Patents

Literature

43 results about "Atomic element" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An atomic element is an element which exists independently as atoms and can still react with other elements forming a compound. They are monoatomic. Examples all metals and some non metals.

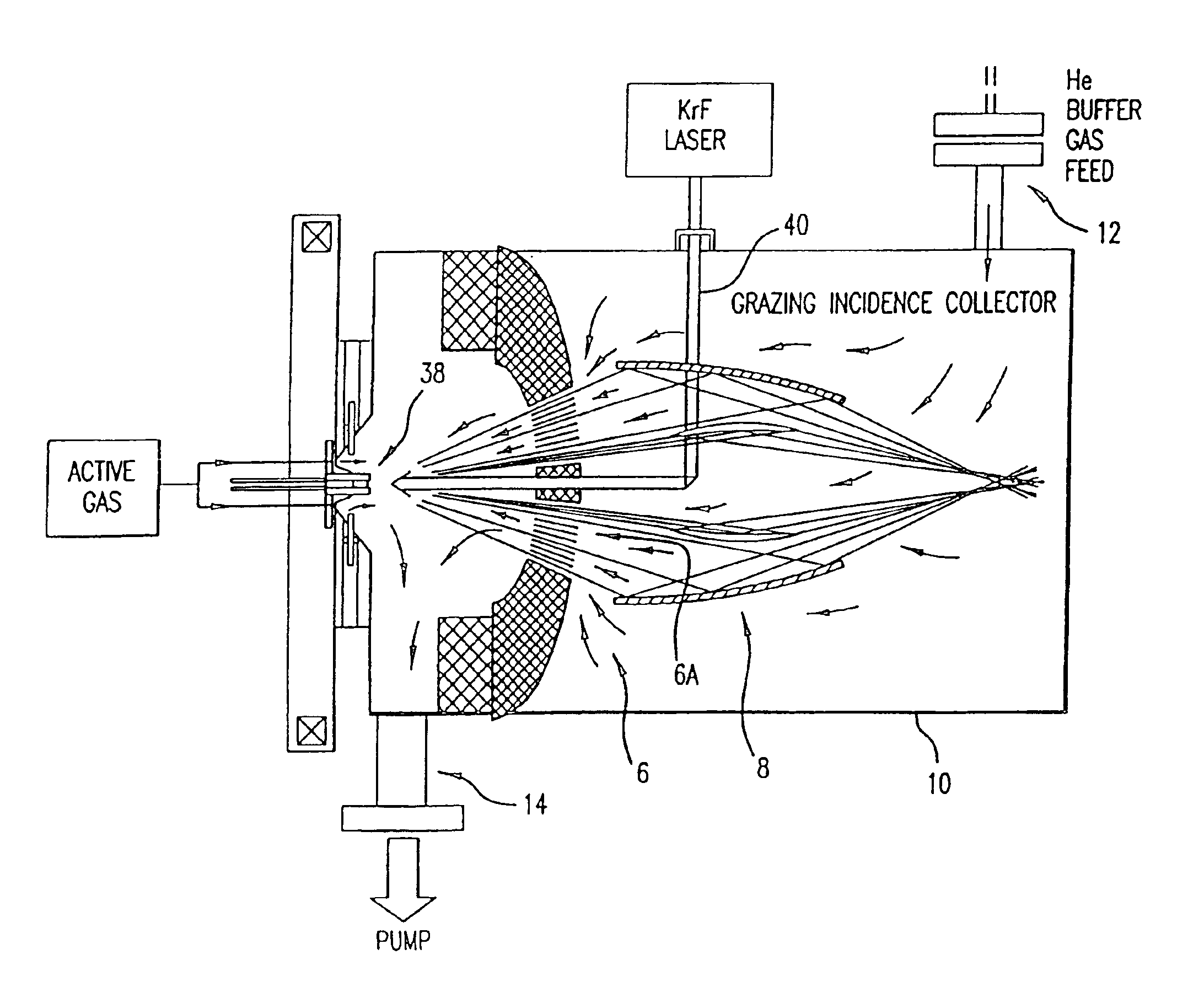

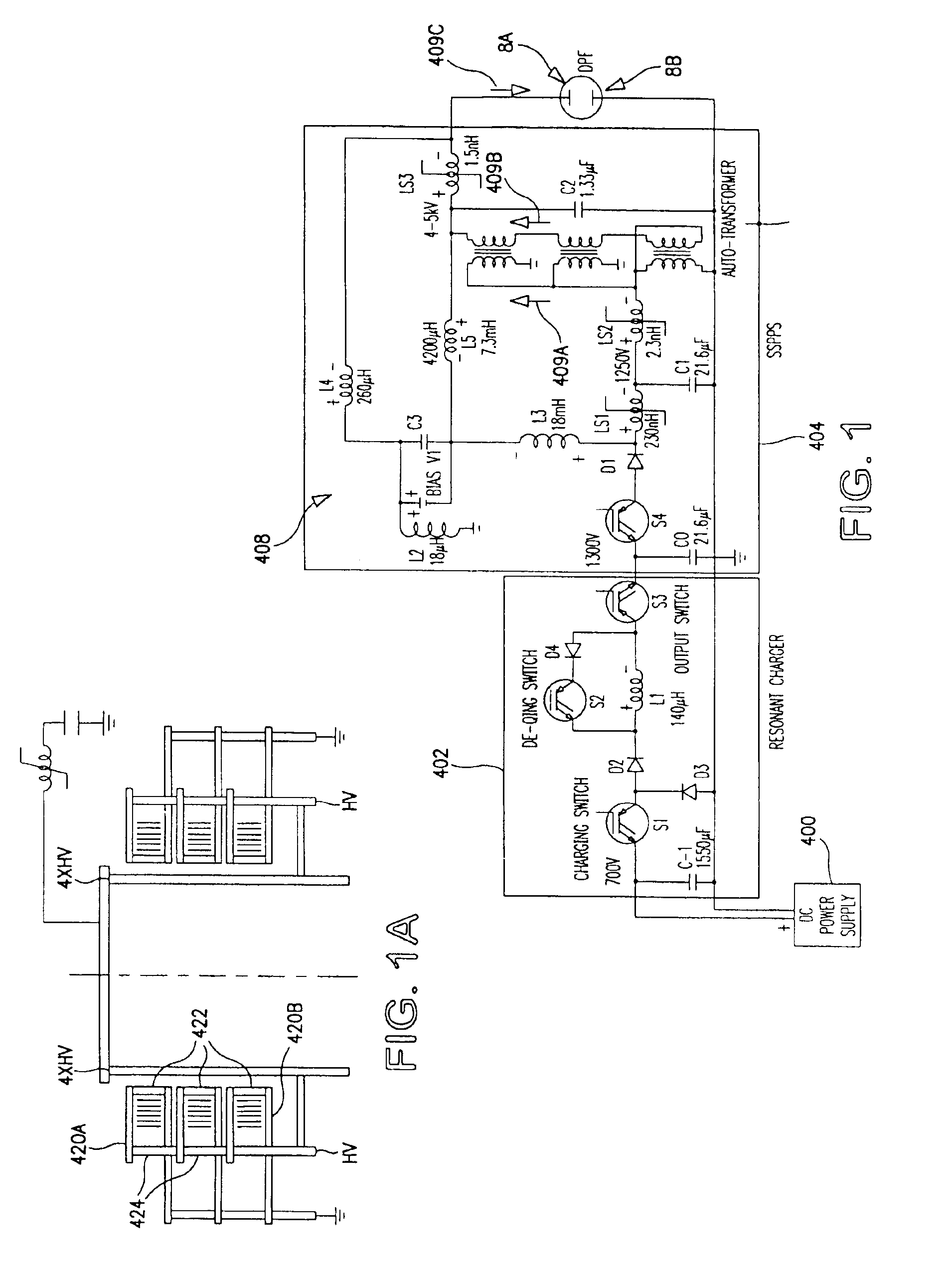

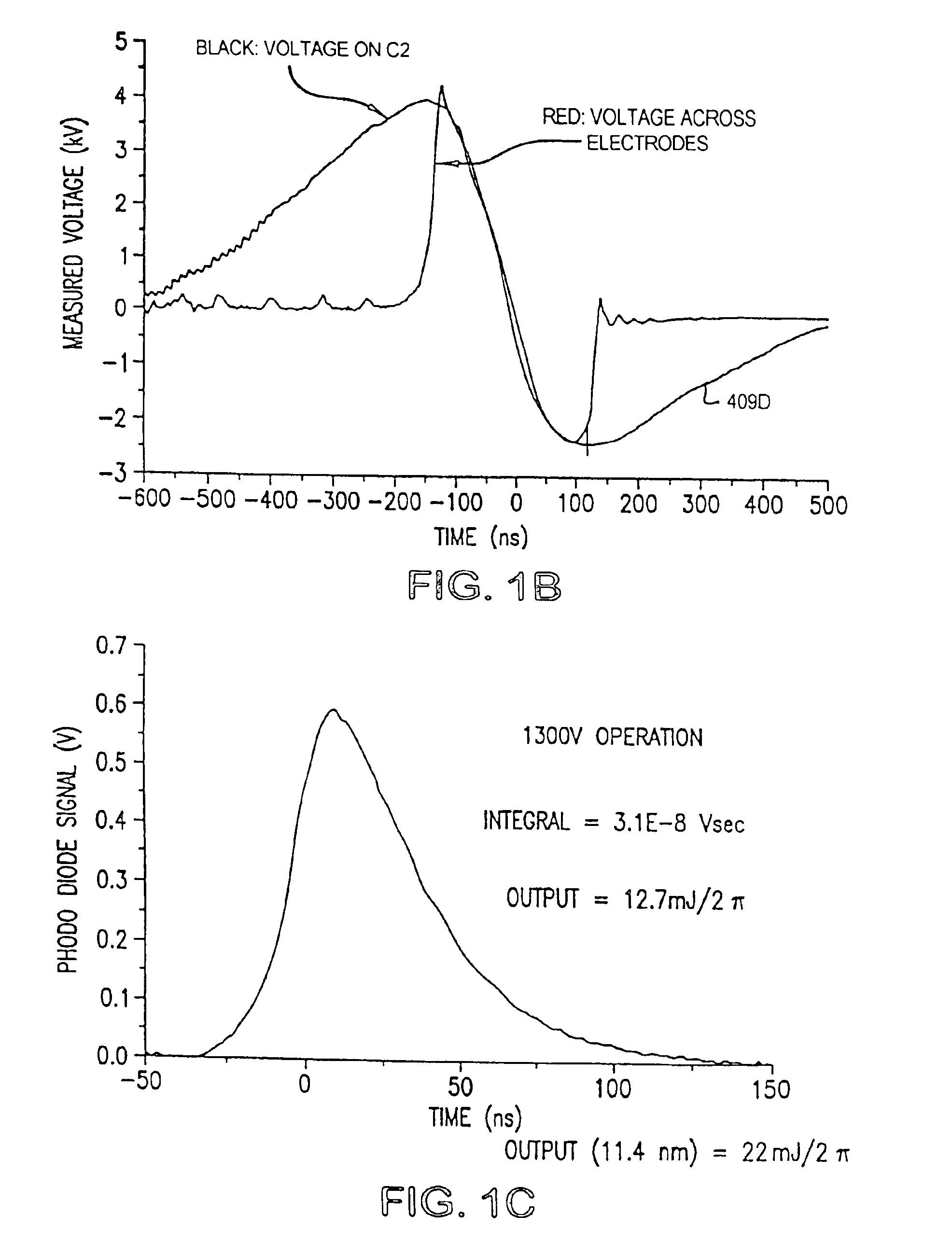

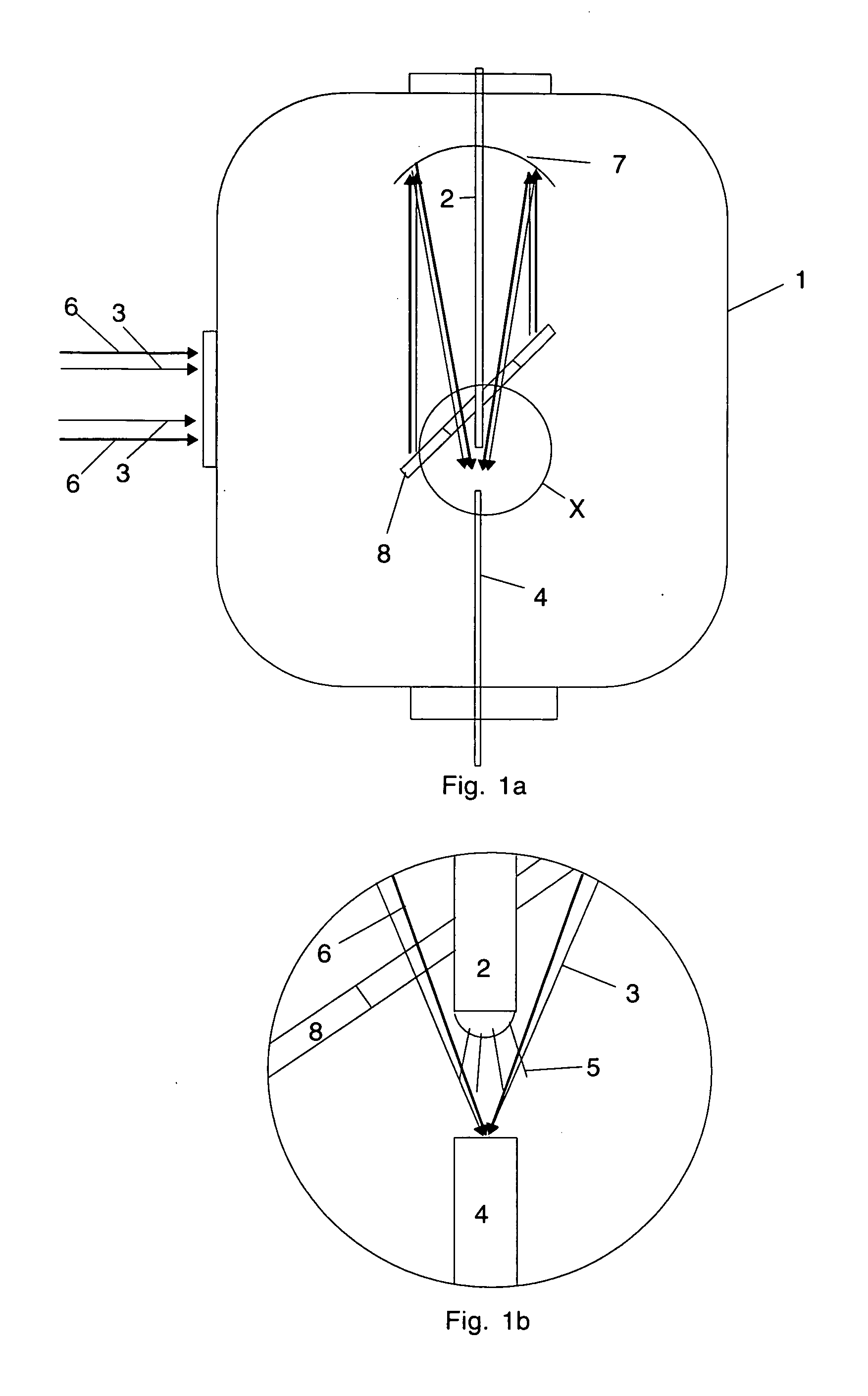

Extreme ultraviolet light source

InactiveUS6972421B2Improve efficiencyImprove performanceNanoinformaticsSemiconductor/solid-state device manufacturingAtomic elementLight energy

The present invention provides a reliable, high-repetition rate, production line compatible high energy photon source. A very hot plasma containing an active material is produced in vacuum chamber. The active material is an atomic element having an emission line within a desired extreme ultraviolet (EUV) range. A pulse power source comprising a charging capacitor and a magnetic compression circuit comprising a pulse transformer, provides electrical pulses having sufficient energy and electrical potential sufficient to produce the EUV light at an intermediate focus at rates in excess of 5 Watts. In preferred embodiments designed by Applicants in-band, EUV light energy at the intermediate focus is 45 Watts extendable to 105.8 Watts.

