Patents

Literature

2073results about How to "Guaranteed firmness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

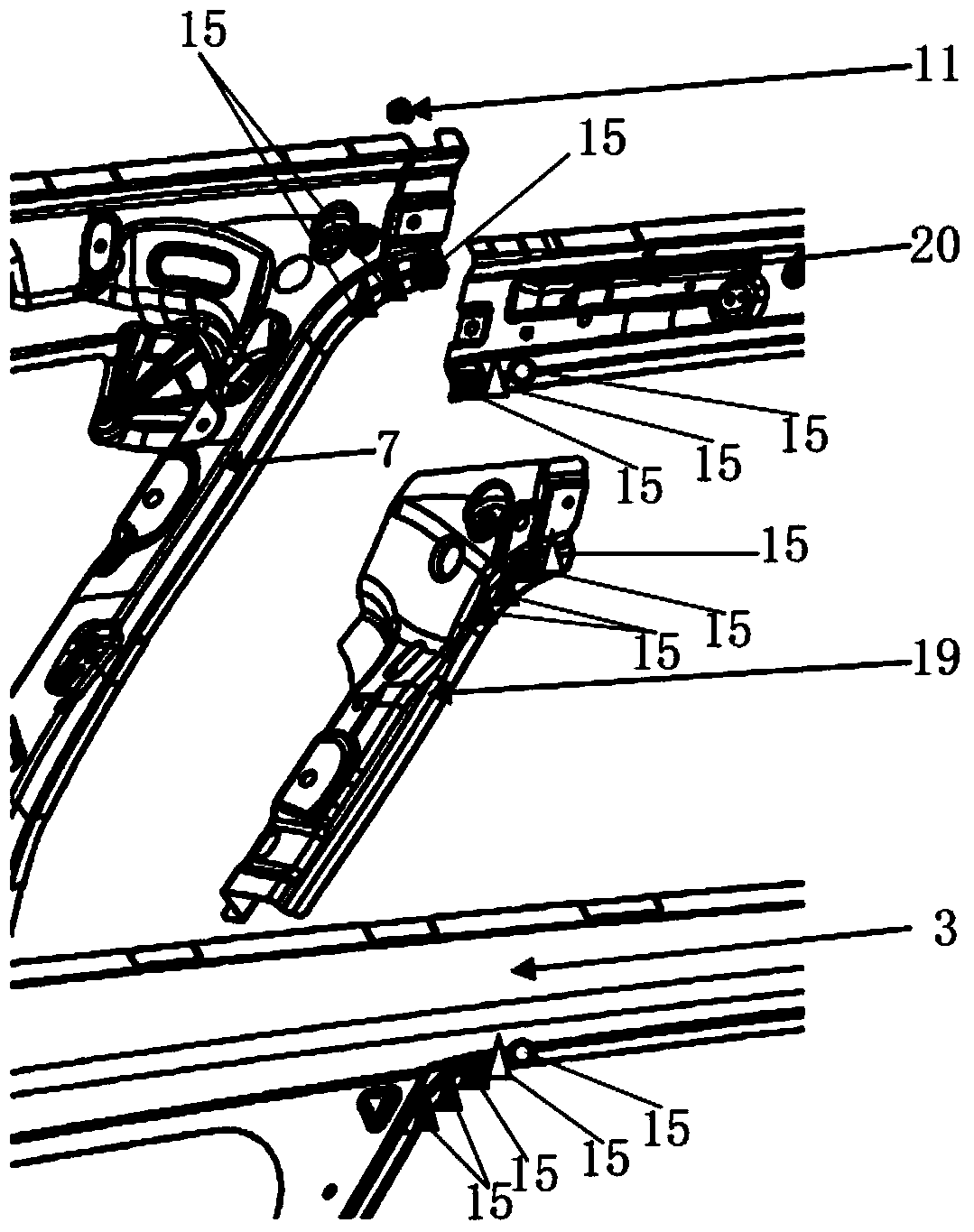

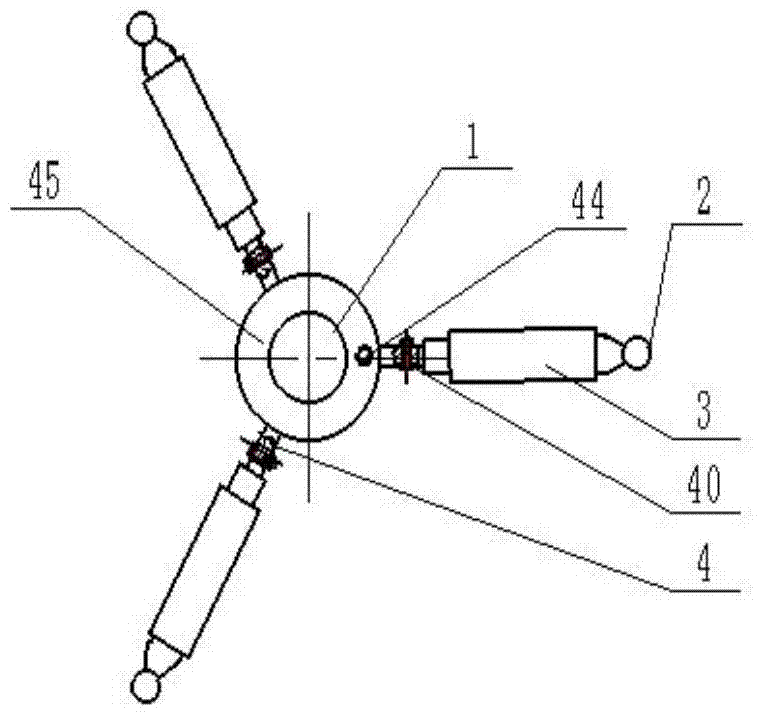

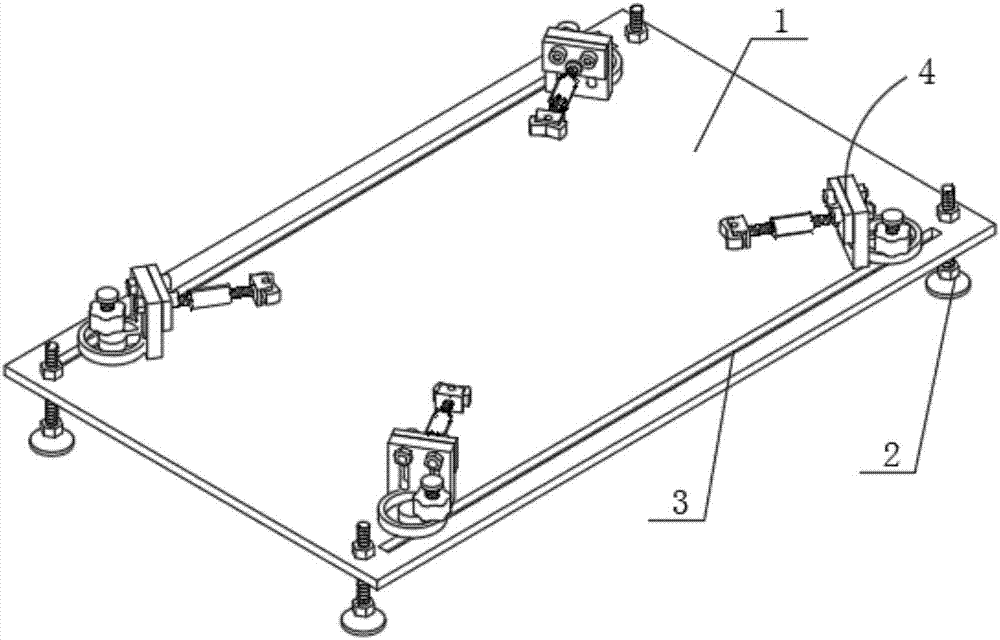

Clamping device for air conditioner shell stamping

InactiveCN107377794AMeet the clamping requirementsImprove stabilityShaping toolsMetal-working feeding devicesEngineeringMechanical engineering

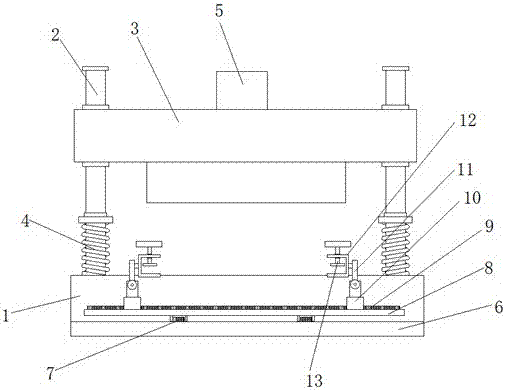

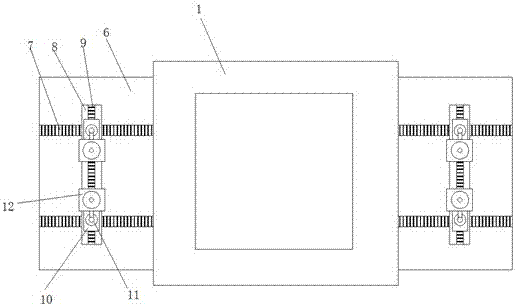

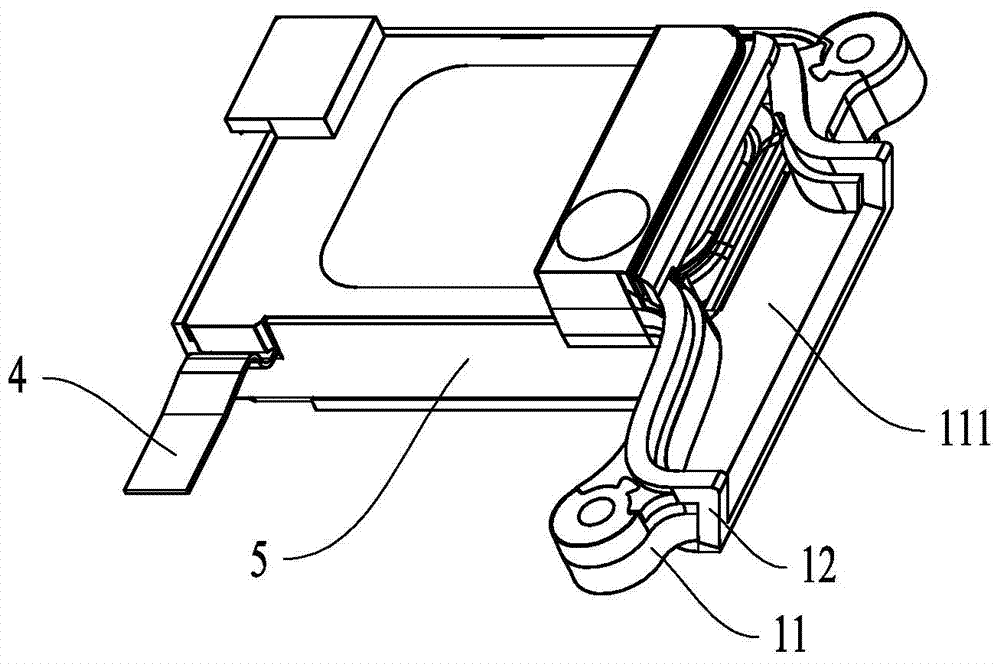

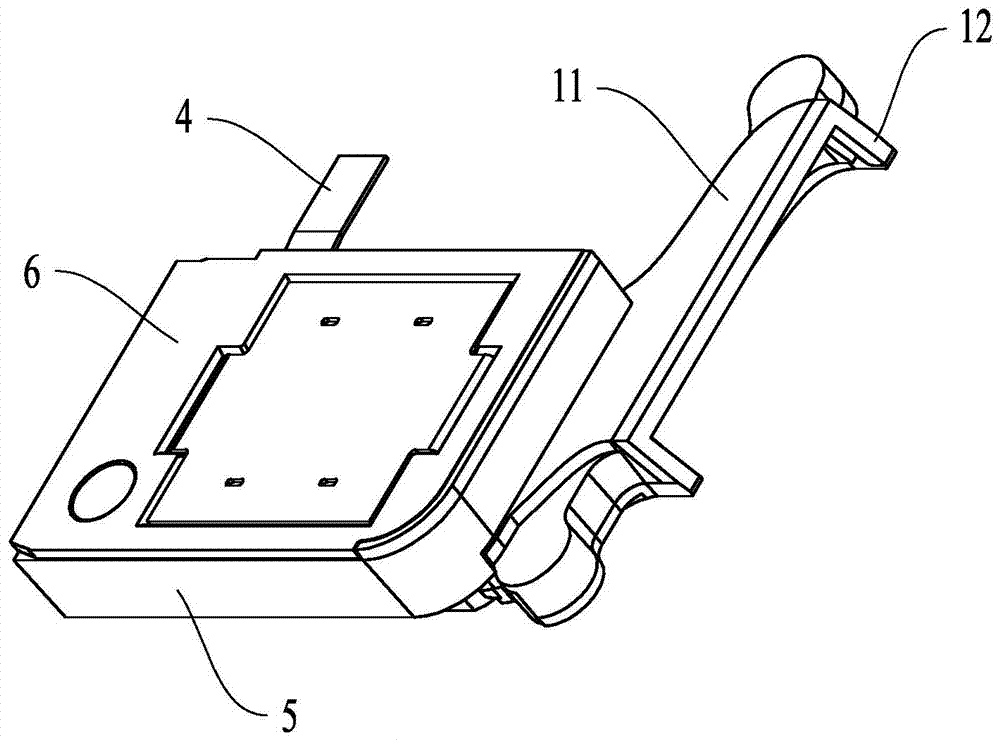

The invention discloses a clamping device for air conditioner shell stamping. The clamping device comprises a lower die base. The four corners of the upper surface of the lower die base are all provided with sliding guide rods, and the sliding guide rods are movably arranged on the four corners of an upper die base in a sleeving manner. The sliding guide rods between the lower die base and the upper die base are provided with buffer springs. A connection base is arranged at the center of the side, far away from the lower die base, of the upper die base. Symmetrical bottom plates are arranged on the two sides of the lower die base. The bottom plate is provided with two sets of parallel first guide rails, the two sets of first guide rails are perpendicular to the side edge of the lower die base, and the two sets of first guide rails are movably provided with a movable bottom plate. A C-shaped fixture can be adjusted in the X direction and the Y direction on the bottom plate so as to meet clamping requirements of stamping raw materials in various specifications, the stamping raw materials are pressed tightly through locking bolts, clamping firmness of the fixture is guaranteed, the success rate of air conditioner shell stamping is increased, and the waste of raw materials is reduced.

Owner:滁州华宇机件有限公司

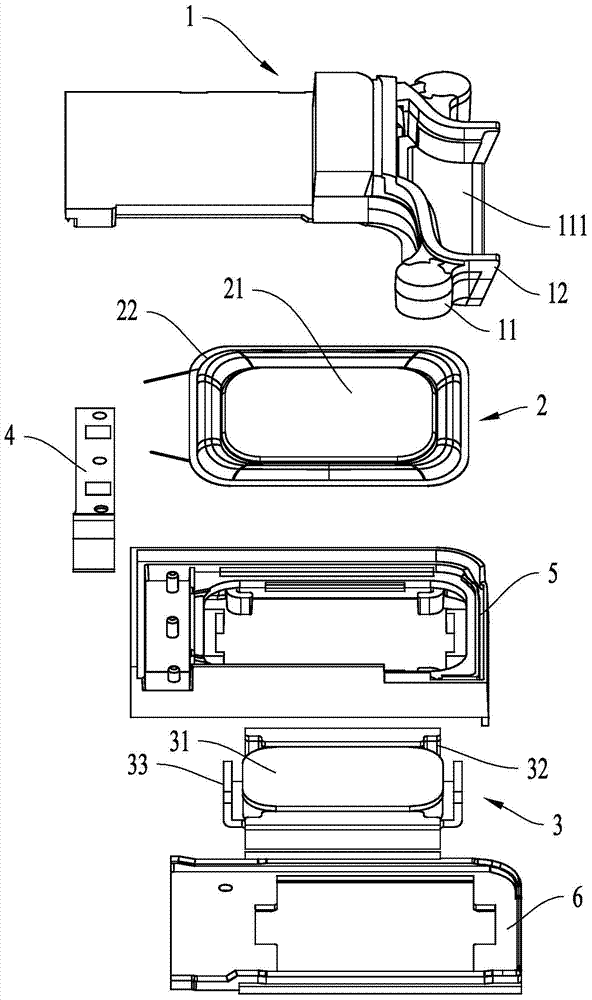

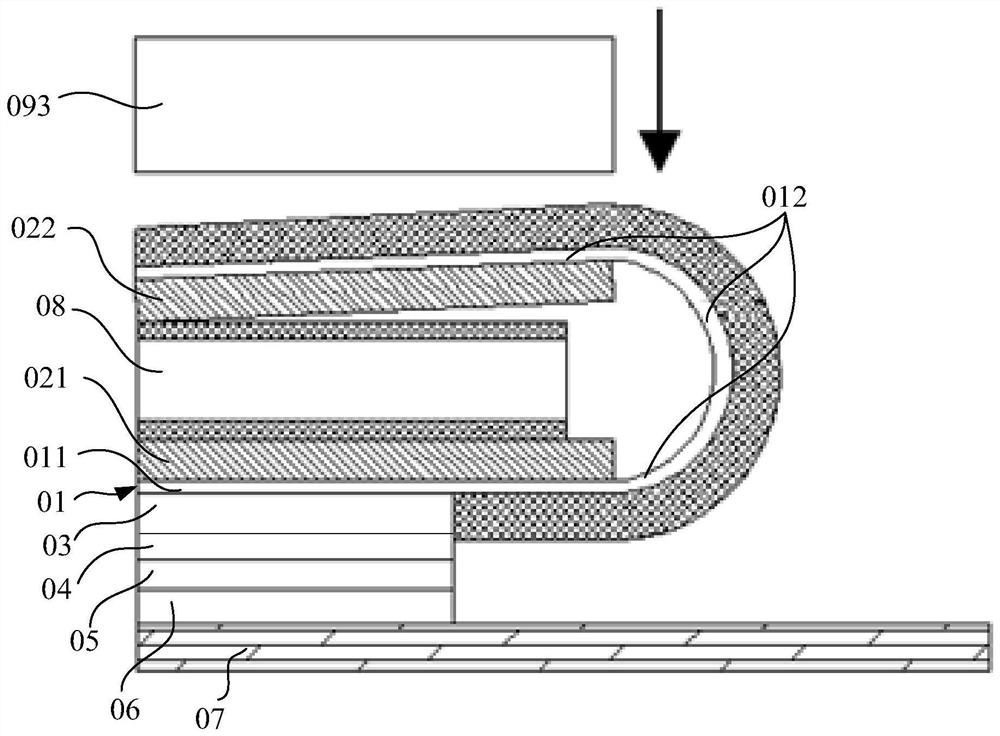

Loudspeaker module and manufacturing method thereof

ActiveCN103618984AReduce sheddingGuaranteed firmnessElectrical transducersDomestic articlesEngineeringSoft materials

The invention relates to the electroacoustic technical field, and provides a loudspeaker module and a manufacturing method thereof. The loudspeaker module comprises a case and a single loudspeaker body combined inside the case. The single loudspeaker body comprises a vibrating diaphragm assembly and a magnetic circuit assembly. A front sound cavity and a rear sound cavity are formed between the single loudspeaker body and the case. The case is provided with an elastic part, the elastic part is combined with the end surface of the opening end of the front sound cavity or the rear sound cavity, and the elastic part and the case are of an integrated structure formed in an injection molding mode. By adopting the structure in the loudspeaker module, the process of attaching the elastic part manually is eliminated, the accuracy and the stability of combination of the elastic part are guaranteed, the elastic part does not fall easily, the sealing property between a sound outlet hole of the loudspeaker module and a sound hole of a mobile phone after the loudspeaker module and a terminal electronic product are assembled can be effectively guaranteed, and the acoustic performance is improved. The manufacturing method for the loudspeaker module can solve the technical problems effectively and can be popularized to production for other structures with soft materials or hard materials needing to be injected into other materials.

Owner:GOERTEK INC

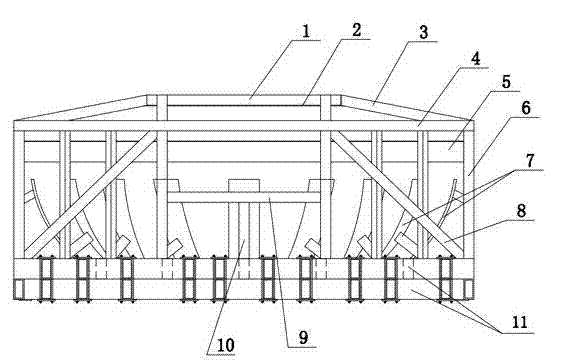

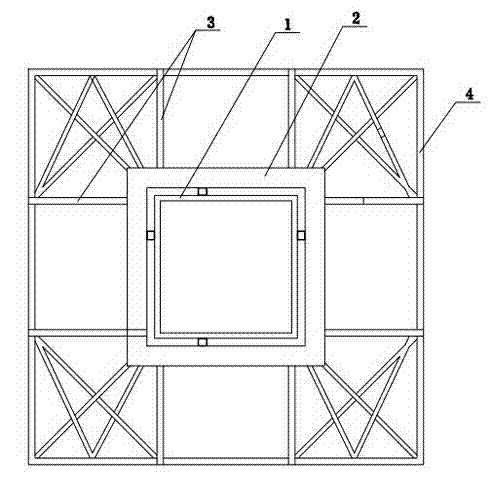

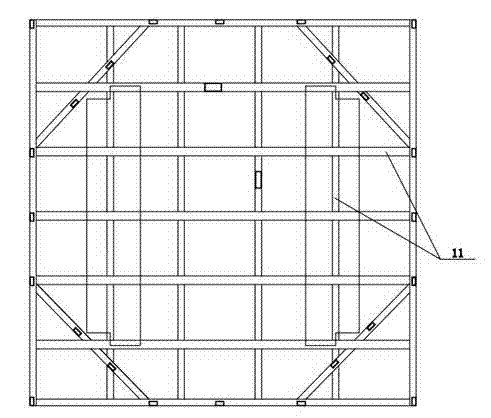

Transplanting method of extra-large ancient cypresses

A transplanting method of extra-large ancient cypresses belongs to the field of transplanting technologies of large trees and includes the steps of firstly, measuring soil; secondly, detecting roots; thirdly, performing balance pruning; fourthly, breaking roots twice, and treating the roots; fifthly, sterilizing; sixthly, protecting trunks; seventhly, digging and binding soil beds; eighthly, lifting and transporting soil balls; and ninthly, treating planting environments, and planting. By scientific transplanting and maintenance management according to the transplanting method of extra-large ancient cypresses, new water balance systems are established after the ancient cypresses are transplanted, survival and germination of a great quantity of roots and shoots are ensured, healthy growth of the ancient cypresses is promoted, and the cypress trees grow are numerous in roots, branches and leaves. In order to guarantee healthy growth of the ancient cypresses, the ancient cypresses are maintained and rejuvenated scientifically 4-6 years after transplanting. The soil balls are packed and transported with specially made structural steel frames in bowled basket structures, firmness of the soil balls is guaranteed maximally, use is facilitated, and survival rate of the transplanted trees is high.

