Patents

Literature

1712results about How to "Improve clamping effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

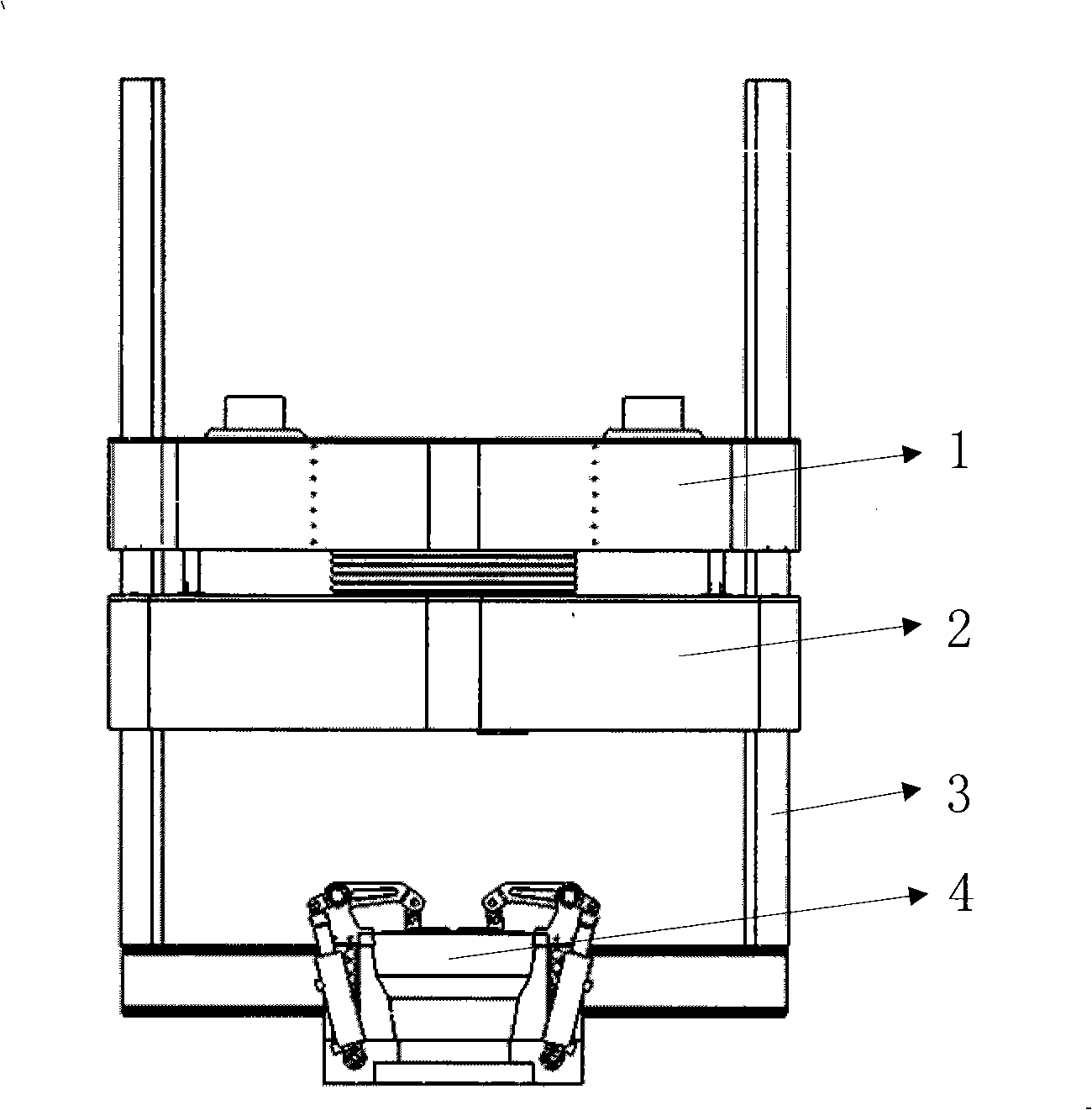

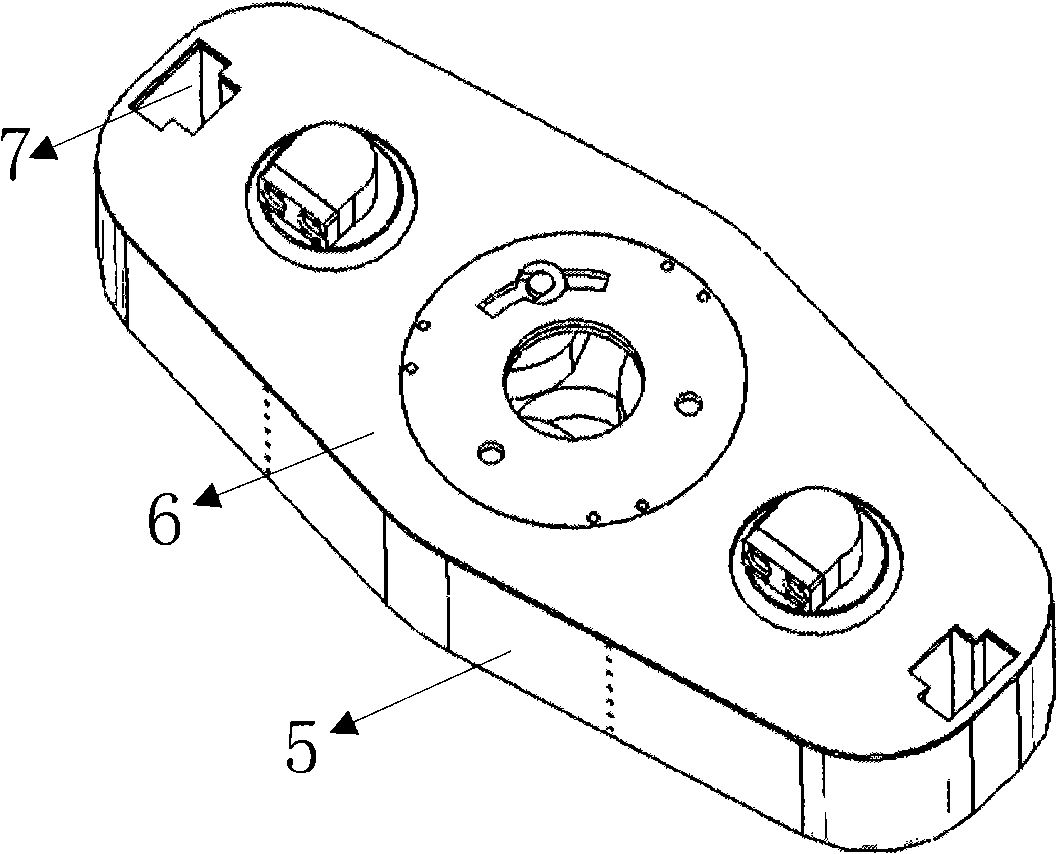

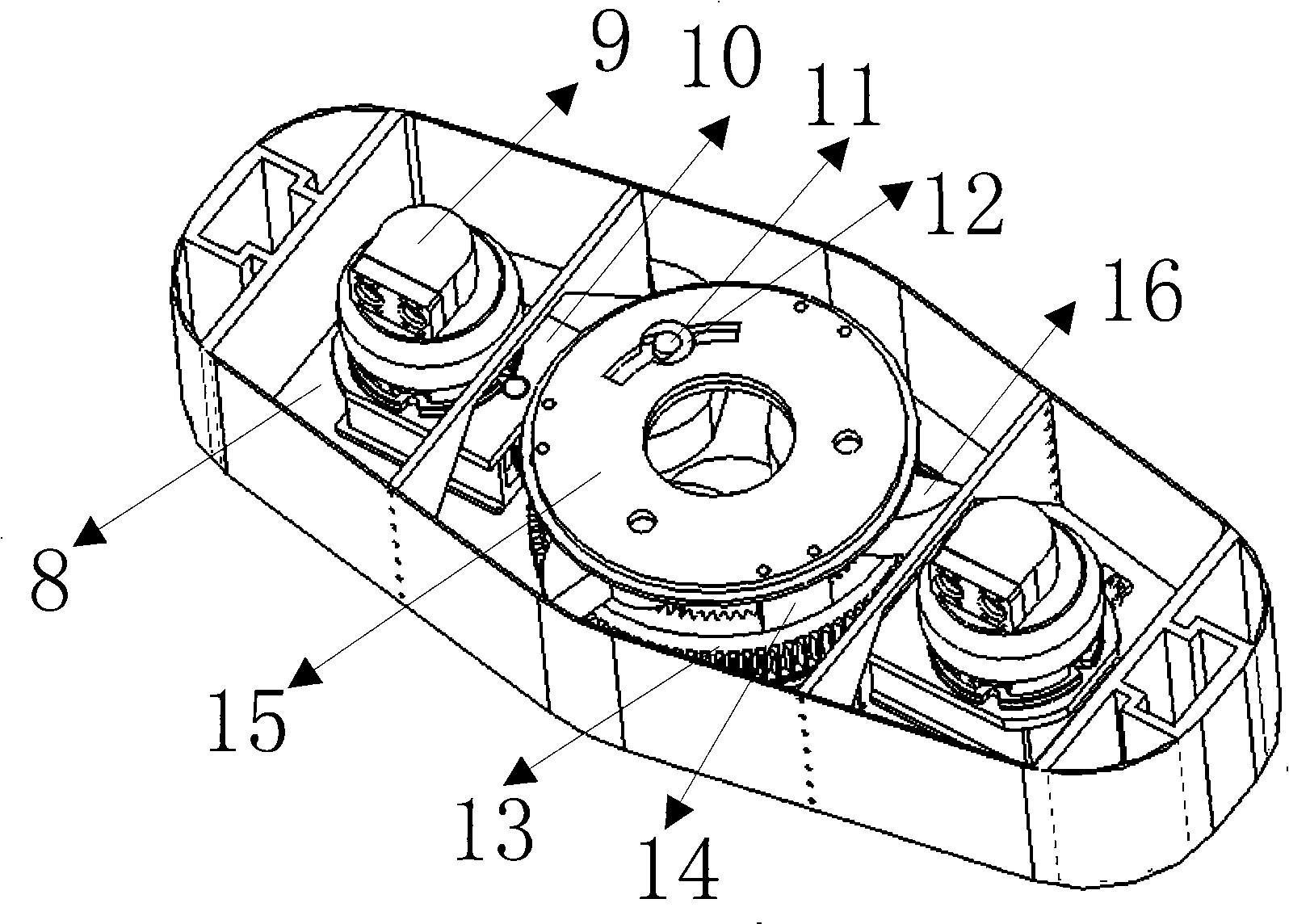

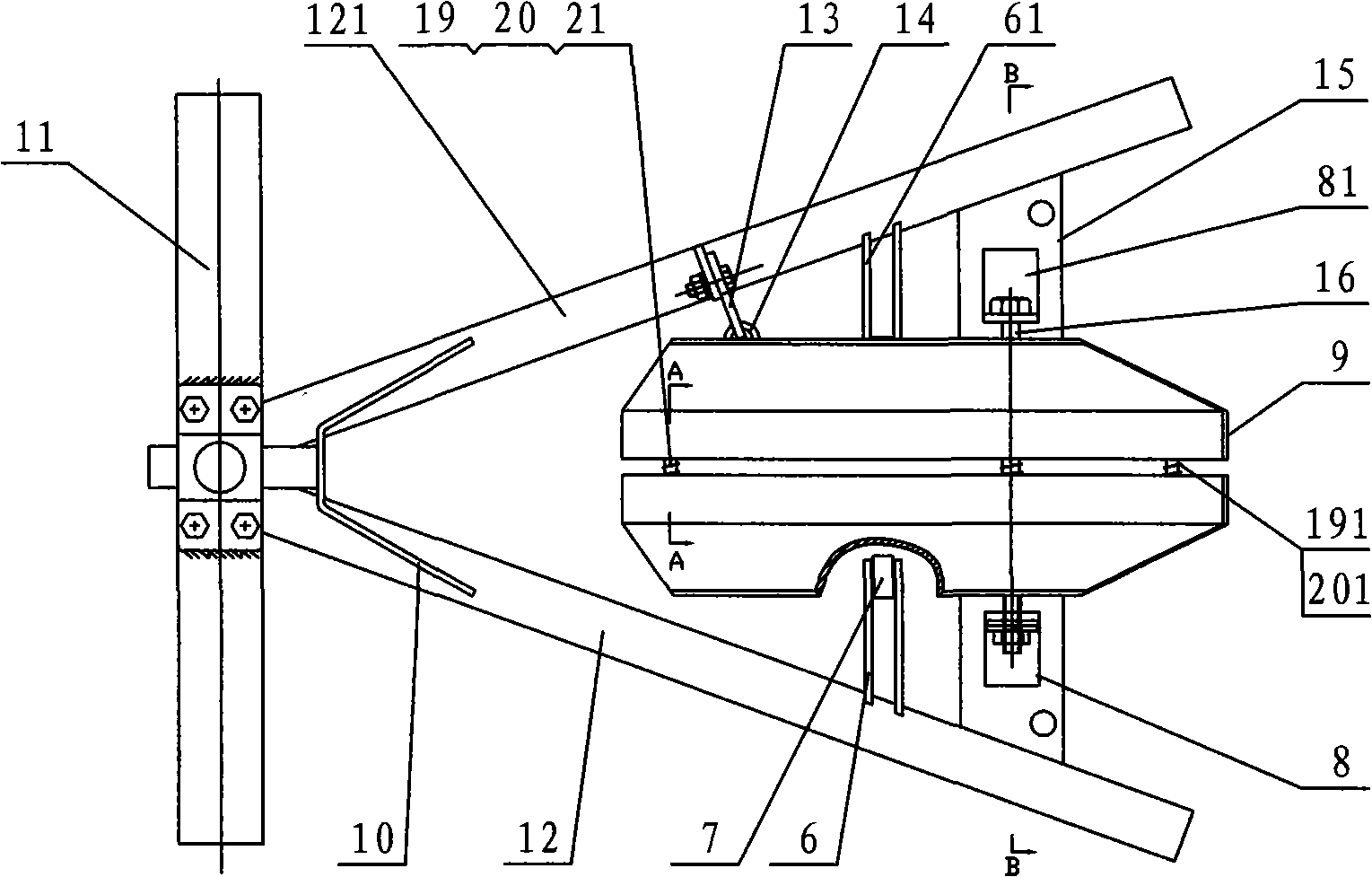

Assembly mechanism of iron core assembly

ActiveCN106078158ASimple structureEasy to operateMetal working apparatusEngineeringMechanical engineering

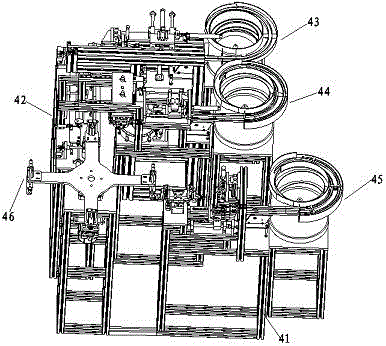

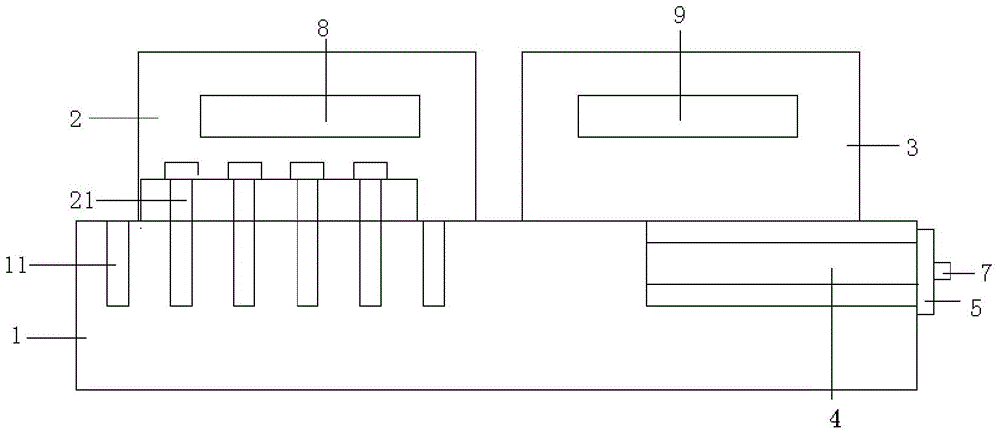

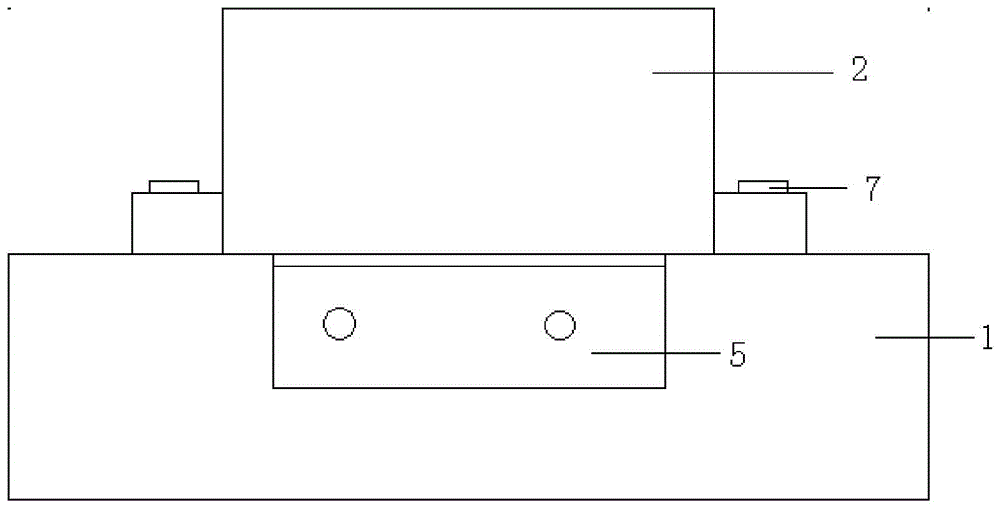

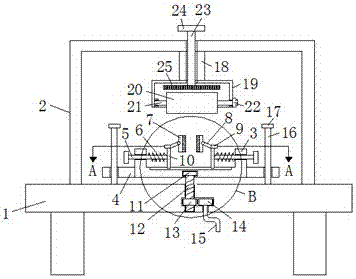

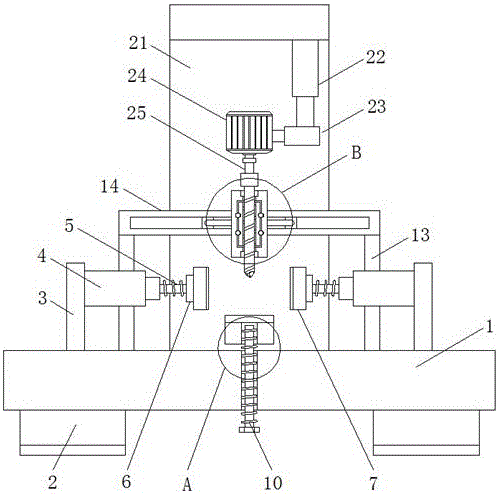

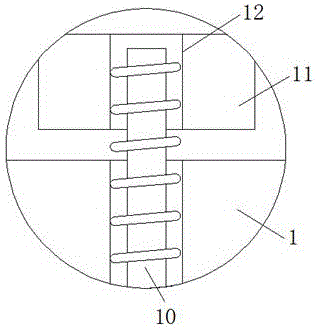

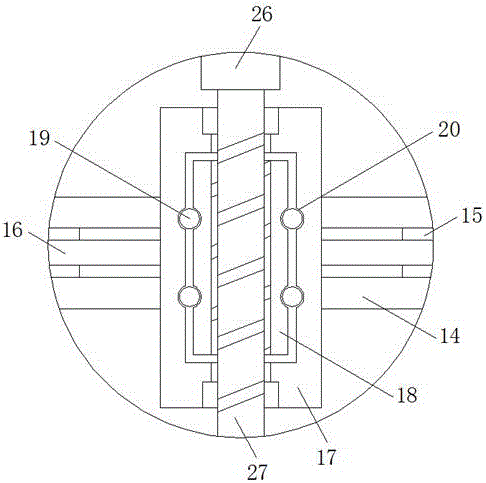

The invention discloses an assembly mechanism of an iron core assembly. The assembly mechanism of the iron core assembly comprises an iron core assembly installation rack installed on the ground, wherein an iron core assembly transportation device and a four-position rotary loading device are installed on the iron core assembly installation rack in succession; the side of iron core assembly installation rack located at the iron core assembly transportation device is successively equipped with an iron core rod loading device and a rubber block loading device; and an iron core spring loading device is installed on one side of the four-position rotary loading device. In this way, the mechanism disclosed by the invention has the advantages of convenient operations, good assembly effects and high working efficiency.