Owner:ASML NETHERLANDS BV

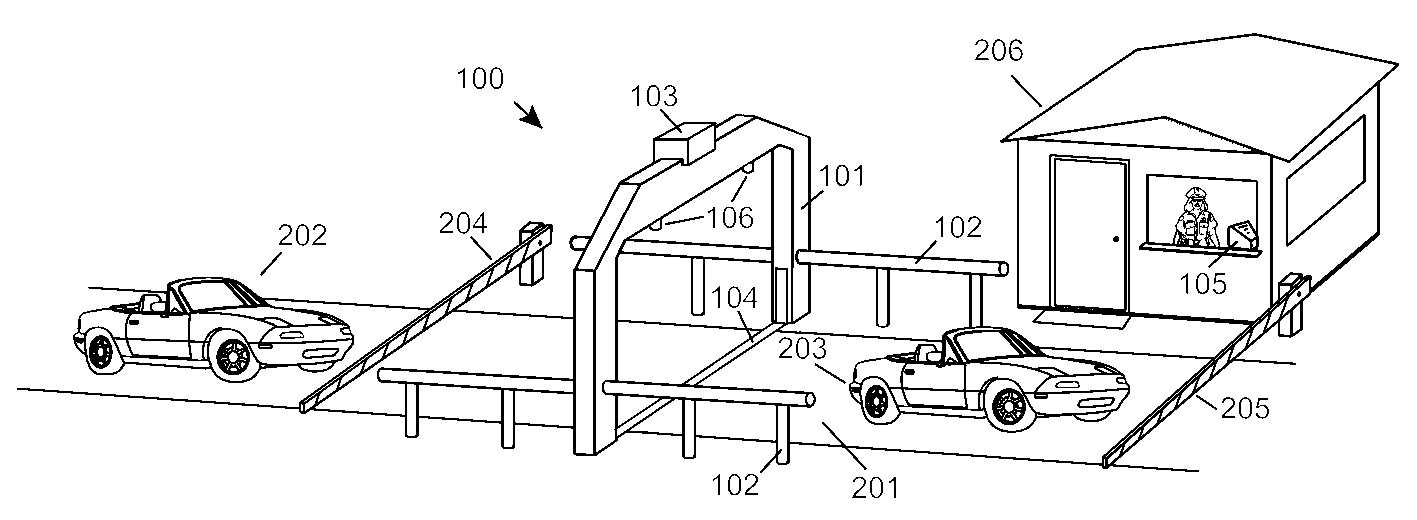

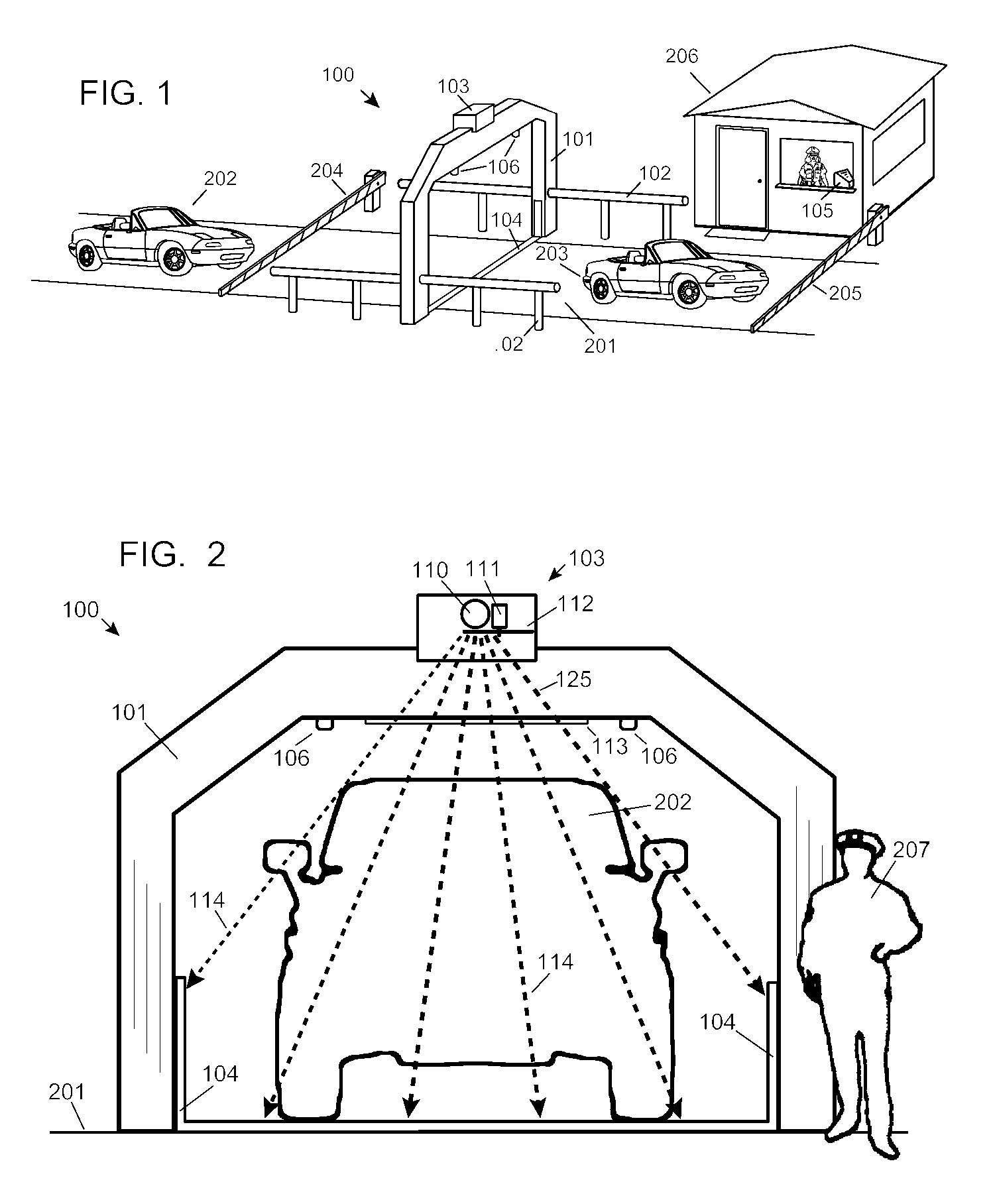

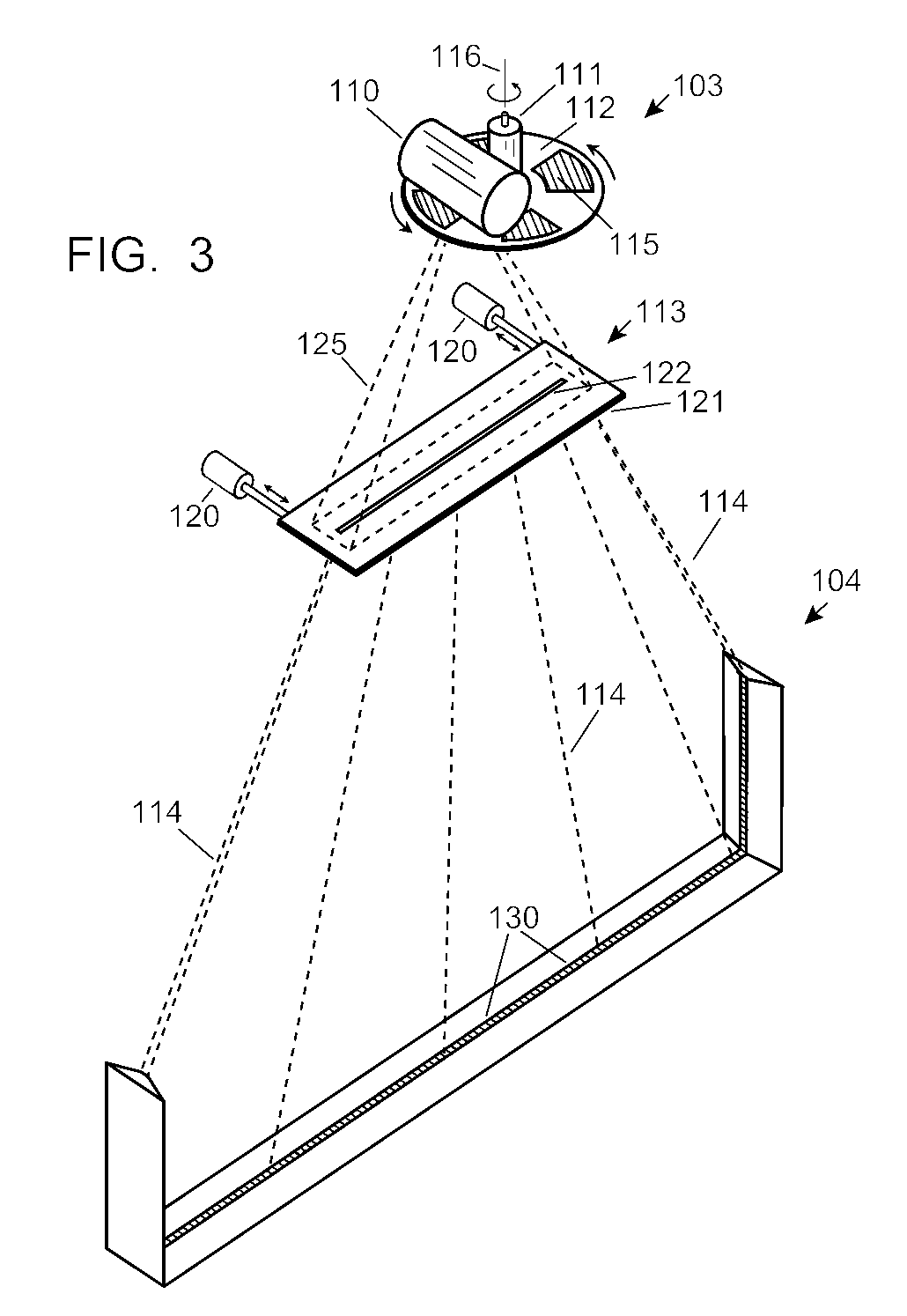

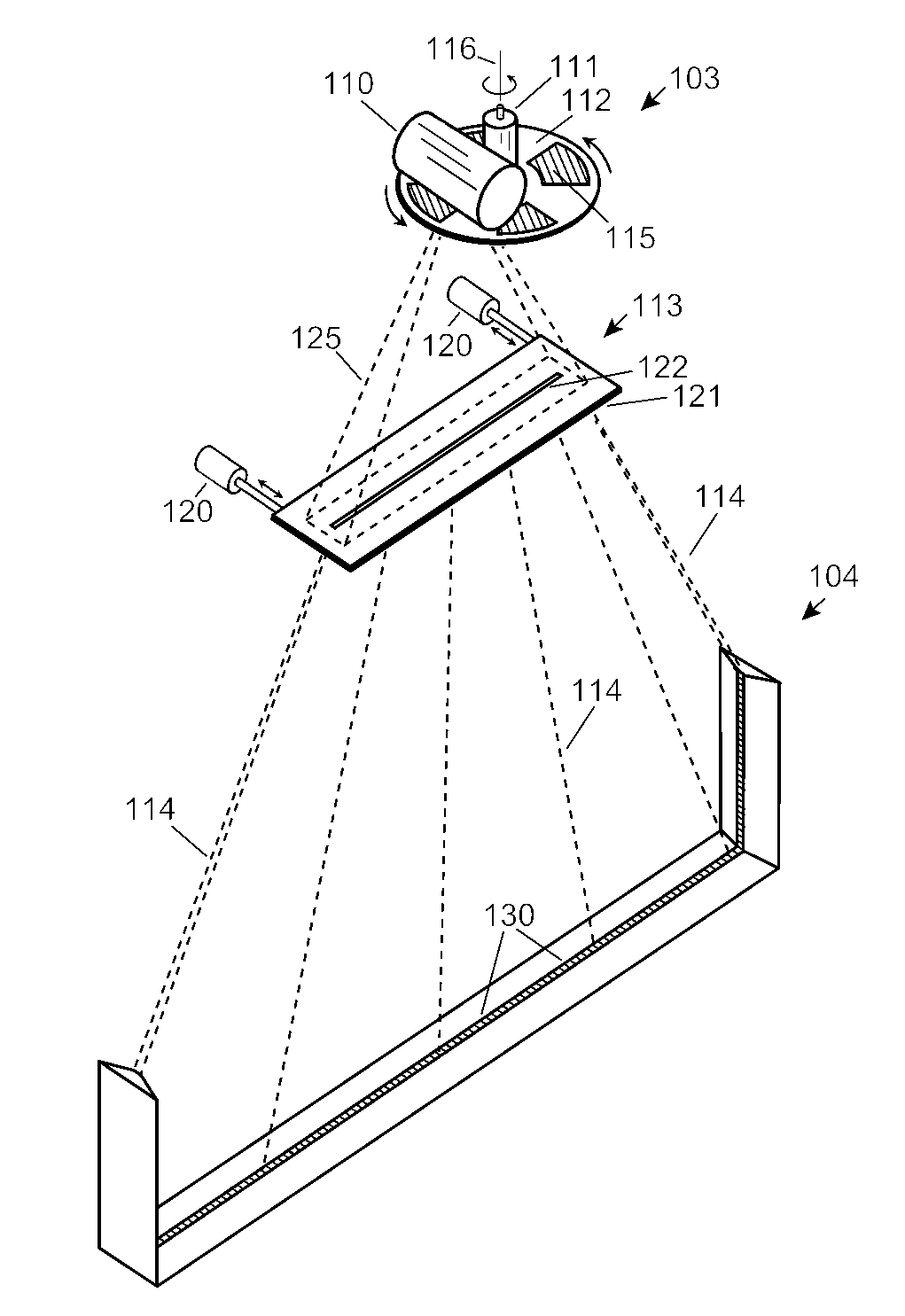

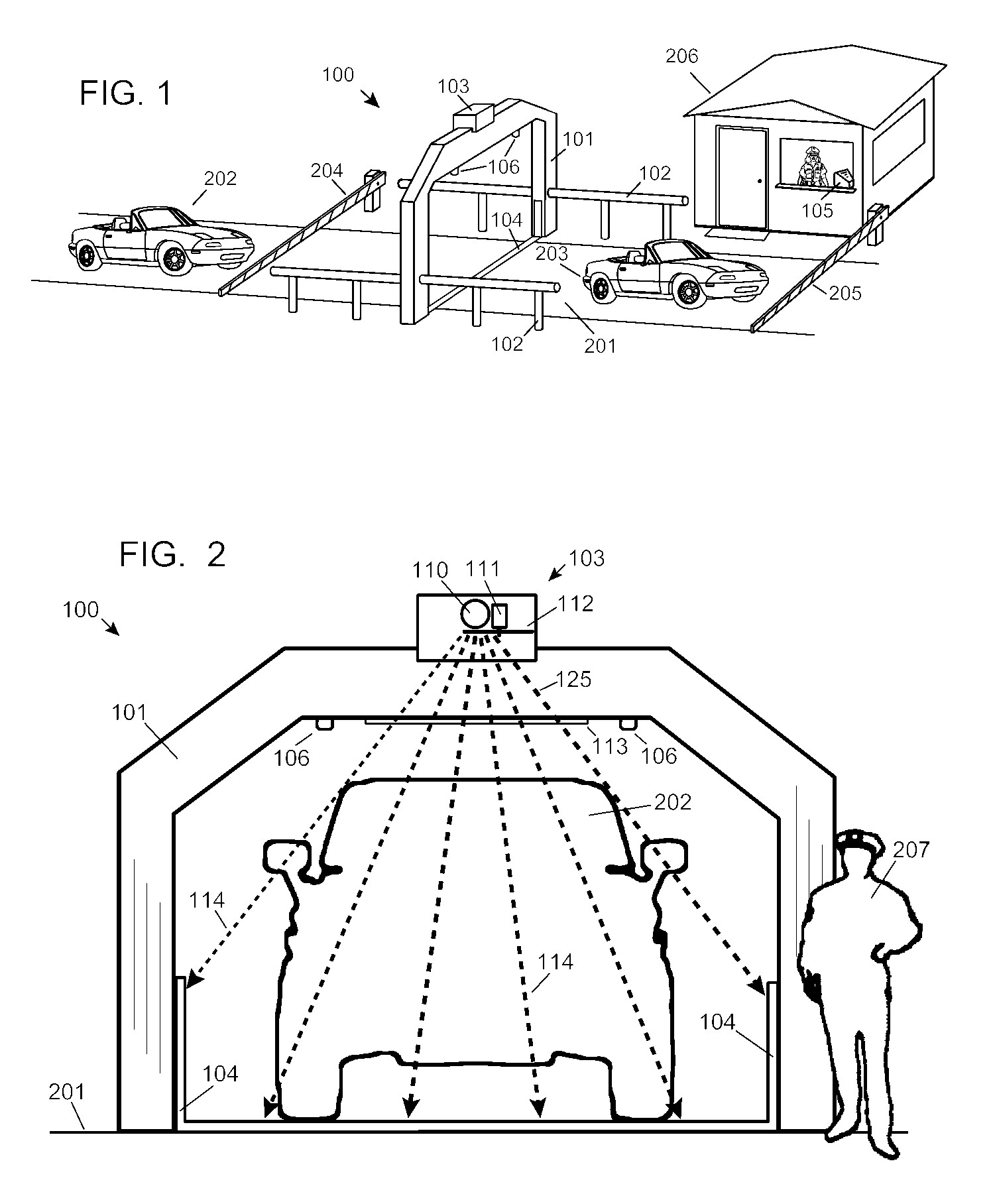

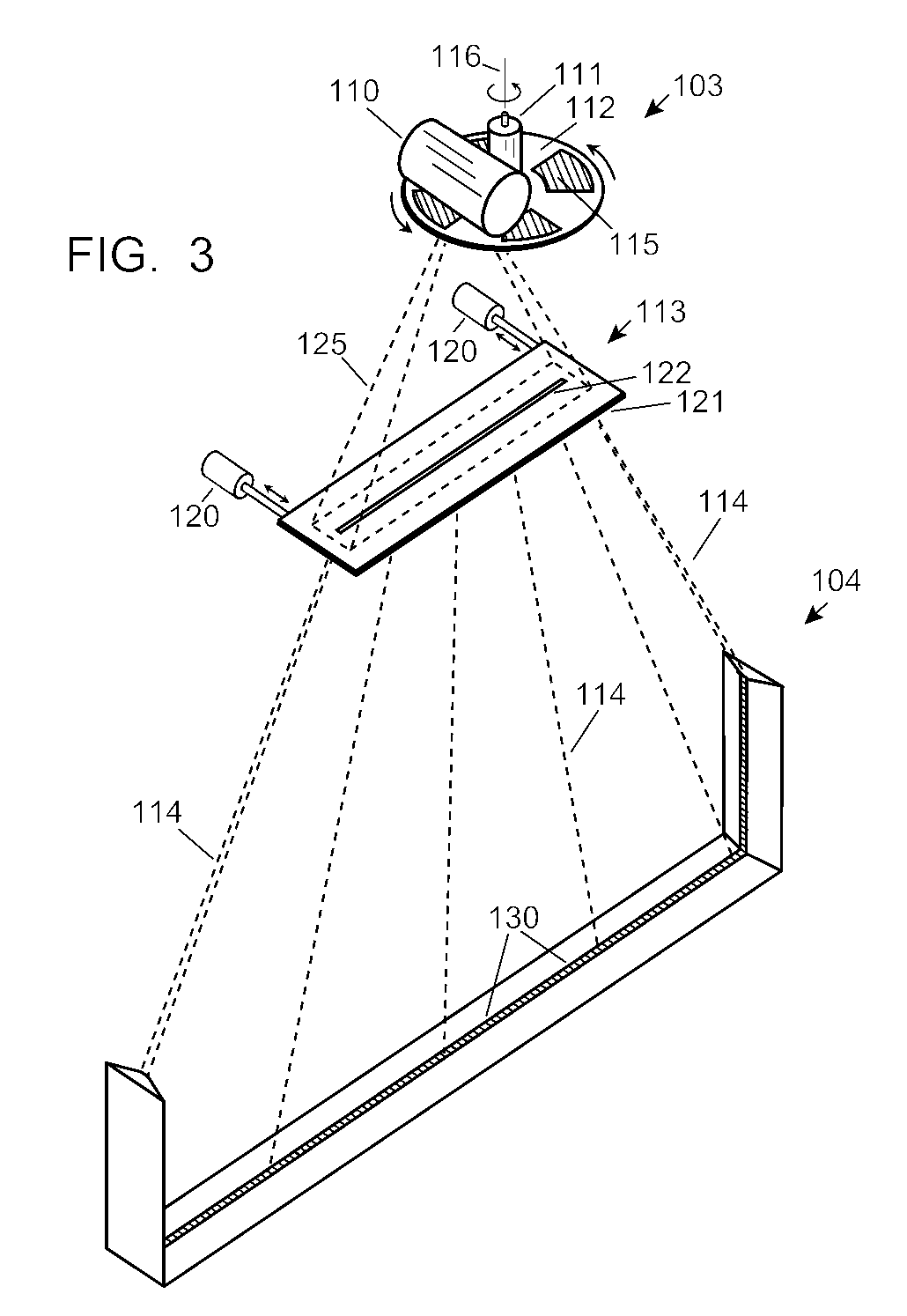

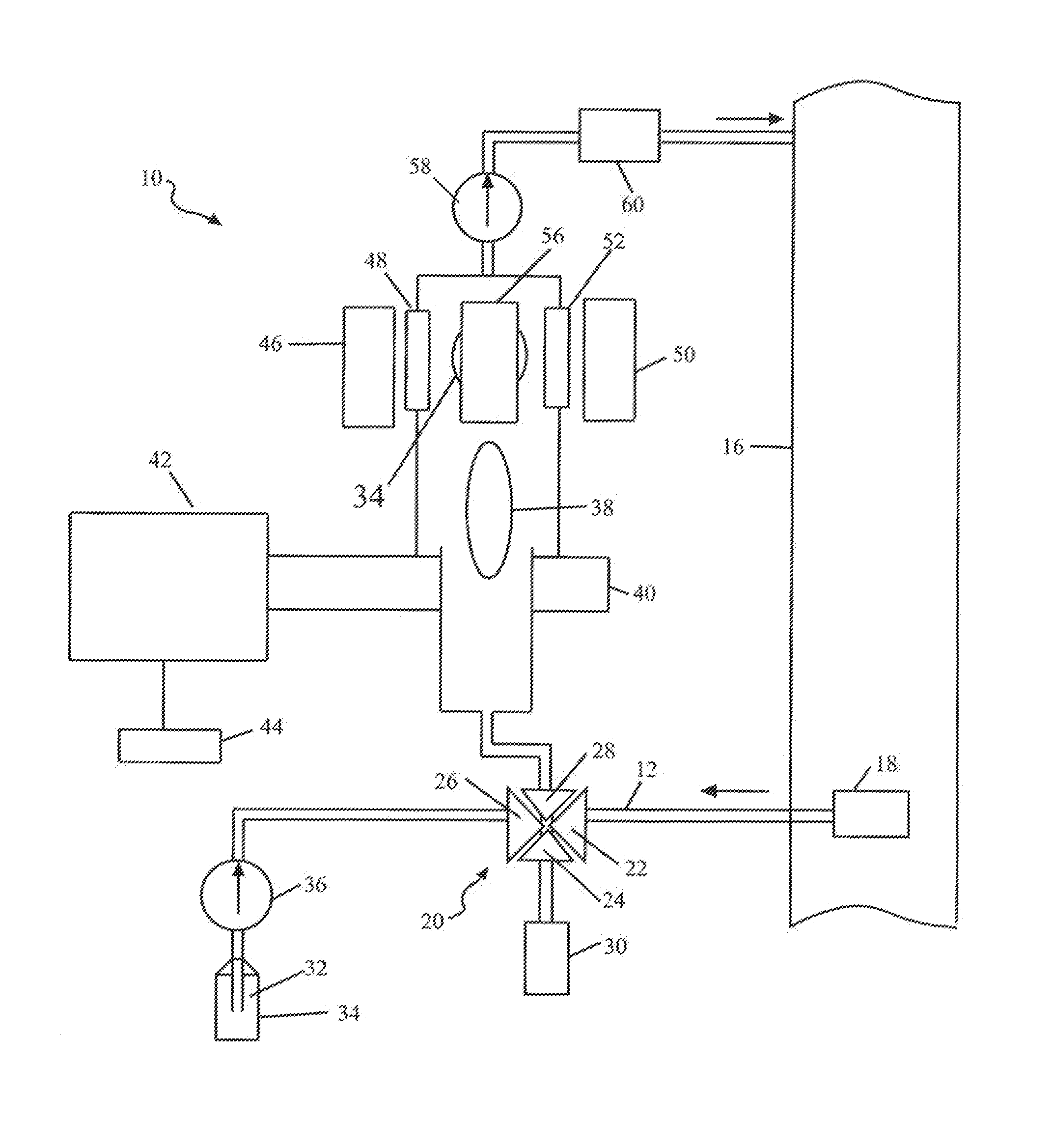

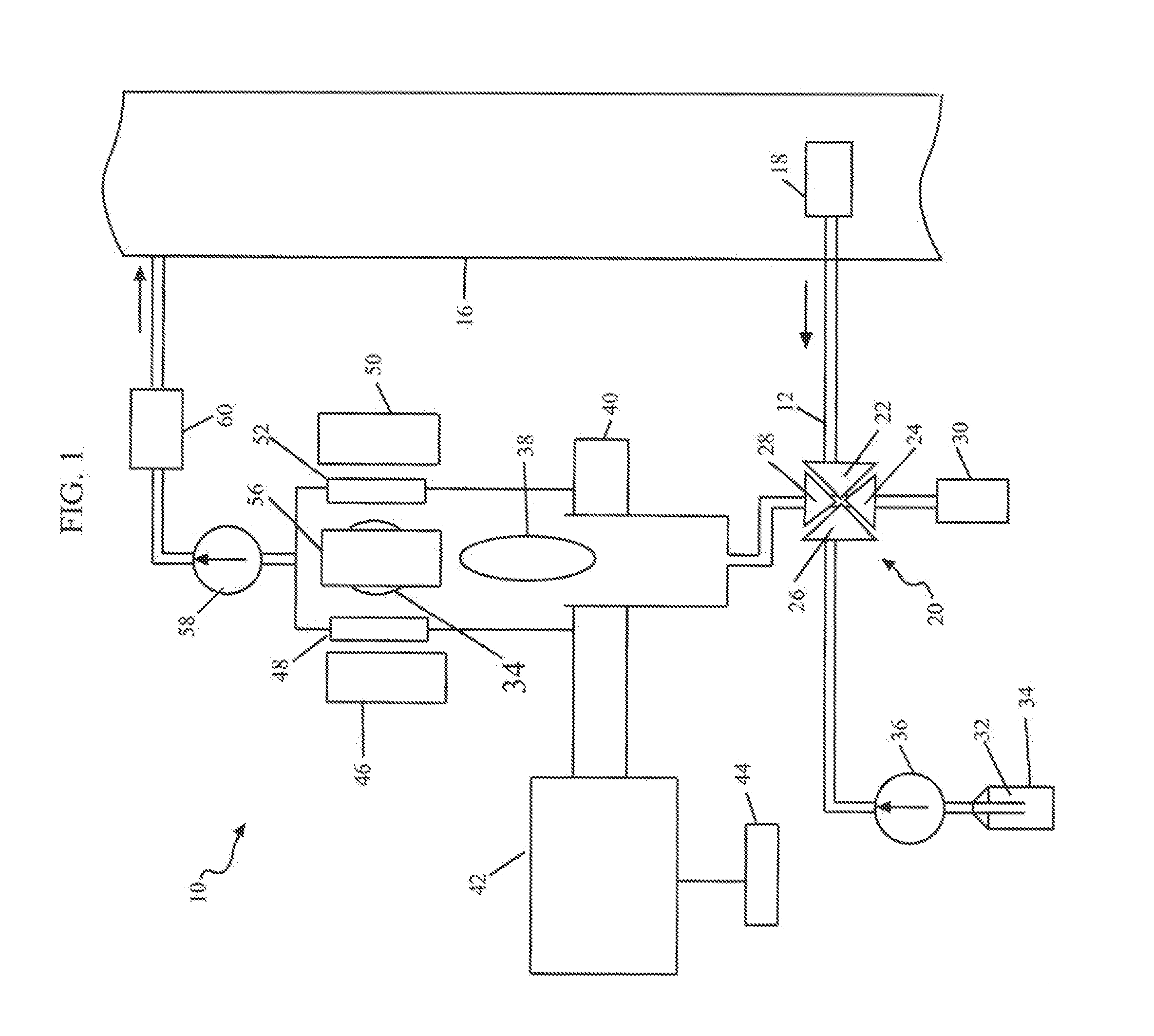

Automobile scanning system

ActiveUS7742568B2Easy to checkUniform exposureX-ray apparatusMaterial analysis by transmitting radiationAtomic elementHigh energy

A dual-energy x-ray imaging system searches a moving automobile for concealed objects. Dual energy operation is achieved by operating an x-ray source at a constant potential of 100 KV to 150 KV, and alternately switching between two beam filters. The first filter is an atomic element having a high k-edge energy, such as platinum, gold, mercury, thallium, lead, bismuth, and thorium, thereby providing a low-energy spectrum. The second filter provides a high-energy spectrum through beam hardening. The low and high energy beams passing through the automobile are received by an x-ray detector. These detected signals are processed by a digital computer to create a steel suppressed image through logarithmic subtraction. The intensity of the x-ray beam is adjusted as the reciprocal of the measured automobile speed, thereby achieving a consistent radiation level regardless of the automobile motion. Accordingly, this invention provides images of organic objects concealed within moving automobiles without the detritus effects of overlying steel and automobile movement.

Owner:LEIDOS

Automobile Scanning System

ActiveUS20090086907A1Easy to checkUniform radiation exposureX-ray apparatusMaterial analysis by transmitting radiationAtomic elementHigh energy

A dual-energy x-ray imaging system searches a moving automobile for concealed objects. Dual energy operation is achieved by operating an x-ray source at a constant potential of 100 KV to 150 KV, and alternately switching between two beam filters. The first filter is an atomic element having a high k-edge energy, such as platinum, gold, mercury, thallium, lead, bismuth, and thorium, thereby providing a low-energy spectrum. The second filter provides a high-energy spectrum through beam hardening. The low and high energy beams passing through the automobile are received by an x-ray detector. These detected signals are processed by a digital computer to create a steel suppressed image through logarithmic subtraction. The intensity of the x-ray beam is adjusted as the reciprocal of the measured automobile speed, thereby achieving a consistent radiation level regardless of the automobile motion. Accordingly, this invention provides images of organic objects concealed within moving automobiles without the detritus effects of overlying steel and automobile movement.

Owner:LEIDOS

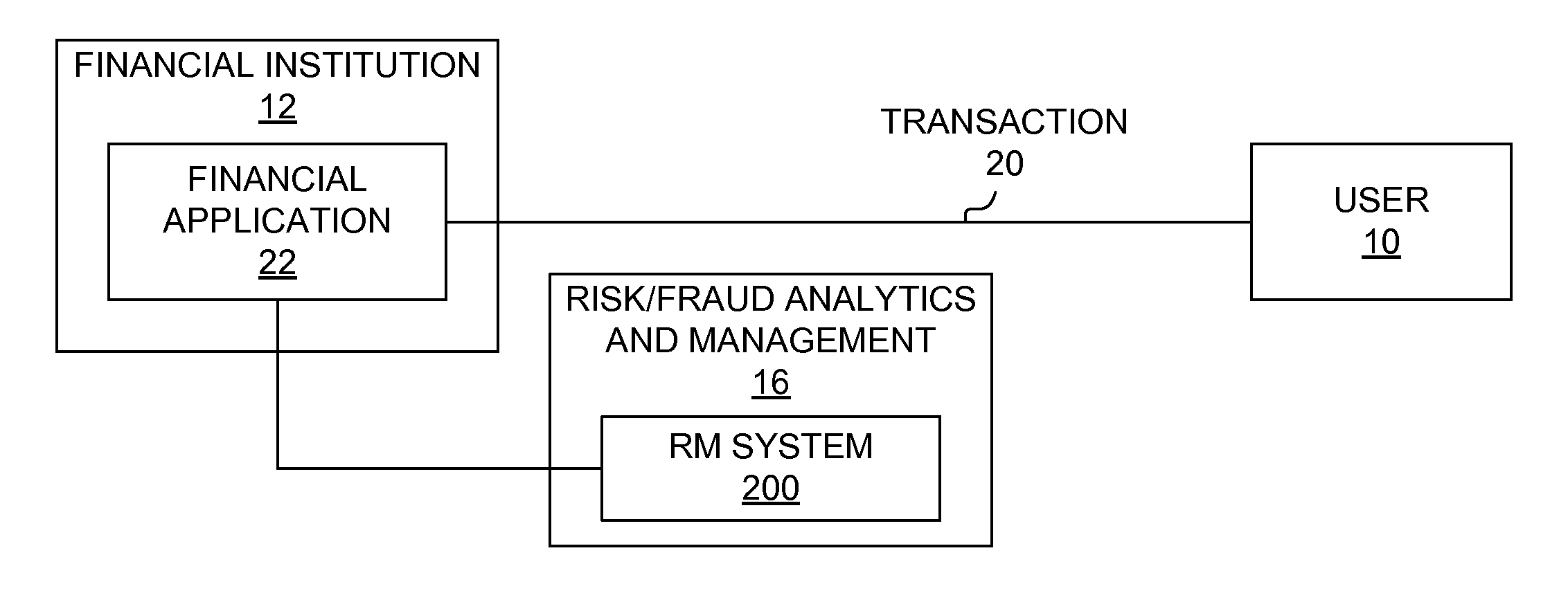

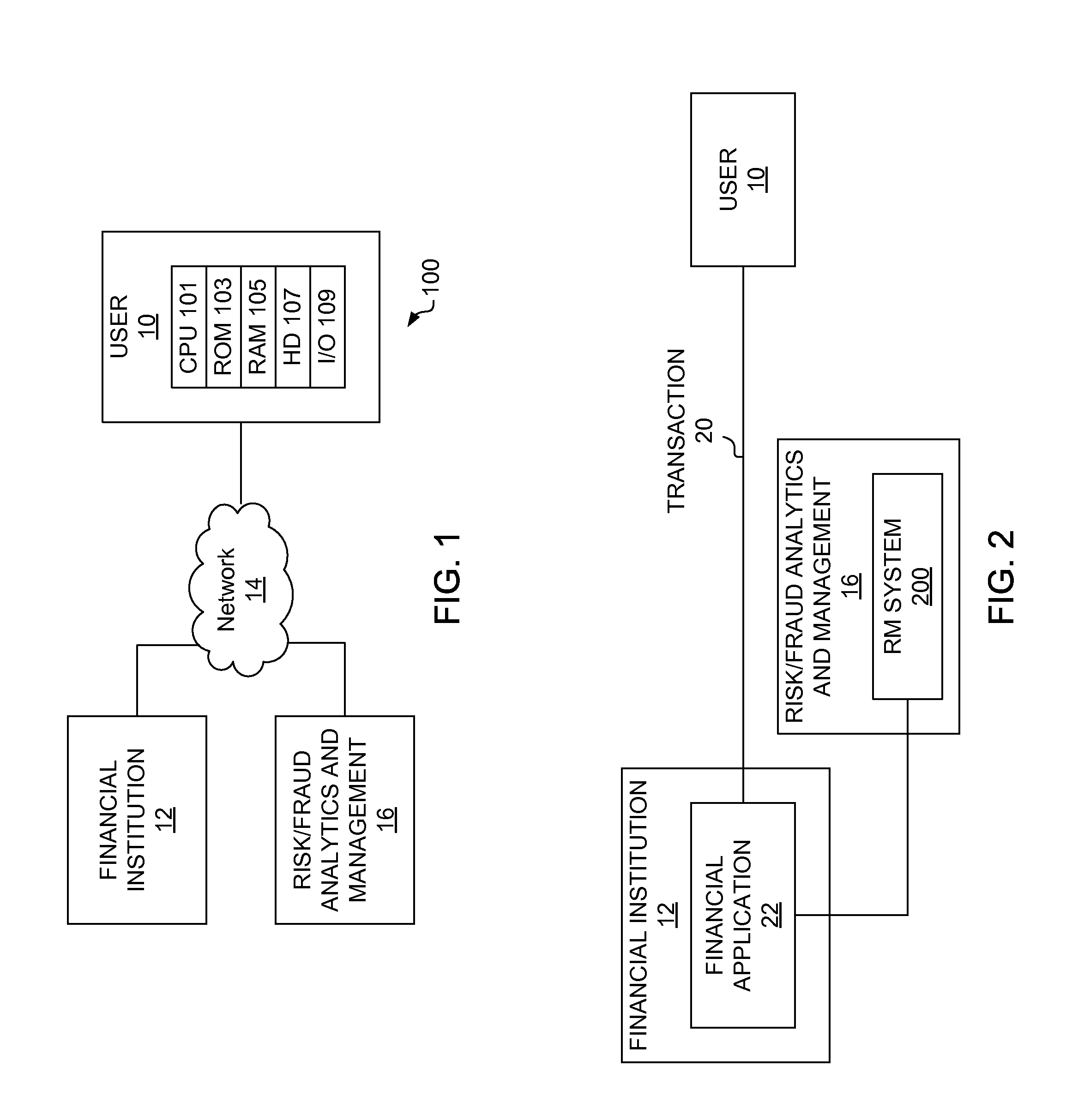

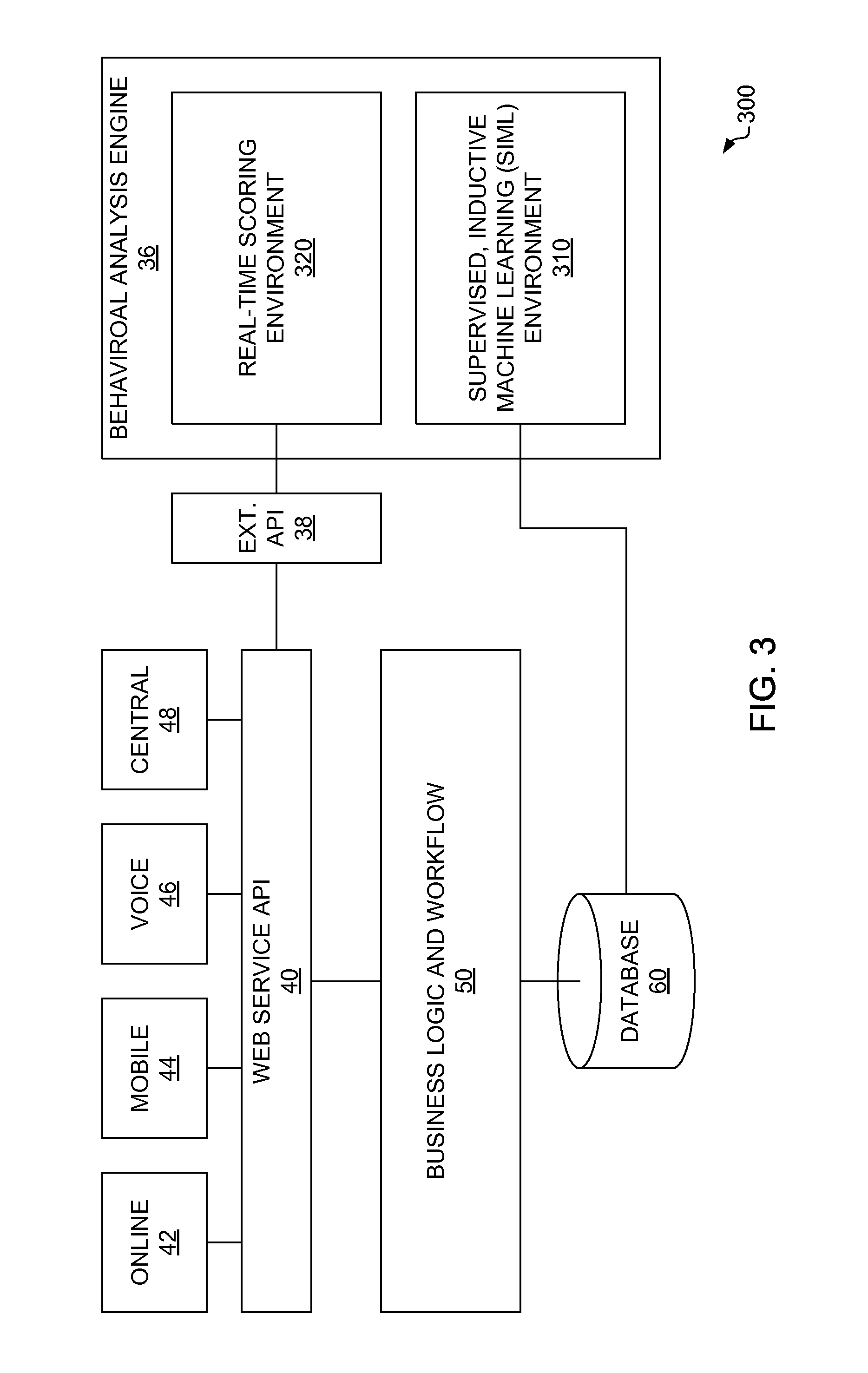

System, method and computer program product for real-time online transaction risk and fraud analytics and management

InactiveUS20120109821A1Difficult to compromiseEliminate “ visibility gap ”FinancePayment architectureAtomic elementRisk model

Embodiments disclosed herein provide a behavioral based solution to user identity validation, useful in real-time detection of abnormal activity while a user is engaged in an online transaction with a financial institution. A risk modeling system may run two distinct environments: one to train machine learning algorithms to produce classification objects and another to score user activities in real-time using these classification objects. In both environments, activity data collected on a particular user is mapped to various behavioral models to produce atomic elements that can be scored. Classifiers may be dynamically updated in response to new behavioral activities. Example user activities may include login, transactional, and traverse. In some embodiments, depending upon configurable settings with respect to sensitivity and / or specificity, detection of an abnormal activity or activities may not trigger a flag-and-notify unless an attempt is made to move or transfer money.

Owner:Q2 SOFTWARE

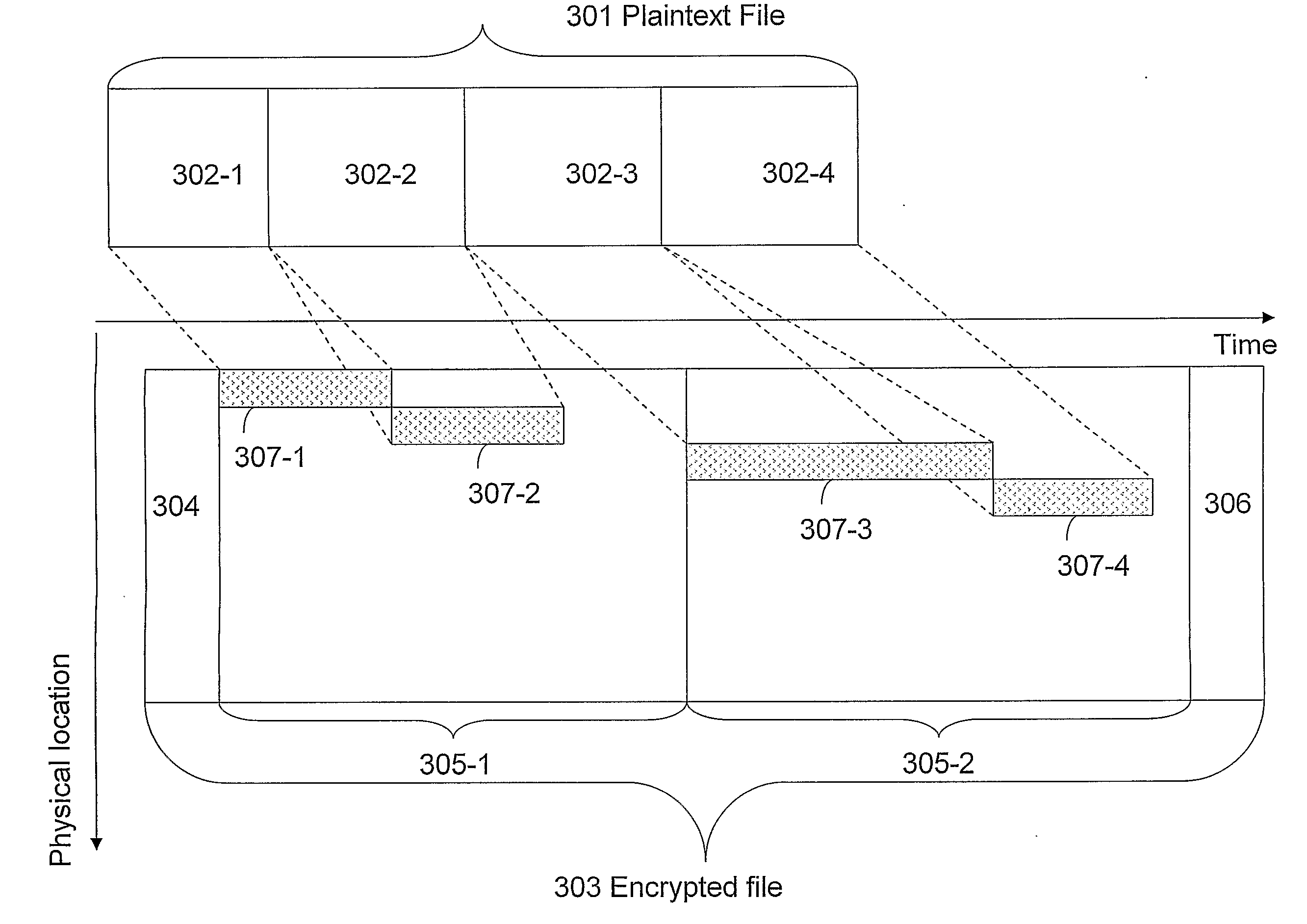

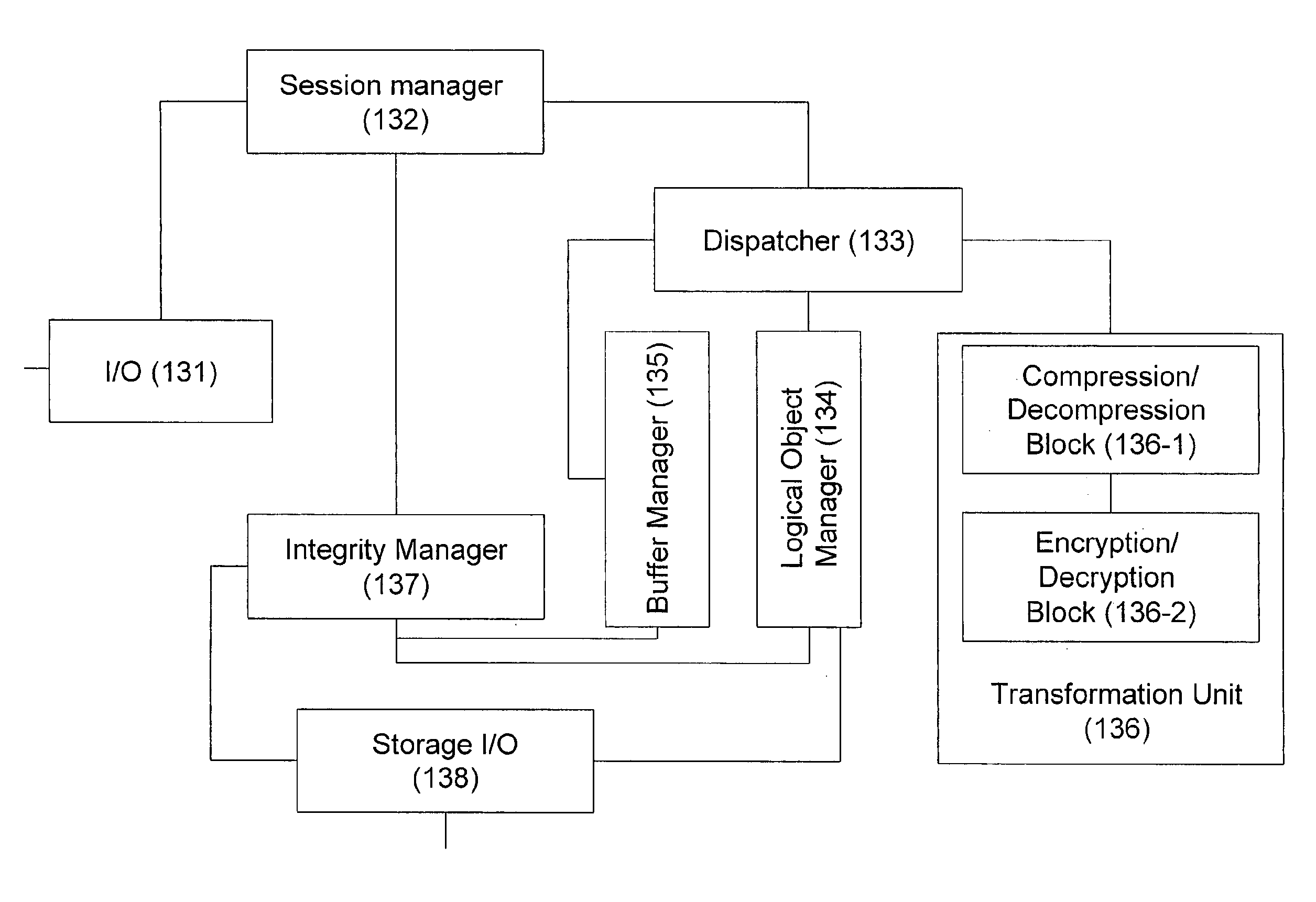

Method and system for transformation of logical data objects for storage

ActiveUS20090327751A1Facilitate accommodationMemory architecture accessing/allocationMultiple keys/algorithms usageComputer hardwareAtomic element

A method and system for encrypting a plaintext logical data object for storage in a storage device operable with at least one storage protocol, creating, reading, writing, optimization and restoring thereof. Encrypting the plaintext logical data object comprises creating in the storage device an encrypted logical data object comprising a header and one or more allocated encrypted sections with predefined size; encrypting one or more sequentially obtained chunks of plaintext data corresponding to the plaintext logical data object thus giving rise to the encrypted data chunks; and sequentially accommodating the processed data chunks into said encrypted sections in accordance with an order said chunks received, wherein said encrypted sections serve as atomic elements of encryption / decryption operations during input / output transactions on the logical data object.

