Patents

Literature

41 results about "Equilibrium phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase equilibrium is related to the dew point of a substance. an example of phase equilibrium can be seen if you take boiling water and pour it into a glass container, and close it tight. As it cools, condensation will take place, and water vapor will condense on the sides of the jar.

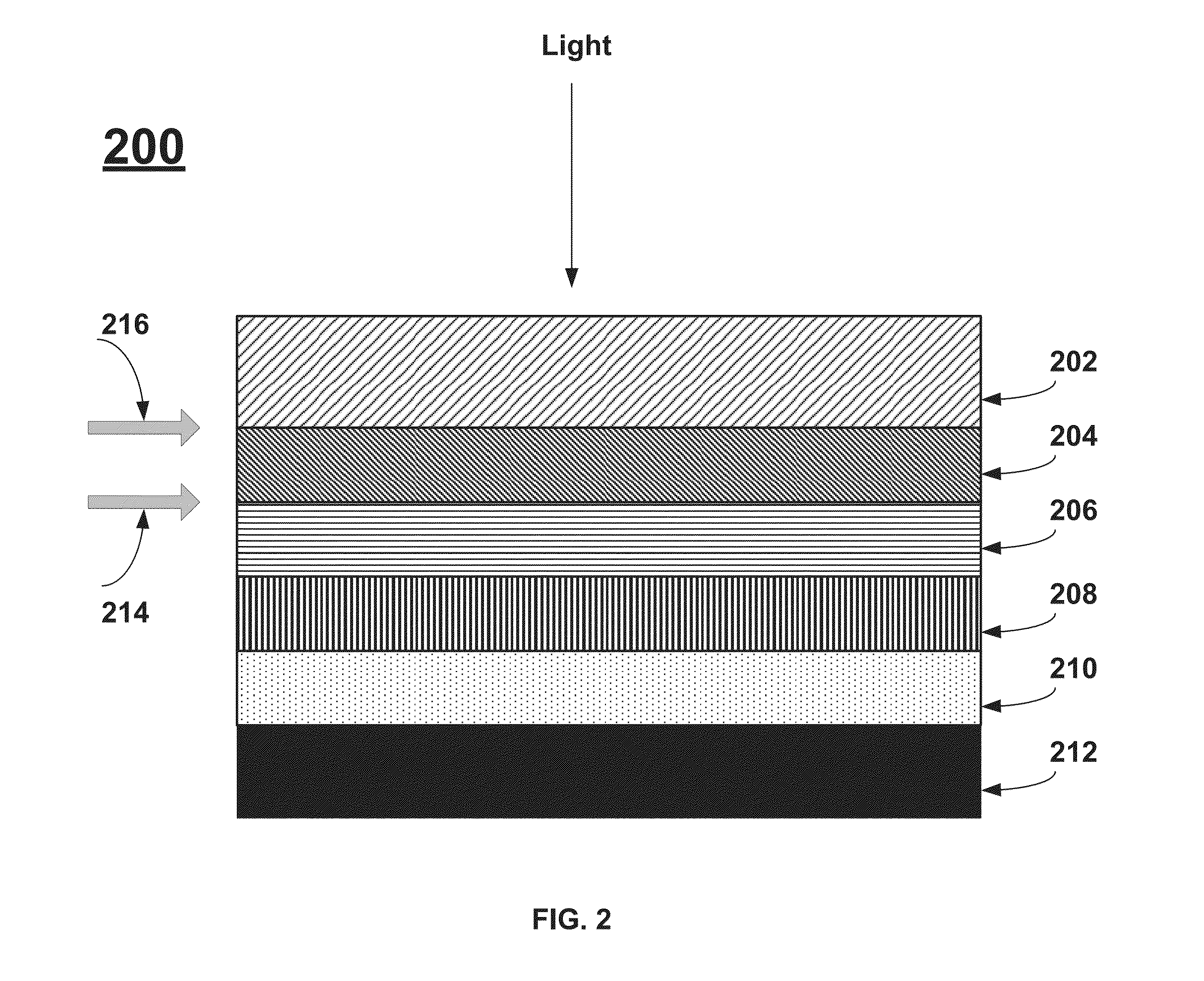

Protective coatings

Protective coatings are described herein. Embodiments of these coatings comprise substantially only specific equilibrium phases therein, and have a CTE that is substantially equal to the CTE of the substrate upon which the coating is deposited. The desired coatings can be obtained by controlling the application of the coating and / or by heat treating the coated substrate to create the desired phases or microstructure in the coating.

Owner:UNITED TECH CORP

High Corrosion Resistance Hot dip Galvanized Steel Material

InactiveUS20090053555A1Improve corrosion resistanceSuppressing degradationHot-dipping/immersion processesThin material handlingAmorphous phaseAlloy

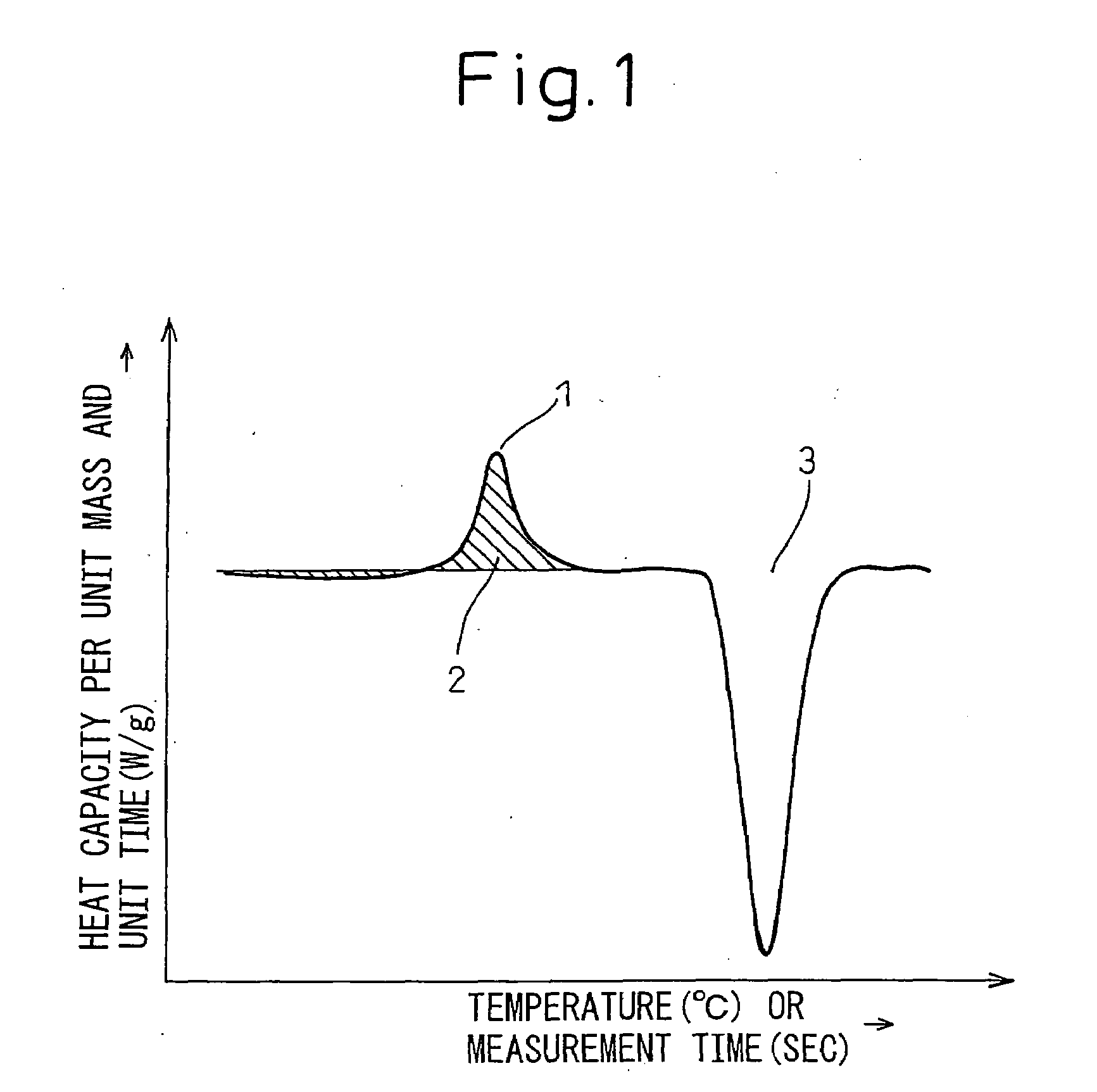

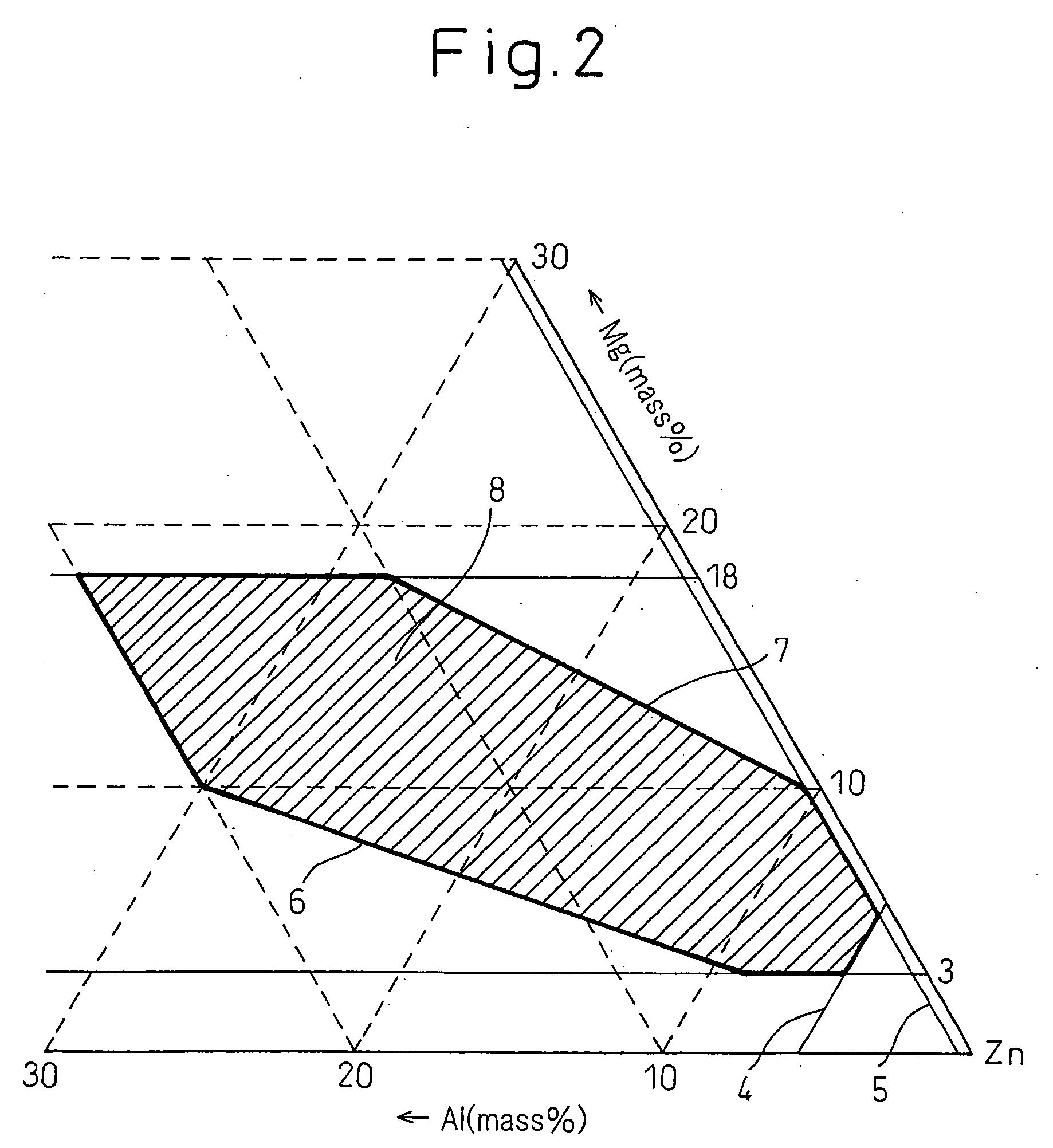

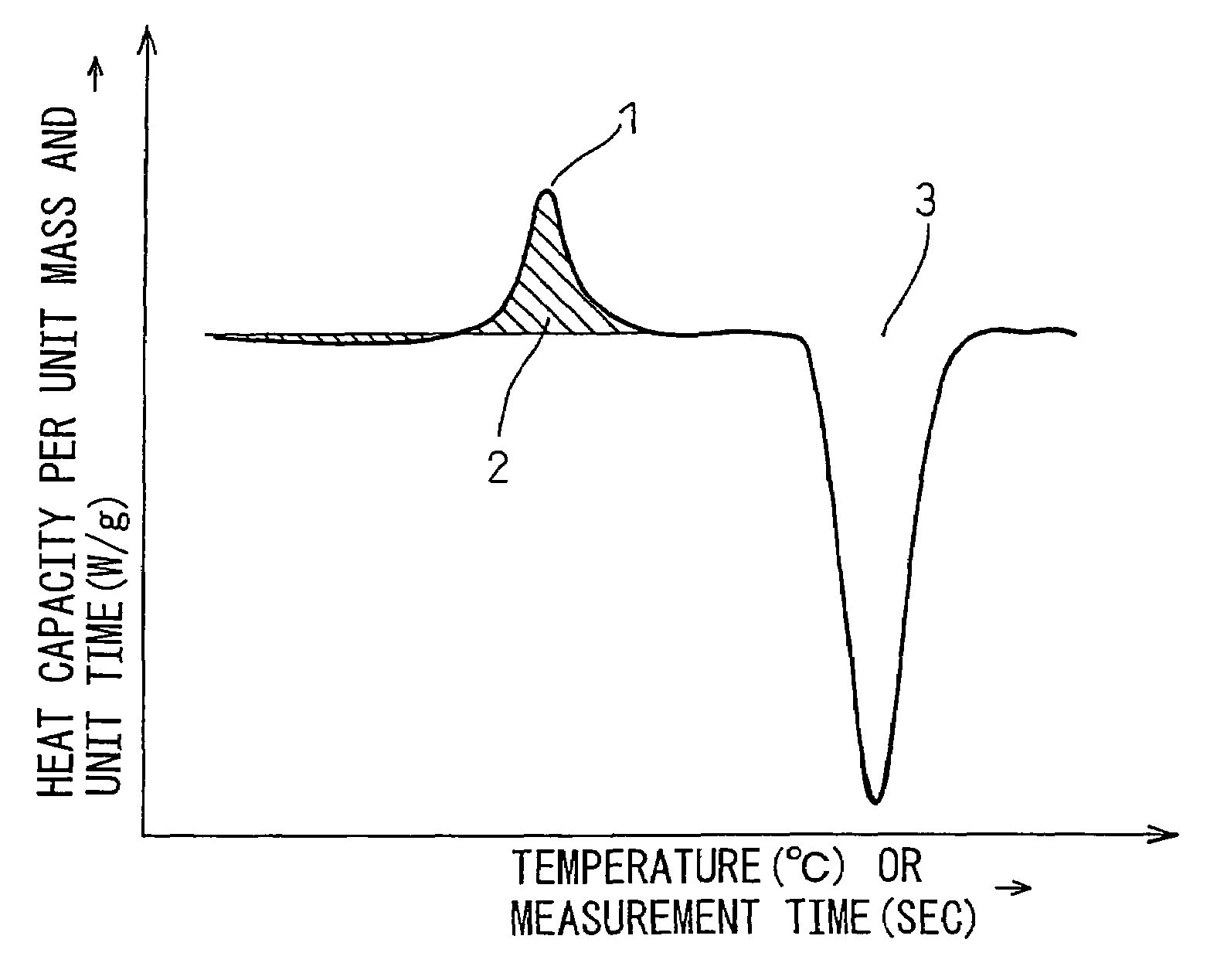

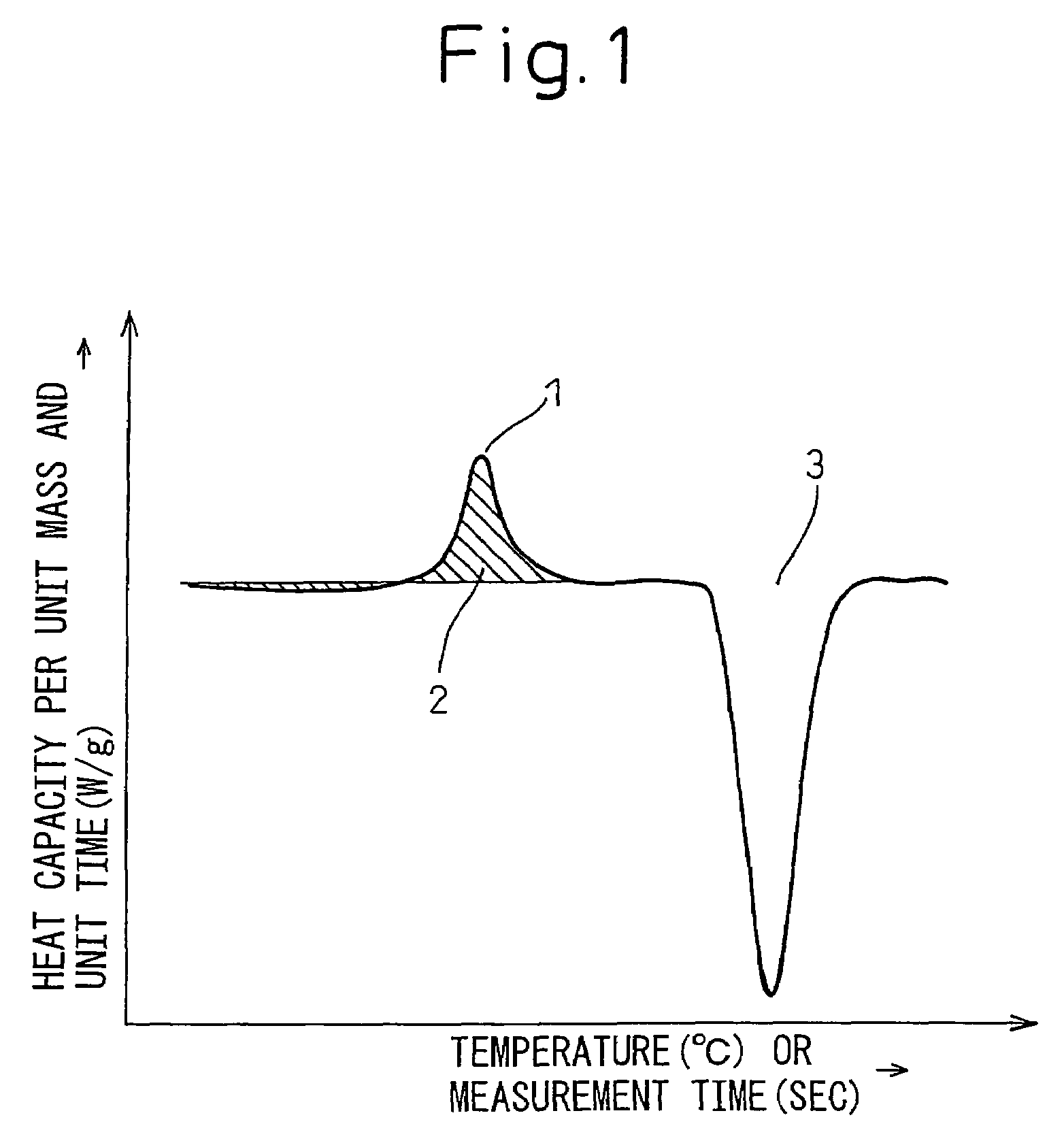

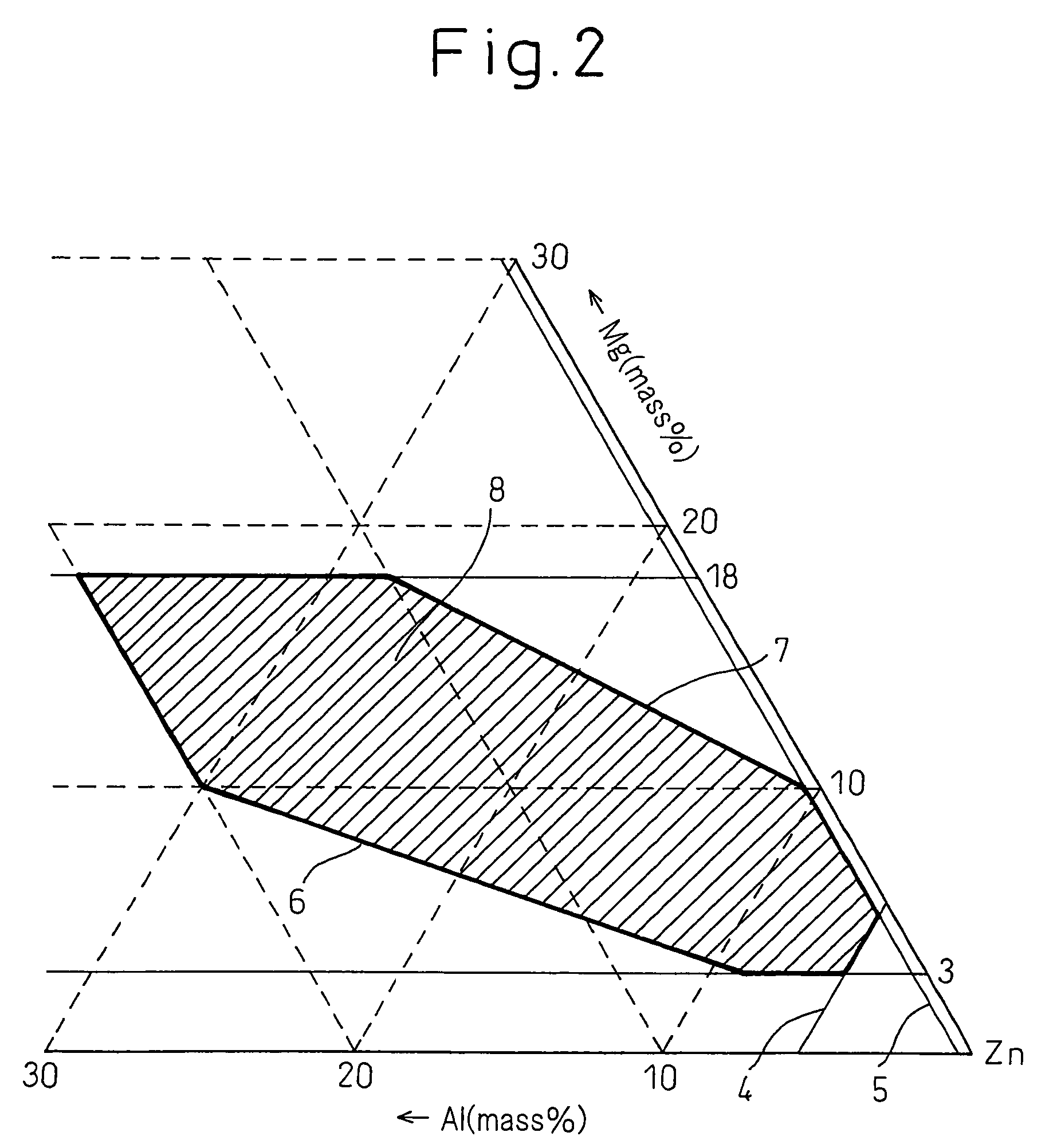

The present invention provides a high corrosion resistance hot dip galvannealed steel material comprised of a Zn-based hot dip plated steel material achieving both a higher corrosion resistance of the plated layer itself by the added elements and sacrificial protection of iron metal by the plated layer or workability free of degradation caused of formation of intermetallic compounds by added elements, that is, a high corrosion resistance hot dip Zn plated steel material characterized in that an alloy plated layer containing Zn: 35 mass % or more, preferably 40 mass % or more, contains a non-equilibrium phase having a heat capacity by differential scanning calorimetry of 1 J / g or more. Furthermore, 5% or more, preferably 50% or more in terms of vol % is an amorphous phase. The alloy layer may contain, by mass %, Mg: 1 to 60% and Al: 0.07 to 59%, may further contain one or more elements selected from Cr, Mn, Fe, Co, Ni, and Cu in a total of 0.1 to 10%, and may in addition contain one or more elements of 0.1 to 10% of La, 0.1 to 10% of Ce, 0.1 to 10% of Ca, 0.1 to 10% of Sn, 0.005 to 2% of P, and 0.02 to 7% of Si.

Owner:NIPPON STEEL CORP

Heat treatment process for scandium-containing Al-Zn-Mg-Cu base squeeze casting aluminum alloy

InactiveCN103866216AAvoid overheatingPrevent excessive solid solution residual crystalline phasesStress concentrationThermal insulation

The invention belongs to the field of aluminum alloy heat treatments, and particularly relates to a heat treatment process for a scandium-containing Al-Zn-Mg-Cu base squeeze casting aluminum alloy. The heat treatment process adopts a three-stage strengthening solid-solution treatment process and a single-stage aging treatment process, wherein the three-stage strengthening solid-solution treatment comprises: carrying out thermal insulation for 24 h at a temperature of 460 DEG C, heating to a temperature of 470 DEG C, carrying out thermal insulation for 8 h, continuously heating to a temperature of 480 DEG C, carrying out thermal insulation for 2 h at a temperature of 480 DEG C, immediately taking, and carrying out water quenching, and then the single-stage aging heat treatment is performed and comprises: carrying out thermal insulation for 24 h at a temperature of 120 DEG C. According to the present invention, the coarse non-equilibrium phase in the alloy can be sufficiently dissolved and homogenized, the supersaturation degree of the solid solution is increased, the stress concentration tendency with the grain boundary eutectic phase is reduced, the matrix structure after aging is fine GP zones distributed in a diffusion manner and an eta<,> phase, the grain boundary is a grain boundary precipitation phase distributed in a discontinuous manner, the ultra high strength ([sigma]s is more than or equal to 500 MPa) is achieved, and the good plasticity (delta is more than or equal to 10%) is provided.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