Owner:HEBEI XINGLONG ELEVATORING EQUIP CO LTD

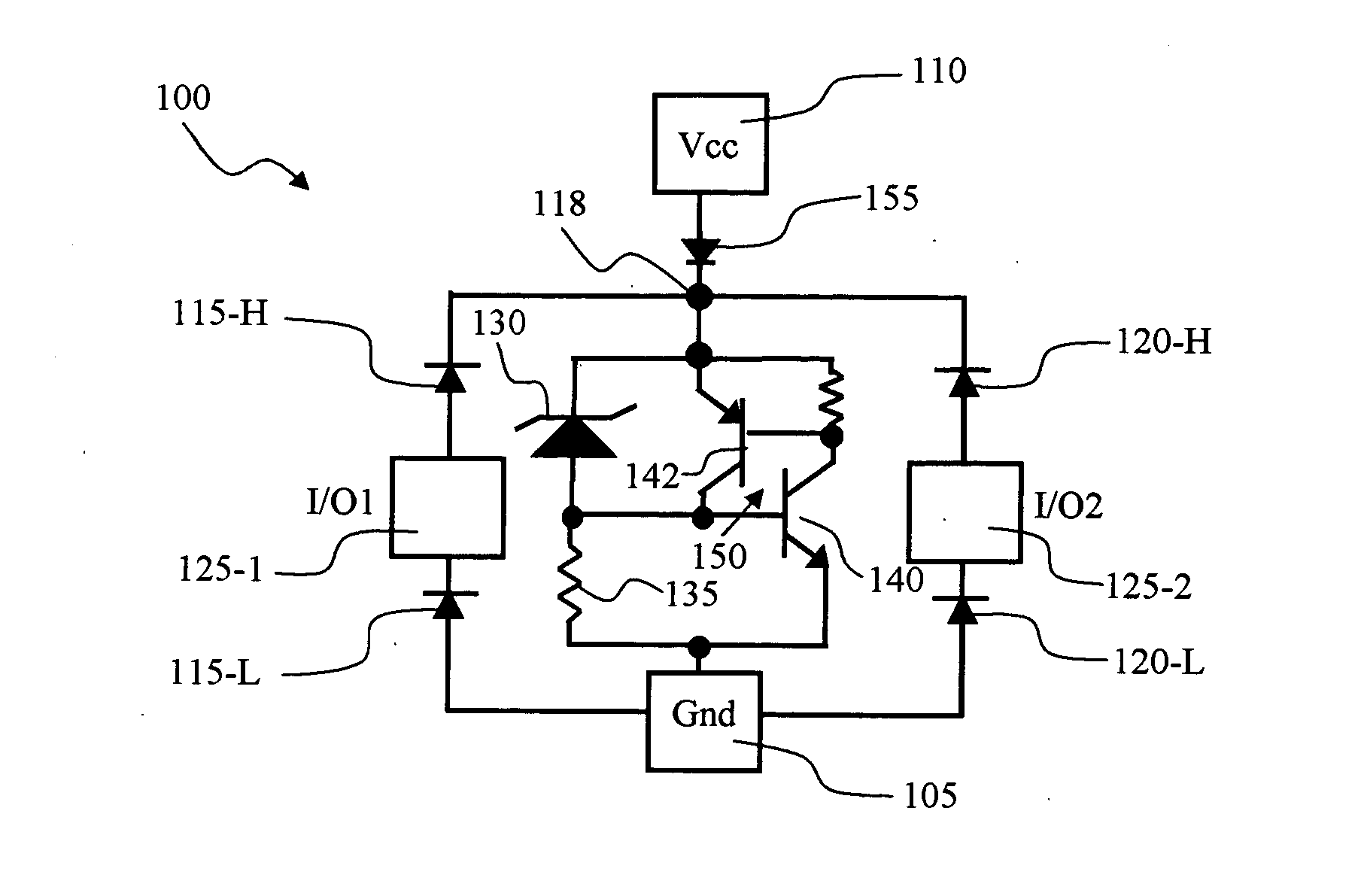

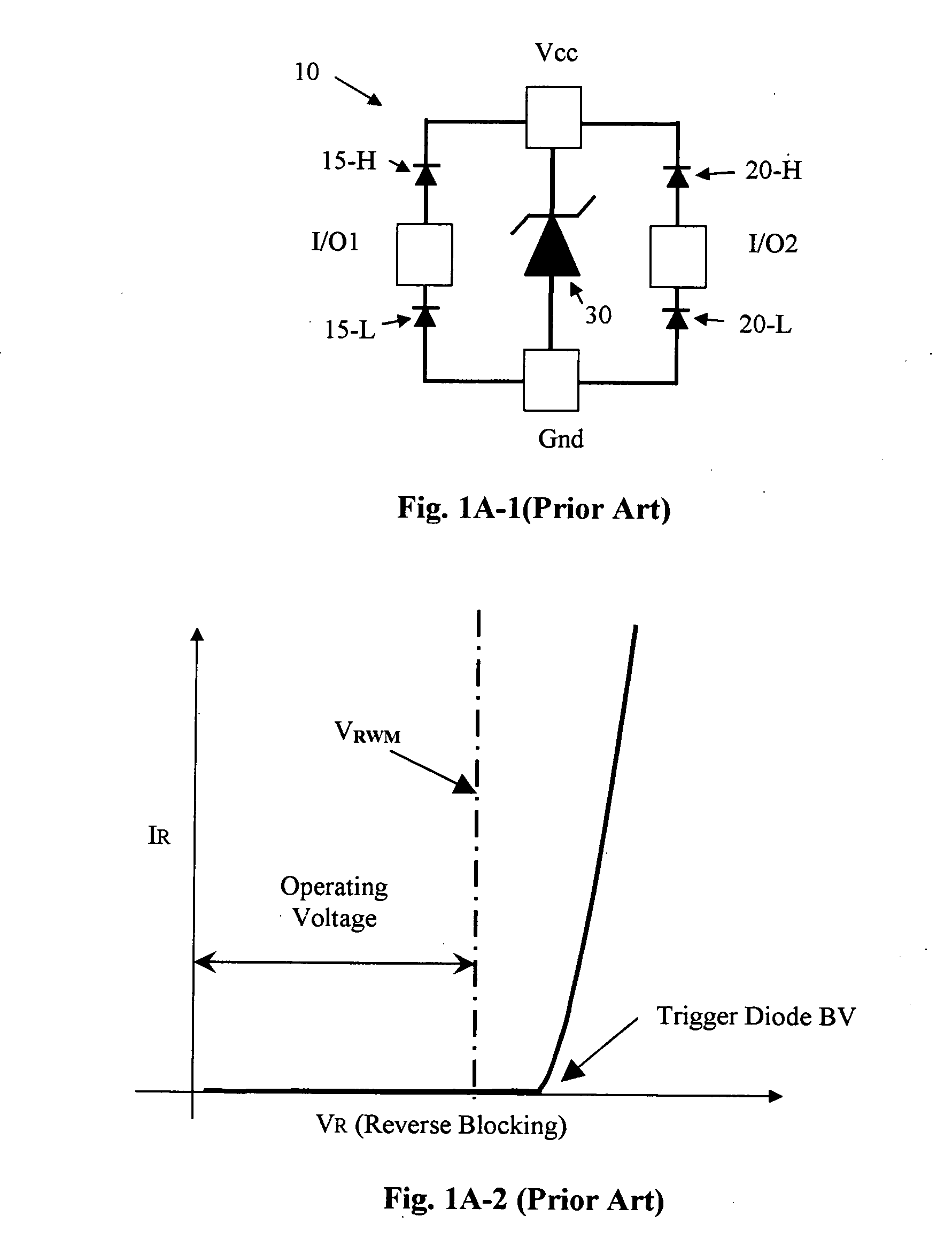

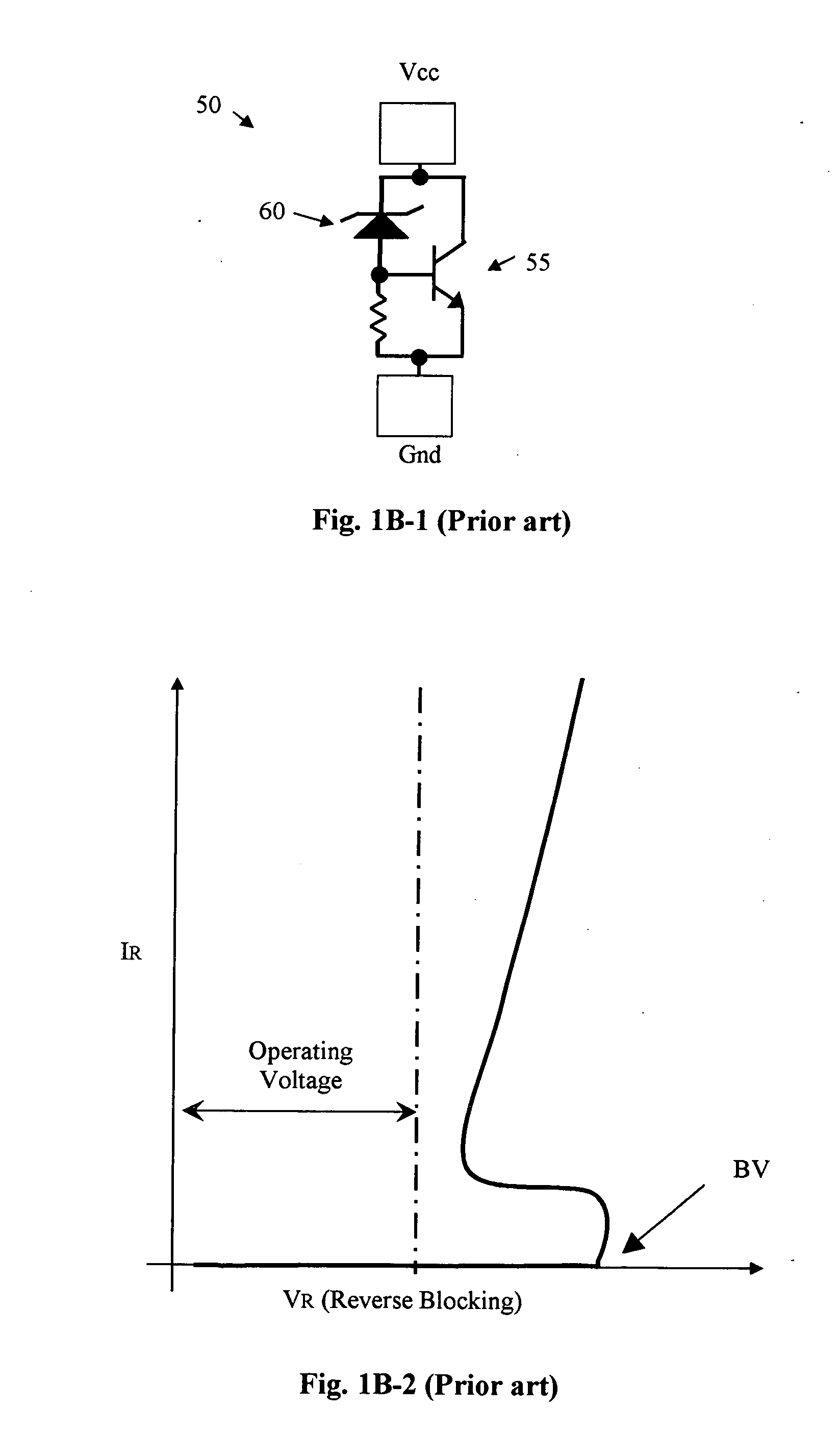

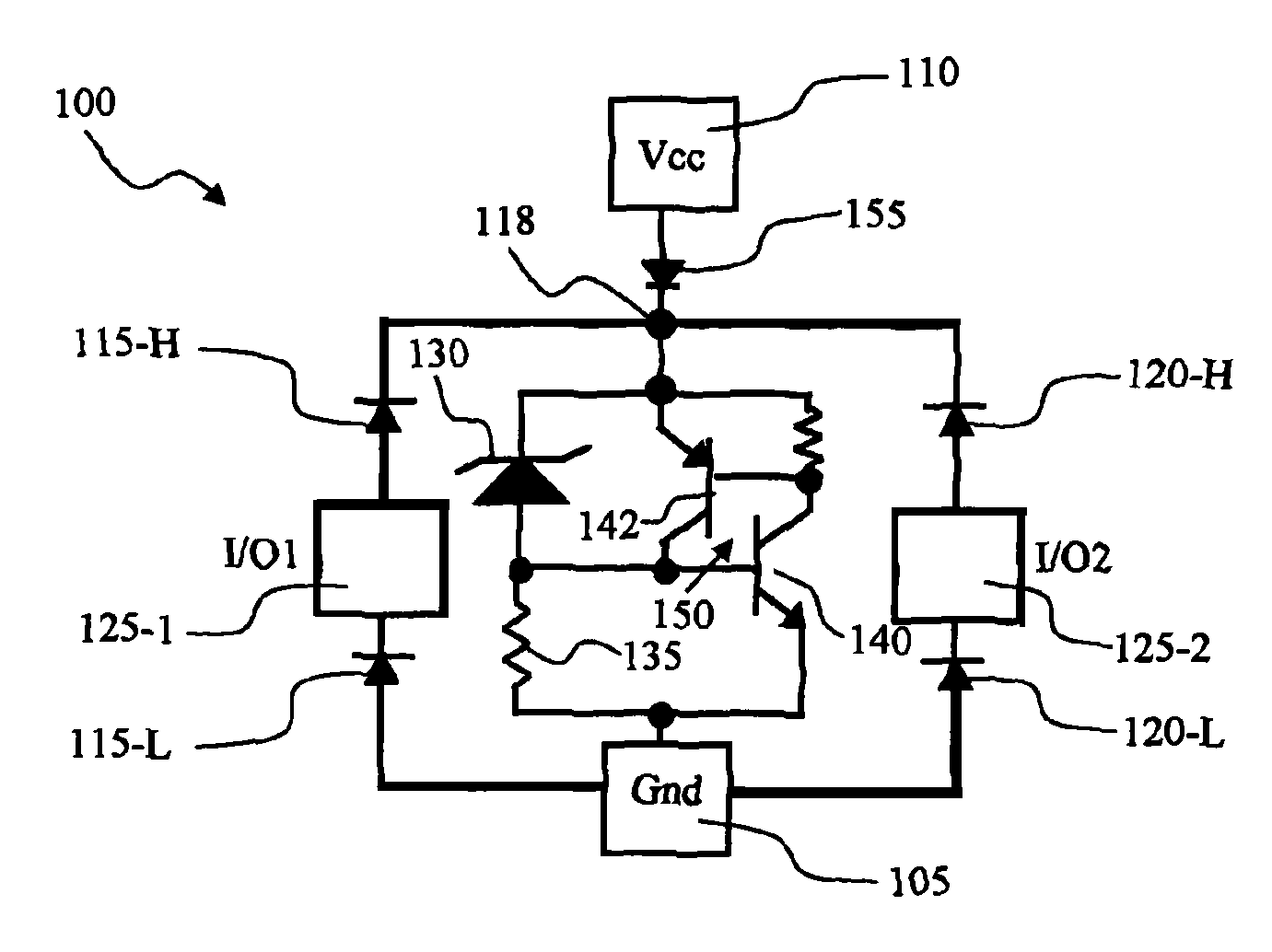

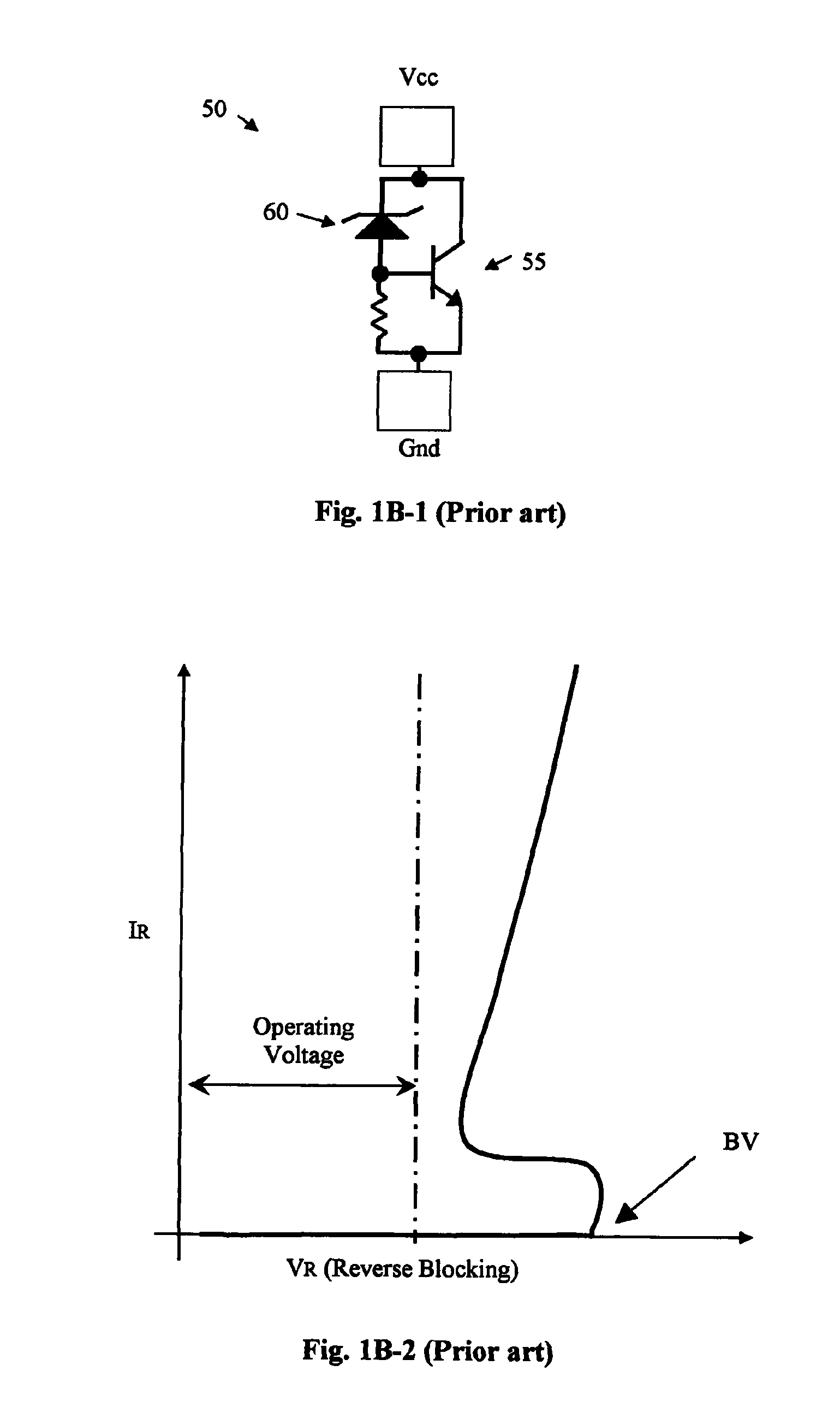

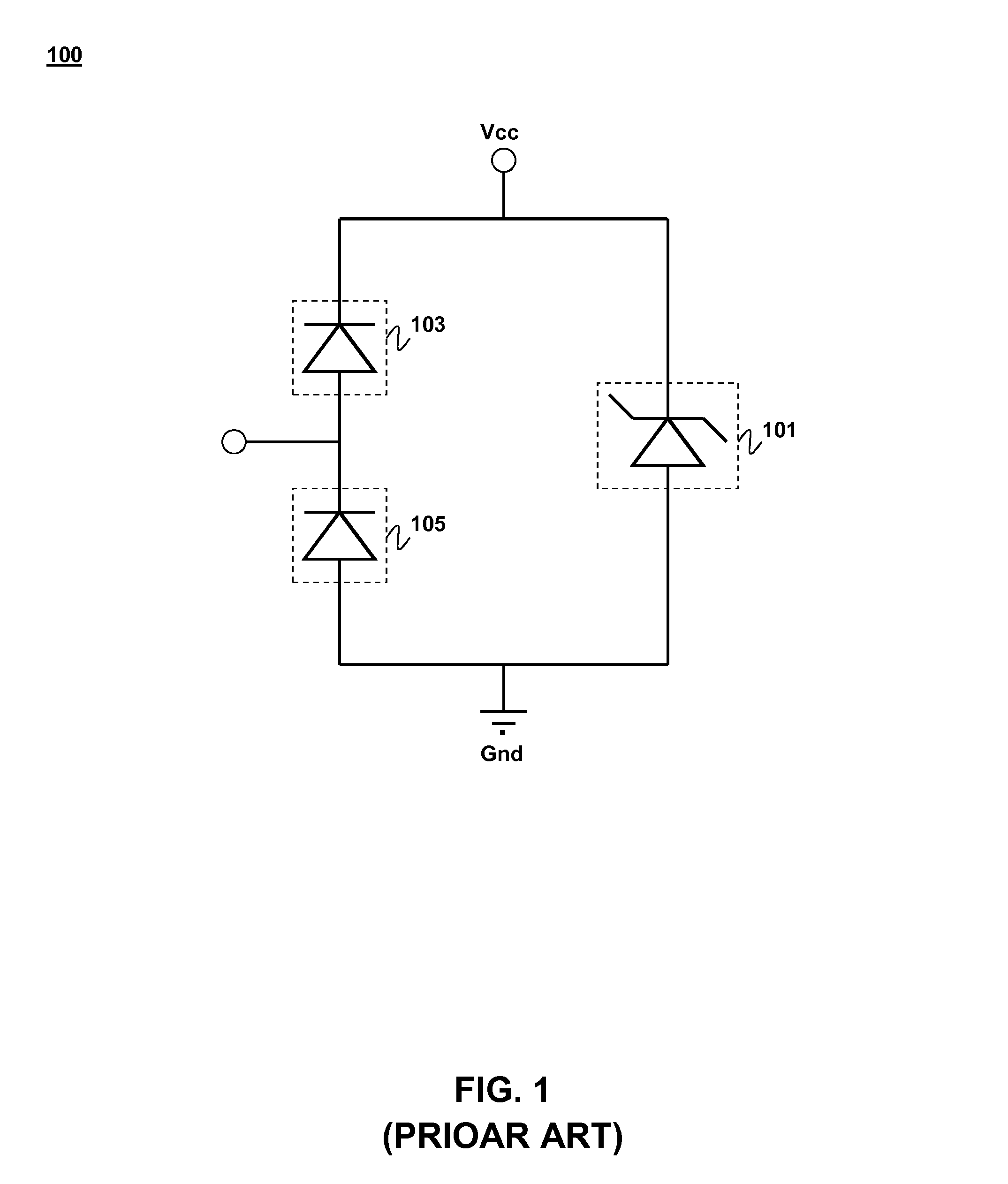

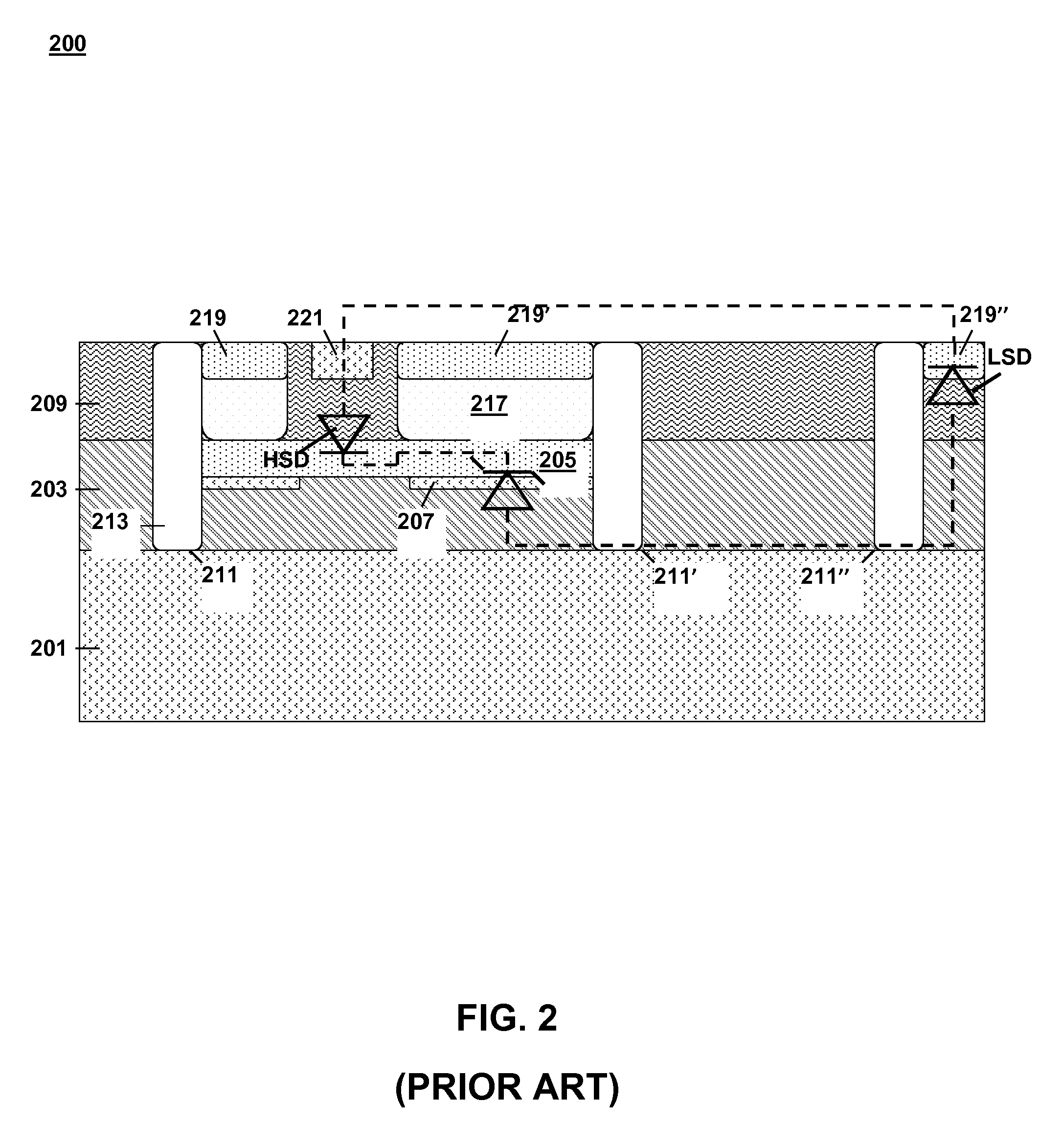

Transient voltage suppressor (TVS) with improved clamping voltage

ActiveUS20090268361A1Reduce reboundImprove clamping effectTransistorEmergency protective arrangements for limiting excess voltage/currentDevice formZener diode

This invention discloses an electronic device formed as an integrated circuit (IC) wherein the electronic device further includes a transient voltage suppressing (TVS) circuit for suppressing a transient voltage. The transient voltage suppressing (TVS) circuit includes a Zener diode connected between a ground terminal and a node for triggering a snapback circuit. In one embodiment, this node may be a Vcc terminal. The TVS device further includes a snapback circuit connected in parallel to the Zener diode for conducting a transient voltage current with a snapback current-voltage (I-V) characteristic upon turning on of the snapback circuit And, the TVS device further includes a snapback suppressing circuit connected in series with the snapback circuit for conducting a current with an I-V characteristic complementary to the snapback-IV characteristic for clamping a snapback voltage.

Owner:ALPHA & OMEGA SEMICON INC

Transient voltage suppressor (TVS) with improved clamping voltage

ActiveUS8218276B2Reduce reboundImprove clamping effectTransistorEmergency protective arrangements for limiting excess voltage/currentDevice formCurrent voltage

This invention discloses an electronic device formed as an integrated circuit (IC) wherein the electronic device further includes a transient voltage suppressing (TVS) circuit for suppressing a transient voltage. The transient voltage suppressing (TVS) circuit includes a Zener diode connected between a ground terminal and a node for triggering a snapback circuit. In one embodiment, this node may be a Vcc terminal. The TVS device further includes a snapback circuit connected in parallel to the Zener diode for conducting a transient voltage current with a snapback current-voltage (I-V) characteristic upon turning on of the snapback circuit And, the TVS device further includes a snapback suppressing circuit connected in series with the snapback circuit for conducting a current with an I-V characteristic complementary to the snapback-IV characteristic for clamping a snapback voltage.