Owner:ZHEJIANG SENHE SEED

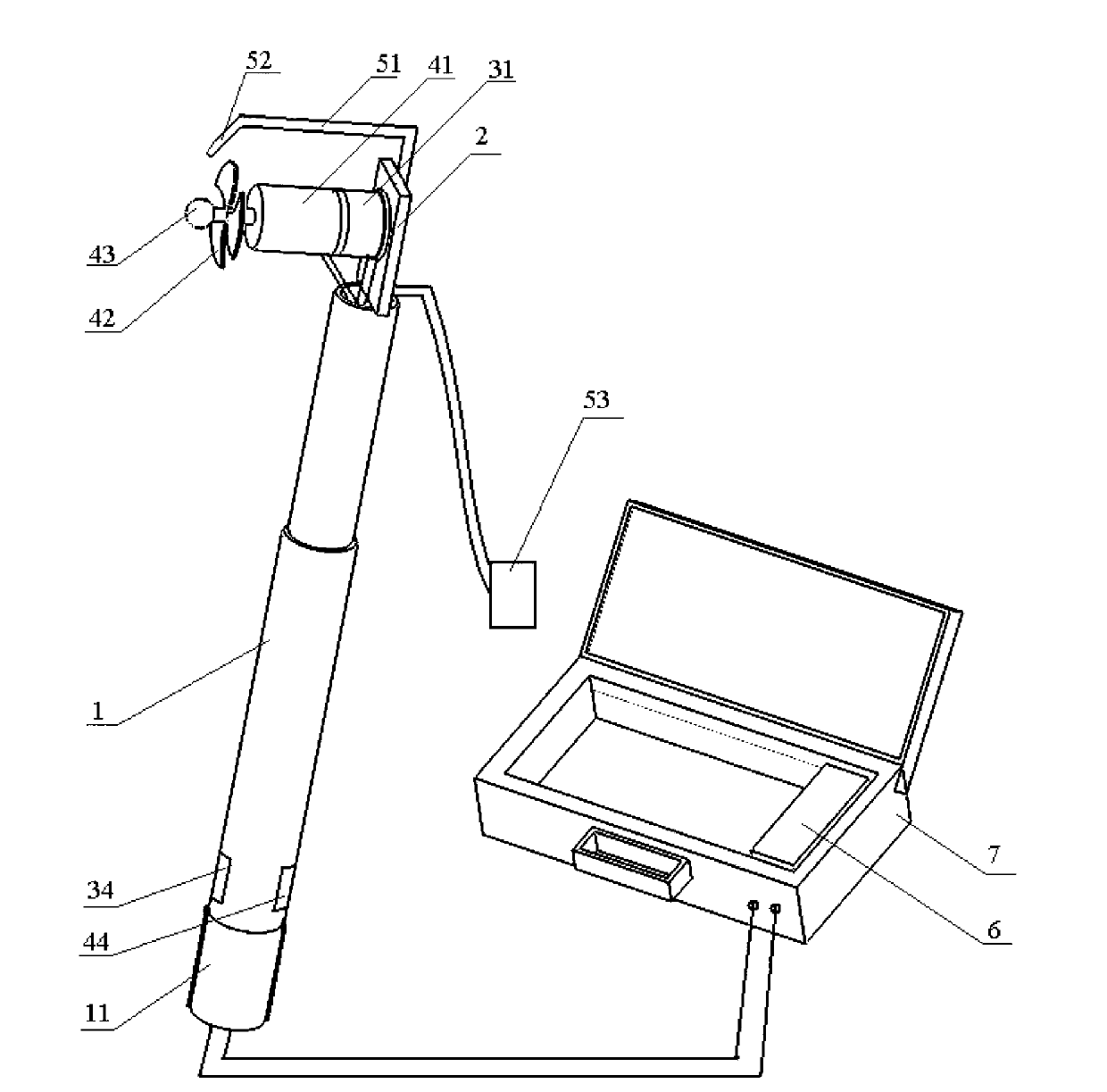

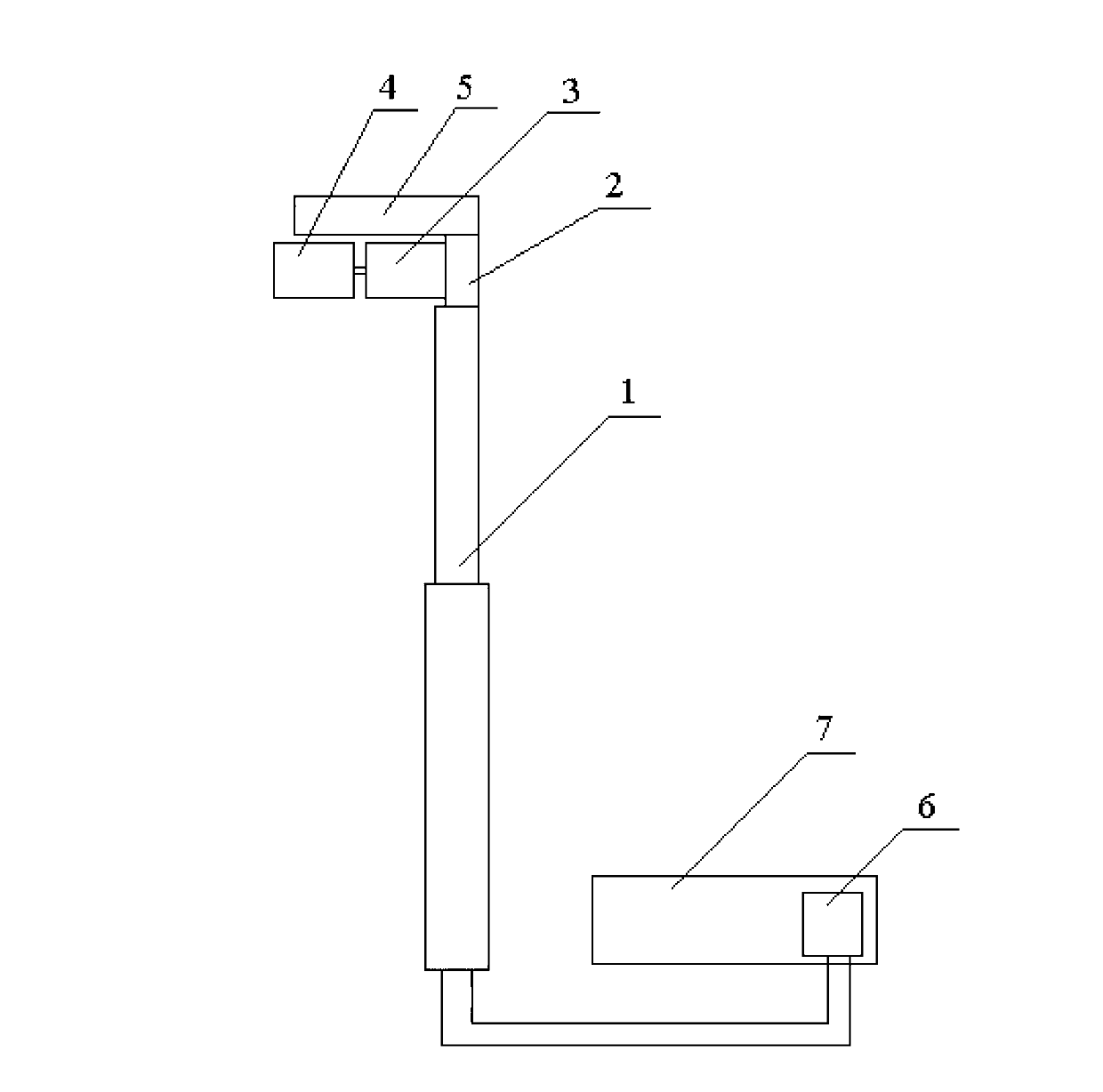

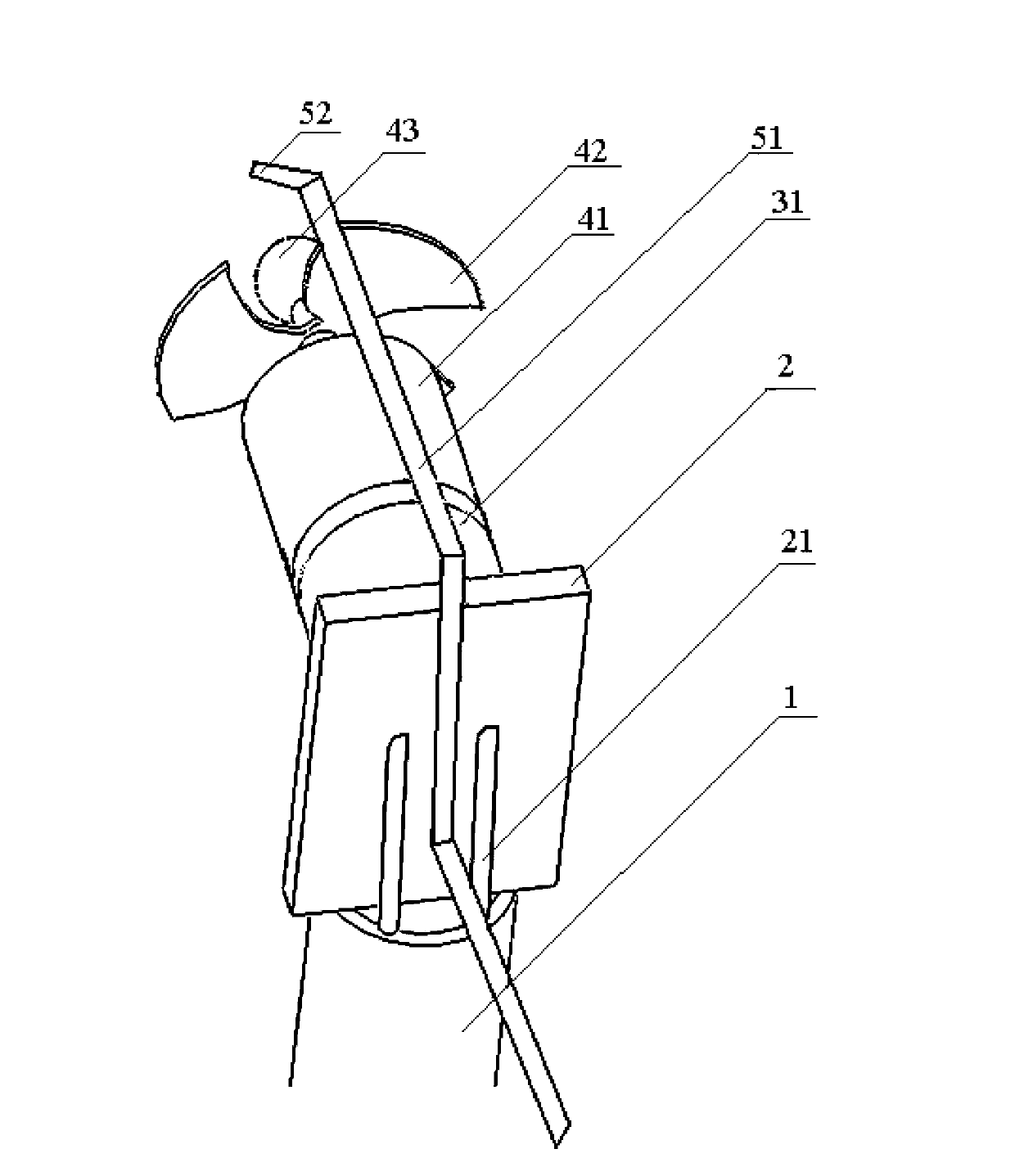

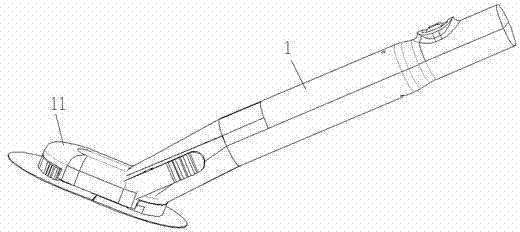

Surveillance camera cleaning device

ActiveCN103272791ASimple structureEasy to makeCleaning using toolsCleaning using liquidsSurveillance cameraHand held

The invention discloses a surveillance camera cleaning device comprising a hollow telescopic rod. A hand-holding end of the telescopic rod is provided with an isolation handle. The top end of the telescopic rod is provided with a cleaning mechanism used for cleaning a surveillance camera. The cleaning mechanism can rotate through a twist driving mechanism arranged at the top end of the telescopic rod. The twist driving mechanism is fixedly connected on a panel at the top end of the telescopic rod. The panel is further fixedly arranged on a water spraying mechanism used for spraying water to the surveillance camera. The surveillance camera cleaning device is simple in structure, convenient to produce and high in automation, cleaning efficiency can be improved greatly, traces of water, foam and the like can be prevented from being left on the surface of the surveillance camera, and cleaning quality is improved.

Owner:STATE GRID CORP OF CHINA +2

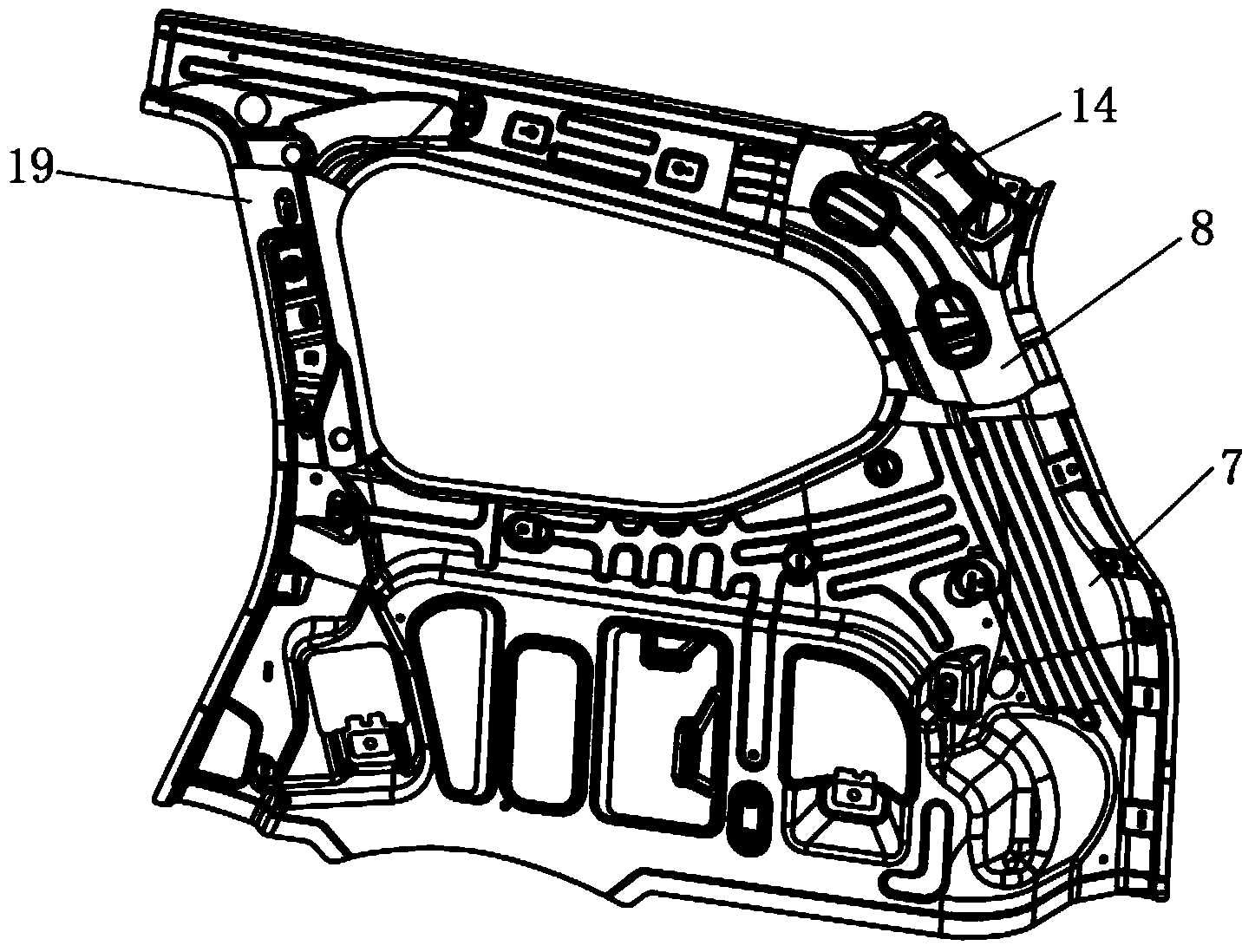

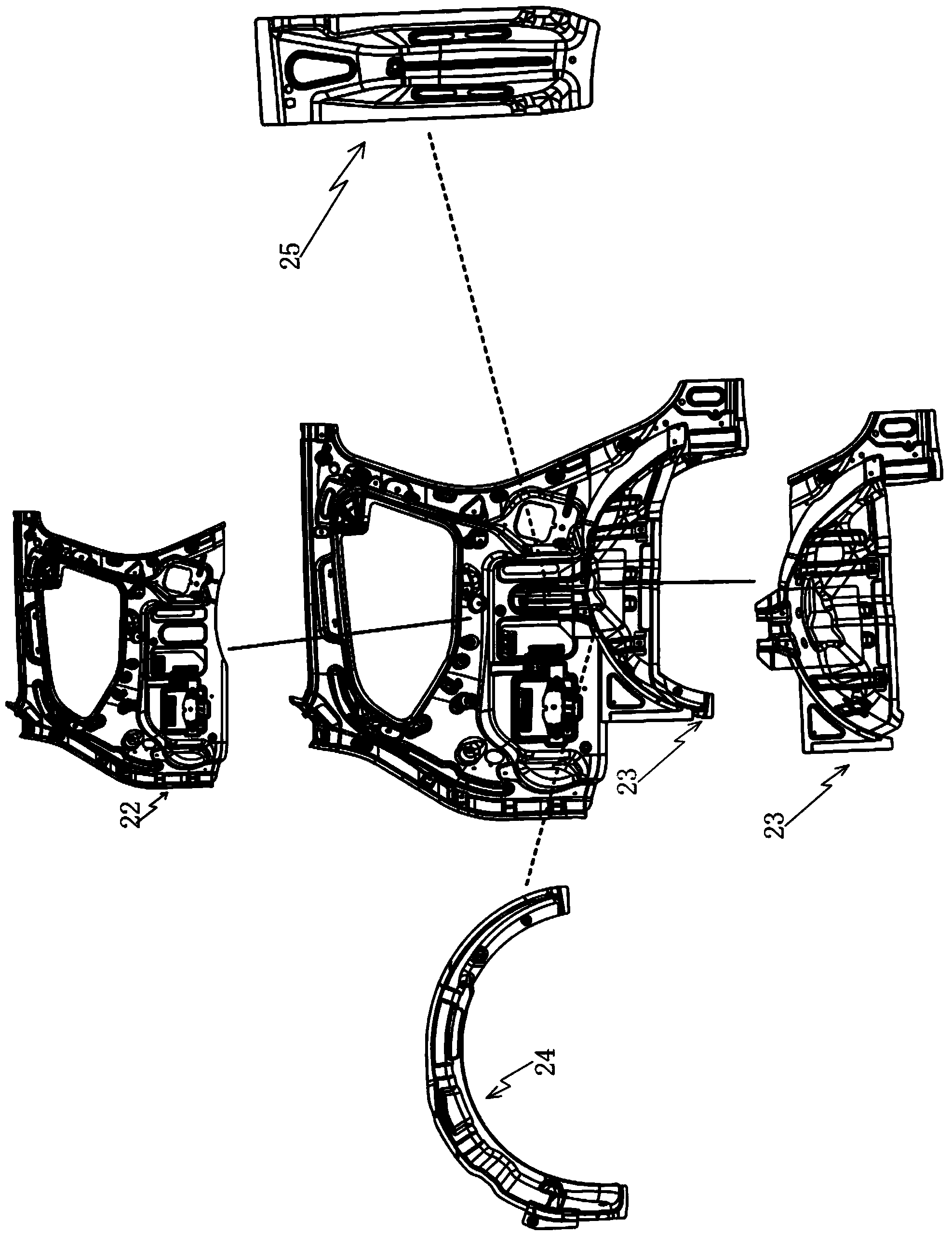

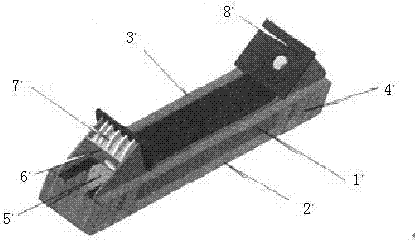

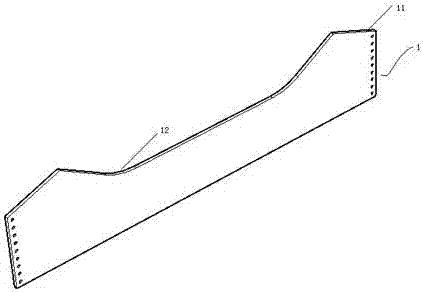

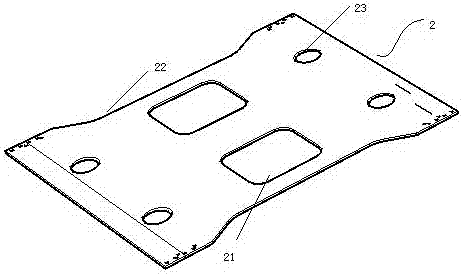

Rear side outer plate welding assembly

ActiveCN103538639AEnsure safetySimple welding processSuperstructure connectionsAgricultural engineeringWelding process

The invention discloses a rear side outer plate welding assembly which comprises a rear side inner plate assembly, a rear wheel cover inner plate welding piece, a rear wheel cover outer plate welding piece and a rear wheel cover outer plate support plate. The rear wheel cover inner plate welding piece comprises a rear wheel cover inner plate and a front protection plate. The rear wheel cover outer plate welding piece comprises a rear wheel cover outer plate. The rear side inner plate assembly comprises a rear side outer plate, an upper side beam inner plate, a rear side inner plate, a C column reinforcing plate and a D column upper end connector. The upper side beam inner plate is welded with the rear side outer plate, the upper side beam inner plate, the C column reinforcing plate and the rear side outer plate are welded, the rear side inner plate, the C column reinforcing plate and the rear side outer plate are welded, the upper side beam inner plate, the rear side inner plate, the C column reinforcing plate and the rear side outer plate are welded, and the upper side beam inner plate, the rear side inner plate and the C column reinforcing plate are fixedly connected. Components of the rear side outer plate welding assembly are welded independently or connected to be assembled, assembly is convenient, a welding process is better, and the middle door frame rigidity can be effectively improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

