Short-time and high efficiency deforming TiAl alloy heat treatment method

A heat treatment method and heat treatment temperature technology, which is applied in the field of metal material preparation, can solve the problems of high heat treatment temperature, long heat treatment time, grain growth, etc., achieve broad engineering application prospects, avoid long-term heat preservation, and short treatment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

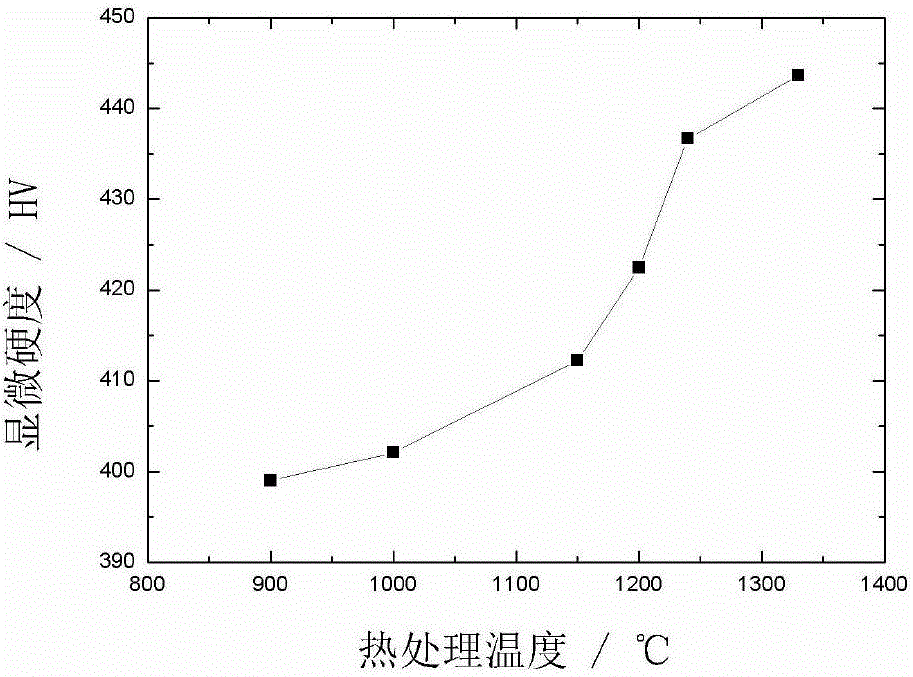

[0017] Electric pulse frequency 200Hz, pulse width 60μs, peak current density 350A mm -2 , the treatment temperature reaches 900°C, and the holding time is 40s. After treatment, the microstructure of the plate has little change, which is a two-state structure in the rolled state, and the hardness is slightly lower than that in the hot-rolled state, reaching 399HV.

Embodiment 2

[0019] Electric pulse frequency 300Hz, pulse width 60μs, peak current density 380A mm -2 , the treatment temperature reaches 1000°C, and the holding time is 40s. After treatment, the microstructure of the plate has little change, and it is a two-state structure in the rolling state, and the hardness reaches 401HV.

Embodiment 3

[0021] Electric pulse frequency 200Hz, pulse width 60μs, peak current density 400A mm -2 , the treatment temperature reaches 1150°C, and the holding time is 40s. After treatment, the microstructure of the plate changed significantly, and the structure was nearly γ structure, accompanied by a small amount of lamellar clusters, the volume fraction increased, and the hardness reached 412HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com