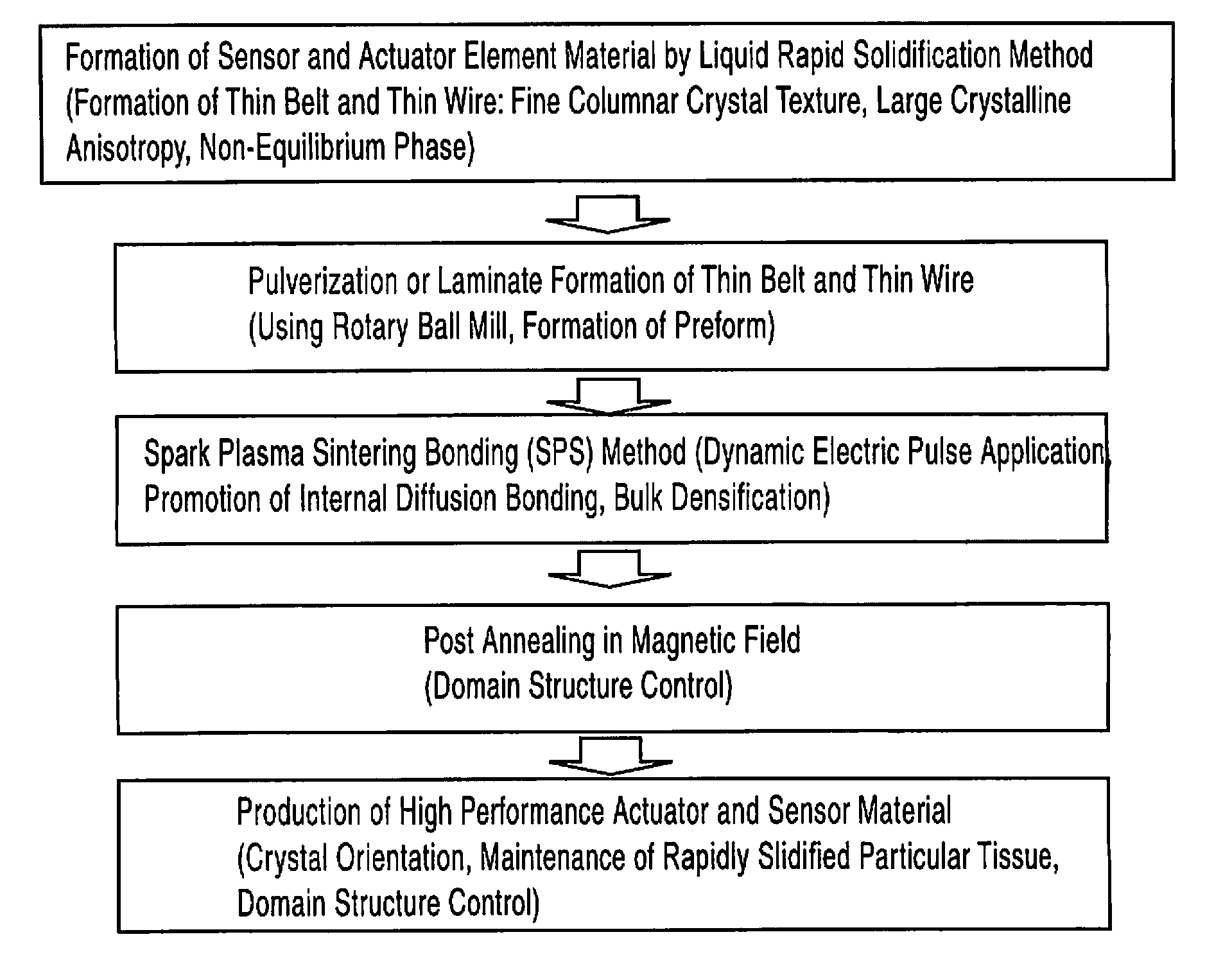

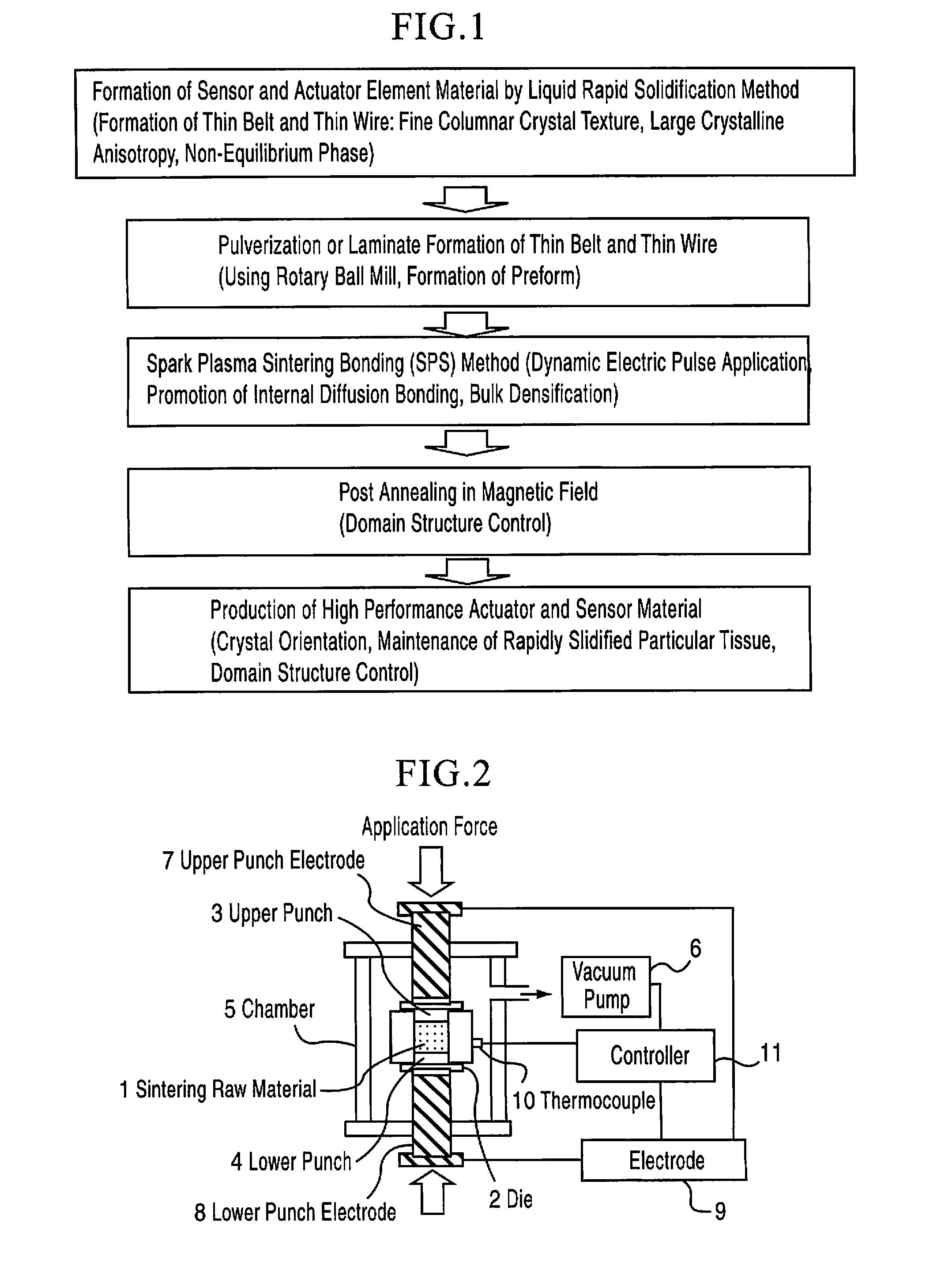

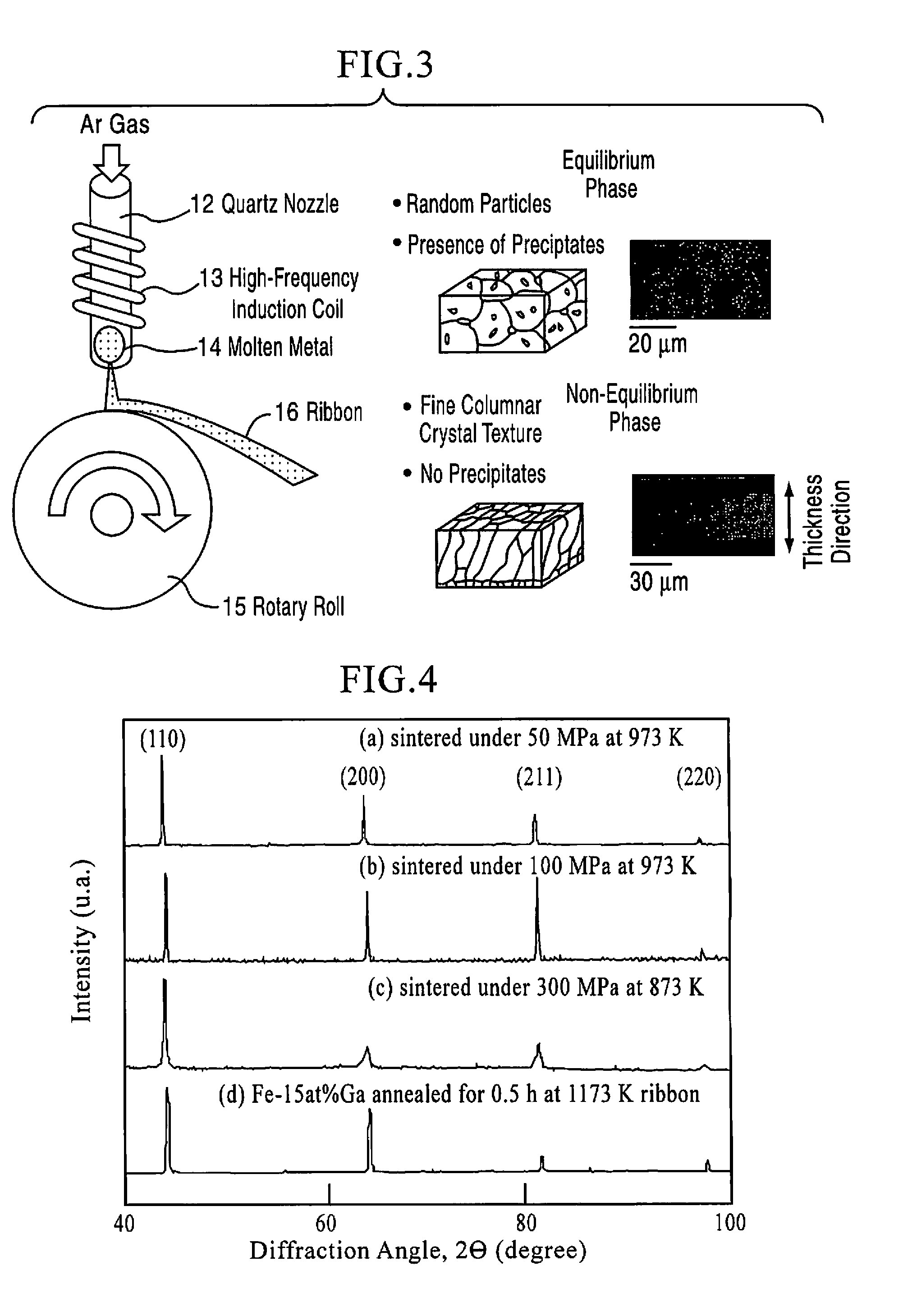

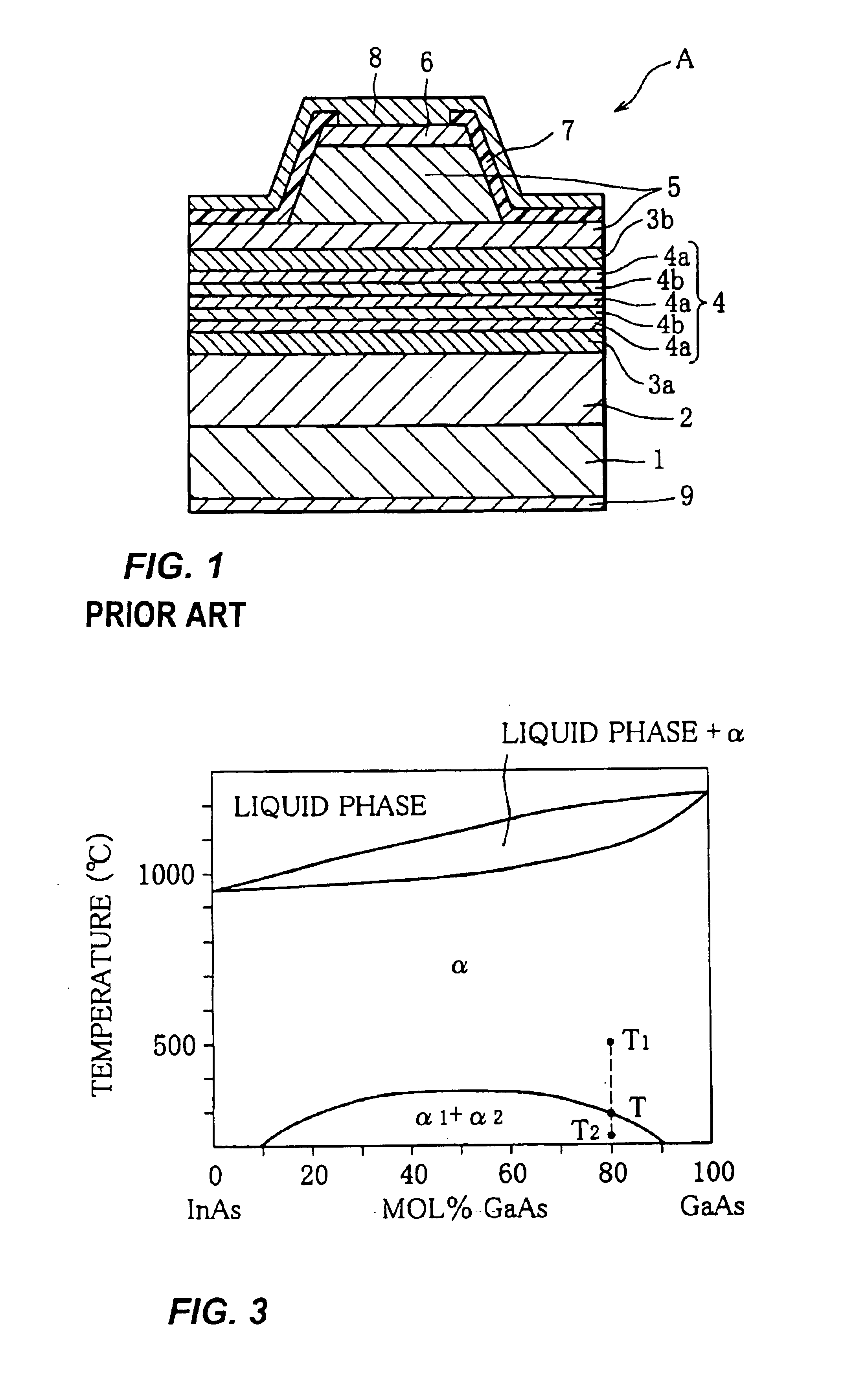

Bulk solidified quenched material and process for producing the same

InactiveUS20070183921A1Improve performanceImprove rigidityPiezoelectric/electrostrictive device manufacture/assemblyMagnetostrictive device manufacture/assemblyHigh densityLiquid state

[Object] A bulk material which is suitably used as a material for actuator and sensor elements is formed from a Fe—Ga base magnetoresistive alloy and a Ti—Ni base shape memory alloy taking advantage of crystal miniaturization and anisotropy as well as reduction of precipitates (equilibrium state in state diagram) and non-equilibrium phases peculiar to liquid rapidly solidified materials, and the performance of the material is enhanced by a production method thereof which has cost advantage over a melt method. [Construction] A rapidly solidified material having a particular rapidly solidified texture of a Fe—Ga magnetostrictive alloy or a TiNi-based shape-memory alloy and properties derived therefrom is formed into slices which are laminated to each other in a die, or is formed into a powder or chops which are filled in the die. Subsequently, spark plasma sintering is performed so that bonds between the slices, grains of the powder, or the chops are formed at a high density to form a bulk alloy, followed by annealing whenever necessary, so that the properties of the alloy are improved.

Owner:JAPAN SCI & TECH CORP

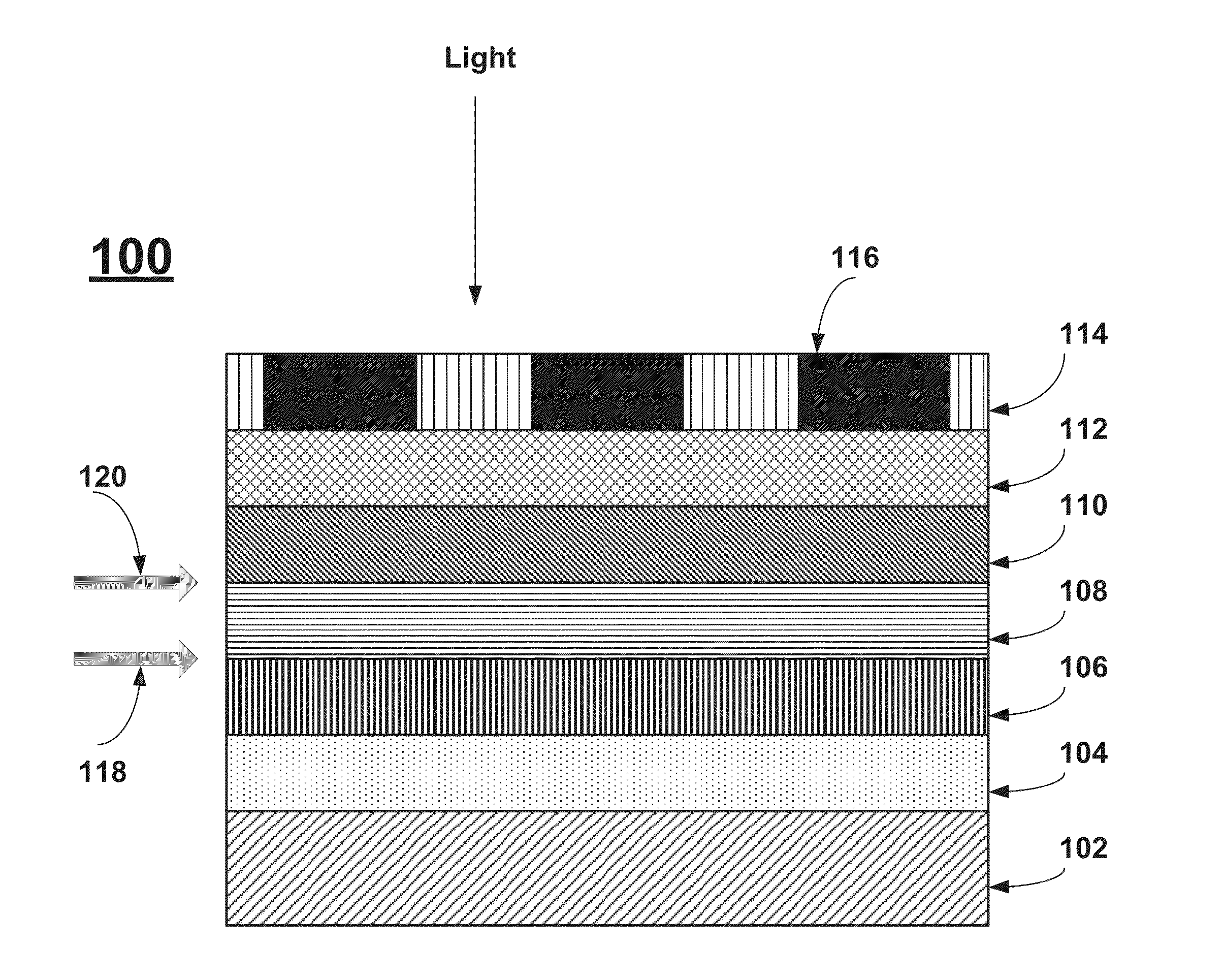

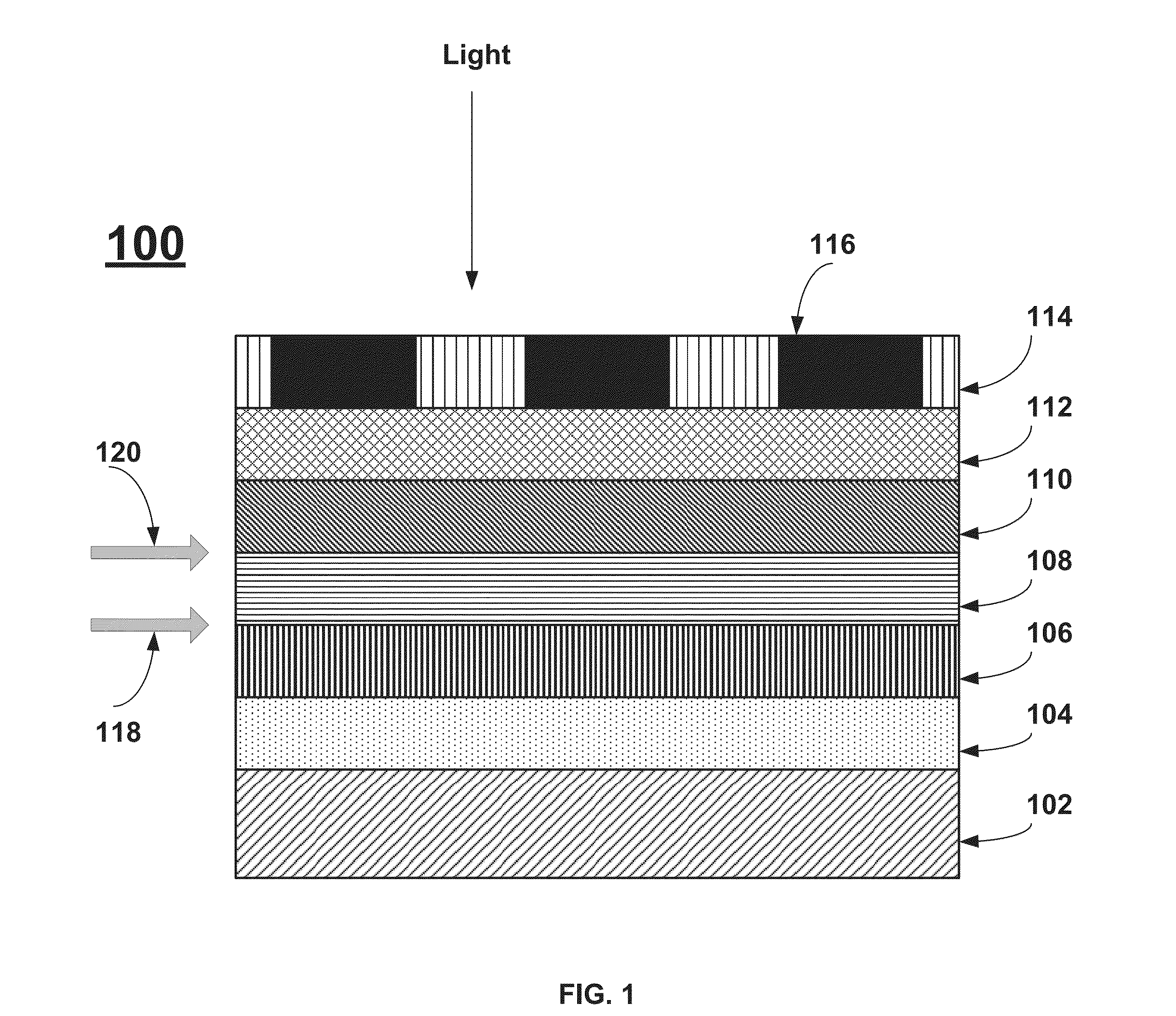

Laser annealing for thin film solar cells

InactiveUS20130065355A1High densityLarge particlesFinal product manufactureSemiconductor/solid-state device manufacturingIndiumSulfide

A method for forming copper indium gallium (sulfide) selenide (CIGS) solar cells, cadmium telluride (CdTe) solar cells, and copper zinc tin (sulfide) selenide (CZTS) solar cells using laser annealing techniques to anneal the absorber and / or the buffer layers. Laser annealing may result in better crystallinity, lower surface roughness, larger grain size, better compositional homogeneity, a decrease in recombination centers, and increased densification. Additionally, laser annealing may result in the formation of non-equilibrium phases with beneficial results.

