Patents

Literature

244 results about "Iron ore sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron ore sintering is a type of powder metallurgy used to pre-treat iron before using it in manufacturing applications. Sintering involves heating iron powder to partially, but not completely, melt the iron particles.

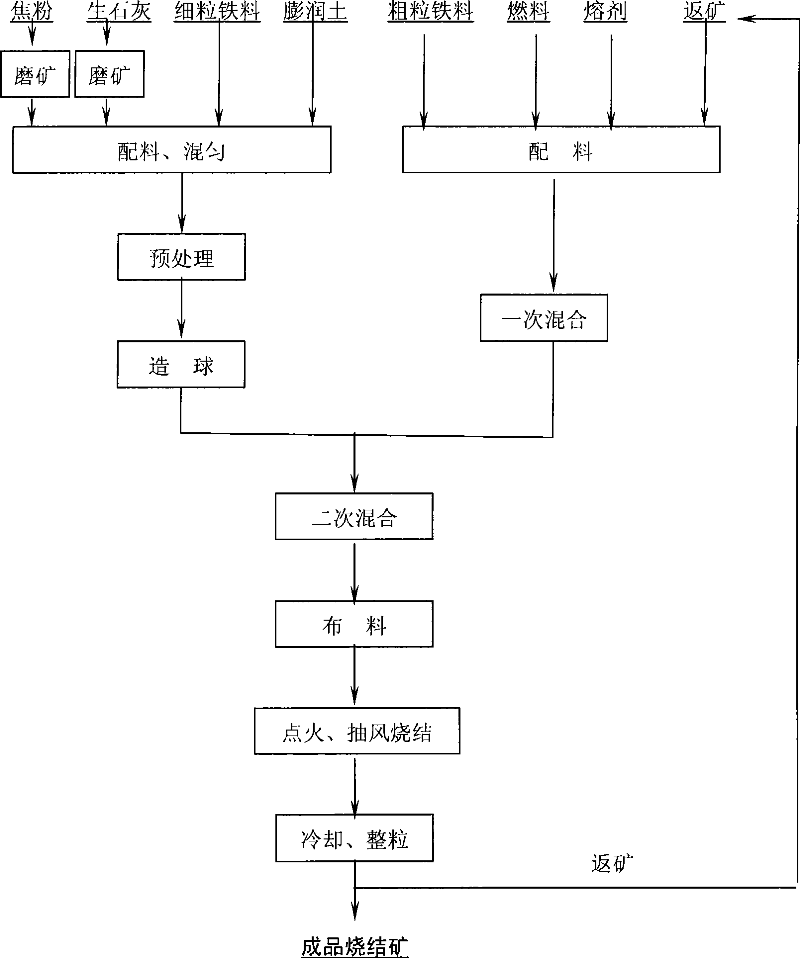

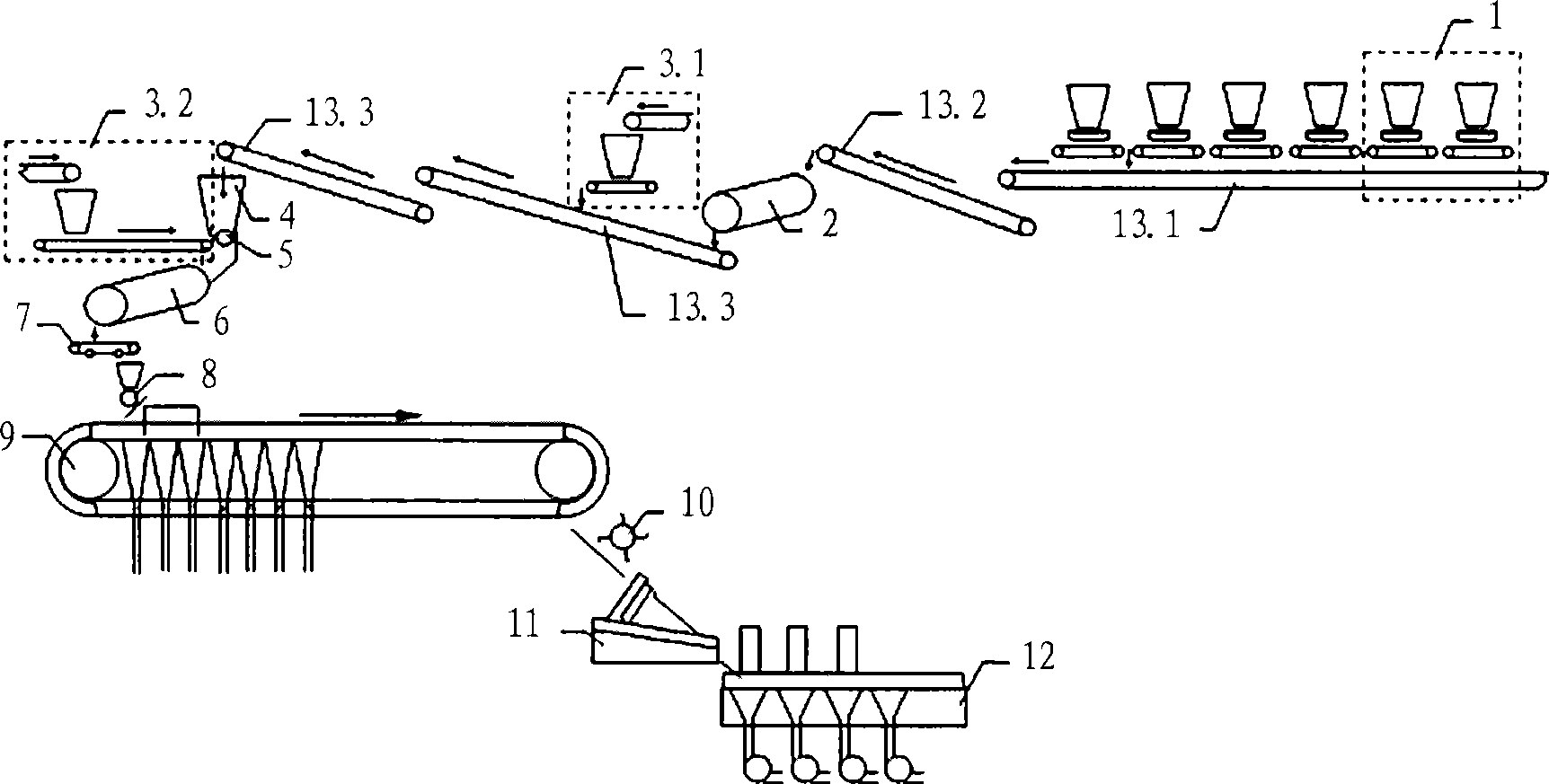

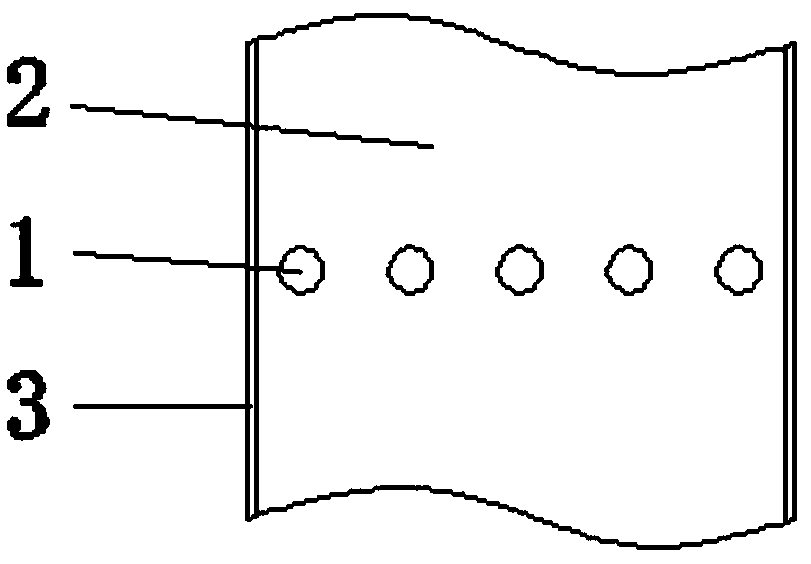

Method for sintering iron ore powder with super high material layer

The invention disclose a method for obtaining ultra high batch layer sintering hematite by improving the thickness of iron ore sintering batch layer. The granule part of less than 0.1mm difficult to pelletize in the tradical art are branched off, separate treating to preparing a green pellets of 7-12mm, then adding to the mix processed by more than 0.1mm coarse ironstone, distributing, igniting, induced draft sintering according to the tradical art, cooling, pelletizing to obtain a sintering mine for refined iron for blast furnace. The air permeability of batch layer is improved in case that a great deal of air-channaels is formed between pellets made of fineiron ore and other the mix, accordingly the thichness of sintering batch layer can be 900-1100mm in case that sintering induced draft negative pressure is not increased, and abtain ultra high batch layer sintering hematite.

Owner:CENT SOUTH UNIV

High-ore-matching-ratio brown iron ore sintering technology

The invention relates to a high-ore-matching-ratio brown iron ore sintering technology. The weight ratio of brown iron ore and powdered iron in raw material proportion is (5-19):1, the moisture content of the first mixing is controlled to be 7%-8%, the mixing time lasts for 2-3minutes, and the temperature of the mixture is 50-62 DEG C; the moisture content of second mixing pelletizing is controlled to be 7-9%, the pelletizing time lasts for 2-3.5minutes, and the temperature of materials is 52-65 DEG C; the thickness of grate-layer materials in distribution is 20mm, and a sintering material layer is 780-900mm thick; the ignition temperature for sintering is1050-1150 DEG C, and the ignition time lasts for 1.8-2.2minutes; and the negative pressure for sintering is 12-15kpa, the machine speed is 0.9-1.2m / min, the vertical sintering speed is 29-34mm / min, the air leakage rate is no more than 40%, the cooling negative pressure is 11-14kpa, the temperature of a cooling section of a sintering machine is reduced to 250 DEG C below. By using the high-ore-matching-ratio brown iron ore sintering technology, energy is saved, consumption is reduced, cost is decreased and benefit is increased.

Owner:唐山瑞丰钢铁(集团)有限公司

Inhibitor addition-based desulfurizing method in iron ore sintering process

ActiveCN102068887AConcentrated emission concentration is highImprove desulfurization efficiencyDispersed particle separationIronstoneFiltration

The invention discloses an inhibitor addition-based desulfurizing method in the iron ore sintering process, and aims to provide a desulfurizing method in the iron ore sintering process, which has the advantages of low investment cost, low operation cost and high desulfurization efficiency. In the method, an ammonia-containing compound is added into a bedding material layer at the bottom of a sintered material layer, ammonium sulfate generated in the reaction of ammonia which is decomposed from the ammonia-containing compound and sulfur oxide in the sintering process is adsorbed to dust and taken away by flue gas; ammonium sulfate-containing dust in the flue gas of an air bellows on the rear half part of a sintering machine is collected by a cyclone dust separator; and the collected dust is washed, filtered and dried to form dry dust, and the filtrate after filtration is concentrated, crystallized and dried to form ammonium sulfate.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

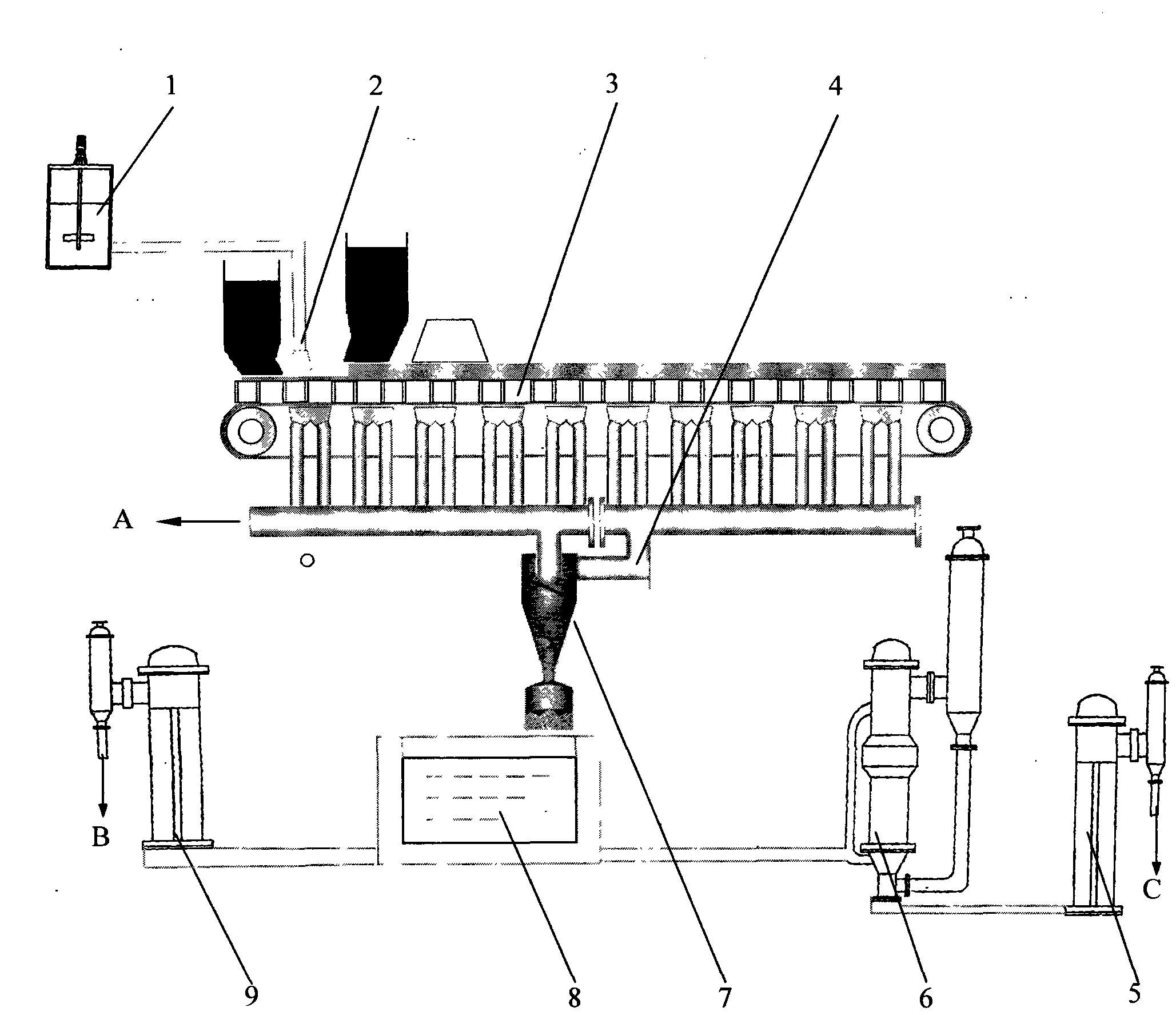

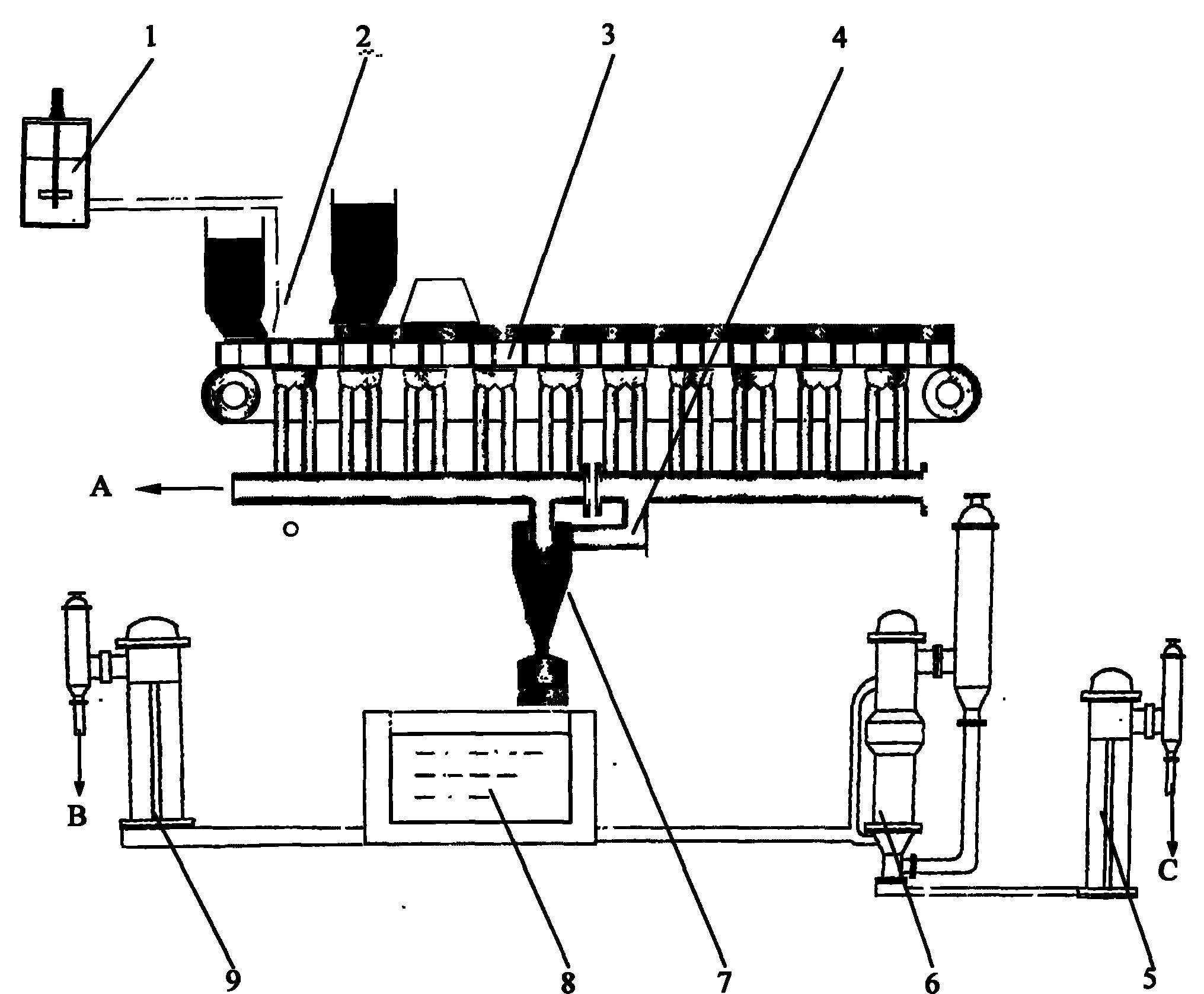

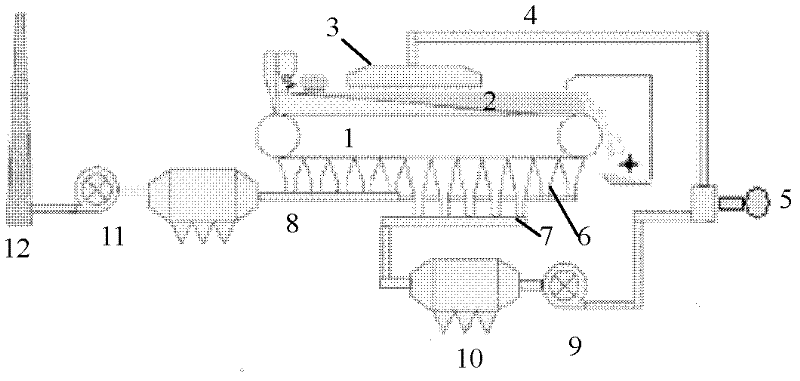

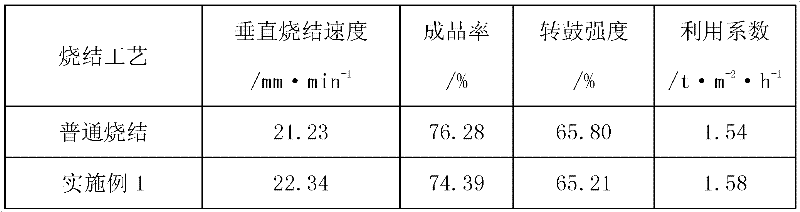

Sintering method and sintering equipment of iron ore

The invention discloses a sintering method and sintering equipment of an iron ore. The sintering method comprises the following steps of: mixing and blending: mixing the iron ore, a fusing agent and fuel to prepare sintered ore granules; then paving the sintered ore granules in a pallet through a cloth; igniting by utilizing a lighter for sintering, and starting to spray steam to the surface of a sintered material after ignition for 5 minutes to 10 minutes, or spraying water or a mixture of steam and the water, wherein the usage amount of the water or the mixture of the steam and the water is the same as the usage amount of independently-sprayed steam. According to the invention, the steam plays a strengthening role on the process of sintering reaction, the yield is increased by accelerating sintering speed, the solid combustion consumption is saved by enhancing the utilization ratio of sintered ore FeO and the fuel, and the air permeation is improved and the yield and quality are increased and enhanced by eliminating an overwet layer.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

