Patents

Literature

543results about How to "Solve the waterproof problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

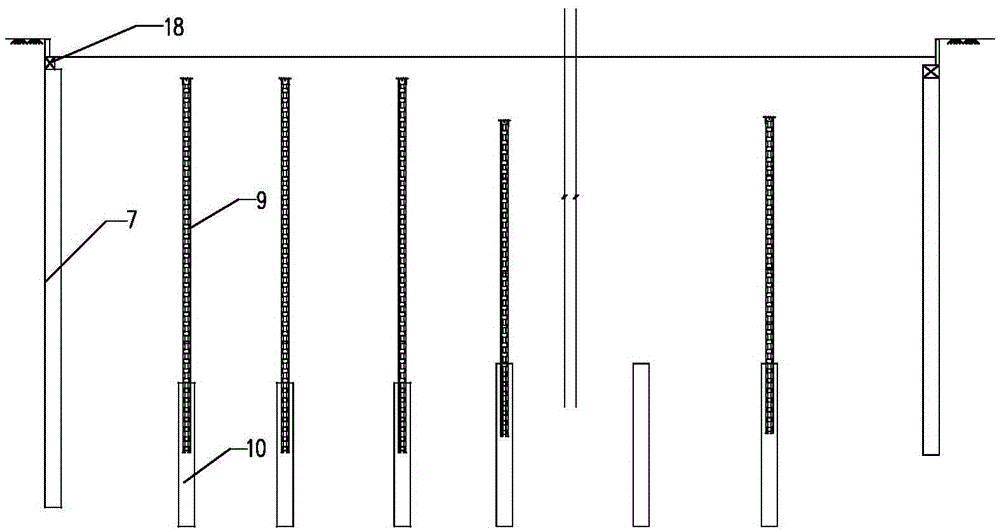

Peaty soft soil stratum subway station construction technology

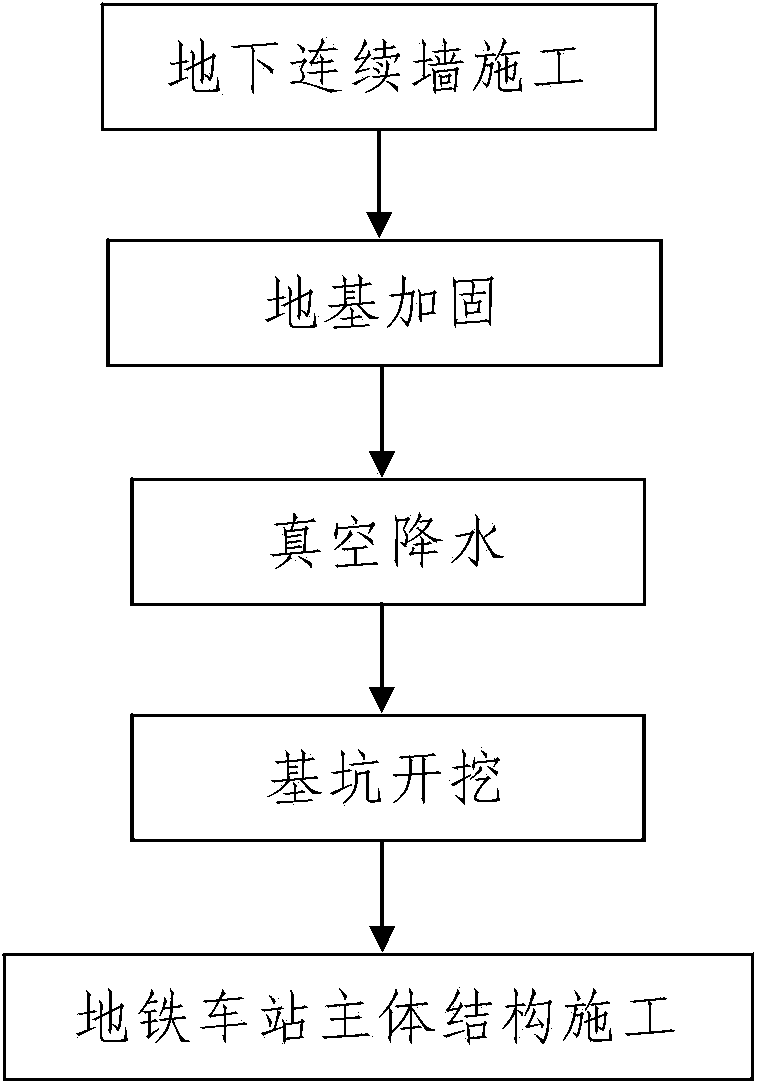

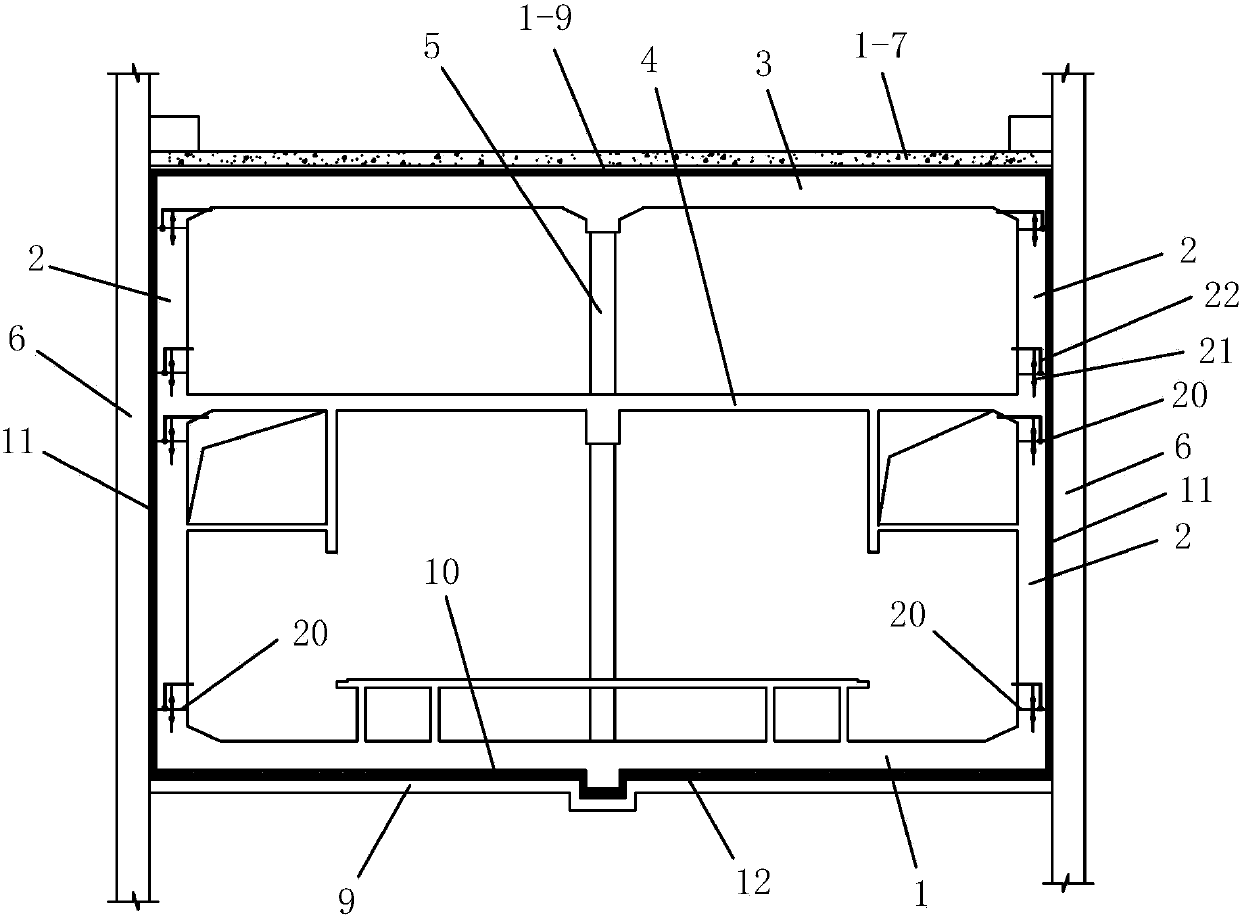

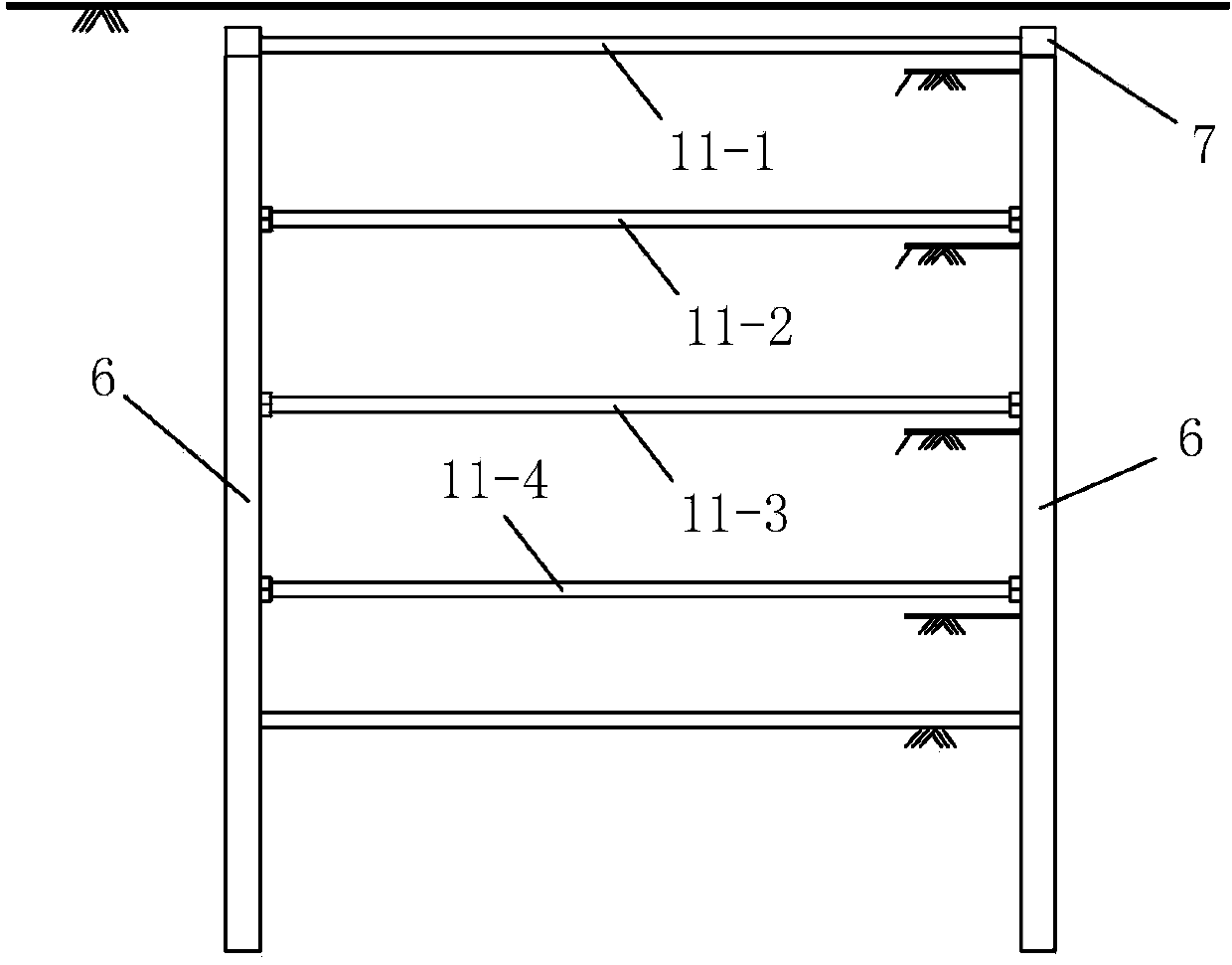

ActiveCN103590425ASimplify construction stepsEasy constructionArtificial islandsProtective foundationSlurry wallReinforced concrete