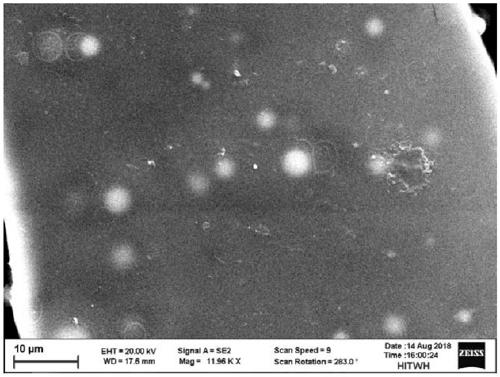

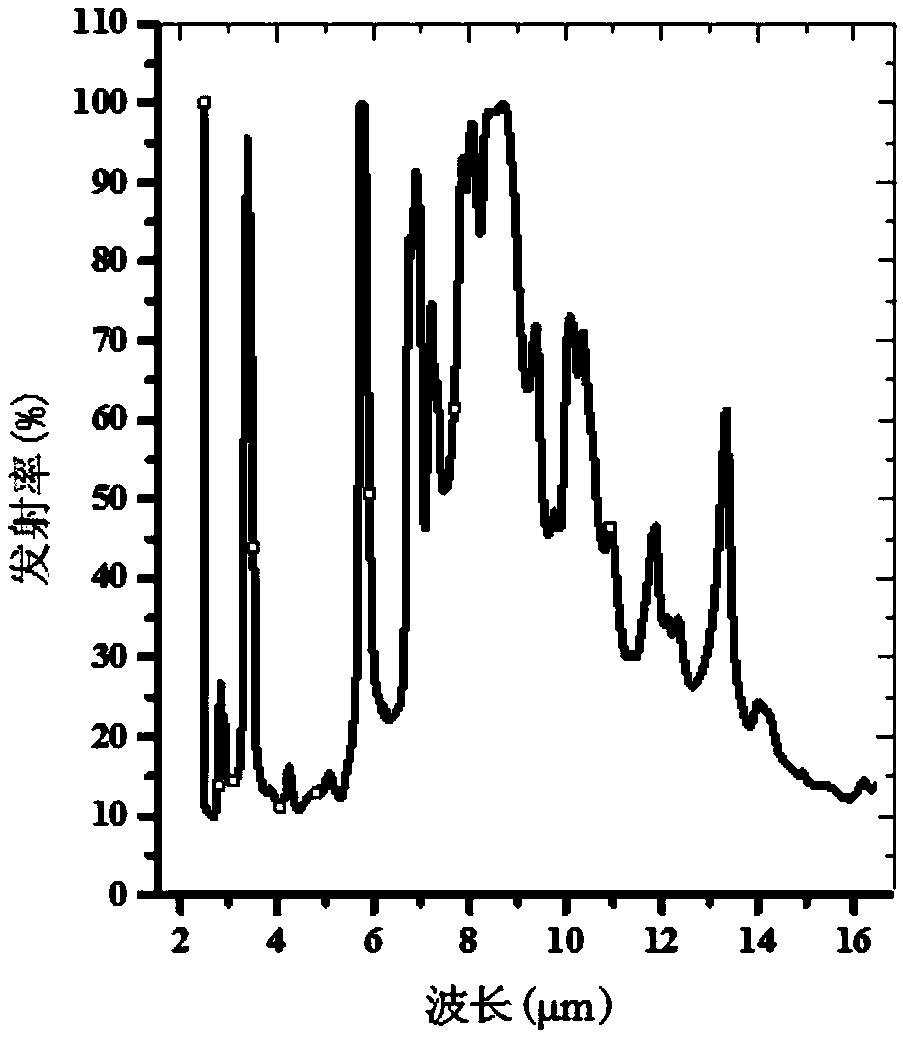

Radiation cooling coating with self-cleaning function and preparation method thereof

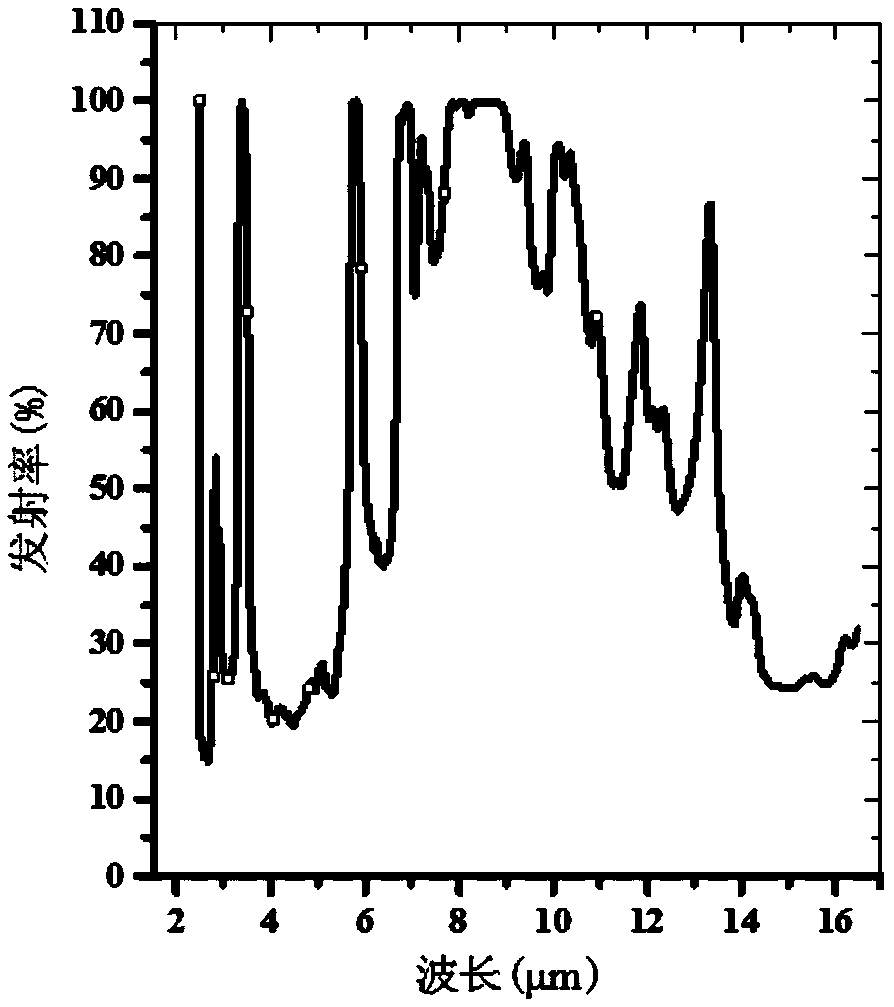

ActiveCN109161241AWith self-cleaning functionWith self-cleaning effectAntifouling/underwater paintsPaints with biocidesEmissivityTransmittance

The invention belongs to the technical field of radiation cooling, and particularly relates to a radiation cooling coating with a self-cleaning function and a preparation method thereof. The radiationcooling coating comprises a bottom layer binder, and a radiator and hydrophobic nano particles, which are covered on the bottom layer binder; and an infrared emission peak of the radiator is positioned within an infrared radiation waveband range of 8 to 13 mum and at least covers one wave band interval in the range of 8 to 13 mum. According to the invention, by utilizing high hydrophobicity of the nano hydrophobic particles, the radiation cooling coating has a self-cleaning effect and a phenomenon of reducing the cooling effect due to dust accumulation is avoided. The radiation cooling coating disclosed by the invention has high emissivity on the wave band of 8 to 13 mum, is large in transmittance on a visible light wave band, is excellent in lighting performance, can also reduce absorption on energy on the rest of wave bands and ensures the cooling effect. The radiation cooling coating further adopts two different particle sizes of radiators, so that the radiation range is widened, ground heat is radiated to the outer space to the greatest degree, and the cooling effect is improved.

Owner:HARBIN INST OF TECH AT WEIHAI

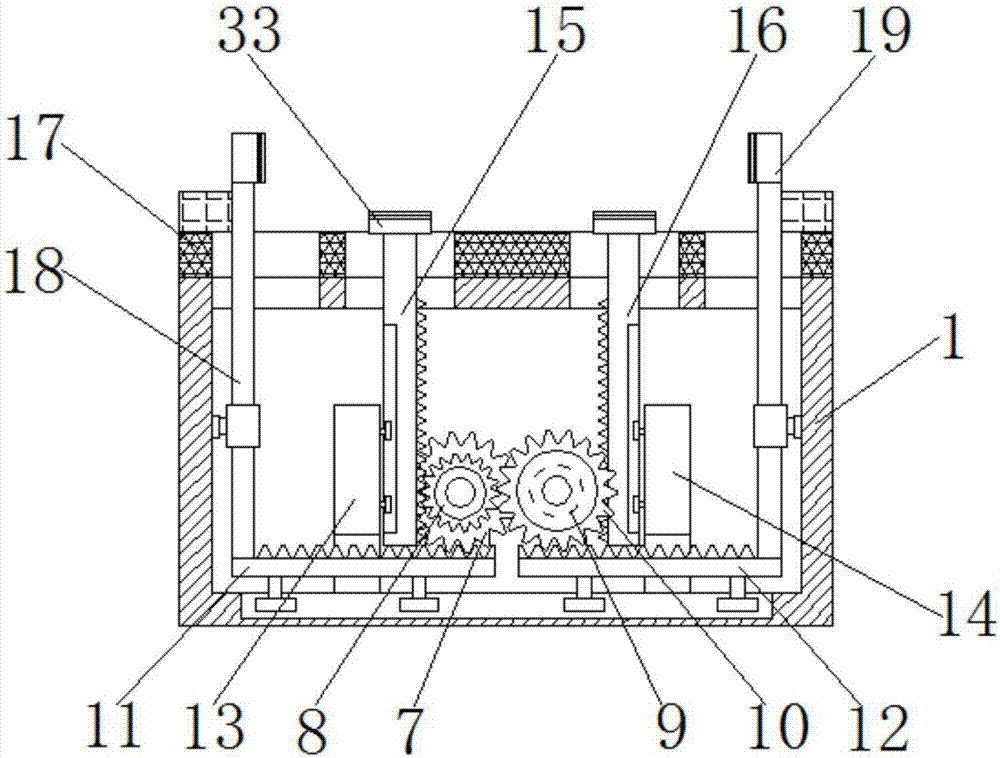

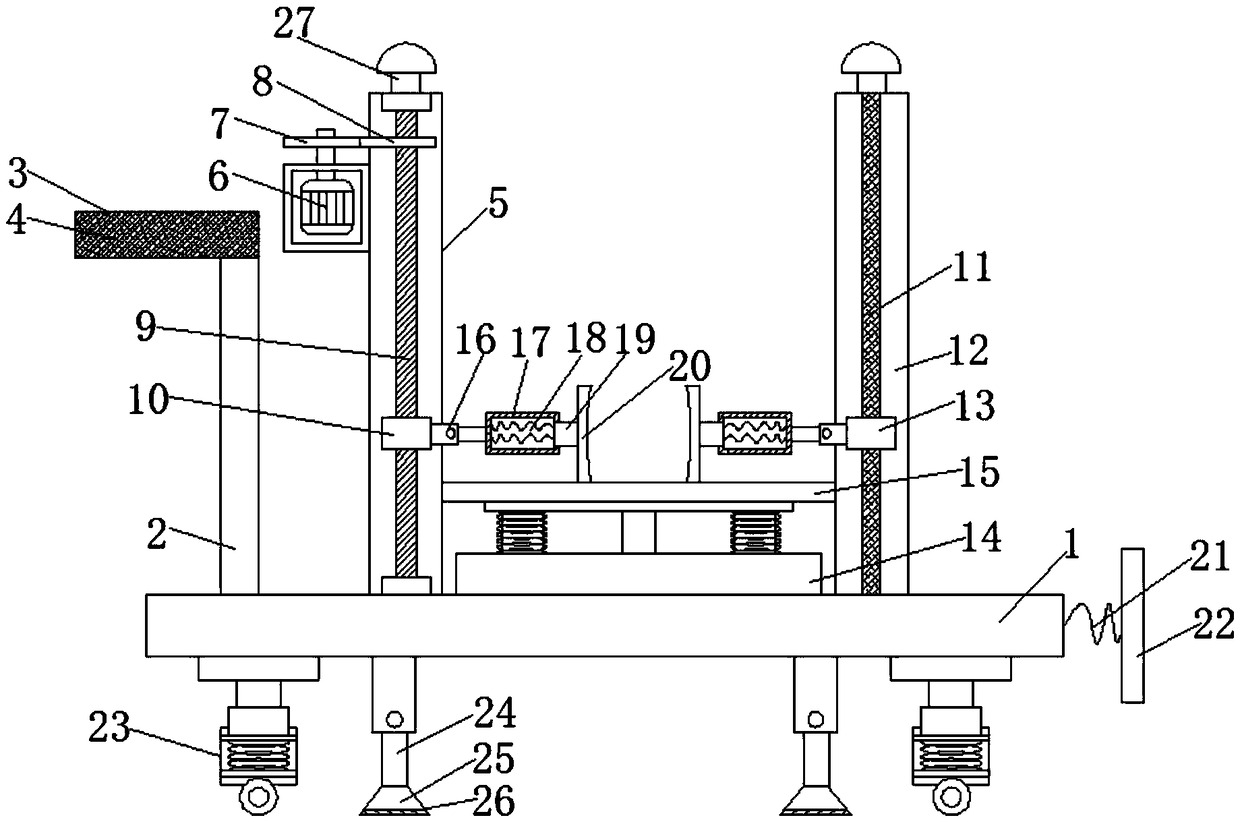

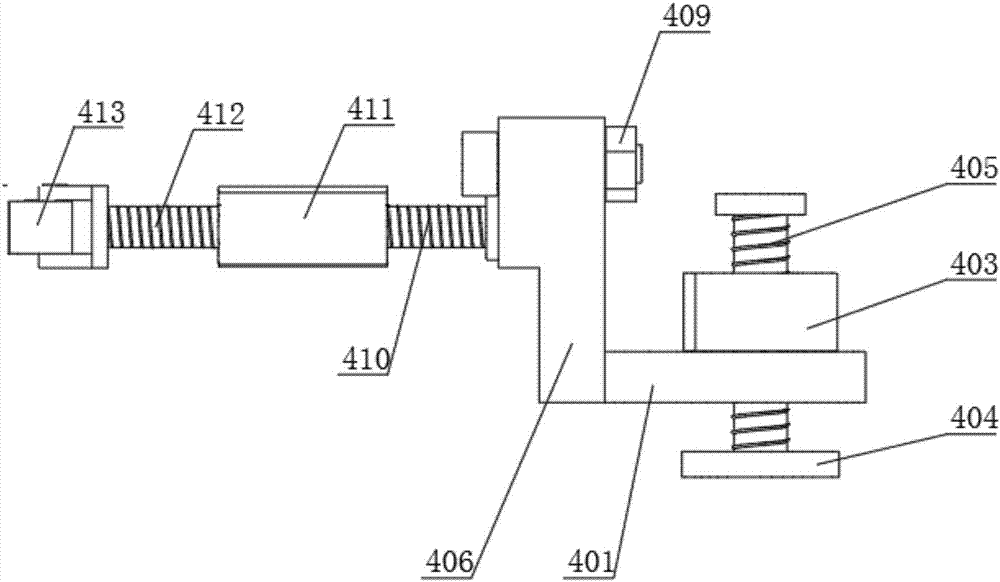

Clamping device for mold production

InactiveCN107214540ATo achieve the purpose of automatic removalEasy to processPositioning apparatusMetal-working holdersBiochemical engineering

The invention discloses a clamping device for mold production, which includes a box body, and is characterized in that: a first motor is fixedly connected to the bottom of the inner wall of the box, and a first bevel gear is sheathed on the surface of the output shaft of the first motor , the bottom of the inner wall of the box is rotatably connected to a first rotating rod and a second rotating rod through a support rod, and both ends of the first rotating rod are respectively rotatably connected to the front and back of the inner wall of the box through bearings, and the second Both ends of the rotating rod are respectively connected to the front and back of the inner wall of the box through bearings. The surface of the first rotating rod is sequentially sleeved with a second bevel gear, a first gear and a second gear from back to front. The invention relates to the field of mold technology. The clamping device for mold production achieves the purpose of automatically taking out the workpiece raised by the workbench, avoids the problem that it is difficult to take out the mold after reprocessing, ensures the processing efficiency, and facilitates the processing of the workpiece by the operator.

Owner:陈杨平

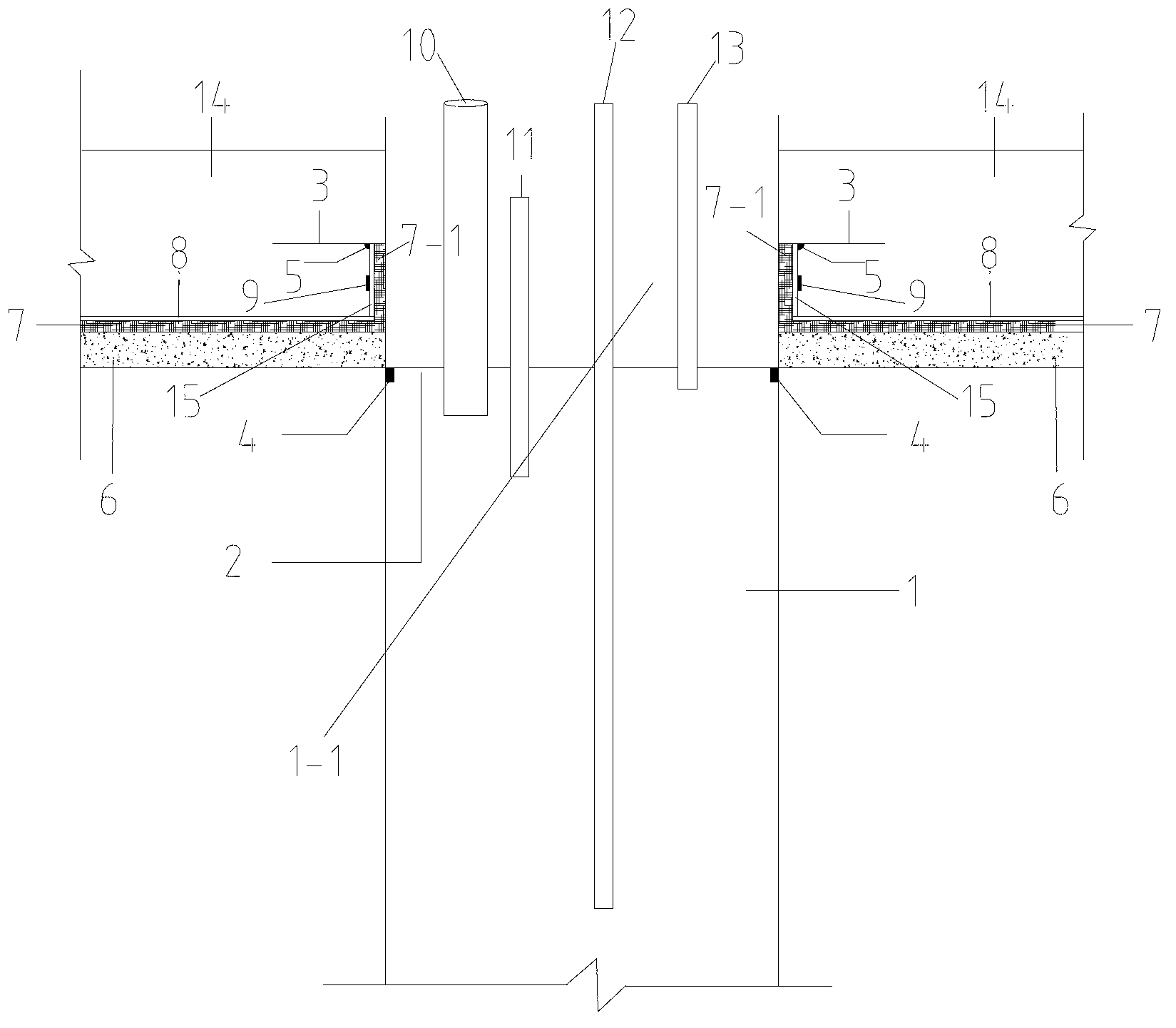

Well sealing waterproof construction method for dewatering well

The invention discloses a well sealing waterproof construction method for a dewatering well. The method comprises the following steps of: (1) constructing a foundation bed on the surrounding of the dewatering well; (2) embedding a steel sleeve for sealing the dewatering well in a foundation pit; (3) laying a waterproof roll material on the foundation bed, and then pouring a fine aggregate concrete protective layer on the waterproof roll material; (4) clamping a waterproof plate on the outer wall of the waterproof roll material on the outer wall of the steel sleeve in an abutted way; (5) clamping the waterproof plate by using a copper strip; (6) injecting a sealing adhesive to the waterproof plate; (7) pouring bottom plate concrete to the fine aggregate concrete protective layer; (8) pumping water; (9) embedding a sealing plate in the steel sleeve; (10) after filling gravels into a filling pipe, injecting a cement paste into a cement paste injection pipe, and stopping the injection of the cement paste until the paste in an overflow pipe flows out; and (11) pouring concrete into the steel sleeve above the sealing plate. Through the adoption of the well sealing waterproof construction method disclosed by the invention, a waterproof treatment problem at the connection of the dewatering well in the foundation pit and the foundation bottom plate in the whole dewatering well sealing waterproof system is solved.

Owner:天津住宅集团建设工程总承包有限公司

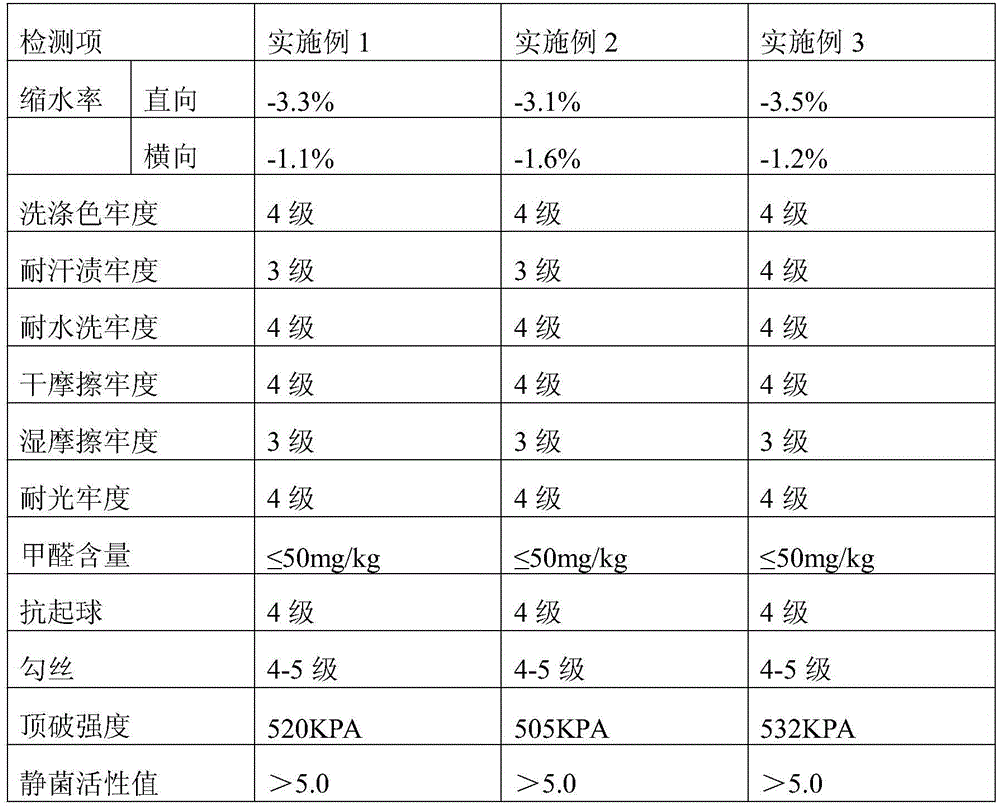

Anti-mite antibacterial healthy knitting fabric and preparation method thereof

ActiveCN105648646ALong-lasting anti-mite and antibacterial effectRapid anti-mite and antibacterial effectWeft knittingBiochemical fibre treatmentPolyesterCotton fibre

The invention discloses an anti-mite antibacterial healthy knitting fabric and a preparation method thereof. Anti-bacterium and bacterium-resistant silver fibers, anti-bacterium and bacterium-resistant polyester fibers, jute fibers and / or cotton fibers and / or regenerated cellulose fibers are adopted as raw materials to be woven into a gray fabric, then preprocessing, dyeing, softening finishing, anti-mite antibacterial finishing and drying shaping are conducted, and the anti-mite antibacterial healthy knitting fabric is obtained. According to the anti-mite antibacterial healthy knitting fabric and the preparation method thereof, independently designed separant and an anti-mite finishing agent are adopted, biological activity of the anti-mite finishing agent and binding firmness of textiles are guaranteed, the relatively durable anti-mite effect is achieved, direct contact between the human body and mites on the fabric can be reduced, sensibility of the skin is protected, and safety of contact with the human body is guaranteed.