Owner:INT BUSINESS MASCH CORP

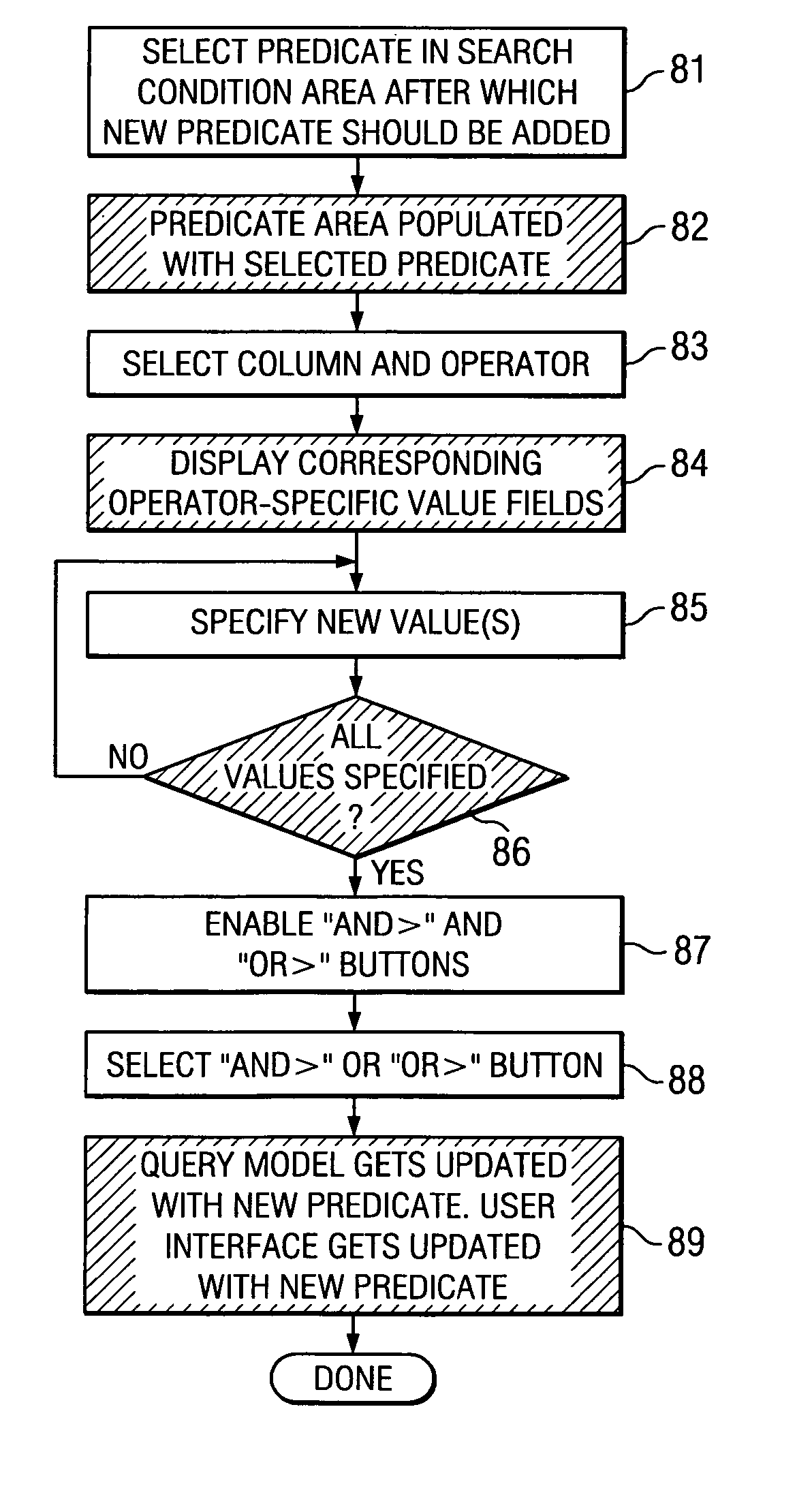

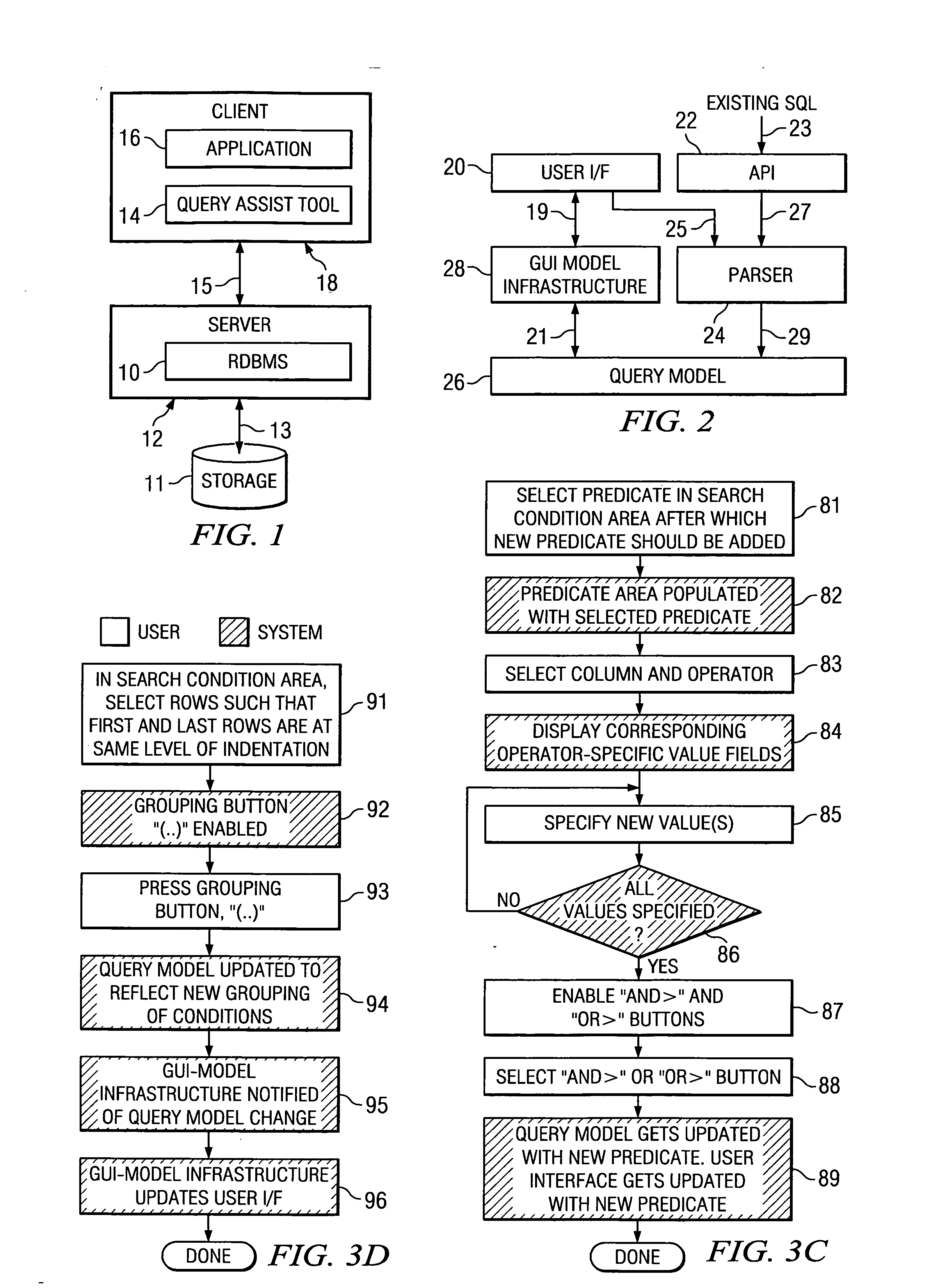

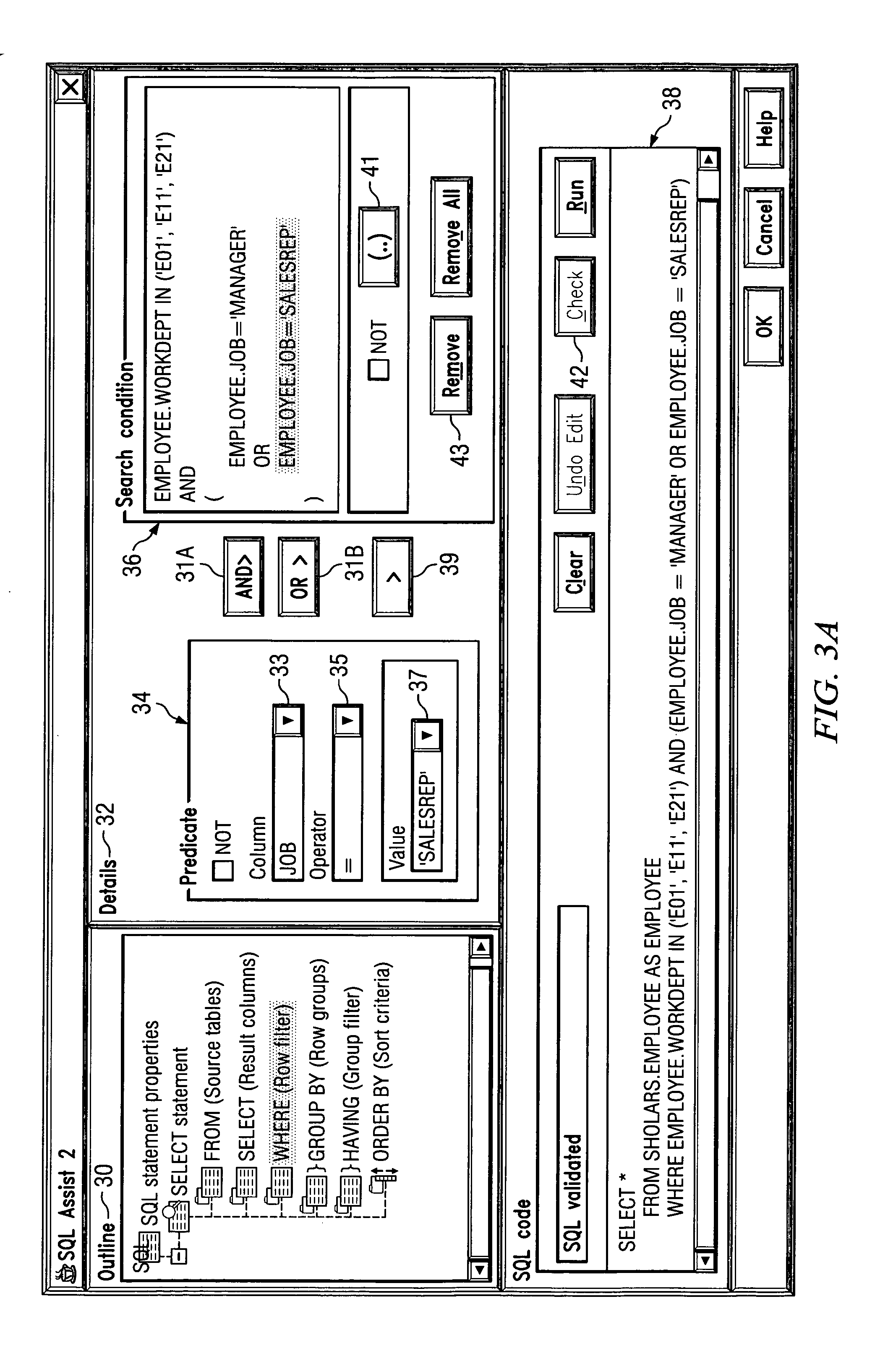

Method and structure for representing complex query elements in a modelling tool

InactiveUS20050015363A1Fine granularityDigital data information retrievalDigital data processing detailsAtomic elementQuery language

A user-friendly query modeling tool and method, for representing, creating, modifying and modeling a query language statement for use in retrieving data from a database. In accordance with the present invention, the tool includes a user interface for receiving or building and manipulating a query, a query model definition for use in populating instances of one or more query models, and a model content provider for receiving query elements from the user interface and providing them to the query model, and conversely, for retrieving query elements from the query model and providing them to the user interface. A query modeling structure and method are provided for clearly representing query statements which include an atomic element, a combined element and a relationship between the two defined by a combined operator.

Owner:IBM CORP

Fake-proof marking of a composition

InactiveUS20060035380A1Ensure reliabilitySmall possible amountCosmetic preparationsHair cosmeticsAtomic elementRadiochemistry

The invention relates to a process for the fake-proof marking of a product, by introducing at least one non-radioactive stable isotope of at least one atomic element, such that the content of the isotope in the product is higher than its natural content, the isotope being chosen from natural isotopes that have a natural isotopic content of less than 1.2%, and better still less than 1%.

Owner:LOREAL SA

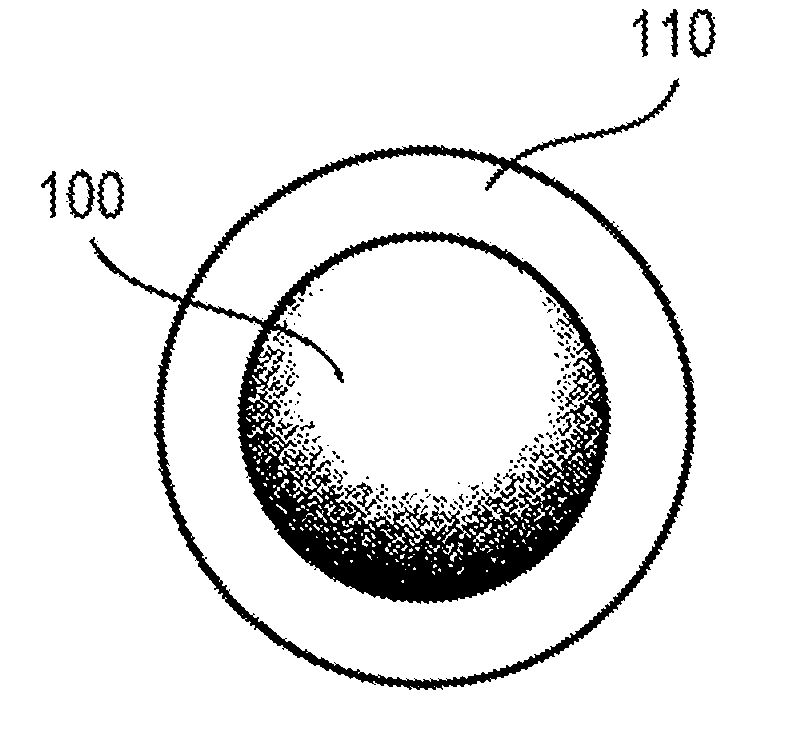

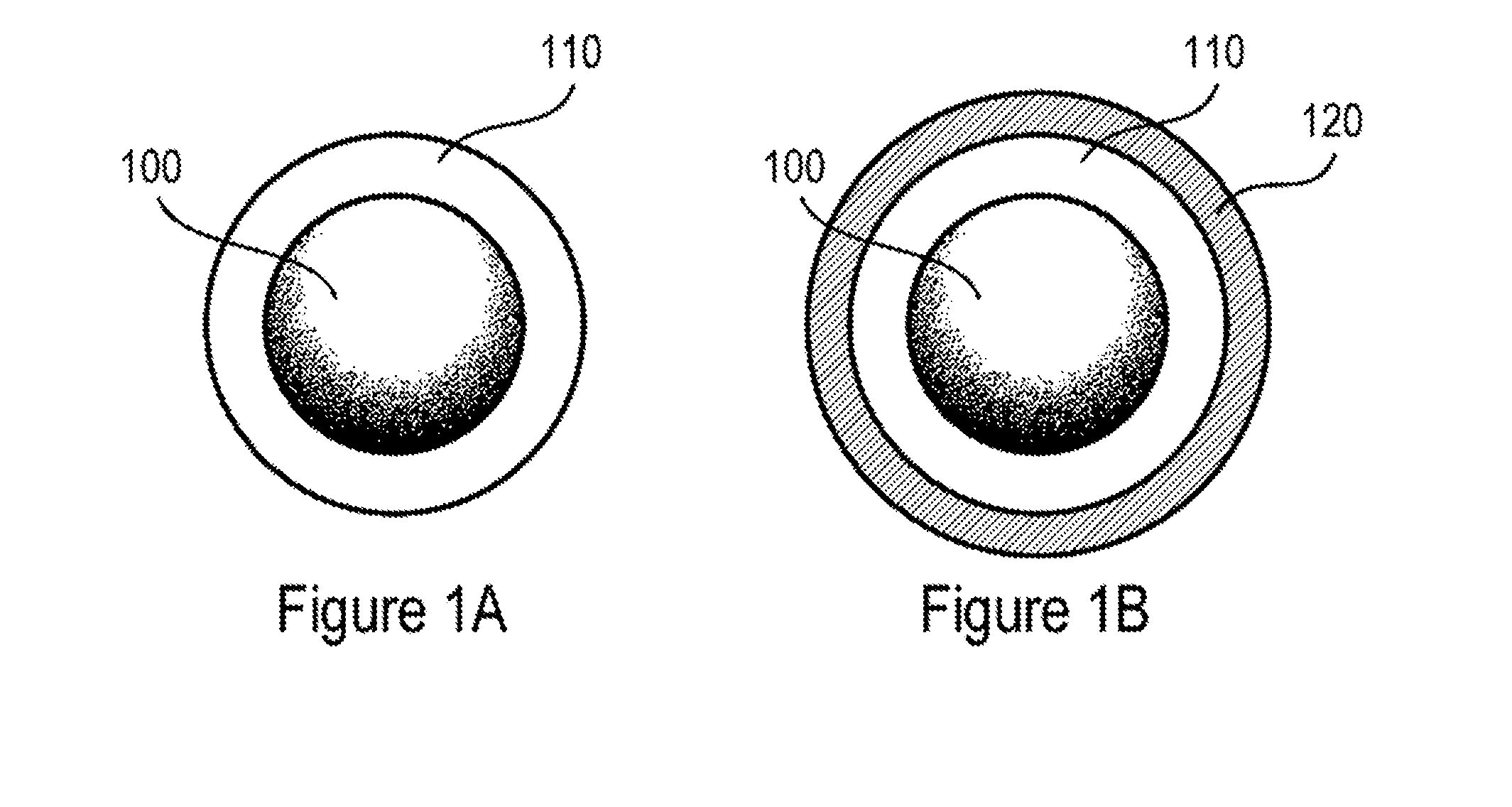

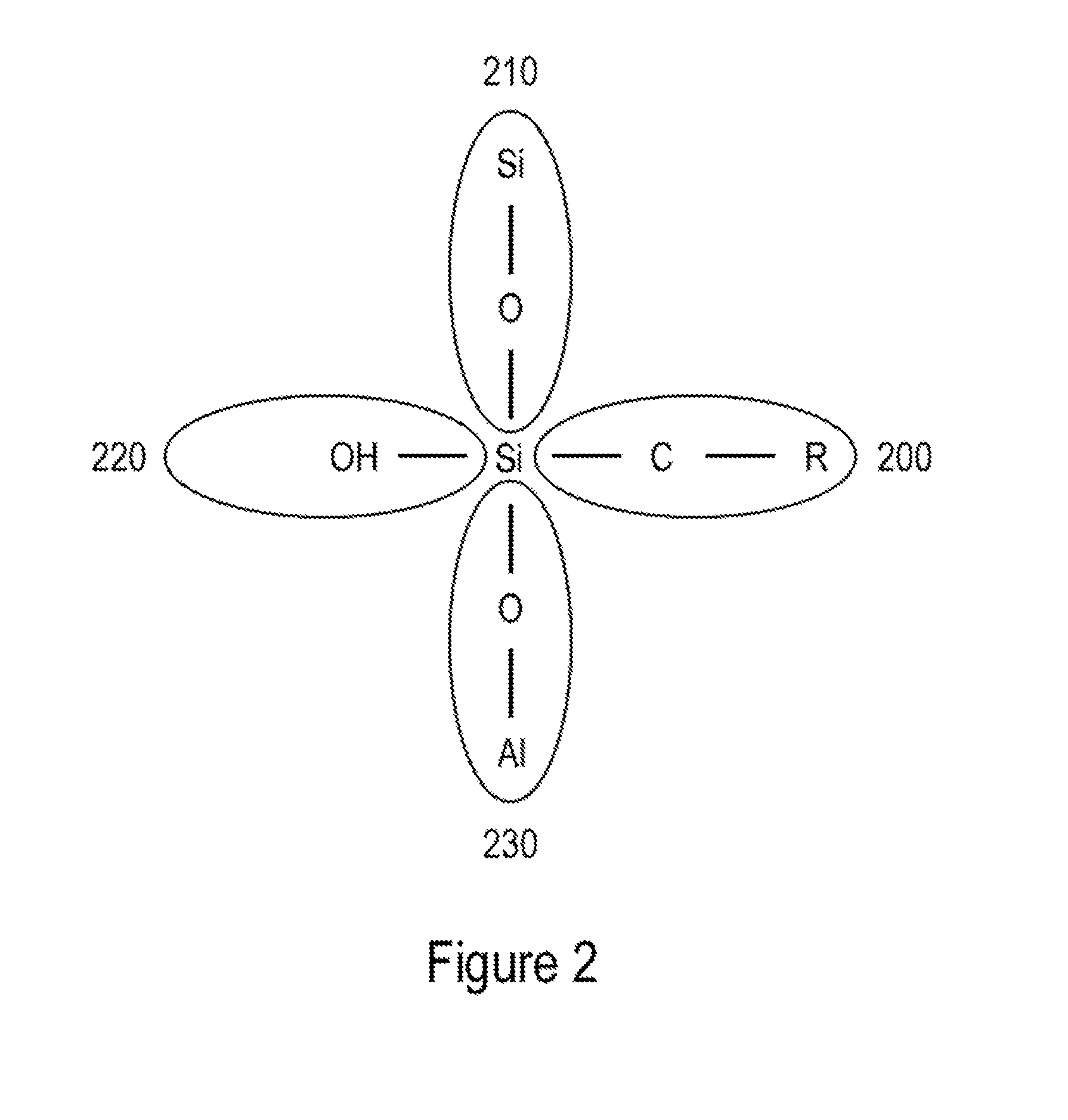

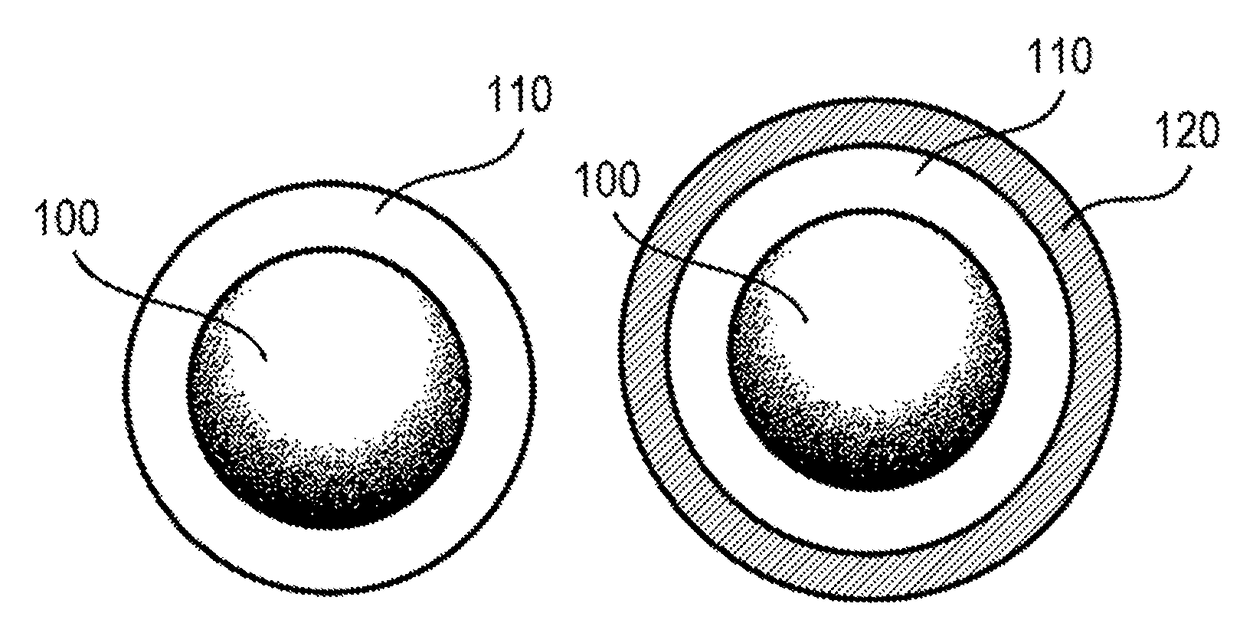

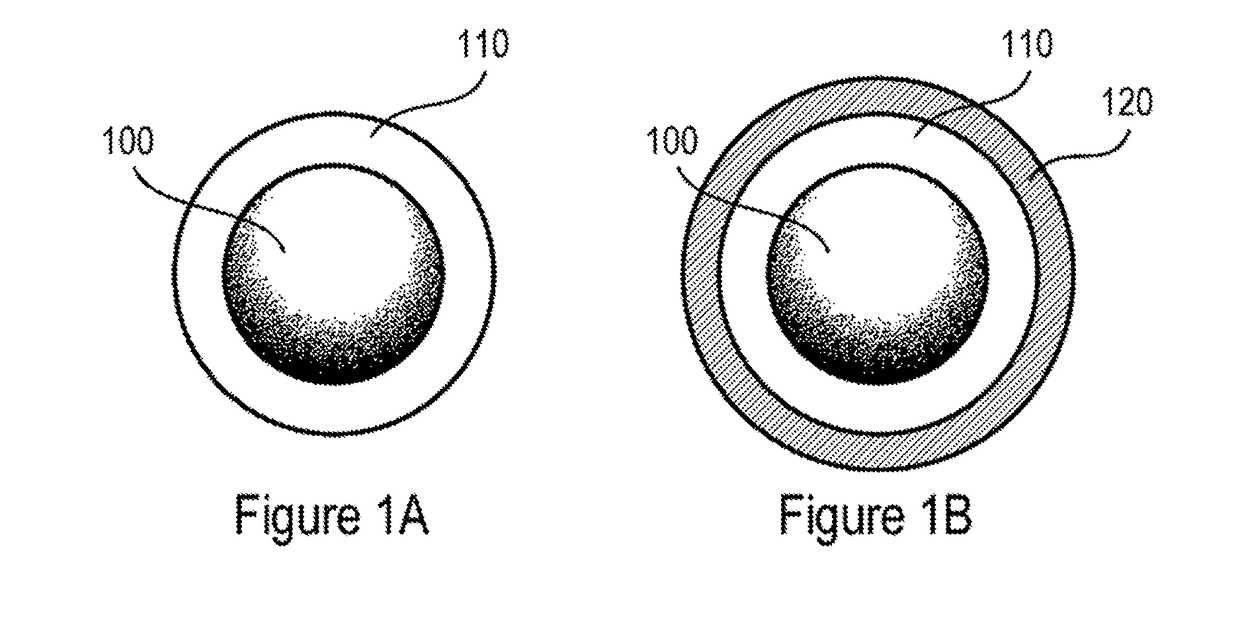

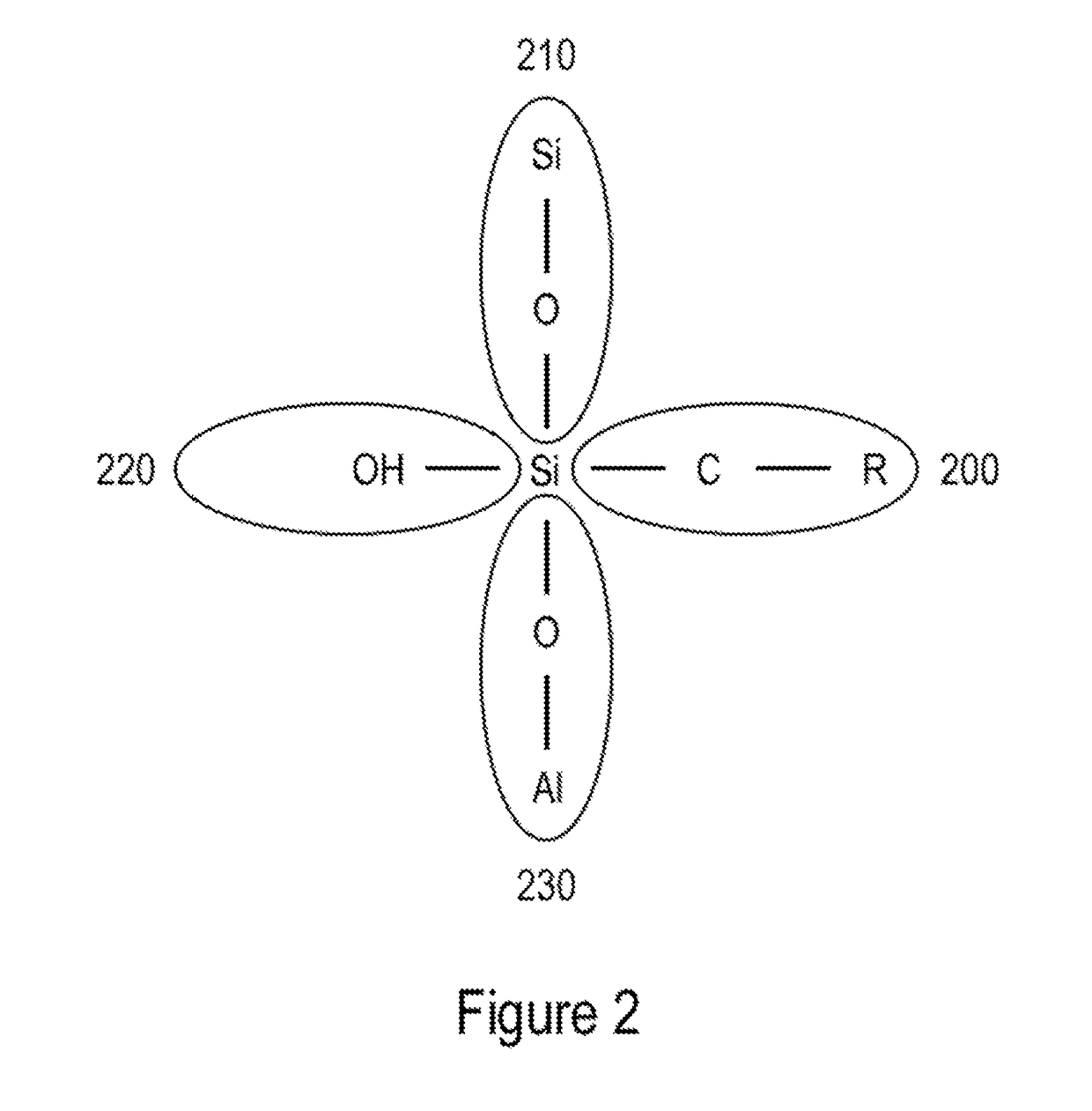

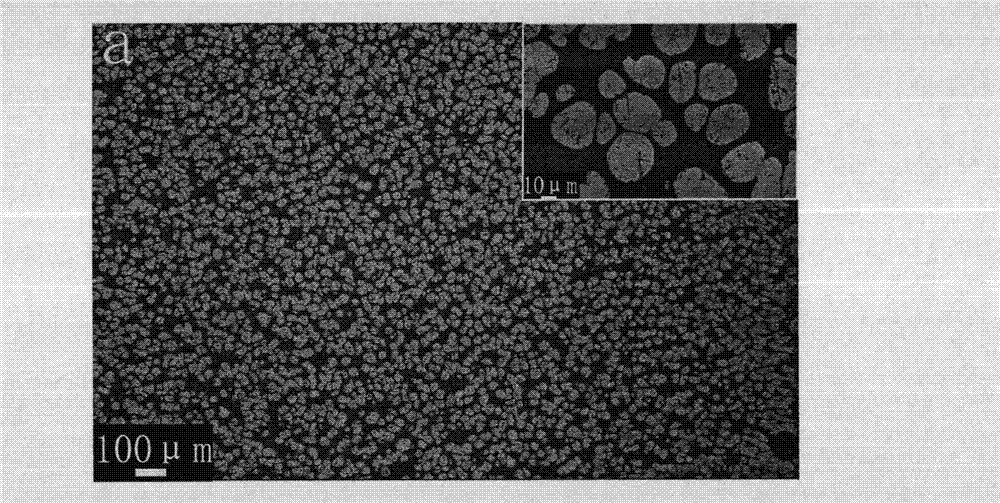

Encapsulated particles

The disclosed technology relates generally to material systems which include a plurality of particles and methods of making the same. The particles have a core and a shell which encapsulates the core and has at least one atomic element not included in the core. The cores of the particles have a median maximum dimension that is less than 10 microns and a median of at least one axial dimension that is between 10 nm and 500 nm. The shells of the particles have a median thickness that is less than 100 nm, a silicon concentration that is between 10% and 50% on the basis of the weight of the shells, and an aluminum concentration that is between 0.01% and 5% on the basis of the weight of the shells.