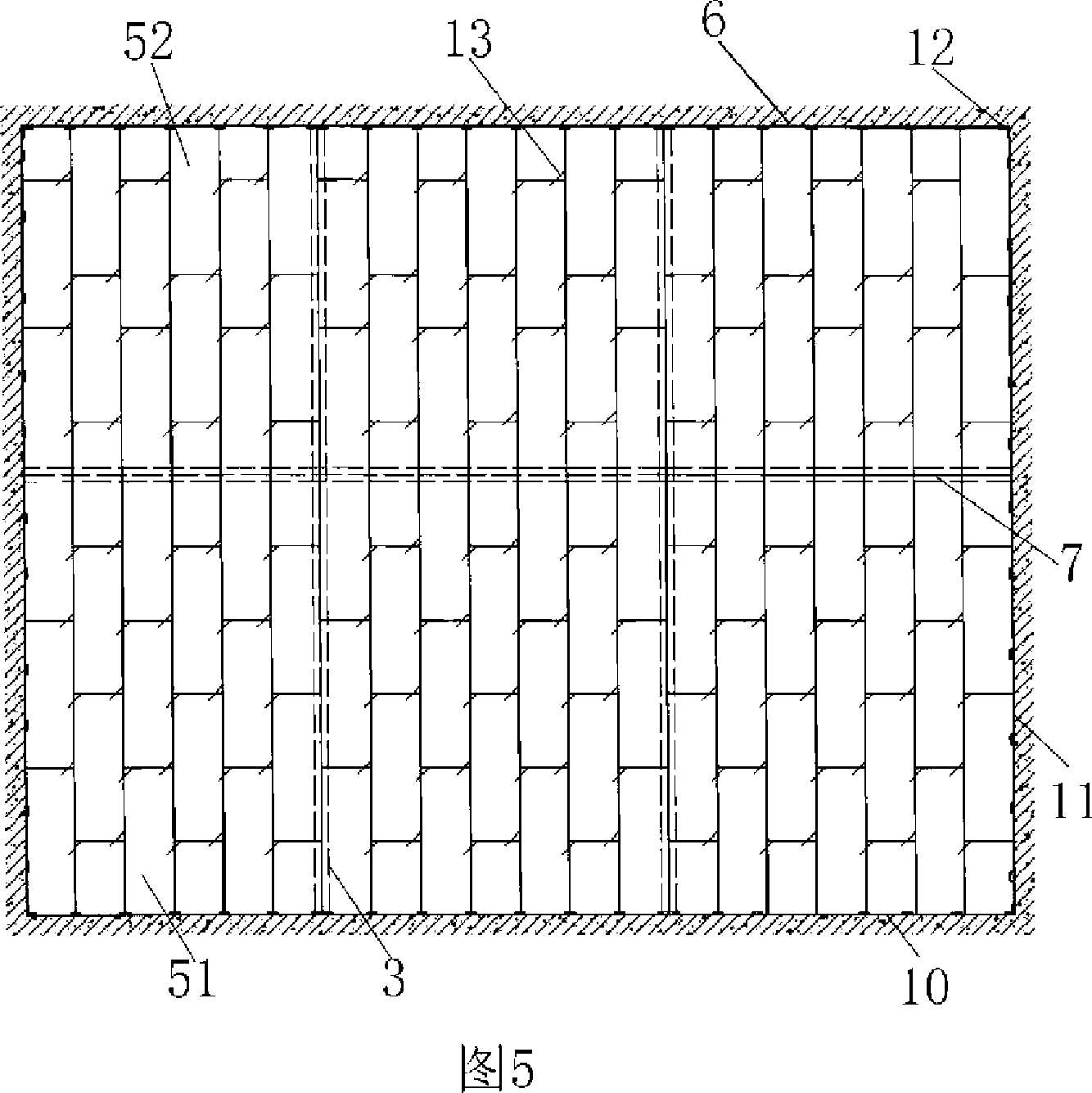

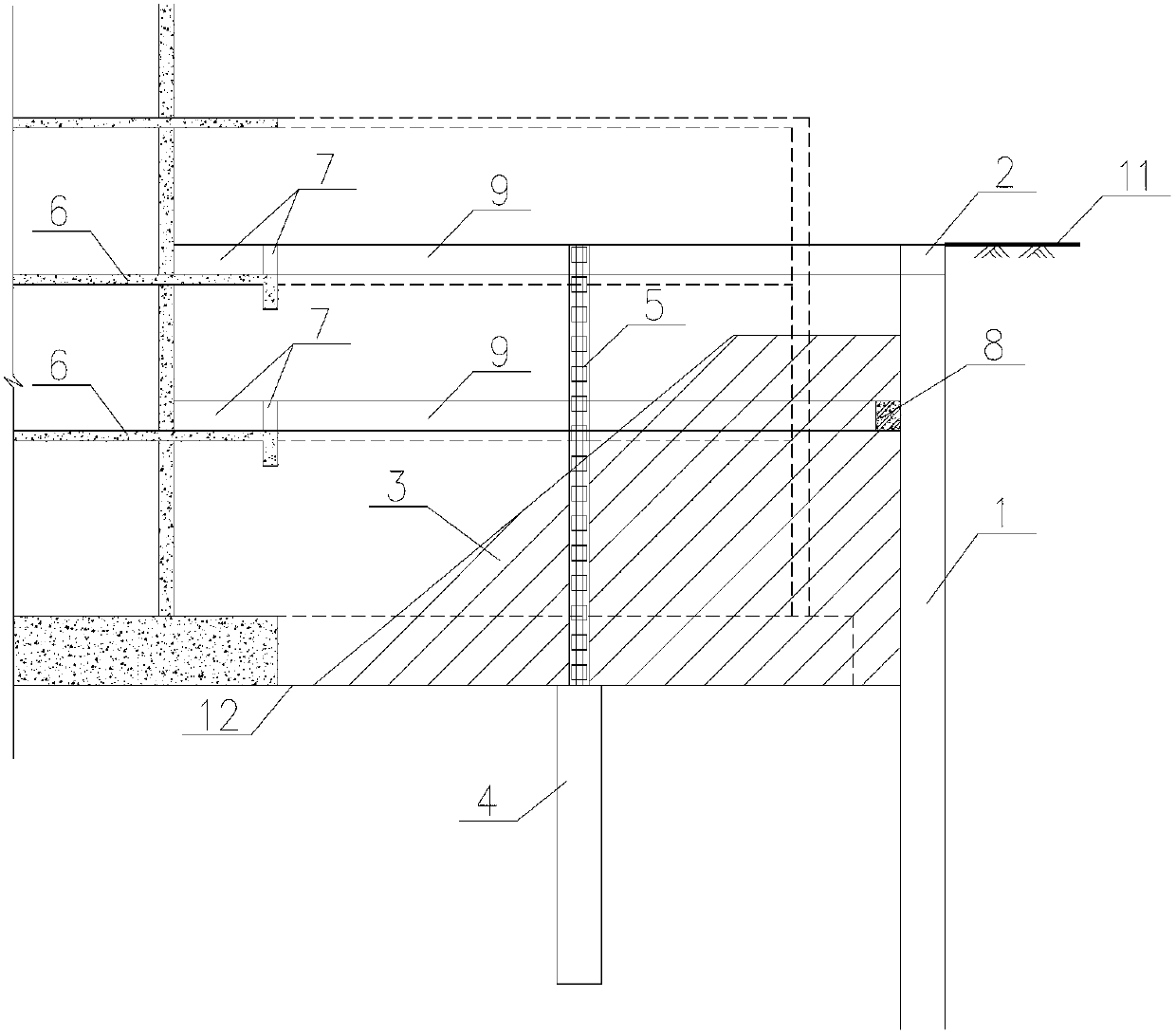

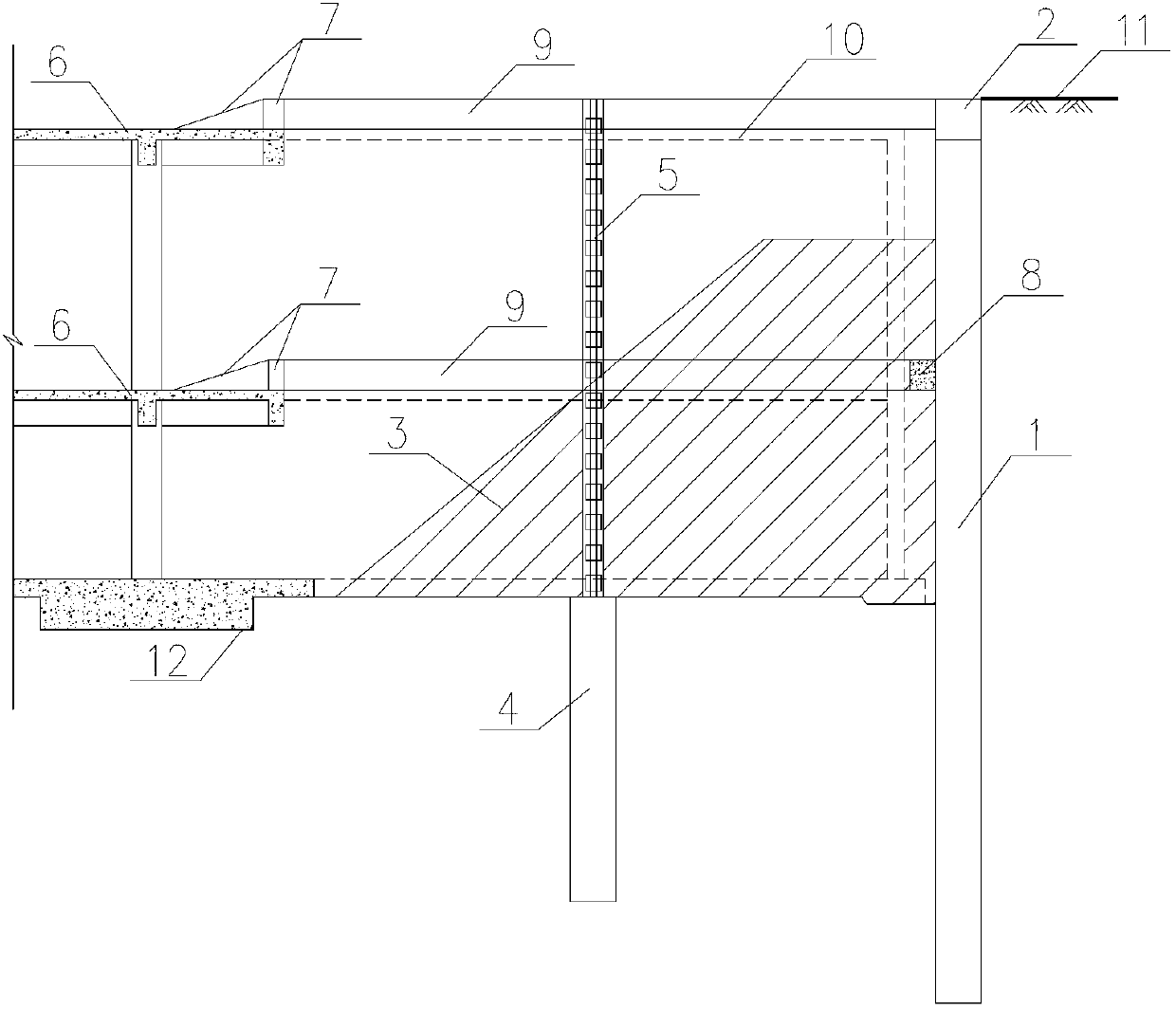

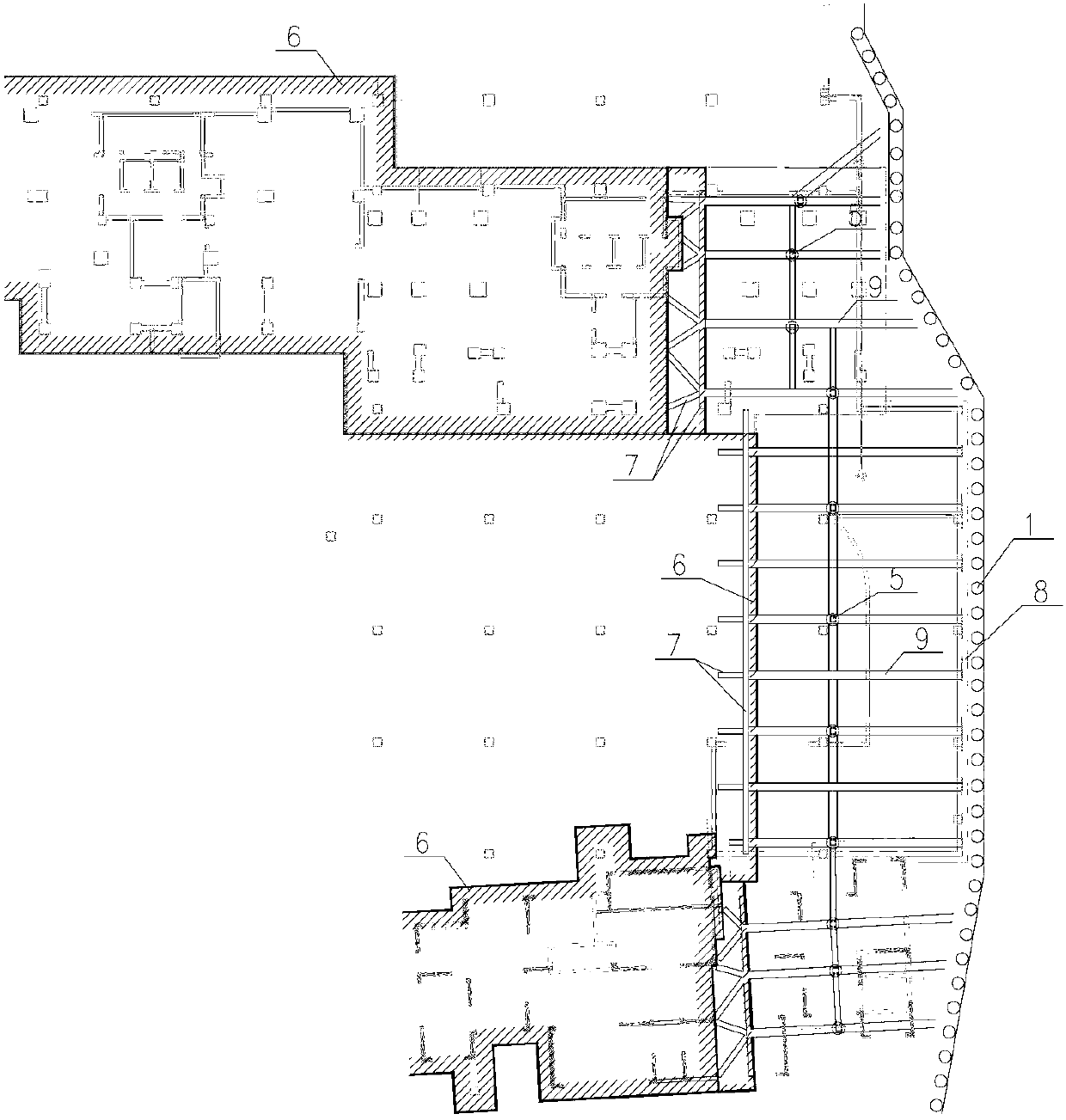

The invention discloses a peaty soft soil stratum subway station construction technology. A main structure of a constructed subway station comprises base plates, side walls, top plates and middle plates distributed between the top plates and the base plates. Underground consecutive walls are arranged on outer sides of the two side walls. The base plates, the side walls, the middle plates and the top plates are all of a rebar concrete structure formed by pouring waterproof concrete. The subway station construction technology comprises the following steps: (1) underground consecutive wall construction, (2) foundation reinforcement, namely, three-shaft stirring piles are used for reinforcing the foundation of excavated foundation pits, (3) vacuum water falling, namely conducting vacuum well point water falling construction on the foundation pits needing excavating, (4) foundation pit excavation, namely, an open excavation method is used for conducting earthwork excavation on the foundation pits needing excavating with a plurality of excavating layers from top to bottom, (5) subway station main structure construction. The method is simple, convenient to realize, quick in construction speed, capable of being ensured in construction quality easily, and good in construction effect, and enables the subway station construction process of peaty soft soil stratum to be completed simply, quickly and with high quality.

Owner:中铁二十局集团第五工程有限公司

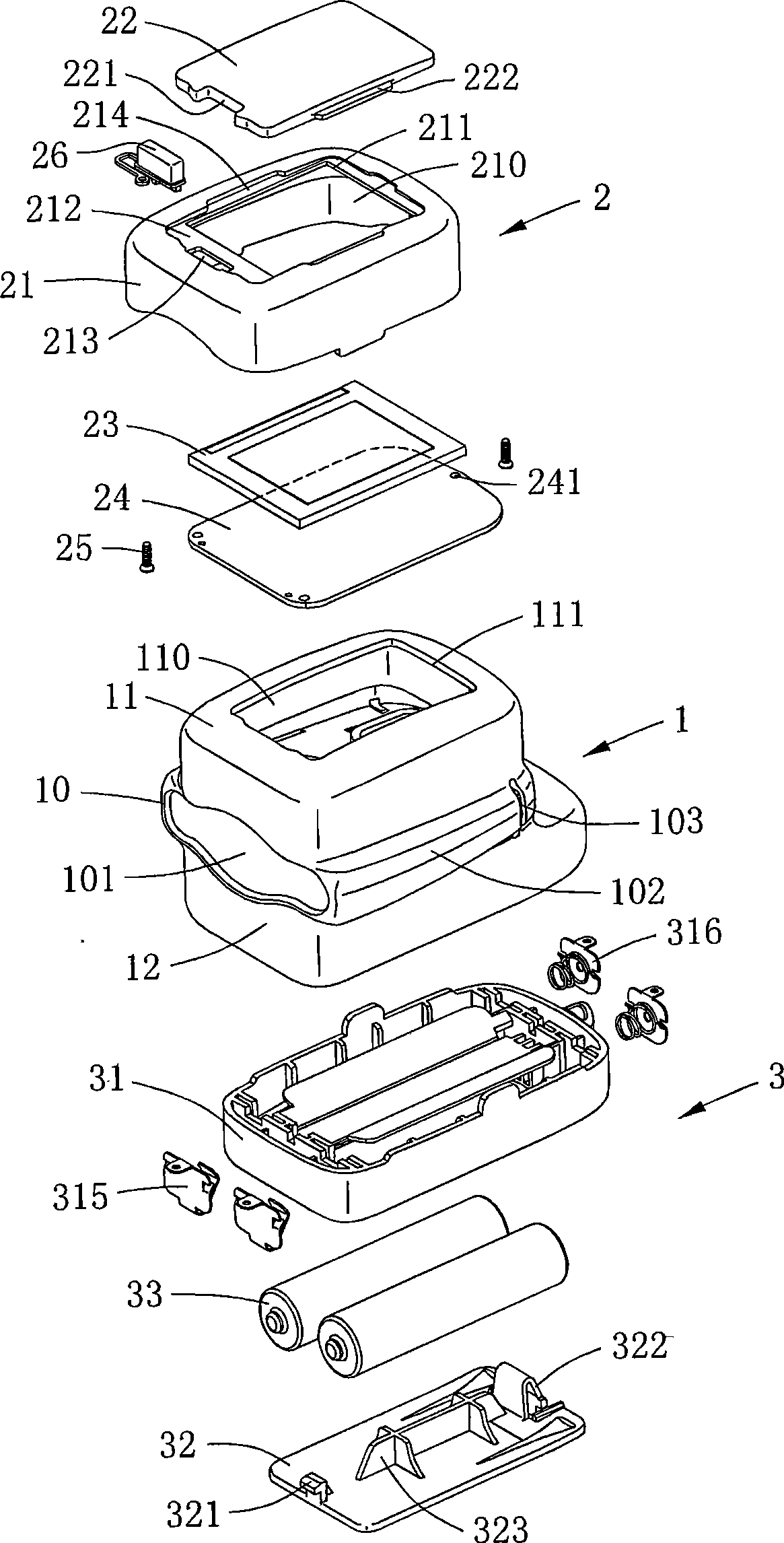

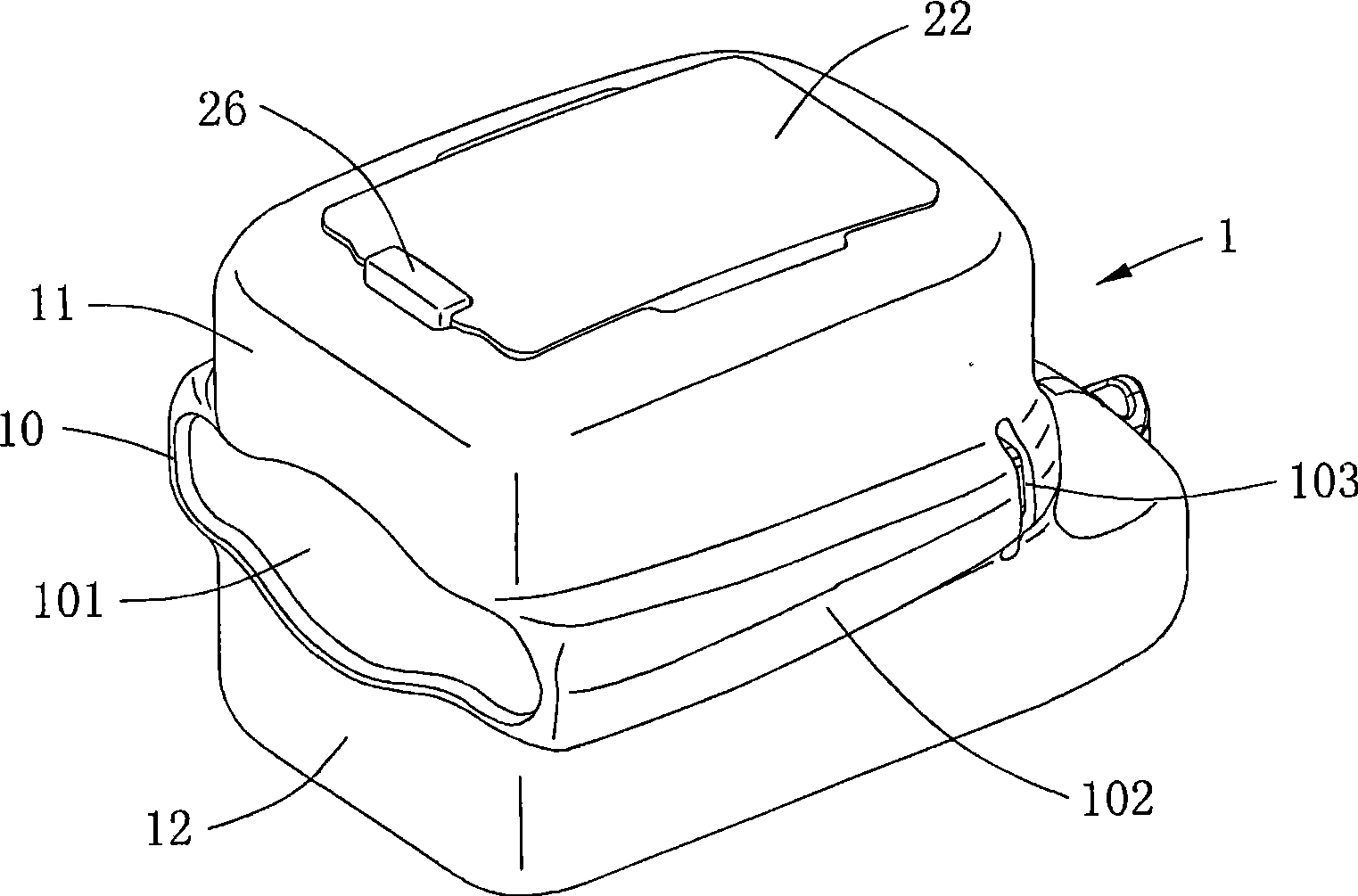

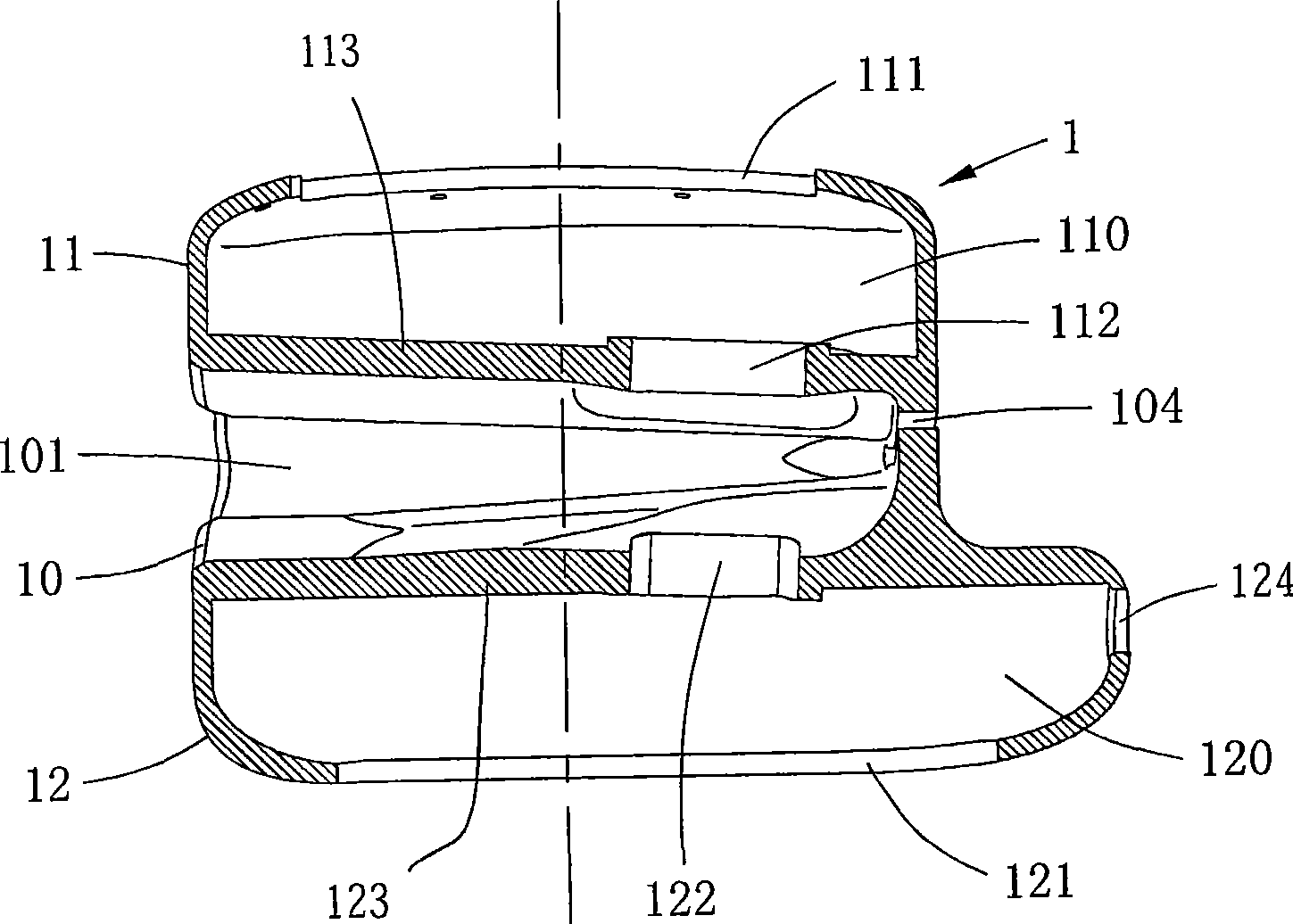

Finger type instrument for detecting sphygmus and blood oxygen saturation

InactiveCN101411618AAvoid sizeEffective protectionDiagnostic recording/measuringSensorsPulse oximetersEngineering

The invention discloses a finger pulse oximeter, which relates to the field of the detection of pulse and blood oxygen saturation. The finger pulse oximeter comprises a detection host and a soft shell, wherein the detection host comprises a circuit board, a display screen electrically connected with the circuit board and so on, the soft shell comprises a soft finger cot which is provided with insert holes for fingers of examinees to insert, and a first receiving part which is integrated with the soft finger cot and is provided with a first receiving chamber, and the circuit board and the display screen of the detection host are received and fixed in the first receiving chamber. The finger pulse oximeter overcomes the pressure difference existing in the prior product caused by different finger thicknesses of the examinees, and ensures that the fingers are closely contacted with a photoelectric device, thereby effectively eliminating the influence of the pressure and ambient light on the detection accuracy, effectively protecting the host, and preventing the break and damage caused by falling or impact.

Owner:潘卫江

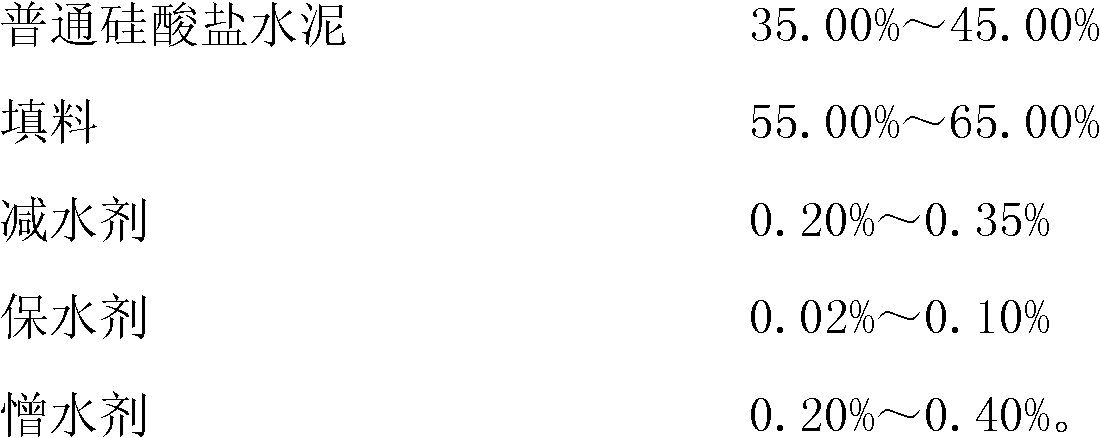

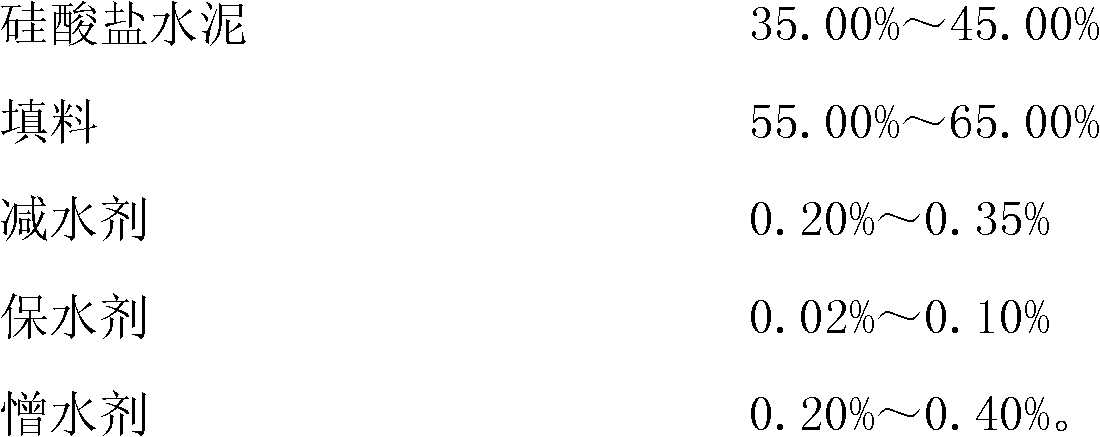

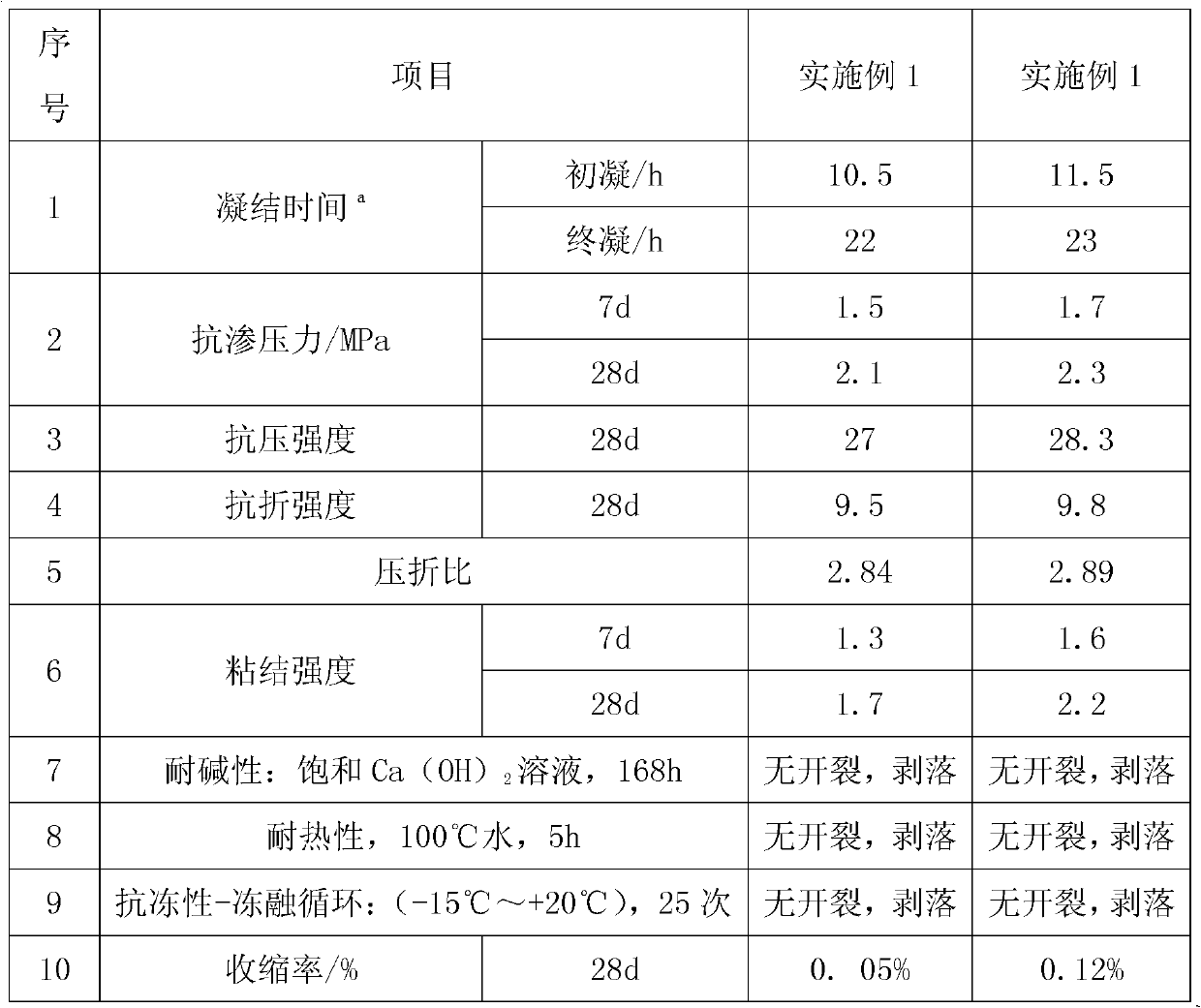

Two-component cement-based polymer rigid waterproof mortar

ActiveCN102701662ASolve the waterproof problemLow costUnderground chambersProtective foundationPolymer sciencePortland cement

The invention discloses two-component cement-based polymer rigid waterproof mortar which comprises liquid components and powder components, wherein the liquid components comprise butadiene-styrene copolymer emulsion, styrene-acrylate copolymer emulsion, coalescing agents, defoamers and water, and the powder components comprise Portland cement, filler, water reducers, water-retaining agents and water repellents. The two-component cement-based polymer rigid waterproof mortar not only has excellent water-proof and impermeable performances so as to effectively solve the waterproof problem of water-attaining surfaces or water-retaining surfaces of concrete structures of underground engineering, interior decoration and the like, but also has high mechanical strength and is capable of resisting external mechanical impact. Besides, the two-component cement-based polymer rigid waterproof mortar has good cementing bond with concrete bases so that proneness to hollowing and shedding is avoided, and the newly stirred mortar low in viscosity facilitates thin coating of roll coating, brush coating or the like, so that construction efficiency is greatly improved, and use space and cost are saved.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +3

Dormant digging and separating construction method for underground two layers and multilayer composite lining structure

This is an underground hidden digging separated working method it is double layers or multiple layers complex lining brick structure. It contains: Use the existing shallow bury hidden digging technology to finish the lining bricks structure upper parts, and use the routine technology to finish the original support and protection. After finished the original protection and support of vault part, to spread out the water-proof plate and finish the middle separated plate to use the ground model, and pouring cement slurry to make the upper part structure. Under the protected of middle separated plate, then to make the structure under the middle separated plate, to finish the whole working process finally.