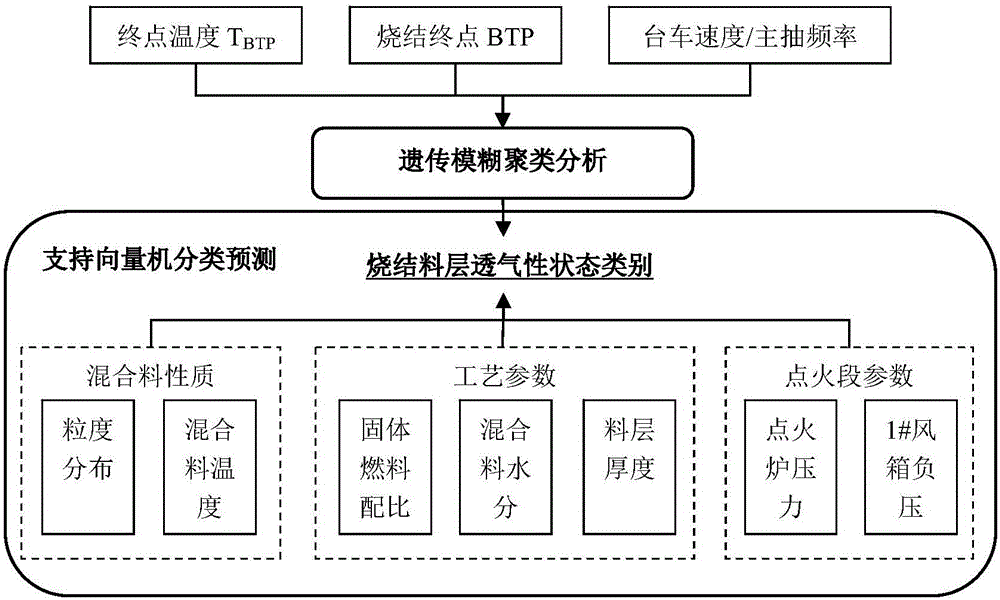

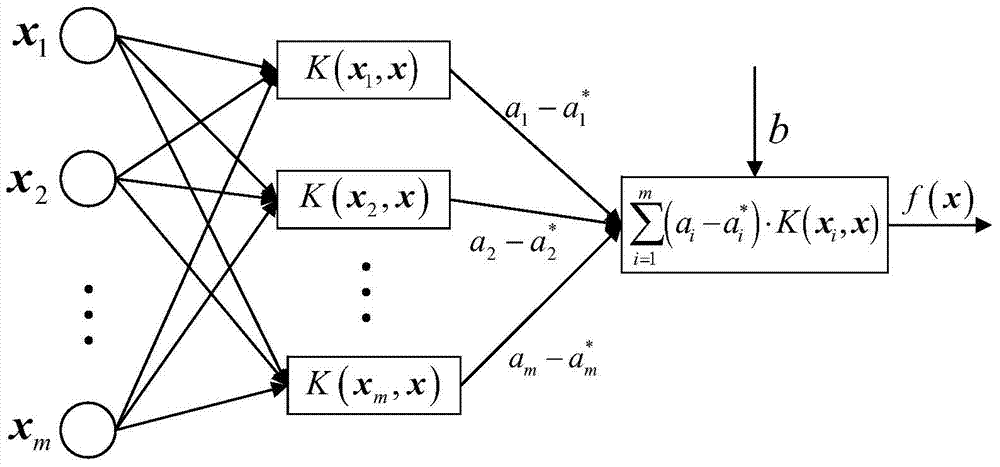

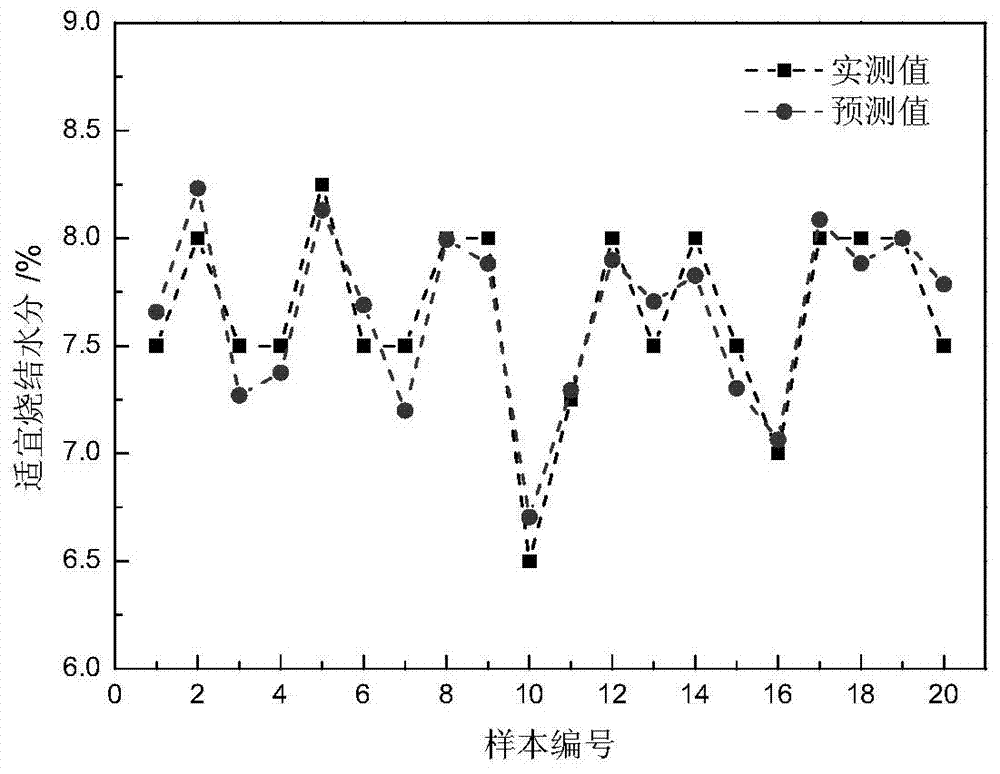

Online prediction method for iron ore sintering bed permeability states

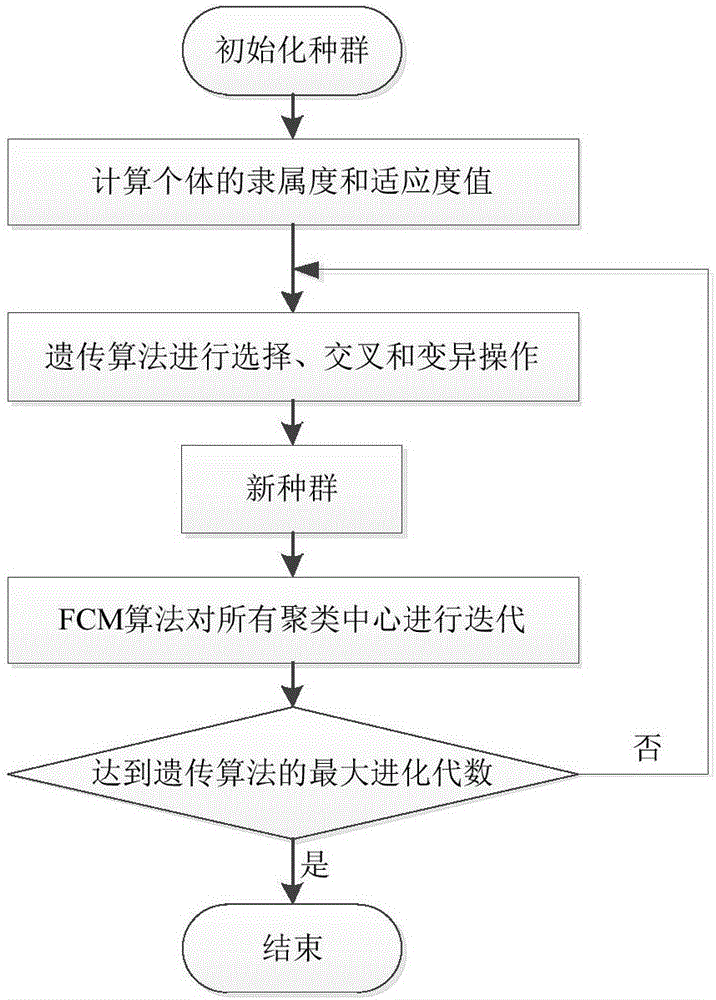

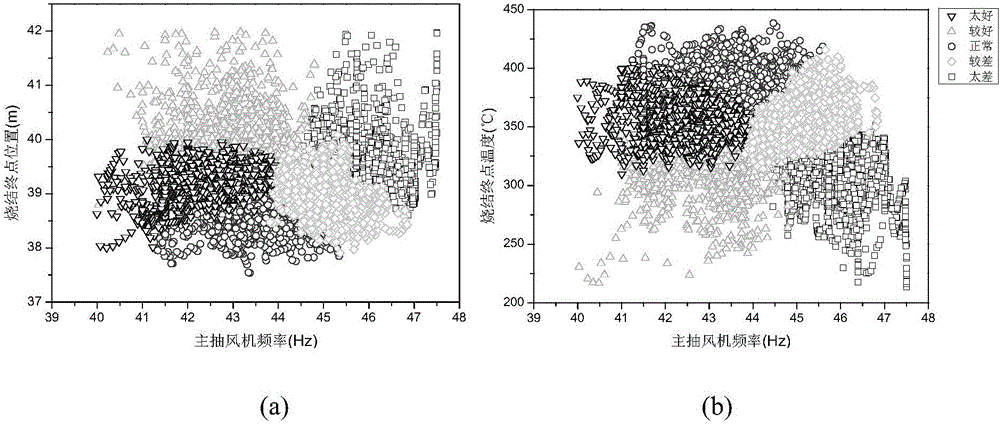

ActiveCN106022377AScientific classificationScientific Modeling IdeasCharacter and pattern recognitionGenetic algorithmsSupport vector machineSolid fuel

The invention discloses an online prediction method for iron ore sintering bed permeability states. According to the method, a fuzzy clustering algorithm is employed; a trolley speed, a sintering end point and an end point temperature are taken as input data; the sintering bed permeability states are classified into five classes; a prediction model for the sintering bed permeability states is established by employing a support vector machine method according to history data of mixture particle size distribution, mixture moisture, a solid fuel proportion, bed thickness, mixture temperature, negative pressure of an ignition furnace and negative pressure of a 1# wind box, and the corresponding permeability state data; and the bed permeability states are predicted by employing the prediction model according to the online detection data of the mixture particle size distribution, the mixture moisture, the solid fuel proportion, the bed thickness, the mixture temperature, the negative pressure of the ignition furnace and the negative pressure of the 1# wind box. The method is scientific and reasonable. Through application of the method, the prediction result is accurate, and the hit rate reaches 87.5%.

Owner:CENT SOUTH UNIV

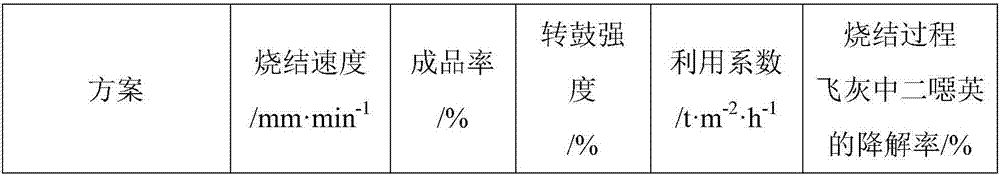

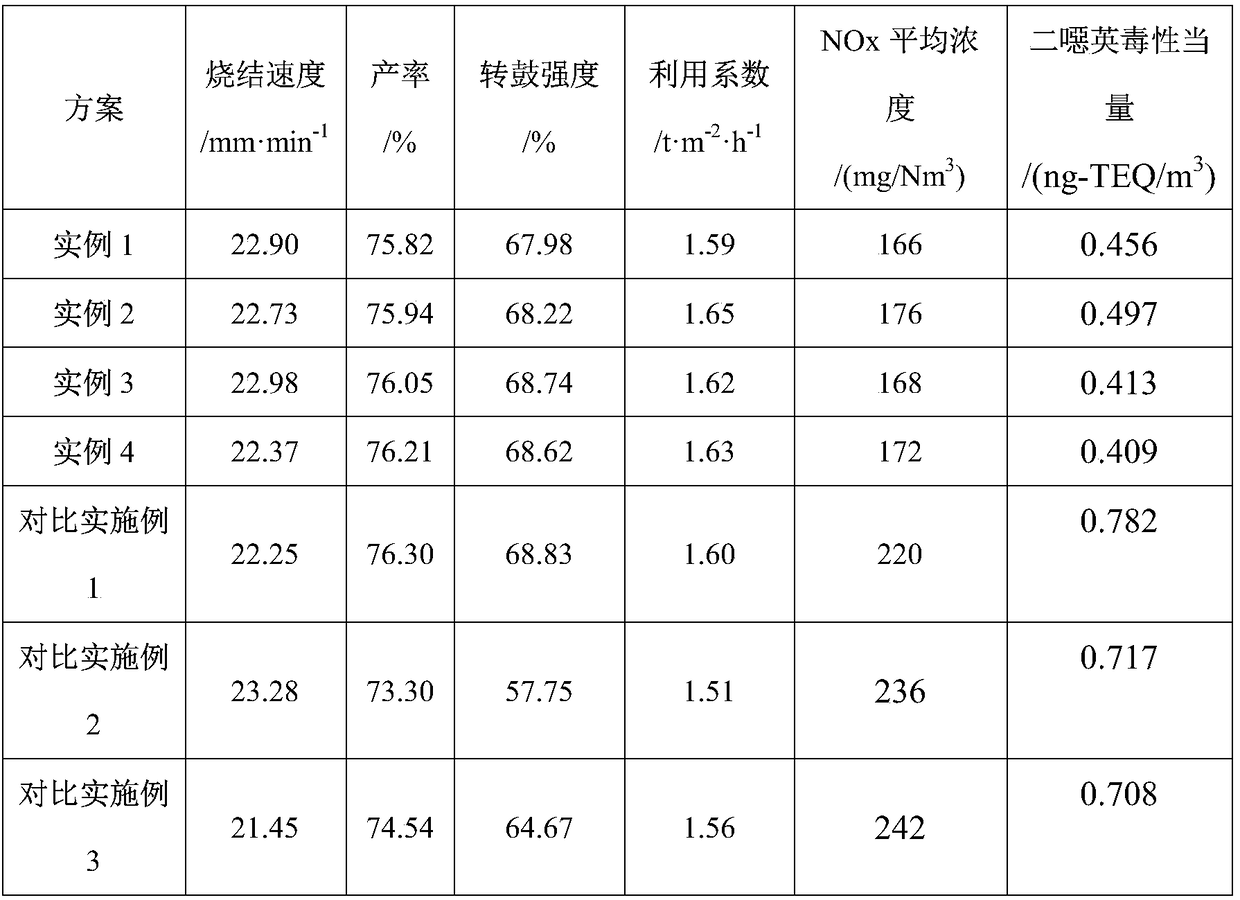

Dioxin control method for iron ore sintering garbage fly ash coprocessing process

ActiveCN107159678ARealize normal sinteringEffectively fixedTransportation and packagingSolid waste disposalSludgeLitter

The invention discloses a dioxin control method for the iron ore sintering garbage fly ash coprocessing process. According to the method, garbage fly ash, lime milk, flammable solid fuel and sludge are subject to mixed granulation and drying, and small balls containing garbage fly ash are obtained; iron core sintering raw materials are granulated and then are mixed with the small balls of the garbage fly ash, and after distribution, ignition and sintering are carried out. According to the method, on the premise that the iron ore sintering is not affected, efficient decomposing of dioxin contained in the fly ash can be achieved, dioxin secondarily formed in the garbage fly ash sintering process is prevented, according to the method, the decomposing rate of the garbage fly ash dioxin reaches 90% or above, meanwhile, effective solidifying of the garbage fly ash can be ensured, and in the sintering process, the aim of cleaning the garbage fly ash is achieved.

Owner:CENT SOUTH UNIV +1

Method for charging iron ore sintering fuel

The invention discloses a method for charging iron ore sintering fuel which includes steps as follows: mixing sintering-waited material with a first adding fuel into a mixer for mixing; mixing the once mixed material with a second adding fuel into a second mixer for mixing; adding the twice mixed material into a sintering machine, wherein, the second adding fuel position locates on a random position after once mixing and before twice mixing, the fuel is a mixture of once coke powder and second coke powder, or once smokeless coal and twice coke powder. The method is suitable for all kinds iron ore sintering containing vanadium titano-magnetite.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

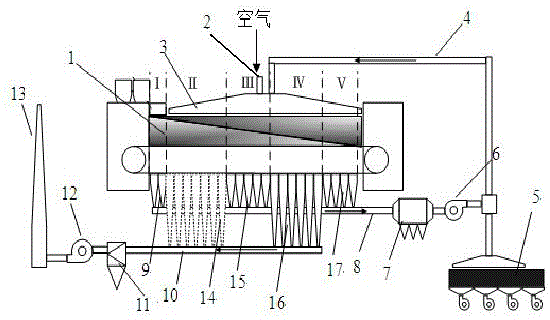

Comprehensive treatment method for iron ore sintering smoke pollutants

ActiveCN105091615AEmission reductionReduce energy consumptionCombination devicesIncreasing energy efficiencyActivated carbonPhysical chemistry

The invention provides a comprehensive treatment method for iron ore sintering smoke pollutants. According to the characteristic that the properties of sintering smoke at different positions of a sintering machine are different, the sintering machine is sequentially divided into a section I, a section II, a section II, a section IV and a section V from the machine head to the machine tail. The length of the section I accounts for one twelfth that of the sintering machine. The length of the section II accounts for one fourth to three tenths that of the sintering machine. The length of the section III accounts for one fifth to one fourth that of the sintering machine. The length of the section IV accounts for one fourth of the sintering machine. The length of the section V accounts for one sixth that of the sintering machine. Smoke in the section I, the section III and the section V circulates to a smoke hood of the sintering machine through a circulating flue. The proportion of circulating smoke is 45%-50%. According to the features of the smoke entering the sintering bed layer, the temperature is 200 DEG C-250 DEG C, the content of O2 is greater than or equal to 17%, the content of CO2 is less than or equal to 6%, H2O (g) is less than or equal to 8%, and the content of SO2 is less than or equal to 500 ppm. The smoke in the section II and the smoke in the section IV are treated by a comprehensive activated carbon desulfurization and denitrification system and then discharged.