Owner:NANOCOMPOSIX LLC

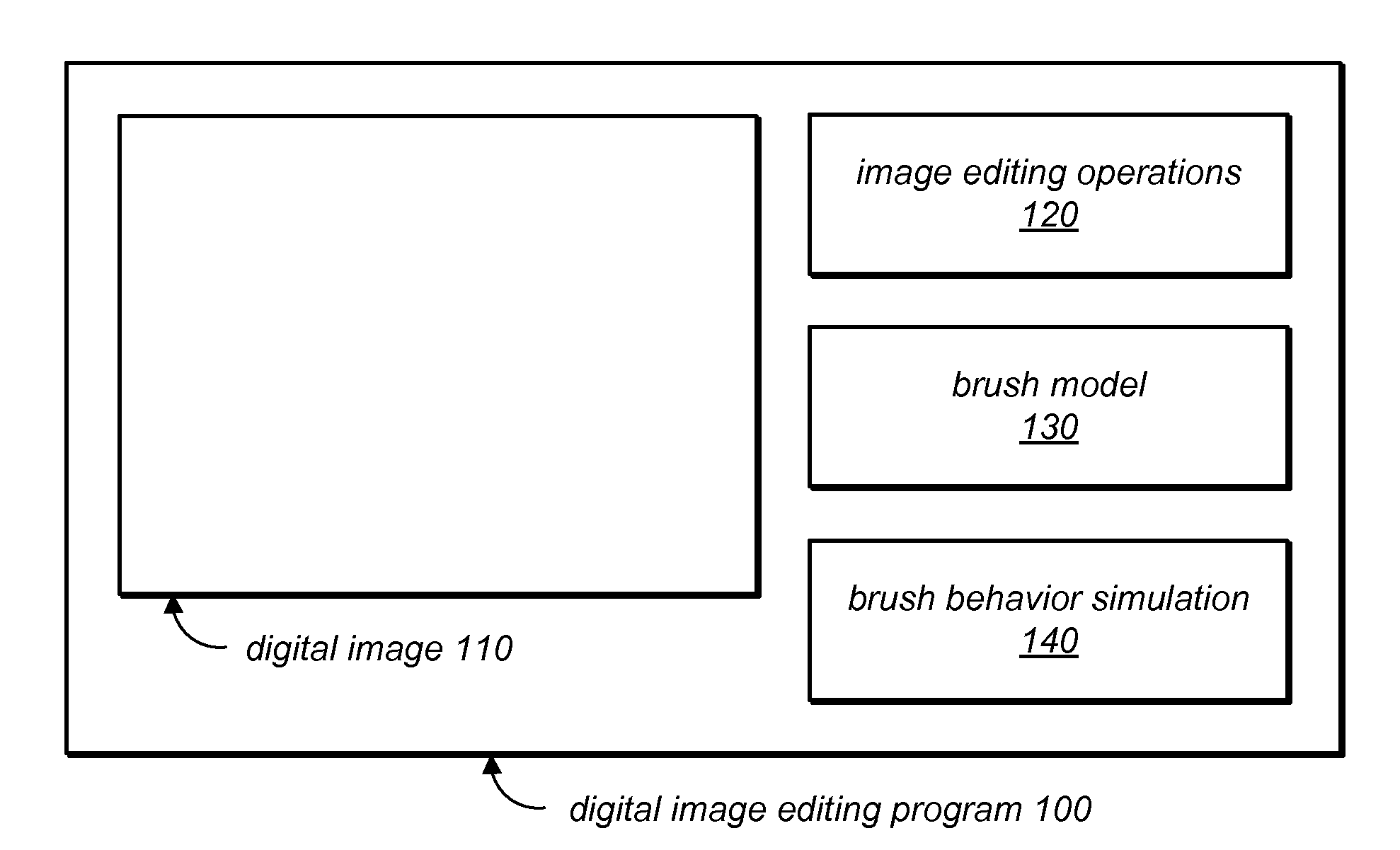

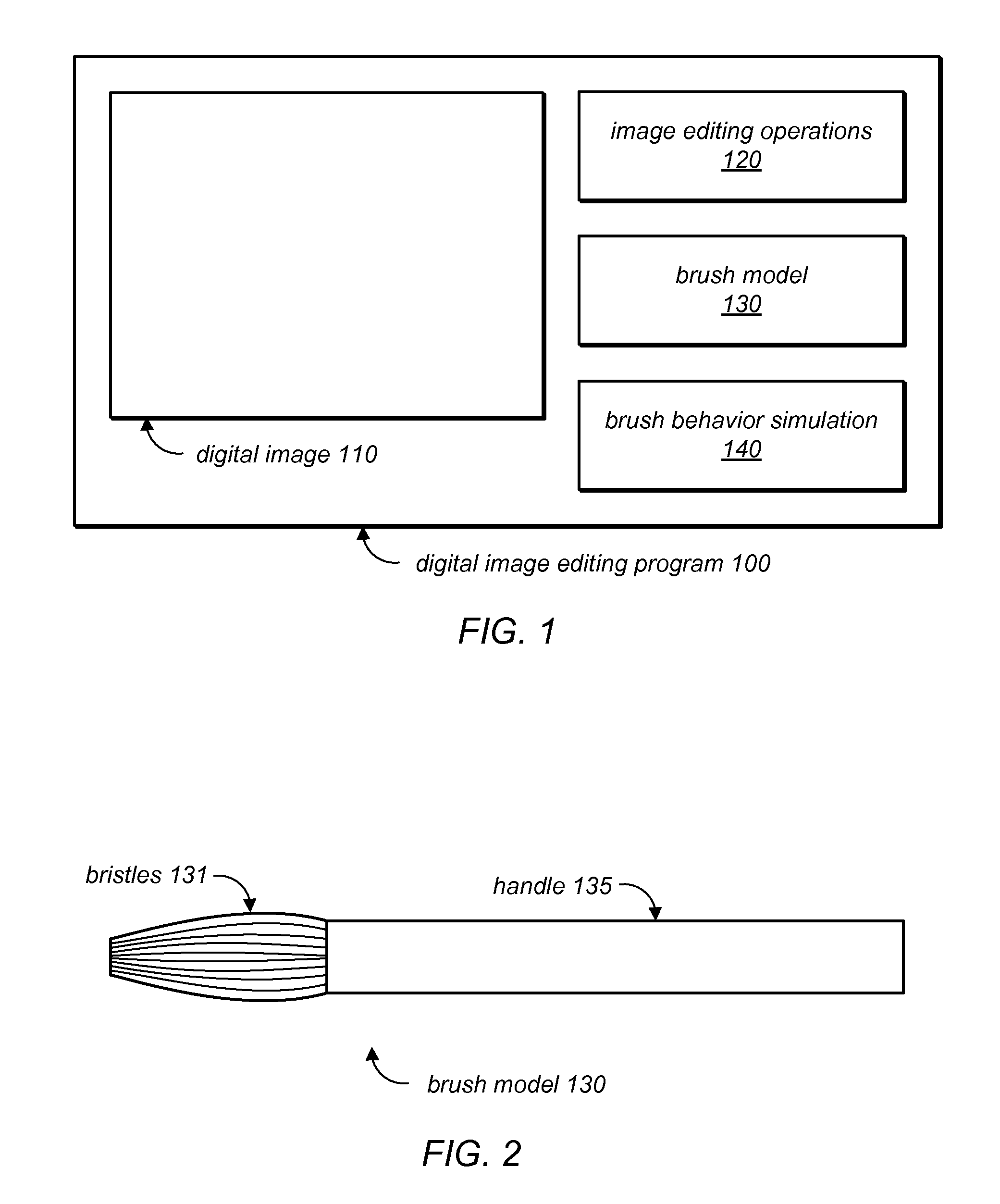

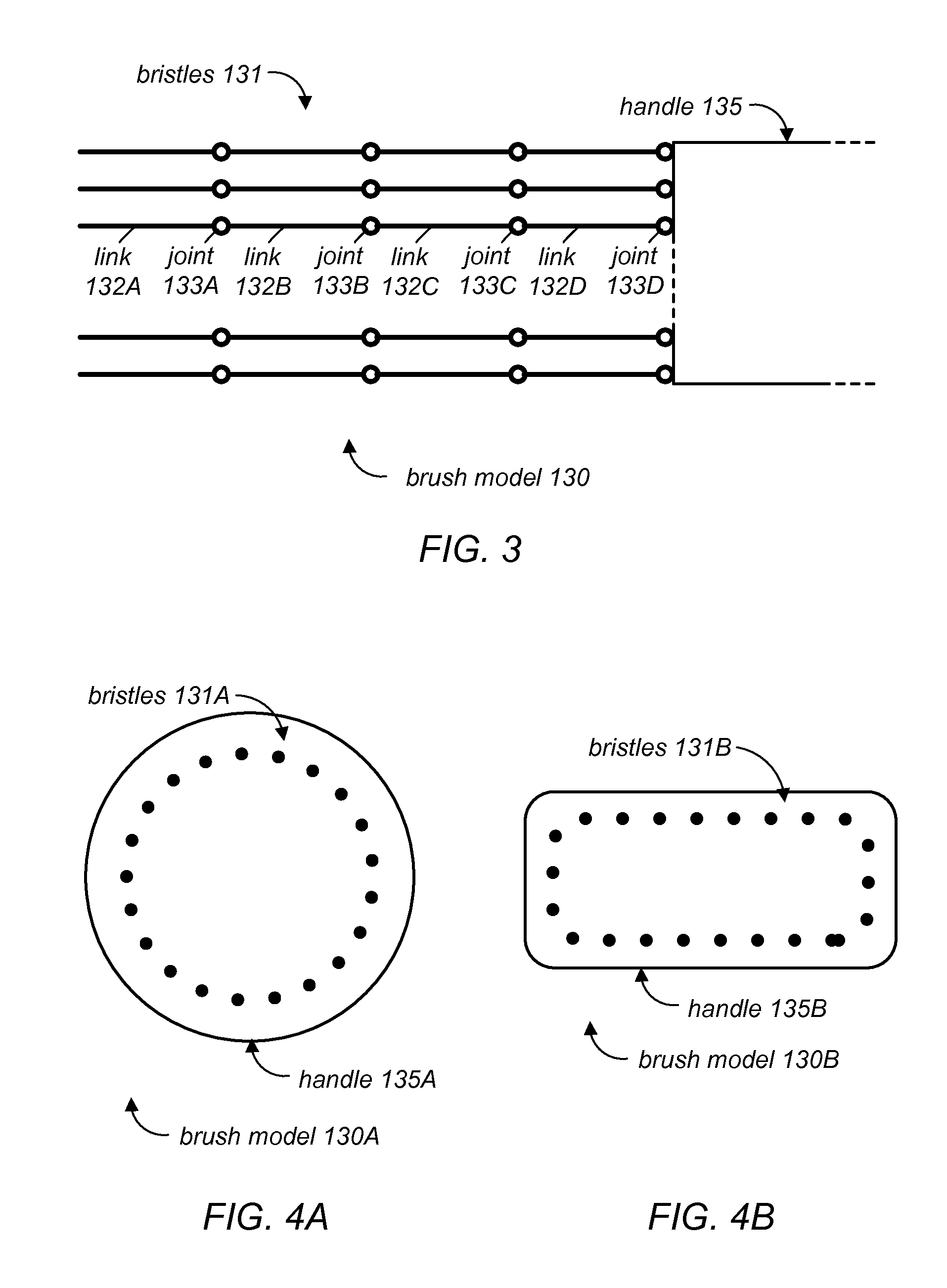

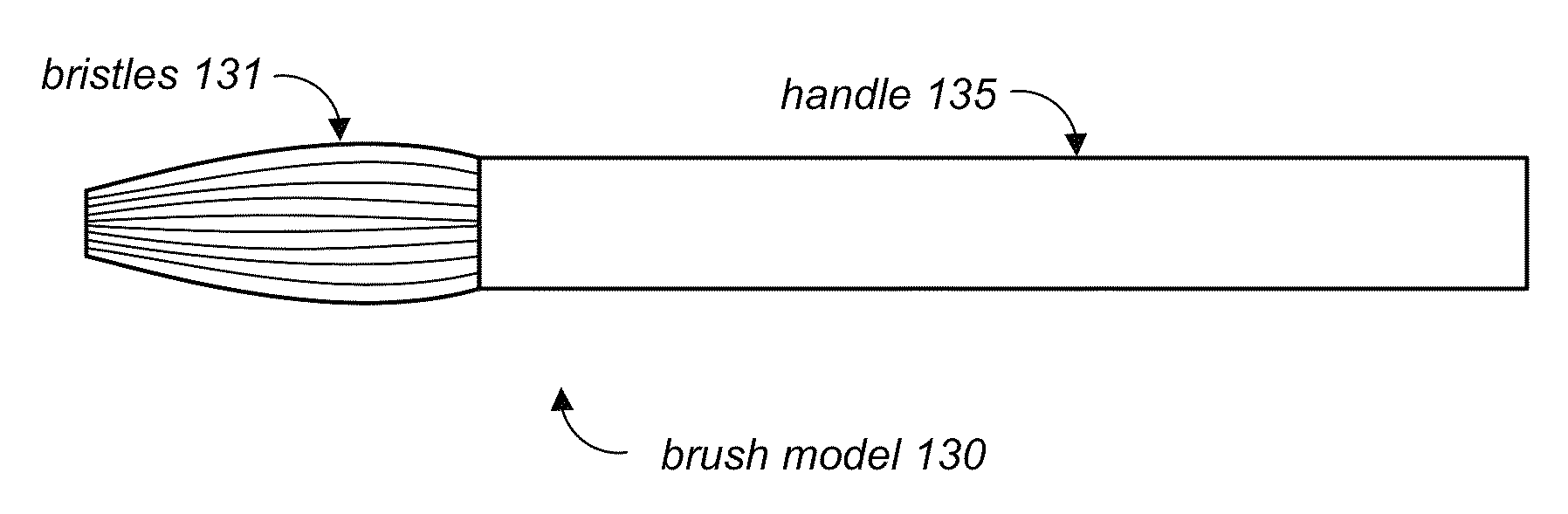

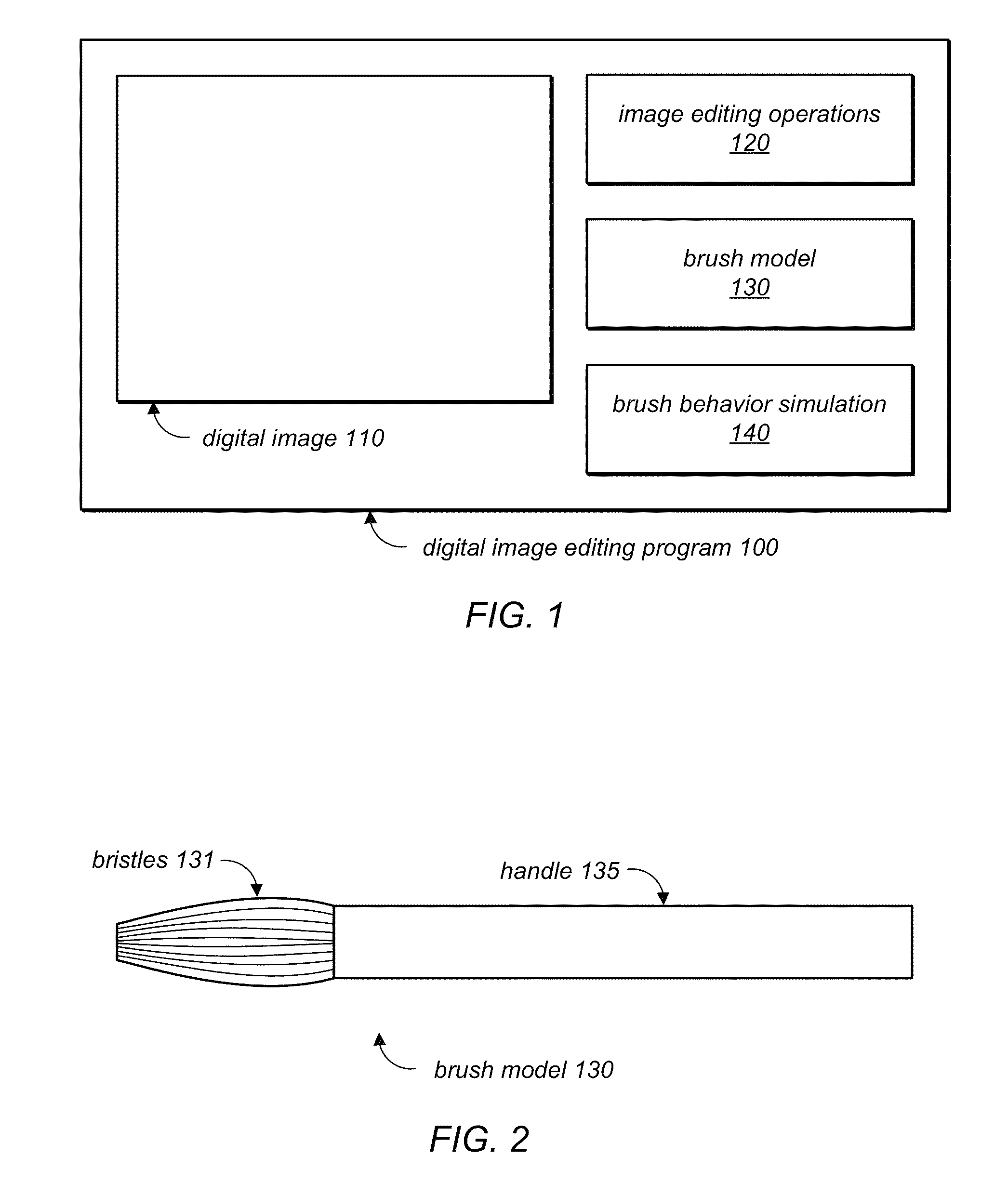

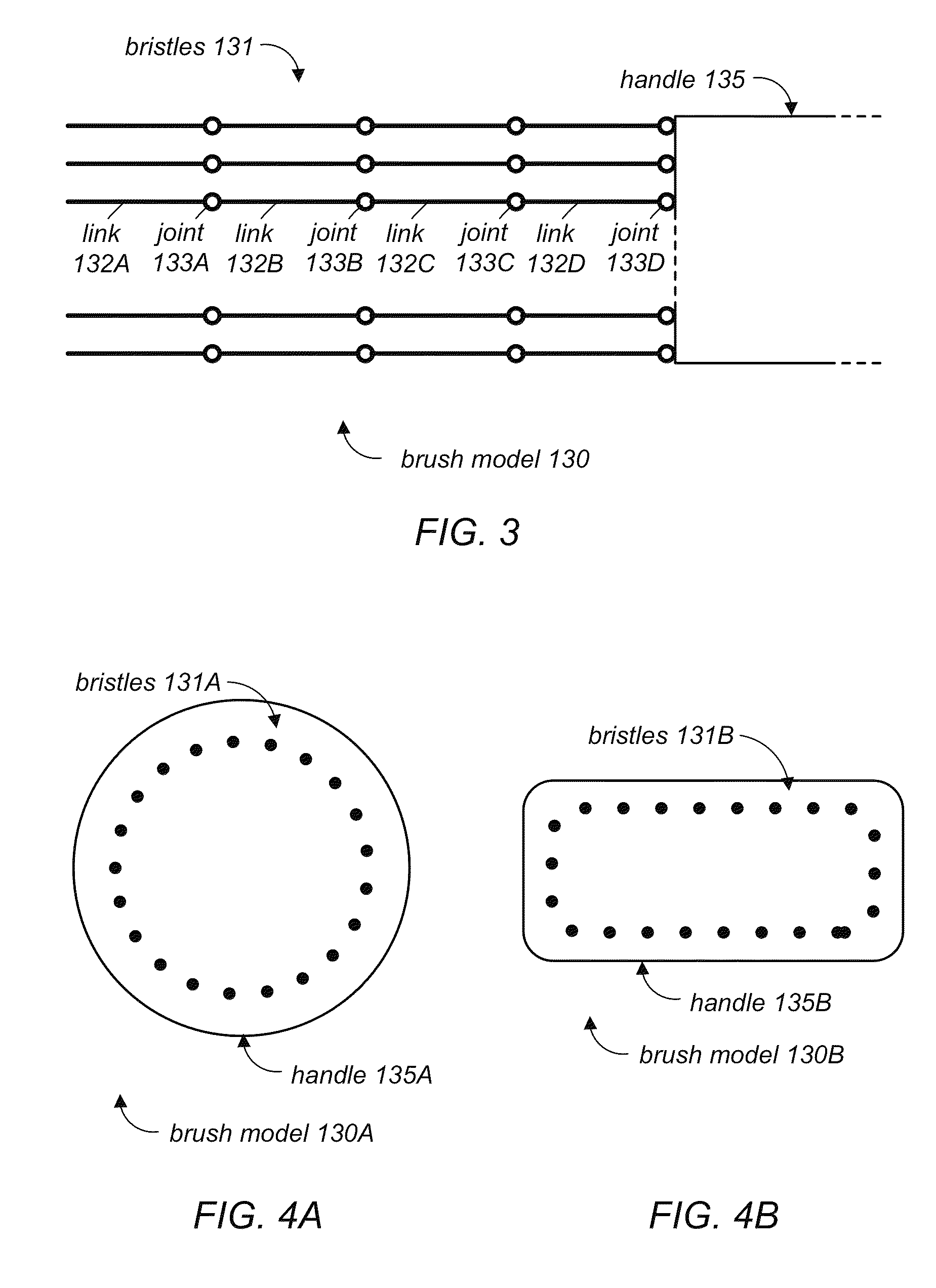

System and Method for Simulation of Brush-Based Painting In a Color Space That Includes a Fill Channel

ActiveUS20130120433A1Increased complexityTexturing/coloringCathode-ray tube indicatorsAtomic elementComputer science

Systems and methods for performing brush behavior simulation in an image editing application may facilitate realistic paint simulation by the addition of a fill channel to a color space representation that includes a set of color channels and an alpha channel representing opacity of the paint. The fill channel value for each pixel of a brush model or canvas may represent the amount of paint stored at the pixel. The system may include logic to support paint compositing, mixing, and depletion operations that calculate a consequent color of a destination pixel resulting from the operations dependent on the fill channel values for the source and / or destination pixels. The resulting color channel, opacity channel, and fill channel values may be converted to a color space that does not include a fill channel or opacity channel for display. A source pixel may be a pixel of an atomic element of a texture.