Owner:刘昌用

Inorganic thermal-insulation mortar used for building exterior walls of buildings and preparation method thereof

InactiveCN101863639AGood chemical stabilityGood weather resistanceSolid waste managementHigh resistanceWeather resistance

The invention relates to inorganic thermal-insulation mortar used for building exterior walls of buildings and a preparation method thereof. The invention is characterized in that the thermal-insulation mortar comprises the following components in part by weight: lightweight aggregate 100-150, binding material 100-150, fly ash 10-60, and additive 8.72-11.36. Compared with the prior art, the inorganic thermal-insulation mortar has the advantages of high weather resistance, high aging resistance, long service life, high fireproofing and flame-retarding performance, energy conservation and environment protection.

Owner:SHANGHAI MINJIANG TONG PROD

Self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover, and insulated wallboard

ActiveCN102249641ASolve insulation problemsSolve fire resistanceSolid waste managementCement mortarStearate

A self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover, and an insulated wallboard solve technical problem in a prior art that self-leveling cement mortar with weak waterproofness causes weak insulation effect of an insulated wallboard. A self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover is employed as a technique. Ingredients of the self-leveling cement mortar dry powder comprise a compound impervious component; and the impervious component is prepared by mixing a redispersible high-molecular polymer and one of an organosilicon waterproof agent and a stearate, or a mixture of the two, and accounts for 0.6-4.3wt% of the self-leveling cement mortar dry powder. A special impervious ingredient is added to enhance compactness, microdilatancy and low dry shrinkage property of the cement based self-leveling mortar, so as to substantially increase waterproof function and endurance of the cement based self-leveling mortar. Therefore, a problem that a cladded super-light foaming cement sheet material loses insulation function due to water penetration and problems of flame resistance and endurance are solved fundamentally.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

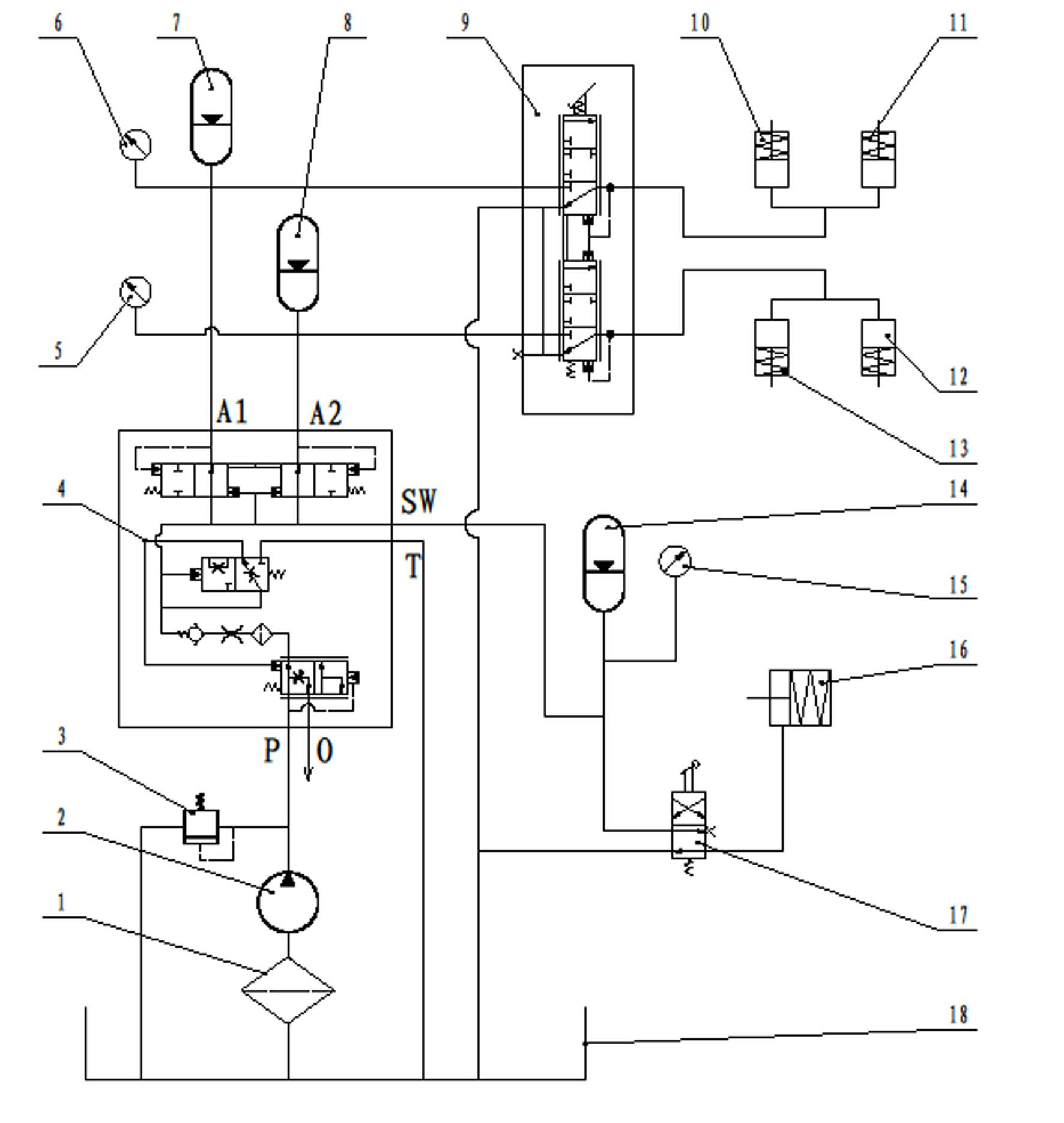

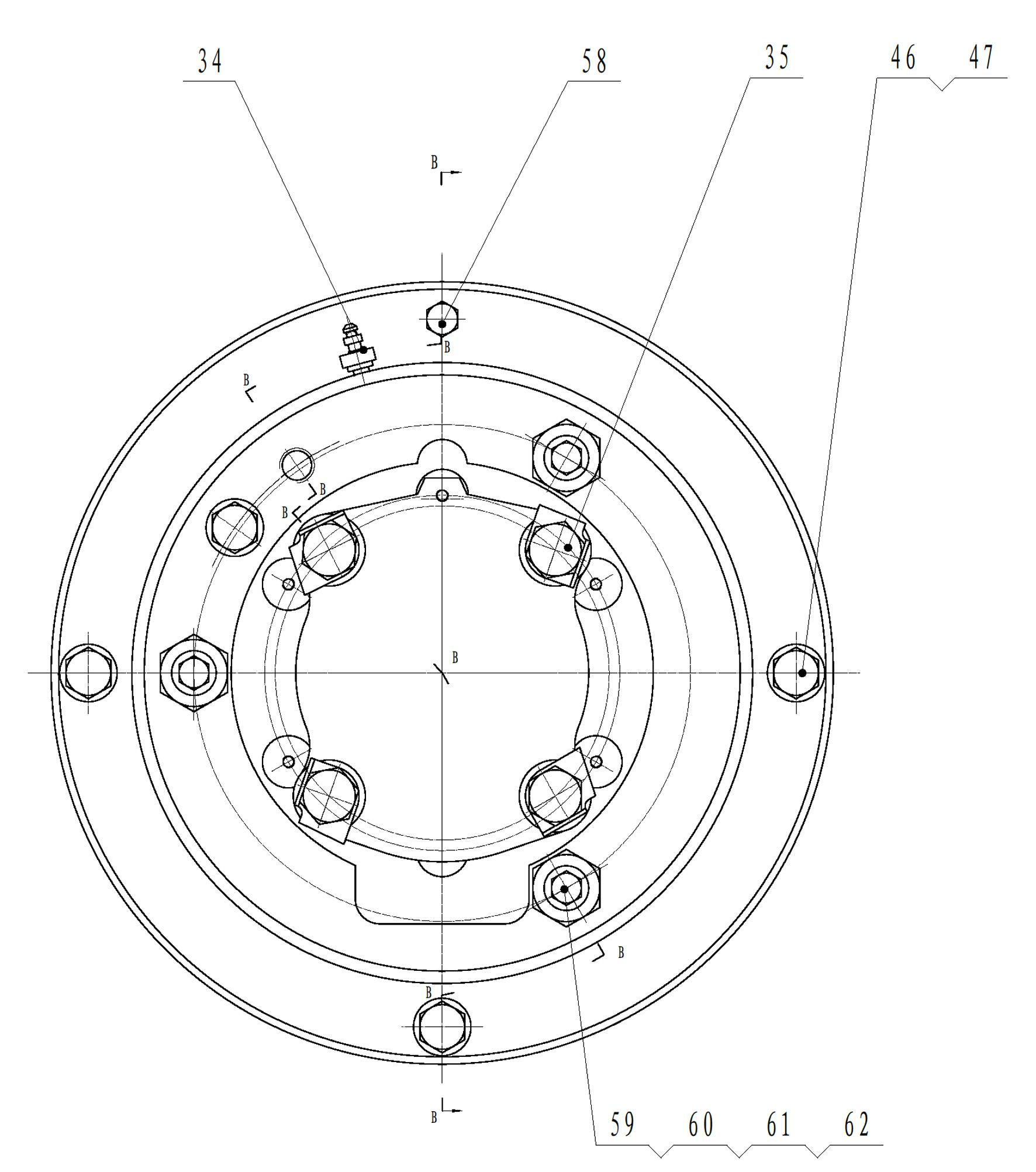

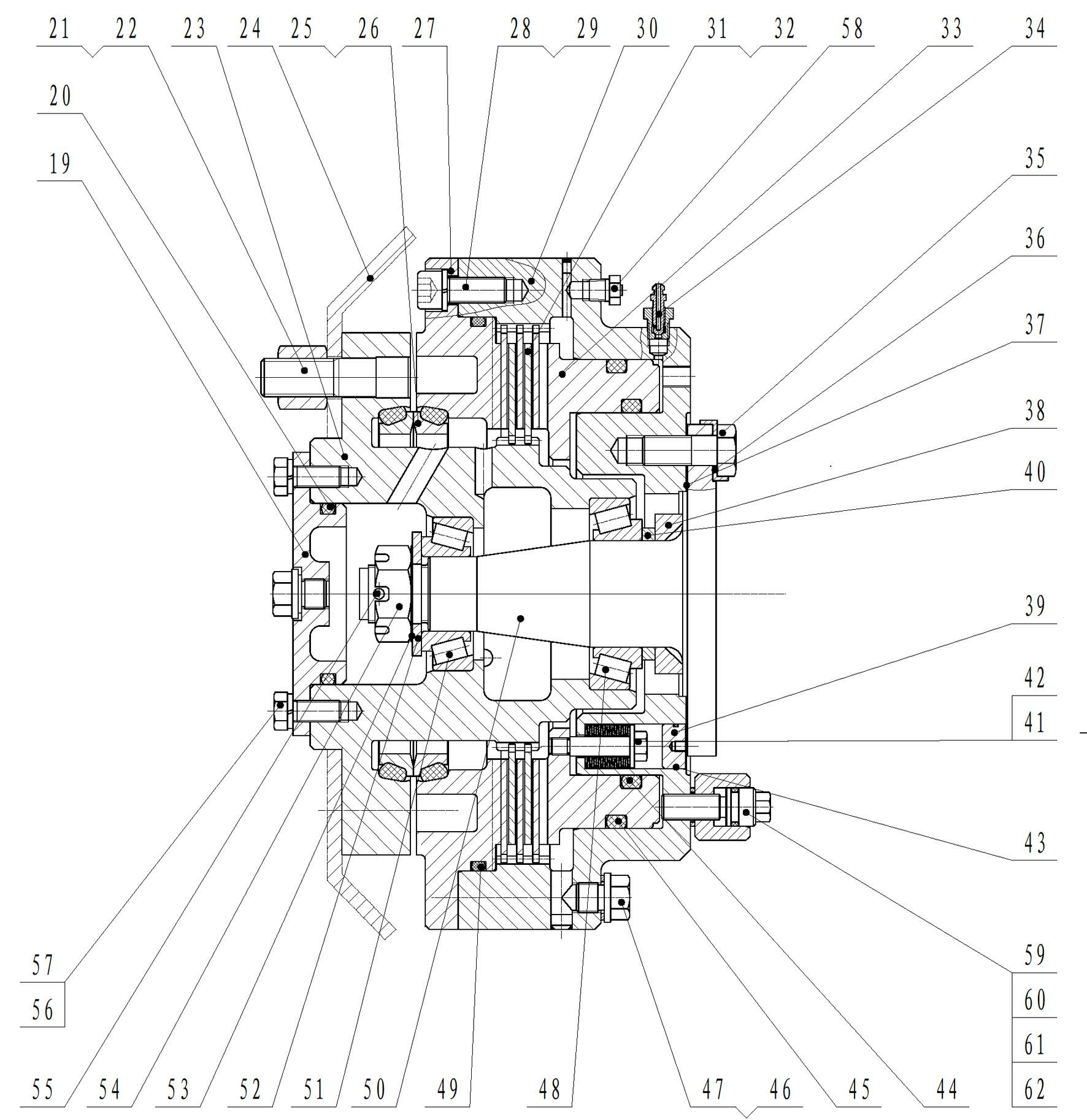

Double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for coal mine explosion-proof vehicle

ActiveCN102514562AImprove braking effectReduce labor intensityFluid braking transmissionDouble tubeHydraulic pump

The invention belongs to the technical field of braking devices of coal mine auxiliary conveying machinery, in particular to a double-tube fully-hydraulic braking device with closed wet-type multi-disc brakes for a coal mine explosion-proof vehicle. The invention aims to provide an explosion-proof, antipollution, stable, reliable and sensitive brand-new braking system. The braking device comprises a charging valve, wherein an oil feeding opening P of the charging valve is connected with a hydraulic pump, the oil opening A1 and opening A2 of the charging valve are connected with a front brake energy accumulator and a rear brake energy accumulator, and the oil opening SW is communicated with a parking braking oil pipe; the front and rear braking energy accumulators are connected with serial pedal braking valves respectively; the serial pedal braking valves are connected with a front service brake and a rear service brake respectively; parking braking energy accumulators are connected with parking braking valves; and parking braking valves are connected with parking brakes. The braking device meets the conditions for use in a special underground environment, can improve the braking efficiency and working efficiency and safety of the underground explosion-proof vehicle, reduce labor intensity, reduce casualty and accident rates and make underground conveying safer.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

New type waterproof electric products

ActiveCN103209560AEasy to rework and repairReduce manufacturing costProgramme controlEnergy efficient ICTElectric power transmissionElectricity

The invention relates to new type waterproof electric products which particularly comprise a waterproof intelligent mobile phone, a waterproof tablet personal computer and a waterproof split type tablet personal computer (comprises a waterproof handheld intelligent terminal and a host), particularly to a new type tablet personal computer and even refers to a cloud tablet personal computer. The new type waterproof electric products are characterized in that firstly no physical externally arranged interface is arranged on a casing, wireless connection is achieved through measures such as a wireless externally arranged interface, a wireless power transmission device, a wireless communication module or a circuit, and accordingly the casing of a product completely achieves the purpose of waterproof due to no physical electrically connected interface; secondly the waterproof performance is improved due to the fact that a circuit board and relative components are coated by films; and thirdly a covering plate (faceplate) of a touch screen is machined into a front casing of a waterproof product through mechanical machining methods such as molding, turning, milling and planning, so that an original juncture between the touch screen covering plate and the casing is avoided, the waterproof performance is improved, optical cement bounding for assembling a functional piece and the covering plate is avoided, yield of the touch screen is greatly improved, the touch screen is easy to repair, and a small-sized second touch display screen can be arranged to replace a traditional button to improve the waterproof performance and save the power.

Owner:罗天成

Nonporous moisture permeable and water-repellent modified polyether ester functional film material and preparation method thereof

The invention discloses a non-porous moisture permeable waterproof modified polyether ester functional film material and a preparation method thereof. The non-porous moisture permeable waterproof modified polyether ester functional film material of the invention contains components with the following weight percent: 50 to 70 percent of polyether ester, 10 to 30 percent of daiamid 6, 5 to 10 percent of hydrophilic polymer, 5 to 10 percent of ethylene-vinyl acetate copolymer, 2 to 4 percent of antibacterial masterbatch, 0.4 to 1 percent of novolac epoxy, 0.2 to 0.5 percent of antioxidant, 0.2 to 0.6 percent of processing additive. The modified polyether ester material of the invention has the advantages of polyester, polyether and daiamid, and has the advantages of good heat resistance, low cost and environmental protection. The film prepared in the process of melting casting has the functions of non-porous moisture permeation and watertightness, etc, and is mainly applicable to the production of clothing, waterproof breathable tape, and roof or wall film in the construction industry, etc.