Owner:ALPHA & OMEGA SEMICON INC

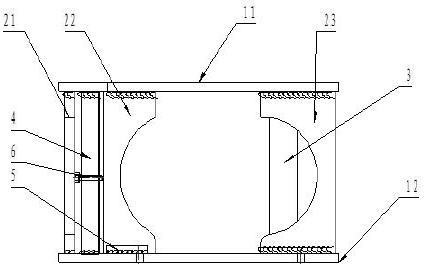

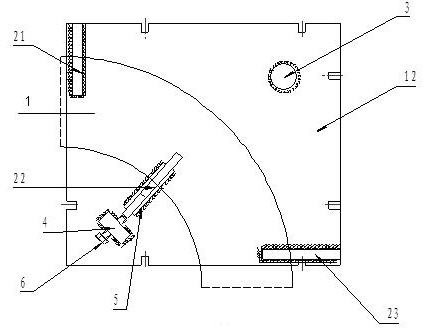

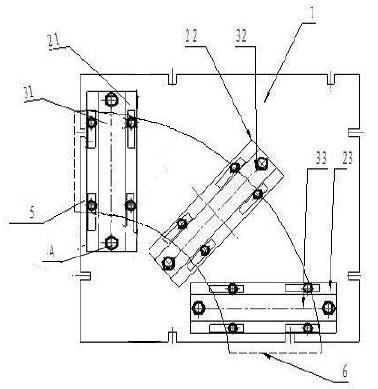

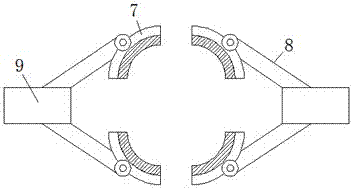

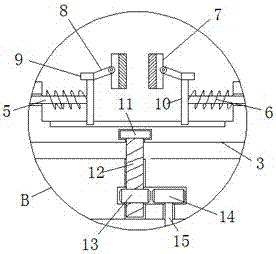

Clamping deformation resistant jig for machining large-diameter elbow

InactiveCN102139457AGuaranteed machining accuracyAbundant resourcesPositioning apparatusMetal-working holdersThin walledEngineering

The invention discloses a clamping deformation resistant jig for machining a large-diameter elbow. Three combined clamping blocks are arranged on a clamping base plate, each combined clamping block consists of an upper clamping block, a lower clamping block, a base plate and connecting bolts, inner sides of the upper clamping blocks and the lower clamping blocks are provided with circular arc-shaped gaps and form a circle consistent with the outer circumference of an elbow to be machined after closed, the upper clamping blocks and the lower clamping blocks are connected and fastened by the connecting bolts, and the base plates are arranged at the bottoms of the lower clamping blocks and are provided with chutes. Lock bolts pass through the chutes on the base plates of the combined clamping blocks and fix the combined clamping blocks on the clamping base plate after being fastened. In the invention, the large-diameter elbow is clamped by adopting a way of directly clamping a pipe blank in a surface-contact manner, thus the elbow does not generate a radial compaction force in the clamping process and is not easy to generate the radial forced deformation and the torsional moment; in addition, the clamping deformation resistant jig disclosed by the invention is applied to machining of a large-diameter thin-wall elbow machine, thereby ensuring the machining precision of the elbow.

Owner:扬州华宇管件有限公司

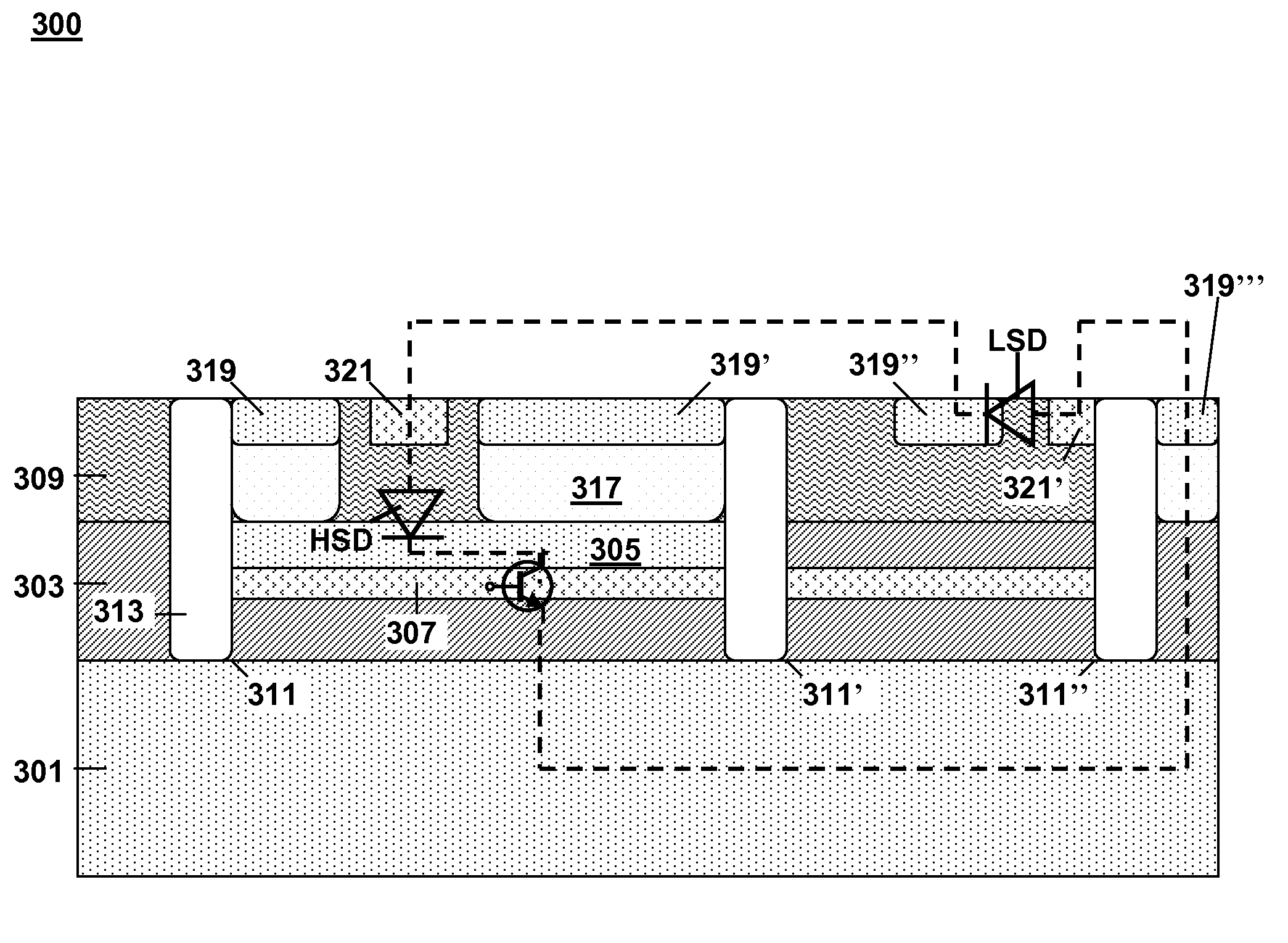

Low capacitance transient voltage suppressor (TVS) with reduced clamping voltage

ActiveUS8698196B2Improve clamping effectReduce capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceEngineering

A low capacitance transient voltage suppressor with reduced clamping voltage includes an n+ type substrate, a first epitaxial layer on the substrate, a buried layer formed within the first epitaxial layer, a second epitaxial layer on the first epitaxial layer, and an implant layer formed within the first epitaxial layer below the buried layer. The implant layer extends beyond the buried layer. A first trench is at an edge of the buried layer and an edge of the implant layer. A second trench is at another edge of the buried layer and extends into the implant layer. A third trench is at another edge of the implant layer. Each trench is lined with a dielectric layer. A set of source regions is formed within a top surface of the second epitaxial layer. The trenches and source regions alternate. A pair of implant regions is formed in the second epitaxial layer.

Owner:ALPHA & OMEGA SEMICON INC

Automatized shaft mouth operation clamp for petroleum well workover

InactiveCN101343986AImprove reliabilityExtend the life cycleDrilling rodsDrilling casingsEconomic benefitsScrew thread

The invention discloses an automatic wellhead operation tong used for petroleum workover. The automatic wellhead operation tong mainly solves the problems that in prior petroleum workover field, low working efficiency, high labor intensity, the bad security, and serious environmental pollutions are caused because the operation for loading and unloading pipe column is accomplished by a manually-operated opening type hydraulic tong and a replacing elevator. The automatic wellhead operation tong is characterized in that the operation tong integrates a close type power tong and a power slip into a whole, and the operation tong is composed of a main tong, a back tong, a slip and vertical guide rails, supporting frames extending from the both sides of the slip are used for installing the two vertical guide rails, the main tong and the back tong can be moved vertically along the guide rails, and the enclosed space between the main tong and the back tong can be used for collecting residual liquid of the pipe column. The automatic wellhead operation tong has the advantages that automatic wellhead operation tong can realize the automatic screwing and unscrewing of the screw threads from the tube and the environment-friendly operation; the tong can be firmly clipped at the tong mouth, thus components are not needed to be replaced in a wide range, and the working efficiency is improved greatly. The clipping performance is good, the working is reliable, and the social and economic benefits are quite remarkable.

Owner:DAQING GASOLINEEUM INST

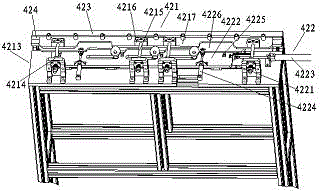

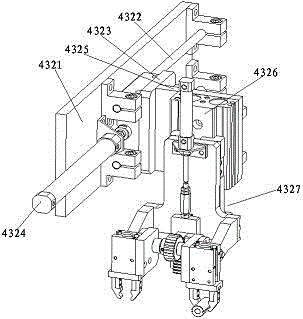

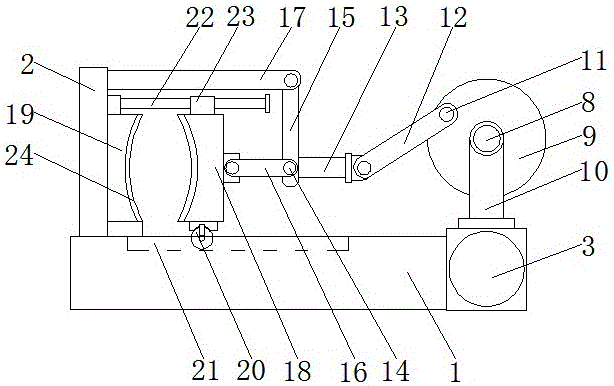

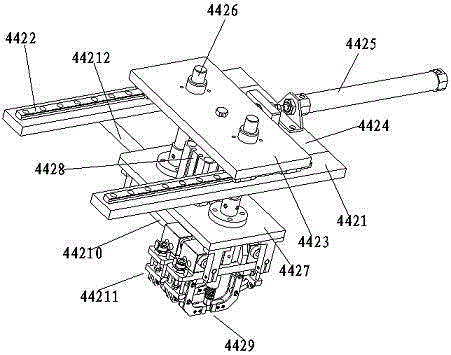

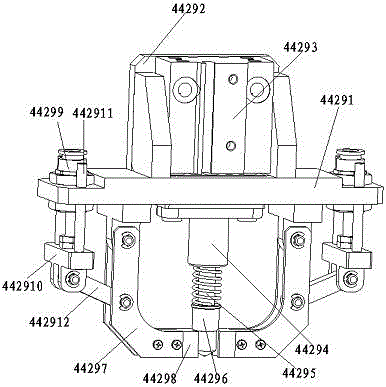

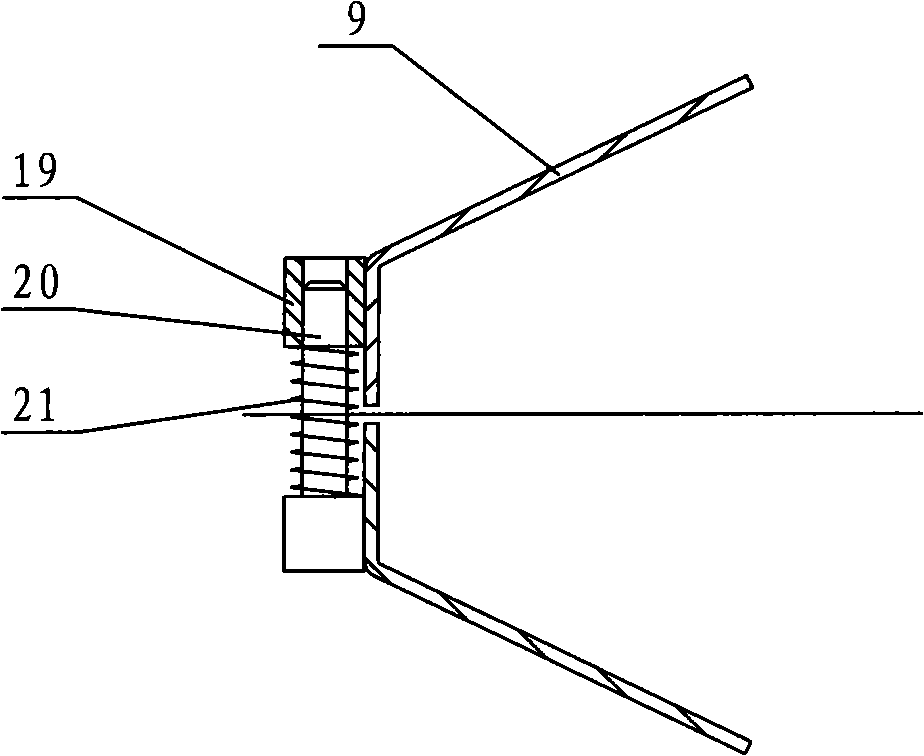

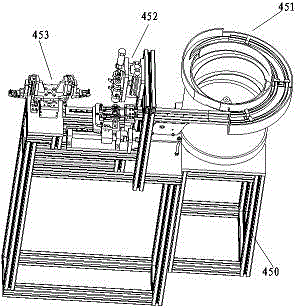

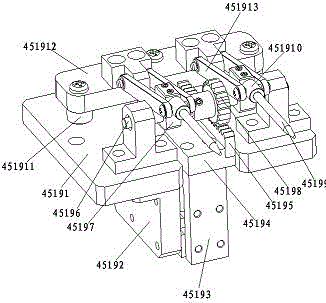

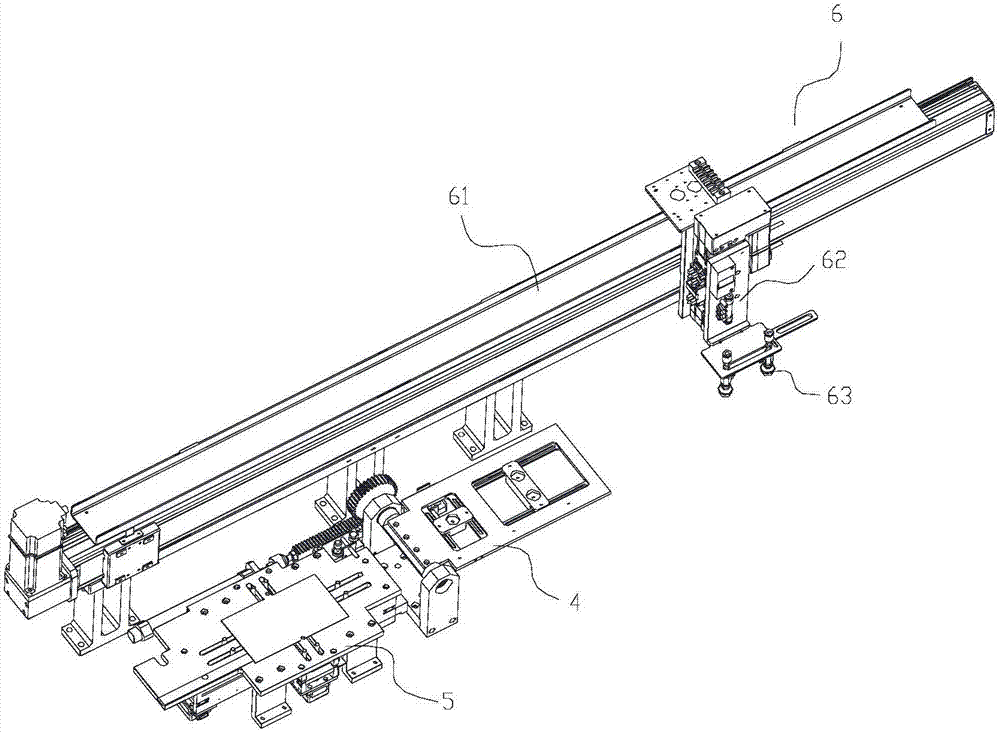

Iron core rod loading manipulator of iron core module assembly mechanism

ActiveCN106112455AExtended service lifeSimple structureProgramme-controlled manipulatorMetal working apparatusEngineeringManipulator

The invention discloses an iron core rod loading manipulator of an iron core module assembly mechanism. The iron core rod loading manipulator of the iron core module assembly mechanism comprises an iron core rod loading mounting plate; two iron core rod shifting guide rods parallel to each other are fixed on the inner side surface of the iron core rod loading mounting plate through two pairs of guide rod brackets; the iron core rod shifting guide rods are coated with linear bearings; the linear bearings coated on the two iron core rod shifting guide rods are fixed with iron core rod taking shifting plates; an iron core rod taking shifting cylinder moving in the horizontal direction is mounted at one end of the inner side surface of the iron core rod loading mounting plate through a cylinder fixing device; the iron core rod taking shifting cylinder and the two iron core rod shifting guide rods are the same in moving direction; and the end of a piston rod of the iron core rod taking shifting cylinder is fixed with the outer side surfaces of the iron core rod taking shifting plates through the cylinder fixing device. Through the mode, the iron core rod loading manipulator of the iron core module assembly mechanism is convenient for operation and loading, and is high in working efficiency.

Owner:江苏盟杰新能源科技有限公司

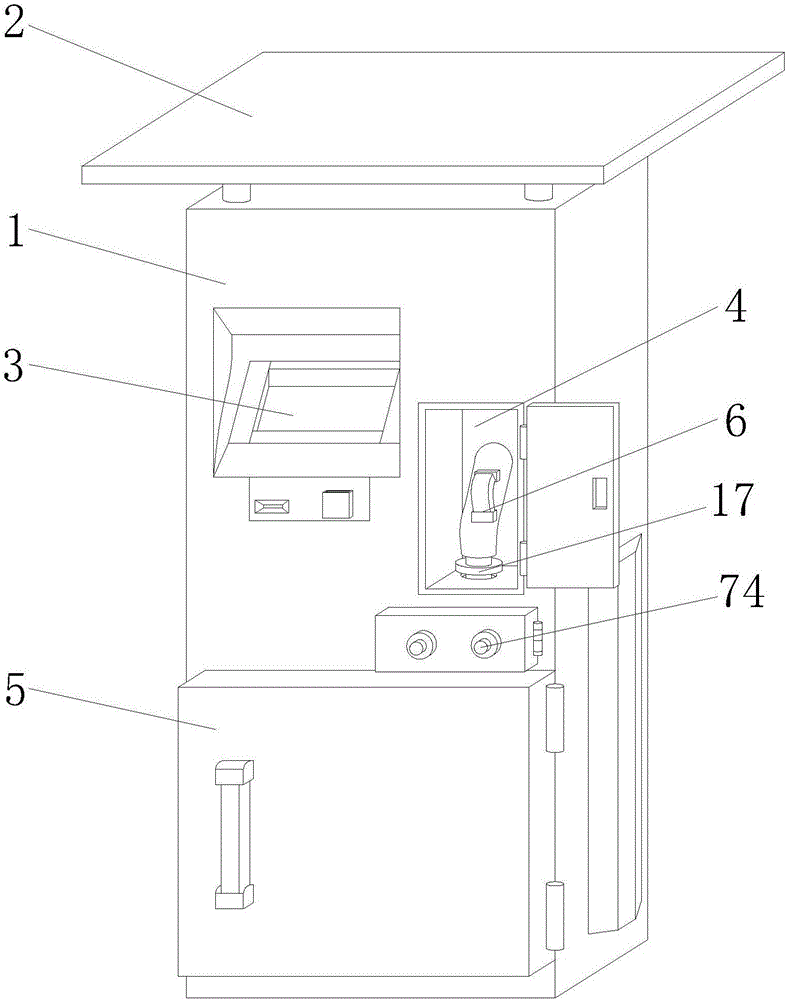

Charging pile for electric vehicle

ActiveCN105835713AEasy to placeAvoid destructionCharging stationsElectric vehicle charging technologyEngineeringElectric vehicle

The invention discloses a charging pile for an electric vehicle. The charging pile comprises an casing, wherein a flashing board is fixedly mounted on a support frame at the top of the casing, a touch panel is arranged in a groove in the front side of the casing, a card inserting device is further arranged on the casing below the touch panel, a storage box and a detection box are further arranged on the casing, the storage box is arranged on one side of the touch panel, the detection box is located below the storage box, a charging head is arranged in the storage box, a first wire at the bottom of the charging head penetrates through a clamping device at the bottom of the storage box and is exposed inside the casing, the exposed end of the first wire is fixedly connected with a second wire, the clamping device comprises a clamping box, and a clamping hole is formed in the top of the clamping box. The charging pile for the electric vehicle protects the first wire and the second wire, the service life of the charging head is prolonged, collection of the first wire and the second wire is facilitated, and the charging head is more conveniently placed.

Owner:晖马中欧汽车科技成都有限公司

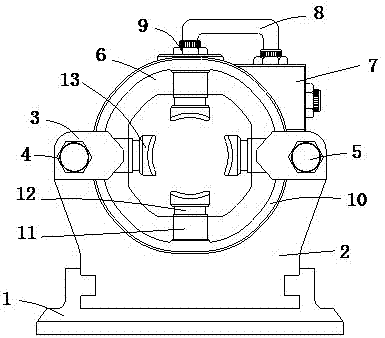

Electromagnetic clamp

ActiveCN103909437AAchieve clampingSuitable for fixingPositioning apparatusMetal-working holdersElectricityEngineering

The invention discloses an electromagnetic clamp. The electromagnetic clamp comprises a base seat, wherein a left clamping portion and a right clamping portion which are connected together in separable mode are oppositely arranged on the base seat, a containing space which contains a work piece is formed after the left clamping portion and the right clamping portion are connected together, the left clamping portion is connected with the base seat in detachable mode, the right clamping portion is connected with the base seat in sliding mode, the left clamping portion and the right clamping portion are both provided with cavities, controllers are arranged in the cavities, a first electromagnet is arranged in the cavity of the left clamping portion, a second electromagnet is arranged in the cavity of the right clamping portion, winding directions of coils of the first electromagnet and the second electromagnet are opposite, the first electromagnet and the second electromagnet are both connected with the controllers, and the controllers are electrically connected with a power source. The electromagnetic clamp can be used in individual product production and large batch production, avoids repeated actions of drawing lines and aligning, improves production efficiency, and guarantees quality of the work piece.

