Iron ore sintering method and quantitative characterization method of mineral phase contents

A quantitative characterization and mineral phase technology, applied in the field of metallurgy, can solve the problems of inability to accurately describe the quantitative relationship between sinter quality, inability to quantitatively describe the influence of sinter phase composition and microstructure, and inability to accurately quantitatively characterize sinter, etc. Achieve accurate test results, reduce experimental errors, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

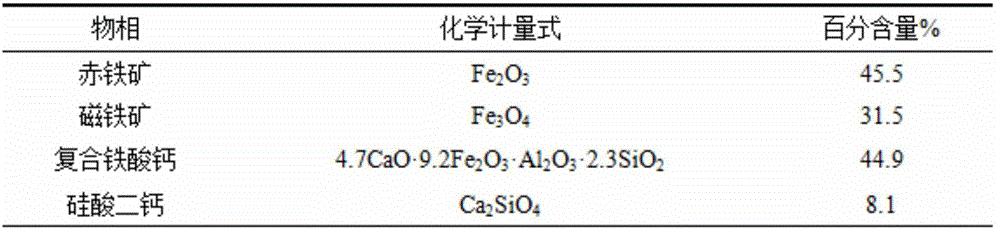

Examples

Embodiment 1

[0021] This embodiment is based on the sinter composition of steel plant A, and the experimental steps are as follows:

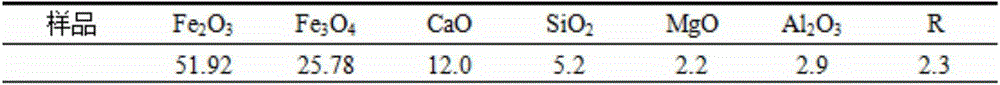

[0022] (1) Using analytically pure grade drug Fe 2 o 3 , Fe 3 o 4 , CaO, SiO 2 , MgO and Al 2 o 3 , prepare the mixture, grind and mix it evenly with an agate mortar, press the powdered material into a cylindrical sample with a diameter of 8mm and a height of 5mm with a pressure molding machine, the composition is shown in Table 1:

[0023] Table 1 Composition of sinter samples, %

[0024]

[0025] (2) The equilibrium sintering experiment was carried out in a silicon-molybdenum rod resistance furnace, the sample was placed in an alumina crucible, and the crucible was placed on the alumina base in the furnace, and the sample was heated by a resistance furnace at 20 °C / min to 1340 °C , at the same time, control the partial pressure of oxygen to 5×10 -3 atm, and kept at this atmospheric temperature for 10h to allow the chemical reaction to reach equi...

Embodiment 2

[0036] This embodiment is based on the sinter composition of steel plant B, and the experimental steps are as follows:

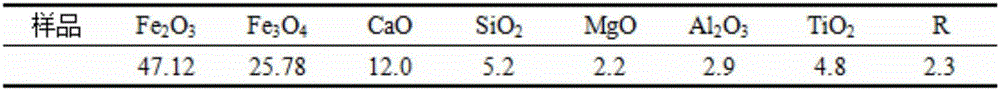

[0037] (1) Using analytically pure grade drug Fe 2 o 3 , Fe 3 o 4 , CaO, SiO 2 , MgO, Al 2 o 3 and TiO 2 , prepare the mixture, grind and mix it with an agate mortar, and press the powdered material into a cylindrical sample with a diameter of 8 mm and a height of 5 mm with a pressure molding machine. The composition is shown in Table 3.

[0038] Table 3 Composition of sinter samples, %

[0039]

[0040] (2) The equilibrium sintering experiment was carried out in a silicon-molybdenum rod resistance furnace, the sample was placed in an alumina crucible, and the crucible was placed on the alumina base in the furnace, and the sample was heated by a resistance furnace at 20 °C / min to 1340 °C , at the same time, control the partial pressure of oxygen to 5×10 -3 atm, the rest is nitrogen, and kept at this atmospheric temperature for 10h to allow the ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com