Well sealing waterproof construction method for dewatering well

A construction method and technology for dewatering wells, applied in infrastructure engineering, protective devices, buildings, etc., can solve problems such as failure to seal, hidden dangers in plugging quality, and inability to fully guarantee the bottom plate, etc., to achieve enhanced strength, tight well sealing system, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

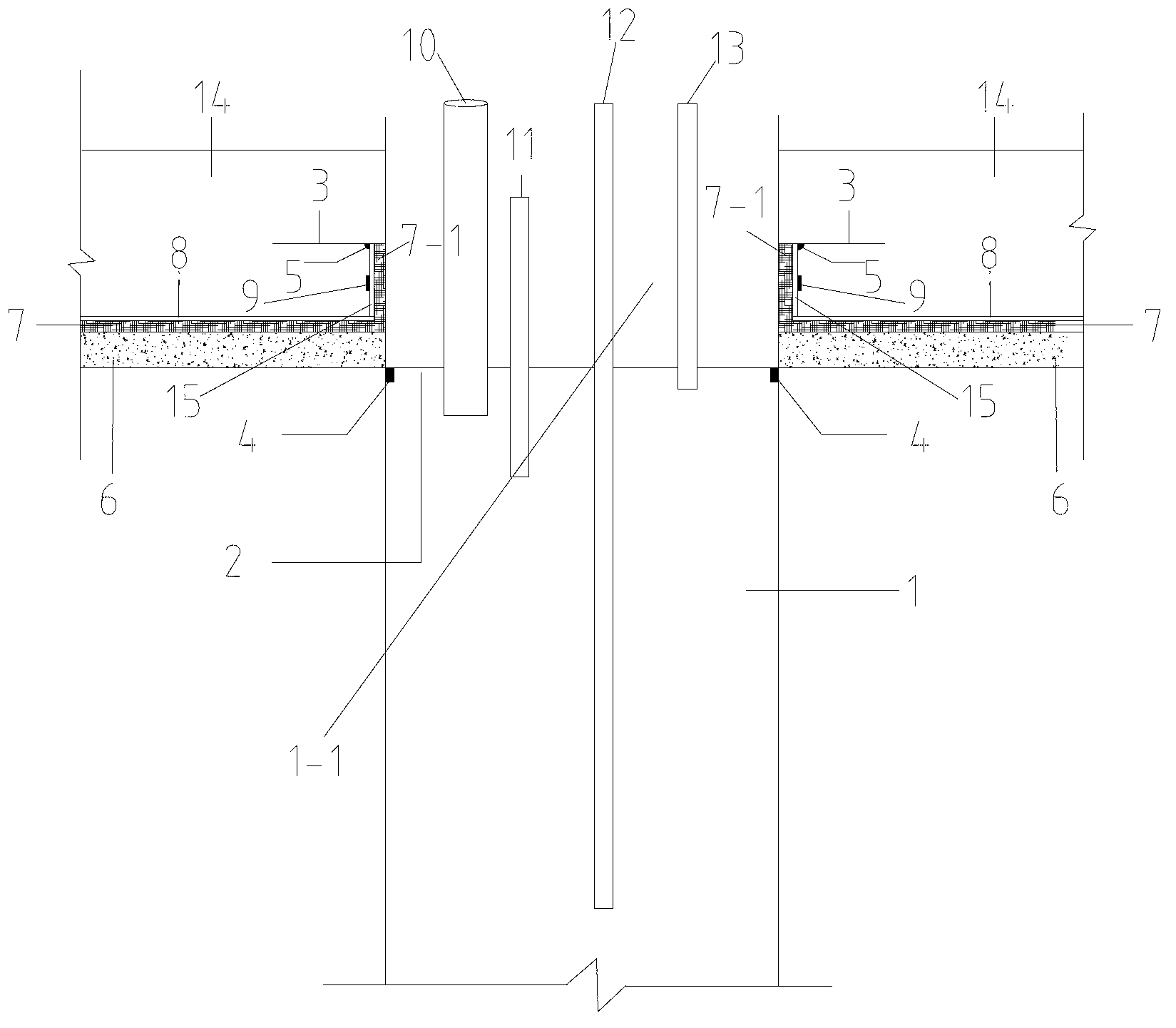

[0037] (1) carry out the construction of base cushion 6 around the dewatering well; (2) bury the steel sleeve 1 that the dewatering well sealing in the foundation pit is used, and the outer wall of the steel sleeve is provided with a water-stop steel plate 3; (3 ) Lay waterproof coiled material 7 on the base cushion 6 and roll the waterproof coiled material 7 along the outer wall of the steel sleeve 1 to the bottom of the waterproof steel plate 3, and then lay the waterproof coiled material 7 on the base cushion 6 Pour fine stone concrete protective layer 8 on the waterproof membrane layer 7; (4) dock two semicircular waterproof boards 15 on the outer wall of the waterproof membrane located on the outer wall of the steel sleeve 1 as shown in Figure 7-1 (5) Use copper bars 9 to tighten the entire waterproof board 15; (6) Inject and seal at the joint position where the two semicircular waterproof boards 15 are docked and the intersection of the top of the entire waterproof board ...

Embodiment 2

[0040] (1) carry out the construction of base cushion 6 around the dewatering well; (2) bury the steel sleeve 1 that the dewatering well sealing in the foundation pit is used, and the outer wall of the steel sleeve is provided with a water-stop steel plate 3; (3 ) Lay waterproof coiled material 7 on the base cushion 6 and roll the waterproof coiled material 7 along the outer wall of the steel sleeve 1 to the bottom of the waterproof steel plate 3, and then lay the waterproof coiled material 7 on the base cushion 6 A protective layer of fine stone concrete 8 is poured on the waterproof coiled material layer 7; (4) two semicircular waterproof boards 15 are docked and clamped on the outer wall of the waterproof coiled material located on the outer wall of the steel sleeve 1; (5) copper strips and 9 hoops are used Tighten the entire waterproof board 15; the copper bar 9 is hooped at the middle position of the outer wall of the waterproof board 15 formed by the two semicircles. (6)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com