Owner:SOUTH CHINA UNIV OF TECH

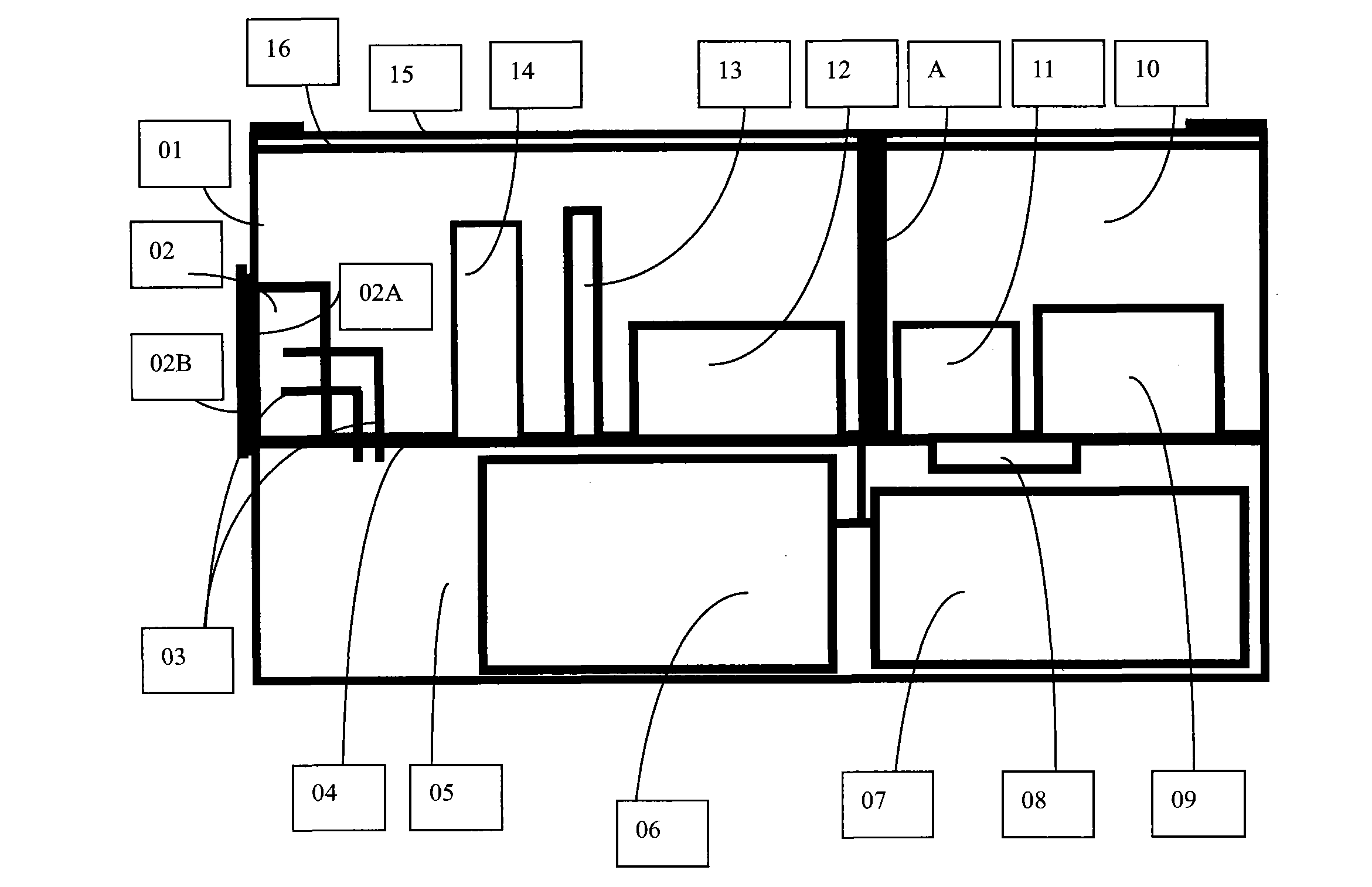

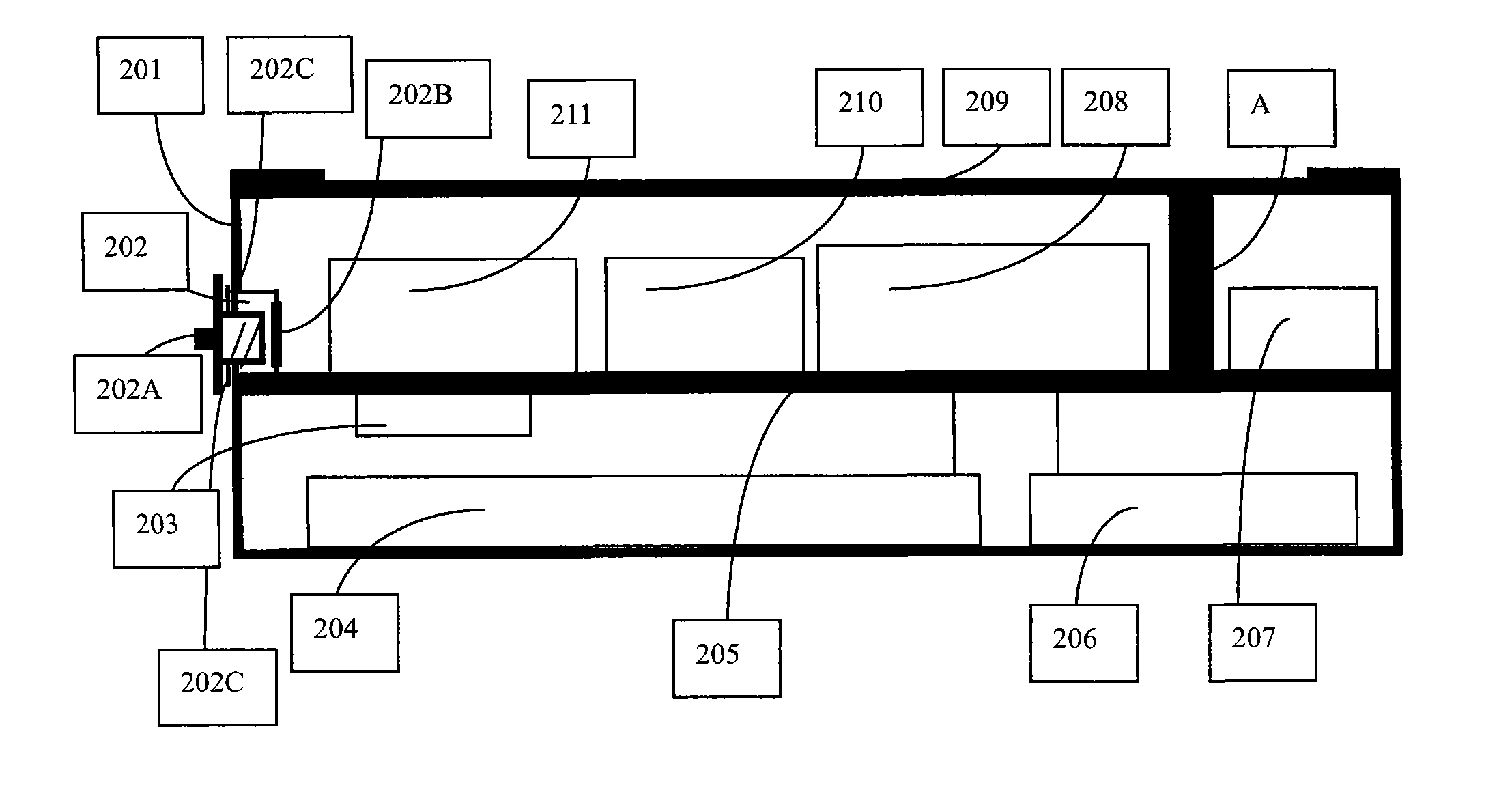

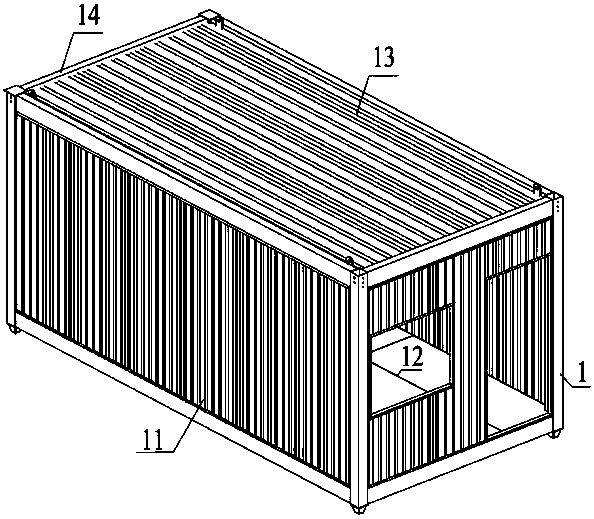

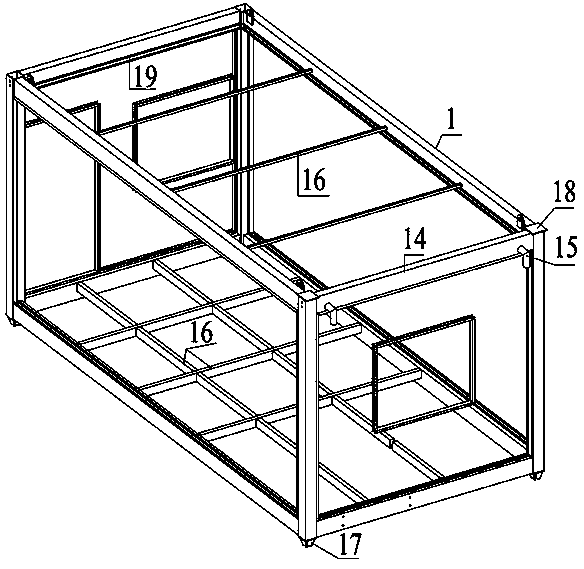

Combined type integrated box room

ActiveCN104018583AImprove carrying capacityImprove fire performanceBuilding constructionsFiberComputer engineering

The invention discloses a combined type integrated box room and belongs to the technical field of movable rooms. The combined type integrated box room comprises a standard box body room, a main frame of the standard box body room comprises stand columns and beams, and the main frame is formed by welding rectangular tubes. Peripheral wall plates embedded into the main frame are fireproof plates, and a bottom plate is a fiber cement pressure plate. A top plate comprises an inner-layer fireproof plate which is horizontally laid and an outer-layer waterproof plate which is obliquely laid. The top beam of at least one side of the standard box body room is a gutter beam. The combined type integrated box room has the better bearing capacity, the fireproof performance, the heat insulation property and the sound absorption and noise lowering effect, installation is convenient, the plate shape is beautiful, construction operation is simpler and faster, and working efficiency is improved.

Owner:广西源冠钢结构制品有限公司

Ventilation encapsulation method for fuel cell pile

InactiveCN101425596AImprove efficiencyEffective waterproofFuel cells groupingFuel cell auxillariesHydrogen concentrationFuel cells

The invention relates to a ventilation and package method of a fuel cell galvanic pile, which comprises a closed package frame. All components of the fuel cell galvanic pile are packaged in the package frame; a ventilation opening is arranged on one surface of the panel of the closed package frame; the ventilation opening is connected with the air blower outlet of the air supplying device of the fuel cell galvanic pile; an air outlet is arranged on the other surface of the panel of the closed package frame; the air outlet is provided with a hydrogen detector which can detect the concentration of the hydrogen inside the closed package frame of the fuel cell galvanic pile. Compared with the prior art, the invention has the advantages that the structure is simple, dust and water can be effectively prevented, the hydrogen concentration can be timely detected, and hydrogen discharging treatment can be timely performed, thereby the explosion caused by the leakage of the hydrogen in the fuel cell galvanic pile can be effectively prevented.

Owner:SHANGHAI SHENLI TECH CO LTD

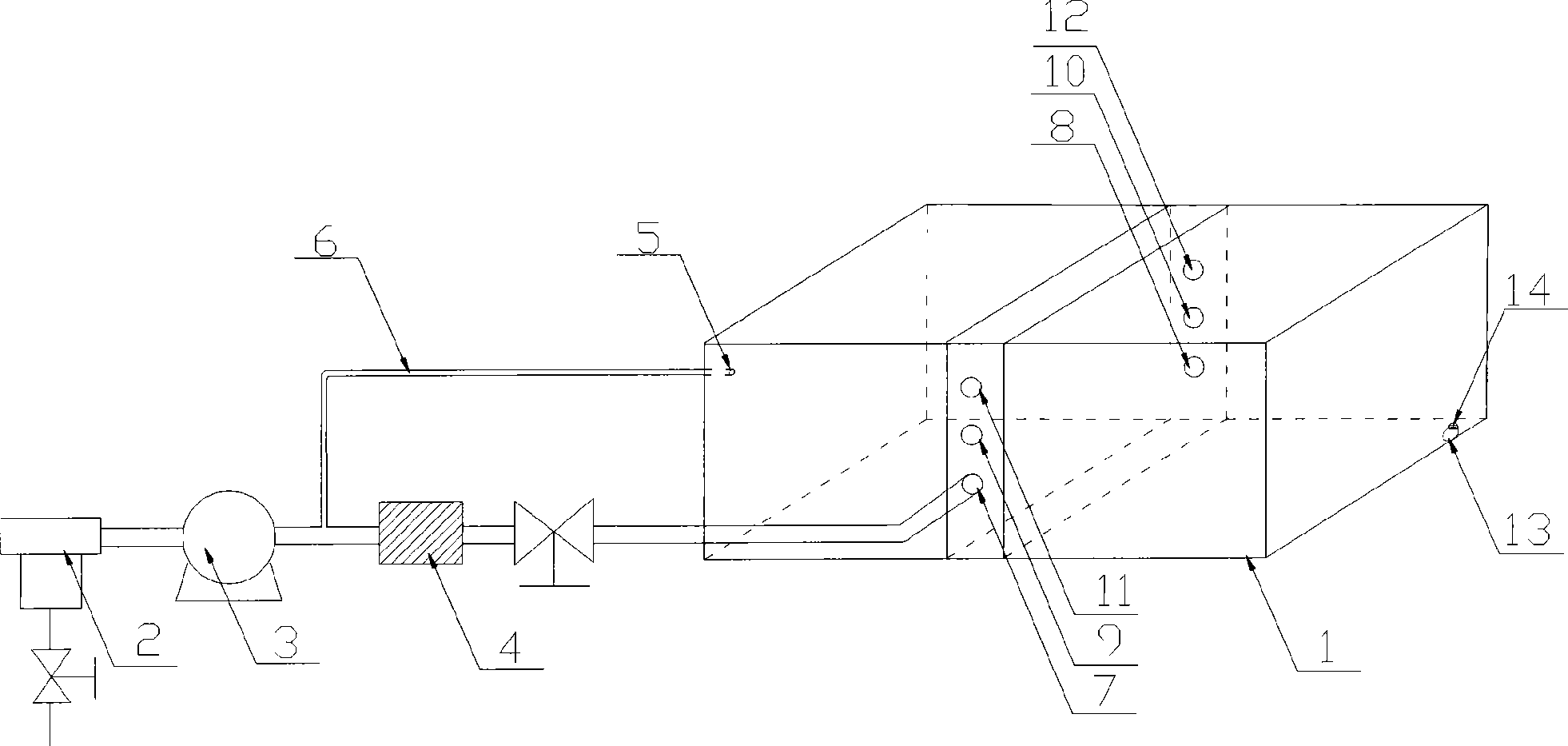

Well sealing waterproof construction method for dewatering well

The invention discloses a well sealing waterproof construction method for a dewatering well. The method comprises the following steps of: (1) constructing a foundation bed on the surrounding of the dewatering well; (2) embedding a steel sleeve for sealing the dewatering well in a foundation pit; (3) laying a waterproof roll material on the foundation bed, and then pouring a fine aggregate concrete protective layer on the waterproof roll material; (4) clamping a waterproof plate on the outer wall of the waterproof roll material on the outer wall of the steel sleeve in an abutted way; (5) clamping the waterproof plate by using a copper strip; (6) injecting a sealing adhesive to the waterproof plate; (7) pouring bottom plate concrete to the fine aggregate concrete protective layer; (8) pumping water; (9) embedding a sealing plate in the steel sleeve; (10) after filling gravels into a filling pipe, injecting a cement paste into a cement paste injection pipe, and stopping the injection of the cement paste until the paste in an overflow pipe flows out; and (11) pouring concrete into the steel sleeve above the sealing plate. Through the adoption of the well sealing waterproof construction method disclosed by the invention, a waterproof treatment problem at the connection of the dewatering well in the foundation pit and the foundation bottom plate in the whole dewatering well sealing waterproof system is solved.

Owner:天津住宅集团建设工程总承包有限公司

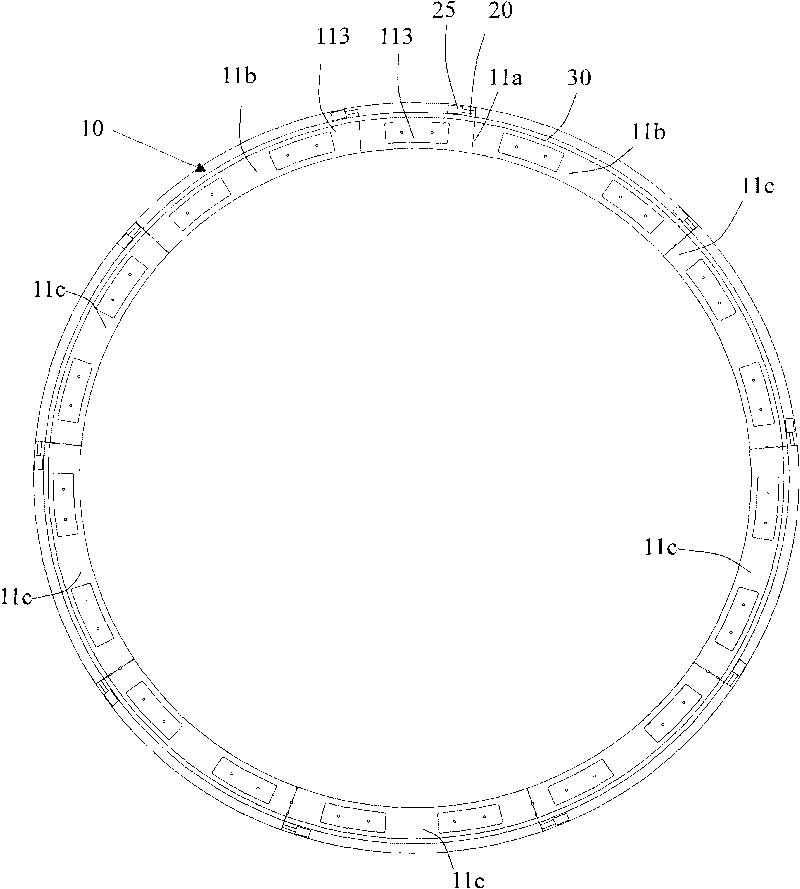

Method for controlling quality of tunnel pipe sheet built by using shield method and pipe sheet structure

ActiveCN101705829AHigh precisionImprove efficiencyUnderground chambersTunnel liningVehicle frameQuality control

The invention provides a method for controlling the quality of a tunnel pipe sheet built by using a shield method, which comprises the steps of pipe sheet structure design, pipe sheet construction detection, pipe sheet assembling quality requirement and tunnel stability control, wherein in the pipe sheet structure design, the water prevention and the bonding strength are improved by the structural design of a connecting way, strength, water prevention, and the like of pipe sheets; in the pipe sheet construction detection, the eight-point measurement is carried out on the pipe sheets in the process of construction, the concentricity relation between the previous ring of pipe sheets and a shield shell is calculated, and the position of the next ring of pipe sheets is selected; in the pipe sheet assembling quality requirement, an assembled ring height difference and a longitudinal joint flare angle are controlled to confirm the assembling quality; and in the tunnel stability control, the floating of the pipe sheets is effectively prevented in a frame weight and synchronous slurry injection matching construction way after assembly. Accordingly, the quality of the pipe sheets is controlled in the whole course from structural design to construction, thereby ensuring the tunnel construction quality.

Owner:SHANGHAI TUNNEL ENG CO LTD

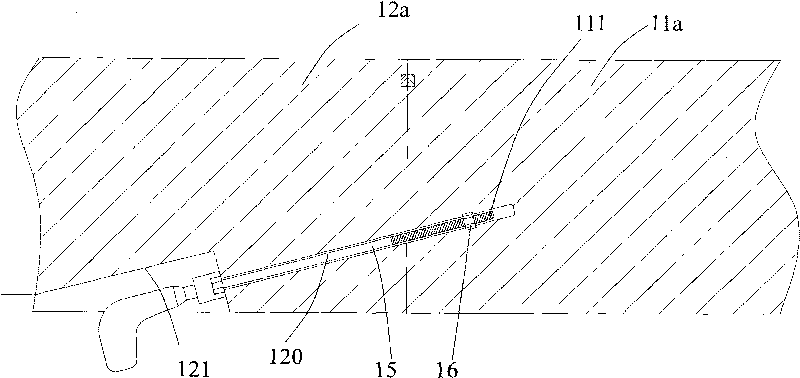

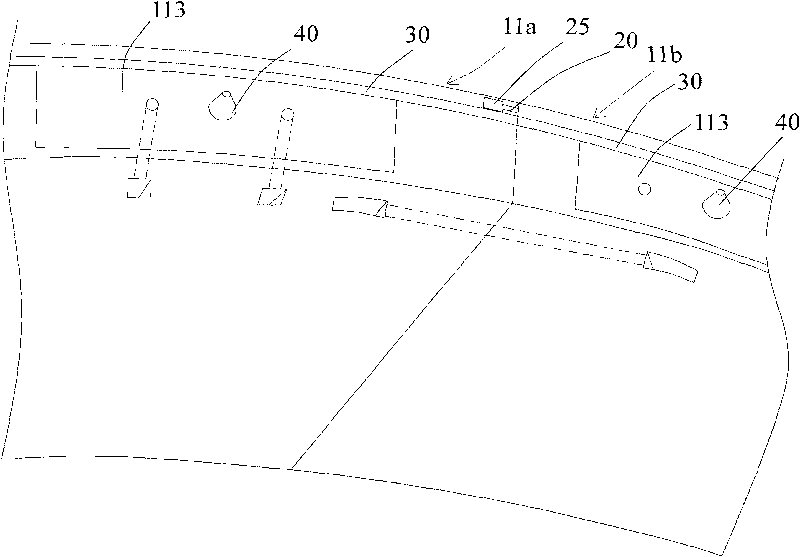

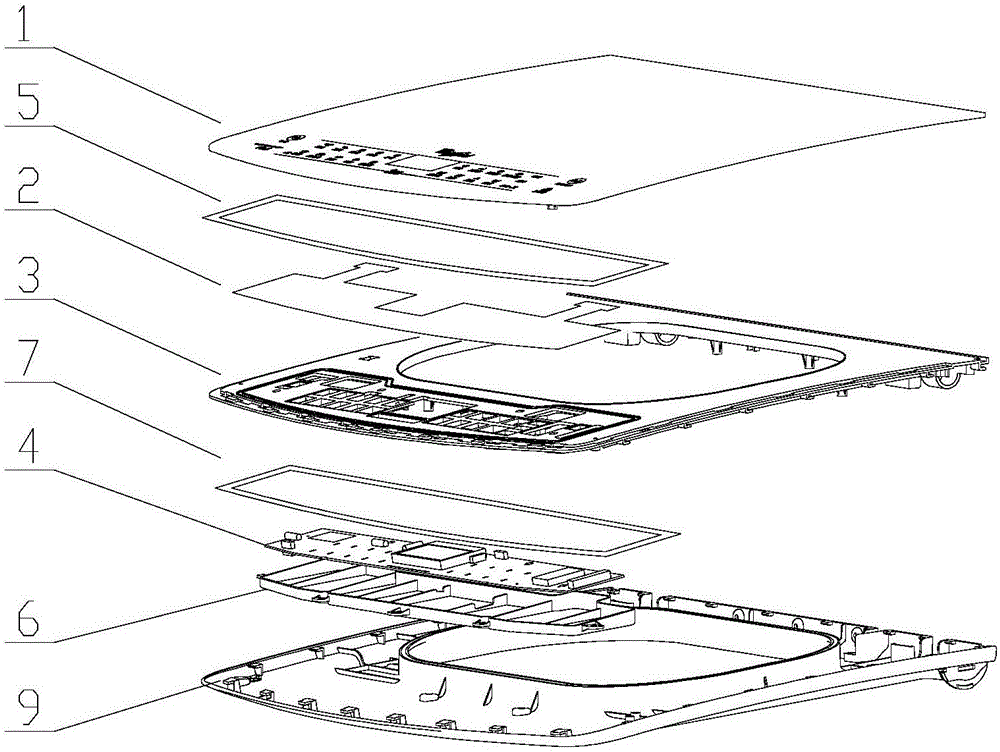

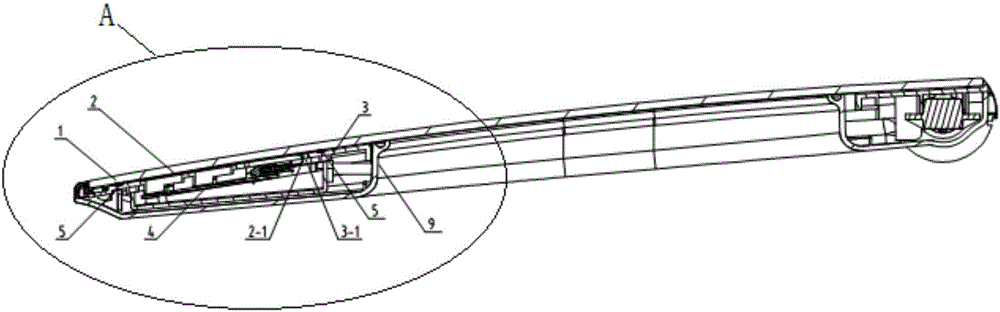

Washing machine cover plate structure with user control and display functions

InactiveCN106436182ASolve the waterproof problemImprove waterproof performanceOther washing machinesTextiles and paperControl functionEngineering

The invention relates to a washing machine cover plate structure with user control and display functions. The washing machine cover plate structure comprises a cover plate A, a glass plate installed on the top face of the cover plate A, an ITO film pasted on the back face of the glass plate, a PCB display panel installed on the cover plate A, and a protecting cover installed on the bottom face of the cover plate A and used for protecting the PCB display panel. An ITO film sealing ring is arranged on the periphery of the ITO film. A sealing strip is arranged between the protecting cover and the PCB display panel. According to the technical scheme, the user control and display functions are integrated in the cover plate structure; by arranging the glass plate pasted with the ITO film on the top face of the cover plate A, the touch control function is achieved, and by installing the PCB display panel on the cover plate A, the display function is achieved; the purpose of making the ITO film and the PCB display panel waterproof can be achieved, the waterproofness of the operation part of a washing machine can be effectively improved, and the service life of the washing machine can be prolonged.