Owner:CENT SOUTH UNIV

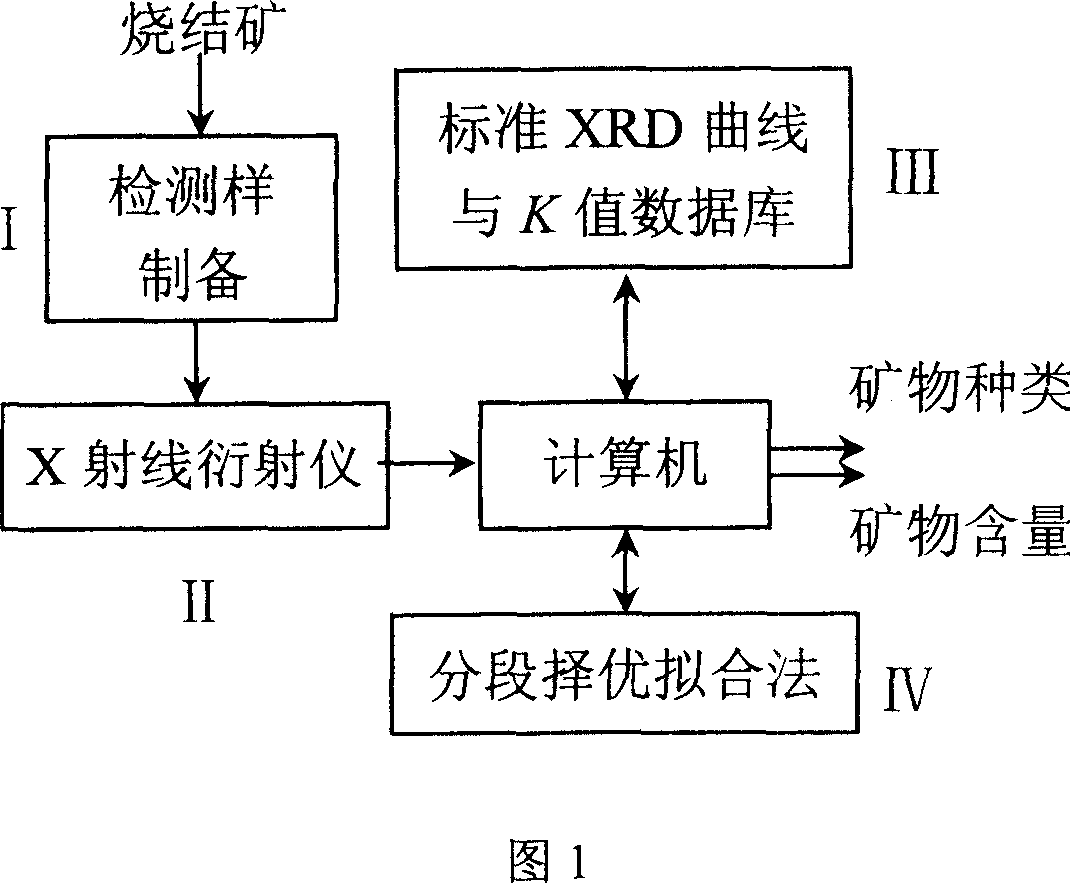

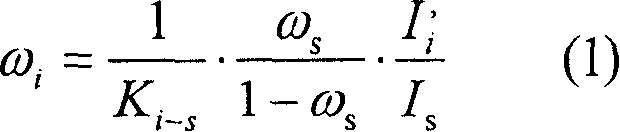

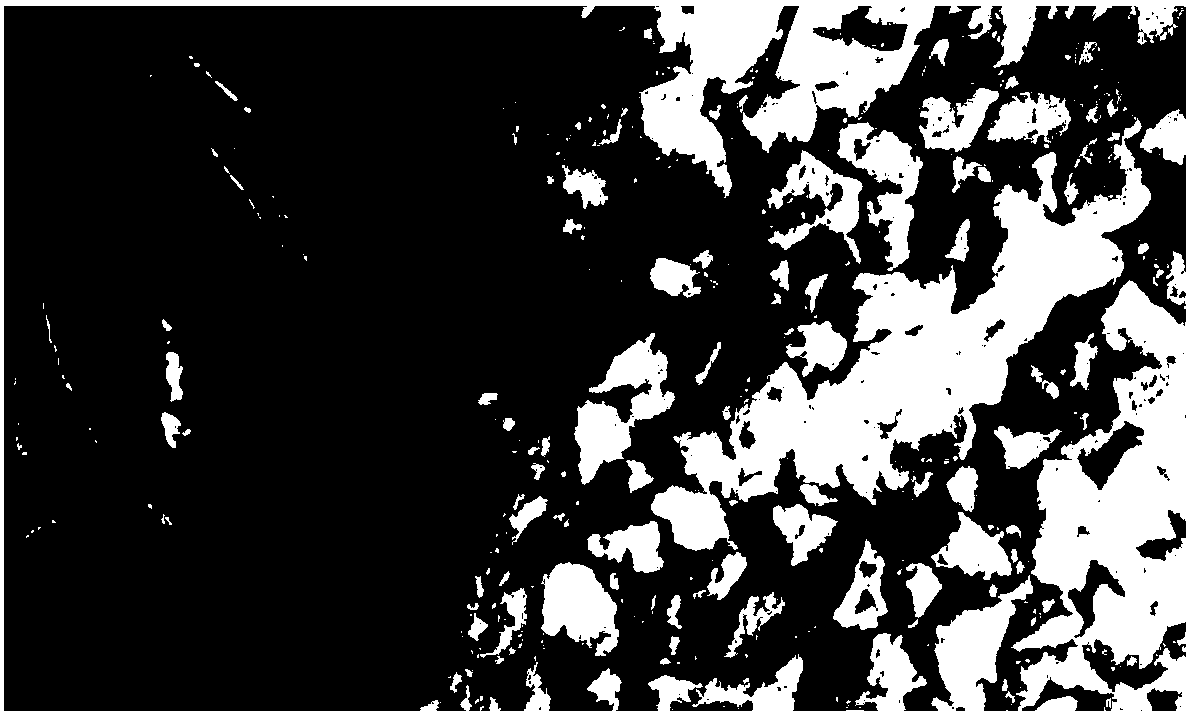

Automatically identifying and quantitatively detecting method for high alkalinity sintered ore main minerals

InactiveCN1945298AQuantitative speedSolve the problem of structural parameter uncertaintySpecial data processing applicationsMaterial analysis using radiation diffractionAlkalinityX-ray

The automatic main mineral identifying and quantitatively detecting method for high alkalinity sintered ore belongs to the field of metallurgical technology. The method includes four parts of preparing sintered ore sample, X ray diffraction condition for quantitative analysis, standard diffraction curve database of high alkalinity sintered ore minerals, and sectional optimizing fitting and computer software. The method of the present invention makes it possible to identify the minerals in high alkalinity sintered ore and measure the content fast automatically. In addition, the present invention has less sampling error and no visual error.