Owner:浙江西塘实业有限公司

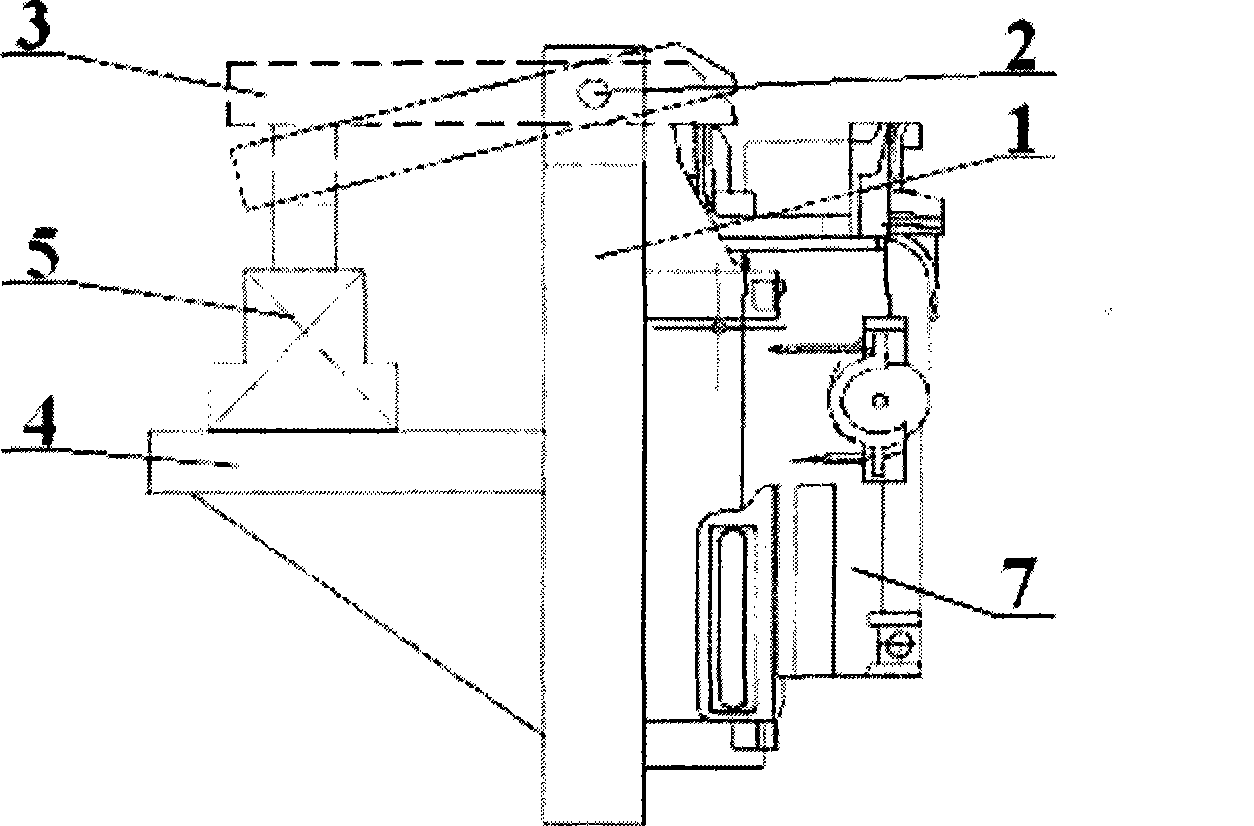

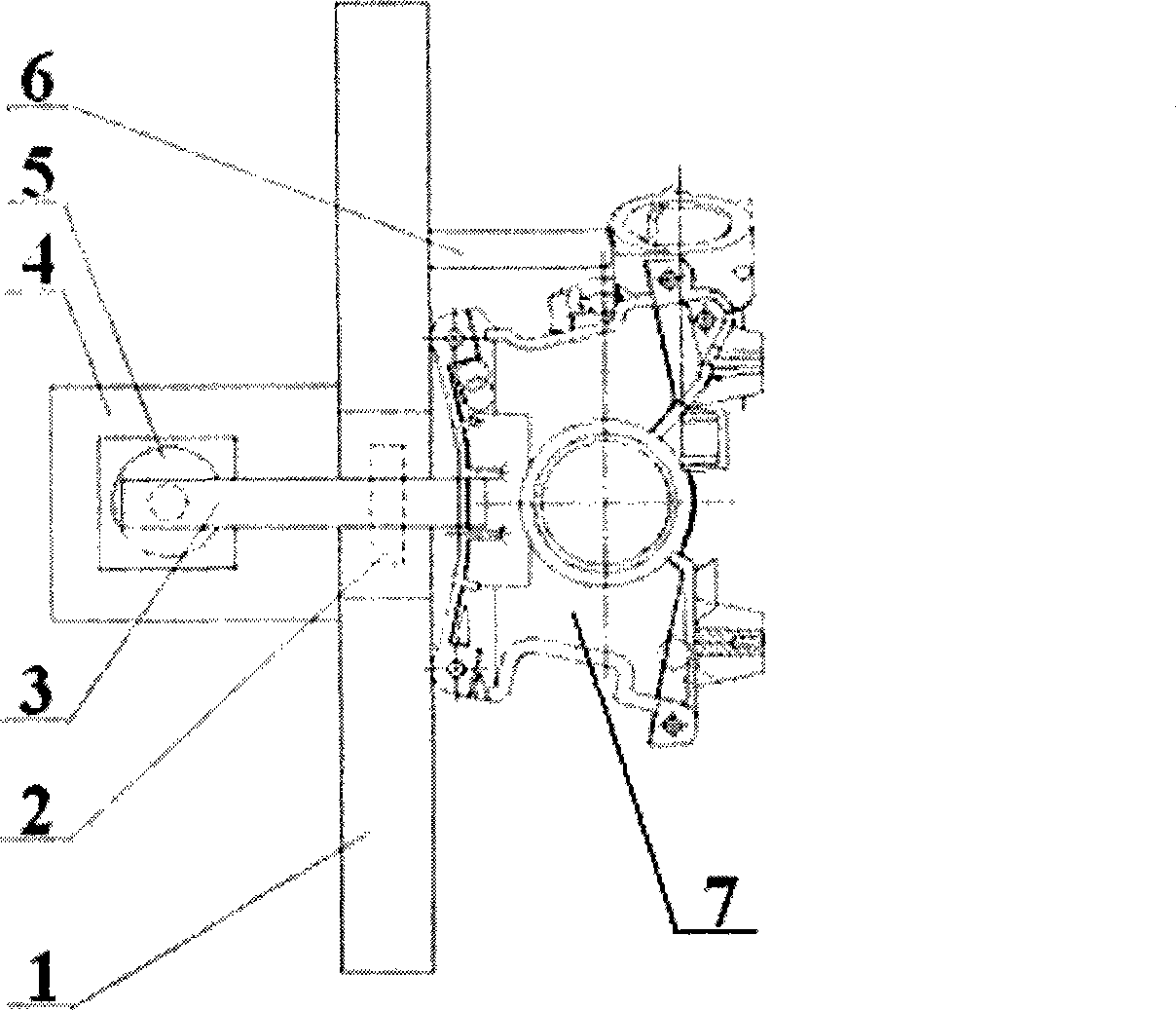

Pneumatic lever type clamping structure

InactiveCN101434040AStrong pressing forceEfficient compressionPositioning apparatusMetal-working holdersHigh rateGyration

The invention discloses a pneumatic lever type clamp structure. A pressure plate (3) is a lever structure, and the gyration center of the pressure plate is hinged with a clamp body (1) through a lever fulcrum (1); and under the state that a workpiece (7) is tightly clamped, one end of the pressure plate (3) is connected with a piston rod on a cylinder (5), while the other end is contacted with the clamped workpiece (7). With the technical proposal, pressing force of the cylinder can be increased through an arm of the lever structure by the lever principle when the cylinder is adopted, so that the processing workpiece can be pressurized conveniently and more effectively. The invention has a simple structure, can effectively improve the efficiency of processing parts, can realize stable processing tempo, and has the advantages of high rate of finished products and safe and convenient use.

Owner:THIXOMAG TECHNOLOGH WUHU

Pipe machining and fixing clamp

InactiveCN105437106AStable clamping effectImprove processing efficiencyWork clamping meansWork holdersEngineeringAtmospheric pressure

The invention discloses a pipe machining and fixing clamp which comprises a fixing clamp bearing groove, a clamp bearing rack and a pipe fixing ring. The clamp bearing rack is installed on the inner wall of the fixing clamp bearing groove. The pipe fixing ring is installed on the outer wall of the top of the clamp bearing frame. The bottom of an air pressure connecting port is connected with one outer air pressure telescopic arm through an air pressure flow division pipeline. Inner air pressure telescopic arms are installed in inner cavities of the bottoms of the outer air pressure telescopic arms. Pipe fixing clamping grooves are formed in the bottoms of the inner air pressure telescopic arms. By the adoption of the pipe machining and fixing clamp, the air pressure telescopic arms are adopted as pipe clamping mechanisms, and the pipe machining and fixing clamp is effectively made more convenient to use; and meanwhile the multiple clamping mechanisms are adopted, the pipe clamping effect of the pipe machining and fixing clamp is more stable, and pipe machining efficiency is greatly improved.

Owner:无锡西源电力装备厂

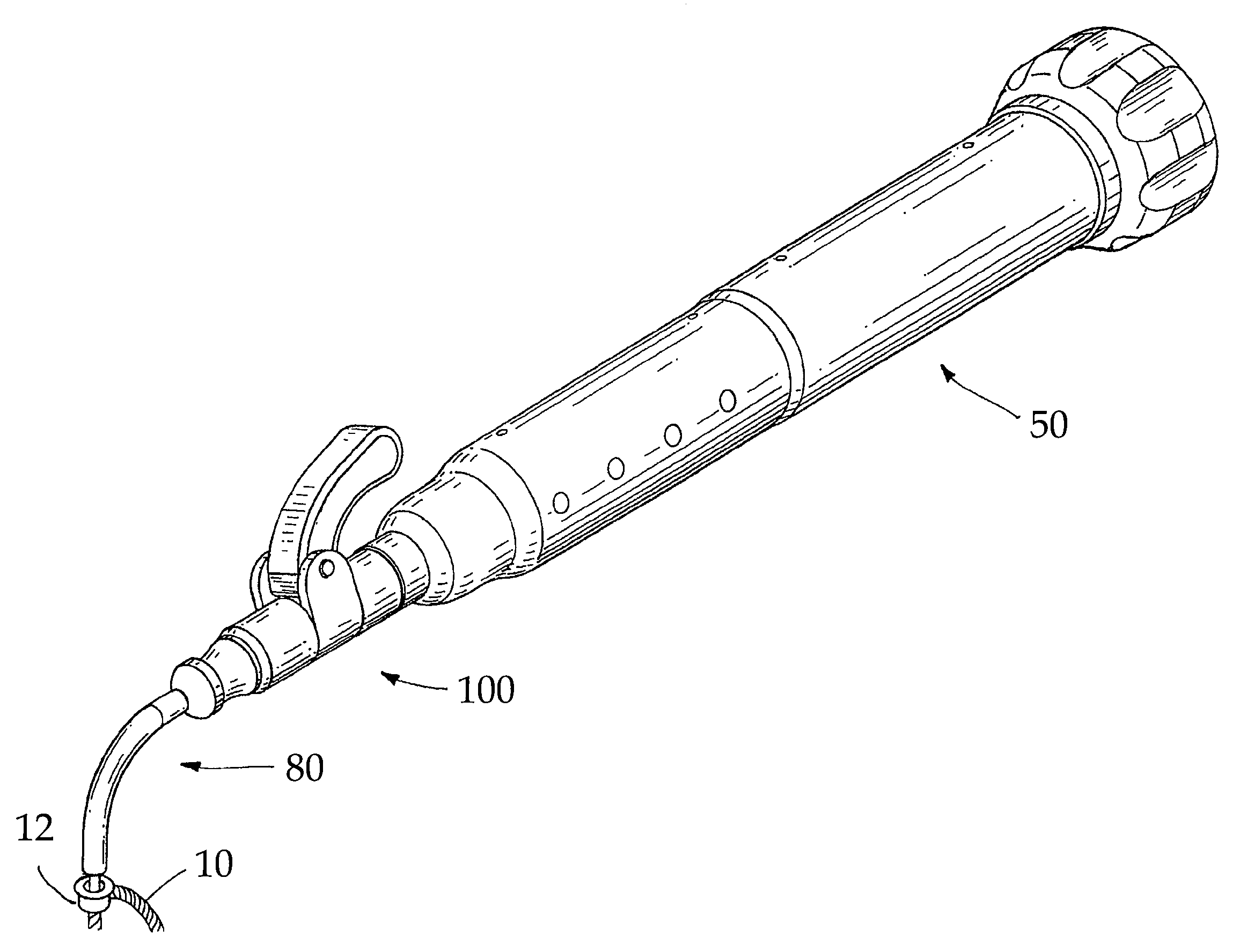

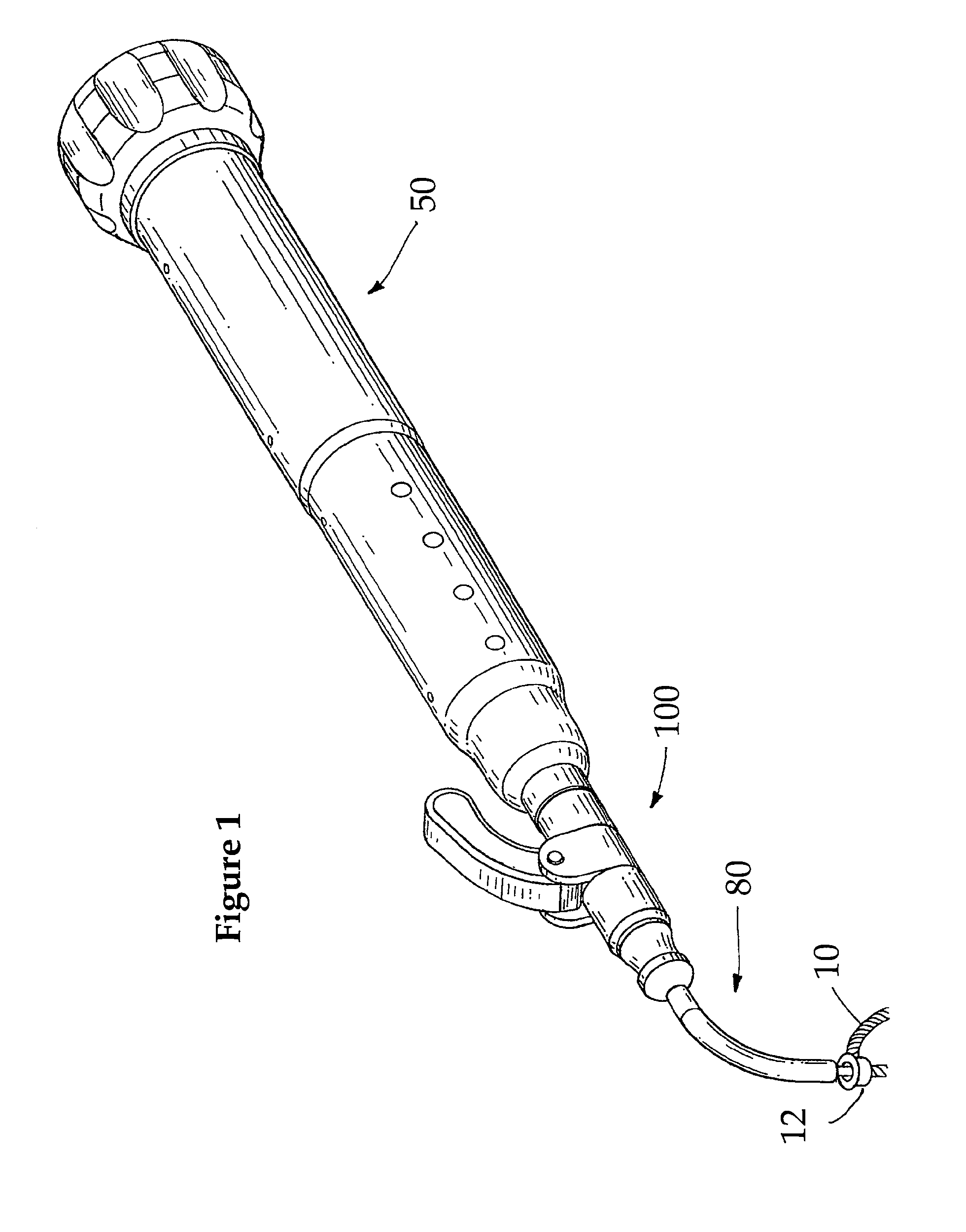

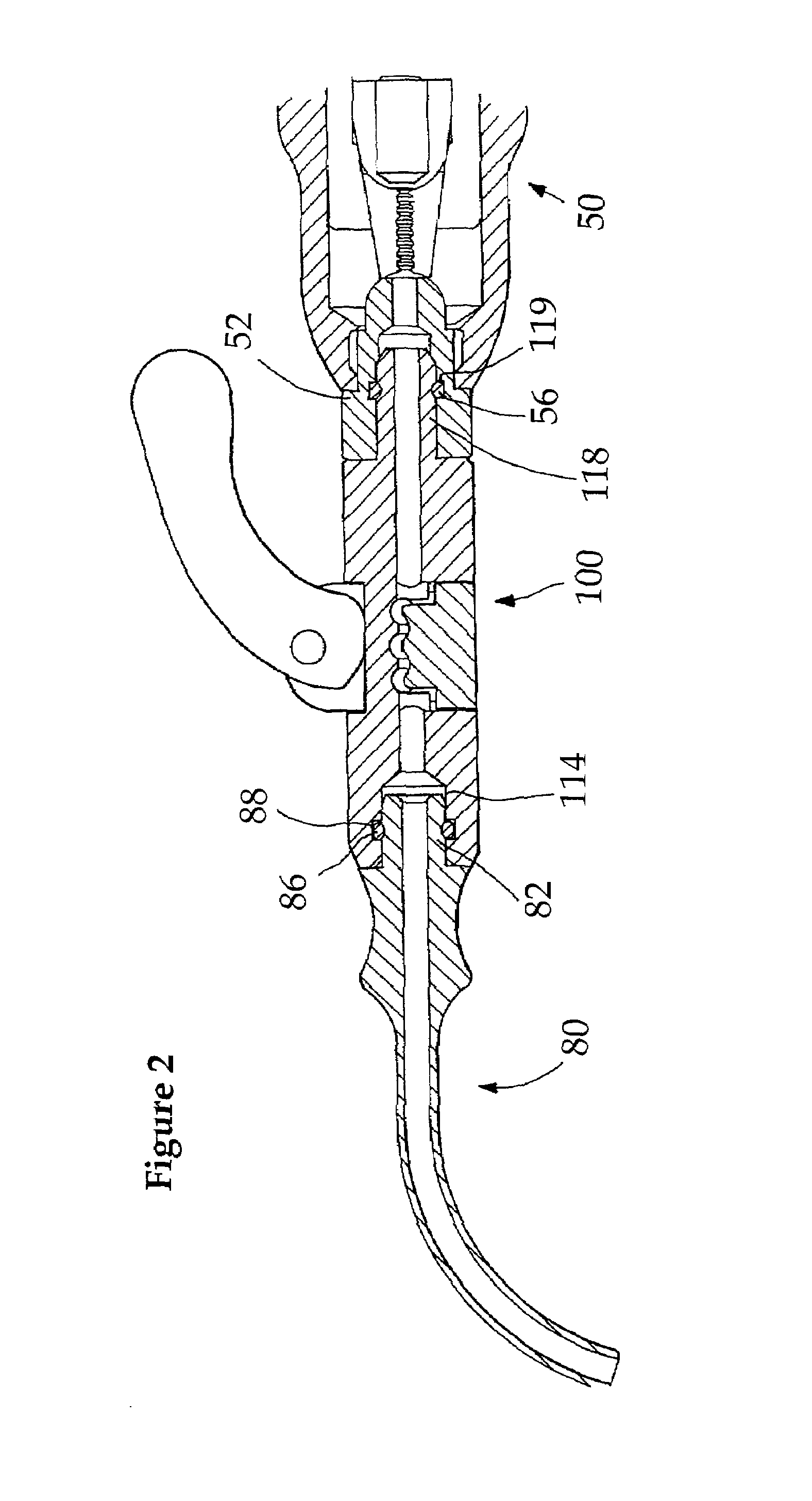

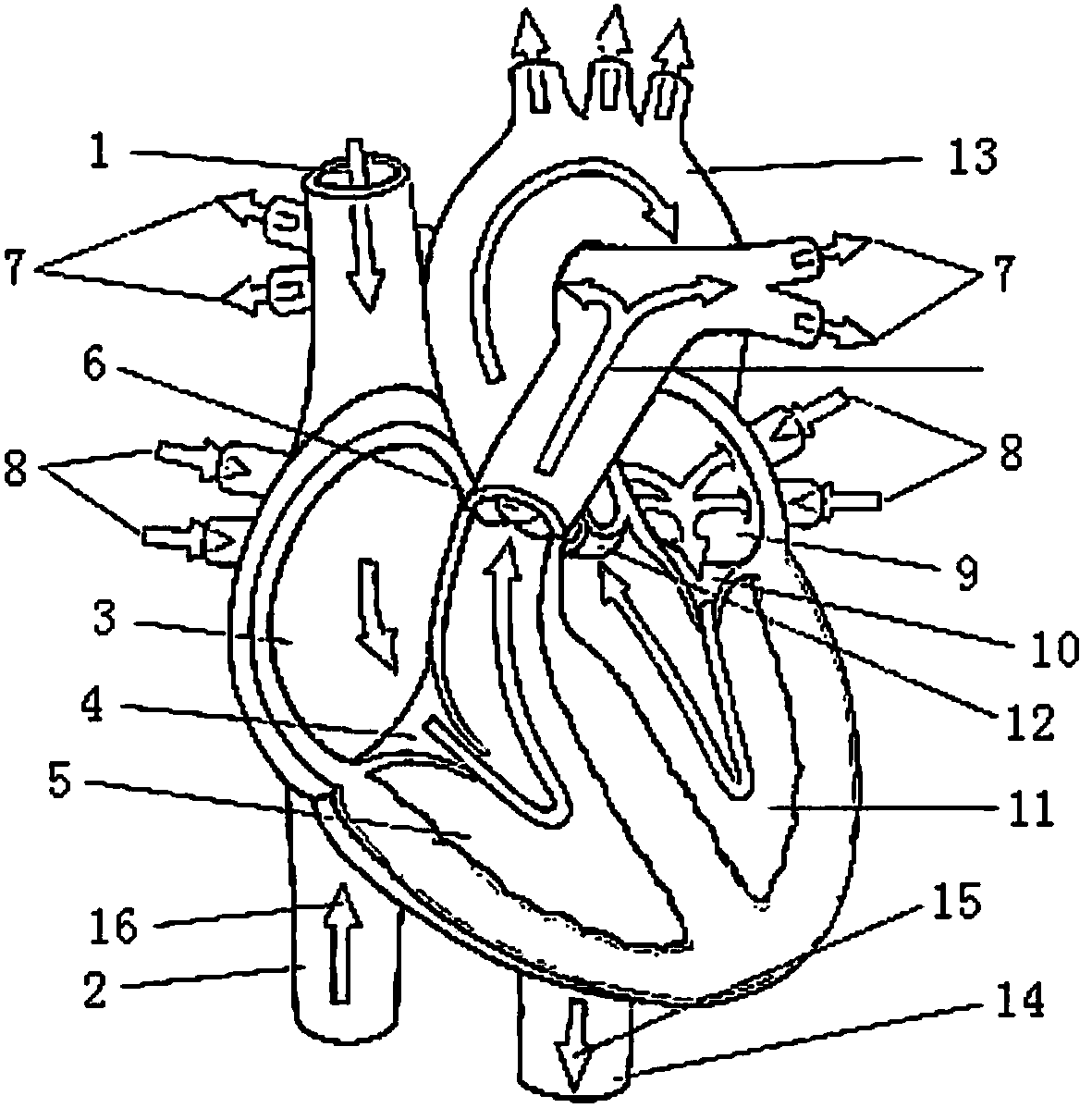

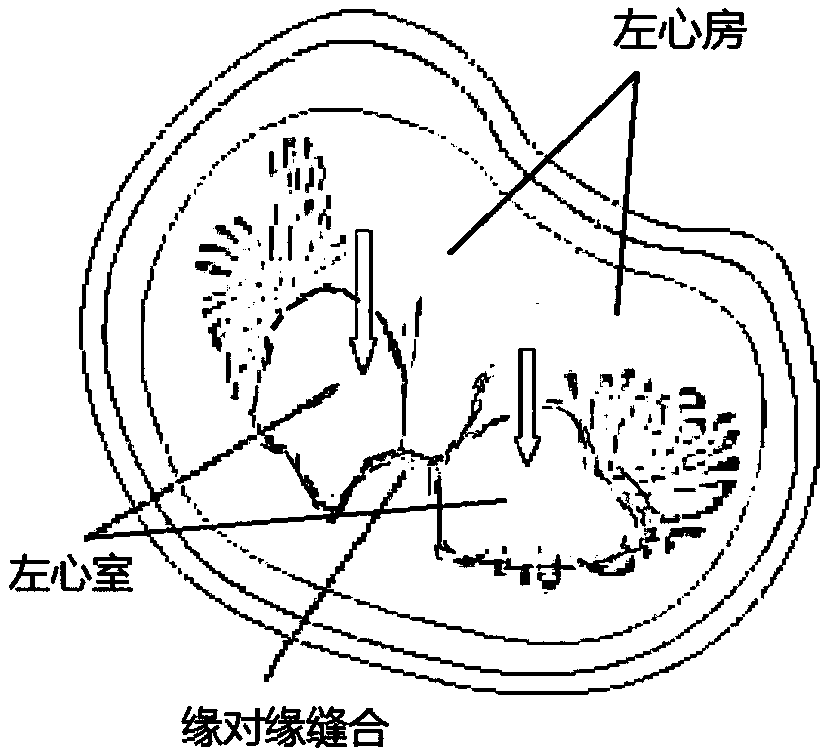

Method and apparatus for clamping surgical wires or cables

InactiveUS7452360B2Improve clamping effectIncrease clamping forceInternal osteosythesisJoint implantsEngineeringCam

Disclosed is a clamp for securing cables or other elongate members used in surgical fastening procedures. The clamp advantageously applies a clamping force to the cable without direct contact with the cable, thereby reducing abrasion and shear forces applied to the cable. The disclosed clamps have a saddle member, platen or both that are movably mounted with respect to the housing and a lever, in cooperation with a cam surface, that allows the saddle member, platen or both to selectively clamp the cable. The lever may have several locking positions to provide optimum clamping force to different sized cables.