Owner:INTERMOLECULAR

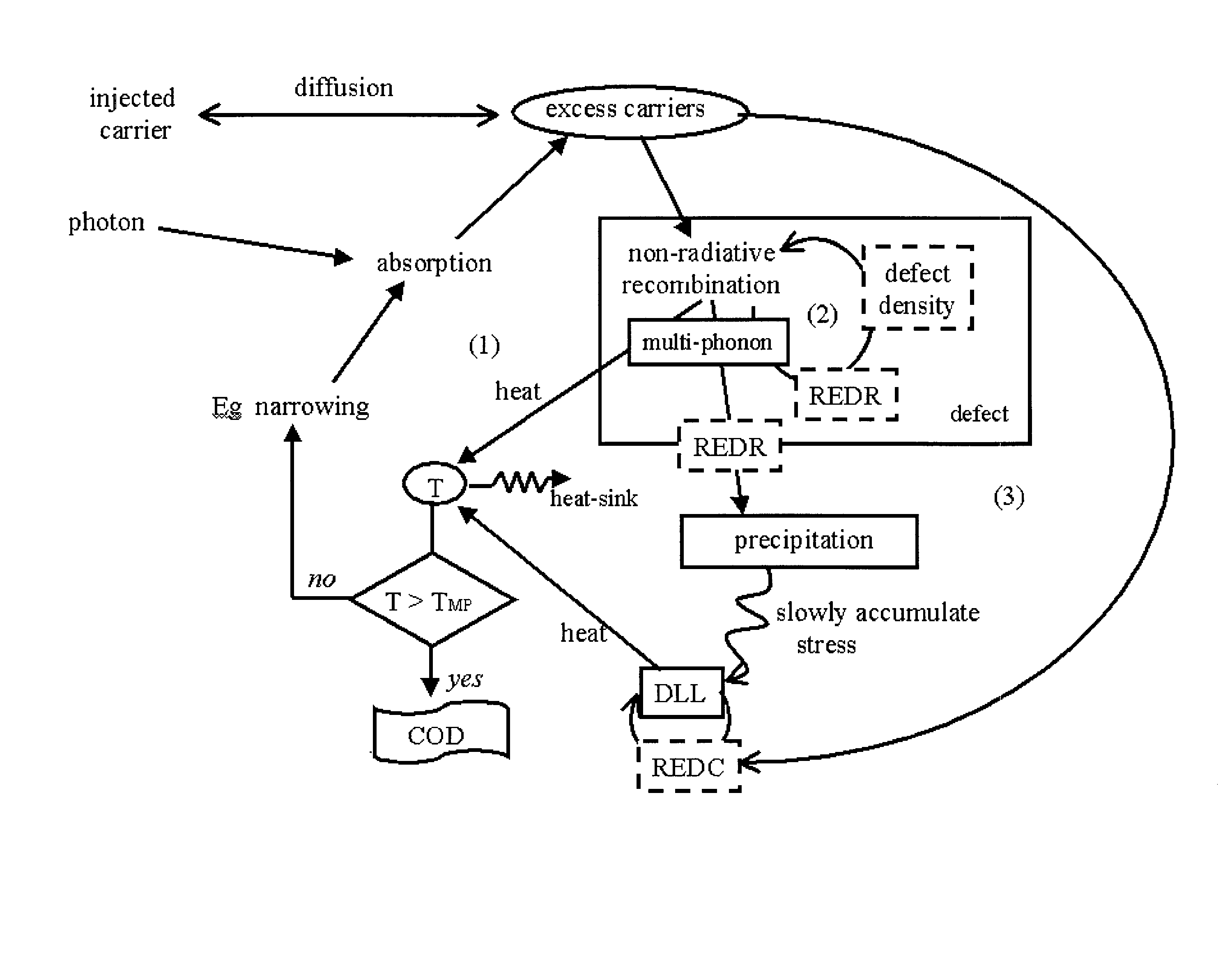

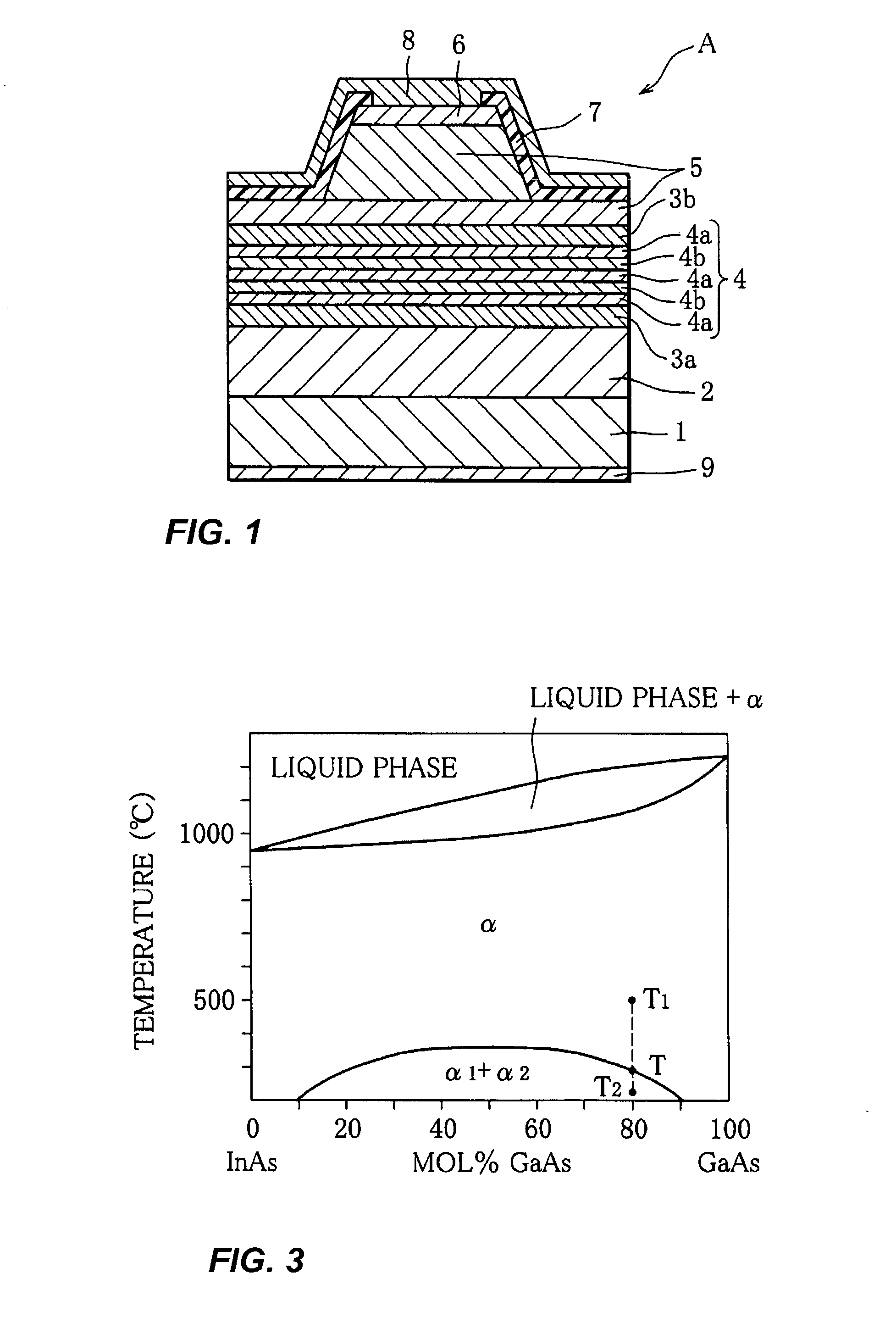

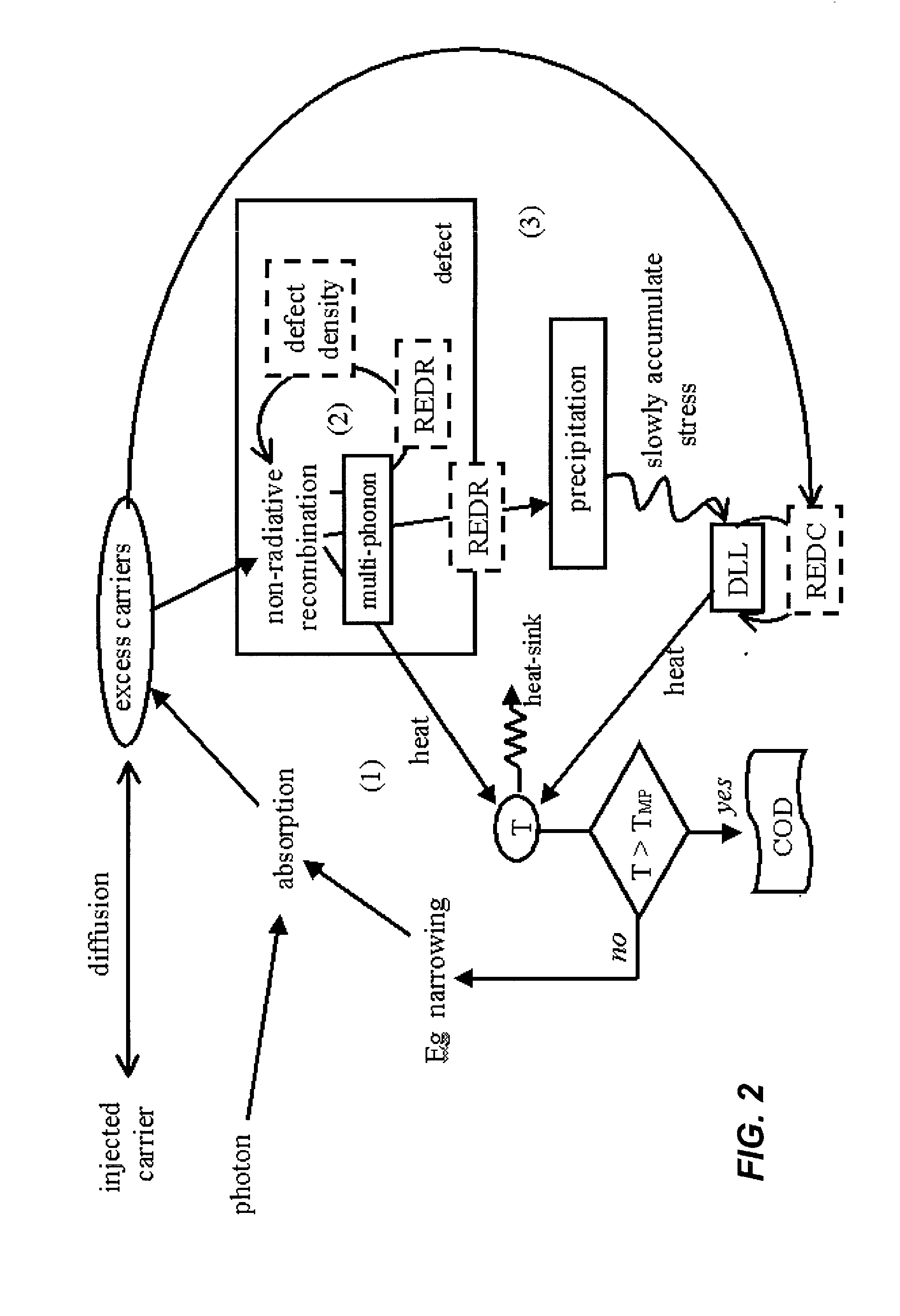

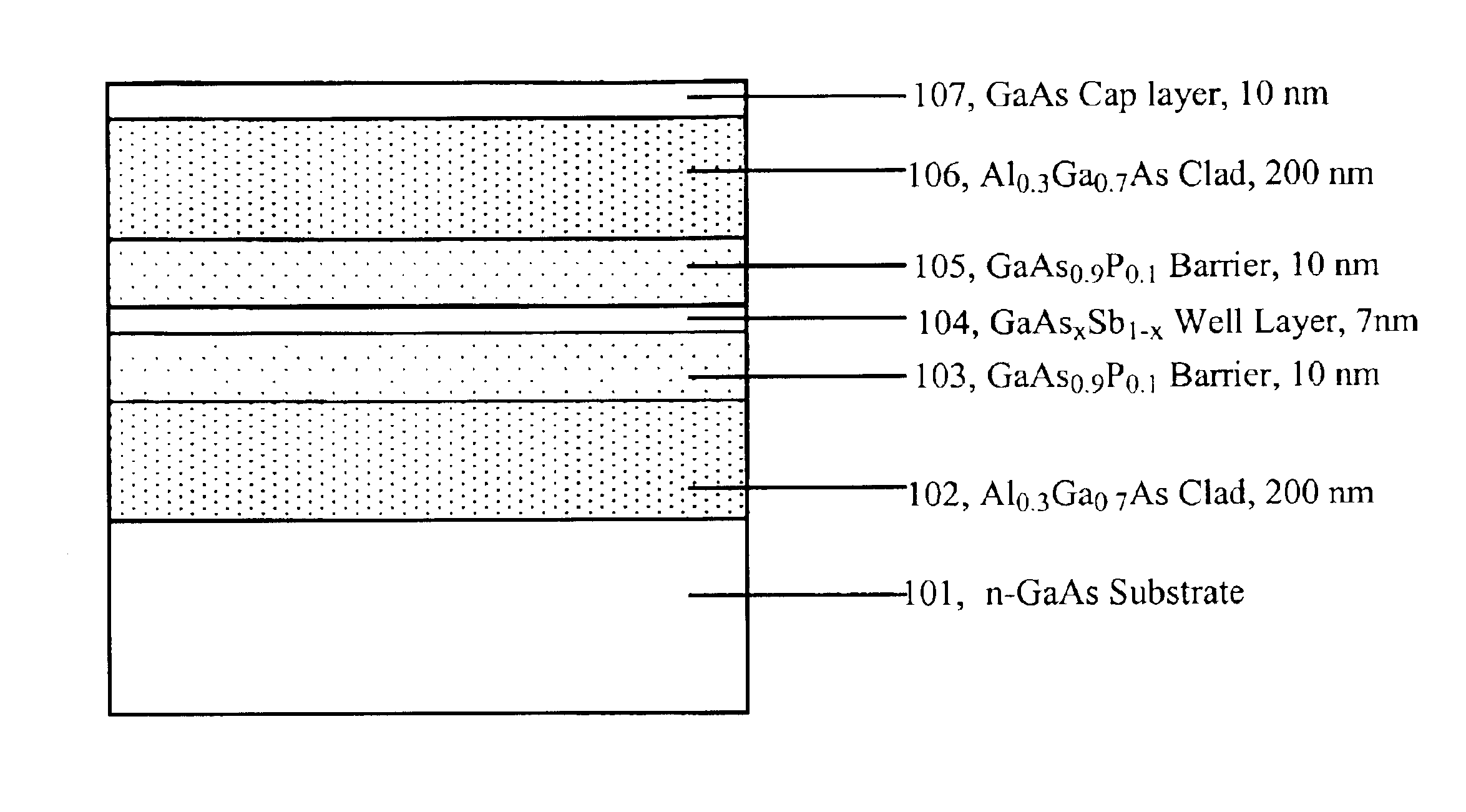

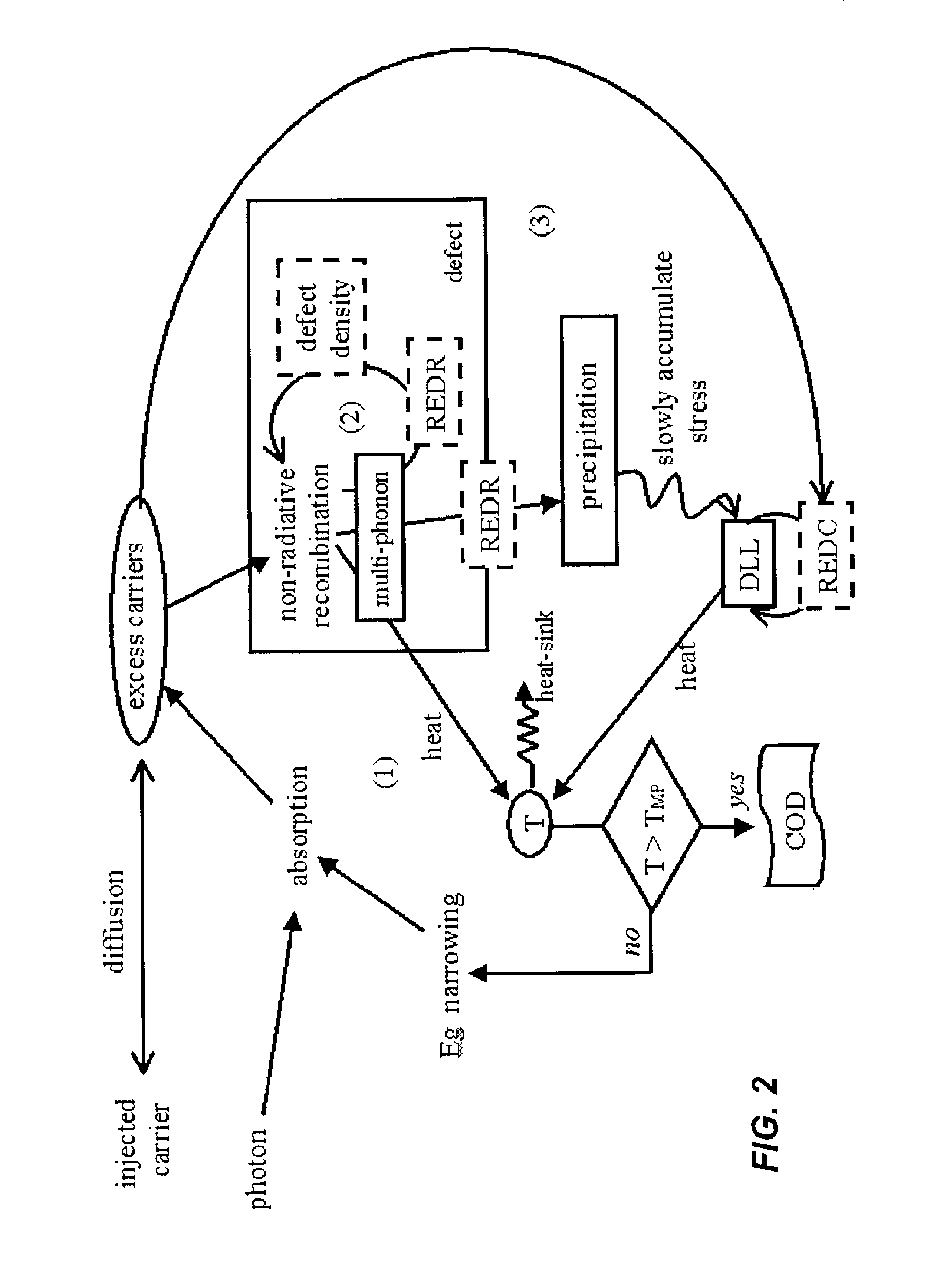

Semiconductor laser device

InactiveUS20030043872A1High thermodynamic stabilityImprove reliabilityOptical wave guidanceLaser active region structureQuantum wellActive layer

Owner:FURUKAWA ELECTRIC CO LTD

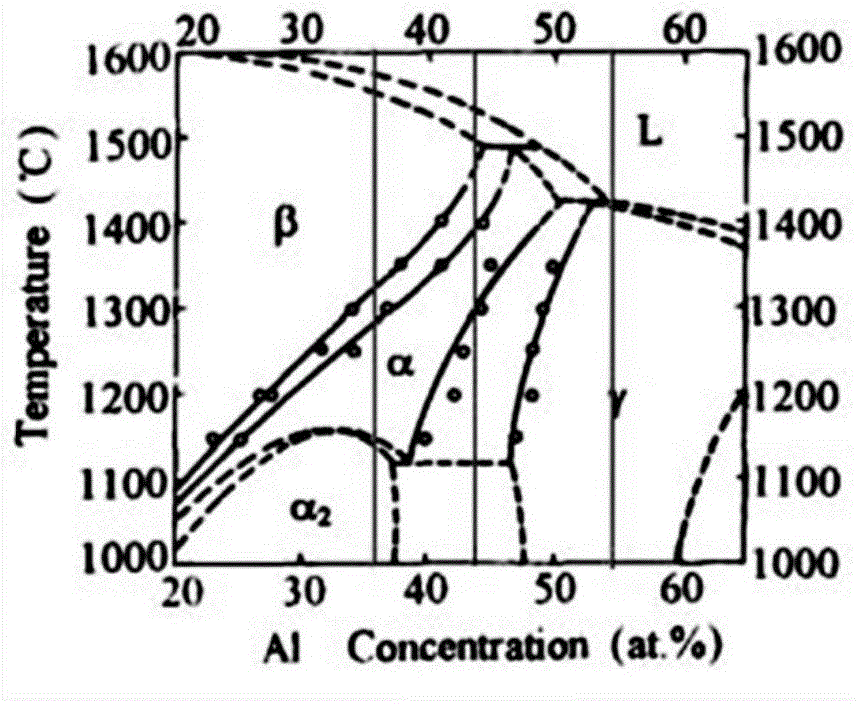

Measuring method of equilibrium phase of multi-component Ti-Al-X intermetallic compound

InactiveCN104535571AReduce workloadMaterial analysis using wave/particle radiationPreparing sample for investigationDiffusionElectron probe microanalysis

The invention relates to a measuring method of the equilibrium phase of a multi-component Ti-Al-X intermetallic compound. The measuring method comprises the steps of firstly carrying out diffusion-couple reference alloy composition design;preparinga diffusion-couple reference alloy casting ingot byadopting a vacuum-induction electric arc melting technology; cutting the melted diffusion-couple reference alloy casting ingot into a test sample; grinding the test sample till the surface is smooth and flat, and then carrying out vacuum prewelding; then carrying out long-time balance diffusion treatment on the pre-welded sample, and forming a diffusion layer between two reference alloys; then preparing a middle diffusion layer into a metallographic sample, andobserving; testing the contents of Al and Ti of the two ends of a phase interface of the sample by adopting an electronic probe technology, drawing concentration distribution curve of the Al and the Ti from an alpha-phase area to a gamma-phase area and obtaining equilibrium compositions of the two phases. Compared with the prior art, the measuring method has important theoretical guidance and practice significance on research ofthe equilibrium phase of multi-component Ti-Al-X intermetallic compound.

Owner:TONGJI UNIV

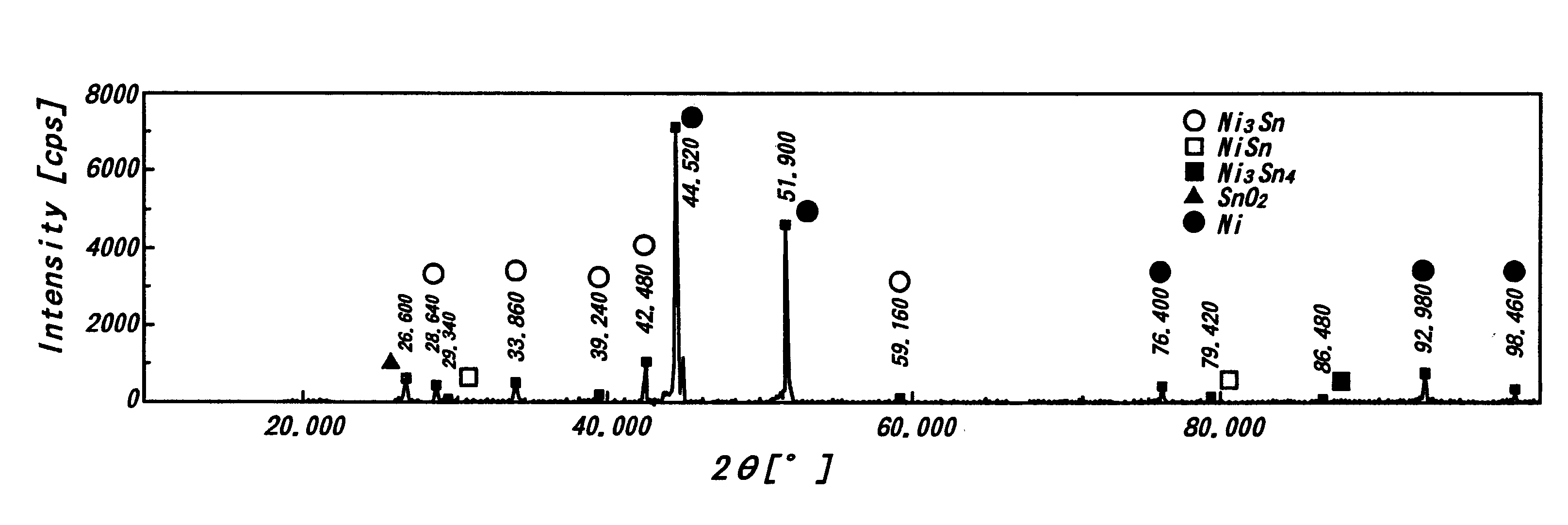

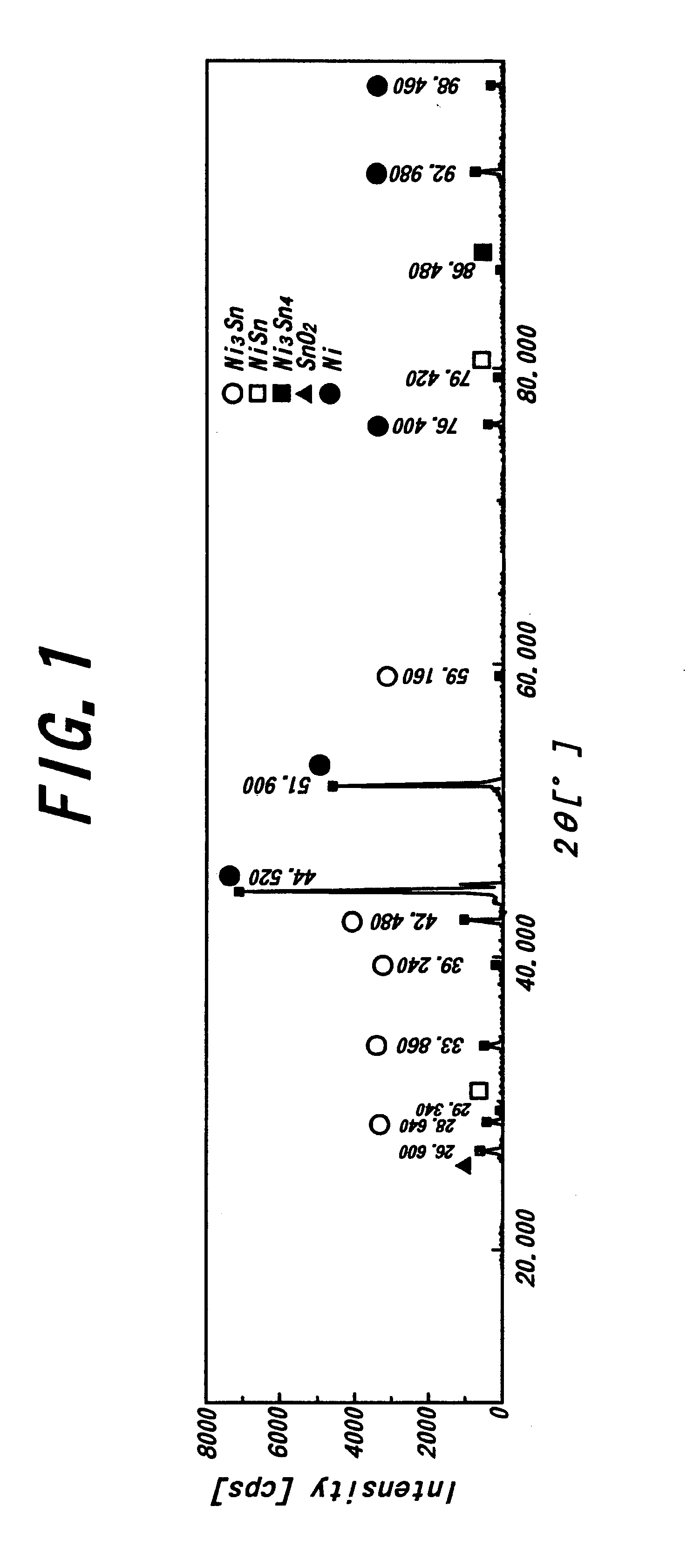

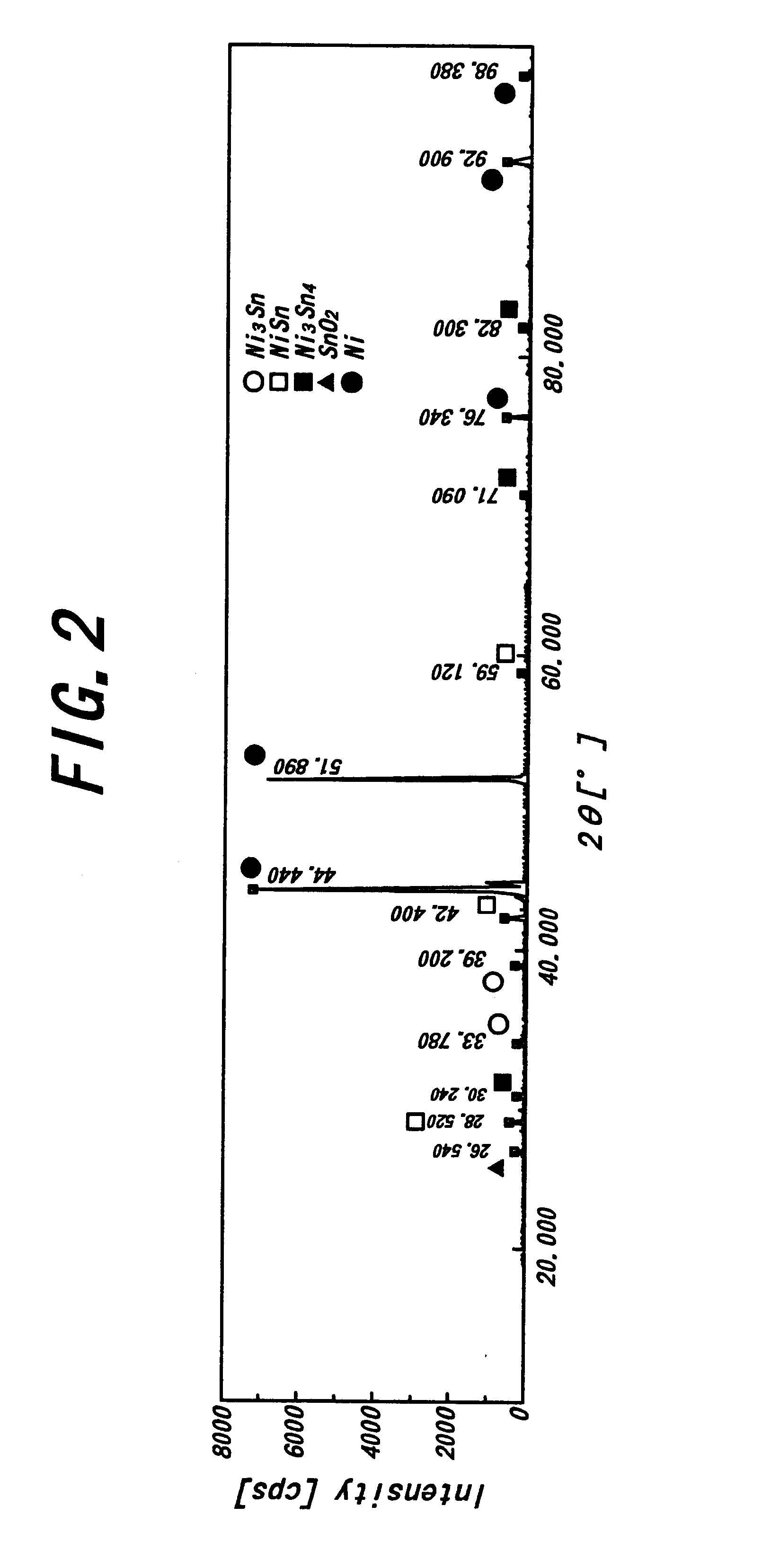

Method for producing a tin-nickel alloy film

InactiveUS6527881B2Maintain propertiesShort timeDecorative surface effectsFurnace typesNickel alloyLaser beams

A tin layer and a nickel layer are stacked sequentially on a given substrate to form a multilayered film composed of the tin layer and the nickel layer. Then, laser beams are irradiated onto the multilayered film to form a tin-nickel alloy film, having stable phases composed of equilibrium phases such as Ni3Sn phase through the diffusion of the tin elements of the tin layer into the nickel layer.

