Patents

Literature

4061results about How to "Ensure reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

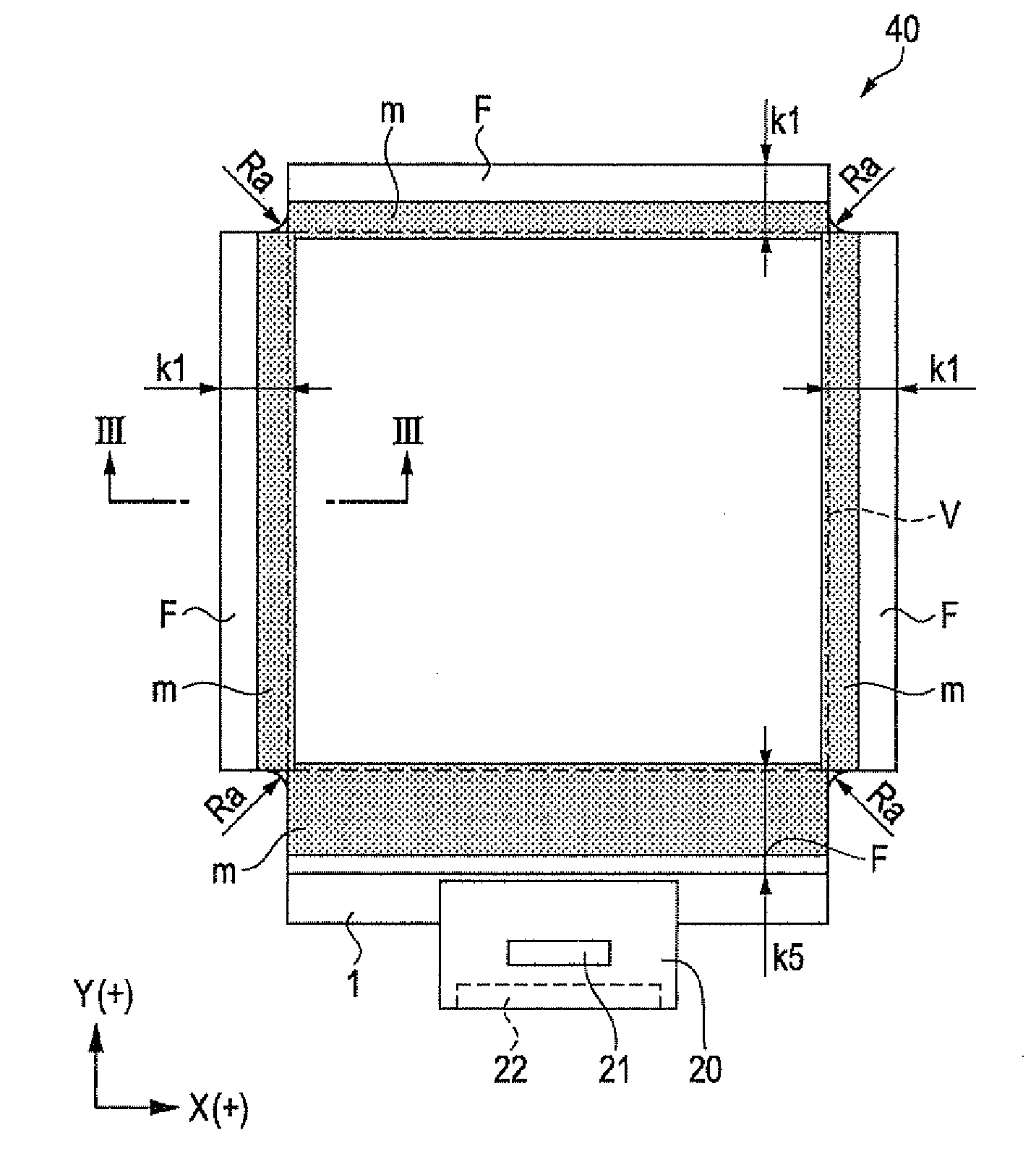

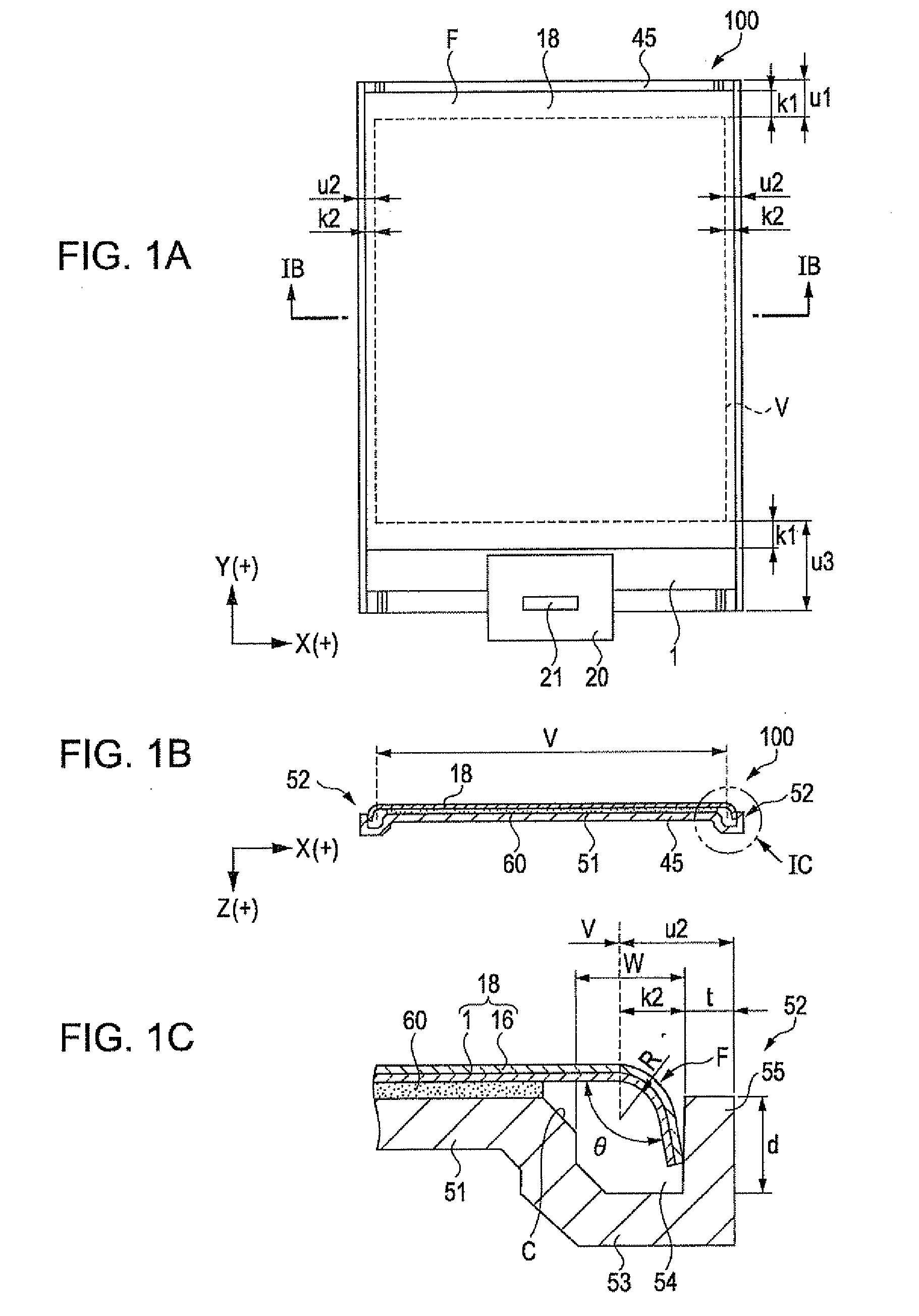

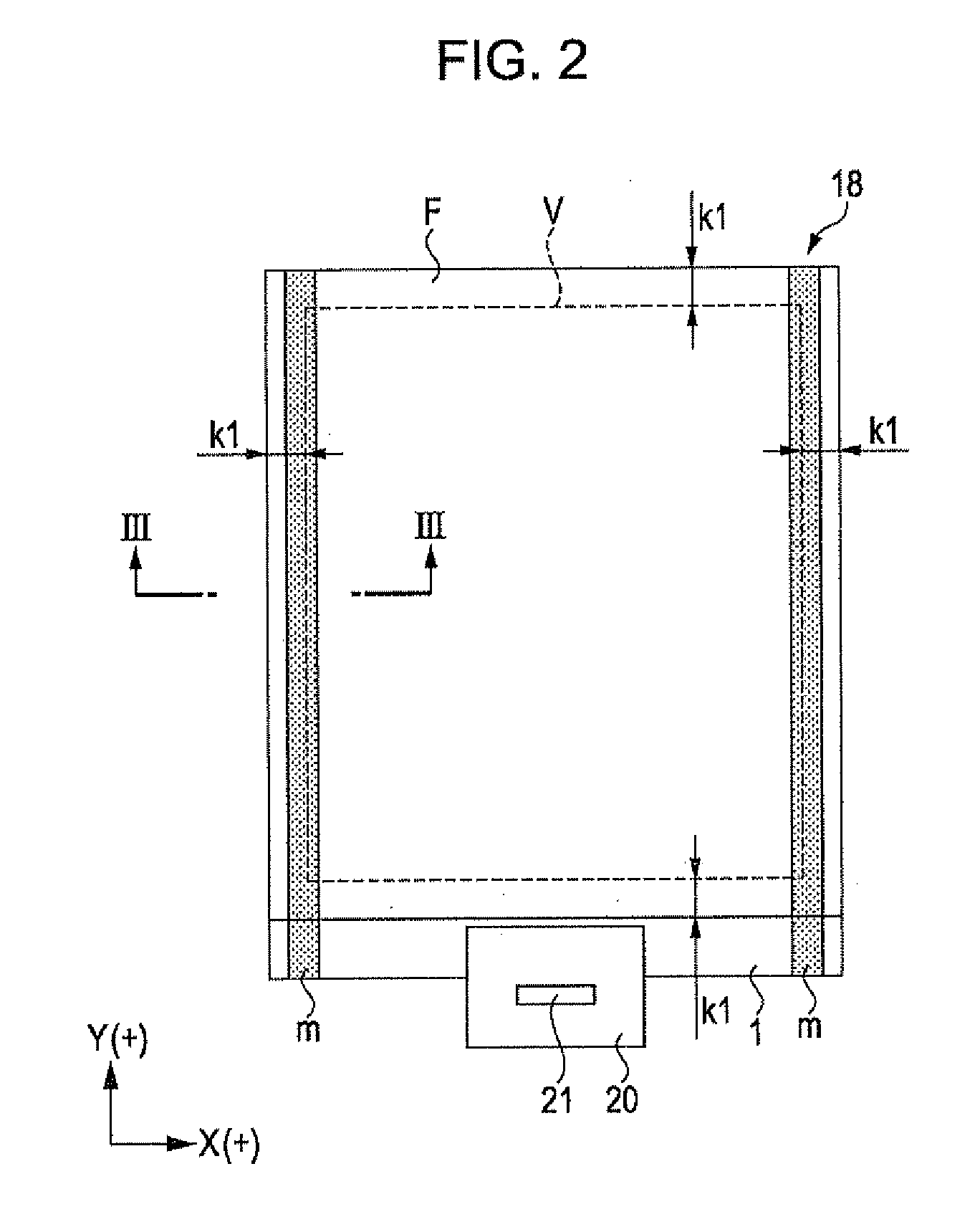

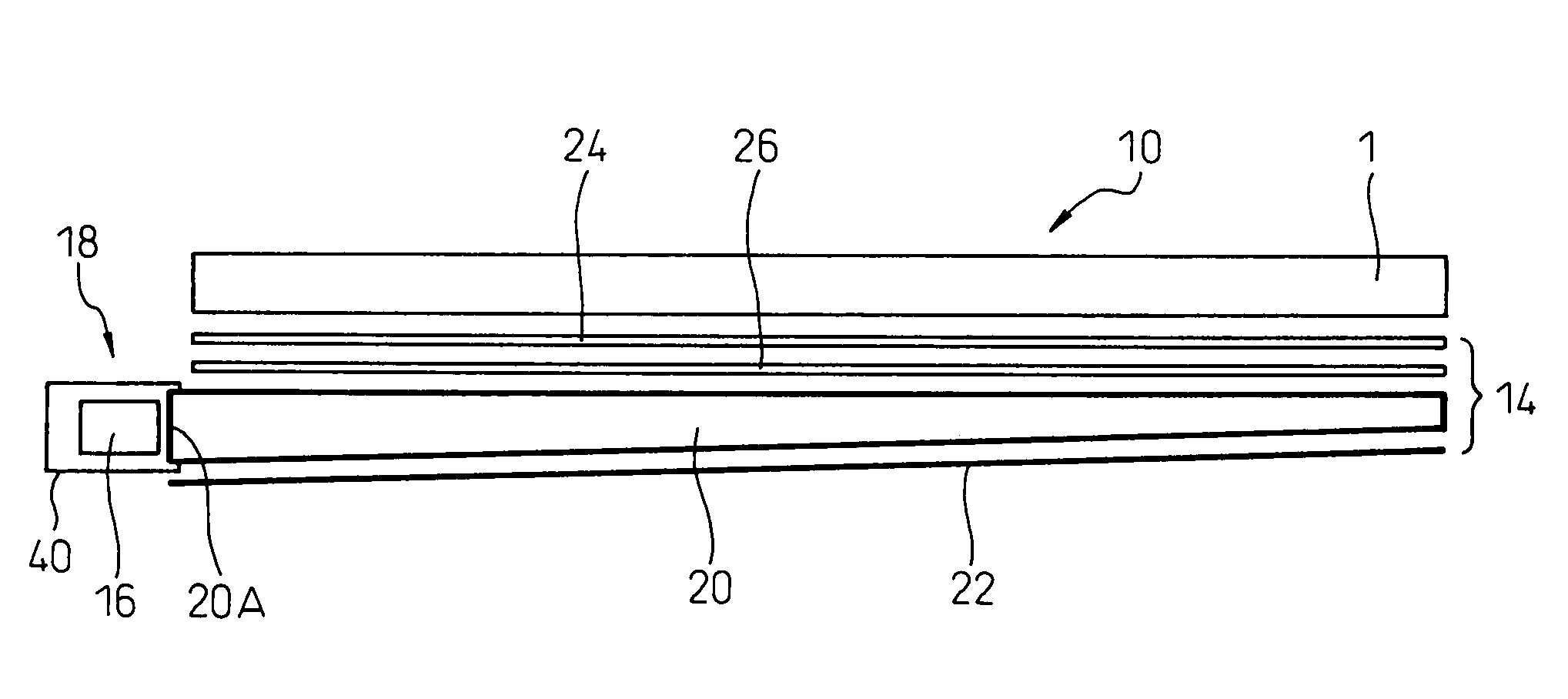

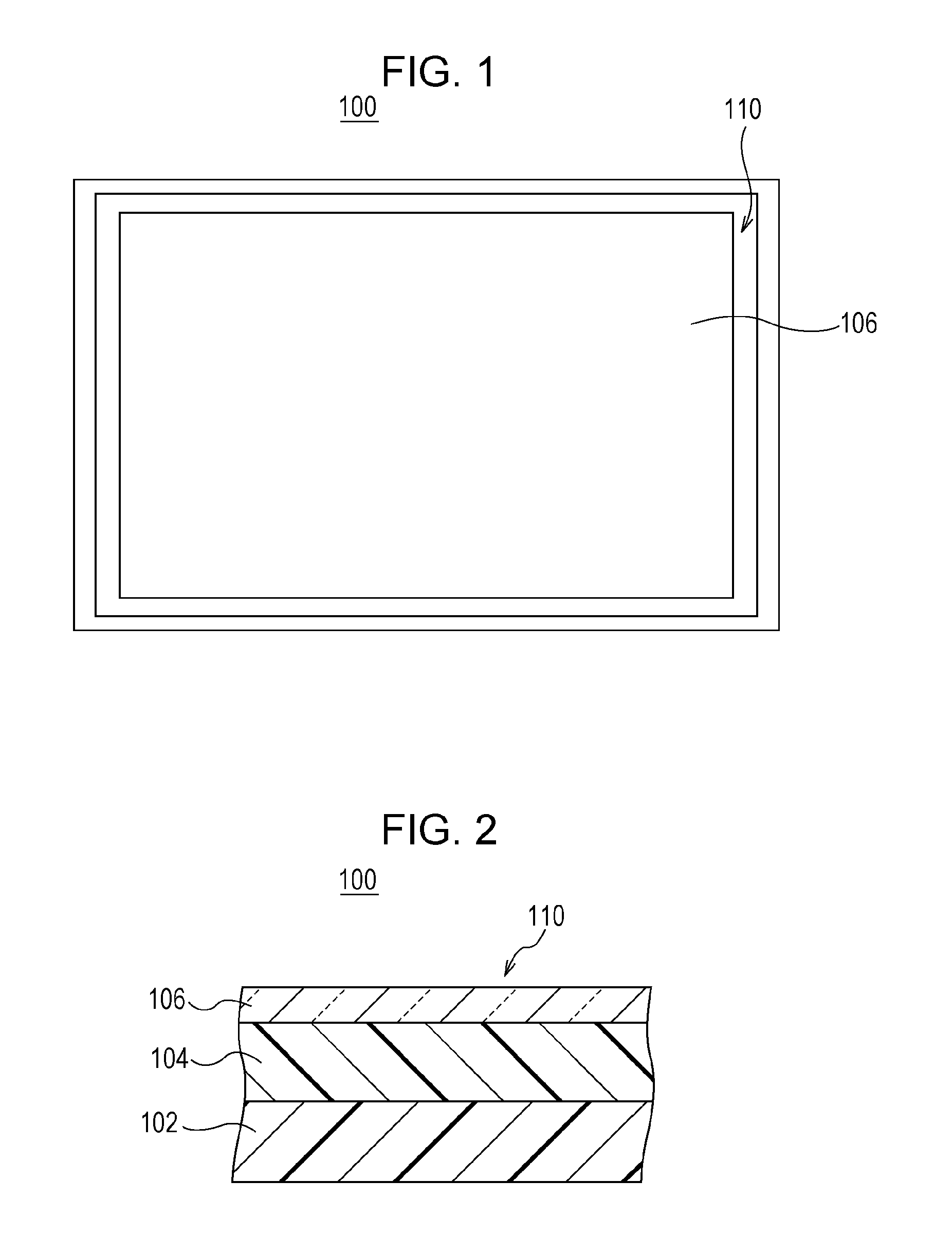

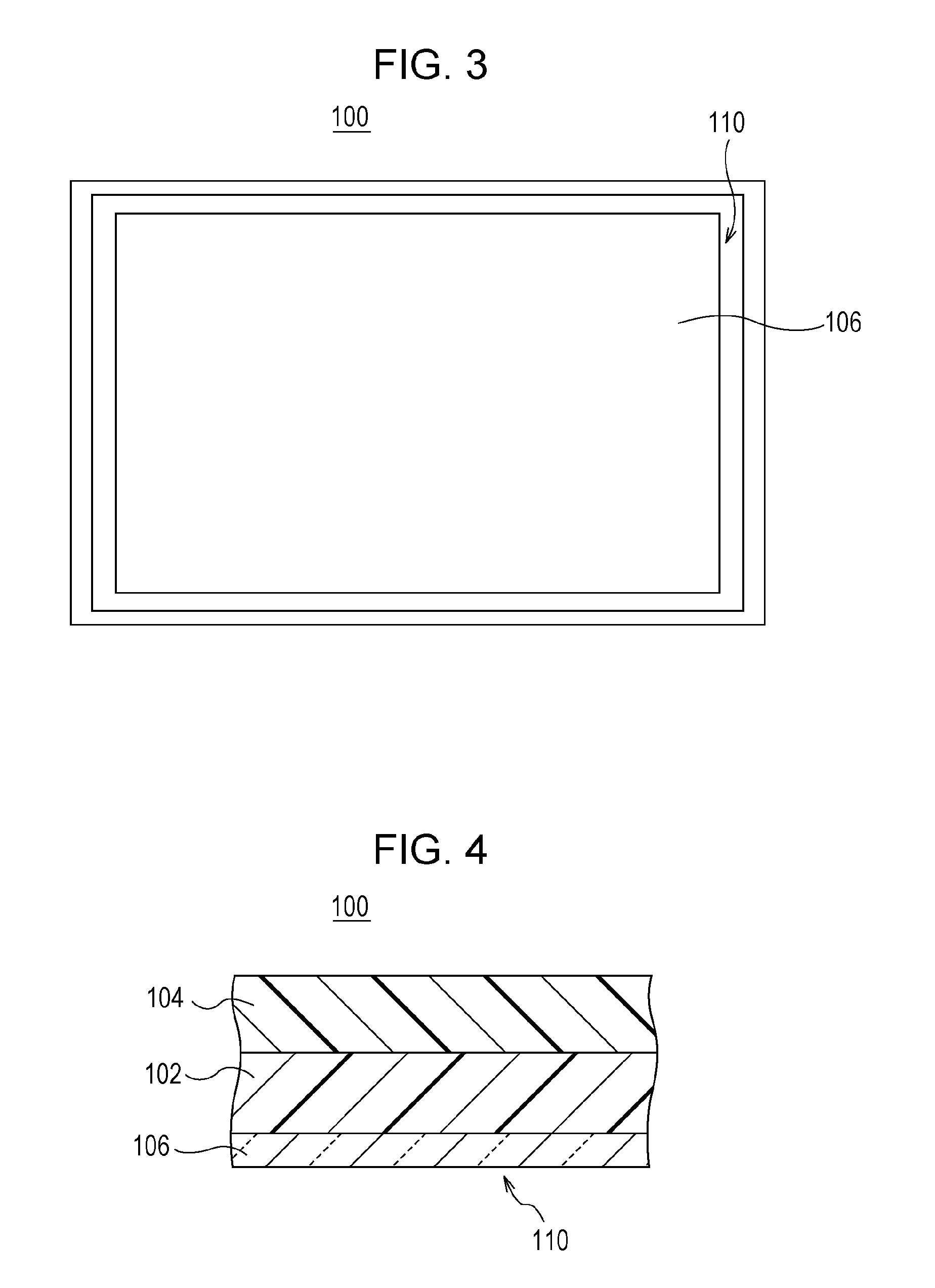

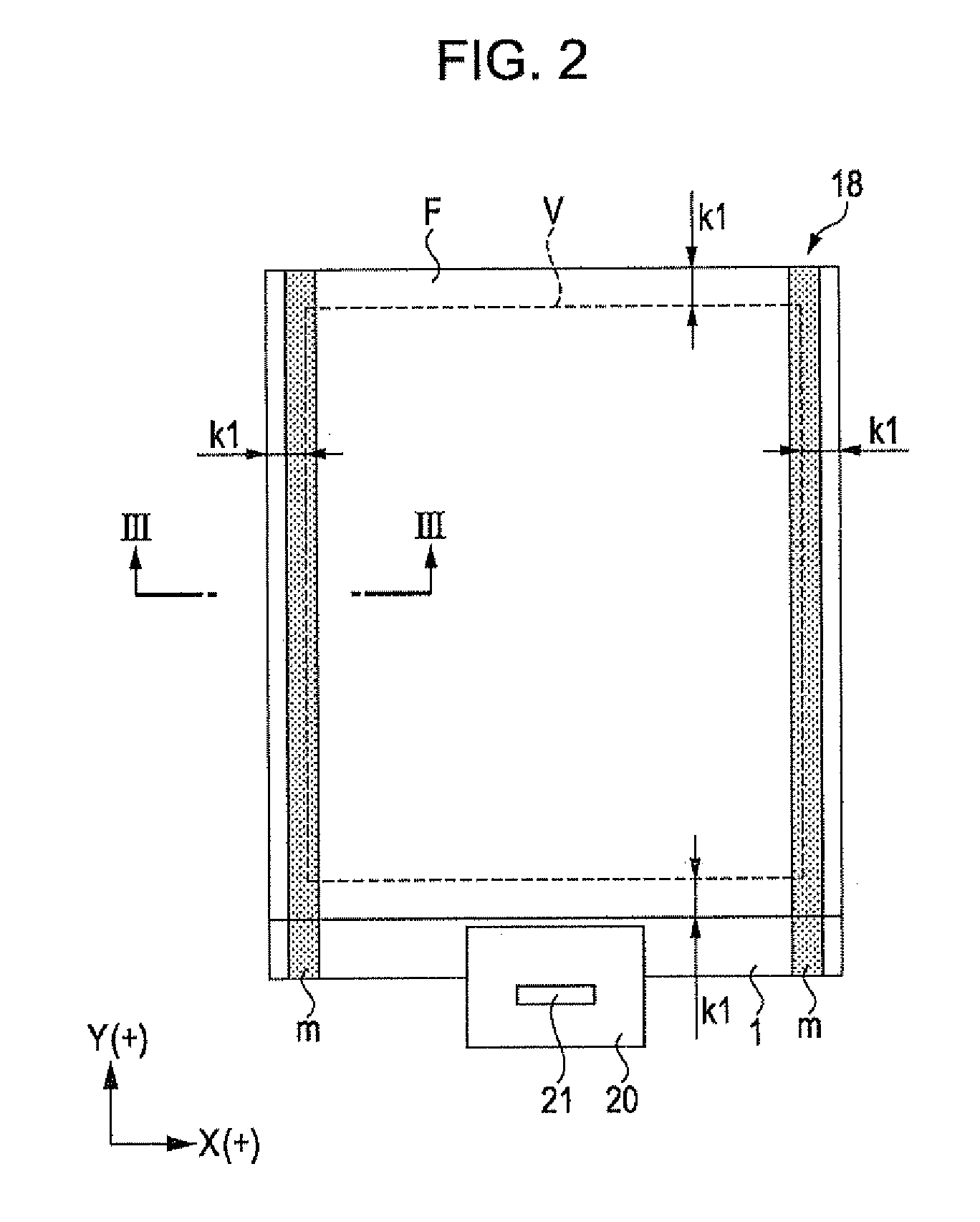

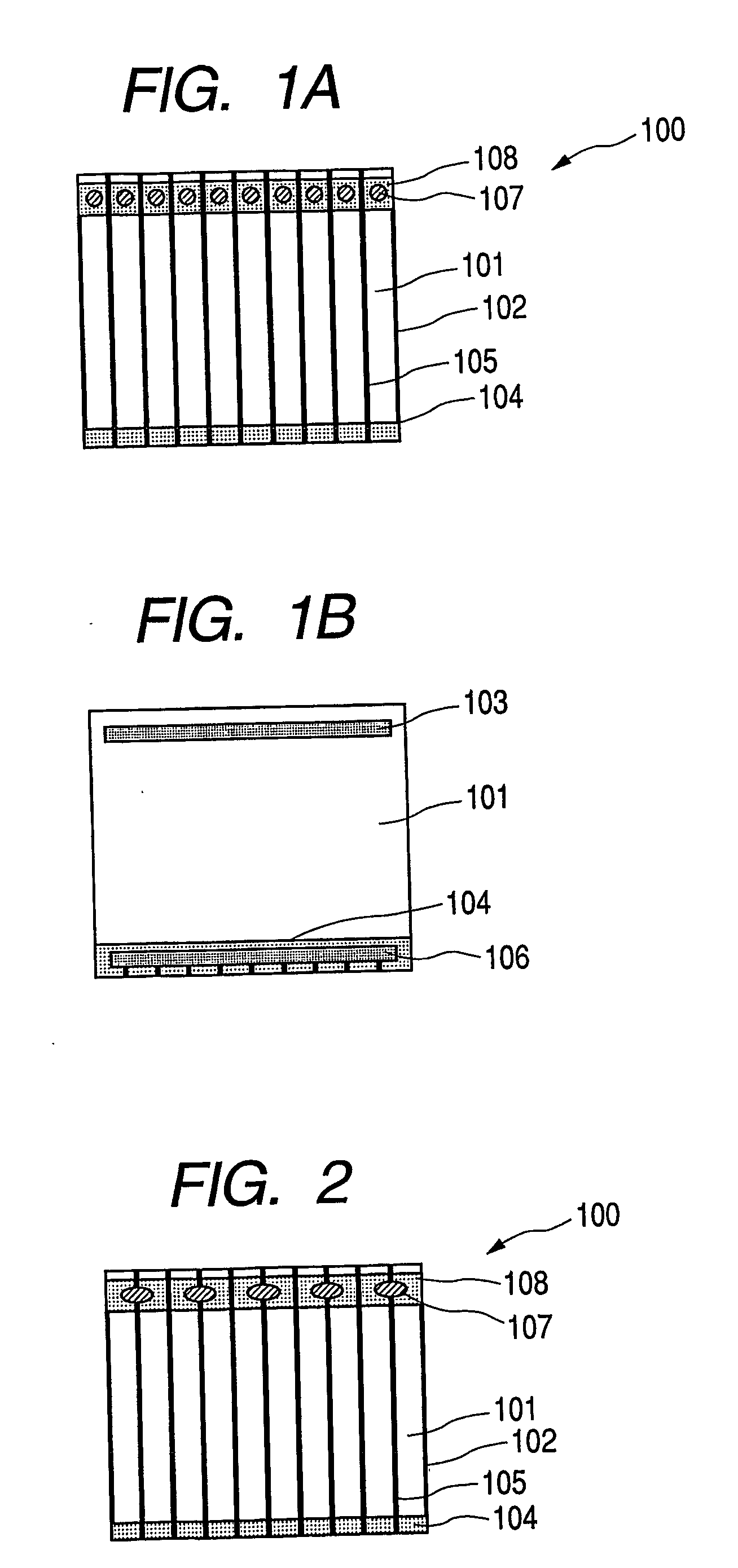

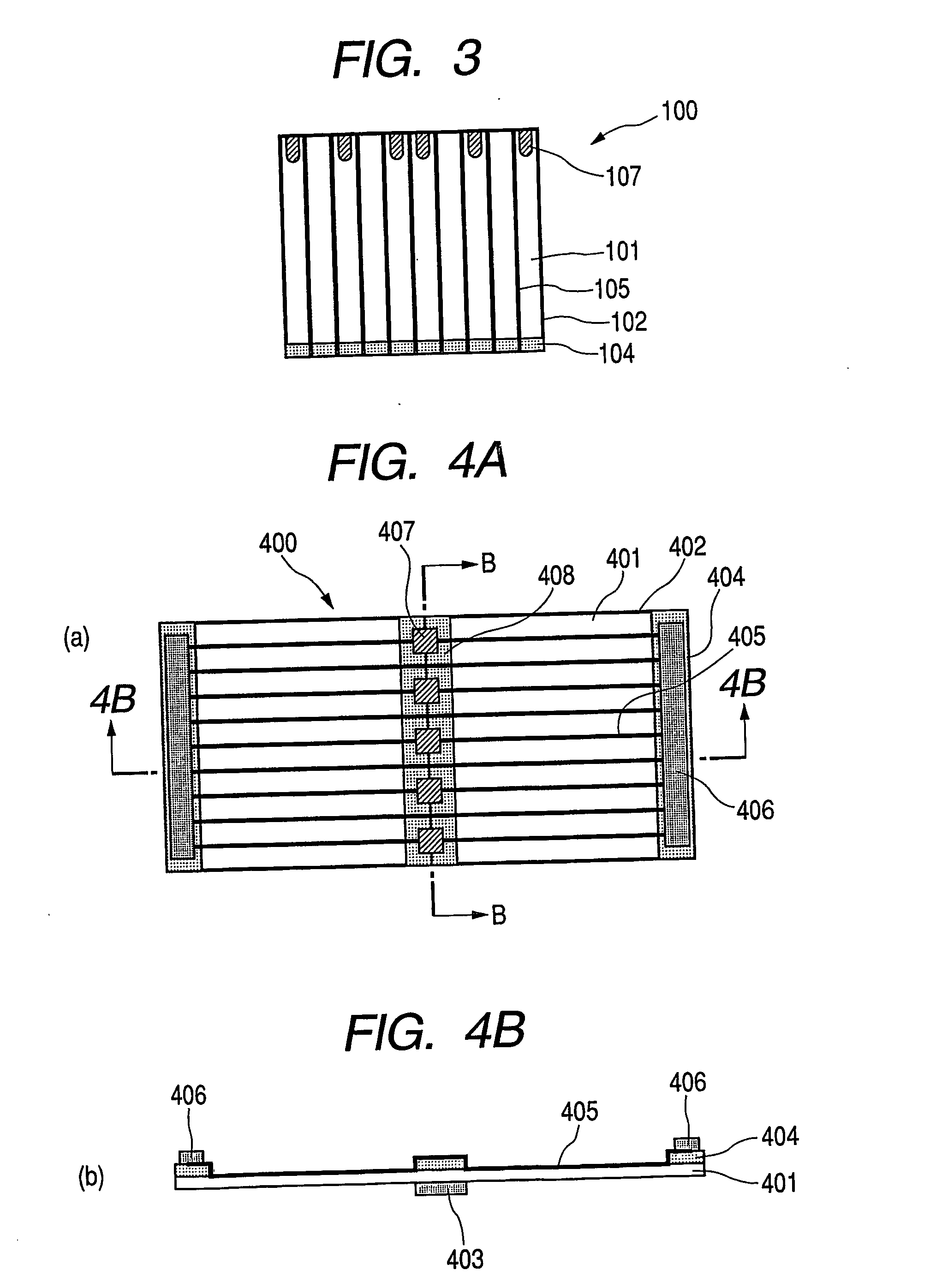

Electro-optical device and electronic apparatus

ActiveUS20110050657A1Ensure reliabilityNarrow frameDischarge tube luminescnet screensLamp detailsMaterials scienceElectrical and Electronics engineering

An electro-optical device includes a display panel obtained by forming an electro-optical layer, in which a plurality of pixels is formed, on a glass substrate having a thickness of 50 μm or less; and a support frame supporting the display panel, wherein the display panel has at least a display region in which the plurality of pixels is formed and frame regions formed outside the display region, and wherein at least one side of each of the frame regions is bent from the vicinity of a circumference of the display region to the support frame side and is fixed to the support frame.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