Owner:PIONEER SURGICAL TECH INC

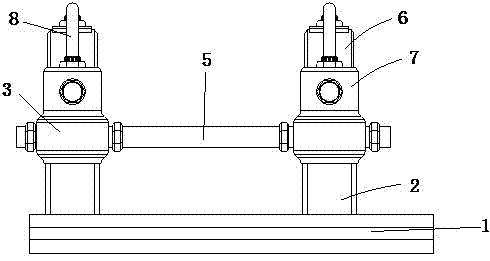

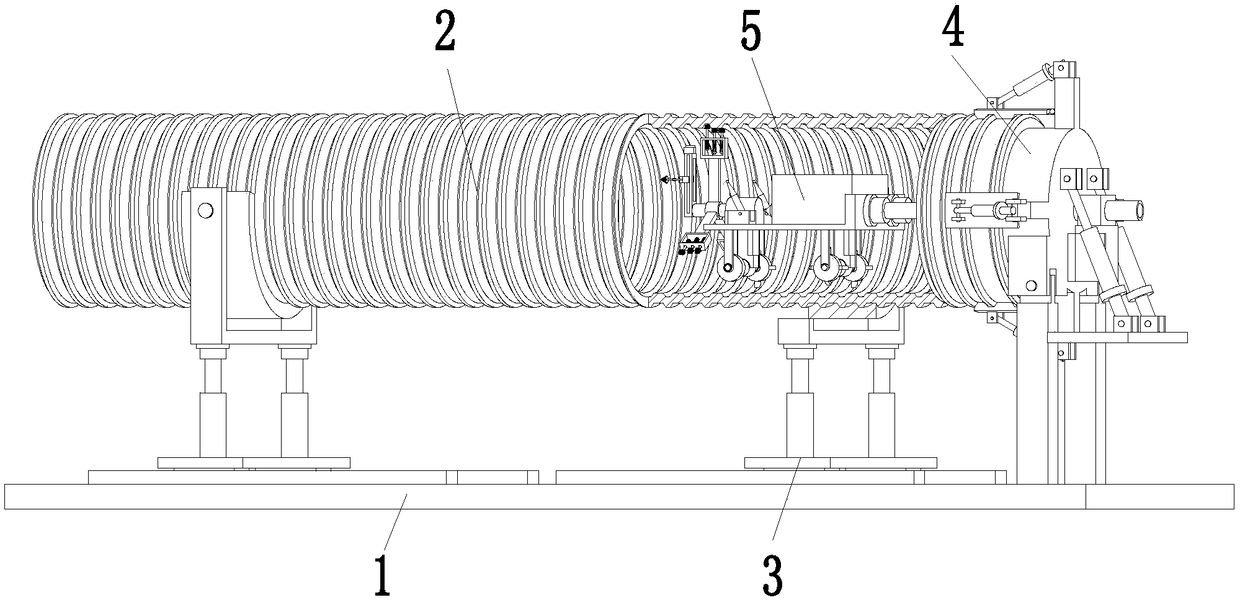

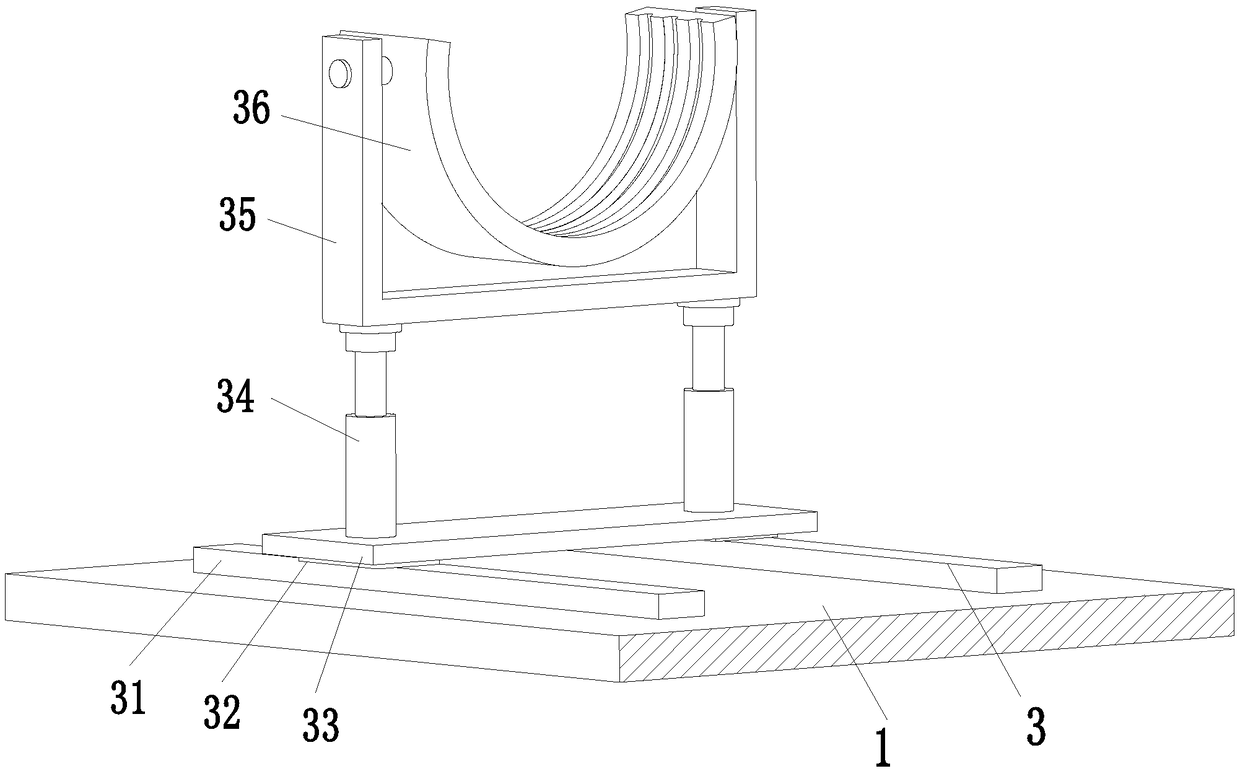

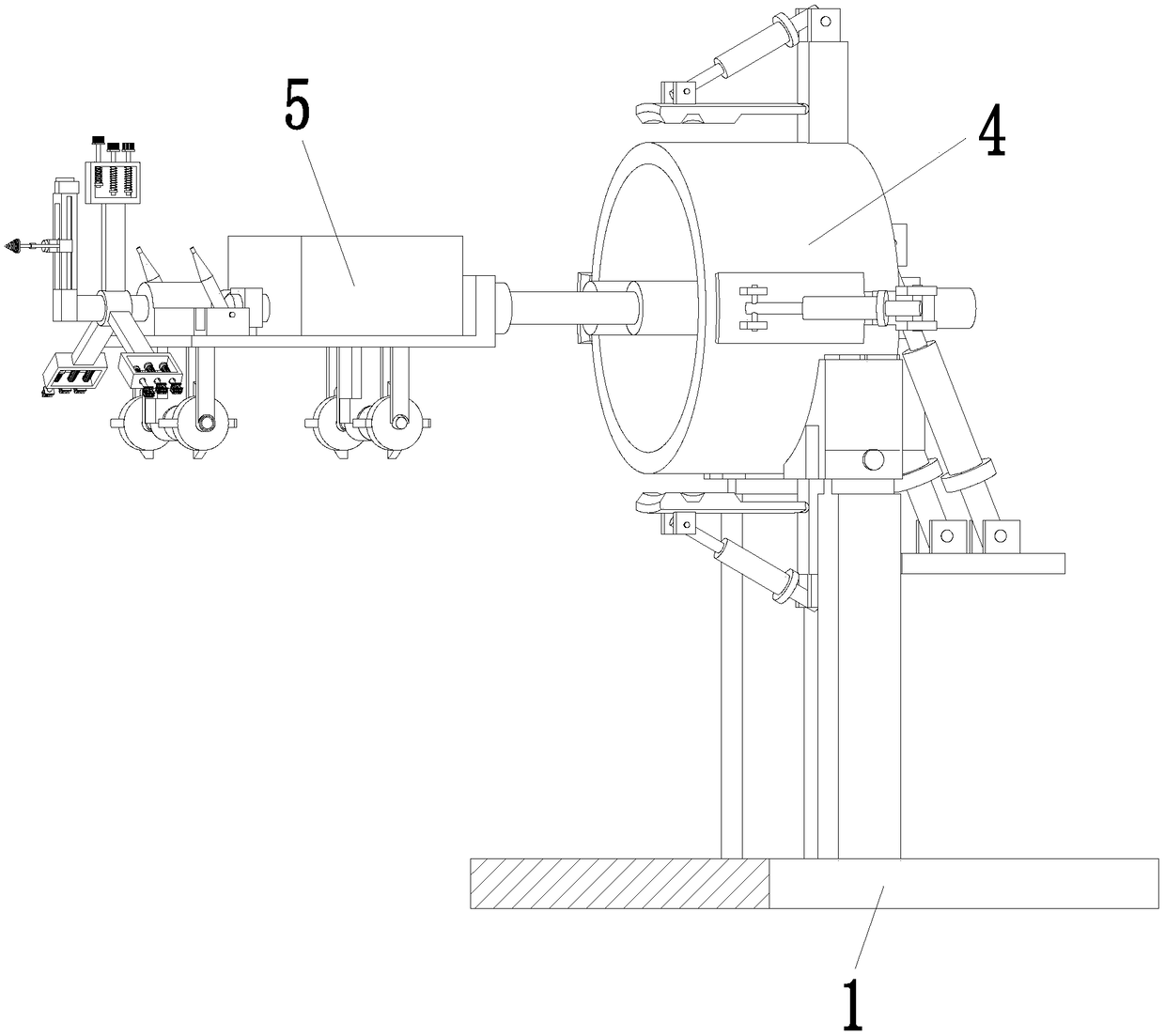

Pipeline automatic dirt-clearing cleaning equipment and pipeline automatic treatment method

The invention relates to pipeline automatic dirt-clearing cleaning equipment and a pipeline automatic treatment method. The pipeline automatic dirt-clearing cleaning equipment comprises a bottom plate, a pipeline body, two translation supporting devices, a clamping device and a cleaning device, wherein the left side of the upper end of the bottom plate is provided with the two translation supporting devices, the pipeline body is placed on the two translation supporting devices, the right sides of the two translation supporting devices are provided with the clamping device, the left end of theclamping device is connected with the pipeline body in a clamped manner and is provided with the cleaning device, and the cleaning device is located inside the pipeline body. By means of the pipelineautomatic dirt-clearing cleaning equipment and the pipeline automatic treatment method, the problems that manual carrying is generally performed in the dirt-clearing cleaning process of existing mud conveying corrugated pipelines, and the labor intensity is high; manual cleaning is generally performed in cleaning, the manual cleaning efficiency is low, and the cleaning effect is poor; and when themanual cleaning is performed, grooves of the inner wall of the pipeline body can not be cleared to cause a large amount of silt to remain inside the grooves of the inner wall of the pipeline body, the use effect is affected, the labor intensity is high, the work efficiency is low and the like can be solved.

Owner:河北承水水务科技有限公司

Artware polishing grinding device bringing convenience to positioning

InactiveCN107350951AIncrease frictionGood positioning and clamping effectPolishing machinesGrinding drivesEngineering

The invention discloses a handicraft polishing and polishing device which is convenient for positioning, which comprises a fixed frame and a workbench. A grinding cover is fixedly connected to the lower end of the grinding cover, and a grinding roller is arranged inside the grinding cover. The limit rod is fixed on the upper end of the fixed frame. A pull rod is connected, the outer wall of the pull rod is sleeved with a spring, and the end of the pull rod is fixedly connected with a movable rod, the upper end of the movable rod is fixedly connected with a fixed block, and the outer wall of the fixed block is symmetrically provided with connecting rods, The end of the connecting rod away from the fixed block is rotatably connected with a clamping block. The invention is simple in structure, easy to operate, can effectively locate handicrafts, has good clamping effect, and avoids damage during polishing.