Owner:SUZUKA NAT COLLEGE OF TECH

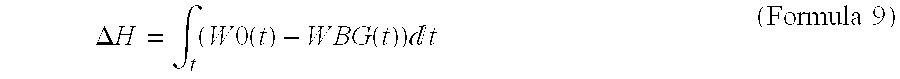

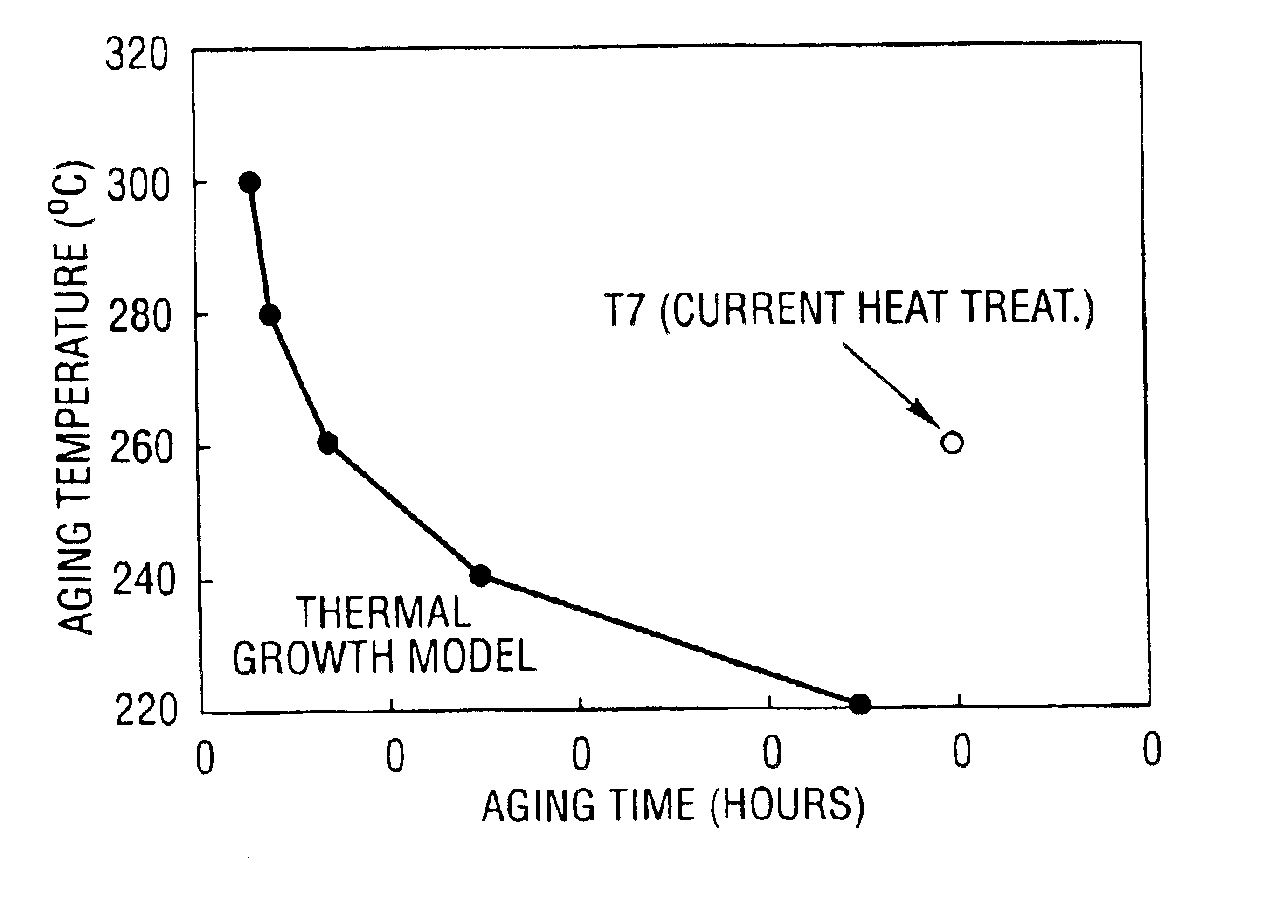

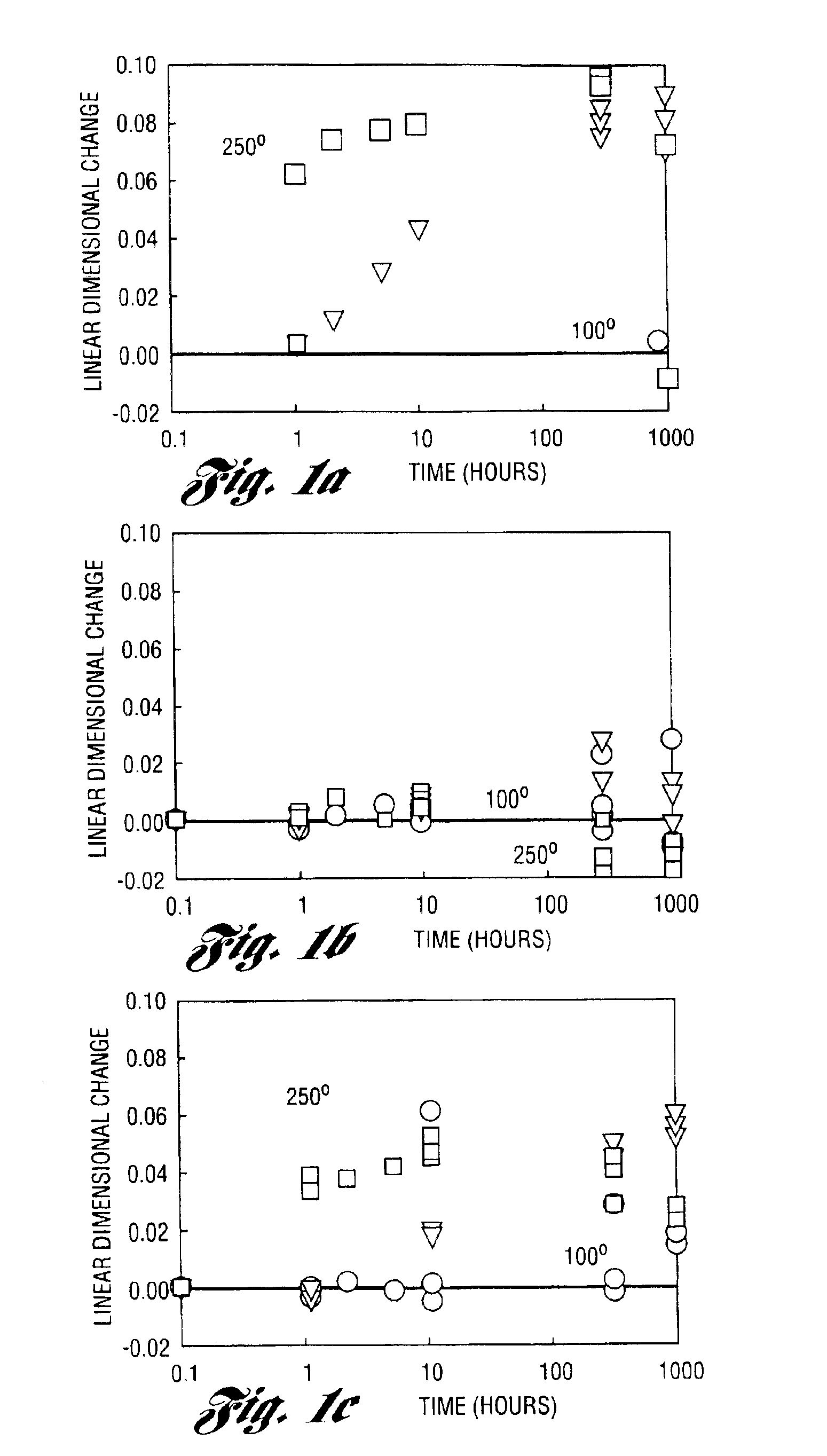

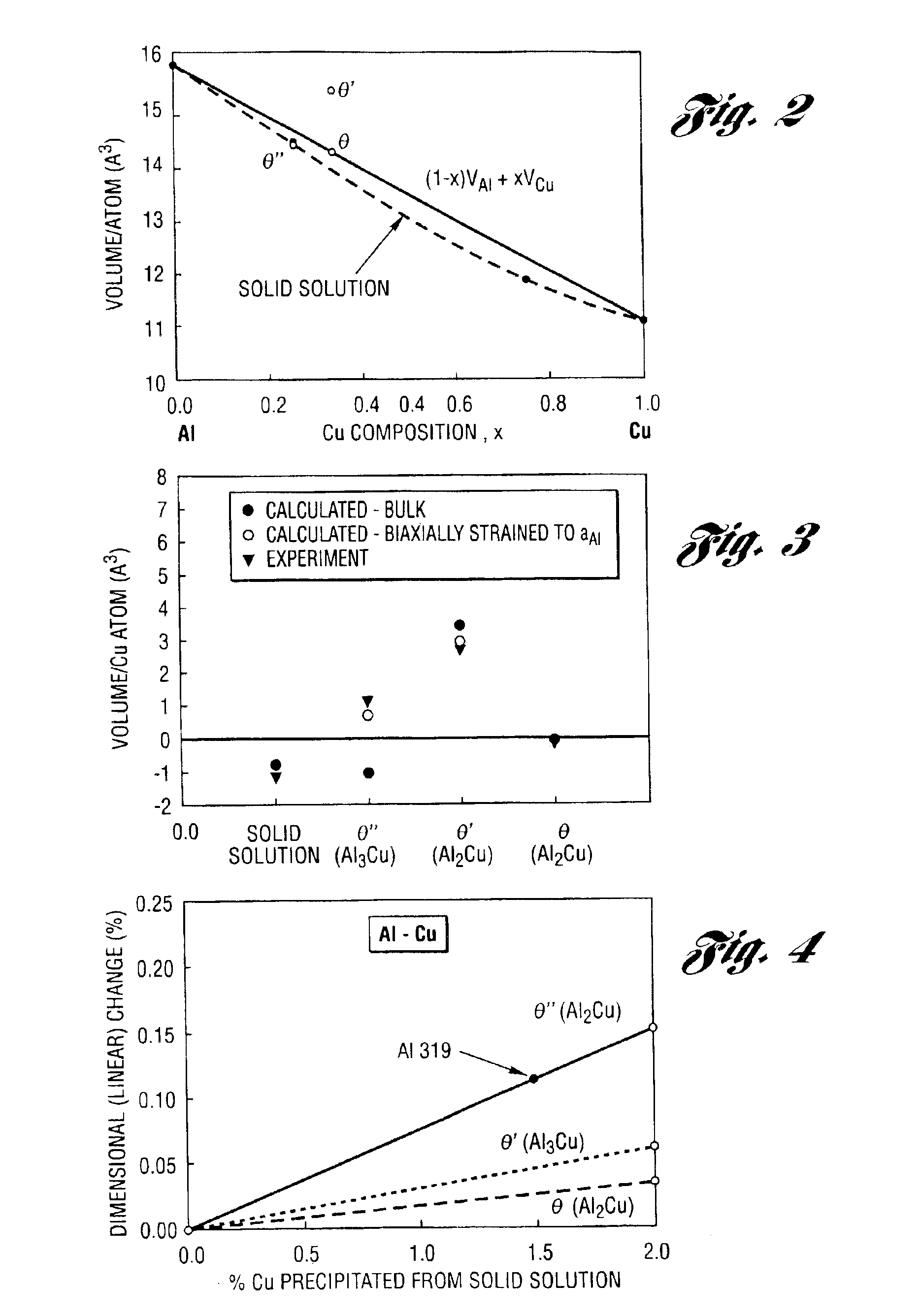

Method of optimizing heat treatment of alloys by predicting thermal growth

InactiveUS6858103B2Convenient heat treatmentThermometer detailsThermometers using material expansion/contactionQuantitative modelThermal growth

The present invention discloses a method for optimizing heat treatment of precipitation-hardened alloys having at least one precipitate phase by decreasing aging time and / or aging temperature using thermal growth predictions based on a quantitative model. The method includes predicting three values: a volume change in the precipitation-hardened alloy due to transformations in at least one precipitation phase, an equilibrium phase fraction of at least one precipitation phase, and a kinetic growth coefficient of at least one precipitation phase. Based on these three values and a thermal growth model, the method predicts thermal growth in a precipitation-hardened alloy. The thermal growth model is particularly suitable for Al—Si—Cu alloys used in aluminum alloy components. The present invention also discloses a method to predict heat treatment aging time and temperature necessary for dimensional stability without the need for inexact and costly trial and error measurements.

Owner:FORD GLOBAL TECH LLC +1

Semiconductor laser device

InactiveUS6898224B2Improved temperature dependenceTotal current dropOptical wave guidanceLaser active region structureQuantum wellActive layer

Owner:FURUKAWA ELECTRIC CO LTD

Novel multi-stage micro/mesoporous solid-state amine sorbent

InactiveCN108079956AReduce the amount of adsorptionGas treatmentOther chemical processesDesorptionSorbent

A novel multi-stage micro / mesoporous solid-state amine sorbent is disclosed. HZSM-5 with MCM-41 are mixed in different mass ratios to obtain composite molecular sieve supports; the composite molecularsieve supports are loaded onto composite molecular sieves by an impregnation method by use of tetraethylene pentamine (TEPA) as a modifier to prepare a series of novel multi-stage micro / mesoporous structural solid-state amine sorbents. When the mass ratio of HZSM-5 to MCM-41 is 1:1, the TEPA loading is 30%, the adsorption temperature is 55DEG C, and the gas inlet flow rate is 30 mL / min, the equilibrium adsorption amount is as high as 3.57 mmol / g, and after 10 cycles of adsorption and desorption, the adsorption amount is decreased by only 8.1%. The adsorption process of the HZSM-5 / MCM-41-30% TEPA for CO2 includes a rapid breakthrough adsorption phase and a relatively-slow gradual equilibrium phase, and the penetration adsorption amount is close to 80% of the equilibrium adsorption amount.The adsorption process of the HZSM-5 / MCM-41-30% TEPA for the CO2 is in accordance with Avrami kinetic model, indicating that CO2 adsorption is a result of physical adsorption and chemical adsorption.

Owner:韩会义

A method of preparing boron-aluminum-magnesium ternary alloy coating by laser rapid remelting

InactiveCN102296290AImprove wear resistanceImprove corrosion resistanceMetallic material coating processesLaser beam welding apparatusSolubilityHeat-affected zone

The invention relates to a method for preparing a boron-aluminum-magnesium ternary alloy coating by using laser rapid remelting. The laser cladding technology is used to obtain a surface alloy coating that is not limited by the solubility and the phase law determined by the equilibrium phase diagram under conventional conditions. layer, this alloy coating has high wear resistance, corrosion resistance and good electromagnetic and thermal properties. Compared with the traditional spraying process, the laser surface cladding technology has the following advantages: (1) The cladding layer has a dense structure, fine grains, and good oxidation resistance, corrosion resistance, and wear resistance; (2) ) The cladding layer has a good metallurgical bond with the substrate, and the bonding strength is high; (3) The heat input to the substrate is small, and the heat-affected zone of the substrate is small; (4) The dilution of the substrate to the coating (5) The laser surface cladding process can be precisely controlled, and the amount of subsequent machining is small; 6) Partial cladding treatment can be performed on the workpiece, the deformation of the treatment part is small, and the cladding process is well controllable.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

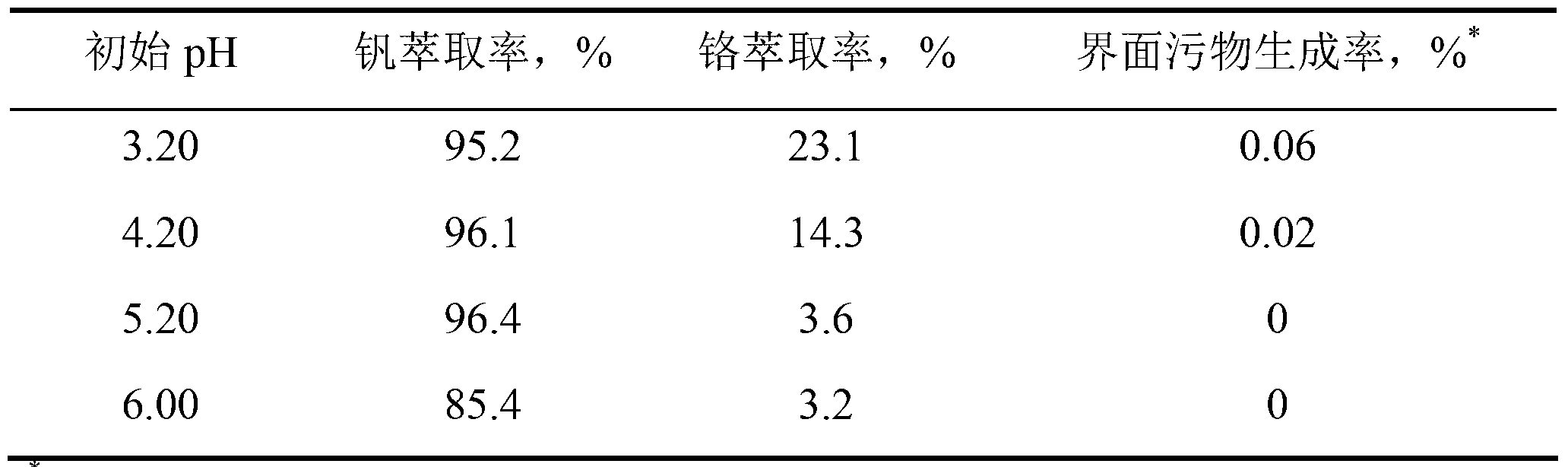

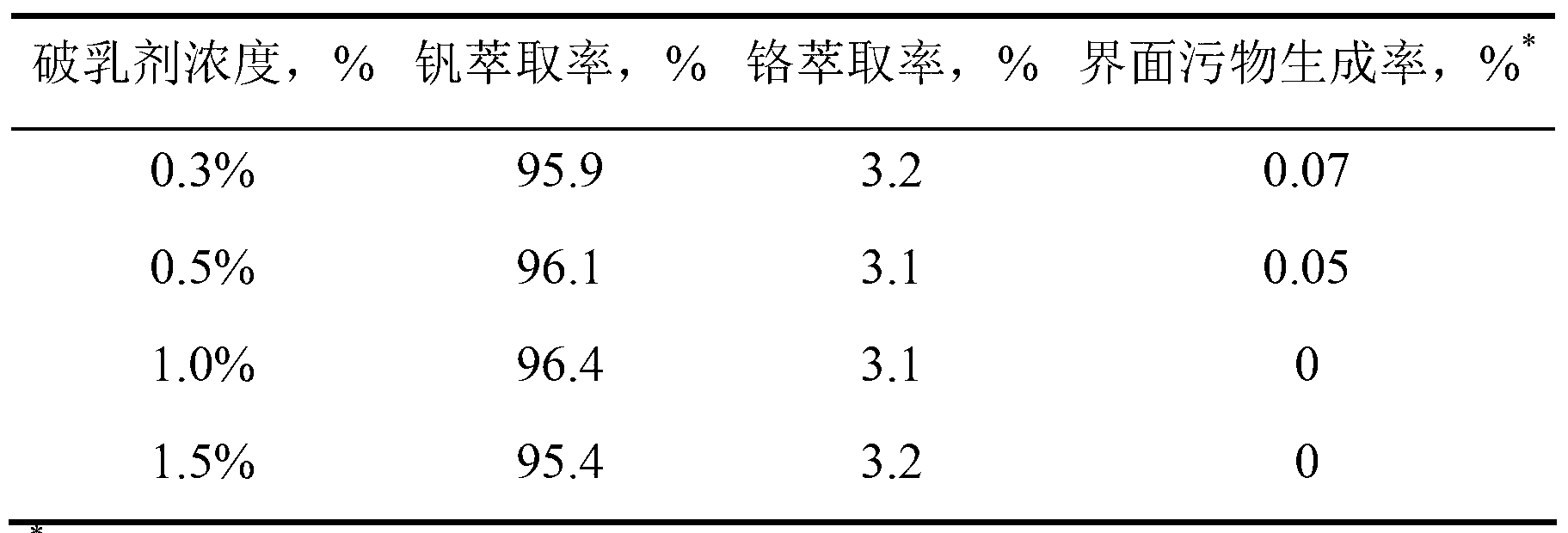

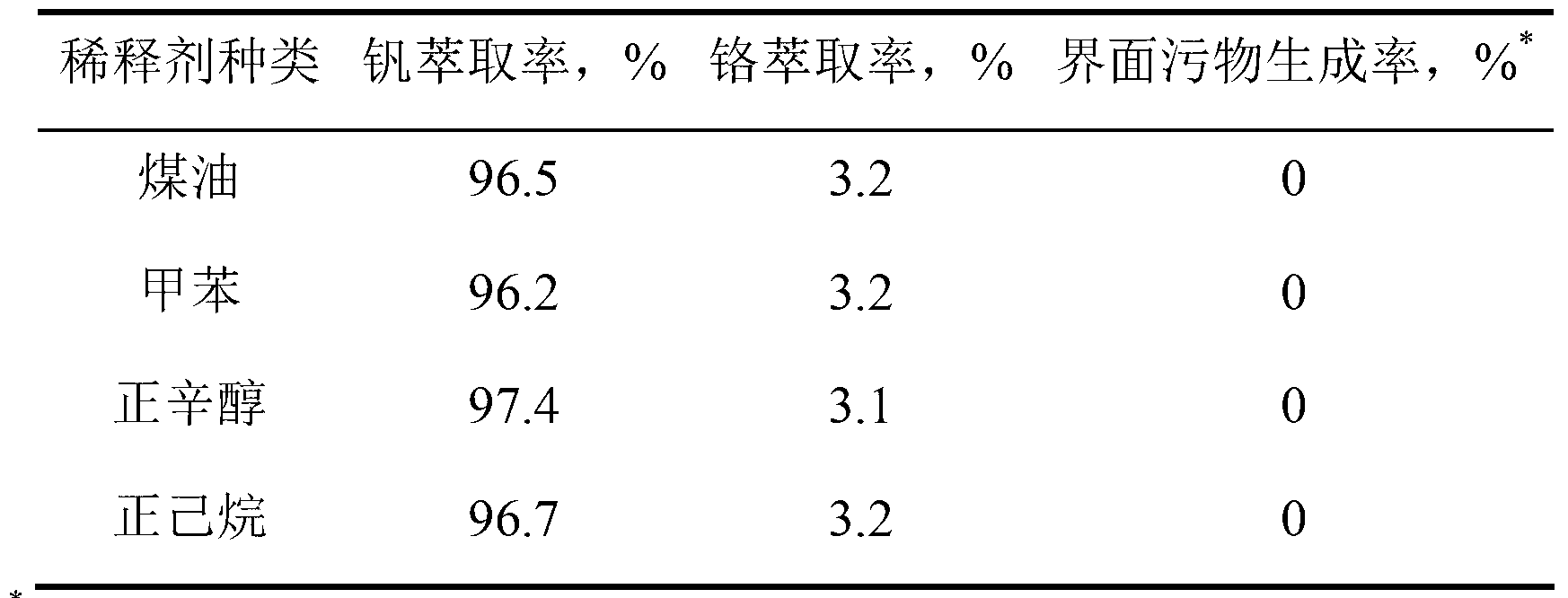

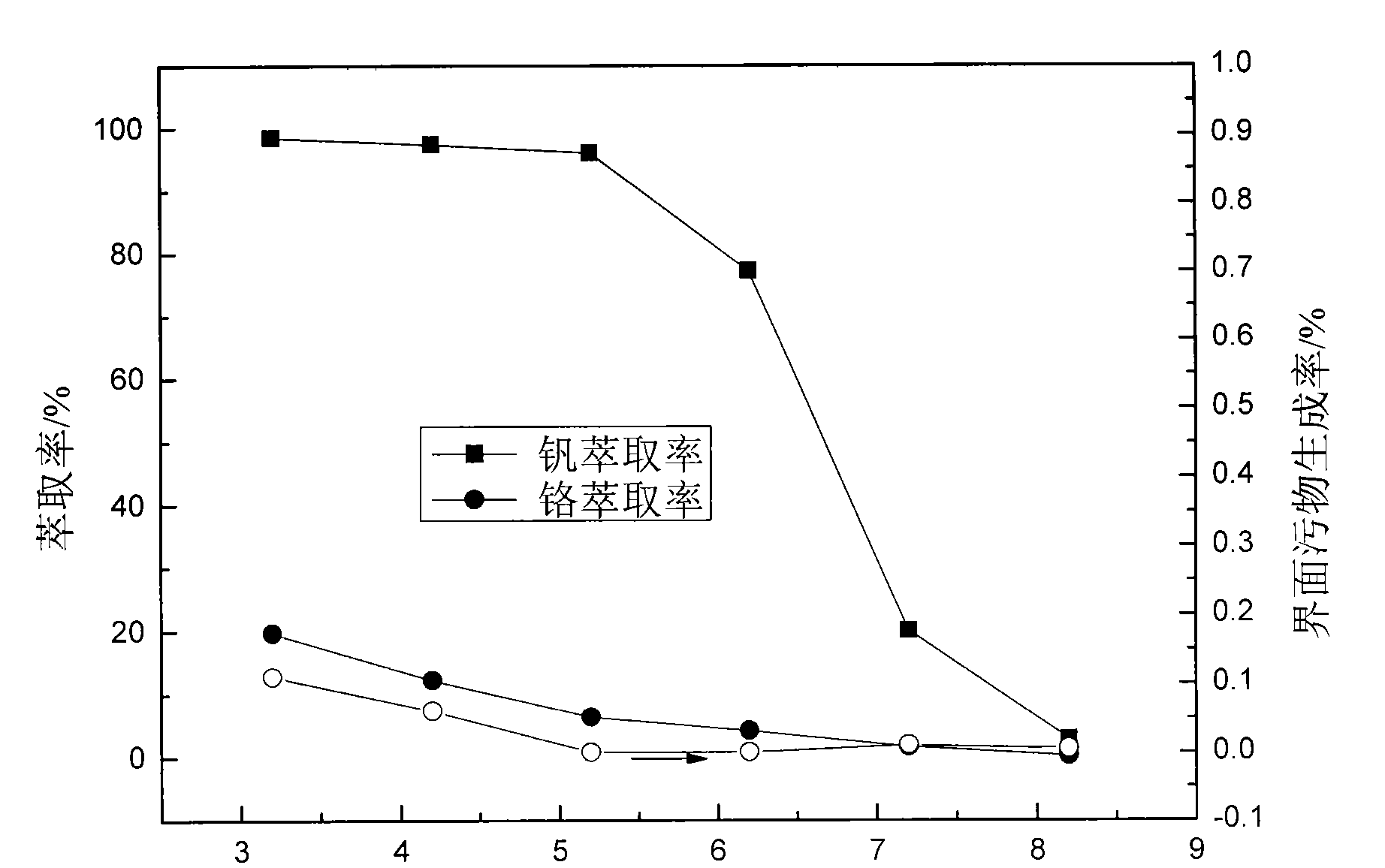

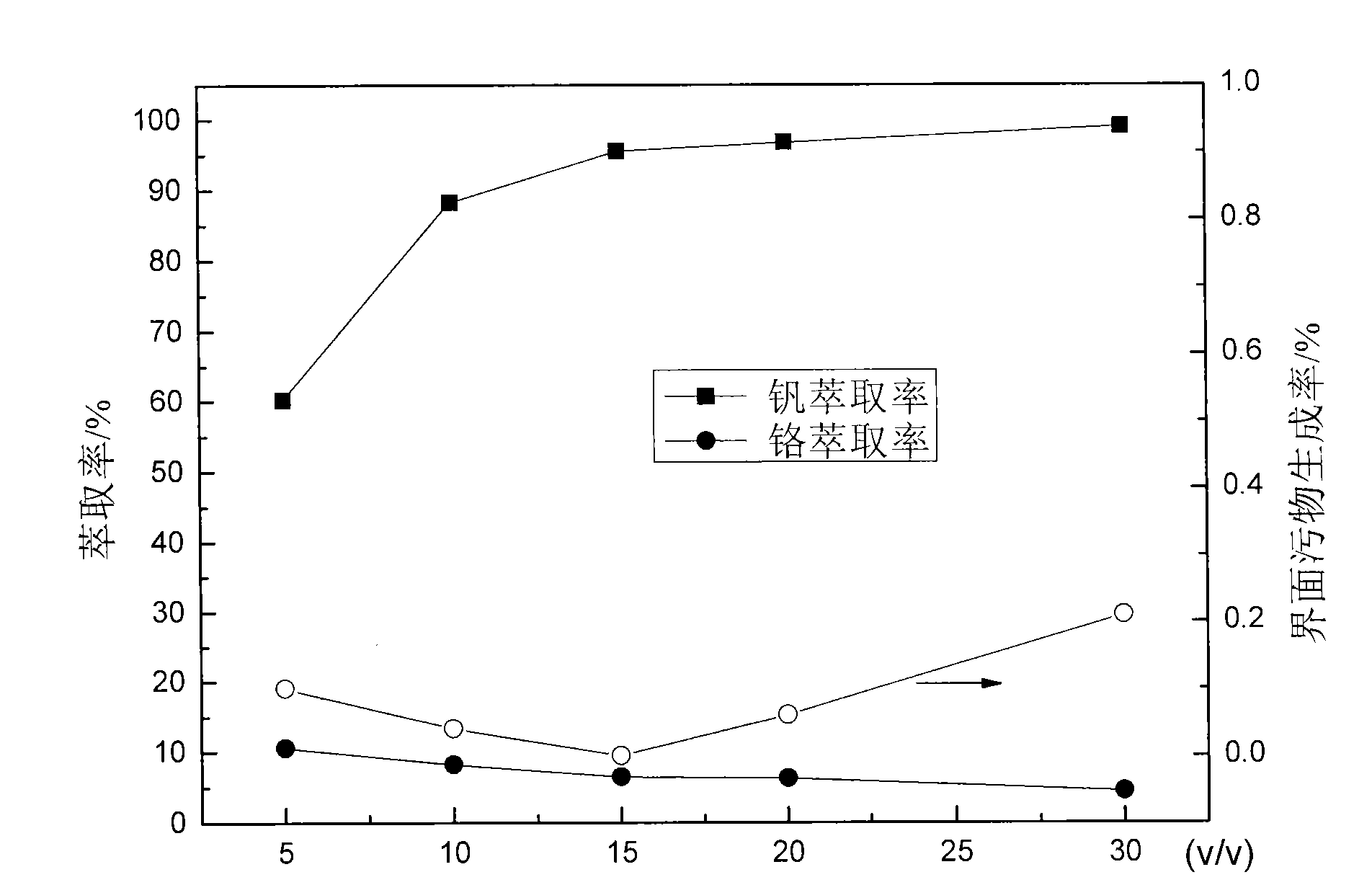

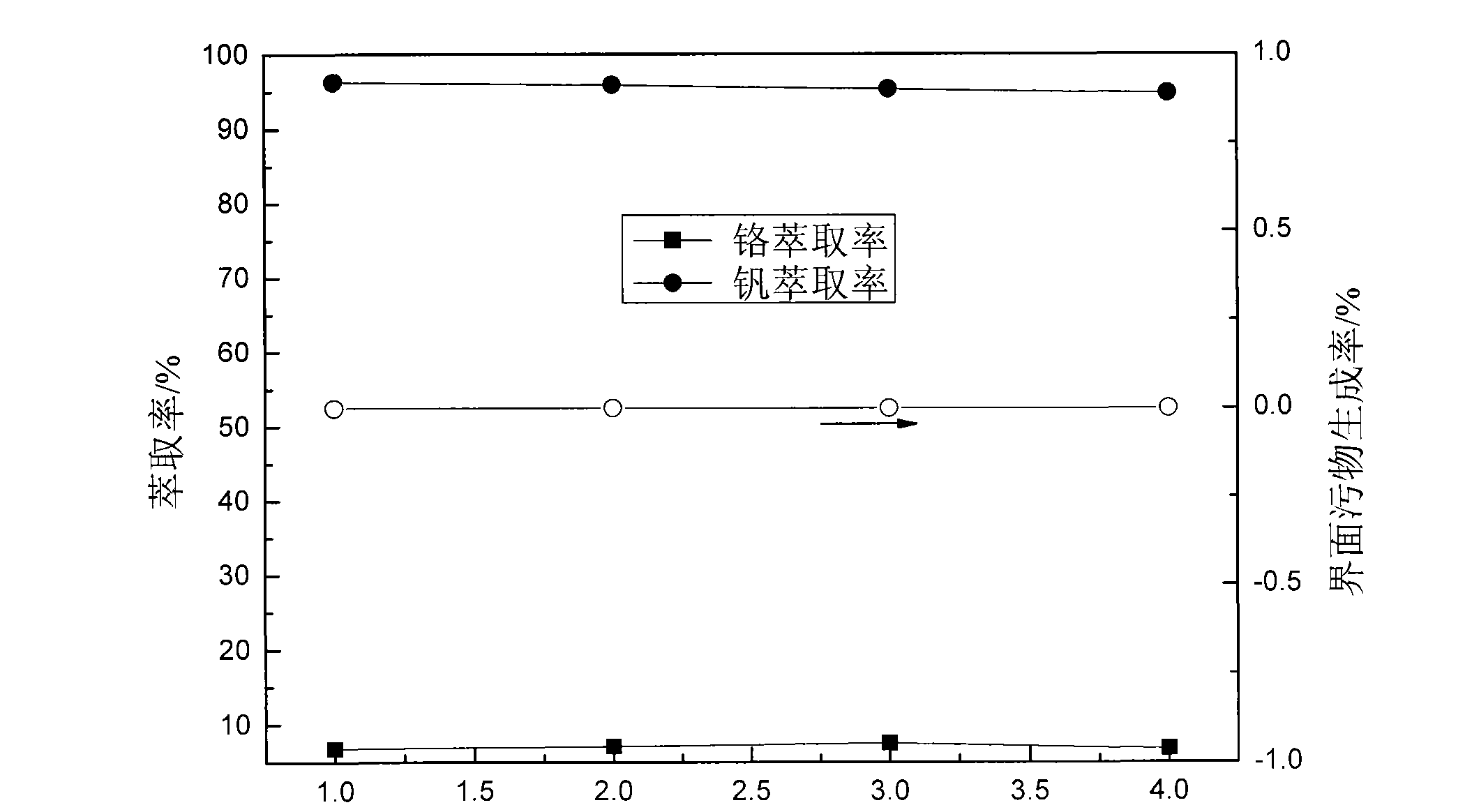

Method of preventing interphase impurity in vanadium-chromium extraction separation process