Owner:ADOBE SYST INC

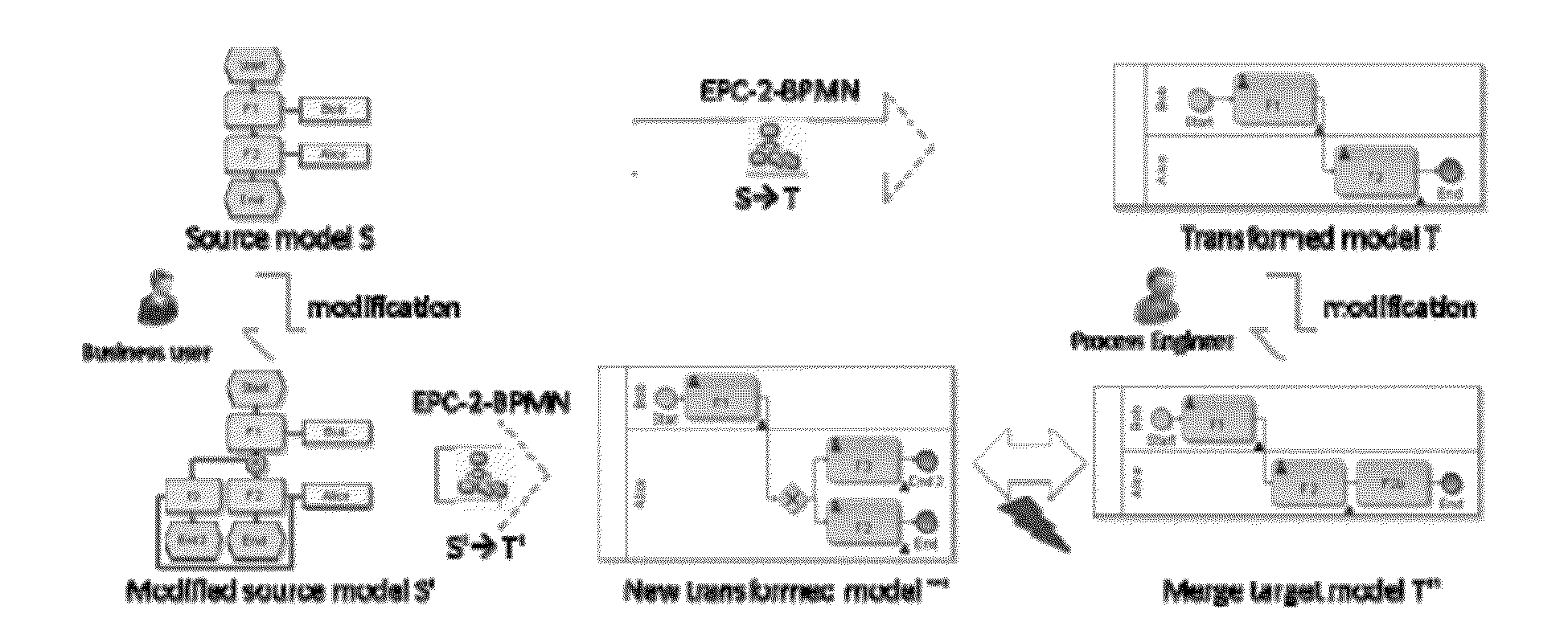

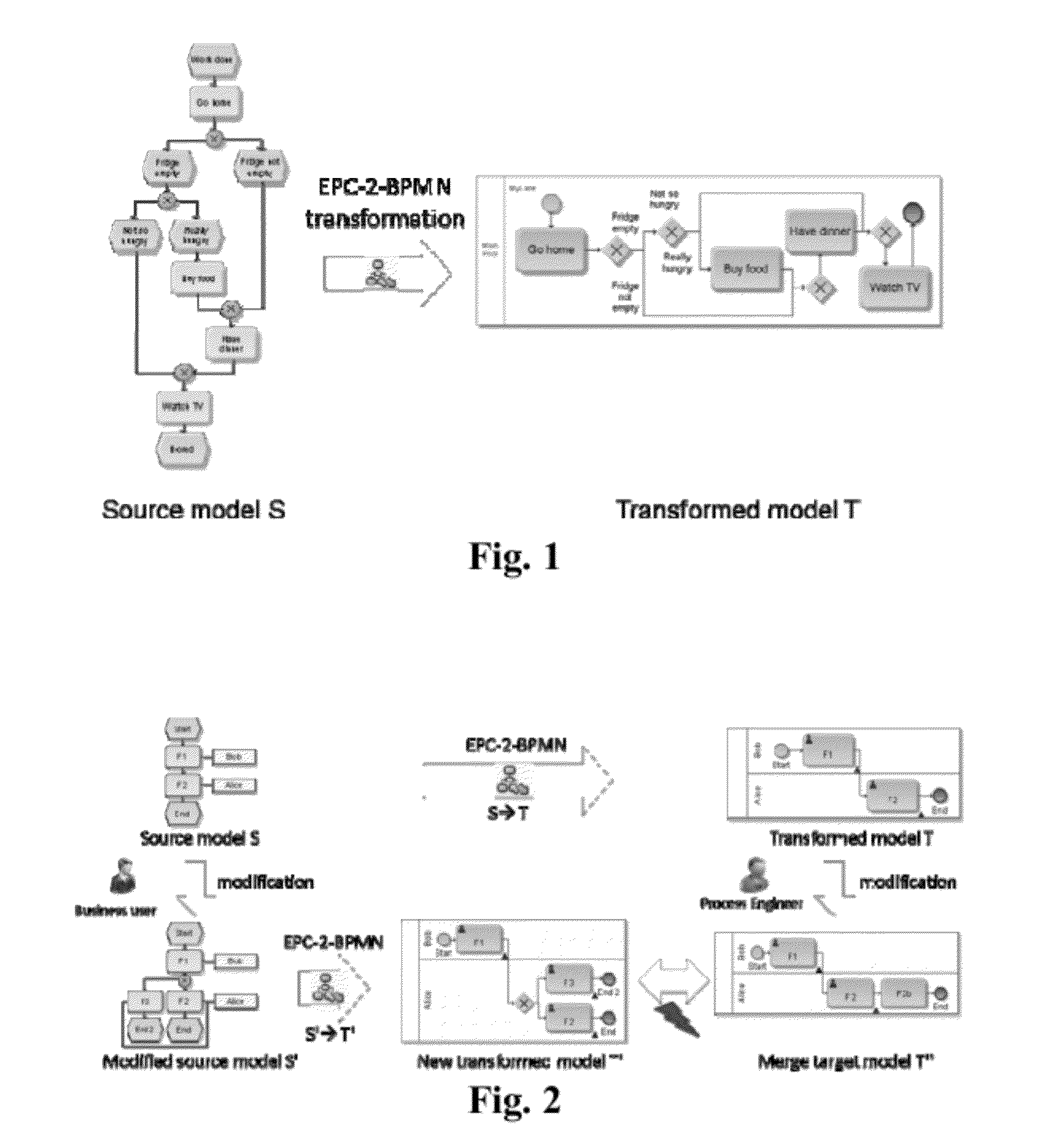

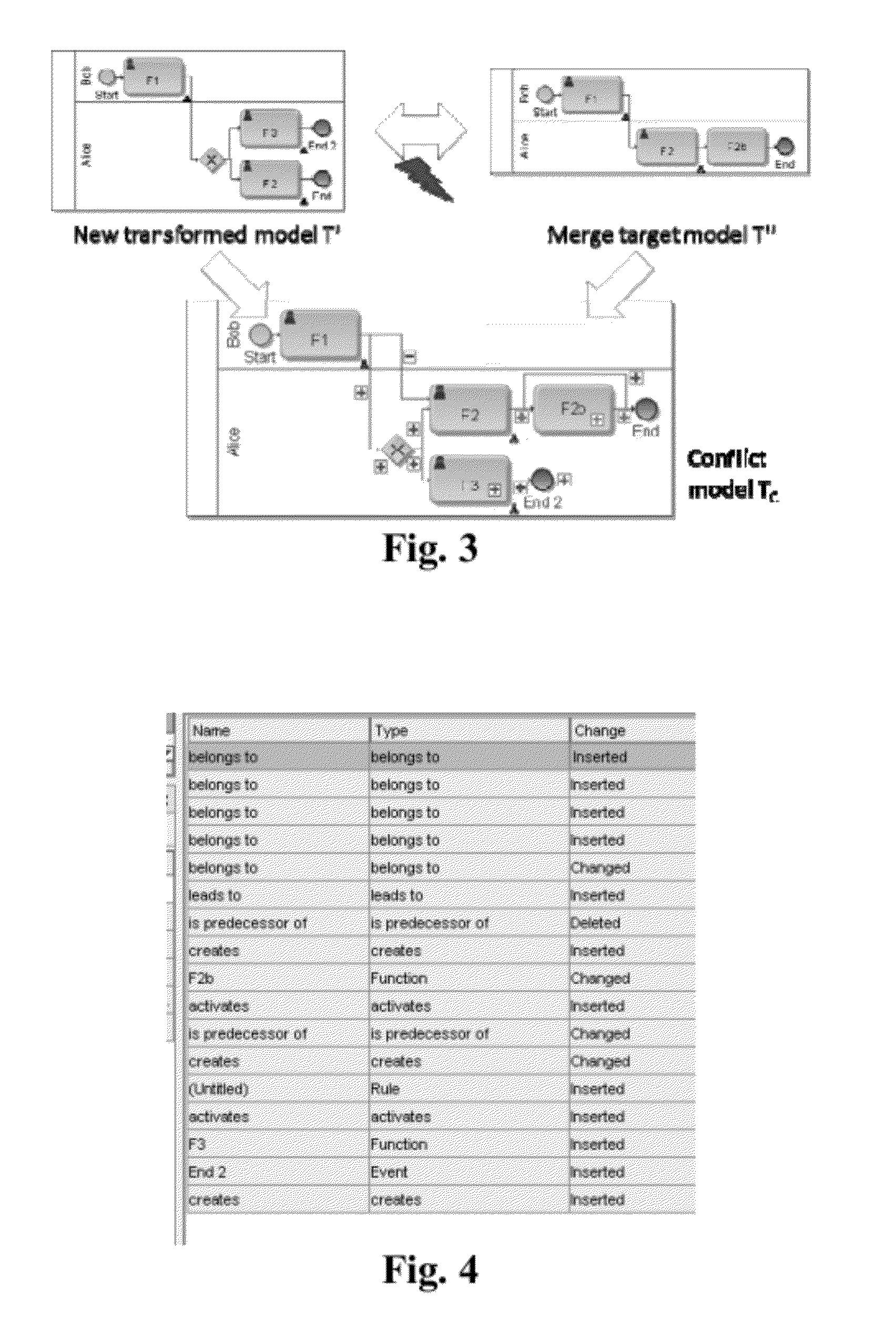

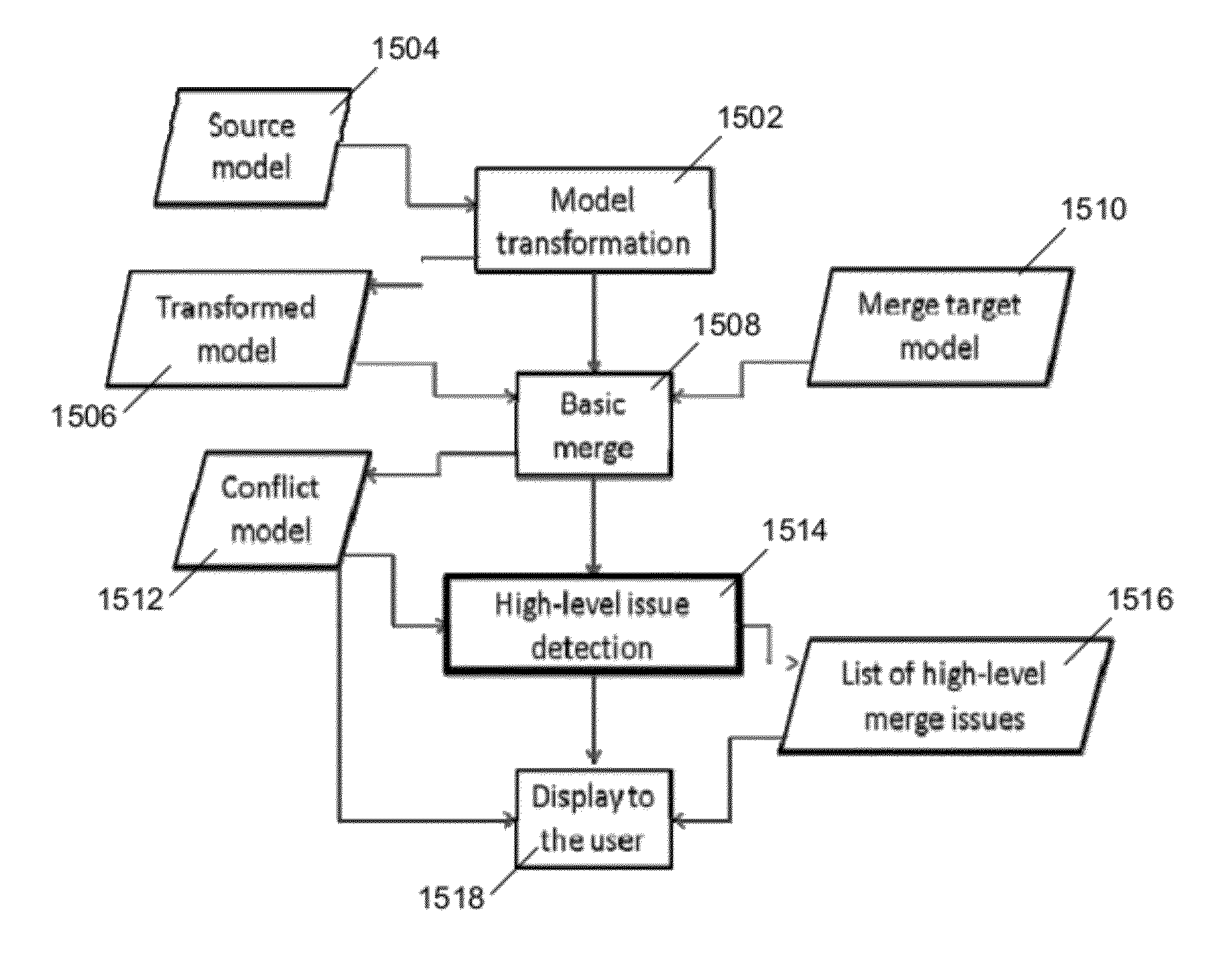

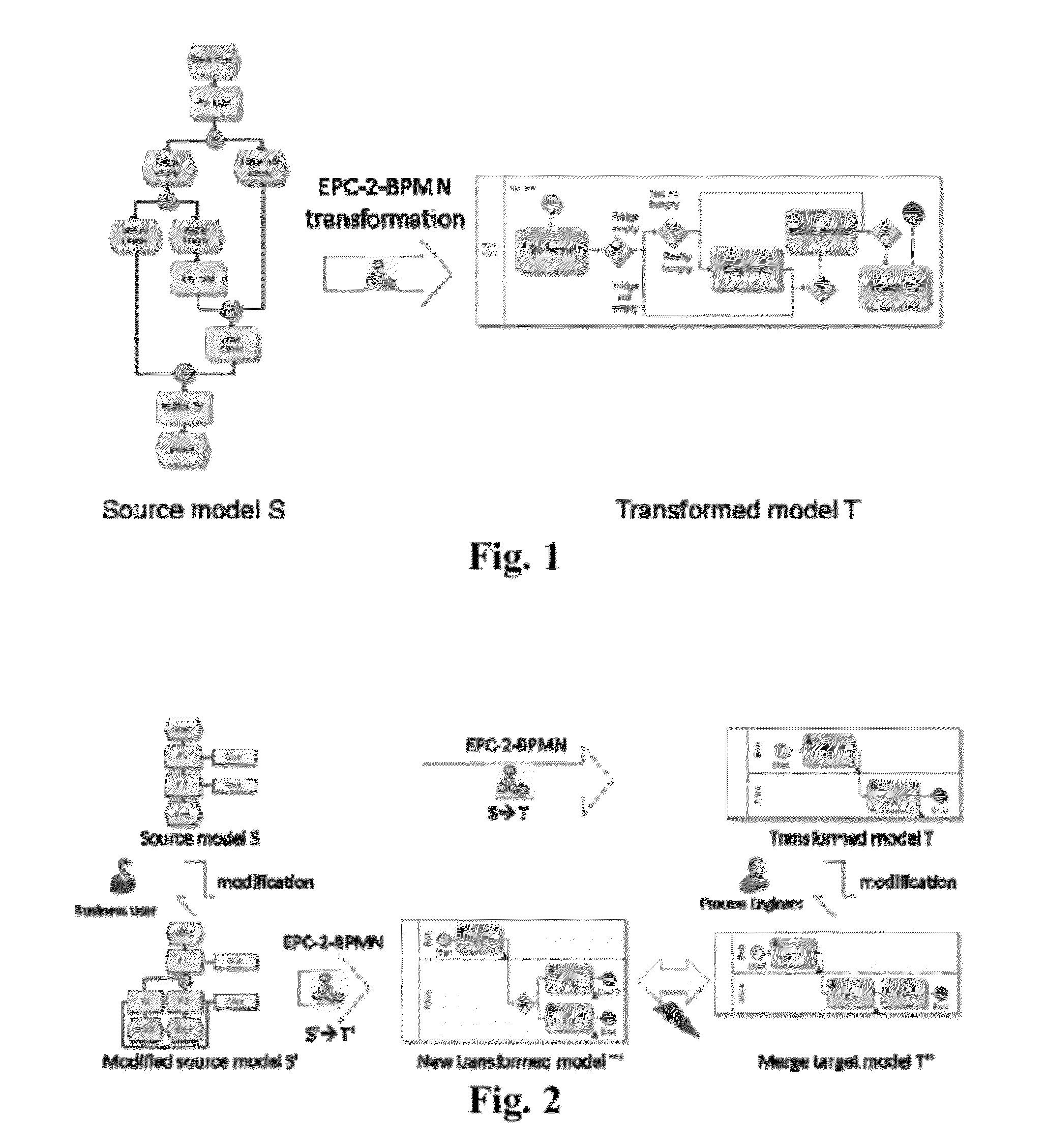

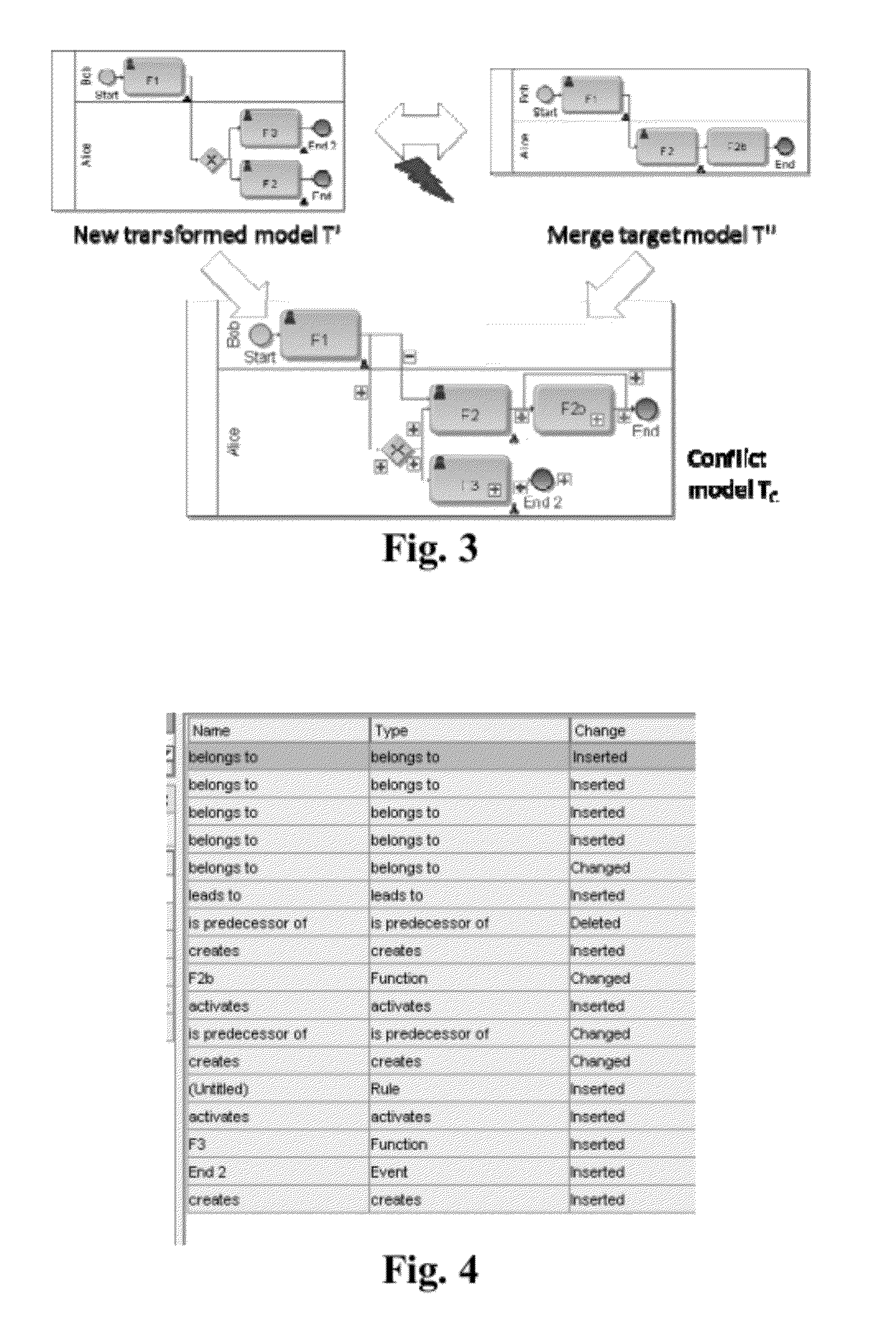

Systems and/or methods for identifying and resolving complex model merge conflicts based on atomic merge conflicts

Certain example embodiments described herein relate to interactive model merging systems and / or methods and, more particularly, to using basic information obtained during merging to help a user resolve high-level merge conflicts. In certain example embodiments, instead of leaving it to the user to resolve the merge conflicts on the level of the atomic elements (e.g., objects and connections with a non-empty merge state), the recognition of high-level merge conflicts may help capture the semantics of the differences between the models being merged on a larger scale (e.g., covering a possibly very large number of model elements in one conflict) and / or also may generally help allow the user to resolve them easily and quickly within a reduced number of operation. The high-level merge conflicts may be resolvable at their high levels or decomposed and resolved at a lower level depending, in part, on the type of conflict involved.

Owner:SOFTWARE AG

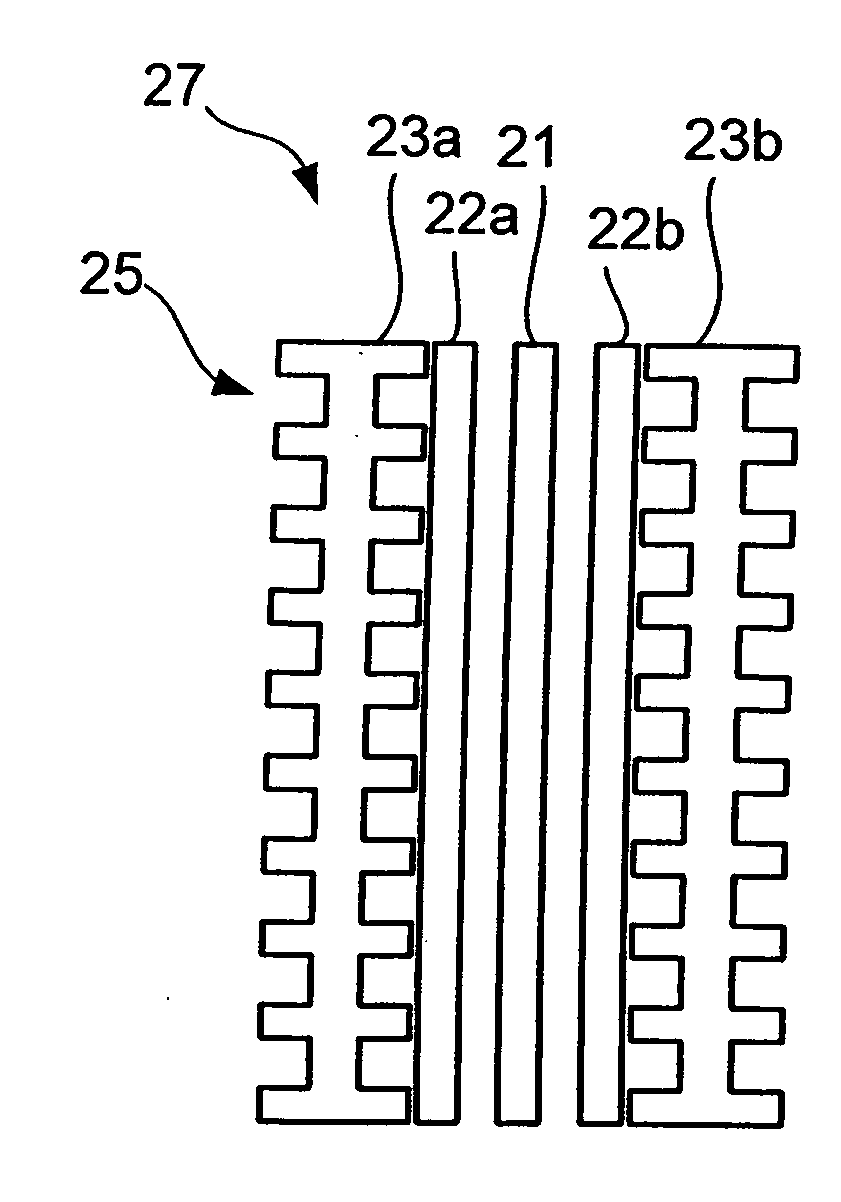

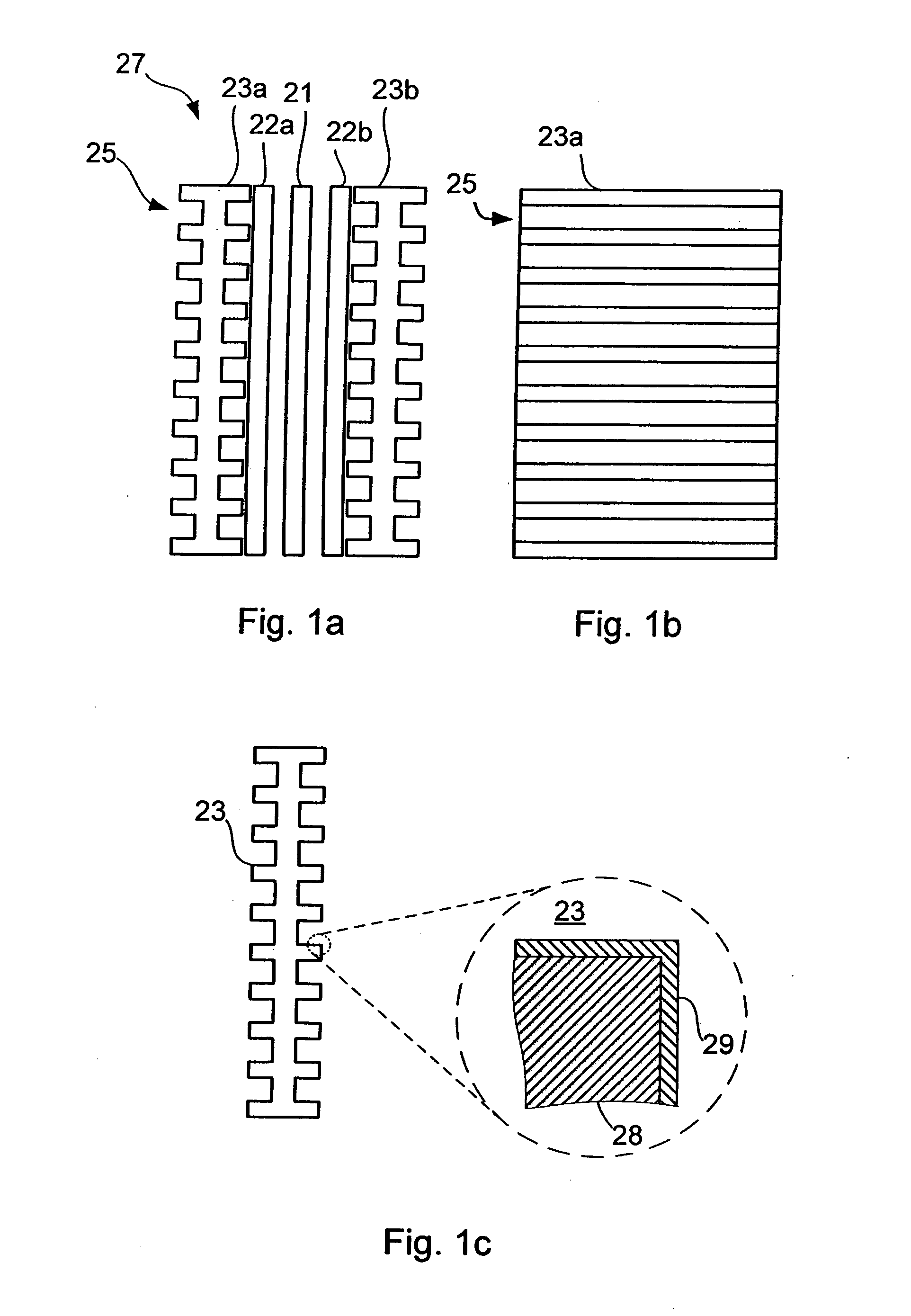

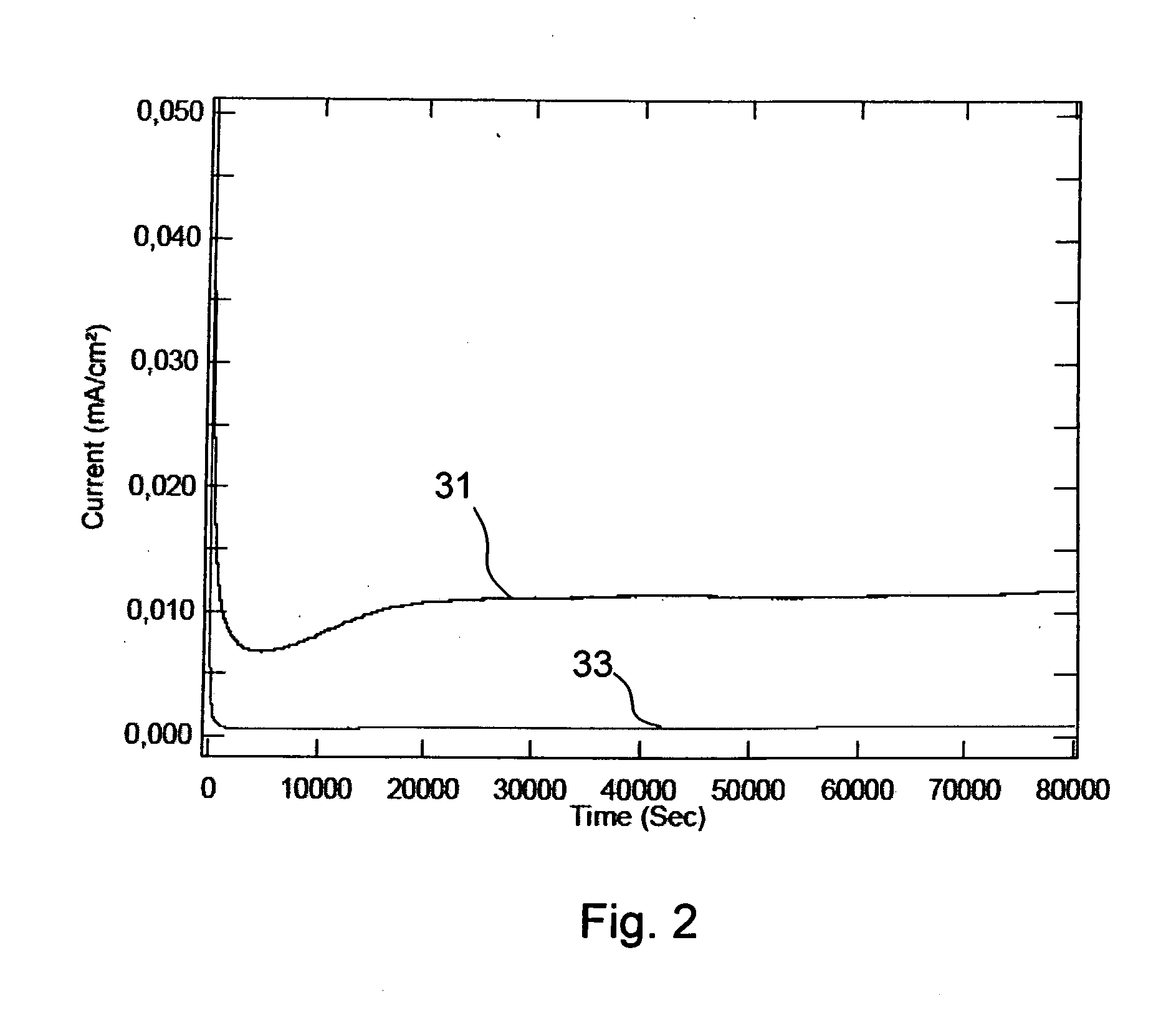

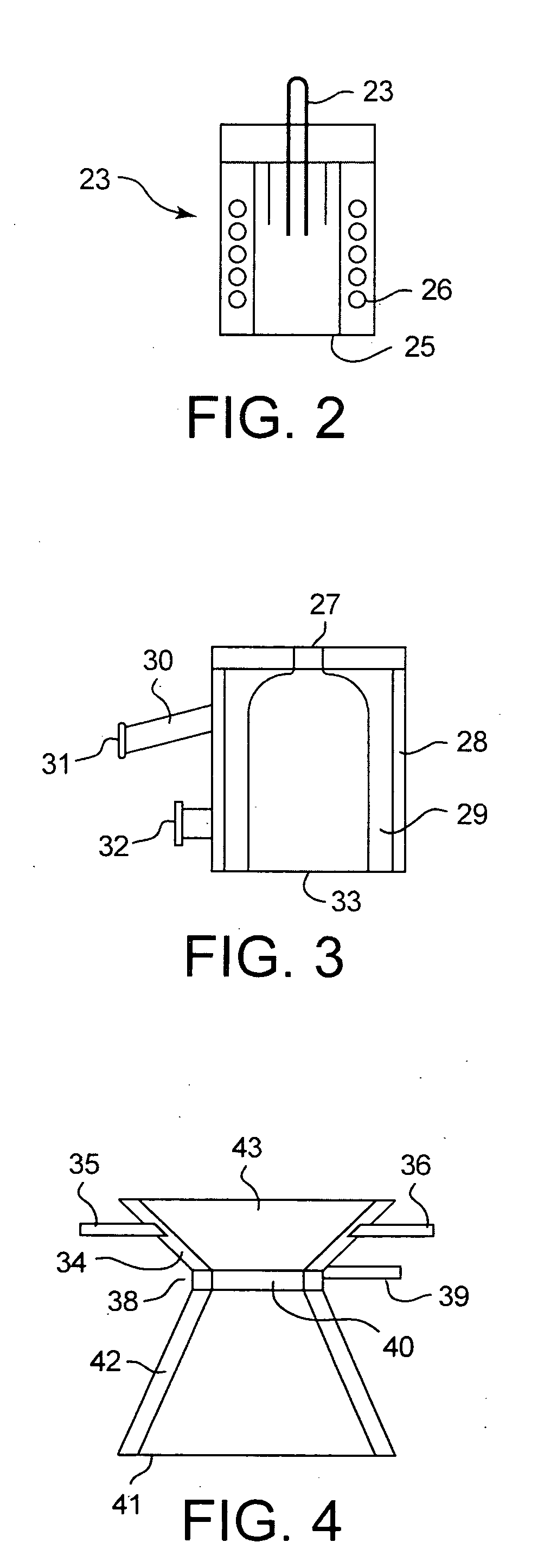

Electrode with a coating, method in production thereof and use of a material

InactiveUS20110033784A1Reduce the impactDecrease risk of weak spotFinal product manufactureVacuum evaporation coatingAtomic elementTernary phase

An element being an electrode (23) for an electrochemical cell (27), which comprises an electrically conductive substrate (28) and an electrically conductive corrosion resistant coating (29) comprising a multielement material, which coating is formed on and at least partially covering said conducting substrate, is disclosed. There is also disclosed a method in manufacturing of such electrode and a use of the multielement material for corrosion protection of an electrode for an electrochemical cell. The multielement material has a composition of at least one of a carbide or nitride described by the formula MqAyXz, where M is a transition metal or a combination of transition metals, A is a group A element or a combination of group A elements, X is carbon or nitrogen or both, and z and at least one of q and y are numbers above zero. The multielement material further comprises at least one nanocomposite (4) comprising single elements, binary phases, ternary phases, quaternary phases or higher order phases based on the atomic elements in the corresponding MqAyXz compound.

Owner:IMPACT COATINGS AB

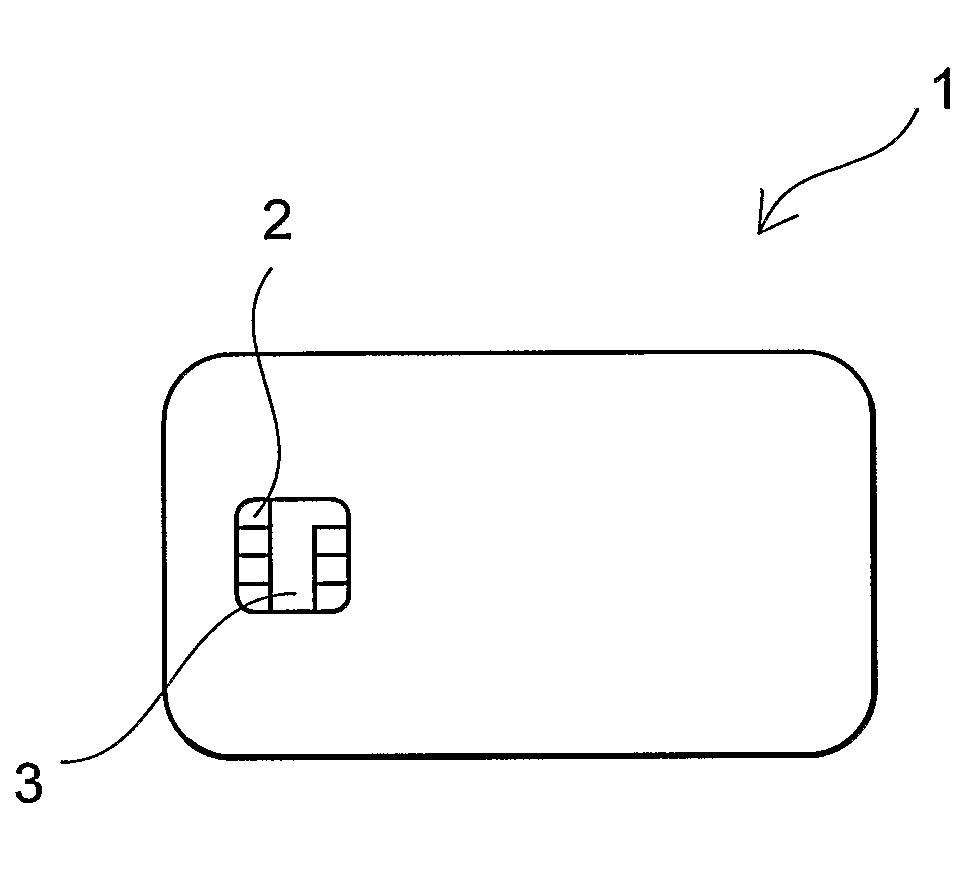

Smart card and smart card reader

InactiveUS20090032593A1Good electrical contactProduced cost-effectivelyCoupling contact membersMetallic material coating processesAtomic elementContact layer

A smart card (1) has a card contact element (2) for establishing an electrical contact with a reader contact element of a smart card reader for reading the smart card (1). The card contact element (2) has a contact surface (3) coated with a contact layer, said contact surface (3) being arranged to be brought into contact with the reader contact element. The contact layer comprises a multiele-ment material that has a composition of at least one of a carbide or nitride described by the formula MqAyXz, where M is a transition metal or a combination of transition metals, A is a group A element or a combination of group A elements, X is carbon or nitrogen or both, and q, y and z are numbers above zero. The multi-element material further comprises at least one nanocomposite comprising single elements, binary phases, ternary phases, quaternary phases or higher order phases based on the atomic elements in the corresponding MqAyXz compound. A reader for reading a smart card (1) is also disclosed.