Owner:NINGBO DAQIAN TEXTILE

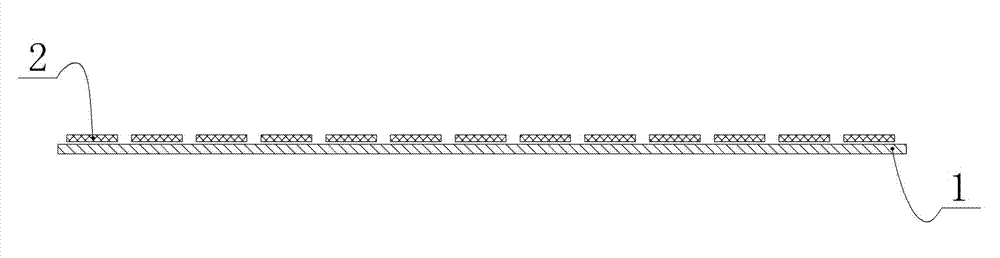

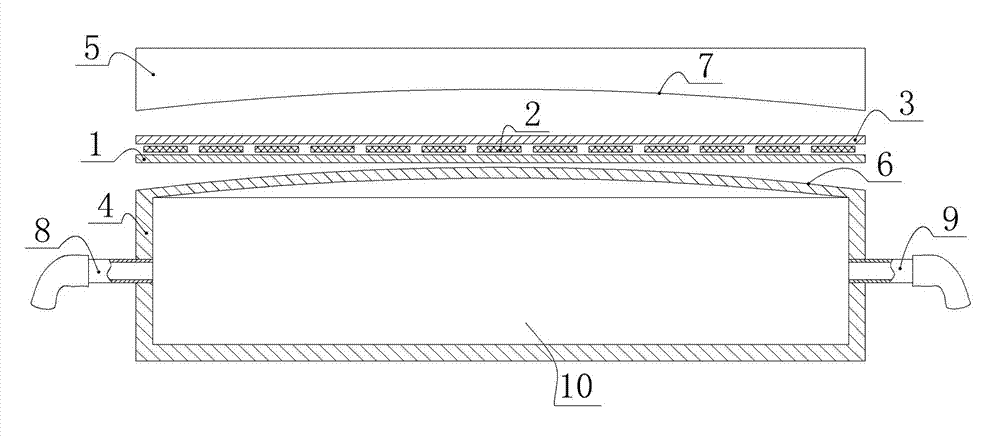

Arc solar panel and processing technology

InactiveCN102856410AExtended service lifeStable in natureFinal product manufacturePhotovoltaic energy generationTransmittancePolyester resin

The invention relates to an arc solar panel which comprises a plastic substrate and a plurality of solar silicon crystal boards regularly arranged on the plastic substrate. The solar silicon crystal boards are used for photovoltaic power generation. The arc solar panel is characterized in that polyester resin layers with light transmittance performance are attached to the upper surfaces of the solar silicon crystal boards; and the lower surface of the plastic substrate is of the same curved surface shape with the outer surface of an automobile top plate. A processing technology of the arc solar panel, which is disclosed by the invention, comprises the following steps of: c, adhering the solar silicon crystal boards; d, arranging the polyester resin layers; 3, loading a die; f, filling a heating medium; g, carrying out hot embossing; and h, carrying out cooling sizing. According to the arc solar panel disclosed by the invention, the firmness of the integral arc solar panel is effectively ensured and the capacity of receiving the sunlight is ensured. The technology for manufacturing the arc solar panel, which is disclosed by the invention, has simple and reasonable steps and can be used for effectively ensuring the quality of the manufactured arc solar panel.

Owner:张正泉

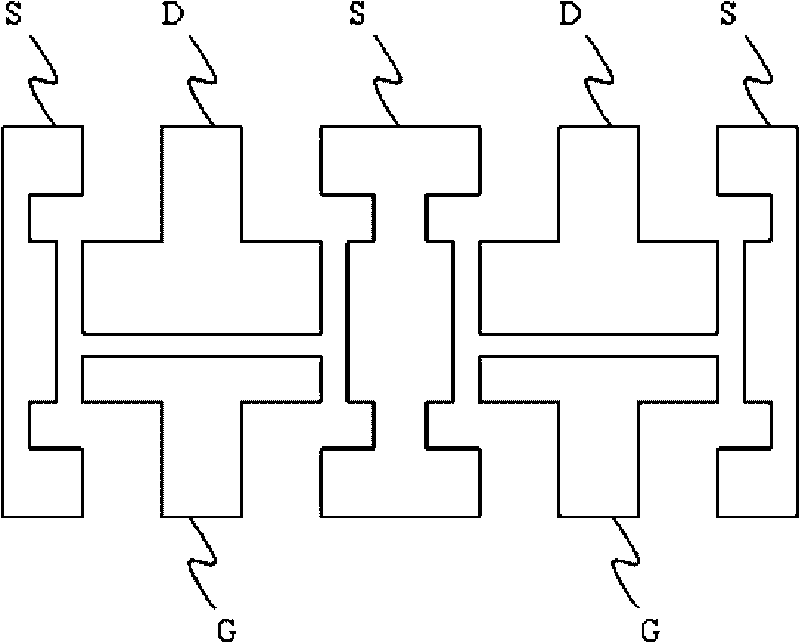

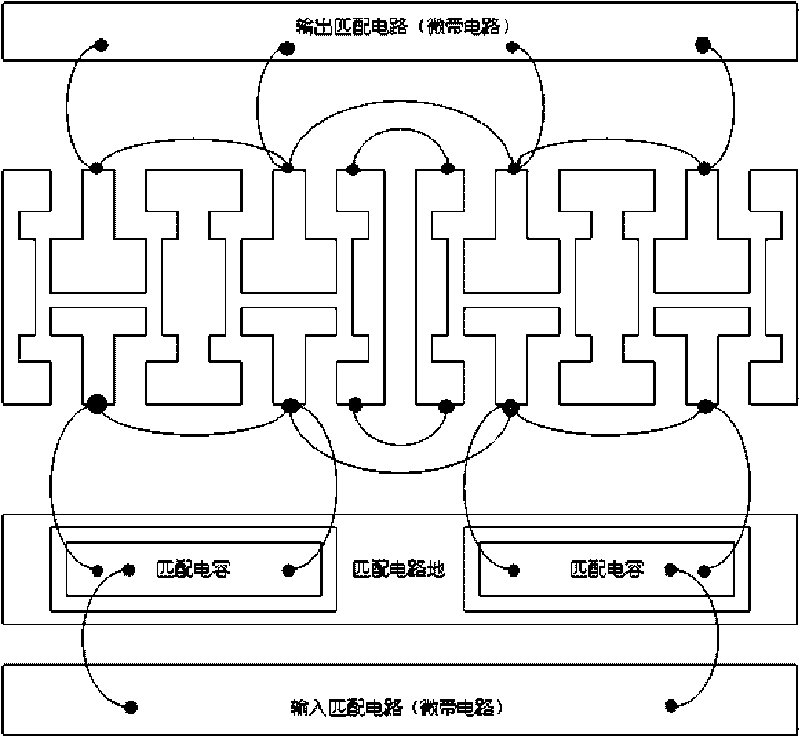

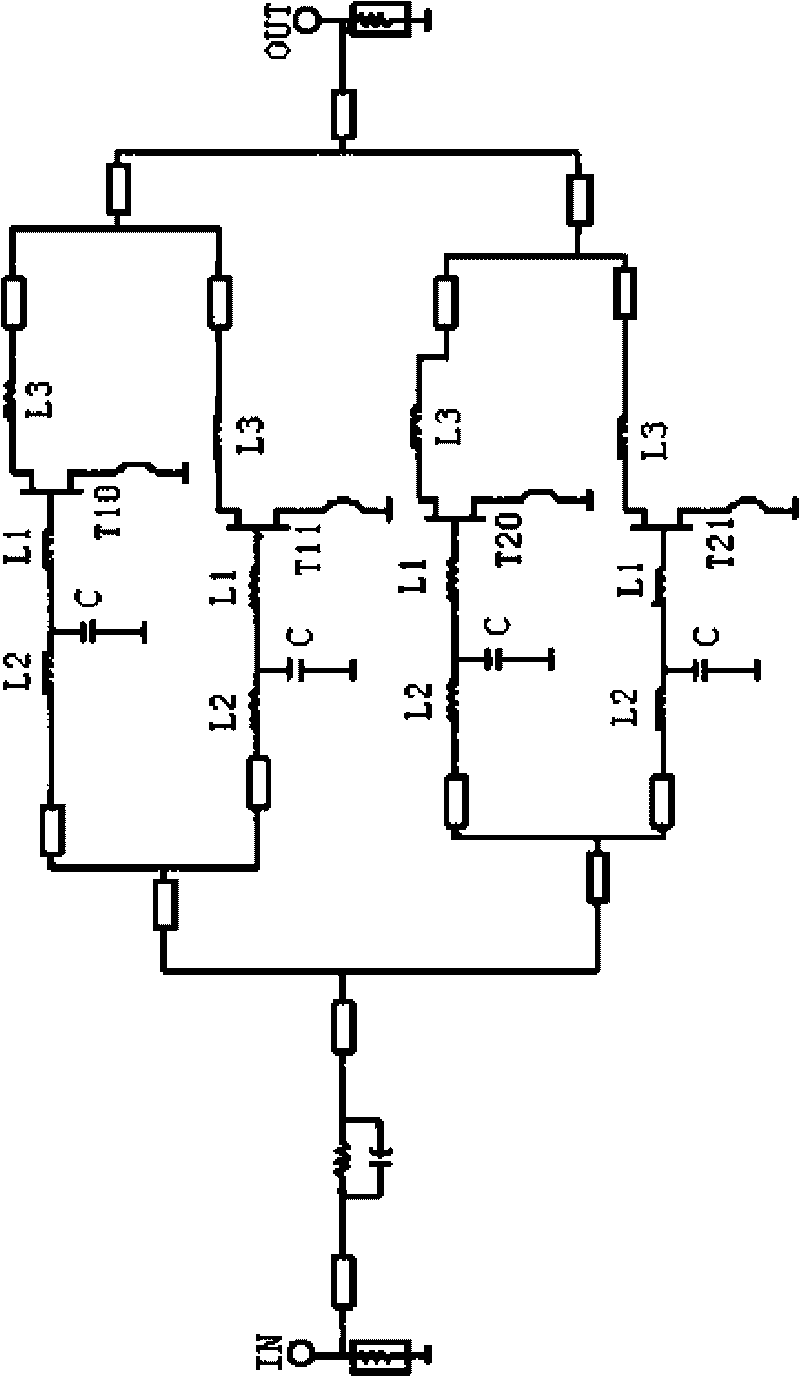

Hybrid microwave integrated circuit

InactiveCN101740556AImprove thermal conductivityFlexible and adjustableSemiconductor/solid-state device detailsSolid-state devicesState of artMicrowave

The invention relates to a hybrid microwave integrated circuit. Aiming at the defects that the hybrid microwave integrated circuit of a large-size high-frequency power device has infirm welding and poor heat conducting performance and is easy to produce oscillation in the prior art, the invention discloses the hybrid microwave integrated circuit suitable for manufacturing the large-size high-frequency power device. In order to solve the technical problems, the invention adopts the technical scheme that the hybrid microwave integrated circuit comprises a substrate encapsulated in a tube shell, and at least two power devices manufactured on the substrate; the power device consists of field effect transistors; a matching circuit and an extraction electrode are manufactured on the substrate; the power device is connected with the extraction electrode through the matching circuit; the extraction electrode is connected with a pin; and gate electrodes of chips of the field effect transistors are welded in parallel through metal wires, drain electrodes of the chips of the field effect transistors are welded in parallel through metal wires, and the gate electrodes and the drain electrodes connected in parallel are welded on the matching circuit through the metal wires respectively.

Owner:SICHUAN LONGRUI MICROELECTRONICS

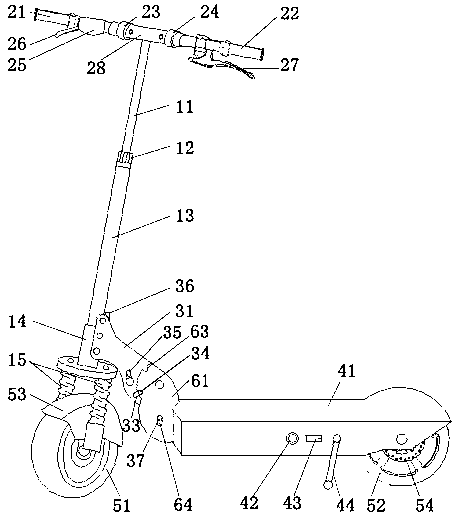

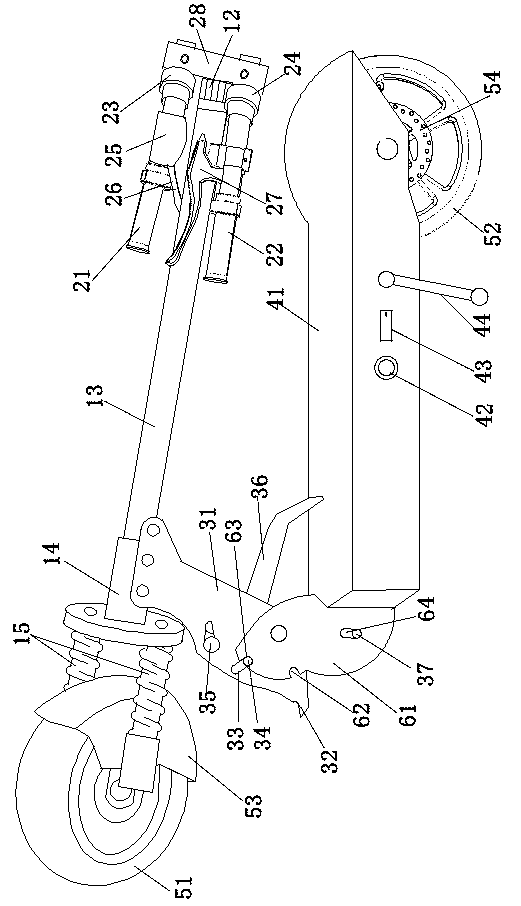

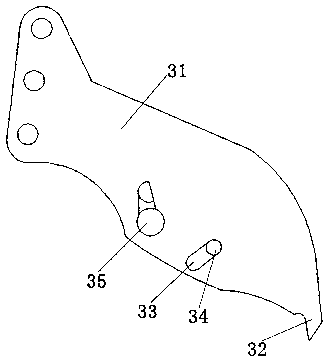

Folding electric scooter

ActiveCN103192928AImprove power systemEasy to foldFoldable cyclesBicyclesControl theoryMechanical engineering

The invention discloses a scooter, and in particular discloses a folding electric scooter. The folding electric scoter comprises a direction component, a handle component, a pedal component, a front wheel, a rear wheel and a connecting component, wherein the handle component is connected with the upper end of the direction component; the lower end of the direction component is connected with the front wheel; the rear wheel is arranged below the rear part of the pedal component; and the two ends of the connecting component are respectively connected with the front ends of the direction component and the pedal component. The folding electric scooter can not only be driven by electricity, but also be used in a folded way. A power system of the scooter is improved, and simultaneously, the structure of the scooter is further improved. By virtue of precise connecting pieces, the scooter can be folded conveniently; by virtue of a safety component, the firmness of the scooter in a using state is ensured, and the scooter is prevented from folding automatically; and therefore, the folding electric scooter has the characteristics of strong power, convenience in use, movement and storage, and the like.

Owner:WUYI SHENGTE VEHICLE CO LTD

Method for preparing coating on surface of intervention catheter, intervention catheter and interventional device

InactiveCN103933616AExcellent abrasion resistanceGuaranteed firmnessPretreated surfacesSpecial surfacesCatheter devicePlasma treatment

The invention discloses a method for preparing a coating on the surface of an intervention catheter, an intervention catheter and an interventional device, the method comprises the following steps: firstly, performing plasma treatment on the surface of the intervention catheter, then grafting acrylic acid on the plasma treated surface of the intervention catheter; preparing a base painting and a top painting; coating the surface of the intervention catheter respectively with the prepared the base painting and top painting; and post treating the intervention catheter to obtain the intervention catheter with a hydrophilic lubricating coating on the surface. The intervention catheter has excellent hydrophilic lubricity and firmness.

Owner:BEIJING DEMAX MEDICAL TECH

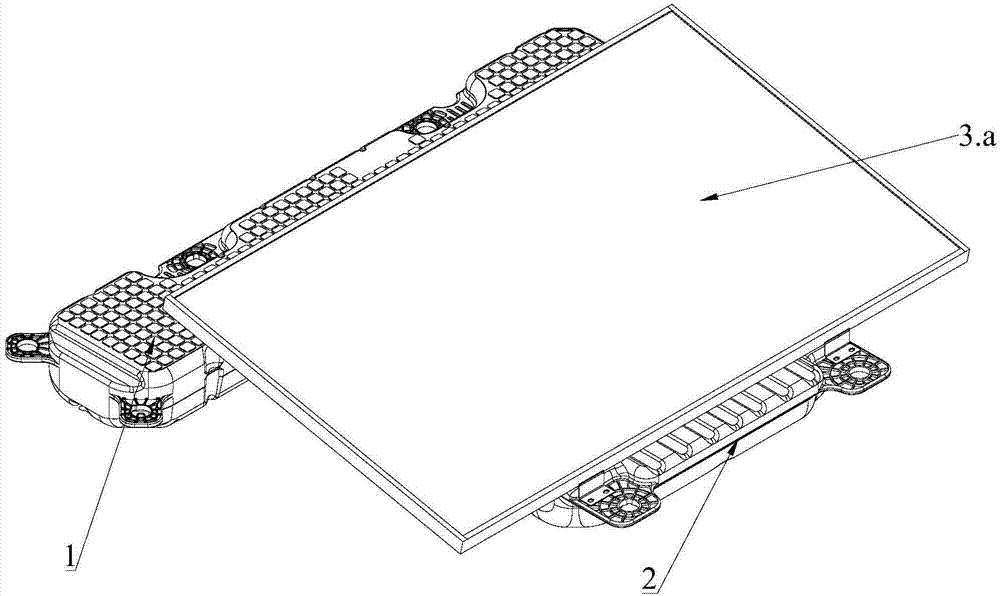

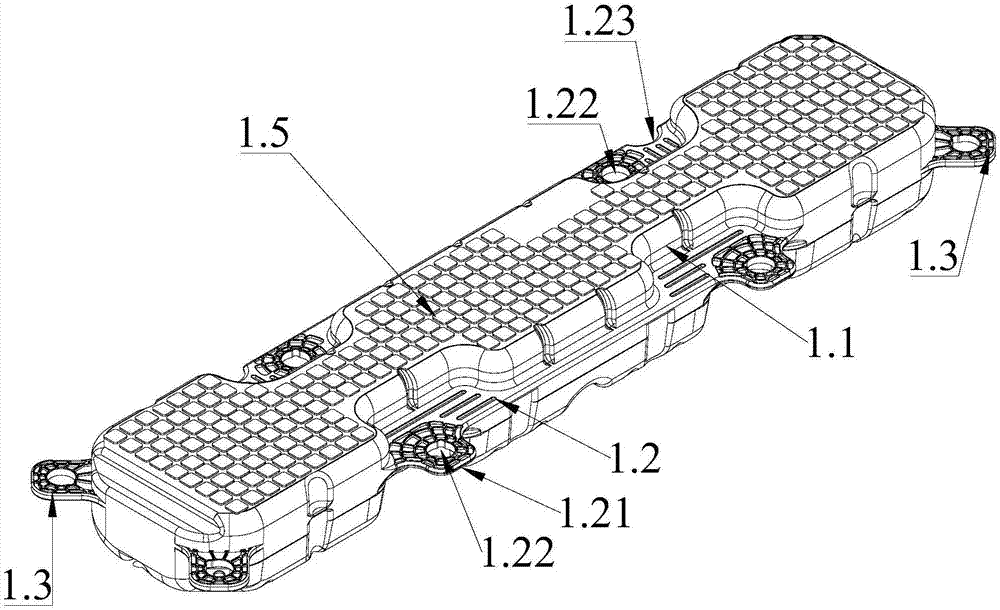

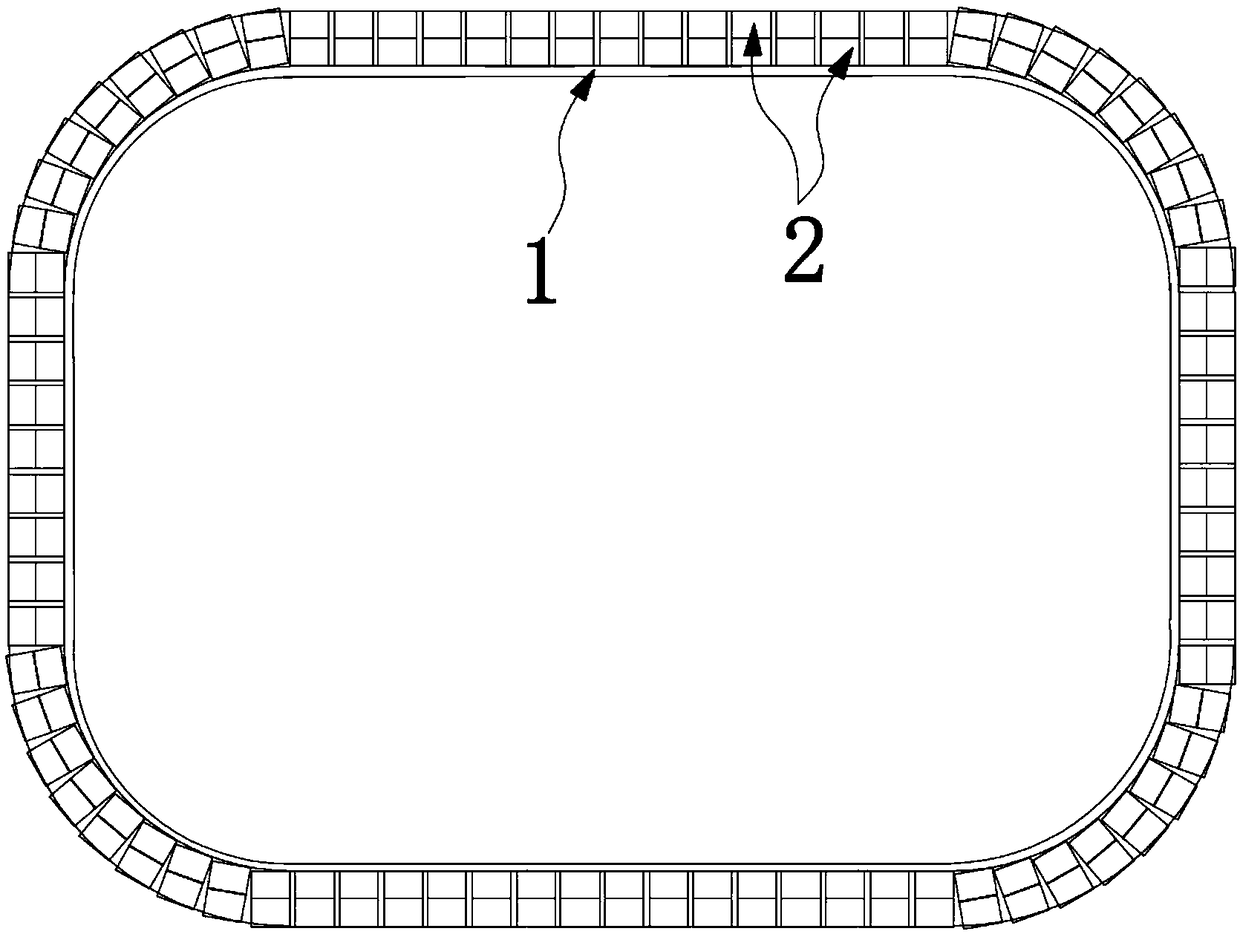

Three-in-one coupling insertion-pull type water surface photovoltaic power generation unit and power generation system thereof