ActiveCN103305693AEasy to separatePrevent interface contaminationProcess efficiency improvementSolid particleImpurity

The invention discloses a method of preventing interphase impurity in a vanadium-chromium extraction separation process. The method is characterized by comprising the following steps of: deeply removing impurities in an extracted solution before extraction, such as phosphorus, silicon, calcium, iron, and the like; extracting the purified extracted solution through a mixed solution of an efficient composite amine extracting agent, a demulsifier and a thinner, regulating the pH of the extracted solution, controlling the extraction temperature, the extraction time, the concentration of the extracting agent and the concentration of the demulsifier in the extraction process. According to the method, solid particles possibly generating emulsification in the solution are deeply removed and the demulsifier is added to reduce the emulsification interphase stability when the extraction is finished so as to reduce the probability of inorganic salts in crystallizing on the interphase to form solid interphase membranes. The method can effectively eliminate the interphase impurity in the vanadium-chromium extraction separation process, improve the extraction equilibrium phase splitting speed, reduce the organic phase loss, save the operating cost and ensure the long-term circulation of the extraction system.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preventing interfacial crud during vanadium-chromium extraction and separation

InactiveCN101665870AInterface contamination preventionEfficient separationProcess efficiency improvementSlagSodium hydroxide

The invention discloses a method for preventing interfacial crud during vanadium-chromium extraction and separation, which is characterized in that during extraction, vanadium and chromium are extracted and separated by use of amine-type extractant in an organic phase containing the amine-type extractant and diluent composition; an aqueous phase adopts a leaching solution which contains vanadium-chromium slag and has acidity adjusted through dilute sulfuric acid or sodium hydroxide solution; and the method comprises the steps of mixing the aqueous phase with the organic phase in a separating funnel at a certain temperature, fixing the separating funnel on an oscillator, oscillating for a certain time, taking out and standing the separating funnel for demixing. The method has the advantagesof effectively preventing interfacial crud produced during vanadium-chromium extraction and separation, improving extraction equilibrium phase-separation speed, reducing the loss of organic phase andsaving operation cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

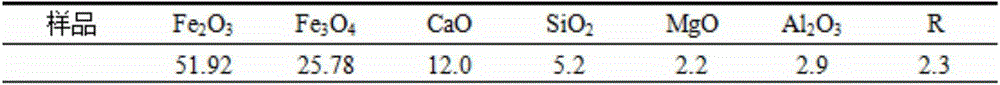

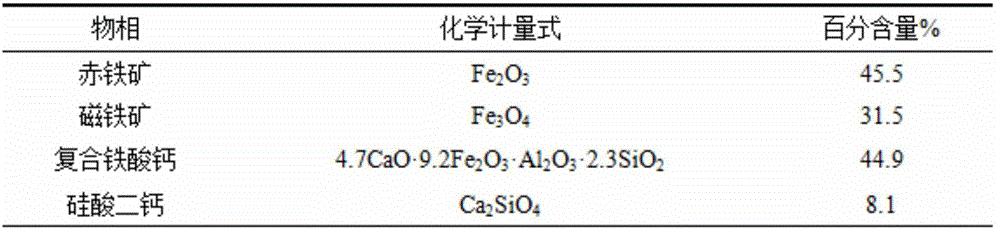

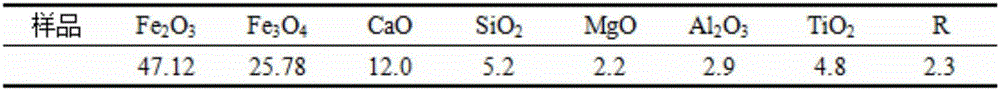

Iron ore sintering method and quantitative characterization method of mineral phase contents

InactiveCN106053503AObvious beneficial effectGuaranteed accuracyMaterial analysis by optical meansMaterial analysis using radiation diffractionScanning electron microscopeIron ore sintering

The invention discloses an iron ore sintering method and a quantitative characterization method of mineral phase contents. By an iron ore equilibrium phase sintering technology, quantitative research on the phase composition of sintered ore is carried out so as to determine the optimum ratio of sintered ore and sintering parameter condition. In comparison with traditional sinter pot experiments and commercial tests, the equilibrium phase sintering technology is adopted in the invention so as to greatly reduce experimental errors. Equipment such as an XRD, a scanning electron microscope, a metallographic microscope and the like is applied for detection of sintered samples. Various detection results confirm one another to ensure phase judgment accuracy. Meanwhile, ImageJ software is used for quantitative calculation of mineral phase contents so as to obtain precise phase type and quantitative composition. Therefore, this method has the characteristic of accurate detection results. By the method, the influence of sintering raw material and condition change on sintered ore phase composition can be analyzed from the perspective of phases, and then changes of metallurgical properties of sintered ore is analyzed. The method is scientific and practical.

Owner:CHONGQING UNIV

High corrosion resistance hot dip galvanized steel material

InactiveUS8663818B2Improve corrosion resistanceSuppressing degradationHot-dipping/immersion processesThin material handlingAmorphous phaseAlloy

The present invention provides a high corrosion resistance hot dip galvannealed steel material comprised of a Zn-based hot dip plated steel material achieving both a higher corrosion resistance of the plated layer itself by the added elements and sacrificial protection of iron metal by the plated layer or workability free of degradation caused of formation of intermetallic compounds by added elements, that is, a high corrosion resistance hot dip Zn plated steel material characterized in that an alloy plated layer containing Zn: 35 mass % or more, preferably 40 mass % or more, contains a non-equilibrium phase having a heat capacity by differential scanning calorimetry of 1 J / g or more. Furthermore, 5% or more, preferably 50% or more in terms of vol % is an amorphous phase. The alloy layer may contain, by mass %, Mg: 1 to 60% and Al: 0.07 to 59%, may further contain one or more elements selected from Cr, Mn, Fe, Co, Ni, and Cu in a total of 0.1 to 10%, and may in addition contain one or more elements of 0.1 to 10% of La, 0.1 to 10% of Ce, 0.1 to 10% of Ca, 0.1 to 10% of Sn, 0.005 to 2% of P, and 0.02 to 7% of Si.

Owner:NIPPON STEEL CORP

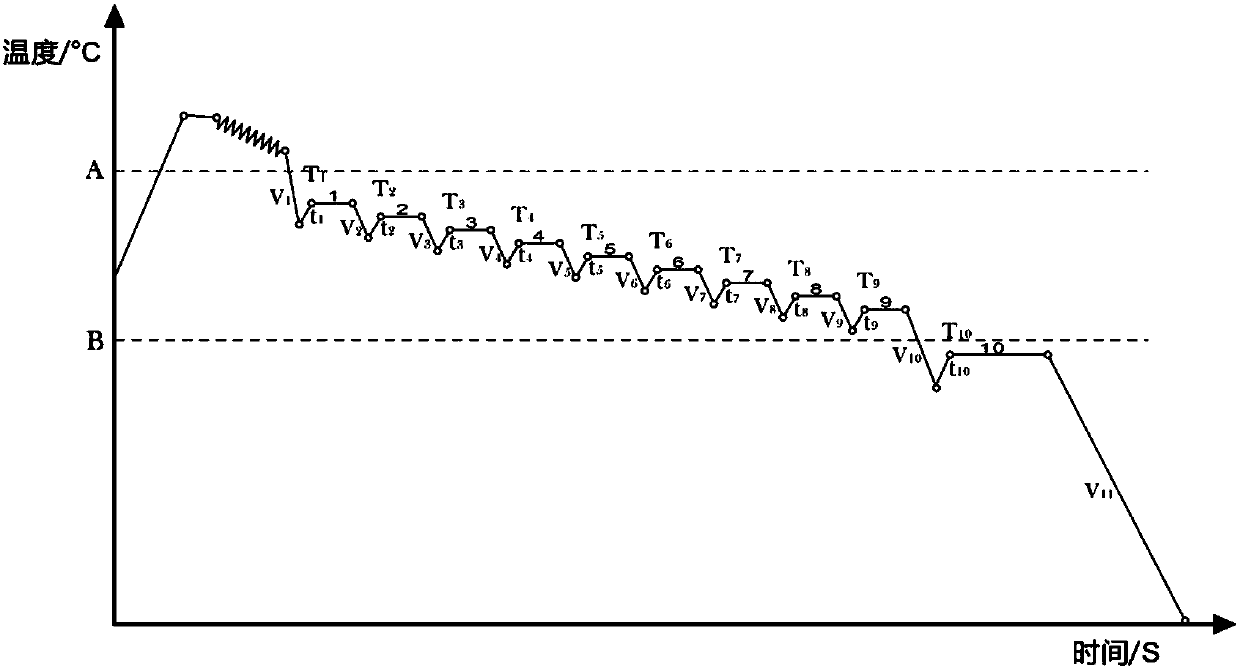

Gas chromatography programmed heating injection system and method using vortex effect

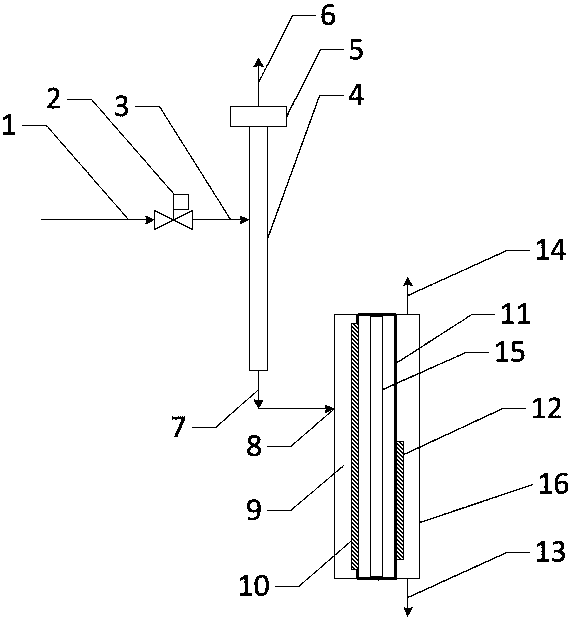

A gas chromatographic temperature-programmed sampling system utilizing the vortex refrigeration effect, comprising a compressed gas regulating valve, a vortex tube, and a temperature-programmed sampling port, characterized in that a heating device and The temperature sensor is equipped with a cold trap outside, and the cold trap wraps the vaporization chamber, the heating device and the temperature sensor, and has a space and a channel for accommodating cooling gas. The cold trap is set There is a cooling gas inlet and an outlet; the compressed gas is connected to the inlet of the vortex tube through the compressed gas regulating valve through a pipeline, and the outlet of the cold end of the vortex tube is connected to the cold trap inlet of the temperature-programmed sampling port through a pipeline. A gas chromatographic temperature programming sampling method utilizing the vortex refrigeration effect, comprising the following steps: S1 high temperature stage of the sample inlet, S2 low temperature stage of the sample inlet, S3 temperature balance stage of the sample inlet, and S4 temperature rise stage of the sample inlet.

Owner:蒋万枫

Heat treatment method for improving comprehensive performance of alloy plate

The invention provides a heat treatment method for improving the comprehensive performance of alloy. The alloy contains the following components of, by weight, 3.5%-4.5% of Cu, 1.4%-1.80% of Li, 0.2%-0.8% of Mg, 0.2%-0.8% of Zn, 0.04%-0.20% of Zr, 0.20%-0.80% of Mn, any one to three kinds of 0.05%-0.35% of Sc, 0.2%-0.8% of Ag and 0.10%-0.25% of Er, less than or equal to 0.08% of Si, less than or equal to 0.10% of Fe, less than or equal to 0.10% of Ti, less than or equal to 0.05% of other impurities individually, less than or equal to 0.15% of the other impurities in total, and the balance Al.The method comprises the following steps that after the alloy is subjected to solid solution and quenching, "spheroidizing aging" treatment is performed for 10 hours to 20 hours at 220 DEG C to 280 DEG C, the micron-scale granular precipitated phase is formed in the crystal, meanwhile, the large-size flake-and-needle-like "Widmanstatten structure" remained at the crystal boundary is converted intothe intermittent granular equilibrium phase, then repeated solid solution treatment, cold deformation treatment and aging treatment are performed, so that re-dissolution of the micron-scale granularprecipitated phase is achieved, moreover, precipitation of the nano-scale precipitated phase is promoted, the characteristic tissue with the uniform and tiny in-crystal precipitated phase and the intermittently-distributed crystal boundary precipitated phase is obtained, then the comprehensive performance of the alloy is improved, and the method is suitable for alloy thick plates, forge pieces andlarge-section extrusion materials used in the fields of aviation and weapons.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

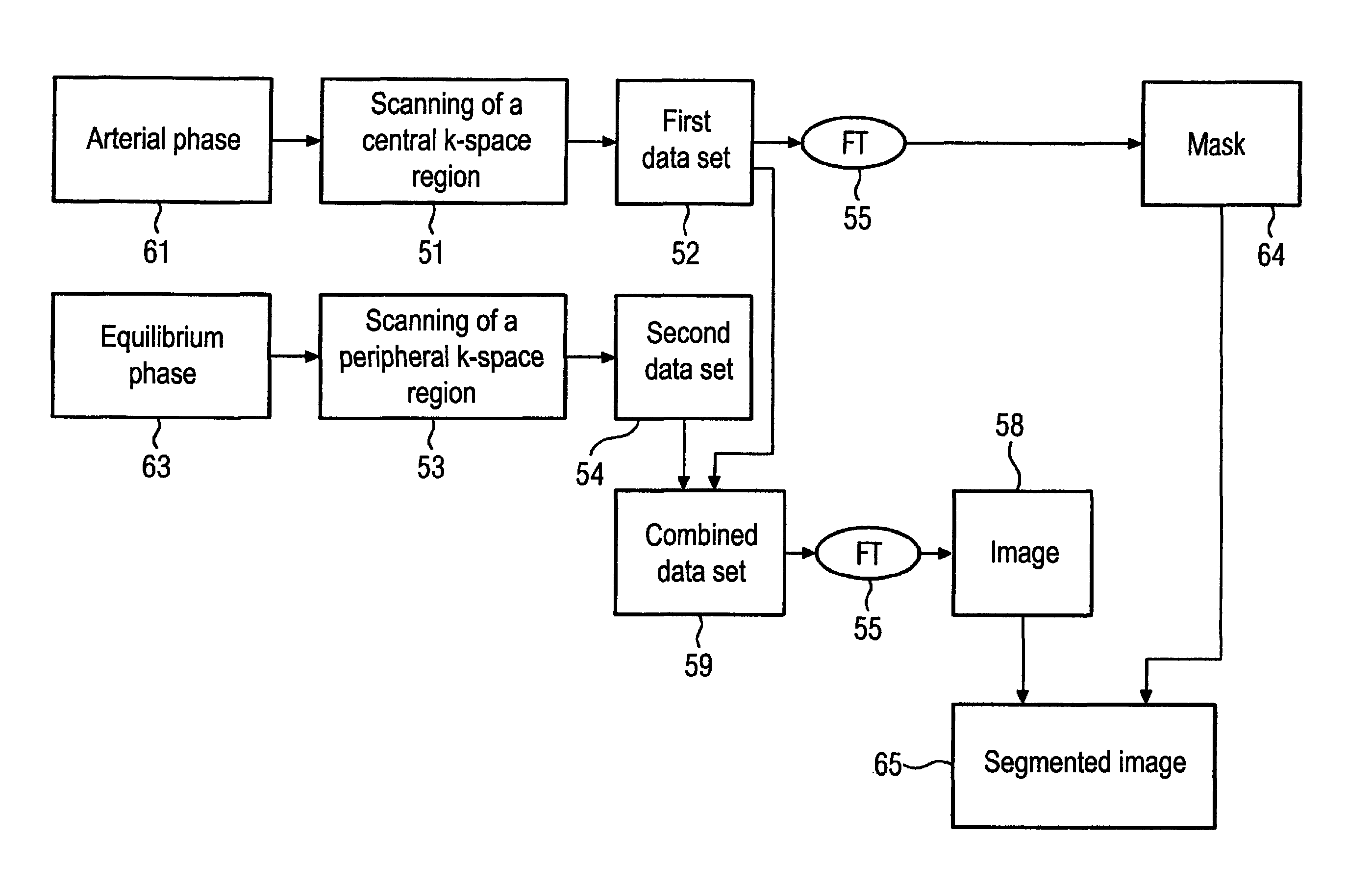

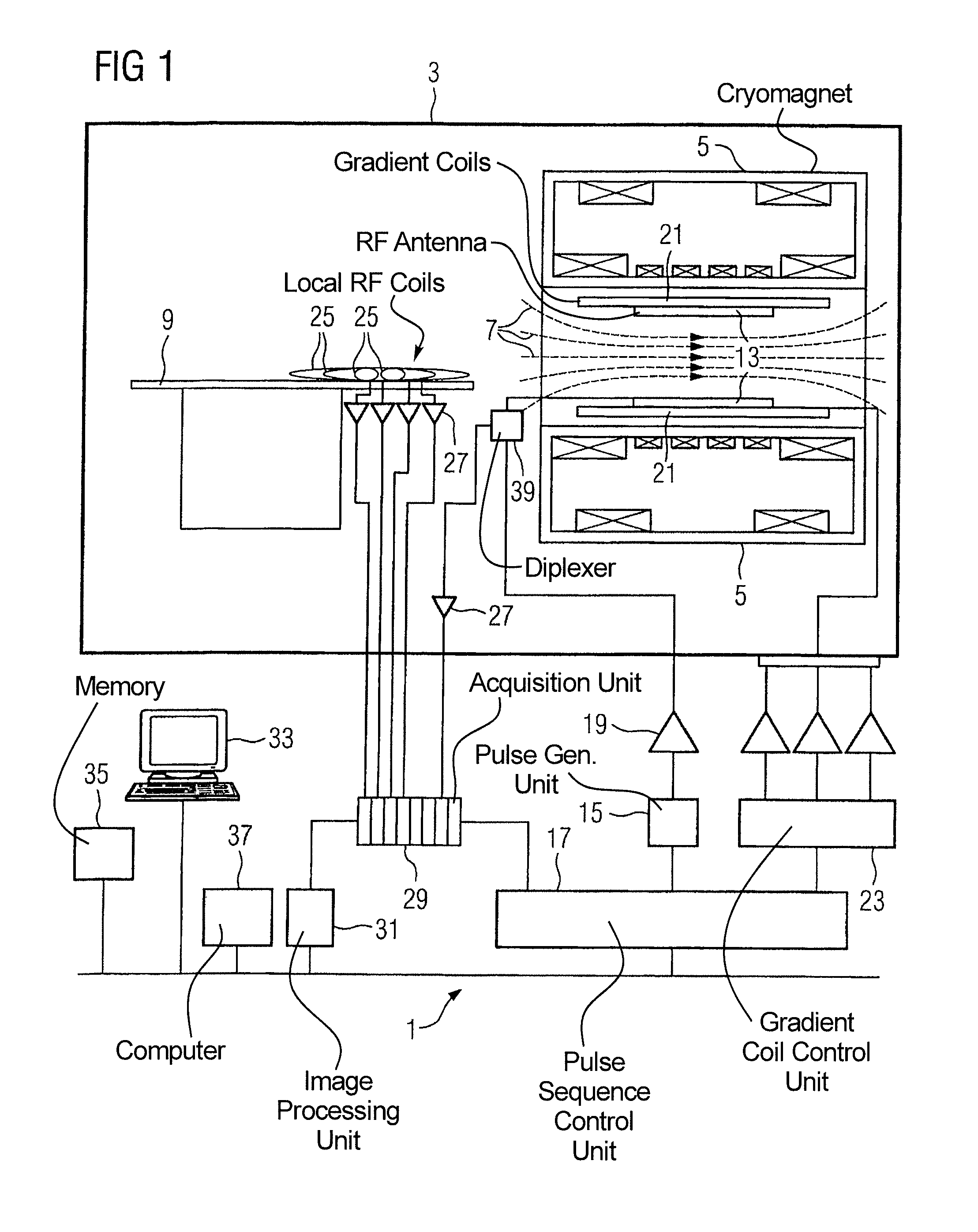

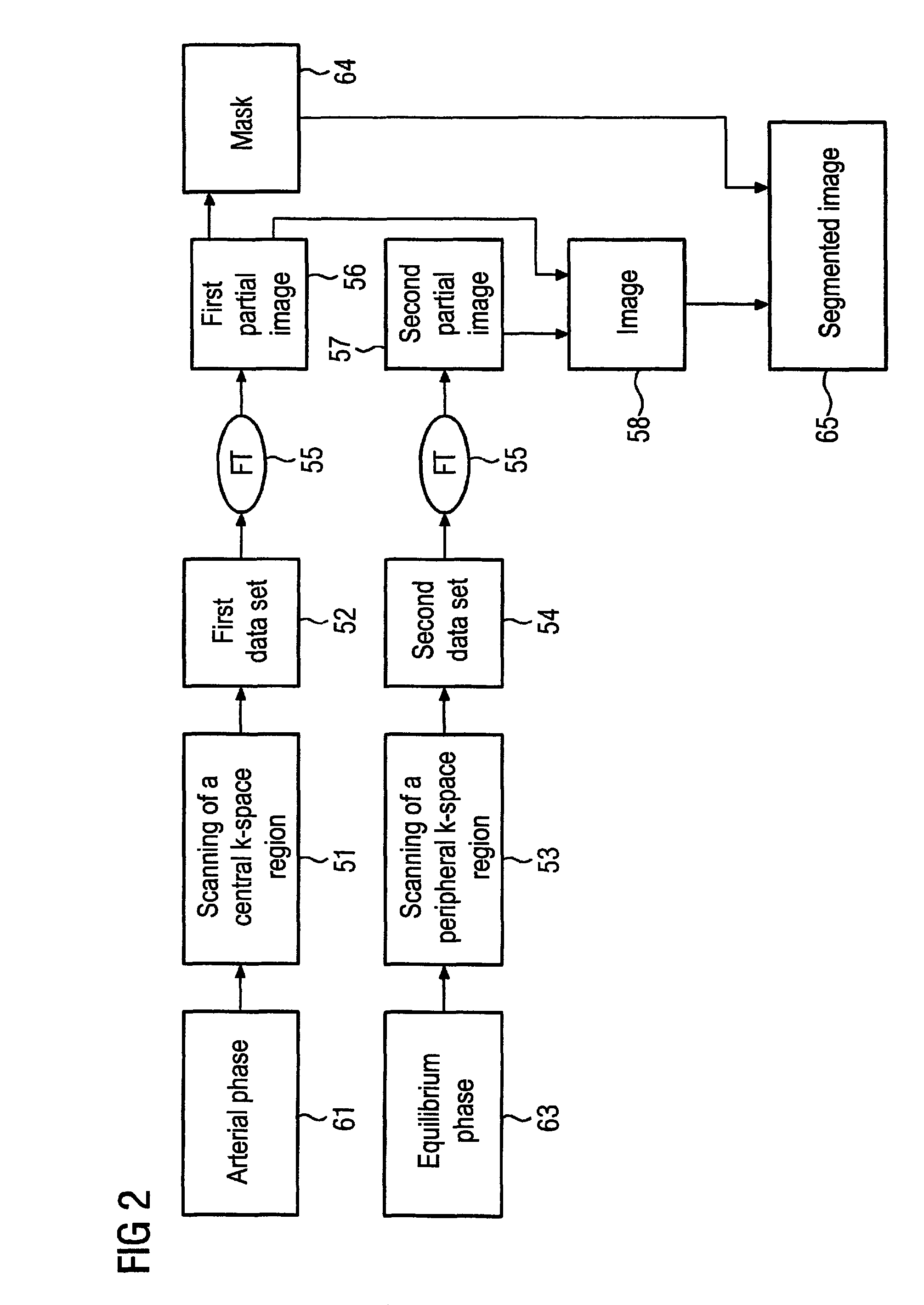

Method for generation of an image in contrast agent-supported MR angiography and magnetic resonance apparatus

InactiveUS7917191B2Fast and simple and automatic implementationThe method is simple and fastMagnetic measurementsCharacter and pattern recognitionResonanceMr angiography

In a method and apparatus for generation of an image in contrast agent-supported magnetic resonance angiography, a first data set is generated during an arterial phase of a distribution of a contrast agent in a vessel system by scanning of a first central k-space region, a second data set is generated during an equilibrium phase of the distribution of the contrast agent in the vessel system by scanning a peripheral k-space region while omitting scanning of a second central region, and the image is generated by merging the first data set and the second data set.

Owner:SIEMENS HEALTHCARE GMBH

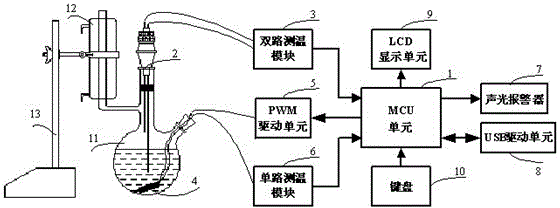

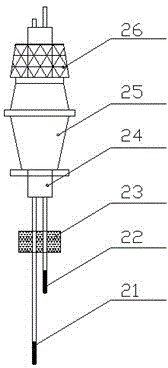

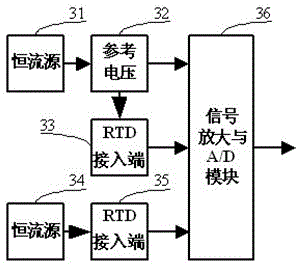

Automatic experiment and analysis device for gas-liquid equilibrium phase diagram of binary liquid solution

ActiveCN103604826APrecise temperature controlRealize synchronized measurementsInvestigating phase/state changeTemperature controlData acquisition

The invention discloses an automatic experiment and analysis device for a gas-liquid equilibrium phase diagram of a binary liquid solution. The automatic experiment and analysis device comprises a fixed bracket, a flask, a heating device, a fractionating device, a temperature measurement device, a micro control unit and a PWM (pulse width modulation) driving unit, wherein a heating stick assembly is adopted as the heating device; one end of the heating stick assembly extends into the flask, and the other end of the heating stick assembly is connected with the micro control unit through the PWM driving unit; the temperature measurement device comprises a double-path RTD (resistance temperature detector) assembly and a double-path temperature measurement module; one end of the double-path RTD assembly extends into the flask, and the other end of the double-path RTD assembly is connected with the micro control unit through the double-path temperature measurement module; an RTD sensor in the double-path RTD assembly extends into the binary liquid solution, and another RTD sensor is positioned above the binary liquid solution. The automatic experiment and analysis device for the gas-liquid equilibrium phase diagram, which is disclosed by the invention, can automatically measure and control the temperature and judge a gas-liquid equilibrium state accurately and sequentially and also finish experiment operations such as data acquisition, data analysis and data displaying; therefore, the precision of temperature control is improved, and the operation is easy.