Owner:IMPACT COATINGS AB

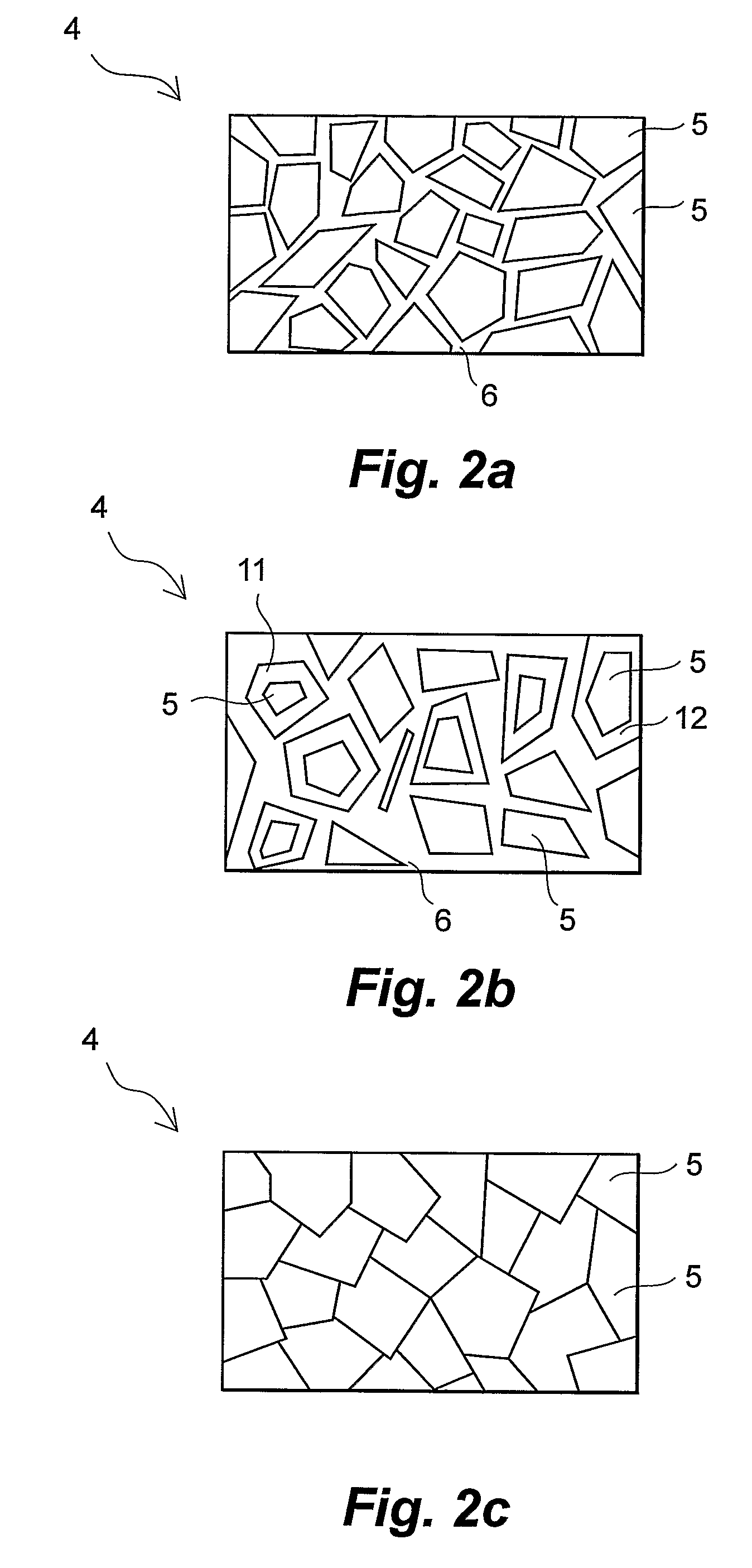

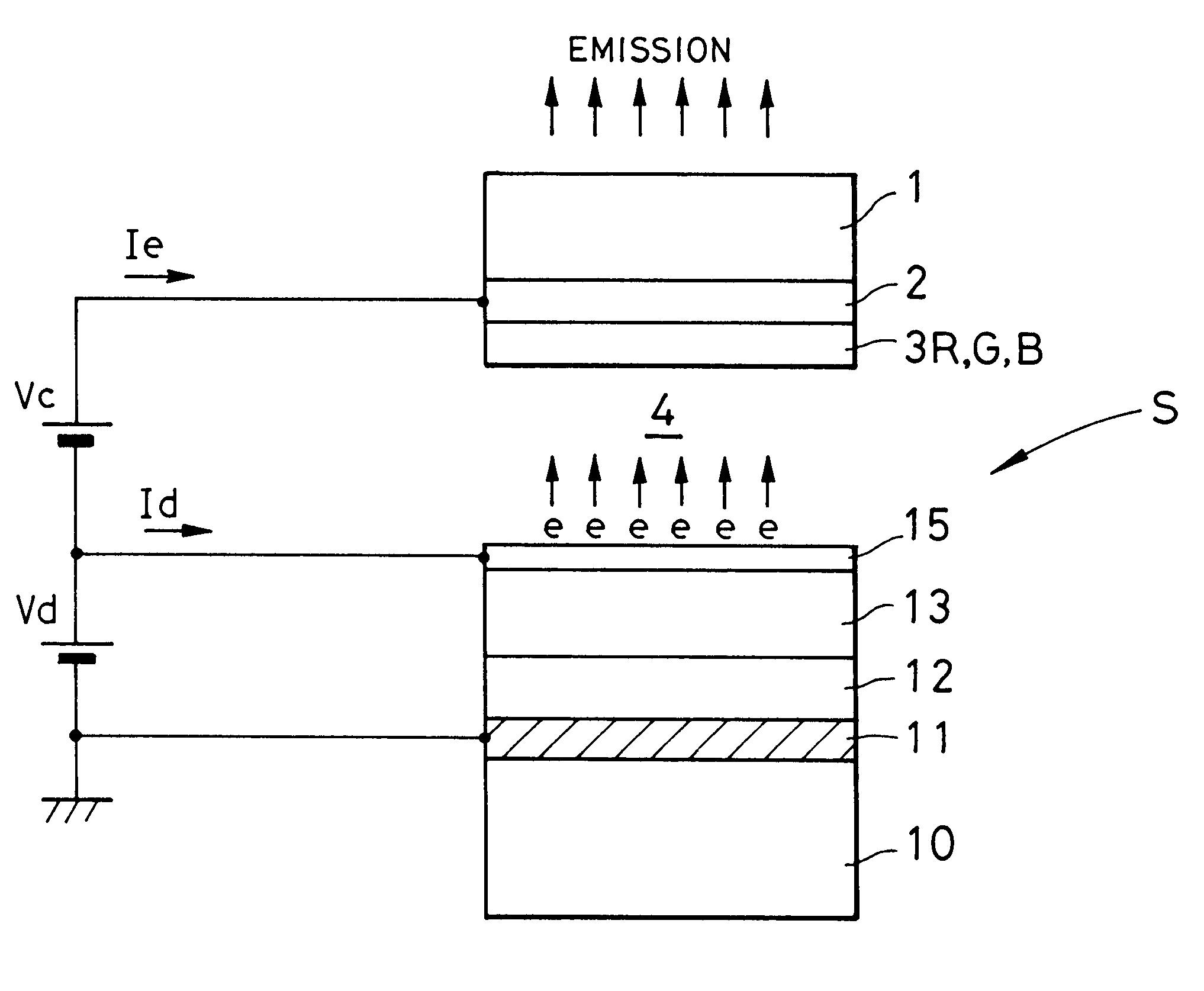

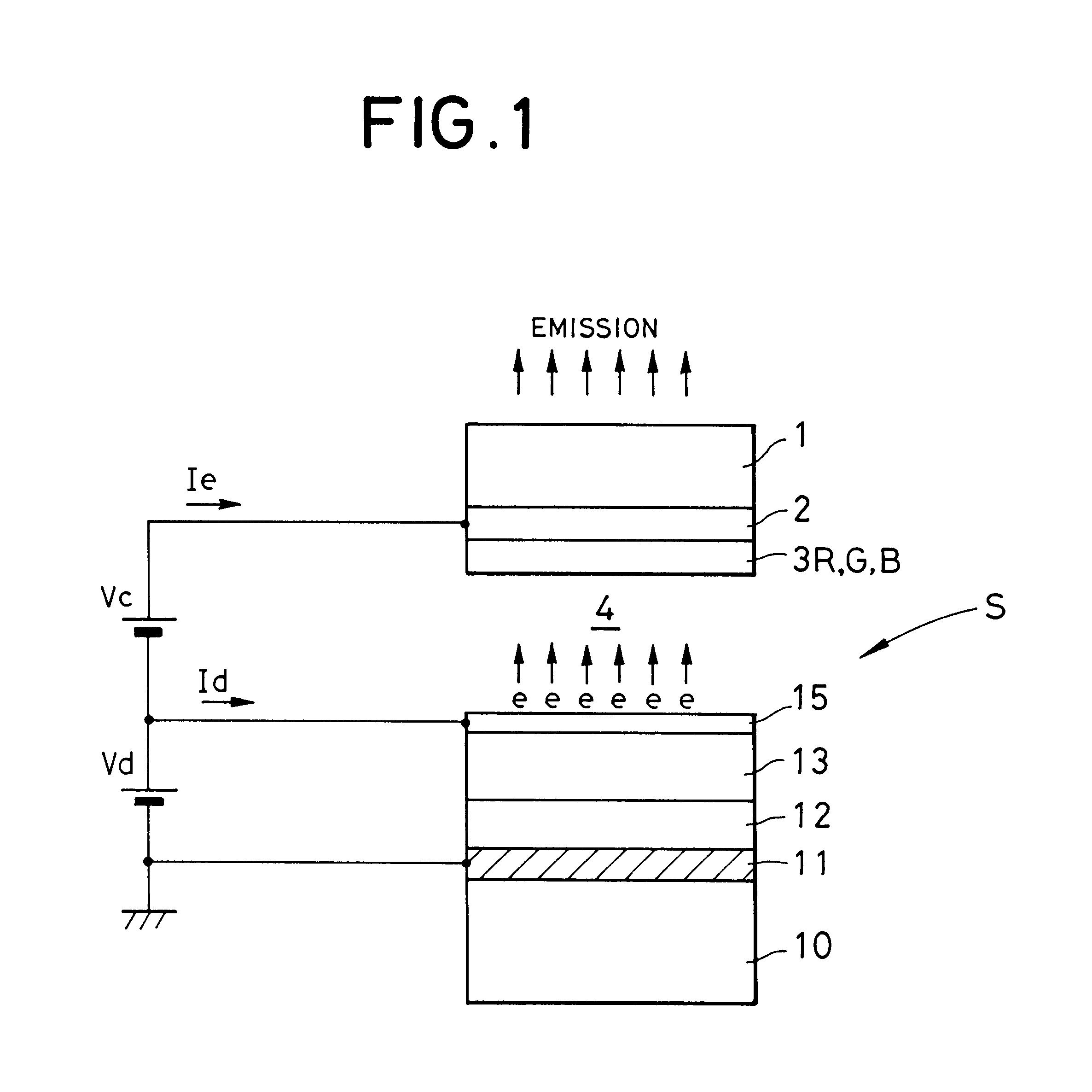

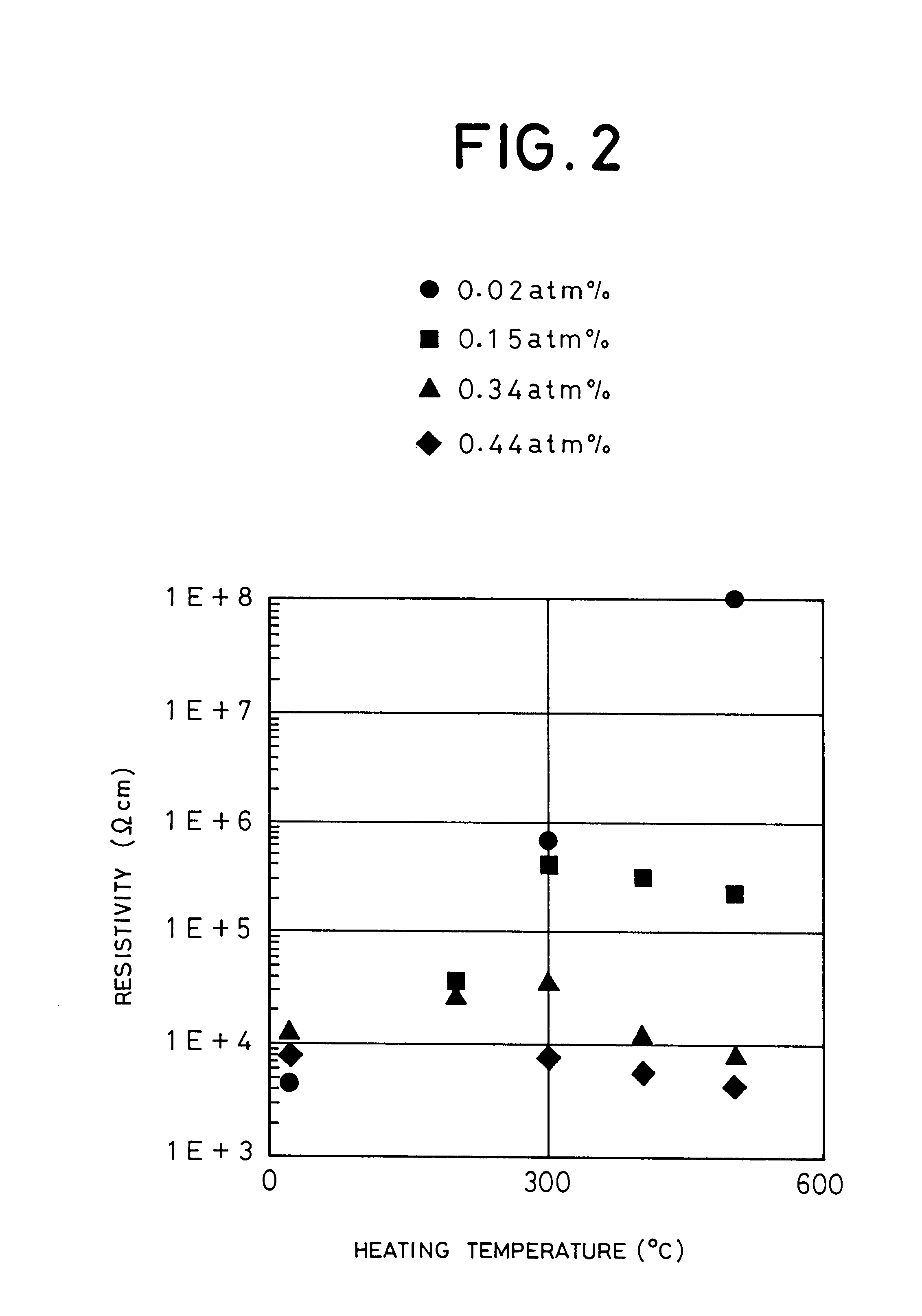

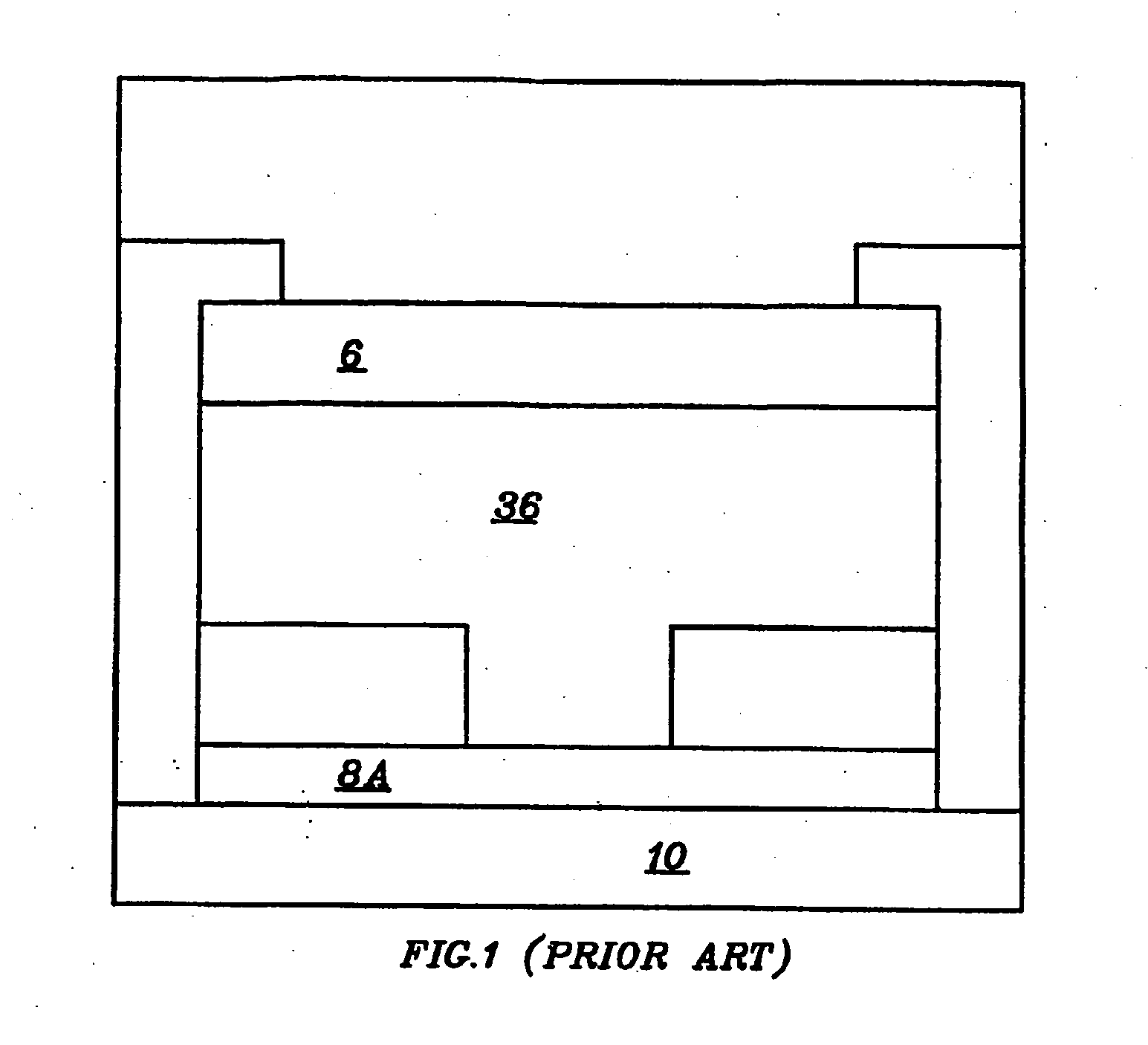

Electron emission device with electron supply layer having reduced resistance

InactiveUS6388376B1Improve production yieldIncrease speedDischarge tube luminescnet screensNanoinformaticsAtomic elementMetal electrodes

An electron emission device comprises an electron-supply layer made of metal or semiconductor and disposed on an ohmic electrode; an insulator layer formed on the electron-supply layer; and a thin-film metal electrode formed on the insulator layer. The electron-supply layer is essentially composed of elements belonging to group IV and contains an additive of at least one material selected from atomic elements belonging to group III or V.

Owner:PIONEER CORP

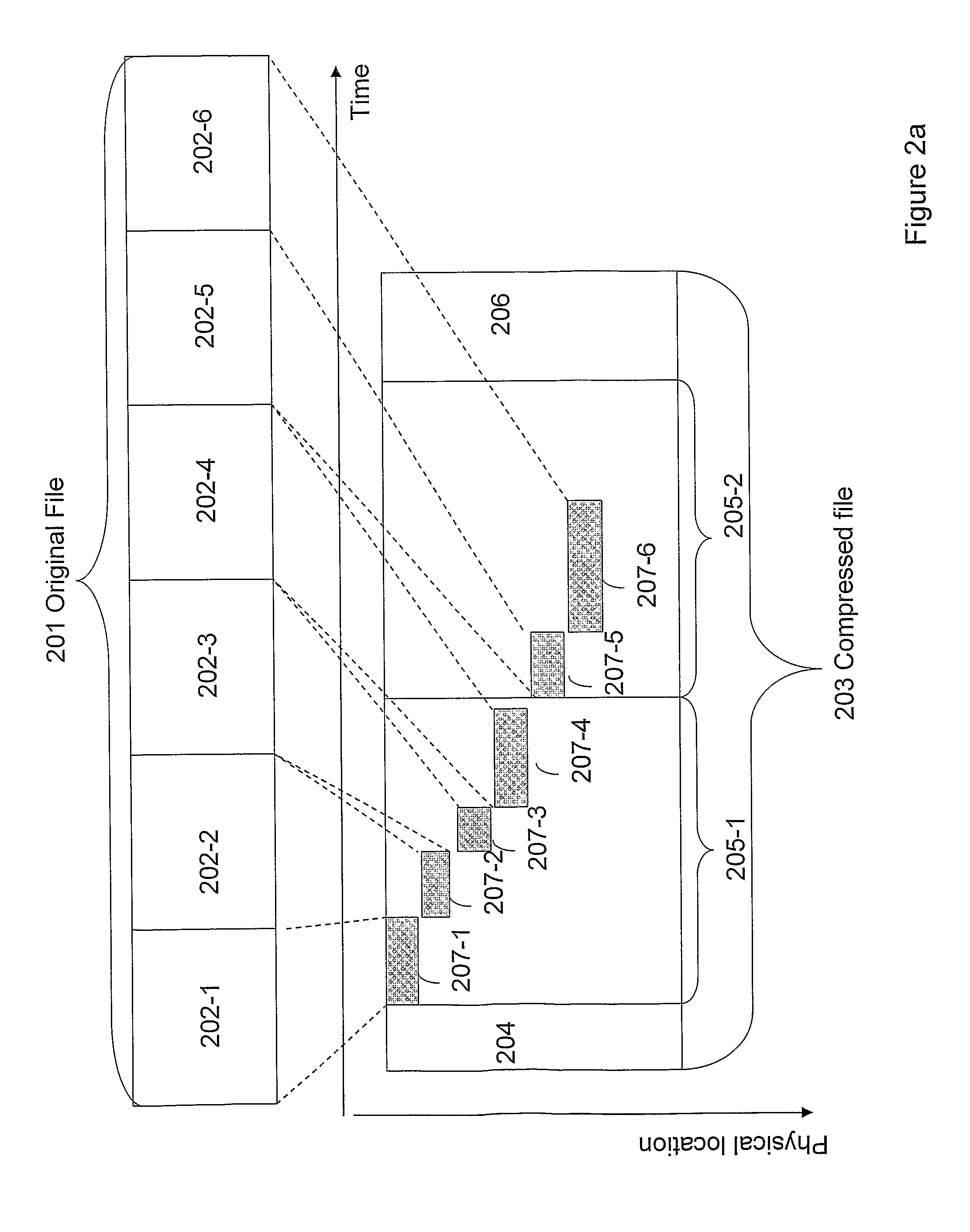

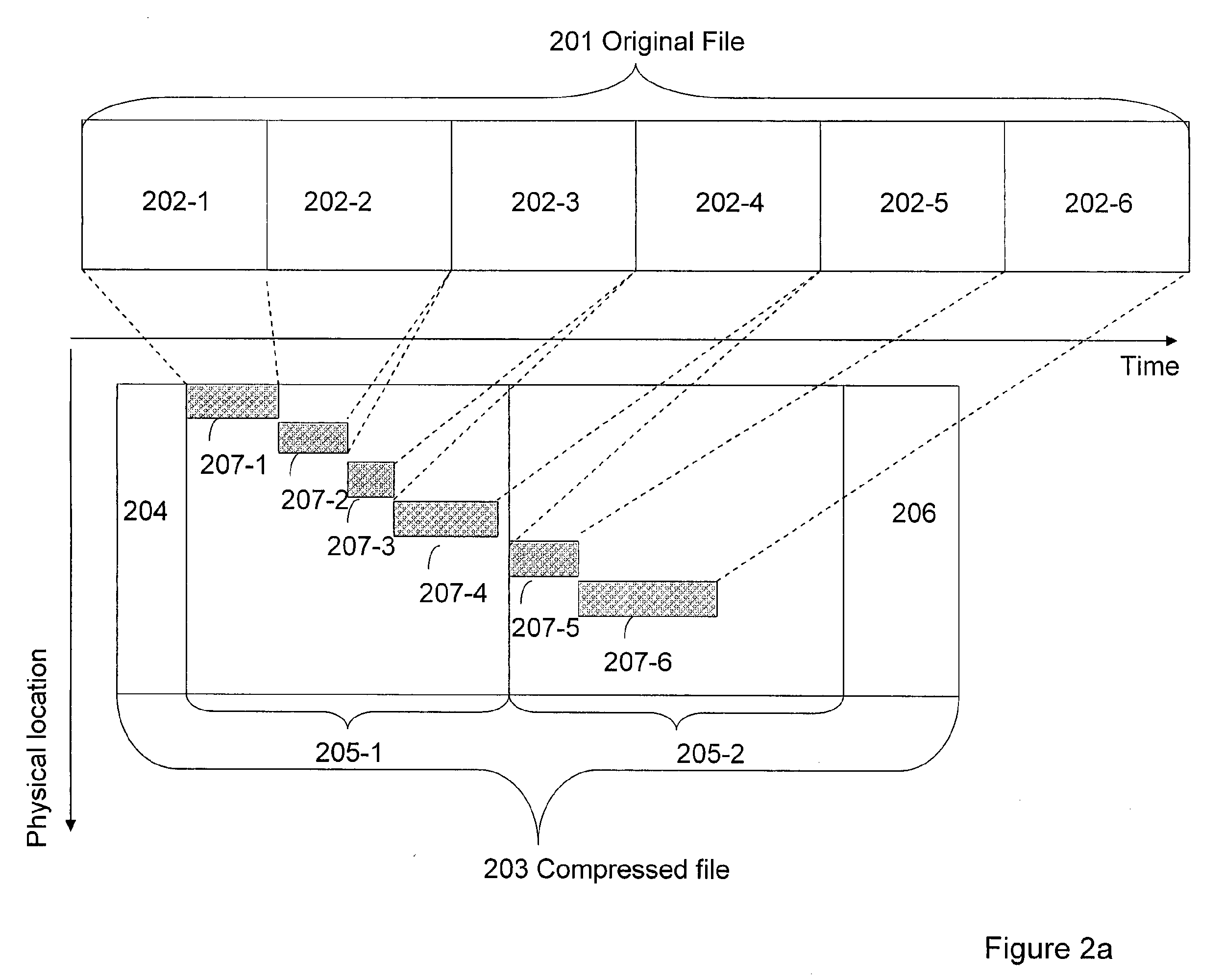

Method and system for transformation of logical data objects for storage

InactiveUS20090307250A1Easy to storeMemory architecture accessing/allocationCode conversionAtomic elementData transformation

A method and system for transforming a logical data object for storage in a storage device operable with at least one storage protocol, creating, reading, writing, optimization and restoring thereof. Transforming the logical data object comprises creating in the storage device a transformed logical data object comprising a header and one or more allocated accommodation sections with predefined size; transforming one or more sequentially obtained chunks of obtained data corresponding to the transforming logical data object thus giving rise to the transformed data chunks; and sequentially accommodating the processed data chunks into said accommodation sections in accordance with an order said chunks received, wherein said accommodation sections serve as atomic elements of transformation / de-transformation operations during input / output transactions on the logical data object. The processing may comprise two or more data transformation techniques coordinated in time, concurrently executing autonomous sets of instructions, and provided in a manner facilitating preserving the sequence of processing and accommodating the processed data chunks.

Owner:IBM CORP

Encapsulated particles

The disclosed technology relates generally to material systems which include a plurality of particles and methods of making the same. The particles have a core and a shell which encapsulates the core and has at least one atomic element not included in the core. The cores of the particles have a median maximum dimension that is less than 10 microns and a median of at least one axial dimension that is between 10 nm and 500 nm. The shells of the particles have a median thickness that is less than 100 nm, a silicon concentration that is between 10% and 50% on the basis of the weight of the shells, and an aluminum concentration that is between 0.01% and 5% on the basis of the weight of the shells.

Owner:NANOCOMPOSIX LLC

Laser fabrication of continuous nanofibers

This invention provides a continuous process of making continuous nanofibers of all kinds, such as SiC, BN, AlN, and C. Laser heating a vapor of feed-material made of all atomic elements needed to grow chosen nanofibers results in growth of nanofibers onto seed-nanostructures attached to a filament, which is then pulled up continuously at a rate controlled by a rate of growth of the nanofibers. More feed-material is supplied at a rate sufficient to enable the nanofibers to grow longer continuously without limit. Laser light focused into a doughnut shape provides a photon density gradient, which constrains the nanofibers to grow parallel to each other and in the form of cylinders, so that industrially useful structures like cables and cylinders can be made in one low cost operation and in large quantities.