Owner:UNIV OF SCI & TECH BEIJING

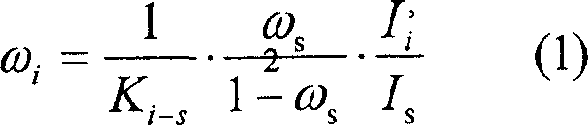

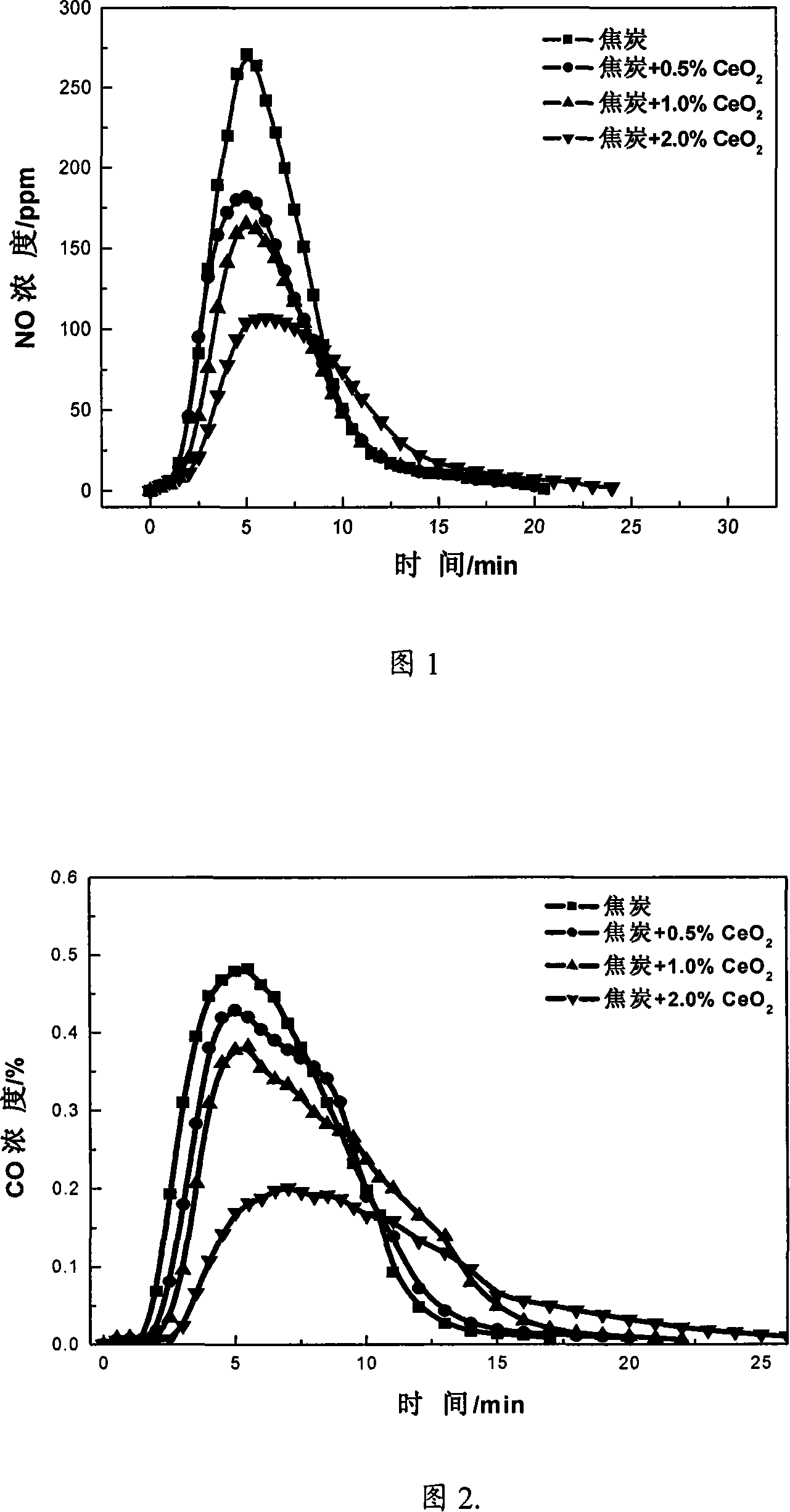

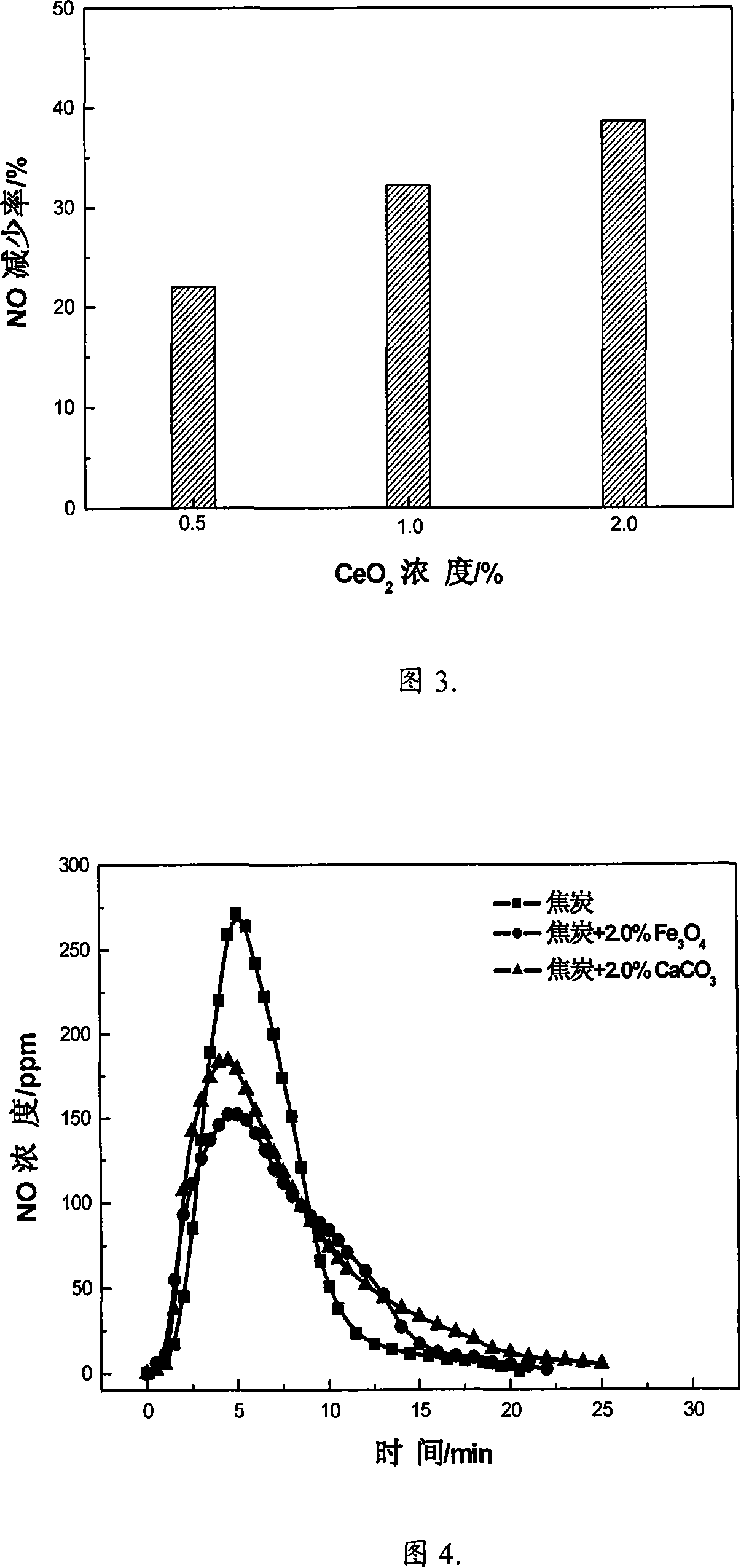

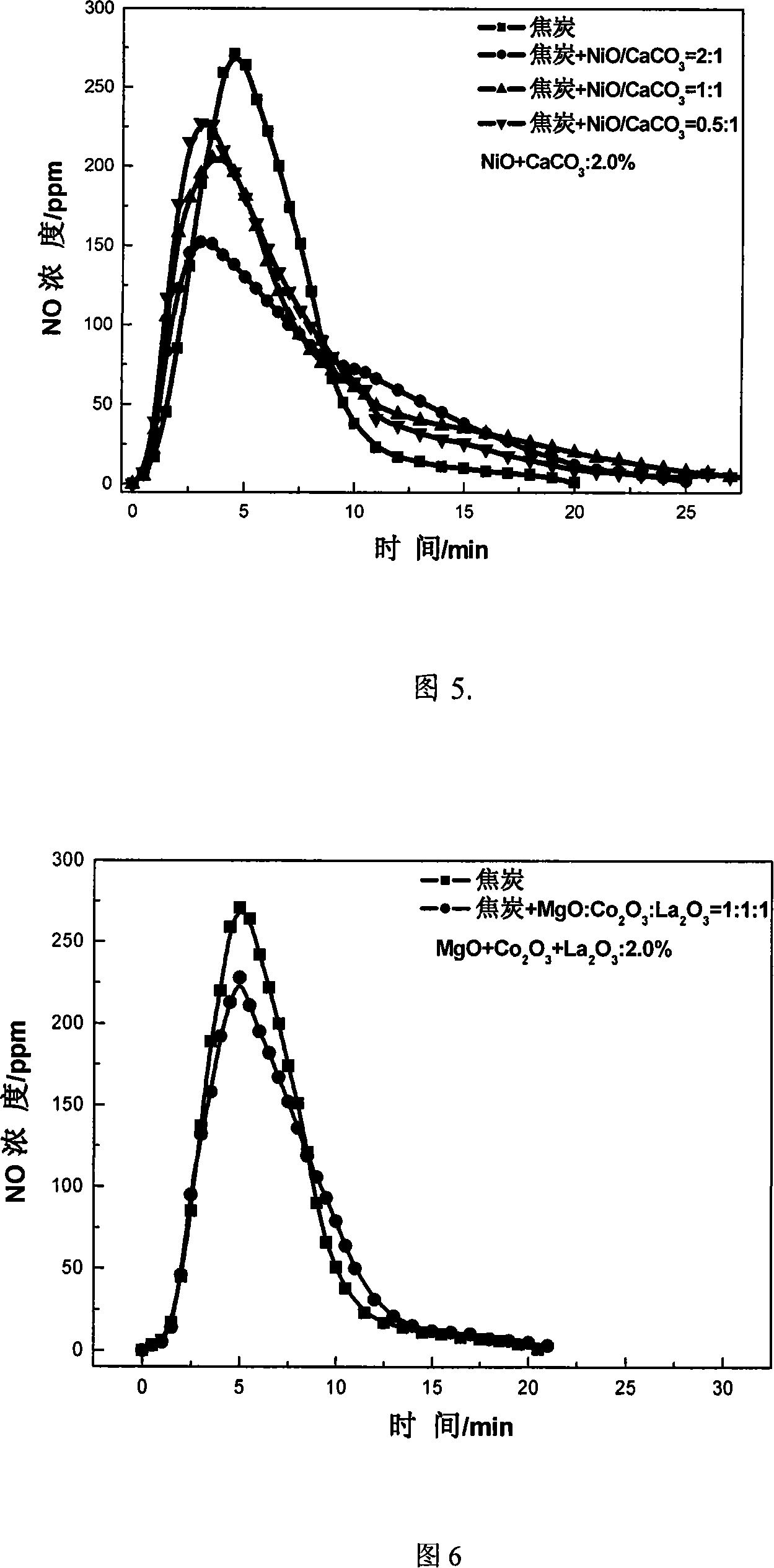

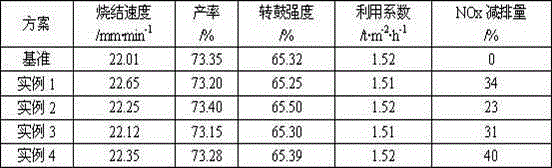

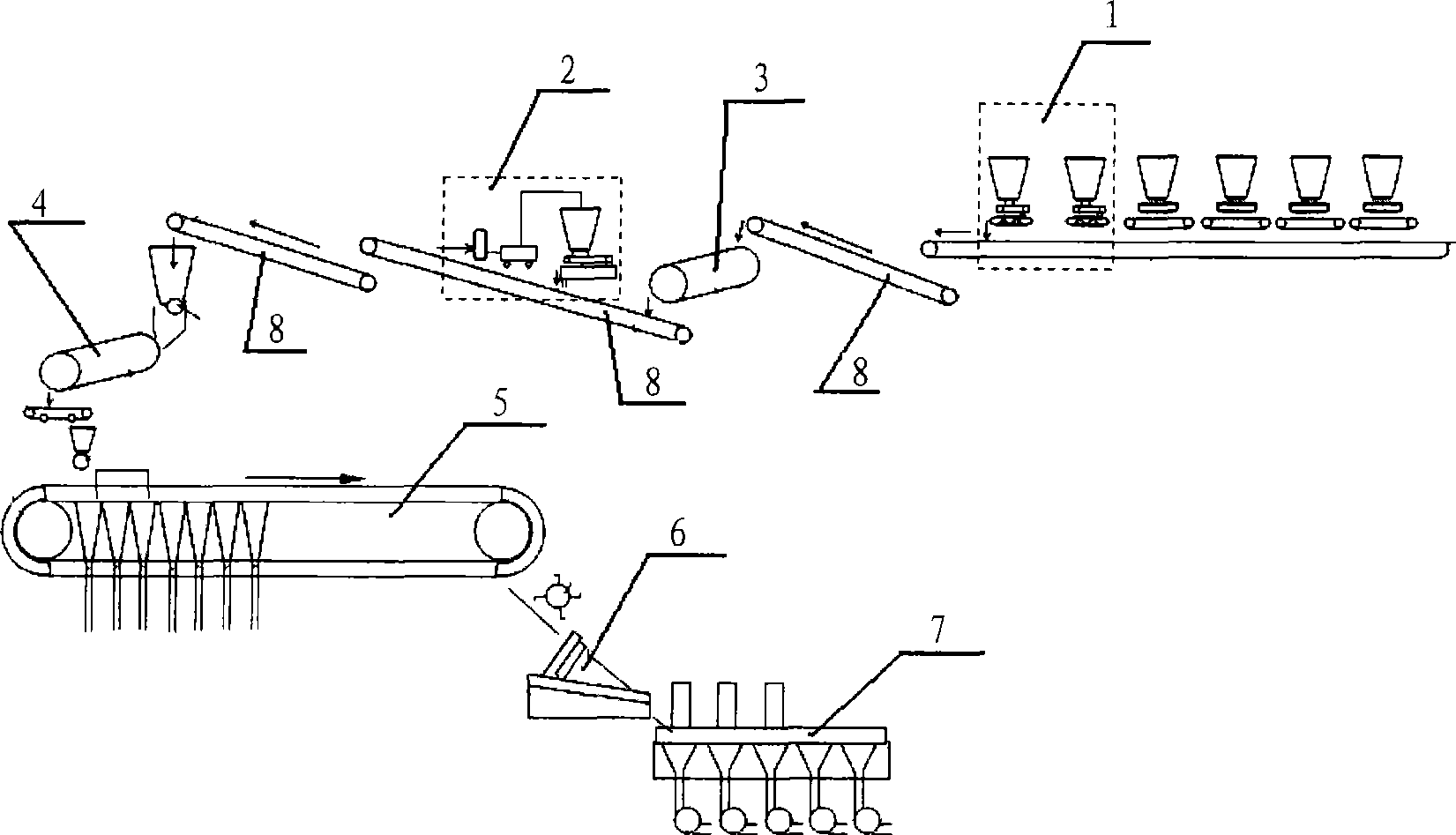

Method for reducing NOx discharge in sintering process by using additive modified coke

The method of utilizing additive modified coke to reduce NOx exhaust during agglomeration belongs to the field of metallurgical environment protecting technology. The technological process includes modifying coke through soaking coke inside 0.5-10.0 wt% concentration additive emulsion to load additive in 0.5-4.0 wt% of coke to the pores and surface, and agglomerating iron ore through burning the modified coke. The technological process can reduce the conversion of nitrogen in the coke to NOx and reduce NOx exhaust by 30-50 % while raising the coke burning rate and lowering the coke consumption.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

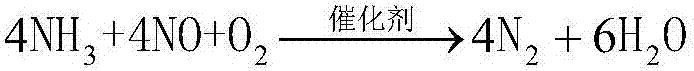

Method for reducing NOx emission in iron ore sintering process

ActiveCN105087906AReduce generationEmission reductionFuel additivesIron ore sinteringMixed materials

The invention discloses a method for reducing NOx emission in the iron ore sintering process. Firstly, conventional sintering fuel coke powder or anthracite is screened into three grain sizes of -1 mm, 1-3 mm and +3 mm; the coke powder or anthracite with the grain size being -1 mm and high-reaction-activity fossil fuel or biomass fuel with the grain size being -1 mm are pressed into fuel particles with the grain size being 1-3 mm; the fuel particles obtained through pressing with the grain size being 1-3 mm and the coke powder or anthracite obtained through screening with the grain size being 1-3 mm are added into fine particle iron ore, part of coarse particle iron ore, flux and return mines to be subjected to granulation in a rotary drum mixer; and the granulated mixed material, modified coke powder or anthracite with the particle size being +3 mm and the remaining coarse particle iron ore are subjected to secondary mixing granulation, and the obtained mixed material is distributed and then ignited and sintered. Generation of fossil fuel NOx in each grain size is controlled specifically according to the features of NOx generated by the fossil fuel in different grain sizes, so that generation of NOx is reduced to a greater extent to reduce NOx emission, and NOx emission is reduced by 20%-40%.

