Self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover, and insulated wallboard

A technology for cement mortar and composite wallboard, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve problems such as low drying shrinkage performance, loss of thermal insulation function, etc. Lightweight effect

Active Publication Date: 2011-11-23

TANGSHAN POLAR BEAR BUILDING MATERIAL

View PDF2 Cites 25 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The impermeability component formed by adding special components improves the compactness, micro-expansion and low dry shrinkage of cement-based self-leveling mortar, greatly improving its waterproof function and durability, which fundamentally solves the problem after coating. Loss of thermal insulation function and durability problems of ultra-light foamed cement board due to water penetration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0025]

Embodiment 2

[0027]

Embodiment 3

[0029]

[0030] (2), in the case where the anti-seepage component adopts the mixture of calcium stearate and redispersible high molecular polymer, the percentage by weight of each ingredient in the dry powder of self-leveling cement mortar is:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Login to View More

Abstract

A self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover, and an insulated wallboard solve technical problem in a prior art that self-leveling cement mortar with weak waterproofness causes weak insulation effect of an insulated wallboard. A self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover is employed as a technique. Ingredients of the self-leveling cement mortar dry powder comprise a compound impervious component; and the impervious component is prepared by mixing a redispersible high-molecular polymer and one of an organosilicon waterproof agent and a stearate, or a mixture of the two, and accounts for 0.6-4.3wt% of the self-leveling cement mortar dry powder. A special impervious ingredient is added to enhance compactness, microdilatancy and low dry shrinkage property of the cement based self-leveling mortar, so as to substantially increase waterproof function and endurance of the cement based self-leveling mortar. Therefore, a problem that a cladded super-light foaming cement sheet material loses insulation function due to water penetration and problems of flame resistance and endurance are solved fundamentally.

Description

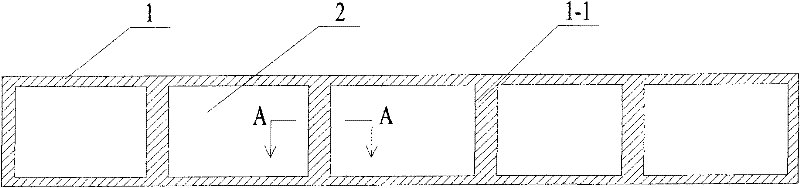

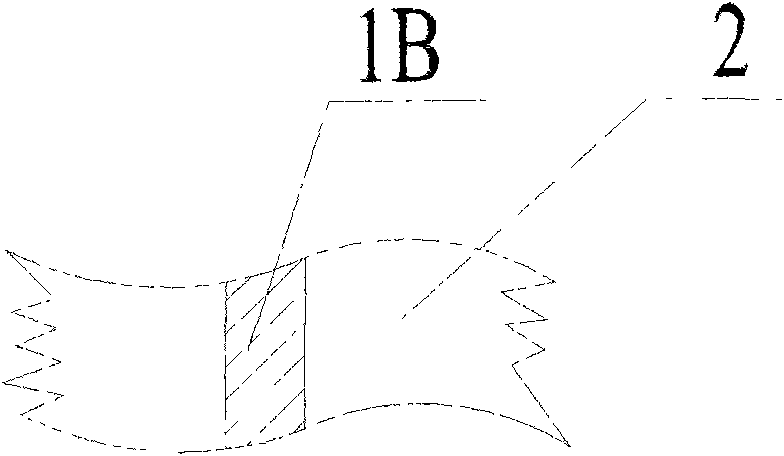

technical field [0001] The invention relates to a self-leveling cement flat mortar dry powder, which is used for preparing the waterproof shell layer of foamed cement insulation boards in the construction field, adding anti-seepage components to the cement-based self-leveling mortar, and adjusting the components of the self-leveling mortar at the same time The matching ratio, obtain an ultra-thin waterproof and thermal insulation shell. Background technique [0002] On February 9, 2009, the fire in the north annex building of CCTV and a series of fire accidents caused by the application of EPS external wall insulation system in Harbin, Jinan and other places aroused great attention from the relevant state departments. On January 5, 2010, the Ministry of Public Security and The Ministry of Housing and Urban-Rural Development issued the "Interim Regulations on Fire Protection of Civil Building External Thermal Insulation System and External Wall Decoration", which stipulates t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B28/36C04B111/62

CPCC04B28/06C04B41/009C04B41/508Y02W30/91C04B14/06C04B18/08C04B22/143C04B24/383C04B2103/0057C04B2103/14C04B2103/24C04B2103/302C04B2103/50C04B2103/65C04B24/2641C04B24/42C04B24/08C04B28/00

Inventor 张振秋刘成健葛仲熙

Owner TANGSHAN POLAR BEAR BUILDING MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com