Screw lever type clamping mechanism

A clamping mechanism and lever-type technology, used in clamping, clamps, metal processing machinery parts, etc., can solve the problems of workpiece damage and low workpiece productivity, avoiding energy waste, convenient clamping and positioning, and firm structure. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following further describes the present invention with reference to the drawings and embodiments, but it is not intended to limit the present invention.

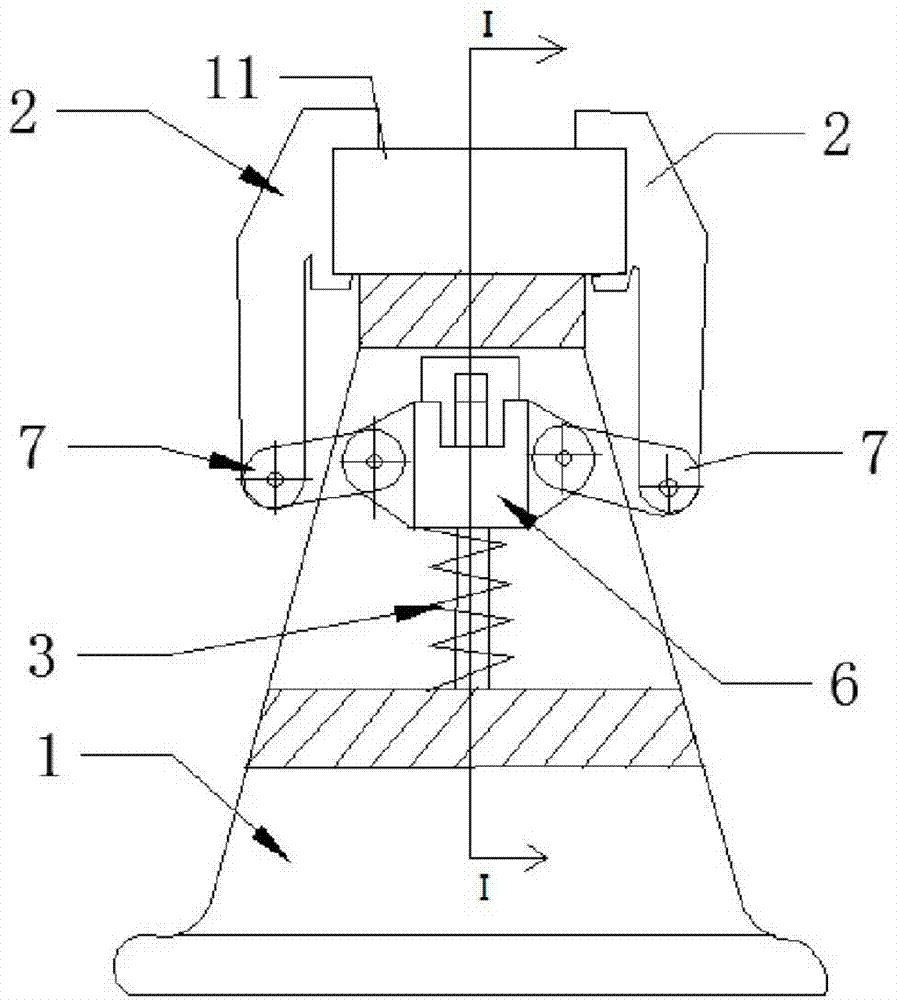

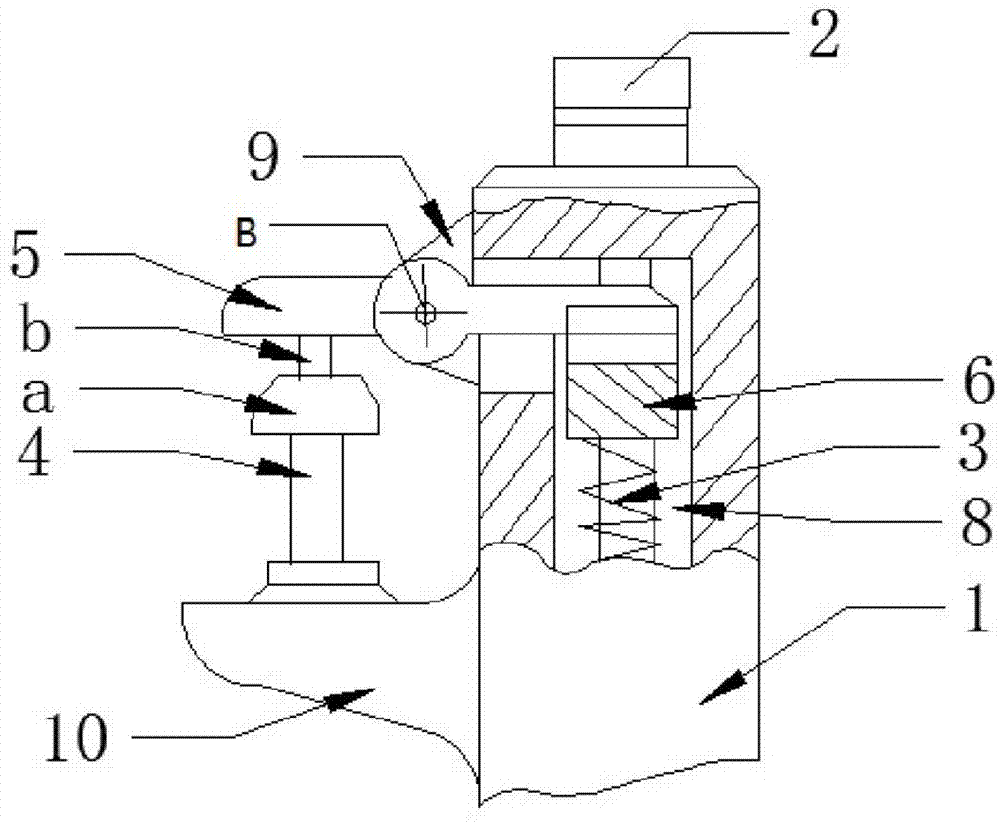

[0015] Such as figure 1 As shown, a screw lever type clamping mechanism includes a supporting table 1, a locking member and a driving member connected to the supporting table 1, and the supporting table 1 is an isosceles trapezoid, such as figure 2 As shown, one side of the support platform 1 is welded with a connecting plate 9 perpendicular to the ground and a support plate 10 parallel to the ground. A slide rail 8 is opened in the support platform 1, and the slide rail 8 is a vertical inverted L shape. Straight groove.

[0016] The driver includes a screw 4, a nut a, a cap b, a first lever 5, a first pin B, a first connecting member 6, a spring 3, and a second connecting member 7. The screw 4 is threadedly connected to the support On the plate 10, the screw 4 connects the nut a and the cap b, and the cap b is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com