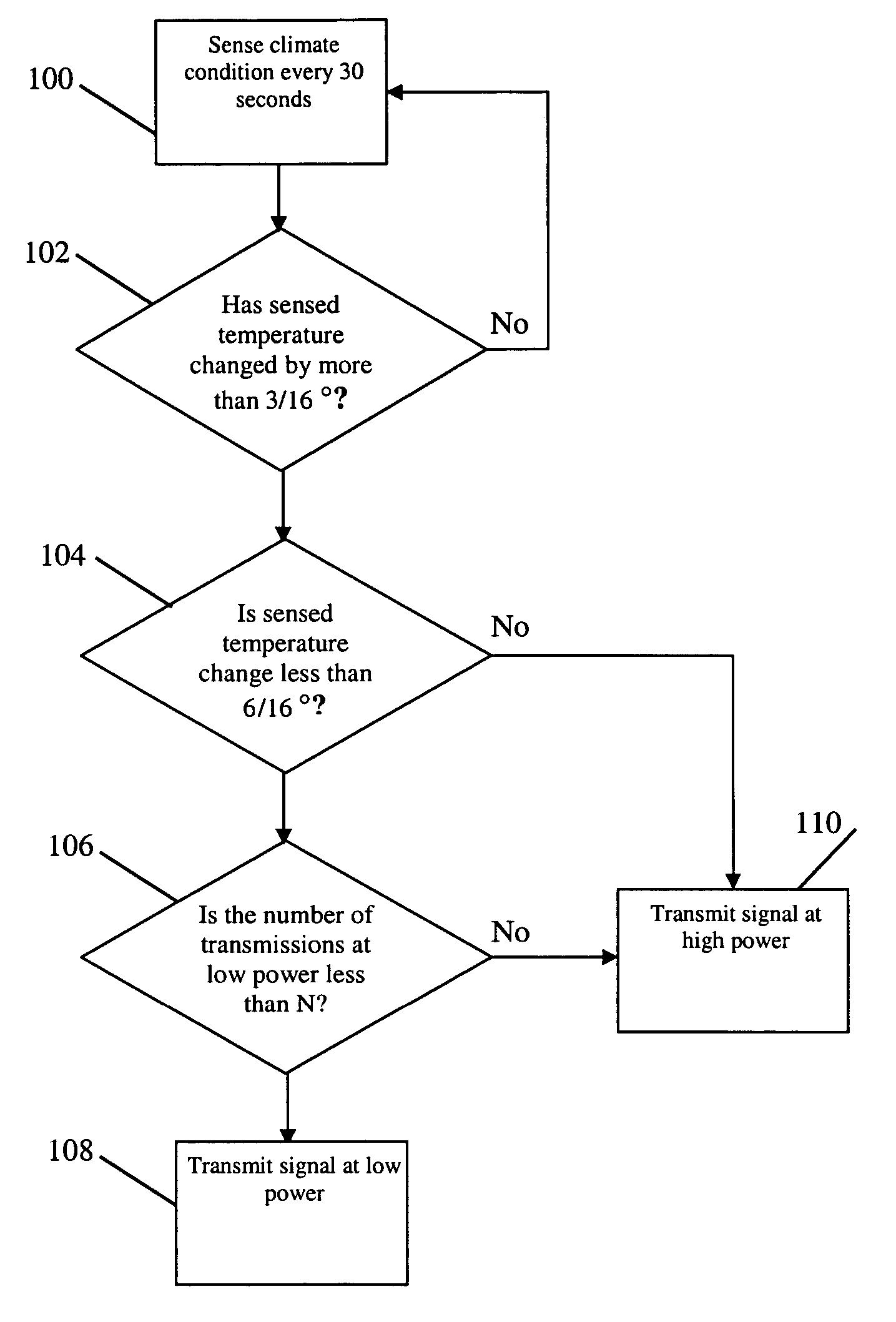

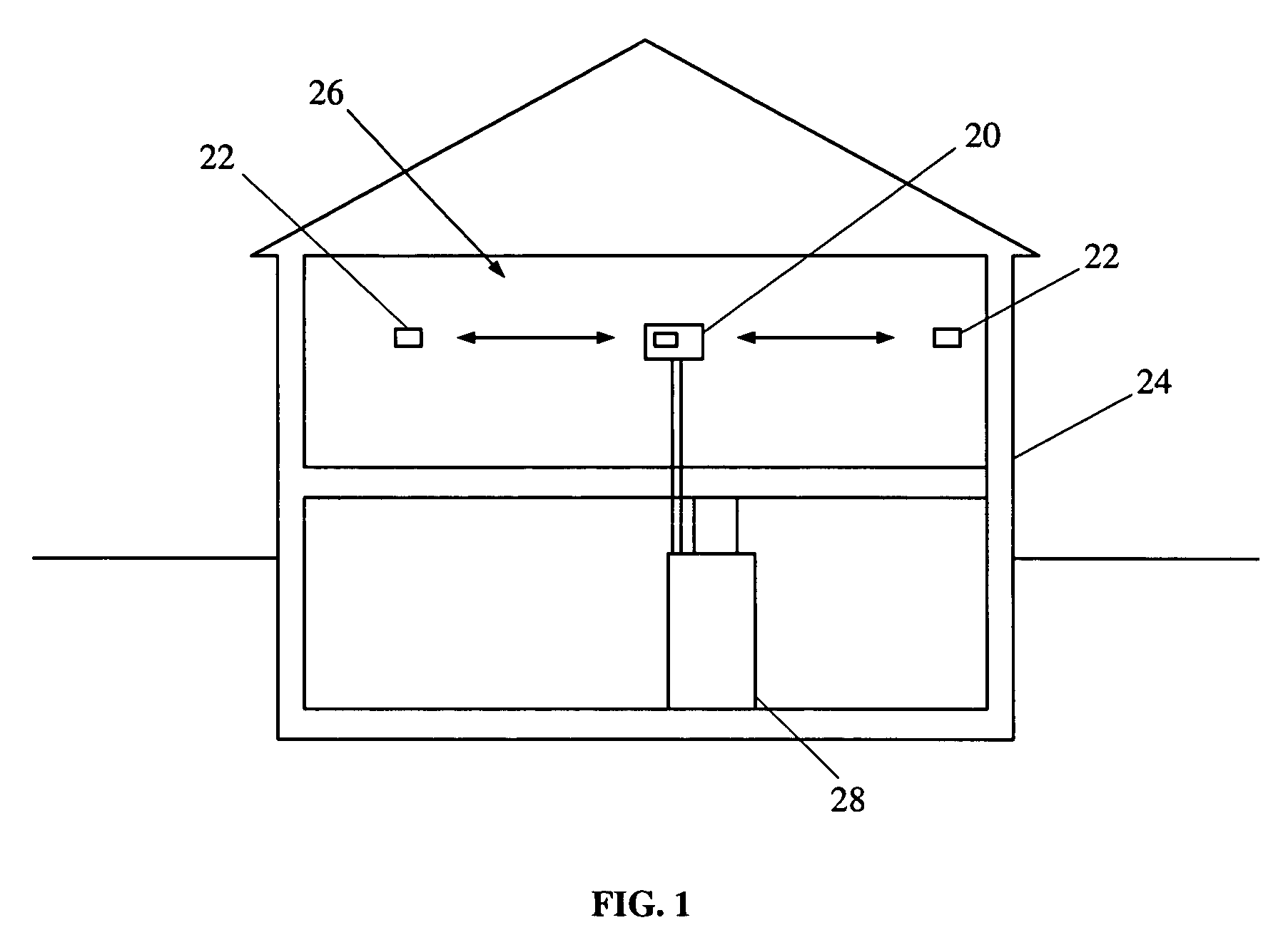

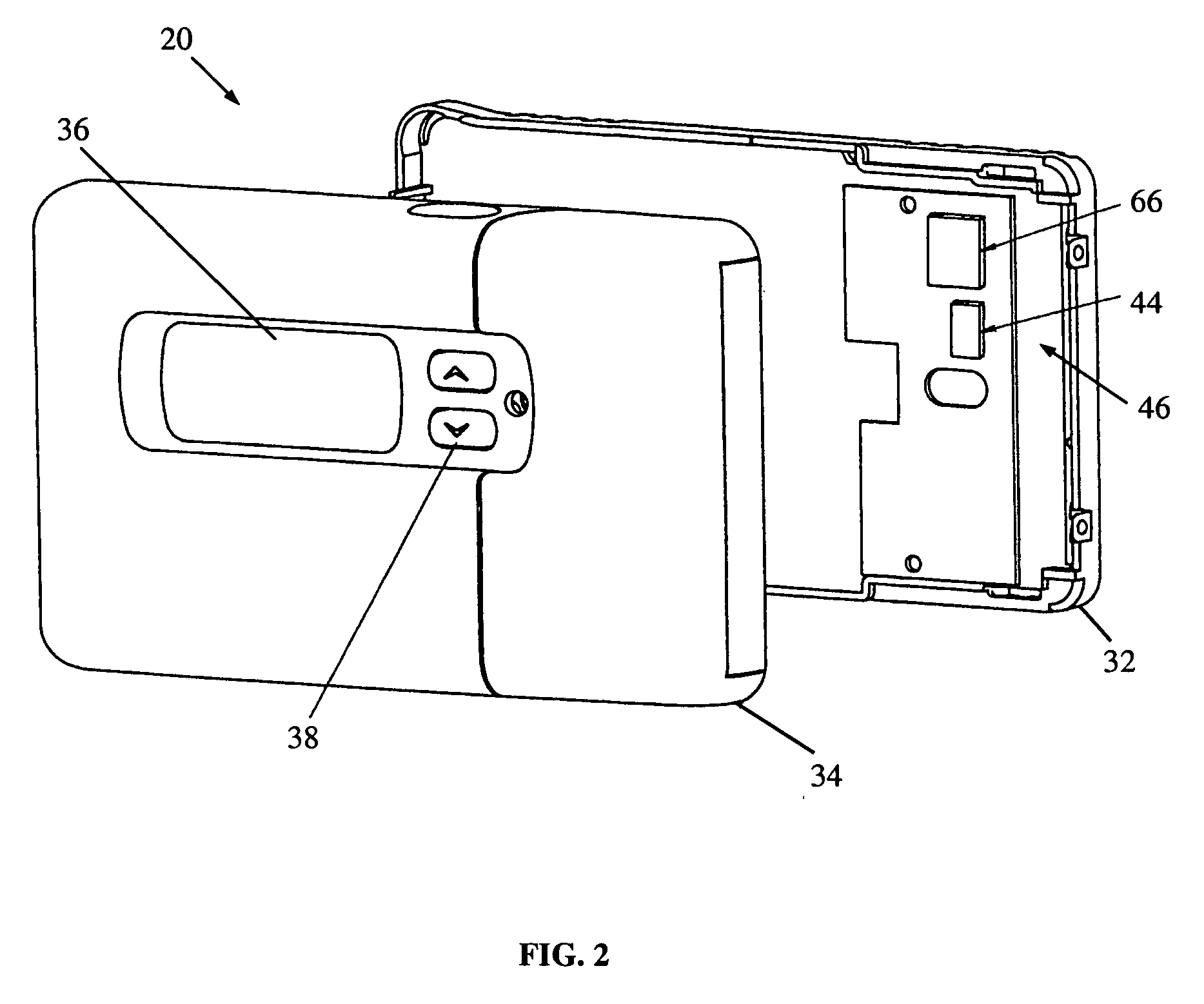

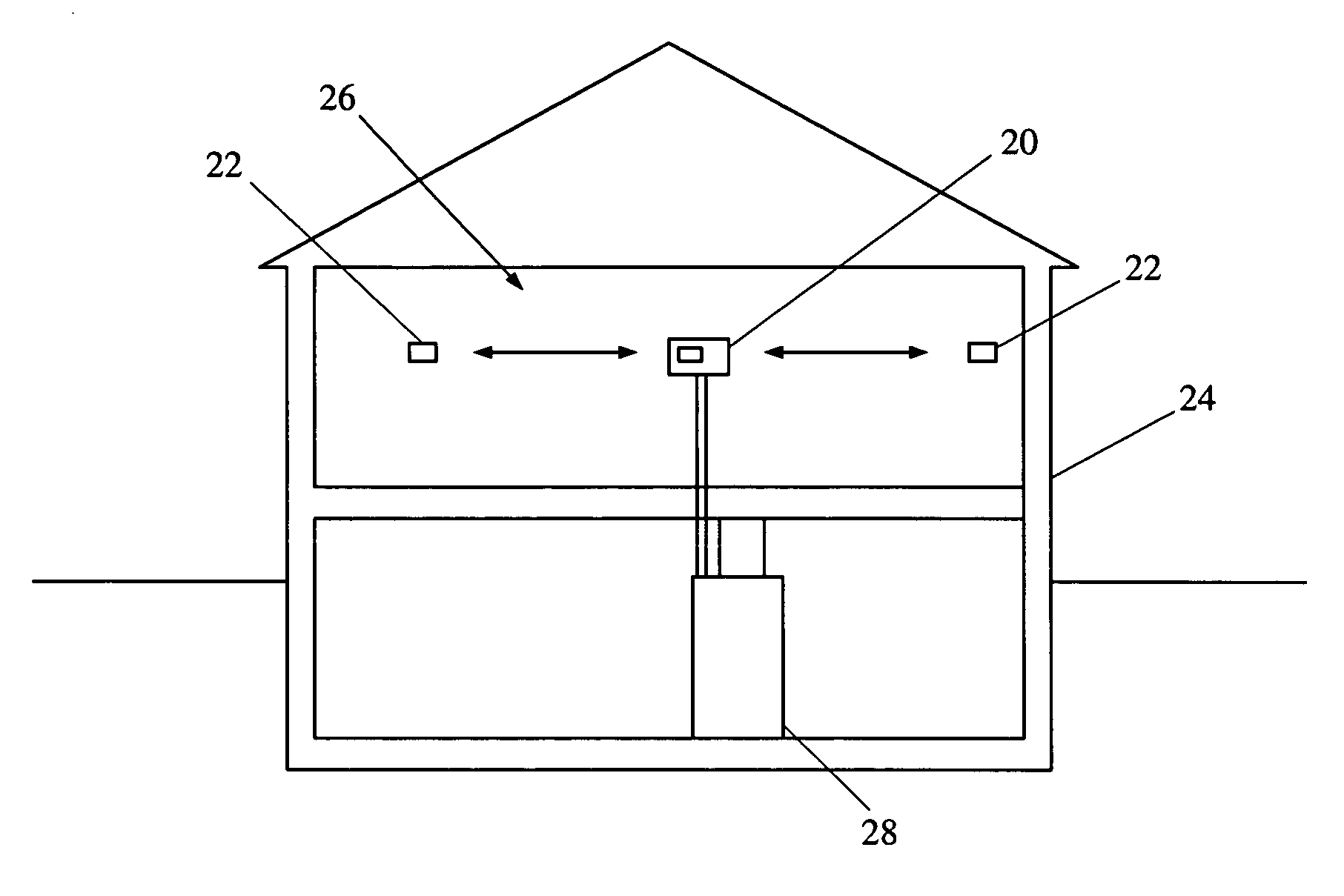

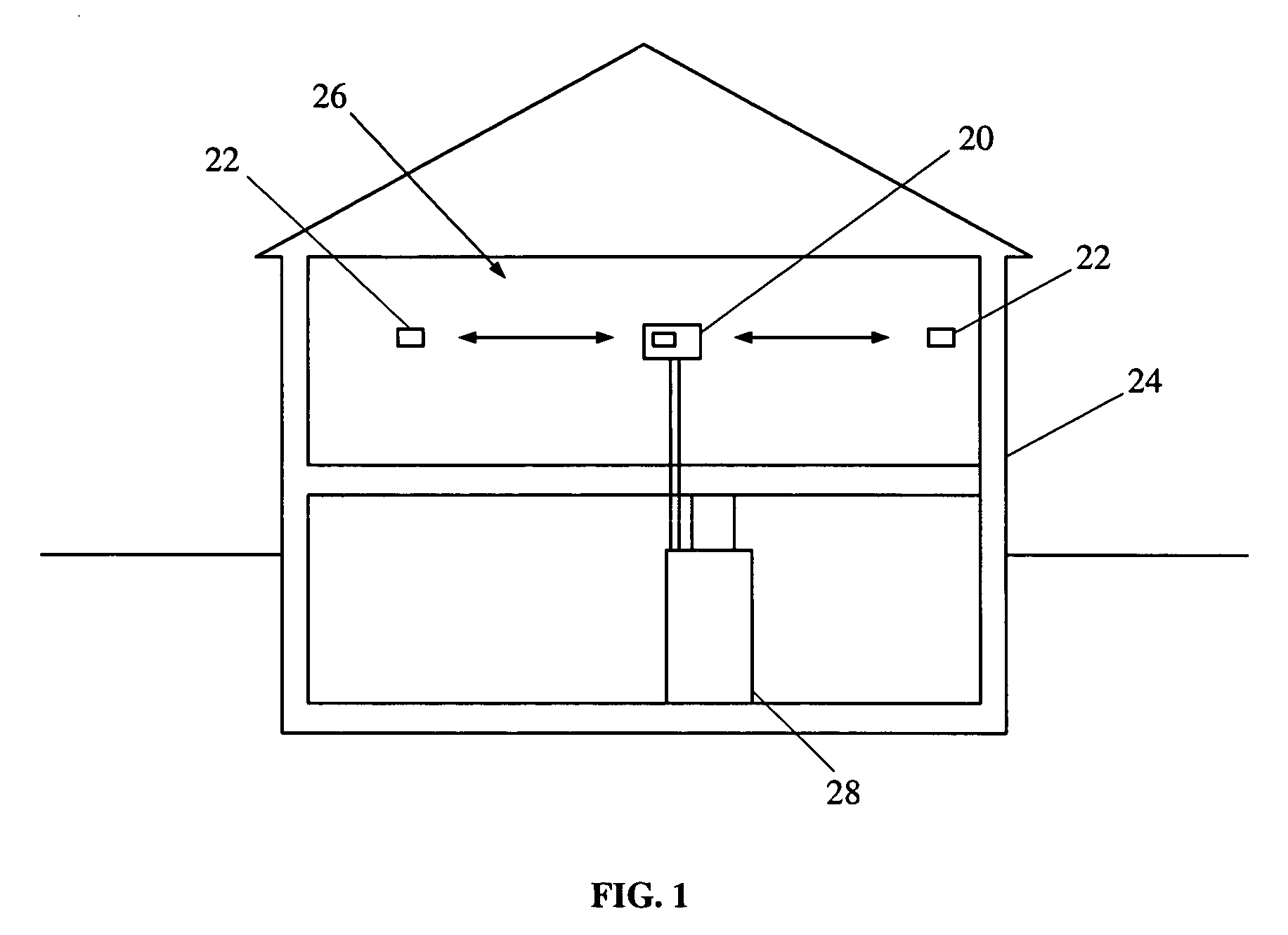

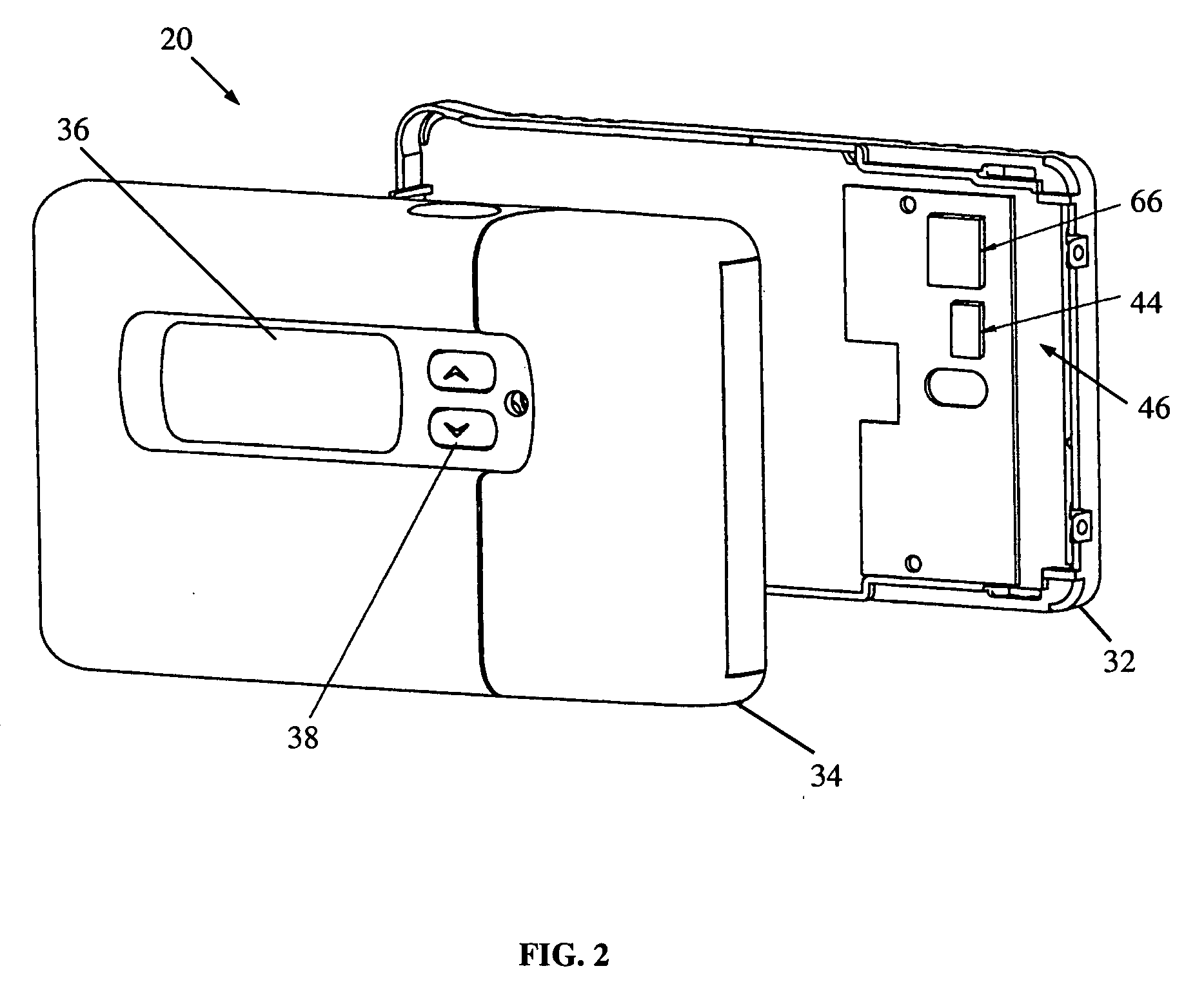

Thermostat control system providing power saving transmissions

ActiveUS7537171B2Reduce power consumptionMaintain reliabilityResonant long antennasTransmission systemsControl systemThermostat

A thermostat control system having remote devices and / or other internally powered devices provides transmissions at different power levels and at different data transfer rates to conserve power life. Thermostat control system components and devices may be powered by replaceable power supplies that are conserved by transmitting at a lower power level more often than at a higher power level. A higher power level transmission is provided at a lower data transfer rate, and a lower power level transmission is provided at a higher data transfer rate. A higher power transmission is provided periodically to ensure reliable communication of temperature information.

Owner:COPELAND COMFORT CONTROL LP

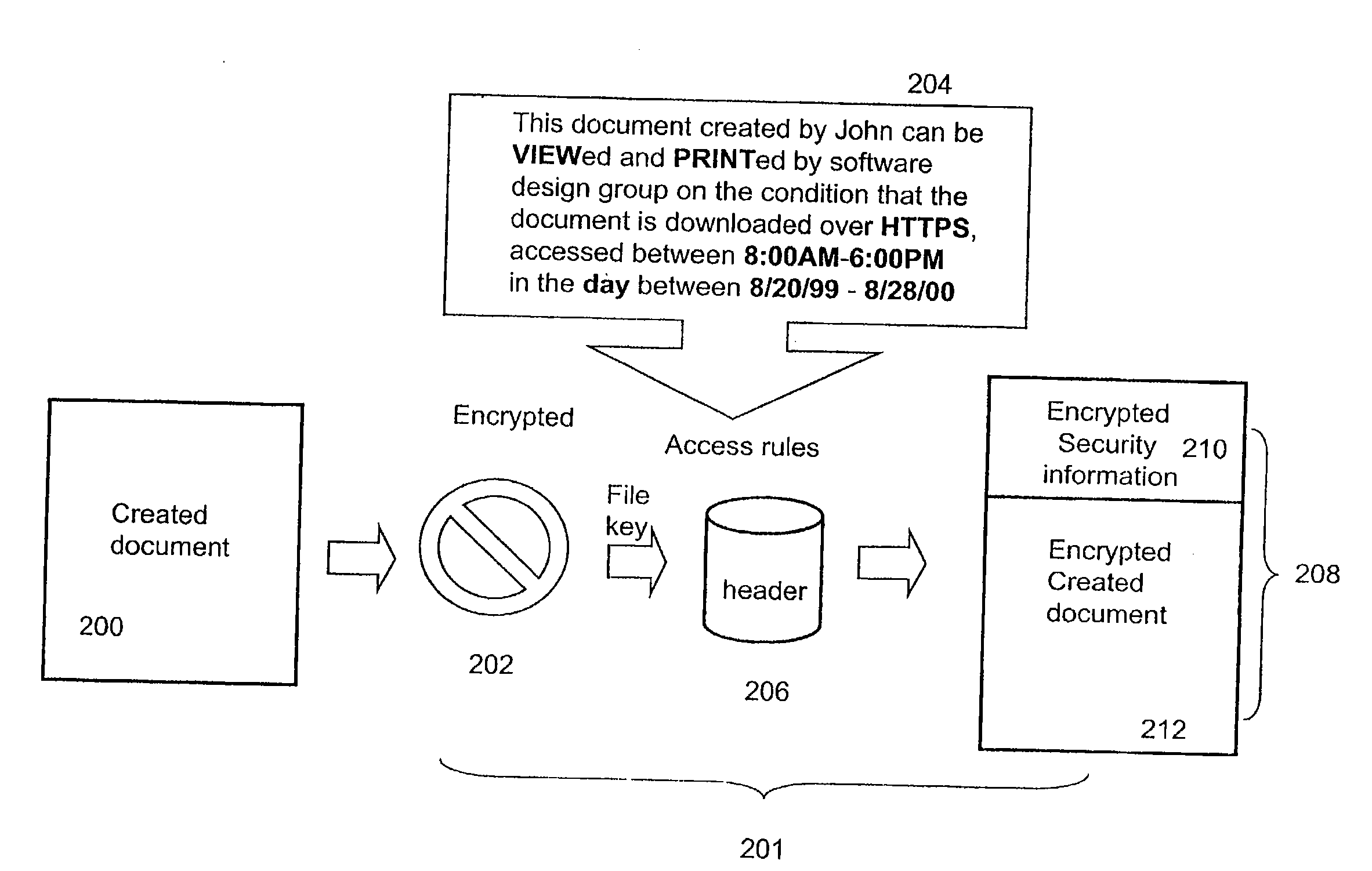

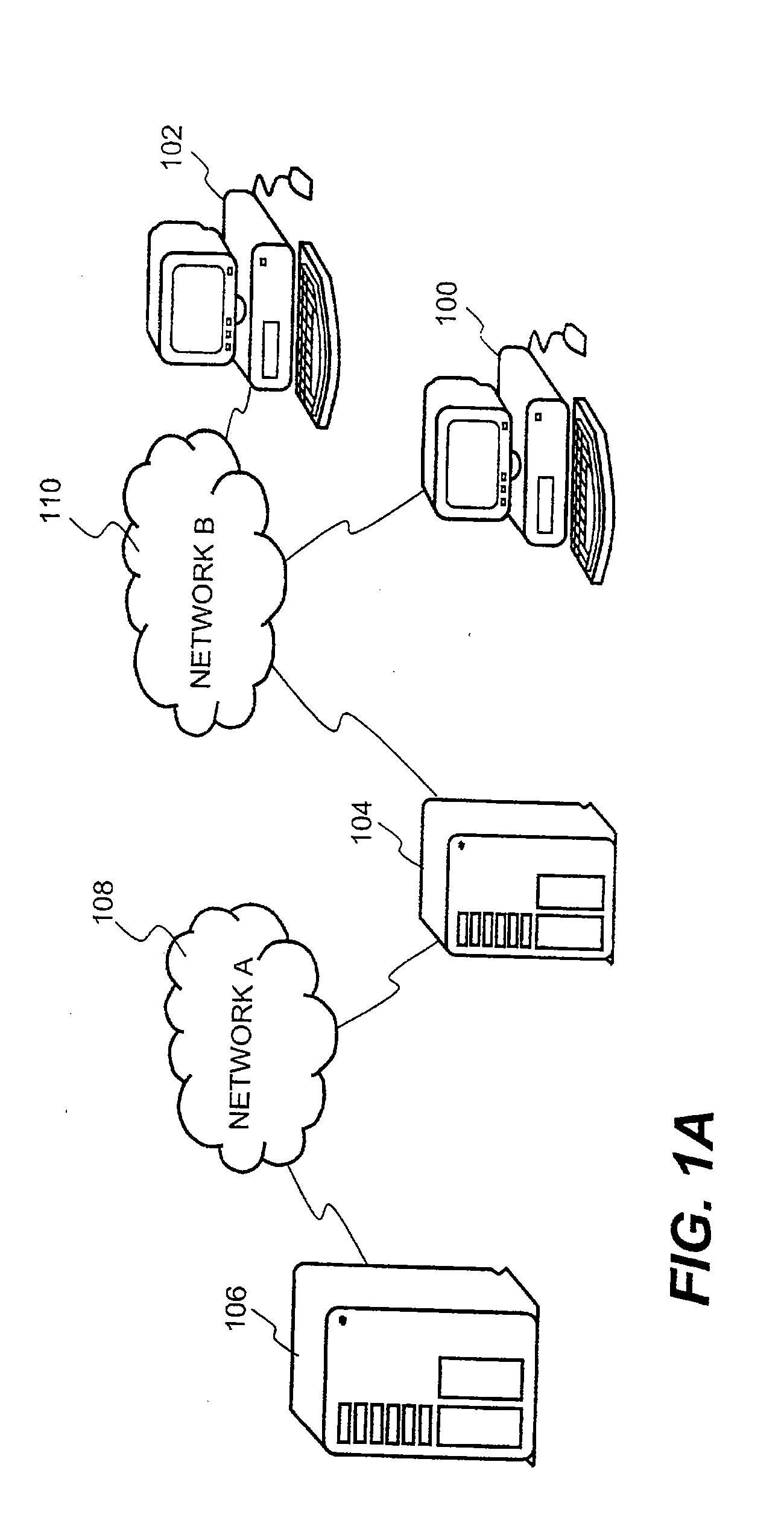

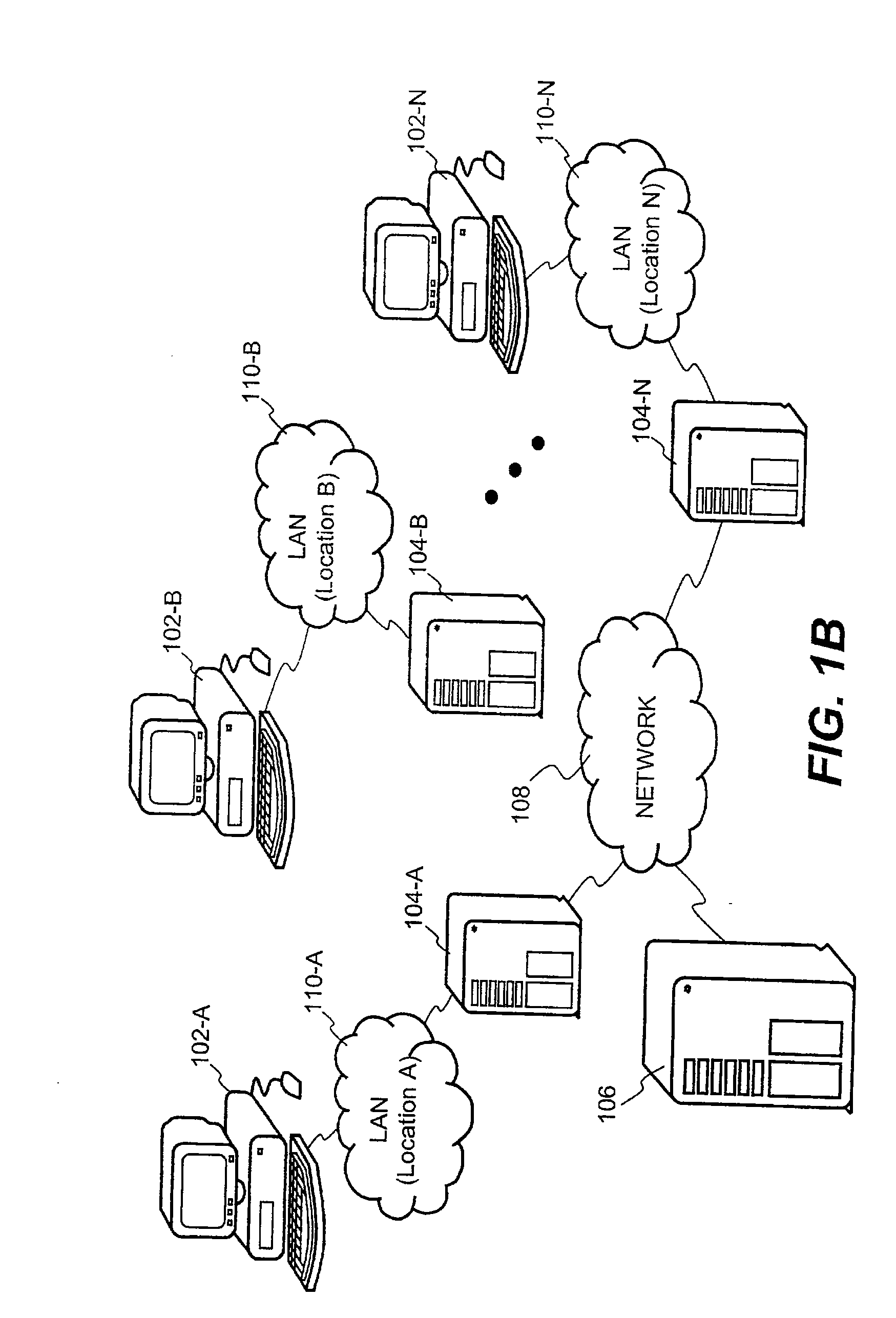

Methods and systems for providing access control to secured data

ActiveUS20090100268A1Ensures dependabilityEnsure reliabilityDigital data processing detailsUser identity/authority verificationEngineeringEncryption decryption

In a system for providing access control management to electronic data, techniques to secure the electronic data and keep the electronic data secured at all times are disclosed. According to one embodiment, a secured file or secured document includes two parts: an attachment, referred to as a header, and an encrypted document or data portion. The header includes security information that points to or includes the access rules and a file key. The access rules facilitate restrictive access to the secured document and essentially determine who / when / how / where the secured document can be accessed. The file key is used to encrypt / decrypt the encrypted data portion. Only those who have the proper access privileges are permitted to retrieve the file key to encrypt / decrypt the encrypted data portion.

Owner:INTELLECTUAL VENTURES I LLC

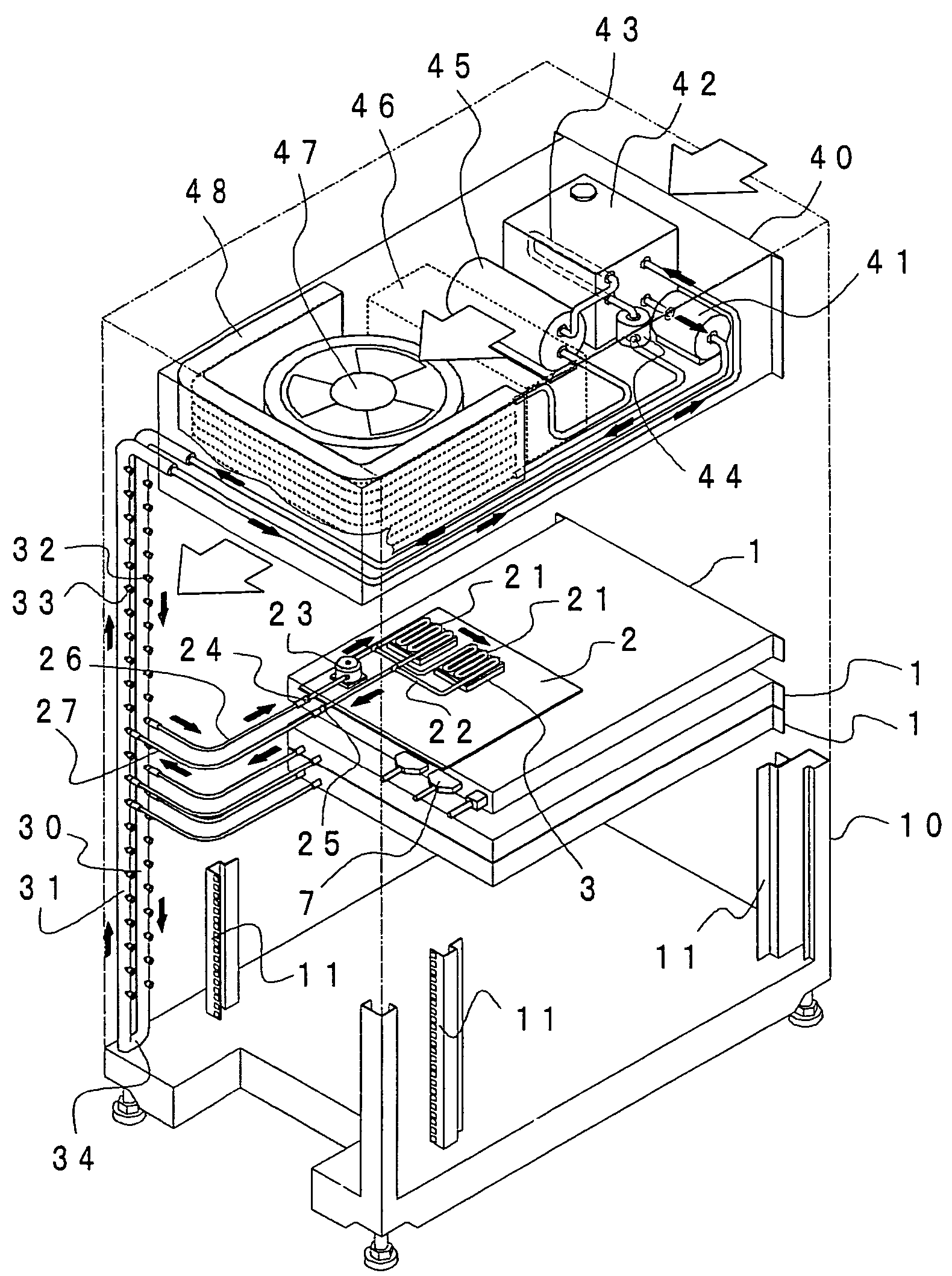

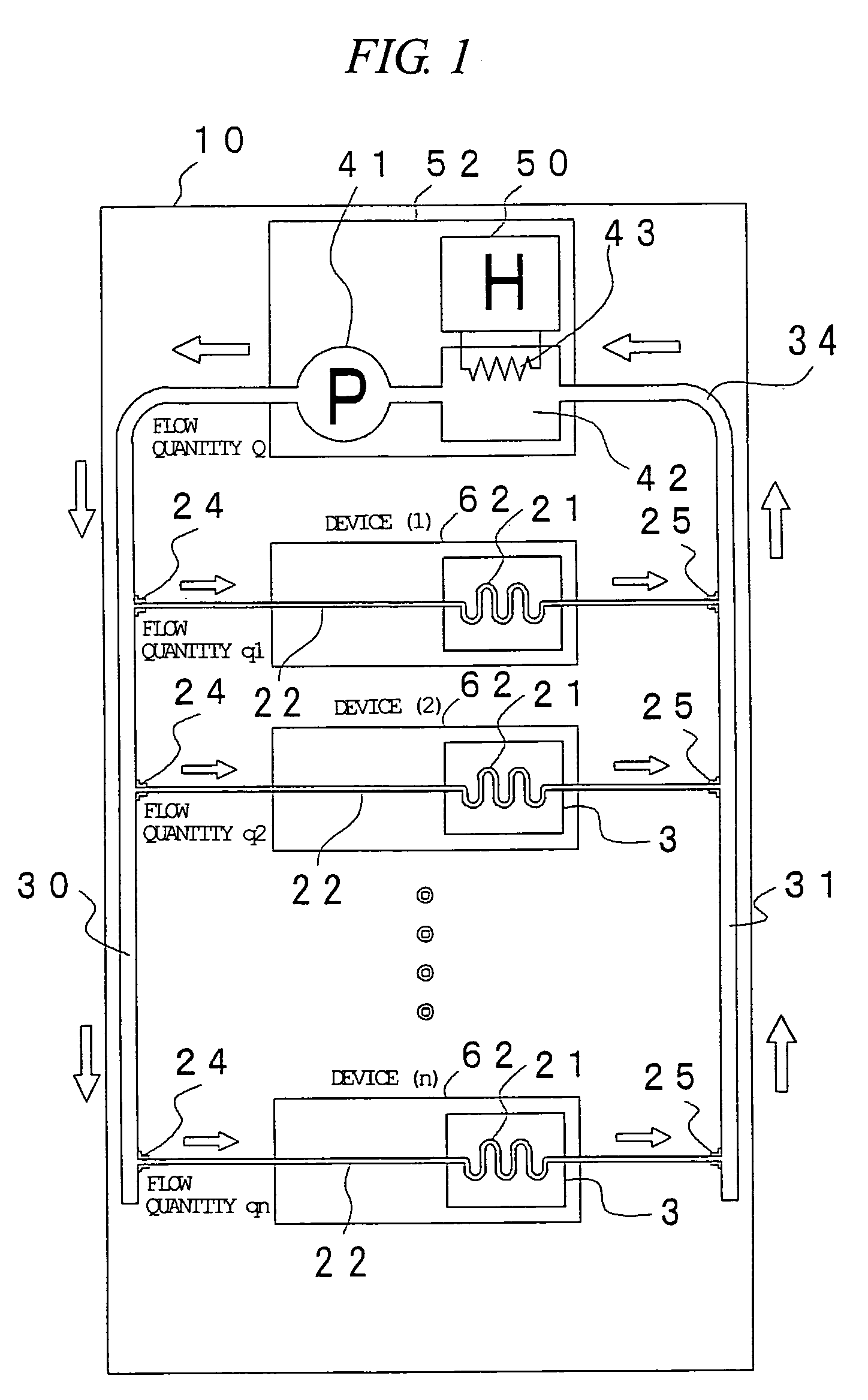

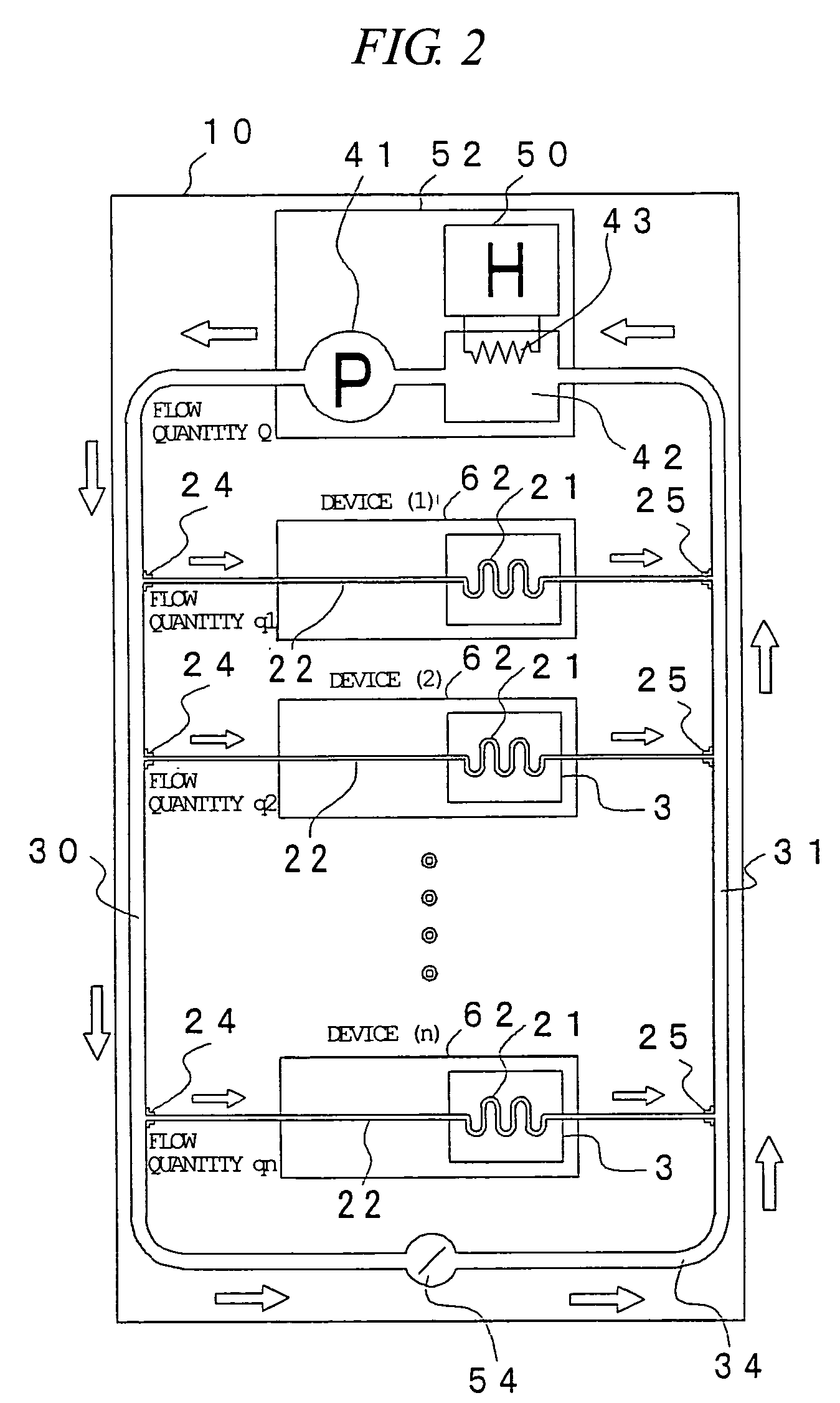

Liquid cooling system for a rack-mount server system

ActiveUS7318322B2Suppress mutationImprove cooling effectDomestic cooling apparatusDigital data processing detailsNuclear engineeringComputer module

A rack-mount server system of a liquid cooling system, in which a heat-generating component such as a CPU is cooled by a coolant has a plurality of server modules with heat-generating components which are cooled by the circulating coolant. The server modules are connected in parallel to a circulation coolant path through which the coolant to cool the server modules is circulated. In the middle of the coolant circulation path is a cooling unit that cools the coolant by radiating its heat to the outside air. Furthermore, a bypass route parallel to the server modules and going around the server modules is provided in the coolant circulation path, and the circulation quantity of the coolant is controlled in the bypass route. Alternatively, the flow quantity of the coolant is controlled in each of the server modules.