ActiveCN107317544ASolve the problem of non-standard water installationSolve the problem of irregular installationPhotovoltaic supportsWaterborne vesselsMulti functionalityPhotovoltaic power generation

Disclosed are a three-in-one coupling insertion-pull type water surface photovoltaic power generation unit and a power generation system thereof. The photovoltaic power generation unit comprises a passage floating body and a connecting floating body arranged on a side wall of the passage floating body, wherein a power generation element is arranged on the connecting floating body. The system is formed by assembling three-in-one coupling insertion-pull type water surface photovoltaic power generation units vertically and horizontally. Horizontally, the passage floating body is assembled with a passage floating body of another three-in-one coupling insertion-pull type water surface photovoltaic power generation unit, and so on, mounting is completed. Vertically, the connecting floating body is assembled with the passage floating body of another three-in-one coupling insertion-pull type water surface photovoltaic power generation unit, and so on, mounting is completed. Finally, connecting floating bodies of a horizontal row of three-in-one coupling insertion-pull type water surface photovoltaic power generation units are independently fixed with passage floating bodies, so as to complete mounting of the whole power generation system. The unit has the characteristics of simple structure, convenient mounting and multi-functionality. The system assembly has the characteristics of simple structure and convenient mounting.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

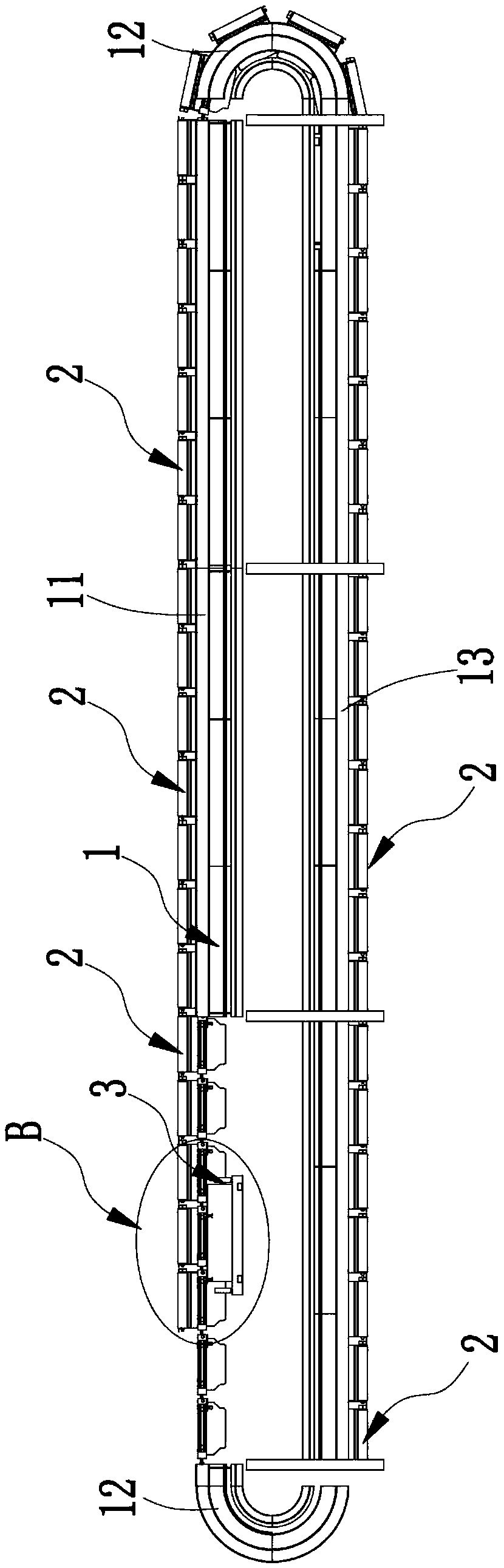

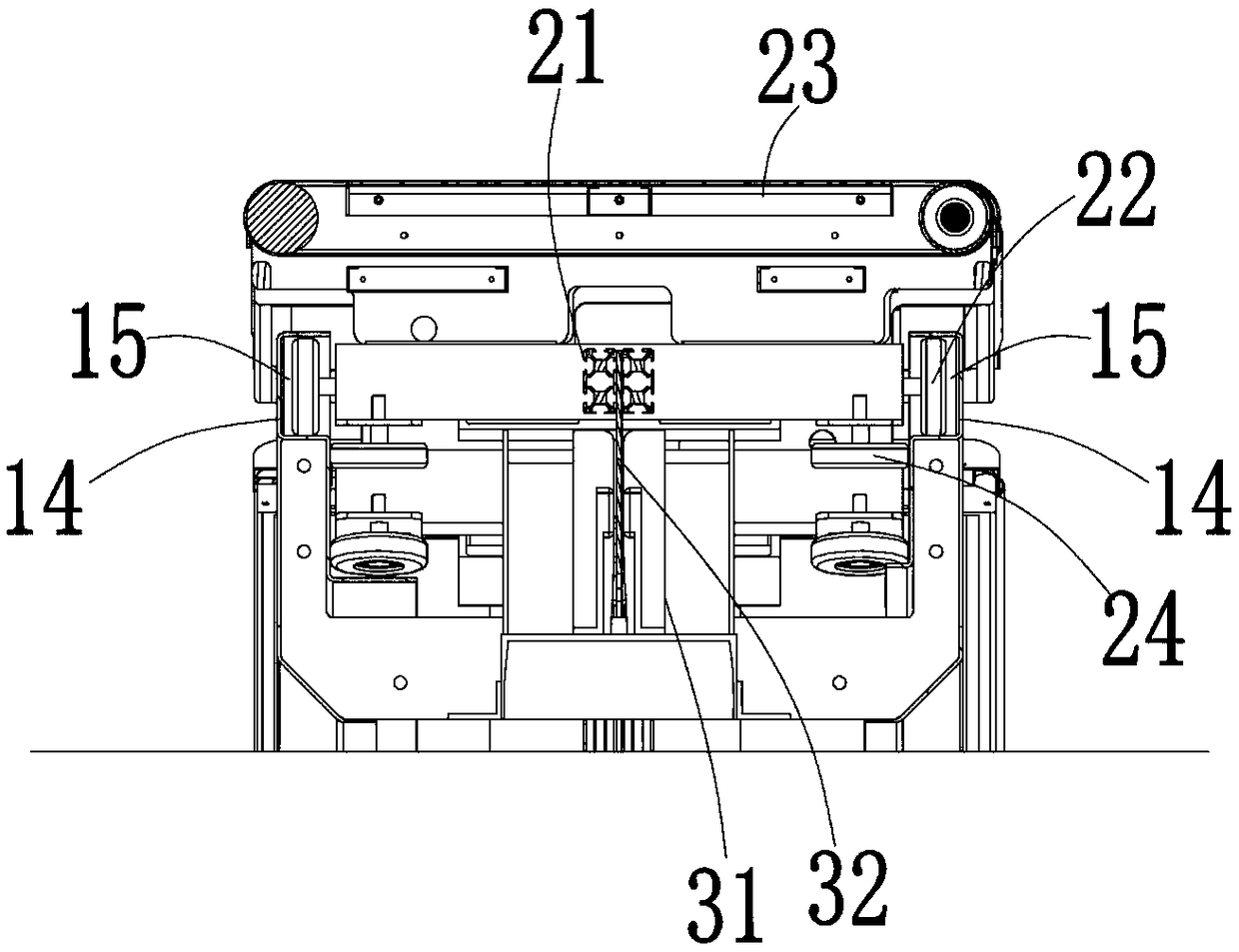

Double-loop-line intersected belt sorting machine, intersected belt sorting system and sorting method thereof

PendingCN109335538AReduce vacancy rateIncrease the number ofPackagingConveyor partsEngineeringMechanical engineering

The invention discloses a double-loop-line intersected belt sorting machine, an intersected belt sorting system and a sorting method thereof. The double-loop-line intersected belt sorting machine comprises at least one annular rail, two sets of intersected belt cars for forming two conveying loop lines circularly rotated on the annular rails side by side, and a power device for driving the two sets of intersected belt cars to move along the annular rails. The double-loop-line intersected belt sorting machine is delicate in design and simple in structure; as two sets of cars are used in one annular rail, the number of the intersected belt cars is increased by using internal space of the loop lines under the precondition of not increasing the floor area to multiply the sorting capacity, theuse efficiency of the sorting machine is improved, and the equipment cost is reduced; and meanwhile, parcels can be transferred between two conveying annular intersected belt cars, so that the idlingrate of the cars can be reduced, meanwhile, the parcel loading flexibility is improved, and the arrangement requirements and the occupied space of a particle loading line are reduced.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

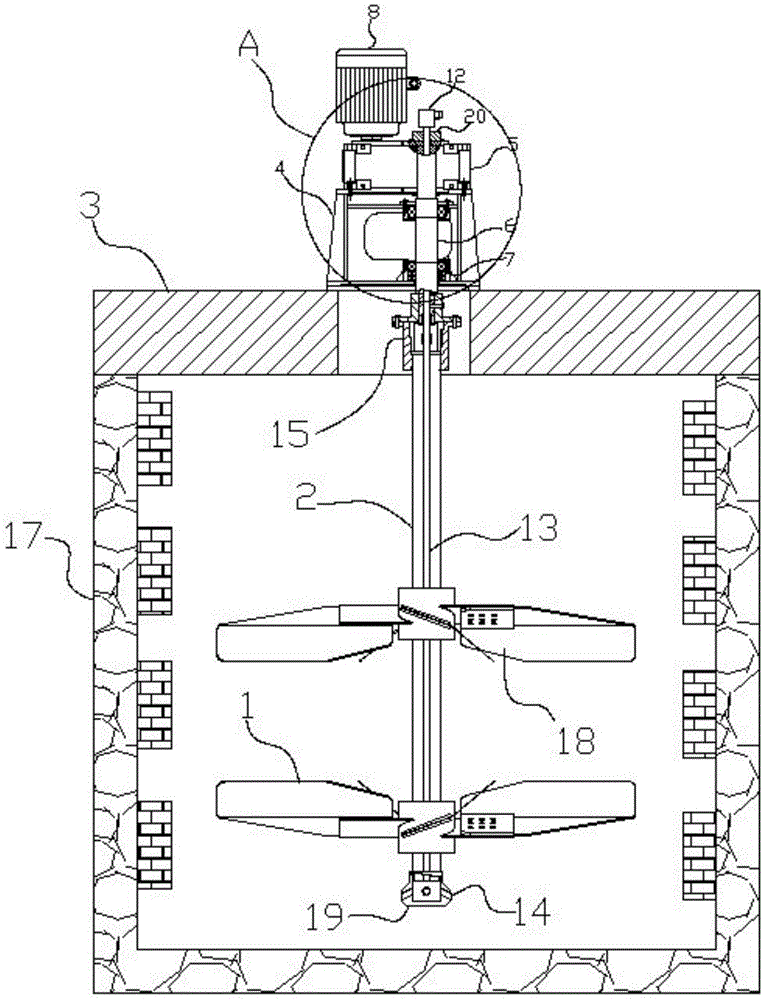

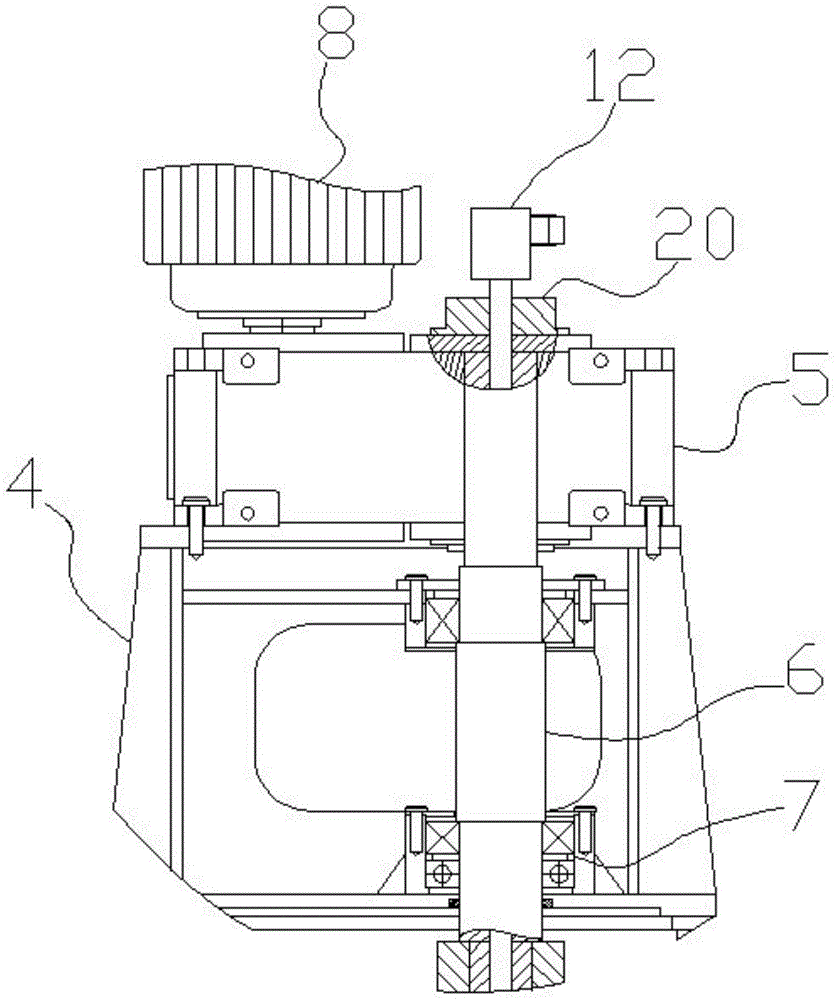

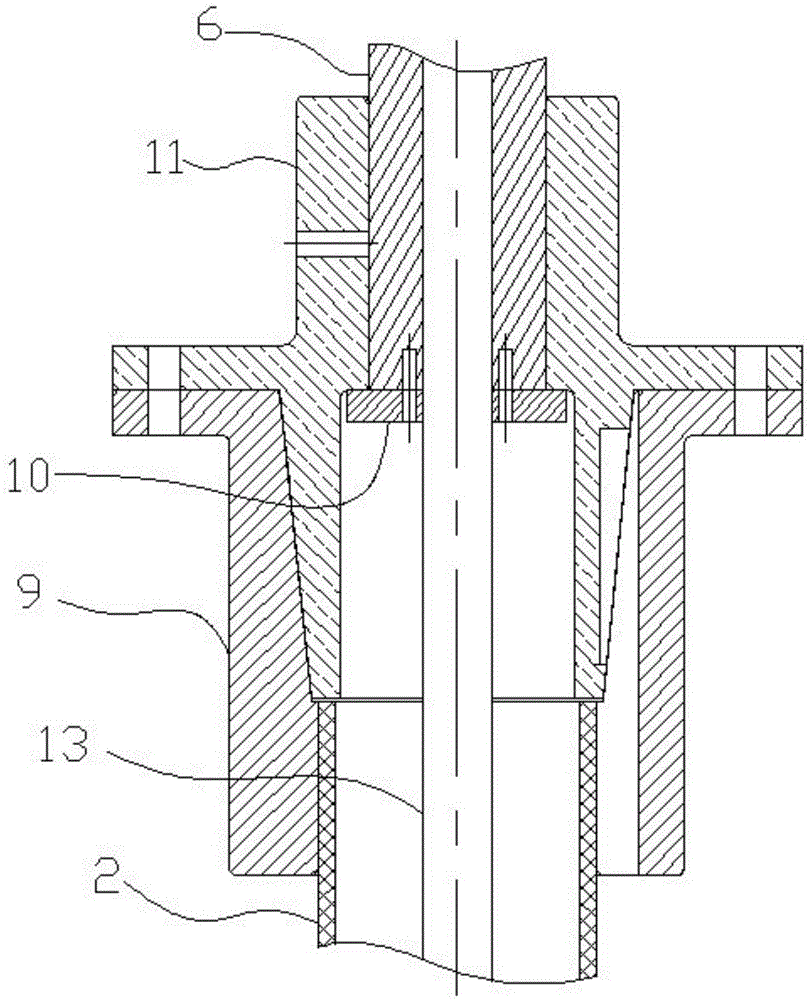

Axial ventilating type high-efficiency stirrer

ActiveCN105478047AEvenly distributedImprove the mixing effectMixing methodsTransportation and packagingImpellerEngineering

The invention discloses an axial ventilating type high-efficiency stirrer. The lower end of a machine base shaft is connected with a stirring rod through a conical centering and coupling device. An upper stirring impeller and a lower stirring impeller are arranged on the stirring rod. Stirring blades of the upper stirring impeller and stirring blades of the lower stirring impellers are symmetrically installed in the vertical direction. Each stirring blade comprises a base plate and a turning plate, wherein the base plate and the turning plate are connected to form an included angle of 100 degrees to 170 degrees, and a tilt angle of 10 degrees to 70 degrees is formed between the base plate and the horizontal plane. An air nozzle is fixed to the bottom end of the stirring rod which is a hollow pipe. An air guide pipe is arranged in the stirring rod. The upper end of the air guide pipe penetrates through a machine base cushion plate and is communicated with an air inlet connector. The lower end of the air guide pipe is communicated with the air nozzle. Air outlets are evenly formed in the air nozzle. A tilt angle of alpha degrees is formed between the air outlets in the circumference of the air nozzle and the diameter line, wherein alpha ranges from 5 degrees to 45 degrees. The traditional mode that air is only pressed in from the wall circumference of a container through a pipeline is changed, the defect of air shortage in the middle area of the container is overcome, the chemical combination effect is made better, and the quality and efficiency of wet metallurgy are greatly improved.

Owner:湖南中资混合搅拌机电科技有限公司

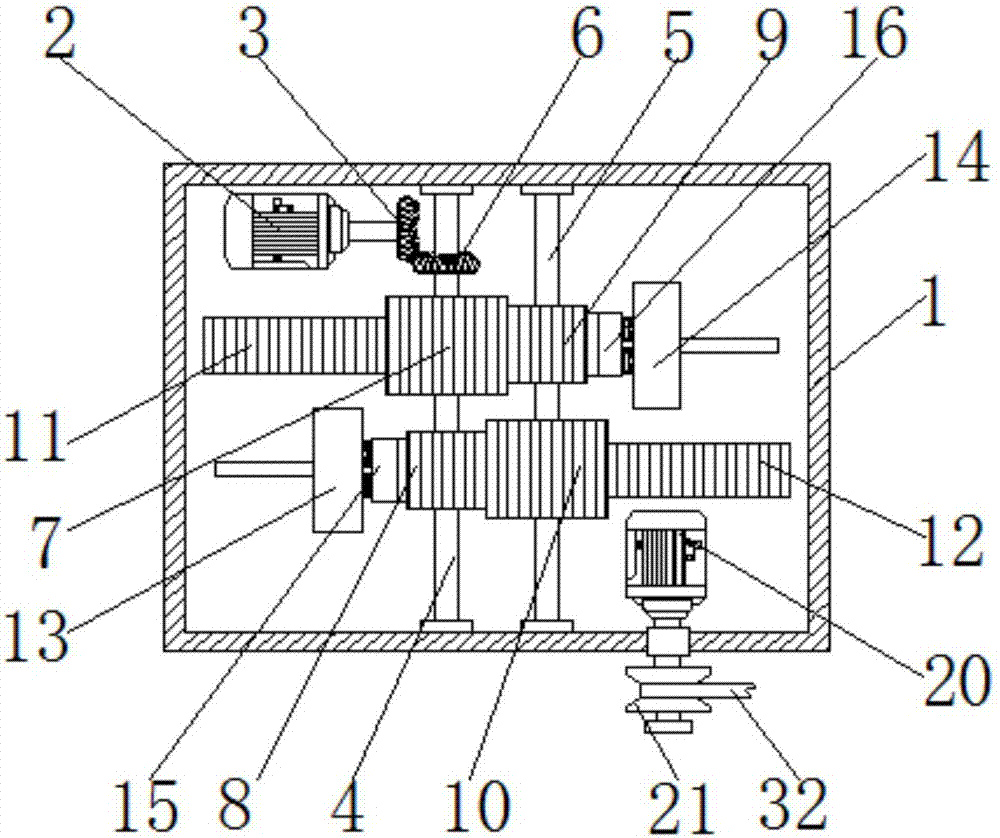

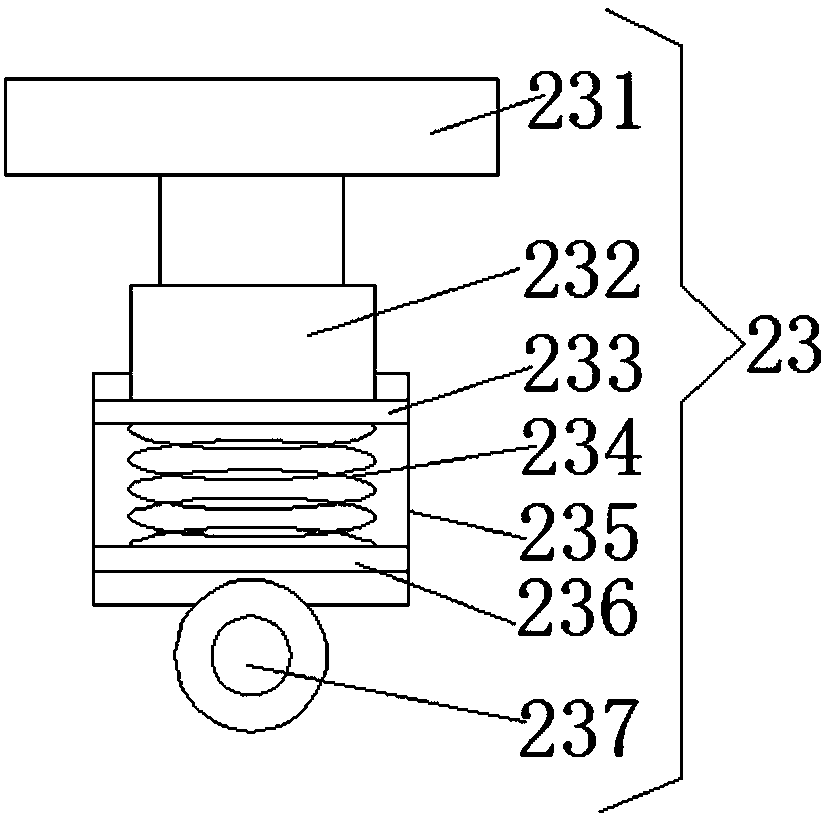

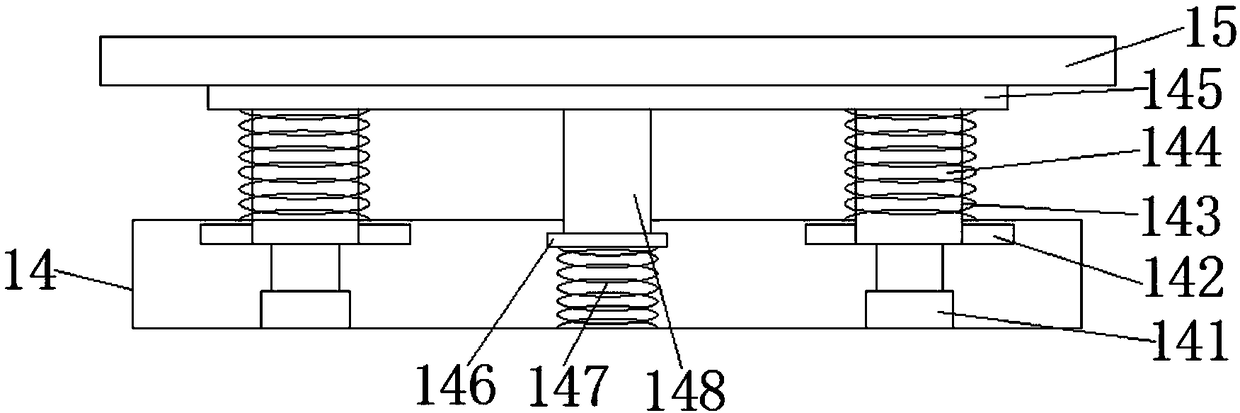

Auxiliary transferring equipment for textile production

InactiveCN108945052AGuaranteed firmnessPrevent dumpingSupporting partsHand carts with multiple axesEngineeringTextile production

The invention provides auxiliary transferring equipment for textile production, and relates to the field of textile equipment. The auxiliary transferring equipment comprises a base, a fixing seat is fixedly mounted at the top of the base, a working table is arranged on the upper side of the fixing seat, a first supporting column is arranged on the left side of the fixing seat, a motor is fixedly mounted on the left side of the first supporting column, a driving gear is arranged on the left side of the first supporting column, a rotating shaft of the motor is in transmission connection with thedriving gear, and a threaded rod is arranged in the first supporting column. According to the auxiliary transferring equipment for textile production, textile cloth can be clamped and fixed through clamping plates, the firming effect on the cloth is ensured during transporting of the textile cloth, the textile cloth is prevented from toppling, the quality of the textile cloth is improved, and damage to the textile cloth is reduced; and the buffering effect can be achieved through a first buffering spring and a second buffering spring, bumping in the transporting process is reduced, and the damage to the textile cloth is greatly reduced.

