Patents

Literature

787 results about "Smoke hood" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A smoke hood is a protective device similar in concept to a gas mask. A translucent airtight bag seals around the head of the wearer while an air filter held in the mouth connects to the outside atmosphere and is used to breathe. Smoke hoods are intended to protect victims of fire from the effects of smoke inhalation.

Smoke hood with oxygen supply device and method of use

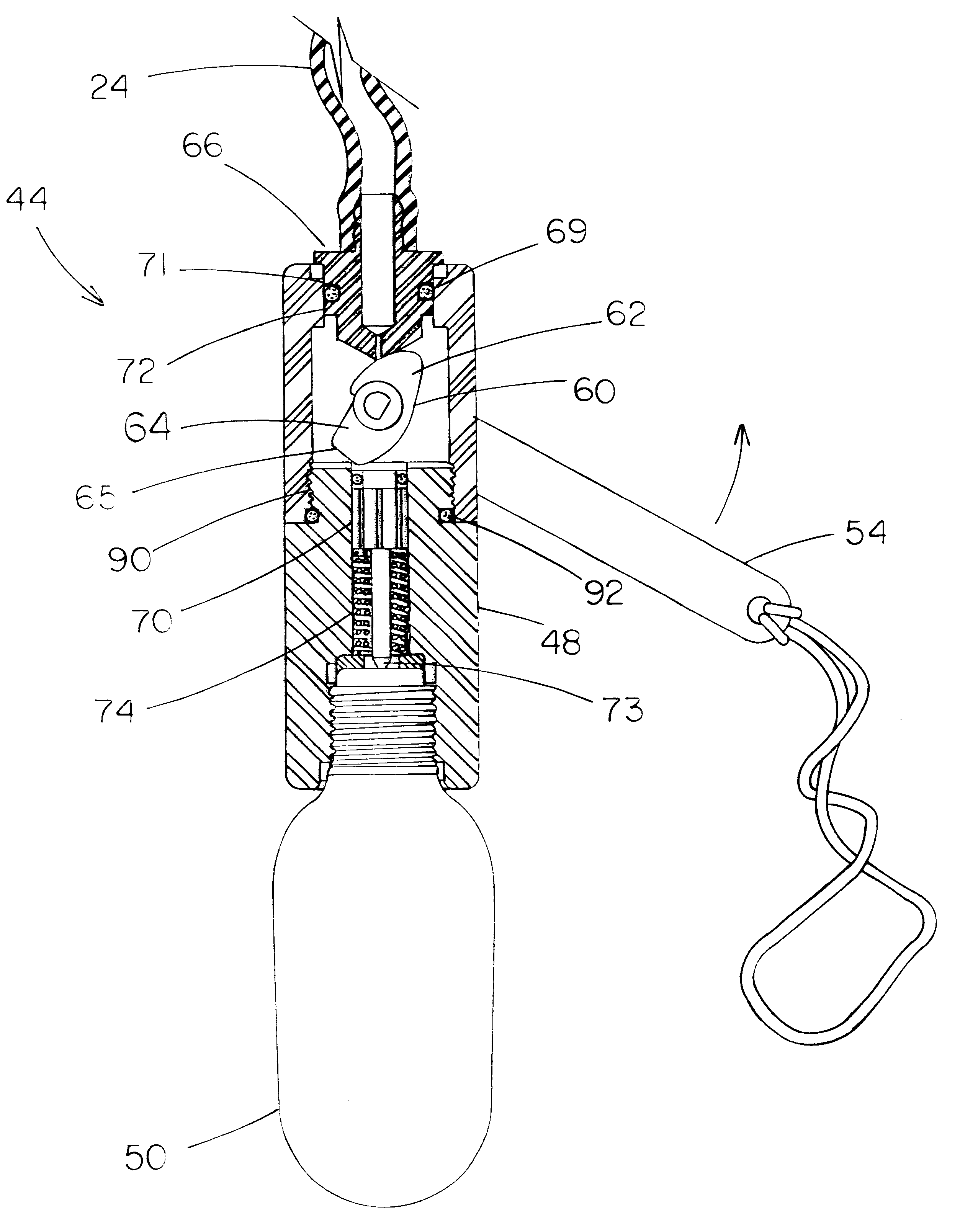

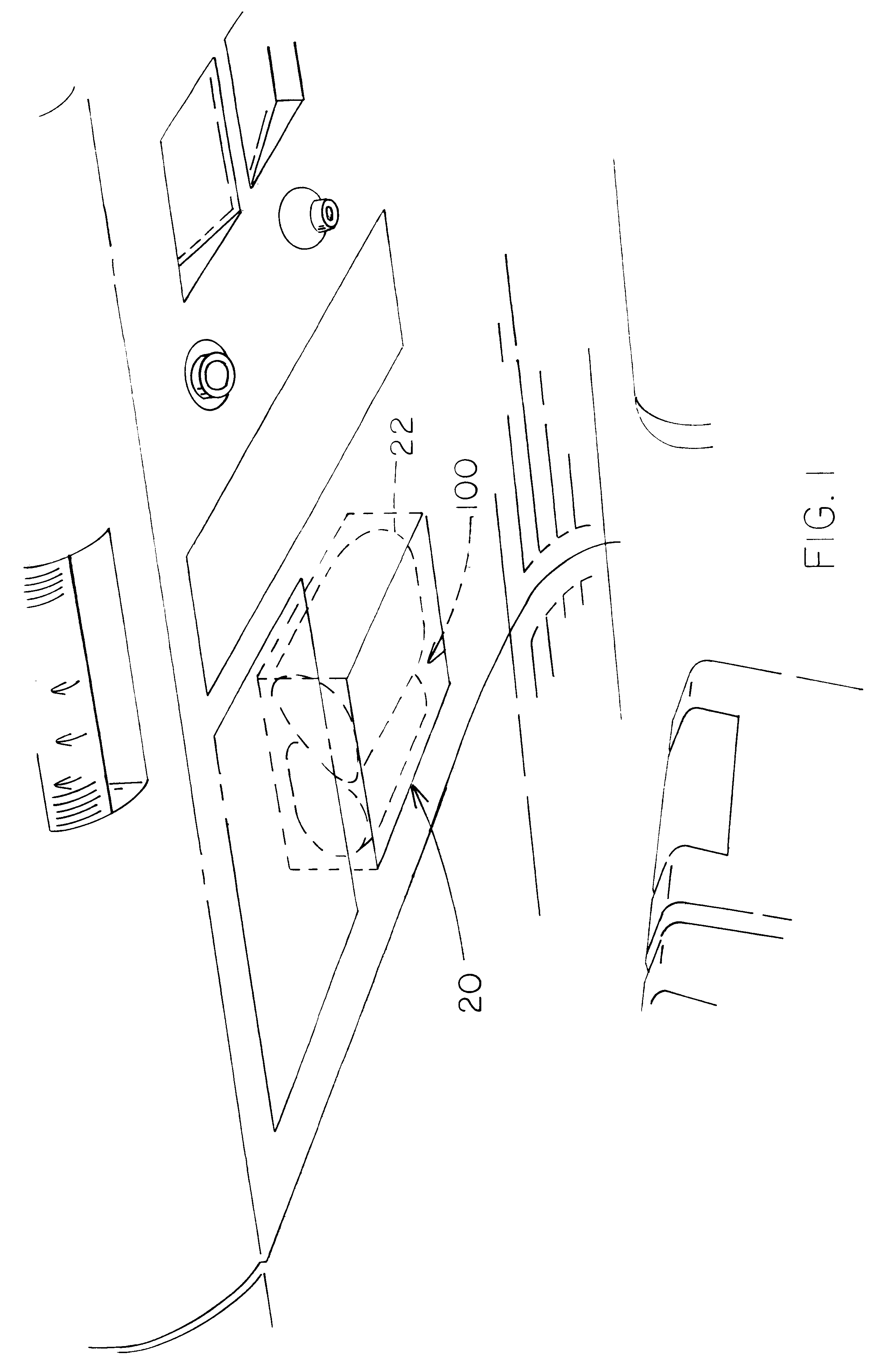

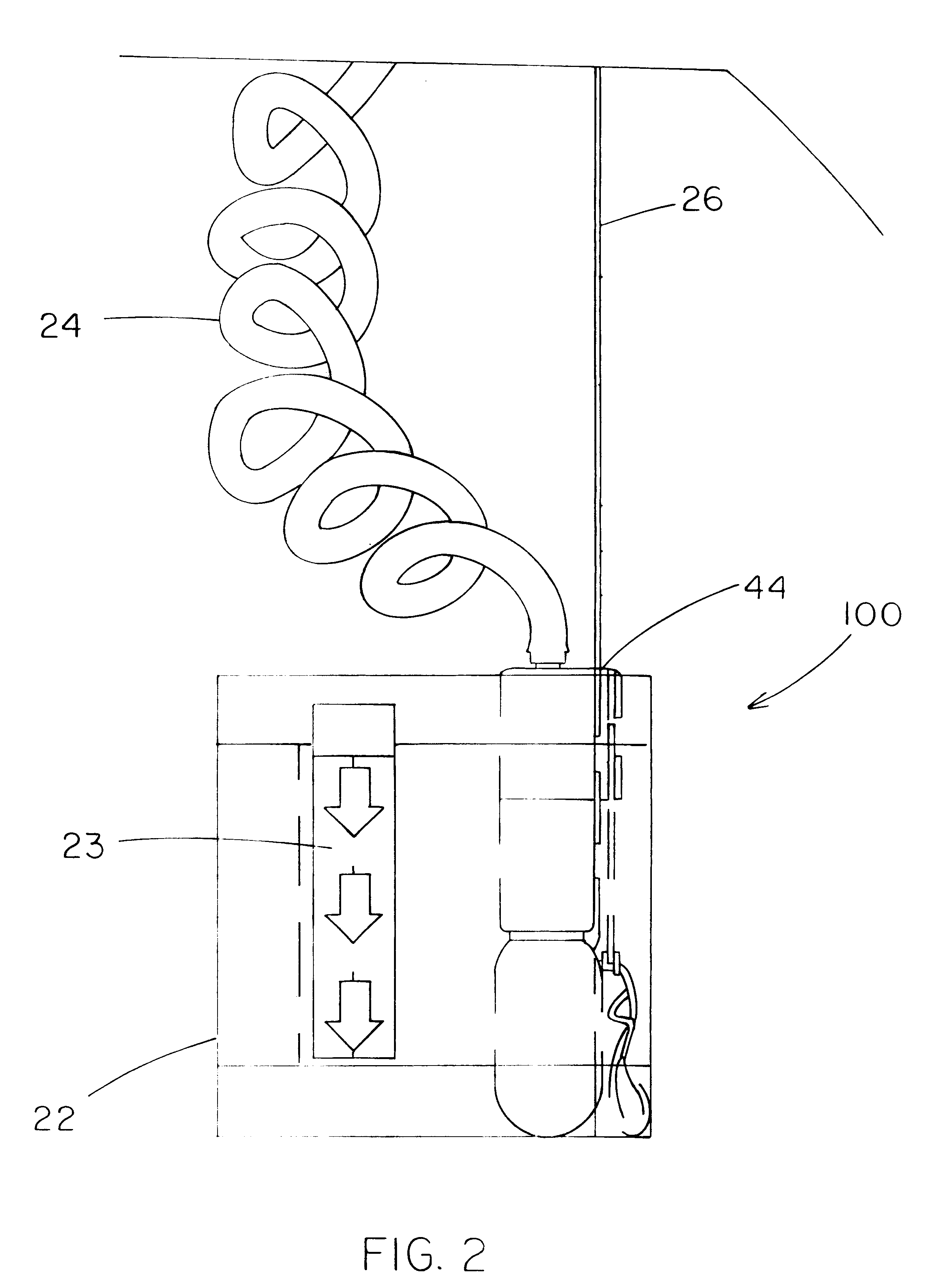

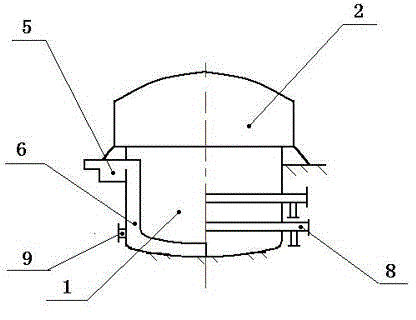

An emergency breathing device including a hood having use and storage configurations, which when compactly wrapped proximate to an oxygen control device for storage is recoverable for use. In use configuration, the hood is capable of being worn upon a user's head, which substantially surrounds the user's head. Hood surface beneath the user's head includes an opening lined with elastic material, which forms a seal about the user's neck at the opening when the hood is donned. An oxygen control device connected to a hood includes a valve body, an actuator, and an oxygen bottle. The valve body provides airflow communication with the interior of the hood, and the oxygen control device is connected to a plumbed breathable oxygen supply through a plumbed source disconnect means removably connected to the valve body. When connected, the oxygen control device permits airflow from the plumbed breathable oxygen supply and valve body to the interior of the hood. A cam within the valve body rotates with the operation of the actuator for engaging a piercing member to pierce the oxygen bottle, causing oxygen to flow from the oxygen bottle to the interior of the hood and forcing the plumbed source disconnect mechanism to simultaneously disconnect from the valve body. The user may therefore don the hood to receive breathable oxygen initially from the plumbed source and then from the oxygen bottle upon operation of the actuator and release from the plumbed source.