Owner:SHIMOJI YUTAKA +1

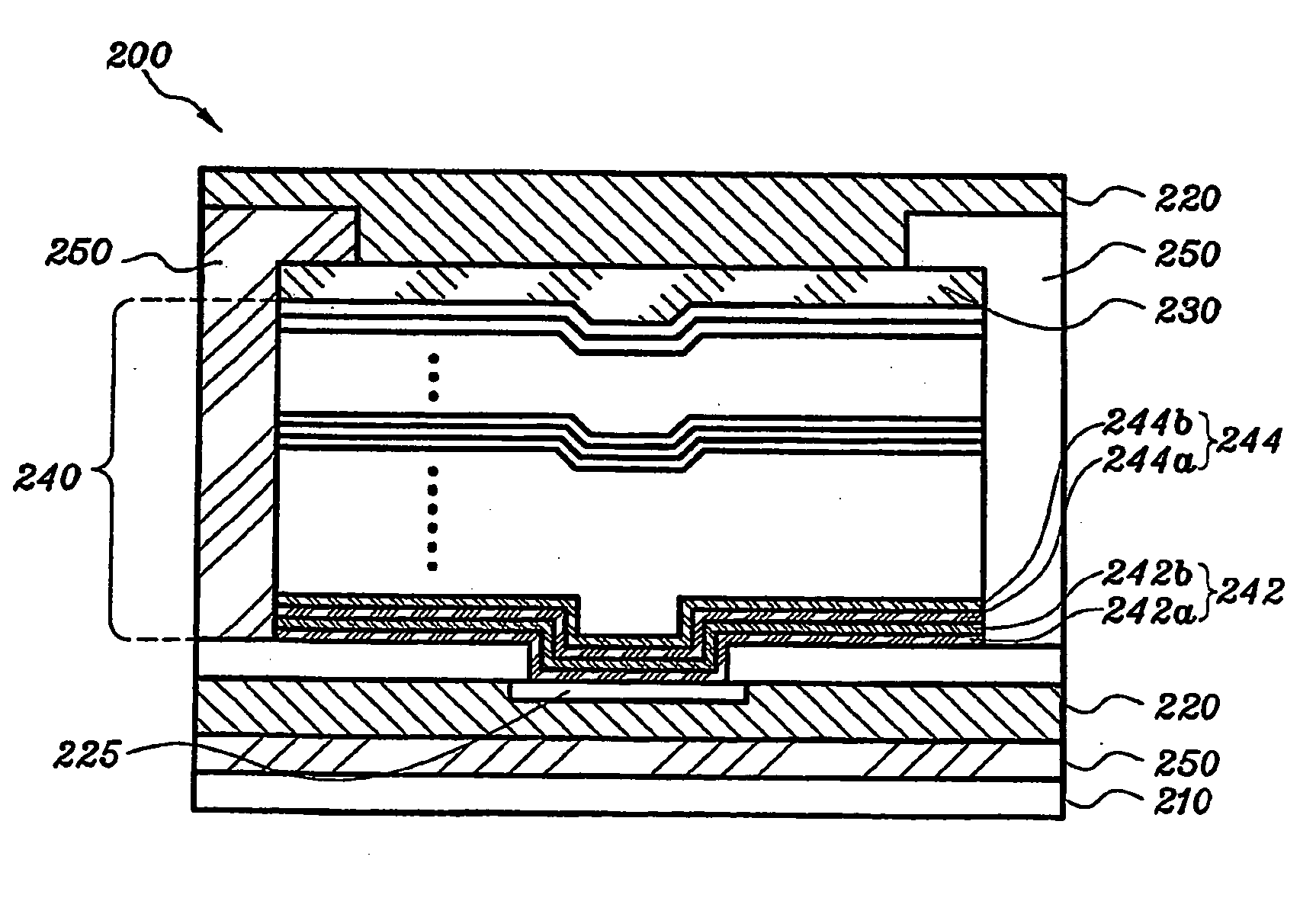

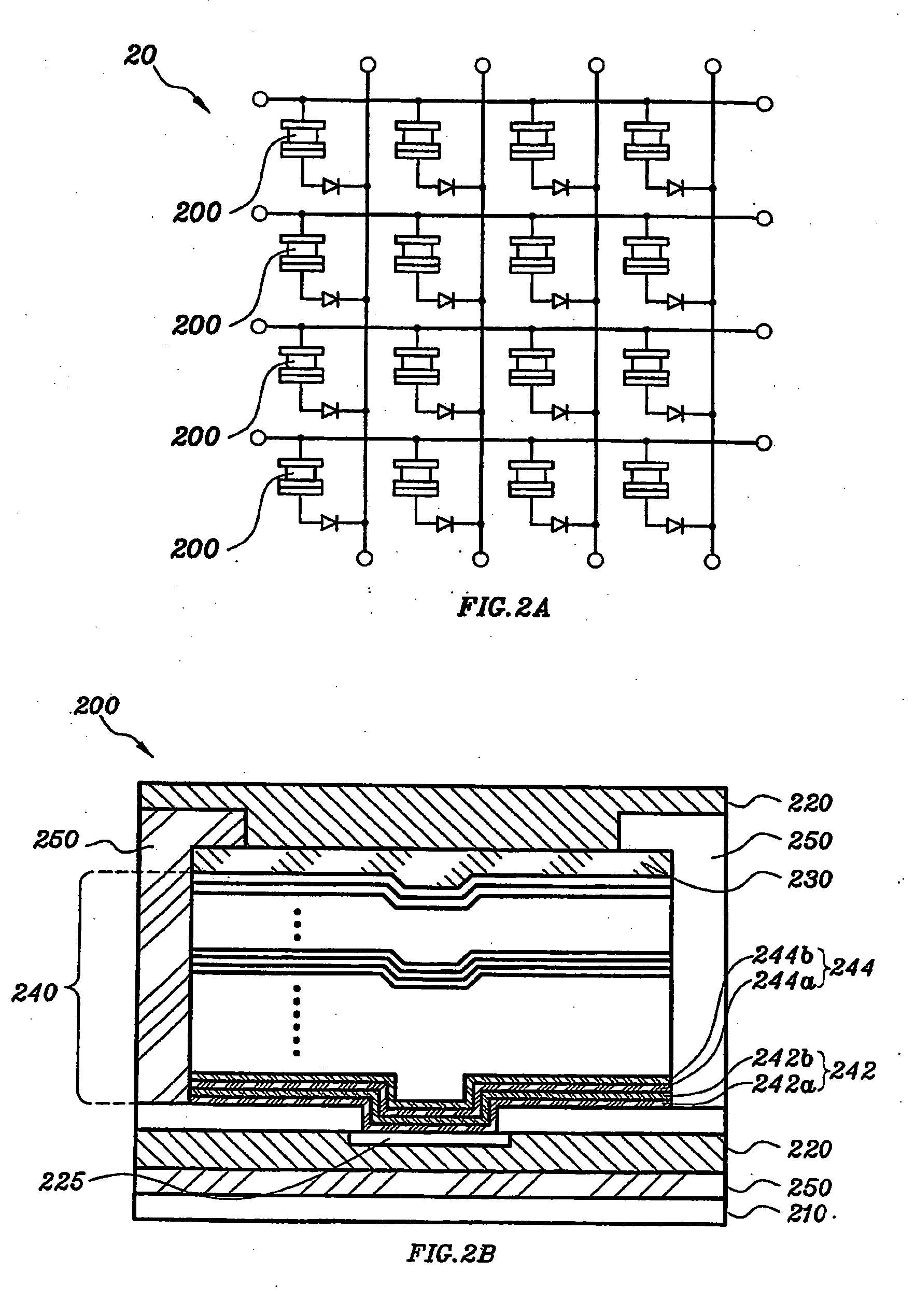

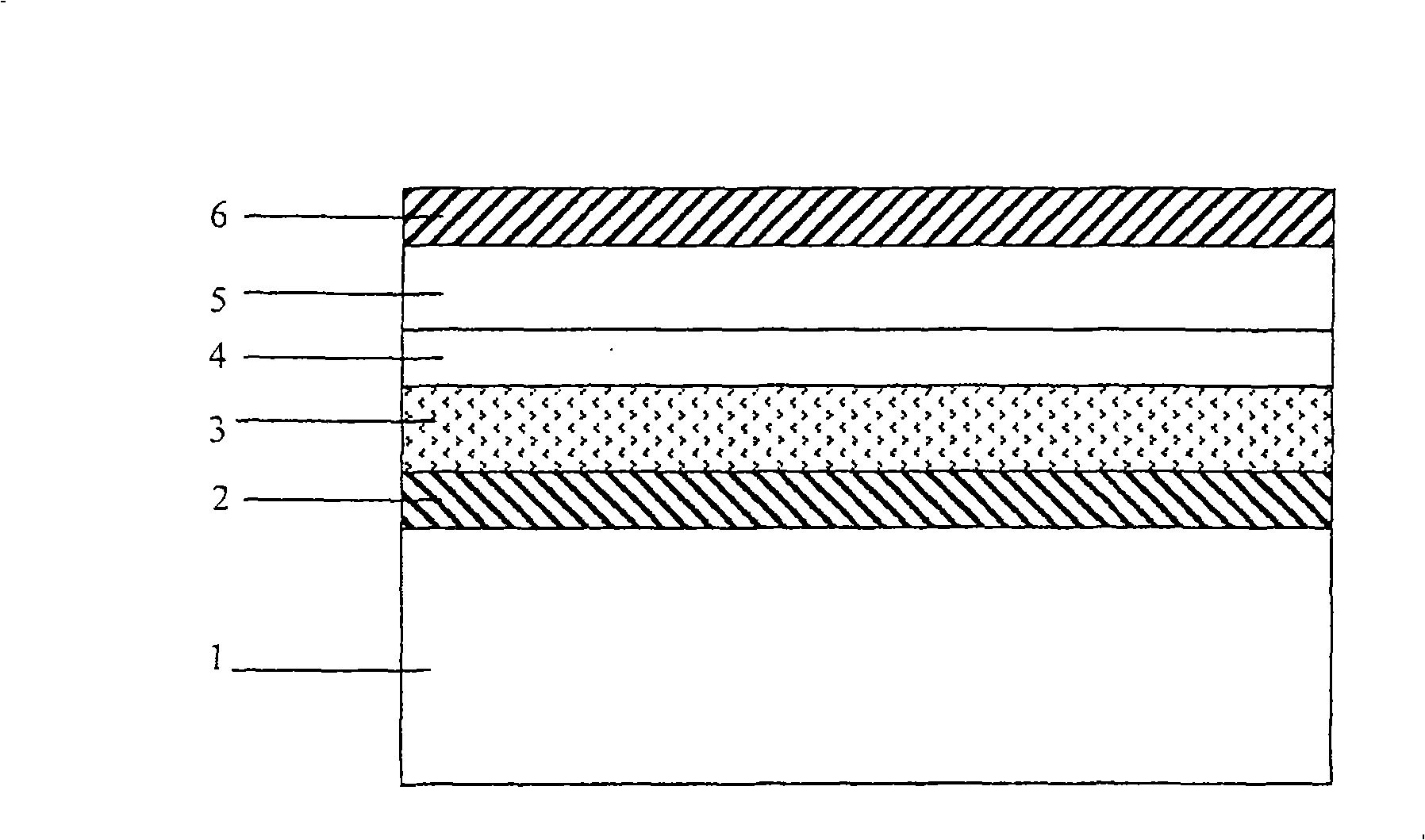

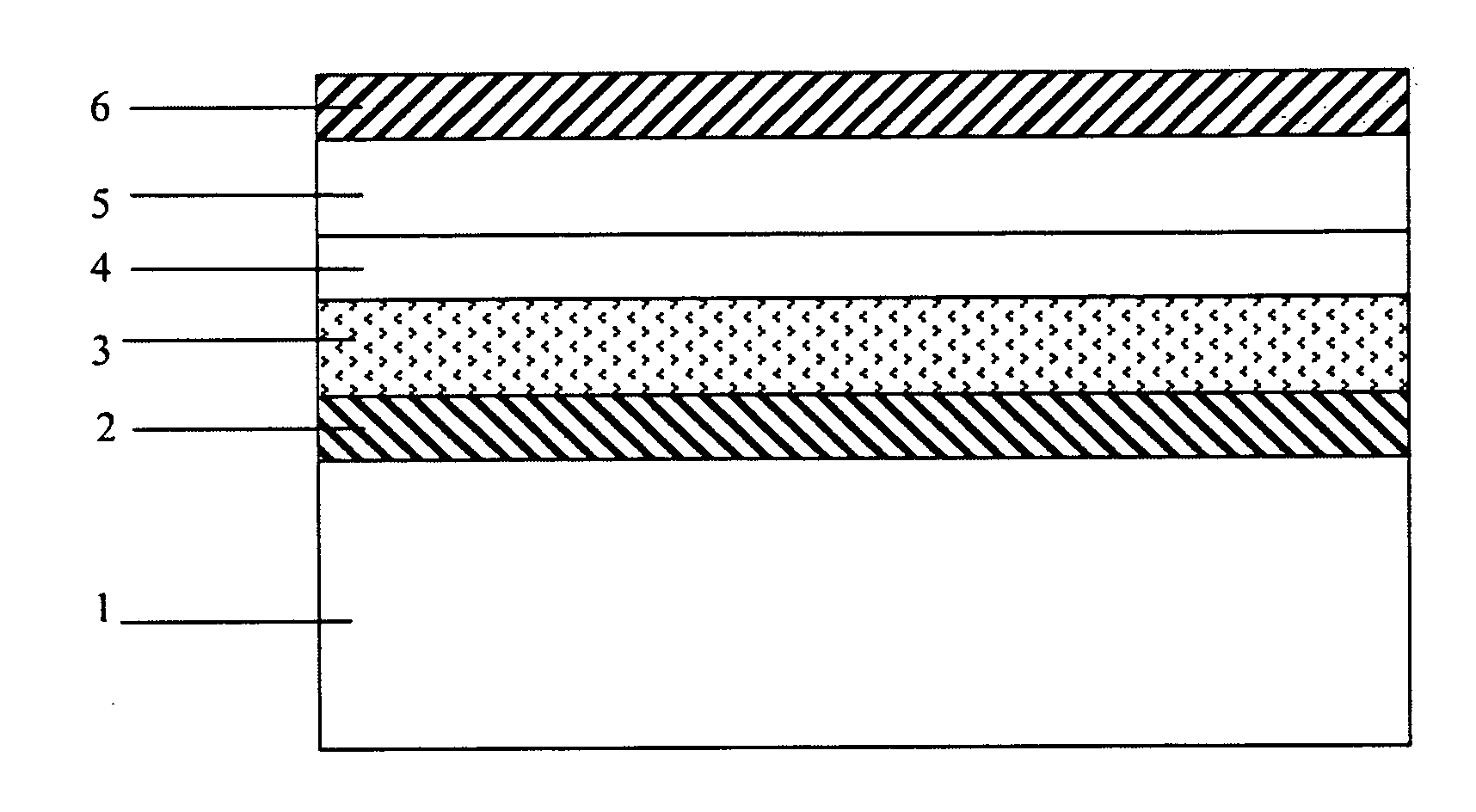

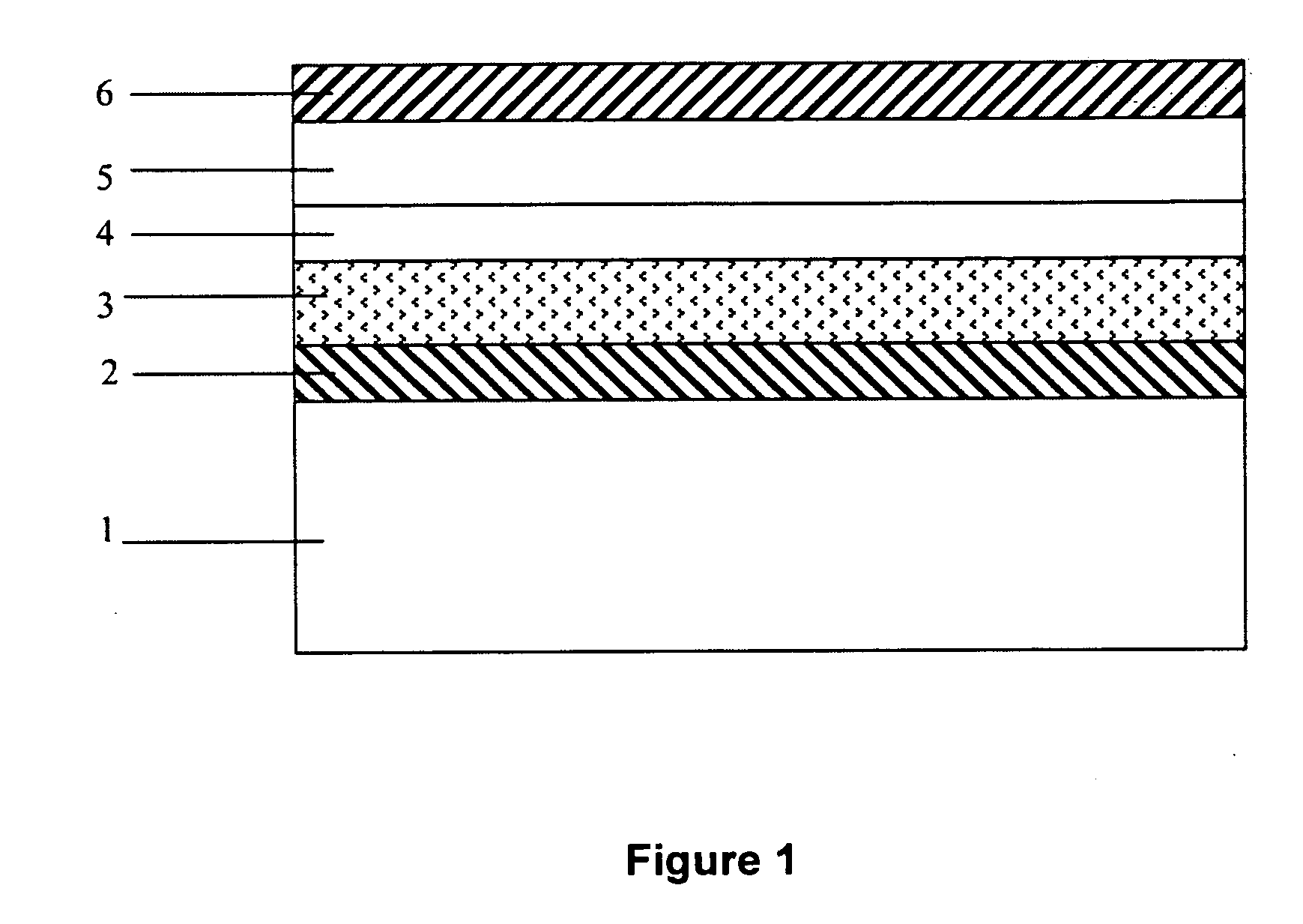

Electrically Writeable and Erasable Memory Medium

InactiveUS20080001136A1Low thermal conductivityReduce diffuseSemiconductor/solid-state device manufacturingDigital storageAtomic elementElectrical impulse

A memory cell for an electrically writeable and erasable memory medium as well as a memory medium thereof is provided. The memory cell comprises a data recording element, the data recording element has a plurality of multiple-layer structure disposed one on top of another, each the multiple-layer structure comprising a plurality of sequentially disposed individual layers. At least one of the plurality of individual layers is capable of changing phase between a crystalline state and an amorphous state in response to an electrical pulse, one of the plurality of individual layers having at least one atomic element which is absent from other one of the plurality of individual layers, and the plurality of multiple-layer structure is of a superlattice-like structure to lower a heat diffusion out of the data recording element to shorten a phase change time of the respective individual layers.

Owner:AGENCY FOR SCI TECH & RES

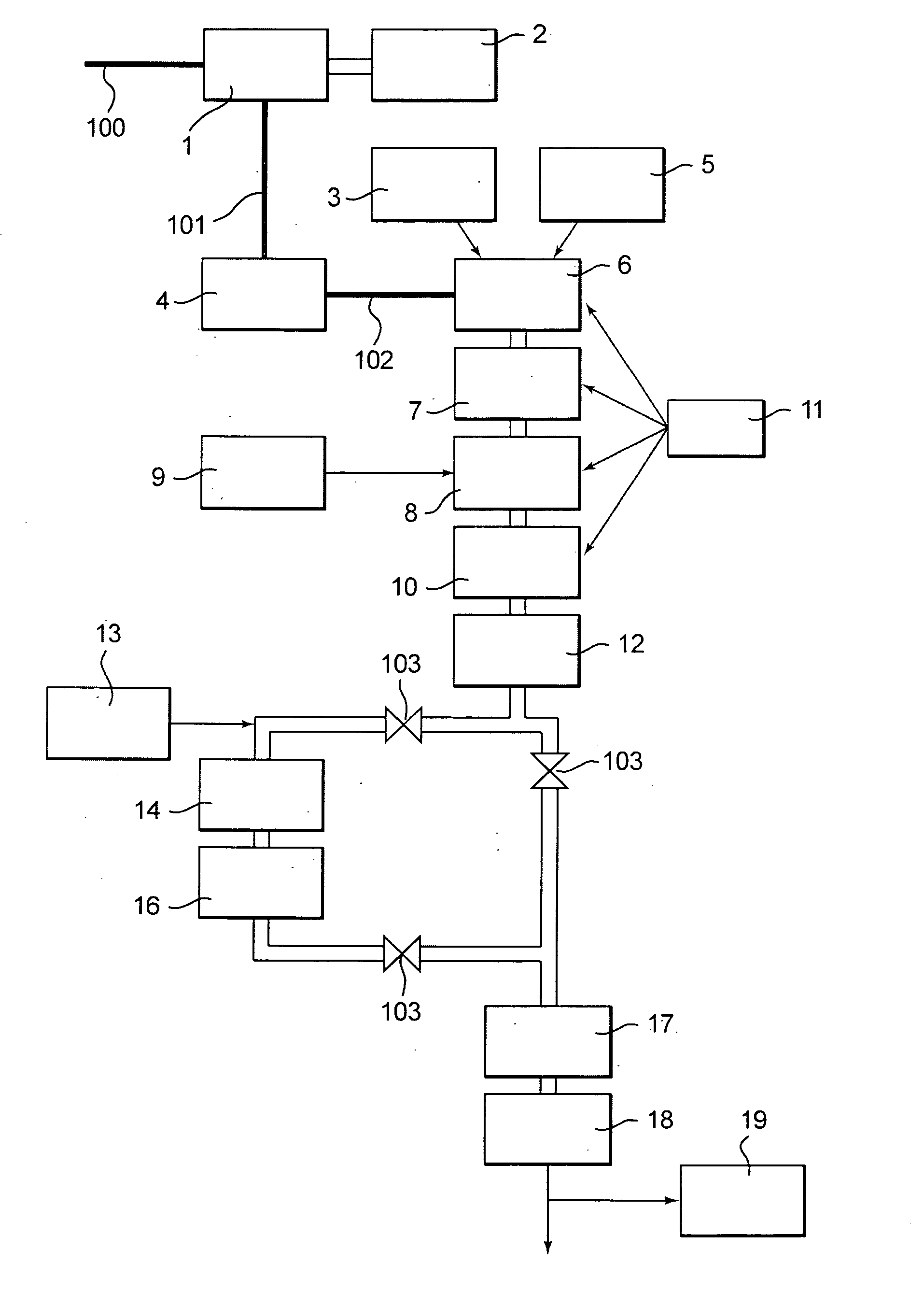

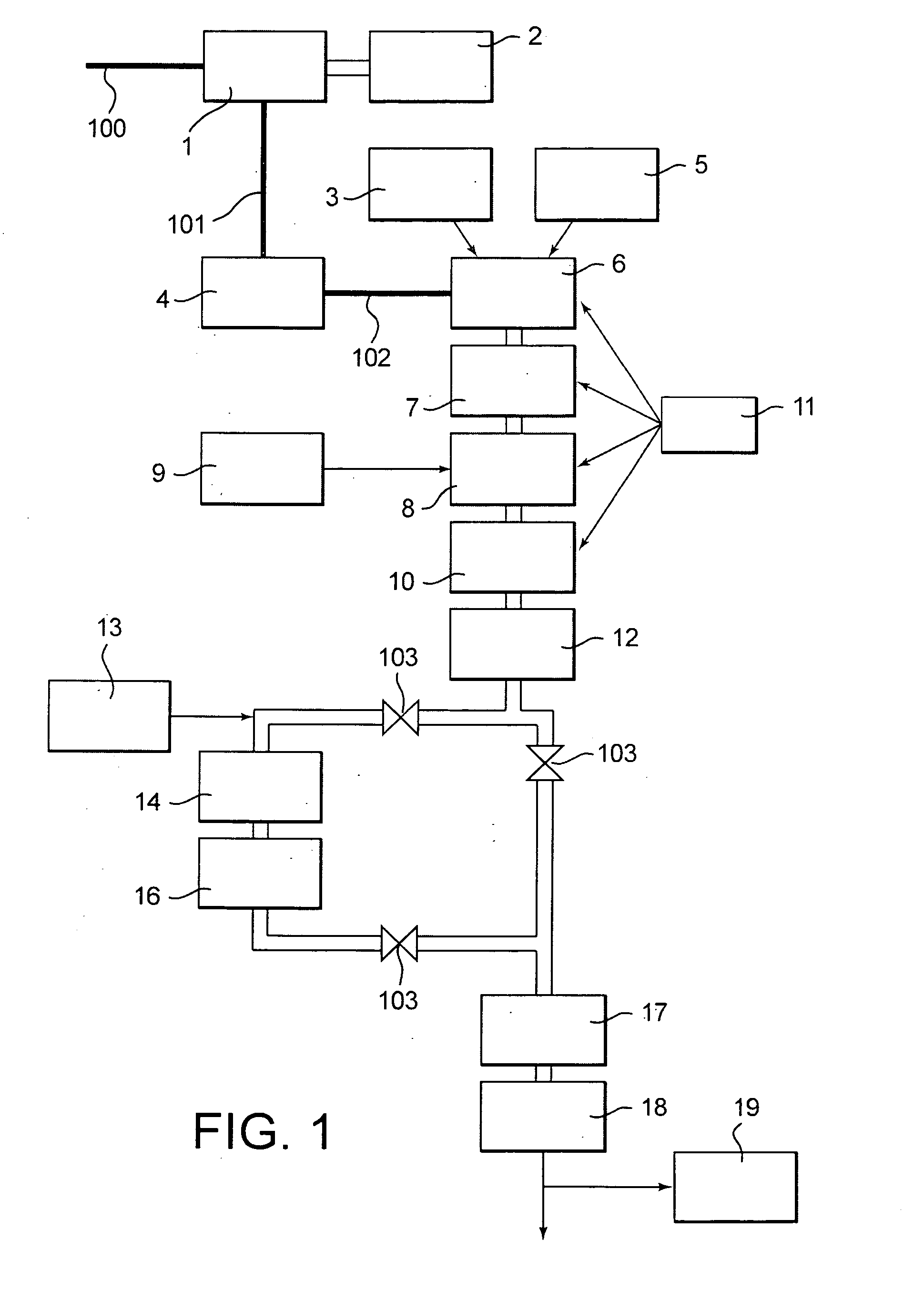

Device and Method for Destroying Liquid, Powder or Gaseous Waste Using an Inductively Coupled Plasma

ActiveUS20080286169A1Reduce the temperatureArc welding apparatusIndirect carbon-dioxide mitigationAtomic elementDecomposition

The invention relates to a thermal destruction process for at least one organic or halogenated organic product in liquid, gaseous or powder form. The process includesmixing:of the aforementioned one or more organic products with water in sufficient quantities to ensure that at least stoichiometric ratios between atoms of carbon and oxygen in the mixture are obtained, orof the aforementioned one or more halogenated organic products with water in sufficient quantities to ensure that at least the stoichiometric ratios for, on the one hand, atoms of carbon and oxygen in the mixture, and on the other hand, for hydrogen and halogen atoms in the mixture are obtained,introduction of this mixture and of plasmagenic gases into the coil of an inductively coupled plasma torch to produce gas in which decomposition into atomic elements has occurred,an initial thermal destruction operation of the aforementioned gas in which decomposition into atomic elements has occurred, this initial destruction operation taking place in a reaction chamber,a second thermal destruction operation of the gas that has undergone the initial destruction operation, this second destruction operation taking place in a stirring device with no energy being added, this gas which undergoes the second thermal destruction operation being stirred with air and / or oxygen,recombination by cooling of at least a part of the gas emerging from the stirring device,discharge of the gas that has been destroyed.The invention also relates to a device that allows this destruction process to be applied.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

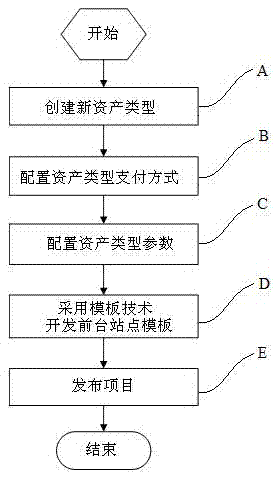

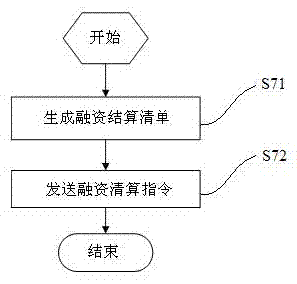

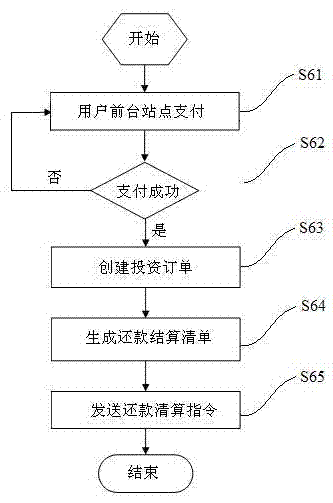

Templatizing and configuring method for standardized investing and financing transaction system

InactiveCN105447760AStrong scalabilityStability is not affectedFinanceAtomic elementProcess configuration

The invention discloses a templatizing and configuring method for a standardized investing and financing transaction system, specifically comprising the following steps: constructing a design mode of asset attribute atomizing, display templatizing and tagging and process configuration; creating a new asset type through atomic element combination; configuring parameters to define a transaction process conforming to the requirements of a variety of asset types; using a templatizing technology to develop a foreground site interface; and providing a template management background. The functions of online editing, real-time preview and instant release are achieved. The application of the invention makes the system have high expansibility and stability. The development workload can be reduced, the work efficiency can be improved, and therefore, the goal of quickly deploying a new platform with high quality and developing new business is achieved.

Owner:GUANGDONG YOUMAI INFORMATION COMM TECH

Microwave plasma atomic fluorescence mercury analysis system

InactiveUS20120224175A1Great contributionRadiation pyrometrySpectrum investigationAtomic elementFluorescence

A method for the detection of mercury or other heavy metals in a gas stream comprises the steps of: providing a pulsed microwave power supply;supplying a microwave generator with power from the pulsed microwave power supply; using the microwave generator to power a short circuited waveguide to create a plasma torch located in a chamber; feeding a sample of the gas stream to the plasma torch; using the plasma torch to transform oxidized elements in the gas stream to atomic elements; and analyzing by atomic fluorescence of the gas stream having the atomic elements with an excitation lamp for the presence of at least one metal.

Owner:MINGHETTI PHILIPPE

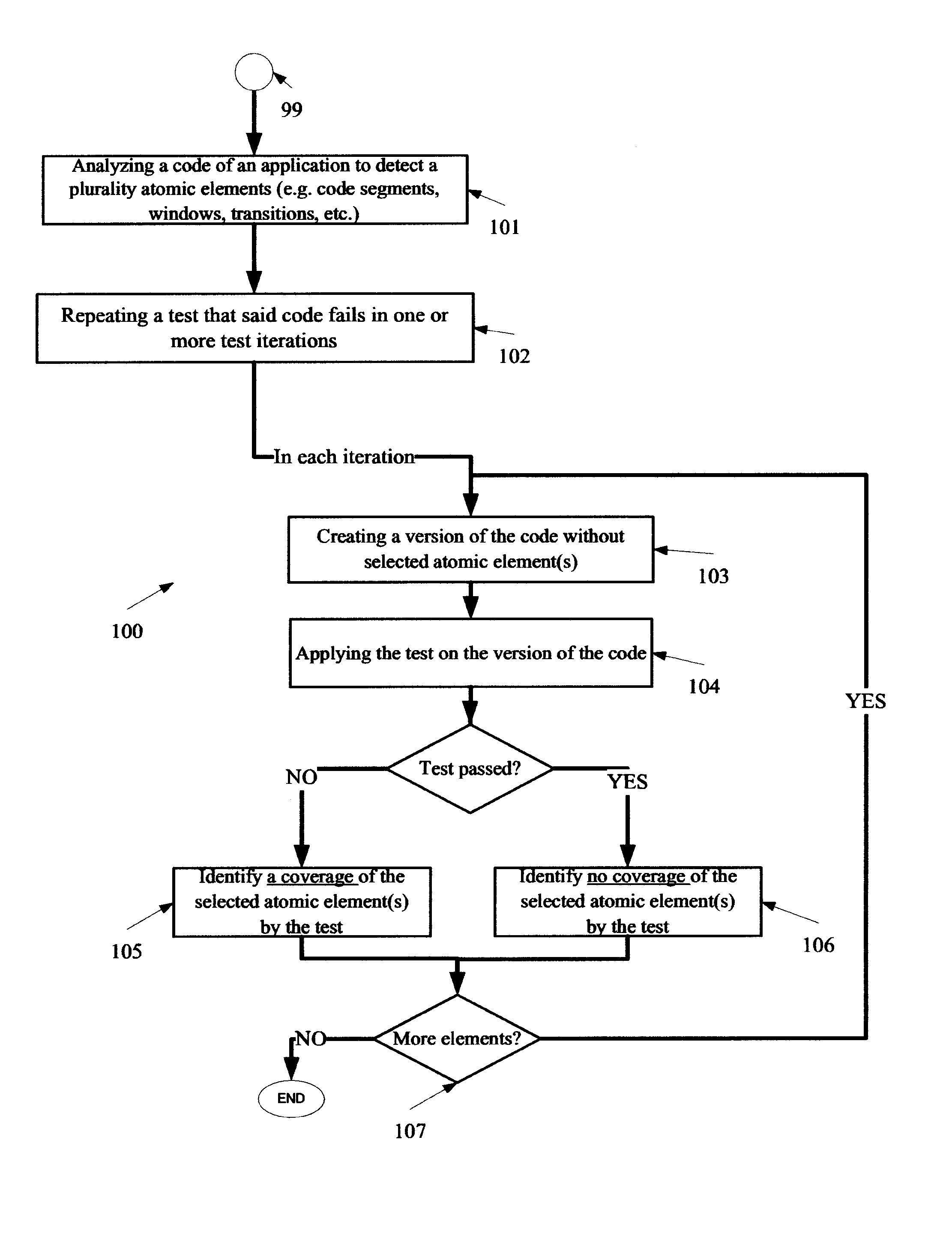

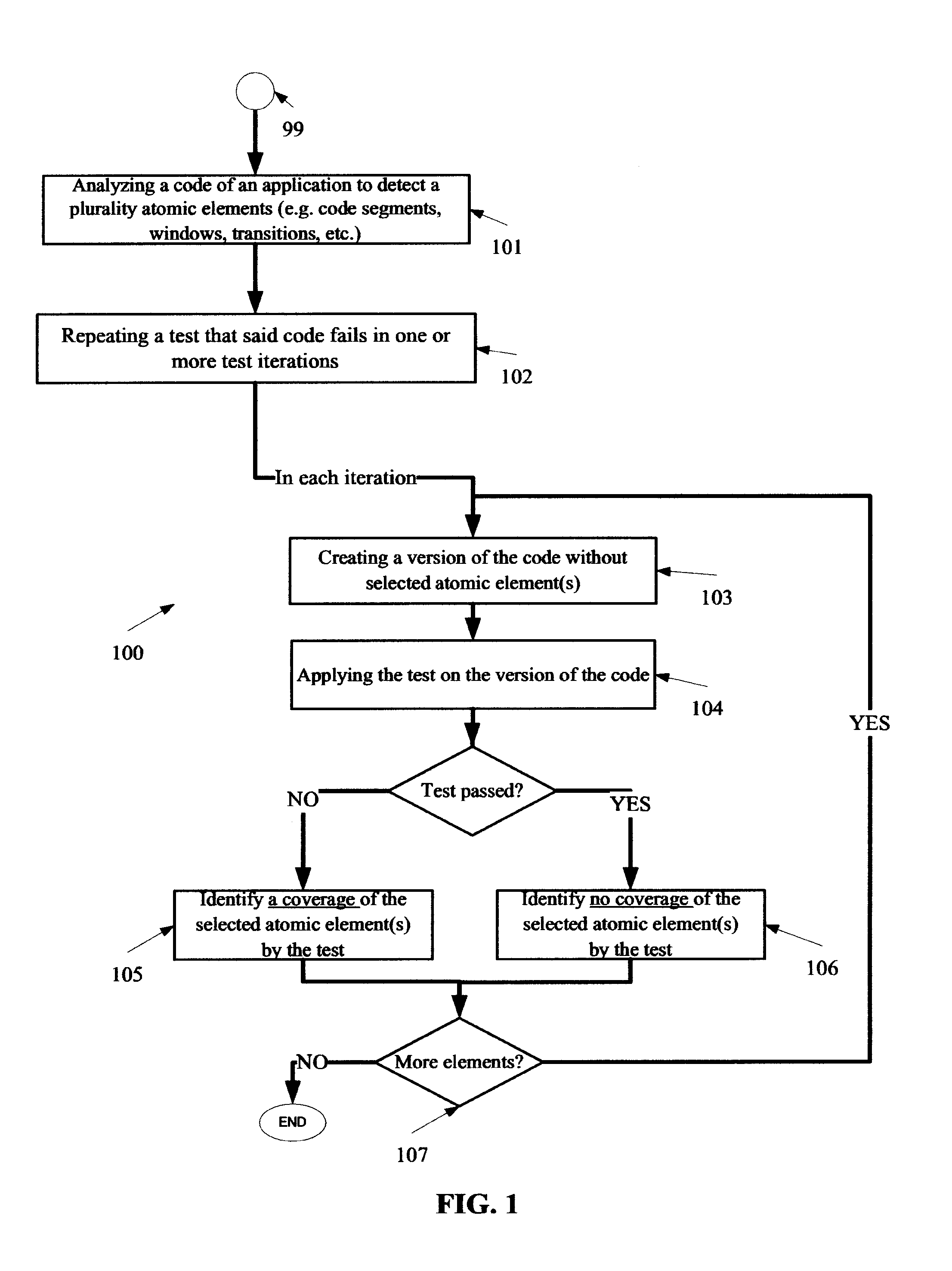

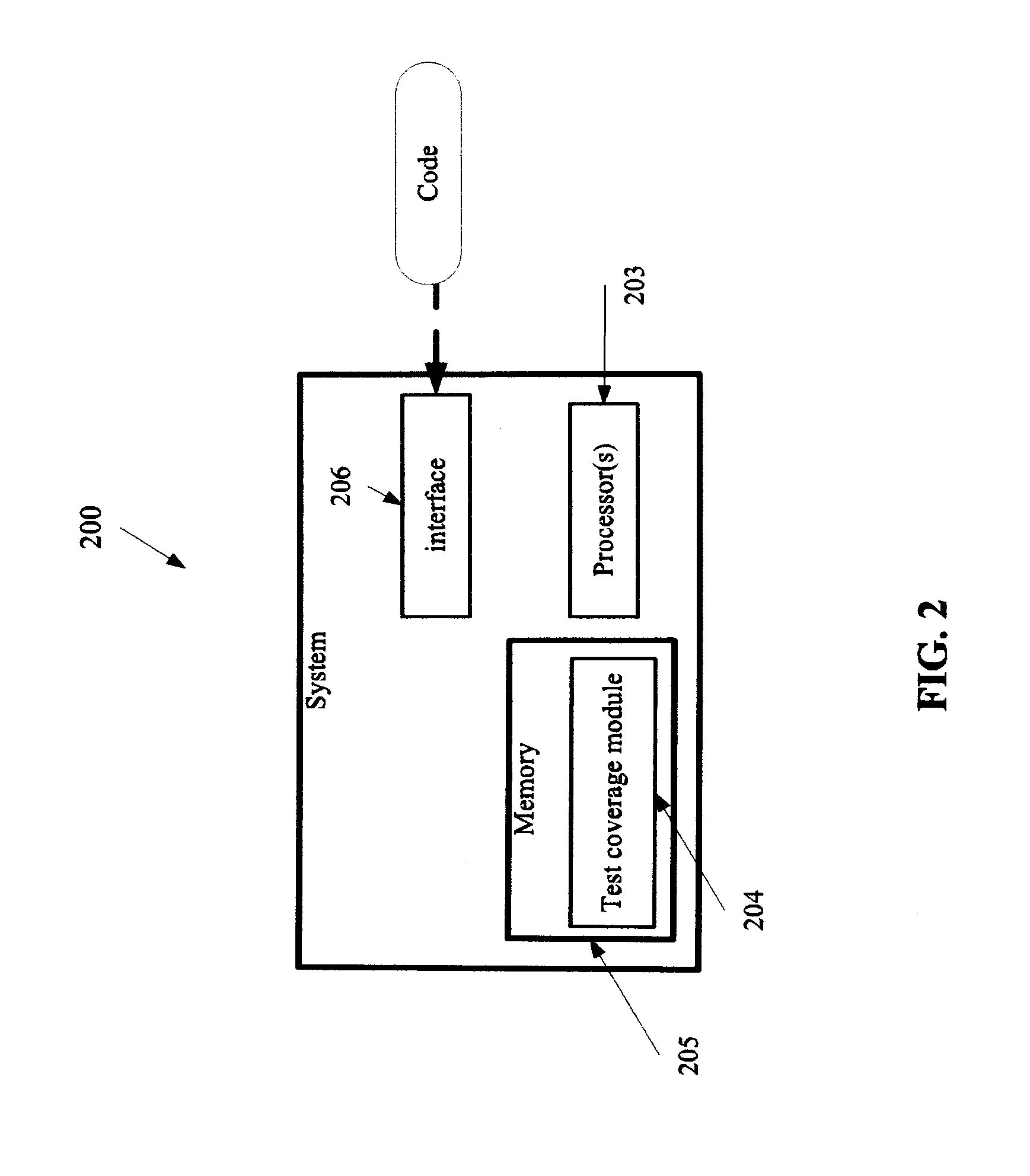

Determining code coverage of an application by test(s)

A method of determining code coverage of an application by test(s) (wherein code may include UI elements). The method comprises executing a code test on at least one portion of a tested code of an application in one or more iterations, wherein in each one of the plurality of iterations, selecting at least one of a plurality of atomic code elements of the tested code, applying the code test on a version of the code that does not include the at least one selected atomic element, and classifying the at least one selected atomic element as covered by the code test when the code test fails and as not covered in the code test when the code test passes.