Owner:MAXELL HLDG LTD

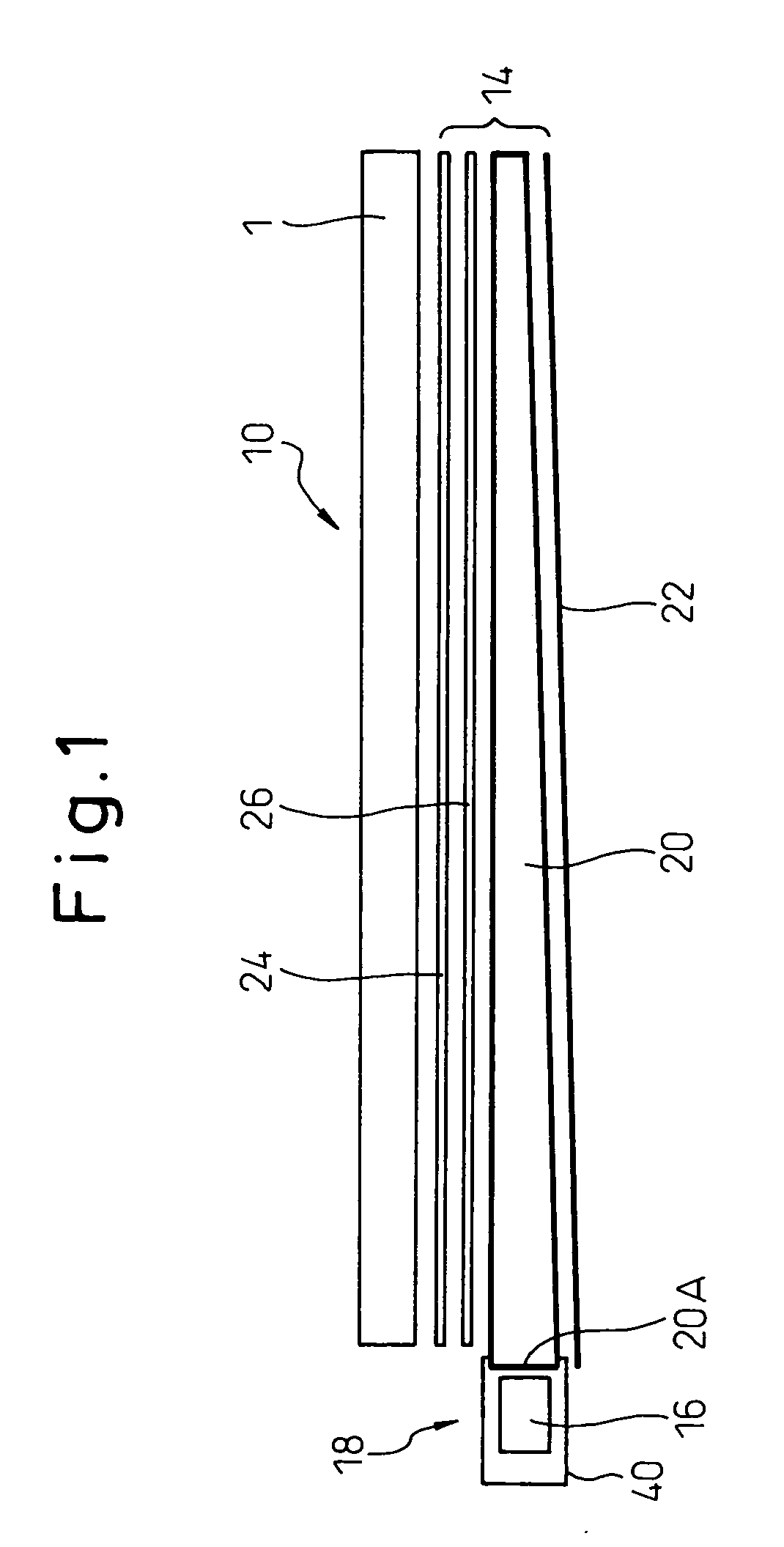

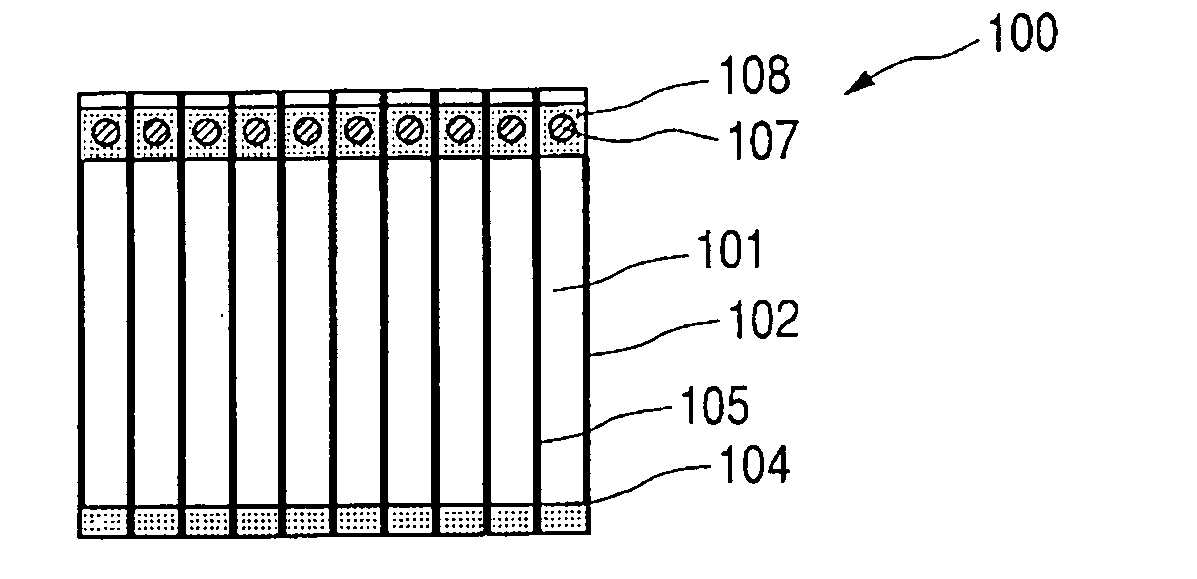

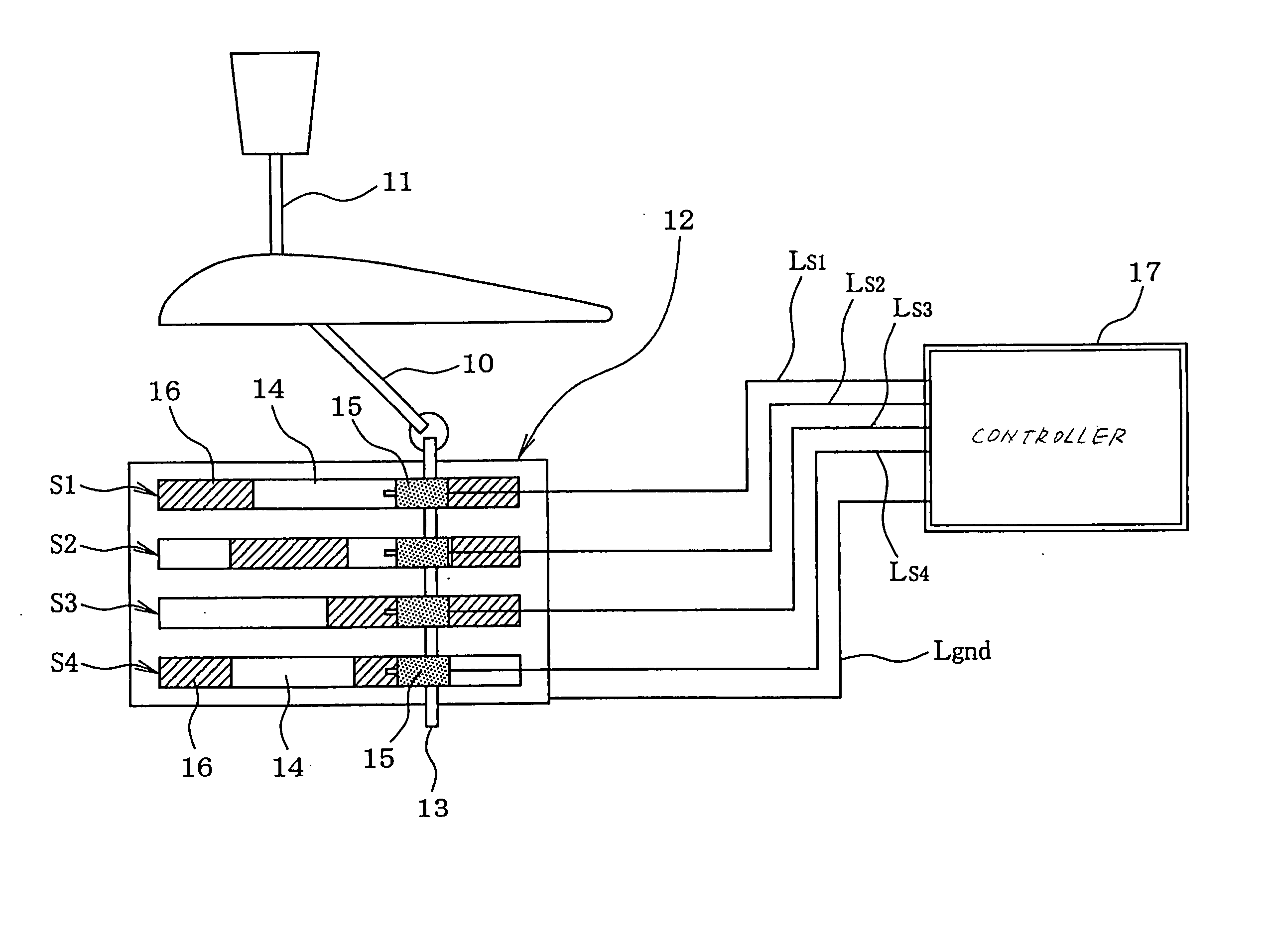

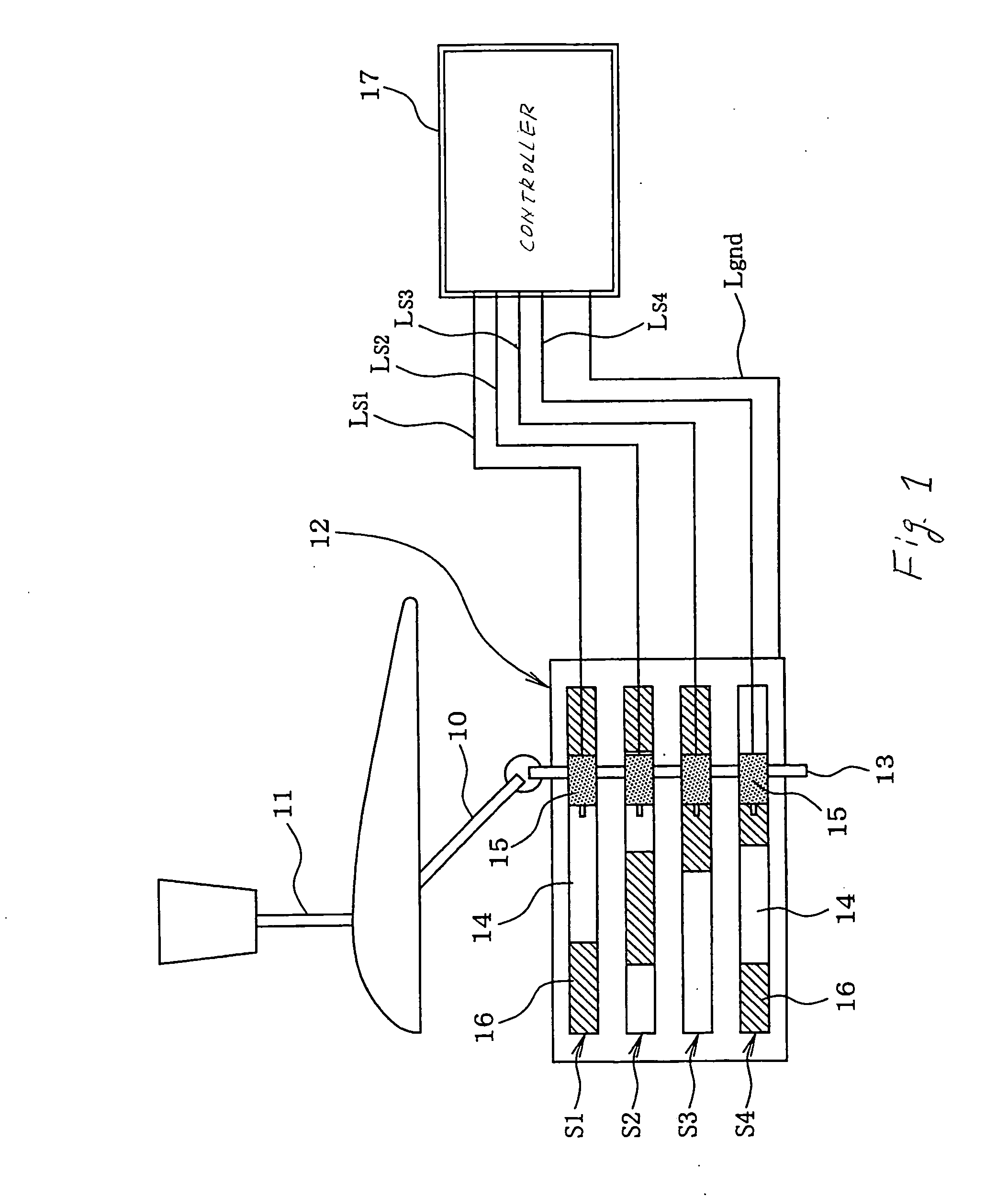

Backlight and liquid crystal display device

InactiveUS20050141244A1Prevent fallingEnsure reliabilityMechanical apparatusPoint-like light sourceElectricityLiquid-crystal display

A side light type backlight includes a light source including a plurality of LEDs, and a light guide plate. One of the end surfaces of the light guide plate is a light incidence surface at which a plurality of R-LEDs, a plurality of G-LEDs and a plurality of B-LEDs are arranged. LEDs satisfy the relationship of: a distribution range of light emitted from G-LEDs <a distribution range of light emitted from R-LEDS, or a distribution range of light emitted from G-LEDs <a distribution range of light emitted from B-LEDs. Also, LEDs are electrically connected to each other.

Owner:SHARP KK

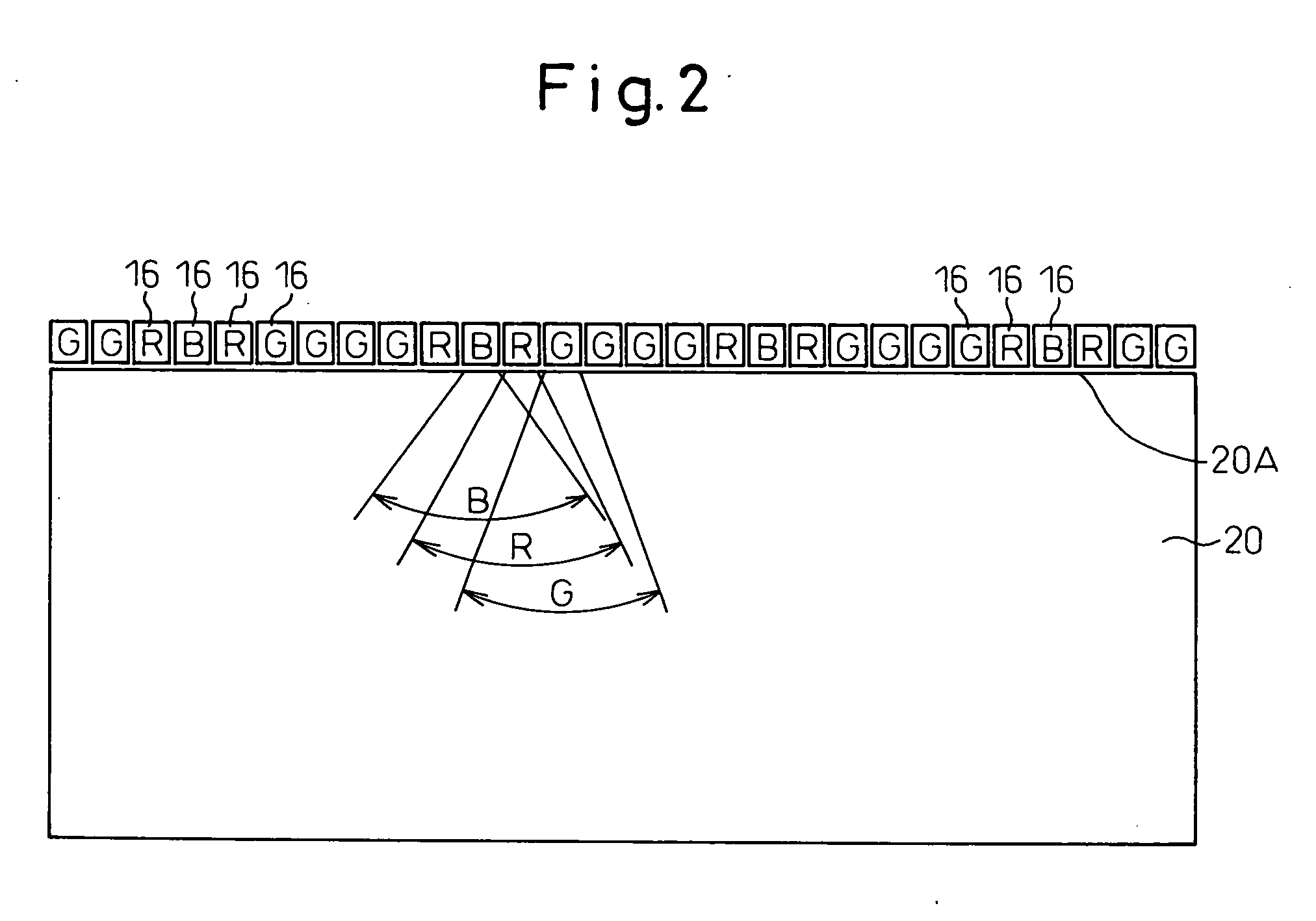

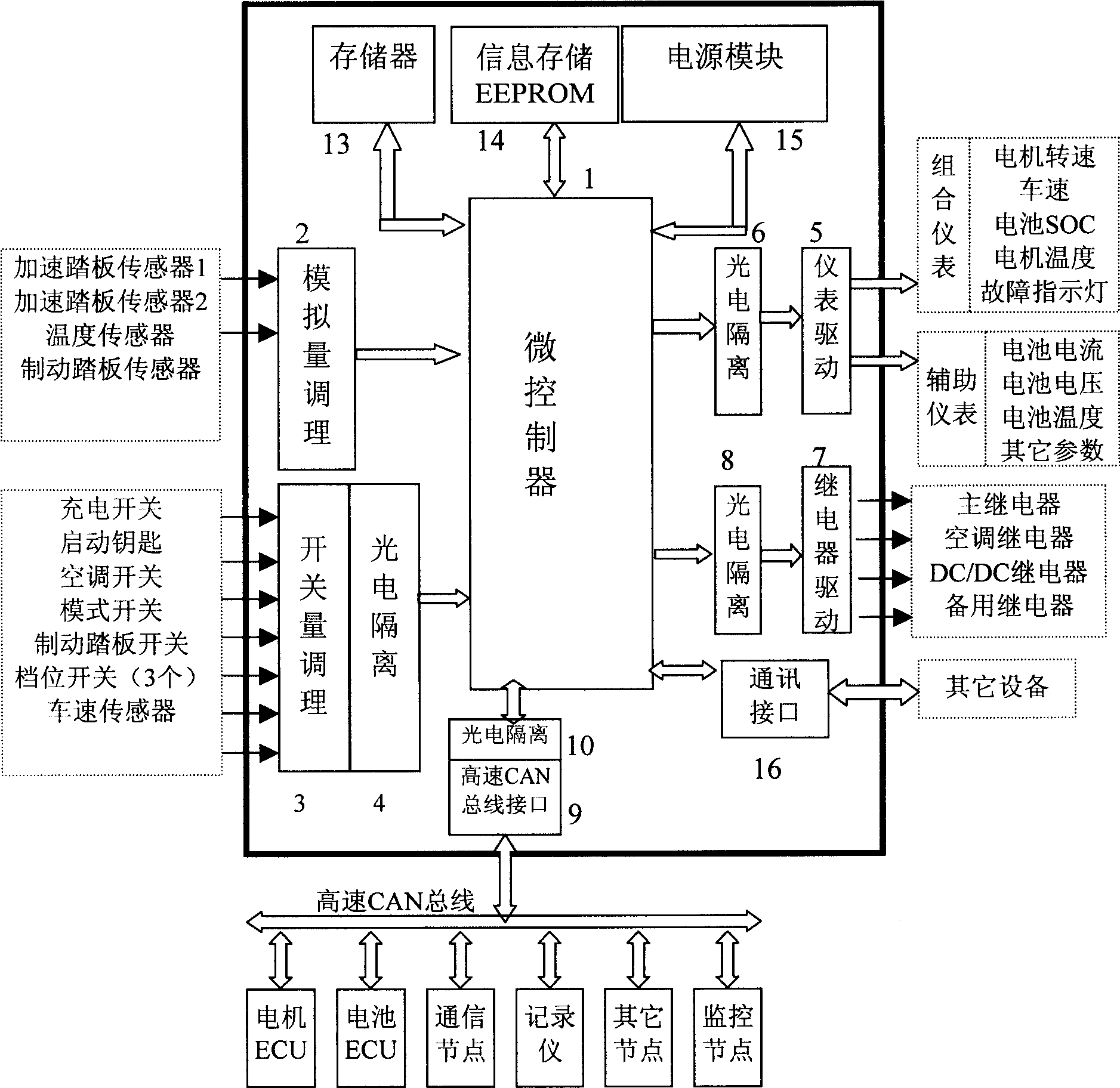

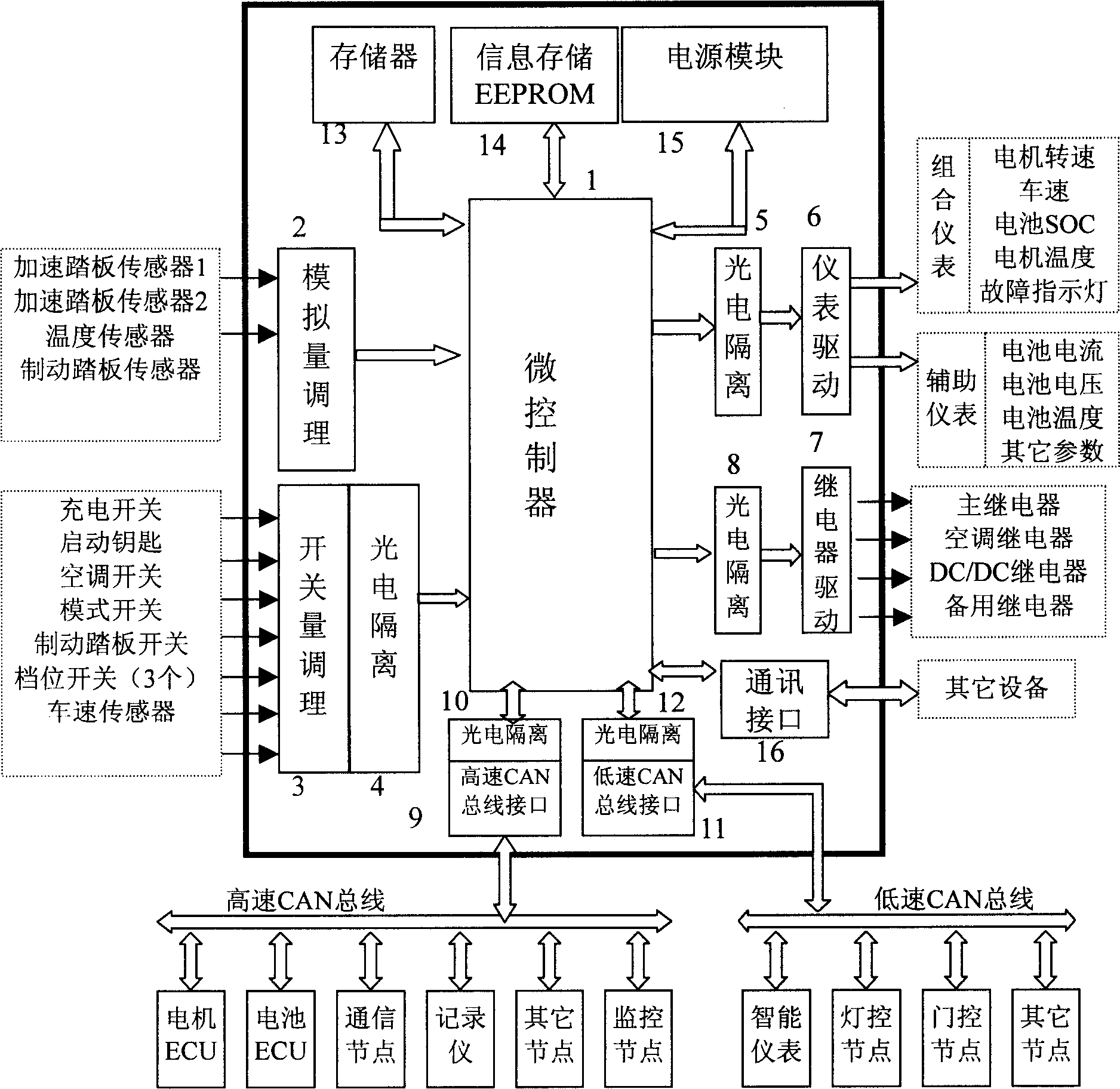

Purely electrical automobile host controller based on CAN bus and control method therefor

InactiveCN1721226AImprove energy efficiencyEnsure vehicle safety and reliabilitySpeed controllerEnergy efficient ICTNetwork managementVehicle dynamics

Owner:TIANJIN UNIV

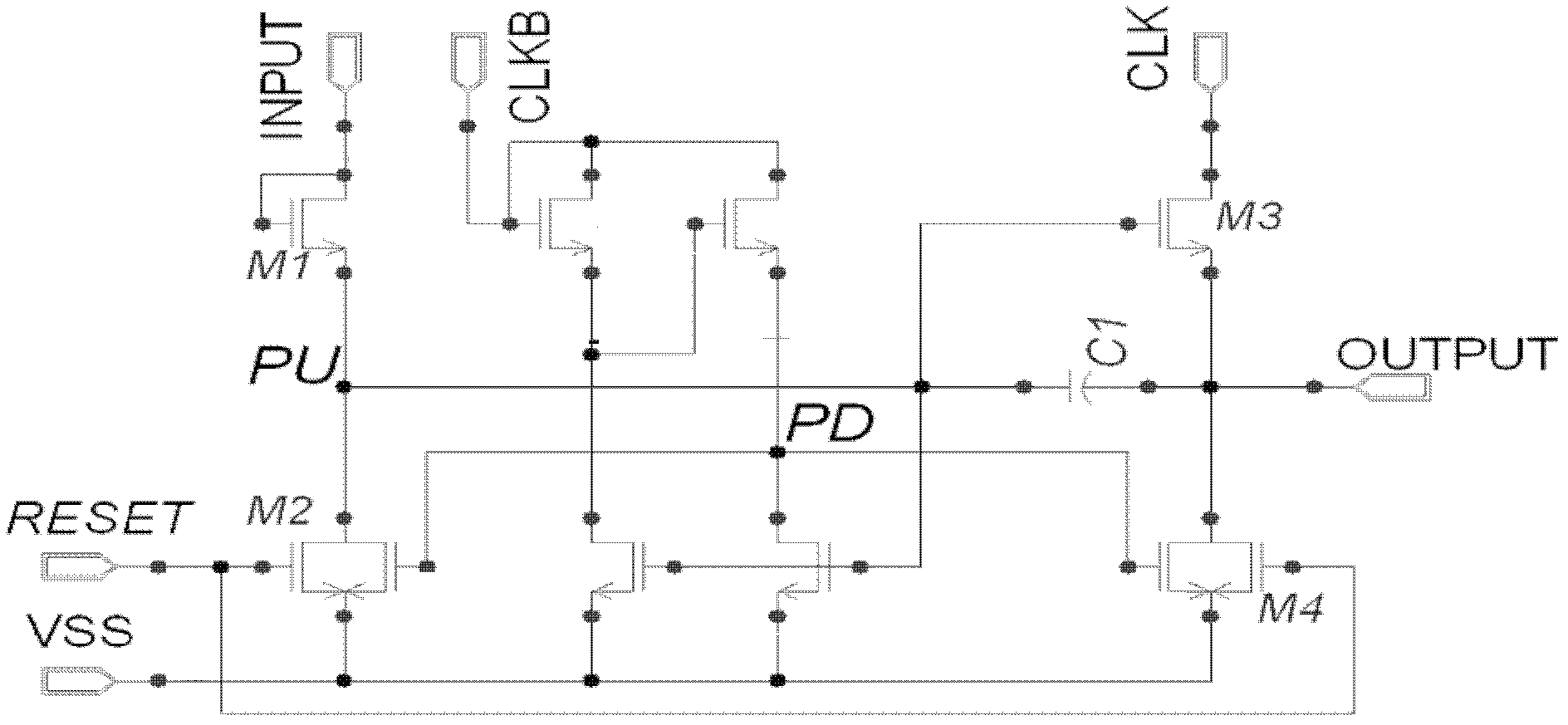

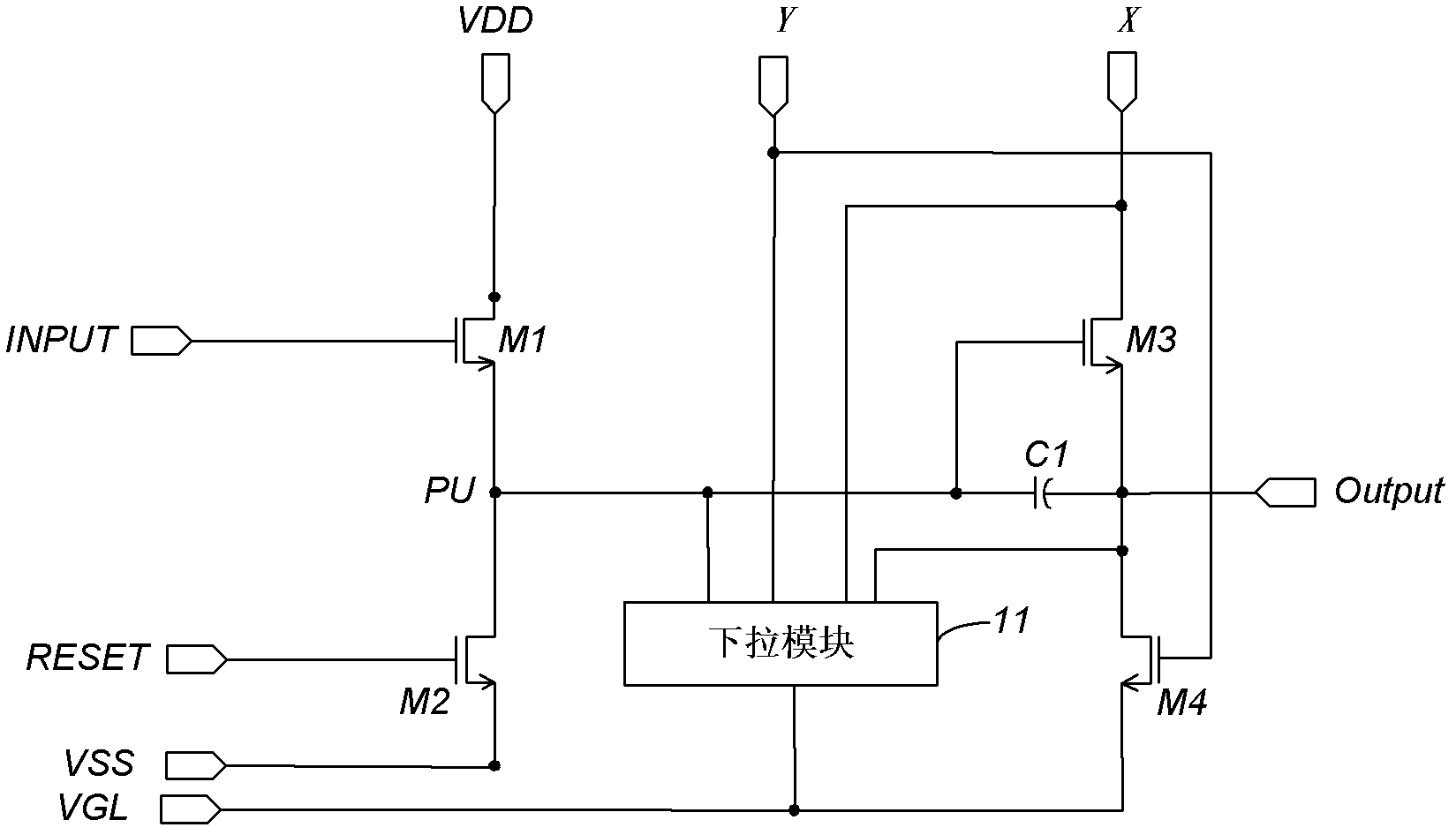

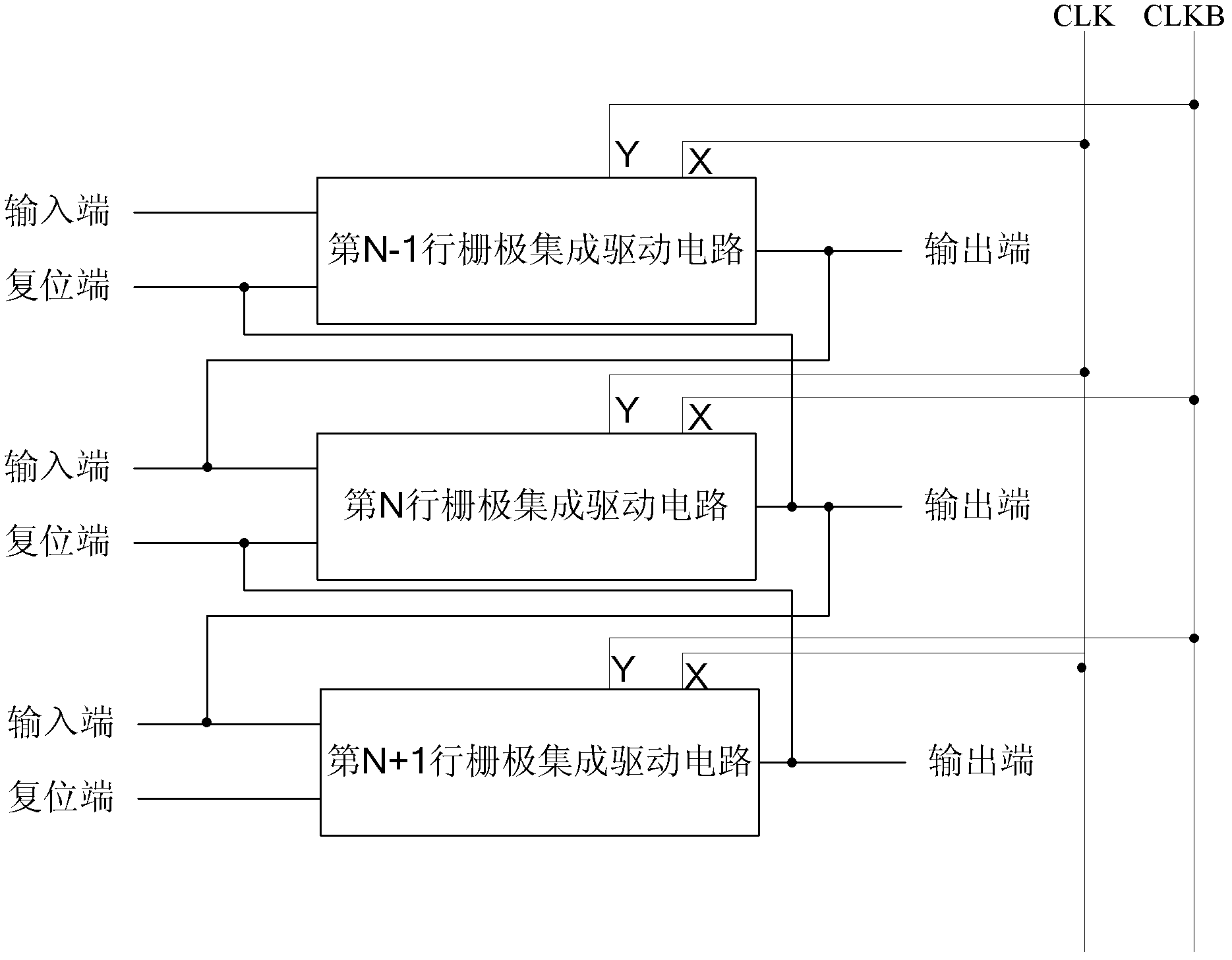

Circuit of gate drive on array, shift register and display screen

ActiveCN102629444AEnsure reliabilityGuarantee stabilityStatic indicating devicesInstant pulse delivery arrangementsCapacitanceDriver circuit

The embodiment of the invention relates to the liquid crystal display technology field, especially to a circuit of gate drive on array (GOA), a shift register and a display screen. The GOA circuit comprises a first thin film transistor (TFT), a second TFT, a third TFT, a fourth TFT, a capacitor and a drop-down module. The drop-down module, which is connected between a first clock signal input terminal, a second clock signal input terminal, a first node and an output terminal and is connected with a low level signal terminal, is used for maintaining the first node and the output terminal to be at a low level within non-working time of the GOA circuit of this row. According to the invention, functions of an input terminal and a reset terminal in the GOA circuit are designed to be symmetrical, so that the GOA circuit can realize bilateral scanning without changing charging and discharging characteristics of a node; and thus reliability and stability of the circuit are ensured.

Owner:BEIJING BOE OPTOELECTRONCIS TECH CO LTD

Thermostat control system providing power saving transmissions

ActiveUS20060102731A1Reduce power consumptionMaintain reliabilityTemperature control without auxillary powerResonant long antennasControl systemThermostat

A thermostat control system having remote devices and / or other internally powered devices provides transmissions at different power levels and at different data transfer rates to conserve power life. Thermostat control system components and devices may be powered by replaceable power supplies that are conserved by transmitting at a lower power level more often than at a higher power level. A higher power level transmission is provided at a lower data transfer rate, and a lower power level transmission is provided at a higher data transfer rate. A higher power transmission is provided periodically to ensure reliable communication of temperature information.