Owner:WHIRLPOOL CHINA

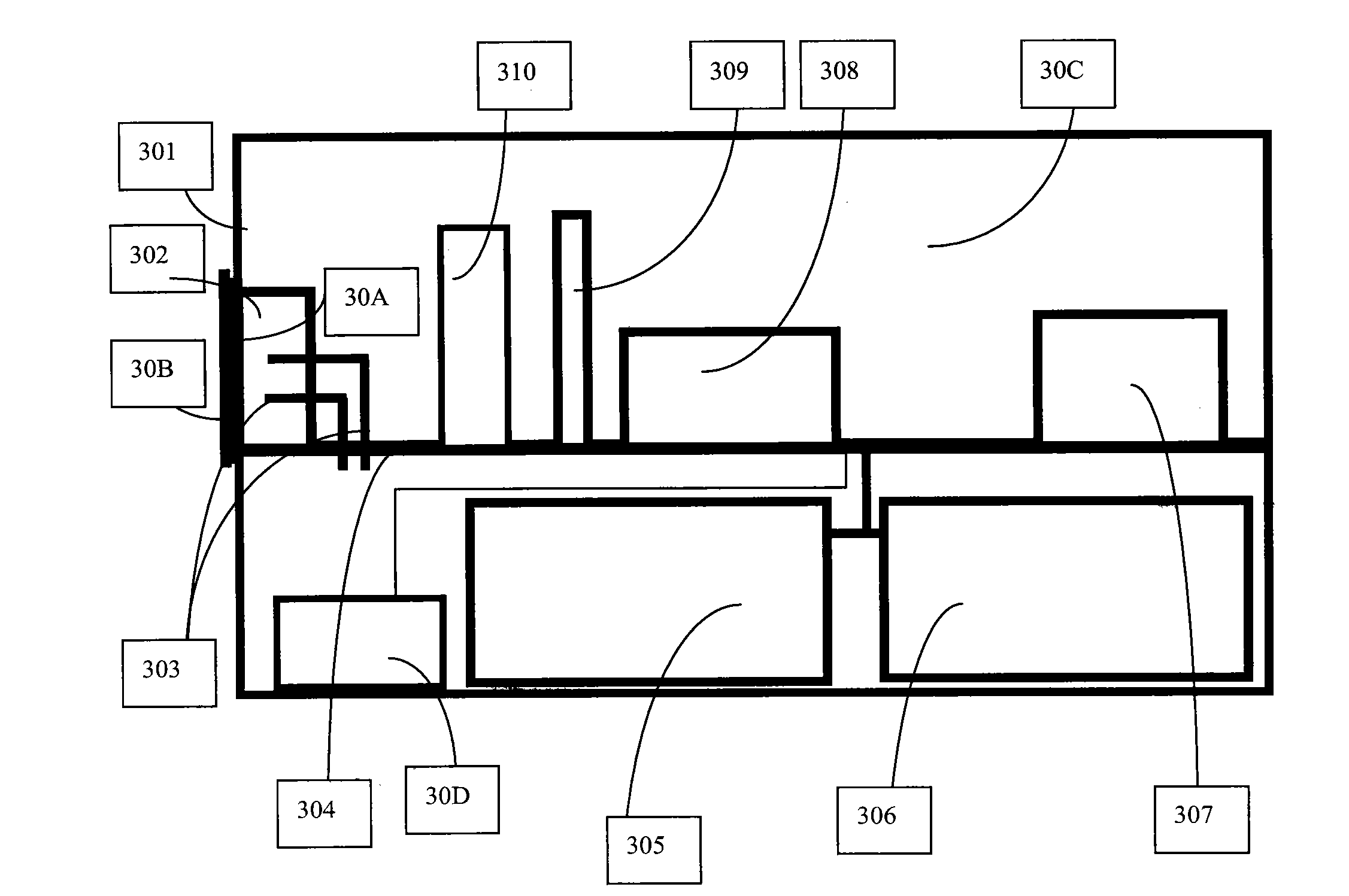

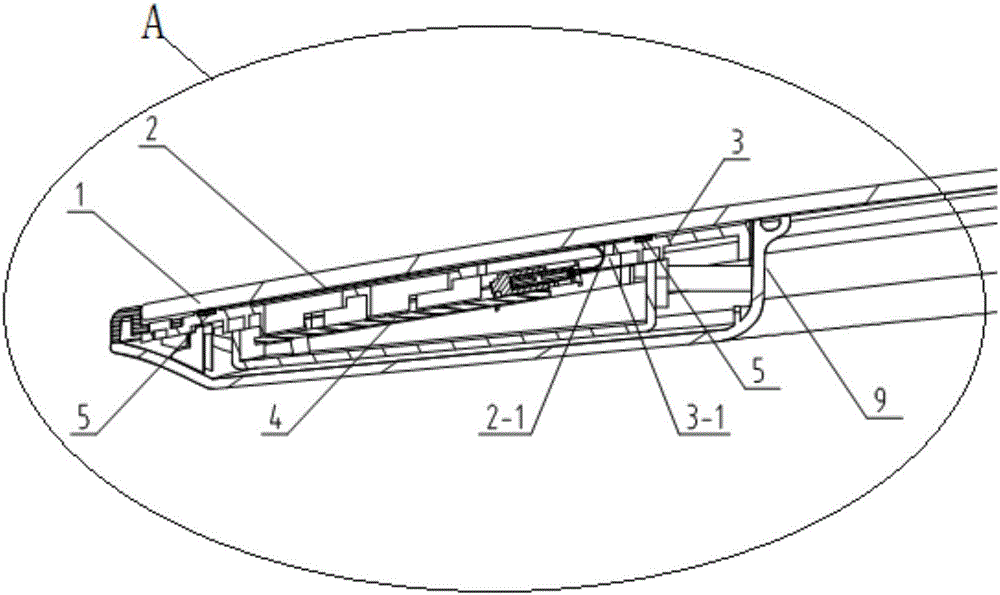

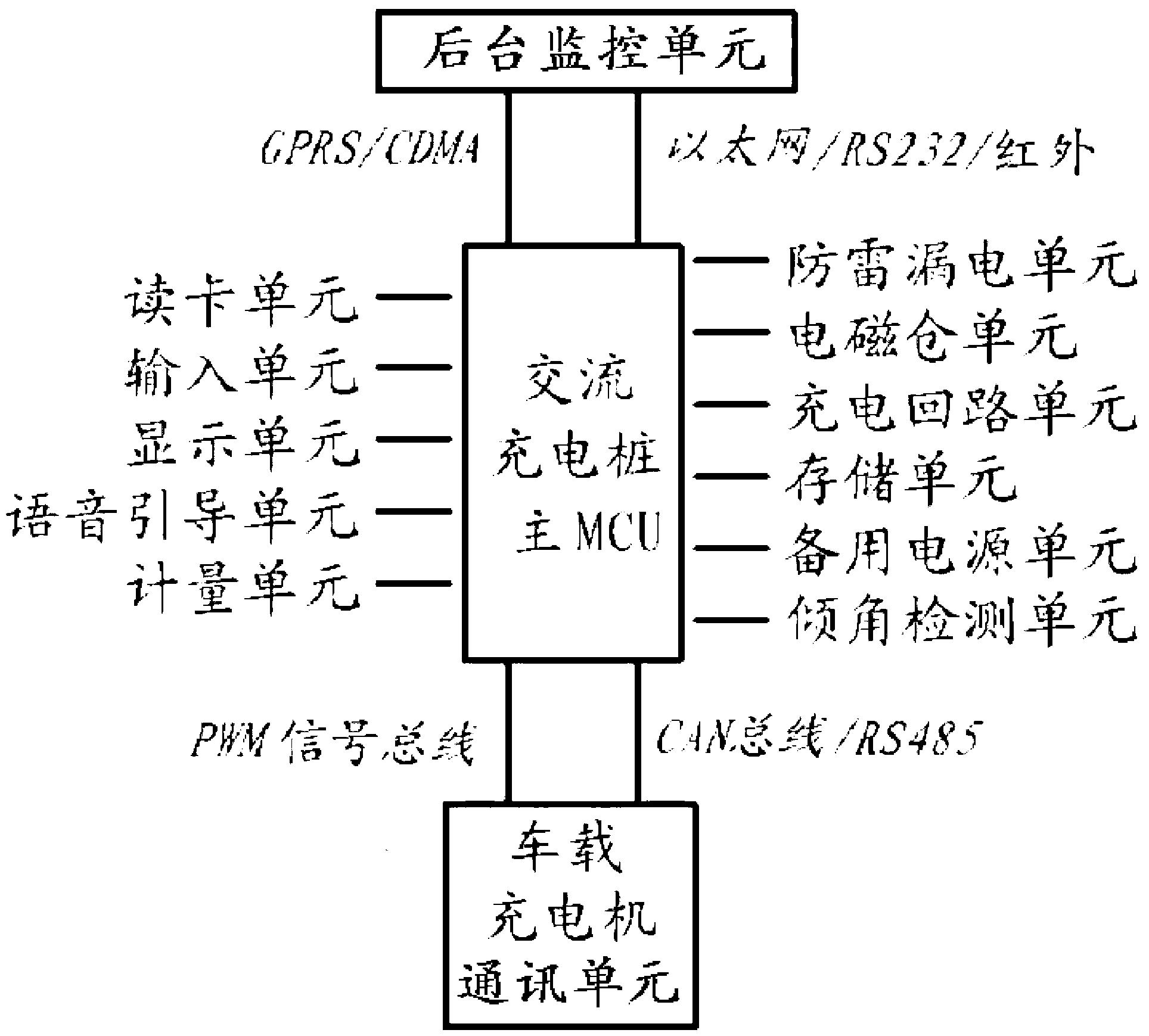

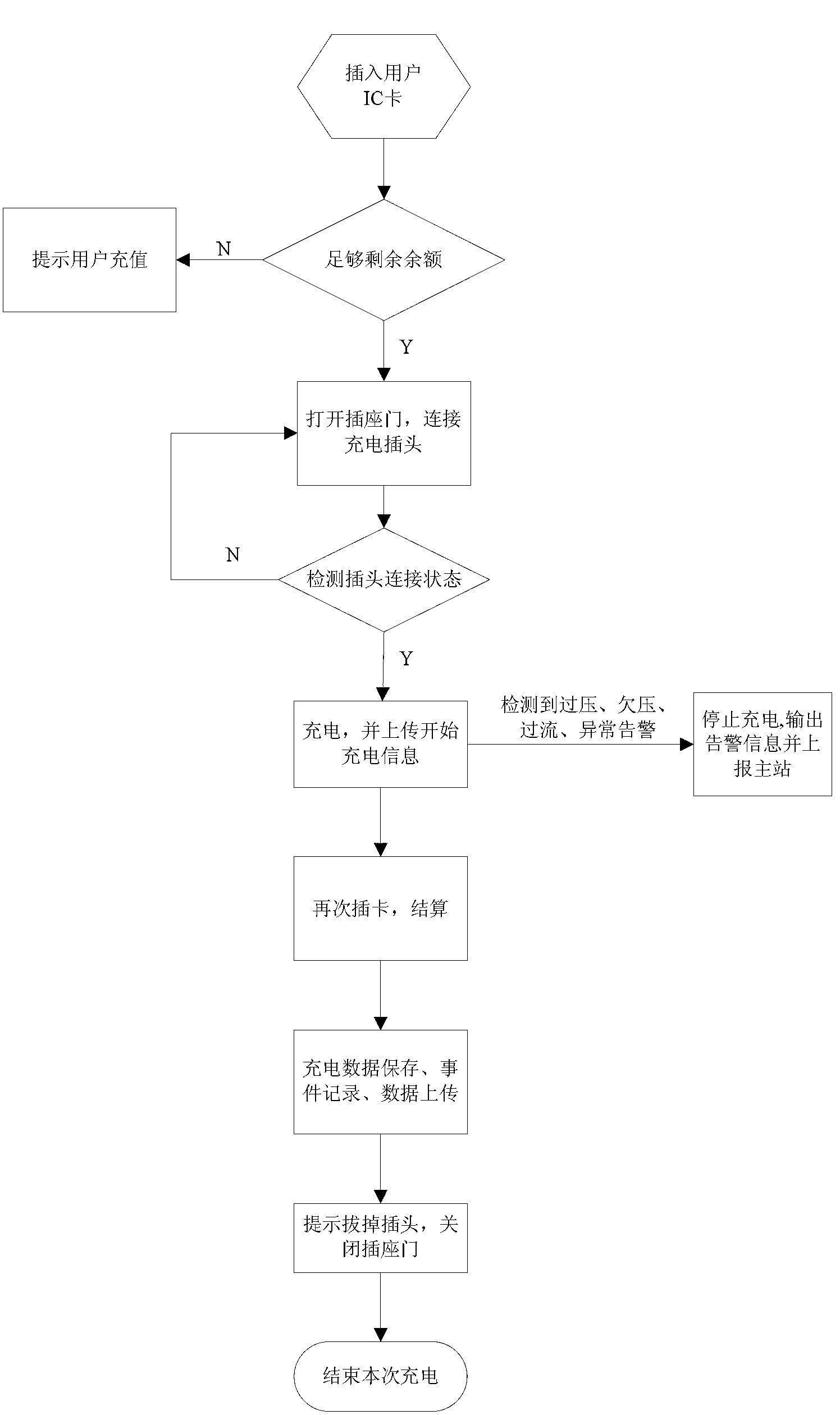

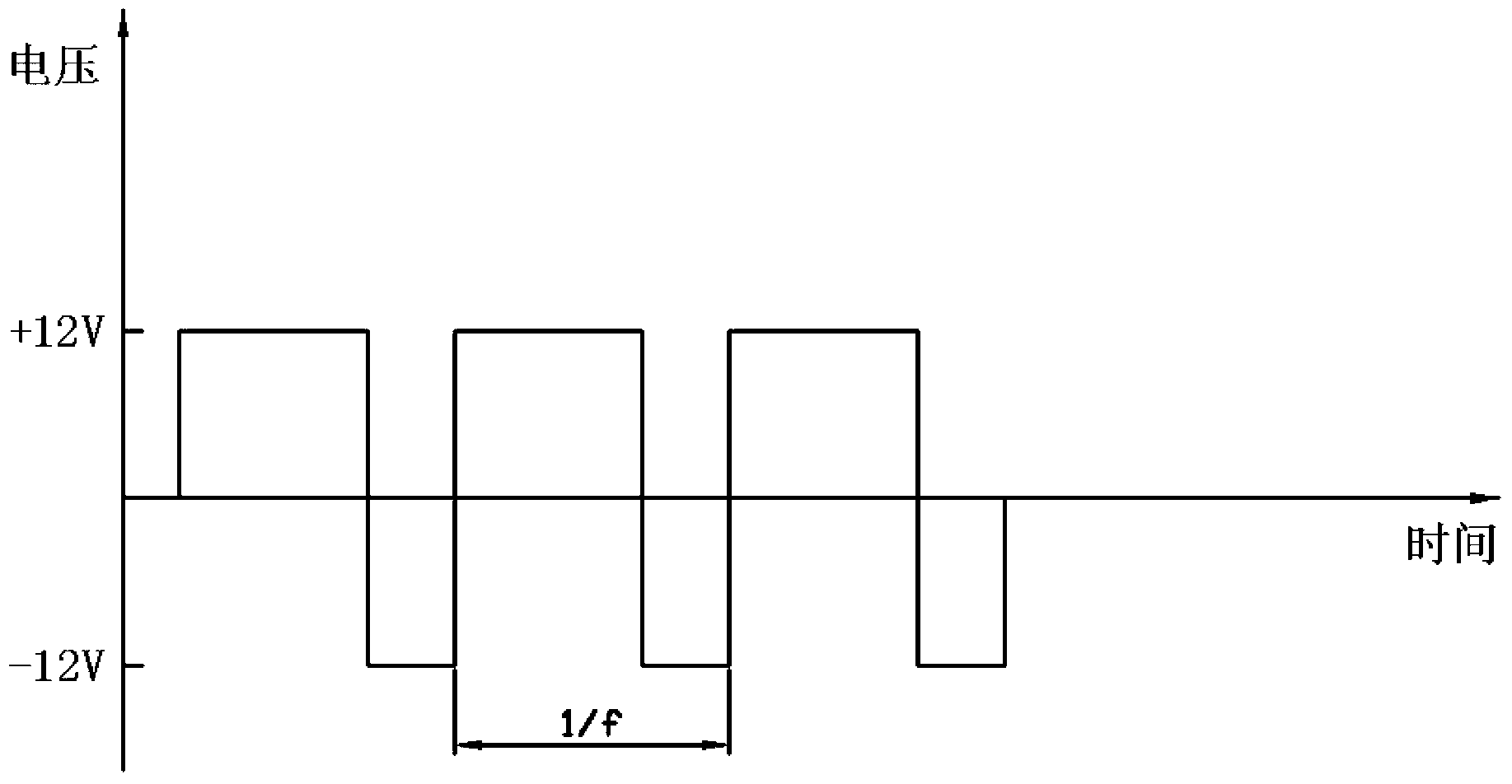

Alternating current charging pile

InactiveCN103023115AExtend your lifeSolve the interactive waterproof problemBatteries circuit arrangementsElectric powerElectrical batteryStandby power

The invention relates to the field of electric automobile charging, in particular to an alternating current charging pile which comprises a main MCU (micro-control unit) unit. The main MCU unit is respectively connected with a card reading unit, a charging loop unit, an input unit, a display unit, a metering unit, an electromagnetic warehouse unit, a voice guide unit, a standby power supply unit, a lightning protection leakage unit, a communication unit and a dip angle detection unit through a total data line, and the display unit comprises an operation display module and an equipment state display module. The alternating current charging pile has the advantages that charging completeness is maintained, charging complaint caused by power failure is reduced, the standby power supply unit can be circularly charged when power is supplied again, and the service lives of the standby power supply unit and a vehicular battery are prolonged.

Owner:ZHEJIANG WANMA NEW ENERGY

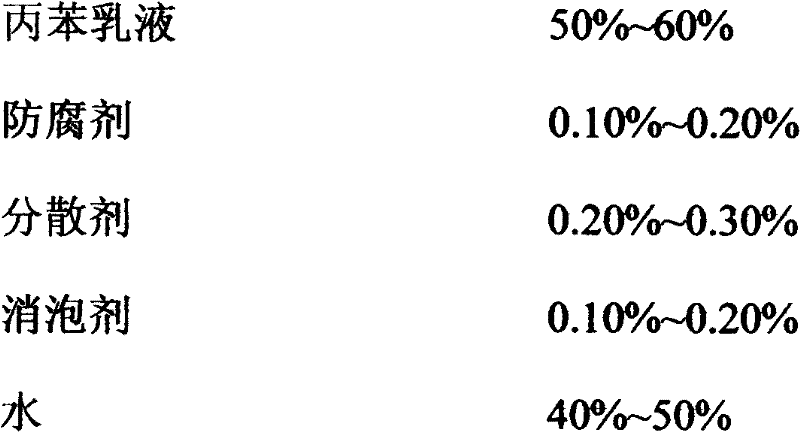

Flame-retardant polymer cement waterproof mortar

The invention relates to a flame-retardant polymer cement waterproof mortar which comprises liquid and powder in a weight ratio of 1.0:(3.5-4.5). The liquid comprises the following raw materials in percentage by weight: 50-60% of styrene-acrylate emulsion, 0.10-0.20% of preservative, 0.20-0.30% of dispersant, 0.10-0.20% of defoaming agent and 40-50% of water. The powder comprises the following raw materials in percentage by weight: 40-45% of ordinary Portland cement, 50-55% of quartz sand, 0.02-0.05% of cellulose ether, 0.4-0.5% of water reducing agent and 1.0-3.0% of flame retardant. The flame-retardant polymer cement waterproof mortar can be used for waterproof and moistureproof treatment, effectively solves the problem of waterproofing on the building waterisde or landside, has the advantages of favorable flame retardancy and high binding firmness, is simple and convenient for production, and has favorable flame retardancy and waterproof property when the construction thickness is 1-2mm.

Owner:JIANGSU WONIUSHAN THERMAL INSULATION & WATERPROOF TEHNOLOGY

Water-proof wiring harness and manufacture method thereof

InactiveCN103366878APrevent infiltrationSolve the waterproof problemInsulated cablesCable fittingsEngineeringCable harness

The invention discloses a water-proof wiring harness and a manufacture method thereof. The structure comprises a wiring harness, an inner filler and an outer wrappage, wherein the outer surface of the wiring harness is coated with the inner filler; and the outer wrappage is wrapped out of the wiring harness of which the outer surface is coated with the inner filler. The manufacture method comprises the following steps of: putting the inner filler on the outer surface of the wiring harness which needs to pass through a sealing cavity part; covering the inner filler with the outer wrappage with the proper internal diameter; heating the outer wrappage by a heat gun; ensuring that the outer wrappage is shrunk when meeting heat so as to extrude the inner filler; enabling the inner filler to be permeated into gaps in the wiring harness; enabling the processed wiring harness to be penetrated into the sealing cavity; and locking the wiring harness covered by the outer wrappage by a cable clip. According to the water-proof wiring harness and the manufacture method disclosed by the invention, the outer wrappage is heated to ensure that the inner filler in the wiring harness fully permeates and can not move so as to take a good water-proof insulating effect.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

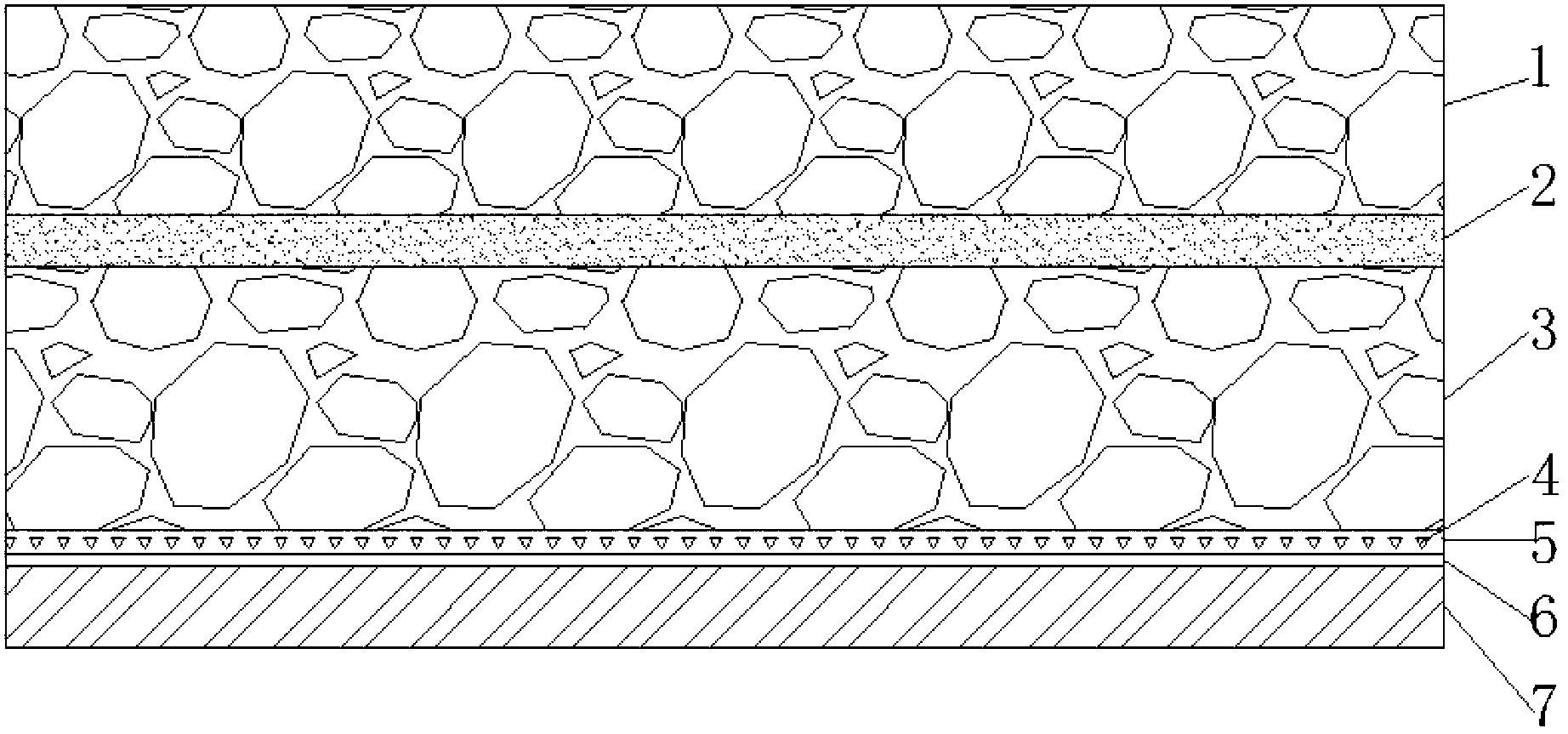

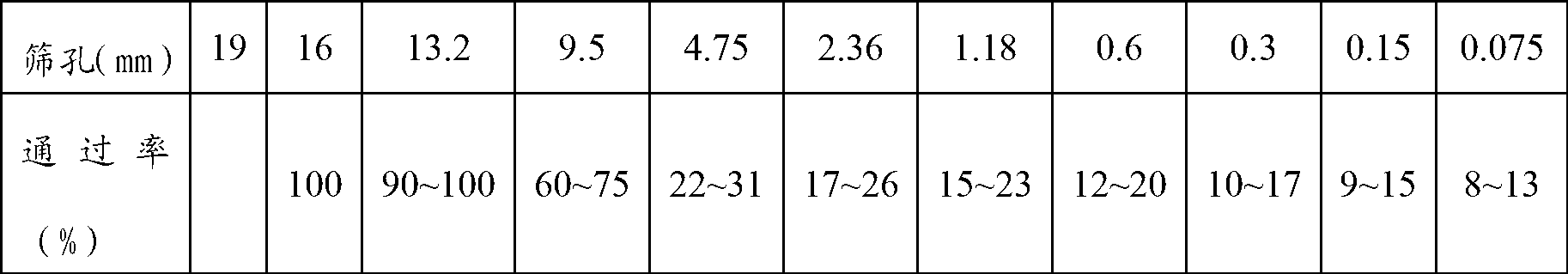

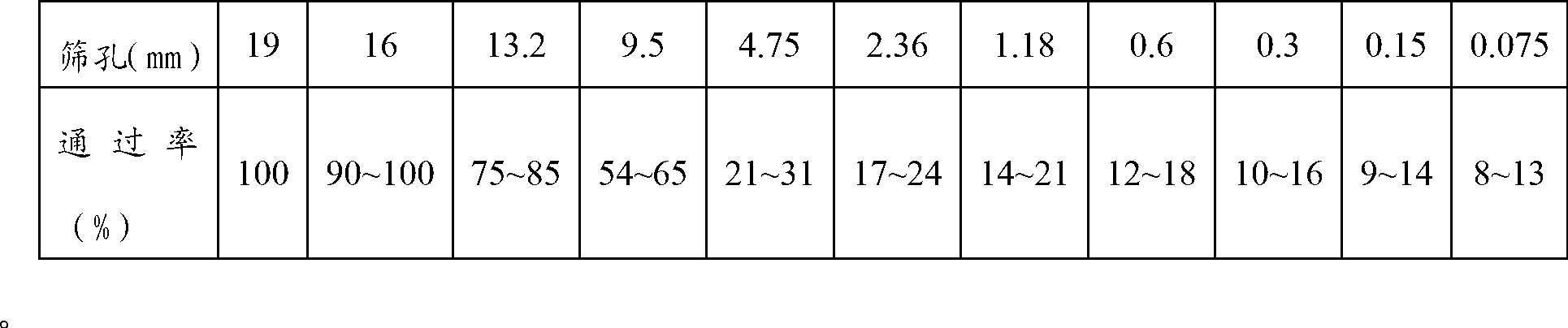

Asphalt concrete steel bridge pavement structure and pavement method thereof

ActiveCN103015316ASolve the problem of permanent deformationStrong adhesionBridge structural detailsBridge erection/assemblySand blastingViscosity