Owner:SOUTHWEST BANK OF ST LOUIS

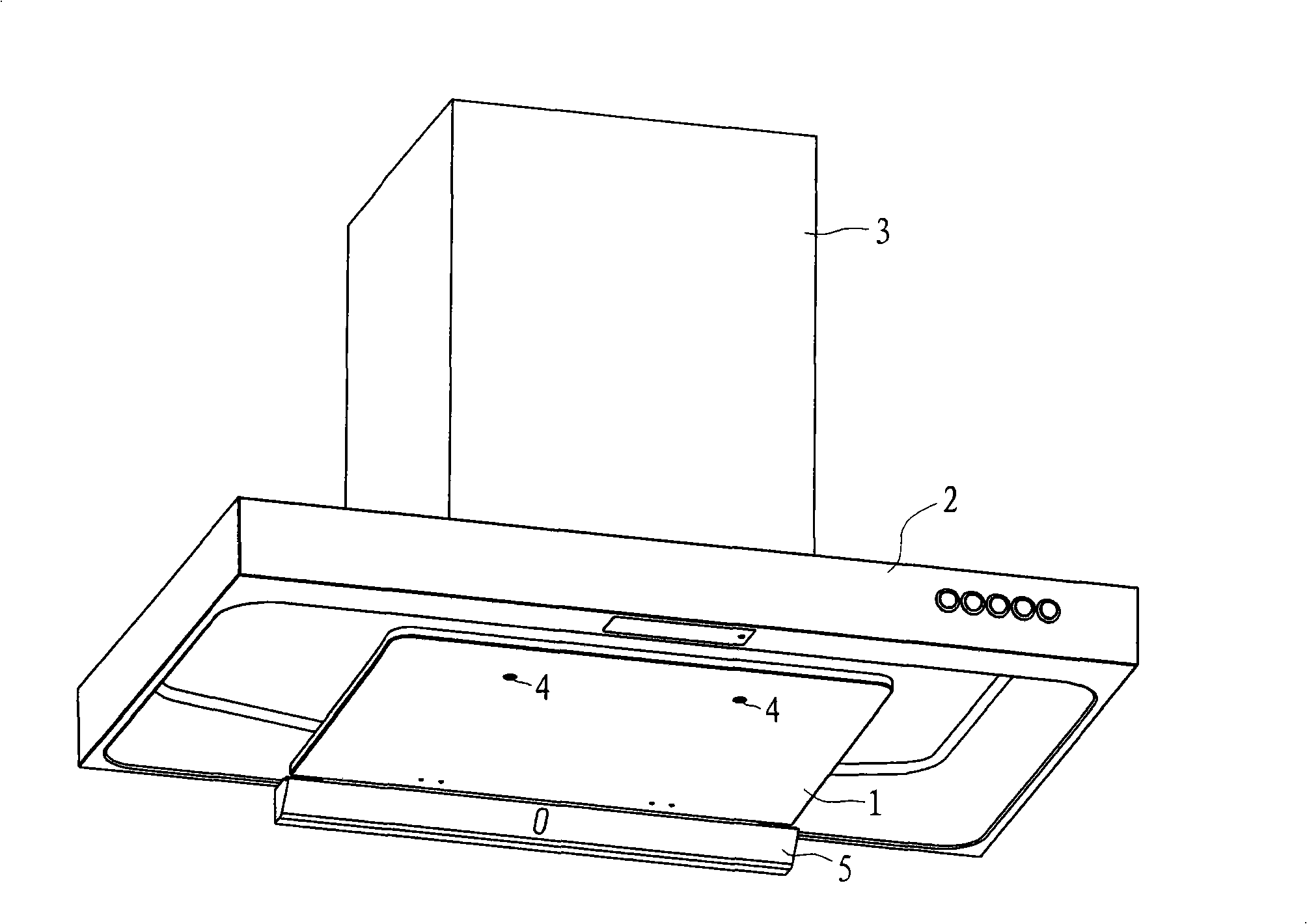

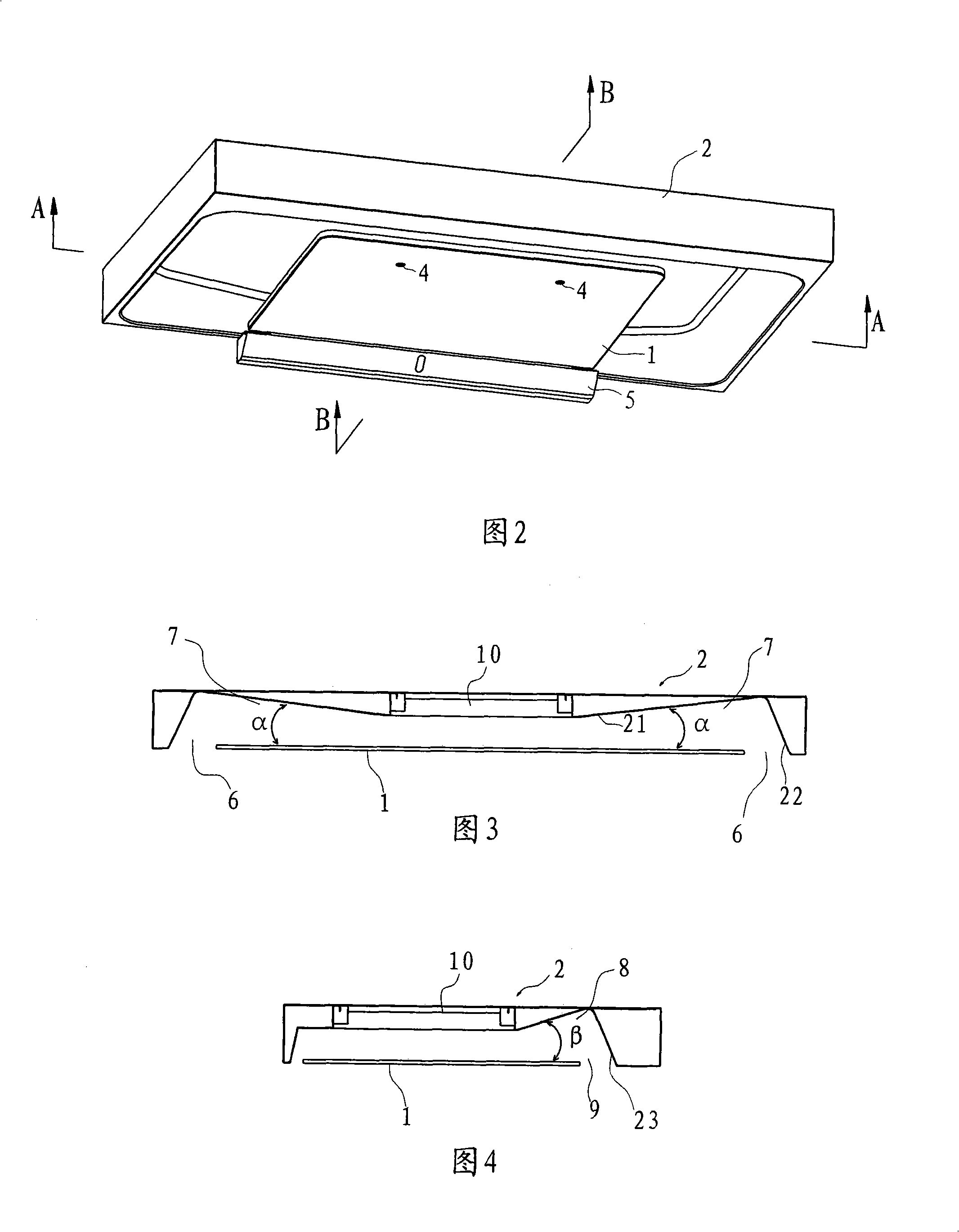

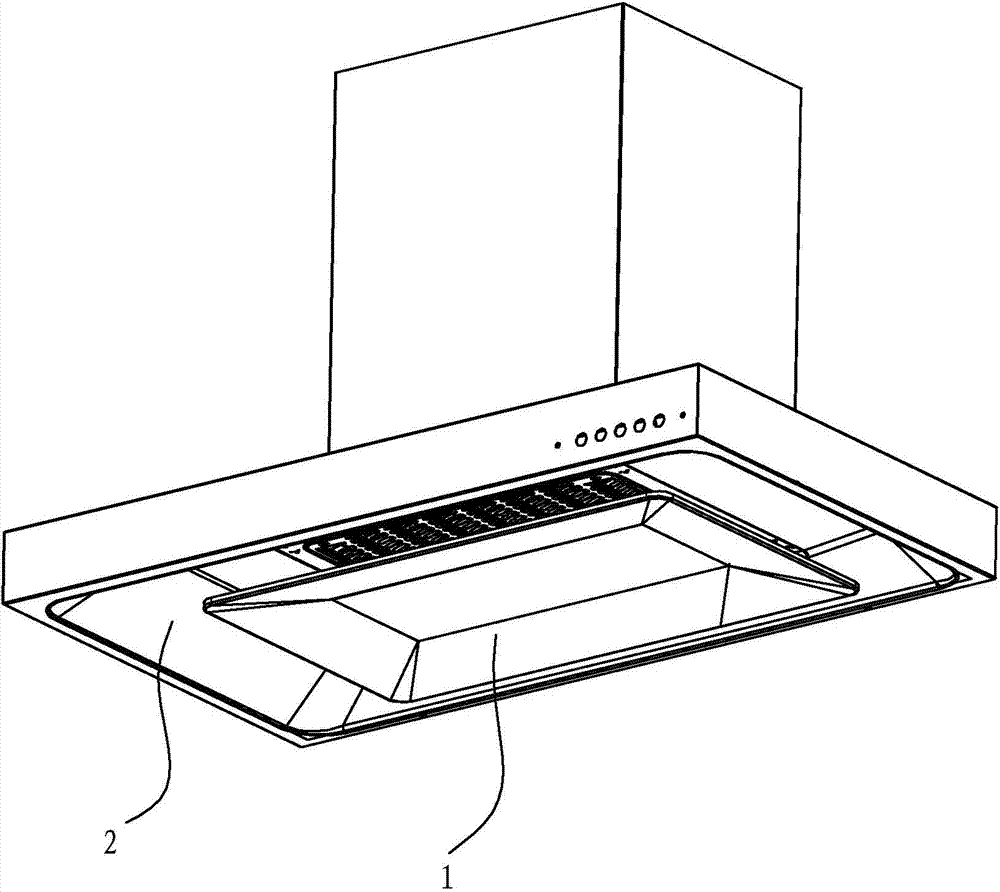

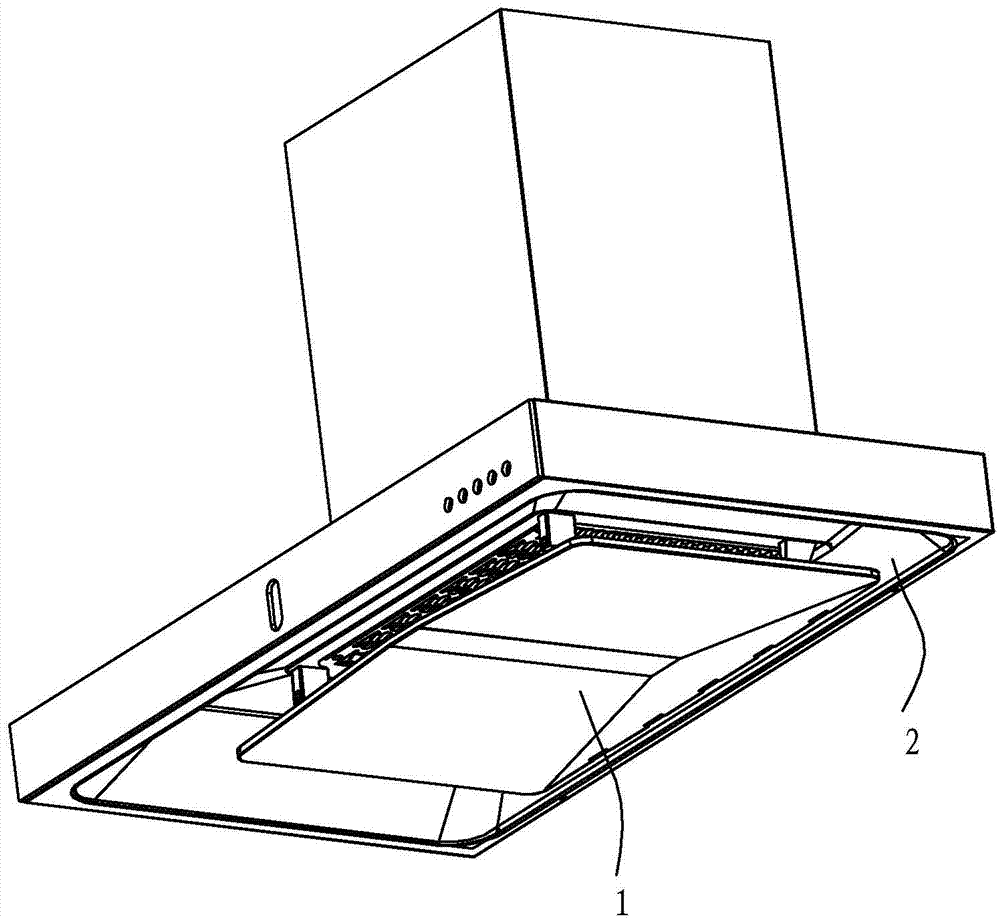

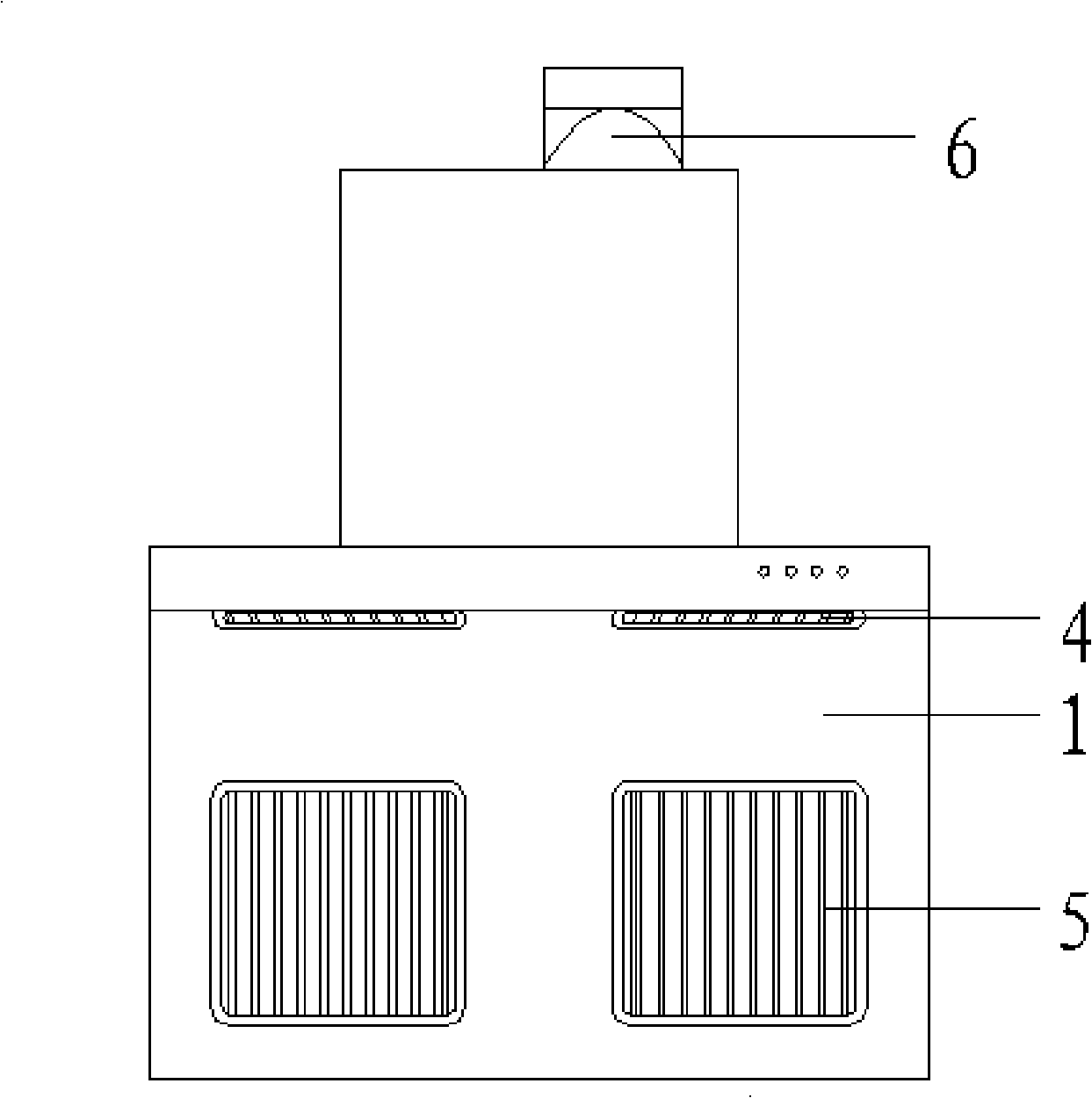

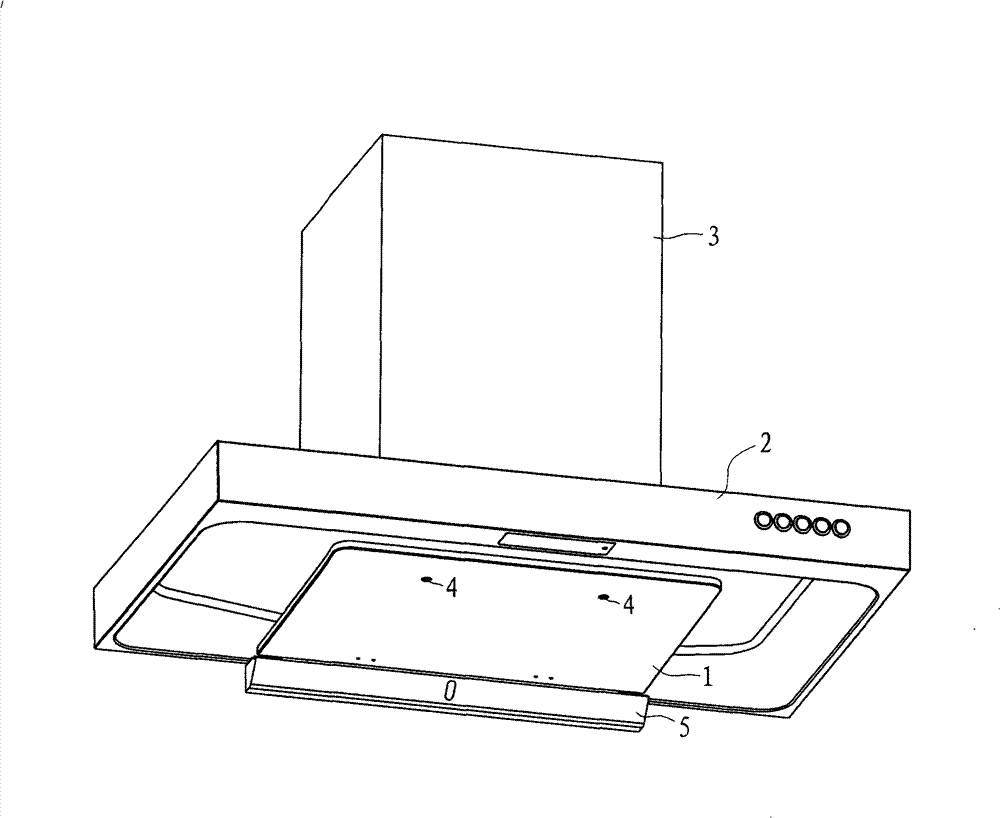

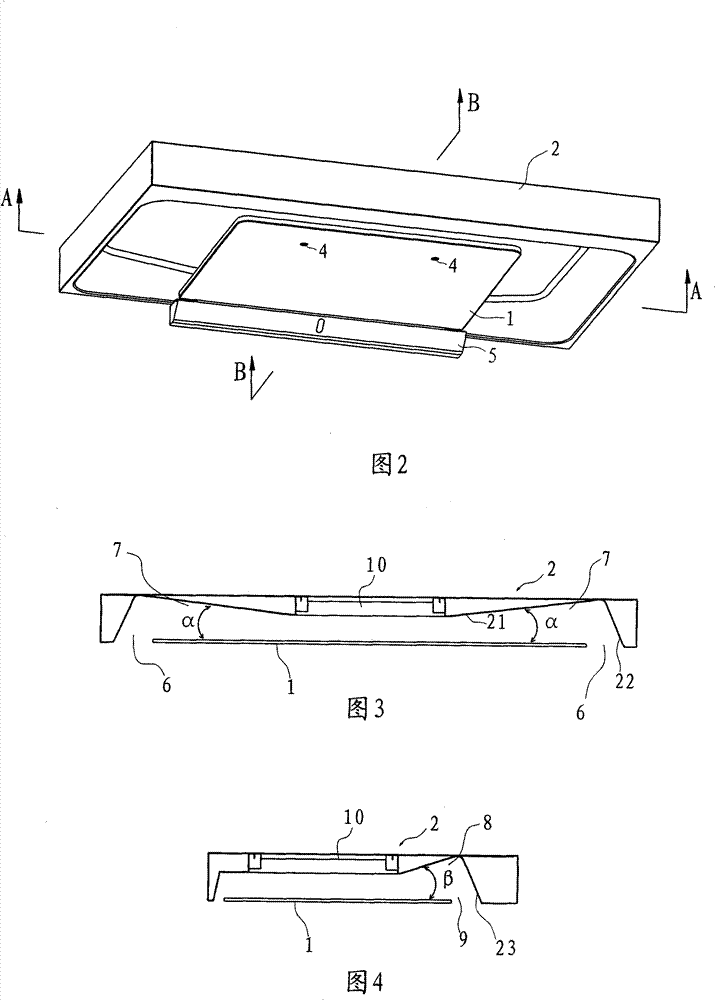

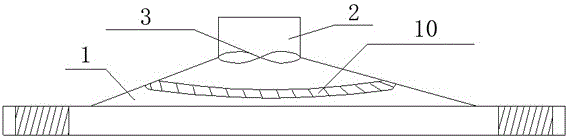

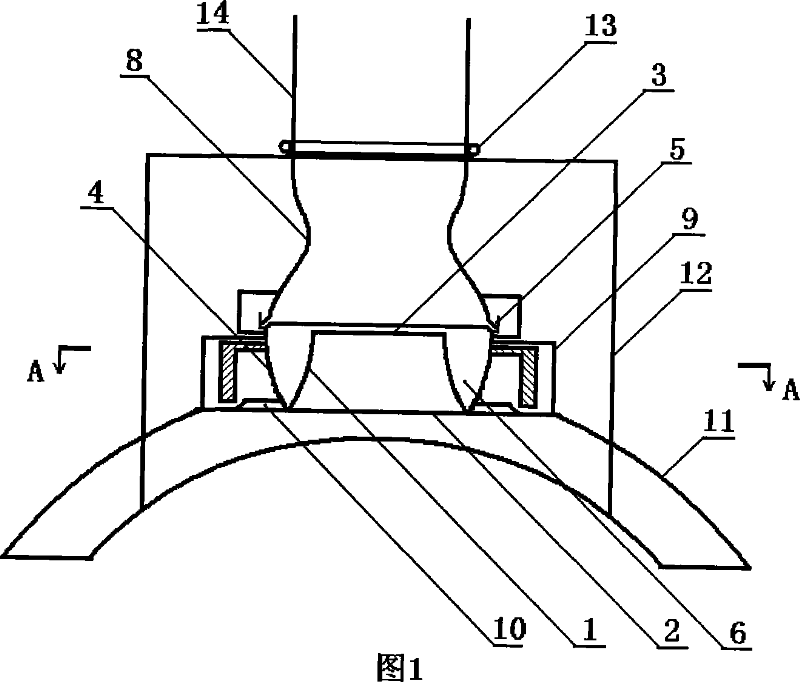

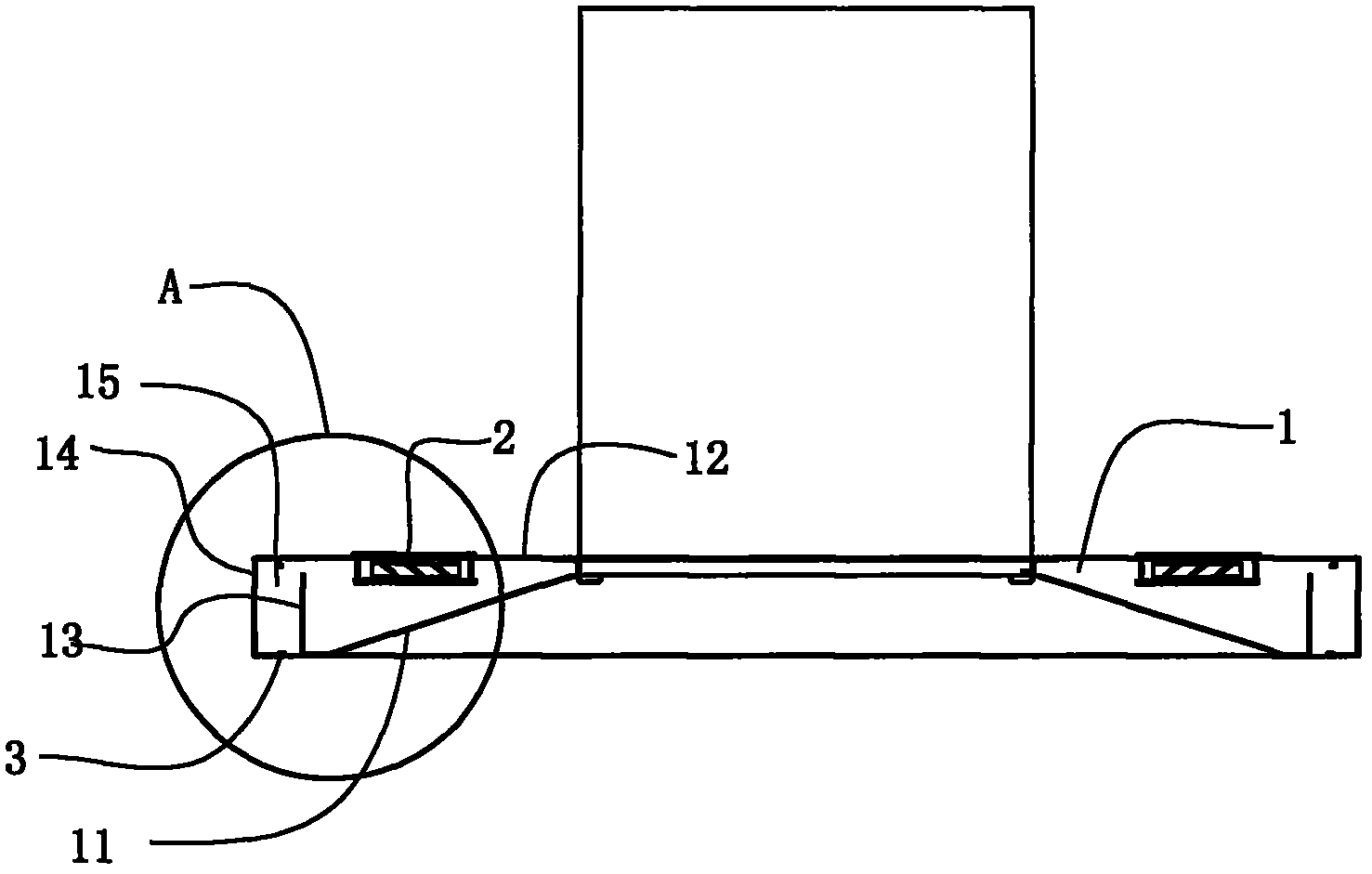

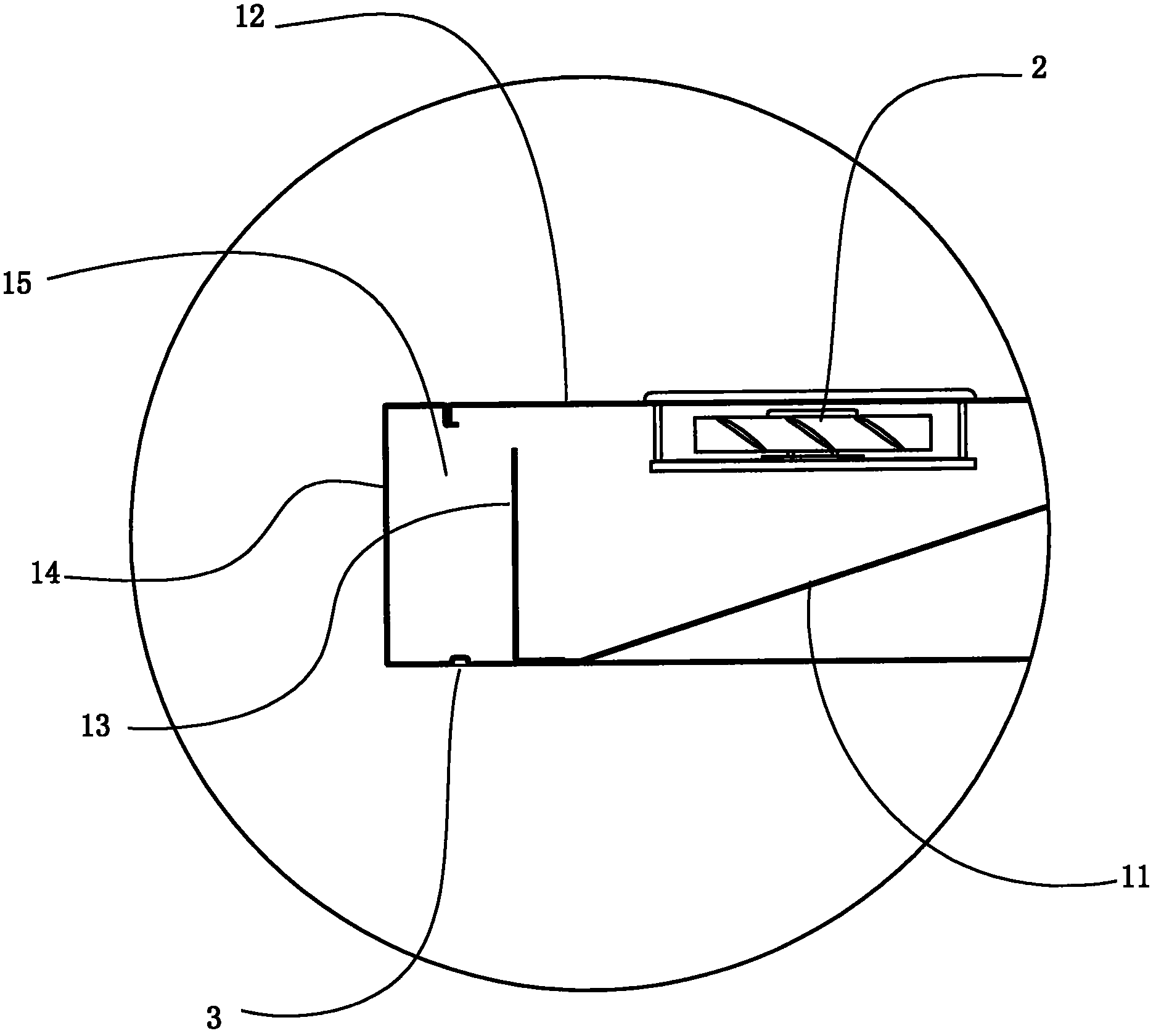

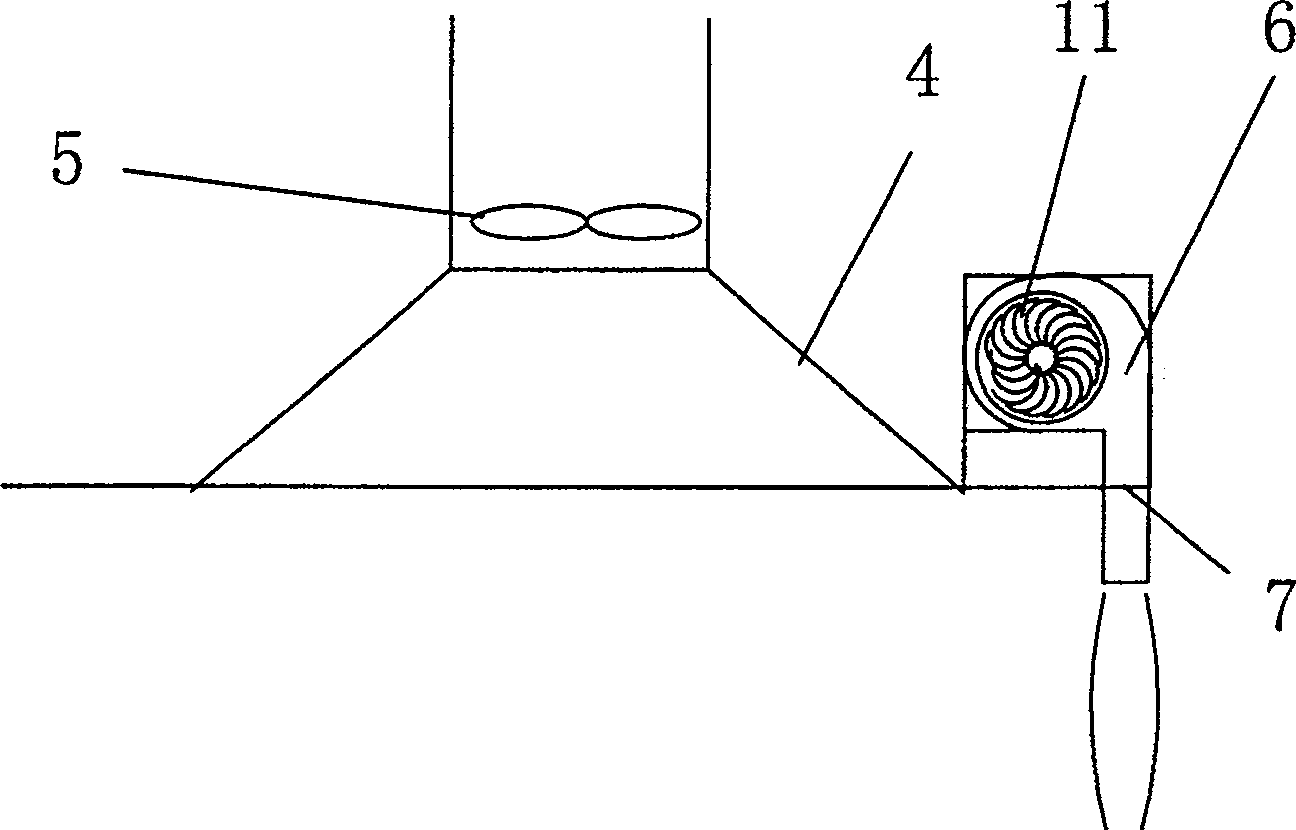

Range hood with smoke deflector

ActiveCN101514823ASpeed up the flowNo streamingDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke hood

A range hood with a smoke deflector, comprises a body, a smoke collecting cover and the smoke deflector, wherein an air inlet is arranged on the smoke collecting cover, the smoke deflector faces to the air inlet and be in the predetermined distance from the smoke collecting cover, thus a oil smoke channel through which the oil smoke can pass is formed between the smoke deflector and the smoke collecting cover, the range hood is characterized in that the distance between the smoke deflector corresponding to the oil smoke channel and the smoke collecting cover is gradually reduced from the periphery of the smoke deflector to the air inlet. Compared with the prior art, the invention has the advantages: the smoke deflector is used for forming the wall-attachment effect, the oil smoke flow uniformly without series flow, the distance between the smoke deflector and the smoke collecting cover is gradually reduced from the periphery of the smoke deflector to the air inlet, so that the Venturi effect is formed conveniently, thus accelerating the sucking of smoke by the blower fan.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