Owner:COPELAND COMFORT CONTROL LP

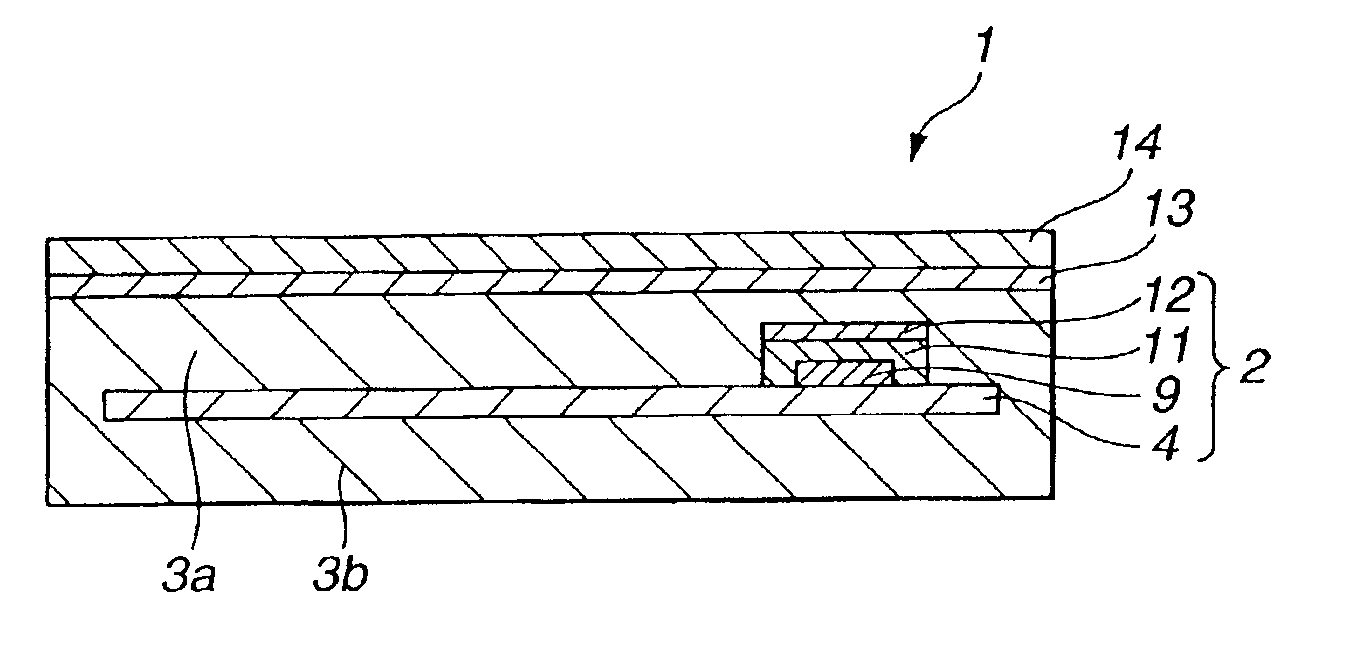

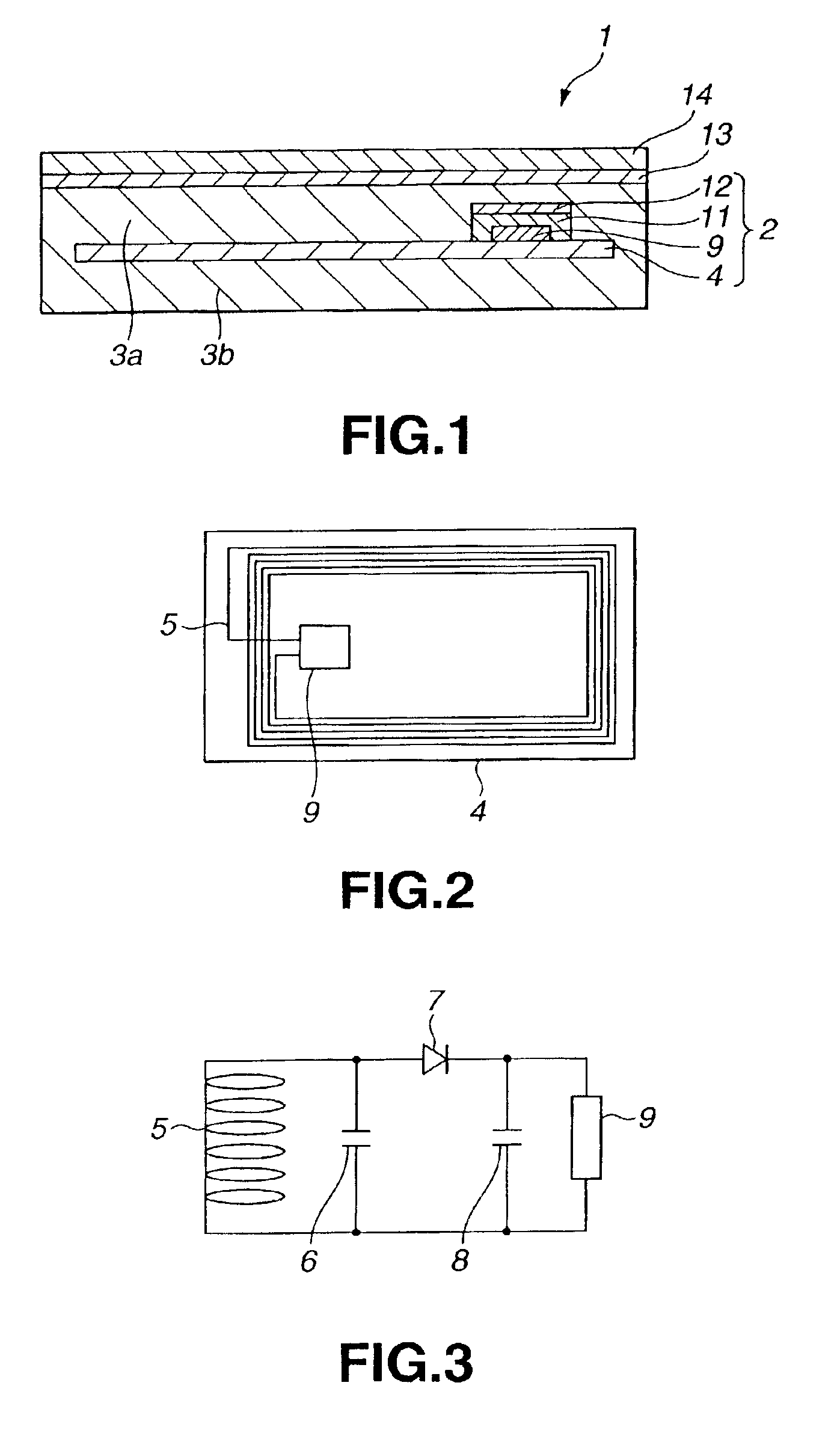

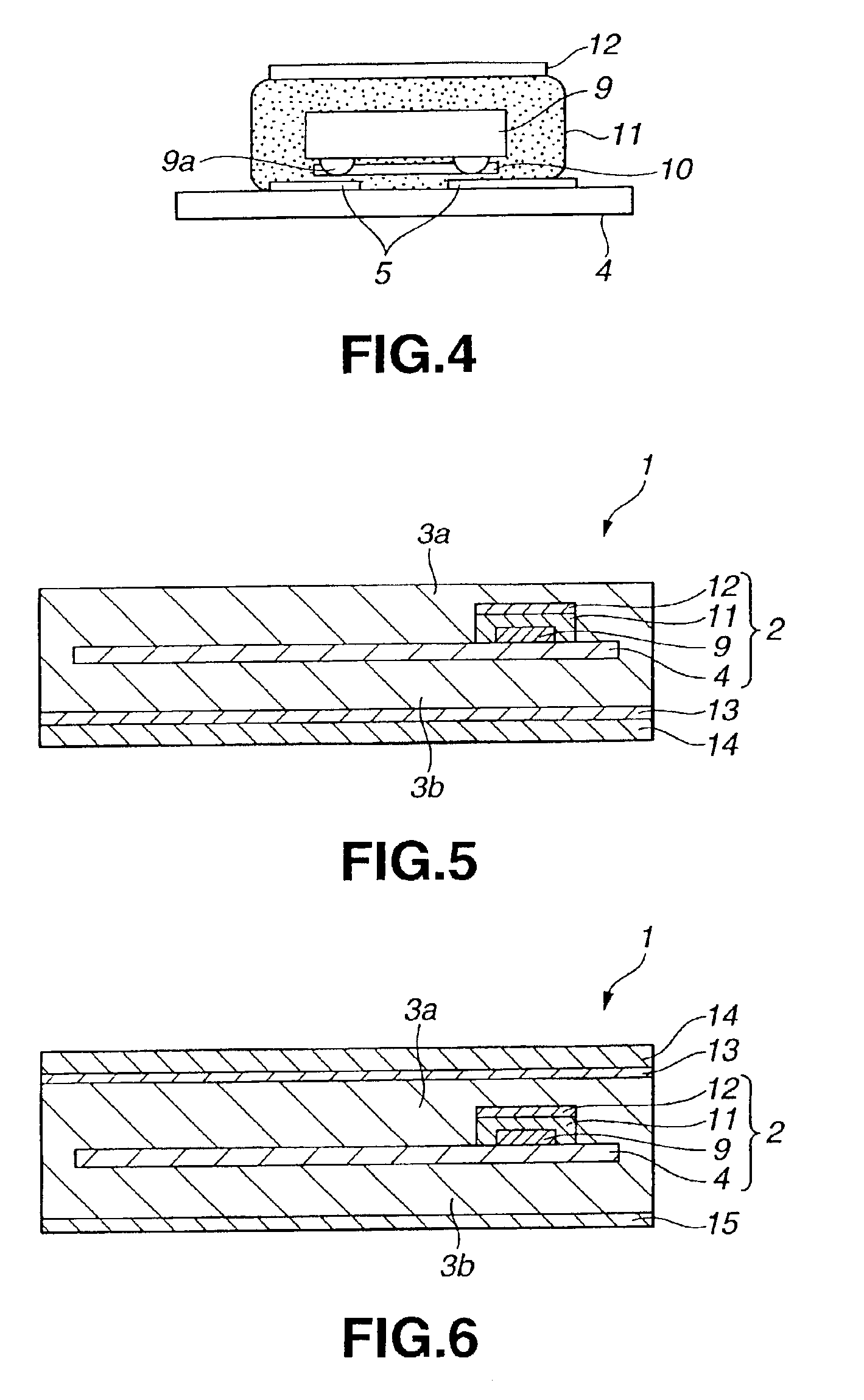

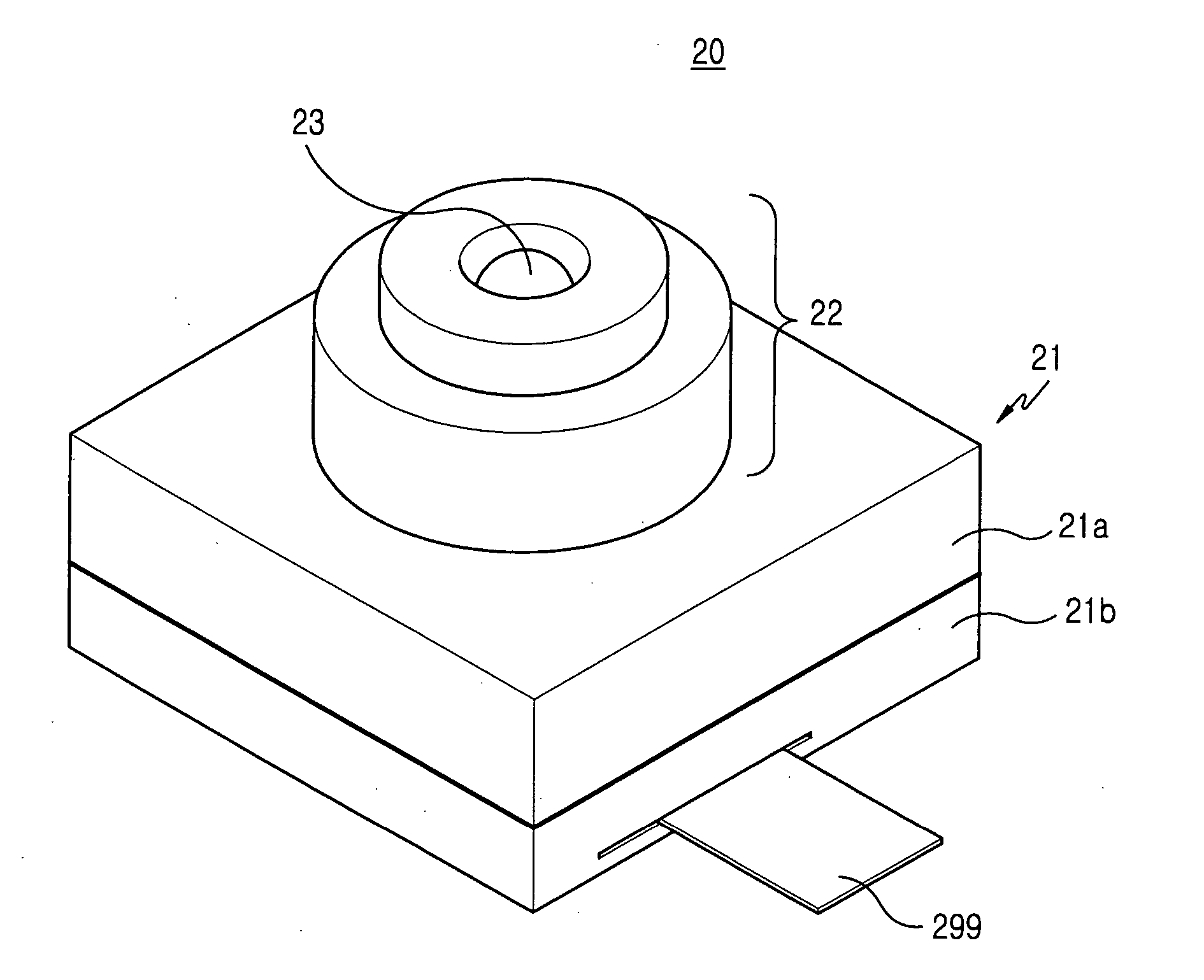

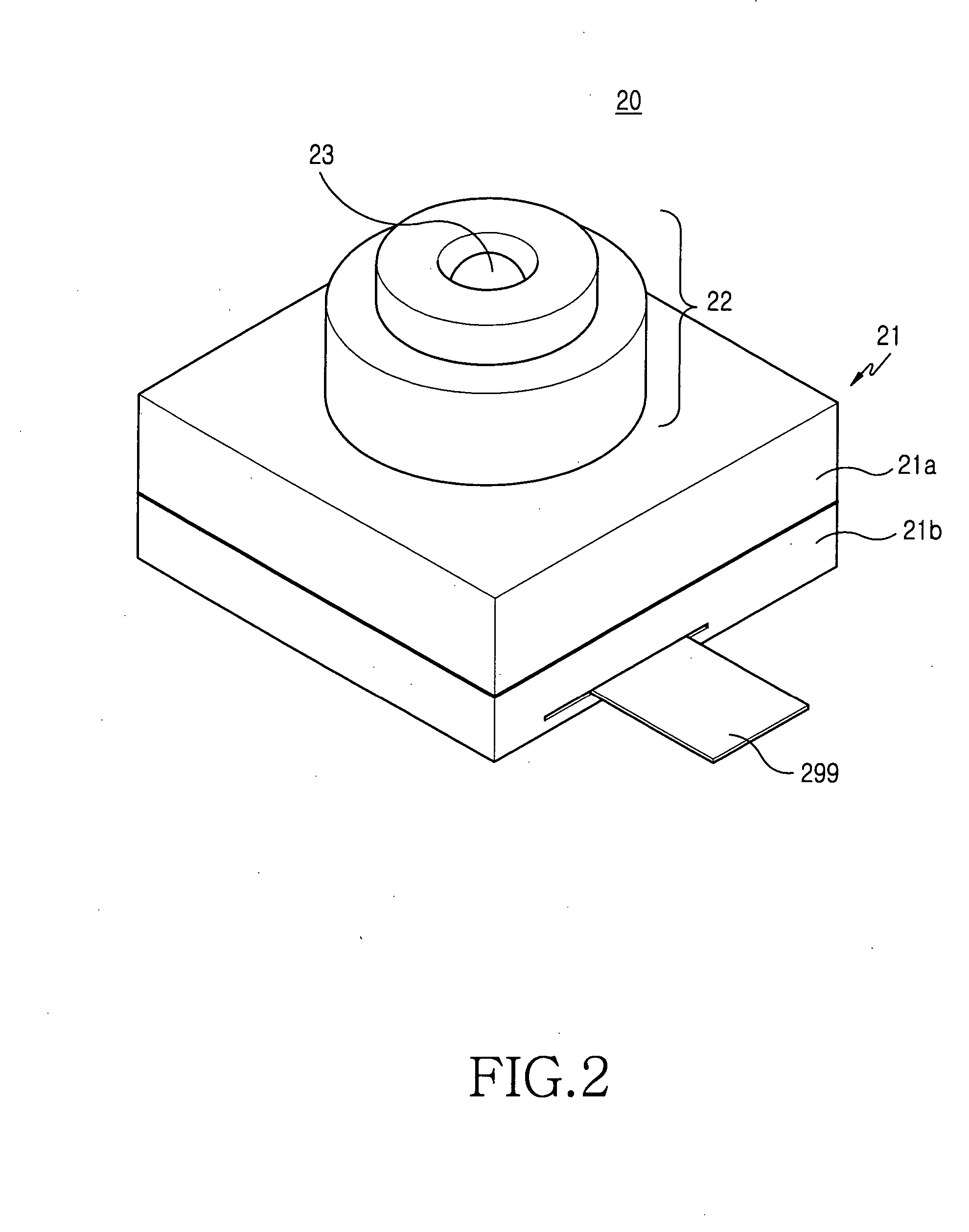

Noncontact IC card

InactiveUS6942156B2Spoiling outer appearanceSpoiling print characteristicOther printing matterSolid-state devicesEngineeringElectrical and Electronics engineering

In an IC card, an IC module constructed by mounting an IC chip and an antenna circuit on a substrate is sandwiched between at least a pair of exterior films. The IC chip is sealed with resin on its outside and reinforced by a reinforcement material having a substantially circular shape with a diameter greater than a longest dimension value of the IC chip. The height variation amount of the shape of the reinforcement material on a surface thereof is within a range of 20 μm or less. The reliability of the IC chip is ensured while the outer appearance of the card and print characteristic are not degraded.

Owner:SONY CORP

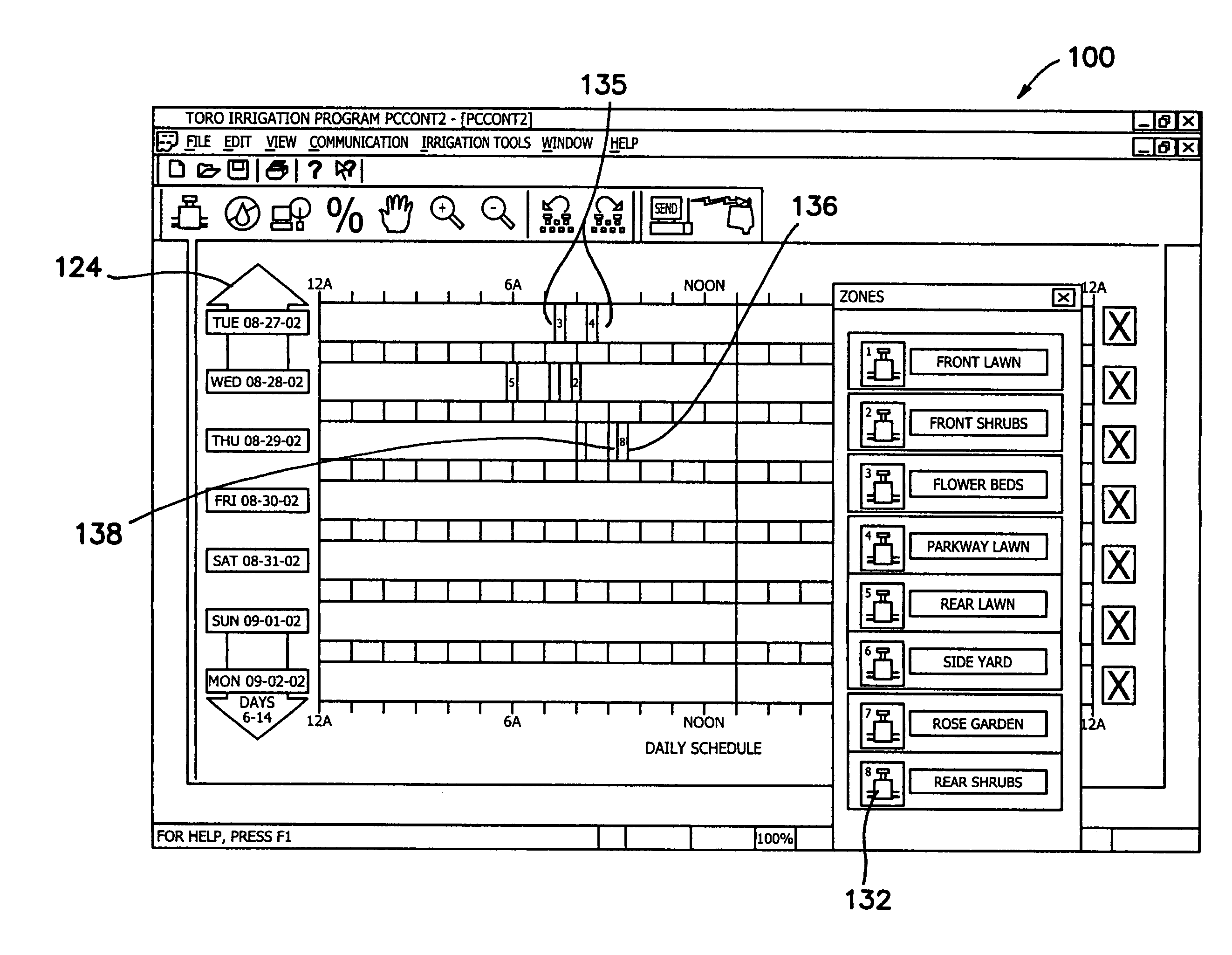

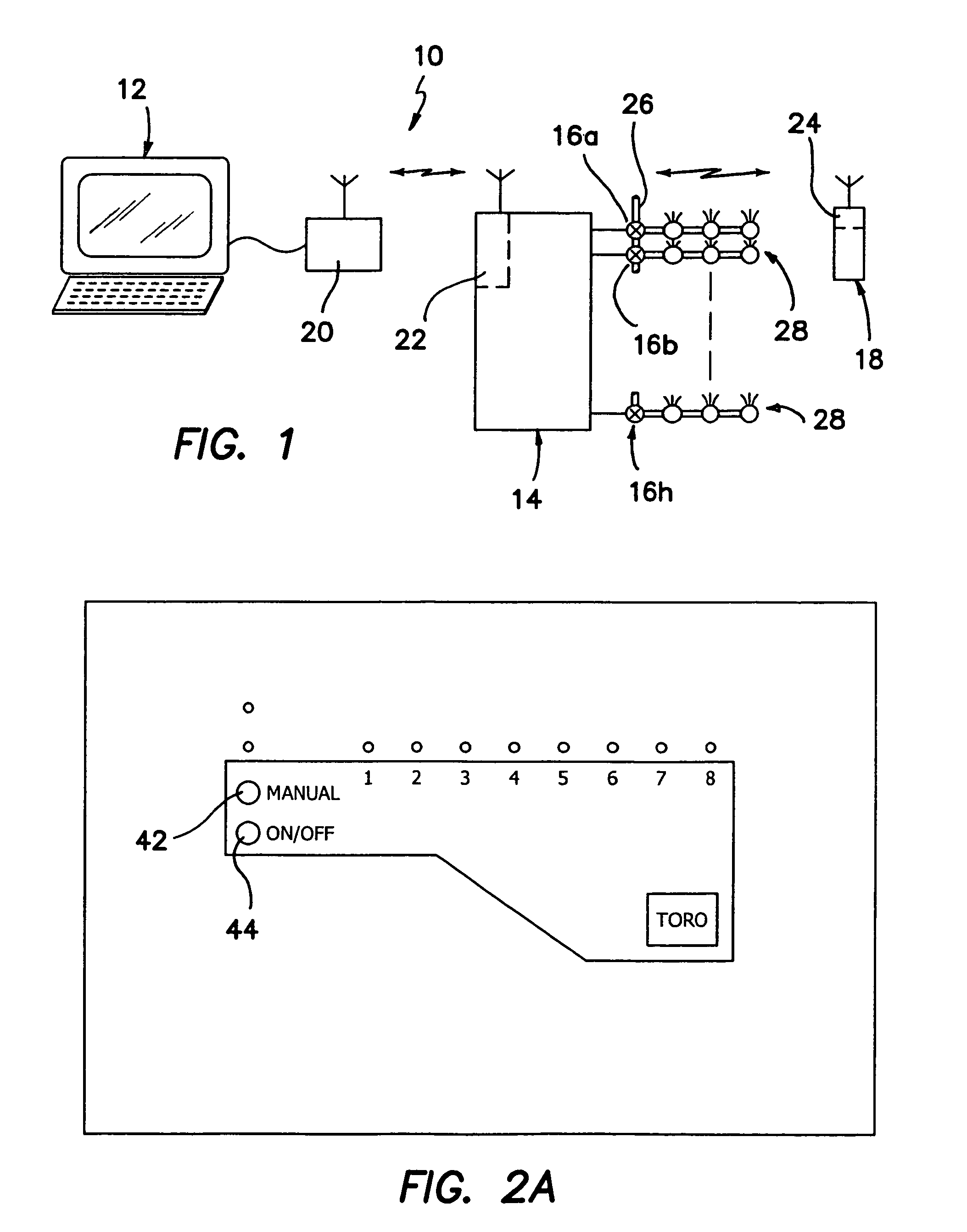

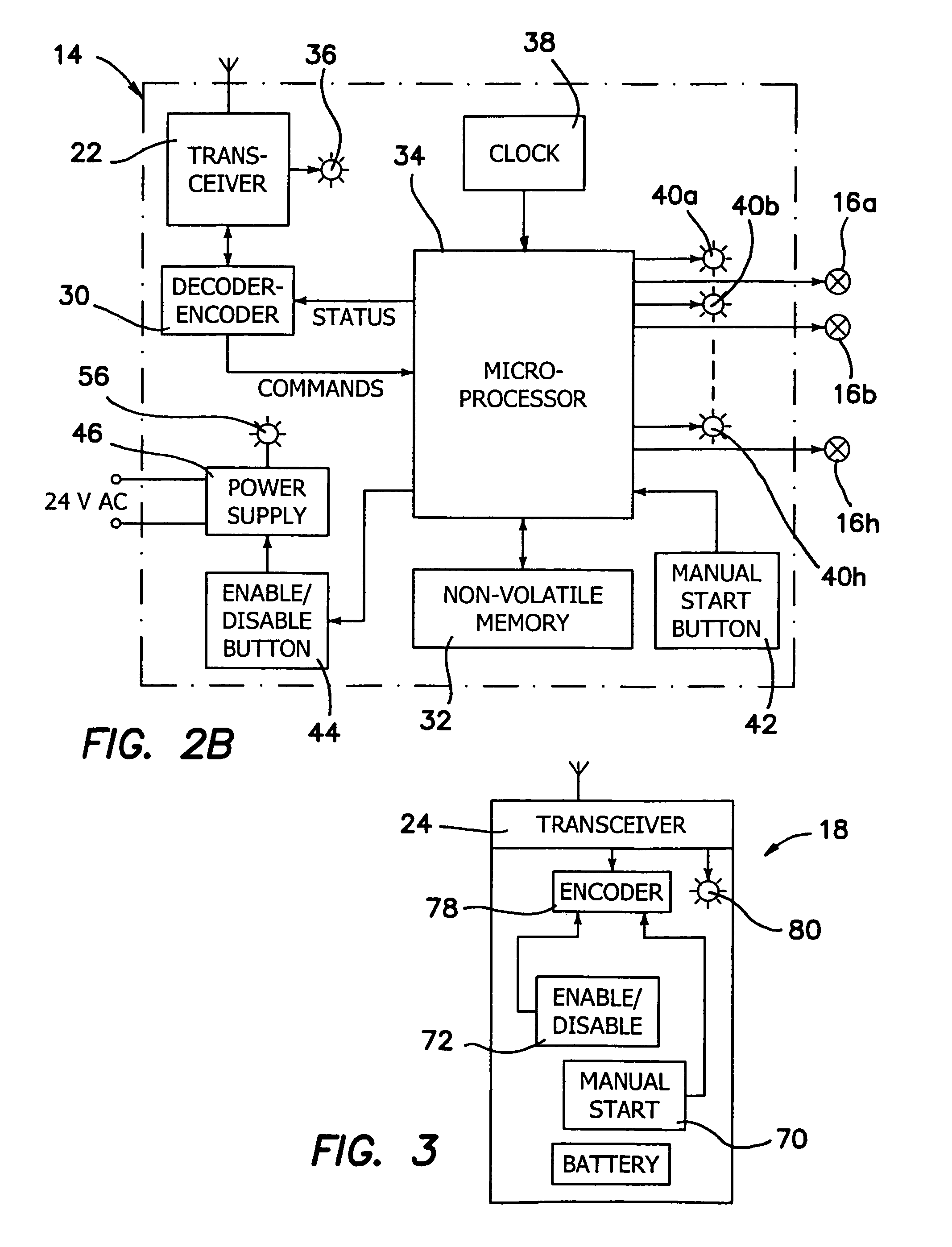

PC-programmed irrigation control system

ActiveUS7010395B1Ensure reliabilityData processing applicationsClimate change adaptationDrag and dropTime schedule

A free-standing field irrigation controller is selectively programmed by a personal computer over a radio link. The computer is equipped with software that displays a screen with seven horizontal time bands representing one day each, arranged vertically to display one week's time. Box icons representing watering settings for a plurality of zones can be dragged and dropped onto the time bands, copied and modified thereon as desired, to form a freely selectable watering schedule. Other selectable screens allow odd-days or even-days watering, sophisticated interval watering, global watering time adjustment, and a variety of manual functions. Selectable portions of the main screen can be enlarged as desired. Based on the selected schedule, the computer calculates and displays the monthly cost of water. Selected zones can be temporarily disabled to deal with weather or maintenance issues. A handheld global shut-off and manual watering remote and / or a separate radio-linked computer may be used in field maintenance.

Owner:TORO CO THE

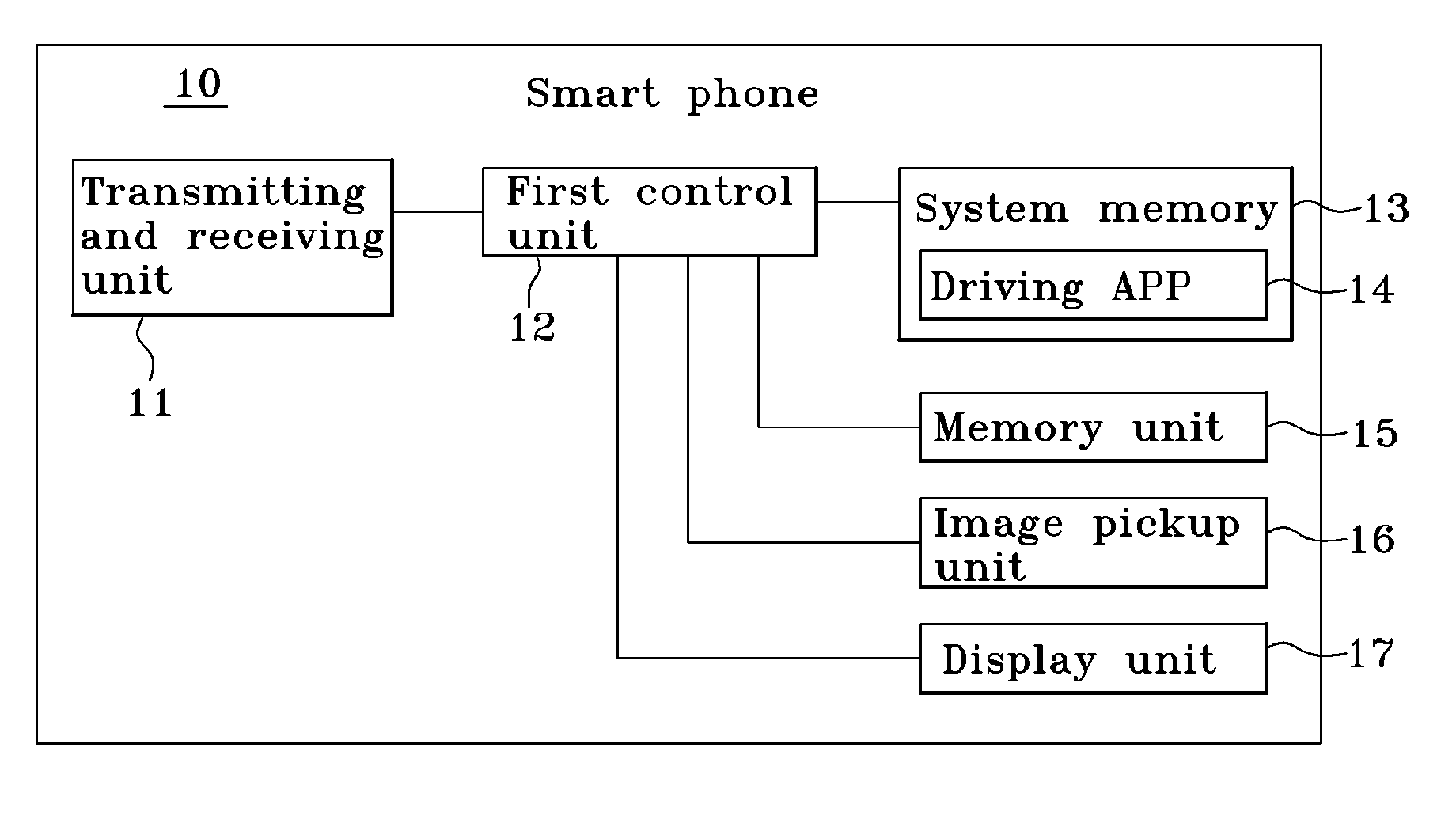

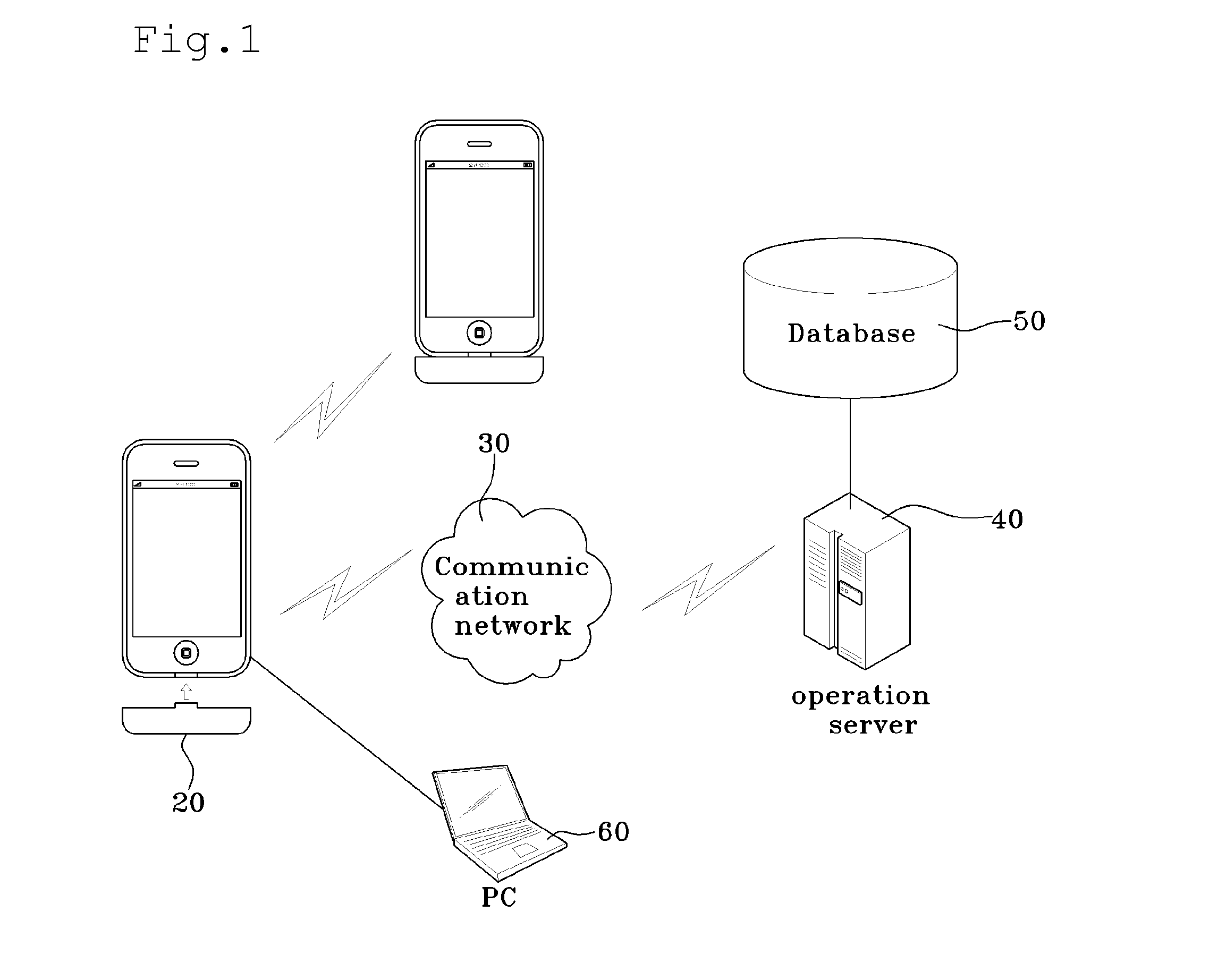

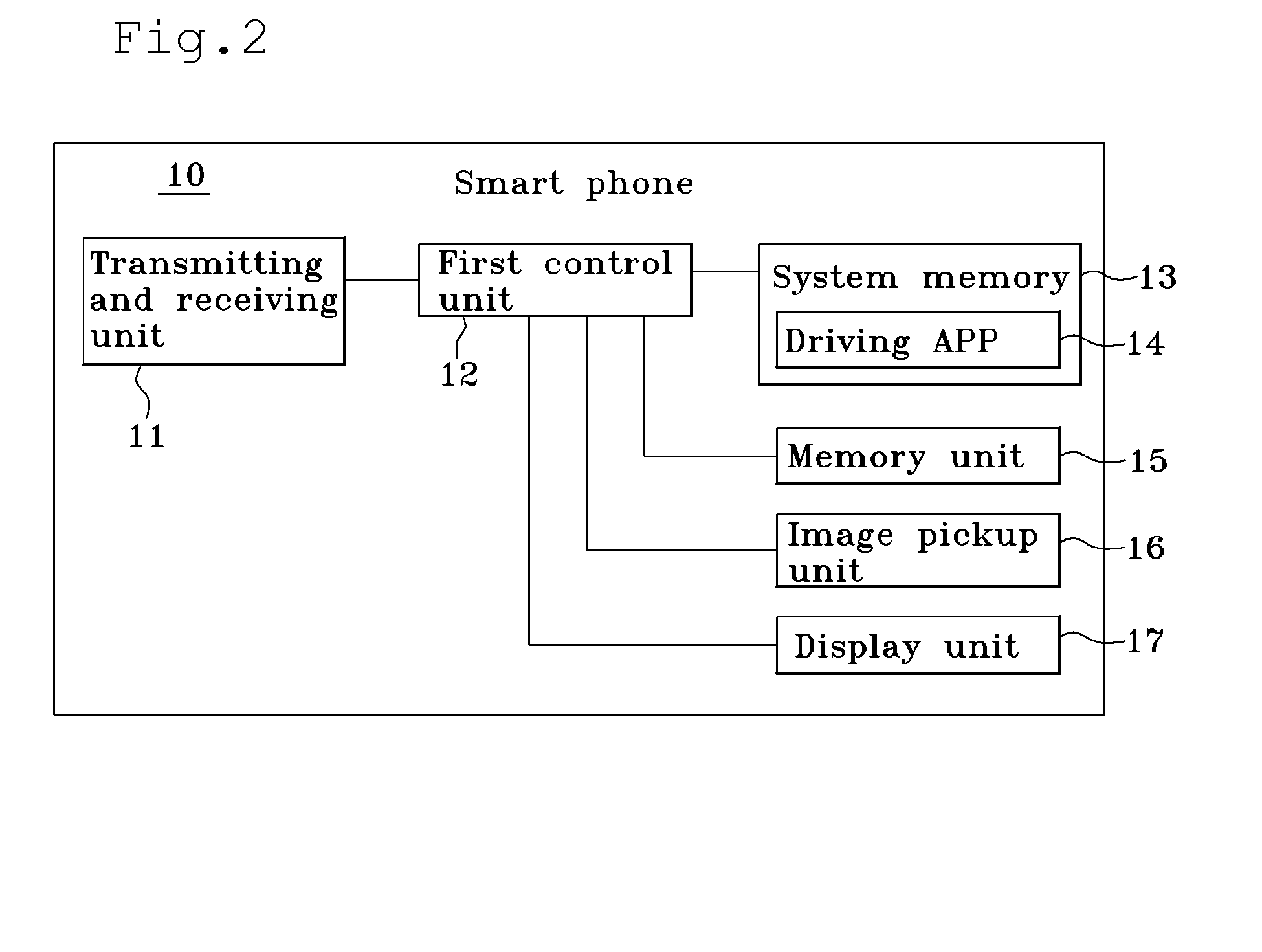

Gas detection system and method using smart phone

ActiveUS20140349707A1Solve the real problemEnsure reliabilityWireless architecture usageAlarmsToxic gasCombustible gas

Disclosed is a gas detection system and method using a smart phone. The gas detection system includes a sensor module detachably mounted to the smart phone and configured to detect and measure a combustible gas or a toxic gas; and a gas detection APP installed inside the smart phone and configured to acquire measurement data by detecting the combustible gas or the toxic gas and measuring the detected combustible gas or toxic gas through the drive of the sensor module, after automatically recognizing user information and location information by reading a radio frequency identification (RFID) tag indicating a user or a location of gas detection, using a contact unit having built therein an RFID reader inside the smart phone, wherein the smart phone transmits the user information, the location information and the measurement data acquired from the gas detection APP to an operation server through a communication network.

Owner:BANG YOUNG KI

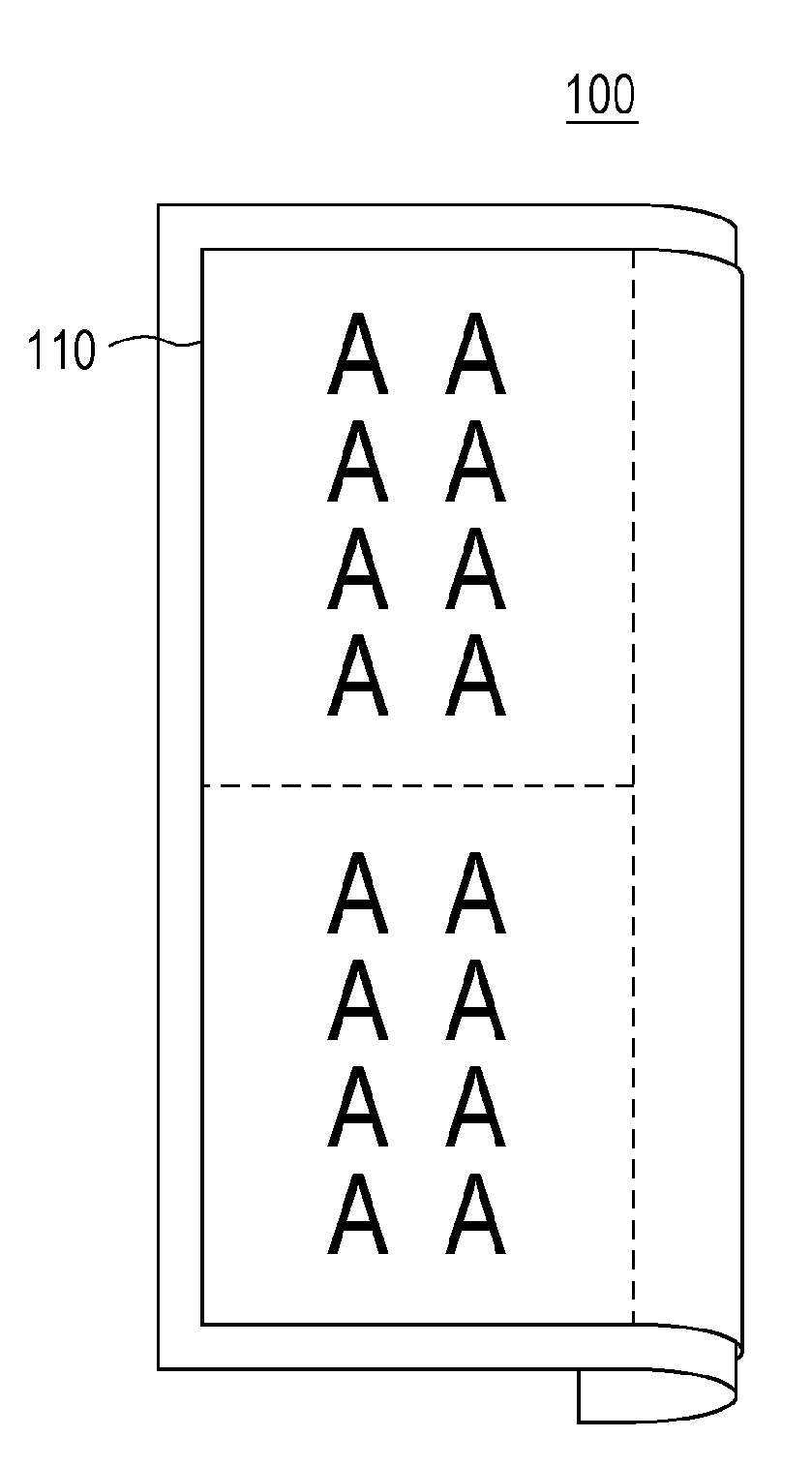

Display device and method of controlling display device

ActiveUS20110134145A1Ensure reliabilityInput/output for user-computer interactionDigital data processing detailsDisplay deviceExecution control

A display device includes a flexible substrate, a display unit including multiple light-emitting elements arranged at the substrate and configured to display an image according to an image signal, a displacement sensor provided to at least one of a front surface and a back surface of the substrate and configured to detect a curved state of the substrate, and a control unit configured to execute a control by which the image is split and displayed in the display unit when a curve of the substrate is detected by the displacement sensor.