The invention discloses an asphalt concrete steel bridge pavement structure comprising a steel bridge (7) derusted by sandblast, an anticorrosive coating (6), a binding layer (5), high-viscosity asphalt embedded compact granular composition concrete bottom layer (3), an oil sticking layer (2) and a high-viscosity asphalt embedded and compact granular composition concrete top layer (1) which are arranged from bottom to top; and furthermore, the invention also provides a pavement method of the asphalt concrete steel bridge pavement structure. According to the asphalt concrete steel bridge pavement structure, the high-viscosity asphalt embedded compact granular composition concrete layers are used as main pavement layers, so that concrete has favorable interlayer binding force and deformation following performance, the generation of cracks can be restrained, so that the whole steel bridge pavement structure has the advantages of favorable track resistance and water seepage resistance.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

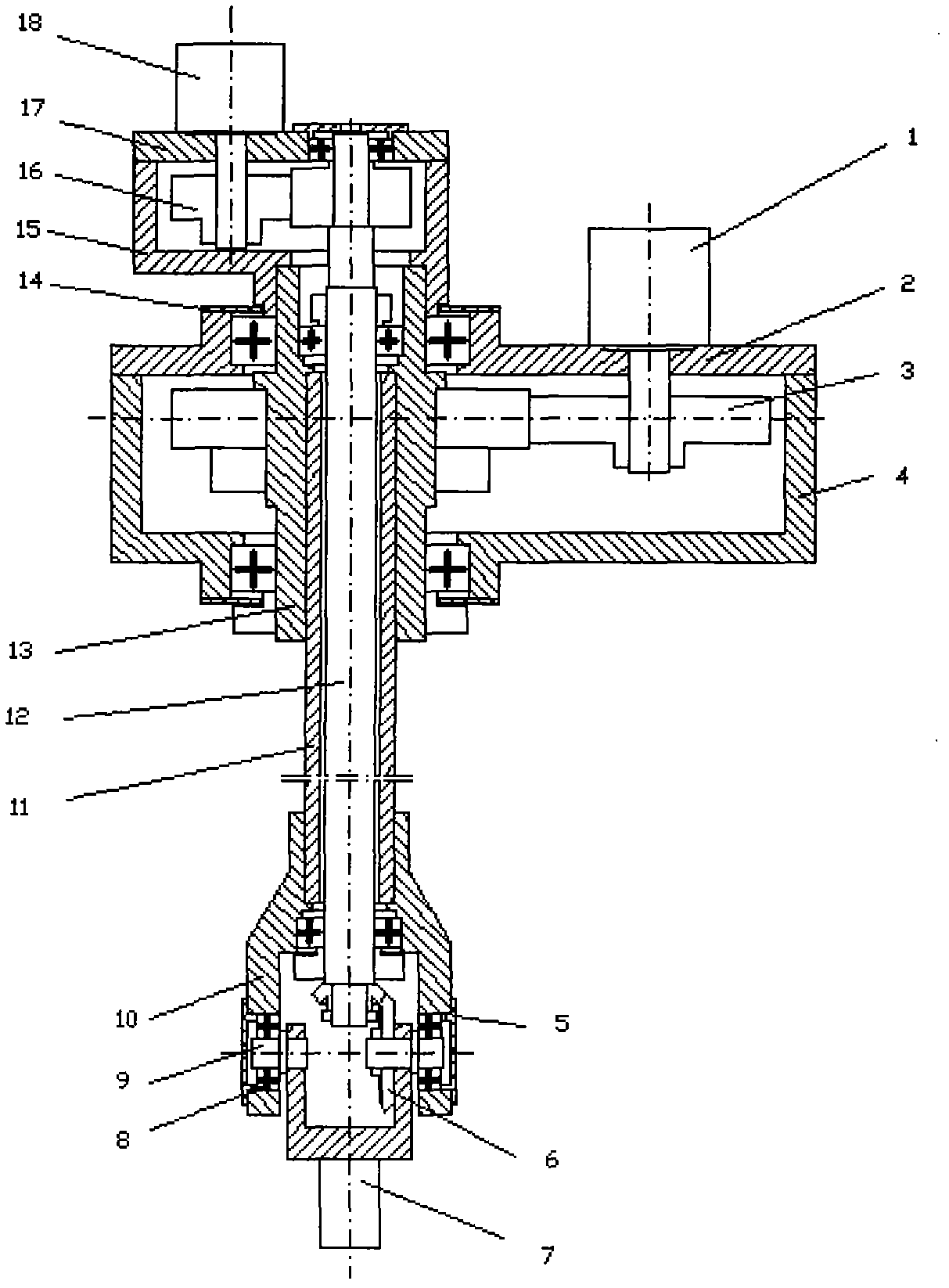

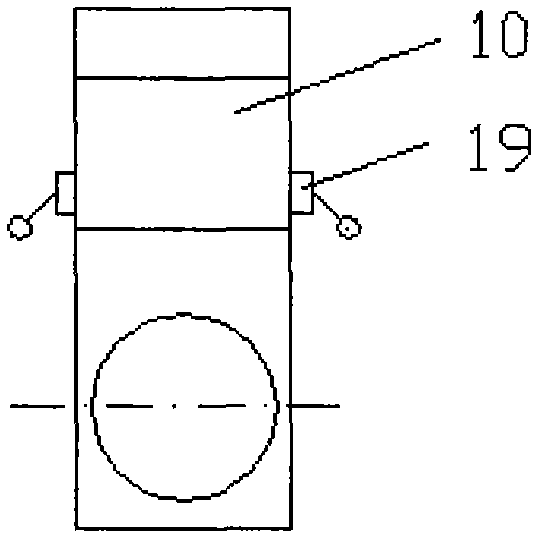

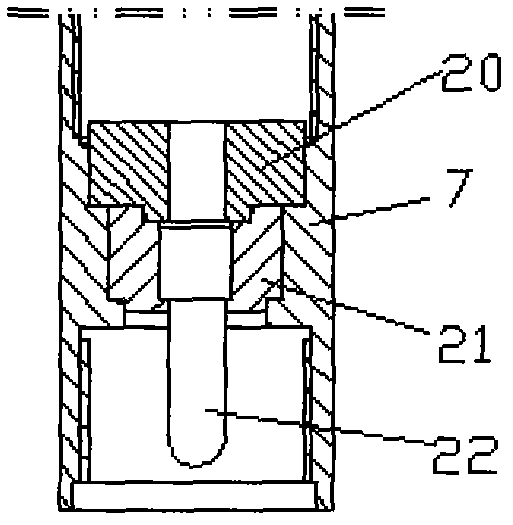

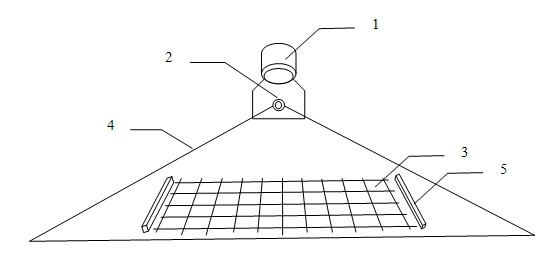

A/B shaft used for ultrasound scanning and examination of complex shape/contour

InactiveCN102507749AMeet the test requirementsImprove detection accuracyMaterial analysis using sonic/ultrasonic/infrasonic wavesLinear motionEngineering

The invention relates to an ultrasound A / B shaft detection device used for a complex structure, which can realize five-axle linkage of an ultrasound detection device and is used for ultrasound detection of various complex surfaces. The conventional three-axle linear motion can not satisfy the requirement that a central axis of a sensor is vertical to the surface of a to-be-detected material when the detection is carried out. Through the A / B shaft device, the rotation at any angle can be realized, as a result, the requirement is satisfied and the accuracy and the reliability of the detection are improved. The A / B shaft provided by the invention is particularly suitable for detecting the complex surfaces, such as inclined surfaces, canal surfaces and grooves.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

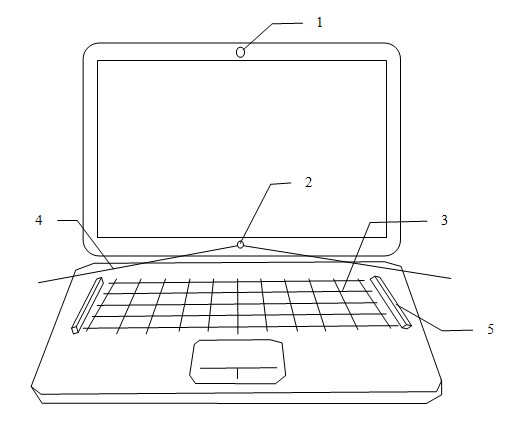

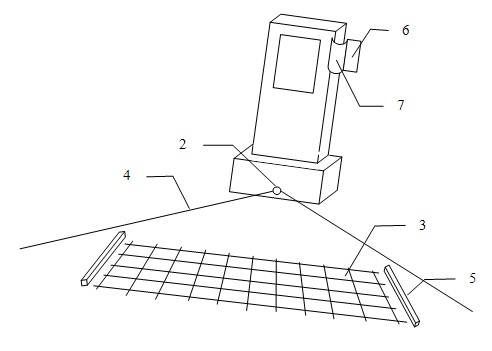

Input method and keyboard based on non-light projection

InactiveCN102520805AImplement the input functionSolve the waterproof problemInput/output for user-computer interactionKey pressingComputer hardware

The invention provides an input method and a keyboard based on non-light projection. The method includes that emergent light of a linear laser covers a plane displaying a keyboard pattern in parallel, users touch a key in the keyboard pattern through fingers, the emergent light generates facula at the fingertip of a finger, an image containing the facula is obtained through a camera, a processor receives imaged obtained by the camera and locates the facula, the coordinate of the facula center in a keyboard pattern area coordinate system is converted through the coordinate of the facula center and corresponds the keyboard key number, and the keyboard key the key number corresponds to is the key in the keyboard pattern and touched by the fingers. The keyboard comprises the keyboard pattern used for an inputting operator to touch and the camera to shoot and the linear laser used for generating the emergent light, and the emergent light covers the keyboard pattern in parallel. The input method and the keyboard completely resolve the problem that the traditional keyboard is not waterproof.

Owner:SOUTH CHINA UNIV OF TECH

Steel structure assisted layered installation and construction method for superhigh PRC partition plate

ActiveCN1970914ASolve the problem that construction is difficult to installEasy to installWallsMaterials scienceTransverse beam

The invention relates to a construction method of assisted layered installation for super-high PRC steel structure of partition board. At first, connectors of steel structure pedestal and transverse beam is installed on the structure; then the steel structure pillar is welded with the connector of steel structure pedestal. After PRC light compound partition board under the steel structure transverse beam is installed, the steel structure transverse beam is installed; then PRC light compound partition board above the steel structure transverse beam is installed. Groove is opened on the PRC light compound partition board along the board width direction and the groove of steel structure transverse beam is filled to level by cement filling mortar; PRC light compound partition board is installed so that the groove at the bottom of PRC light compound partition board is aligned to steel structure transverse beam and fixed with it. There are cement filling mortar between the top face of board and the structure. After PRC light compound partition board is installed, the board sews of PRC light compound partition board is sealed by building glue. The problem that super high wall is difficult to build is solved.

Owner:BEIJING URBAN CONSTR GROUP

Foundation ditch construction method of horizontal bracing structure of central island floor slaps

InactiveCN103103988AControl deformationIncrease horizontal stiffnessExcavationsFloor slabStructural engineering

The invention discloses a foundation ditch construction method of a horizontal structure of central island floor slaps. The method comprises the following steps: constructing an envelope enclosure on the side wall of the foundation ditch; excavating the earthwork of the middle portion of the foundation ditch to the bottom and naturally carrying out the construction to plus-minus zero to form the central island structure; leaving a soil slope on the foundation ditch except for the central island structure; arranging supporting seats and the horizontal supporting structures on the edges of the floor slaps of the plus-minus zero layer from the floor slaps of the central island to floor slaps of the foundation ditch bottom layer in sequence, and fixing one end of the horizontal supporting structure on each supporting seat and fixing the other end of the horizontal supporting structure on the envelope enclosure structure and evacuating the soil slope which is under the horizontal supporting structure arranged by the floor slaps of the layer to the bottom elevation of the horizontal supporting structure of the next layer of floor slaps; and constructing naturally the surrounding areas to the plus-minus zero. The foundation ditch construction method of the horizontal bracing structure of central island floor slaps has the advantages that the central island floor slaps are used for adding horizontal supportings to the surrounding envelope enclosure structures. Compared with the existing steel inclined sturts which are used frequently, horizontal stiffness is improved, supporting atress is more clear, the deformation of the foundation ditch can be better controlled and safety is increased.