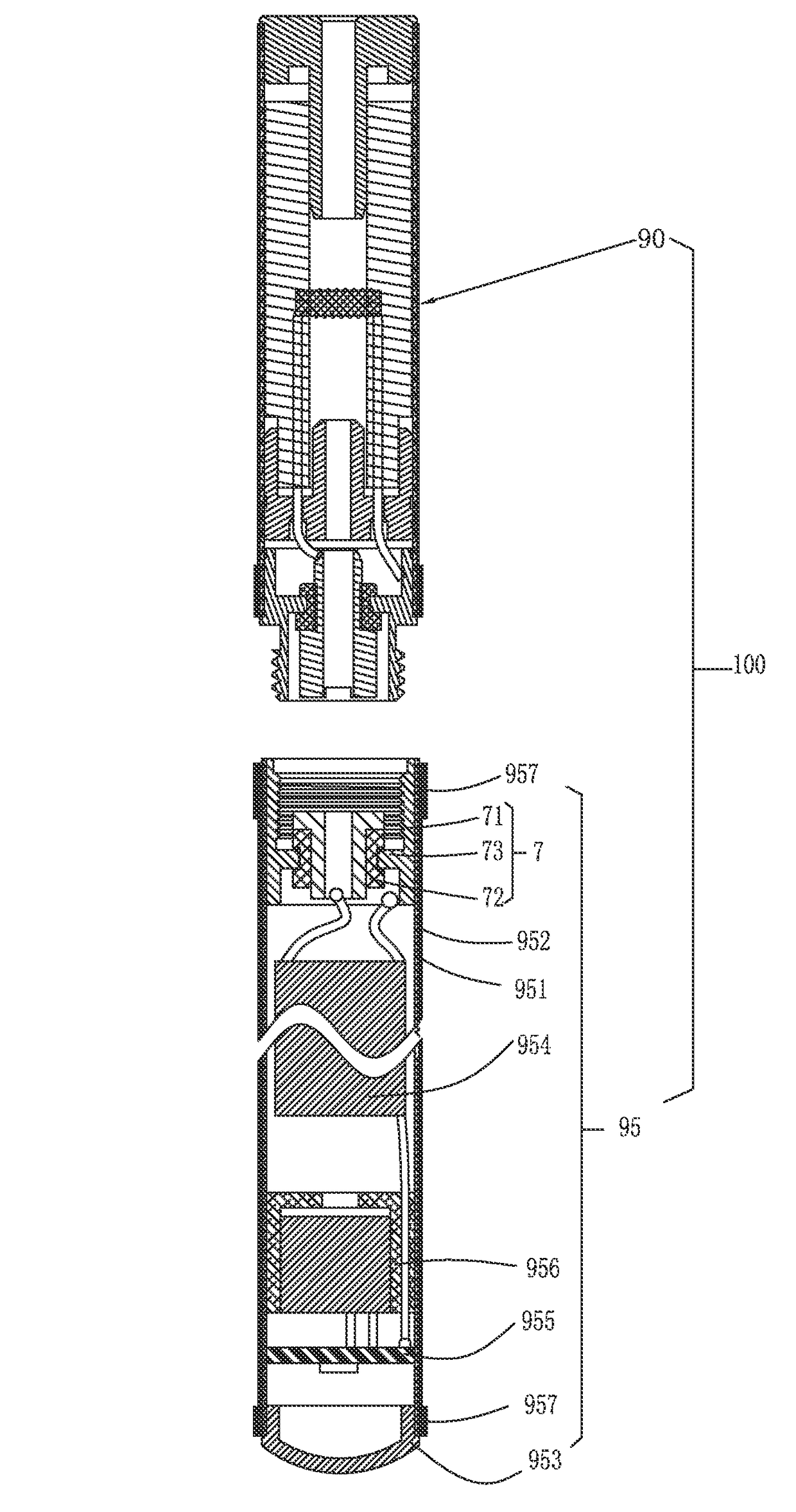

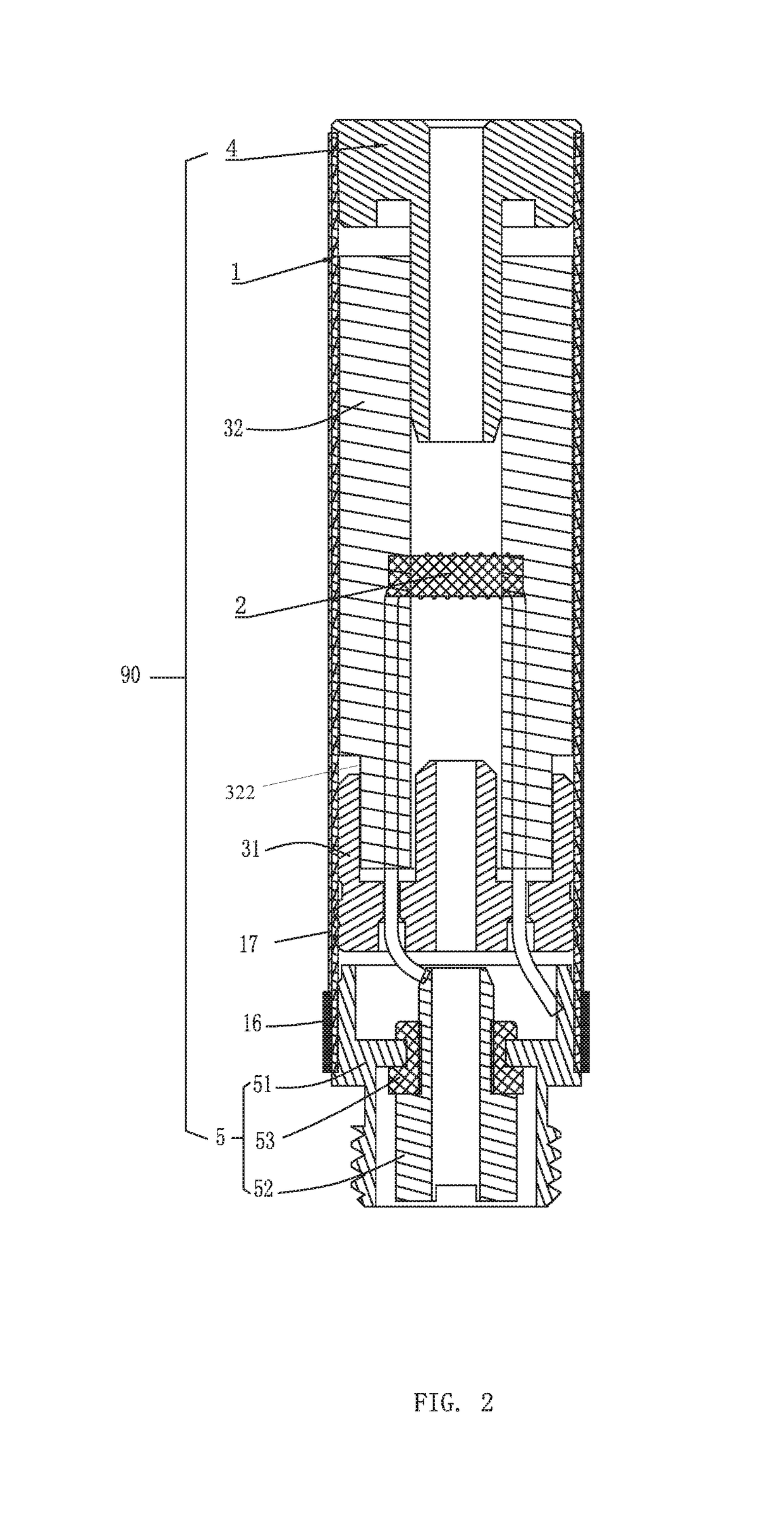

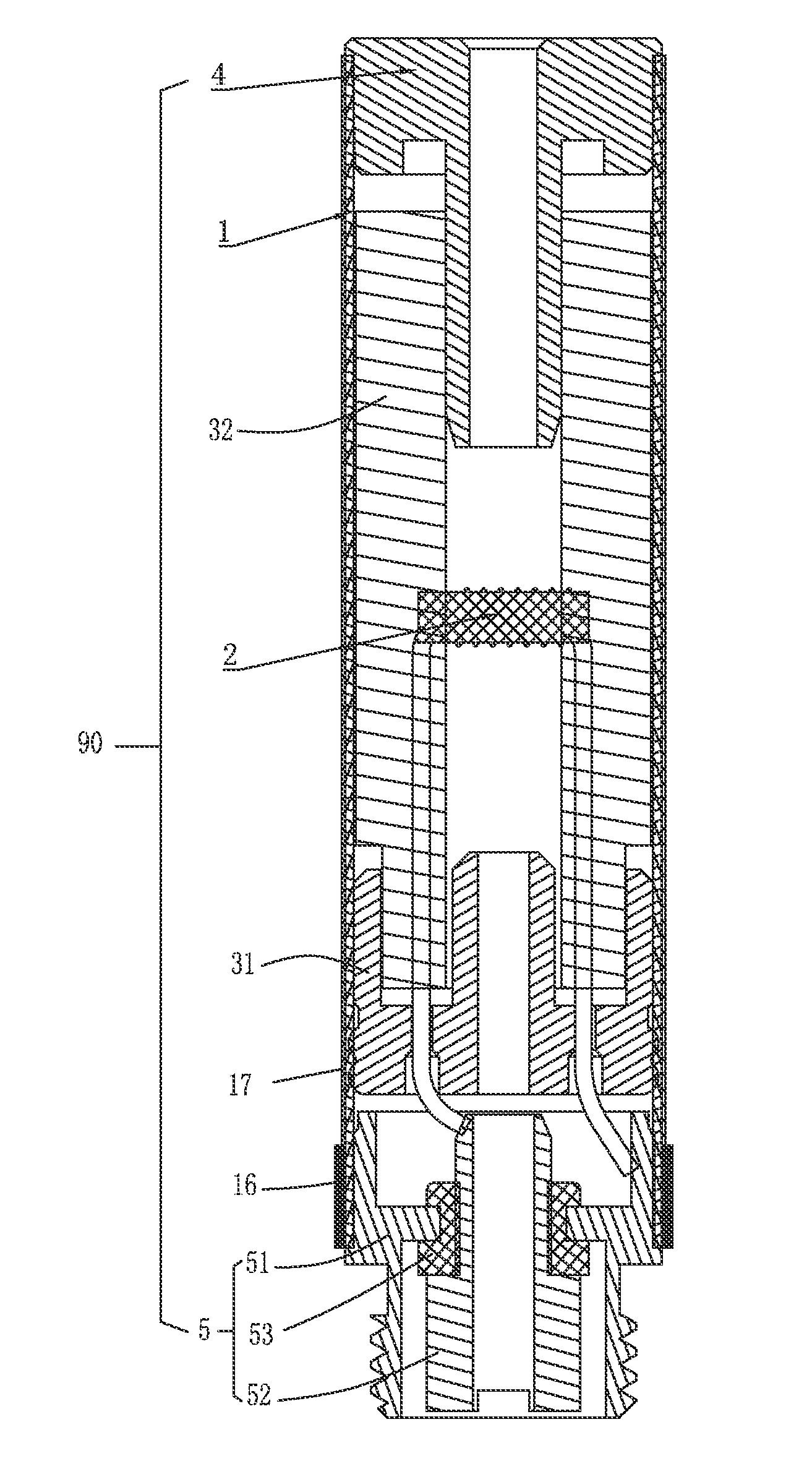

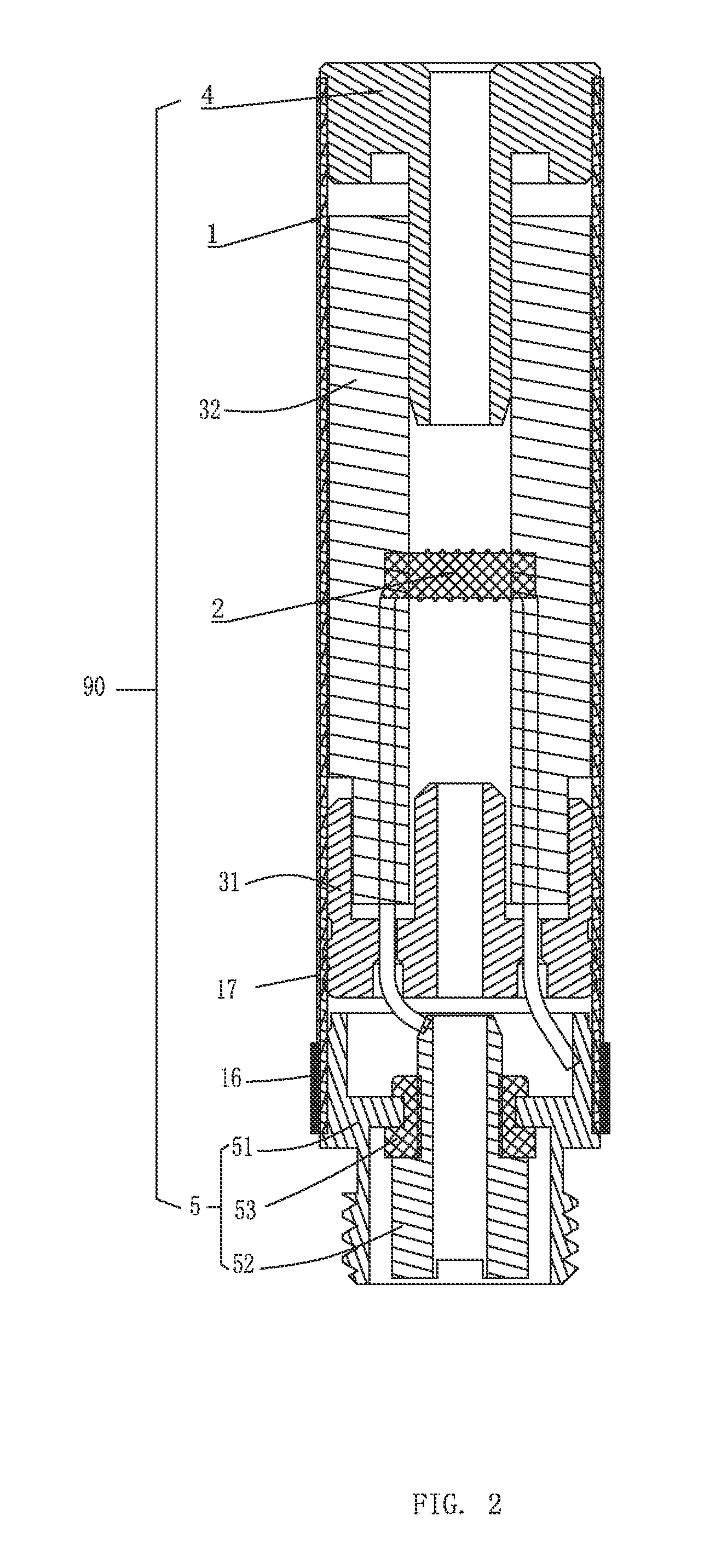

Electronic cigarette and its soft sucking rod

InactiveUS9603387B2Good touch feel and mouth feelSimple and compact internal structureOhmic-resistance electrodesTobacco pipesLiquid smokeSoft materials

The present invention relates to a soft sucking rod for electronic cigarette, the soft sucking rod includes a sucking rod sleeve and a liquid smoke cup configured within the sucking rod sleeve and an atomizer; the sucking rod sleeve is made of soft materials, the liquid smoke cup is configured with a liquid storage component therein for accommodating liquid smoke, the liquid storage component defines a through hole coaxially extended therethrough as a smog channel, the atomizer is configured in the smog channel of the liquid smoke cup, the atomizer atomizes the liquid smoke which is near the atomizer and stored in the liquid storage component. The soft sucking rod has good touch feel and mouth feel when hold in hand, and has simple and compact internal structure and low manufacturing cost.

Owner:HUIZHOU KIMREE TECH

Electronic Cigarette and Its Soft Sucking Rod

InactiveUS20150296884A1Good touch feel and mouth feelSimple and compact internal structureOhmic-resistance electrodesTobacco pipesLiquid smokeEngineering

The present invention relates to a soft sucking rod for electronic cigarette, the soft sucking rod includes a sucking rod sleeve and a liquid smoke cup configured within the sucking rod sleeve and an atomizer; the sucking rod sleeve is made of soft materials, the liquid smoke cup is configured with a liquid storage component therein for accommodating liquid smoke, the liquid storage component defines a through hole coaxially extended therethrough as a smog channel, the atomizer is configured in the smog channel of the liquid smoke cup, the atomizer atomizes the liquid smoke which is near the atomizer and stored in the liquid storage component. The soft sucking rod has good touch feel and mouth feel when hold in hand, and has simple and compact internal structure and low manufacturing cost.

Owner:HUIZHOU KIMREE TECH

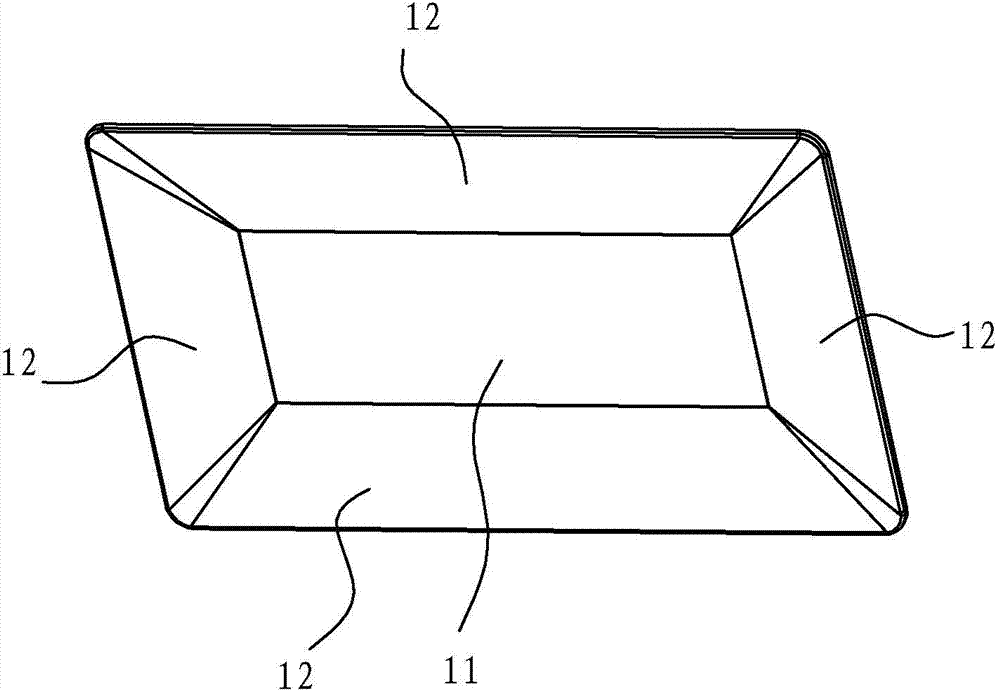

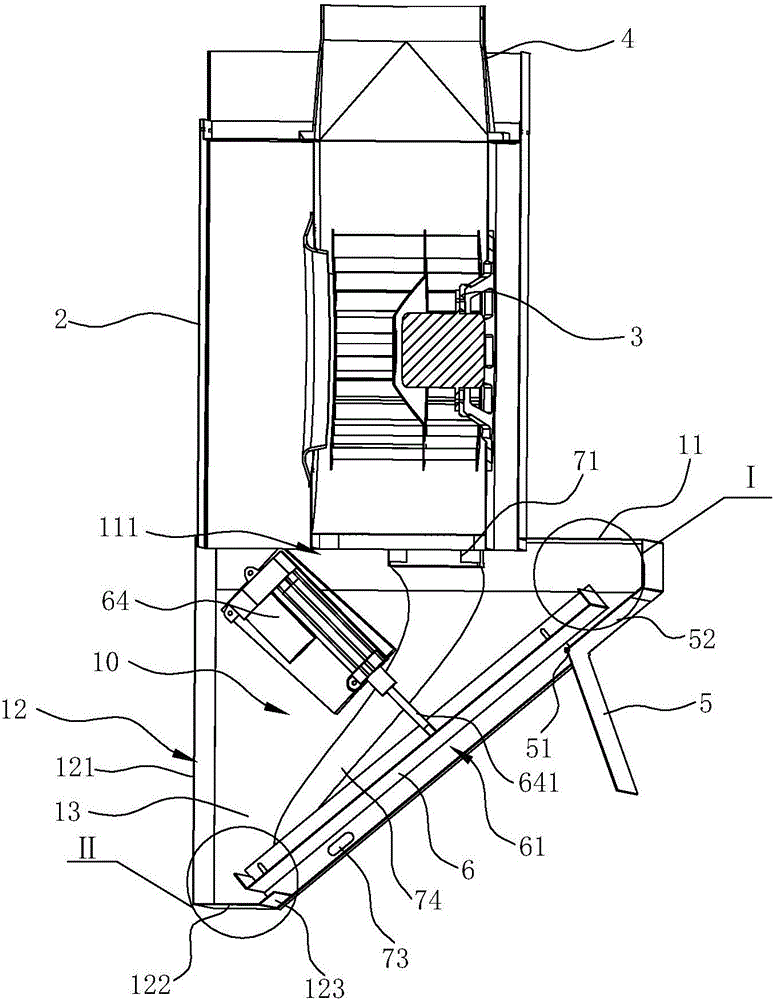

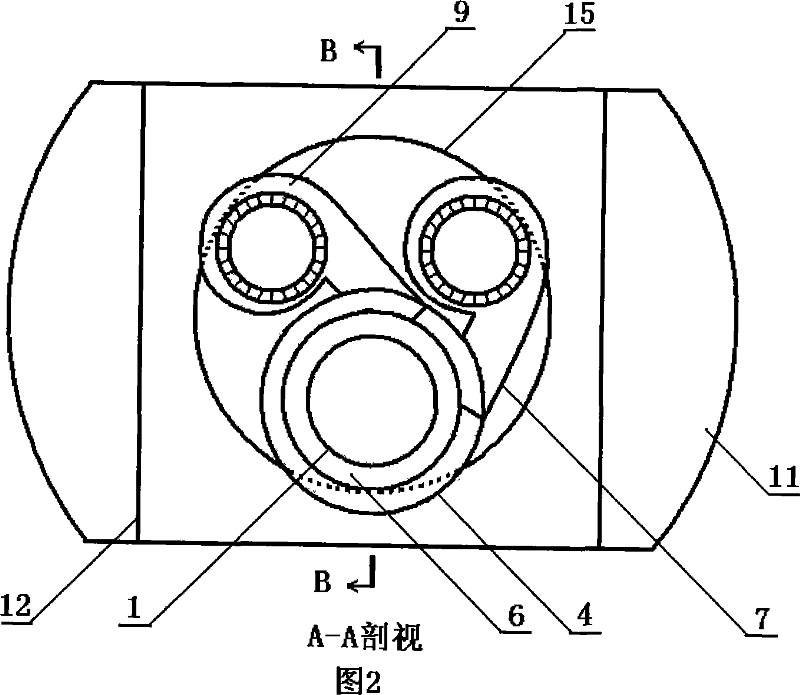

Diffusion drainage device of range hood

ActiveCN103697511AFacilitated DiffusionReduce flowDomestic stoves or rangesLighting and heating apparatusExhaust fumesEngineering

The invention relates to a diffusion drainage device of a range hood. The diffusion drainage device comprises a diffusion drainage smoke control plate which is just opposite to an exhaust fume collecting hood air inlet of the ceiling type range hood, and is characterized in that the diffusion drainage smoke control plate has an inwards concave structure with a high middle part and a low periphery. Compared with the prior art, the diffusion drainage device disclosed by the invention has the advantages that the diffusion drainage smoke control plate having the inwards concave structure with the high middle part and the low periphery can ensure that the pressure distribution on the lower side and the edges of the range hood is improved and reconstructed; compared with a conventional range hood, the range hood has the advantages that the periphery of the diffusion drainage smoke control plate has a venturi effect to ensure that negative pressure is expanded outwards to the edges of the diffusion drainage smoke control plate, and an effective area for sucking oil fume is enlarged by about twice; after oil fume gas rises and contacts the edges of the diffusion drainage smoke control plate, the oil fume gas can move upwards quickly, a negative pressure passage is defined by the diffusion drainage smoke control plate and the inner surface of a smoke collecting cavity at the upper part of the diffusion drainage smoke control plate at the same time, and then the oil fume gas flows inwards to an air inlet of a blower along the negative pressure passage; by virtue of the inwards concave area, the oil smoke diffusion is greatly promoted.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Side-absorption ventilator

ActiveCN101270892AAbsorb thoroughlySolve the problem of residual oil fume escaping upwardsDomestic stoves or rangesLighting and heating apparatusHead-hittingEngineering

The invention relates to a range hood, which especially relates to an air inlet structure of the range hood. Aiming to the incomplete smoke and oil suction shortcoming of the range hood of the prior art, the invention discloses a range hood which has both the advantages of a top inlet range hood and a side inlet range hood. The invention has the technical scheme that the top-side range hood comprises a panel, a smoke collection cover and a blower; the panel is connected with the smoke collection cover; the panel comprises a lateral panel and a top panel; a lateral air inlet is mounted on the lateral panel; and a top air inlet is mounted on the top panel. The invention has the beneficial effects that the range hood has the shore distance smoke and oil suction effect of the side inlet range hood and effectively solves the upward escaping problem of the residue smoke and oil of the side inlet range hood; the range hood has both the advantages of the top inlet range hood and the side inlet range hood with a more complete smoke and oil suction effect; the range hood is also characterized in the avoidance of head hitting and oil dripping and the beautiful appearance.

Owner:中山市开力厨具科技有限公司

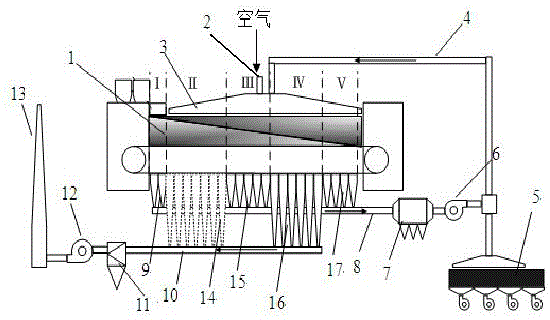

Comprehensive treatment method for iron ore sintering smoke pollutants

ActiveCN105091615AEmission reductionReduce energy consumptionCombination devicesIncreasing energy efficiencyActivated carbonPhysical chemistry

The invention provides a comprehensive treatment method for iron ore sintering smoke pollutants. According to the characteristic that the properties of sintering smoke at different positions of a sintering machine are different, the sintering machine is sequentially divided into a section I, a section II, a section II, a section IV and a section V from the machine head to the machine tail. The length of the section I accounts for one twelfth that of the sintering machine. The length of the section II accounts for one fourth to three tenths that of the sintering machine. The length of the section III accounts for one fifth to one fourth that of the sintering machine. The length of the section IV accounts for one fourth of the sintering machine. The length of the section V accounts for one sixth that of the sintering machine. Smoke in the section I, the section III and the section V circulates to a smoke hood of the sintering machine through a circulating flue. The proportion of circulating smoke is 45%-50%. According to the features of the smoke entering the sintering bed layer, the temperature is 200 DEG C-250 DEG C, the content of O2 is greater than or equal to 17%, the content of CO2 is less than or equal to 6%, H2O (g) is less than or equal to 8%, and the content of SO2 is less than or equal to 500 ppm. The smoke in the section II and the smoke in the section IV are treated by a comprehensive activated carbon desulfurization and denitrification system and then discharged.

Owner:CENT SOUTH UNIV

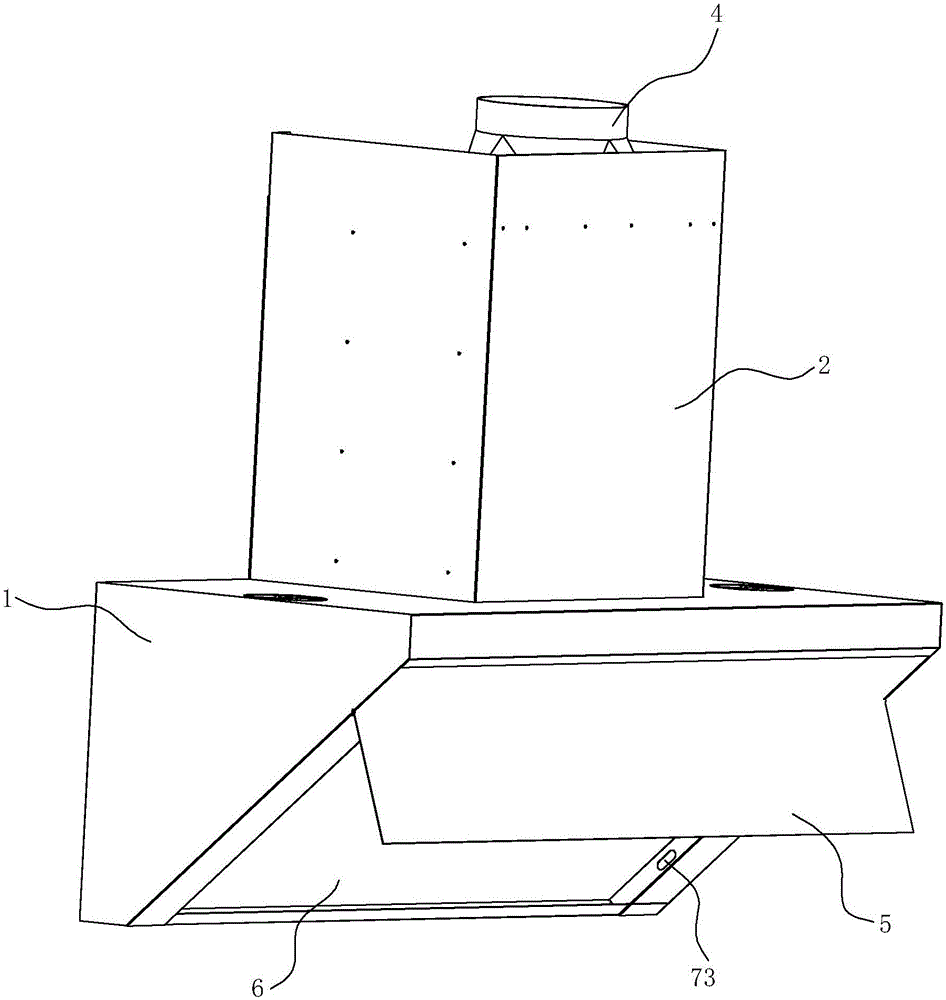

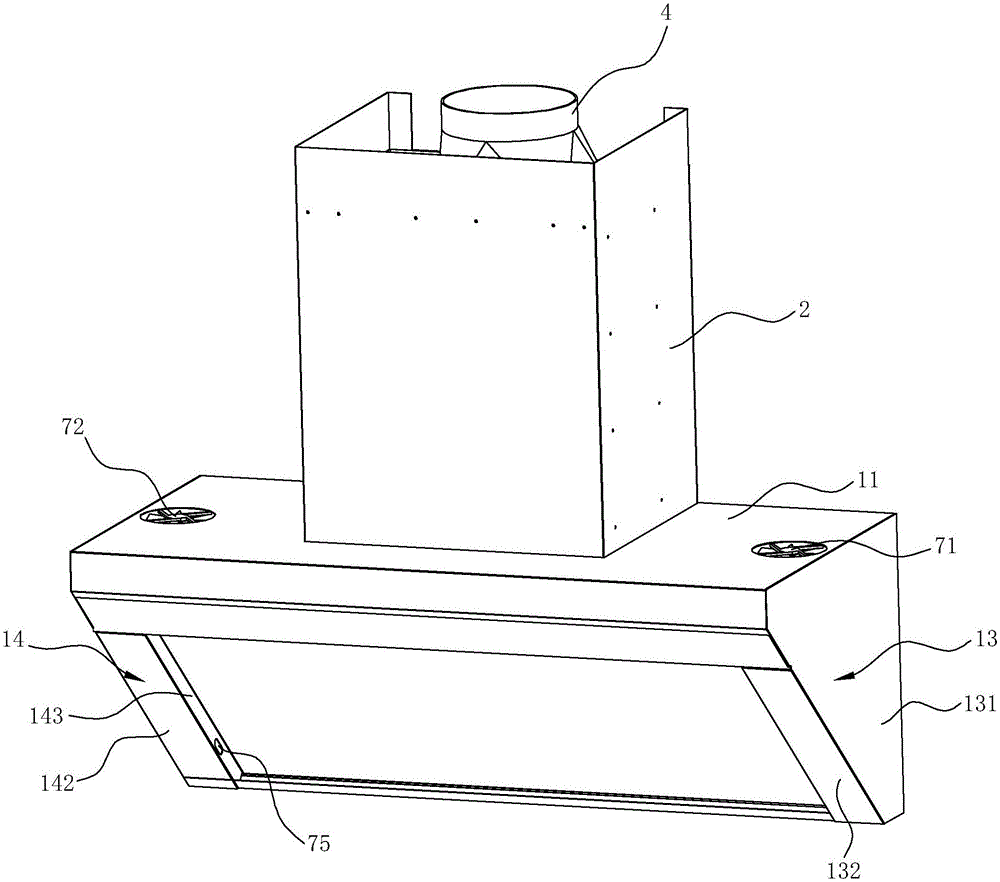

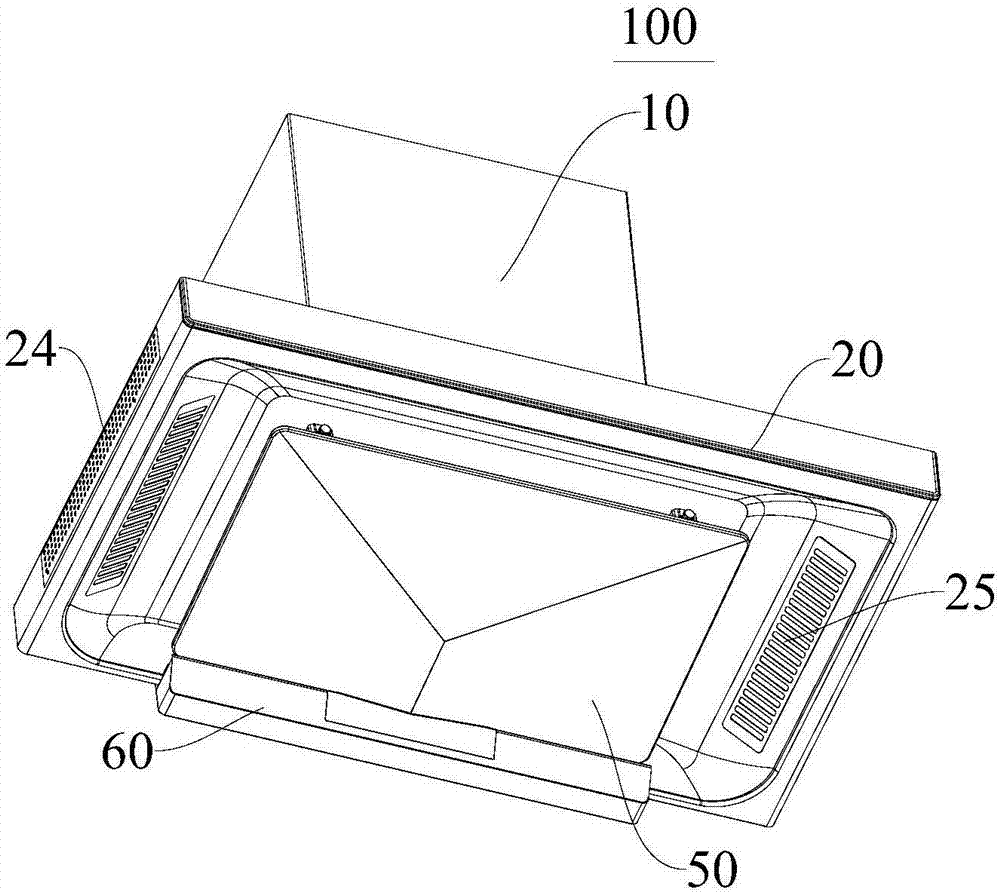

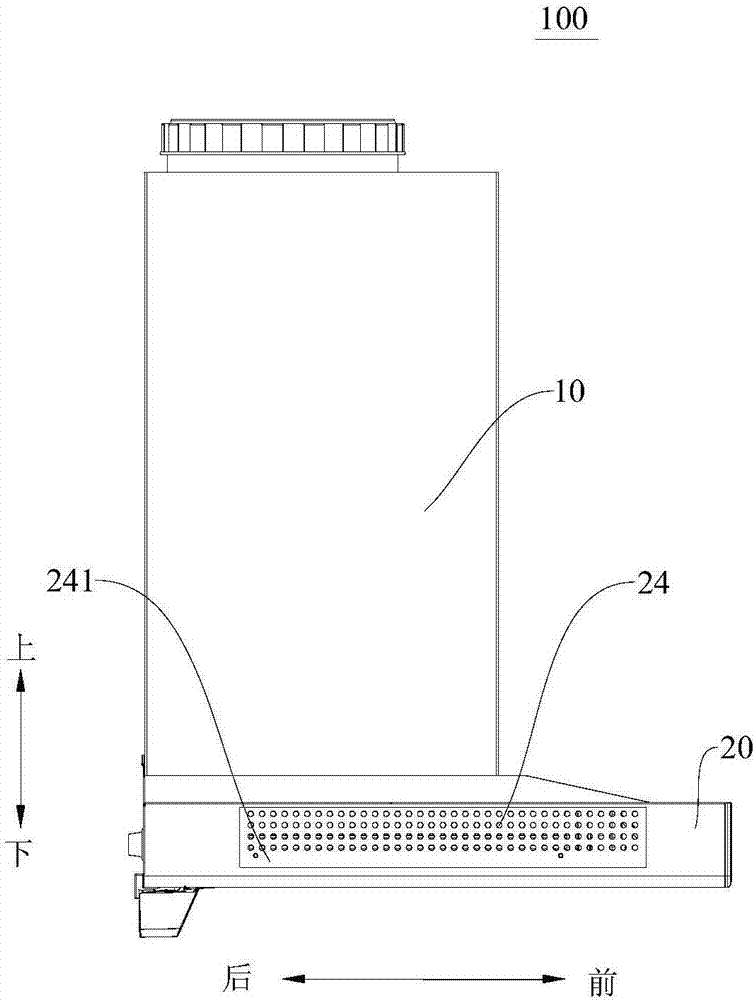

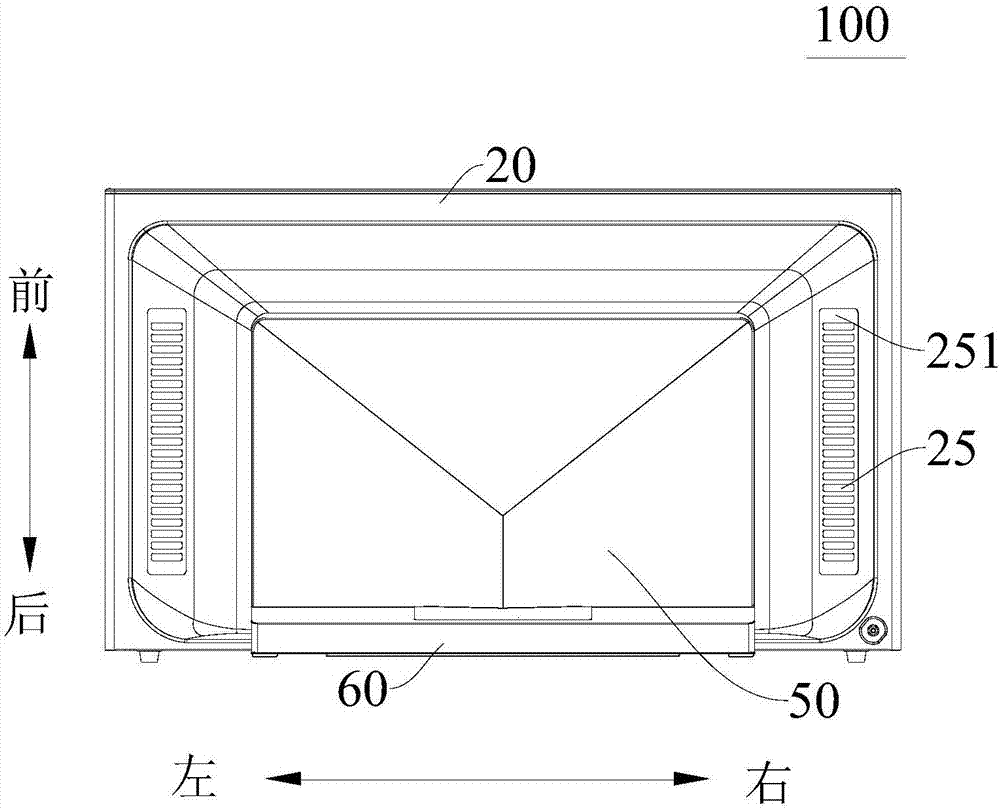

Range hood with smoke deflector

ActiveCN101514823BSpeed up the flowNo streamingDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke hood