Owner:湖州南浔富龙纺织有限公司

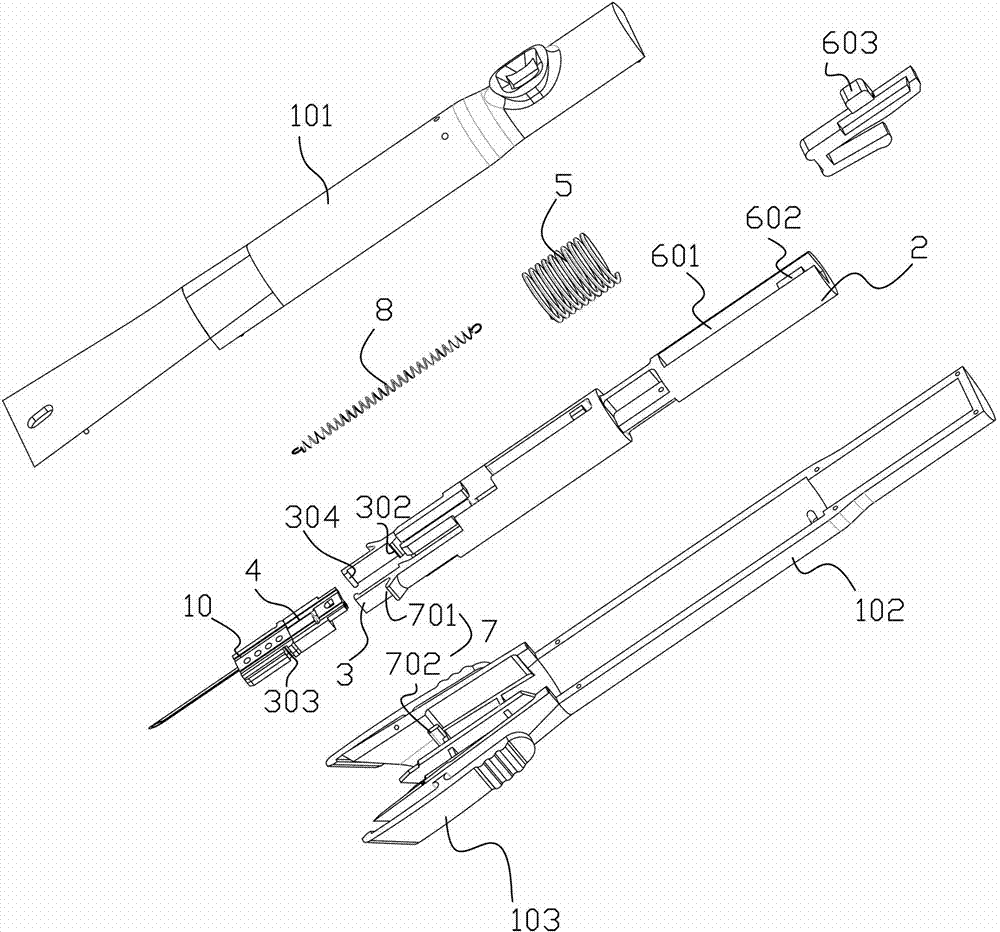

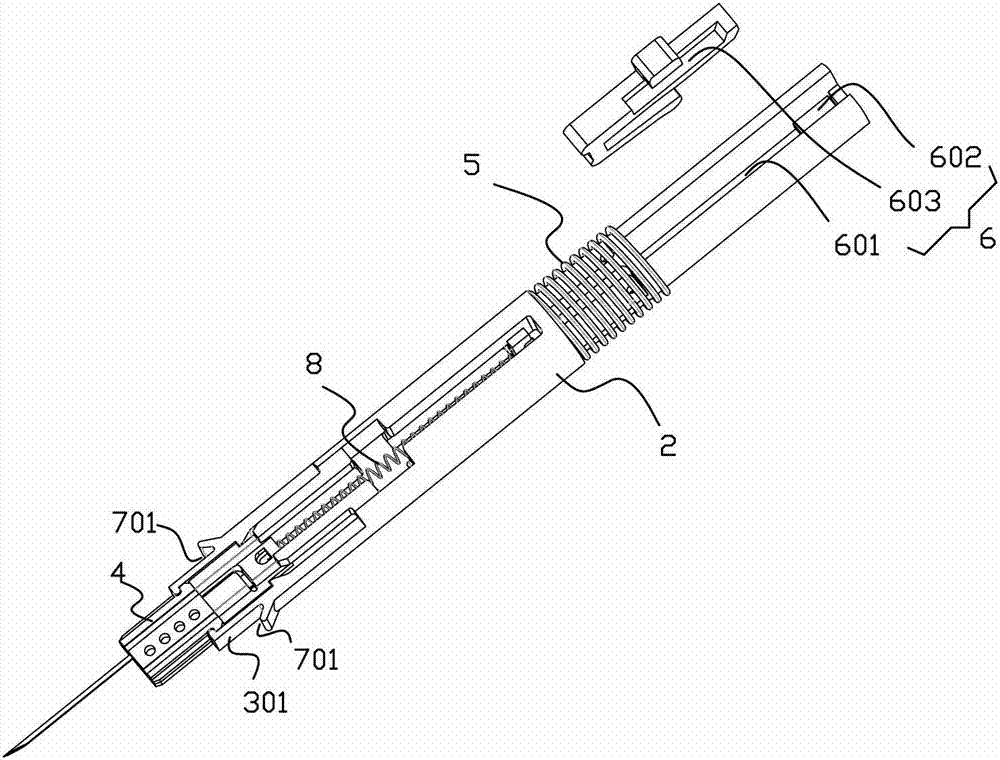

Quick implant used for implantable biosensor

ActiveCN103750818AQuick pullRelieve painDiagnostic recording/measuringSensorsBiomedical engineeringBiosensor

The invention discloses a quick implant used for implantable biosensors. The quick implant comprises an implant shell, a sliding seat installed in the implant shell, and a mounting mechanism; an elastic force part which enables the sliding seat to slide in the implant shell, and a control part used for controlling the sliding seat to leave from the original position and slides under the action of the elastic force part; a separation mechanism; an elastic reset device, wherein when a sensor mounting assembly is separated from the sliding seat in the preset position, the elastic reset device applies acting force back to an implantation opening onto the sensor mounting assembly. The quick implant can conveniently, quickly and accurately complete the implantation and the exit of the implantable biosensor. Short time is spent in the whole process, and the pain feeling of a patient in the process of implanting the sensor is greatly reduced, thereby improving the working efficiency.

Owner:ZHEJIANG POCTECH

Heat treatment method for high ferrochrome roll requiring stepped hardness of roll body

ActiveCN102321795ALow thermal conductivitySmall heat capacityFurnace typesHeat treatment process controlFiberHardness

The invention discloses a heat treatment method for a high ferrochrome roll requiring stepped hardness of a roll body. The method mainly comprises the following steps of: before the roll is preheated, coating ceramic fibers on parts, which have low hardness requirement on the roll body, close to the roll necks of the roll; performing preheating treatment, differential temperature heat treatment and quenching treatment; before tempering, removing the ceramic fibers on two end parts of the roll; and performing tempering treatment on the roll in a low temperature tempering furnace. By the heat treatment method, the technical requirement that the roll body of the roll has stepped hardness can be met.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

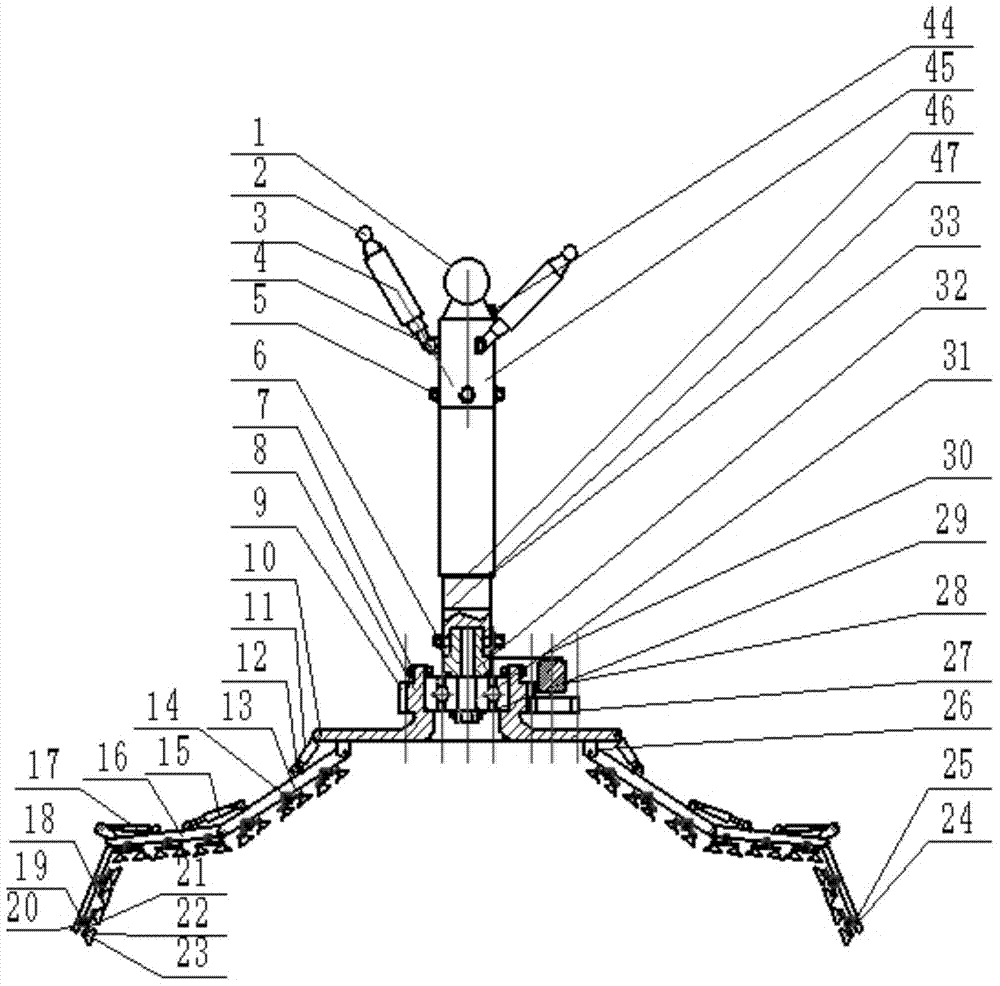

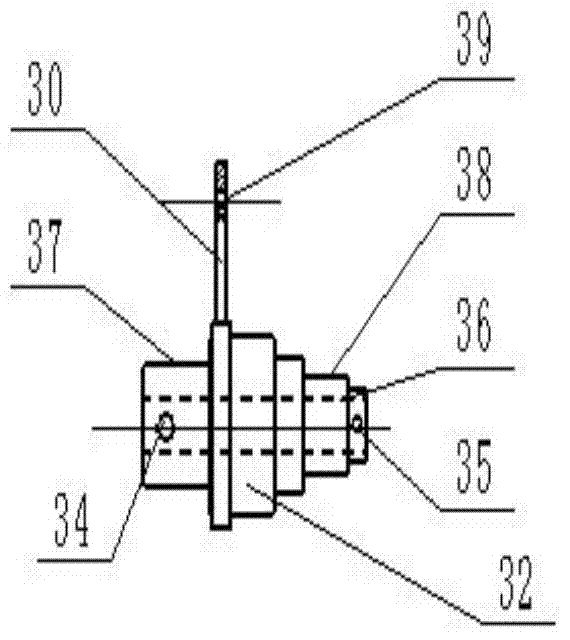

Sucking-type underwater manipulator and sucking method thereof

InactiveCN103921277AImprove efficiencyGuaranteed firmnessGripping headsUnderwater equipmentHydraulic motorHydraulic cylinder

The invention relates to a sucking-type underwater manipulator and a sucking method thereof. A main oil pump of a robot hull provides hydraulic oil for hydraulic cylinders and hydraulic motors of the manipulator through multilevel flexible hydraulic oil pipes. A manipulator base is connected with the hull through a universal ball at the top and is connected with three hydraulic cylinders which control the manipulator base. A single-level hydraulic cylinder is fixed on the lower portion of the manipulator base. A telescopic shaft of the single-level hydraulic cylinder is connected with the base through a sleeve shaft. A hydraulic motor is mounted on the sleeve shaft and is used for driving the manipulator base to rotate. Eight manipulator wrists controlled by the hydraulic cylinders are mounted on the base. A certain quantity of sucking disc rod groups are mounted on the bottom surface of each manipulator wrist. The object grabbing and adsorbing method of the sucking-type underwater manipulator is similar to that of an octopus living under the sea, sucking discs are squeezed and liquid in cavities of the sucking discs is drained under the acting force of the manipulator wrists to objects, and the sucking discs are enabled to be adsorbed to the surfaces of the objects. Under the joint action of grabbing force of the manipulator wrists and adsorbing force of the sucking discs, the manipulator has a better object grabbing capability.

Owner:JILIN UNIV

Method for calibrating digital oscilloscope

InactiveCN101655542AGuaranteed firmnessReduce calibration costsElectrical measurementsCalibration resultInstrumentation

The invention relates to a method for calibrating a digital oscilloscope, comprising the following steps: S1: inputting a standard signal; S2: judging whether calibration is required, if so, performing S3, otherwise, performing S4; S3: adjusting corresponding parameters and performing S2; and S4: terminating. The above method for calibrating digital oscilloscopes needs no special calibrating instruments, and can finish various calibration processes only by inputting a standard signal and adjusting corresponding parameters, thus lowering calibration cost greatly. A user can use the above calibrating method for calibrating digital oscilloscopes at any time, therefore, the stable degree of the calibration results can be ensured.

Owner:秦轲 +2

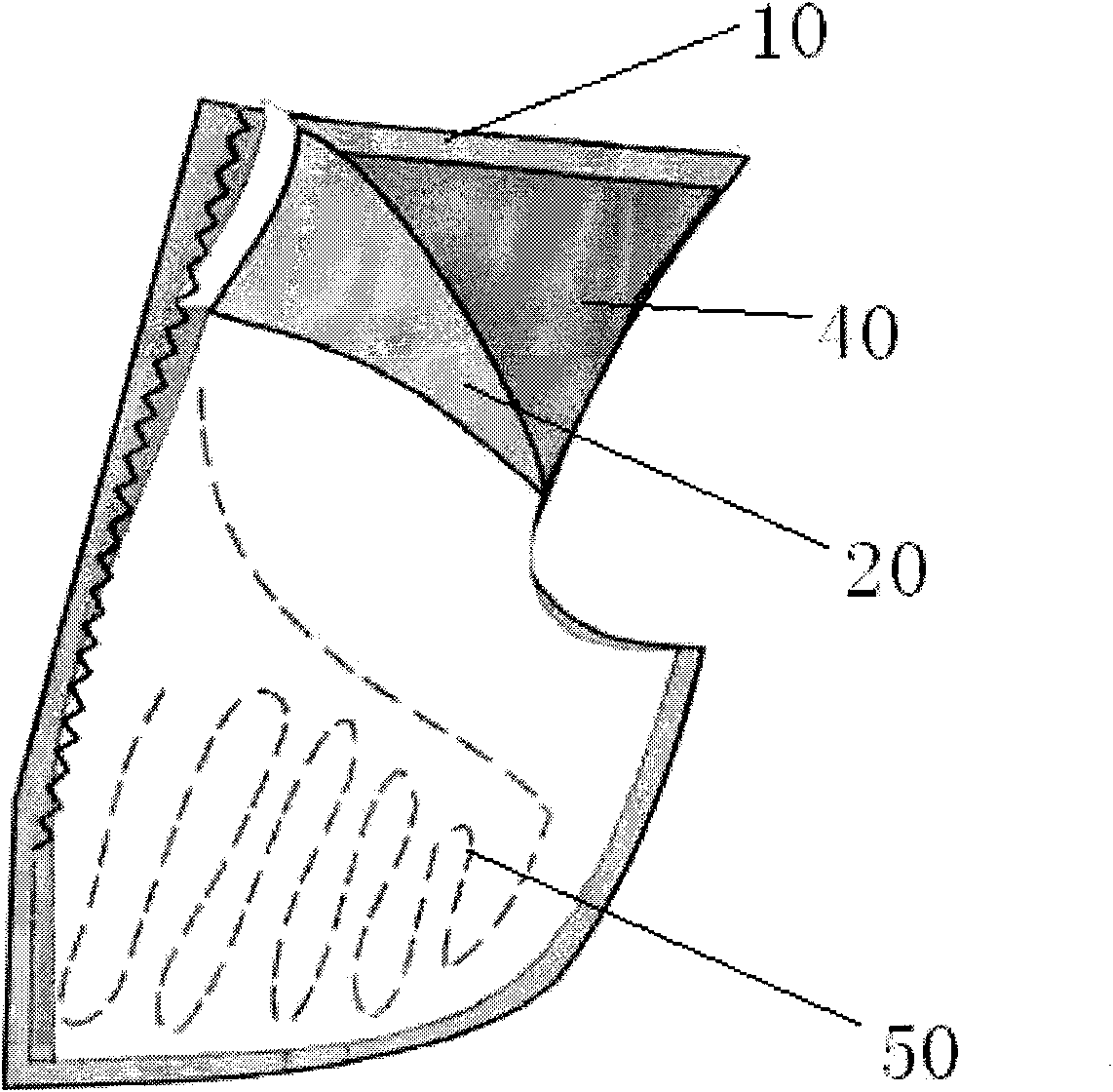

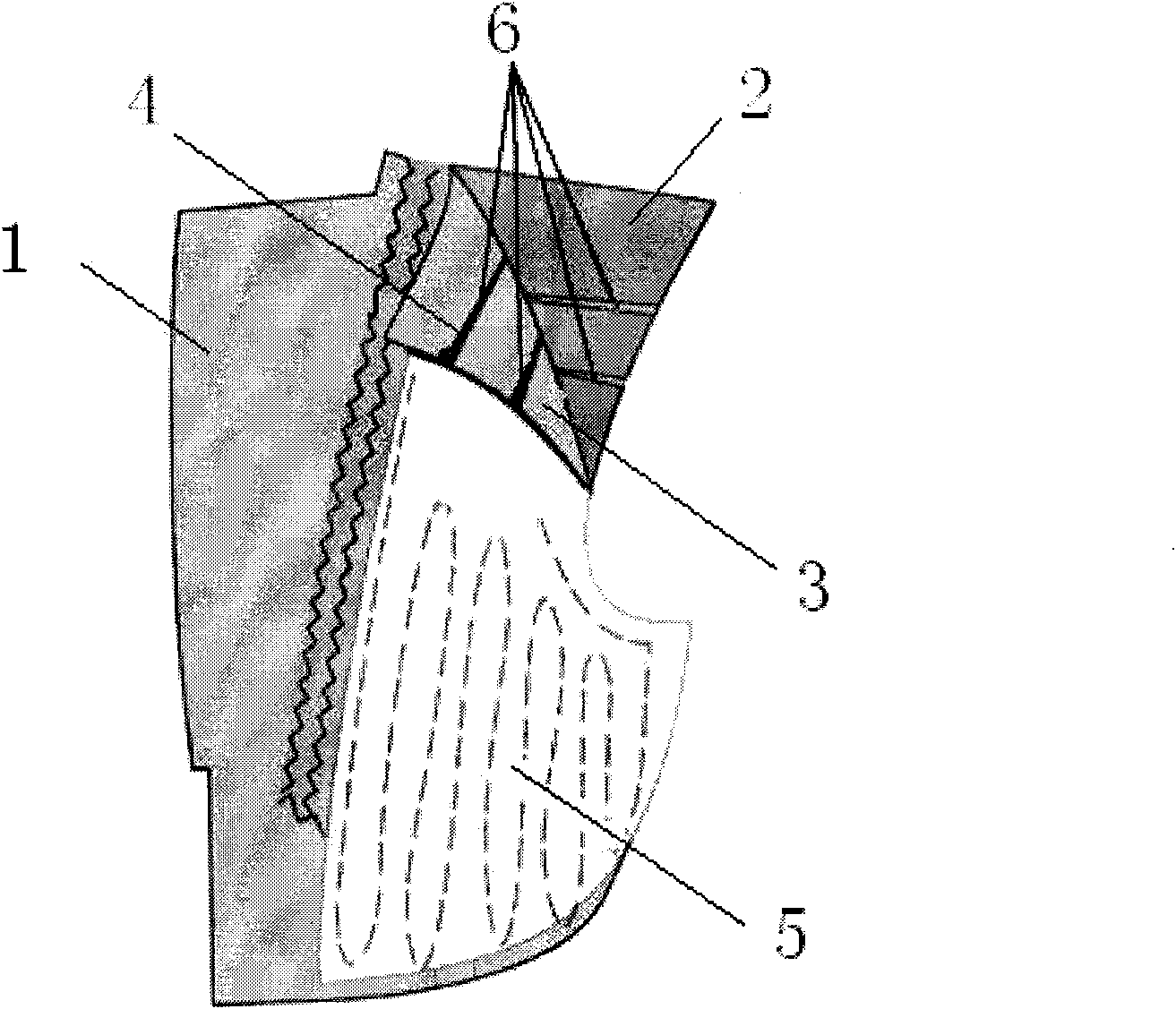

Chest piece of western-style clothes, manufacturing method thereof and manufacturing method of western-style clothes

The invention discloses a chest piece of western-style clothes, a manufacturing method thereof and a manufacturing method of western-style clothes. The chest piece of the western-style clothes comprises the following matters from the front cut piece fabric of the western-style clothes to the human body direction: a main lining arranged on the first layer, a shoulder squaring lining on the second layer, a main lining on the third layer, a horse tail on the fourth layer and cotton on the fifth layer. The chest piece of the western-style clothes is provided with multiple channels of openings which are in parallel mutually on the shoulder squaring lining on the second layer; the multiple channels of openings are parallel to the weft yarn direction of the shoulder squaring lining on the secondlayer; the main lining on the third layer is provided with multiple channels of openings which are in parallel mutually; the multiple channels of openings are parallel to the weft yarn direction of the main lining on the third; and a certain distance is pulled out between the openings on the shoulder squaring lining on the second layer and the openings on the main lining on the third layer. The invention can ensure that the position of the western-style clothes on the shoulder is good-fitting with human body; and the western-style clothes are comfortable to wear with no feelings of pressing the shoulder.