Owner:ANHUI URBAN CONSTR DESIGN & RES INST

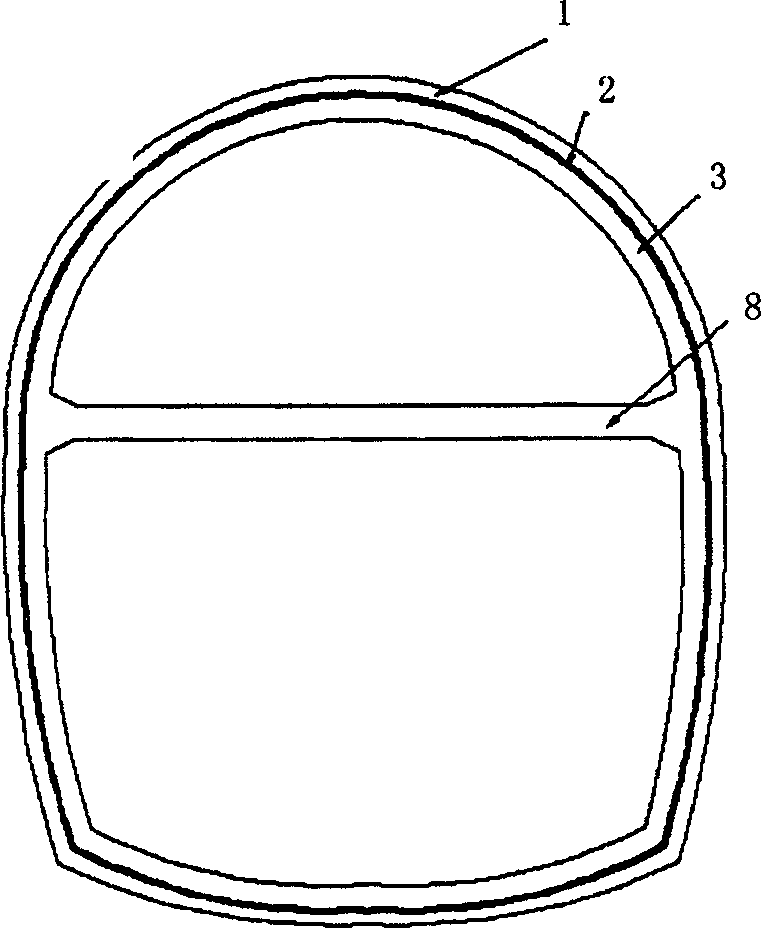

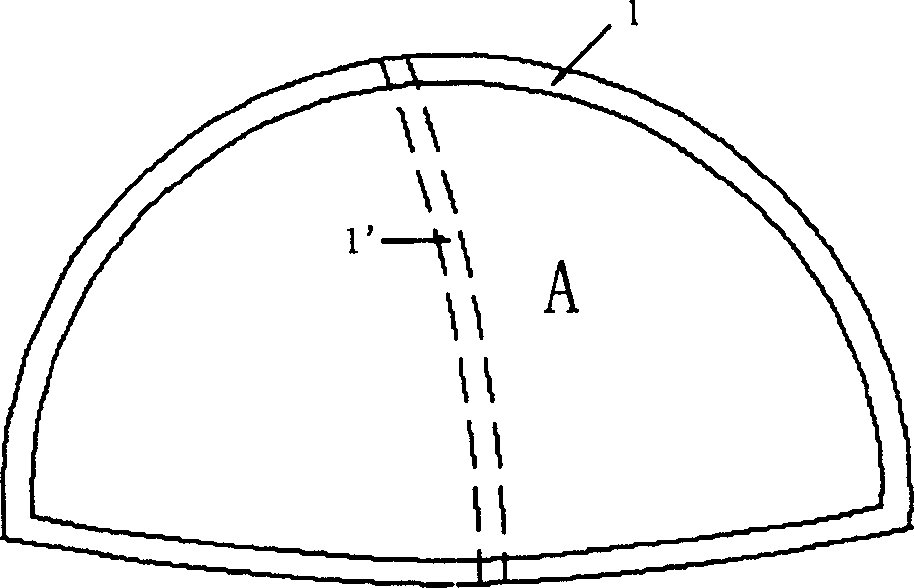

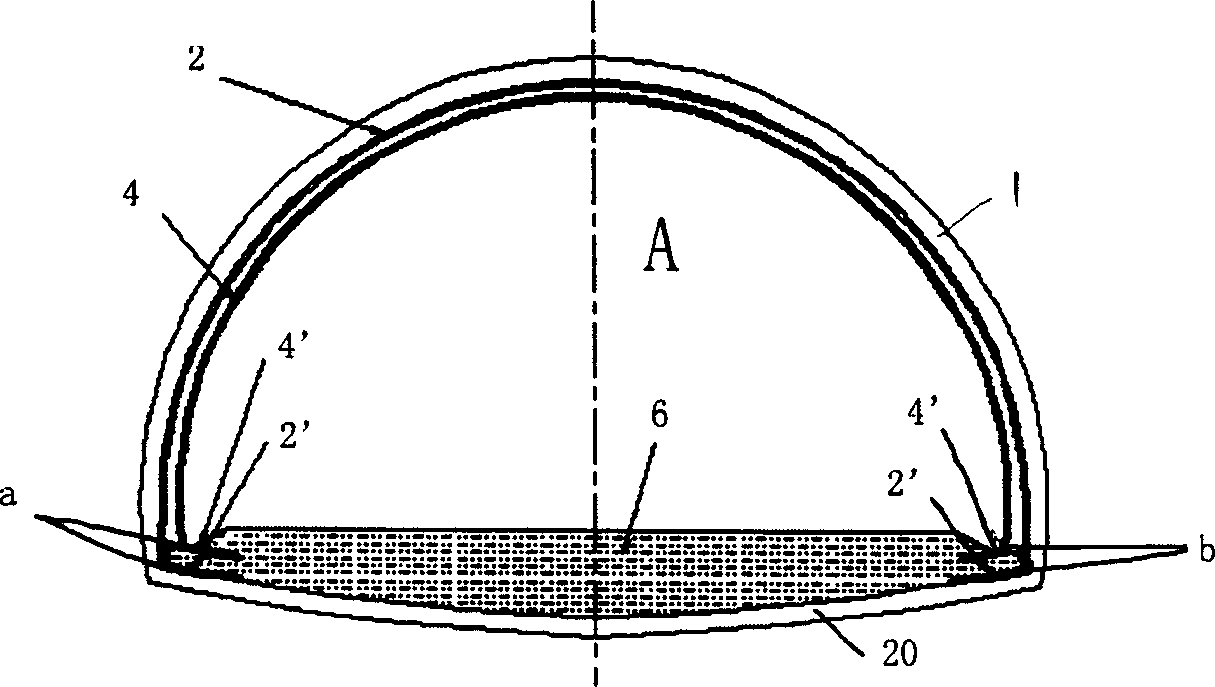

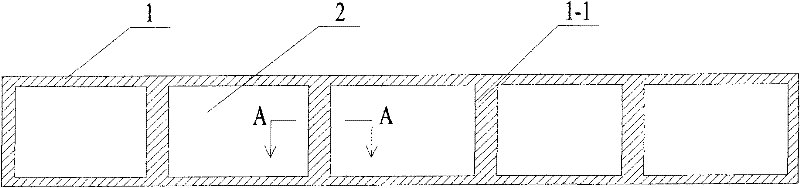

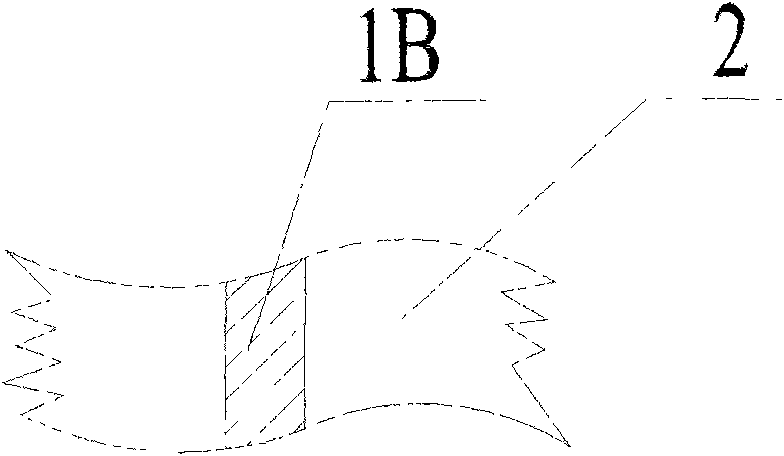

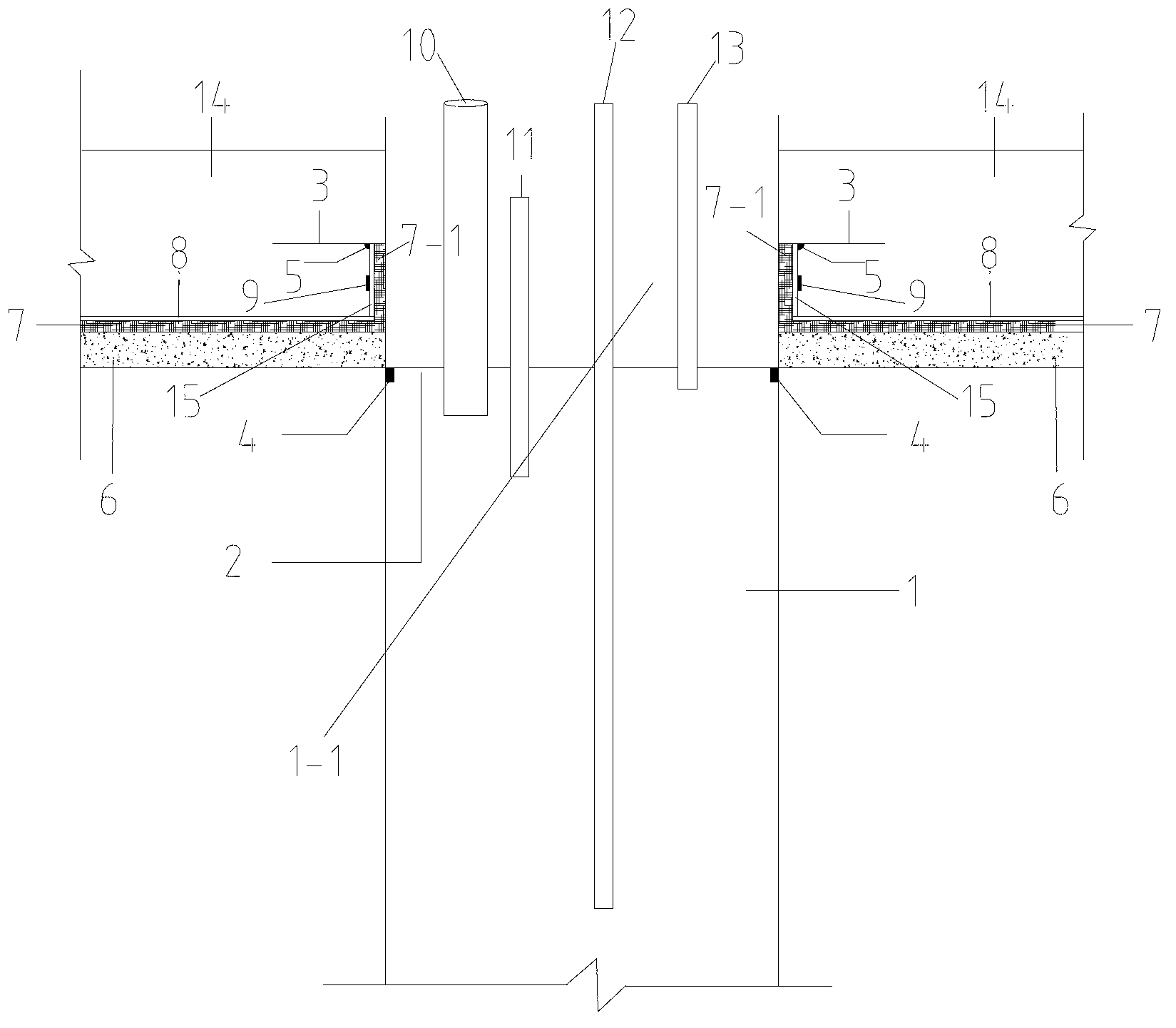

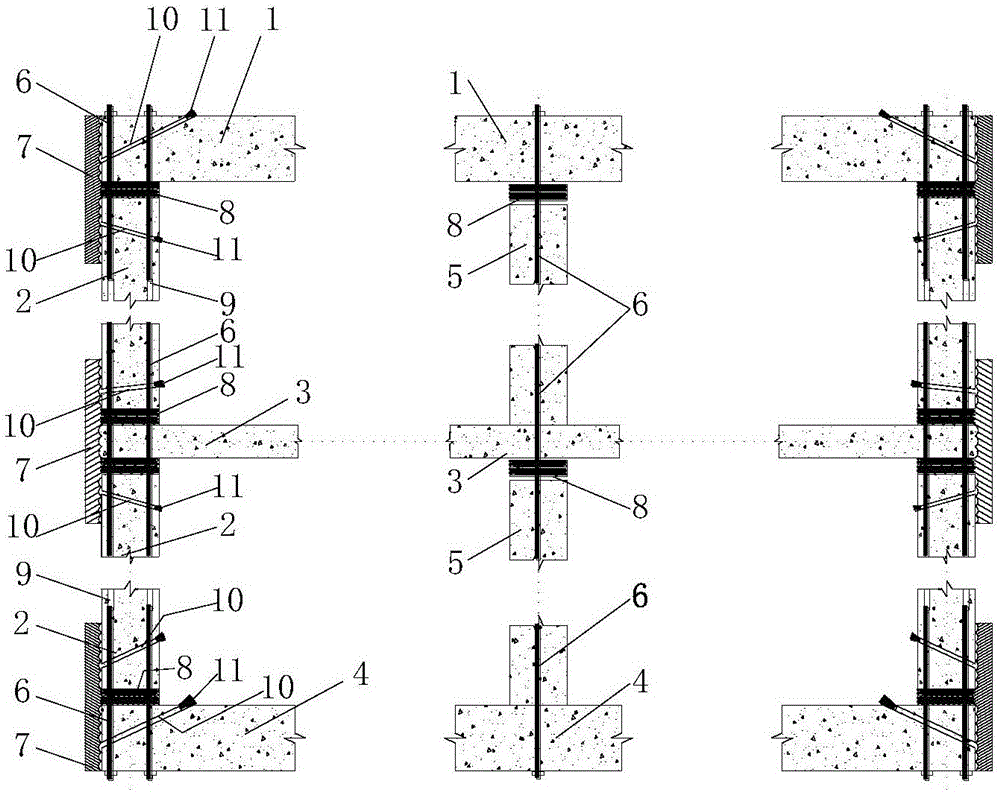

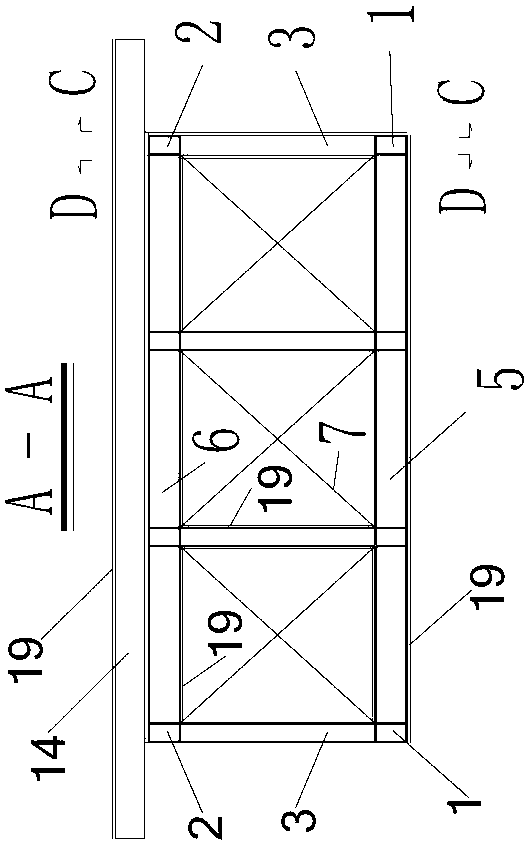

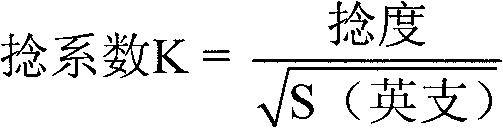

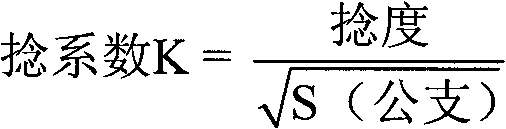

Self-resetting assembly type subway station flexible antiseismic structure

ActiveCN106351494AImprove seismic performanceSolve the waterproof problemArtificial islandsProtective buildings/sheltersBending momentPre stress

The invention discloses a self-resetting assembly type subway station flexible antiseismic structure, which consists of prefabricated components, prestressed bars, waterproof rubber and rubber support seats, wherein a station main body structure is formed by connecting the prestressed bars and the prefabricated components; the fixed connection of structure connecting nodes can be changed into hinged connection, so that a subway station becomes a flexible system; meanwhile, the structure resetting function can be realized through the prestress; rubber waterproof pads and the rubber support seats are combined into T and TT systems; the systems are arranged at the connection components of the prefabricated components; the multiplex waterproof problems can be solved; the seismic reduction effect can also be achieved. The self-resetting assembly type subway station flexible antiseismic structure has the advantages that the assembly type component connection structure can be solved; the underground station structure can become the flexible system through releasing the bending moment at the connecting parts of the prefabricated components; the deformation capability of the subway station is improved; the antiseismic capability of the underground subway station is improved.

Owner:BEIJING UNIV OF TECH

Method for preparing adhesive material for aqueous paint

ActiveCN102971387AImprove adhesion strengthHigh film stabilityStarch dervative coatingsStarch adhesivesPolymer scienceEmulsion

The present invention provides a method for preparing an emulsion type adhesive material for an aqueous paint, containing a core-shell structured copolymer having a dual layer with a core comprising a starch-based copolymer, a natural polymer, and a shell comprising a hydrophobic polymer. The adhesive material for an aqueous pain obtained through the preparation method of the present invention has particularly excellent water-resisting qualities, film characteristics, and viscosity characteristics.

Owner:DAESANG

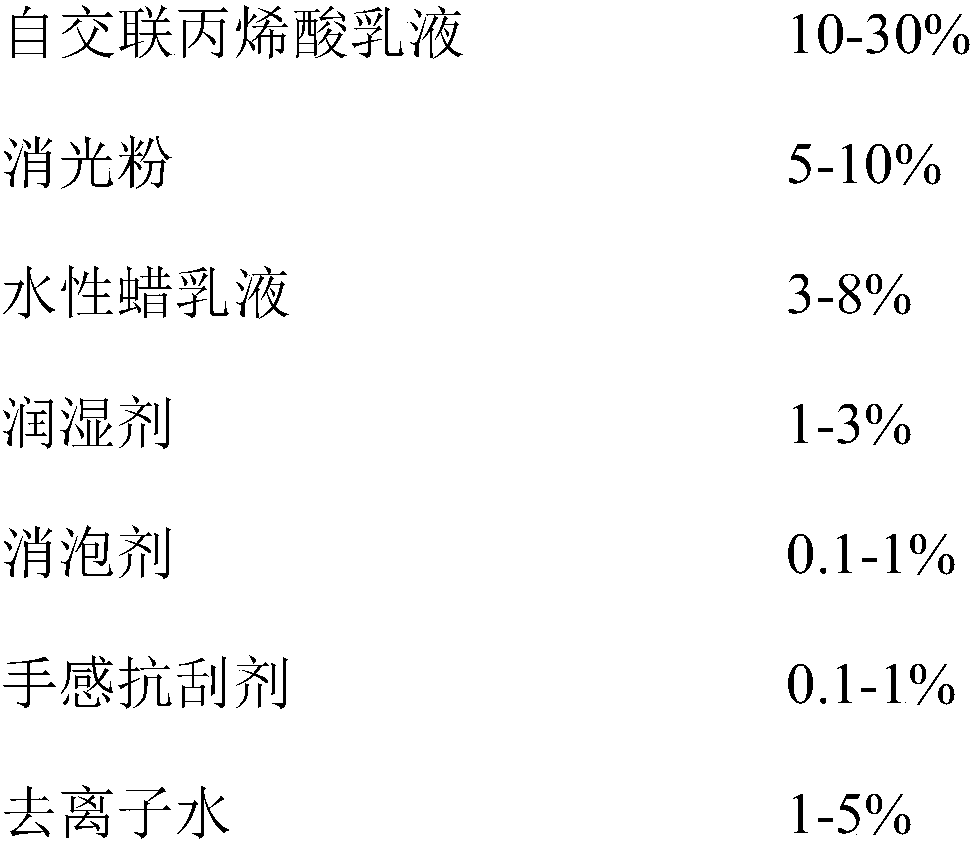

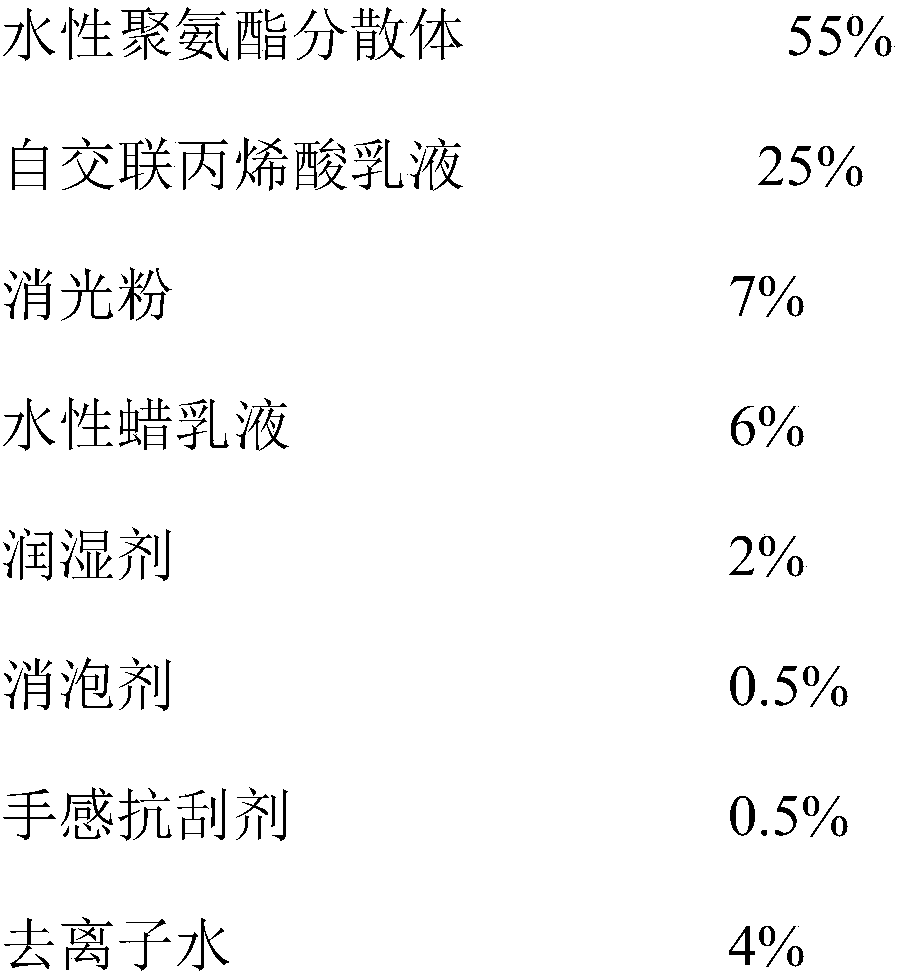

Matt prevention film waterborne matt varnish and preparation method thereof

InactiveCN109266189AGood flexibilitySolve the non-explosion-proofPolyurea/polyurethane coatingsWaxPolyurethane dispersion

The invention provides a matt prevention film waterborne matt varnish and a preparation method thereof. The matt prevention film waterborne matt varnish is prepared from the following components in percentage by mass: 50-80 percent of waterborne polyurethane dispersion, 10-30 percent of self-crosslinking acrylic acid emulsion, 5-10 percent of matting powder, 3-8 percent of waterborne wax emulsion,1-3 percent of wetting agent, 0.1-1 percent of defoamer, 0.1-1 percent of hand scratch-resistant agent and 1-5 percent of deionized water. The matt prevention film waterborne matt varnish has the advantages of high flexibility, difficulty in breaking, very low glossiness and high abrasion resistance after film formation and can replace a BOPP matt film covering product. The invention also provides the preparation method of the matt prevention film waterborne matt varnish.

Owner:ZHONGSHAN FLASHLIGHT POLYTECHNIC

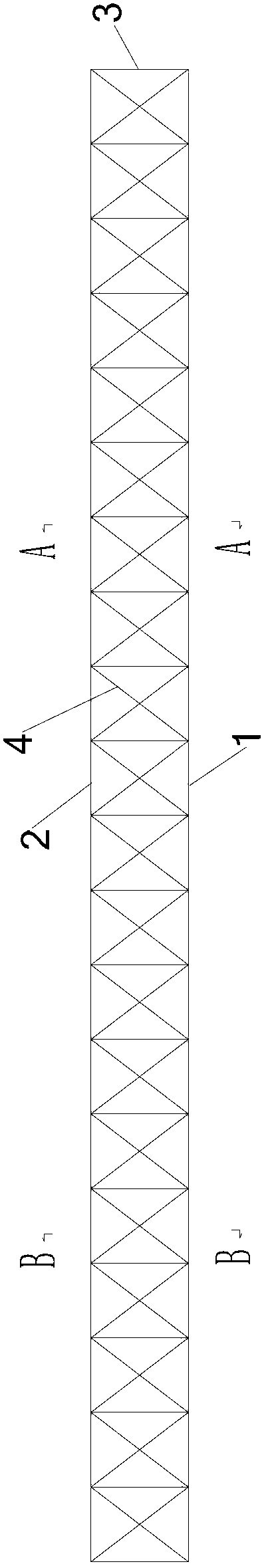

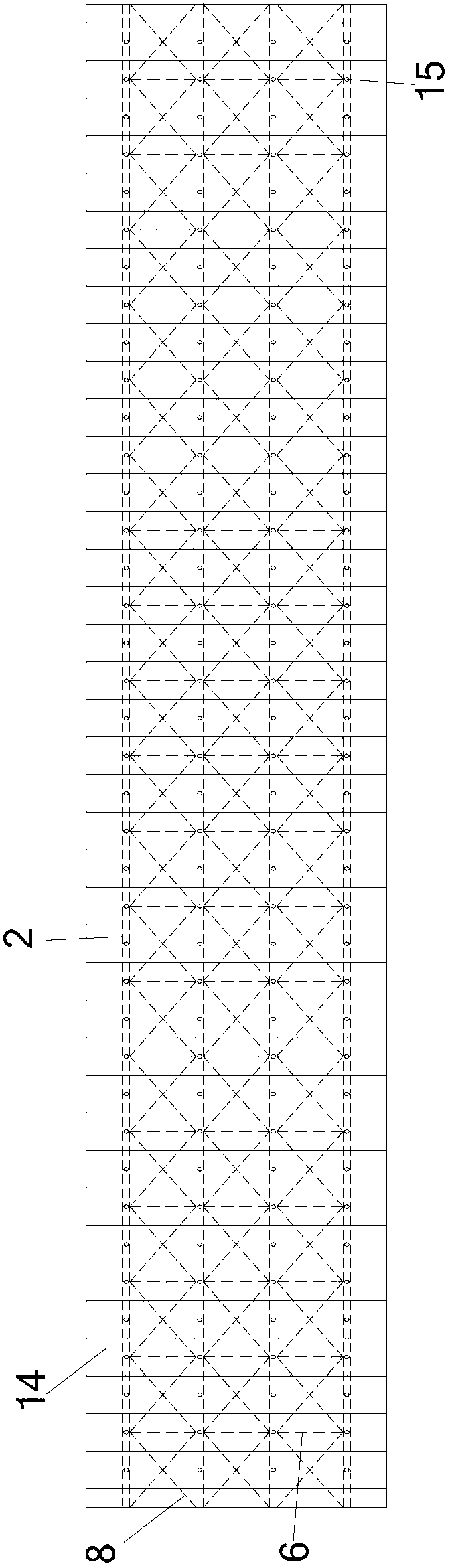

Steel truss-prestressed concrete bridge deck combined bridge girder and construction method thereof

InactiveCN103306189ARealize industrial constructionUnlimited storage timeBridge erection/assemblyBridge materialsFiberPre stress

The invention discloses a steel truss-prestressed concrete bridge deck combined bridge girder which comprises a steel truss and a bridge deck laid on the steel truss, wherein the steel truss comprises a plurality of vertical truss pieces and two horizontal bracing systems, namely the upper horizontal bracing system and the lower horizontal bracing system; the vertical truss pieces are arranged side by side in the direction of a bridge span; the two horizontal bracing systems parallel to each other are respectively arranged at the tops and the bottoms of the vertical truss pieces; FRP (Fiber Reinforced Polymer) structures are stuck to the surfaces of the components of the vertical truss pieces; FRP structures are laid onto the left surfaces and the right surfaces of the vertical truss pieces to enable the vertical truss pieces to form webs; an FRP structure is stuck to the surface of the component of the upper horizontal bracing system; FRP structures are stuck to the upper surface and the lower surface of the upper horizontal bracing system to enable the upper horizontal bracing system to form a top plate; an FRP structure is stuck to the surface of the component of the lower horizontal bracing system; FRP structures are stuck to the upper surface and the lower surface of the lower horizontal bracing system to enable the lower horizontal bracing system to form a bottom plate; each FRP structure comprises FRP woven roving and FPR chopped strand mats are stuck to two surfaces of the FRP structure. The invention further discloses a construction method of the steel truss-prestressed concrete bridge deck combined bridge girder.

Owner:CHONGQING JIAOTONG UNIVERSITY +1

Waterproof and oilproof soil-release fabric and production method thereof

InactiveCN103046382ASimple processing methodIncrease productivityBiochemical fibre treatmentSingeingCotton fibrePolyester

The invention discloses a waterproof and oilproof soil-release fabric and a production method thereof. In the fabric, the content of cotton fibers is 40%-85%, and the waterproof and oilproof soil-release fabric is obtained by forming a grey fabric from cotton / spandex wrap yarns with a twist coefficient being 1.45-4.55 and polyester yarns with the twist coefficient being 35-195, dyeing the grey fabric and then processing the dyed fabric by using a fluorinated acrylate finishing solution; in addition, at least one type of yarns in weft yarns of the fabric is the cotton / spandex wrap yarns; and after being washed for 20 times according to a standard JIS, the waterproof property, the oilproof property and the soil-release property of the fabric are all above grade 3.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

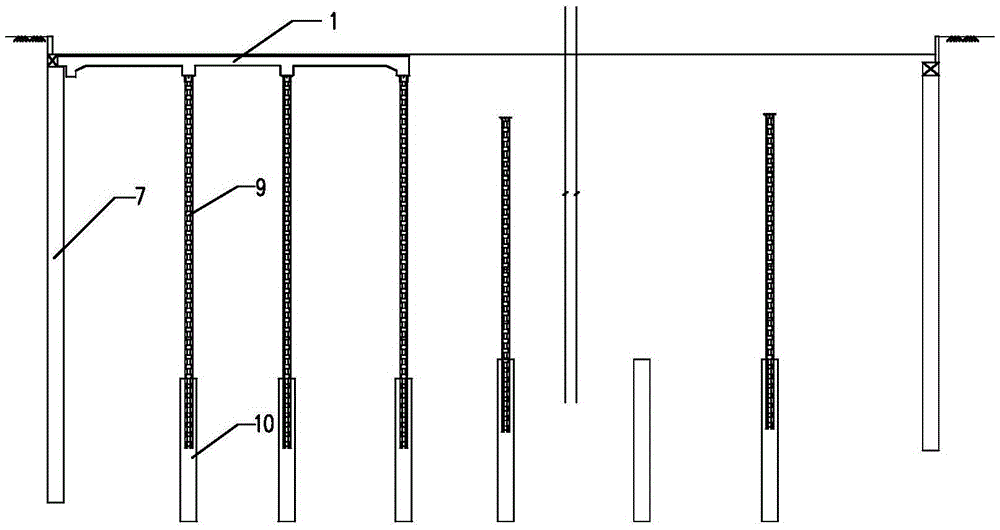

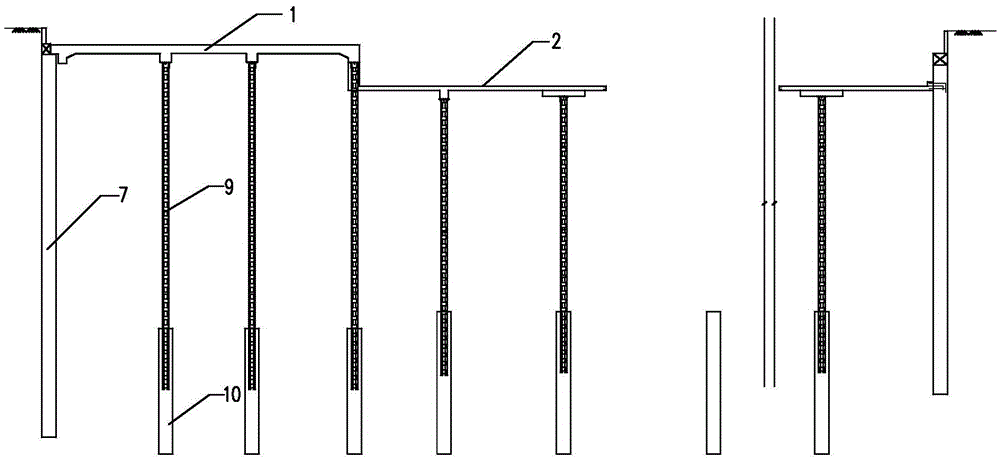

Exterior-covered waterproof construction method for subway station side walls with hanging plate girders

ActiveCN105544607AAdaptableSolve the waterproof problemArtificial islandsProtective foundationSlurry wallEngineering

The invention provides an exterior-covered waterproof construction method for subway station side walls with hanging plate girders. The method comprises the following particular steps that firstly, underground diaphragm walls, embedded bars, uplift piles and lattice columns are constructed; secondly, a first layer of an earthwork is excavated, and roofs of a subway station and a commercial real estate are constructed; thirdly, a second layer of the earthwork and a second last layer of the earthwork are continuously excavated, pouring of middle plates and the hanging plate girders of all layers of the subway station is completed, and waterproof treatment is performed before the middle plates and the hanging plate girders of all the layers are poured; fourthly, the bottommost layer of the earthwork is excavated, bottom plates of the subway station and the commercial real estate are constructed, waterproof structures at the bottom plates are constructed, and the station side wall at the bottommost layer is poured; fifthly, all layers of the hanging plate girders are sequentially removed in a chiseling mode from bottom to top, and the station side walls are sequentially poured after waterproof treatment is performed on the layers.