A range hood with a smoke deflector, comprises a body, a smoke collecting cover and the smoke deflector, wherein an air inlet is arranged on the smoke collecting cover, the smoke deflector faces to the air inlet and be in the predetermined distance from the smoke collecting cover, thus a oil smoke channel through which the oil smoke can pass is formed between the smoke deflector and the smoke collecting cover, the range hood is characterized in that the distance between the smoke deflector corresponding to the oil smoke channel and the smoke collecting cover is gradually reduced from the periphery of the smoke deflector to the air inlet. Compared with the prior art, the invention has the advantages: the smoke deflector is used for forming the wall-attachment effect, the oil smoke flow uniformly without series flow, the distance between the smoke deflector and the smoke collecting cover is gradually reduced from the periphery of the smoke deflector to the air inlet, so that the Venturieffect is formed conveniently, thus accelerating the sucking of smoke by the blower fan.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

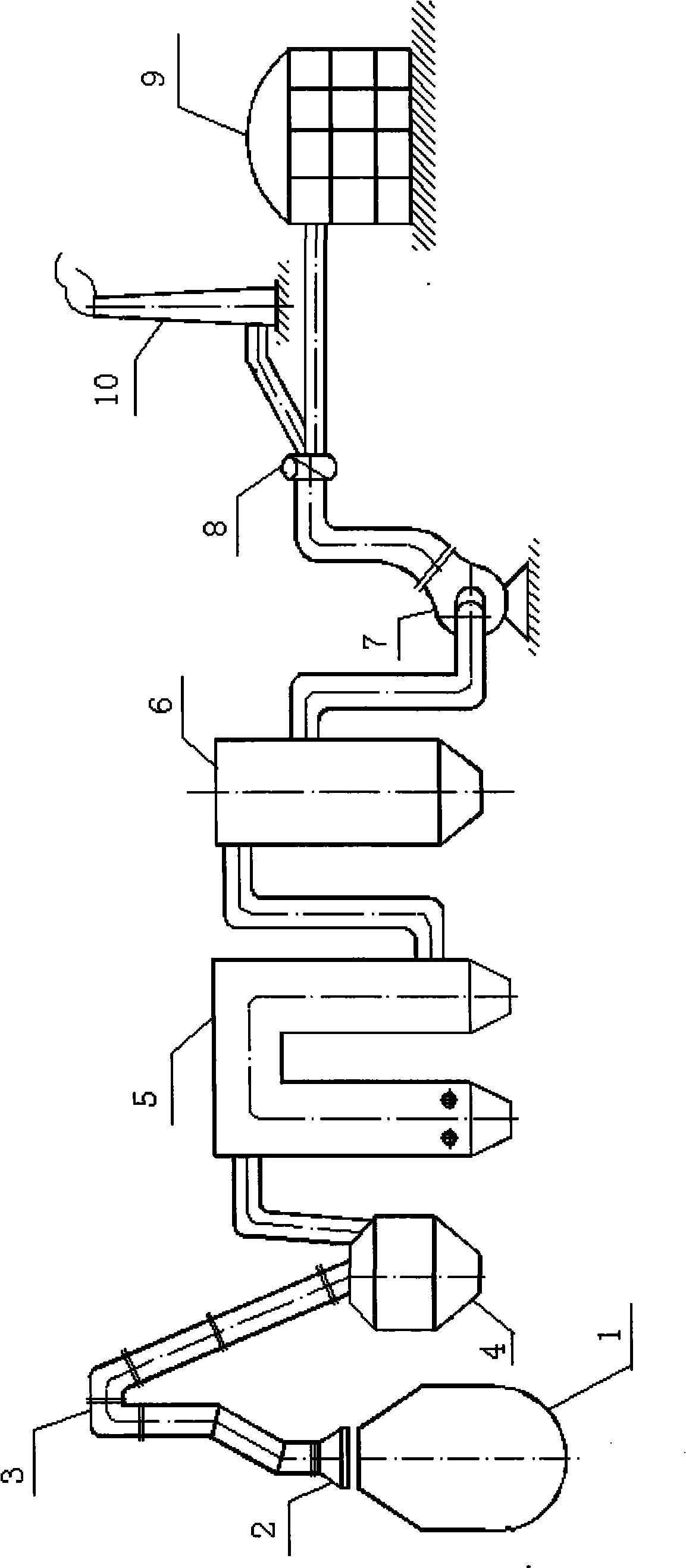

Full dry purification and residual heat utilization equipment and method for converter gas

InactiveCN101492756ALess dustLess waterIncreasing energy efficiencyManufacturing convertersSuperheated steamMoisture

The invention provides devices for purifying converter gas by dry process and using afterheat of the converter gas and a method thereof. In a converting period, waste gas exhausted from the converter is cooled by a movable gas hood and a vaporizing cooling duct, then is sent into a gravity dust collector to reduce dust content thereof, is conducted into a flue and then to an afterburning afterheat boiler; the afterburning afterheat boiler generates overheated vapor by using large quantity of sensible heat of the converter gas and sends the converter gas after being cooled into a bag dust collector through the flue to purify; the purified converter gas is sent to a draft fan to be pressurized through the flue, then passes through a three-way valve, and is sent to a converter gas cabinet; in a non-blowing period of the converter, converter gas is not generated; afterburning afterheat boiler burns a certain amount of blast furnace gas to stabilize load thereof and vapor yield. The three-way valve is switched to cause the afterheat boiler waster gas exhausted from the draft fan to flow to a waste gas discharging chimney. The converter gas processed by the method and devices has very low dust and moisture contents and is an ideal purified gas. During the operation process, large quantity of industrial water is saved, and large quantity of secondary energy is recycled.

Owner:袁长胜

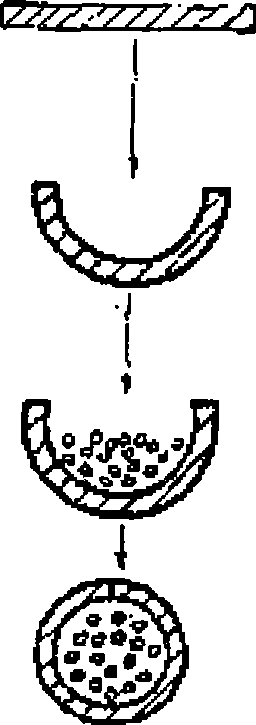

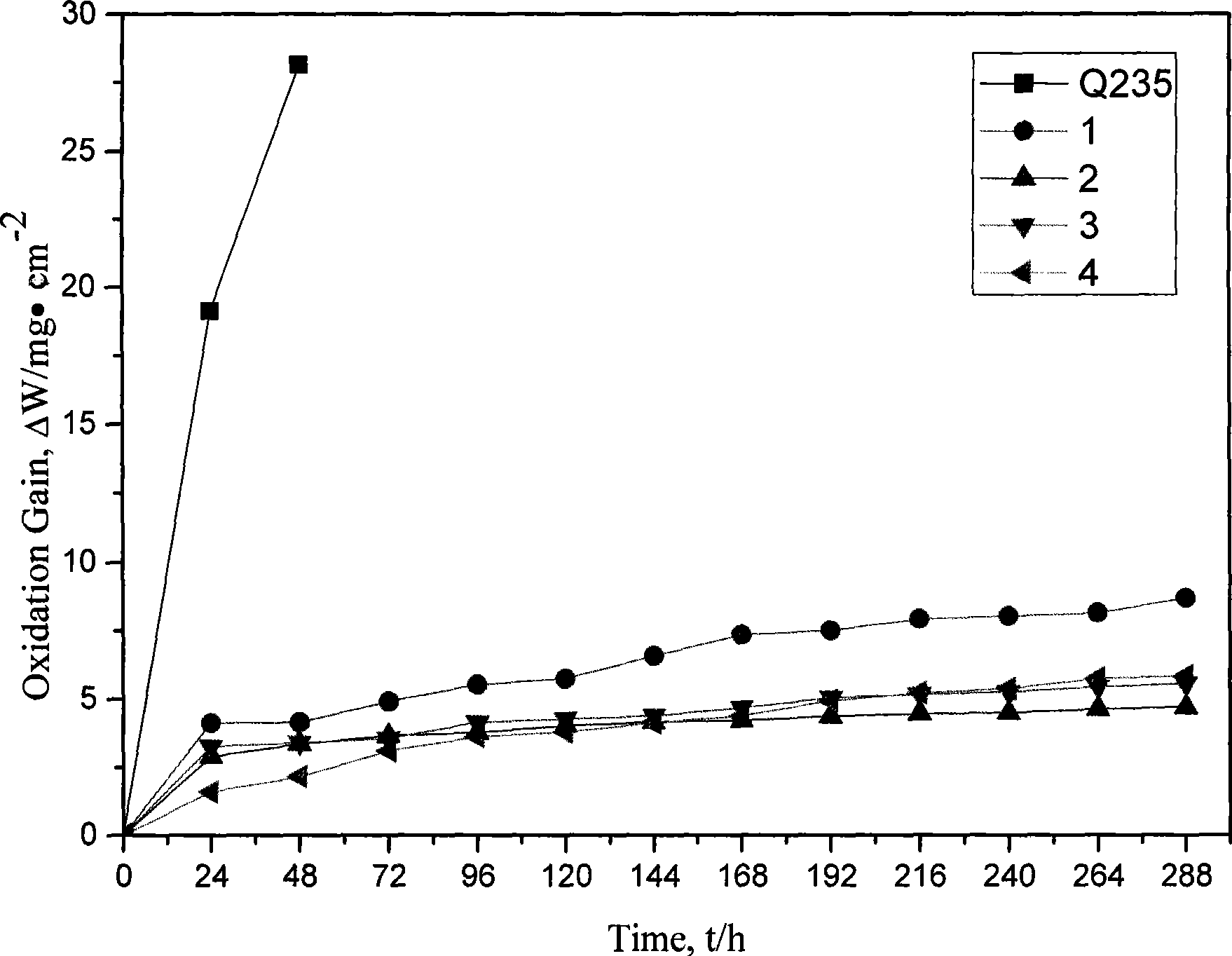

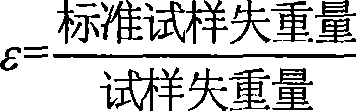

Powder core wire material for high chrome molybdenum alloy arc spraying

InactiveCN101497978AGood resistance to high temperature oxidationGood high temperature corrosion-abrasion resistanceMolten spray coatingThermal sprayingMetallic aluminum

The invention relates to a high-hardness high-sulfur-corrosion-resistant electric arc spraying powder core wire which belongs to electric arc spraying powder cored wires which resist high-temperature oxidation and corrosion and used for the surface protection of metal materials. The high-hardness high-sulfur-corrosion-resistant electric arc spraying powder core wire belongs to the field of hot spraying in material processing engineering and is mainly used for the high-temperature corrosion, erosion and abrasion resistance of four tubes of a general coal-powder boiler of a coal-fired power station boiler, the corrosion prevention and the abrasion resistance of a converter smoke hood and a flue in a steel works and the repair of various axles, crankshafts, plunger pistons, paper-making drying cylinders, and the like. The high-hardness high-sulfur-corrosion-resistant electric arc spraying powder core wire is characterized by comprising the powder core components according to percentages by weight of 22-29 percent of crome metal, 5-9 percent of metallic molybdenum, 2.5-10 percent of metallic nickel, 4.0-6.5 percent of metallic aluminum, 0.5-1 percent of carbon, 1.0-3.0 percent of rare-earth, and metallic iron. A preparation method of the high-hardness high-sulfur-corrosion-resistant electric arc spraying powder core wire adopts the prior processes of firstly rolling a low-carbon cold-rolled strip into a U shape, adding powder core powders which account for 30-40 percent of the gross weight of spraying wires into the U-shaped groove, closing the U-shaped groove and wrapping the powder cores in the U-shaped groove, drawing gradually and lightening through a wire-drawing die to lead the diameter to reach 3.0mm.

Owner:北京赛亿表面工程技术有限公司

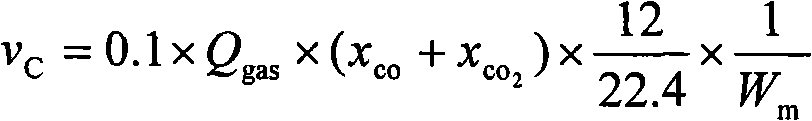

Method for continuously predicting carbon content of converter molten pool

ActiveCN101832967AGuaranteed to meltUniform compositionMaterial analysis by electric/magnetic meansMelting tankCommunications system

The invention discloses a method for continuously predicting carbon content of a converter molten pool, which comprises data acquisition, raw material control, operation control and technical process and specifically comprises the following steps of: in the data acquisition, detecting converter gas flow by using a converter gas flow meter, transmitting all detection information to a computer through a data communication system, and analyzing and calculating the detection information through the following two mathematical models w[C]=0.1*(sigma Cori-sigma Cde) / Wm (1); in the raw material control, controlling a waste steel ratio to be 8 to 13 percent, and controlling the weight percentage of light waste steel and heavy waste steel to be 14 to 70 percent; in the operation control, holding a fixed gun position and a fixed smoke hood in 2 to 3 minutes before finishing blowing; and in the technical process, ensuring that the carbon content of the molten pool meets the formula (1) when the oxygen blowing amount accounts for less than or equal to 75 percent of the total oxygen blowing amount and the carbon content of the molten pool meets the formula (2) when the oxygen blowing amount accounts for over 75 percent of the total oxygen blowing amount. The method fulfills the purpose of continuously predicting the carbon content of the converter molten pool by combining the mathematical models and the technical process.

