Cylindrical workpiece outer circle machining clamp and using method thereof

A workpiece and cylindrical technology, which is applied in the field of cylindrical workpiece cylindrical processing fixtures, can solve problems such as uneven force, and achieve the effects of enhanced clamping effect, uniform force, and improved processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

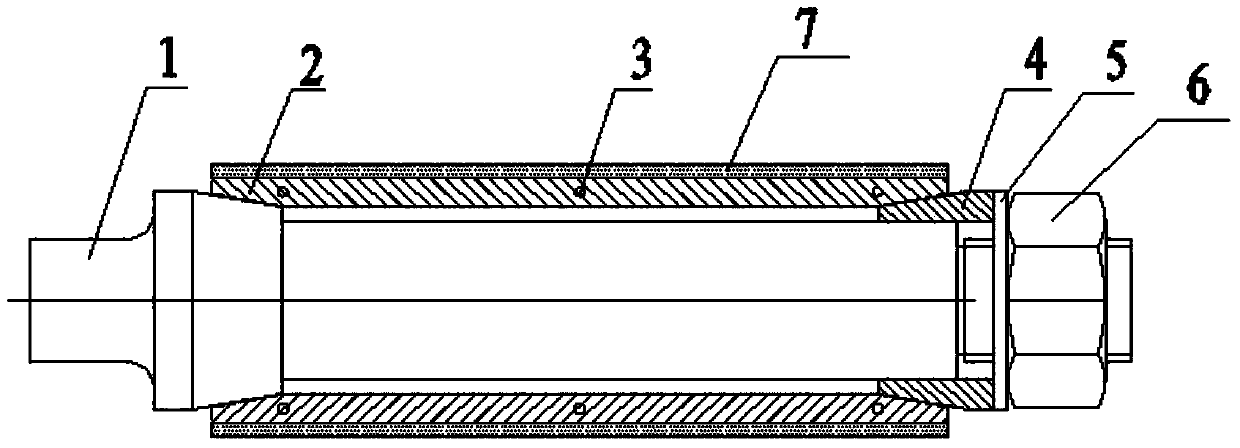

[0029] Such as figure 1 As shown, a cylindrical workpiece external machining fixture provided by the present invention mainly includes a fixed core 1, an expansion sleeve 2, a movable core 4, a gasket 5, and a lock nut 6, the expansion sleeve 2, the movable core 4 , The gasket 5 is sleeved on the fixed core 1, the expansion sleeve 2 is located between one end of the fixed core 1 and the movable core 4, and the lock nut 6 is located at the other end of the fixed core 1. . The expansion sleeve 2 is composed of multiple identical expansion strips, and each expansion strip has a concentric inner arc surface and an outer arc surface.

Embodiment 2

[0031] Such as figure 1 As shown, a cylindrical workpiece external machining fixture provided by the present invention mainly includes a fixed core 1, an expansion sleeve 2, a movable core 4, a gasket 5, and a lock nut 6, the expansion sleeve 2, the movable core 4 , The gasket 5 is sleeved on the fixed core 1, the expansion sleeve 2 is located between one end of the fixed core 1 and the movable core 4, and the lock nut 6 is located at the other end of the fixed core 1. . The expansion sleeve 2 is composed of multiple identical expansion strips, and each expansion strip has a concentric inner arc surface and an outer arc surface.

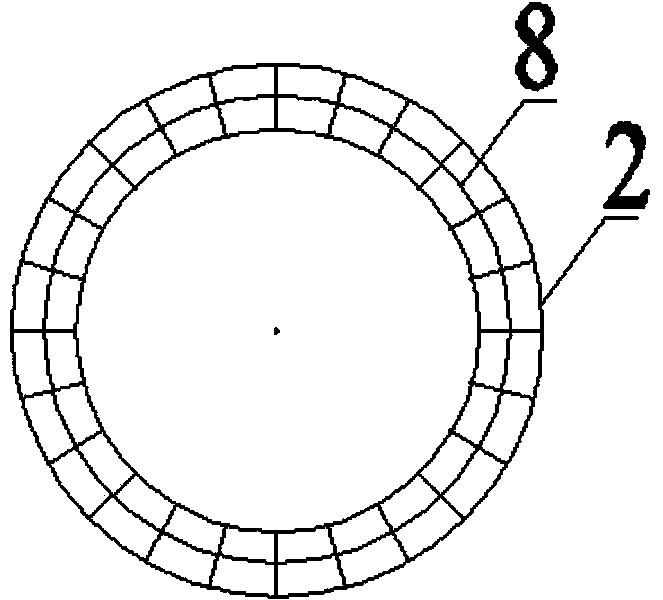

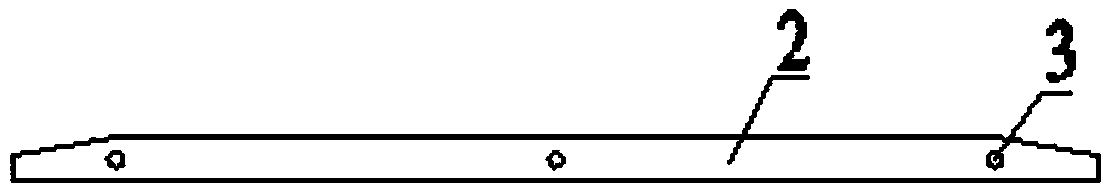

[0032] Such as figure 2 , As shown in 3, the expansion sleeve 2 is a cylindrical structure composed of 24 identical expansion strips. Each expansion strip of the expansion sleeve 2 has a through hole 3 in the middle and both ends. The 24 identical expansion strips An elastic rubber cord 8 passes through the through holes between the same parts of the ...

Embodiment 3

[0035] Such as figure 1 As shown, a cylindrical workpiece external machining fixture provided by the present invention mainly includes a fixed core 1, an expansion sleeve 2, a movable core 4, a gasket 5, and a lock nut 6, the expansion sleeve 2, the movable core 4 , The gasket 5 is sleeved on the fixed core 1, the expansion sleeve 2 is located between one end of the fixed core 1 and the movable core 4, and the lock nut 6 is located at the other end of the fixed core 1. . The expansion sleeve 2 is composed of multiple identical expansion strips, and each expansion strip has a concentric inner arc surface and an outer arc surface.

[0036] The circular washer 5 is located between the movable core and the lock nut.

[0037] The expansion sleeve 2 has a cylindrical shape, and both ends of the expansion sleeve 2 are both inner cone structures. One end of the fixed core 1 has an optical axis structure, the fixed core 1 close to the optical axis structure has an outer cone structure, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com