Owner:报喜鸟控股股份有限公司

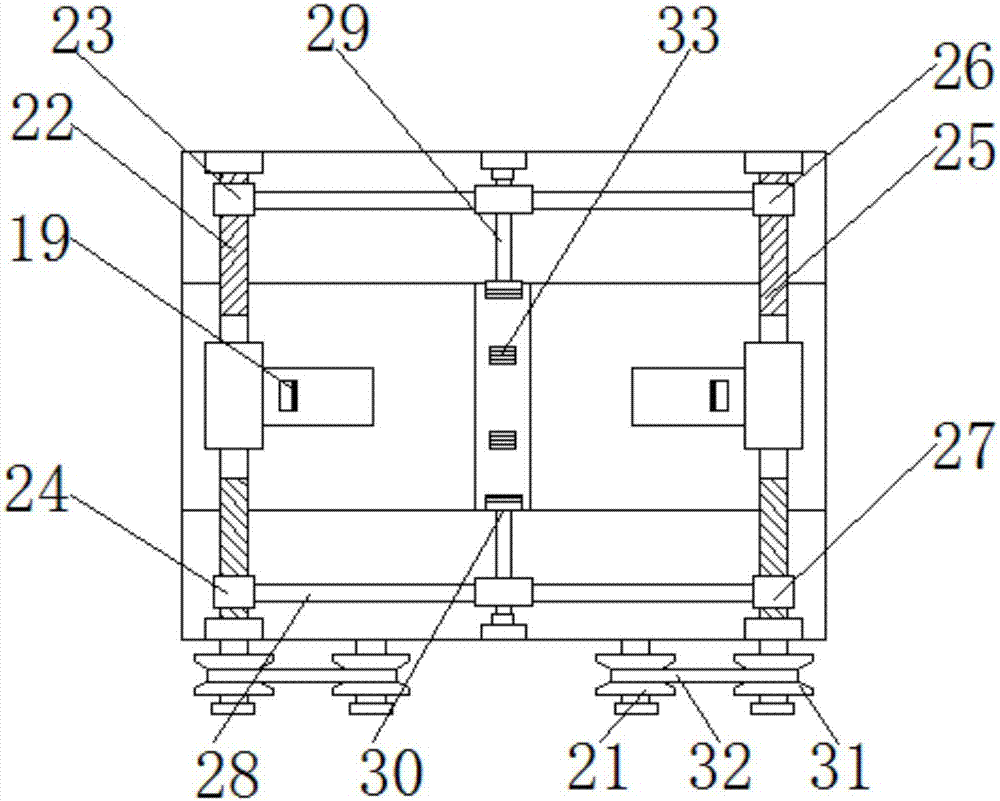

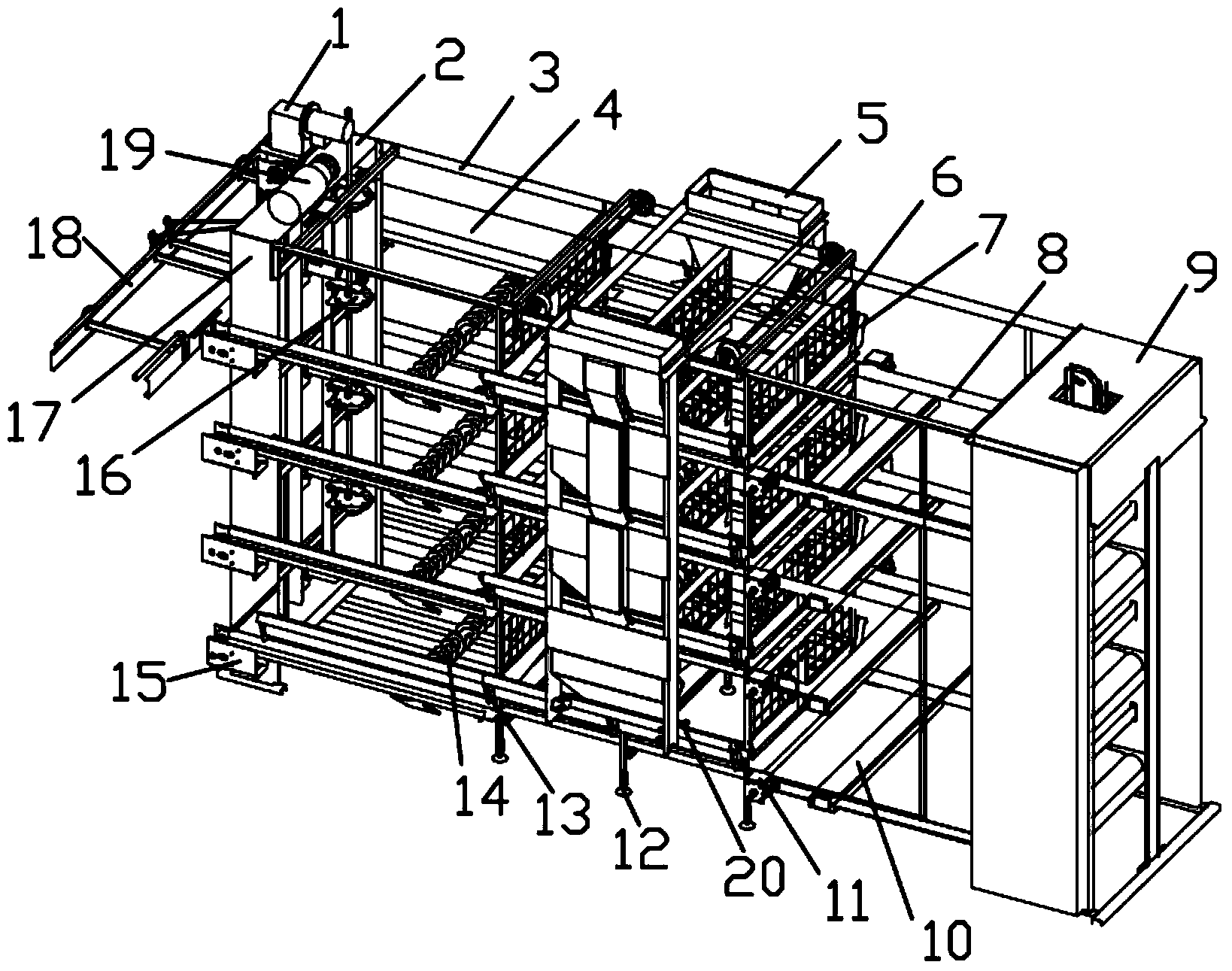

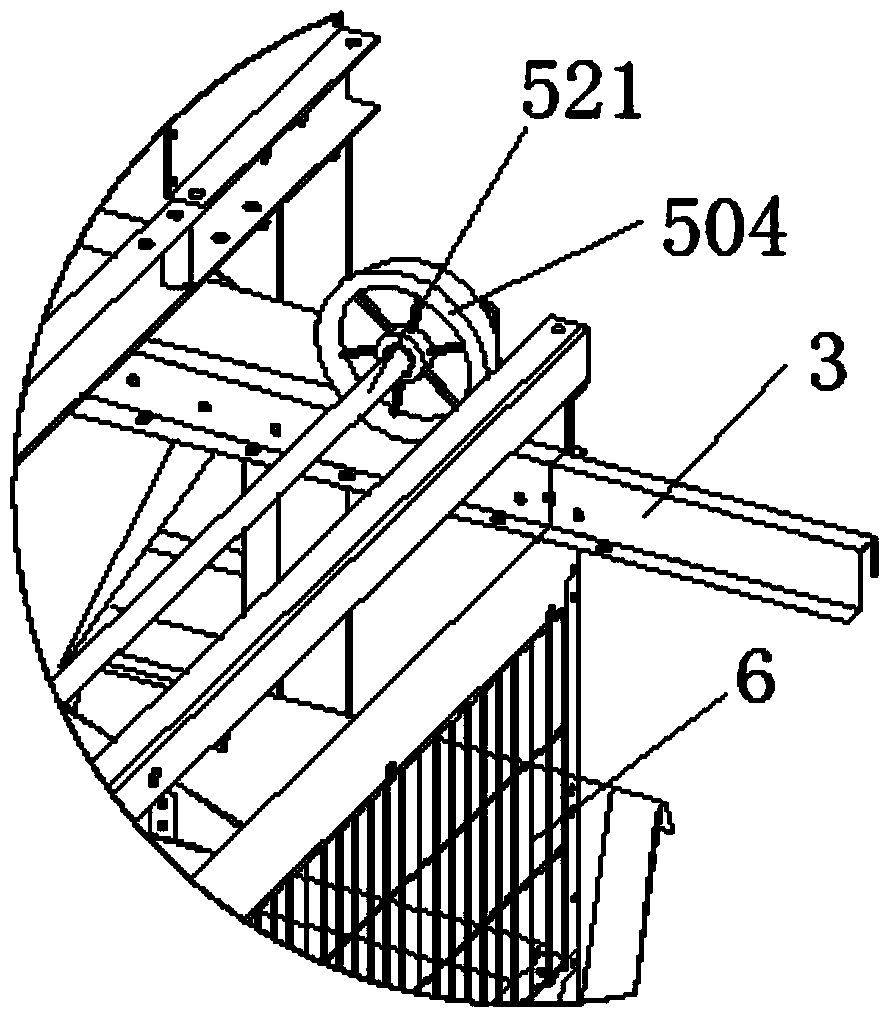

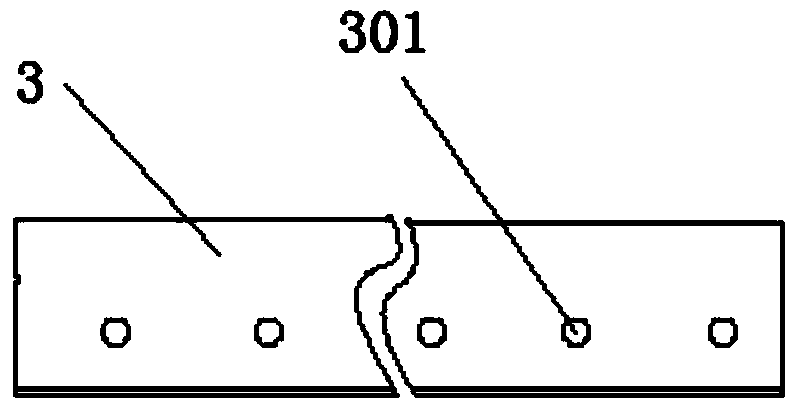

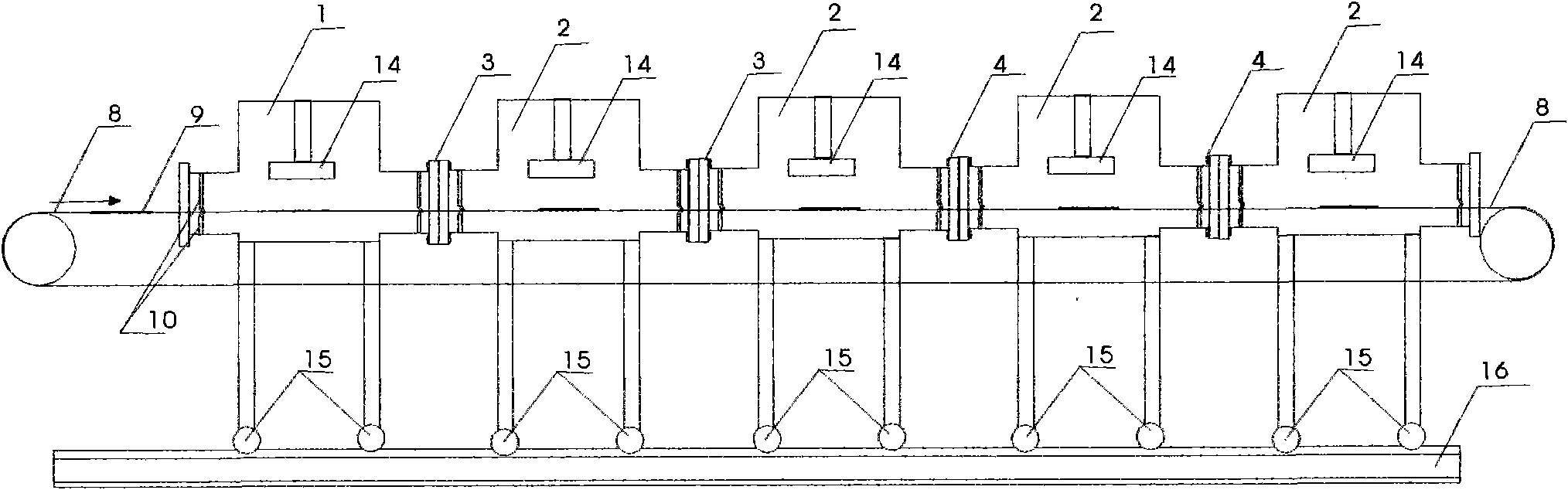

Laminated poultry raising equipment

The invention relates to the technical field of poultry raising equipment, in particular to laminated poultry raising equipment. The laminated poultry raising equipment provided by the invention comprises a machine frame adopting a framework structure, wherein a plurality of poultry cages adopting reticular structures are arranged in the middle part of the machine frame in a laminated way, a food tough support frame fixedly connected with the two sides of the machine frame is arranged in an outer lower position of the cage wall of each layer of poultry cage, a U-shaped food tough with an upward opening is fixedly arranged on the food tough support frame, walking guide rails in symmetrical arrangement are arranged on the top of the machine frame, a feeding machine doing reciprocating movement in the horizontal direction is arranged on the walking guide rails, an opening of each discharging hopper arranged at feeding machine is in corresponding arrangement to the opening of the U-shaped food tough, the feeding machine is provided with a material homogenizing device, an egg collecting device is fixedly arranged at the outer side of one end of the machine frame, water level pressure regulating devices with the same number as the layer number of the poultry cages are arranged at the inner side of one end of the machine frame, and the other end of the machine frame is provided with an excrement cleaning machine.

Owner:HENAN JINFENG POULTRY EQUIP

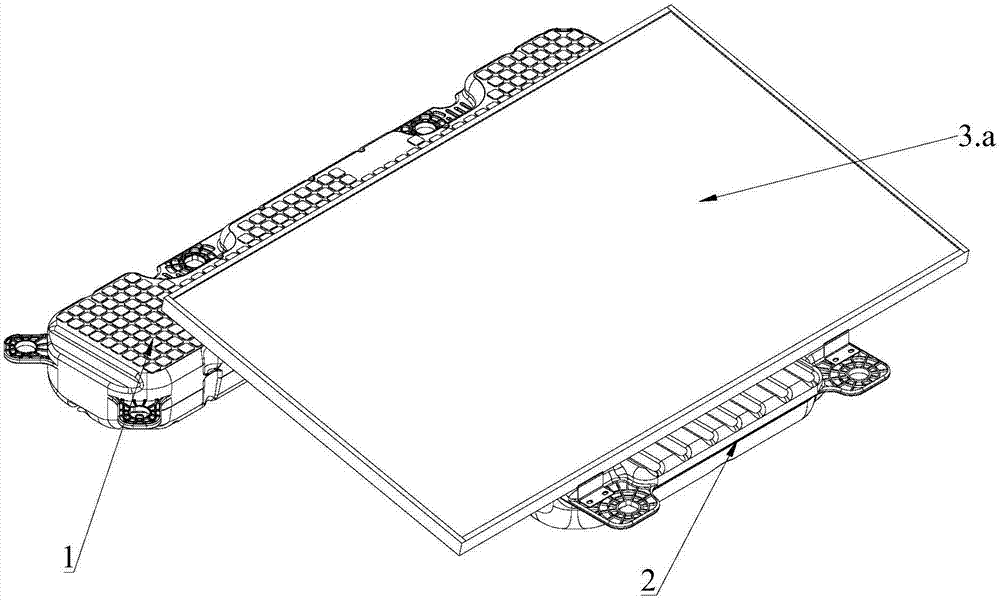

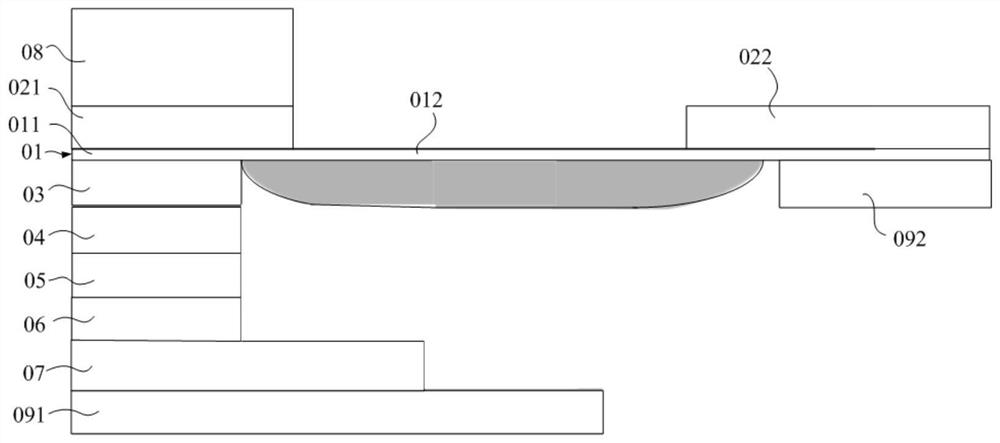

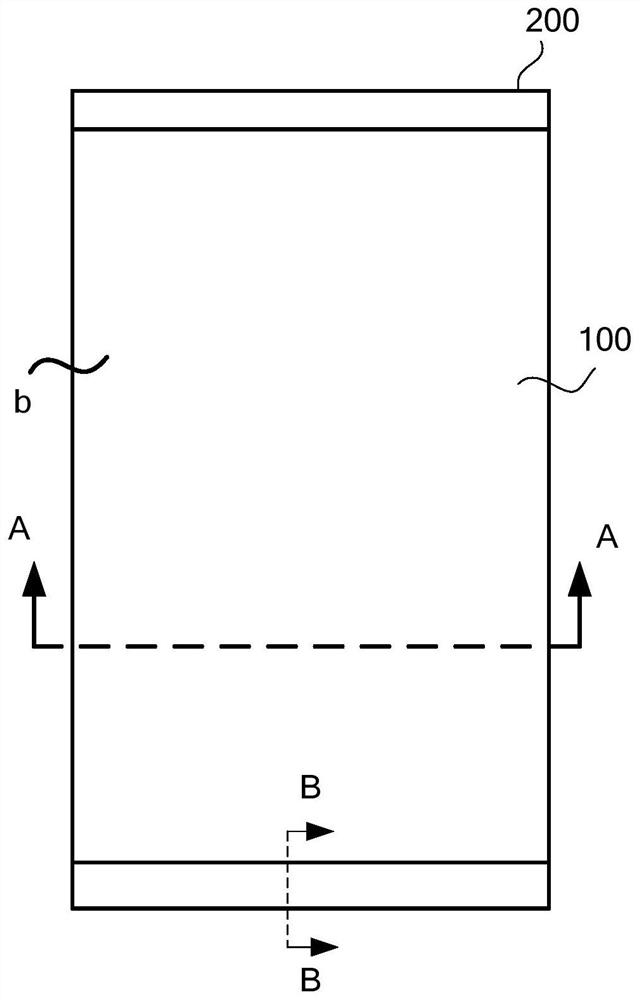

Display assembly and assembling method thereof, and display device

PendingCN111816082AAvoid bending deformationPrevent peelingInput/output processes for data processingIdentification meansDisplay deviceStructural engineering

The invention discloses a display assembly and an assembling method thereof, and a display device, relates to the technical field of display, and aims to solve the problem that a flexible display panel is easy to peel off from other film layers after being bent. The display assembly comprises a flexible display panel, a circuit board, a diaphragm assembly, a cover plate, a first supporting layer and a second supporting layer, wherein the flexible display panel comprises a panel body and a bent part, the first end, in the extending direction of the bent part, of the bent part is connected withthe edge of one side of the panel body, the circuit board is arranged on the back side of the panel body and is connected with the second end of the bent part, the diaphragm assembly is arranged on the display side of the panel body in a stacked mode, the cover plate is arranged on the side, away from the panel body, of the diaphragm assembly in a stacked mode, the first supporting layer is arranged on the back side of the panel body in a stacked mode and located between the panel body and the bent part, and the second supporting layer is arranged at the first end of the bent part and locatedbetween the cover plate and the bent part. The display assembly can be used in display devices such as mobile phones and the like.

Owner:BOE TECH GRP CO LTD

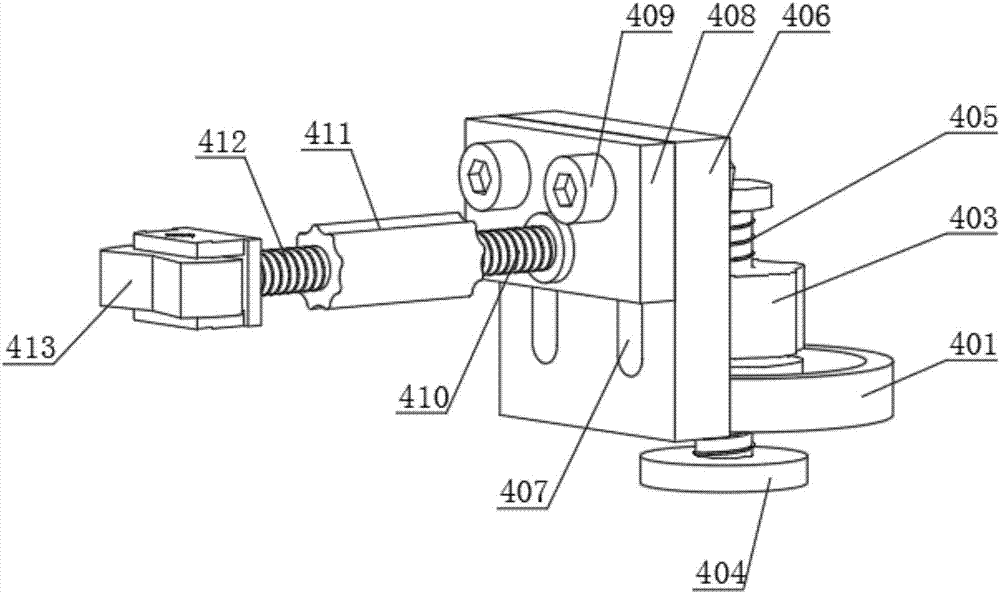

New structure fixing fixture for metal irregular workpiece machining

InactiveCN107877216AIncrease clamping forceGuaranteed firmnessPositioning apparatusMetal-working holdersEngineeringMechanical engineering

The invention provides a new structure fixing fixture for metal irregular workpiece machining. The new structure fixing fixture comprises adjusting sliding grooves, clamping devices, a rotary disc, aheight adjusting groove, a first double-screw bolt, an adjusting nut, a second double-screw bolt and a clamping block; and the two adjusting sliding grooves are formed in the two sides of the workingtable, the clamping devices are installed on the adjusting sliding grooves, adjusting screw rods are inserted into ring grooves and penetrate the adjusting sliding grooves, pressing blocks are fixedlyinstalled at the bottoms of the adjusting screw rods, a jacket is fixedly welded to the tail end of the second double-screw bolt, and the clamping block is fixed to the jacket through a rotating shaft. According to the new structure fixing fixture, irregular workpieces are clamped through the four clamping devices, the fixing angle of the clamping block to the irregular workpieces can be changedthrough the rotary disc and the sliding grooves, and the height of the clamping block can be changed through the height adjusting groove; and through adjustment of the first double-screw bolt, the second double-screw bolt and the adjusting nut, the clamping force to the irregular workpieces can be improved, the clamping firmness is guaranteed, and the using stability is improved.