Owner:SONY CORP

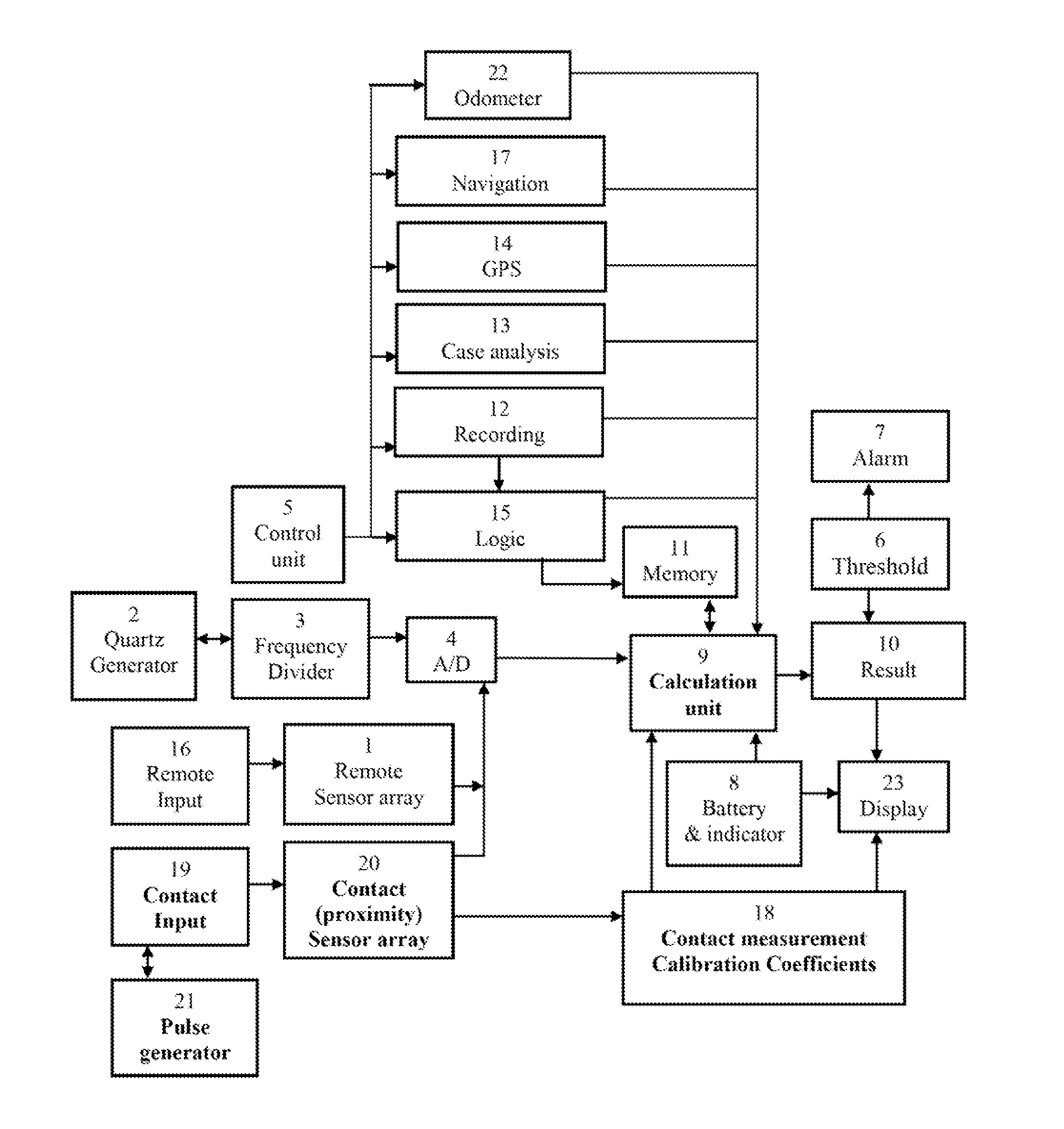

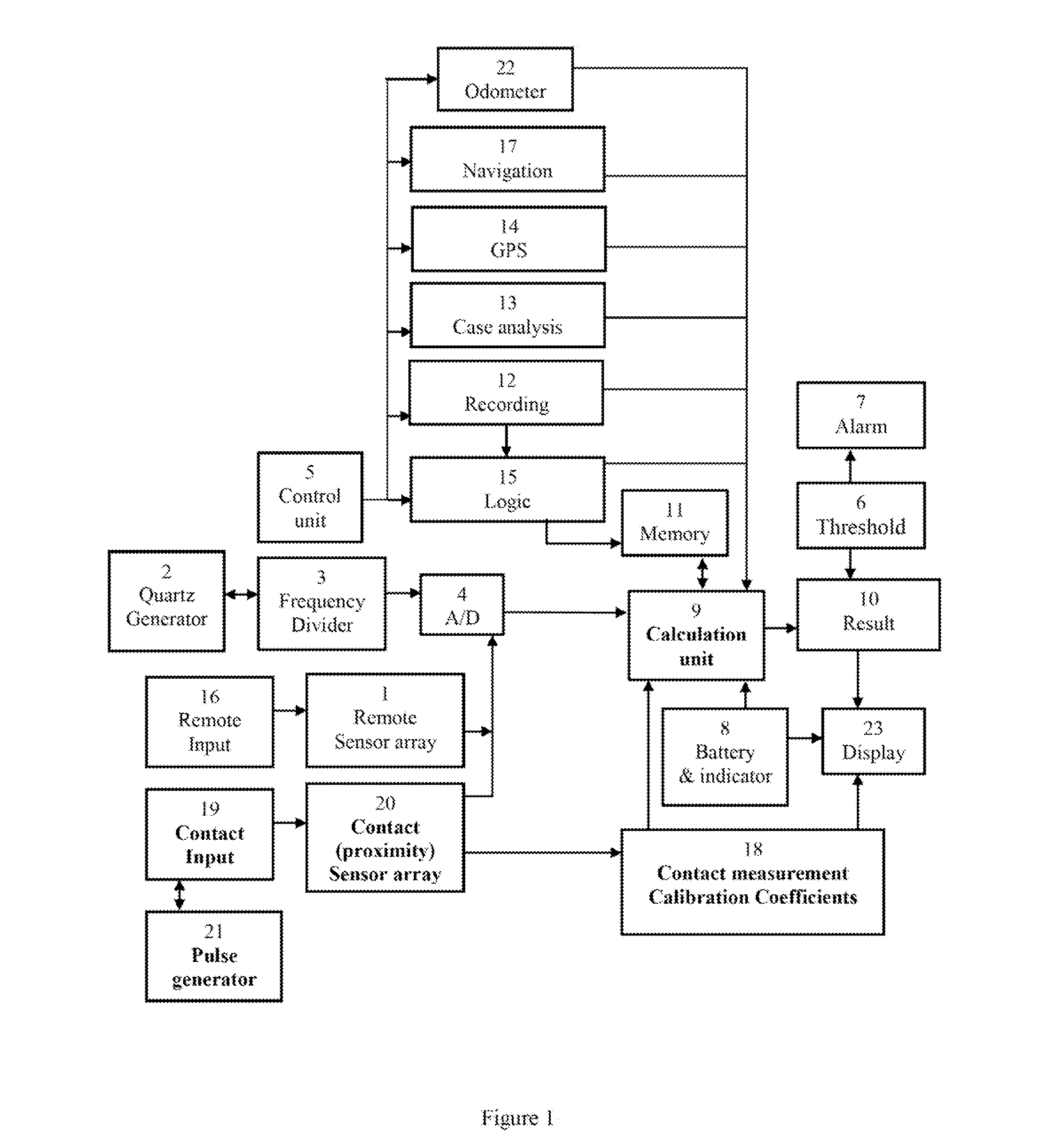

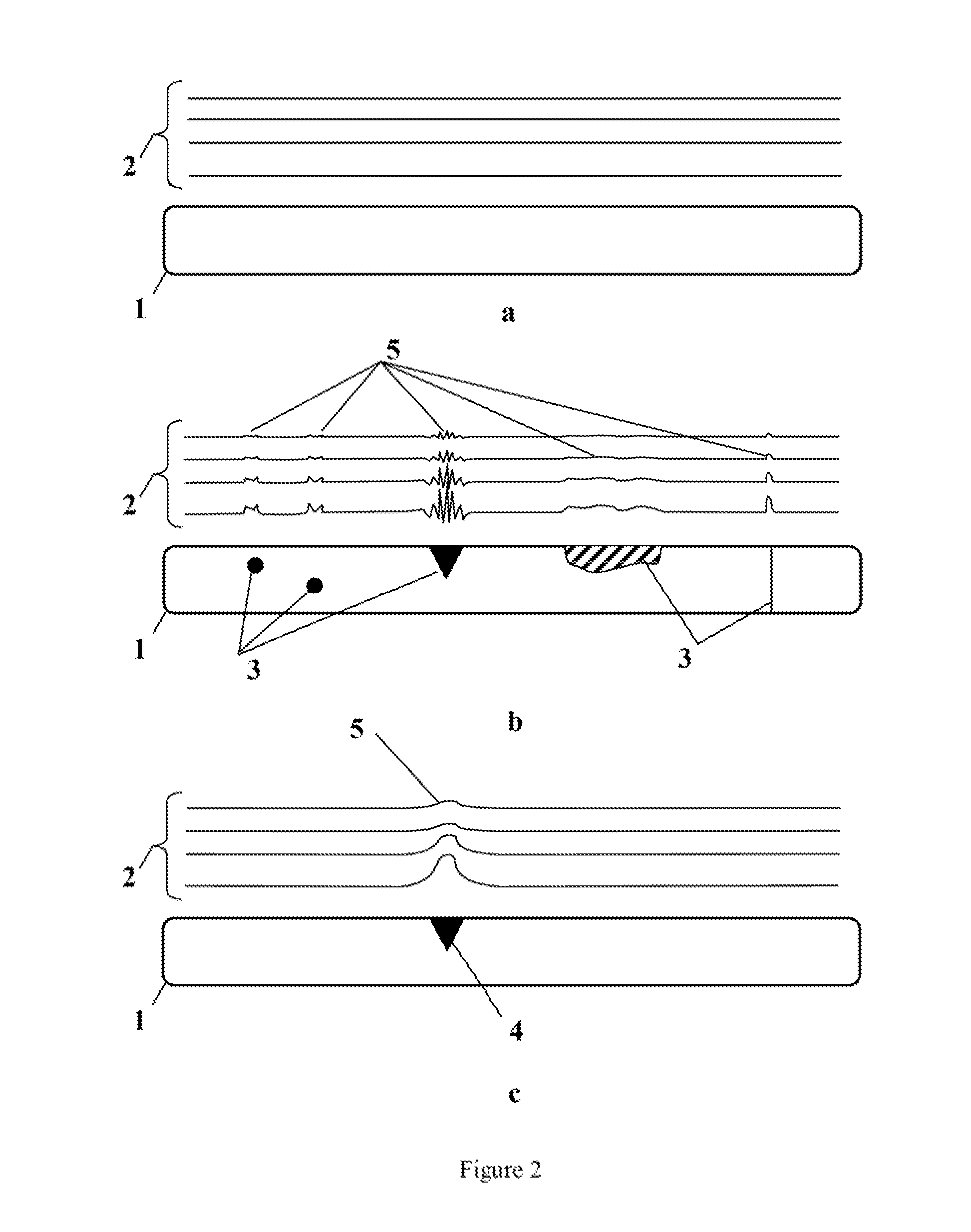

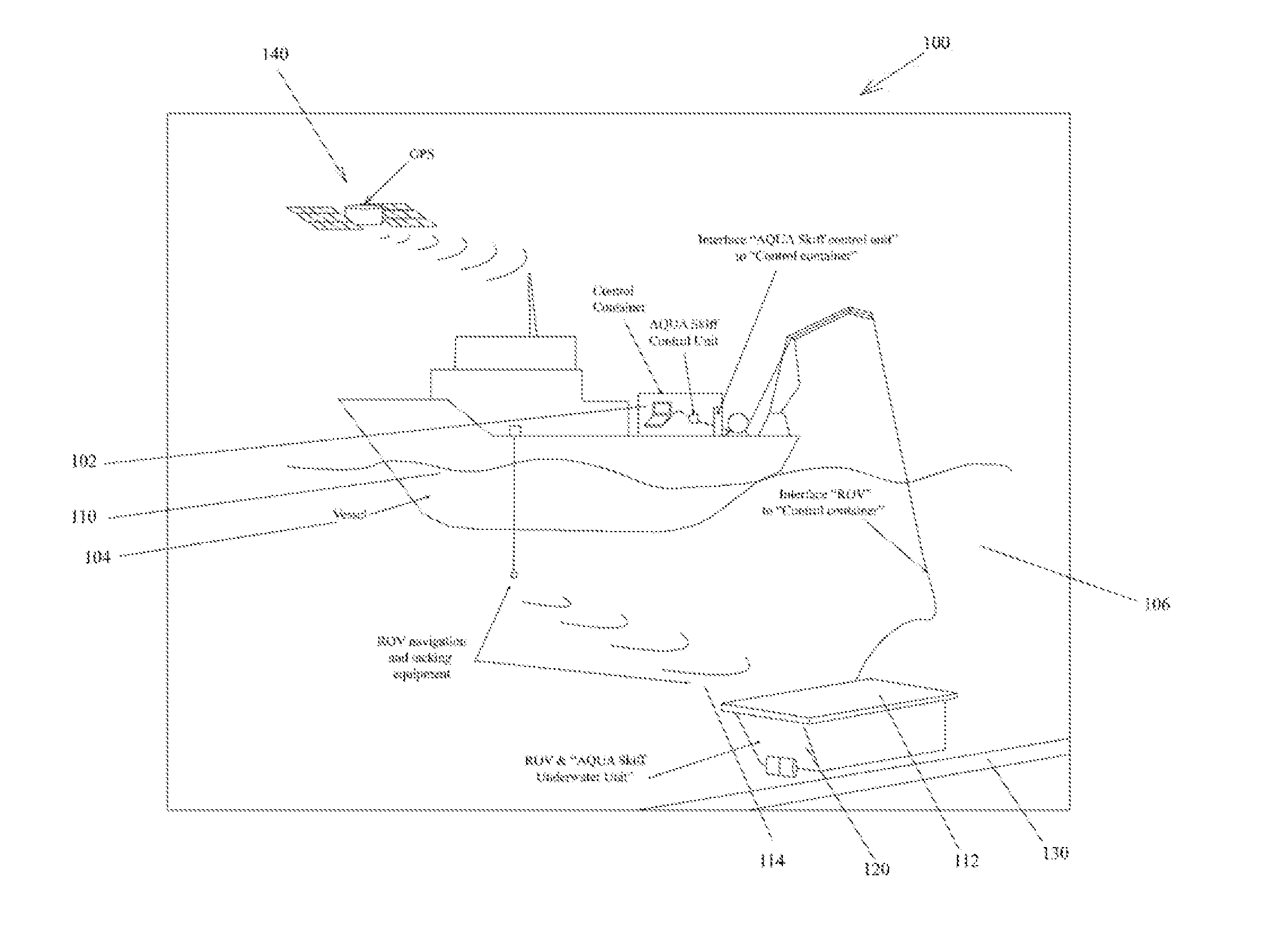

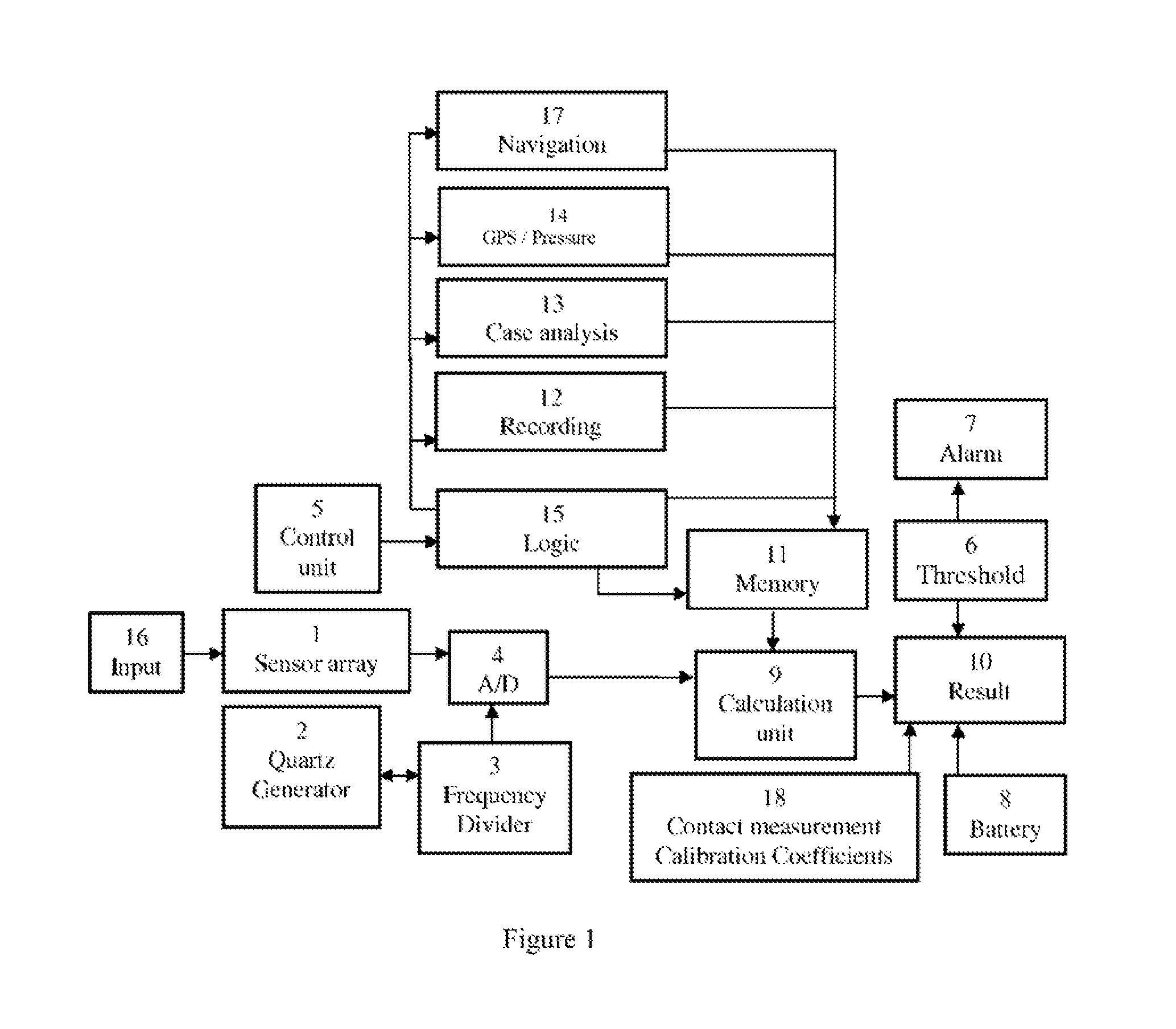

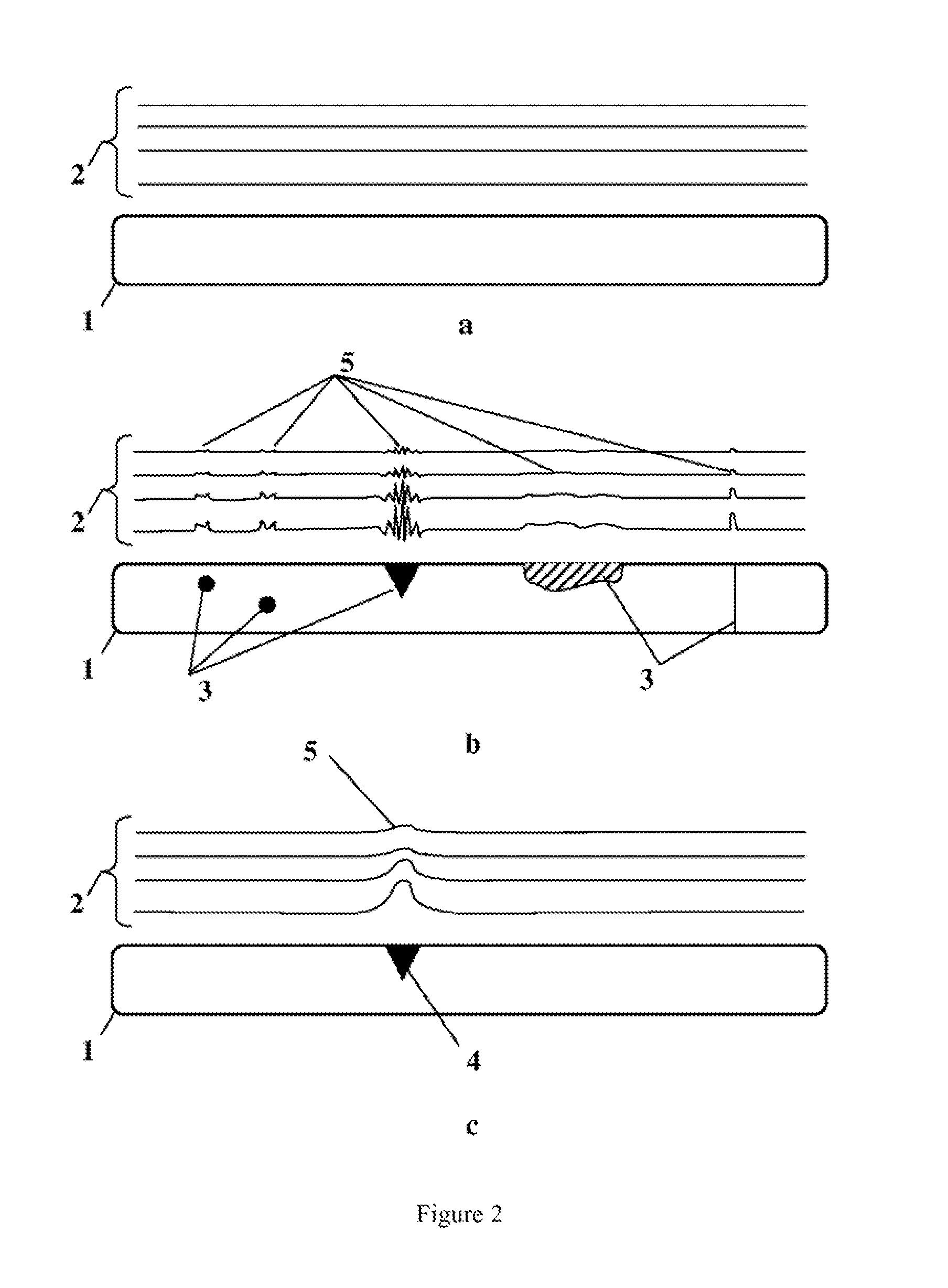

Apparatus and method for metallic constructions assessment

ActiveUS20140368191A1Improve accuracyEnsure qualitySusceptibility measurementsMaterial magnetic variablesEngineeringHeavy duty

A device for discovering, identification and monitoring, of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The device includes registration means that optimized for use with metallic structures of various types, shapes and sizes. Applications include a real-time quality control, monitoring and emergency alarms, as well structural repairs and maintenance work recommendations and planning. Examples of the device implementation include pipes for oil and gas industry monitoring, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs. etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

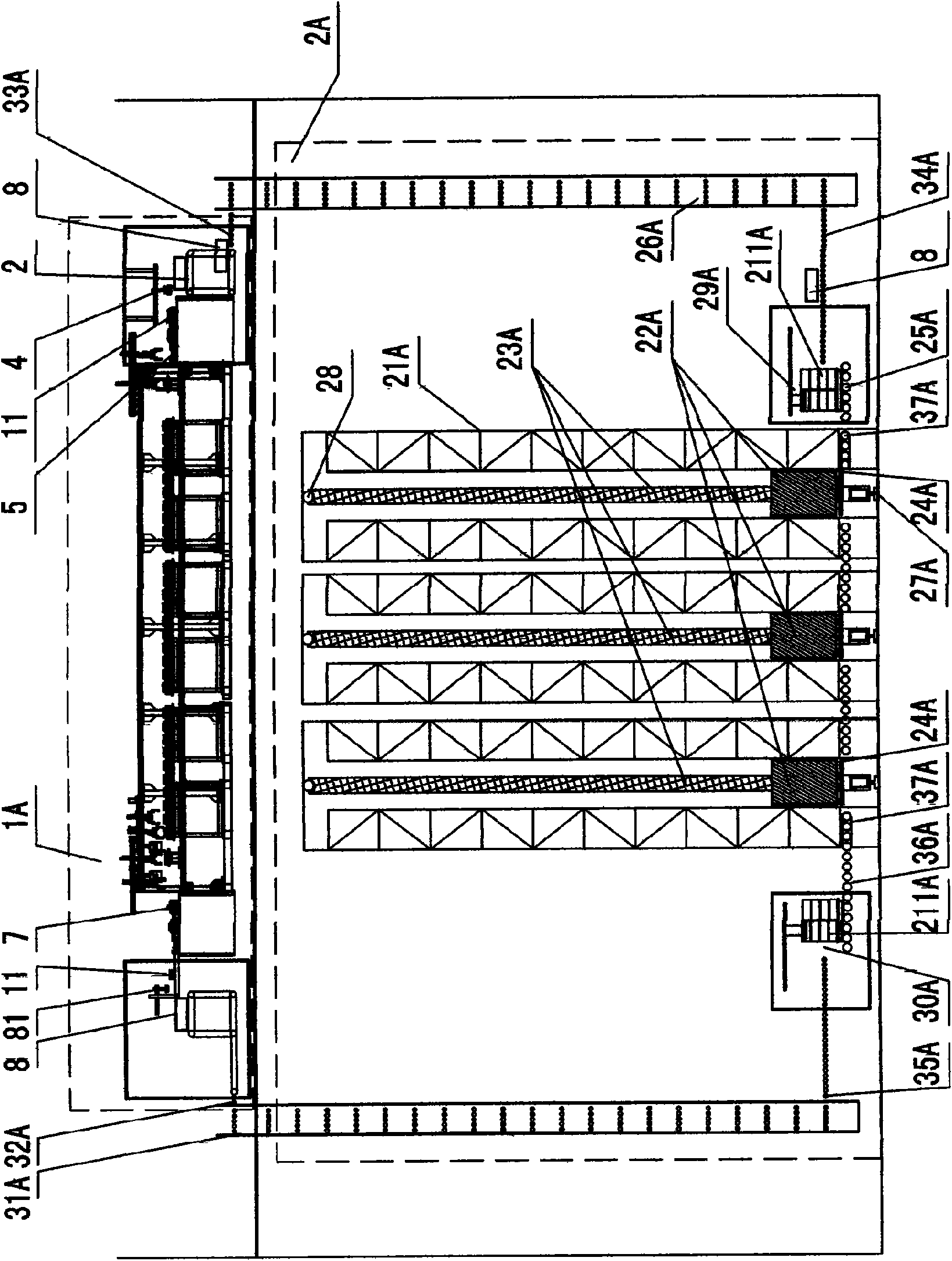

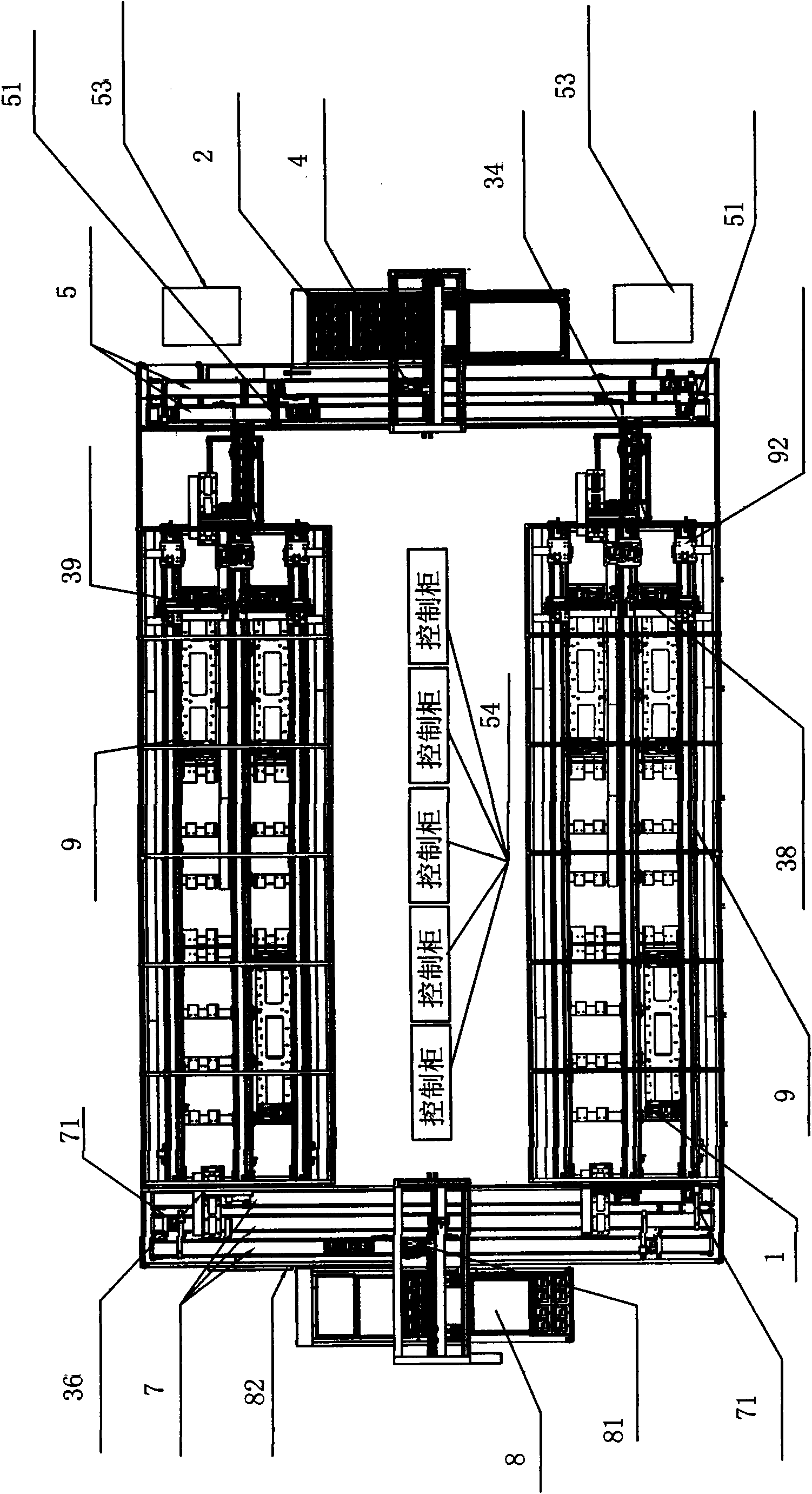

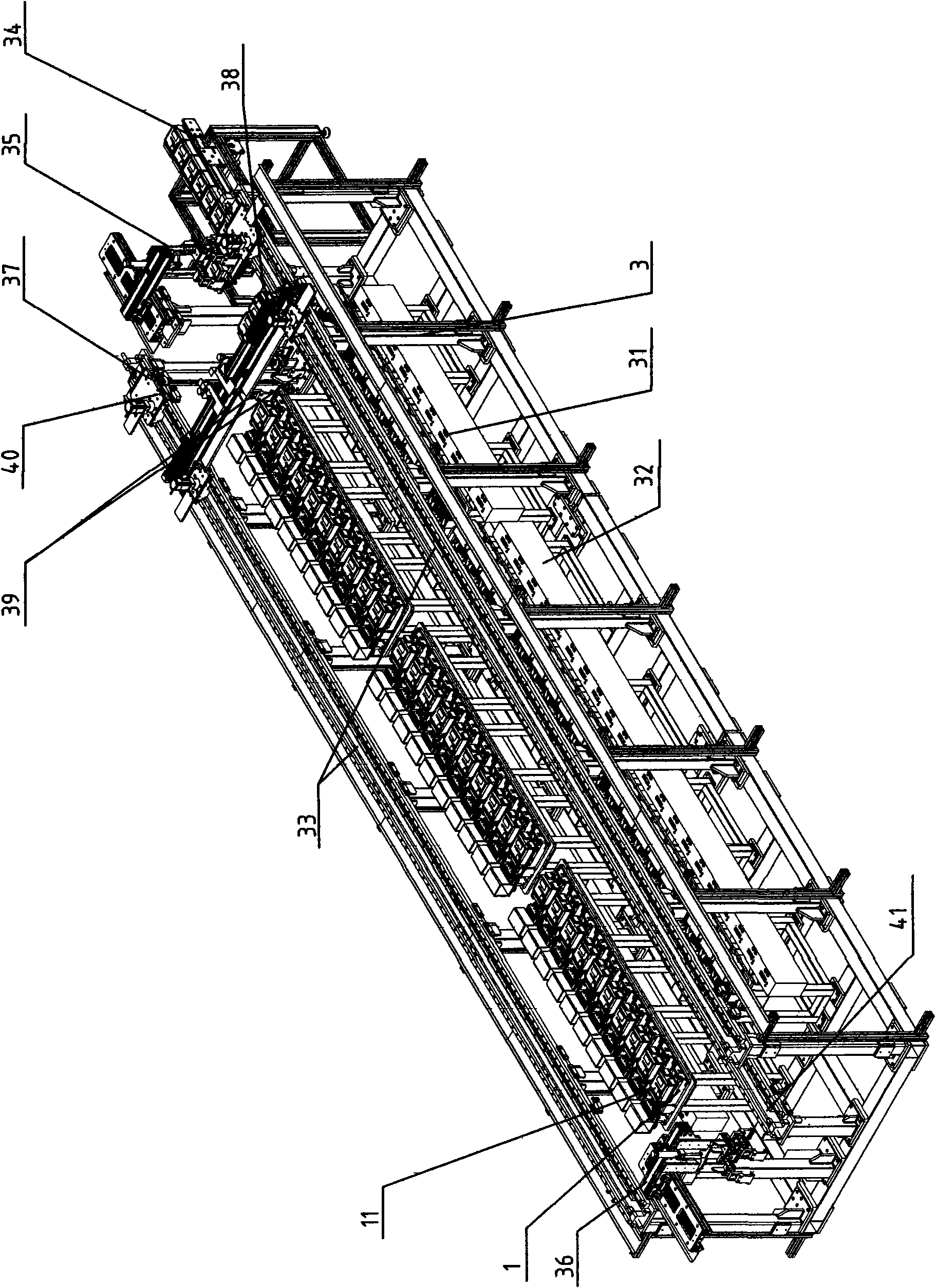

Automatic holographic management system integrating detection of electric energy meter and warehousing management

ActiveCN101539617ARealize automatic feeding processAchieve contactRadiation pyrometryElectrical measurementsTemperature monitoringEngineering

The invention discloses an automatic holographic management system integrating detection of an electric energy meter and warehousing management, comprising an automatic pipelining standard device for detection of the electric energy meter, an unboxing machine, a boxing machine and a three-dimensional table library; wherein the three-dimensional table library is respectively connected with the boxing machine and the unboxing machine; and the boxing machine and the unboxing machine are respectively connected with the automatic pipelining standard device for detection of the electric energy meter by a conveying belt. The system changes large amount of repeated and mechanical manual modes in the whole process of the operation of the electric energy meter, and has the automatic functions of automatic delivery from the warehouse, automatic distribution, automatic feeding, automatic positioning, automatic wire connection, automatic image recognition, automatic temperature monitoring, automatic wire disconnection, automatic discharging, automatic boxing, automatic disc packing and automatic warehouse entry.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +1

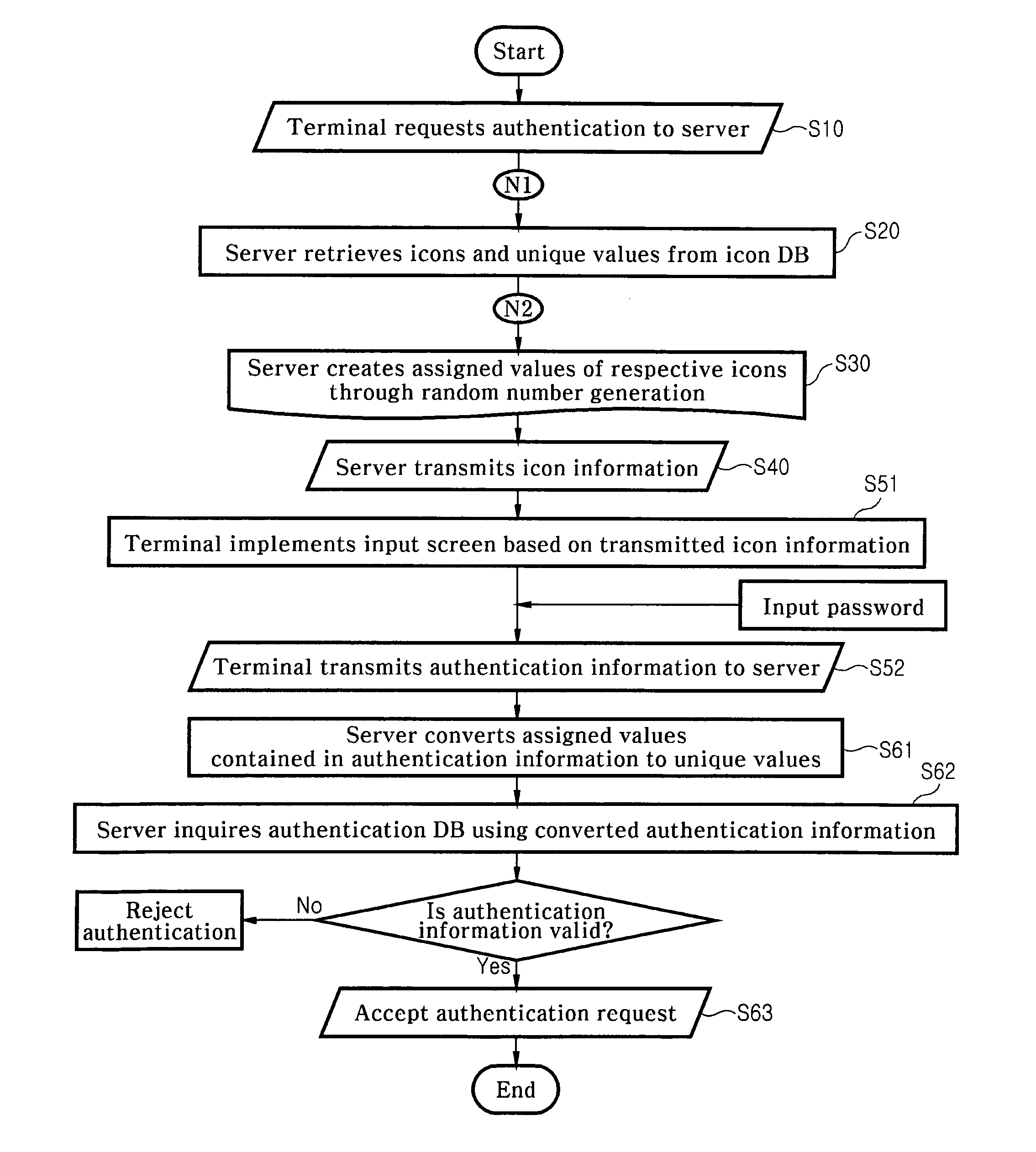

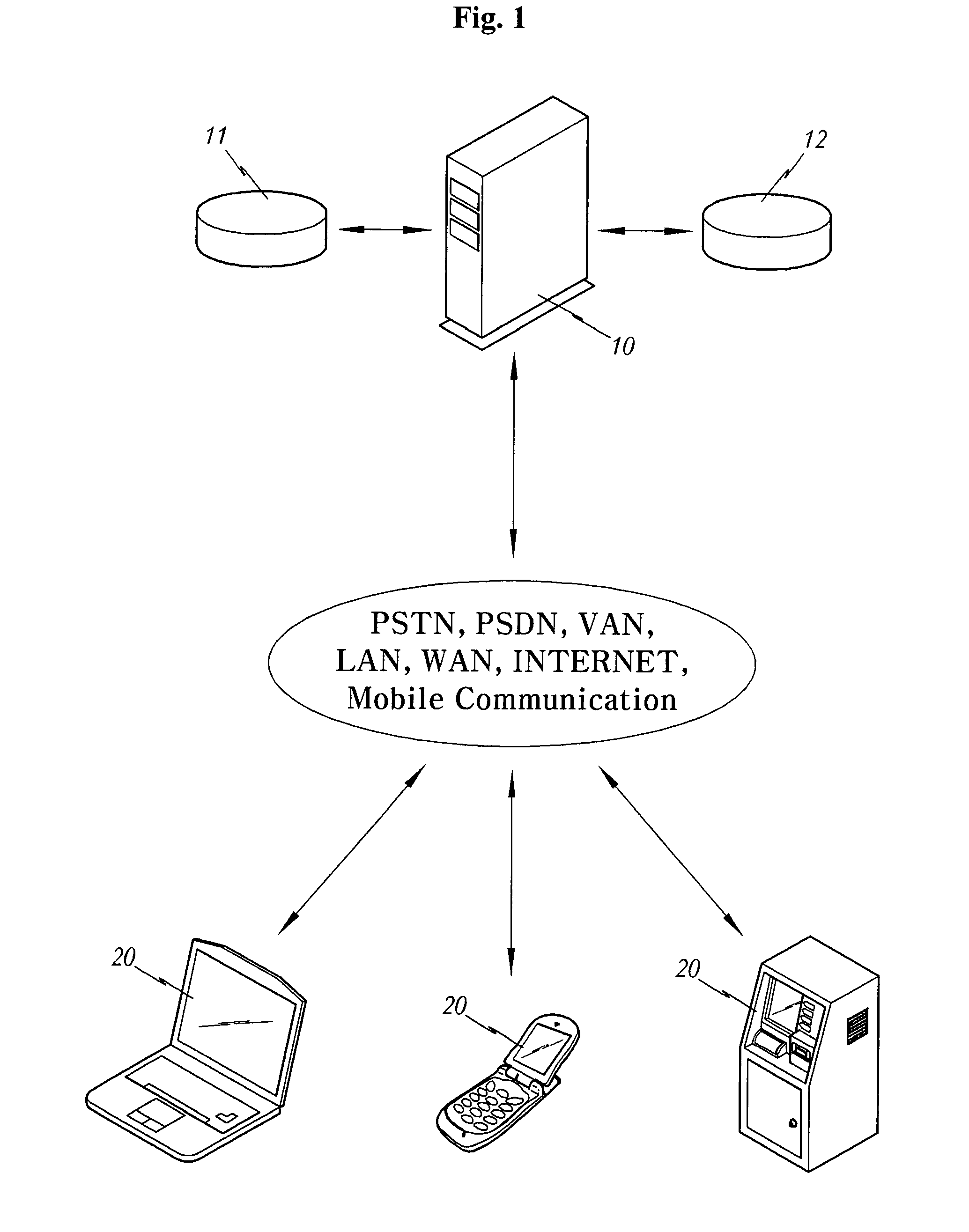

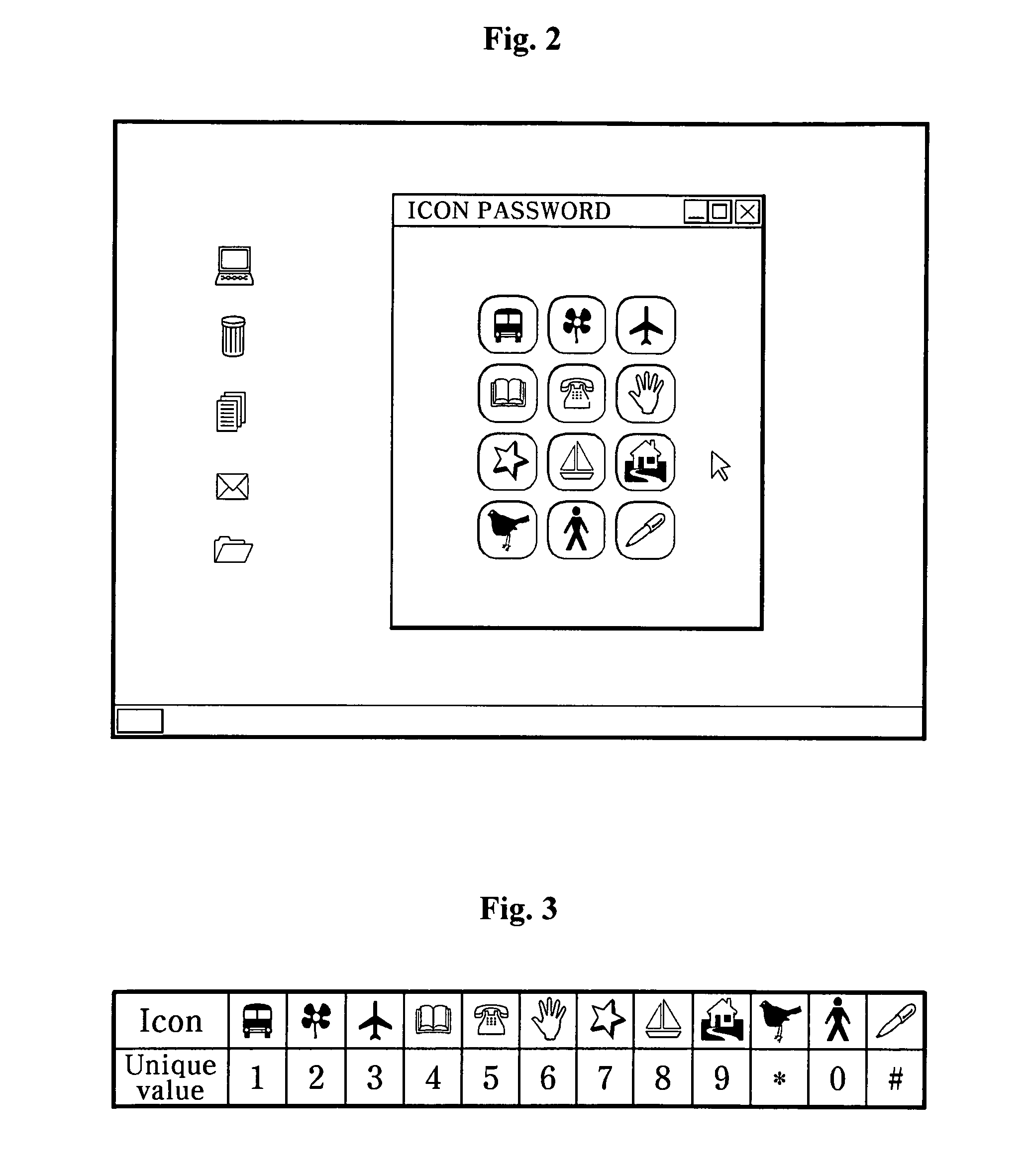

Authentication method using icon password

ActiveUS8336086B2Improve securityPrevent leakageDigital data processing detailsAnalogue secracy/subscription systemsInformation processingPassword

A method of authenticating a user of a terminal operating a server and connected to the terminal through a communication network, in which a password needed for authentication is inputted as icons, rather than numerals or characters, thereby preventing leakage or theft of the password. Through the present invention, security is improved in processing a password in an information processing device or a communication network, and furthermore, leakage of the password is fundamentally prevented in the process of inputting the password by a user. Therefore, an effect of securing reliability of the overall authentication process may be obtained.