Owner:ANGANG STEEL CO LTD

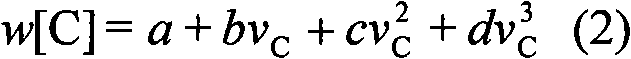

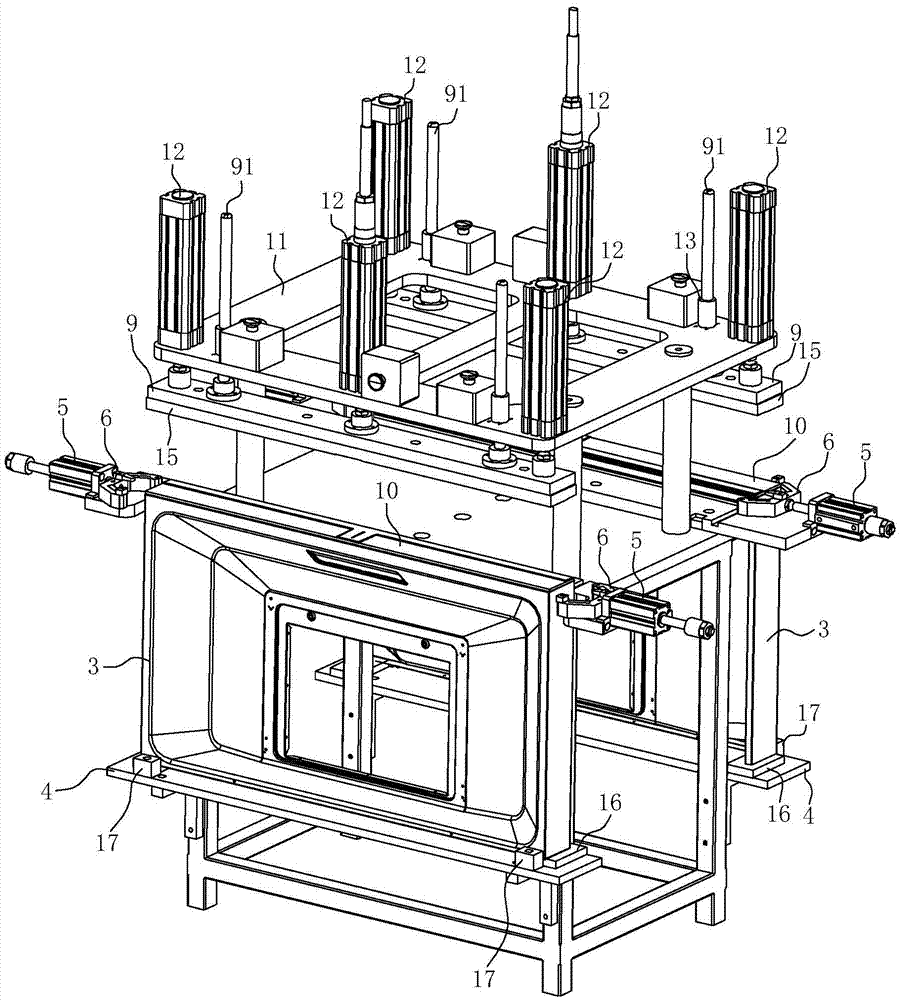

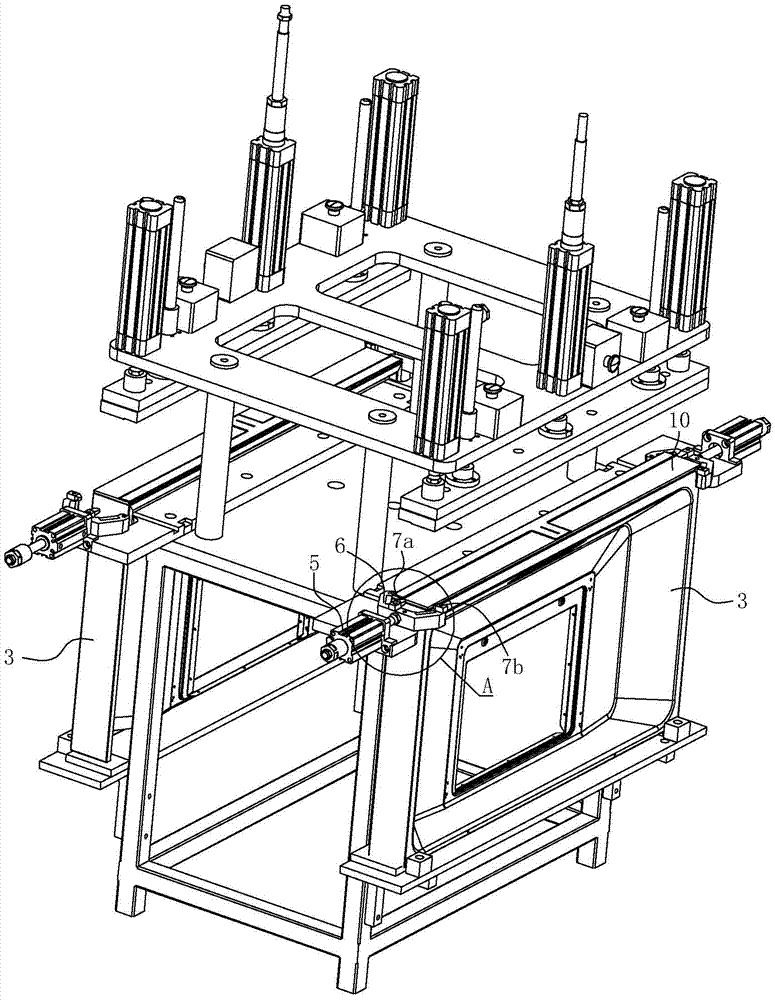

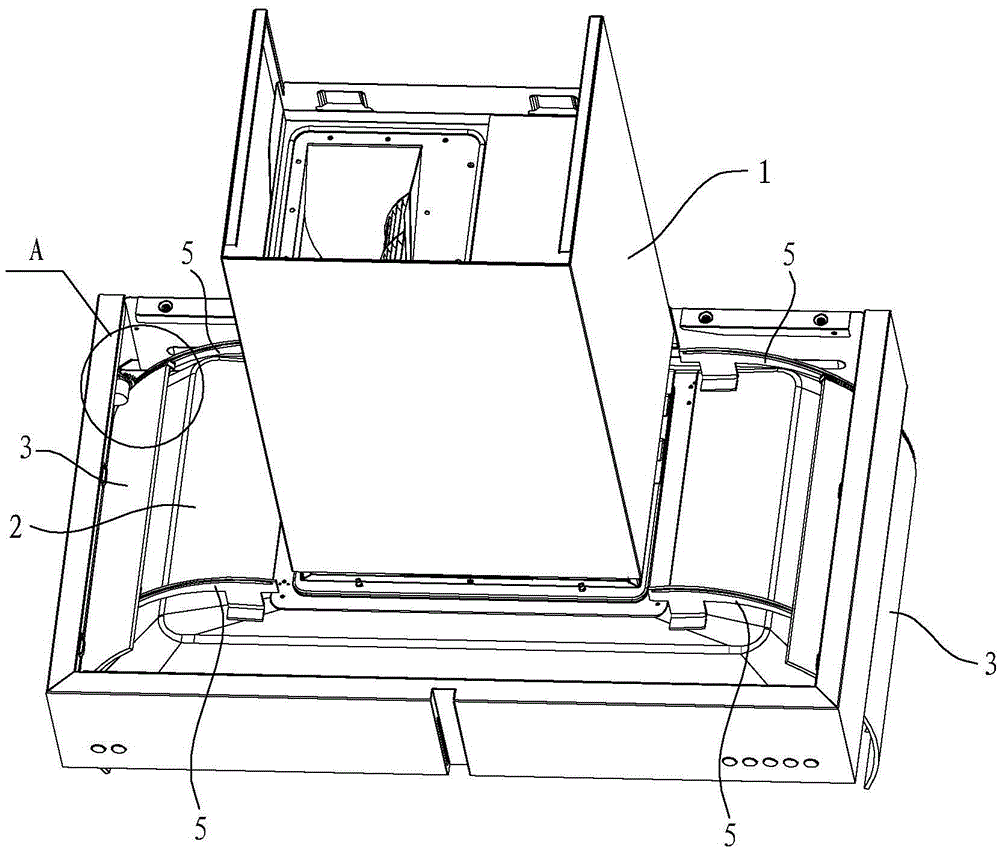

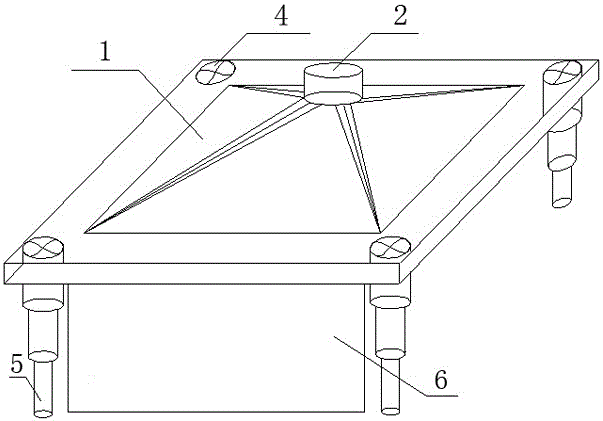

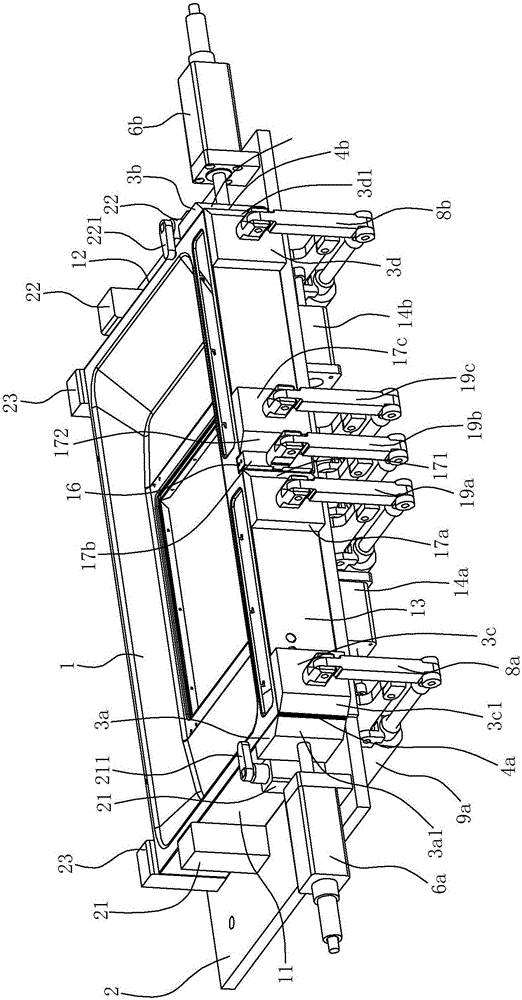

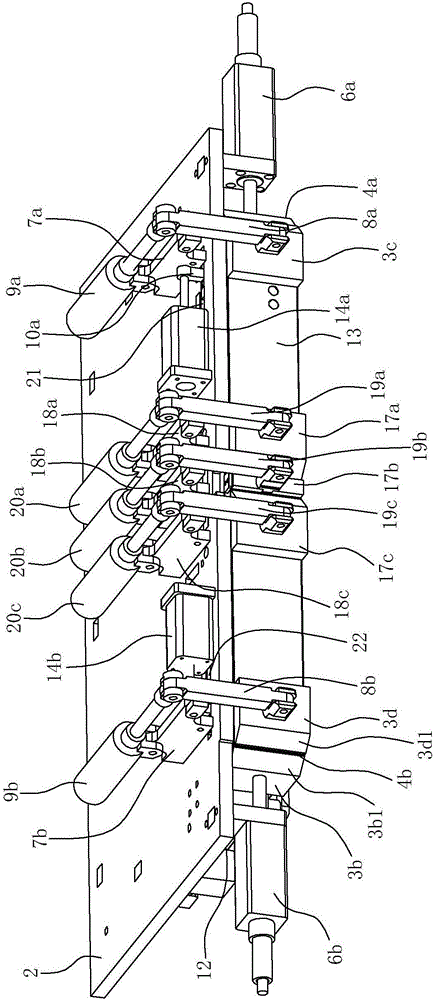

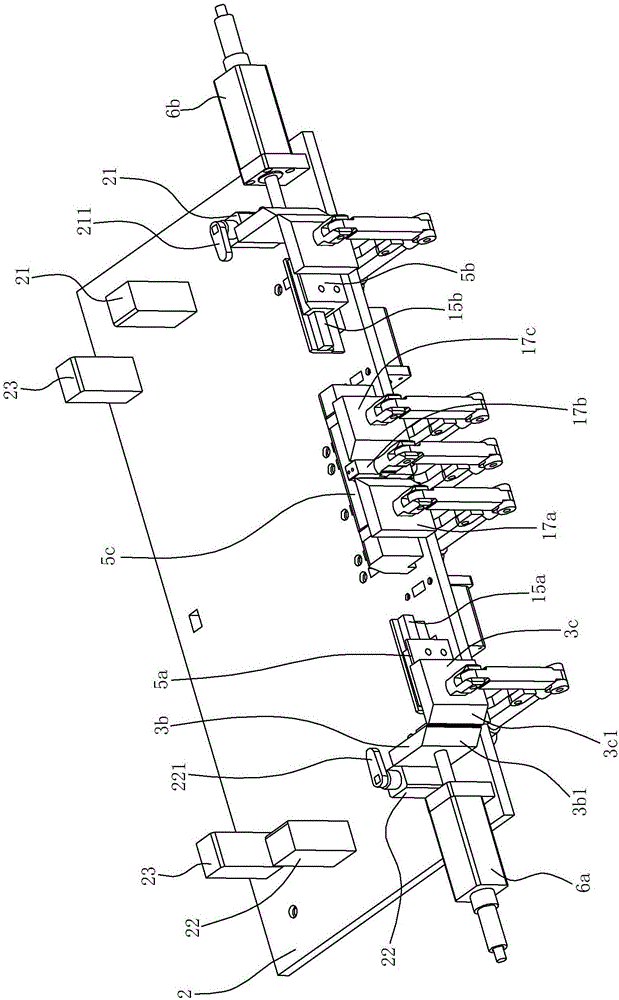

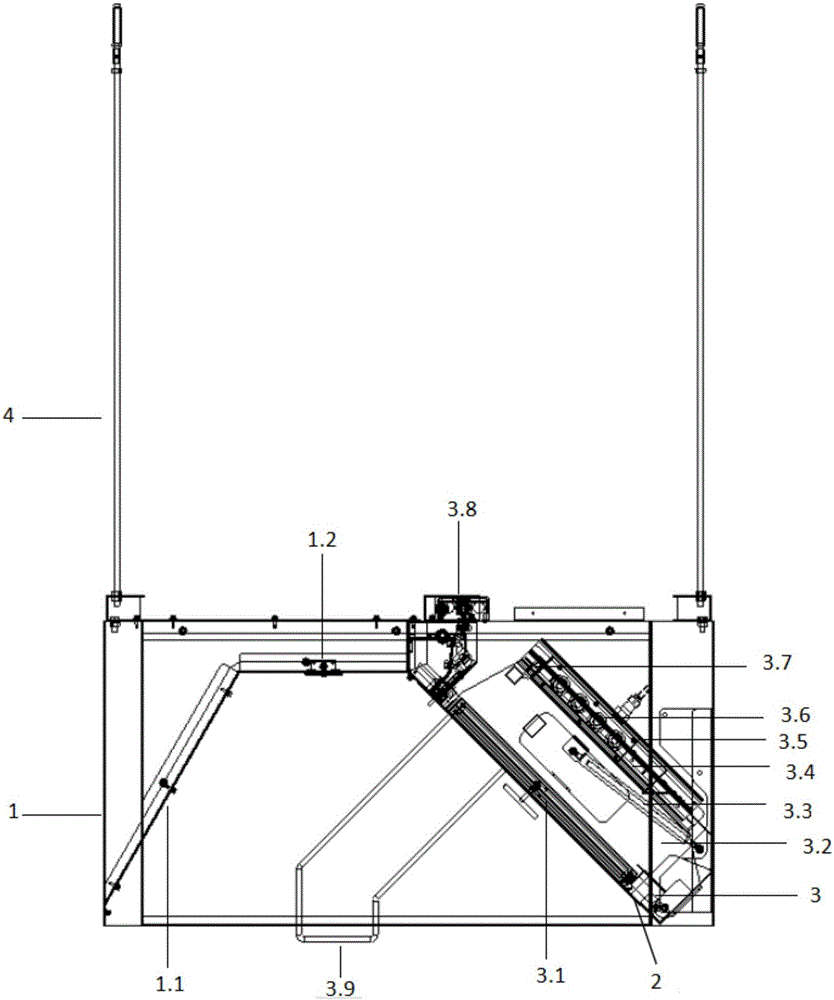

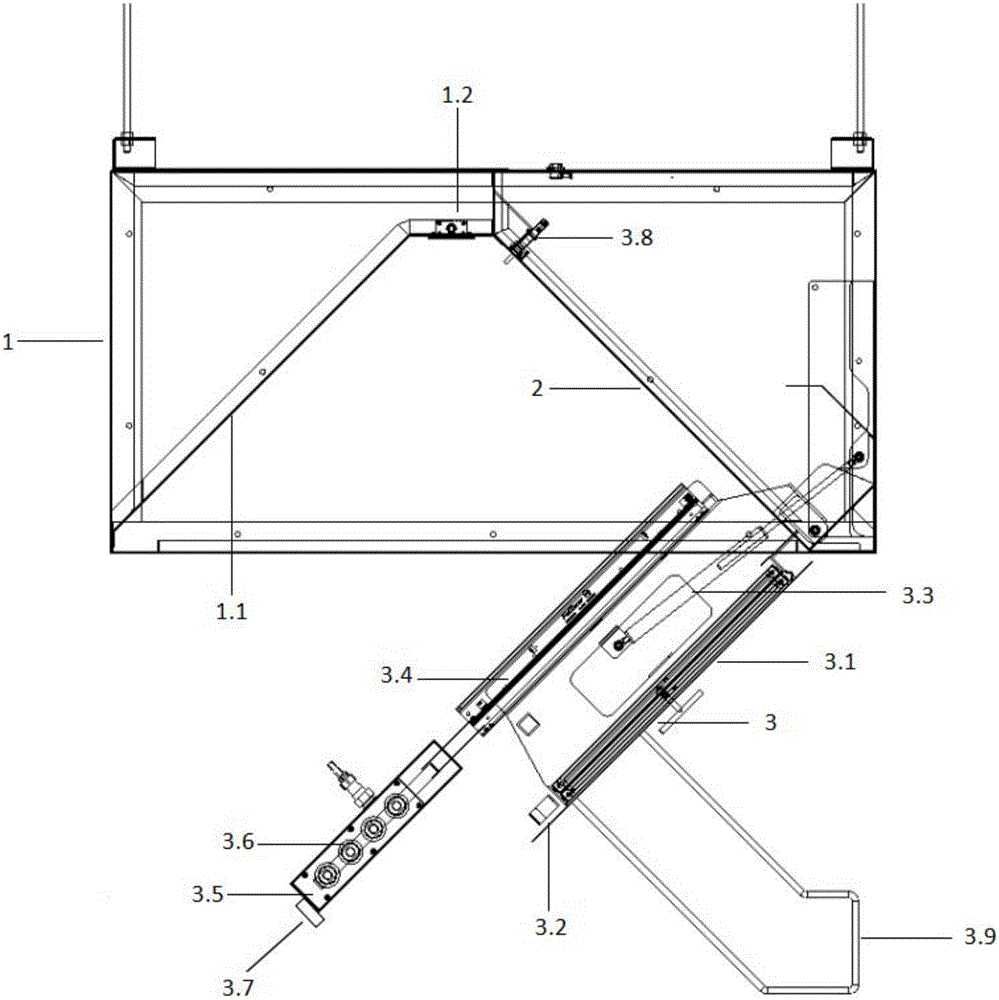

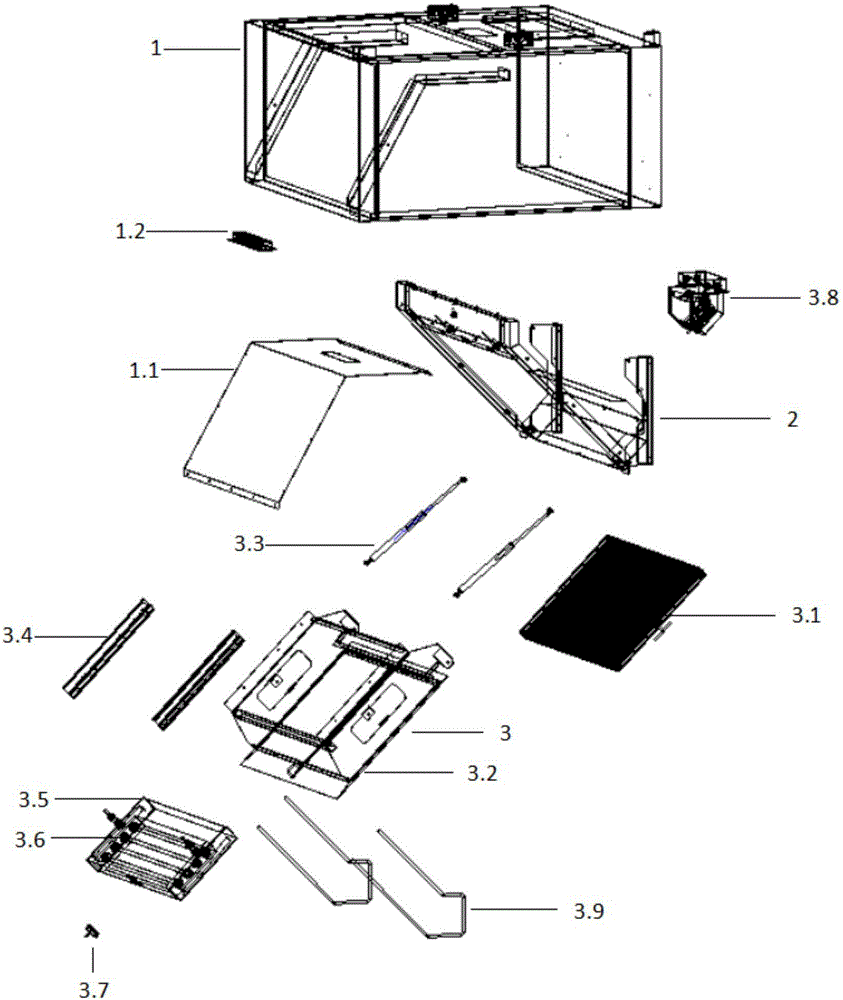

Adhering tool for adhering glass panel to exhaust fume collecting hood

The invention relates to an adhering tool for adhering a glass panel to an exhaust fume collecting hood. The adhering tool comprises a support, and an adhering structure is at least arranged on one side of the support. The adhering tool is characterized in that the adhering structure comprises an upper bearing board, a lower bearing board, two positioning air cylinders, an upper installation board and compression blocks, wherein locating detents are installed on piston rods of the positioning air cylinders and provided with horizontal arms and inclined arms; first positioning blocks are fixed to the horizontal arms; second positioning blocks are fixed to the ends of the inclined arms on at least one side; the upper installation board is fixed above the support; the upper installation board and a top board of the support are spaced vertically; the compression blocks are located over the upper bearing board and driven by a compression air cylinder to vertically and perpendicularly move; the compression blocks press downwards to compress the glass panel to the front end face of the exhaust fume collecting hood for pressure maintaining. The adhering tool has the advantages that structural design is reasonable, the glass panel adheres to the exhaust fume collecting hood accurately and firmly, the binding efficiency and precision are high, a few procedures are needed, and operation is convenient.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

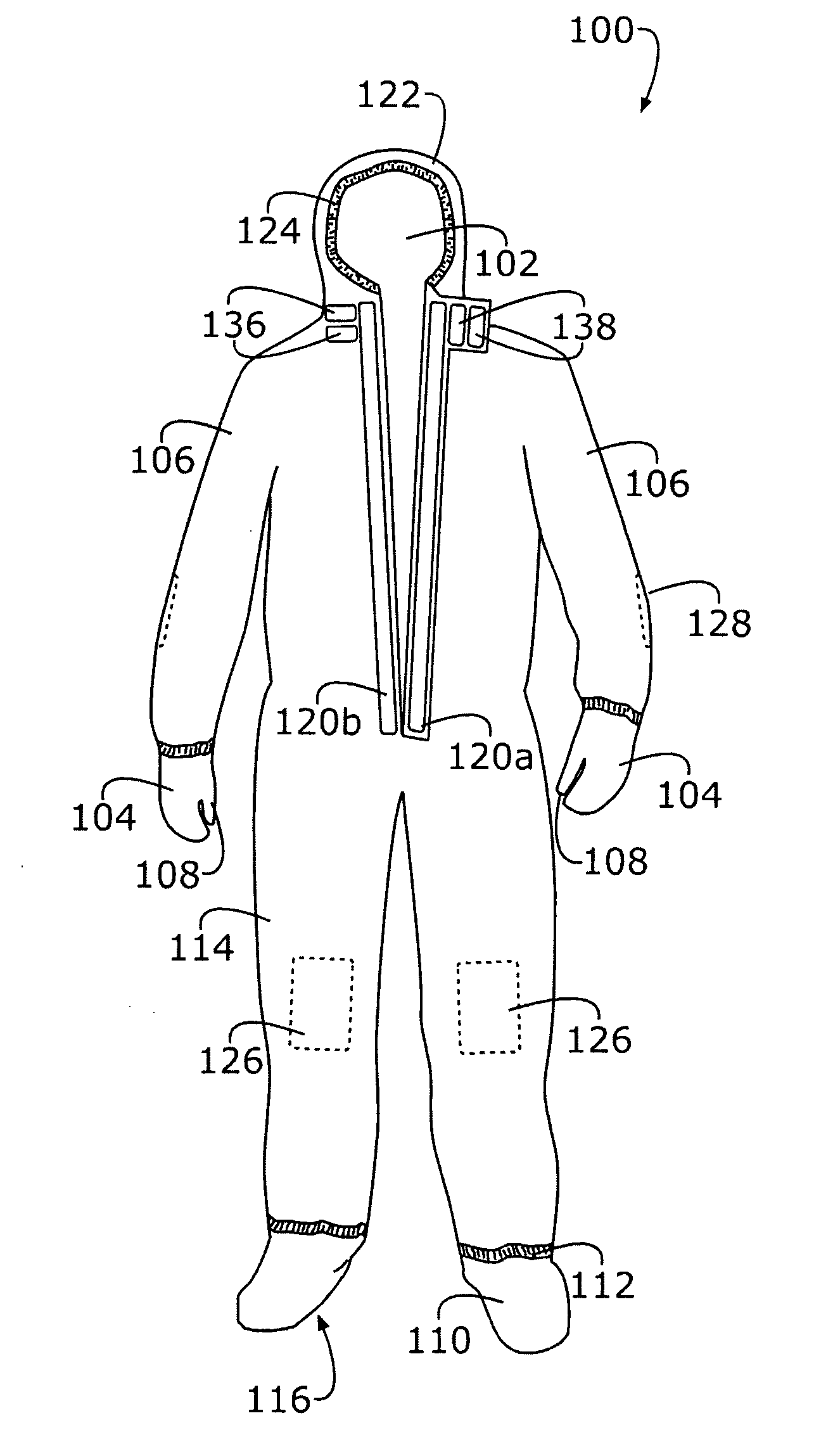

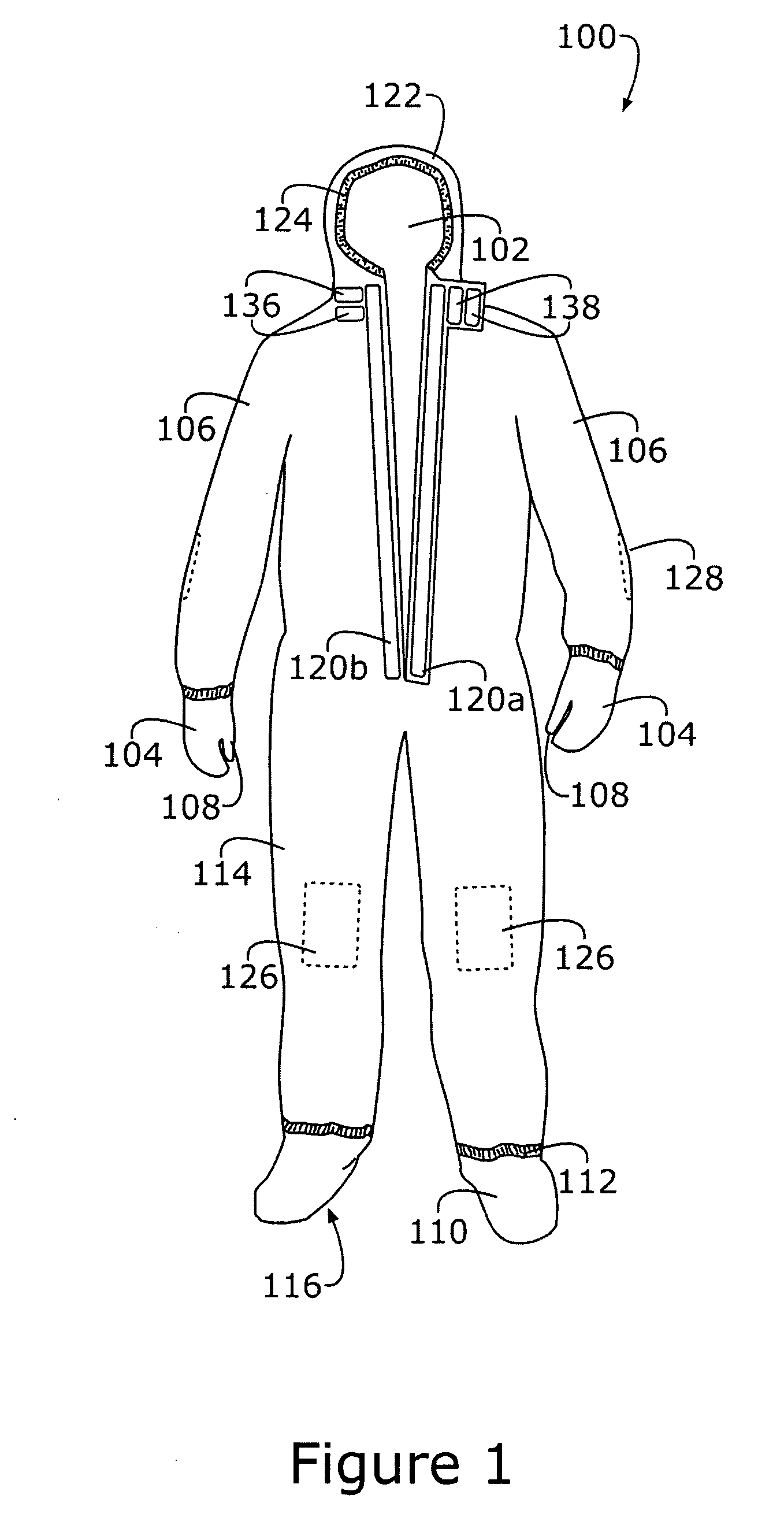

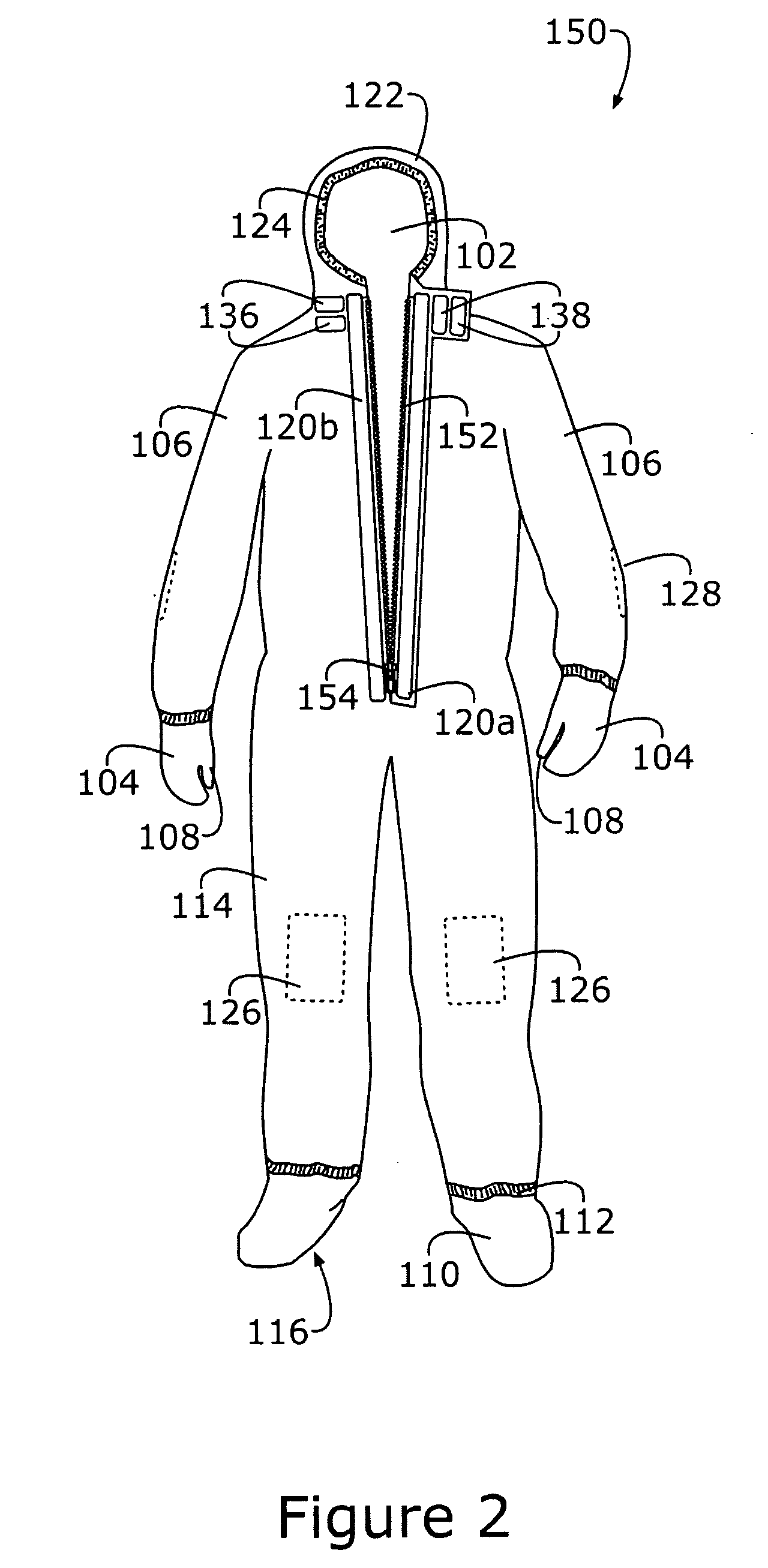

Flameproof, heat resistant, one-piece escape suite

ActiveUS20080276357A1Low enough in costLow costChemical protectionHeat protectionEngineeringSmoke hood

A flameproof, heat resistant, lightweight, one-piece escape suit which includes attached integral mitts or gloves, covered footing, and a hood. The fire and heat resistant one piece suit is designed to be worn over a commercial smoke hood, is formed from a metalized fabric, and meets the requirements of ASTM standard D6413. The suit is designed to be easily slipped onto a wearer's body over typical street clothing, and allows a wearer to wear his or her accustomed footwear for improved safety and comfort. The durable fabric provides protection to a wearer when crawling low to the ground on his or her knees and elbows as is often recommended as a preferred escape posture. The fire and heat resistant one piece suit may be provided in multiple sizes to fit adults and children. The fire and heat resistant one piece suit, as well as a smoke hood, may be packaged into compact, lightweight emergency escape kit bag with unique “glow in the dark” lettering; FIRE ESCAPE KIT suitable for carrying between home and work, etc.

Owner:SIGMON KENNIS L

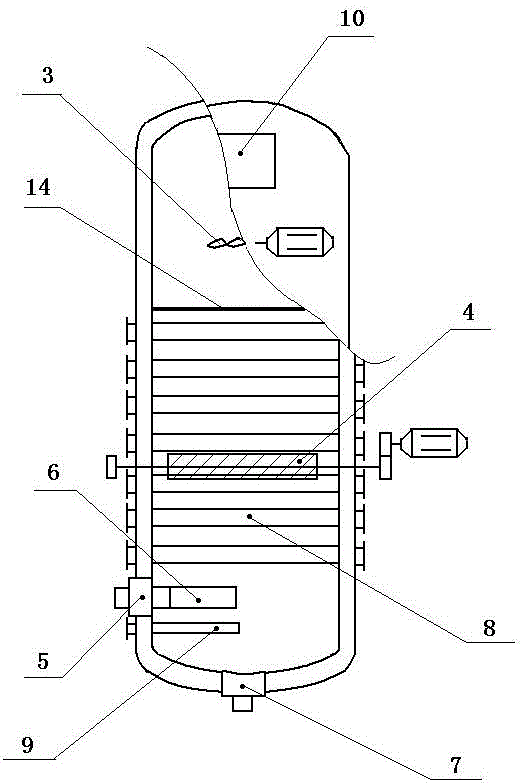

Device and method for continuously removing copper from liquid crude lead

ActiveCN102978416AContinuous copper removal achievedImprove energy savingSiphonRefining (metallurgy)

The invention relates to a device and a method for removing copper in crude lead pyro-refining in nonferrous metallurgy field, and in particular relates to a device and a method for continuously removing copper from liquid crude lead. The device comprises a pot body and a smoke hood which is covered on the pot body, wherein a stirrer, the stirring paddle of which extends to the liquid lead in the pot body, is fixedly arranged on the smoke hood; the pot body is divided into a stirring reaction region and a cooling liguation region by a baffle plate; the liquid lead and copper dross overflow to the upper part of the cooling liguation region from the stirring reaction region through the upper side of the baffle plate; a charging hole is arranged at the end part of the smoke hood on the stirring reaction region; a drossing hole and a lead discharging hole are arranged at the end part of the cooling liguation region; a smoke outlet is arranged at the end part of the smoke hood above the cooling liguation region; dross stirrers for stirring the copper dross floating on the liquid lead are fixedly arranged on the two side surfaces of the cooling liguation region; cooling water tubes for cooling the liquid lead are welded on the two sides of the pot; a siphon lead discharging tube is arranged on the pot side at the lead discharging hole; and the lower hole of the siphon lead discharging tube extends to the bottom of the pot body. According to the device and the method provided by the invention, energy is saved, environment-friendly effect is good, recovery rate of lead is high, automation degree is high, and labor intensity is low.

