Dust removing device for flue gas

A dust removal device and flue gas technology, applied in the use of liquid separation agent, lighting and heating equipment, separation of dispersed particles, etc., can solve the problems of mixed contact, low dust removal performance and efficiency, and incomplete dust removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

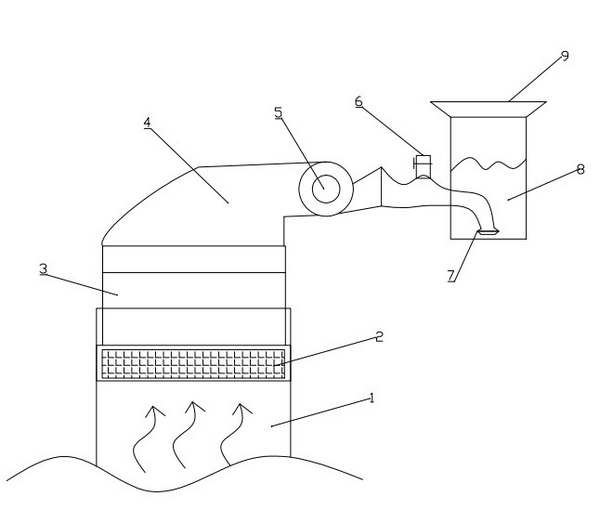

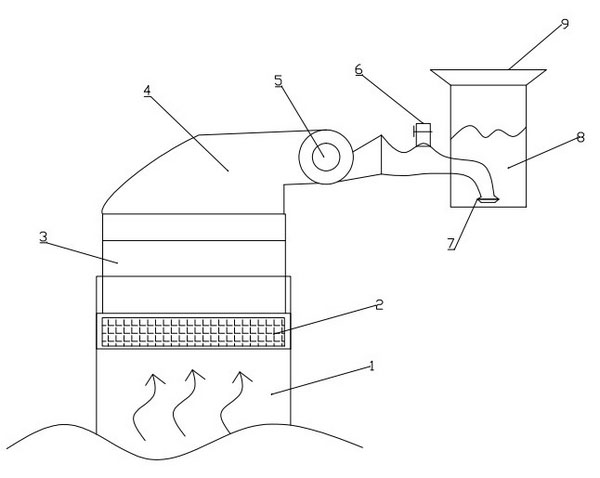

[0009] In order to gain an in-depth understanding of the structure of the improved flue gas dedusting device, combined with figure 1 described as follows:

[0010] Flue gas dedusting device, heat exchange device 2 is installed at the outlet of flue 1, and then connected to fume hood 3 to guide the cooled flue gas to shroud 4 connected to fume hood 3; Pass into exhaust valve 7, exhaust valve 7 is placed in the bottom in water tank 8, fill water in water tank 8, water surface height has not crossed exhaust valve 720cm, and protective cap 9 is installed on the top of water tank 8. The exhaust valve 7 leads into the water, with the opening downward, and the flue gas passes through the exhaust valve 7 into the water and is filtered; the exhaust valve 7 is provided with a one-way pressure valve to prevent water from entering the exhaust valve 7. A pressure reducing valve 6 is arranged on the pipeline connecting the exhaust fan 5 and the exhaust valve 7 .

[0011] The flue gas prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com