Owner:RSUPPORT

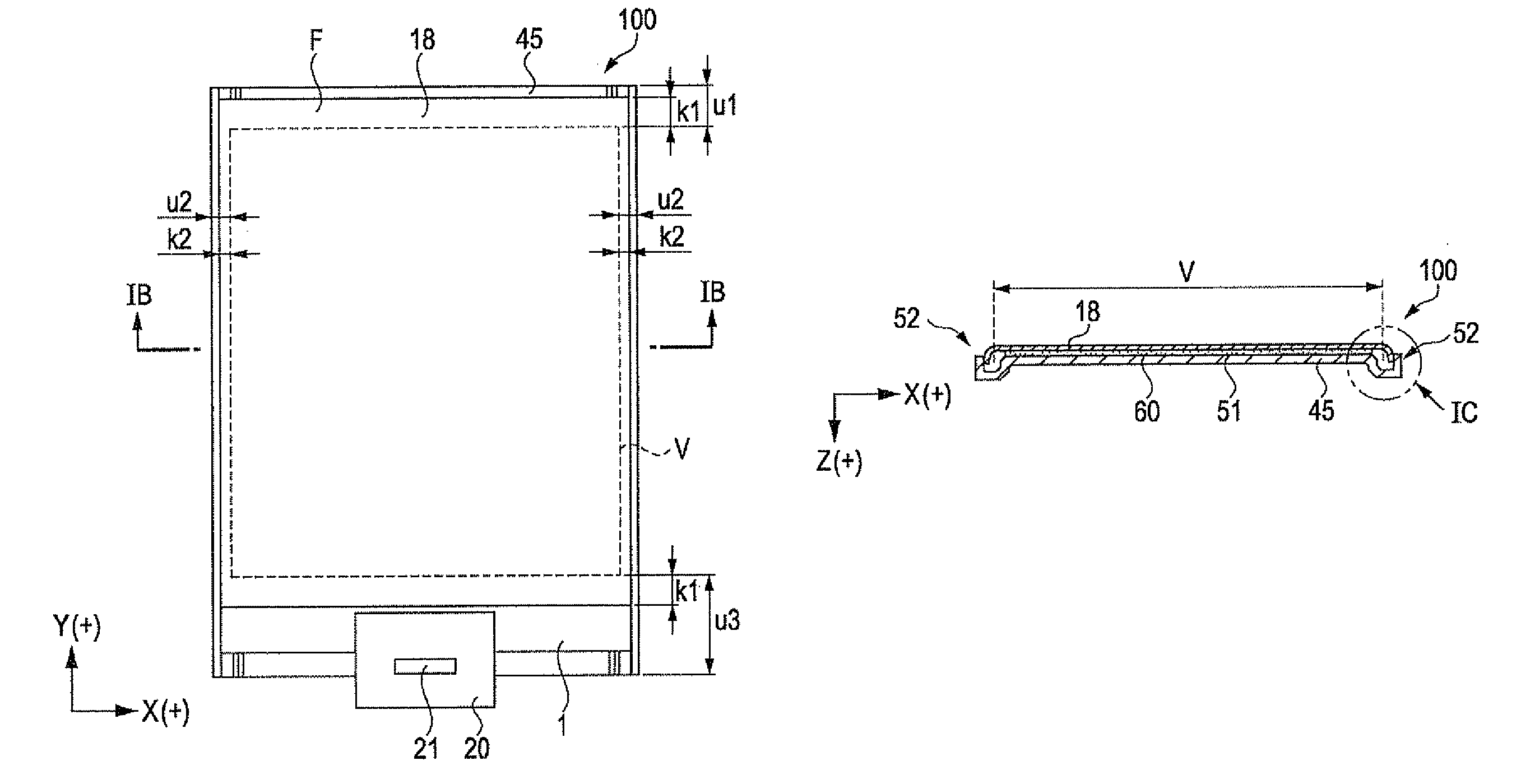

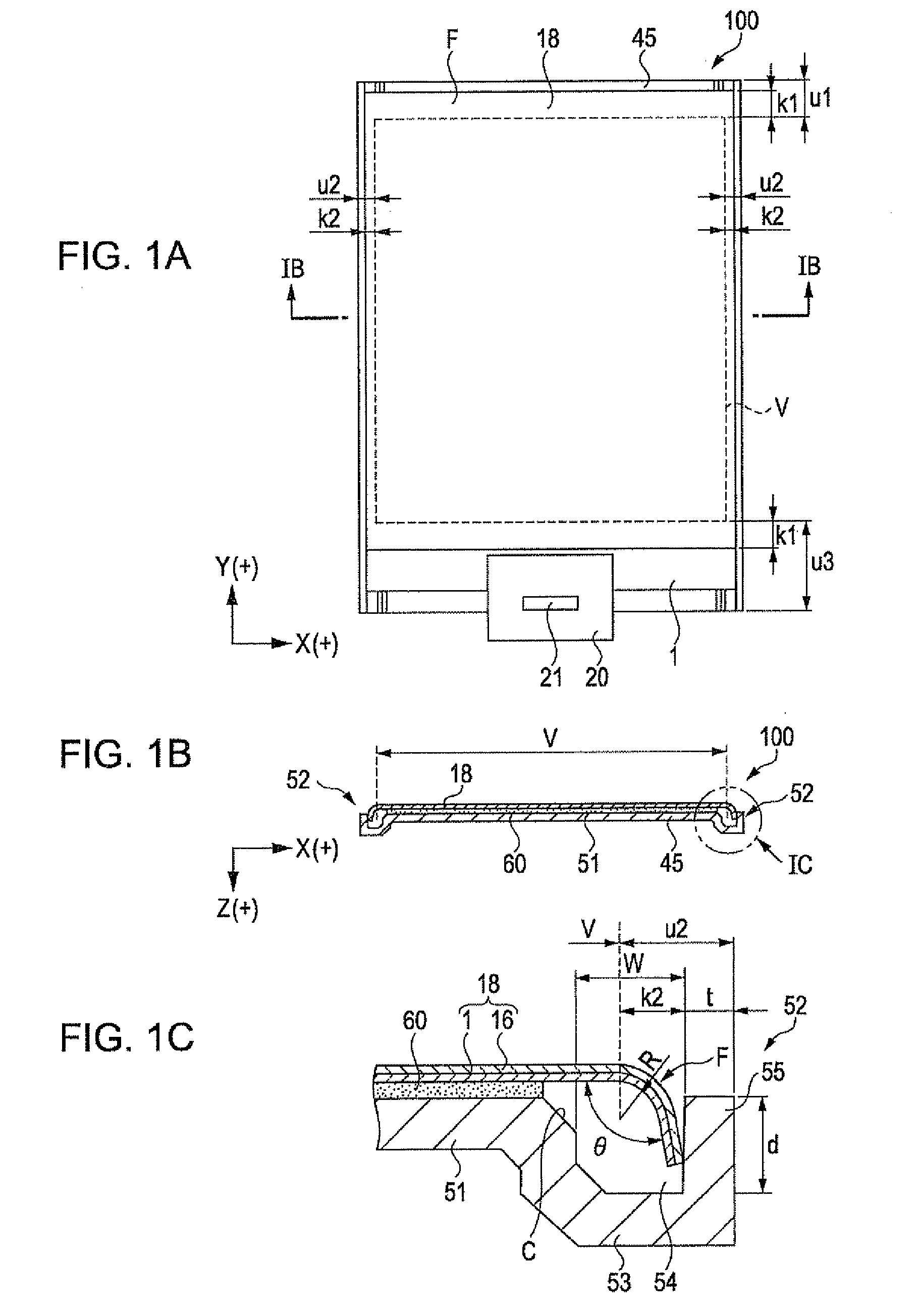

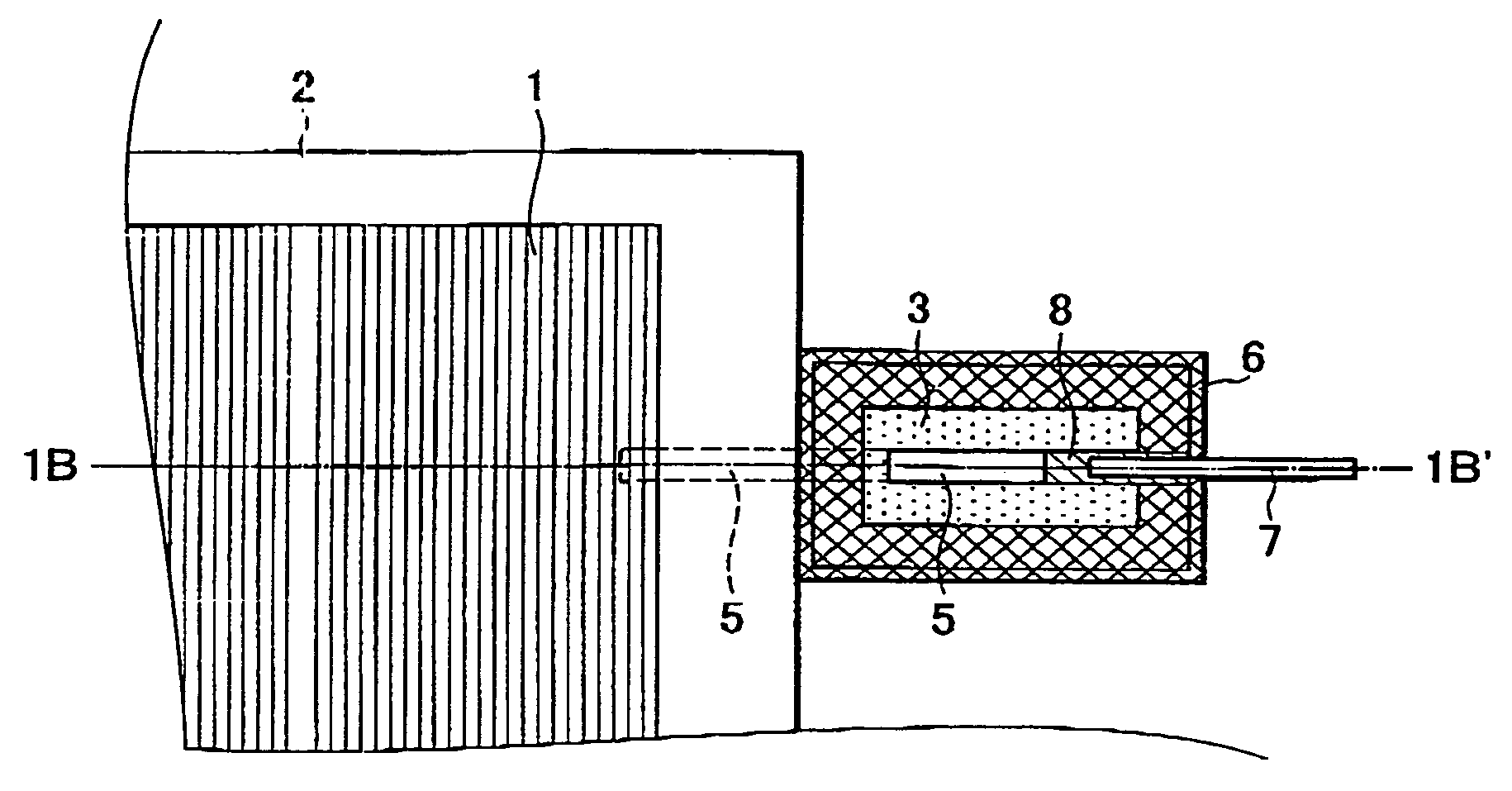

Electro-optical device and electronic apparatus

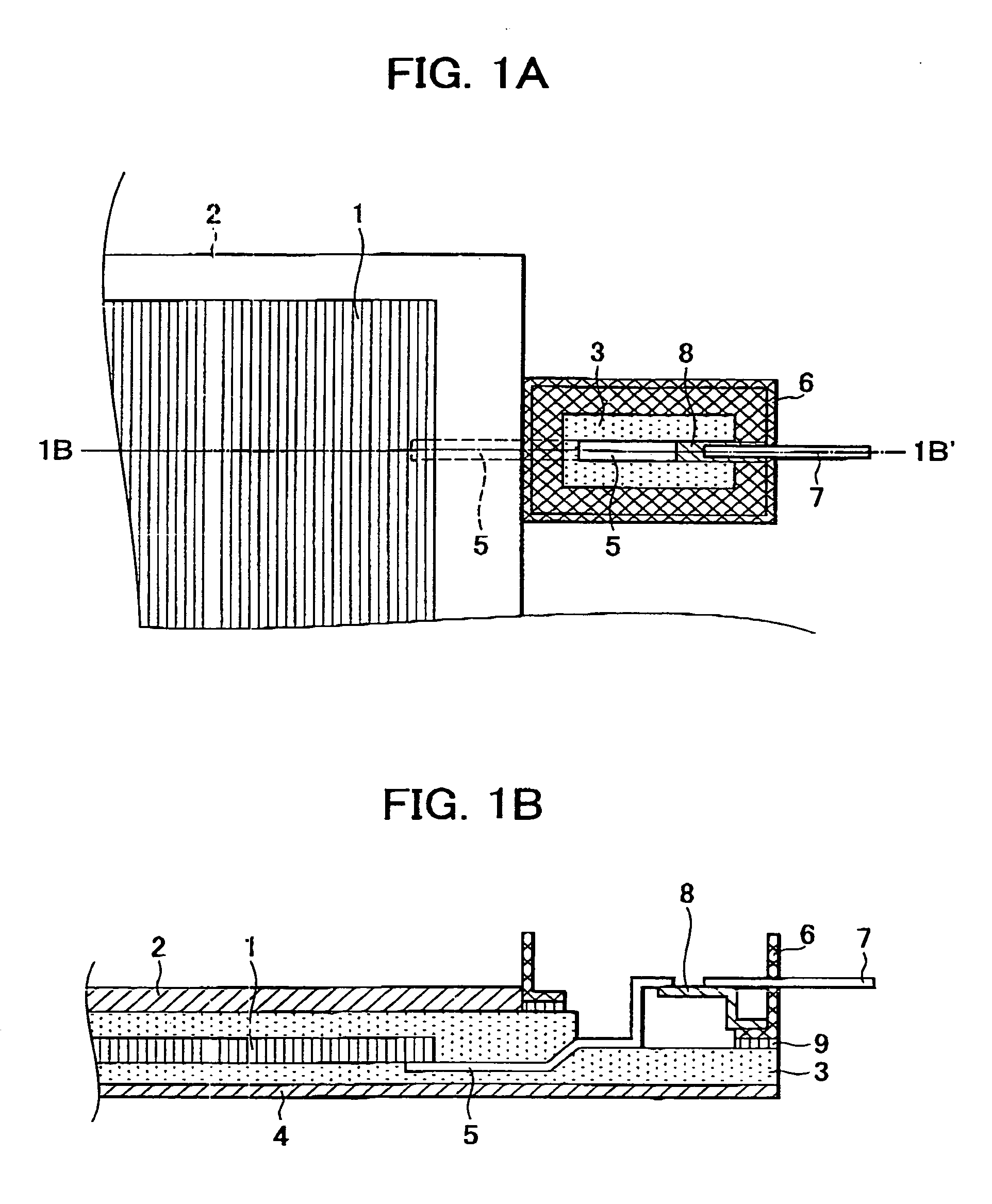

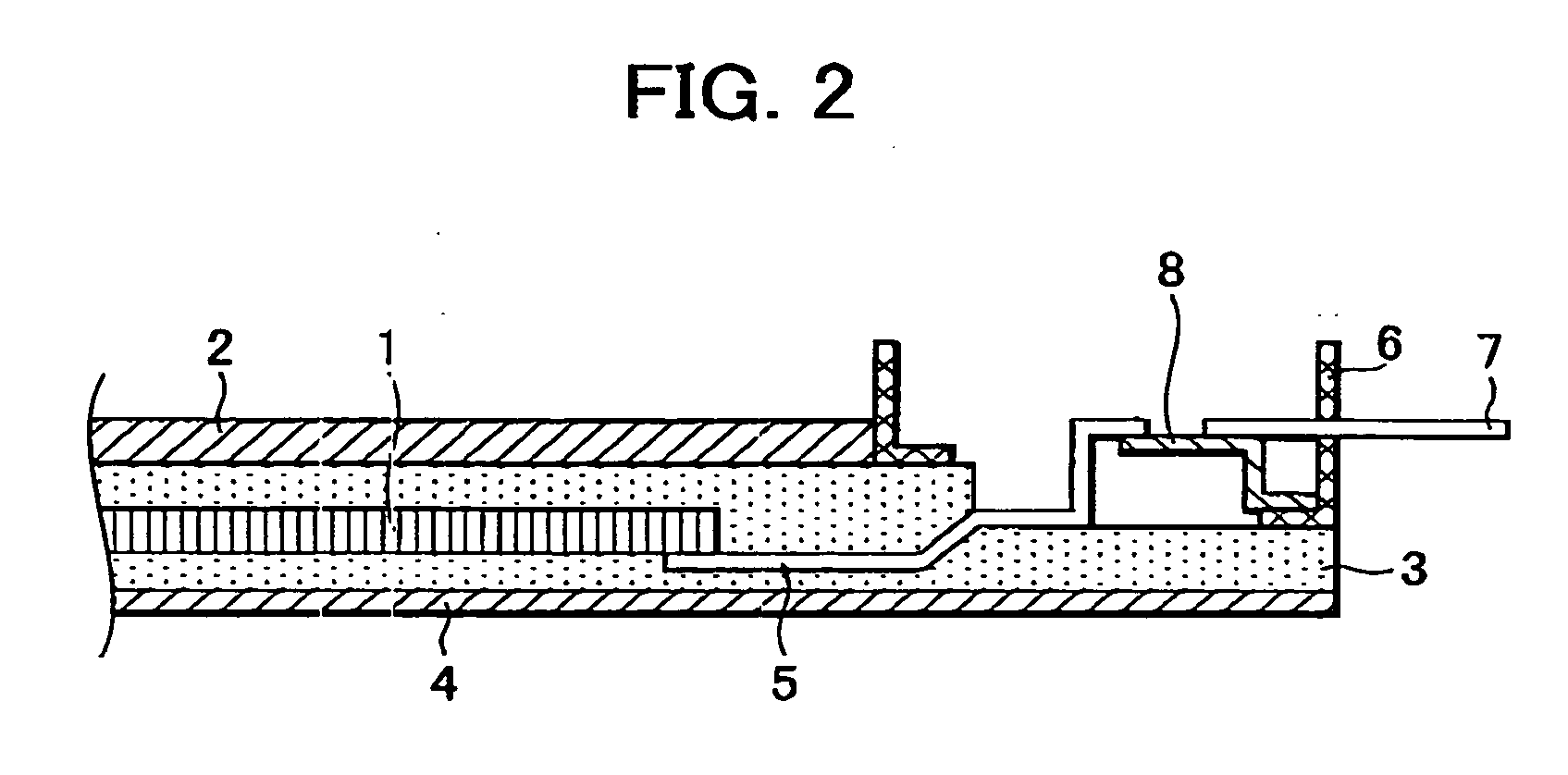

ActiveUS8593061B2Shorten planar lengthEnsure reliabilityDischarge tube luminescnet screensLamp detailsEngineeringElectron

An electro-optical device includes a display panel obtained by forming an electro-optical layer, in which a plurality of pixels is formed, on a glass substrate having a thickness of 50 μm or less; and a support frame supporting the display panel, wherein the display panel has at least a display region in which the plurality of pixels is formed and frame regions formed outside the display region, and wherein at least one side of each of the frame regions is bent from the vicinity of a circumference of the display region to the support frame side and is fixed to the support frame.

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

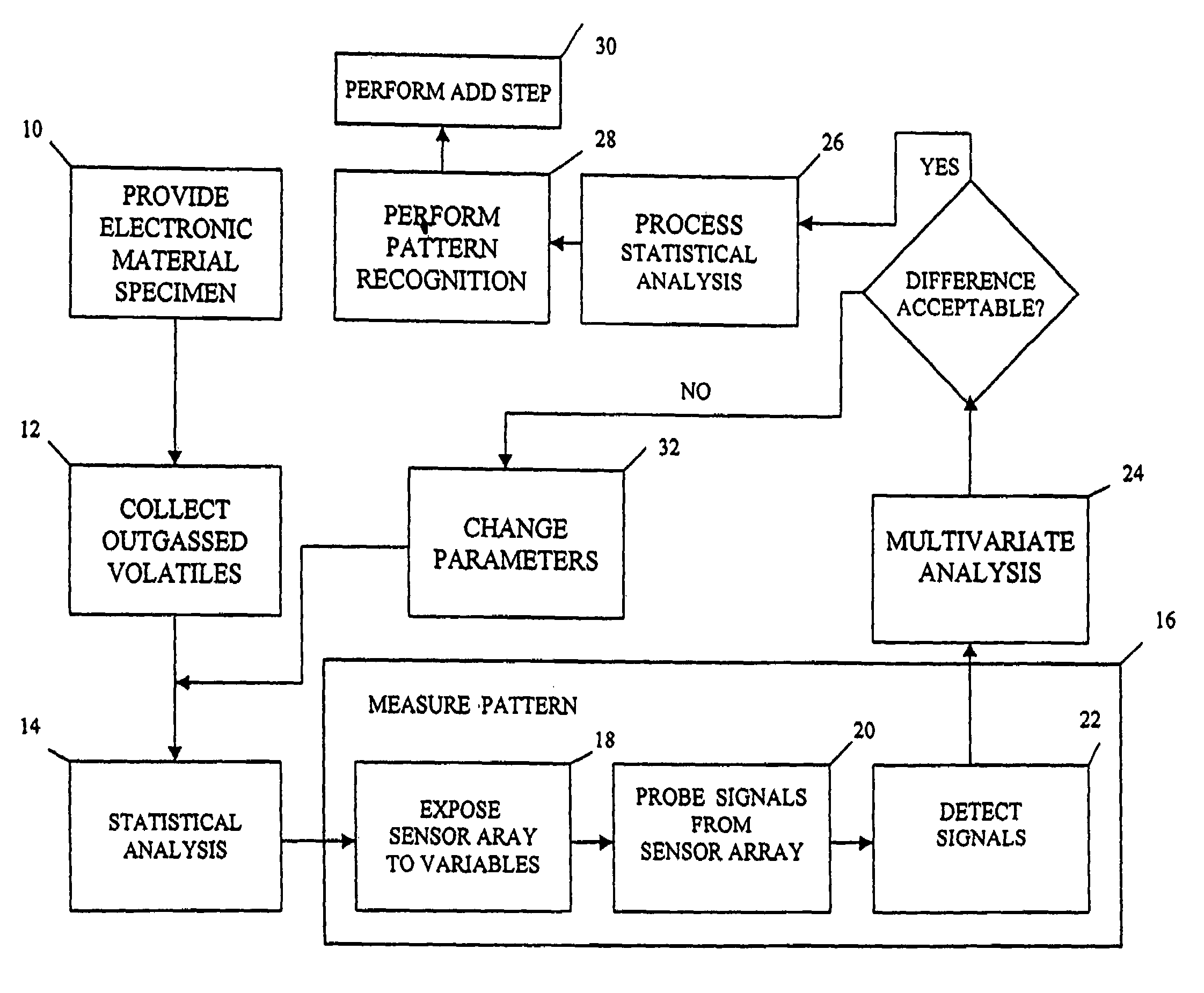

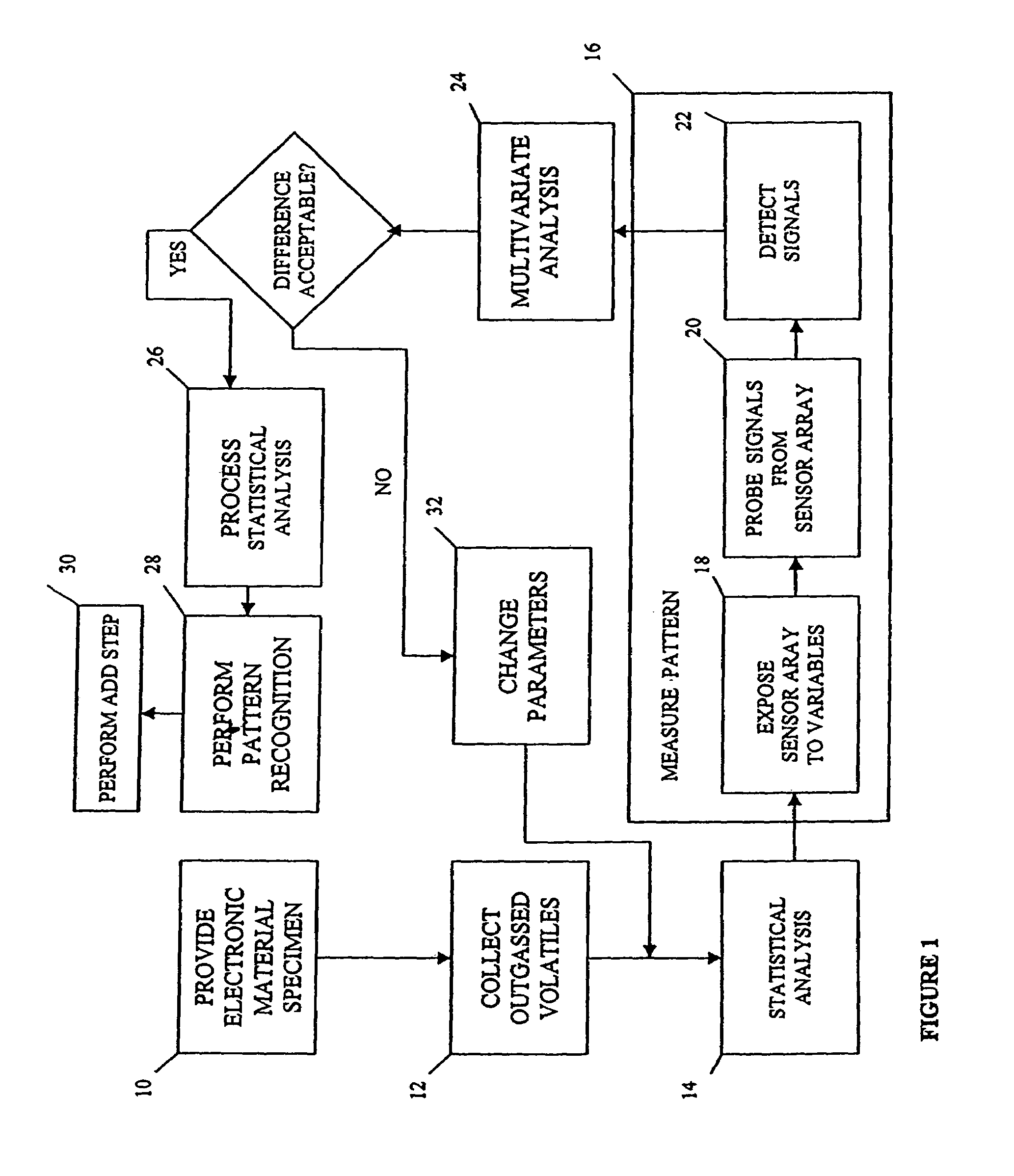

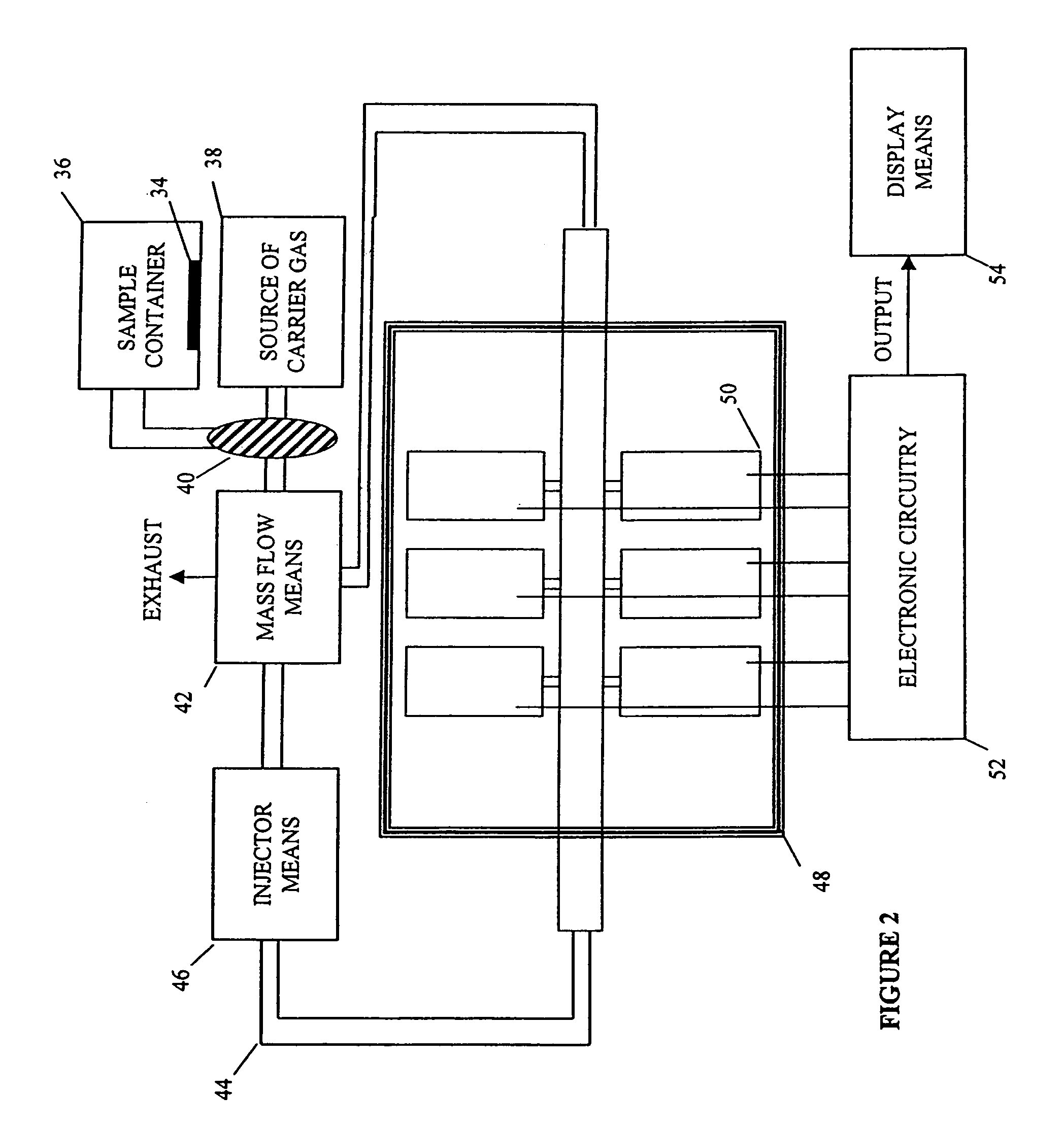

Method and apparatus for monitoring materials used in electronics

InactiveUS6975944B1Quality controlFast and conveniently curableMaterial resistanceSpecial data processing applicationsIntegrated circuitSensor array

A method and apparatus suitable for monitoring the quality and / or performance of a processing aid or a component during manufacture, storage, or use of electronics or electronic assemblies is provided. The apparatus incorporates a sampling device, a multivariate sensing system (e.g., a multi-sensor array or at least one sensor capable of measuring multiple variables) capable to process an analysis of low vapor pressure or vaporizable constituents in electronics by detecting some changes in the physico-chemical properties of the sensor and / or electronics and applying multivariate analysis. In one embodiment, the sensing system comprises an array of metal oxide sensors and a multivariate analysis algorithm for data processing. This method and apparatus can be employed for various quality control purposes such as contamination analysis or failure analysis of integrated circuits components.

Owner:ALPHA MOS

Solar cell module having an electric device

InactiveUS20050000562A1Efficient extractionReduce manufacturing costPV power plantsSolid-state devicesElectricityEngineering

A solar cell module includes a front member placed at a light-incident side of the module; a sealing member having an exposed section that is not covered with the front member; solar cell elements that are sealed with the sealing member and covered with the front member; and an electric device, stored in a housing, for extracting electricity generated by the solar cell elements. The housing is fixed on the exposed section and is located at a light-incident side of the module.

Owner:CANON KK

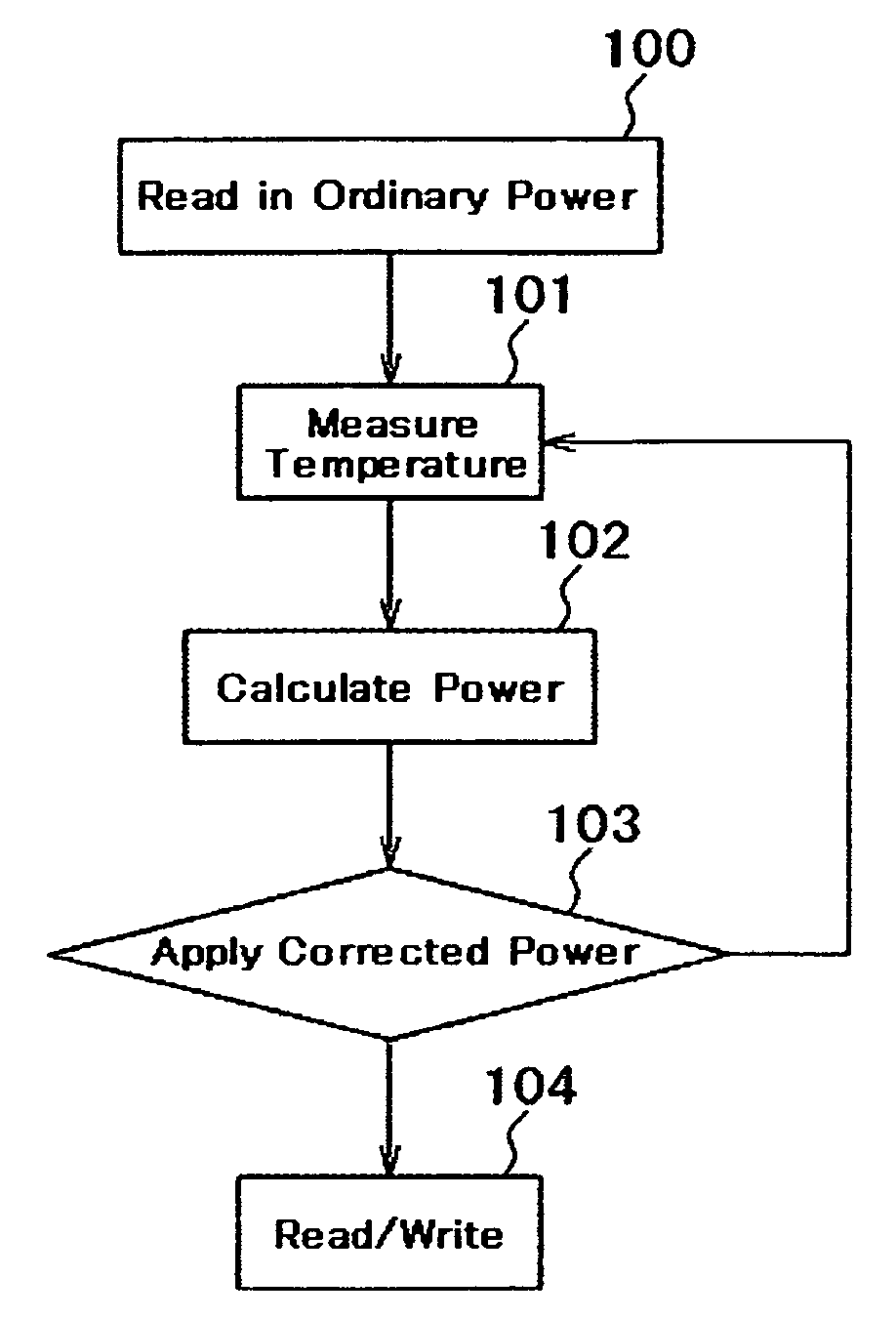

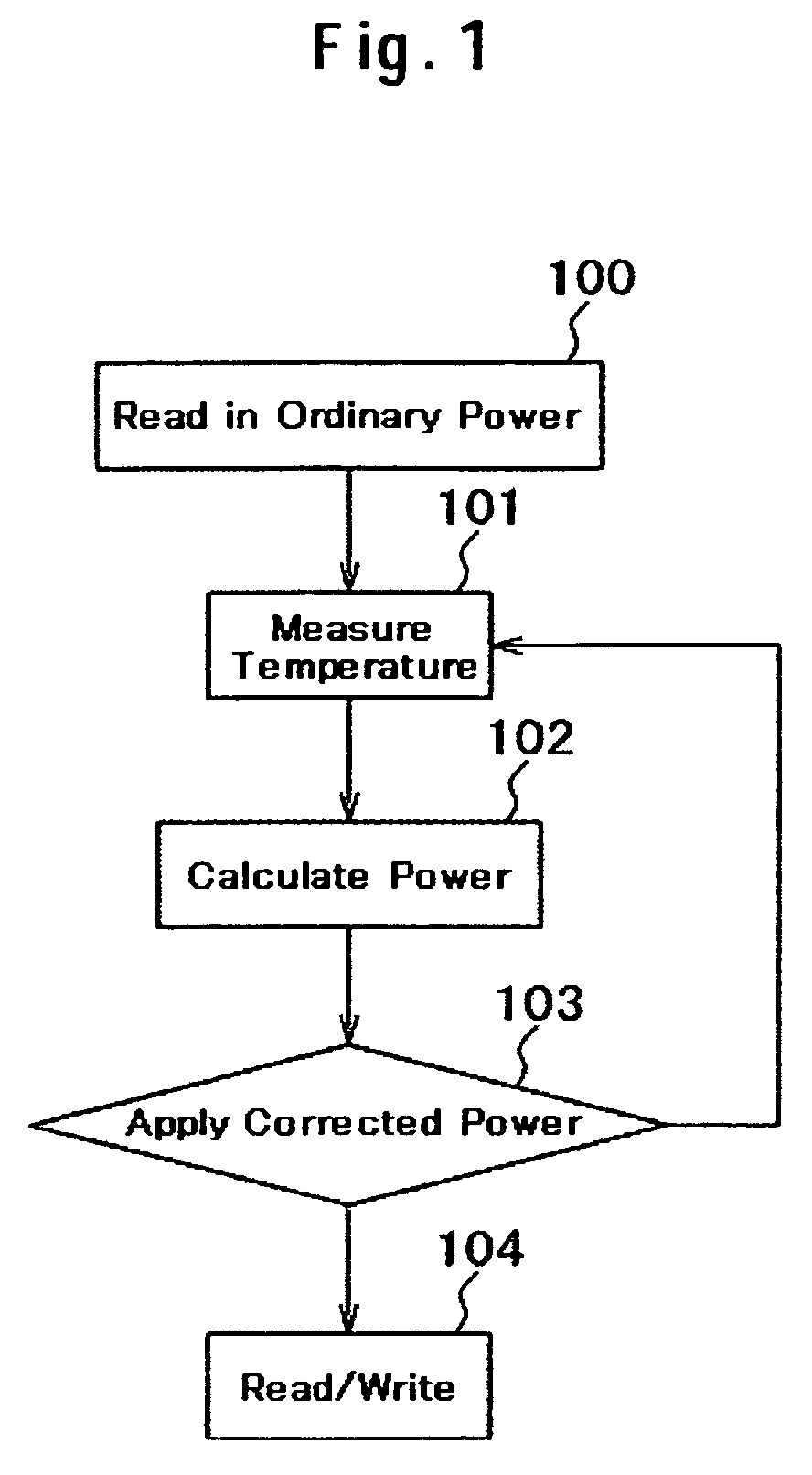

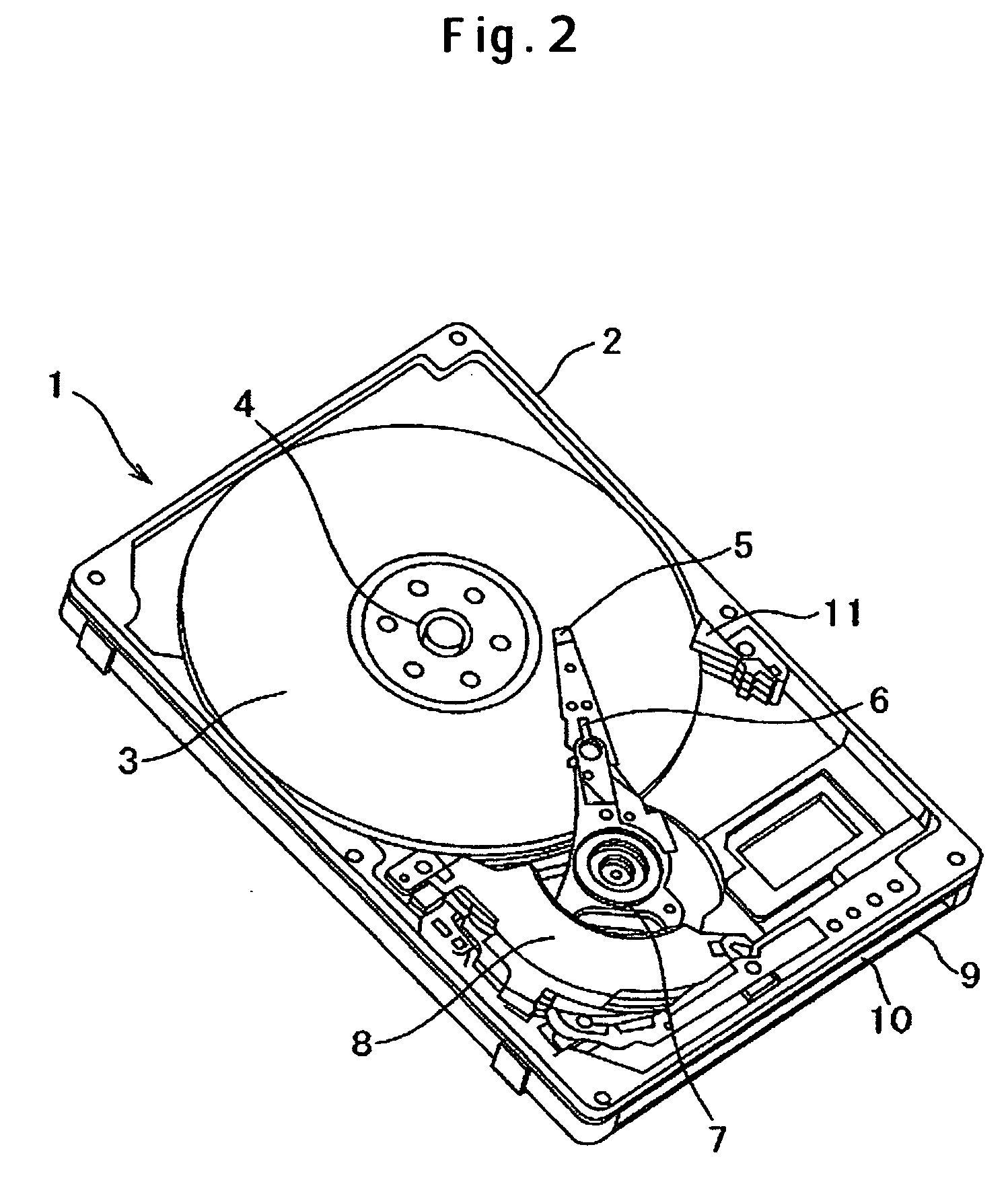

Magnetic disk drive with flying height control system

InactiveUS20060119974A1Improve reliabilityLarge storage capacityDriving/moving recording headsFilamentary/web record carriersInternal memoryControl system

Embodiments of the invention appropriately control the flying height of a magnetic head slider as necessary without making the magnetic head slider touch the magnetic disk. In one embodiment, when a magnetic disk drive is started, the level of electric power predefined for the ordinary temperature (room temperature) is read in from the internal memory of an MPU. A temperature sensor measures the internal temperature of the magnetic disk drive and sends it to the MPU. According to the temperature sent from the temperature sensor, the MPU calculates the level of electric power which should be applied to a flying height adjustment structure. According to the calculated electric power, the MPU increases or decreases the electric power applied to the flying height adjustment structure. At a flying height controlled (corrected) by the flying height adjustment structure, a magnetic head slider performs read / write on a magnetic disk.

