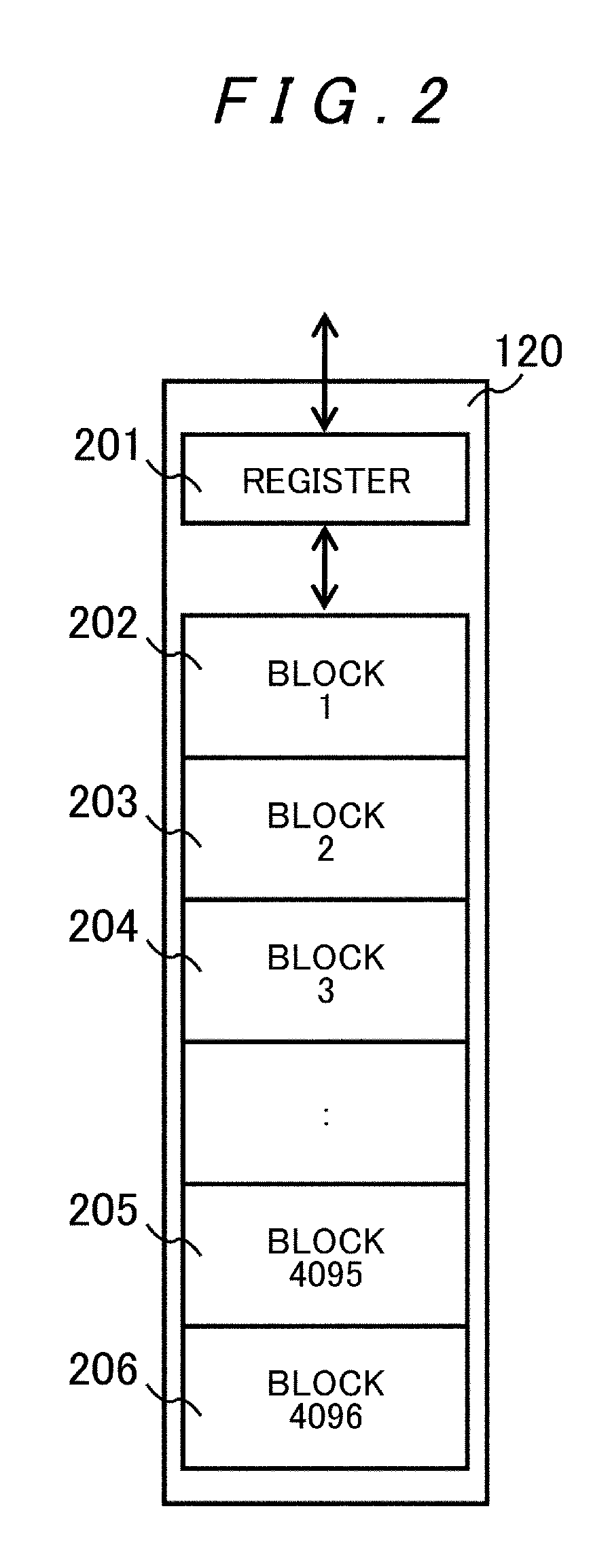

Semiconductor storage apparatus and method for controlling semiconductor storage apparatus

ActiveUS20120278533A1Maintain reliabilityAvoid performance degradationMemory architecture accessing/allocationMemory adressing/allocation/relocationMemory controllerDependability

A reliability maintained period is calculated for each storage area based on the degree of deterioration and read frequency for each storage area of a flash memory, and refresh is executed on each storage area in a planned manner based on the calculated reliability maintained period.A semiconductor storage apparatus 100A is configured so that flash memories 120 to 128 and a memory controller 110 are connected and the flash memories 120 to 128 include a plurality of blocks as storage areas; and the memory controller 110 manages the degree of deterioration and read frequency of the blocks for each of the plurality of blocks, obtains a reliability maintained period of data stored in the block based on the managed degree of deterioration and read frequency of the block, and executes refresh for correcting failure bits of the relevant data by newly storing the data stored in the block in another block based on the obtained reliability maintained period.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com