Owner:HENAN YUGUANG GOLD & LEAD

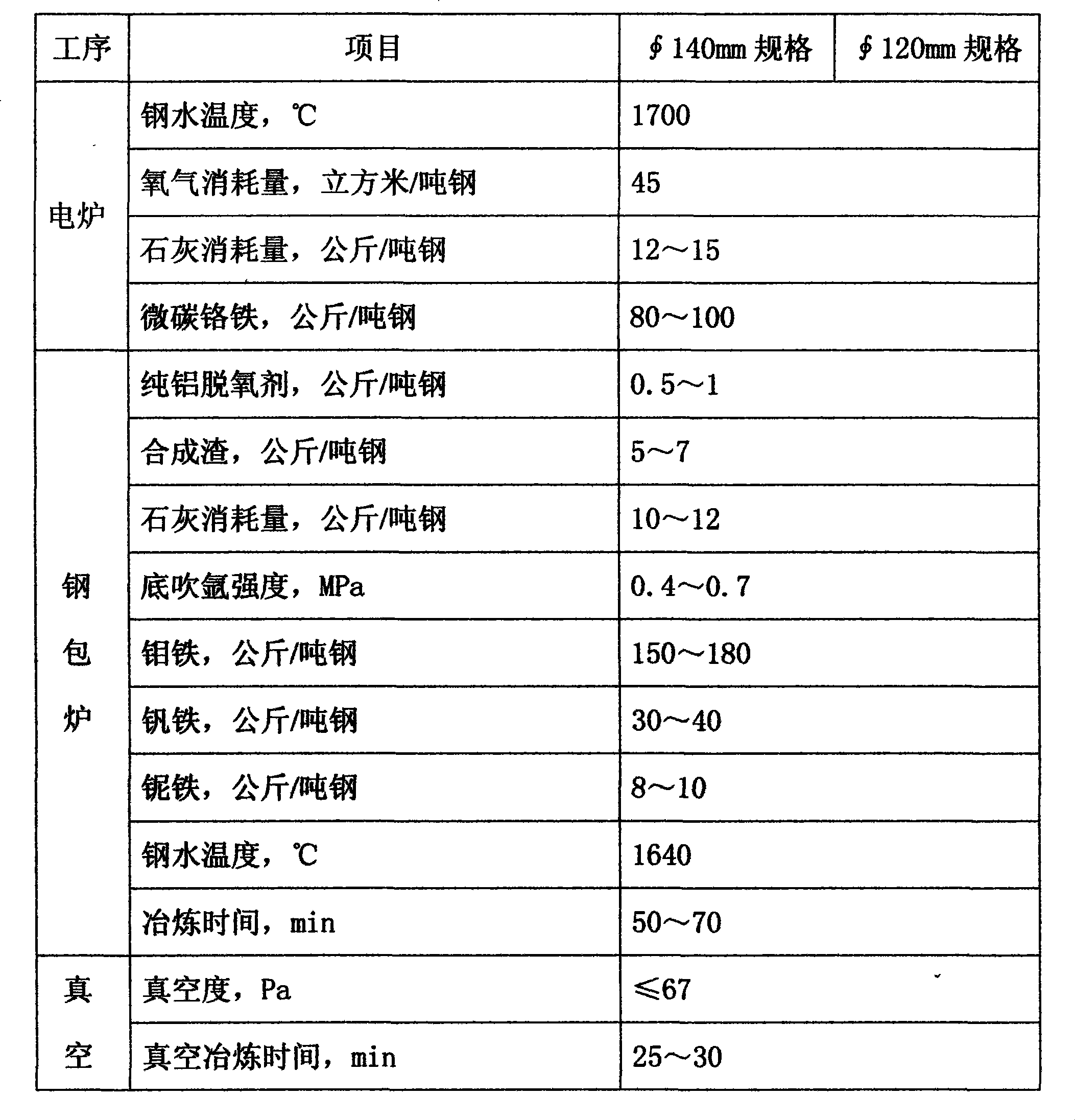

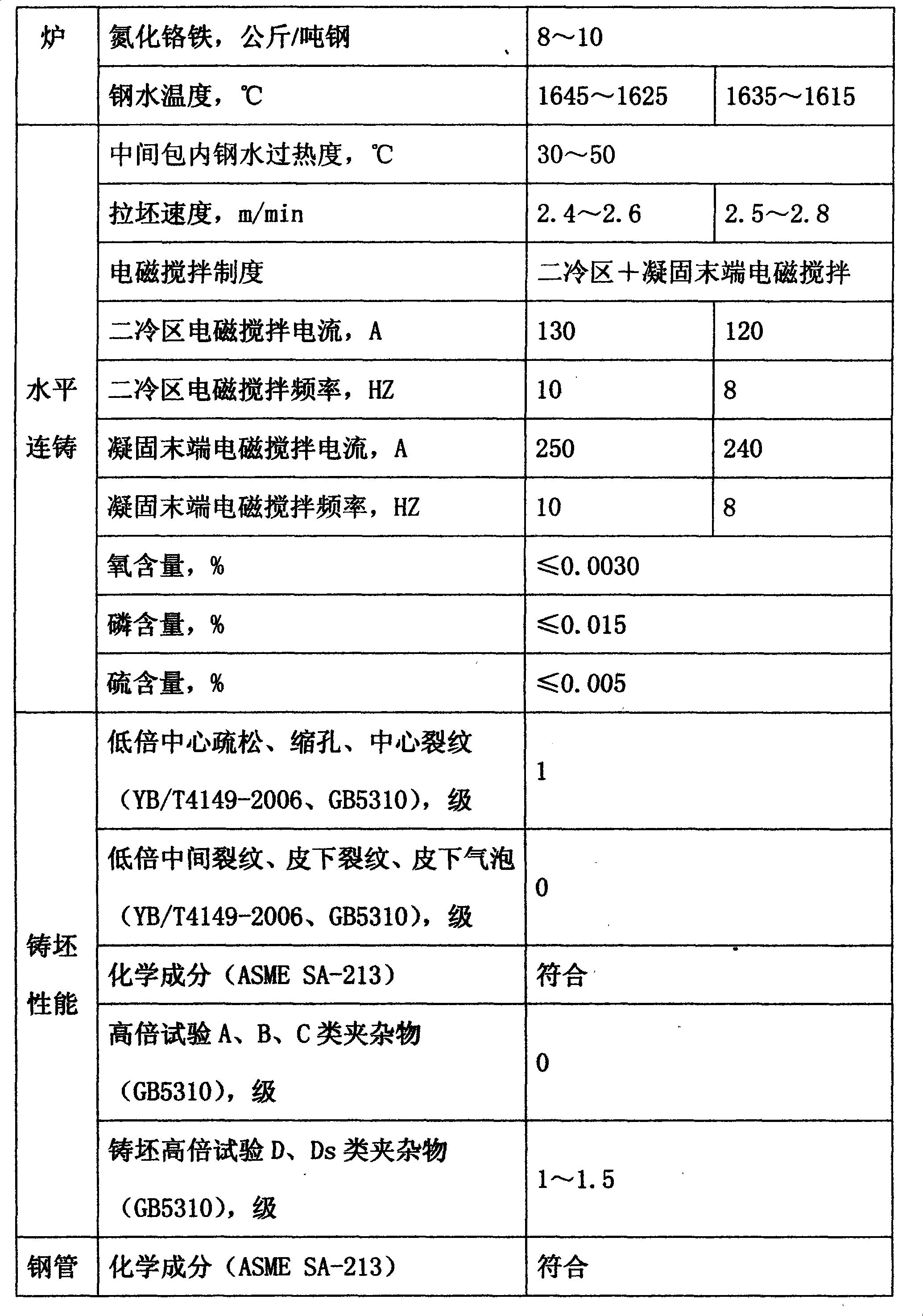

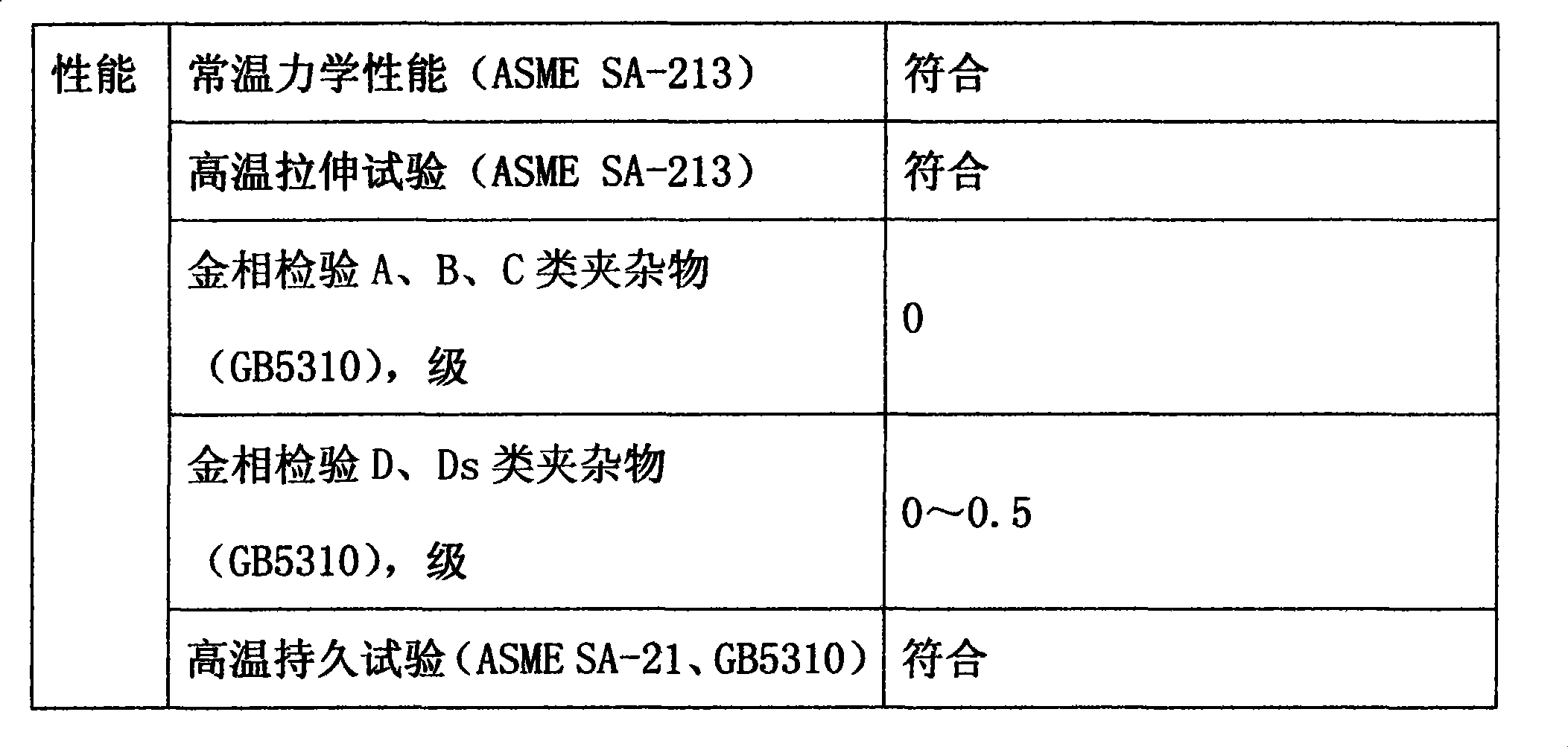

Method for horizontal continuous casting 10Cr9Mo1VNbN ferrite heat-resistant steel to tube round blank through electric stove smelting

ActiveCN101381790AEasy to controlFew linksElectric furnaceProcess efficiency improvementSlagAlternating current

The invention provides a method for smelting 10Cr9Mo1VNbN ferrite refractory steel to form a circular tube billet by horizontal continuous casting in an electric furnace. The method comprises the following process flow: primary smelting in a 30-ton alternating current electric furnace (steel is tapped from the bottom of an eccentric furnace; refined pre-smelting slag, various alloys and a deoxidizer are added), a 40-ton ladle refining furnace (the bottom is blown with argon), a 40-ton vacuum furnace for degassing and horizontal continuous casting. All the alloys are roasted; the alloy roasting is carried out through the following steps: pores are pricked on an iron barrel filled with ferrochrome nitride, ferromolybdenum, ferrovanadium and ferrocolumbium; the alloys are put in a large smoke hood of the refining furnace and are roasted; micro-carbon ferrochromium is added into a ladle ahead of 60 minutes before tapping and is roasted; and the replenished micro-carbon ferrochromium after the tapping is roasted in an offline middle ladle ahead of eight hours.

Owner:衡阳华菱连轧管有限公司

Oil fume guide type range hood

ActiveCN106152219ASpeed up the flowTo accelerateDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke hood

The invention discloses an oil fume guide type range hood which comprises a draught fan hood and a fume collecting hood. A draught fan is arranged inside the draught fan hood. A fume baffle is arranged on the upper portion of the front side of the fume collecting hood. The oil fume guide type range hood is characterized in that a fume guide plate is arranged on the rear side of the fume baffle; the space between the fume guide plate and the fume baffle forms a fume guide cavity; the space between the fume guide plate and the fume collecting hood forms a fume collecting cavity; further, clearances are reserved between at least two lateral sides of the fume guide plate and the position, corresponding to the fume collecting hood, of the shell, so that the fume guide cavity communicates with the fume collecting cavity; and the range hood further comprises an air blowing guide device which comprises air blowing ports, the air blowing ports are used for blowing out airflow which is close to the fume guide plate and flows obliquely upwards and towards the middle, and the air blowing ports are formed in the two sides of the front portion of the fume collecting hood correspondingly and close to the bottom of the fume collecting hood.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

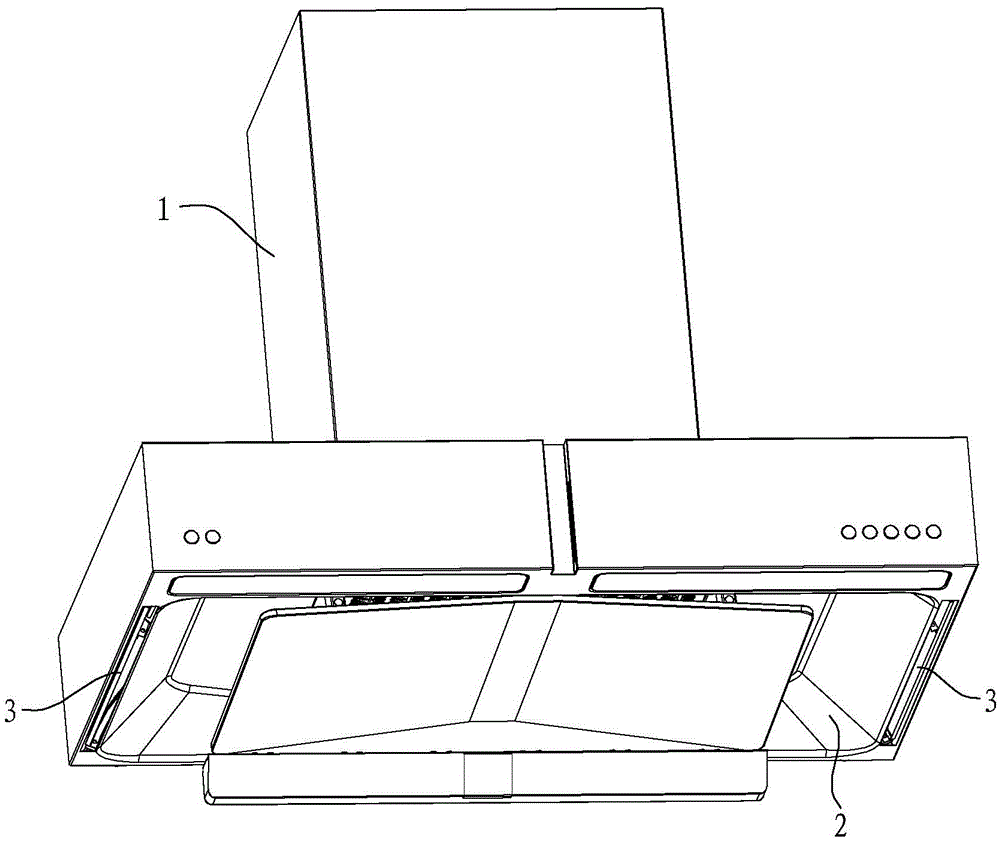

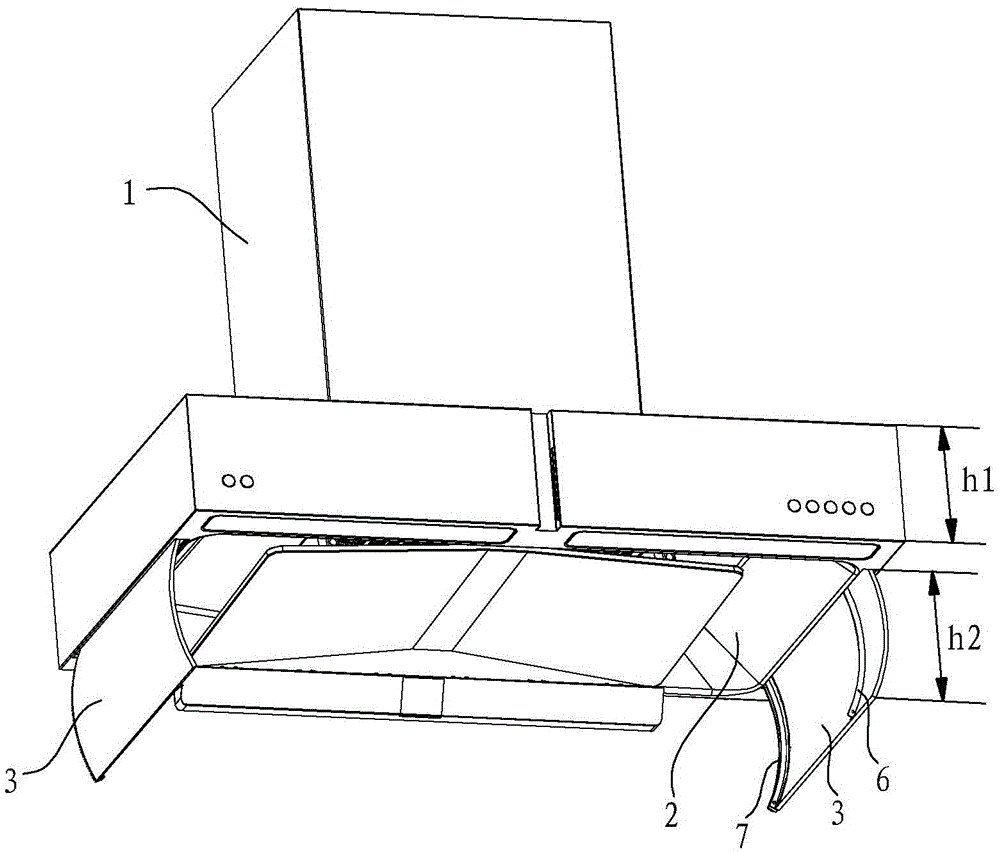

Extractor hood

InactiveCN105650707AReduce the chance of escapeIncrease the working distanceDomestic stoves or rangesLighting and heating apparatusBlock effectEngineering

An extractor hood comprises a fan outer cover and a smoke collection cover. The extractor hood is characterized in that a movable smoke blocking plate is mounted on each of the left side and the right side of the smoke collection cover, is arc-shaped and is provided with a concave face downward, and the movable smoke blocking plate is driven by a driving mechanism to upwards contract into the smoke collection cover or downwards extend out of the same along an arc-shaped track. The extractor hood has the advantages that the arc-shaped movable smoke blocking plates are mounted on the left side and the right side of the inside of the smoke collection cover, contract into the smoke collection cover when not working and extend out of the smoke collection cover when working, so that acting distance of left and right cavity negative pressure areas of the smoke collection cover is expanded, and opportunity that rising oil smoke escapes from two sides of the smoke collection cover is reduced. In addition, the smoke collection cover is generally small in own height, so that after the arc-shaped smoke blocking plates are adopted, the arc-shaped smoke blocking plates can rotate to contract or extend, height of an extending portion can reach or exceed original height of the smoke collection cover, extending distance is relatively long, and better smoke blocking effect is acquired.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

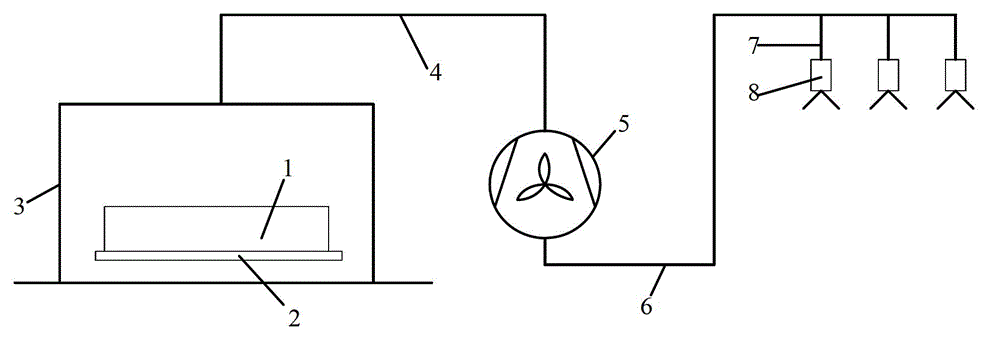

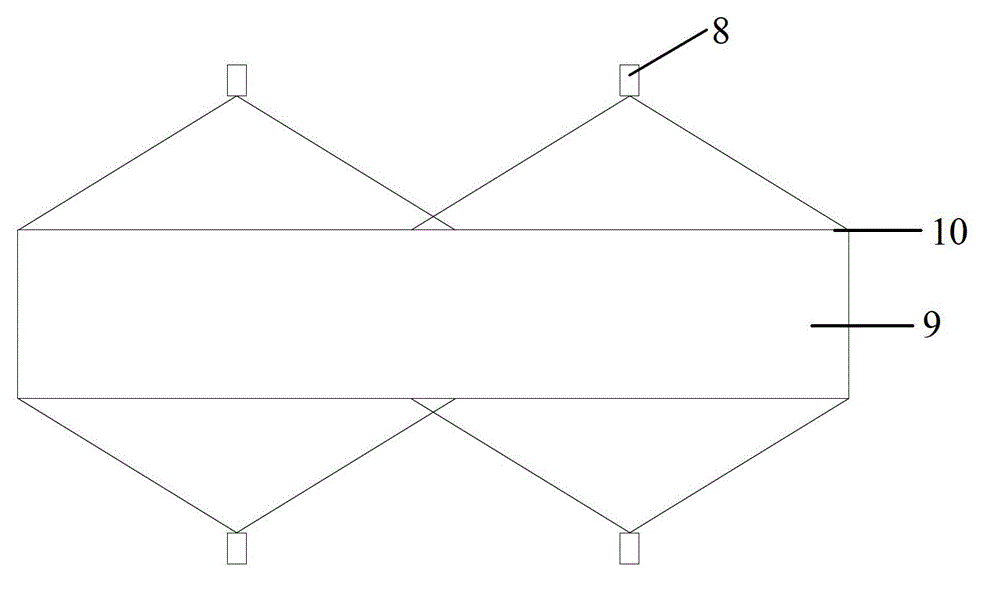

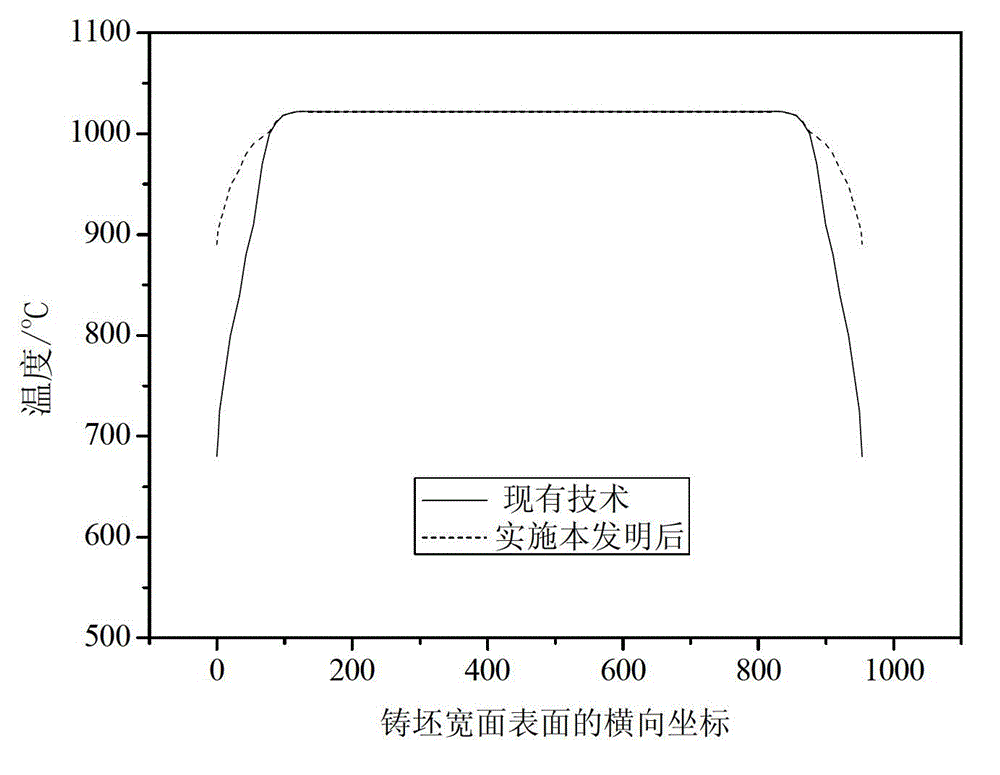

Method and device for deceasing transverse corner cracks of casting blanks

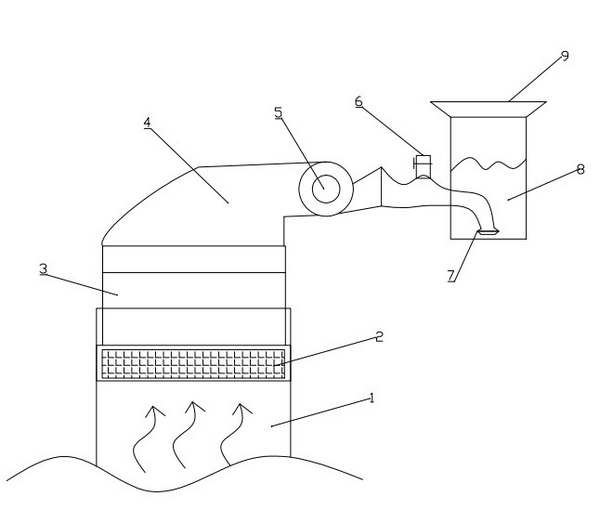

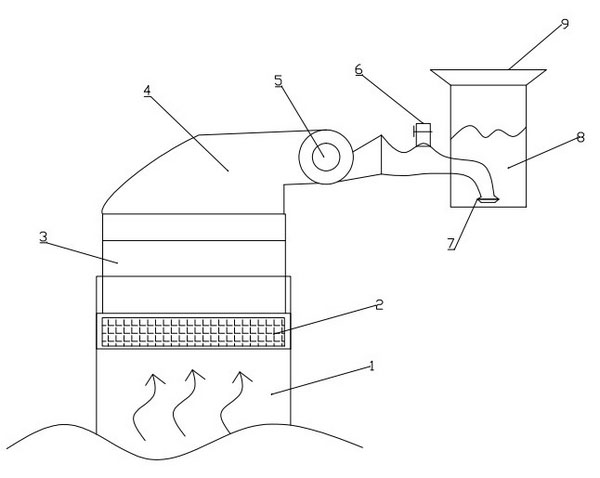

The invention relates to a method and device for decreasing transverse corner cracks of castling blanks. The method includes the steps of S1, disposing a smoke hood above a conveying roller way for cut casting blanks to collect high-temperature air; S2, delivering the collected high-temperature air under pressure; S3, delivering the high-temperature air to air nozzles disposed in a second casting blank cooling area and at corners of the casting blanks; and S4, allowing the high-temperature air to pass through the air nozzles to cover the corners of the casting blanks. The device comprises the smoke cover (3), a first heat-resistant pipe (4), a booster fan (5), a second heat-resistant pipe (6), heat-resistant branch pipes (7) and the air nozzles (8). The high-temperature compressed air can be blown to the corners of the casting blanks to prevent excessively fast cooling of the corners of the casting blanks, so that the corners of the casting blanks can be kept at the temperature higher than the upper limit of a low-temperature brittleness area before entering a straightening area, precipitation of various carbo-nitrides from the corners of the casting blanks is avoided, corner plasticity of the casting blanks is improved and transverse cracking of the corners of the casting blanks is effectively prevented during straightening.

Owner:WISDRI ENG & RES INC LTD

Lampblack exhauster capable of preventing smoke from diffusing

InactiveCN105928028APrevent proliferationChange sizeDomestic stoves or rangesLighting and heating apparatusCollection systemEngineering

A lampblack exhauster capable of preventing smoke from diffusing is mainly composed of a main exhaust system, a smoke diffusion prevention system and a liquid collection system. The main exhaust system is composed of a smoke collection hood, a main exhaust fan and an exhaust pipe. The main exhaust fan is arranged at the top end of the upper portion of the smoke collection hood, and the exhaust pipe is arranged at the upper end of the main exhaust fan and fixedly connected with the smoke collection hood; the smoke diffusion prevention system comprises four baffles, and the baffles are arranged on the four edges of the bottom of the smoke collection hood correspondingly; the smoke diffusion prevention system further comprises smoke collection fans and four telescopic air pipes, the telescopic air pipes are arranged on the four corners of the bottom of the smoke collection hood and located in gaps between two adjacent baffles, a column of air outlet holes is formed in the pipe wall of each telescopic air pipe, and the smoke collection fans are arranged at the upper ends of the telescopic air pipes; and the liquid collection system is composed of a liquid collection groove and a liquid collection box, the liquid collection groove is formed in the inner wall of the upper portion of the smoke collection hood and connected with the liquid collection box through a special delivery pipeline. The lampblack exhauster is simple in use, good in effect and capable of being used flexibly according to the lampblack condition, and energy saving and environment protection are achieved.