Owner:WESTERN DIGITAL TECH INC

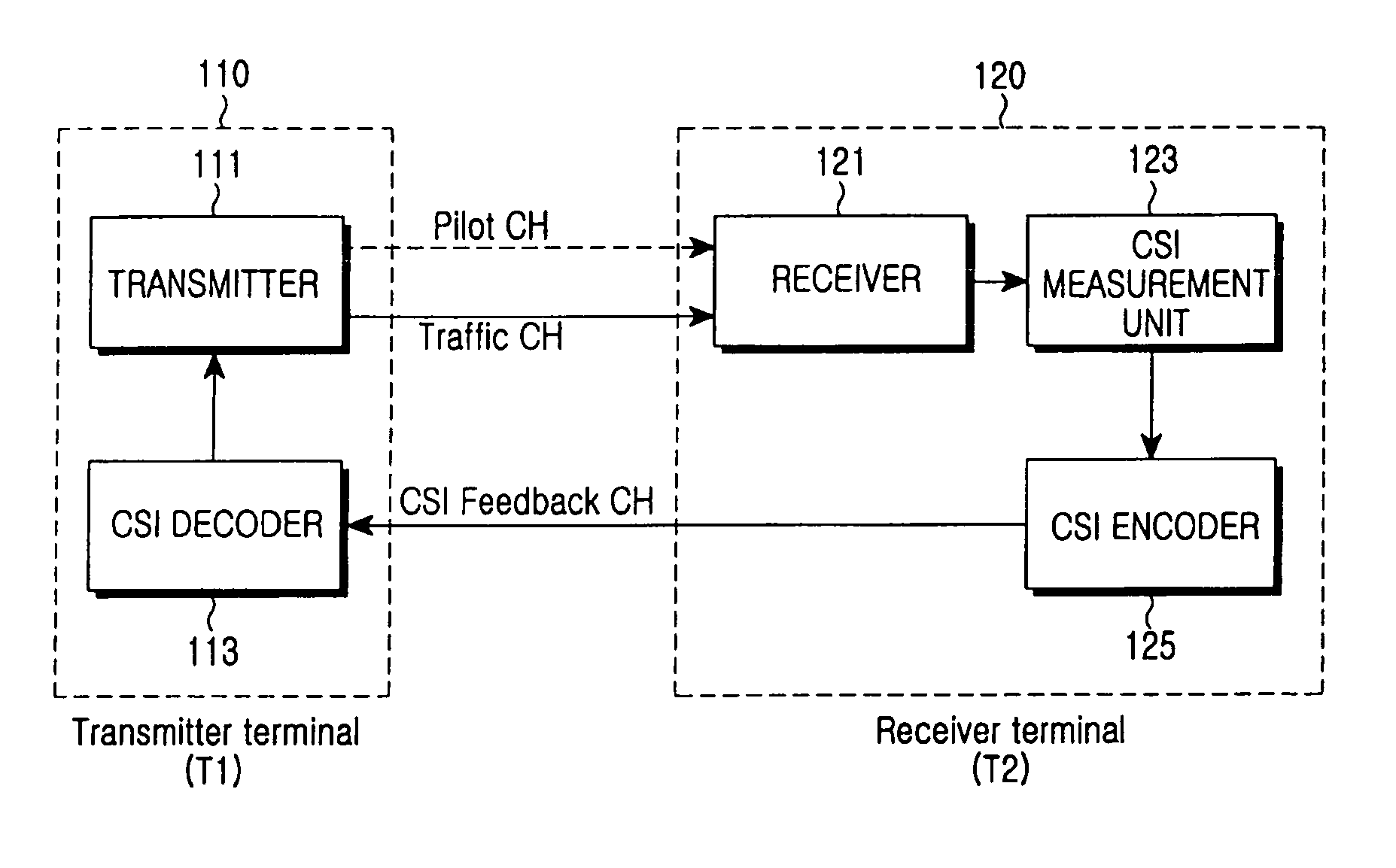

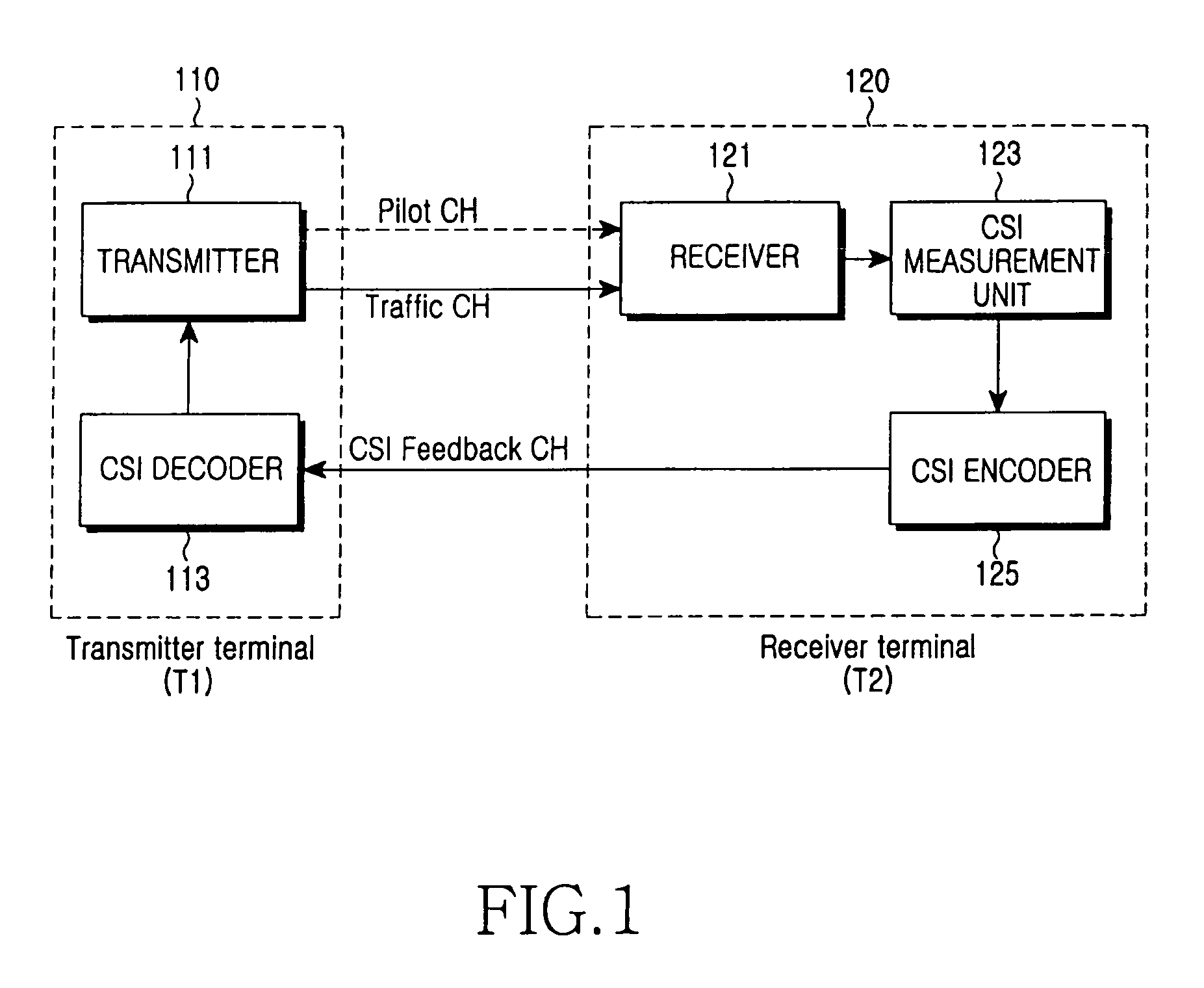

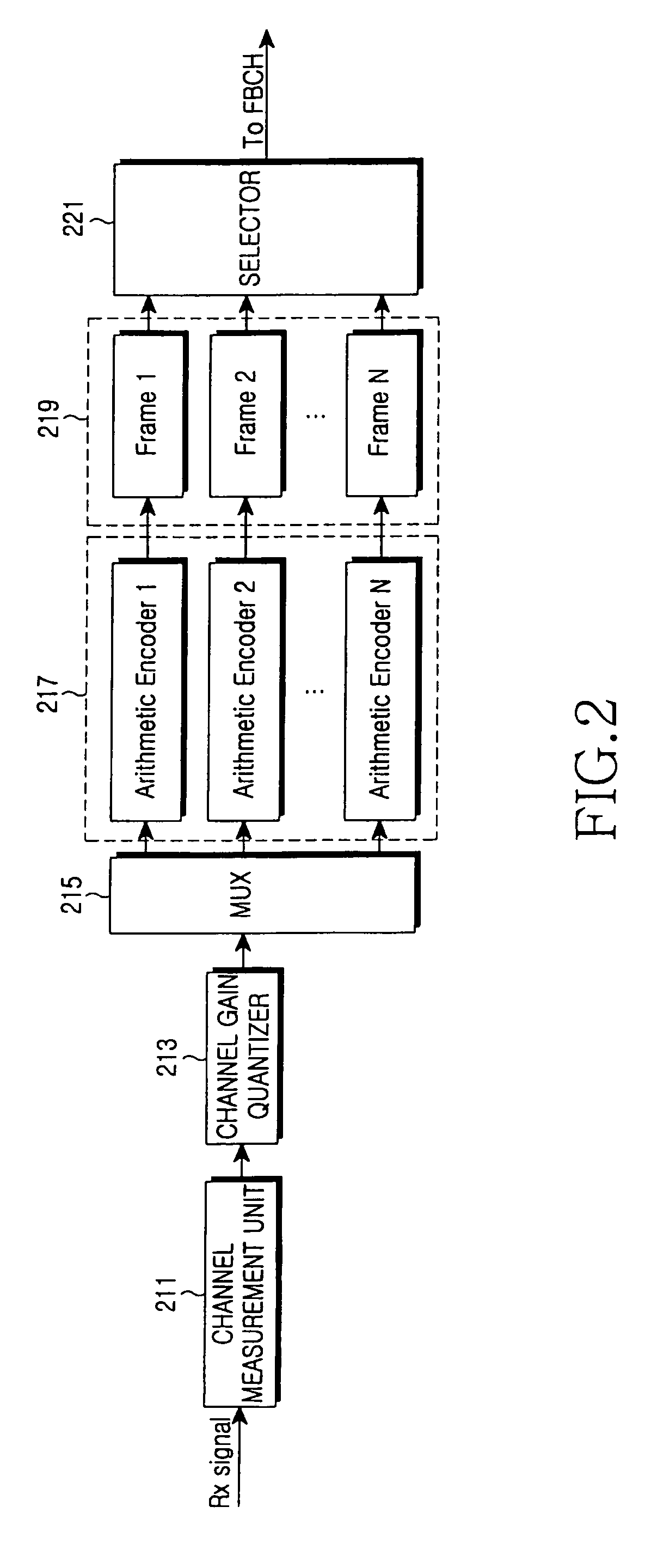

Method and apparatus for channel state feedback using arithmetic coding

ActiveUS7746802B2Reduce impactImprove system performanceFrequency-division multiplex detailsModulated-carrier systemsCommunications systemEngineering

Disclosed are the design and implementation of a CSI feedback channel in a multi-carrier wireless communication system. An apparatus and a method for channel state feedback using arithmetic coding are provided to ensure efficiency and reliability of a system by transmitting the CSI while compressing the CSI with a predetermined compression rate selected depending on a channel state. The apparatus for CSI feedback in a wireless communication system performing channel estimation at a transmitter or a receiver by using a communication channel includes a transmitter terminal transmitting a signal for CSI measurement by using the communication channel, and a receiver terminal receiving the signal from the transmitter terminal, checking a channel state based on the received signal, and transmitting the signal to the transmitter terminal after compressing the signal according to the channel state.

Owner:SAMSUNG ELECTRONICS CO LTD +1

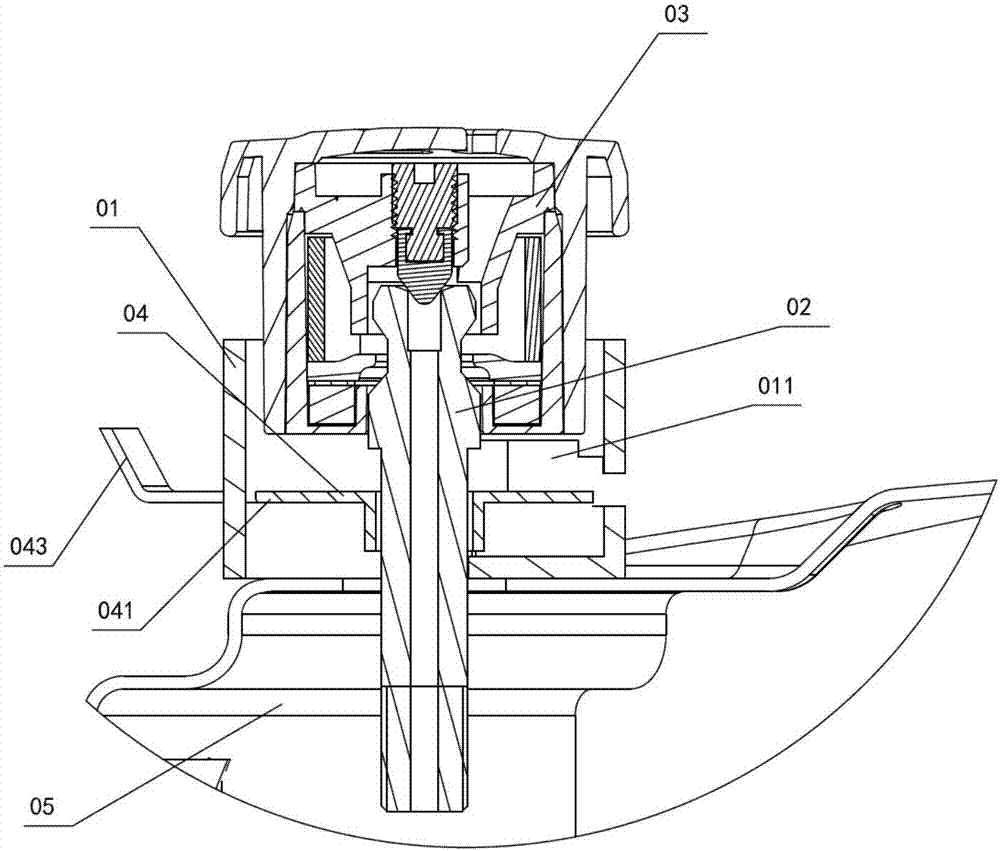

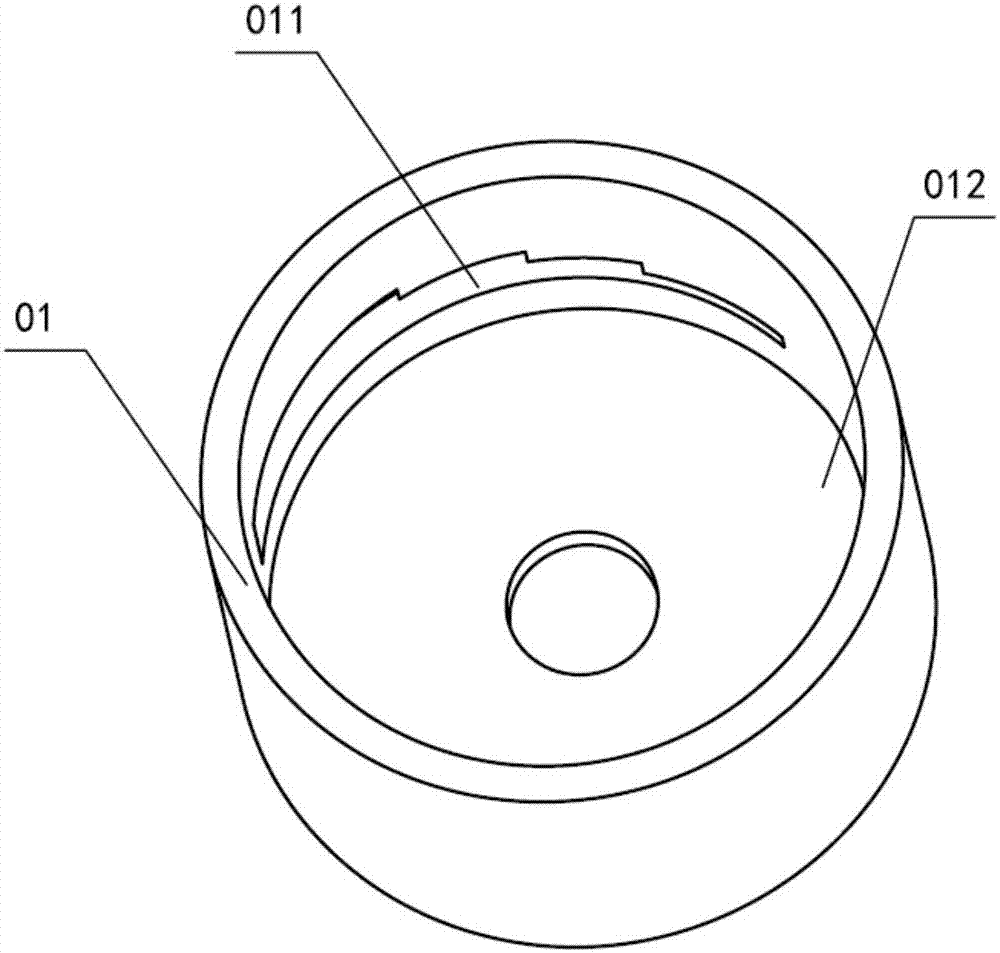

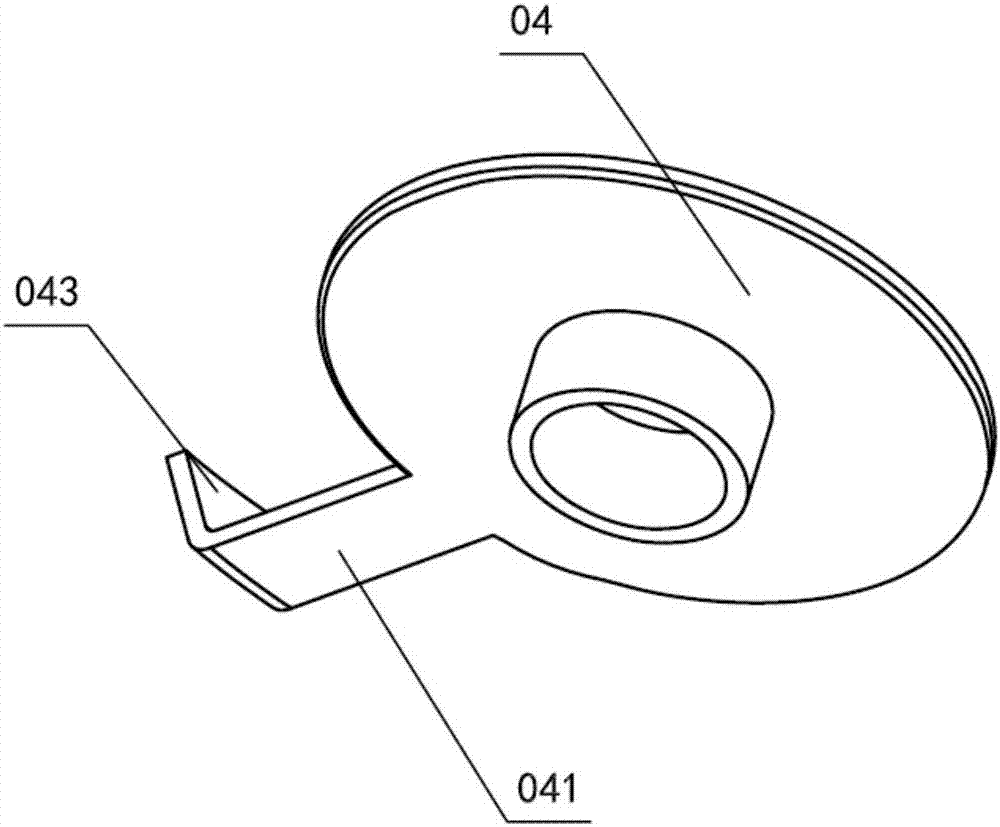

Pressure adjusting structure and pressure cooker having same

ActiveCN107136911AAchieve regulationImprove food cookingPressure-cookersElastic componentEngineering

The invention provides a pressure adjusting structure comprising a valve seat, an exhaust tube and a magnetic valve body. The lower end of the exhausting tube passes through the valve seat; the magnetic valve body sleeves the upper end port of the exhausting tube; a magnetic cushion block is arranged between the valve seat and the magnetic valve body; and the magnetic cushion block is connected with the valve seat via a magnetic cushion block adjusting structure adjusting up-down positions of the magnetic cushion block. When a pressure limiting value of a pressure-limiting valve has to be adjusted, the up-down positions of the magnetic cushion block is adjusted by the magnetic cushion block adjusting structure, so a distance from the magnetic gasket to the magnetic valve body can be changed; when the distance changes, magnetic field force between the magnetic cushion block and the magnetic valve body can be changed; the pressure limiting value of the pressure limiting valve is the self weight of the magnetic valve body and the magnetic field force between the pressure limiting valve and the magnetic valve body; the pressure limiting value of the pressure limiting valve can be adjusted and food cooking effect of the pressure cooker can be improved; meanwhile, the use of elastic components such as springs can be avoided in the adjusting structure, so fewer components are required; and the pressure adjusting structure is simply structured, convenient to assembly and has high reliability.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Photovoltaic element and method of producing photovoltaic element

InactiveUS20060260673A1Reliability of photovoltaicEasy to connect in seriesPhotovoltaic energy generationSemiconductor devicesOptoelectronicsDegrees of freedom

A photovoltaic element is provided which has at least a photovoltaic layer and a transparent electrode layer deposited on a metal substrate, a portion of the transparent electrode layer being continuously removed at a peripheral part of the metal substrate, wherein an island-shaped transparent-electrode-layer-removed-portion is provided in the transparent electrode layer in a power-generating region surrounded by the removed portion of the transparent electrode layer, a rear surface side bus-bar electrode electrically connected to the metal substrate is disposed on the rear surface side of the metal substrate at the rear of the island-shaped transparent-electrode-layer-removed-portion, and the rear surface side bus-bar electrode is connected to the metal substrate at a portion corresponding to the island-shaped transparent-electrode-layer-removed-portion, and which can enhance the degree of freedom for the shape of a photovoltaic element module while ensuring the reliability of the photovoltaic element.

Owner:CANON KK

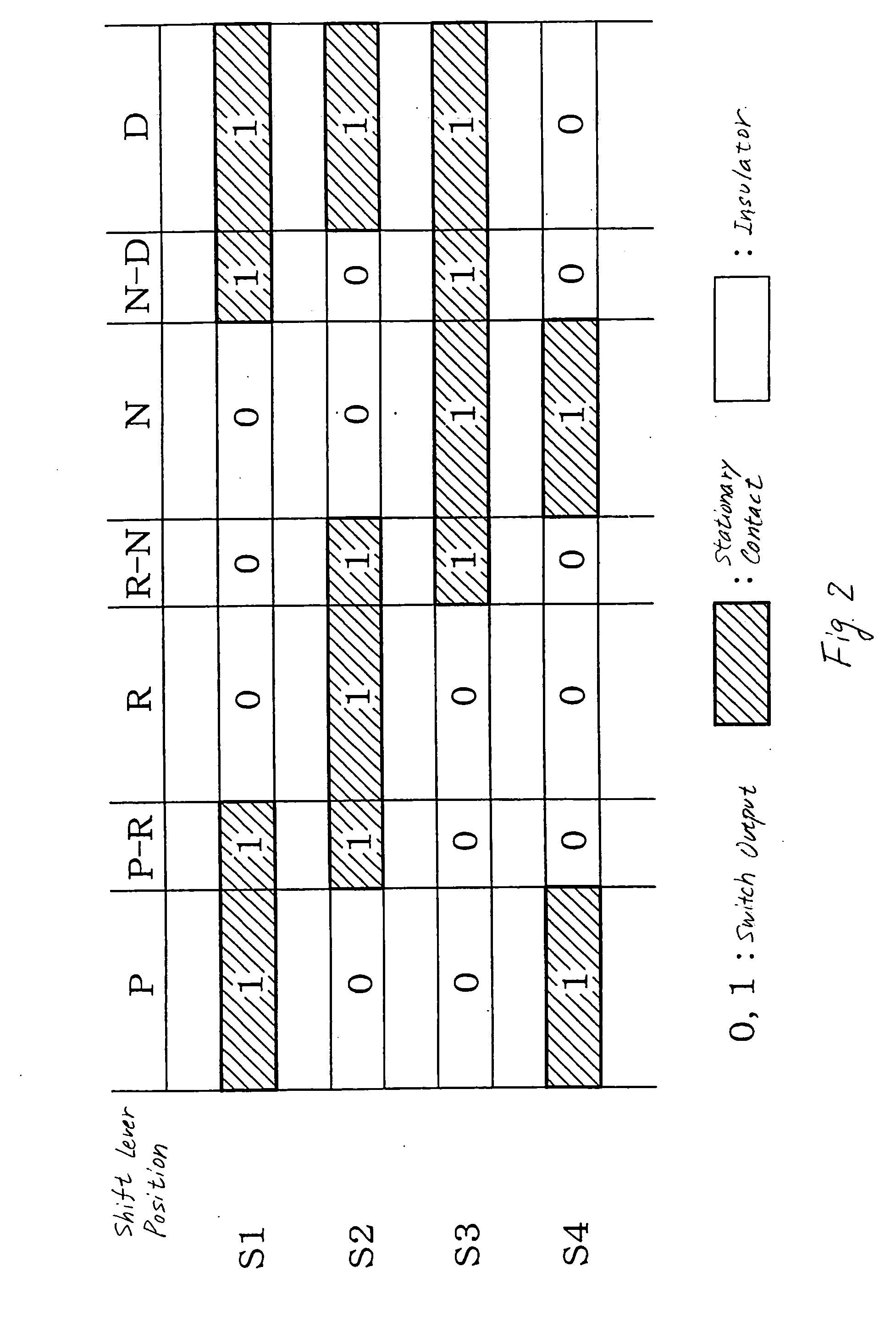

Automatic transmission control system with shift lever position sensor

InactiveUS20050126322A1Operation failureEnsure reliabilityGearing controlAutomatic transmissionControl system

An automatic transmission control system equipped with a shift lever position sensor which includes a plurality of switches which output binary signals following a shifting motion of a gear shift lever. Patterns of combinations of the switch outputs are preselected so as to represent positions to which the gear shift lever is manually shiftable. The switches are broken down into two groups each of which produces a binary code carrying information about the position of the gear shift lever to monitor a failure in operation of the shift lever position sensor. The control system also works to perform a deemed D-position hydraulic transmission control to ensure the running of the vehicle even if the shift lever position sensor is failing.

Owner:DENSO CORP

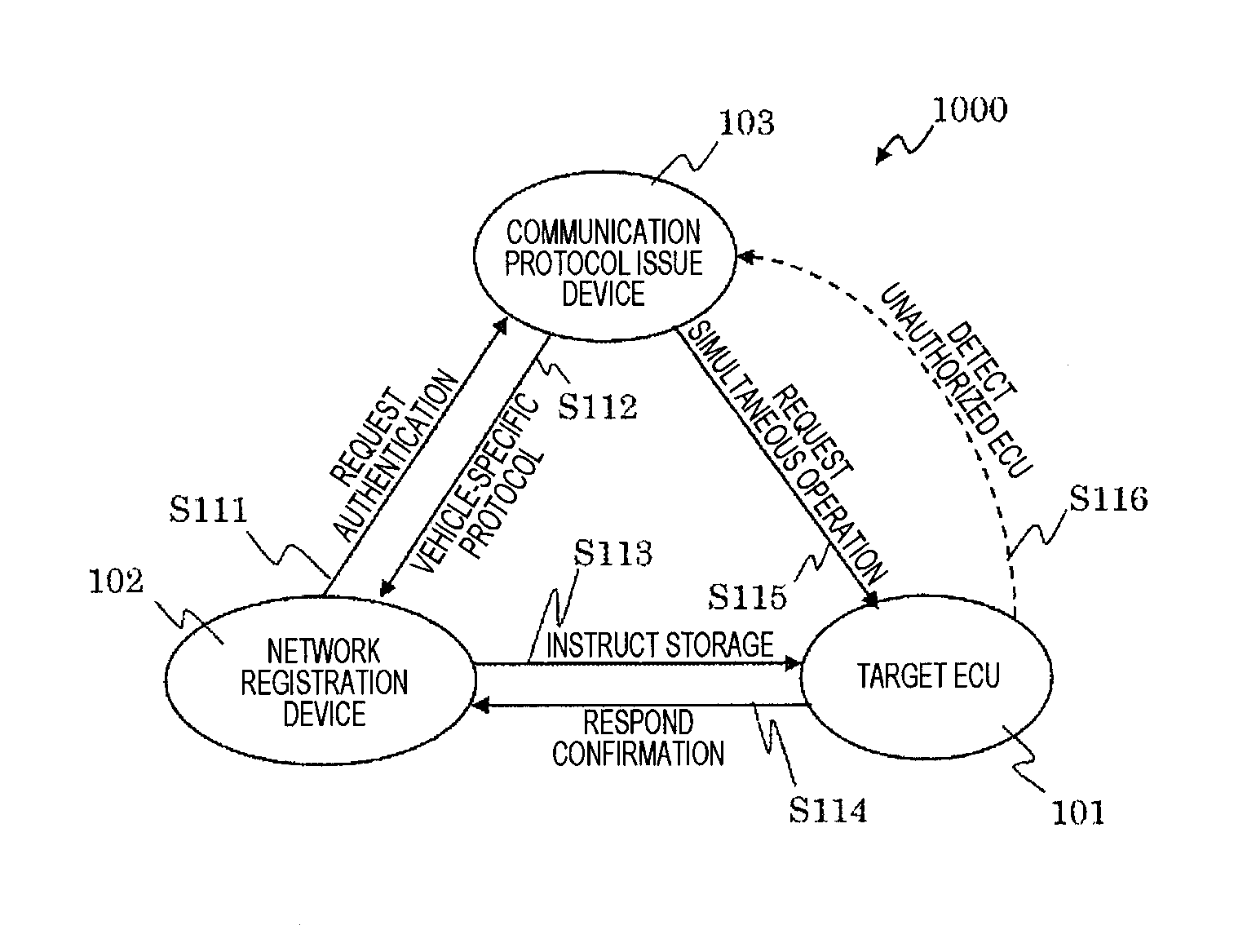

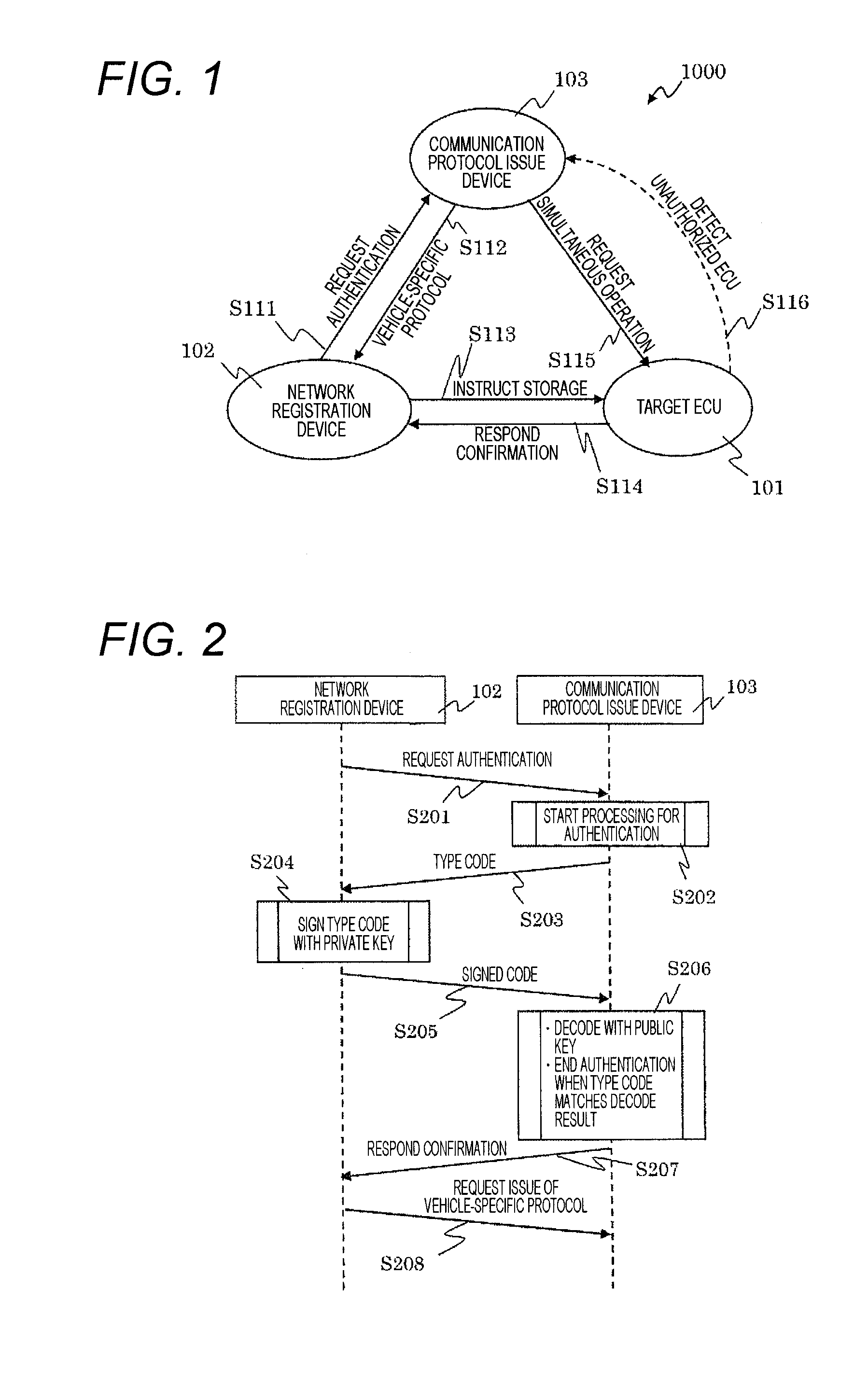

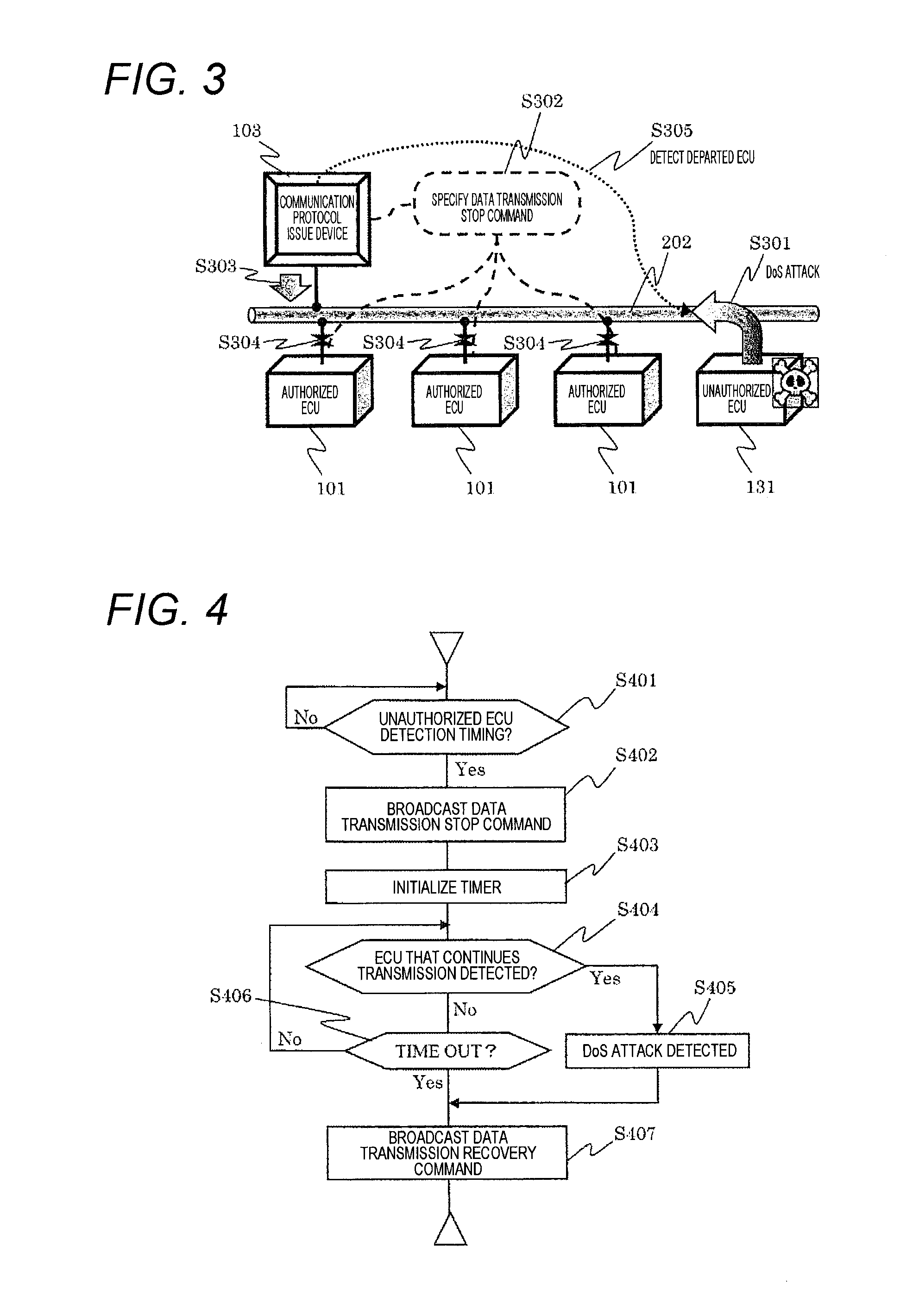

Vehicle-Mounted Network System

InactiveUS20160173530A1Secure reliabilityEnhanced securityDigital data processing detailsMultiple digital computer combinationsReal-time computing

Provided is a vehicle-mounted network system that enhances security of a vehicle by detecting or eliminating an attack on a vehicle-mounted network from an unauthorized ECU while reducing an increase in a processing load (and cost) of each vehicle-mounted control device.The vehicle-mounted network system according to the present invention provides a communication protocol issue device having a function of distributing definition data that defines a portion that is based on implementation on the vehicle-mounted network among communication protocols to the vehicle-mounted control device via a registration device that allows the vehicle-mounted control device to register in the vehicle-mounted network.