Owner:CENT SOUTH UNIV

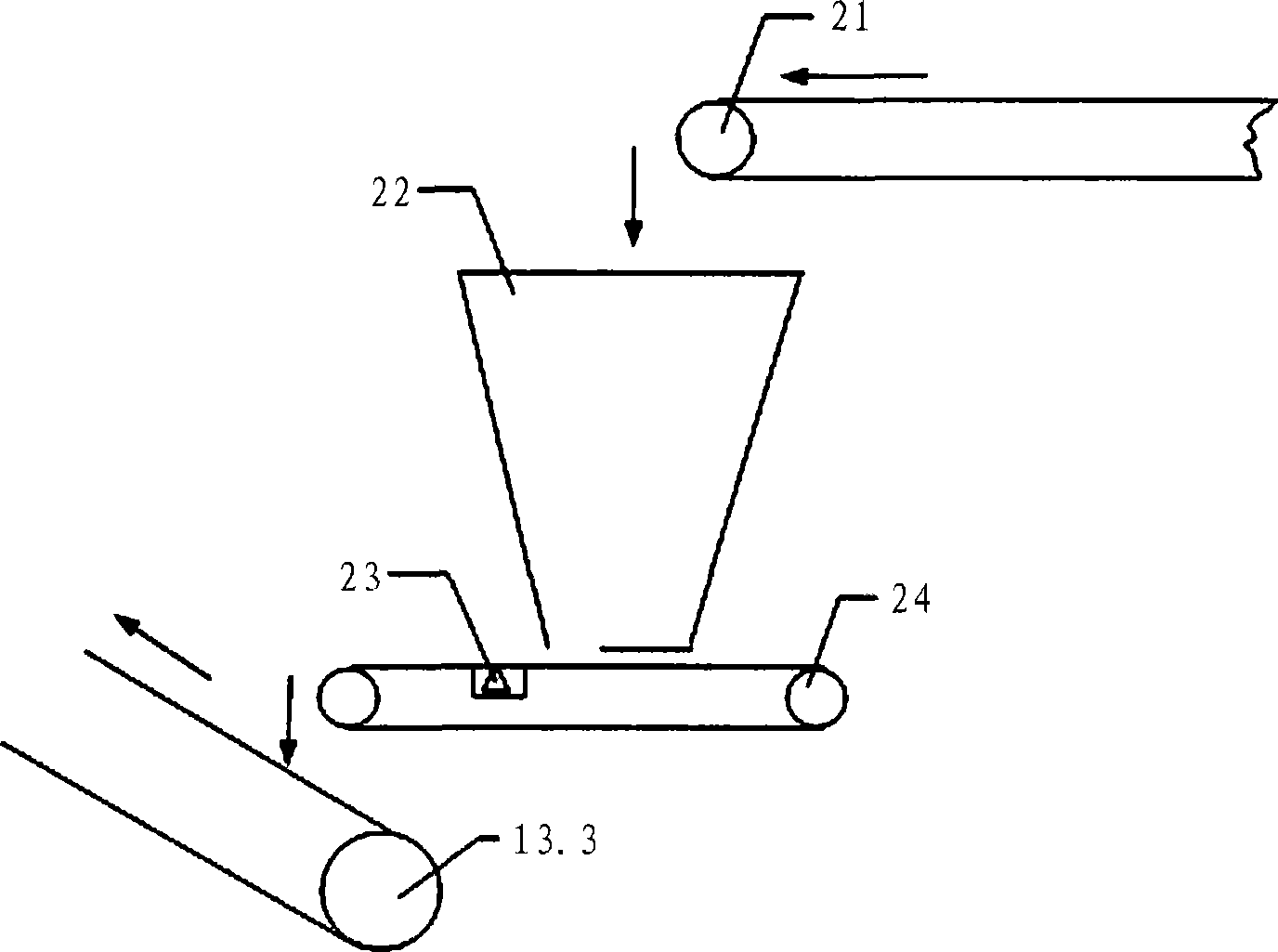

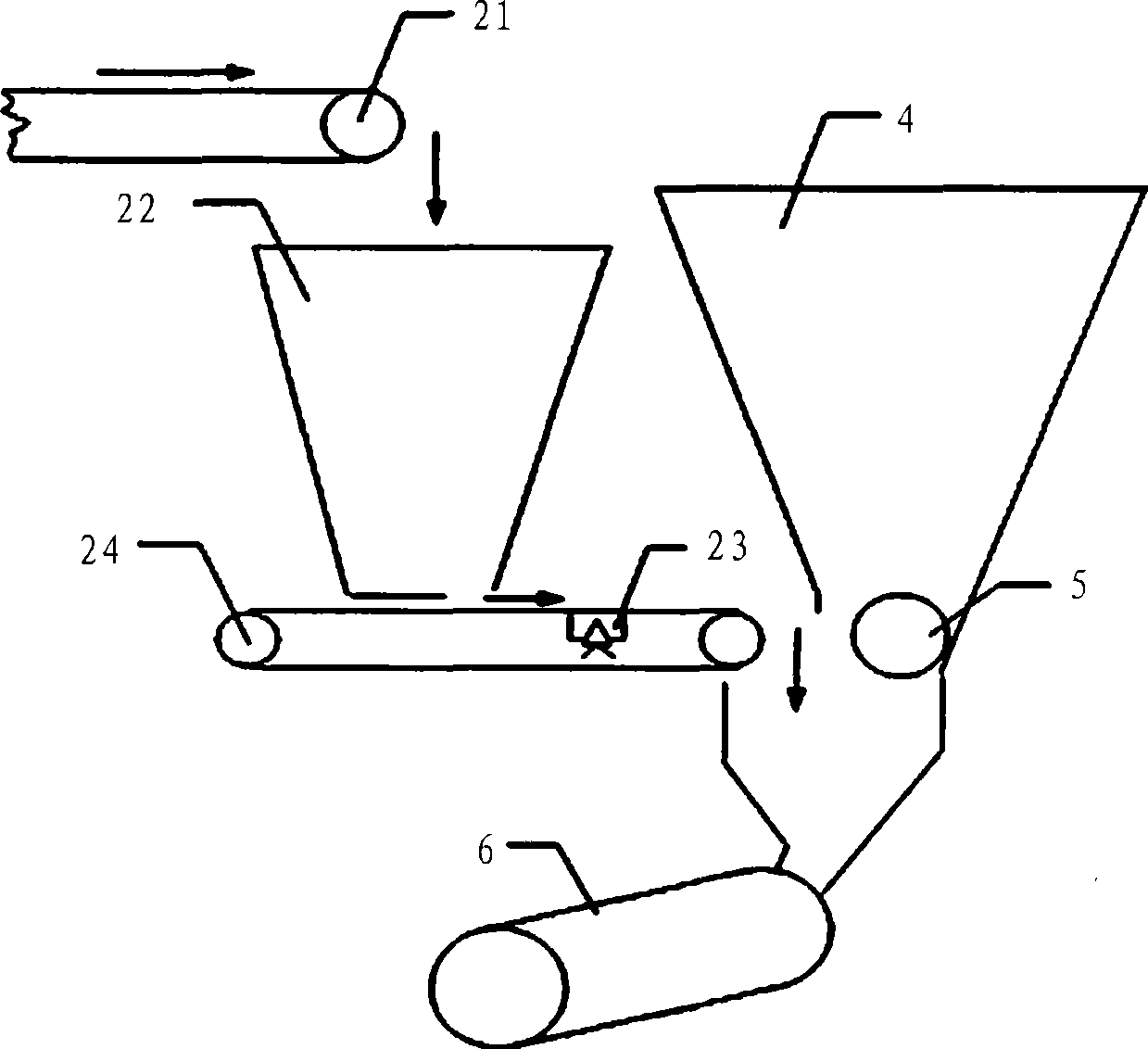

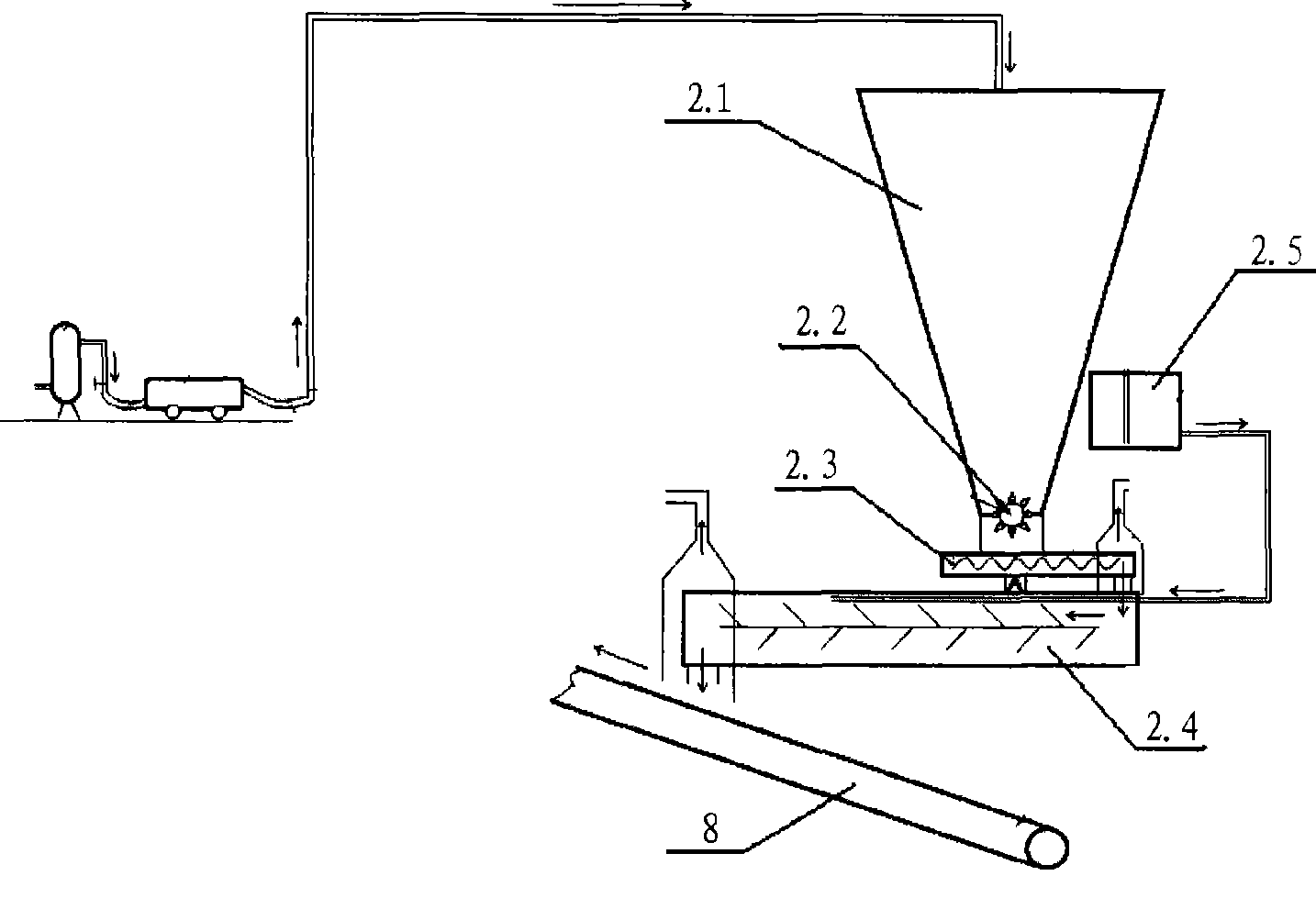

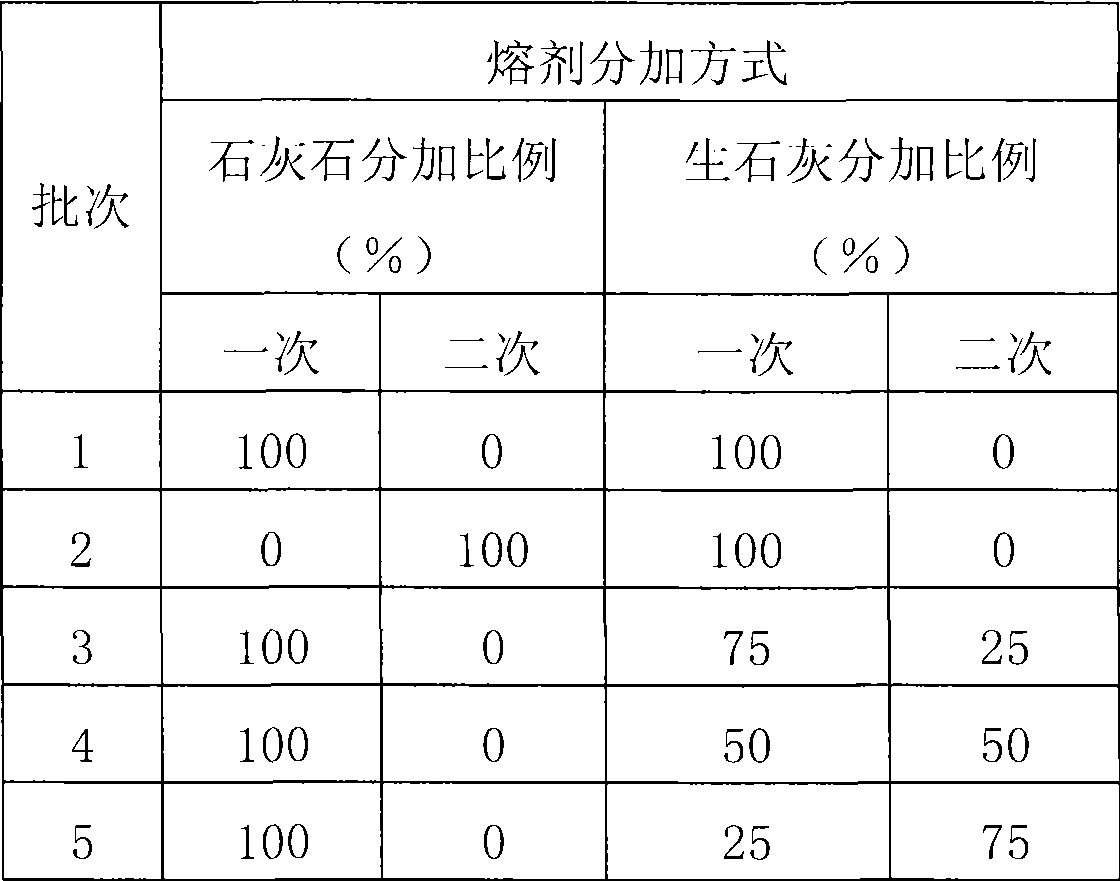

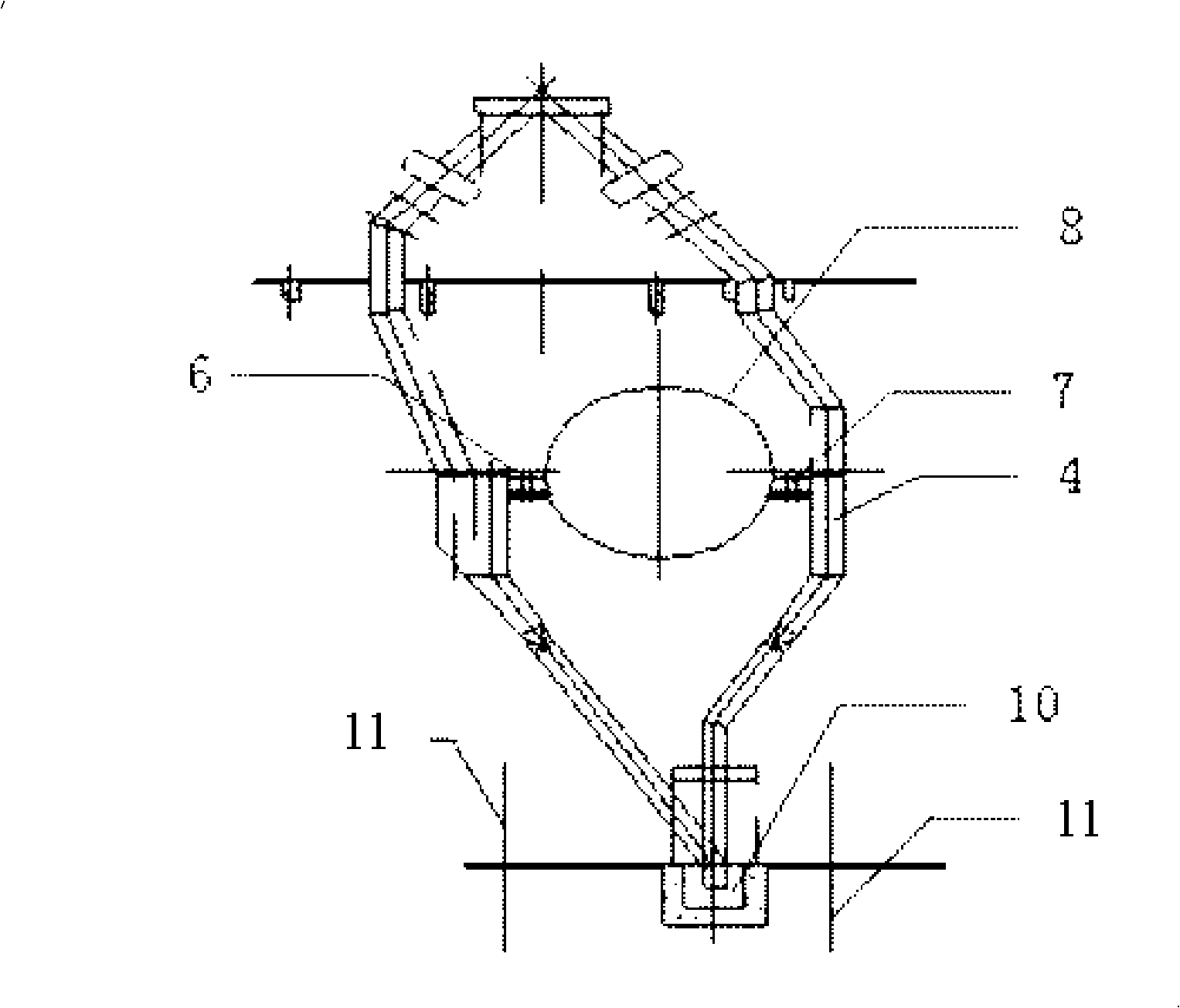

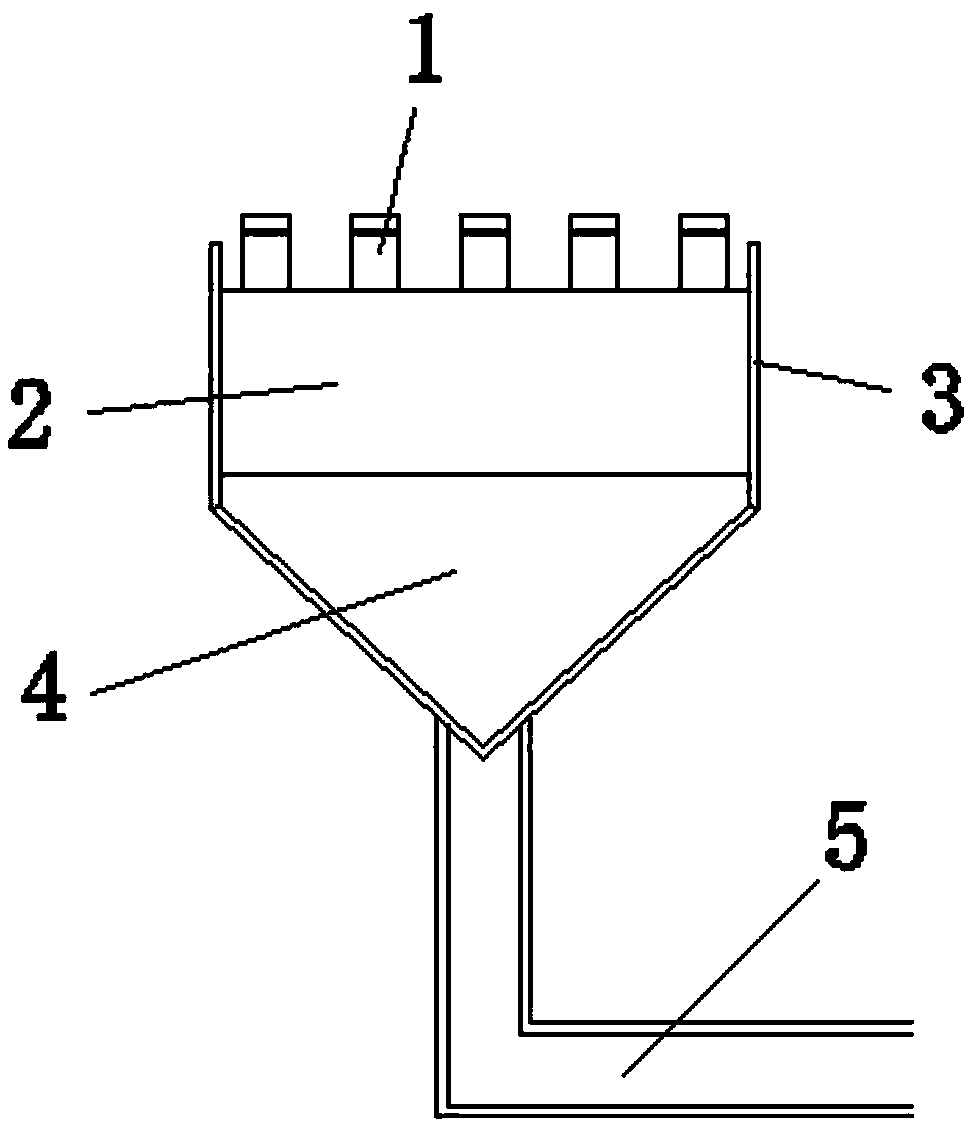

Method for charging iron ore sintering flux and device thereof

InactiveCN101532083AImproving the strength of sinter drumImprovement of Sinter Drum StrengthResidual fluxIron ore sintering

The invention provides a method for charging iron ore sintering flux and a device thereof, an essential exists in that the charged flux is charged into a sintering material twice in various phase, firstly part flux is charged using a batching room, the residual flux is charged after mixing one time for sintering on a sintering machine after two times mixing. A flux charging device is used in charging flux which is set between a first mixing machine and a second mixing machine, wherein, a dust discharge value of two times flux charging chamber transmits the two times charging flux into a feeder machine set on the dust discharge value down part, the feeder machine transmits the flux into a proportion hydrate device set on down part, the flux after alimentary reaction enters into a twice mixing machine for mixing and is transmitted into the sintering machine for sintering. The flux sintering discharging technique can improve defects of poor intension, low yield, bad metallurgical property of vanadium titano sintering ore, increase vanadium titano sintering yield and quality.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

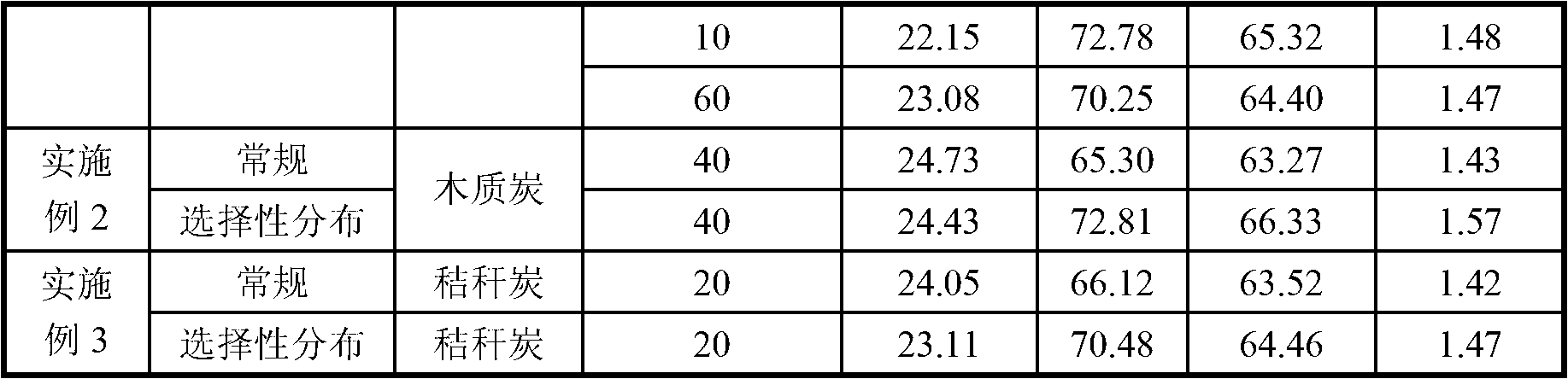

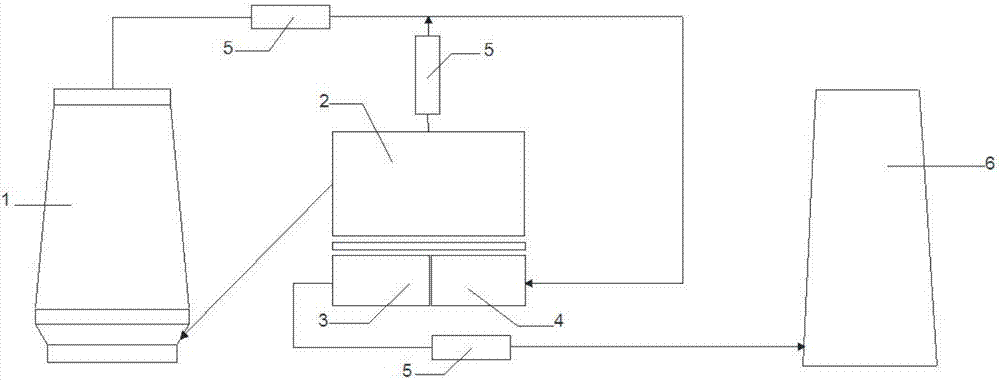

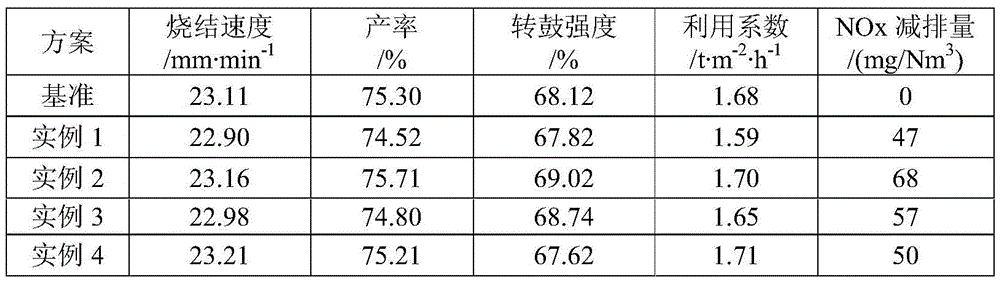

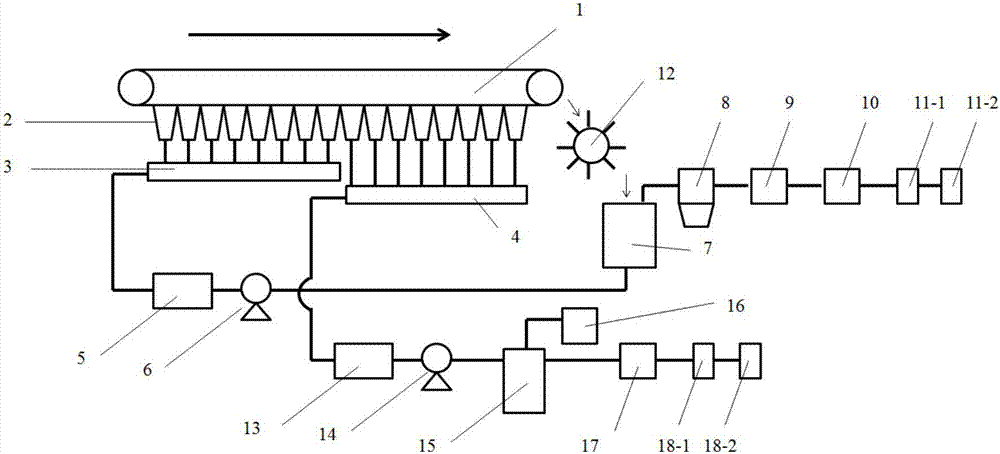

Flue gas circulation and biomass energy combined iron ore sintering method

The invention relates to a flue gas circulation and biomass energy combined iron ore sintering method. In the method, sintering flue gas which is positioned at the tail of a sintering machine and has high pollutant concentration is circulated to a sinter layer taking biomass as a fuel; the performance and using amount of the biomass fuel are controlled by controlling the components, temperature and circulating mode of circulating flue gas, so that flue gas circulation and biomass energy combined sintering heat transfer behavior and burning behavior have high matching property; therefore, the emission of harmful gas such as dioxin, NOx, CO and the like is reduced by flue gas circulation and CO2, SOx and the NOx are reduced by the biomass on the premise of ensuring the yield and quality index of a sintering ore, and the zero emission of COx is realized and the emission of dust, the dioxin, the NOx, the SOx and the like is greatly reduced through the synergic emission reduction effects of the flue gas circulation and the biomass.