Owner:LUOYANG INST OF SCI & TECH

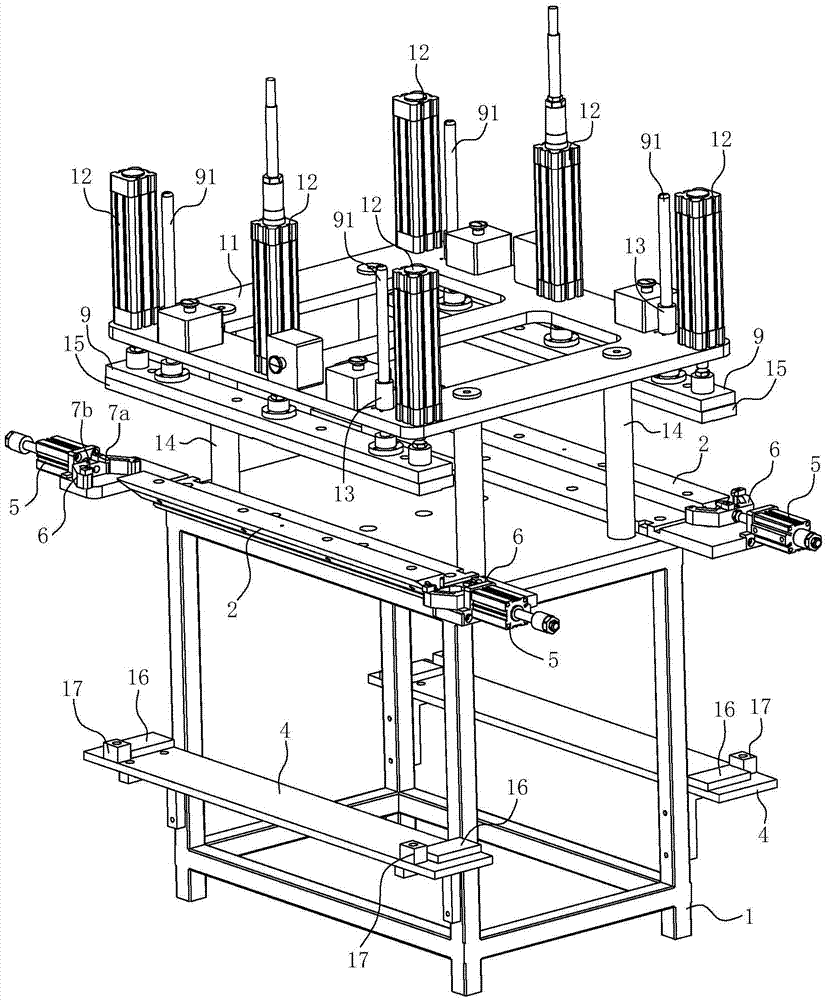

Clamp used for welding of smoke collecting hood

ActiveCN106002035AGuaranteed flatnessGuaranteed straightnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSmoke hood

The invention relates to a clamp used for welding of a smoke collecting hood. The clamp comprises a platform used for containing the smoke collecting hood with folded edges; and a positioning structure used for positioning the smoke collecting hood is arranged on the platform. The clamp is characterized in that outer pressing blocks and inner pressing blocks are arranged on the platform; the outer pressing blocks are driven by a driving structure to be capable of pressing or being away from the outer end faces of the portions, adjacent to a welding position, of the folded edges of the smoke collecting hood; the inner pressing blocks are used for pressing the inner end faces of the portions, adjacent to the welding position, of the folded edges of the smoke collecting hood; and the pressing positions of the inner pressing blocks correspond to those of the outer pressing blocks. By means of pressing of the inner pressing blocks and the outer pressing blocks on the portions, adjacent to the welding position, of the folded edges, the folded edges adjacent to the welding position are free of arched welding deformation caused by welding, the flatness and the straightness of the folded edges are effectively guaranteed, and therefore the quality of the smoke collecting hood is improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

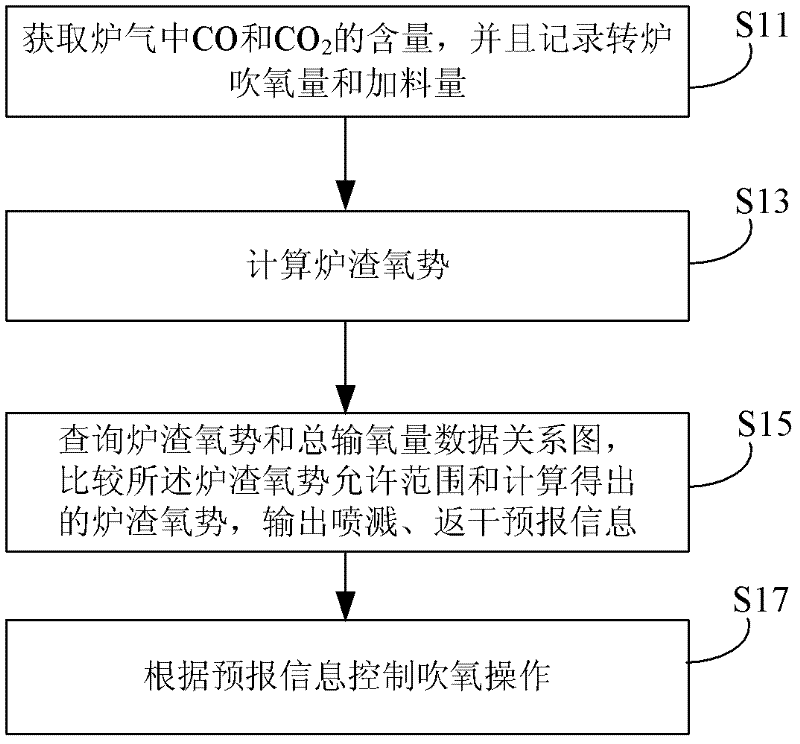

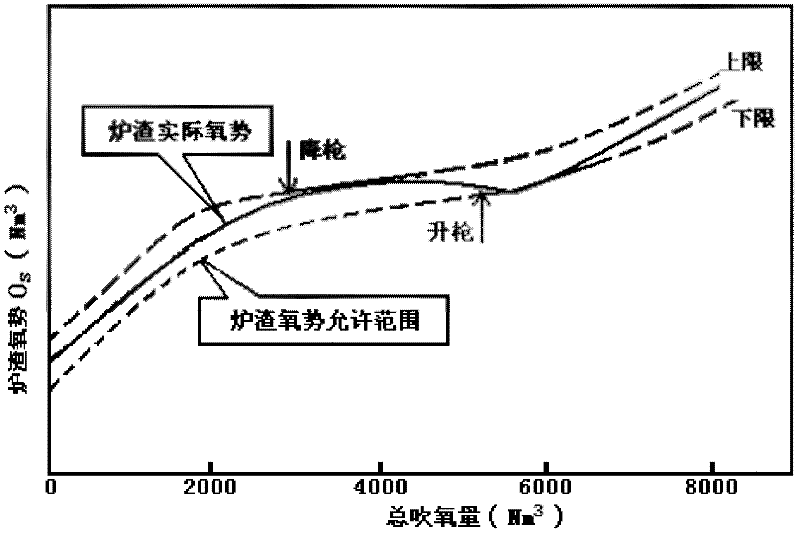

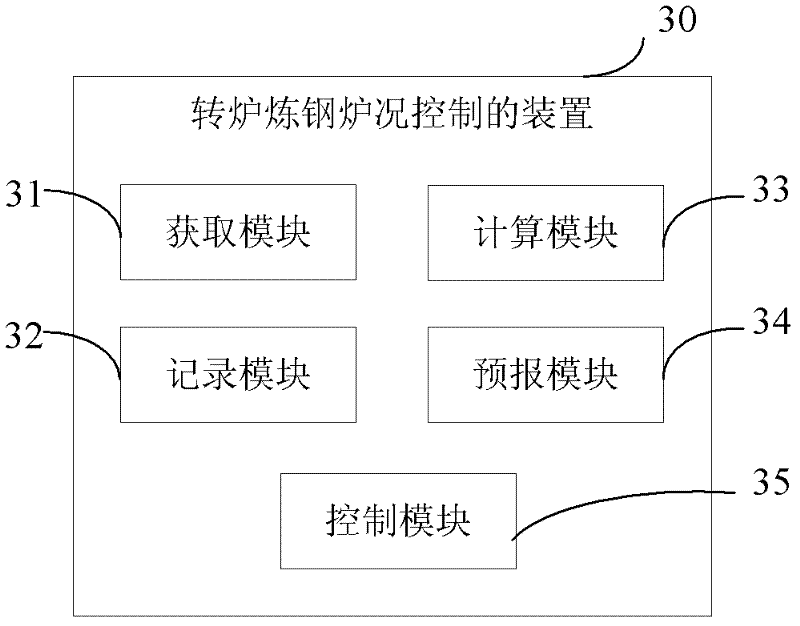

Method, device and system for controlling furnace conditions of convertor steelmaking

ActiveCN102363825AOvercome the disadvantage of poor stability of artificial experience controlEasy to controlManufacturing convertersSteelmakingSmelting process

The invention provides a method, a device and a system for controlling furnace conditions of convertor steelmaking. By the method, the device and the system, the problem that a control effect is influenced by the descending of a convertor smoke hood and accumulated slag at a furnace mouth and the problem of poor control accuracy in the prior art are solved. The method comprises the following steps of: acquiring the content of CO and CO2 in furnace gas ingredients, and recording the oxygen blowing amount of a convertor and charging quantity; calculating slag oxygen potential according to the content of the CO and the CO2, the oxygen blowing amount of the convertor and charging information; inquiring the permission range of the slag oxygen potential from a data relational graph of the slag oxygen potential and the total oxygen blowing amount according to the oxygen blowing amount of the convertor, comparing the permission range of the slag oxygen potential with the calculated slag oxygen potential, and outputting spattering forecast information or drying return forecast information according to a comparison result; and controlling the oxygen blowing operation according to the forecast information. Due to the adoption of the technical scheme, the defect of poor stability of control by artificial experience is overcome; and compared with the conventional sonar slag-reducing method, the method has the advantages that: the control effect is not influenced by the descending of the convertor smoke hood and the accumulated slag at the furnace mouth; the control is more accurate; and the stability of the smelting process is improved.

Owner:田陆

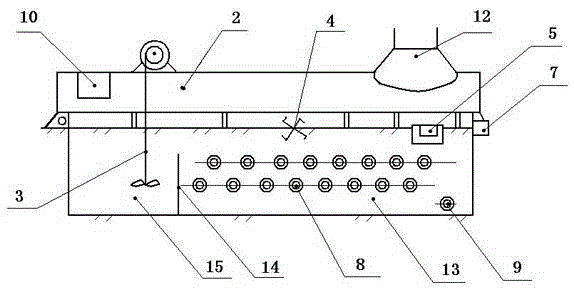

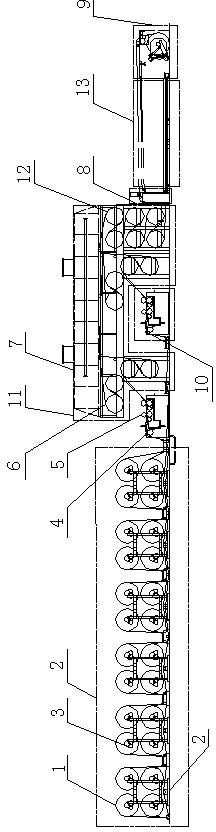

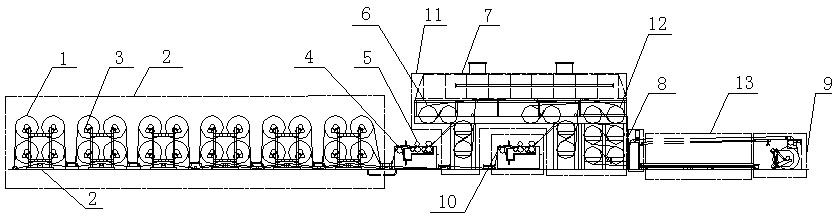

Intelligent high-speed sizing machine

InactiveCN102330300AImprove weaving performanceGuaranteed sizing rateLiquid/gas/vapor removalTextile treatment carriersIntelligent lightingYarn

The invention relates to the technical field of sizing machines, in particular to an intelligent high-speed sizing machine which comprises a beam creel, a slurry tank, a drying room, a URM (Ultrasonic Rapid Manufacturing) device, a lease region and a nose. The intelligent high-speed sizing machine is sequentially provided with the beam creel, a yarn guide roller, the slurry tank, the drying room, the URM device, the lease region and the nose along the movement direction of yarns; a pan head and a support plate assembly are arranged on the beam creel, the slurry tank is connected with the yarn guide roller which is connected with a squeezing roller, the drying room is connected with the URM device which is connected with the lease region, the lease region is connected with the nose, the drying room is internally provided with a pre-drying barrel and a main-drying barrel, a smoke hood is arranged above the pre-drying barrel and the main-drying barrel, and the pan head is arranged in the nose. According to the invention, a pressure sensor is arranged on the yarn guide roller, the tension of the yarns entering the slurry tank can be detected; the sizing speed can be regulated at any time through the nose; and thus the sizing rate is ensured and the warp weaving performance is improved.

Owner:KARL MAYER CHINA

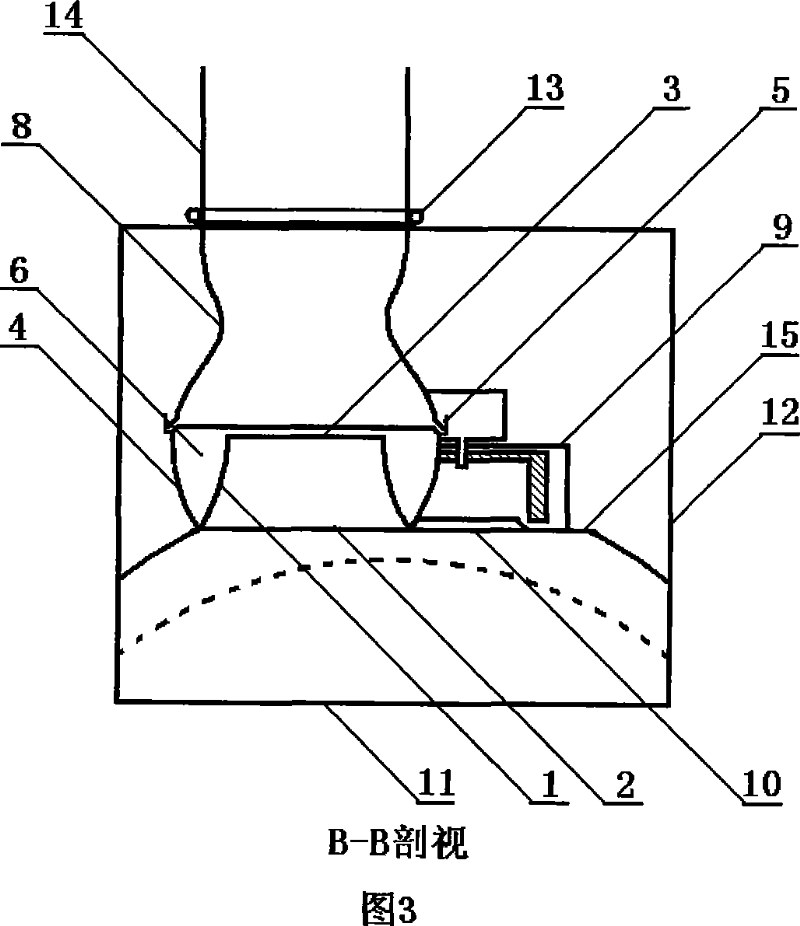

Easy-to-clean UV smoke hood with overturning structure

ActiveCN106839040AEasy to cleanEasy to disassembleDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke hood

The invention discloses an easy-to-clean UV smoke hood with an overturning structure. The UV smoke hood comprises an smoke hood outer frame, a filter screen fixing outer frame and a filter screen overturning assembly, wherein the filter screen fixing outer frame is welded on the inner side of the smoke hood outer frame, two sides of the lower end of the filter screen overturning assembly are respectively in shaft connection with the filter screen fixing outer frame, the upper end of the filter screen overturning assembly is locked on the filter screen fixing outer frame, the outer side of the filter screen overturning assembly is provided with a filter screen, and the inner side of the filter screen overturning assembly is provided with a UV lamp, and a support and a guide rail of the UV lamp. The UV smoke hood is reasonable and scientific in structure, and convenient to use and clean; by the overturning structure on a smoke hood filter screen supporting frame, the filter screen and a UV lamp tube can be overturned and descended to a place where a worker can touch, thus achieving the aim of easily disassembling and cleaning the filter screen and the UV lamp tube, and facilitating product popularization.

Owner:弗兰卡餐饮设备安装技术服务(中国)有限公司

Whirl entraining type cooking fume exhauster

InactiveCN101042247AHighlight substantive featuresSignificant progressDomestic stoves or rangesLighting and heating apparatusWinding machineEngineering

A swirl drawing oil exhaust ventilator features in the stacked arrangement of two wind machine and ring swirl slot, two wind blower pipe tangentially cutting the ring swirl slot with an included angle of 60-180, outside barrel connected to the radius change connecting pipe, slot at their juncture and outside slanted slot, a ring oil stop slot, radius change minimum diameter being 0.9 to 1.3 times of the up opening diameter of the connecting pipe, length being 1 to 2 times of the minimum diameter, radius connecting pipe installed with dual sealing rolling door at the joint position of the smoke exhaust chimney. It adopts reasonable assembly method, linear structure and ball smoke hood, free from big power wind blower to achieve better bump effect, getting rid of may setbacks of existing electric smoke extraction machine with high efficiency, energy saving, environment protective and easy cleaning.