Owner:IBM CORP

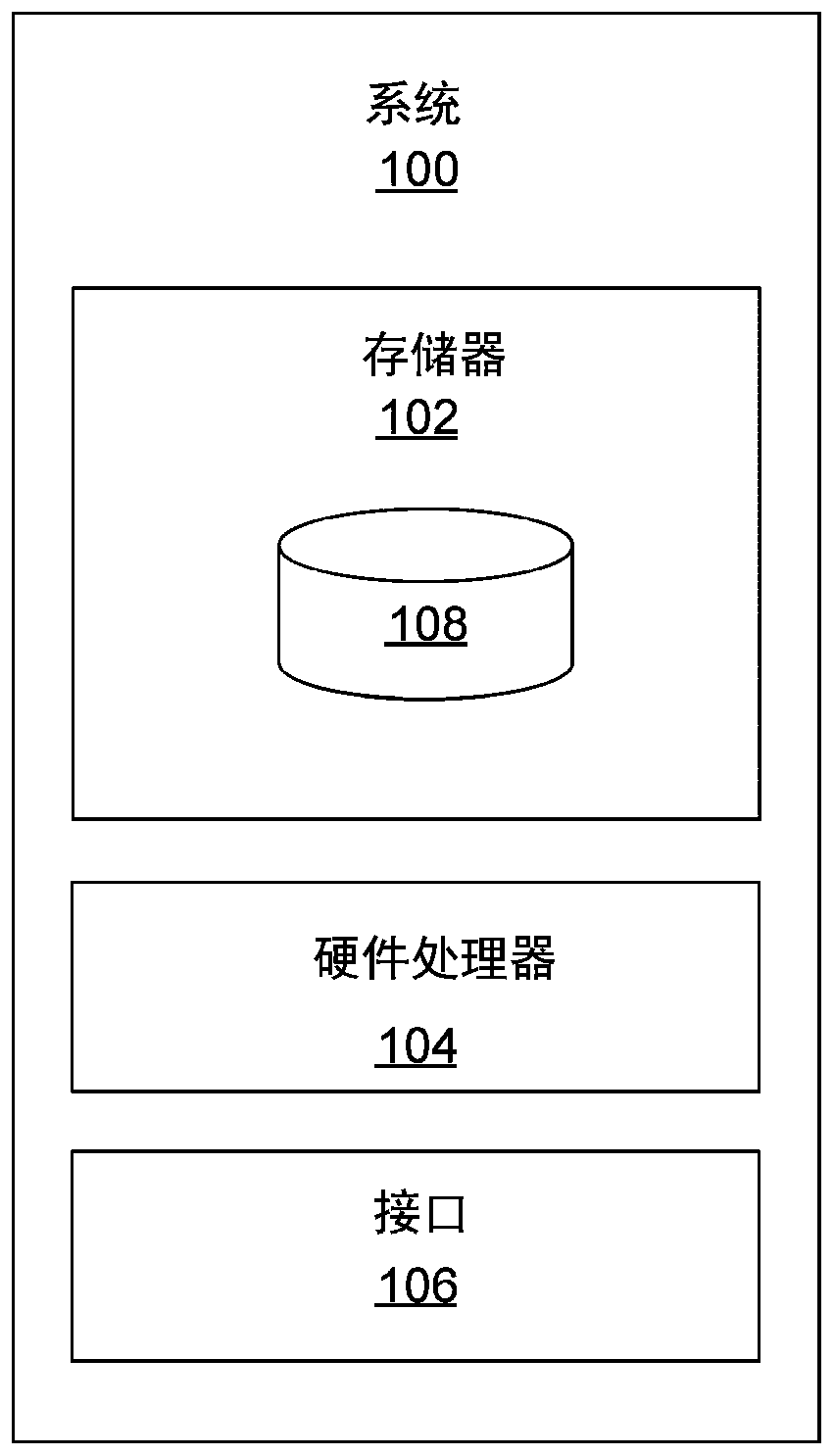

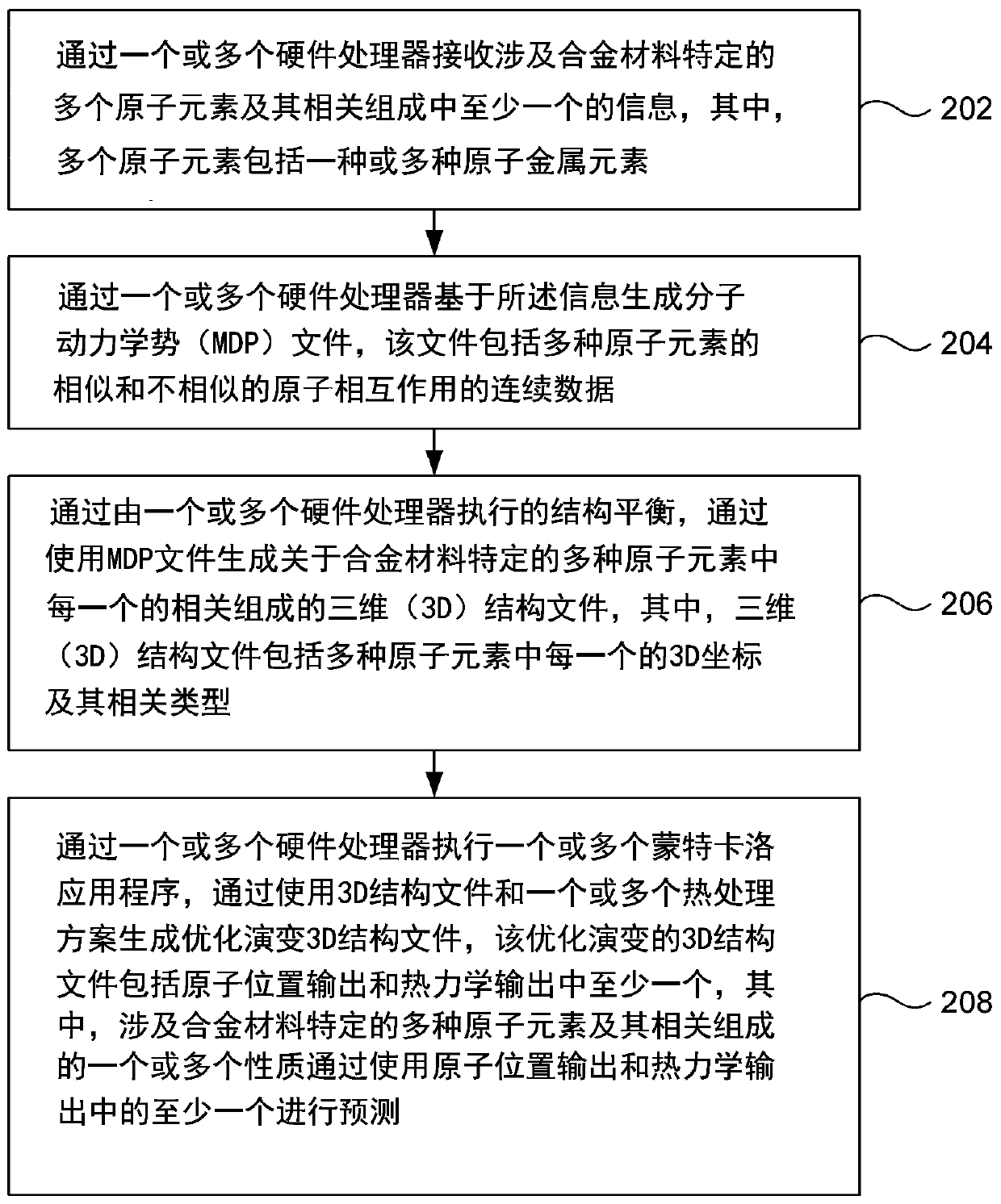

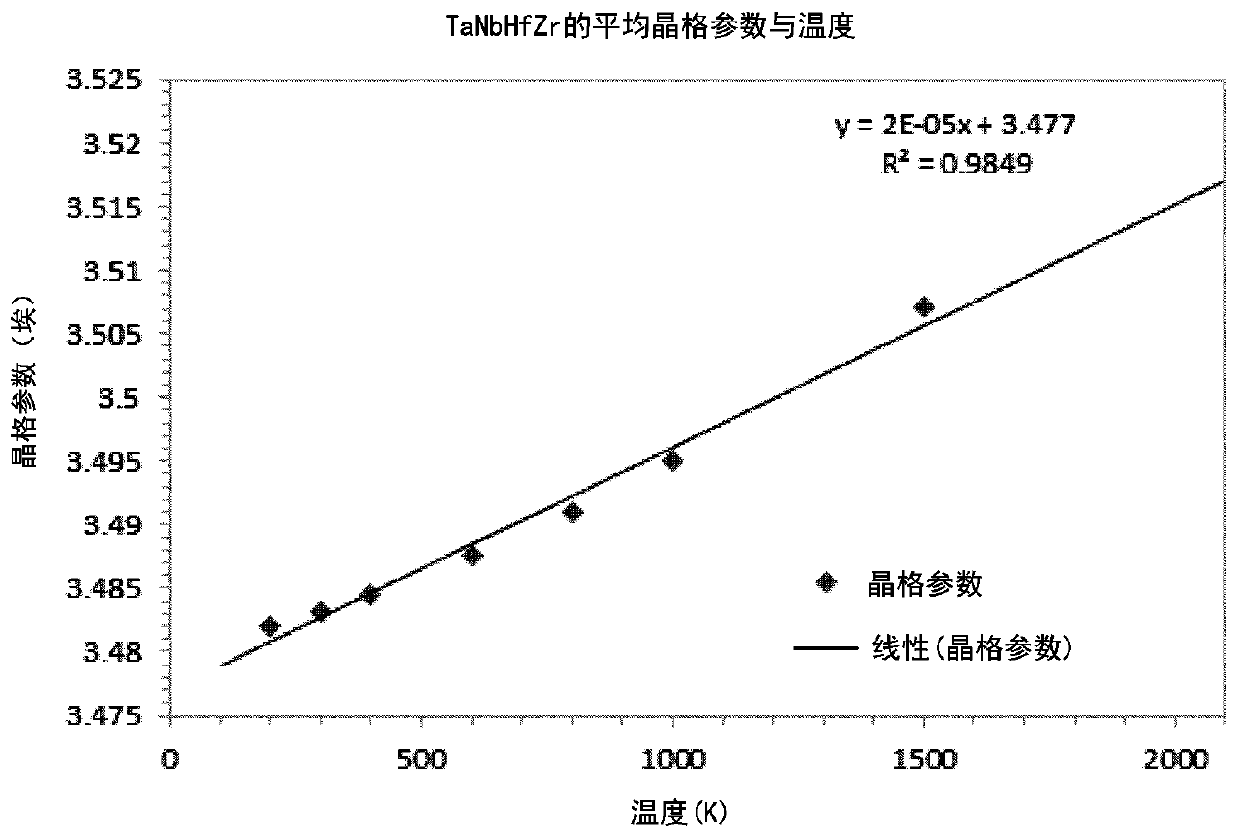

Systems and methods for predicting structure and properties of atomic elements and alloy materials thereof

ActiveCN110858505AChemical property predictionMolecular entity identificationAtomic elementStructural evolution

Metallic alloy development has been traditionally based on experimental or theoretical equilibrium phase diagrams and the like. The synthesis, processing and mechanical testing of small and large realsamples are a challenging task requiring huge amount of effort in terms of time, money, resource, tedious testing and processing equipment and man-hour for which conventional Calphad calculations etc. alone do not help much in their local structure and related property prediction. Embodiments of the present disclosure provide simulation systems and methods for structure evolution and property prediction Molecular Dynamics (MD) combined with accelerated Monte Carlo techniques, wherein information on atomic elements and composition specific to alloy material is obtained to generate a MD potential file that is further used to generate a 3D structure file by executing a structure equilibration technique. An optimized evolved 3D structure file is then generated that has atomic positions outputand / or thermodynamic output for predicting properties.

Owner:TATA CONSULTANCY SERVICES LTD

System and method for simulation of brush-based painting in a color space that includes a fill channel

ActiveUS8749572B2Increased complexityDigitally marking record carriersTexturing/coloringAtomic elementCompositing

Systems and methods for performing brush behavior simulation in an image editing application may facilitate realistic paint simulation by the addition of a fill channel to a color space representation that includes a set of color channels and an alpha channel representing opacity of the paint. The fill channel value for each pixel of a brush model or canvas may represent the amount of paint stored at the pixel. The system may include logic to support paint compositing, mixing, and depletion operations that calculate a consequent color of a destination pixel resulting from the operations dependent on the fill channel values for the source and / or destination pixels. The resulting color channel, opacity channel, and fill channel values may be converted to a color space that does not include a fill channel or opacity channel for display. A source pixel may be a pixel of an atomic element of a texture.

Owner:ADOBE SYST INC

Isotopically enriched luminescent materials and methods of making same

InactiveUS6838020B2Increase brightnessIncreased longevityLuminescent compositionsAtomic elementPhosphor

Owner:TENOROC

Systems and/or methods for identifying and resolving complex model merge conflicts based on atomic merge conflicts

Certain example embodiments described herein relate to interactive model merging systems and / or methods and, more particularly, to using basic information obtained during merging to help a user resolve high-level merge conflicts. In certain example embodiments, instead of leaving it to the user to resolve the merge conflicts on the level of the atomic elements (e.g., objects and connections with a non-empty merge state), the recognition of high-level merge conflicts may help capture the semantics of the differences between the models being merged on a larger scale (e.g., covering a possibly very large number of model elements in one conflict) and / or also may generally help allow the user to resolve them easily and quickly within a reduced number of operation. The high-level merge conflicts may be resolvable at their high levels or decomposed and resolved at a lower level depending, in part, on the type of conflict involved.

Owner:SOFTWARE AG

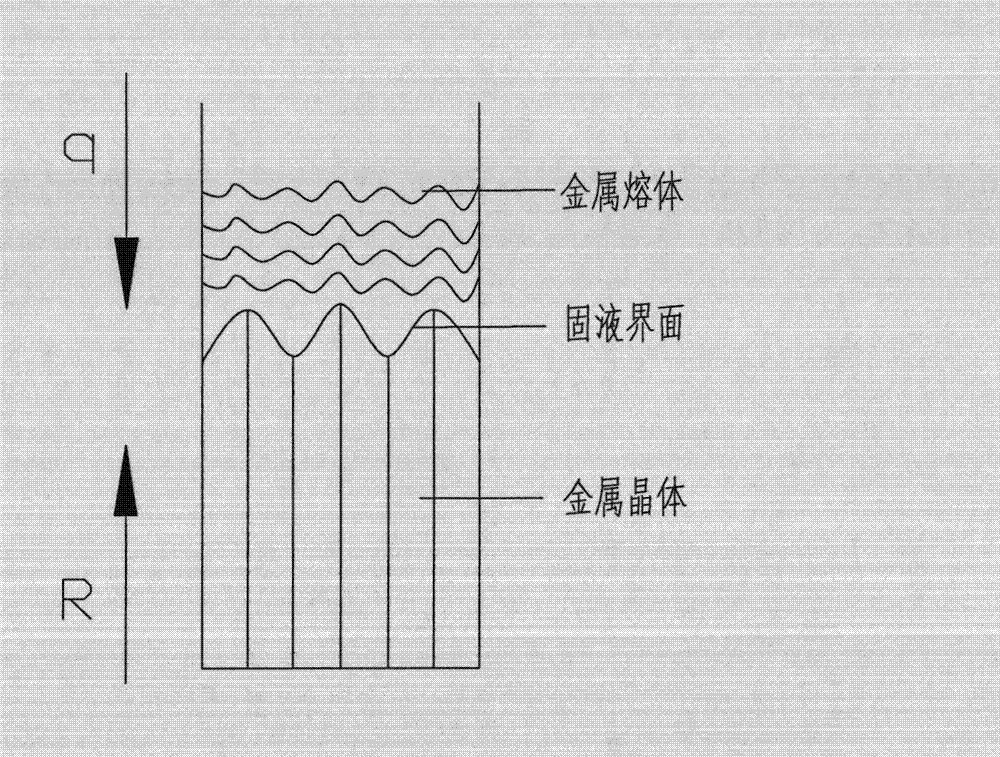

Method for preparing spherocrystal toughening amorphous-based composite

The invention relates to a method for preparing a ZraTibNbcCudNieBef (atomic ratio) spherocrystal toughening amorphous-based composite through adopting a semisolid thermal insulation composite liquid metal directional solidification method. The method comprises: selecting raw materials and proportioning according to the atomic elements of ZraTibNbcCudNieBef; using a high vacuum non-self-consuming arc melting furnace, and melting the raw materials into a master alloy button ingot under the protection of high-purity Ar; mechanically breaking an ingot to be contained in an alundum tube, vacuumizing to the protection of high-purity Ar, using an induction coil of a directional solidification furnace to heat the alundum tube to 1200 DEG C, and 1 minutes later, cooling to 900-920 DEG C; thermally insulating for 10 minutes at 900-920 DEG C; and directionally solidifying, controlling the axial temperature gradient of about 45K / min, selecting a drawing rate of 0.2-1.0 mm / s, and adopting Ga-In liquid alloy as a cooling medium. When uniaxial compression is carried out at room temperature, the strength and fracture ductility of the spherocrystal toughening amorphous-based composite Zr60.0Ti14.7Nb5.3Cu5.6Ni4.4Be10.0 respectively reach 1500MPa and 12.0%, and the fracture ductility strain is greatly improved.

Owner:TAIYUAN UNIV OF TECH

Electronic component comprising a p-doped organic semiconductor

ActiveCN101405890ASolid-state devicesSemiconductor/solid-state device manufacturingAtomic elementAcceptor dopant

The invention relates to an electronic component comprising a layer of an organic semiconductor material in which a dopant is dispersed, the energetic difference between the output energy of the dopant and the HOMO level of the organic semiconductor material being lower than 0.5eV. The dopant is an atomic element having an evaporation temperature lower than 13000C, at a pressure of 10<-8> Torr. The invention eliminates any toxicity problems related to usual organic acceptor dopants, and especially applies to organic electroluminescent diodes.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Electronic Component With P-Doped Organic Semiconductor

ActiveUS20090015154A1Limit ohmic lossLow toxicityDischarge tube luminescnet screensLamp detailsAtomic elementWork function

An electronic component comprising a layer of organic semiconducting material in which a dopant is dispersed having an energy difference between the work function of the dopant and of the HOMO level of said organic semiconducting material that is less than 0.5 eV. The dopant is an atomic element having an evaporation temperature lower than 1300° C. for a pressure of 10−8 Torr. The invention enables the toxicity problems connected with usual organic acceptor dopants to be avoided. It applies in particular to organic light-emitting diodes.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

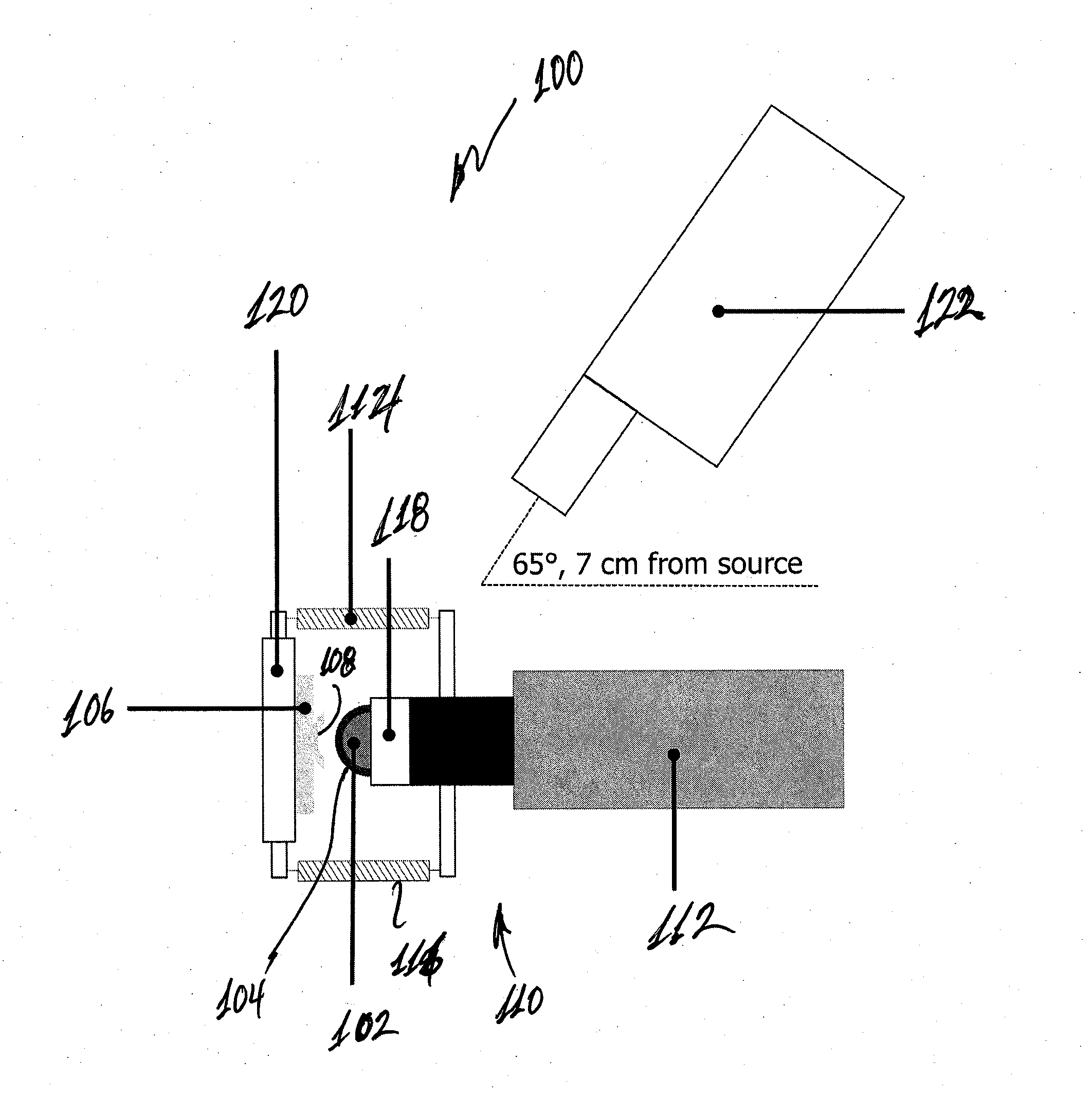

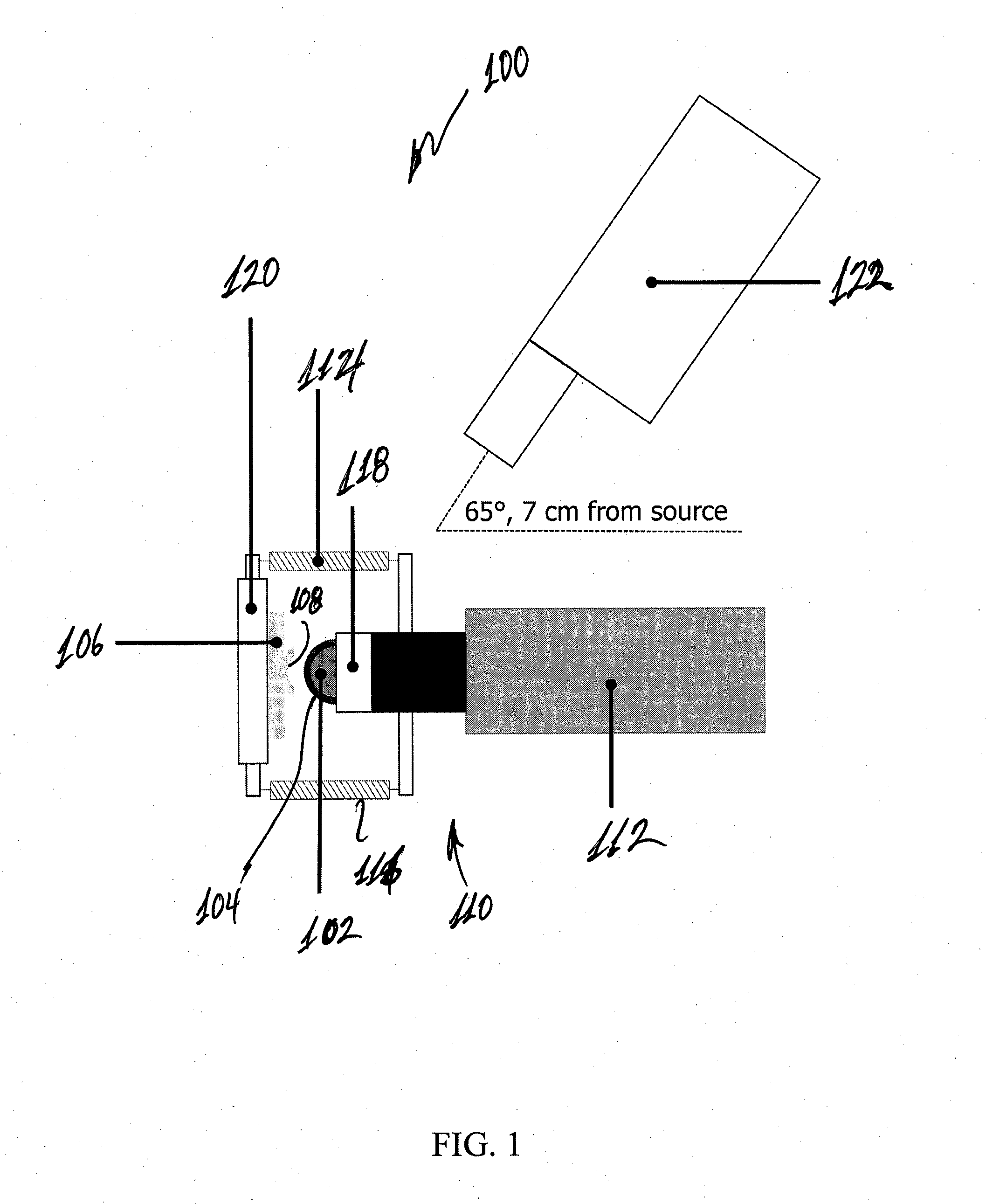

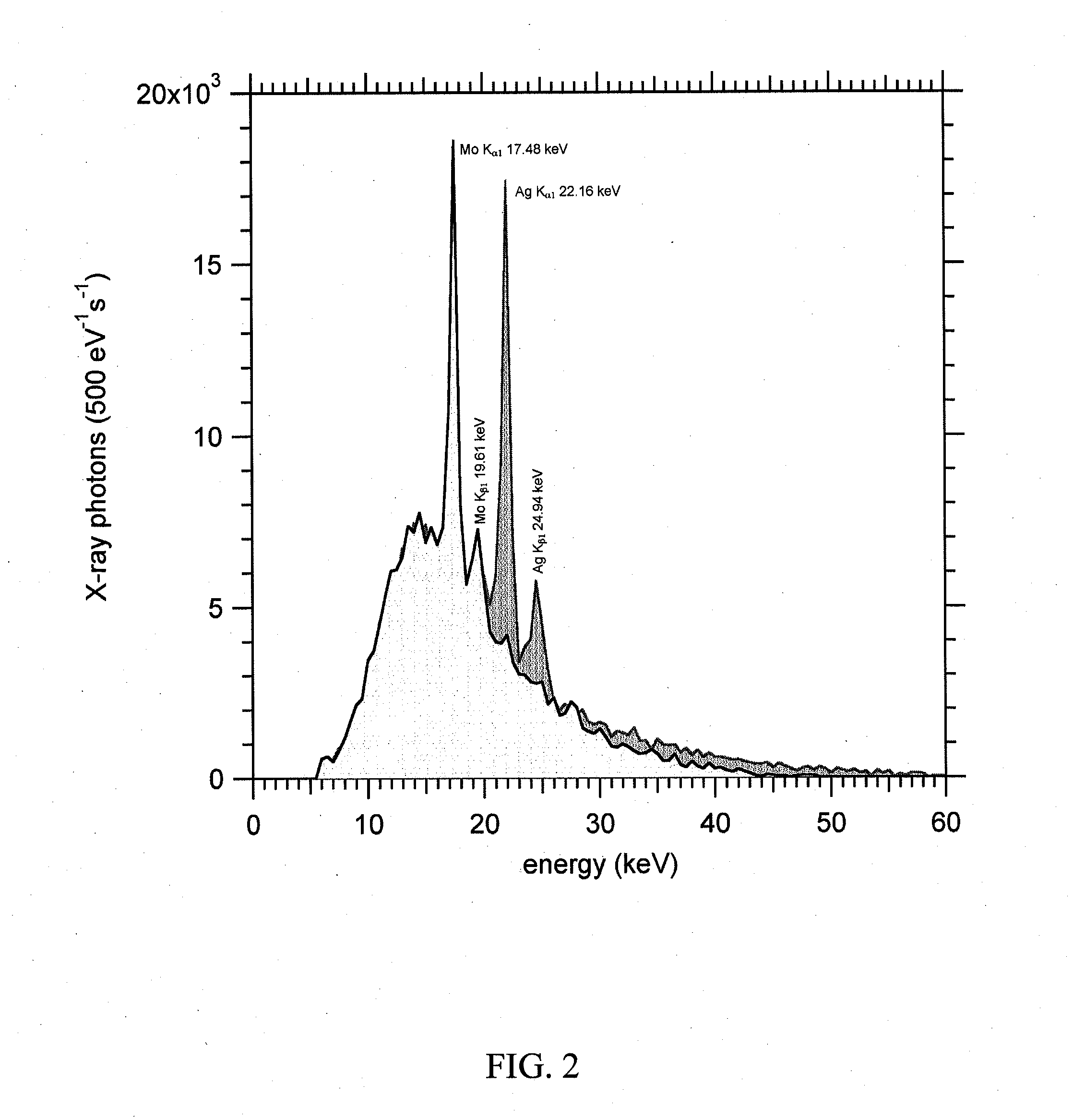

Triboelectric x-ray source

An x-ray source for generating x-rays with at least one narrow energy band includes an enclosing vessel, a first contact arranged with a first contact surface in the enclosing vessel, a second contact arranged with a second contact surface in the enclosing vessel, and an actuator assembly operatively connected to at least one of the first and second contacts. The actuator assembly is structured to cause the first contact surface and the second contact surface to repeatedly come into contact, and separate after making contact, while in operation. The first contact surface is a surface of a first triboelectric material and the second contact surface is a surface of a second triboelectric material, the surface of the first triboelectric material having a negative triboelectric potential relative to the surface of the second triboelectric material. The second contact includes a material that includes an atomic element in its composition that has an excited quantum energy state that can be excited by electrons traveling from the first contact surface to the second contact surface such that the atomic element emits x-rays having an energy within the at least one narrow energy band upon transition from the excited state into a lower energy state. The enclosing vessel is structured to provide control of an atmospheric environment to which the first and second contact surfaces are exposed.

Owner:TRIBO LABS +1

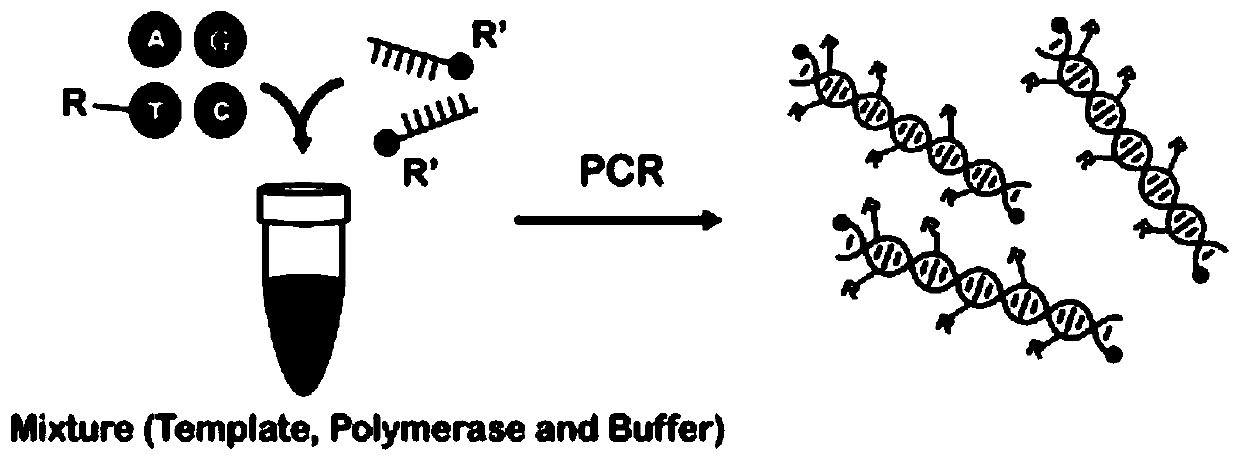

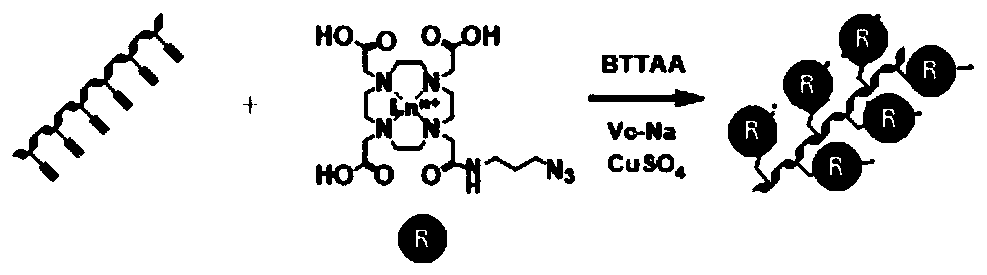

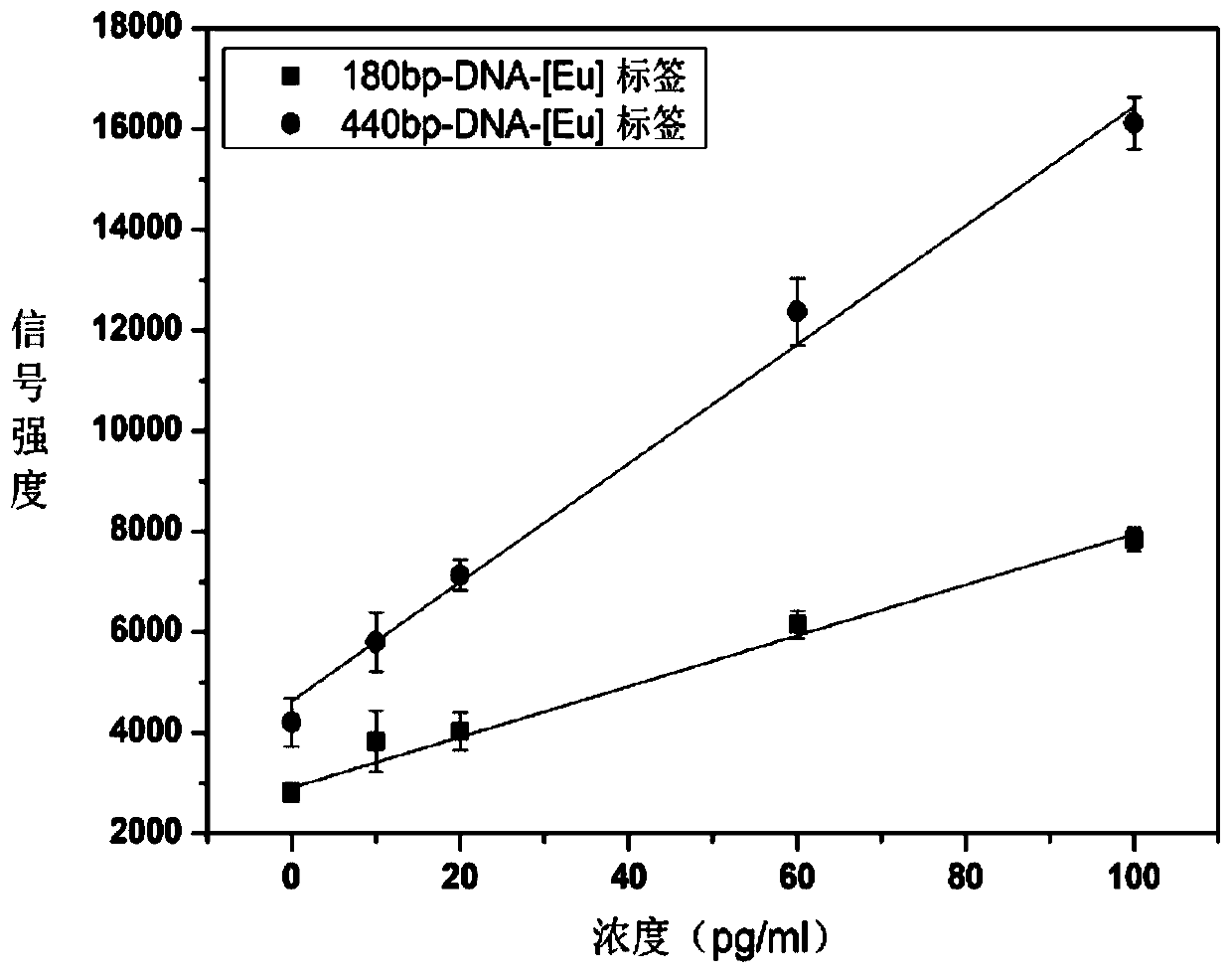

Polyatomic element labeling probe and preparation method and application thereof

ActiveCN109828107AEfficiently obtainedEasy to purifyMicrobiological testing/measurementMaterial analysis by electric/magnetic meansAtomic elementPcr ctpp

The invention discloses a polyatomic element labeling probe and a preparation method and application thereof. The method comprises the steps: synthesizing a DNA molecule containing multiple active groups rapidly by using the PCR technology, taking the DNA molecule as a skeleton structure, coupling a metal macrocyclic compound into the skeleton structure through an orthogonal reaction, and efficiently preparing a multi-labeled element label. The element label is used for traditional immunization, the sensitivity of the element label reaches pg / ml, and the element label is suitable for the fieldof trace analysis and detection of biomacromolecules.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com