Owner:CENT SOUTH UNIV

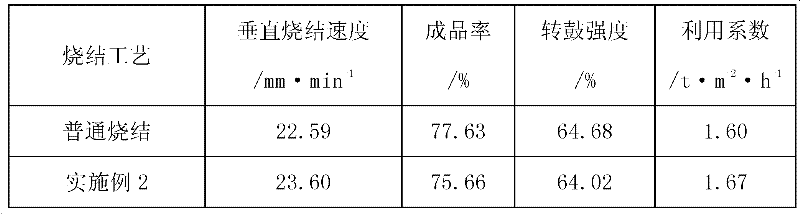

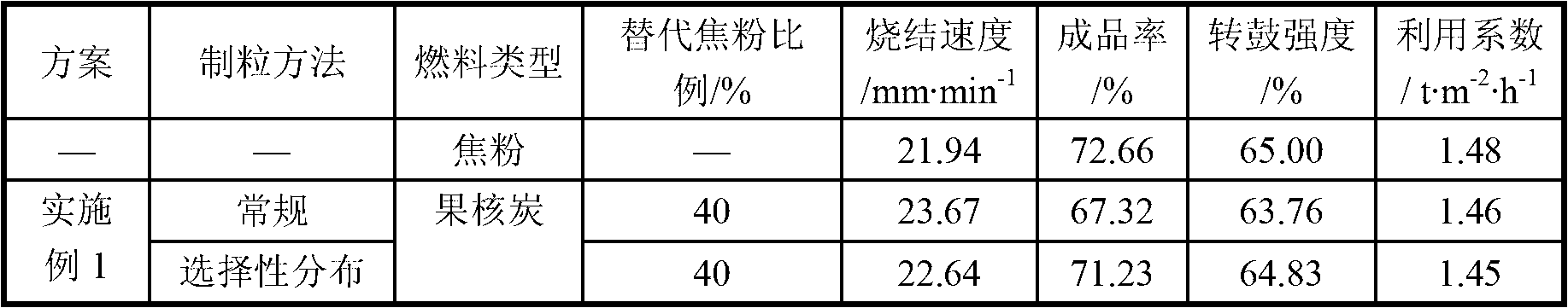

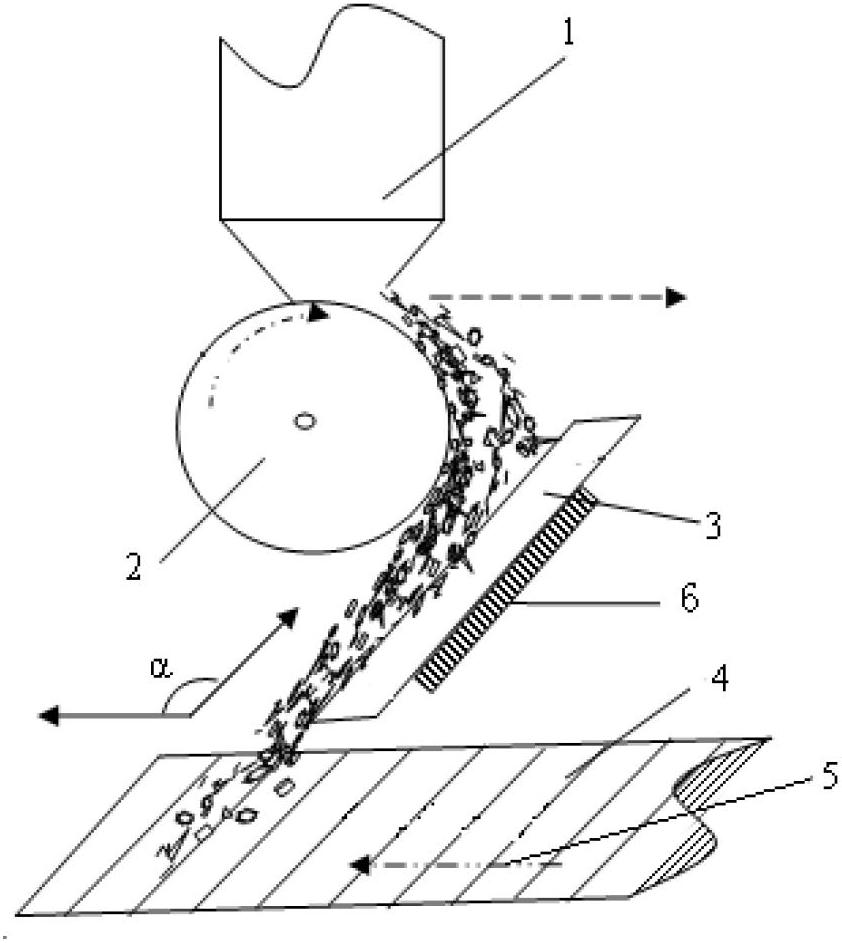

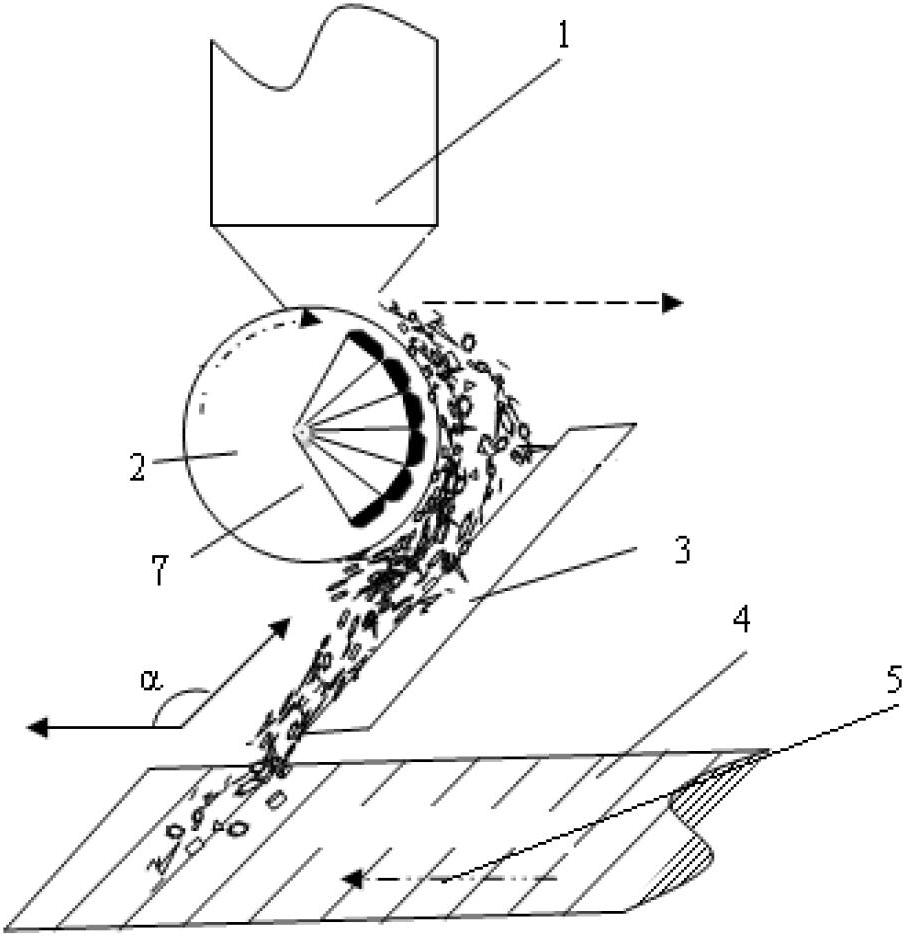

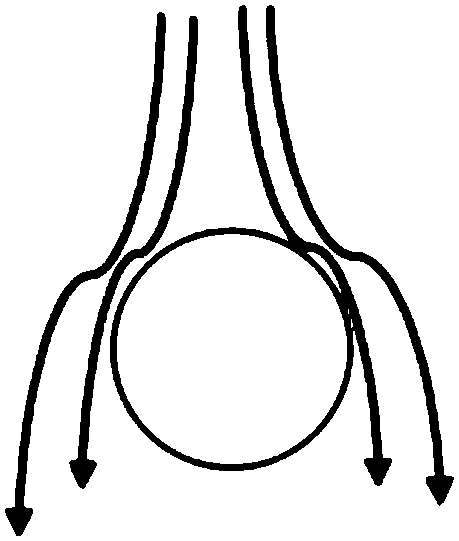

Selective distribution and granulation method of fuel for enhancing iron ore sintering with biomass energy

A selective distribution and granulation method of fuel for enhancing iron ore sintering with biomass energy distributes biomass fuel at the core part of a mixture before sintering by two-stage granulation to properly reduce the burning rate of the biomass fuel and improve the burning degree of the biomass fuel, so as to achieve the purpose of enhancing biomass energy sintering, wherein the two-stage granulation comprises the steps of: firstly preparing biomass fuel, iron ore and quicklime in a granulating disc into mother nuclide with the granularity of 3-5mm, then mixing with iron ore, limestone, dolomite, quicklime, sinter returns and coke powder (or coal), and carrying out second granulation for 3-6min in a granulating drum, so as to obtain the mixture before sintering with the biomass fuel wrapped at the core part. By selective distribution technology of the biomass fuel, the biomass fuel can be applied to iron ore sintering so as to successfully substitute for 10-60% of coke powder and not to influence the yield and quality indexes of the sintered ore.

Owner:CENT SOUTH UNIV

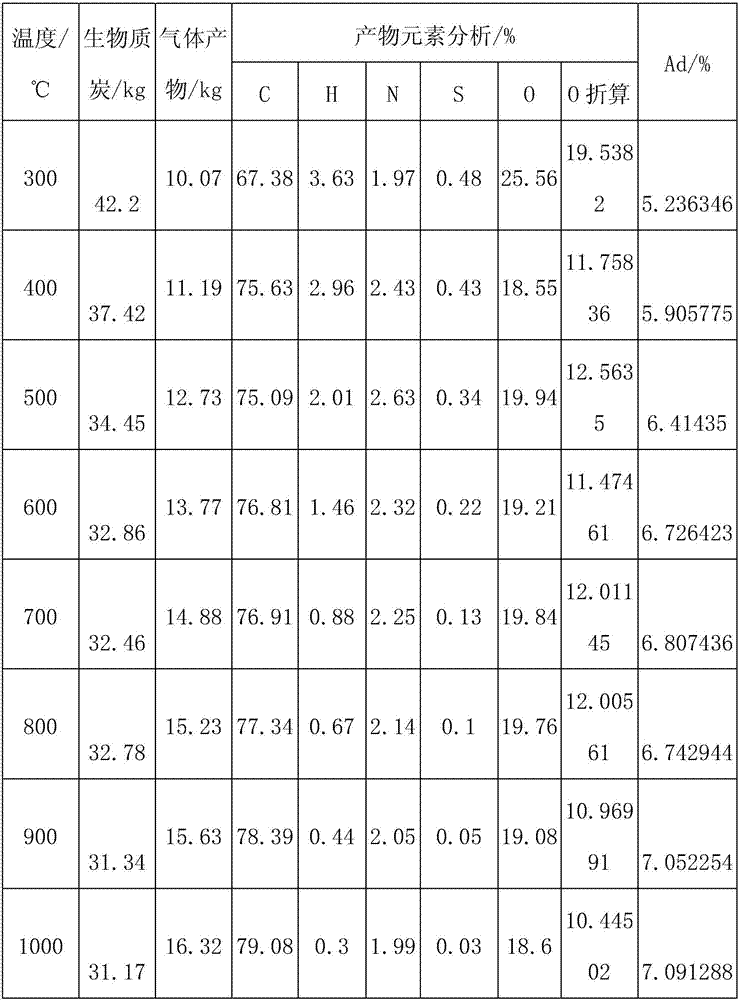

Method for biomass carbonization instead of pulverized coal injection in blast furnace

InactiveCN108003959AExpand the range of optionsIncrease production capacityBiofuelsSolid fuelsCombustion chamberCarbonization

The invention provides a method for biomass carbonization instead of pulverized coal injection in a blast furnace. Dried straw and other biomass raw materials are extruded to obtain a machine-made rod, and the machine-made rod is carbonized by a carbonization furnace to obtain carbon powder at a temperature of 300 to 1000 DEG C. The carbon powder obtained by the furnace is mixed with pulverized coal and injected into the blast furnace to greatly reduce a coal ratio and flux usage amount and improve production efficiency; latent heat of flue gas is fully utilized to reduce emission of exhaust gas; the exhaust gas discharged from a combustion chamber is filtered and discharged into air through a microporous ceramic tube. Biomass resources and sensible heat of the flue gas, and oxygen and carbon monoxide in the flue gas are used in ironmaking production. In addition, the biomass resources can also be used as a substitute for the pulverized coal or coke powder used in iron ore sintering machines. The method comprehensively utilizes existing equipment to treat waste materials such as biomass raw materials and the flue gas, saves coking coal resources, fully exerts potential advantages of biomass energy, protects environment, and reduces costs.

Owner:UNIV OF SCI & TECH BEIJING

Nitric oxide (NOx) control method based on inhibiting fuel nitrogen conversion during iron ore sintering process

The invention discloses a nitric oxide (NOx) control method based on inhibiting fuel nitrogen conversion during an iron ore sintering process. The method comprises the steps of screening particles less than 1mm from sinter return fines; after burdening the sinter return fines less than 1mm, fine hematite, quicklime, sinter fuel and hydrocarbon with cohesive action, performing prepelletisation of iron ore concentrate in a rotary drum mixer; performing pelletization on the obtained mixture, residual iron-bearing materials, solvents and the sinter return fines; laying out, igniting and sintering the obtained particles. By the method disclosed by the invention, emission reduction methods are respectively designed aiming at the conversions from volatile nitrogen and char nitrogen to NOx; through inhibiting the oxidizing reaction of fuel nitrogen (N) and promoting the reduction reaction of NOx, the emission of NOx during the sintering process is controlled; the method is strong in pertinence and good in emission reduction effect.

Owner:CENT SOUTH UNIV

Method for segmental gathering, waste-heat utilization and SOx-NOx emission reduction of iron ore sintering flue gas

ActiveCN106996702ALow running costTo achieve the purpose of economical denitrificationWaste heat treatmentFlue gasIron ore sintering

The invention relates to a method for segmental gathering, waste-heat utilization and SOx-NOx emission reduction of iron ore sintering flue gas. The method is particularly suitable for an iron ore sintering flue gas treatment process in the iron and steel industry. The method can serve as enterprise supporting construction for an existing sintering desulfurization process and also can serve as new construction for a mature sintering flue gas desulfurization process. The method includes a low-temperature high-NOx low-SOx flue gas and sintering ore heat exchange and NOx removal process and a high-temperature high-SOx low-NOx heat recovery and SOx removal process. The technological method provided by the invention can be used for fully recovering sintering ore and sintering flue gas waste heat and reducing emission of SOx and NOx at the same time, has the advantages of being short in process flow, high in applicability, low in investment and operation cost and the like, and has quite high application value.

Owner:钢研晟华科技股份有限公司

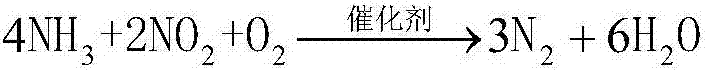

Negative-pressure ignition control device for sintering iron ore

The invention discloses a subpressure ignition control device which is hard to loss effect and is used for sintering an iron ore. The device includes an air box body, the vertical tube of the air box connected on the body of the air box as well as a large flue and a by-pass pipe connecting the vertical tube of the air box and the large flue; a clapboard is arranged in an access between the vertical tube of the air box and the by-pass pipe; the clapboard is fixed on the inner wall of the access so as to lead an air flow to pass through from the lower part of the access. A bending tube provided with the clapboard is connected between the air box and the by-pass pipe to lead the air box to have the function of dust removing and lead a bulk to be deposited at the bottom part of the bending tube and to be incapable of entering the by-pass tube, thus avoiding the by-pass tube from plugging; an electric flap the opening of which can be controlled is arranged in the by-pass tube to control the subpressure of the lower surface of an ignition air box; the bottom part of the bending tube is provided with a double-layer ash discharge valve which is convenient for cleaning sediments. The subpressure ignition control device of the invention can flexibly and effectively control the subpressure of the ignition air box and the subpressure of a hearth, maintain the normal running of the sintering process, save the energy consumption for ignition and is applicable for the ignition and sintering of a sintering machine by a v-ti magnetite concentrate ore in particular.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

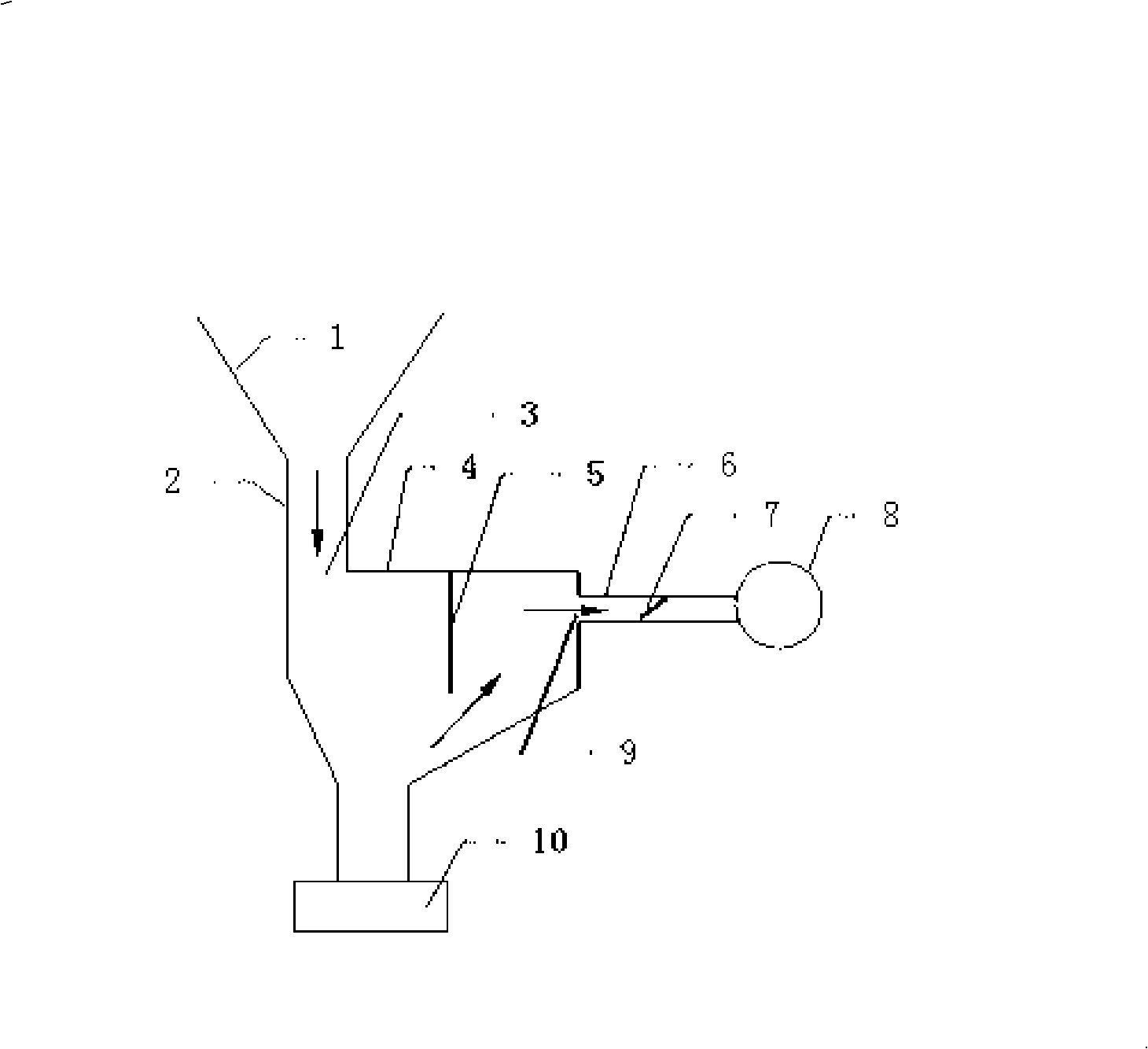

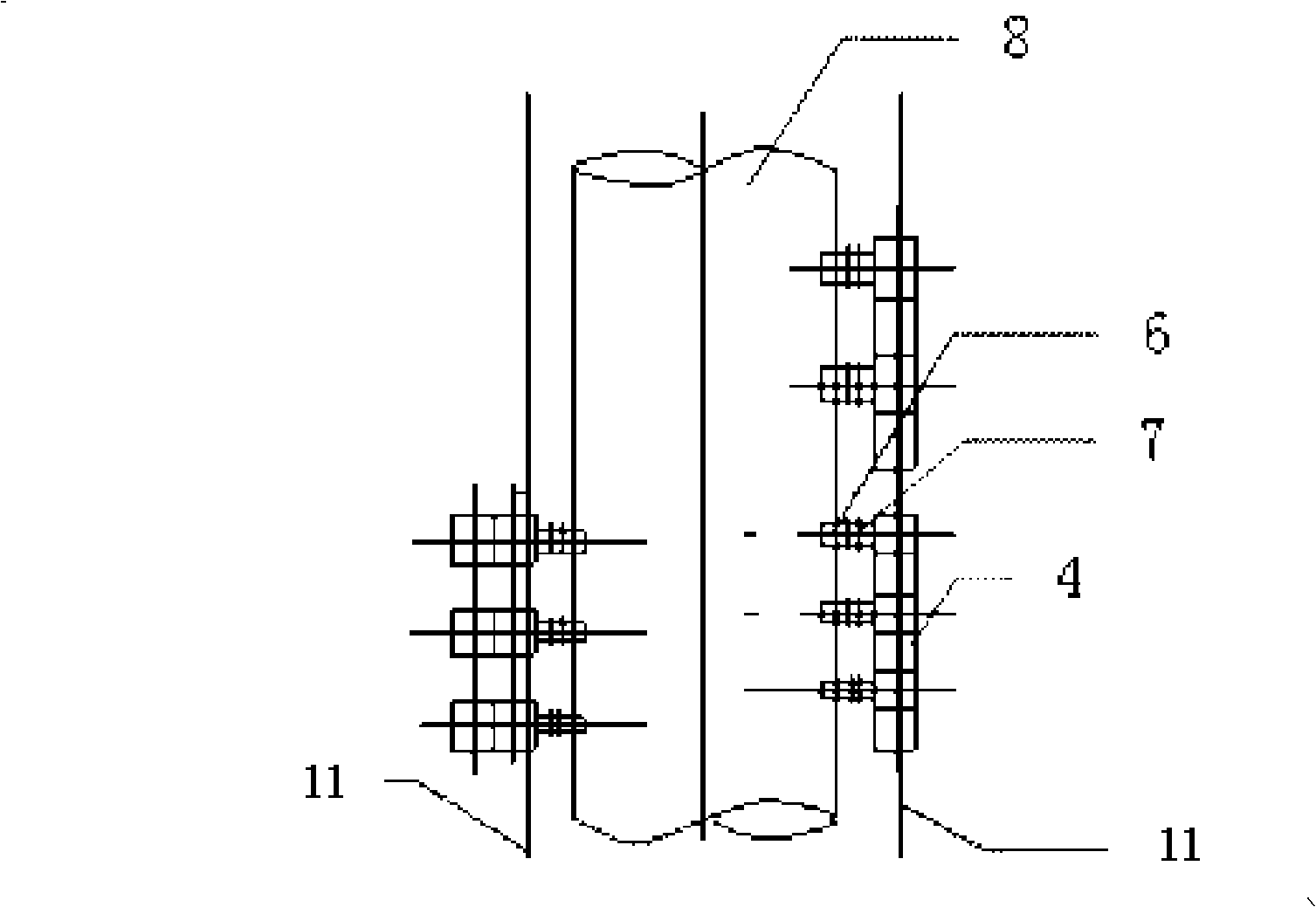

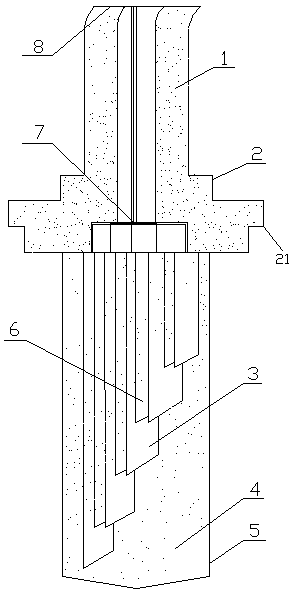

Interior temperature measuring equipment for material bed of belt-type sinterer

ActiveCN102840926AAvoid enteringQuick responseThermometers using electric/magnetic elementsUsing electrical meansFiberIron ore sintering