Owner:URBAN MASS TRANSIT ENG CO LTD OF CHINA RAILWAY 11TH BUREAU GRP +1

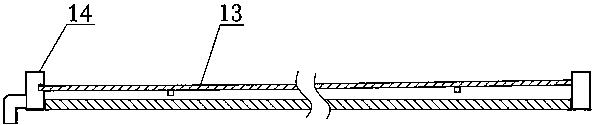

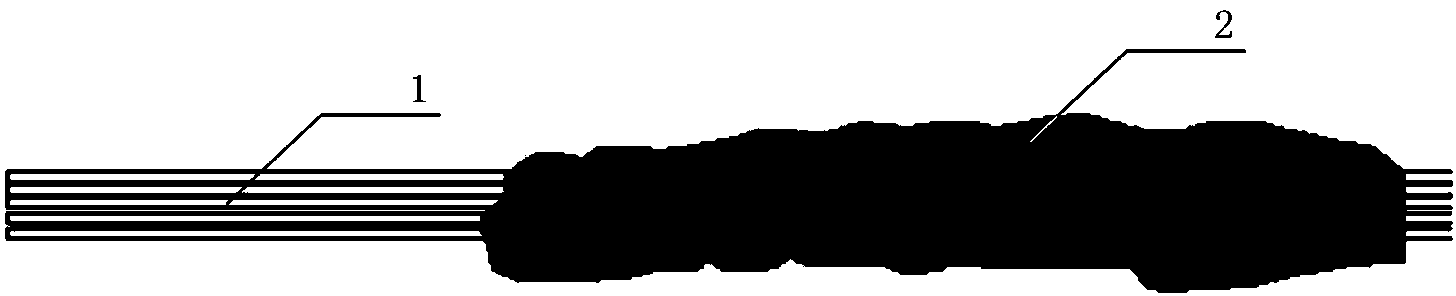

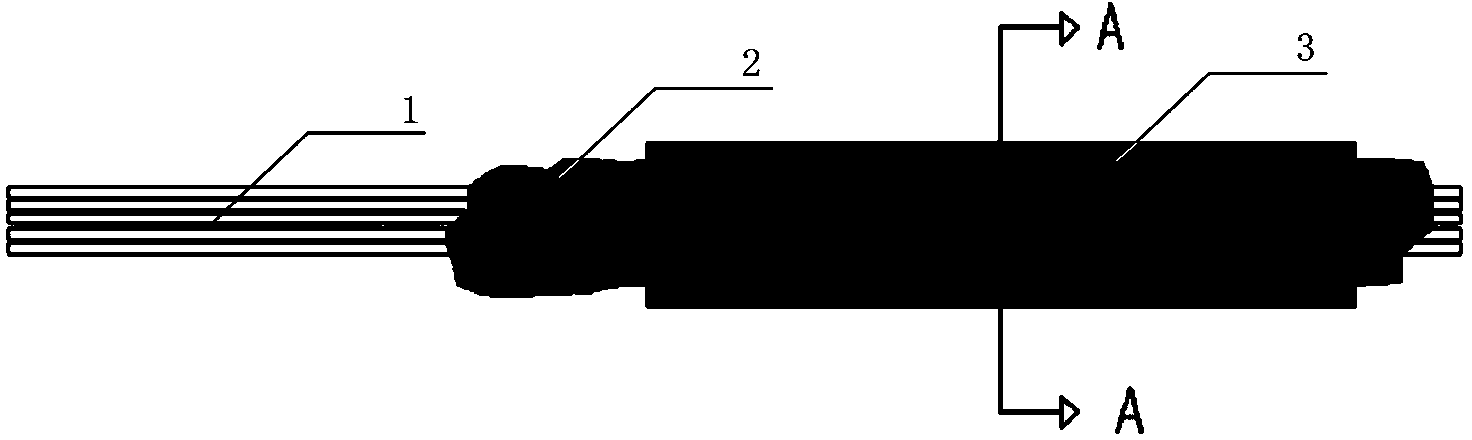

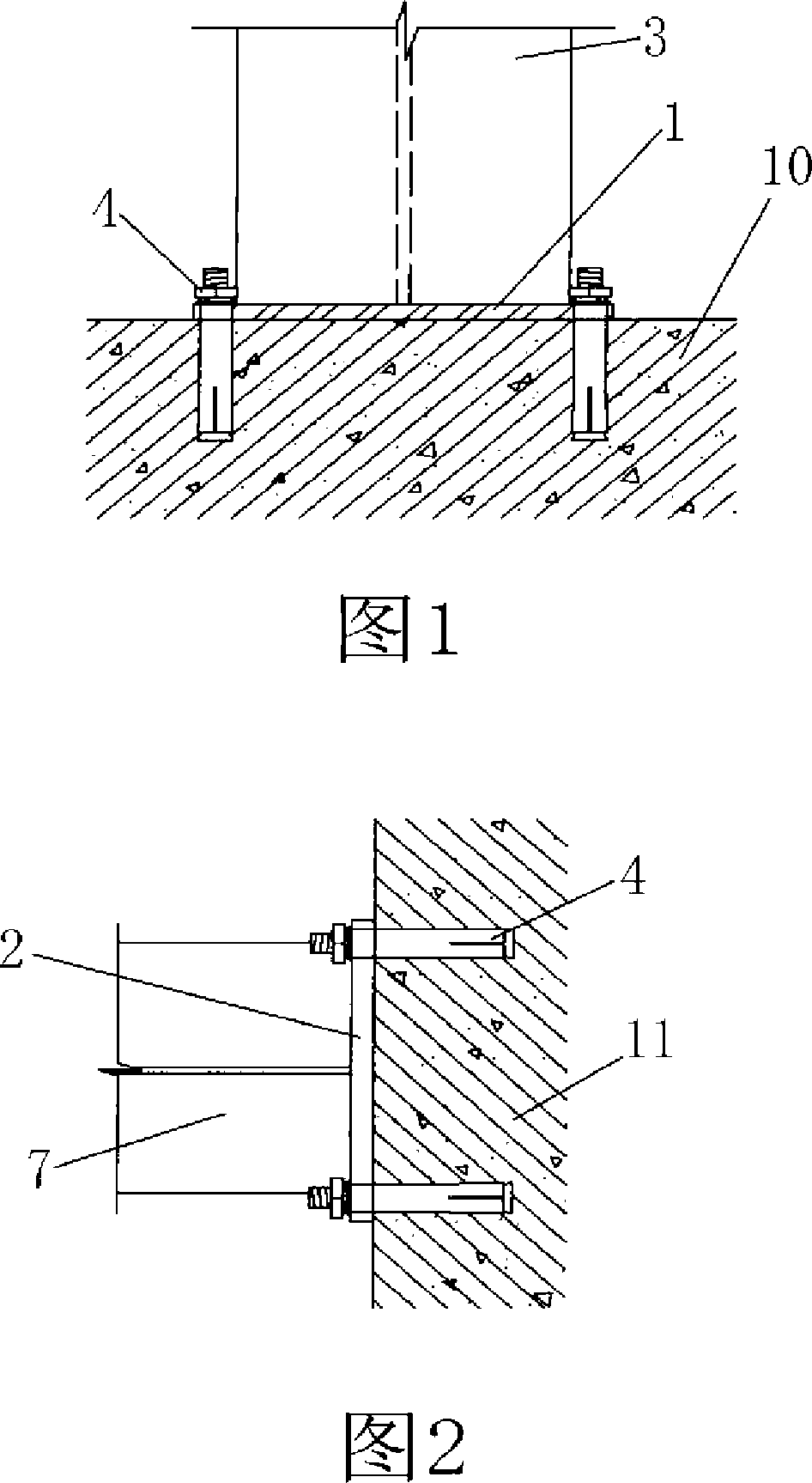

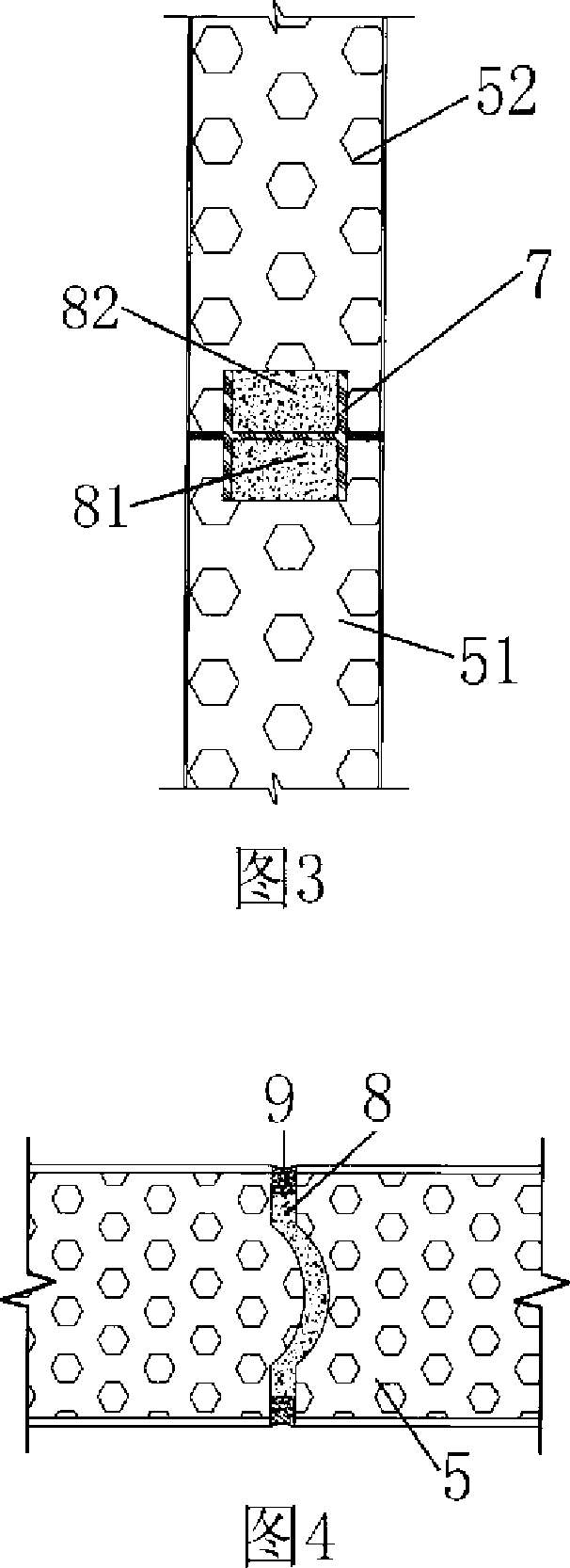

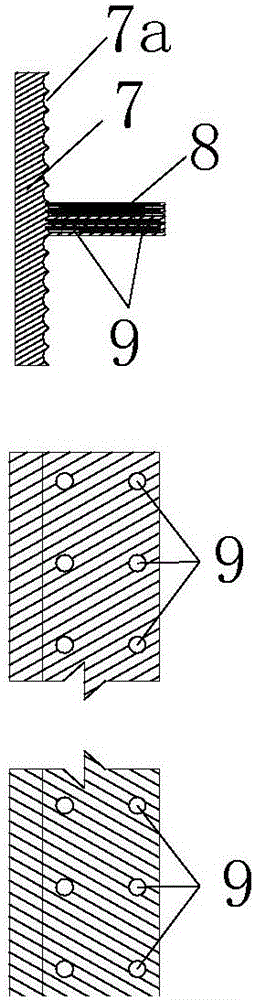

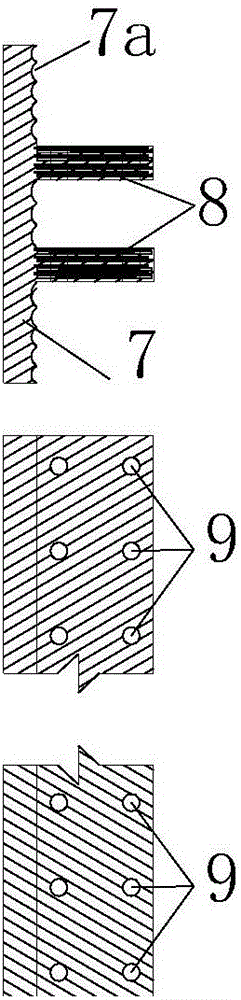

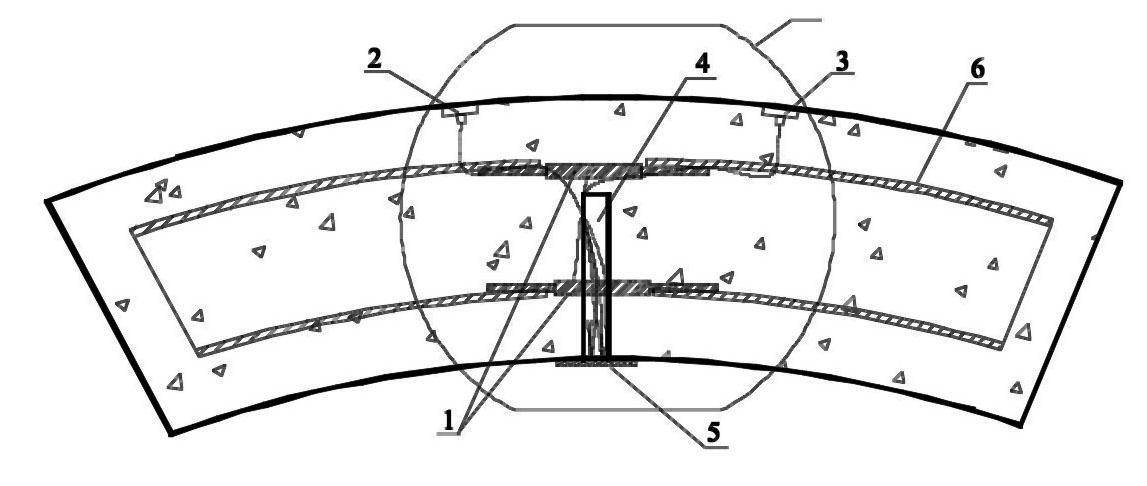

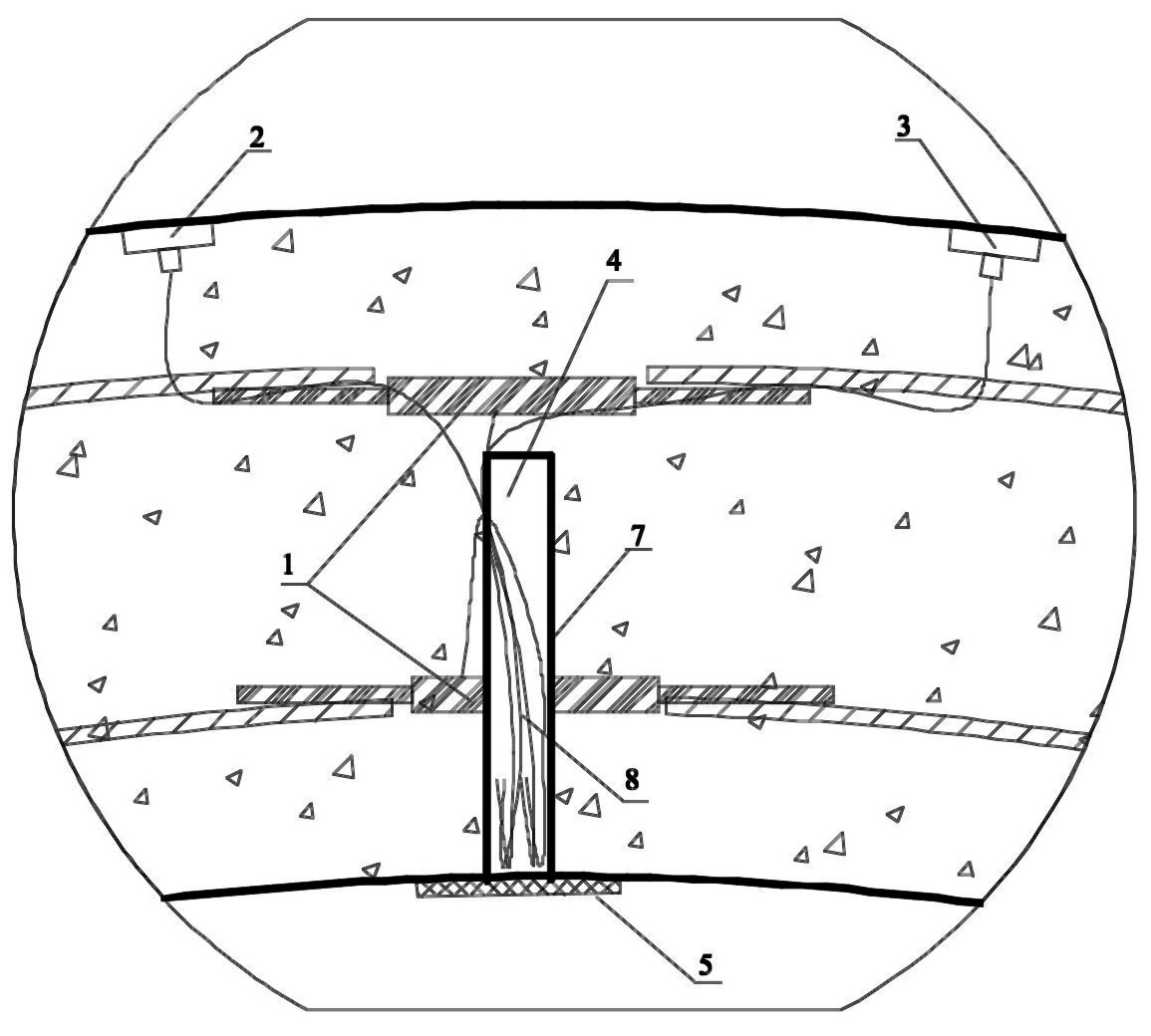

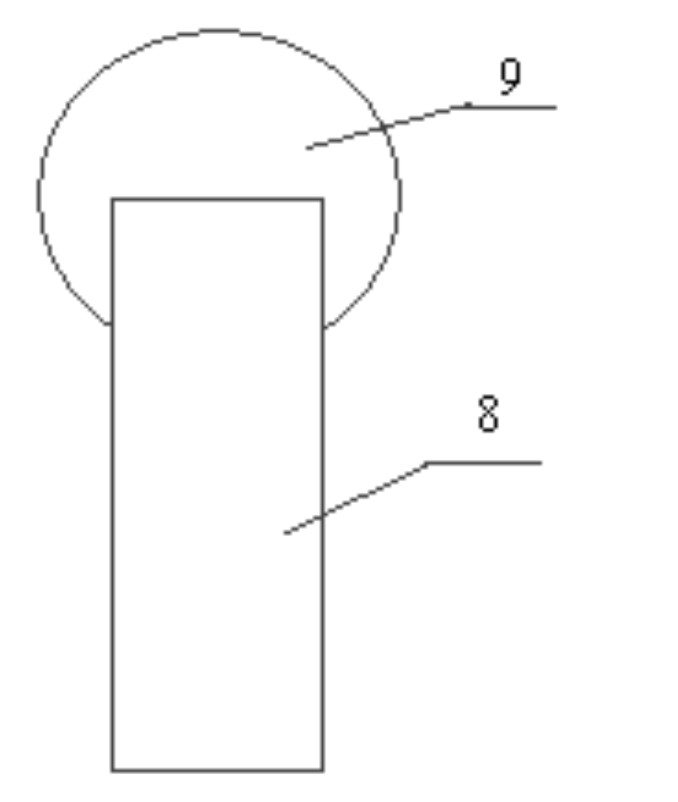

Waterproofing method for stress monitoring cable joints for reinforced concrete segments

ActiveCN102694361AImprove test resultsTo achieve the purpose of double waterproofCable terminationsReinforced concreteRebar

The invention belongs to the technology of stress testing for reinforced concrete segment structures in shield tunnel engineering, and discloses a waterproofing method for stress monitoring cable joints for reinforced concrete segments. The waterproofing method includes using bars containing hot melt adhesive (9) to realize a sealing and waterproofing effect for the joints of monitoring element cables (8); storing the cables (8) preserved by monitoring elements in grouting holes (4); and sealing the grouting holes (4) by plastic plates (5) and silicon sealant. By the aid of the double-effect waterproofing method for the cables (8), waterproofing of the stress monitoring element for the reinforced concrete segments is successfully realized, and normal usage of all the stress monitoring elements is guaranteed.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Waterproof colored solid paint and preparation method thereof

InactiveCN101942253ASolve the waterproof problemImprove waterproof performanceFlooringPolyester coatingsAcrylic resinSolvent free

The invention relates to a hot-melt waterproof paint for enhancing the waterproofness of the circumference of a composite wood floor and a preparation method thereof. The invention is characterized in that the waterproof colored solid paint is prepared from the following raw materials in parts by weight: 100 parts of acrylic resin, 1-10 parts of sunflower seed oil, 1-10 parts of polymer flax oil, 1-10 parts of solvent-free alkide resin, 1-10 parts of high chlorinated polyethylene resin, 1-10 parts of pigment, 0.01-0.5 part of vanadium isooctoate and 0.01-0.5 part of cobalt isooctoate. The invention has the characteristics of good waterproof effect, beautiful appearance and environment friendliness, and the hot-melt waterproof coating obtained at the circumference of the enhanced composite wood floor has the advantages of smoothness, flatness, uniform color and no odor and looks extremely attractive.

Owner:湖北万利环保节能材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com