Owner:CHUZHOU SEEK ELECTRONICS

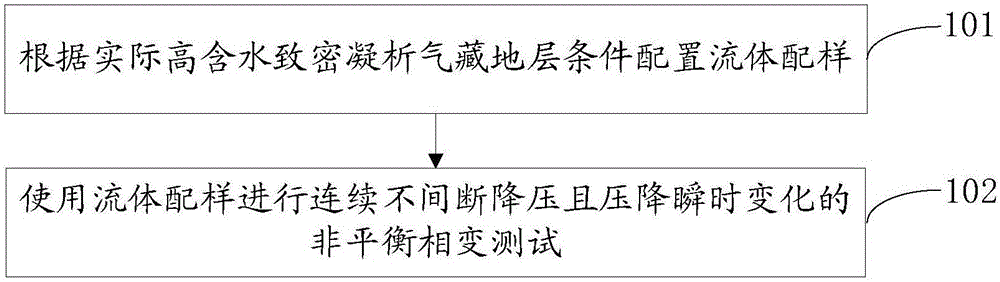

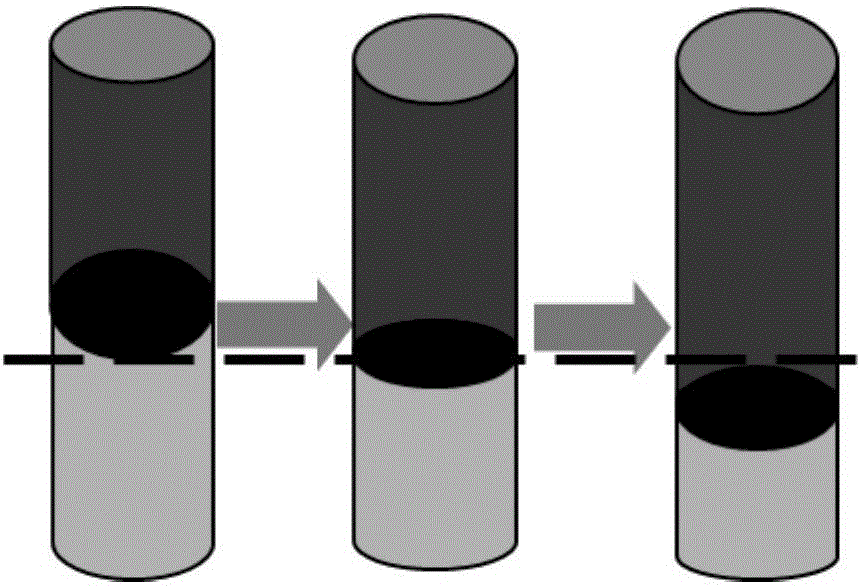

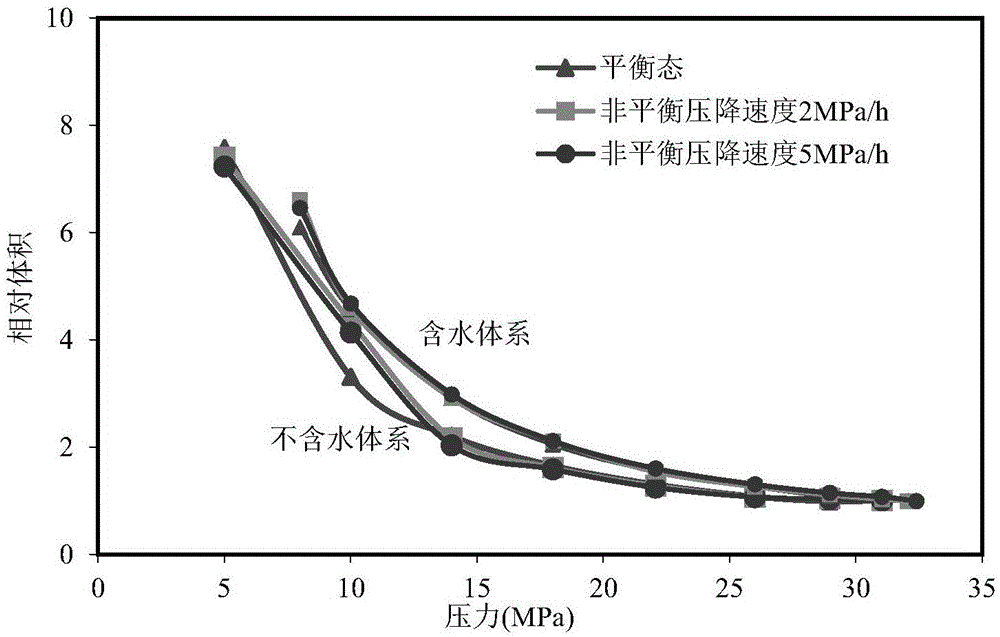

High-water-content compact condensate gas reservoir non-equilibrium phase transition testing method

InactiveCN106501300AGet saturationThe impact of obtaining recovery factorsInvestigating phase/state changeContinuous/uninterruptedPorous medium

The invention discloses a high-water-content compact condensate gas reservoir non-equilibrium phase transition testing method, belonging to the technical field of oil-gas field development. A fluid sample is prepared according to the actual high-water-content compact condensate gas reservoir geologic conditions, and continuous uninterrupted pressure drop non-equilibrium phase transition testing with pressure drop transient variation is carried out; the testing mode is based on the non-equilibrium phase transition theory; non-equilibrium phase transition testing in a PVT cylinder and non-equilibrium phase transition testing in porous media are established, so that the testing mode conforms to the actual exploitation; and thus, the influence of the non-equilibrium phase transition on the condensate oil saturation degree and natural gas / condensate oil recovery ratio can be better acquired, thereby instructing the actual production work.

Owner:PETROCHINA CO LTD

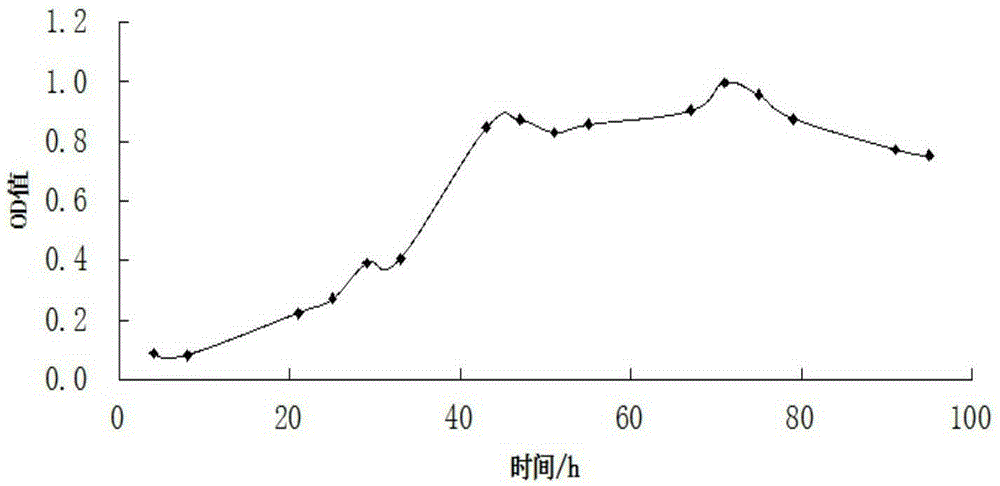

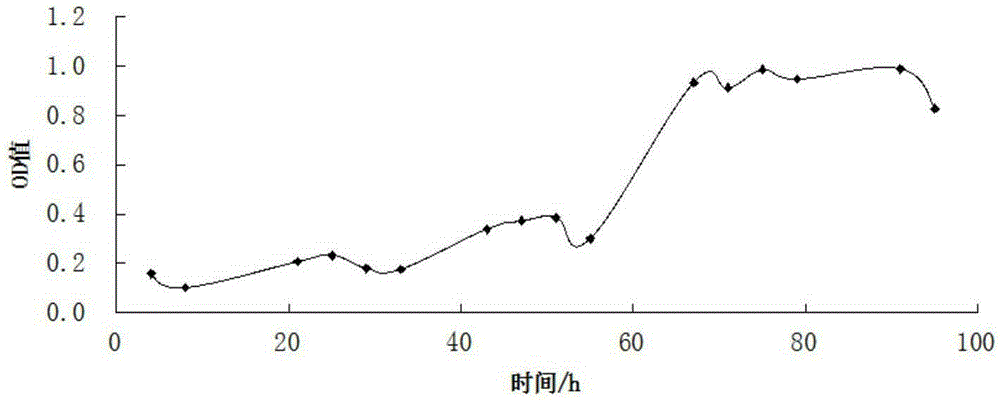

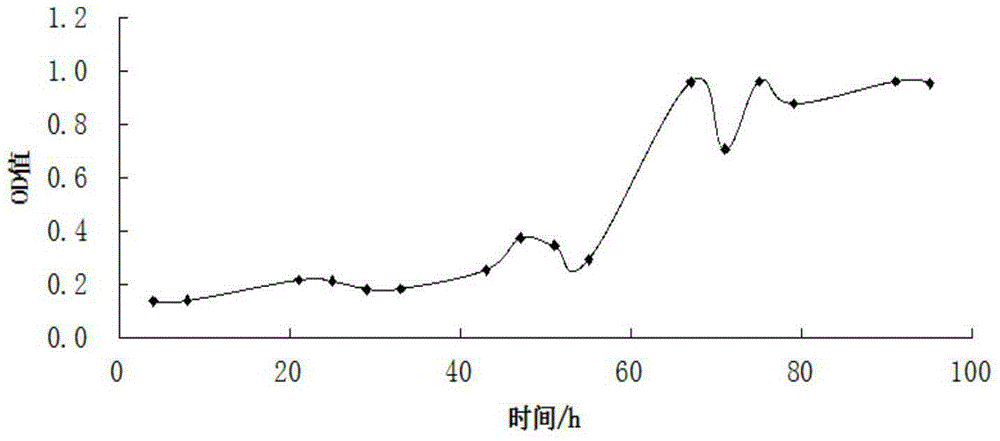

High-sugar-tolerant yeast and application thereof

ActiveCN105420131AShort lag periodImprove stress resistanceFungiMicroorganism based processesYeastAlcohol

The invention relates to the technical field of microbial fermentation, in particular to high-sugar-tolerant yeast and an application thereof. The high-sugar-tolerant yeast is Zygosaecharomyces mellis LGL-1, and the preservation number of the high-sugar-tolerant yeast is CCTCC No.M2015545. The high-sugar-tolerant yeast is relatively short in lag phase and long in logarithmic phase and equilibrium phase, and cost can be reduced when the high-sugar-tolerant yeast is applied to actual production. Especially, the high-sugar-tolerant yeast has good stress resistance, for example, the high-sugar-tolerant yeast can tolerate 70% (w / v) total sugar and 12% (v / v) ethyl alcohol, and when the pH is 2.5, the high-sugar-tolerant yeast can normally and rapidly grow, and is high in acid resistance.

Owner:ZHONGKAI UNIV OF AGRI & ENG

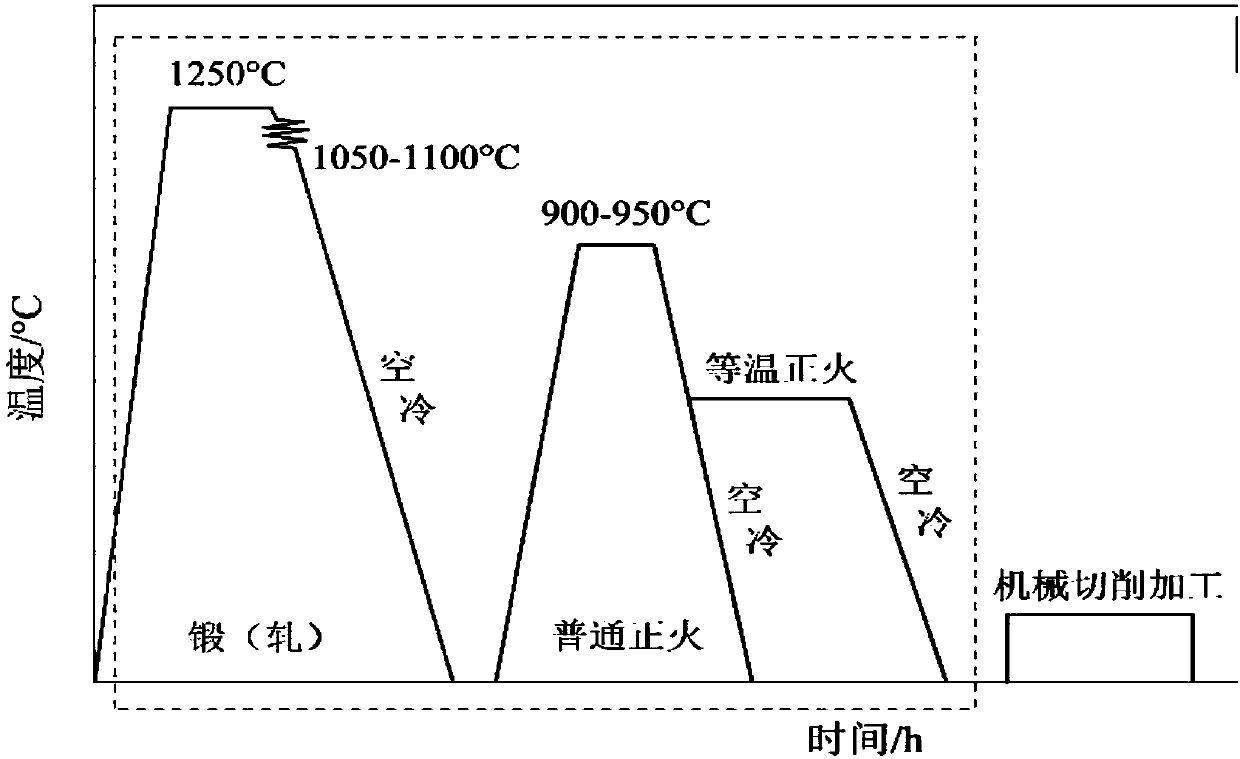

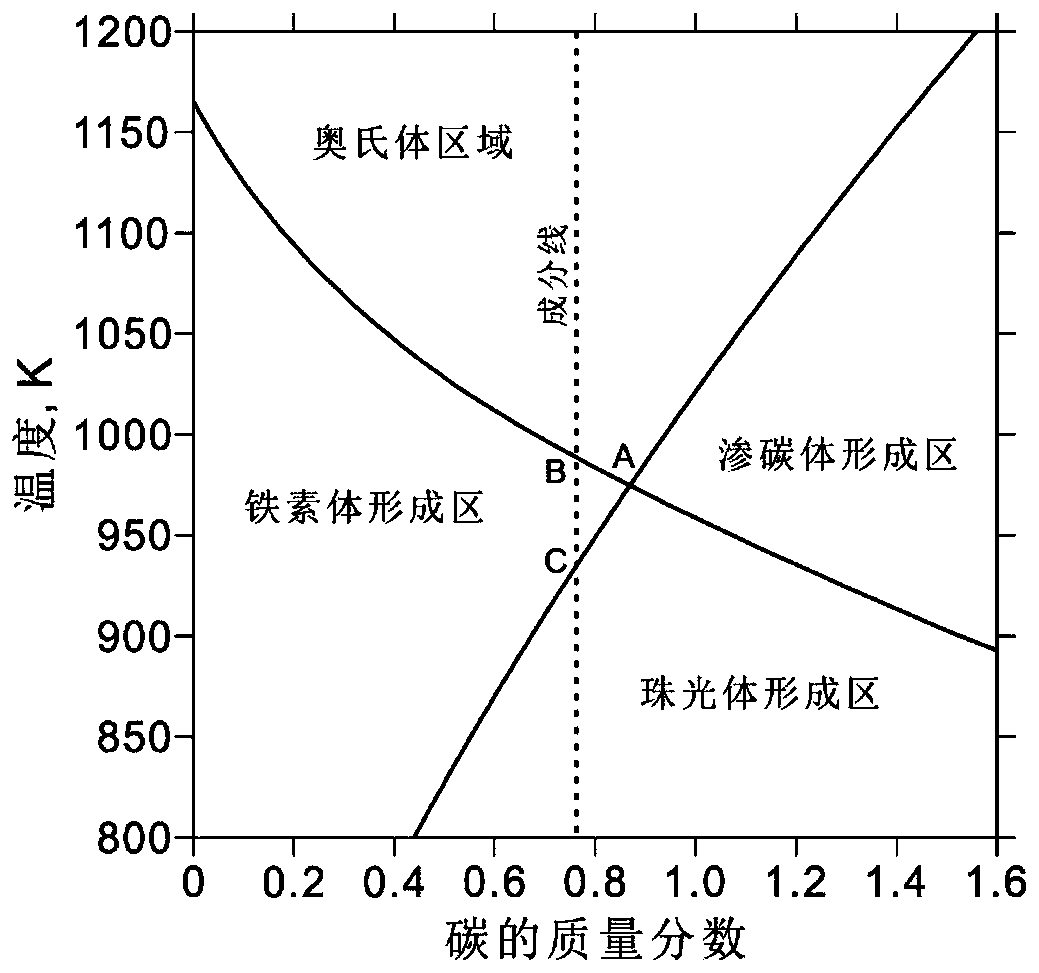

Alloy carburizing steel pretreatment method for changing network ferrites and acicular ferrites in microstructure

ActiveCN107858492ATo ensure the relative stability of carbon contentGuaranteed stabilityPretreatment methodAlloy

The invention discloses an efficient and energy-saving pretreatment method for changing network ferrites and acicular ferrites in an alloy carburizing steel pretreatment microstructure. A forged-rolled alloy carburizing steel part is continuously subjected to primary cooling and heat insulation, at least one one-time intermediate cooling and heat insulation, and last-time cooling and heat insulation, and finally cooled to achieve a pearlite transformation temperature zone of the equilibrium phase diagram of the alloy carburizing steel part. According to the alloy carburizing steel part preheating treatment method disclosed by the invention, network proeutectoid ferrites and proeutectoid ferrites with other non-block morphologies in the alloy carburizing steel pretreatment microstructure are changed into block ferrites, so that control for the subsequent cutting machining, and carburizing and quenching deformation for the part is facilitated; and the method is simple in procedures and capable of greatly saving energy.

Owner:刘澄 +1

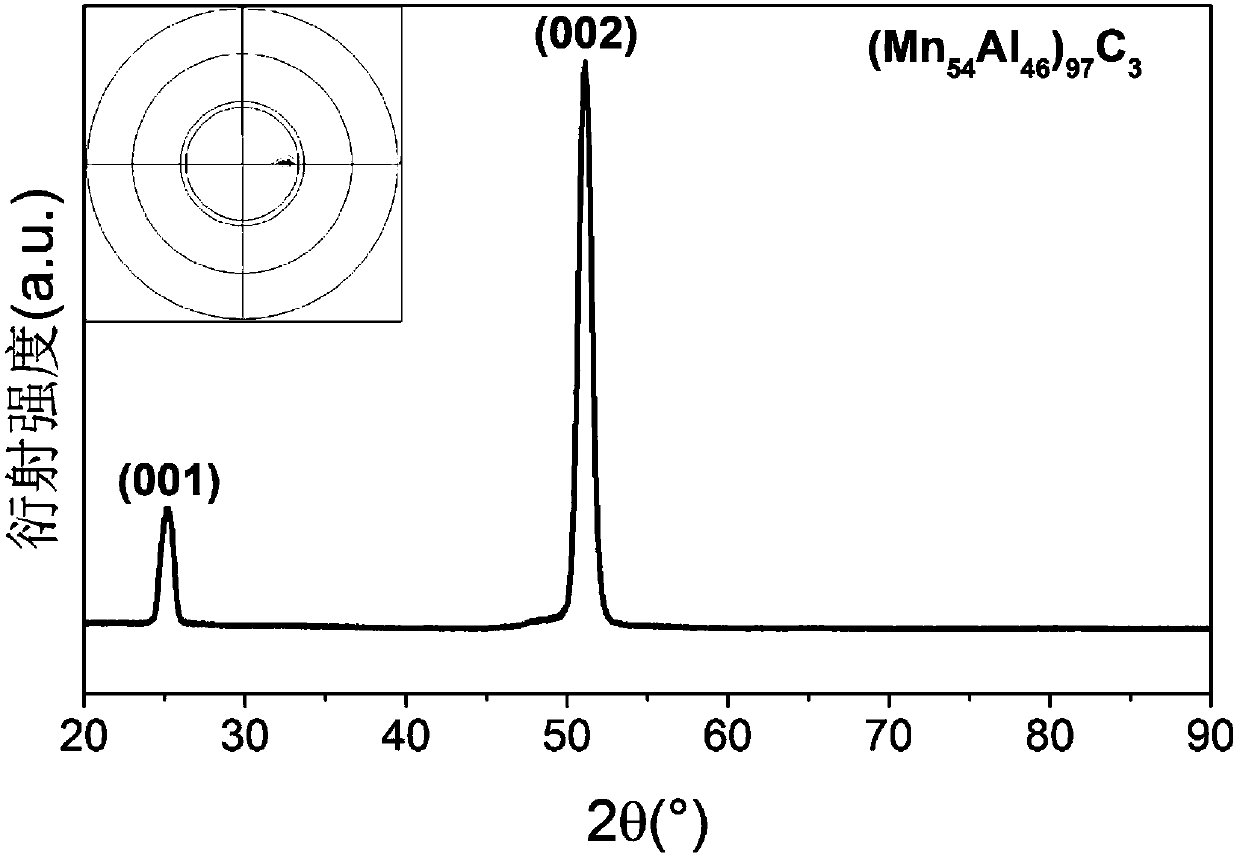

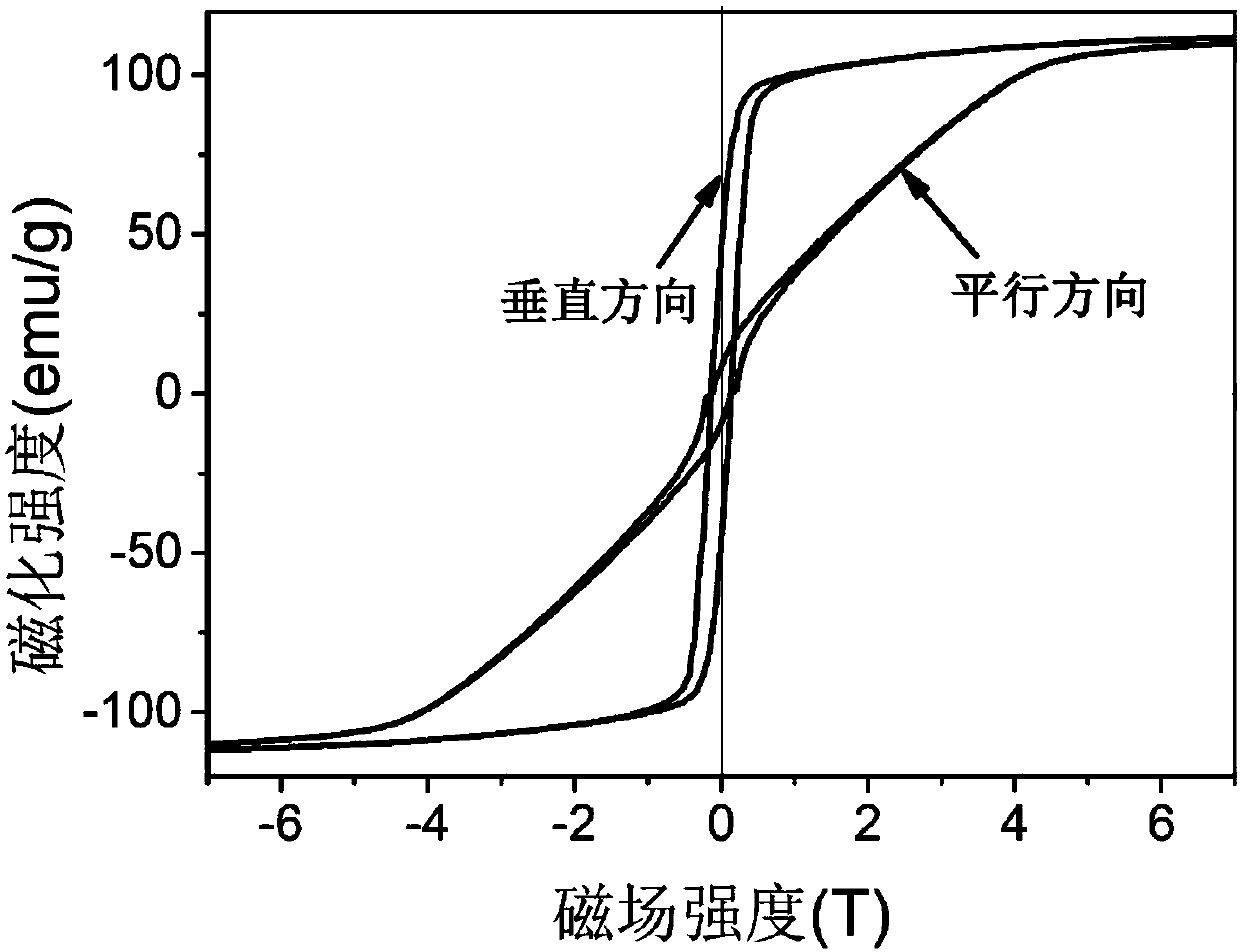

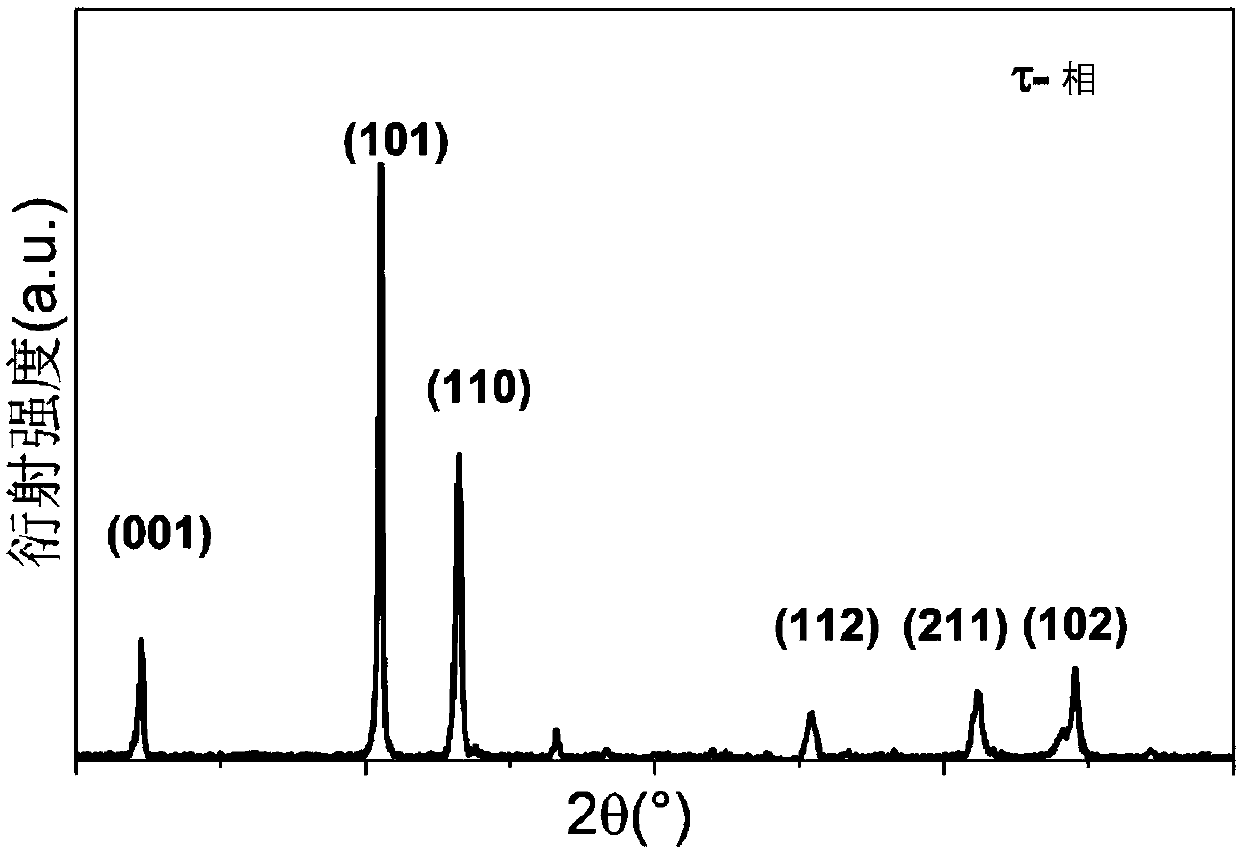

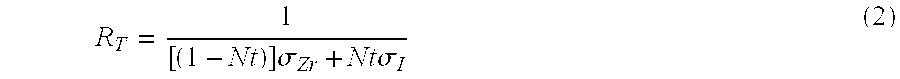

Method for preparing anisotropy MnAlC single variant through uniaxial pressure constraint transformation

InactiveCN108281247AElimination of twinningAnisotropy hasInductances/transformers/magnets manufactureMagnetic materialsConstraint transformationMagnetization

The invention provides a method for preparing an anisotropy MnAlC magnetic single variant through uniaxial pressure constraint transformation and the MnAlC single variant prepared by the method. The method comprises the steps of carrying out smelting, rod casting and single crystal growth on MnAlC raw materials to form a MnAlC-epsilon phase single crystal; and annealing the MnAlC-epsilon phase single crystal for 3-10 min under uniaxial pressure of 250-350MPa and temperature of 580-680 degrees centigrade, thereby preparing a MnAlC-tau phase single variant. The MnAlC-tau phase single variant prepared by the method has saturation magnetization intensity exceeding 100emu / g and complete anisotropy, and an equivalent magnetocrystalline anisotropy field is greater than 4T. The method and the MnAlC single variant have the advantages that (1), bicrystals in alloy can be effectively eliminated, the single variant organization is realized, the material has anisotropy, and the relatively good permanent magnet performance is obtained; (2), the technology is simple, and bad influences of produced microdefects and precipitated equilibrium phases on the magnetic performance can be completely avoided.