Owner:HITACHI AUTOMOTIVE SYST LTD

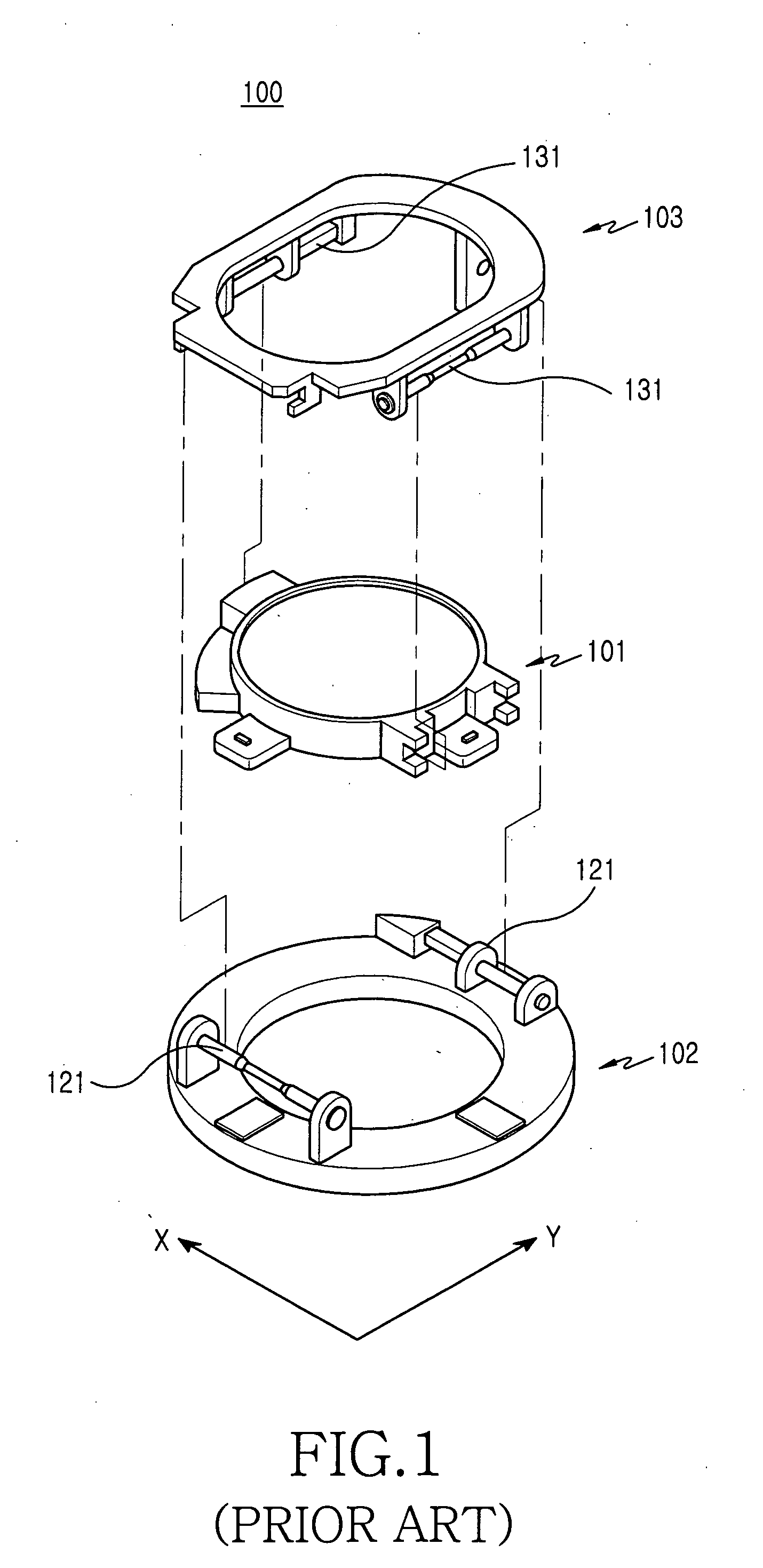

Optical image stabilizer for camera lens assembly

InactiveUS20060092285A1Facilitate downsizingEnsures solidityTelevision system detailsColor television detailsCamera lensEngineering

An optical image stabilizer for a camera lens assembly includes: a board that has an image sensor on a top surface thereof and disposed movably in the housing, the board and the housing being spaced apart from each other; at least one magnetic body disposed between the board and the housing, the magnetic body providing a magnetic force acting in a direction along which the board is closely contacted to inner surface of the housing; at least three balls interposed between the board and the inner surface of the housing for maintaining the board in such a state that it is spaced apart from the housing; and a driving unit for correcting the position of the image sensor by moving the board according to the degrees of trembling of user's hands. In the optical image stabilizer for a camera lens assembly, the driving unit for driving the board, on which an image sensor is mounted, is present substantially on the same surface as the board itself. As a result, the optical image stabilizer can downsize a product equipped with a camera lens assembly and can improve the reliability of the product.

Owner:SAMSUNG ELECTRONICS CO LTD

Fake-proof marking of a composition

InactiveUS20060035380A1Ensure reliabilitySmall possible amountCosmetic preparationsHair cosmeticsAtomic elementRadiochemistry

The invention relates to a process for the fake-proof marking of a product, by introducing at least one non-radioactive stable isotope of at least one atomic element, such that the content of the isotope in the product is higher than its natural content, the isotope being chosen from natural isotopes that have a natural isotopic content of less than 1.2%, and better still less than 1%.

Owner:LOREAL SA

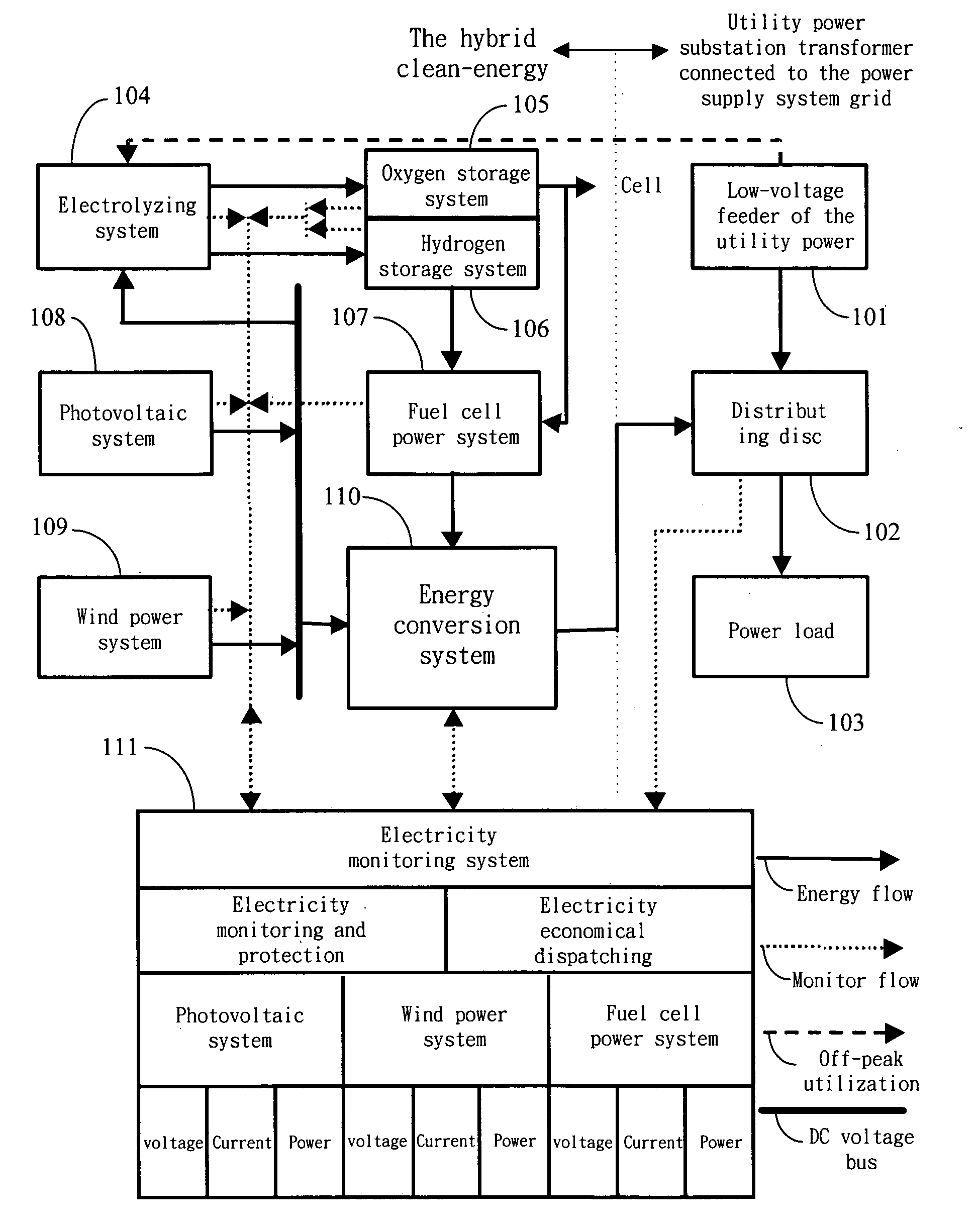

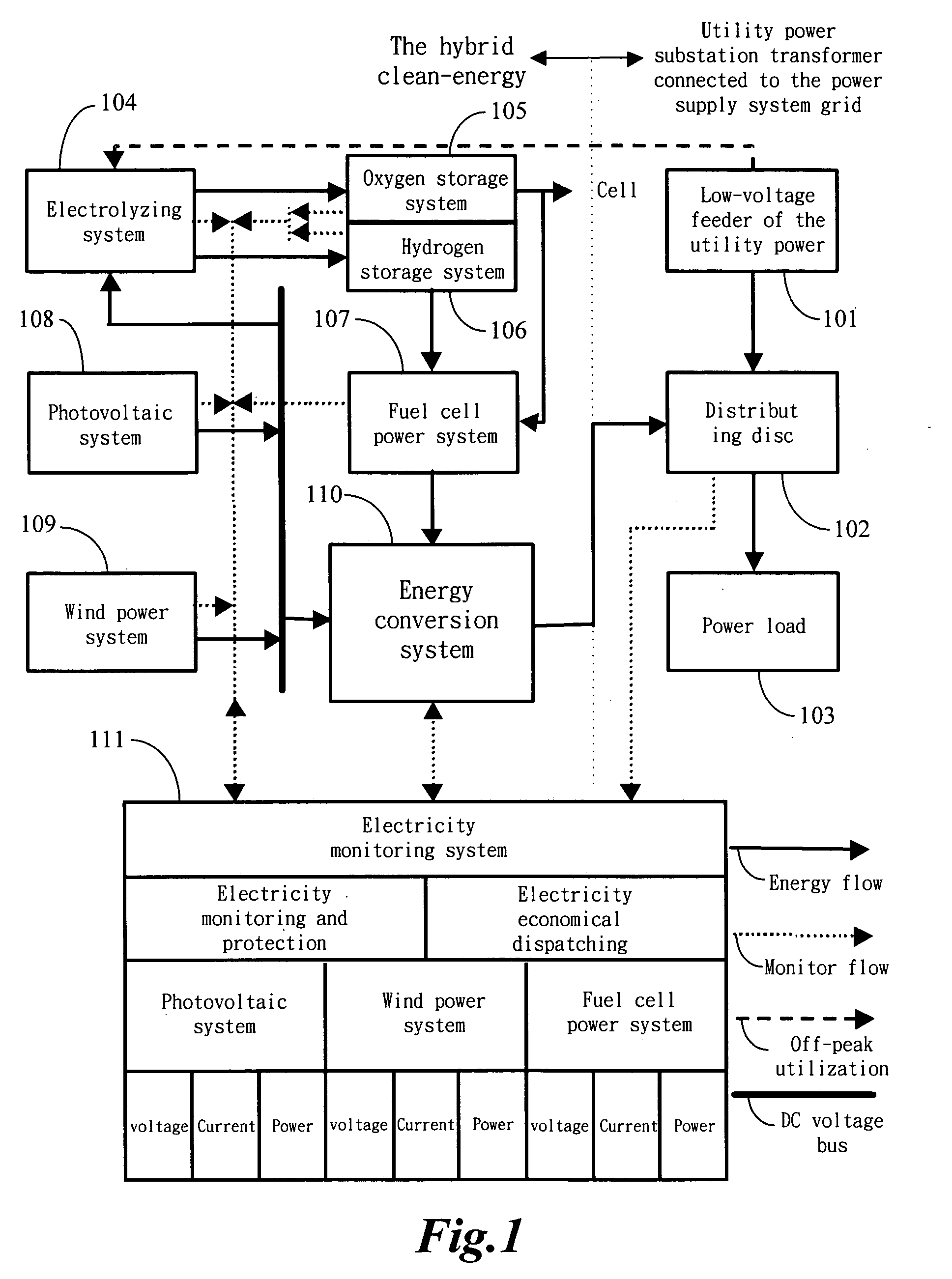

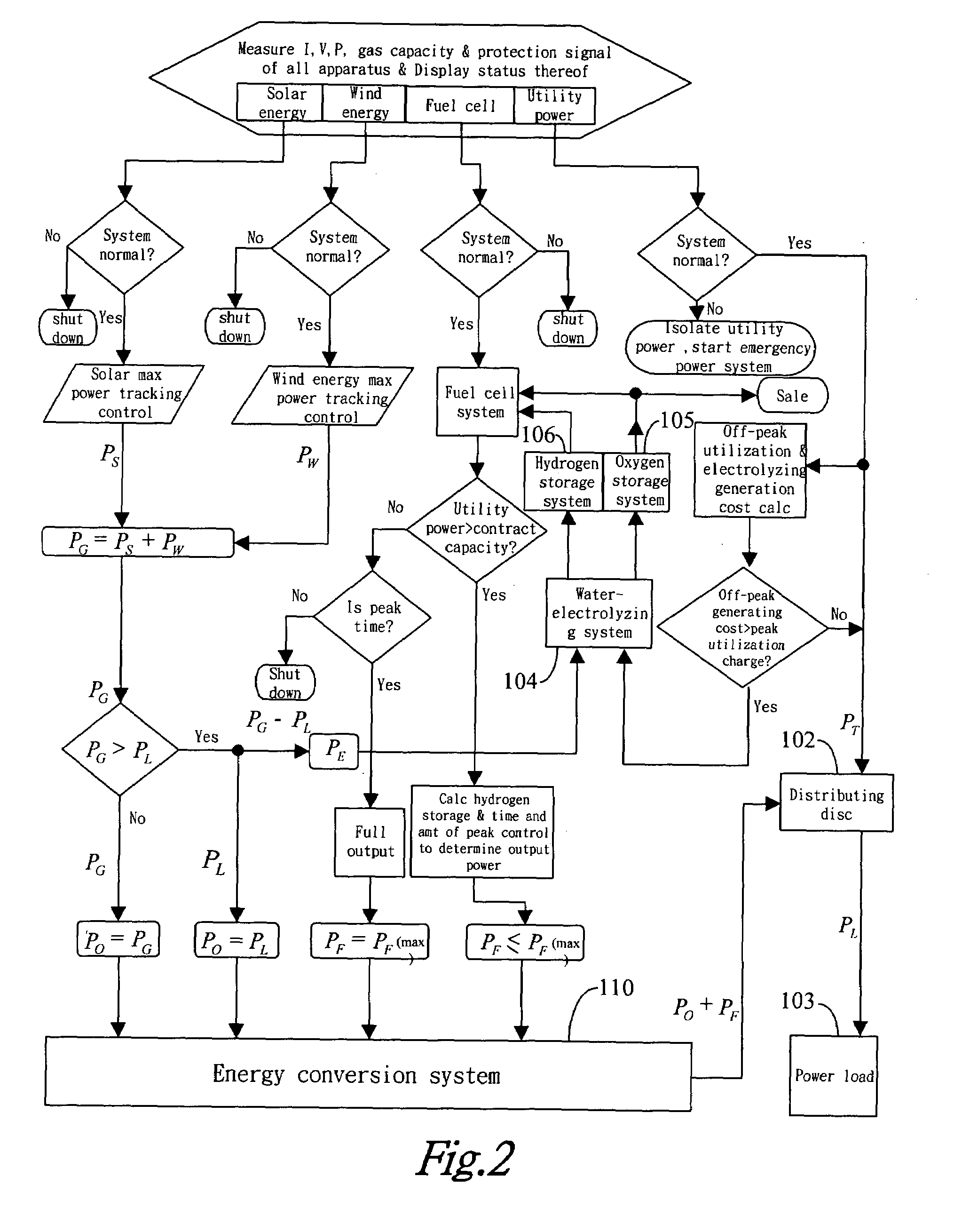

Hybrid clean-energy power-supply framework

ActiveUS7000395B2Accurate calculationEnsure reliabilityReciprocating combination enginesBatteries circuit arrangementsElectrical batteryClean energy

A hybrid clean-energy power-supply framework integrates a fuel cell, solar cell, and wind energy, applies a max power tracking rule, raises the output power of a solar cell and wind energy to supply a power load and transfer the surplus electrical energy to a water-electrolyzing apparatus for producing hydrogen and oxygen, and provides a fuel for a fuel cell power generating system. Furthermore, the present invention utilizes features of each clean-energy power generating system, depends on the powerful calculation capacity of a central processing unit to monitor and dispatch each power generation and supply system, and thus ensures the reliability of supply power and reduces the power generation cost. Such a framework can selectively grid-connect with the utility power or run as a stand-alone power supply system and has a mechanism for preventing the island effect.

Owner:YUAN ZE UNIV

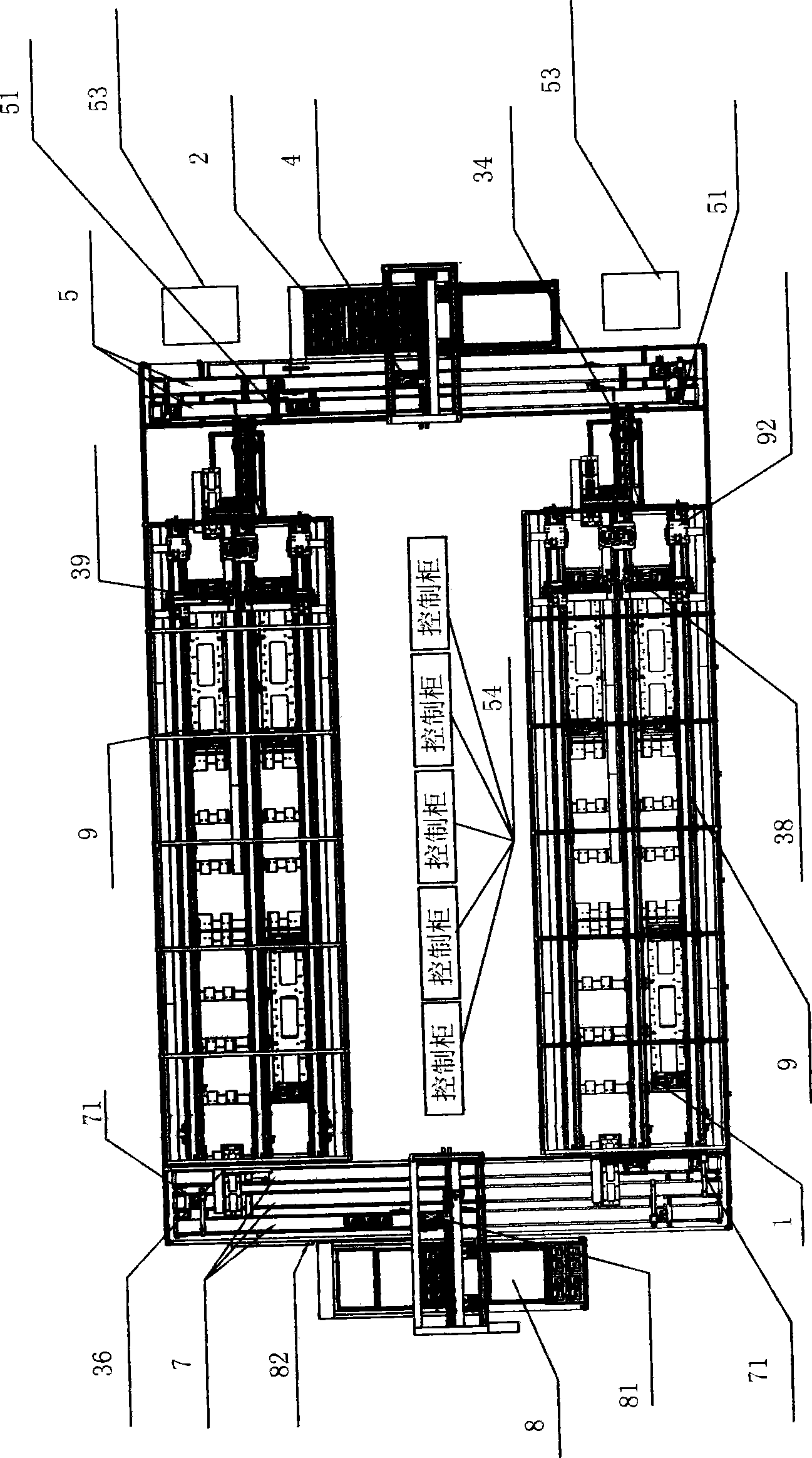

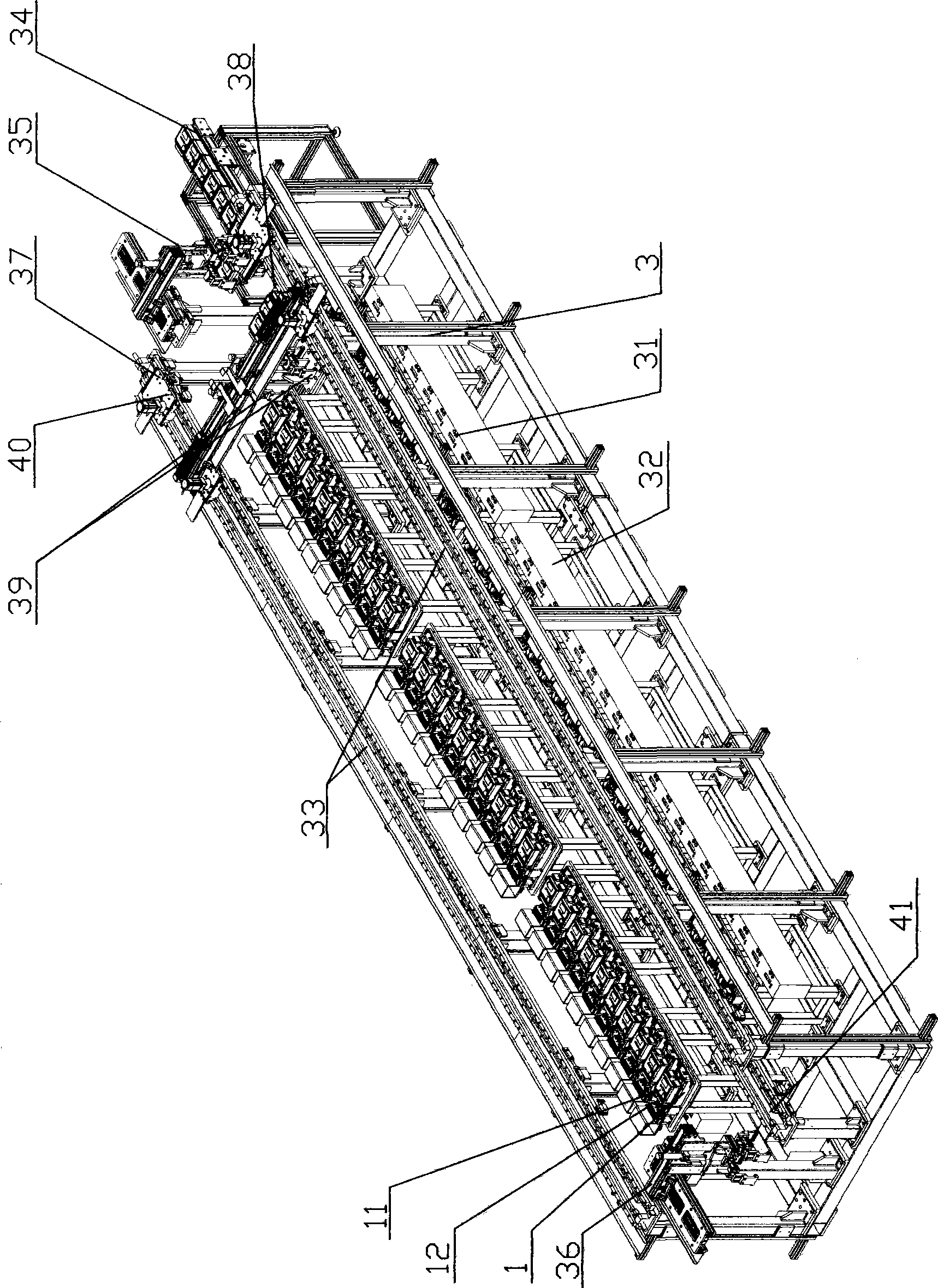

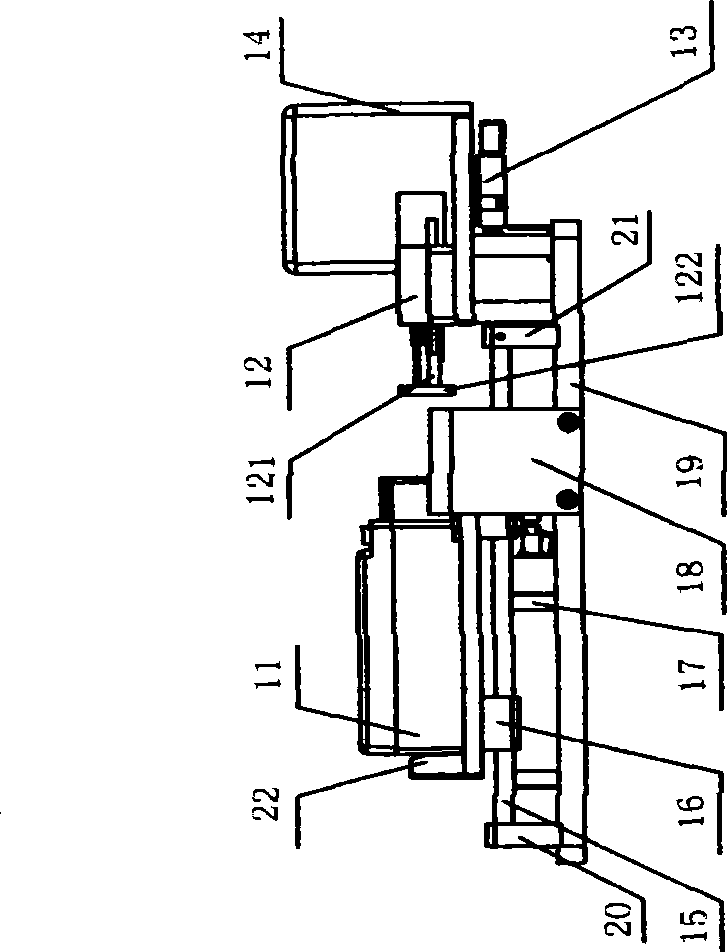

Automatic assembly line standard apparatus for electric energy meter calibration

ActiveCN101464504ARealize automatic feeding processAchieve contactElectrical measurementsProduction lineElectrical connection

The invention discloses an automatic production line standard device detected by an electric energy meter, which comprises a loading platform, a feeding loop line belt and an electric energy meter automatic standard device. The loading platform is connected with the feeding loop line belt; a material taking manipulator and a bar code reader are mounted on the feeding loop line belt; the feeding loop line belt is connected with the electric energy meter automatic standard device; the electric energy meter automatic standard device is simultaneously connected with a blanking conveying loop line belt; a loading manipulator and another bar code reader are mounted on the blanking conveying loop line belt; the loading manipulator is connected with an electric energy meter feeding box; an unqualified product outlet is formed on the blanking conveying loop line belt; the working process of the whole production line in the whole device is controlled by a computer program through a production line control cabinet; and the calibration / detection of the electric energy meter is controlled by a computer calibrating procedure through a calibrating control cabinet. The invention has the advantages of completely improving the calibrating / detecting work efficiency, reducing the labor intensity, improving the work quality, achieving the reliability and the safety of electrical connection, etc.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD SHAOXING POWER SUPPLY CO +1

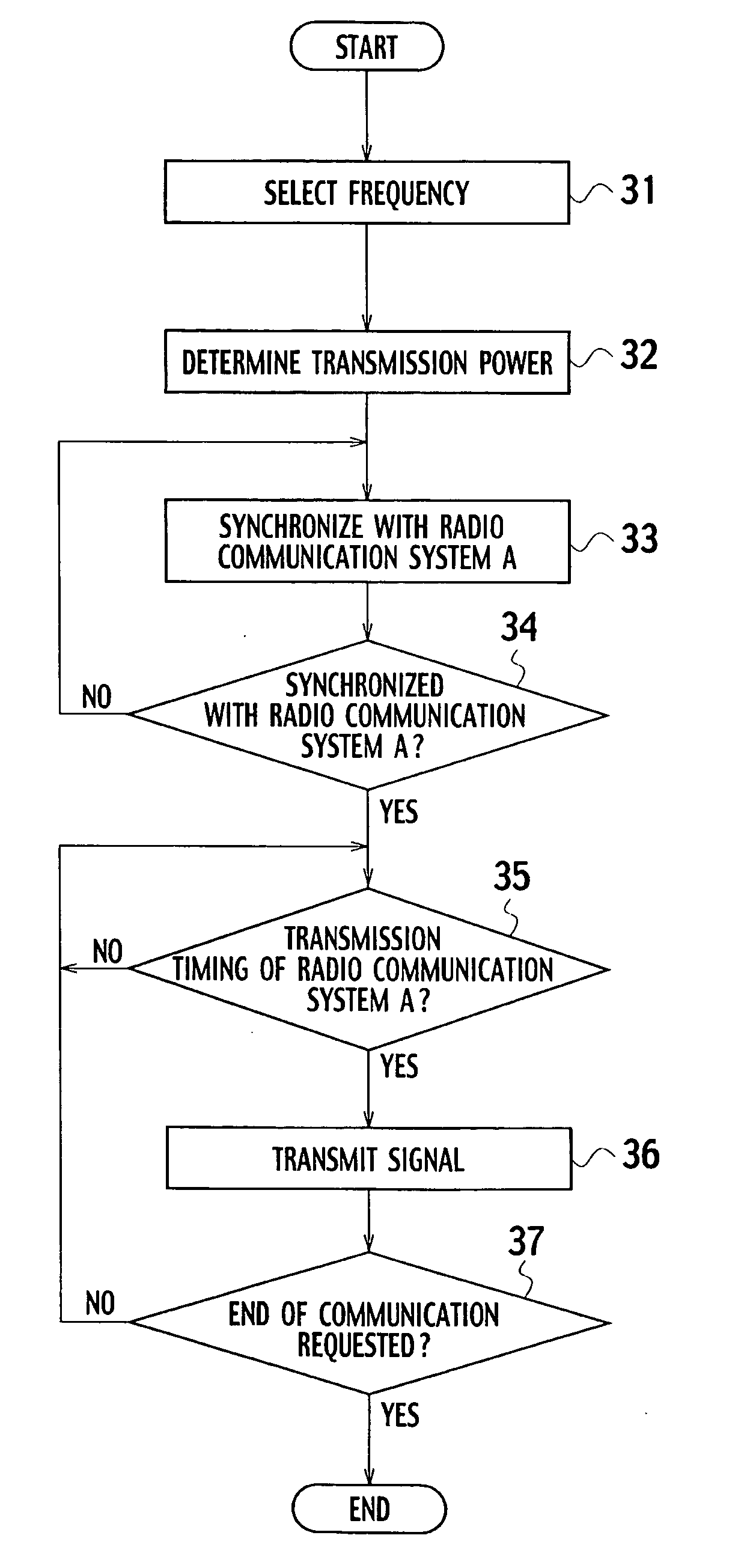

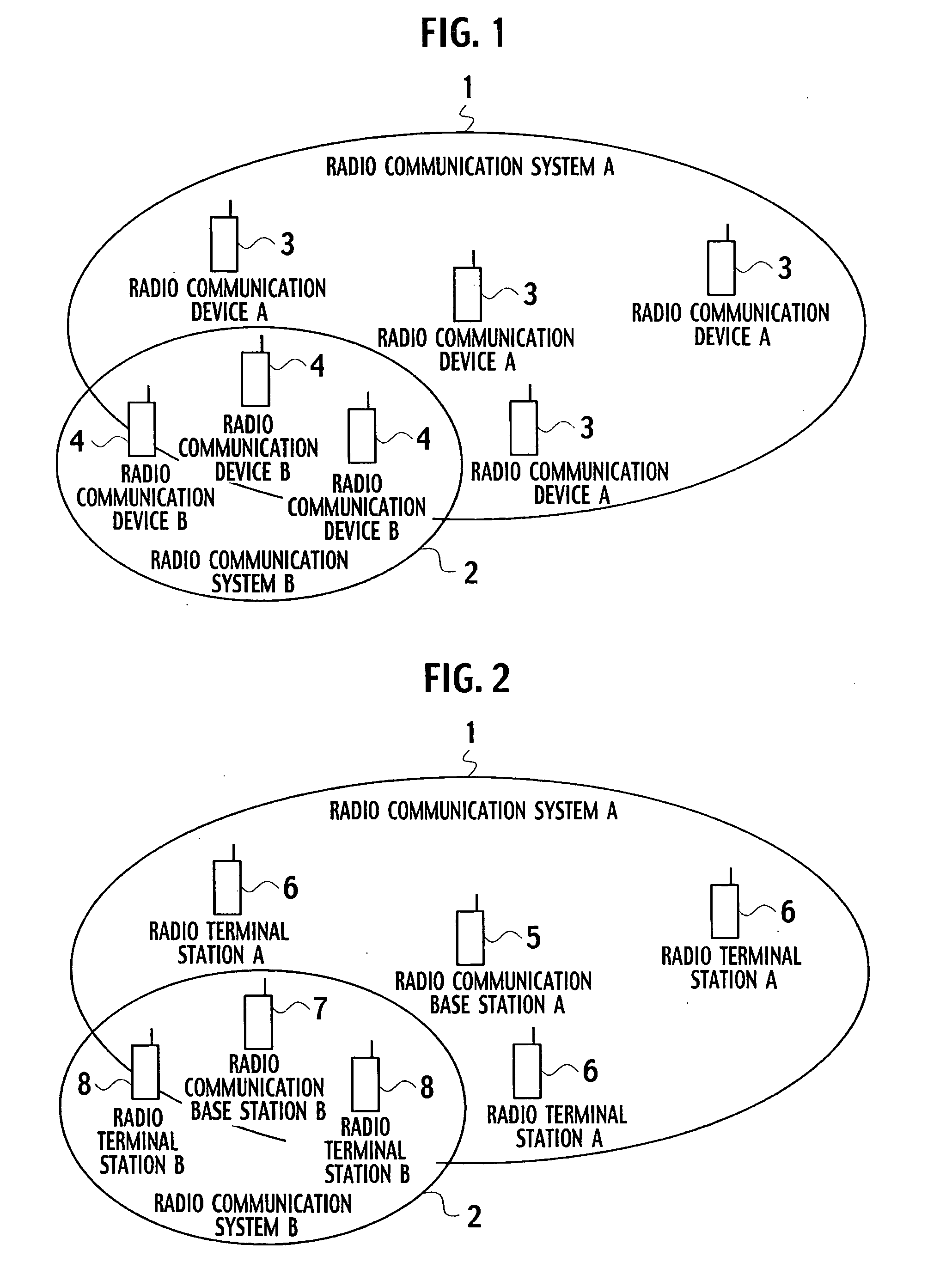

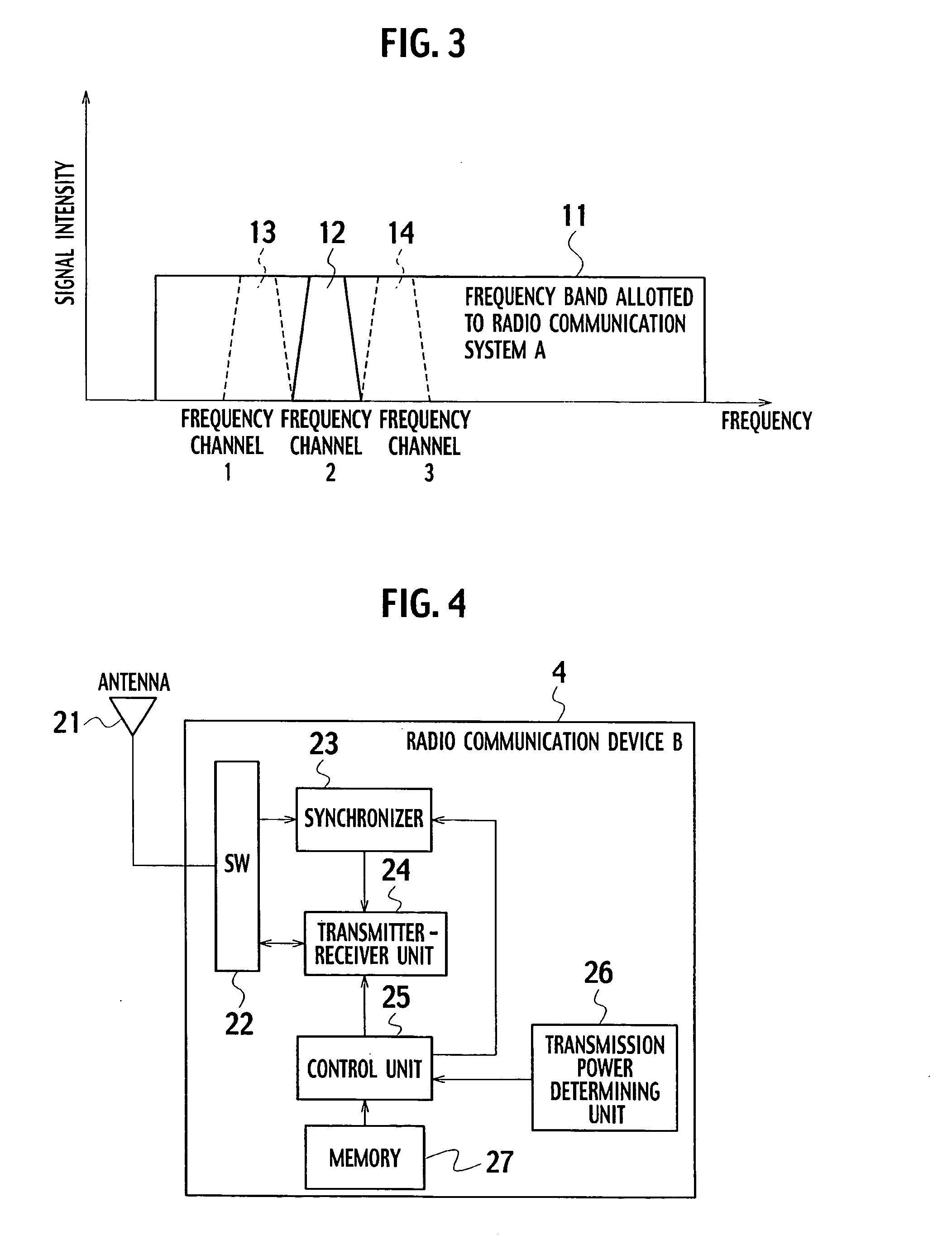

Radio communication device, radio communication method, and radio communication program

InactiveUS20070183392A1Radio communication can be reliablyEnsure reliabilityPower managementError preventionCommunications systemRadio Base Station

A terminal station radio communication device belongs to a second radio communication system which shares a frequency channel with a first radio communication system in which a radio terminal station communicates with a radio base station in a predetermined time period using a predetermined frequency channel. The terminal station radio communication device includes: a transmission power determining unit which sets up signal transmission power, the signal transmission power being usable for communications between radio communication devices belonging to the second radio communication system, and being determined such that reception power at the radio base station is below a predetermined threshold; a synchronizer enabling the radio terminal station to obtain timing information to start signal transmission; and a signal transmitter starting transmitting the signal at the timing represented by the timing information and terminating the signal transmission within a predetermined time period.

Owner:KK TOSHIBA

System and method for inspecting subsea vertical pipeline

ActiveUS20160231278A1Improve accuracyEnsure qualityForce measurement by measuring magnetic property varationMaterial magnetic variablesTomographyGas industry

A device for discovering, identification and monitoring, of mechanical flaws in metallic structures is disclosed, based on magneto-graphic / magnetic tomography technique to identify stress-related defects. The device can determine the position of the defect or stress including depth information. The device includes registration means that optimized for use with metallic structures of various types, shapes and sizes. Applications include a real-time quality control, monitoring and emergency alarms, as well structural repairs and maintenance work recommendations and planning. Examples of the device implementation include pipes for oil and gas industry monitoring, detection of flaws in rolled products in metallurgical industry, welding quality of heavy duty equipment such as ships, reservoirs. etc. It is especially important for loaded constructions, such as pressured pipes, infrastructure maintenance, nuclear power plant monitoring, bridges, corrosion prevention and environment protection.

Owner:GOROSHEVSKIY VALERIAN +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com