Owner:浙江千鹤工艺品有限公司

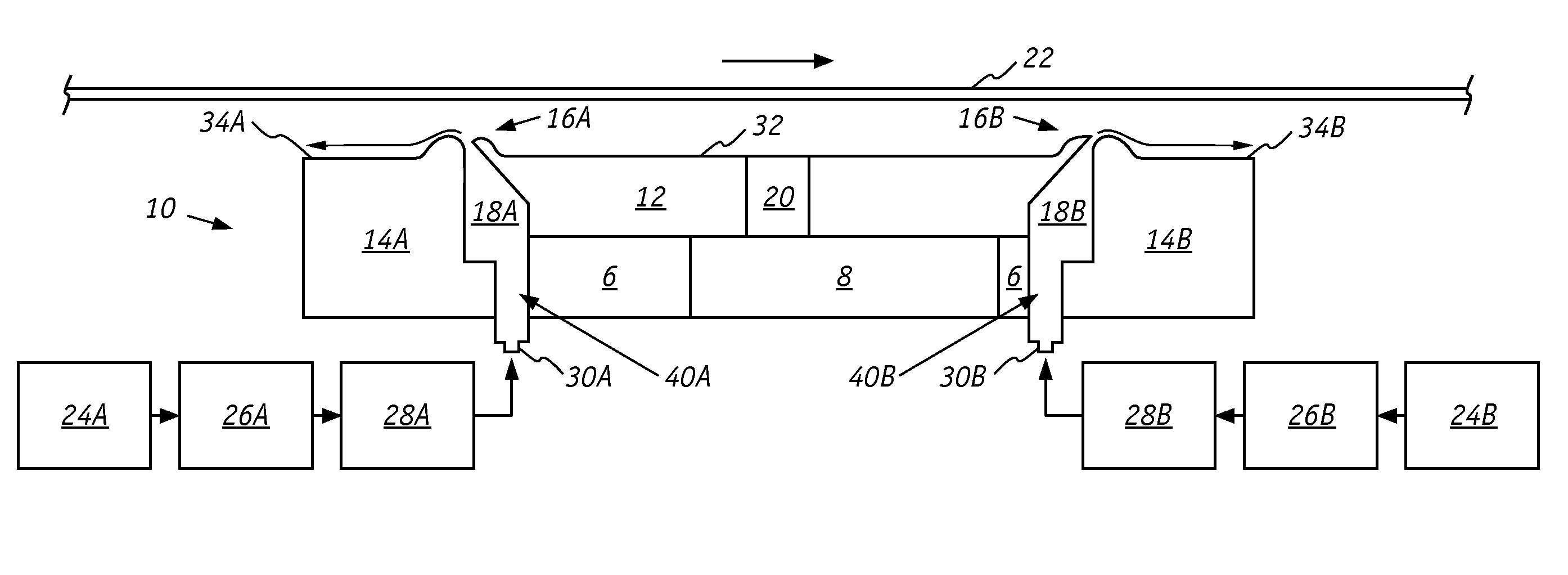

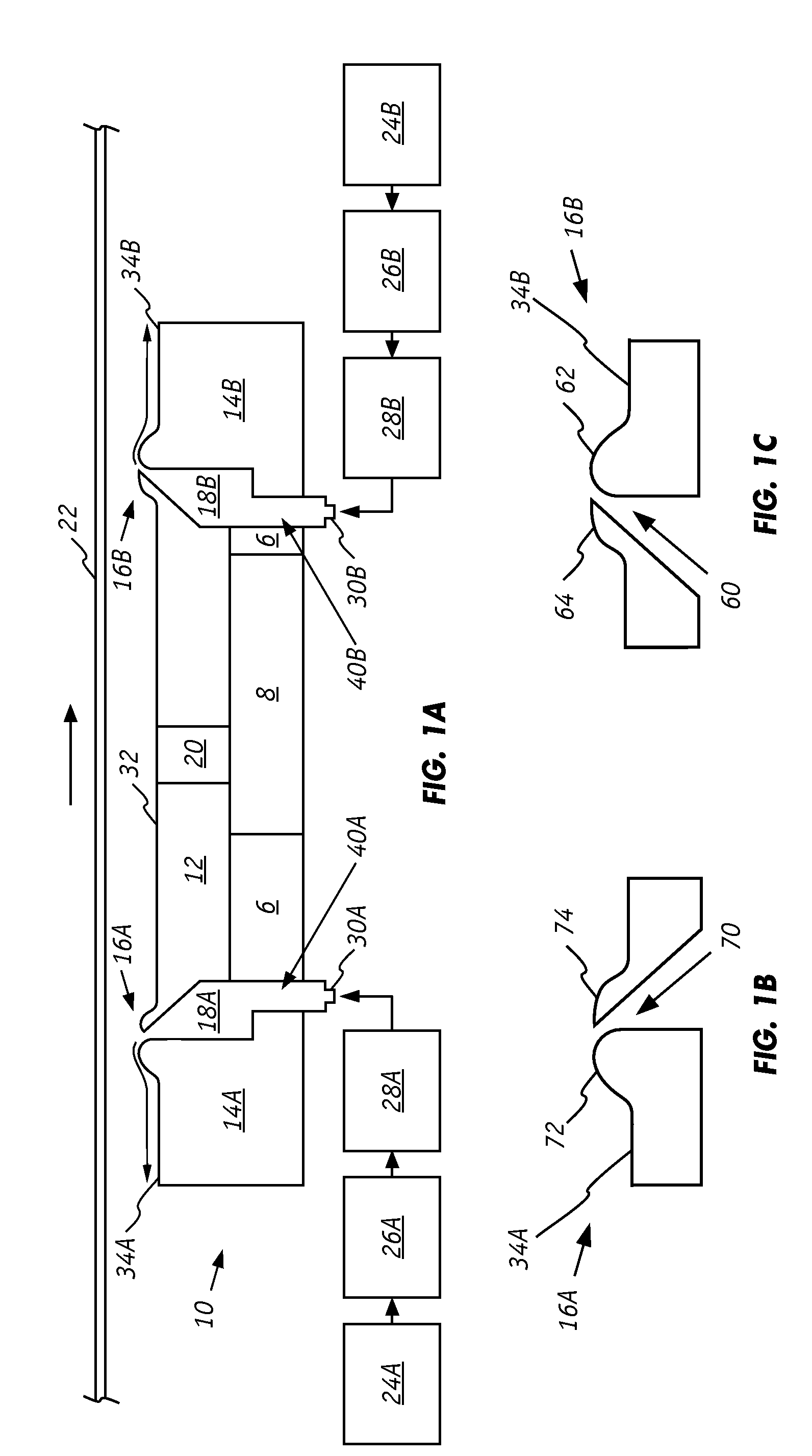

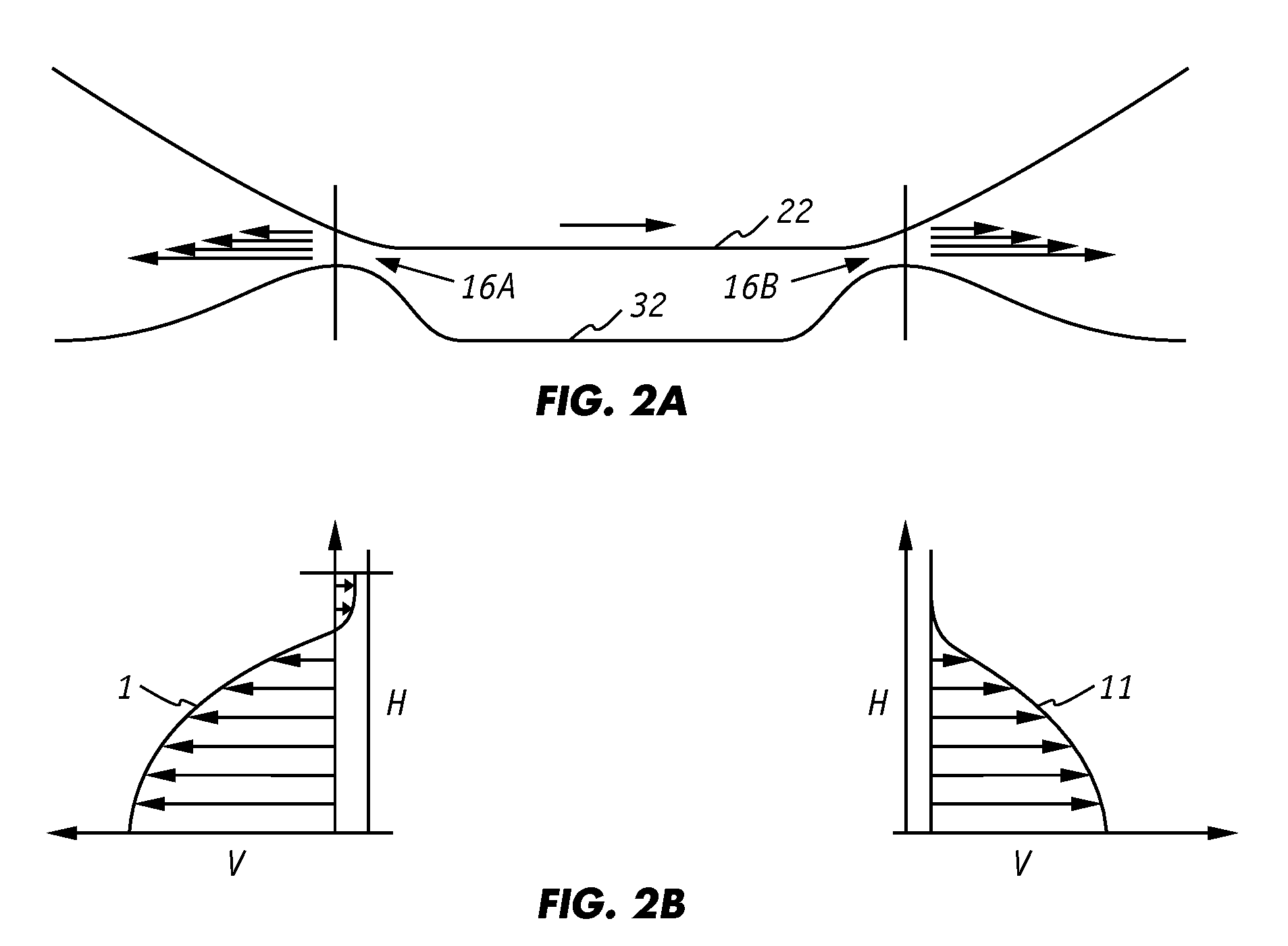

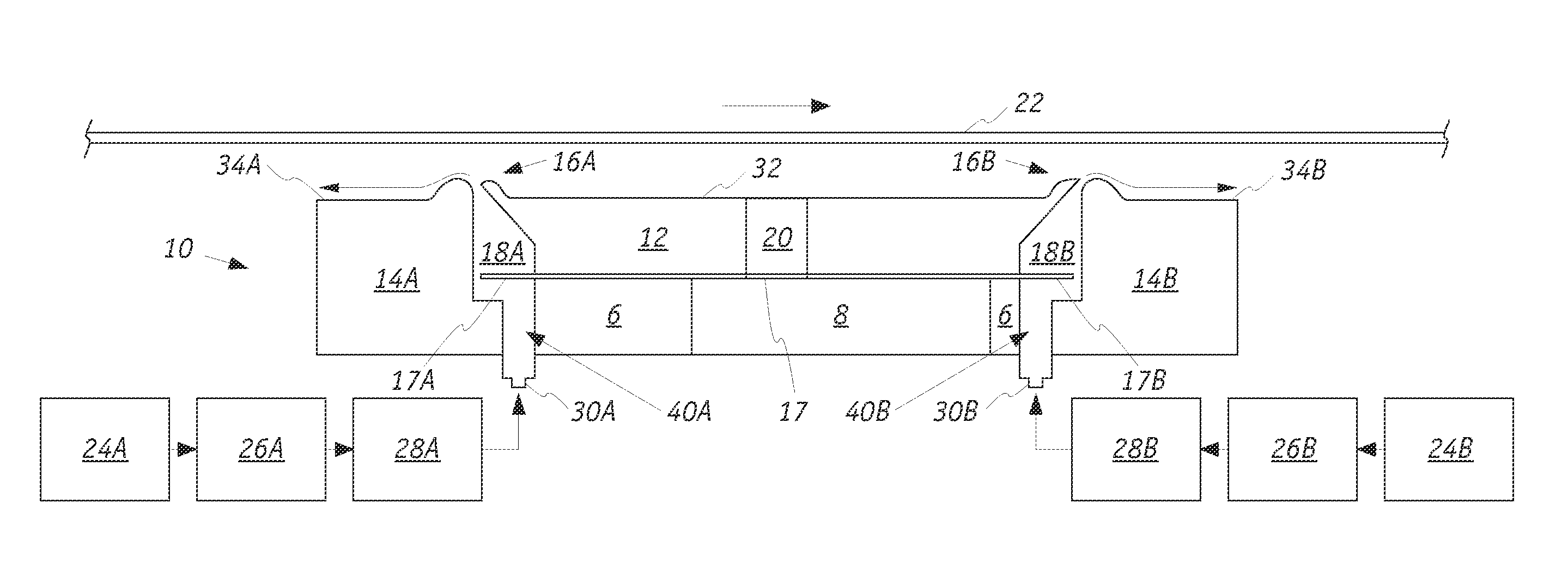

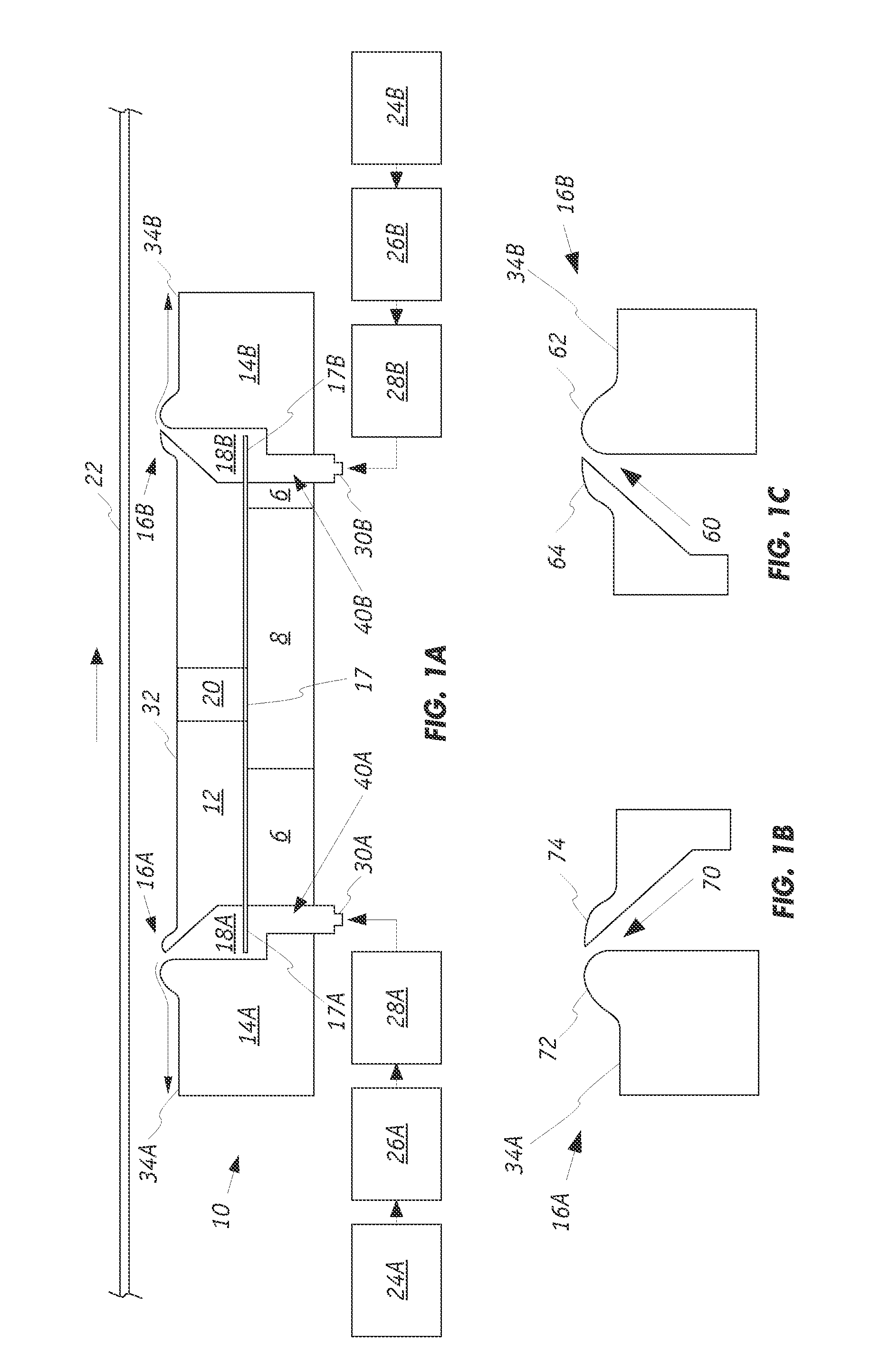

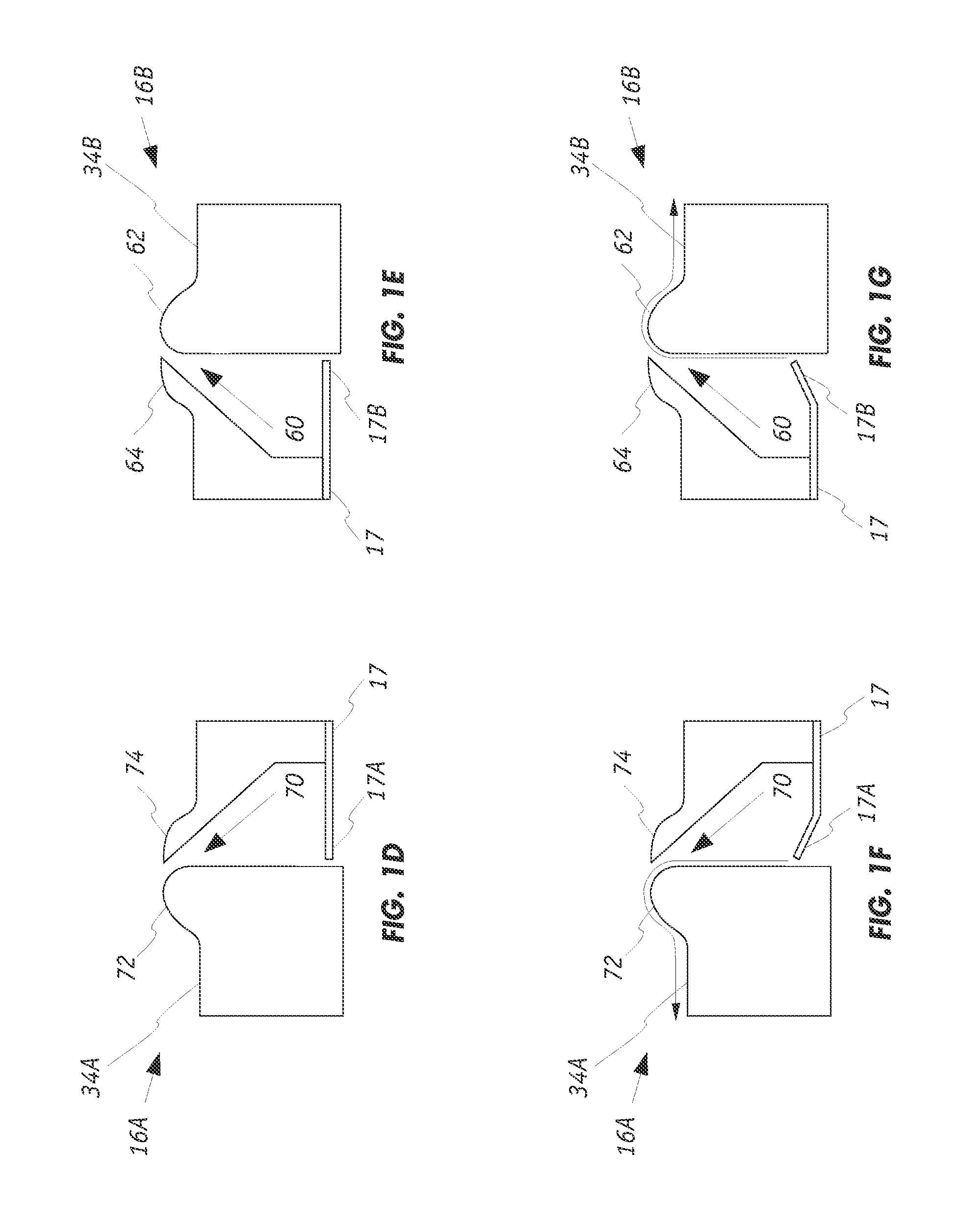

Local tension generating air stabilization system for web products

ActiveUS7892399B2Create tensionAccurate thicknessMachine wet endUsing optical meansImage stabilizationSelf-stabilization

An air stabilization system employing two parallel, opposite-facing Coanda nozzles, with each nozzle exhausting gas at opposite directions, subjects a moving flexible web to opposing forces effective to create local tension within the web. Each nozzle includes an elongated slot that is perpendicular to the path of the moving web. The nozzles serve as separate points along the machine direction for controlling the height of the web. The operative surface with the nozzles can exhibit a flush surface. The nozzles can be formed on elevated structures on the operative surface. The operative surface can be covered with a transparent substrate to minimize shape distortions on the moving web and to prevent debris from collecting around the sensor. By modulating the velocities of gases exiting the nozzles, the shape of the web can be manipulated to present a planar contour. The air stabilization system can be incorporated into a caliper scanner.

Owner:HONEYWELL ASCA INC

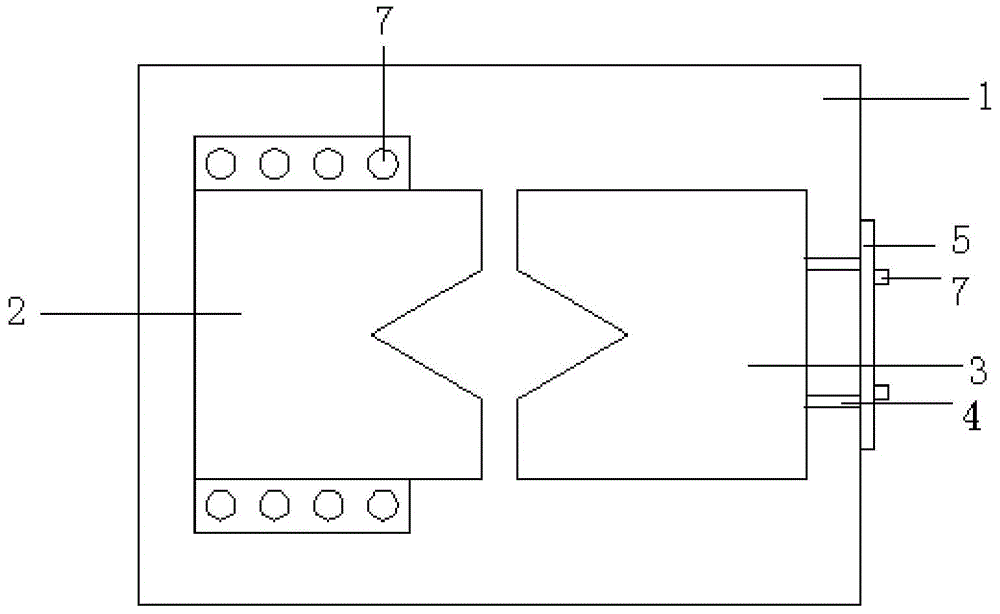

Clamping device for electrical mechanical equipment production

ActiveCN105904252AStructural solutionSolve the situationPositioning apparatusClampsCouplingMechanical equipment

The invention discloses a clamping device for electrical mechanical equipment production. The clamping device comprises a bottom plate. One side of the top of the bottom plate is fixedly connected with a vertical plate. One side of the bottom plate is fixedly connected with a motor. A rotating shaft of the motor is fixedly connected with a connecting rod through a coupler. The surface of the end, far away from the motor, of the connecting rod is fixedly connected with a belt wheel. The belt wheel is in transmission connection with a rotation wheel through a belt. A rotation rod is fixedly connected to the rotation wheel. The surface of the rotation rod is fixedly connected with a disk. A supporting device is arranged at the end, far away from the rotation wheel, of the rotation rod. The clamping device for electrical mechanical equipment production solves the problems that existing clamping equipment is commonly single in structure and complex in operation, and the clamping device can be used by a user more conveniently. The using effect is greatly improved, the work time is shortened, the clamping effect of the clamping equipment is improved, the phenomenon that loosening is likely to happen is avoided, the normal clamping effect is guaranteed, and the work efficiency is improved.

Owner:WUXI KING MO MACHINERY

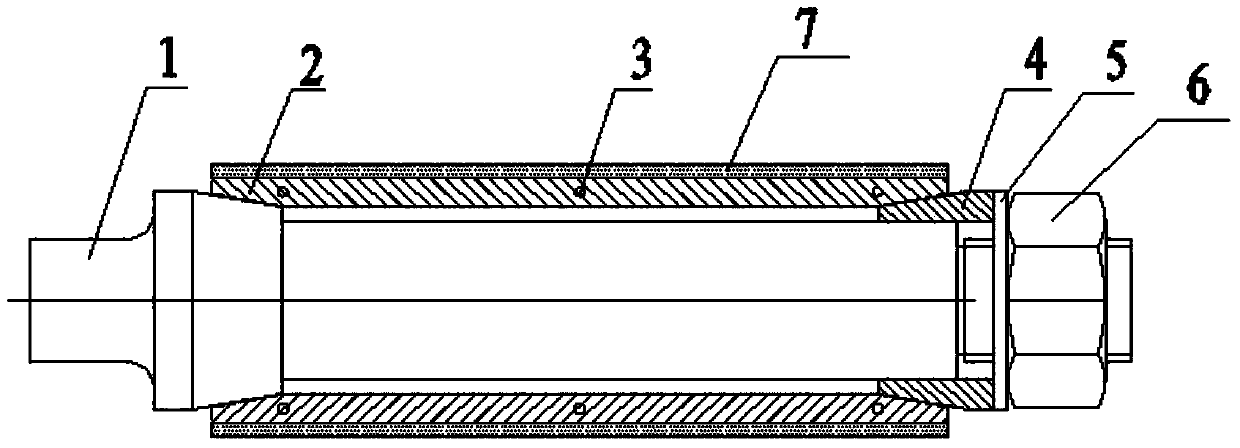

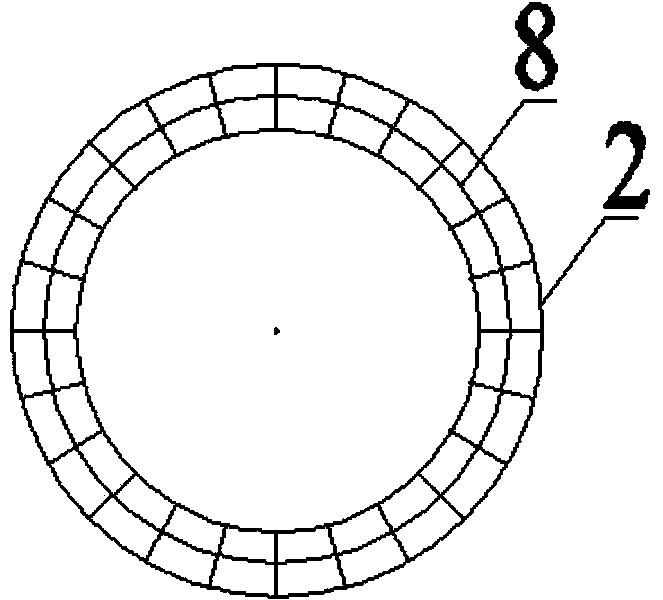

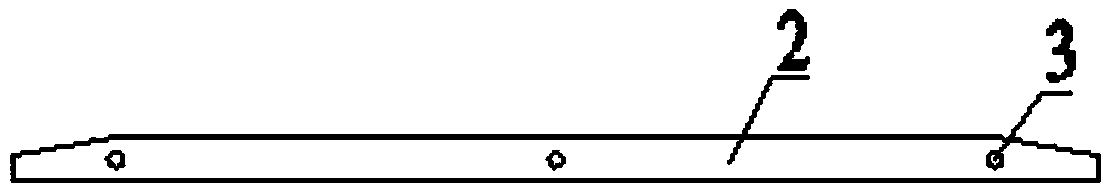

Cylindrical workpiece outer circle machining clamp and using method thereof

The invention relates to a cylindrical workpiece outer circle machining clamp and a using method thereof. The cylindrical workpiece outer circle machining clamp mainly comprises a fixed core, an expansion sleeve, a movable core, a gasket and a locking nut. The using method of the machining clamp is that the locking nut is rotated to push the movable core to move so as to squeeze the expansion sleeve, the expansion sleeve expands outwards in the radial direction under the combined action of a conical face of the fixed core and a conical face of the movable core, and therefore a cylindrical workpiece is clamped. Compared with an elastic clamp in the prior art, the dual-directional conical face expansion type design is adopted by the cylindrical workpiece outer circle machining clamp, in the expansion process, the overall expansion sleeve expands outwards to enable a machined workpiece to be evenly stressed, the clamping effect of the clamp is enhanced, and machining precision is greatly improved.

Owner:NANTONG INST OF TECH

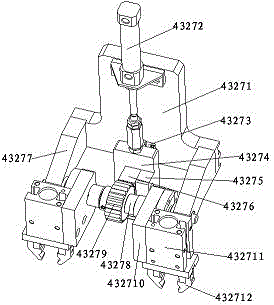

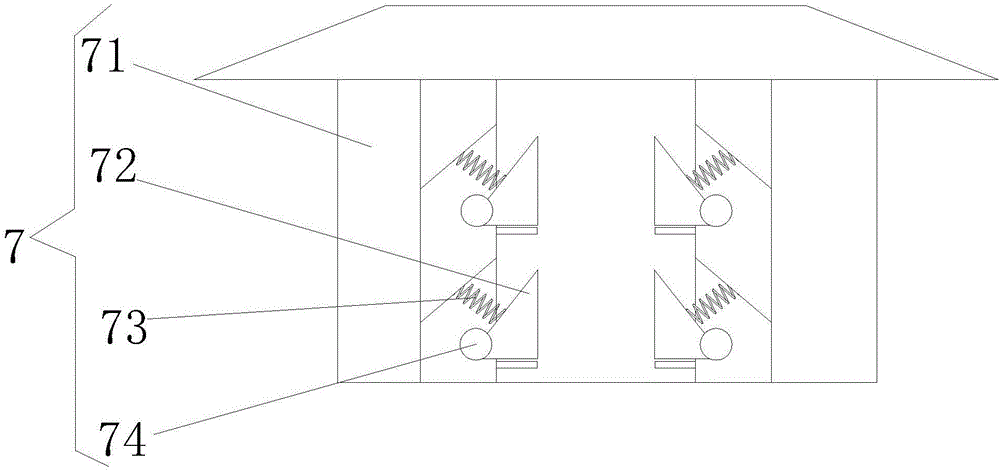

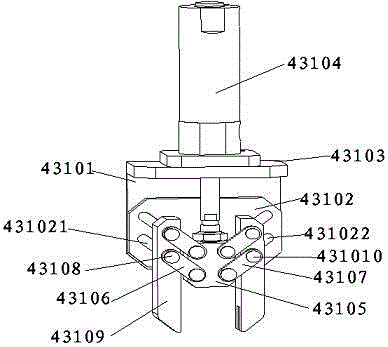

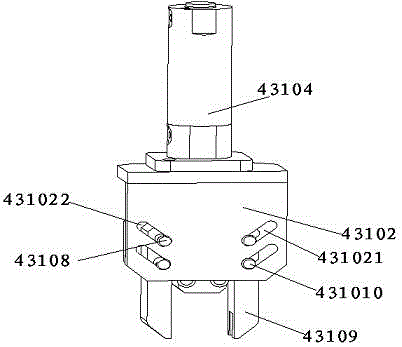

Mechanical taking hand of electronic drain valve controller assembly machine

ActiveCN106002145AGuaranteed uptimeImprove clamping effectGripping headsMetal working apparatusEngineeringManipulator

The invention discloses a mechanical taking hand of an electronic drain valve controller assembly machine. The mechanical taking hand of the electronic drain valve controller assembly machine comprises a clamping jaw opening-closing cylinder fixing plate, wherein a clamping jaw separation guide plate is mounted on the side surface of the clamping jaw opening-closing cylinder fixing plate; two first inclined chutes and two second inclined chutes are arranged in corresponding positions of the clamping jaw separation guide plate and the clamping jaw opening-closing cylinder fixing plate; the two first inclined chutes and the two second inclined chutes are symmetrically distributed along the central line of the clamping jaw separation guide plate; the two first inclined chutes are parallel to each other; the two second inclined chutes are parallel to each other as well; a clamping jaw opening-closing cylinder mounting plate vertical to the upper end face of the clamping jaw opening-closing cylinder fixing plate is mounted on the upper end face of the clamping jaw opening-closing cylinder fixing plate; and a clamping jaw opening-closing cylinder is longitudinally mounted on the clamping jaw opening-closing cylinder mounting plate. According to the mechanical taking hand, through the manner, the structure is simple, the operation is convenient, the material taking is convenient, the service life is long, and the production efficiency is greatly improved.