The invention relates to the field of iron ore sintering equipment, in particular to interior temperature measuring equipment for a material bed of a belt-type sinterer. The interior temperature measuring equipment for the material bed of the belt-type sinterer comprises a fire-resistant tube, a thermocouple set, a protective sleeve and a dataline joint. The protective sleeve is fixedly connected with the fire-resistant tube. The dataline joint is installed in the fire-resistant tube. The thermocouple set is installed in the protective sleeve and is formed by arranging a plurality of thermocouples. The tops of the thermocouples are connected with the dataline joint. The bottoms of the thermocouples are stair-stepping. A slice for shielding an electrical insulating fiber body is arranged between two adjacent thermocouples. The gap in the fire-resistant tube is filled by high temperature resistant asbestos, and the gap in the protective sleeve is filled by high temperature resistant insulating particles. According to the interior temperature measuring equipment for the material bed of the belt-type sinterer provided by the invention, the temperature instantaneous values at different positions in the height direction in the sintering material bed can be tested with rapid response speed and small temperature measuring error. The interior temperature measuring equipment for the material bed of the belt-type sinterer can work in a comparatively severe environment in the production process. A bump is arranged on the fire-resistant tube, so that the measuring precision is further improved.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Method for realizing iron ore sintering NOx and dioxin emission reduction by recycling waste activated carbon

ActiveCN109248673AHigh adsorption activityEnhanced reductive degradationDispersed particle separationCombustible gas purificationWater immersionIron ore sintering

The invention discloses a method for realizing iron ore sintering NOx and dioxin emission reduction by recycling waste activated carbon, the method comprises the following steps: water immersion, grinding and drying pretreatment are performed on the waste activated carbon to obtain activated carbon powder, after a urea solution is sprayed on the surface of the activated carbon powder, the activated carbon powder is mixed with raw materials comprising a coarse grain fuel, slaked lime and fine-grain hematite for granulating to obtain a granular material I; raw materials comprising an iron-containing raw material, a fusing agent and a fine granular material are mixed for granulating to obtain a granular material II; the granular material I and the granular material II are uniformly mixed andsequentially subjected to material distribution, ignition and sintering. According to the method, under the condition that the sintering production quality index is not influenced, the waste activatedcarbon is used to replace part of coke powder or anthracite, the waste activated carbon can be recycled, NOx and dioxin emission in the sintering process can be reduced, follow-up tail end treatmentpressure is reduced, and the sintering production cost is reduced.

Owner:CENT SOUTH UNIV

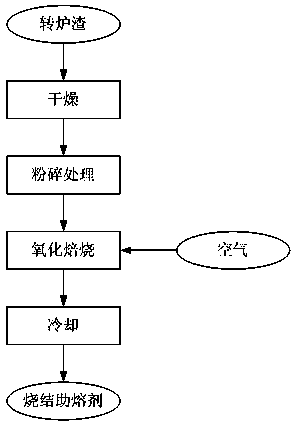

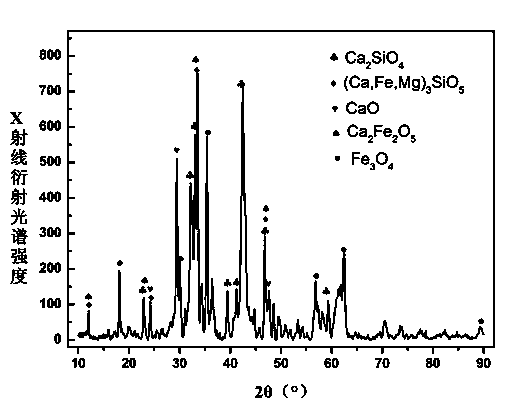

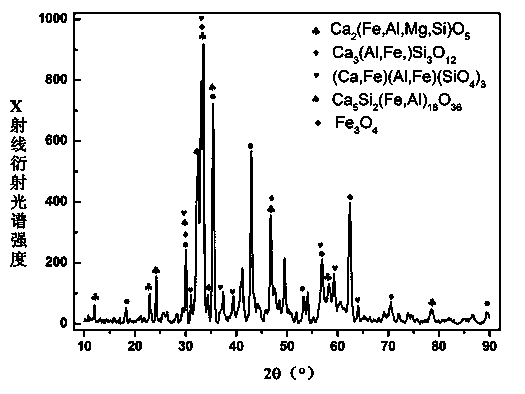

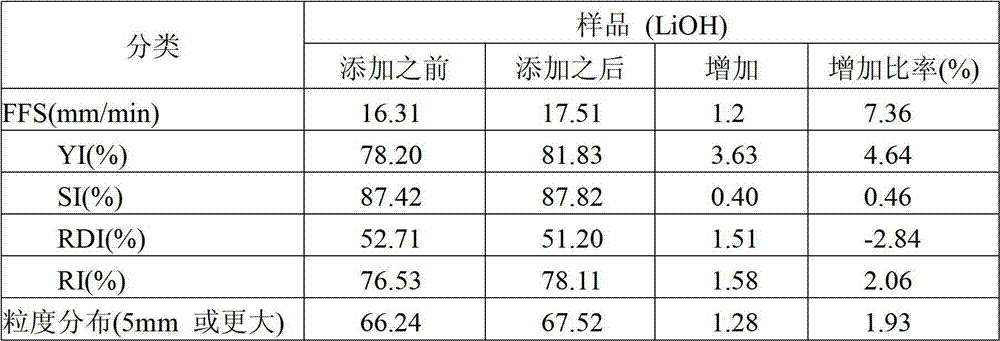

Preparation method of sintering flux for iron ore sintering

The invention provides a preparation method of a sintering flux for iron ore sintering, which can solve the problem of waste recycling of converter slags, also can produce a low-cost sintering flux, and reduces the damages of converter slags on the environment. According to the invention, converter slags and air are fully reacted at a high temperature of 800-1100 DEG C, a main ingredient SFCA (complex calcium ferrite) in an obtained sintering flux product can reduce the melting point of the flux, so that the formation of a liquid phase in the process of sintering is facilitated, therefore, the energy consumption is reduced, conditions are provided for the improvement of the efficiency of a blast furnace, the maximum value of converter slags is utilized as much as possible, the recycling of metallurgical slags is implemented, and the energy conservation and emissions reduction of enterprises are facilitated. The preparation method of a sintering flux for iron ore sintering disclosed by the invention provides products and technical supports for the reduction of ironmaking and steelmaking production costs and the implementation of energy conservation and emission reduction.

Owner:CHONGQING UNIV

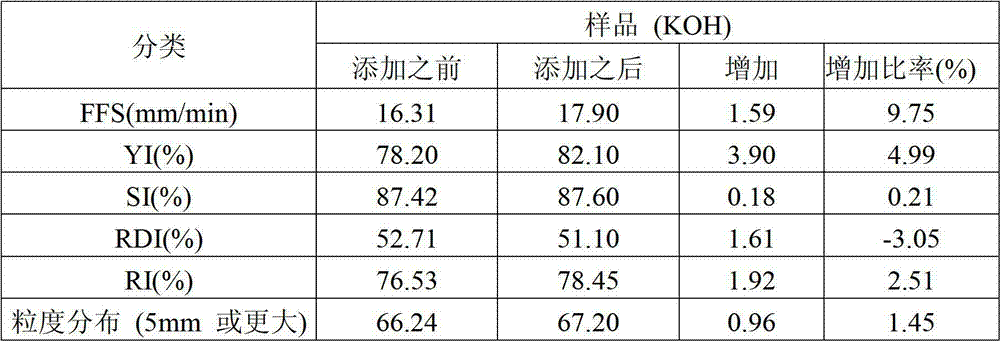

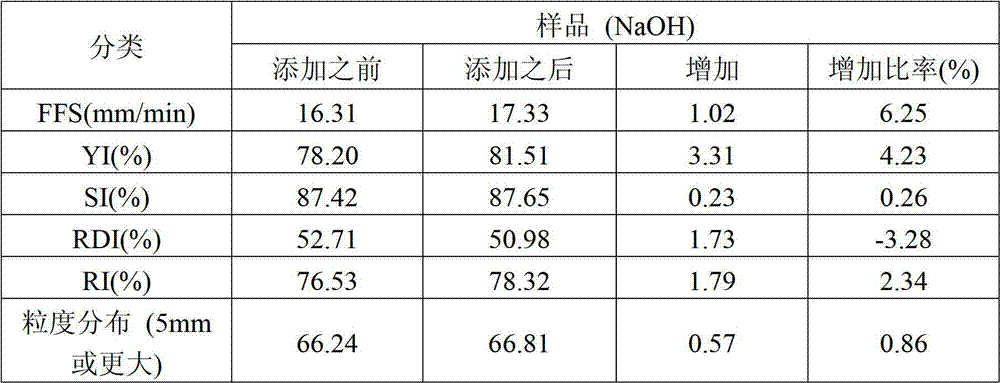

Method for researching sintering performance of iron ore by utilizing mini-sintering test

InactiveCN102213659AFlexible adjustmentSimple test methodChemical methods analysisStrength propertiesLiquid phaseSintering

The invention relates to a method for researching the sintering performance of iron ore by utilizing a mini-sintering test, which belongs to the technical field of a physical and chemical detection. The method provided by the invention is used for disclosing the law of the influence of a liquid phase fluidity index of the iron ore on a sintering ore strength index. The method provided by the invention is carried out according to the following steps: selecting tested iron ore according to the liquid phase fluidity index of iron ore; drying and pelletizing the selected iron ore, coke powder and quicklime; adding quicklime or mixed lime to the prepared material particles to obtain evenly mixed material according to the required alkalinity and carbon proportion and carrying out the mini-sintering test in a mini-sintering device; carrying out the strength measurement on the sintering ore with different size fractions in an strength testing device; and summarizing the law of the influence of the liquid phase fluidity index on the sintering ore strength index according to the test data. According to the method provided by the invention, the law of influence of the liquid phase fluidity index of the iron ore on the sintering ore strength index can be reflected conveniently and quantitatively through the test result and the optimized sintering ore proportioning scheme can be provided timely according to the quality requirements of the sintering ore. In the invention, the test method is simple; the parameter adjustment in the test process is flexible; and the repeatability is good.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

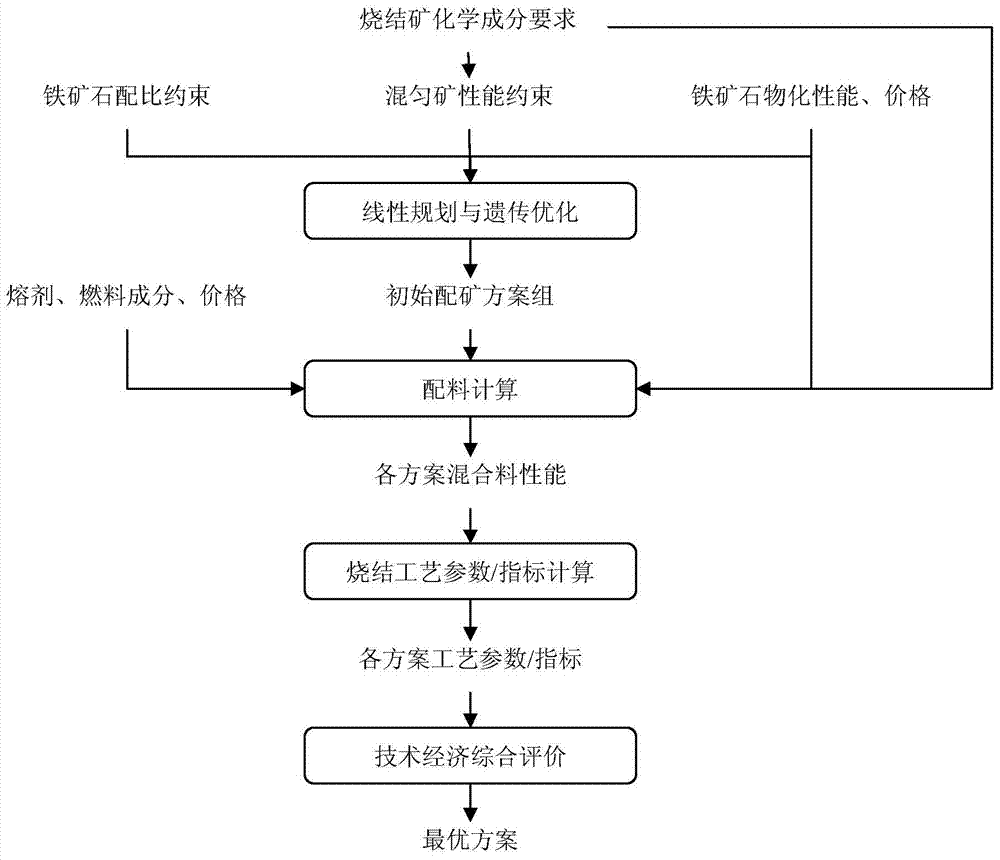

Method for calculating optimum preparing and adding proportion of iron ore sintering

The invention discloses a method for calculating the optimum preparing and adding proportion of iron ore sintering. According to the method, according to the uniformly mixed ore chemical ingredient requirements and raw material physical and chemical properties and proportioning constraints, a method of combining linear planning and a genetic algorithm is adopted for calculating an initial ore proportioning scheme group; sintering process parameters, production quality indexes and ore proportioning costs of each ore proportioning scheme are calculated; the technical economic integral evaluation index of the ore proportioning scheme is calculated according to the ore proportioning cost, the sintering solid fuel mixture ratio and the sintering ore rotating drum intensity by using the coefficient, and the highest integral evaluation index is used as the selection basis of the best ore proportioning scheme; the iron ore purchase and the sintering production are guided; the technical support is provided for the popularization and the application of new ore types.

Owner:CENT SOUTH UNIV

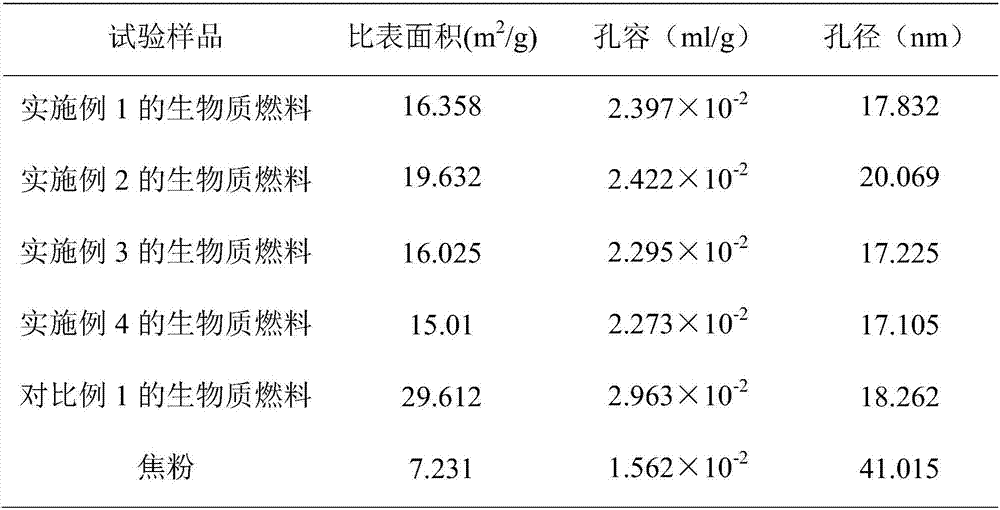

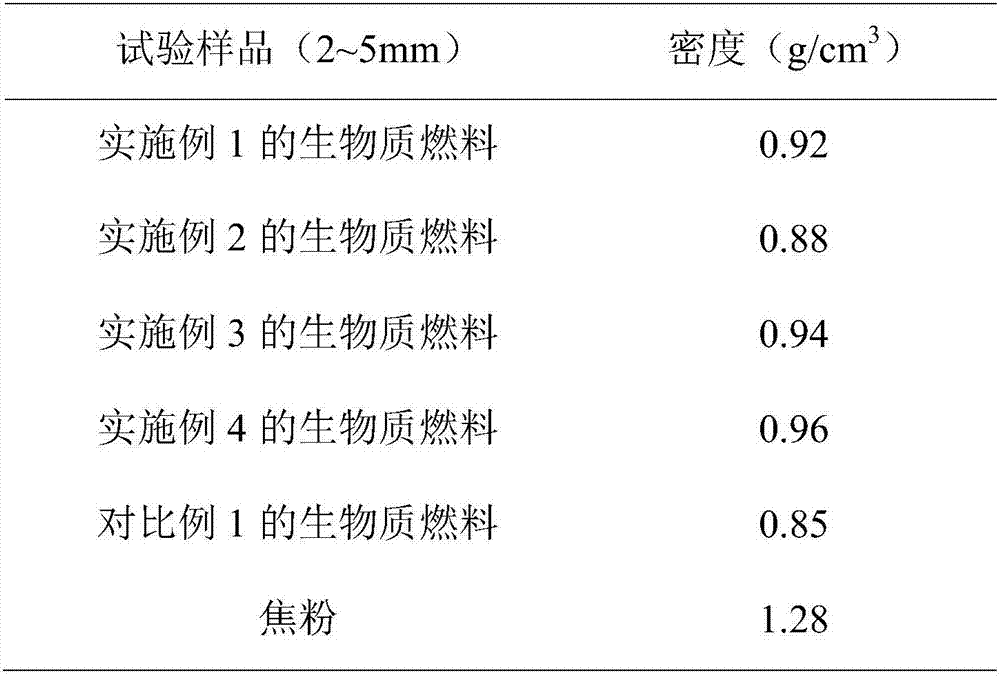

Biomass fuel for iron ore sintering and preparation method and application of biomass fuel

The invention discloses biomass fuel for iron ore sintering and a preparation method and application of the biomass fuel. The biomass fuel is prepared through the steps that molding and carbonizing are conducted on the biomass fuel, and then filling and packing are conducted on the biomass fuel by means of a urea solution and CaO powder according to the requirements of iron ore sintered fuel. Theproblems that biomass is loose, porous, large in specific surface area, low in fixed carbon content, too fast in reaction and the like are solved, the performance index of the prepared biomass fuel isclose to that of coke powder, part of the coke powder can be replaced to conduct sintering production, and meanwhile the discharge amount of pollutant in the iron ore sintering production process canbe effectively inhibited.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