Owner:UNIV OF SCI & TECH OF CHINA

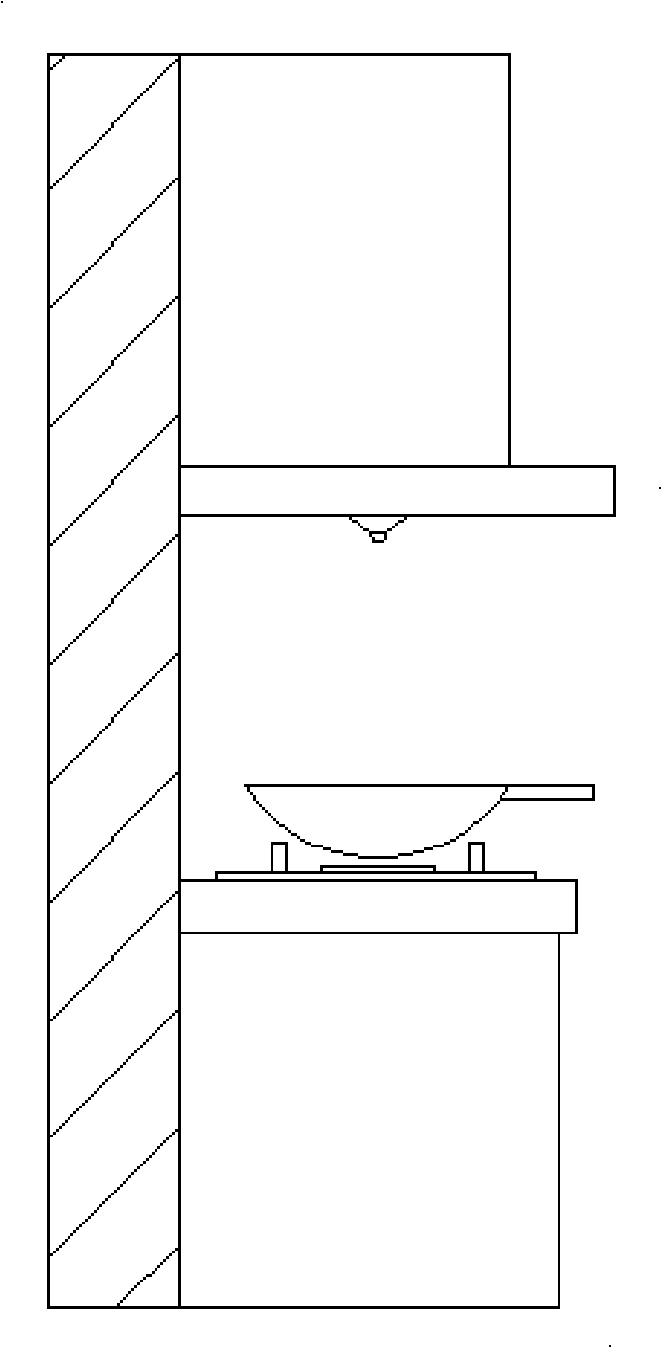

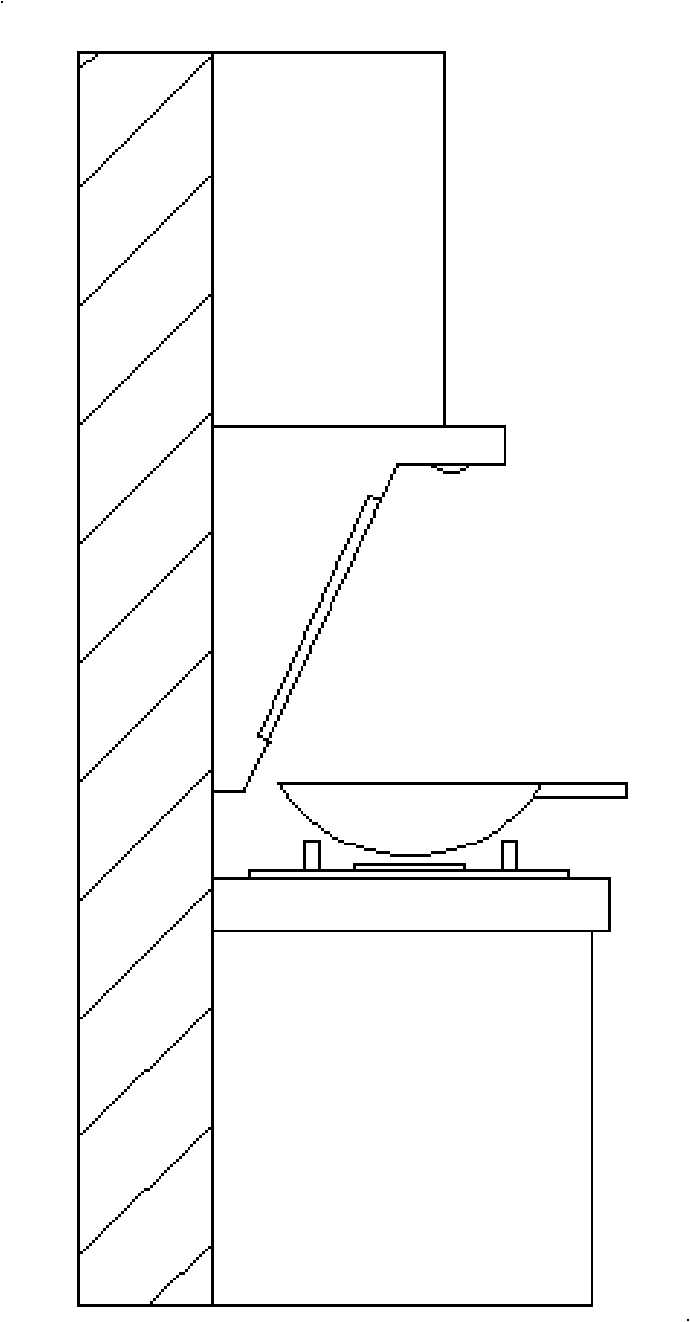

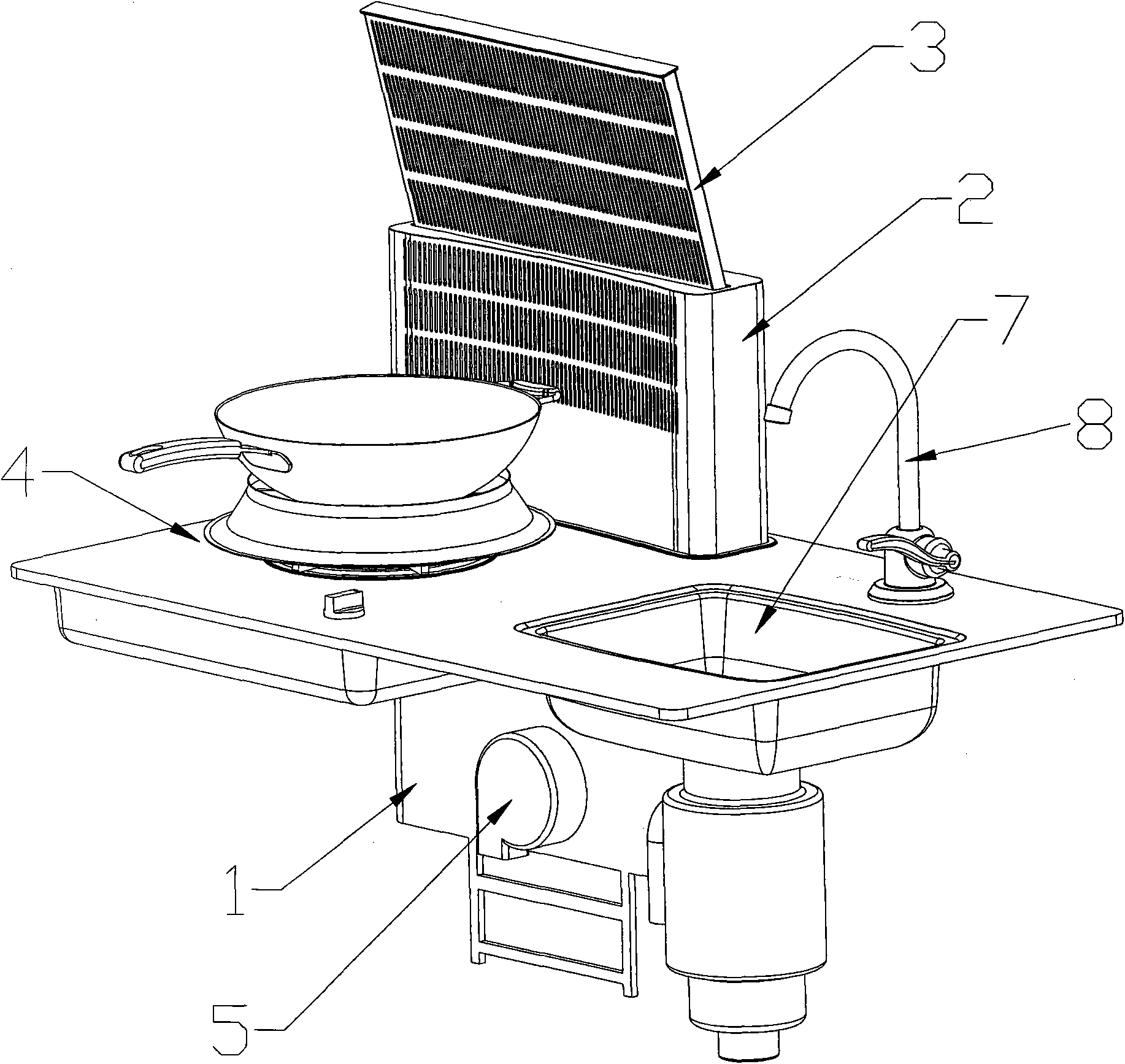

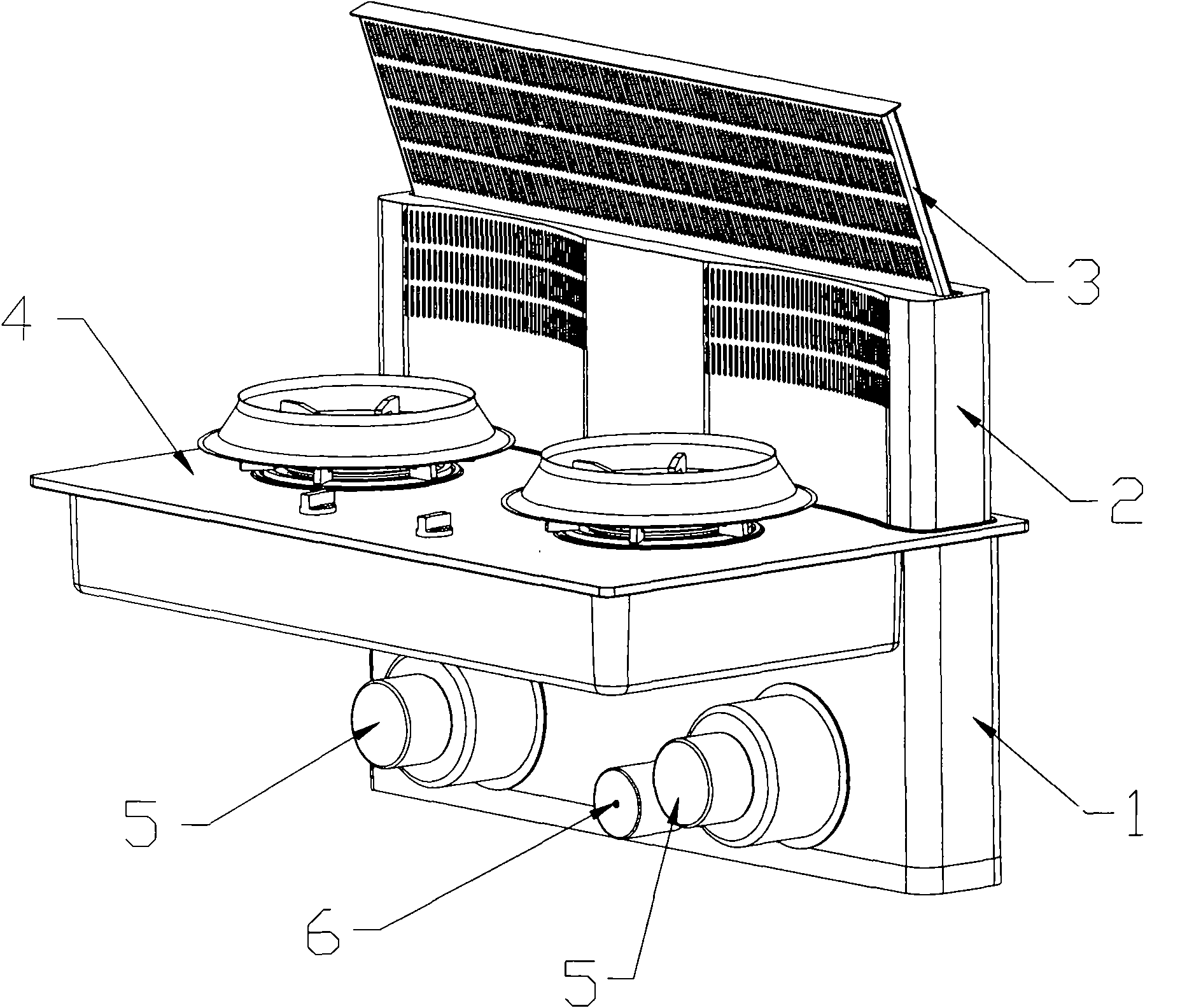

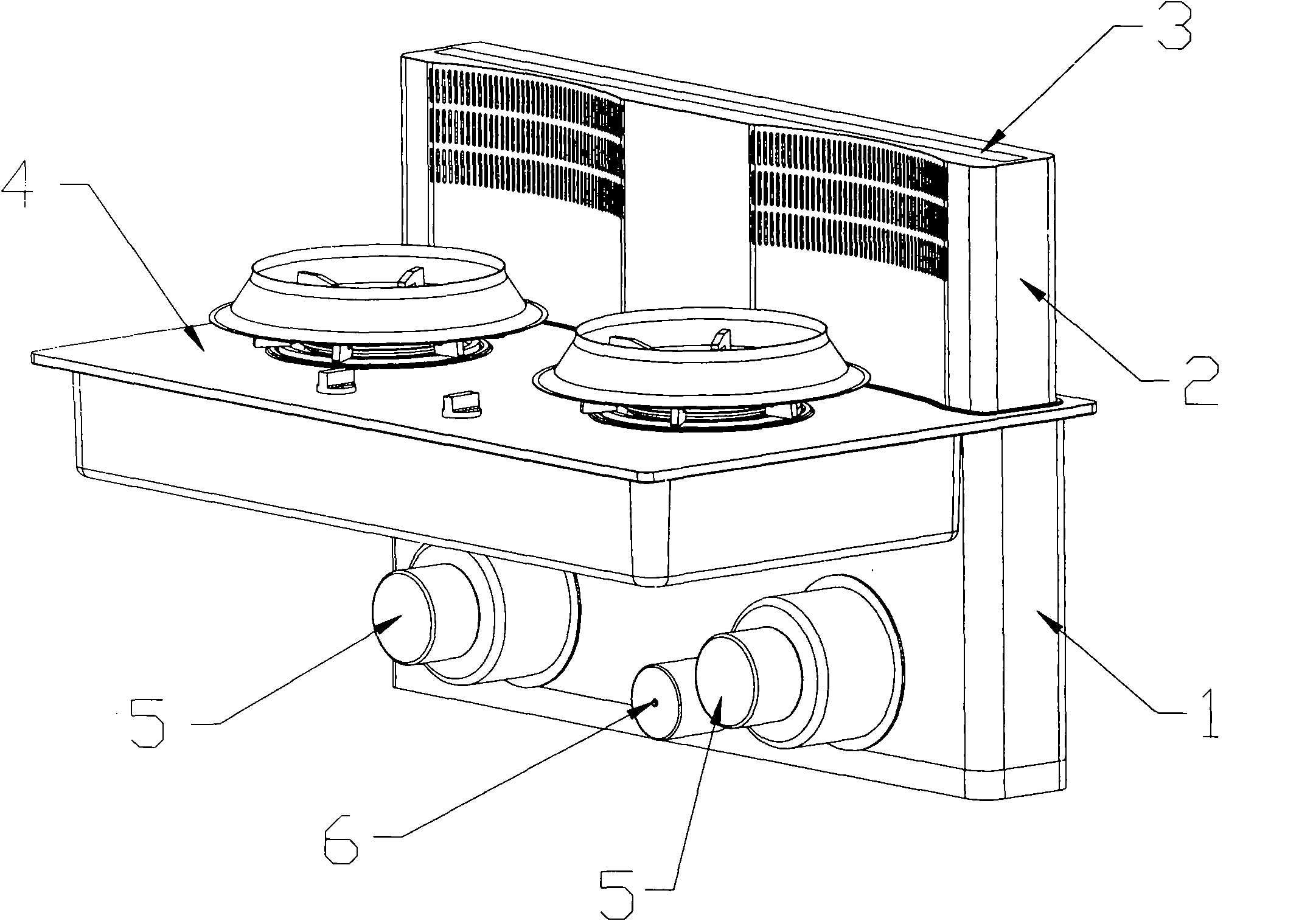

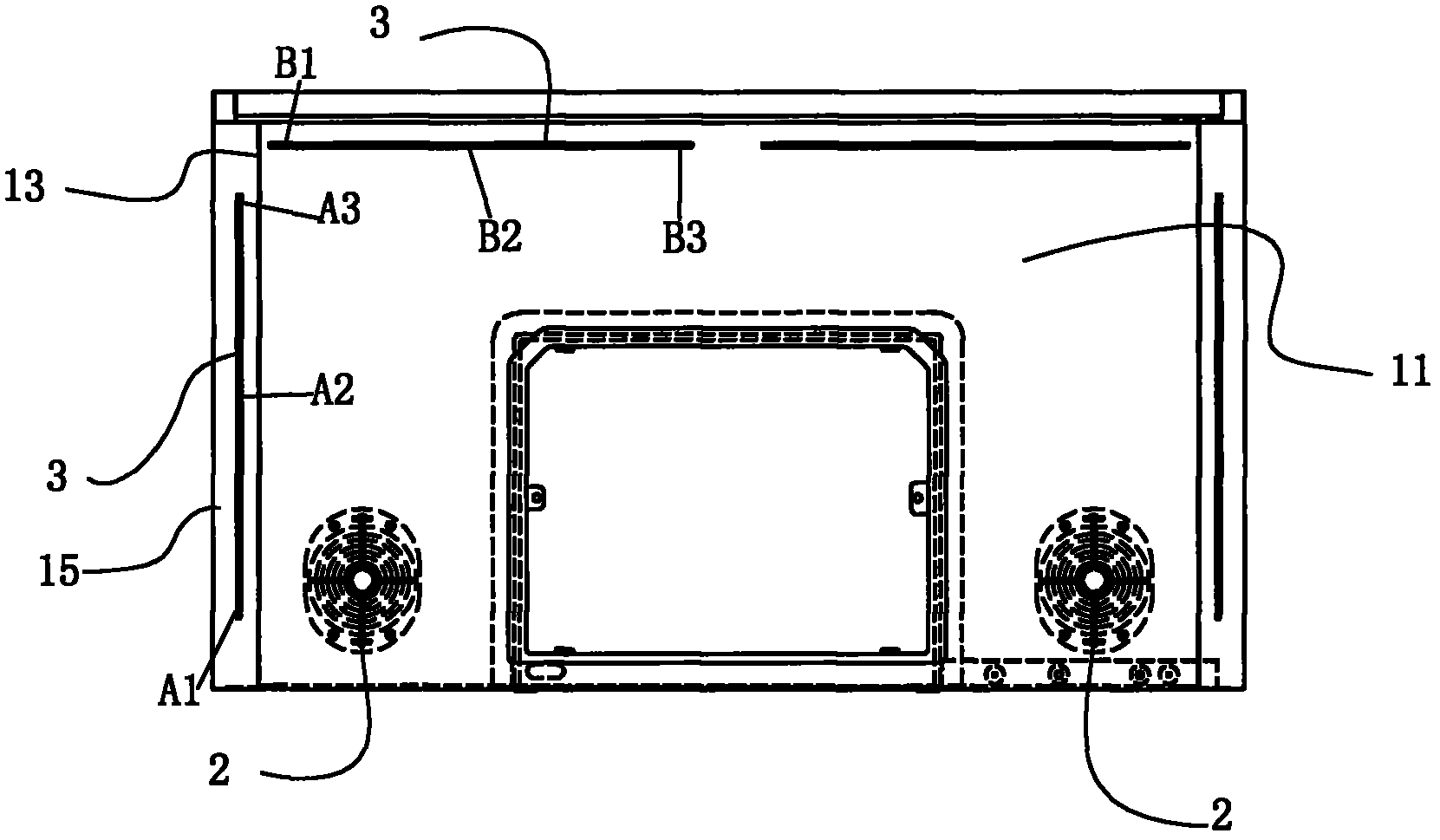

Vertical lifting fume extracting system, gas stove and integral cabinet

InactiveCN101813331APrevent proliferationImprove the smoke effectDomestic stoves or rangesLighting and heating apparatusEngineeringSmoke hood

The invention discloses a vertical lifting fume extracting system, which comprises a support body and a range hood for removing fume. The range hood is arranged on the support body; the range hood further comprises a fume collecting hood, a fan main body and a flue; the fume collecting hood is arranged on the support body; the flue comprises an air inlet and an air outlet; the fume collecting hood is the air inlet of the flue; the air outlet of the flue is formed outside the support body; and the fume collecting hood is movably connected to the support body through a lifting mechanism. A gas stove comprises the fume extracting system. An integral cabinet comprises facilities such as the fume extracting system, the gas stove, a sink and the like. The fume extracting system has the advantages of good fume absorbing effect, space economization, attractive appearance and the like.

Owner:蔡木生

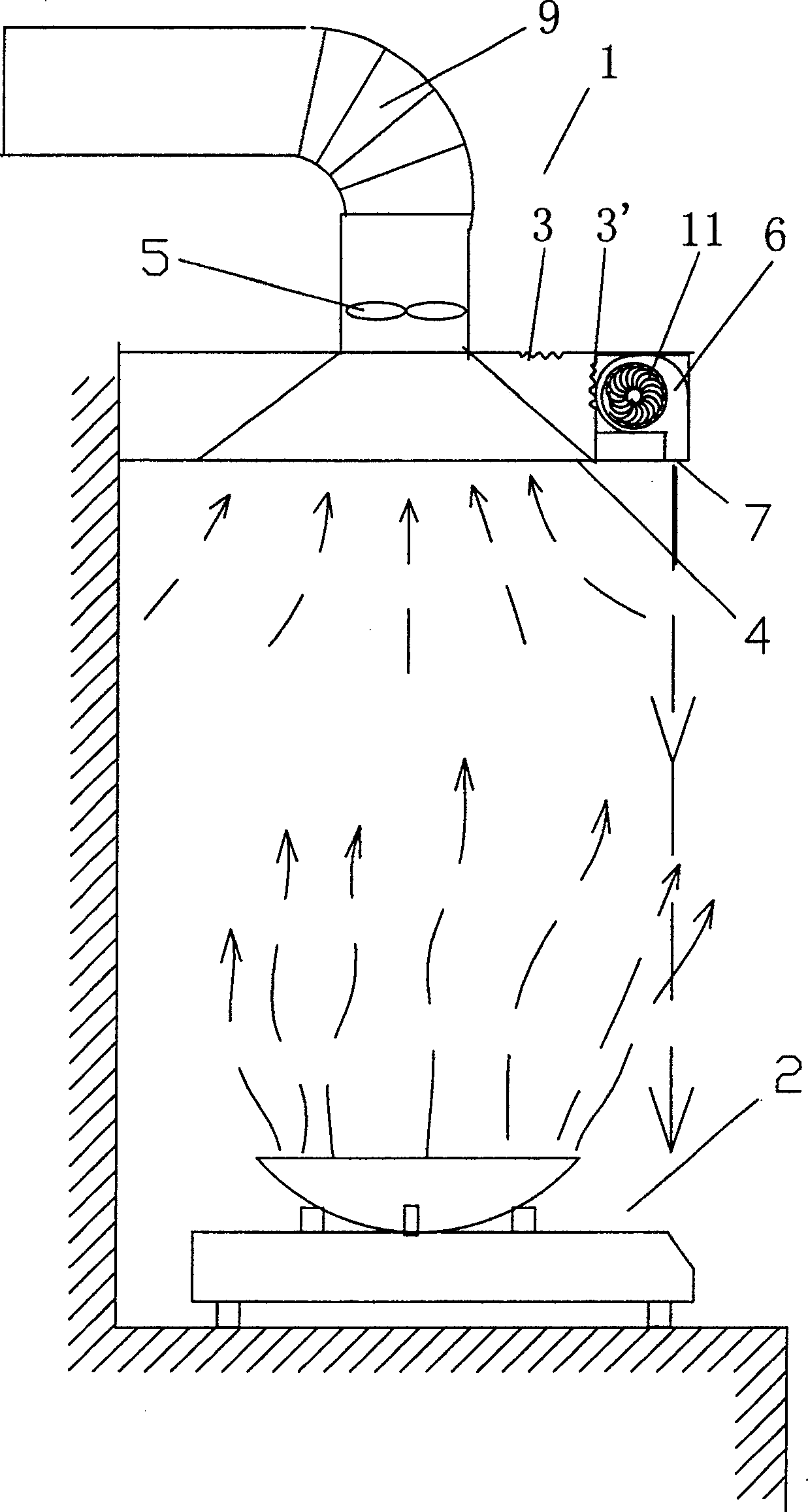

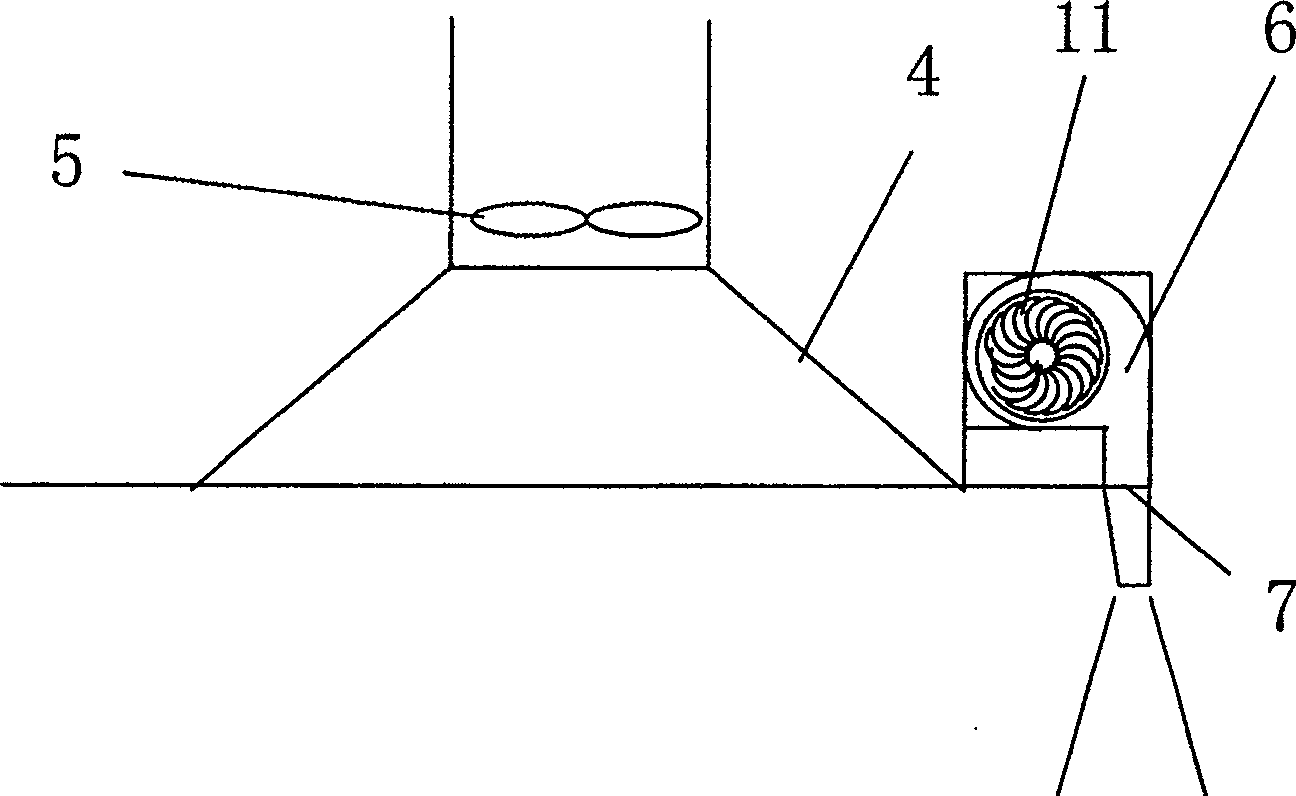

Air curtain apparatus for smoke ventilator

InactiveCN102200313ADoes not affect appearanceBeautify the appearanceDomestic stoves or rangesLighting and heating apparatusSmoke hoodAir channel

Disclosed is an air curtain apparatus for a smoke ventilator, comprising blower fans fixed in the housing of the smoke ventilator. A smoke collecting cover is provided on the bottom of the housing. Between the smoke collecting cover and the top board and lateral walls of the housing forms a space for wind to pass through, and the blower fan is located in the space. The air curtain apparatus is characterized in that: along two sides of the smoke collecting cover are arranged air outlets and extend separator plates which are located in the housing and separate the outlets from the blower fans; the separator plates extend from the smoke collecting cover towards the top board, and there are gaps between the tops of the separator plates and the top board, thereby forming air channels between the separator plates and the lateral walls. The installation of the separator plates enables a uniform air curtain with a wide scope of an air-out speed to appear around the smoke collecting cover, thereby preventing oil smoke from going out without extra installation of air curtain pipelines. The air curtain apparatus provided in the invention has a beautiful shape and a simple structure.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

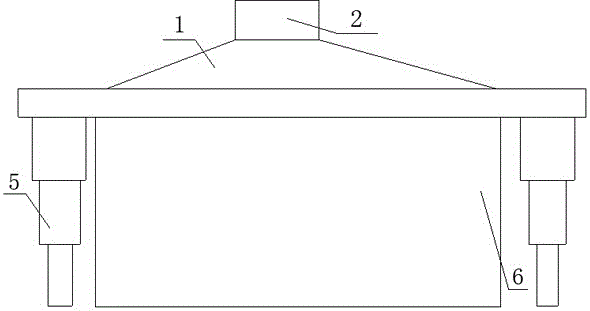

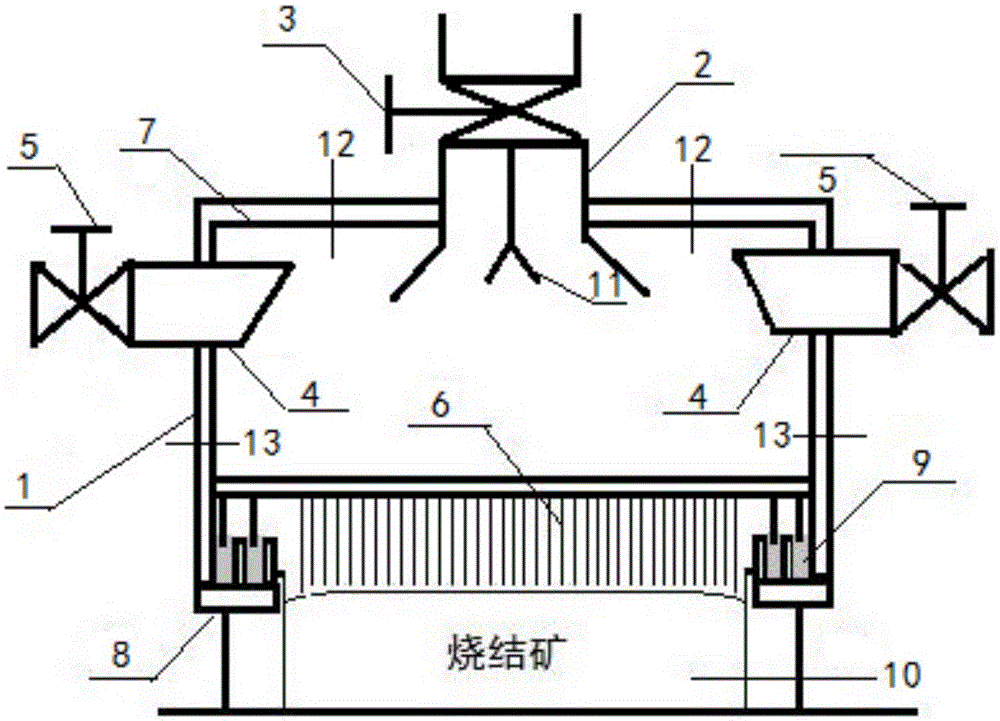

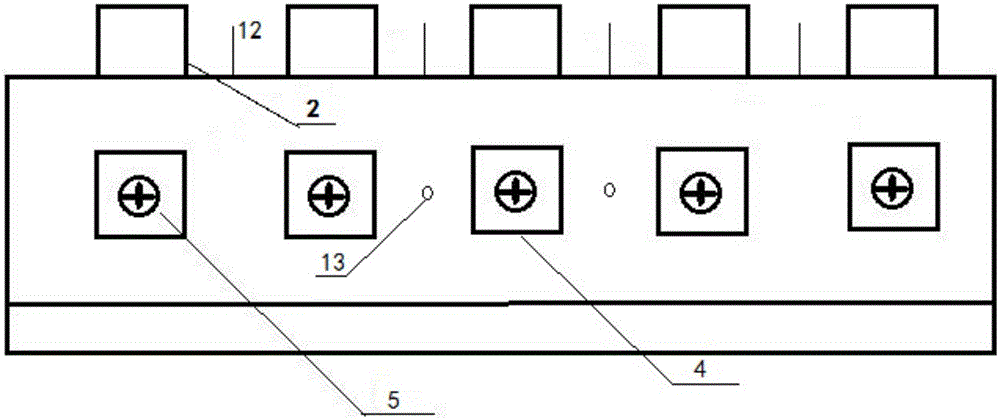

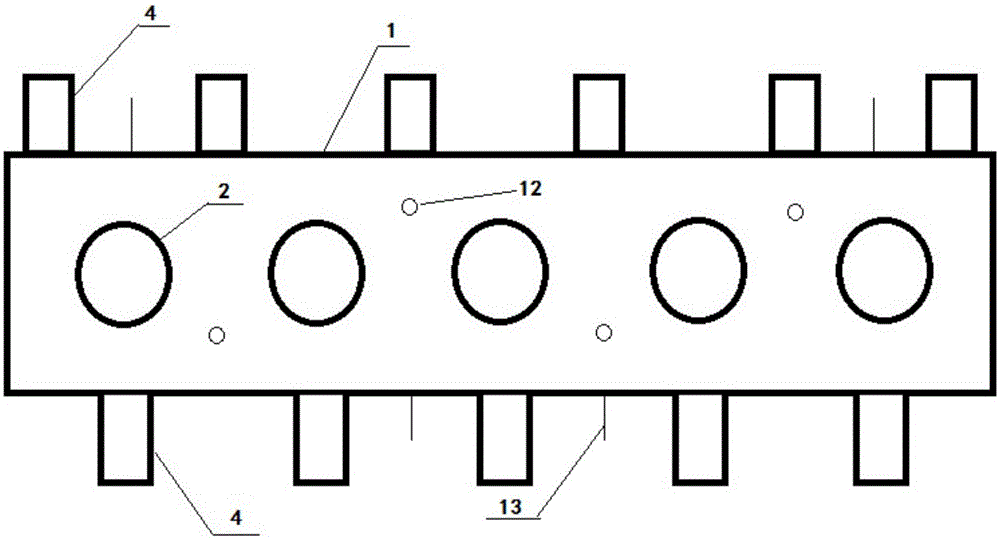

Sealed hot blast cover device

ActiveCN105066700AImprove distribution uniformitySpeed up the draft sintering processEngine sealsFurnace typesSmoke hoodHot blast

The invention relates to a sealed hot blast cover device and application thereof. The sealed hot blast cover device comprises a smoke hood (1) which is mounted at a circulating smoke using part of a sintering machine; the sintering machine is covered by the smoke hood (1); a circulating air charging pipe (2) is arranged at the top of the smoke hood (1); a stop valve (3) is mounted on the circulating air charging pipe (2); emergency air vents (4) are formed in the two sides of the smoke hood (1); electric valves (5) are mounted on the emergency air vents (4); clearances between the front and rear end faces of the smoke hood (1) and a bed surface of a sintering material layer (10) are sealed. The sealed hot blast cover device disclosed by the invention can be used for remarkably reducing normal-temperature air leaked into the smoke hood, guaranteeing the circulation effect of sintering smoke and also increasing the uniformity degree of the circulating smoke in the smoke hood.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Range hood

InactiveCN107270353AIncrease powerReduce work stressDomestic stoves or rangesLighting and heating apparatusEnvironmental engineeringSmoke hood

The invention discloses a range hood comprising a fume exhaust hood, a fume collection hood, a main draught fan system and auxiliary draught fan systems. An oily fume channel is defined in the fume exhaust hood. The fume collection hood is connected with the fume exhaust hood. The fume collection hood defines a fume collection cavity and auxiliary air channels communicating with the fume collection cavity, wherein the fume collection cavity communicates with the oily fume channel. The lower surface of the fume collection hood is open and forms an oily fume inlet. At least one of the outer top wall and the outer side wall of the fume collection hood is provided with an air inlet communicating with the auxiliary air channels. The inner side wall of the fume collection hood is provided with air outlets communicating with the auxiliary air channels and the fume collection cavity. The main draught fan system is arranged in the oily fume channel and used for sucking the oily fume in the fume collection cavity into the oily fume channel and discharging the oily fume in the oily fume channel out. The auxiliary draught fan systems are arranged in the auxiliary air channels and are used for sucking the oily fume around the air inlets into the auxiliary air channels and discharging the oily fume in the auxiliary air channels into the fume collection cavity. According to the range hood, the work noise and the energy consumption of the main draught fan system can be lowered, and oily fume leakage can be prevented.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Dust removing device for flue gas

InactiveCN102500180AAdjustable pressureLighting and heating apparatusUsing liquid separation agentExhaust valveFlue gas

A dust removing device for flue gas belongs to the field of manufacturing of metallurgy equipment. A heat exchange device is arranged at an outlet of a flue duct and connected with a smoke hood; cooled flue gas is guided to an air guide sleeve connected with the smoke hood; an exhaust blower is mounted on the air guide sleeve; flue gas is pumped in an exhaust valve through a pipeline; the exhaust valve is arranged at the bottom of a water tank; the water tank is filled with water, and the water surface submerges the exhaust valve for 20 cm; and a protective cap is mounted at the top end of the water tank. Flue gas generated when fuels are combusted can be guided in the bottom of the water tank and forms intensive small air bubbles in water to rise; the flue gas containing dust can fully contact with water, solid dust and certain harmful gas soluble in water are adsorbed by water, so that the flue gas is purified and is discharged from the upper end of the water tank; and a pressure reducing valve can adjust the pressure when the flue gas is pumped in the water tank.

Owner:SHENYANG CHUANGDA TECH TRADE MARKET

Air curtain kitchen fumes ventilator

ActiveCN100480586CReduce the impactPrevent flutteringDomestic stoves or rangesLighting and heating apparatusSmoke hoodAirflow

The present invention provides one kind of kitchen fume sucking wind curtain method and corresponding kitchen fume exhauster. Narrow slot is formed in the edge of at least one side of the kitchen fume collecting hood to spray air flow forming wind curtain inwards deviating to the work area, with the inwards deviating airflow being turbulent airflow formed with the so-called arced inwards airflow or laminar airflow formed with multiple nozzle thin airflow. Meanwhile, the exhauster of the kitchen fume exhauster makes the kitchen fume rolled into the exhauster. The kitchen fume exhauster can form separating wind curtain between the cook and the fume while exhausting kitchen fume effectively.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com