Owner:南通如港船舶配套机械有限公司

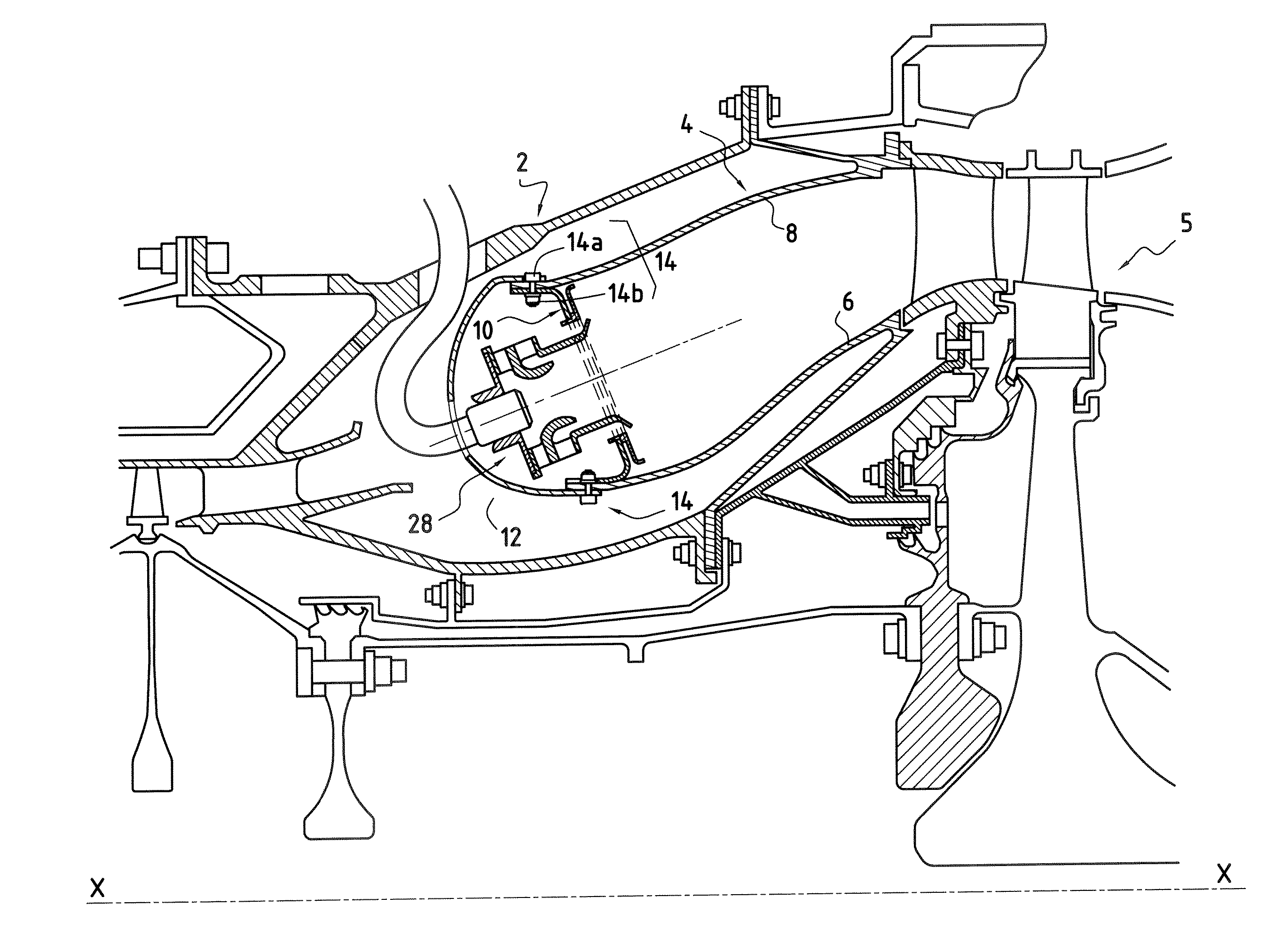

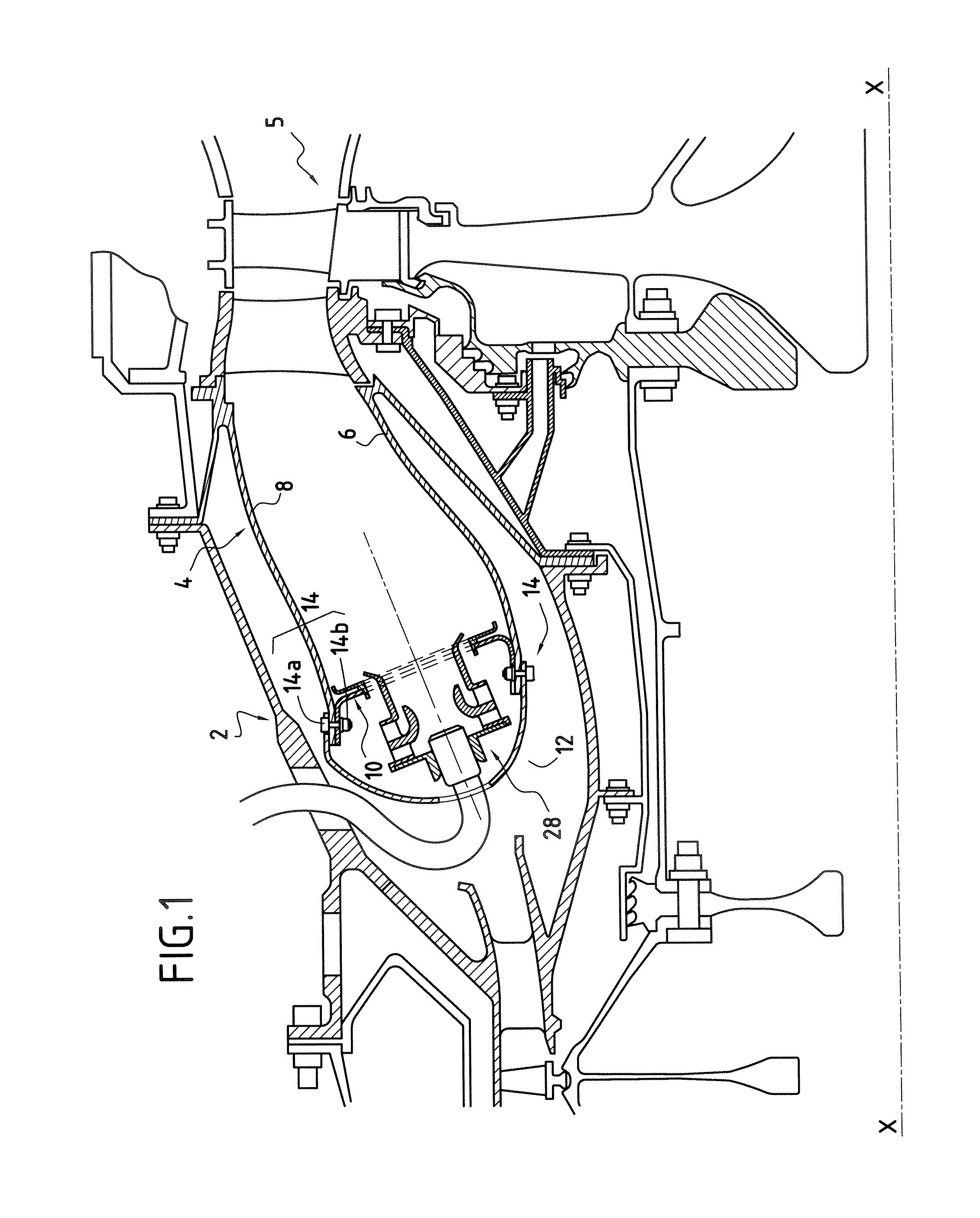

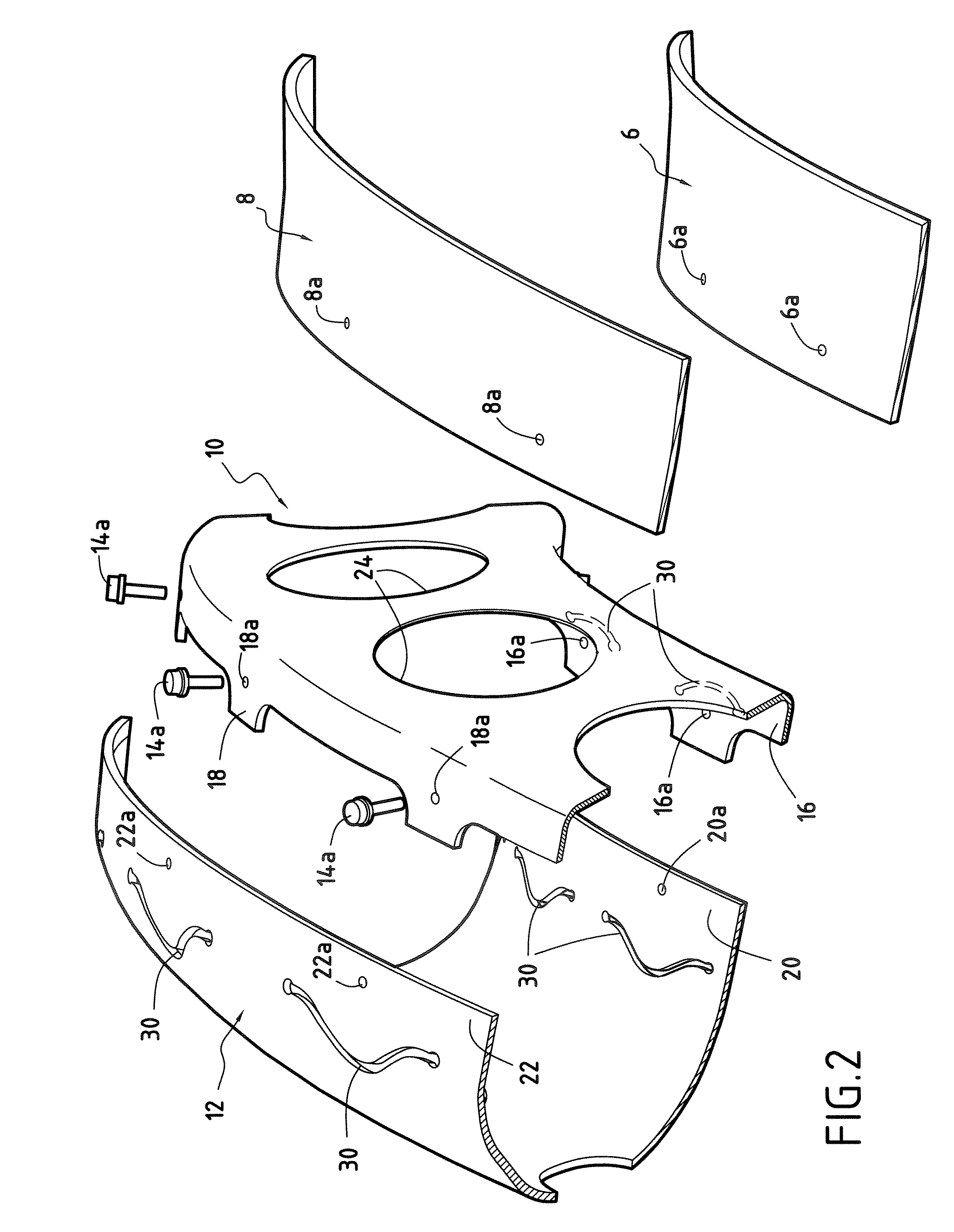

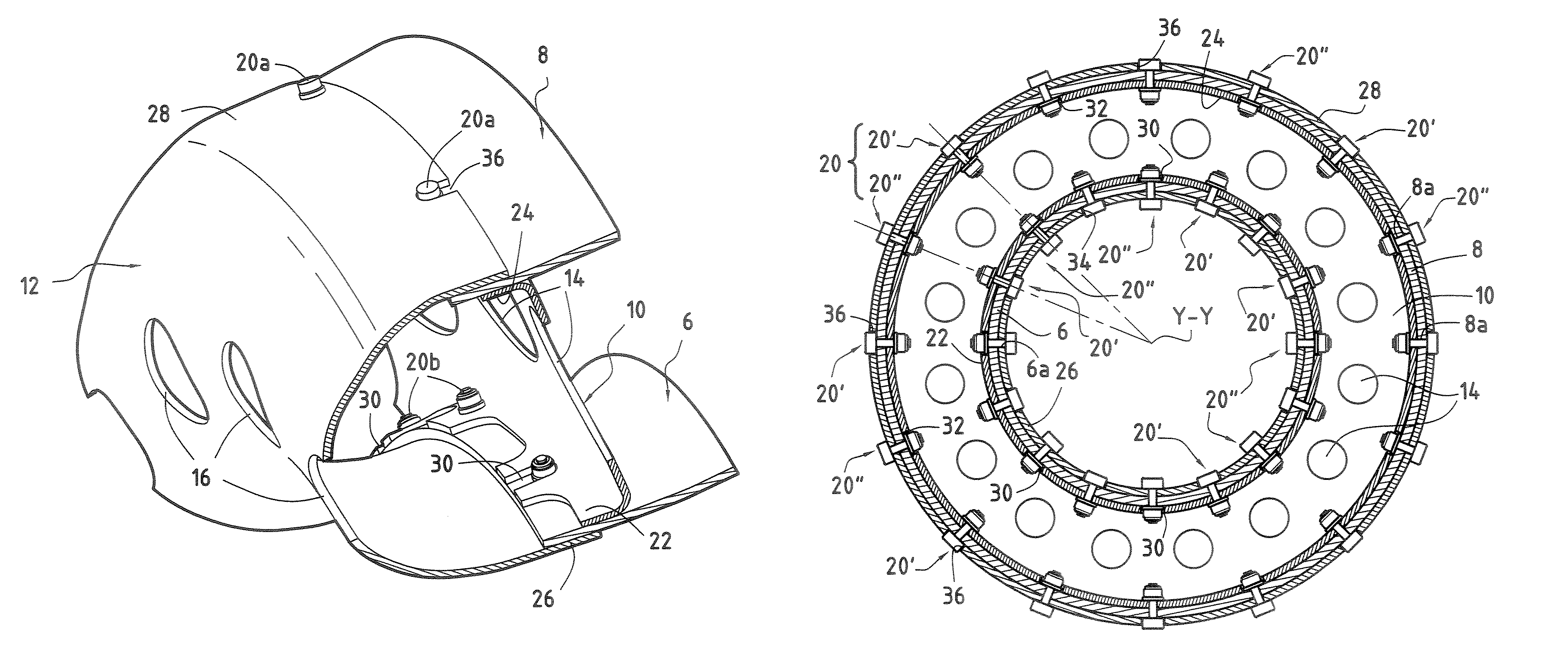

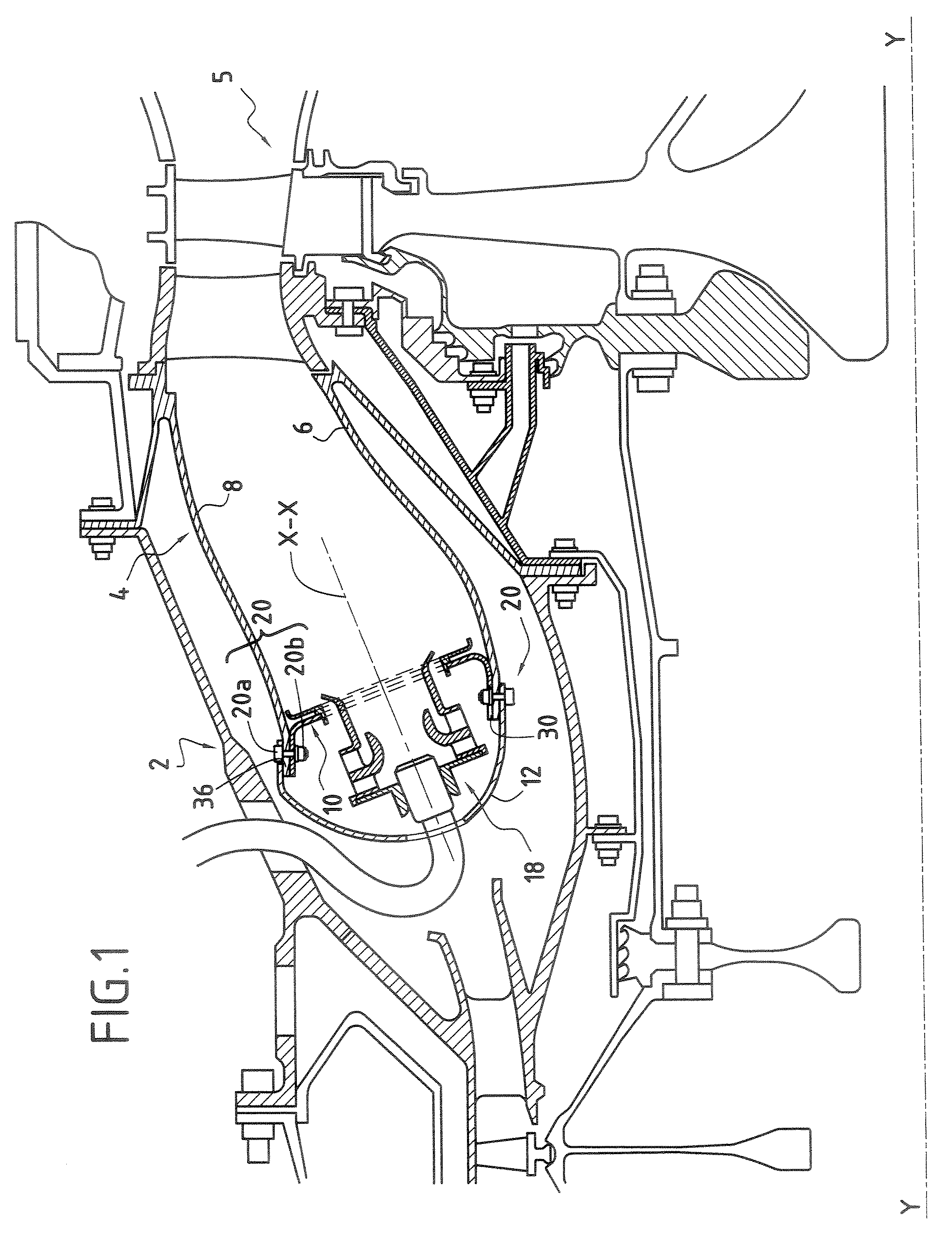

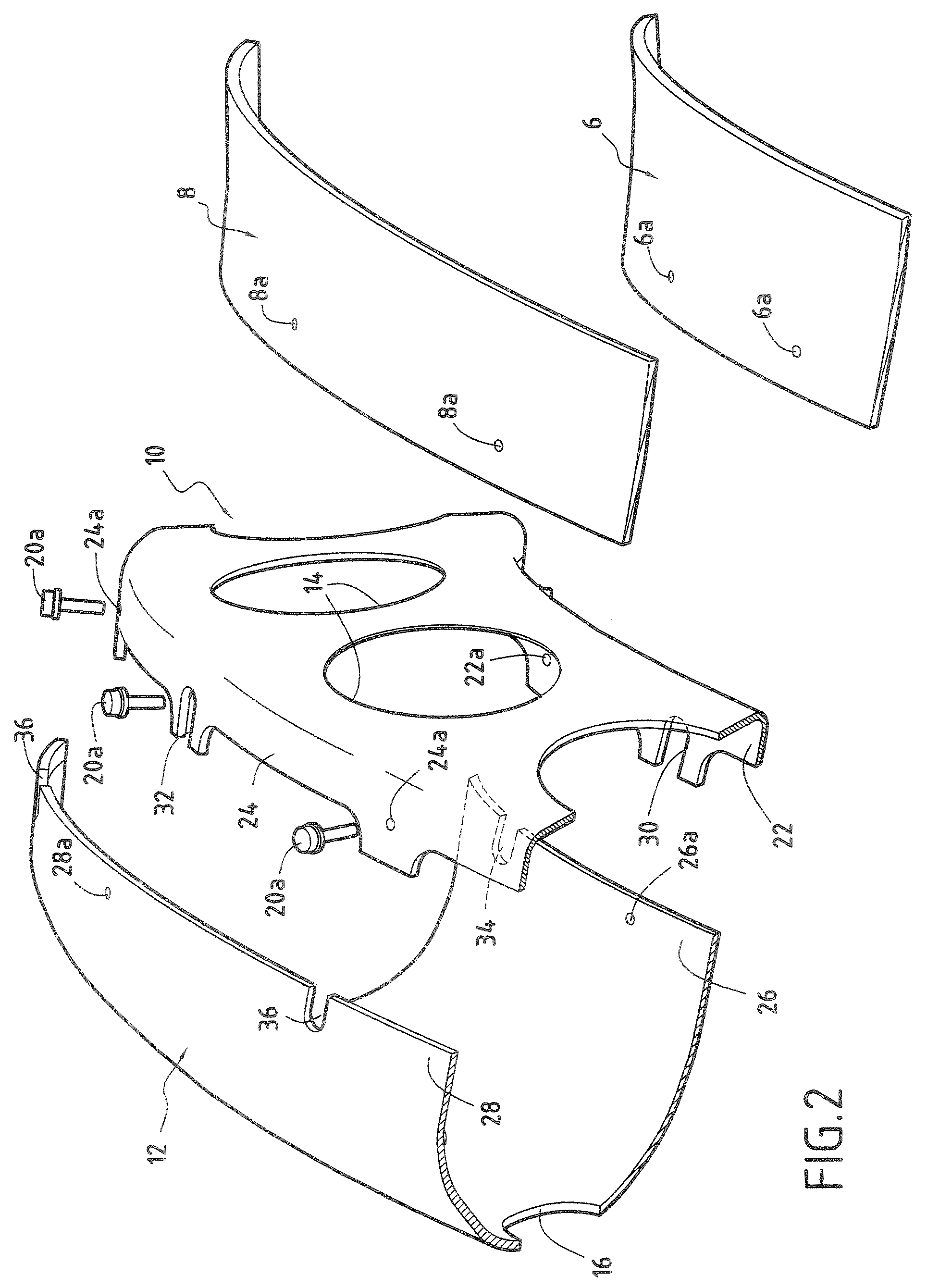

Turbine engine combustion chamber with tangential slots

ActiveUS20080010997A1Easy to assembleSufficient flexibilityBurnersContinuous combustion chamberCombustion chamberTurbine

The invention concerns a turbine engine annular combustion chamber, comprising longitudinal walls (6, 8) connected by a transverse chamber bottom (10) and a single-piece cowling (12), the chamber bottom (10) and the cowling (12) each comprising an inner flange (16, 20) and an outer flange (18, 22) each with a plurality of holes made in it for the passage of fixing systems (14a, 14b) for fixing the cowling on the chamber bottom. Each fixing system has associated with it at least one tangential slot (30) formed on the corresponding flange (16, 18) of the chamber bottom (10) and / or on the corresponding flange (20, 22) of the cowling (12), each slot (30) being formed in the immediate vicinity of the corresponding fixing system (14a, 14b).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

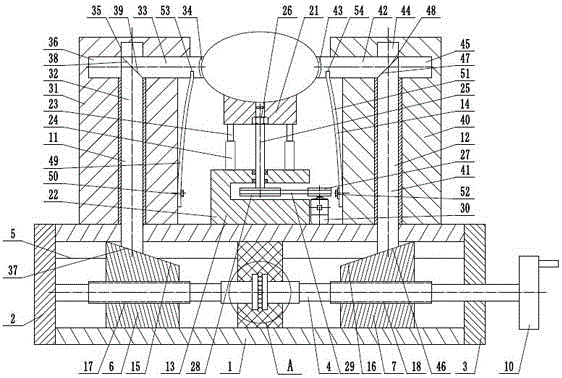

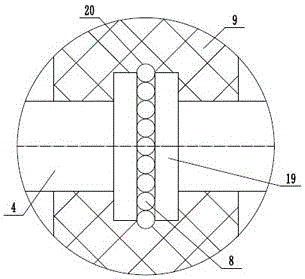

Centering clamping apparatus of ellipsoidal workpiece

PendingCN106826294APrevent axial slippageAchieve peace of mindPositioning apparatusMetal-working holdersLever pressingScrew thread

The invention provides a centering clamping apparatus of an ellipsoidal workpiece, which belongs to the technical field of a clamping device. The centering clamping apparatus comprises a screw, a left slide block, a right slide block, a left centering clamping assembly, a right centering clamping assembly, a height adjusting assembly and a return assembly, wherein both the left slide block and the right slide block can be arranged on a guiding seat in a sliding manner, a left threaded section of the screw is connected with the left slide block in a threading manner, a right threaded section of the screw is connected with the right slide block in a threading manner, a carrier frame of the height adjusting assembly is arranged on a fixed seat in an up-down sliding manner by virtue of a guide rod and a guide column, a left centering clamping assembly and a right centering clamping assembly are symmetrically arranged at the left side and the right side of the height adjusting assembly, the lower end of a left leaf spring of the return assembly is installed on a left supporting frame by virtue of a left nail, and the upper end of a right leaf spring is inserted into a right clamping groove of a right centering pressure rod. The centering clamping apparatus not only rapidly centers and clamps the ellipsoidal workpiece and is reasonable in structure, but also can be suitable for various models of ellipsoidal workpieces, and is high in universality.

Owner:全彬强

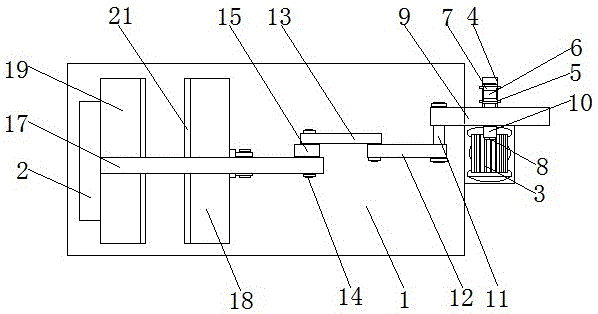

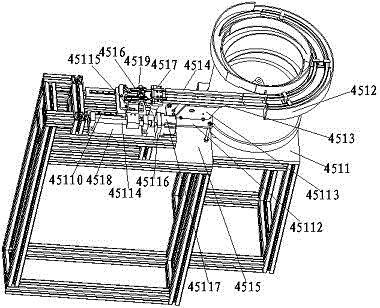

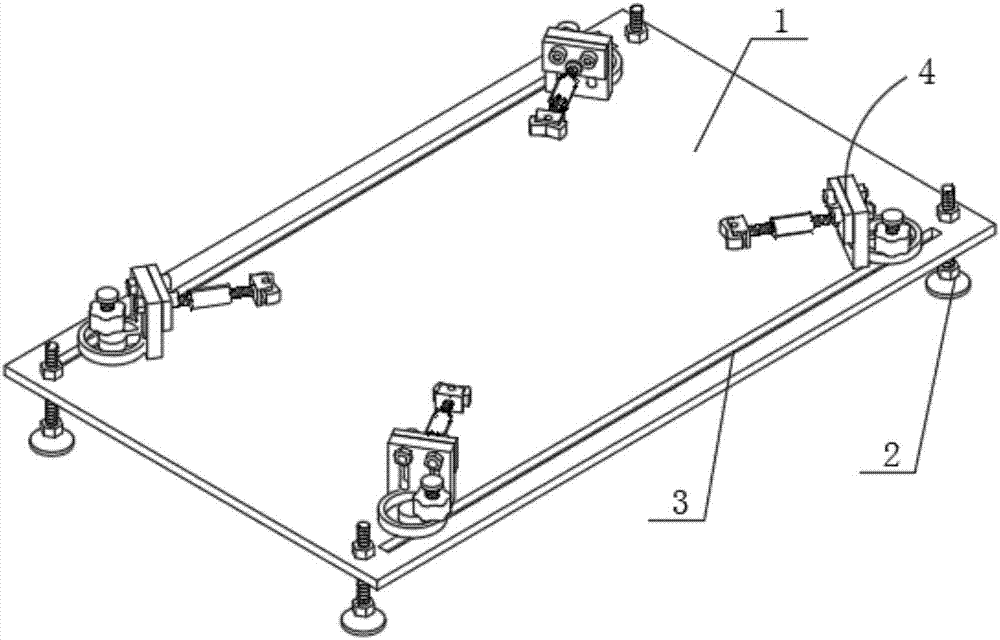

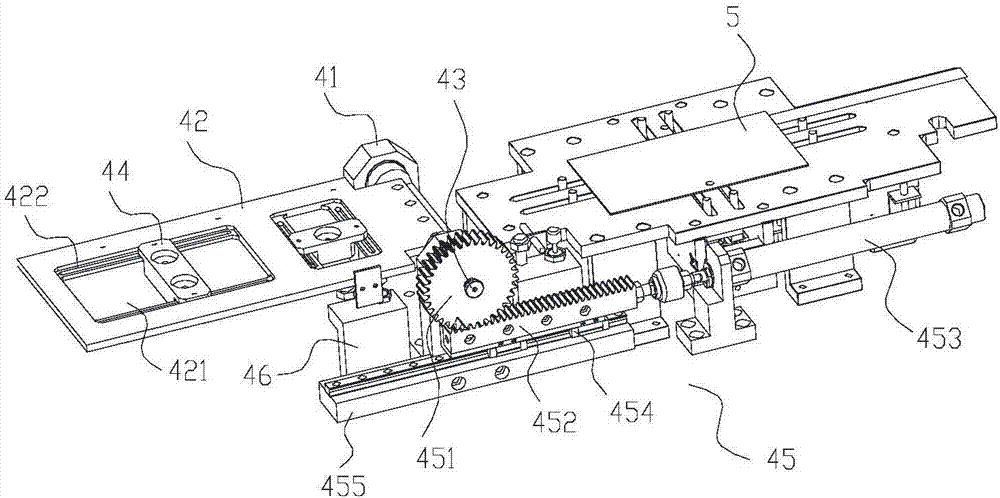

Rubber block feeding manipulator for core component assembly mechanism

The present invention discloses a rubber block feeding manipulator for a core component assembly mechanism, comprising two rubber block shift guide mounting plates; upper planes of the two rubber block shift guide mounting plates are each fitted with a rubber block shift guide, the two rubber block shift guides are parallel to each other, the parts of the two rubber block shift guide mounting plates close to an end port of a turnover discharge unit are fitted with feeding guide cylinder mounting plates on a mounting frame, a feeding guide cylinder is mounted on each feeding guide cylinder mounting plate, an end of a piston rod of each feeding guide cylinder is fixedly provided with a rubber block feeding shift plate through a cylinder fixing device, and the rubber block feeding shift plates are fixed to sliders of the two rubber block shift guides. In this way, the rubber block feeding manipulator is convenient to operate, facilitates feeding and is high in working efficiency.

Owner:嘉善罗星创业投资有限公司

Pressure Equalizing Baffle and Coanda Air Clamp

ActiveUS20100078140A1Accurate thicknessAccurate other measurementDryer sectionMachine wet endCalipersDistortion

An air stabilization system employing two parallel, opposite-facing Coanda nozzles, with each nozzle exhausting gas at opposite directions, subjects a moving flexible web to opposing forces effective to create local tension within the web. Each nozzle includes an elongated slot that is perpendicular to the path of the moving web. The nozzles serve as separate points along the machine direction for controlling the height of the web. The operative surface with the nozzles can exhibit a flush surface. The nozzles can be formed on elevated structures on the operative surface. The operative surface can be covered with a transparent substrate to minimize shape distortions on the moving web and to prevent debris from collecting around the sensor. An internal baffle is employed to channel air flow within each nozzle. The baffle equalizes the gas pressure across the nozzle and directs air flow towards it. By modulating the velocities of gases exiting the nozzles, the shape of the web can be manipulated to present a planar contour. The air stabilization system can be incorporated into a caliper scanner.