Owner:BEIHANG UNIV

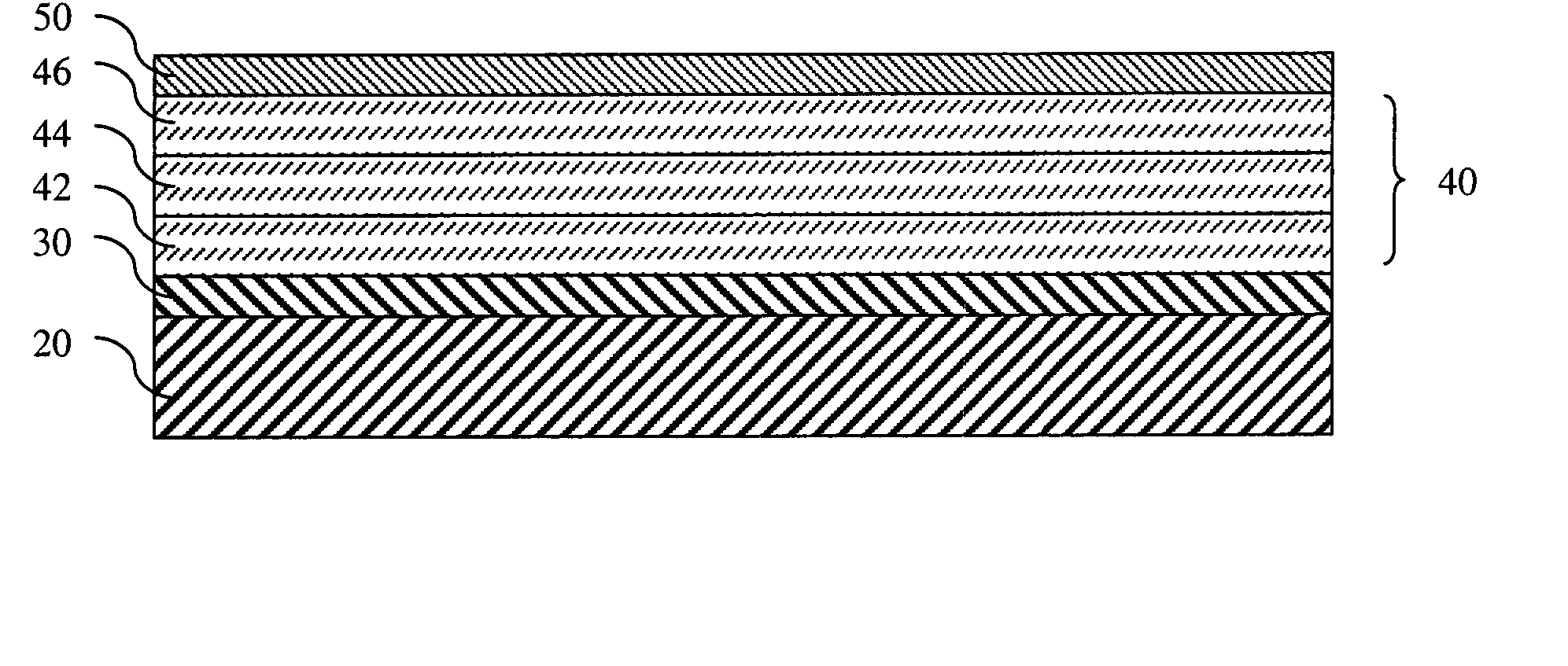

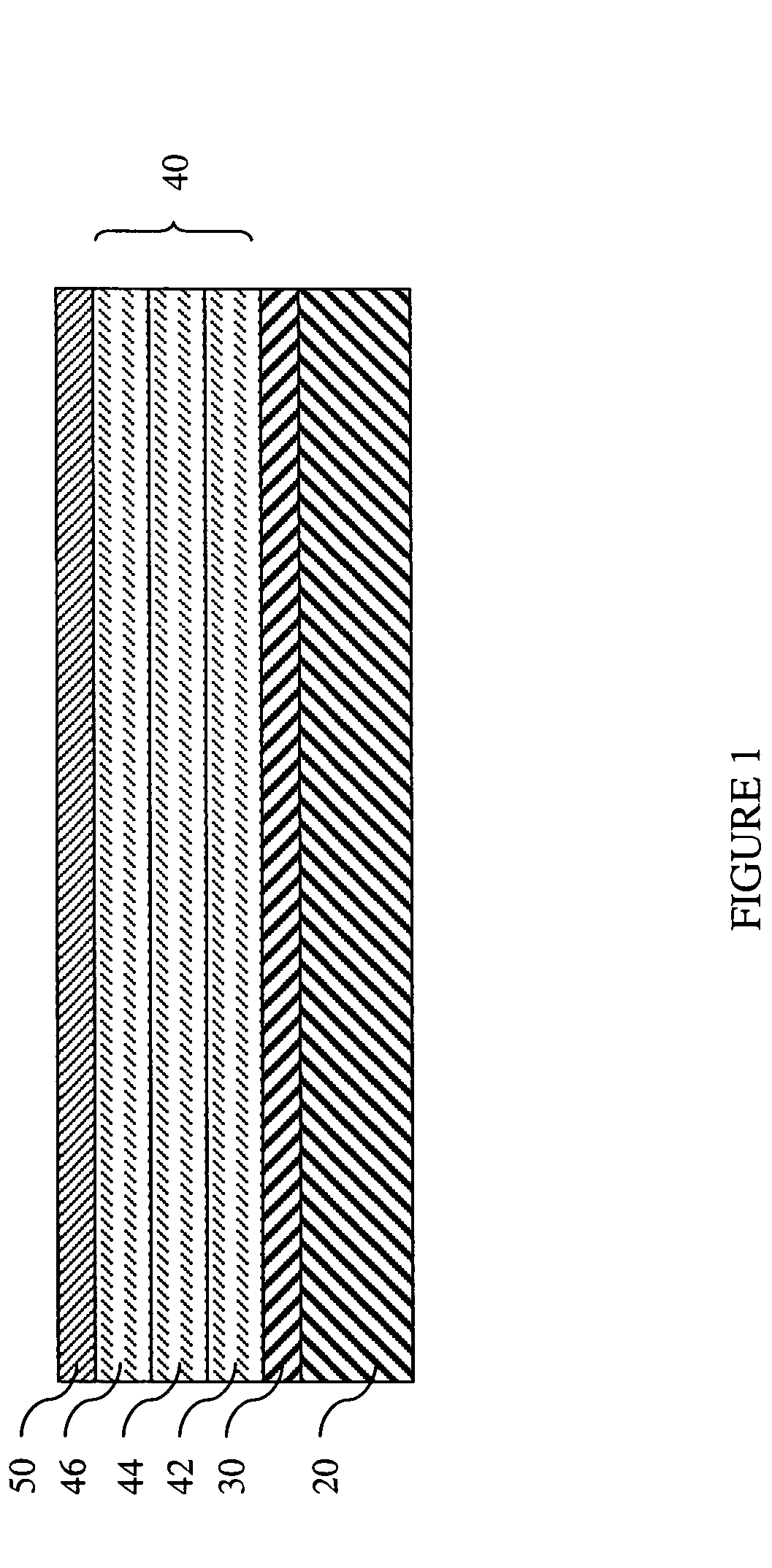

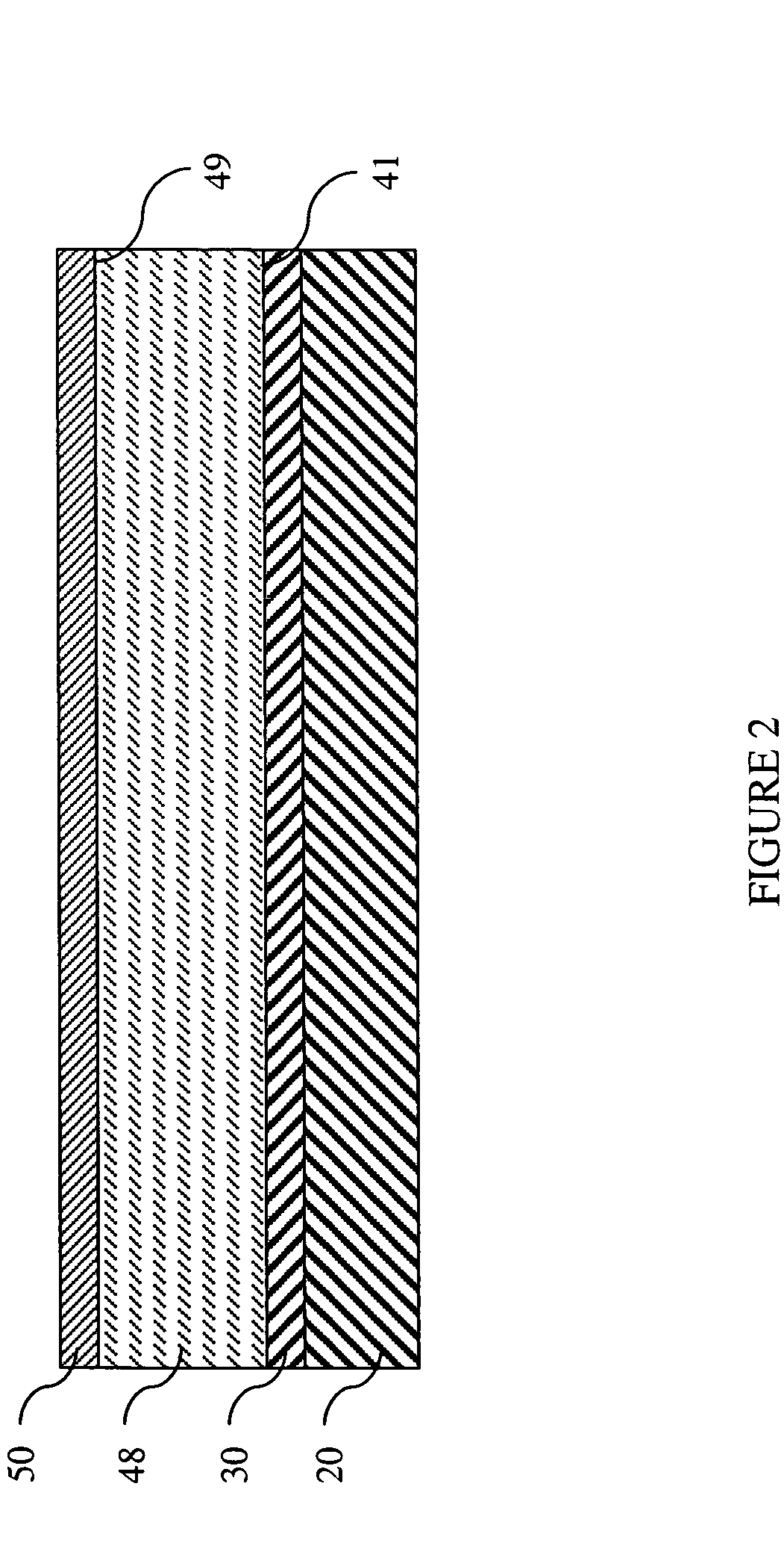

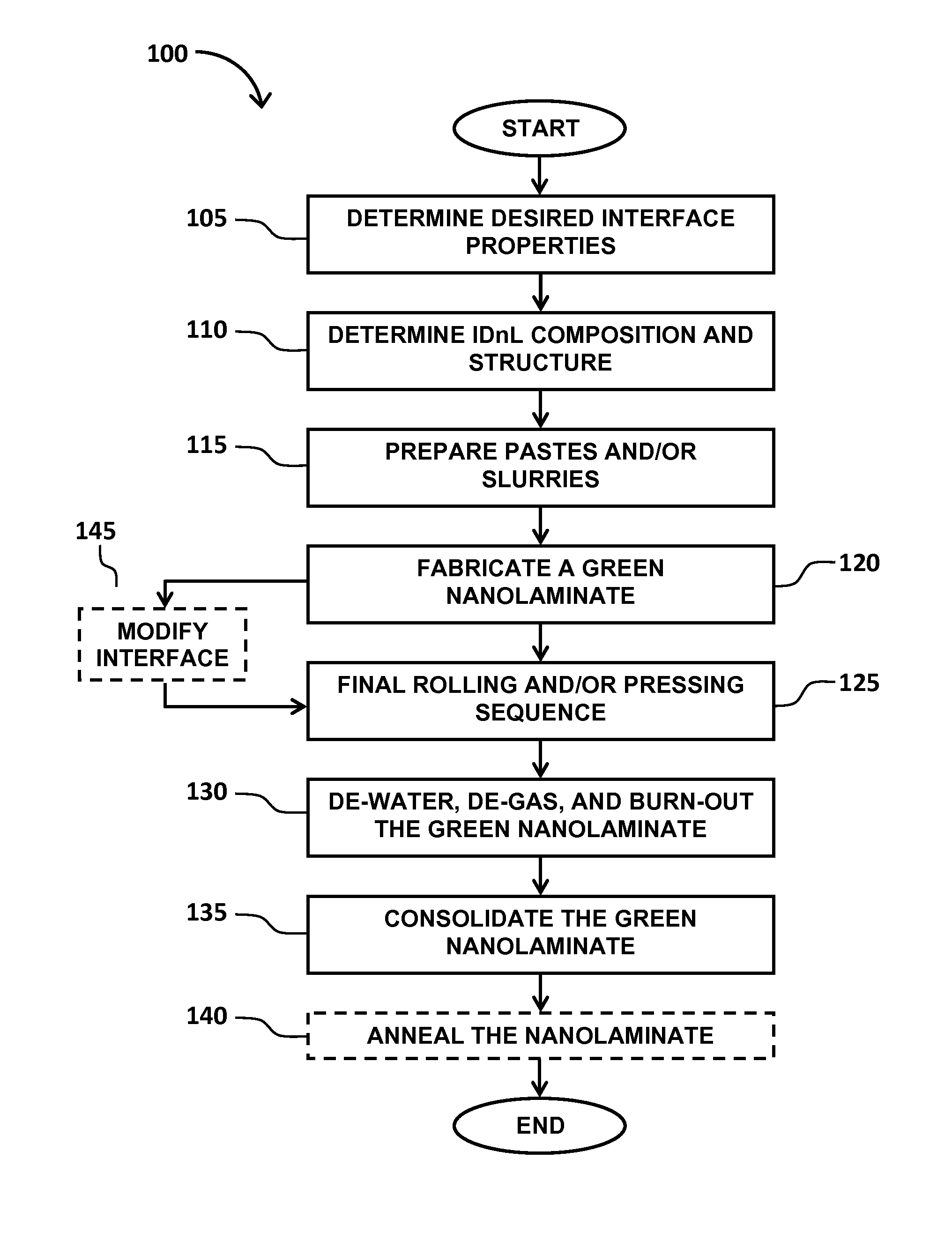

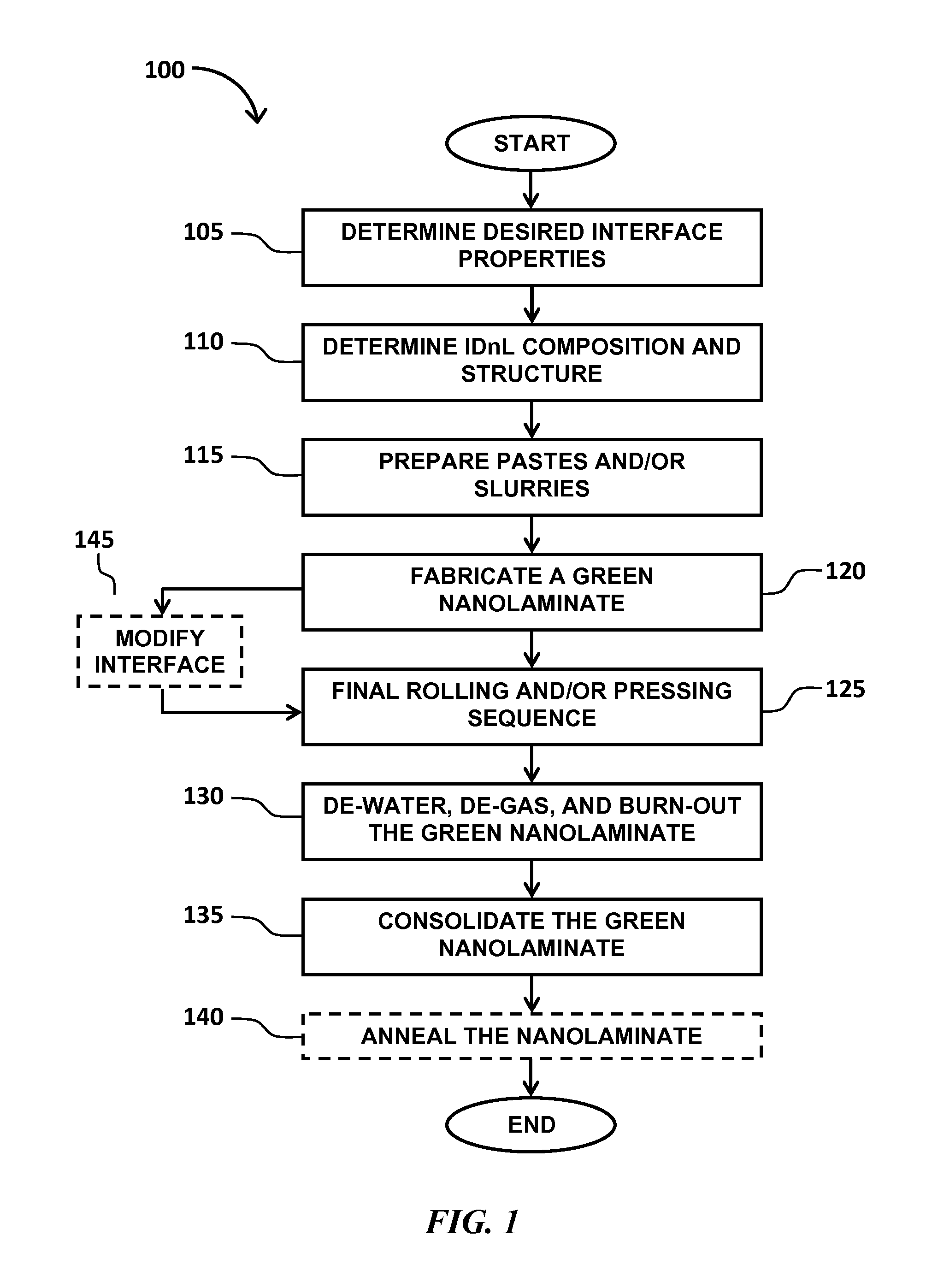

Bulk low-cost interface-defined laminated materials and their method of fabrication

InactiveUS8617456B1Improve fracture toughnessRemarkable phase stabilityCeramic shaping apparatusNanotechnologyLayer thicknessLarge size

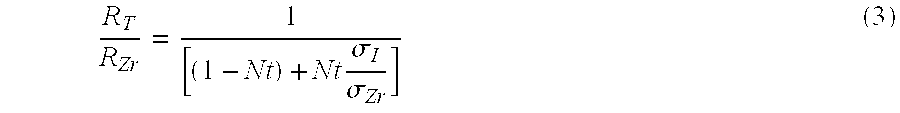

This invention describes a novel type of materials named by the inventors as Interface-Defined nano-Laminates (IDnL), and a new method for fabricating these materials from ceramic, metallic, and other powders. The laminate layer thickness in IDnL is smaller than that of ordinary laminates, but greater than that of superlattices. IDnL are fundamentally different from ordinary laminates in that their properties are defined by interfaces, and not by the properties of the bulk materials comprising individual layers. In contrast to superlattice materials, IDnL can be made thermally stable, due to the wide selection of interface-defining materials, which allows judicial use of equilibrium phase diagrams, and the “entropic stabilization” approach discovered by the authors; and in addition IDnL can be manufactured inexpensively in bulk, industrial quantities and large sizes by the techniques revealed in this invention. The degree of interface coherency in an IDnLs can be varied to optimize material properties.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

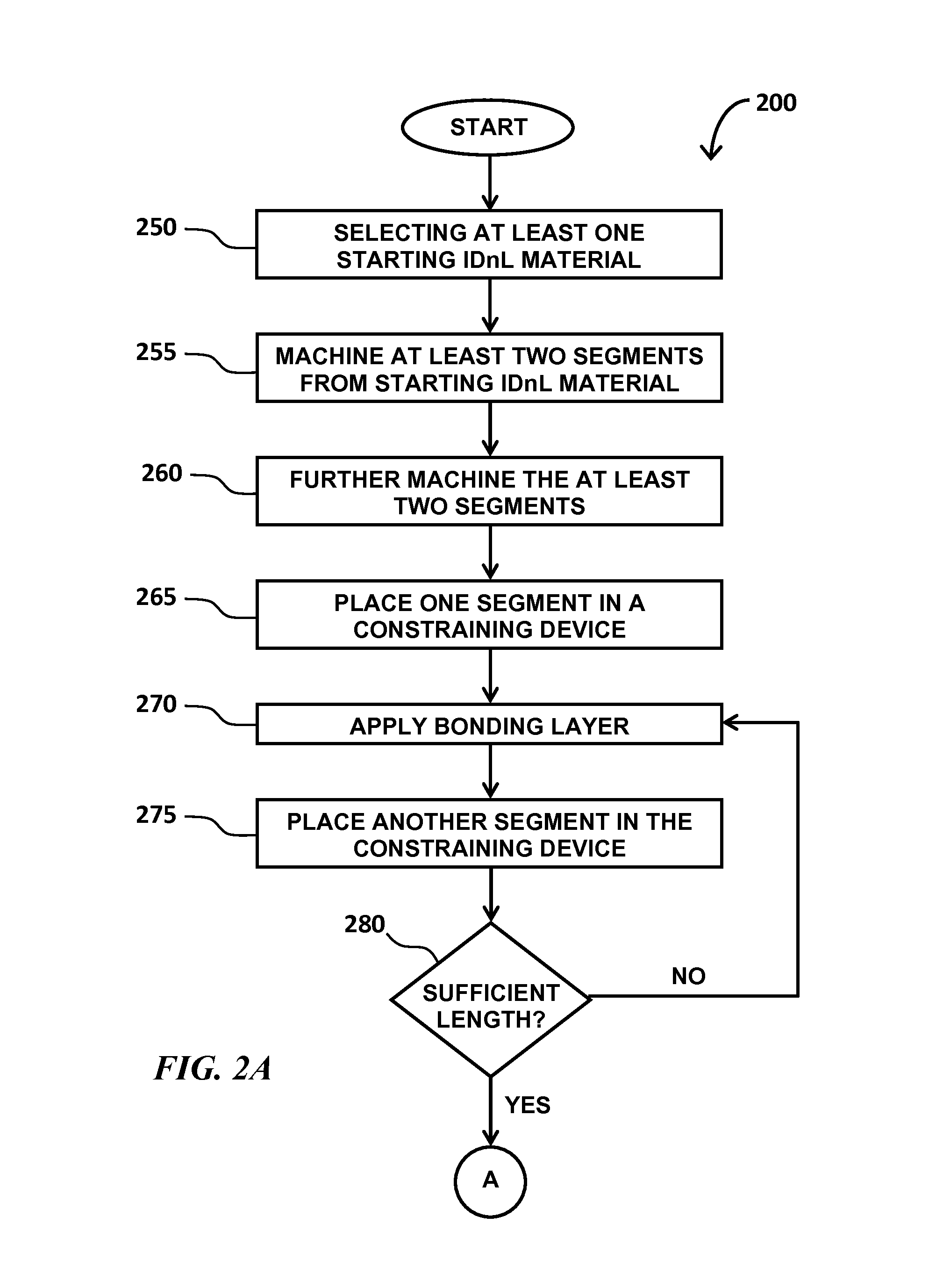

Methods for fabrication of parts from bulk low-cost interface-defined nanolaminated materials

InactiveUS9120245B1Novel and highly-desirable propertyMaximize another propertyNanotechnologyCeramic layered productsRational useLarge size

This present invention describes interface-defined nanolaminates (IDnLs), which are novel nanolaminate materials fabricated from metals and ceramics, and new methods for fabricating these IDnL materials, including new methods for manufacturing high aspect ratio parts comprising IDnL materials according to the present invention. IDnLs are fundamentally different from ordinary laminates in that their properties are defined by the interfaces between the layers rather by the properties of the bulk materials comprising the individual layers. In contrast to superlattice materials, IDnLs may be made thermally stable due to the wide selection of interface-defining materials, which allows judicial use of equilibrium phase diagrams. The degree of interface coherency in IDnLs may be varied to optimize material properties. In addition, IDnLs may be manufactured inexpensively in bulk, industrial quantities and large sizes by the techniques disclosed in this invention.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

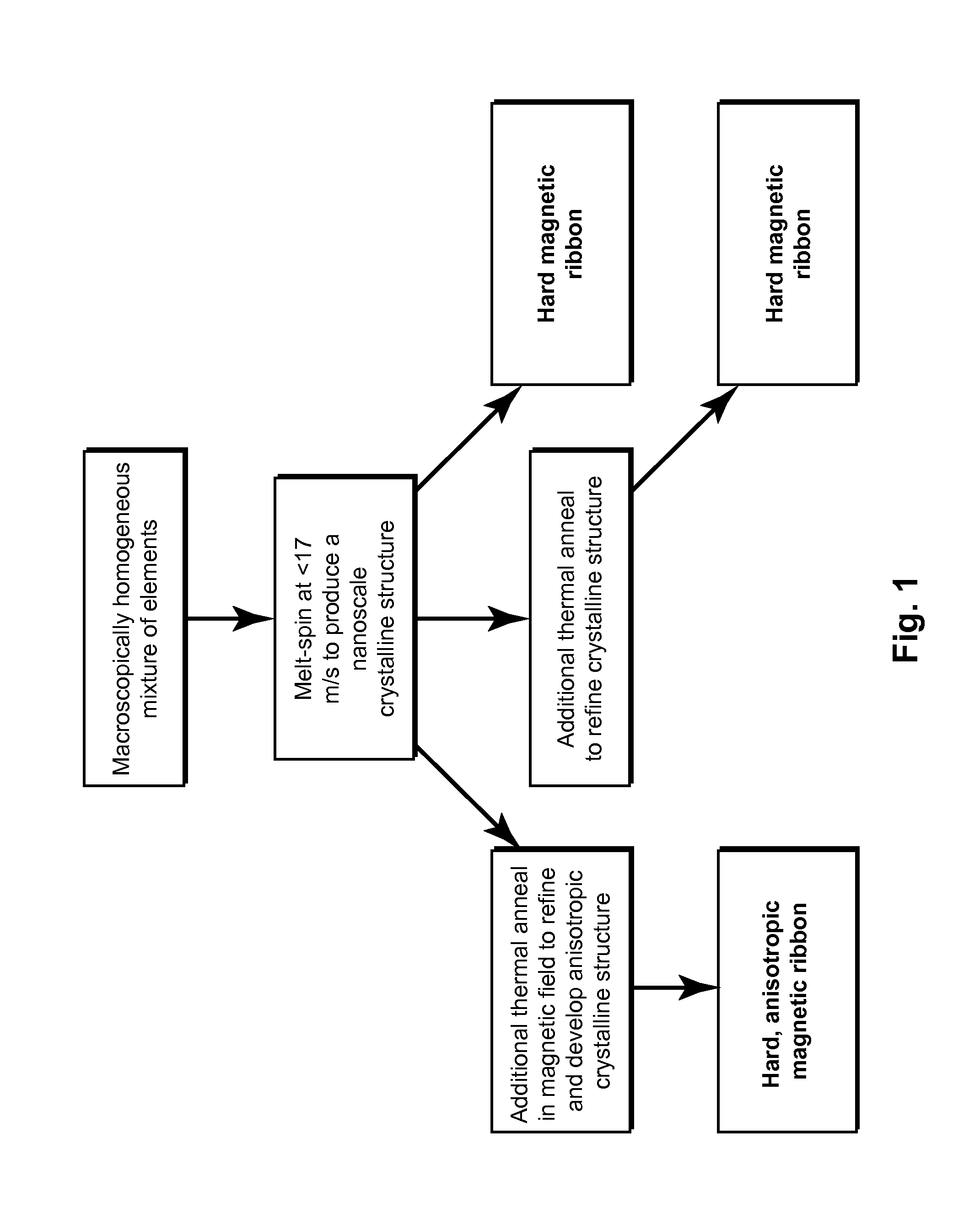

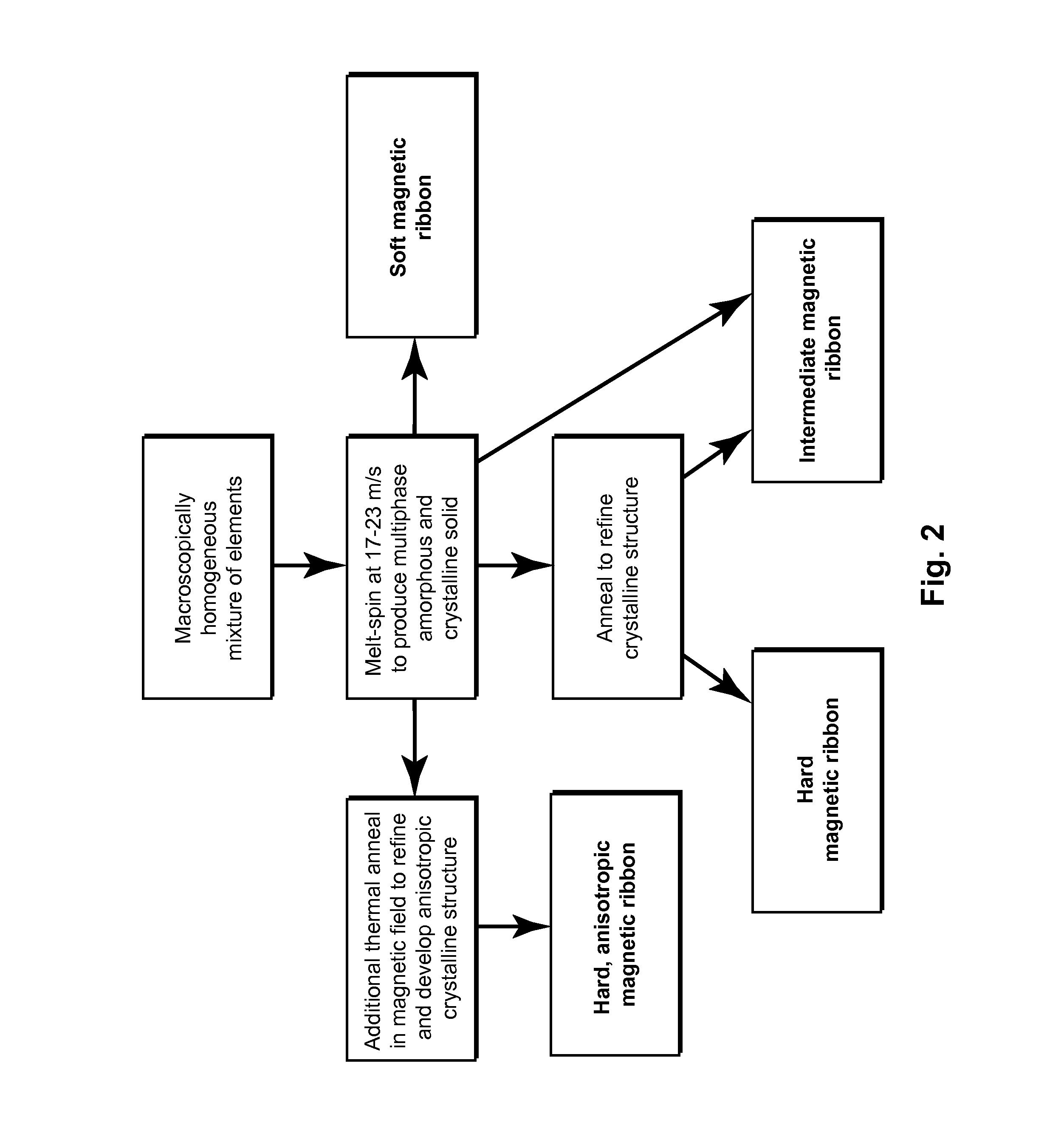

Hf-Co-B Alloys as Permanent Magnet Materials

An alloy composition is composed essentially of Hf2-XZrXCo11BY, wherein 0<X<2 and 0<Y≦1.5. Moreover, an alloy composition is composed essentially of ferromagnetic Hf2-XZrXCo11BY, wherein 0≦X<2 and 0<Y≦1.5, and has a nanoscale crystalline structure comprising at least one non-equilibrium phase. The alloys can be melt-spun with in-situ and / or ex-situ annealing to produce the nanoscale crystalline structure.

