Polyester (PET) plastic geogrid and manufacturing method thereof

A geogrid, polyester technology, applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of unsatisfactory physical and chemical properties, material utilization rate of only 75%, and increase production costs, and achieve anti-corrosion resistance. Good chemical stability, good dimensional stability and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The invention is described in detail below with specific embodiments:

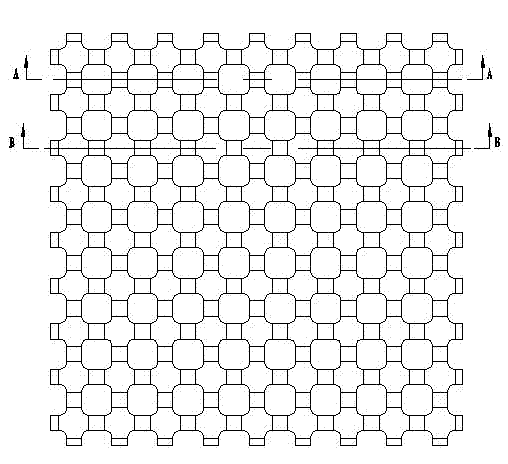

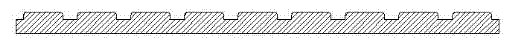

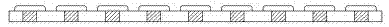

[0039] A kind of polyester (PET) plastic geogrid, the local geogrid material is polyester plastic material, this polyester (PET) plastic geogrid can be made by the following method, its process flow chart is as follows Figure 4 , the device connection diagram is as follows Figure 5 Shown:

[0040] After mixing and adding, the mixture is extruded through extruder 1, and then enters water tank 3 to cool and shape after passing through the forming head, and then stretched through traction device 2, preheating device 4, 5 and stretching machine 6, and then counted and wound 7 and 8 form a one-way geogrid, and then after the preheating machine 9 and the transverse stretching oven 10 are drawn, counting and winding 11 form a two-way geogrid.

[0041] The implementation mode is described in detail below:

[0042] a. Heat and knead polyester (PET) plastic particles with an extruder, extrude longitudina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com