Owner:HONEYWELL ASCA INC

Turbine engine annular combustion chamber with alternate fixings

ActiveUS7757495B2Easy to assembleSufficient flexibilityContinuous combustion chamberGas turbine plantsCombustion chamberTurbine

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

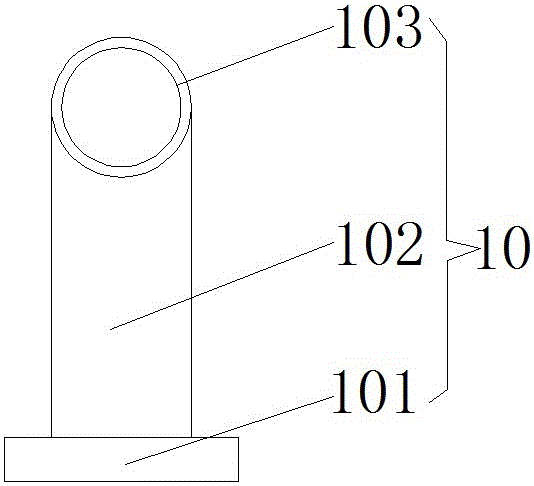

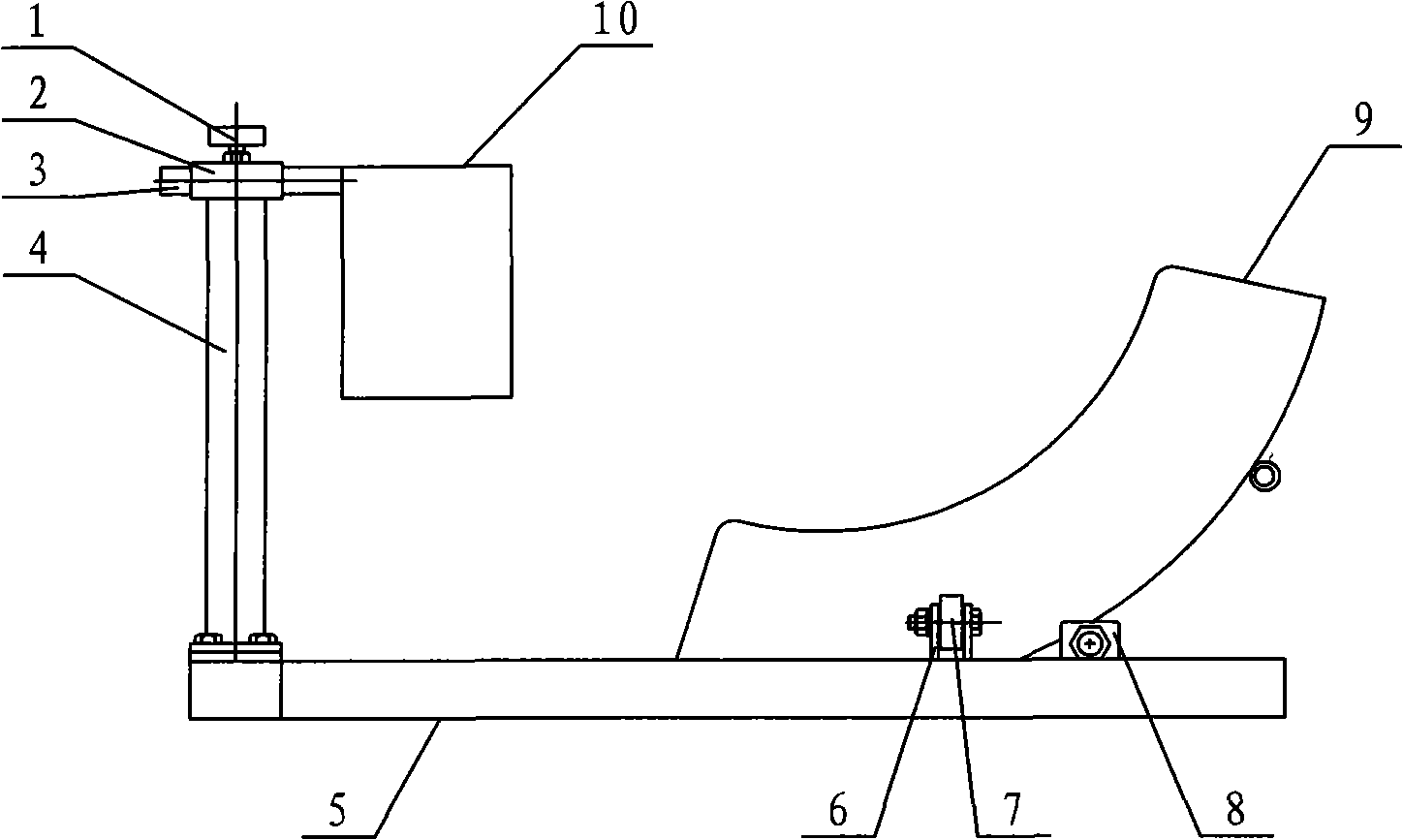

Motorcycle front-wheel fixation rack

ActiveCN101492076ASimple structureCompact structureCycle standsItem transportation vehiclesSeparated stateEngineering

The invention relates to a motorcycle front wheel fixing bracket, which comprises a vertical bracket, a bottom supporting seat, a wheel clamp, and a front wheel baffle plate, wherein the bottom supporting seat consists of a base, two bottom brackets and a bottom plate; the bottom plate is provided with two support saddles; the vertical bracket is fixed on the base; the wheel clamp consists of two connected clamp plates and is in a boat shape; the bottom surface of the wheel clamp is provided with a shaft housing passing through a pin roll; two ends of the pin roll are fixed on the two support saddles; the two bottom brackets are provided with supporting plates respectively; and the supporting plates are provided with rollers respectively which are in rolling clamping state or separating state with two outer lateral surfaces of the wheel clamp. The fixing bracket has the advantages of simple and compact structure, easy processing, convenient and quick operation, stable clamping and good clamping effect, can fix tires with different sizes, retreat from the front wheel without labor consumption, and is suitable to be used for maintaining and transporting motorcycles, and the like.

Owner:谢翠斌

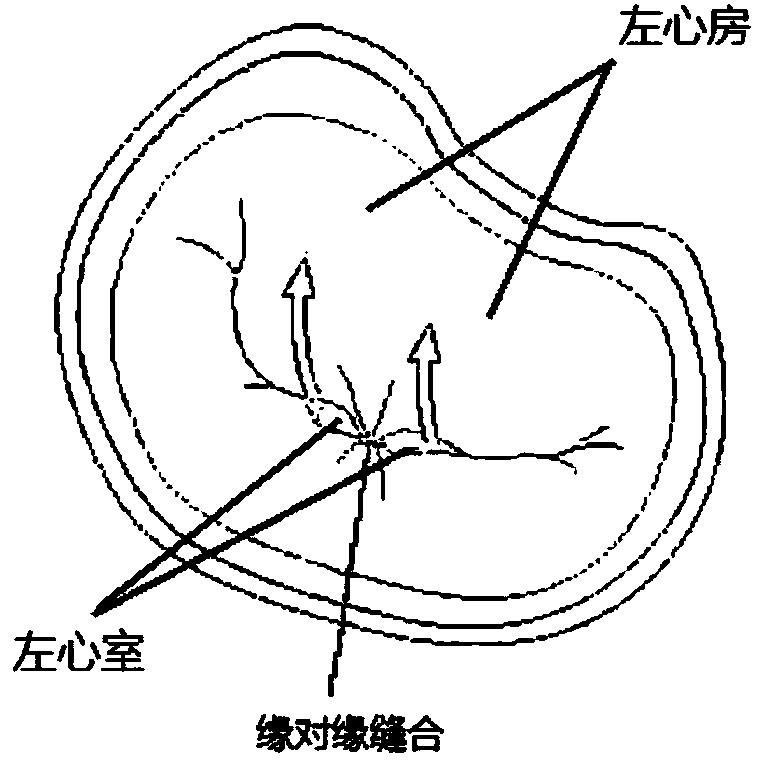

Valve clamping device

The invention discloses a valve clamping device. The valve clamping device comprises a first clamping component, a second clamping component and a fixing component. The fixing component is used for fixing the first clamping component and the second clamping component. The first clamping component comprises at least two first clamping arms. The second clamping component comprises a corresponding number of second clamping arms. A pair of clamps can be formed by each first clamping arm and the corresponding second clamping arm. The valve clamping device has the advantages that the valve clampingdevice can employ the smooth-transition top design, the high-clamping-stability clamping tooth design and the 'one-stripe-for-dualpurpose' fixing ring deign, so that damage to valves during movement of the clamping device is reduced, users capture the valves conveniently, and clamping performance is improved while damage to the valves is reduced; the overall structure of the clamping device has high machinability, and production and manufacture of factories are facilitated.

Owner:SHANGHAI HANYU MEDICAL TECH CO LTD

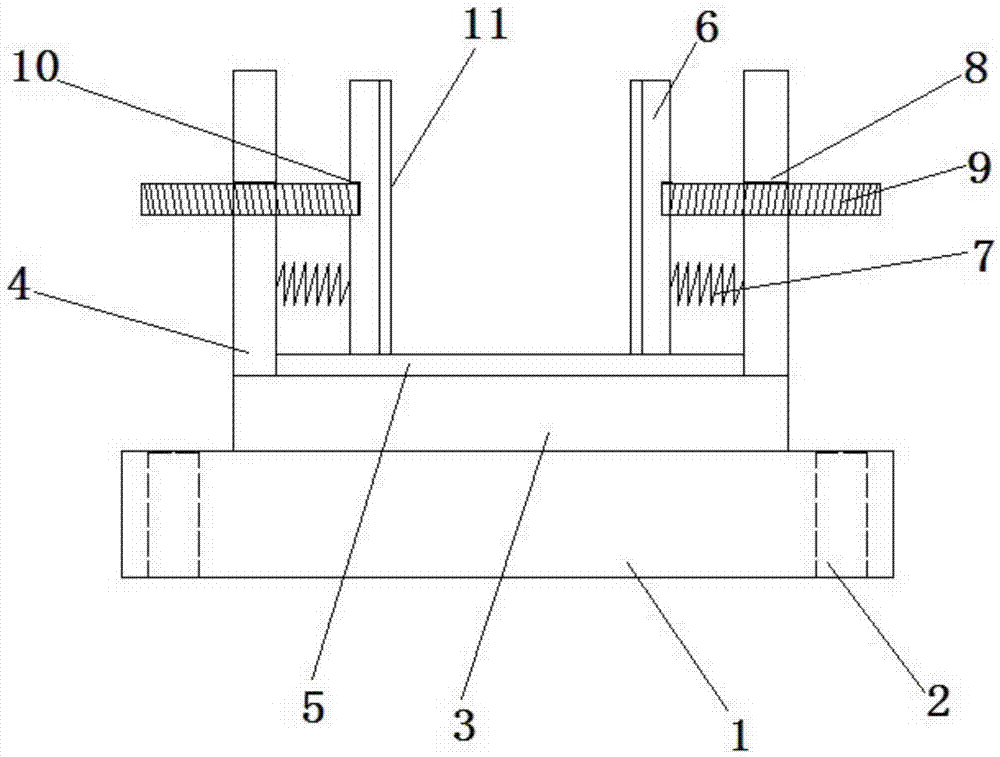

Clamping assembly for milling machine

InactiveCN106891178AImprove clamping effectPrevent vibration looseningPositioning apparatusMetal-working holdersContact positionPulp and paper industry

The invention discloses a clamping assembly for a milling machine, comprising a fixed frame, a long hole, a fixed seat, a fixed plate, a chute, a movable plate, a spring, a screw hole, an adjustment screw and a groove, and the upper end of the fixed frame is provided with a fixed seat, the two sides of the fixed frame are provided with long holes, the two ends of the fixed seat are symmetrically provided with fixed plates, a chute is provided between the two fixed plates, and two symmetrically arranged The movable plate is provided with a spring between the fixed plate and the movable plate arranged on the same side, and the fixed plate is provided with a screw hole, and an adjusting screw is arranged in the screw hole, and the adjusting screw passes through the screw hole to contact the For the movable plate, a groove is provided at the contact between the adjustment screw and the movable plate, and the adjustment screw extends into the groove. The invention has the advantages of simple structure, convenient use, good clamping effect, convenient adjustment and high processing precision.

Owner:天津顺鑫福泰机械加工有限公司

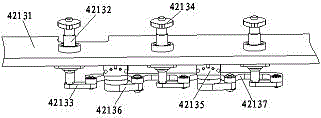

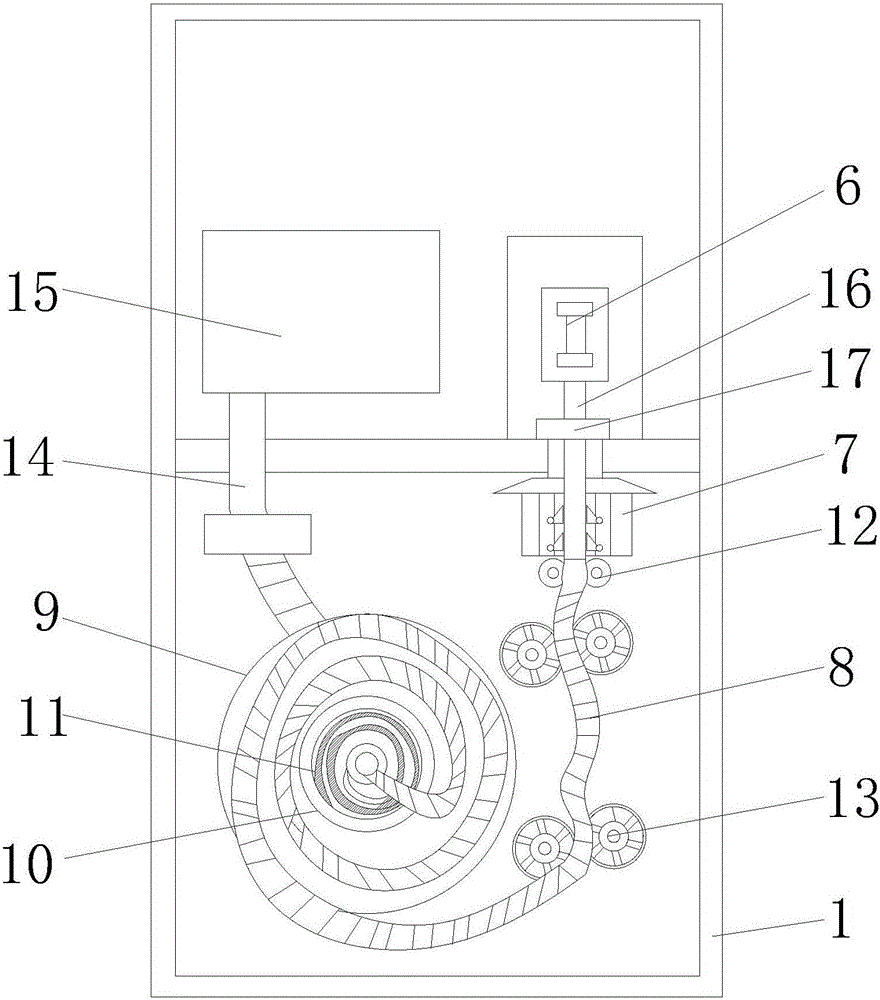

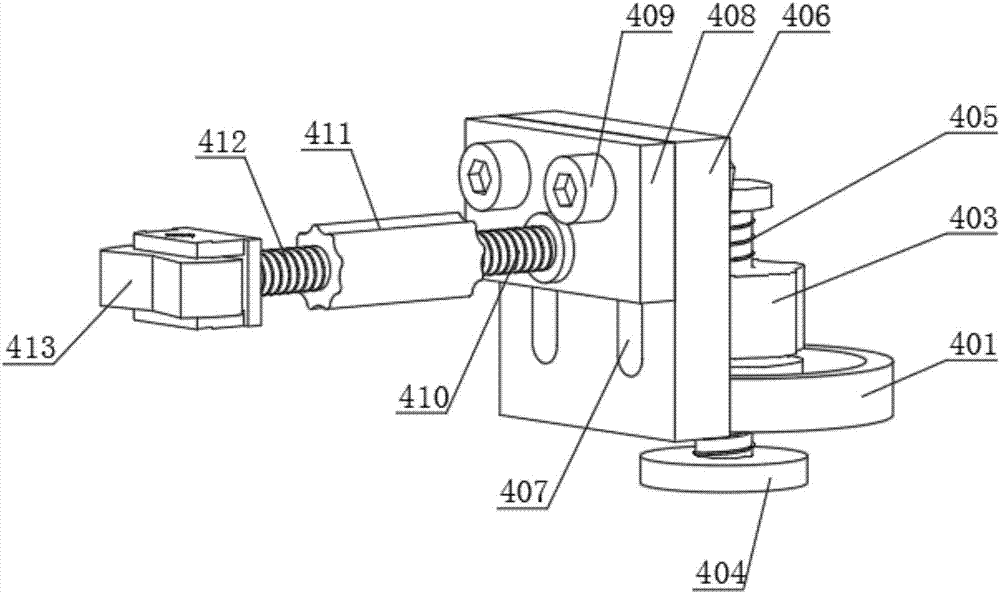

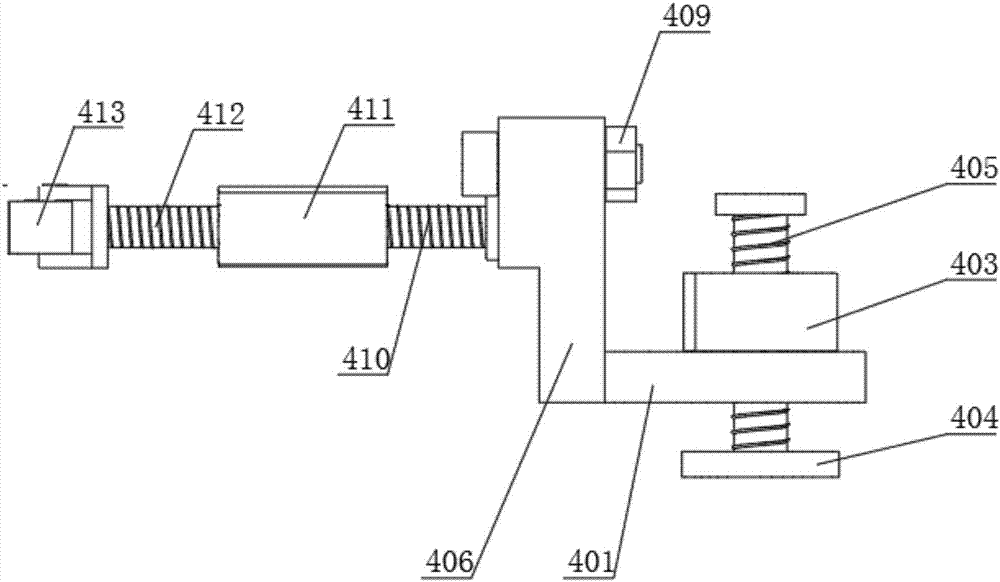

Core spring feeding device for core component assembly mechanism

The invention discloses a core spring feeding device for a core component assembly mechanism, comprising a mounting frame mounted on a ground; a core spring discharging component is mounted on the mounting frame and includes a core spring vibrating disc mounting plate mounted on the mounting frame, a core spring vibrating disc is mounted on the upper plane of the core spring vibrating disc mounting plate, two outlets of the core spring vibrating disc are each fitted with a core spring conveyer trough, the two core spring conveyer troughs are each fixedly provided with a retaining plate that may cover springs, a core spring discharging bottom plate is mounted on the mounting frame below the two core spring conveyer troughs, an upper plane of the core spring discharging bottom plate is fitted with a core spring vibrator through a core spring vibrator support, and the core spring vibrator is fixed to the lower surfaces of the two core spring conveyer troughs. In this way, the core spring feeding device is convenient to operate, facilitates feeding and is high in working efficiency.

Owner:江苏盟杰新能源科技有限公司

New structure fixing fixture for metal irregular workpiece machining

InactiveCN107877216AIncrease clamping forceGuaranteed firmnessPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention provides a new structure fixing fixture for metal irregular workpiece machining. The new structure fixing fixture comprises adjusting sliding grooves, clamping devices, a rotary disc, aheight adjusting groove, a first double-screw bolt, an adjusting nut, a second double-screw bolt and a clamping block; and the two adjusting sliding grooves are formed in the two sides of the workingtable, the clamping devices are installed on the adjusting sliding grooves, adjusting screw rods are inserted into ring grooves and penetrate the adjusting sliding grooves, pressing blocks are fixedlyinstalled at the bottoms of the adjusting screw rods, a jacket is fixedly welded to the tail end of the second double-screw bolt, and the clamping block is fixed to the jacket through a rotating shaft. According to the new structure fixing fixture, irregular workpieces are clamped through the four clamping devices, the fixing angle of the clamping block to the irregular workpieces can be changedthrough the rotary disc and the sliding grooves, and the height of the clamping block can be changed through the height adjusting groove; and through adjustment of the first double-screw bolt, the second double-screw bolt and the adjusting nut, the clamping force to the irregular workpieces can be improved, the clamping firmness is guaranteed, and the using stability is improved.

Owner:GUIZHOU UNIV

Drilling device for coupling

InactiveCN106799506APrecise positioningHeight adjustablePositioning apparatusMetal-working holdersCouplingPetroleum engineering

The invention discloses a drilling device for a coupling. The drilling device comprises a working platform, wherein support legs which are uniformly distributed are arranged at the bottom of the working platform; support plates are arranged on two sides of the top of the working platform; hydraulic telescopic rods are arranged on opposite sides of the two support plates; horizontal adjusting screw rods are arranged at opposite ends of the two hydraulic telescopic rods; opposite ends of the two horizontal adjusting screw rods are connected with inner rings of connecting bearings; and outer rings, far away from sides of the horizontal adjusting screw rods, of the connecting bearings, are connected with a horizontal positioning plate. By adopting the drilling device for the coupling, the height of a drilling base can be adjusted, so that the coupling can be relatively conveniently positioned by an operator, relatively great convenience can be brought to operation of the operator, the position of an outer drilling position cylinder can be relatively conveniently adjusted, the drilling device is simple in structure and convenient to operate, and the coupling can be relatively conveniently positioned and drilled by the operator.

Owner:方瑞松

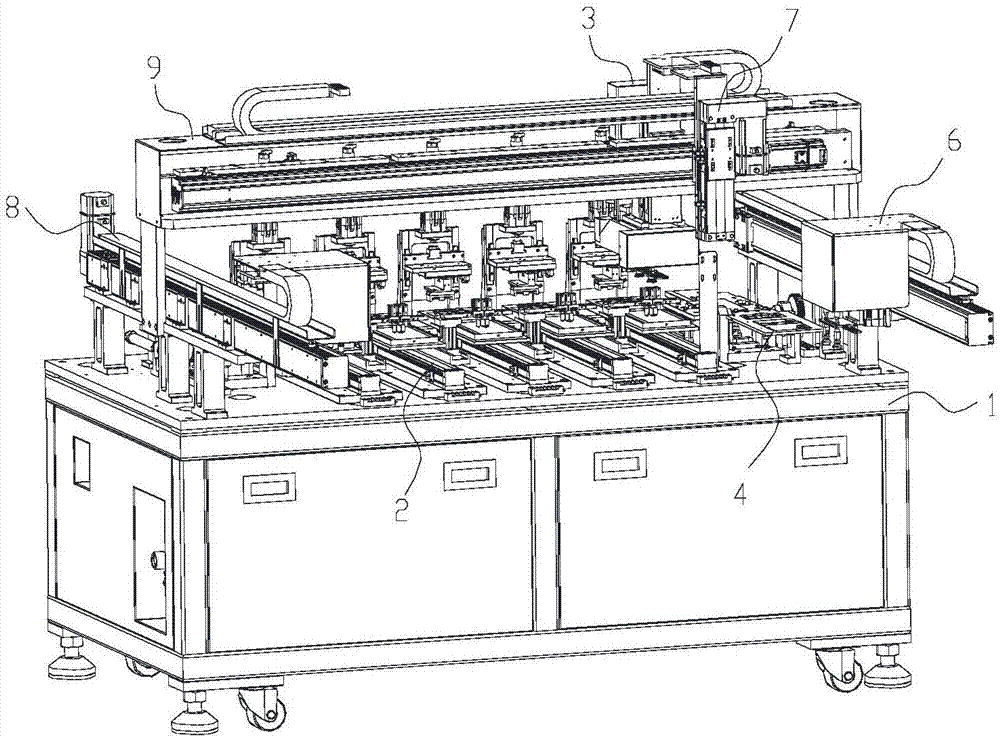

Test device and method for computer function of mobile phone screen connector

The invention discloses a test device and method for the computer function of a mobile phone screen connector. The test device comprises a machine body, a test tool, a positioning mechanism, a transfer mechanism and a discharging mechanism, wherein the test tool, the positioning mechanism, the transfer mechanism and the discharging mechanism are installed on the machine body. The test tool is provided with a detection station. A mobile phone screen connector of a to-be-tested mobile phone screen is subjected to adjustment and angle positioning to a required angle through the positioning mechanism so as to adapt to the detection station position, so that the crimping detection of the mobile phone screen connector is enabled to achieve precise positioning, the detection process is fast, the degree of automation is high, and the detection efficiency is high. The test device is simple and reasonable in structure, the usage is convenient, the space is saved, the application is stable, the cost performance is high, and the accurate positioning is achieved.

Owner:深圳眼千里科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com