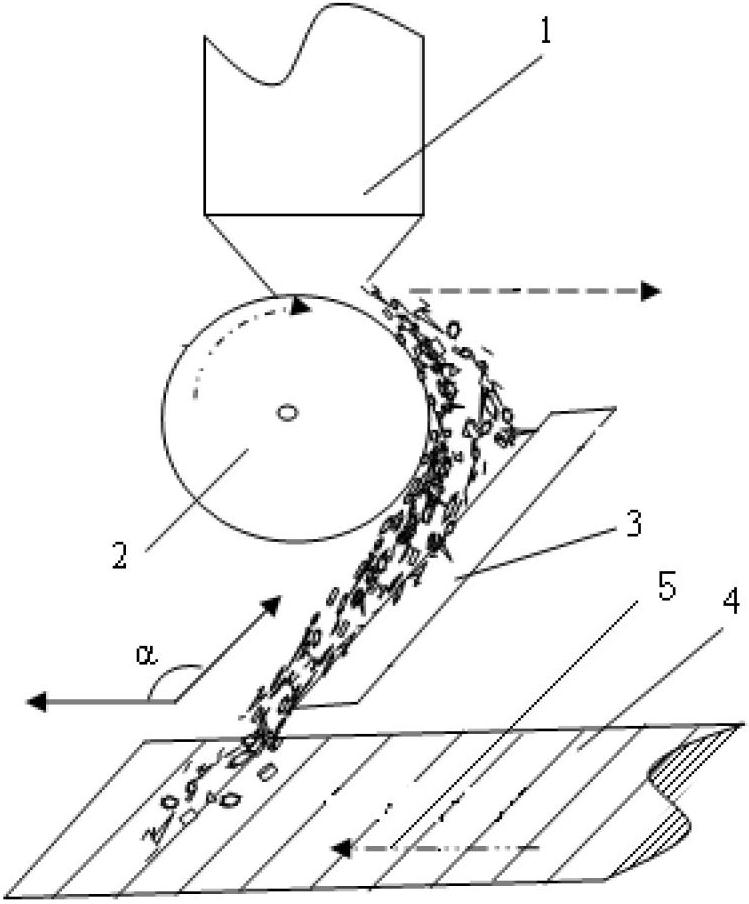

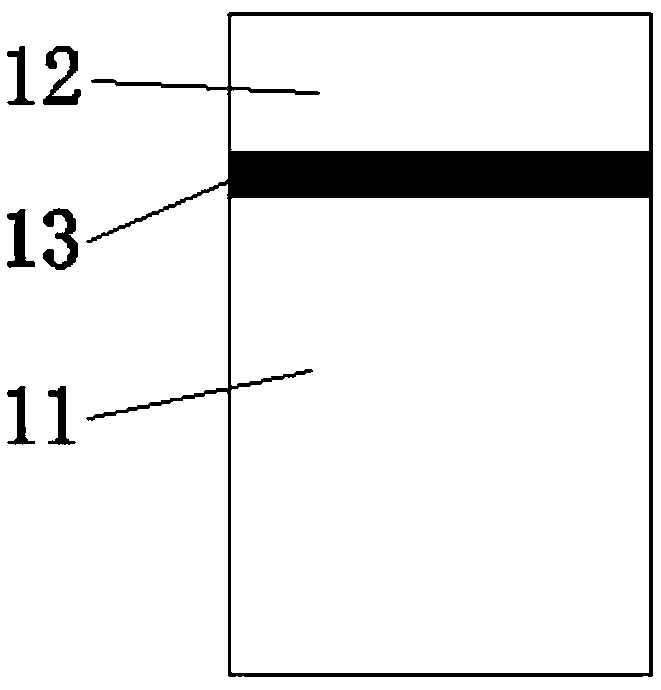

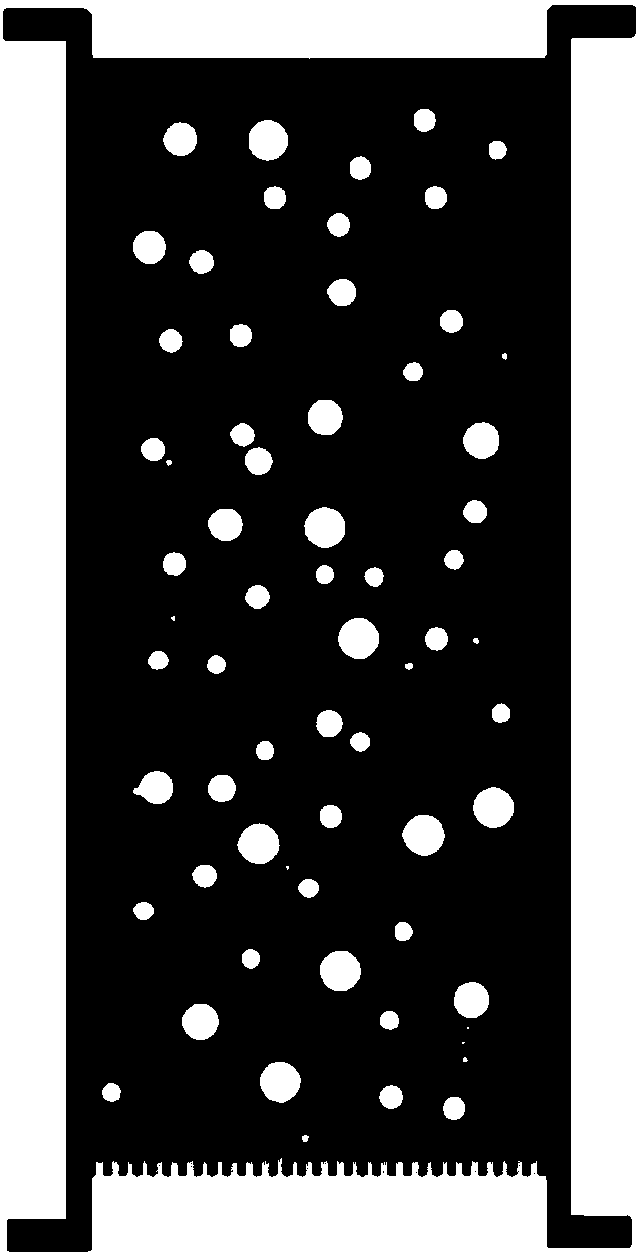

Iron ore sinter mixture distribution method

ActiveCN102676797AImprove magnetic susceptibilityImprove stressFurnace typesIronstoneMachine utilization

The invention discloses an iron ore sinter mixture distribution method. By adopting a mixture preparation technology of pre-mixing magnetite concentrate and coke powder and a matched mounting mode with a round roller, a magnetic system and a reflecting plate, the particle size segregation, the fuel segregation and the segregation of materials such as the magnetite concentrate and the like in the mixture distribution can be enhanced; the air permeability of a sinter bed can be further improved by enhancing the particle size segregation; through the enhancement of the fuel segregation, the heatdistribution is more reasonable, the uniform-heat sintering is realized, and the fuel usage is reduced; and through the segregation of the magnetite concentrate, the oxidation of the magnetite is sufficiently utilized to release heat, so that the heat accumulation effect is enhanced, and the fuel usage is further reduced. The method disclosed by the invention can comprehensively improve the air permeability, the heat distribution and the heat transfer condition of the sinter bed, reduce the fuel usage and obviously improve the yield and quality indexes of sinter; and the indexes such as the vertical sintering speed, the sintering machine utilization coefficient, the finished sintering product rate, the sinter tumbler strength, the reducing degree and the like can be improved to different degrees.

Owner:CENT SOUTH UNIV

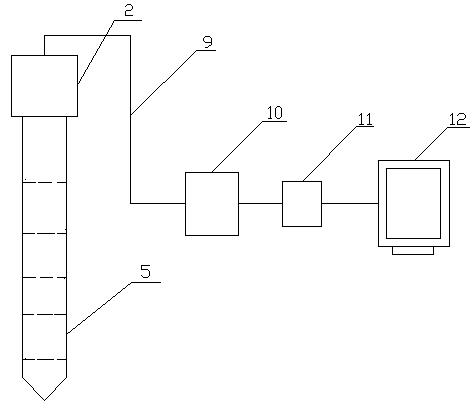

Detecting method for iron ore sintering machine air leakage rate

ActiveCN109490001ACompact structureEasy to useFurnace componentsStructural/machines measurementIron ore sinteringEnergy consumption

The invention discloses a detecting method for the iron ore sintering machine air leakage rate. The detection method comprises the following steps that detection devices are made firstly, and a row ofthe detection devices are arranged on a sinter bed; when sintering is conducted, wind speeds measured by all the detection devices are recorded, the material surface of the sinter bed is subjected tomesh generation, all wind speeds recorded by the detection devices from beginning to end sequentially serve as the wind speeds of all grid points on longitudinal boundary lines where the detection devices are located, and the effective air amount QY passing through the bed within unit time is calculated; the total flue gas amount QZ in a flue within unit time is calculated; the amount QE of vapour generated within the unit time is calculated; the QY, the QZ and the QE are converted into the amount under the standard state, the sintering system air leakage QLstandard within unit time is calculated, and the sintering system air leakage rate K within unit time is calculated. Accordingly, by means of an optimized sintering effective air amount measurement and calculation method, the calculation accuracy of the sintering air leakage rate is improved, maneuverability is high, rapidness and convenience are achieved, and then the theoretical basis is provided for lowering energy consumption and increasing the yield for sintering production.

Owner:MAANSHAN IRON & STEEL CO LTD

Iron ore sintering method by using light-burnt magnesium ball

ActiveCN108070713AReduce contentOptimizing technical indicators of sintering productionBlast furnace detailsBlast furnace smeltingIron ore sintering

The invention discloses an iron ore sintering method by using light-burnt magnesium ball. During the iron ore sintering process, light-burnt magnesium ball, iron ore powder, return mine, coke powder,and a flux are configured in proportion, and then steps of uniform mixing by adding water, granulation, material distribution, ignition, sintering, cooling, and fragmentation are carried out to obtainan agglomerate finished product. The light-burnt magnesium ball can substitute dolomite powder, so that a sintering mineralization rate is increased, a reasonable mineral composition and an ore-phasestructure are obtained, the method can guarantee the requirement of blast-furnace smelting on an agglomerate chemical component MgO, cannot deteriorate a sintering process, and has important practical significance.

Owner:BAOSHAN IRON & STEEL CO LTD

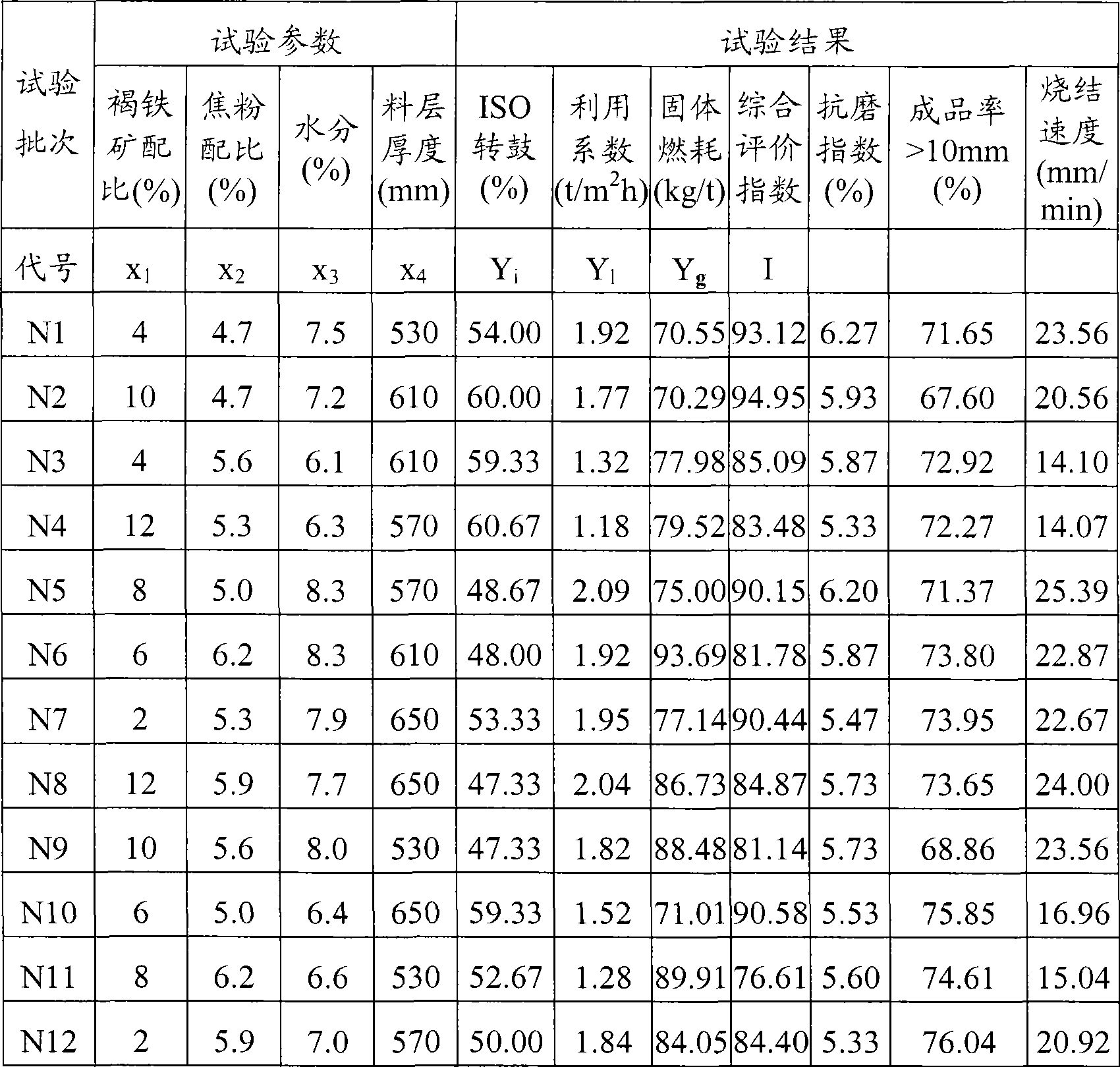

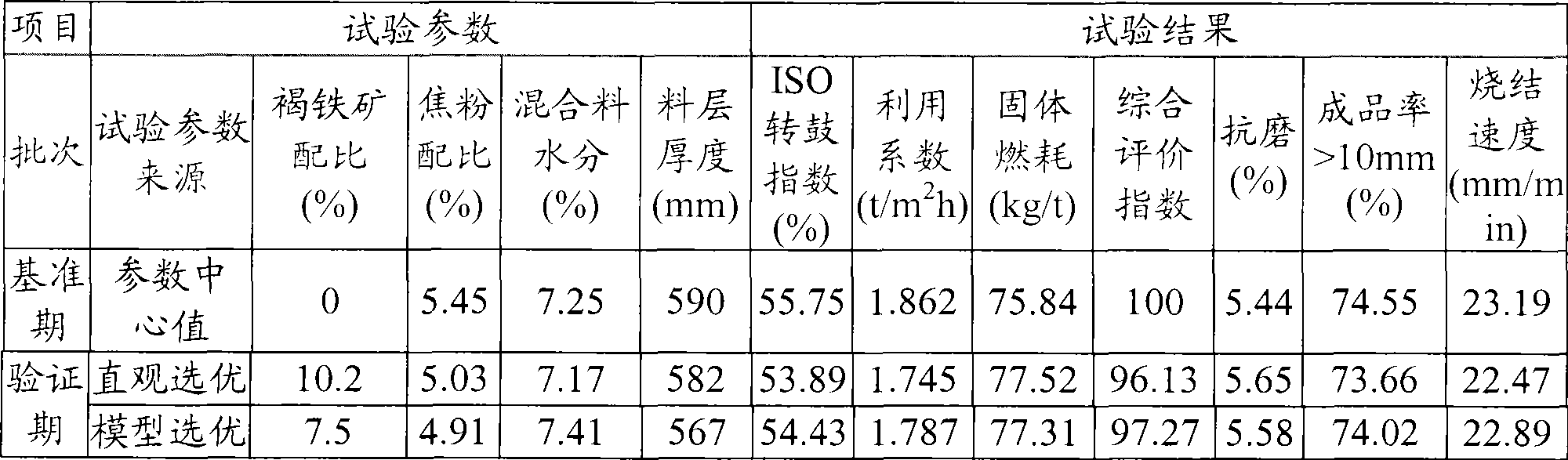

Iron ore sintering test method

The invention discloses an iron ore sintering test method which includes steps as follows: confirming object and influence factor of the iron ore sintering test method for processing multi-factor multi-level test; selecting suitable uniform design test method for confirming a used uniform design table; processing iron ore ingredient, mixing, igniting and air suction sintering test according with the confirmed uniform design table for obtaining a series test result; utilizing the test result corresponding to the factor level of the uniform design table for analyzing, using method of direct preferential and model optimum for confirming an optimum parameter combination of the iron ore sintering, and processing must validated test. The method can shorten test time, reduce energy consumption and obtain test result with high efficiency and high quality.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES

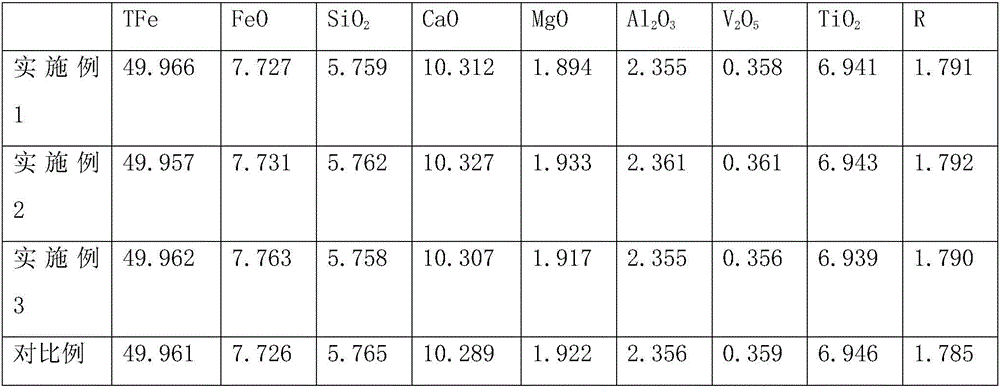

Sintering method of high-titanium vanadium-titanium magnetite concentrates

InactiveCN106244800AIncrease oxygen potentialImprove the utilization factor of sinteringMagnetiteIron ore sintering

The invention belongs to the field of iron ore sintering, and particularly relates to a sintering method of high-titanium vanadium-titanium magnetite concentrates. According to the problem that the sintering performance of the high-titanium vanadium-titanium magnetite concentrates is poor in the prior art, the sintering method of the high-titanium vanadium-titanium magnetite concentrates is provided and comprises the following steps that a, the high-titanium vanadium-titanium magnetite concentrates, a sintering aid, return ore and potassium permanganate are mixed evenly to obtain a mixture; and b, the mixture in the step a is sintered, and when the temperature of sintering waste gas reaches the maximum value and starts to drop, sintering is finished. When the high-titanium vanadium-titanium magnetite concentrates are sintered, a potassium permanganate solution is added, and the sintering utilization factor, the sintered ore drum index and the sintering yield are increased. The method is easy to operate, the improvement effect of the sintering performance is remarkable, potassium permanganate raw materials are easy to obtain and low in price, and a brand-new manner is provided for improving the sintering performance of the high-titanium vanadium-titanium magnetite concentrates.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com