Owner:UNIV OF TENNESSEE RES FOUND +1

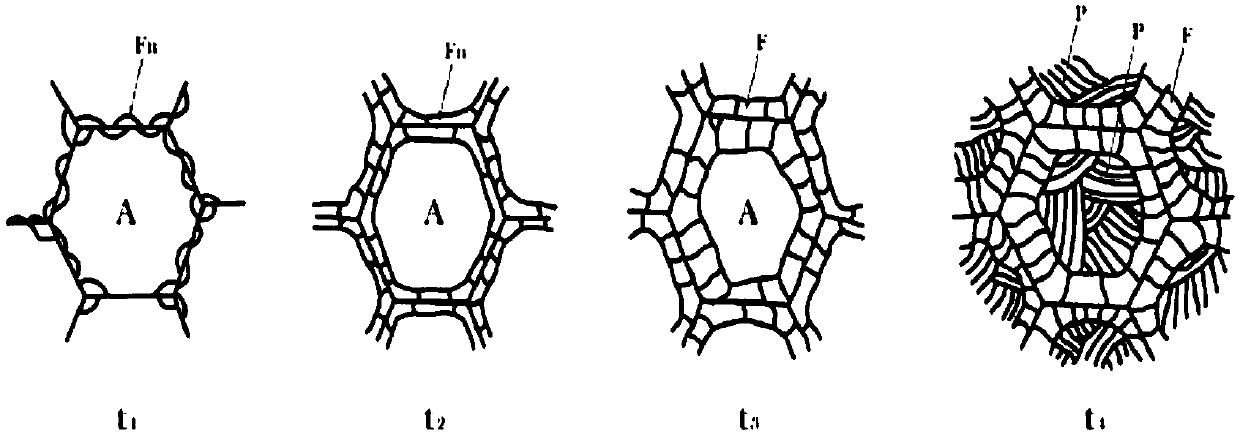

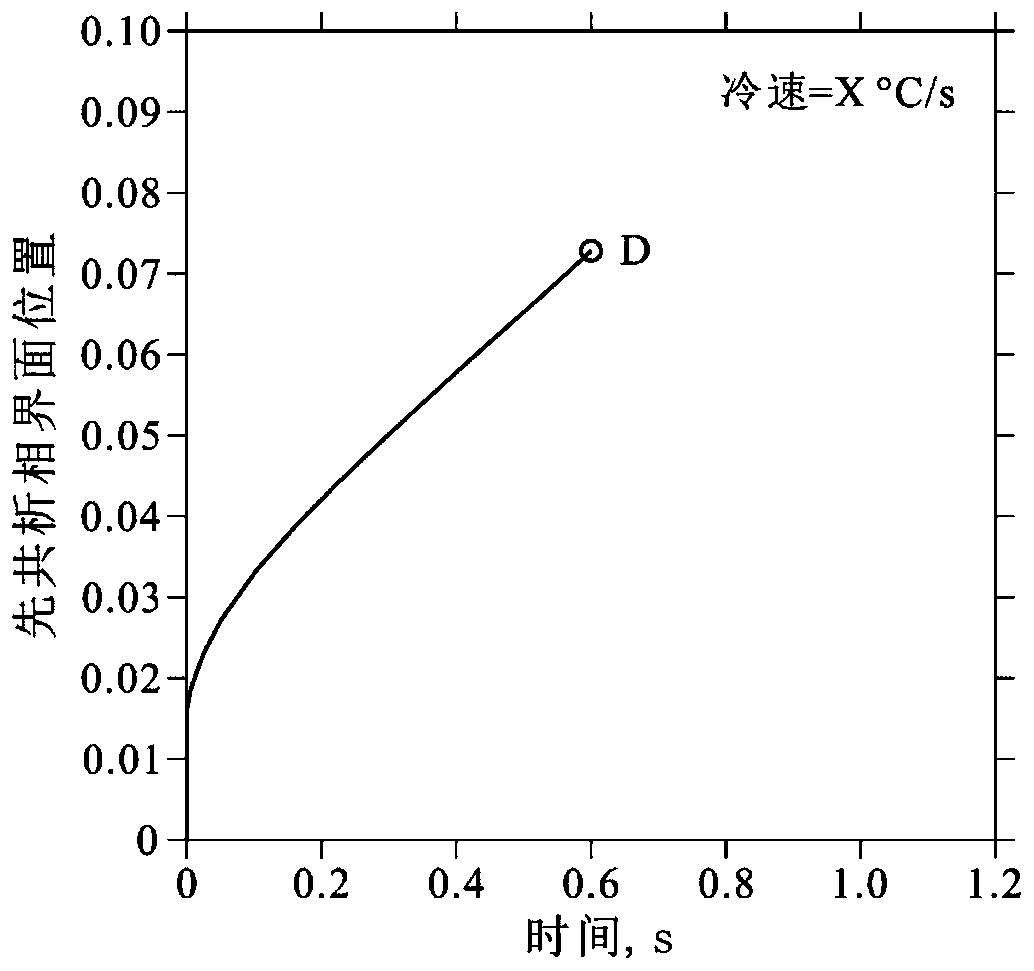

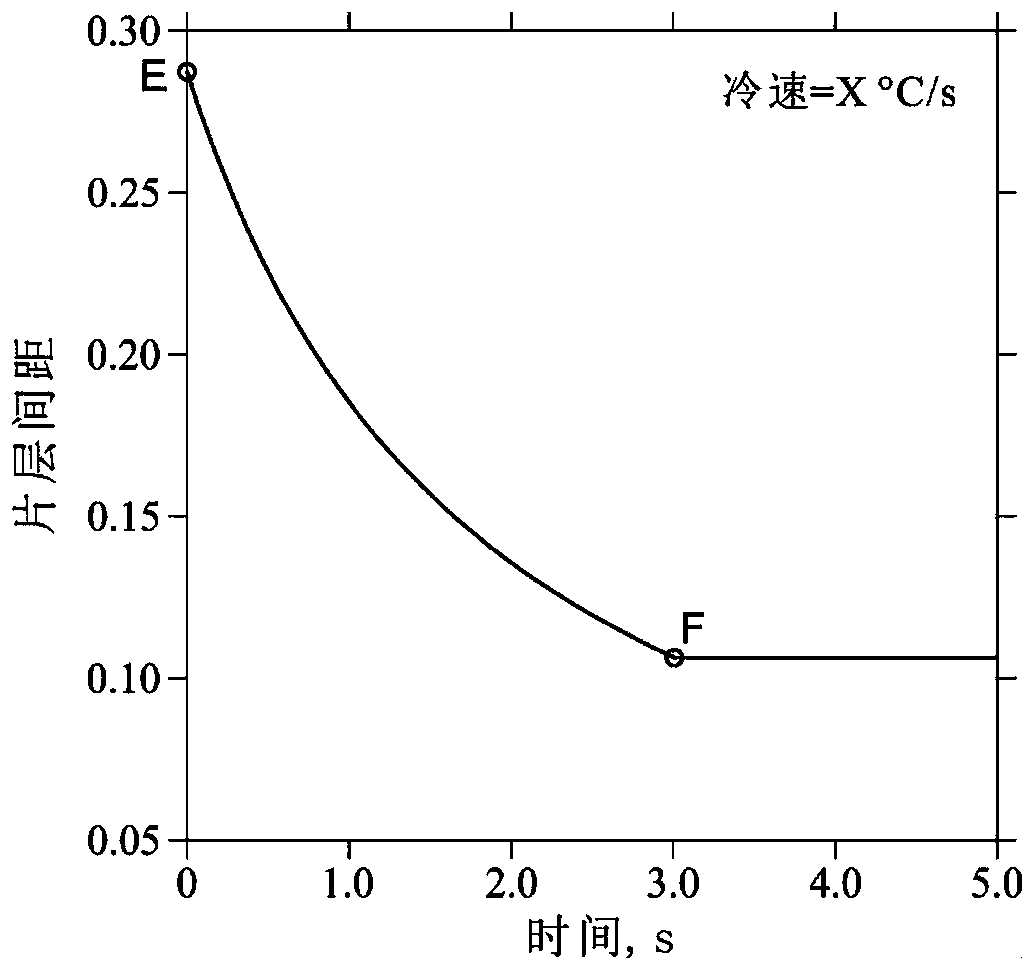

Method for predicting pearlitic steel microstructure based on thermodynamics and dynamics

ActiveCN110472322AAvoid or reduce experimental proceduresSpecial data processing applicationsTime-ConsumingMaterials science

The invention provides a method for predicting a pearlitic steel microstructure based on thermodynamics and dynamics, and belongs to the field of pearlitic steel microstructure calculation. Accordingto the method, a quasi-equilibrium phase diagram of pearlitic steel is calculated through thermodynamics, and eutectoid point components, eutectoid point temperature, proeutectoid phase types and forming temperature are extracted. Then, parameters such as pearlite steel components, cooling speed, proeutectoid phase forming temperature, eutectoid point temperature and model size are used as input for dynamic calculation, and a proeutectoid phase interface position and pearlite lamellar spacing curve is obtained and then converted into proeutectoid phase content and pearlite lamellar spacing. According to the thermodynamics, dynamics and data extraction method, microscopic structure characteristic parameters under the conditions of specified pearlitic steel components and cooling speed can be predicted, so that microscopic structure prediction of the pearlitic steel is realized, and complicated and time-consuming experimental processes are avoided or reduced.

Owner:UNIV OF SCI & TECH BEIJING +1

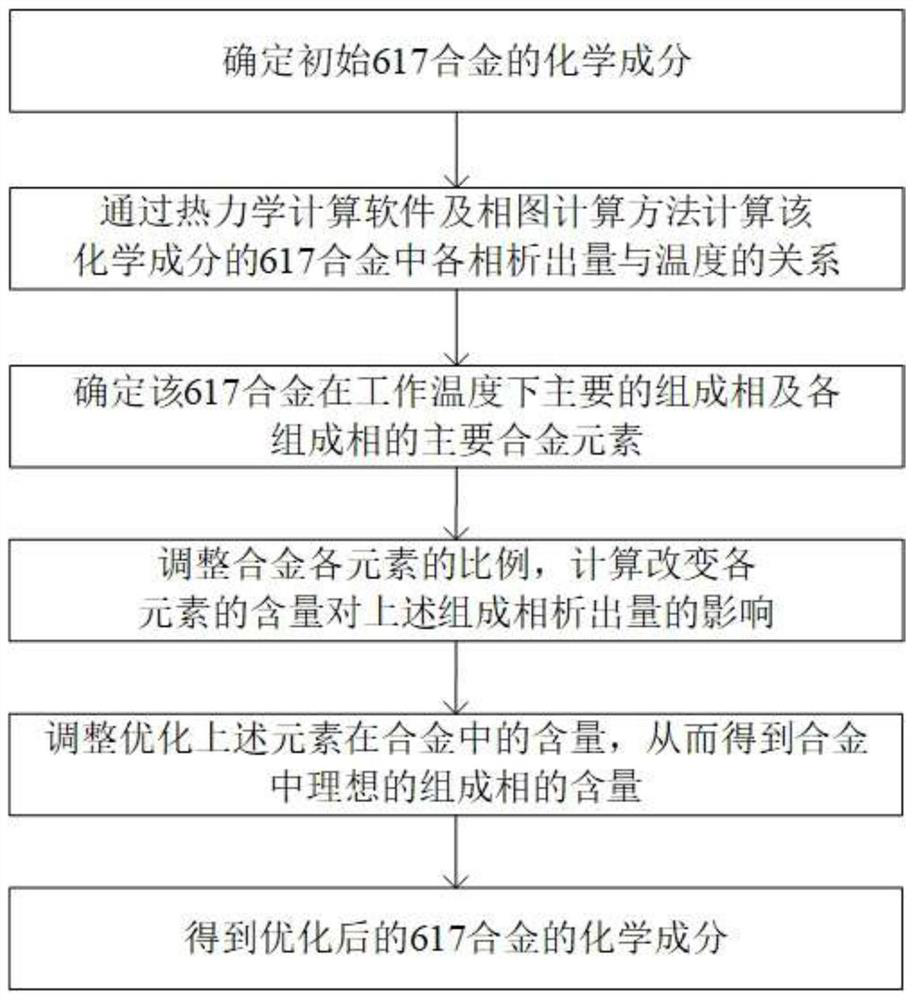

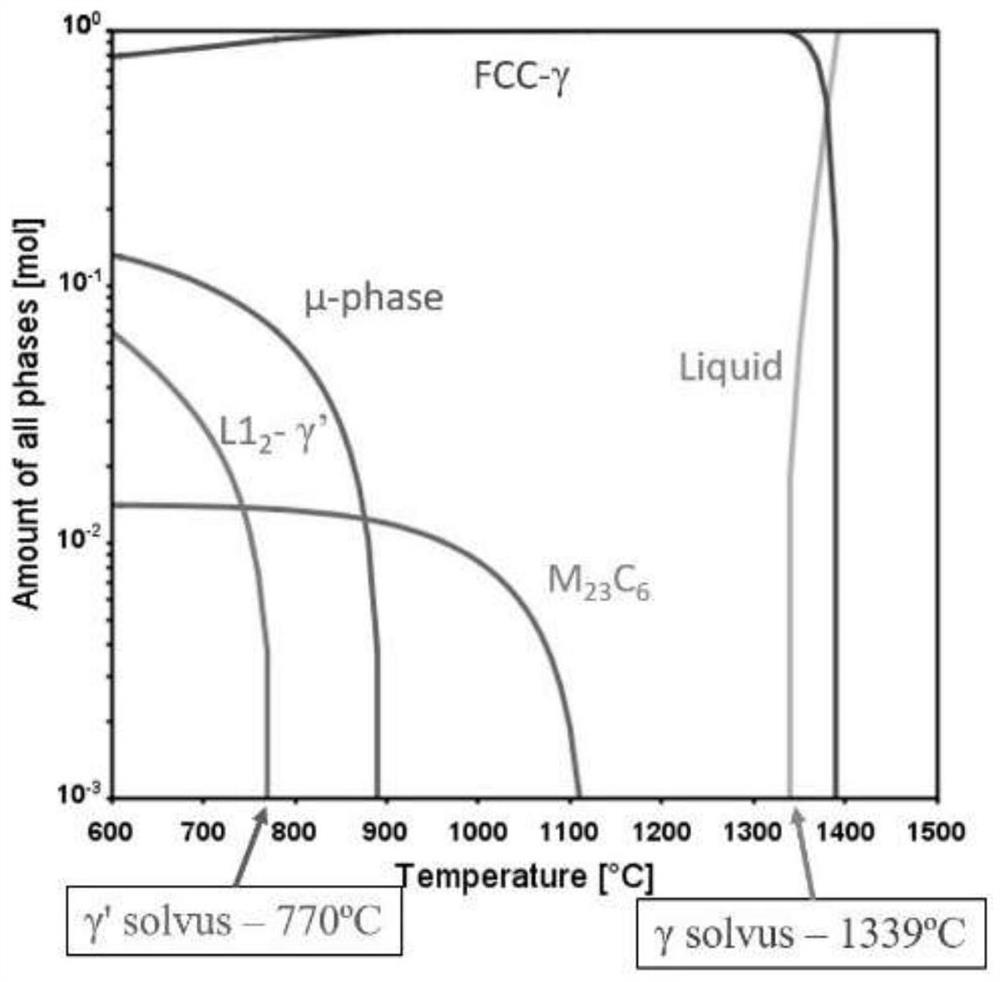

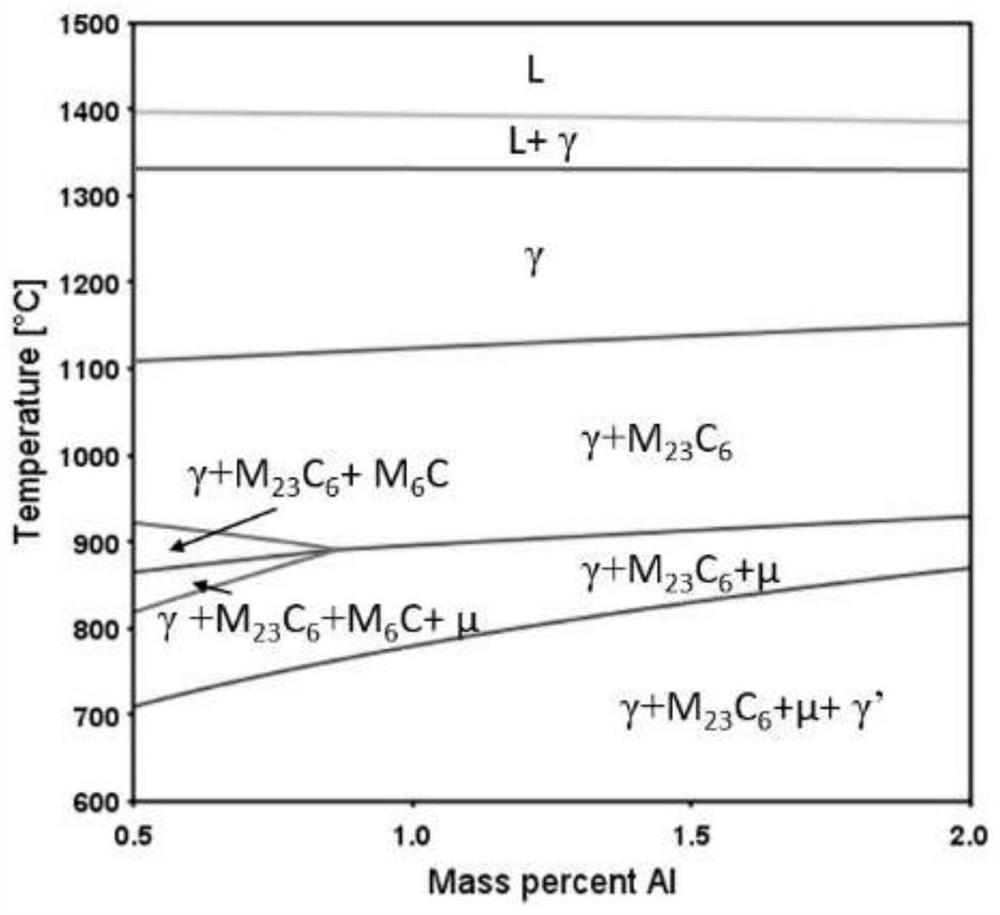

Component optimization design method of 617 nickel-based superalloy

PendingCN111681716AExact equilibrium phase diagramSimple compositionChemical property predictionComputational theoretical chemistryChemical compositionSuperalloy

The invention discloses a component optimization design method of 617 nickel-based superalloy, comprising the following steps of: calculating the relationship between each precipitation amount in thealloy with a typical chemical composition and the temperature based on the chemical composition defined by the alloy; obtaining main equilibrium phases of the alloy, and simultaneously obtaining the relationship between the precipitation amount of each phase and the temperature; determining main composition phases of the alloy and main alloy elements of each composition phase at the working temperature, and adjusting and optimizing the content of Al, Ti, Cr, Mo and C elements in the alloy to obtain the content of an ideal composition phase; obtaining the value range of the adjusted alloy element components, and finally obtaining the optimized chemical components of the alloy. By the method, a relatively accurate equilibrium phase diagram is obtained, and a theoretical basis is provided forthe design and production of the alloy; more ideal alloy components are obtained; the complicated and time-consuming experimental process is reduced, and a theoretical basis is provided for the design and production of the alloy.

Owner:国能锅炉压力容器检验有限公司

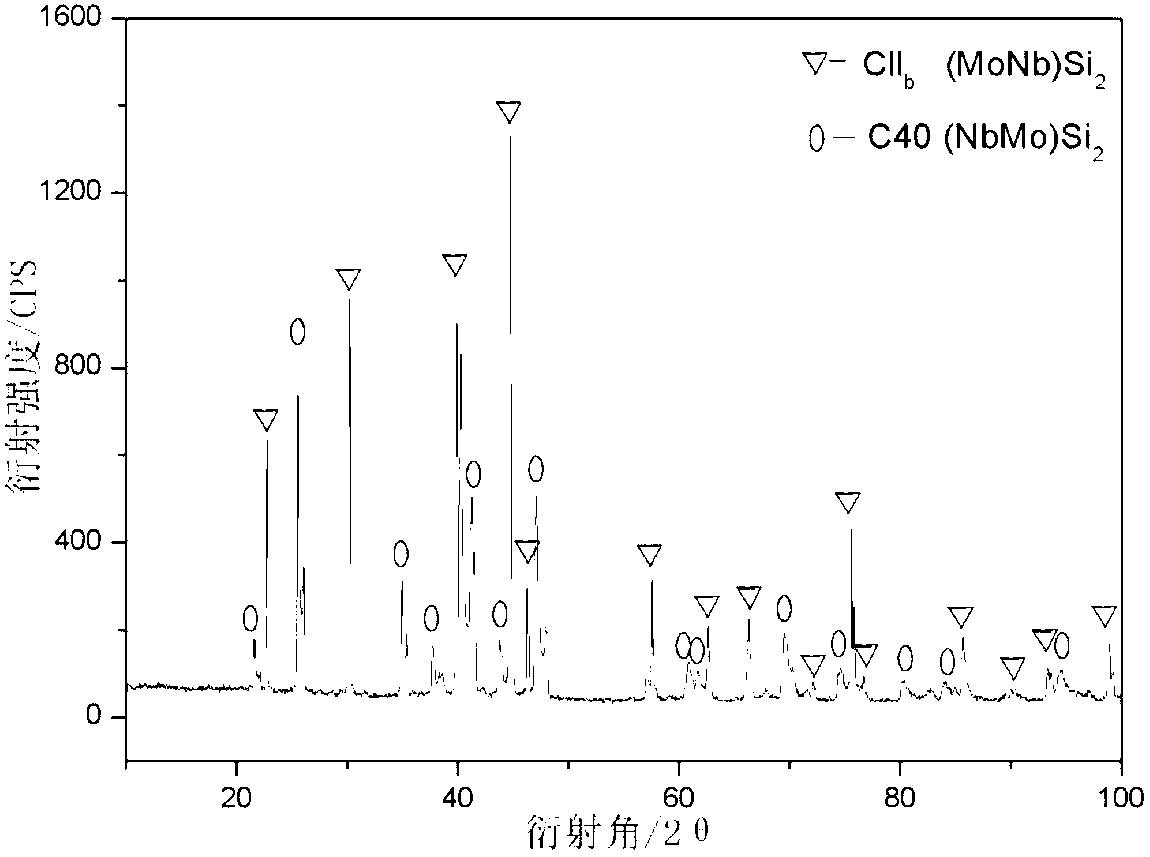

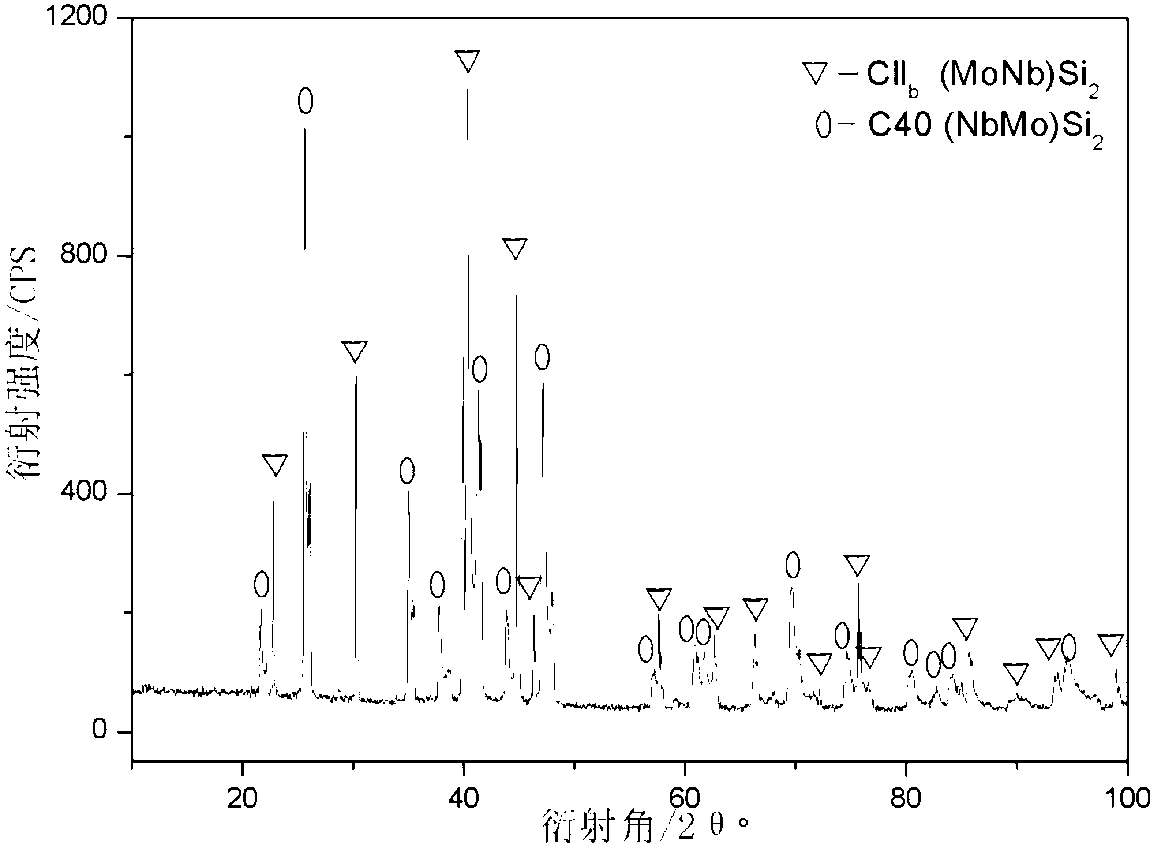

Molybdenum-niobium-silicon alloy and preparation method thereof

The invention discloses a molybdenum-niobium-silicon alloy and a preparation method thereof, and belongs to the technical field of intermetallic compounds. A chemical expression of the molybdenum-niobium-silicon alloy is (Mo1-xNbx)Si2, wherein X is within 0-1. The preparation method comprises the steps that molybdenum power, niobium power and silicon power are mixed uniformly according to 0-33.3mol%Mo, 0-33.3mol%Nb and 66.7mol% Si, wherein the sum of molar proportions of Mo and Nb is 33.3%; mixed powder is pressed to a billet and put into a reaction kettle; the mixed powder billet is ignited in a protective atmosphere and synthesized to the molybdenum-niobium-silicon alloy; and synthesized molybdenum-niobium-silicon alloy powder is subjected to densification sintering by a vacuum hot pressed sintering method. Compared with the prior art, with the adoption of the molybdenum-niobium-silicon alloy and the preparation method, a non-equilibrium phase can be obtained, and properties of a material can be improved. Compared with technologies such as arc melting, the molybdenum-niobium-silicon alloy and the preparation method have the advantages of simple technology, simple and convenient equipment, time saving, energy saving, low cost and small pollution.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com