Comprehensive treatment method for iron ore sintering smoke pollutants

A technology for sintering flue gas and comprehensive treatment, applied in waste heat treatment, separation methods, chemical instruments and methods, etc., can solve the problems of low flue gas circulation ratio, low efficiency of desulfurization system, low concentration, etc., and achieve energy saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

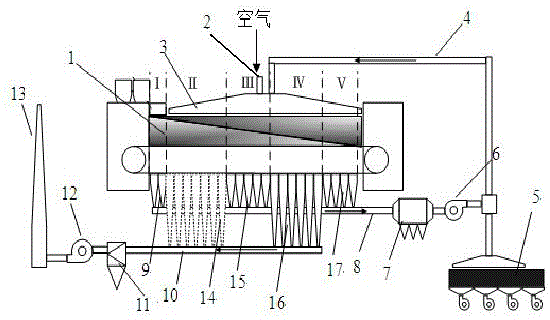

[0021] A comprehensive treatment method for iron ore sintering flue gas pollutants of the present invention, the specific process is as follows: in the sintering granulation process, on the basis of the heat released by the digestion of quicklime in the sintering material, the sintering high-temperature steam is used to preheat the mixed material, The temperature of the sintered material reaches 80°C; the nine-roller material distribution technology is used in the material distribution, so that the content of coke powder in the sintered bottom layer material is 0.4% lower than that of the surface layer material; there are 24 bellows in the sintering machine, and the sintering end is reached in the 22nd bellows, and the machine head The flue gas of No. 1~2 wind boxes (Area Ⅰ), No. 11~14 wind boxes in the machine (Zone III) and No. 21~24 wind boxes (Zone V) at the rear of the machine are circulated to the sintered material surface of the sintering machine, and the flue gas circula...

Embodiment 2

[0023] A comprehensive treatment method for iron ore sintering flue gas pollutants of the present invention, the specific process is as follows: in the sintering granulation process, on the basis of the heat released by the digestion of quicklime in the sintering material, the sintering high-temperature steam is used to preheat the mixed material, The temperature of the sintered material reaches 90°C; the nine-roller material distribution technology is used in the material distribution, so that the content of coke powder in the sintered bottom layer material is 0.8% lower than that of the surface layer material; there are 24 bellows in the sintering machine, and the sintering end is reached in the 22nd bellows, and the machine head The flue gas of No. 1~2 wind boxes (Area Ⅰ), No. 11~14 wind boxes in the machine (Zone III) and No. 21~24 wind boxes (Zone V) at the rear of the machine are circulated to the sintered material surface of the sintering machine, and the flue gas circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com