Owner:GUIZHOU UNIV

Construction method of laid tiles of sloping roof

InactiveCN103334554AGuaranteed firmnessExtended service lifeRoof covering using tiles/slatesBuild-up roofsCopper wireThermal insulation

The invention discloses a construction method of laid tiles of a sloping roof, and relates to the technical field of architectural engineering, in particular to a construction technology for hanging tiles of the sloping roof. The construction method comprises the following steps of: pre-burying a vertical steel bars, one ends of which stretch out of a foundation concrete layer, in the foundation concrete layer of a roof; constructing a mortar waterproof layer on the foundation concrete layer; sticking thermal insulation boards on the waterproof mortar waterproof layer, and inserting the corresponding steel bar into each thermal insulation board; binding a reinforcing mesh on the roof outside the thermal insulation boards, and fixing the reinforcing mesh through the steel bars pre-buried in the foundation concrete layer; drilling holes on each laid tile, inserting a copper wire into the hole of each laid tile, straightening the copper wire, tightly and firmly binding the copper wire and the reinforcing mesh, and tamping the laid tiles and the thermal insulation boards through fine aggregate concrete. According to the invention, construction of the laid tiles is realized on the thermal insulation layer, due to the action of the vertical reinforcement and the reinforcing mesh, the thermal insulation boards and the laid tiles are firmly located to withstand the test of monsoon climate in spring and autumn, so that the laid tiles of the roof have longer service life.

Owner:华新建工集团有限公司

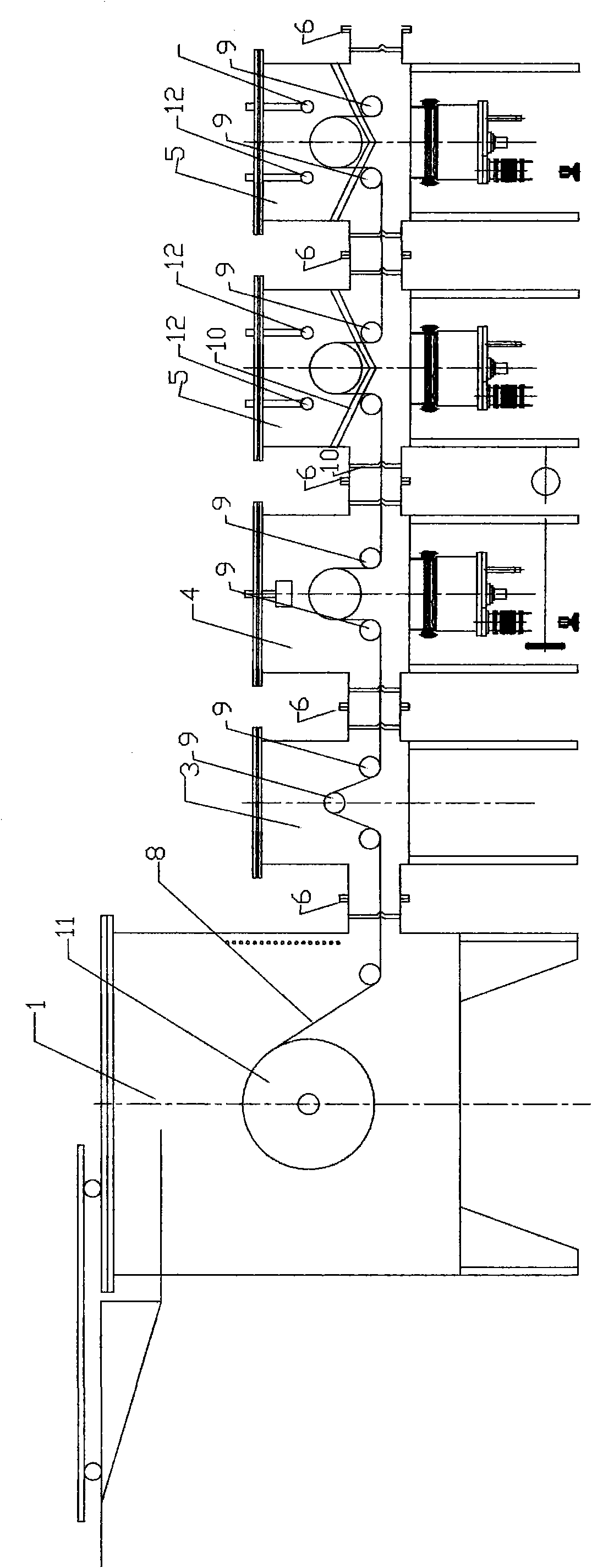

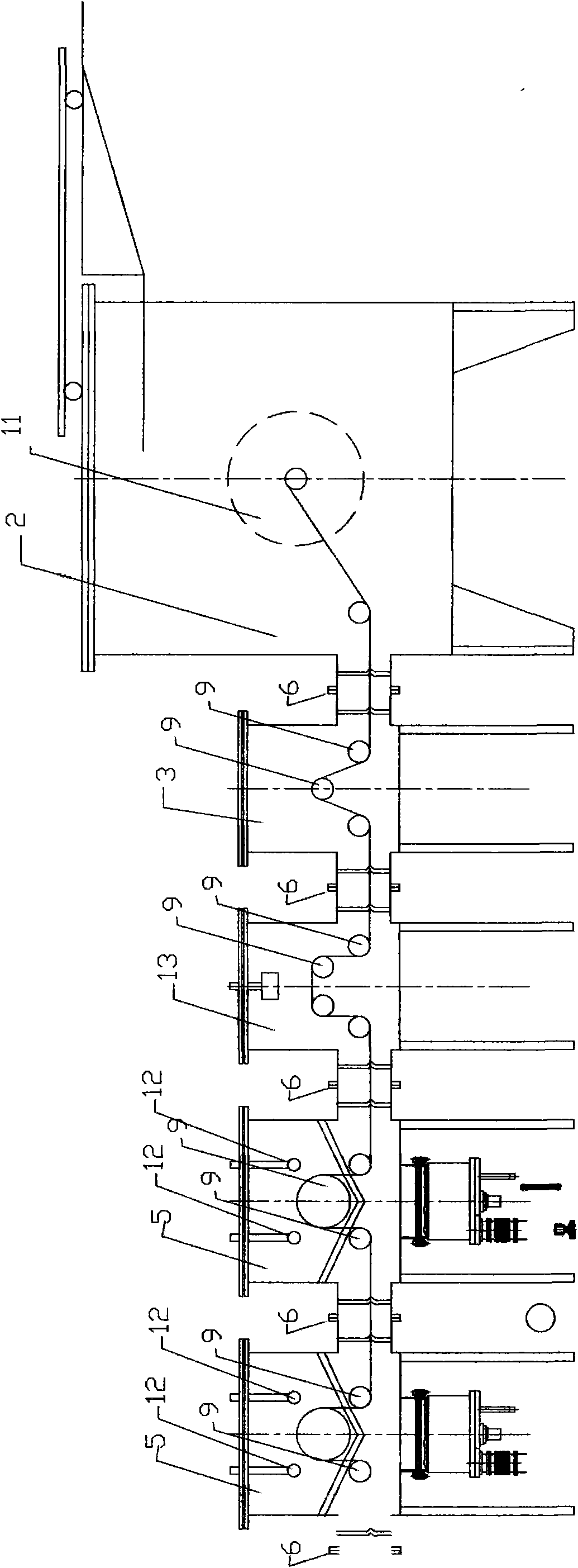

Modularization solar selective coat continuous coating device

InactiveCN101781754AFully playGuaranteed tightnessVacuum evaporation coatingSputtering coatingProduction lineEngineering

The invention belongs to the field of the heat collection plate coating in the solar equipment, and relates to a continuous solar selective absorption film coating production device which adopts the modularization design, can be flexibly assembled and adjusted and is applicable to different coating processes. The modularization solar selective coat continuous coating device comprises a pretreatment chamber and at least one process chamber, wherein both the pretreatment chamber and the process chamber are provided with a vacuum pump, two ends of the pretreatment chamber and the process chamber are respectively provided with a feeding port and a discharging port, both the feeding port and the discharging port on two ends of the pretreatment chamber and the process chamber are provided with a connection device with the same size and shape or being matched with each other, and the pretreatment chamber and the process chamber are sequentially connected through the connection devices to form an integral continuous coating device. The invention can provide a novel coating production device which adopts the modularization design and realizes different production and processing technologies by reducing different process chambers or by adjusting the position of the process chambers in the production line.

Owner:SHENZHEN PROSUNPRO SOLAR ENERGY

Method for preparing coating on surface of interventional catheter, interventional catheter and interventional device

ActiveCN104558658AExcellent abrasion resistanceGuaranteed firmnessSurgeryCatheterCatheter devicePlasma treatment

The invention discloses a method for preparing a coating on the surface of an intervention catheter, an intervention catheter and an interventional device, the method comprises the following steps: firstly, performing plasma treatment on the surface of the intervention catheter, then grafting acrylic acid on the plasma treated surface of the intervention catheter; preparing a base painting and a top painting; coating the surface of the intervention catheter respectively with the prepared the base painting and top painting; and post treating the intervention catheter to obtain the intervention catheter with a hydrophilic lubricating coating on the surface. The intervention catheter has excellent hydrophilic lubricity and firmness.

Owner:BEIJING DEMAX MEDICAL TECH

Manufacturing method of multi-direction four-anchor-head integral steel anchor beam

ActiveCN107253026AReasonably preparedSmooth manufacturing qualityBridge structural detailsManufacturing qualityWelding

The invention relates to a manufacturing method of a multi-direction four-anchor-head integral steel anchor beam. The manufacturing method comprises the following steps of (1) manufacturing of a web unit, (2) manufacturing of a bottom board unit, (3) manufacturing of an anchor backing plate, (4) assembly welding of an anchor head unit, (5) assembly of the web unit with the anchor head unit, (6) assembly of the bottom board unit, and (7) assembly of other functional boards. The manufacturing method of the multi-direction four-anchor-head integral steel anchor beam has the advantages that the manufacturing method mainly comprises the steps of manufacturing of the web unit, manufacturing of the bottom board unit, manufacturing of the anchor backing plate, assembly welding of the anchor head unit, assembly of the web unit with the anchor head unit, assembly of the bottom board unit, and assembly of other functional boards, the manufacturing process is reasonable, and the manufacturing quality and assembly welding smoothness are ensured. The manufacturing method further has the advantages of being simple, convenient to implement and high in precision.

Owner:中铁山桥(南通)有限公司

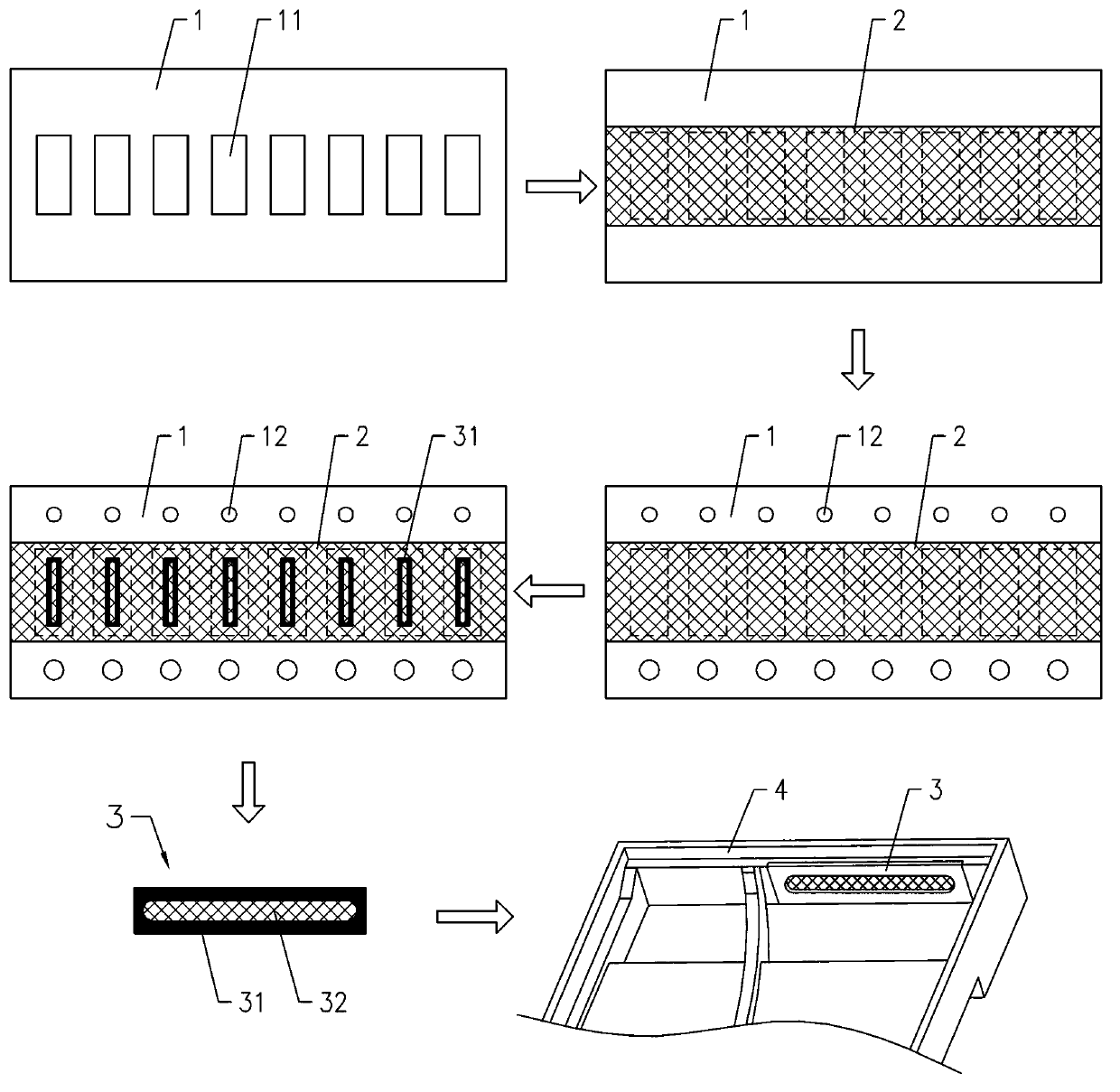

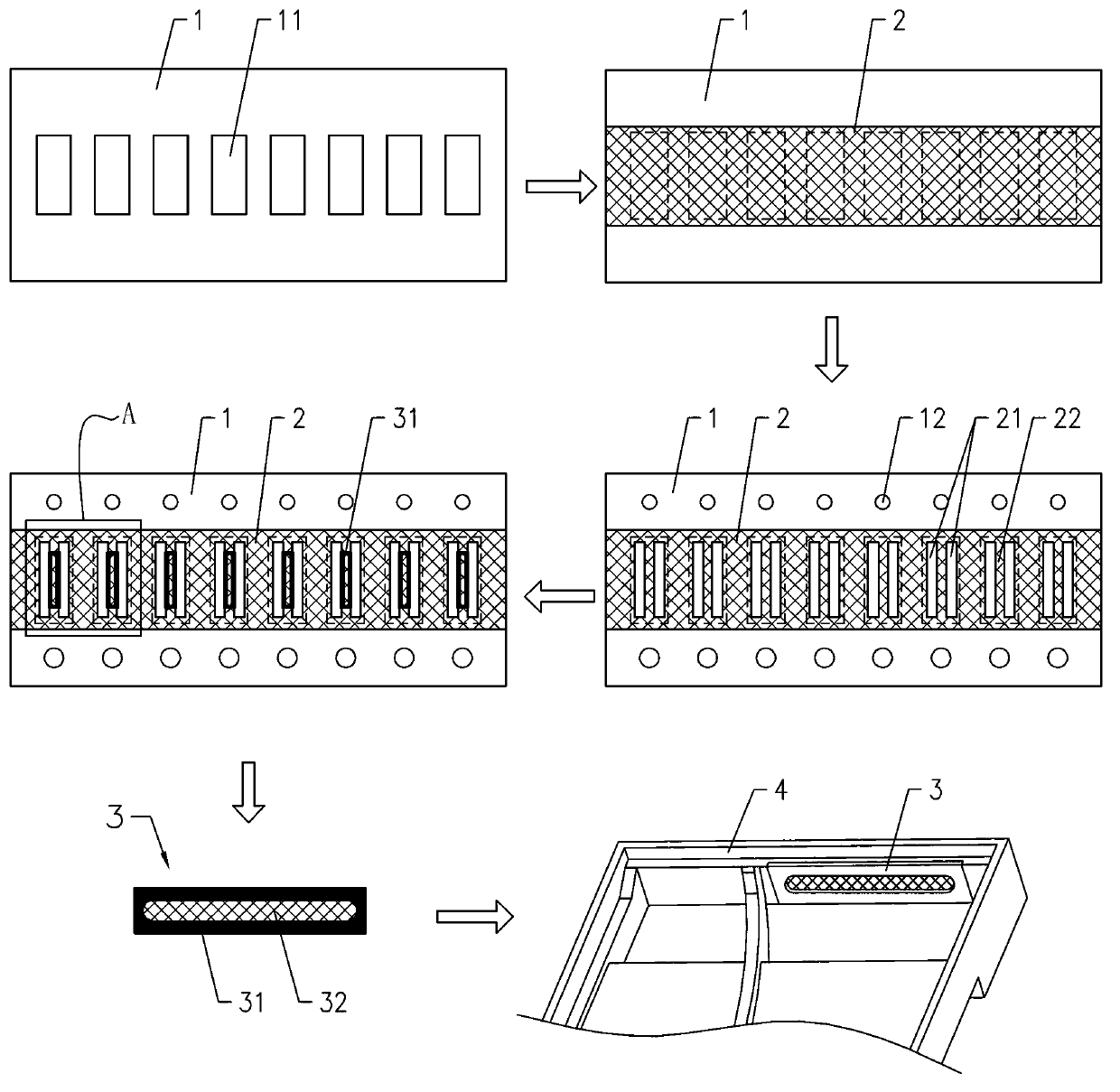

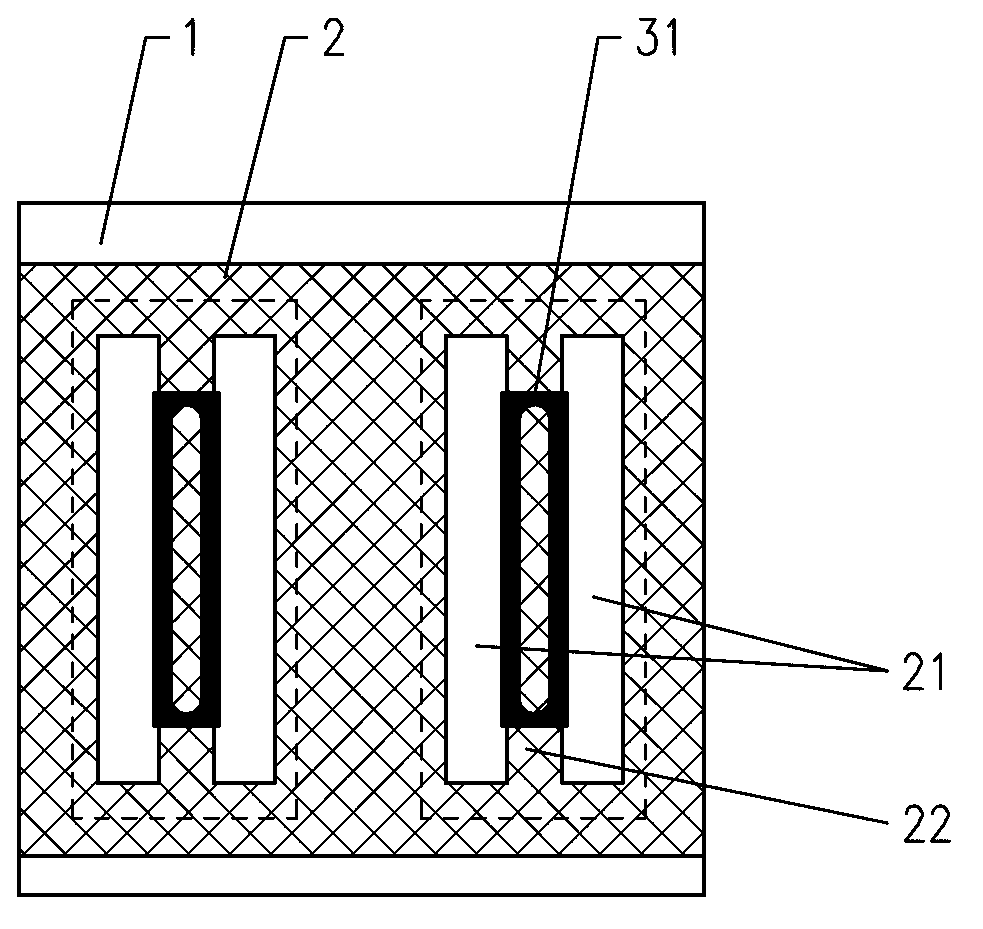

Method for assembling non-metallic flexible net at sound holes of acoustic device

ActiveCN103281665AImprove binding stabilityRealize the assemblyElectrical transducersEngineeringMechanical engineering

The invention discloses a method for assembling a non-metallic flexible net at sound holes of an acoustic device. The method comprises the following steps of (1) manufacturing a base plate, and forming a plurality of hollow holes in the base plate; (2) manufacturing a non-metal flexible net belt, adhering the flexible net belt to the base plate, and covering all hollow holes; (3) putting the base plate adhered with the flexible net belt into a first injection mold, and carrying out injection molding on the flexible net belt corresponding to each hollow hole to form annular first injection molding bodies which are combined together with the flexible net belt; (4) cutting the flexible net belt around the first injection molding bodies, so as to obtain an independent first injection molding piece; and (5) putting the first injection molding piece into a second injection mold, carrying out secondary injection molding to form an acoustic device casing which is combined together with the first injection molding piece, and using inner holes of the first injection molding bodies as the sound holes of the acoustic device. The method has the advantages that the assembly of the non-metal flexible net belt is convenient for operation, and the assembly efficiency and the assembly quality are improved.

Owner:GOERTEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com